Patents

Literature

424 results about "Production order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A production order is an order issued within a company to produce a specific quantity of material within a certain timeframe. A production order may be issued pursuant to a sales order, and its issuance triggers a number of events.

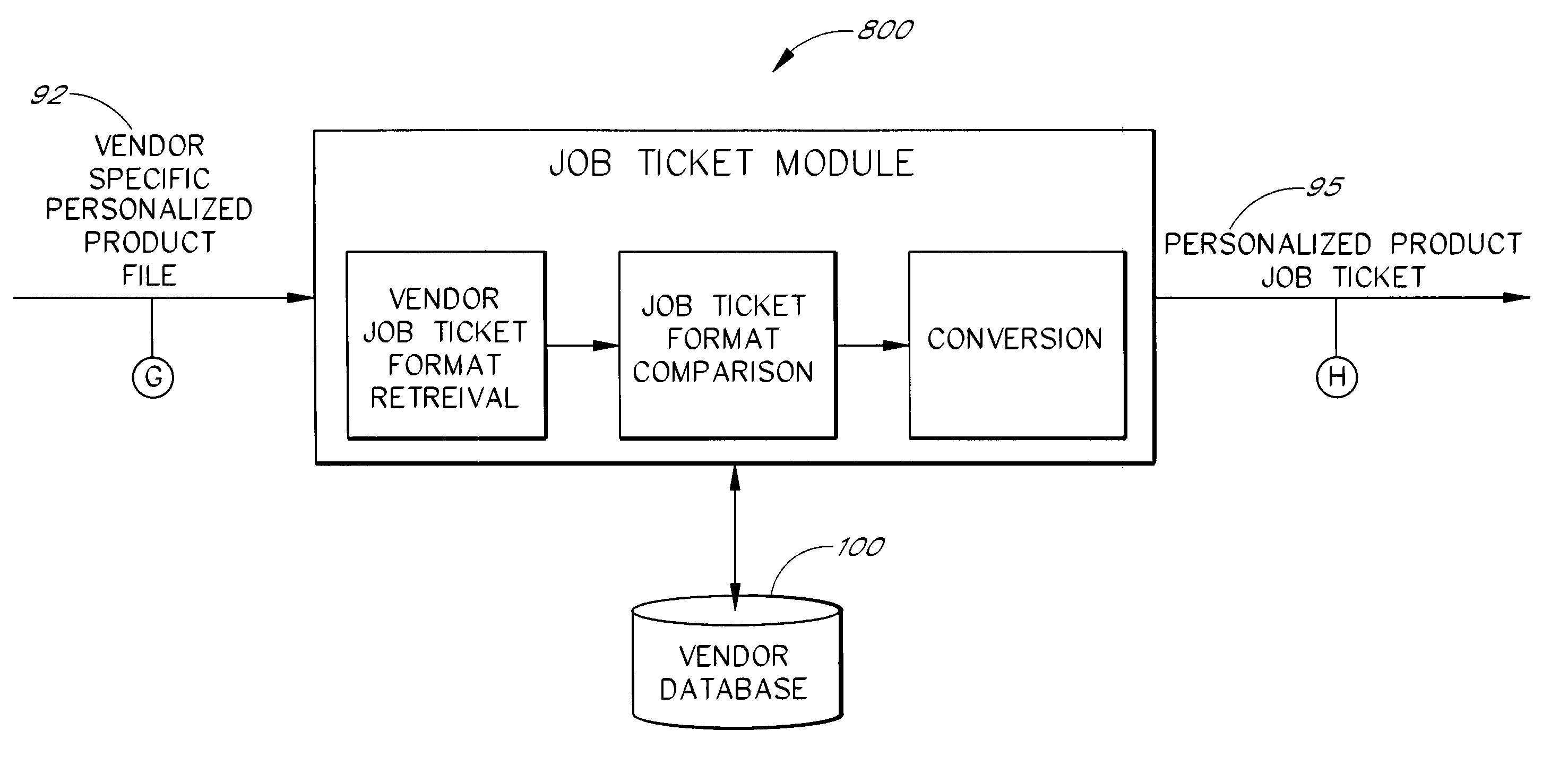

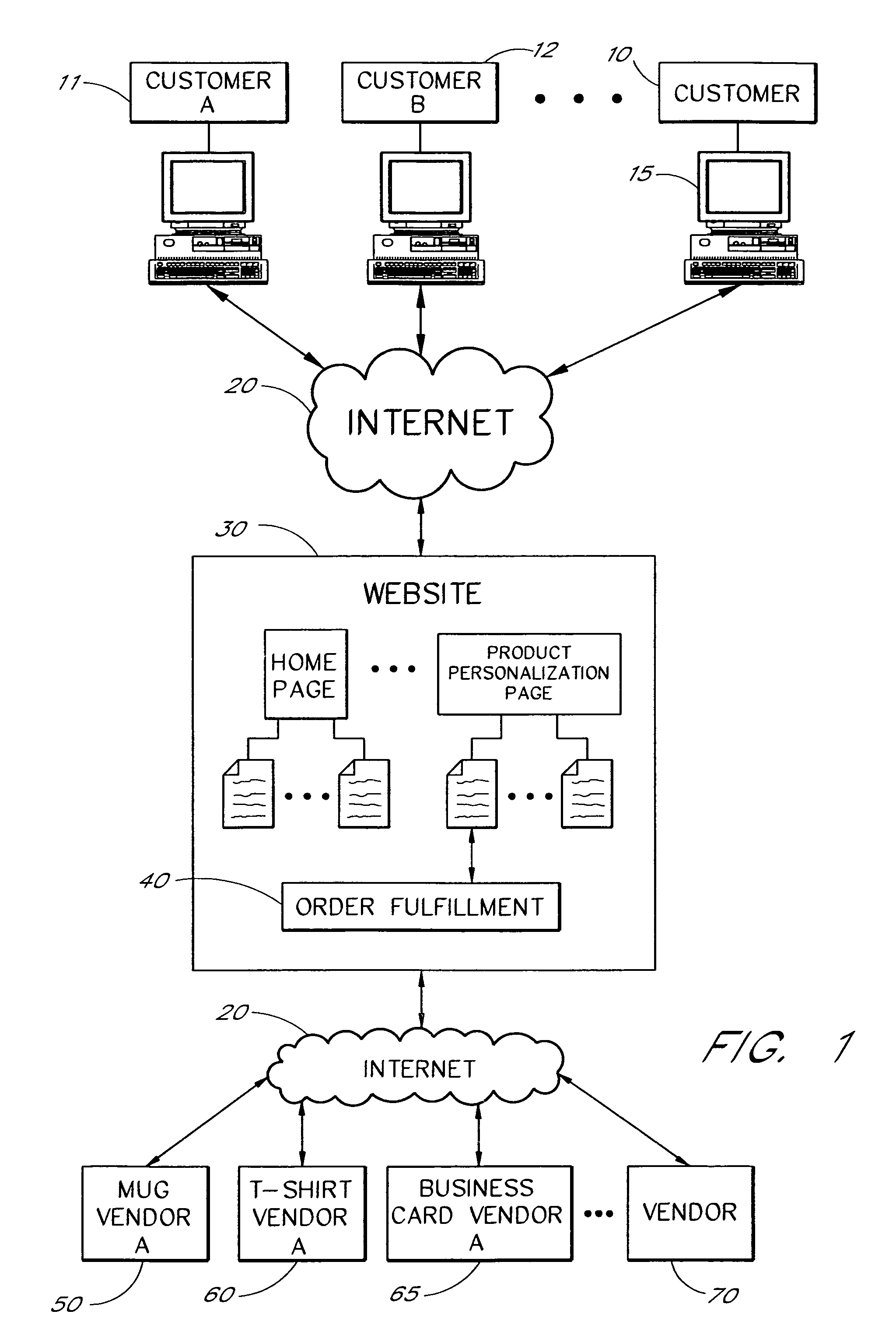

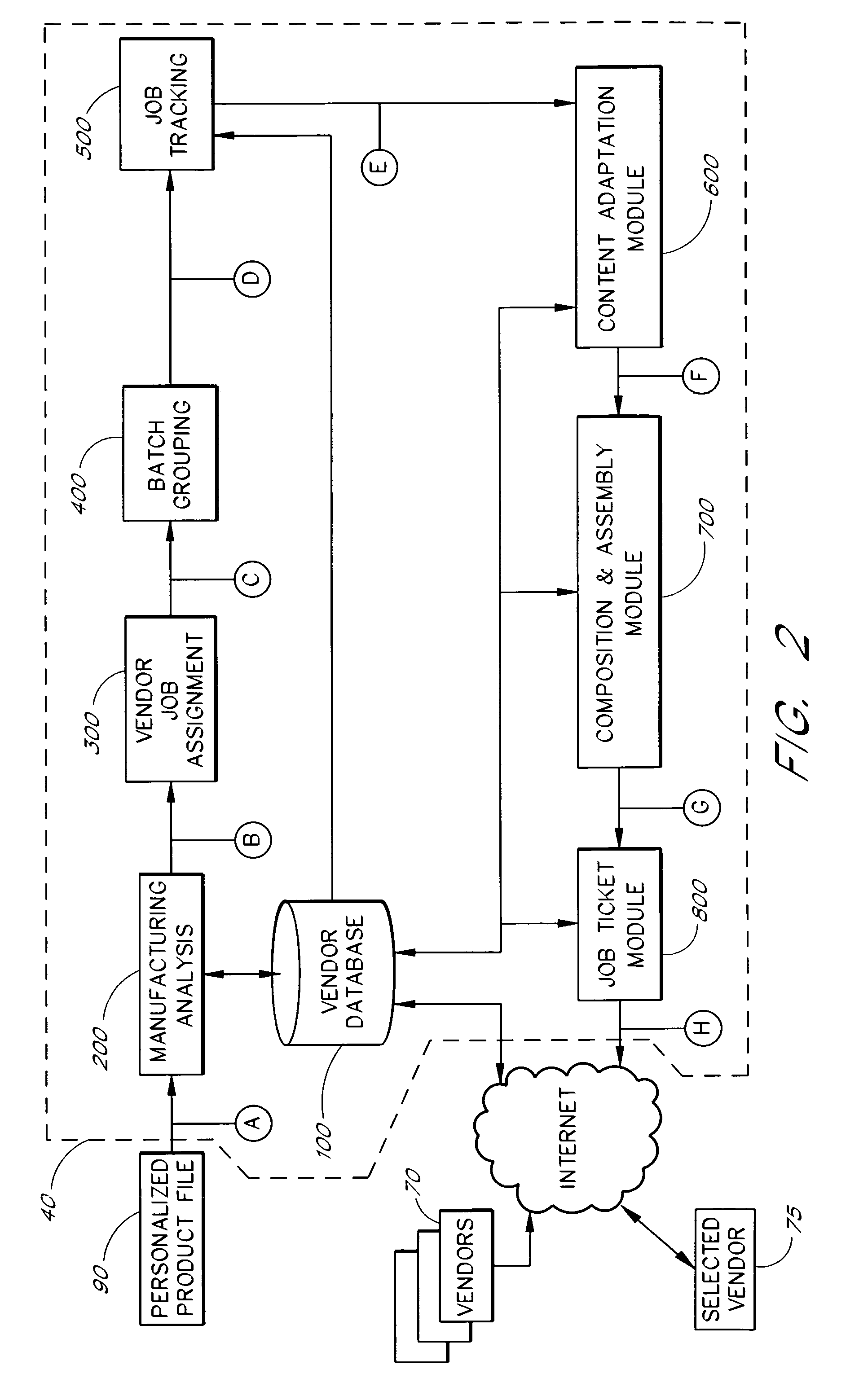

Personalization format converter system and method

A system and method for conveying information about a personalized product are disclosed. A web server processes product personalization information for a vendor. The web server accepts the personalization that a customer has provided and performed on a product. The web server further accepts a submission from the customer for an order for the production of that personalized product. The web server determines the vendors capable of producing the personalized product and may accept either customer selection of a vendor or automatic selection of a vendor to produce the personalized item. The web server can describe the personalized product in a manner consistent with a data specification or a production request format as defined by the vendor.

Owner:DELUXE CORPORATION

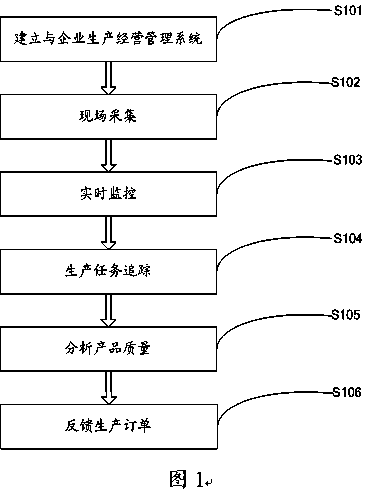

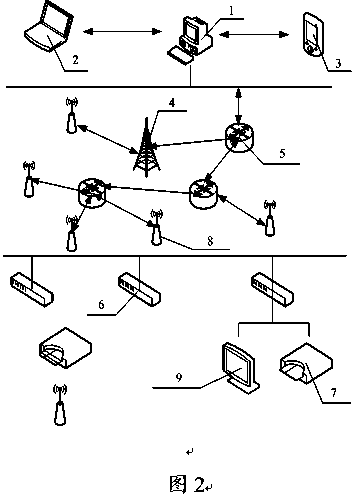

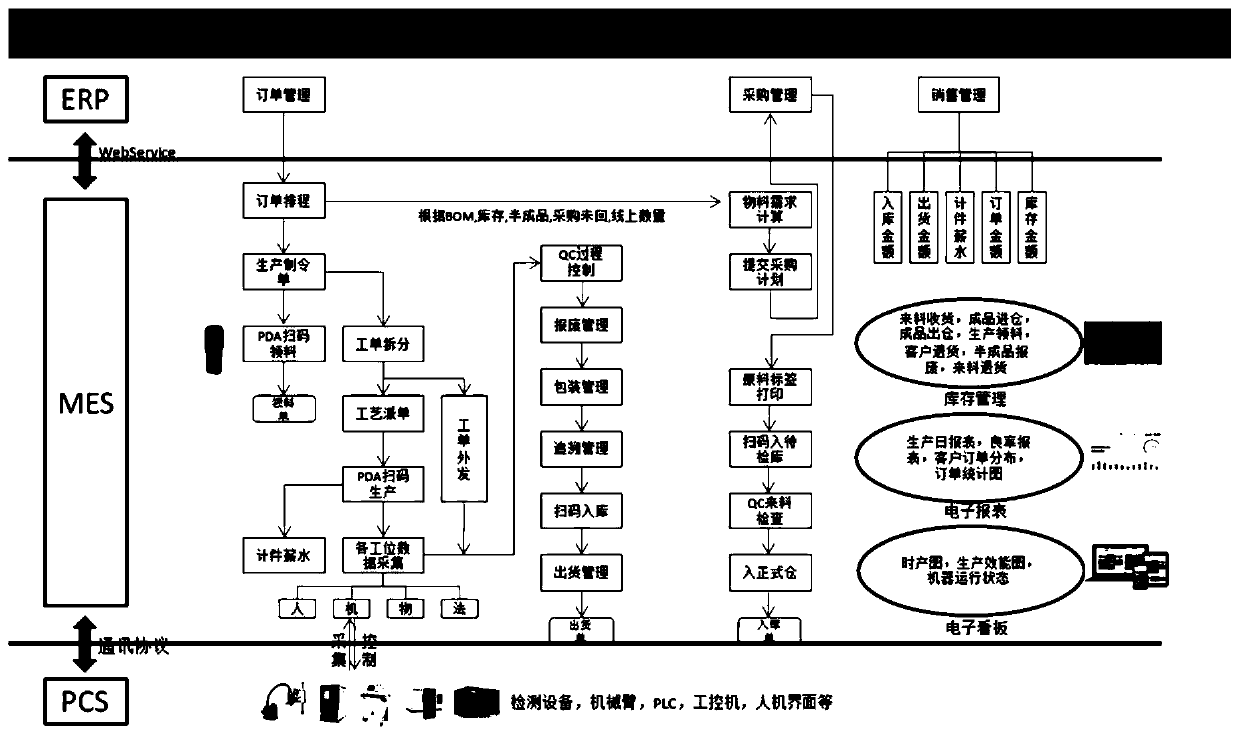

Workshop production management method and system based on Internet of Things

InactiveCN103810576AAchieve integrationAchieve sharingCo-operative working arrangementsResourcesData informationManufacturing execution system

The invention discloses a workshop production management method and system based on Internet of Things. The management method includes the steps of establishment of an enterprise production and operation management system, on-site acquisition, real time monitoring, productive task tracking, product quality analyzing and production order feeding back. The workshop production management system based on Internet of Things comprises a terminal management server, a receiving computer, a mobile phone with bluetooth or wireless fidelity (WiFi), a ZigBee coordinator, a ZigBee router, a station controller, a radio frequency identification (RFID) reader-writer, an electronic tag and a process displayer. According to the workshop production management method and system based on Internet of Things, workshop site is connected with an upper decision system by the aid of the RFID reader-writer and electronic tag manufacturing execution system (MES), integration and sharing of various data information of workshops can be achieved, thereby, the 'fault' phenomenon caused by incomplete sharing and exchange of enterprise data information in enterprises can be avoided, the management process is simplified, and the management efficiency is increased.

Owner:XIAN TECHNOLOGICAL UNIV

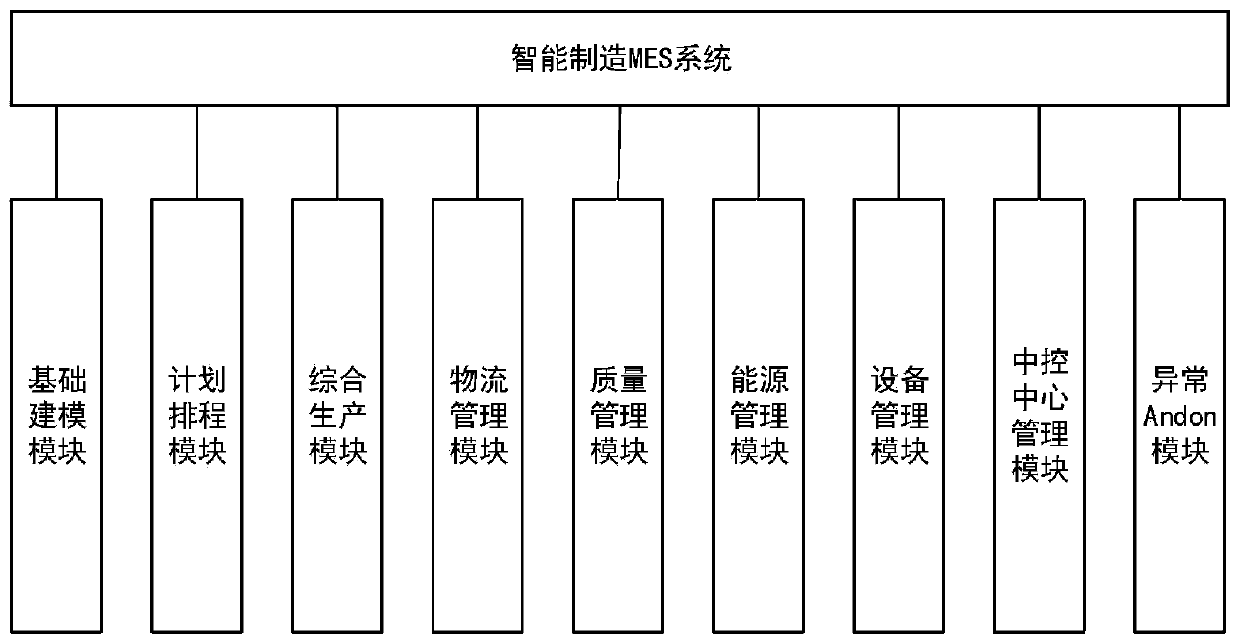

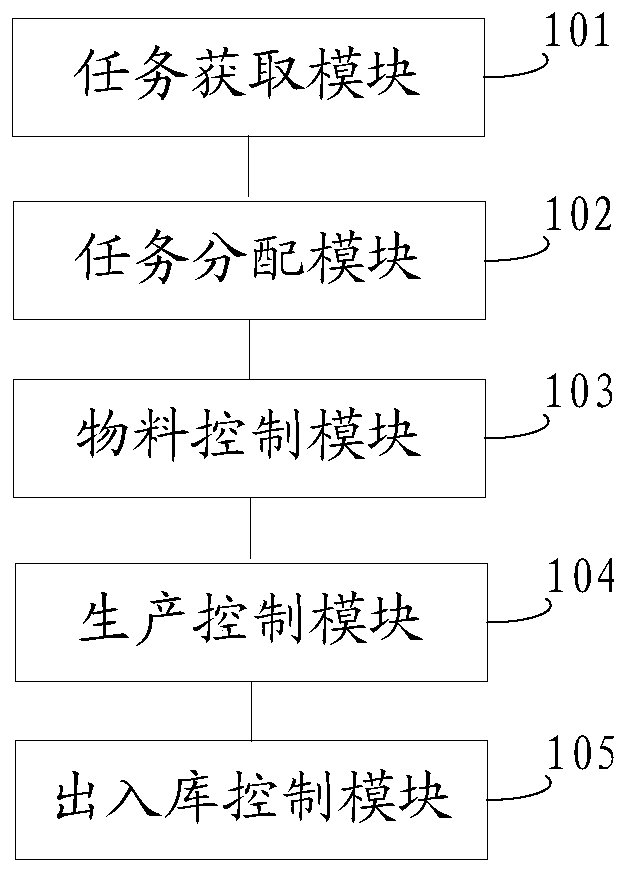

intelligent manufacturing MES system

InactiveCN110580026AIntelligent manufacturing whole process monitoringRealize the whole process monitoringEnergy industryTechnology managementMaterials preparationLogistics management

The invention discloses an intelligent manufacturing MES system which comprises a basic modeling module, a plan scheduling module, a comprehensive production module, a logistics management module, a quality management module, an energy management module, an equipment management module, a central control center management module and an abnormal Andon module. The basic modeling module is used for completing establishment of factory layout, establishment of product information and establishment of external resources. The plan scheduling module is used for establishing a production order, carryingout material preparation and distribution for a warehouse, work order scheduling, production execution, inspection, packaging and production warehousing. The comprehensive production module is used for managing a generated full-service process. The logistics management module is used for managing a production material taking management process and a production warehouse-in management process; andthe quality management module is used for carrying out inspection object maintenance on a purchasing department, a workshop department and a sales department. The invention provides a perfect intelligent manufacturing MES system, thereby realizing intelligent manufacturing full-process monitoring.

Owner:工业云制造(四川)创新中心有限公司

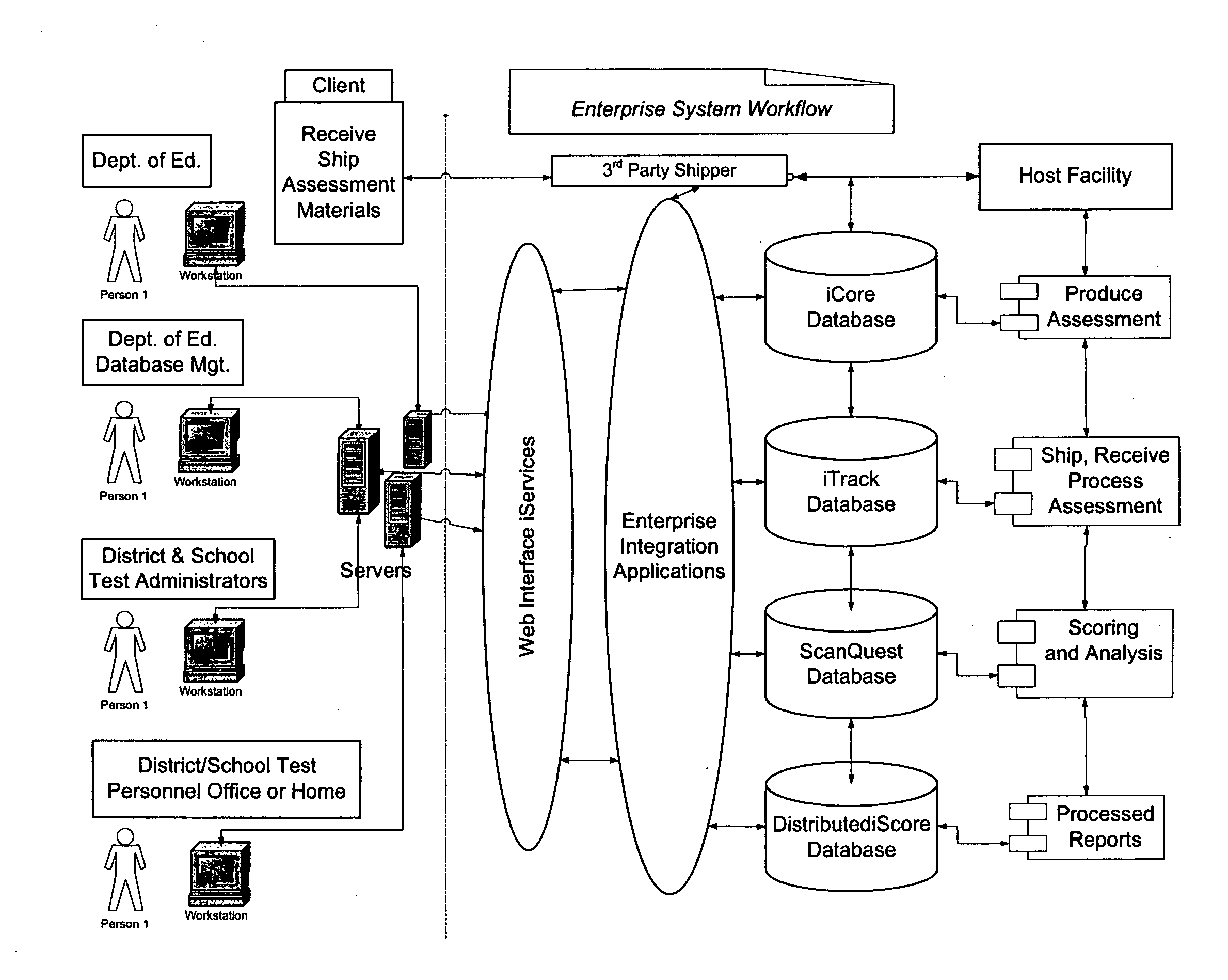

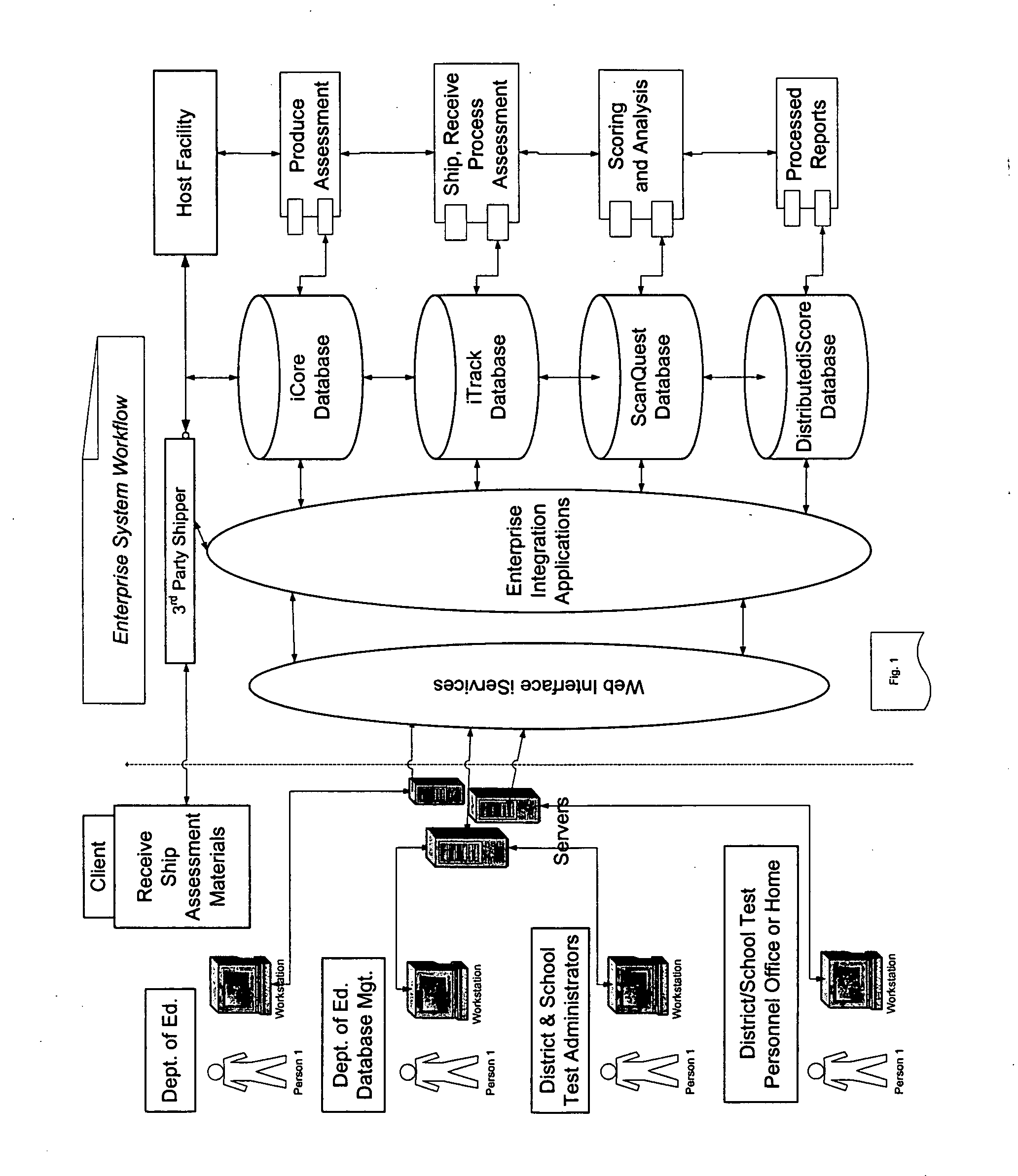

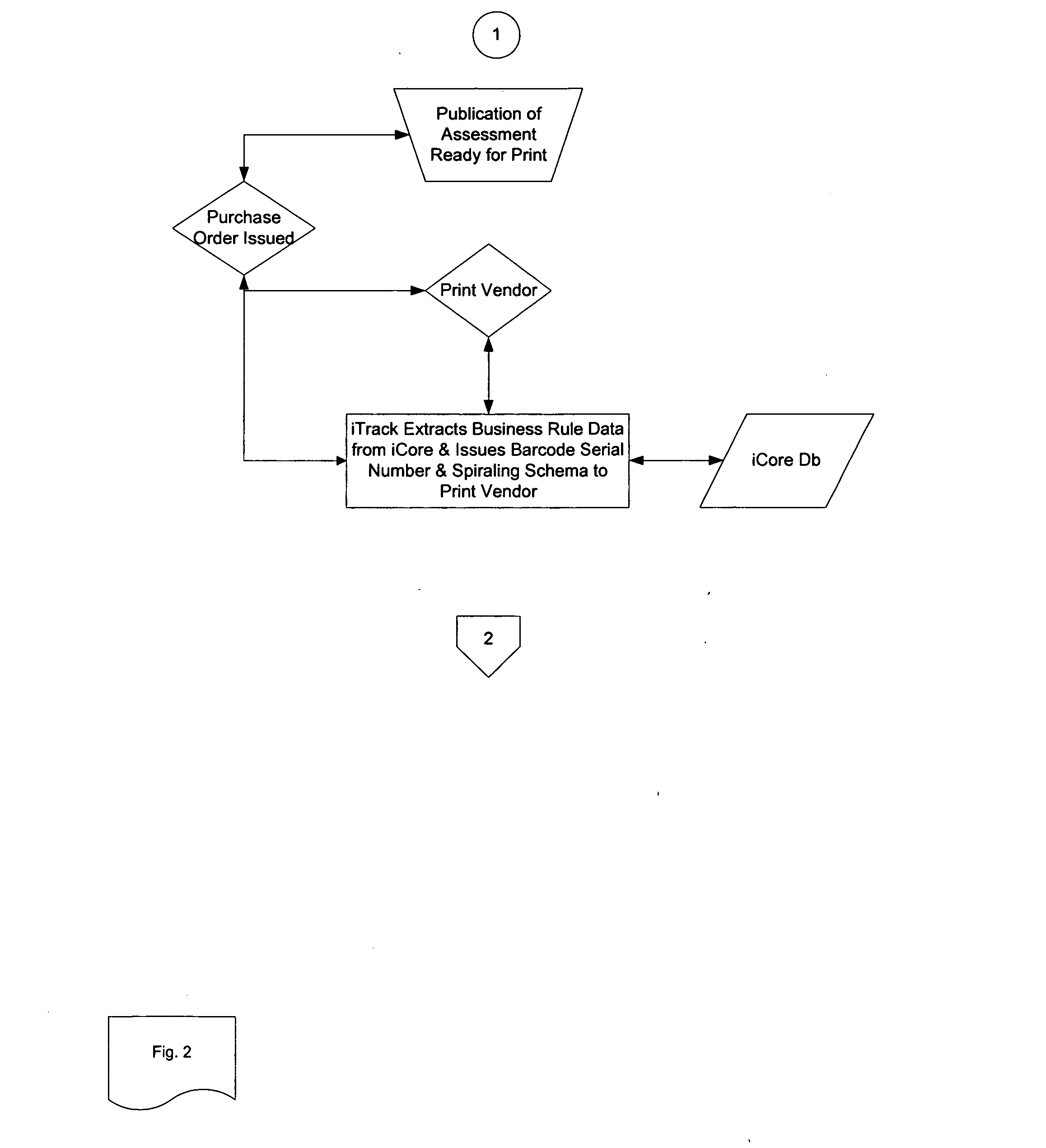

Item tracking, database management, and relational database system associated with multiple large scale test and assessment projects

InactiveUS20050086257A1Flexibility in capacityConvenient to accommodateOffice automationSpecial data processing applicationsTest documentRelational database

A system and process includes: a relational database that has a core database of global rules and project data, an item tracking database, a scanning and image management database, and a scoring database; an enterprise integrated application software program and computer network; and a web interface linking host operations and users; all of which is used for generating a production order and packing schedule of test documents from the rules and project data, for tracking production, packing, shipping, return shipping, and processing of actual test documents by using unique identifiers assigned to every document and monitoring and recording every movement of every document and appending all records of movement and other changes of condition to the original project data in the relational database, for scanning all documents into image form and storing and scoring the images, and for generating reports based on the scores and demographics of the testees.

Owner:MEASURED PROGRESS

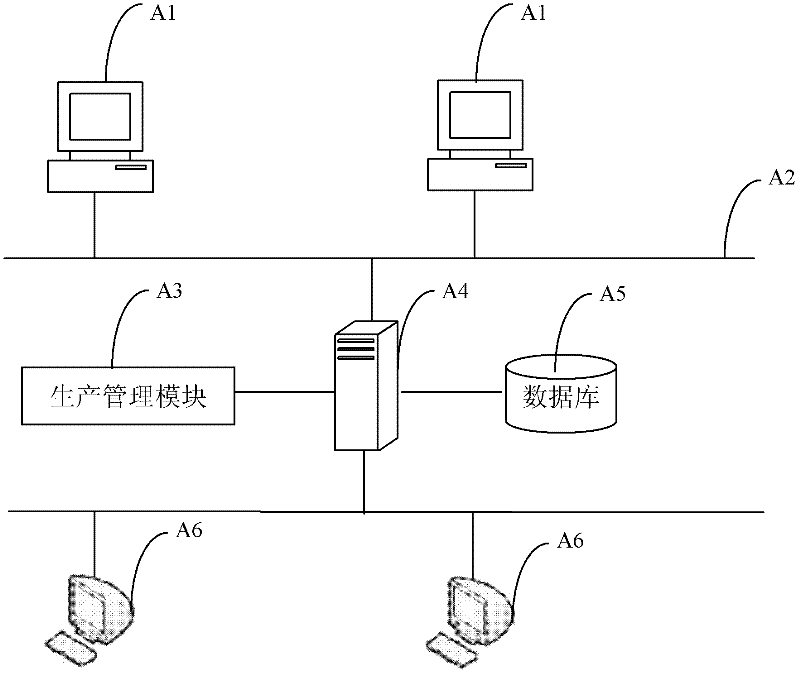

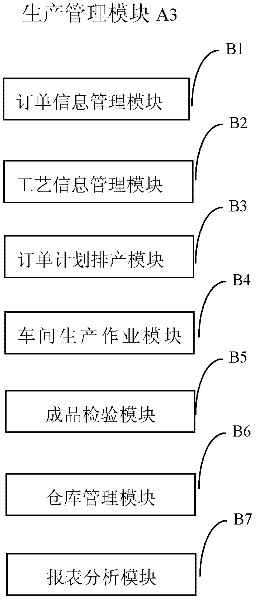

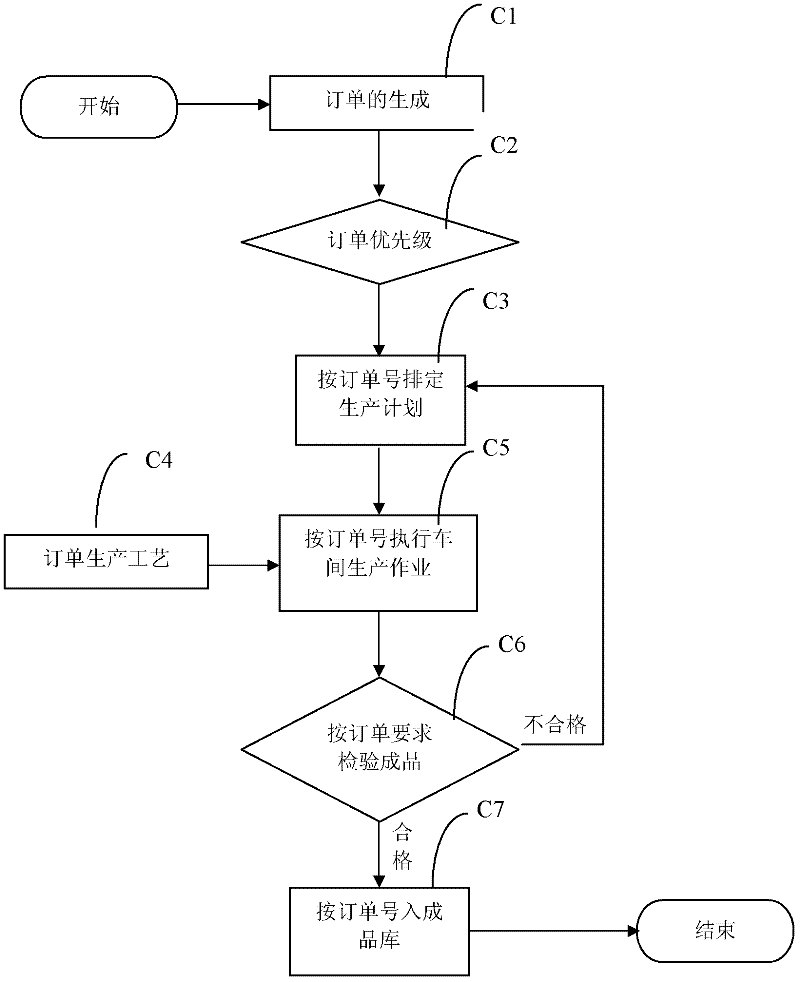

Production management system and method adopting order lists as core

The invention discloses a production management system adopting order lists as a core, comprising a WEB server, a database and series clients, wherein the WEB server comprises a production management module for receiving an inquiry condition of production management information, which is input by a user, retrieving the production management information according to the input inquiry condition of the production management information, processing the production management information and giving commands; the database is connected with the WEB server and used for storing and collecting the production management information; the series clients are connected with the WEB server through a network; each client logs on the WEB server in a browser manner to obtain an interactive interface of the production management module; and the interactive interface is used for inputting and displaying the production management information. The production management system disclosed by the invention can be used for clearly and conveniently tracking and managing each order list through the production management module, and calculating the cost of each production order list through a statement analysis module, thereby enabling the management to have more pertinence and scientificity, and improving operation efficiency of enterprises.

Owner:杭州开源电脑技术有限公司

Real time asset optimization

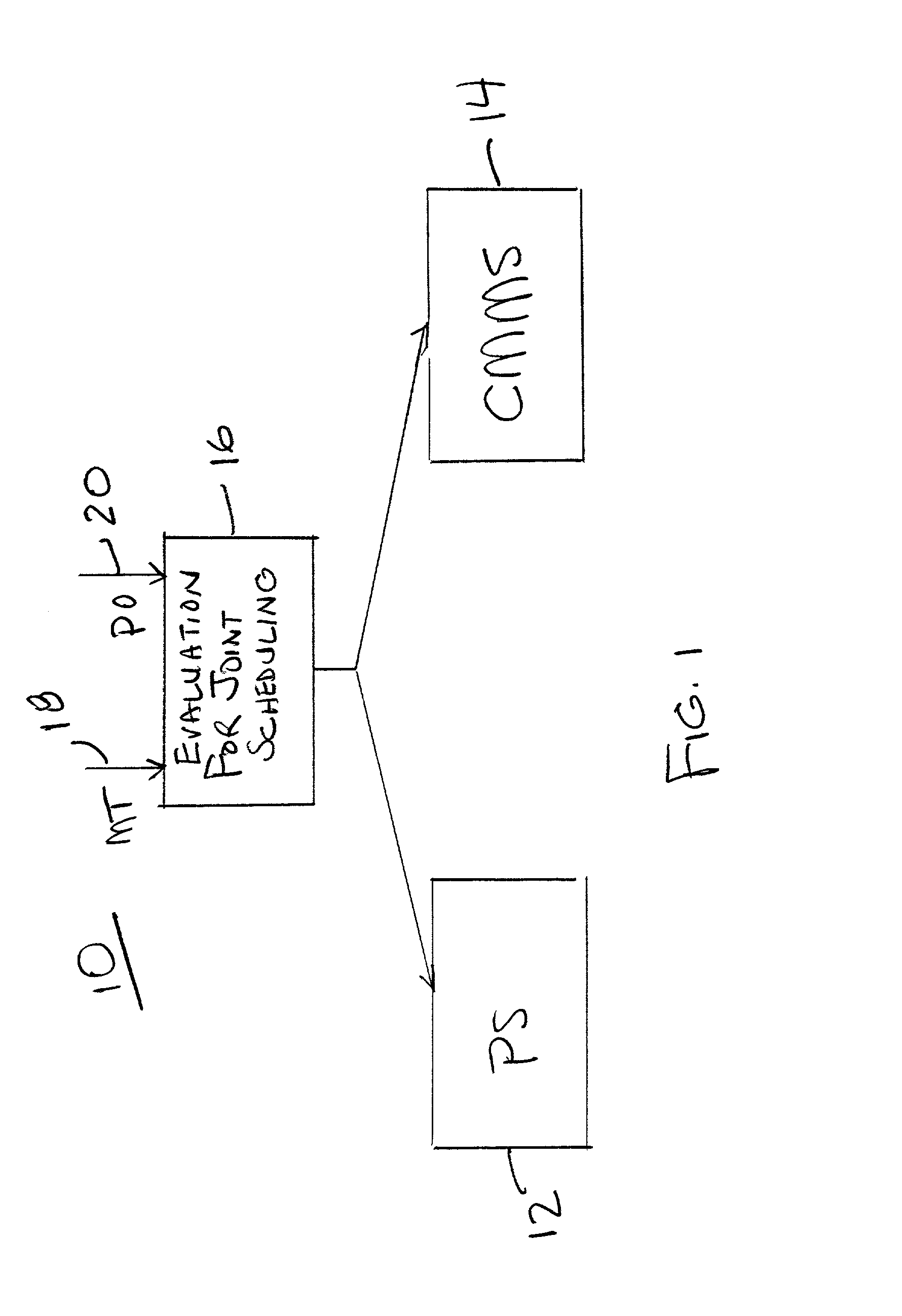

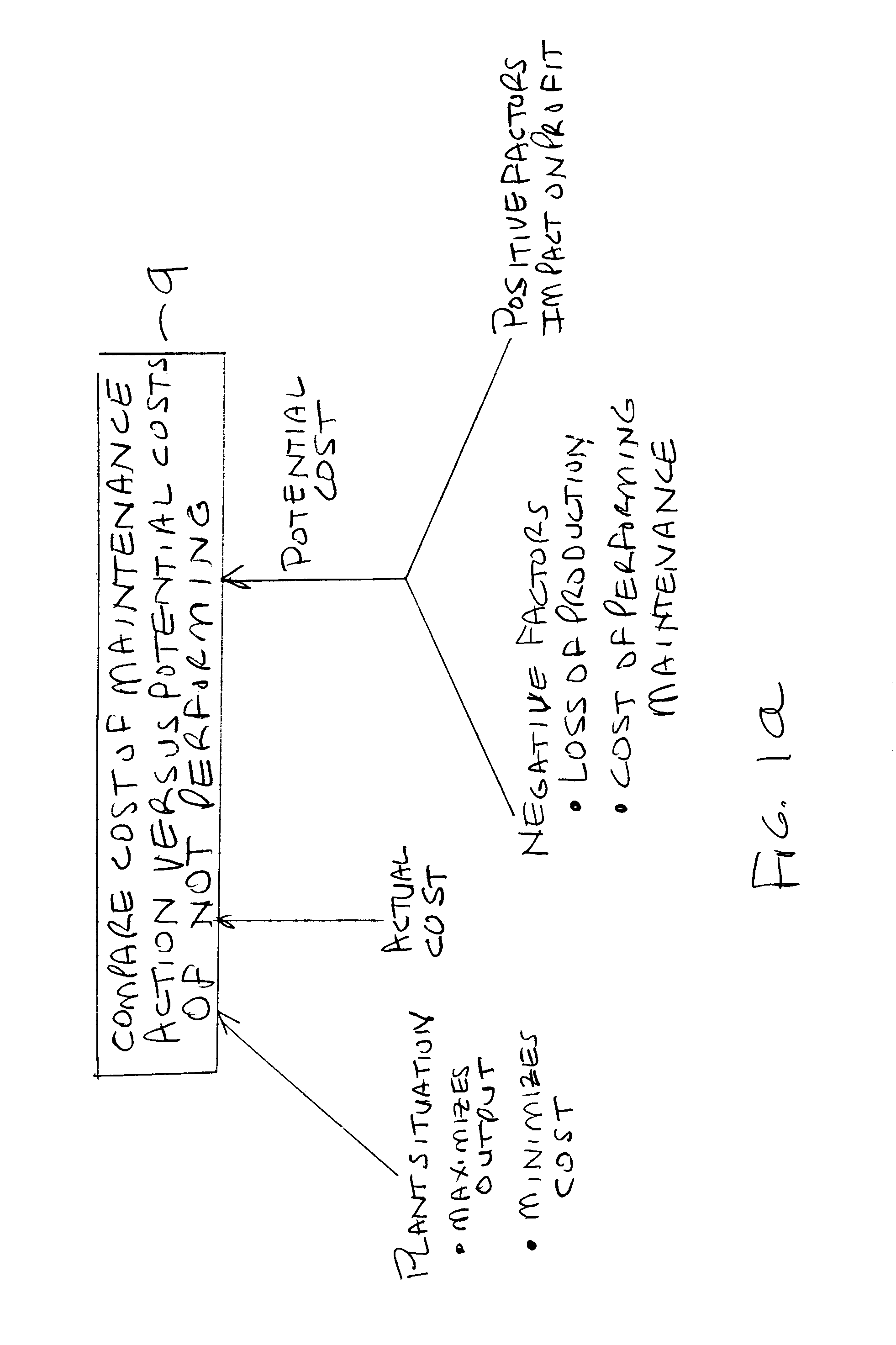

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

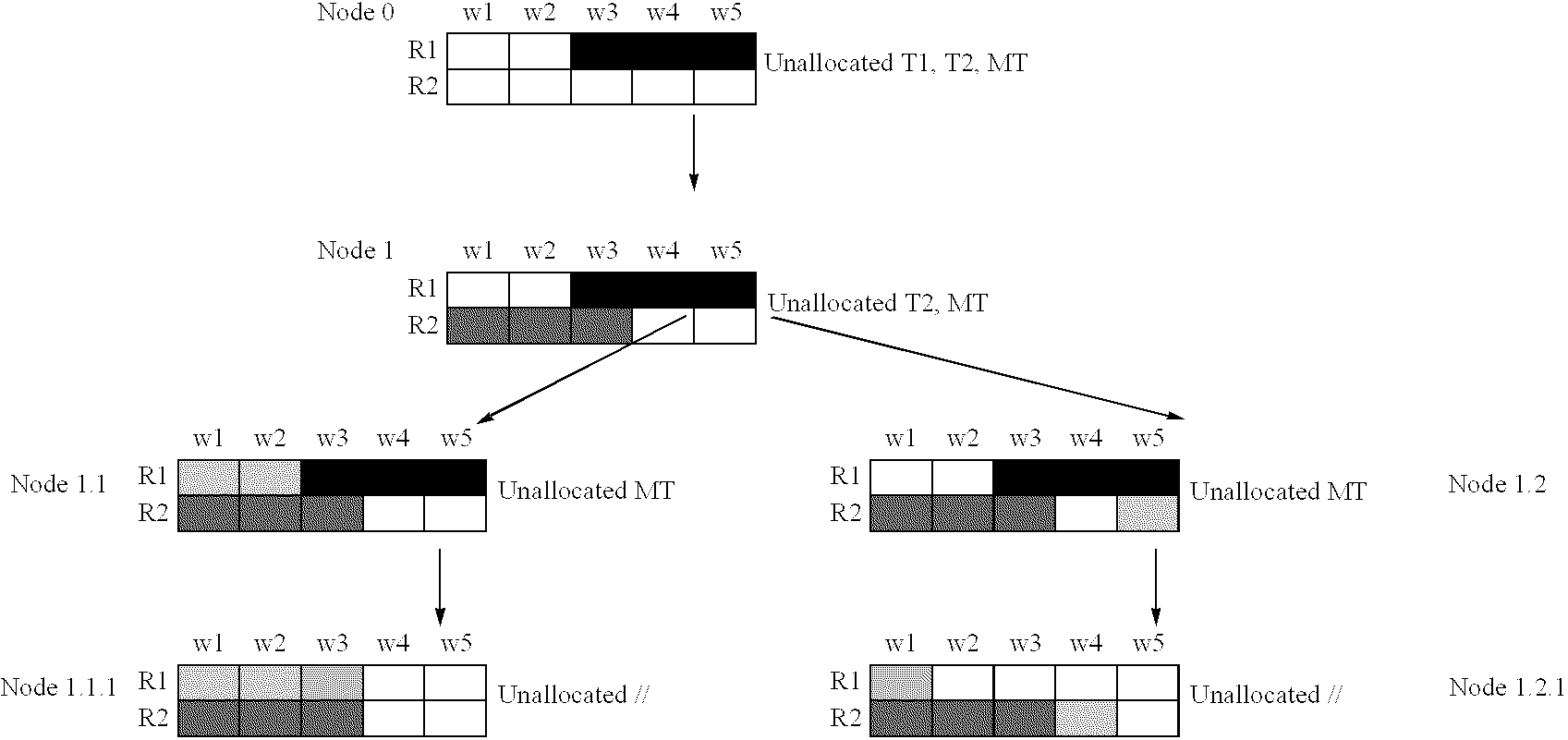

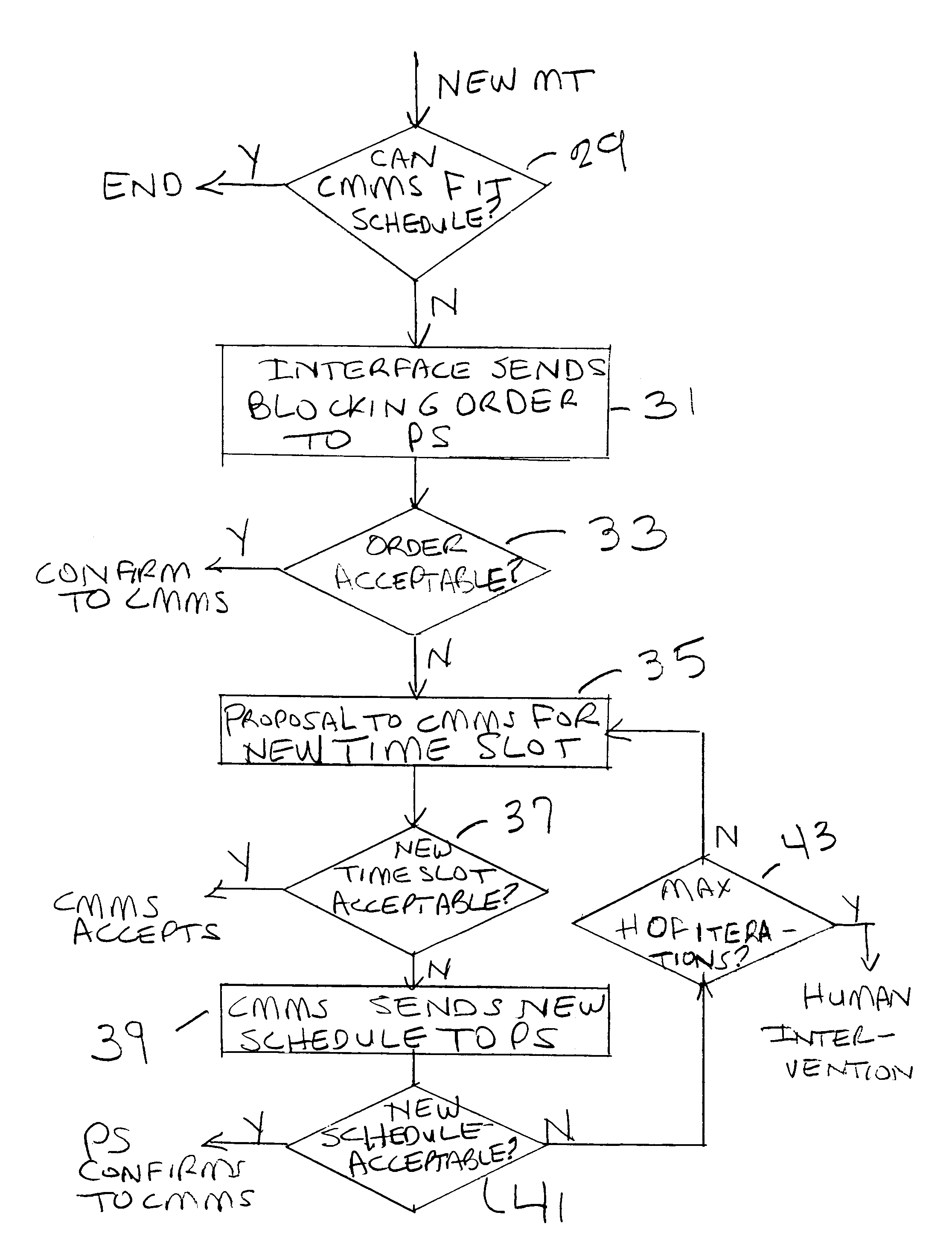

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

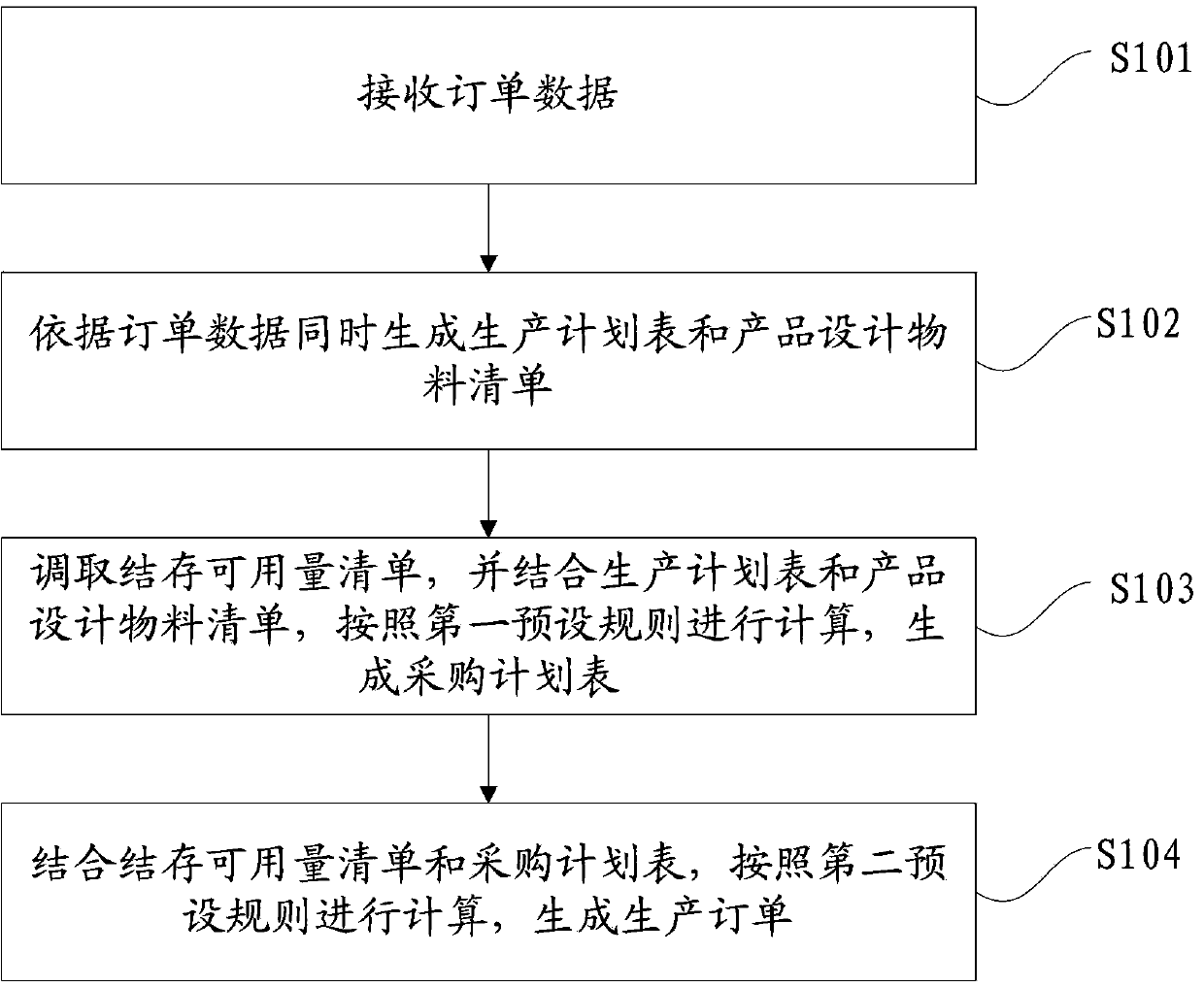

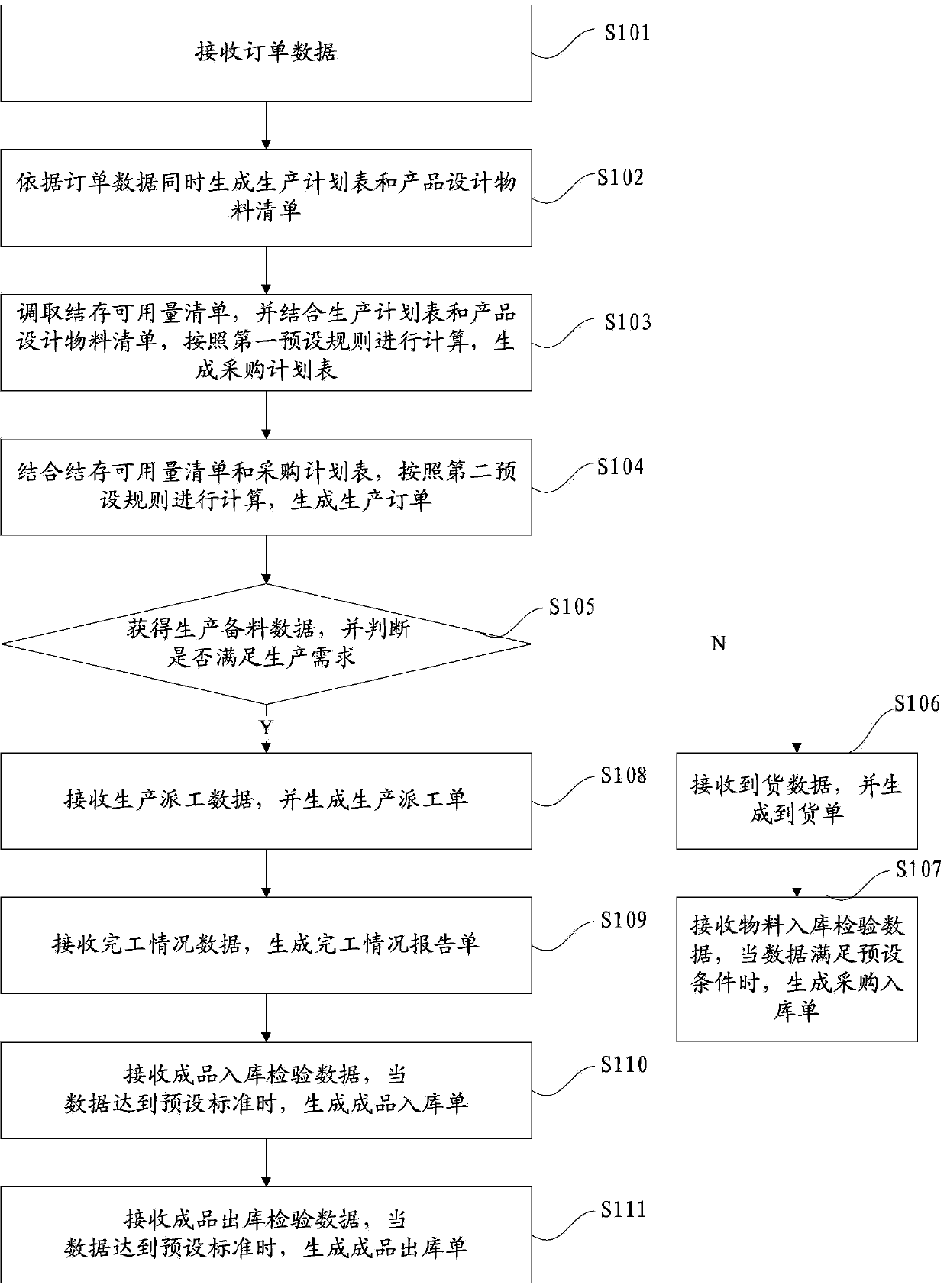

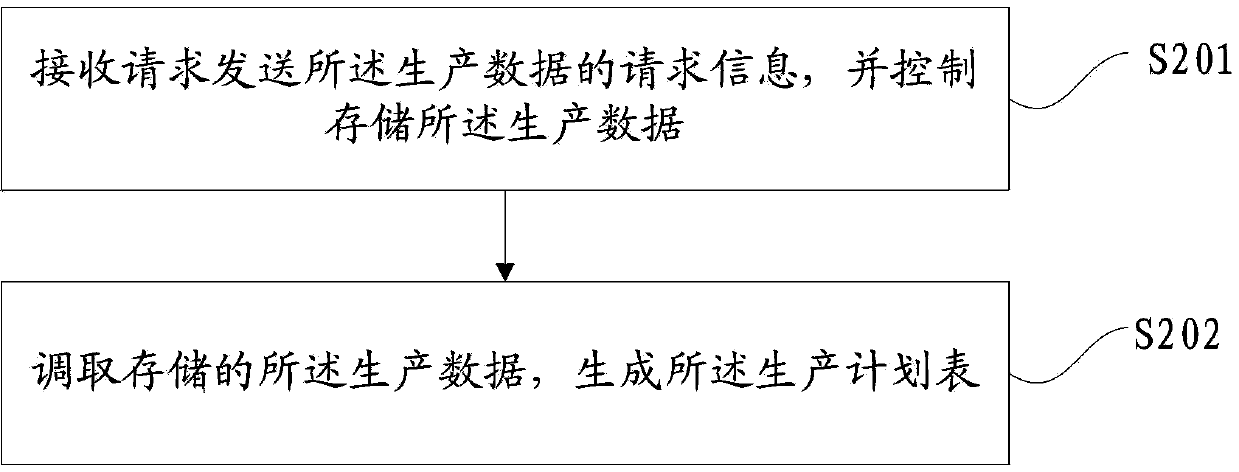

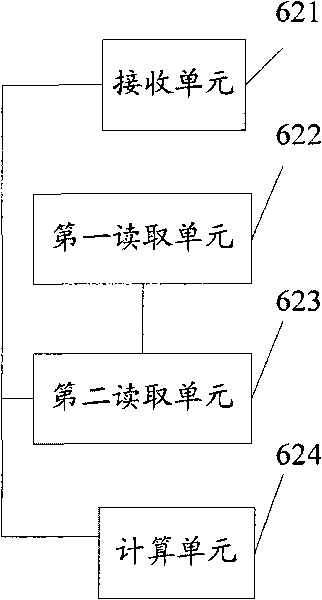

Production data processing method, device thereof, and system thereof

The invention discloses a production data processing method, a device thereof and a system thereof. The method comprises a step of receiving order data comprising production data and material data, a step of generating a production schedule according to the obtained production data and generating a product design material list according to the obtained material data at the same time, a step of calling a pre-stored balance amount, carrying out calculation according to a first preset rule with the combination of the production schedule and the product design material list, obtaining purchase material data and generating a purchase schedule corresponding to the purchase material data, a step of carrying out calculation with the combination of balance amount and the purchase schedule and according to a second preset rule, obtaining product order data, and generating a product order corresponding to the product order data. According to the above production data processing method, the product design material list and the production schedule are determined at the same time according to the concretely received order data, the flexibility is high, and the method, the device and the system are suitable for most small and medium enterprises.

Owner:HANGZHOU FUTURE POWER TECH +1

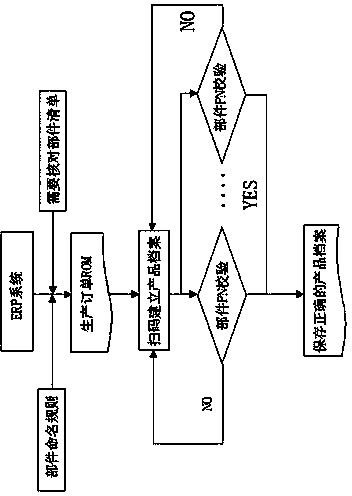

Automatic calibrating method of make-to-order production materials by server

InactiveCN103971223AImprove controlVersatileLogisticsSpecific program execution arrangementsMaterial DescriptionEnterprise resource planning

The invention discloses an automatic calibrating method of make-to-order production materials by a server. The method comprises the following steps: each machine automatically generates an SN (Serial Number) number according to a production order BOM (Bill of Materiel) established in ERP (Enterprise Resource Planning), wherein the SN number is associated with the production order number and the production order BOM comprises PN (Part Number) codes of all materials, material description, standard quantity of the materials, make-to-order number and the production order number; quality guarantee bar codes are adhered to all materials, wherein each quality guarantee bar code comprises two pieces of association information: PN code and QN (Quality Notification) code; based on existing file code scanning program, an automatic calibrating script program is compiled; after wall parts are code-scanned, the save button is clicked, thus, a background calibrating program further checks the PN, quantity and BOM of all code-scanning parts; when the result is inconsistent, mistaken material rows are prompted; and if no mistakes are found, the product record is successfully stored. By adopting the technology provided by the invention, under a mode of customerized production of a server product, manual checking work can be completed by system and program.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

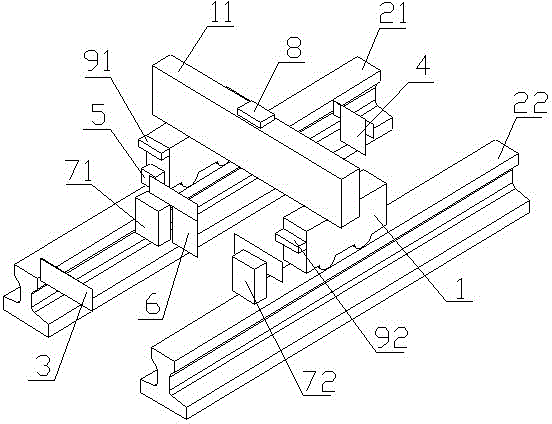

Online detection method for crane tracks

InactiveCN105651221AGuaranteed uptimeReal-time measurementUsing optical meansLoad-engaging elementsHeight differenceElevation data

The invention discloses an online detection method for crane tracks. The method comprises that the track at the triboelectric side of a crane is provided with a laser collimator and a fixed laser reception target to establish a collimation reference system; and the crane is provided with a mileage sensor, a mobile laser reception target, a laser displacement sensor and a one-dimensional inclination sensor to measure mileage data, real-time displacement data, data of distance between the tracks, the track linearity data, relative elevation data of the tacks and relative height difference data of the tracks in real time, and thus, the crane tracks are detected in real time. The crane and the tracks are provided with the corresponding measuring components, the movement locus of the crane and the relative relation between the crane and the tracks are measured to obtain track parameters, the production order is not interfered, the measuring efficiency is improved, and safe and reliable operation of the crane is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

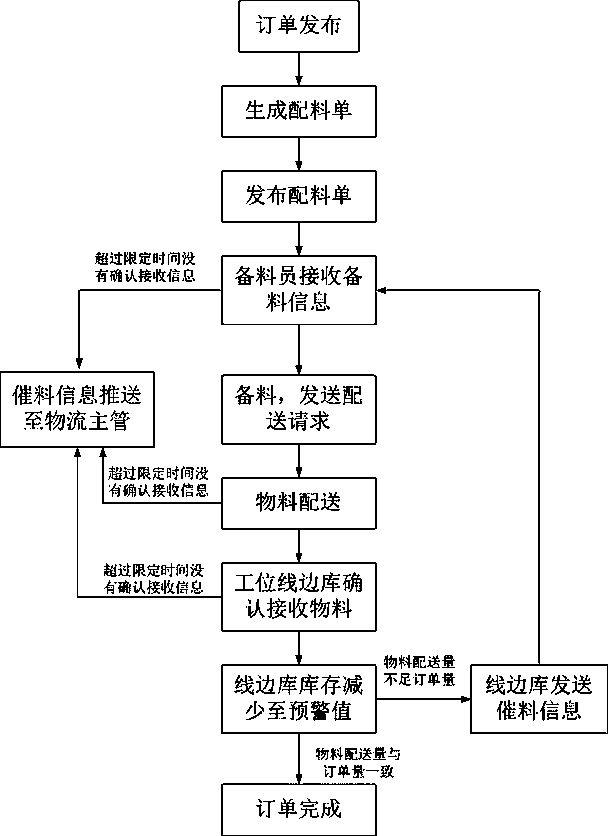

A material distribution method and system for an air-conditioning workshop based on a MES system

ActiveCN109359903AImprove distribution efficiencyEasy to trackLogisticsManufacturing computing systemsMaterials preparationDistribution method

The invention discloses a material distribution method and a material distribution system of an air conditioning workshop based on a MES system. The method comprises the following steps: the materialdistribution method and the material distribution system of an air conditioning workshop based on the MES system are monitored and generated by downloading a production order and a batching list in real time through the MES system; the batching list is audited and the batching list information is issued; The material storer receives the batching list information, checks the material staging information, and arranges the distribution according to the capacity of the line side warehouse. The material stationer completes the material preparation and sends the distribution request; The distributorreceives the distribution request, starts to distribute the materials to the station line side warehouse, and sends the received information after the station line side warehouse receives the materials; When the remaining material quantity of the workstation line side warehouse is reduced to the warning value and the total material distribution quantity is less than the demand quantity of the order, the workstation line side warehouse alarms, sends the material urging information, and the MES system pushes the material urging information to the material warehouse, and re-executes the step A03until the order is completed; The distribution method effectively tracks the flow direction of the material, timely replenishes the material, reduces the phenomena of wrong delivery, missed deliveryand multiple delivery, and effectively improves the distribution efficiency of the material.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

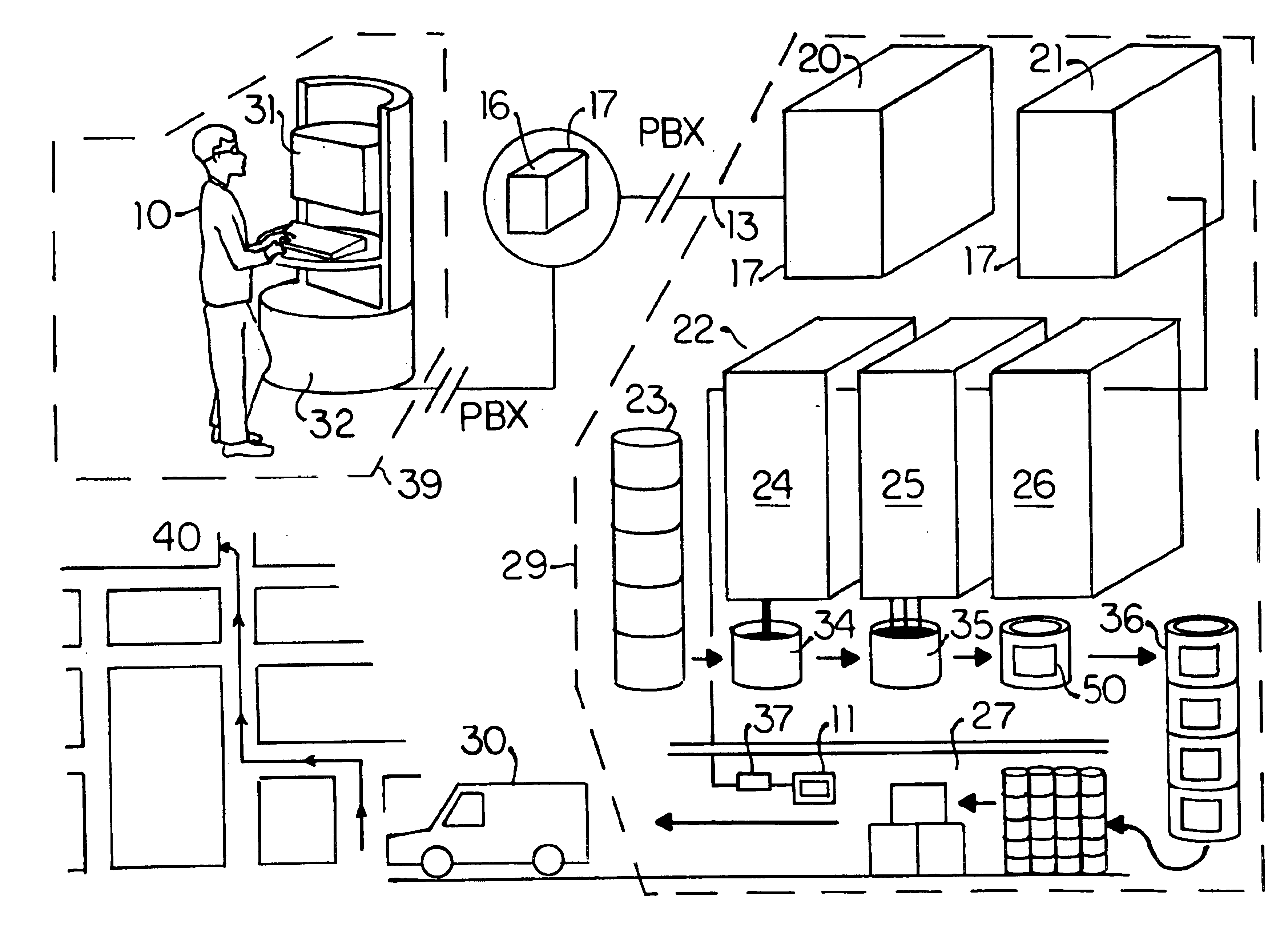

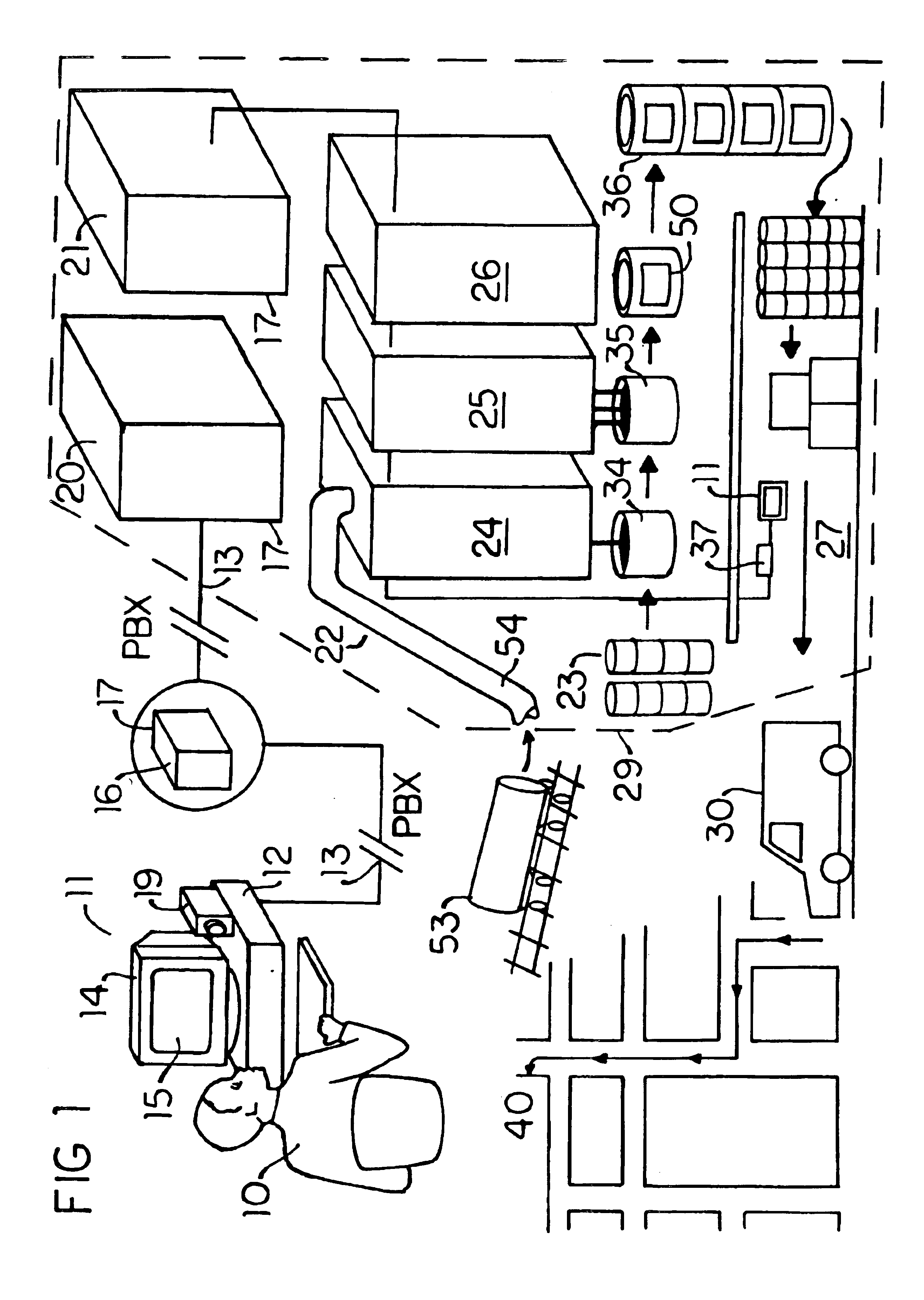

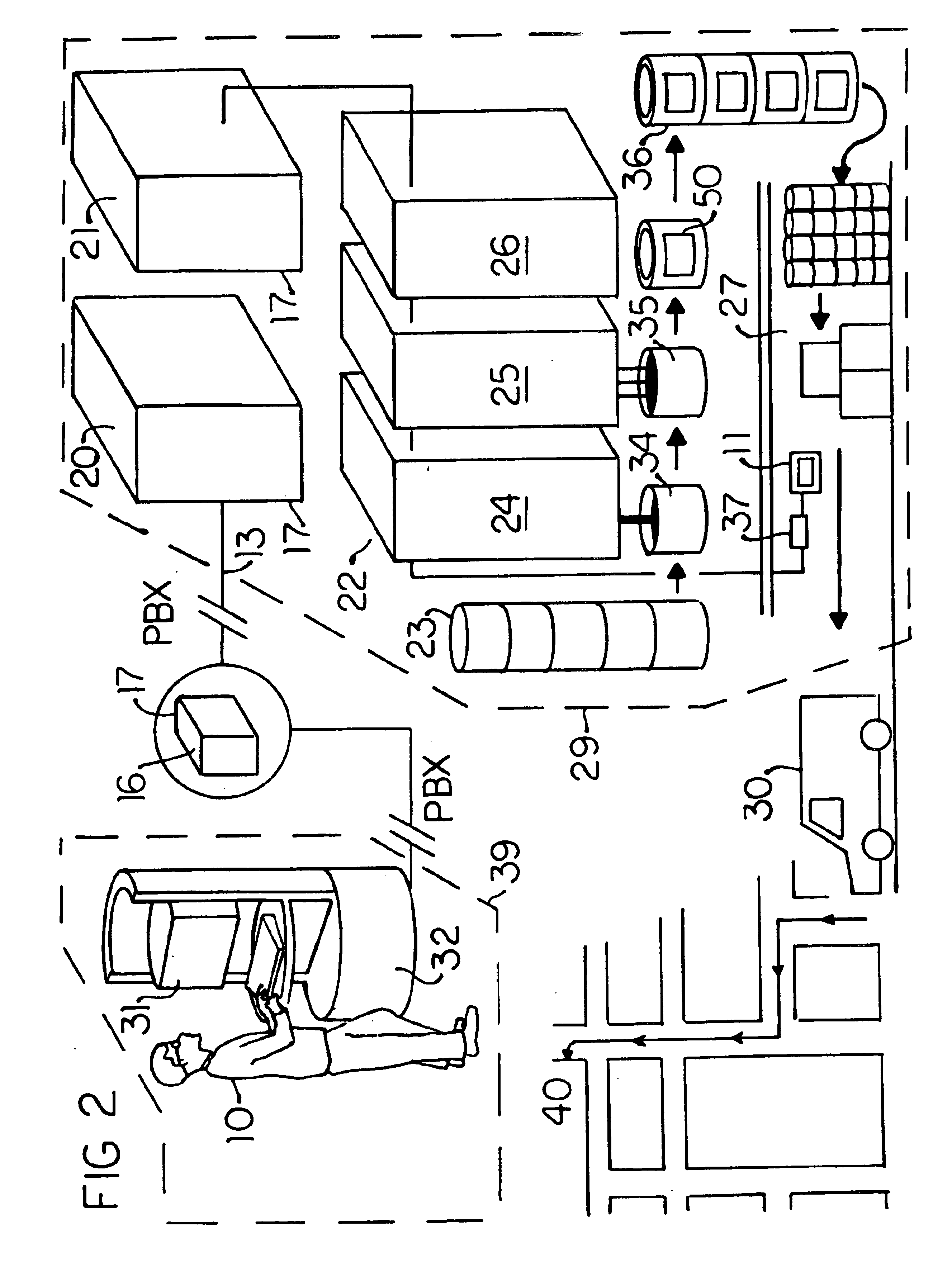

Containerized liquid coating product supply business method

InactiveUS6959284B1Easy accessWell as to enableFinanceDigital data processing detailsWeb siteProduction line

A consumer places an order for liquid coating product directly with a supplier via the internet or telecommunications. Customer order information is entered into a customer order subsystem on a computer, is compiled, processed and then utilized by a production subsystem governing a production line for containerized liquid coating product inclusive of all colorants required to obtain particular, non-standard, colors. Batching with regard to liquid coating base, delivery date and geographic delivery address is suggested. Shipping assemblies and packages specific customer orders for commercial transport service directly to the delivery address given by the consumer. Customer order information including verified content is indicated by a container identifier in assurance of quality. Attachment of a label upon each container after filling with blended liquid coating base and colorant with information printed and / or a bar or other digital code is suggested. Superior precision in colorant addition than that obtainable by a local retailer ensures consistent color, tone, and shade for particular, non-standard, colors in diverse containers and orders. Standard containers may be partially filled and non-standard volume plastic containers may also be utilized in fulfillment of precise order quantities. Production to order minimizes inventory. Product information including digital assistance in selection of base, color, and volume for a given-application and placing an order is readily provided on an internet web site or a dedicated terminal in a kiosk.

Owner:COLORS DIRECT

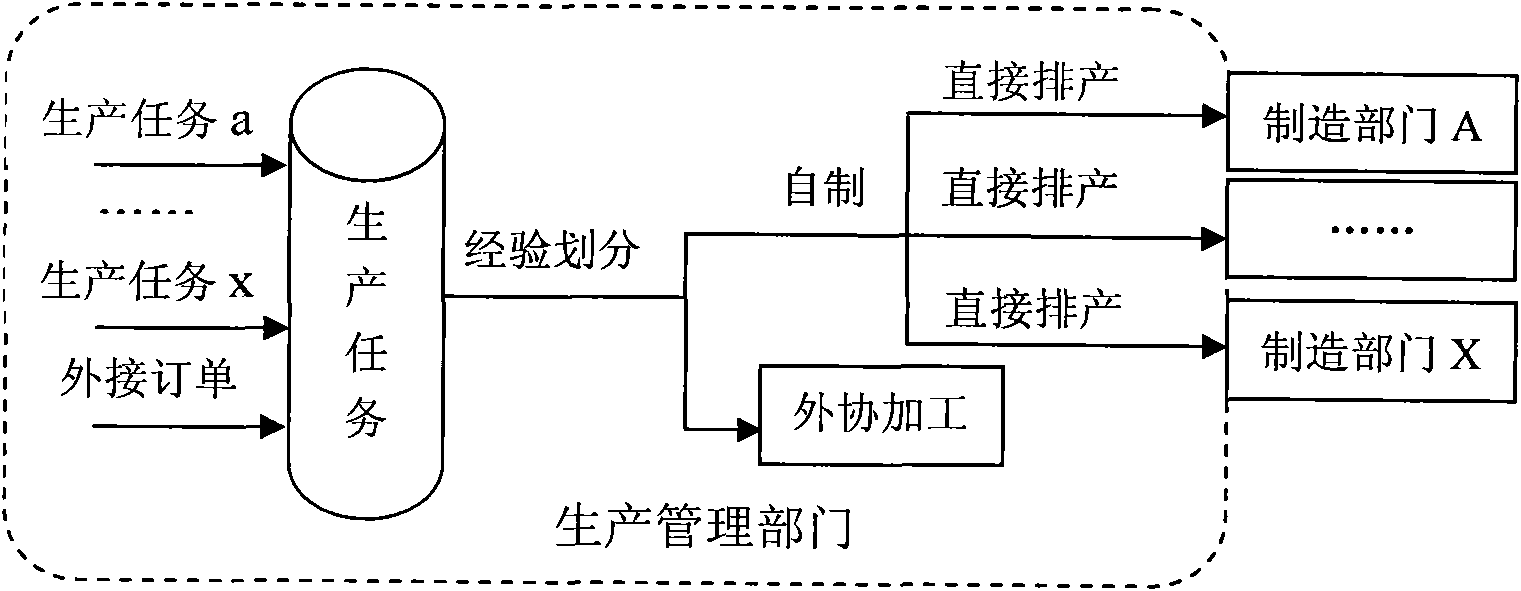

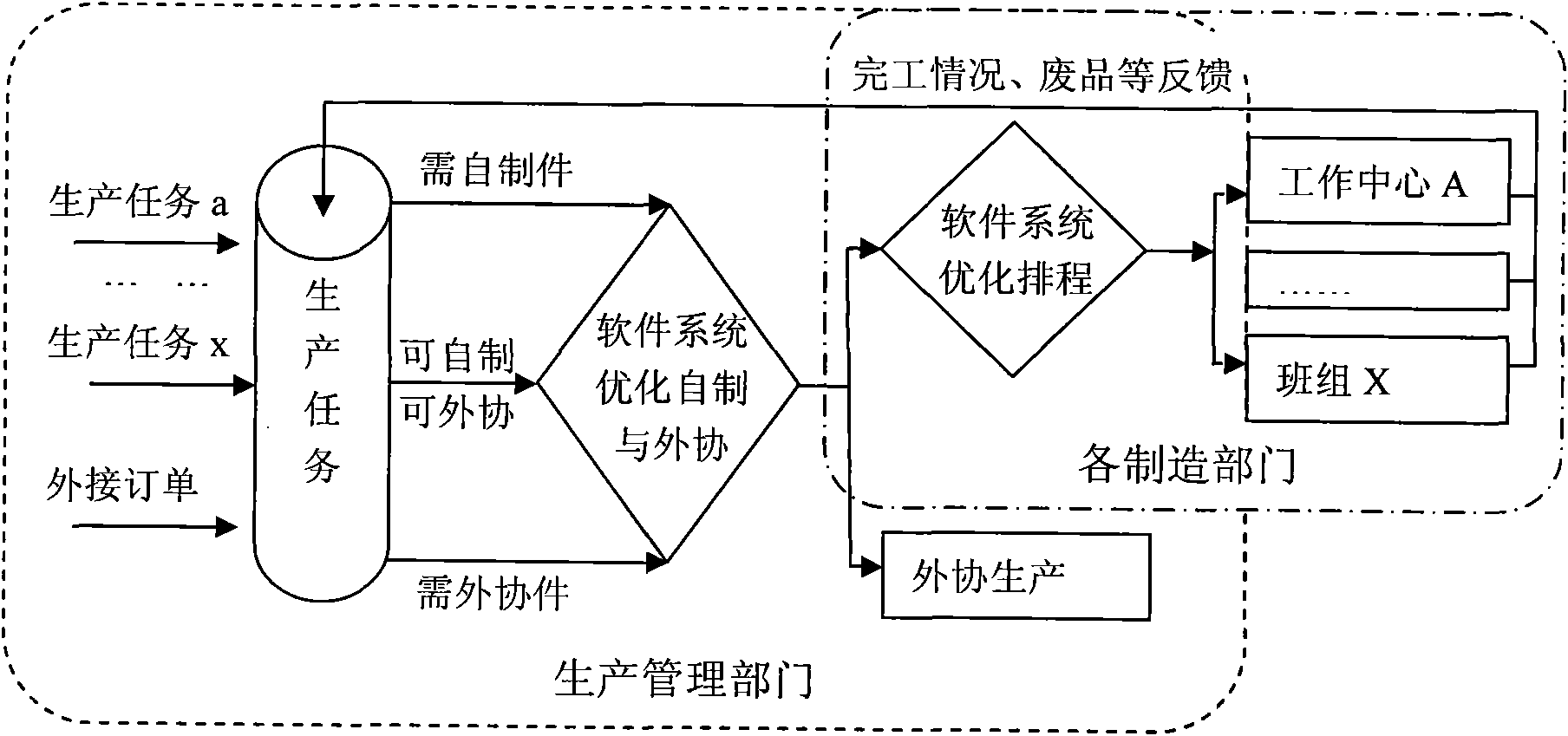

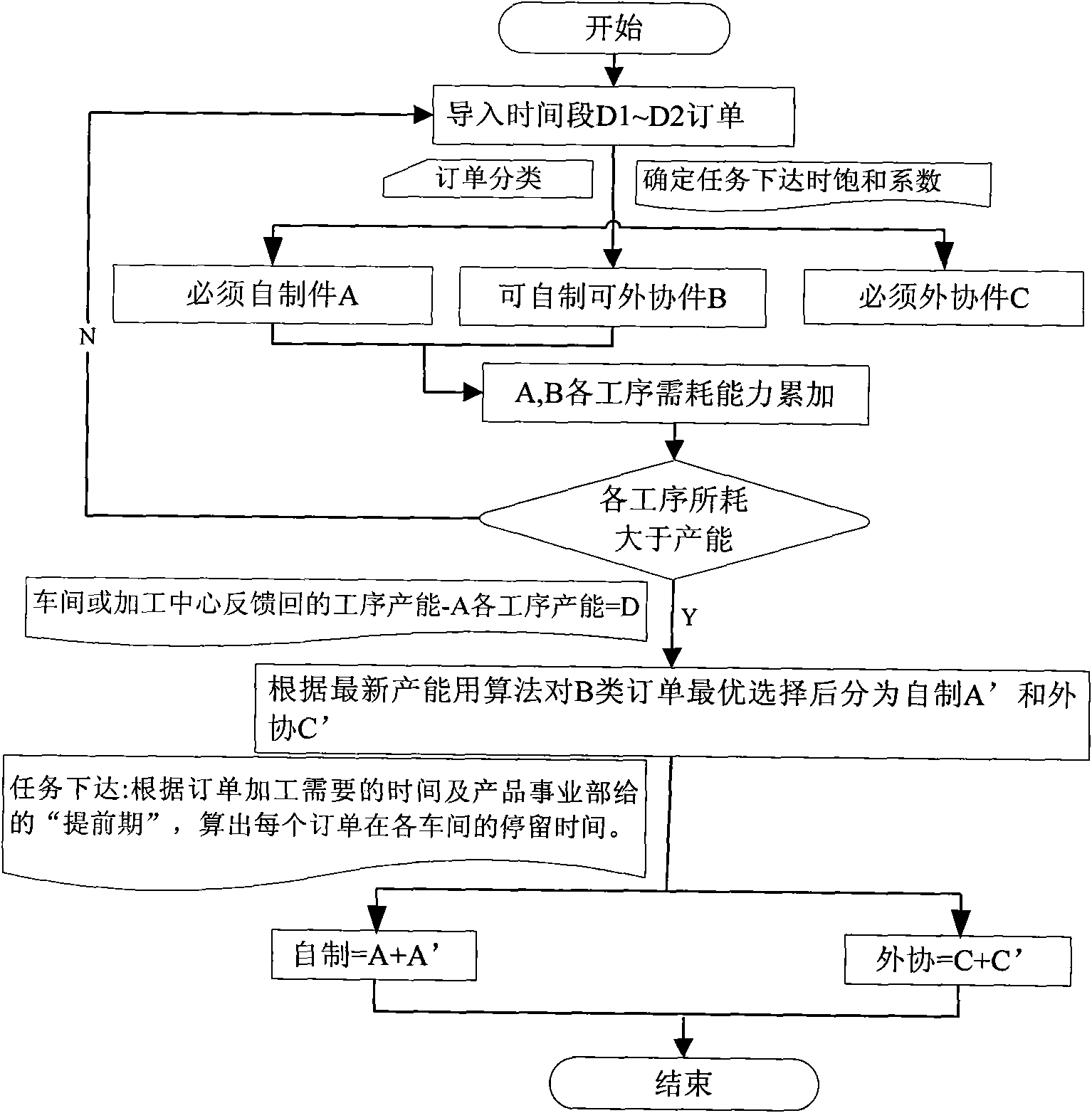

Management and control optimizing method of discrete manufacture production

The invention relates to a management and control optimizing method of discrete manufacture production, which comprises the following steps of: 1, classifying received production orders into following three classes: class A: items must manufactured per se; class B: items manufactured per se or in cooperation with others; and class C: items must manufactured in cooperation with others; 2, further classifying the class B including items manufactured per se or in cooperation with others into items manufactured in cooperation with others and items manufactured per se; 3, respectively issuing production tasks to corresponding cooperation or self manufactured production executing departments; and 4, carrying out optimal scheduling production on the self manufactured production tasks according to production conditions of current equipment, workers, raw materials, date of delivery, and the like. Compared with the prior art, the invention has the advantages and the technical characteristics of simple operation, easy implementation, wide application, convenient use and the like.

Owner:SHANGHAI DIANJI UNIV

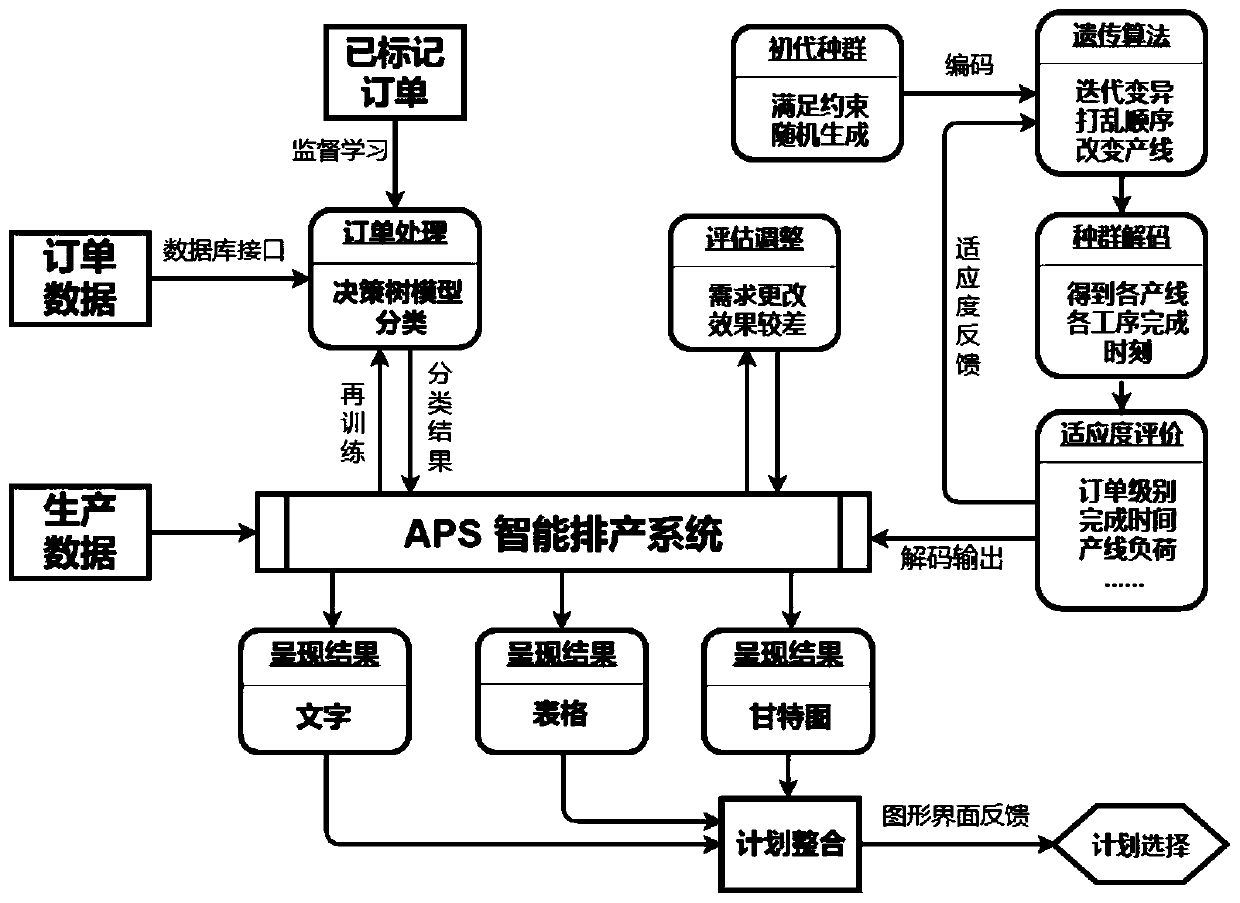

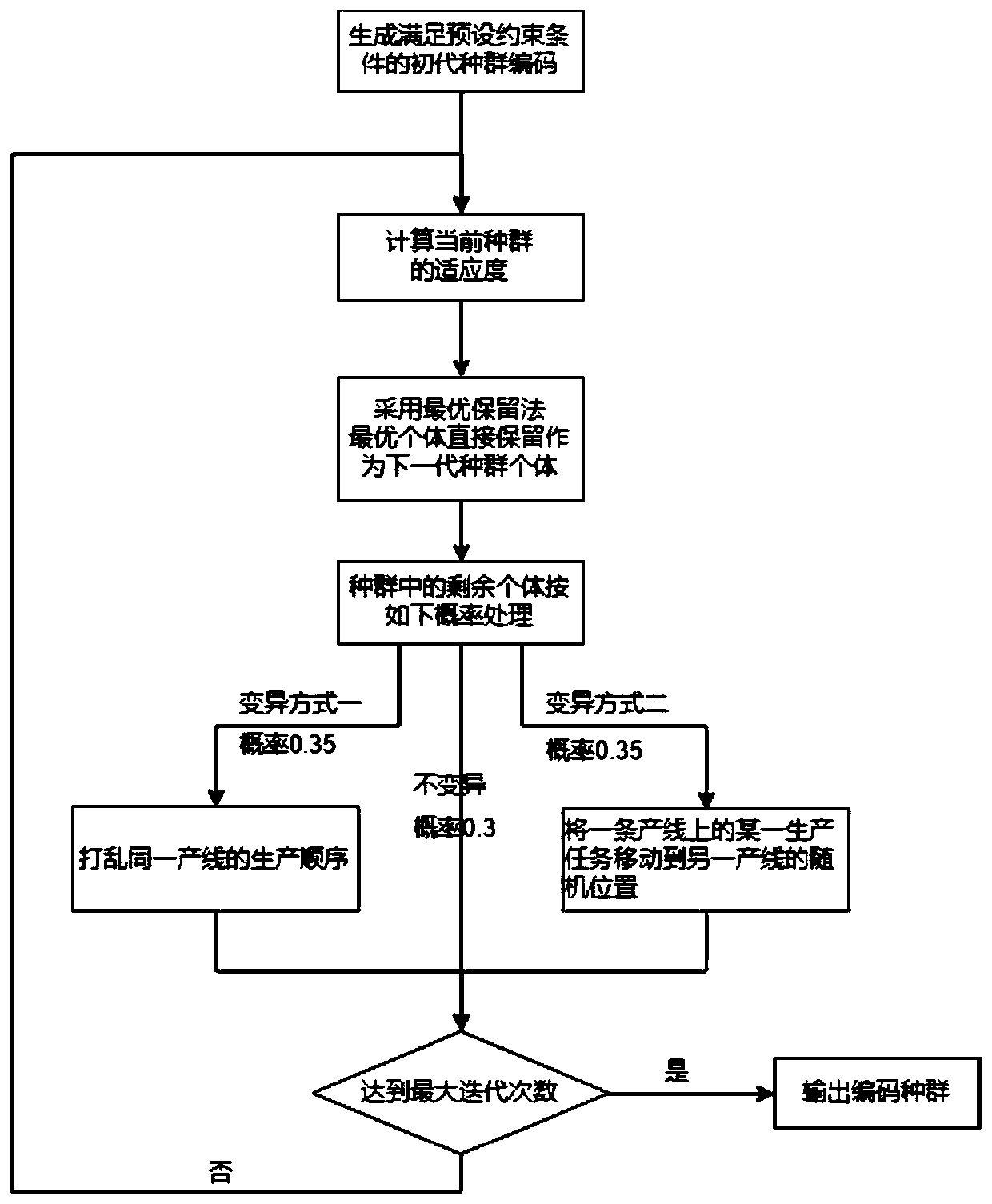

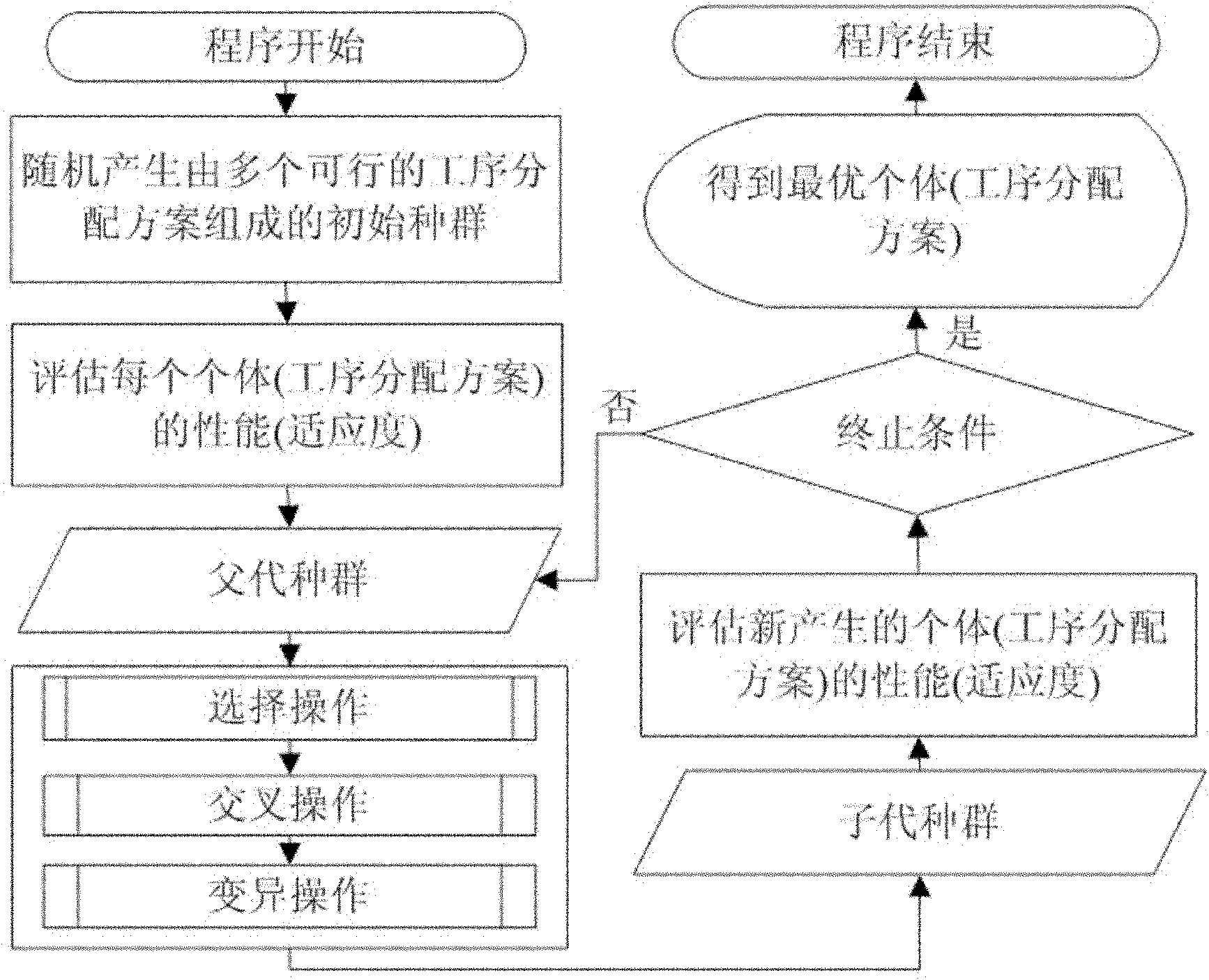

Workshop production scheduling method and system based on genetic algorithm

ActiveCN110378528AImprove execution efficiencyClose to actual productionForecastingResourcesProduction lineDecision model

The invention discloses a workshop production scheduling method based on a genetic algorithm, and the method comprises the steps: constructing and training a decision tree model based on labeled orderdata, and inputting to-be-produced order data into the trained decision tree model to obtain the priority of a to-be-produced order; based on comprehensive consideration of a genetic algorithm, constraint conditions, encoding and decoding, fitness calculation and the like, finding an optimal production scheduling plan and finally, presenting a specified number of encoding schemes to production scheduling personnel in a graphical interface form for selection. Furthermore, the invention also discloses a workshop production scheduling system based on the genetic algorithm corresponding to the workshop production scheduling method. In the process of using the genetic algorithm to participate in decision making, the factors such as production efficiency, overall balance of the production line,multi-objective optimization and possible emergencies are comprehensively considered, the production efficiency is improved, the balance of the production line is realized, and the maximization of enterprise benefits is facilitated.

Owner:NANJING UNIV

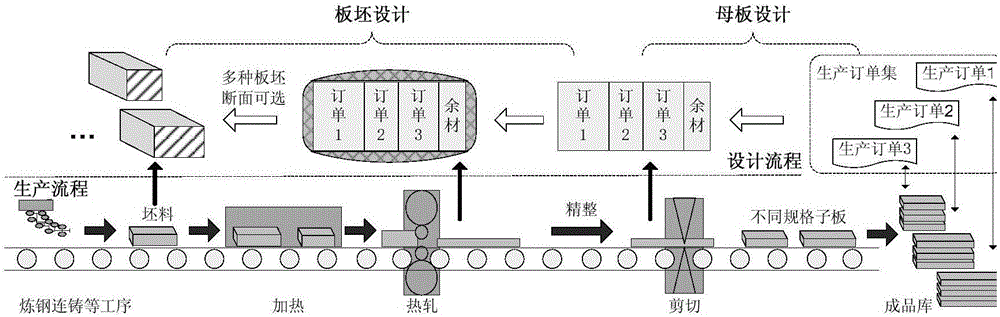

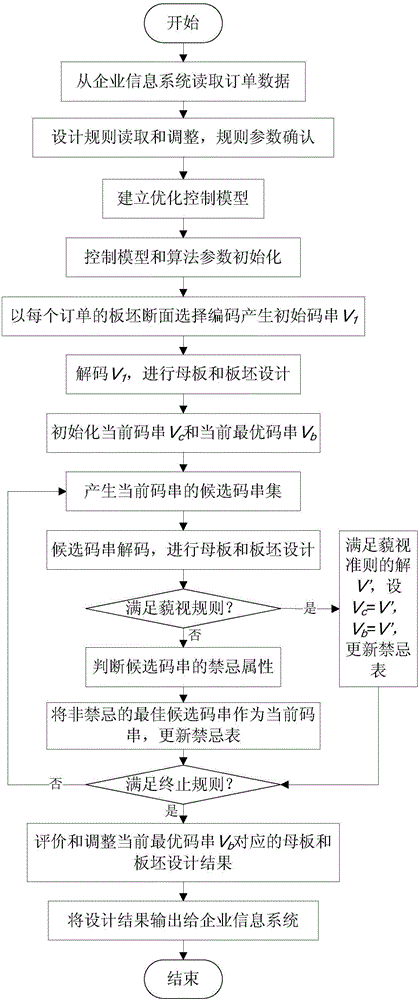

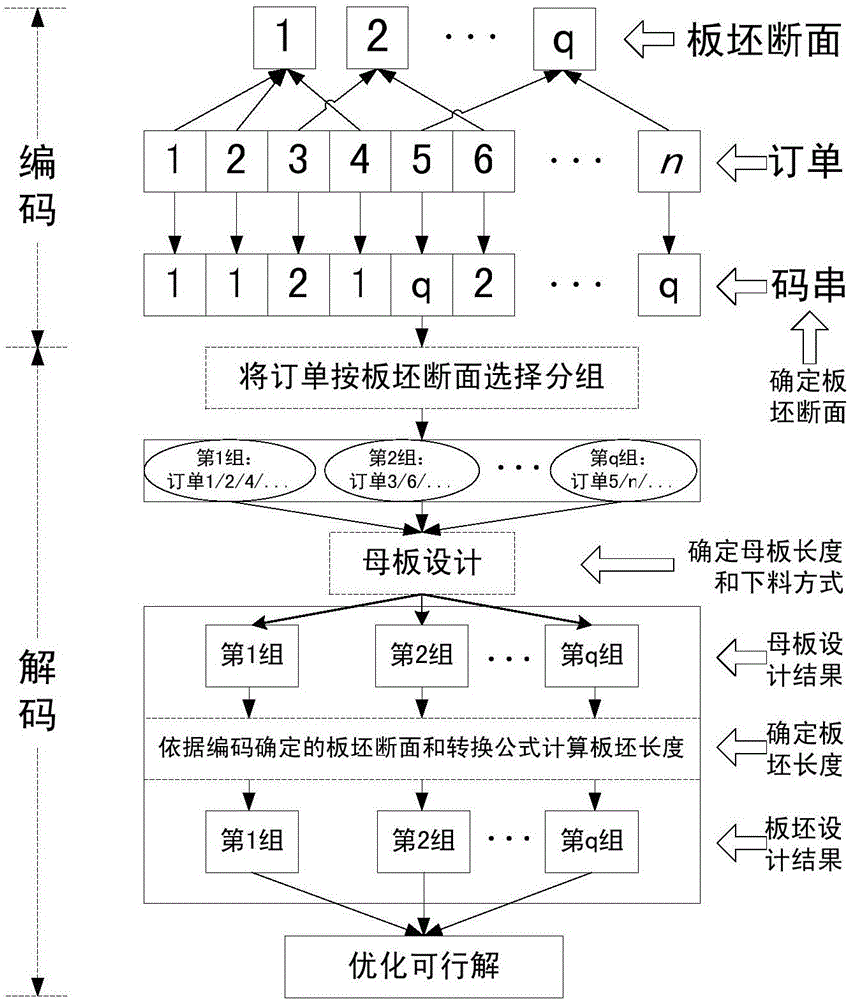

Collaborative design method and system for parent plate and plate blank of medium plate oriented to production order combined optimization

ActiveCN106599519AEase of tuning design rulesEasy parameter adjustmentDesign optimisation/simulationResourcesDecoding methodsOn column

The invention provides a collaborative design method and system for a parent plate and a plate blank of a medium plate oriented to production order combined optimization. The method comprises the following steps: specific to a sub-plate one-dimensional combined optimization design in a medium plate production order, building an optimized control model under the consideration of the constraints of complicated production processes, equipment and the like specific to the aim of minimizing residual materials and material loss, deciding a sub-plate combination way, the length of the parent plate and the length of the plate blank, selectively coding the plate blank section of each order after orders are received, designing a decoding method based on column generation, and generating plate blank and parent plate design schemes; then, searching for a better code string in neighborhood through repeated iterations based on tabu search; and when an end condition is satisfied, selecting a current optimal code string for evaluation and adjustment, and outputting corresponding plate blank and parent plate design results lastly. A system controller controls the design processes of the parent plate and the plate blank of the medium plate according to the method. Through adoption of the collaborative design method and system, residual parent plates and material loss are reduced, and the production demand can be met better.

Owner:CHONGQING UNIV

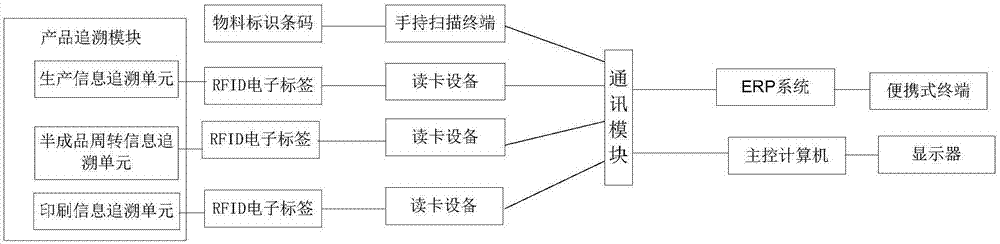

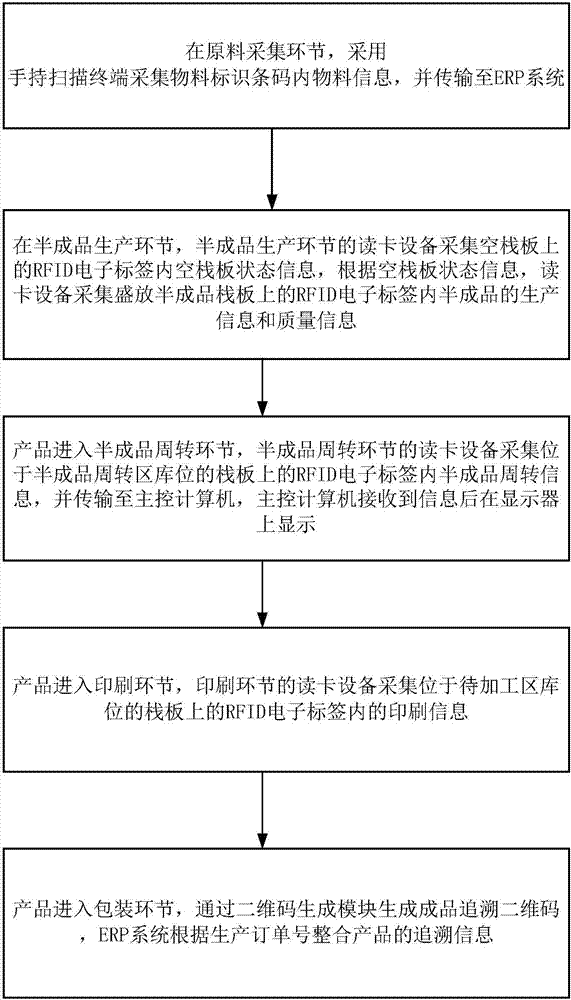

Product tracking method and system based on RFID tag

ActiveCN107368868AGuaranteed accuracyImprove work efficiencyCo-operative working arrangementsCommerceDisplay deviceComputer terminal

The invention discloses a product tracking method and system based on a RFID tag. The method comprises steps of a handheld scanning terminal is used for acquiring material information in material identification codes in a raw material acquisition process; a card reading device acquires production information and quality information of half-finished products placed in RFID tags on half-finished product pallets in a half-finished product production process; the products enter a half-finished product cycling process, the card reading device acquires half-finished product cycling information and transmits the half-finished product cycling information to a main control computer and the main control computer displays the half-finished product cycling information on a display after receiving the information; the products enter a printing process, and the card reading device acquires printing information; and the products enter a packaging process, product tracking two-dimensional codes are generated through a two-dimensional code generation module and an ERP system integrates the tracing information of the products according to production order numbers. According to the invention, working efficiency is improved; manual input errors are avoided; the product producing processes are controllable; the product processes are traceable; tedious storing and delivery operation is avoided; seamless connection with the ERP is achieved; and the material management is quite proper.

Owner:山东鲁信天一印务有限公司

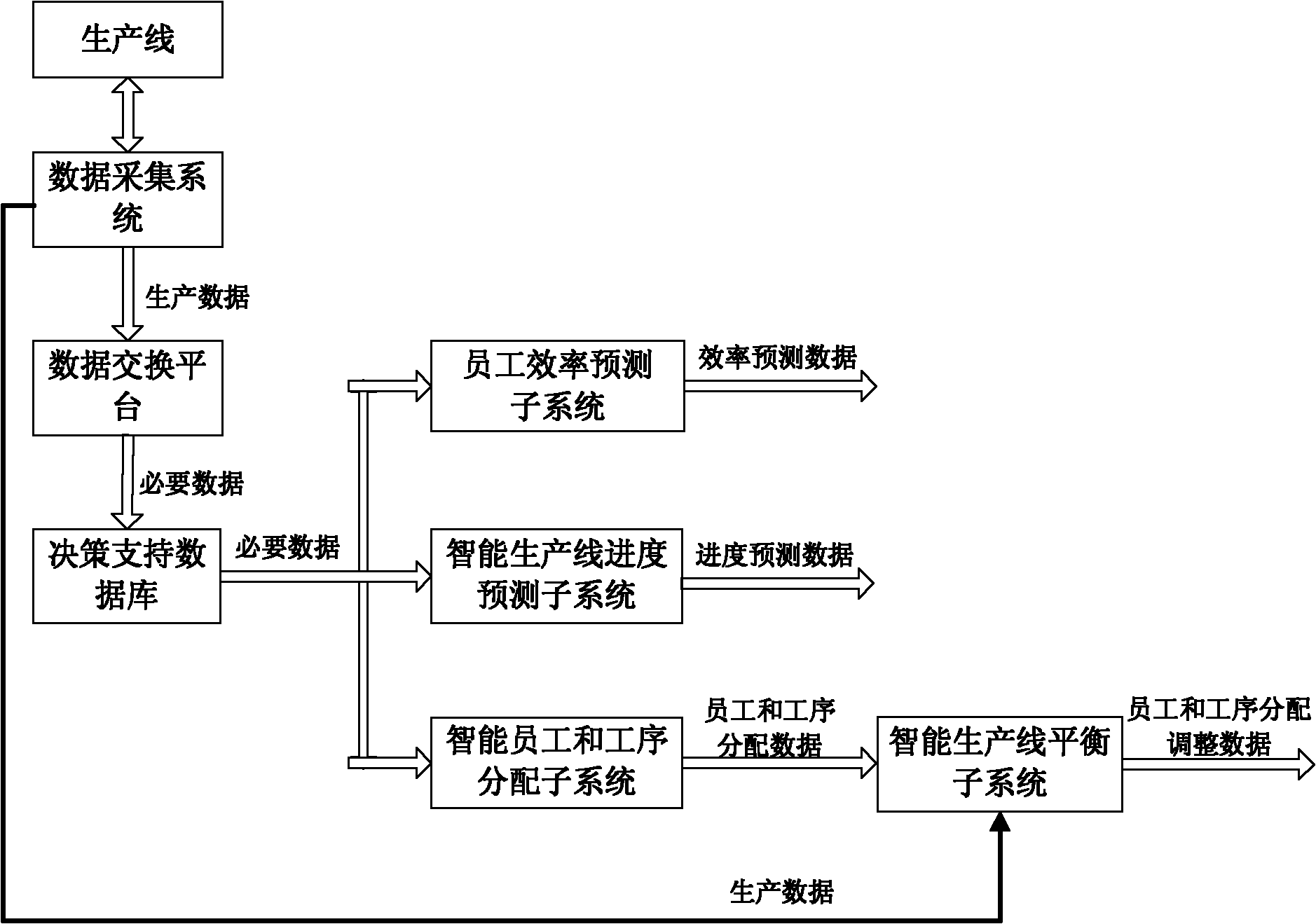

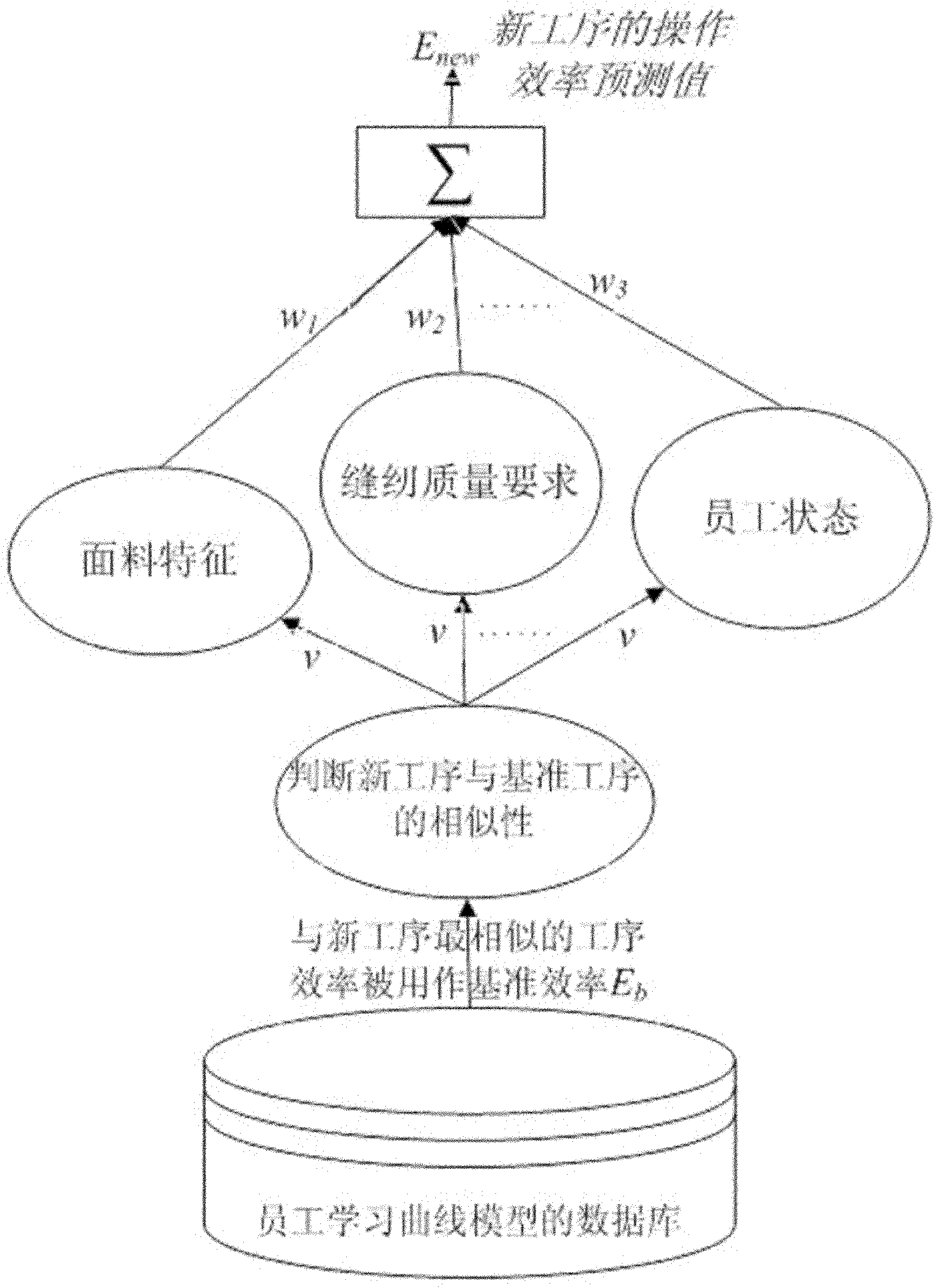

Intelligent production decision support system

InactiveCN102402716AForecasting Operational EfficiencyEfficient use ofData processing applicationsManufacturing computing systemsProduction scheduleData acquisition

The invention relates to an intelligent production decision support system, which is used for making production decision according to real-time production data acquired by a data acquisition system. The intelligent production decision support system comprises a data exchange platform, a decision support database and a staff efficiency forecasting subsystem, wherein the data exchange platform is used for receiving real-time production data from the data acquisition system, separating necessary data needed by the production decision and storing the necessary data to the decision support database, and the staff efficiency forecasting subsystem is used for reading the necessary data in the decision support database and outputting staff efficiency forecasting data according to internal factors and external factors affecting staff efficiency. The intelligent production decision support system further comprises a staff efficiency forecasting subsystem, an intelligent production line balancing subsystem and a schedule forecasting subsystem, wherein the staff efficiency forecasting subsystem is used for generating an optimal production procedure distribution scheme, the intelligent production line balancing subsystem is used for adjusting procedure distribution according to real-time production conditions and then ensuring balance of a production line, and the schedule forecasting subsystem is used for accurately forecasting the production schedule and the completion time of each production order.

Owner:THE HONG KONG POLYTECHNIC UNIV

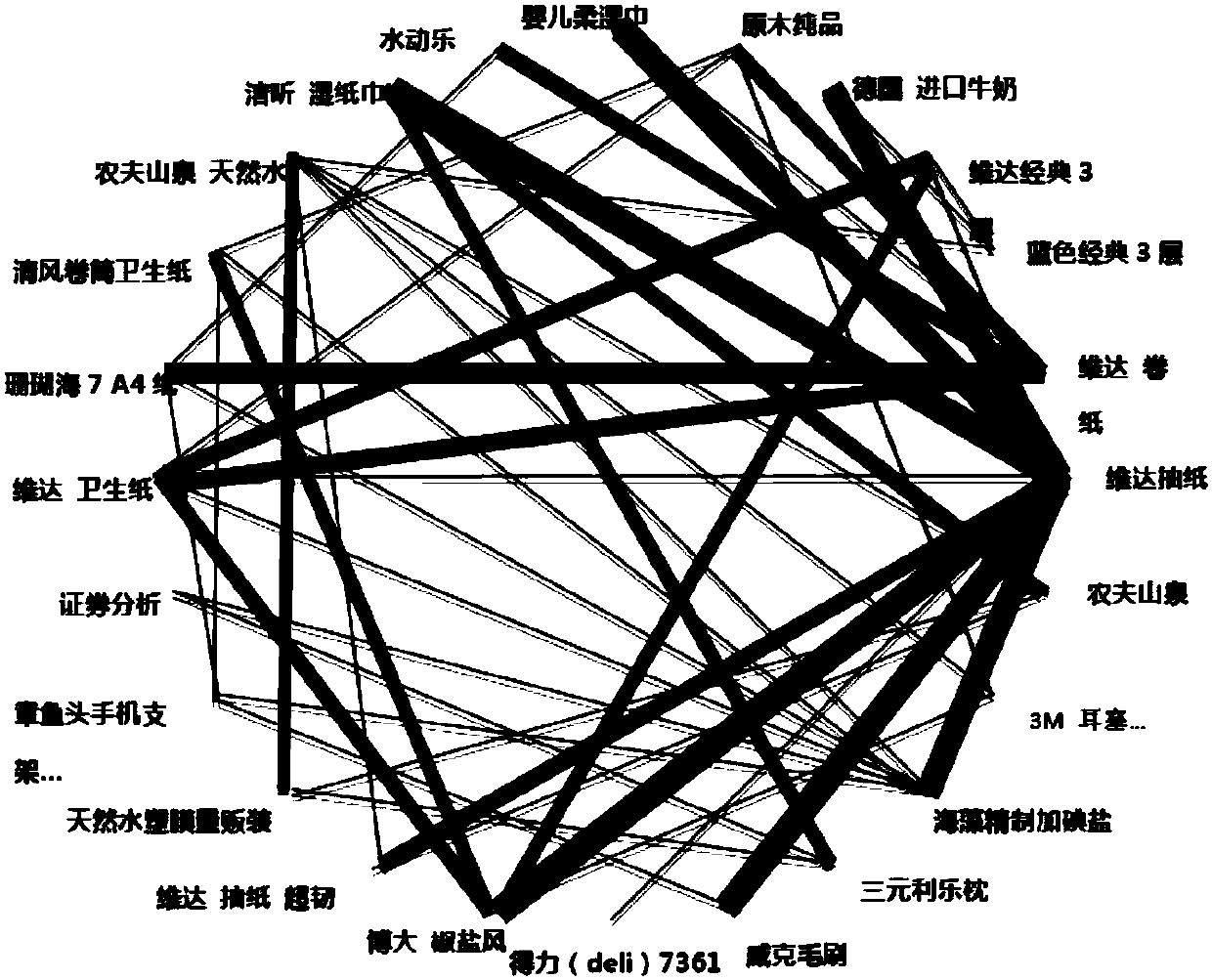

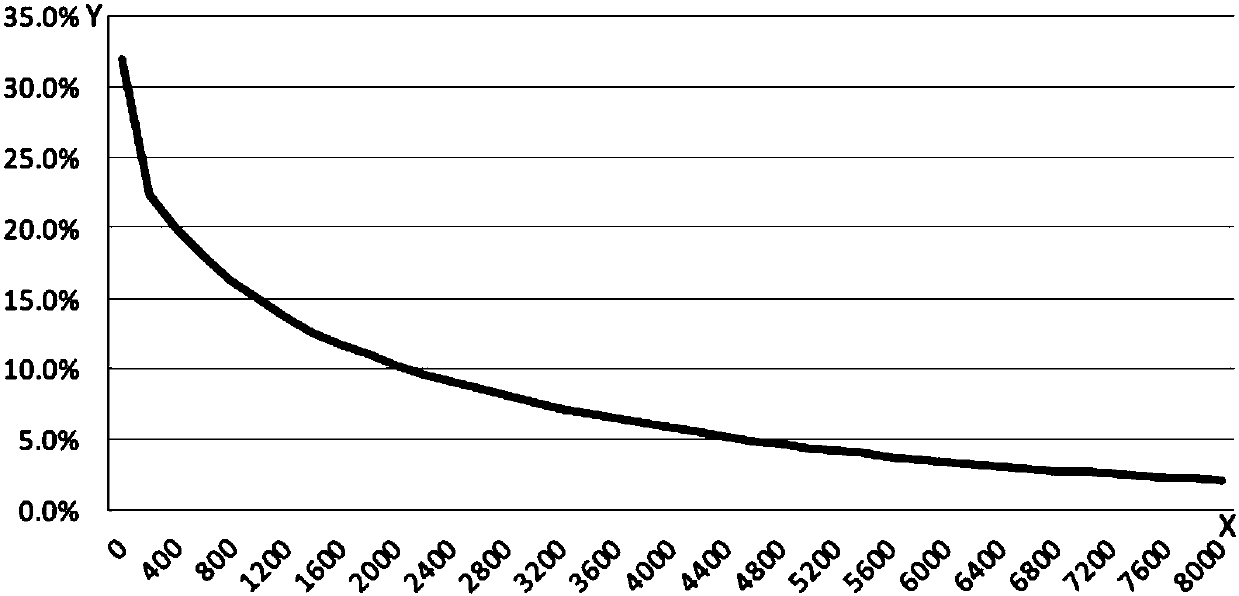

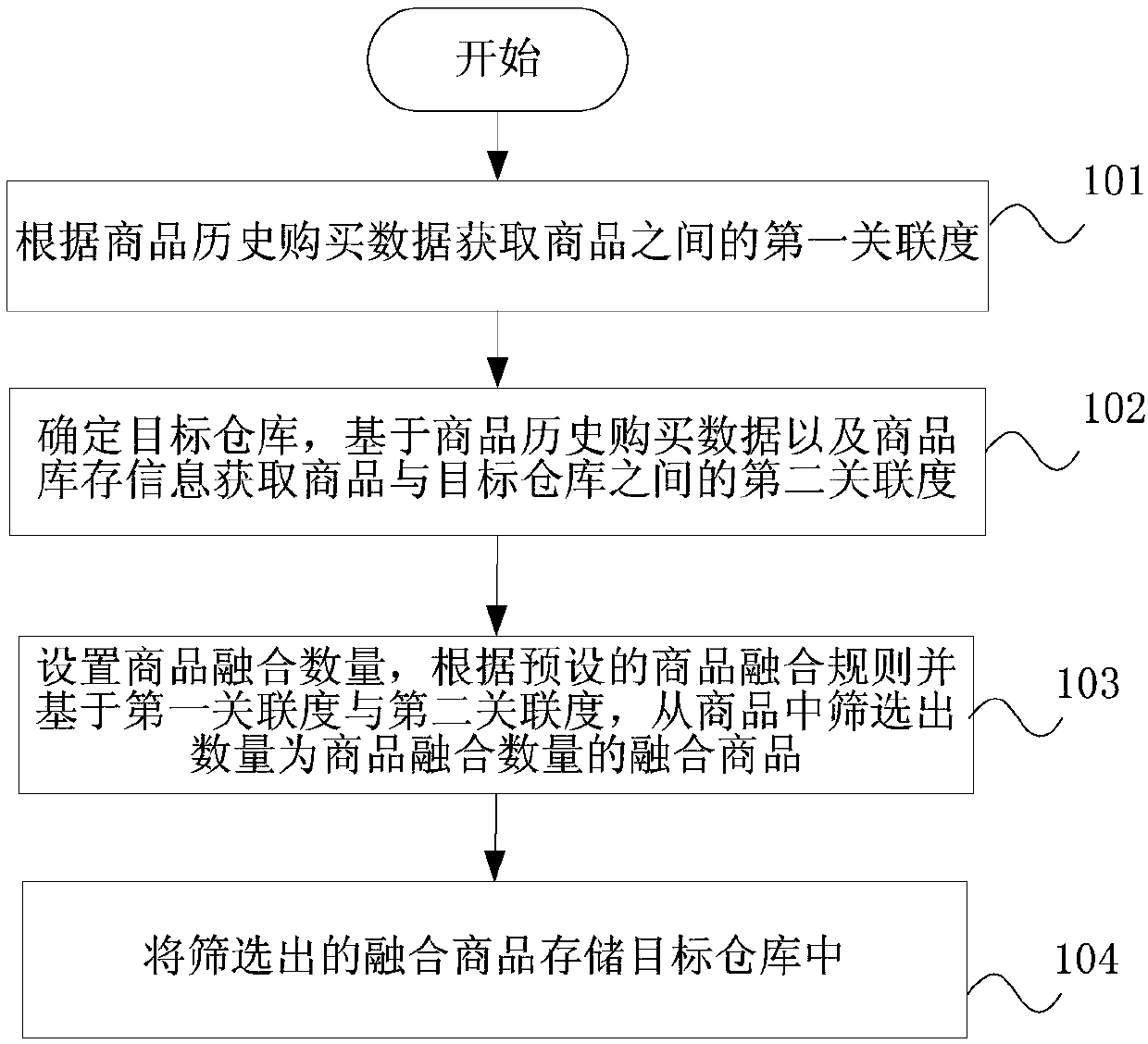

Commodity storage allocation method and device and storage medium

ActiveCN107563702AReduced number of splitsReduce operating costsLogisticsLogistics managementWorkload

The invention discloses a commodity storage allocation method and device and a storage medium. The method comprises the steps that the first correlation between the commodities is acquired according to the historical purchasing data of the commodities; the second correlation between the commodities and a target warehouse is acquired according to the historical purchasing data of the commodities and commodity inventory information; the fusion commodities of which the number is the commodity fusion number are selected out of the commodities through screening according to the preset commodity fusion rules and based on the first correlation and the second correlation; and the selected fusion commodities are stored in the target warehouse. According to the method, the device and the storage medium, the order separating rate can be greatly reduced, the separating number of times after order placing of the customer can be reduced by multi-storage inventory of a small quantity of commodities,the workload of the production order can be reduced, the packaging efficiency can be enhanced, the logistics operation cost can be reduced, increasing of packaging caused by order separating can alsobe reduced, the foundation can be laid for green and environmental protection and the customer experience can be enhanced.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

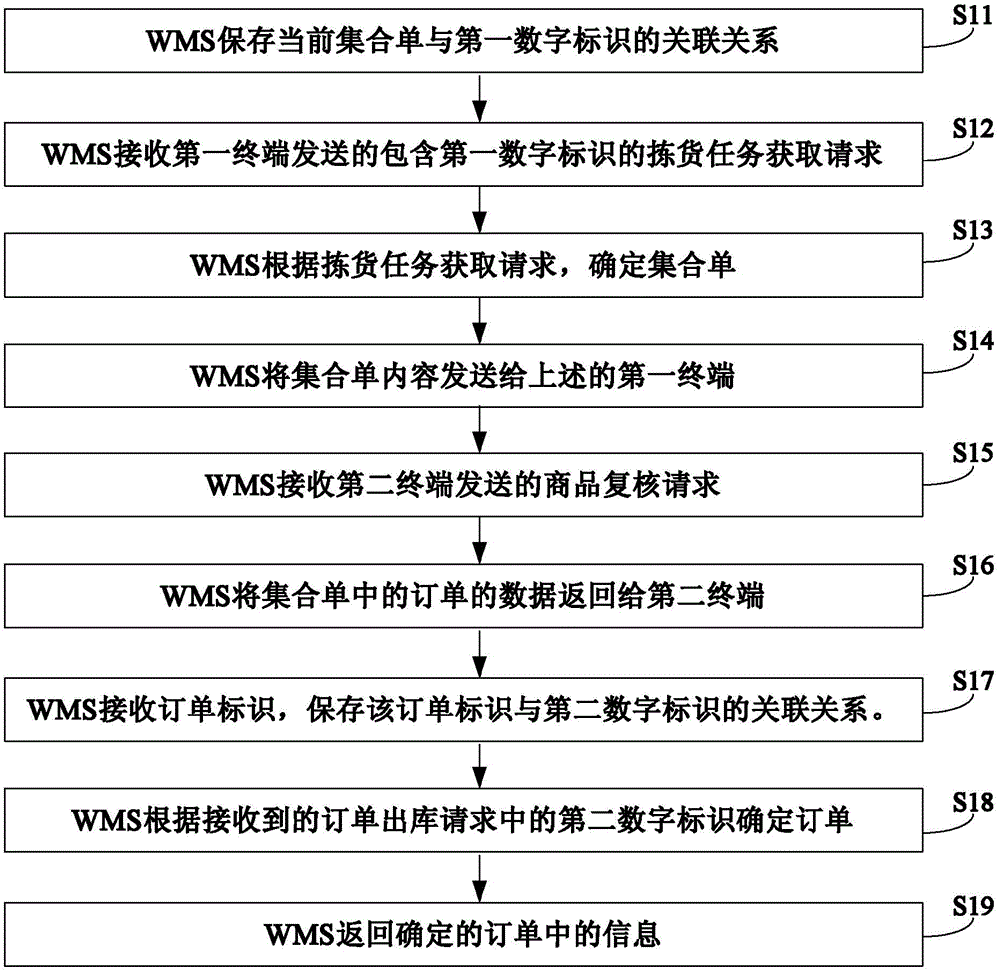

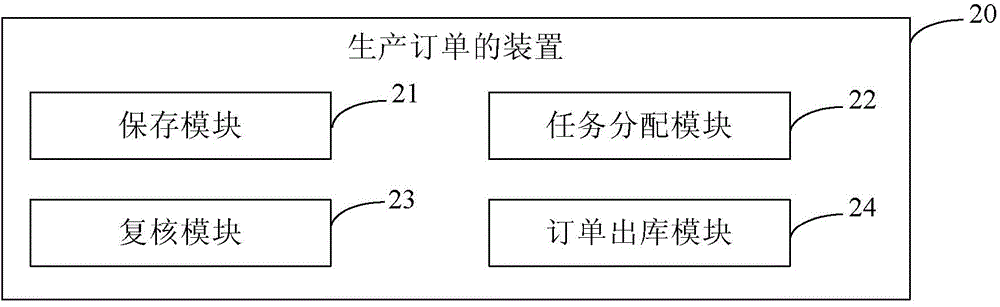

Order producing method and device as well as warehouse management system

The invention provides an order producing method and an order producing device as well as a warehouse management system. According to the technical scheme, use of a paper set order and paper orders is avoided, so that the order producing efficiency is improved and errors are reduced. In the order producing method, a digital identifier is set to be related to order picking information in an order producing process and paper set order information in a rechecking process, and another digital identifier is set to be related to paper customer order information in rechecking and packaging processes, so that the use of the paper set order and the paper orders is avoided, the printing time and a printing material are saved, and the efficiency is improved; the errors, possibly appearing in the transfer process, of the paper orders are avoided, so that the order producing reliability is improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

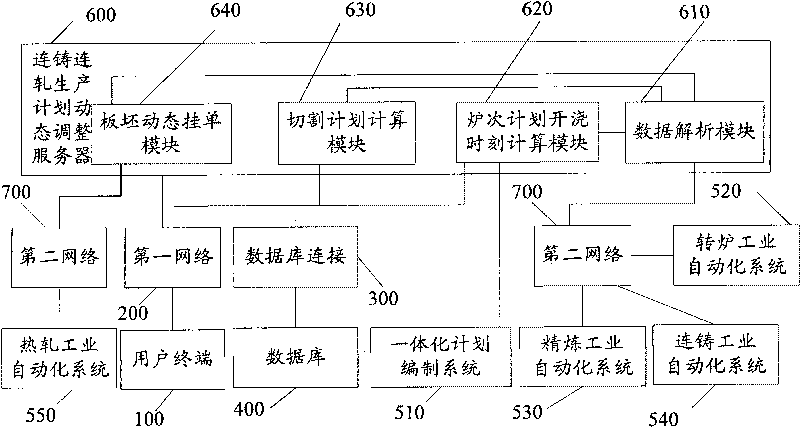

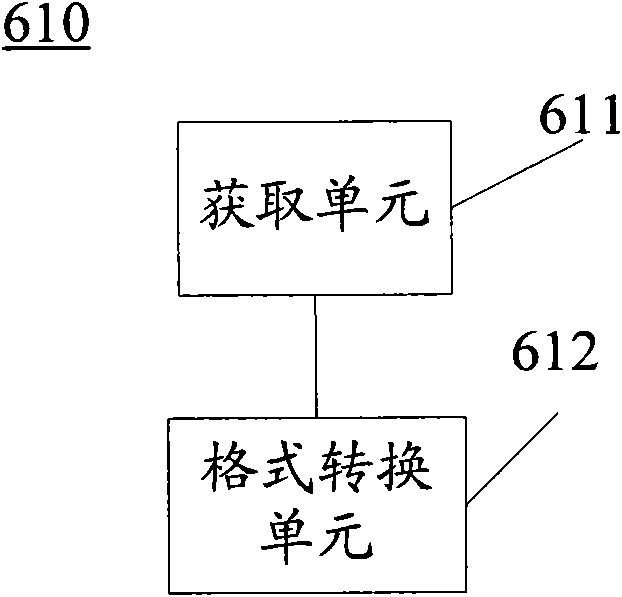

Dynamic adjustment system for metallurgical continuous casting and continuous rolling production plan

InactiveCN101727103AMeet the production process requirementsMaximize steel production capacityTotal factory controlProgramme total factory controlSteelmakingContinuous rolling

The invention discloses a dynamic adjustment system for a metallurgical continuous casting and continuous rolling production plan. The system comprises a dynamic adjustment server for the continuous casting and continuous rolling production plan, database connection and a database, a network, a converter industrial automation system, a refining industrial automation system, a continuous casting industrial automation system, a hot-rolling industrial automation system, and an integral planning system. The dynamic adjustment server for the continuous casting and rolling production plan can acquire the moment data of the converter industrial automation system, the refining industrial automation system and the continuous casting industrial automation system, calculate the cast-on moment of a heat plan in real time and dynamically generate a casting machine cutting plan according to the moment data and a rolling plan stored in the database by the integral planning system, and produce an order according to actual distributed slabs so as to guide the production. Therefore, the dynamic adjustment system for the metallurgical continuous casting and continuous rolling production plan can adapt to the order-oriented production mode, accord with the requirement on production technology, and realize maximized productivity of the steelmaking production and the optimized rolling process.

Owner:武钢集团有限公司

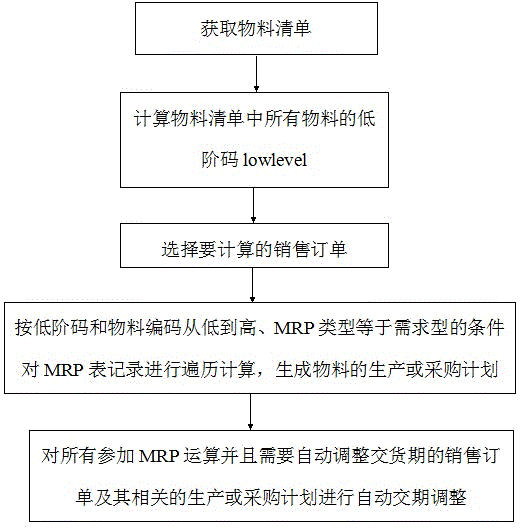

Adaptive material requirement plan (MRP) calculation method

InactiveCN105389653AIncrease flexibilityAvoid restrictionsResourcesLogisticsBill of materialsOrder form

The invention discloses an adaptive material requirement plan (MRP) calculation method. The method comprises steps: a material list is acquired; lowlevel codes of all materials in the material list are calculated; sales orders in need of calculation are selected; according to conditions that the lowlevel codes and the material codes are ranked from low to high and the MRP type is equal to a requirement type, traverse calculation is carried out on MRP table records, and a production or procurement plan on the materials is generated; and automatic delivery date adjustment is carried out on all orders which participate in MRP calculation and need to automatically adjust the delivery dates. Delivery date adjustment can be automatically carried out on orders, whose delivery dates can not be met, and the generated plans, the process comprises steps in which the delivery dates of the sales orders are properly adjusted automatically, and the plan starting dates and the plan ending dates for a production order and a procurement order related to the sales order can be automatically adjusted, system flexibility is improved, and management by a manager is facilitated.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

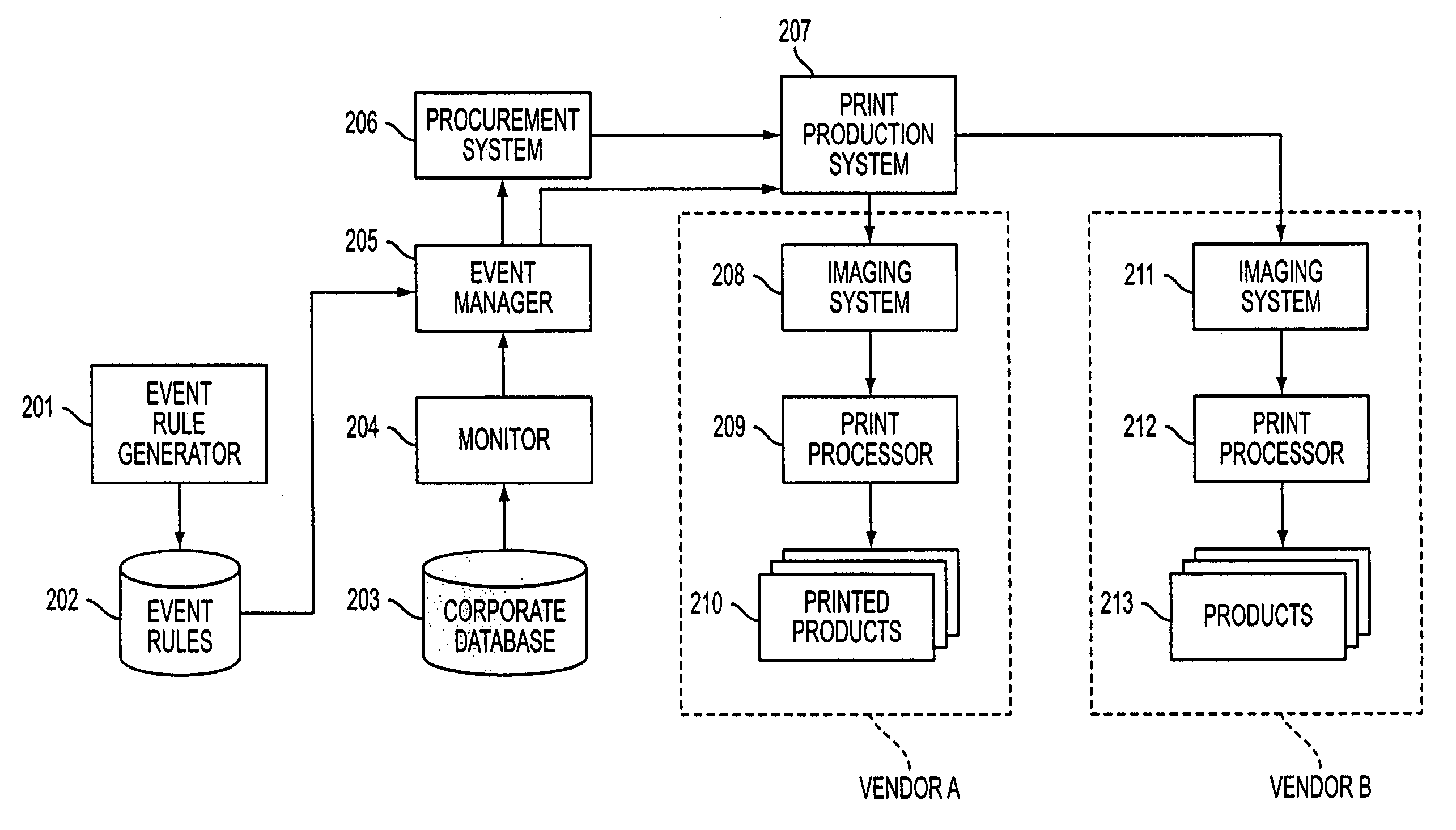

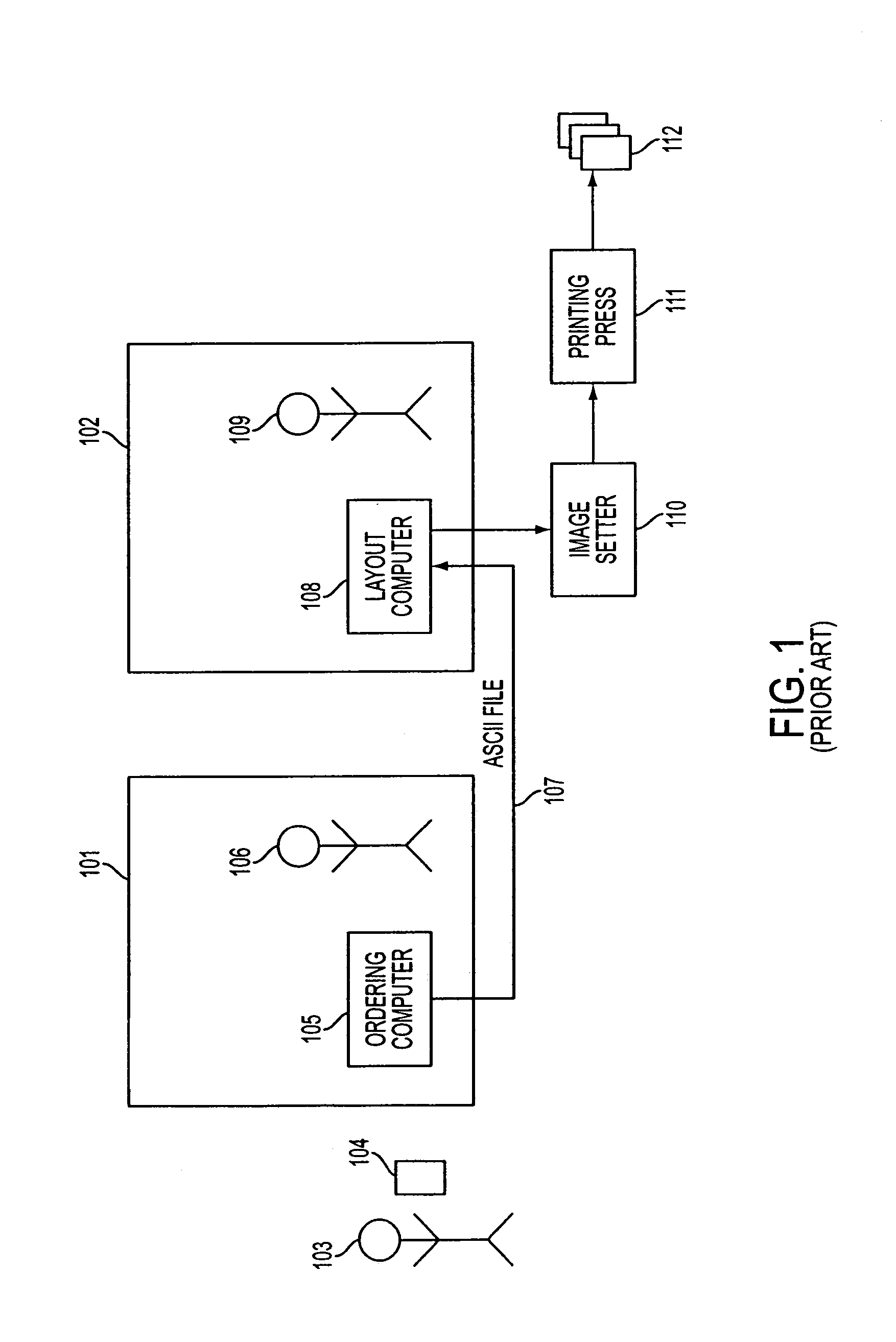

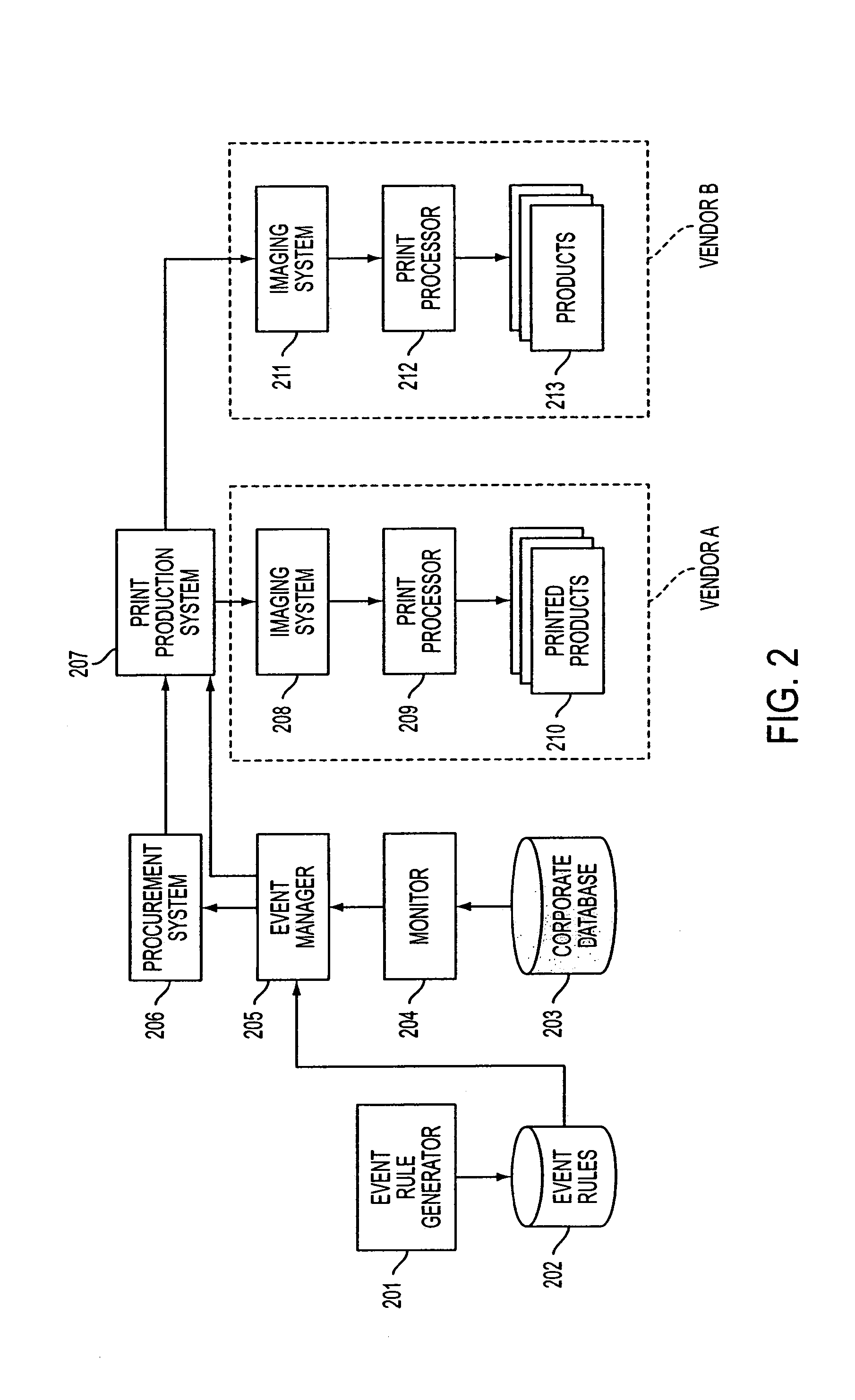

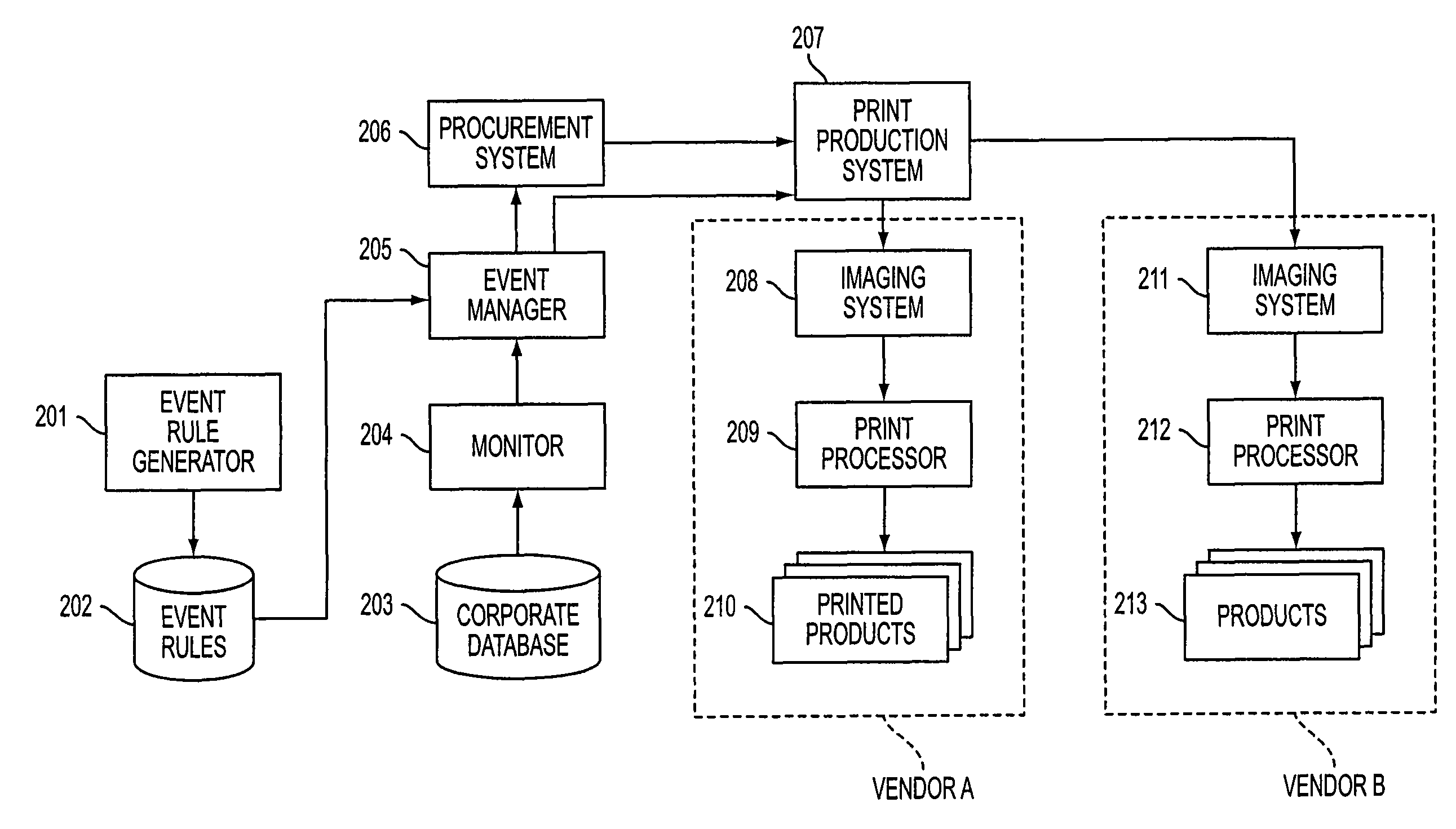

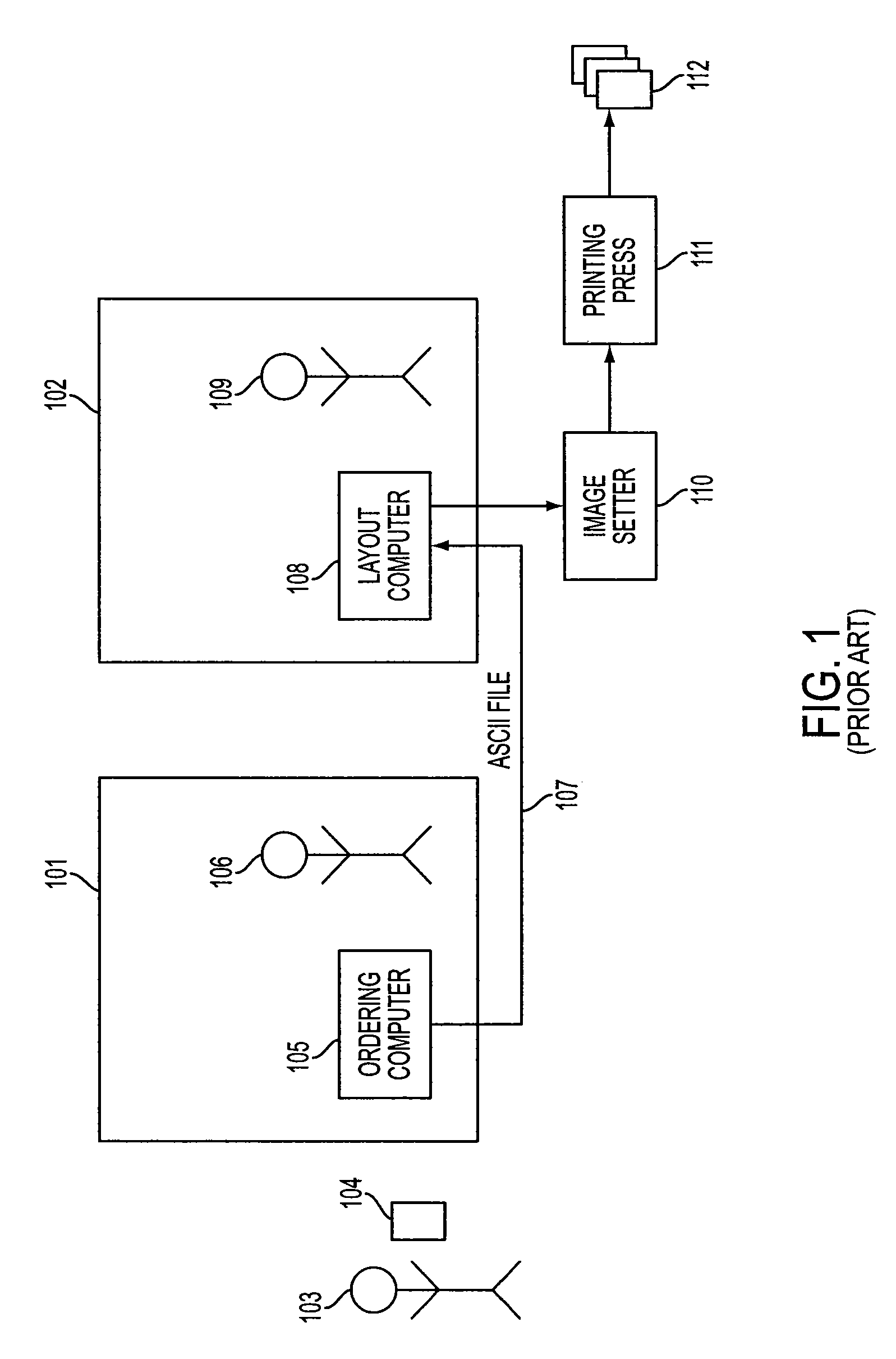

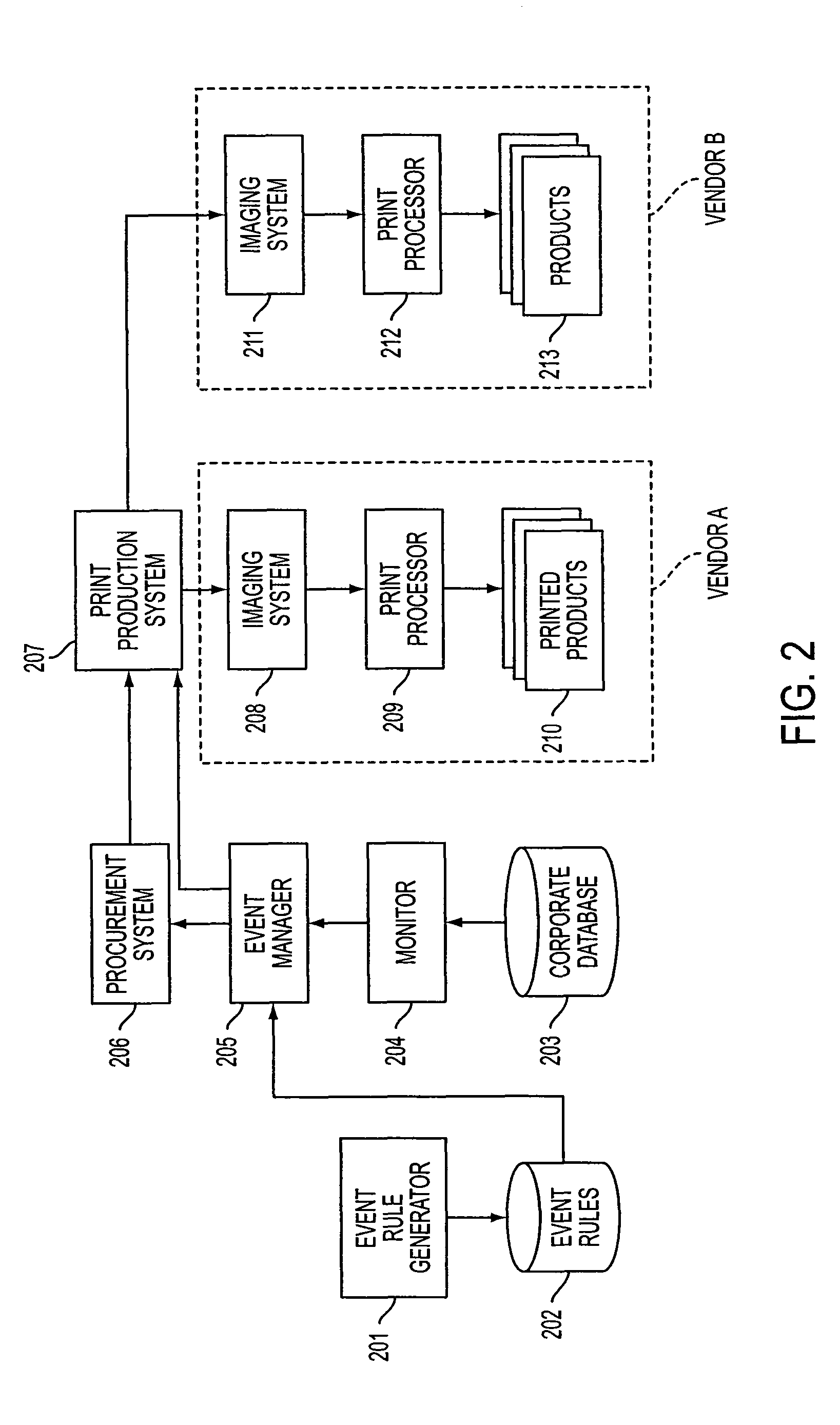

System and method of using human resources data to generate printed products

InactiveUS7113959B1Widespread applicationOffice automationSpecial data processing applicationsThe InternetData mining

Information stored in a corporate database is monitored and used to determine when certain business-related events have occurred. Event information is transmitted over the Internet to a print production facility, where it is used to fire one or more event rules, which in turn automatically generate print requisitions or print production orders. In one variation, print requisitions are routed through an existing and commercially available procurement system before a print production order is generated. The system can monitor and handle events from multiple corporations, each having its own business-related event rules, and each potentially having its own procurement approval system.

Owner:IMAGEX

System and method of using a sales management system to generate printed products

Information stored in a corporate database is monitored and used to determine when certain business-related events have occurred. Event information is transmitted over the Internet to a print production facility, where it is used to fire one or more event rules, which in turn automatically generate print requisitions or print production orders. In one variation, print requisitions are routed through an existing and commercially available procurement system before a print production order is generated. The system can monitor and handle events from multiple corporations, each having its own business-related event rules, and each potentially having its own procurement approval system.

Owner:KINKOS WASHINGTON +1

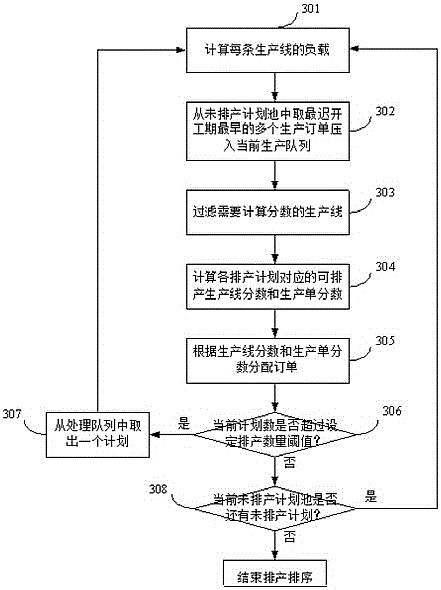

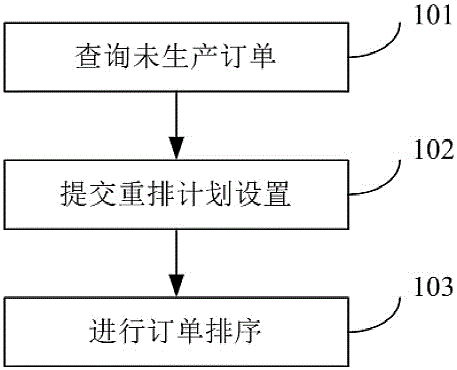

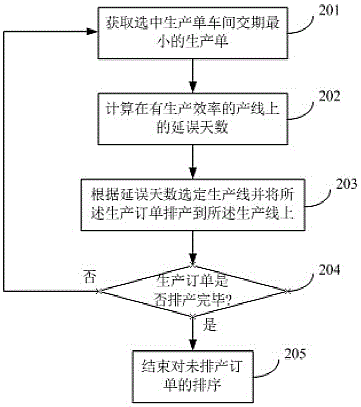

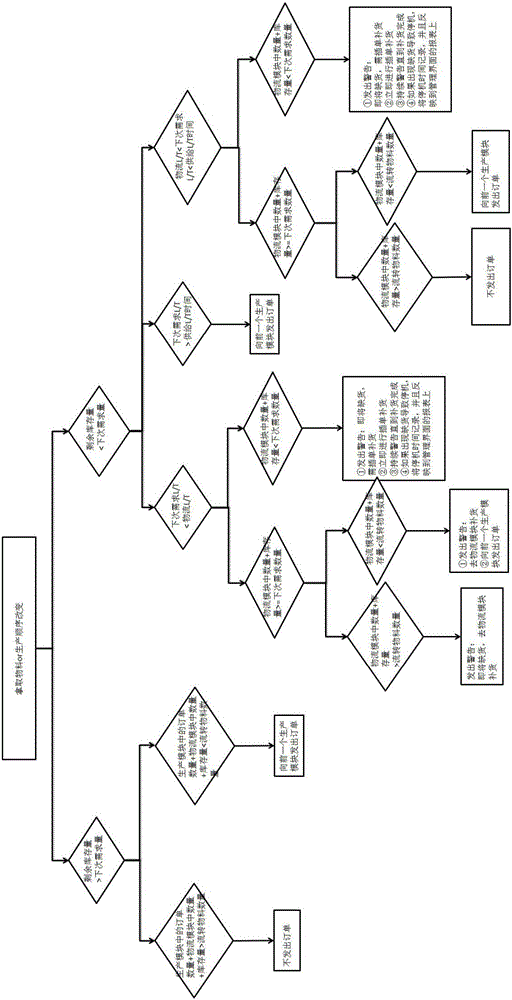

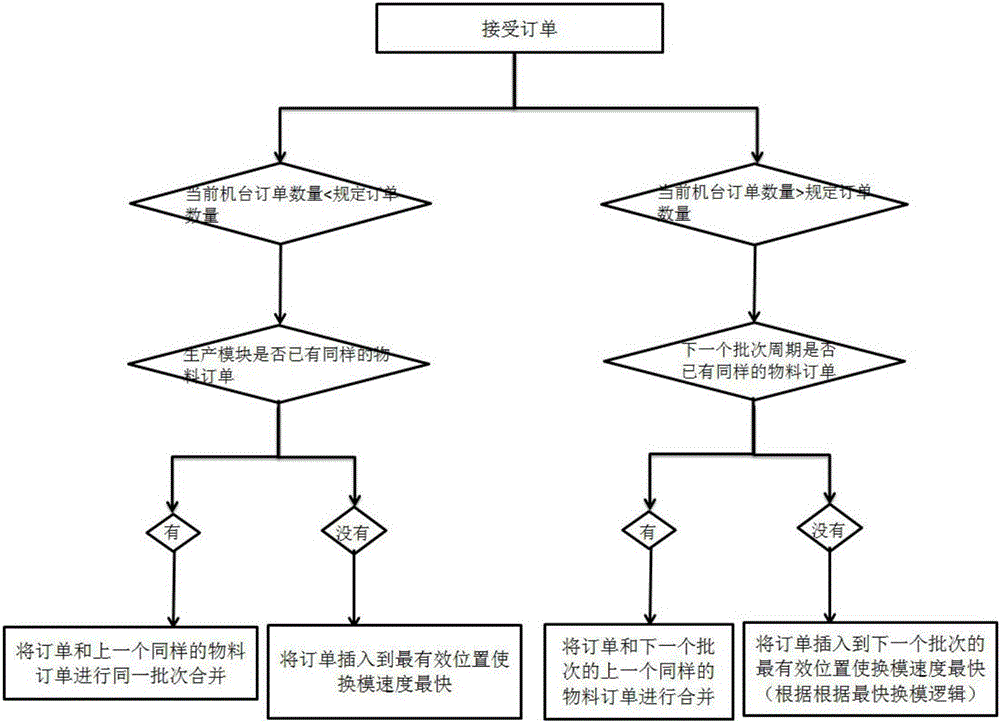

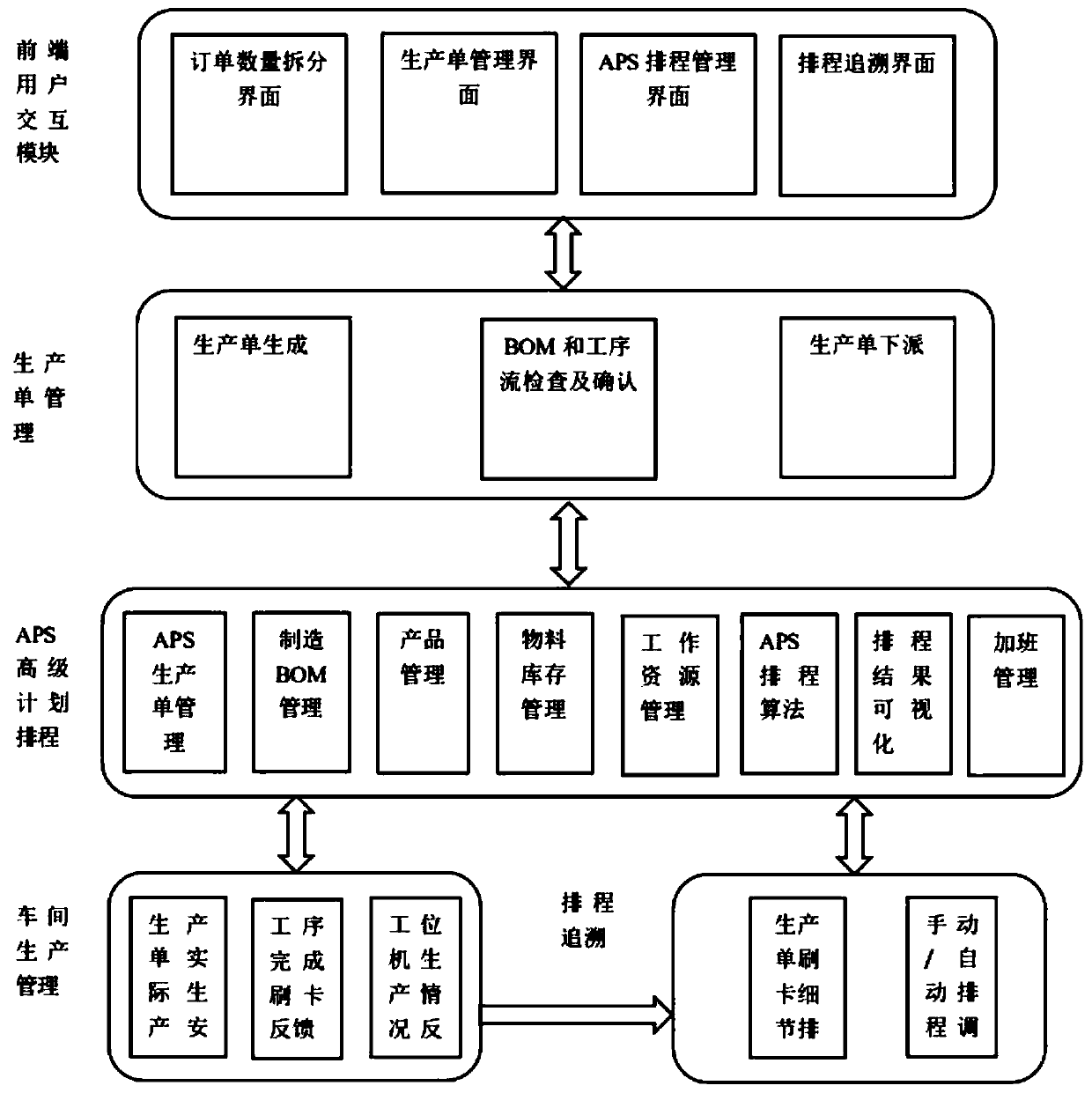

Production order production scheduling management method and production scheduling optimizer system

PendingCN106408112ARealize scientific managementImprove management efficiencyForecastingResourcesProduction lineOrder scheduling

Owner:广州亿澳斯软件股份有限公司

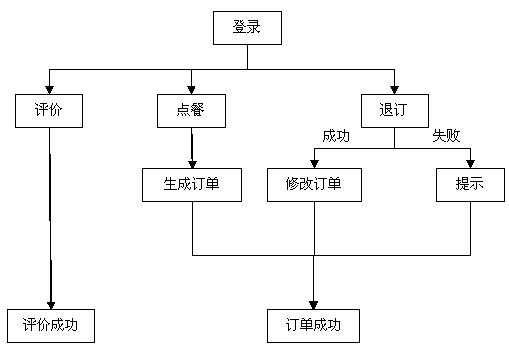

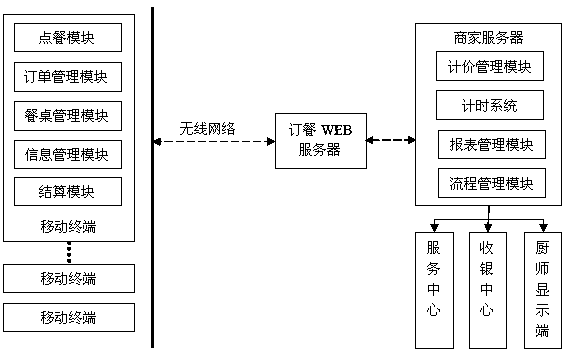

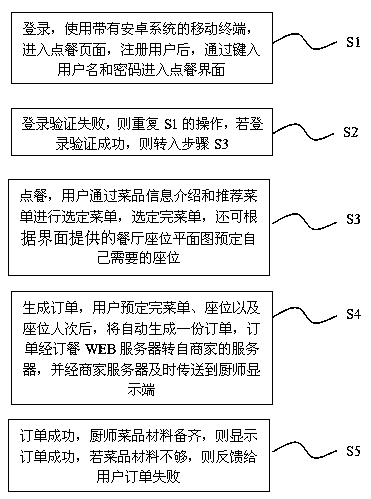

Food ordering method based on android system

InactiveCN103646289AAvoid lossAvoid inconvenient viewingReservationsMerchant servicesWaiters/waitresses

The invention discloses a food ordering method based on an android system. The android system includes a food-ordering WEB server, a merchant server and a plurality of android clients. The android clients are connected with the food-ordering WEB server through a wireless network. The food-ordering WEB server is connected with the merchant server through a network. The method includes methods for entering and logging in, food ordering, order production and subscription cancellation and also a method for evaluation of dishes by users at the same time. The food ordering method based on the android system abandons traditional manual ordering methods and prevents mistakes, omissions and loss of the orders and feed backs the orders to a chef in time at the same time so that order-omission and time-delay phenomena when traditionally the orders are transferred to the chef only through waiters are prevented and a user evaluation item is set and thus information feedbacks among users can be increased so that deficient points of the dishes are improved.

Owner:CHENGDU BOYUE CHUANGXIN TECH

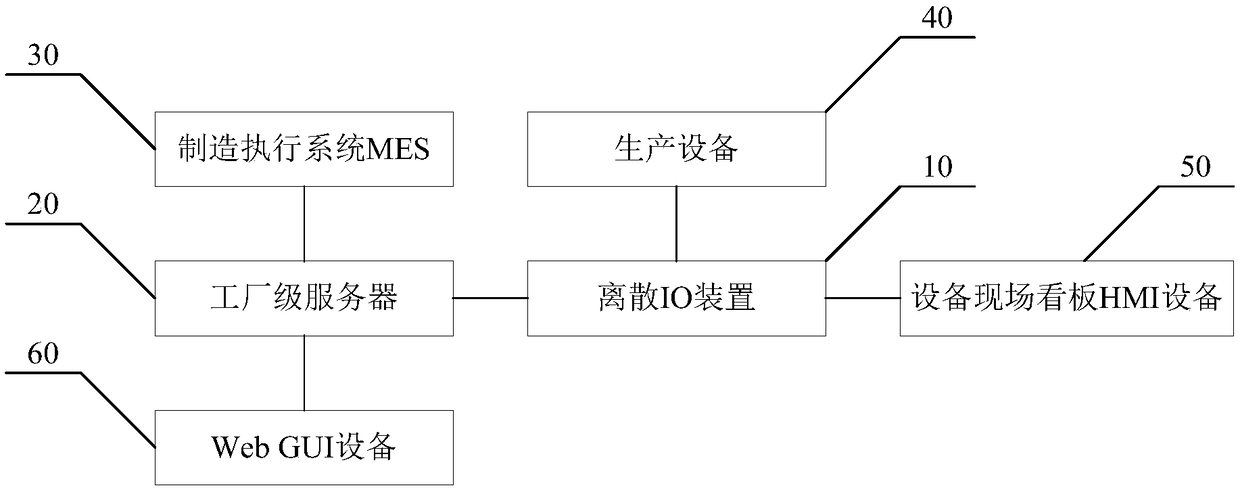

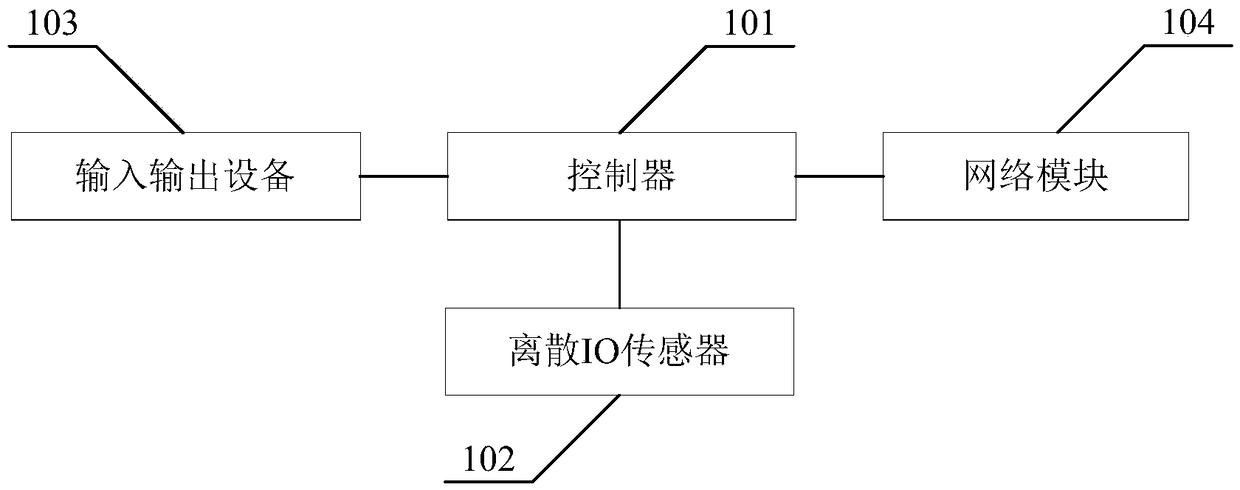

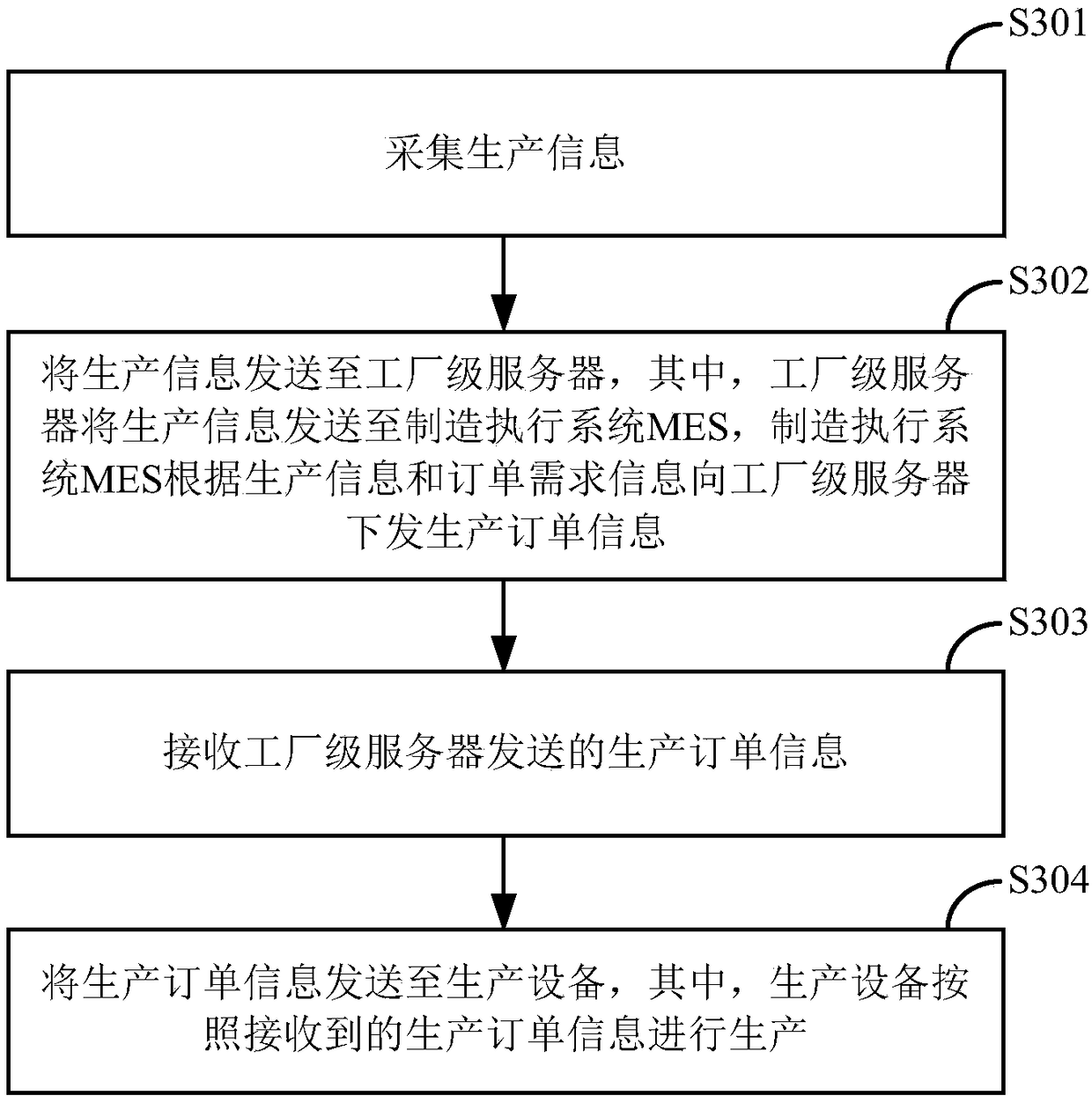

Intelligent factory management method and system

InactiveCN109308057AIncrease productivityReduce manufacturing costTotal factory controlProgramme total factory controlOrder formManufacturing execution system

The invention provides an intelligent factory management method and system. The system comprises a discrete IO device used for collecting production information, a factory-level server communicating with the discrete IO device and used for receiving the production information sent by the discrete IO device, and a manufacturing execution system (MES) communicating with the factory-level server andused for receiving the production information sent by the factory-level server and issuing production order information according to the production information and order demand information, wherein the factory-level server is further used for receiving the production order information issued by the MES, and sending the received production order information to production equipment through the discrete IO device; and the production equipment is used for carrying out production according to the received production order information. According to the intelligent factory management method and system, the technical effect of carrying out comprehensive digital information management on a production process of a discrete manufacturing enterprise is achieved.

Owner:SOOAR BEIJING INVESTMENT MANAGEMENT GRP

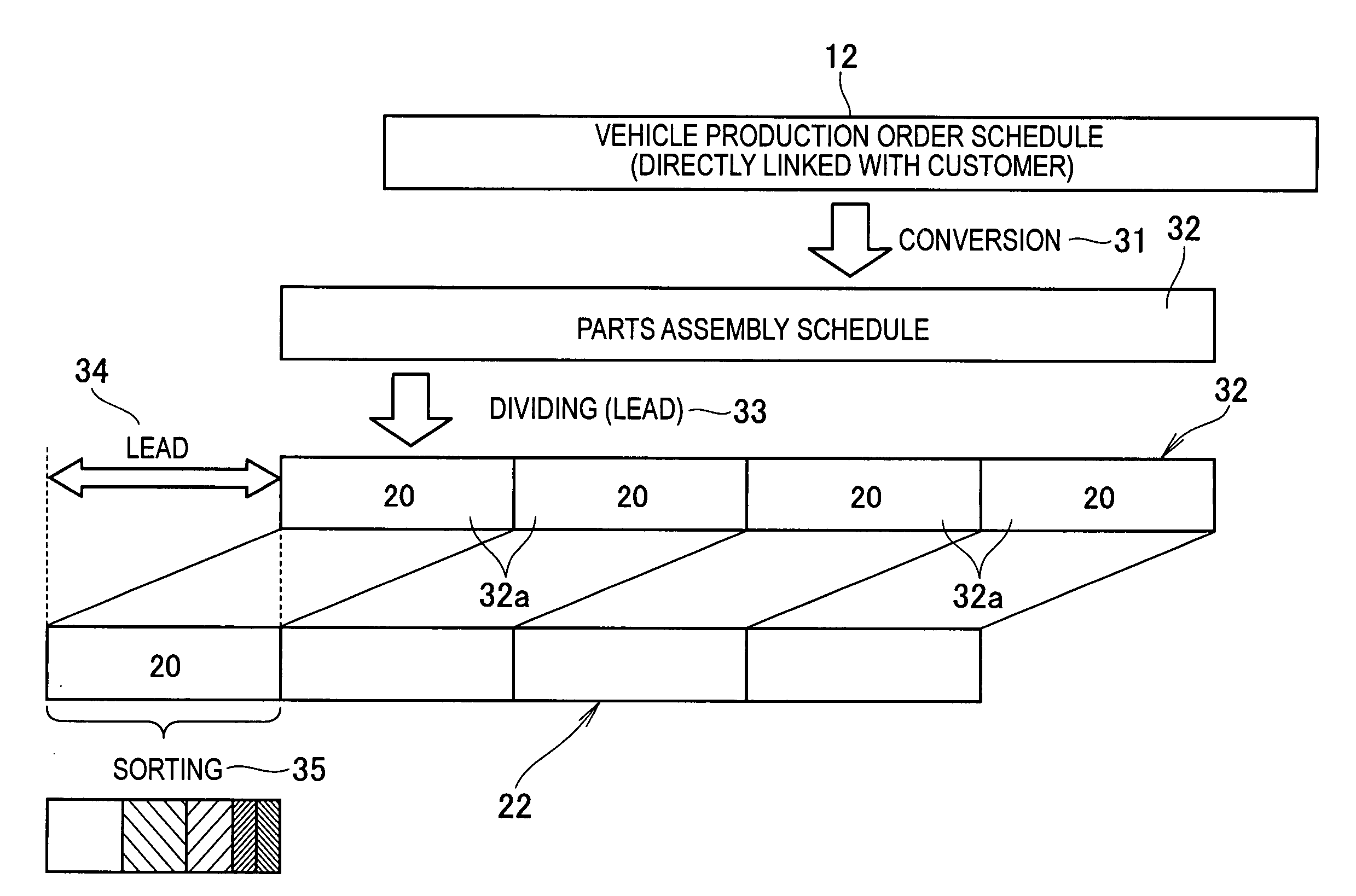

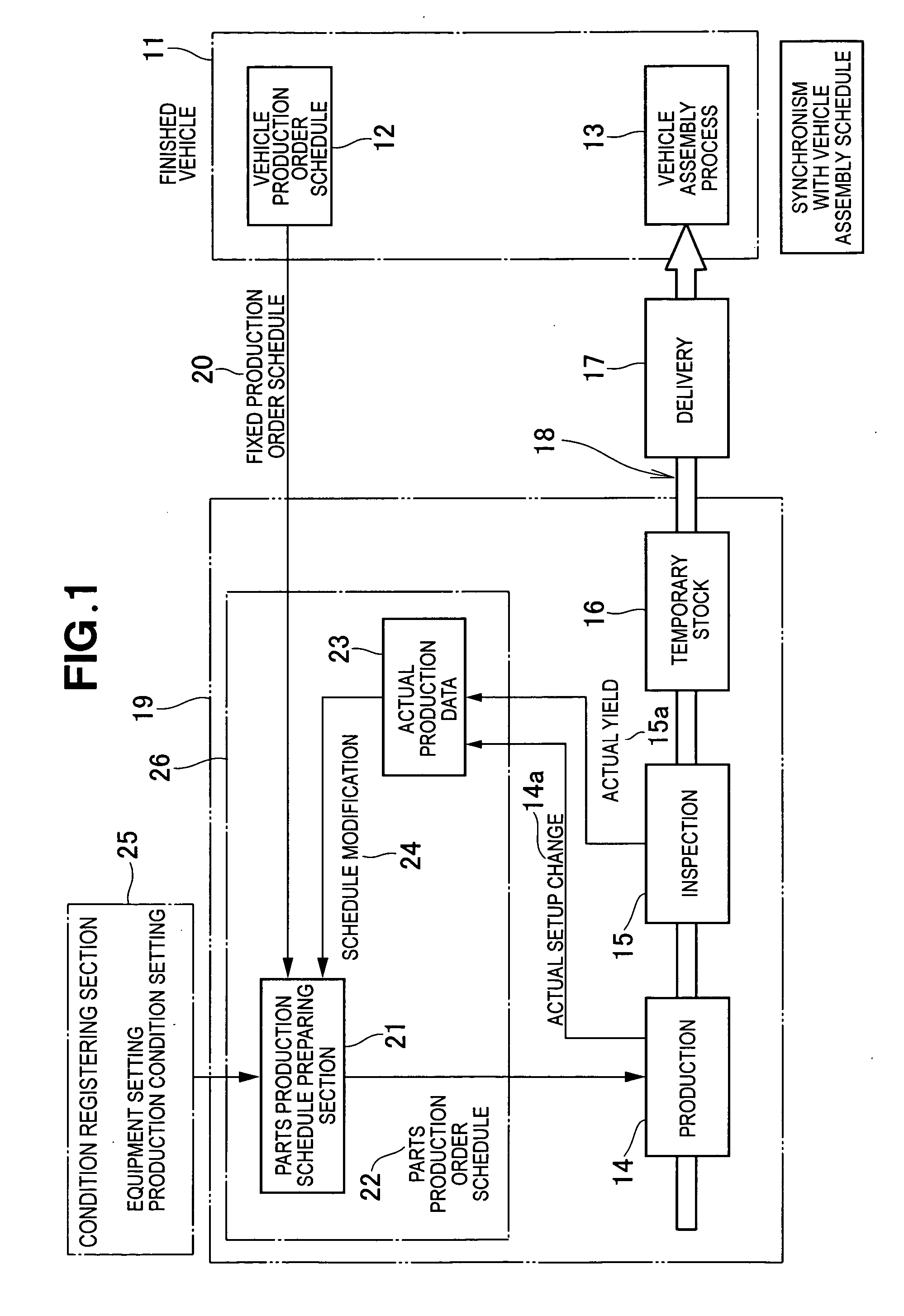

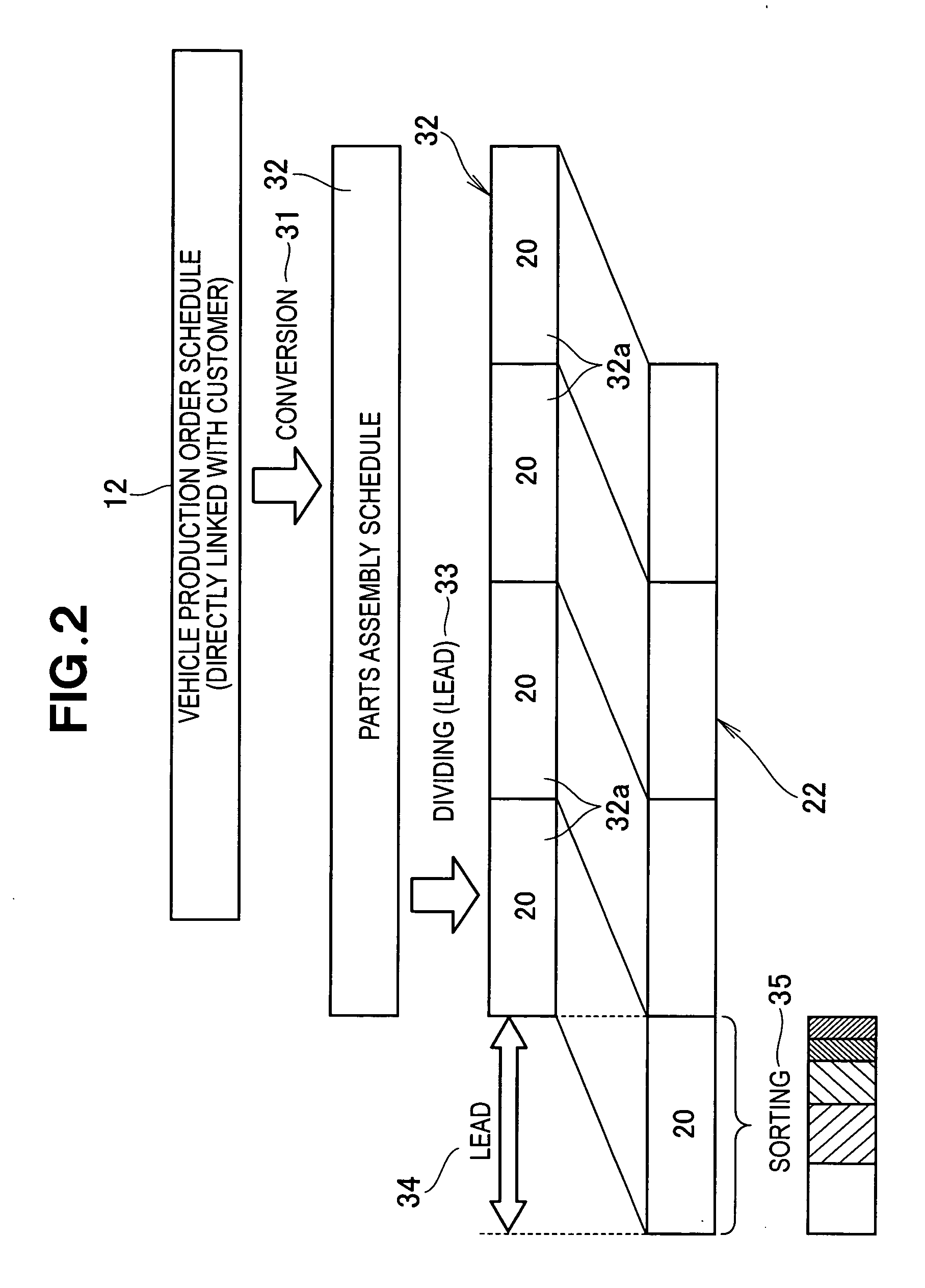

Parts production scheduling method

A parts production scheduling method is provided for preparing, after receipt of a production order schedule of finished vehicles, a production order schedule of parts necessary for the production of the finished vehicles, wherein the production order schedule of the parts, which is divided into plural zones each equivalent to production of a predetermined number of consecutive products in the product order schedule of the higher products, is shifted so that it is ahead of the production order schedule of the higher products by one zone, thereafter, for each zone, parts to be produced on a parts production line are converted into corresponding pieces of parts identification information registered in advance, and the converted pieces of parts identification information are sorted by pre-registered inter-parts similarity information and collated with pre-registered part-by-part production order pattern information.

Owner:HONDA MOTOR CO LTD

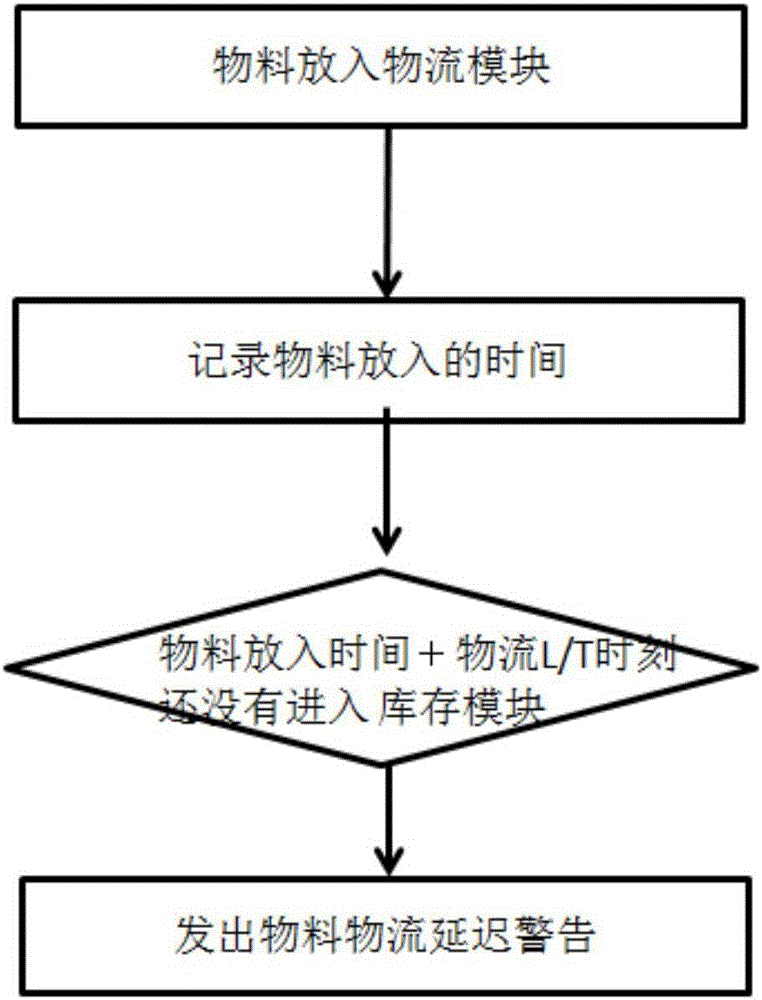

JIT (Just In Time) production supply system and control method thereof

InactiveCN105931002AEnsure coordinationReduce manufacturing costLogisticsLogistics managementOrder form

The invention discloses a JIT (Just In Time) production supply system and a control method thereof. The control method of the JIT production supply system comprises the steps of: when materials are taken or a production plan is changed, detecting a demanded quantity of of a next order for materials; detecting a remaining inventory level of the materials; detecting a logistics quantity of the materials; and comparing the demanded quantity of the next order for the materials with the remaining inventory level and the logistics quantity of the materials, and according to a comparison result, regulating material production. According to the control method of the JIT production supply system, which is disclosed by the invention, links of material production, material transportation and the like can be regulated in real time according to information of the demanded quantity of the next order for the materials, the remaining inventory level of the materials, the logistics quantity of the materials and the like so as to ensure the minimum inventory, ensure real-time follow-up of a production order and material transportation, ensure integral coordination of the production supply system, improve maximum efficiency operation of the JIT production supply system on the basis of reducing the inventory, reduce production cost and improve production efficiency.

Owner:周理

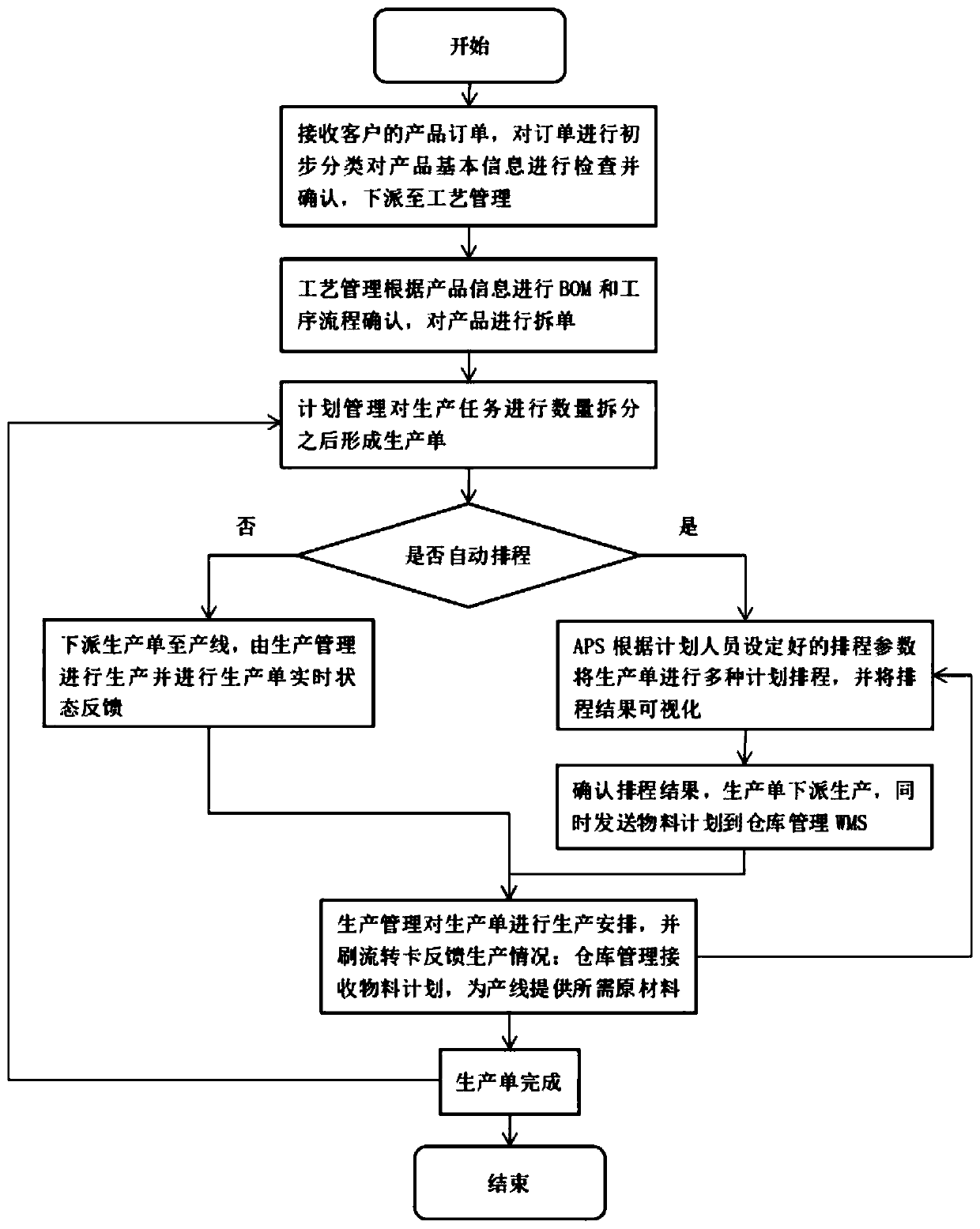

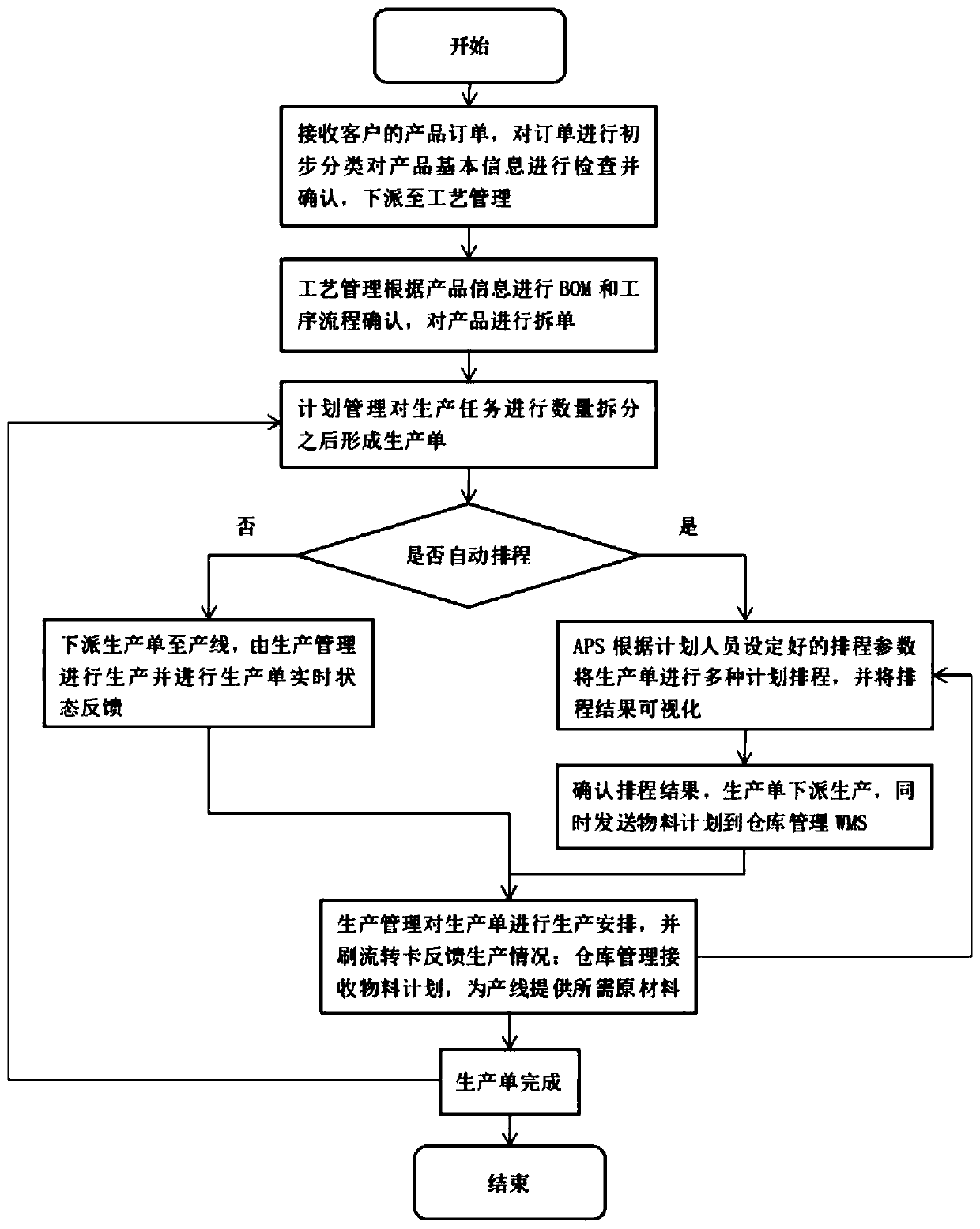

Discrete manufacturing industry-oriented dynamic production plan scheduling method

PendingCN111126748ARealize dynamic adjustmentAvoid influenceResourcesManufacturing computing systemsClosed loop feedbackResource utilization

The invention discloses a discrete manufacturing industry-oriented dynamic production plan scheduling method, which comprises the following steps of: firstly, a customer order is received, and a process management module splits the customer order to generate a production task according to product information; a plan management module generates a production order according to the production task, and an advanced plan scheduling module automatically schedules the production order according to scheduling parameters set by a planner and dispatches the production order for production according to ascheduling result; a production management module receives the production list and arranges production; a warehouse management module receives the material plan and prepares raw materials for the production line; and a scheduling tracing module feeds back the actual production information to the plan management module, dynamically adjusts a scheduling result, and forms closed-loop feedback from plan scheduling to actual production. According to the method, the scheduling result is dynamically adjusted according to unstable factors in actual production, the reasonable resource utilization rateis ensured, and the visual material plan and production plan are generated from multiple angles under the condition of considering enterprise resources, a production field and a dispatching method.

Owner:盐城雷来钧智能制造技术有限公司

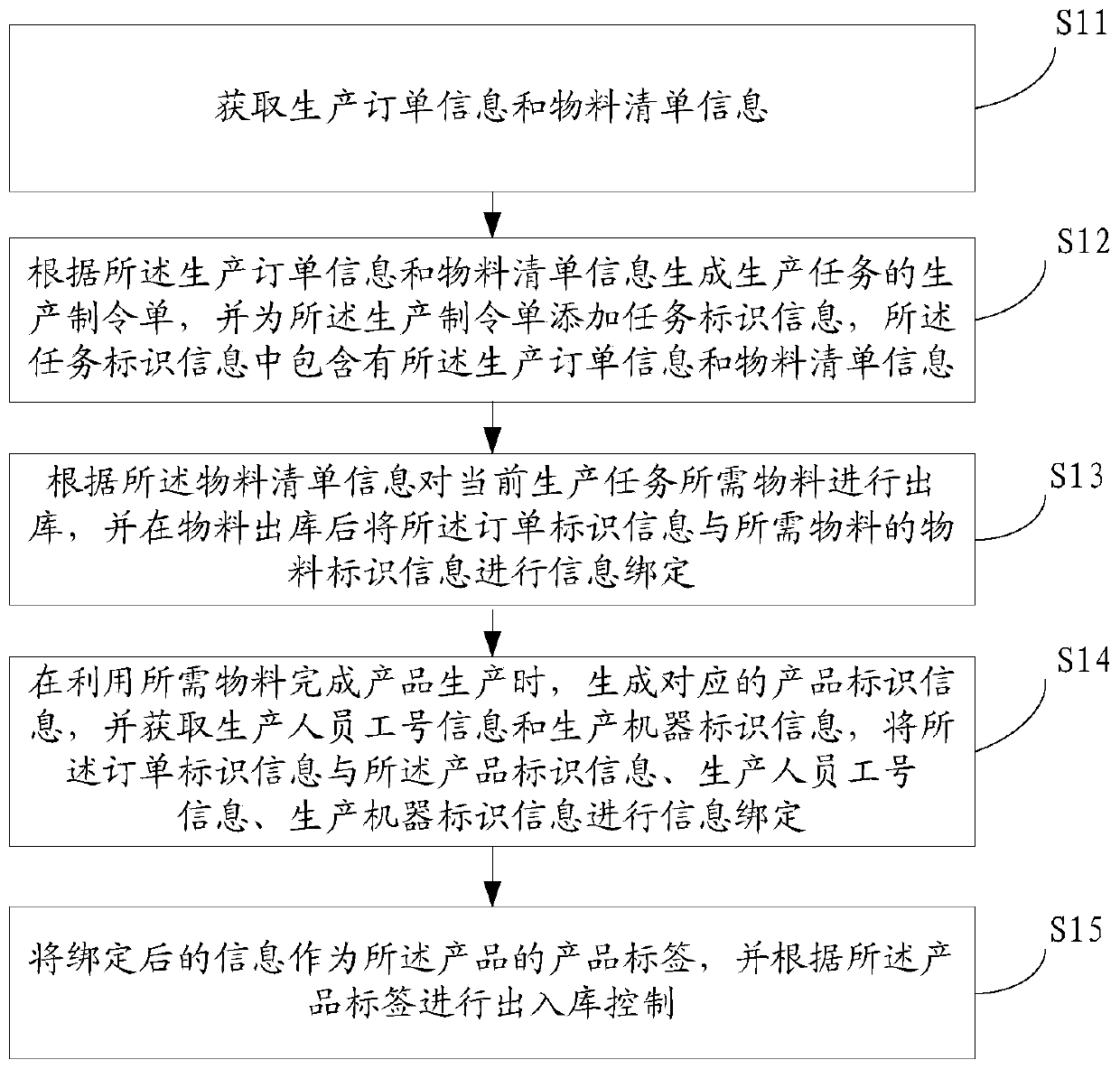

Method and system for realizing production process tracing, storage medium and electronic equipment

PendingCN110675163AEasy to controlImprove efficiencyLogisticsCommerceBill of materialsIndustrial engineering

The invention provides a method and system for realizing production process tracing, a storage medium and electronic equipment. The method comprises the following steps: acquiring production order information and bill of material information; generating a production command list of the production task according to the obtained information, and adding task identification information to the production command list; delivering the required materials according to the material list information, and binding the order identification information and the material identification information of the required materials after the materials are delivered; when product production is completed, generating product identification information, obtaining production personnel job number information and production machine identification information, and binding the order identification information with the product identification information, the production personnel job number information and the productionmachine identification information; and taking the bound information as a product label of the product, and performing warehouse-in and warehouse-out control according to the product label. Accordingto the method, all links related to production are associated in an identification information binding mode, so that the product has traceability, and the control ability of the enterprise productioncapacity is improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com