Patents

Literature

62results about How to "Reduce thermal expansion and contraction" patented technology

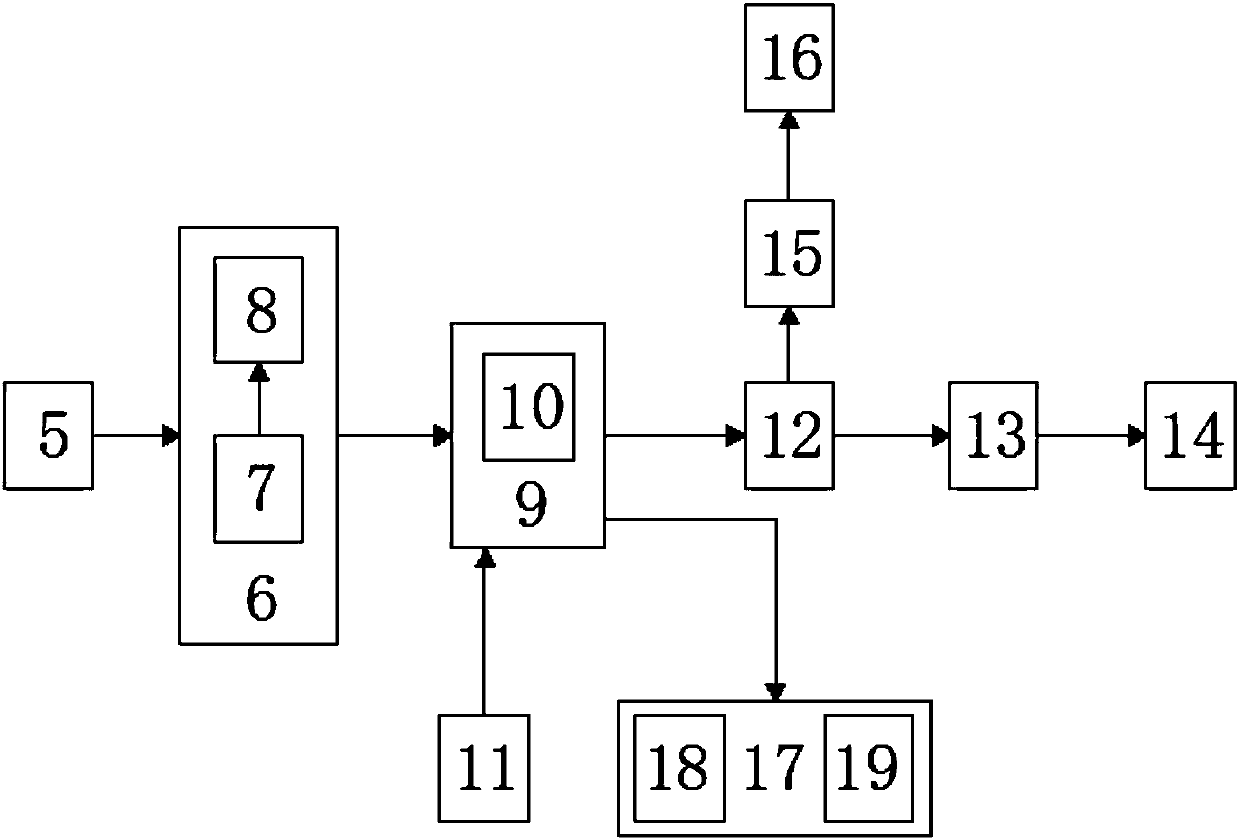

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

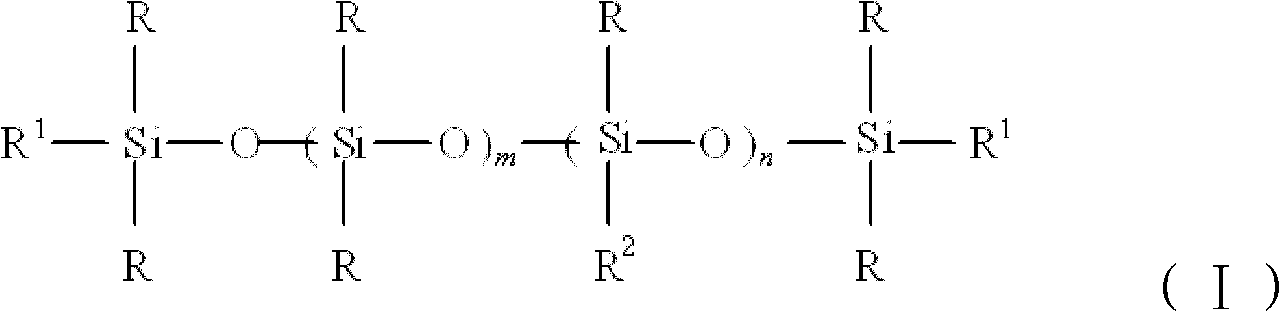

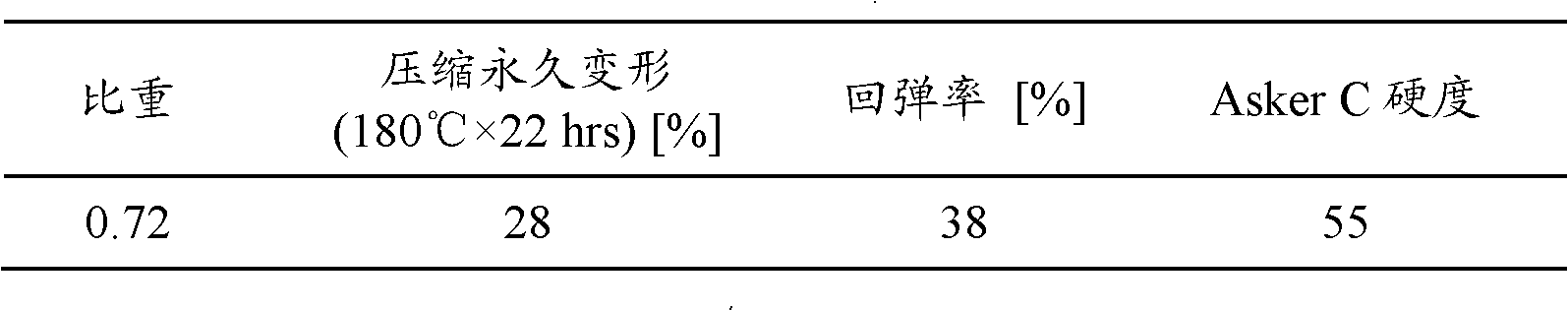

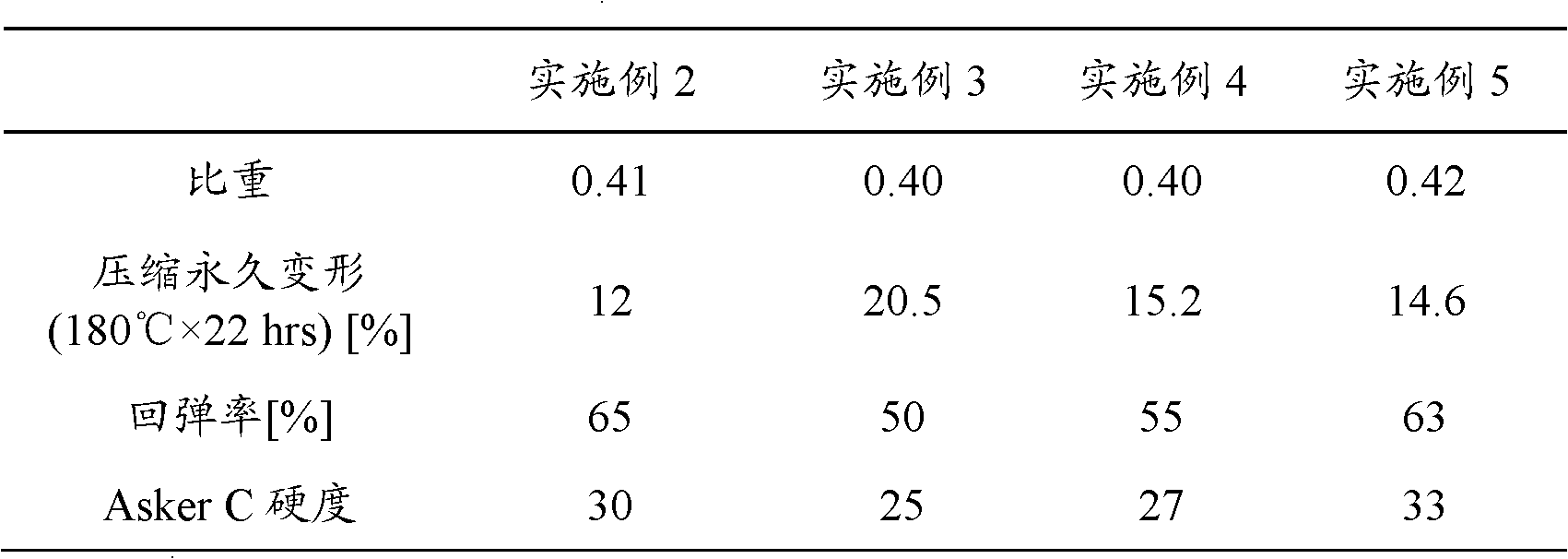

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Thermal insulation material

The invention discloses a novel thermal insulation material, and the composition comprises expanded perlite, cement, gypsum powder, fibers, redispersible rubber powder, casein glue, and the like. The thermal insulation material has the advantages of high strength, aging resistance, excellent thermal insulation effect, energy conservation, environmental protection, fire protection, sound insulation, low cost, convenient use, and the like. The novel thermal insulation material can be directly applied on buildings, containers, pipelines, reactors, household appliances and the like through a plurality of construction methods, thereby achieving the effects of thermal insulation and energy conservation.

Owner:ORDOS DONGRONGCI TECH DEV

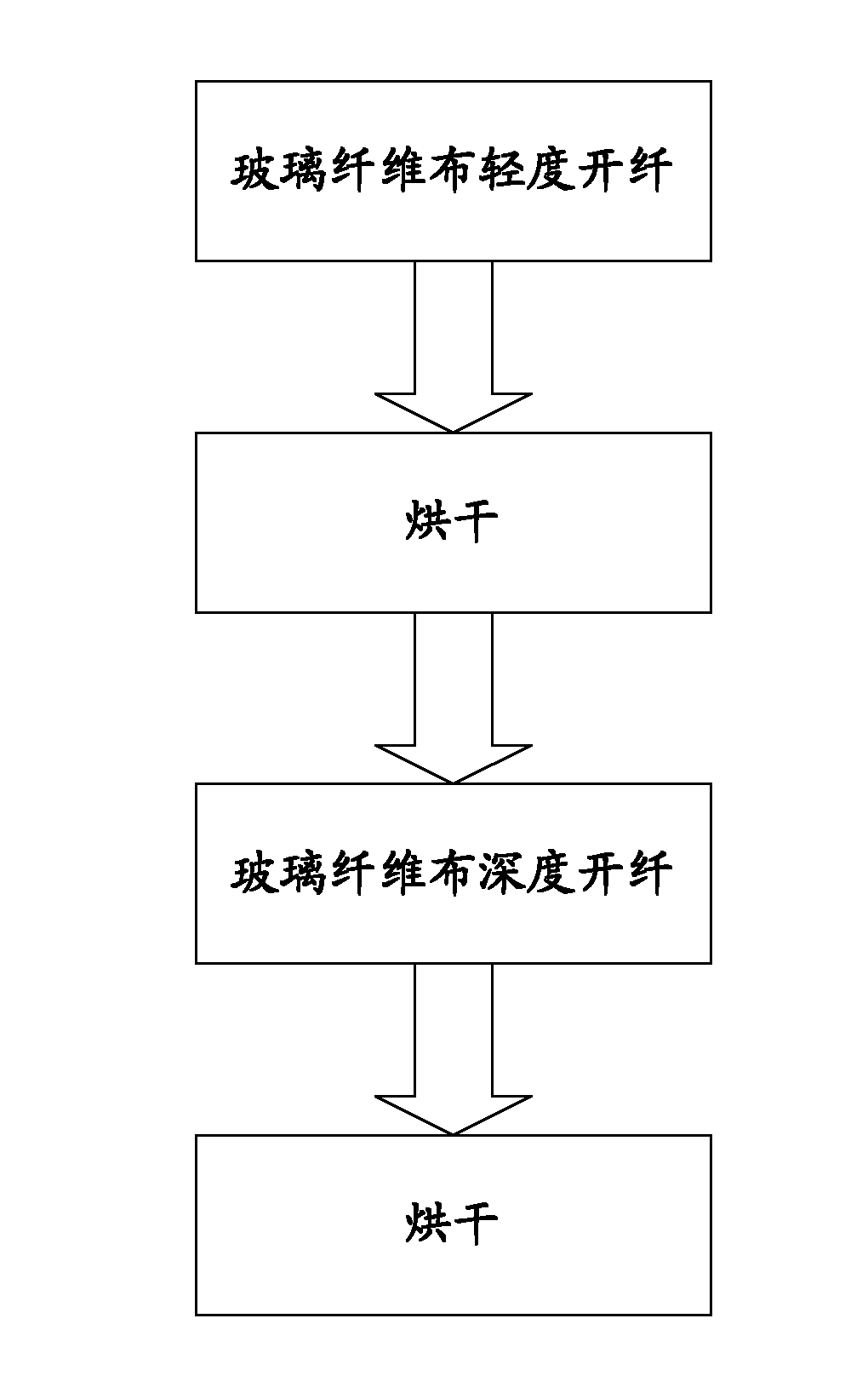

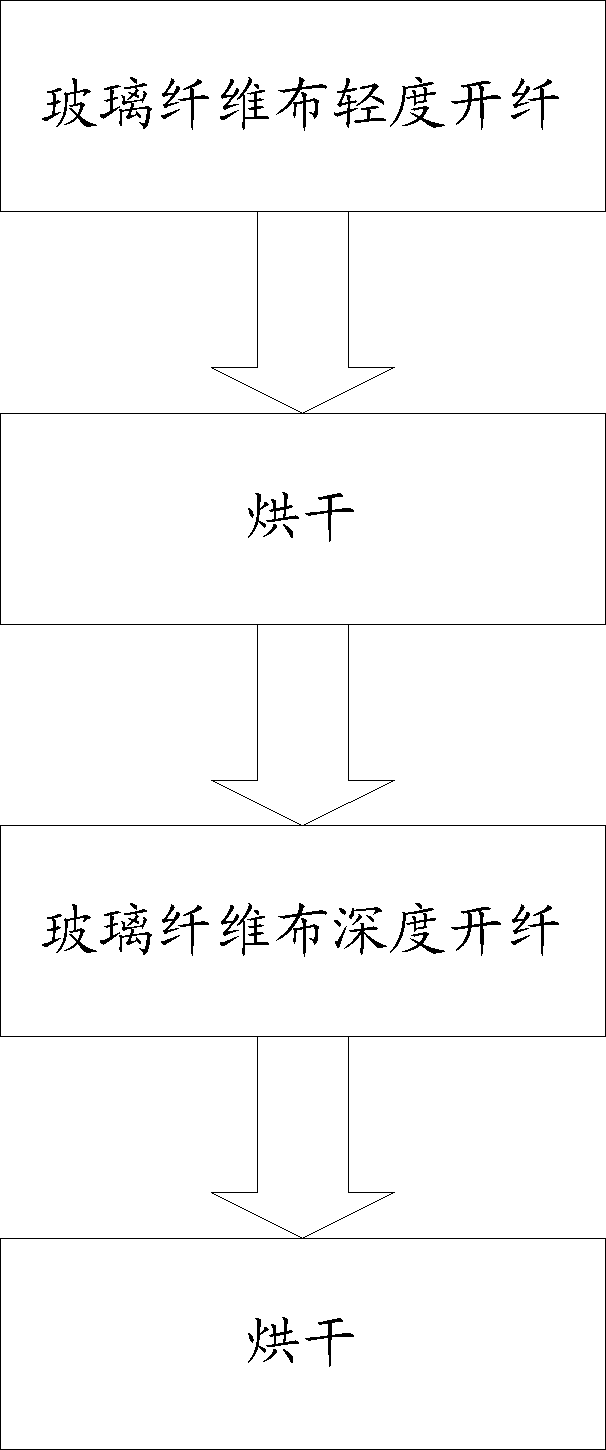

Ultra-high-performance electronic glass fiber cloth production process

ActiveCN102758335ADense surfaceFlat surfaceTextile treatment by spraying/projectingTextile shapingWeft yarnImpact pressure

The invention discloses an ultra-high-performance electronic glass fiber cloth production process which specifically includes the steps: A, slightly splitting electronic glass fiber cloth; B, drying the slightly split electronic glass fiber cloth; C, deeply splitting the dried electronic glass fiber cloth; and D, drying the deeply split electronic glass fiber cloth so that ultra-high-performance electronic glass fiber cloth is obtained. During slight splitting, cloth surfaces are humidified by a water-washing oscillating trough, so that warp and weft yarns are bulked, and fibers are loosened; and during deep splitting, purified water is sprayed from holes of nozzles to be directly jetted to the cloth surfaces, the front and the back of the glass fiber cloth are sprayed by water columns, the warp and weft yarns are broken apart after the cloth surfaces are subjected to impact pressure of the purified water columns, the compactness of the glass fiber cloth is greatly reduced, and gaps among the warp and weft yarns are mostly filled by loose single fibers to be smaller, so that the surfaces of the glass fiber cloth become dense and uniform, and the surfaces of the glass fiber cloth are smoother after splitting.

Owner:建滔(清远)电子材料有限公司

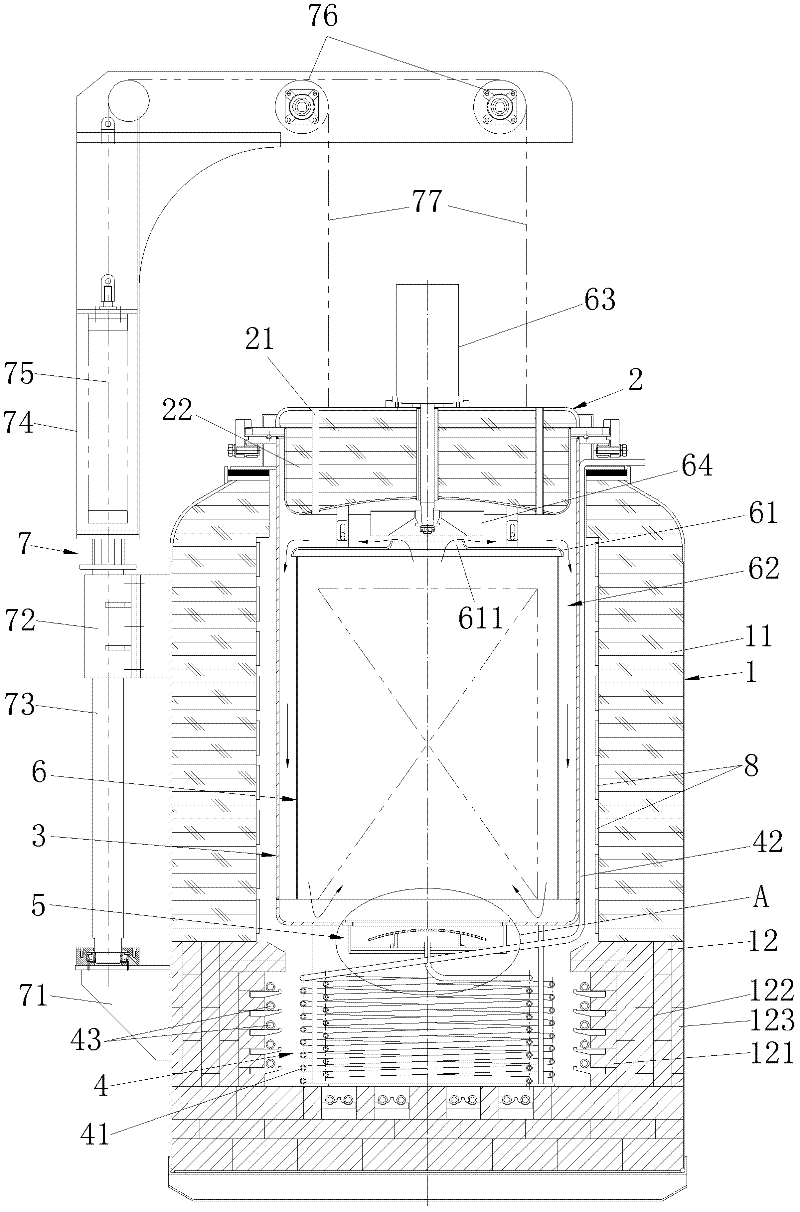

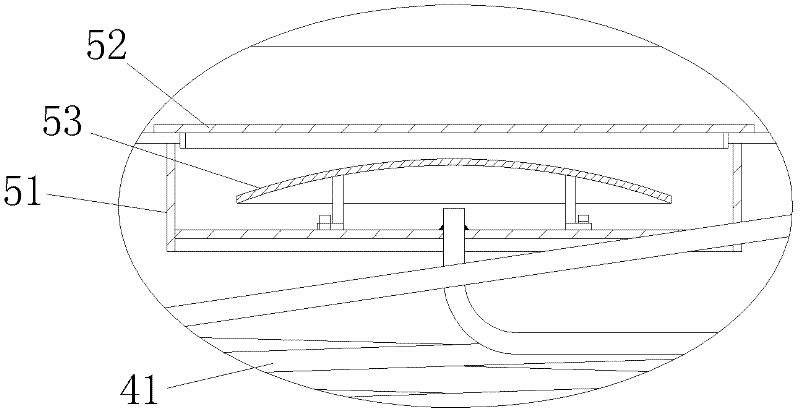

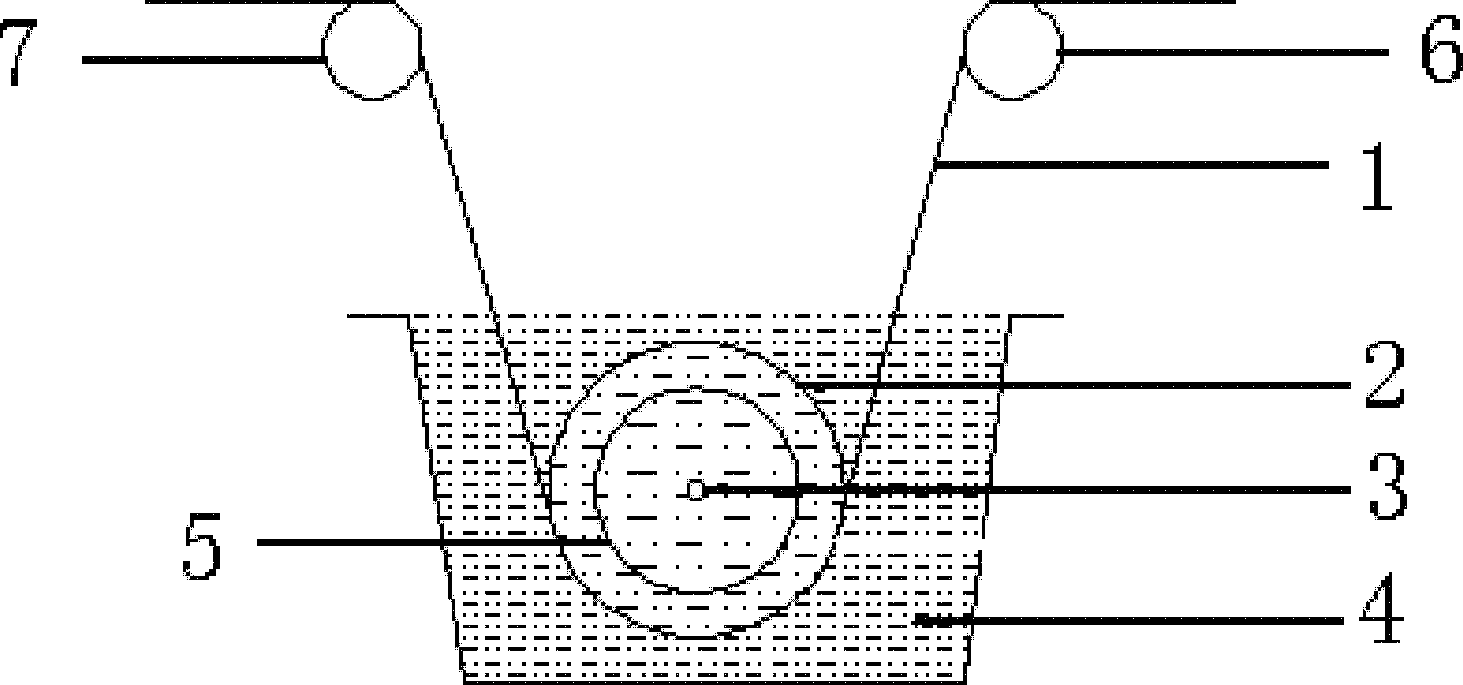

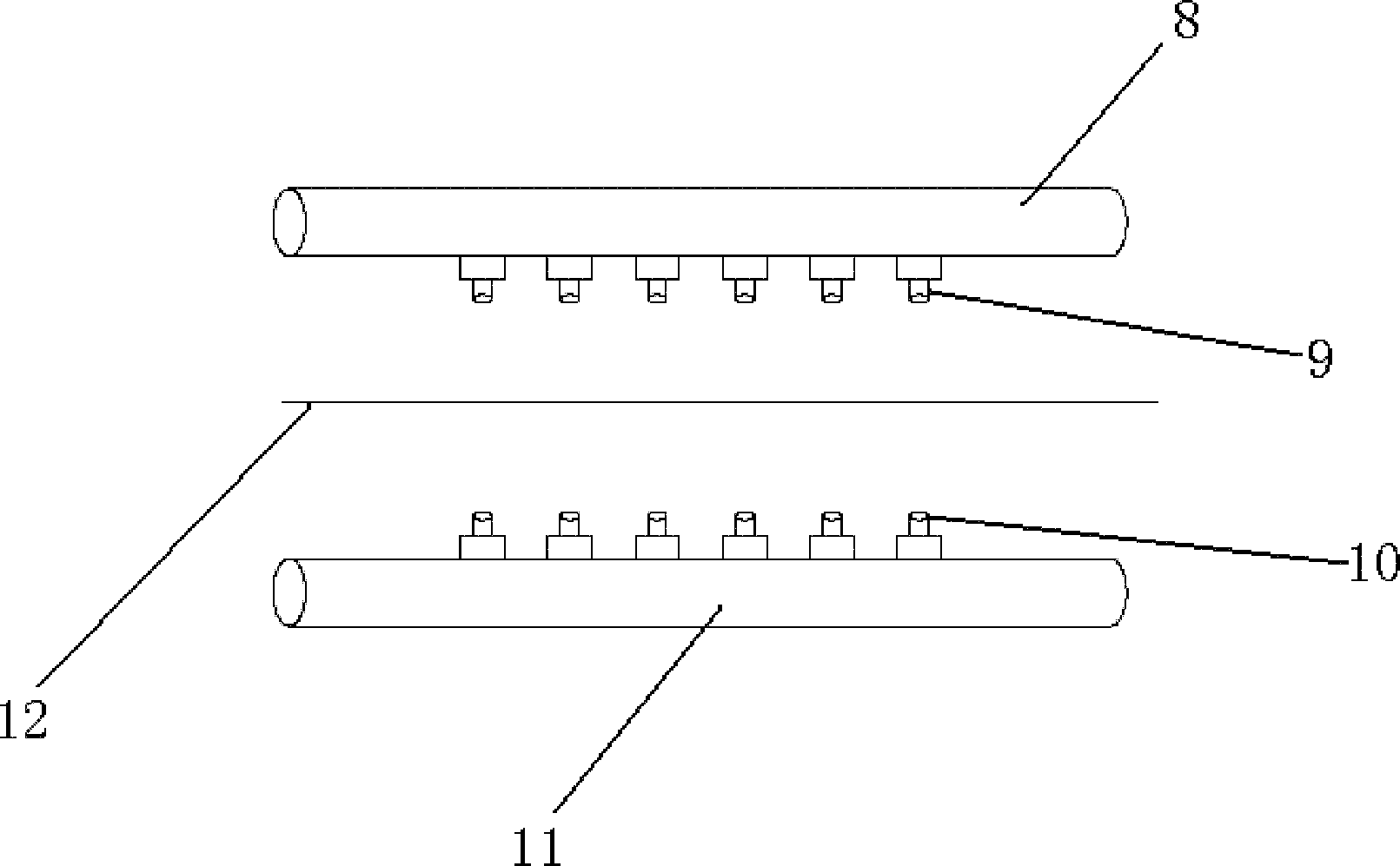

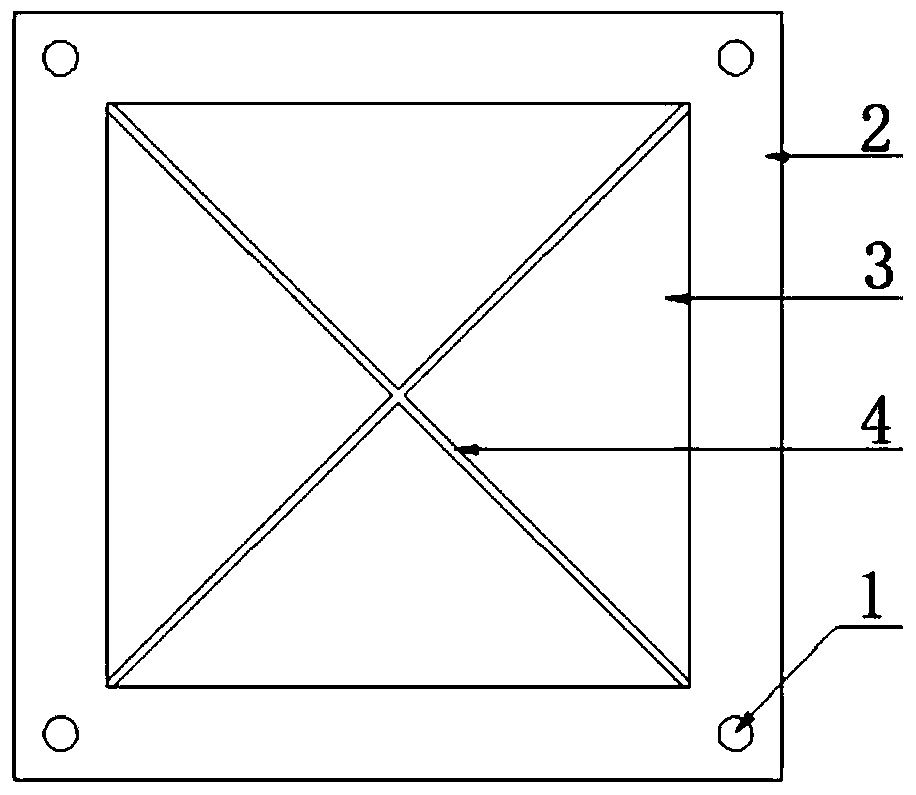

A Steam Oxidation Pit Furnace

ActiveCN102297583ASmall temperature fluctuationsReduce thermal expansion and contractionSolid state diffusion coatingVertical furnacesThermal expansionEngineering

The invention discloses a steam oxidation well furnace which comprises a furnace shell, a furnace cover, a furnace tank and a heating mechanism, wherein the furnace tank is arranged in the furnace shell; the heating mechanism is used for heating work pieces in the furnace tank; the bottom part of the furnace shell is provided with a steam preheating mechanism which is connected with an external steam source; and the steam preheating mechanism is communicated with the bottom part of the furnace tank through the steam diffusion structure. An individual steam preheating mechanism is added below the furnace tank, steam enters the furnace tank after the steam is heated by the steam preheating mechanism and is diffused uniformly by the steam diffusion structure, the temperature vibration in the furnace tank is reduced greatly, the expansion and contraction phenomenon in the furnace body is reduced, the welding point of the steam pipeline is difficult to drop off, and the steam pipeline is difficult to crack; and simultaneously the steam can be fused with metal work pieces more uniformly, the oxidation effect is improved obviously, the density of oxidizing materials on the surfaces of the metal work pieces is better, and the content of ferroferric oxide can reach more than 90%.

Owner:浙江省长兴精工电炉制造有限公司

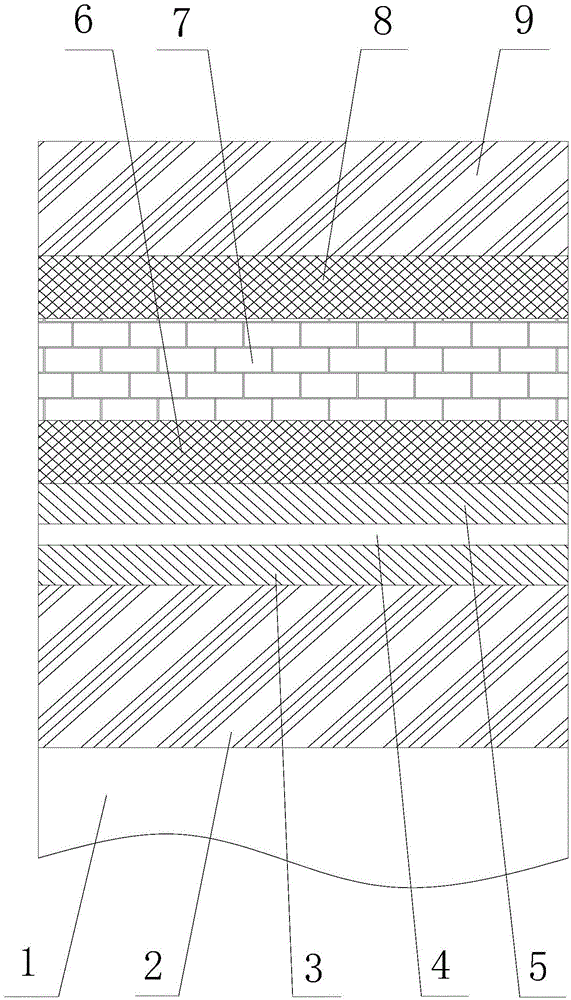

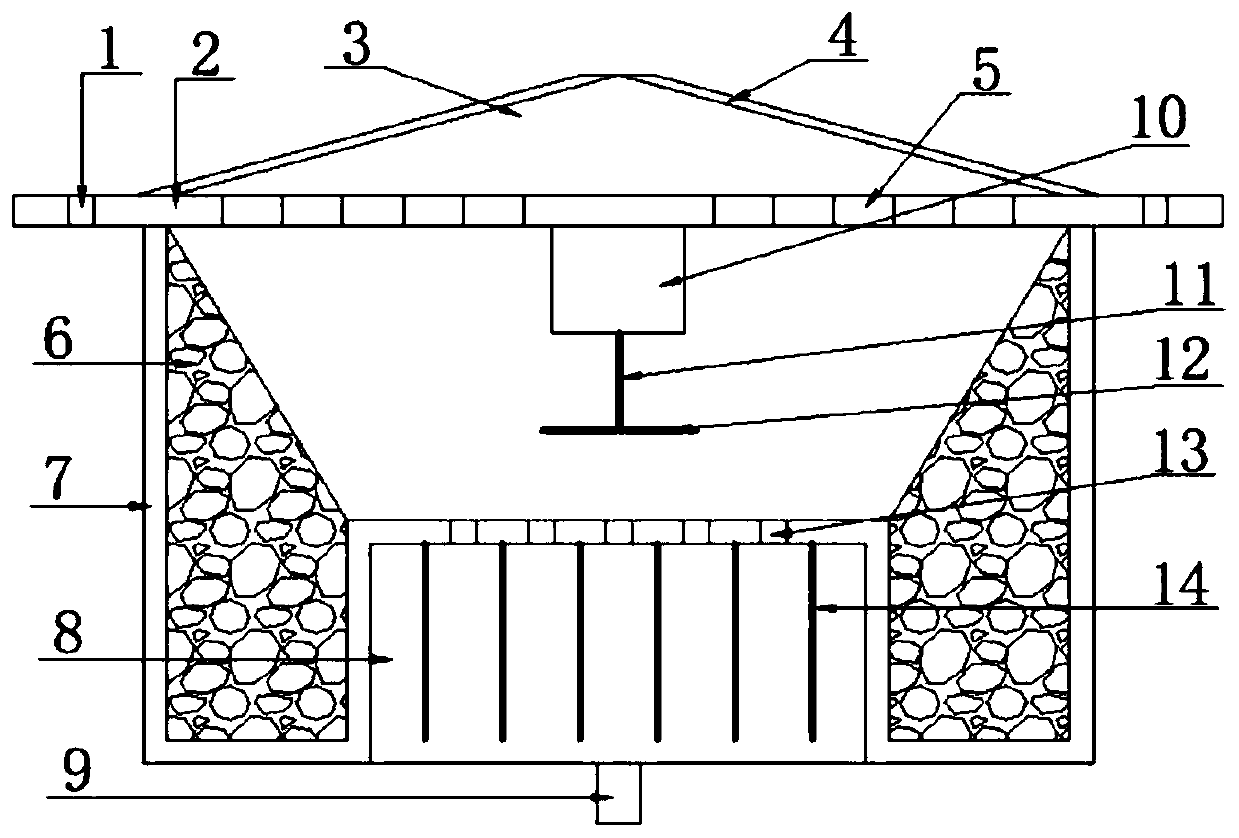

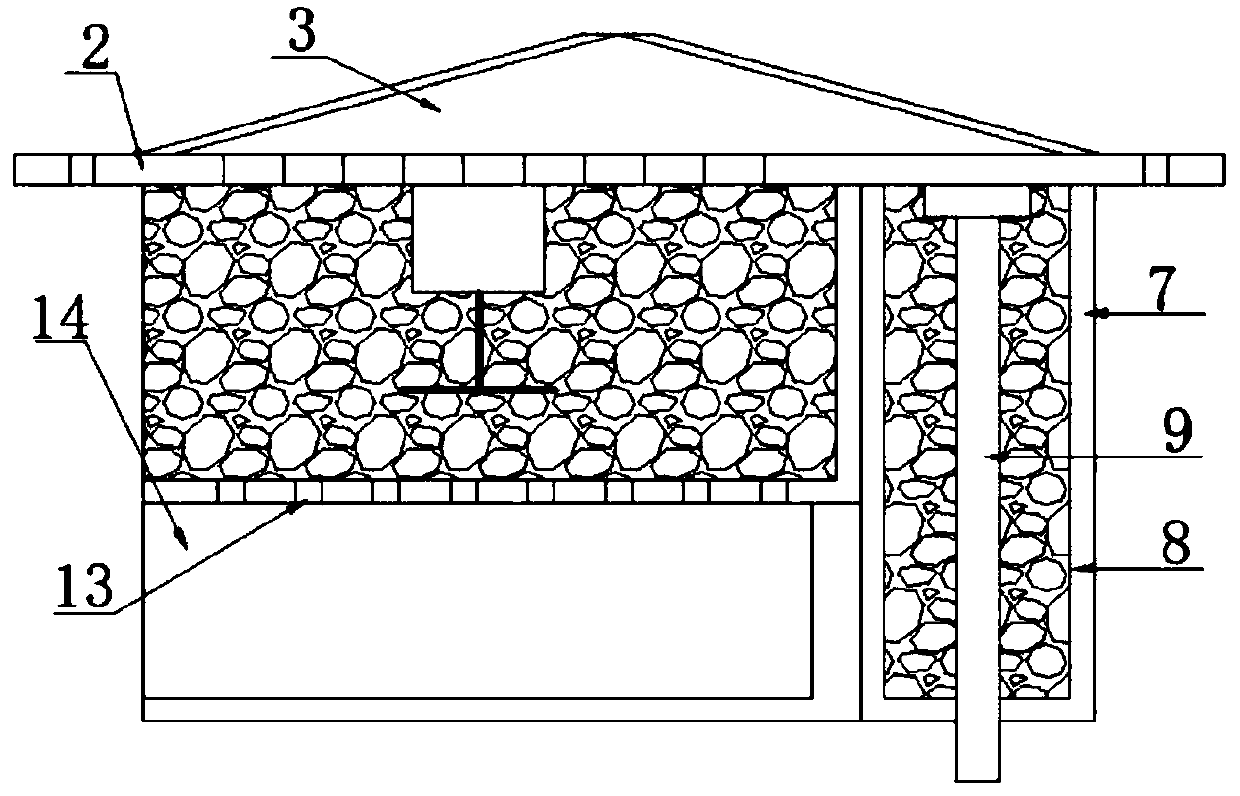

Inversion type energy conservation roofing system and construction method thereof

InactiveCN106760245AReduce thermal expansion and contractionAvoid destructionBuild-up roofsRoof drainageRoof tileThermal insulation

Provided is an inversion type energy conservation roofing system and a construction method thereof. The system comprises from bottom to top a concrete base layer, a cement mortar screeding layer, a waterproof cushion layer, a heat preservation drainage layer, transverse tile hanging battens and roofing tiles; the heat preservation drainage layer comprises from bottom to top a heat preservation plate layer, a cement mortar protection layer, a longitudinal downstream batten and an aluminum foil coiled material; the longitudinal downstream batten is fixedly connected to the cement mortar protection layer through an anchoring part. According to the inversion type energy conservation roofing system and the construction method thereof, the construction of the system is simple and the construction is convenient; an inversion structure is adopted, a heat preservation layer is laid on a waterproof layer, the cement mortar protection layer is added to cover the heat preservation layer, so that the heat preservation layer and the waterproof layer are protected, destroying of thermal stress, ultraviolet light and other factors is effectively avoided, the heat preservation, thermal insulation and waterproofness effects of the roofing are ensured, and the roofing structure is reinforced; a wooden support is not used, the situation that the anchoring part is knocked in the cement mortar screeding layer and the concrete base layer of a house is avoided, thus the integrity of the screeding layer and a structure layer of the house are guaranteed, the heat preservation effect is better, and the possibility that water seepage occurs in a tack hole place is reduced.

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

Aluminum cellular composite board manufacture method

ActiveCN101357522AReduce degradationReduce thicknessLamination ancillary operationsLaminationAluminum honeycombHot melt

The present invention discloses a manufacturing method of an aluminum honeycomb composite plate. The method mainly comprises the following steps: 1. aluminum honeycomb core is treated by thermoplastic powder so as to have a powder coating on the surface; 2. the treated aluminum honeycomb core utilizes hot-melt adhesive film and aluminum alloy panel for hot-pressure composite and then is cooled to obtain the finished product. The aluminum honeycomb composite plate manufactured by the method is characterized by small stress, difficult bending and deformation, high adhesive strength, good anti-corrosion performance, convenient recovery and utilization.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and production method

InactiveCN108442645APaving is simple and convenientPaving is simple, fast and convenientFlooring insulationsTemperature resistanceMoisture

The invention discloses a fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and a production method. According to the production method of the environmentally-friendly ceramic tile, a waterproof substrate layer is composited on the back surface of a ceramic tile body layer by a pressing overlaying process or an in-mold forming process. The environmentally-friendly ceramic tile comprises the ceramic tile body layer located on the upper layer, the waterproof substrate layer is composited on the bottom surface of the ceramic tile body layer, a clamping slot or a clamping tenon is formed in the side surface of the waterproof substrate layer, and the clamping slot and the clamping tenon are connected with each other in a clamped and matched mode, sothat every two environmentally-friendly ceramic tiles can be assembled and connected together. The fireproof moisture-proof easily-laid environmentally-friendly ceramic tile has simple structure, thewaterproof substrate layer enables the environmentally-friendly ceramic tile to have high temperature resistance, fireproof, moisture proof and waterproof functions, and the environmentally-friendlyceramic tile is directly laid on the ground during laying; during the laying process, the clamped connection is directly achieved by the clamping slot or the clamping tenon, and the clamped connectionis simple and convenient; the environmentally-friendly ceramic tile is automatically leveled by the waterproof substrate layer, and no hollowing phenomenon exists; and after the laying, the laid environmentally-friendly ceramic tile can be used without brushing the ground or pre-filling or flattening cement sand, and the ceramic tile laying is simpler, faster and more convenient.

Owner:郑素梅

Water-based alkali-resistant seal primer

InactiveCN104845530AImprove heat resistanceImprove light resistanceEpoxy resin coatingsEpoxyWater based

The invention relates to a water-based alkali-resistant seal primer which is composed of the following components in parts by weight: 300 parts of water, 3-5 parts of dispersing agent, 2-3 parts of wetting agent, 1-2 parts of multifunctional assistant, 50-70 parts of talcum powder, 180-200 parts of heavy calcium carbonate powder, 100-120 parts of emulsion for epoxy alkali-resistant primers, 200-250 parts of emulsion for waterproof paints, 1-3 parts of bactericide, 30-50 parts of titanium white, 20-30 parts of film-forming assistant, 1-2 parts of defoaming agent, 2-3 parts of thickener, 0.5-1 part of leveling agent and 20-30 parts of antifreezing agent. The water-based alkali-resistant seal primer has the advantages of favorable water resistance, favorable sealability, favorable alkali resistance, favorable antifreezing property, long service life and the like, and is harmless to the environment and human body.

Owner:ANHUI MEILIN BUILDING MATERIAL

Method for preparing fire-proof, flame-retardant, ultra-light and high-strength paper pulp foam by using lignocellulose raw material

The invention provides a formula and a preparation method of fire-proof, flame-retardant, ultra-light and high-strength paper pulp foam. The formula comprises the following components in part by weight: 100 parts of natural wood fiber raw material, 0.5-10 parts of fire-proof cross-linking aid, 1-20 parts of inorganic filler, 0-20 parts of chitosan, 0.5-10 parts of foaming agent and a plurality ofparts of water, wherein the natural wood fiber raw material in the water is 0.5-5 wt%. The preparation method comprises the following steps: adding the mechanically-crushed natural wood fiber raw material into a fire-proof cross-linking aid solution and performing cross-linking reaction under heating and stirring conditions; continuously adding the inorganic filler and an appropriate amount of chitosan and continuously stirring till the reaction ends; then adding the foaming agent, mechanically stirring and foaming; removing excessive moisture and foam, drying and forming to obtain the paper pulp foam. By utilizing aid compounding and beneficial interaction among the different components, the prepared paper pulp foam is excellent in performance and has wide industrial prospect and expectedeconomic benefit.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

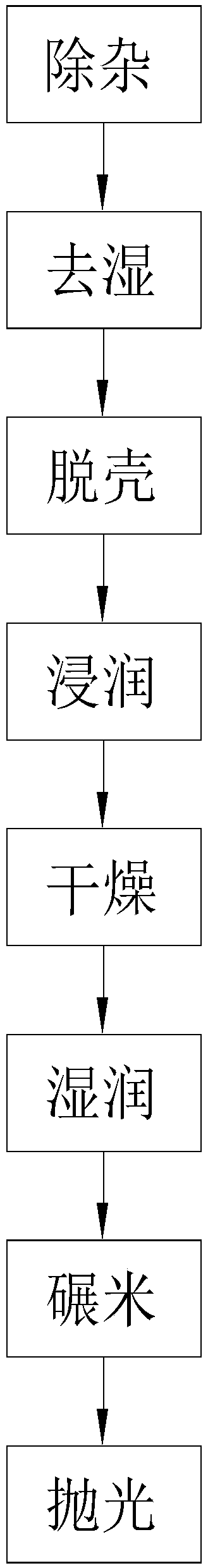

Rice processing technology

InactiveCN109622110AReduce thermal expansion and contractionPrevent verminGrain treatmentsDiseaseSerum cholesterol

The invention discloses a rice processing technology. The technology comprises the steps of dust removal, dehumidification, shell removal, soaking, drying, wetting, rice grinding and polishing; according to the rice processing technology, soaking treatment is performed by adopting tea water, the obtained rice looks, smells and tastes good, meanwhile, due to the fact that tea water contains abundant tea polyphenol, the tenacity of blood vessels can be enhanced, serum cholesterol can be lowered, atherosclerosis is restrained, the effect of preventing heart cerebrovascular diseases is achieved, tea water contains abundant tannin, the tannin has the effect of restraining generation of lipid peroxidase, and therefore strokes can be effectively prevented, and the good healthcare effect is achieved; a tea water mixing solution soaked with pepper powder is adopted for performing spray wetting, and therefore the surface of the rice is stained with the special flavor of pepper; due to the fact that the pepper is a natural antioxidant, the special flavor has the effect of expelling parasite, rice hemiparasite can be effectively avoided, and the storage life of the rice is prolonged.

Owner:颍上县锡安山米业有限公司

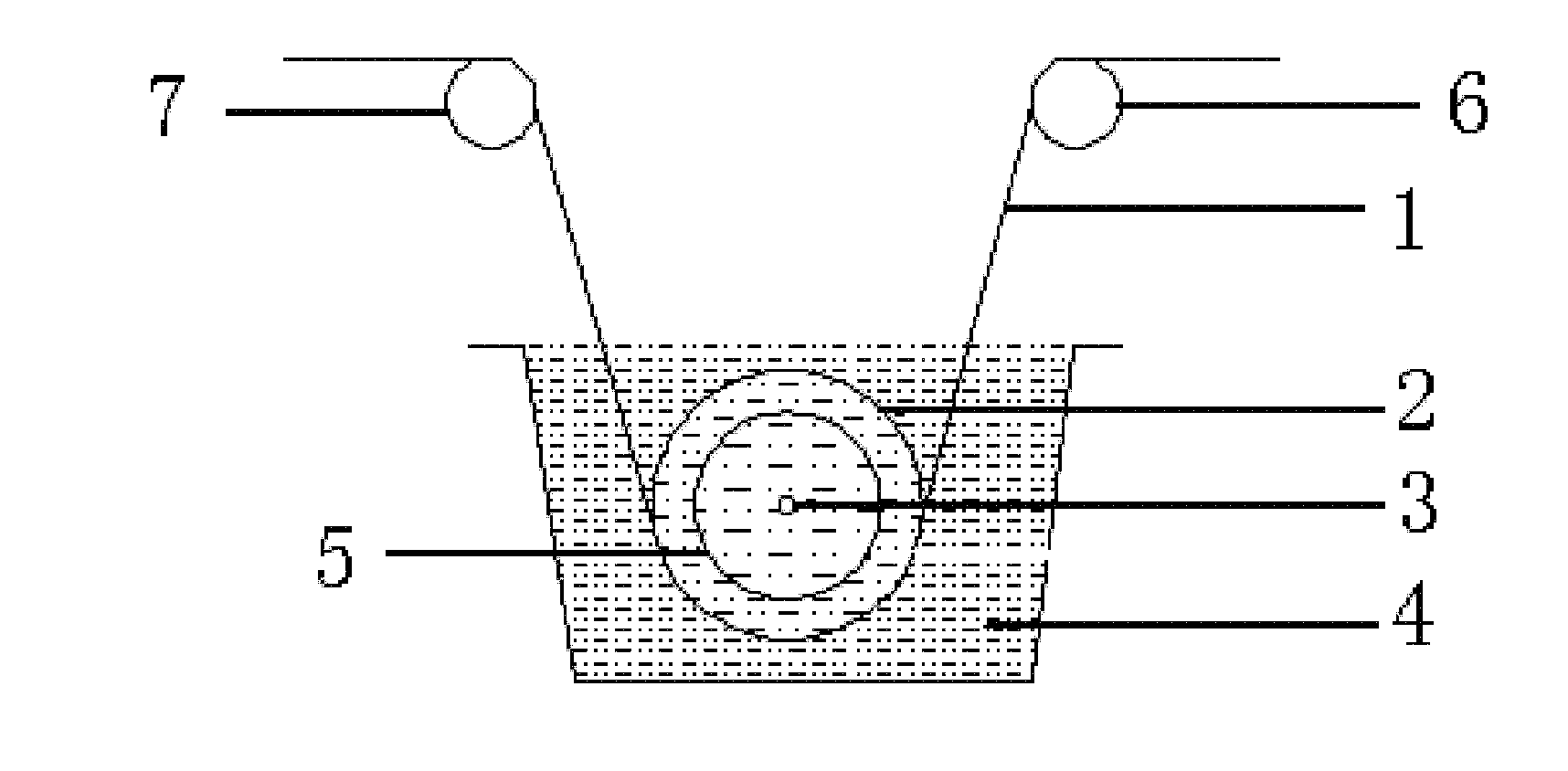

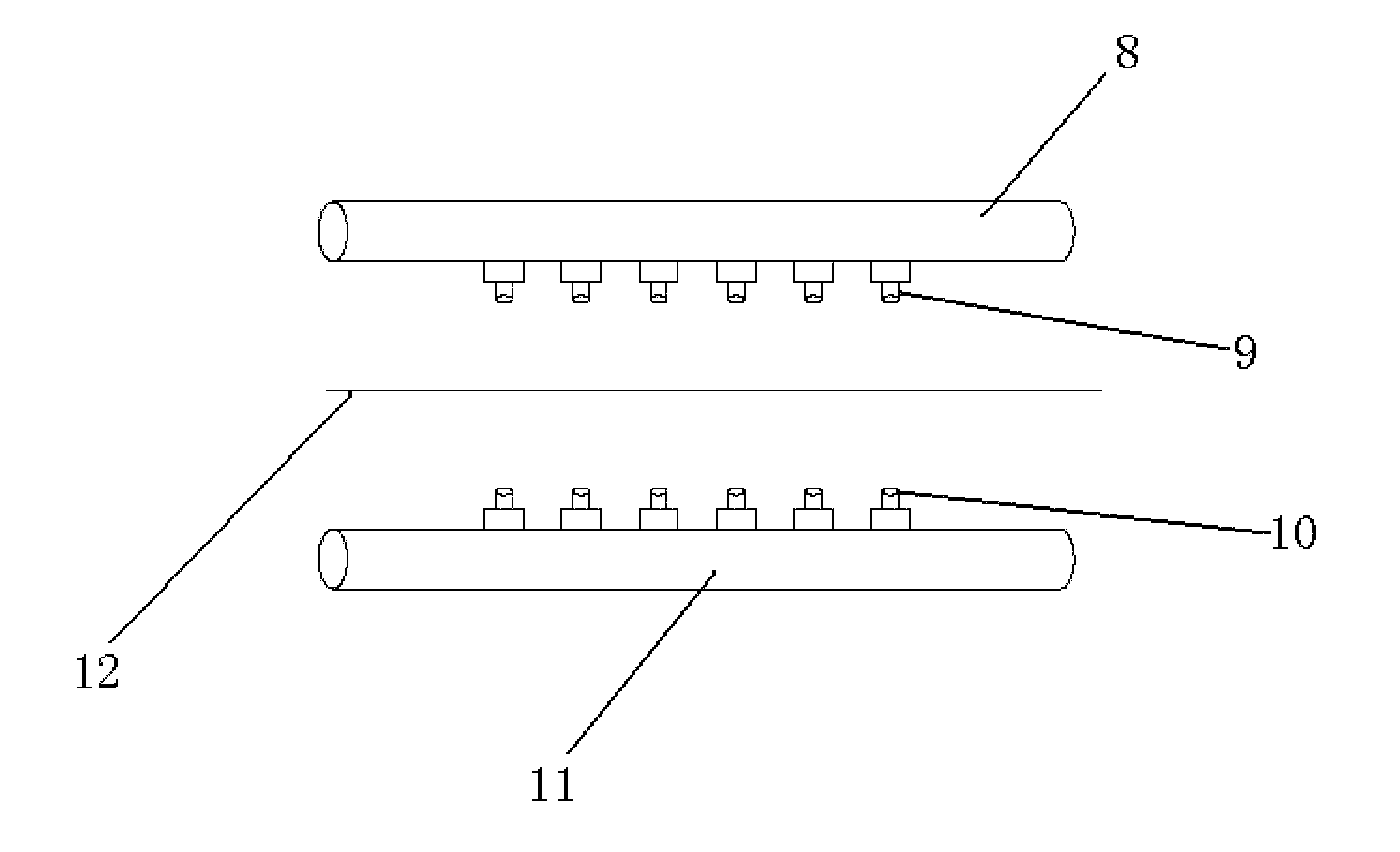

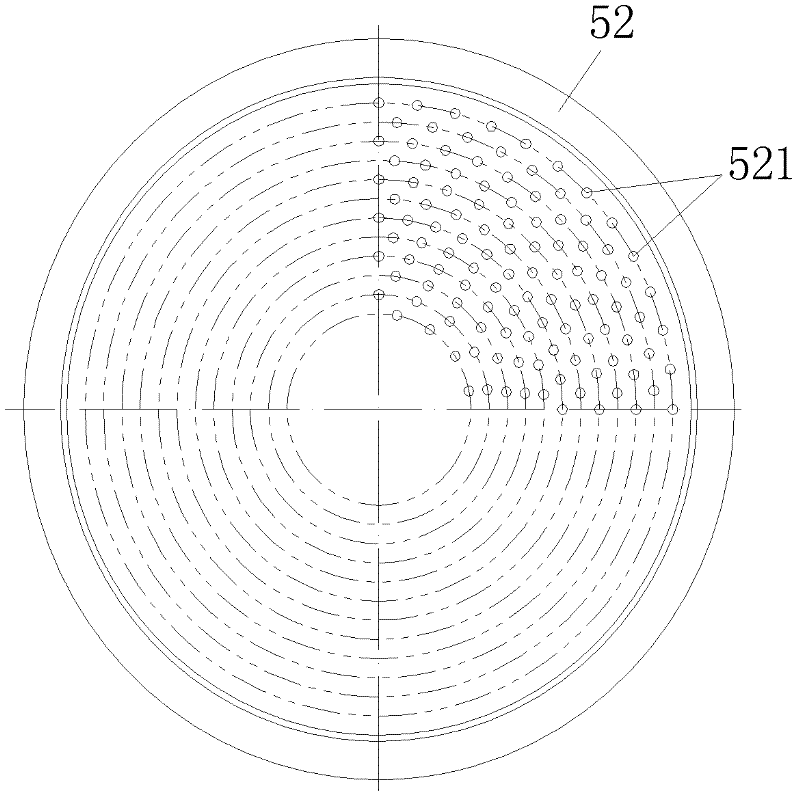

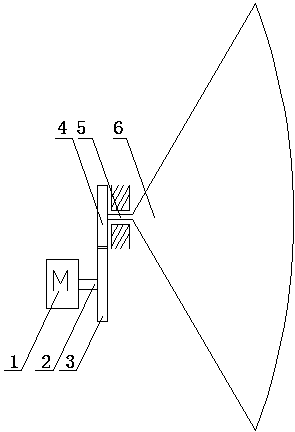

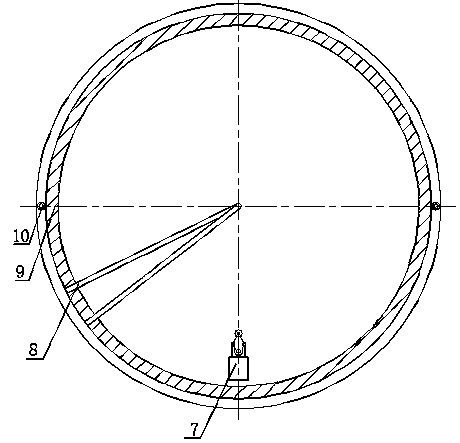

Automatic cleaning device for surface of disc type solar condenser

InactiveCN103406294AGuarantee job stabilityThe transmission part is simpleCleaning using toolsCleaning using liquidsPhysicsElectric machinery

The invention relates to an automatic cleaning device for the surface of a disc type solar condenser. The automatic cleaning device is provided with a motor (1), and is characterized in that an input shaft (2), a first gear (3), a second gear (4), an output shaft (5), a travel switch (7), a sliding groove (9) and a temperature sensor (10) are all arranged on a condenser (6); a cleaning brush (8) is formed by two cleaning brushes which are arranged in an angle; one end of the cleaning brush (8) is connected with the output shaft (5) of a rotating center, and the other end of the cleaning brush (8) is connected with the sliding groove (9); the cleaning brush (8) is driven to make intermittent back and forth movement on the surface of the condenser (6) along the sliding groove (9) by a transmission mechanism driven by the motor (1).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Basalt fiber composite novel wall material and preparation method thereof

The invention discloses a basalt fiber composite novel wall material and a preparation method thereof, wherein the basalt fiber composite novel wall material is prepared from the following raw materials by weight: 0.6-0.8% of basalt fiber yarns, 0.3-0.7% of basalt fiber grid cloth, 24-25% of fast hardening sulphoaluminate cement, 40-45% of river sand, 1-3% of screw thread steel, 5-7% of reinforcing steel bars, 2-5% of channel steel, 0.3-0.4% of flame-retardant foam, 13-15% of water, 0.24-0.3% of expanded perlite, 2.9-3.2% of an adhesive, 0.12-0.15% of an early strength agent or a retarder, 0.6-0.8% of a styrene-acrylic emulsion, 0.24-0.26% of ferrous sulfate, 0.49-0.51% of calcium and magnesium powder, and 0.98-1% of a concrete surface reinforcing agent. According to the invention, the wall material prepared from the components according to the specific ratio according to the architectural conventional method has characteristics of uniform thermal expansion and cold contraction, goodtoughness and breakage resistance, has weak alkality so as not to easily corrode iron, aluminum and other metal materials, further has advantages of light weight, environmental protection, high strength, good toughness and low energy consumption, can be freely modeled according to molds, and is suitable for popularization in the building material field.

Owner:乐山一拉得电网自动化有限公司

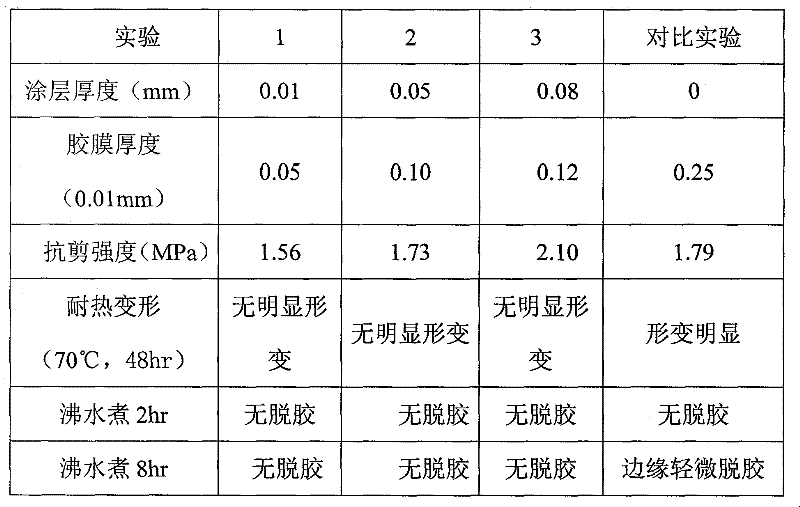

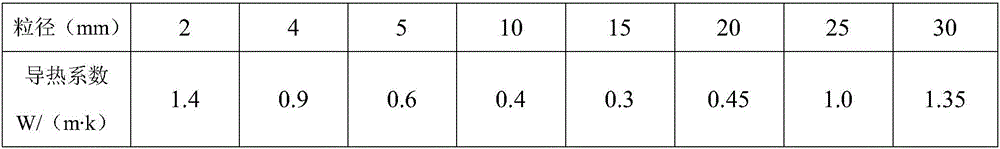

Two-component polymer ceramic tile adhesive and preparation method thereof

InactiveCN110698125AReduce thermal expansion and contractionIncrease tensile bondabilityEpoxyCellulose

The invention discloses a two-component polymer ceramic tile adhesive which is prepared from two groups of mixtures, wherein an A group of mixture comprises hydroxypropyl methylcellulose, calcium formate and epoxy resin; a B group of mixture comprises an acrylate copolymer, benzene rubber powder and epoxy resin; the A group of mixture is prepared from the following components in parts by weight: 250 to 450 parts of cement, 35 to 55 parts of gravel, 5 to 30 parts of redispersible latex powder, 3 to 10 parts of hydroxypropyl methylcellulose, 4 to 10 parts of calcium formate, 10 to 20 parts of epoxy resin, 40 to 50 parts of water, 40 to 60 parts of an emulsion and 5 to 20 parts of cellulose. The invention also discloses a preparation method of the two-component polymer ceramic tile adhesive.According to the preparation method, epoxy resin is adopted to weaken the thermal expansion and cold contraction of the adhesive, so that the tensile cohesiveness of the adhesive is increased, and ceramic tiles are prevented from falling off; gravel is adopted, so that the mechanical occlusion effect between gravels is greater, the bonding strength is increased; and meanwhile, silica fume is doped, the interface compactness is improved, and the interface bonding strength is remarkably improved.

Owner:广东楼管家新材料科技有限公司

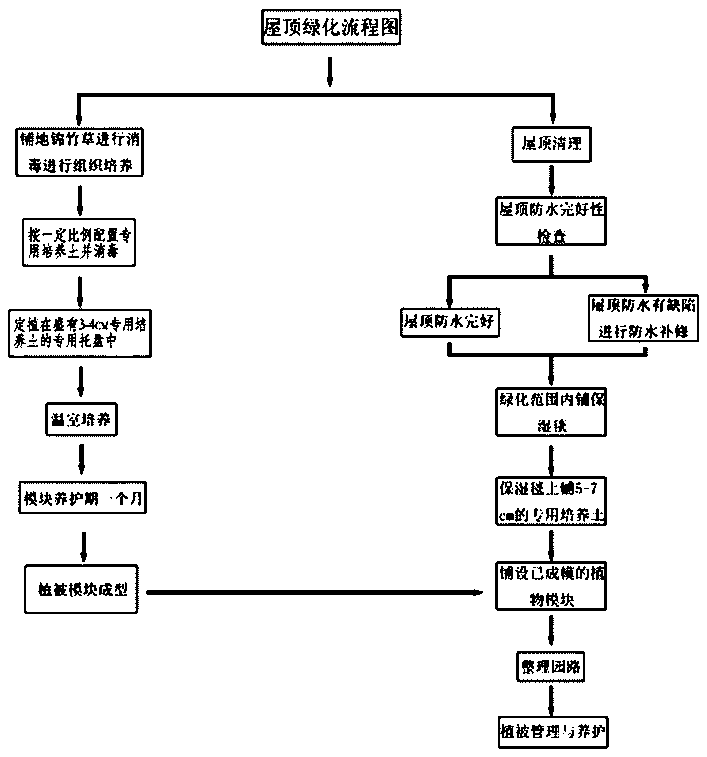

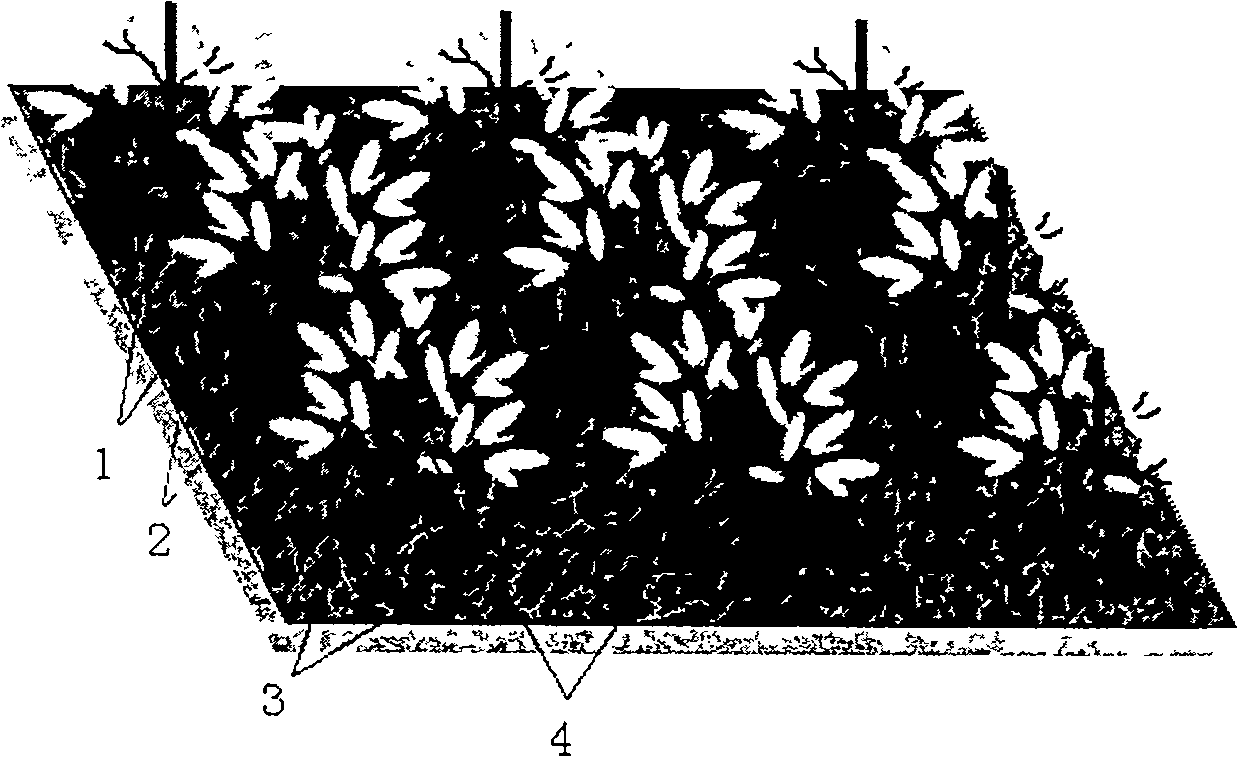

Roof greening method of energy-saving system with maintenance-free and automatic cycle growth performance

InactiveCN105493946AImprove sustainabilityImprove stabilityGrowth substratesCulture mediaGreeningEngineering

The invention discloses a roof greening method of an energy-saving system with maintenance-free and automatic cycle growth performance. The method comprises steps as follows: (1) factor-like module production: 1.1 disinfection, tissue culture and stock seed planting are performed on stems of wild creeping inchplant; 1.2 plantation soil, special humus and a water retaining agent are evenly mixed in the volume ratio of (3-3.5):6:(0.5-1), disinfected and dried in the sun, and special culture soil is prepared for use; 1.3 special square plastic trays with the size of 50-60 cm*30 cm are customized, and 200 g / m<2>-300 g / m<2> of geotextile of is spread at bottoms of the trays; (2) roof greening engineering construction. The plant adopted in the method is a wild herb which is selected naturally and excellent and resistant to drought and high temperatures, and persistence and stability of the plant in outdoor cycle growth of many years are higher than that of plants in roof greening; a wild herbaceous plant module is combined with a special matrix and matched measures, the characteristics of the original plant are greatly enhanced, and annual non-watering irrigation, fertilization and disinsection of roof greening, automatic cycle growth for many years and the like are realized.

Owner:WUHAN CHART GARDENING LANDSCAPE ENG CO LTD

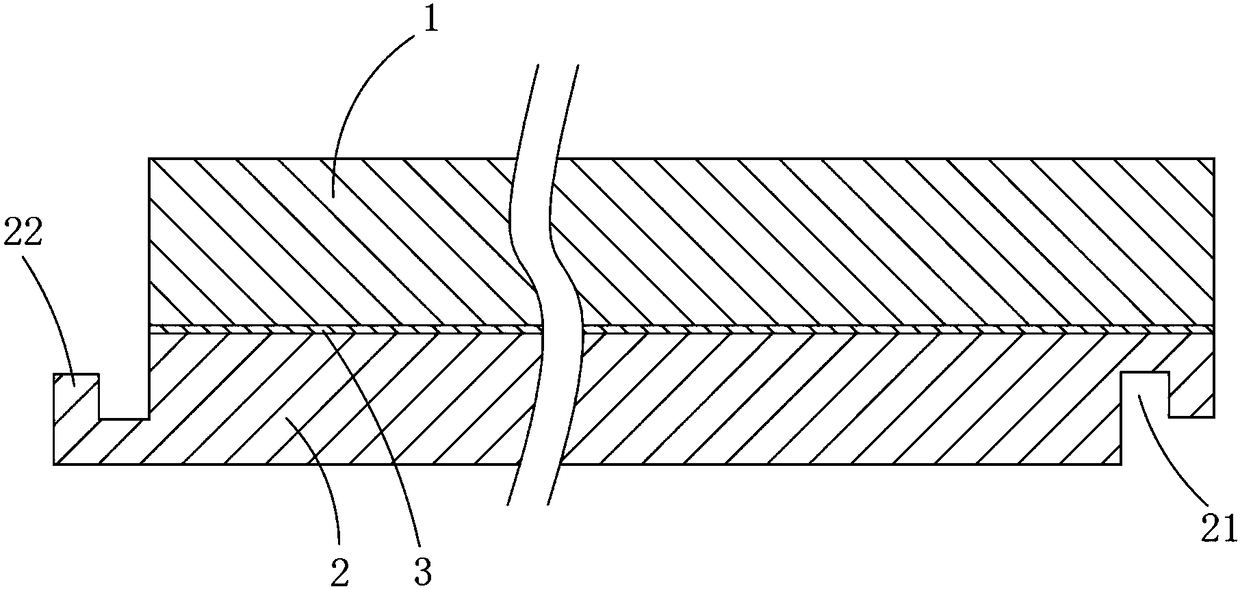

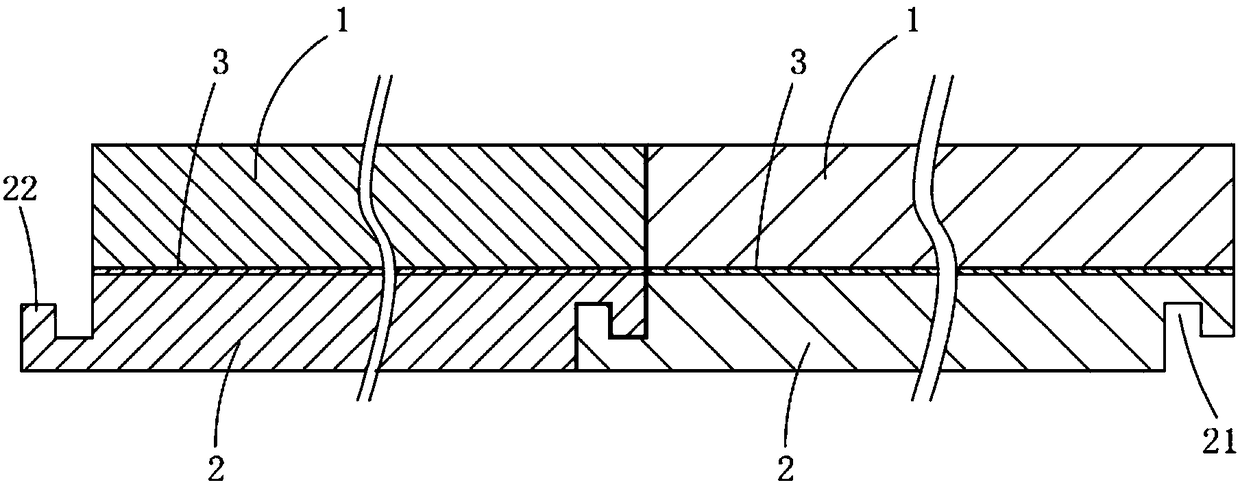

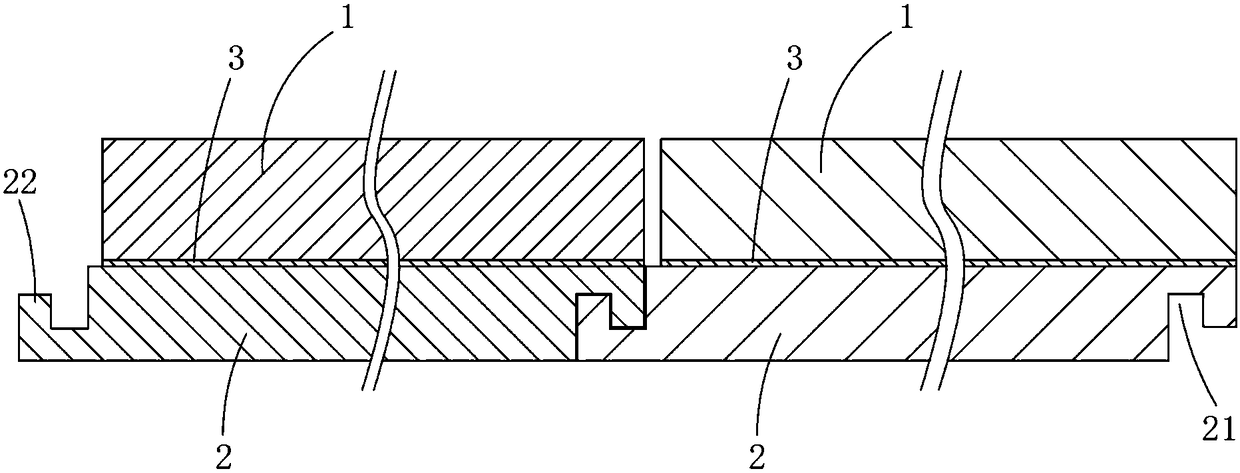

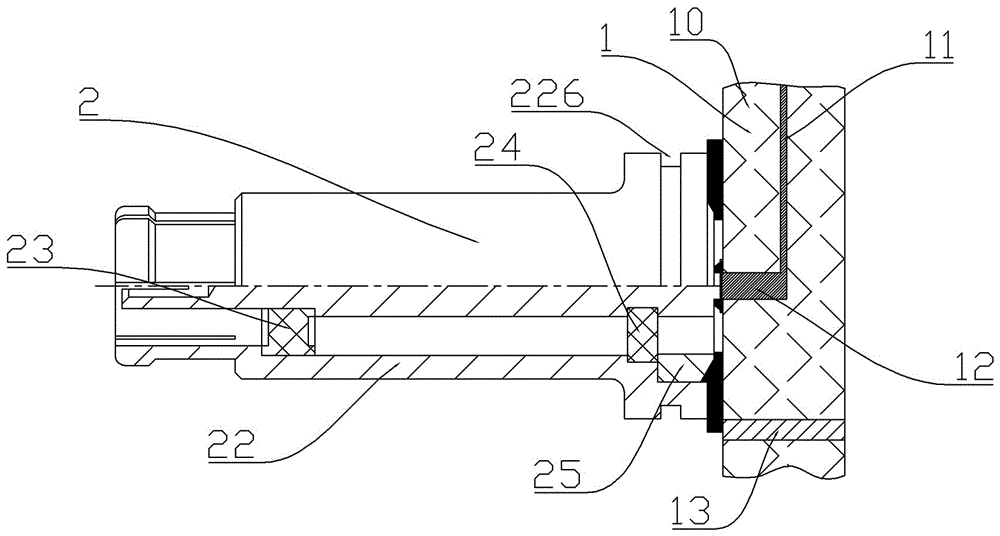

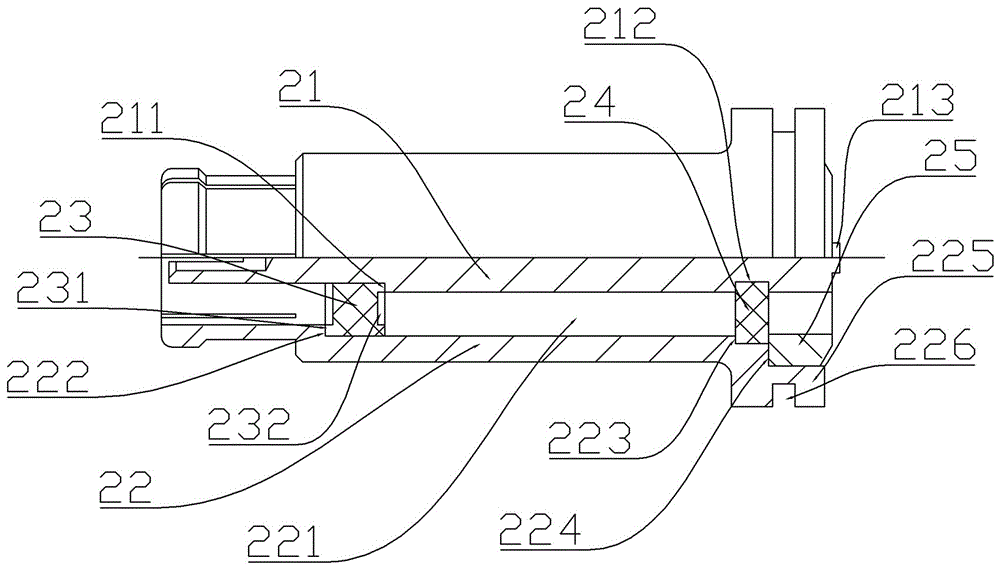

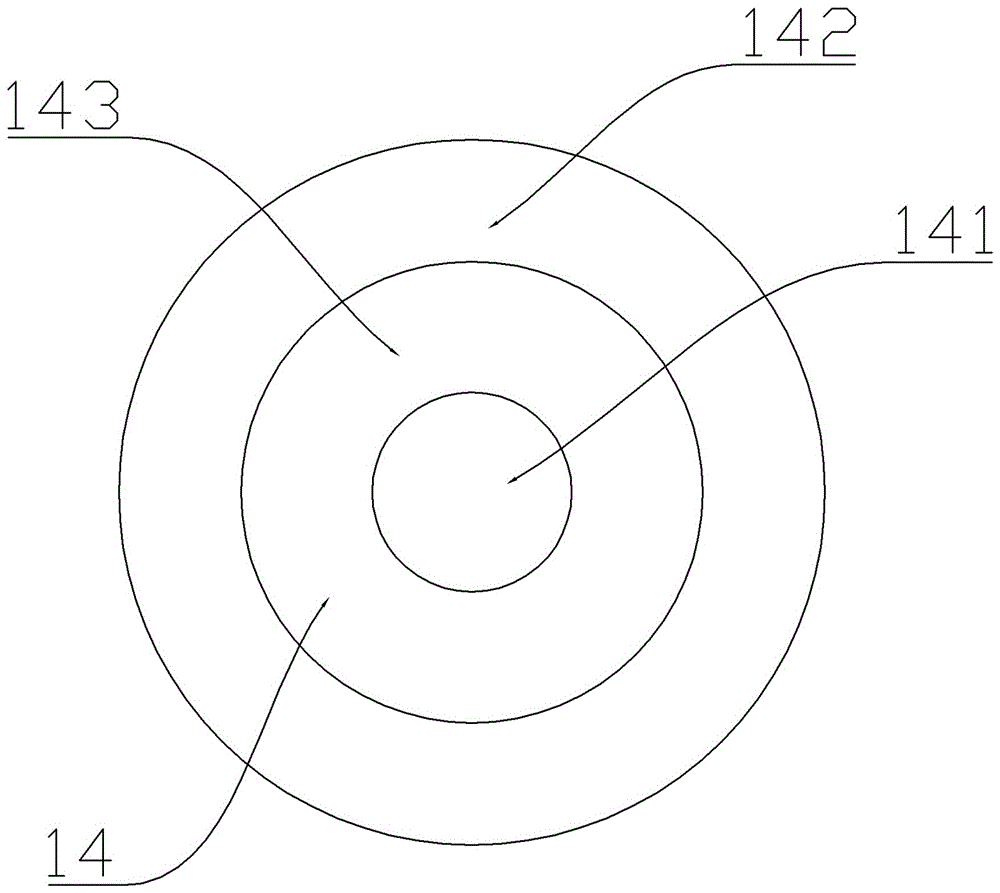

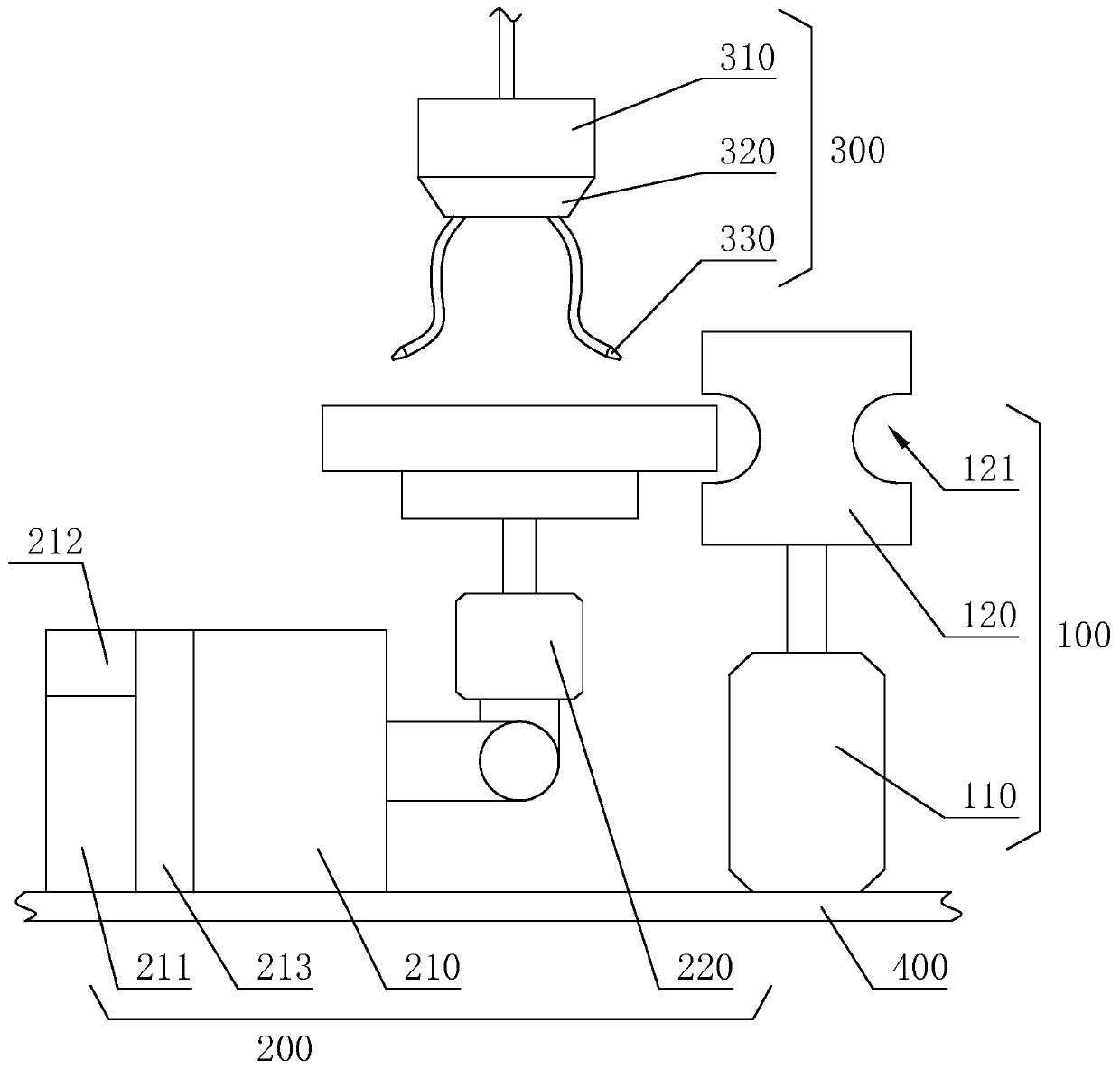

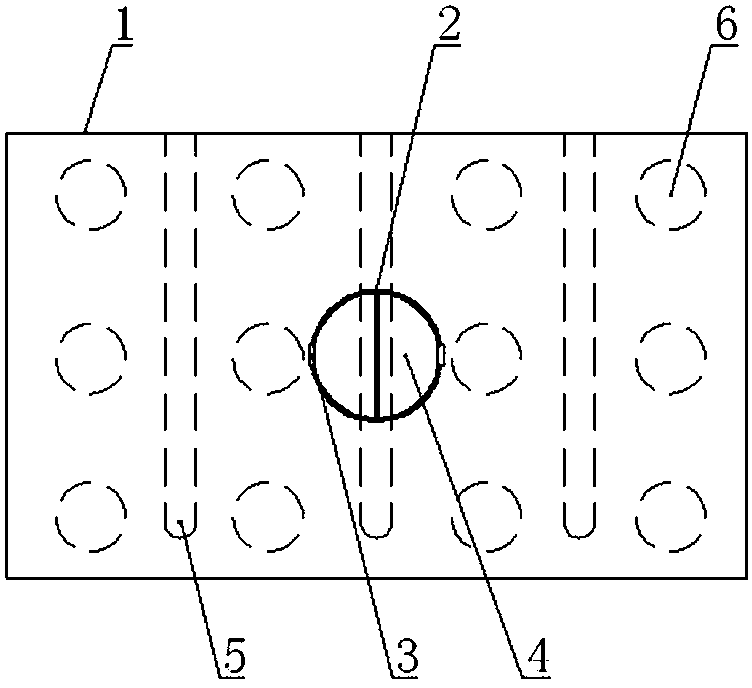

Printed board and radio frequency contact connection structure, connector, contact and printed board

ActiveCN106785740AReliable electrical connectionImprove reliabilitySecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorElectrical connection

The present invention relates to the connector field, especially to a printed board and radio frequency contact connection structure, a connector, a contact and a printed board. The printed board and radio frequency contact connection structure comprises a printed board, the printed board comprises a body and a signal conducting layer arranged in the body, a radio frequency contact is fixed installed at the front side of the body, the radio frequency contact comprise an inner conductor extending along the front and back direction and an outer conductor sleeved at the outer portion of the inner conductor, the body is provided with a signal post electrically connected with the signal conducting layer, and the rear end of the inner conductor is welded and fixed with the signal post. The inner conductor of the radio frequency contact in the printed board and radio frequency contact connection structure is directly welded and fixed on the signal post of the body of the printer board to ensure the reliable electrical connection between the inner conductor and the signal post, improve the reliability of the electrical connection of the inner conductor and the printed board and solve the problem that the reliability of electrical connection between the inner conductor of the current printed board and radio frequency contact connection structure and the printed board is bad.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Fiber plastic profile outdoor floor and preparation method thereof

The invention discloses a fiber plastic profile outdoor floor and a preparation method thereof, and belongs to the technical field of composite materials. According to the fiber-plastic profile outdoor floor, the fiber-plastic composite material made of the waste textile fabric and the waste plastic serves as the raw material, the cost is low, the floor is green and environmentally friendly, meanwhile, recycling of the waste textile fabric and the waste plastic is achieved, and in addition, the environment-friendly effect is achieved. The fiber-plastic composite material used by the fiber-plastic profile outdoor floor provided by the invention has more excellent mechanical properties than a single component in the fiber-plastic composite material.

Owner:上海纤苏新材料科技有限公司

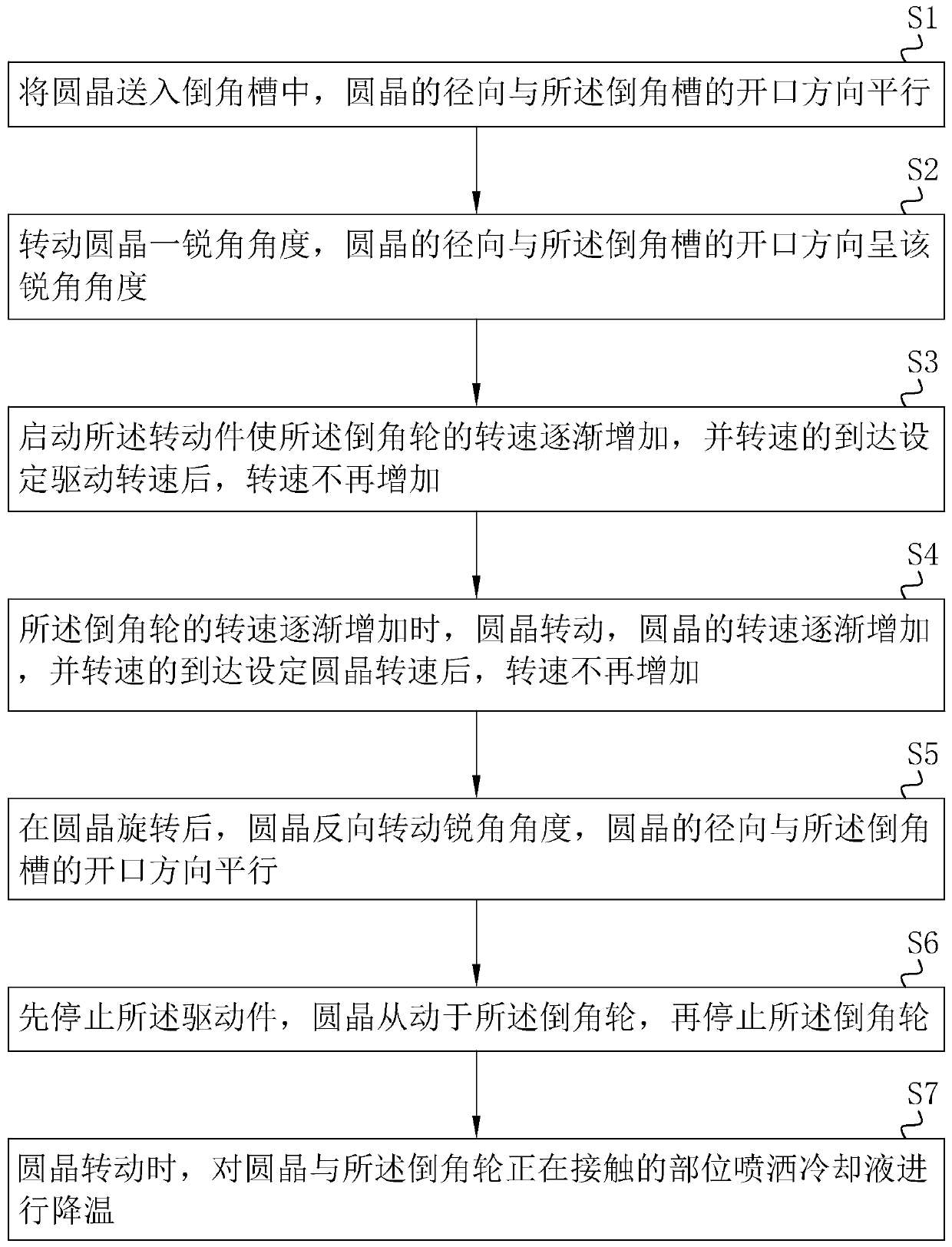

Wafer chamfering process

ActiveCN111037370AReduce the size of the siteReduce contact areaEdge grinding machinesGrinding carriagesAcute angleEngineering

The invention relates to the technical field of wafer machining, and discloses a wafer chamfering process based on a wafer chamfering device. The wafer chamfering device comprises a rotating piece, the rotating piece is connected with a chamfering wheel, the chamfering wheel is provided with a chamfering groove, and the opening direction of the chamfering groove is perpendicular to the axial direction of the chamfering wheel; the process comprises the following steps that S1, wafers are fed into the chamfering groove; S2: the radial direction of the wafers is at an acute angle with the openingdirection of the chamfered groove; S3, the rotating piece is started to gradually increase the rotating speed of the chamfering wheel, and after the rotating speed reaches a set driving rotating speed, the rotating speed is no longer increased; S4, when the rotating speed of the chamfering wheel is gradually increased, the rotating speed of the wafers is gradually increased, and after the rotating speed reaches the set wafer rotating speed, the rotating speed is no longer increased; and S5, the wafers rotate the acute angle in a reverse mode, and the radial direction of the wafers is parallelto the opening direction of the chamfering groove; and when the chamfering is conducted, the contact area between the wafers and the inner wall of the chamfering groove is reduced, the volume of theparts affected by the temperature change of the wafers is reduced, and the chamfering effect of the edge of the wafers is improved.

Owner:上海磐盟电子材料有限公司

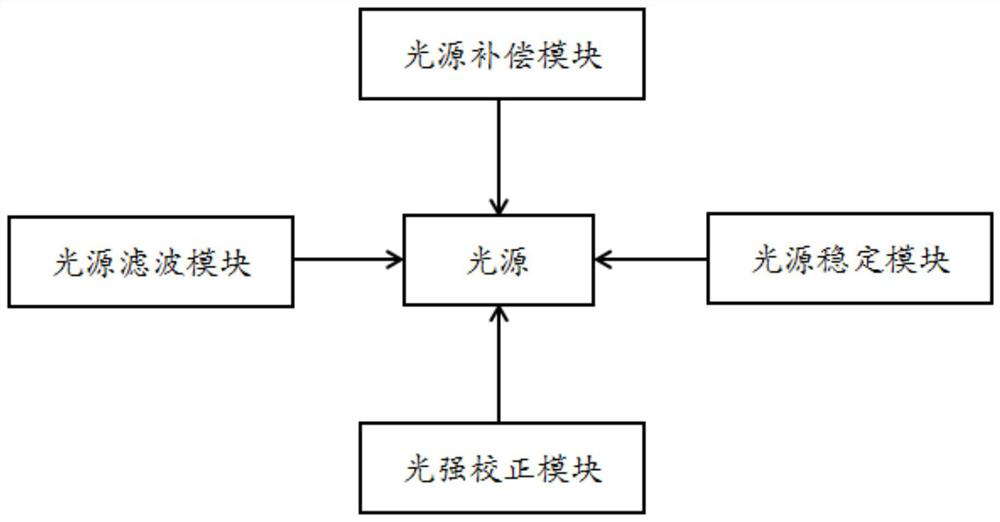

Distributed optical fiber light source control system suitable for wide temperature range

PendingCN113015298AReduced stabilityLow costElectrical apparatusThermometers using physical/chemical changesLong-period fiber gratingControl system

The invention relates to the technical field of optical fiber sensor light sources, in particular to a distributed optical fiber light source control system suitable for a wide temperature range. The system comprises a light source; a light source filtering module which comprises a positive temperature coefficient long-period fiber grating and a negative temperature coefficient long-period fiber grating, wherein the central wavelength of the positive temperature coefficient long-period fiber grating is increased along with temperature rise, the average wavelength acting on the light source is in a progressively decreasing interval when the average wavelength is in parabolic change, the central wavelength of the negative temperature coefficient long-period fiber grating is reduced along with the rise of the temperature, and the average wavelength acting on the light source is in a progressively increasing interval when the average wavelength is in parabolic change; and a light source compensation module which is used for performing compensation calculation on each component of the light source according to a pre-established light source wavelength compensation model to obtain a compensation result of the light source wavelength and performing combination matching on each component according to a compensation result to obtain a finally selected component of the super light source. Temperature compensation can be carried out on the light source.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD +1

Aluminum cellular composite board manufacture method

ActiveCN101357522BReduce degradationReduce thicknessLamination ancillary operationsLaminationAluminum honeycombComposite plate

The present invention discloses a manufacturing method of an aluminum honeycomb composite plate. The method mainly comprises the following steps: 1. aluminum honeycomb core is treated by thermoplastic powder so as to have a powder coating on the surface; 2. the treated aluminum honeycomb core utilizes hot-melt adhesive film and aluminum alloy panel for hot-pressure composite and then is cooled toobtain the finished product. The aluminum honeycomb composite plate manufactured by the method is characterized by small stress, difficult bending and deformation, high adhesive strength, good anti-corrosion performance, convenient recovery and utilization.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Treatment process for improving thermal expansion and cold contraction deformation of hollow plastic template

InactiveCN112250947AInhibition of cold shrinkage deformationInhibit thermal expansion and deformationFiberPolymer

The invention discloses a treatment process for improving thermal expansion and cold contraction deformation of a hollow plastic template, and relates to the technical field of plastic template processing, and the treatment process specifically comprises the following steps: S1, preparation of a polymer organic framework material, S2, preparation of a composite fiber material, and S3, processing and manufacturing of the plastic template. According to the preparation method, the prepared polymer organic framework material and the composite fiber material are subjected to injection molding melting with premix particles respectively, a melt containing the polymer organic framework material is used as a middle layer of a plastic template, and the melt containing the composite fiber material ispoured on the periphery of the middle layer to form a coating layer; accordingly, a large number of independent supporting pieces which are evenly distributed are formed in the middle of the plasticformwork, the periphery of the plastic formwork is wrapped with a layer of composite fiber net, cold shrinkage deformation of the plastic formwork can be restrained through the supporting effect of the independent supporting pieces, and the composite fiber net wrapped on the periphery can restrain thermal expansion deformation of the plastic formwork. Therefore, the thermal expansion and cold contraction deformation of the plastic template can be reduced.

Owner:界首市晟翔新型建材有限公司

Temperature controlled electric oven

InactiveCN108042003AExtended service lifeBarrier deliveryRoasters/grillsElectricityTemperature control

The invention discloses a temperature controlled electric oven, which comprises an electric oven main body and a cooling water tank; the right side on a front panel of the electric oven main body is provided with a control device, a temperature sensor is further arranged on the left wall of the inner part; the temperature sensor is electrically connected with the control device through a lead, andthe outer surface of the electric oven main body is provided with a heat isolating plate; a radiating layer is arranged between the heat isolating plate and the inner wall of the electric oven; ta radiating hole is arranged in the middle of the outer wall of the electric oven main body, two baffles are arranged on the radiating hole; the position of the radiating hole corresponding to the inner wall of the electric oven main body is provided with a driving device, the left side of the inner wall of the front panel of the electric oven main body is further provided with a MCU micro-control unit, and electrically connected with the driving device and the temperature sensor; multiple groups of springs are arranged in the radiating layer and evenly distributed. The temperature controlled electric oven has the beneficial effects of fully improving the problem of easily scalding of oven surface, realizing intelligent cooling, reducing risk of thermal expansion and cold contraction, and prolonging the service life; besides, the safety is high.

Owner:成都泰和顺信息技术有限公司

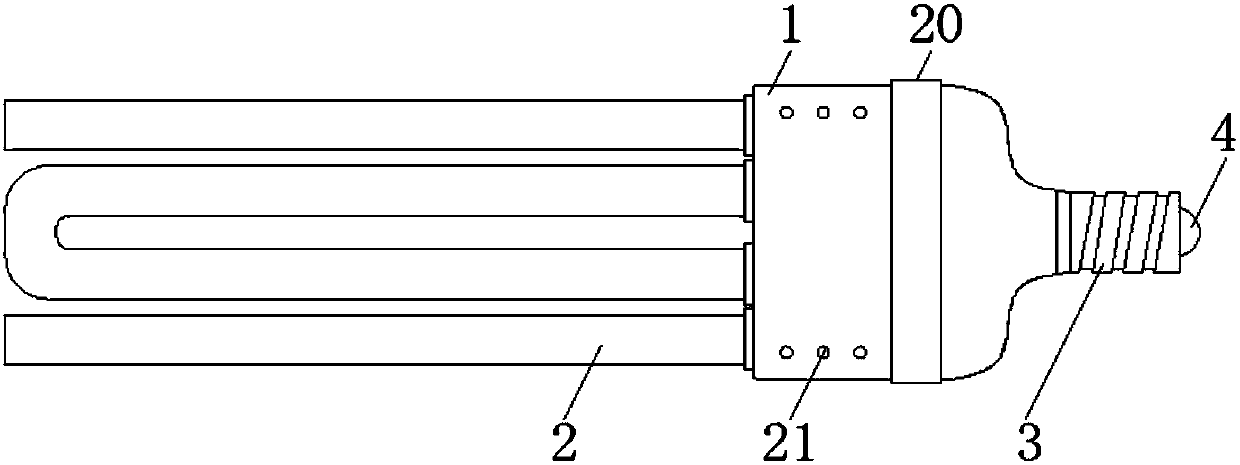

Energy-saving lamp with preheating function

InactiveCN107906397AExtended service lifeEnsure safetyElectrical apparatusLighting heating/cooling arrangementsInformation transmissionComputer module

The invention discloses an energy-saving lamp with a preheating function. The energy-saving lamp comprises an energy-saving lamp body, wherein at least three energy-saving lamp tubes are arranged on the left side of the energy-saving lamp body, a threaded lamp holder is arranged on the right side of the energy-saving lamp body, a threaded groove is formed in the surface of the threaded lamp holder, a conduction block is arranged on the left side of the threaded lamp holder, and the output end of a temperature sensor is in one-way electrical connection with the input end of an information collection module. According to the energy-saving lamp, the temperature sensor, the information collection module, a signal conversion module, an information transmission module, a processor, a storage module, a power supply, a switching module, an electronic ballast, a filament, a rheostat and a low temperature heating wire are arranged, so that the lamp tubes can be preheated before the energy-savinglamp is turned on, thereby effectively reducing the degree of thermal expansion and contraction of the lamp tubes, prolonging the service life of the energy-saving lamp and guaranteeing the safety ofthe energy-saving lamp during use.

Owner:叶侃

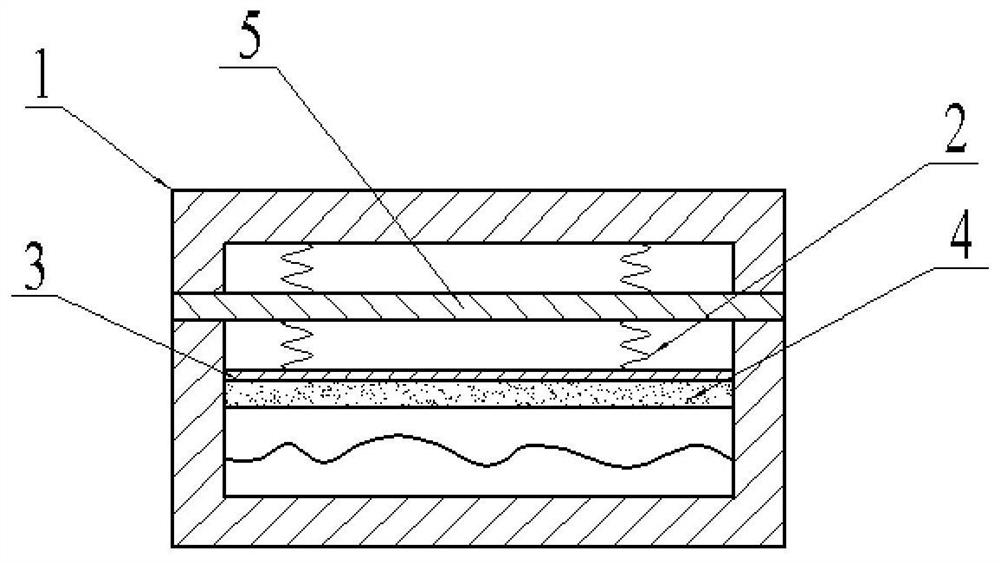

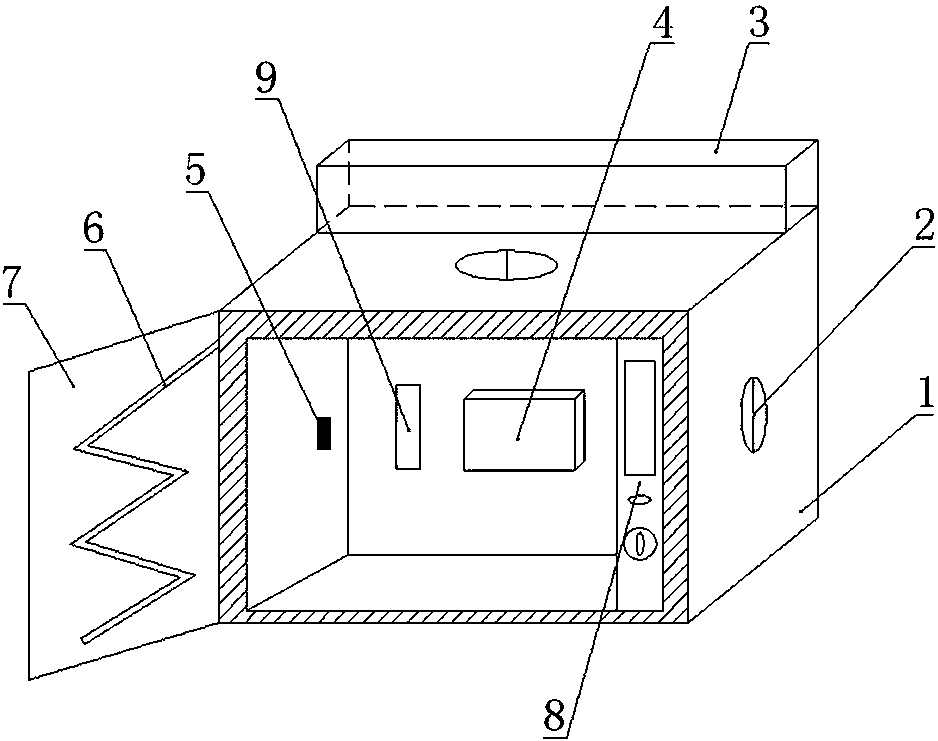

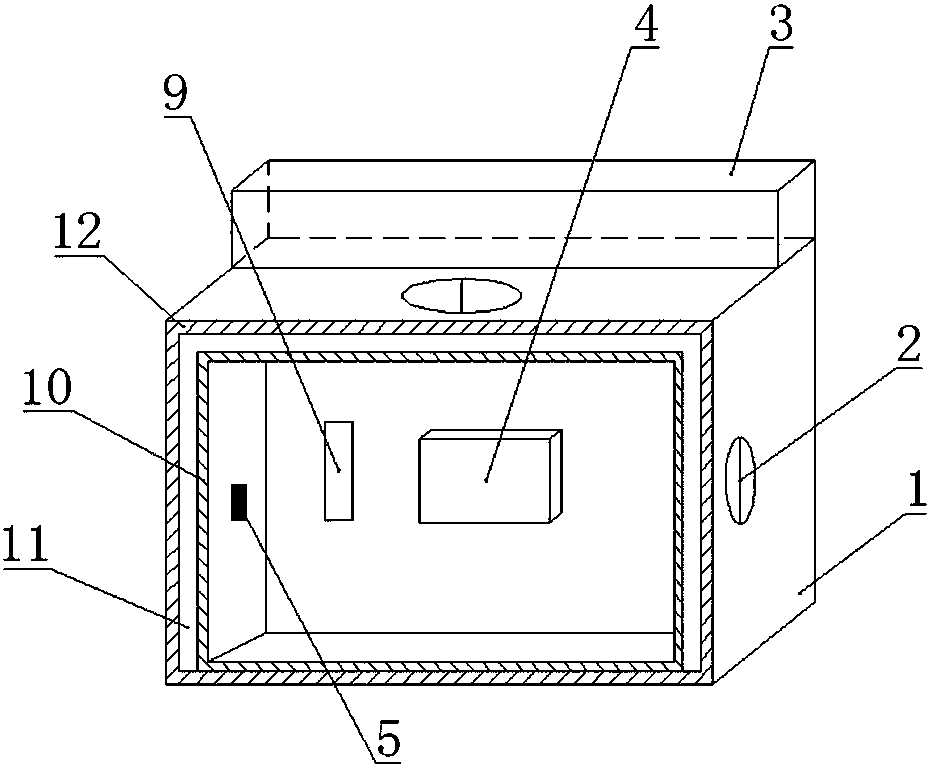

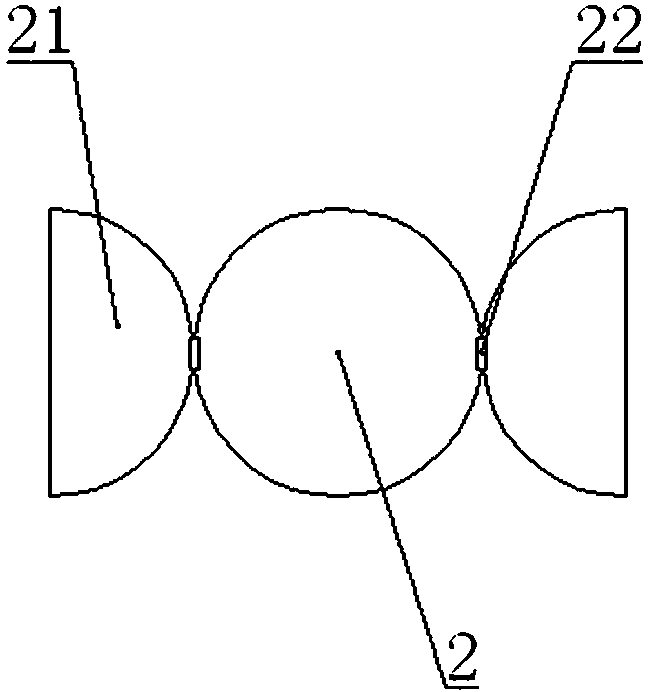

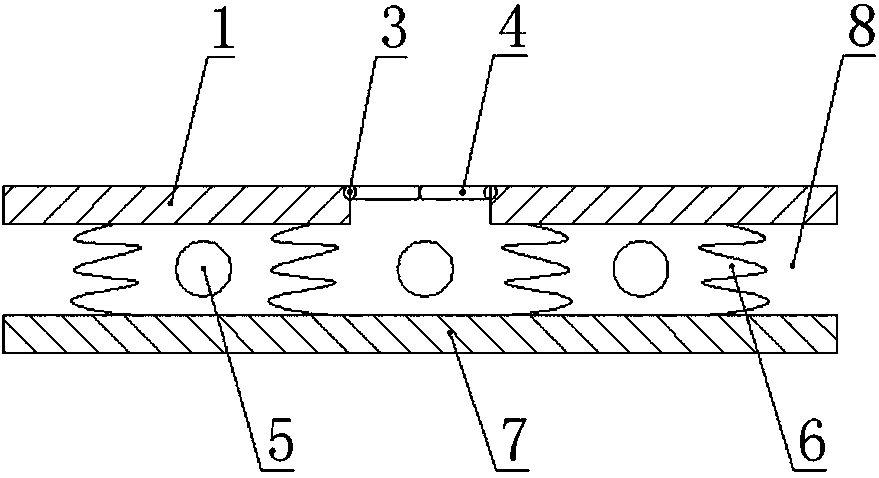

Anti-deformation device of electric oven

InactiveCN108030407ABarrier deliveryExtended service lifeRoasters/grillsThermal expansionEngineering

The invention discloses an anti-deformation device of an electric oven. The anti-deformation device of the electric oven mainly comprises a heat-insulating plate (1) and an electric oven inner wall (7), and a cavity layer (8) between the heat-insulating plate and the electric oven inner wall. The heat-insulating plate (1) is placed at the outer side of the electric oven. The center position of theheat-insulating plate (1) is provided with a radiating hole (2). The radiating hole (2) is provided with two baffles (4). The baffles (4) are connected with the heat-insulating plate (1) through a hinge (3). The cavity layer (8) is internally provided with a plurality of groups of springs (6) and a cooling water pipe (5). The springs (6) are uniformly distributed in the cavity layer (8), and fixedly connected with the heat-insulating plate (1) and the electric oven inner wall (7). The cooling water pipe (5) is installed between two groups of the springs (6), and does not contact with the heat-insulating plate (1) and the electric oven inner wall (7). The beneficial effect of the anti-deformation device of the electric oven is that the thermal expansion and cold contraction danger of the electric oven cavity wall is reduced, the service life is prolonged, a problem that the scalding is easily caused by the high temperature of the surface of the oven is improved, and the safety is high.

Owner:成都泰和顺信息技术有限公司

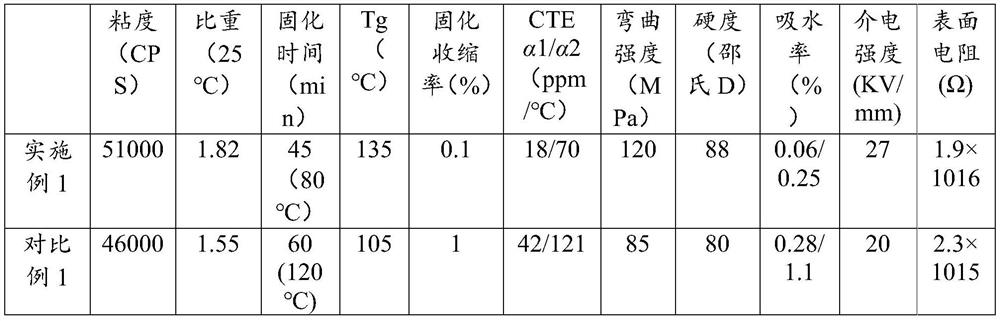

Single-component thermosetting packaging adhesive and preparation method thereof

PendingCN113652188AReduce thermal expansion and contractionLow viscosityNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention relates to the technical field of high polymer materials, in particular to a single-component thermosetting packaging adhesive and a preparation method thereof. The single-component thermosetting packaging adhesive is prepared from the following components in parts by weight: 100 parts of epoxy resin, 15 to 30 parts of a curing agent, 0.1 to 0.3 part of a defoaming agent, 0.2 to 1.5 parts of a dispersing agent, 0.1 to 0.5 part of pigment and 150 to 350 parts of a filler. The single-component thermosetting packaging adhesive disclosed by the invention can be cured at a low temperature and is high in curing speed, the expansion and shrinkage rate of a cured system is greatly reduced by adopting the proportion of spherical fillers with different diameters, the purposes of reducing the viscosity of the system and realizing maximum filling are achieved, and the single-component thermosetting packaging adhesive has excellent insulating property, mechanical property, heat resistance and flowability and small water absorption rate. The preparation method of the single-component thermosetting packaging adhesive is simple in process, low in production cost, friendly to environment and wide in application prospect.

Owner:苏州艾迪亨斯新材料科技有限公司

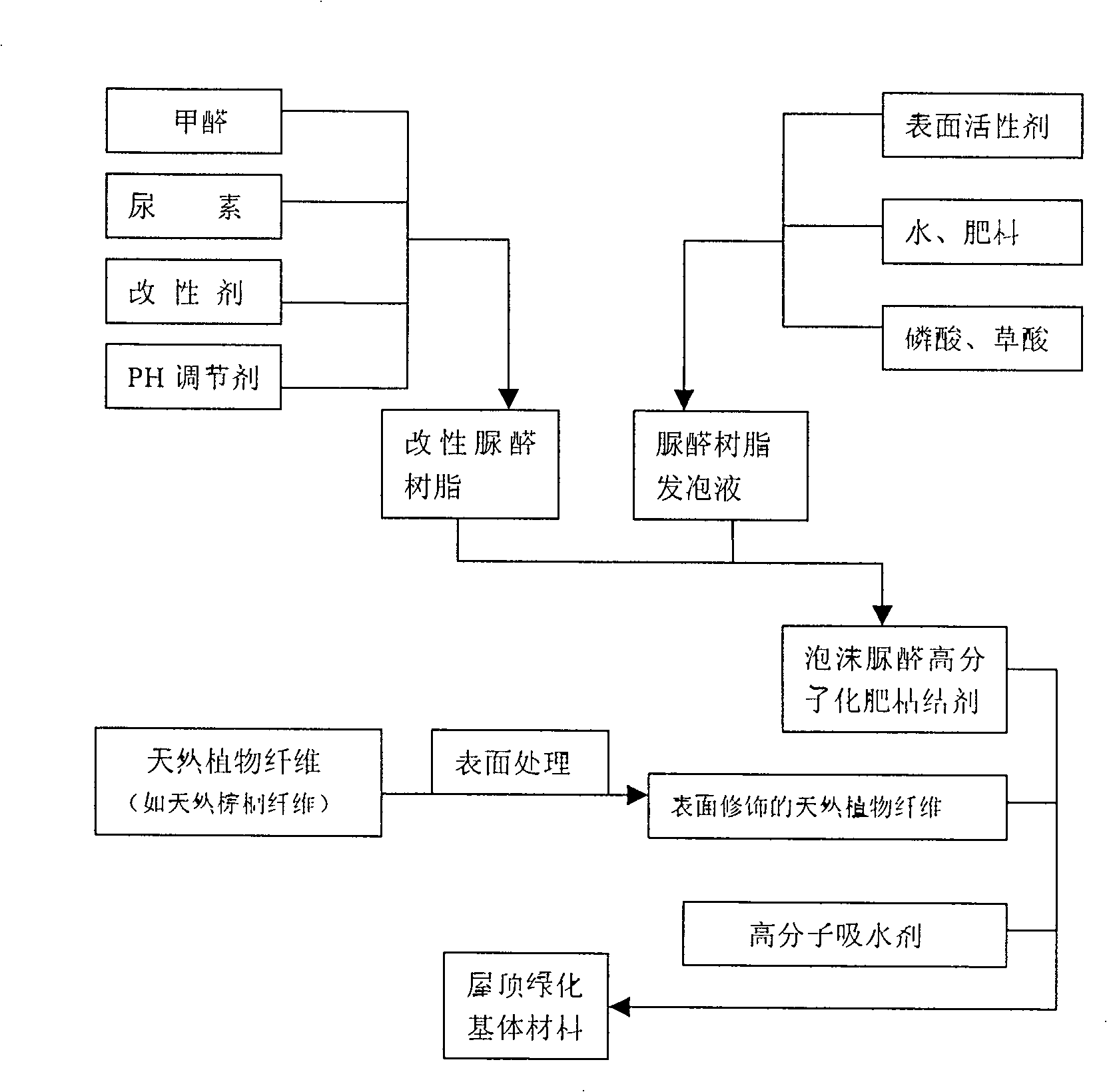

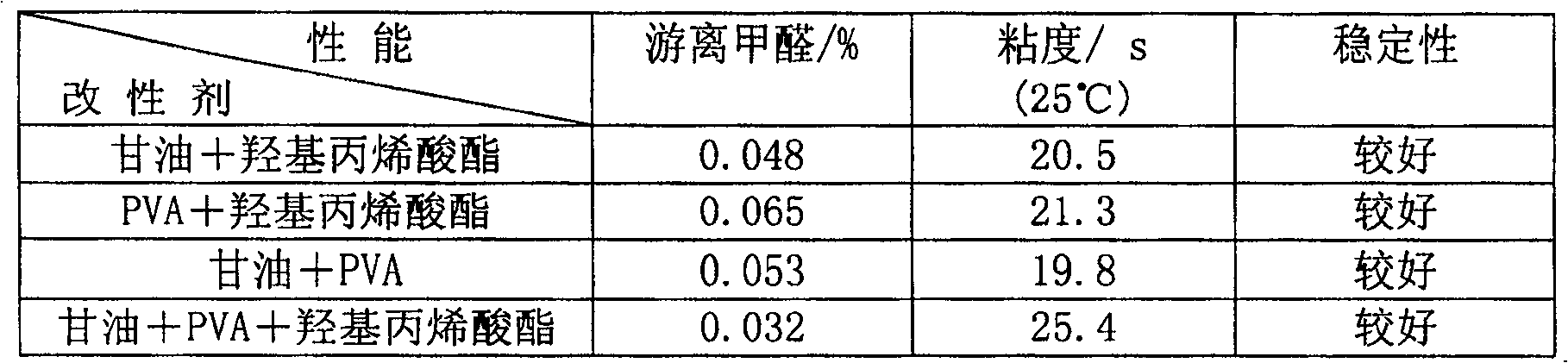

Matrix material for making green by planting on housetop and preparation process thereof

InactiveCN100419021CImproved microclimate aboveReduce thermal expansion and contractionCultivating equipmentsSoilless cultivationFiberBlowing agent

This invention relates to a roofing greening base material and the method. Its main primary materials includes 10-35 portions foam urea formaldehyde fertilizer adhesive, 40-95 portions natural fabric, 1-5 portions polymer water absorption agent. The foam urea formaldehyde fertilizer adhesive is made by frothing modified urea-formaldehyde resin and urea-formaldehyde resin blowing agent in frother, at a quality proportion of 100-150:40-60.

Owner:WUHAN UNIV OF TECH

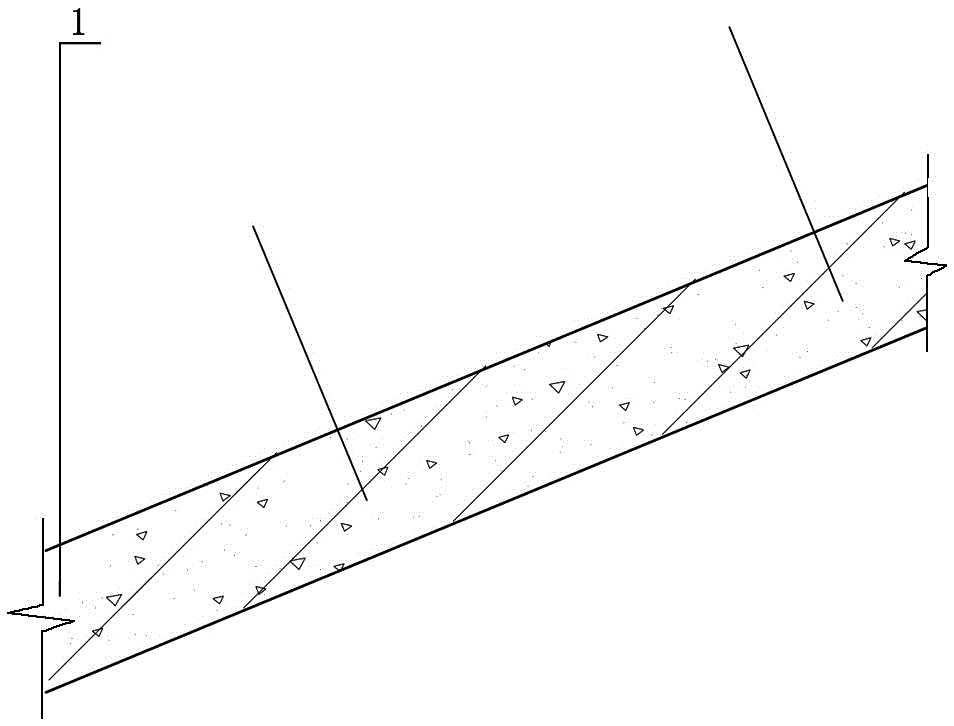

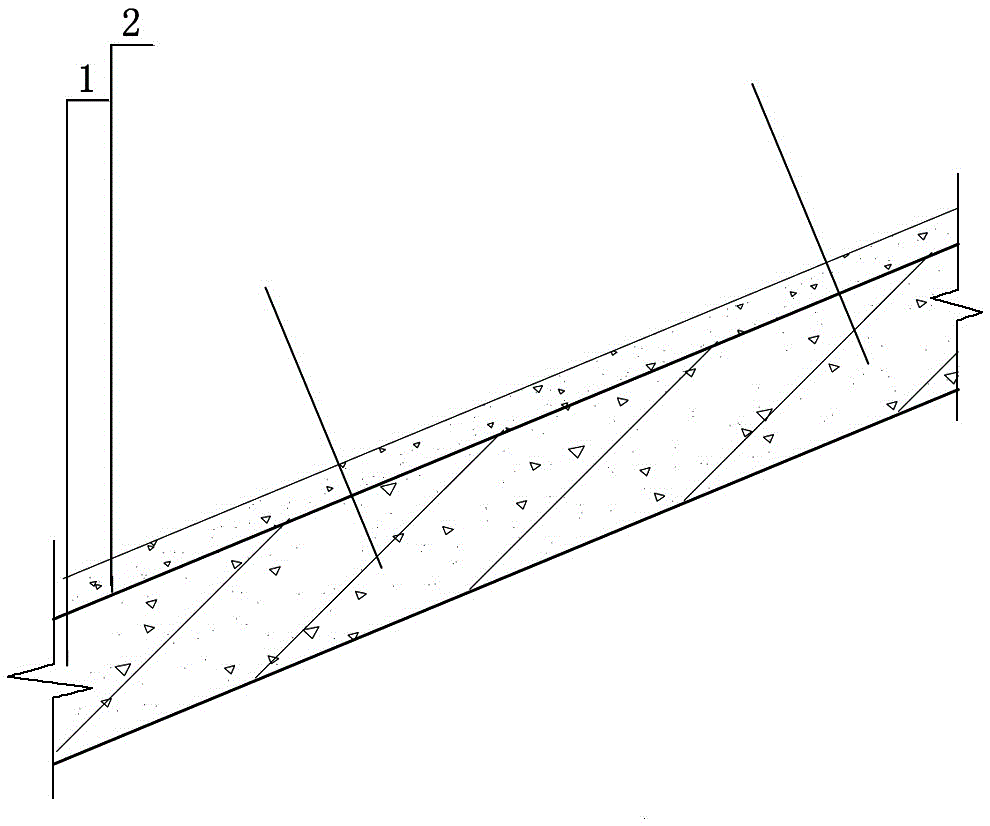

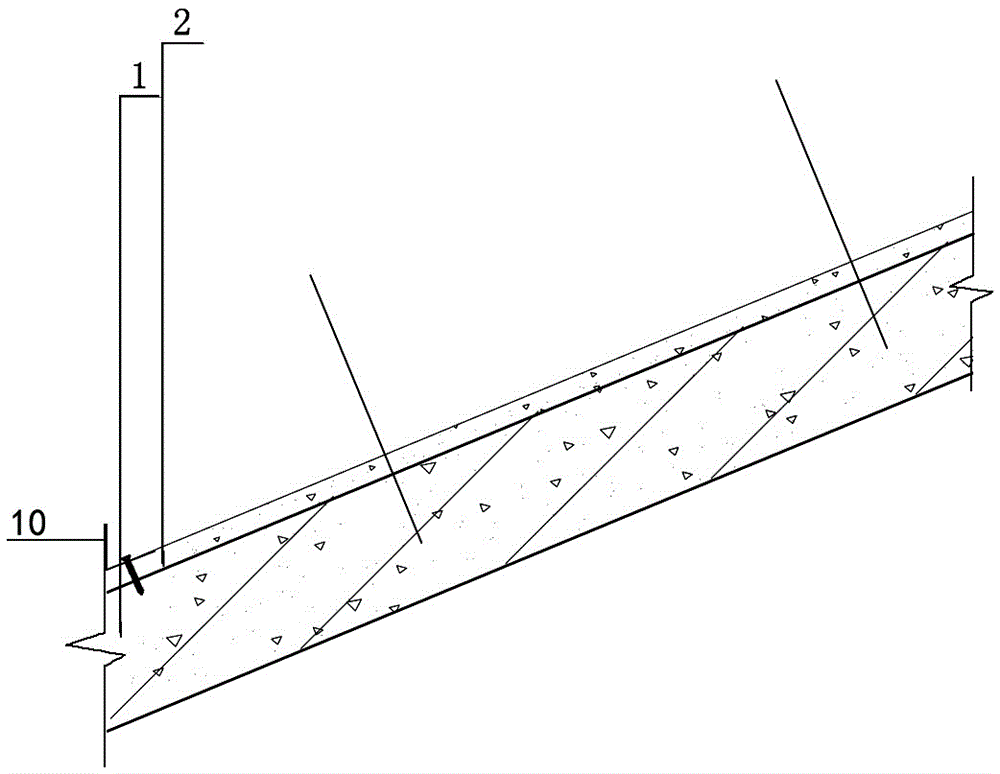

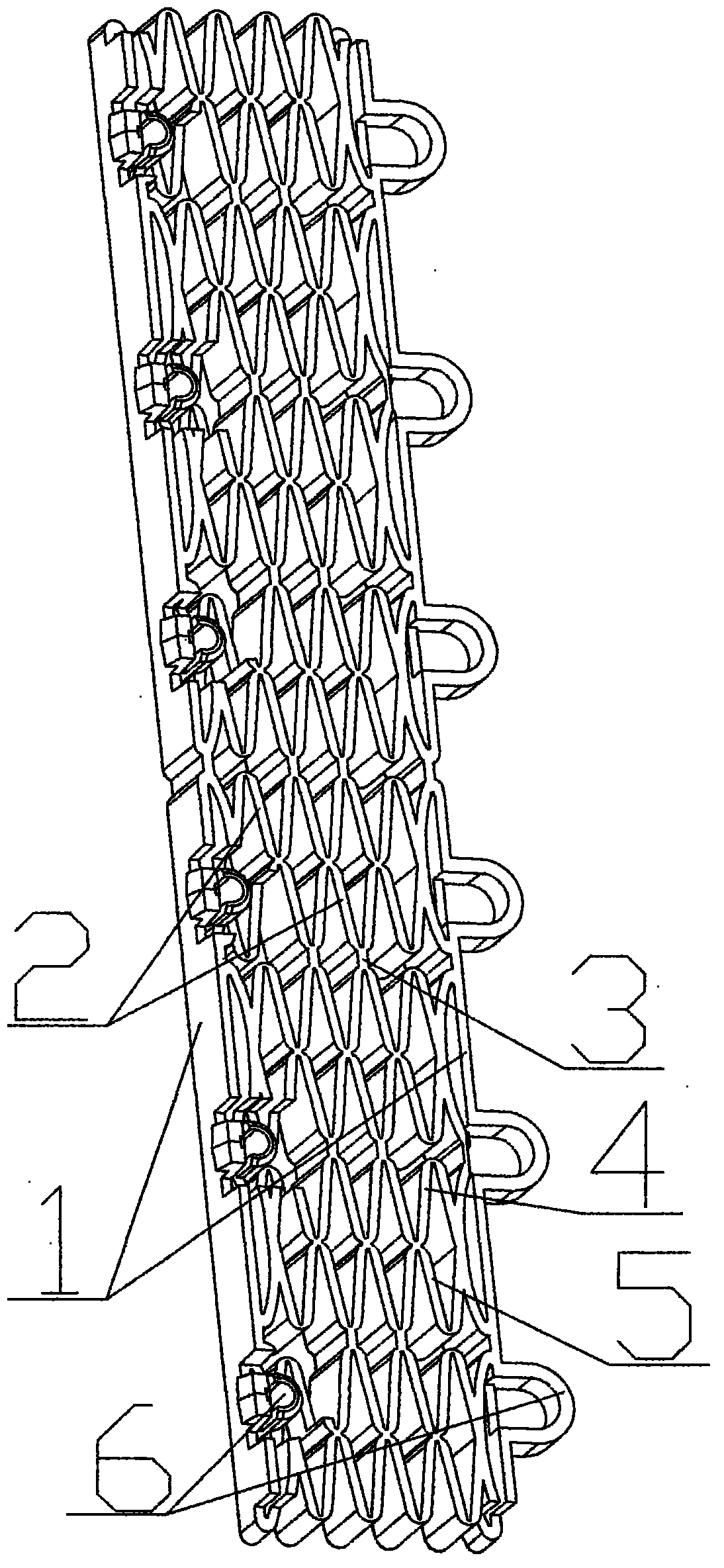

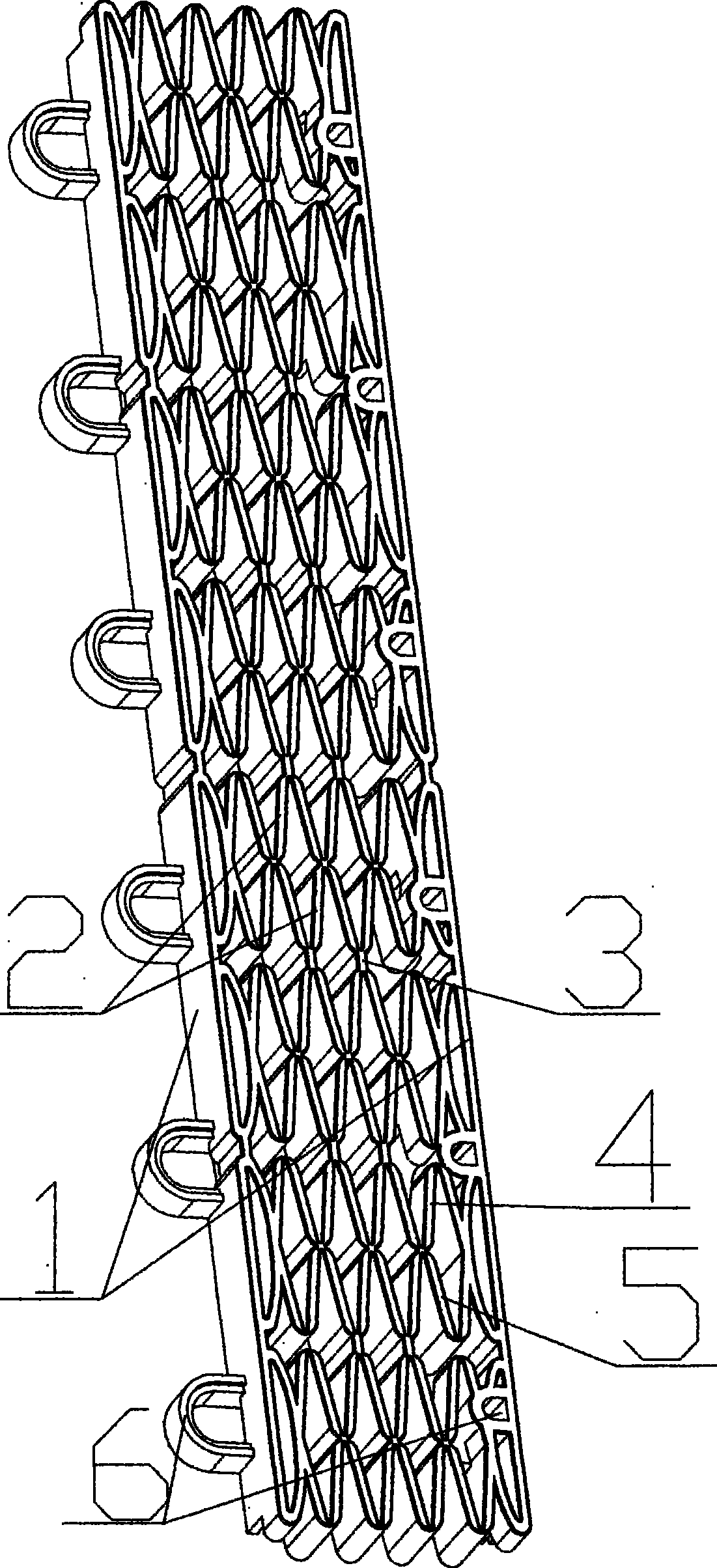

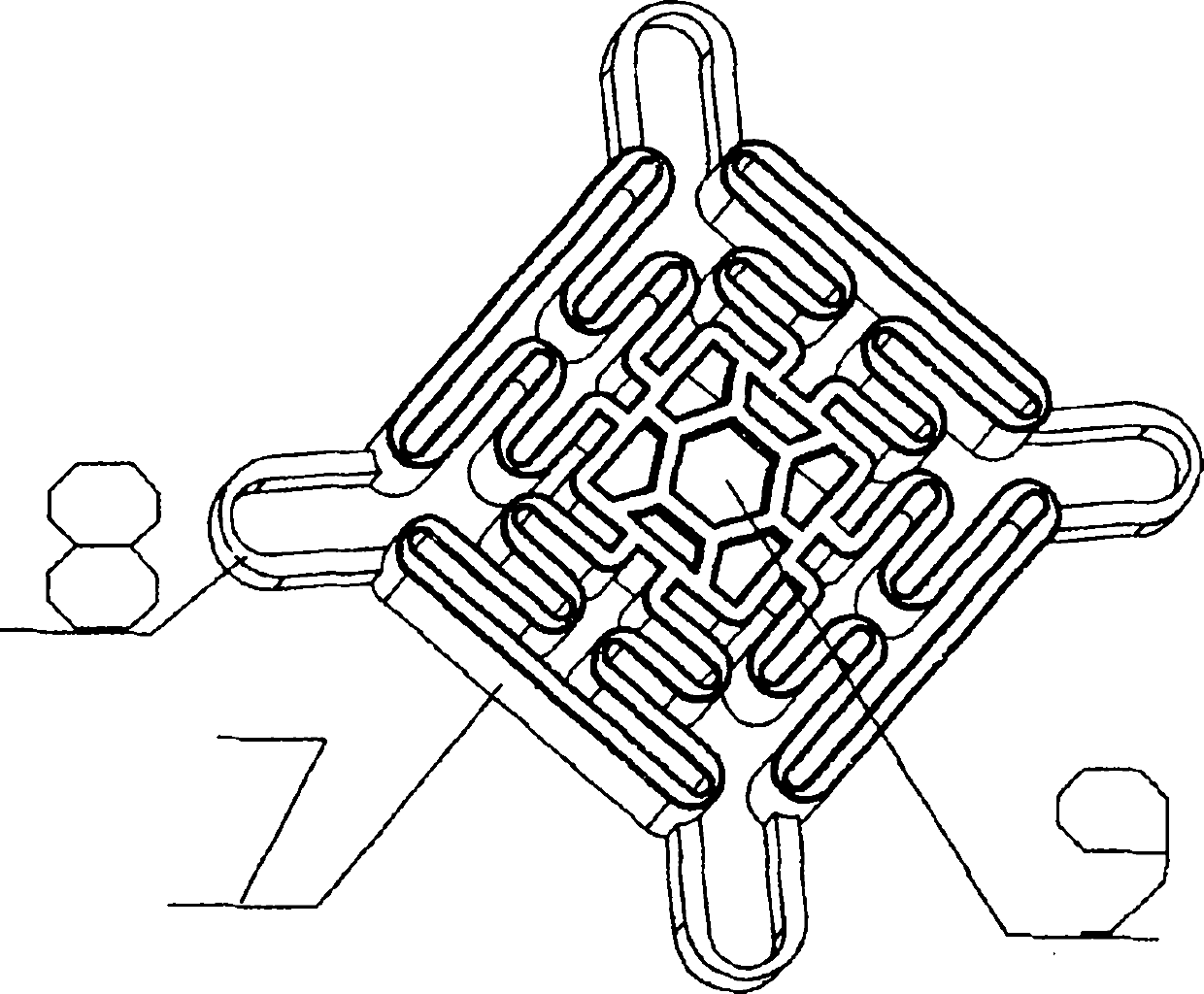

Swelling strip

ActiveCN103276875AThermal expansion and contraction cushioningWith compressionFlooringEngineeringThermal expansion

A swelling strip comprises two lengthwise long-strip outer plates which are vertically arranged, wherein a plurality of inclined pieces which are vertically arranged are arranged between the two lengthwise long-strip outer plates, inclined plates or extended lines of the inclined plates are crossed with the lengthwise long-strip outer plates in an oblique mode, and the inclined plates are connected through a cross plate. The swelling strip is mainly used for buffering thermal expansion and cold contraction, has the compression function, and can also be used as a sign of a drawing line.

Owner:FOSHAN LOKANG PLASTIC PROD CO LTD

Waterproof layer structure for parking lot ground

InactiveCN106760402AGuaranteed levelImprove protectionFlooring insulationsLeaking waterReinforced concrete

The invention discloses a waterproof layer structure for a parking lot ground. The waterproof layer structure comprises a packed soil bottom layer, and a concrete base plate, a cement mortar screeding layer, an SBS modified asphalt waterproof sheet material, a cement mortar protection layer, a first reinforced concrete layer, a ceramsite concrete layer, a second reinforced concrete layer and a concrete surface layer are sequentially laid on the packed soil bottom layer from bottom to top. The waterproof layer structure for the parking lot ground solves the problem that an existing waterproof layer is likely to lose efficacy and leaks water, and achieves the purposes of improving the waterproof effect and prolonging the service life.

Owner:CHINA MCC5 GROUP CORP

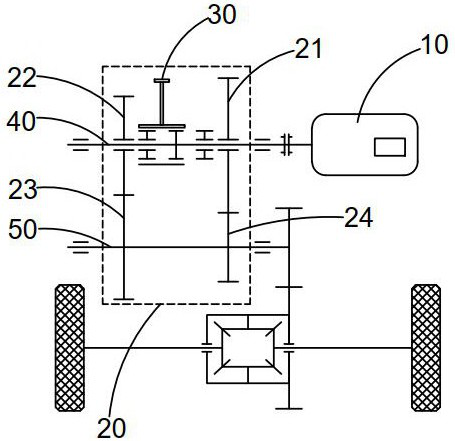

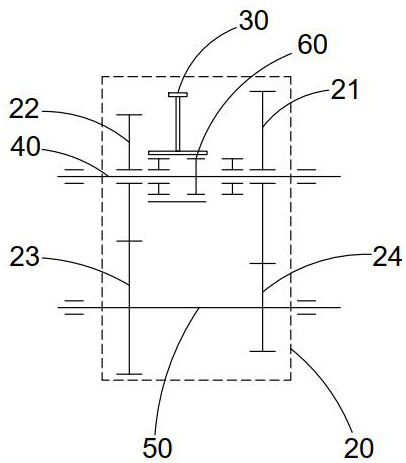

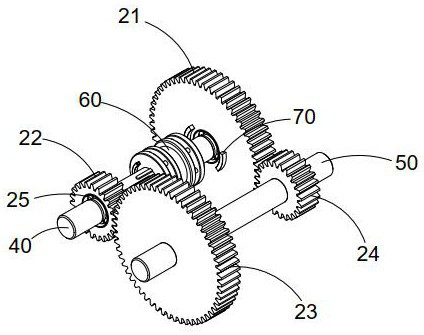

Two-speed transmission for new energy vehicles

ActiveCN113738831BReduce thermal expansion and contractionGuaranteed contactHybrid vehiclesGear vibration/noise dampingManufacturing technologyNew energy

The invention discloses a two-speed transmission for new energy vehicles, belonging to the field of new energy vehicle transmissions. The device comprises: a first case body, a first shaft body, and the first shaft body sequentially passes through two opposite sides of the first case body and Bearings are arranged at the connection, the first shaft body is provided with a second driving gear and a first driving gear respectively located in the two opposite inner wall directions of the first box body, and the first shaft body between the second driving gear and the first driving gear is arranged on the first shaft body Equipped with a slidable shift assembly, a second shaft body, the second shaft body is arranged in parallel with the axis of the first shaft body, and the second shaft body is provided with a third driven gear meshing with the second driving gear and The fourth driven gear meshed with the first driving gear, the present invention adjusts the reduction ratio through shifting, reduces the energy loss of the battery of the new energy vehicle, increases the cruising capacity, reduces the complexity of the transmission structure and the requirements of the manufacturing process, and can also Reduce the development difficulty and manufacturing cost of traction motors.

Owner:杭州骑遇科技有限公司

Ultra-high-performance electronic glass fiber cloth production process

ActiveCN102758335BGap narrowingSignificant improvement in impregnationTextile treatment by spraying/projectingLiquid/gas/vapor yarns/filaments treatmentGlass fiberSingle fiber

The invention discloses an ultra-high-performance electronic glass fiber cloth production process which specifically includes the steps: A, slightly splitting electronic glass fiber cloth; B, drying the slightly split electronic glass fiber cloth; C, deeply splitting the dried electronic glass fiber cloth; and D, drying the deeply split electronic glass fiber cloth so that ultra-high-performance electronic glass fiber cloth is obtained. During slight splitting, cloth surfaces are humidified by a water-washing oscillating trough, so that warp and weft yarns are bulked, and fibers are loosened; and during deep splitting, purified water is sprayed from holes of nozzles to be directly jetted to the cloth surfaces, the front and the back of the glass fiber cloth are sprayed by water columns, the warp and weft yarns are broken apart after the cloth surfaces are subjected to impact pressure of the purified water columns, the compactness of the glass fiber cloth is greatly reduced, and gaps among the warp and weft yarns are mostly filled by loose single fibers to be smaller, so that the surfaces of the glass fiber cloth become dense and uniform, and the surfaces of the glass fiber cloth are smoother after splitting.

Owner:建滔(清远)电子材料有限公司

Radar box body for safe auxiliary driving system

PendingCN111443332AImprove cooling effectImprove waterproof performanceWave based measurement systemsHermetically-sealed casingsSynchronous motorRadar

The invention discloses a radar box body for a safe auxiliary driving system, and belongs to the technical field of vehicle auxiliary equipment. The radar box body comprises a box cover and a box body; a mounting plate is arranged at the top end of the box body; connecting holes are uniformly formed in the left side and the right side of the mounting plate; heat dissipation exhaust holes I are uniformly formed in the middle position of the mounting plate; a box cover is arranged at the top end of the mounting plate; water guide grooves are uniformly formed in the outer side of the box cover; apermanent magnet synchronous motor is fixedly arranged in the middle of the bottom end of the mounting plate; glass wool is adhered to the left and right sides of the inner cavity of the box body; heat dissipation exhaust holes II are uniformly formed in the middle of the bottom end of the inner cavity of the box body; and radiating fins are uniformly and fixedly arranged at the middle position of the bottom end of the box body. According to the radar box, the situations that the radar box body is deformed due to expansion and contraction caused by temperature change, and a radar in the box body is prone to being affected with damp due to the fact that water or fog exists outside the radar are reduced, working performance of the radar is guaranteed, and the service life of the box body and the service life of the radar are prolonged.

Owner:扬州华强不锈钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com