Patents

Literature

86 results about "Heat penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat penetration test is conducted to determine the heating and cooling characteristics in the coldest point of a given product, in a given container, under specified process conditions. usually at the coldest zone of the retort .The cold spot of the product is the point inside the product where it experiences minimum heating effect during ...

Complex alloy permeation agent and method for preparing permeation layer

InactiveCN102127732ASmooth appearanceUniform thicknessSolid state diffusion coatingHeat penetrationAlloy

The invention relates to a complex alloy permeation agent and a method for preparing a permeation layer, designed aiming at the surface antisepsis of common steel spare parts, such as railway track fasteners, bolts, elastic bars, concrete preembedded parts, and the like. The complex alloy permeation agent comprises zinc powder, aluminum powder, alumina powder, lanthanum hydroxide powder and ammonium chloride. The process line for preparing the permeation layer comprises the following steps of: pretreating a working piece; loading the working piece into a furnace and adding the permeation agent; heating a converter and keeping the temperature for permeation; and cooling the working piece when reaching a temperature and discharging the working piece. Heat penetration is carried out under confirmed process specifications so as to form corrosion-resistant and wearable complex alloy permeation layer with a certain thickness and a compact structure on the surface of the working piece. The invention has simple process and is easy to implement. A Zn-Al-Fe-La complex alloy permeation layer obtained by adopting the conventional process has the thickness about 100 micros, the hardness up to 240-320 HV and the salt-air corrosion up to 680 h.

Owner:安徽天通达克罗涂复科技有限公司

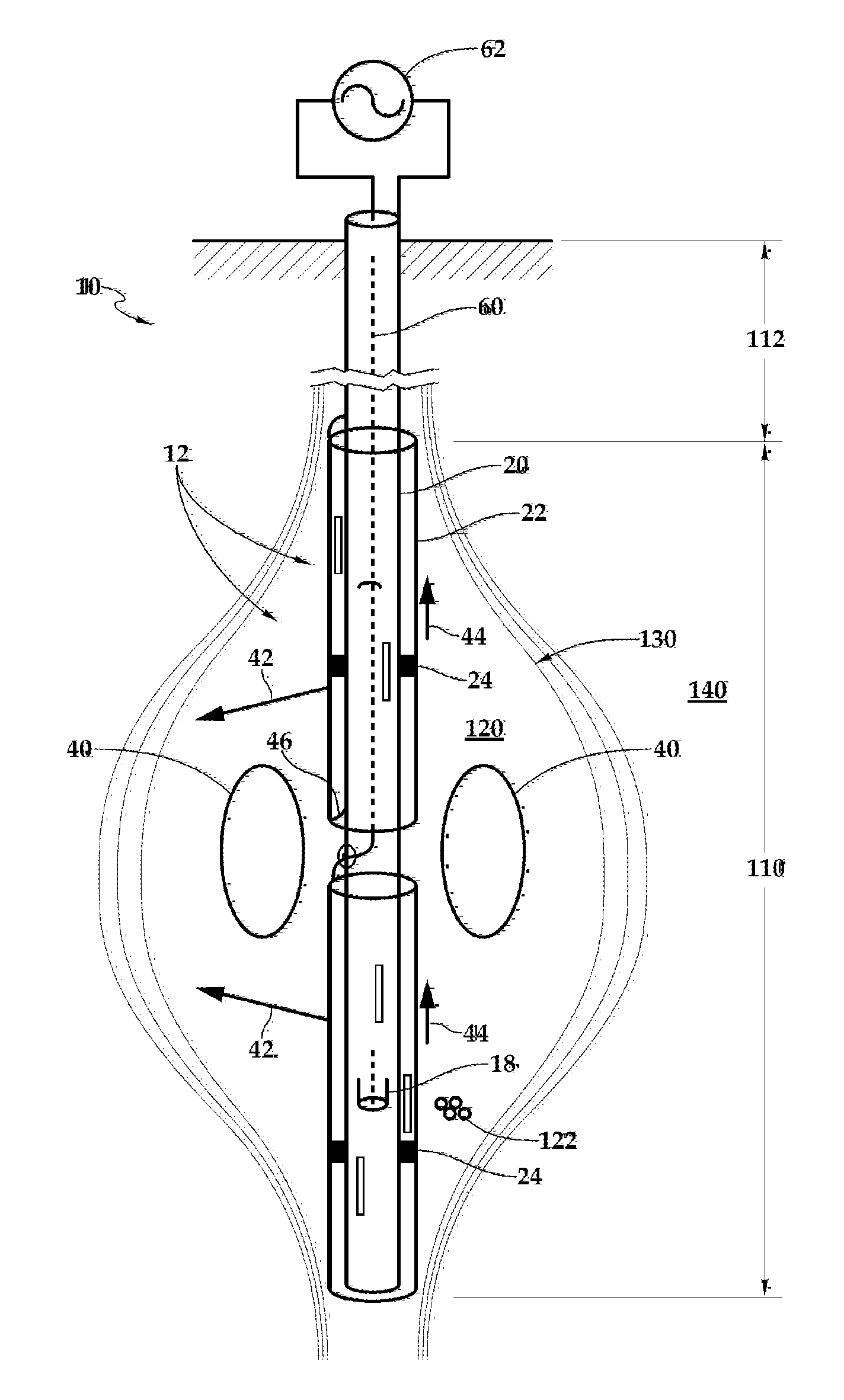

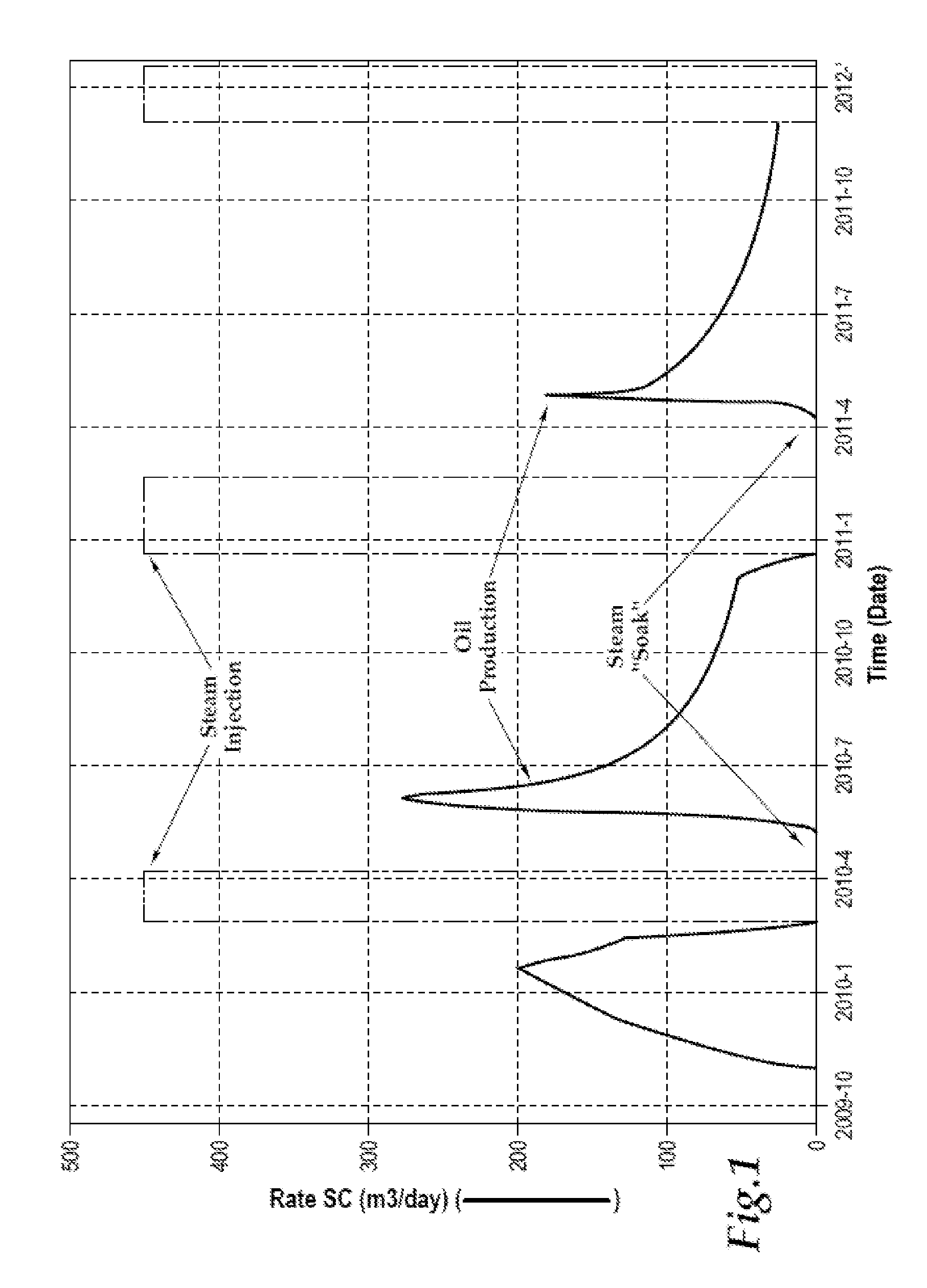

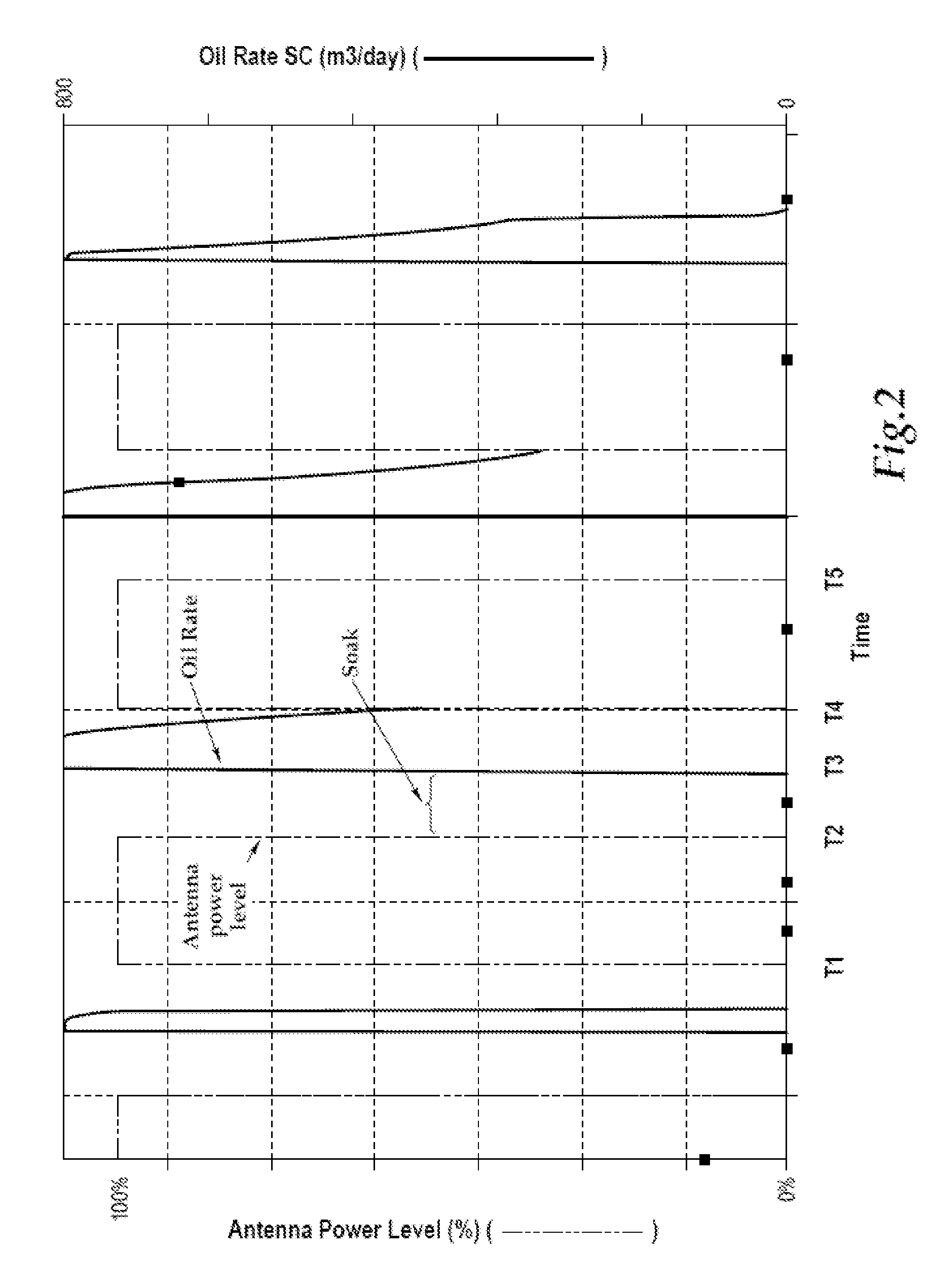

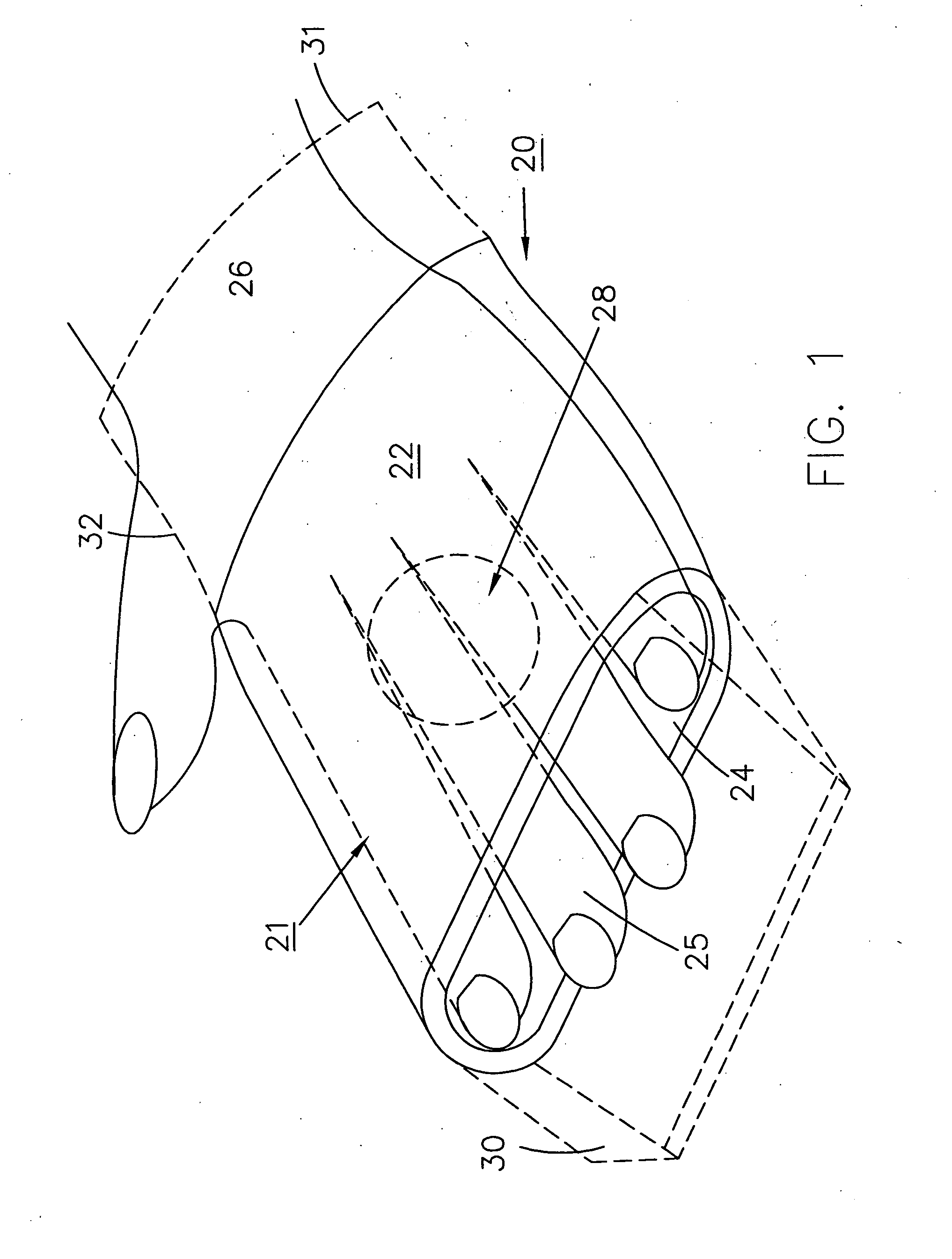

Cyclic radio frequency stimulation

ActiveUS20120305239A1Reduce operating costsLess electricityFluid removalElectricityOperational costs

Production of heavy oil and bitumen from a reservoir is enhanced by cyclic radio frequency (RF) radiation of the well. The invention utilizes RF radiation to introduce energy to the hydrocarbon reservoir in cycles in order to heat the reservoir directly, yet conserves energy over the prior art processes that more or less continuously apply RF or microwave energy. The advantage of cyclic RF is it uses less electricity, and thus lowers operating costs. This is achieved by the soak cycle that allows heat to conduct into the formation and assists the heat penetration that is directly radiated into the formation by the antenna. The invention can also be advantageously combined with cyclic steam stimulation.

Owner:HARRIS CORP +1

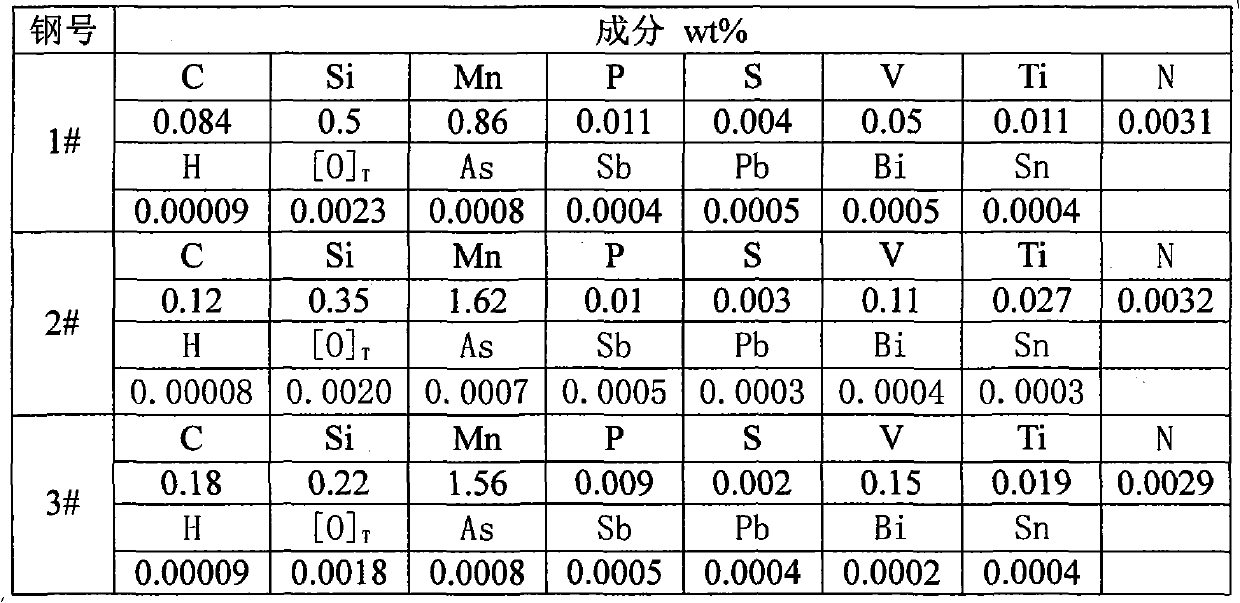

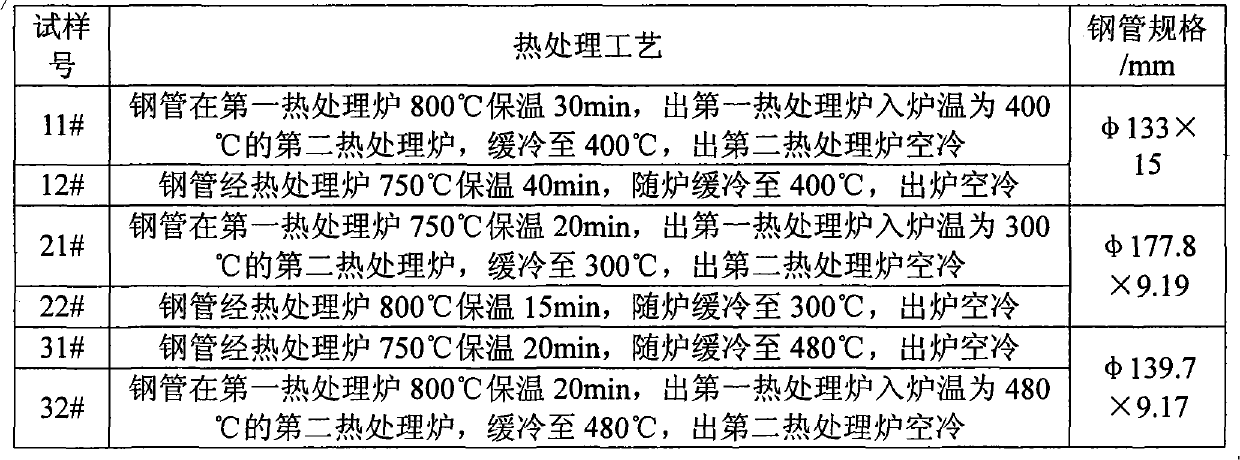

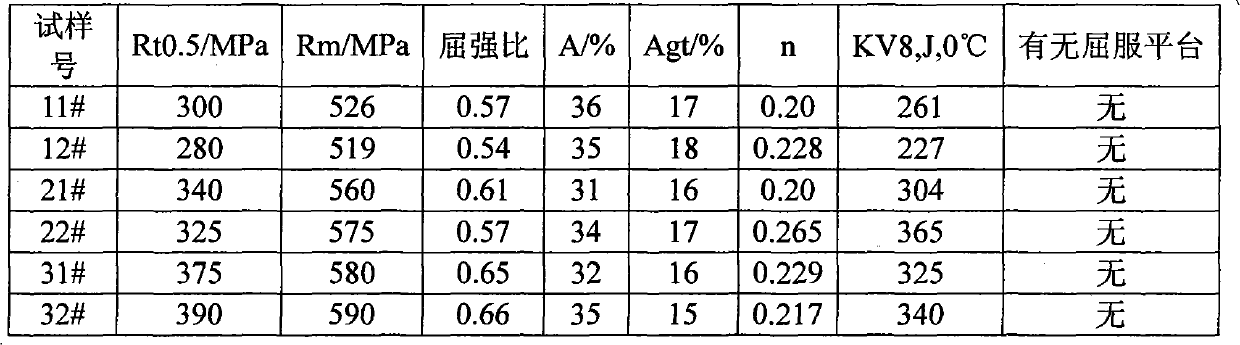

Economical seamless oil well pipe for expansion pipe and manufacturing method thereof

ActiveCN102022086AHigh elongationUniform elongationDrilling rodsManufacturing convertersChemical compositionHeat penetration

The invention provides an economical seamless oil well pipe for an expansion pipe and a manufacturing method thereof. The oil well pipe comprises the following chemical components in percentage by weight: 0.08 to 0.18 percent of C, 0.2 to 0.5 percent of Si, 0.6 to 1.7 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.005 percent of S, 0.04 to 0.15 percent of V, 0.01to 0.03 percent of Ti and the balance of Fe and inevitable impurities. A heat treatment process in the manufacturing method comprises the following steps of: incompletely quenching a hot-rolled seamless pipe, controlling the temperature of a heating furnace at 750 to 800 DEG C, keeping the temperature of the steel pipe in the range of 30 to 40 DEG C higher than Ac1 and 30 to 40 DEG C lower than Ac3 between the two phase regions of ferrite and austenite, performing calculation at the heat penetration speed of 1mm / min, preserving the heat of the oil well pipes for 10 to 60 min after the hot-rolled oil well pipes with different wall thicknesses reach the temperature of the furnace, and then cooling the oil well pipes at the speed of not higher than 0.2 DEG C per second. In the economical seamless oil well pipe and the manufacturing method thereof, the manufacturability and expandability performance of the steel pipe, the mechanical properties of the expanded steel pipe and the manufacturing cost are taken into account.

Owner:ANGANG STEEL CO LTD

Gloss level adjustment

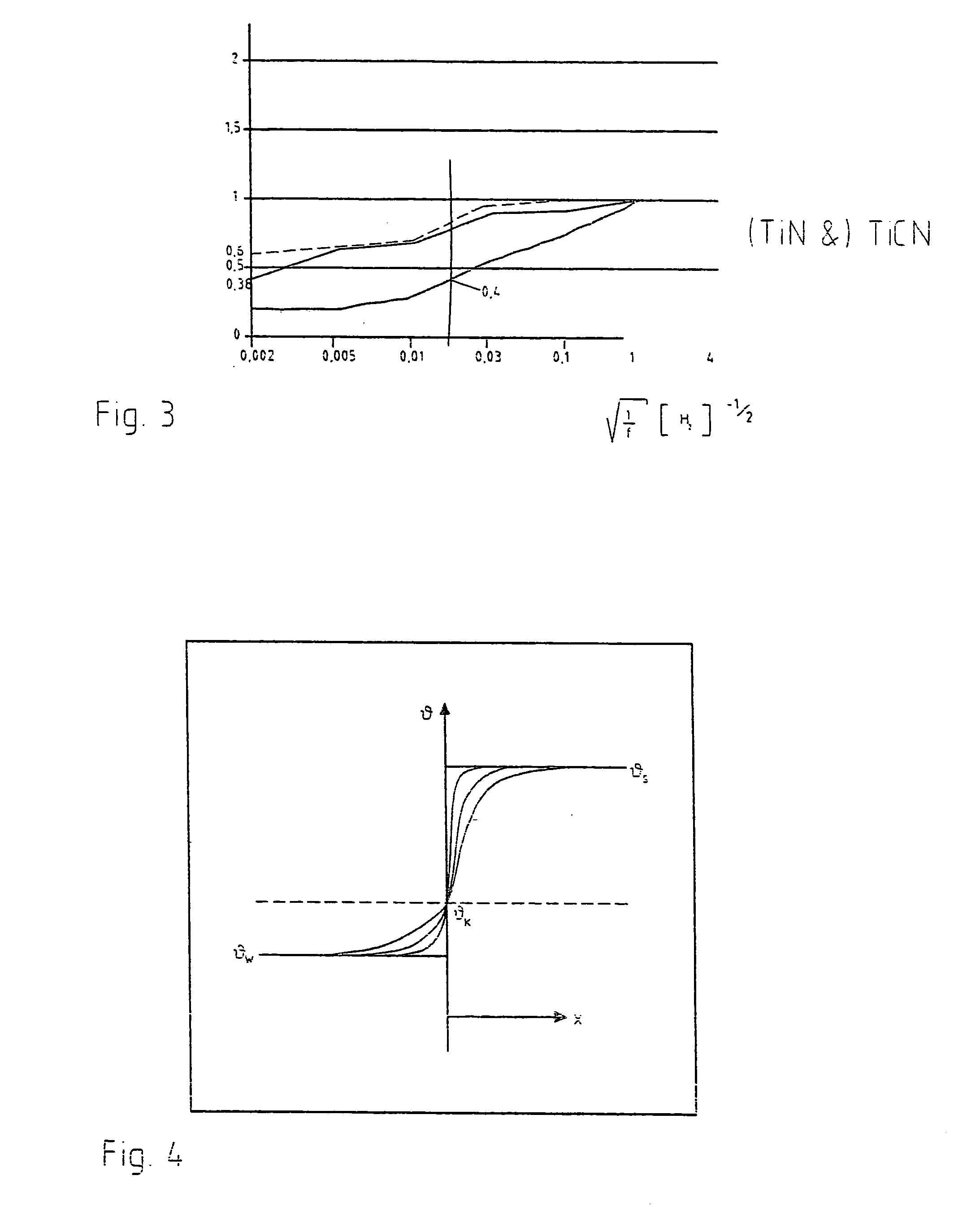

ActiveUS20050133962A1Highly accurate reproductionAvoid differencesDischarging arrangementMouldsTemperature controlHeat penetration

In a method for injection molding molten materials, especially plastic, in a mold that has a mold surface which comes into contact with the material, at least one coating on the mold surface and a temperature-control means for the mold surface, the mold surface is cooled by the temperature-control means so that the molten material solidifies at the interface with the coating and an injection-molded part can be removed from the form. During this process the molten material is brought into contact with the coating on the mold surface, the thickness of said coating being selected in coordination with the heat penetration coefficient of the coating material such that a specified 60° gloss level and / or color value L is obtained for the injection-molded part.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

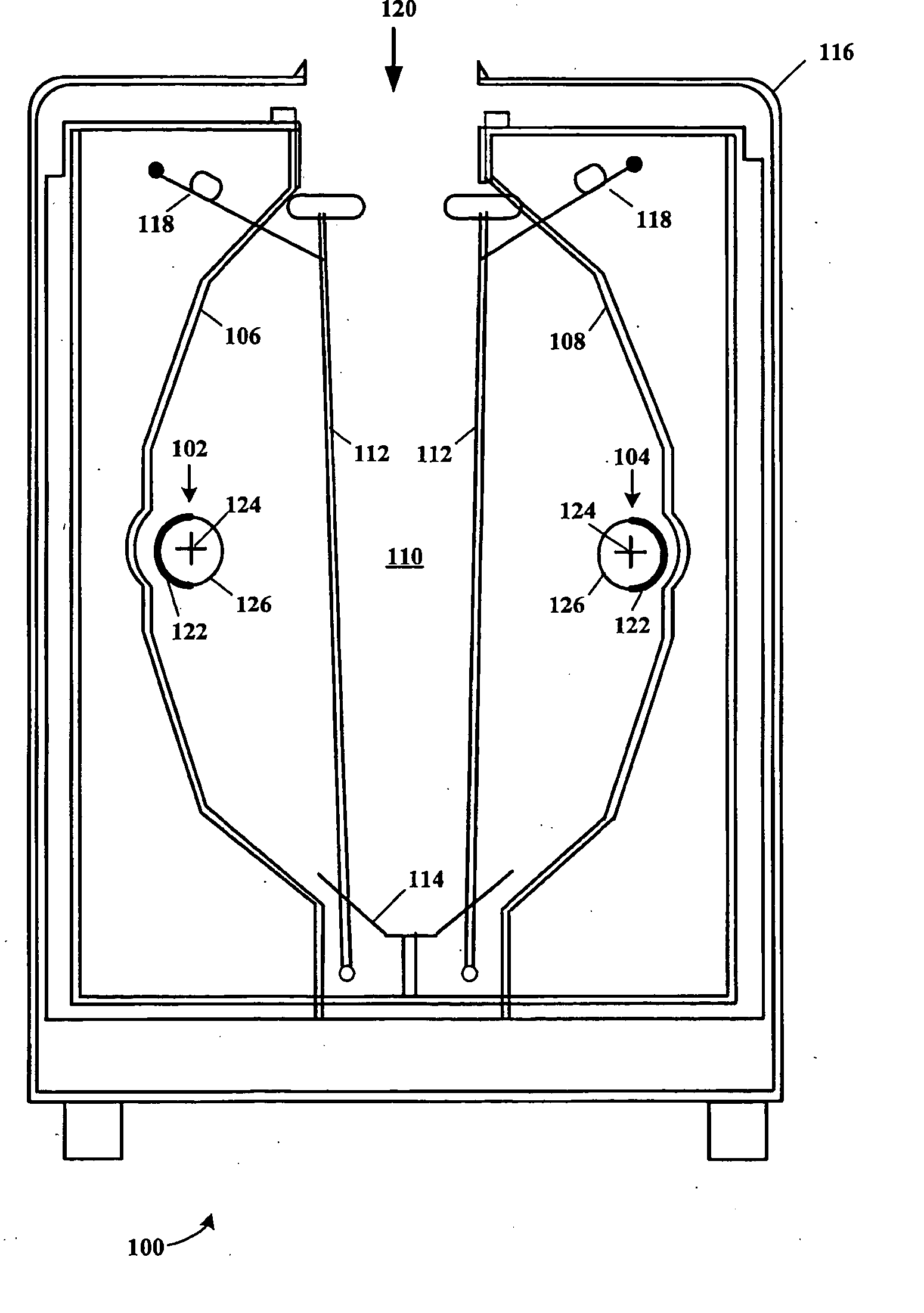

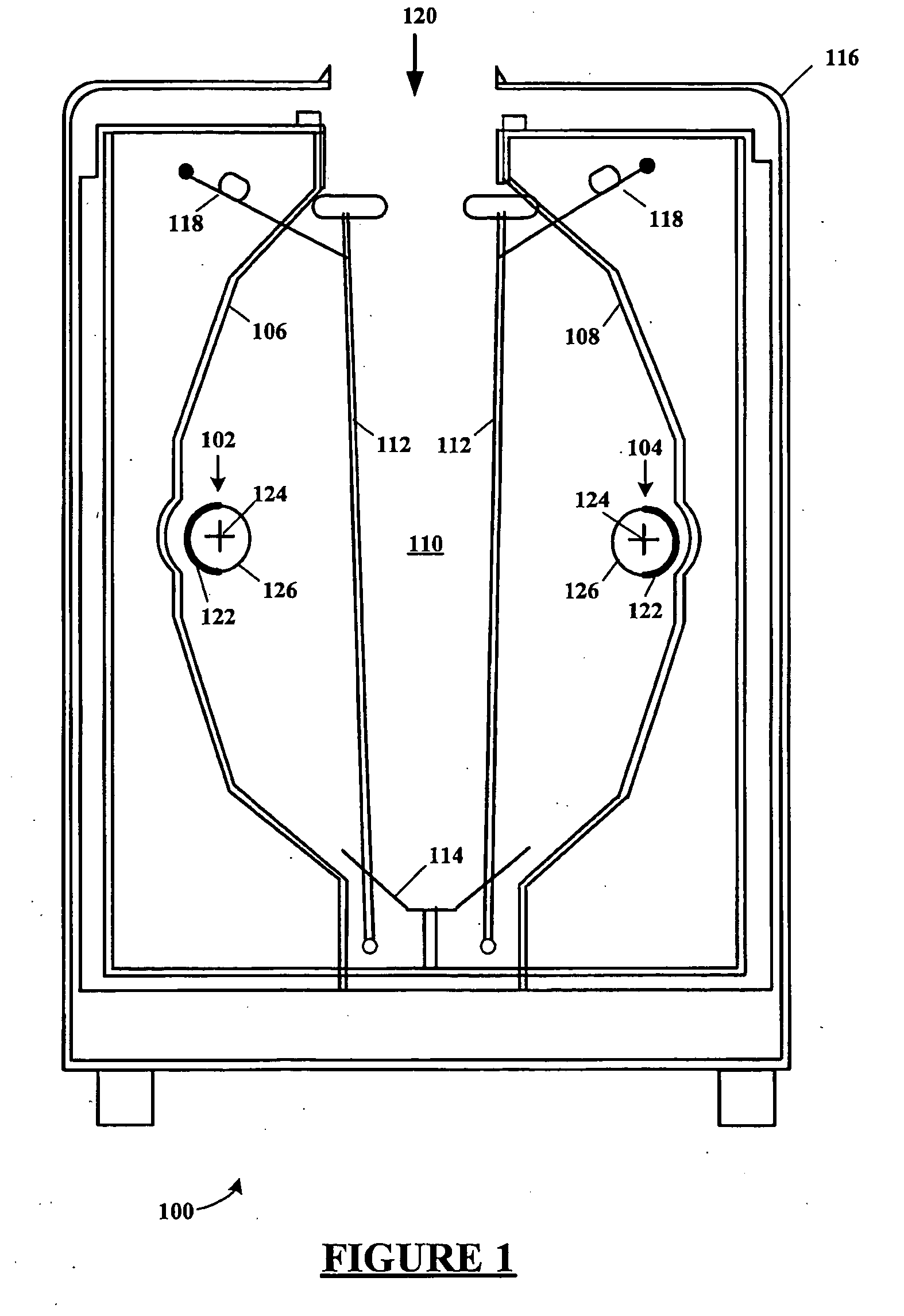

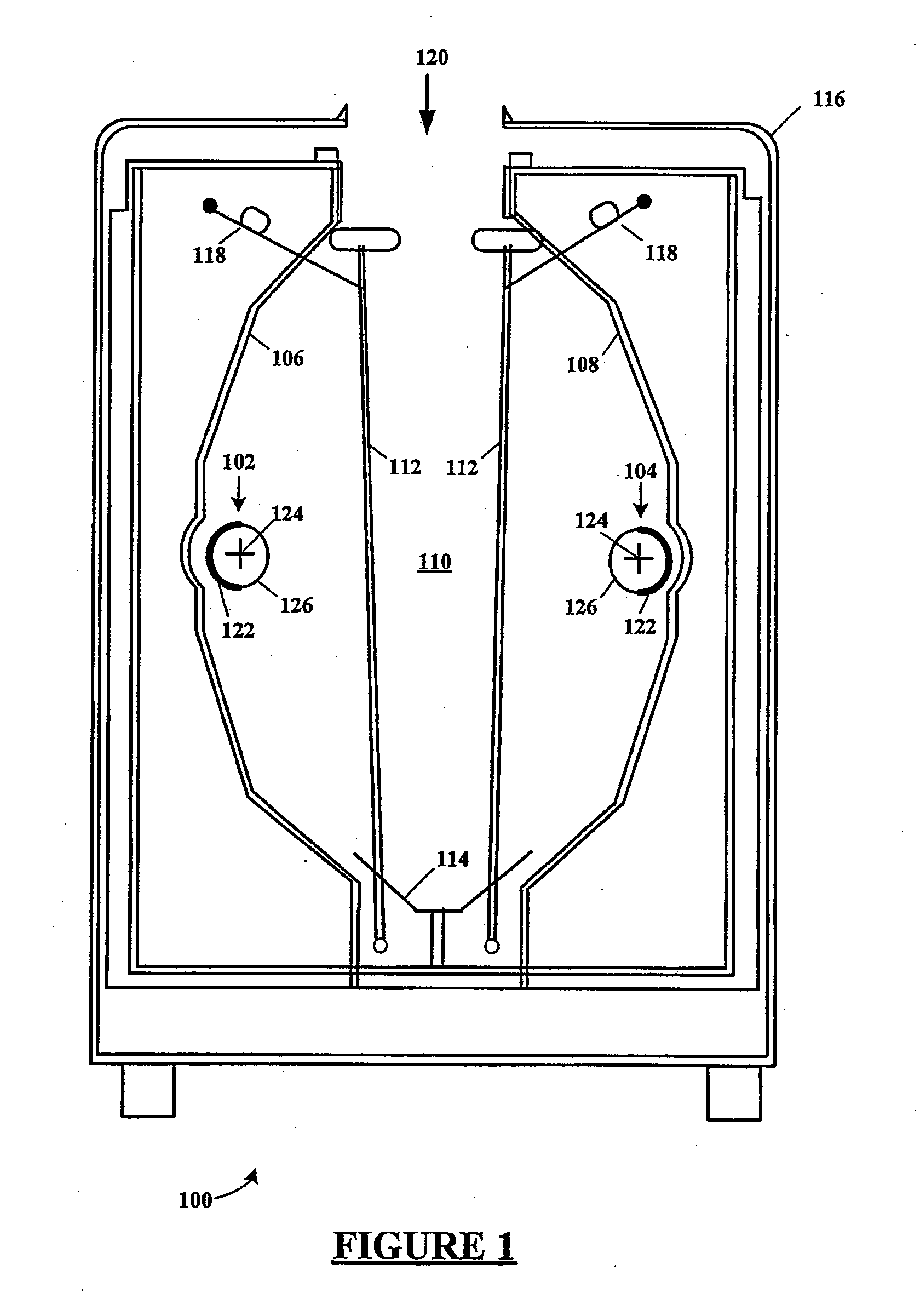

Toaster using infrared heating for reduced toasting time

ActiveUS20050132900A1Faster toastingFaster and even toastingDomestic stoves or rangesDrying solid materials with heatHeat penetrationProcess engineering

A toaster uses radiant heat at infrared wavelengths optimized for producing rapid and uniform toasting of a food product. The infrared wavelengths of the radiated heat are selected for optimum speed and quality (browning and moisture content) of the food product. The selected infrared wavelengths of the radiated heat may also effectively defrost a food product. Defrosting of the food product by the infrared radiated heat adds very little time in obtaining a desired toast color to the food product. A plurality of infrared wavelengths of radiated heat may also be used, wherein the plurality of infrared wavelengths are selected for optimal heat penetration and surface browning of the food product. Shorter wavelengths for browning and slightly longer wavelengths to penetrate the food product for evaporating the moisture therein to allow surface browning by the shorter wavelengths. In addition, the heating energy within the toaster may be further elongated (longer wavelengths) once the infrared radiation is re-radiated off of reflectors within the toaster. The wavelengths of infrared radiated heat may be from about 1 to about 3 microns, and preferably from about 1.96 to about 2.5 microns, and most preferably at about 2.11 microns.

Owner:APPLICA CONSUMER PRODS

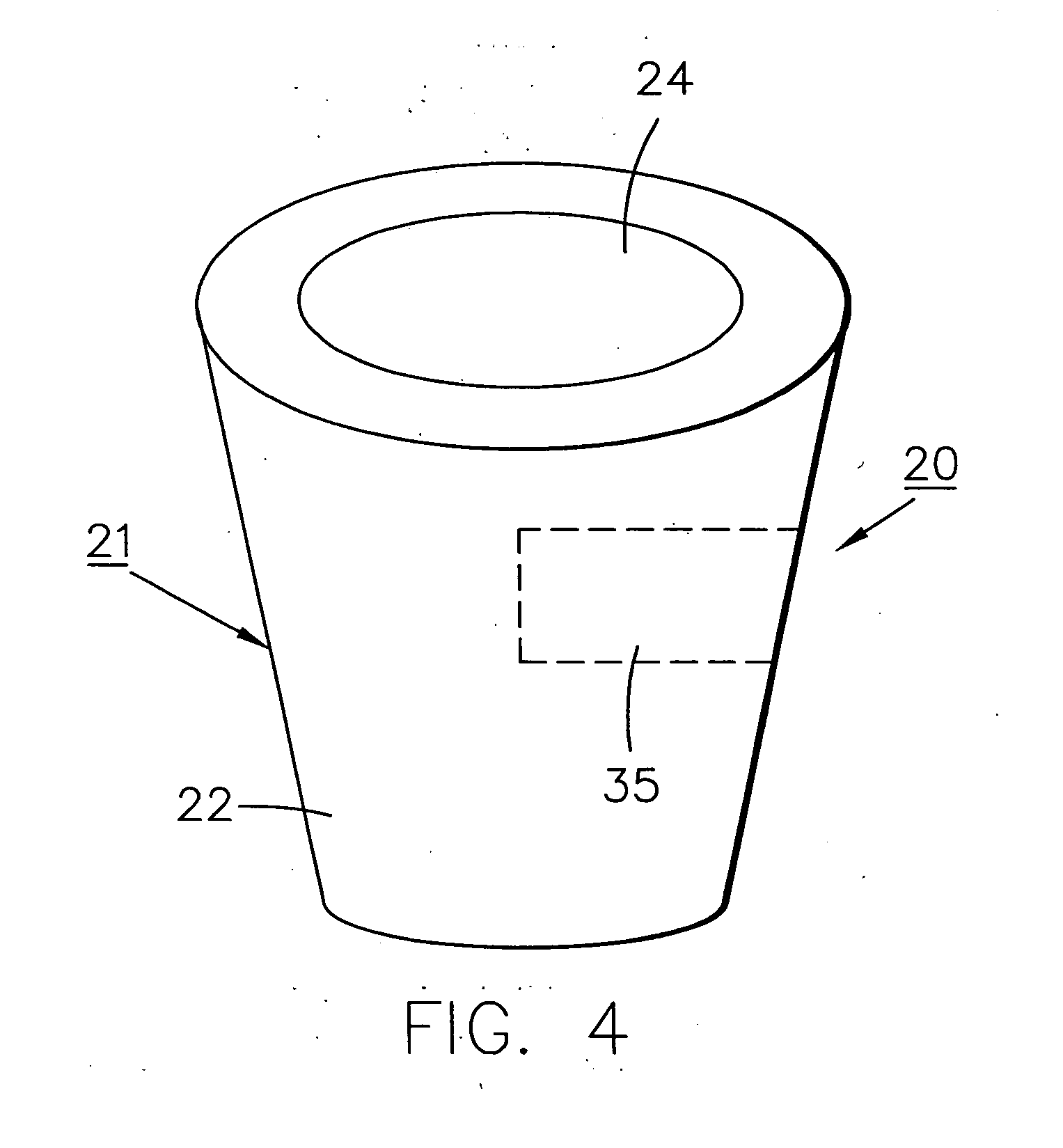

Multi-purpose combined drug delivery and heat therapy treatment system

InactiveUS20050208115A1Reduce deliveryWide applicabilityElectrotherapyAdhesive dressingsHeat penetrationSubcutaneous tissue

By providing an integrated, easily employed holding or support member which is uniquely constructed for cooperating with a heat delivery patch or exothermic pad for optimizing the application of heat directly to a precisely desired location, in combination with a selected medicine, a local, easily employed convenient, consumer oriented treatment system for providing heat therapy and medicine delivery for a wide variety of medical problems is achieved. In accordance with the present invention, a fully integrated treatment system is realized which possesses broad applicability for a wide range of medical conditions which can be treated or improved by heat penetration into the skin, subcutaneous tissues, joints, muscles, blood streams, etc. In addition, the delivery of drugs, penetration enhancing agents and / or cosmetics through the skin for the purpose of achieving a non-oral and / or non-parenteral, systemic, transdermal delivery is effectively enhanced by the presence of a controlled heat gradient.

Owner:DVORETZKY ISRAEL +1

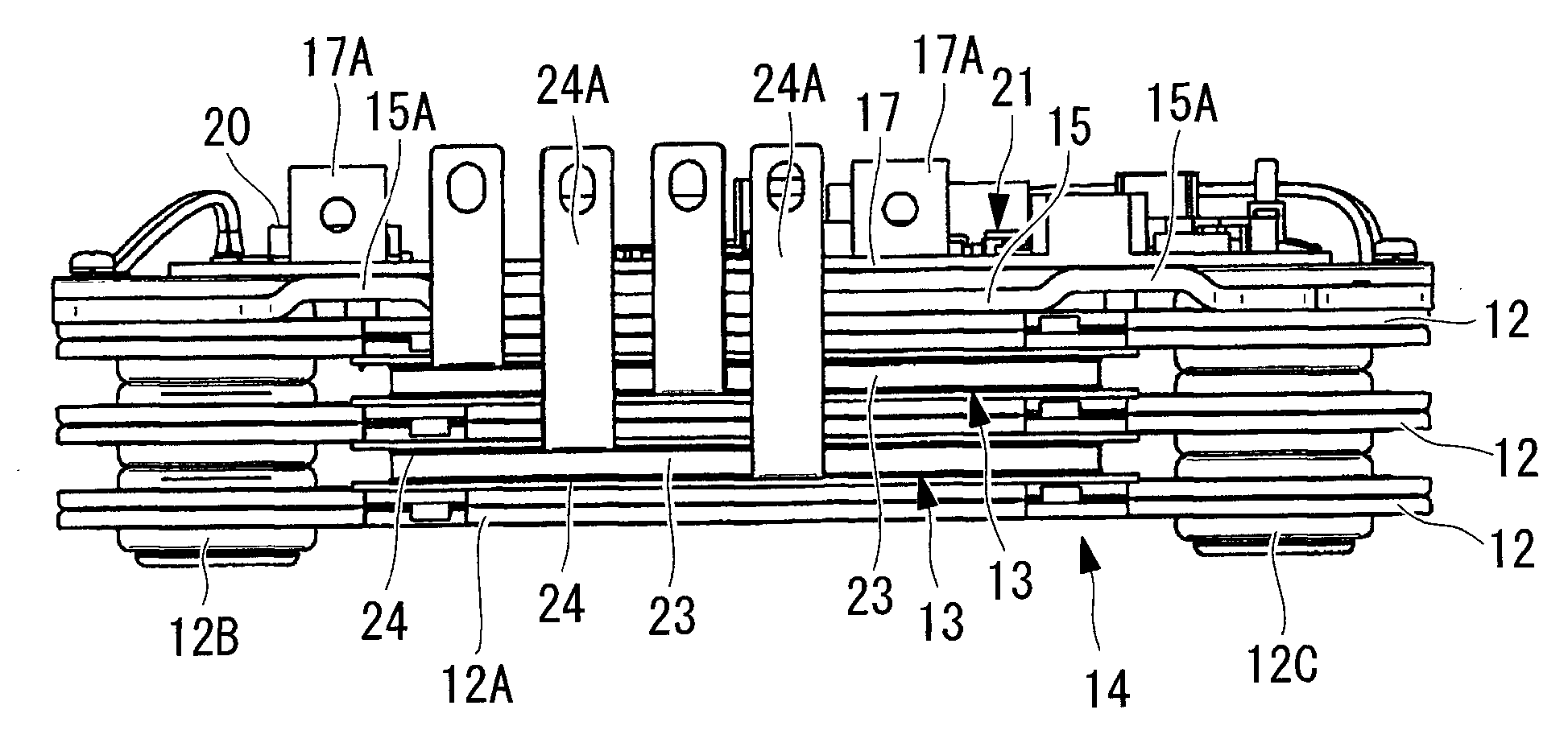

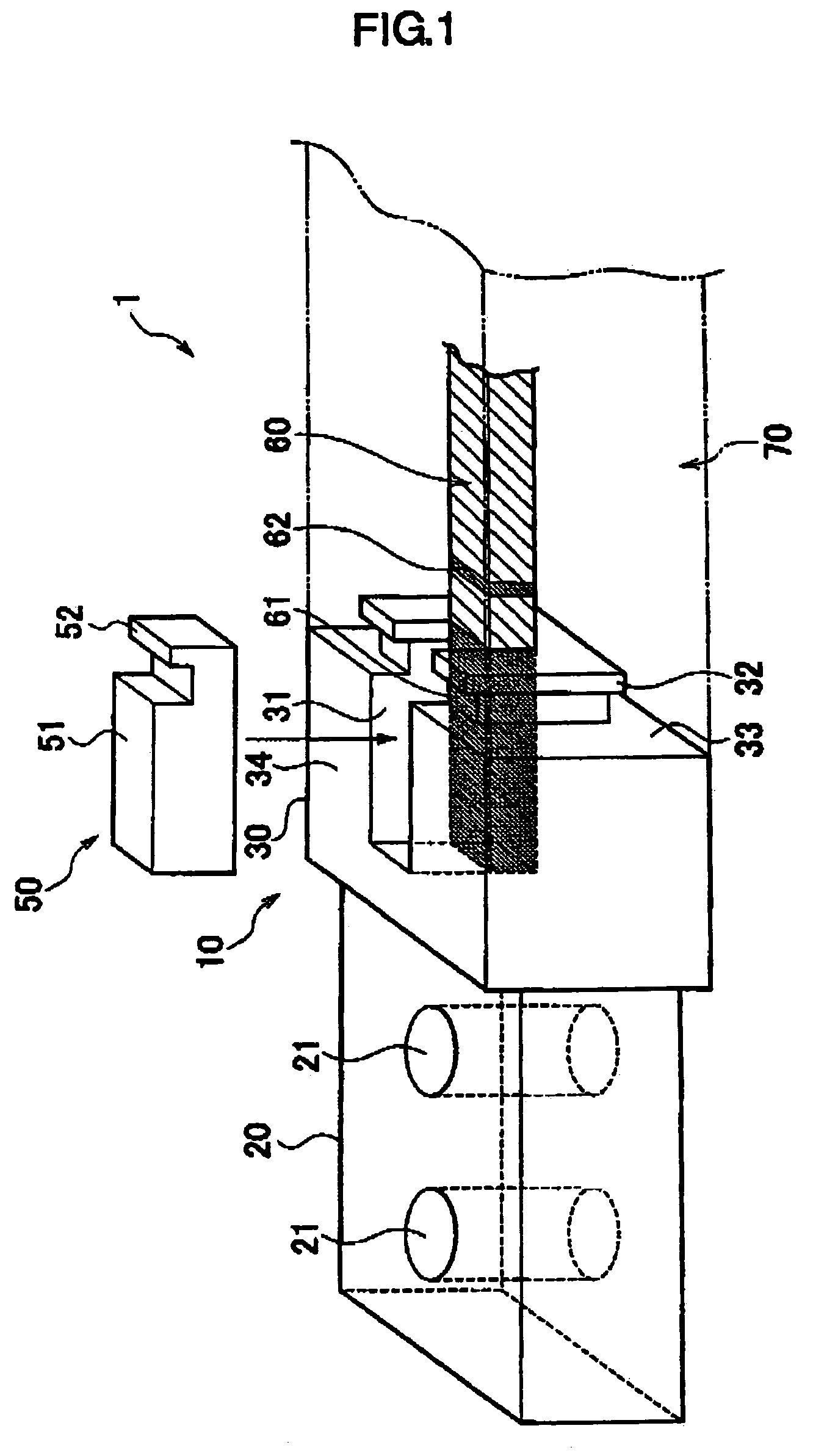

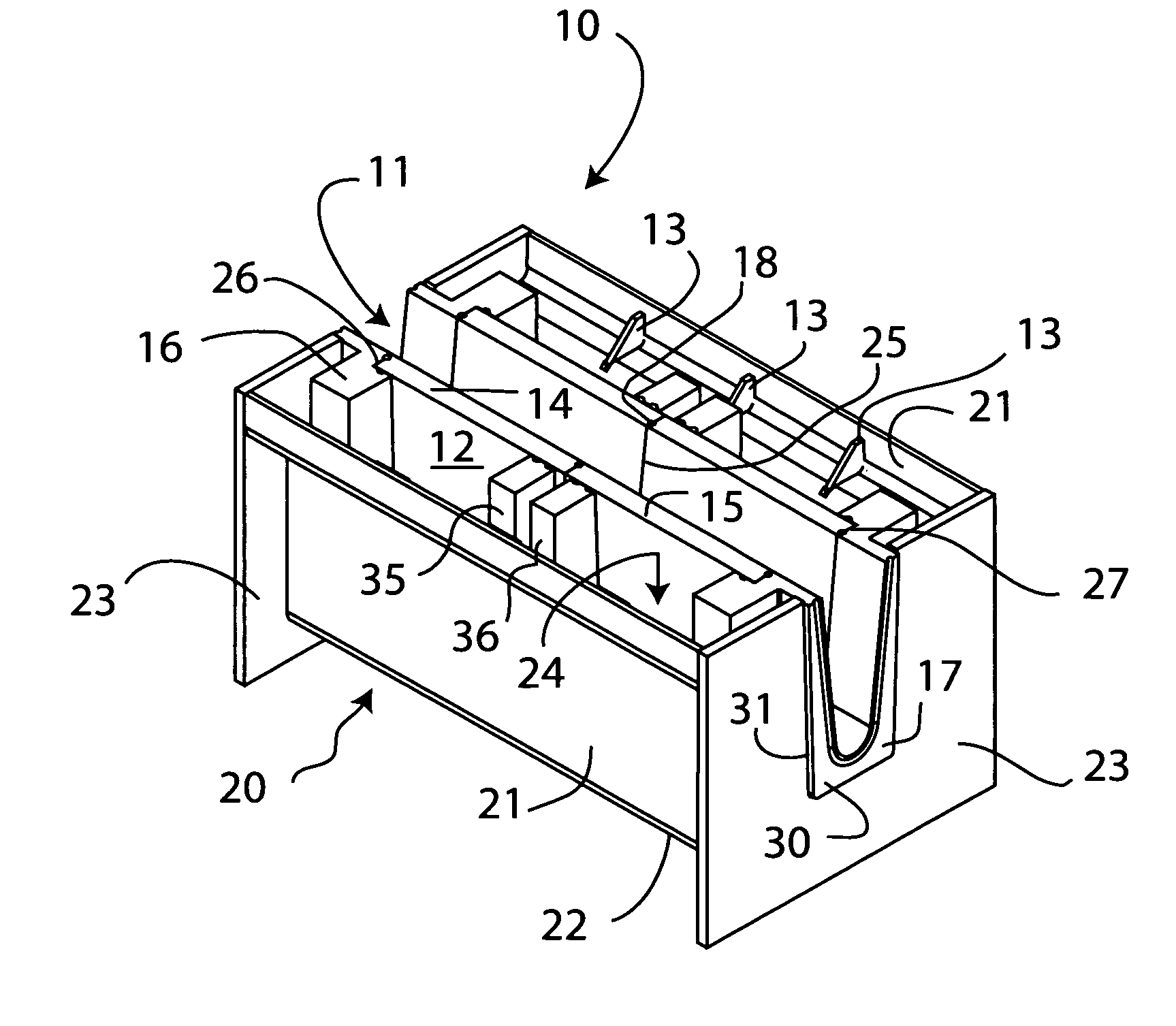

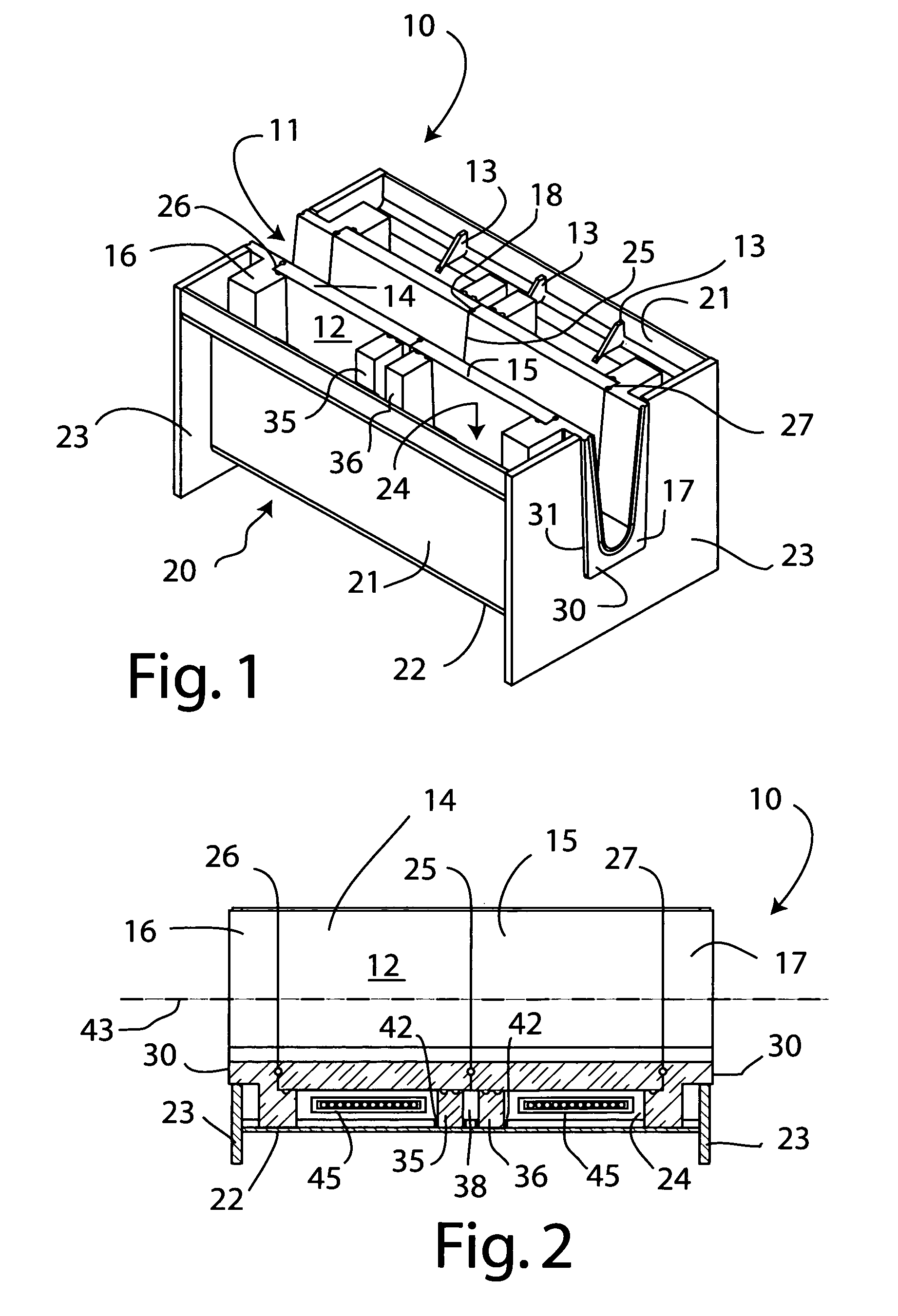

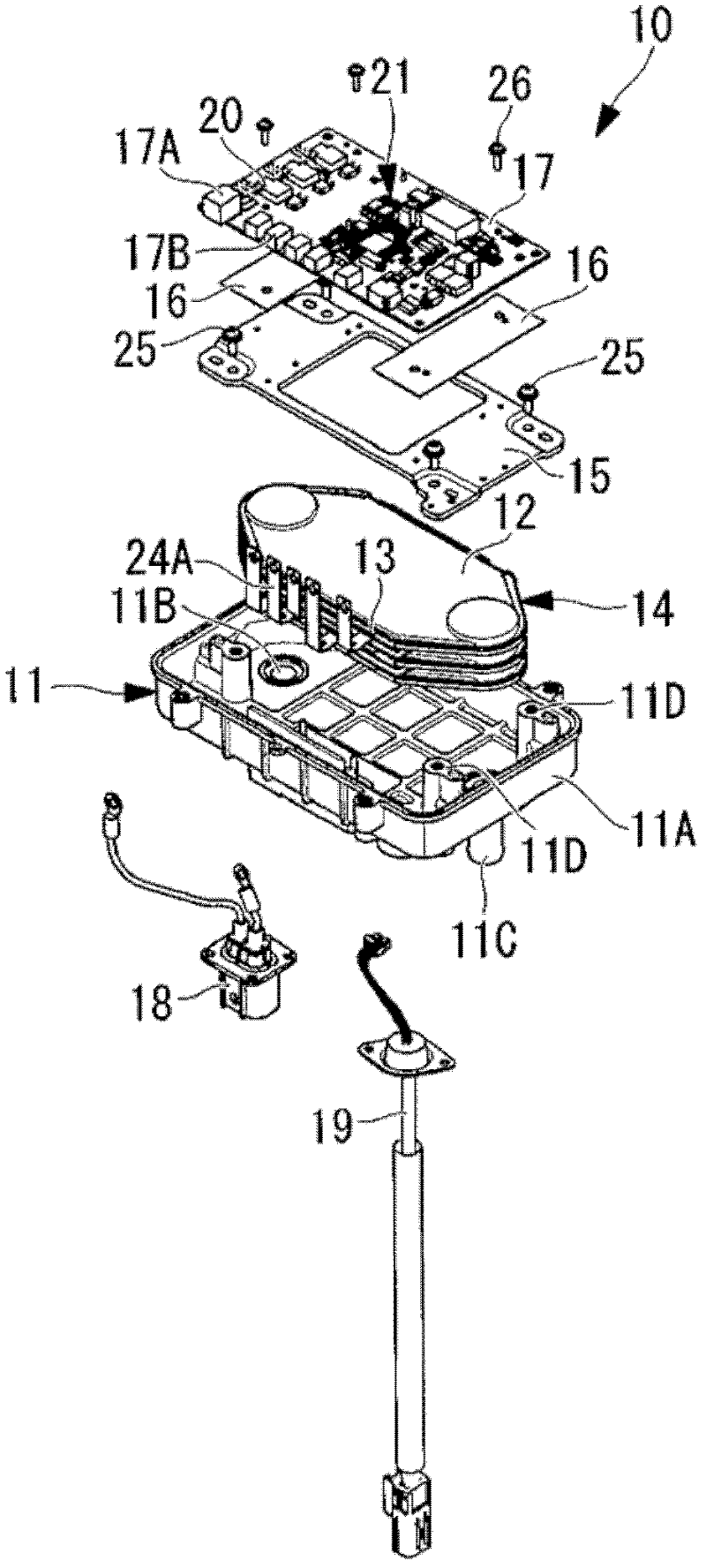

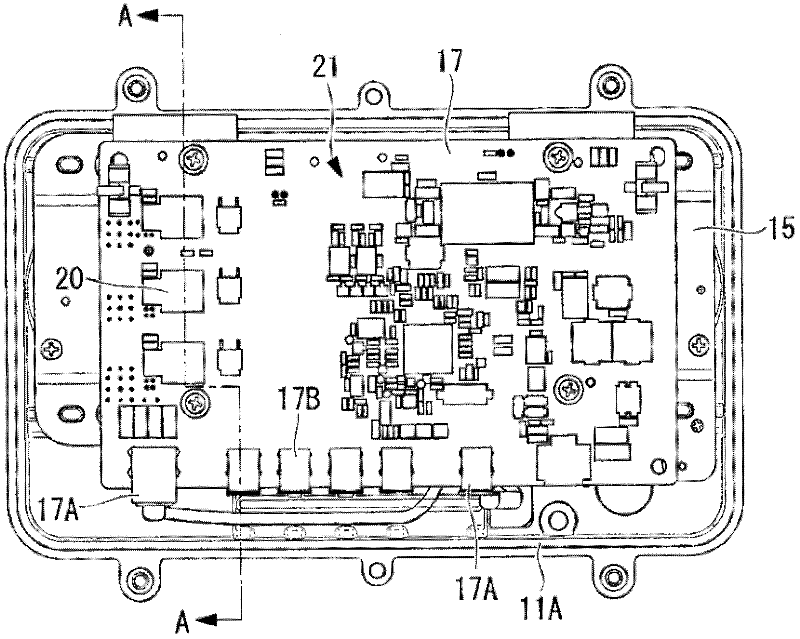

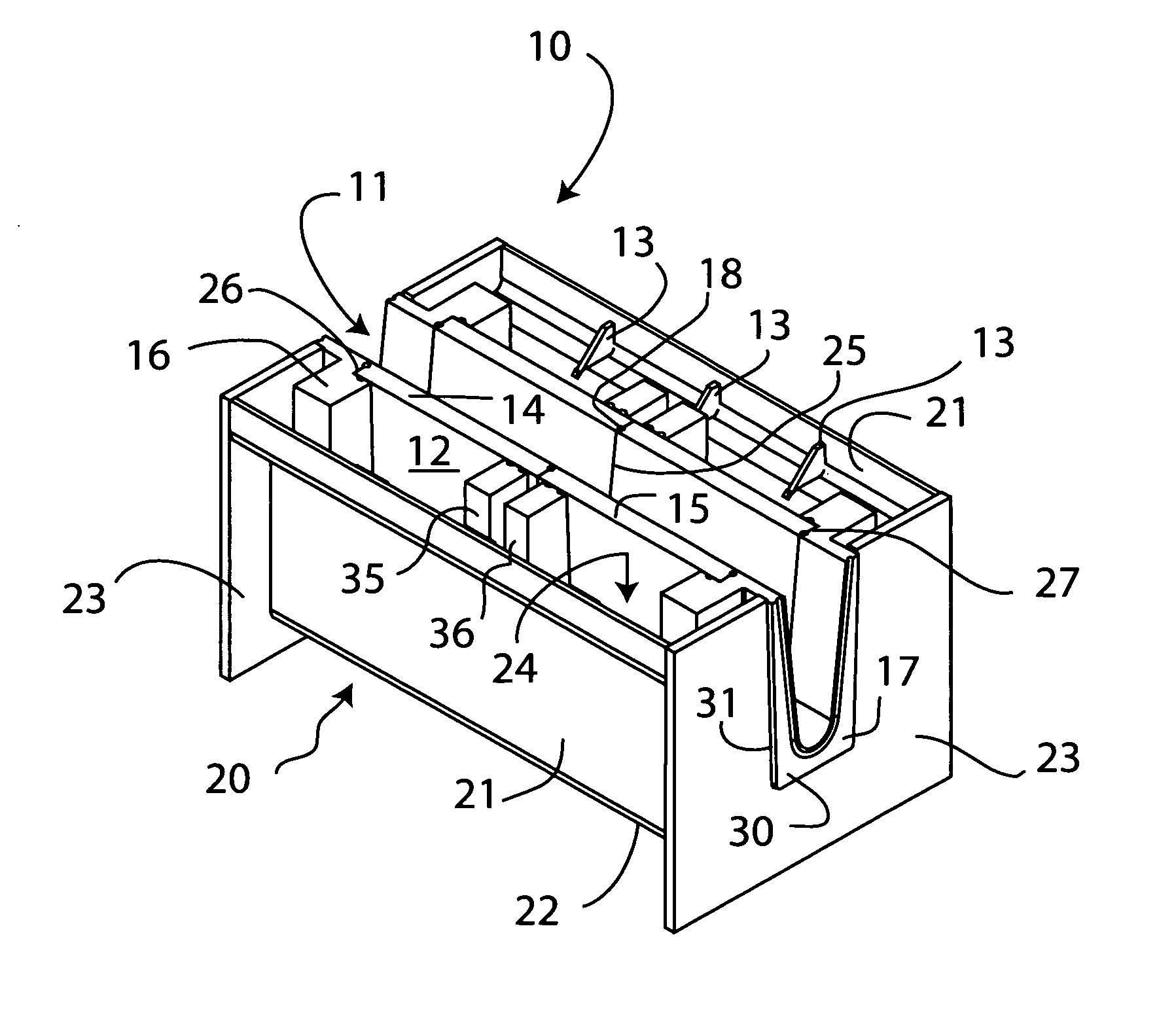

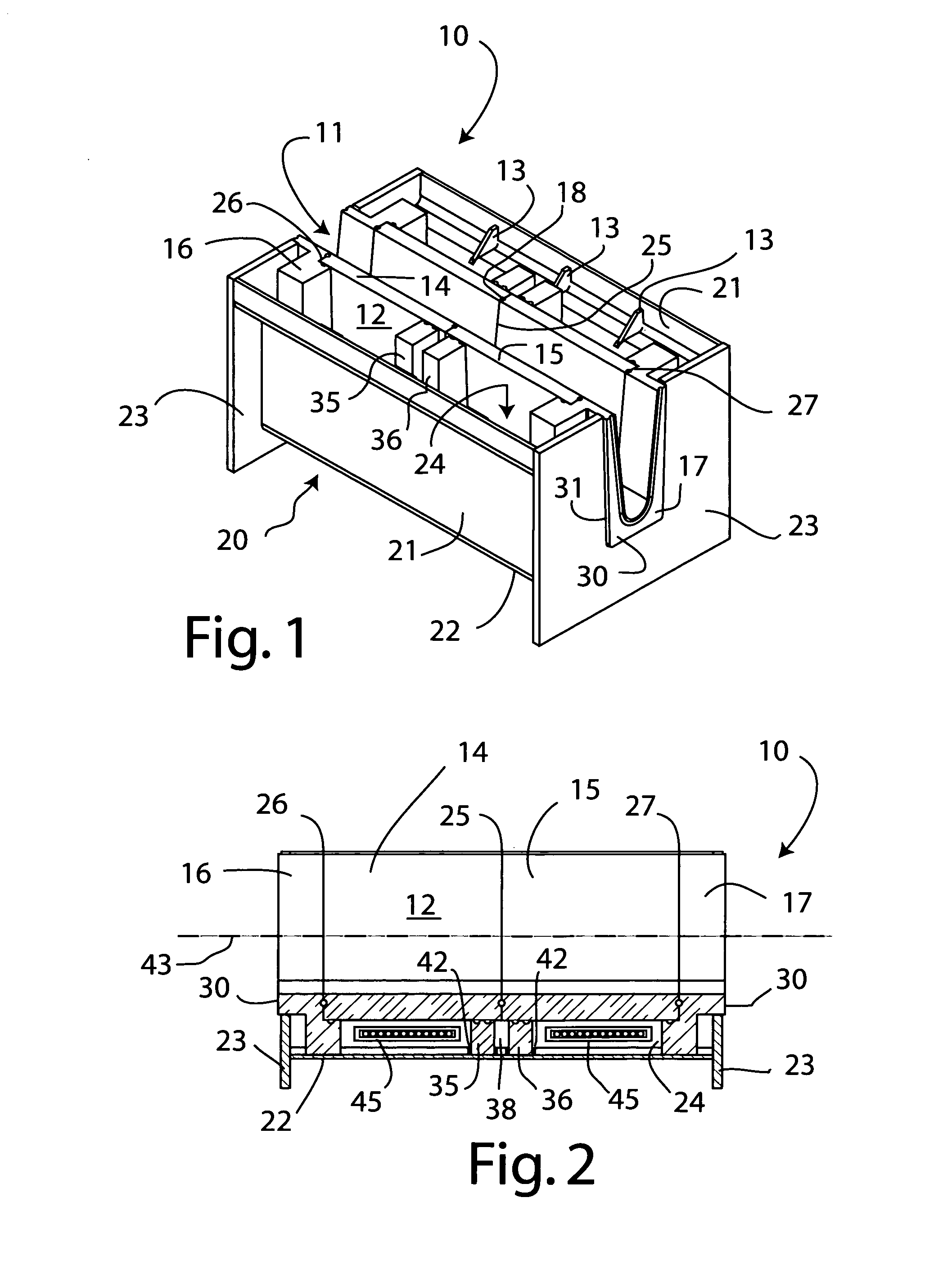

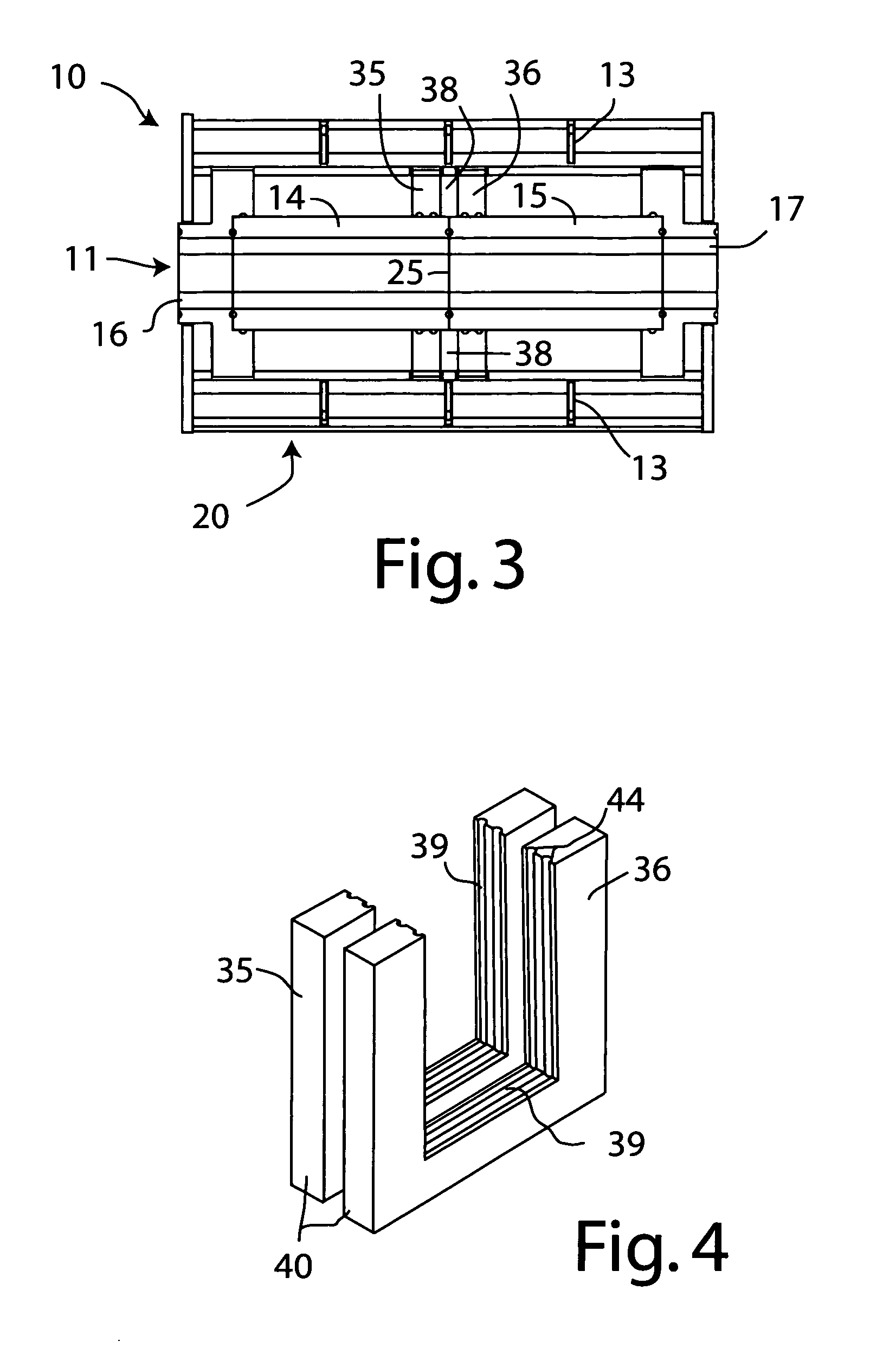

Heat medium heating apparatus and vehicular air-conditioning system including the same

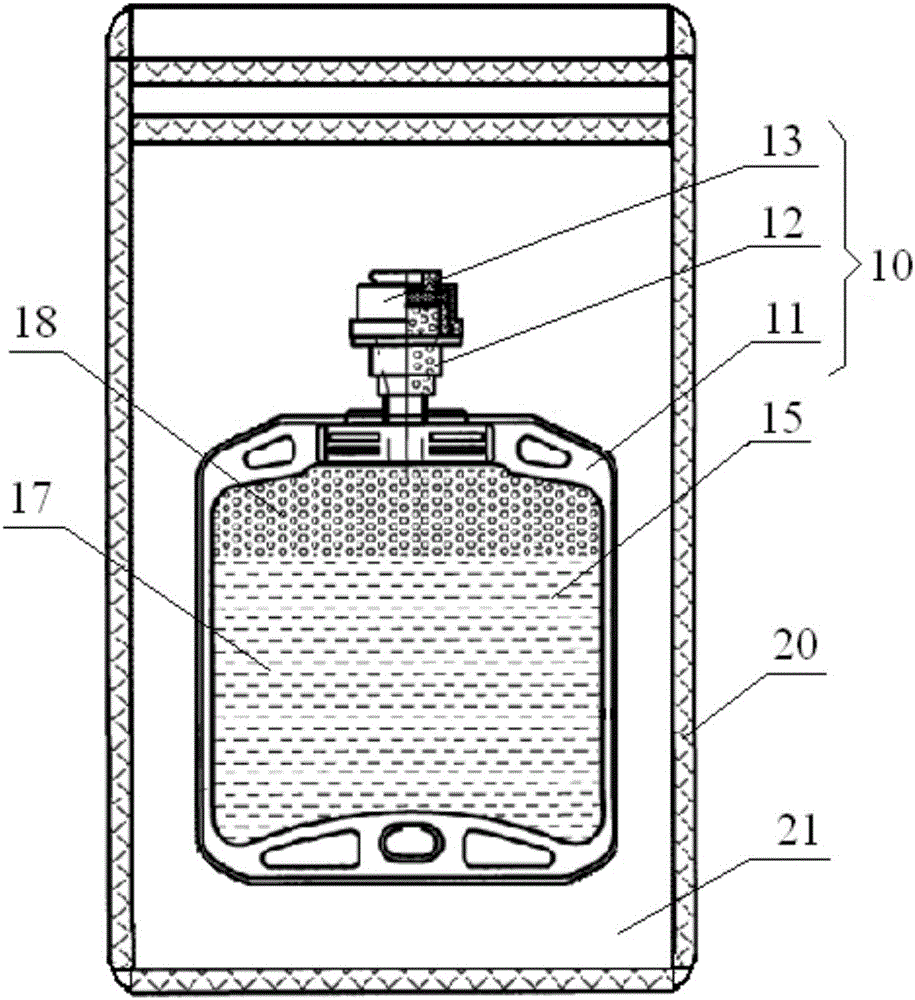

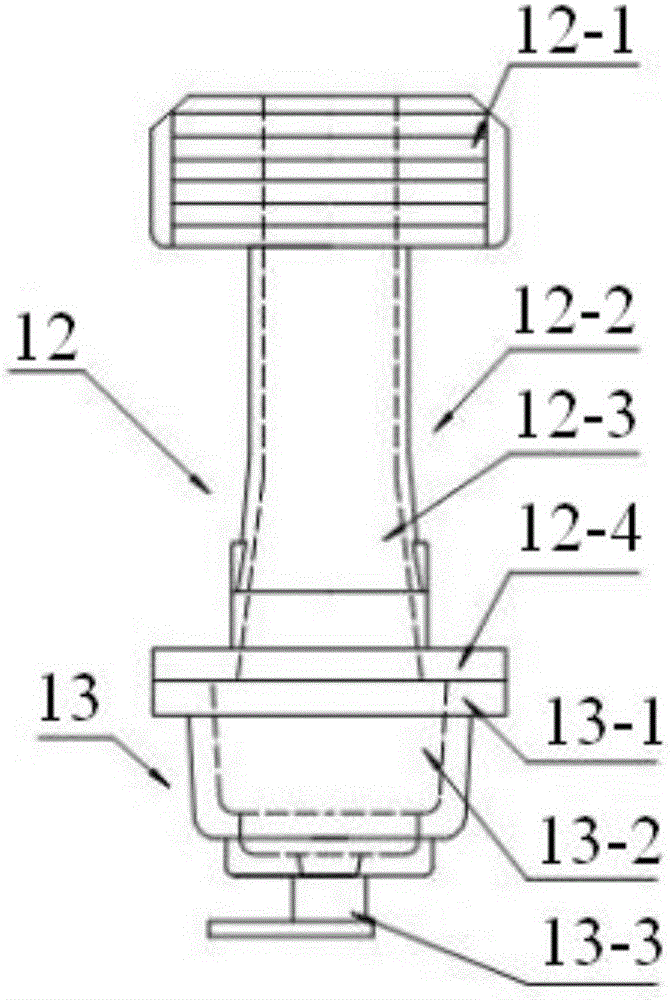

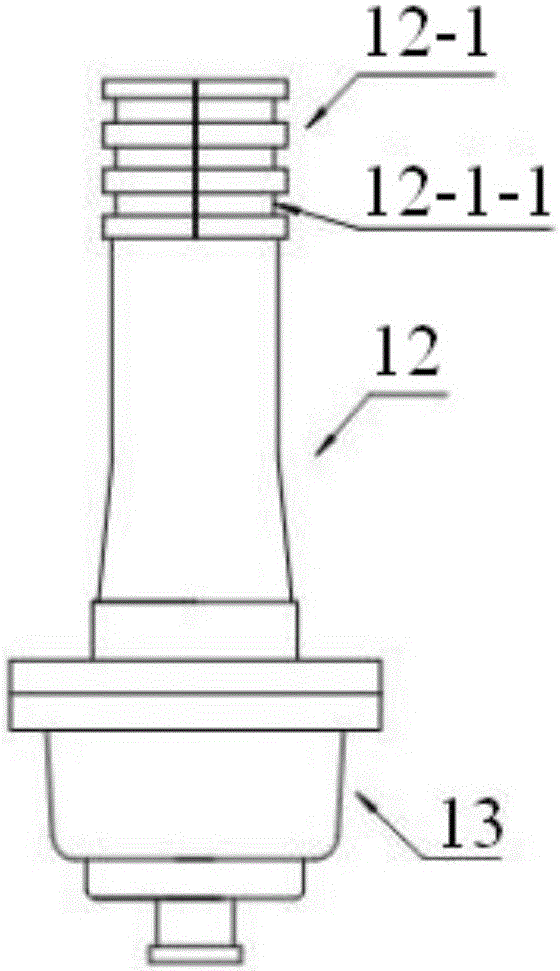

InactiveUS20120237192A1Small sizeImprove performanceAir heatersVehicle heating/cooling devicesPlate heat exchangerHeat penetration

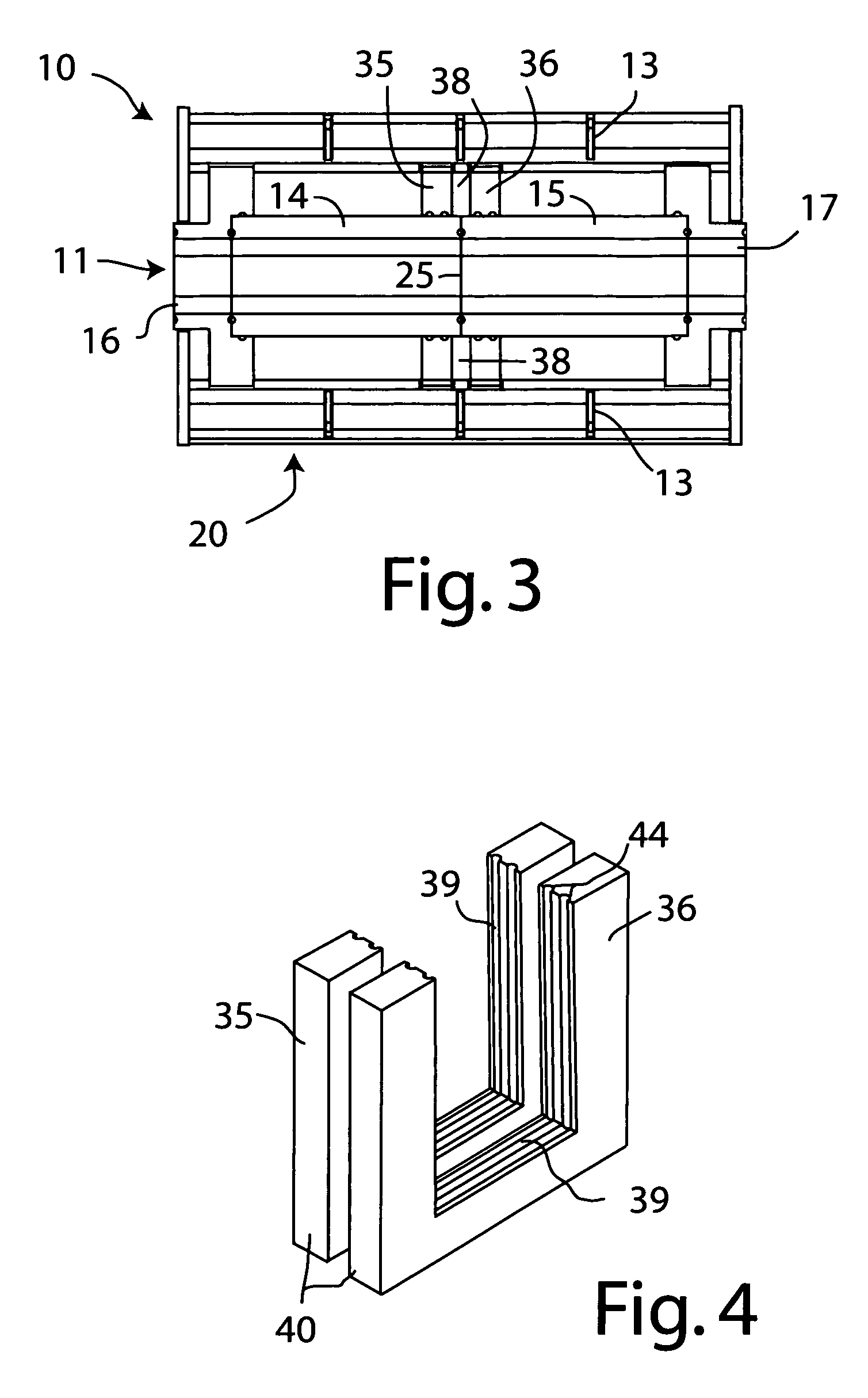

Provided is a heat medium heating apparatus including: a plurality of flat heat exchanger tubes 12; PTC heaters 13 that are respectively incorporated between flat tube parts of the flat heat exchanger tubes 12; a heat exchanger holding member 15 that press-fixes the flat heat exchanger tubes 12 and the PTC heaters 13, from one side of the flat heat exchanger tubes 12 to an inner surface of a casing 11; and a control board 17 that has a surface on which a control circuit 21 is mounted, the control circuit 21 including heat-generating electrical components 20 that control the PTC heaters 13, in which the control board 17 includes heat penetration parts that are formed so as to pass through the control board 17 correspondingly to mounting positions of the heat-generating electrical components 20, and the heat-generating electrical components 20 are mounted so as to be cooled via the heat penetration parts.

Owner:MITSUBISHI HEAVY IND LTD

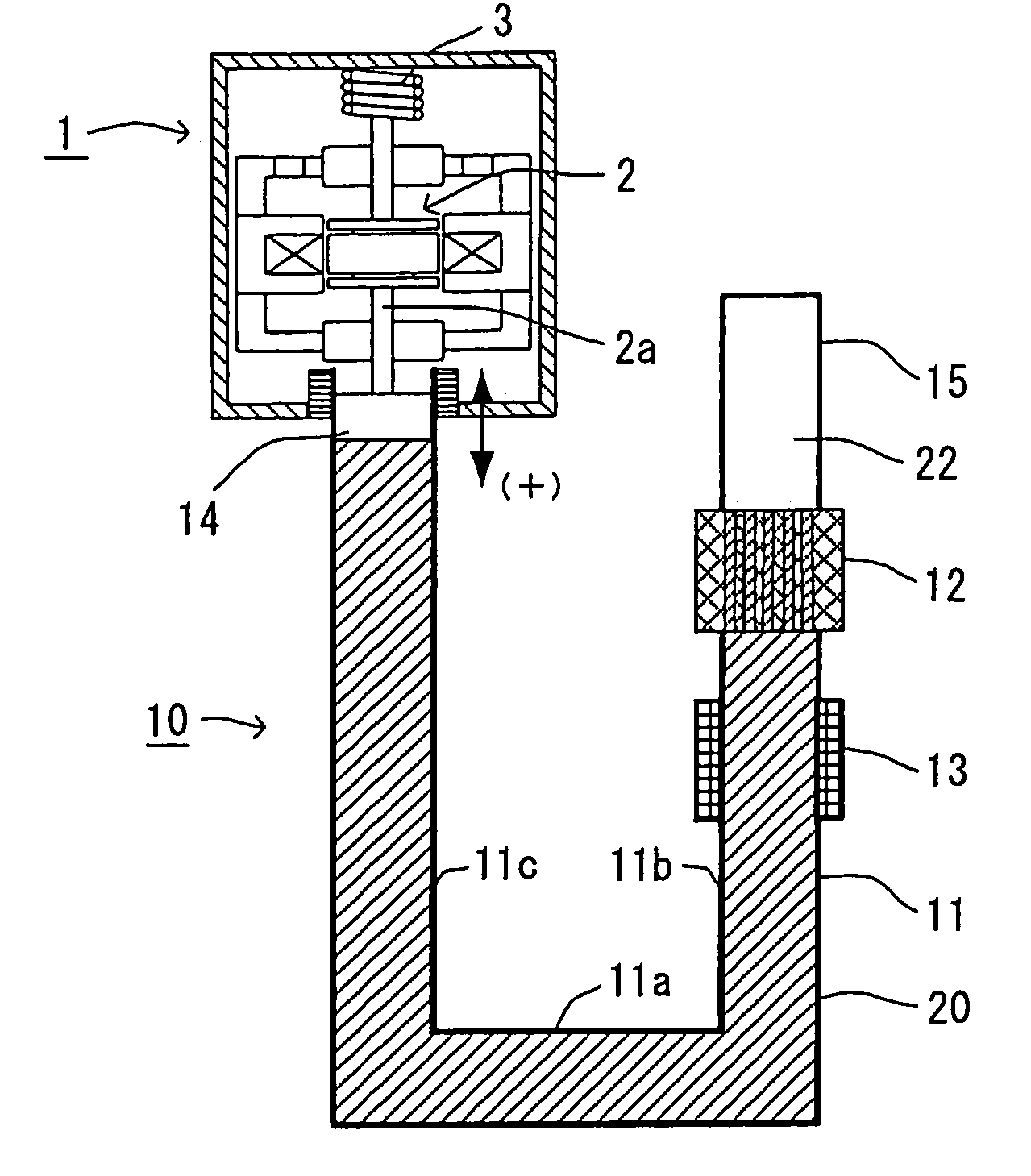

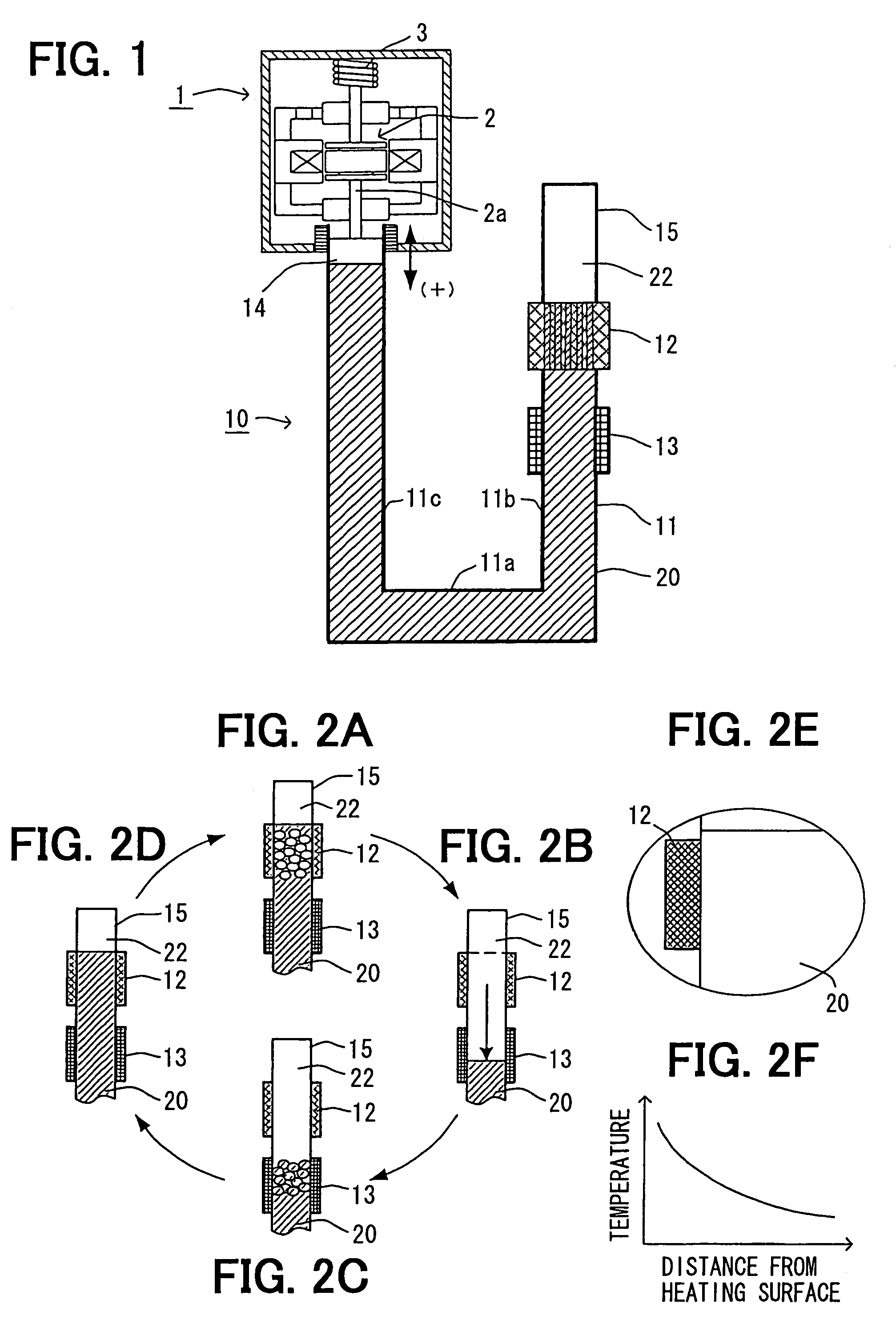

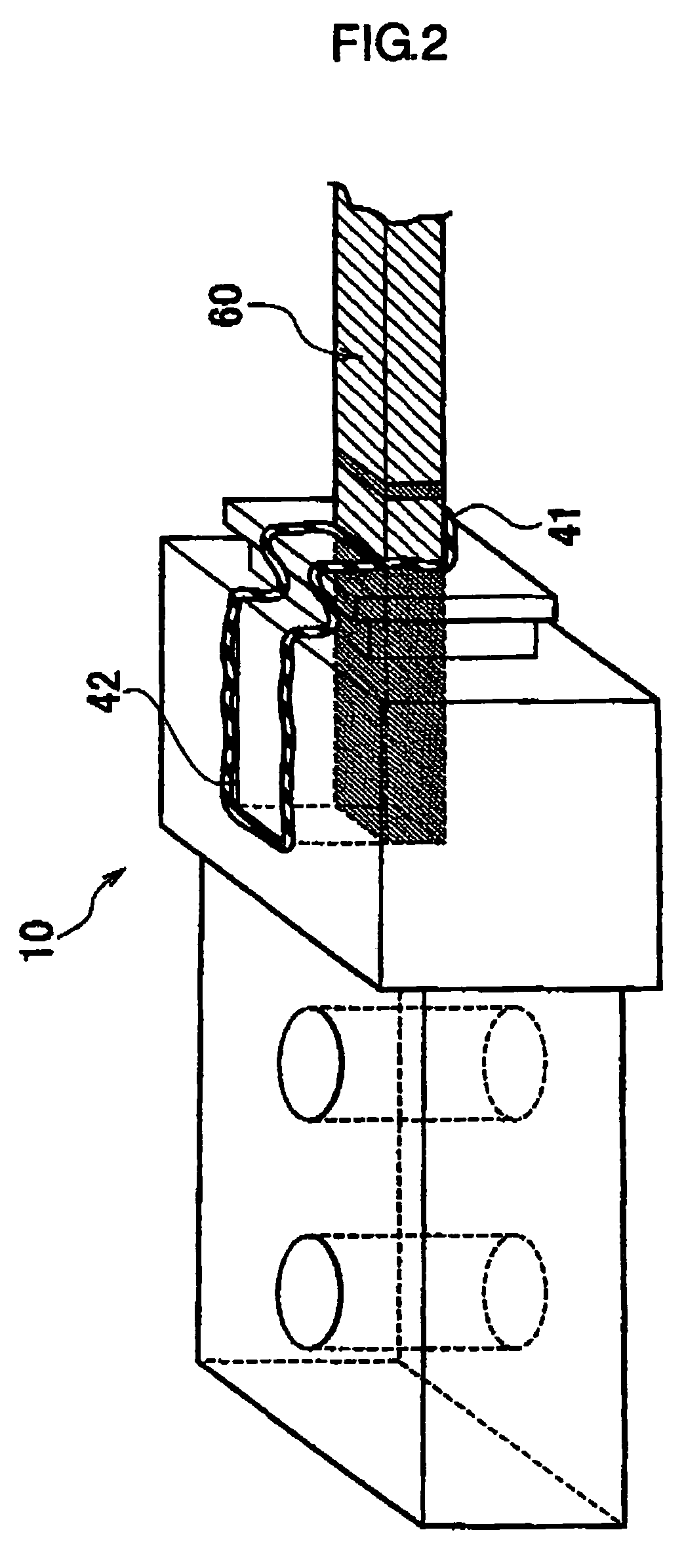

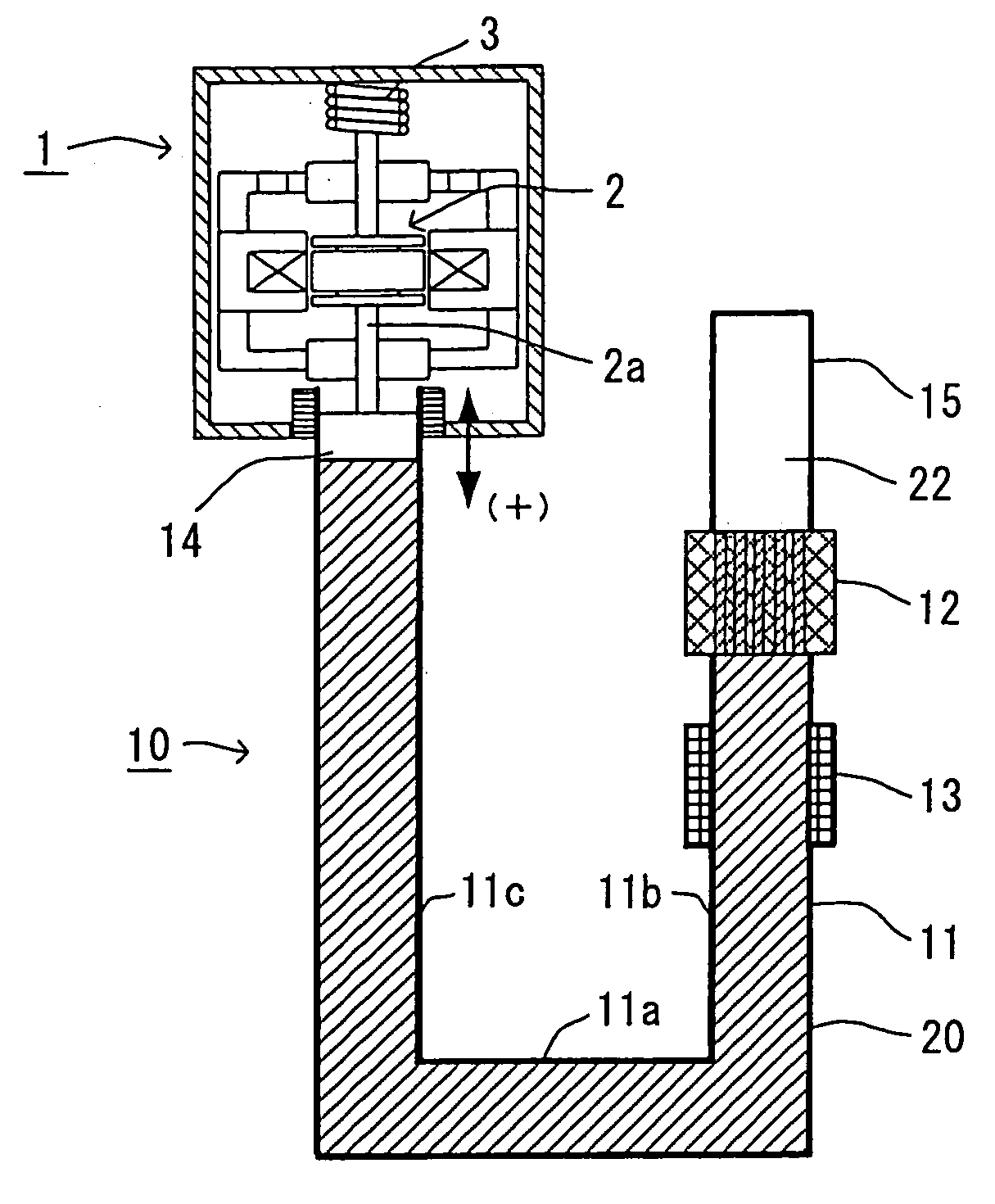

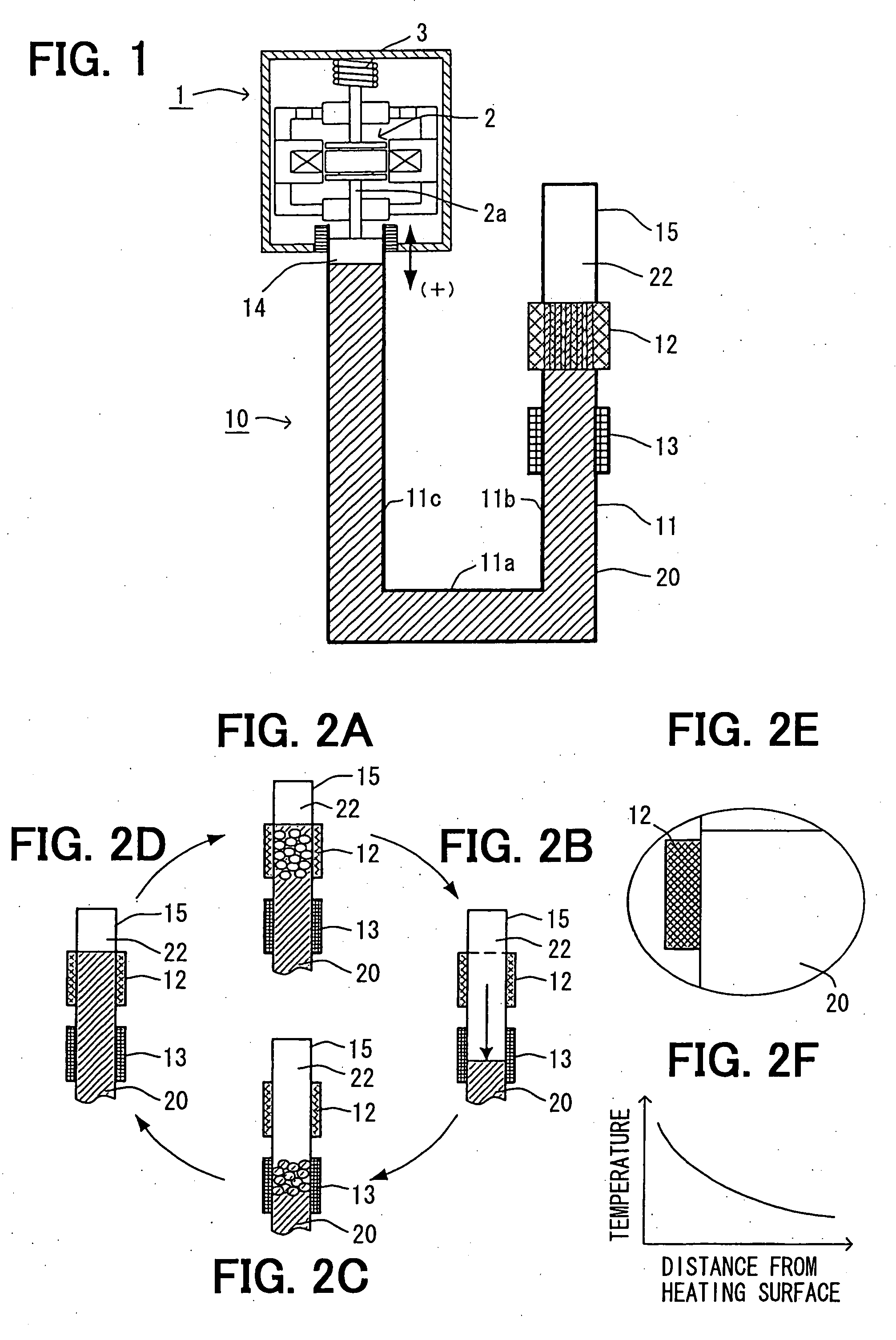

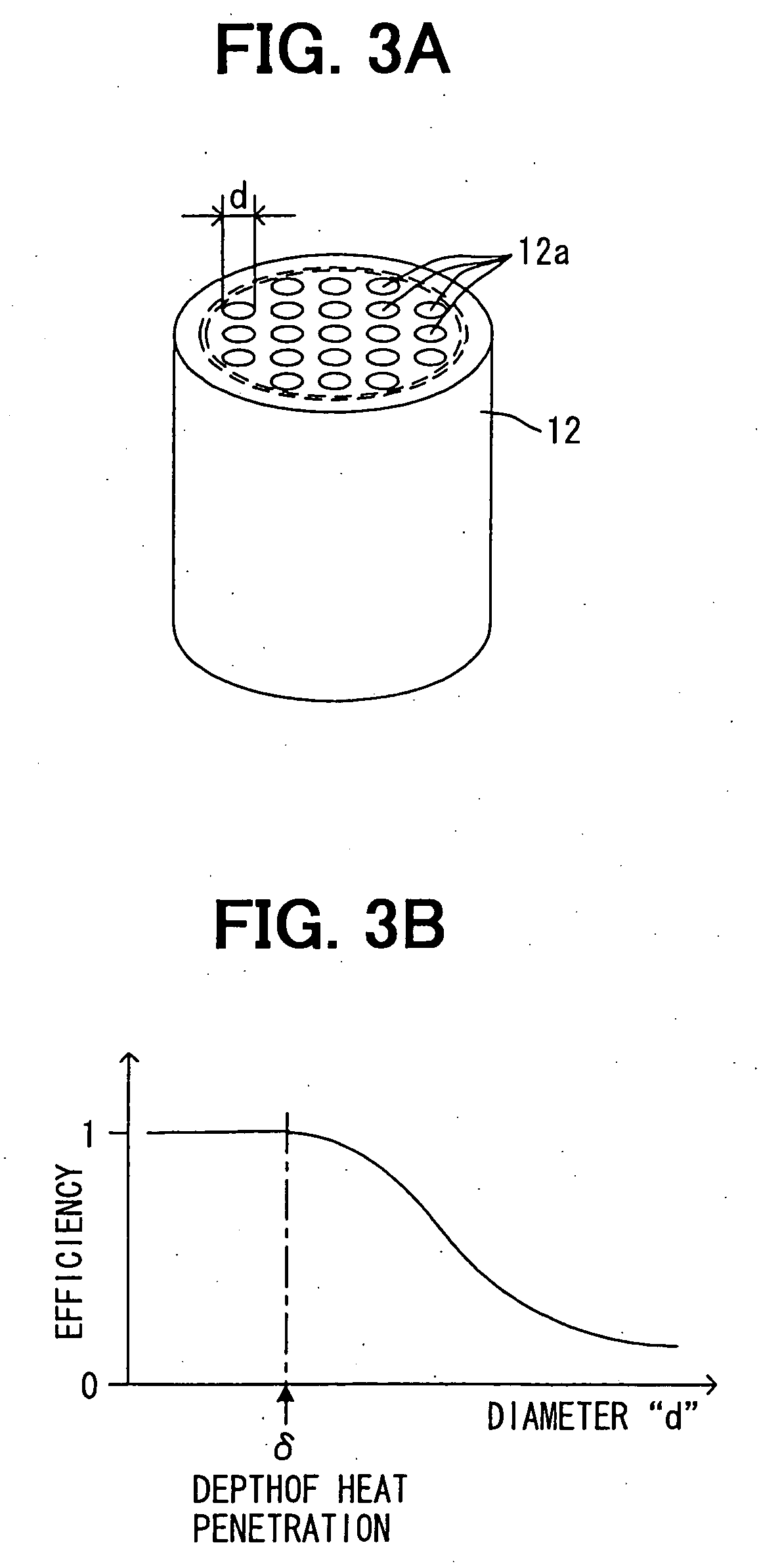

Steam engine

InactiveUS6976360B1Heat generationReduce heat lossSteam accumulatorsSteam engine plantsWorking fluidThermal diffusivity

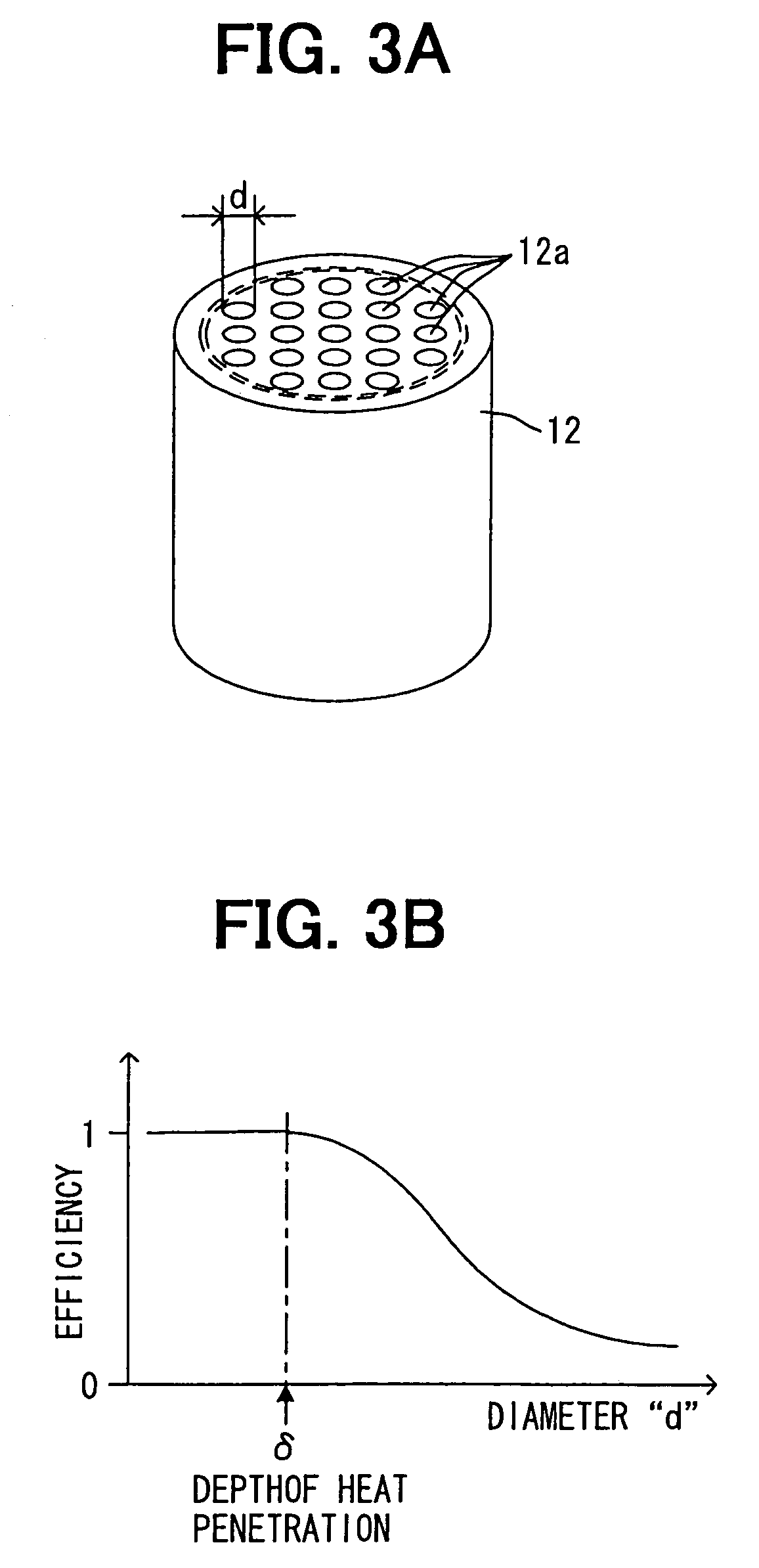

A steam engine has a fluid container, a heating device and a cooling device provided at the fluid container for heating and cooling working fluid filled in the fluid container, so that a part of the working fluid is heated and vaporized to move the liquid-phase working fluid in one direction. When the vaporized steam is cooled and liquidized, the pressure of the working fluid in the fluid container is decreased, to thereby move the liquid-phase working fluid in the backward direction. Kinetic energy is thereby generated by using the back and forth movement of the working fluid. The heating device has multiple through-holes, through which the working fluid flows and heated by a heating surface (an inner surface of the through-holes) of the heating device, wherein a diameter “d” of the through-hole is made almost equal to or smaller than a depth of heat penetration “δ”, which is determined by the following formula:δ=√{square root over (2a / ω)}wherein “a” is a heat diffusivity of the working fluid, and“ω” is an angular frequency of the working fluid during the working fluid is periodically moved back and forth.

Owner:DENSO CORP

Single-cone drier for feeding liquid continuously

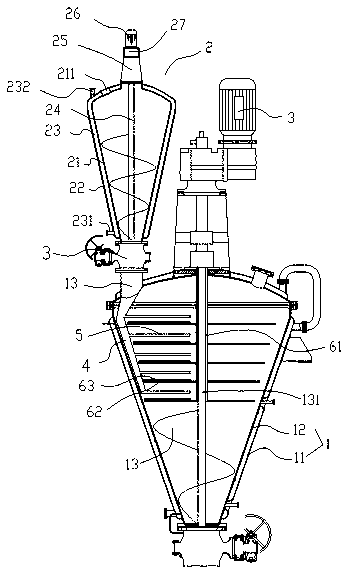

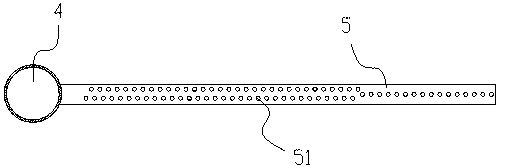

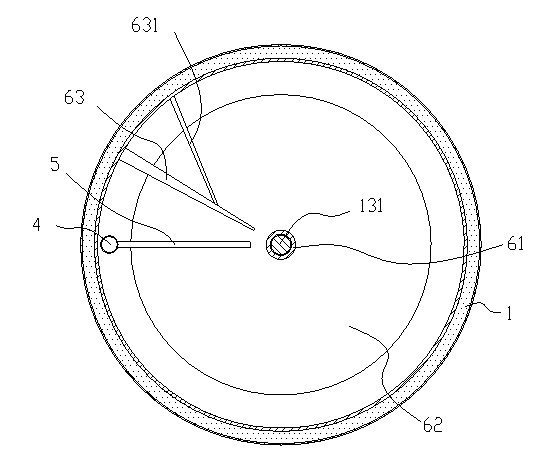

InactiveCN103234334ARealize continuous feedingVoid physicalEvaporationDrying machines with non-progressive movementsChemical reactionLiquid state

The invention discloses a single-cone drier for feeding liquid continuously. The single-cone drier comprises a conical drier body, wherein a stirrer is arranged inside the drier body, and is driven by a motor through a spindle; the drier is provided with a liquid-flow type predrying continuous feeding device; the continuous feeding device comprises two parts, namely a liquid-flow structure and a predrying structure; the liquid-flow structure is arranged on a feed opening of the drier body, and comprises a feeding barrel; the lower part of the feeding barrel is communicated with a liquid flow path stretching into the drier body through a valve; a plurality of branch tubes are inwardly arranged in the liquid flow path; and a plurality of small liquid-flow holes are formed in the lower side of each branch tube and corresponding to the predrying structure. By adopting the single-cone drier for feeding liquid continuously, for solid state feeding of materials, solvation of the materials due to physical, chemical reactions can be avoided, and then the material huddle into blocks can be avoided; for liquid state direct feeding of materials with poor heat penetration capacities, lumping solidification and wall-hanging coaking in the drying process can be avoided; and moreover, the application range of the single-cone drier can be greatly expanded, and emission of atmospheric pollutant can be greatly reduced.

Owner:马锡林

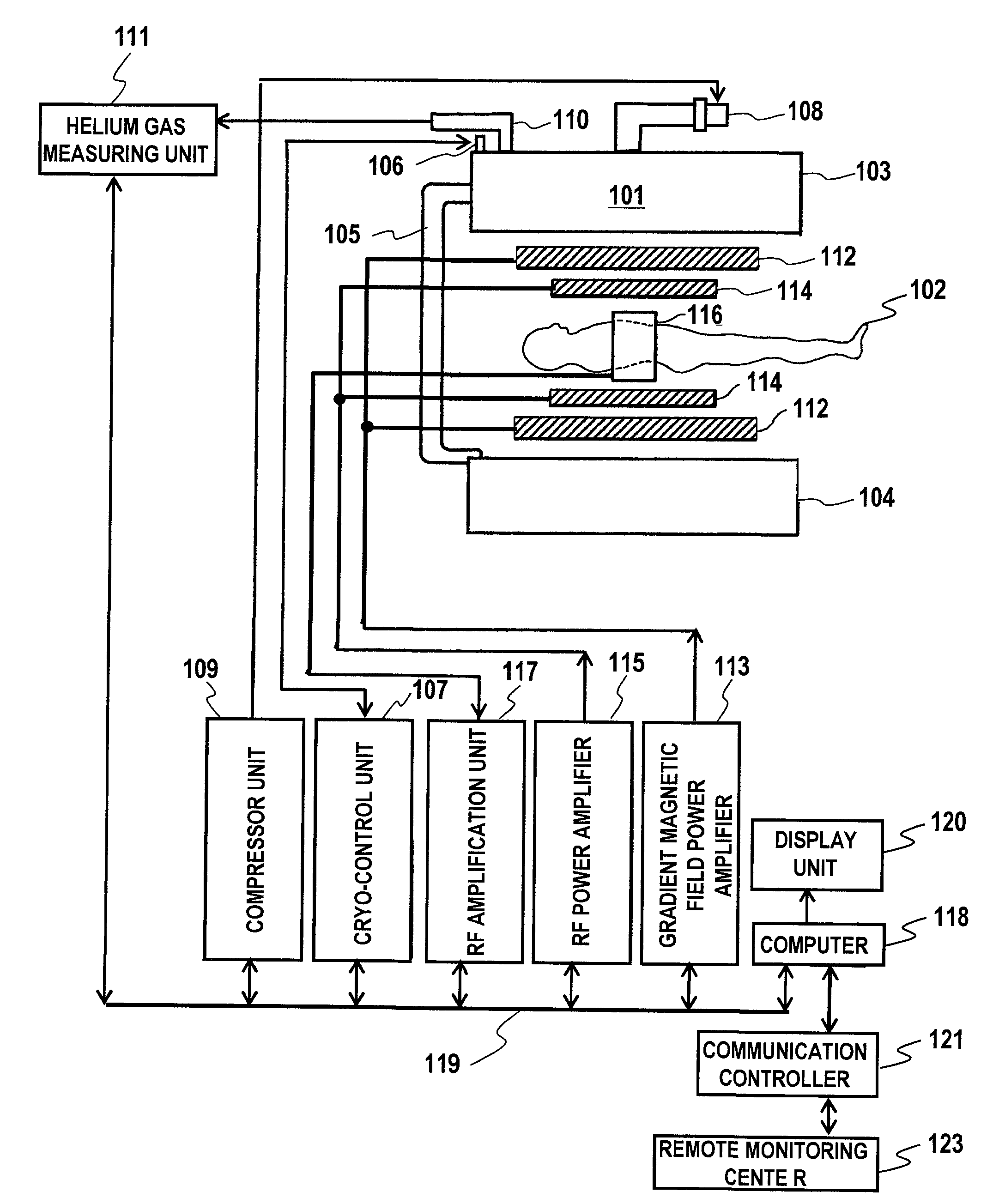

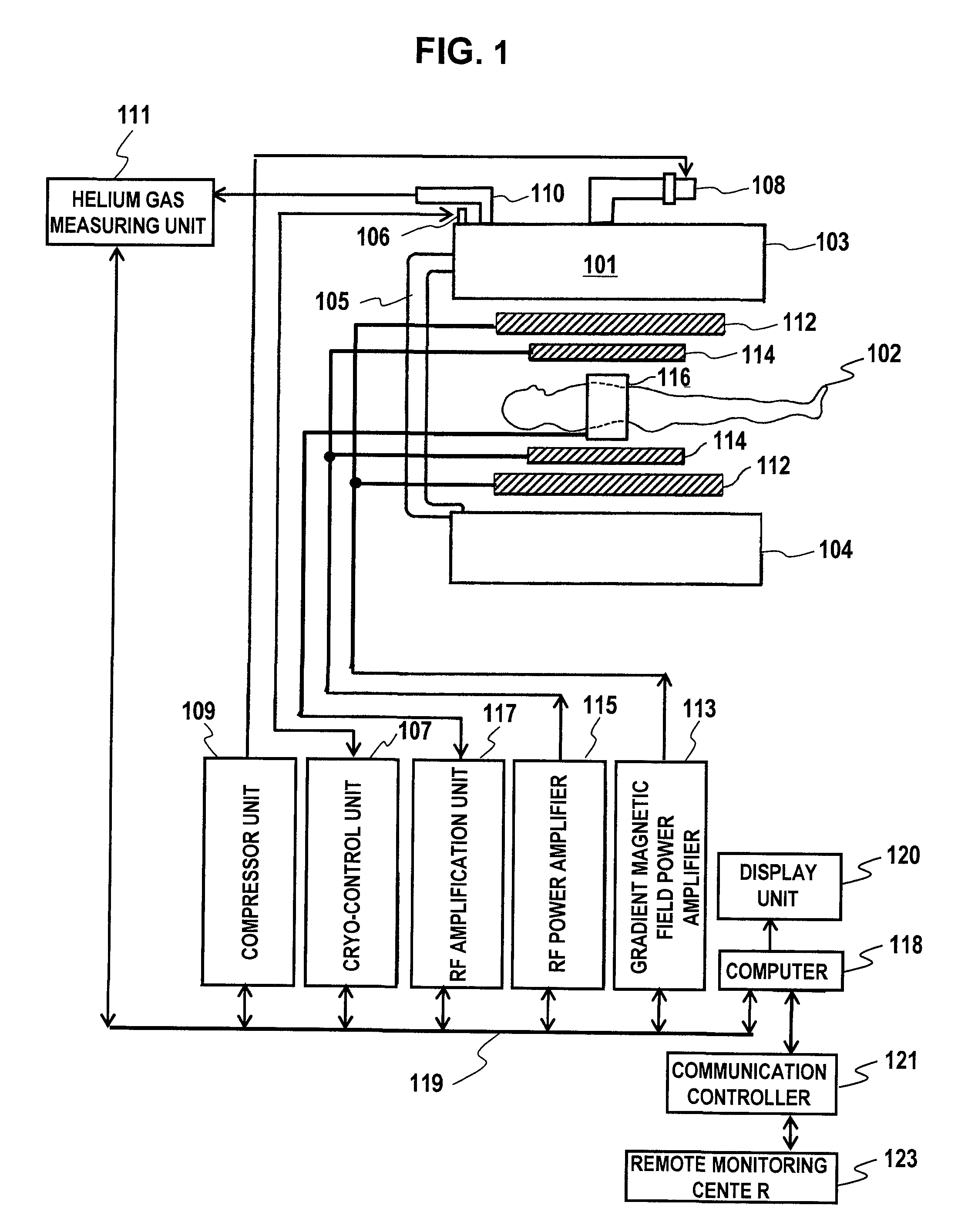

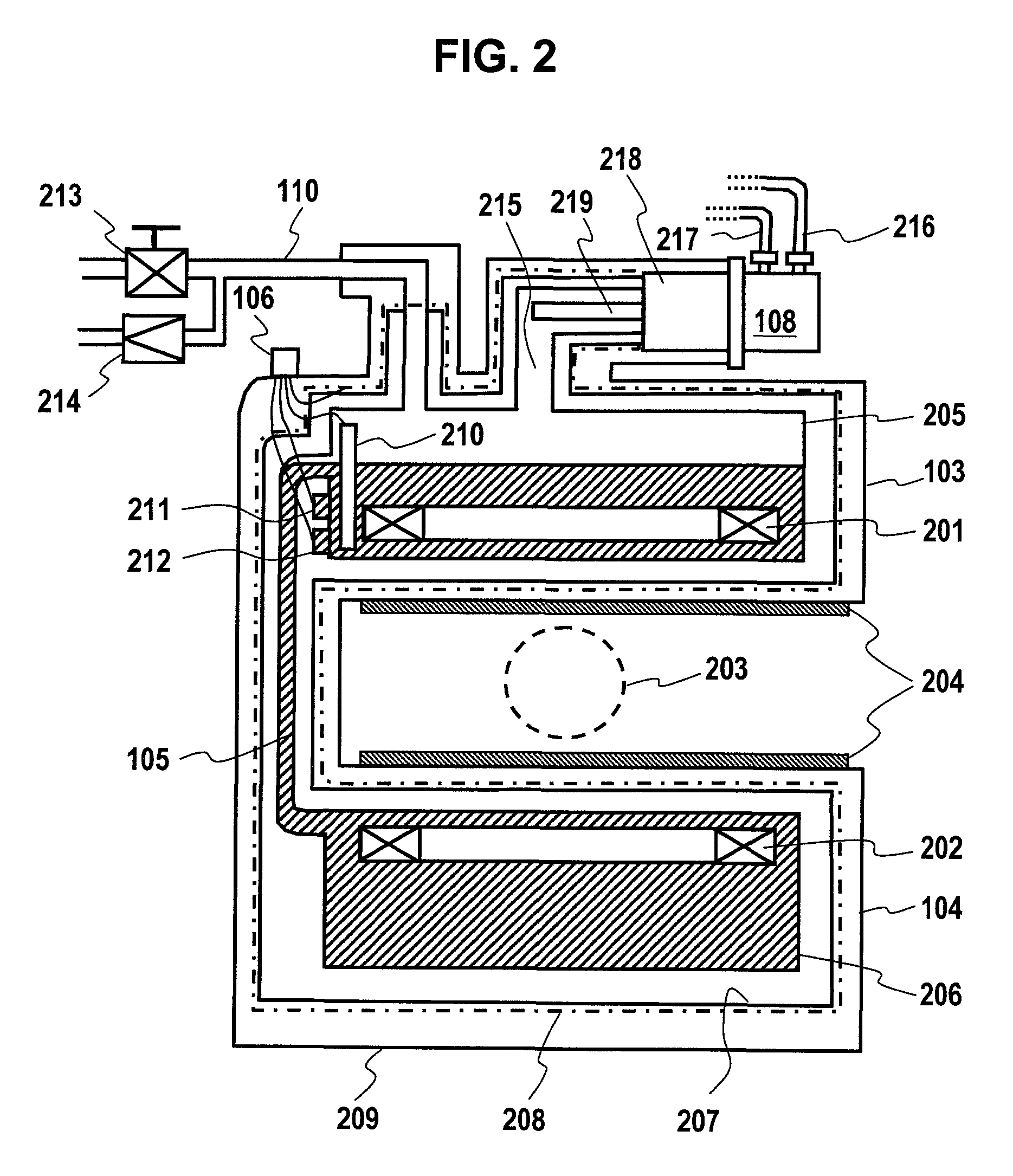

Superconducting magnet, magnetic resonance imaging apparatus, and method of calculating coolability of cryo-cooler

InactiveUS20090210199A1Accurate heat penetration amountCoolabilityMagnetic measurementsError detection/correctionSuperconducting CoilsHeat penetration

An MRI apparatus is provided in which a heat quantity penetrating into the helium tank of a superconducting magnet can be grasped to select a cryo-cooler to be incorporated, whereby consumption of liquid helium is suppressed and a static magnetic field is generated stably. The superconducting magnet includes a superconducting coil, containers 209 and 203 for accommodating the superconducting coil and a refrigerant, a cooler 208 for liquefy gas once again, the gas having been obtained by vaporizing the refrigerant in the containers, and a means for measuring the amount of vaporized refrigerant, while keeping the pressure in the containers at a constant level. The heat quantity penetrating into the containers and the coolability of the cooler are measured accurately, thereby enabling a combination in which the coolability of the cooler to be combined has capacity more than the heat penetration amount.

Owner:HITACHI LTD

Therapeutic film forming composition and treatment system therefor

By providing a film forming composition incorporating one or more therapeutic substances for application to nails and / or skin surfaces which can be employed independently or, if desired, in combination with an easily employed holding or support member for delivering heat directly to the application site an easily employed, convenient, consumer-oriented treatment system is achieved for treating nails and / or skin surfaces for a wide variety of medical problems. The treatment system of the present invention possesses broad applicability for a wide range of medical conditions, including the numerous diseases, disorders, and medical problems, all of which are capable of being treated using the present invention. In particular, diseases, disorders, and medical conditions which include, but are not limited to, psoriasis, skin cancers, warts, leishmaniasis, mycobacteria, and granuloma annulare can be specifically treated or improved due to the efficacy of the present invention and, when employed, the efficacy of heat penetration in treating these disorders.

Owner:DVORETZKY ISRAEL +1

Ceramic shell for inhibiting sands sticking on surface of high-temperature alloy turbine blades and preparation method thereof

ActiveCN109909445ALow wettabilityChemical sticky sand suppressionFoundry mouldsFoundry coresHexagonal boron nitrideTurbine blade

The invention discloses a preparation method of a ceramic shell for inhibiting sands sticking on a surface of high-temperature alloy turbine blades. The preparation method comprises the following steps: 1, preparing surface coating of the ceramic shell, adding fused corundum powder, composite powder of hexagonal boron nitride, calcined kaolin and titanium dioxide, latex, wetting agent, defoaming agent, dispersing agent and preservative into silica solution under a stirring state, and continuously stirring for 2-12 hours to obtain the surface coating of the ceramic shell; and 2, preparing the ceramic shell. The invention further discloses the ceramic shell for inhibiting the sands sticking on the surface of the high-temperature alloy turbine blades. Chemical sand sticking caused by wetting-reaction can be inhibited by the ceramic shell, and the sand sticking caused by mechanical heat penetration of the metal melt can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

Method for toasting a food product with infrared radiant heat

ActiveUS20080044167A1Faster toastingFaster and even toastingDomestic stoves or rangesDrying solid materials with heatThermal energyHeat penetration

A toaster uses radiant heat at infrared wavelengths optimized for producing rapid and uniform toasting of a food product. The infrared wavelengths of the radiated heat are selected for optimum speed and quality (browning and moisture content) of the food product. The selected infrared wavelengths of the radiated heat may also effectively defrost a food product. Defrosting of the food product by the infrared radiated heat adds very little time in obtaining a desired toast color to the food product. A plurality of infrared wavelengths of radiated heat may also be used, wherein the plurality of infrared wavelengths are selected for optimal heat penetration and surface browning of the food product. Shorter wavelengths for browning and slightly longer wavelengths to penetrate the food product for evaporating the moisture therein to allow surface browning by the shorter wavelengths. In addition, the heating energy within the toaster may be further elongated (longer wavelengths) once the infrared radiation is re-radiated off of reflectors within the toaster. The wavelengths of infrared radiated heat may be from about 1 to about 3 microns, and preferably from about 1.96 to about 2.5 microns, and most preferably at about 2.11 microns.

Owner:APPLICA CONSUMER PRODS

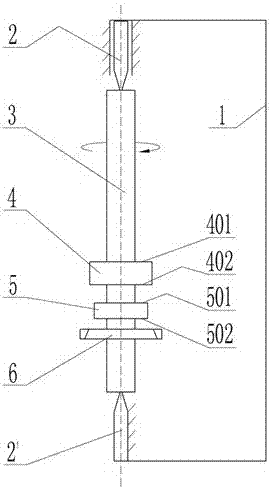

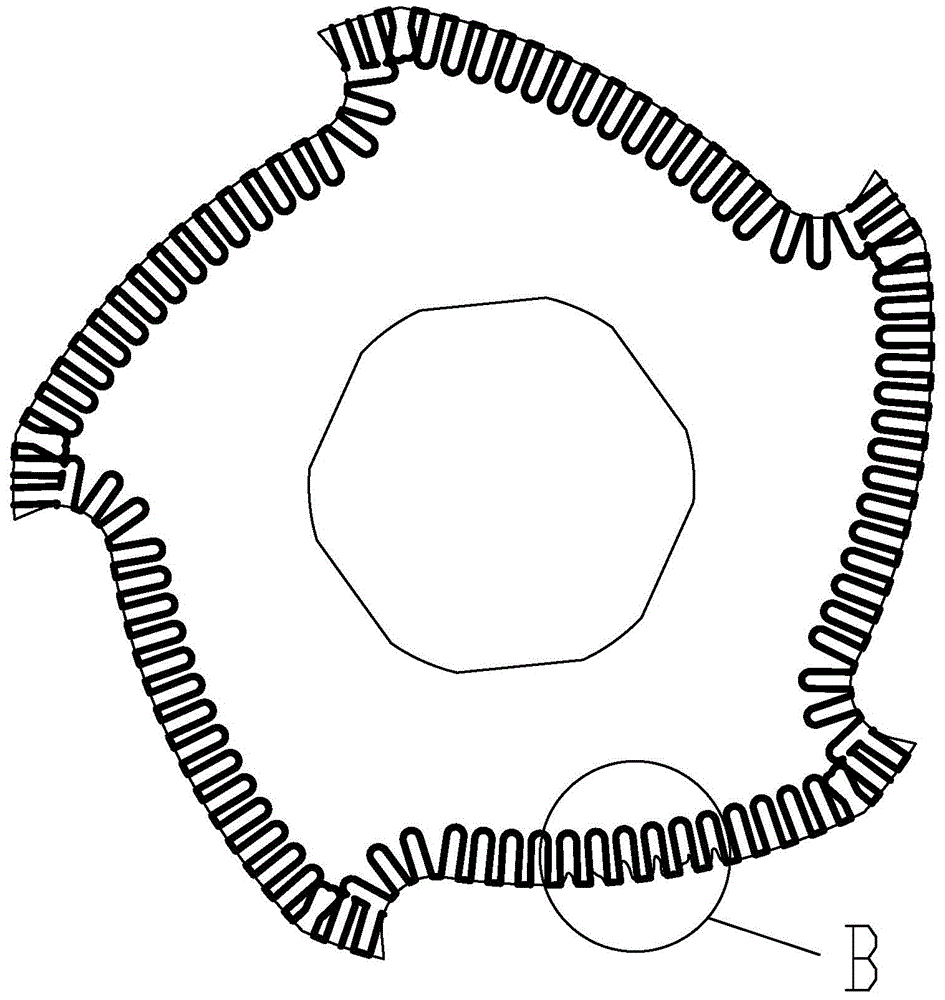

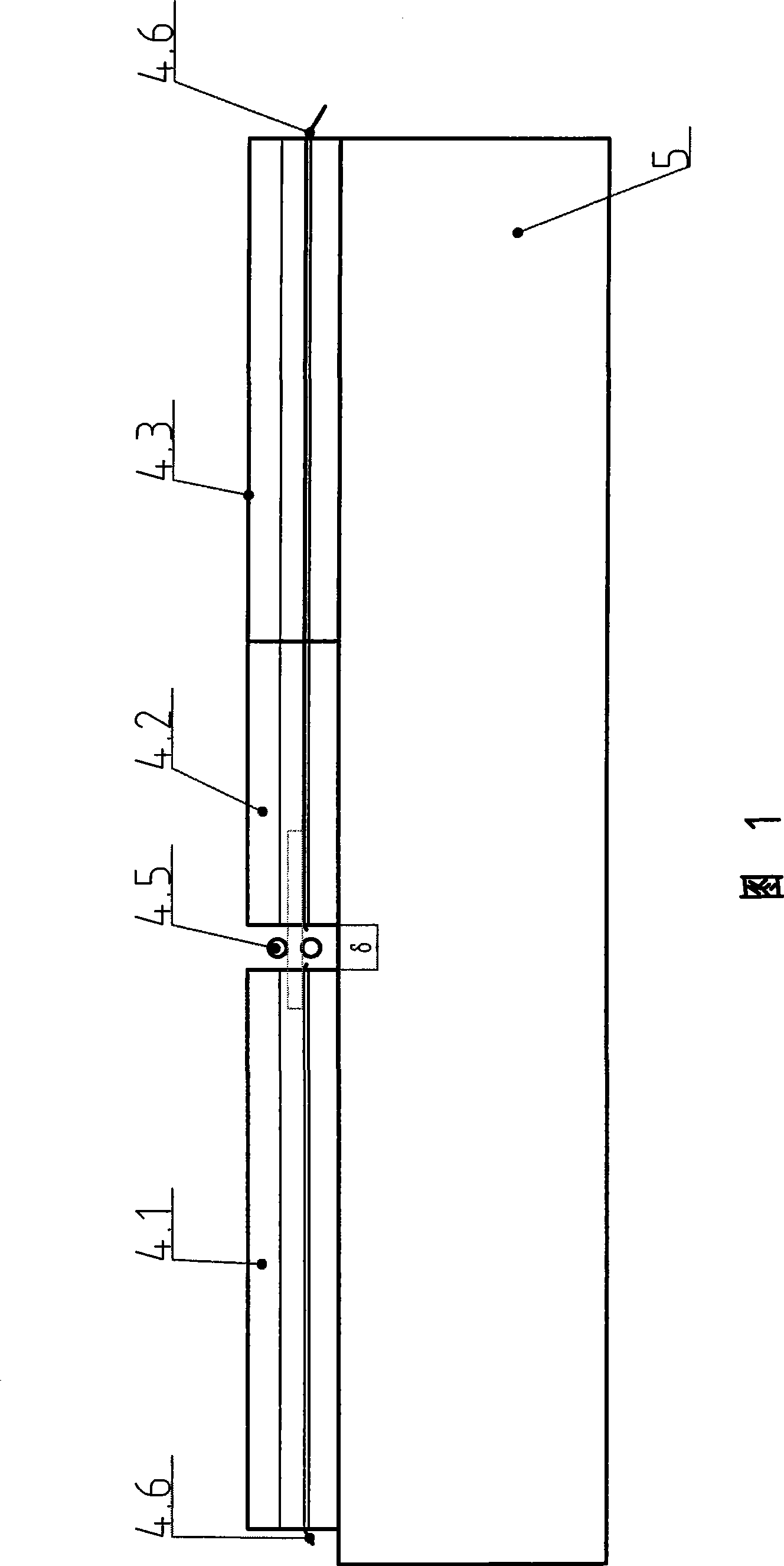

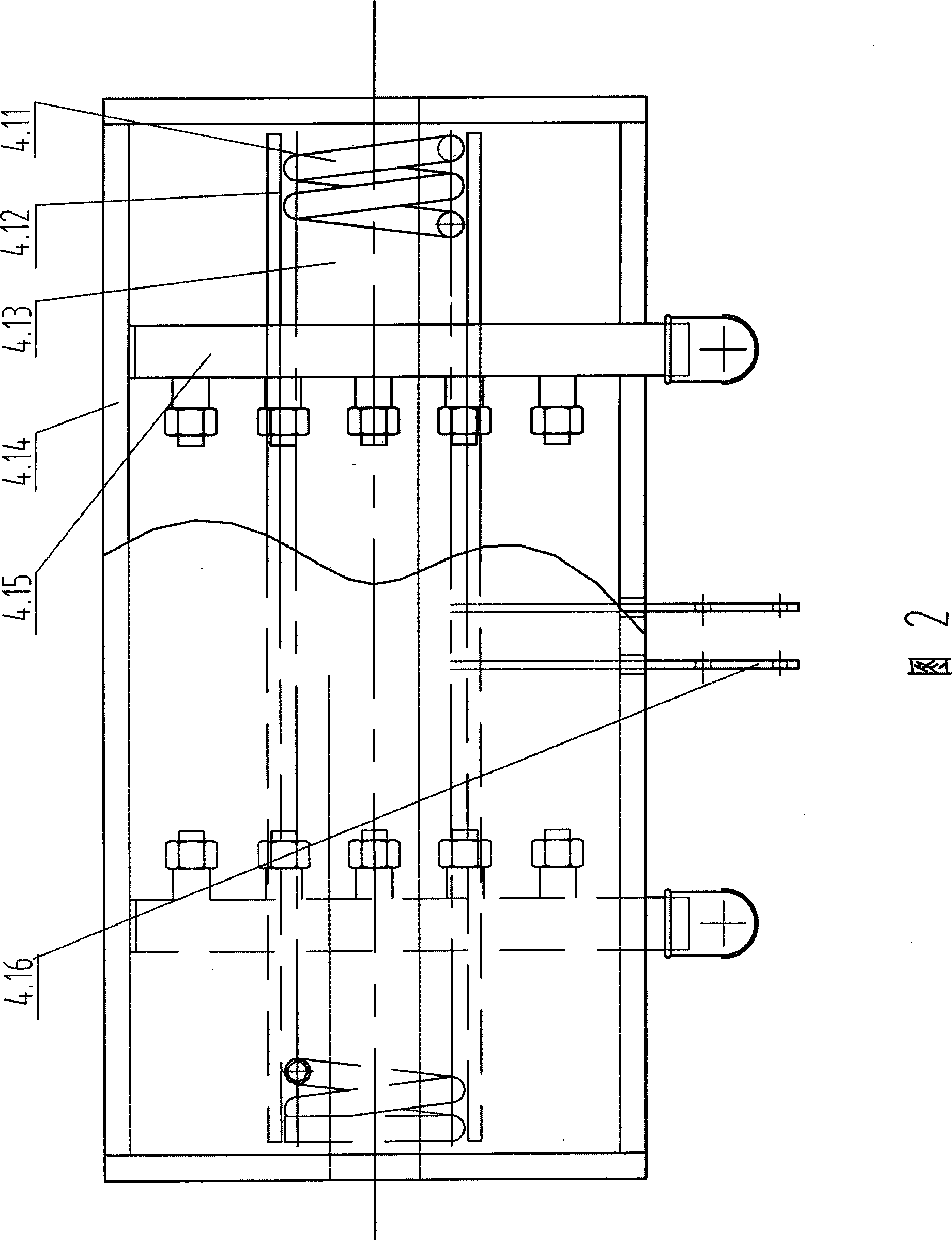

Two-frequency heat treatment and quenching process and device for D2 steel roller

The invention relates to a two-frequency heat treatment and quenching process and device for a D2 steel roller. The two-frequency heat treatment and quenching process is conducted on a two-frequency induction quenching machine tool, the power frequency of an upper heating inductor is 50Hz, and the preheating power ratio is 1-3kw / cm2. A lower heating inductor adopts an intermediate frequency of 1000Hz, and the heating power ratio is 0.5-1.5kw / cm2. During induction quenching, the heating temperature of materials is generally larger than 800 DEG C, and the heat penetration depth delta 800 DEG C=500. According to the formula, the heat penetration depth of the power frequency for the roller is 71mm, and the diameter of the D2 steel roller is generally 80-120mm, and therefore the upper heating inductor can conduct heat penetration for the roller. The working frequency of the lower heating inductor is 1000Hz, the heating depth is 16mm according to the heat penetration formula, and therefore the depth of hardening layer is not less than 8mm. By limiting the quantity and the diameters of water spray holes in a water spray ring, the process controls the water spray quantity of quenching. Therefore, the D2 steel roller 3 can still maintain the original quenching and tempering tissue under the hardening layer, the surface hardness of the roller can be met, and the comprehensive mechanical property of the roller can also be met.

Owner:ZHONGJUXIN OCEAN ENG EQUIP CO LTD

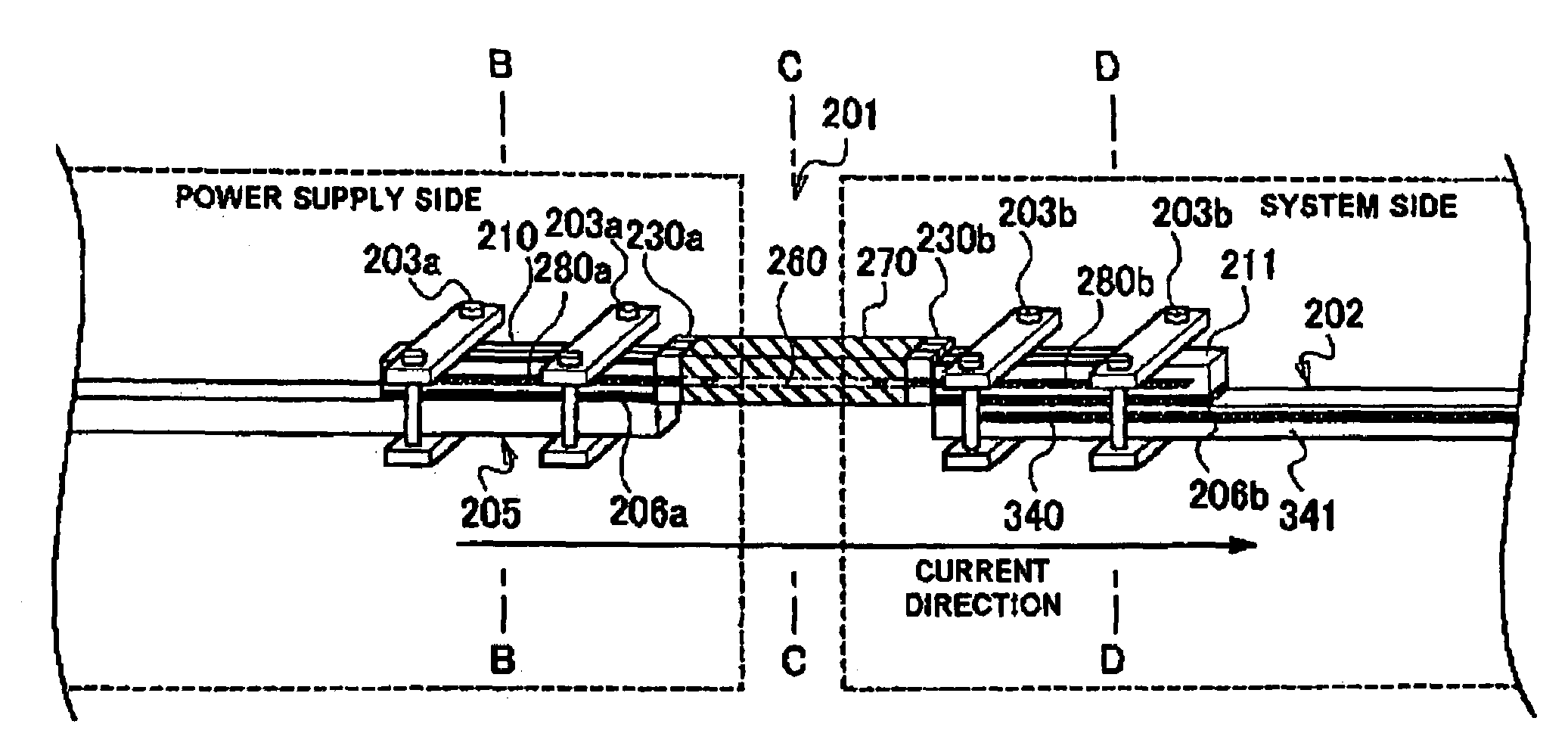

Oxide superconductor current lead and method of manufacturing the same, and superconducting system

InactiveUS7394024B2Prevents joule heatEasy to placeSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentMetallic electrodeElectrical conductor

An oxide superconductor current lead in which generation of Joule heat at joint portions with a system side conductor and a power supply side conductor is reduced with use of an oxide superconductor with less heat penetration into a super conducting equipment system is provided. A columnar oxide superconductor molten bodies (interelectrode superconductor 260, in-electrode superconductors 280a and 280b) are produced, the in-electrode superconductor 280a and a left end portion of the interelectrode superconductor 260 are placed into a power supply side metallic electrode 210, and the in-electrode superconductor 280b and a right end portion of the interelectrode superconductor 260 are similarly placed in a system side metallic electrode 211, then degassed joining metal is used to join them to form an oxide superconductor current lead 201, a power supply side conductor 5 from a power supply is joined to the power supply side metallic electrode 210, and a system side conductor 202 from a superconducting system side is joined to the system side metallic electrode 211 with use of respective clamps 203a and 203b.

Owner:DOWA ELECTRONICS MATERIALS CO LTD +1

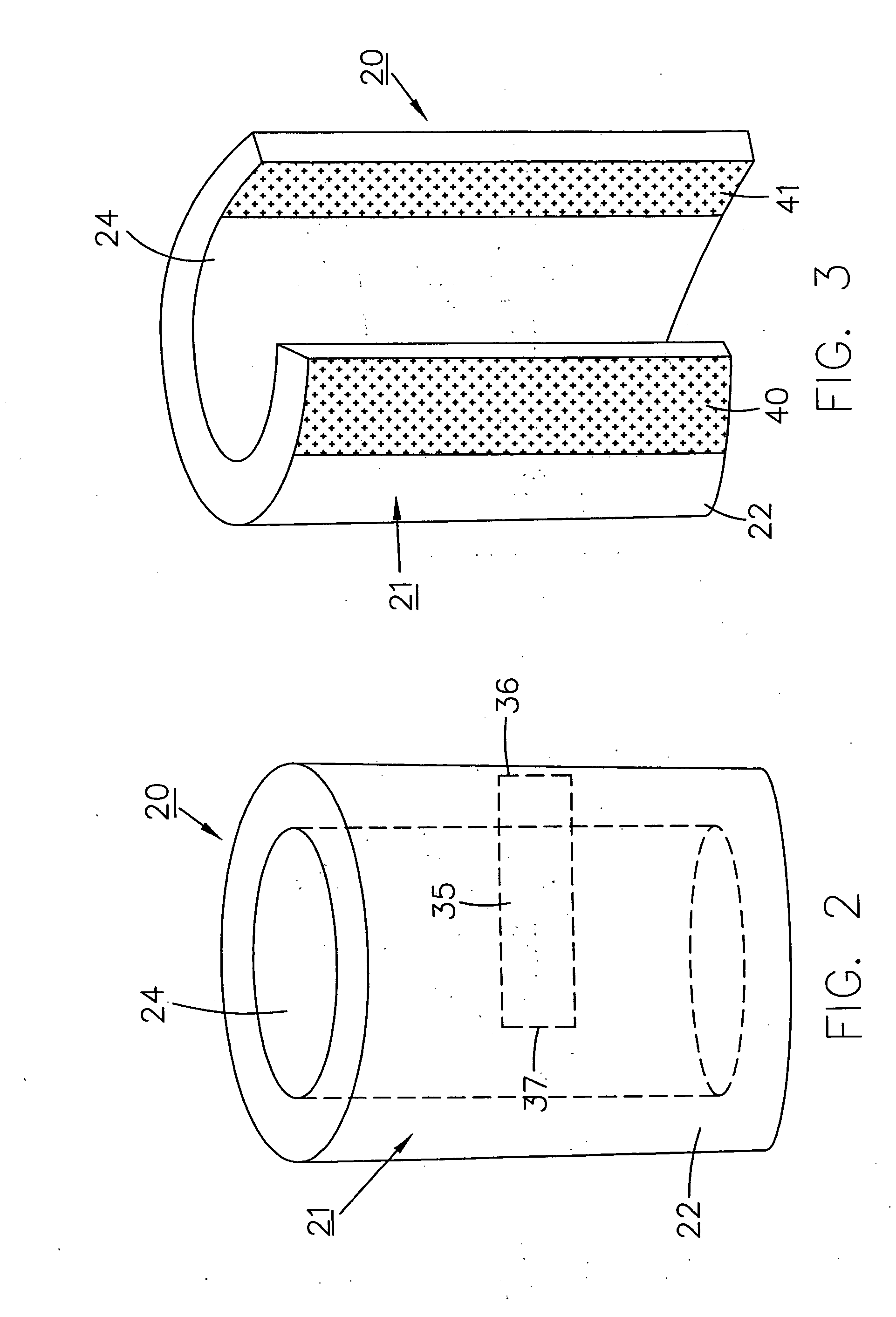

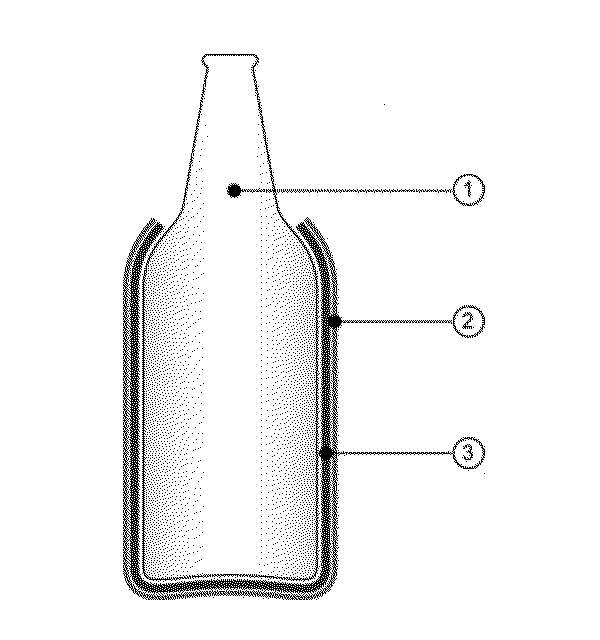

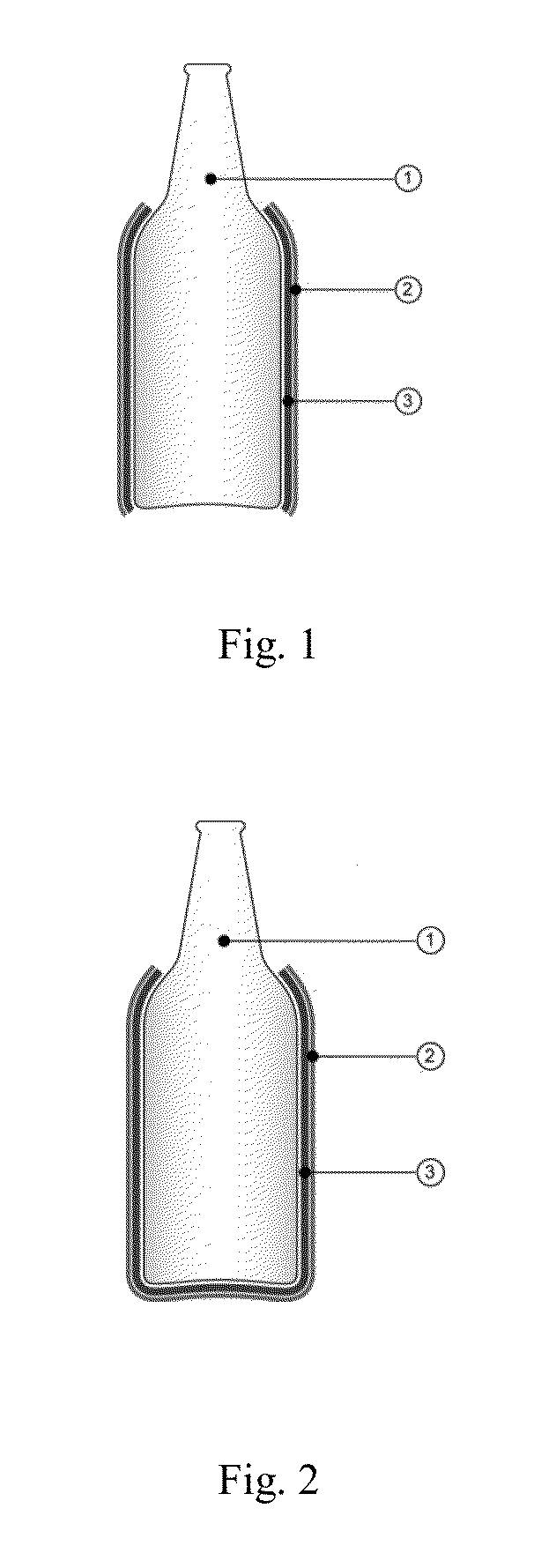

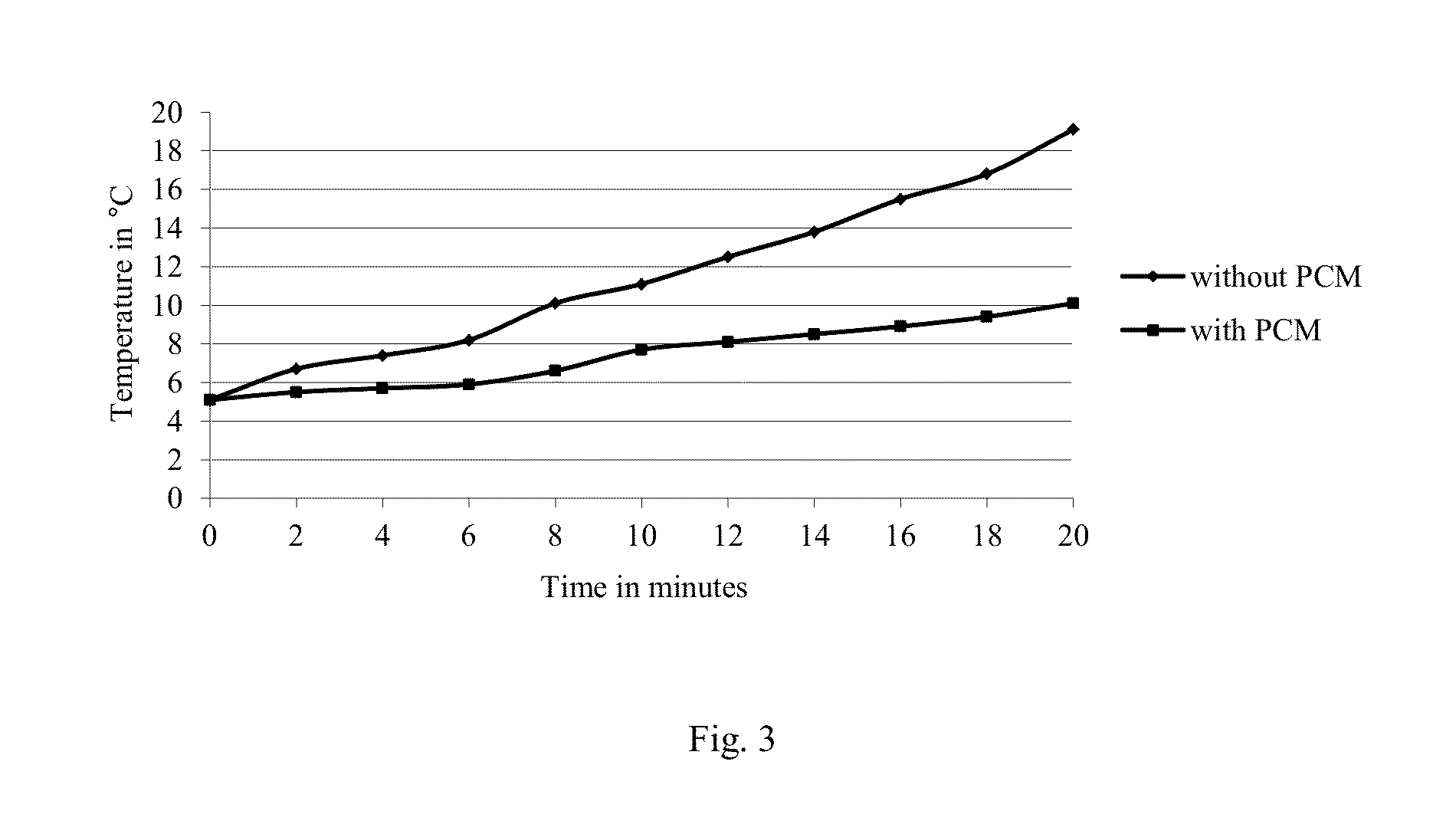

Surface treatment of beverage containers to keep the beverage cool

InactiveUS20140026595A1Right melting pointHigh latent heat storage capacityHeat storage plantsHeat-exchange elementsTime segmentSpray coating

The invention pertains to a method suitable to reduce the heat transfer into a beverage container in order to keep the beverage cool over an extended period of time after taken from the refrigerator. The method is based on a surface treatment of the beverage container which comprises a binder in which phase change material is incorporated. By absorbing latent heat without a temperature increase, the phase change material creates a thermal barrier against heat penetration. The binder with the phase change material contained wherein is applied to the surface of the beverage container, for instance, by spray coating. The coating layer covers most of the container's surface. A second coating layer which does not contain phase change material is applied on top of the first coating layer in order to provide protection against mechanical stress during high speed filling and packaging.

Owner:PAUSE BARBARA HILDEGARD

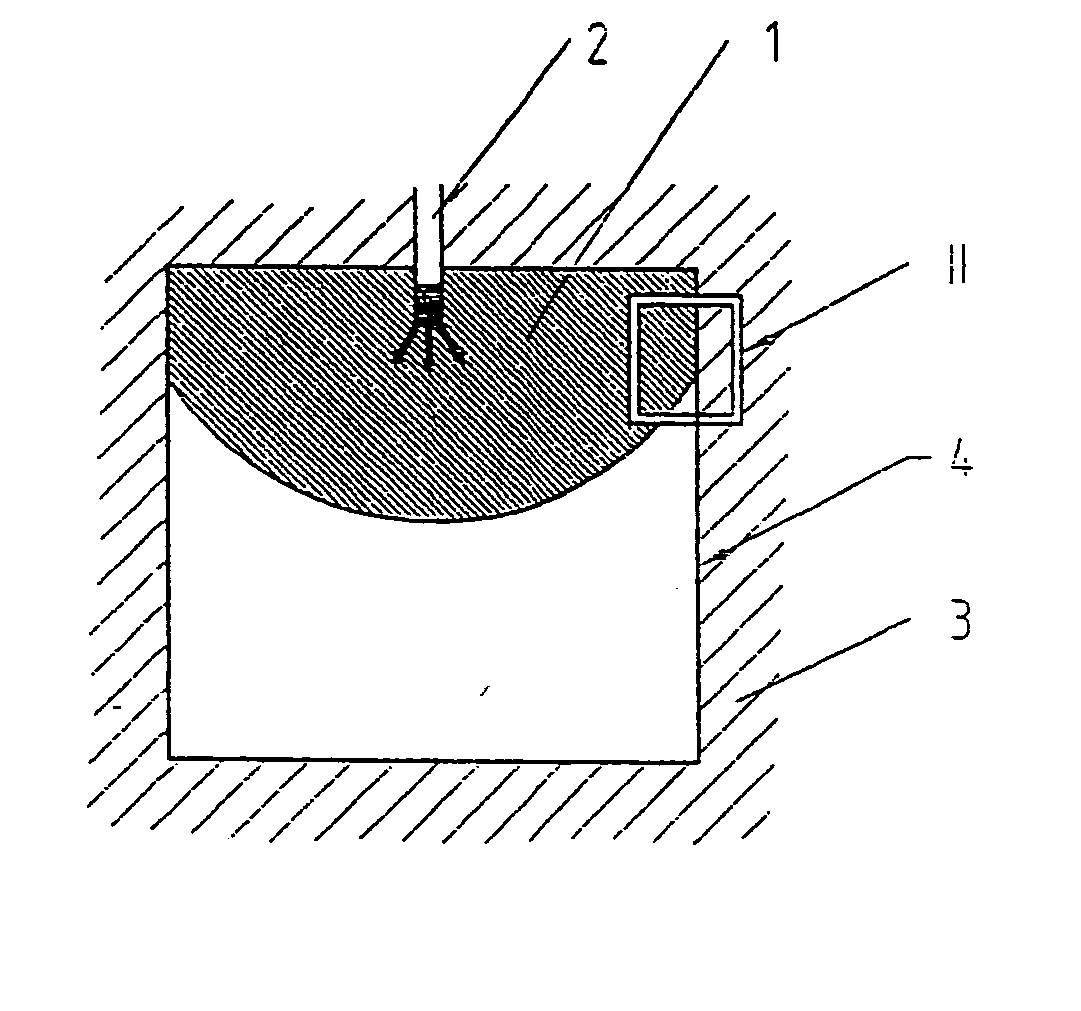

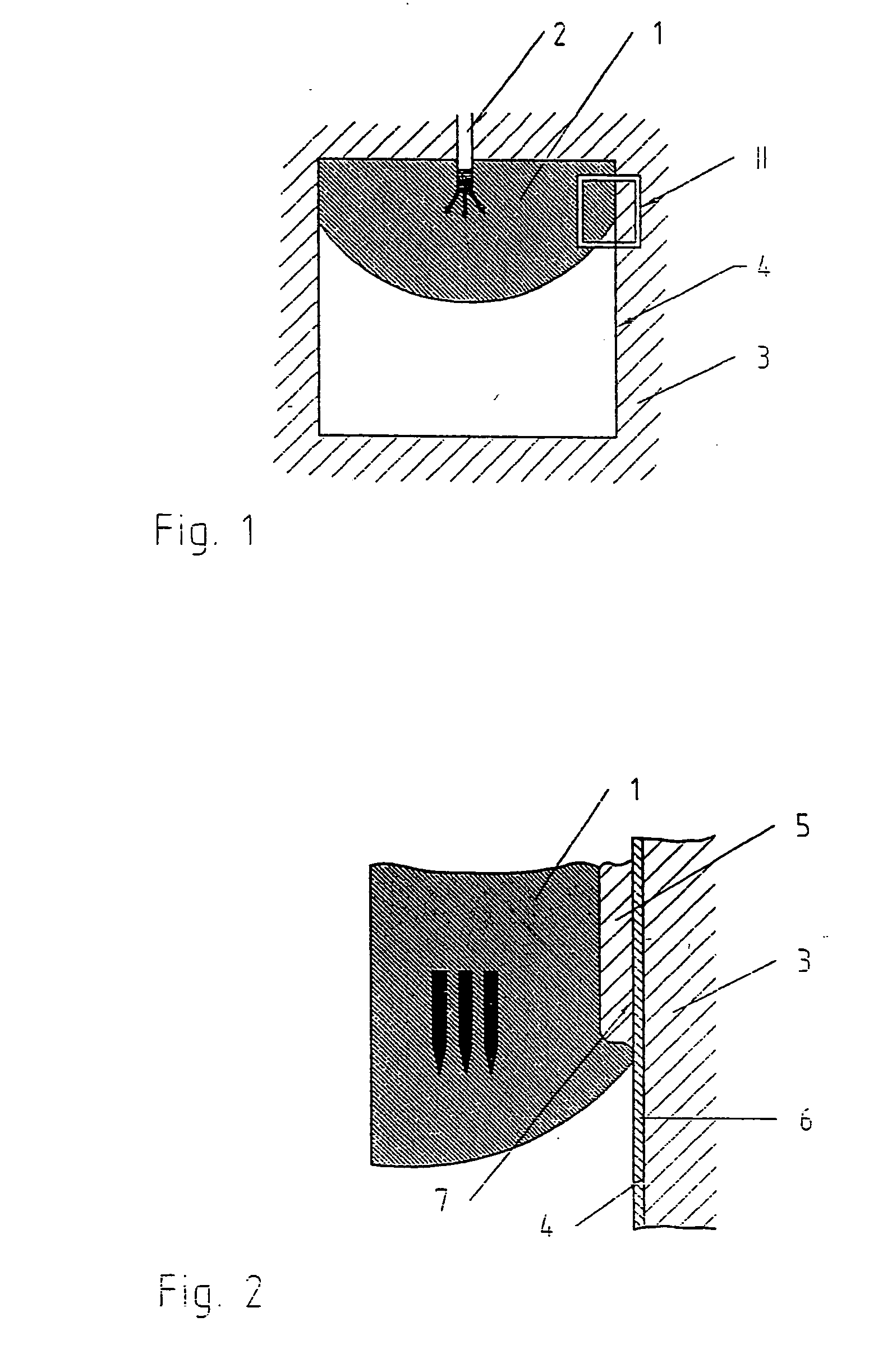

Molten metal leakage confinement and thermal optimization in vessels used for containing molten metal

ActiveUS8657164B2Prevent penetrationLow thermal conductivityMelt-holding vesselsBlast furnace detailsMetallurgyHeat losses

A vessel used for containing molten metal, e.g. a trough section for conveying molten metal from one location to another. The vessel has a refractory liner made of at least two refractory liner units positioned end to end, with a joint between the units, the units each having an exterior surface and a metal-contacting interior surface. A housing at least partially surrounds the exterior surfaces of the refractory liner units with a gap present between the exterior surfaces and the housing. Molten metal confinement elements, impenetrable by molten metal, are positioned on opposite sides of the joint within the gap, at least below a horizontal level corresponding to a predetermined maximum working height of molten metal held within the vessel in use, to partition the gap into a molten metal confinement region between the elements and at least one other region that may be used to hold equipment such as electrical heaters that may be damaged by contact with molten metal. Another embodiment employs refractory liner units of different thermal conductivity to maximize heat penetration into the molten metal from heaters in the gap, but to minimize heat loss at the inlet and outlet of the vessel where the end units contact the housing.

Owner:NOVELIS INC

Seat dewrinkling method and apparatus

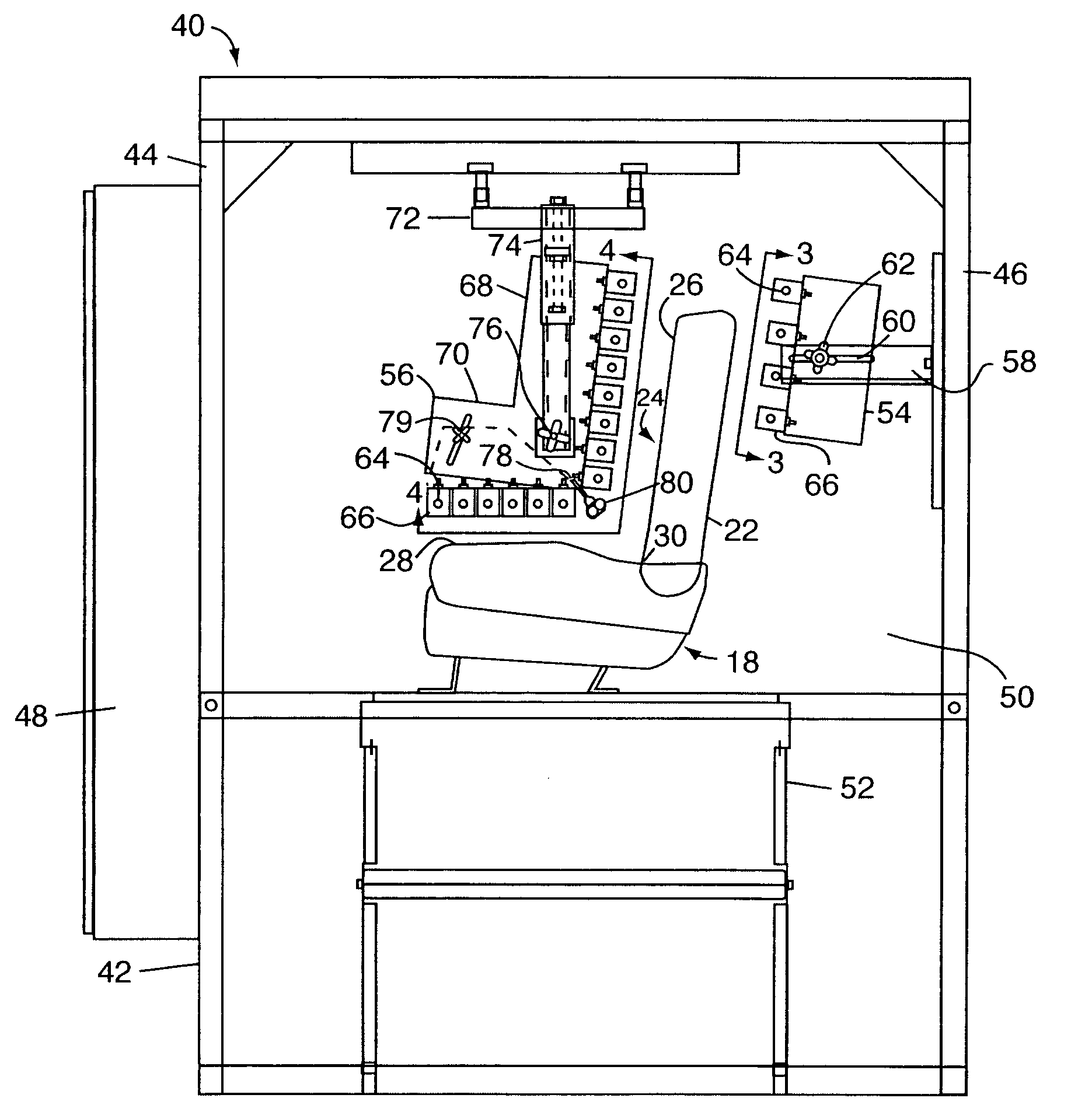

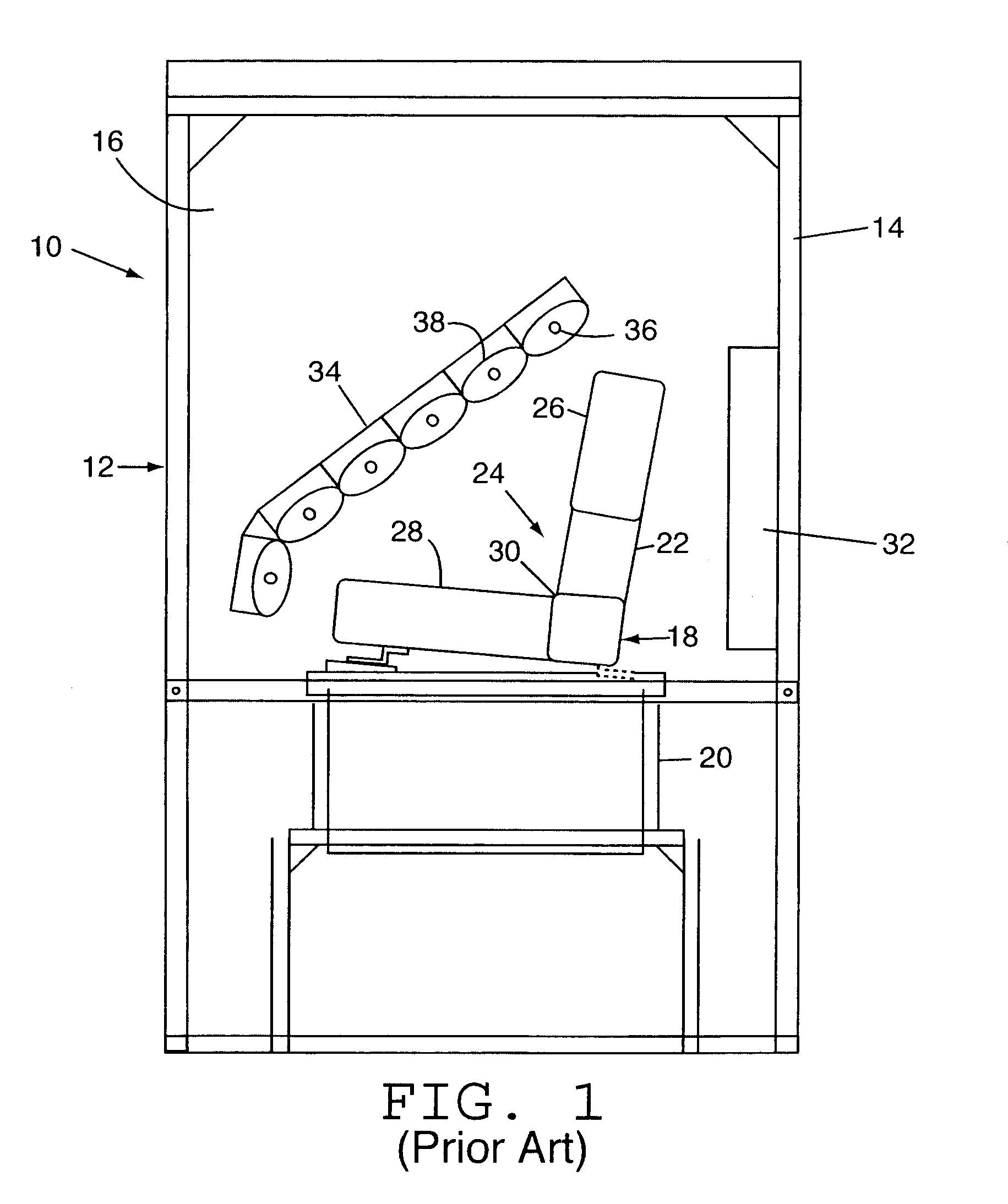

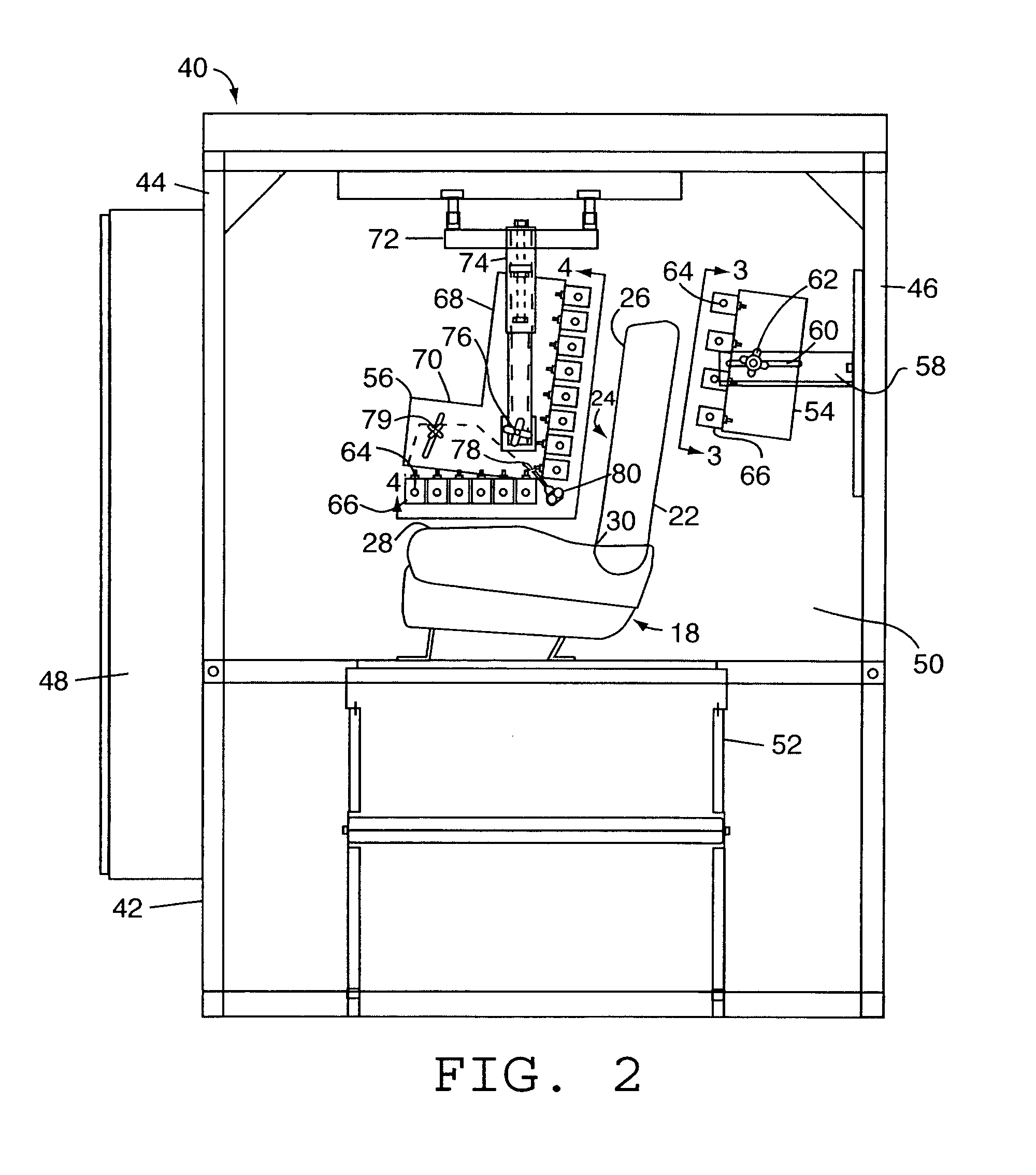

InactiveUS7197239B1Reduce risk of damageEliminate wrinklesVehicle seatsDrying solid materials with heatEngineeringHeat penetration

A system and method for removing wrinkles from the covering material of seats for automobiles and other vehicles. The invention may be implemented in a seat dewrinkling oven that includes front and rear heaters that conform to the shape of the seat being heated. In particular, a front heater may be employed that includes a vertically oriented portion for directing heat at the vertically oriented back portion of a front seat surface and a horizontally oriented portion for directing heat at the horizontally oriented bottom portion of the seat front surface. Preferably medium wavelength infrared heating elements are employed in the heaters to provide better heat penetration and dewrinkling.

Owner:WISCONSIN OVEN

Steam engine

InactiveUS20050193736A1Improve efficiencyHeat loss causedSteam accumulatorsSteam engine plantsWorking fluidThermal diffusivity

A steam engine has a fluid container, a heating device and a cooling device provided at the fluid container for heating and cooling working fluid filled in the fluid container, so that a part of the working fluid is heated and vaporized to move the liquid-phase working fluid in one direction. When the vaporized steam is cooled and liquidized, the pressure of the working fluid in the fluid container is decreased, to thereby move the liquid-phase working fluid in the backward direction. Kinetic energy is thereby generated by using the back and forth movement of the working fluid. The heating device has multiple through-holes, through which the working fluid flows and heated by a heating surface (an inner surface of the through-holes) of the heating device, wherein a diameter “d” of the through-hole is made almost equal to or smaller than a depth of heat penetration “δ”, which is determined by the following formula: δ={square root}{square root over (2a / ω)}wherein “a” is a heat diffusivity of the working fluid, and “ω” is an angular frequency of the working fluid during the working fluid is periodically moved back and forth.

Owner:DENSO CORP

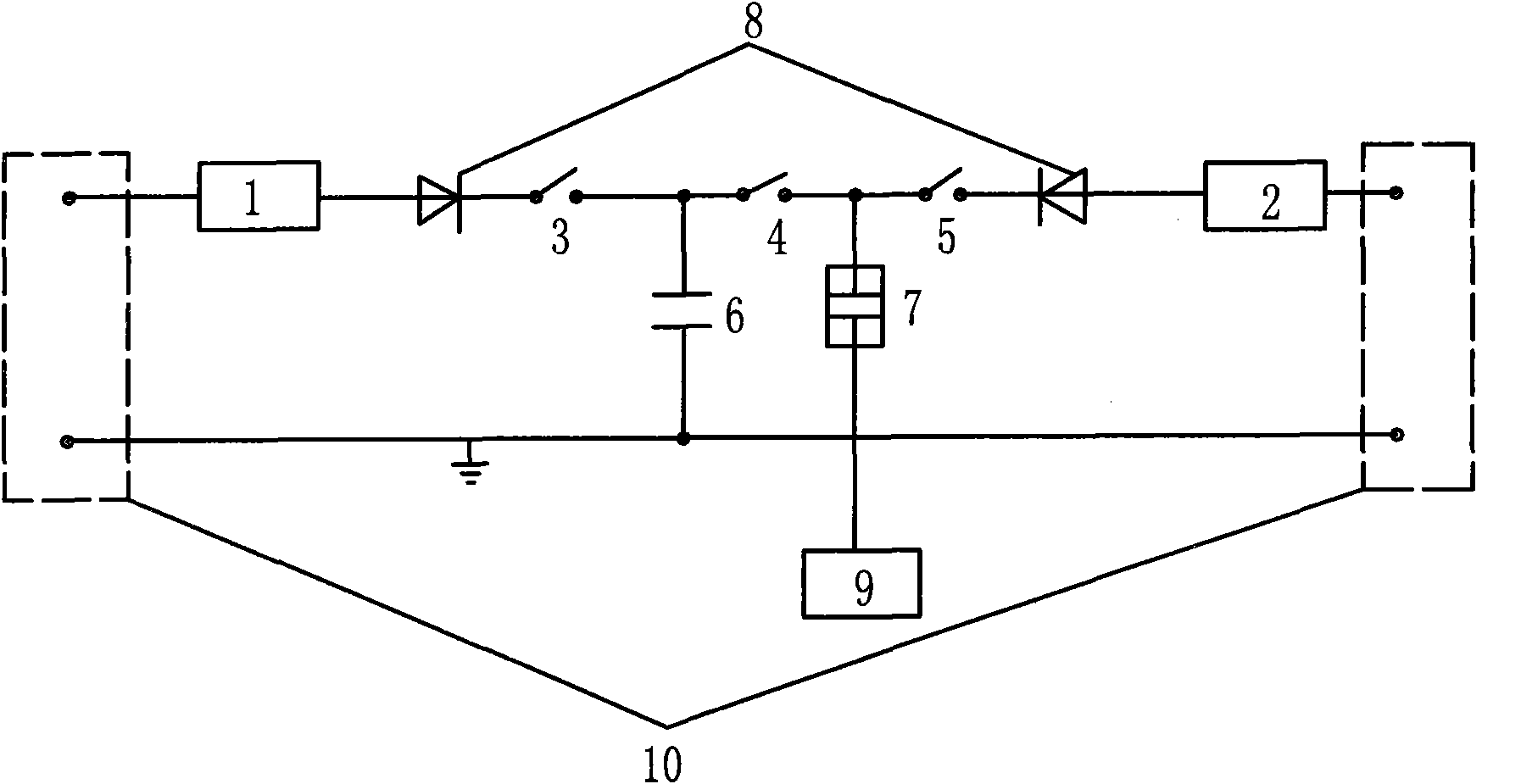

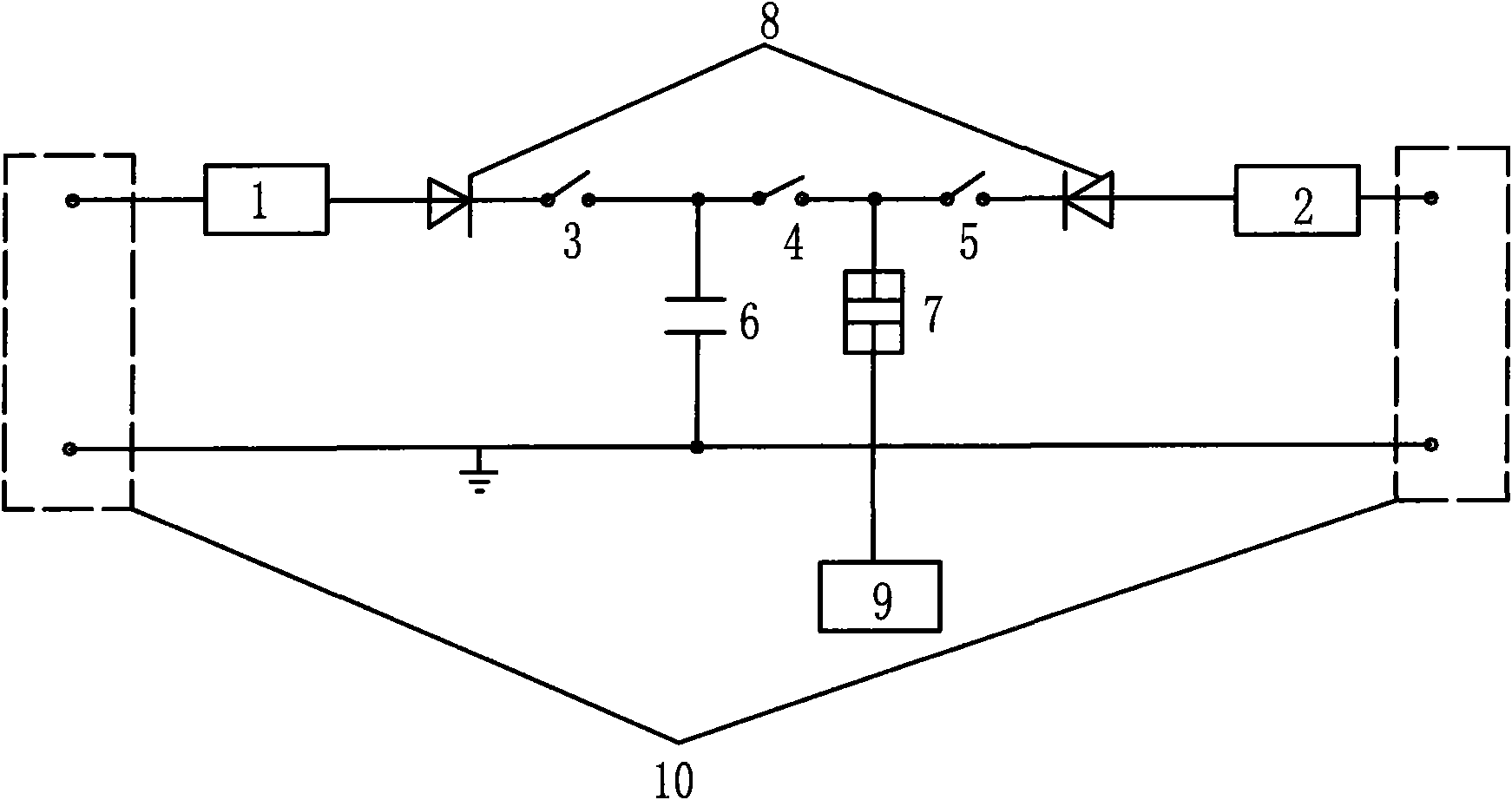

Vacuum arc extinguish chamber capacitive treating method and device

ActiveCN102103940AReduce reburn rateReduce NSDD phenomenonHigh-tension/heavy-dress switchesAir-break switchesElectricityHeat penetration

The invention discloses vacuum arc extinguish chamber capacitive treating method and device. The method is characterized by comprising the following steps: treating an arc extinguish chamber in a small current arcing state through instant current generated after a capacitor discharges electricity; and simulating the actual flashy flow of the vacuum arc extinguish chamber in a closed state. The method and the device ensure that the heat penetration depth of contact treatment of the vacuum arc extinguish chamber is deeper, so the restriking rate and non-sustained disruptive discharge (NSDD) phenomenon of the vacuum arc extinguish chamber can be effectively reduced, the structure is simple, and the cost is lower.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

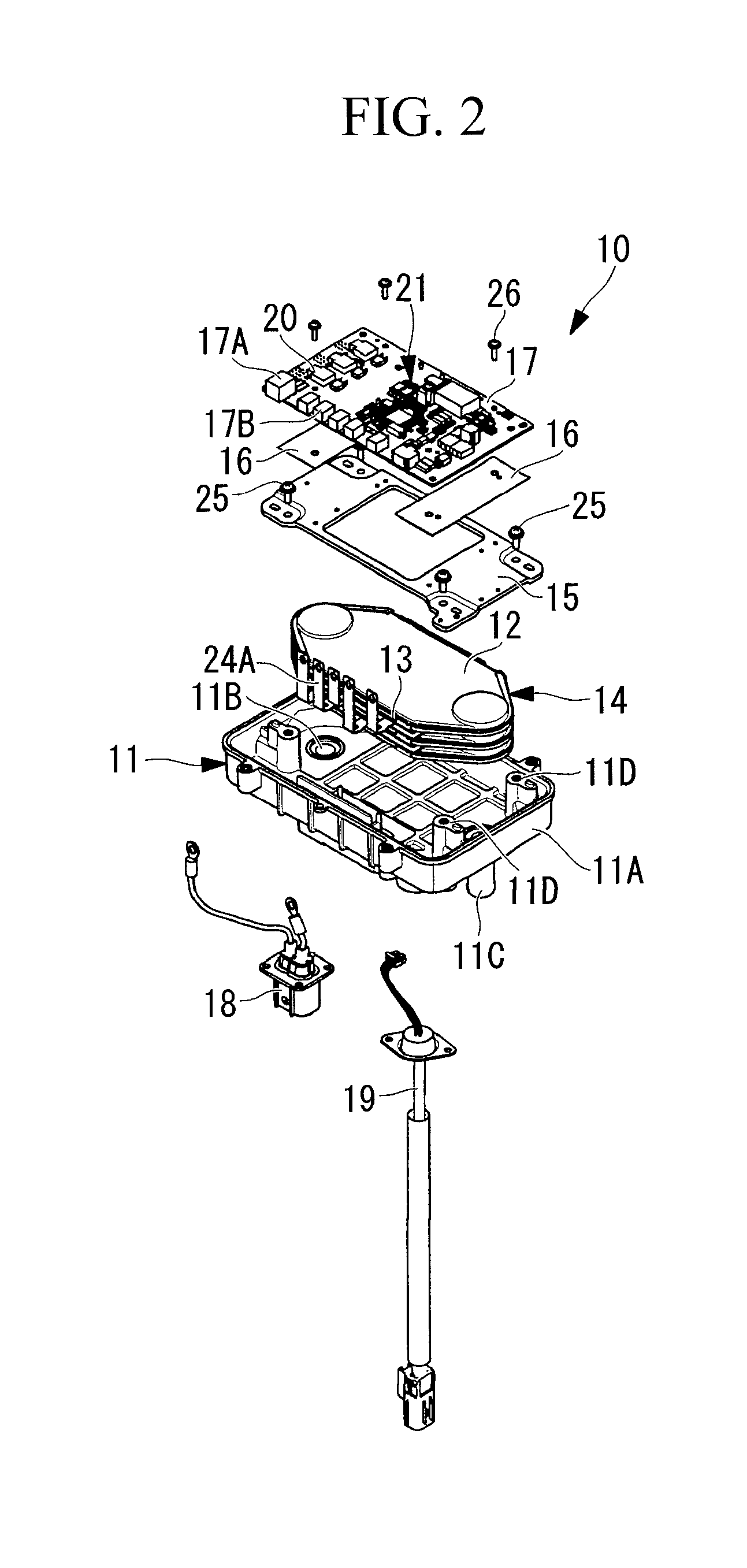

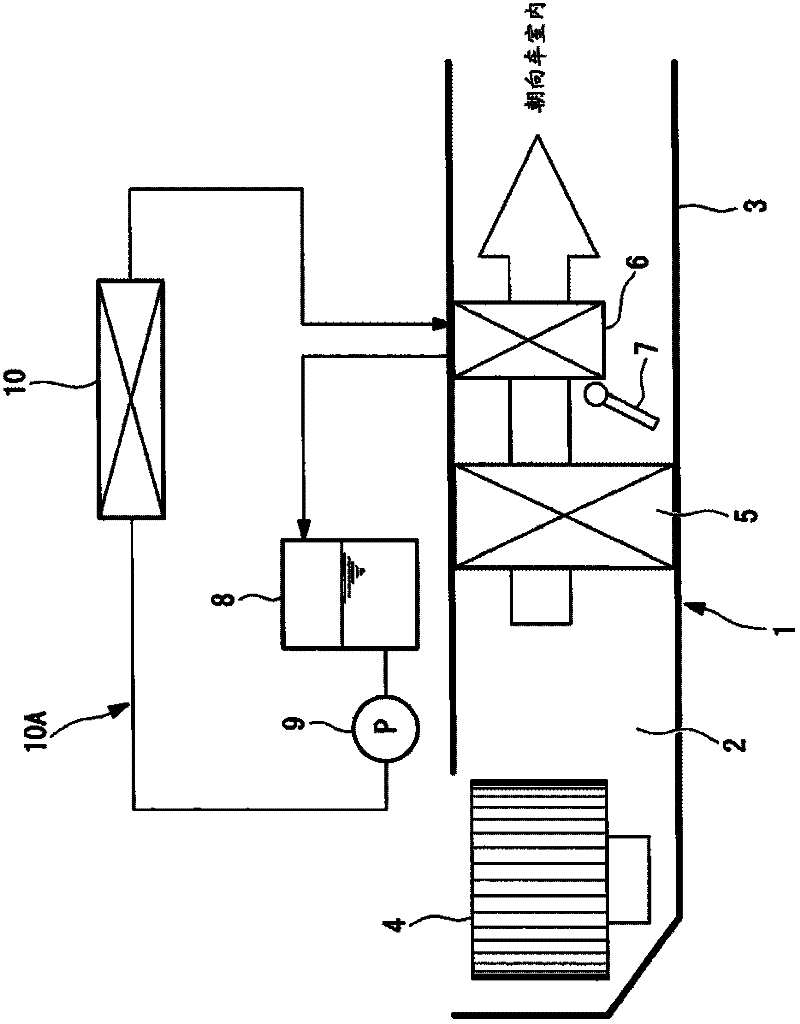

Heat medium heating apparatus and vehicular air-conditioning system including same

InactiveCN102673347AImprove air conditioning performanceImprove heating effectAir-treating devicesAir heatersPlate heat exchangerHeat penetration

Provided is a heat medium heating apparatus, which can reduce the thermal contact resistance between flat heat exchanger tubes and PTC heaters, improve the heat transfer performance, efficiently cool and control heat-generating electrical components on a board of the the PTC heaters and realize reduction in weight and low cost. The heat medium heating apparatus includes: the plurality of flat heat exchanger tubes 12; the PTC heaters 13 that are respectively incorporated between flat tube parts of the flat heat exchanger tubes 12; a heat exchanger holding member 15 that press-fixes the flat heat exchanger tubes 12 and the PTC heaters 13, from one side of the flat heat exchanger tubes 12 to an inner surface of a casing 11; and a control board 17 that has a surface on which a control circuit 21 is mounted, the control circuit 21 including heat-generating electrical components 20 that control the PTC heaters 13, in which the control board 17 includes heat penetration parts that are formed so as to pass through the control board 17 correspondingly to mounting positions of the heat-generating electrical components 20, and the heat-generating electrical components 20 are mounted so as to be cooled via the heat penetration parts.

Owner:MITSUBISHI HEAVY IND LTD

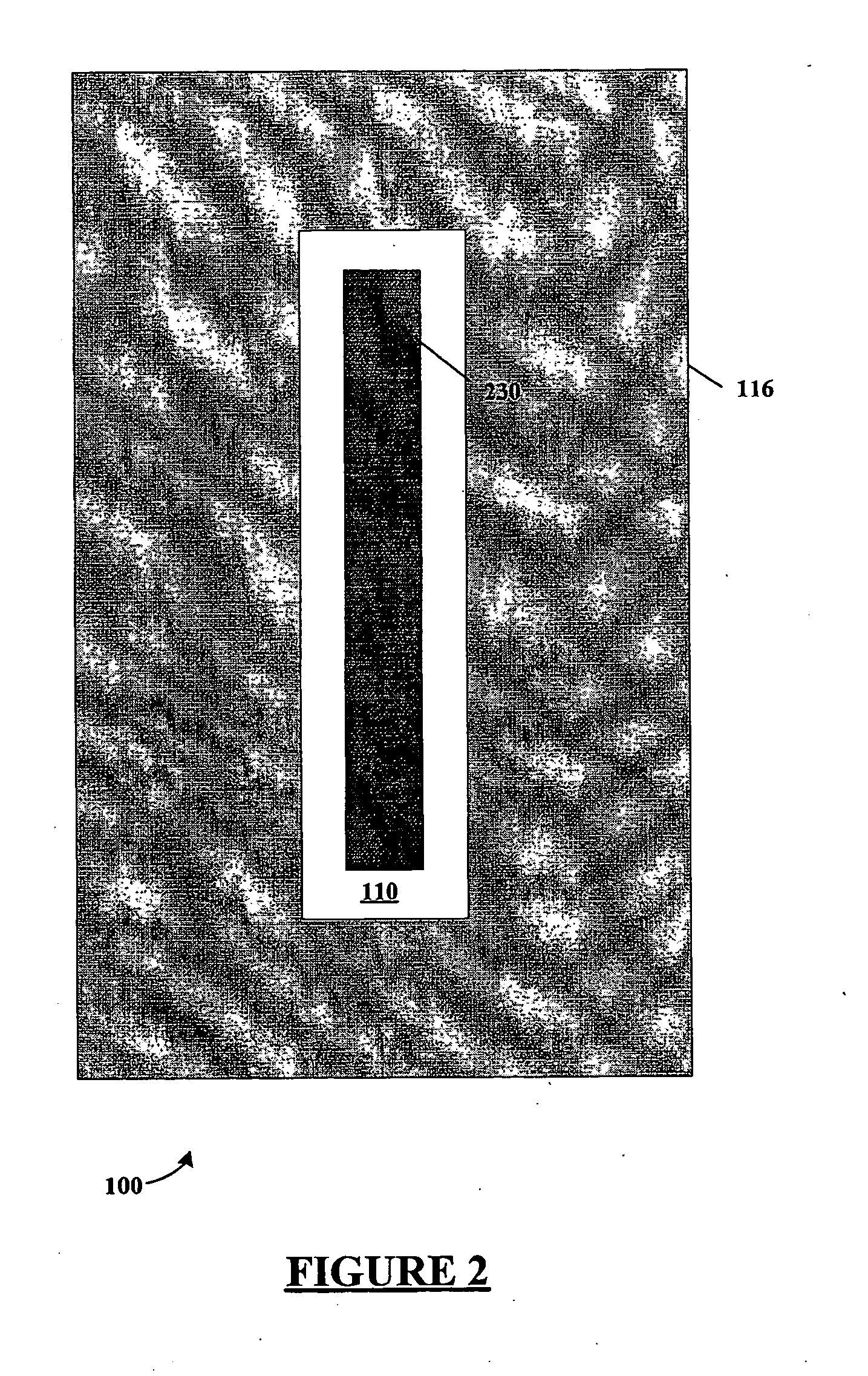

Soft bag infusion packaging system with high barrier property to gas and manufacturing method thereof

ActiveCN105012143AHigh barrierQuality assurancePharmaceutical containersMedical packagingShielding gasEngineering

The invention discloses a soft bag infusion packaging system with the high barrier property to gas and a manufacturing method thereof. The packaging system comprises a non-PVC co-extruded film inner bag and a barrier protection bag; a drug cavity used for containing injection drug liquor and protecting gas is formed in the non-PVC co-extruded film inner bag, a seal cavity used for containing the non-PVC co-extruded film inner bag is formed in the barrier protection bag, the non-PVC co-extruded film inner bag is contained in the seal cavity, and the seal cavity is a vacuum seal cavity. According to the soft bag infusion packaging system with the high barrier property to gas, the vacuum seal cavity is formed in the barrier protection bag, the non-PVC co-extruded film inner film is contained in the vacuum seal cavity, therefore, the problem of gas permeation can be solved, and meanwhile the defects of bag body deformation or bag broken caused by gas expansion when high-temperature sterilization is performed can be overcome due to the fact that gas is filled in the seal cavity; the quality security of infusion packaging is improved, heat penetration force in the sterilization process is further enhanced, and the sterilization effect is improved.

Owner:SHIJIAZHUANG NO 4 PHARMA

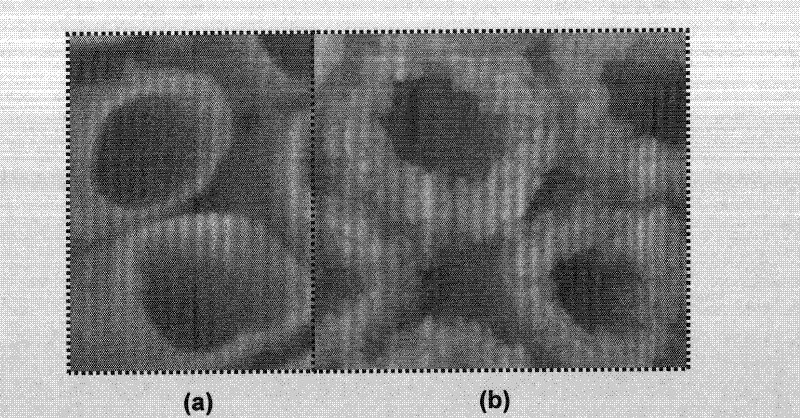

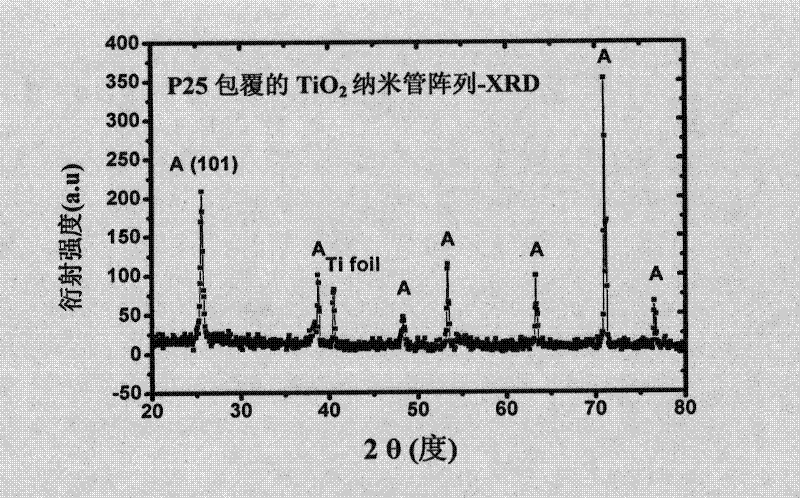

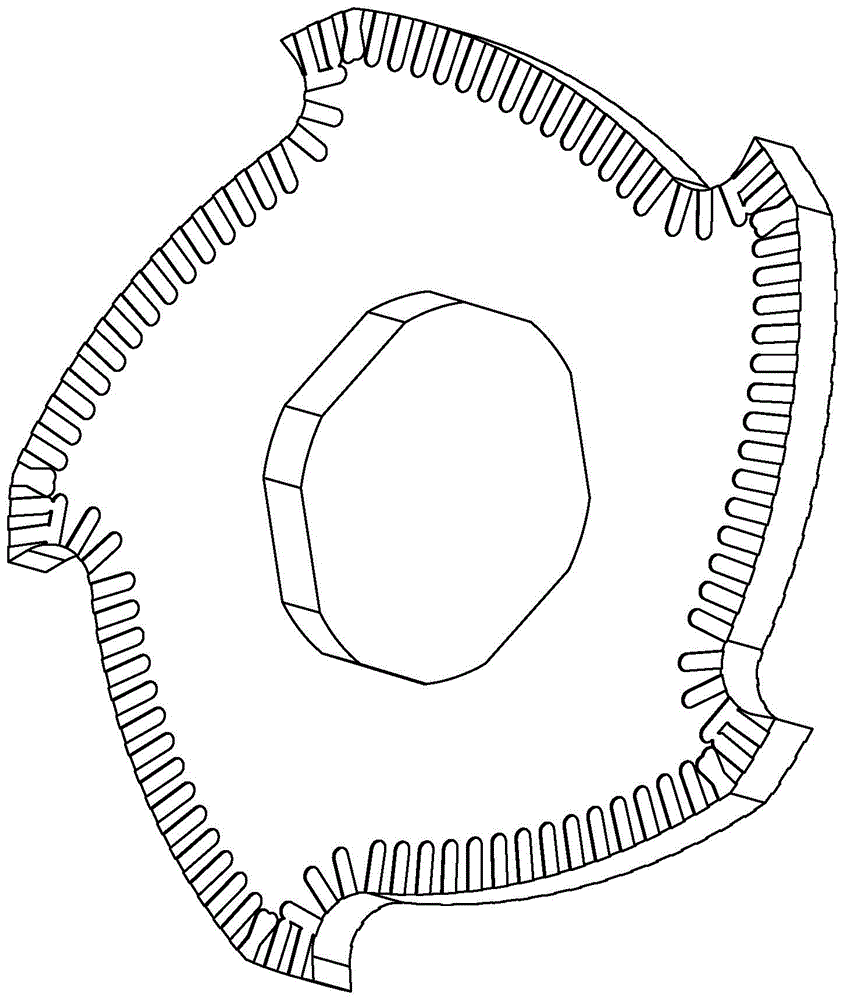

Preparation process of a p25-coated titanium dioxide nanotube array electrode material

InactiveCN102260898AHighly ordered orientation featuresLarge specific surface areaPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeHeat penetration

The invention provides a preparation process of a P25-coated titanium dioxide nanotube array electrode material. Firstly, an anodic oxidation method is used, with titanium foil as the anode, and a mixed solution of ammonium fluoride, lactic acid and dimethylsulfame as the electrolyte to pre-prepare a large diameter. , tube spacing and long tube length, rough surface TiO2 nanotube array with large gap space; then, put the above pre-prepared array into a high-pressure reactor filled with commercial P25 coating solution for thermal infiltration and thermal deposition, and then rinse, After ultrasonication and annealing, the P25-coated titanium dioxide nanotube array electrode material can be obtained. This electrode material can be assembled into a working electrode of nano-devices such as dye-sensitized cells, photoelectrochemical cells, and photocatalysis after corresponding treatment processes. Electrode blank material with application value. Moreover, the preparation process has low cost, simple process and easy productization.

Owner:XIANGFAN UNIVERSITY

Composite carbon tool steel/plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life

InactiveCN102154537AHigh hardnessImprove uniformityIncreasing energy efficiencyFurnace typesHigh resistanceWear resistant

The invention discloses a composite carbon tool steel / plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life. Aiming at characteristics of an explosive composite wear-resistant material and operating requirements of a metallurgical wear-resistant lining board, the surface induction heating principle and the metal phase transformation theory are used for controlling the depth of heat penetration, the hardness of an appropriate layer interface, and the depth and uniformity of a quench hardening layer so that the hardness of the composite layer is distributed in gradient, and the complete martensite phase change is avoided from occuring in the composite interface layer during quenching so to reduce the structure stress formed on the interface and keep the original combination state of the composite board to the greatest extend. The composite metallurgical lining board with high resistance, high uniformity and long service life has surface hardness of larger than 61HRC (rockwell hardness) and uniformity of hardness of less than 3 HRC (rockwell hardness); A 5mm place of the composite layer in the thickness direction has a hardness value of larger than 50HRC (rockwell hardness); and the three fifth to four fifth place of the composite layer thickness has the hardness value of less than 35HRC (rockwell hardness).

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Manufacturing technology of novel moving blades of crusher

ActiveCN104480255ATemperature controlControl depthFurnace typesHeat treatment furnacesProduction lineManufacturing technology

The invention discloses a manufacturing technology of novel moving blades of a crusher. According to the technical scheme, the manufacturing technology is characterized by comprising steps as follows: cutting a profile into a plurality of moving blades along patterns, placing the moving blades on a machine tool for laser quenching, transferring the moving blades to a grinding machine for finish grinding, cooling the moving blades and the like. Surfaces of the moving blades can be heated and self-cooled at the high speed with the laser surface quenching technology, temperatures of the surfaces of the moving blades and heat penetration depths can be effectively controlled through control on the laser scanning speed and the laser power, and the heat affected zone is small and quenching stress and deformation are very small due to the high laser heating speed. The laser quenchingtechnology is short in period, the production efficiency is high, the technological process can be controlled by a computer easily, the automation degree is high, and the technology can be applied to a production line.

Owner:OMS MASCH CO LTD

Intermediate frequency induction heating furnace for bearing steel pipe blank

InactiveCN101376919AAccurate control of heating rateMeet temperature requirementsTemperature control deviceFurnace typesIntermediate frequencyHeat penetration

The invention relates to a bearing steel tube blank medium-frequency sensitive heating furnace which is characterized in that the sensitive heating furnace is divided into a pre-heating furnace section, a temperature rise furnace section and an even temperature furnace section which are lined in the straight line on a heating bed; a guide wheel is arranged in the spacing between the pre-heating furnace section and the temperature rise furnace section; the temperature rise furnace section is connected with the even temperature furnace section; a guide rail is arranged in the heating furnace; the tube blank has linear movement on the guide rail of the heating furnace. The medium-frequency sensitive heating furnace can strictly control the temperature rise of the heated bearing steel tube blank in all the furnace sections of the heating furnace to accord to the design heating code; different furnace sections are heated separately and the heat penetration is even, which makes sure the surface temperature difference of the tube blank core is less than 15 DEG C and the head and tail temperature difference is less than 30 DEG C, and fully meets the requirement of hot rolled through hole for the temperature of the tube blank.

Owner:张志远

Molten metal leakege confinement and thernal optimization in vessels used for containing molten metal

ActiveUS20110253581A1Prevent penetrationLow thermal conductivityCharge manipulationPackaging corrosive chemicalsHeat lossesHeat penetration

Exemplary embodiments of the invention relate to a vessel used for containing molten metal, e.g. a trough section for conveying molten metal from one location to another. The vessel has a refractory liner made of at least two refractory liner units positioned end to end, with a joint between the units, the units each having an exterior surface and a metal-contacting interior surface. A housing at least partially surrounds the exterior surfaces of the refractory liner units with a gap present between the exterior surfaces and the housing. Molten metal confinement elements, impenetrable by molten metal, are positioned on opposite sides of the joint within the gap, at least below a horizontal level corresponding to a predetermined maximum working height of molten metal held within the vessel in use, to partition the gap into a molten metal confinement region between the elements and at least one other region that may be used to hold equipment such as electrical heaters that may be damaged by contact with molten metal. Another embodiment employs refractory liner units of different thermal conductivity to maximize heat penetration into the molten metal from heaters in the gap, but to minimize heat loss at the inlet and outlet of the vessel where the end units contact the housing.

Owner:NOVELIS INC

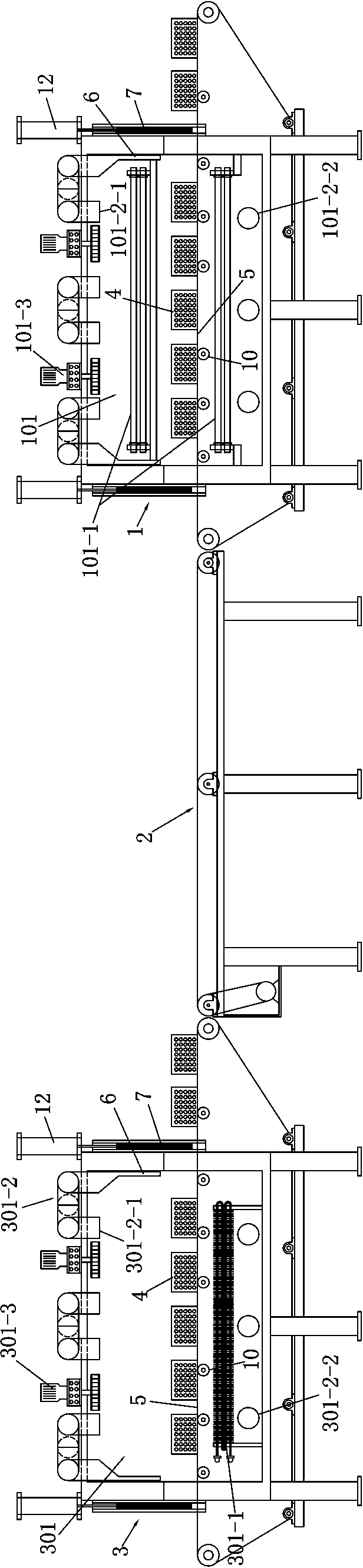

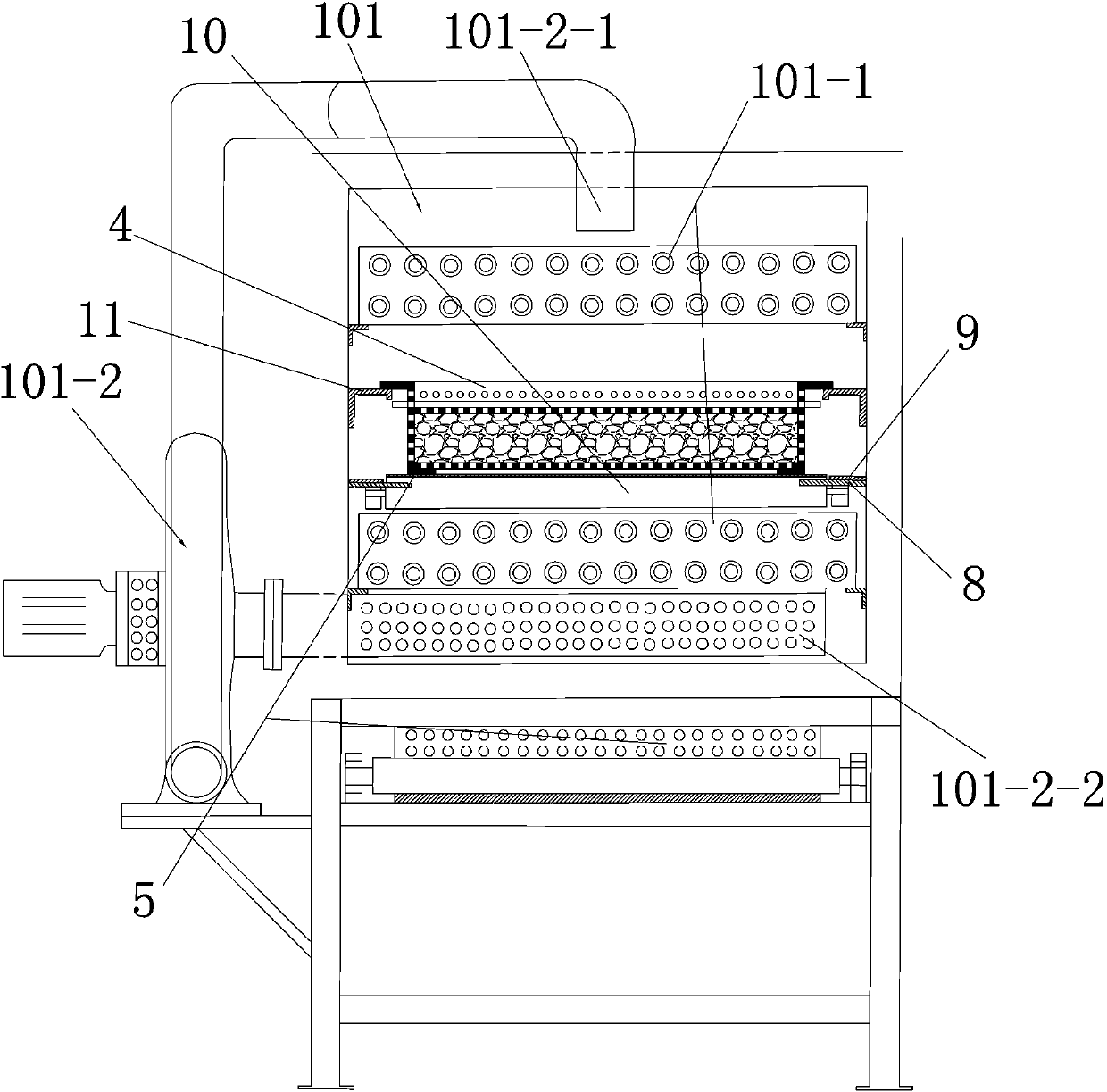

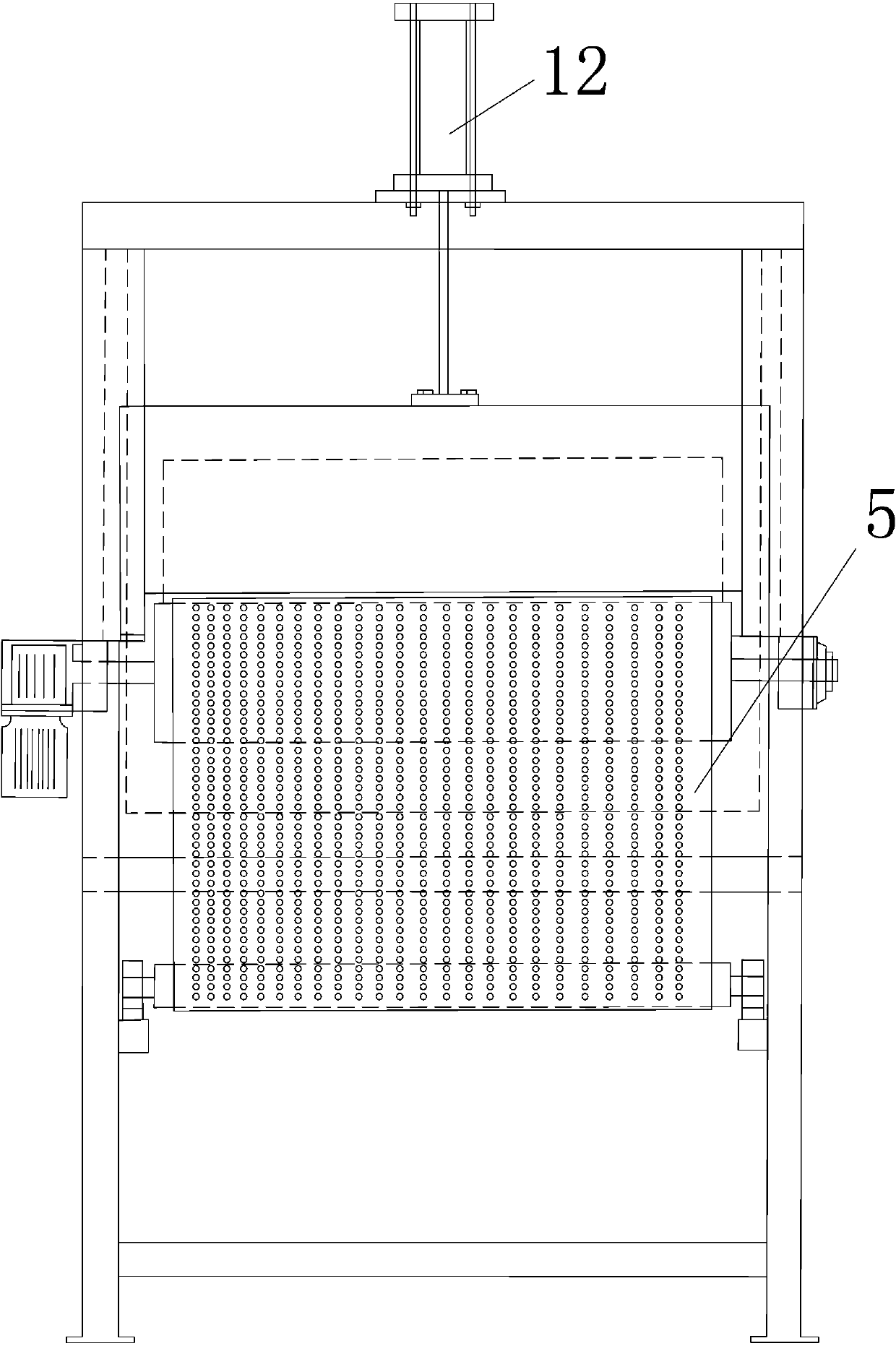

Multifunctional setting production line capable of producing pillow inners of high, medium and low densities

InactiveCN103431700AHigh degree of automationHigh degree of automation and high efficiencyPillowsFiberCooling chamber

The invention provides a multifunctional setting production line capable of producing pillow inners of high, medium and low densities. The production line comprises a heat penetration fiber material setting machine, a natural cooling belt, a cold penetration fiber material machine and a porous ventilation setting die. The natural cooling belt is arranged between the heat penetration fiber material setting machine and the cold penetration fiber material machine and is respectively connected with the heat penetration fiber material setting machine and the cold penetration fiber material machine, porous conveying belts are respectively adopted in the heat penetration fiber material setting machine and the cold penetration fiber material machine to bear the porous ventilating setting die, ventilating holes of the porous ventilating setting die are overlapped and communicated with corresponding ventilating holes of the porous conveying belts, the heat penetration fiber material setting machine is provided with a heat insulation chamber, the cold penetration fiber material machine is provided with a cooling chamber, and high pressure nozzles and movable doors are respectively arranged at the positions of inlets and outlets of the heat insulation chamber and the cooling chamber. The multifunctional setting production line capable of producing pillow inners of high, medium and low densities is suitable for production of the pillow inners of the high, medium and low densities, is high in automation degree, and has the advantages of being high in efficiency, capable of saving energy consumption and labor cost, controllable in quality and the like.

Owner:黎显镇

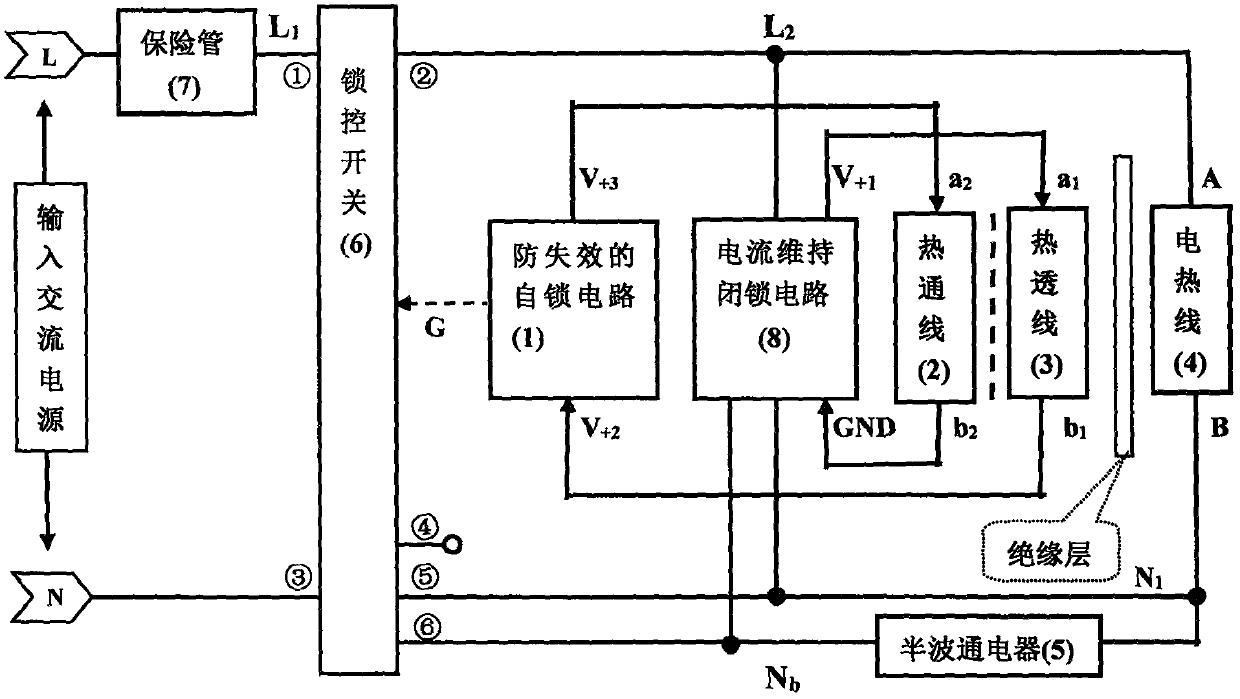

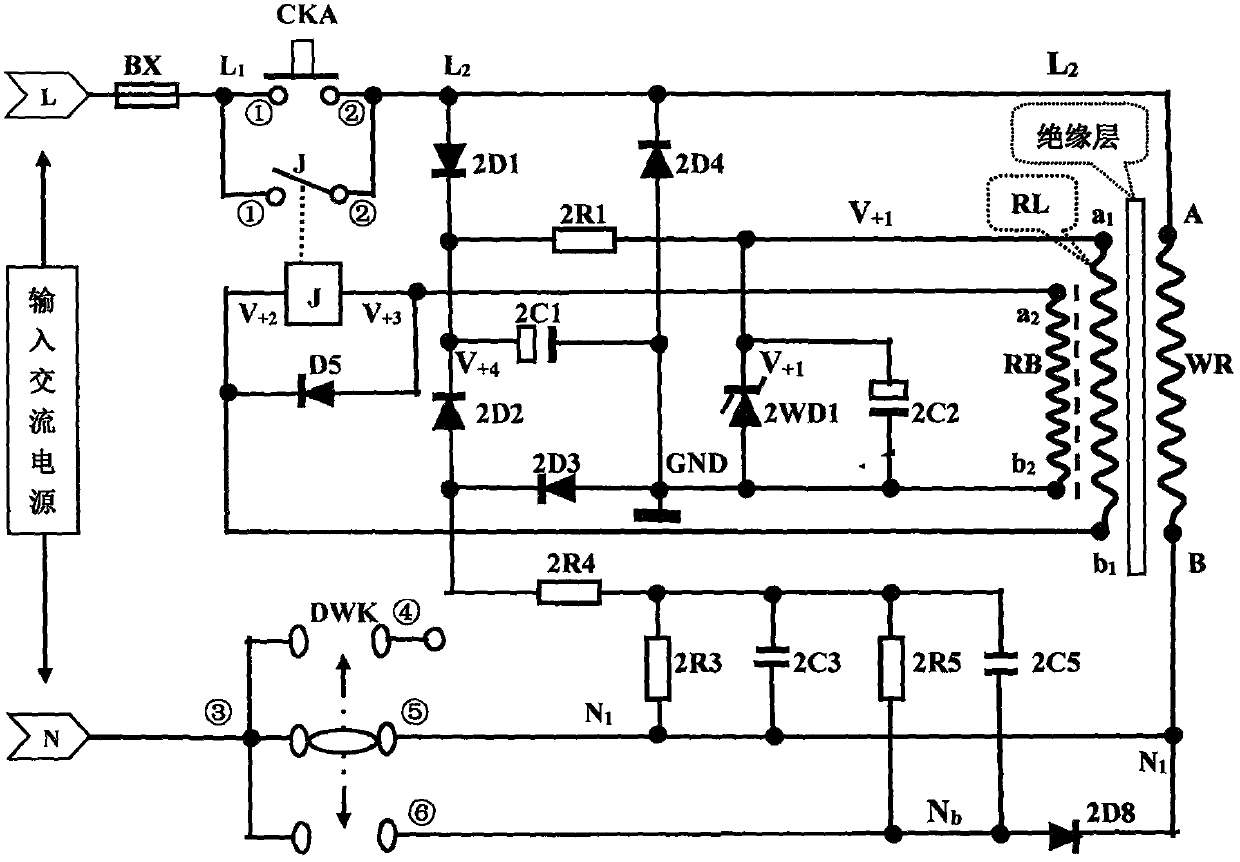

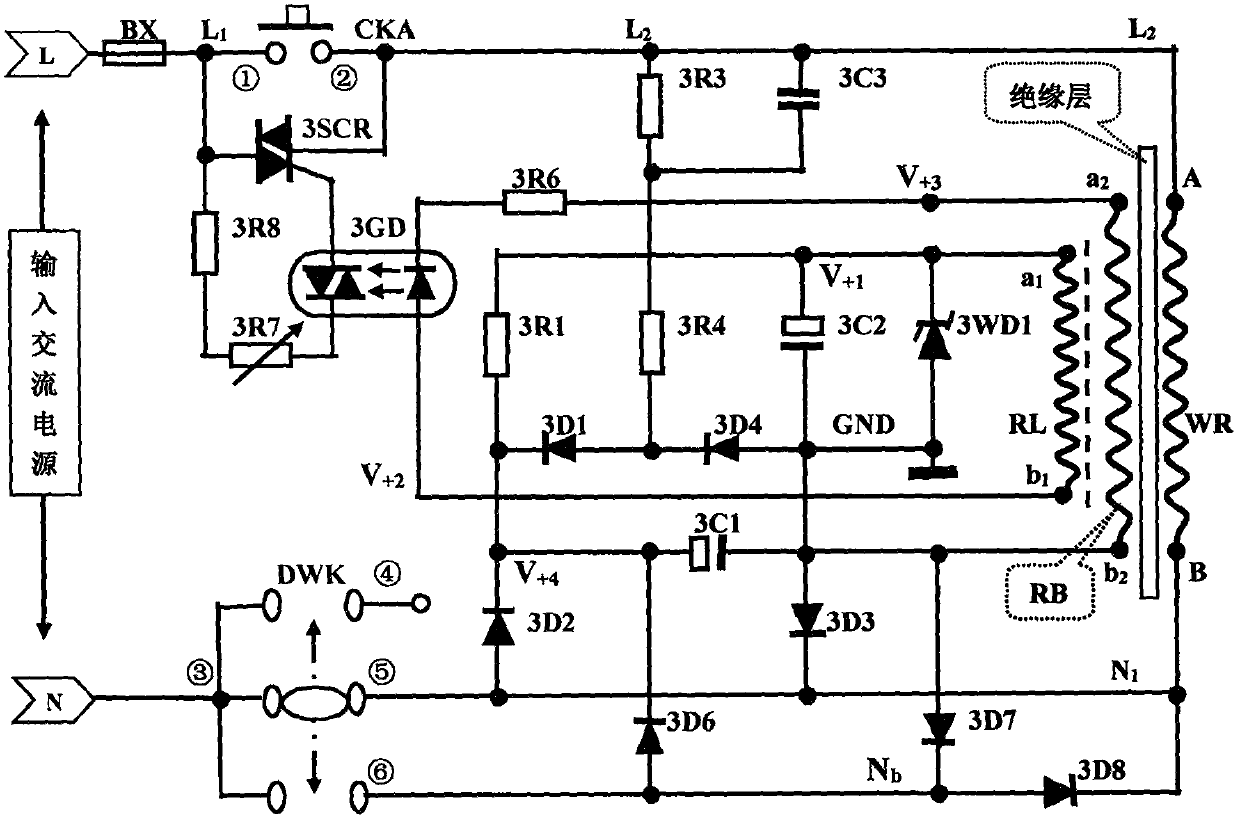

Stably safe electric heating body controller capable of comprehensively preventing overheating protection failure

The present invention relates to a Wenan electrothermal body controller that comprehensively prevents failure of overheating protection. The adopted technical scheme is: firstly, the current maintenance locking circuit provides the current for maintaining locking for the self-locking circuit that prevents failure through the heat-through wire and the heat-through wire, and then the The anti-failure self-locking circuit controls the lock control switch to connect the blocking circuit and the AC power of the heating wire; use the half-wave power supply and the gear temperature adjustment switch to manually adjust the temperature of the heating wire; use the isolation between the heat flux line and the heat penetration line The overheating, melting and short-circuit characteristics of the layer control the anti-failure self-locking circuit and the lock control switch to unlock and power off, and realize the overheat protection function; use the maintenance blocking current to control the anti-failure self-locking circuit and the lock control switch to close the lock, and the lock will be unlocked when an open circuit fault occurs Power failure prevents loss of control, ensures that the overheating protection function will never fail, and completely eliminates the false safety hazards and defects that existed in the past electric heaters or electric blankets. It can be seen that the present invention is a stable electric heater controller that comprehensively prevents overheating protection failure.

Owner:刘少华

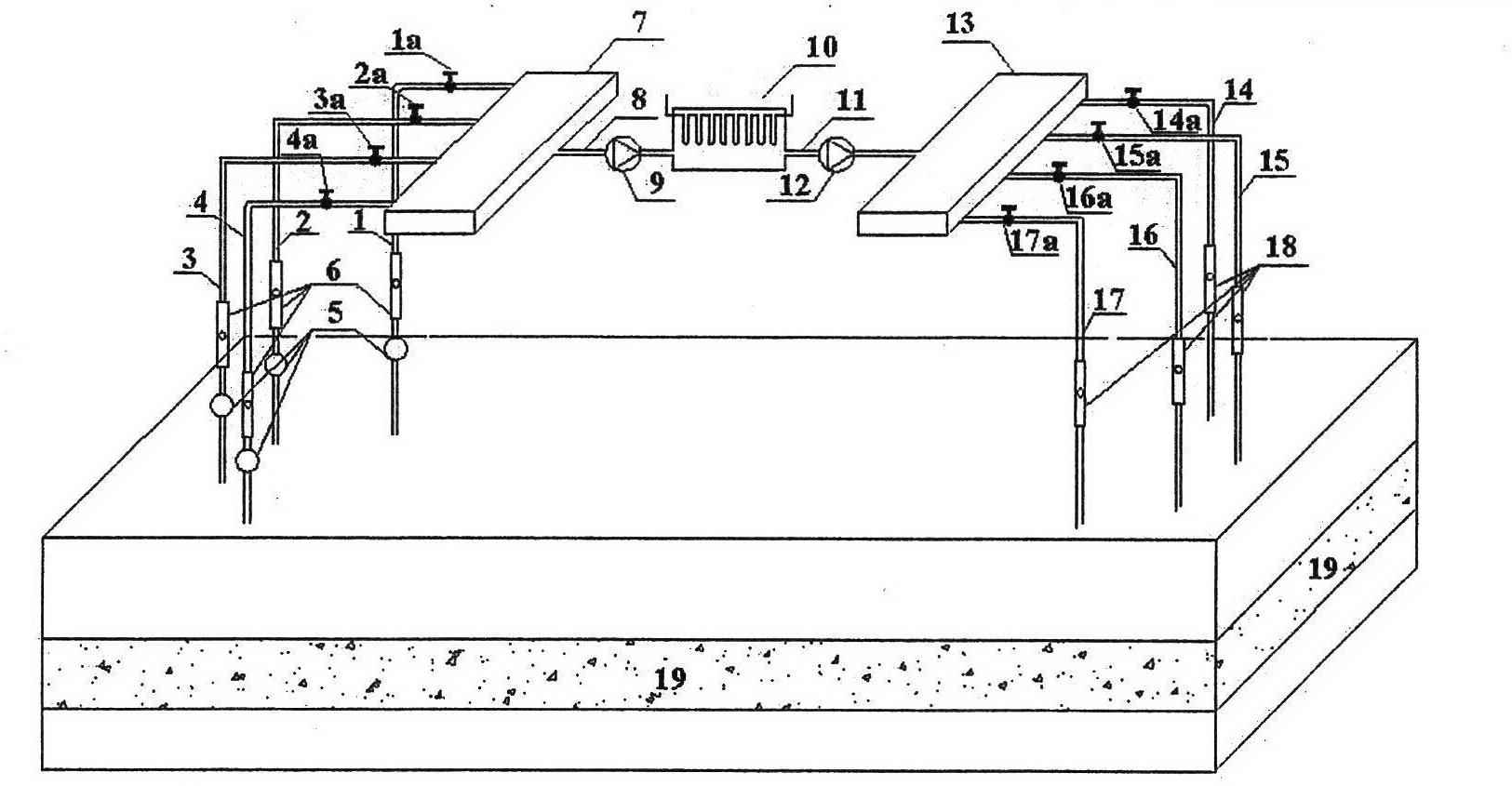

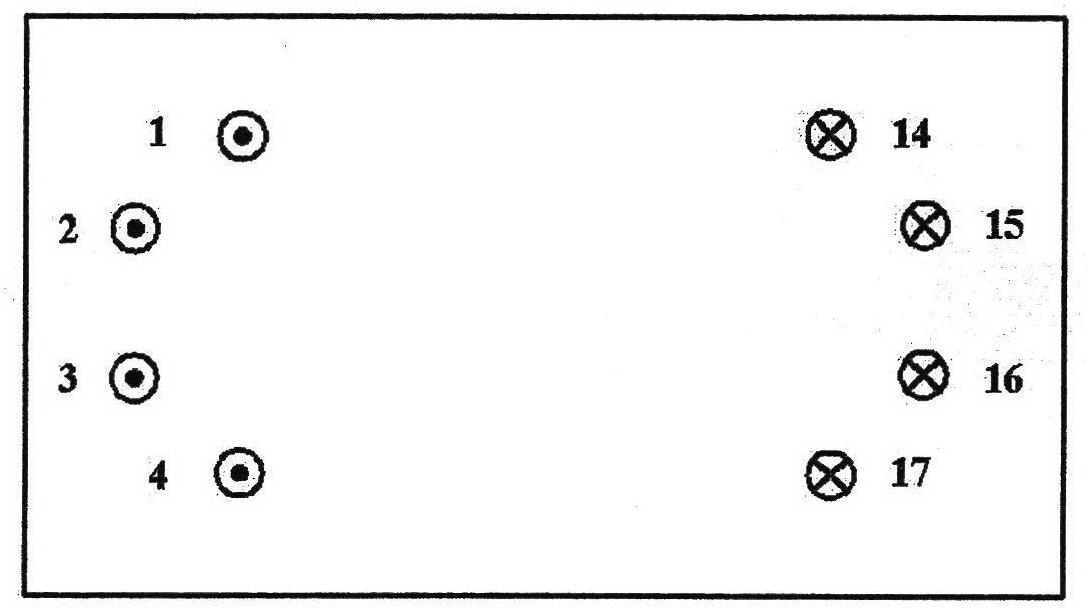

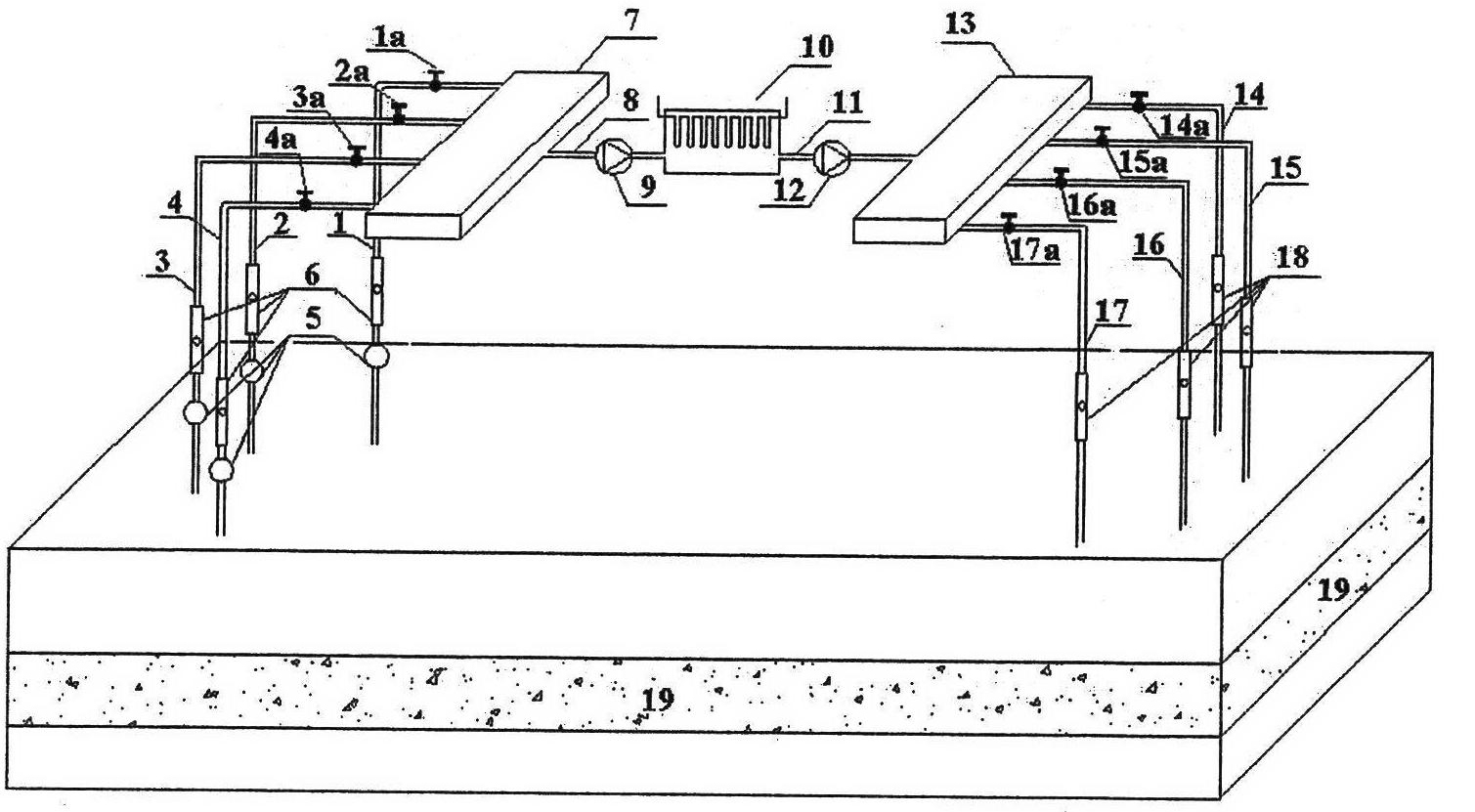

Arrangement method and pumping and recharging mode of pumping and recharging wells

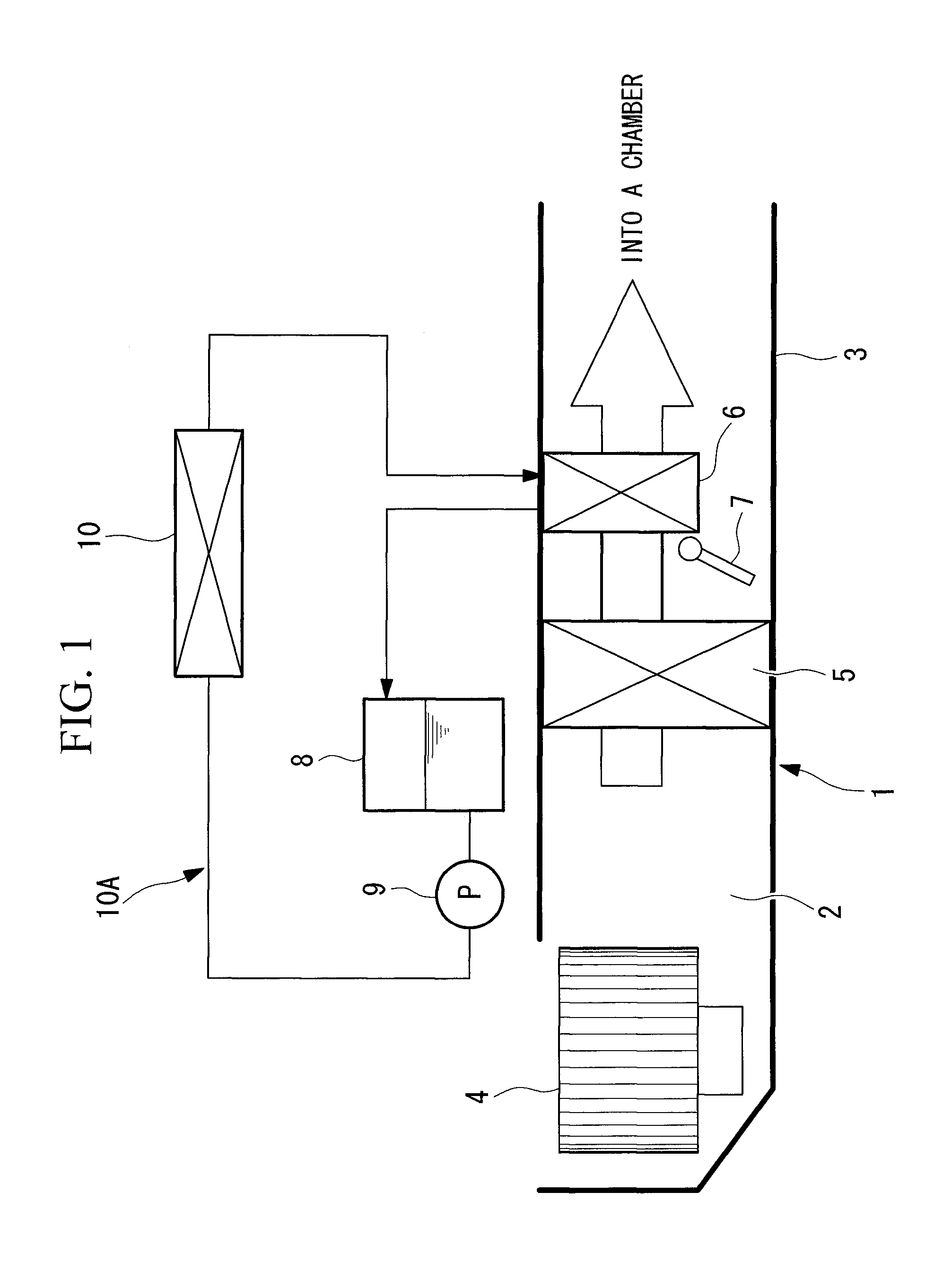

InactiveCN102661635AImprove work efficiencyDelay or avoid thermal shoot-throughHeat pumpsOther heat production devicesWater sourceNuclear engineering

The invention relates to the technical field of ground source heat pump, in particular to an arrangement method and a pumping and recharging mode of a ground water heat pump pumping and recharging wells. The arrangement and pumping and recharging system comprises a first pumping well, a second pumping well, a third pumping well, a fourth pumping well, filters, a pumping well flowmeter, a first valve, a second valve, a third valve, a fourth valve, a water collector, a pumping main pipe, a suction pump, a heat exchanger, a recharging main pipe, a recharging water pump, a water distributor, a fifth valve, a sixth valve, a seventh valve, an eighth valve, a first recharging well, a second recharging well, a third recharging well, a fourth recharging well, recharging well flowmeters and a target aquifer. The pumping wells and the recharging wells are respectively staggerly arranged in a row, flow load of pumping or recharging of each well is adjusted in real time, and accordingly, occurrence of heat penetration is delayed to the maximum extent, thermal interaction influence is relieved, utilization of earth energy and work efficiency of a heat pump unit are enhanced, and service life is prolonged.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com