Evaluation method and device for examining operation condition of welders

An evaluation method and a technology of the work industry, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of waste of human resources and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

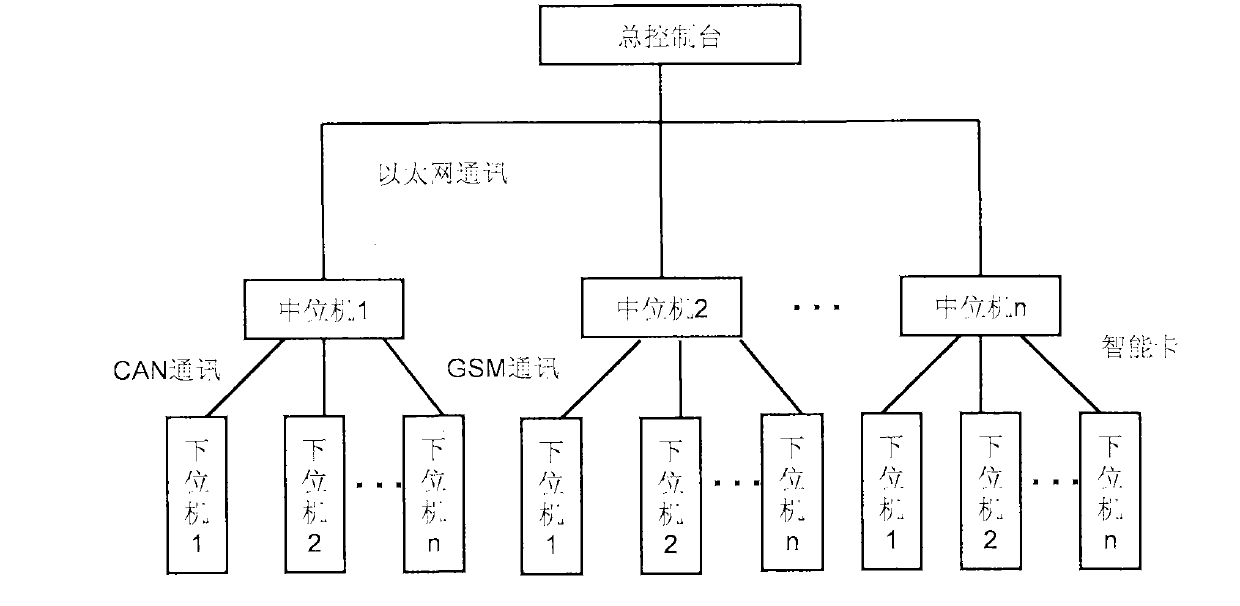

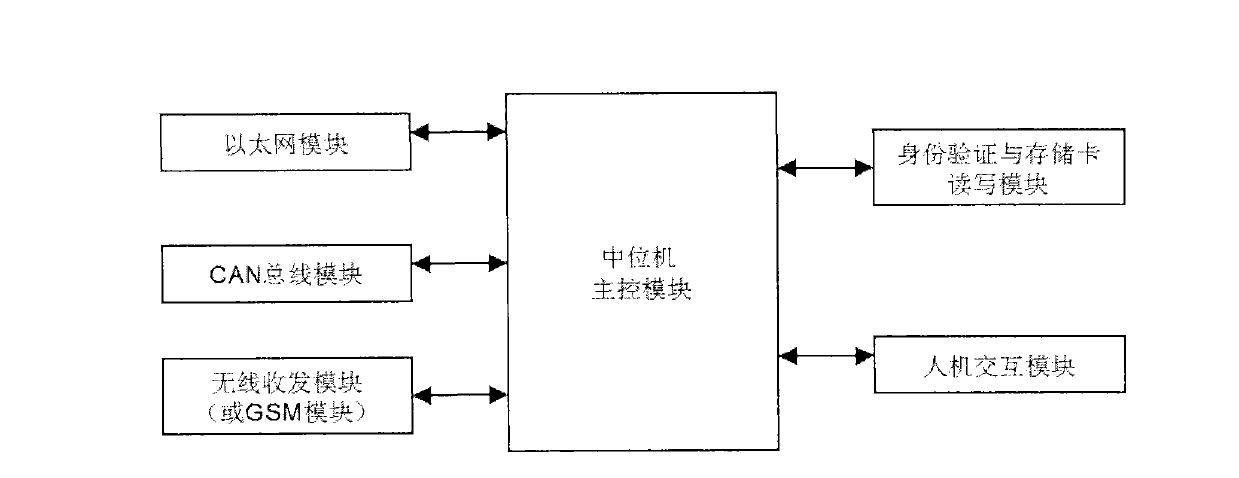

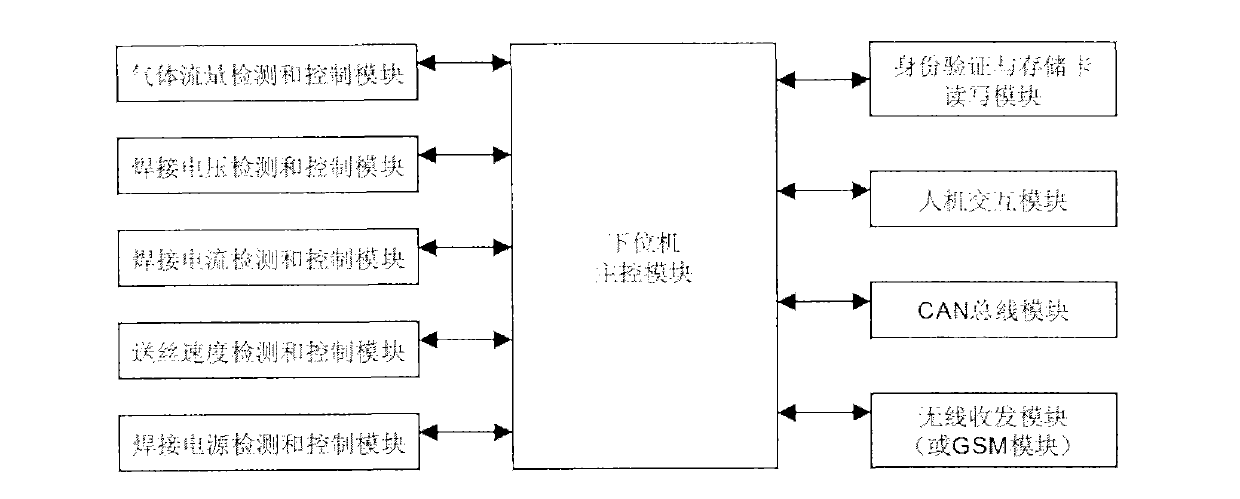

[0015] The interconnection mode of this system is shown in Figure 1. The first layer is the console computer to complete the overall control of the system, the second layer is the middle computer to complete the data interaction between the lower computer and the control center, and the third layer is the lower computer to complete the collection and control of welding parameters and the interaction with the welder.

[0016] The console computer is the control center of the system, which is operated by the staff of the control center to complete the overall control of the system. The invention develops the control software for the upper computer, which can monitor the welding parameters (mainly including: gas flow, welding voltage, welding current, wire feeding speed, etc.), welding machine number and user identity information of all welding machines in real time. , and can automatically save related data. The console computer can be a general desktop computer or PC, and it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com