Patents

Literature

733results about How to "Small overall deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

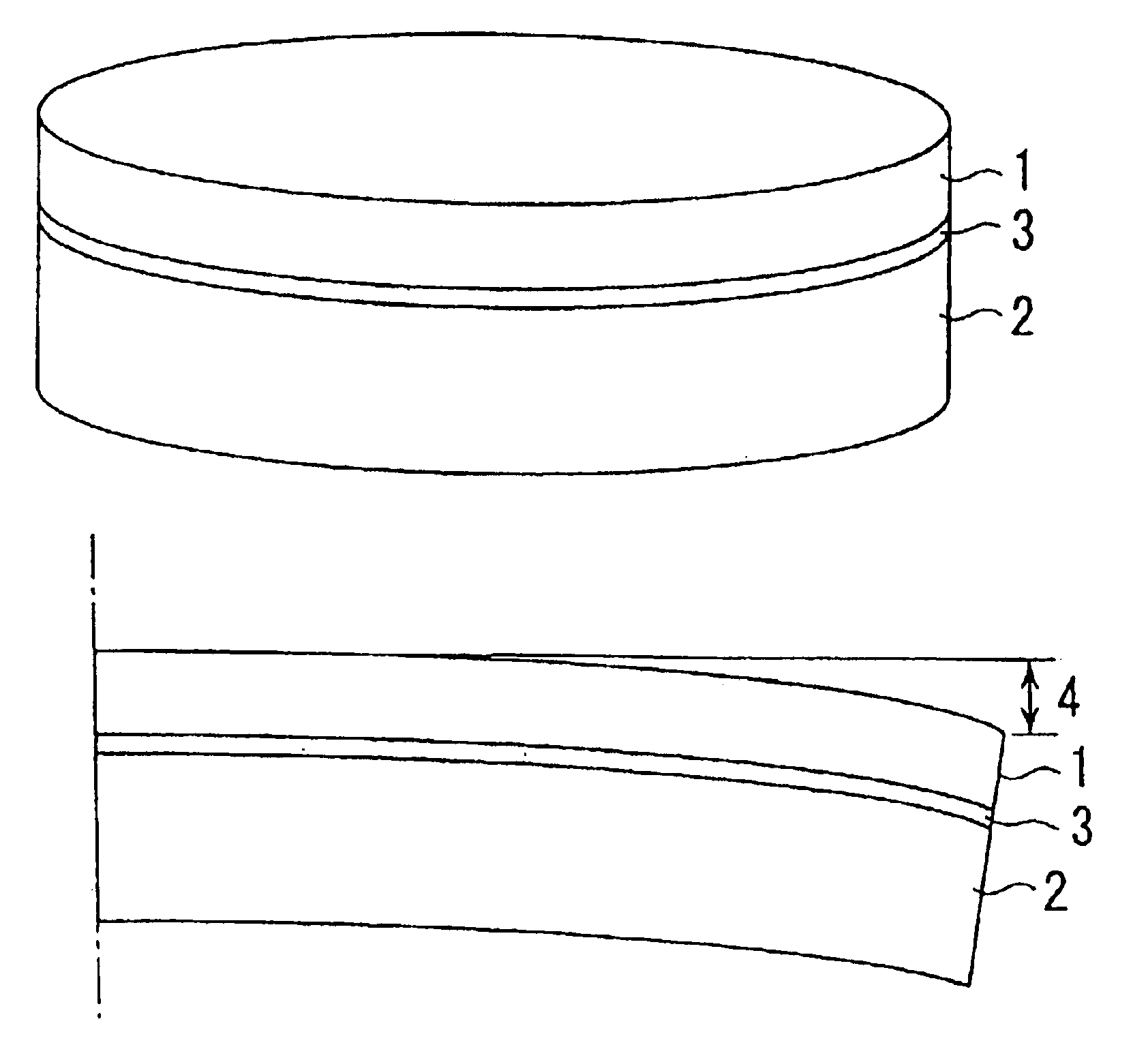

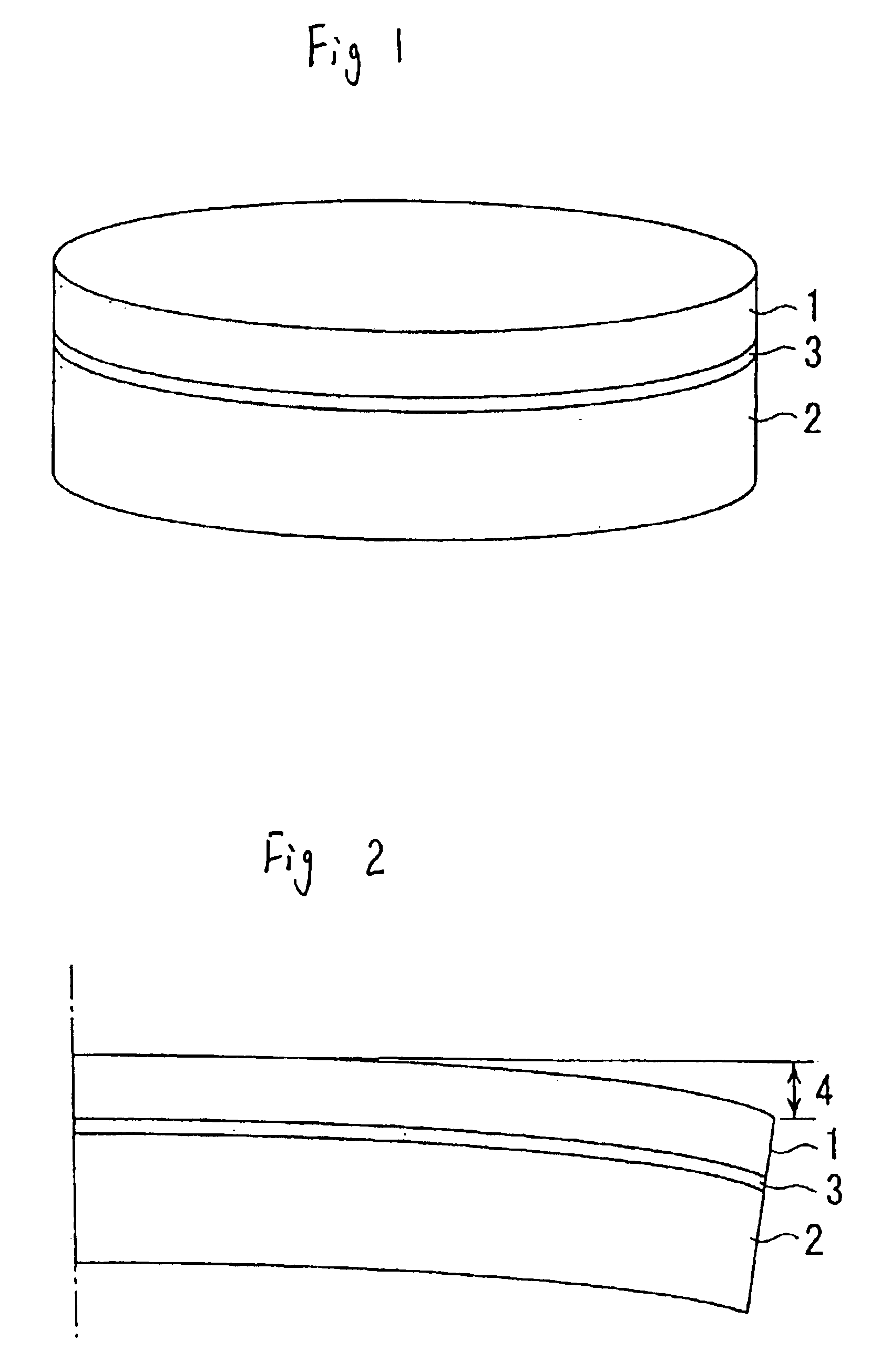

Wafer holding, wafer support member, wafer boat and heat treatment furnace

InactiveUS7204887B2Small deformationLess slip dislocationDrying solid materials with heatCharge supportsDislocationProduction rate

Owner:NIPPON STEEL CORP

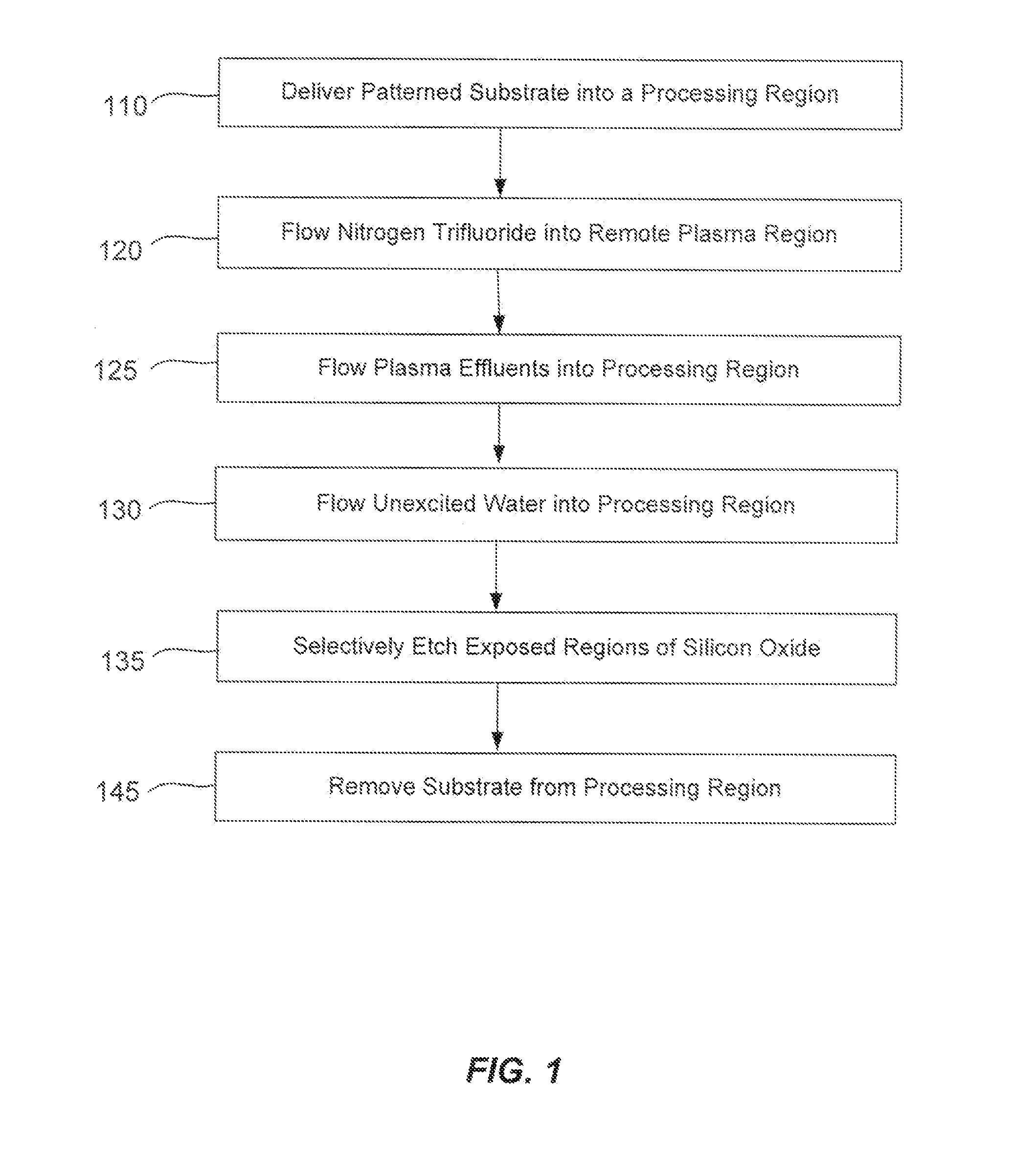

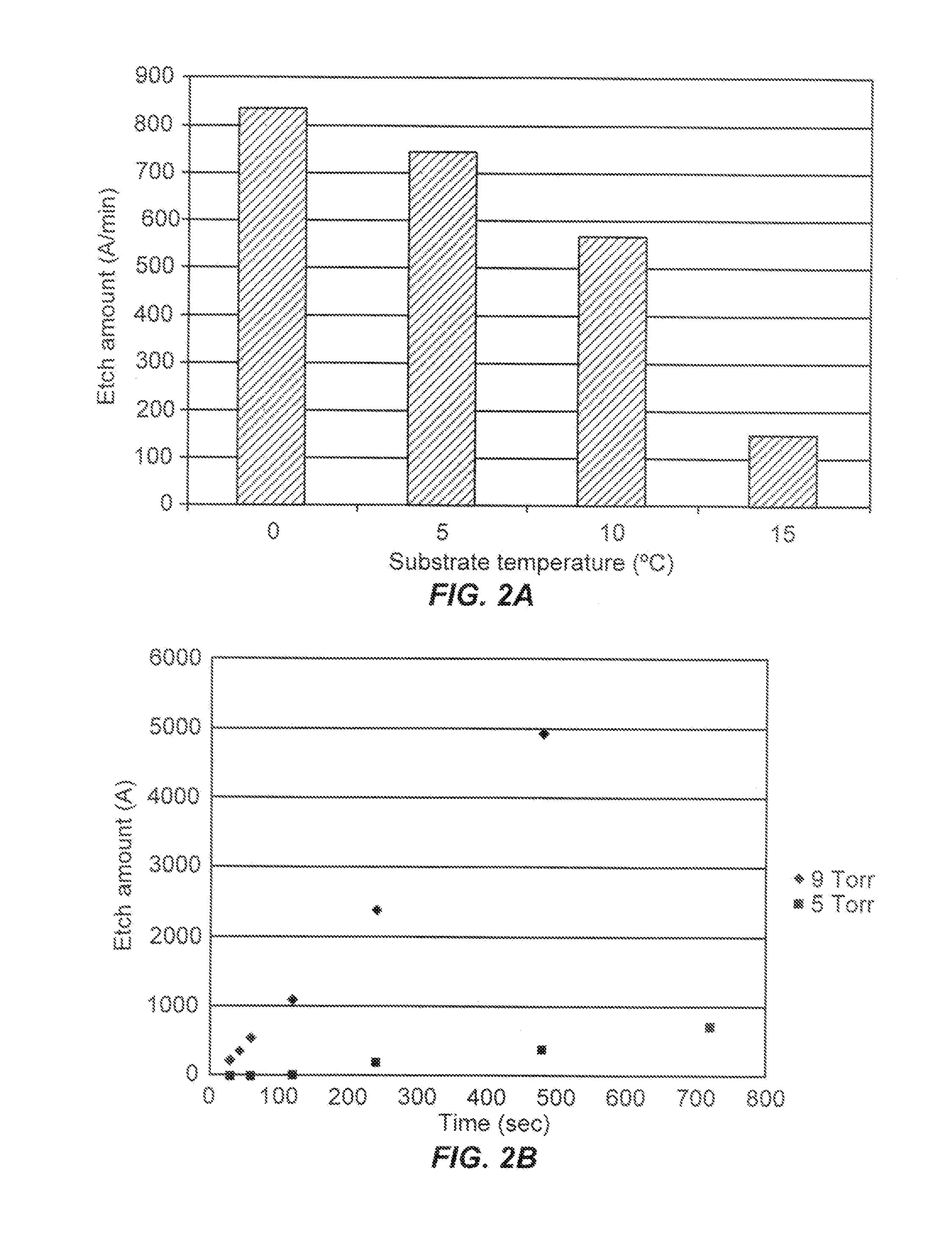

Remotely-excited fluorine and water vapor etch

ActiveUS20120211462A1Small overall deformationElectric discharge tubesDecorative surface effectsChemical reactionRemote plasma

A method of etching exposed silicon oxide on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents combine with water vapor. The chemical reaction resulting from the combination produces reactants which etch the patterned heterogeneous structures to produce, in embodiments, a thin residual structure exhibiting little deformation. The methods may be used to conformally trim silicon oxide while removing little or no silicon, polysilicon, silicon nitride, titanium or titanium nitride. In an exemplary embodiment, the etch processes described herein have been found to remove mold oxide around a thin cylindrical conducting structure without causing the cylindrical structure to significantly deform.

Owner:APPLIED MATERIALS INC

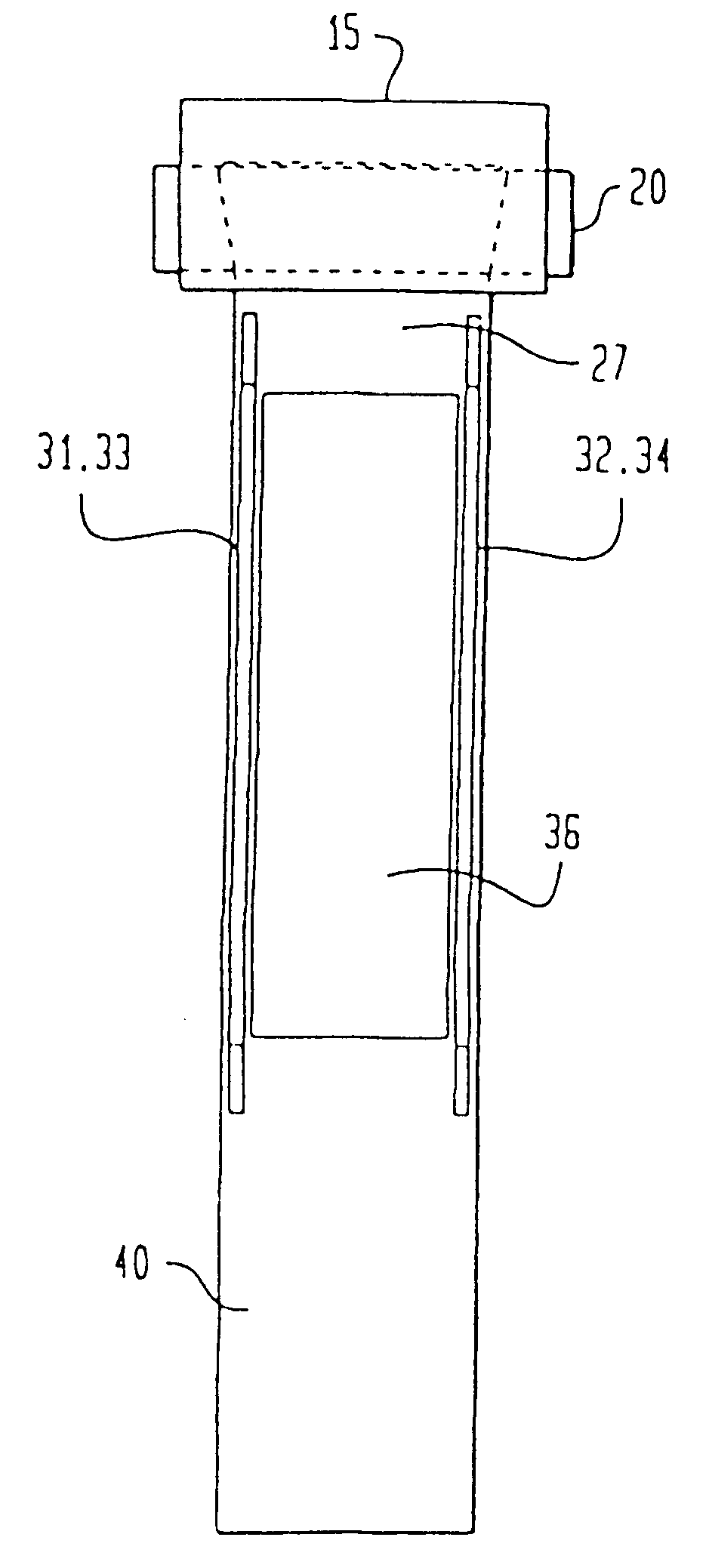

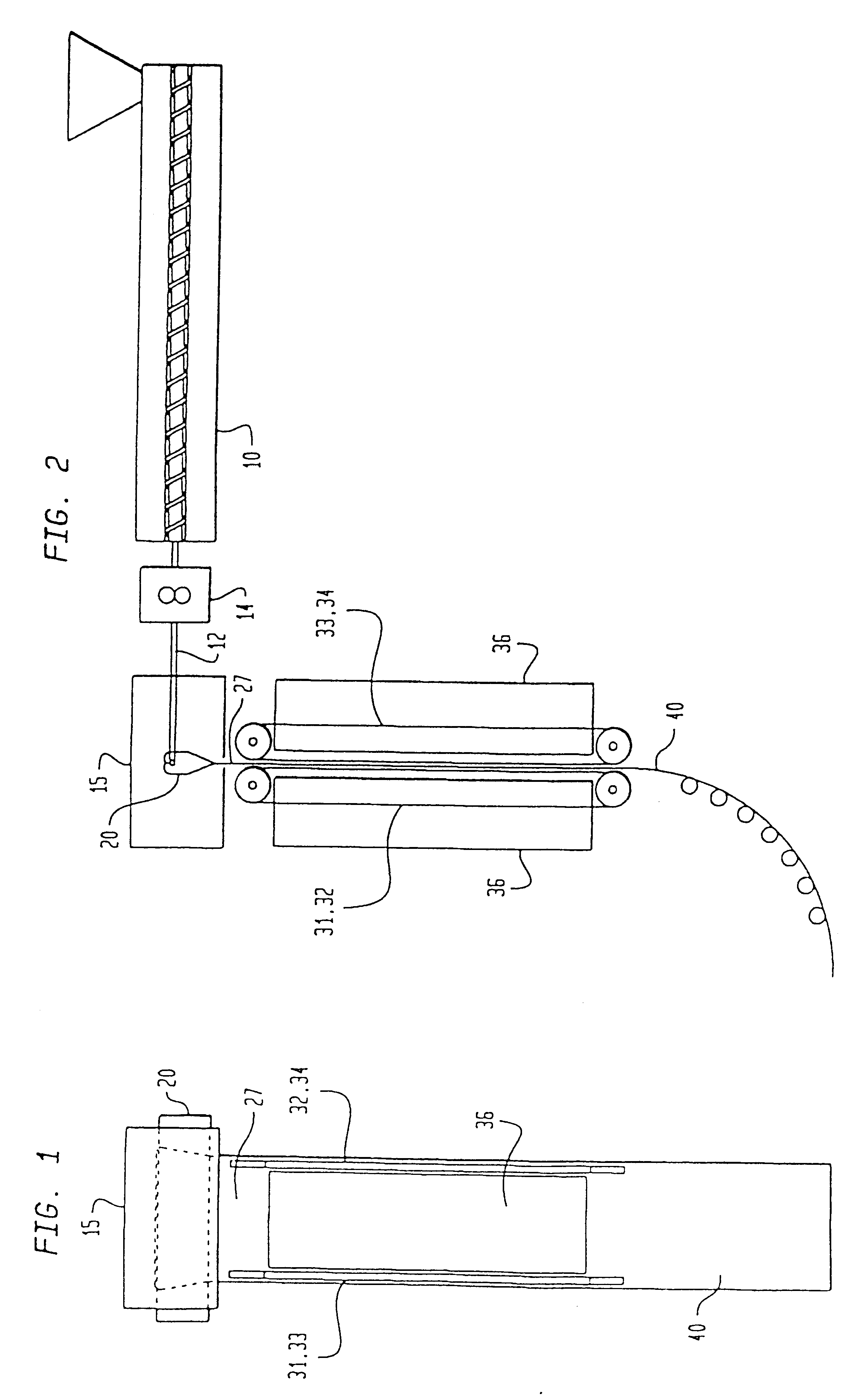

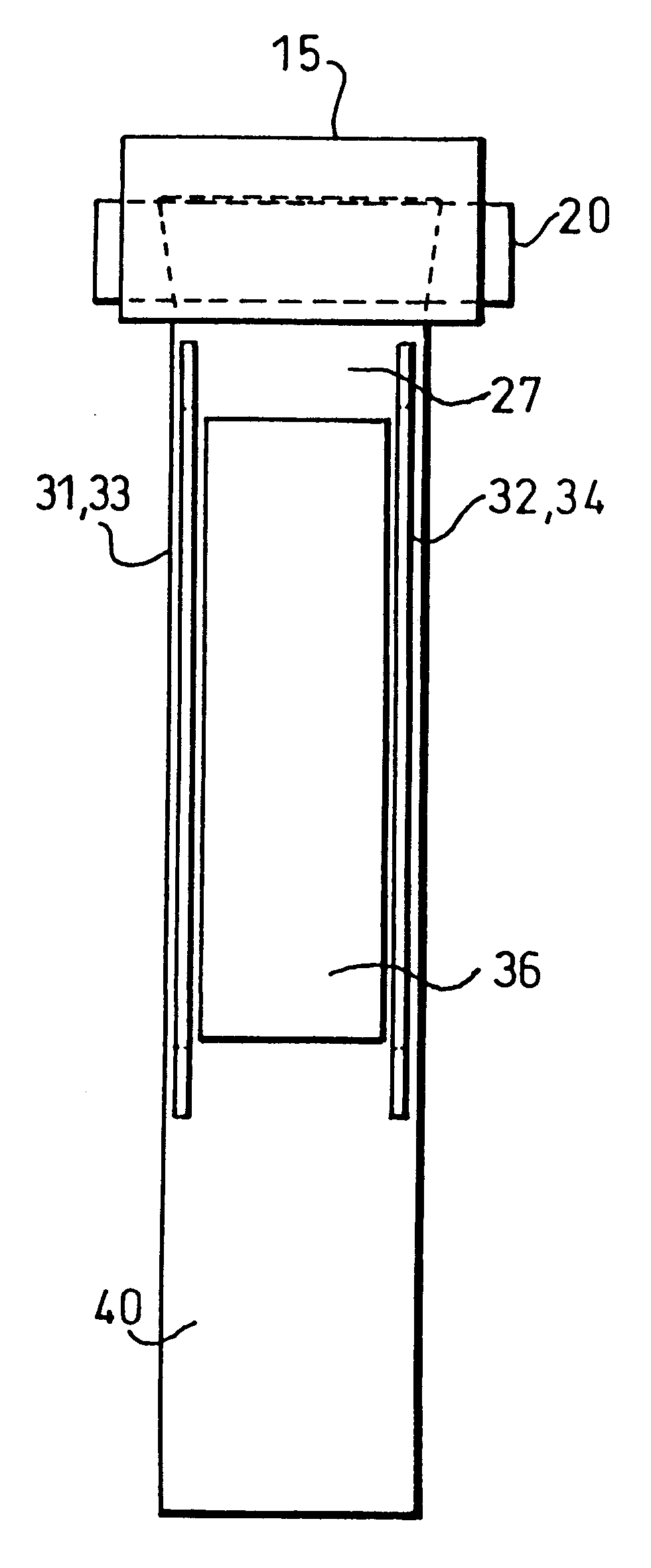

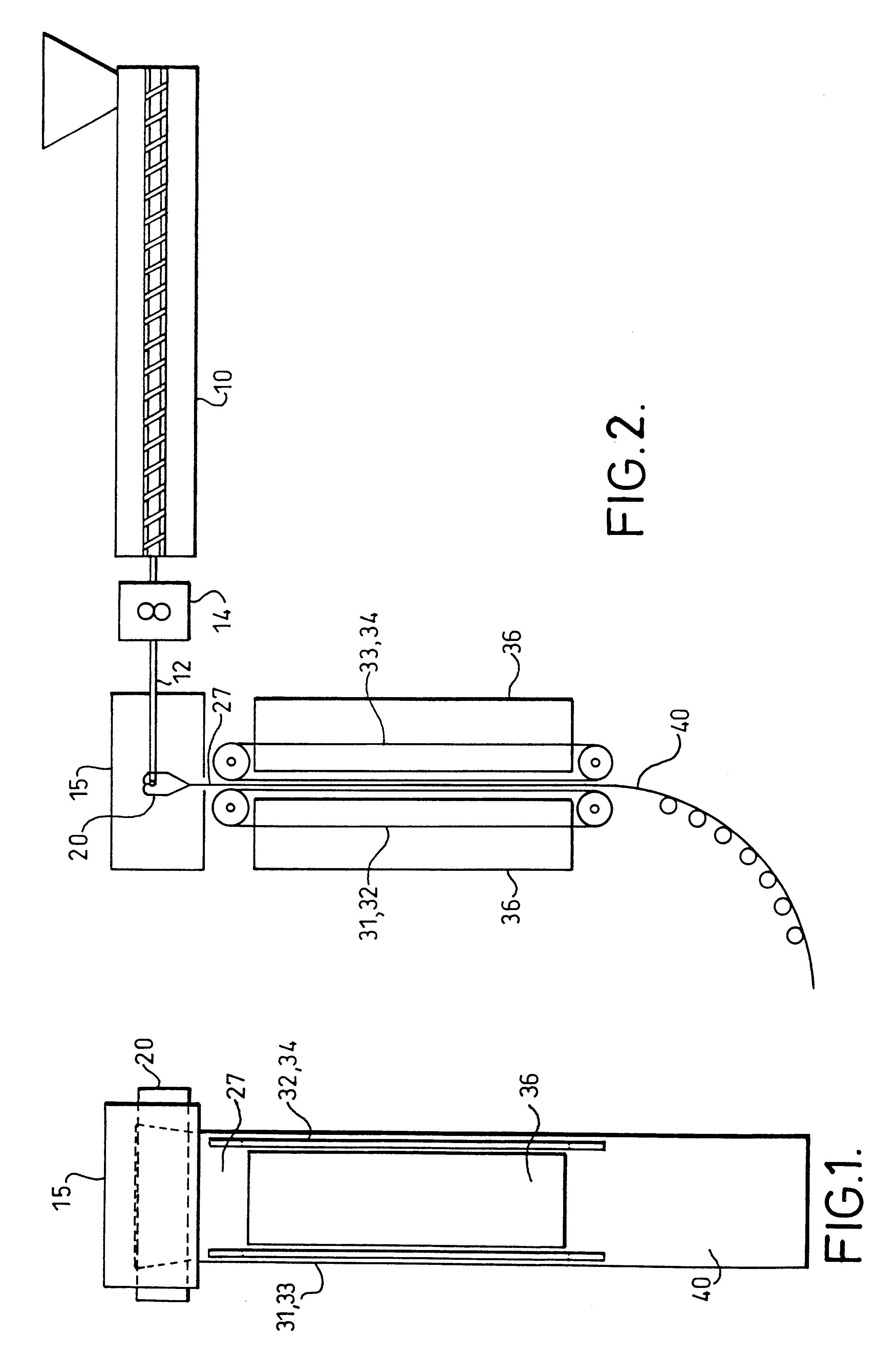

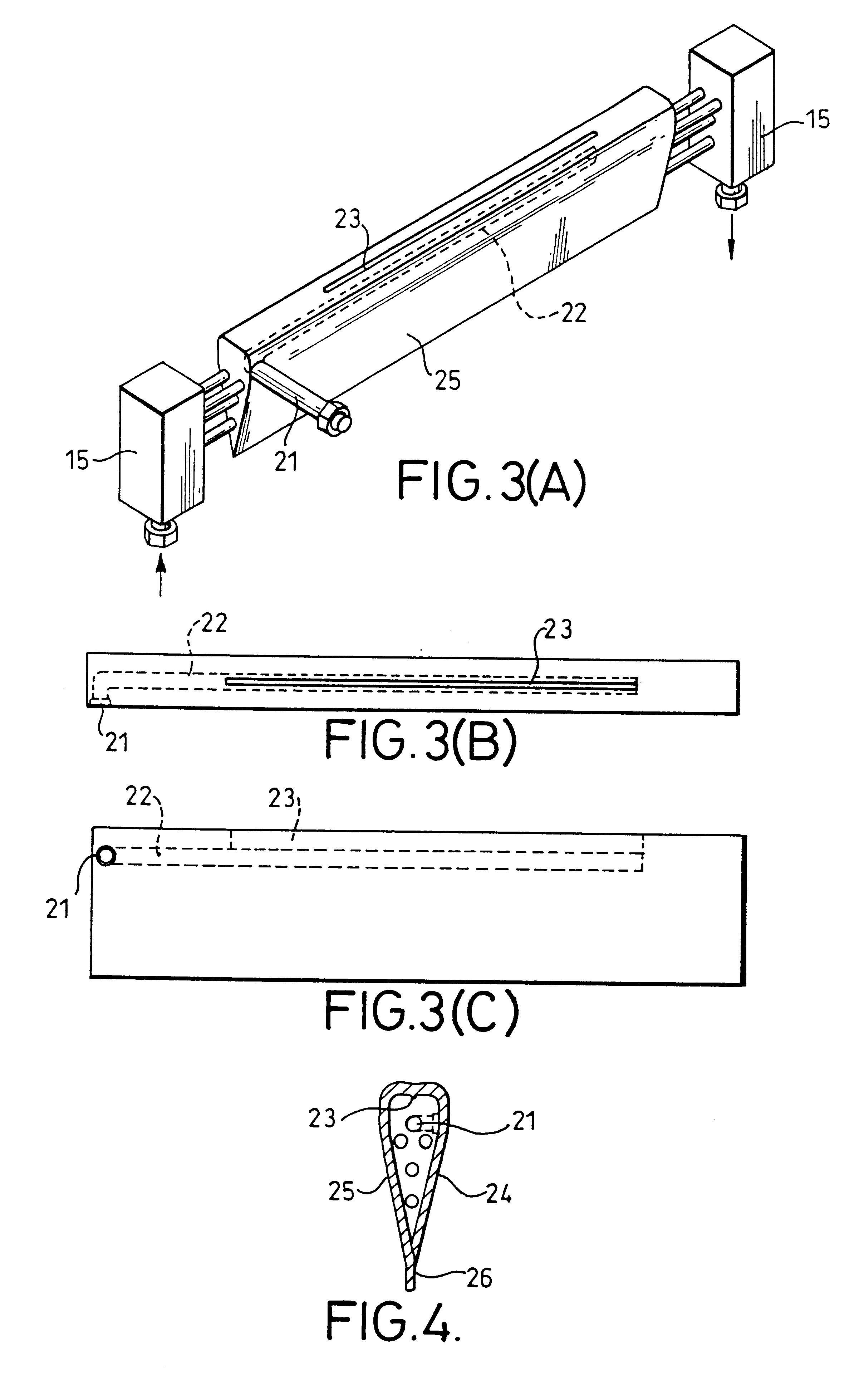

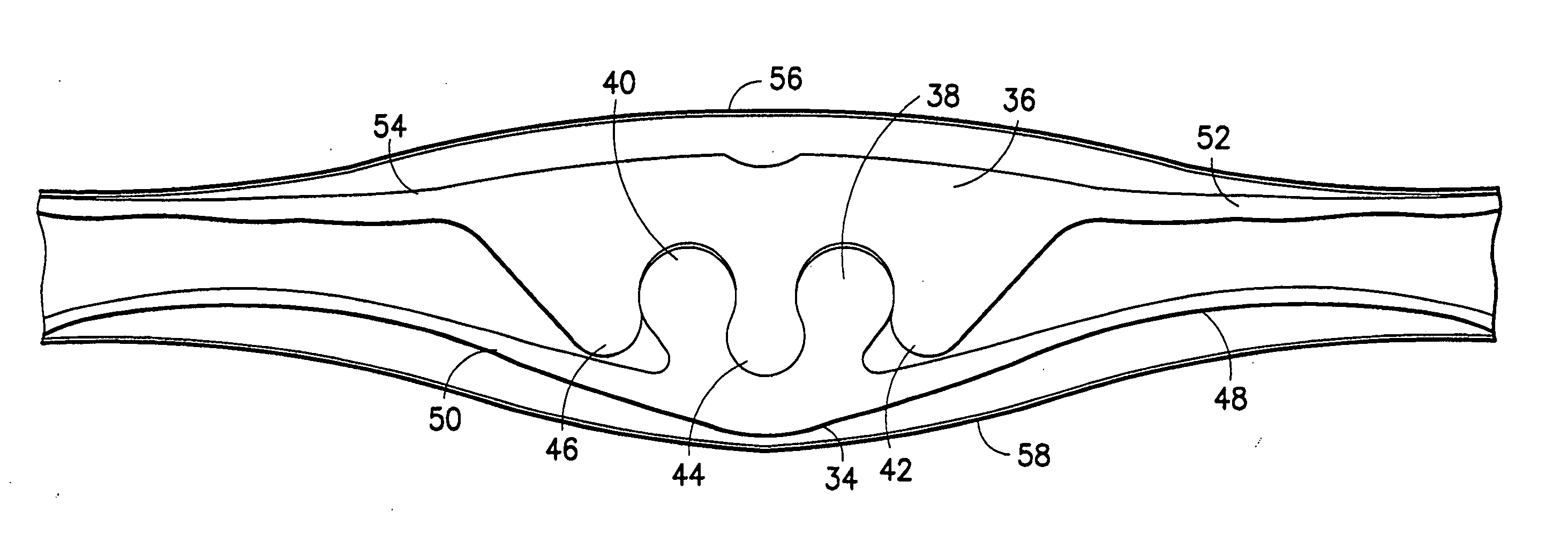

Process and apparatus for forming plastic sheet

InactiveUS6183829B1Avoid mistakesLow birefringenceRecord carriersPhotosensitive materialsEngineeringMechanical engineering

Owner:ROHM & HAAS CO

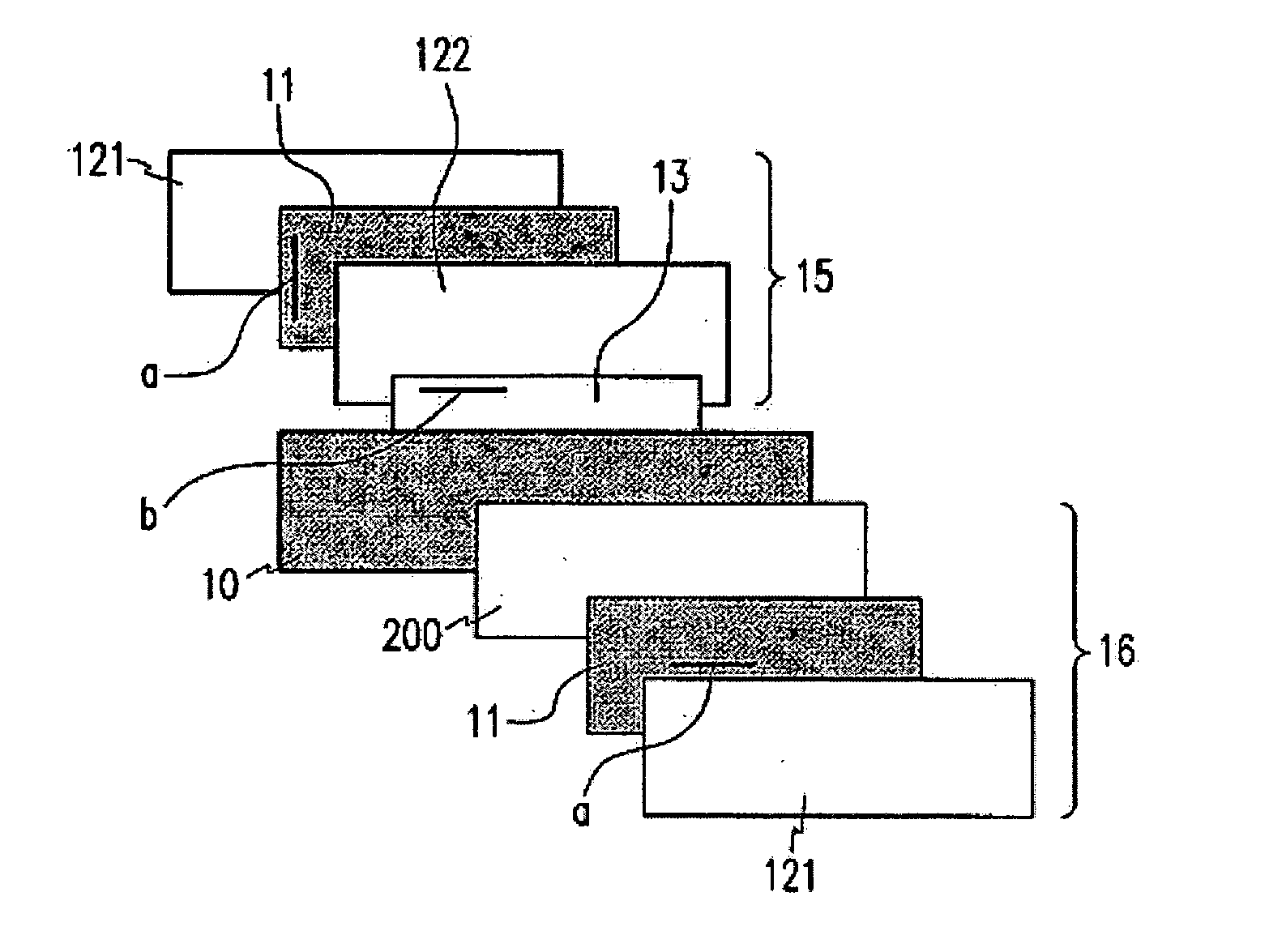

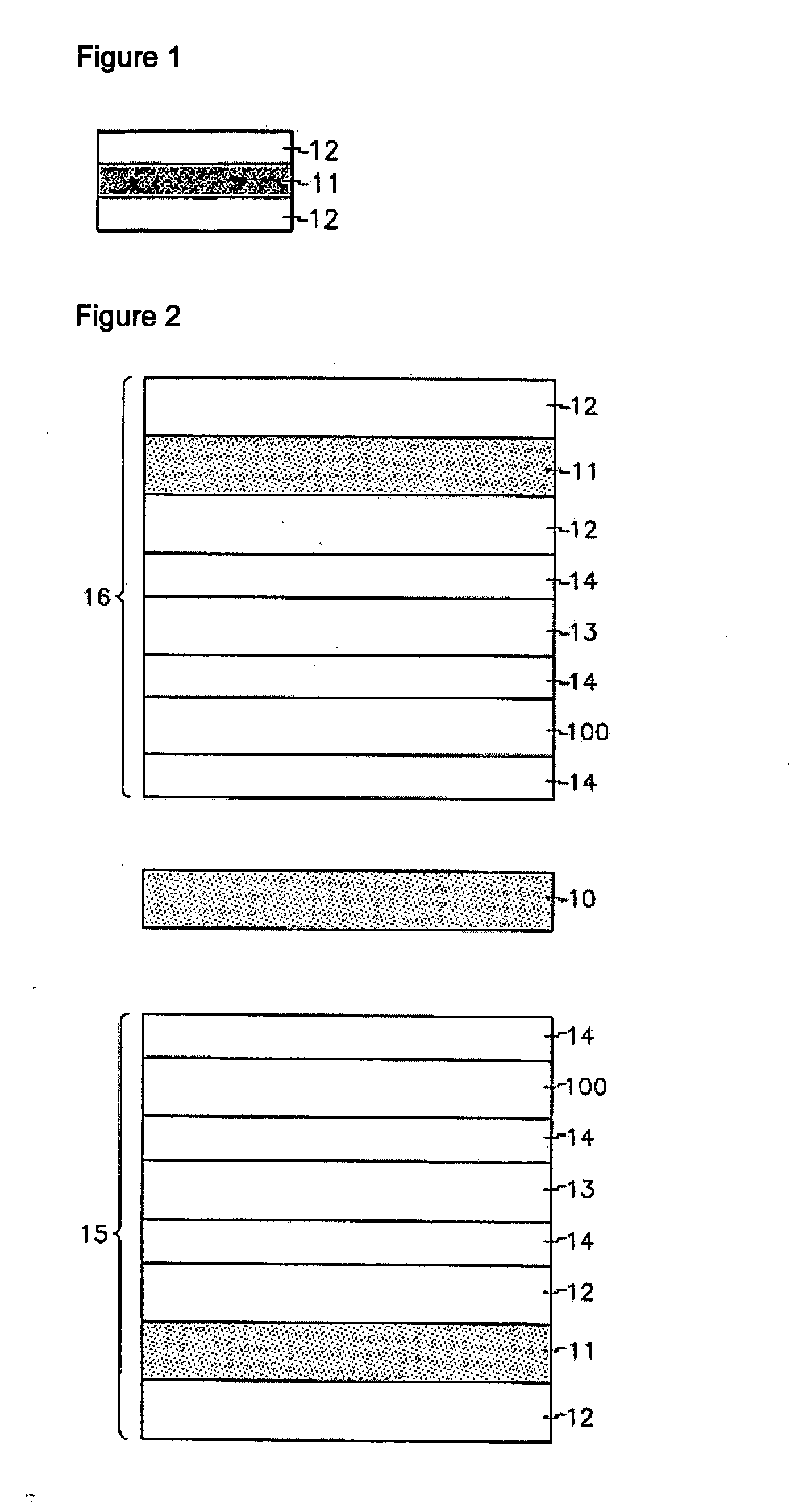

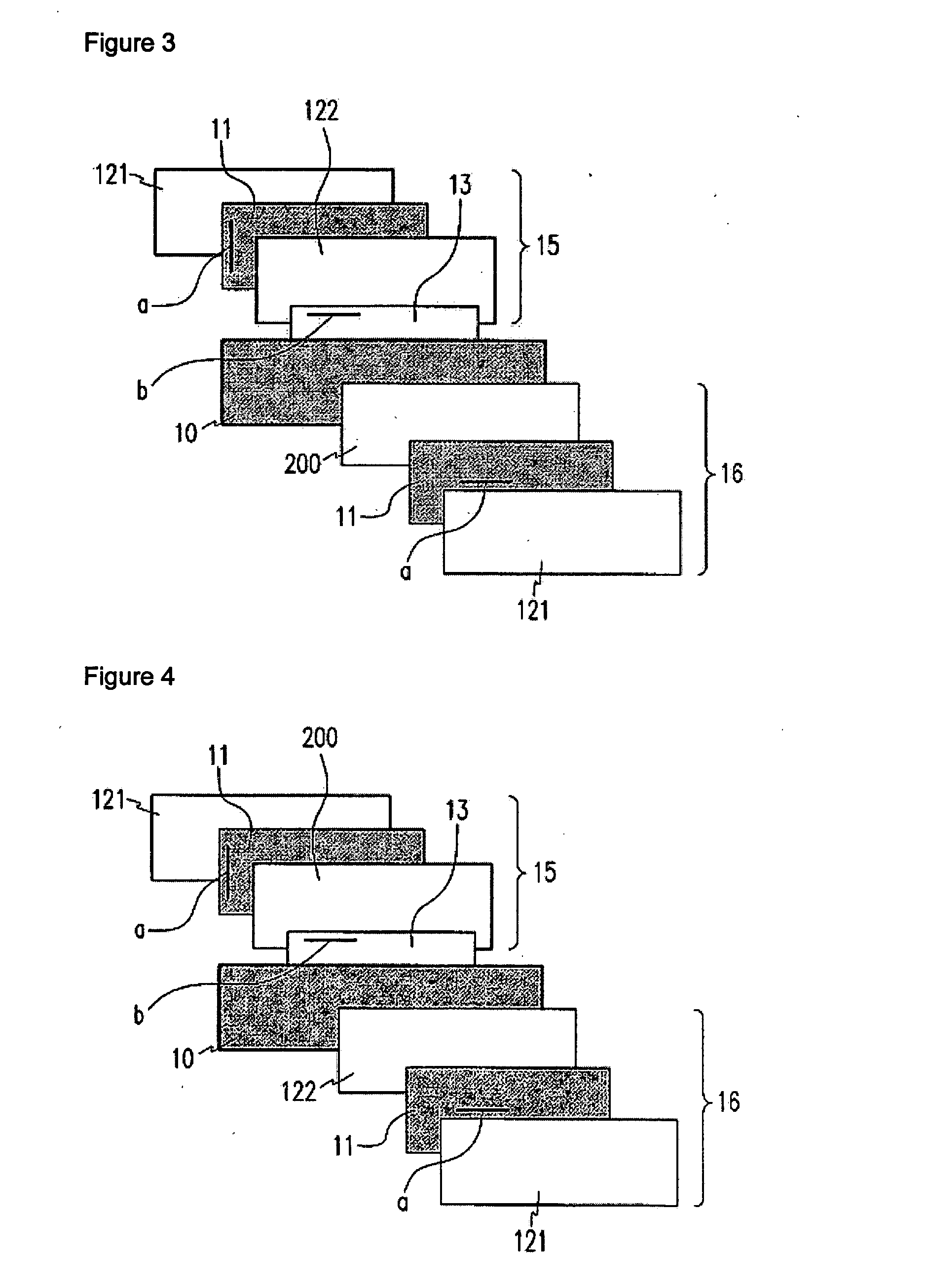

Stacked microelectronic assemblies and methods of making same

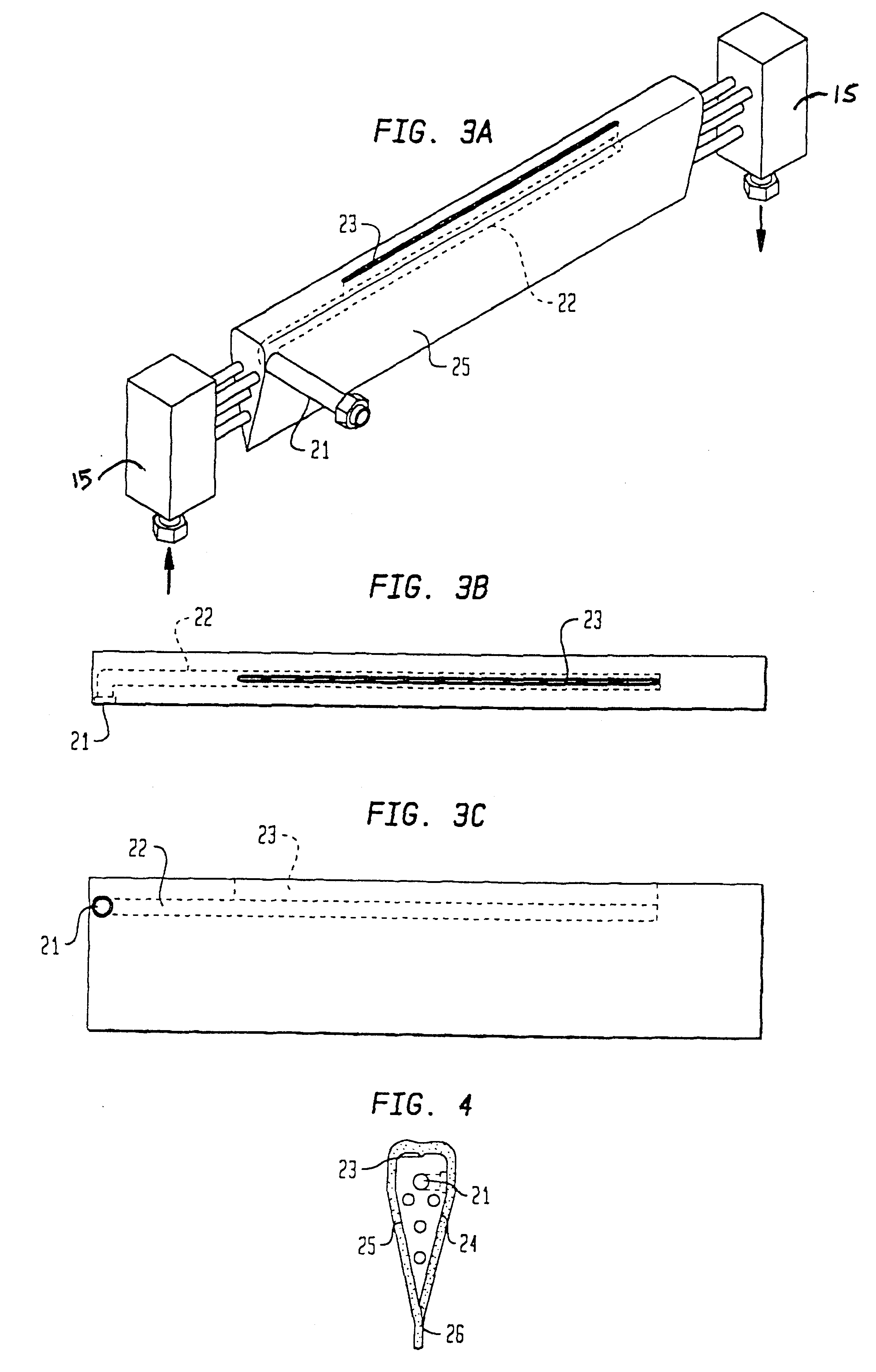

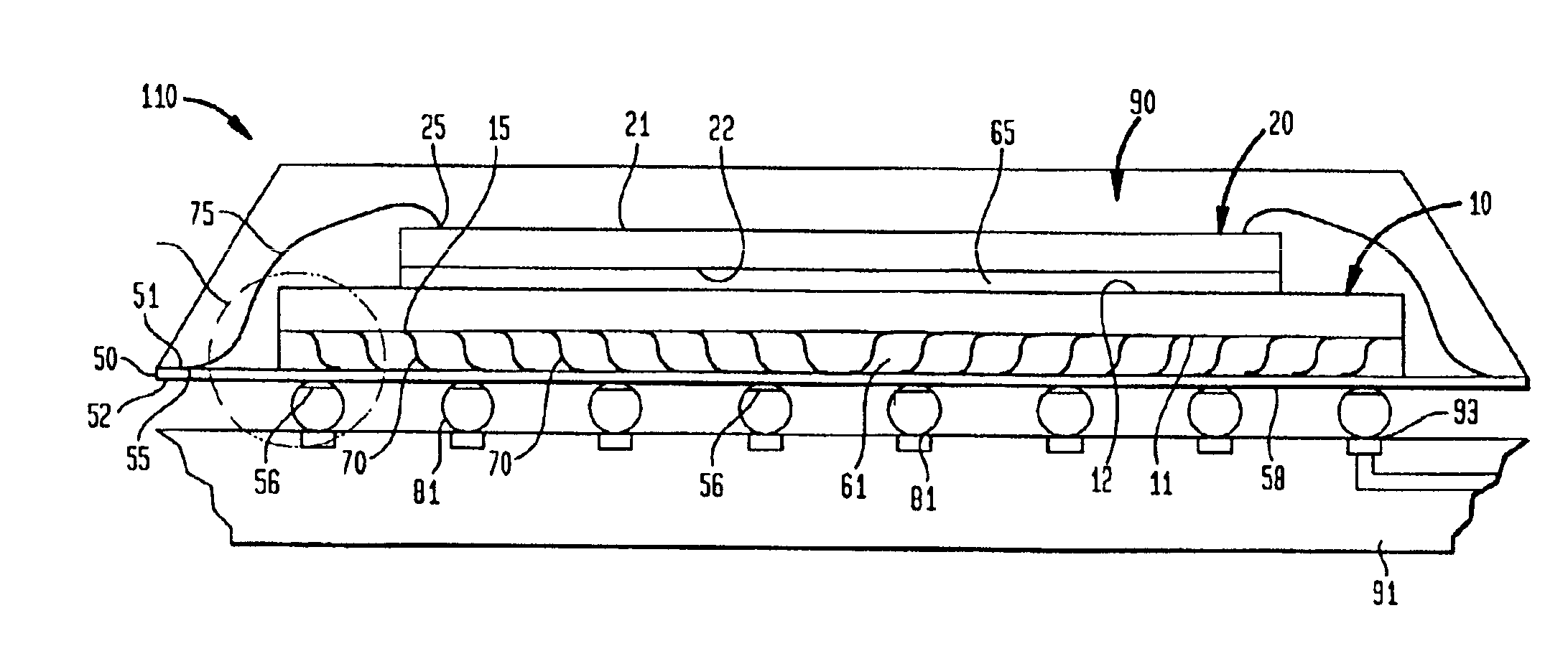

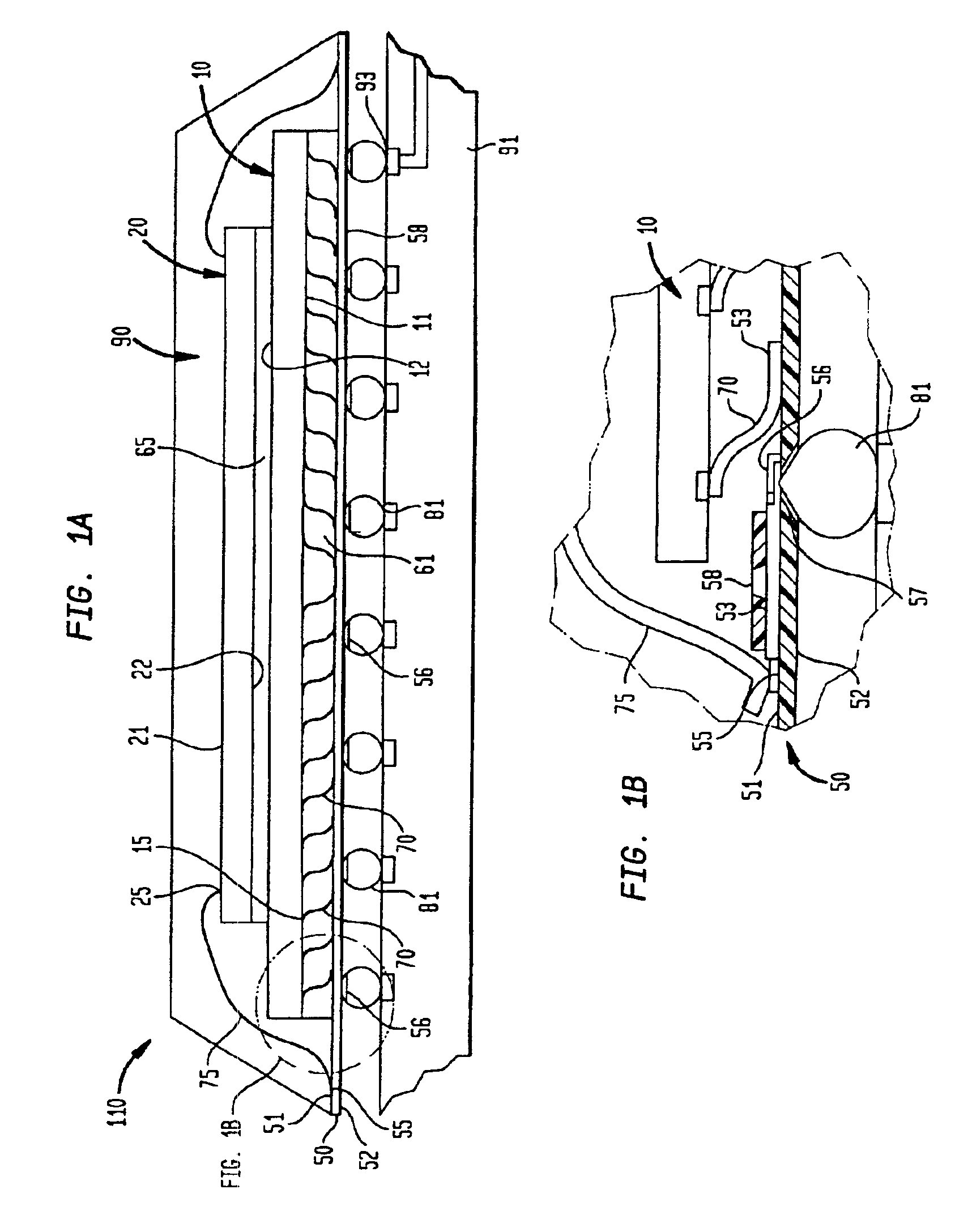

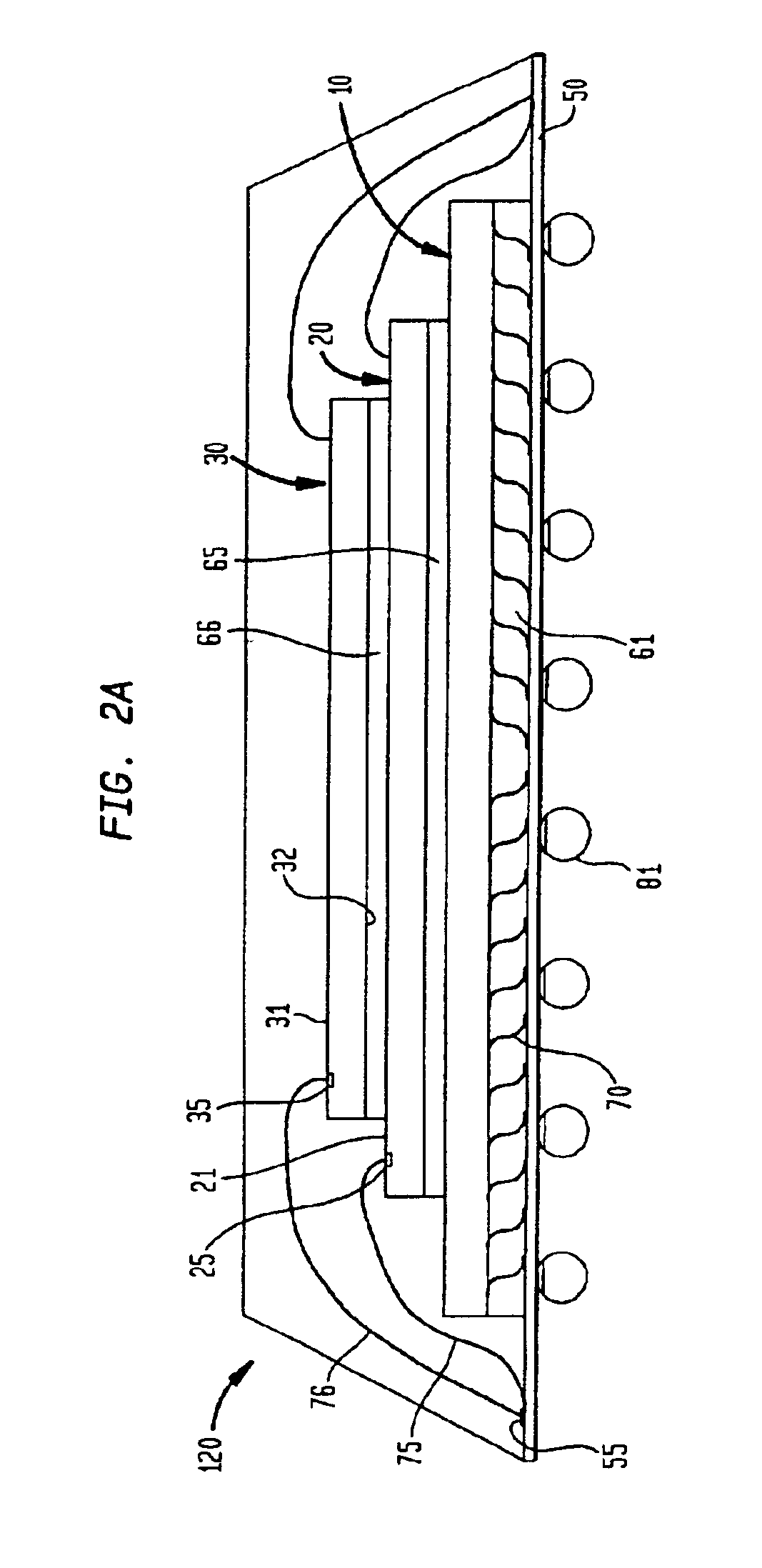

InactiveUS6885106B1Compact structureEasy to testSemiconductor/solid-state device detailsSolid-state devicesDielectricEngineering

A stacked microelectronic assembly includes a dielectric element and a first and second microelectronic element stacked one atop the other with the first microelectronic element disposed between the second microelectronic element and the dielectric. The dielectric element has opposed first and second surfaces with conductive features exposed at the first surface and terminals exposed on the second surface. Preferably, the contact-bearing face of the first microelectronic element confronts the first surface of the dielectric with at least some of the conductive features being movable with respect to the contacts or terminals. By providing such movable features, joining units have heights of about 300 microns or less may be joined to the terminals thereby reducing the overall height of the microelectronic assembly to 1.2 mm and less.

Owner:TESSERA INC

Vertically aligned liquid crystal display using polynorbornene based polymer film

ActiveUS20050190326A1Improve viewing angle characteristicsEnhanced Contrast FeaturesNon-linear opticsTectorial membranePolynorbornen

Provided are a vertically aligned liquid crystal display (VA-LCD) with good viewing angle characteristics, which has liquid crystals with negative dielectric anisotropy (Δε<0). In the VA-LCD, a polynorbornene based polymer film is used as a protection film and / or as a negative C-plate retardation film for an upper polarization plate and / or a lower polarization plate. Therefore, high contrast characteristics for a front view and an oblique angle view are realized and color change for an oblique angle view can be minimized.

Owner:LG CHEM LTD

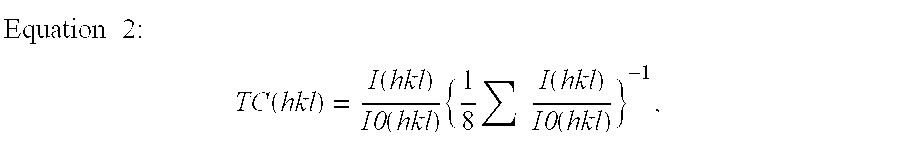

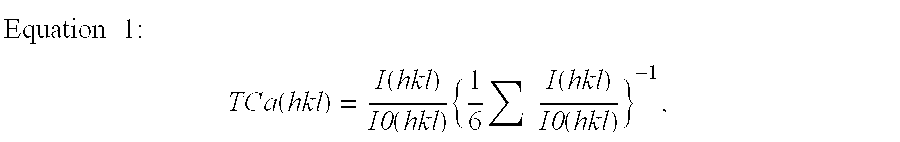

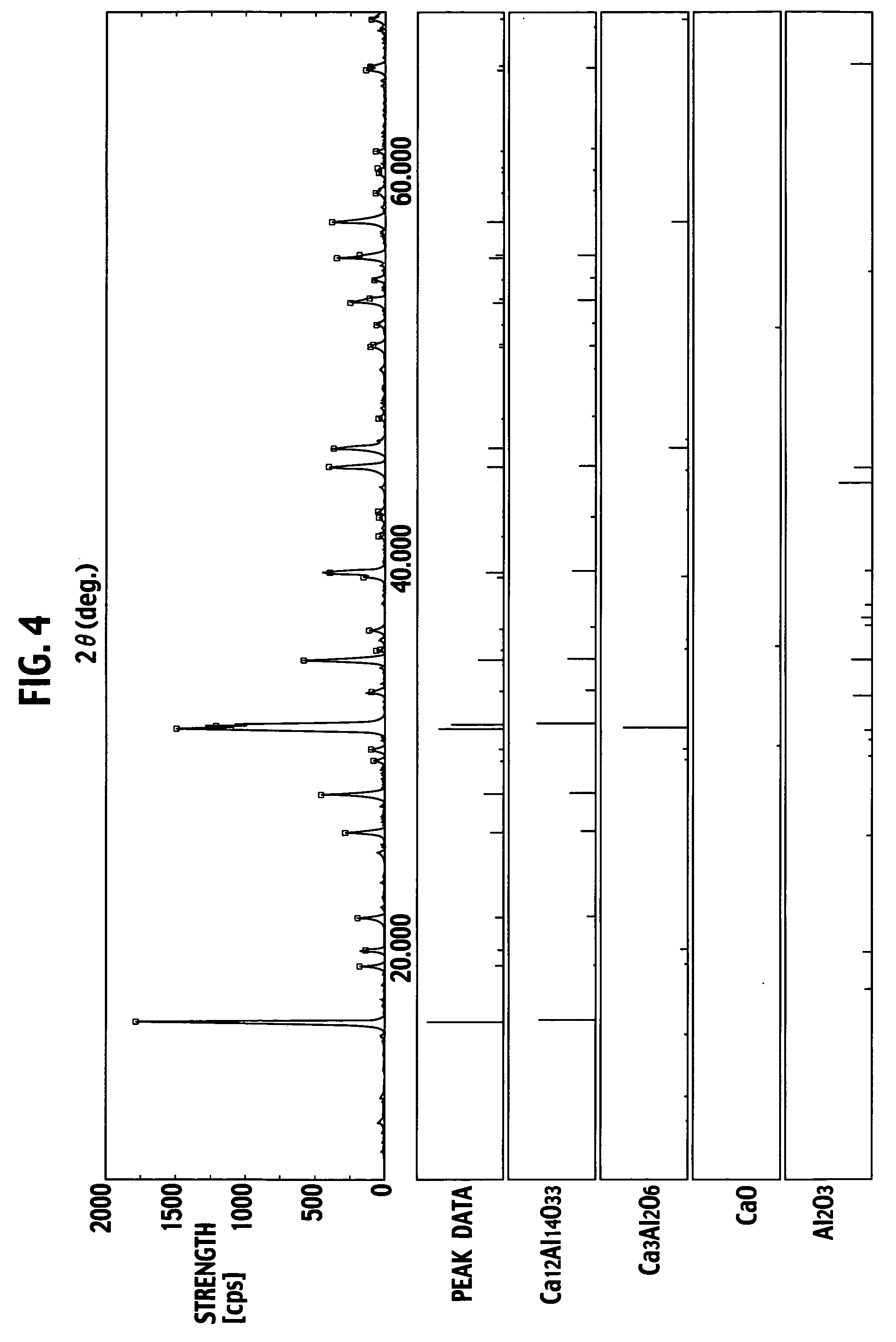

Coated cemented carbide cutting tool

InactiveUS6293739B1Extended service lifeImproving flaking resistance of coating layerLayered productsTurning toolsCrystal structureAlloy

The invention is to prolong the life time of tools dramatically by (1) considerably improving the flaking resistance of the coating layer at the time of cutting, (2) increasing the wear resistance and crater resistance of the coating layer itself, and (3) enhancing the breakage strength of the coating layer in comparison with the conventional coating cutting tools. In order to achieve the object, the coated cemented carbide of the invention has the following structure in the coating layer on the surface of the cemented carbides: The outer layer has an Al2O3 layer practically having an alpha-type crystal structure. The Al2O3 layer has a region where alpha-type and kappa-type crystal grains coexist in the first row of the crystal grains that grow on the inner layer. In addition to that, the crystal grains of alpha-Al2O3 in the region include no pores.

Owner:SUMITOMO ELECTRIC IND LTD

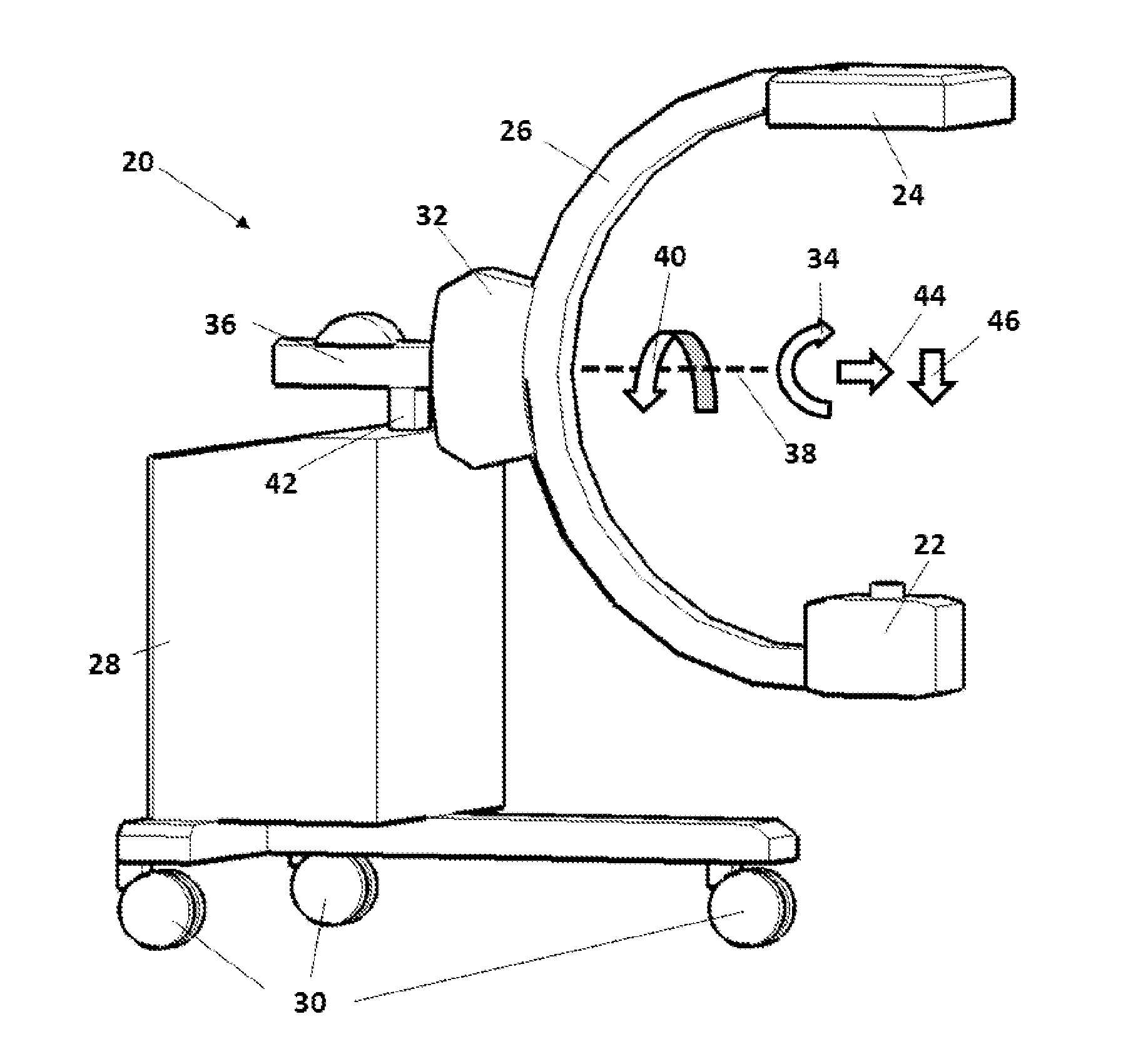

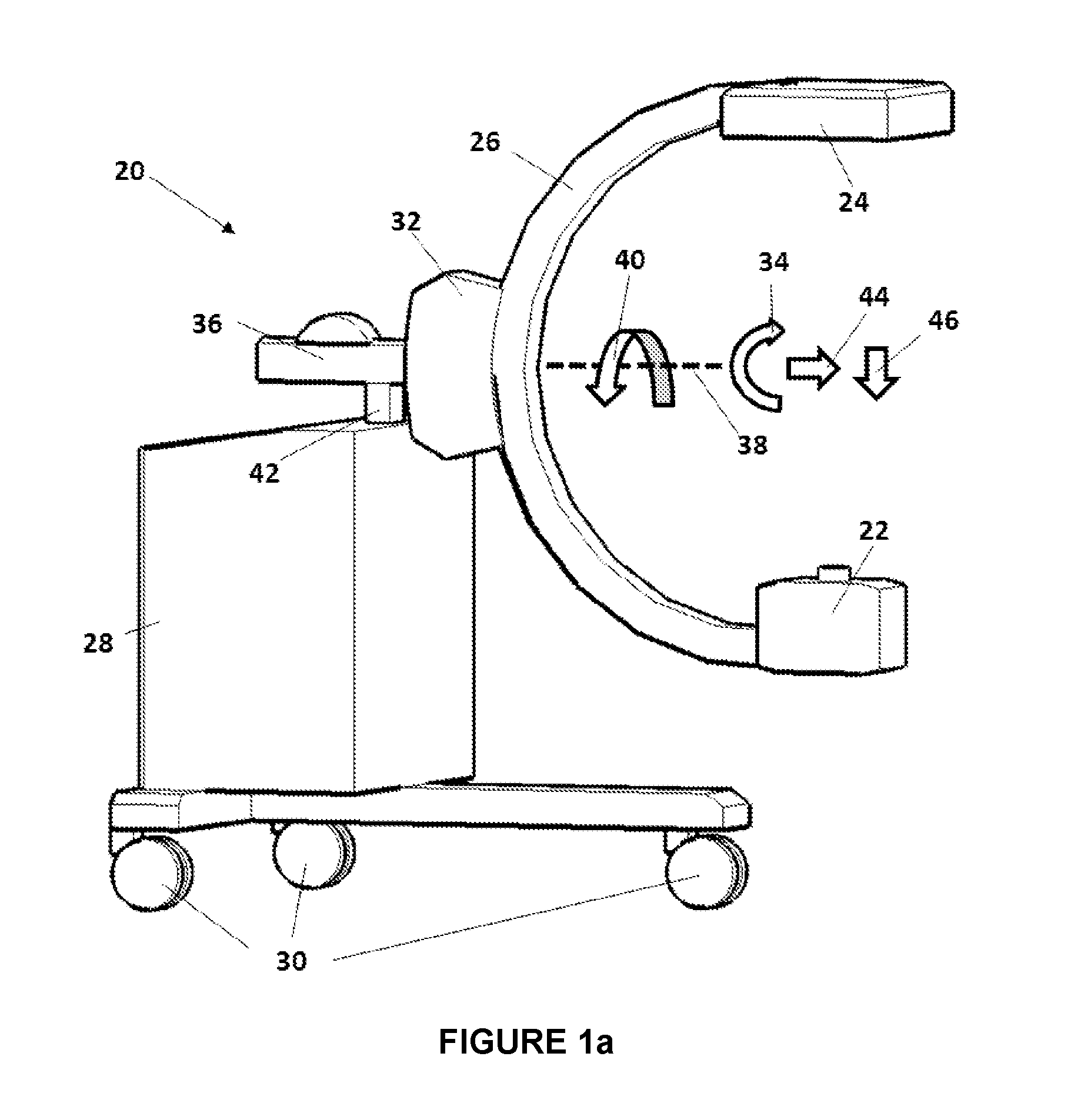

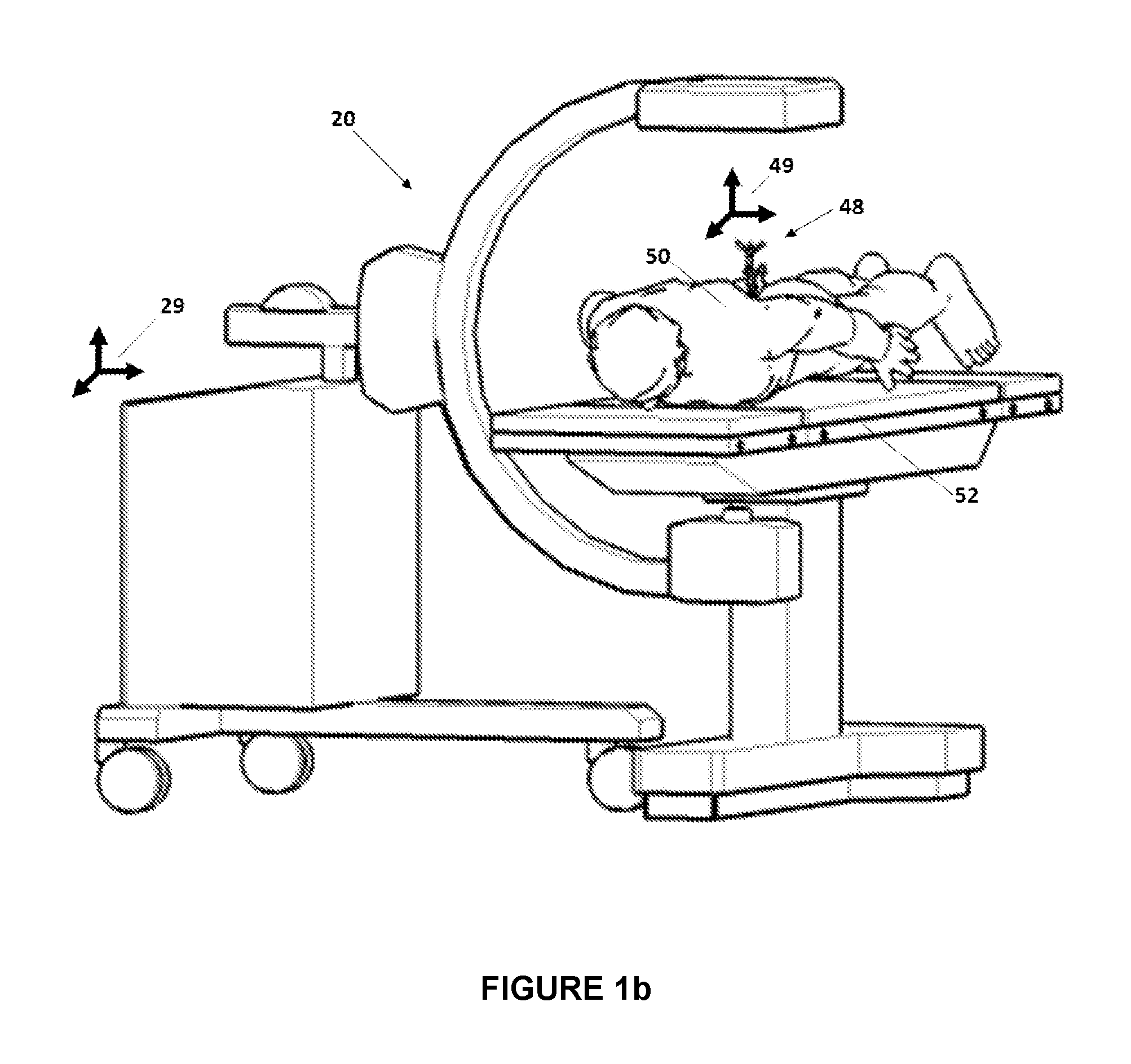

Method for reconstructing a 3D image from 2d x-ray images

ActiveUS20160242724A1Improve reconstruction qualityImprove accuracyImage enhancementReconstruction from projectionX-rayX ray image

The present invention relates to a method for reconstructing a 3D image from 2D X-ray images acquired with an X-ray imaging system, said method comprising the steps of:a) receiving a set of 2D X-ray images of a region of a patient with said X-ray imaging system,b) computing an initial 3D image within the coordinate system of the X-ray imaging system by using at least part of said 2D X-ray images with their respective projective geometry data;c) projecting said initial 3D image on at least part of said 2D X-ray images and adjusting the respective projective geometry data of said images, said adjustment comprising registration of said images with the projection of the initial 3D image using an image-to-image registration technique;d) computing an updated 3D image using the complete set of 2D X-ray images with their respective adjusted projective geometry data.

Owner:ECENTIAL ROBOTICS

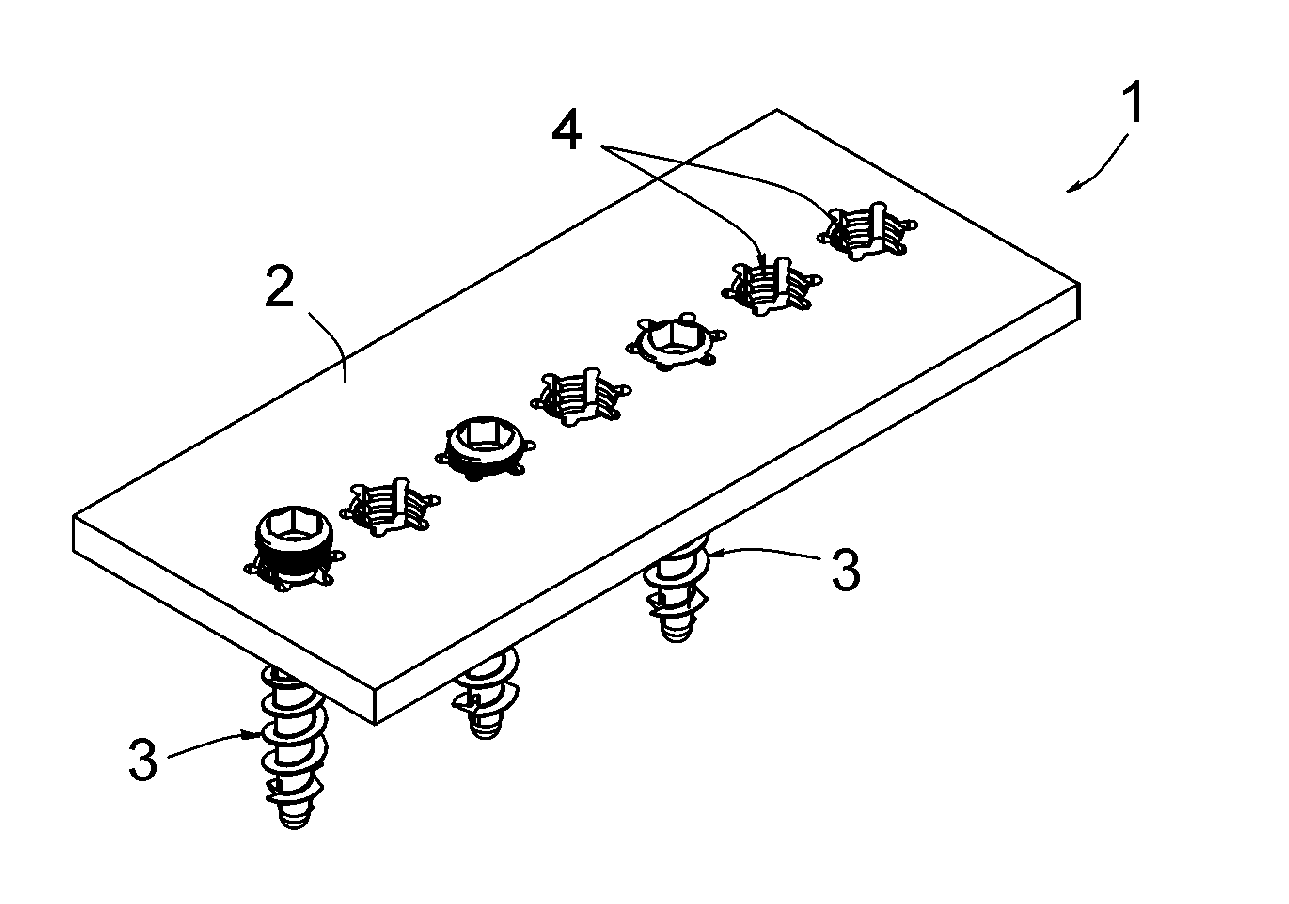

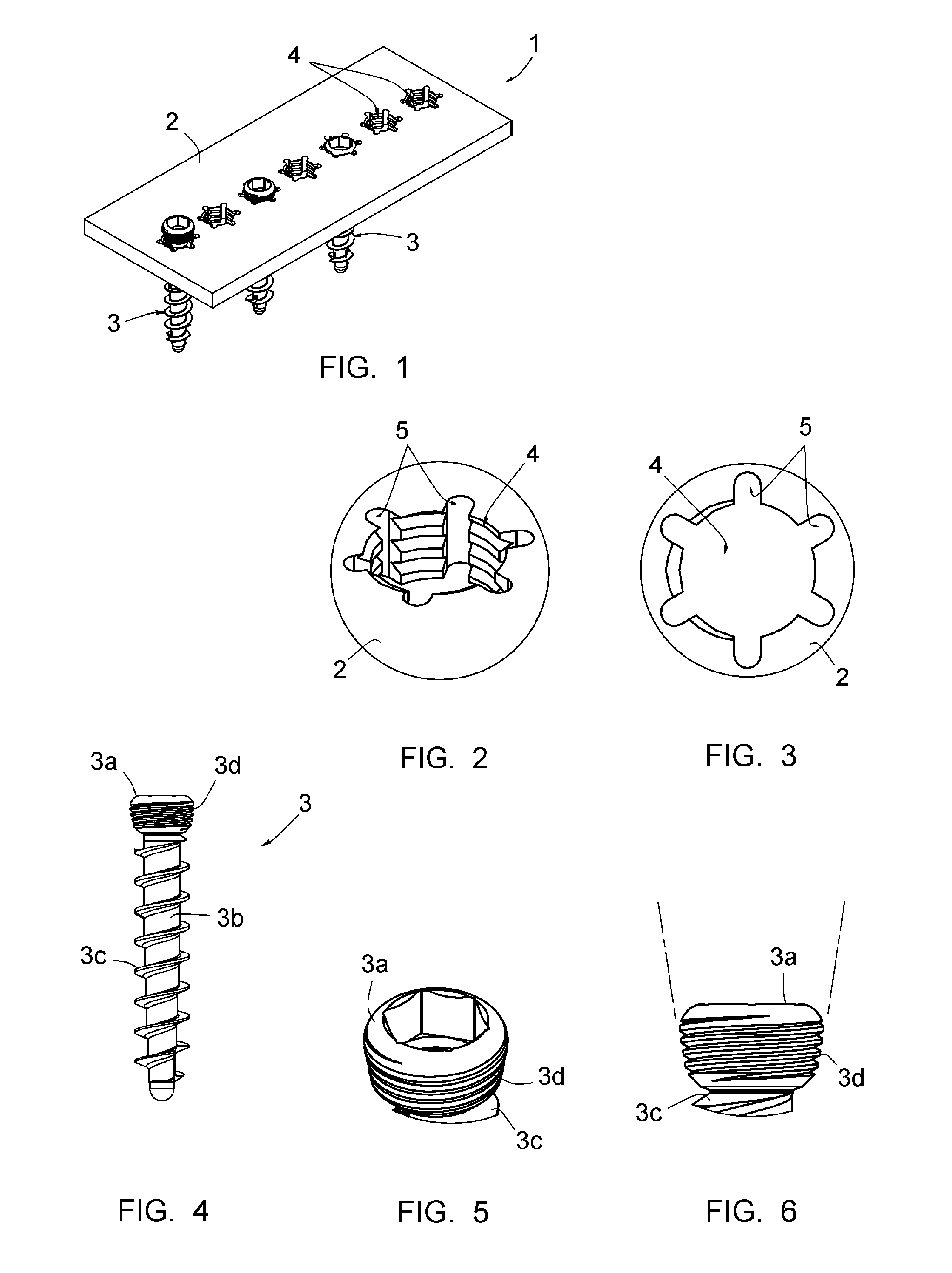

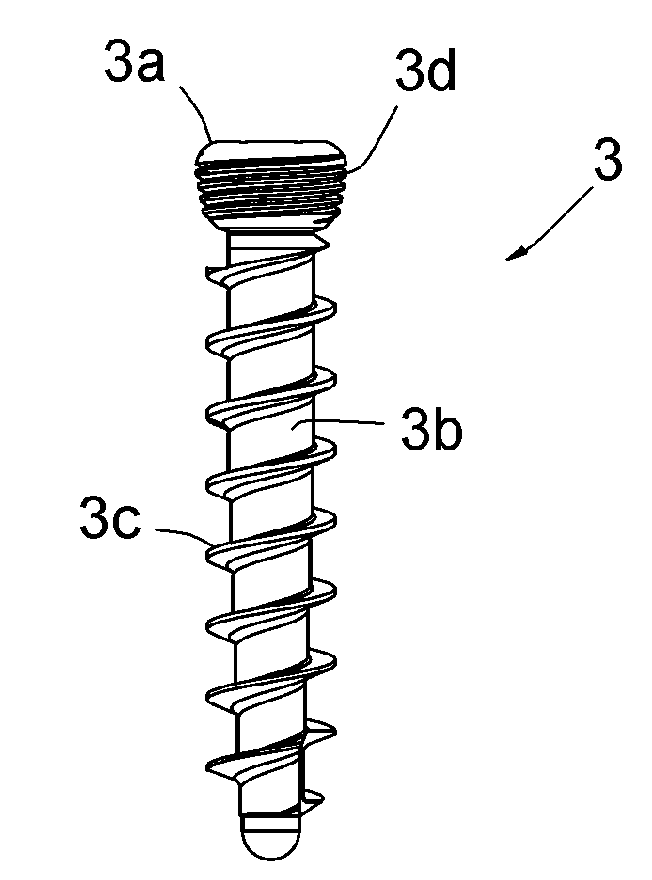

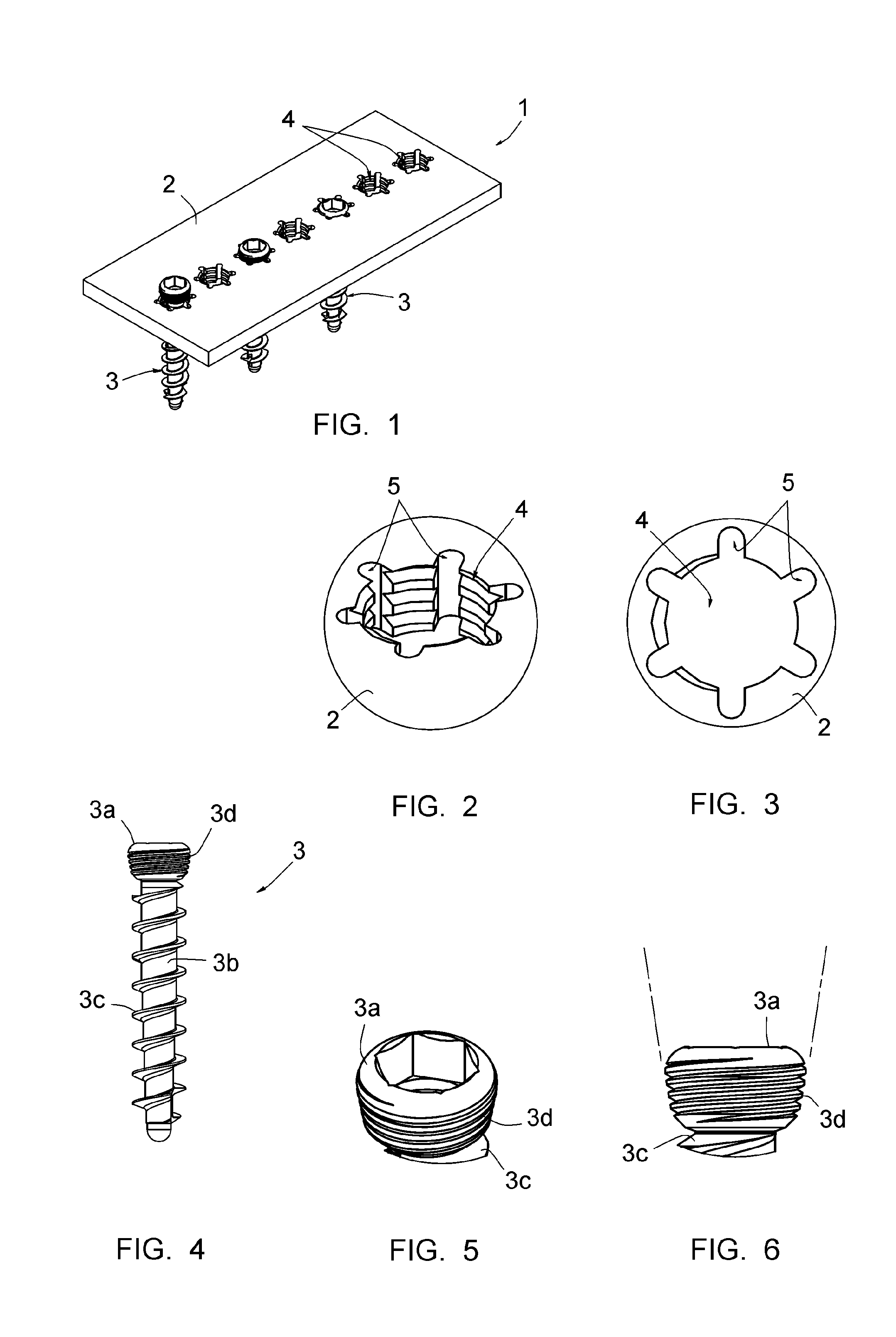

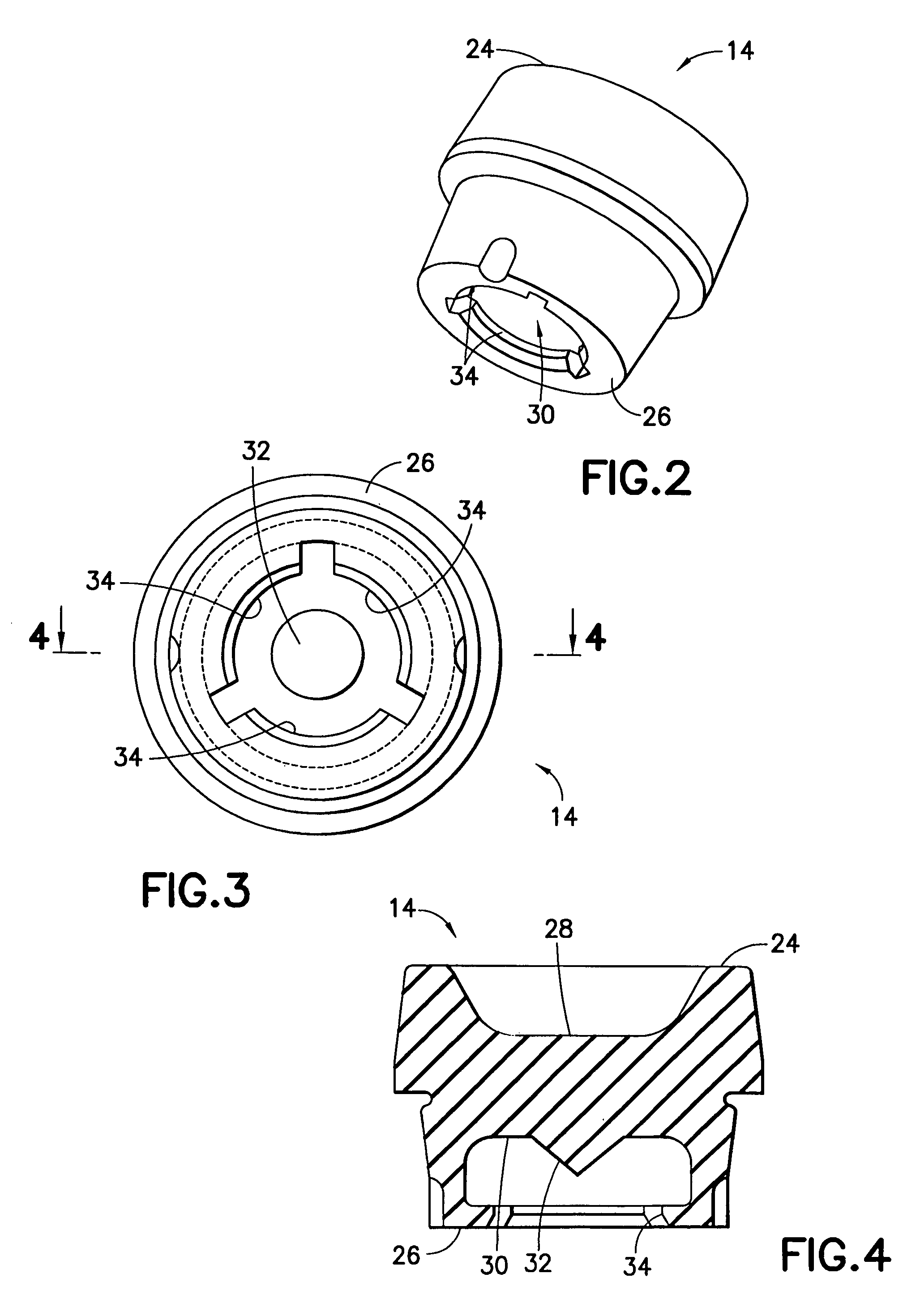

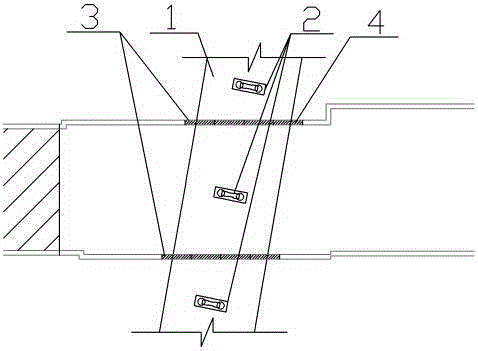

Assembly comprising an implantable part designed to be fastened to one or more bones or bone portions to be joined, and at least one screw for fastening the implantable part to said bone(s)

ActiveUS20150327898A1Small overall deformationProtected from riskFastenersBone platesRadial notchBiomedical engineering

An assembly including an implantable part designed to be fastened to at least one bone or bone portions to be joined and at least one screw for fastening the implantable part to the at least one bone or bone portions. The implantable part includes at least one tapped hole and the screw includes a head designed to be engaged in the tapped hole. The tapped hole is cylindrical and includes at least one radial notch emerging in a surface of the implantable part through which the screw is designed to be engaged in the tapped hole. The radial notch produces an interruption in the tapping included by the tapped hole. The head of the screw is conical, with an apical angle of between 15 and 25°.

Owner:FX SOLUTIONS

Process and apparatus for forming plastic sheet

InactiveUS6280808B1Avoid mistakesLow birefringenceRecord carriersPhotosensitive materialsMechanical engineeringEngineering

Owner:ROHM & HAAS CO

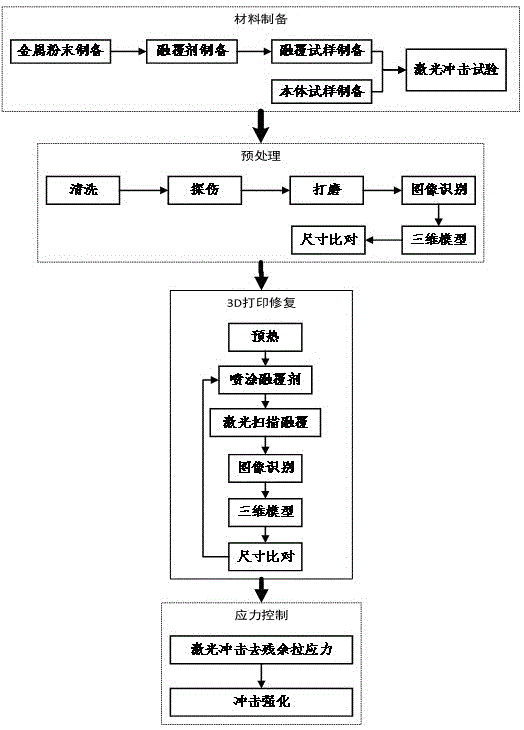

Metal part remanufacturing method adopting stress control and 3D printing

InactiveCN105154870ALarge deformationDimensional accuracy is easy to controlAdditive manufacturing apparatusMetallic material coating processesUltimate tensile strength3d printer

The invention discloses a metal part remanufacturing method adopting stress control and 3D printing. The metal part remanufacturing method comprises steps as follows: firstly, a body sample and a cladding sample of a metal part are prepared, and laser parameters required by the same residual compressive stress are acquired through laser shock; secondly, a to-be-repaired metal part is preprocessed, a repairing area and a repairing allowance of the part are determined with an image recognition method; the metal part is subjected to cladding repair layer by layer by the aid of a laser 3D printer, and the size of a repaired part reaches the originally designed size of the part; finally, residual tensile stress is eliminated through the laser shock, and then a residual compressive stress layer is formed on the working surface of the metal part with a laser shock processing method. According to the metal part remanufacturing method, the part repairing is performed by adopting laser 3D printing, the overall deformation of the part is not large, further, the repairing size precision is easy to control, and follow-up processing is not required; the repaired parts acquire equal overall strength, a value of residual compressive stress of a part surface strengthening layer after the laser shock processing keeps balance, and the service life of the remanufactured part is prolonged.

Owner:GUANGDONG UNIV OF TECH

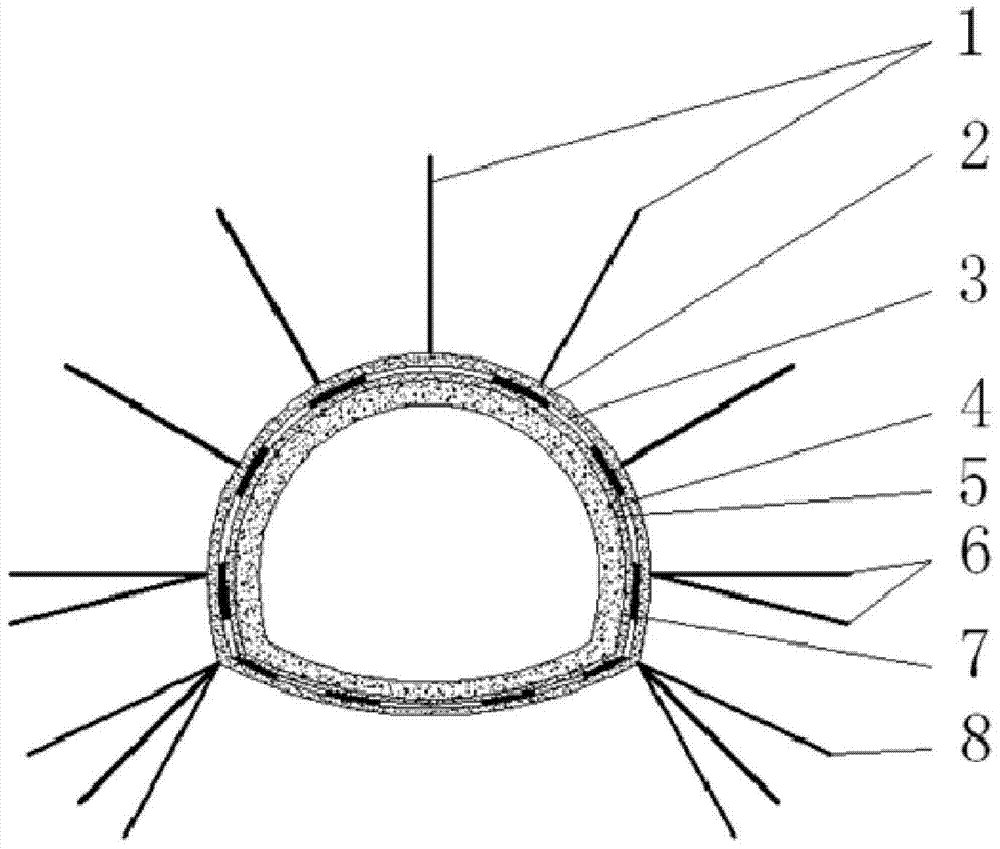

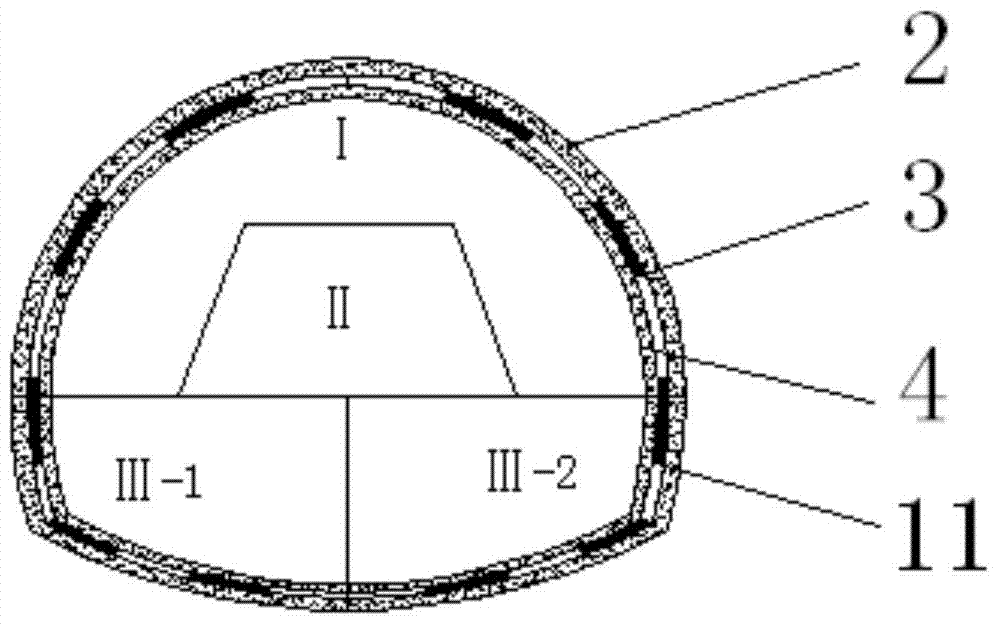

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

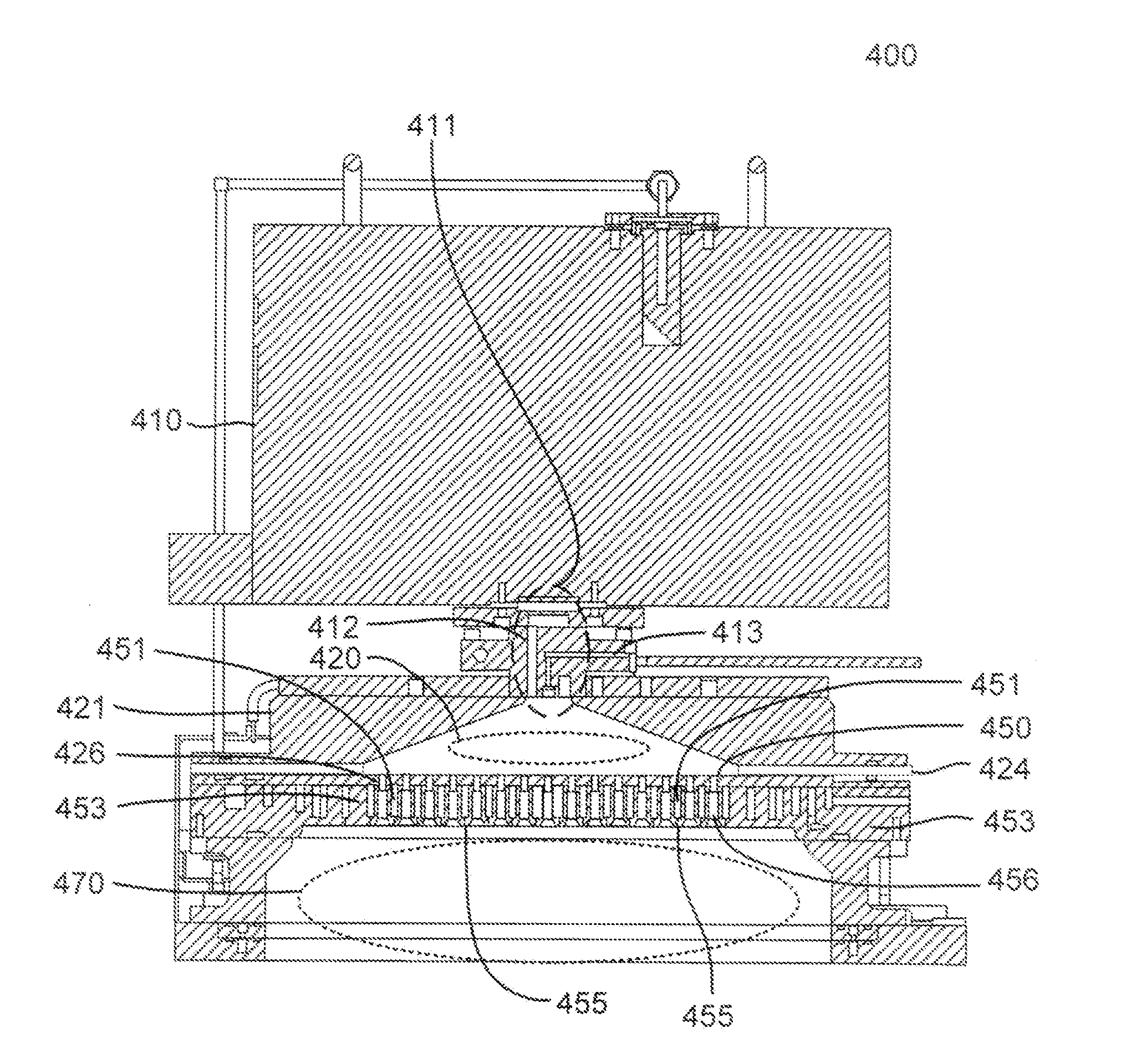

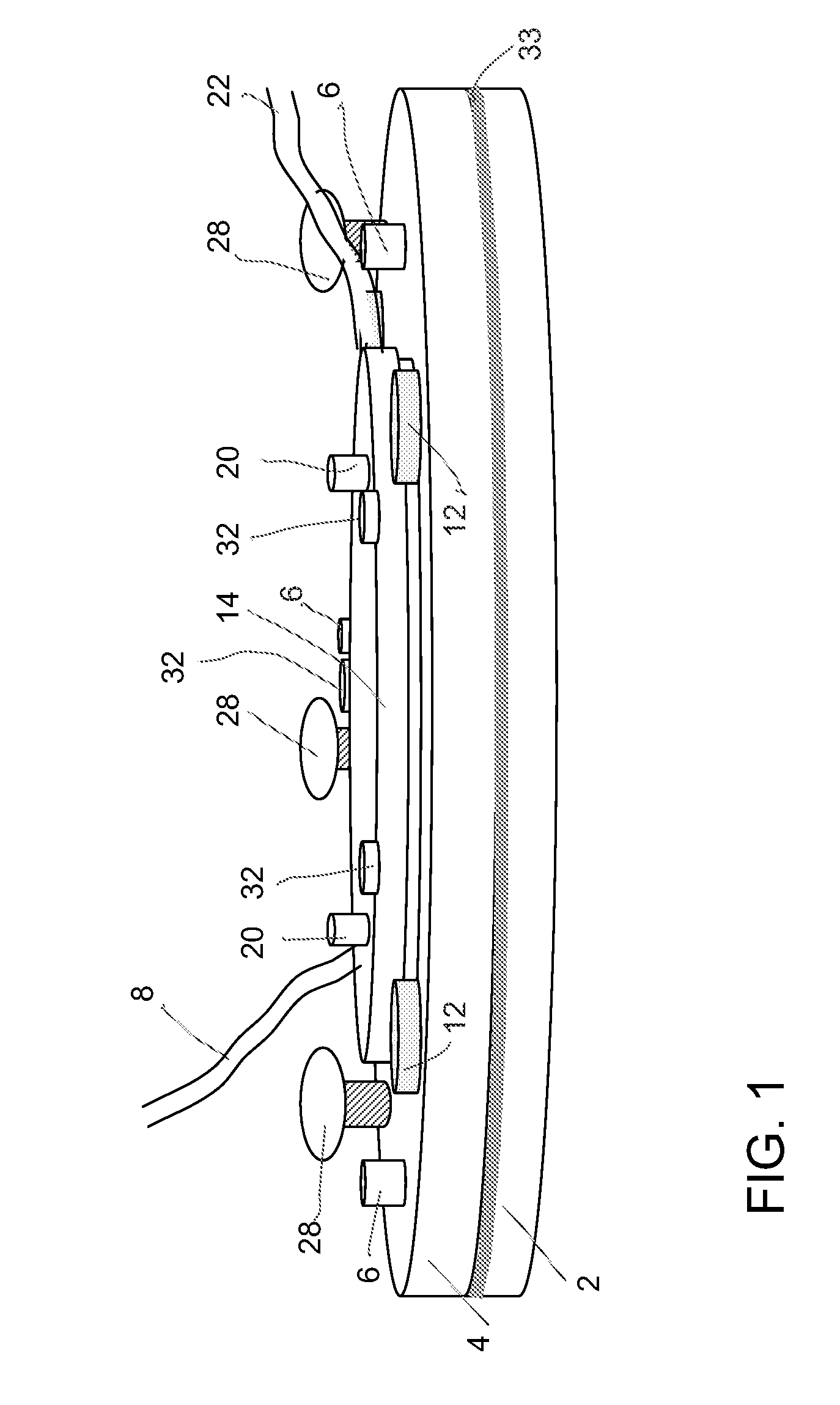

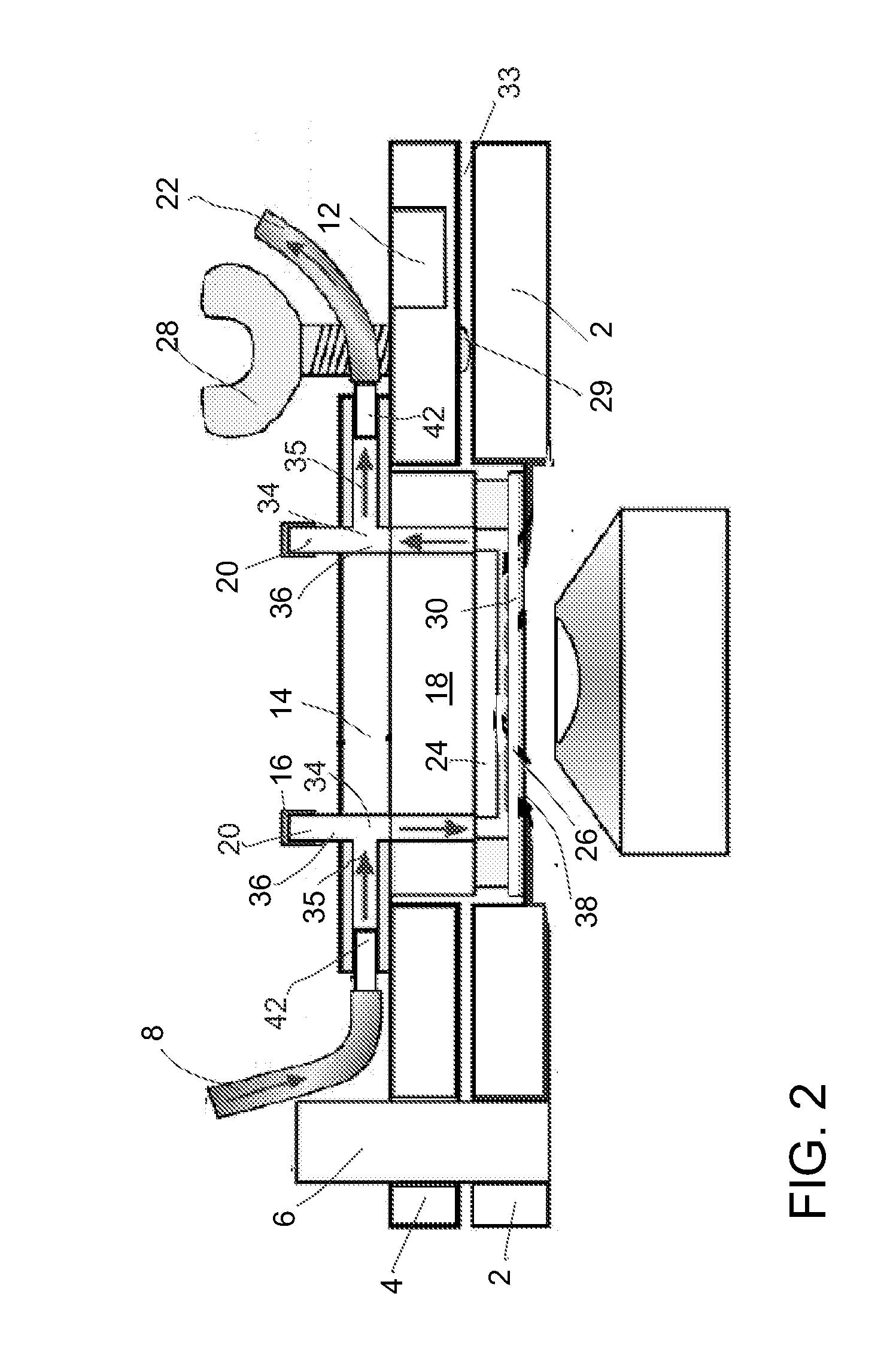

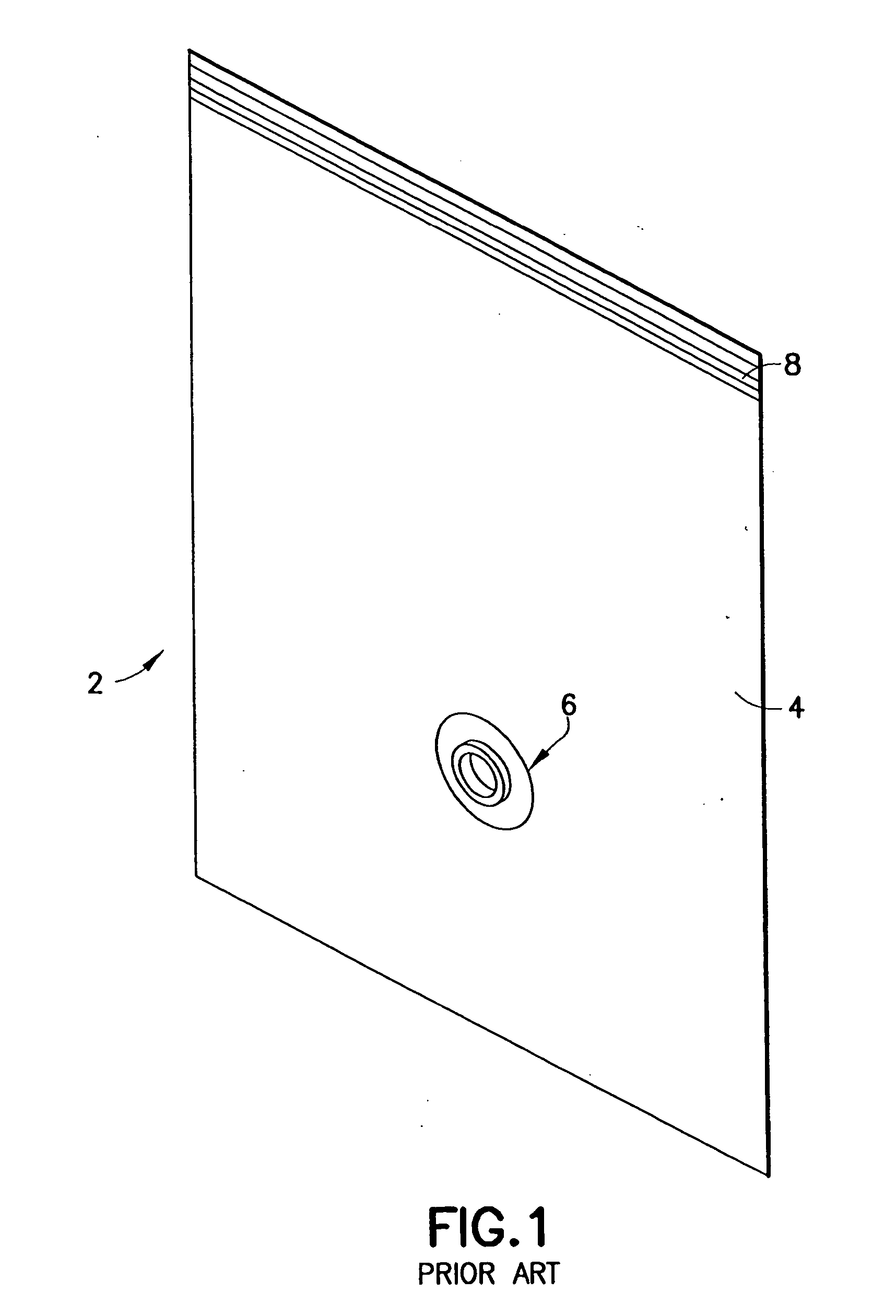

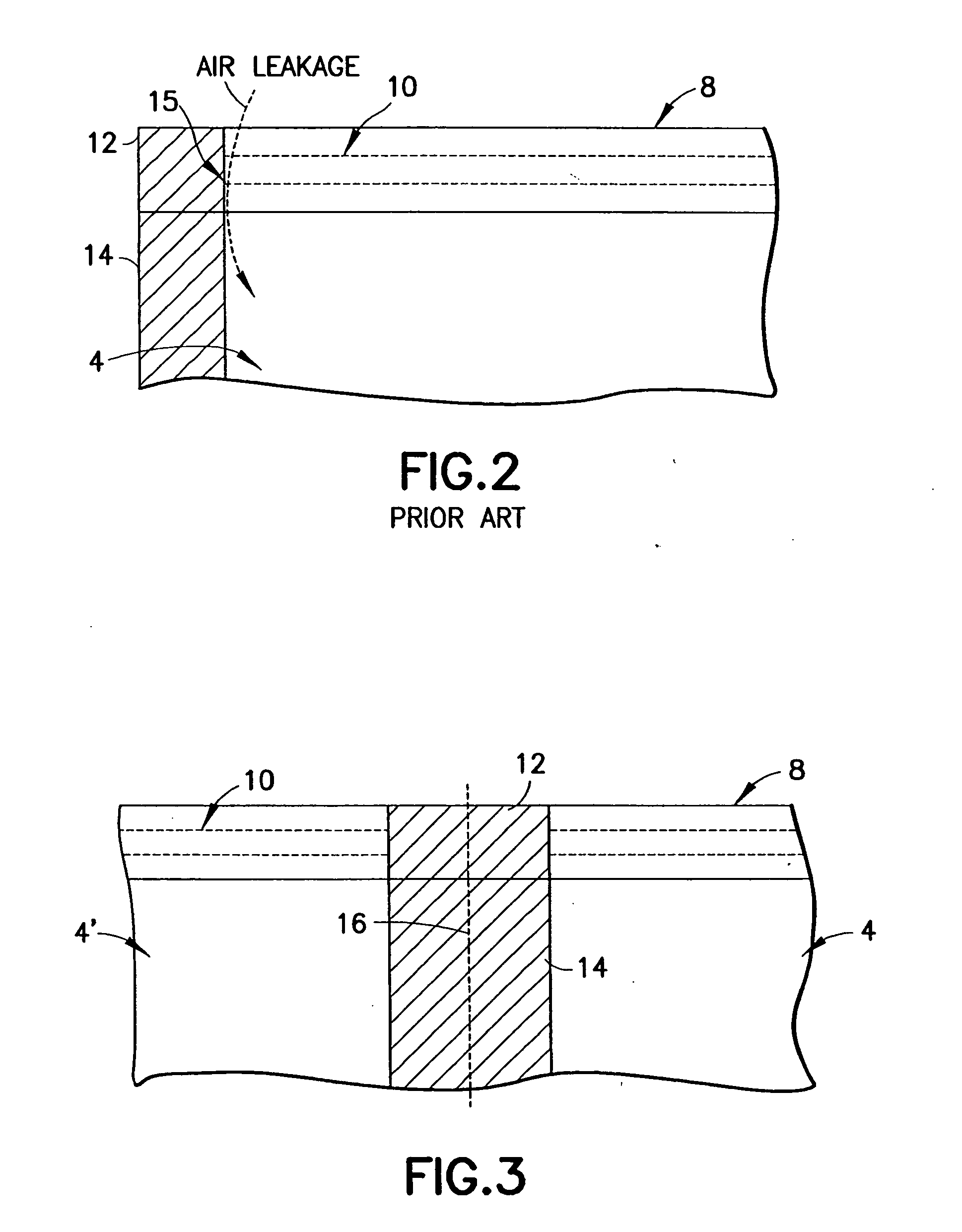

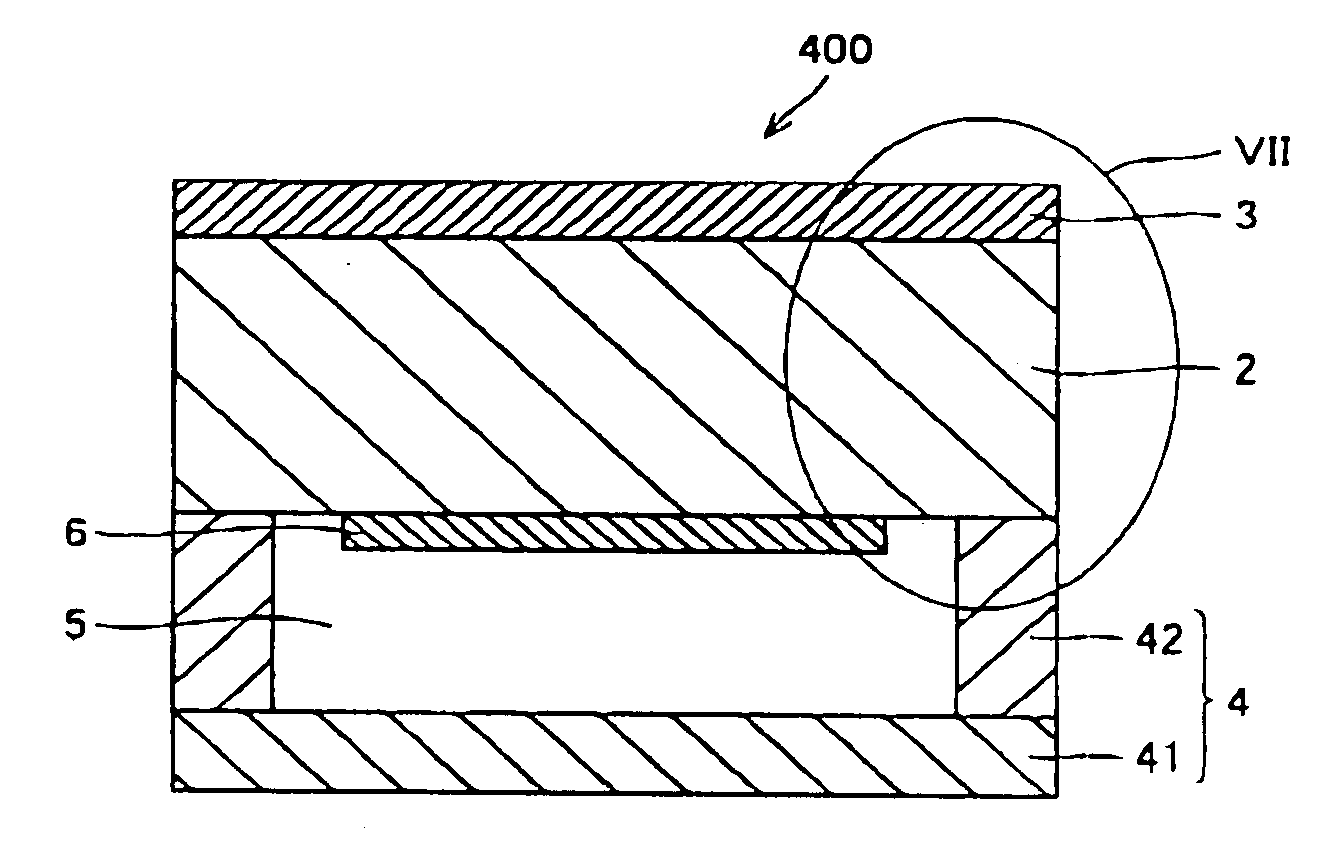

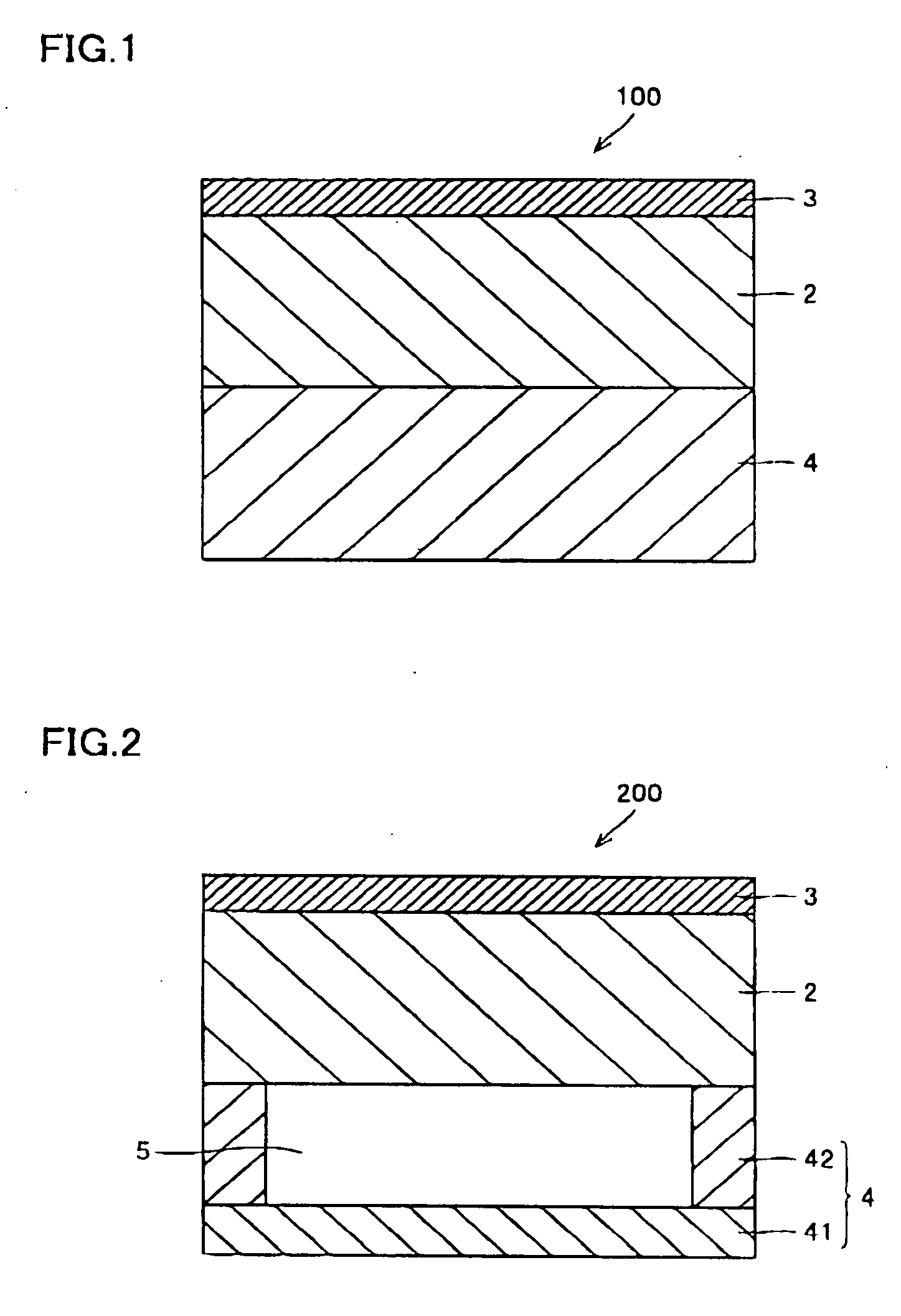

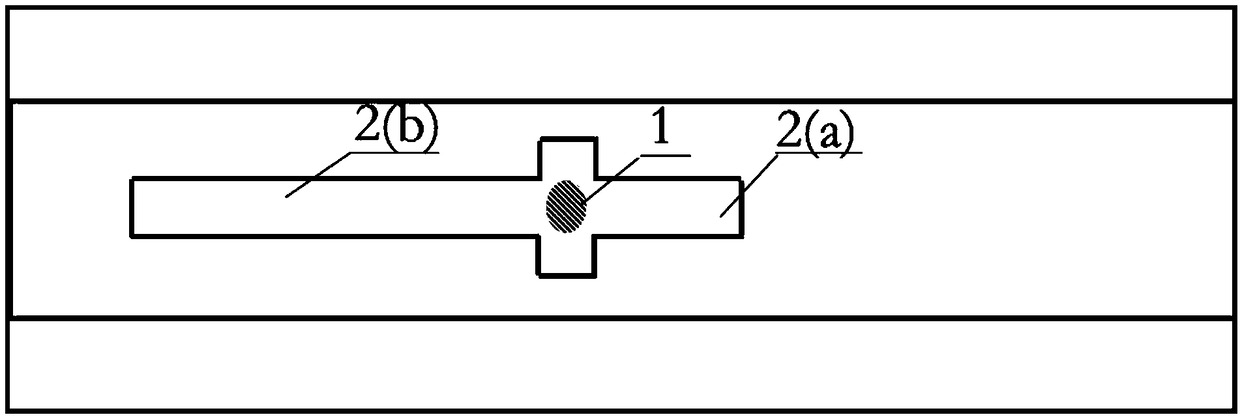

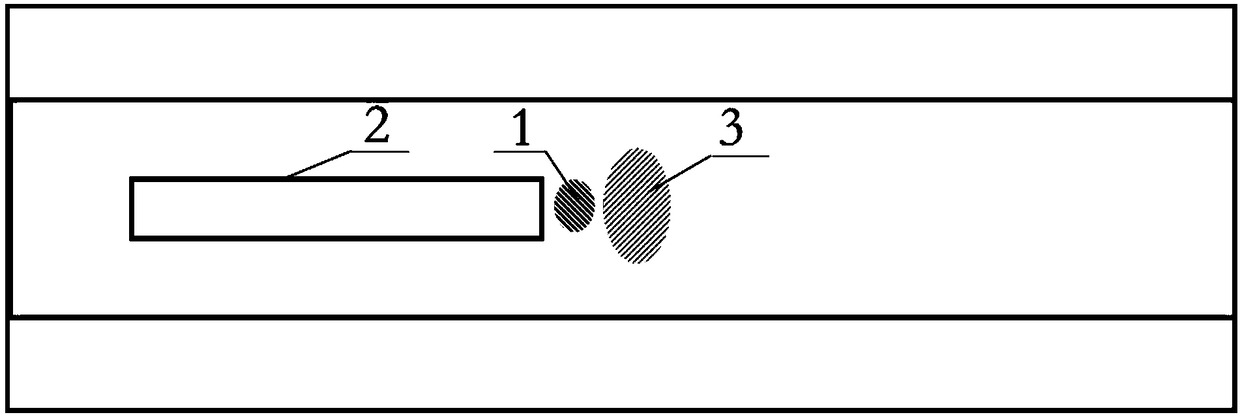

Microfluidic system and method for using same

InactiveUS20110044865A1Increase flexibilityQuick sealBioreactor/fermenter combinationsBiological substance pretreatmentsElastomerEngineering

In a microfluidic system, a magnetic clamp for sealing a flexible microchannel chip includes a base formed from a magnetically-attractable material. The base supports a window for viewing the face of the microfluidic chip. A ring with magnets uniformly distributed around it is disposed over the base. A transparent disk attached to the top of the ring has an inlet and an outlet for introducing and removing a fluid medium into a cavity defined the disk, the window, the center opening of the ring and the base. An elastomer cushion is attached to the inner surface of the disk. The magnetic force between the base and the magnets on the ring compresses the cushion against the microfluidic chip so that the microchannels are sealed against the window with a uniform and reproducible pressure.

Owner:RGT UNIV OF CALIFORNIA

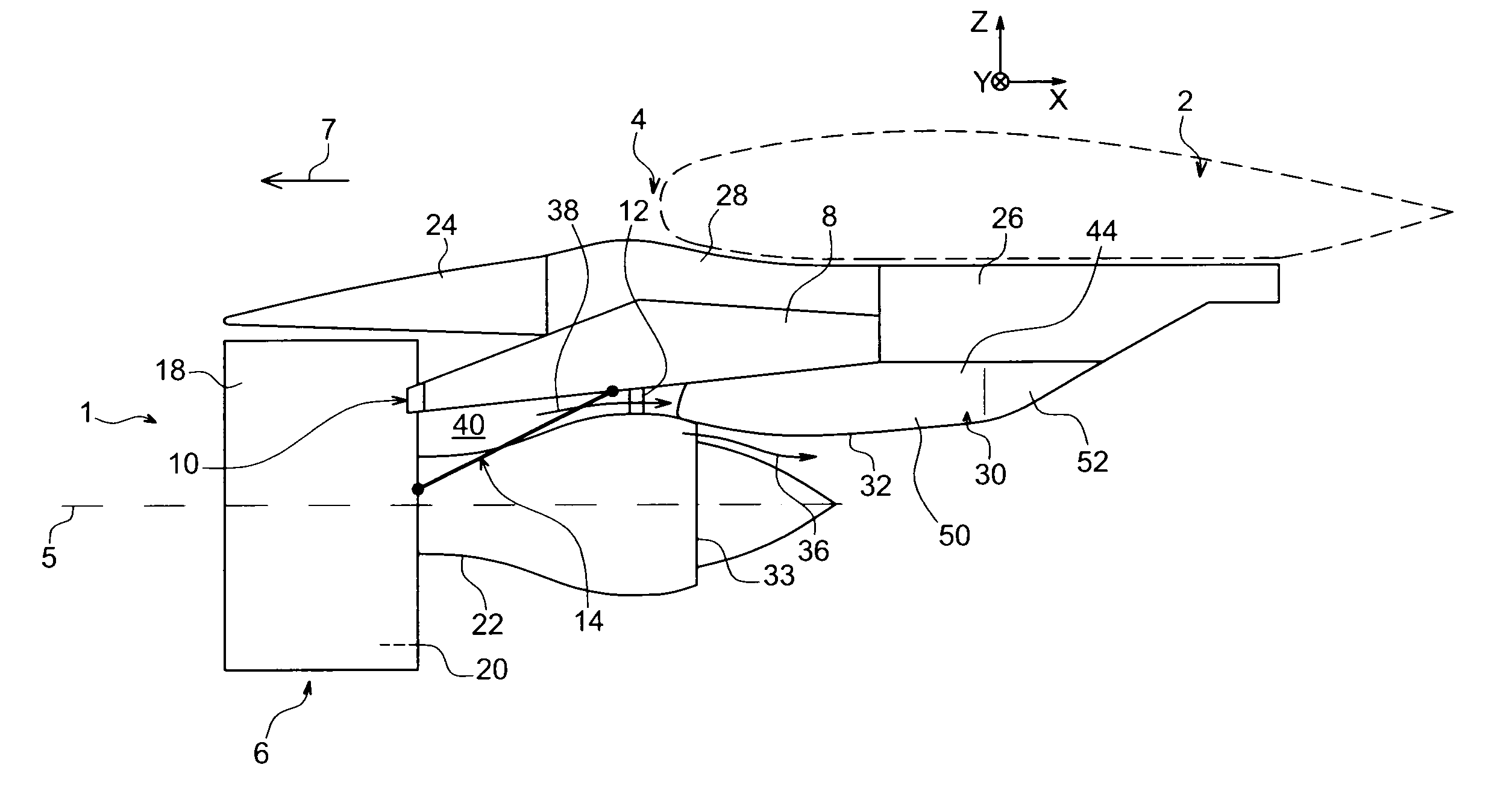

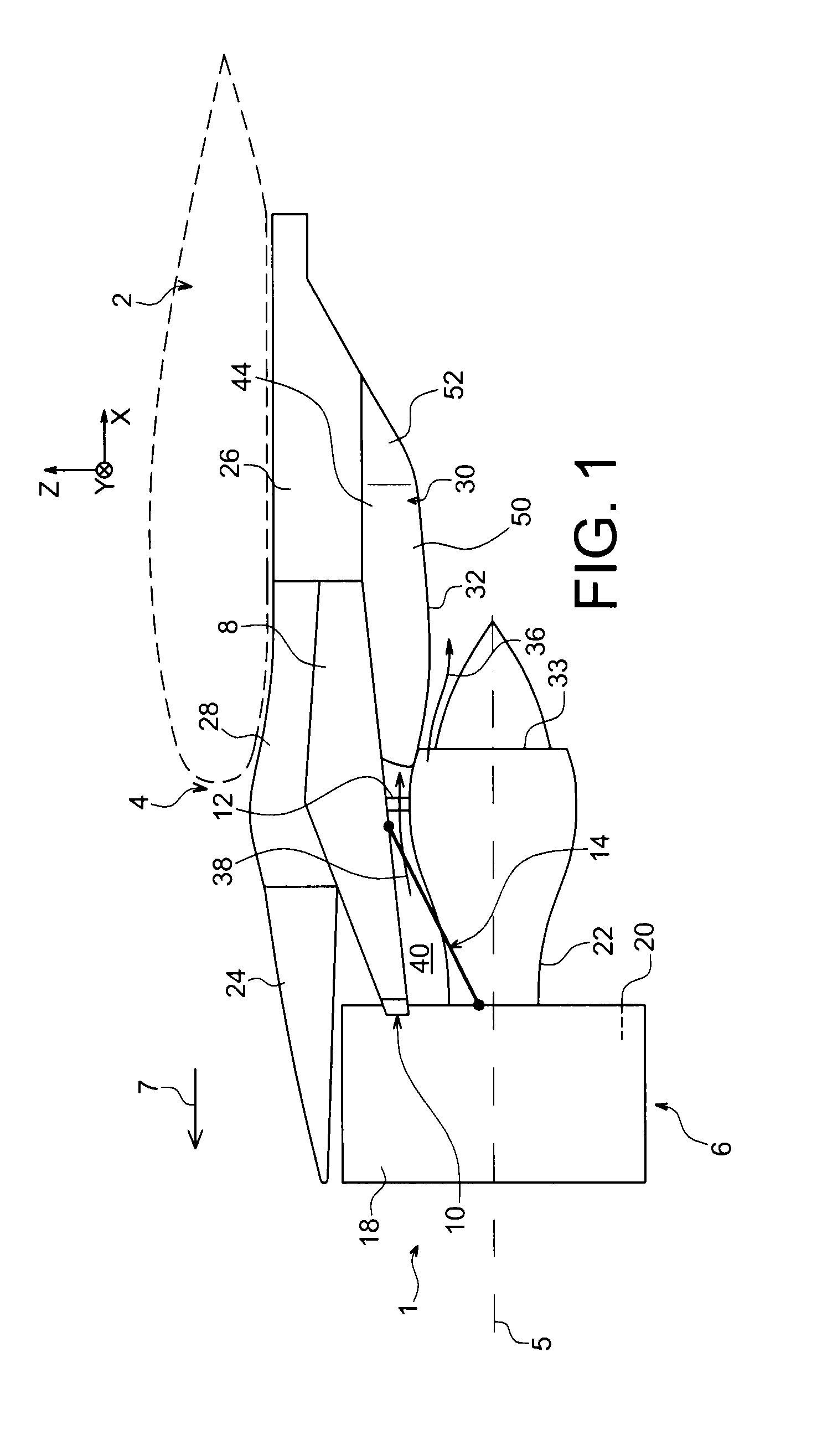

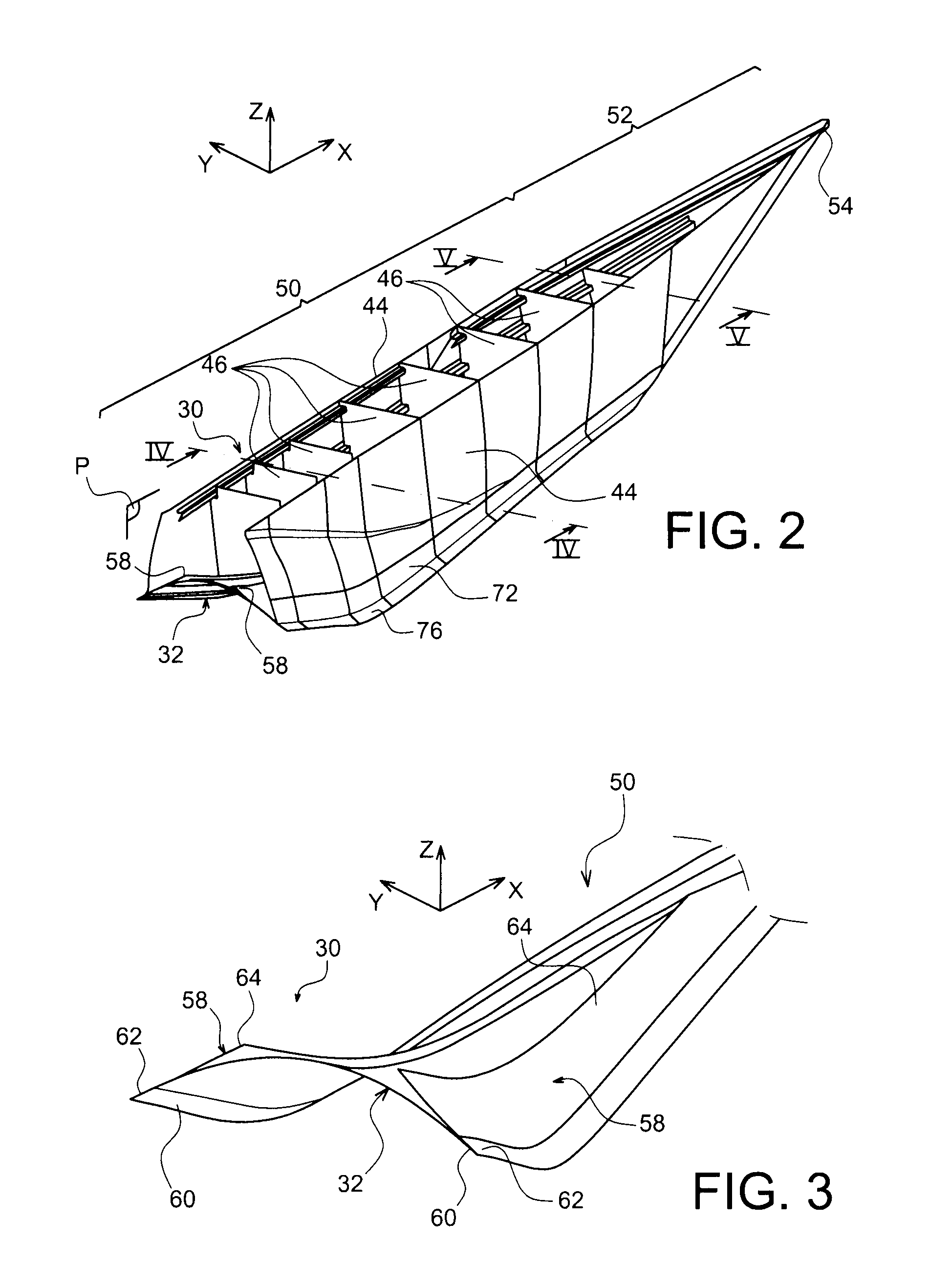

Aft pylon fairing for an aircraft engine suspension system

ActiveUS20110155847A1Raise the ratioSmall overall deformationSenses disorderNervous disorderCowlingAirplane

This invention relates to an aft pylon fairing (30) for a suspension system of an aircraft engine, comprising two side panels (44) assembled to each other by inner cross stiffening ribs (46) spaced at intervals from each other along a longitudinal direction (X) of the fairing, and also comprising a heat protection deck (32) designed to delimit an engine core flow (36). According to the invention, it also comprises two longitudinal connecting walls (58) offsetting the deck (32) from the ribs (46), each of these two longitudinal walls (58) being provided with a first side end (62) fixed to one or the other of the two side ends (60, 60) of the deck (32), and a second side end (64) rigidly fixed to the ribs (46).

Owner:AIRBUS OPERATIONS INC AS A

Assembly comprising an implantable part designed to be fastened to one or more bones or bone portions to be joined, and at least one screw for fastening the implantable part to said bone(s)

InactiveUS20140066998A1Protected from riskSmall overall deformationSuture equipmentsLigamentsRadial notchBiomedical engineering

An assembly including an implantable part designed to be fastened to at least one bone or bone portions to be joined and at least one screw for fastening the implantable part to the at least one bone or bone portions. The implantable part includes at least one tapped hole and the screw includes a head designed to be engaged in the tapped hole. The tapped hole is cylindrical and includes at least one radial notch emerging in a surface of the implantable part through which the screw is designed to be engaged in the tapped hole. The radial notch produces an interruption in the tapping included by the tapped hole. The head of the screw is conical, with an apical angle of between 15 and 25°.

Owner:COMPAGNIE FINANCIERE & MEDICALE

Tantalum or tungsten target-copper alloy backing plate assembly and production method therefor

InactiveUS6759143B2Small overall deformationSurviving high power sputteringVacuum evaporation coatingSputtering coatingSputteringBond interface

A tantalum or tungsten target-backing plate assembly which comprises a tantalum or tungsten target and a copper alloy backing plate that are subject to diffusion bonding via an aluminum- or aluminum alloy-sheet insert material at least 0.5 mm thick, and which is provided with diffusion bonded interfaces between the respective materials, wherein the assembly suffers only a small deformation after diffusion bonding and is free from separation between the target and the backing plate or from cracking even when the target material and the backing plate differ greatly in thermal expansion, and can survive high power sputtering; and a production method therefor.

Owner:JX NIPPON MINING & METALS CO LTD

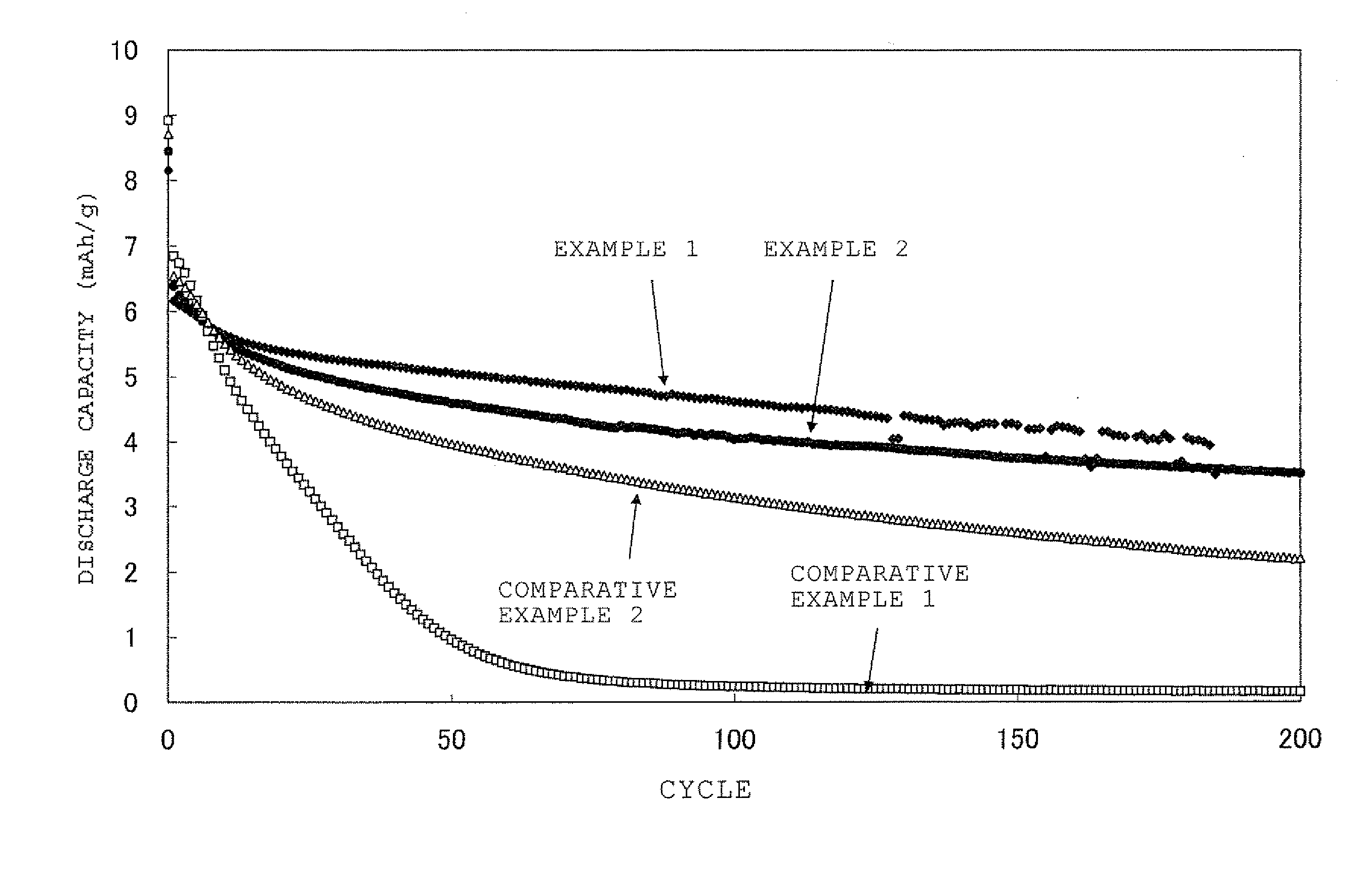

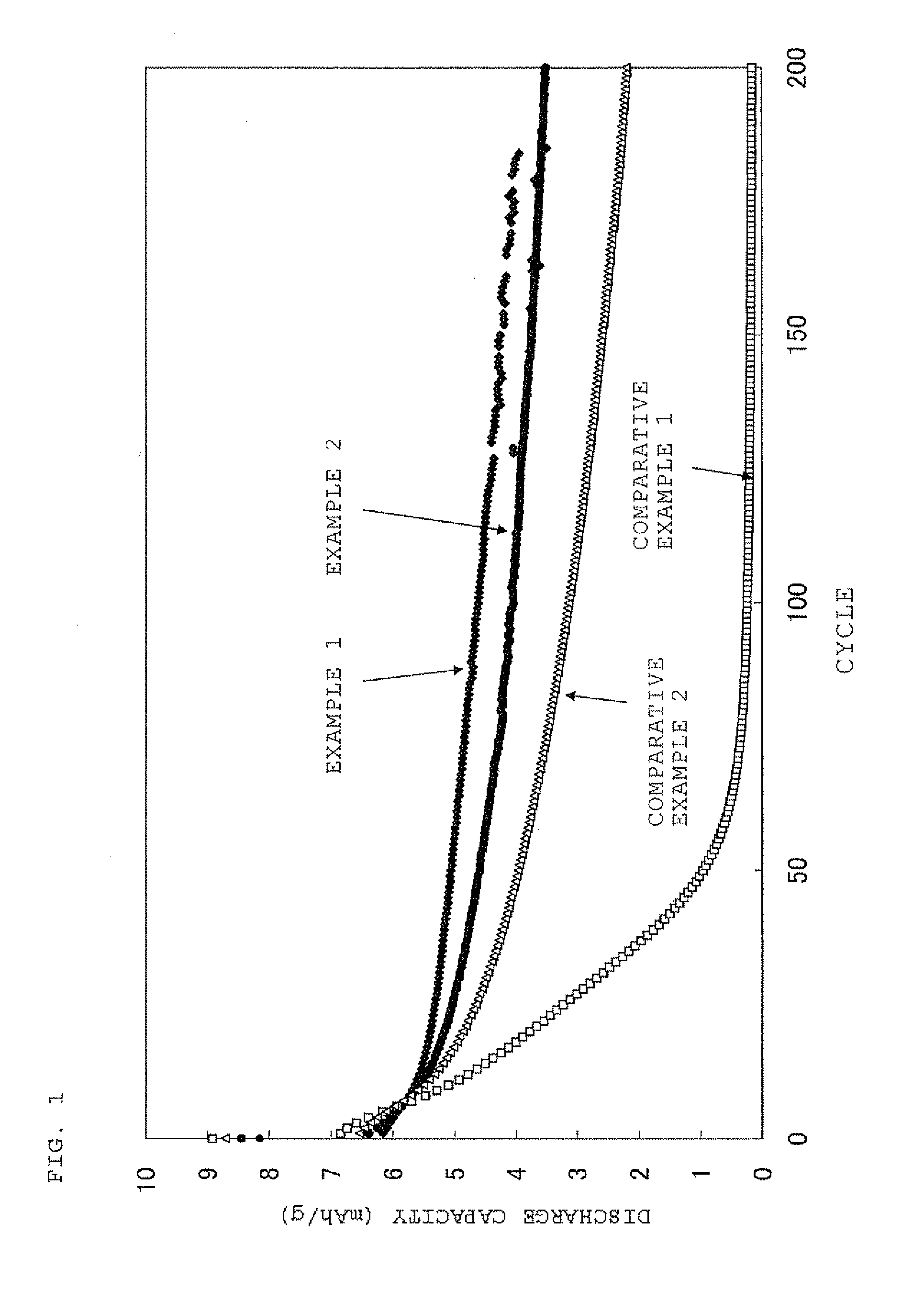

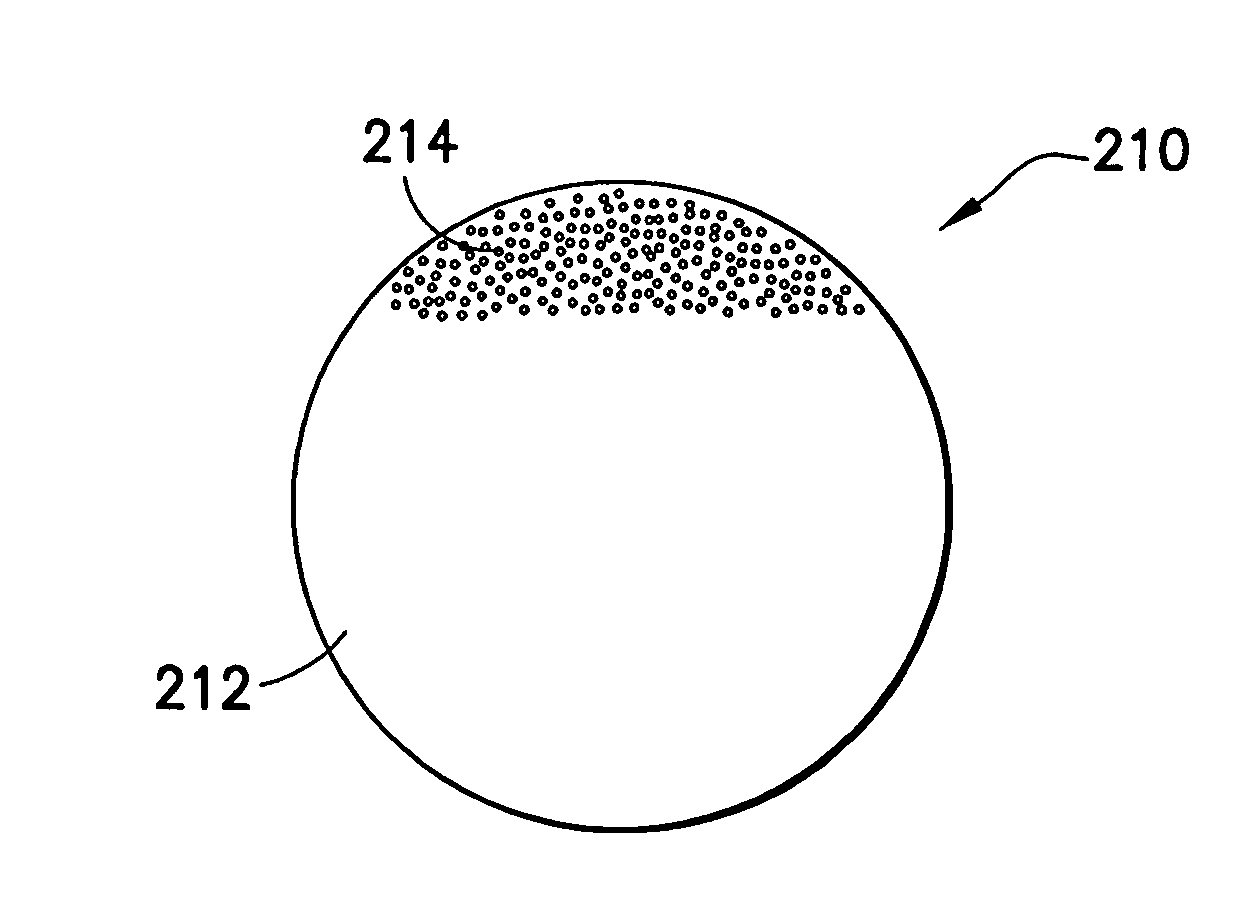

Method for manufacturing negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode material for non-aqueous electrolyte secondary battery, negative electrode for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

ActiveUS20110287317A1Reduce capacitySmall overall deformationSiliconElectrode thermal treatmentGas phaseElectrical battery

The present invention is a method for manufacturing a negative electrode active material for a non-aqueous electrolyte secondary battery comprising at least depositing silicon on a substrate by vapor deposition by using a metallic silicon as a raw material, the substrate having a temperature controlled to 300° C. to 800° C. under reduced pressure, and pulverizing and classifying the deposited silicon. As a result, there is provided a method for manufacturing a negative electrode active material composed of silicon particles that is an active material useful as a negative electrode of a non-aqueous electrolyte secondary battery in which high initial efficiency and high battery capacity of silicon are kept, cycle performance is superior, and an amount of a change in volume decreases at the time of charge and discharge.

Owner:SHIN ETSU CHEM IND CO LTD

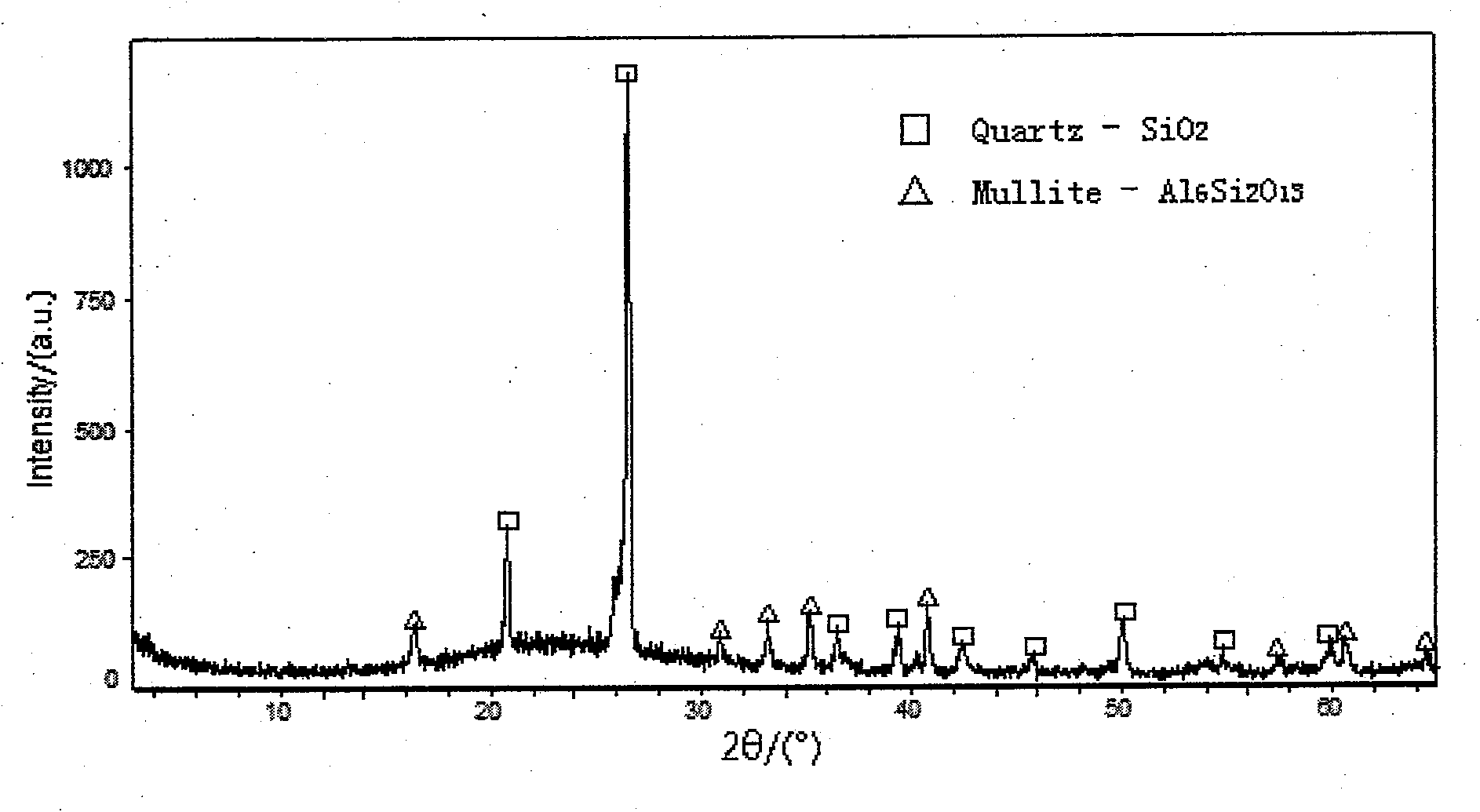

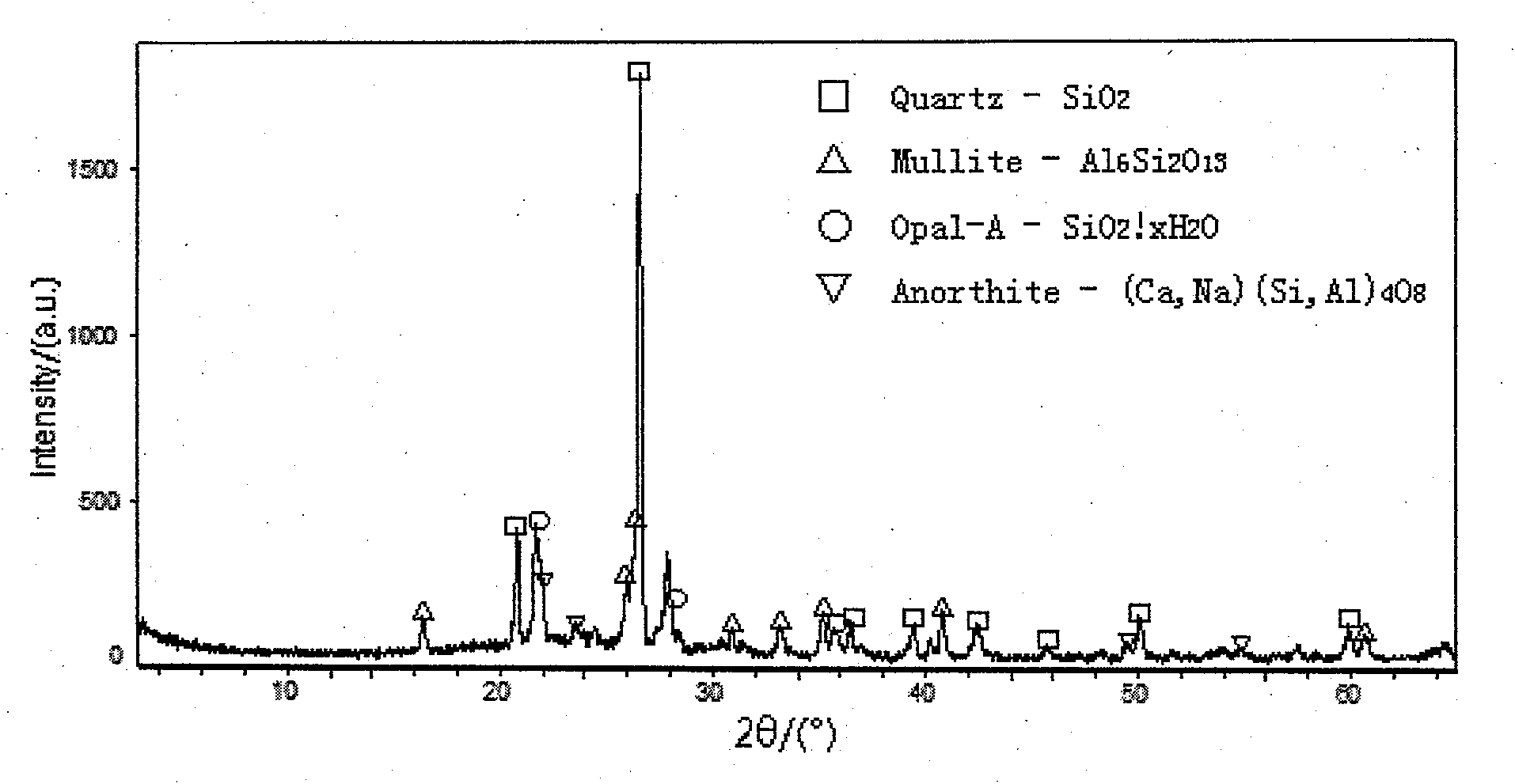

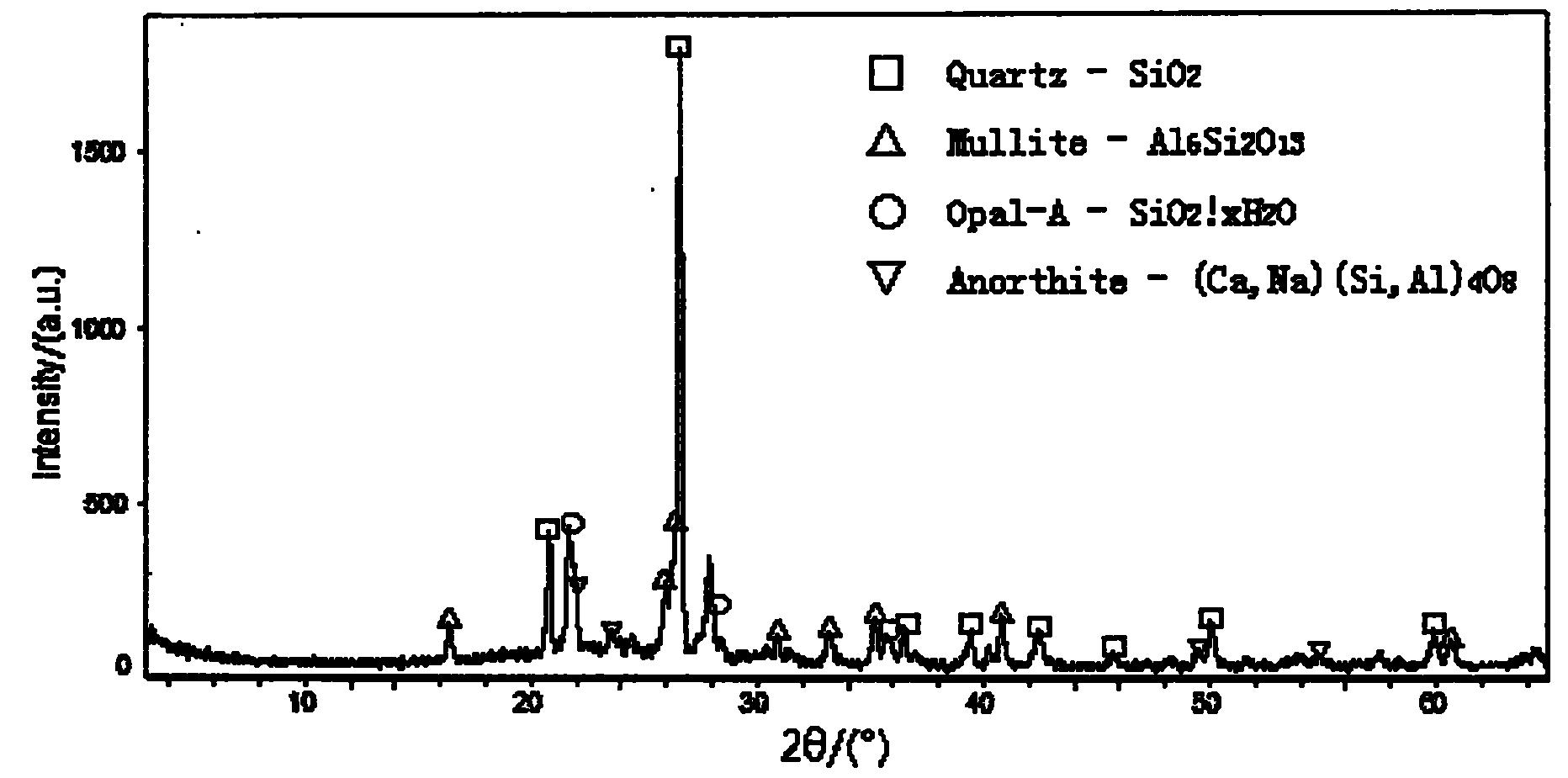

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

Leakproof zipper end crush for reclosable bag and related method of manufacture

ActiveUS20060029299A1Sufficient wave energySmall overall deformationEnvelopes/bags making machinerySlide fastenersEngineering

A reclosable bag that can be hermetically sealed. The bag comprises a pair of zipper strips that are joined in respective zones without substantial deformation of the longitudinal profiled closure elements. These zones of zipper strip joinder assist in providing a leakproof transition from the openable section of the zipper to the corner seals, where the longitudinal profiled closure elements are either substantially deformed (e.g., crushed) or absent. The method of manufacture involves the steps of ultrasonically welding a wide area and then thermally crushing a narrower area overlapping the wide welded area to form leakproof zipper joints. This method can be applied to string (flangeless) zippers as well as flanged zippers.

Owner:ILLINOIS TOOL WORKS INC

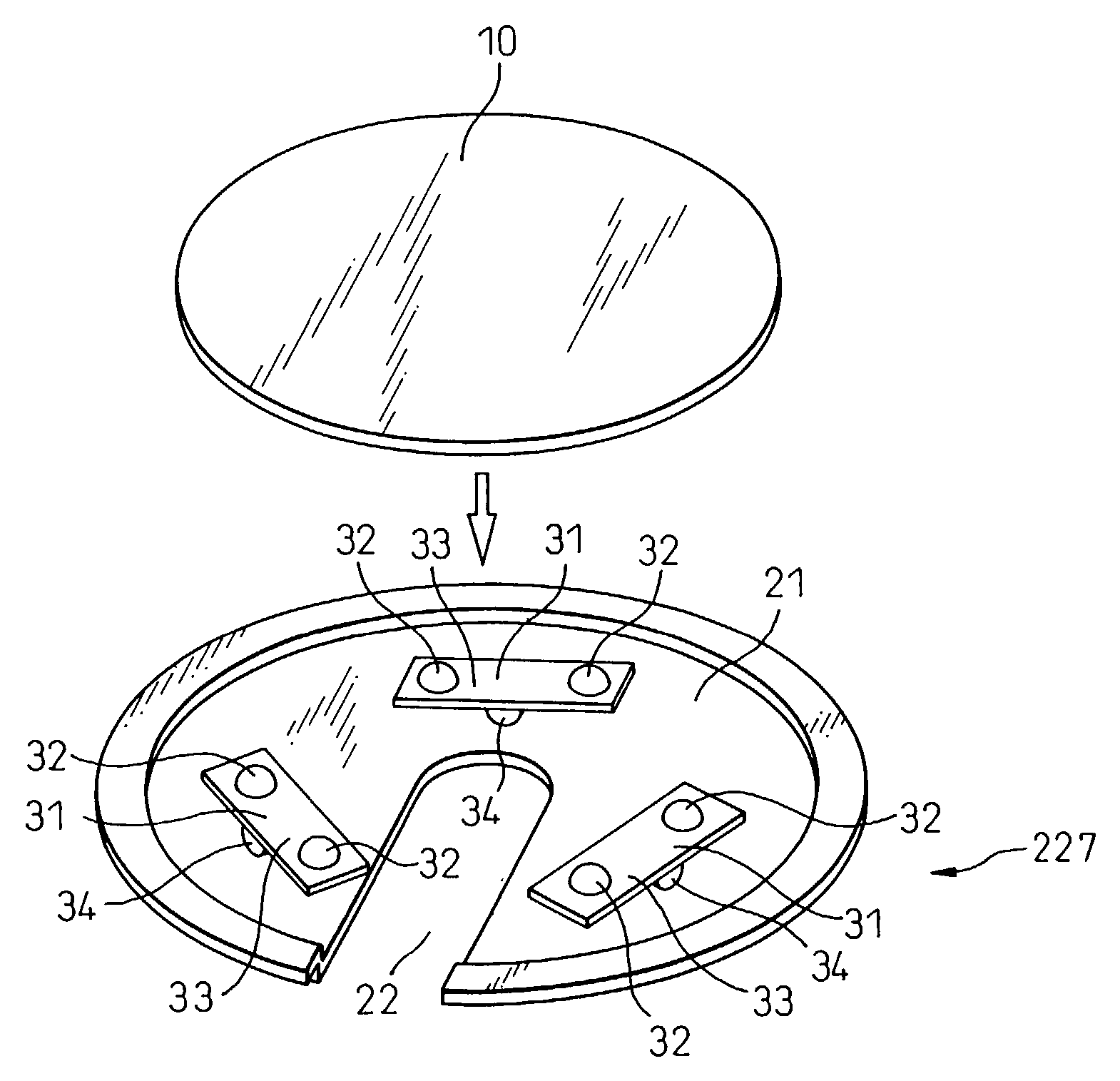

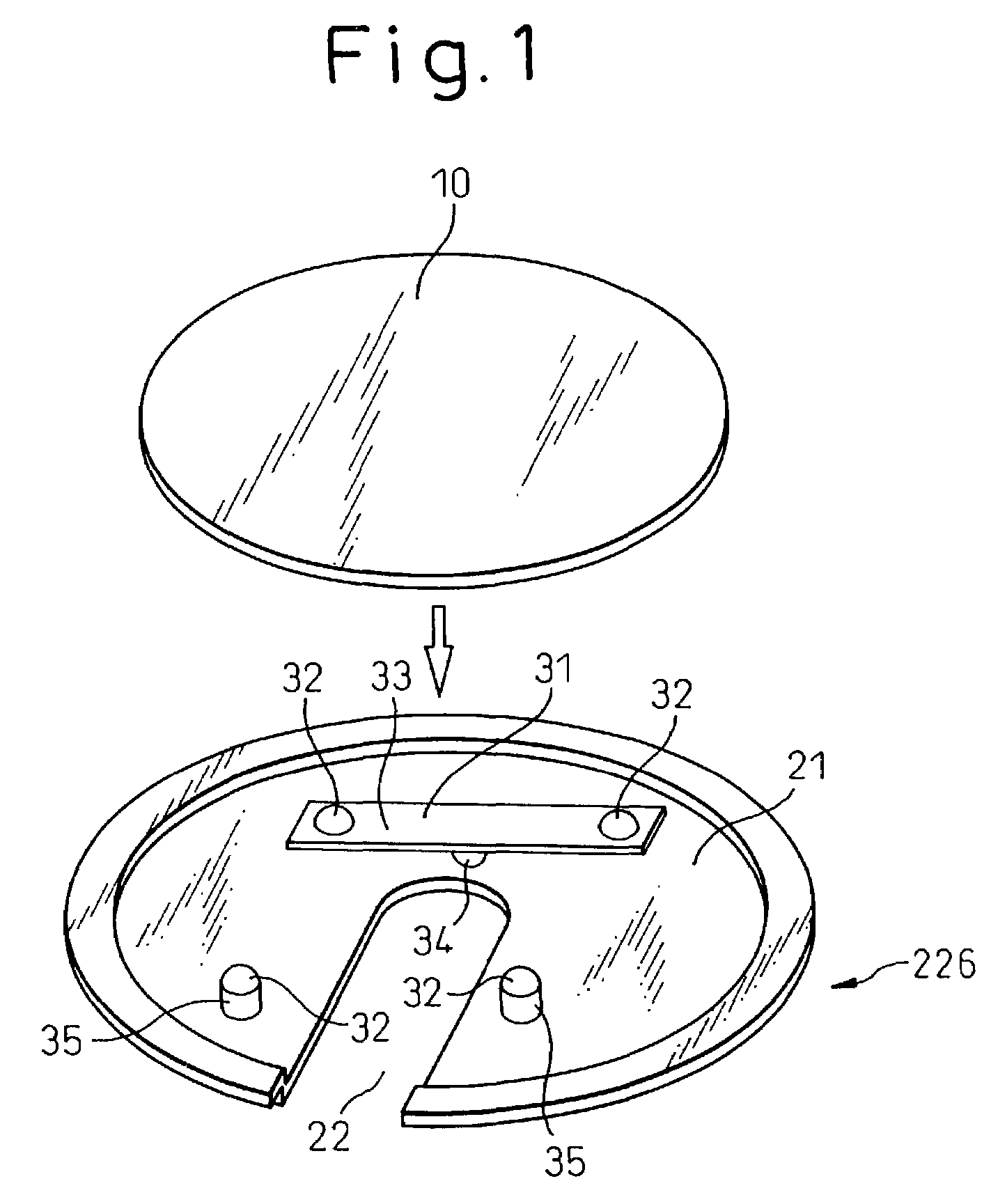

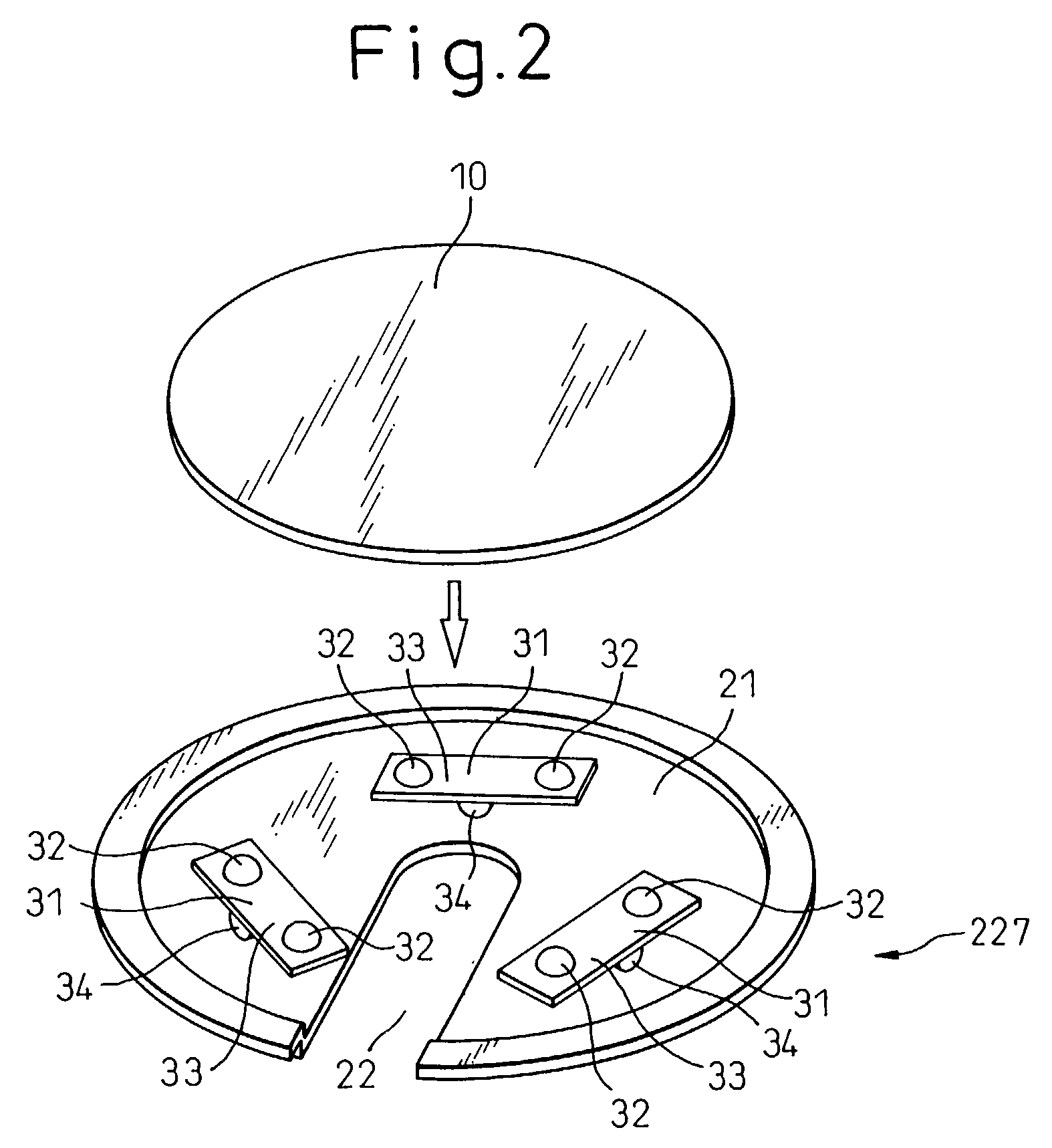

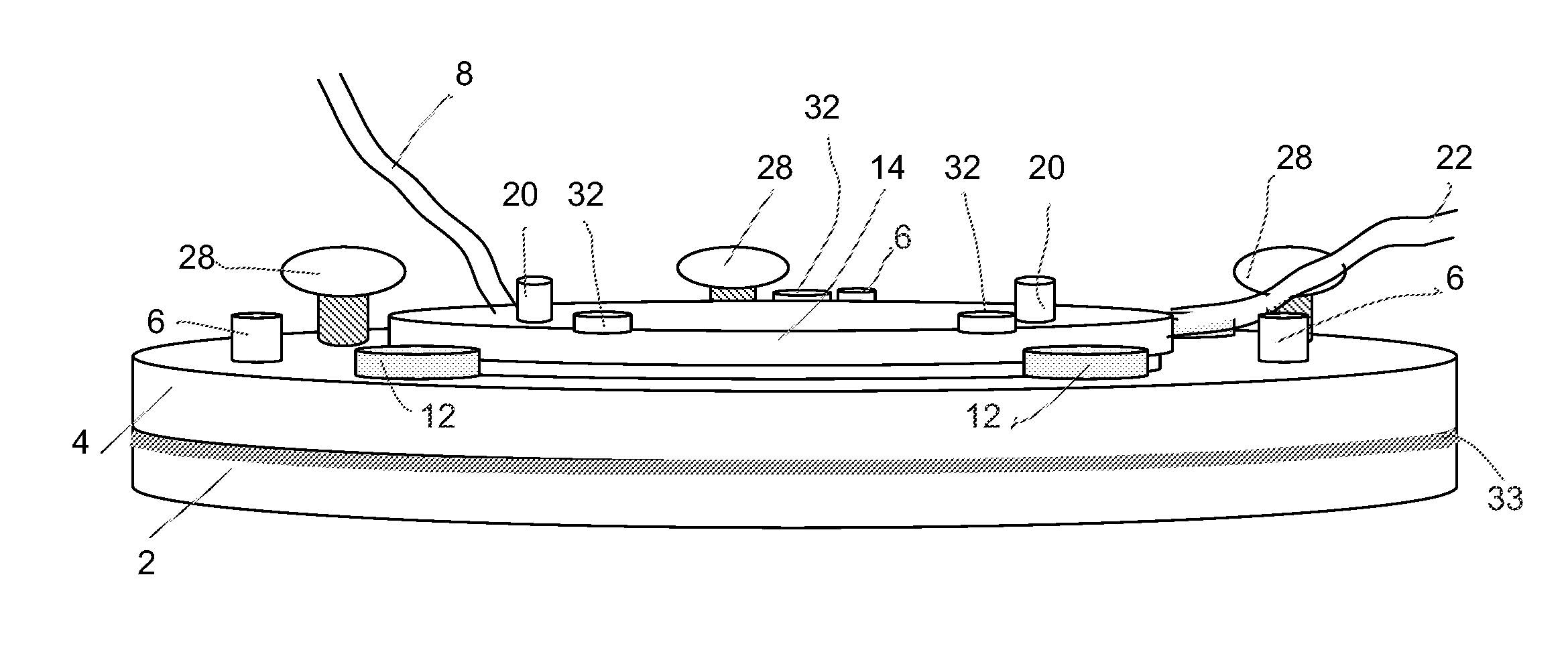

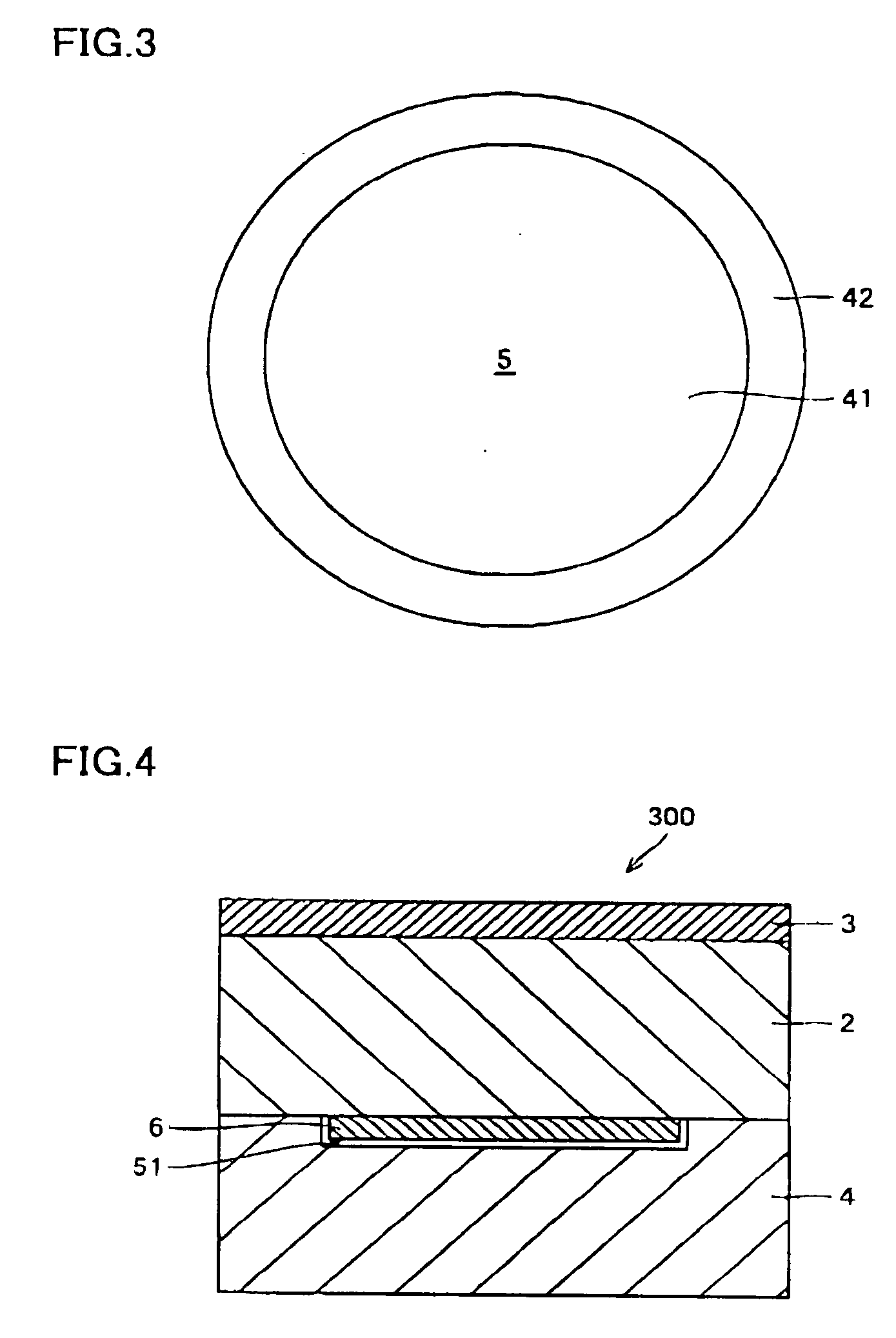

Wafer holder, heater unit having the wafer holder, and wafer prober having the heater unit

InactiveUS20070023320A1Avoid contact failureDeformationSemiconductor/solid-state device manufacturingOther accessoriesContact failureEngineering

A wafer holder hardly deformable under high load and capable of effectively preventing a contact failure with a wafer and further capable of preventing temperature increase of a driving system of a wafer prober is provided. In a wafer holder having a chuck top and a supporter, variation in thickness of the chuck top from a wafer-mounting surface to a contact surface with the supporter, and variation in thickness of the supporter from a bottom surface to a contact surface with the chuck top are both set to at most 50 μm. When the supporter is of a structure having a circular tube portion and a base portion separate from each other, variation in thickness of the circular tube portion from a contact surface with the chuck top to a contact surface with the base portion, and variation in thickness of the base portion from a bottom surface to a contact surface with the circular tube portion are preferably both set to at most 25 μm.

Owner:SUMITOMO ELECTRIC IND LTD

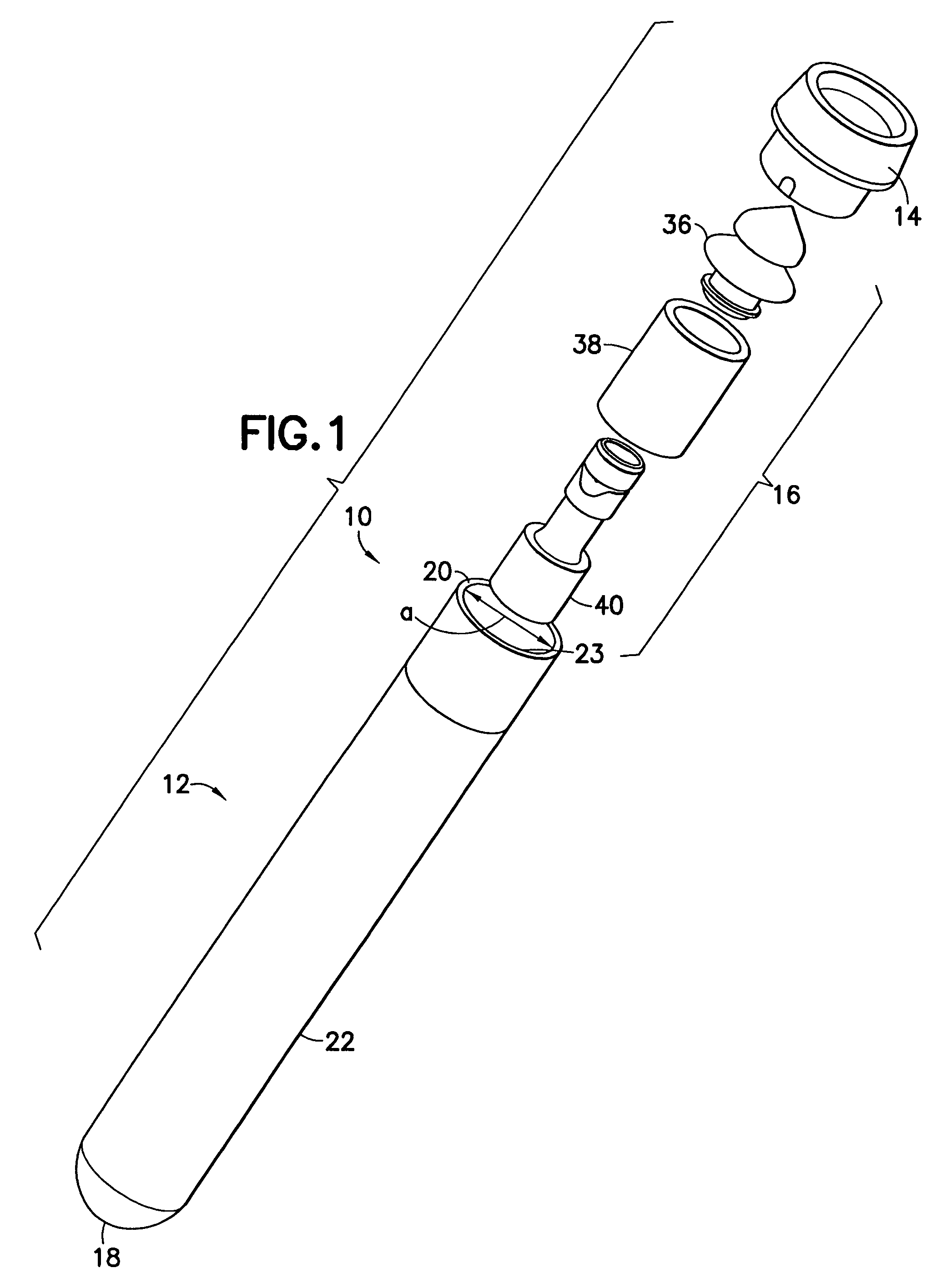

Device for separating components of a fluid sample

ActiveUS7947236B2Reduce overall outer diameterSmall overall deformationAnalysis using chemical indicatorsDispersed particle separationCentrifugationVolumetric Mass Density

A device for separating heavier and lighter fractions of a fluid sample is provided, the device including a container and a unitary separator located therein, the separator having an overall density between the heavier and light fractions. The separator is capable of moving between the fractions upon centrifugation, and sealing the fractions from one another when centrifugation ends.

Owner:BECTON DICKINSON & CO

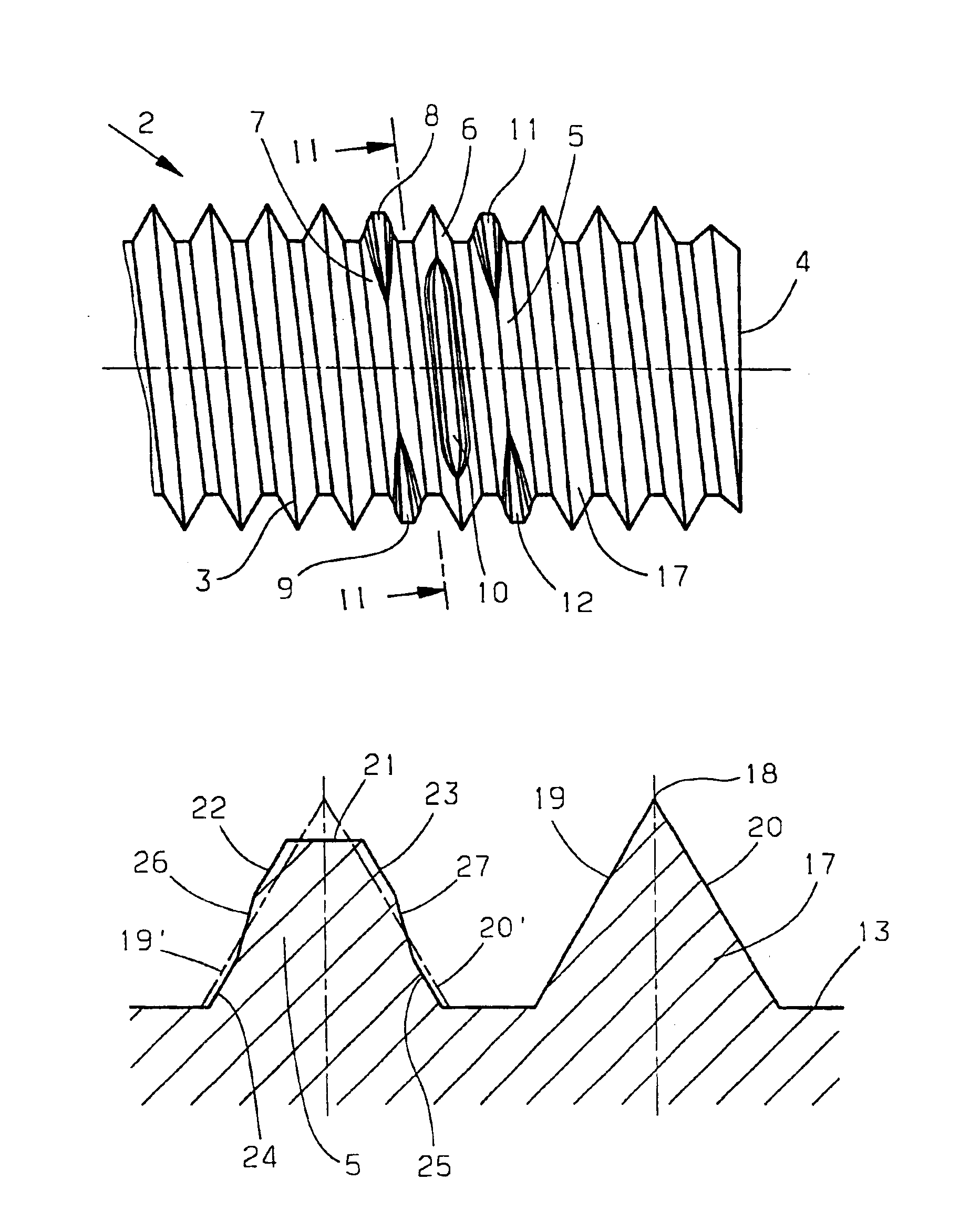

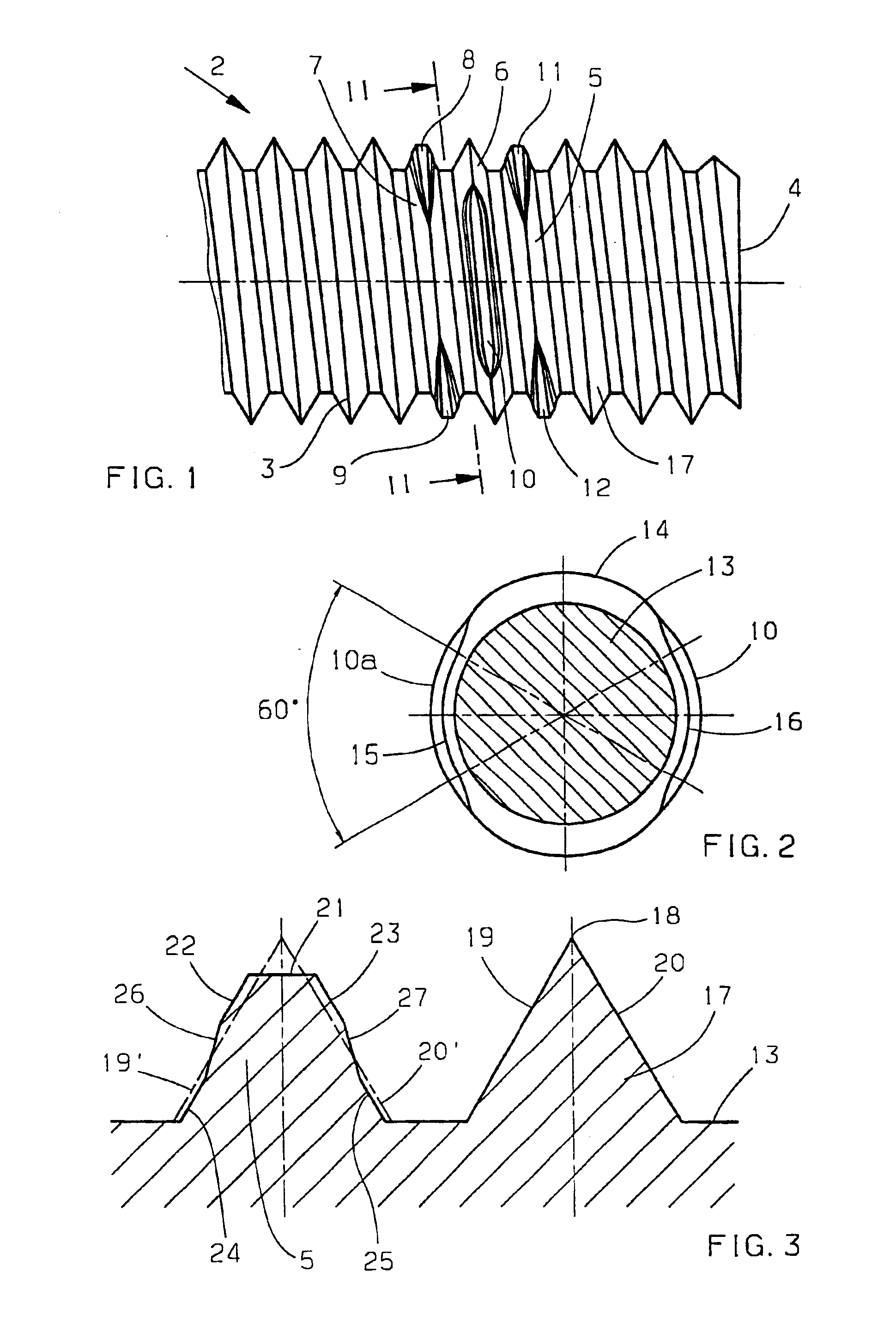

Screw provided with self-locking thread

Screw provided with self-locking rolled thread, wherein, in a plurality of places along its extent, the thread is deformed in relation to the normal thread cross section in that the thread outside diameter is reduced by radial compression of limited thread portions, the area of the thread cross section being substantially identical to that of the undeformed thread. While maintaining the slant of the thread flanks, the thread cross section is symmetrically widened in the outer region and reduced in the adjoining inner region, the transition from the widened to the reduced thread cross section lying approximately in the centre of the respective thread flank, and the limited thread portion extends over two parts of a thread turn such that there result two symmetrically opposite thread portions each of approximately ⅙ of the thread turn.

Owner:EJOT GMBH & CO KB

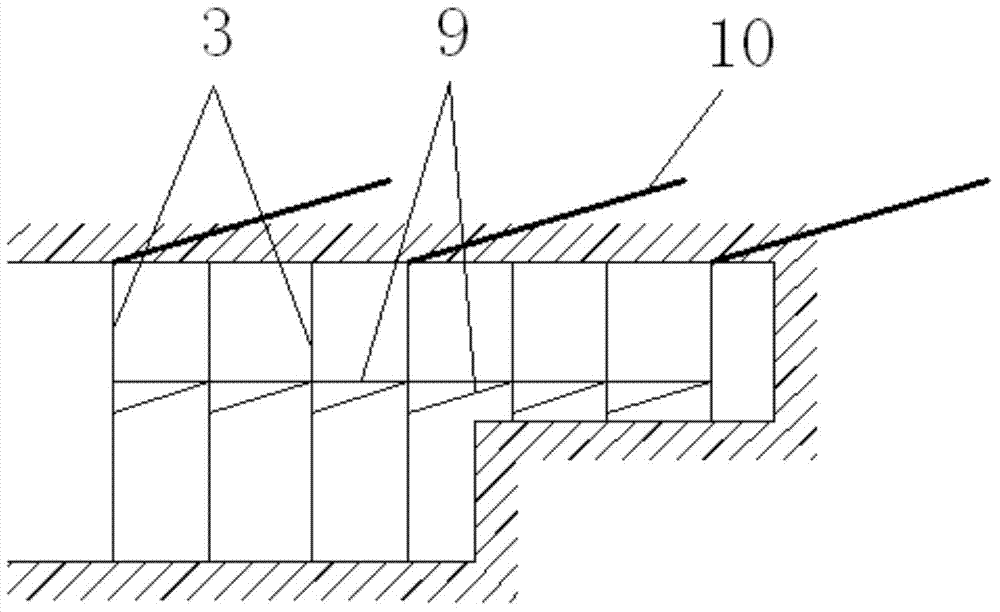

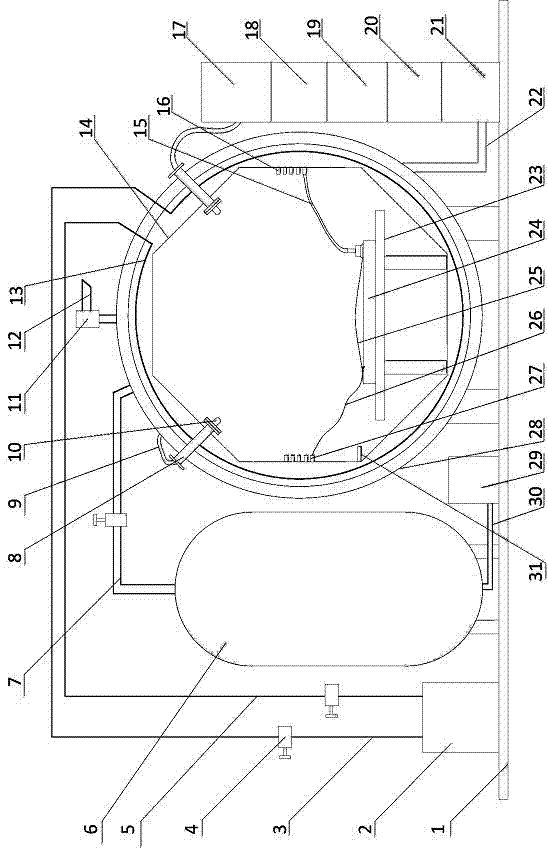

Method and device for forming high-performance composite material structural member through microwave-pressure tank

ActiveCN103587128AShorten the timeMicrowave heating and curing time is shortResonant cavityEngineering

The invention discloses a method and a device for forming a high-performance composite material structural member through a microwave-pressure tank. The device mainly comprises a cooling system (2), a gas storage tank (6), microwave transmission lines (9), microwave radiation antennas (10), a pressure safety valve (11), a polygonal multi-mode resonant cavity (14), a microwave generation and measurement module (17), a temperature measurement and control module (18), a vacuumizing and control module (19), a pressure measurement and control module (20), a power supply module (21), a material platform (23), a forming mold (24), a temperature sensor (26) and a tank body (28). The equipment is microwave forming equipment for the high-performance composite material structural member; a non-solidified composite material structural member is put into the equipment, and the high-performance composite material structural member can be quickly formed by technologies of vacuum bag vacuumizing, gas pressurization and microwave heating; the quality and the performance of the composite material structural member can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

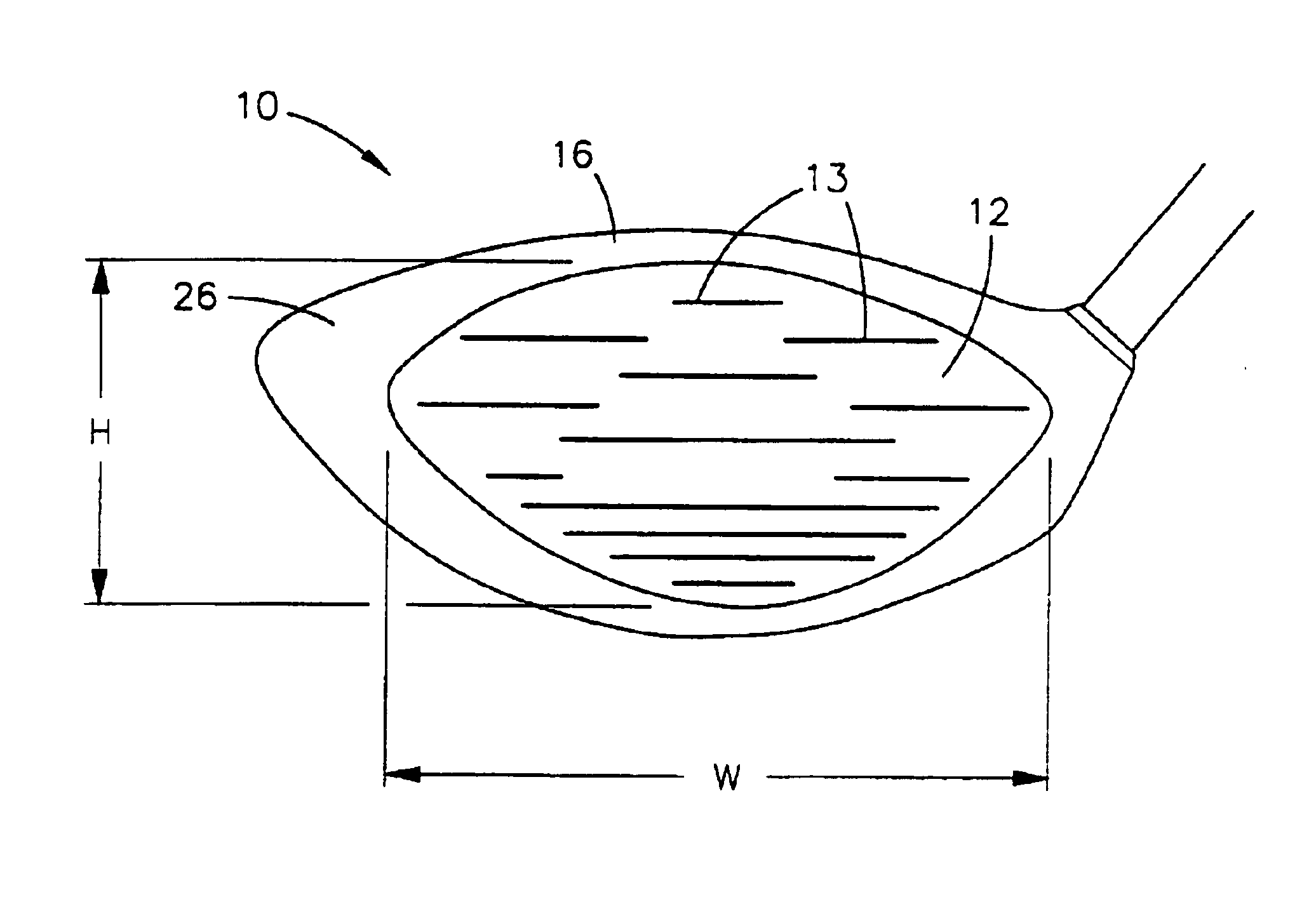

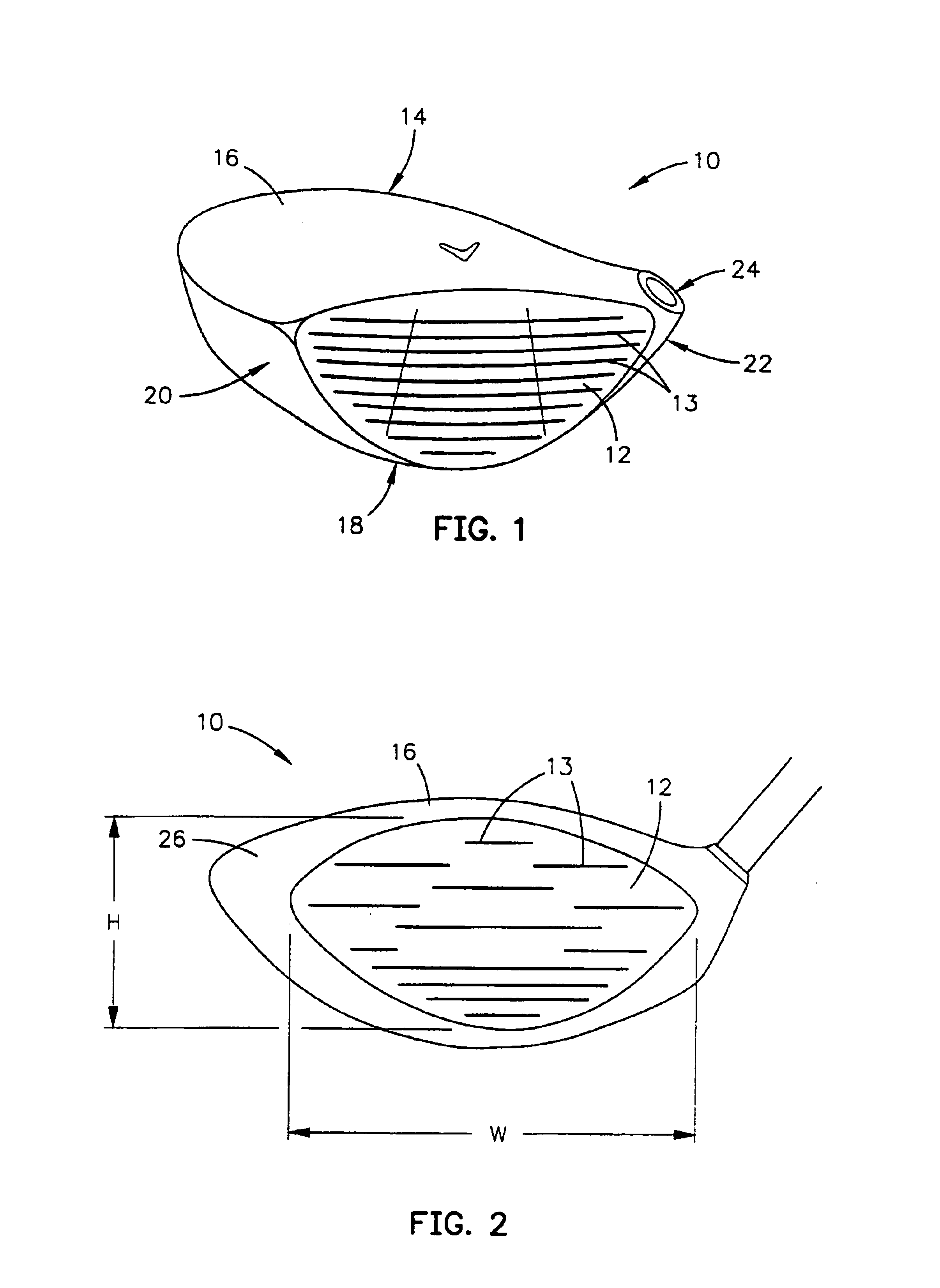

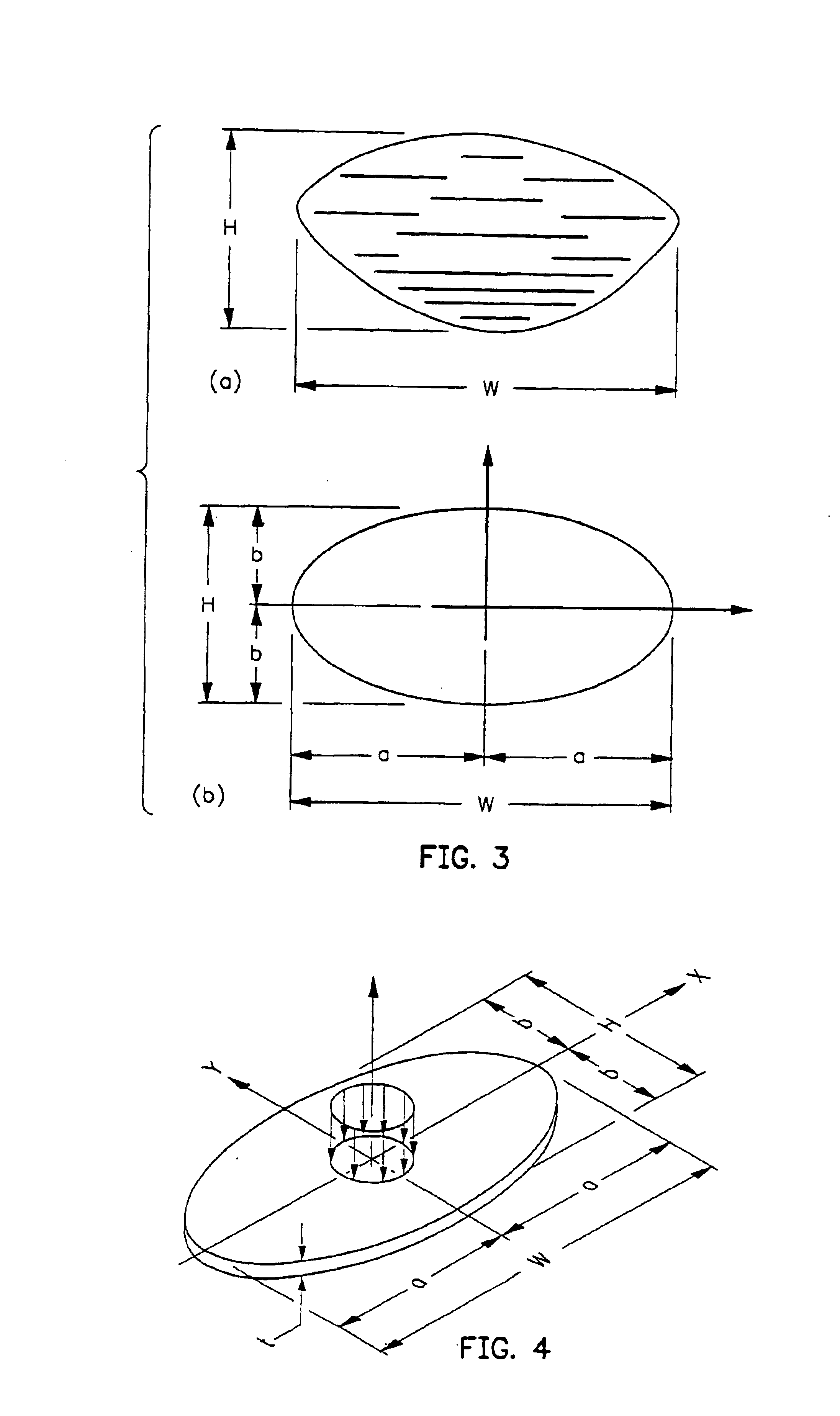

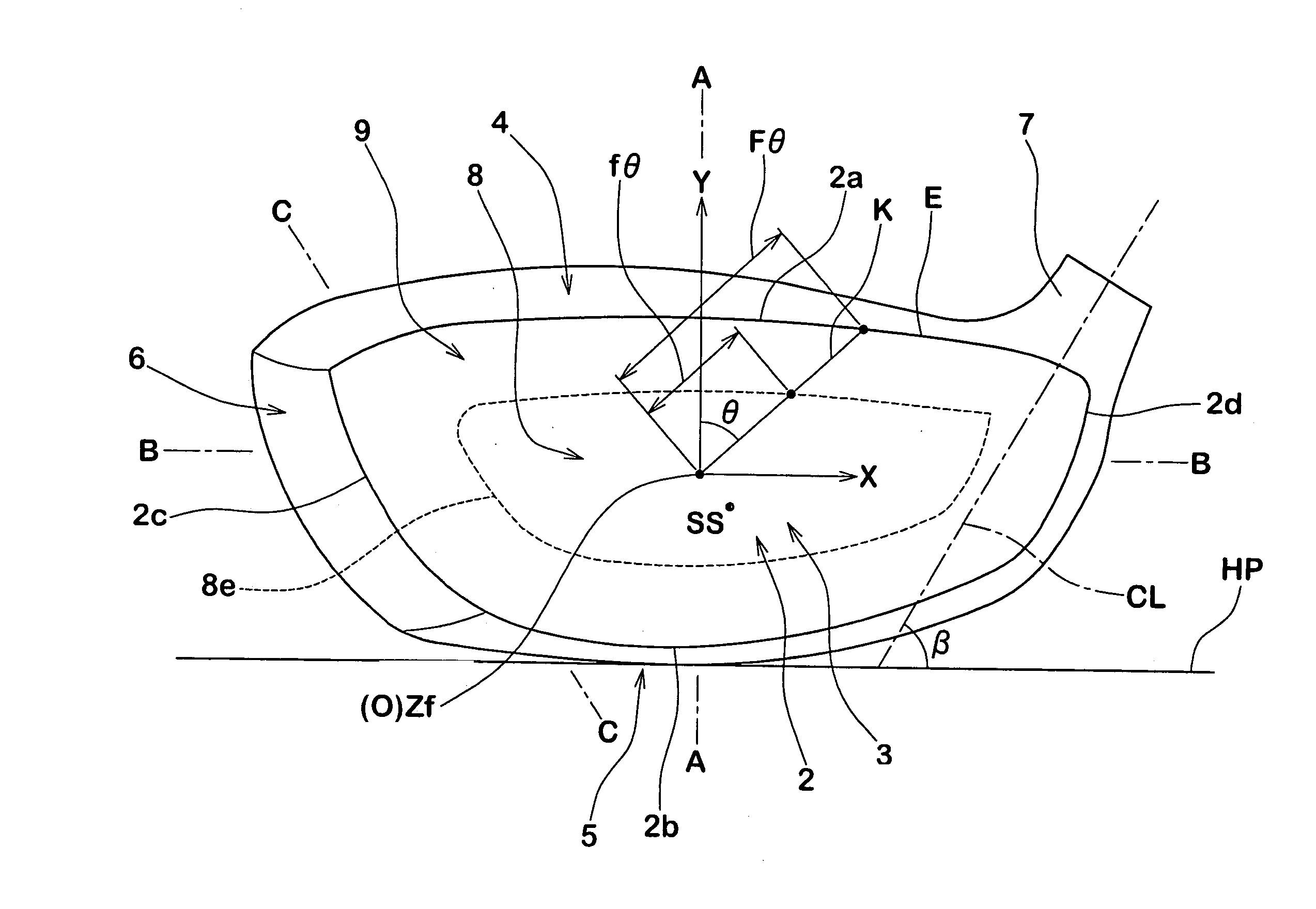

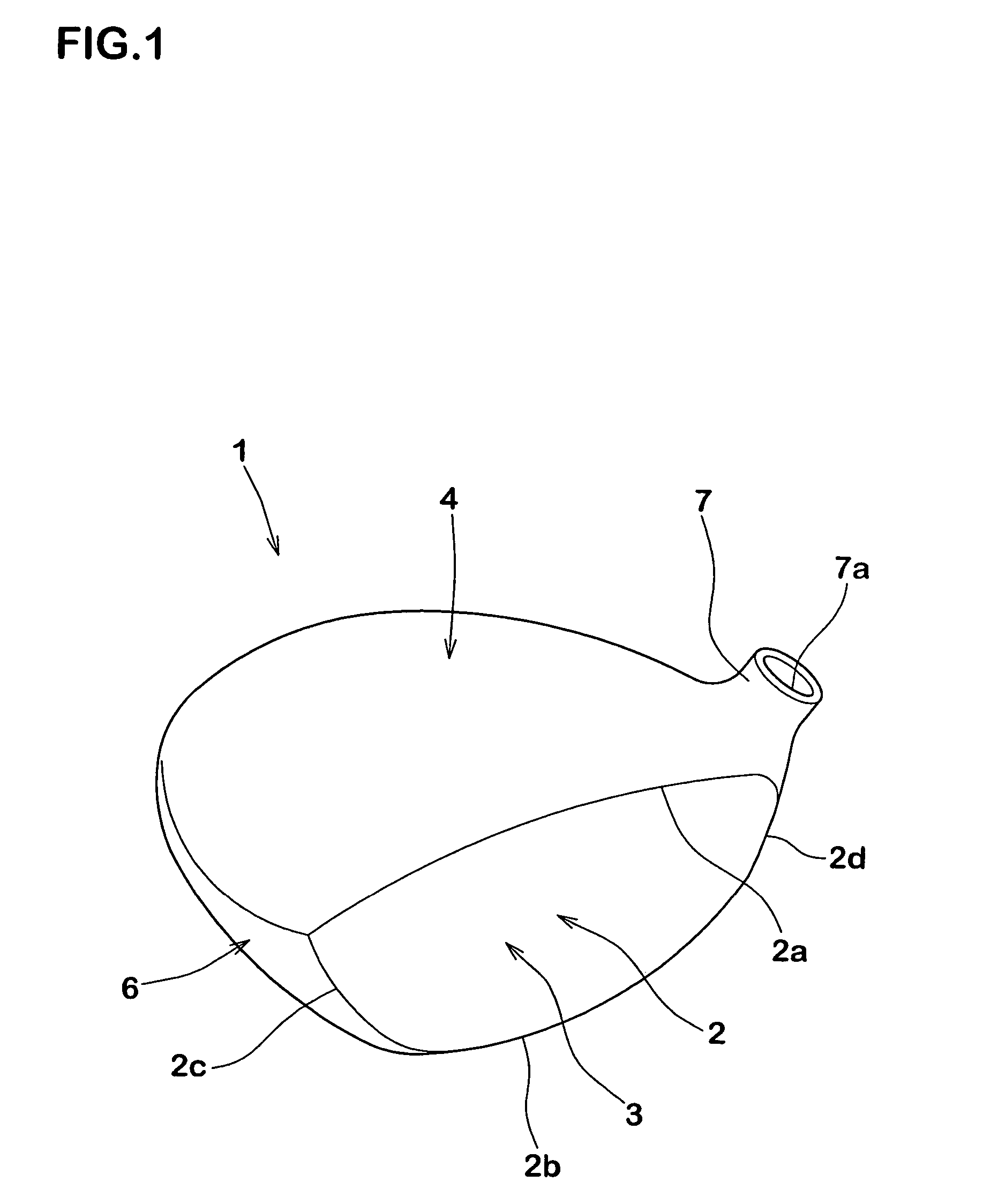

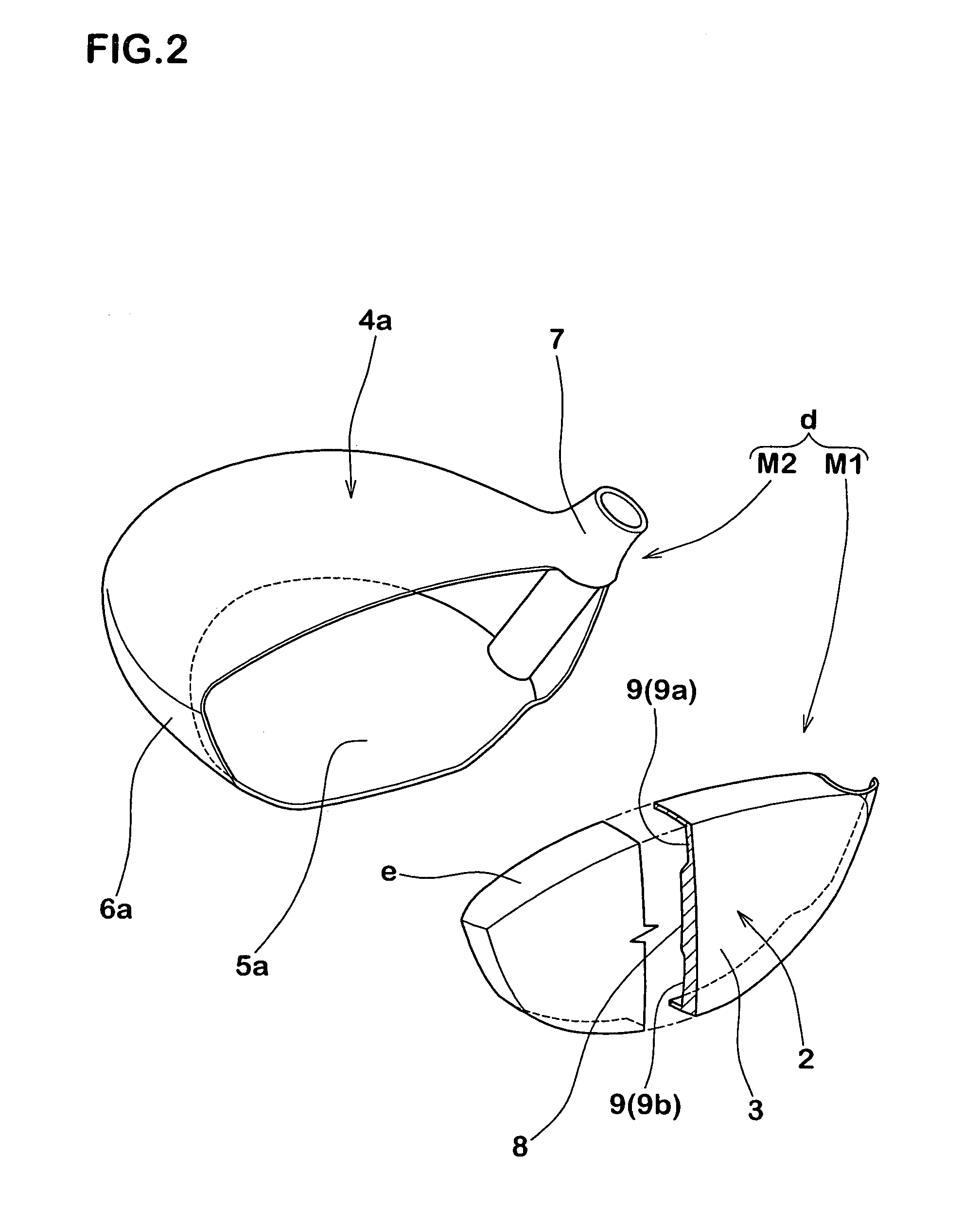

Golf club head having a striking face with improved impact efficiency

InactiveUS6949032B2Improve energy efficiencyReduced magnitudeGolf clubsRacket sportsStrain rateEnergy loss

A compliant golf club head permits a more efficient impact between a golf ball and the golf club head. Material and geometry constraints of a striking plate of the golf club head can reduce energy losses caused by large strain and strain rate values of the golf ball, these constraints on the striking plate yield a measure of the impact efficiency of the golf club head. Designating a required natural frequency range of the striking plate provides improved impact efficiency between the golf ball the golf club head.

Owner:CALLAWAY GOLF CO

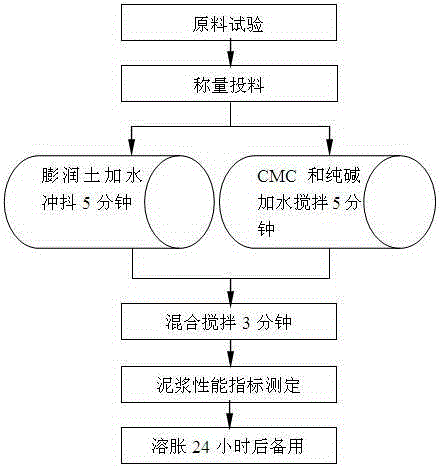

Construction method of underground continuous wall below viaduct

The invention relates to a construction method of an underground continuous wall below a viaduct. The method specifically includes the first step of staking out in a survey, the second step of guiding wall manufacturing, the third step of width adjustment of the underground continuous wall, the fourth step of slurry preparation, the fifth step of grooving construction, the sixth step of reinforcement cage manufacturing, hoisting and releasing, the seventh step of concrete grouting, the eighth step of repeatedly executing the fifth step, the sixth step and the seventh step till construction of a to-be-formed single-width undergrou nd continuous wall construction unit ends, and the ninth step of underground continuous wall joint processing. By means of the construction method, construction of the underground continuous wall can be fast completed while the quality and the quantity are guaranteed, and a viaduct pier will not be affected. Compared with a cast-in-situ bored pile construction method, the construction method has the beneficial effects that construction speed is high in the construction progress, stratum disturbance is small, and therefore the influences on the viaduct pier are small.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

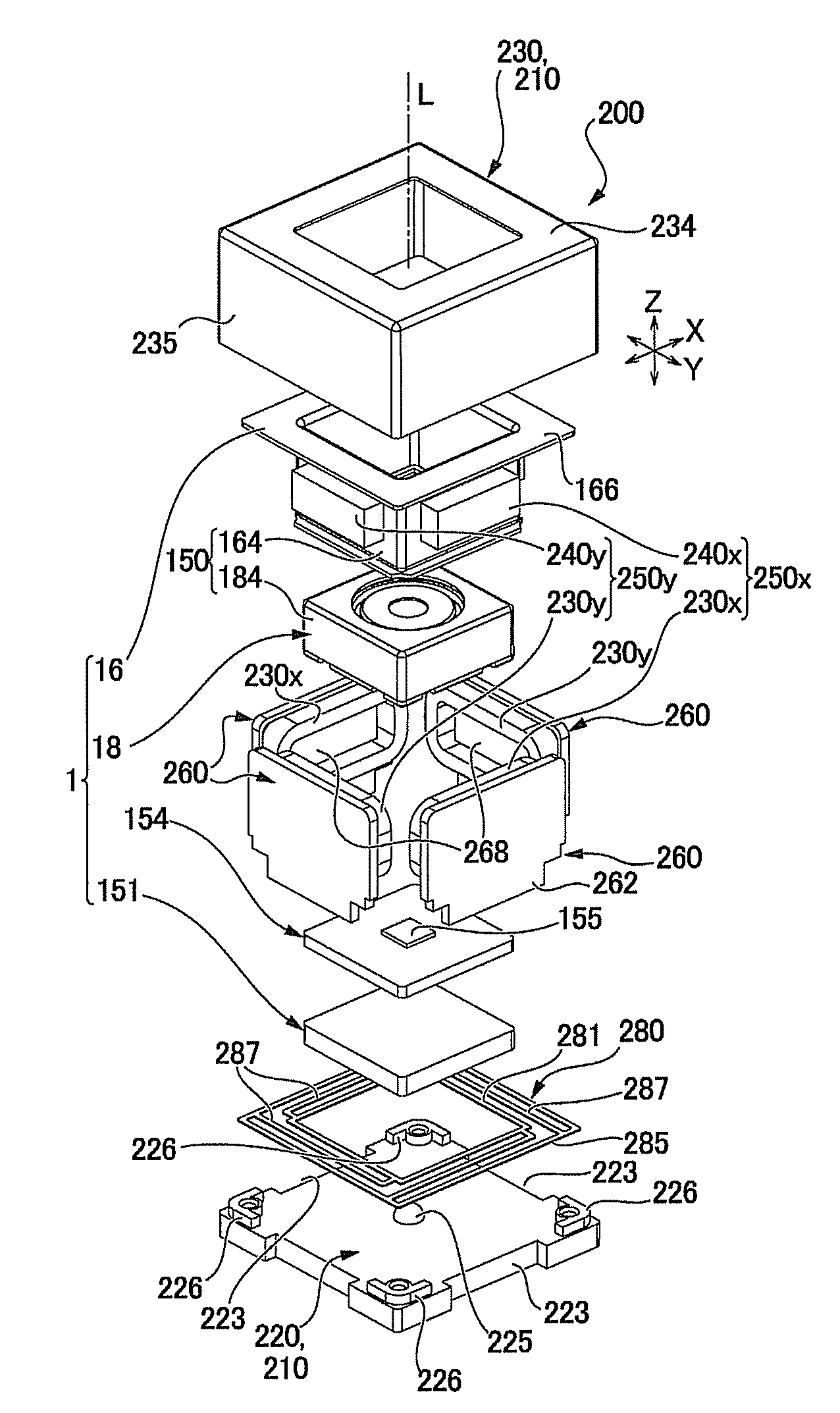

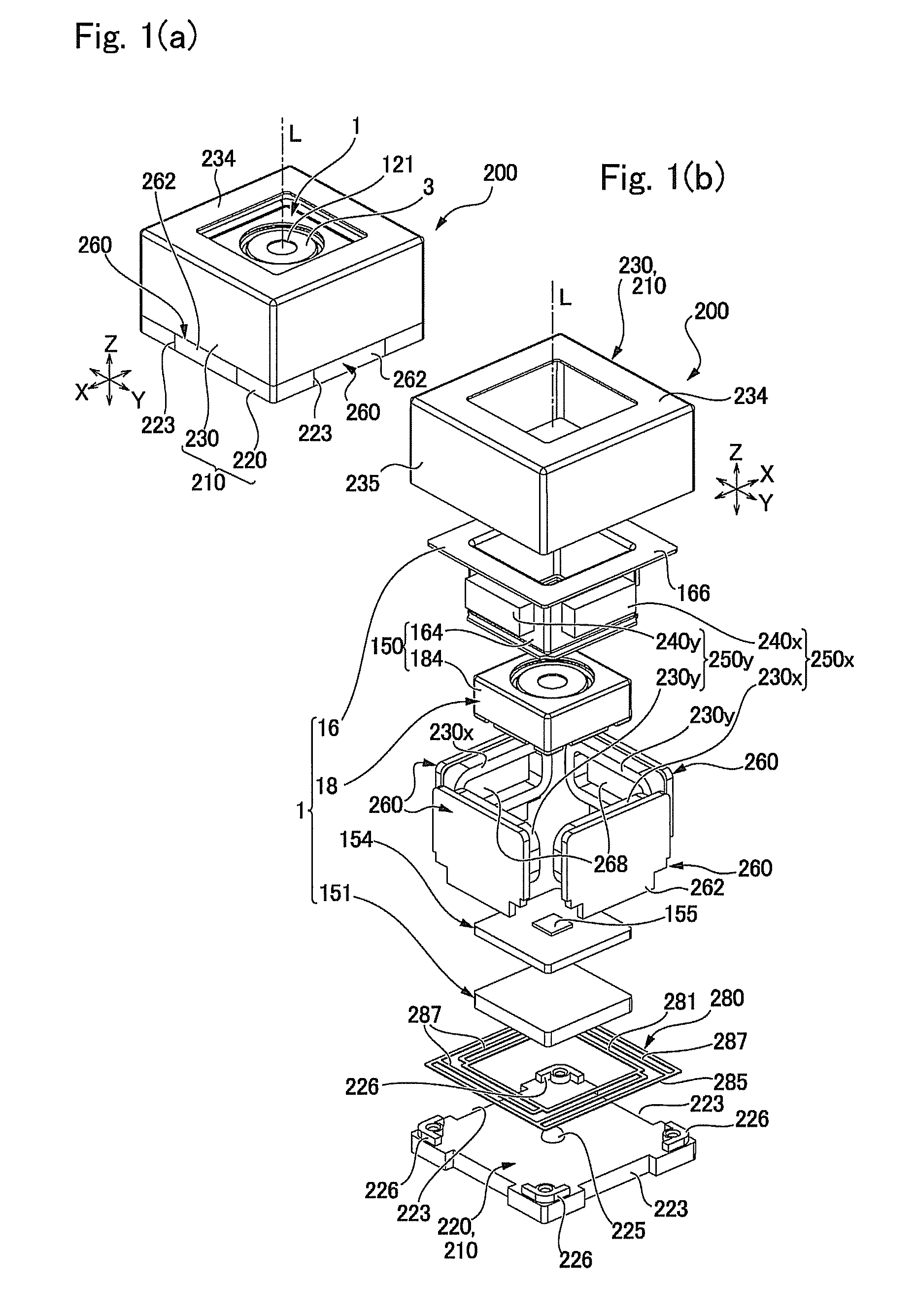

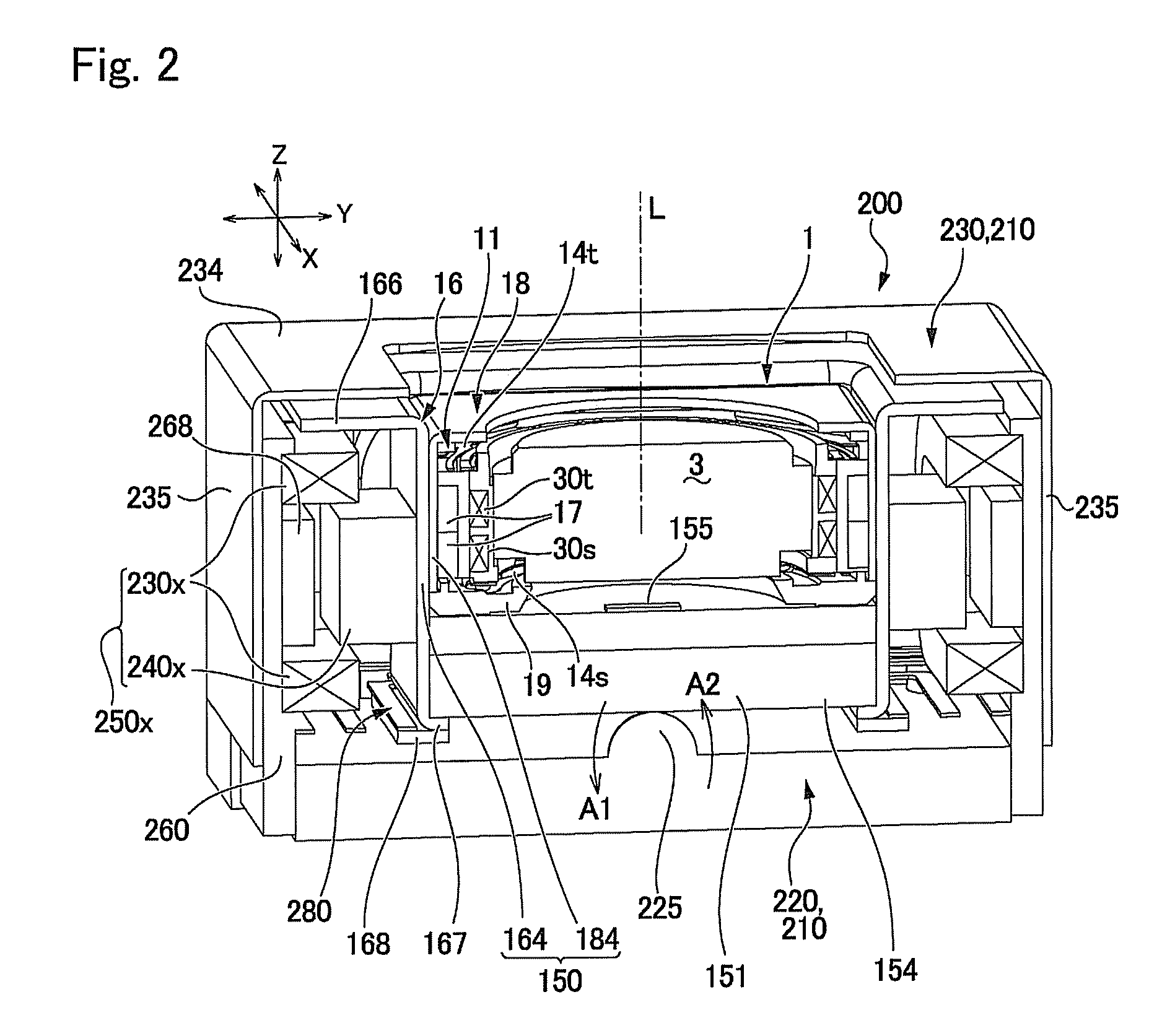

Optical unit with shake correcting function and photographic optical device

ActiveUS8238736B2Efficiently interlinkedHigh torqueTelevision system detailsPrintersEngineeringMagnet

Provided is a photographing optical device, which is able to reliably correct an unintentional movement by hand of a user by improving the constitution of a camera unit driving mechanism for correcting the deflection of a camera unit. In order that a camera unit is made to be rocked to correct the unintentional movement, a photographing optical device includes a first camera unit drive mechanism and a second camera unit drive mechanism, which are so disposed at two side portions sandwiching a pivot portion therebetween as to make a pair. In these camera unit drive mechanisms, camera unit driving magnets are held on the side of the camera unit as a movable body side, and camera unit driving coils are held on the side of a stationary body. The camera unit is pushed toward the pivot portion by a gimbal spring.

Owner:SANKYO SEIKI MFG CO LTD

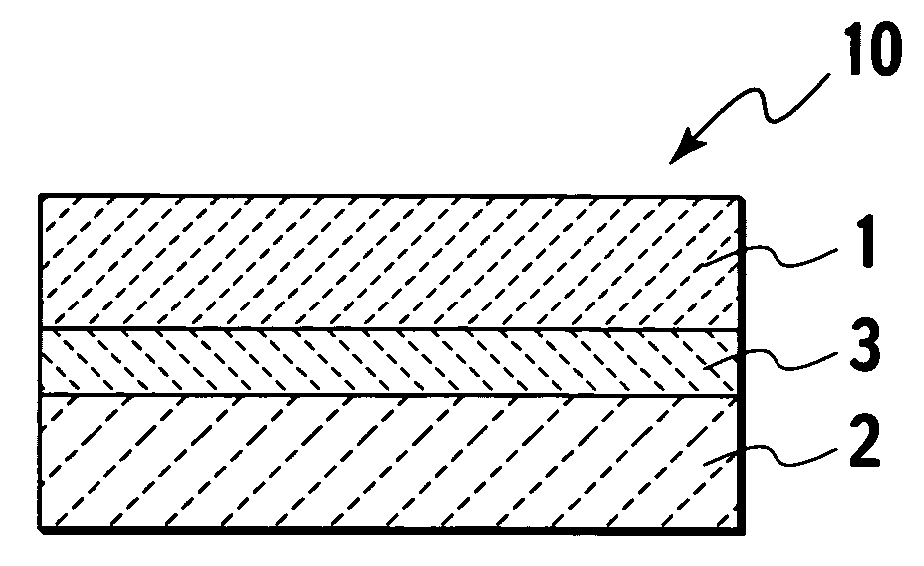

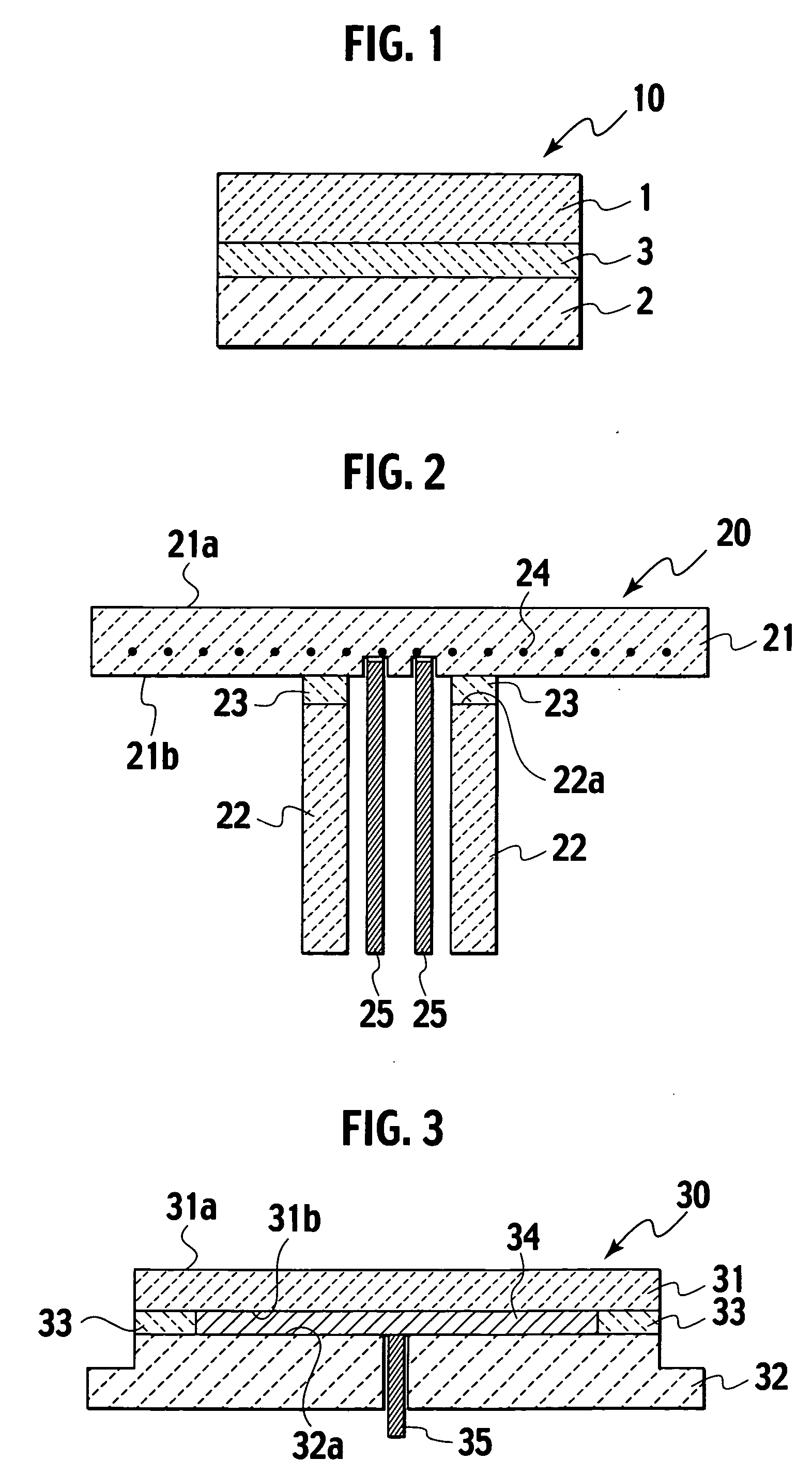

Bonding agent, aluminum nitride composite body, and manufacturing method of the same

InactiveUS20060110624A1Improve abilitiesLower bonding temperatureCeramic layered productsInorganic adhesivesRare-earth elementCalcium aluminates

Owner:NGK INSULATORS LTD

Golf club head

This present invention relates to a hollow golf club head comprising a face portion whose front face defines a club face for hitting a ball, wherein said face portion comprises a center portion forming an area having a sweet spot, and a peripheral portion surrounding the center portion and having the thickness smaller than the thickness of said center portion, wherein the thickness of the peripheral portion is reduced from the sole portion side of the head toward the crown portion side.

Owner:SUMITOMO RUBBER IND LTD

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

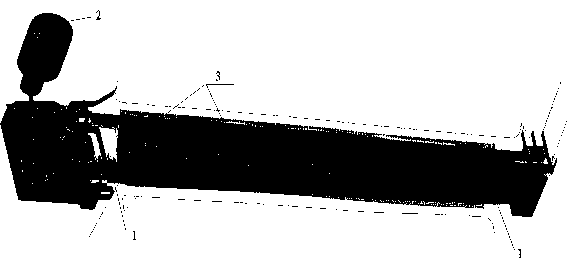

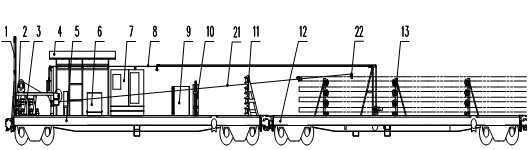

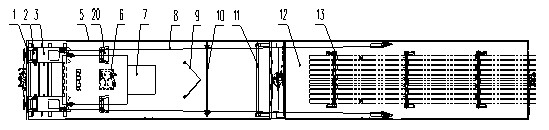

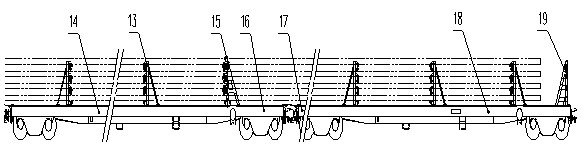

Long steel rail transport vehicle set capable of rapidly unloading steel rails

ActiveCN102009657AAchieve longitudinal movementEasy to adjustWagons/vansRailway device loading/unloadingTransportation costAutomotive engineering

The invention relates to a long steel rail transport vehicle set capable of rapidly unloading steel rails, which is characterized by comprising an unloading operation vehicle, wherein the unloading operation vehicle is provided with a steel rail unloading device; the steel rail unloading device comprises a winding device for pulling and unloading the steel rails and a pusher for pushing the steelrails; tracks are controlled by a guiding device, a tracking device and a lifting rail door at the time of unloading the steel rails; and the winding device, the pusher, the guiding device, the tracking device, the lifting rail door are fixed on the unloading operation vehicle body in sequence along with the running direction. The long steel rail transport vehicle set is formed by grouping six types of vehicles which are successively hung in serials, namely an unloading operation vehicle, a rail transporting heading vehicle, front rail transporting vehicles, a locking vehicle I, a locking vehicle II, rear rail transporting vehicles, and a rail transporting tail vehicle, wherein the number of the front rail transporting vehicles and the rear rail transporting vehicles depends on length of the transported steel rails. The long steel rail transport vehicle set has the advantages of large carrying capacity, simple structure, safety and reliability, high working efficiency of transporting and unloading the steel rails, and lower transportation cost.

Owner:株洲新通铁路装备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com