Patents

Literature

124 results about "Job number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, job numbers are used with computer software and hardware to help distinguish each job needing to be performed and the order they should be processed. 2. When referring to a computer processor, a job number refers to a number assigned to each job needed to be processed by the computer processor.

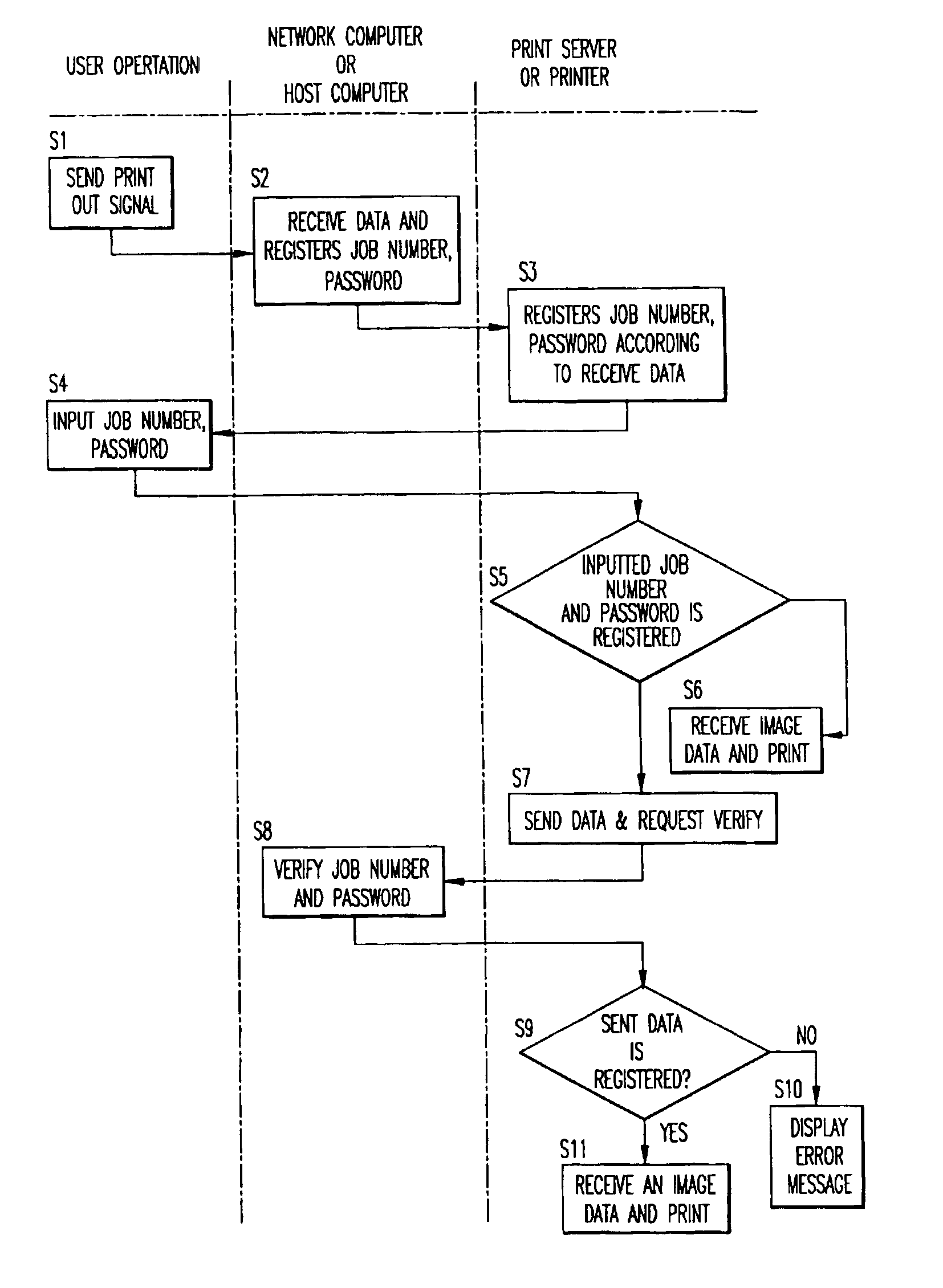

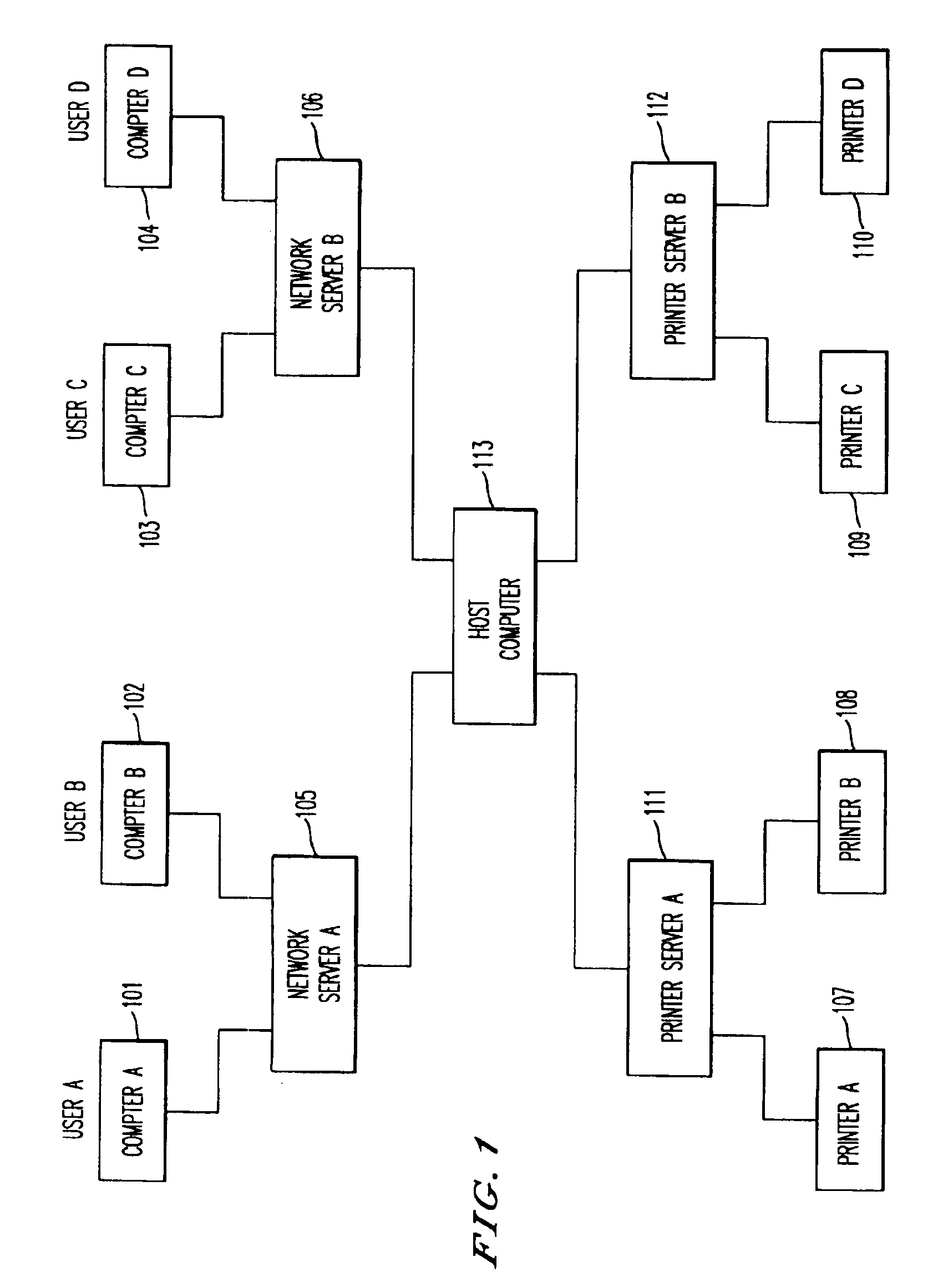

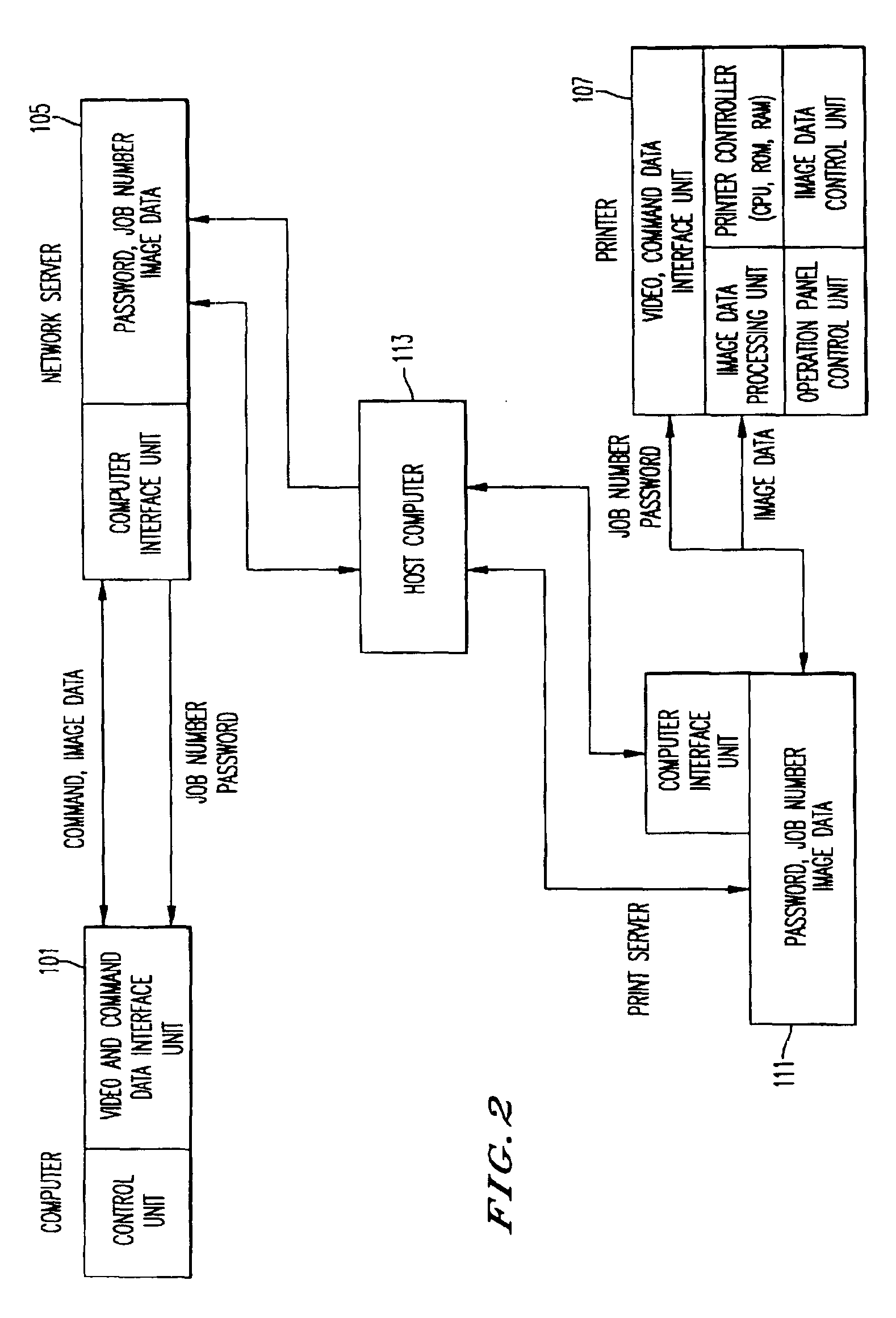

Computer-based network printing system and method

Owner:RICOH KK

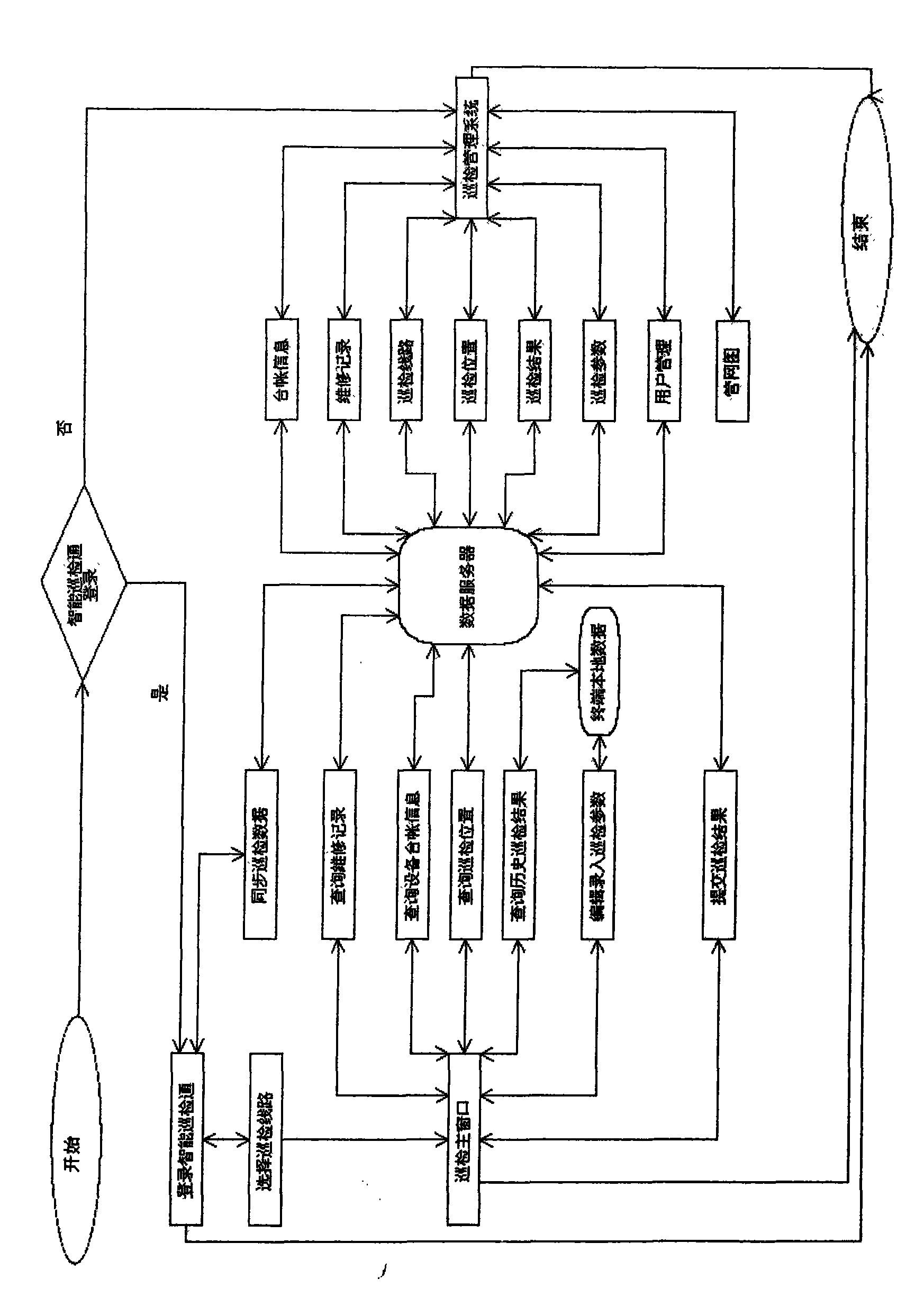

Method for examining and managing thermodynamic system

InactiveCN101540069ADiscover hidden dangers in timePrevent breakdowns and even accidentsChecking time patrolsChecking apparatusReverse orderJob number

The invention relates to a method for examining and managing a thermodynamic system, which comprises the following main steps: scanning information of an examiner, inquiring records of an examining spot, inquiring an examining route, inquiring an examining position and equipment and recording data. Firstly, the information of a job number or a bar code of a working card of the examiner is scanned by a bar code scanner; secondly, the history records of the examining spot are inquired, if no examining spot is found, a prompting message is given, and if the examining spot is found, parameter details are displayed according to a reverse order mode of examining time; thirdly, the examining route is inquired, and the examined examining position is displayed on a display screen; fourthly, the examining position and the equipment are inquired; and finally, a bar code of the examining position is scanned by the bar code scanner to record the data. The invention has simple principle, safe and reliable operation, high degree of automation and wide application range.

Owner:青岛能源热电集团有限公司 +1

Evaluation method and device for examining operation condition of welders

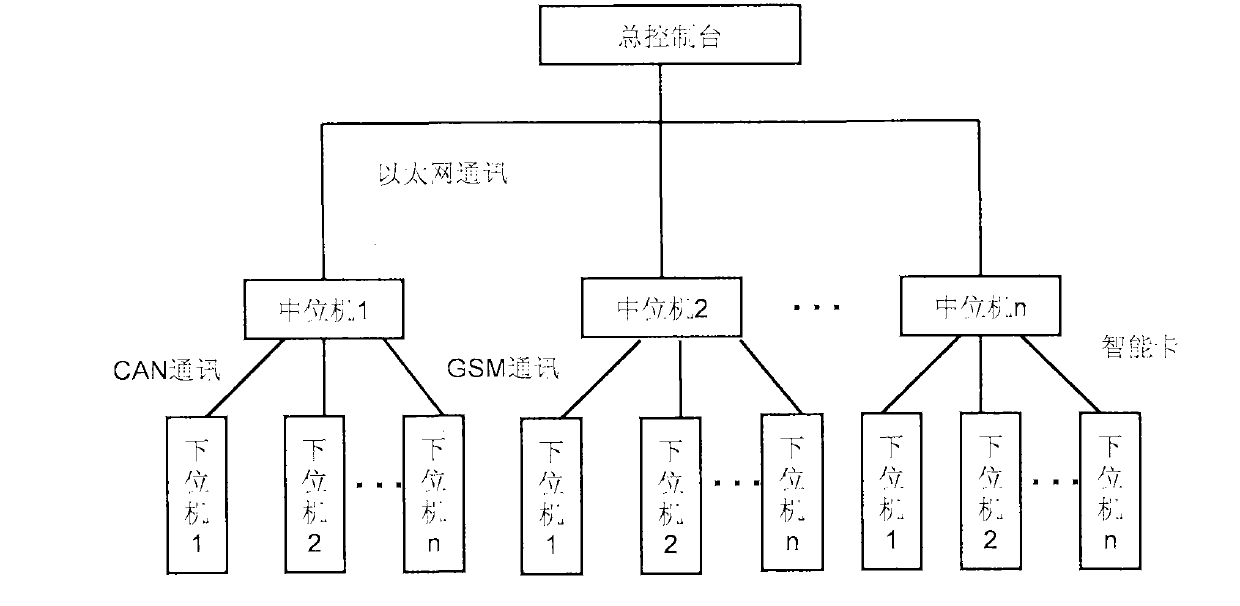

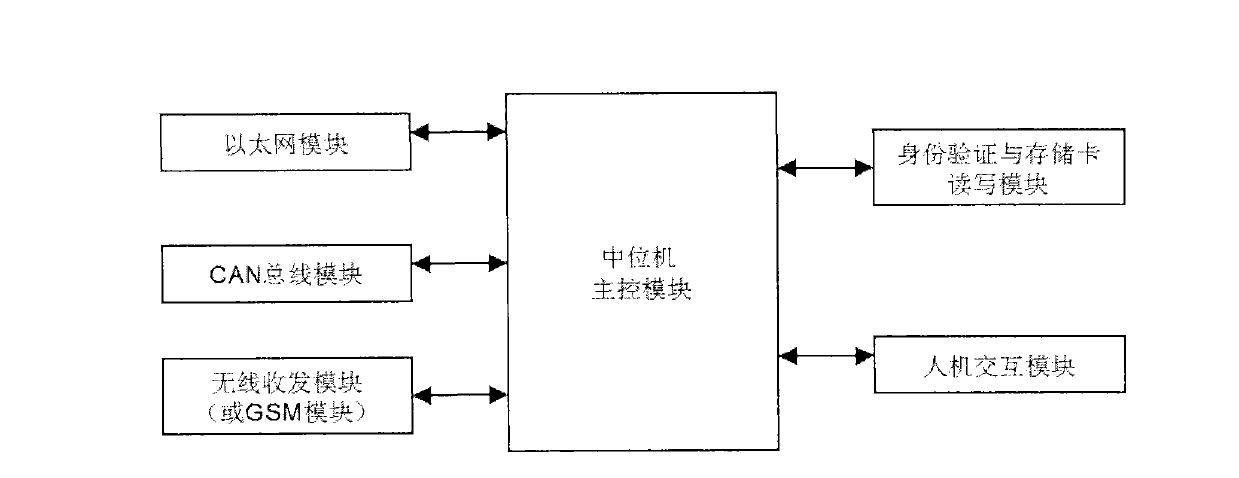

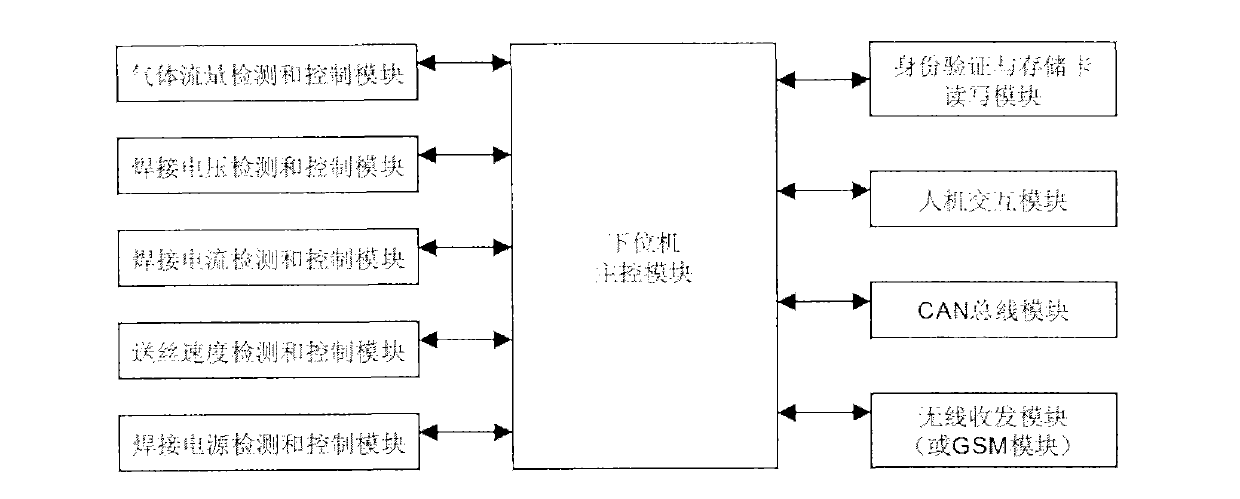

The invention provides an evaluation method and an evaluation device for examining the operation condition of welders, which are used for carrying out remote supervision and control on the welders who carry out field operation so as to ensure the welding quality. Job numbers of welding machines used by all the welders who carry out operation on the field are monitored in real time; an operating welding power supply is remotely monitored; whether the gas flow, the welding current and the welding voltage meet the requirements of a welding process specification is monitored in real time; and whether the welding power supply abnormally supplies power is monitored and related data is recorded for calling. The device consists of three architectures, i.e. a console, a middle computer and a lower computer. The console communicates with the middle computer by the Ethernet. Three modes of CAN (Controller Area Network) wire communication, GSM (Global System for Mobile Communications) wireless communication and intelligent card application can be respectively adopted between the middle computer and the lower computer according to the working environments of the welding machines.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

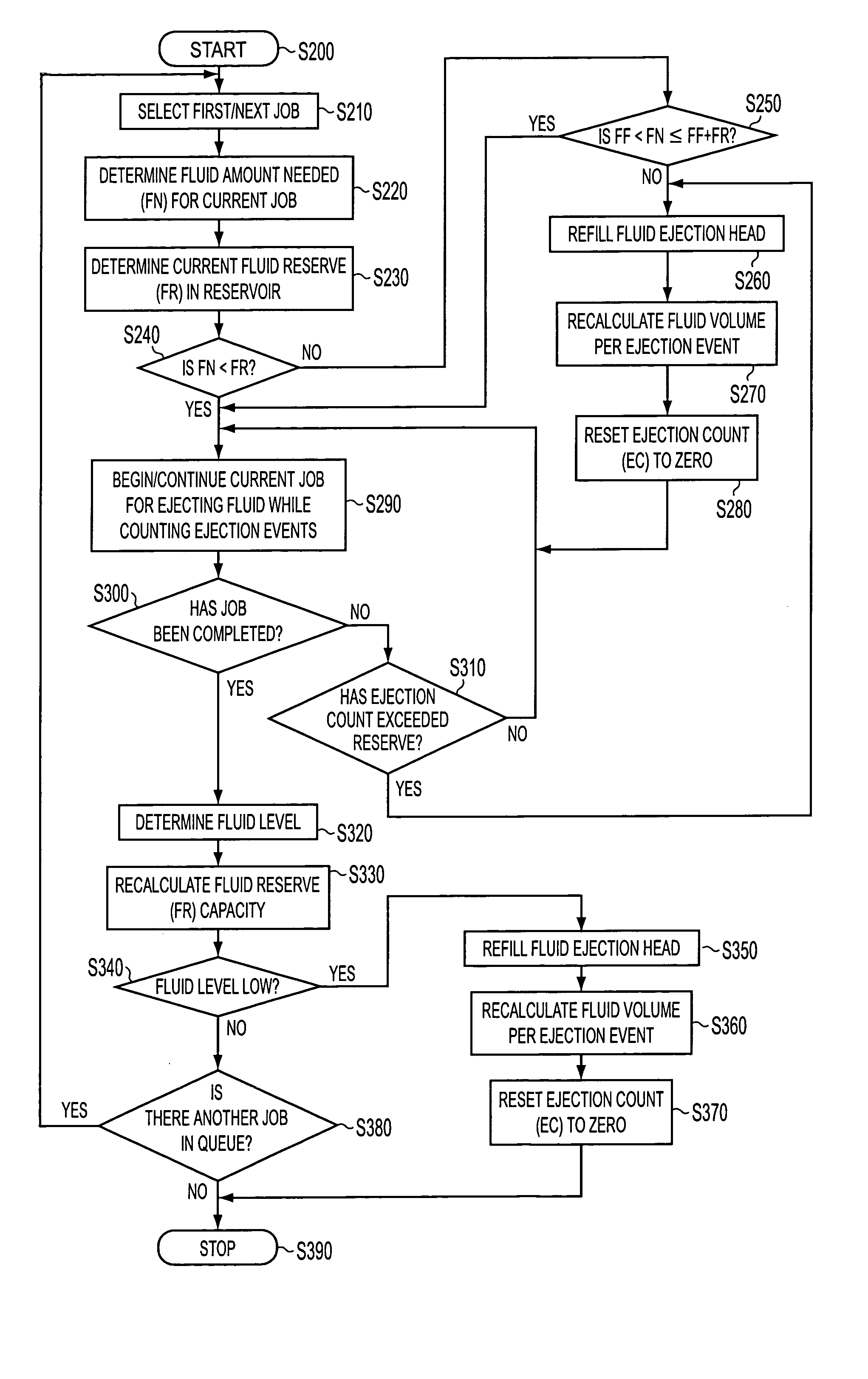

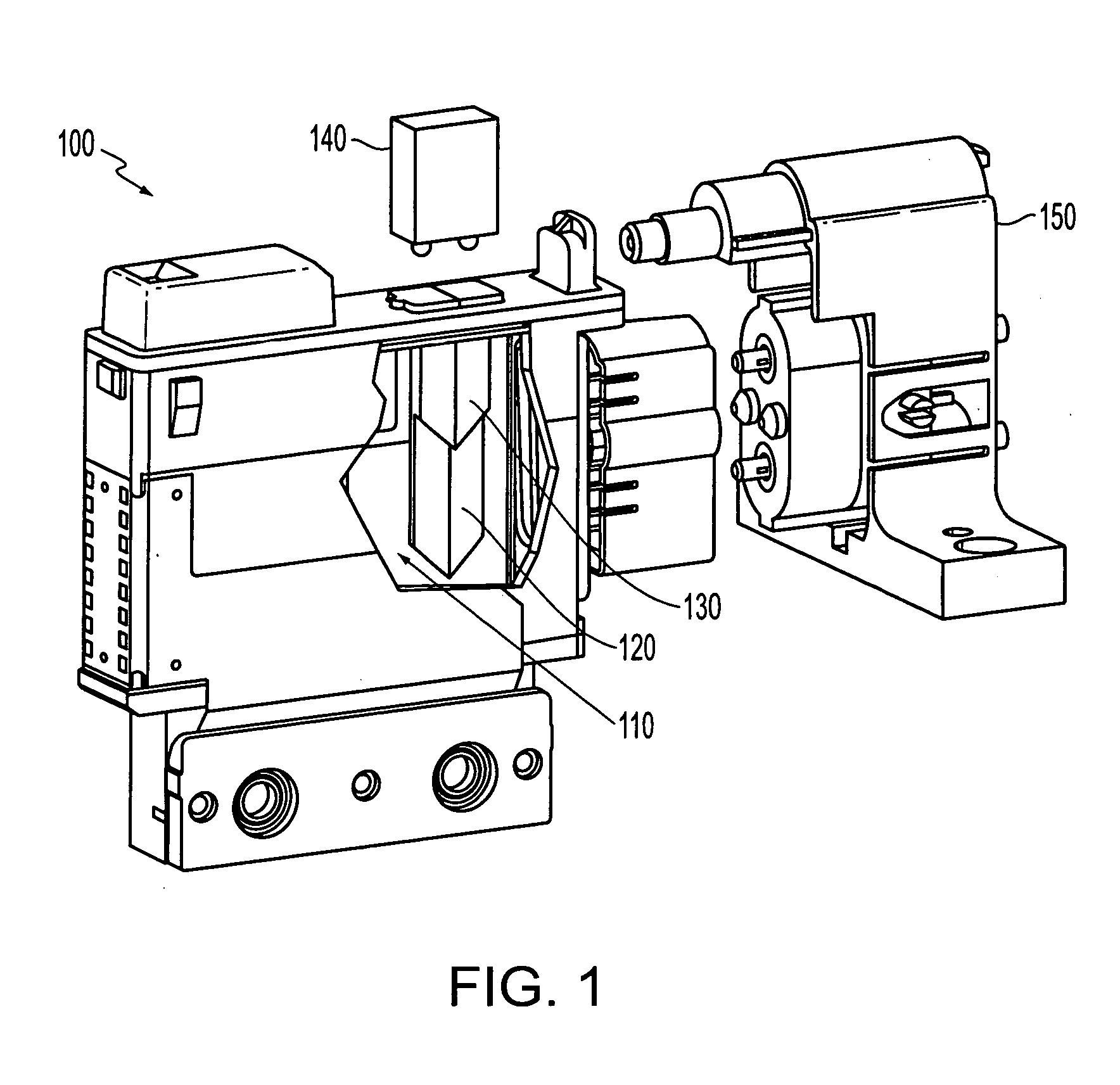

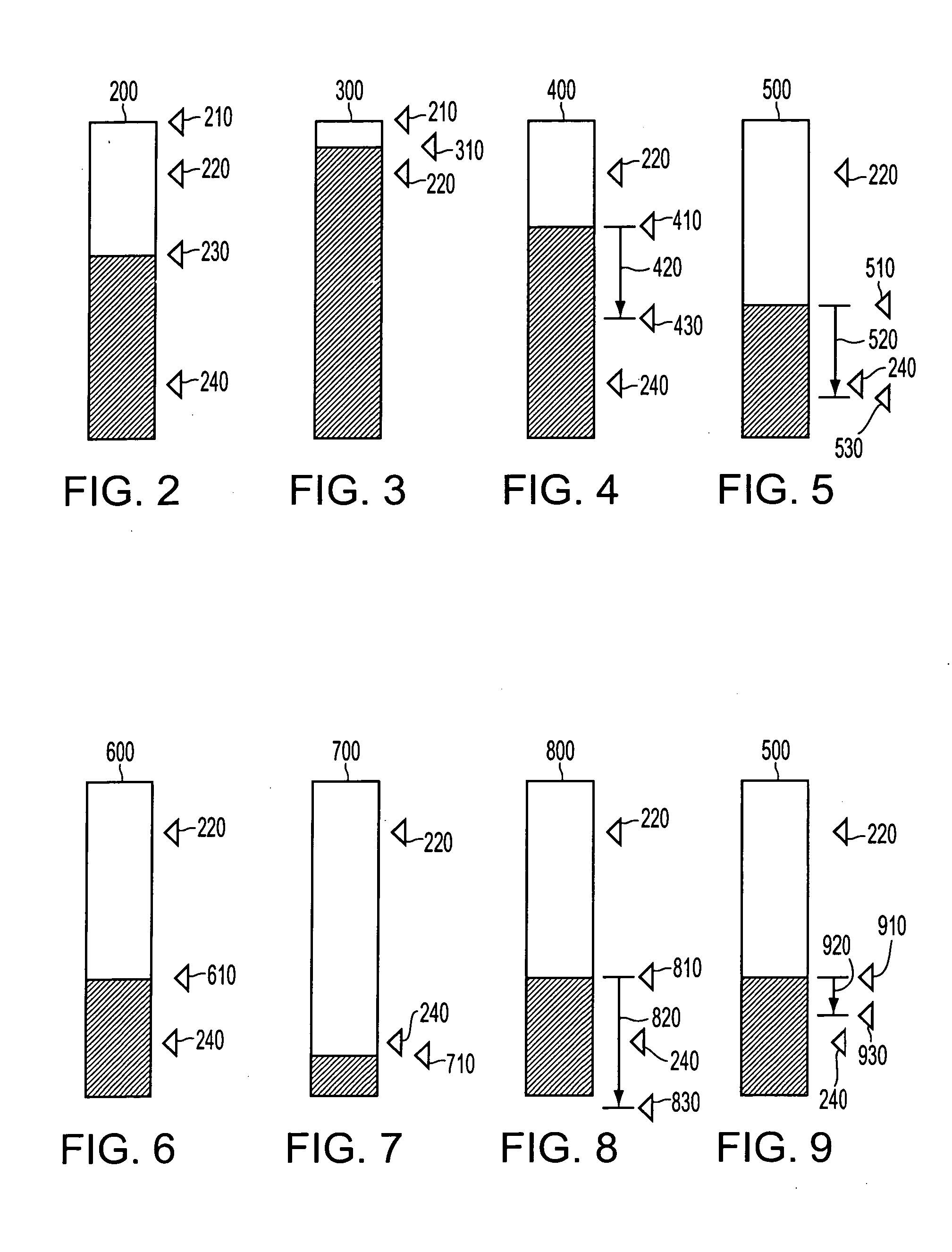

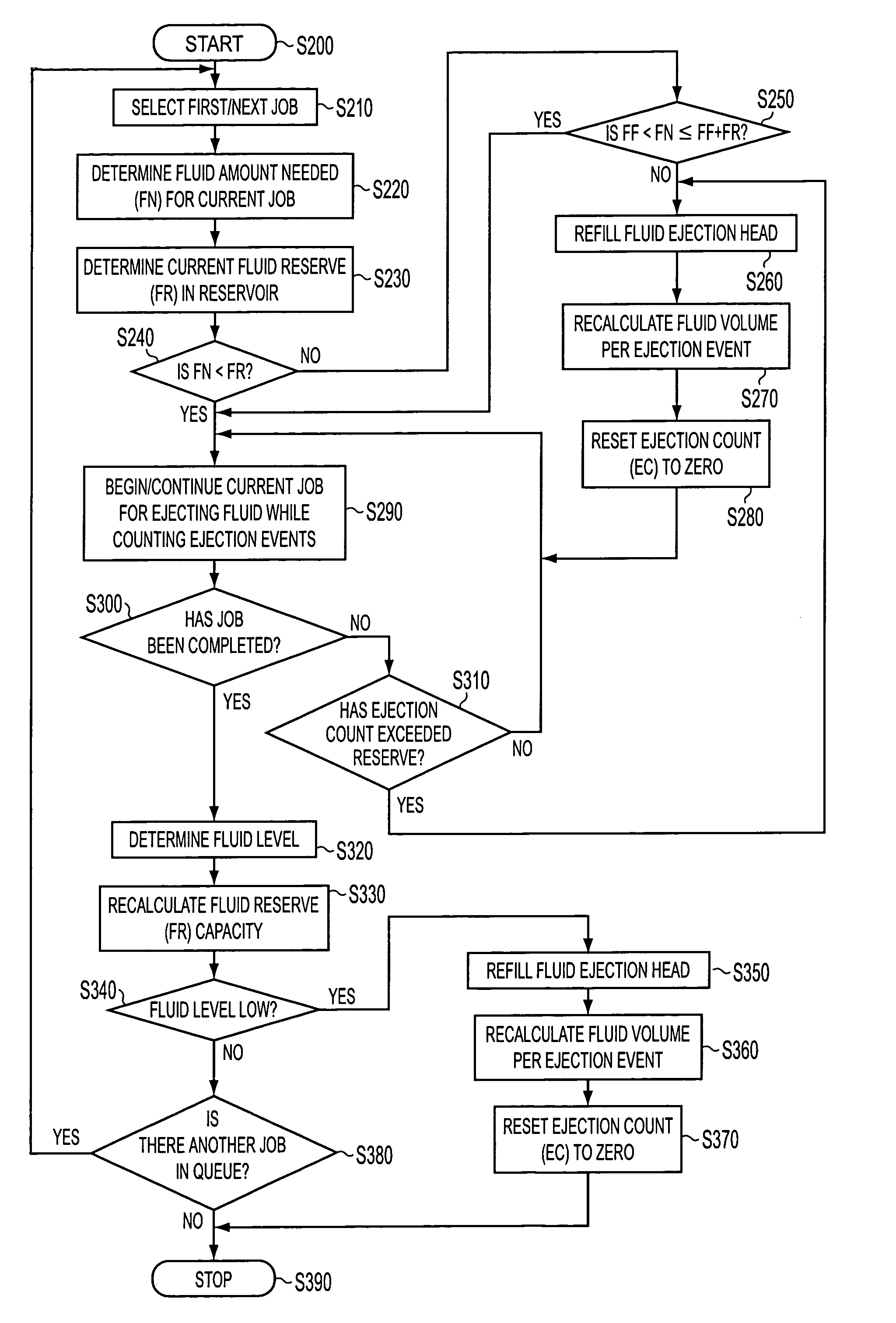

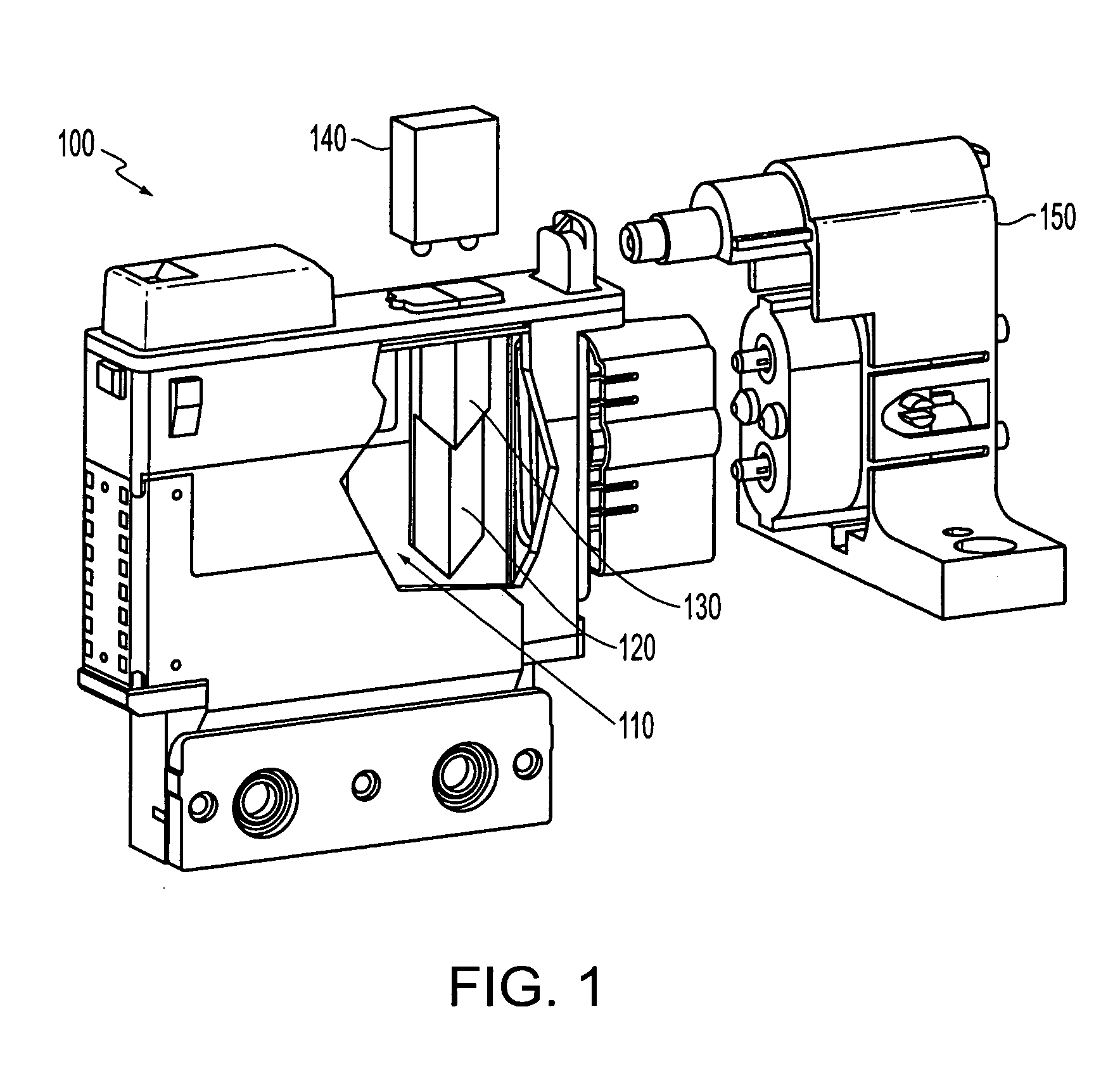

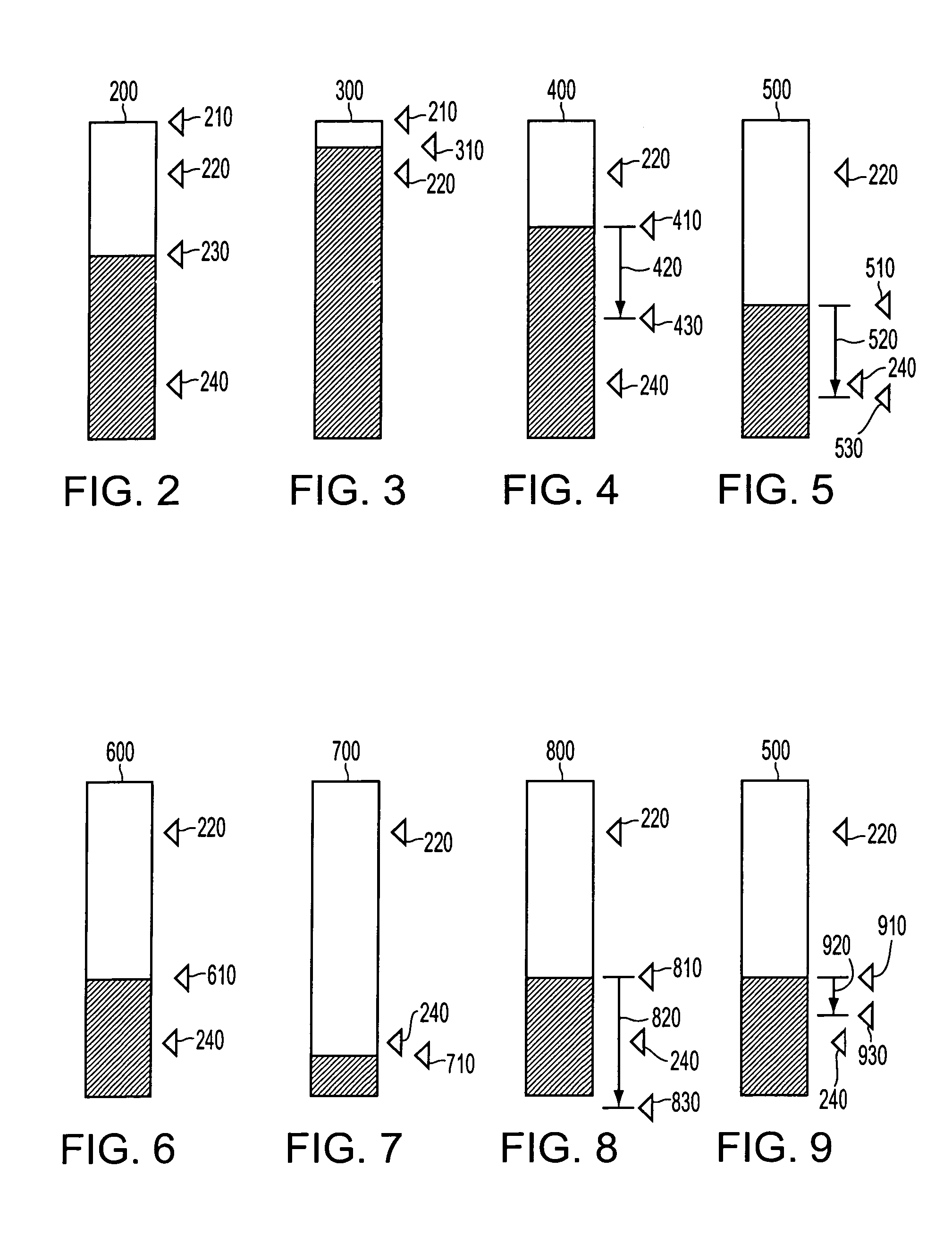

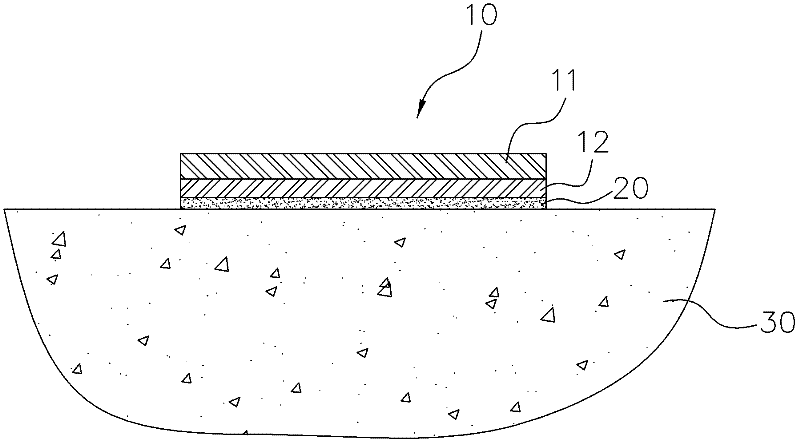

Systems and methods for controllably refilling a fluid quantity sensing fluid ejection head

A controller for a fluid ejecting system having a refillable container includes an ejection count initializing circuit, routine or application, a count incrementing circuit, routine or application, at least one fluid level indicator, and a fluid quantity circuit, routine or application for determining an expended quantity of fluid, a fluid reserve capacity circuit, routine or application for determining a fluid reserve capacity in the container, an ejection job determining circuit, routine or application for determining a fluid job requirement, a reserve comparing circuit, routine or application to compare the fluid reserve capacity and the fluid job requirement, and a refill condition determining circuit, routine or application to determine that the container is to be refilled. Counts for a ejection amount and a reserve capacity are incremented in response to a specific amount of fluid being ejected from the container. The expended quantity of fluid is based on the ejection amount count subsequent to the fluid level being indicated. The fluid reserve capacity is based on the reserve capacity count and the expended quantity of fluid. The fluid job requirement is based on the expended quantity of fluid and a job number of ejected amounts of fluid. The container is determined to be refilled upon at least a condition wherein the fluid job requirement exceeds the fluid reserve capacity, and a condition wherein the fluid level is below a refill threshold.

Owner:FUJIFILM BUSINESS INNOVATION CORP

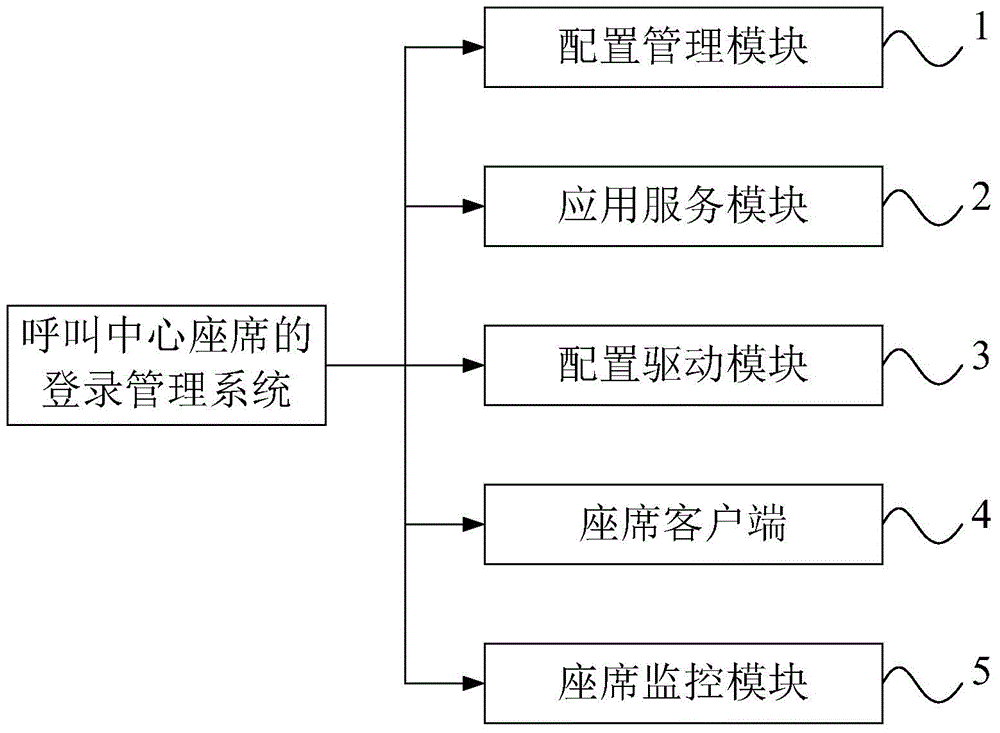

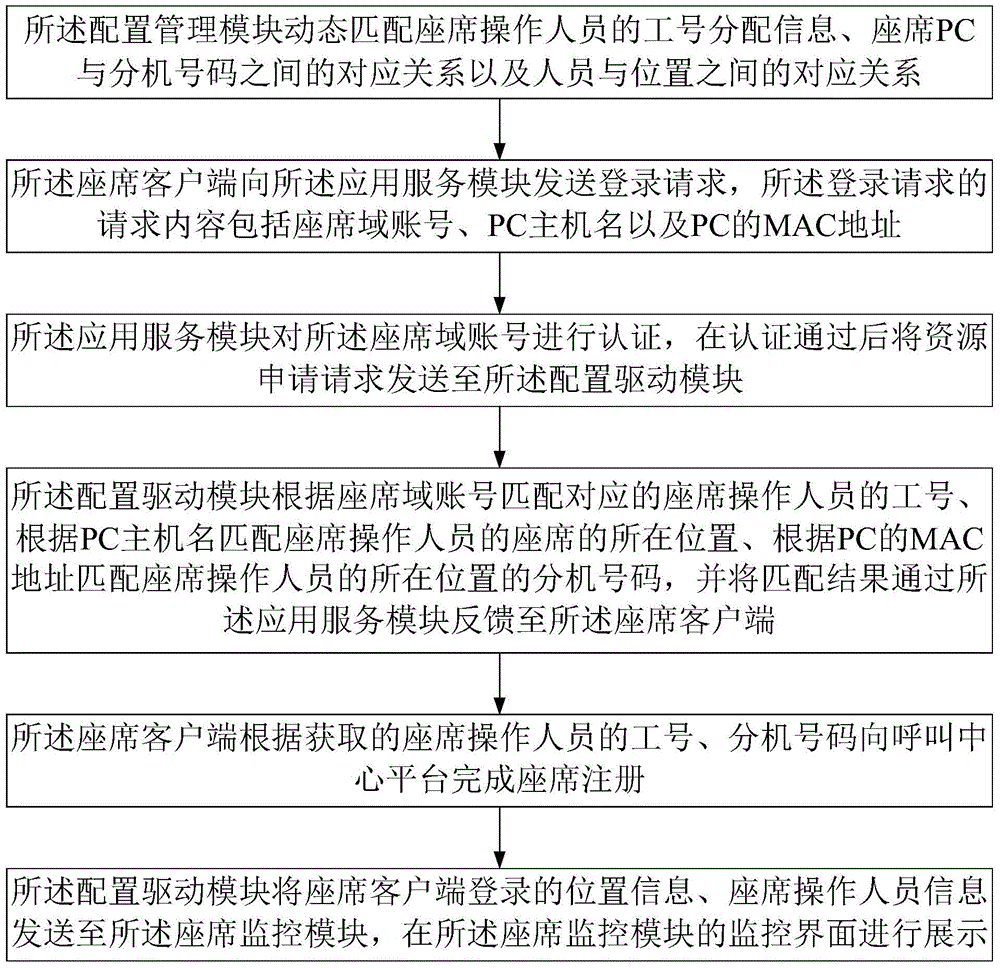

Login management system and method for call center seat

ActiveCN105072118AImplement dynamic allocationReduce construction costsAutomatic exchangesTransmissionJob numberComputer module

The invention discloses a login management system and method for a call center seat. The method comprises the following steps: a configuration management module dynamically matches various information of seat operating personnel; a seat client sends a login request; an application service module authenticates a seat domain account, and sends a resource application request to a configuration driving module after authentication pass; the configuration driving module matches the job number of corresponding seat operating personnel according to the seat domain account, matches the location of the seat of the seat operating personnel according to a PC (Personal Computer) host name, matches the extension number of the position of the seat operating personnel according to the MAC (Media Access Control) address of a PC, and feeds back matching results to the seat client; and the seat client finishes seat registration to a call center platform according to the acquired job number of the seat operating personnel and the extension number. Through adoption of the login management system and method, dynamical allocation of call center seat resources and login management without regional limits are realized.

Owner:SHANGHAI CTRIP COMMERCE CO LTD

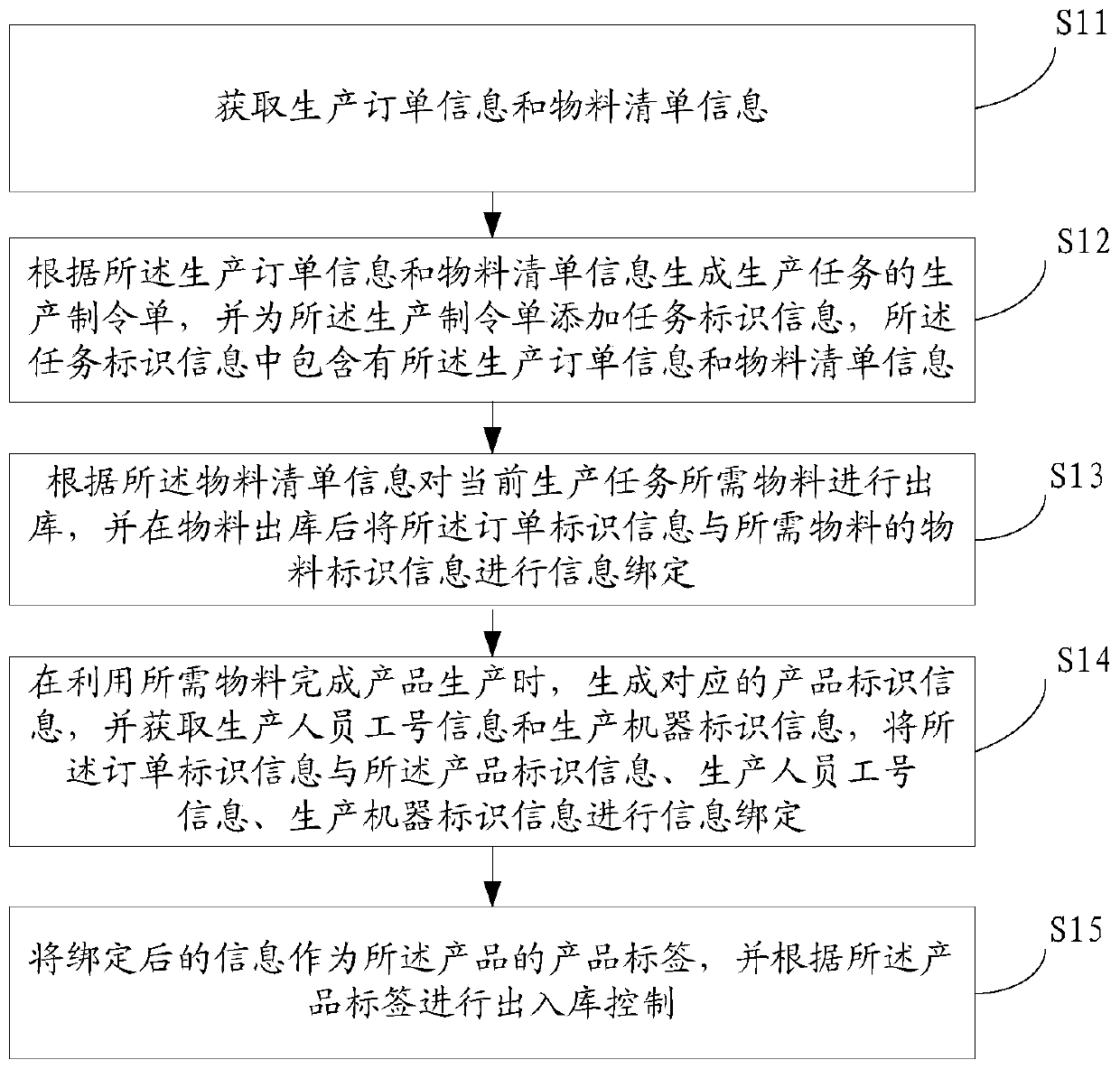

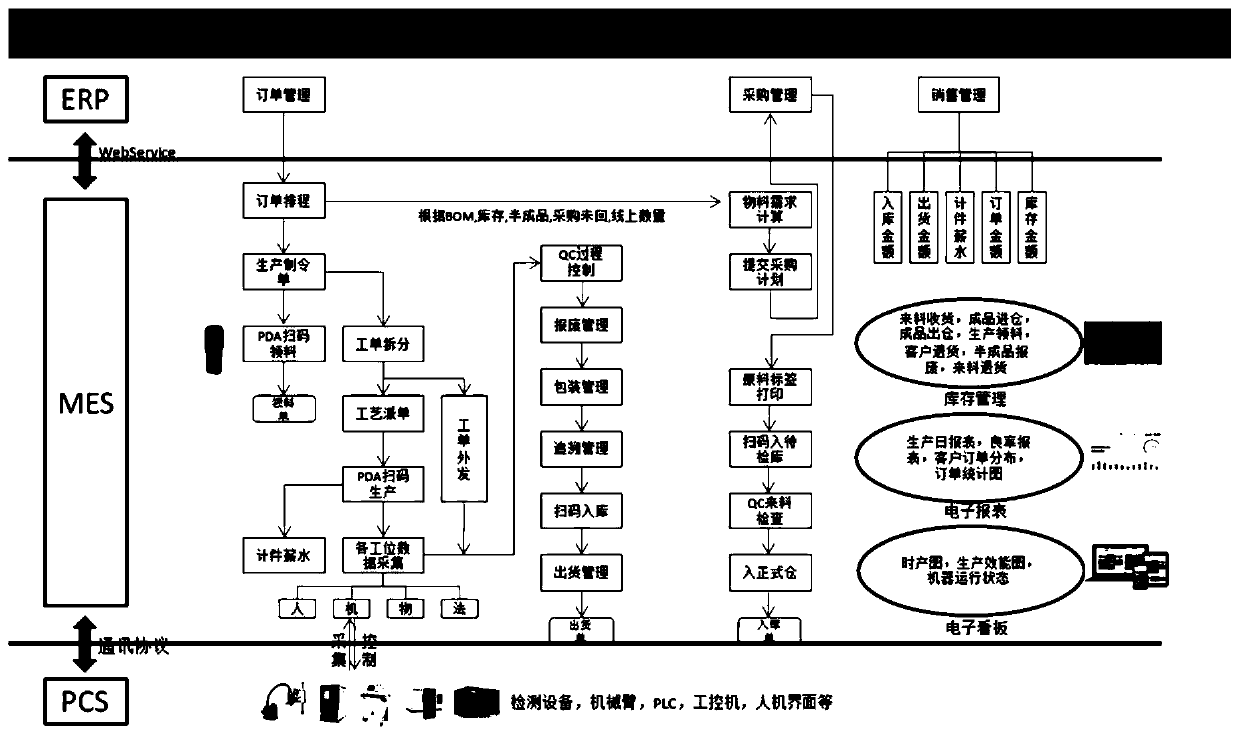

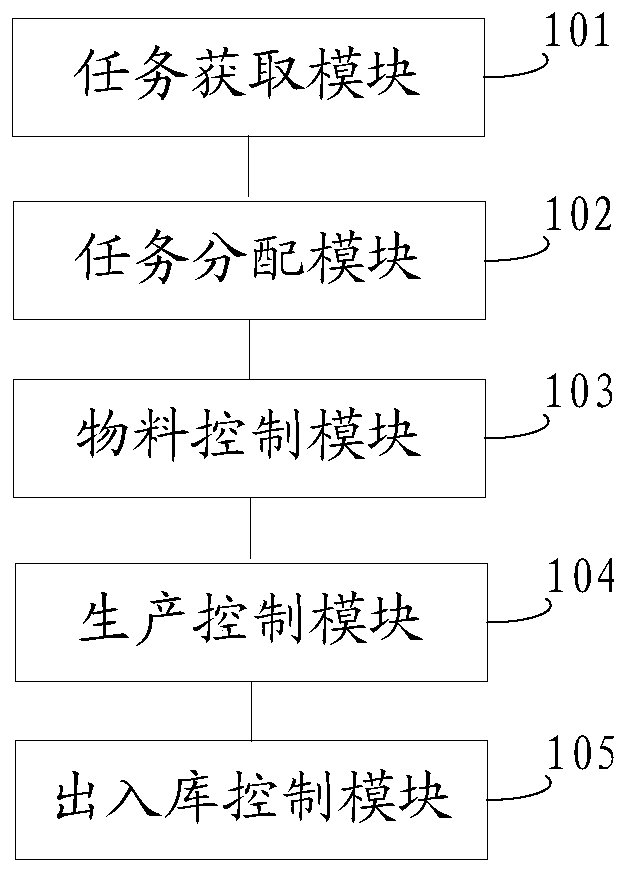

Method and system for realizing production process tracing, storage medium and electronic equipment

PendingCN110675163AEasy to controlImprove efficiencyLogisticsCommerceBill of materialsIndustrial engineering

The invention provides a method and system for realizing production process tracing, a storage medium and electronic equipment. The method comprises the following steps: acquiring production order information and bill of material information; generating a production command list of the production task according to the obtained information, and adding task identification information to the production command list; delivering the required materials according to the material list information, and binding the order identification information and the material identification information of the required materials after the materials are delivered; when product production is completed, generating product identification information, obtaining production personnel job number information and production machine identification information, and binding the order identification information with the product identification information, the production personnel job number information and the productionmachine identification information; and taking the bound information as a product label of the product, and performing warehouse-in and warehouse-out control according to the product label. Accordingto the method, all links related to production are associated in an identification information binding mode, so that the product has traceability, and the control ability of the enterprise productioncapacity is improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

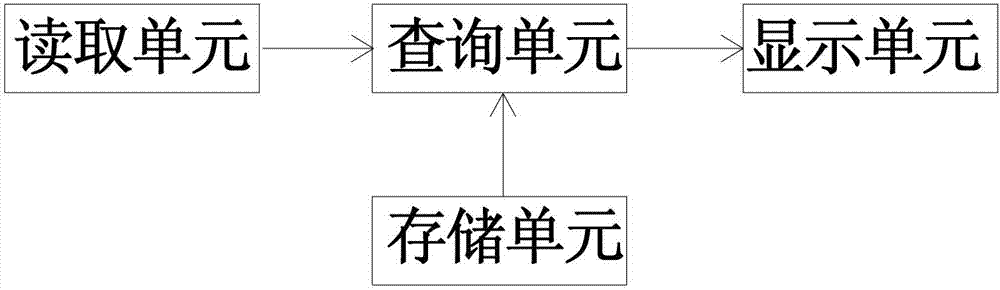

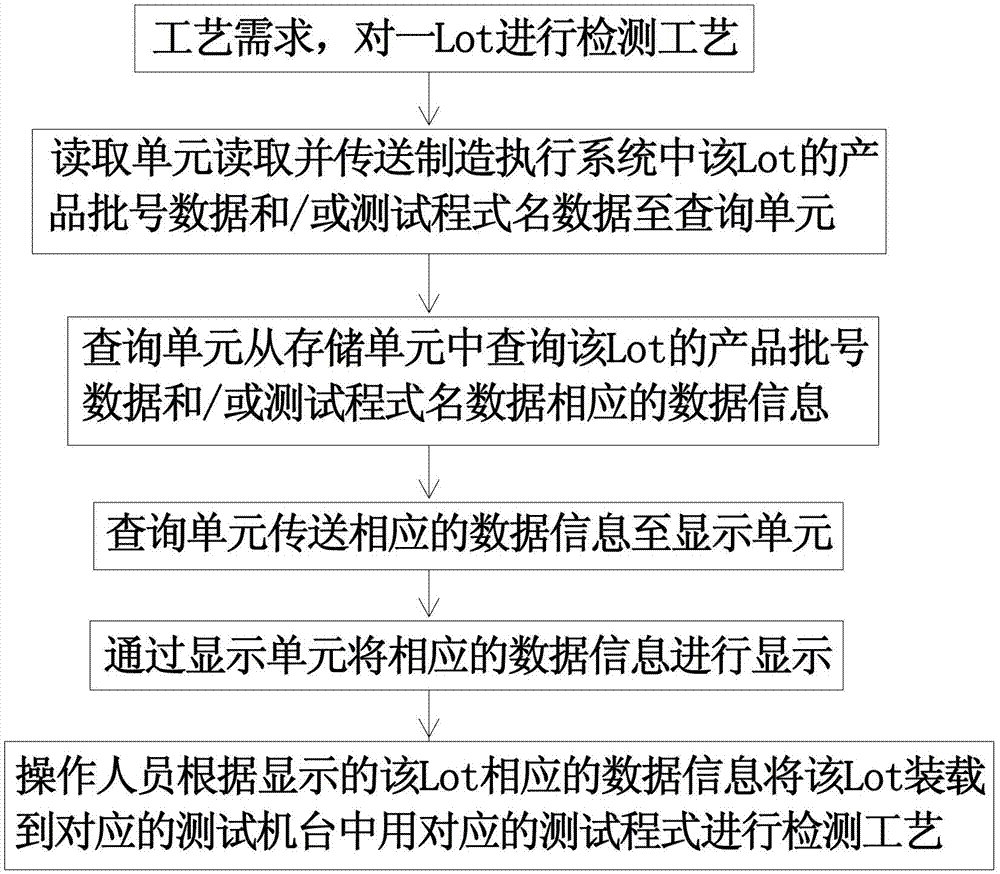

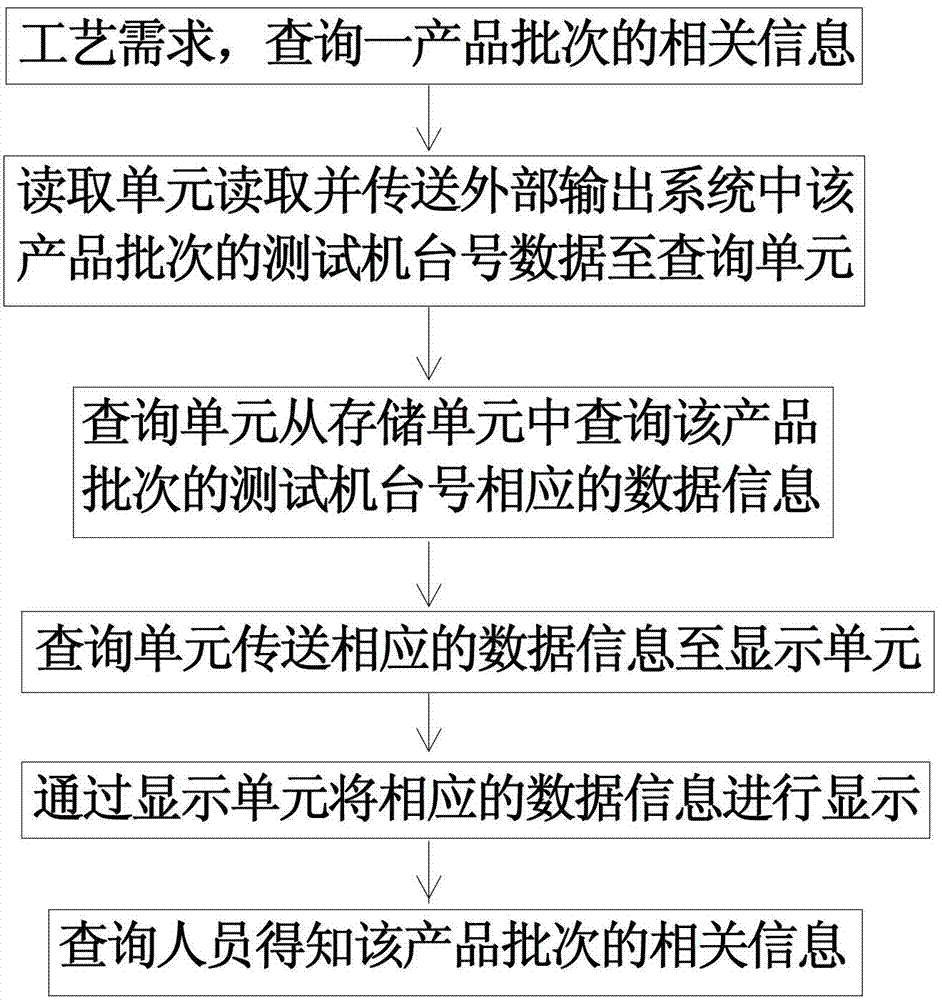

Management system of wafer acceptable test procedure and application method thereof

ActiveCN103199041AReduce factory costImprove test efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest efficiencyProbe card

The invention relates to a management system of a wafer acceptable test procedure and an application method of the management system. The management system of the wafer acceptable test procedure comprises a reading unit, a storage unit, an inquiry unit and a display unit. The storage unit is provided with product lot number data of a plurality of batches of products, testing machine number data, testing procedure name data, probe procedure name data, probe card type data, procedure grouping name data, machine property data, copper / non-copper wiring data, procedure establishing personnel job number data and test procedure detailed description data, wherein the testing machine number data, the testing procedure name data, the probe procedure name data, the probe card type data, the procedure grouping name data, the machine property data, the copper / non-copper wiring data, the procedure establishing personnel job number data and the test procedure detailed description data correspond to the product lot identification numbers of the various batches of products. The reading unit obtains operational data as required and transmits the operational data to the inquiry unit. The inquiry unit inquires data information which is stored in the storage unit and corresponds to the operational data and the corresponding data information is displayed through the display unit. According to the management system of the wafer acceptable test procedure and the application method, an operator is enabled to be clear about the fact that the wafer acceptable test procedure is carried out in a corresponding testing machine, testing efficiency is improved, and the factory cost of semiconductors is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

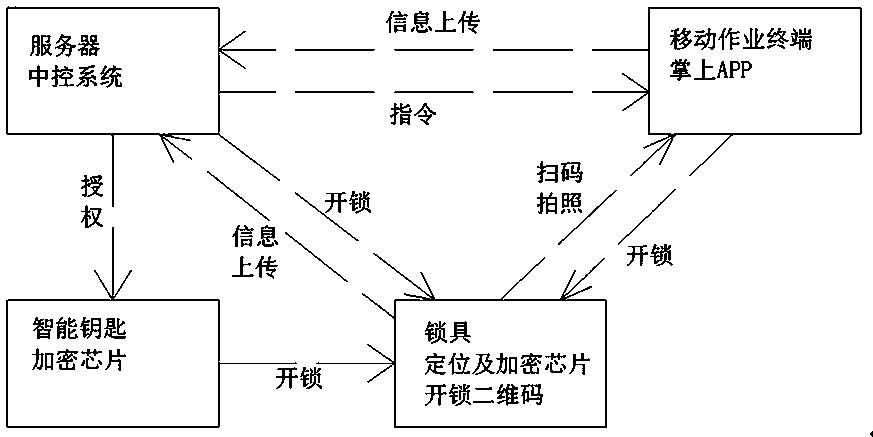

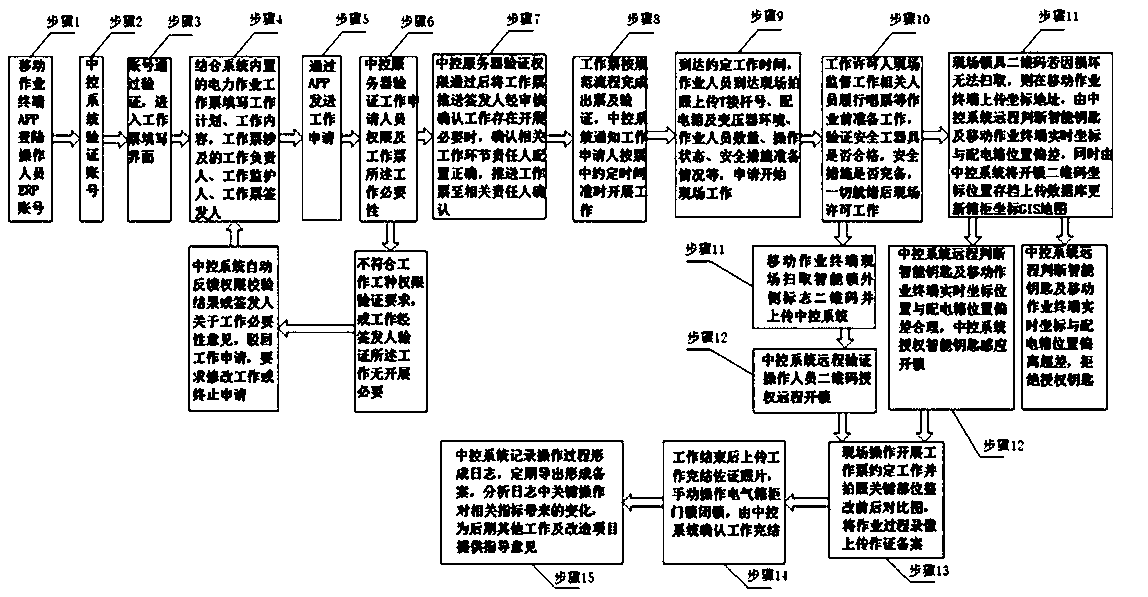

Work ticket managing system for electrical cabinet based on intelligent lock

PendingCN109326034ALock accuratelyEasy to operateData processing applicationsIndividual entry/exit registersJob numberControl system

The invention provides a work ticket managing system for an electrical cabinet based on an intelligent lock. The managing system comprises a server, a central control system, a palm APP, an ERP job number, a mobile work terminal, an electrical cabinet, a lock, and an unlocking two-dimensional code. The palm APP is installed on the mobile work terminal. The lock is fixed on the electrical cabinet and is provided with electronic and mechanical double encryption. The lock is internally provided with an integrated chip which has the functions of positioning, encryption, communication, storage, andrecording. The unlocking two-dimensional code is provided on the outer surface of the electrical cabinet. The palm APP and the intelligent lock are connected to the central control system through thenetwork. According to the work ticket managing system for an electrical cabinet based on an intelligent lock, the account map management and work ticket management of the electrical cabinet are standardized, the automated operation process related to the opening and closing of the electrical cabinet is effectively standardized, the loss cost of the physical lock of the cabinet and the labor costof manually replacing the lock are reduced, and the operation is convenient, so that the efficiency of on-site work is effectively improved, the intensive and lean management is realized, and the enterprise management efficiency is improved.

Owner:XINING POWER SUPPLY CO OF STATE GRID QINGHAI ELECTRIC POWER CO +2

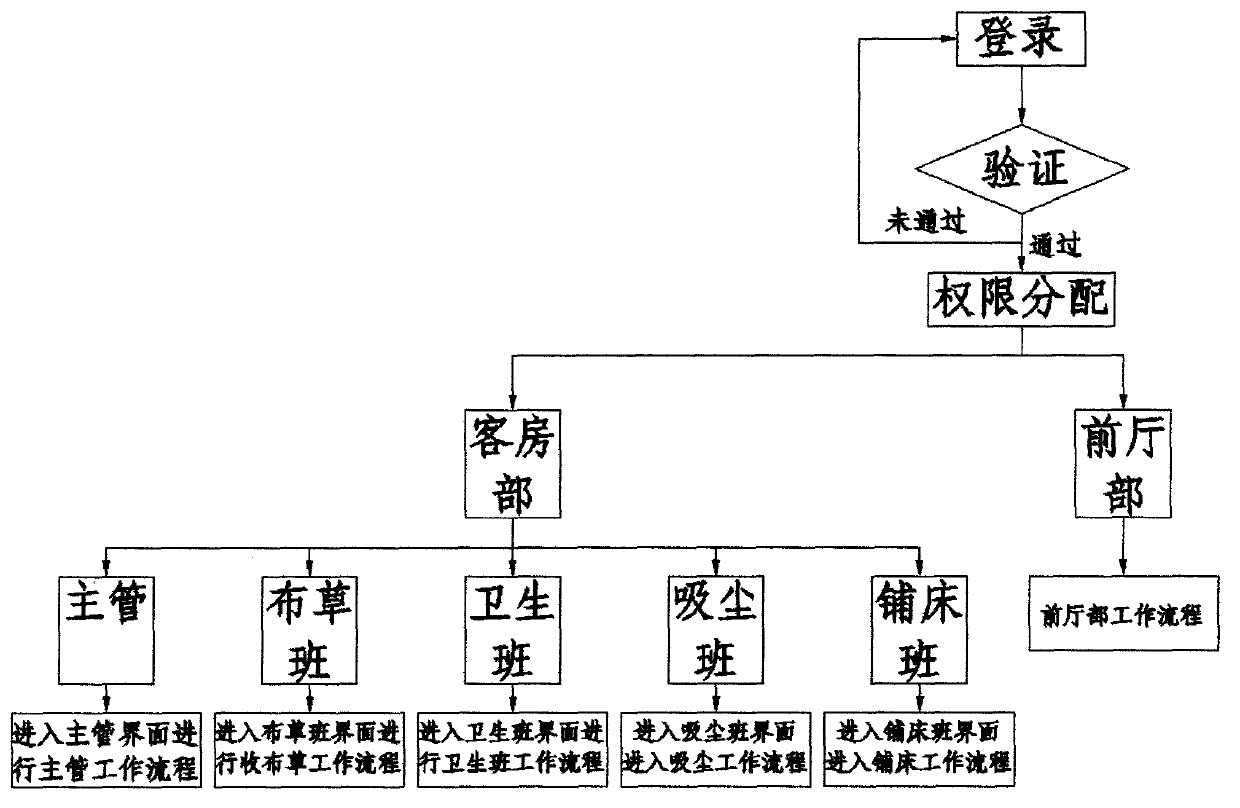

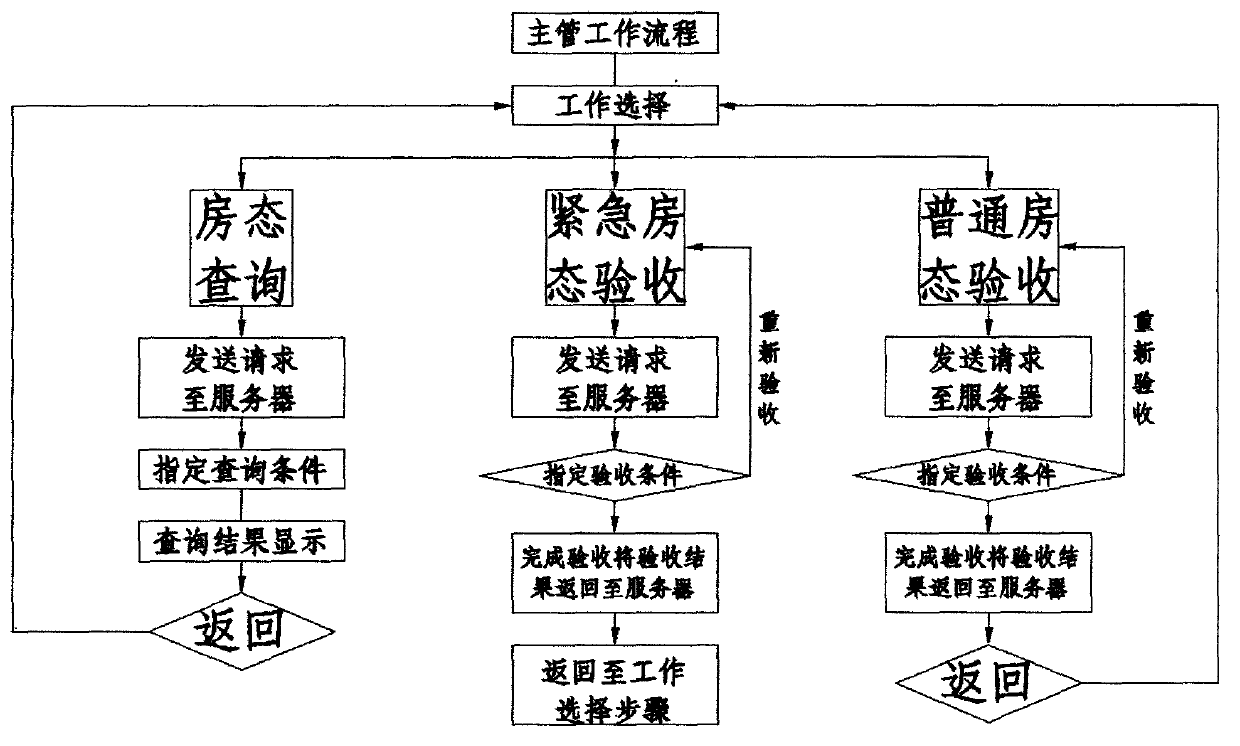

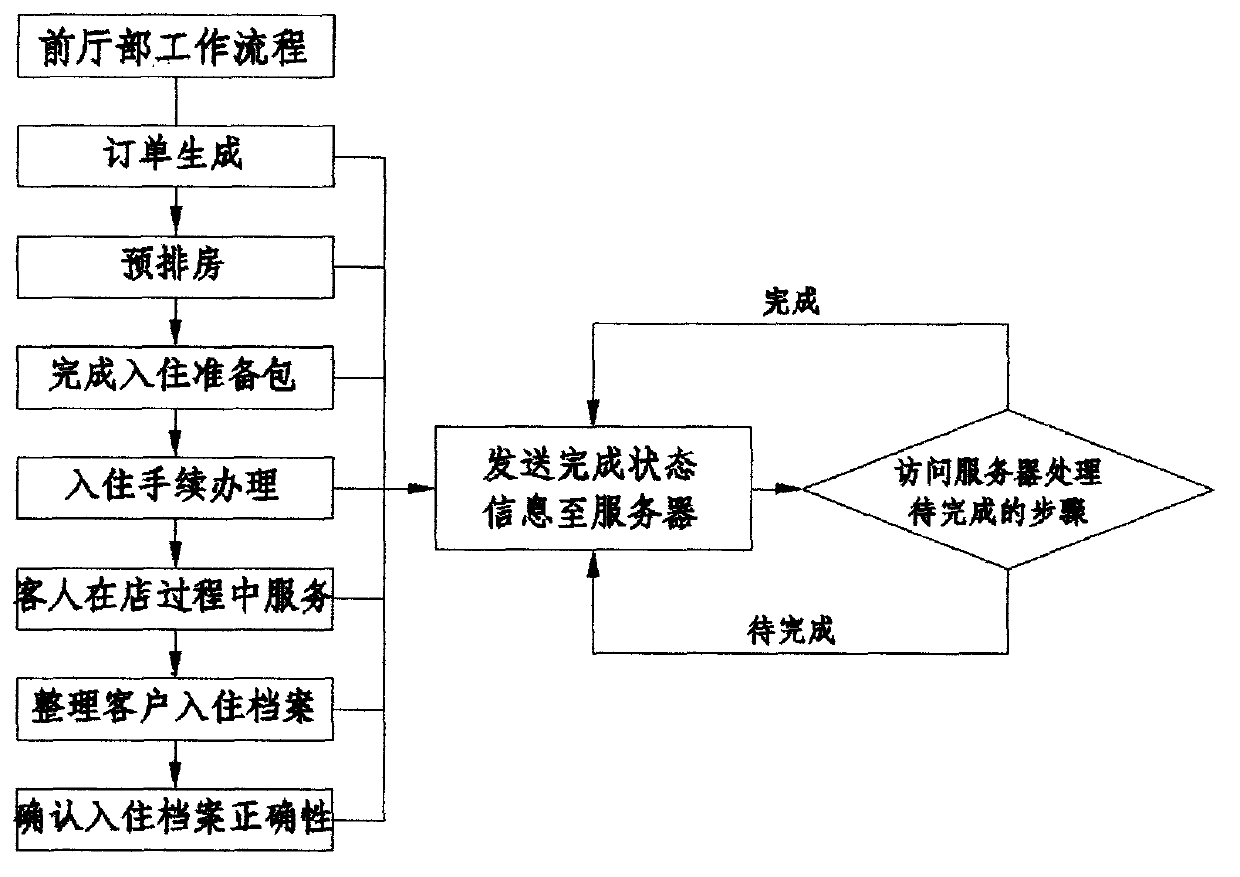

Hotel management method based on workflow

InactiveCN103136628AEliminate the disadvantages of subjective judgmentAchieve fairnessResourcesSecurity arrangementJob numberSoftware engineering

The invention provides a hotel management method based on workflow, achieves efficient operation of a hotel, and meanwhile improves the enthusiasm of staff. The hotel management method based on the workflow comprises the following steps: the staff use individual information to login through a mobile terminal, wherein the staff input job numbers and codes to login; a server-side in wireless connection with the mobile terminal verifies log-in information, wherein the server carries out the matching and verification of the job numbers, the codes and the machine codes of the mobile terminal; if the verification does not pass, error prompting is sent out, and the step returns to the first step; if the verification passes, a permission division step is entered, wherein sub permission steps corresponding to a housekeeping department and a front office department are entered according to the staff individual information corresponding to the log-in information, and the housekeeping department comprises a supervisor, a napkin and a table cloth arrangement group, a sanitation group, a dust absorption group and a bed-making group; and the step of workflow of specific permission is entered, wherein the housekeeping department enters the workflow of the supervisor, the napkin and table cloth arrangement group, the sanitation group, the dust absorption group and the bed-making group, and the front office department enters the workflow of the front office department.

Owner:张劲松

Application of bar code management system in hub machining

InactiveCN104268689AEasy to manageResourcesManufacturing computing systemsProgramming languageJob number

The invention discloses application of a bar code management system in hub machining. Firstly, bar code labels are automatically distributed through the bar code system, and the bar code labels are associate with the information of the cast date, the personal responsibility number, the machine table number, the production team, the mold number and the product model; then, once one product is produced, one bar code label is stuck to the product; when the product enters a next link, the bar code label is firstly scanned, the information of the job number of an operator and the date is input to the system, the information of the job number of an operator and the date is automatically bound with all information of previous procedures so that an information chain can be formed, and then corresponding machining is performed; when the bar code label is covered with other things or falls off after machining, a new bar code label is stuck to the product again, the bar code label is scanned again, the information of the bar code label is uploaded to the system again, and the information of the bar code label is automatically associated with the information of all the previous procedures. The bar code management system is applied in the hub machining process so that machining information of all links can be associated, and a factory manager can conveniently track and perform statistics on production of the products.

Owner:中南铝车轮制造(佛山)有限公司

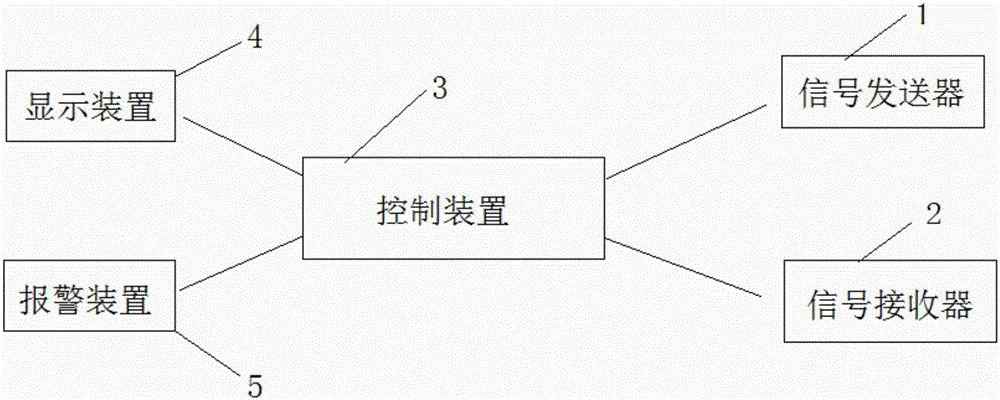

Corporate vehicle management system

InactiveCN105139101AIncrease flexibilitySimplified Assignment ApplicationResourcesJob numberSystems management

The invention provides a corporate vehicle management system. The corporate vehicle management system comprises a signal transmitter, a signal receiver, a control device and a display device. The signal transmitter is used for sending notification information and approval application information. The signal receiver is used for receiving approval result information and vehicle application information, and the vehicle application information includes riding personnel job numbers, destination information, an applicant job number and a sender job number. The control device comprises a system management module, a fleet daily management module, a trip information module and a control module, and the control module is in communication connection with the system management module, the fleet daily management module, the trip information module, the signal transmitter, the signal receiver and the display device. By adopting the corporate vehicle management system, the corporate vehicle application and statistic and other tedious items are effectively simplified, and the travelling personnel and the vehicle information can be checked conveniently.

Owner:LEADZONE SMART GRID TECH

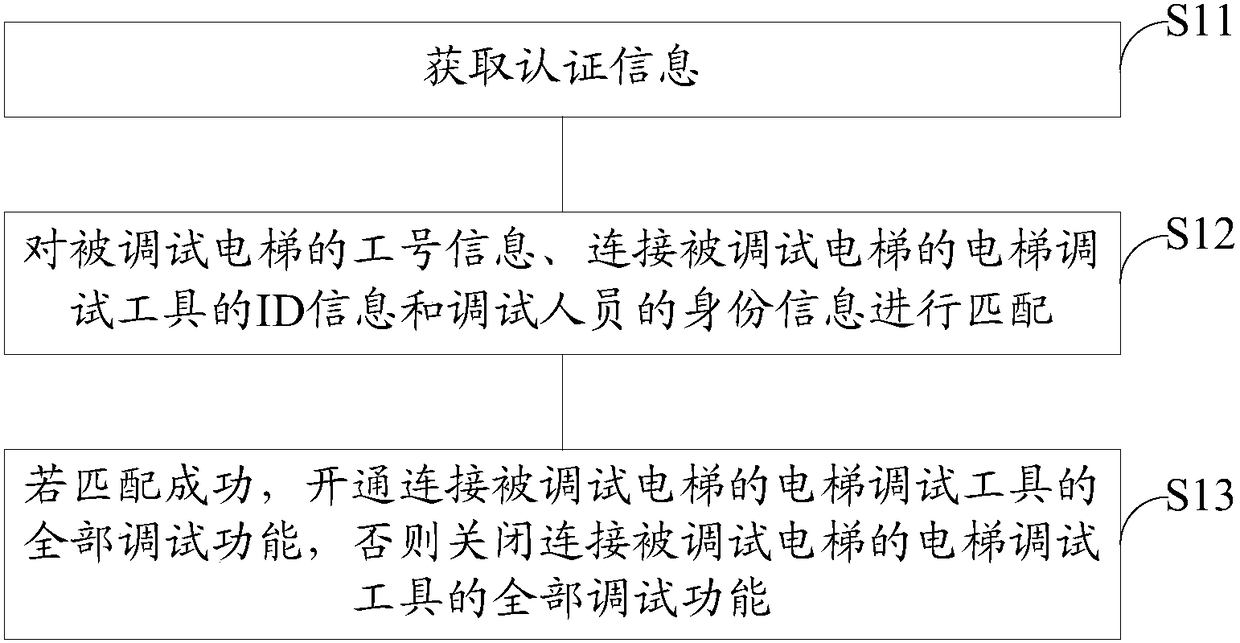

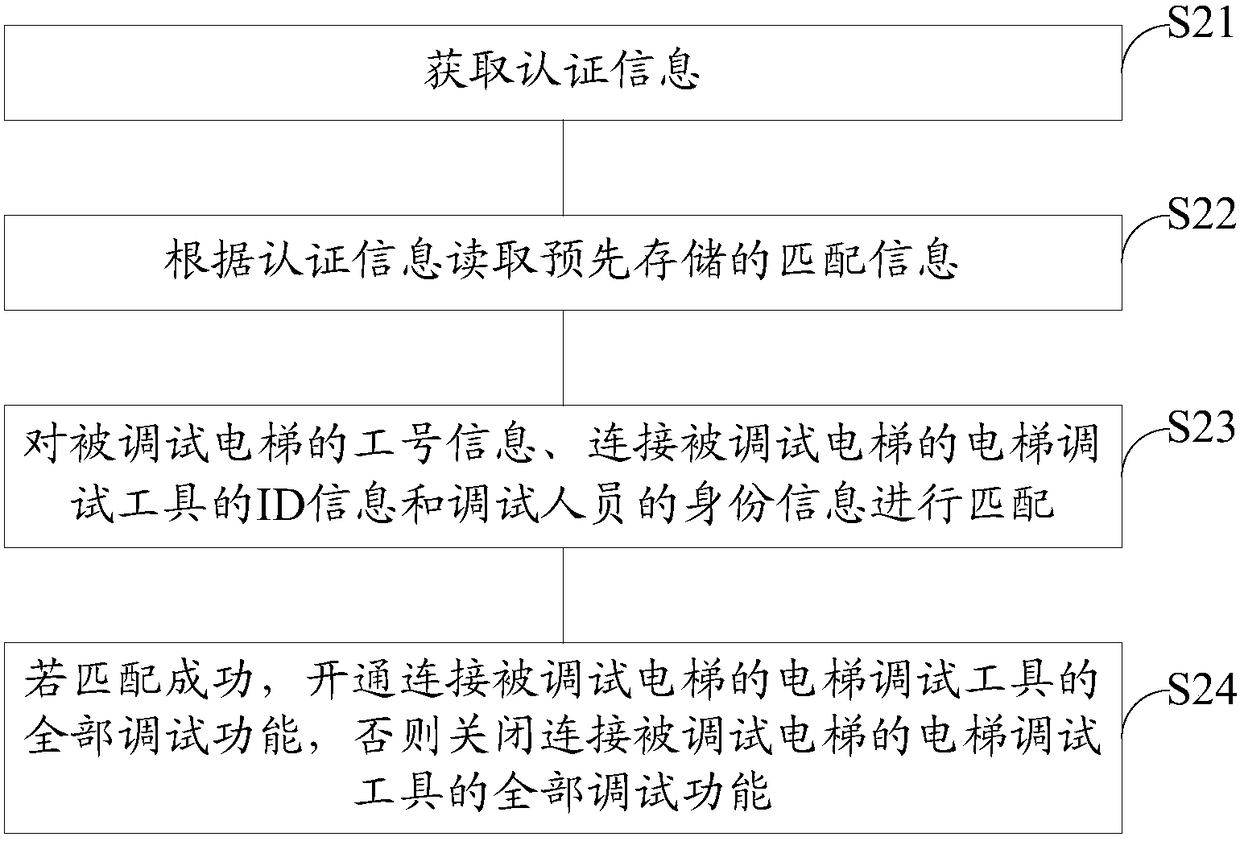

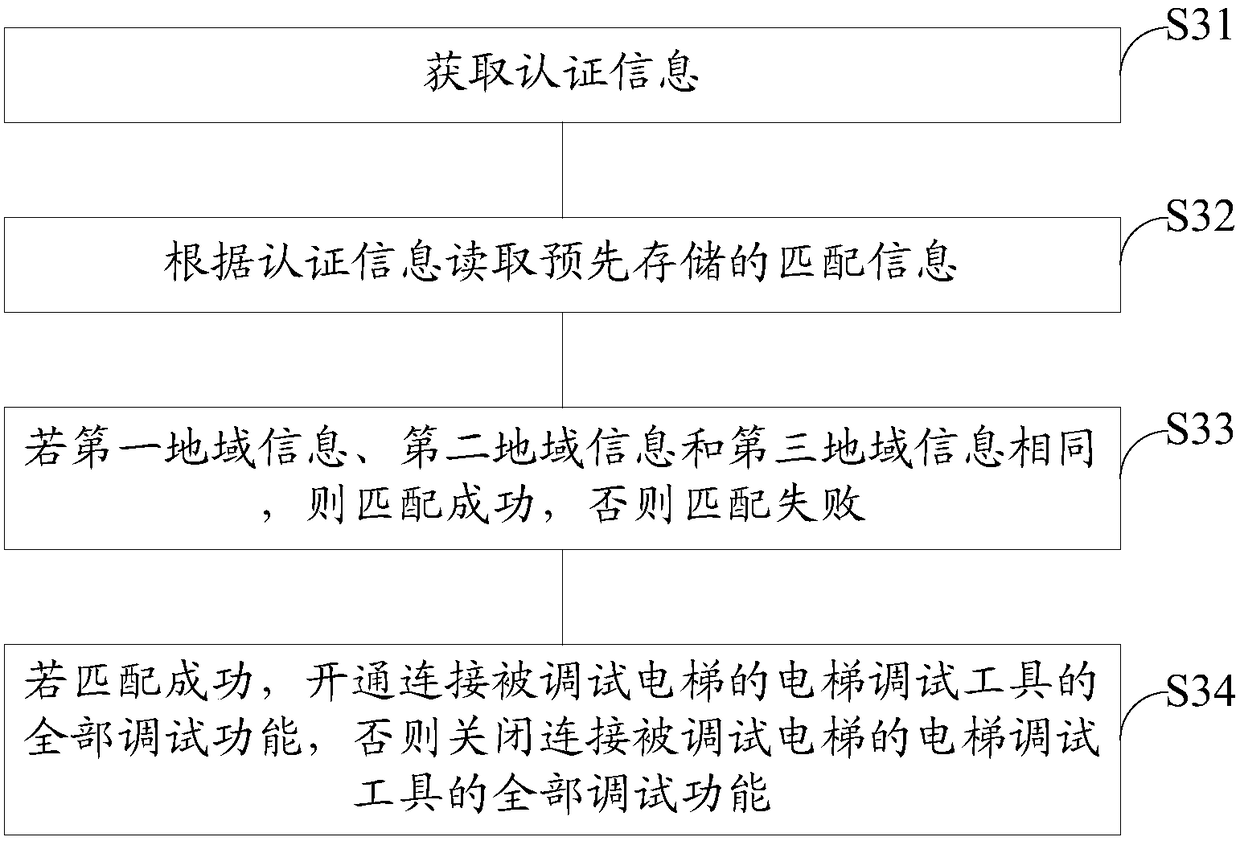

Authentication method and device of elevator debugging tool

The invention relates to an authentication method and device of an elevator debugging tool. Job number information of a debugged elevator, ID information of the elevator debugging tool connected withthe debugged elevator and identity information of a debugging person are matched, under the condition that matching succeeds, all debugging functions of the elevator debugging tool connected with thedebugged elevator are opened up, or, all debugging functions of the elevator debugging tool connected with the debugged elevator are closed. On the basis of the method and device, the elevator debugging tool not passing through authentication is prevented from debugging the elevator maliciously, meanwhile, data leakage of an elevator control system is prevented, and safety of the elevator controlsystem is improved.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

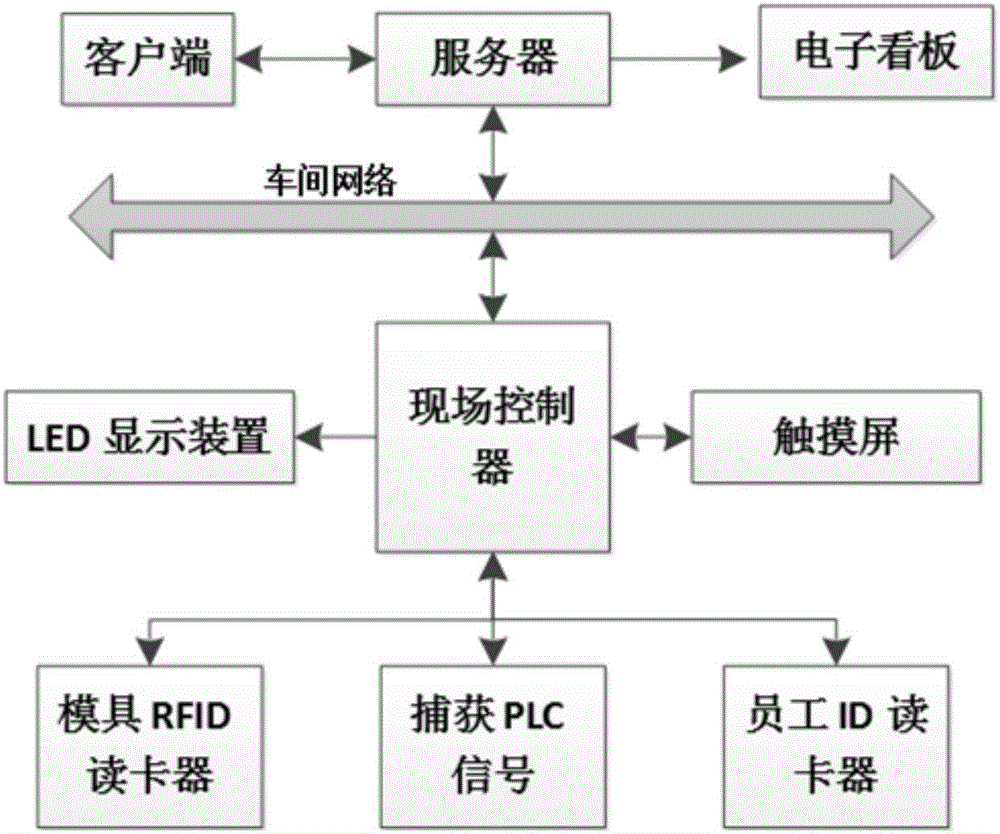

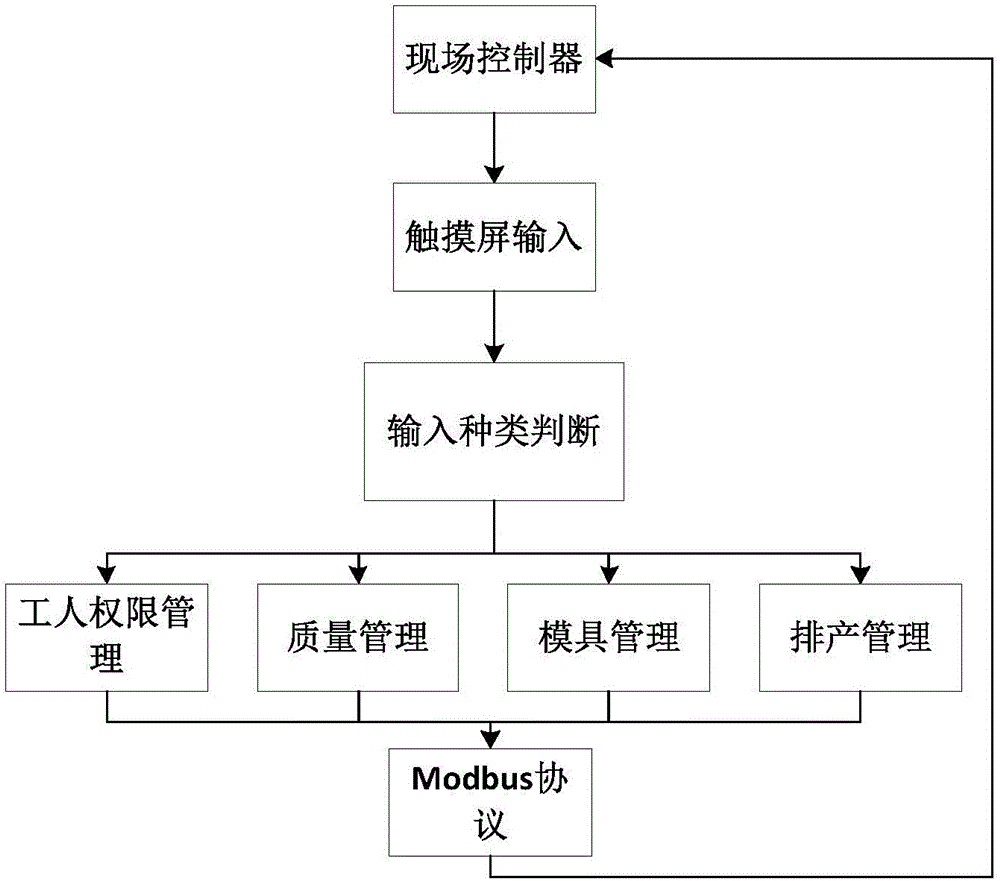

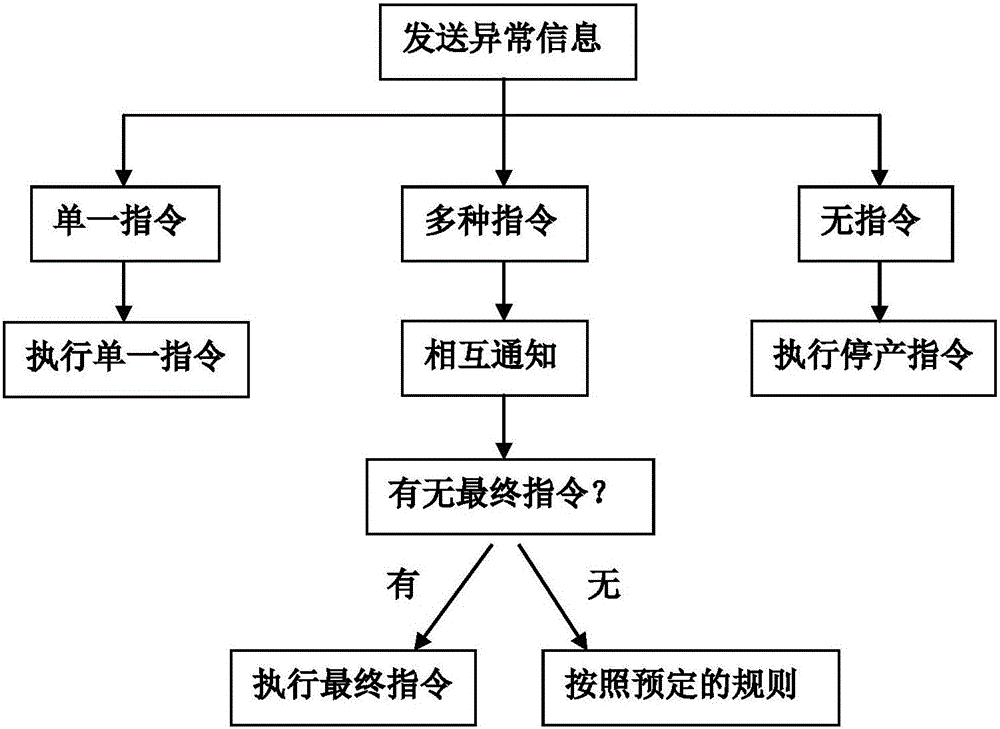

Production management method and system for stamping workshop

ActiveCN106444659AImprove management levelImprove production efficiencyTotal factory controlProgramme total factory controlRelational databaseJob number

The invention provides a production management method for a stamping workshop. The method comprises the following steps: a server receives and stores a production order in a relational database thereof; a field controller acquires the serial number of a mold and the job number of a worker, and acquires the production data of a stamping press to obtain a stamping production count; the field controller uploads the acquired serial number of the mold, the job number of the worker and the stamping production count to the server to form a real-time updated production record; the server judges whether the stamping production count meets the requirement of the order or not according to the production order, and if the requirement of the order is met, transmits a production stopping instruction to the field controller, wherein the field controller regularly sends acquired data to the server, and after receiving the data, the server verifies the data, performs invalid data processing if the data is failed to be verified, and if the data is successfully verified, performs data parsing and data processing and generates and stores a production record in the relational database for real-time updating.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

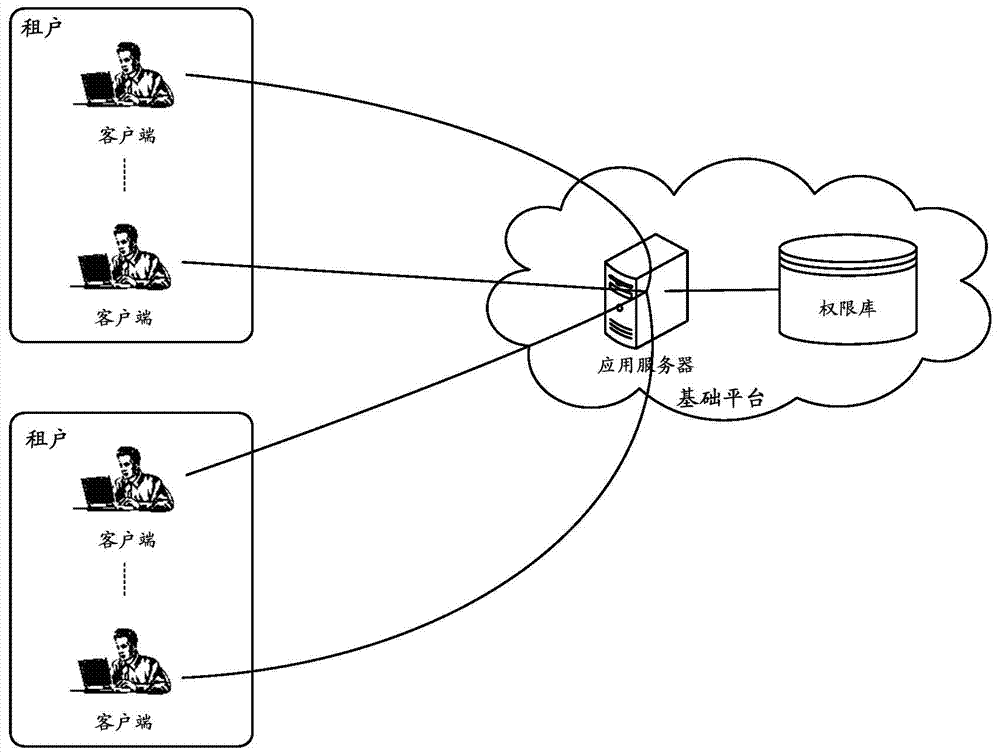

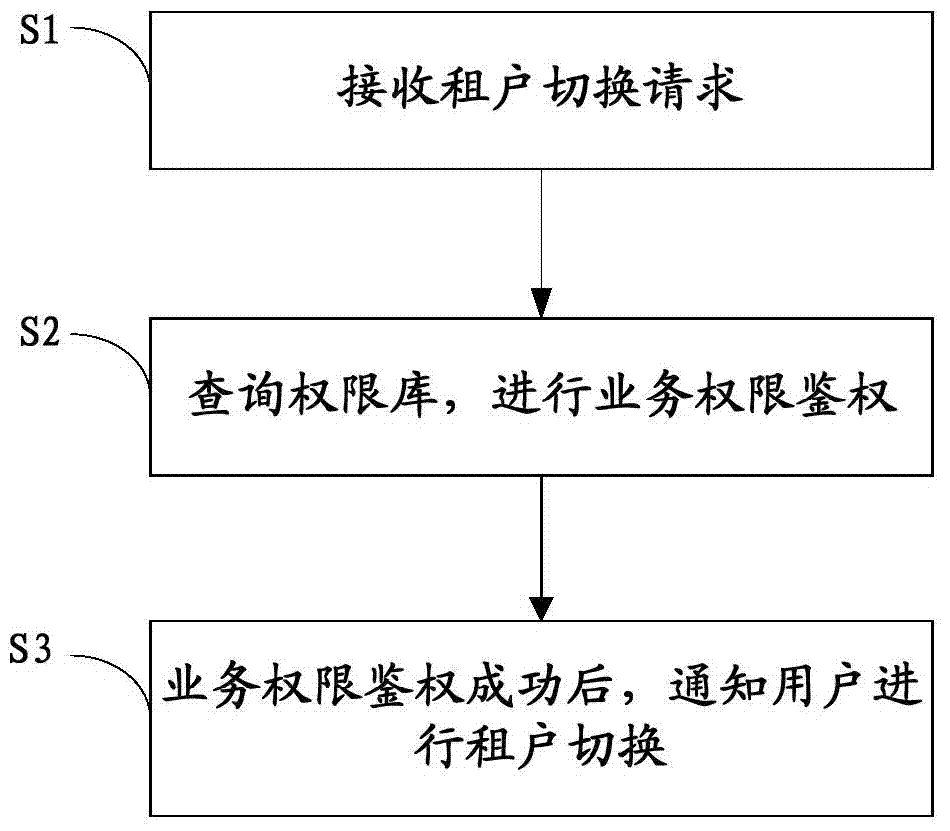

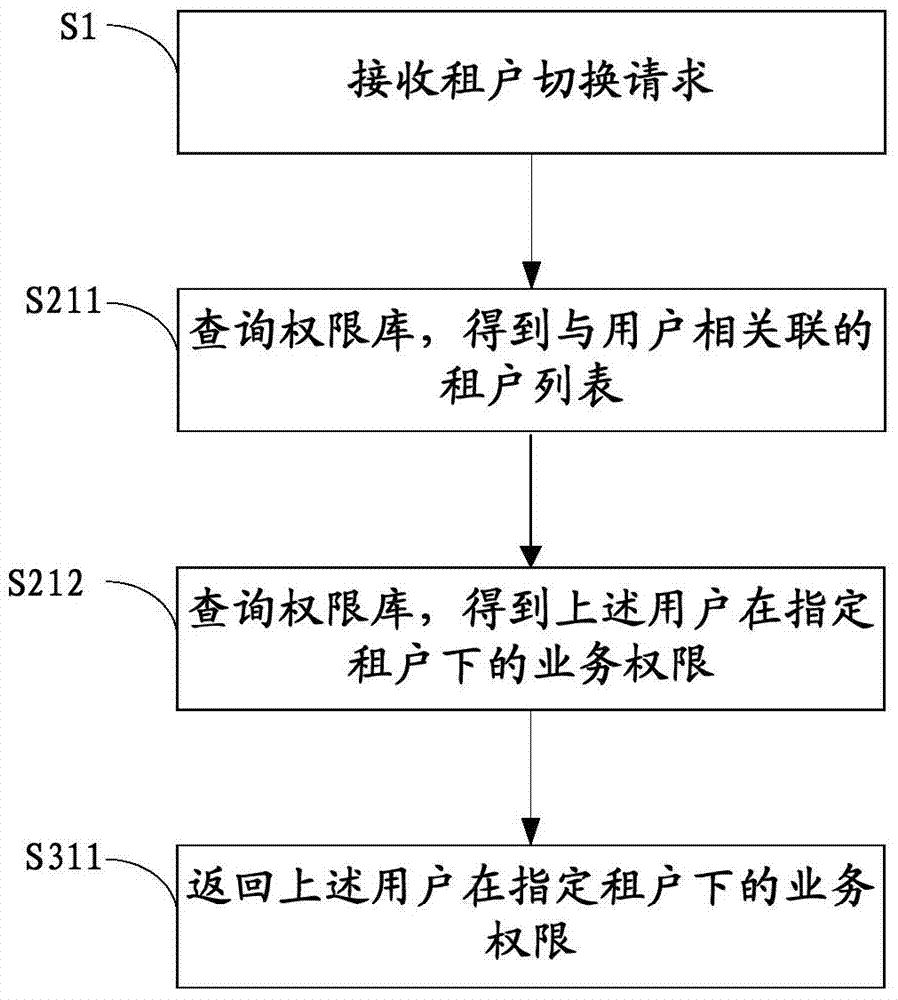

Lessee switching method and device

The embodiment of the invention discloses a lessee switching method and device. The problem that job numbers need to be switched when lessees are switched is solved. On the basis of an authority library prestoring service authorities of users under related lessees, the method includes the steps of receiving lessee switching requests sent by the users, wherein the lessee switching requests indicate designated lessees or designated services or designated lessees and designated services; inquiring the authority library and authenticating the service authorities for the users; informing the users of lessee switching after the service authorities are successfully authenticated. It can be seen that the authority library contains the service authorities of the users under the related lessees, and a basis is provided for the users for switching the lessees. When the users switch the lessees, the service authorities can be authenticated by inquiring the authority library, the lessees are switched after the authorities are authenticated successfully, the users do not need to be switched in the process, and therefore the users are not switched when the lessees are switched, and the operation of a user side is simplified.

Owner:HUAWEI TECH CO LTD

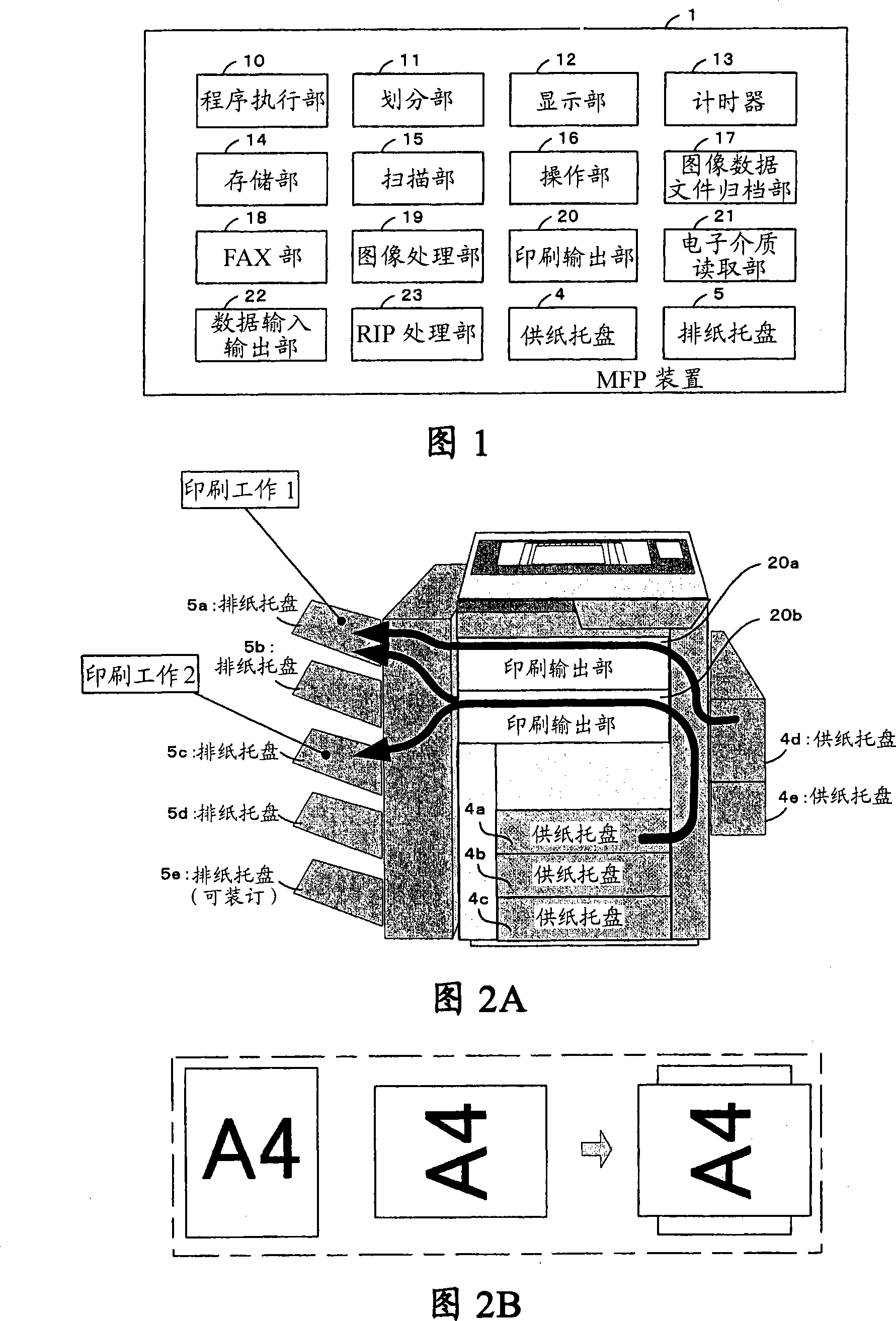

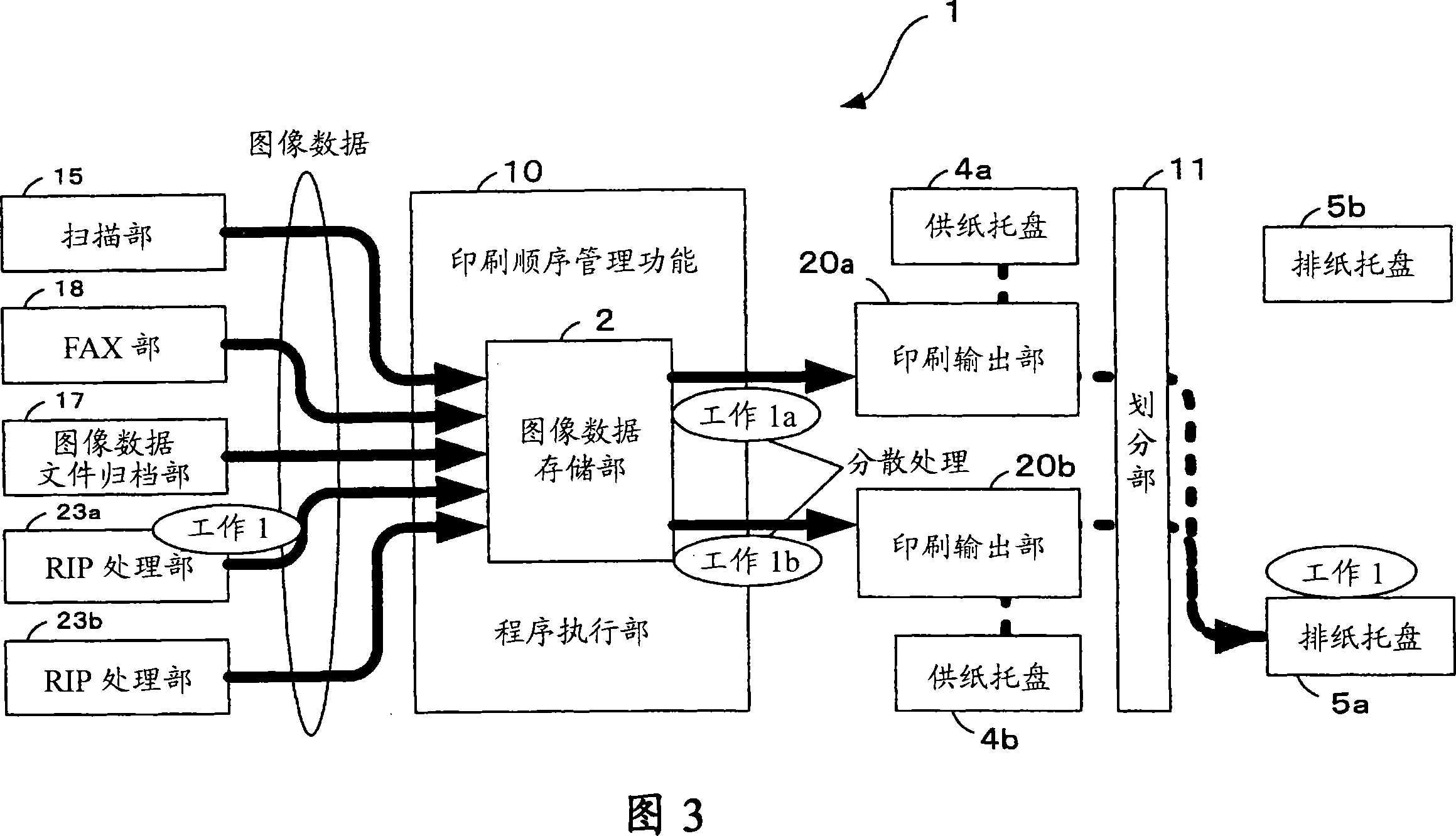

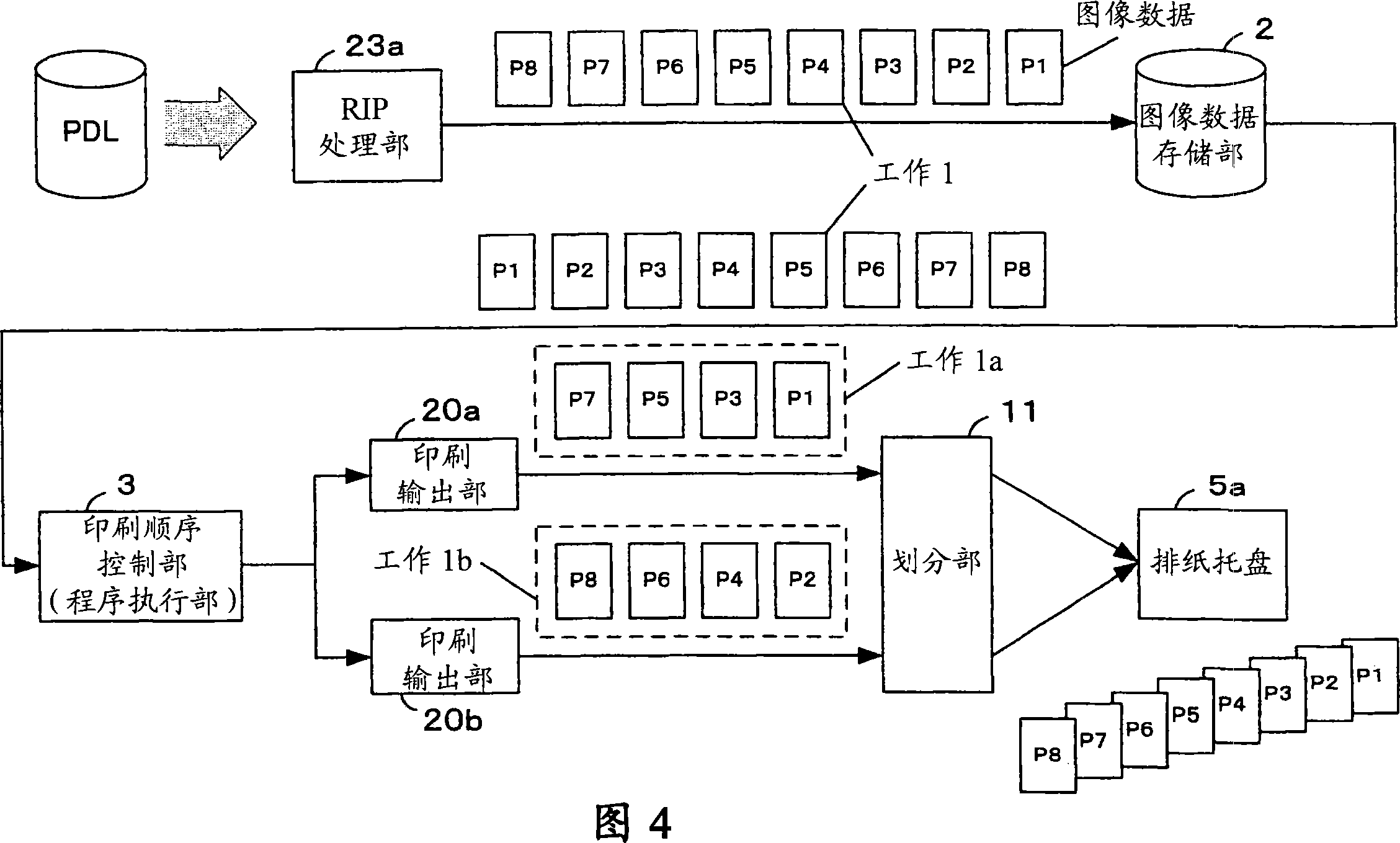

Multi function peripheral apparatus and printing method for the same

InactiveCN101246346AElectrographic process apparatusPictoral communicationJob numberPriority setting

The present invention provides an MFP device and a printing method in the MFP device, wherein, in the MFP device, a print order registration unit registers multiple print jobs composed of multiple image data for each print job. The printing order of each image data of a plurality of image data, the priority setting unit sets the priority for each printing job of a plurality of printing jobs, and the image data distribution unit assigns each image of a plurality of image data according to the printing order and priority Data is distributed to any one of the print processing units for processing, thereby shortening the waiting time for printing.

Owner:KK TOSHIBA +1

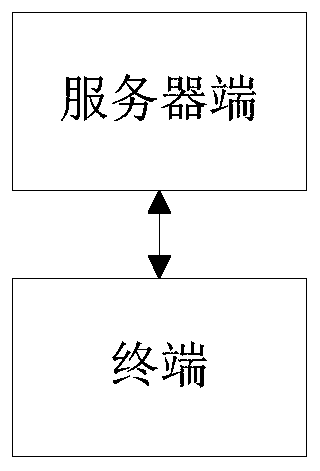

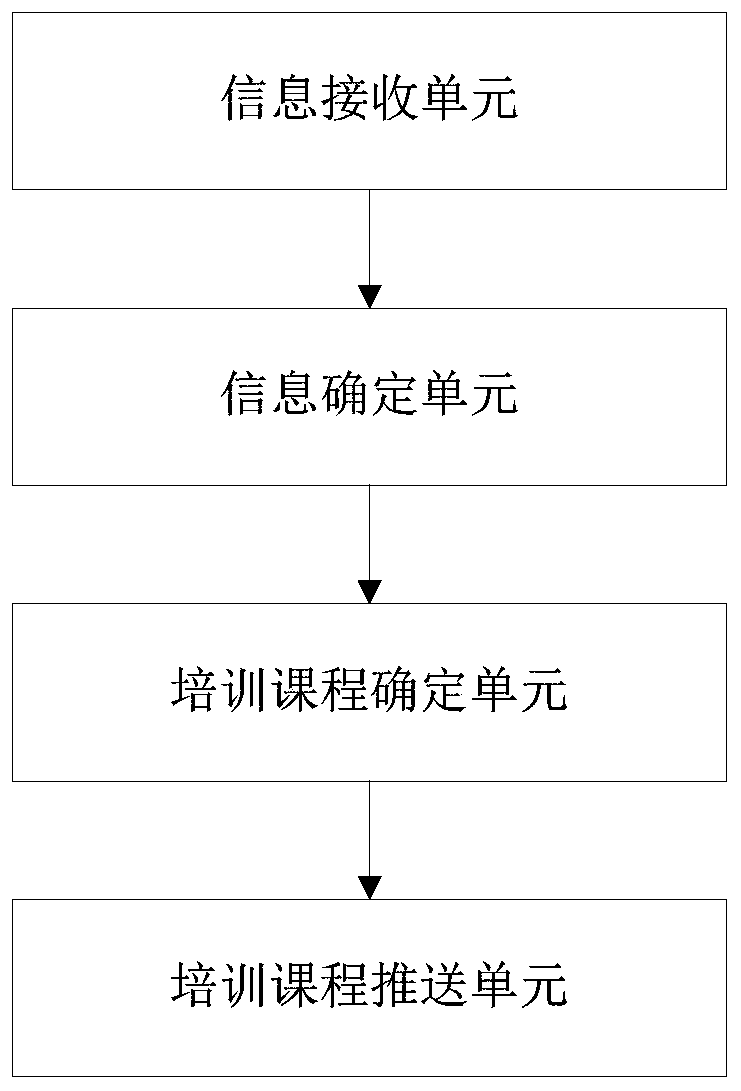

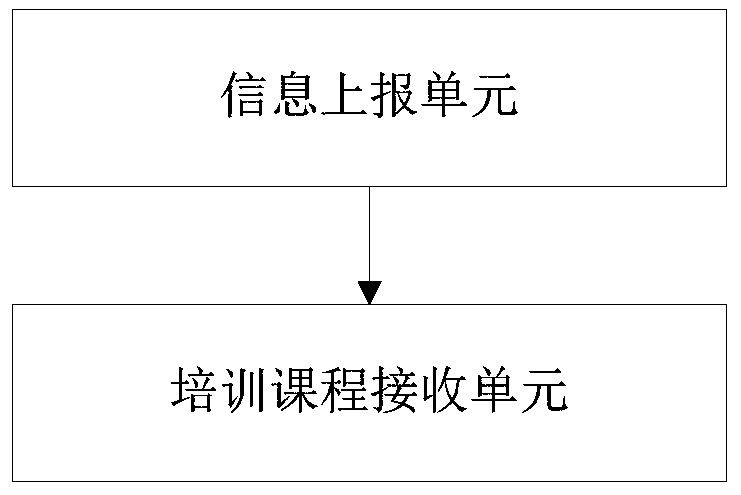

A staff training content pushing and receiving method and system based on working posts

InactiveCN109727169AMeeting Training NeedsRealize personalized customizationData processing applicationsTransmissionStaff trainingJob number

The invention discloses a staff training content pushing and receiving method and system based on working posts. The server side receives the employee name and job number information reported by the terminal, the server side stores the one-to-one correspondence of the employee name, the employee job number, the employee working position code and the employee grade in advance, and the working position code and the employee grade of the employee are determined according to the employee name, the job number information and the correspondence; The server determines the current working position code and the training course information corresponding to the employee level according to the working position architecture, the knowledge point and the skill point pre-stored in the database, and pushesthe obtained training course information to the terminal; The method has the advantages that training projects are in one-to-one correspondence with post requirements of trained employees, and the training requirements of employees of different ability levels can be met.

Owner:STATE GRID CORP OF CHINA +2

Systems and methods for controllably refilling a fluid quantity sensing fluid ejection head

A controller for a fluid ejecting system having a refillable container includes an ejection count initializing circuit, routine or application, a count incrementing circuit, routine or application, at least one fluid level indicator, and a fluid quantity circuit, routine or application for determining an expended quantity of fluid, a fluid reserve capacity circuit, routine or application for determining a fluid reserve capacity in the container, an ejection job determining circuit, routine or application for determining a fluid job requirement, a reserve comparing circuit, routine or application to compare the fluid reserve capacity and the fluid job requirement, and a refill condition determining circuit, routine or application to determine that the container is to be refilled. Counts for a ejection amount and a reserve capacity are incremented in response to a specific amount of fluid being ejected from the container. The expended quantity of fluid is based on the ejection amount count subsequent to the fluid level being indicated. The fluid reserve capacity is based on the reserve capacity count and the expended quantity of fluid. The fluid job requirement is based on the expended quantity of fluid and a job number of ejected amounts of fluid. The container is determined to be refilled upon at least a condition wherein the fluid job requirement exceeds the fluid reserve capacity, and a condition wherein the fluid level is below a refill threshold.

Owner:FUJIFILM BUSINESS INNOVATION CORP

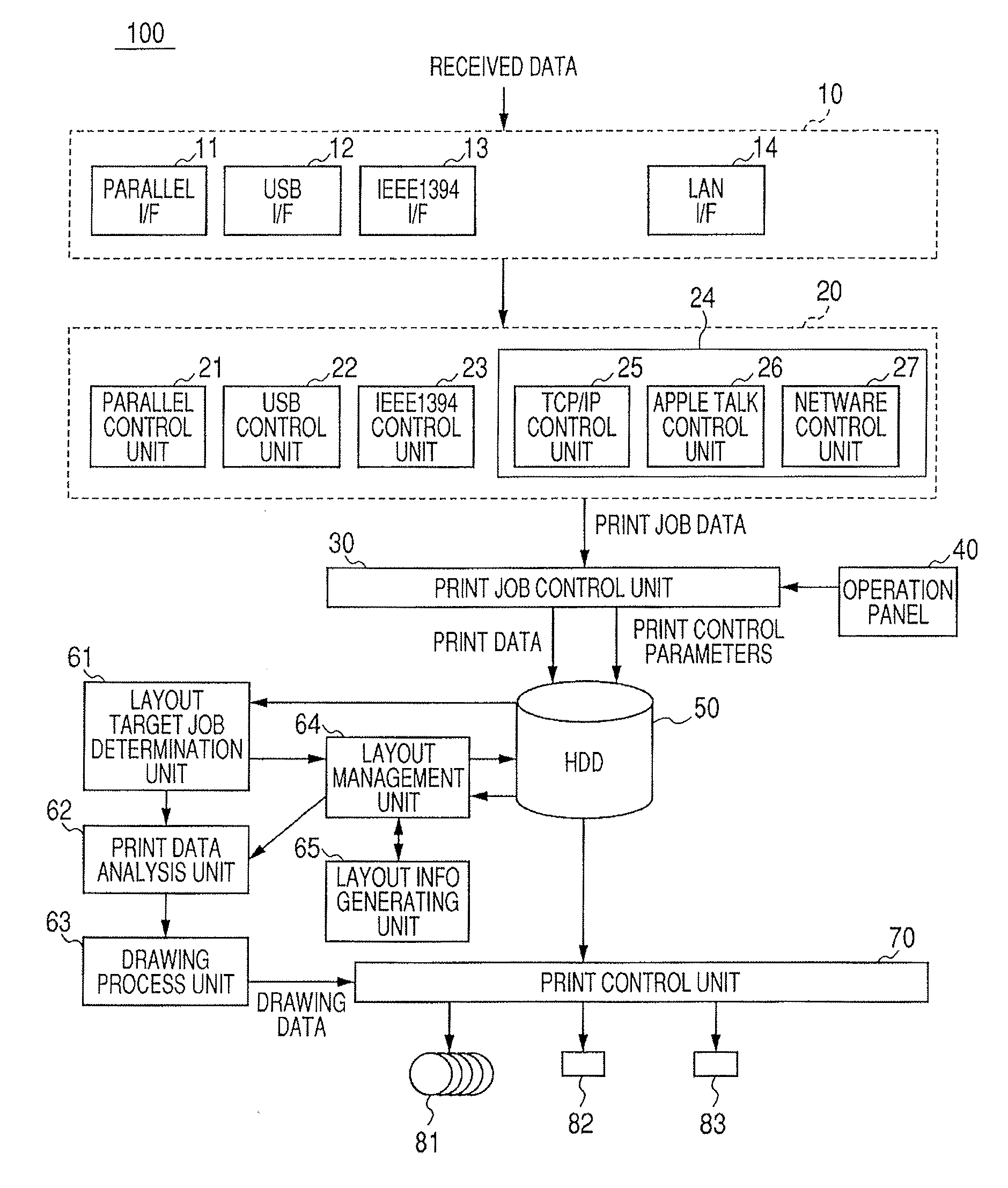

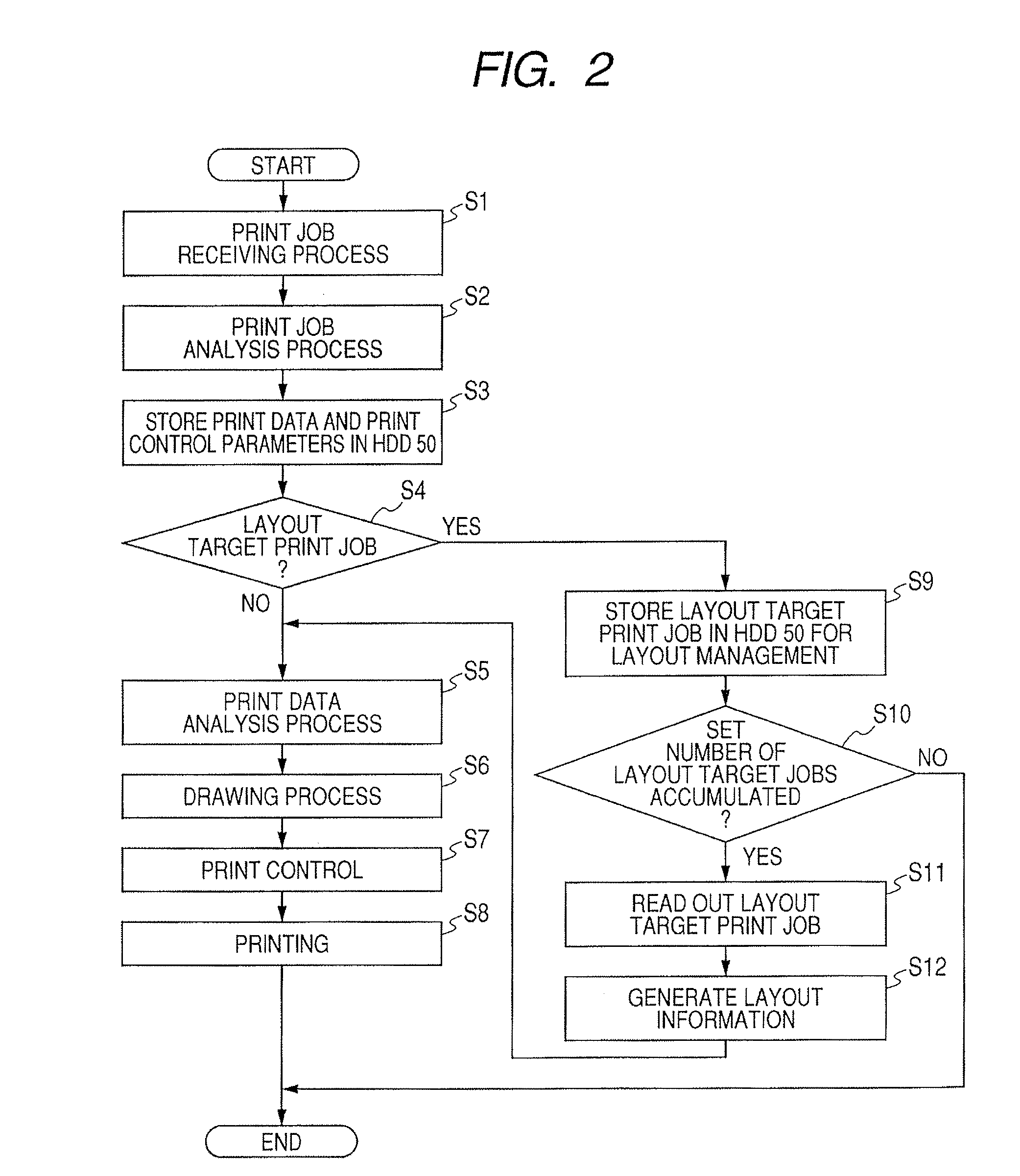

Printing apparatus and control method thereof

InactiveUS20080049255A1Digital computer detailsNatural language data processingJob numberImaging quality

It is an object to provide a printing apparatus and a control method thereof that enable printing at an image quality that a user intends when a plurality of print jobs are laid out to be printed. A printing apparatus laying out a plurality of print jobs to perform printing on paper includes a print job number setting unit for setting the number of layout target print jobs. Moreover, the present invention concerns a printing apparatus characterized by including a layout target job determination unit for determining layout target print jobs according to the print conditions of the print jobs.

Owner:CANON KK

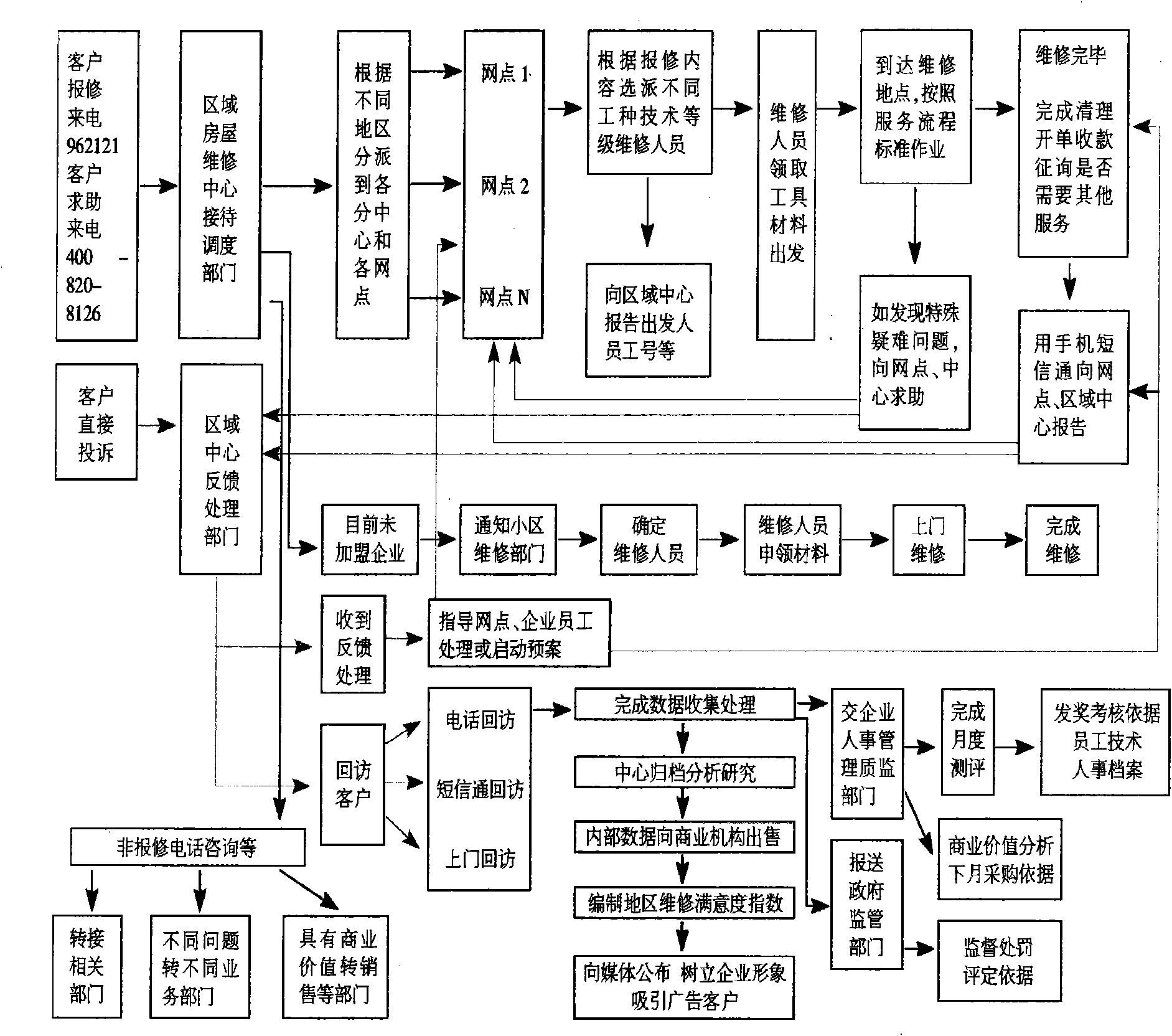

Systemization mode and implementation thereof for maintaining buildings in urban areas

The invention discloses a systemization mode and implementation thereof for maintaining buildings in urban areas, which belong to the field of estate management. The main scheme is that: when a client calls for repair and recourse, a regional building maintenance center receives the client and dispatches departments; the regional center allocates tasks to each branch center and each branch according to different areas; the branch received the allocated task designates maintainers with different work type technical levels according to the reported repair content and reports the job number and the like of the designated maintainer to the regional center, and then the maintainer gets tools and materials and sets out; the maintainer performs standard operations according to the service procedure after arriving, and gives a bill for receiving the payment and consults the needs of other services after finishing the maintenance and cleaning; and finally, the maintainer sends mobile phone short messages to report to the branch and the regional center, and the regional center pays a return visit to the client after receiving the feedback. Thus, a systemized, modularized and standardized management system is formed. The systemization mode and the implementation thereof have the advantages of low cost, high efficiency and resident satisfaction.

Owner:上海黄嘉历史文化传播有限公司 +1

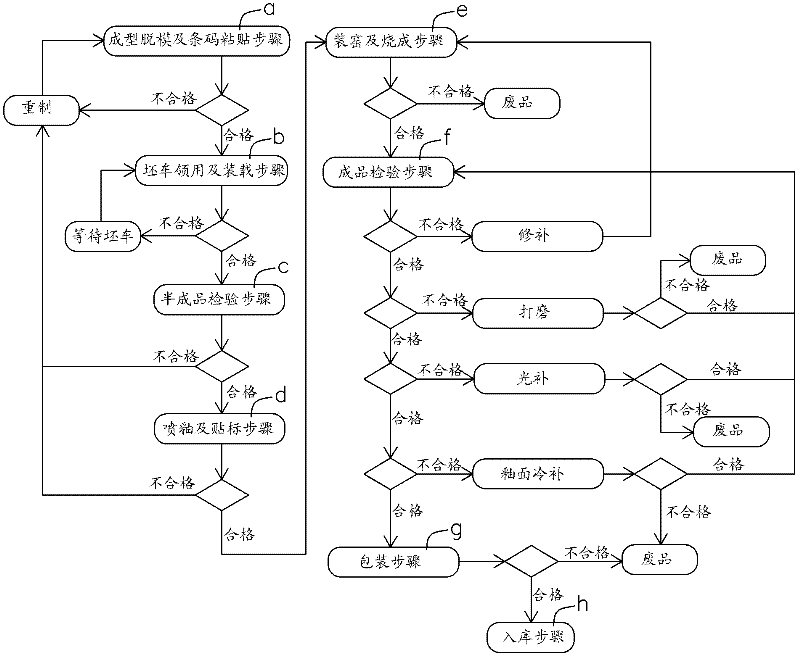

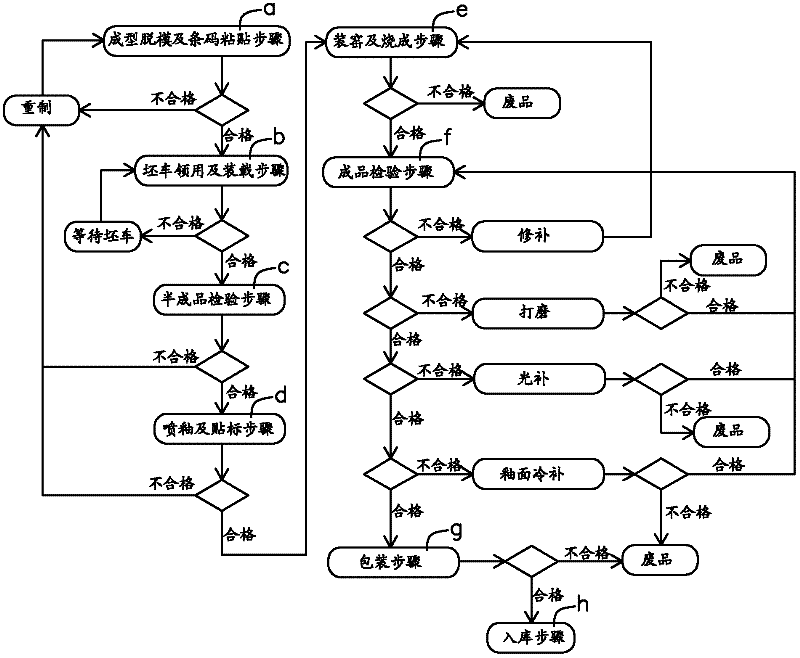

Ceramic product method using bar code to control

ActiveCN102609829AReal-time and sufficient controlPrecise managementLogisticsRecord carriers used with machinesInformatizationJob number

The invention is applicable to a ceramic product and discloses a ceramic product method using a bar code to control. In the ceramic product method, the product bar code is particularly stuck on a molded and de-molded blank and a scanning or inputting way is matched to connect important information such as the product bar code, a job number of an operating personnel and a car number of a blank vehicle with an ERP (Enterprise Resource Planning) system of a company, so that information of the relevant personnel and products in the method can be timely and sufficiently controlled; and therefore, the ceramic product method is good for the company to carry out informatization on personnel capacity, work quality, production efficiency and piece wage, and a production condition of each flow, and effectively and accurately manage and control.

Owner:GLOBE UNION INDAL

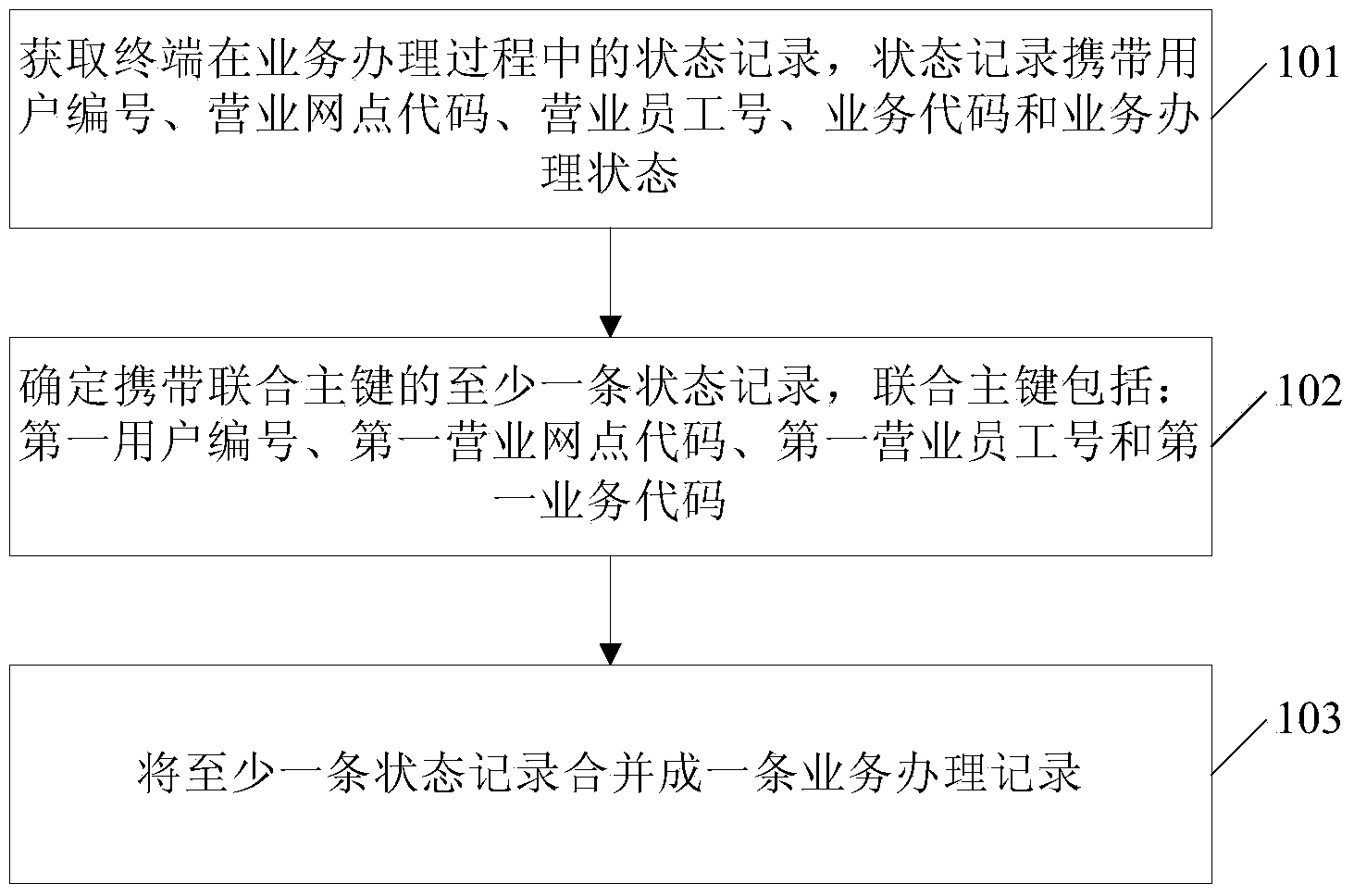

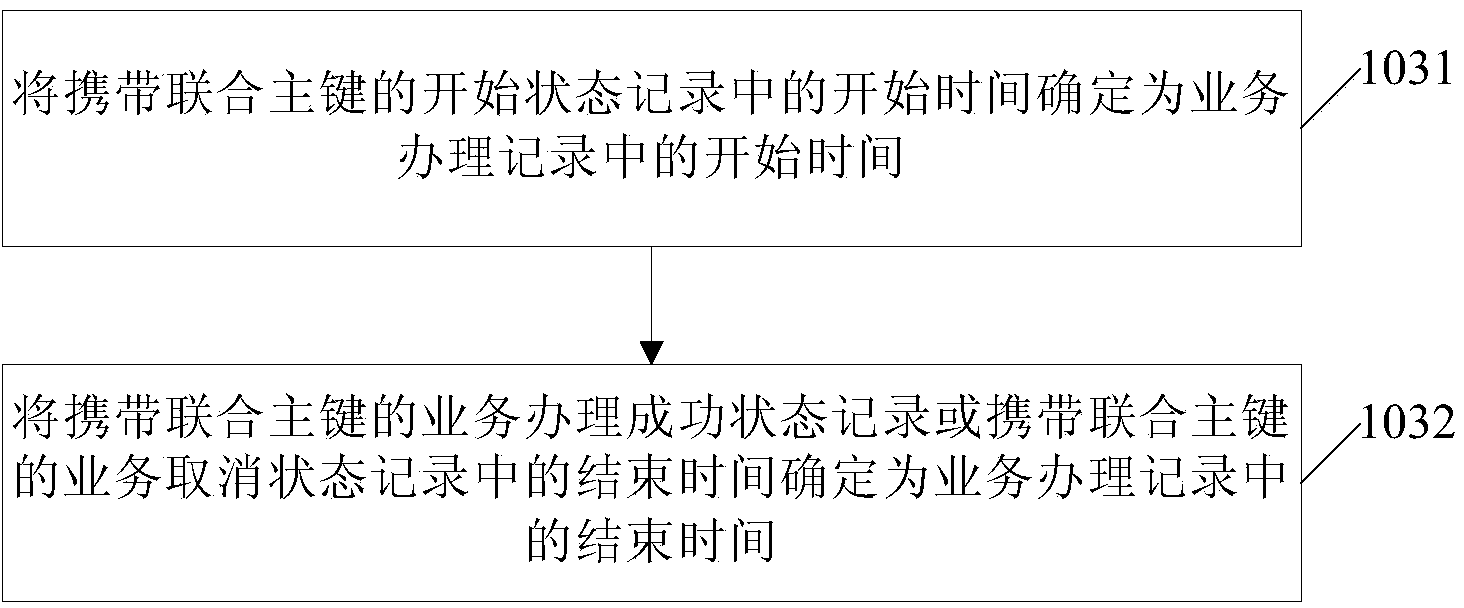

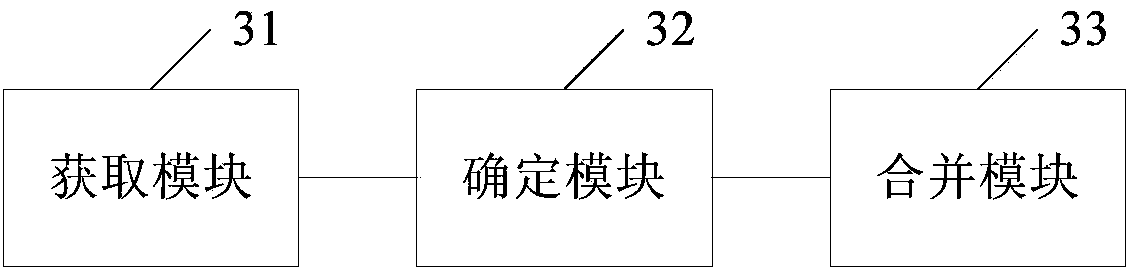

Business handling data processing method and device

InactiveCN103903097AImprove processing efficiencyReduce statistical analysis timeSpecial service for subscribersResourcesJob numberStatistical analysis

The invention relates to a business handling data processing method and device. The business handling data processing method comprises the steps that status records of a terminal in the business handling process are obtained, wherein the status records comprise a user serial number, a sales network code, a sales person job number, a business code and the business handling status; at least one status record comprising composite keys is determined, wherein the composite keys comprise a first user serial number, a first sales network code, a first sales person job number and a first business code; at least one status record is merged into a business handling record. Therefore, a telecom operator can directly conduct statistic analysis on the business handling records obtained after merging, data processing efficiency is improved, and the time for statistic analysis is shortened.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

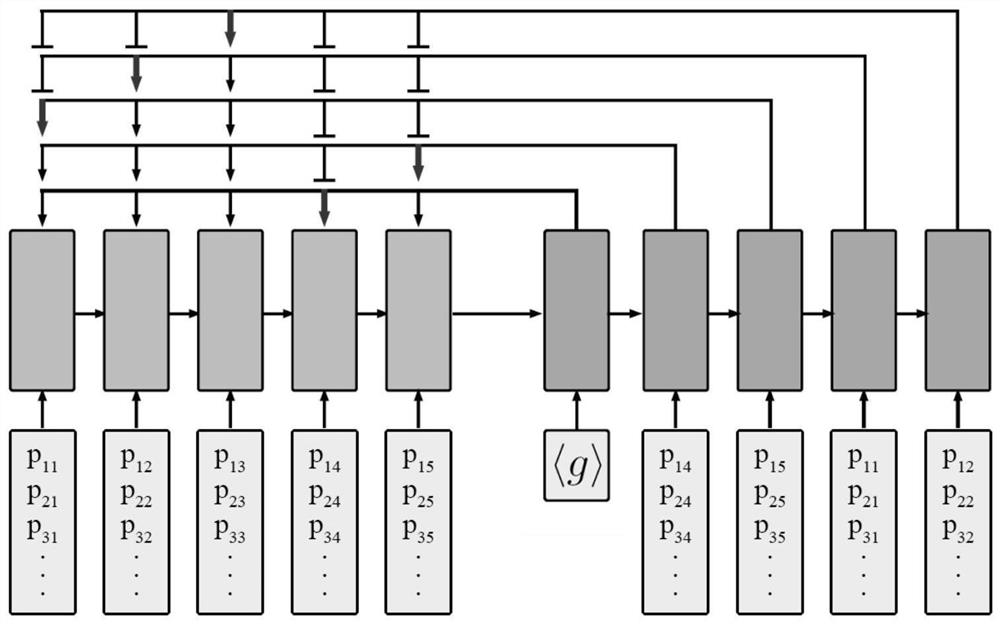

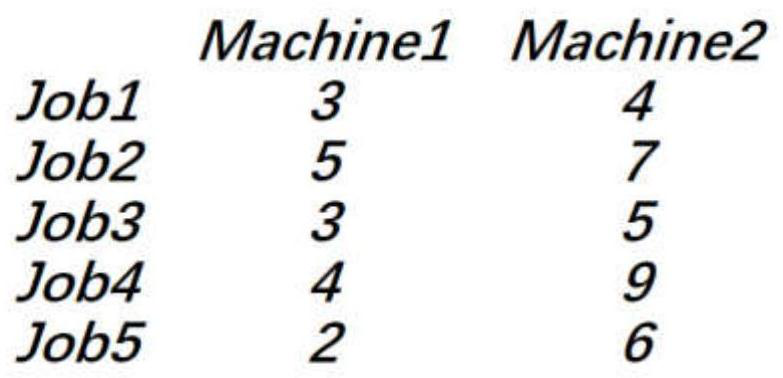

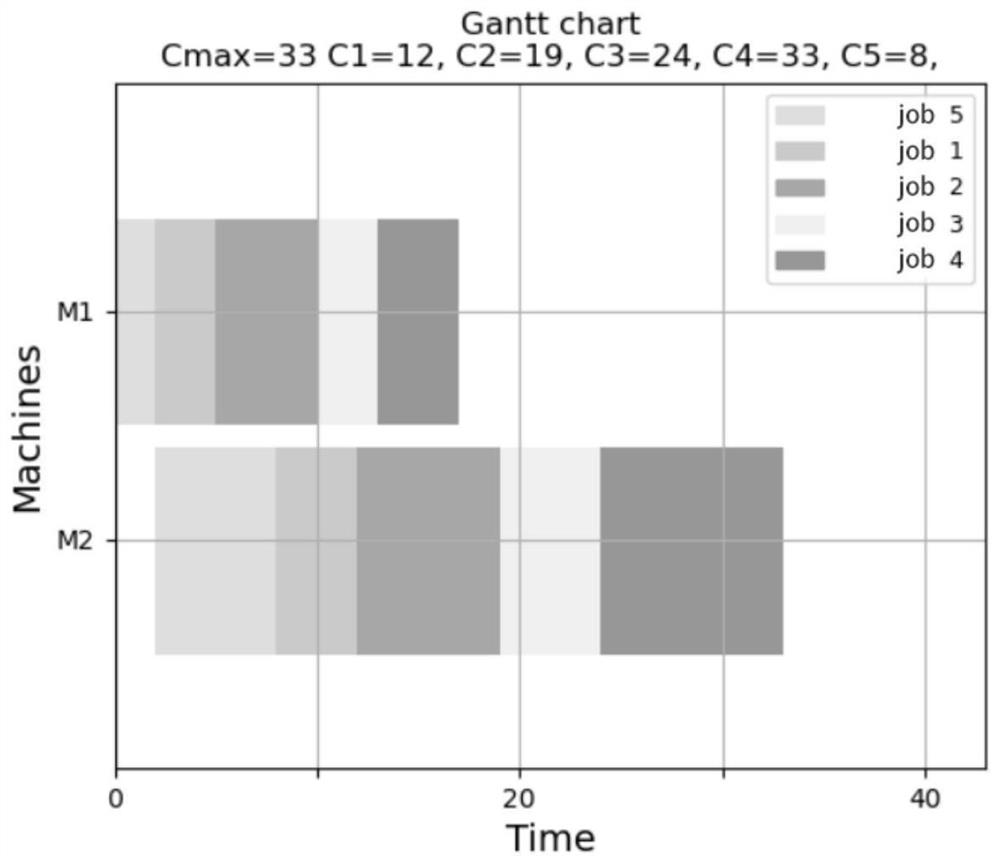

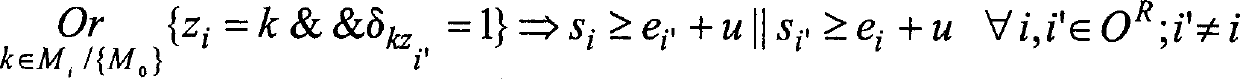

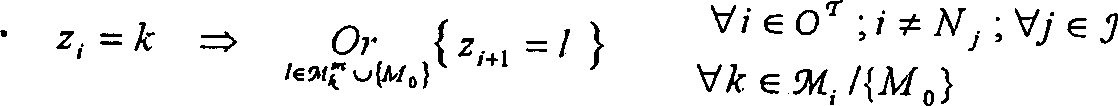

Flow shop scheduling method based on deep reinforcement learning

ActiveCN112987664ASolve the scheduling problem of flow shopSolve scheduling problemsProgramme total factory controlCompletion timeAlgorithm

The invention discloses a flow shop scheduling method based on deep reinforcement learning. Each workpiece is used as a node, and processing time of a working procedure is used as node information to be aggregated to obtain embedded representation. A strategy network is fit by using a pointer network, the maximum completion time is used as an award, the strategy network is trained and parameters are stored. In the actual problem, the embedded representation of each workpiece is used as the input of the strategy network, and the workpiece with the highest probability is selected in sequence until all the workpieces are selected to obtain a complete scheduling sequence. According to the flow shop scheduling method, a near-optimal solution can be obtained on a small-scale problem, a better solution superior to a heuristic algorithm and a genetic algorithm can be obtained on a large-scale problem, and the flow shop scheduling method is expanded to the problems of different machine numbers and job numbers; the limitation that the model needs to be trained again on different problem scales and problem data is broken through, and the universality is wider.

Owner:NORTHEASTERN UNIV

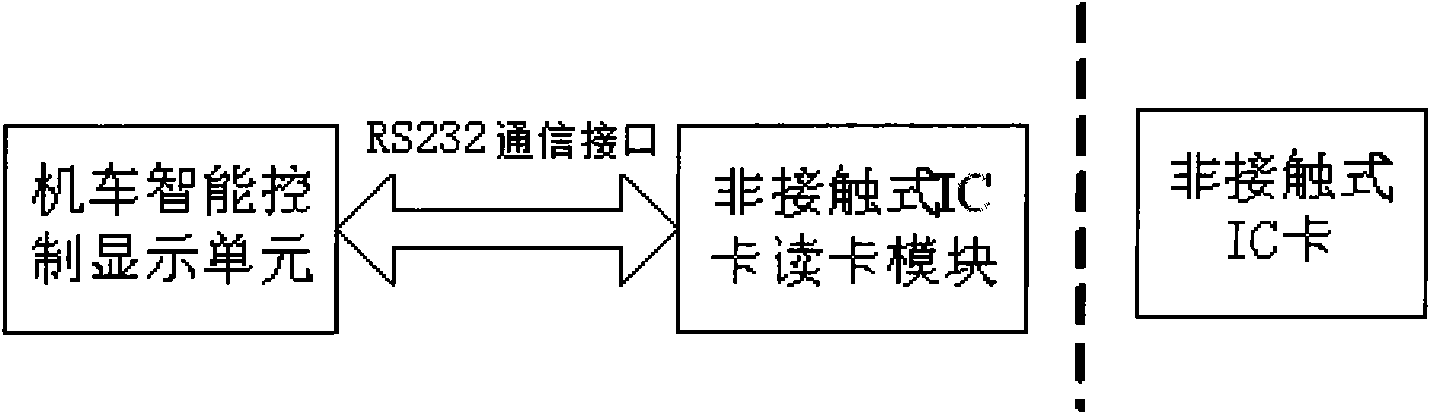

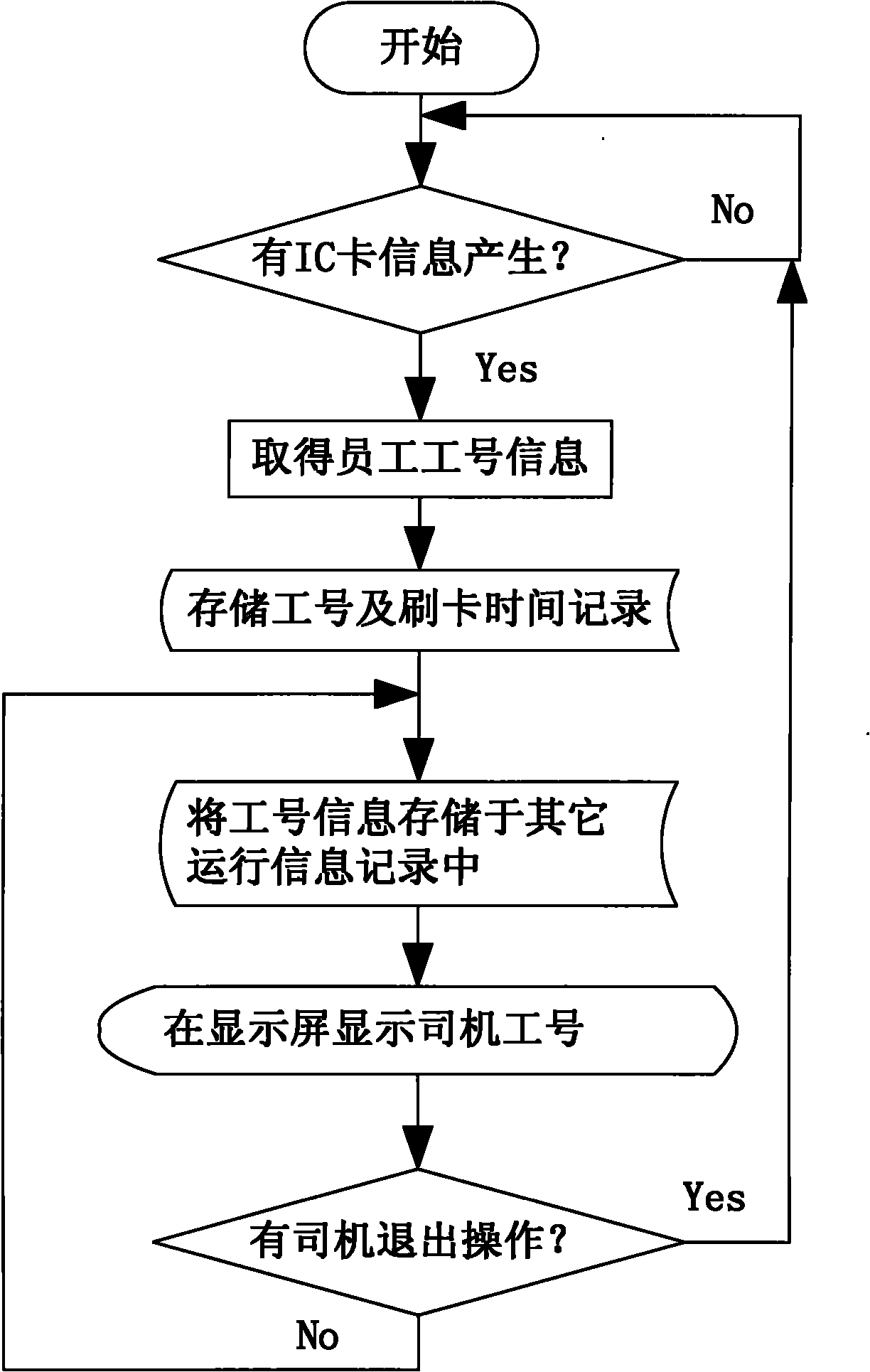

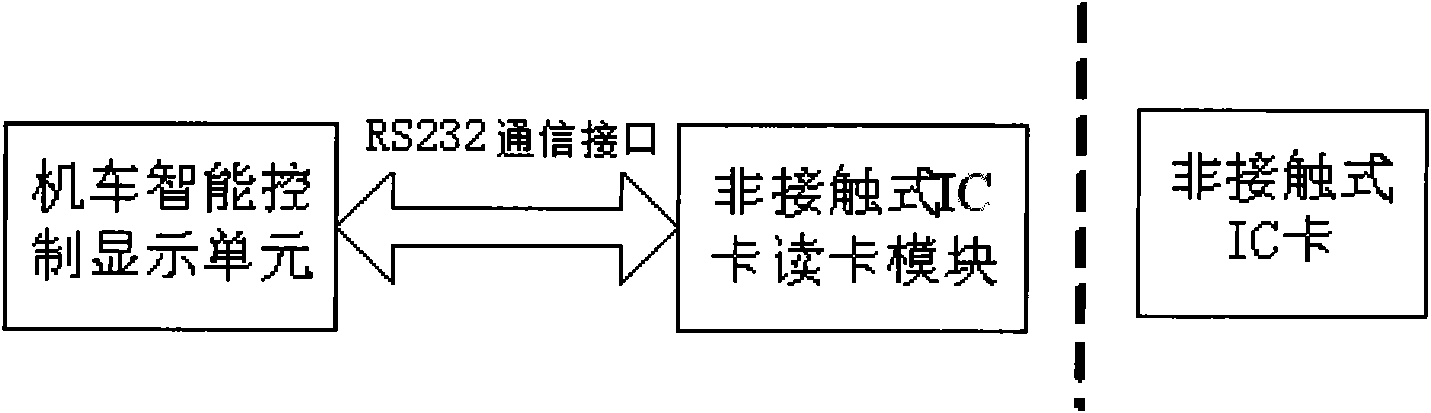

Intelligent locomotive control display device with attendance checking function

InactiveCN101976469ALow costIncrease spaceRegistering/indicating time of eventsOperational systemDisplay device

The invention discloses an intelligent locomotive control display device with an attendance checking function, comprising an intelligent locomotive control display unit, an RS232 communication interface, and a non-contact type IC (Integrated Circuit) card reading module. The intelligent locomotive control display unit is connected with the non-contact type IC card reading module through the RS232 communication interface, and the non-contact type IC card reading module completes communication with a non-contact type IC card through radio frequency. The operation system of the intelligent locomotive control display device is further provided with a non-contact type IC card attendance checking functional module which is mainly used for realizing the functions of reading and recording employee job numbers of employee cards and applying employee job number information to other information records in a locomotive control process so as to facilitate the analysis and statistics on attendance and vehicle driving habits of employees by locomotive operating companies. Therefore, an attendance checking machine is omitted on a locomotive, the cost is saved and an equipment space is saved on hardware configuration, thereby facilitating the design of locomotive cabs.

Owner:CHINA CNR LIMITED DALIAN ELECTRIC TRACTION R&D CENT

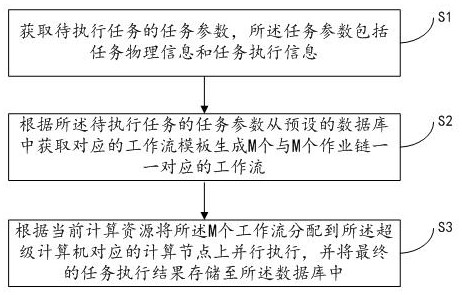

High-throughput task processing method based on super computer

ActiveCN112882810AWidely used valueImprove computing efficiencyProgram initiation/switchingResource allocationSupercomputerJob number

The invention relates to a supercomputer-based high-throughput task processing method, and the method comprises the following steps: obtaining the task parameters of a to-be-executed task, wherein the task parameters comprise task physical information and task execution information, the task physical information comprises a job chain type and an application program type, and the task execution information comprises a job chain number M corresponding to a to-be-executed task, a logical relationship between job chains, a job number N of each job chain, a job structure file, a logical relationship between jobs and execution precision; obtaining a corresponding workflow template from a preset database according to the task parameters of the to-be-executed task to generate M workflows in one-to-one correspondence with the M job chains; distributing the M workflows to the computing nodes corresponding to the super computer according to the current computing resources for parallel execution, and storing a final task execution result in the database. According to the method, the calculation efficiency of the high-throughput calculation task is improved.

Owner:国家超级计算天津中心

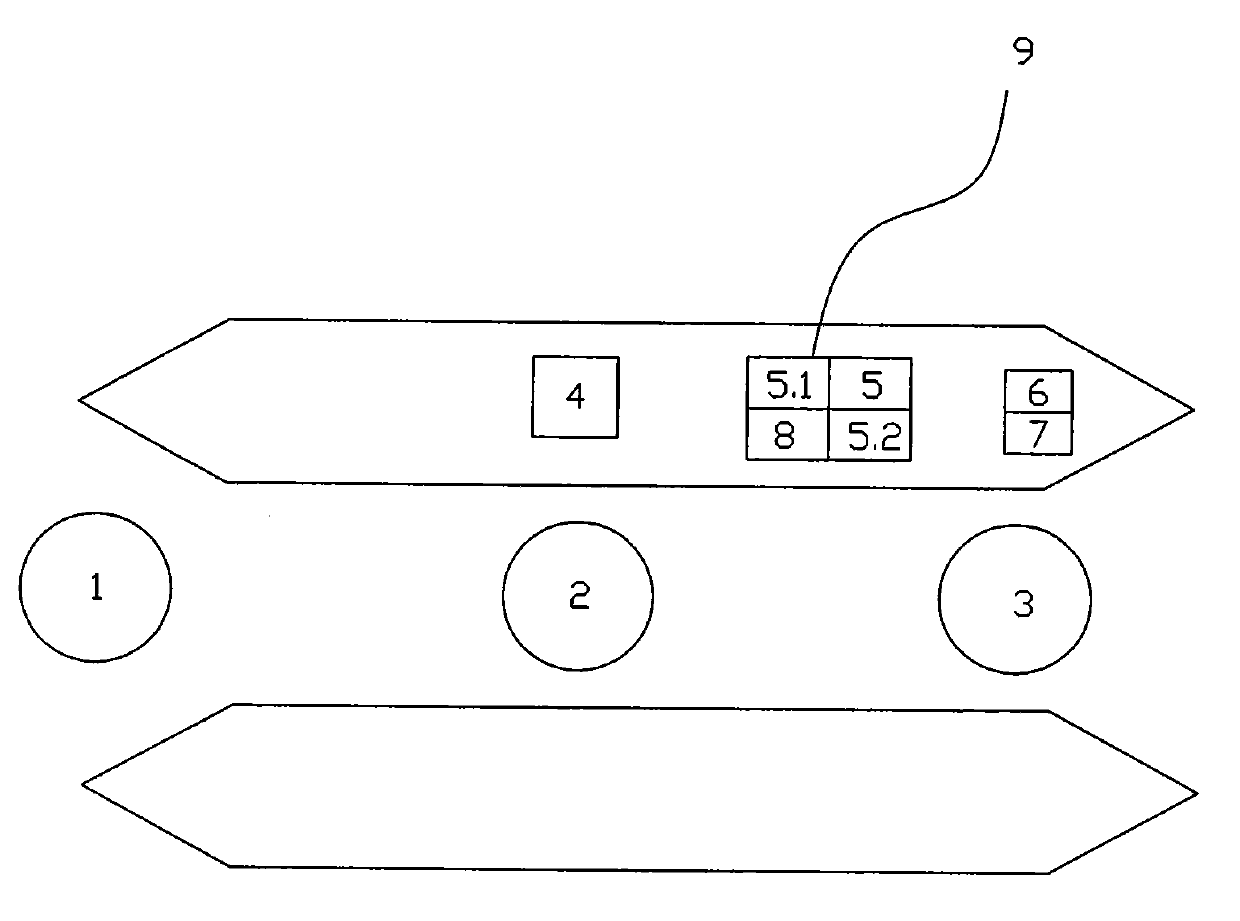

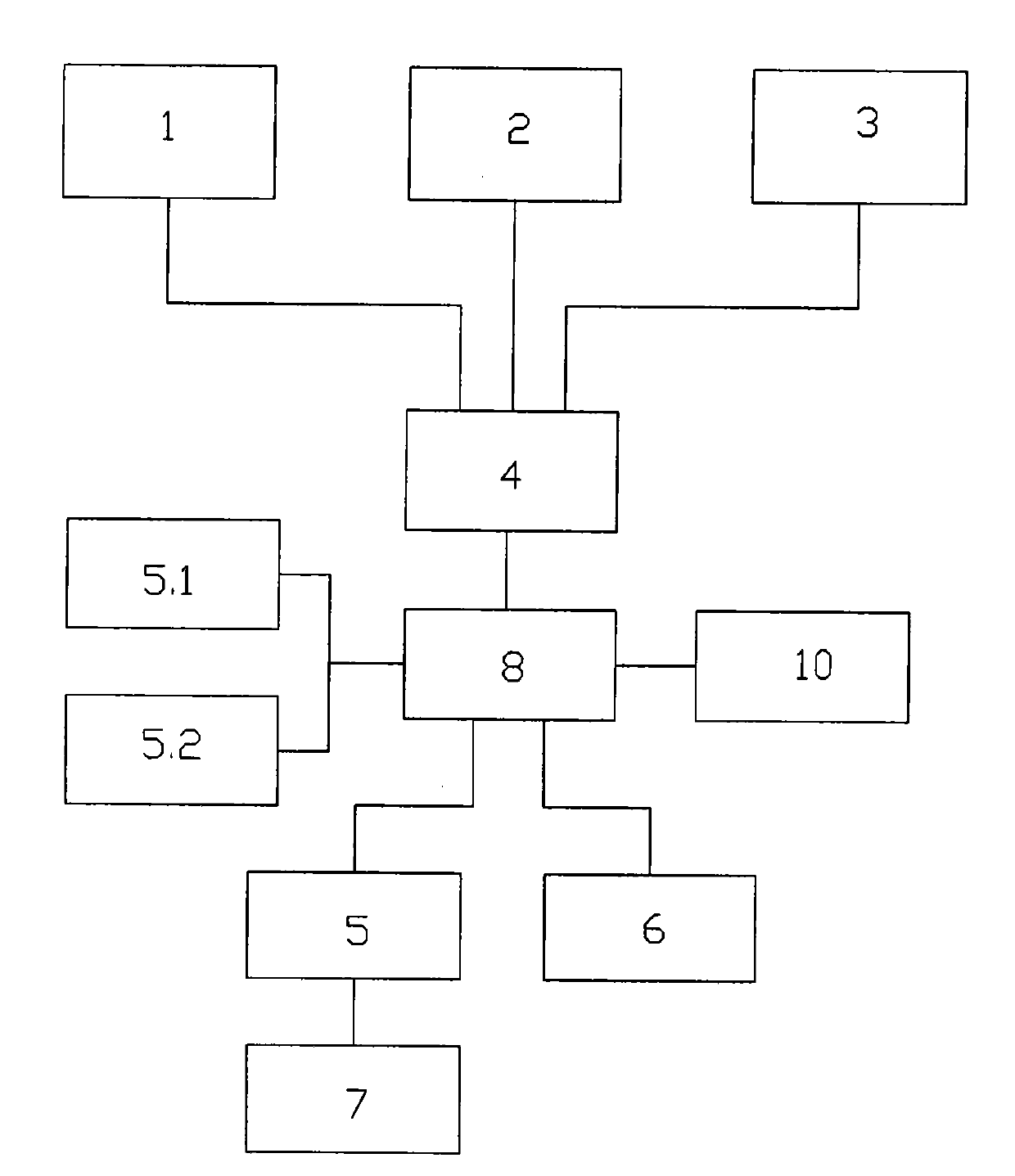

Vehicle base inner shunting plan implementing device, method and program

InactiveCN1622110AAvoid burdenEfficient change operationRailway traffic control systemsSpecial data processing applicationsShunt DeviceProgram planning

Provided is an in-yard shunting plan creating device for a vehicle base that can efficiently create an in-yard shunting plan independent of the layout structure of the vehicle base and the number of formations. The vehicle base layout network creation device 0111 creates vehicle base layout information with the numbered routes and travel route definition information; the shunting sequence initialization device 0112 arranges the dispatching sequence from the job content and the numbered routes between jobs according to the vehicle base layout network for each formation The metadata of the grouping of the car operation diagram is the initialization of the shunting sequence; the shunting operation diagram selection and time determination device 0113 selects the shunting operation diagram from the shunting sequence and makes a schedule for determining the execution time for all the groups of the planning objects. The processed tentative solution of the on-site shunting plan; the shunting sequence changing means 0114 uses the vehicle base layout network to change the shunting sequence so as to eliminate the contention of numbered routes and travel routes included in the obtained tentative solution.

Owner:HITACHI LTD

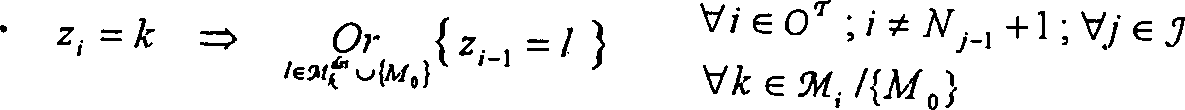

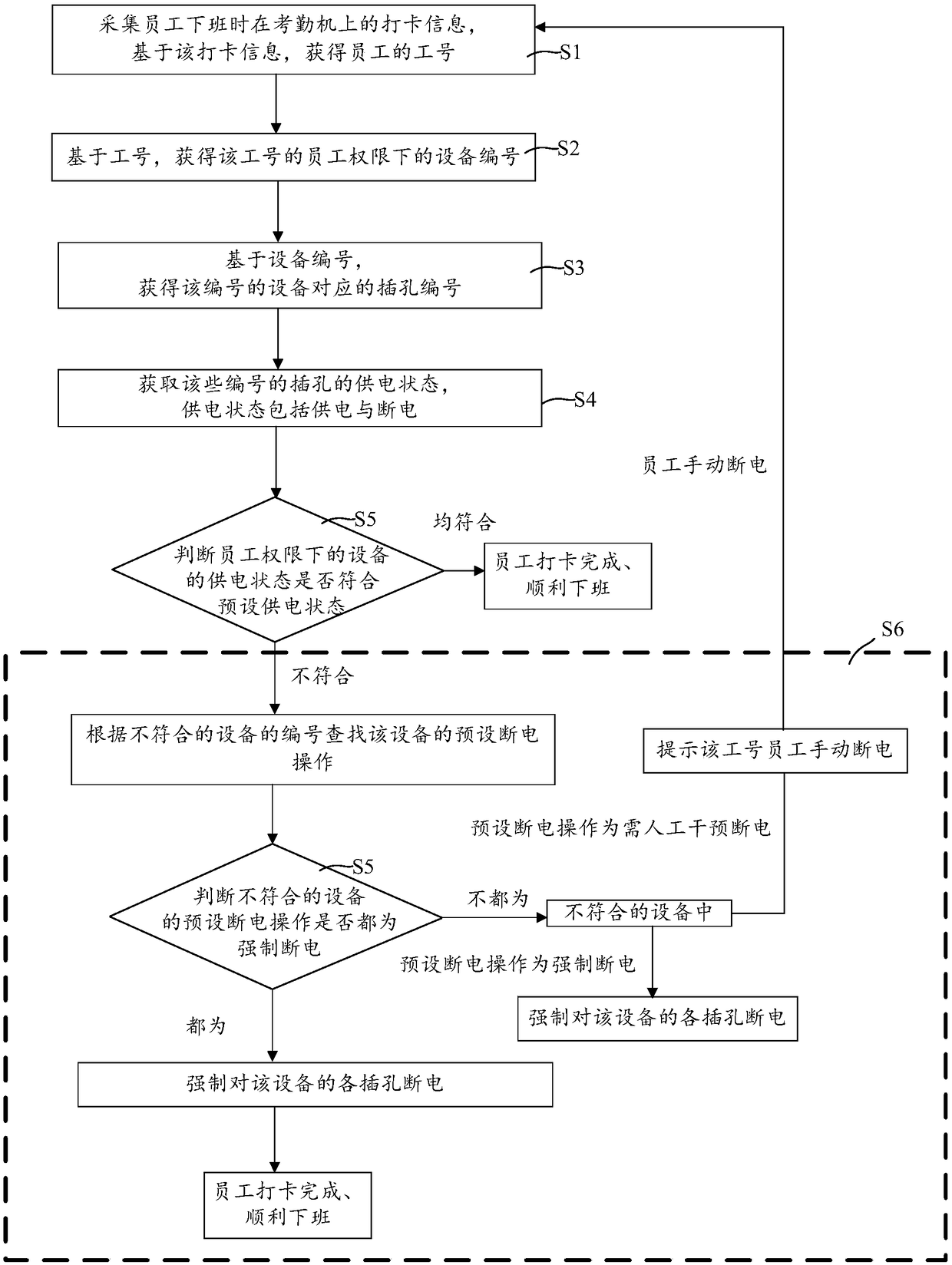

Electricity saving method and electricity saving system

InactiveCN108898690ALow costAutomatic power savingRegistering/indicating time of eventsElectricityJob number

The invention provides an electricity saving method and an electricity saving system. The electricity saving method comprises the following steps: detecting the power supply state of a jack in each number based on a job number-equipment number corresponding table and an equipment number-jack number corresponding table, so as to acquire the power supply state of equipment under the employee authority when an employee clocks out; checking employees who cut off the power according to the requirements and the employees who do not cut off the power according to the requirements based on an equipment number-preset power supply state corresponding table, finishing the clock out of the employees with the qualified power supply state under the authority, and enabling the employees to smoothly get off work; carrying out compelled power off on equipment which does not meet the requirements by virtue of an equipment number-preset power off operation corresponding table, and reminding the employeesof cutting off the power through manual intervention; and after the manual intervention, enabling the employees to clock out, repeatedly carrying out the steps until the clock out is finished, and enabling the employees to smoothly get off work. According to the electricity saving method, an attendance machine and the power-off operation are correlated together, so that the electricity saving isautomatically realized in a humanized and low-cost manner.

Owner:SICHUAN FEIXUN INFORMATION TECH CO LTD

Material control system

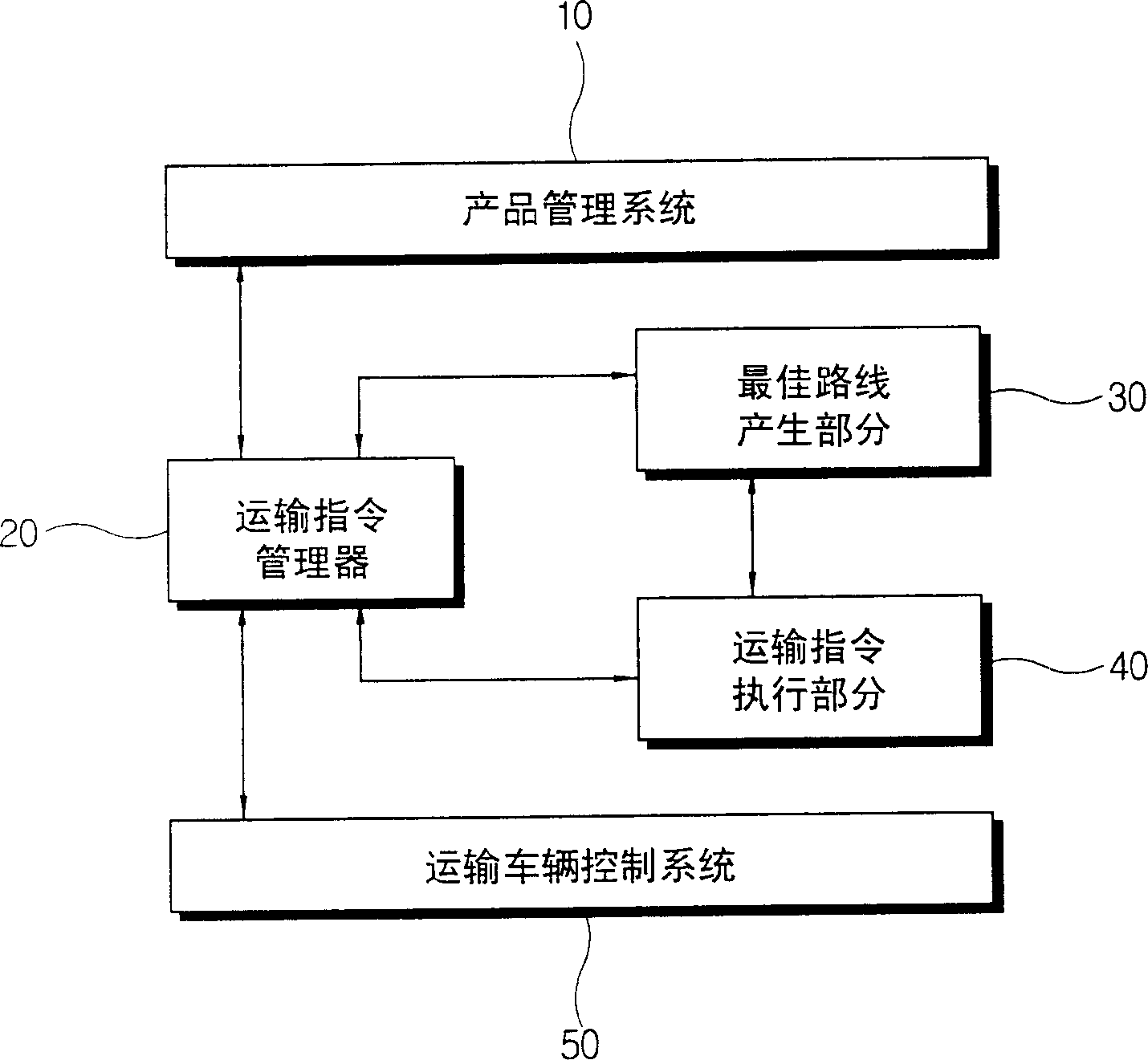

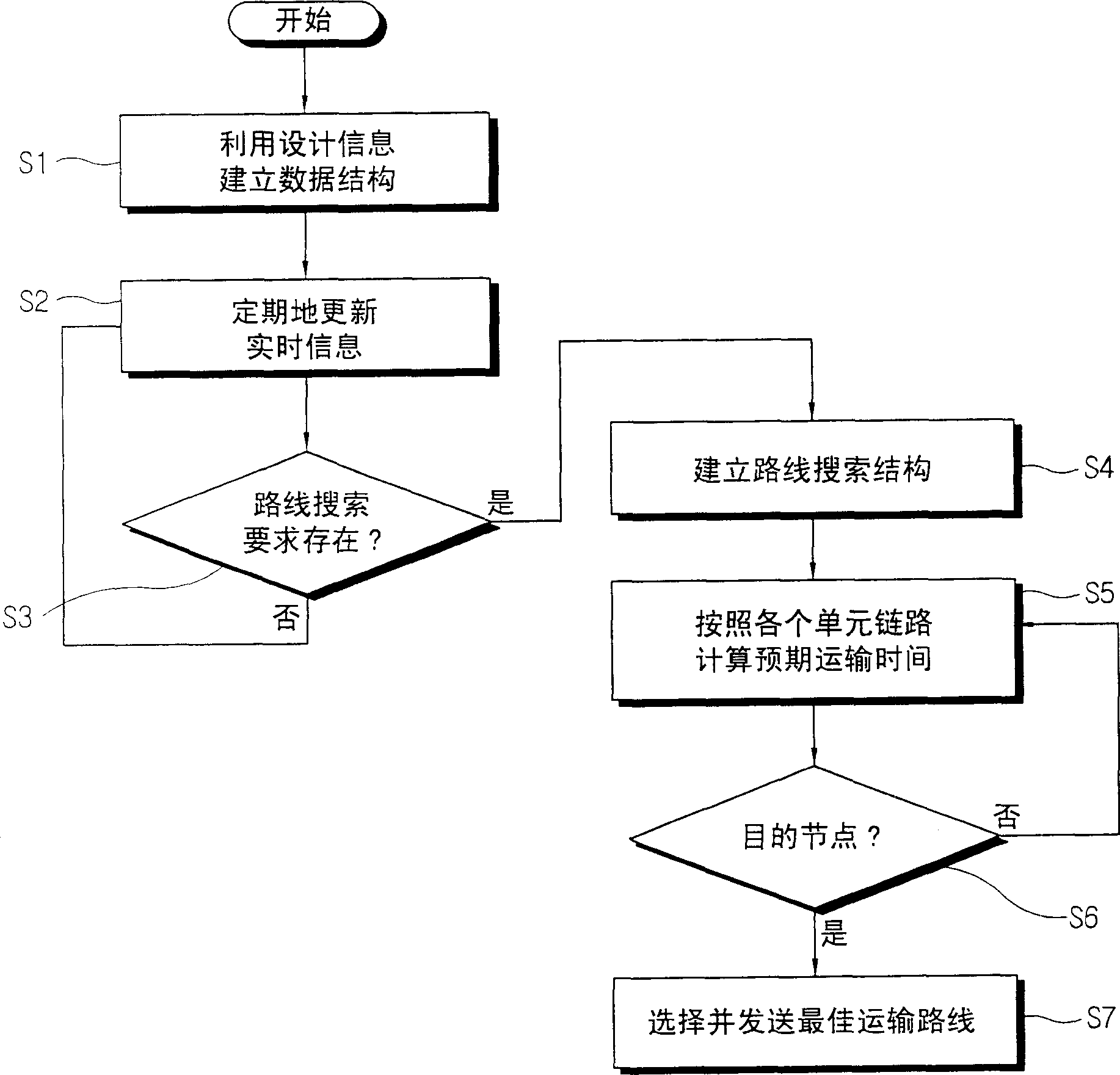

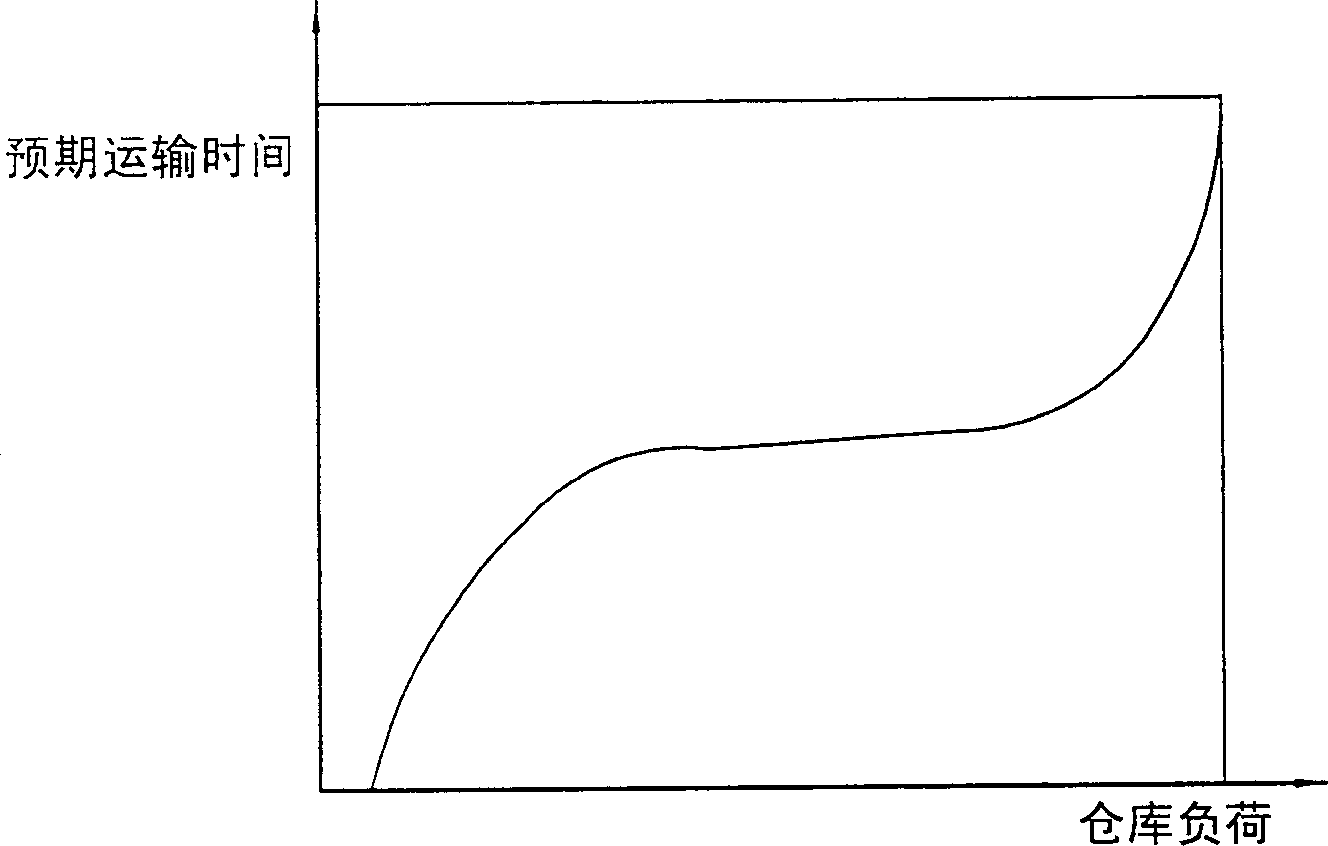

InactiveCN1521676AReduced expected transit timeInstruments for road network navigationRoad vehicles traffic controlTime informationProduction line

A material control system (MCS) to select an optimum transport route by calculating a prospective transport time between a source node and a destination node includes a transport order manager to receive and manage layout information, and real-time job information of a load and a waiting job number of a storehouse according to respective unit links. The MCS also includes an optimum route generating part to calculate the prospective transport time by receiving the layout information and the real-time job information in a predetermined period of time from the transport order manager and by modeling the information. The optimum route generating part also selects a transport route having a minimum prospective transport time as the optimum transport route. Thus, a transport flow of production lines may be balanced, and interruption between transport vehicles may be minimized, thereby enabling overall transport efficiency to be maximized.

Owner:SAMSUNG ELECTRONICS CO LTD

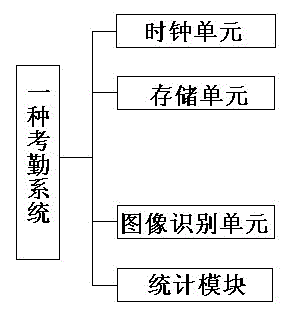

Attendance checking system

InactiveCN102622790AConvenient attendanceEasy to manageRegistering/indicating time of eventsJob numberComputer module

The invention discloses an attendance checking system, which includes a clock unit for providing time and a storage unit for storing user attendance information. The attendance checking system is characterized in that it is arranged on a terminal, and an image identification unit is mounted beside the clock unit simultaneously. Moreover, the storage unit is provided with a user information display area, which can match attendance time with users totally, thus effectively avoiding the substitute attendance phenomenon. The user information display area contains names, job numbers, departments, positions and working hours respectively, so that employee information can be acquired clearly. Besides, the attendance checking system is also provided with a statistic module, thus facilitating the statistical work at the at the end of a month and enabling accurate and fast finding of employees that come to work late and leave early. Facilitating enterprise management, the attendance checking system of the invention has strong practical applicability and is easy to extend.

Owner:SUZHOU WINNDOO NETWORK TECH CO LTD

Attendance monitoring method for construction personnel

InactiveCN108765645ARegistering/indicating time of eventsIndividual entry/exit registersJob numberComputer science

The invention relates to an attendance monitoring method for construction personnel. The attendance monitoring method comprises the following step: step 101, constructing an attendance area: respectively arranging access passages in an entrance and an exit of a closed construction area, and arranging two barrier gates on the access passages; step 102, constructing attendance verification data: entering job number or fingerprint information of the construction personnel, meanwhile, detecting and grabbing posture information comprising a weight, a face image and a standing image of the construction personnel based on a posture grabbing device, analyzing to obtain the posture data comprising the weight, a human face and a height of the construction personnel; and step 103, performing attendance and verification of identity of the construction personnel based on the access passages. According to the attendance monitoring method provided by the invention, the access passages are respectively arranged at the entrance and the exit of the closed construction area; the two barrier gates are arranged on the access passages in the entrance and the exit; the job number or fingerprint information of the construction personnel is verified by a first barrier gate, and the posture information of the construction personnel is verified by a second barrier gate to perform attendance on the construction personnel and verify the identity of the construction personnel.

Owner:廖强

Toll screen display and voice prompt satisfaction measurement system

The invention relates to a toll screen display and voice prompt satisfaction measurement system matched with rapid tolling, release and mount guard of staff hanging out shingles of a freeway toll station. The toll screen display and warm prompt satisfaction measurement system comprises an information subsystem, a control subsystem, a toll subsystem and a satisfaction measurement subsystem. The measurement system is characterized in that a toll computer in a duty room is an intersection of the four subsystems. The toll screen display and voice prompt satisfaction measurement system has the advantages that a toll display screen is multipurpose and displays job numbers of operators on duty, trip distance, toll amount, warm prompt information and toll countdown information in a time-phased manner on lines, high and low satisfaction measurement is configured, pressing is facilitated, the toll countdown information ensures civilized and efficient service, a voice circuit board realizes polite greeting to incoming vehicles, rapid release, thanks for leaving vehicles and good-bye. By the aid of the toll screen display and voice prompt satisfaction measurement system, freeway traffic efficiency can be improved, a civilized toll window is created, and the service image of a city is shaped.

Owner:王玉强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com