Patents

Literature

156 results about "Process specification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process specification is a generic term for the specification of a process. Its context is not unique to "business activity" but can be applied to any organizational activity. Within some structured methods, the capitalized term Process Specification refers to a description of the procedure to be followed by an actor within an elementary level business activity, as represented on a process model such as a dataflow diagram or IDEF0 model. A common alias is minispec short for miniature specification.

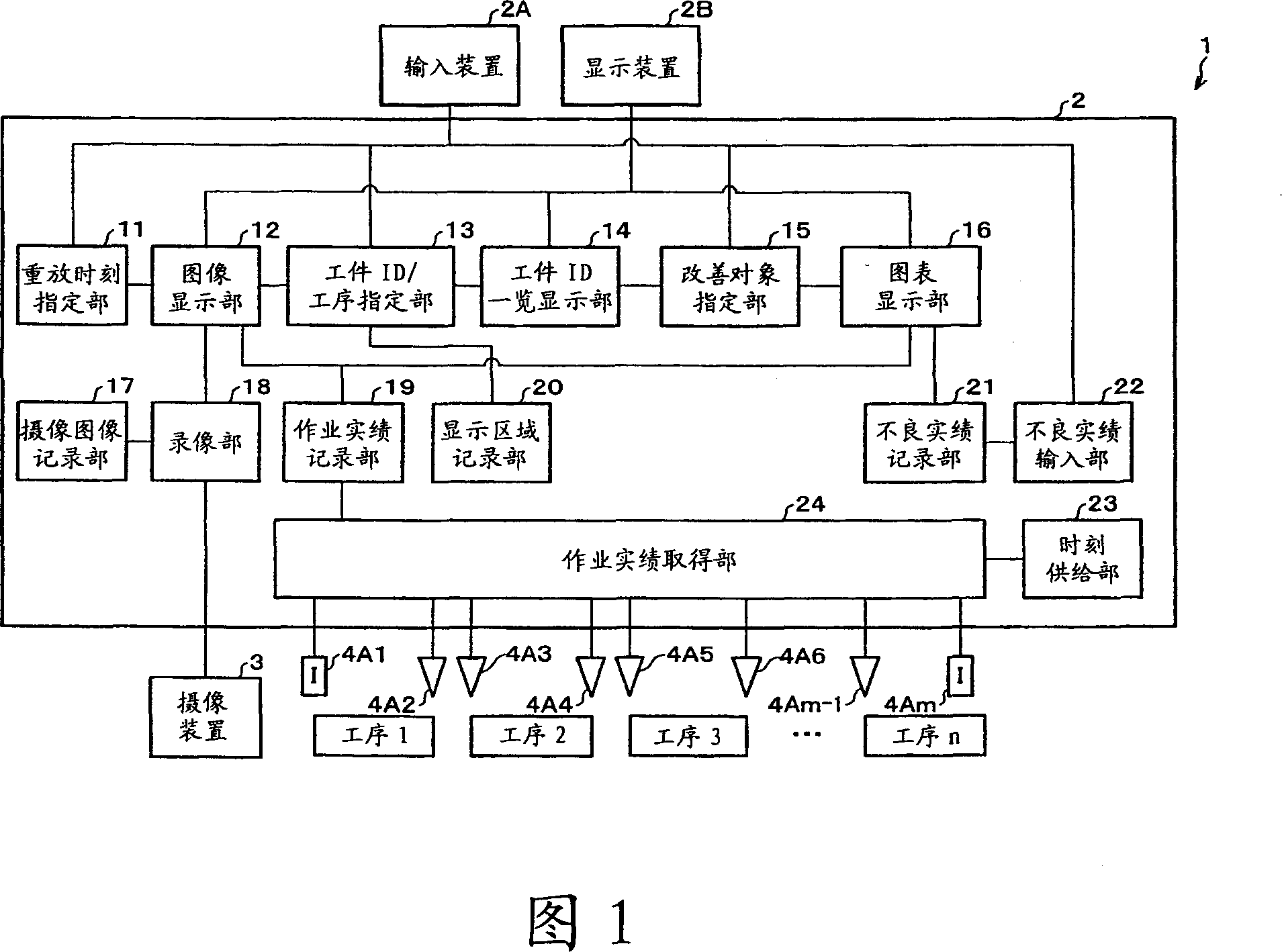

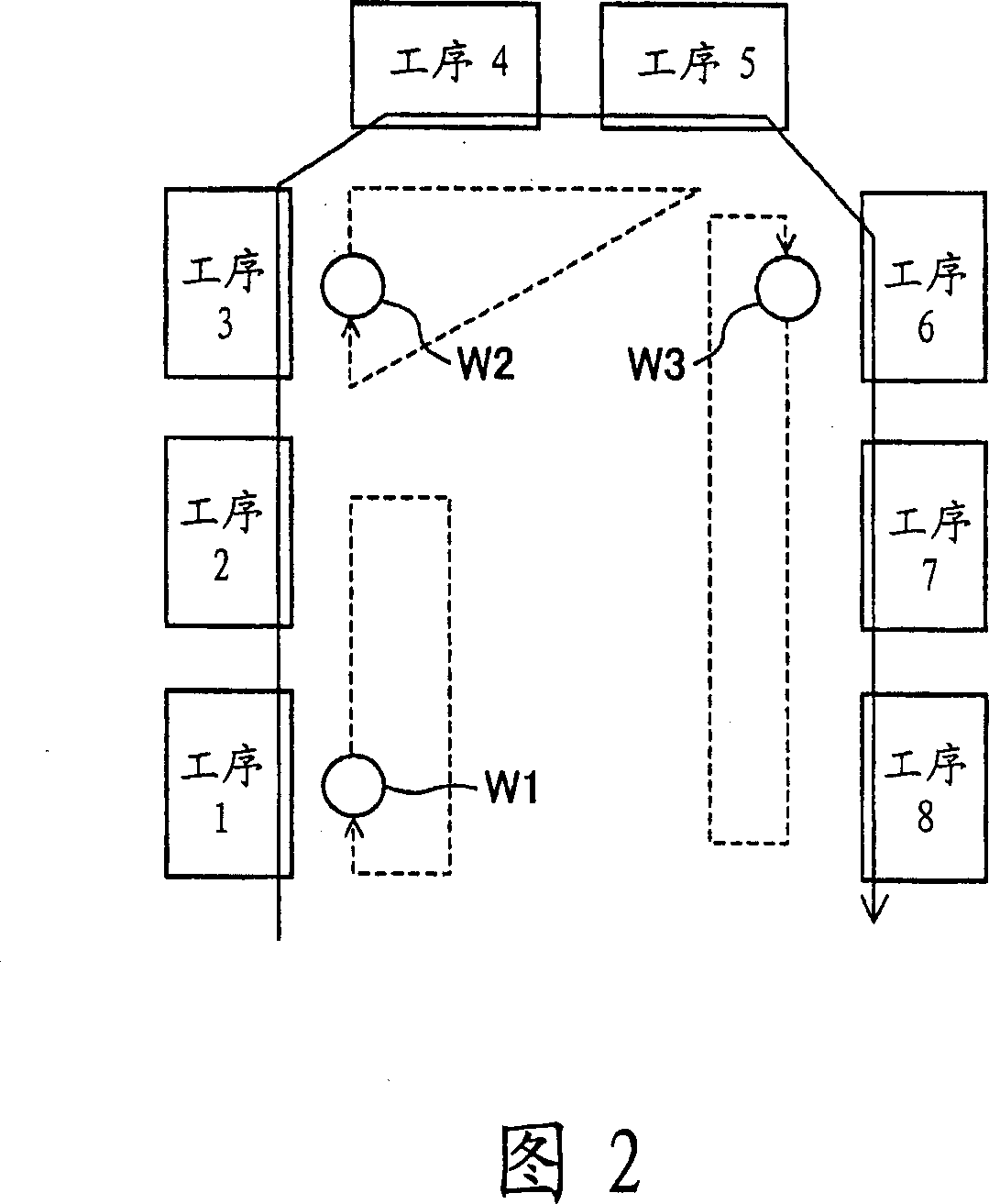

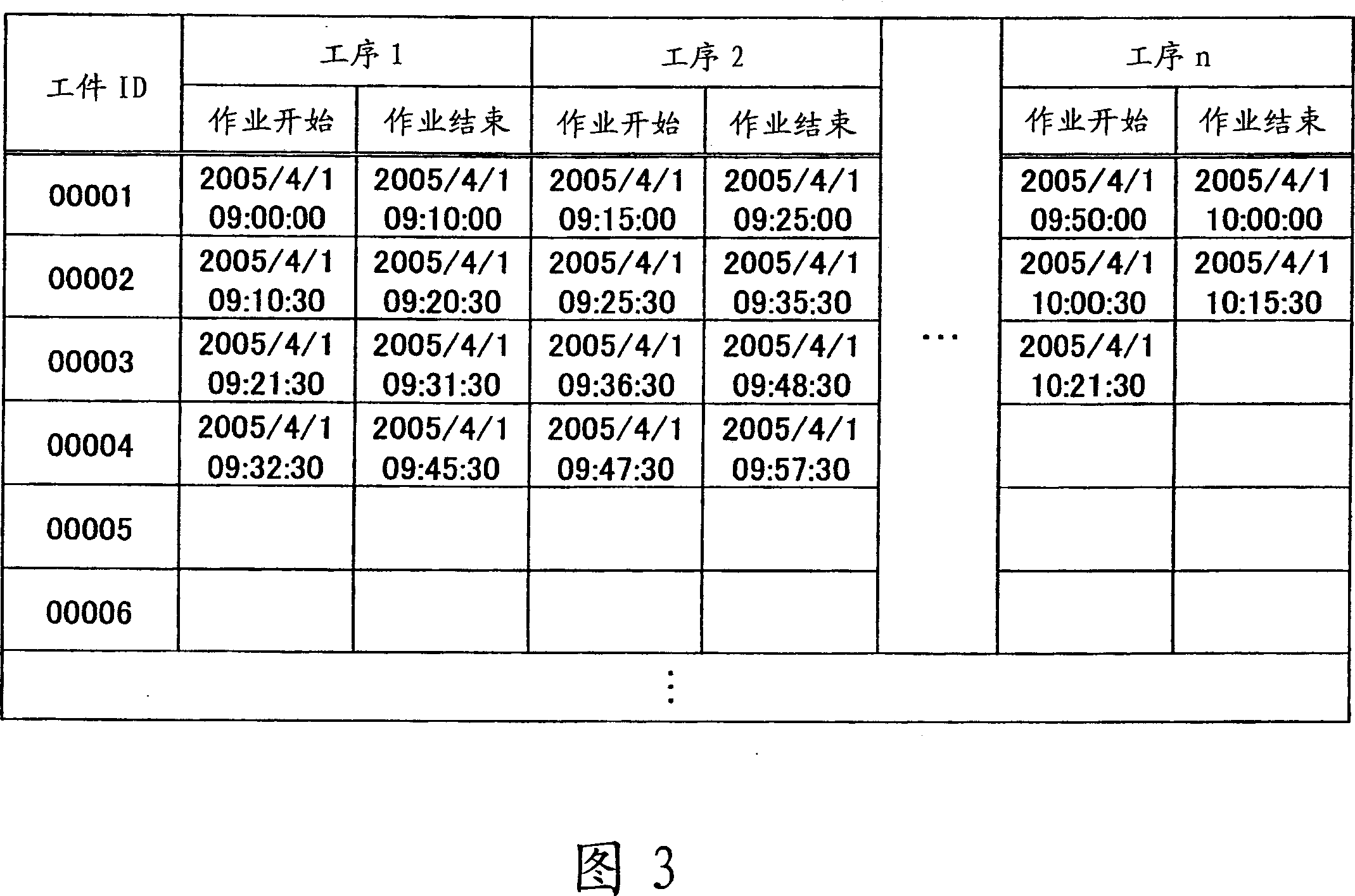

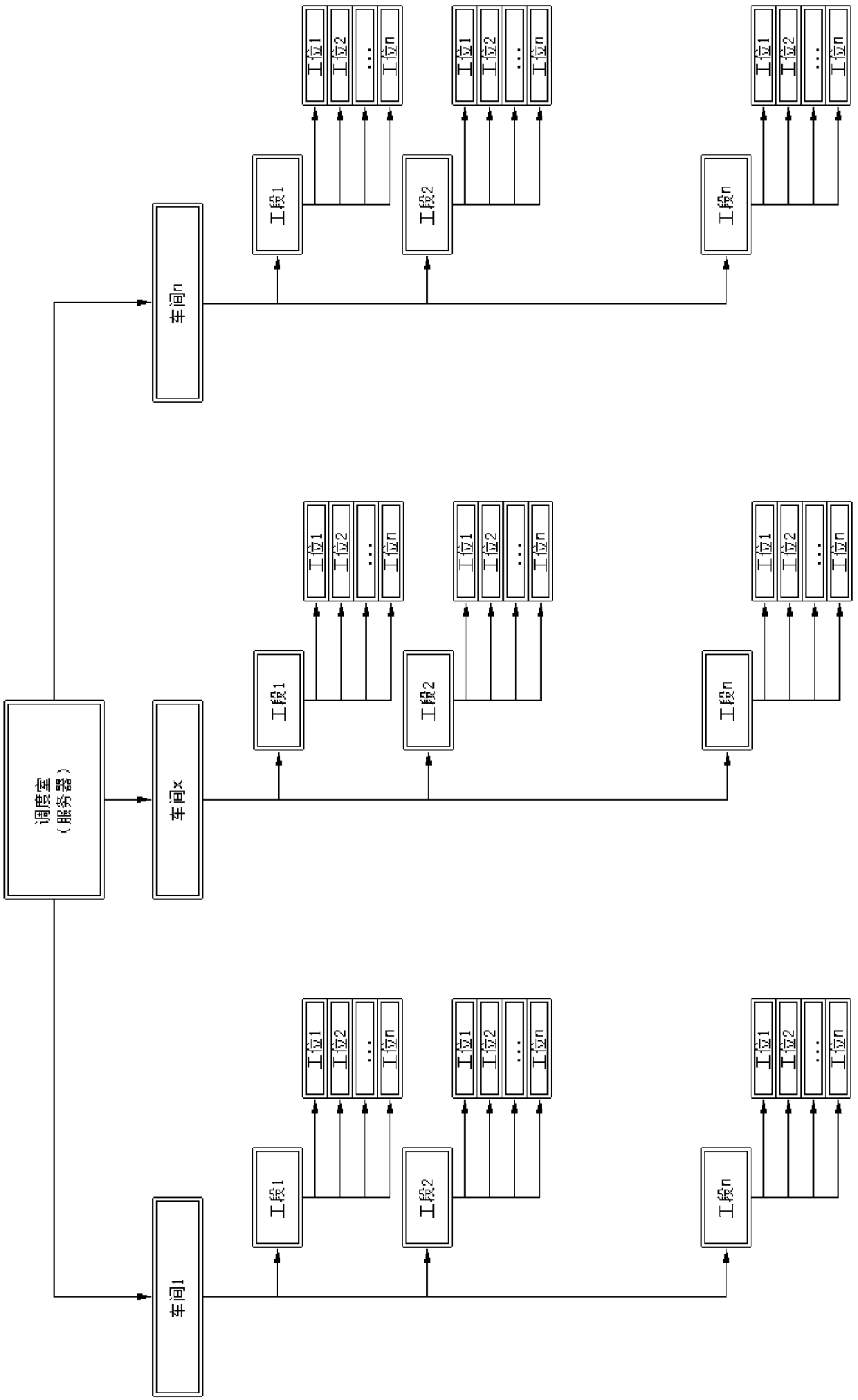

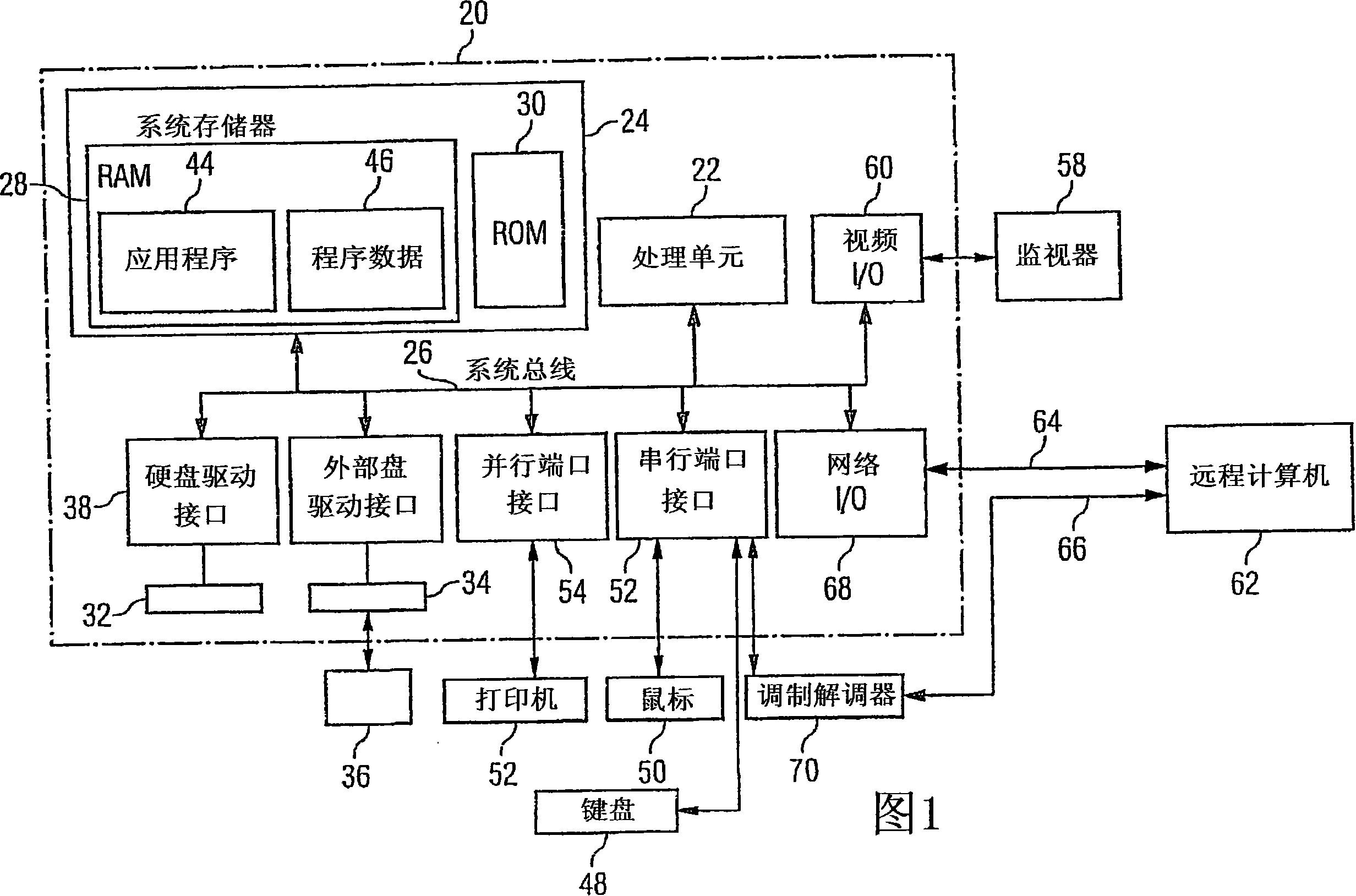

Production management device, method and system

PROBLEM TO BE SOLVED: To provide a production management device capable of reducing man-hour required from discovery of a task to factor analysis in a production system. ŽSOLUTION: A graph display part 16 totals information indicating processing statuses regarding the respective work IDs and performs control for displaying processing status analysis information based on at least one parameter on a display device 2B as an analysis result of processing statuses. When an improvement object specification part 15 accepts input of a parameter value of an event for improvement from a user, a work ID list display part 14 displays a list of applicable work IDs. A work ID / process specification part 13 recognizes a work ID selected by the user from the list of work IDs and a selected process and an image display part 12 displays a pickup image regarding the selected work ID and the process on the display device 2B. Ž

Owner:ORMON CORP

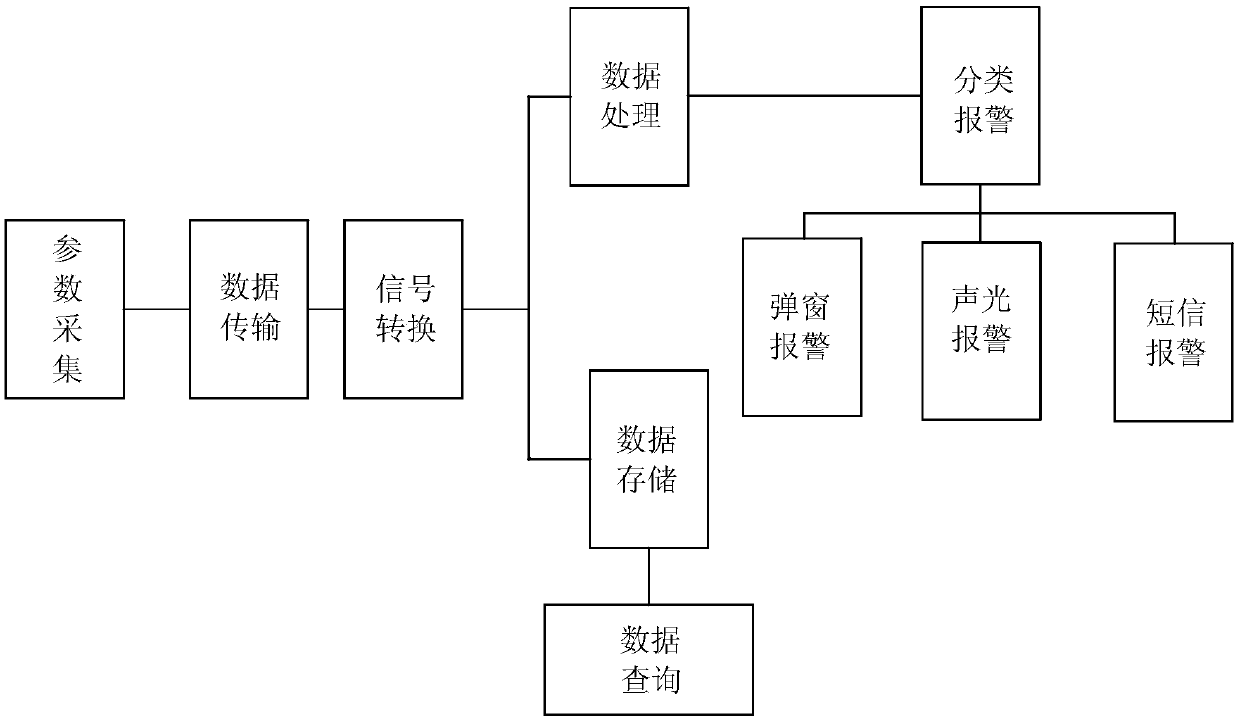

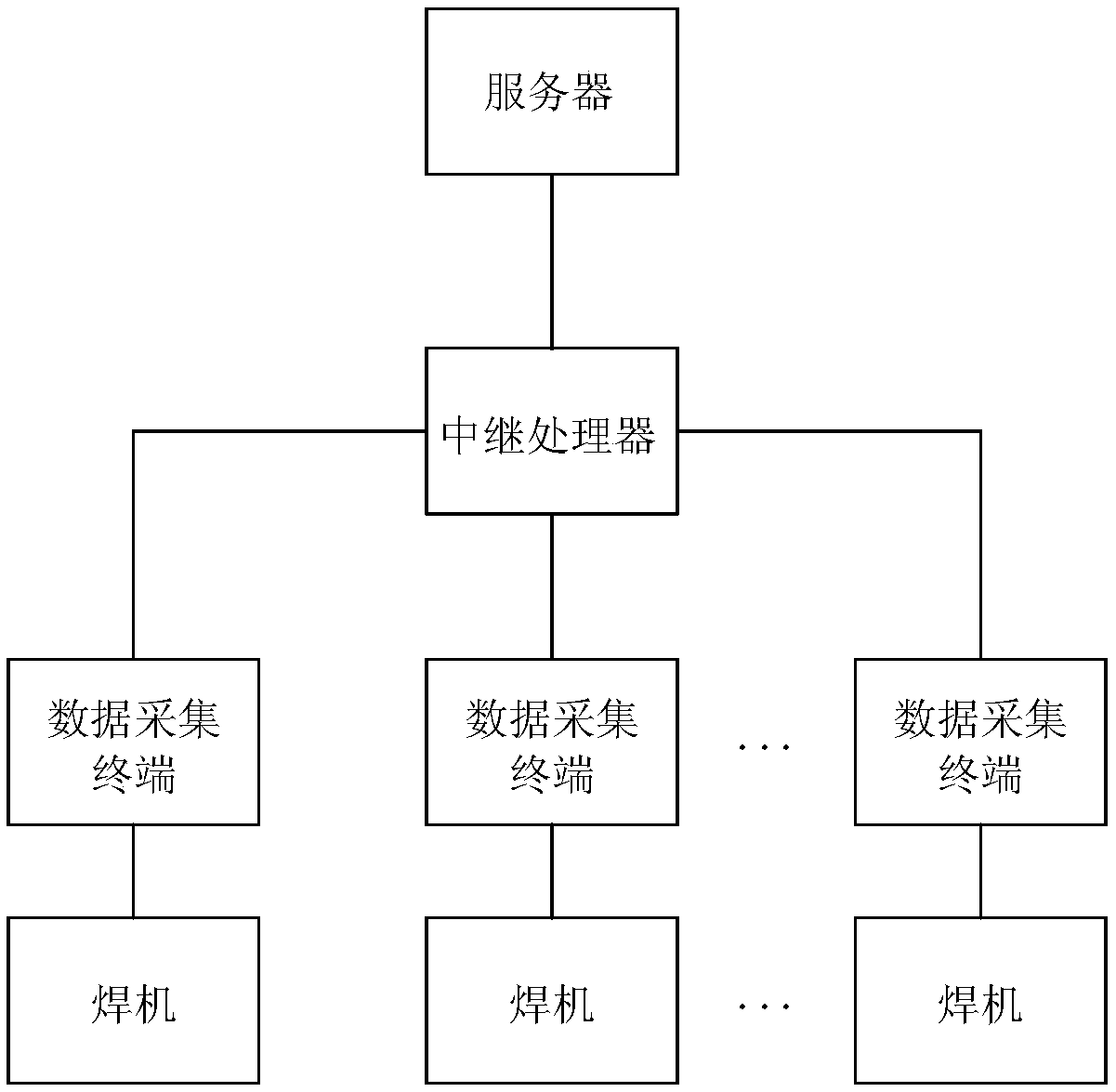

Welding parameter intelligent monitoring system

InactiveCN109093228ASolve the disadvantages of not implementing according to the process specificationFacilitate complianceArc welding apparatusProcess specificationOriginal data

The invention discloses a welding parameter intelligent monitoring system which comprises a plurality of data collecting terminals, a relay processor and a server. The multiple data collecting terminals are used for reporting collected welding parameters to the relay processor in real time. The relay processor is used for summarizing the welding parameters sent by the multiple data collecting terminals and then outputting the welding parameters to the server. The server is used for analyzing, storing and displaying received data. The welding parameter intelligent monitoring system can monitorand automatically record the welding parameters in working of welding equipment; the disadvantage that onsite operators do not conduct implementation according to process specifications is avoided; personnel correspond to the welding data, and detailed records of the weld joint original data can be provided for tracing of the welding process; managers can remotely learn the onsite welding condition in an office area through various client sides; and the product quality control demands are met, and the situations such as welding labor hours of the operators are managed in real time.

Owner:WUXI SANHONG MACHINERY EQUIP

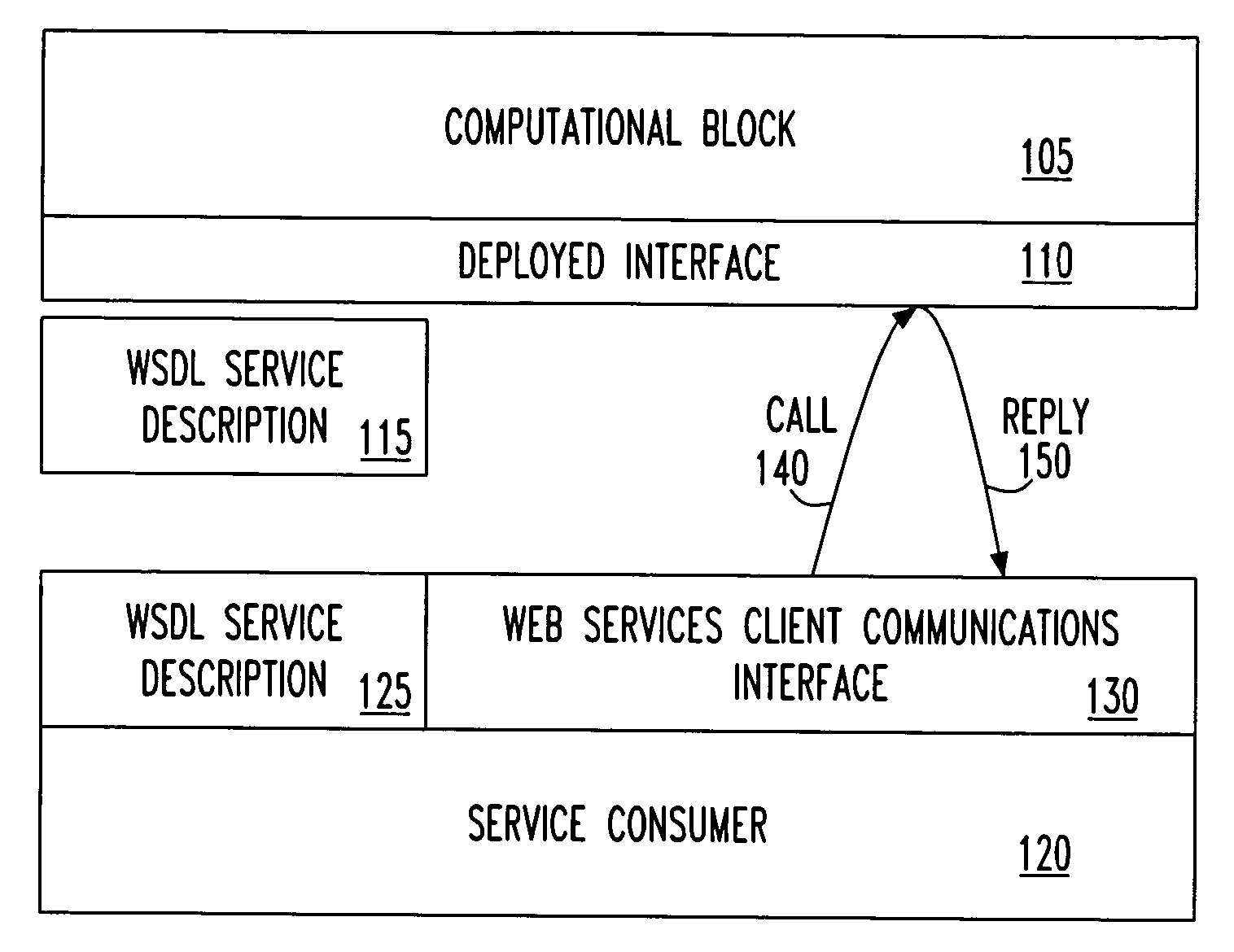

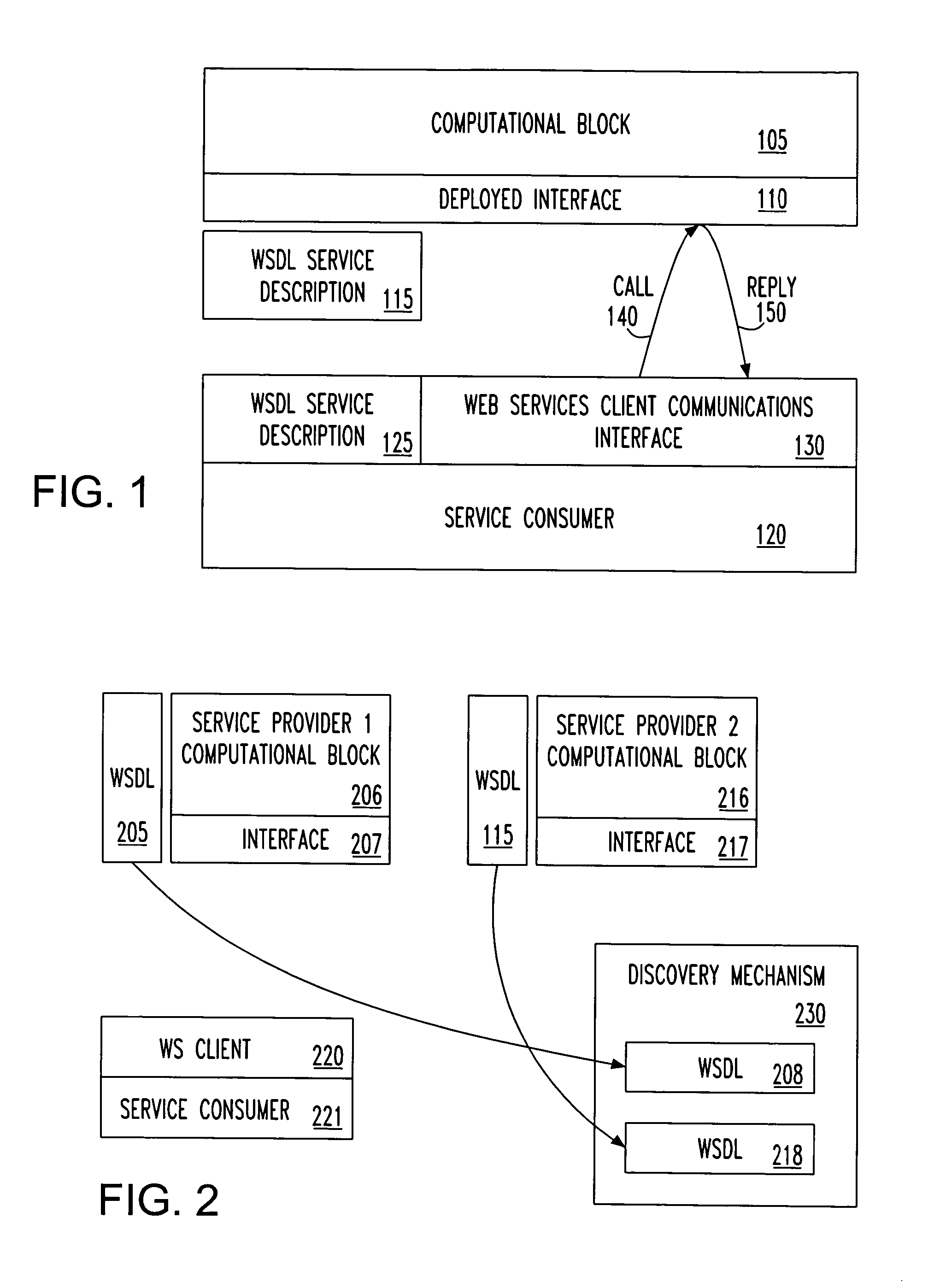

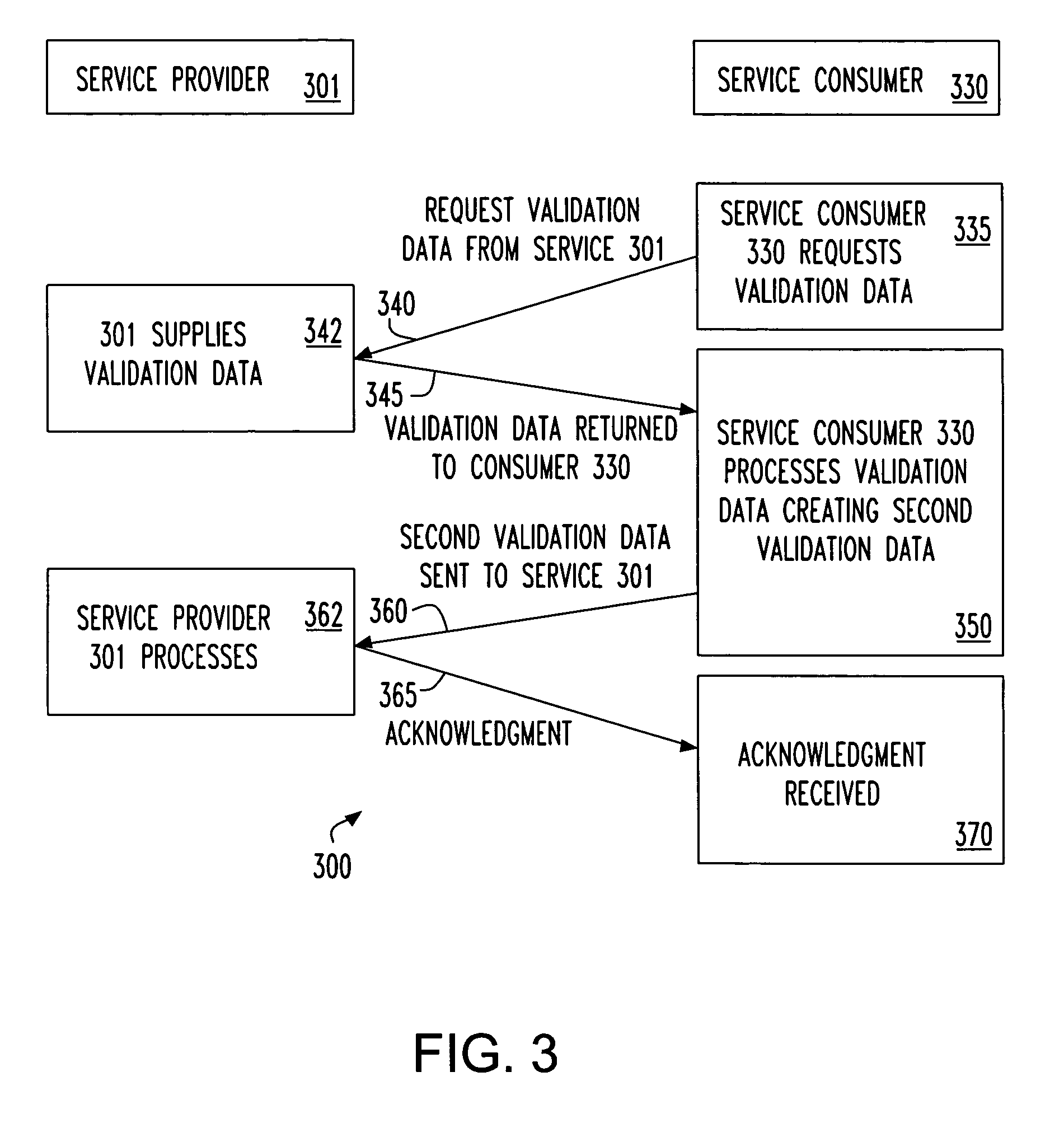

Method and system for validation of service consumers

InactiveUS20050086102A1Customer communicationsSpecial data processing applicationsProcess specificationDatabase

A service Provider tests and validates the ability of a customer to carry out its part of the service process, to specify parameters of the process and / or to use the output of the process supplied to it by supplying to the Consumer a set of first validation data that is processed by the Consumer to produce a second set of validation data that is compared with a set of criteria and a process specification to determine if the Consumer has successfully processed the first set of validation data.

Owner:IBM CORP

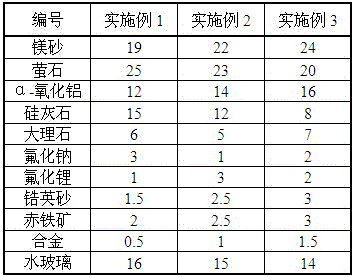

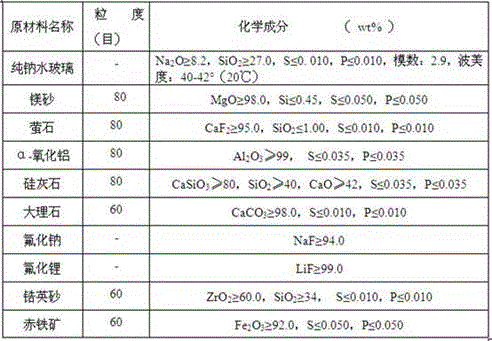

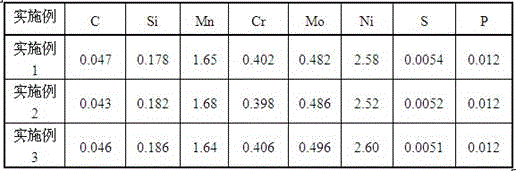

Sintered flux for welding of high-strength steel for ocean engineering and preparation method of sintered flux

ActiveCN106271218AGood workmanshipArc stabilizationWelding/cutting media/materialsSoldering mediaProcess specificationHydrogen

The invention discloses sintered flux for welding of high-strength steel for ocean engineering and a preparation method of the sintered flux. The sintered flux belongs to fluoride-basic type sintered flux and is prepared from components in parts by weight as follows: 19-24 parts of MgO, 20-25 parts of CaF2, 12-16 parts of Al2O3, 4-8 parts of SiO2, 8-10 parts of CaO, 2-4 parts of BaO, 1-3 parts of NaF, 1-3 parts of LiF, 1-2 parts of ZrO2, 2-3 parts of Fe2O3, 0.5-1.5 parts of an alloy and 14-16 parts of water glass. The sintered flux has good manufacturability, has arc stability under broader process specification, can meet requirements for welding of E550 steel plates with yield strength higher than 550 MPa and E690 steel plates with yield strength higher than 690 MPa and has lower diffusible hydrogen, slag removal is easy, and welding bead forming is attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Complex alloy permeation agent and method for preparing permeation layer

InactiveCN102127732ASmooth appearanceUniform thicknessSolid state diffusion coatingHeat penetrationAlloy

The invention relates to a complex alloy permeation agent and a method for preparing a permeation layer, designed aiming at the surface antisepsis of common steel spare parts, such as railway track fasteners, bolts, elastic bars, concrete preembedded parts, and the like. The complex alloy permeation agent comprises zinc powder, aluminum powder, alumina powder, lanthanum hydroxide powder and ammonium chloride. The process line for preparing the permeation layer comprises the following steps of: pretreating a working piece; loading the working piece into a furnace and adding the permeation agent; heating a converter and keeping the temperature for permeation; and cooling the working piece when reaching a temperature and discharging the working piece. Heat penetration is carried out under confirmed process specifications so as to form corrosion-resistant and wearable complex alloy permeation layer with a certain thickness and a compact structure on the surface of the working piece. The invention has simple process and is easy to implement. A Zn-Al-Fe-La complex alloy permeation layer obtained by adopting the conventional process has the thickness about 100 micros, the hardness up to 240-320 HV and the salt-air corrosion up to 680 h.

Owner:安徽天通达克罗涂复科技有限公司

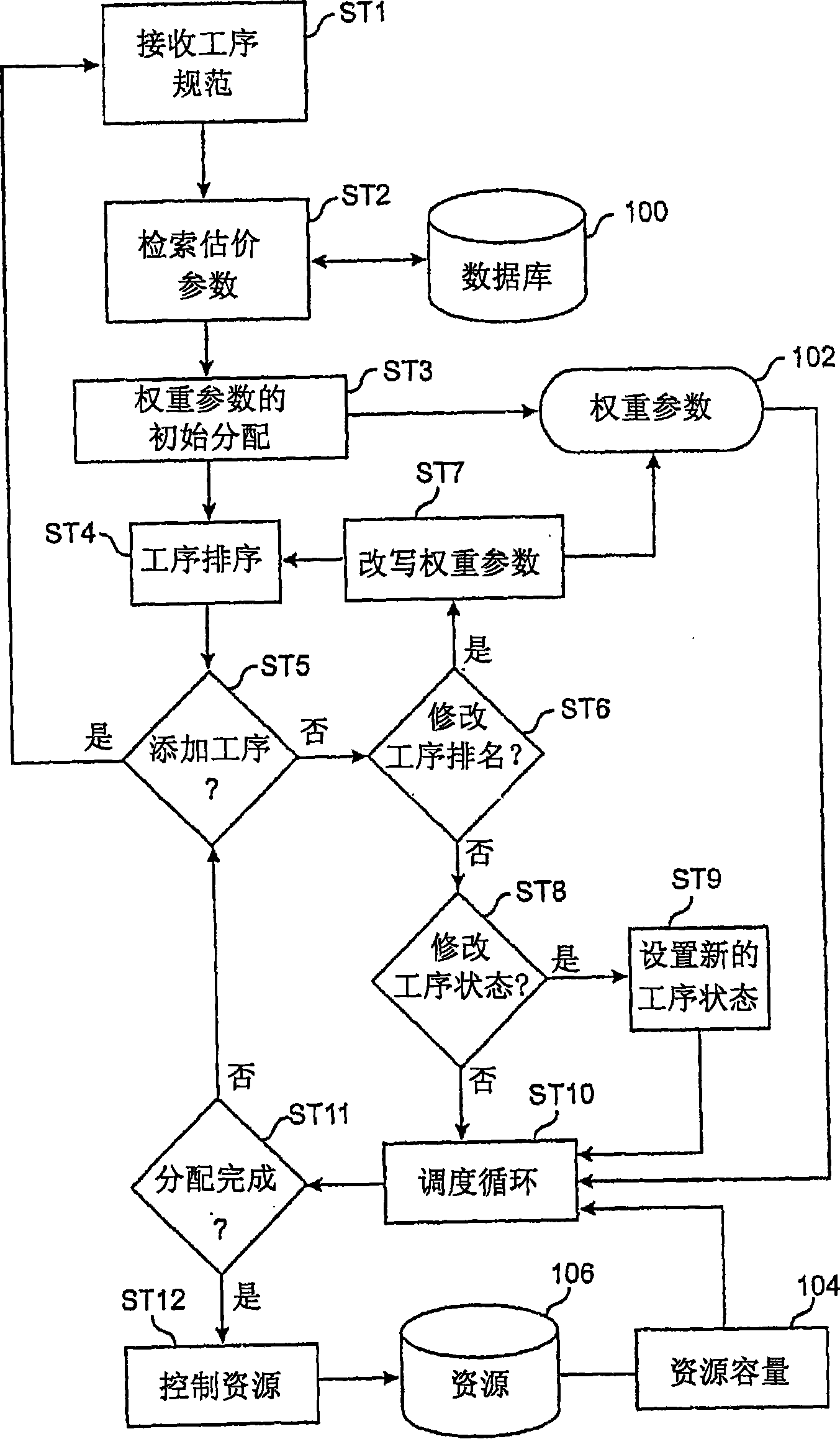

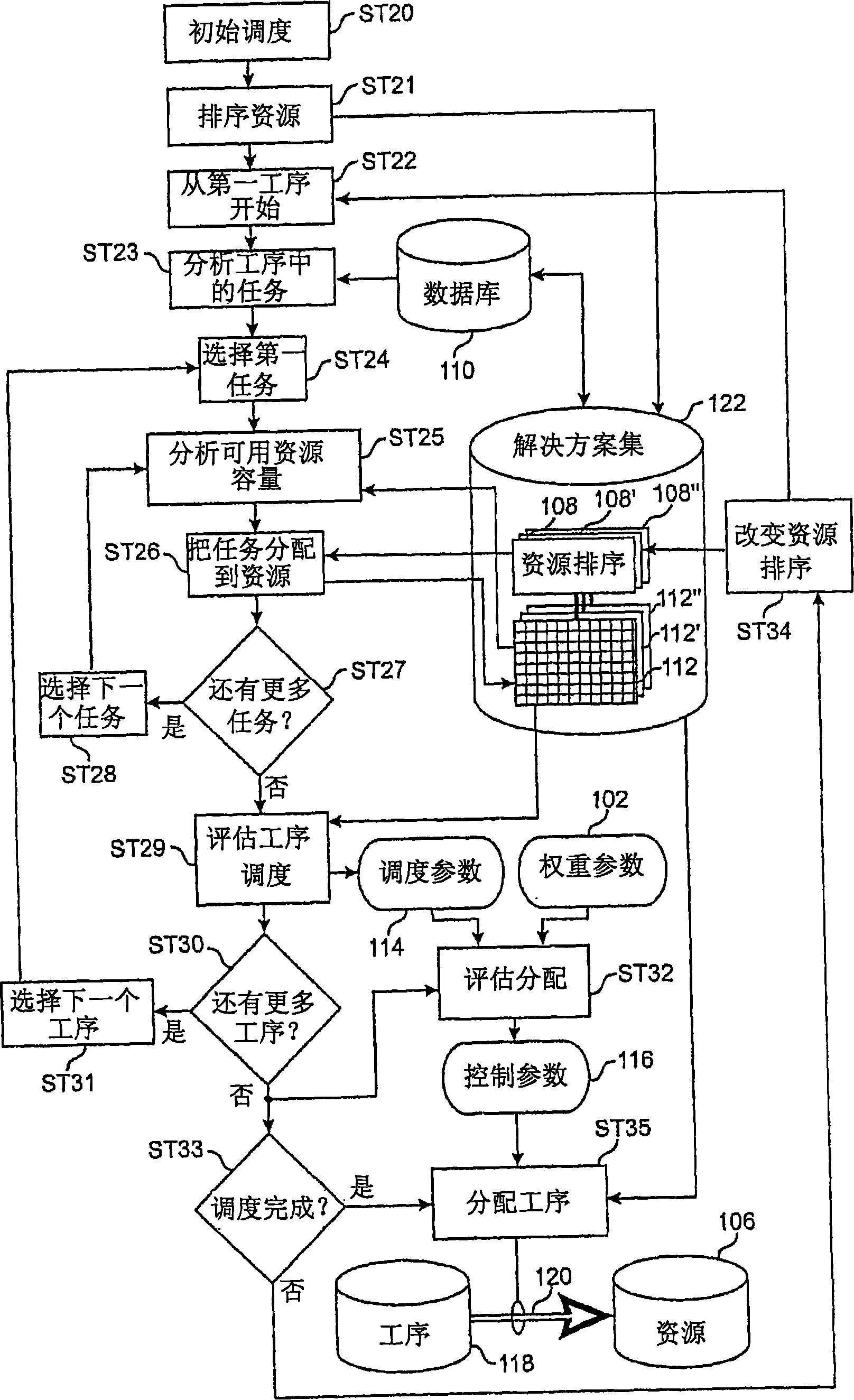

Work allocation model

The invention refers to a computer-implemented method, a computer program product and a system for allocating processes (118) to a plurality of resources (106), where the method comprises the steps of: receiving a process specification defining a plurality of processes, each process having a weighting parameter (102) and comprising at least one task belonging to a task category; analyzing an available resource capacity (104) for each of a plurality of resources, each of which is capable of performing tasks within at least one task category; establishing a first resource-task assignment set (112) defining an assignment of the plurality of tasks to the plurality of resources depending on the task categories, where the first resource-task assignment set defines a first scheduling of the tasks depending on the available resource capacities, and evaluating for each of the processes a first schedule parameter (114) depending on the established scheduling of the tasks belonging to the respective process; establishing at least one further resource-task assignment set an assignment of the plurality of tasks to the plurality of resources depending on the task categories, where the at least one further resource-task assignment set defines at least one further scheduling of the tasks depending on the available resource capacities, and evaluating for each of the processes at least one further schedule parameter depending on the established scheduling of the tasks belonging to the respective process; evaluating a control parameter (116) for each of the established resource-task assignment sets depending on the weighting parameters and the schedule parameters; selecting one of the established resource-task assignment sets depending on a selection criterion for the control parameter; and allocating the tasks to the resources according to the selected resource-task assignment set.

Owner:ACCENTURE GLOBAL SERVICES LTD

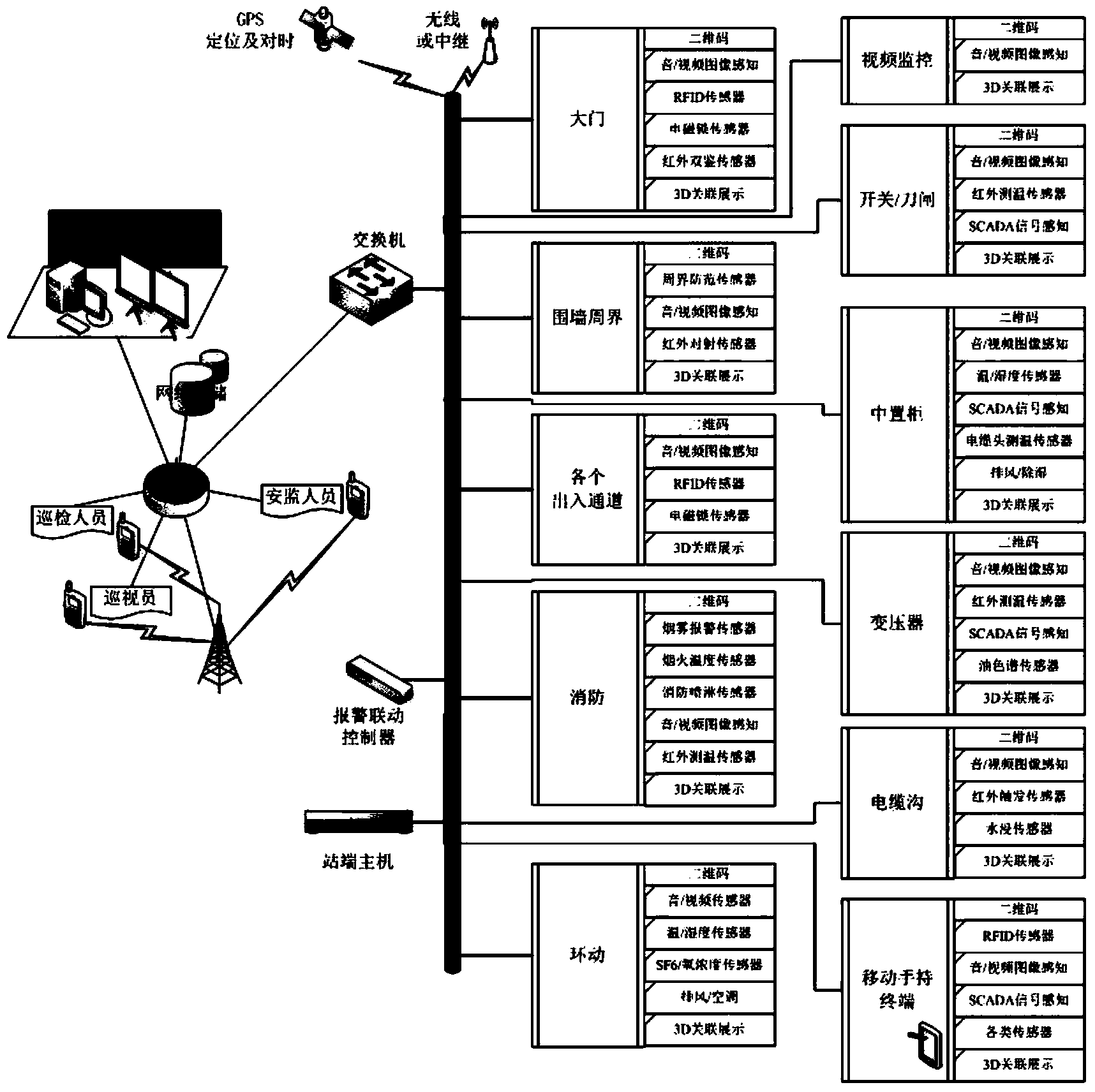

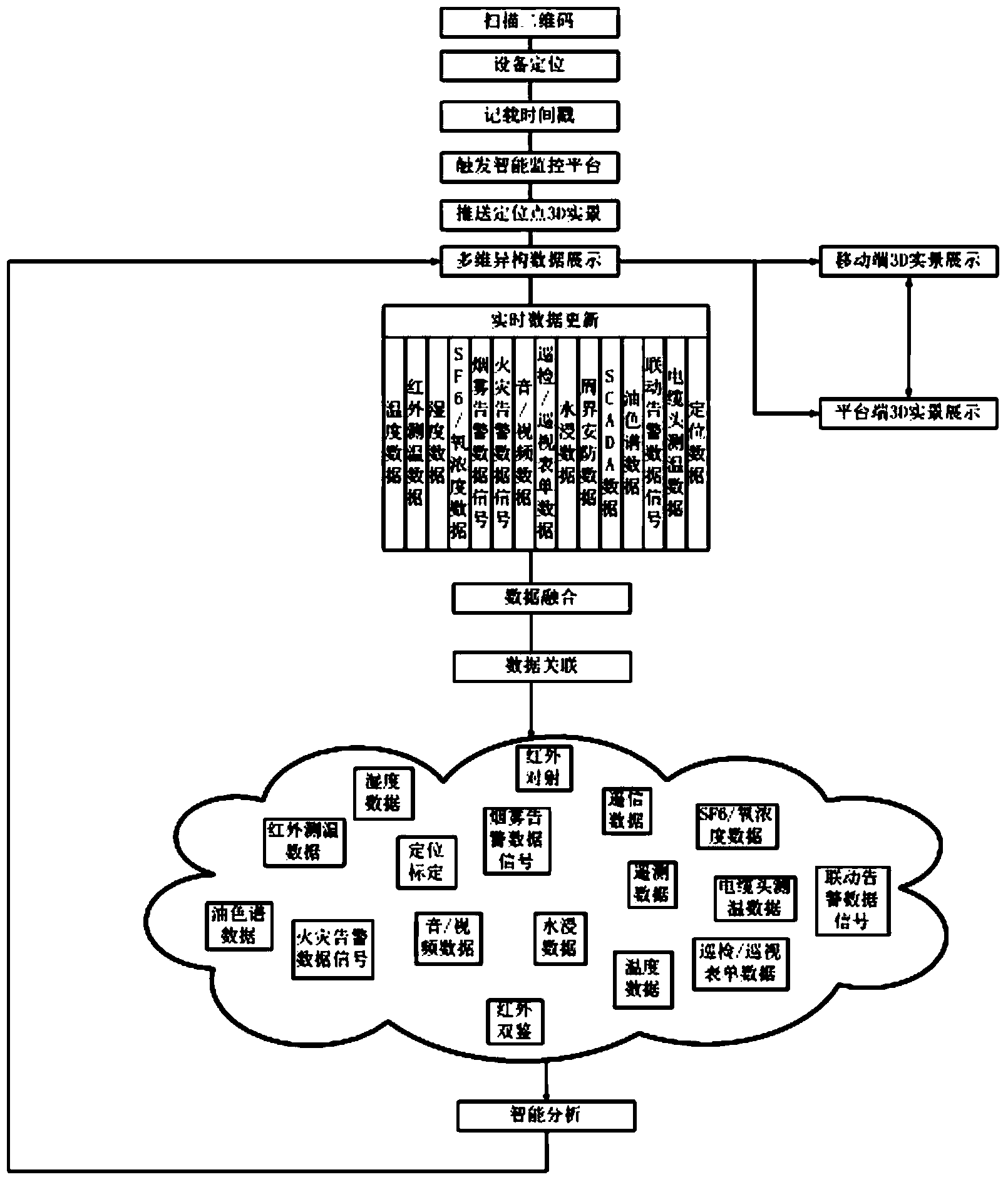

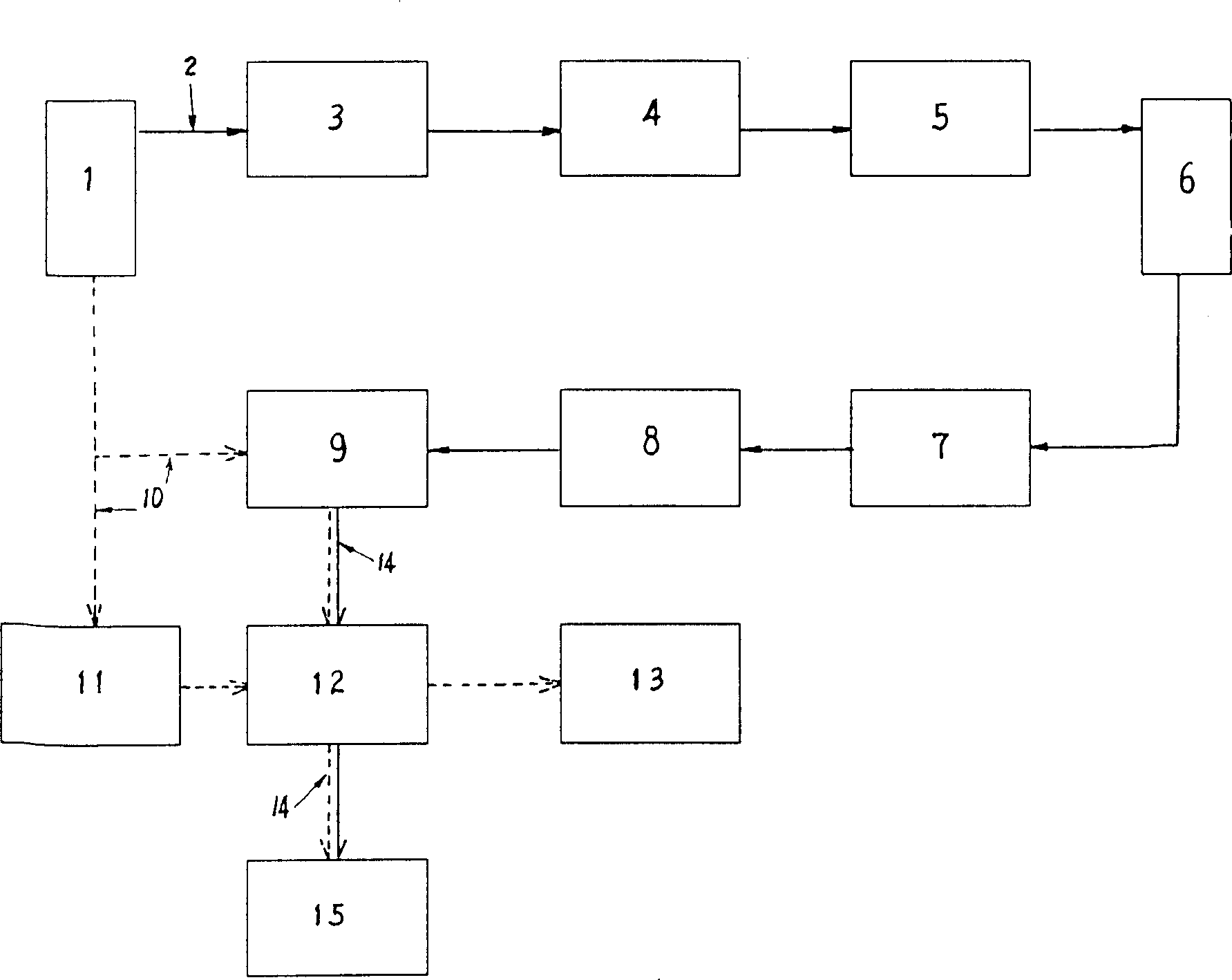

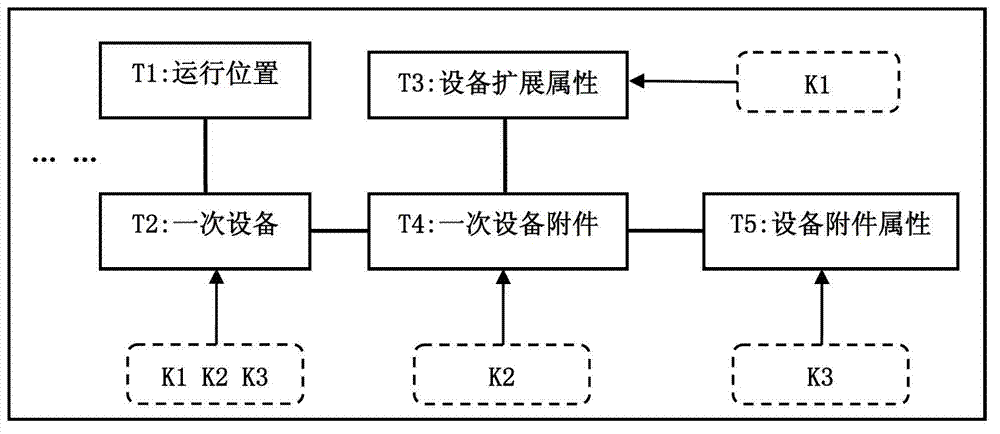

System used for controlling process specifications and full equipment lifecycle in electric power system

InactiveCN104134246AComprehensive operation managementOperation management in placeChecking time patrolsData processing applicationsVideo monitoringTransceiver

The invention discloses a system used for controlling process specifications and full equipment lifecycle in an electric power system. Controlled units in each transformer substation comprise all or part of components as follows: a door unit, a wall perimeter unit, a passageway unit, a firefighting unit, an environment actuation unit, a video monitoring unit, a switch isolator unit, a centrally installed switchgear unit, a transformer unit, a cable trench unit and a mobile hand-held terminal; the controlled units are all connected with a substation-end host in each transformer substation, are connected with an intelligent monitoring platform and a database through an exchanger, and are connected with the mobile terminal outside the substation through a signal transceiver. The equipment can improve routing inspection efficiency, and can perform data retrieve, query and memory to realize a paperless office.

Owner:STATE GRID CORP OF CHINA +1

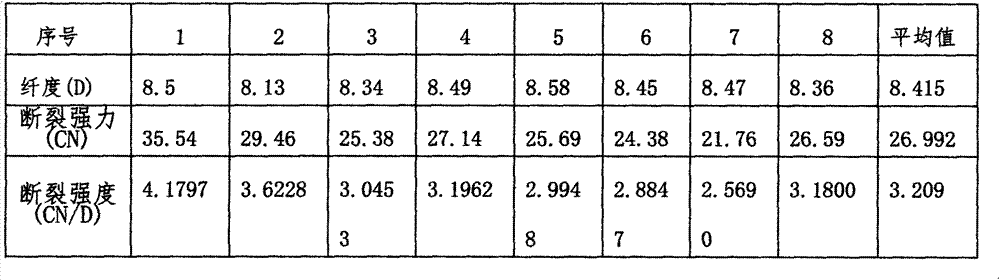

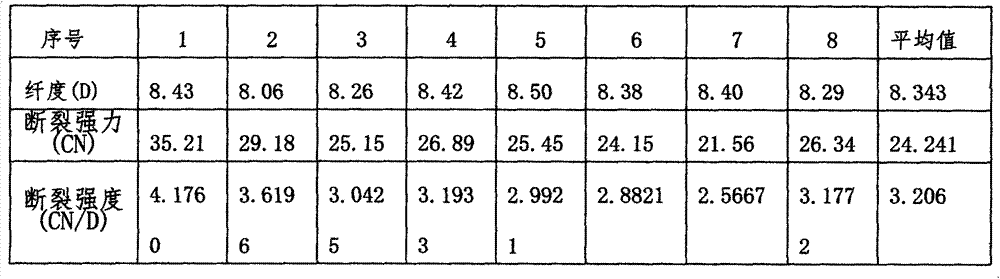

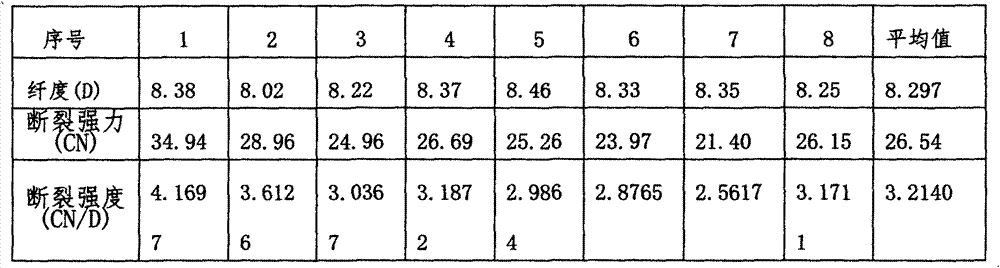

Production process of superfine mulberry silk fiber woven fabric

ActiveCN103243447AIdeal anti-spill effectSimple processWoven fabricsProcess specificationEngineering

The invention discloses a production process of superfine mulberry silk fiber woven fabric. The production process includes that warp and weft in process specification design are 1 / 7D / 9D mulberry silk, loom warp / weft density and plain weaving are determined, tension and hardness of winding and barreling are 1.5-3CN, 22-24, 2-4CN, 24-26 respectively, upper stretching force and upper axial tension of warping are 0.5CN-1.5CN and 15CN-17CN respectively, 8 flat steel healds in male-female matching and a smooth heald method are adopted in a weaving preparation process, porter and reed penetration number are determined, plain weaving tension is 11CN-13CN, heald frame stroke is 9-10cm, and process conditions of whitening and finishing includes that concentration of refining liquid is 3-4g / l, bath ratio is 1:50, and temperature is 95-98 DEG C. The production process is high in productibility, tension of each process is optimized, and processes are mutually matched reasonably, so that warp-direction defects are greatly reduced; and a soaking process is not needed, so that the production process is high in productibility, and the thin-texture woven fabric with the thickness of 2M / M obtained by the production process is high in quality.

Owner:DALI SILK ZHEJIANG

Modified superfine zinc oxide and its prepn

InactiveCN1398923AEffective control of particle sizeGood dispersionPigmenting treatmentZinc oxides/hydroxidesChemical industryDistillation

The present invention belongs to the field of nanometer material producing technology. Modified nanometer and subnanometer class superfine zinc oxide powder is produced with zinc oxide in the ammonia distillation process through adding surface modifier, or superdispersing polymer, or amphoteric structure coupling agent or other modifying solvent, and using the proper modifying process specification and method. The present invention utilizes the space steric effect to control the particles size and obtain the modified superfine zinc oxide with high dispersivity and powerful functions. The modified superfine zinc oxide powder may be used widely in rubber, ceramic, textile and daily-use chemical industries.

Owner:骆天荣

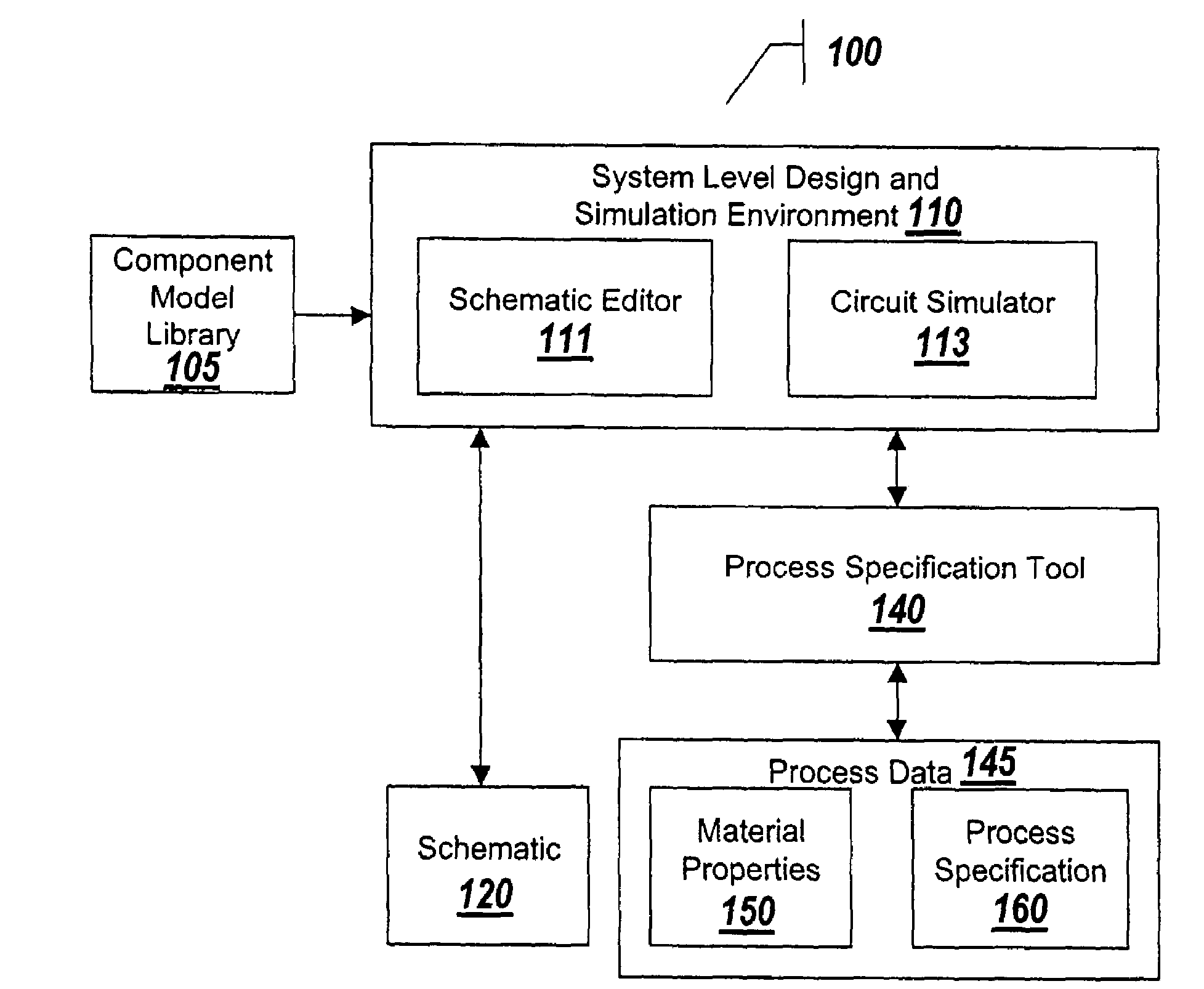

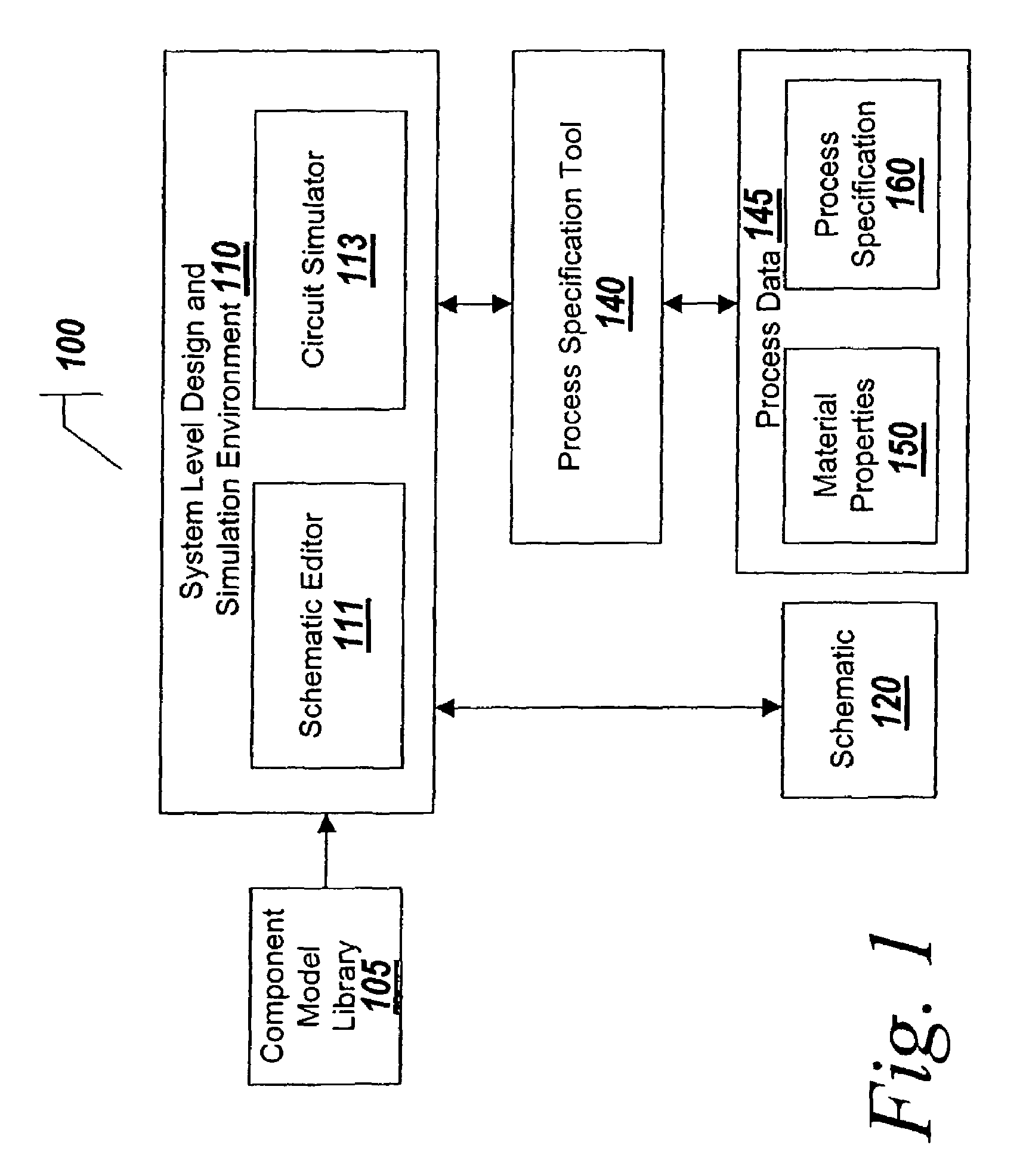

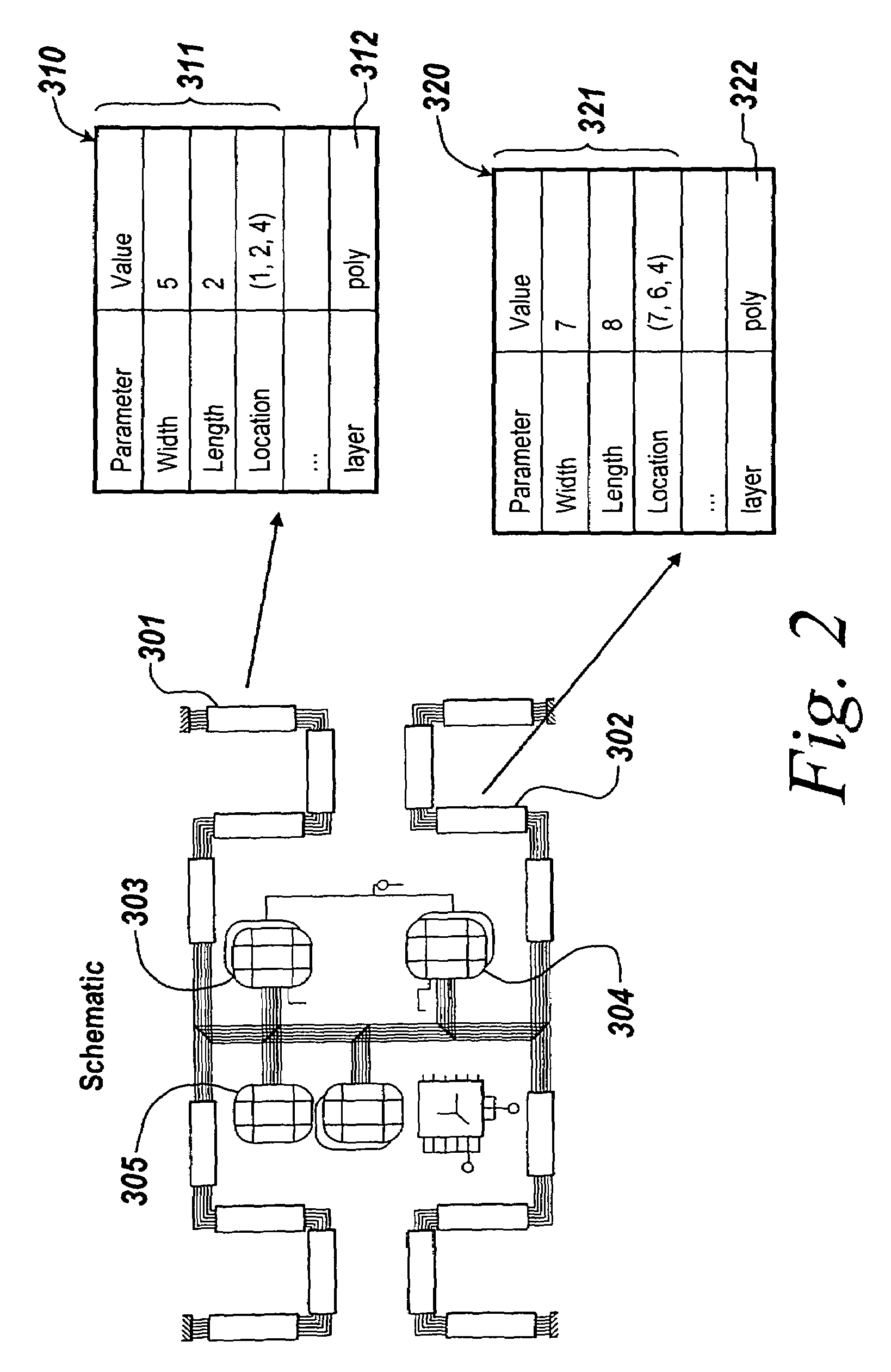

System and method for process-flexible MEMS design and simulation

ActiveUS7272801B1The process is fast and efficientDetecting faulty computer hardwareDesign optimisation/simulationSoftware toolProcess specification

A system-level design and simulation environment utilizing a process specification tool that is programmatically integrated with the system level design and simulation environment thereby enabling the process-flexible design and simulation of Micro Electro-Mechanical Systems (MEMS) devices and other micro-fabricated devices is disclosed. The process specification tool is a software tool for specifying the details of the fabrication process and enables the separation of the process data from the system-level design and simulation environment. The process specification tool retrieves the process data, which may include both the process specification and material properties data. The separation of this process data from the system-level design and simulation environment allows the system-level model to have process-related parameters whose specification is not fixed, but rather is tied by reference to the process data. The tying of components to the process data allows the system-level environment to extract multiple process parameters for each component model instead of requiring duplicate entry of these parameters in each component model, a time-consuming and error prone process. Modifications of the process data are programmatically communicated to the system-level environment. The dynamic response to changes in the process data allows alternative simulations to be run more effectively and quickly than in traditional IC design environments.

Owner:COVENTOR

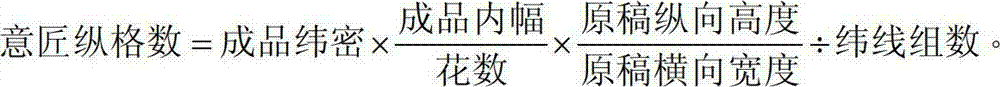

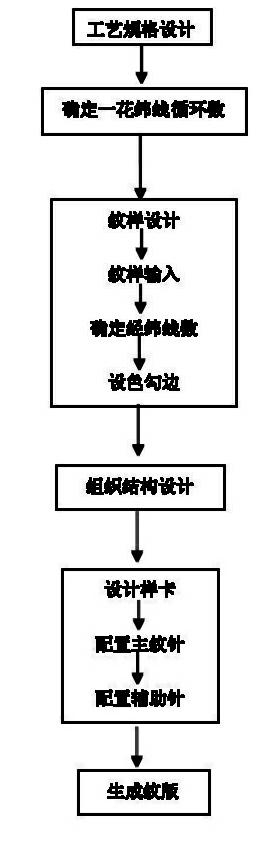

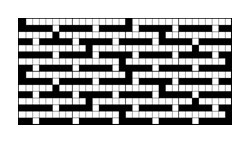

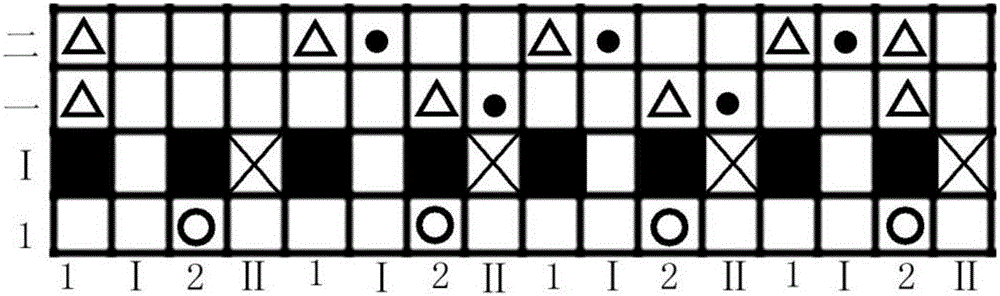

Method for producing dobby-jacquard jointly-shedded multilayer jacquard fabric

The invention relates to a method for producing a dobby-jacquard jointly-shedded multilayer jacquard fabric, which comprises the following steps in sequence: (a) designing the process specifications; (b) designing the artistic conception; (c) designing the organizational structure; (d) generating a pattern card; and (e) weaving by using a machine. In the step (a), a double-warp-shaft weaving machine which comprises an upper warp shaft and a lower warp shaft is used for weaving two or more groups of warp yarn, and the warp yarn on the upper warp shaft and the warp yarn on the lower warp shaft are arrayed in sequence at the same amount on the double-warp-shaft weaving machine. In the step (c), two shedding controlling mechanisms including a jacquard shedding controlling mechanism and a dobby shedding controlling mechanism are used for designing the organizational structure independently and combining in the weaving process. In the step (e), 8 to 16 heald frames are used for controlling the warp yarn of the lower warp shaft in the process of weaving of the double-warp-shaft weaving machine, and the jacquard weave information is inputted into a jacquard head. Due to the adoption of the method, the multilayer jacquard fabric with high warp and weft density, good shading performance and different usual jacquard effects on two sides can be woven.

Owner:浙江兴澳科技有限公司

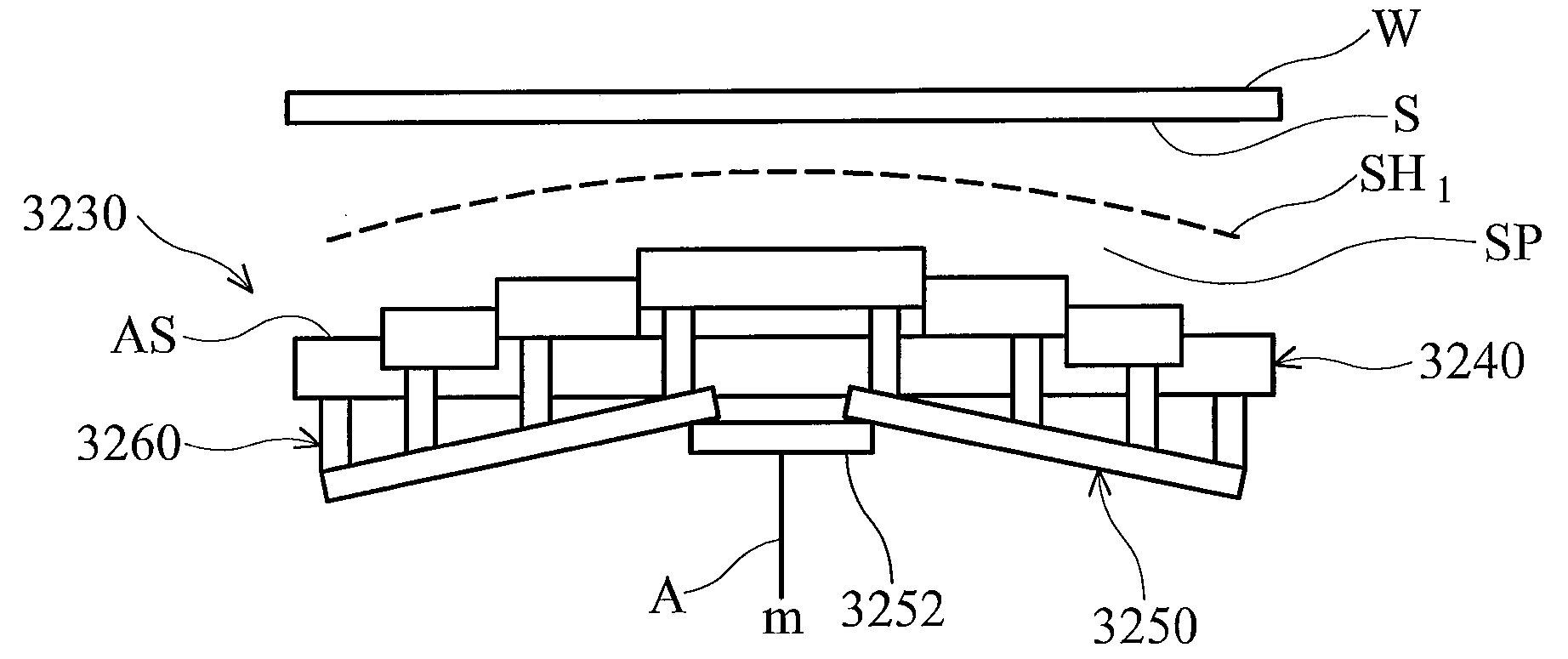

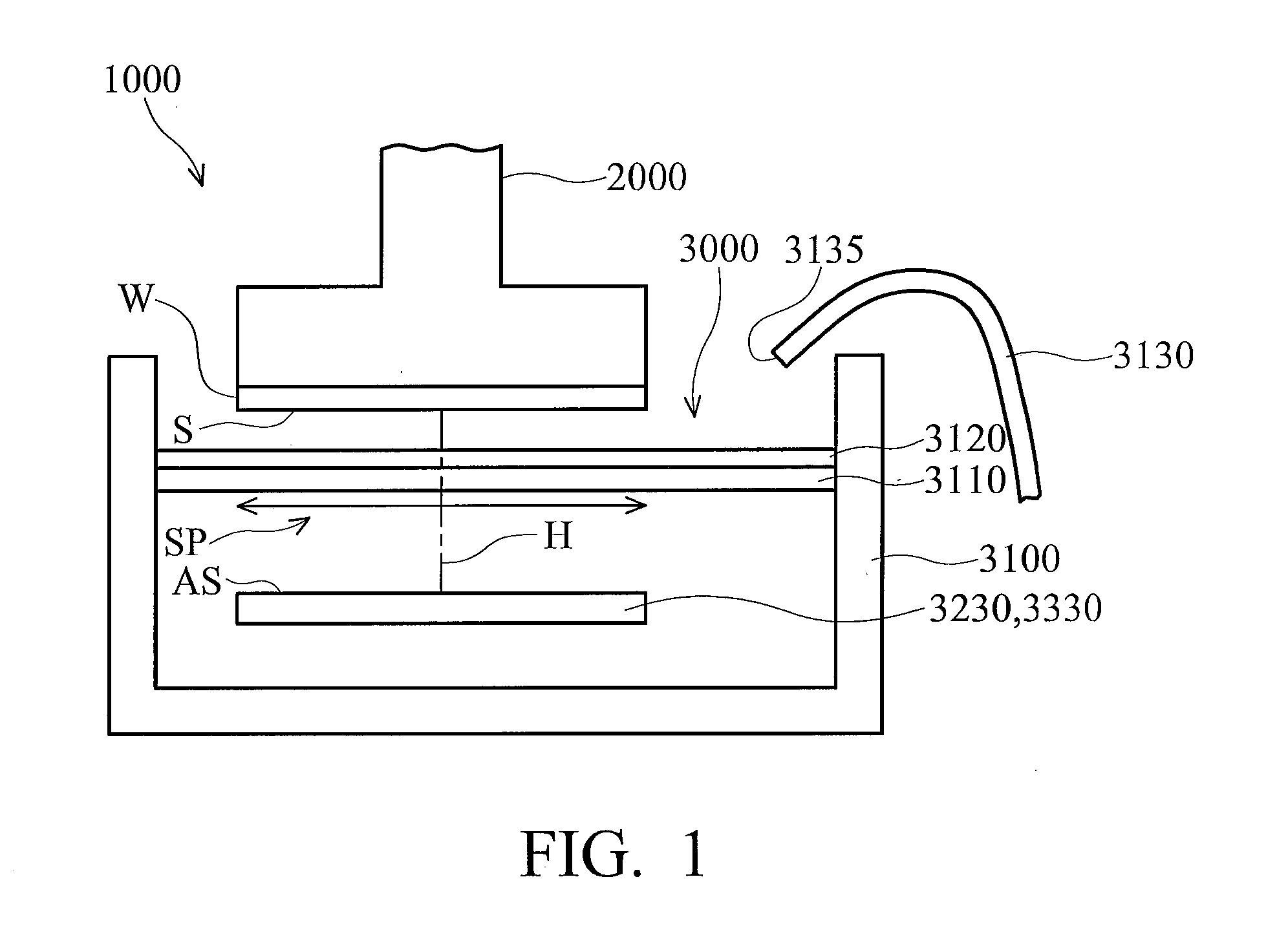

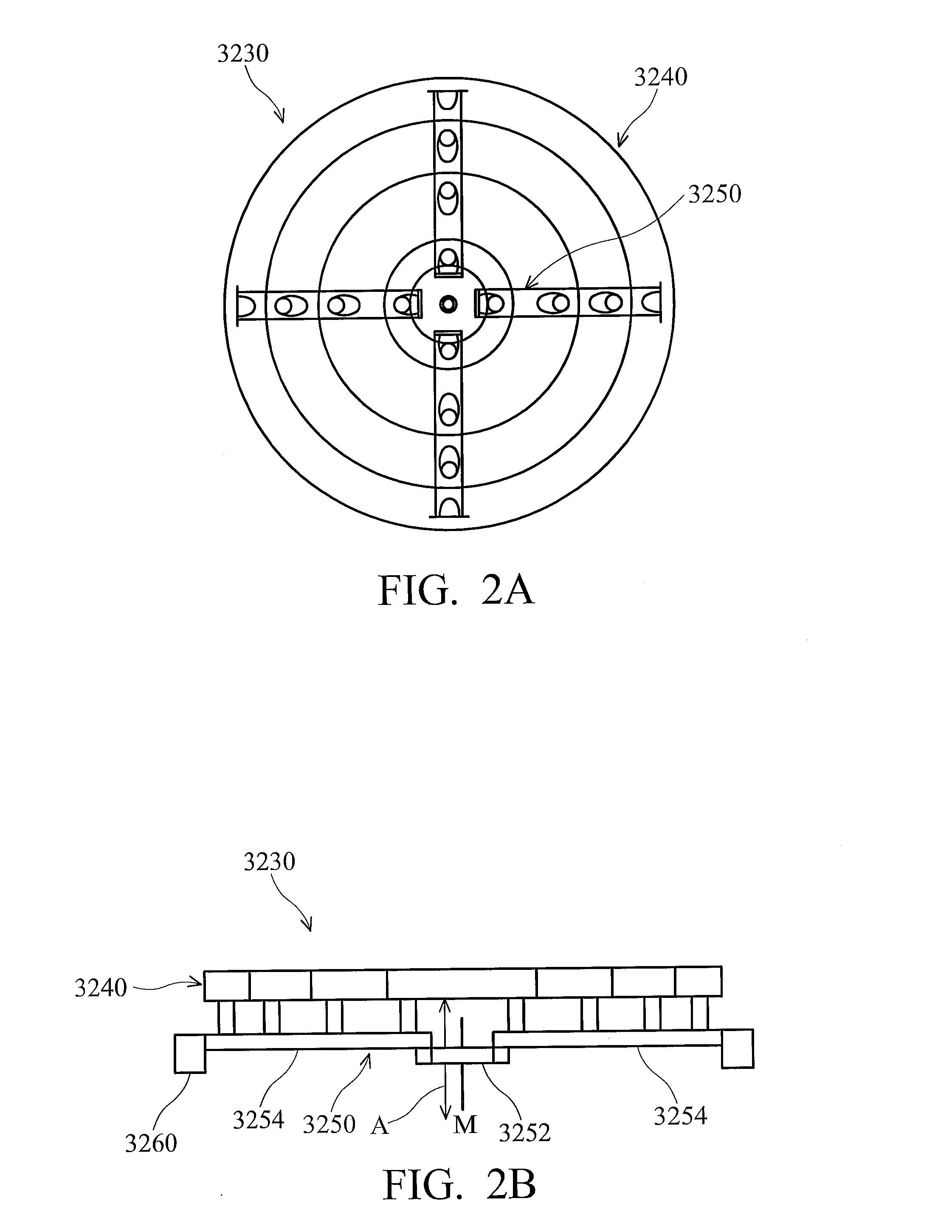

Adjustable anode assembly for a substrate wet processing apparatus

An adjustable anode assembly for a wet processing apparatus to allow selective tuning of the electrical field density distribution within a wet process chemical of the apparatus, which in turn allows the process specification or specifications to be selectively varied across the process surface of a wafer when processed by the apparatus. The adjustable anode assembly includes an anode which may be divided into several plates, at least one of which is capable of being moved from a first plane to at least a second plane.

Owner:TAIWAN SEMICON MFG CO LTD

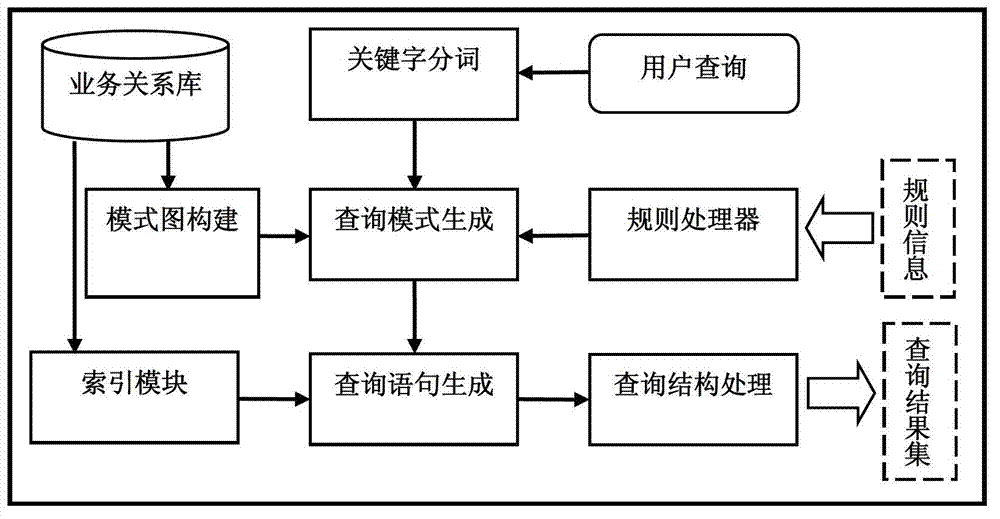

Keyword searching method facing to relational database of power production management system

ActiveCN102819600ANarrow down the search spaceImplement query mode extensionsResourcesSpecial data processing applicationsProcess specificationData query

The invention provides a keyword searching method facing to a relationship database of a power production management system. The keyword searching method comprises the following steps of: positioning a relational table according to keywords; specifying the query process according to a service dictionary; taking the keywords as central query data; expanding a query mode according to a service rule; and returning the query result. According to the keyword searching method, different relational tables of a service database can be effectively correlated, the global data query is realized by combining service knowledge with the process specification and the complexity of service data query is reduced, so that users can acquire the required search results quickly and conveniently.

Owner:STATE GRID CORP OF CHINA +4

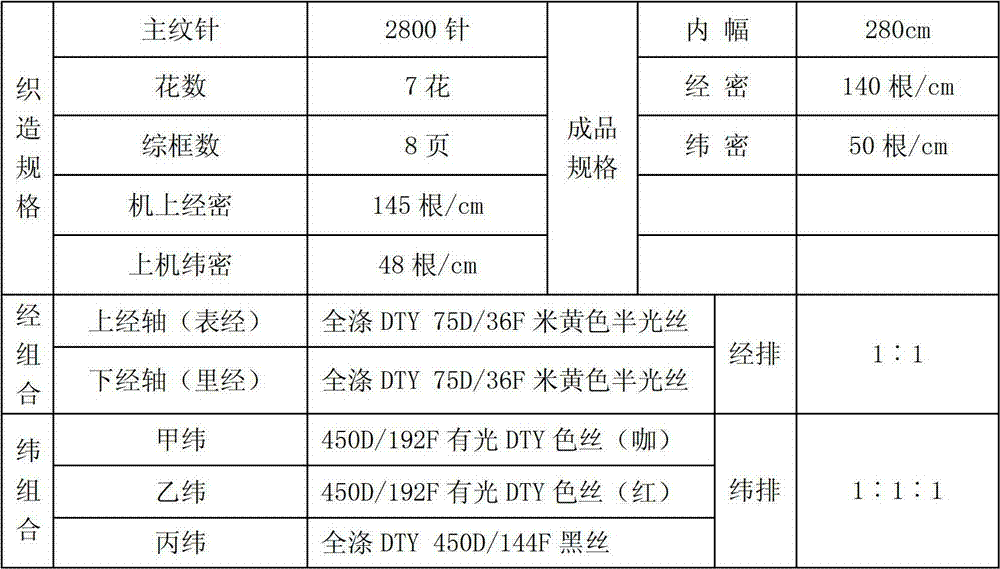

Method for manufacturing pattern card of jacquard fabric with straight stitching effect

ActiveCN102181984AGood effectThe effect is: the invention provides a computerized straight needle embroidery machine with obvious effect.Pattern cardsYarnProcess specification

The invention discloses a method for manufacturing a pattern card of a jacquard fabric with a straight stitching effect, which comprises the following process steps of: (1) by a process specification design, determining small sample parameters and calculating to obtain a small sample circulating filling yarn number; (2) designing the pattern card according to the small sample parameters and the small sample circulating filling yarn number; (3) then manufacturing the pattern card by a tissue structure design; and (4) and generating the pattern card. The pattern card manufactured by the method disclosed by the invention has the characteristics of obvious effect, low requirement on equipment and short production flow when being applied to fabric weaving.

Owner:ZHEJIANG SCI-TECH UNIV

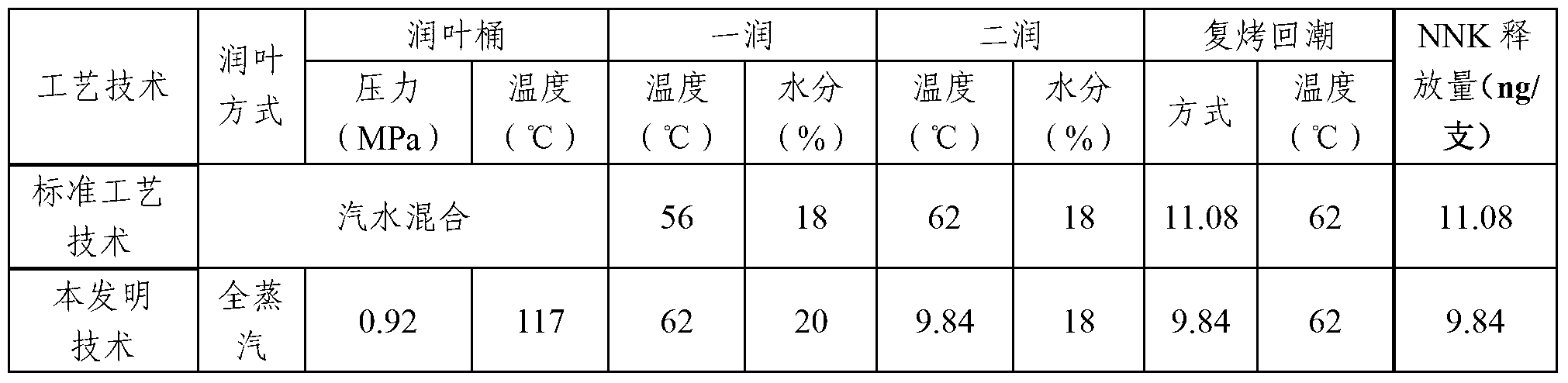

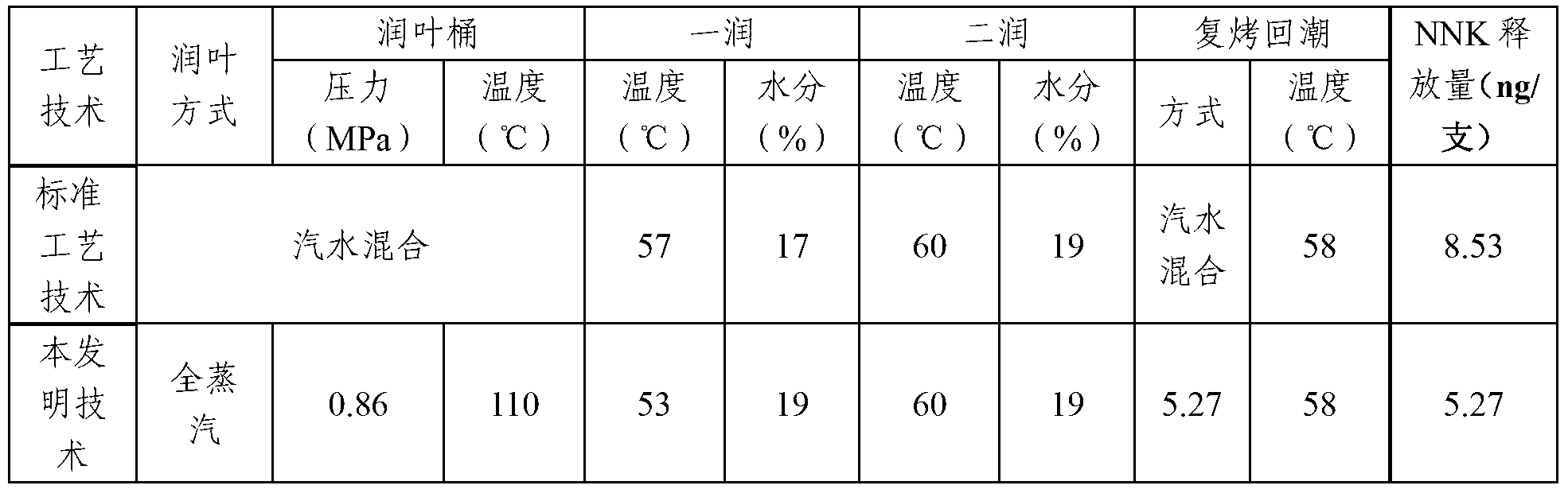

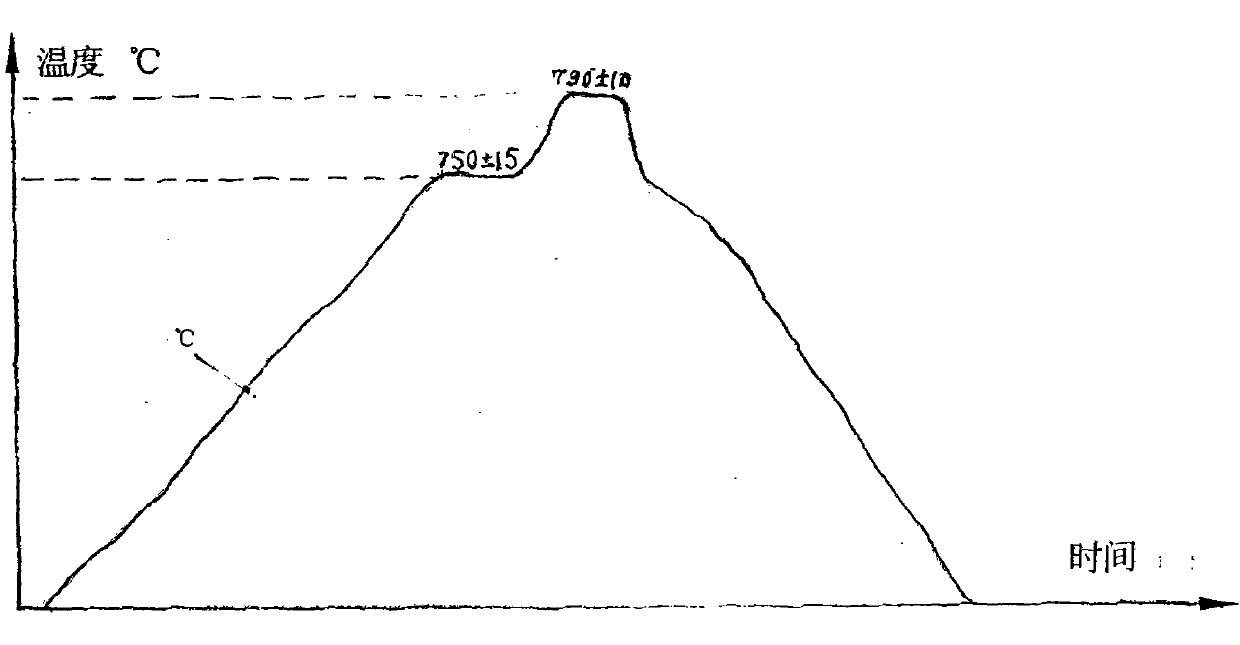

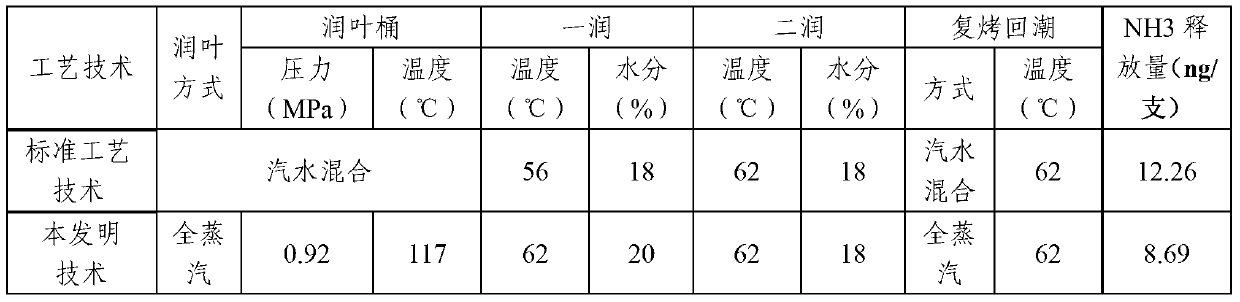

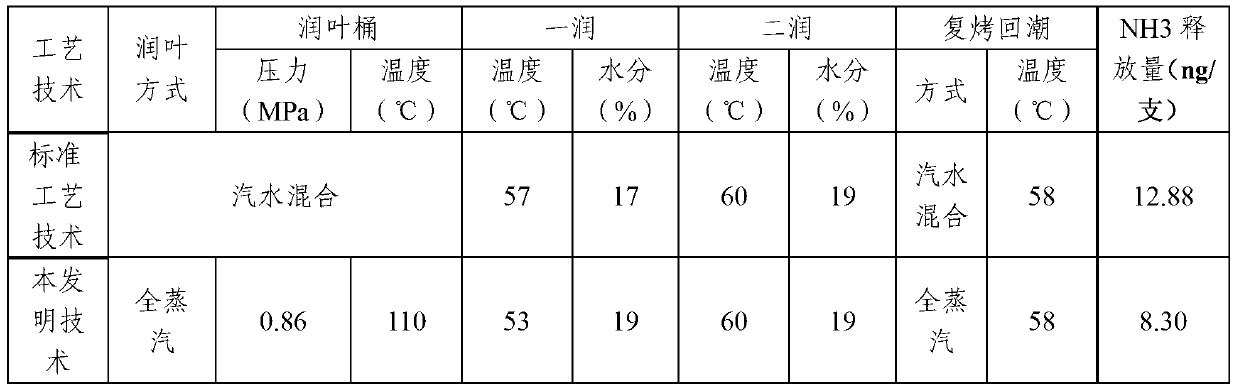

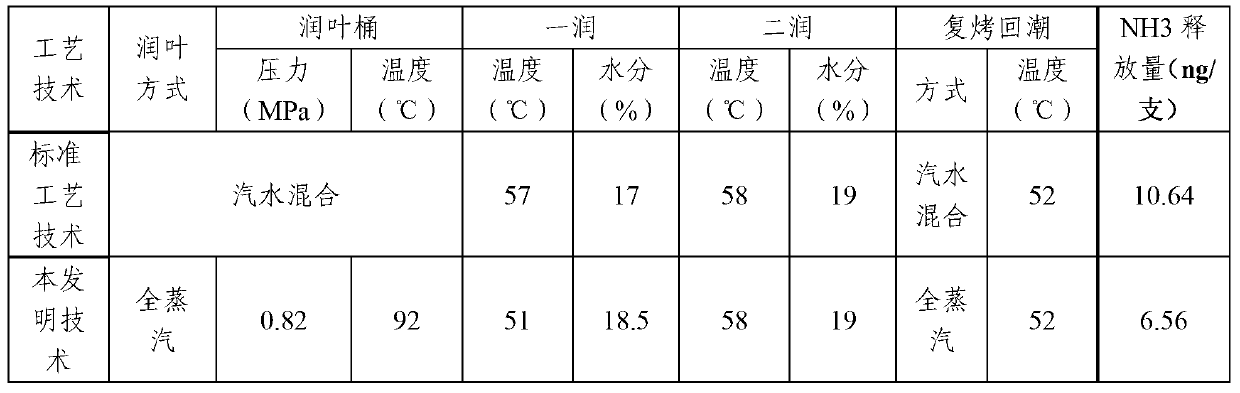

Leaf tobacco processing method capable of selectively reducing release amount of NNK (Nitrosamine) in cigarette smoke

InactiveCN103238915AReduce releaseThe method is feasible and practicalTobacco preparationProcess specificationWet steam

The invention discloses a leaf tobacco processing method capable of selectively reducing a release amount of NNK (Nitrosamine) in cigarette smoke. The leaf tobacco processing method comprises the steps of: firstly, preheating wet leaf barrel, and charging when circulatory hot wind is at 80 DEG C to 120 DEG C; then adjusting a hot steam valve and a wet steam valve based on the positions of the processed leaf tobacco, and respectively controlling a temperature and a moisture content of the wet leaf tobacco; and finally, processing by adopting full steam at a temperature which is accordance with the technical requirements of YC / T146-2010 Leaf Tobacco Threshing and Redrying Process Specification. The method has obvious effects of selectively reducing the release amount of the NNK in the cigarette smoke, achieves the reduction amplitude of 11.20-38.21%, has good repeatability, is applicable to the practical threshing and redrying production, expands the leaf tobacco processing technology of reducing harmful components in the cigarette smoke, and has relatively good practical significance and reference function for harm reduction and tar reduction in the industry.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

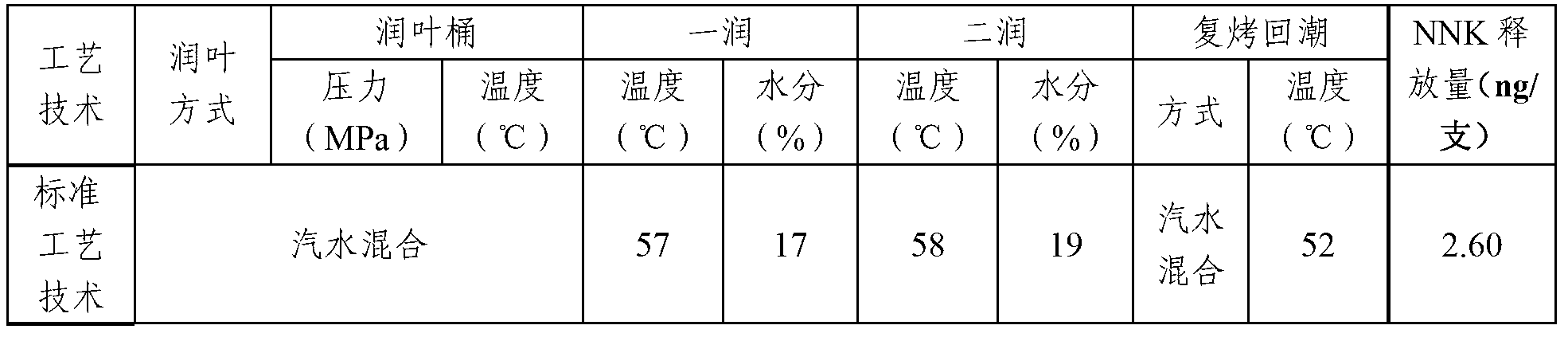

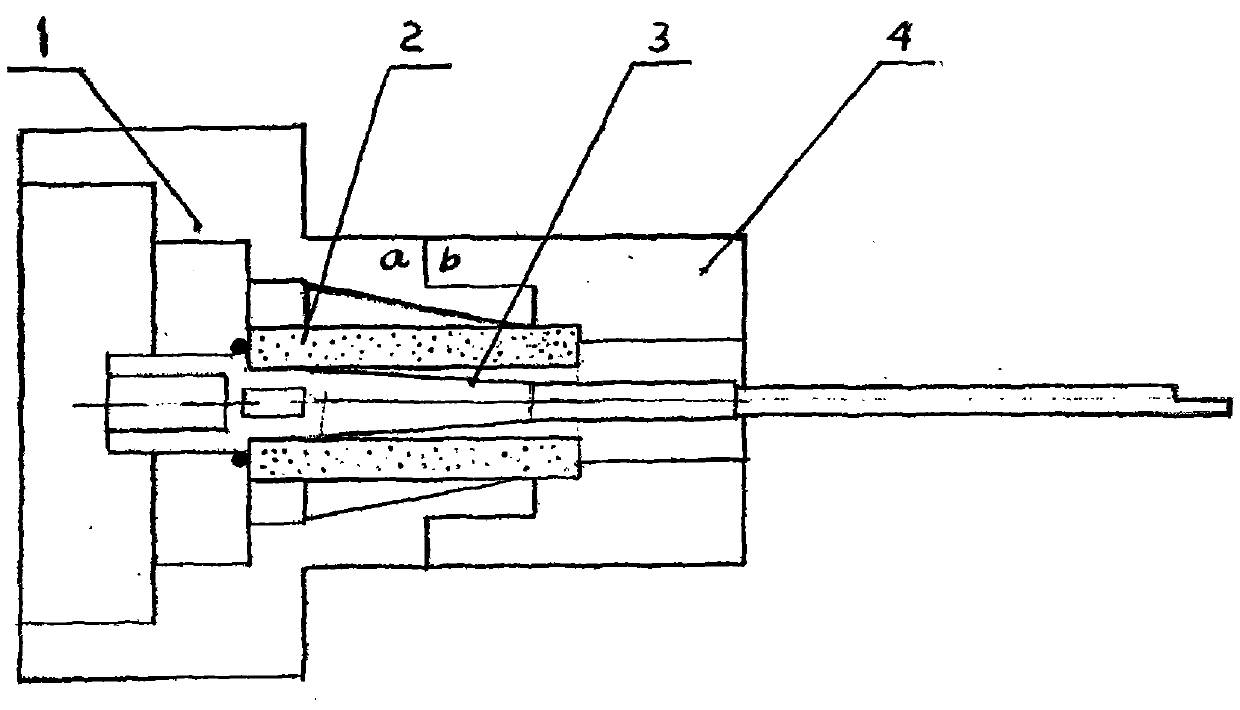

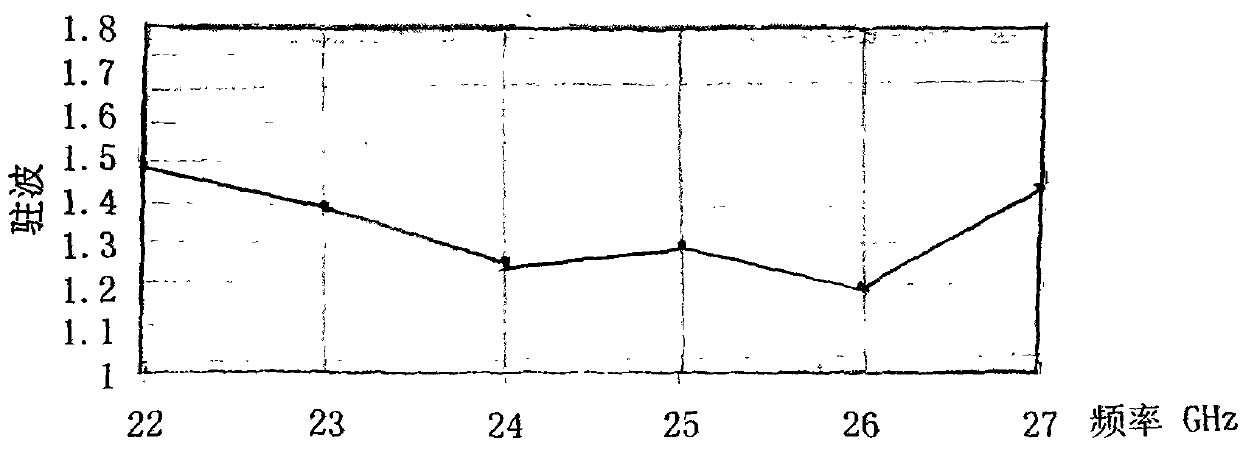

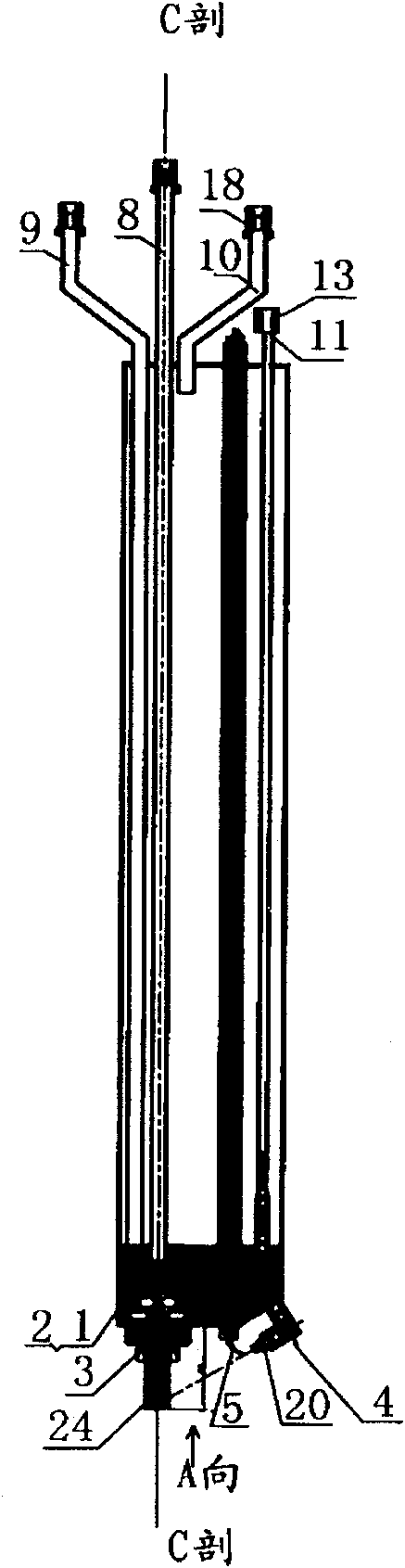

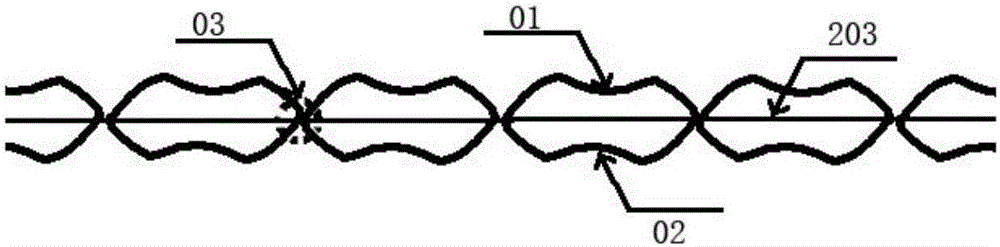

Millimeter wave band traveling wave tube output window and manufacturing method thereof

InactiveCN101770920AGood vacuum air tightnessTransit-tube coupling devicesCold cathode manufactureElectrical conductorEngineering

The invention discloses a millimeter wave band traveling wave tube output window and a manufacturing method thereof, belonging to the field of microwave vacuum electron devices. The output window comprises a core bar-shaped inner conductor and cylindrical dielectric ceramic components arranged at the periphery and connected with each other by welding, wherein the components are then welded with outermost cylindrical outer conductors. The manufacturing method is as follows: utilizing electromagnetic simulation software to carry out stimulation experiment adjustment on the output window; selecting the inner conductor, the dielectric ceramics and the outer conductors; plating nickel on the inner conductor and the outer conductors; metalizing the alumina ceramics; assembling the inner conductor, the ceramics and the outer conductors on a corresponding welding jig and carrying out welding in a hydrogen furnace according to the corresponding process specification; detecting the vacuum air tightness of the output window; and testing the standing-wave ratio of the output window, wherein the requirement that the standing-wave ratio is less than 1.5 is satisfied in the working band. The structure of the output window has good vacuum air tightness, and the output window can bear direct current power transmission of 80W and can be widely used for the millimeter wave band low-frequency spiral traveling wave tubes.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

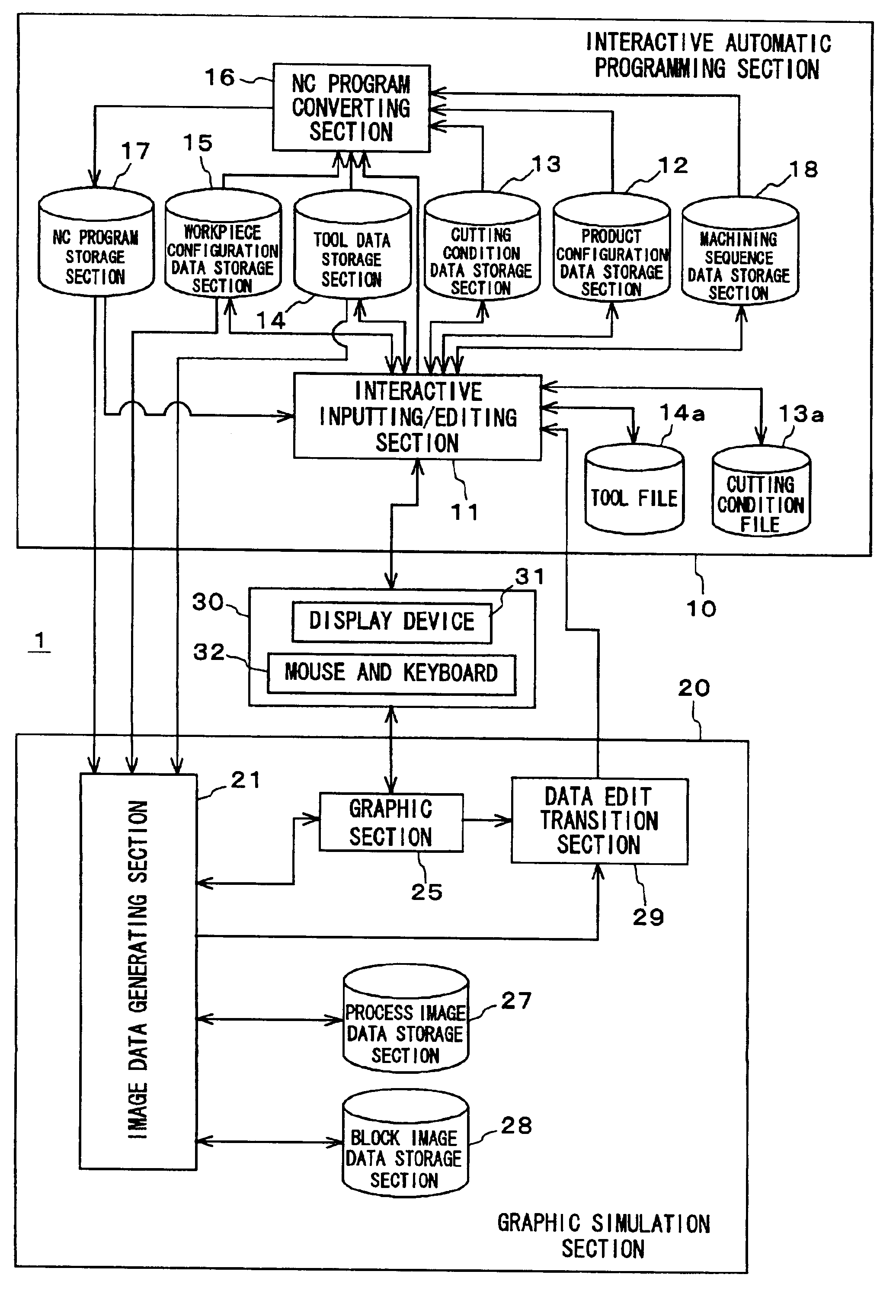

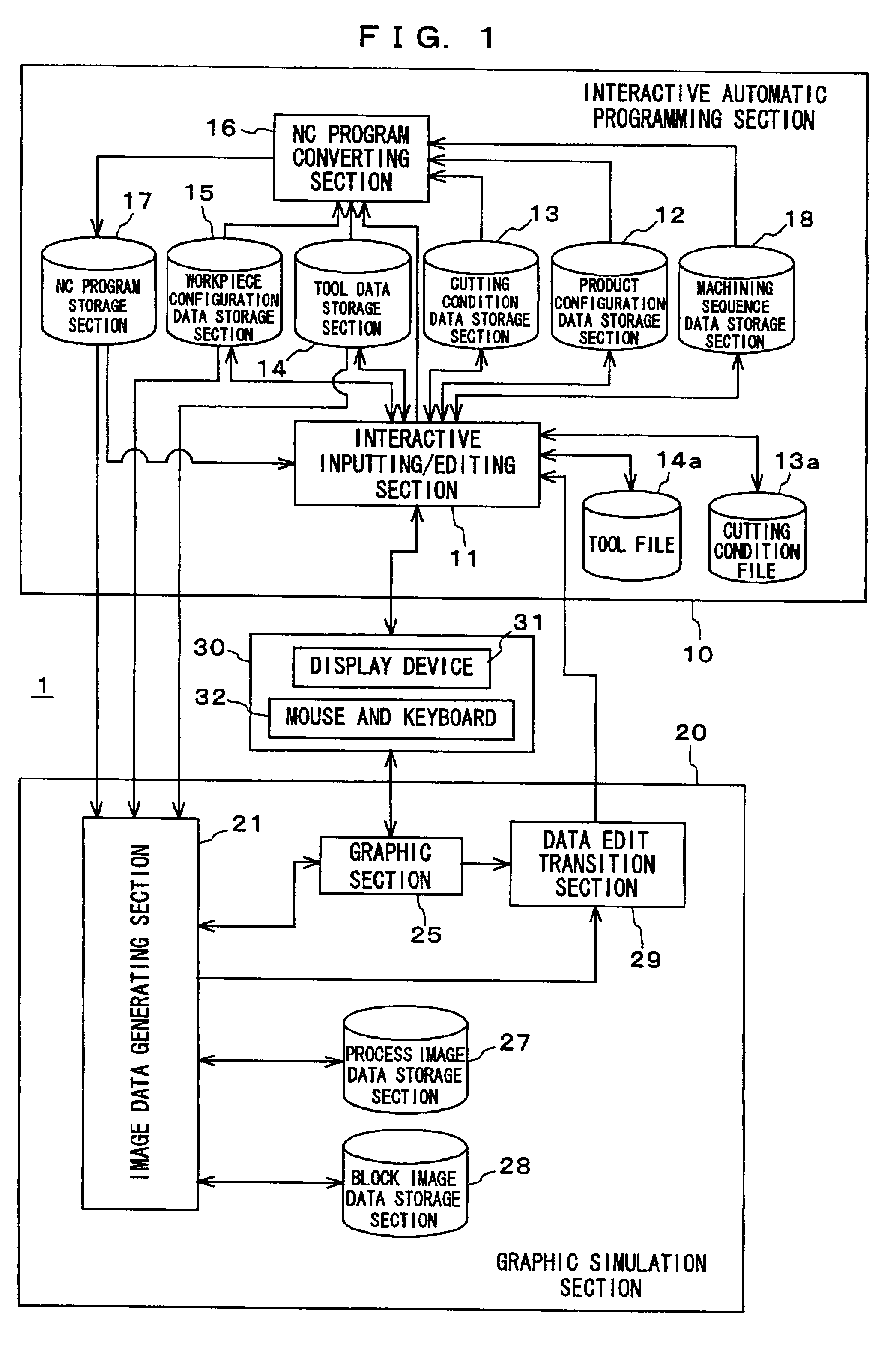

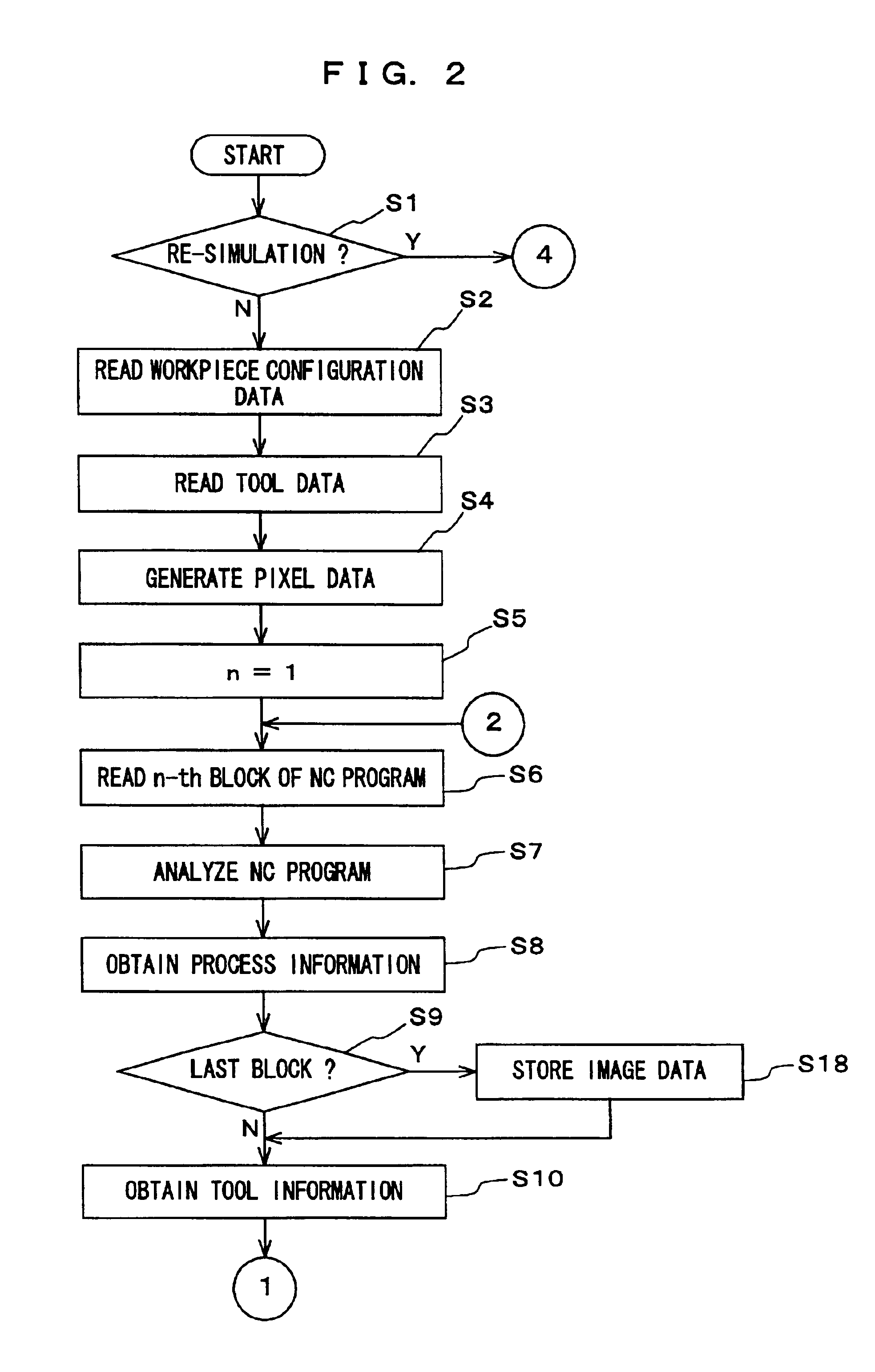

Automatic programming and simulation apparatus

InactiveUS6889114B2Changed very speedilyAutomatic detectionAutomatic control devicesComputer controlProcess specificationDisplay device

The present invention relates to an automatic programming and simulation apparatus which can easily modify an automatically created NC program and start a machining simulation from a modified portion of the NC program. The automatic programming and simulation apparatus comprises: A simulation section (20) adapted to receive a coordinate position linputted on a screen image displayed on the display device (31), to detect process specification related to a pixel corresponding to the inputted coordinate position, to transmit the detected process specification information to an interactive inputting / editing section (11), and to cause the interactive inputting / editing section to perform a data editing operation for a machining process specified by the process specification information received by the interactive inputting / editing section.

Owner:DMG MORI CO LTD +1

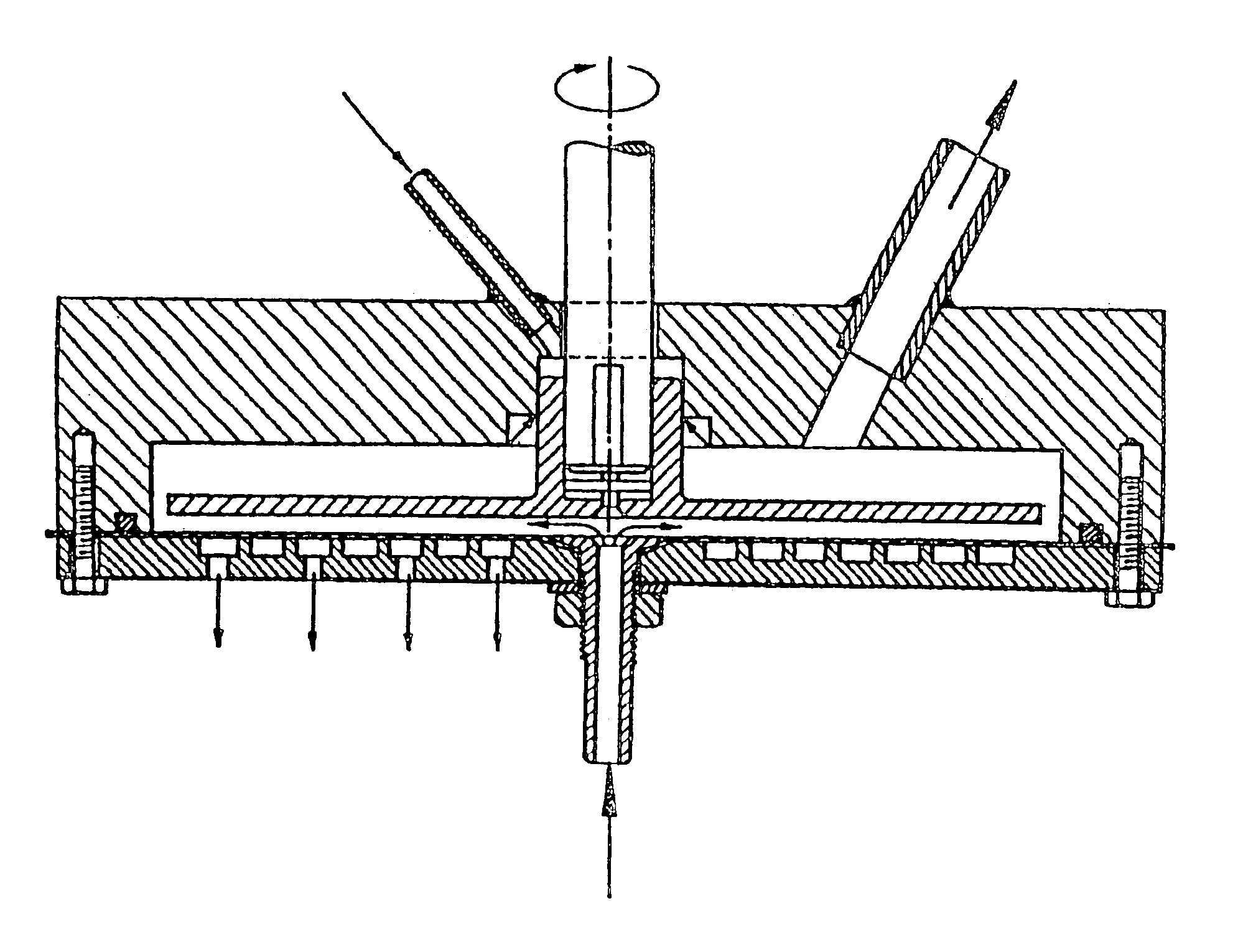

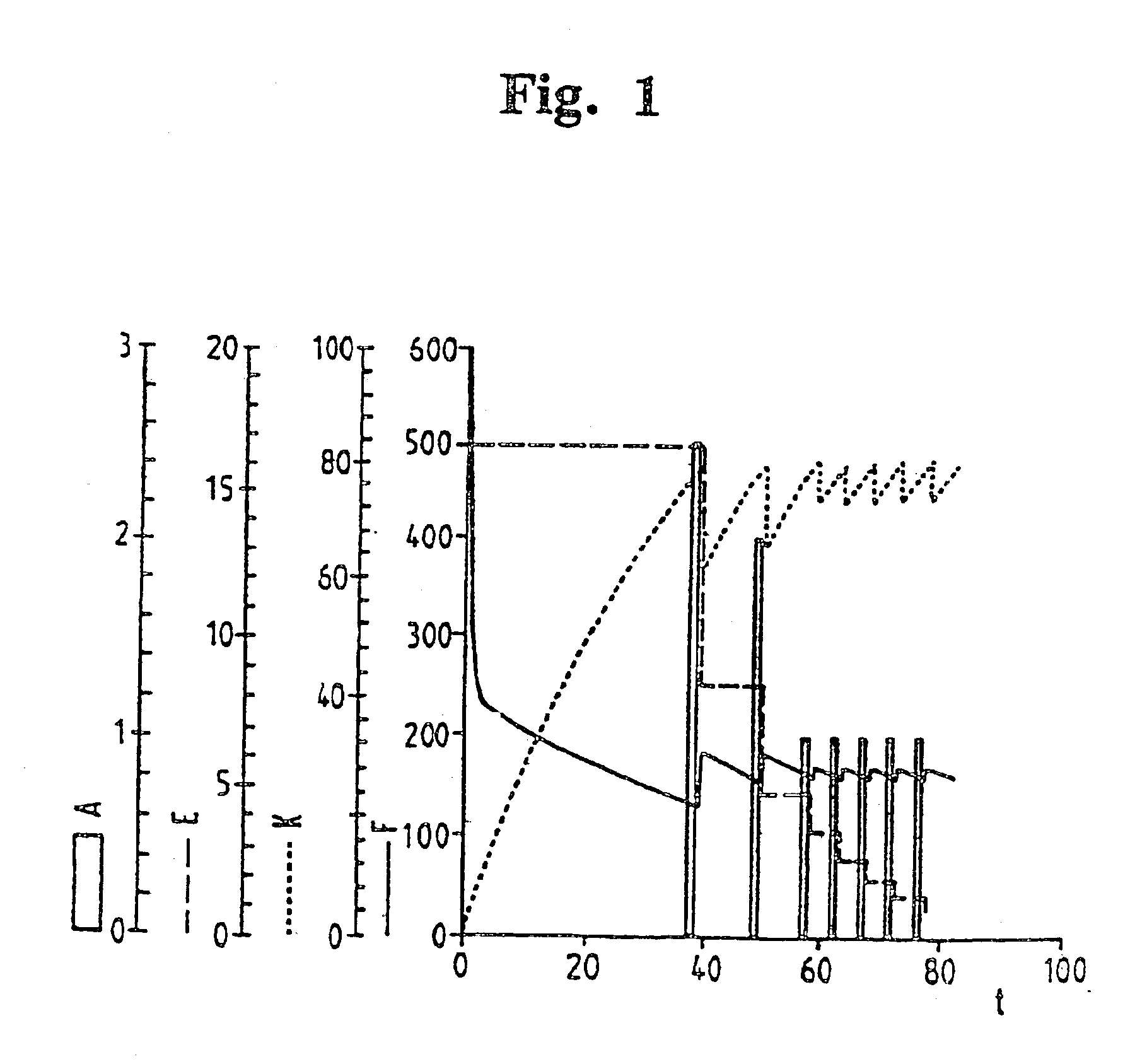

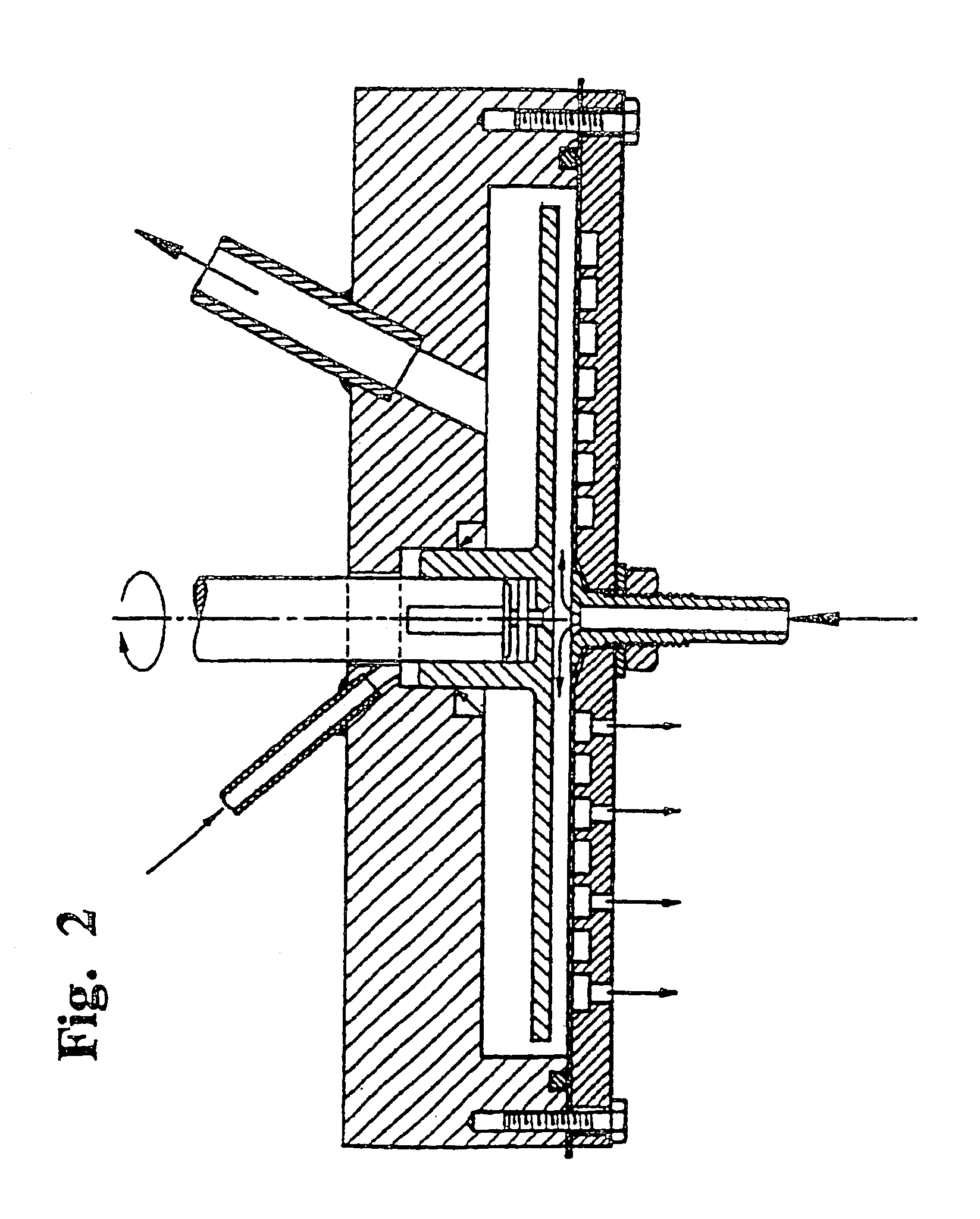

Mashing process

InactiveUS6916425B2High yieldNew controlSemi-permeable membranesWort preparationProcess specificationCross-flow filtration

Specification discloses the use of a dynamic cross-flow filtration system for the filtration of mash. Also disclosed are a mashing process, wherein mash is filtered and wort is obtained, and a process for the preparation of beer, as well as apparatuses and devices for performing one or more of these process.

Owner:PALL CORP

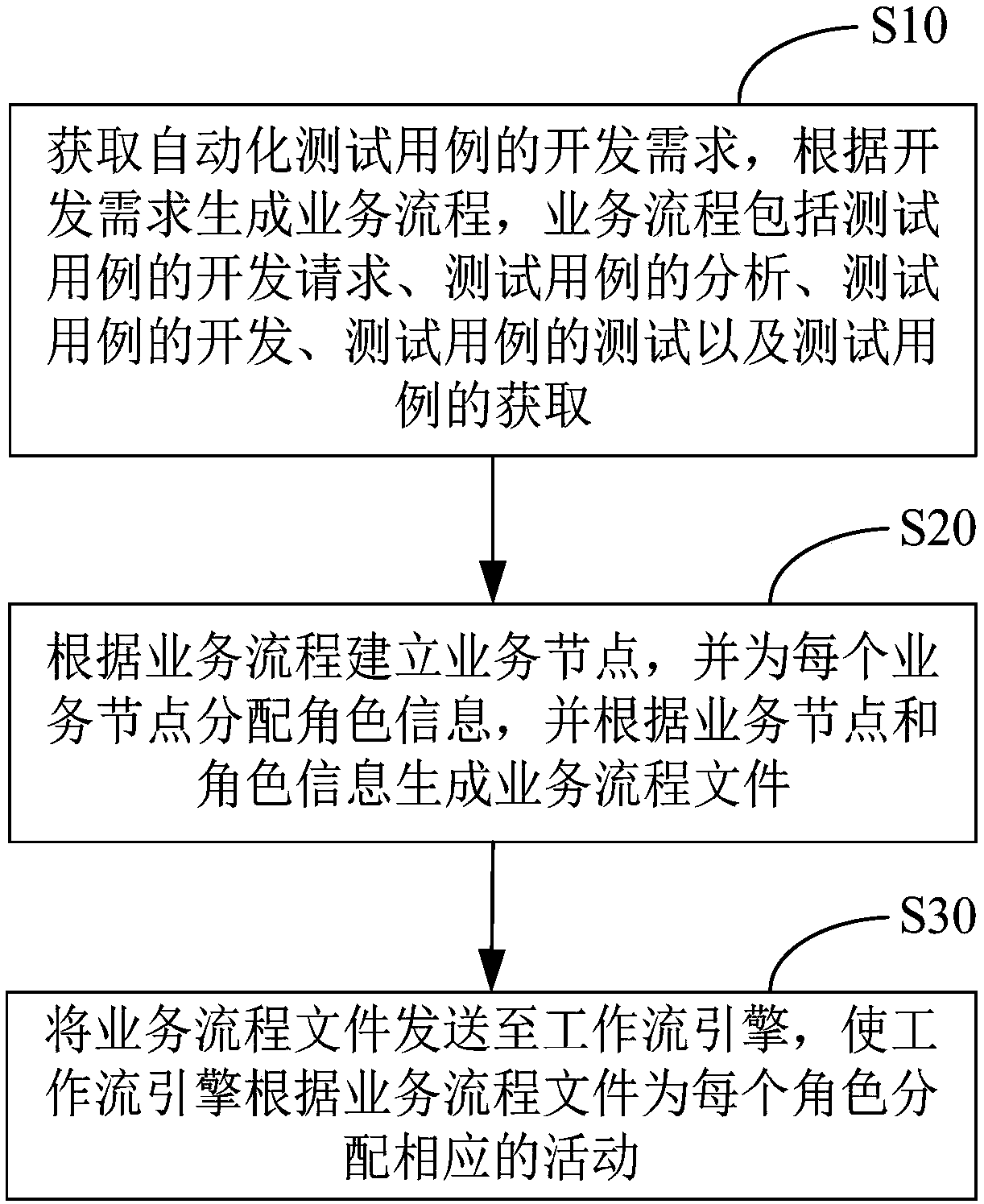

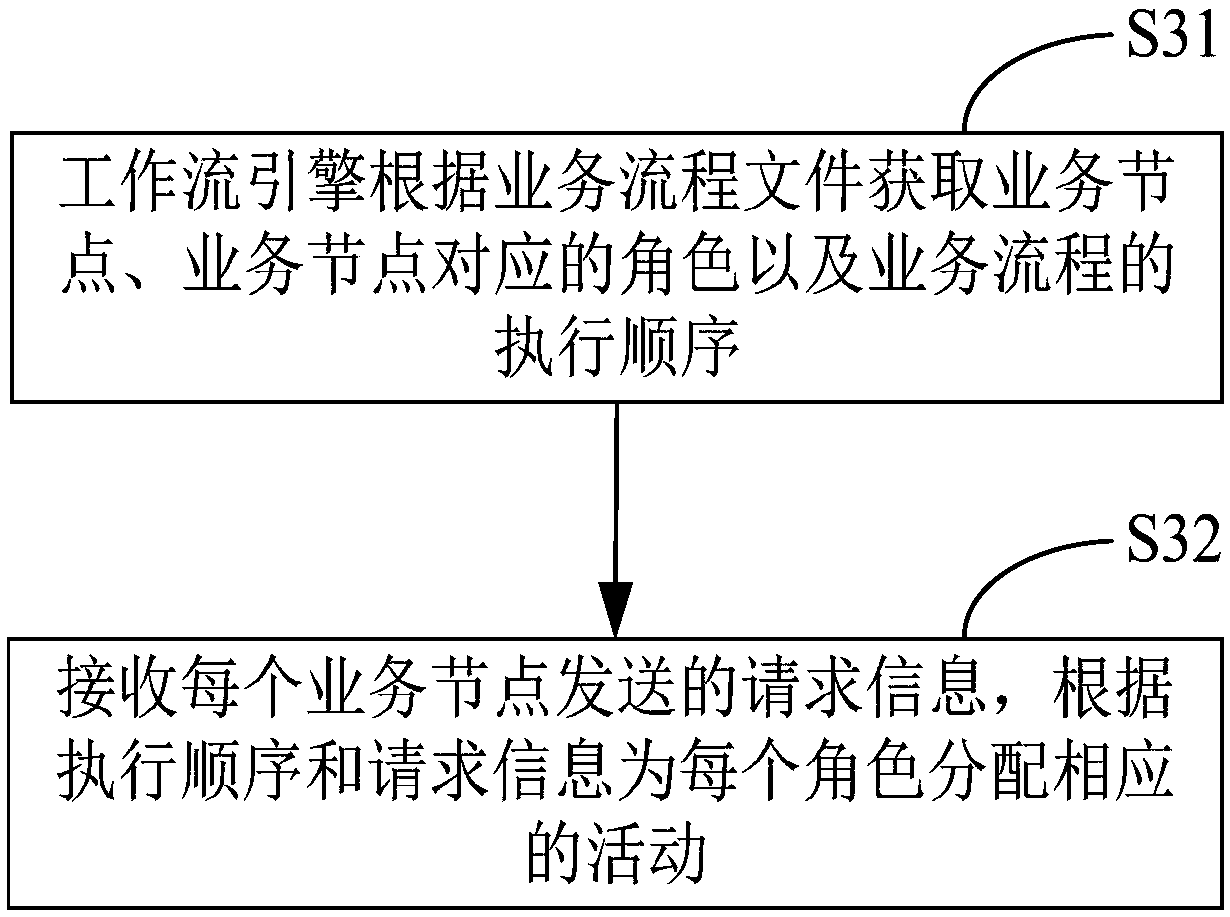

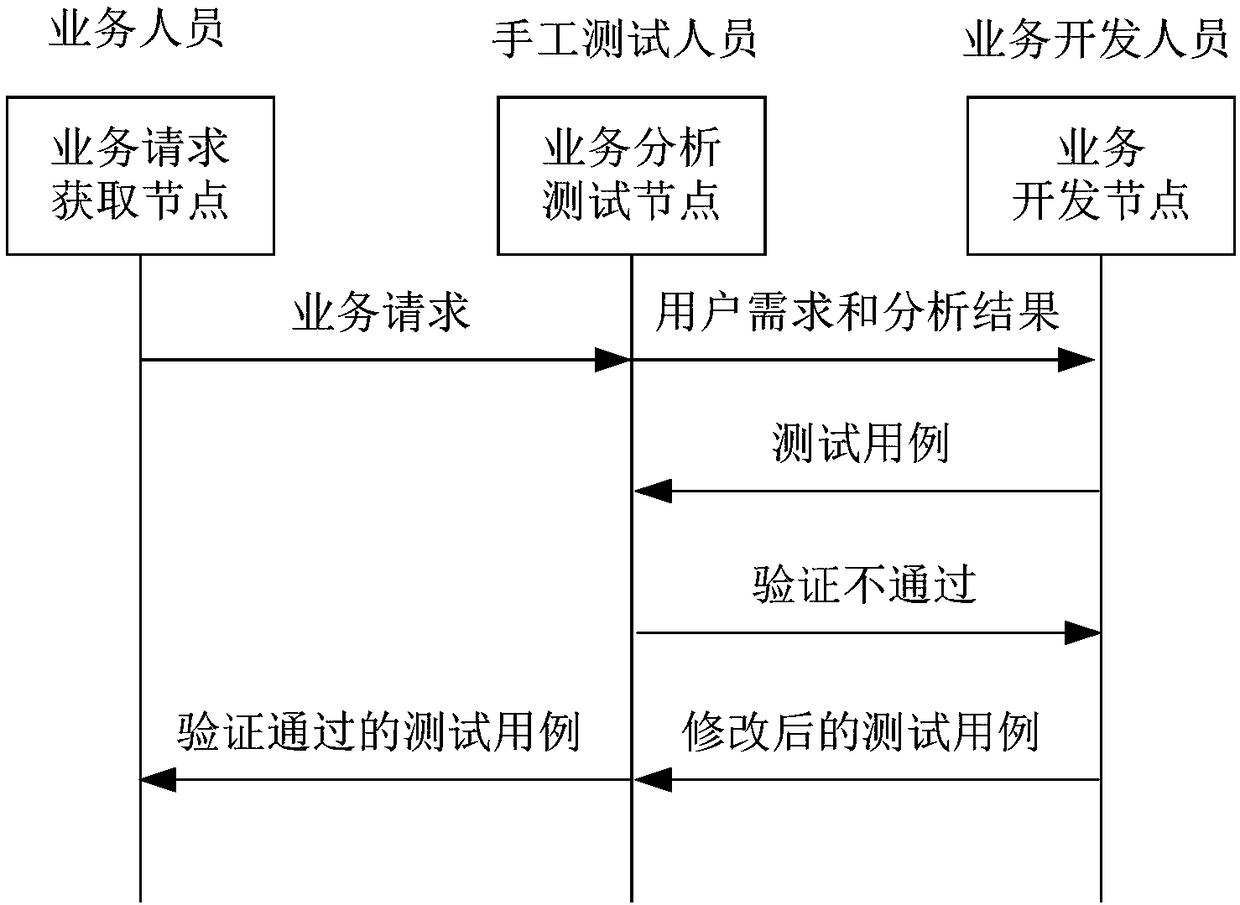

Development role creation method and apparatus for test case, device and storage medium

ActiveCN108255707ASimplify business processesFacilitate communicationSoftware testing/debuggingResourcesProcess specificationCommunication effects

The invention relates to the technical field of automation testing, and provides a development role creation method and apparatus for a test case, a device and a storage medium. The development role creation method for the test case comprises the steps of obtaining development demands of the automation test case, and according to the development demands, generating business processes, wherein thebusiness processes include test case development requesting, test case analysis, test case development, test case testing and test case obtaining; according to the business processes, establishing business nodes, allocating role information for the business nodes, and according to the business nodes and the role information, generating business process files; and sending the business process filesto a working flow engine, thereby enabling the working flow engine to allocate corresponding activities for roles according to the business process files. Through the development role creation of thetest case, the business processes are standardized; the circulation of the business processes is not influenced by time and communication capabilities of the development roles; and the communicationeffect and the working efficiency are improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

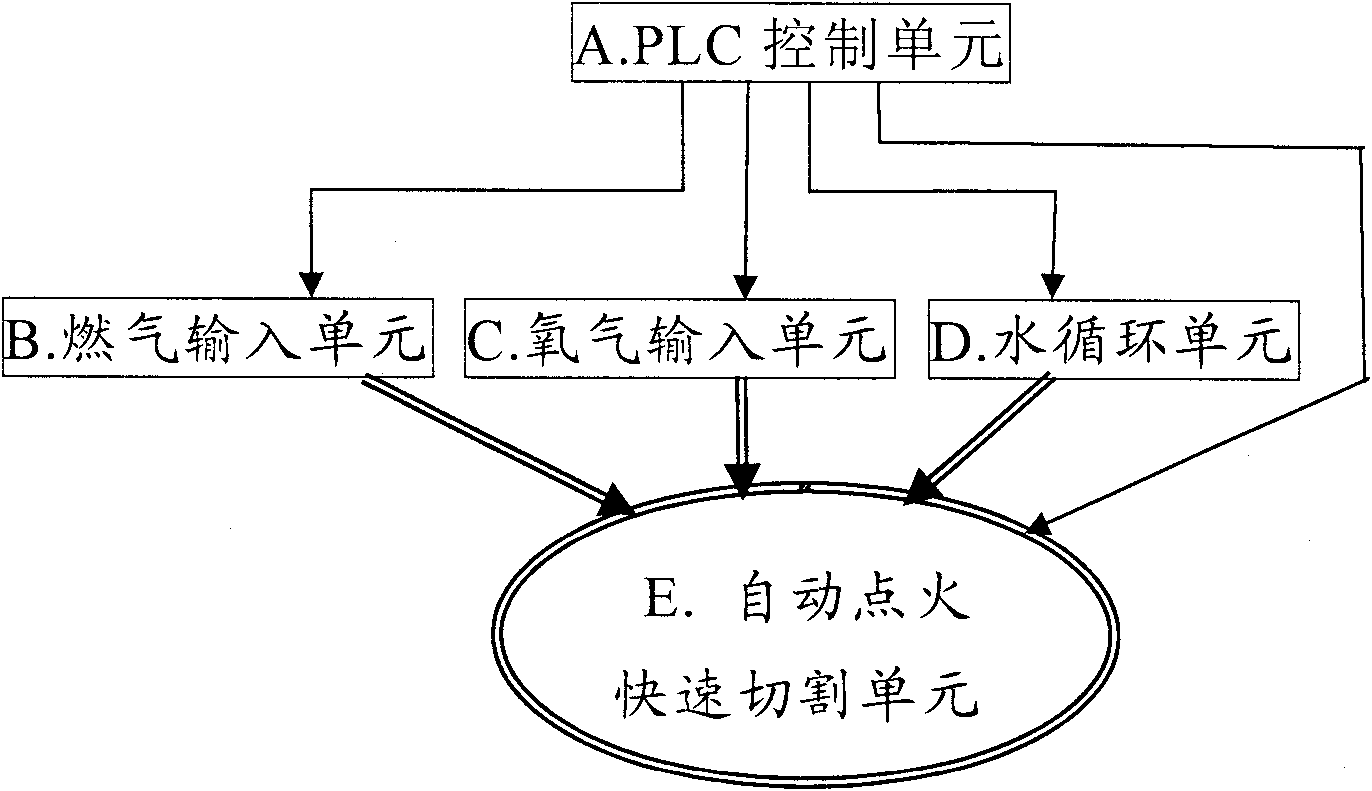

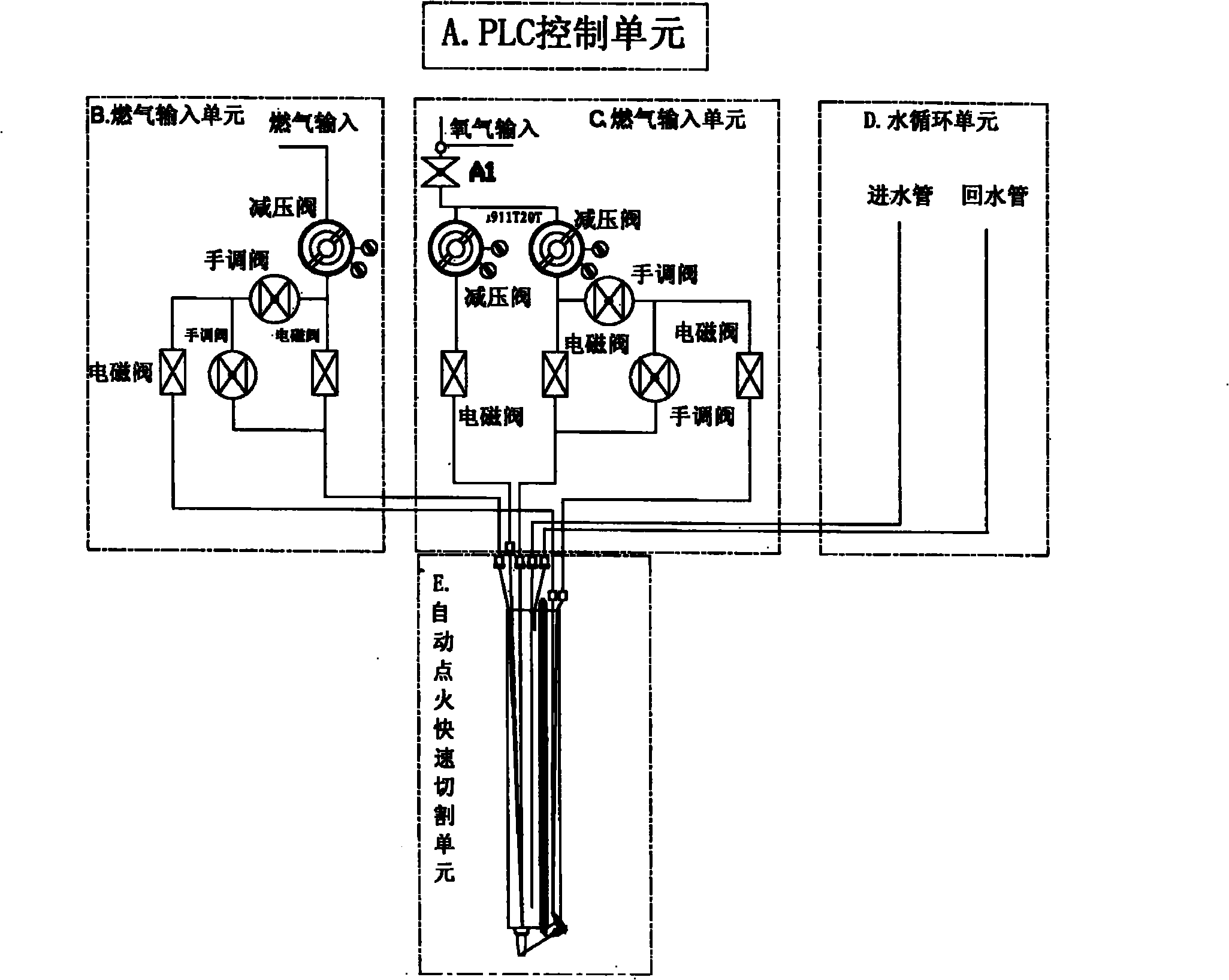

Autoignition dual ring fast cutting torch

InactiveCN101839485AReduce consumptionFast cutting speedGaseous fuel burnerChemical industryMetallic materials

The invention relates to an autoignition dual ring fast cutting torch, which consists of a PLC control unit A, a fuel gas input unit B, an oxygen input unit C, a water circulation unit D, and an autoignition fast cutting unit E. The cutting torch has the advantages of igniting and cutting during a working stroke, stopping gas and quenching during a noncutting stroke and the like because of the functions of autoignition and water circulation cooling. The autoignition dual ring fast cutting torch further reduces consumption of fuel gas and oxygen and greatly improves the service life of cutting heads; and cutting nozzles can be replaced during the noncutting stroke namely quenching so that the cutting torch has high safety. The technical performance of the cutting torch can exceed the national standard, industry standard and process specification requirements of users. The autoignition dual ring fast cutting torch has over 98 percent of cut-to-length billet yield, saves 35 to 45 percent of cutting oxygen and 55 to 75 percent of fuel gas, and reduces slits from 8 to 10 mm to 2 to 2.5 mm. The autoignition dual ring fast cutting torch is ideal equipment for cutting billets of steel rolling lines of continuous casting machines of steel mills to length and has better popularization and application value. The autoignition dual ring fast cutting torch is suitable for industries such as metallurgy, shipbuilding, petroleum, chemical industry, metal structure and the like, and is particularly used for fast and continuously cutting metal materials with temperature(less than or equal to 950 DEG C).

Owner:温州上冶机械设备有限公司

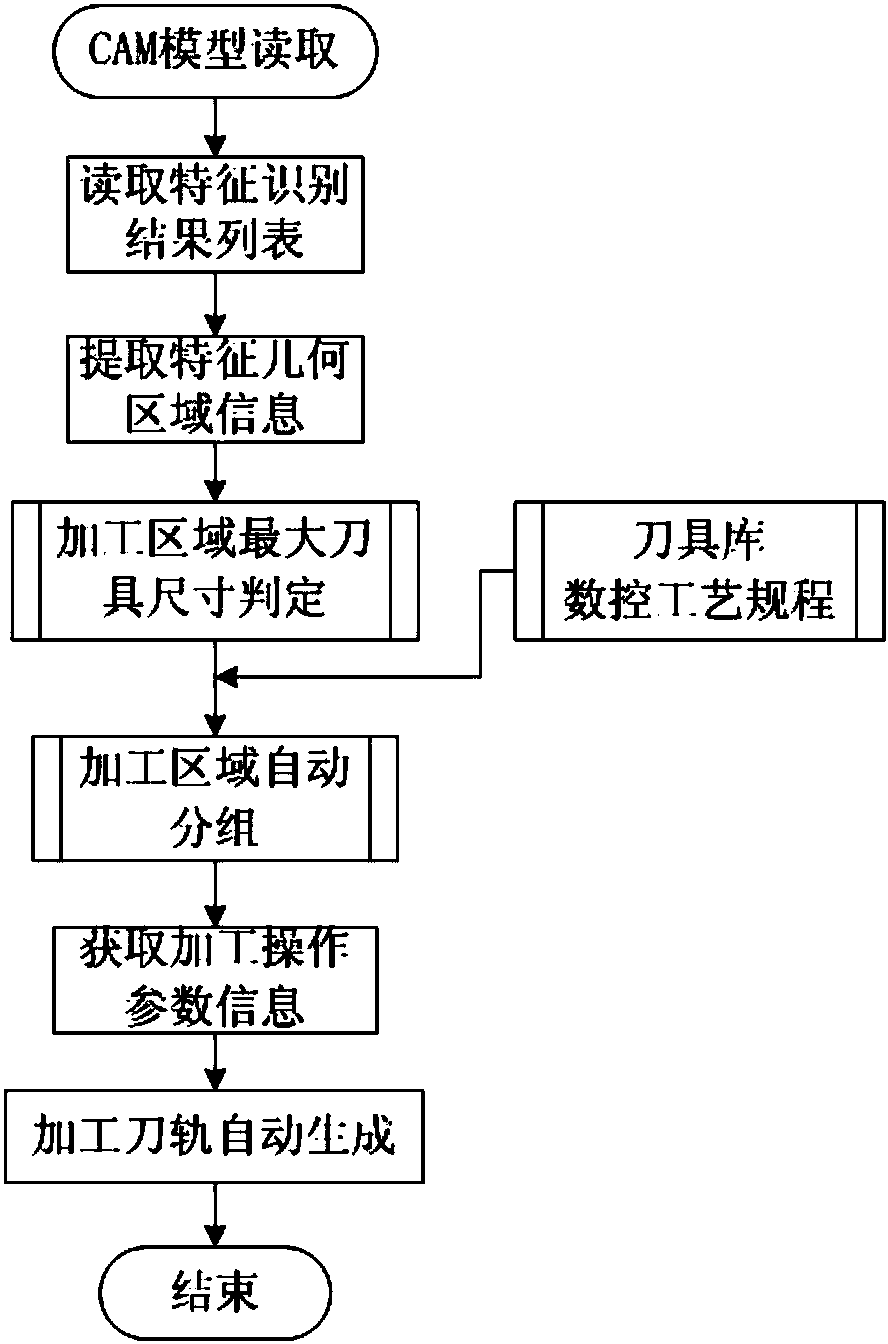

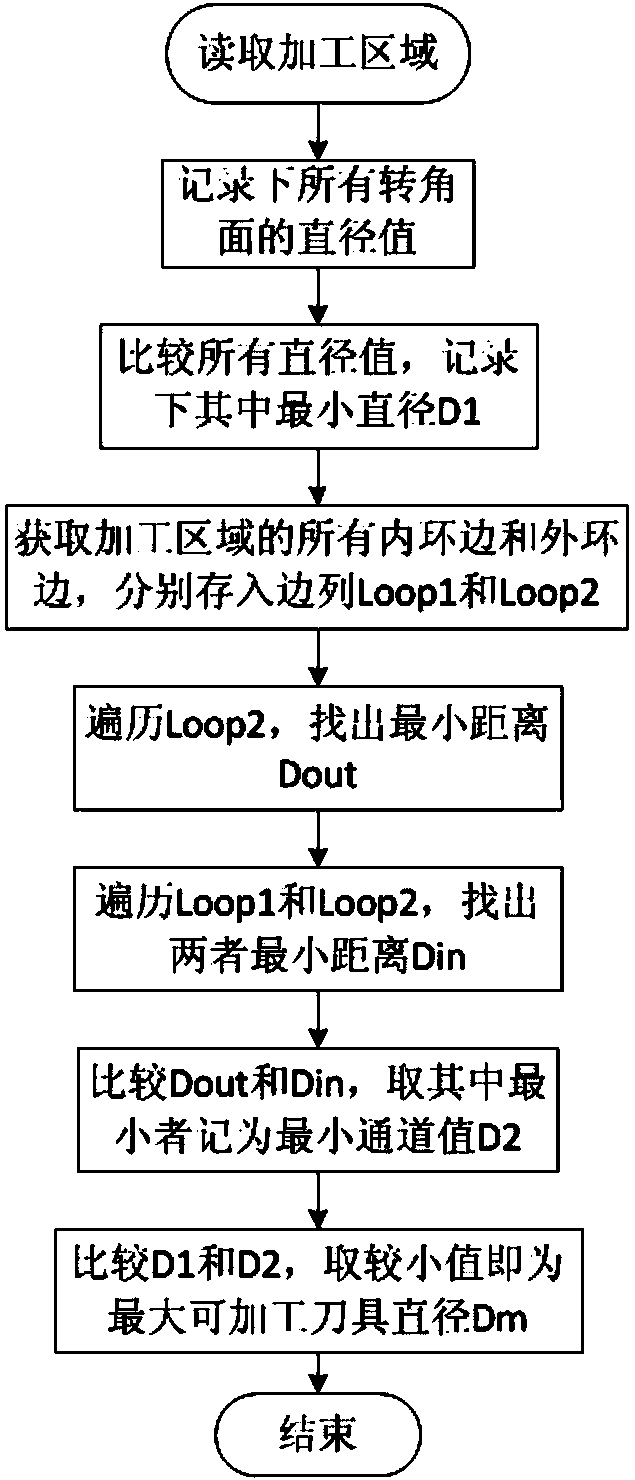

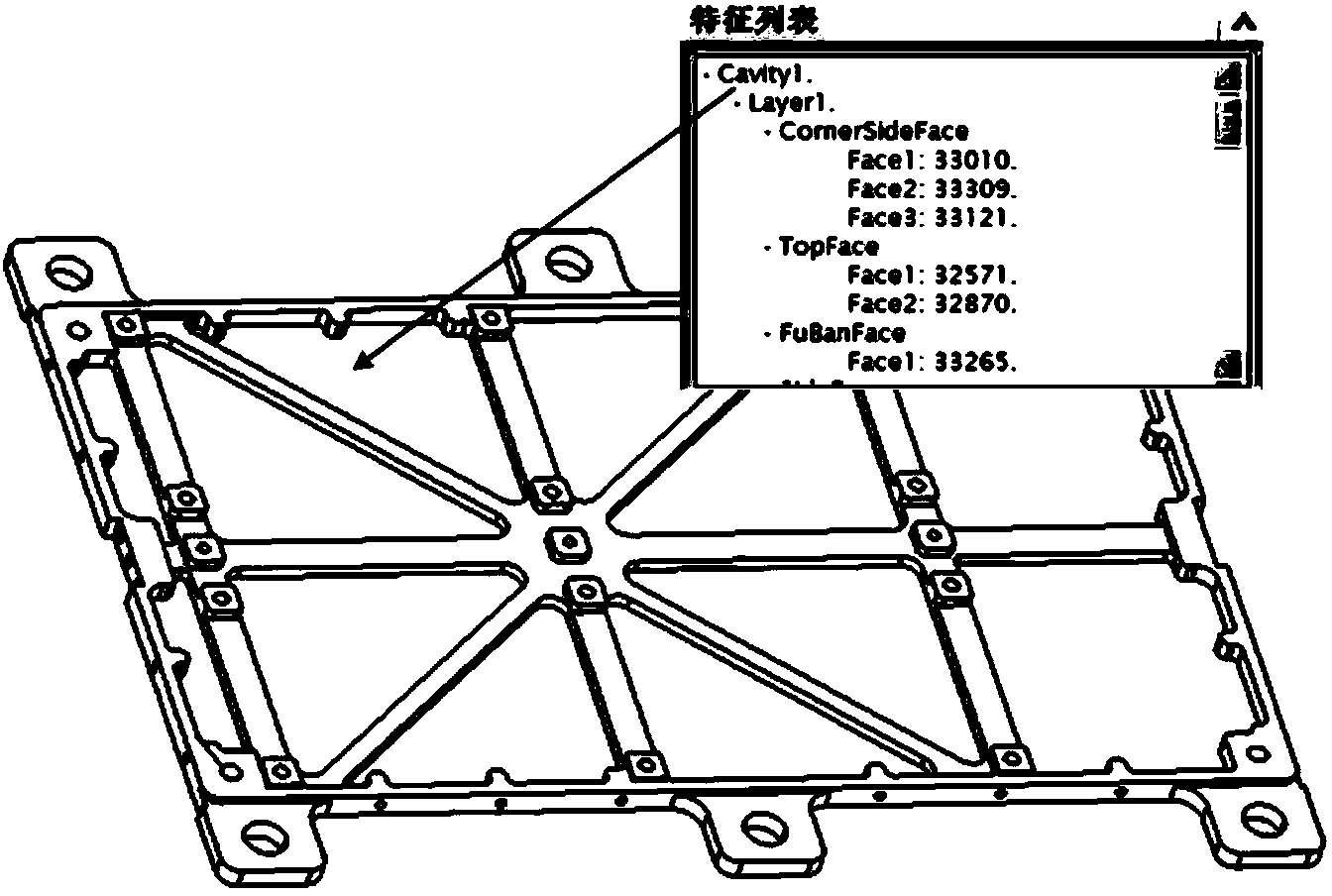

Feature-based automatic groove feature grouping machining method for plate parts

ActiveCN104317249ASmall sizeReduce error rateProgramme controlComputer controlProcess specificationNumerical control

The invention provides a feature-based automatic groove feature grouping machining method for plate parts. The machining method is characterized in that a feature identification result information list of a part model is extracted, geometrical information of machining regions corresponding to groove features is extracted, the maximum machining cutter diameters of the machining regions are calculated, the maximum machining cutter diameters of the machining regions are contrasted with a cutter table and a numerical control process specification to realize grouping of all the groove feature machining regions, and each group of groove feature machining regions is provided with an optimal cutter. The machining method can automatically conduct cutter selection for technologists, and reduces repeated manual work compared with the mode of manually selecting cutters according to experience; meanwhile, machining operations using the cutter of the same size can be combined due to automatic grouping machining, time is saved for the technologists, and machining efficiency is improved for enterprises.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

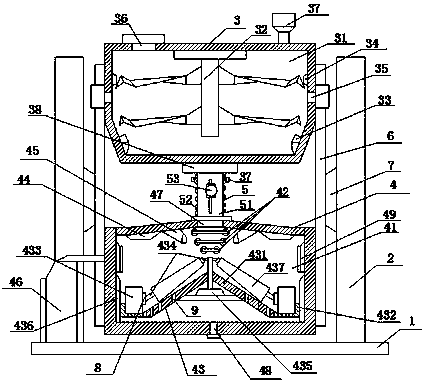

Efficient bone powder preparing system and using method

PendingCN107552202AIncrease productivityImprove product qualityGrain treatmentsProcess specificationUltrasonic vibration

Owner:郑州中技联创环境技术有限公司

Welding process for stainless steel pipelines

InactiveCN105665890AImprove mechanical propertiesReduce welding stressArc welding apparatusProcess specificationDrying time

The invention discloses a welding process for stainless steel pipelines. The welding process for the stainless steel pipelines is characterized by comprising the following steps that 1, materials are prepared, and specifically, SUS304 is selected as the material of the pipelines; A132 is selected as the material of a welding rod, the diameter of the welding rod is phi 2.0 mm, and the length of the welding rod is 300 mm; H0Cr21Ni10 is selected as the material of a welding wire; 2, the drying temperature of the welding rod is 250 DEG C-300 DEG C, and the drying time is 2-3 h; 3, beveled edges are cleaned; 3, the beveled edge end surfaces of pipe openings need to be perpendicular to the center line, and the aligned clearance of the two pipe openings needs to be uniform; 4, the beveled edges are machined; 5, the pipelines are welded; 6, welding treatment is conducted; 7, argon filling is treated; and 8, metal welding spatter, molten slag, an oxide skin, burrs, weld beading, concave pits and greasy dirt on the inner and outer surfaces of the pipes are cleaned up. According to the welding process for the stainless steel pipelines, all the phase parameters of the process are controlled strictly and reasonably, the procedures are standard, the welding stress and deformation are reduced, and accordingly the mechanical properties of the welded pipelines are improved.

Owner:CHONGQING SHANGKE MACHINERY MFG CO LTD

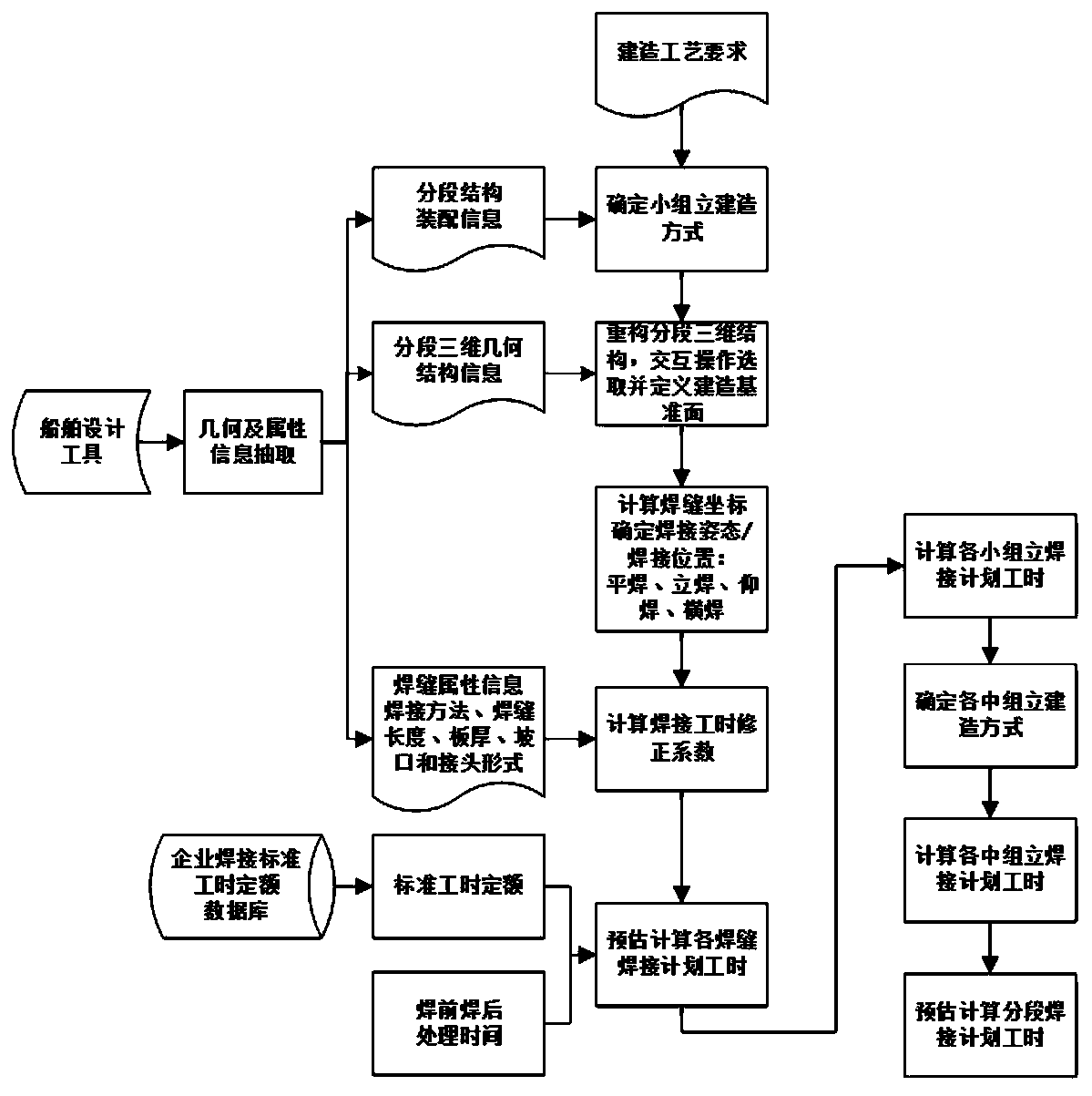

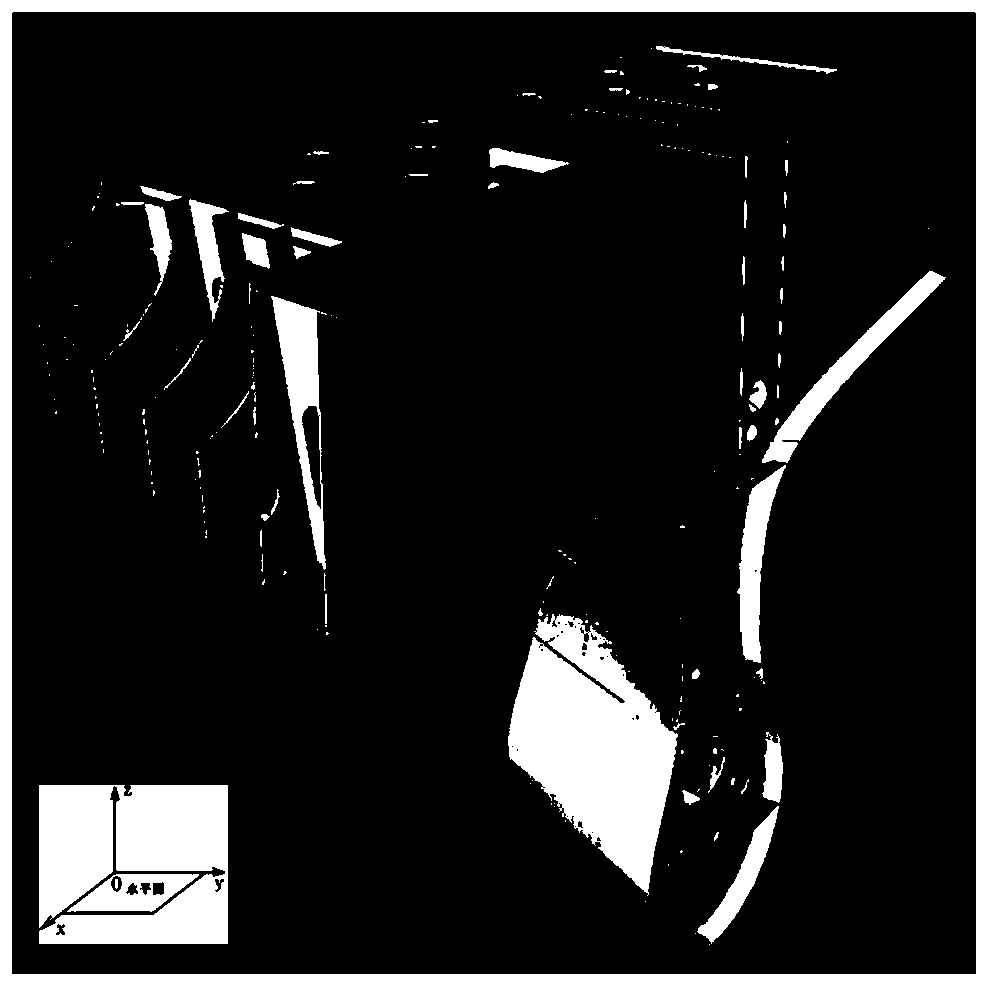

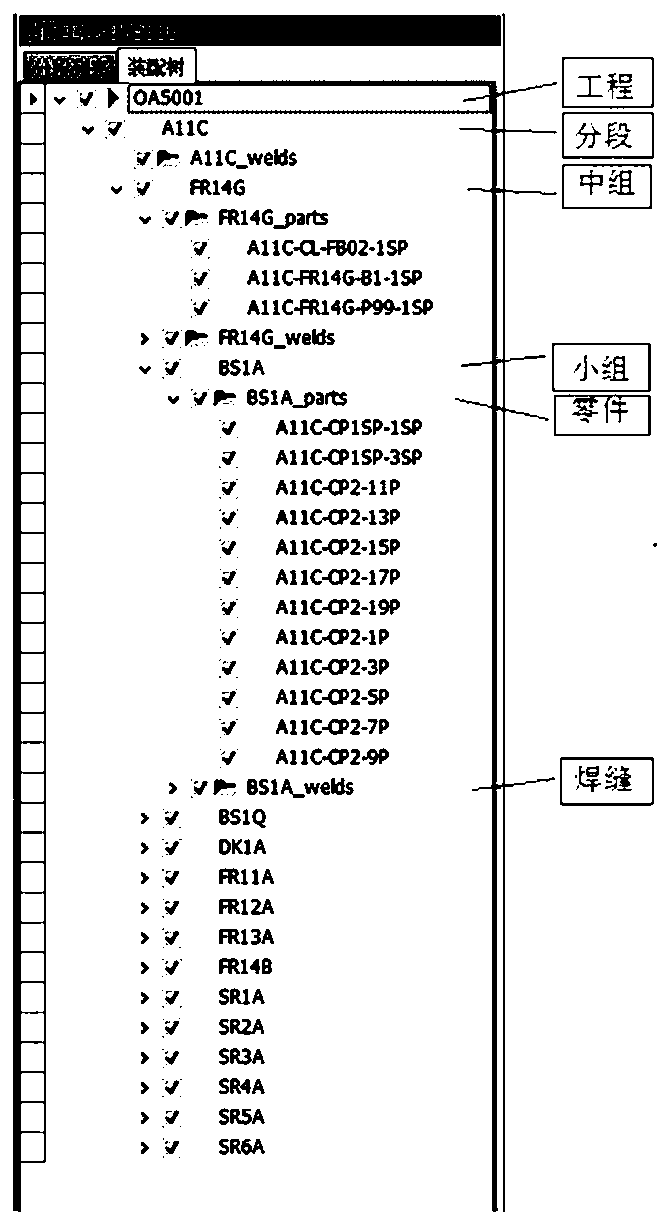

A method for calculating welding man-hour based on ship block construction mode

ActiveCN109460606AImprove accuracyImprove convenienceGeometric CADData processing applicationsProcess specificationMan-hour

The invention discloses a welding man-hour calculation method based on a ship block construction mode, comprising the following steps: extracting three-dimensional geometric model, assembly structurehierarchy information and weld seam information from ship design software; According to the construction process specifications and requirements, At that visual interface of the three-dimensional geometric model, input the construction mode of group erection, middle erection and section, obtain the construction datum level information, calculate the angle information of the weld seam under the construction state, determine the welding posture of the weld seam, determine the correction coefficient of the welding man-hour, and determine the preparation time before welding and the post-welding treatment time; It is helpful to improve the accuracy and convenience of calculation of weld planning man-hour, change the influence coefficient from discrete skip type to continuous one, improve the accuracy of calculation of weld planning man-hour is also helpful to reduce the cost of welding man-hour, and help to scientifically and reasonably determine the construction mode of segments.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所)

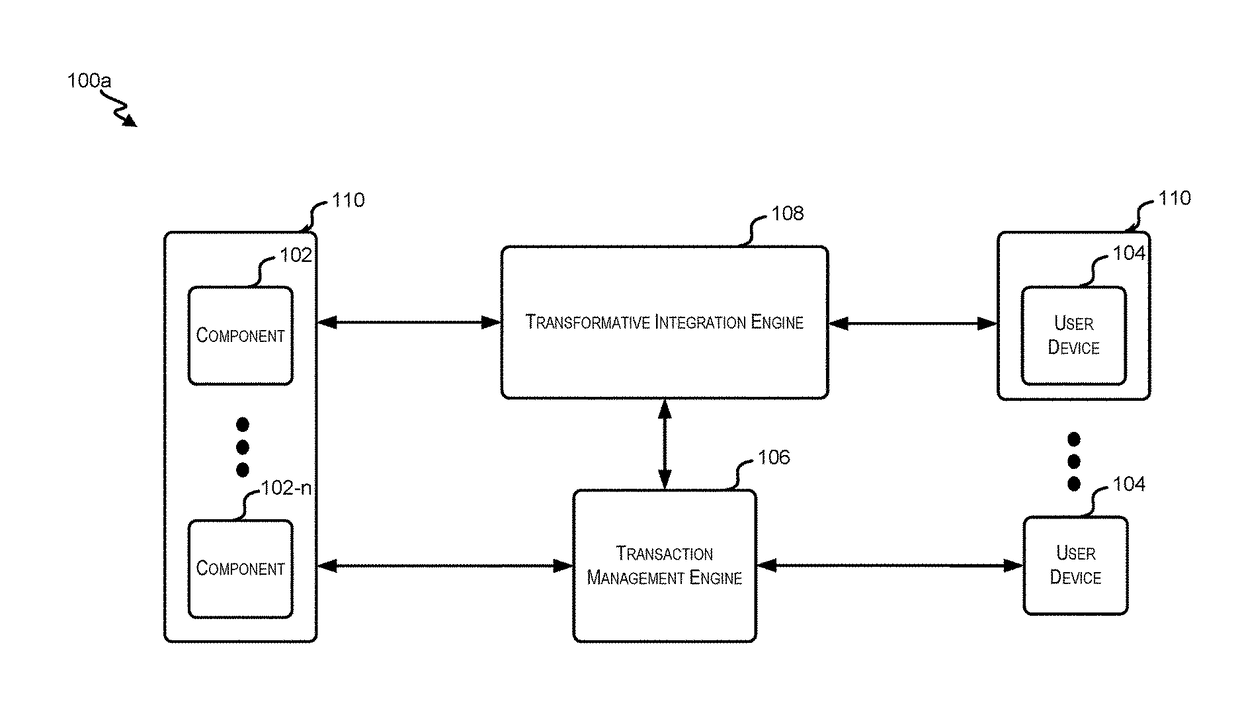

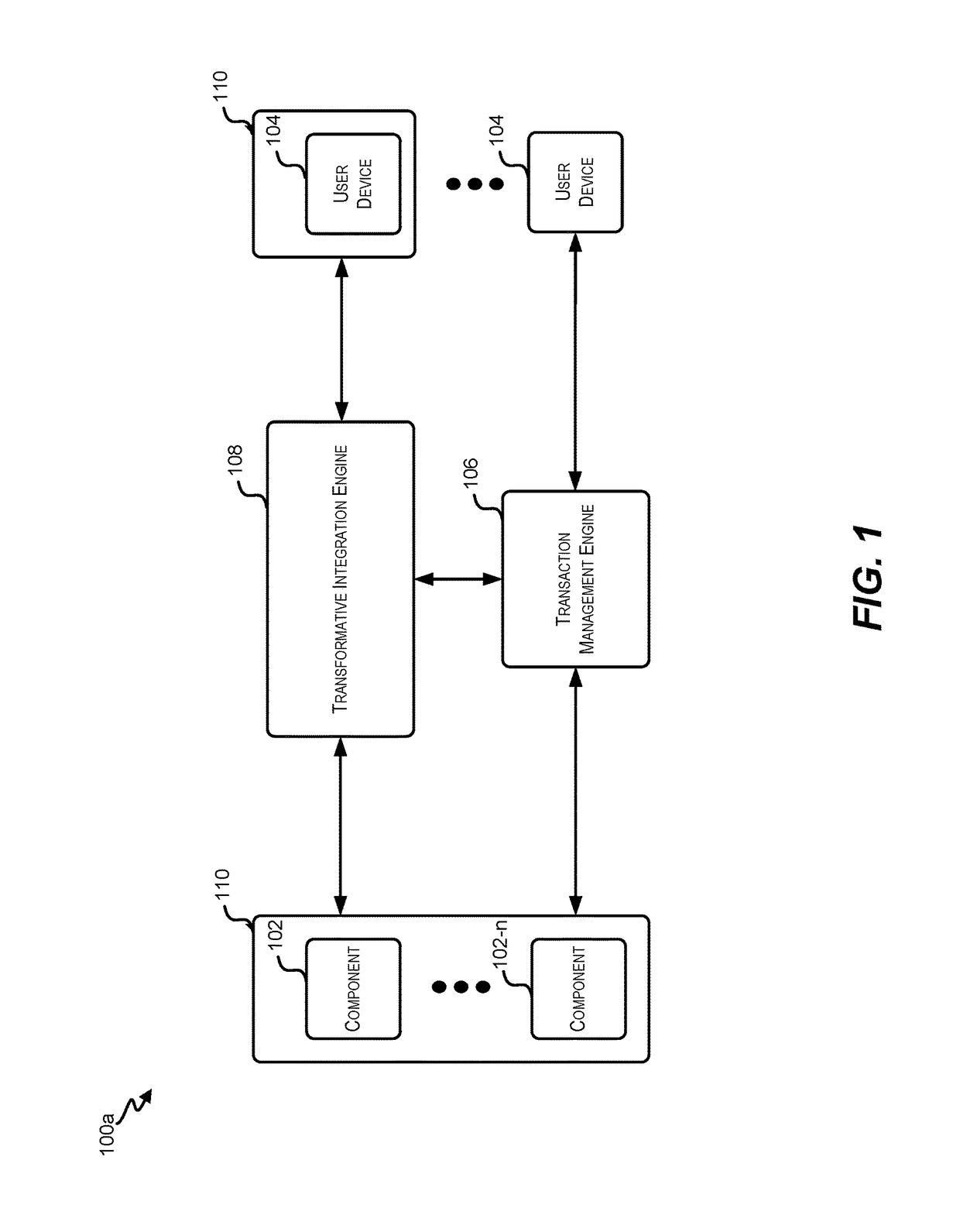

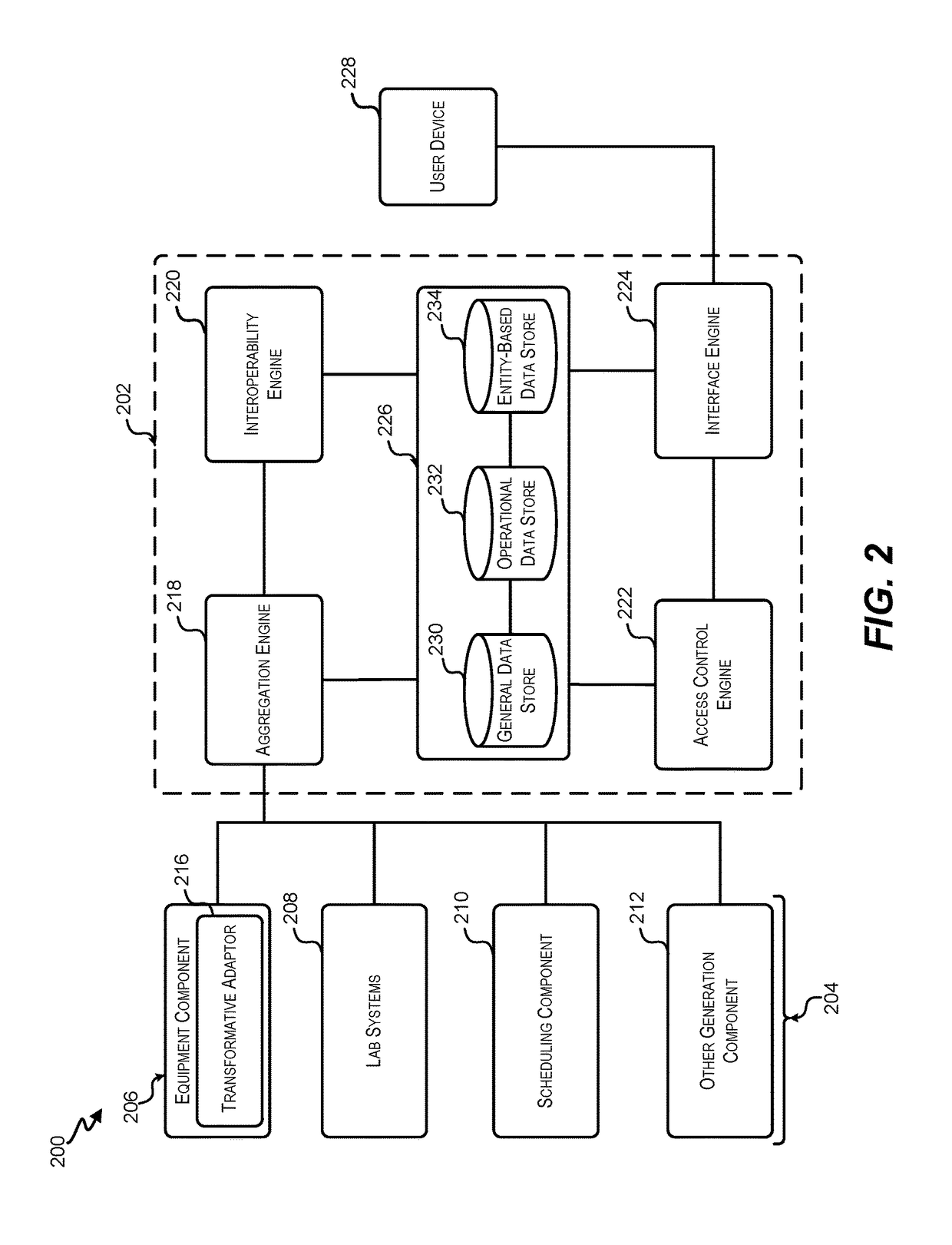

Multi-tier resource and load orchestration

ActiveUS9880881B1Efficiency of process performanceResource allocationData switching networksProcess specificationOrchestration

Systems, methods, and machine-readable media for process-performing resources and process specifications particularized to loads are provided. A provisional electronic composite for a load may be created. A type of process-performing resource may be identified. Performance data may be accessed to identify a process-performance duration that corresponds to a process type, the type of process-performing resource, process-performance locations, and process-performance times. A process-assignment duration may be defined, and an availability of a process-performing resource may be detected. A performance time may be determined based on the availability of the process-performing resource. Instruction to perform the process at the performance time may transmitted to at least one resource-controlling device. The provisional electronic composite for the load may be modified based on the performance time and the instruction to form an updated electronic composite.

Owner:CHCA

High-strength steel welding process

InactiveCN105983761AProcess specificationReduce welding stressArc welding apparatusProcess specificationButt welding

The invention discloses a high-strength steel welding process. The high-strength steel welding process is characterized in that the high-strength steel welding process aiming at downhand butt welding of high-strength steel plates with base metal being Q420 and thickness being 6mm includes process parameters and steps: (1) preparation; (2) welding grooves; (3) preheating temperature; (4) welding temperature; (5) shielding gas; (6) welding sequence; (7) welding materials; (8) welding parameters. The high-strength steel welding process has advantages of strict and reasonable control of parameters of each stage, normative procedures, reduction of welding stress and deformation and improvement of mechanical properties after welding.

Owner:重庆展申机械厂

Tobacco leaf processing method for selectively reducing cigarette smoke gas NH3 releasing quantity

InactiveCN103271427AReduce releaseThe method is feasible and practicalTobacco preparationProcess specificationTar

The invention discloses a tobacco leaf processing method for selectively reducing the cigarette smoke gas NH3 releasing quantity. At first, a leaf moistening cylinder is preheated to enable circulating hot wind to reach the 80 DEG C-120 DEG C temperature, and then materials are began to feed. Secondarily, a hot steam valve and a moist steam valve are adjusted according to parts of processed tobacco leaves to respectively control the temperature and the water content of a tobacco moistening leaf. At last, steam is fully adopted, the temperature accords with technological requirements of <YC / T146-2010 tobacco leaf breaking re-roasting process specification>, and processing is carried out. The tobacco leaf processing method for selectively reducing the cigarette smoke gas NH3 releasing quantity is obvious in effect, reduces the amplitude by more than 30%, is good in repeatability and suitable for leaf breaking re-roasting actual production, expands the tobacco leaf processing technology for reducing harmful ingredients of cigarette smoke gas, and has good practical significance and reference functions for harmful ingredient-reduction tar-reduction work of the industry.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Making method for concave-convex elastic real silk jacquard fabric

InactiveCN105113101AStrong three-dimensional sense of double-sided concave-convexImprove visual effectsMulti-ply fabricsSwivel-woven fabricsYarnProcess specification

The invention discloses a making method for concave-convex elastic real silk jacquard fabric. The method comprises the following steps of 1 whole process specification formulating; 2 pattern designing and weave structure designing; 3 weaving process procedure performing. A weave structure comprises surface weave, back weave and binding weave; the ratio of first warp yarns to second warp yarns in all the weave structures of the jacquard fabric is 1:1, and the picking ratio of first weft yarns to second weft yarns to third weft yarns is 1:1:2; the first weft yarns and the first warp yarns are interweaved in a one-up-one-down mode and both floated on the second warp yarns; the second weft yarns are all sunk to the first warp yarns and interweaved with the second warp yarns in a one-up-one-down mode; every two third weft yarns are partially and simultaneously lifted or fell to perform tabby interweaving through the first warp yarns and the second warp yarns. According to the making method for the concave-convex elastic real silk jacquard fabric, mulberry silk is adopted as raw materials, the made jacquard fabric has the advantages of being high in third dimension, good in visual effect, hand feeling and elasticity and wide in application range, and the making method has the advantages of being high in production efficiency, low in cost and suitable for individualized requirements of consumers.

Owner:ZHEJIANG SCI-TECH UNIV

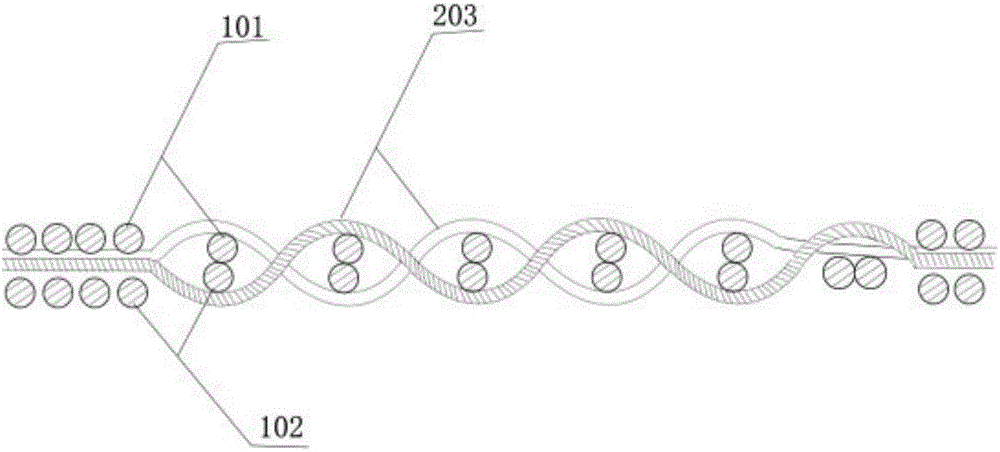

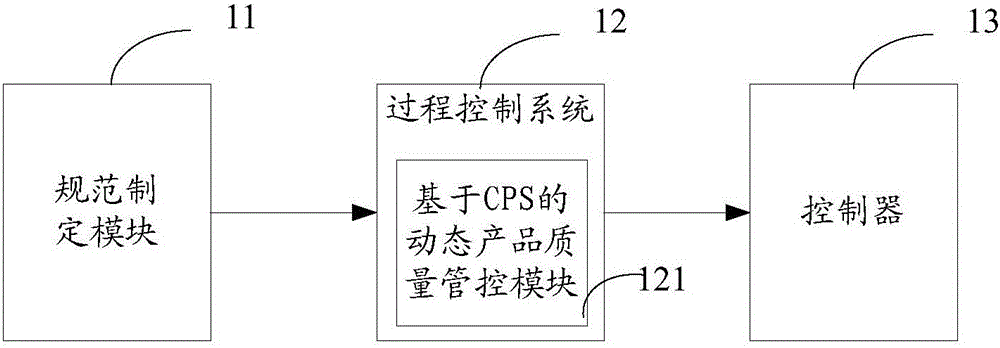

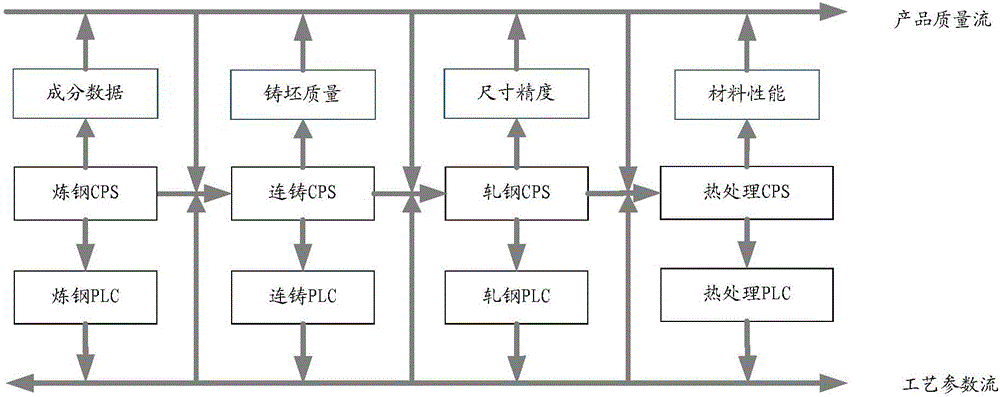

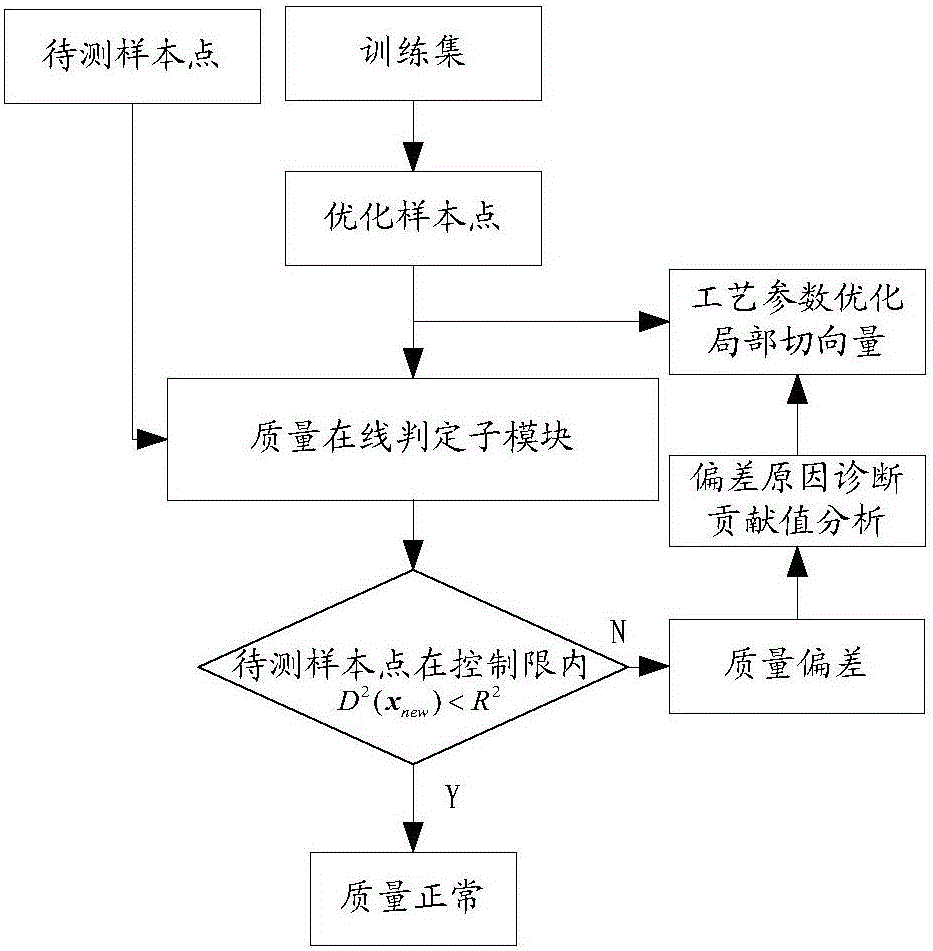

Whole process product quality online control system

ActiveCN106054840AGuaranteed stabilityTotal factory controlProgramme total factory controlProcess specificationAutomatic control

The invention provides a whole process product quality online control system, which can achieve the on-line dynamic optimization of the product quality of procedures of the whole process, and thus improving the stability of the product quality. The system includes a specification making module, a process control system of each procedure, and a controller, the process control system includes a CPS-based dynamic product quality control module, the specification making module sets the quality indexes of the whole process and technological standards, the dynamic product quality control module acquires the product quality information of a previous procedure and the technological parameter setting value in the previous procedure, performs dynamic quality control and optimization of the obtained product quality information and the technological parameter setting value according to the set quality index and process specification of the whole process, and sends the optimized technological parameters to the controller, and the controller executes the optimized technological parameters. The whole process product quality online control system is applicable to the technical field of automatic control.

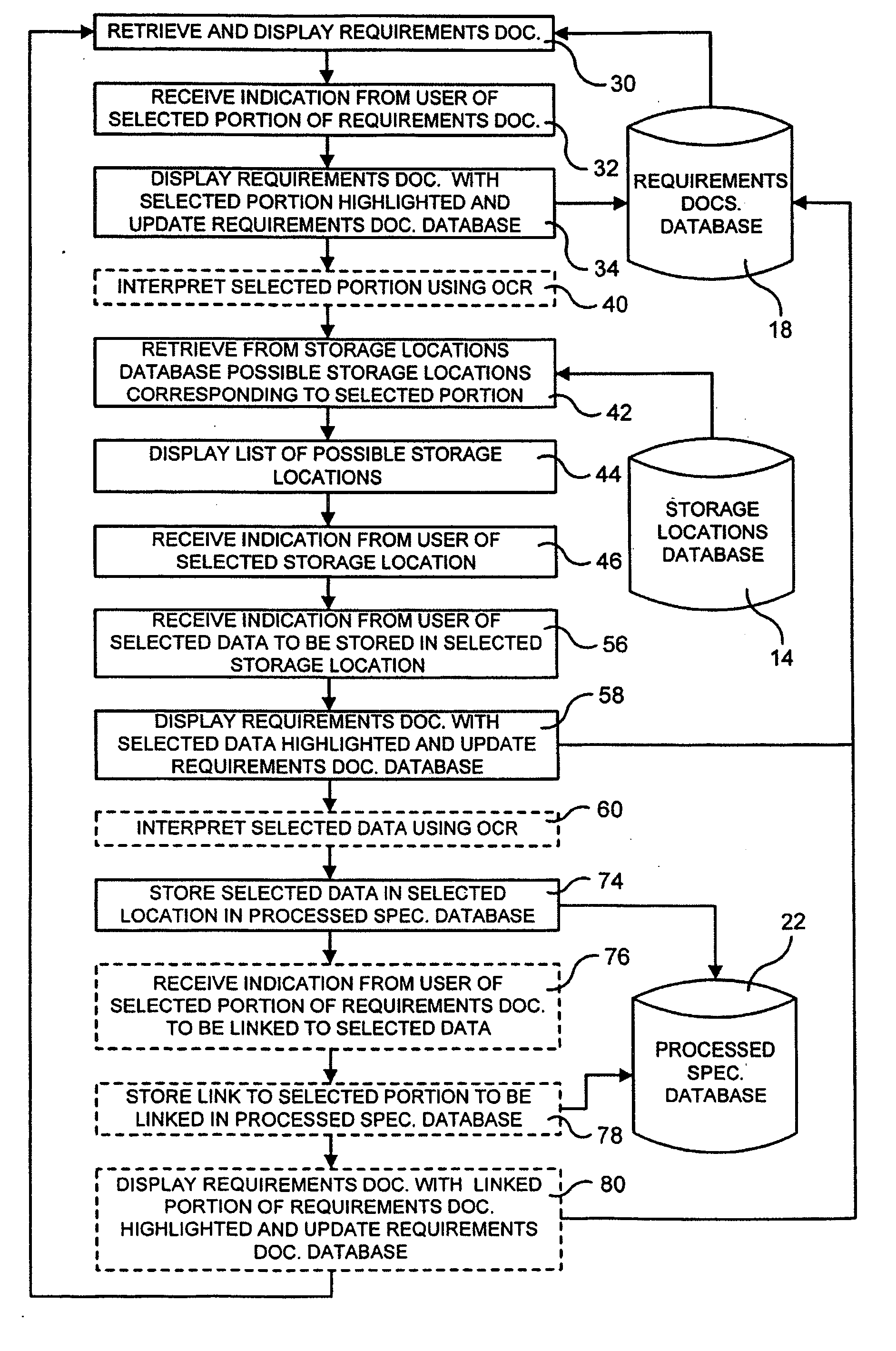

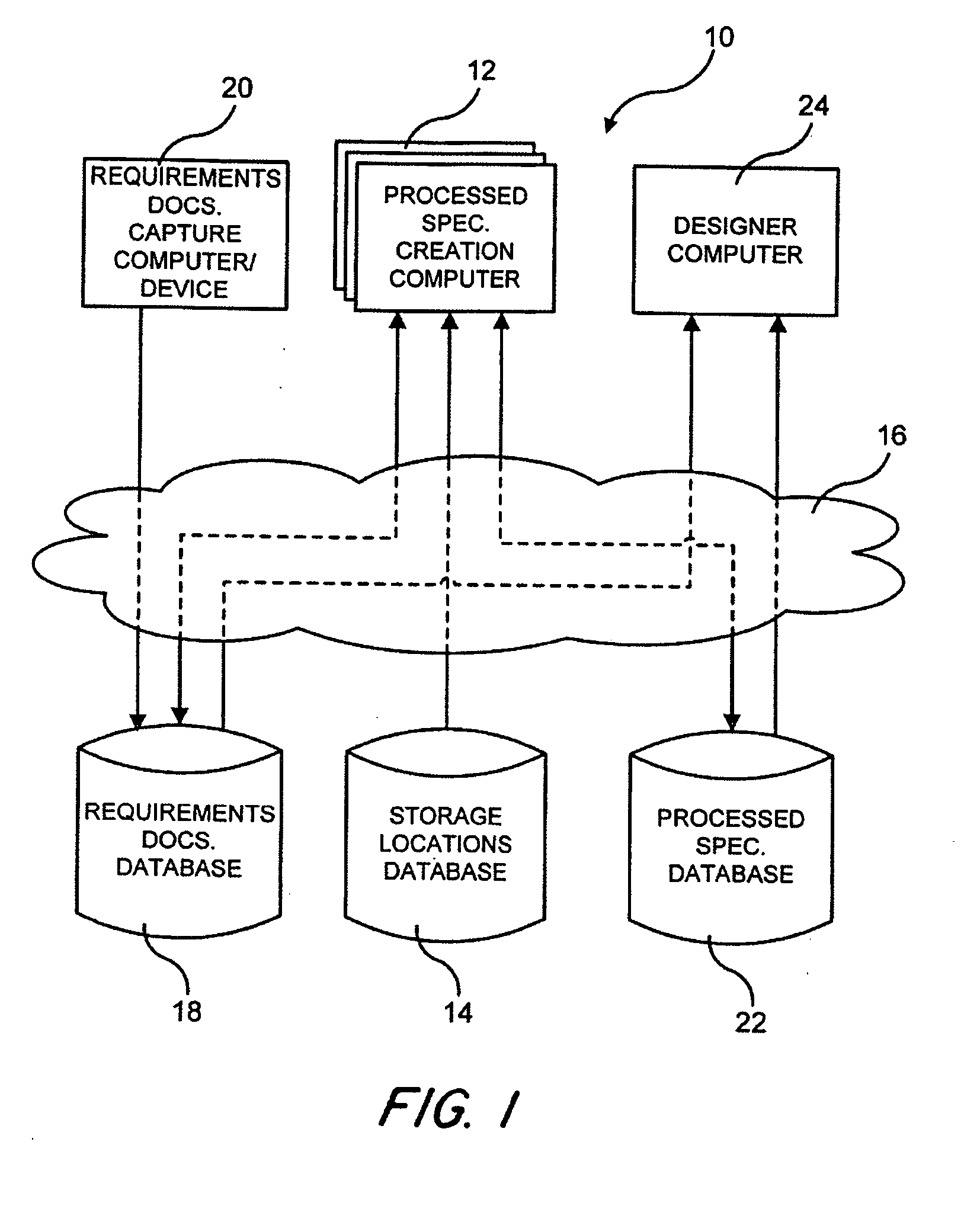

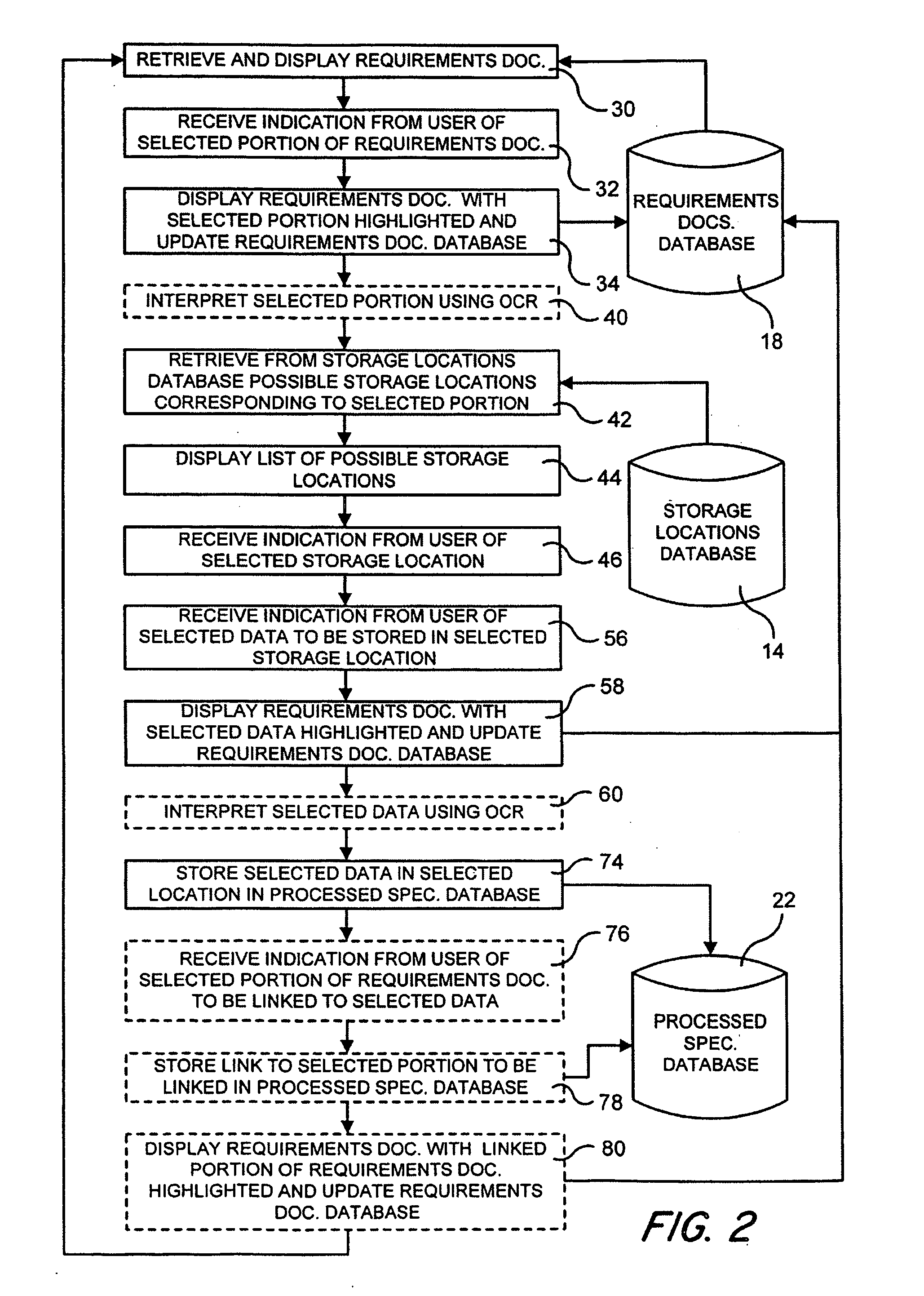

Specification wizard

InactiveUS20070168916A1Easy to createStreamlined and efficientOffice automationSpecific program execution arrangementsProcess specificationPaper document

A system for facilitating the creation of design specifications includes a computer and a database having stored thereon data indicative of a plurality of storage locations in a processed specification into which data may be entered. Software executing on the computer: displays a requirements document; receives an indication of a selected portion of the requirements document; based at least in part upon the indication of the selected portion of the requirements document, retrieves from the database a list of possible storage locations corresponding to the selected portion of the requirements document; displays the list of possible storage locations corresponding to the selected portion of the requirements document; receives an indication of a selected storage location; receives an indication of data selected in the requirements document to be stored in the selected storage location; and stores the selected data in the selected storage location in the processed specification.

Owner:ABB TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com