Manufacturing technology of novel moving blades of crusher

A manufacturing process and mobile technology, applied in the field of mechanical processing, can solve the problems such as the failure of the movable knife to be used normally, long heating time, deformation of the movable knife, etc., and achieve the effects of small quenching stress and deformation, fast heating speed and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

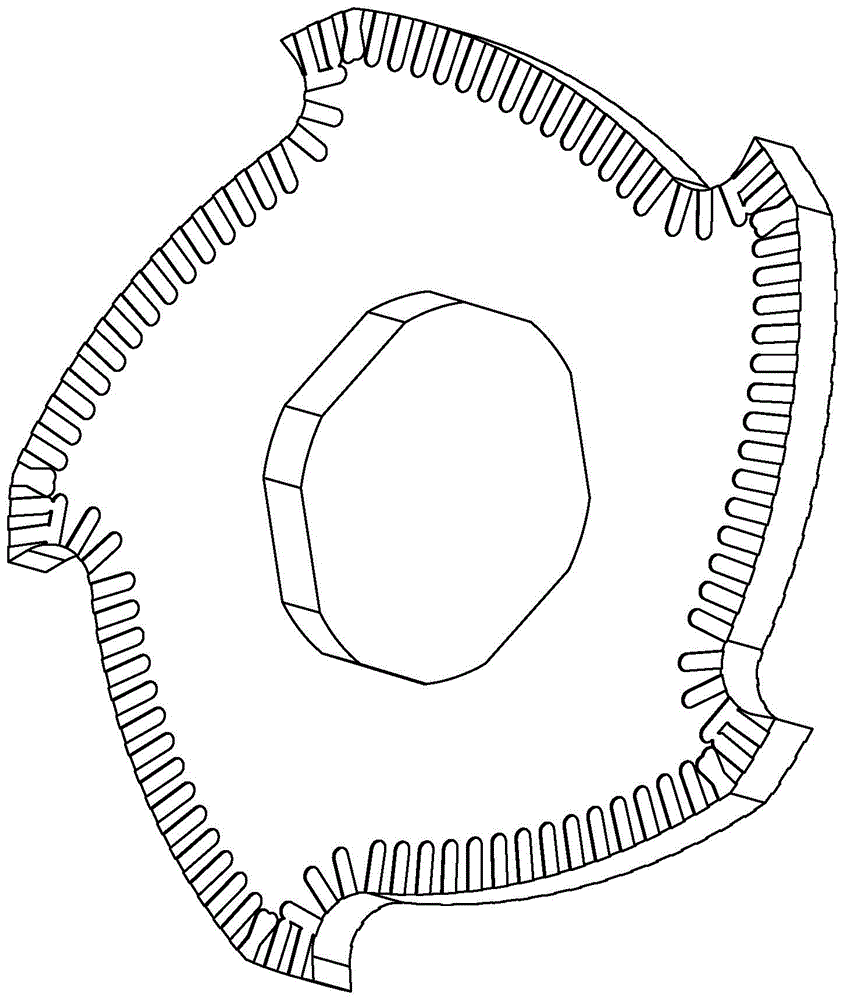

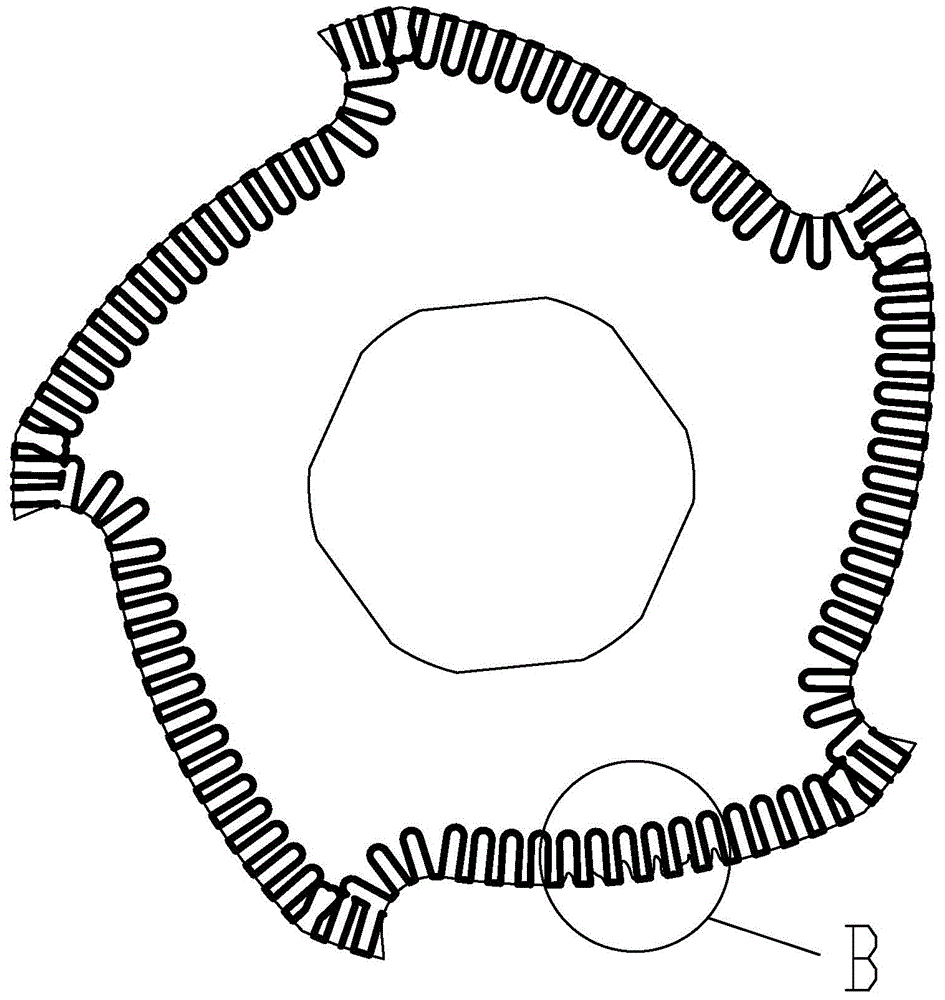

[0034] The present invention will be further described below in conjunction with the drawings:

[0035] The manufacturing process of a new type of crushing mobile knife includes the following steps:

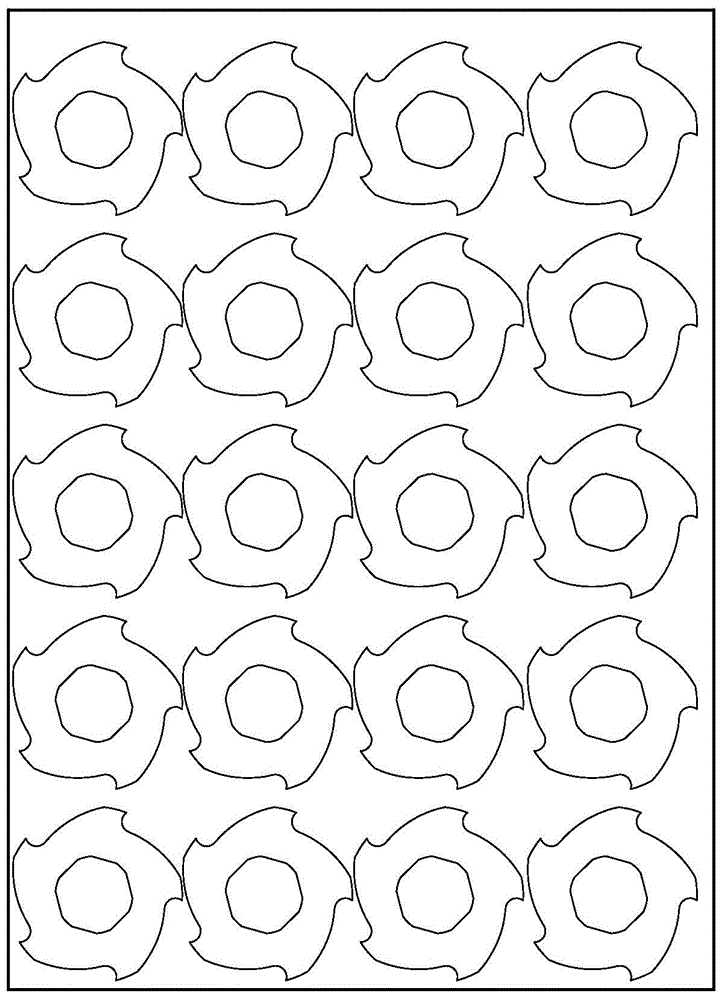

[0036] A1. Cut the profile with the broken motorized knife pattern along the pattern into multiple movable knives;

[0037] A2. Place the movable knife on the machine tool, with the side to be processed facing upwards, turn on the laser and connect it to the computer;

[0038] A3. Clear the laser fault alarm;

[0039] A4. Call the programmed processing program, adjust the machine tool to the processing zero position, and set the distance between the laser head and the upper surface of the movable knife;

[0040] A5. The laser pulse is applied to the upper surface of the movable knife to scan and quench to form a high-hardness oxide layer according to the program setting;

[0041] A6. After scanning the upper surface of the moving knife, transfer the moving knife to a water grinder to fine gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com