Applying and recovering system and method for core tubes and recovering system for core tubes

A recycling system and recycling method technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of paper core tube trouble, occupation, multiple processing sites, etc., to save site area, reduce costs, Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

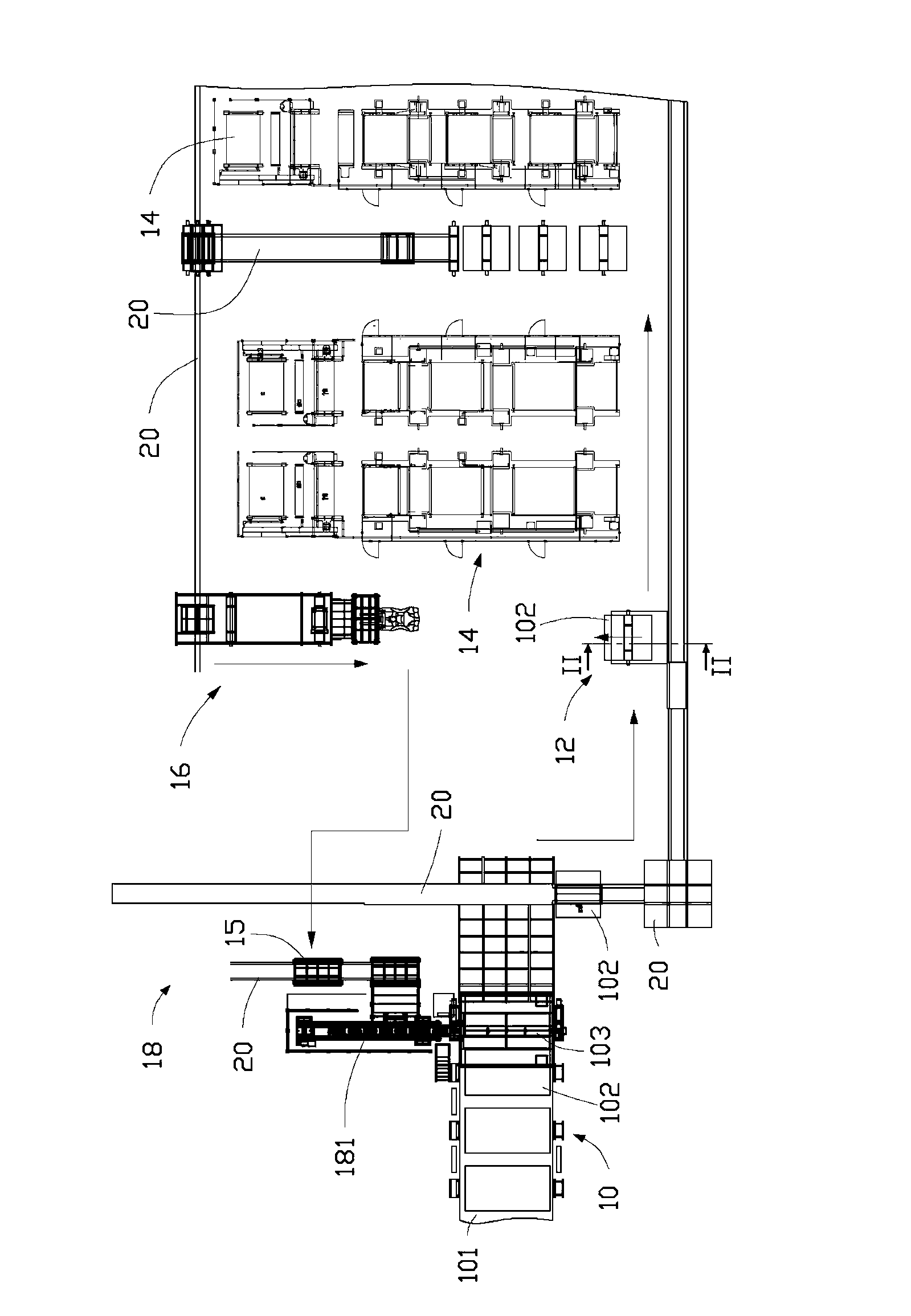

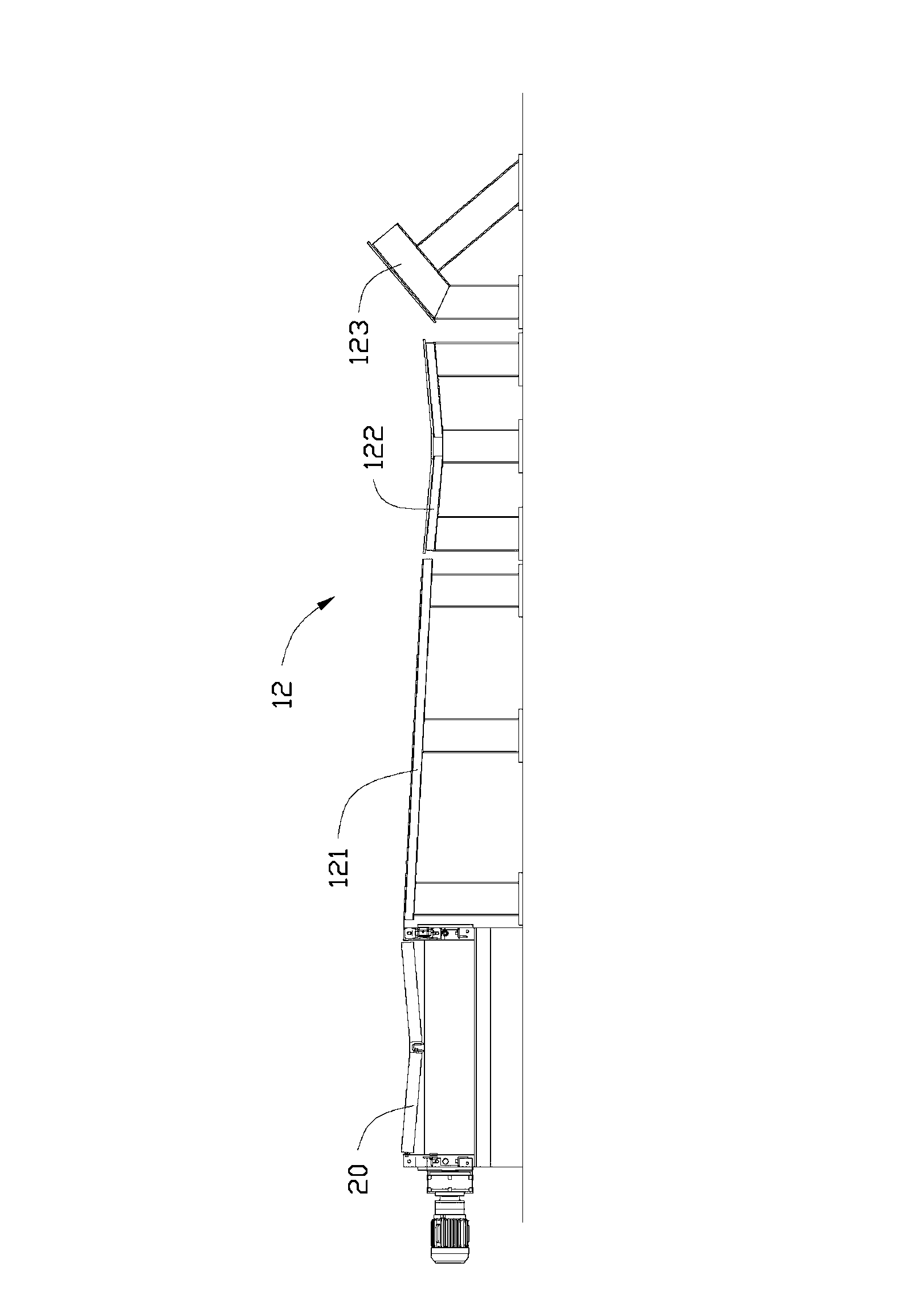

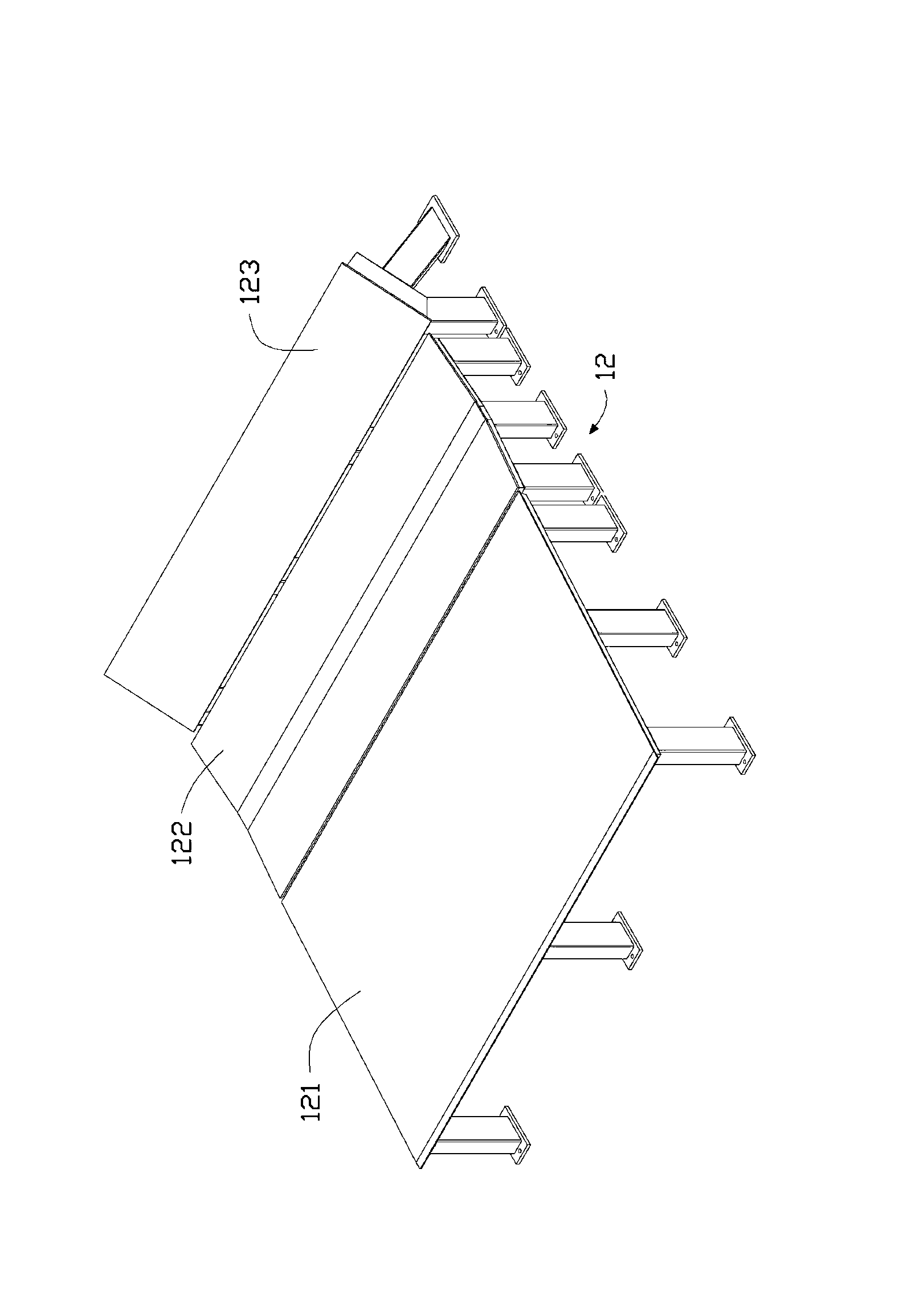

[0028] like figure 1 As shown, the core tube application recycling system involved in the present invention includes a coil forming unit 10, a shaft head installation unit 12, a coil processing unit 14, a centralized disassembly processing unit 16, a core tube storage unit 18, and a connection between each unit. Between the delivery unit 20.

[0029] The present invention will take the core tube as an example for carrying large paper rolls during papermaking, and illustrate the application of the core tube to the recycling system. It should be pointed out that the core tube application recycling system can also recycle the core tube carrying other coils such as film, so that the core tube can be efficiently and repeatedly used in the process of processing coils.

[0030] The coil forming unit 10 is used to wind the material on the core tube 15 to form a coil 102 . The coil forming unit 10 generally has a bracket for supporting the core tube 15 and a power device for driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com