Fine-pottery sanitary ceramic body and manufacturing method thereof

A technology of sanitary ceramics and fine ceramics, applied in the field of ceramic products, can solve the problems of shortened product service life, low product qualification rate, complicated production process, etc., to reduce pinholes, improve product qualification rate, and improve anti-cracking performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

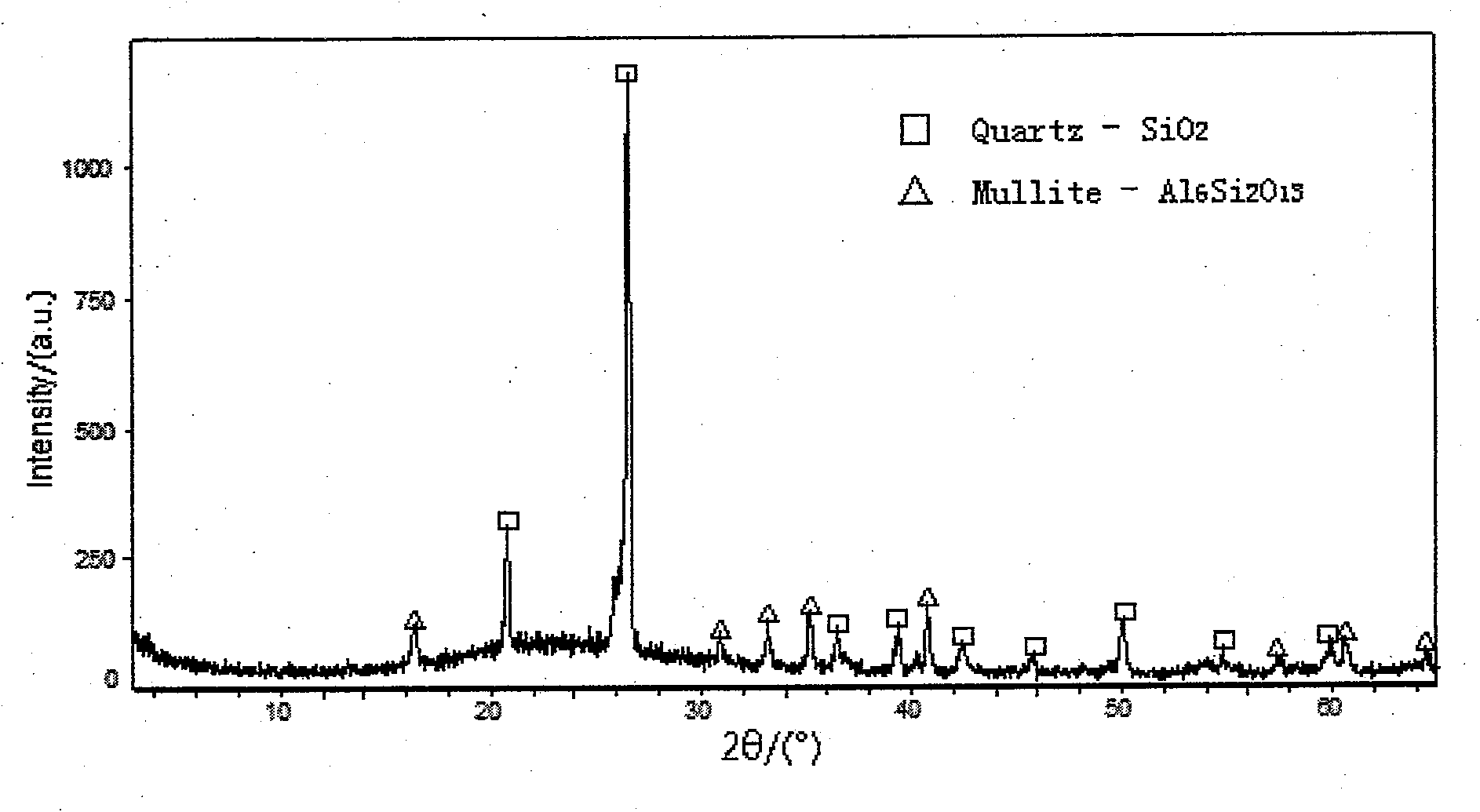

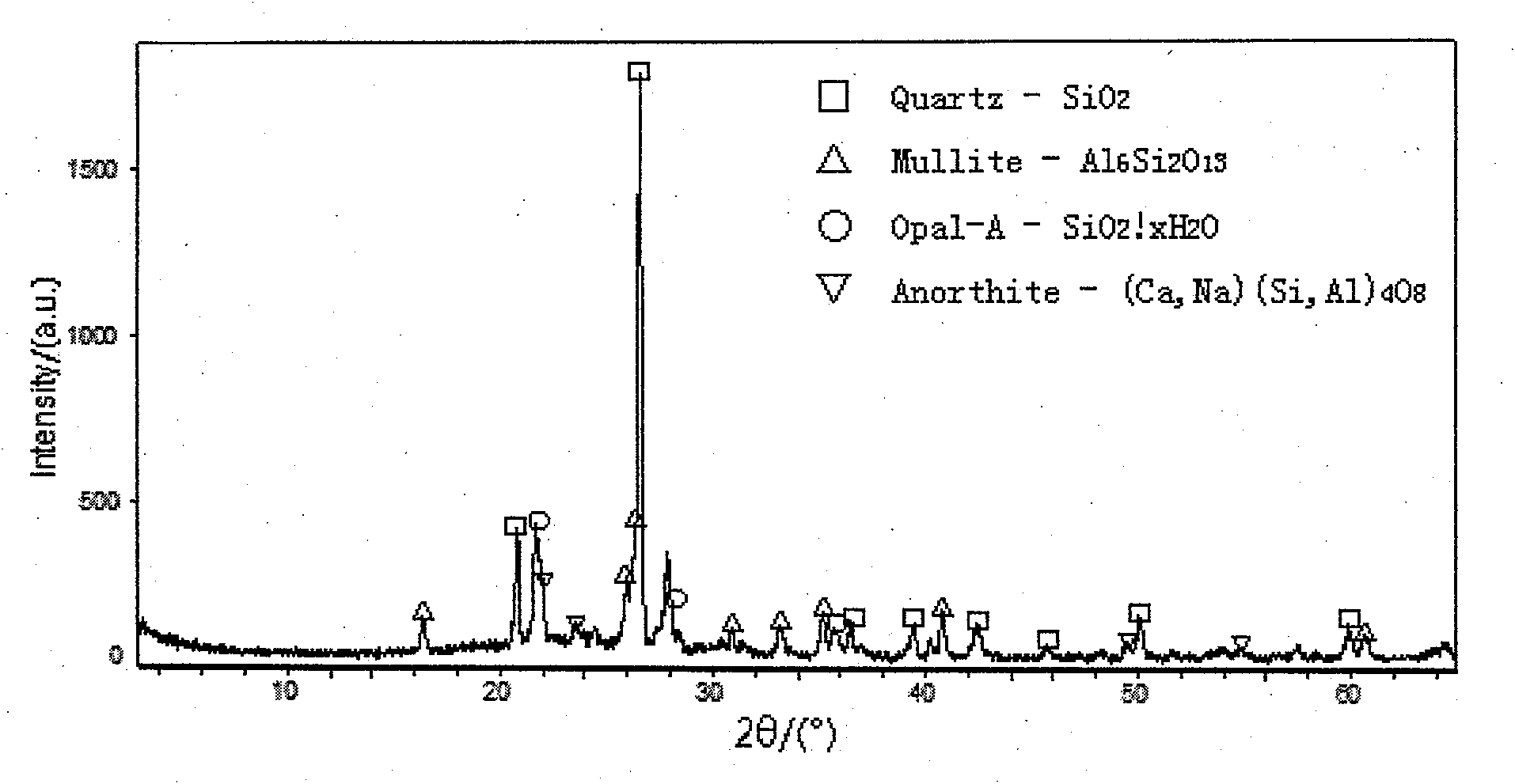

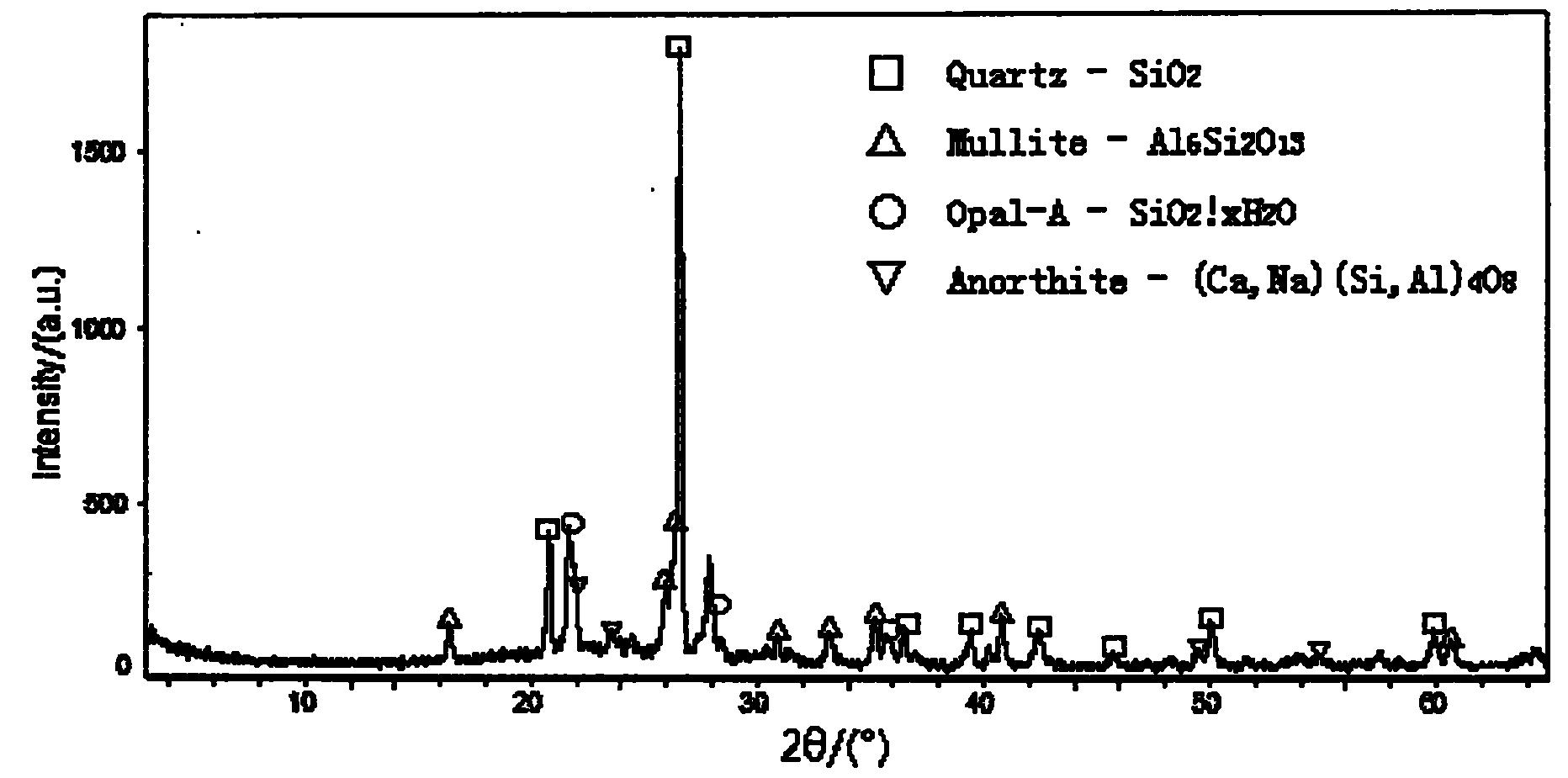

Image

Examples

Embodiment 2

[0027] The content of wollastonite in embodiment 2 is the same as that in embodiment 4, but the content of kaolinite and quartz in embodiment 4 is less, and the content of calcined kaolin is more, resulting in SiO in the formula chemical composition 2 content decreased, Al 2 o 3 As the content increases, the coefficient of thermal expansion at 200°C decreases, resulting in a decrease in the compressive stress on the glazed surface of the green body in Example 4, so sparse cracks appear on the glazed surface. This indicates that with high SiO in the formulation 2 The content of kaolinite and quartz is reduced, and the corresponding high Al 2 o 3 The increase of the content of calcined kaolin, the anti-cracking ability of the body decreases; therefore, to improve the anti-cracking ability of the glaze, it is necessary to increase the high SiO 2 content of raw materials.

Embodiment 6

[0028] Both Example 6 and Example 2 have no cracks on the glaze surface of the green body, but the increase in the feldspar content in Example 6 reduces the water absorption of the green body and increases the flexural strength of the green body. The shrinkage, total shrinkage, and deformation increase significantly; therefore, in order to balance water absorption, firing flexural strength, shrinkage, and deformation, the content of feldspar must be controlled within a reasonable range, preferably less than 5 (parts by mass) .

Embodiment 7

[0029] Compared with Example 2, the content of ball clay in Example 7 is greatly increased, and the dry strength of the green body is greatly improved, which is conducive to reducing the cracking of the formed green body; but it also significantly reduces the slurry suction speed of the green body, which It will significantly prolong the operation time of grouting workers, reduce production efficiency, and shorten the service life of the grouting model. Therefore, the content of ball soil should be controlled within a reasonable range, preferably less than 30 (parts by mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com