Patents

Literature

149results about How to "Reduce the size of the site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

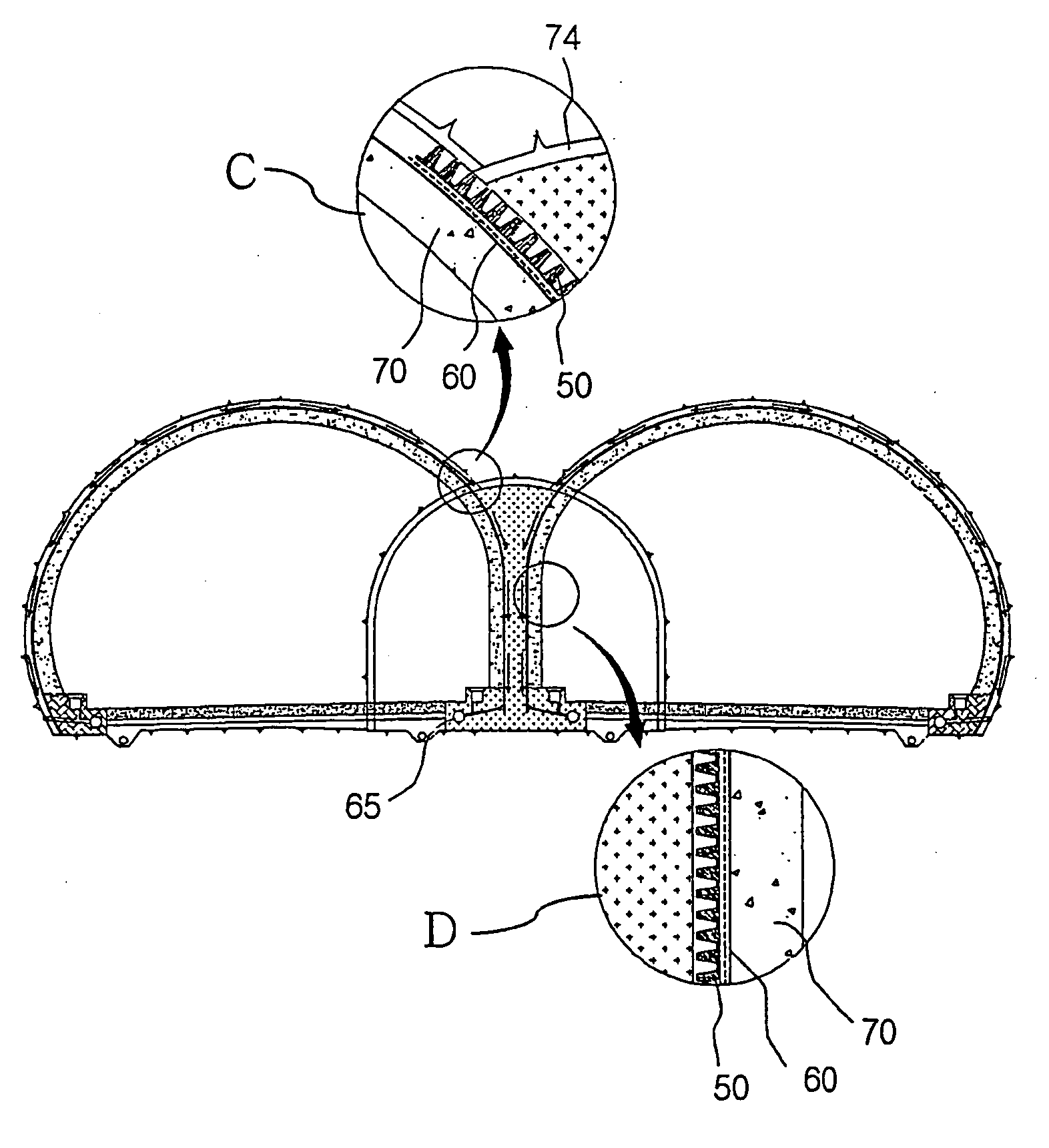

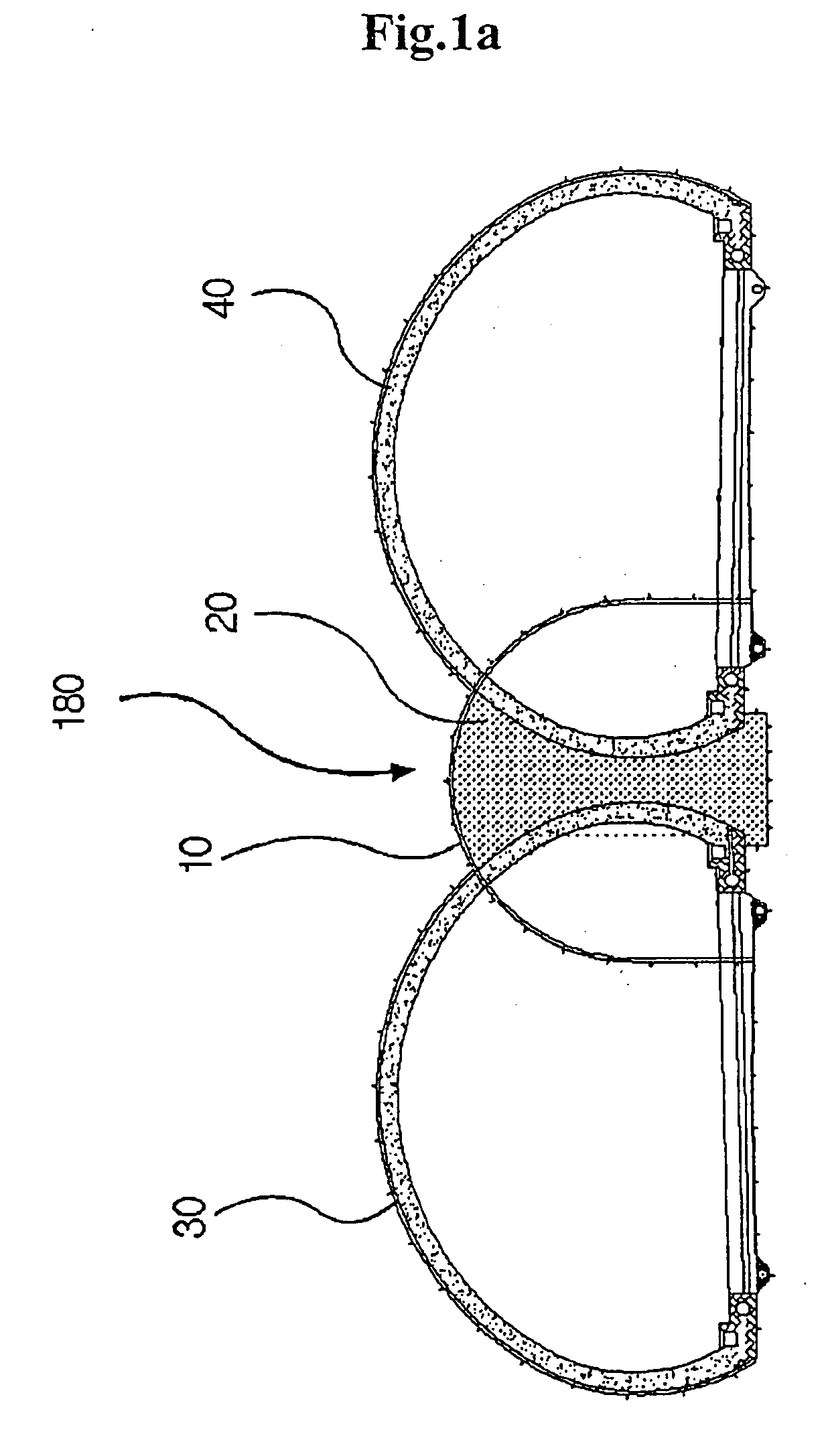

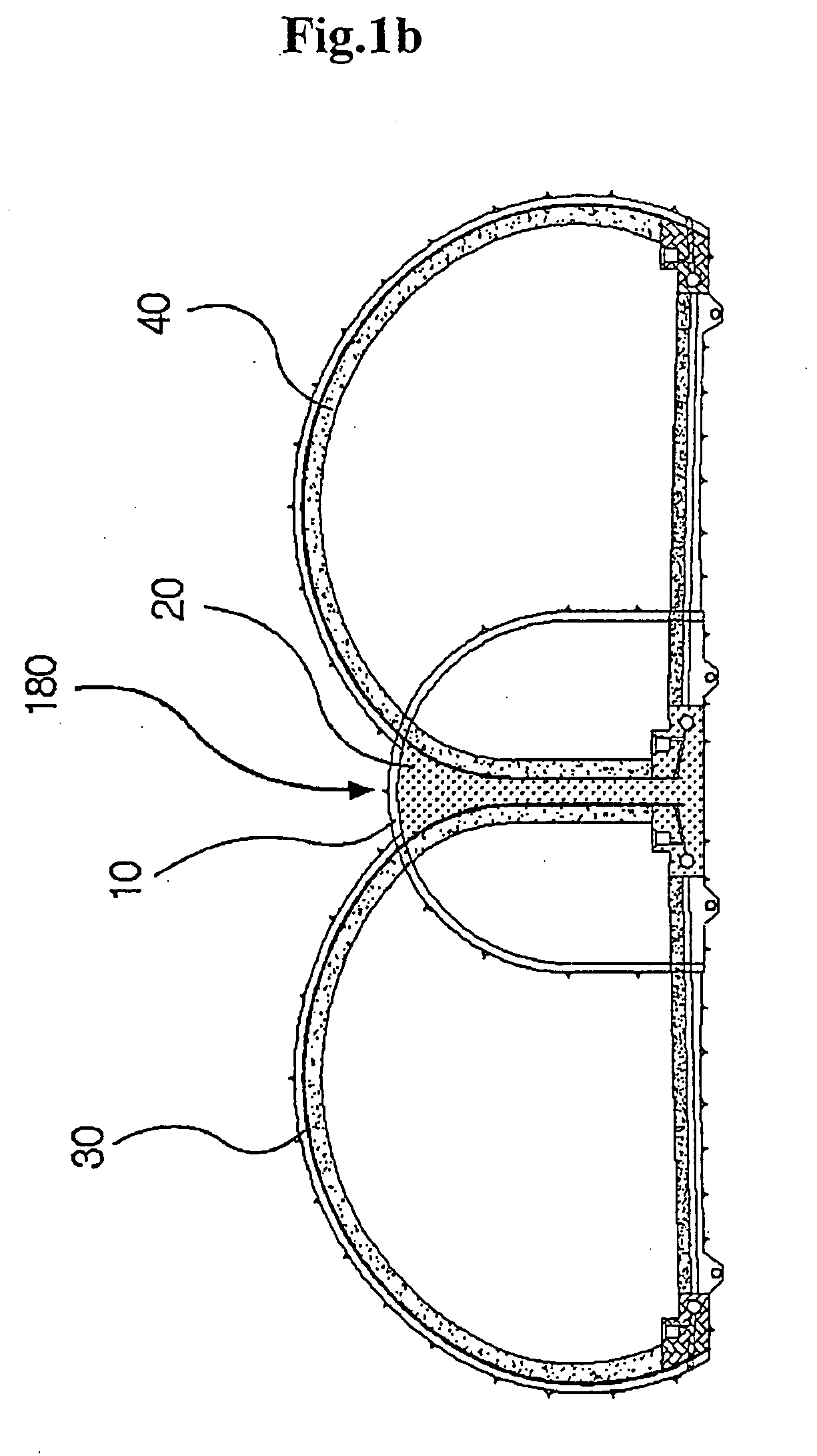

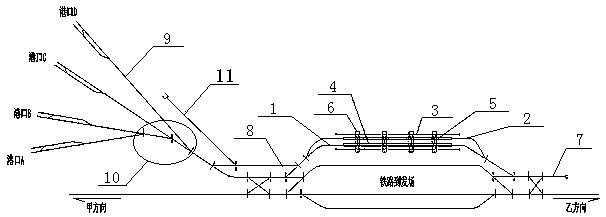

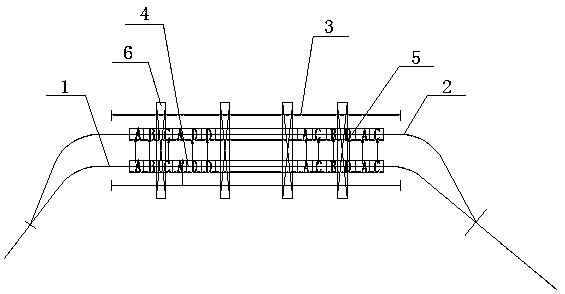

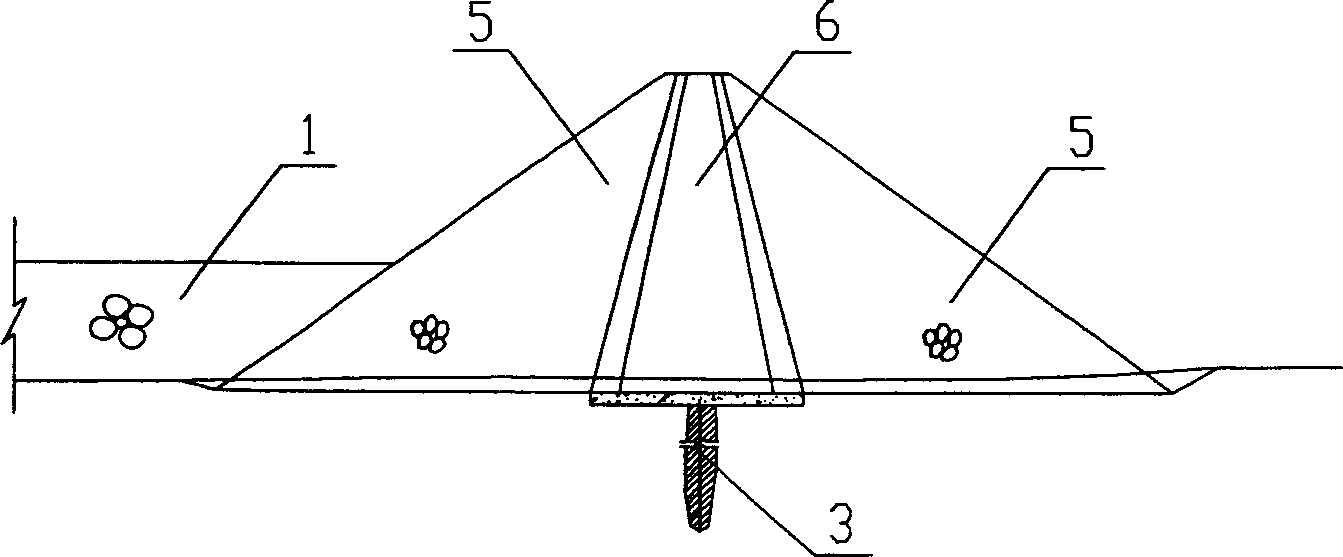

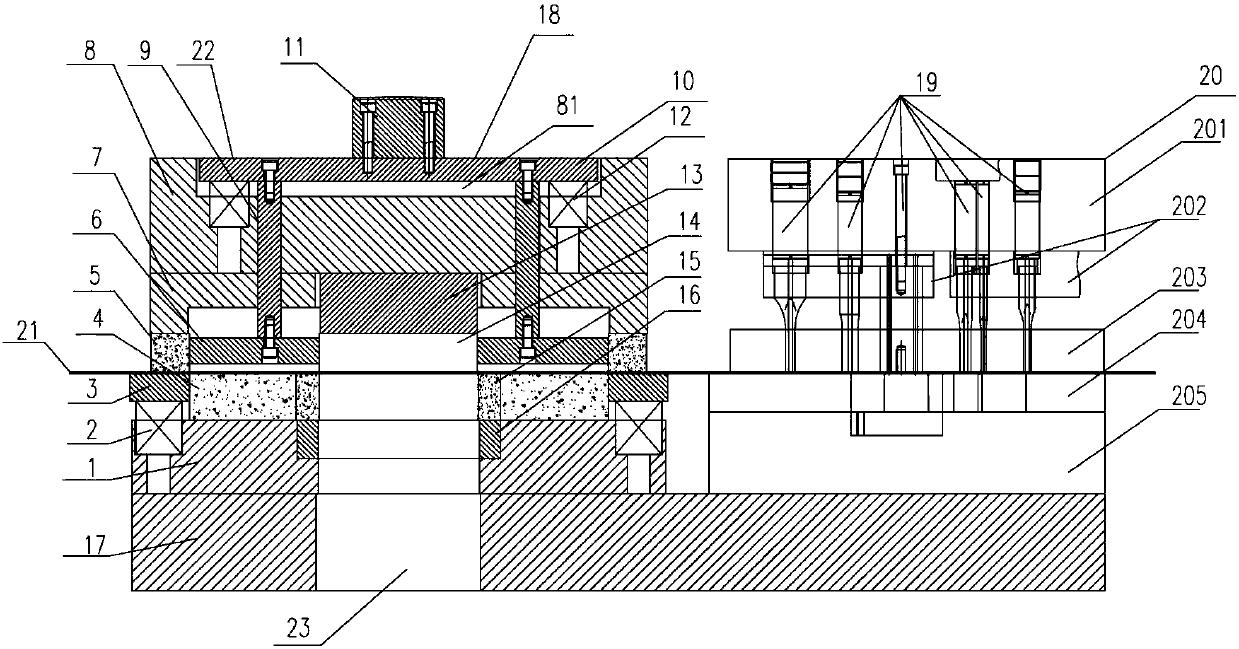

Structure of intermediate wall of three arch excavated tunnel and method for constructing the same

InactiveUS20060165489A1Reduce vibrationReduce the size of the siteUnderground chambersBuilding constructionsStructural engineeringGroundwater

Disclosed are a structure of an intermediate wall of a three arch excavated tunnel, which effectively exhausts subterranean water from a peripheral ground, and a method for constructing the tunnel. The method comprising the steps of: (a) excavating an upper portion of a central tunnel 10; (b) excavating a lower portion of the central tunnel 10; (c) forming an intermediate wall 20 and grouting a gap formed in the intermediate wall 20; (d) excavating an upper portion of a left main tunnel 30; (e) excavating an upper portion of a right main tunnel 40; (f) excavating a lower portion of the left main tunnel 30; (g) excavating a lower portion of the right main tunnel 40; and (h) installing a drain board 50 and a waterproof layer 60 and casting lining concrete 70 therein so that the tunnel is easily drained through drain pipes 65 and residual water pressure is eliminated.

Owner:DONG HYUNG SEO

Charcoal fertilizer as well as preparation method and application thereof

InactiveCN105753546AImprove carbonization rateImprove the carbonization effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdjuvantCarbonization

The invention discloses a charcoal fertilizer, prepared from the following raw materials in percentage by weight: 10-50% of charcoal powder, 20-70% of compound fertilizer and 5-30% of adjuvant, wherein the charcoal powder is obtained by putting straws in a carbonization furnace for dehydration and deoxygenation treatment and smashing the straws to a particle size of not more than 0.5mm after high-temperature carbonization. A preparation method of the charcoal fertilizer comprises the following steps: feeding the straws into the carbonization furnace; performing the dehydration and deoxygenation treatment for 1-2 hours at a temperature of 100-250 DEG C; carbonizing the straws at a high temperature of 600-700 DEG C for 30-240min; cooling the carbonized product and then smashing the carbonized product to form the charcoal powder with the particle size of not more than 0.5mm; uniformly mixing the charcoal powder, the compound fertilizer and the adjuvant in proportion to obtain a mixture and then pelleting the mixture to obtain pellets; cooling and screening the pellets to a particle size of 1.5-4.75mm; packing the screened pellets. The charcoal fertilizer disclosed by the invention has the advantages of an extensive source of the raw material straws, a good carbonization effect, high carbon content, conformity with the concept of environmental protection, simplicity in preparation technique, low energy consumption, high product strength and capability of processing the raw materials in a centralized manner and obviously increasing the utilization rate and quality stability of the fertilizer. The invention further discloses an application of the charcoal fertilizer in crop growth.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

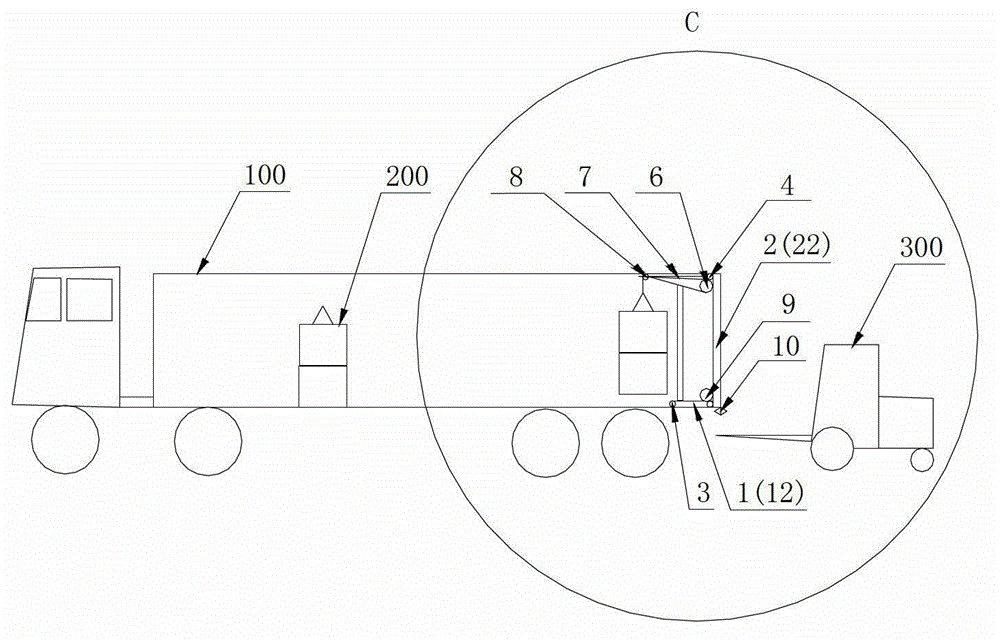

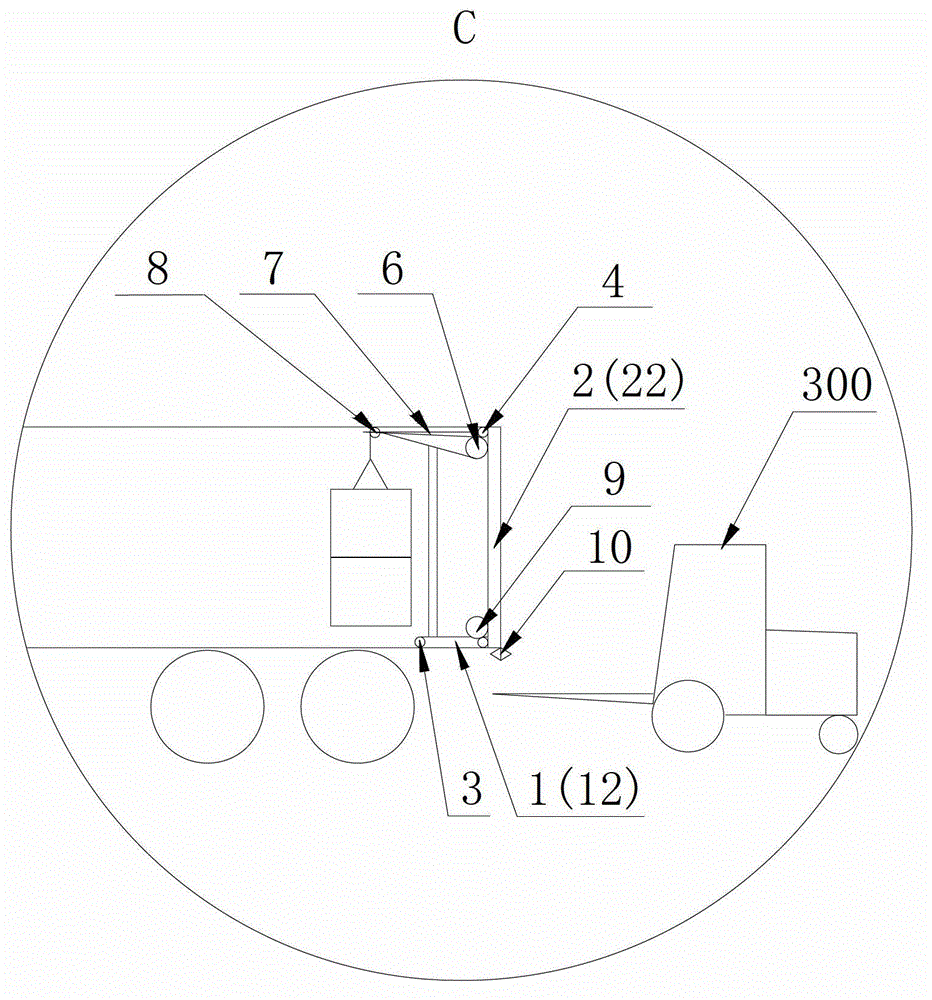

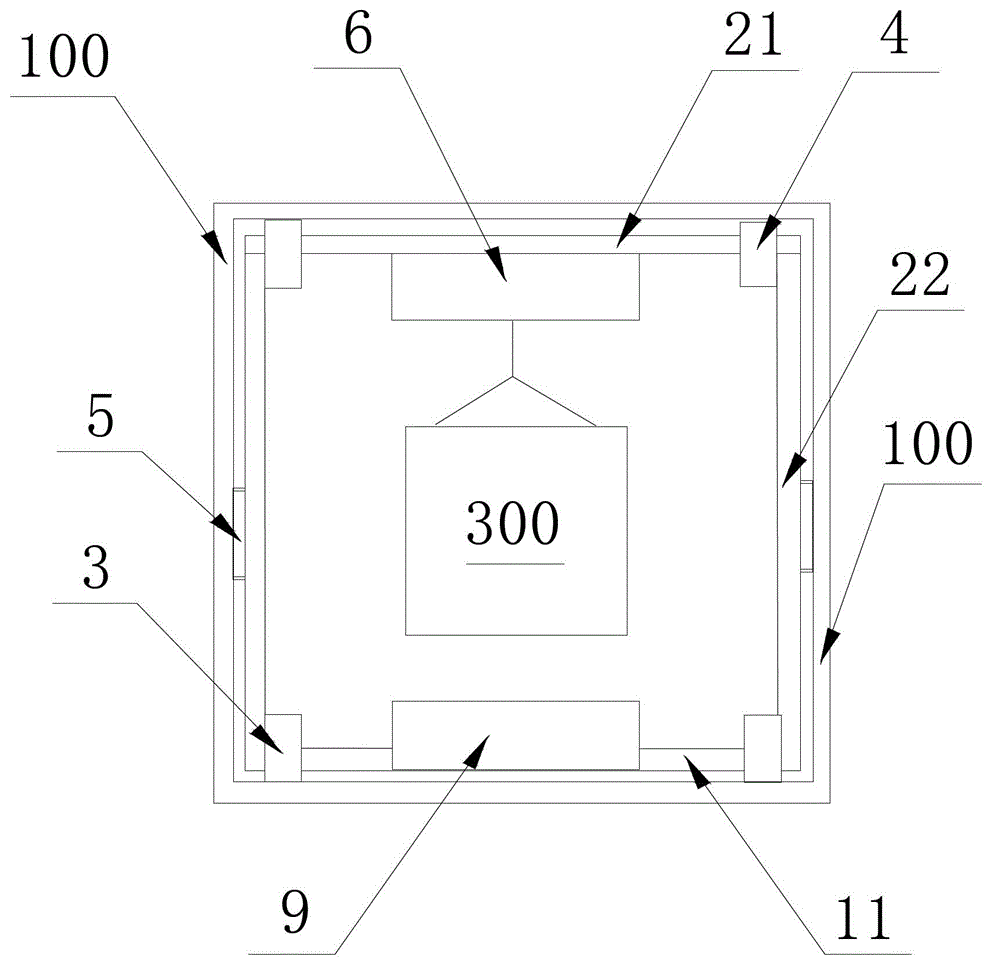

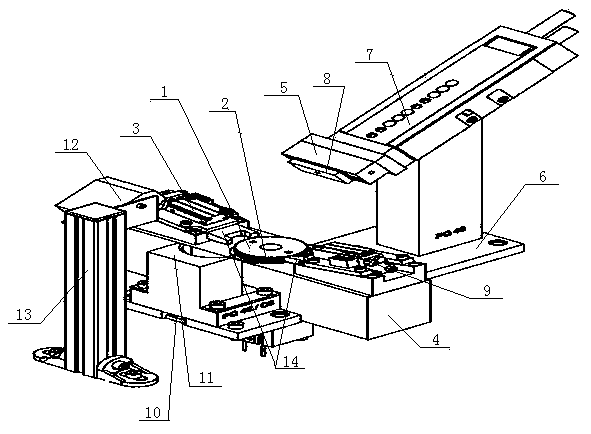

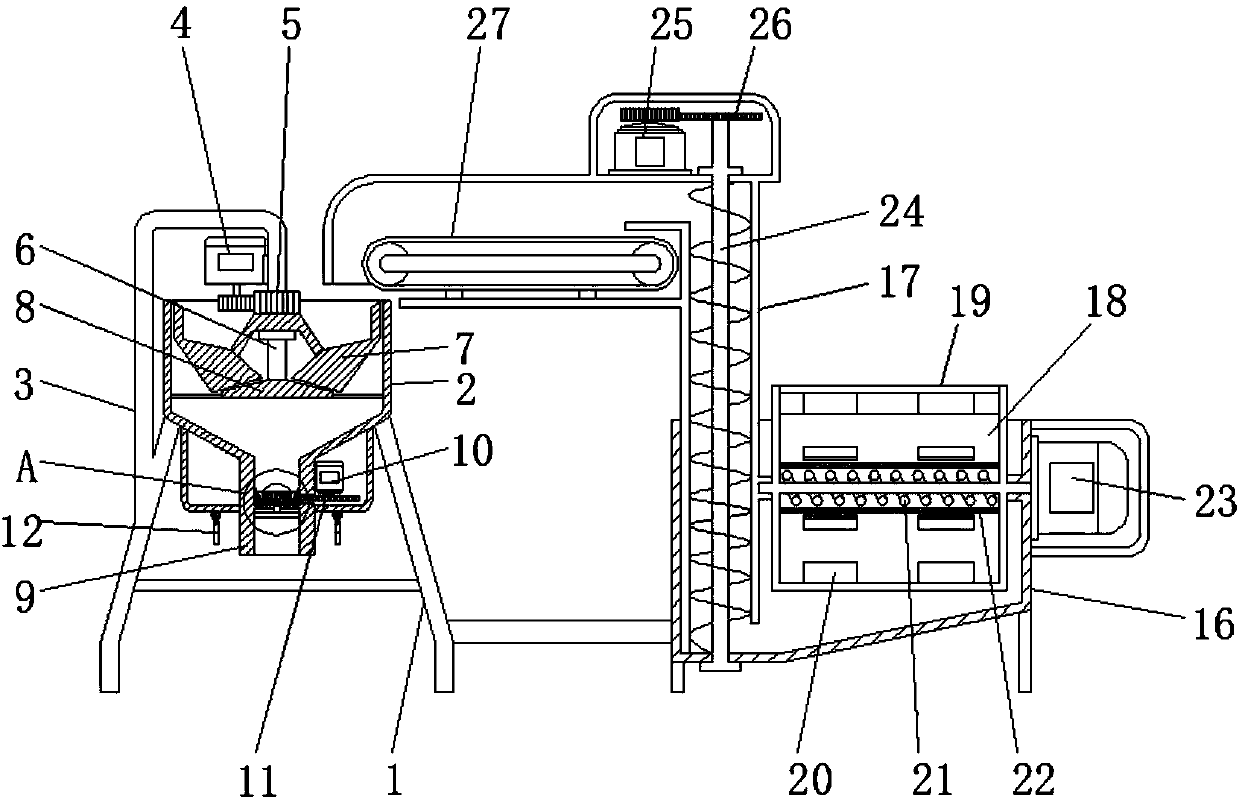

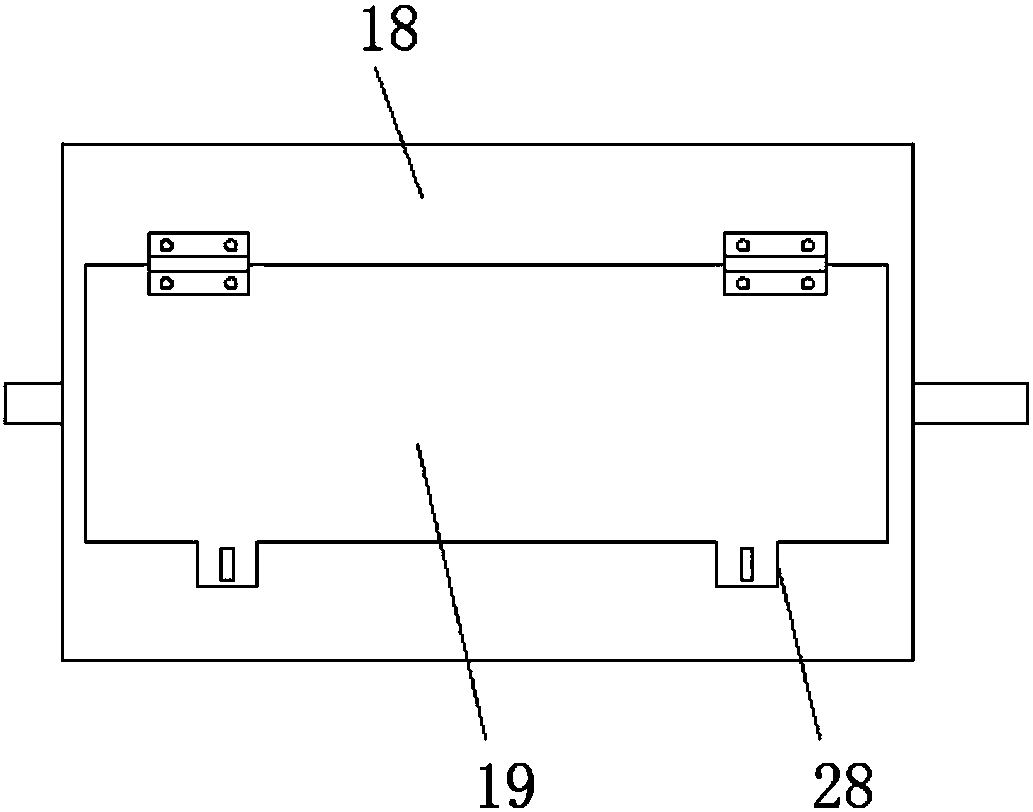

Container unloading device

ActiveCN103935925AEliminate potential safety hazardsSmall unloading areaPortable liftingTrolley cranesEngineeringMechanical engineering

The invention discloses a container unloading device. The device comprises a travelling mechanism, a travel actuating mechanism and a hoisting mechanism, wherein the travelling mechanism is arranged in a container and can move in the container, the travel actuating mechanism is used for at least moving the container unloading device to the tail part of the container from the inside of the container, and the hoisting mechanism is arranged on the traveling mechanism and used for hoisting cargo (200) loaded in the container. The container unloading device can be used for moving a starch ton bag and the like loaded in the container to the tail part of the container from the inside of the container, and the starch ton bag can be further moved out of the container from the tail part of the container by ways such as a forwarder forklift (300), therefore, the use of a boarding bridge is avoided, potential risk is eliminated, and the area of required unloading site is small; moreover, the container unloading device is applicable for container unloading under conditions of no landing platform and poor site, site area is saved, and unloading efficiency can be greatly improved.

Owner:COFCO FOOD SCI & TECH WUHAN CO LTD

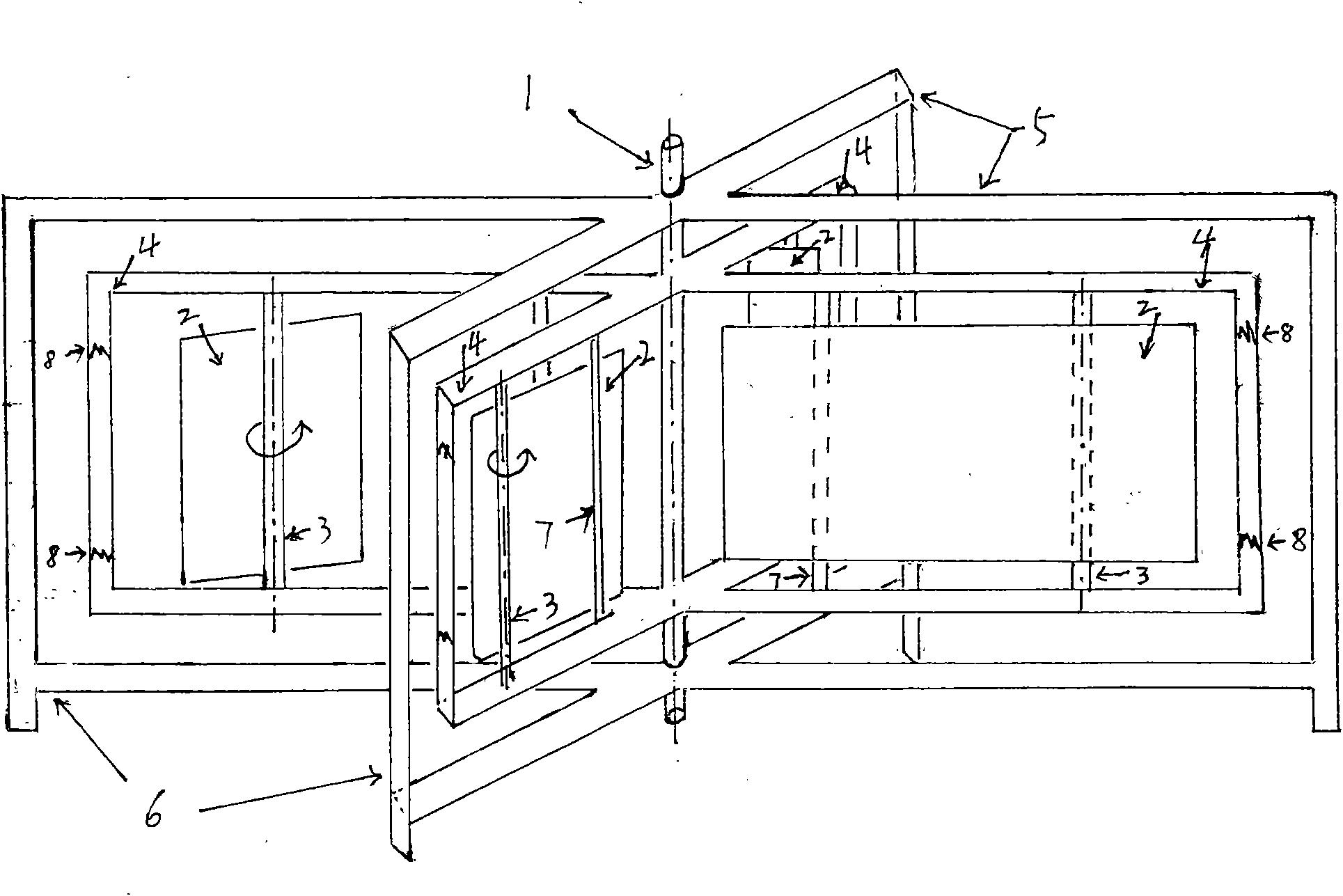

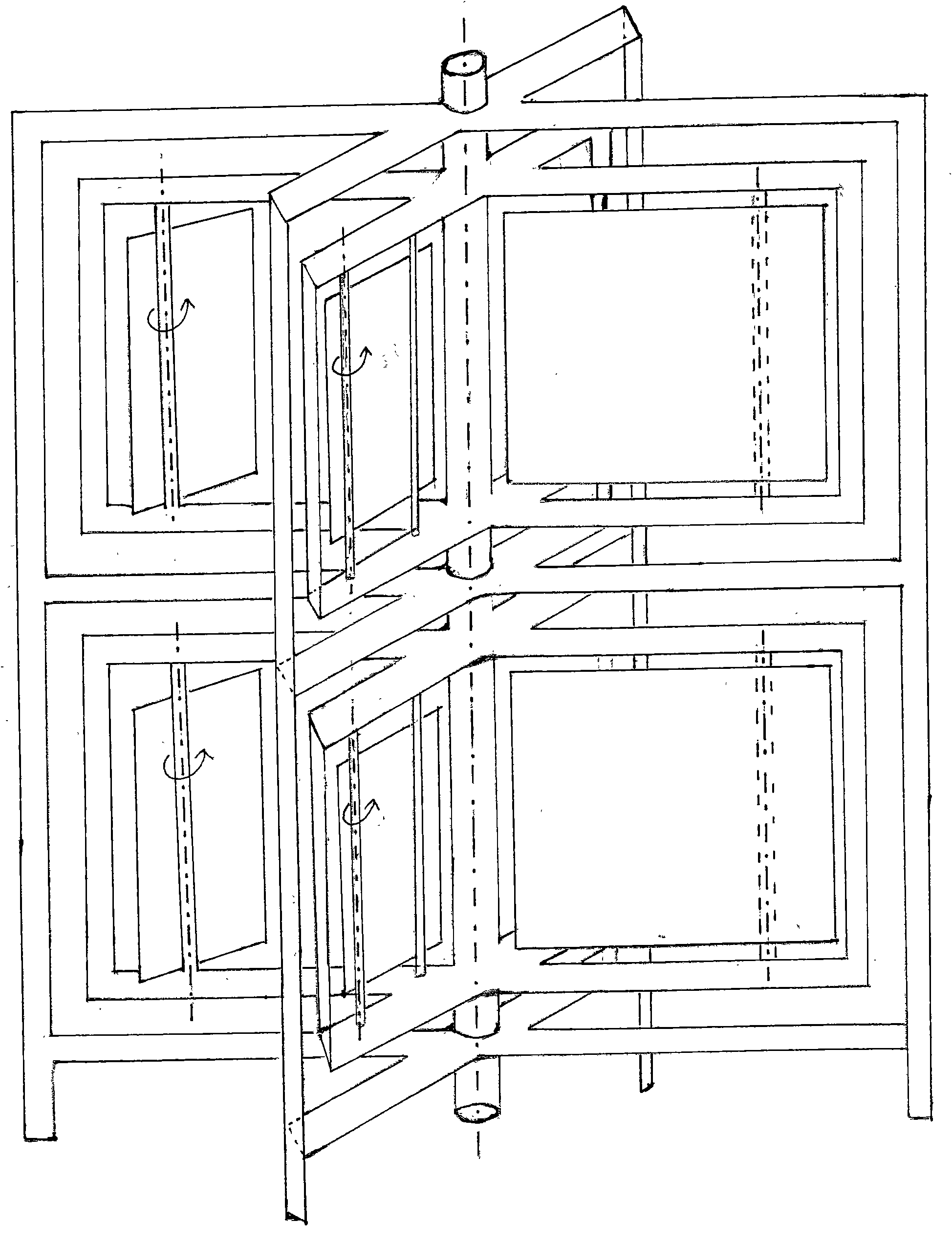

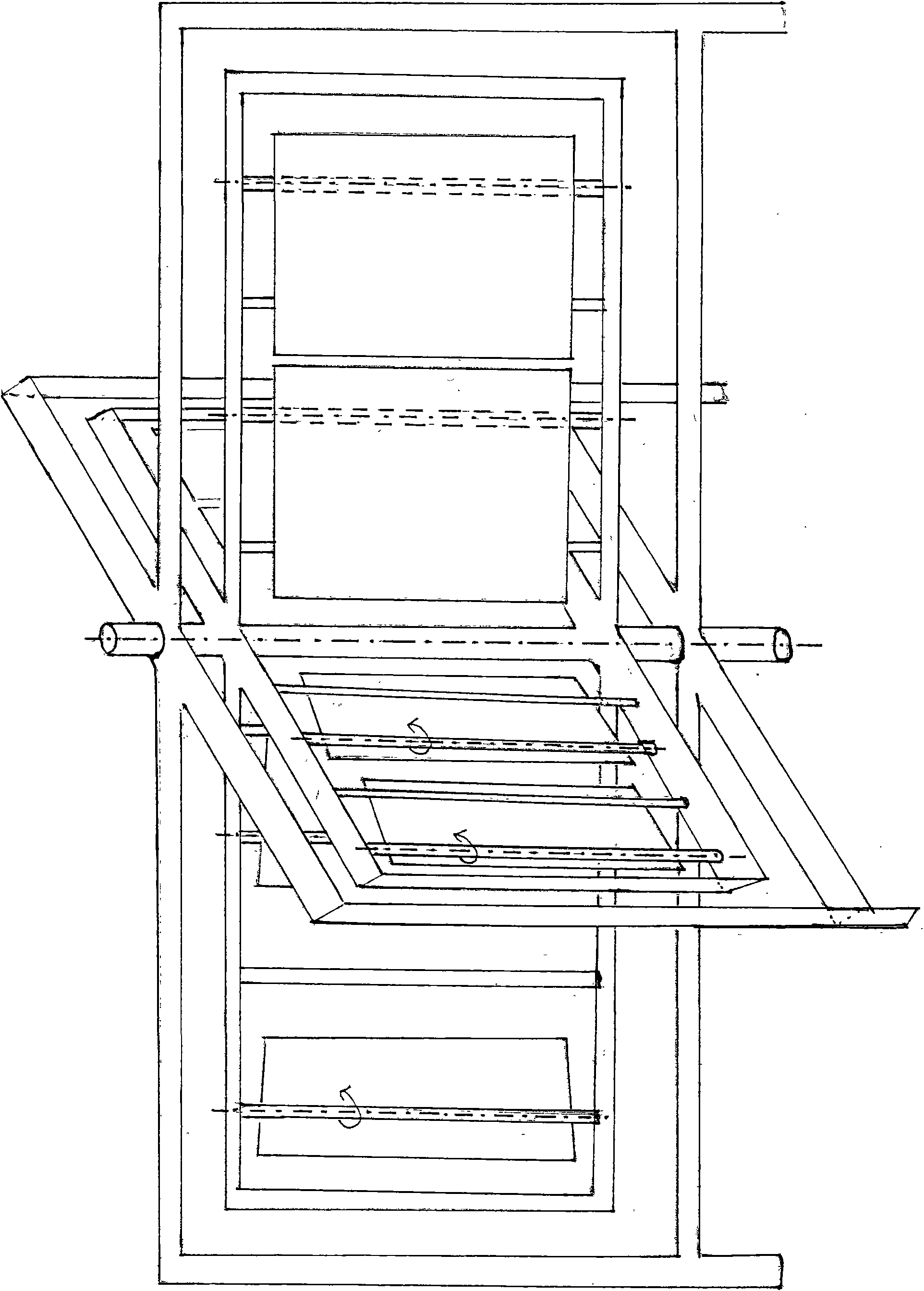

Door type self-return vertical shaft geomantic vehicle

InactiveCN101566125AIngenious ideaIngenious manufacturingMachines/enginesEngine componentsNew energyEngineering

The invention relates to a door type self-return vertical shaft geomantic vehicle which belongs to air collecting equipment with superiority in the new energy field. Each layer of the door type self-return vertical shaft geomantic vehicle is provided with a crisscross symmetrical door frame. One or a plurality of doors can be installed in one door frame according to needs. The door type self-return vertical shaft geomantic vehicle with the up-down structure can be made into one layer by design and installation and can also be made into a plurality of layers by design and installation on the same central rotating vertical shaft and can adopt the design and installation mode of one layer with one door, one layer with a plurality of doors, a plurality of layers with one door, or a plurality of layers with a plurality of doors. A plurality of door type self-return vertical shaft geomantic vehicles can be combined to be beneficial to saving raw materials and fields, increasing power and enlarging scale. The special computing formula for the door type self-return vertical shaft geomantic vehicle solves many problems which are difficult to explain in theory and provides a theoretical foundation for guiding practical application.

Owner:王文清

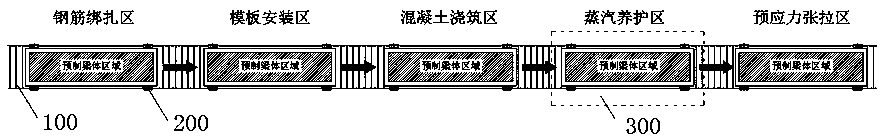

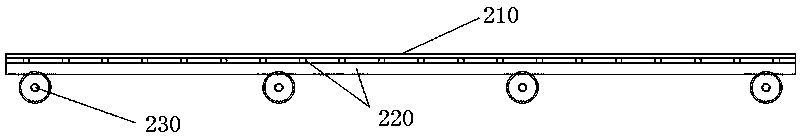

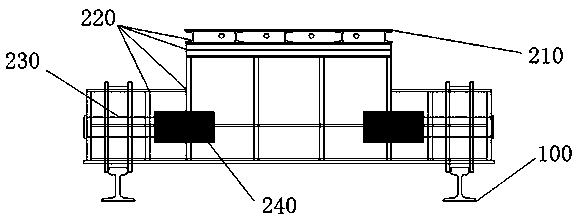

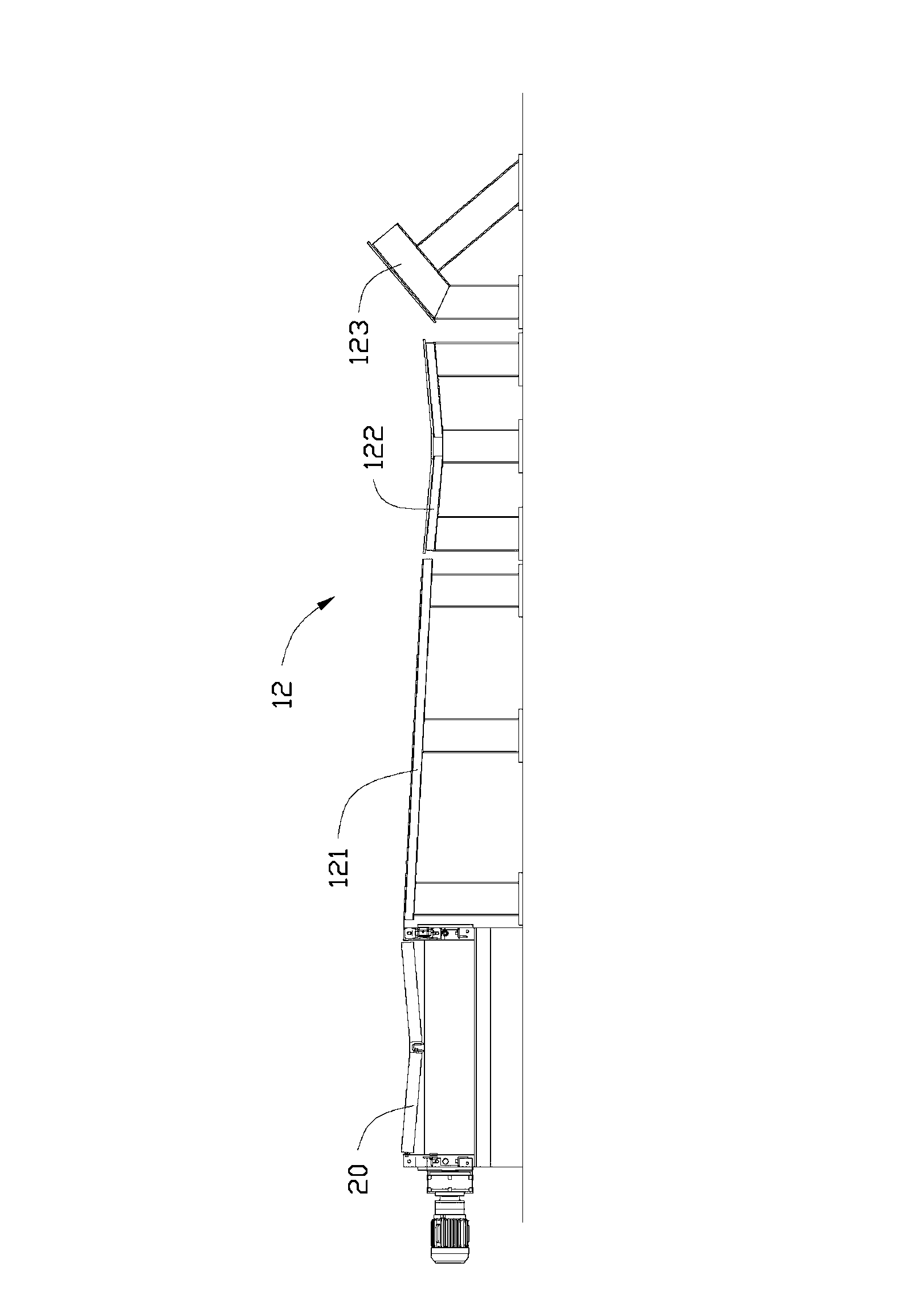

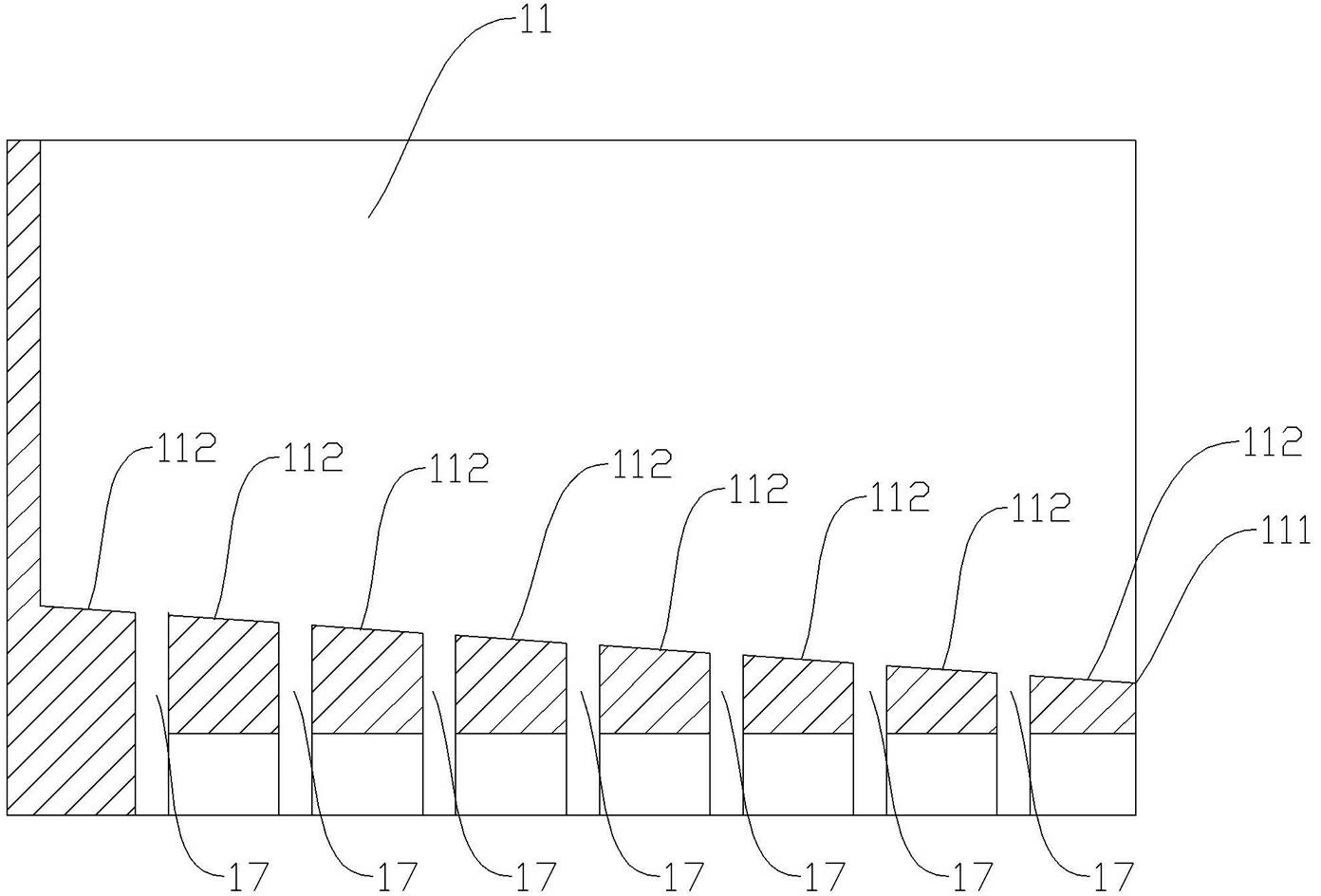

Bridge prefabricating device adopting self-propelled line production and method thereof

InactiveCN107584650AImprove efficiencyPromote circulationCeramic shaping plantsSocial benefitsPre stress

The invention relates to a bridge prefabricating device adopting self-propelled line production and a method thereof. The bridge prefabricating device comprises a steel rail arranged at the bottom, wherein a trolley which can move along the steel rail is arranged on the steel rail, a reinforcement binding region, a template mounting region, a concrete pouring region, a steam curing region and a prestress tension region are sequentially arranged from the front to the back along the length direction of the steel rail, and a steam curing shed is arranged on the steel rail of the steam curing region. The bridge prefabricating device provided by the invention realizes an operation mode that construction procedures of a bridge prefabricating process are fixed and task of each working procedure is complete in regions and can improve use efficiency of tool equipment, shorten construction period, save floor space and improve bridge prefabricating efficiency, thereby having good popularization and application values and economic and social benefits.

Owner:FUZHOU UNIV +1

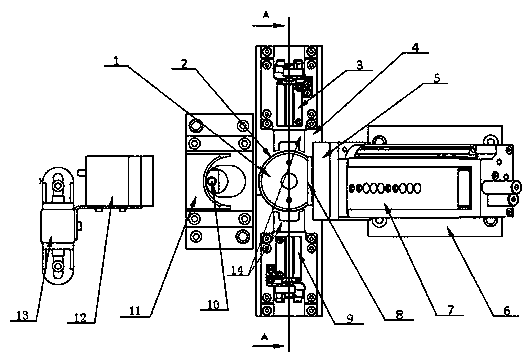

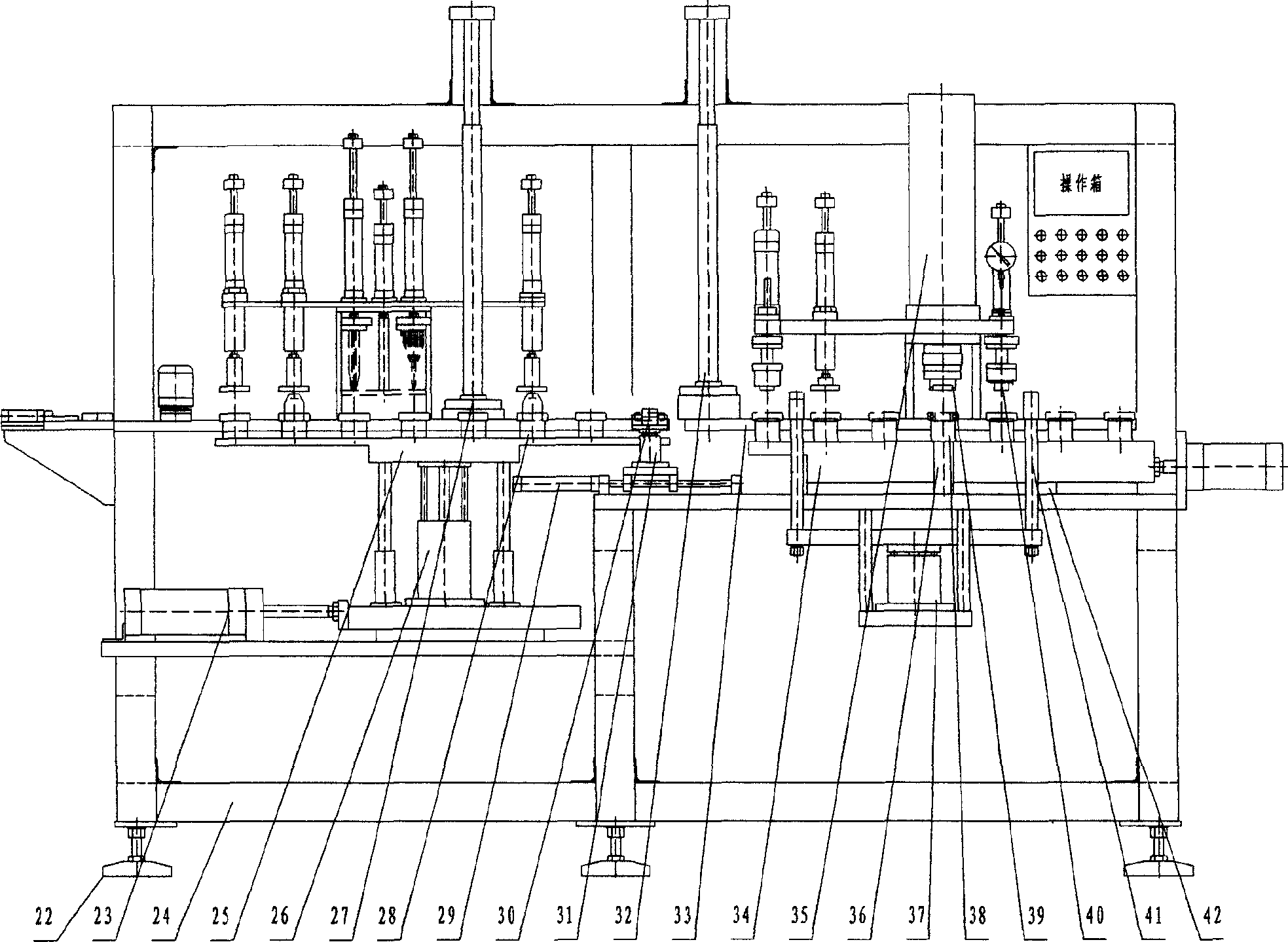

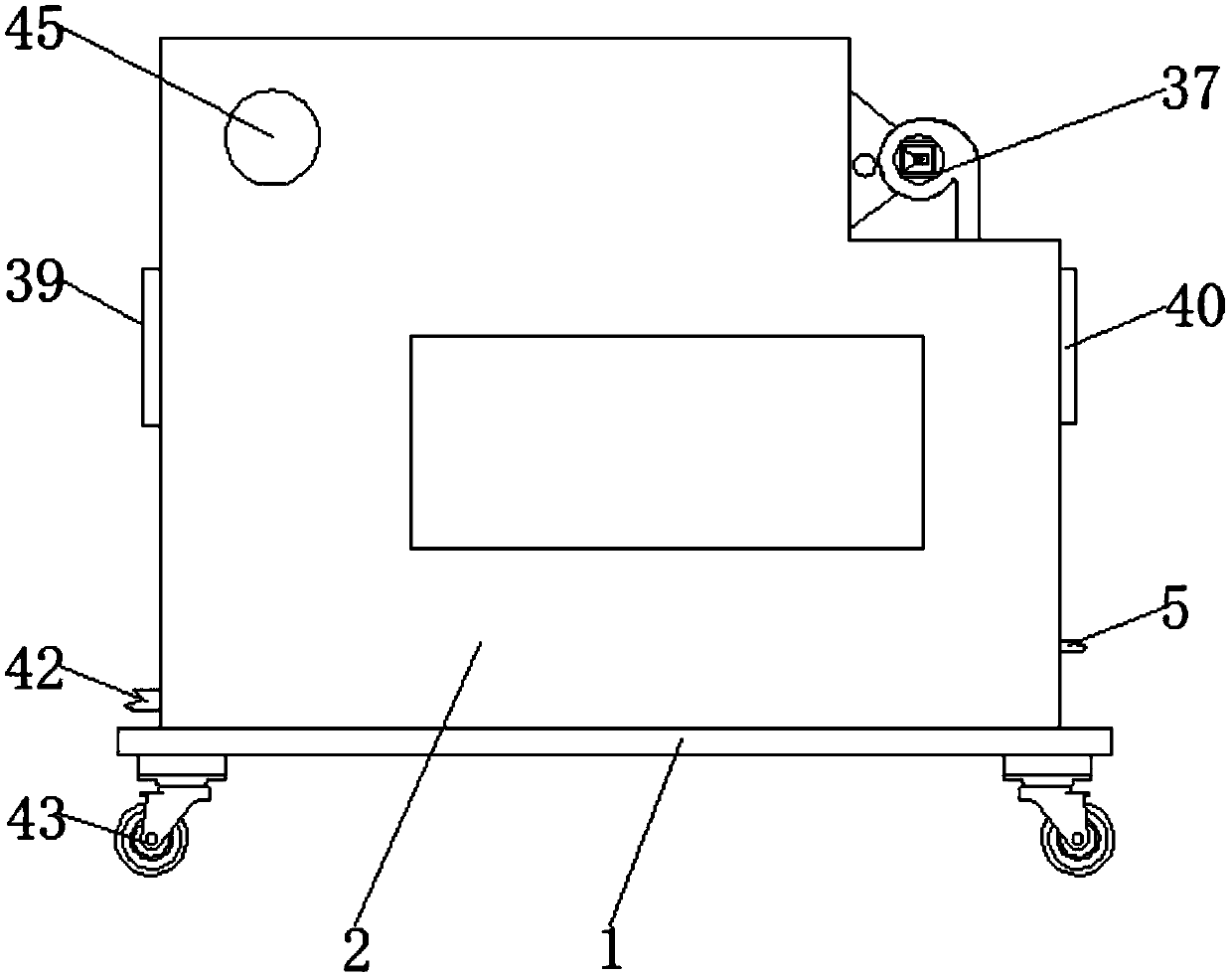

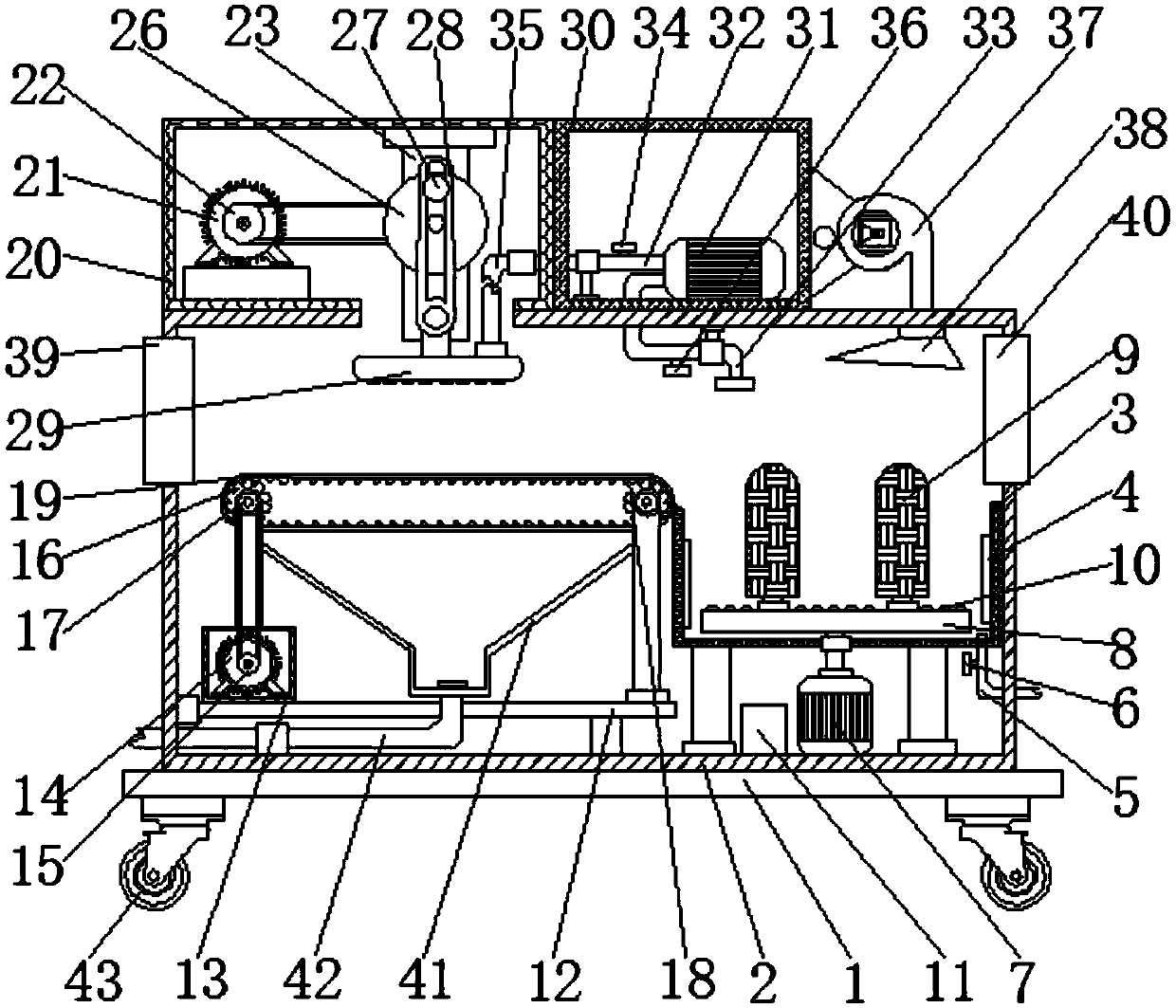

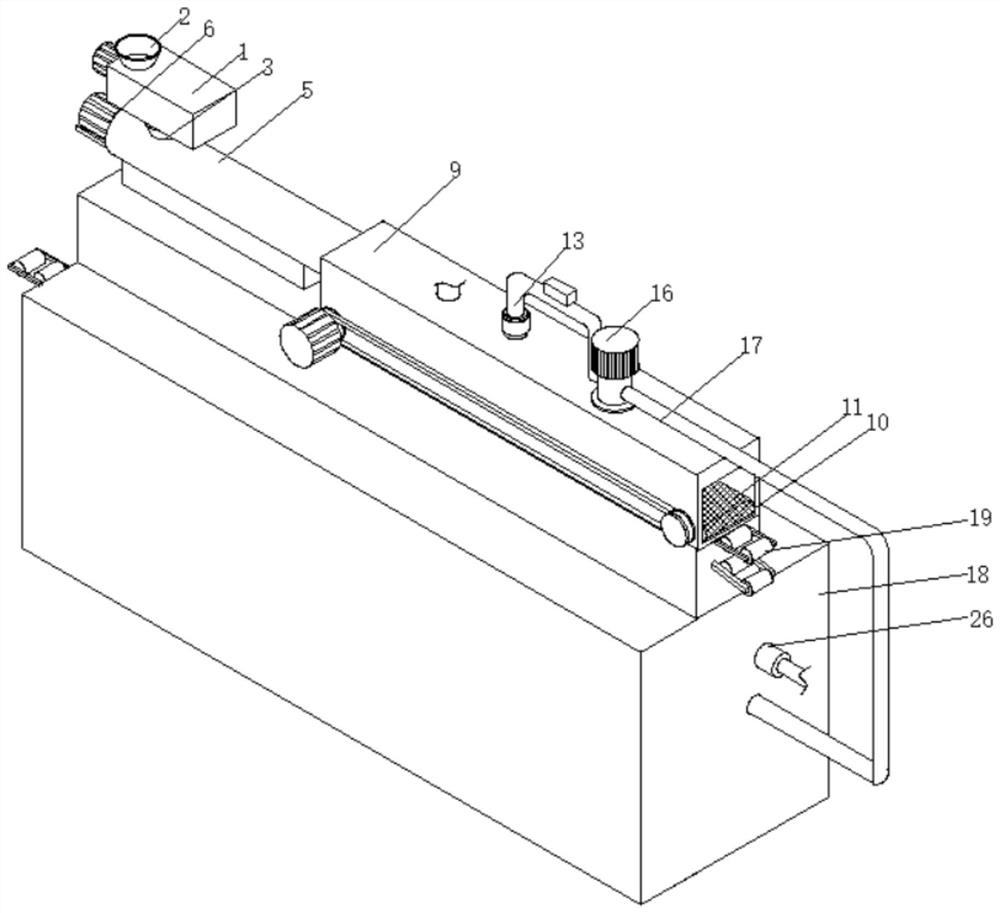

Air tightness detection device

ActiveCN103398827AReduce production cost inputQuality improvementMeasurement of fluid loss/gain rateProduct testingAssembly line

The invention belongs to the technical field of detection of assembling air tightness of a plastic electronic product and discloses an air tightness detection device. The air tightness detection device comprises a sealing device, a product clamping fixing and testing device and a product testing and identifying device. The air tightness detection device has the following advantages that 1, the sealing device, the product clamping fixing and testing device and the product testing and identifying device are reasonably integrated and can be widely embedded into various types of assembling testing equipment and are seamlessly joined with all assembling measuring procedures, so that the field area of the equipment is reduced, and the field cost is effectively reduced; 2, continuous and batch product detection can be rapidly carried out, and the detection period is shortened; the labor cost is reduced, and the product detection efficiency is effectively improved; 3, the production detection can be accurately carried out and the quality of outgoing products is improved, so as to guarantee the market competitiveness of enterprise products. To sum up, the difficulty in a detection aspect of assembly line products of existing enterprises is solved, the requirements on rapid and accurate detection of the products are realized, and the investment of enterprise production cost is reduced.

Owner:OECHSLER PLASTIC PROD TAICANG

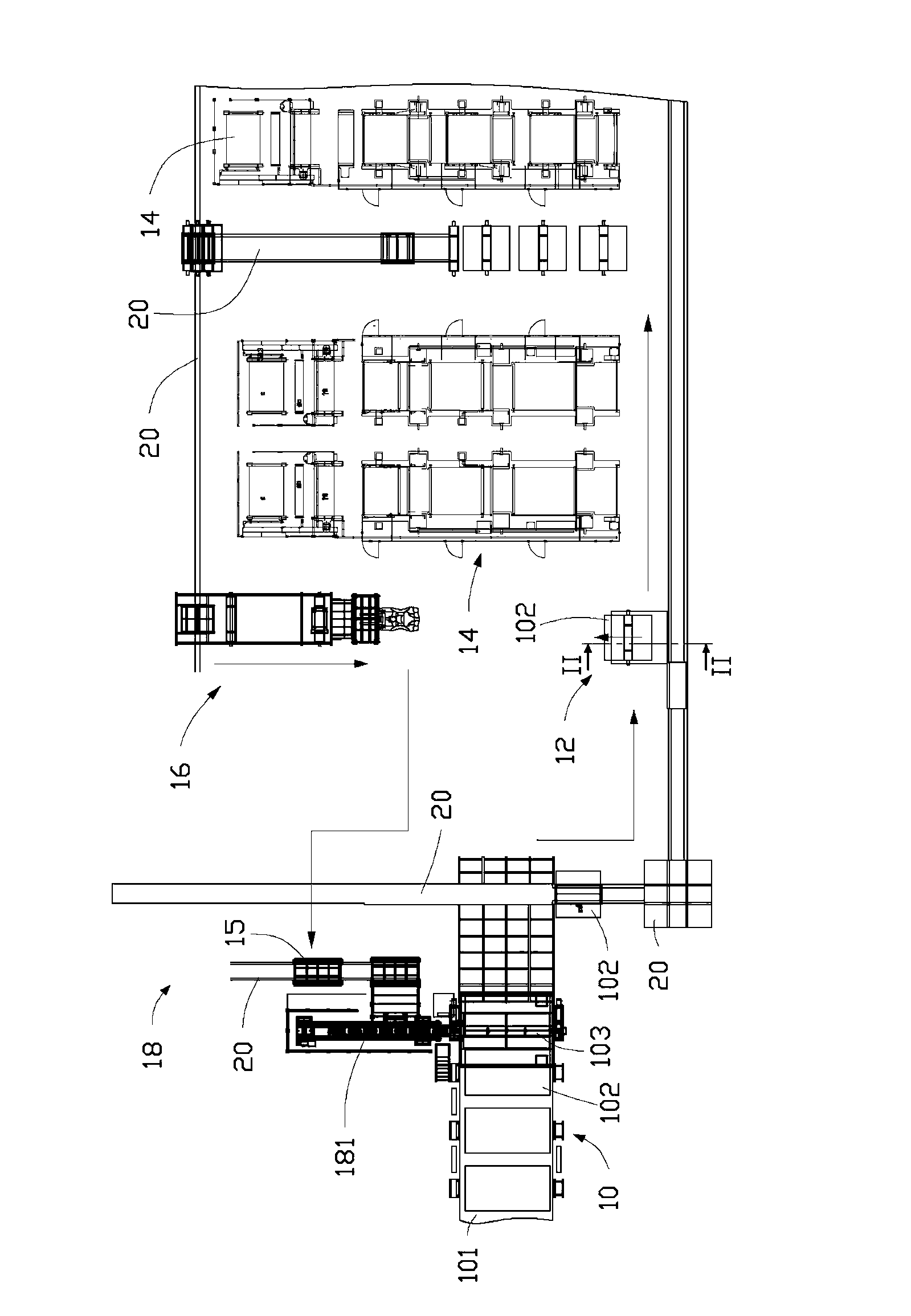

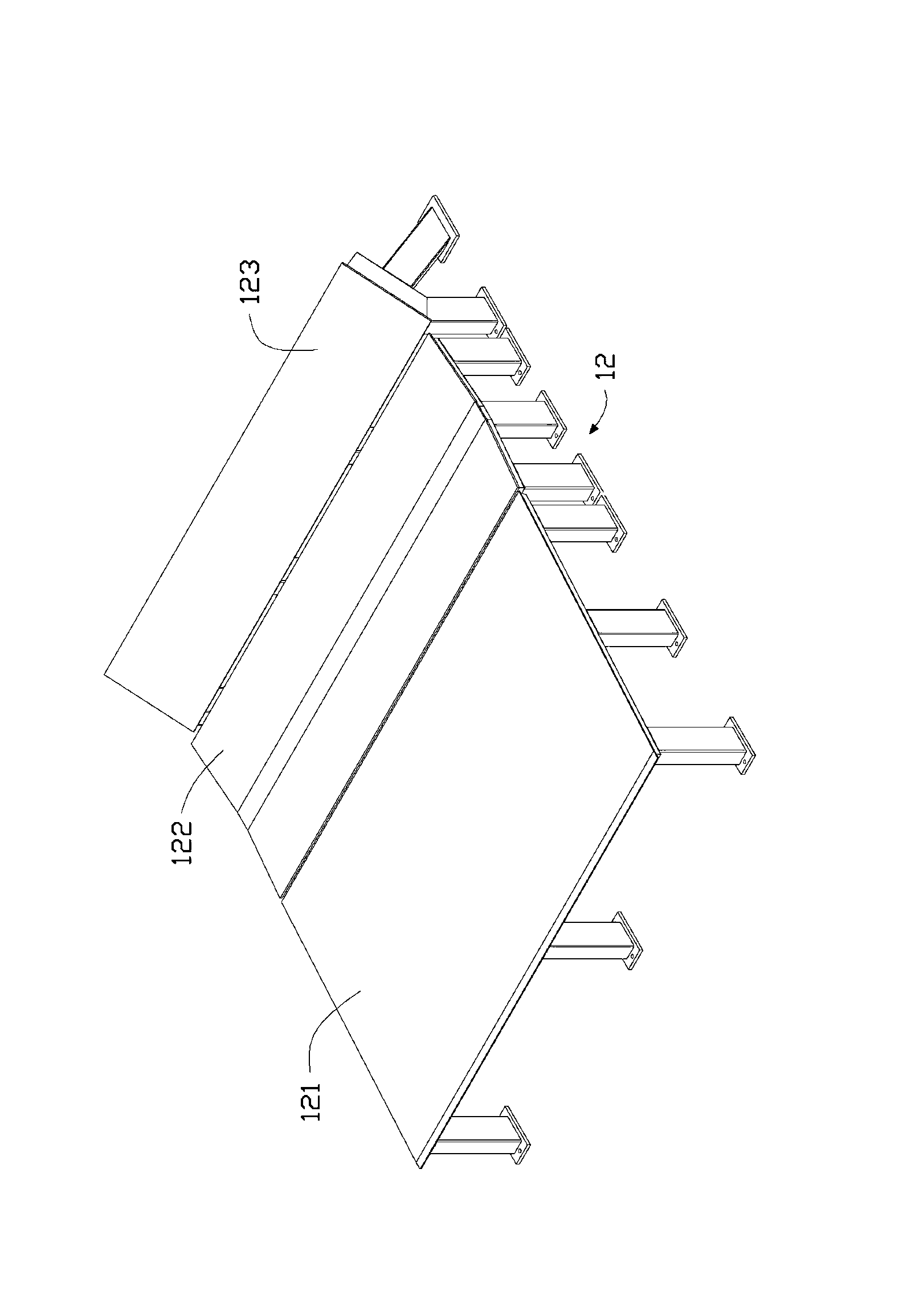

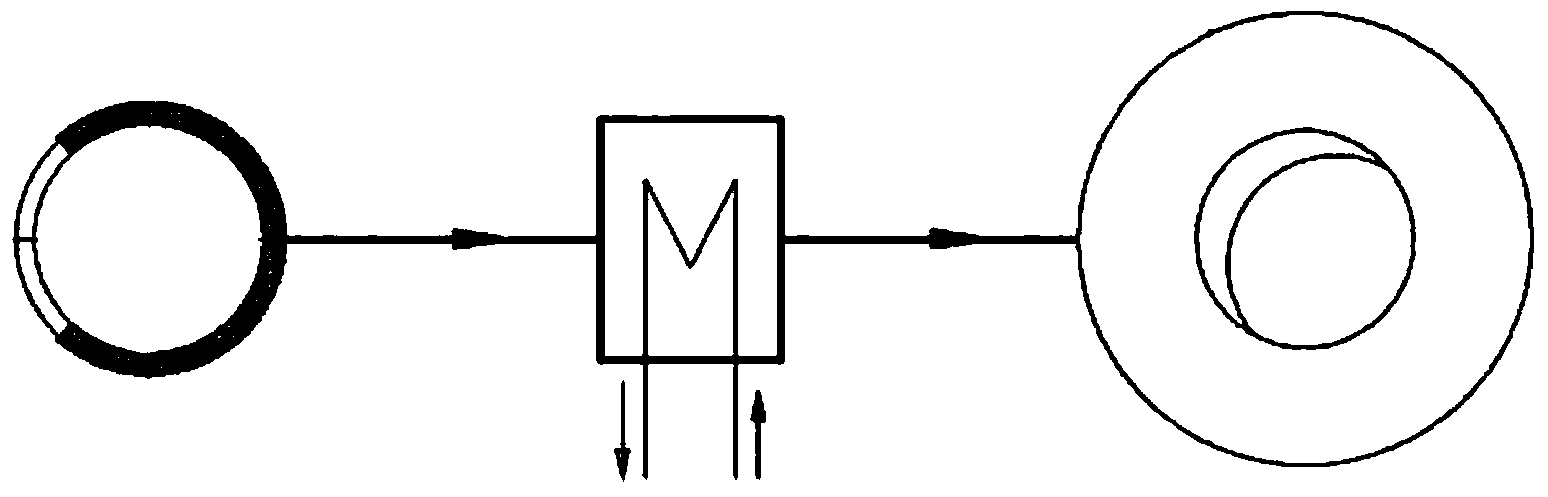

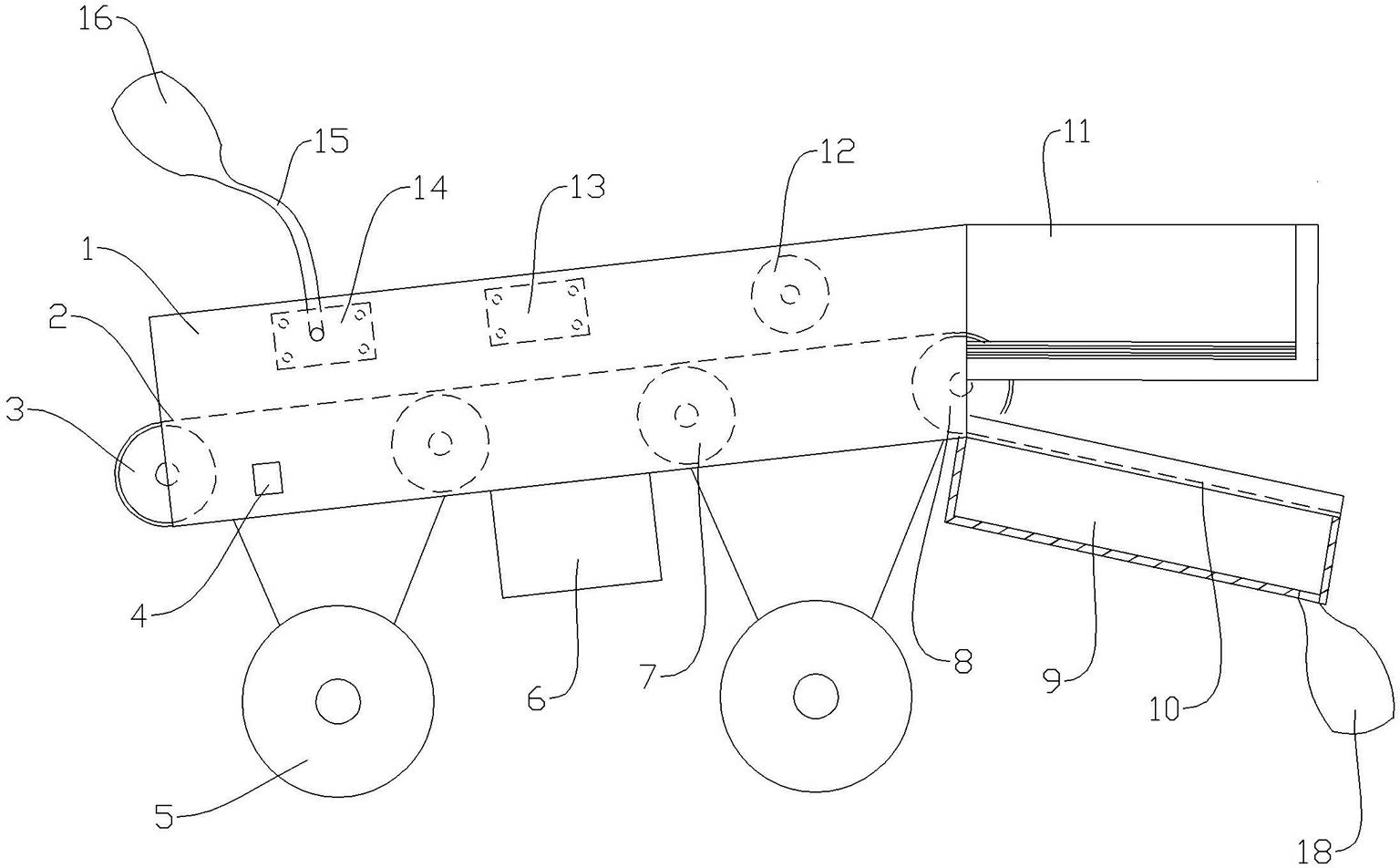

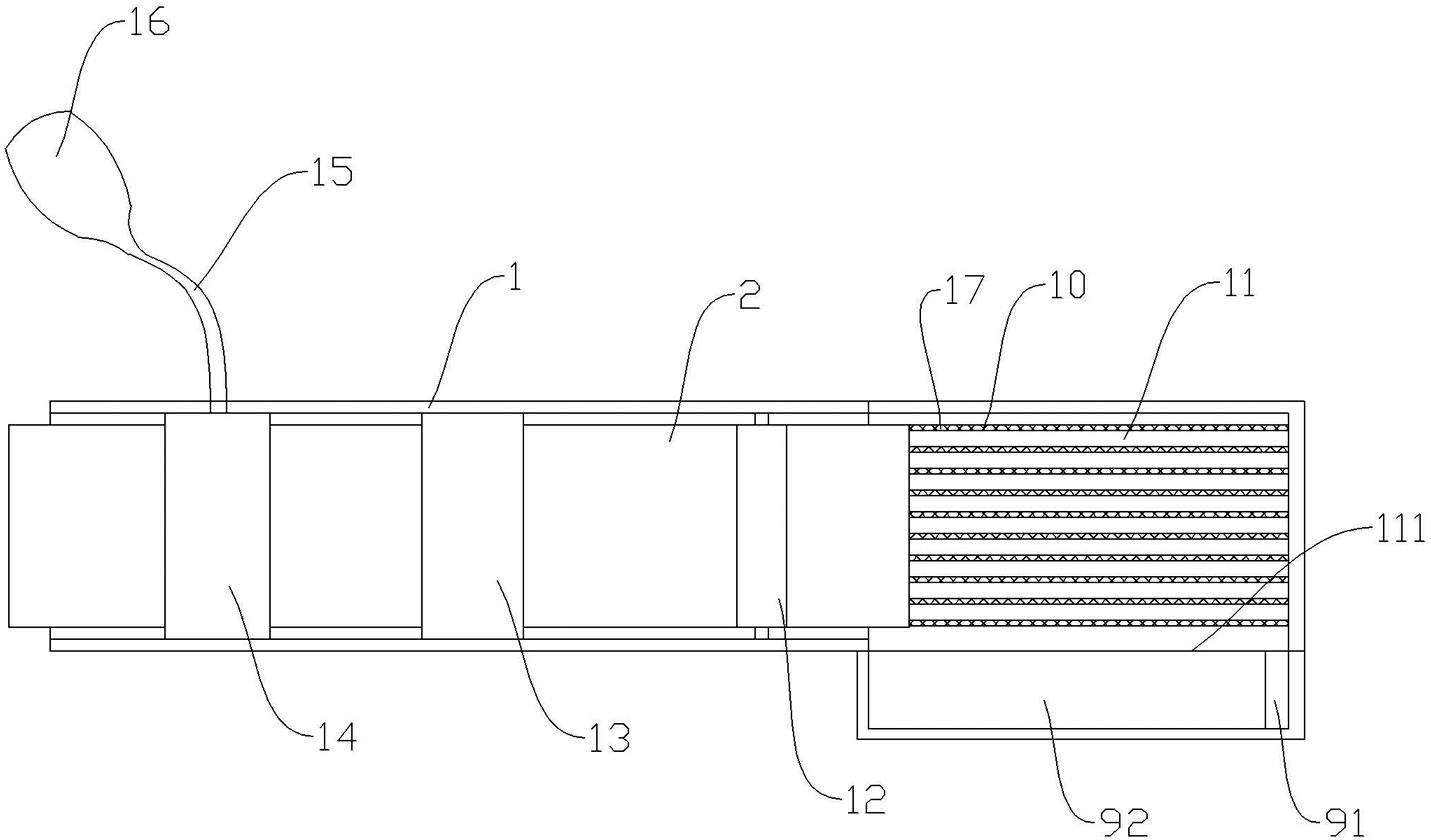

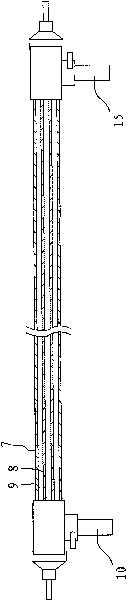

Applying and recovering system and method for core tubes and recovering system for core tubes

ActiveCN103072840AImprove work efficiencyReduce the size of the siteWebs handlingRecovery methodNuclear engineering

The invention relates to an applying and recovering system for core tubes, which comprises a forming unit for coiled materials, an installing unit for shaft heads, a processing unit for the coiled materials, a centralized disassembling treatment unit, a storing and placing unit for core tubes and conveying units, wherein the forming unit for the coiled materials is used for coiling materials on the core tubes so as to form the coiled materials; the installing unit for the shaft heads is used for installing the shaft heads to both ends of the core tubes; the processing unit for the coiled materials is used for processing the coiled materials with the shaft heads; the centralized disassembling treatment unit is used for taking out the shaft heads on the coiled materials after being processed; the storing and placing unit for the core tubes is used for storing and placing the core tubes of which the shaft heads are taken out; and the conveying units are arranged between every two units in a connecting way. The invention also provides an applying and recovering method for the core tubes and a recovering system for the core tubes. By designing the entire system according to the applying and recovering system for the core tubes, the applying and recovering method for the core tubes and the recovering system for the core tubes, the core tubes which are already used are conveyed and placed in a centralized way, and the treatment of drawing off the shaft heads in a centralized way and the like is also carried out. The working efficiency can be enhanced, the area of a site is saved, the manpower is saved, and the cost is lowered.

Owner:GOLD HONG YE PAPER

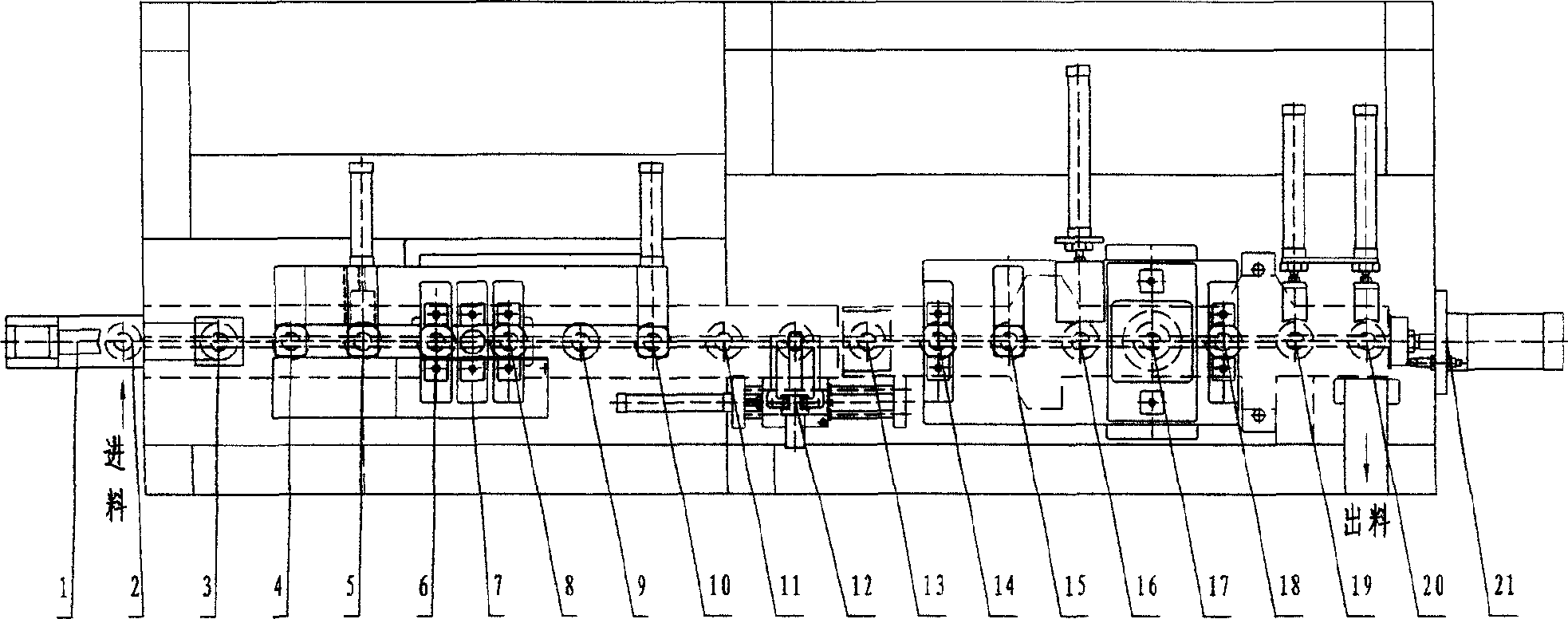

Ball separating and riveting method for assembling small-sized deep groove ball bearing

The present invention is ball separating and riveting process of assembling small deep flute ball bearing. The assembling process includes two parts of separating balls and riveting arranged linearly, and the workpiece shifting equipment for shifting the workpiece from the ball separating part to the riveting part has workpiece shifting mechanism including ball separating shift tray and riveting shift tray. The present invention adopts the advanced technologies of photoeleectronic sensing, on-line detection, pneumatic pressurizing, etc. and has convenient linearly arranged work sites. The present invention has high production efficiency, high assembling quality and other advantages, and the assembled bearing has less vibration noise and high flexibility.

Owner:上海莱必泰数控机床股份有限公司

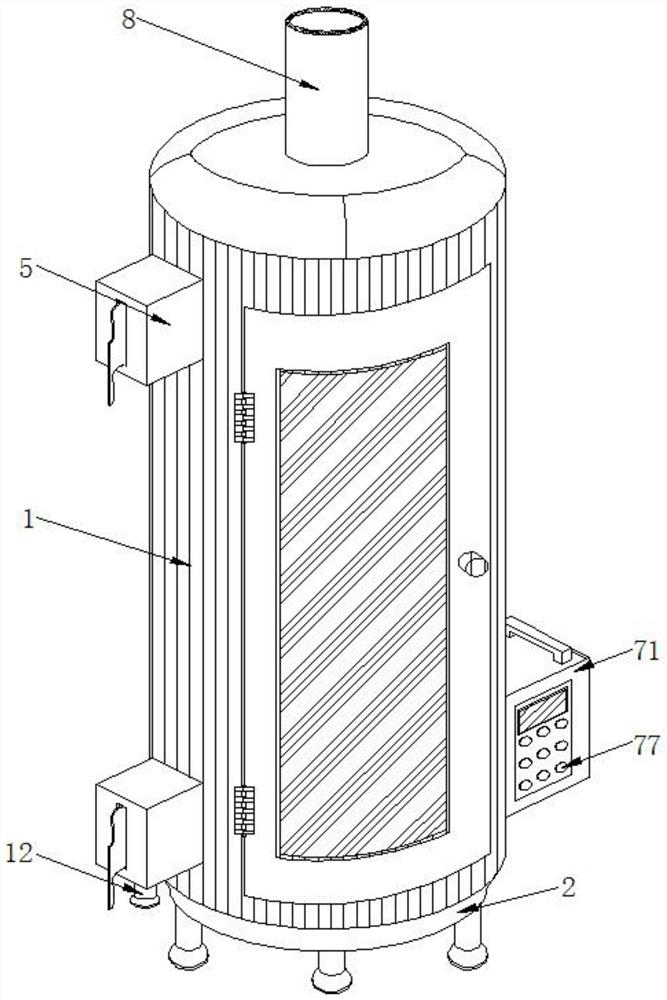

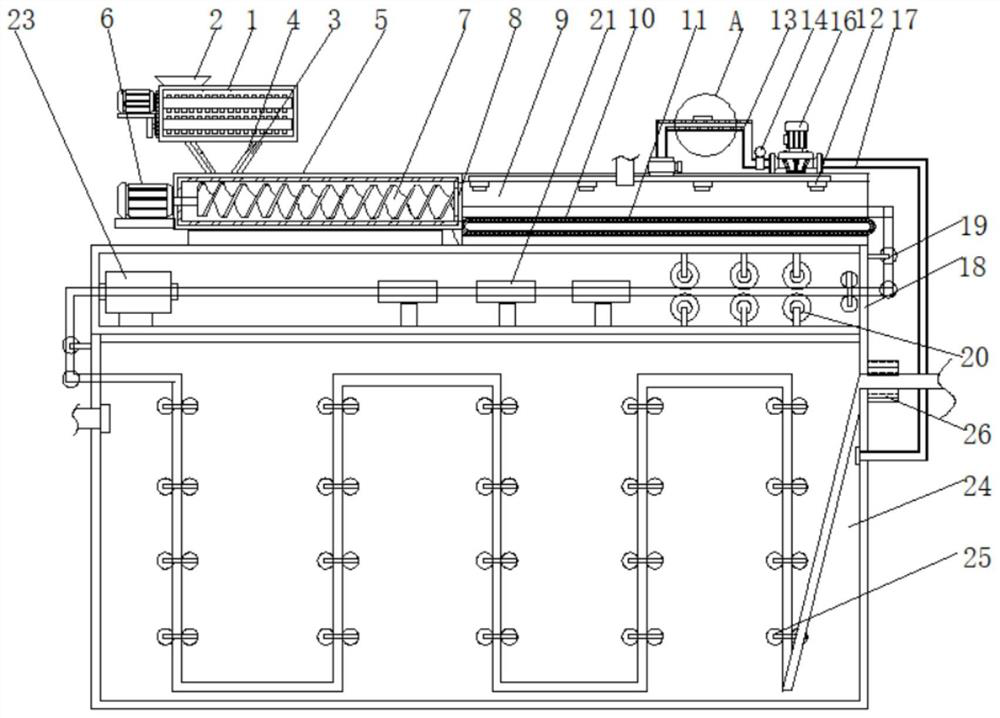

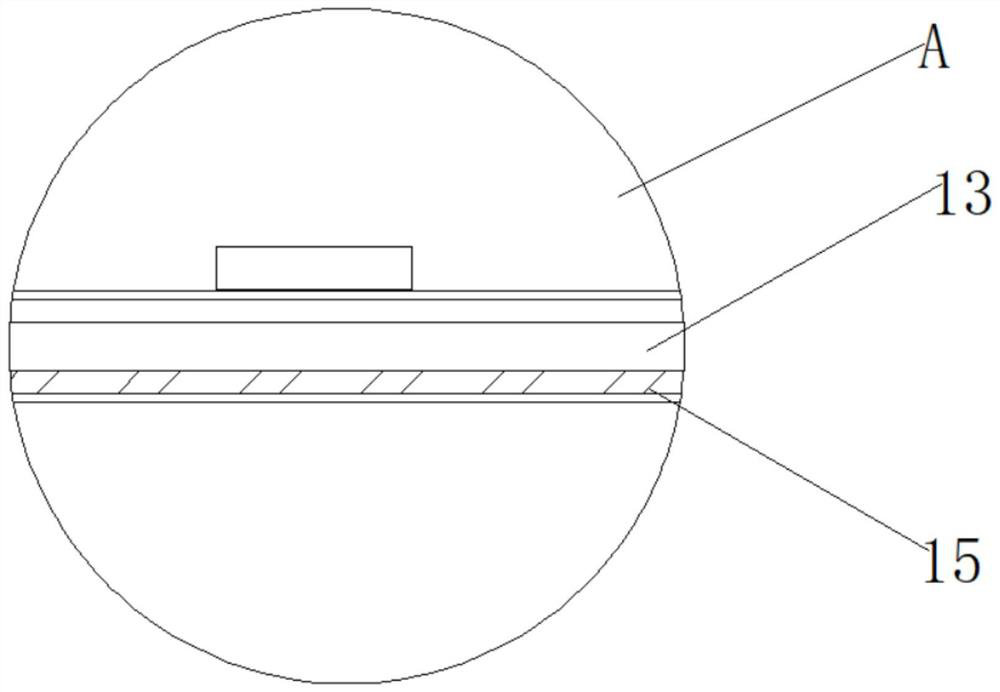

Drum-type drying system for textile fabric production

InactiveCN111637697AReduce manufacturing costImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsManufacturing engineeringTextile

The invention discloses a drum-type drying system for textile fabric production, and relates to the technical field of textile fabric production. The drum-type drying system for textile fabric production comprises a barrel body and a bottom box fixedly connected to the bottom of the barrel body through bolts, an outer drum drying assembly is fixedly installed on the inner wall of the barrel body through bolts, an inner drum drying assembly is fixedly installed on the top of the inner wall of the barrel body through a U-shaped frame, and material clamping mechanisms are fixedly mounted at the top and the bottom of one side of the barrel body correspondingly. According to the drum-type drying system for textile fabric production, through the vertical winding design, the occupied area of drying equipment is greatly reduced, the workshop site area is well saved, spiral winding type inner and outer double-layer drying of a textile fabric can be achieved, the long-distance textile fabric canbe dried at a time, the drying efficiency is greatly improved, meanwhile, an extrusion mechanism can be directly installed on drying equipment to conduct water extrusion treatment on the fabric, theproduction cost is saved, and the drying efficiency is improved.

Owner:葛伟

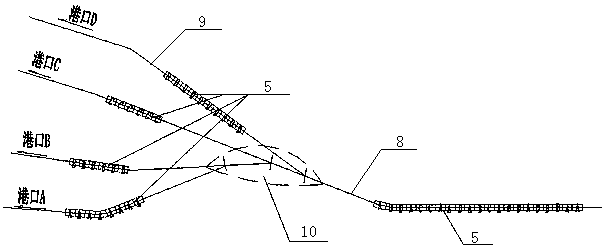

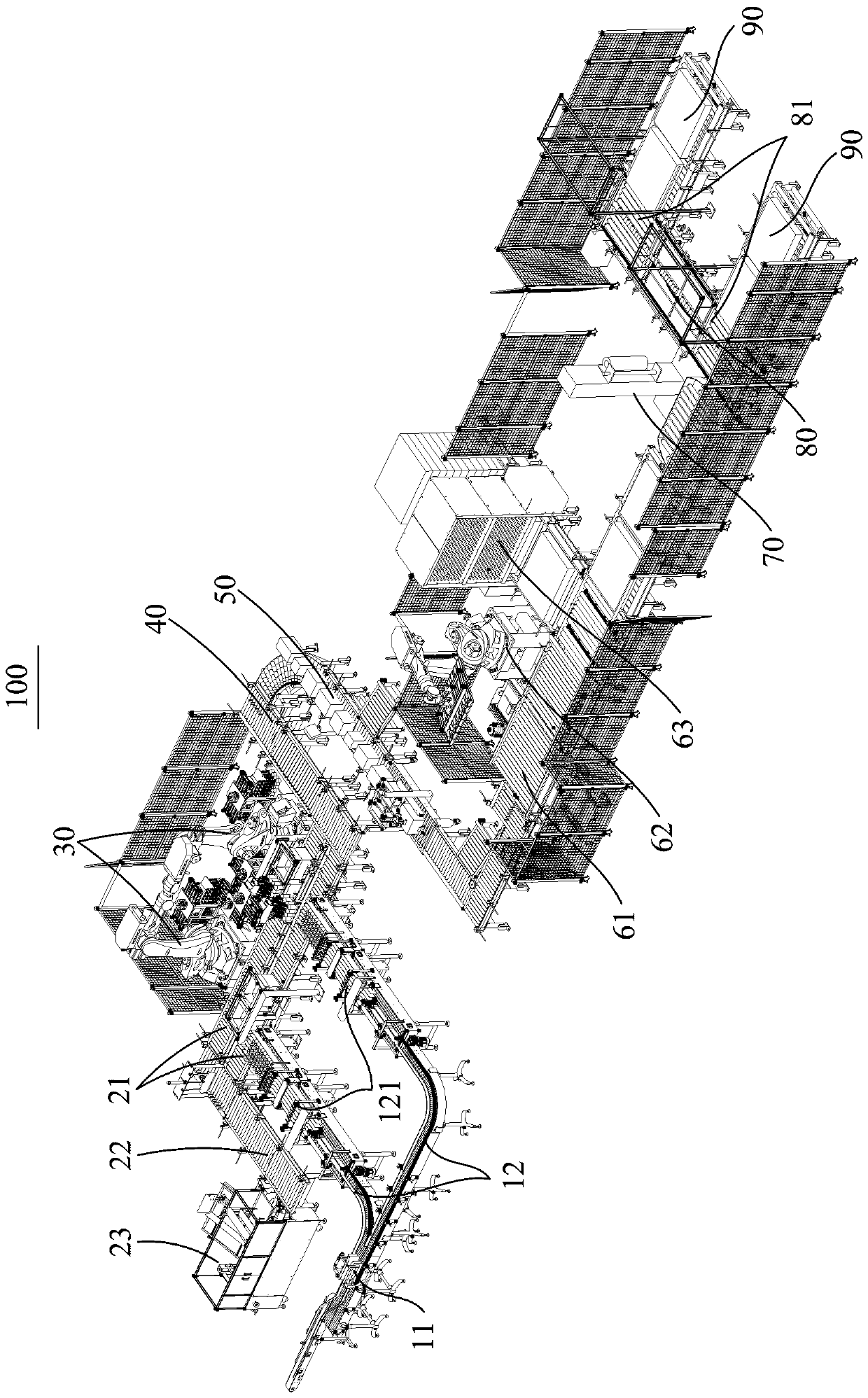

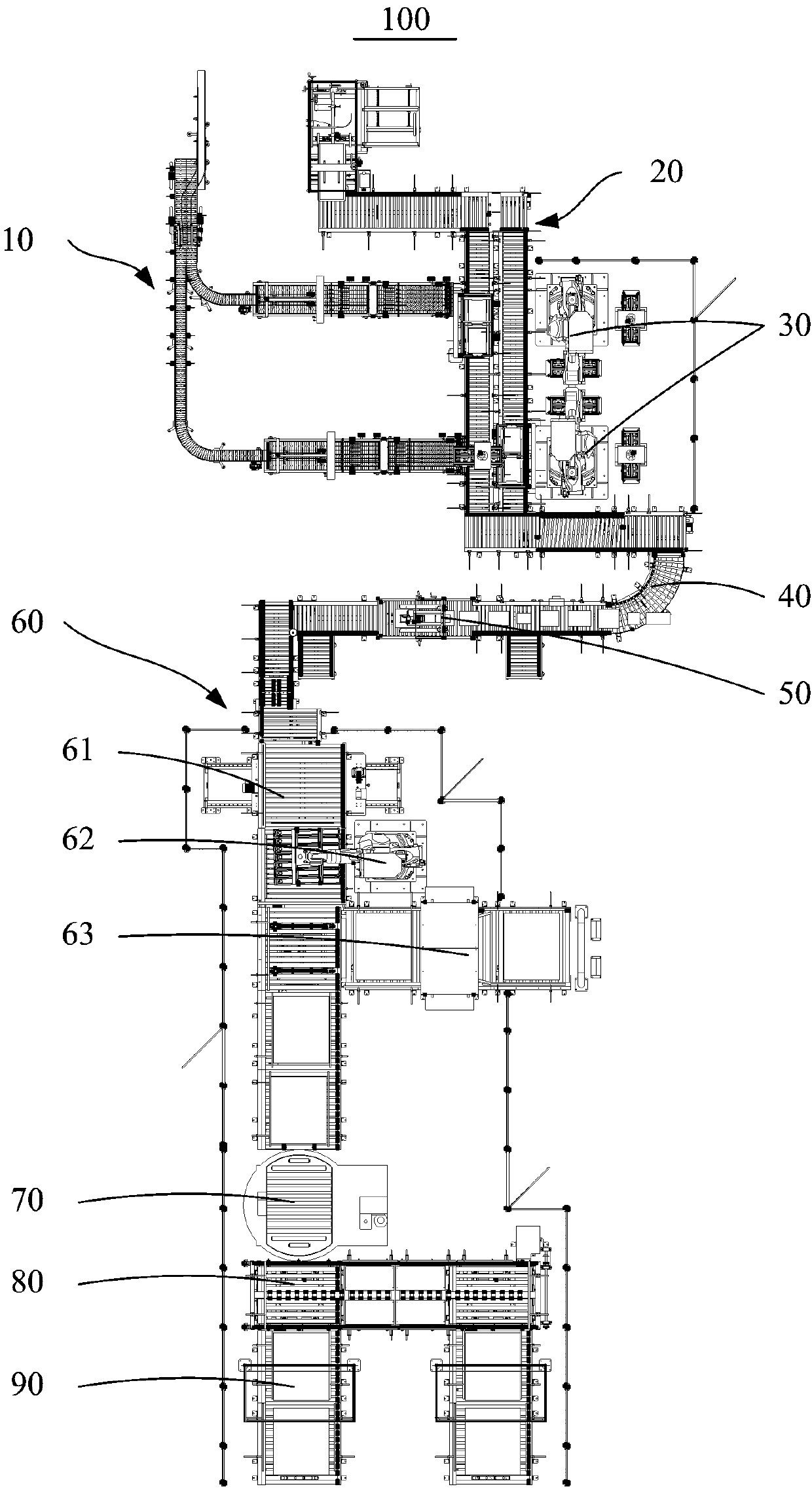

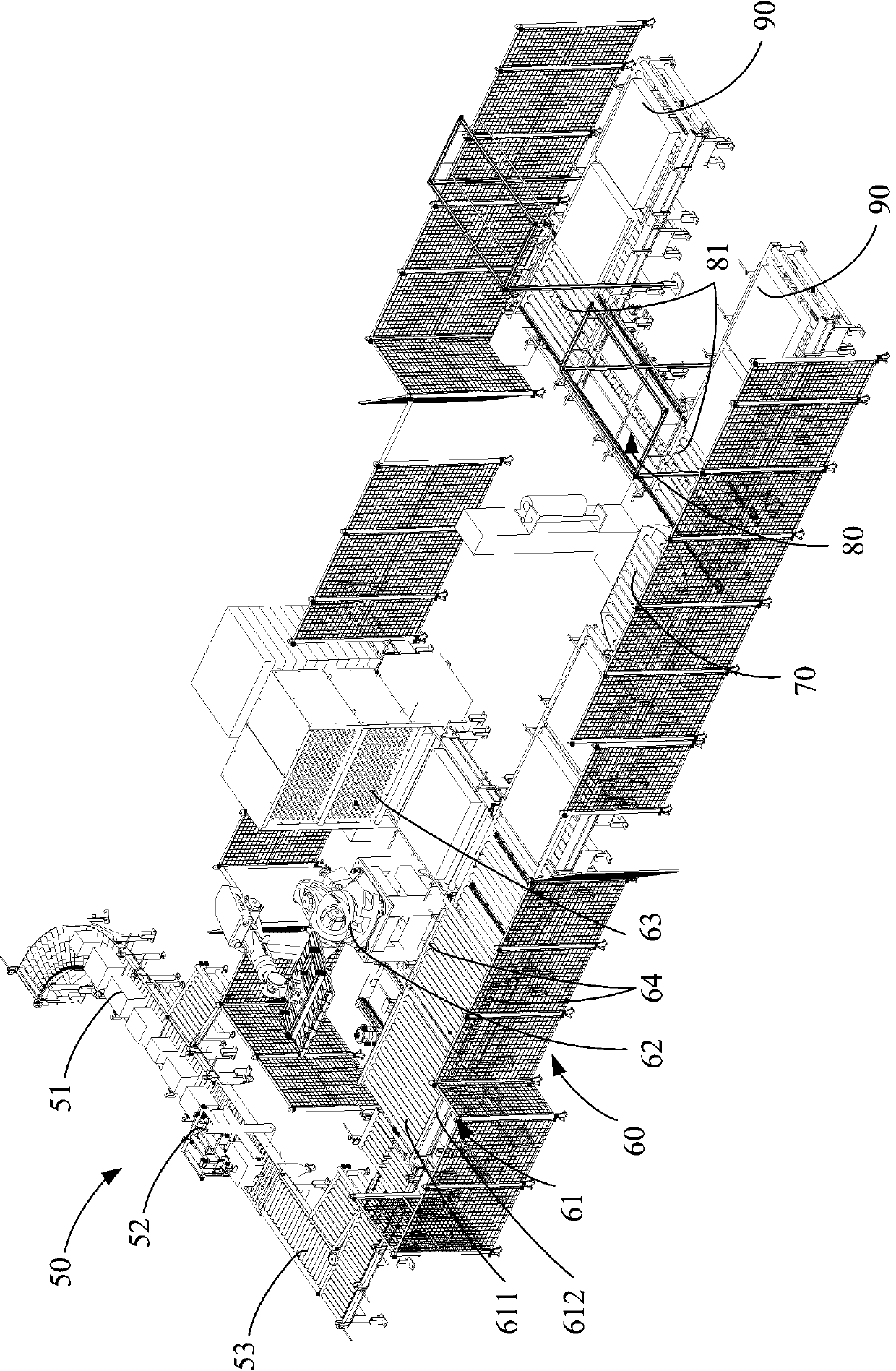

Operation system and method for unloading from railway and waterway combined transportation railway harbour station to harbour district stacking yard

The invention provides an operation system and method for unloading from a railway and waterway combined transportation railway harbour station to a harbour district stacking yard. The system comprises a railway receiving and departure yard and a plurality of harbour districts corresponding to the railway receiving and departure yard; the railway receiving and departure yard is provided with at least one receiving and departure line; a dumping and loading yard arranged adjacent to the receiving and departure line is further included, and is provided with at least one dumping and loading line parallel with the receiving and departure line; the dumping and loading line communicates with the harbour districts; a plurality of track power flatcars run on the dumping and loading line; the railway harbour station is further provided with a container loading and unloading machine and tool; and the receiving and departure line and the dumping and loading line are located in an loading and unloading range of the container loading and unloading machine and tool. According to the operation system and method for unloading from the railway and waterway combined transportation railway harbour station to the harbour district stacking yard, the trace power flatcars serve as transferring carrying tools, transferring marshalling operation containers do not fall onto the ground for stacking, thusthe railway harbour station does not need a container stacking place, it is only needed to arrange the dumping and loading line, the container dumping and loading yard is small in occupied area, landfor use is saved, and station yard arrangement is flexible.

Owner:CREEC WUHAN SURVEY DESIGN & RES

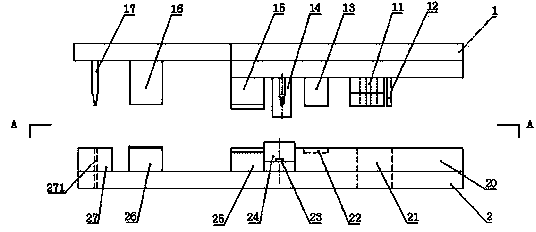

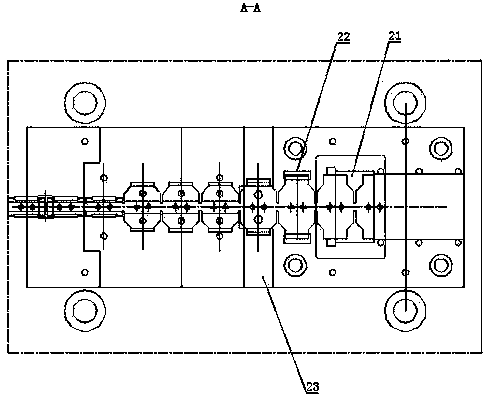

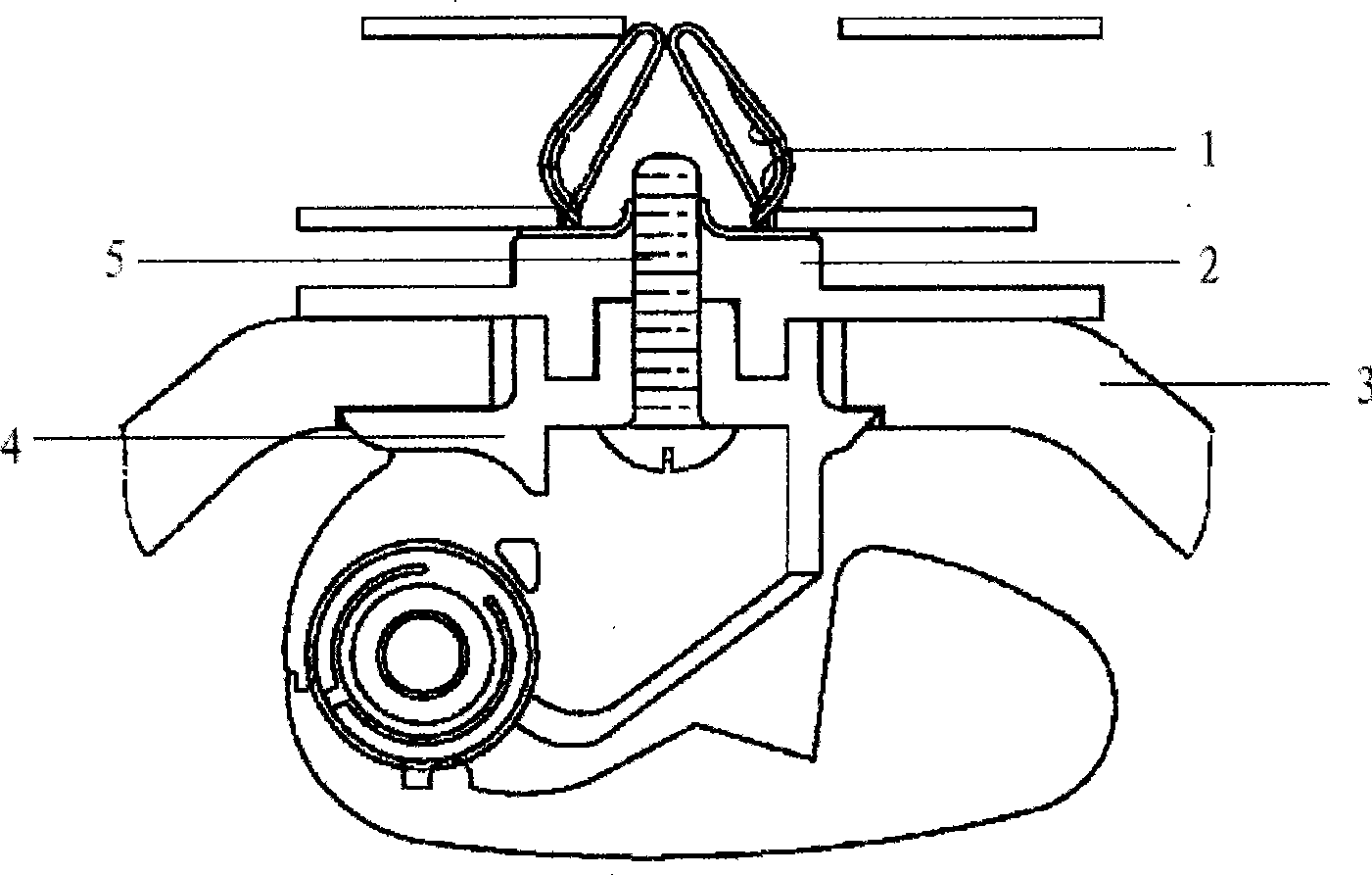

Clamp body die of spring grounding clamp

The invention relates to a clamp body die of a spring grounding clamp. A clamp body is manufactured by adopting a copper strip, and the clamp body die is characterized in that the die comprises an upper die plate and a lower die plate, and a punching edge cutting work position, an edge cutting work position, a pre-circling work position, a circling work position, a performing protruding point punching work position, a first idle work position, a second idle work position, a forming work position, a third idle work position and a cutting-off work position are arranged between the upper die plate and the lower die plate in the horizontal direction in sequence. The processes of punching edge cutting, edge cutting, pre-circling, circling, performing protruding point punching, forming and cutting-off are achieved in sequence when the copper strip passes, and a high production rate is achieved. The area of a punch press and the area of a field can be reduced, and the transportation and occupied storage space of half-finished products can be reduced.

Owner:RUGAO KK TELECOM MATERIALS

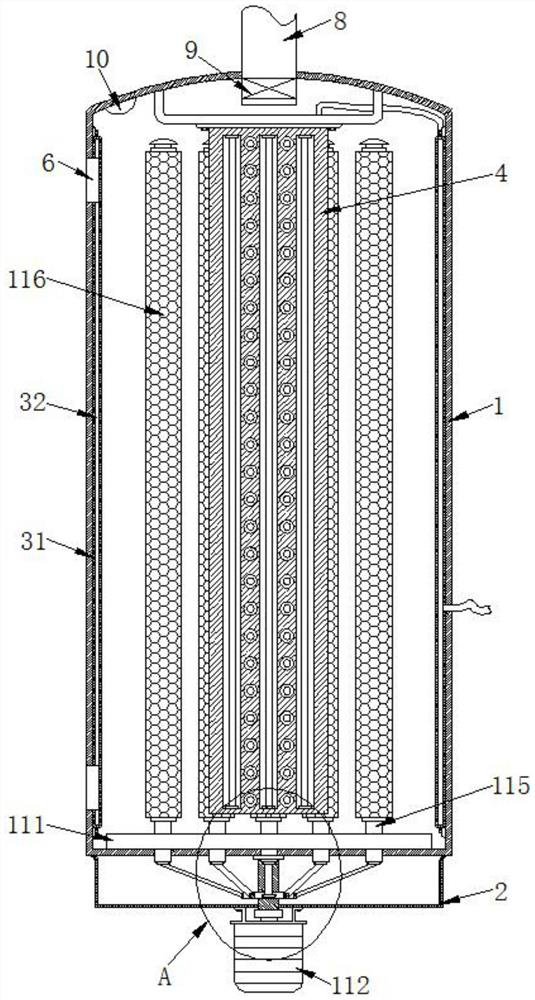

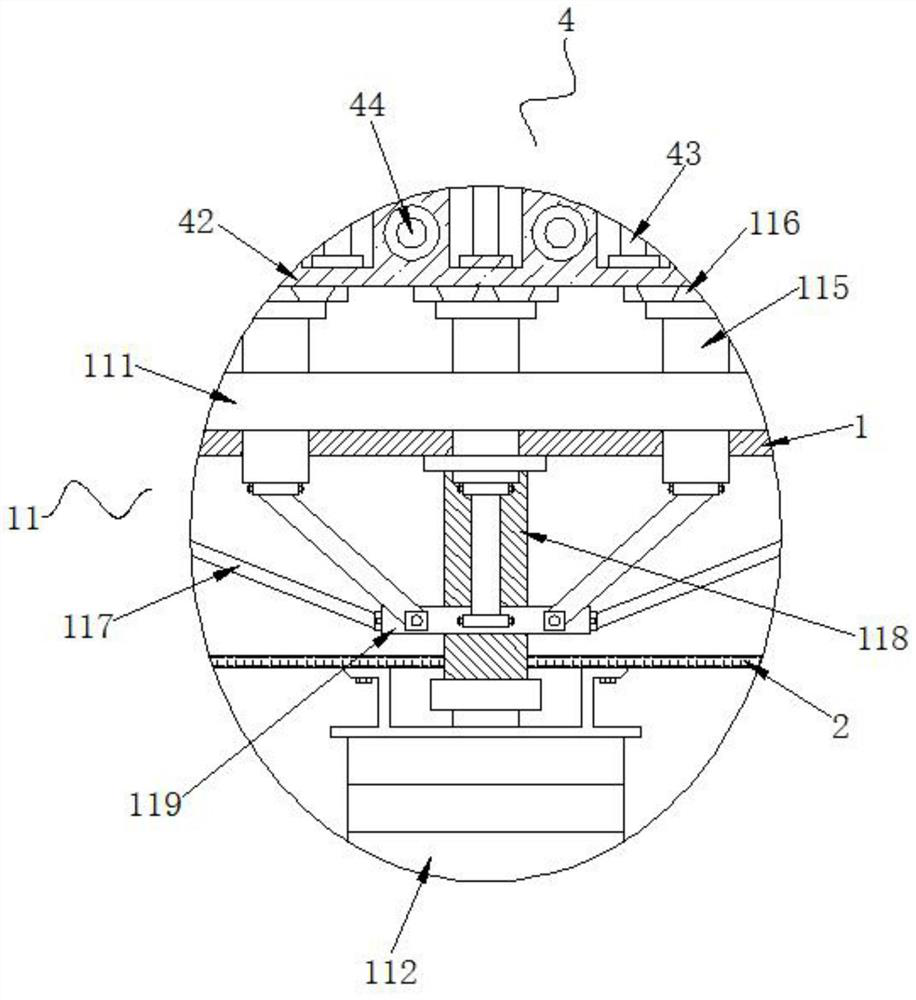

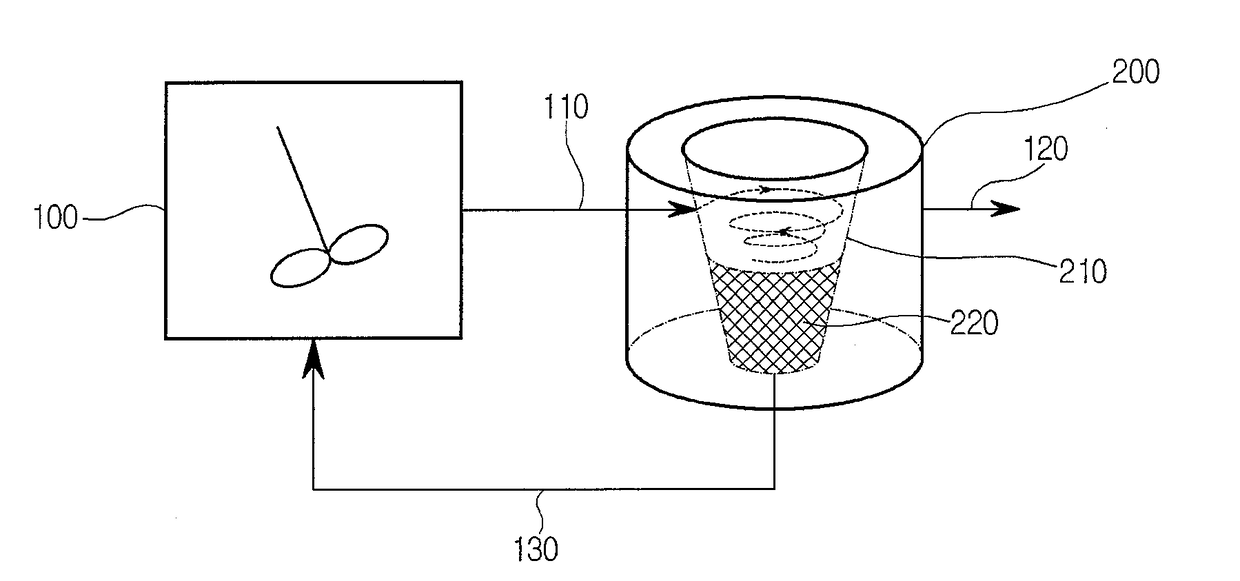

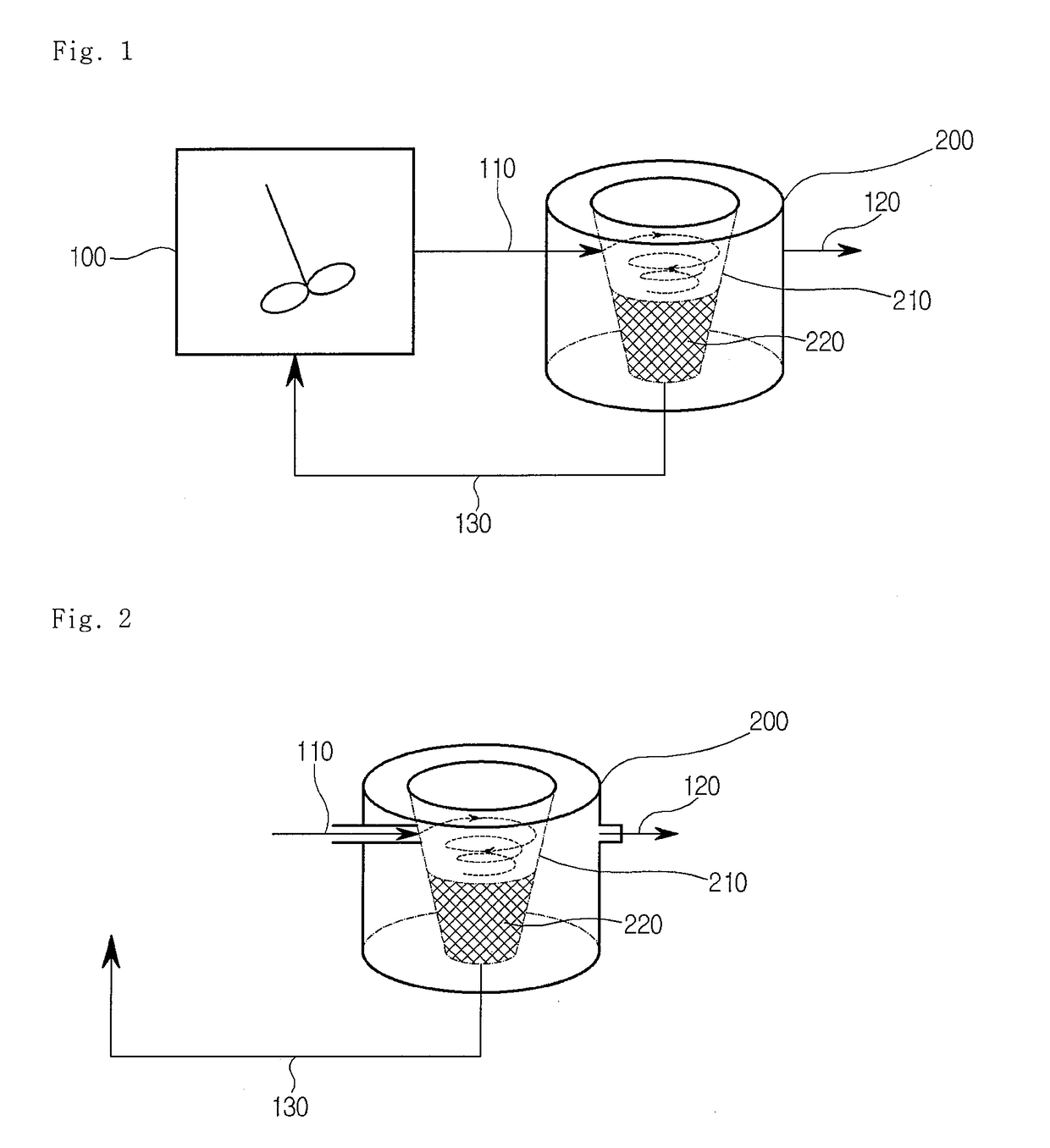

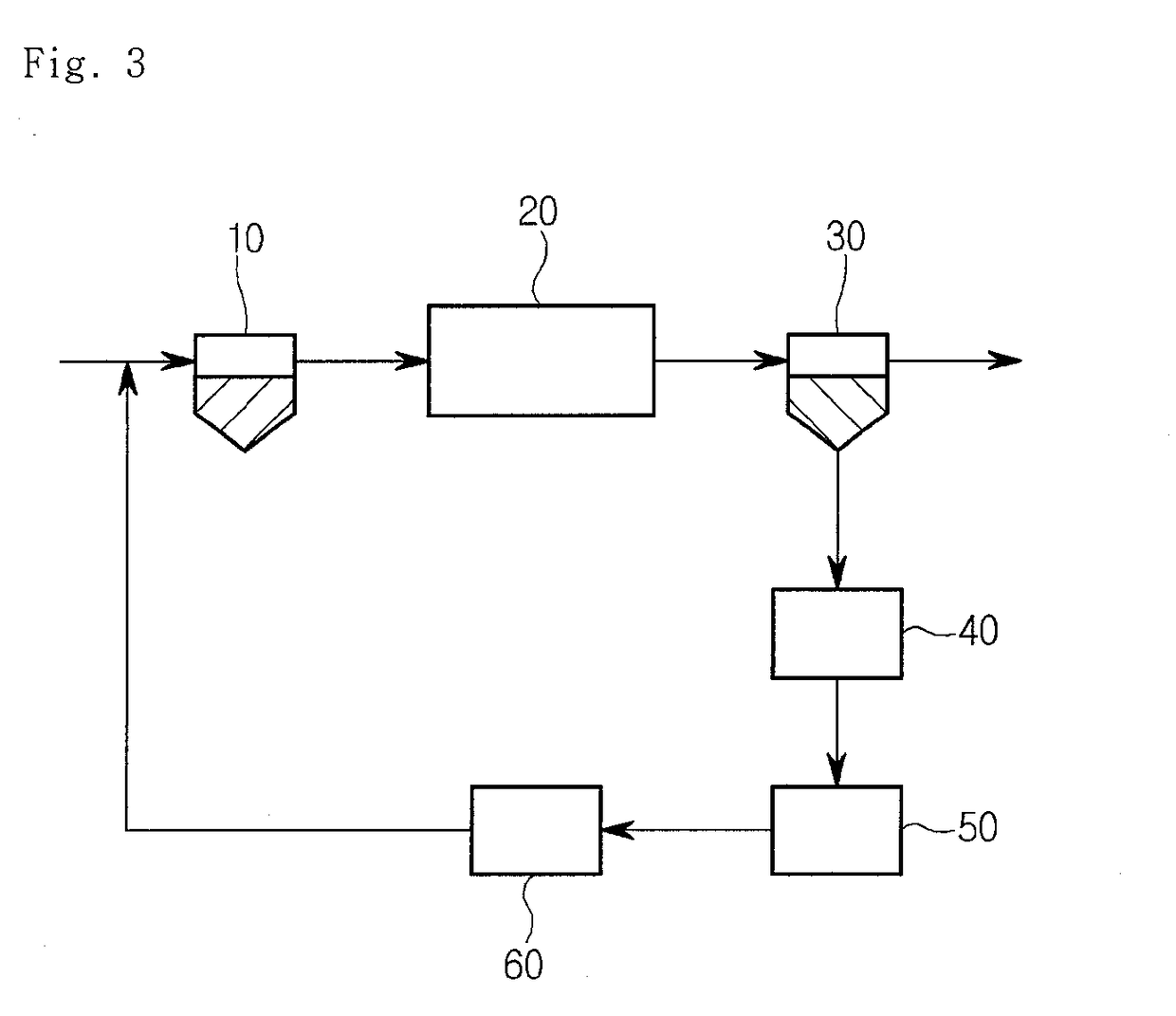

Sequencing batch reactor for sewage treatment and sewage treatment system comprising same

ActiveUS20180297875A1Reduce contentImproving energy production efficiencyWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningSequencing batch reactorActivated sludge

Disclosed is a sequencing batch reactor (SBR) for sewage treatment. The SBR is applicable to an energy-producing sewage treatment system. The SBR includes a treatment tank and a hybrid bacterial strain screening tank. The treatment tank removes ammonium contained in supernatant liquid using anaerobic ammonium-oxidizing (anammox) bacteria. The hybrid bacterial strain screening tank screen anammox bacteria granules out by passing the supernatant liquid discharged from the treatment tank through the hybrid bacterial strain screening tank. The SBR generates biogas using the anammox bacteria and reduces the nitrogen content in the supernatant liquid. The SBR can separate the anammox bacteria granules with high separation efficiency, thereby shortening sewage treatment time and recycling activated sludge, resulting in a dramatic decrease in the amount of waste sludge.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

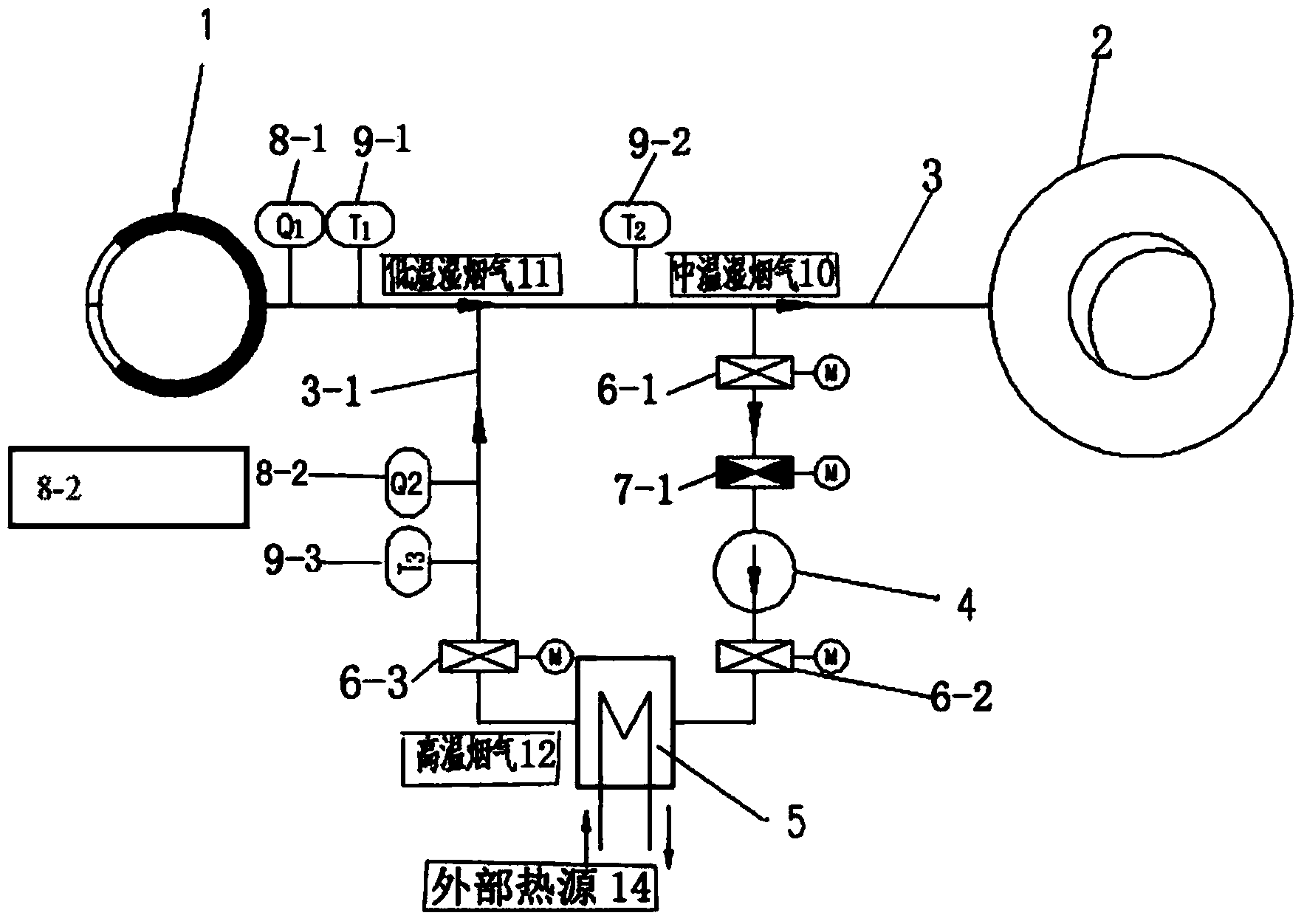

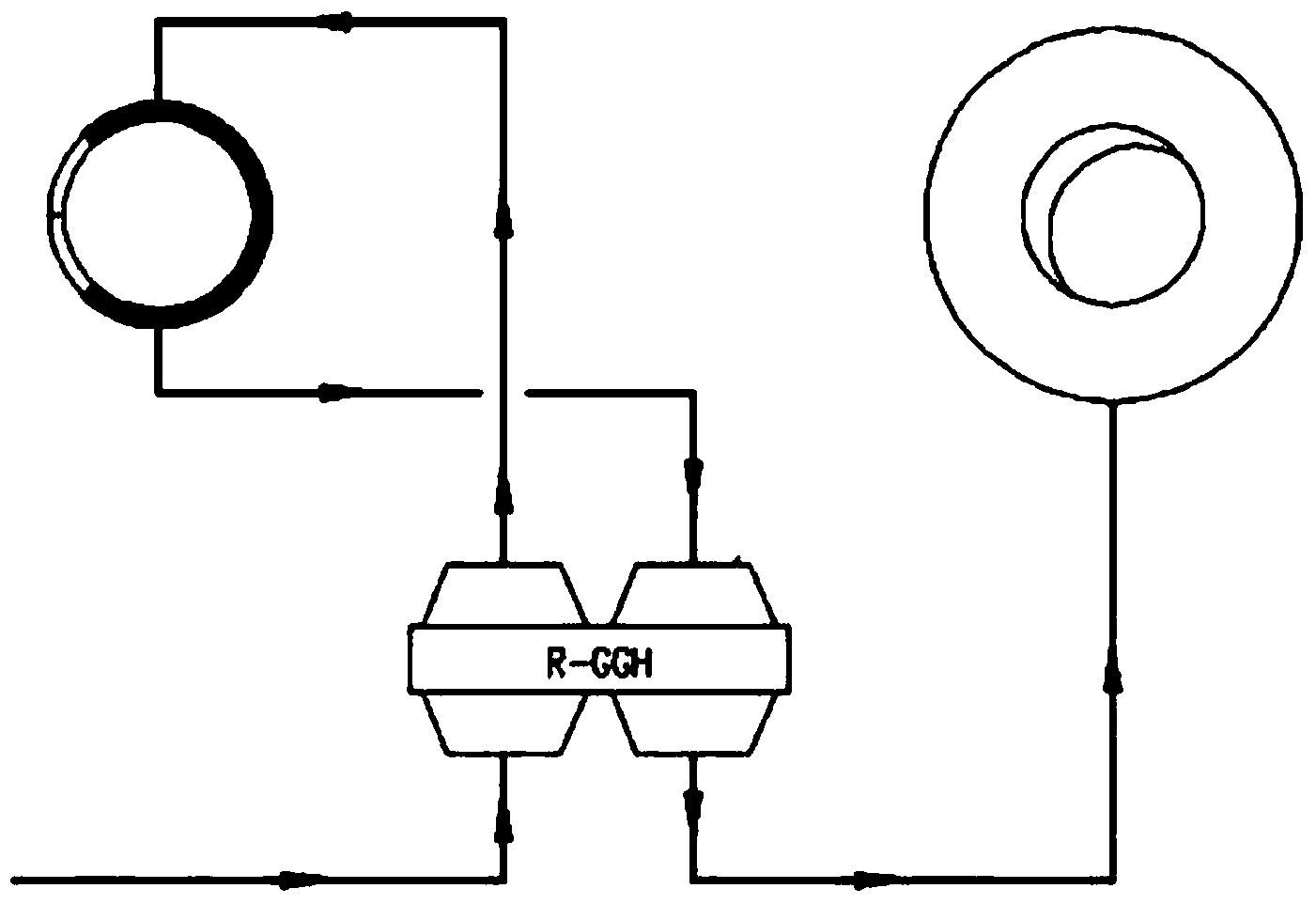

Externally heating type wet flue gas dehumidifying method and system

ActiveCN103638784AExtended service lifeSolve the problem of "white smoke" when dischargingDispersed particle separationFlue gasSmall footprint

The invention relates to an externally heating type wet flue gas dehumidifying method and system. The externally heating type wet flue gas dehumidifying method is characterized in that the externally heating type wet flue gas system is arranged, part of wet flue gas is extracted and reheated, and the heated wet flue gas is changed into high-temperature flue gas and is refilled into low-temperature wet flue gas to increase the final exhaust temperature of the flue gas; part of medium-temperature flue gas is extracted from the inlet of a chimney and is fed into an external steam heat exchanger of the externally heating type wet flue gas system, the heating steam is from auxiliary steam of a thermal power plant or other heat sources of heat supply systems, the medium-temperature flue gas is heated to high-temperature flue gas of 160 DEG C by the externally heating type wet flue gas system and then is fed into low-temperature wet flue gas after being boosted by a booster fan, and all the low-temperature wet flue gas is heated into the medium-temperature flue gas and is exhausted into the chimney to realize dehumidification of the wet flue gas. The externally heating type wet flue gas dehumidifying method can eliminate 'white smoke' phenomenon when the flue gas is exhausted from the chimney, and has the characteristics of having small occupied area and capability of operating continuously and safely.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

High efficiency automatic die cleaning device

InactiveCN107552457AImprove drying efficiencyGuaranteed stabilityCleaning using liquidsWater resourcesEngineering

The invention discloses an automatic cleaning device for high-efficiency molds, which comprises a bottom plate, a box body is fixedly connected to the top of the bottom plate, and a cleaning tank is fixedly connected to the bottom of one side of the inner wall of the box through a supporting column. Both sides of the inner wall are fixedly connected to the heating block, and the bottom side of the inner wall of the cleaning tank is connected with a first water outlet pipe. The end of the first water outlet pipe away from the cleaning tank runs through the box and extends to the outside of the box. A water outlet valve is fixedly installed inside a water outlet pipe. The invention relates to the technical field of cleaning equipment. The high-efficiency mold automatic cleaning device can clean, recycle and reuse the mold very well. Such a facility can save water resources very well, and also play a great role in saving costs and protecting the environment. It is necessary to manually wipe the mold with a dust-free cloth, directly in the cleaning tank, and use the cleaning shaft to rotate and clean, which improves the mold cleaning efficiency.

Owner:许凯杰

Assembly method and connection mode of roof, parts and plates of automobile

InactiveCN101519085AQuick installationSimplify the installation processVehiclesAutomotive engineeringStructural engineering

The invention relates to an assembly method and connection mode of a roof, parts and plates of an automobile, which can effectively reduce assembly procedures and save production cost. The assembly method and the connection mode of a roof, parts and plates of an automobile are characterized in that firstly parts needing to be fixedly connected with the automobile roof are installed on the roof the automobile and screws or buckles used for connecting the plates of the body of the automobile are pre-arranged on the roof; and then the roof and the plates are fixed through the pre-arranged screws or buckles.

Owner:CHERY AUTOMOBILE CO LTD

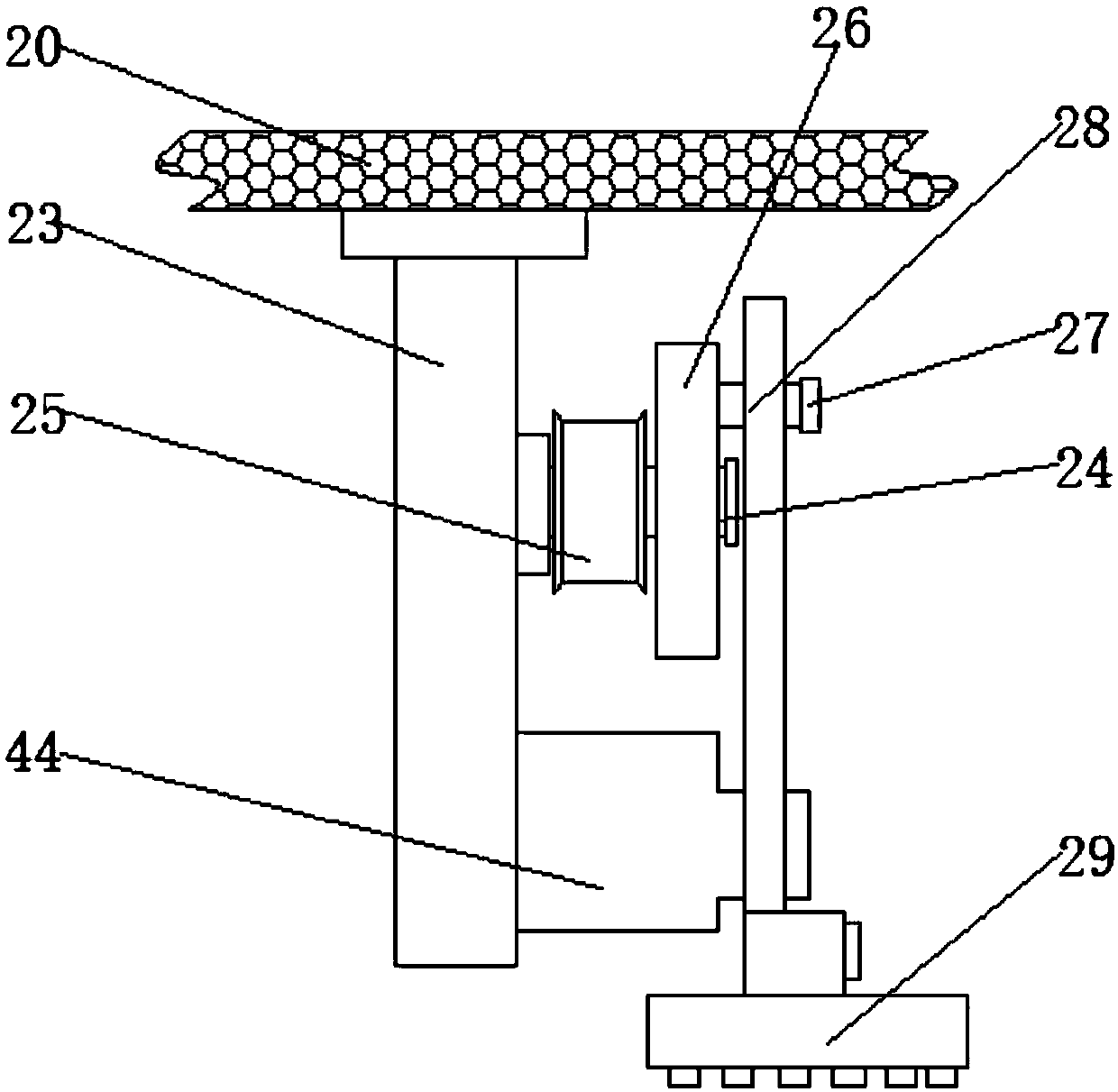

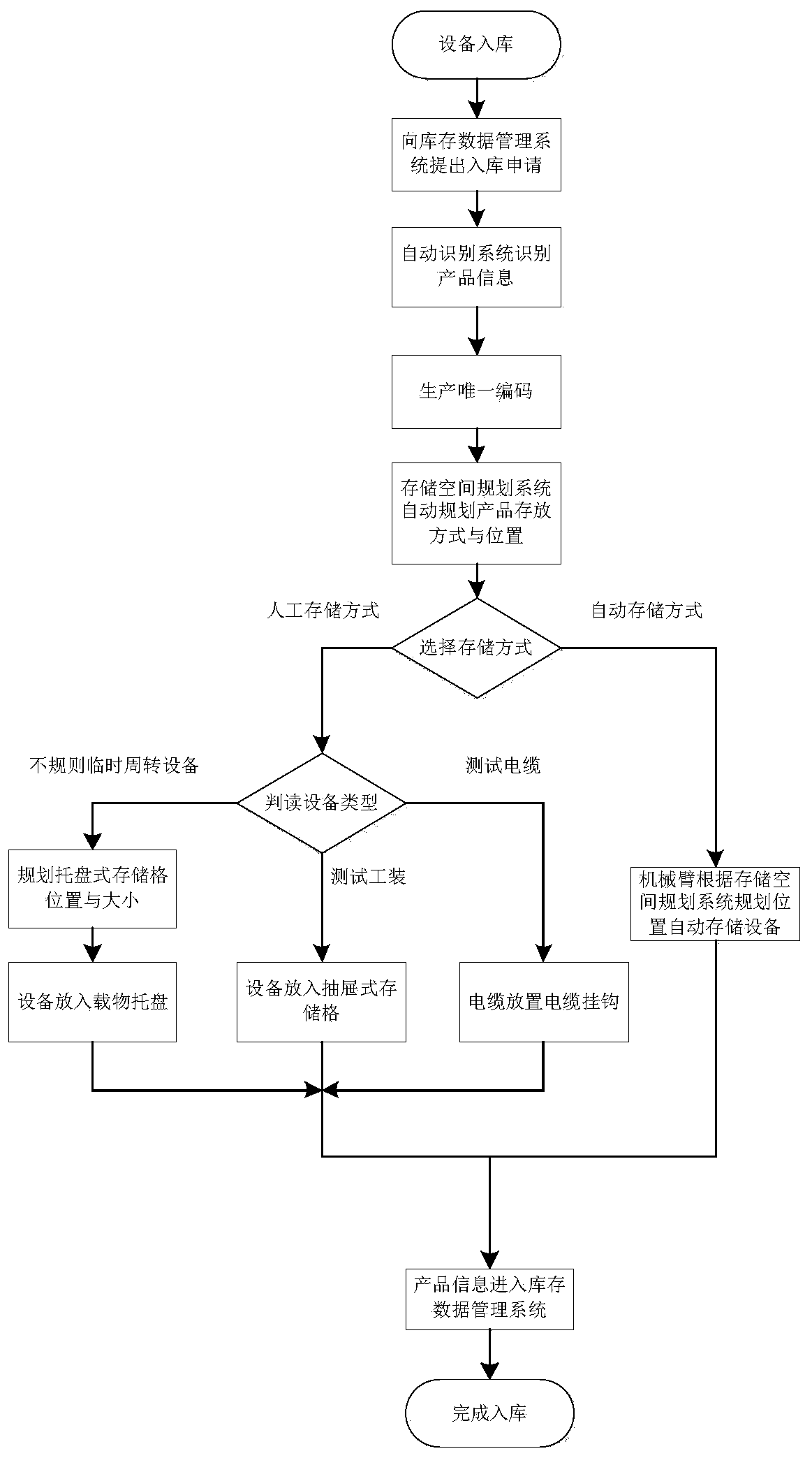

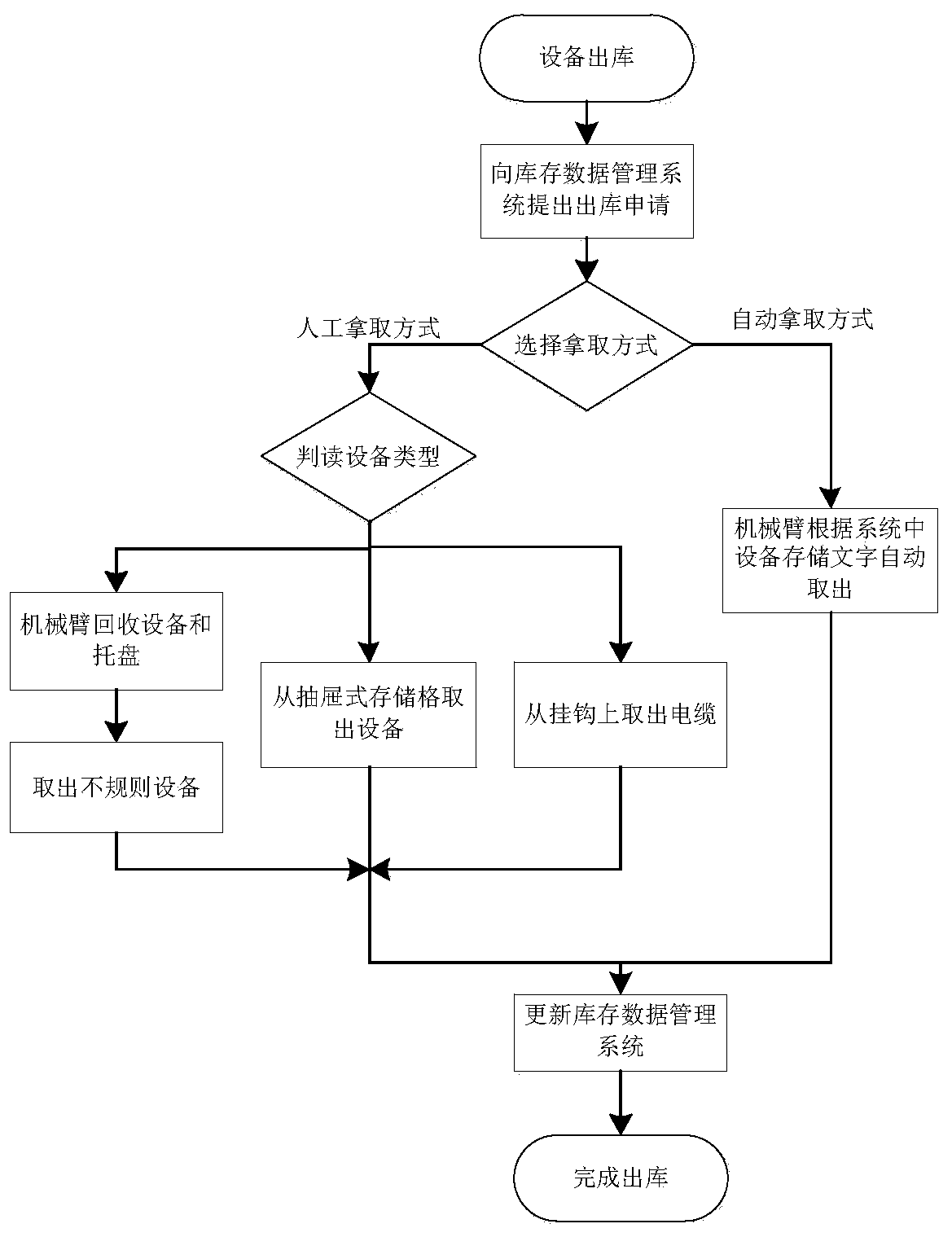

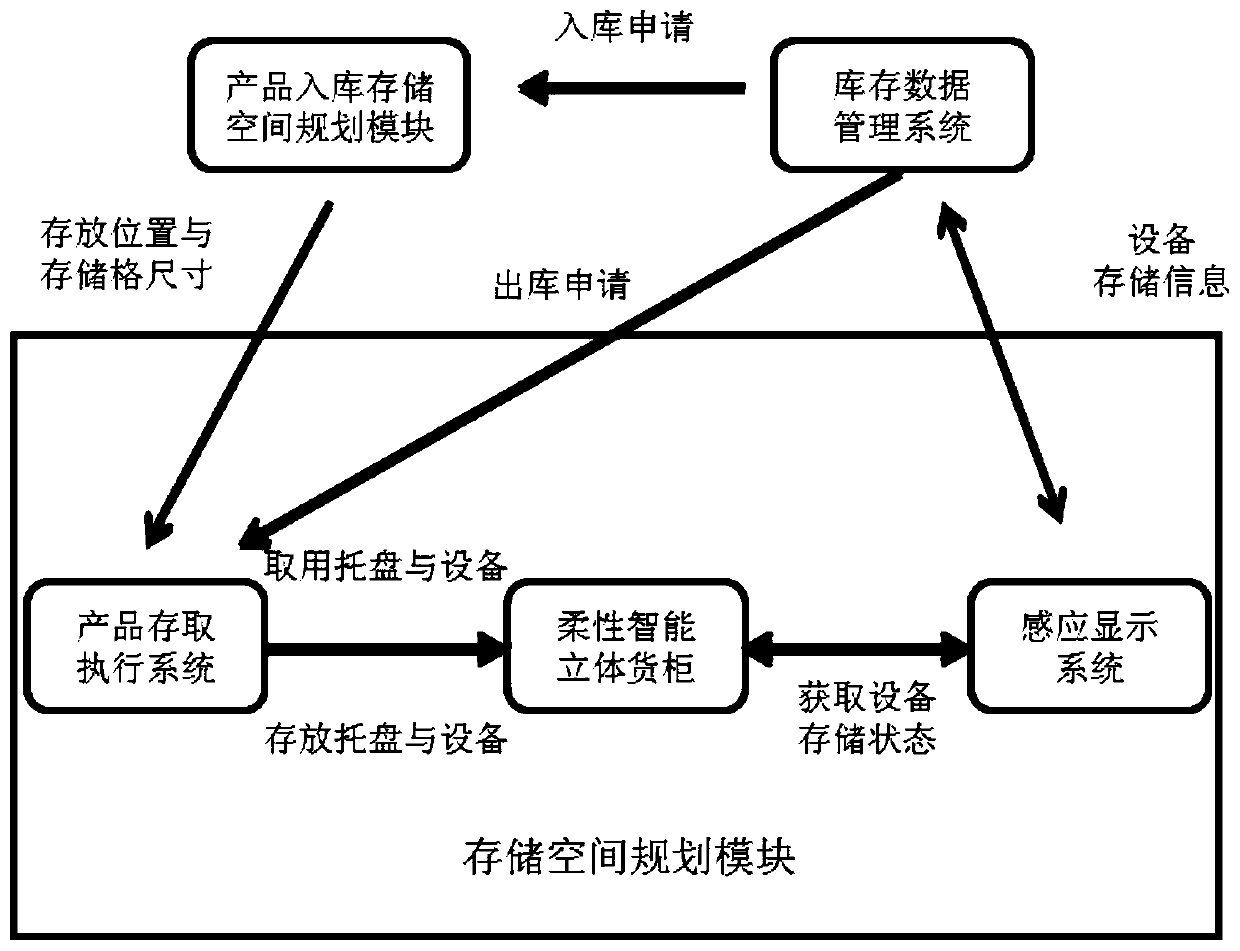

Spaceflight control system product inventory intelligent management system

InactiveCN110991949ASolve the problem of large amount of management work dataFree laborLogisticsManagement planningSpaceflight

The invention discloses a spaceflight control system product inventory intelligent management system. The system comprises a product warehousing management planning module and an intelligent storage module. The product warehousing management planning module comprises a product automatic identification system and a storage space planning system. The product automatic identification system comprisesa product information acquisition device, a product database and a bar code generator. The product information acquisition device is used for acquiring a product appearance image and a nameplate, matching with a standard template in a product library, generating unique product codes, the storage space planning system sets different weights according to the product information, the size, the weight and the use frequency information through a space planning algorithm, an optimal storage scheme is designed according to the remaining inventory capacity in the current container, and the intelligent storage module is composed of a product access execution system, a flexible intelligent three-dimensional container and an inventory data management system.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

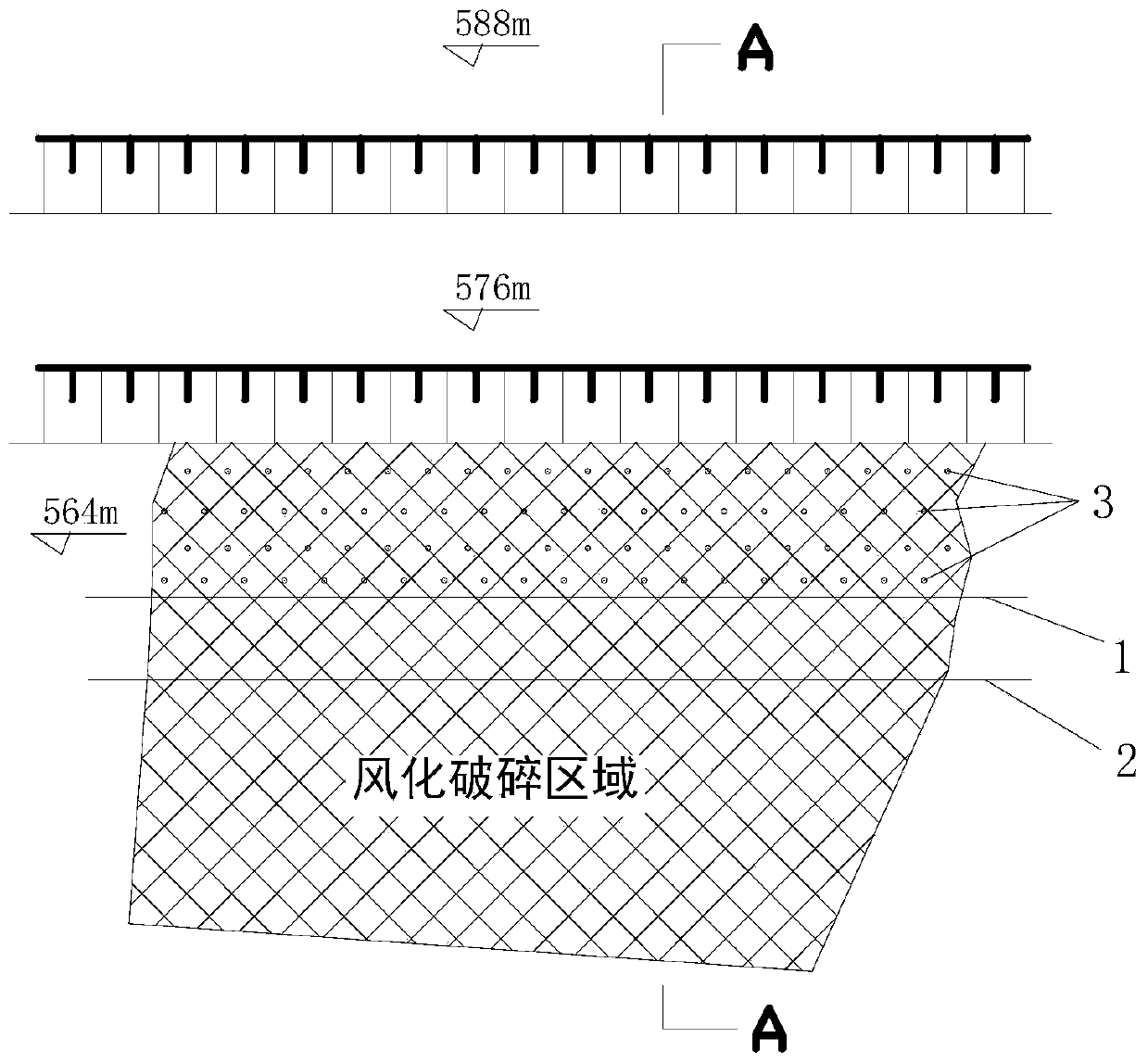

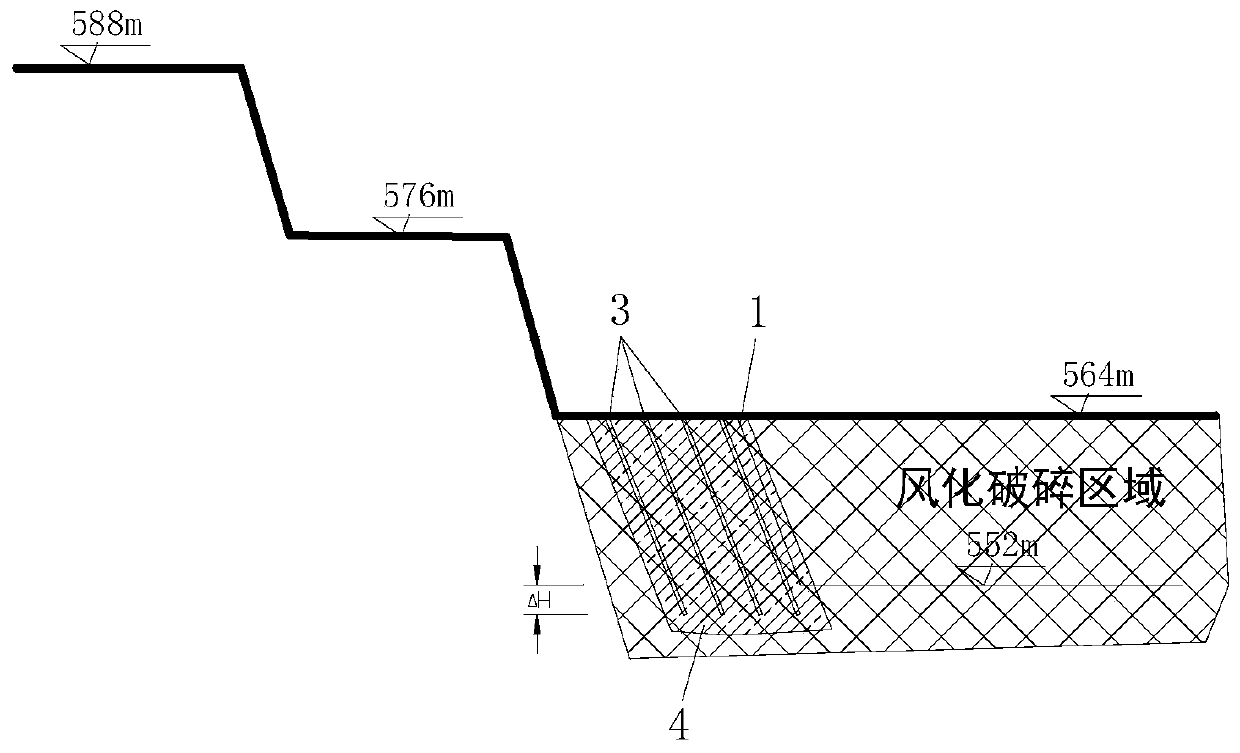

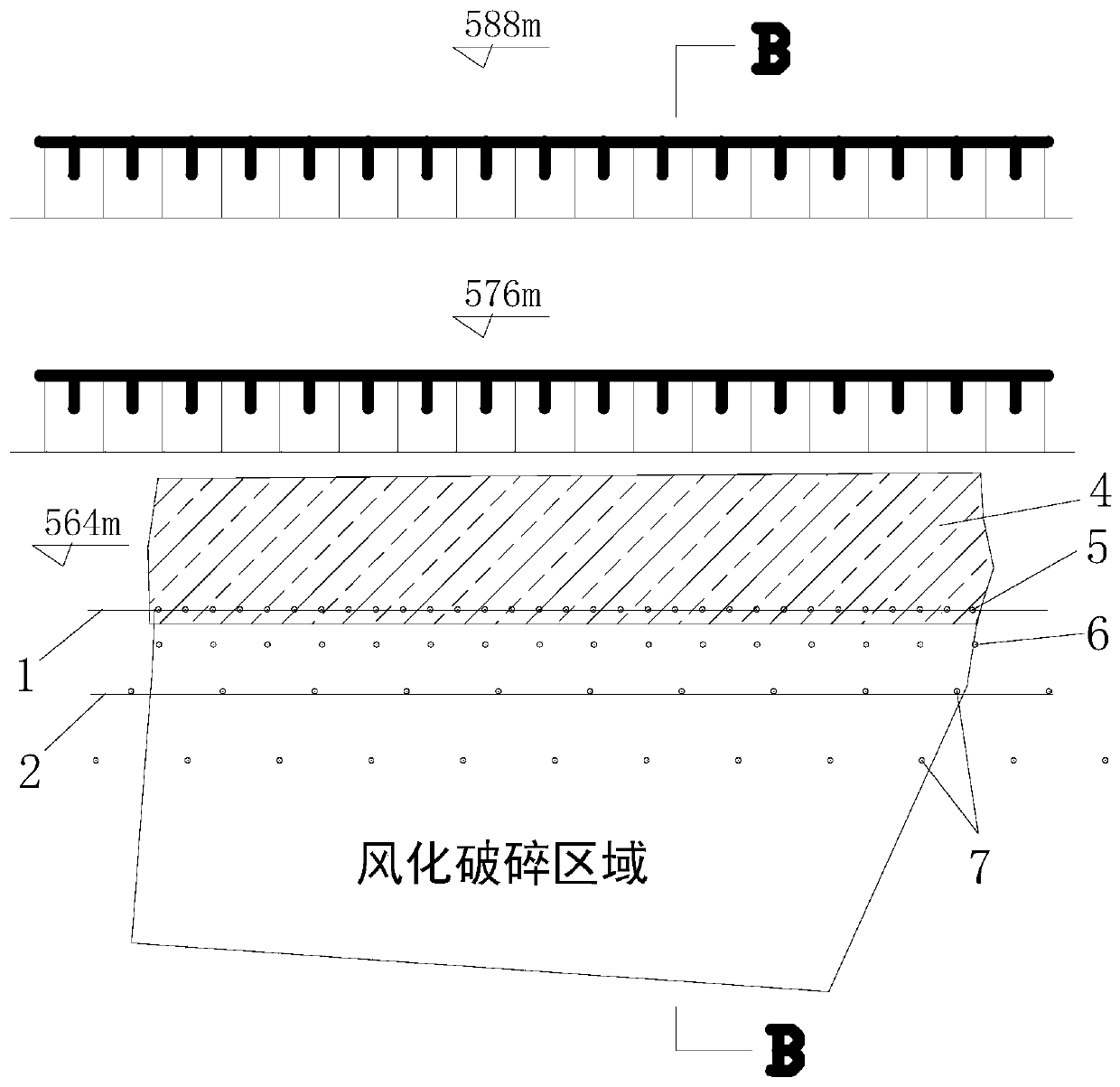

Method for improving pre-splitting crack-forming effect by pre-grouting and reinforcing surrounding rock of side slope

ActiveCN110158621AReduce dosageFast constructionClimate change adaptationBlastingSoil scienceStructural engineering

The invention relates to a method for improving pre-splitting crack-forming effect by pre-grouting and reinforcing a surrounding rock of a side slope, and the method comprises the following steps of:determining a weathering and crushing area near to an ending slope, carrying out the ending slope setting-out, and defining the range of grouting and reinforcing; carrying out setting-out to a grouting hole and a drilling hole in a pre-grouting and reinforcing range; molding the grouting hole and the drilling hole; carrying out cleaning to the grouting hole; carrying out pressure grouting to the grouting hole; and confirming that the grouting pressure and grouting amount in the grouting hole reach the requirements. The process consolidates the fractured rock mass into a whole by pre-grouting and blocking a groundwater seepage channel in a rock stratum. Measures such as blasting, pre-cracking and shock absorption are supplemented to increase the half-hole ratio and ensure the stability of the side slope; and favorable conditions are provided for safe and efficient mining of mines.

Owner:福建省新华都工程有限责任公司

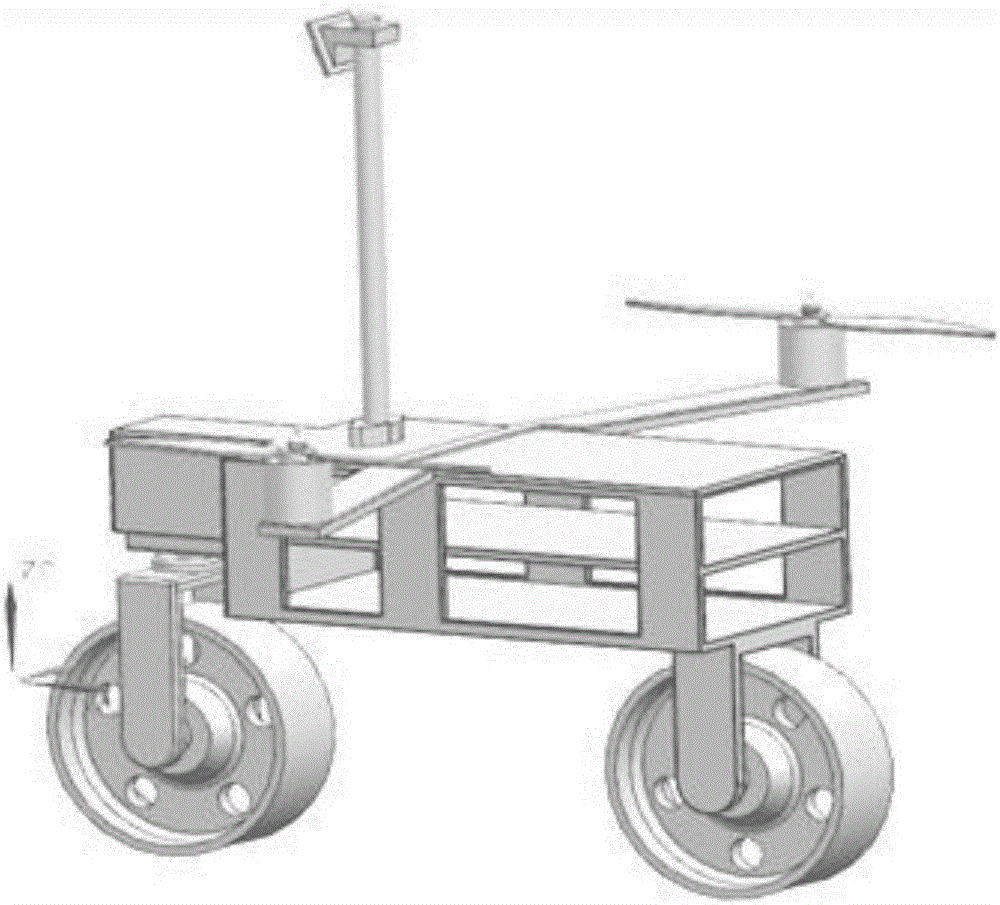

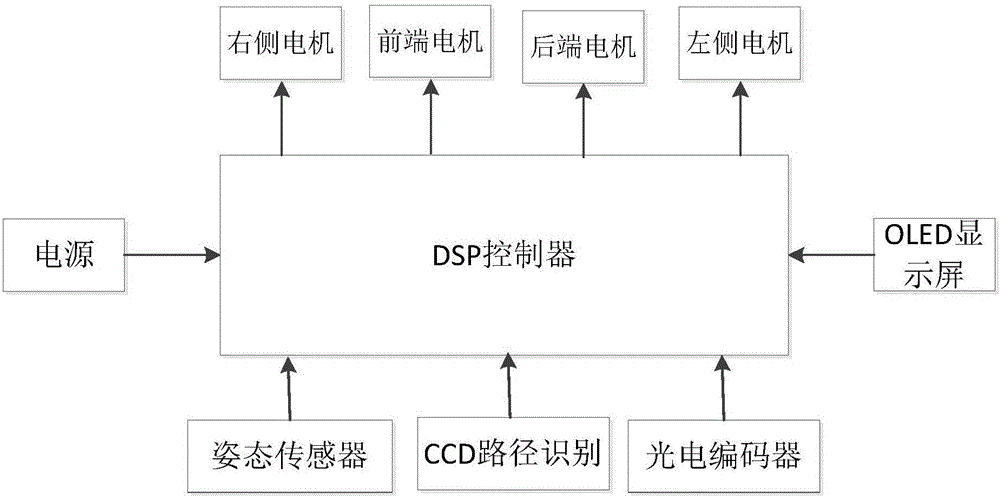

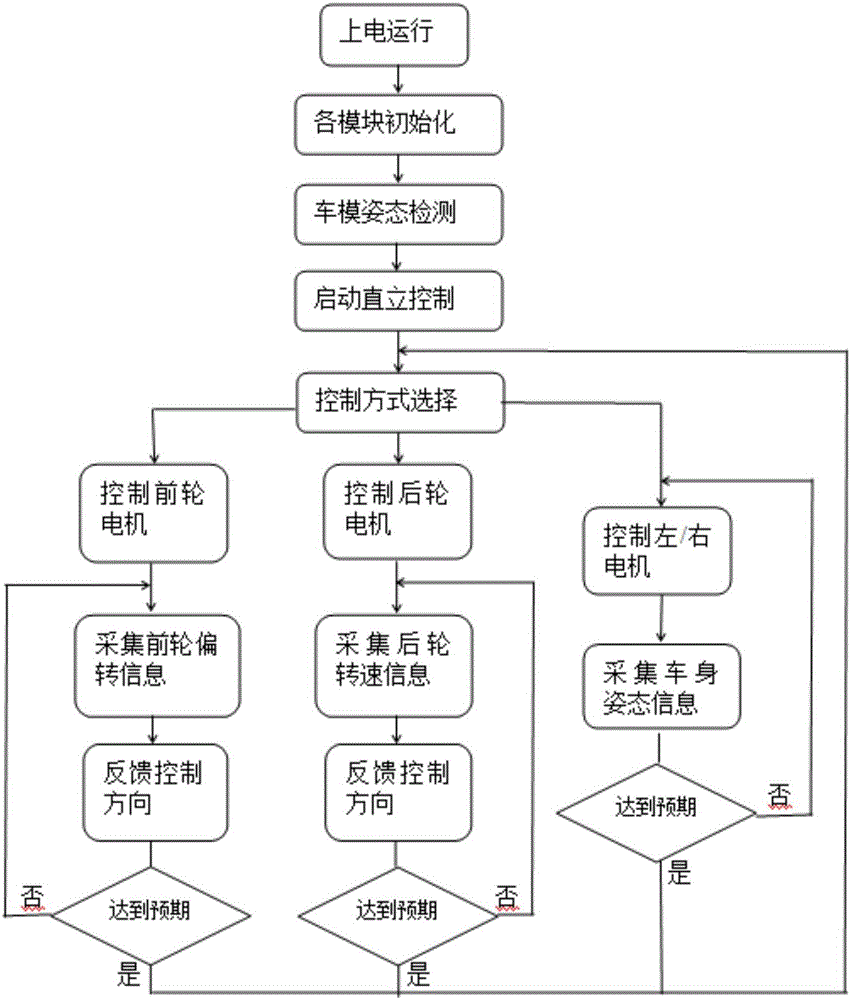

Front and rear two-wheeled self-balancing cart based on grey neural network prediction algorithm

ActiveCN106240705AMake up for the shortcomings of the layoutFlexible steeringRider propulsionBicyclesBody balanceAutomatic control

The invention provides a front and rear two-wheeled self-balancing cart based on a grey neural network prediction algorithm. The front and rear two-wheeled self-balancing cart comprises a cart body, an attitude sensor, a rear wheel rotating speed sensor, a front wheel deflection sensor, a digital signal processor (DSP) controller and a CCD path identification module. The grey neural network prediction algorithm is used to predict a cart attitude, cart body balance and corresponding control over advancing and steering are achieved after a comparison with current road conditions and standard attitudes, and finally steady running of the cat body is maintained. The cart can receive priority control instructions sent by a mobile phone or a controller through a bluetooth module, so as to control motions of the cart. A grey neural network prediction algorithm model is arranged in the DSP controller, cart attitude information, acceleration information, rear wheel rotating speed information and front wheel deflecting direction information serve as input quantities of the grey neural network prediction algorithm model to obtain prediction attitude information of the cart, and automatic control information of the cart is obtained according to predicted attitude information of the cart and road conditions in front of the cart.

Owner:SHANGHAI INST OF TECH

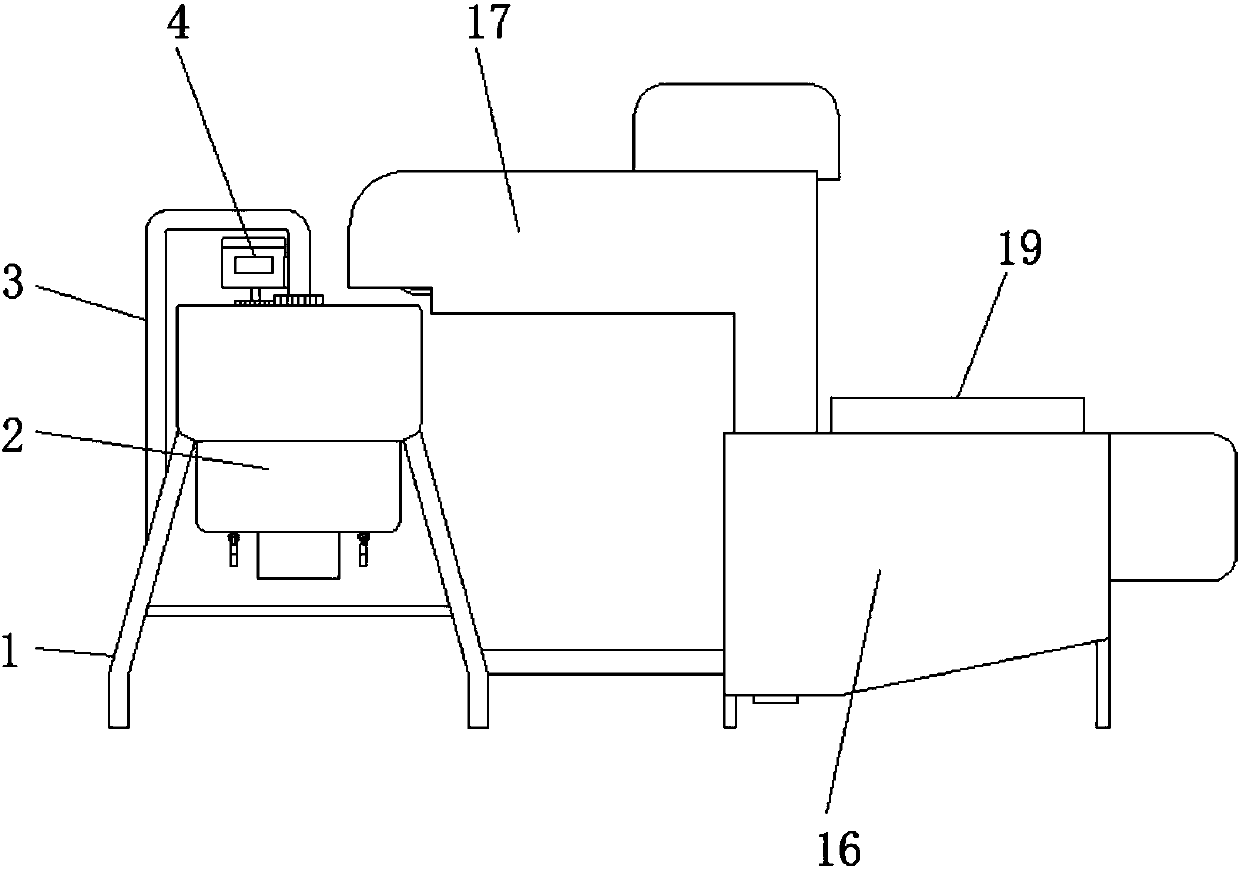

Automatic material drying feeding and grinding integrated machine

InactiveCN107774426ADry evenlyEasy to dryCocoaDrying machines with non-progressive movementsEngineeringMaterials processing

The invention relates to an integrated machine for material drying, automatic feeding and grinding, which includes a frame, a fixed grinding disc, a loading clamp, a rotating grinding sleeve, a box door, a spiral feeding shaft and a fixed card, and a grinding wheel is fixed above the frame. box, and a support rod is fixed on the left side of the frame, a first motor is installed above the support rod, and a gear set is arranged below the first motor, a fixed shaft is connected to the right side of the support rod, and the fixed shaft A rotating grinding disc is inlaid in the center, the screw feeding shaft is set inside the feeding pipe, and the fourth motor is installed above the screw feeding shaft, and the fixing card is set on one side of the box door, so that the design can improve material processing The production efficiency is high, and compared with the traditional independent machine, the material drying and automatic feeding and grinding machine saves more space and reduces the input cost of the manufacturer. In addition, the device reduces the number of operating and controlling personnel, saves labor, and reduces The cost of production and processing.

Owner:薛迪宋

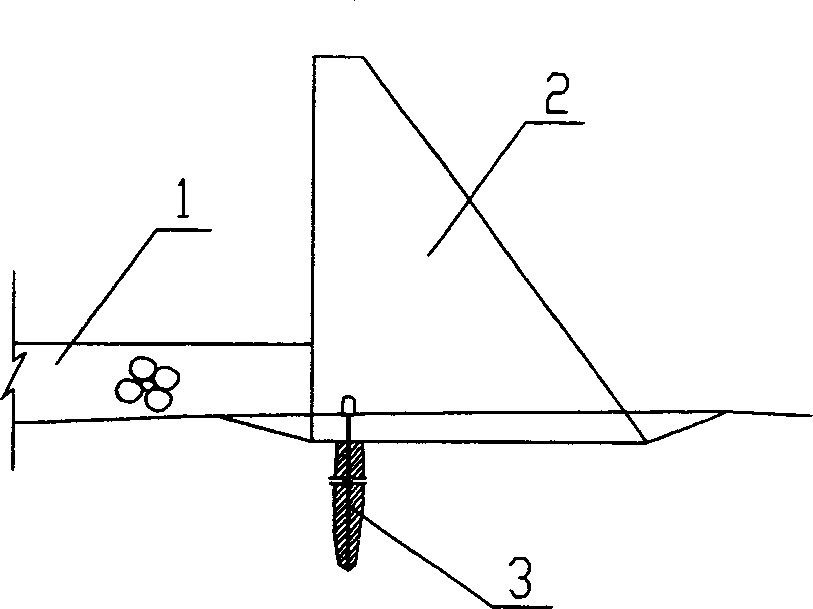

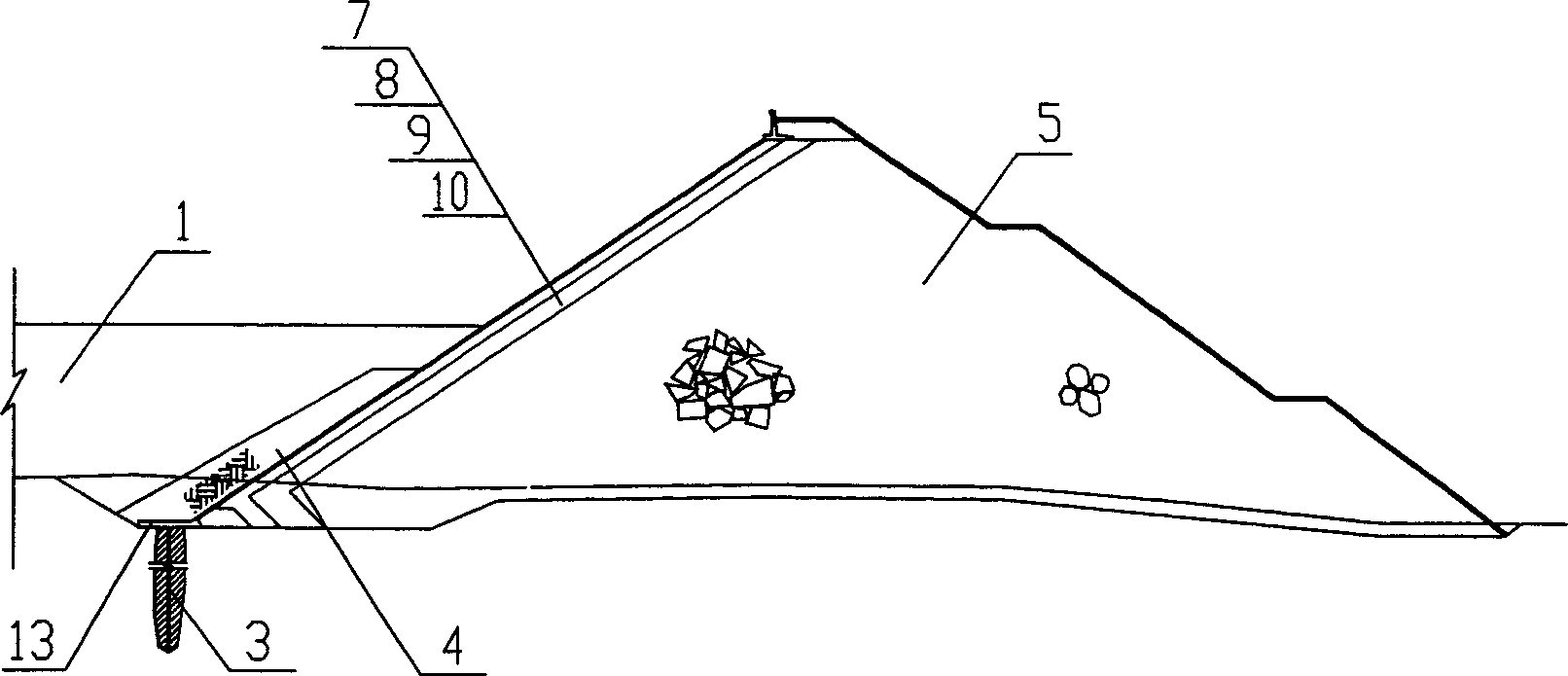

Mechanism for burying waste residue in reservoir bottom

ActiveCN1837492AReduce difficultyReduce the size of the siteBarrages/weirsBulk storage containerSlagEngineering

The invention relates to a reservoir bottom slag-embedding structure, which can reduce occupied area and reduce the cost without polluting the environment. It is characterized in that: embedding slag into the dead reservoir at the water accumulation side of reservoir dam. The invention can be used in small reservoir with small flow section.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

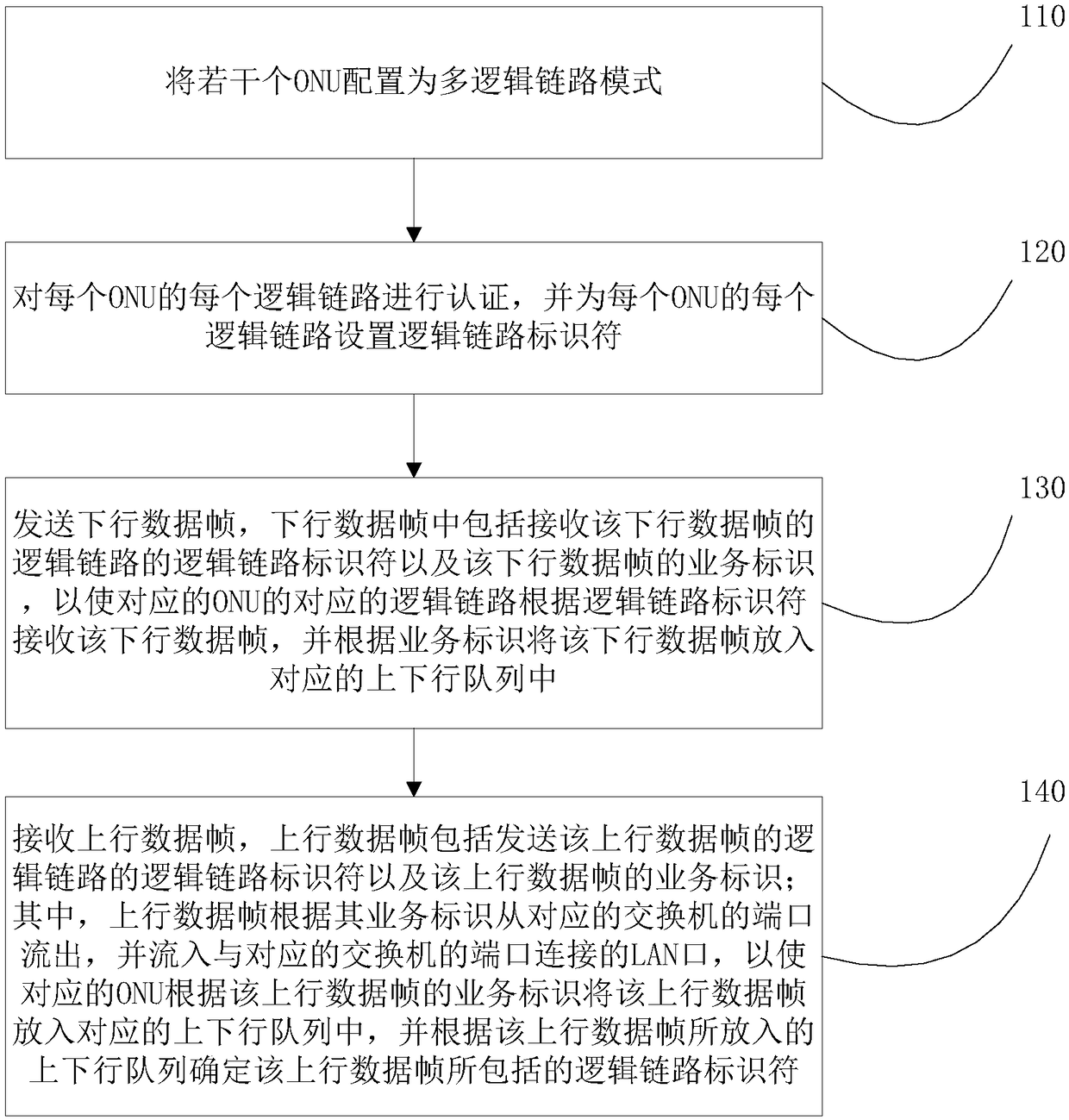

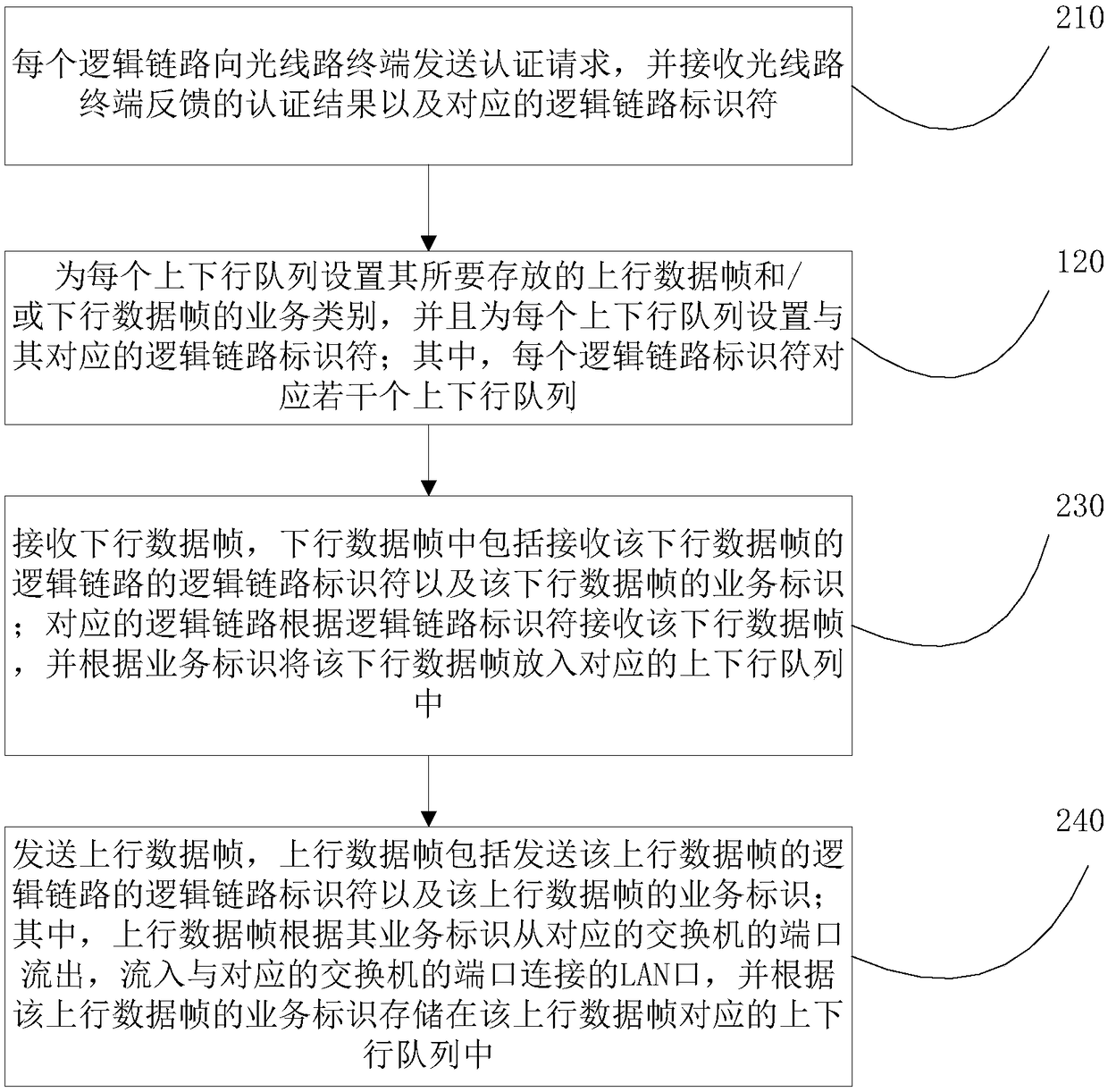

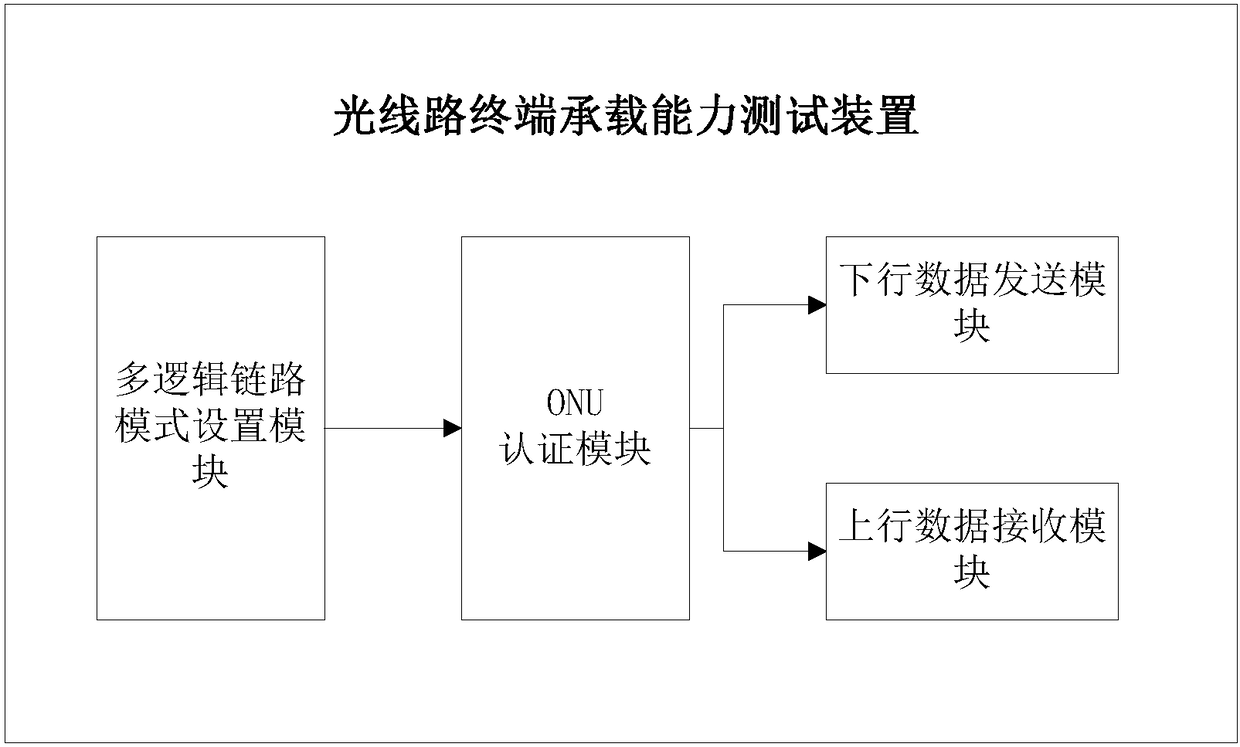

Optical link terminal bearing capability testing method, optical link terminal bearing capability testing device, and optical link terminal bearing capability testing system

InactiveCN108337581AReduce in quantityReduce the size of the siteMultiplex system selection arrangementsElectromagnetic transmissionComputer terminalEngineering

The invention provides an optical link terminal bearing capability testing method, an optical link terminal bearing capability testing device, and an optical link terminal bearing capability testing system. An optical network unit (ONU) is configured in a mode of a plurality of logical links, and each logical link is provided with a logical link identifier and an uplink-downlink queue, and each uplink-downlink queue is provided with a business type. An optical line terminal (OLT) is used to transmit a downlink data frame, and the corresponding logical link is used to receive the downlink dataframe, and according to the business identifier, the downlink data frame is disposed in the corresponding uplink-downlink queue. An uplink data frame is output through a port of a corresponding switchaccording to the business identifier, and the corresponding ONU is used to arrange the uplink data frame in the corresponding uplink-downlink queue according to the business identifier of the uplinkdata frame, and then the logical link identifier included by the uplink data frame is determined, and the OLT is used to receive the uplink data frame. According to the abovementioned technical scheme, each ONU is used to simulate a plurality of ONUs by adopting the design of a plurality of logical links, and therefore the number of the ONUs required in an OLT bearing capability test and an area occupied by the test are effectively reduced.

Owner:LUSTER TERABAND PHOTONICS TECHNOLOGY CO LTD

Intelligent extrusion molding machine for cable pipe

InactiveCN111791450AReduce local diameter varianceIncrease specificationCable/conductor manufactureMolding machineElectric machinery

The invention discloses an intelligent extrusion molding machine for a cable pipe, and relates to the technical field of intelligent equipment for molding. The intelligent extrusion molding machine comprises a crushing bin, the bottom end of the crushing bin is connected with a flow guide pipe, a first heating layer is arranged in the flow guide pipe, the bottom end of the flow guide pipe is connected with an extrusion bin, and one end of the extrusion bin is provided with a motor; and the output end of the motor is connected with a screw rod, an extrusion head is arranged at one end of the interior of the extrusion bin, and the outer side of the extrusion bin is connected with a transportation bin. According to the intelligent extrusion molding machine, through the arrangement of a shaping bin, a conveying wheel, a first shaping wheel, a second shaping wheel, a shaping groove and a fixing block, when a cable sleeve is extruded and not cooled yet, the cable sleeve has a certain deformation capacity, the extruded cable sleeve is placed between the first shaping wheel and the second shaping wheel, and the cable is shaped through the shaping groove in the cable sleeve, so that the whole cable is uniform, the situation that the local diameter of the cable is not uniform is reduced to a certain extent, the specification of the cable is higher, and the extrusion effect is better.

Owner:广州市秀全电线电缆有限责任公司

Animal waste fermented organic feed and preparation method thereof

PendingCN111802510AImproves levels of nutrient absorptionGood for healthFungiBacteriaNutritionHermetia

The invention discloses an animal waste fermented organic feed and a preparation method thereof. The organic feed comprises the following components in parts by weight: 50 parts of animal waste, 50 parts of dried materials and 0.1 part of enzymes, wherein the enzymes comprise 25 parts of potato streptomyces scabies, 10 parts of lactobacillus casei, 10 parts of cetobacter xylinium, 15 parts of saccharomyces cerevisiae, 10 parts of bacillus subtilis and 15 parts of bifidobacterium. The organic feed contains various high-quality lactic acid bacteria, anti-nutritional factors in the feed can be effectively degraded, the nutritional value and the digestibility of the feed are improved, the feed flavor and palatability are improved, feed mildewing and aflatoxin generation are effectively prevented, the safety of the fermented feed is guaranteed, nutrient and weight losses caused by fermentation heat production and gas production are avoided, and the purposes of animal waste recycling, reduction and harmlessness can be achieved at the same time by adopting animal waste-fermented organic feed to breed hermetia illucens.

Owner:昆山理清生物科技有限公司

Edible oil bottle boxing and stacking conveying line

ActiveCN111332523ARealize one-to-one correspondenceReduce the size of the siteWrappingPackaging automatic controlCartonEdible oil

The invention discloses an edible oil bottle boxing and stacking conveying line. The edible oil bottle boxing and stacking conveying line comprises an oil bottle conveying line, a paper box conveyingline and boxing robots. A feeding port of the oil bottle conveying line is connected with a discharging port of an upstream conveying line. The oil bottle conveying line is provided with a one-into-two way dividing machine, and the oil bottle conveying line forms two oil bottle runners through the one-into-two way dividing machine. The paper box conveying line is adjacent to the oil bottle conveying line and comprises two parallel paper box runners, one paper box runner is provided with a first boxing station, the other paper box runner is provided with a second boxing station, and the first boxing station and the second boxing station are arranged in a staggered manner. The two boxing robots are arranged, one boxing robot is close to the first boxing station, and the other boxing robot isclose to the second boxing station. The oil bottle runners, the paper box runners and the boxing robots are in a one-to-one correspondence relation. According to the technical scheme, providing the edible oil bottle boxing and stacking conveying line is the purpose, accordingly, the occupied area is reduced, and the production efficiency and stability are improved.

Owner:EFORT INTELLIGENT EQUIP CO LTD

Crawler-type grain impurity-clearing machine

InactiveCN102626692AImprove cleaning efficiencyReduce the size of the siteGas current separationElectric machineStructural engineering

The invention relates to a crawler-type grain impurity-clearing machine, which comprises a main bracket, and a crawler conveying mechanism, a motor, an air blower, a draught fan, a high-position intercepting device, a mesh sieve plate and a baseplate storage box that are arranged on the main bracket, wherein the conveying tail end of the crawler conveying mechanism is higher than the conveying start end of the crawler conveying mechanism; the air blower and the draught fan are positioned above a crawler, and the air outlet direction of the air blower is opposite to the conveying direction of the crawler; the draught fan is positioned between the conveying start end of the crawler and the air blower, the introduction end of the draught fan faces to the air blower, and the discharge end of the draught fan is connected with an impurity storage bag; the high-position intercepting device is arranged behind the conveying tail end of the crawler and used for intercepting impurities with volume being larger than that of grains, the high-position intercepting device is shaped as a dustpan, the dustpan opening is positioned below the conveying tail end of the crawler, and the inner bottom surface of the high-position intercepting device is provided with a grain circulating channel; the mesh sieve plate is used for filtering impurities with volume being smaller than that of grains and arranged right below the grain circulating channel; the rear end of the mesh sieve plate is lower than the front end of the mesh sieve plate; the baseplate storage box is arranged below the mesh sieve plate, the inner bottom surface of the baseplate storage box is obliquely arranged, and the lowest part of the inner bottom surface is provided with an impurity collecting port, and the impurity collecting port is communicated with an external impurity bag. The crawler-type grain impurity-clearing machine can finish impurity clearing in one step and has high impurity clearing efficiency.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

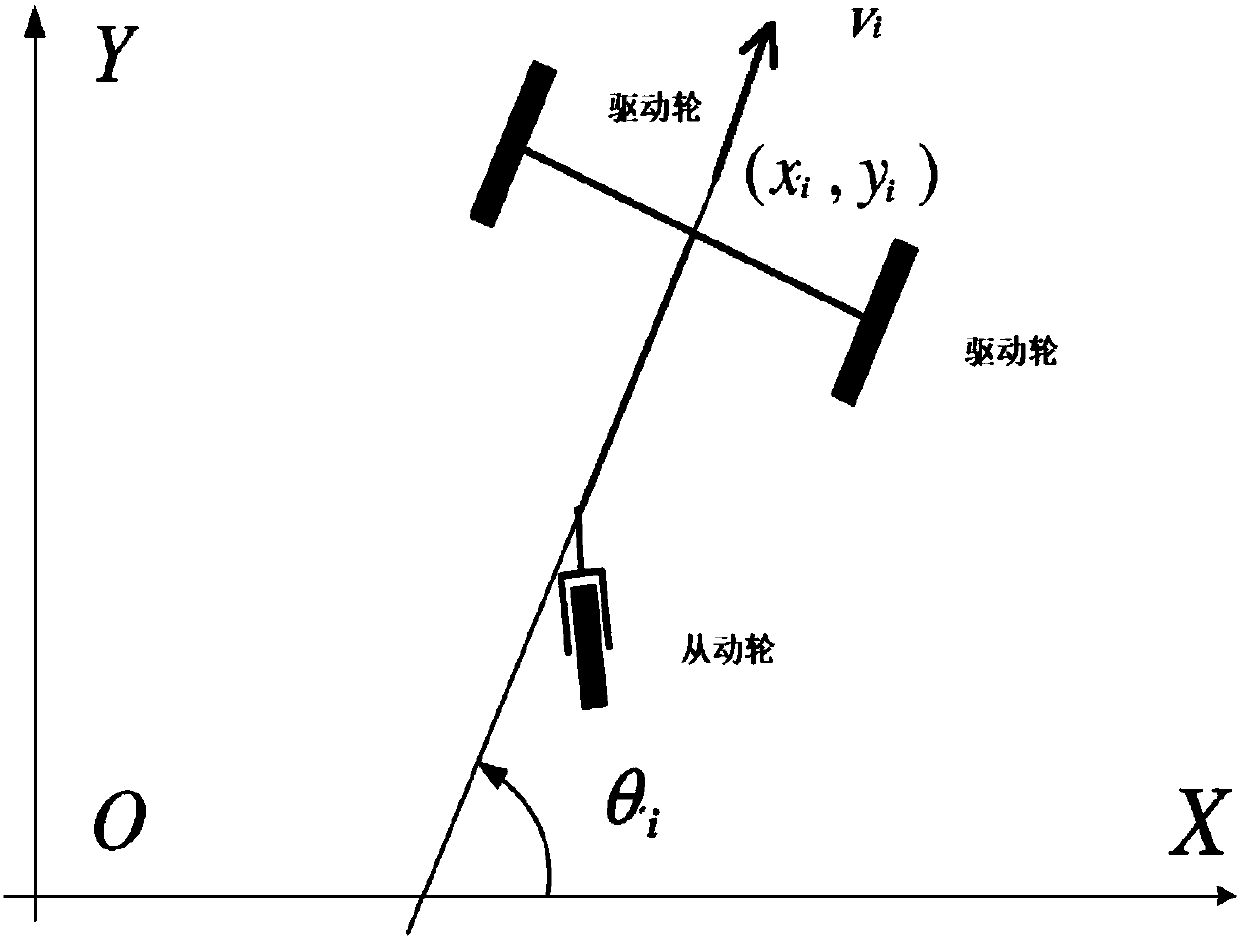

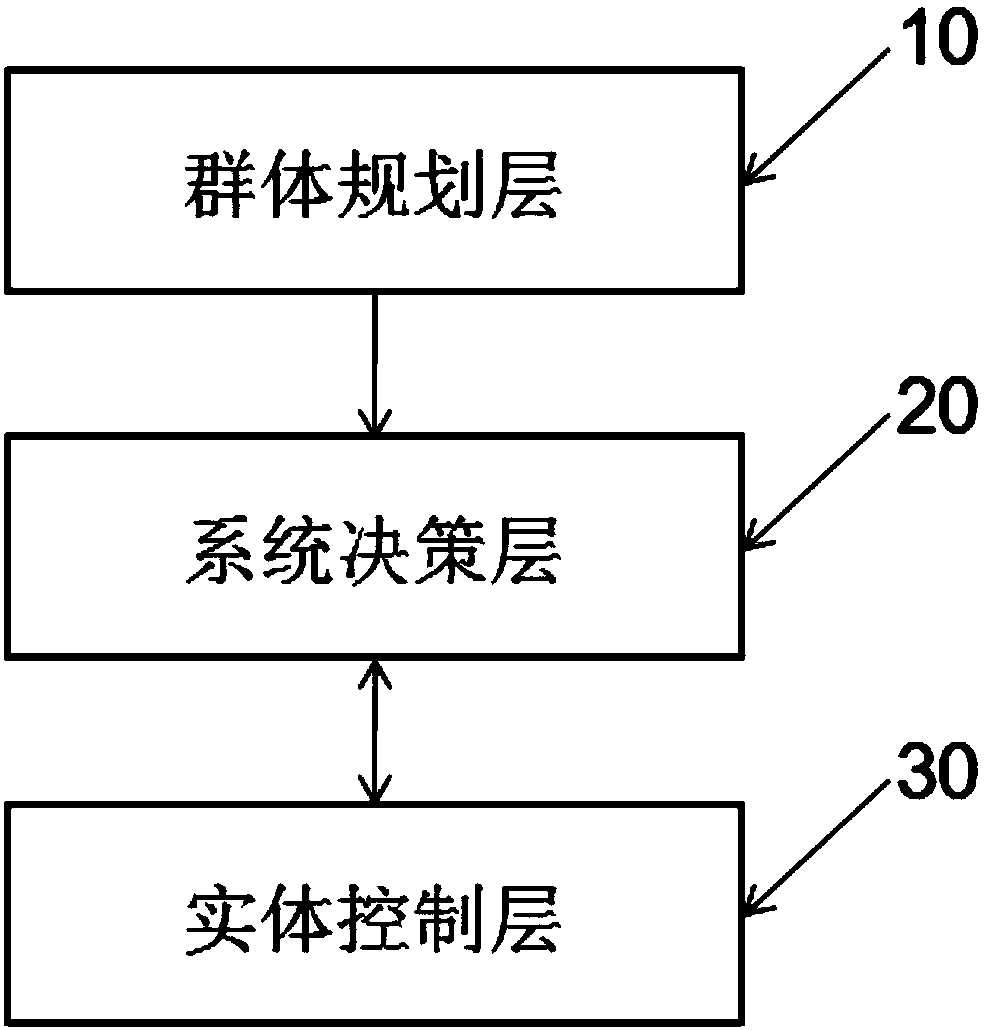

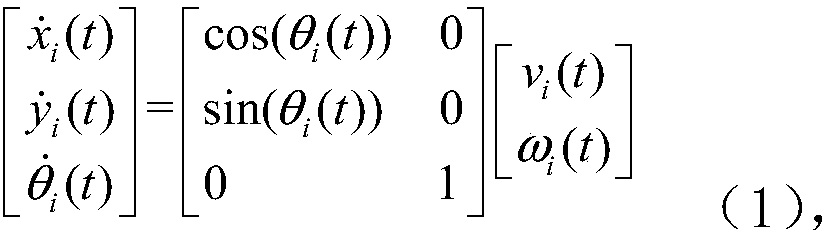

Self-adaptive cooperative control algorithm and system of multi-wheeled robot

The invention discloses a self-adaptive cooperative control algorithm and system of a multi-wheeled robot. The control algorithm comprises the following steps that 1, a multi-wheeled robot system including N wheel-type robots and non-linear kinetic models of single wheel-type robots are established; 2, through linear feedback and conversion, the non-linear kinetic models of single wheel-type robots are converted into a second-order linear system, and a self-adaptive cooperative controller is designed; 3, after the self-adaptive cooperative controller is designed, the evolution laws of acceleration and angular acceleration are obtained through inverse transformation, the acceleration and angular acceleration are obtained, thus corresponding control force and a control torque are obtained, and self-adaptive cooperative control of the multiple wheel-type robots is completed. The self-adaptive cooperative control algorithm and system can effectively overcome the uncertain nonlinear terms of a system structure and parameters, automatically update communication coupling coefficients of different robots, adapt to dynamically changing environments and communicating topological-structure change and efficiently complete consistent formation actions.

Owner:上海神添实业有限公司

Progressive die

ActiveCN107774803AReduce the size of the siteReduce transportationShaping toolsPerforating toolsPunch pressEngineering

The invention discloses a progressive die. A porous punching dire and a compound punching die are fixed on a lower die seat base plate, wherein a concave groove is formed in the top of an upper die seat of the compound punching die; a push plate is arranged in the concave groove; a force transmission rod is fixed on the bottom surface of the push plate; a concave part of a blanking concave die fixing plate is correspondingly matched with a through hole of a blanking concave die to form a die cavity; a beating plate is arranged in the die cavity; the bottom of the force transmission rod is fixed with the beating plate; an inner hole convex die fixing plate is fixed on the bottom surface of the upper die seat; an inner hole convex die is arranged in a die hole of the beating plate; after theinner hole convex die penetrates through the blanking concave die fixing plate, the inner hole convex die is fixed with the inner hole convex die; an unloading plate is internally provided with a blanking convex die; an inner hole concave die is formed in the blanking convex die; a die hole of the inner hole concave die is correspondingly matched with the inner hole convex die and a die hole of alower die seat; a discharging hole is formed in the lower die seat base plate; a spring I is arranged between the unloading plate and the lower die seat. According to the structure of the progressivedie, punching work can be finished through work of a pair of dies on a punching machine; the rate of finished products and the working efficiency are improved and the manufacturing requirements of the products are met.

Owner:NINGBO ZHENYU TECH

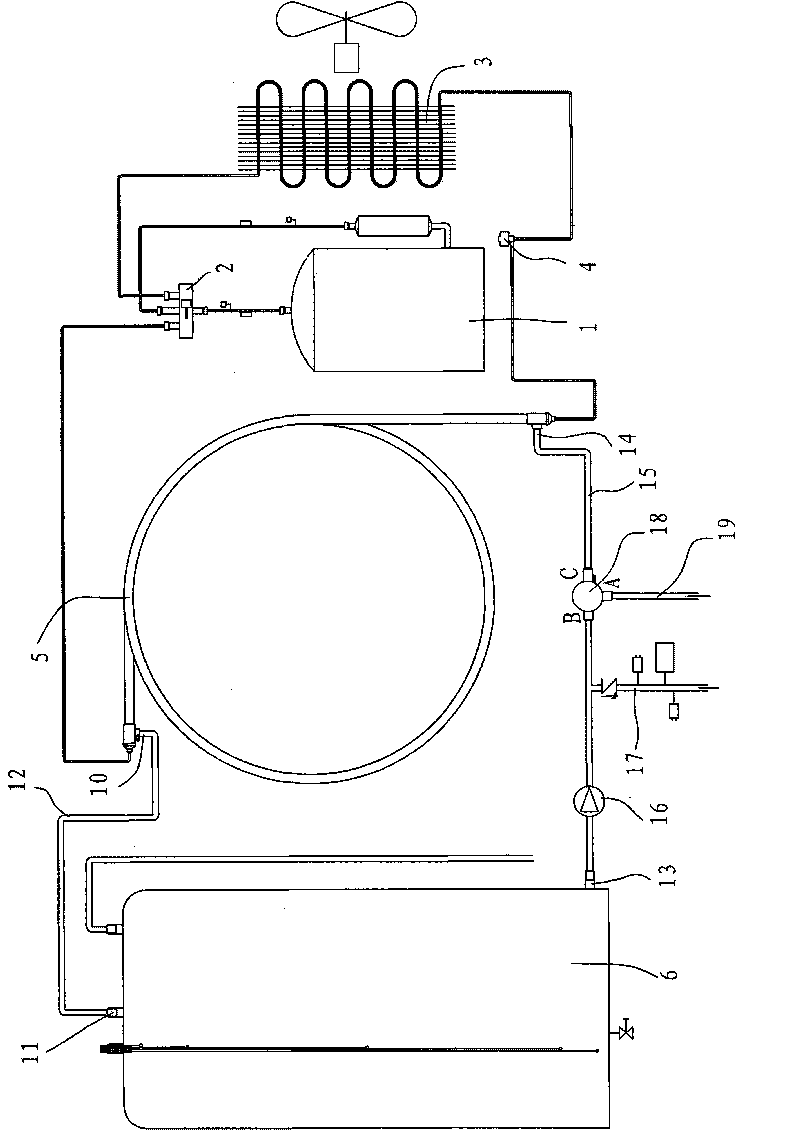

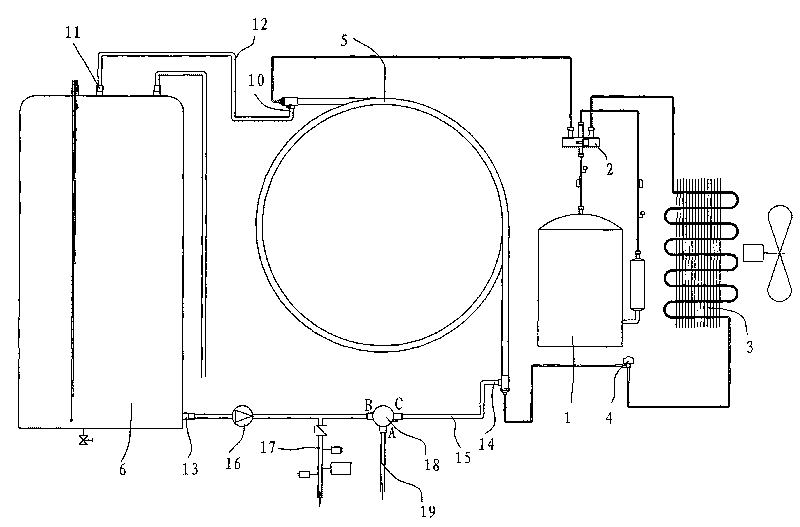

Heat pump water heater

InactiveCN101696824ASimple designReduce the size of the siteFluid heatersFour-way valveWater channel

The invention relates to a device for making hot water, specifically to an air source heat pump water heater, comprising a compressor, a four-way valve, an evaporator, an expansion valve, a condenser and a water tank. The condenser comprises a refrigerant channel and a water channel that are isolated from each other. The refrigerant channel, the compressor, the four-way valve, the evaporator and the expansion valve form a refrigerant loop. An outlet of the water channel is communicated with an inlet of the water tank. An outlet of the water tank is connected with the inlet of the water channel through a pipe directly. The pipe is provided with a water pump, a heat water outlet and electric three-way valves. Ports of the rest electric three-way valves are connected with a water inlet of tap water. The invention has reasonable and simple pipeline design, thereby reducing the site area required by mounting and saving the materials. Hot water supply for users, defrosting and circular heating can be realized through one water pump so that the installation speed is improved.

Owner:GUANGDONG BILAI ENERGY SAVING EQUIP

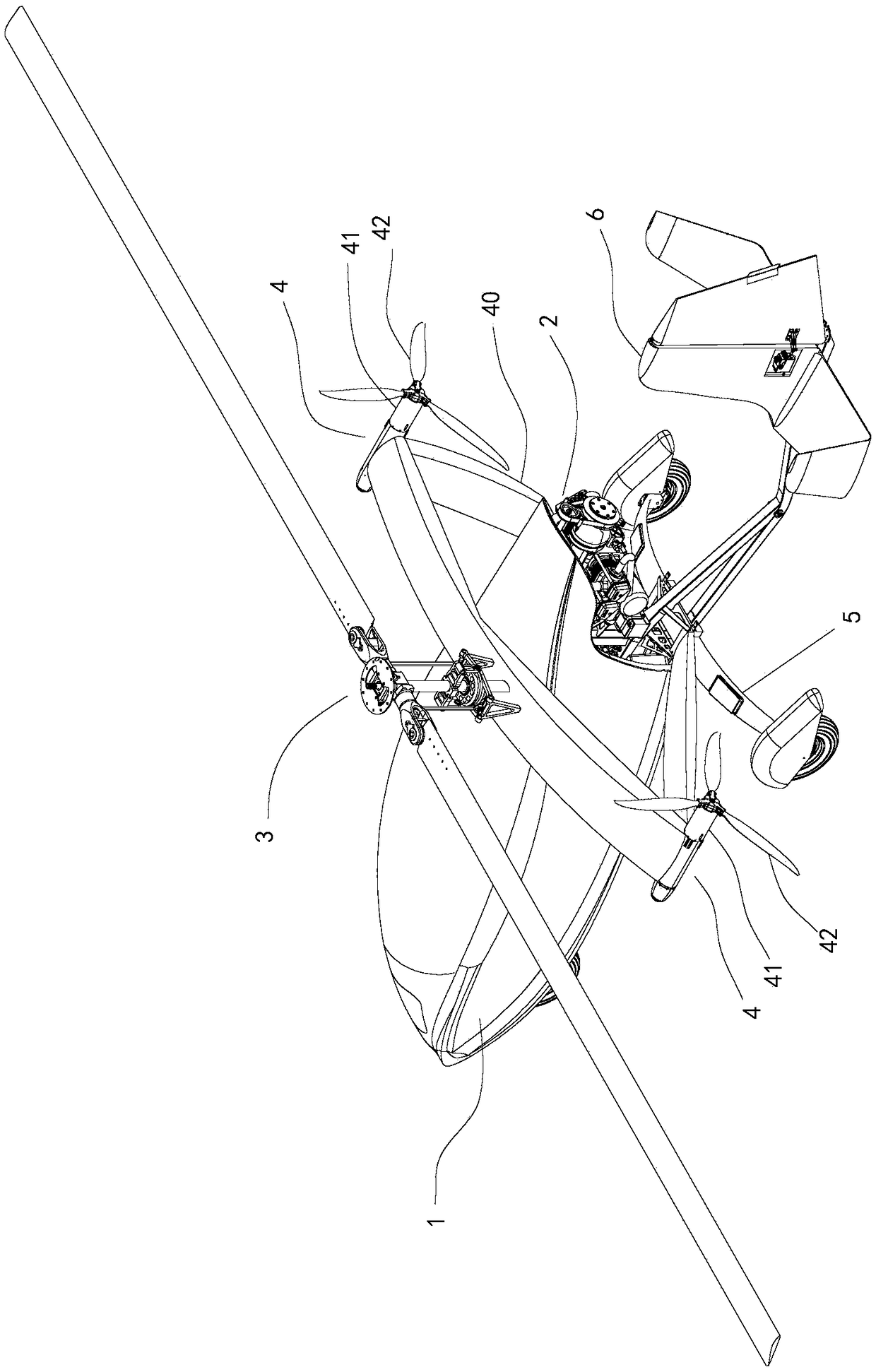

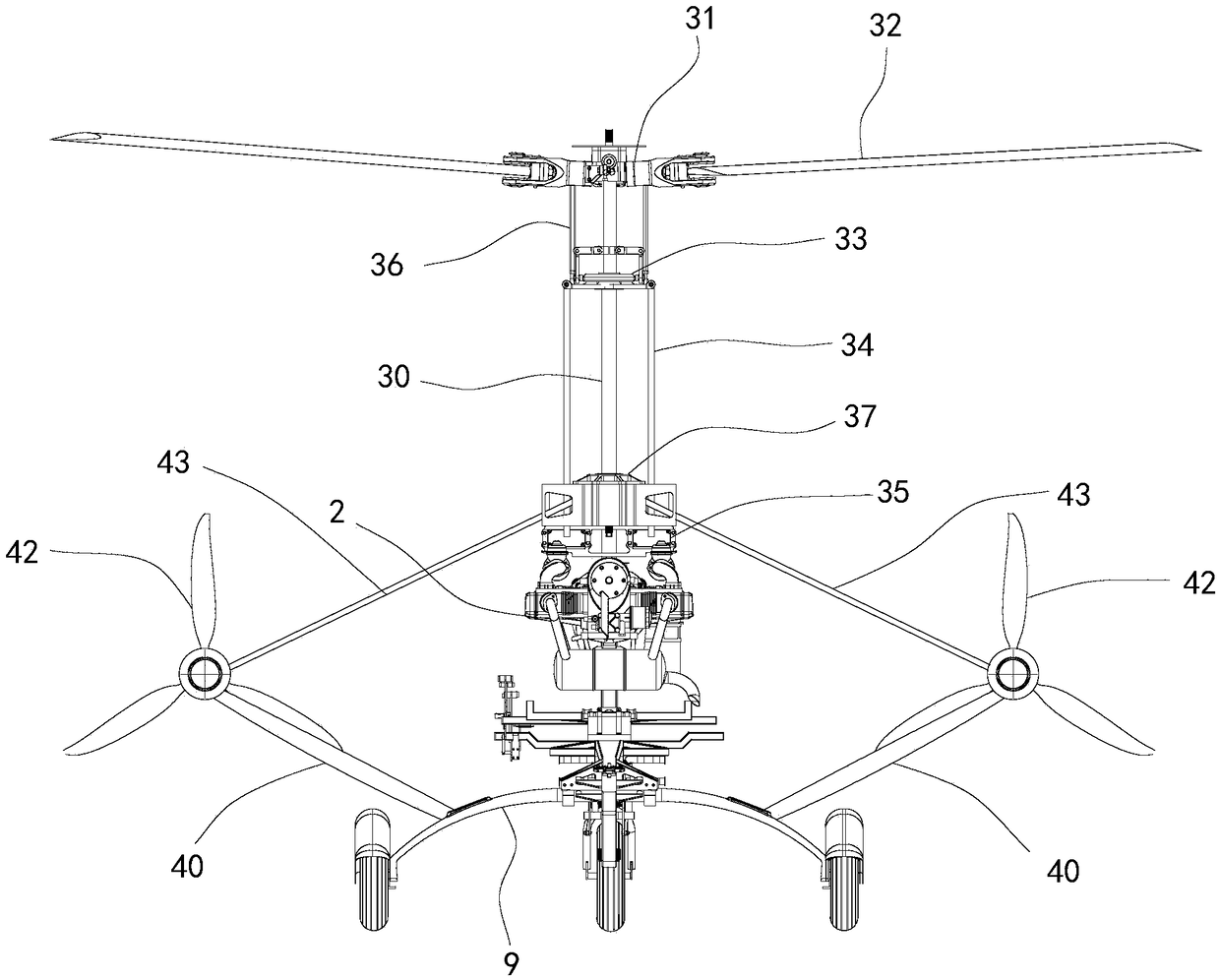

Helicopter type rotorcraft

PendingCN109466751AReduce the size of the siteRestraint torsionPropellersDrive shaftAgricultural engineering

The invention belongs to the technical field of rotorcrafts and relates to a helicopter type rotorcraft. The helicopter type rotorcraft comprises a body, an engine, a main rotor mechanism, a feed mechanism, a tail vane and an undercarriage, and is characterized in that the main rotor mechanism comprises a rotationally assembled spindle, a main rotor is mounted at the upper end of the spindle through a variable-distance rotor handpiece assembly, and the lower end of the spindle is connected with a main speed reduction box of the engine through a main clutch; the feed mechanism comprises two angle gearboxes which are symmetrically mounted on brackets on the left and right sides of the body, power input ends of the two angle gearboxes are in drive connection with the main speed reduction boxof the engine through correspondingly arranged drive shaft assemblies respectively; variable-distance propeller assemblies are mounted on power output shafts on the backs of the two angle gearboxes respectively. The rotorcraft can realize vertical take-off and landing, the site area required for taking off of the rotorcraft is small, and the use range of the rotorcraft is wide.

Owner:SUN HAWK HENAN AVIATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com