A sand casting mold and a method for preparing bucket tooth tips using the mold

A sand casting and mold technology is applied in the field of sand casting molds and the preparation of bucket teeth tips by using the sand casting molds, which can solve the problems of reduced fluidity of molten iron, difficulty in obtaining density, and increased casting rejection rate, thereby reducing thermal expansion. Shrinkage rate, reduction of porosity, and effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

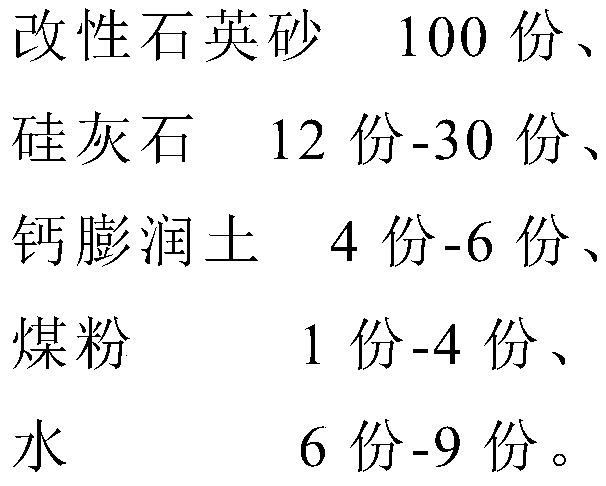

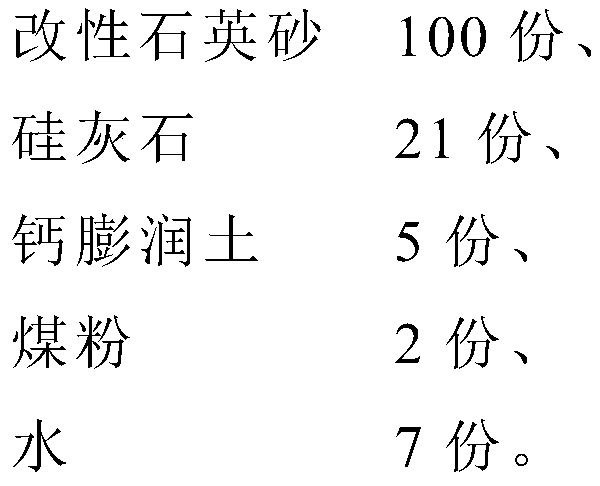

[0027] The sand casting mold in the present embodiment is made from the raw material of following parts by weight:

[0028]

[0029] The preparation method of described modified quartz sand is, Al(NO 3 ) 3 Dissolved in water to make 2.6% Al(NO 3 ) 3 solution, soak the quartz sand in Al(NO 3 ) 3 Add NaOH solution to the solution to adjust the pH value to 7.7, stir evenly and let it stand for 30 minutes, then filter, heat the obtained quartz sand at a heating rate of 16°C / min to 950°C for high-temperature calcination, and keep it for 1.5h to obtain a surface Coated with a layer of nano-Al 2 o 3 of quartz sand, nano-Al 2 o 3 The particle size distribution is 30nm-40nm, that is, modified quartz sand.

Embodiment 2

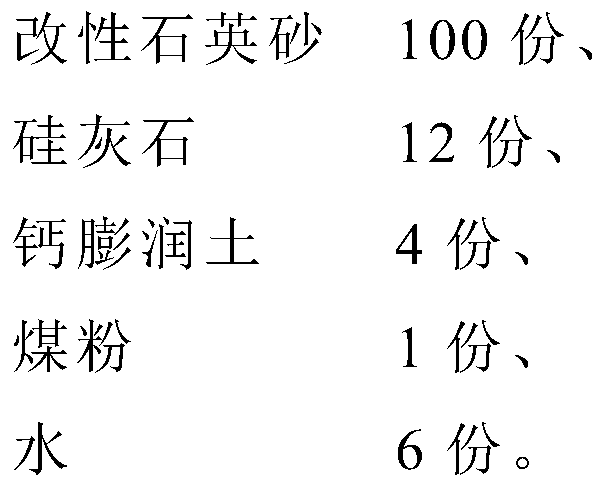

[0031] The sand casting mold in the present embodiment is made from the raw material of following parts by weight:

[0032]

[0033] The preparation method of described modified quartz sand is, Al(NO 3 ) 3 Dissolved in water to make 1.5% Al(NO 3 ) 3 solution, soak the quartz sand in Al(NO 3 ) 3 Add NaOH solution to the solution to adjust the pH value to 7.5, stir evenly, let it stand for 30 minutes, and then filter, heat the obtained quartz sand to 900°C at a heating rate of 13°C / min for high-temperature calcination, and keep it for 2h to obtain a surface coating Coated with a layer of nano-Al 2 o 3 of quartz sand, nano-Al 2 o 3 The particle size distribution is 20nm-30nm, that is, modified quartz sand.

Embodiment 3

[0035] The sand casting mold in the present embodiment is made from the raw material of following parts by weight:

[0036]

[0037] The preparation method of described modified quartz sand is, Al(NO 3 ) 3 Dissolved in water to make 3.8% Al(NO 3 ) 3 solution, soak the quartz sand in Al(NO 3 ) 3Add NaOH solution to the solution to adjust the pH value to 8.0, stir evenly, let it stand for 30 minutes, and then filter, heat the obtained quartz sand to 1000°C at a heating rate of 20°C / min for high-temperature calcination, and keep it for 1h to obtain surface coatings. Coated with a layer of nano-Al 2 o 3 of quartz sand, nano-Al 2 o 3 The particle size distribution is 40nm-50nm, that is, modified quartz sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com