Patents

Literature

338results about "Mass flow measurement devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

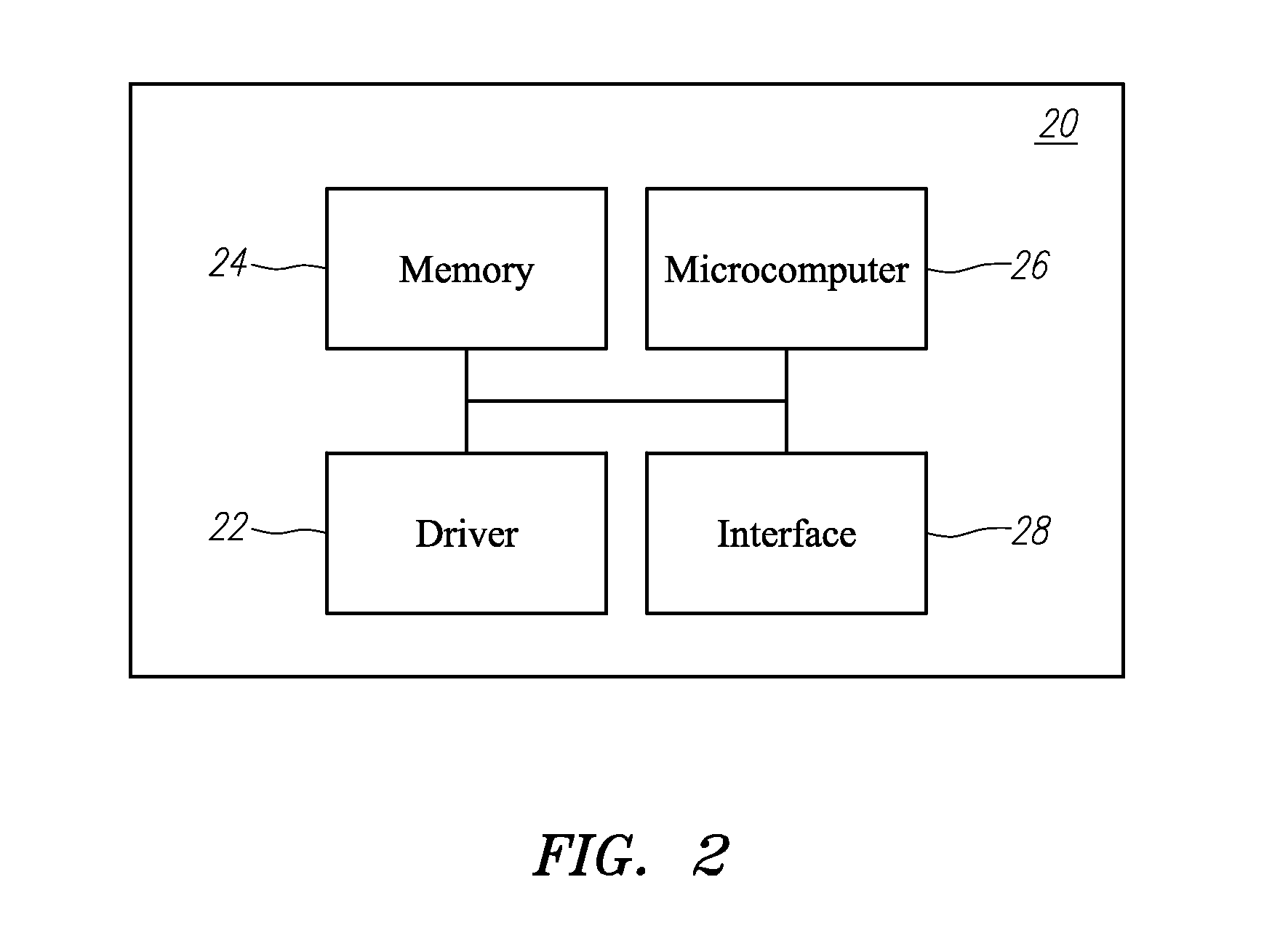

Device and method for sensing mass airflow

A system, a method, a device and a computer program are provided for detecting and monitoring medium flow. The device comprises a flow sensor (350) that includes a thermopile (352), wherein the thermopile (352) may include a first thermocouple and a second thermocouple. The device can further comprise a microcontroller (340) that can be configured to generate a reference baseline and can further be configured to compare an output of the mass airflow sensor to the reference baseline (503). The heater element may comprise a heater resistor.

Owner:FONTEM HLDG 1

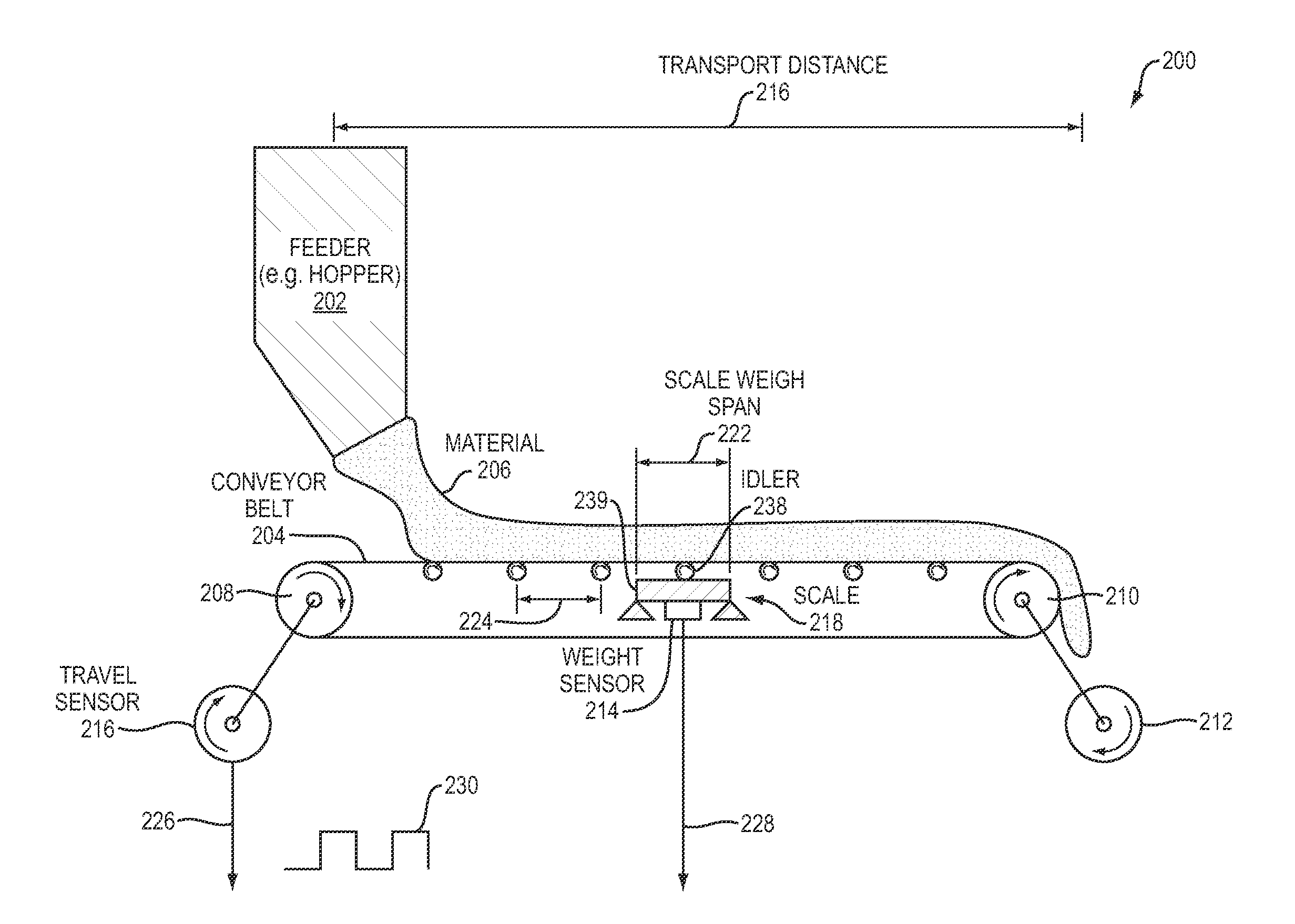

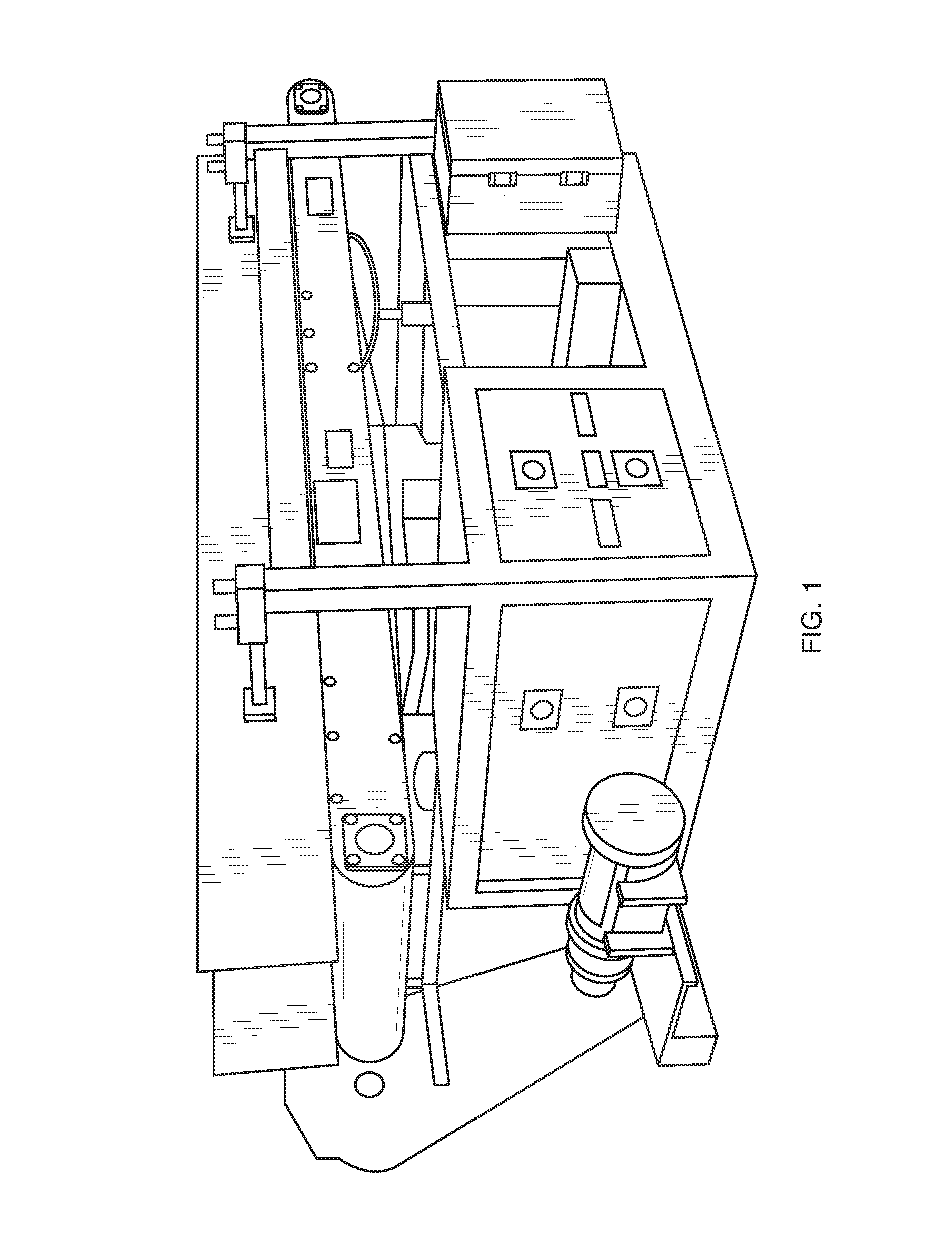

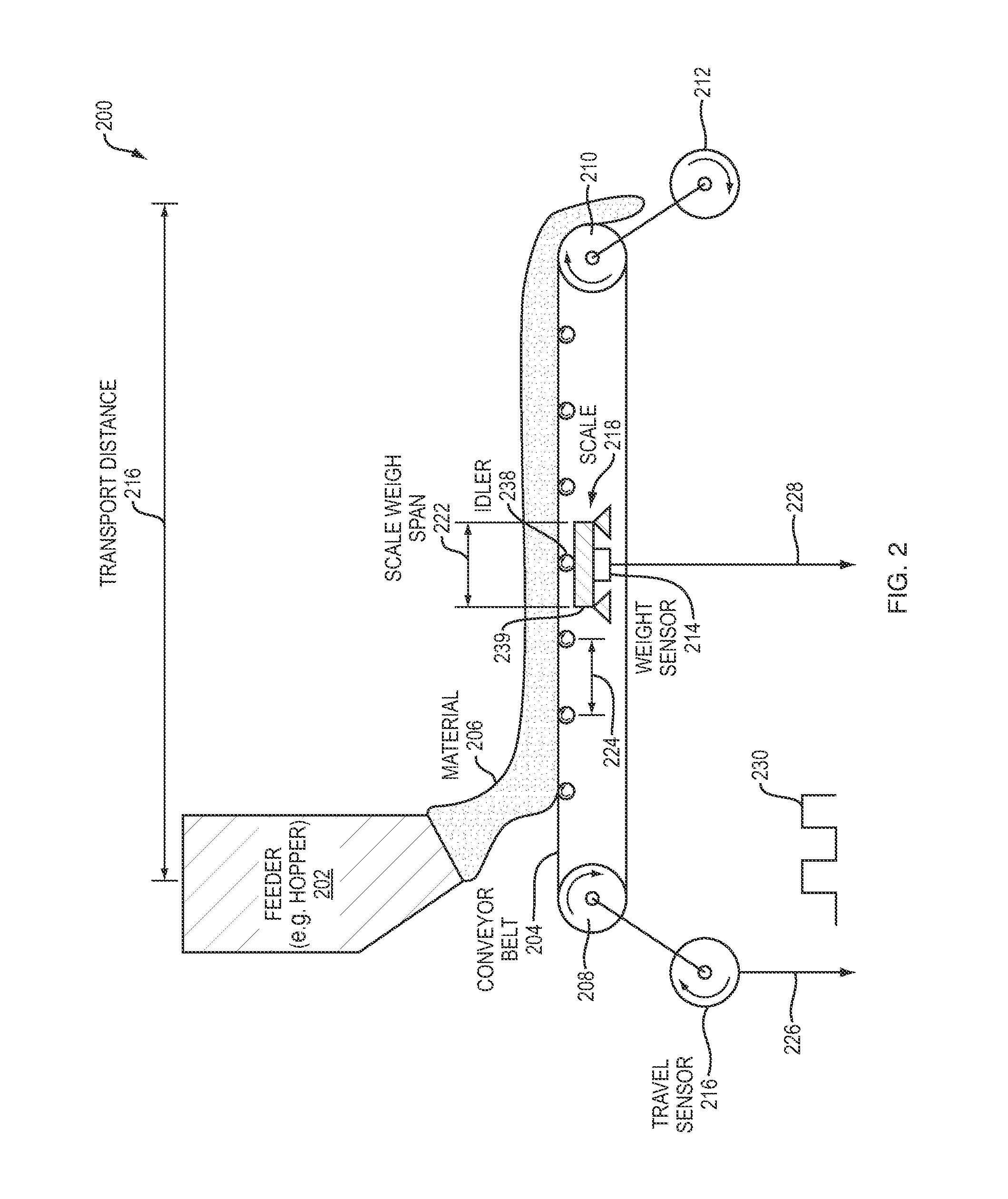

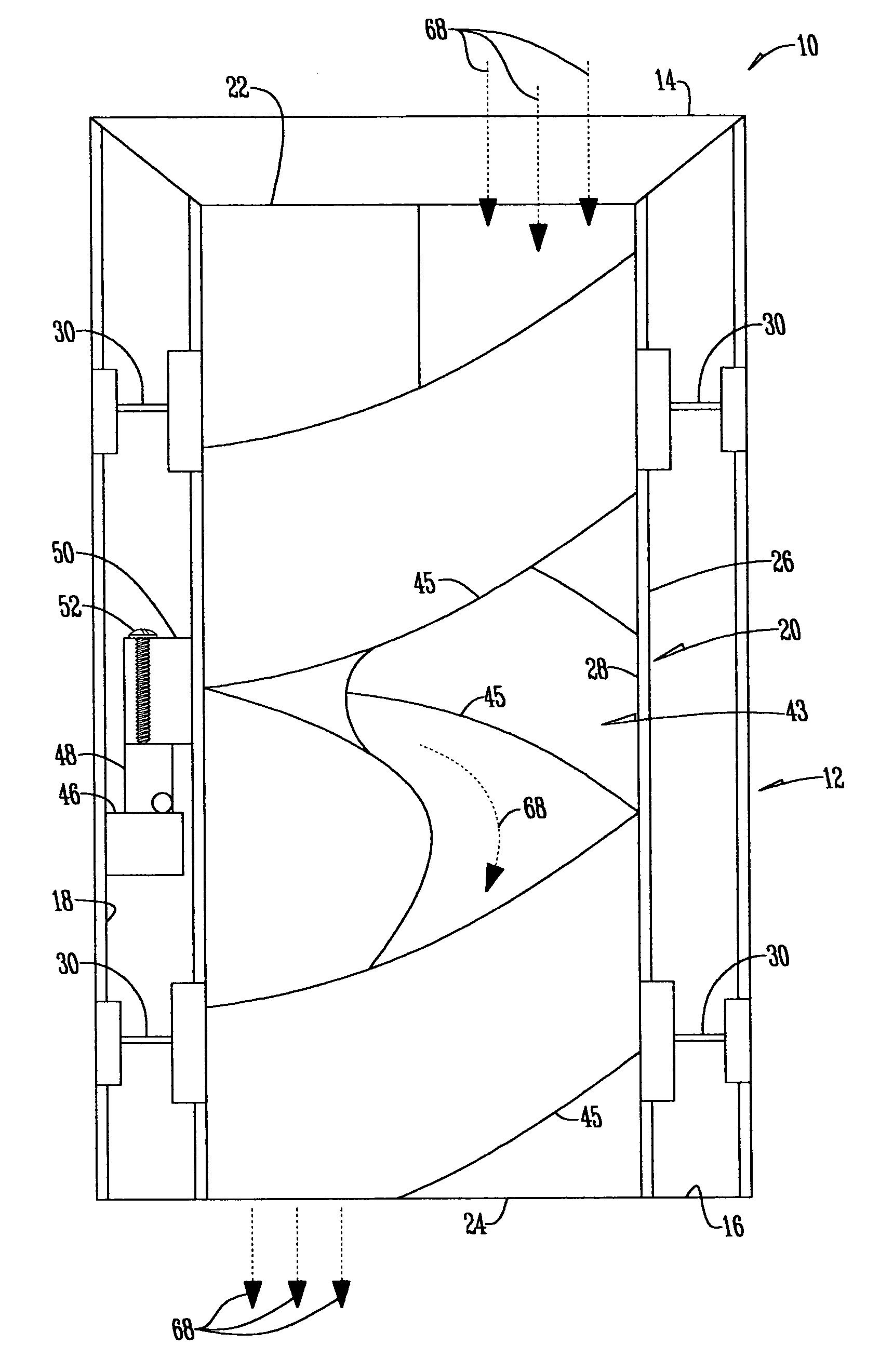

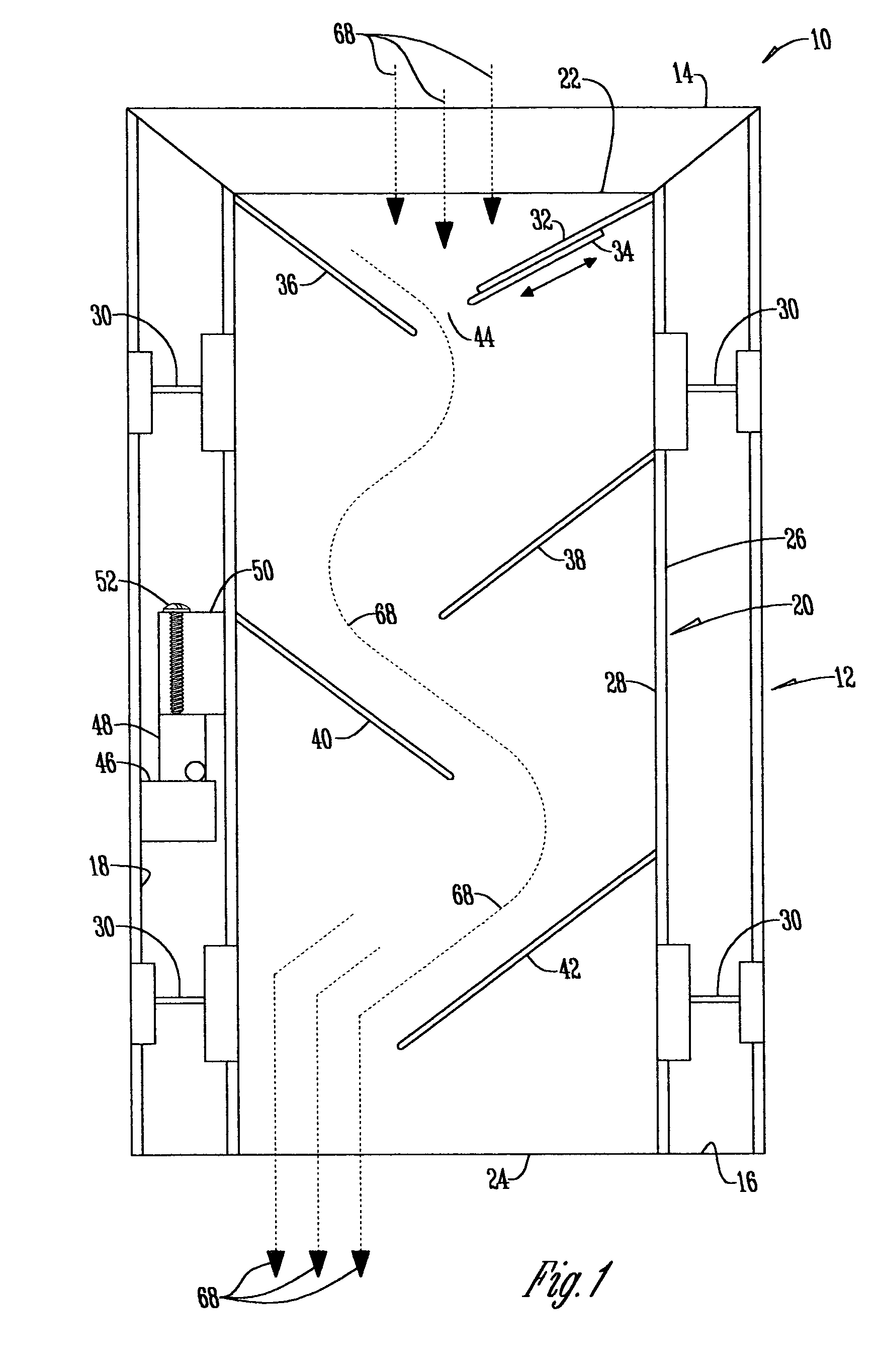

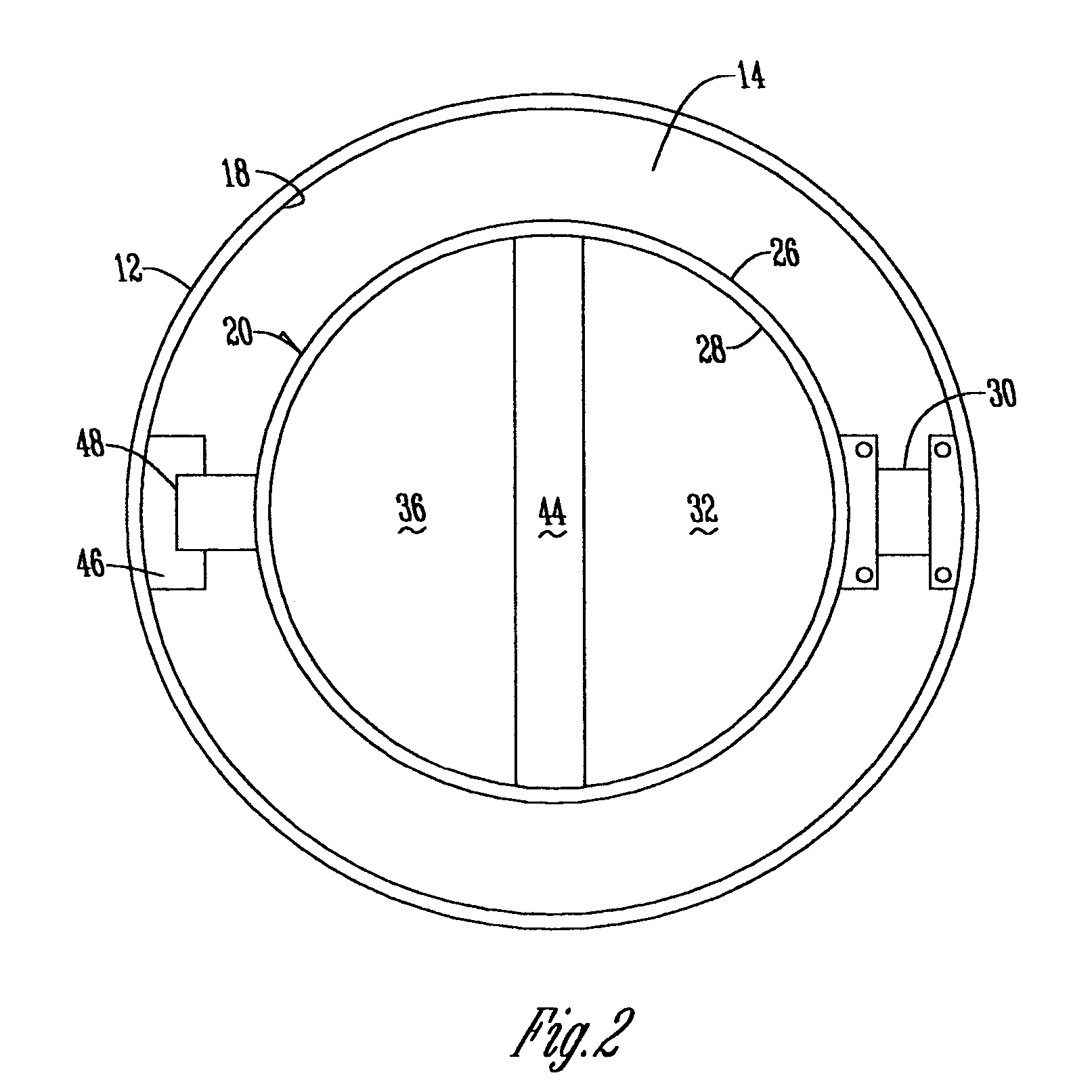

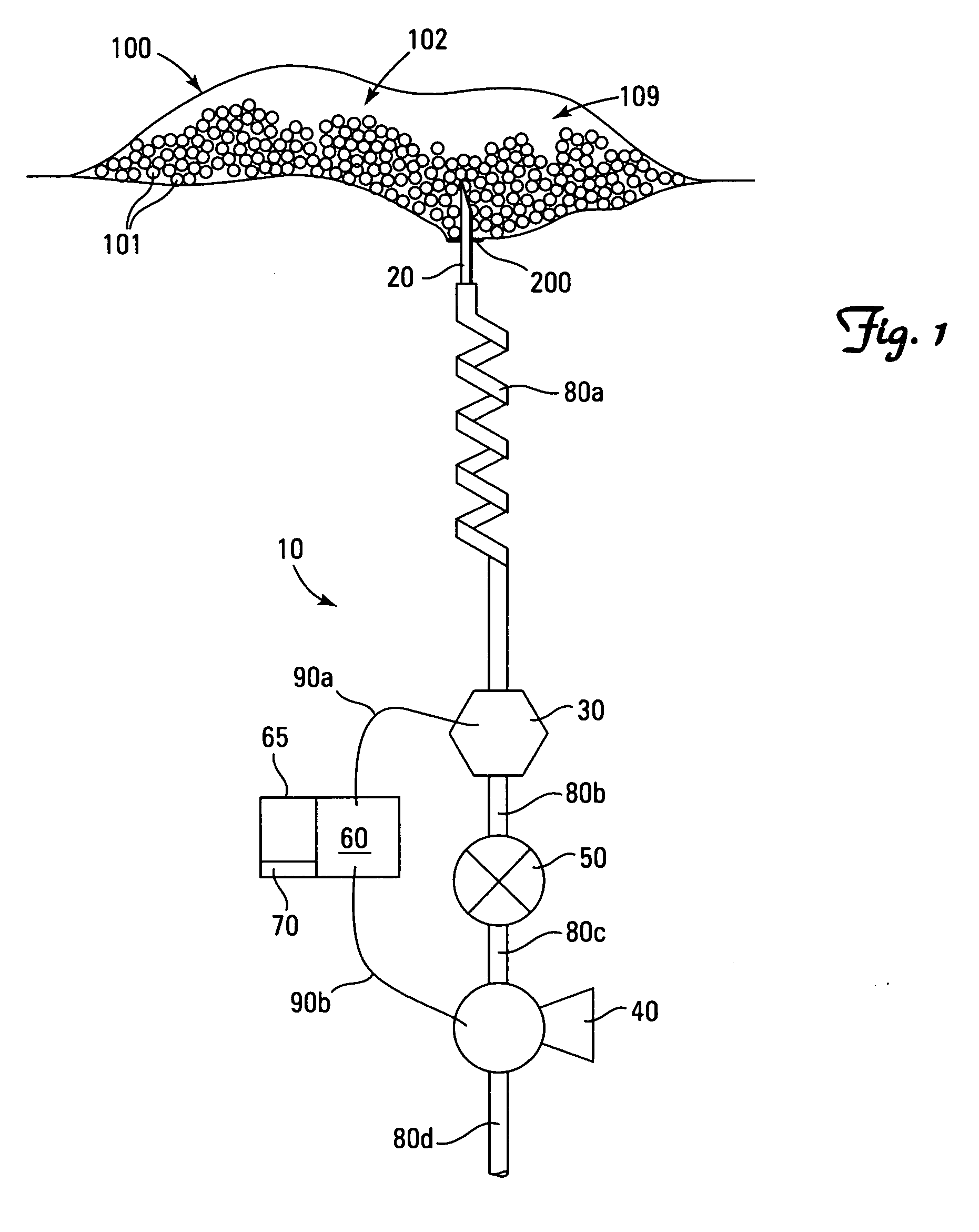

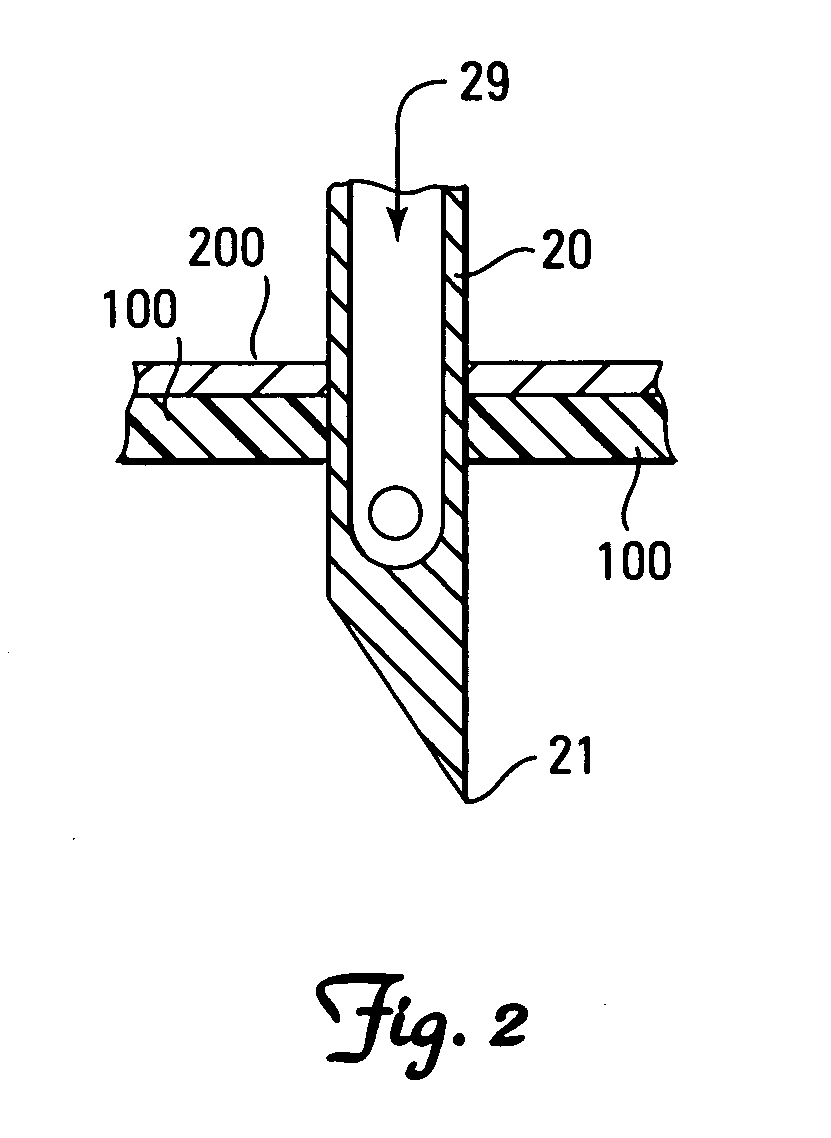

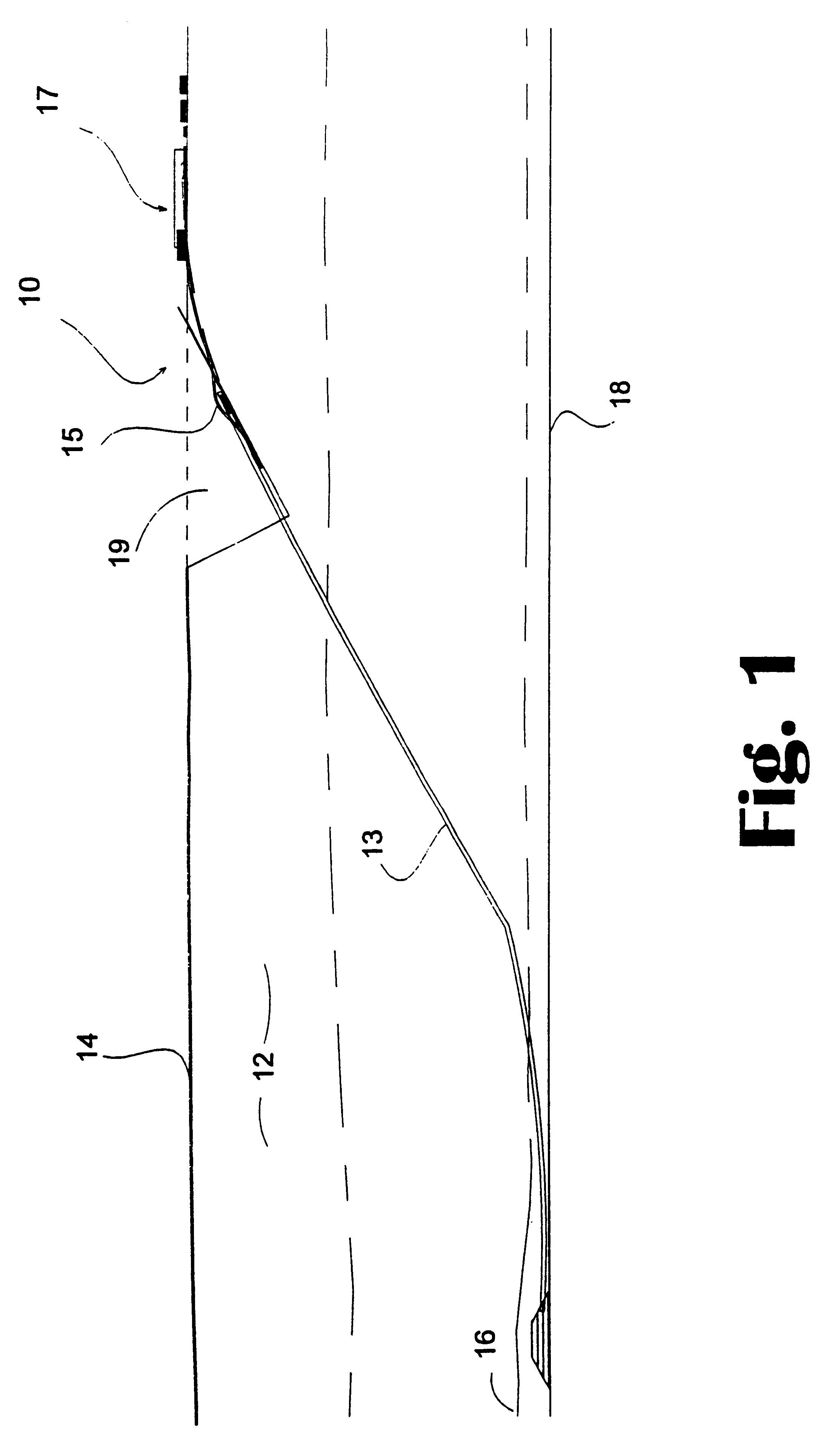

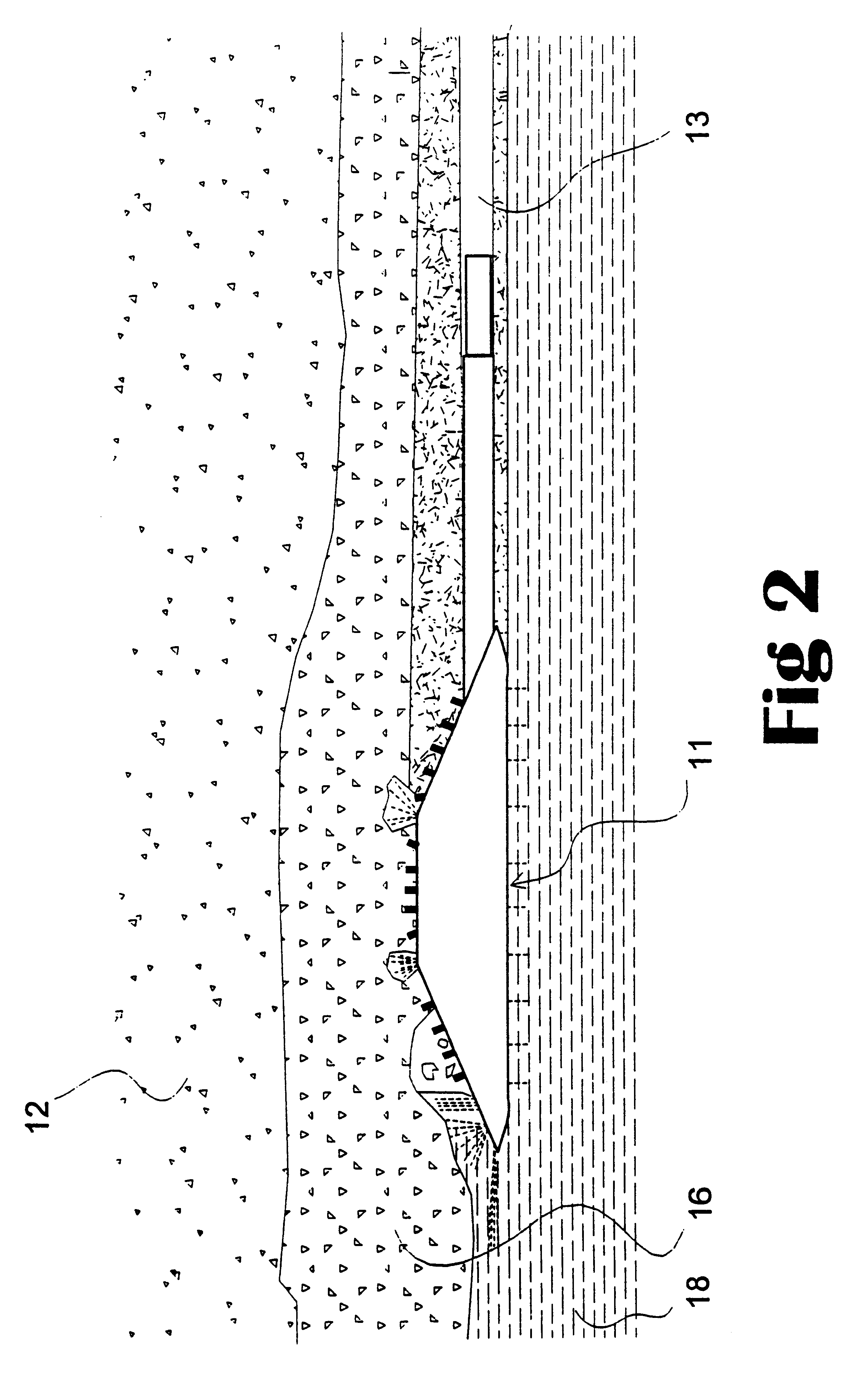

System and methods for belt conveyor weighing

ActiveUS20140062709A1Mass flow measurement devicesWeighing apparatus for materials with special property/formObservational errorSnack food

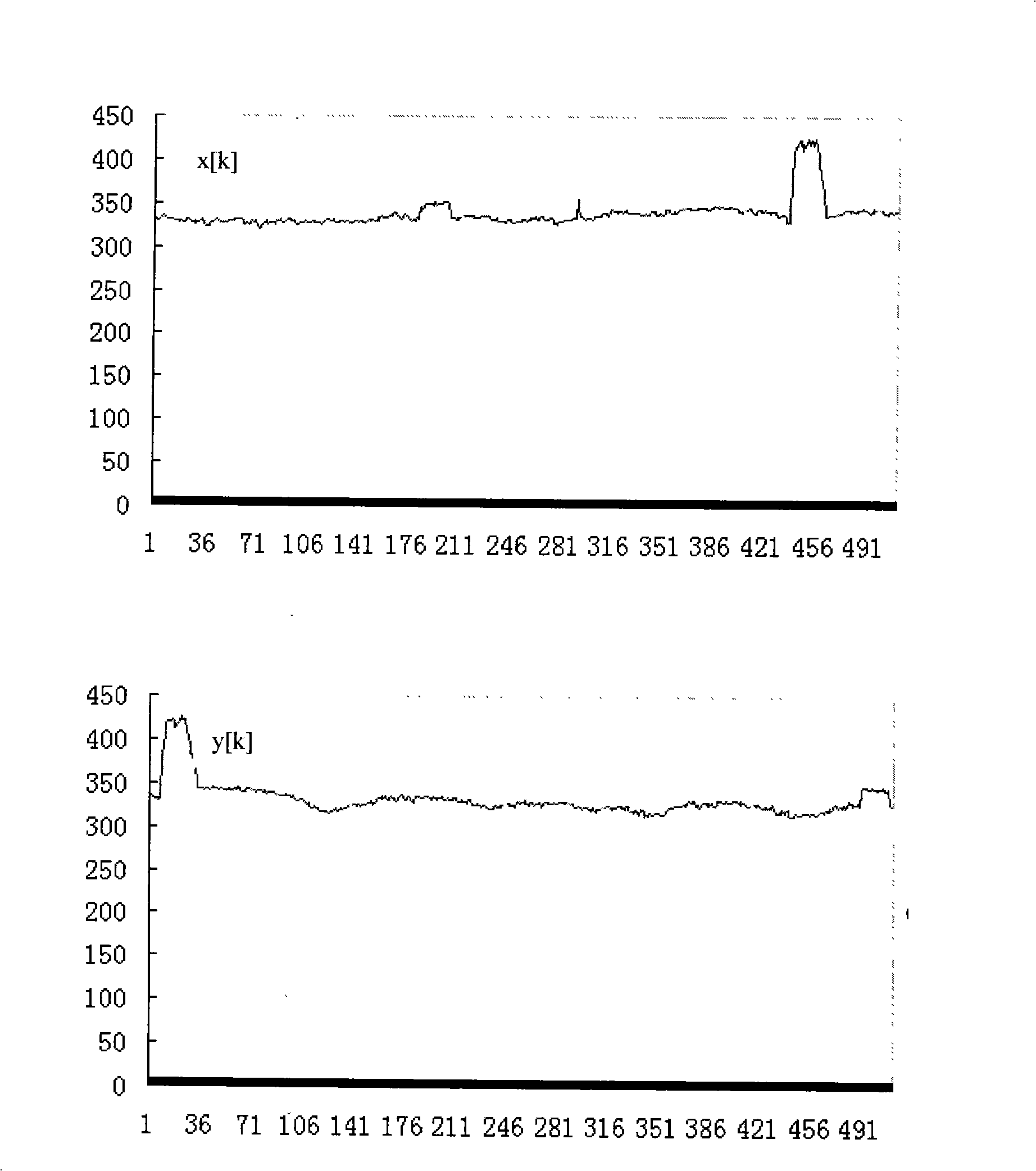

Imperfections in conveyor belting and its supporting elements can adversely affect weighing accuracy of belt scales, particularly when weighing and / or metering low density materials, such as those encountered in the snack food industry. A system and methods for a belt conveyor according to an embodiment of the present invention provide simultaneous benefits of both short and long weigh spans. According to an embodiment of the present invention, a virtual weigh span may be programmably set to adjust for variations in the belt conveyor weighing system. Advantages include, higher degrees of accuracy and calibration to account for changes in the belt or belting system over time using non-mechanical adjustments. In addition, weight measurement error producing effects, some that may not be particularly known, may be reduced.

Owner:HYER IND

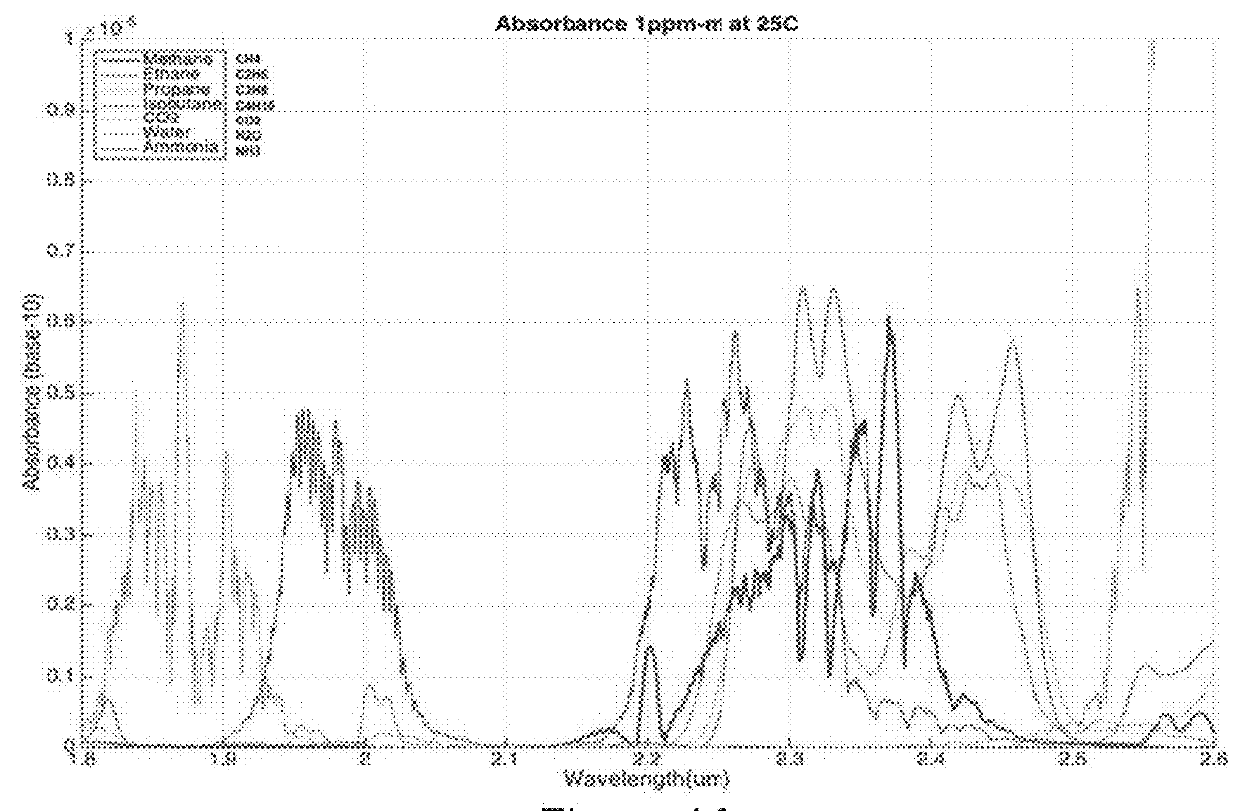

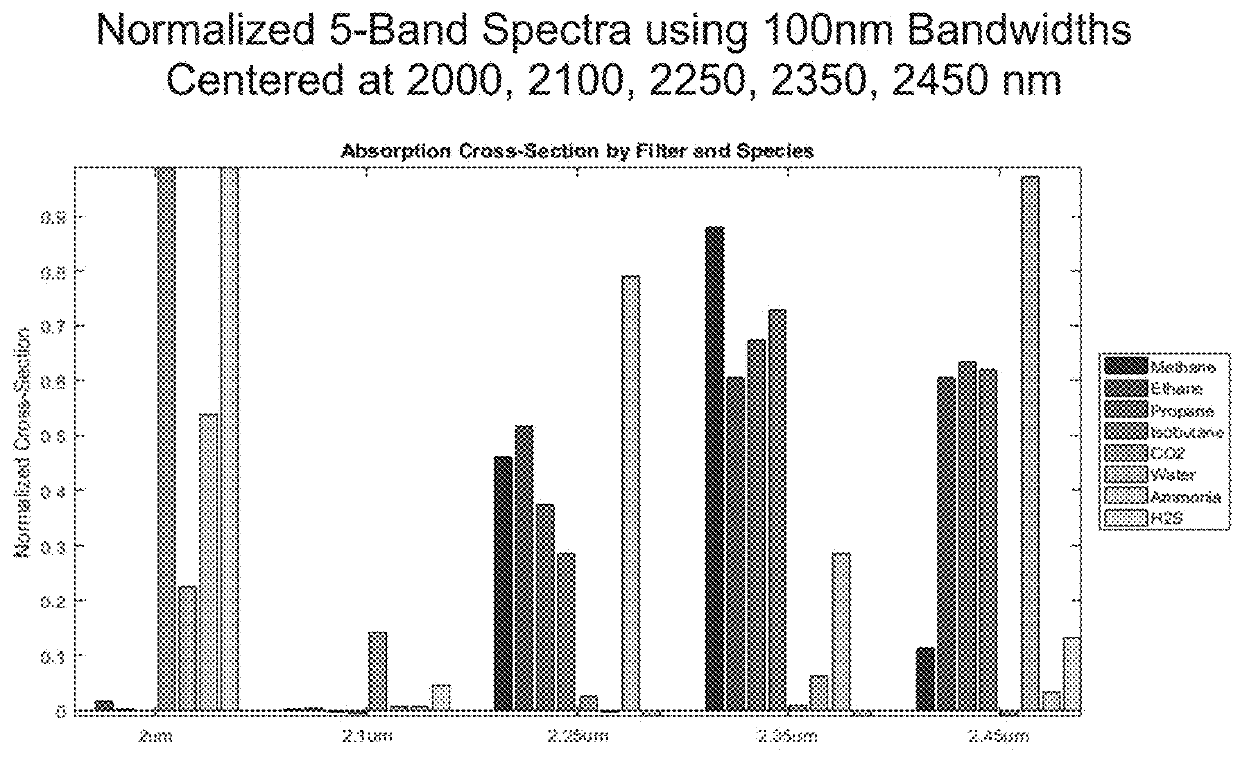

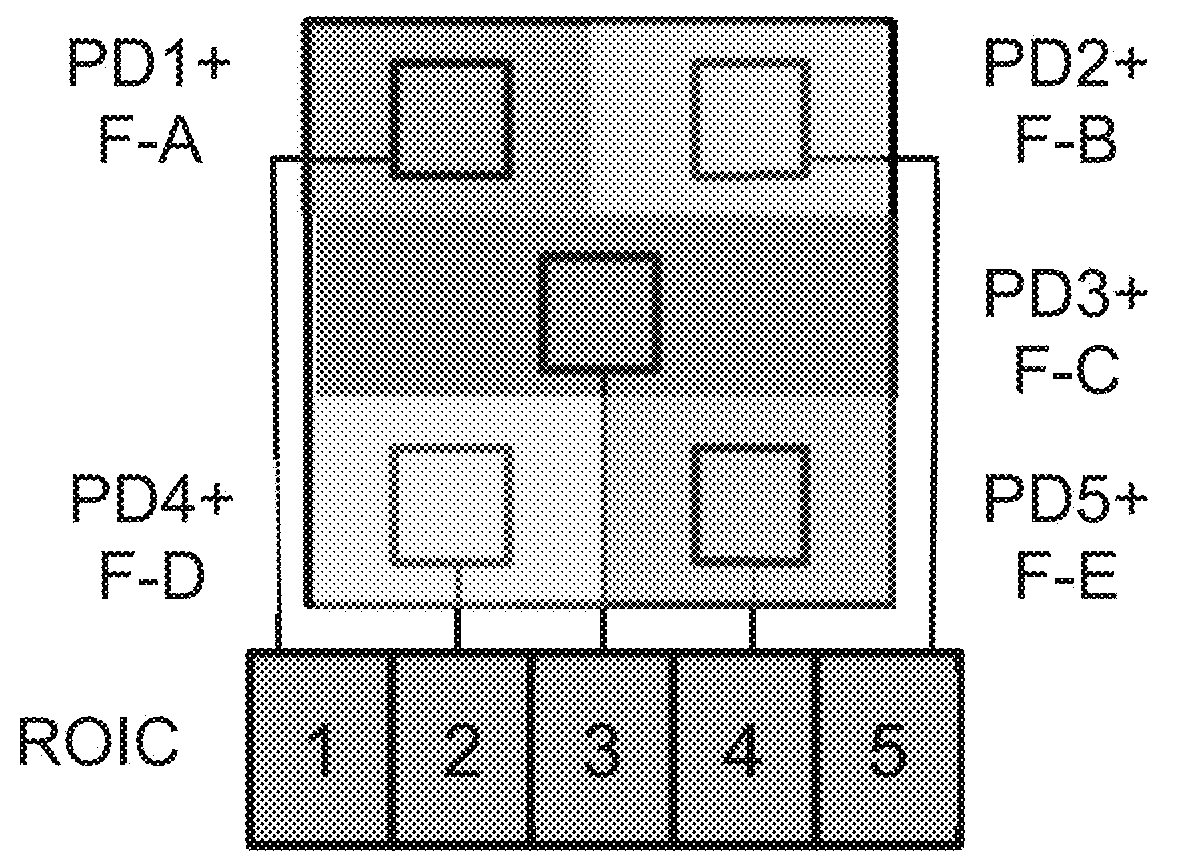

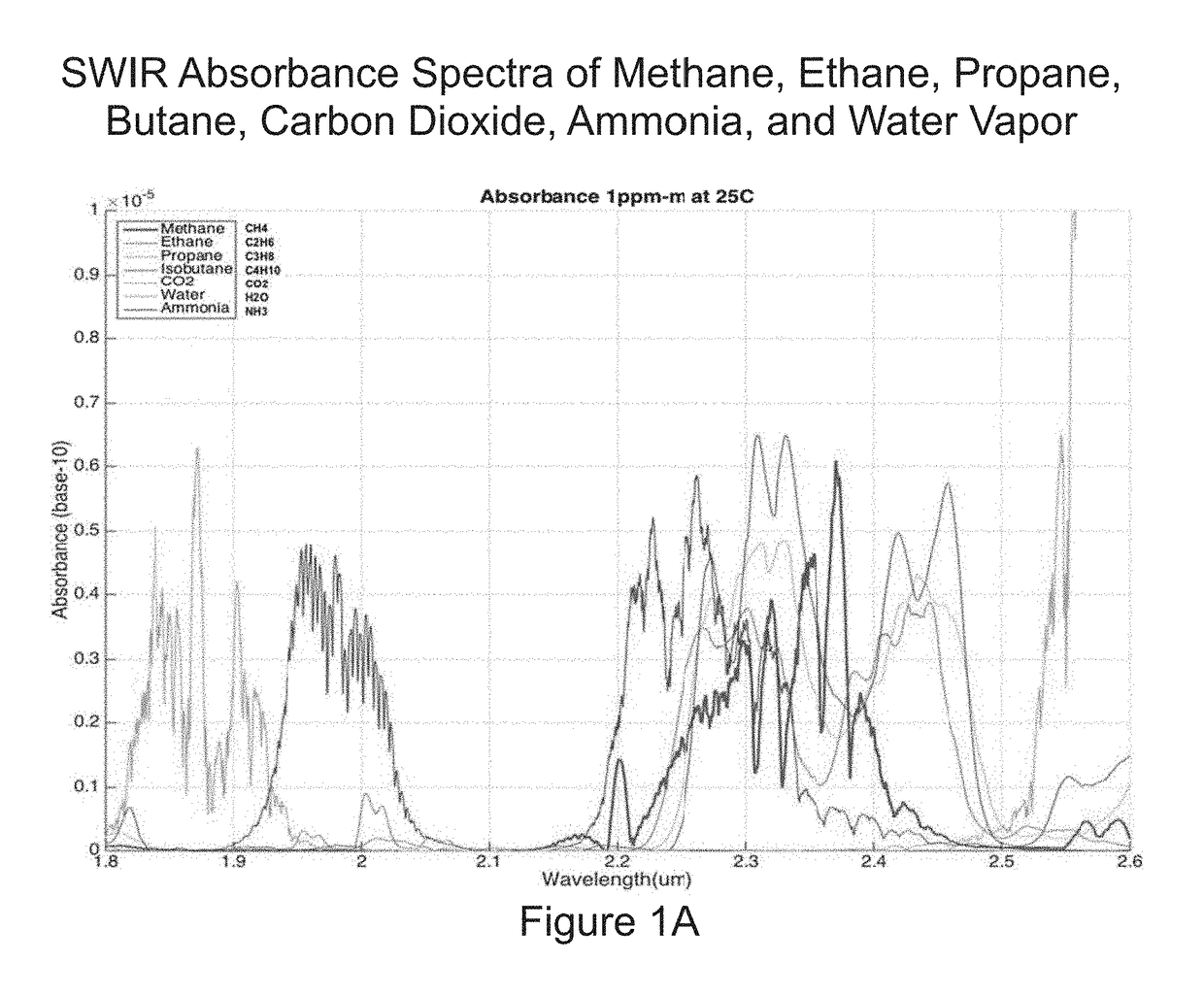

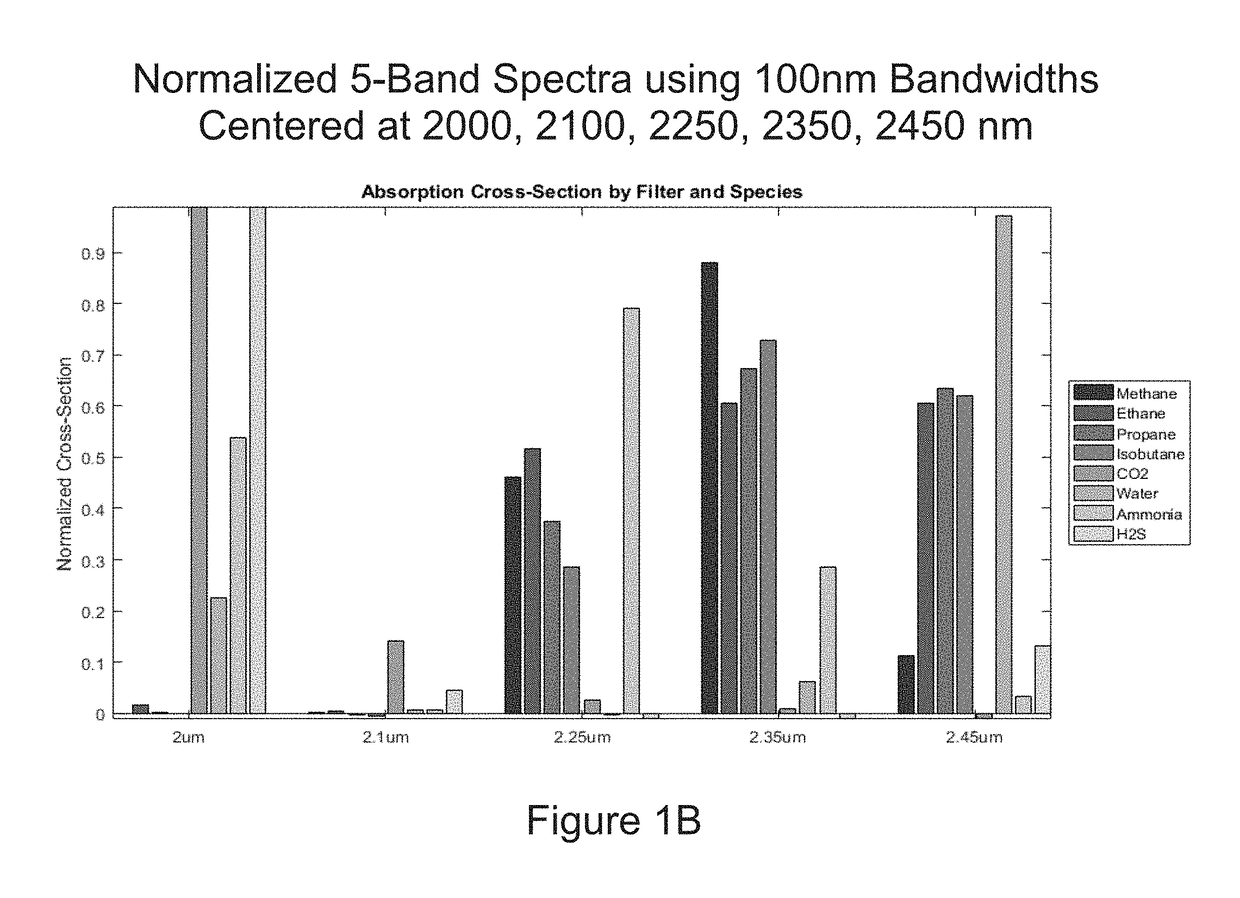

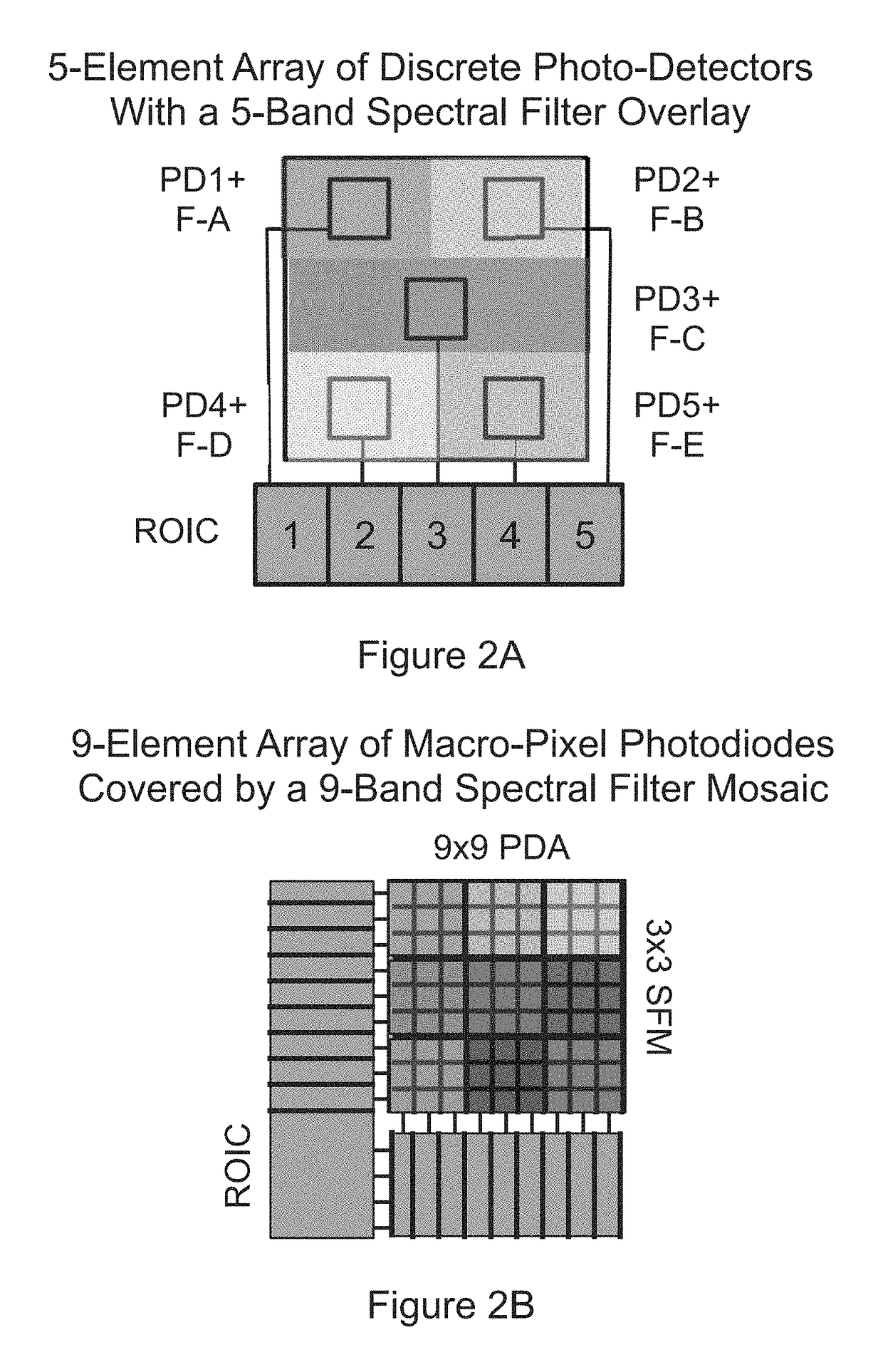

Scanning ir sensor for gas safety and emissions monitoring

ActiveUS20180266944A1More reliableLess expensiveMass flow measurement devicesRaman/scattering spectroscopyConfocalOptical depth

Apparatus and methods for rapidly detecting, localizing, imaging, and quantifying leaks of natural gas and other hydrocarbon and greenhouse gases. Scanning sensors, scan patterns, and data processing algorithms enable monitoring a site to rapidly detect, localize, image, and quantify amounts and rates of hydrocarbon leaks. Multispectral short-wave infrared detectors sense non-thermal infrared radiation from natural solar or artificial illumination sources by differential absorption spectroscopy. A multispectral sensor is scanned to envelop an area of interest, detect the presence and location of a leak, and raster scan the area around the leak to create an image of the leak. The resulting absorption image related to differential spectral optical depth is color mapped to render the degree of gas absorption across the scene. Analysis of this optical depth image, with factors including known inline pressures and / or surface wind speed measurements, enable estimation of the leak rate, i.e., emission mass flux of gas.

Owner:MULTISENSOR SCI INC

Scanning IR sensor for gas safety and emissions monitoring

ActiveUS10190976B2More reliableLess expensiveMass flow measurement devicesRaman/scattering spectroscopyGratingSpectroscopy

Apparatus and methods for rapidly detecting, localizing, imaging, and quantifying leaks of natural gas and other hydrocarbon and greenhouse gases. Scanning sensors, scan patterns, and data processing algorithms enable monitoring a site to rapidly detect, localize, image, and quantify amounts and rates of hydrocarbon leaks. Multispectral short-wave infrared detectors sense non-thermal infrared radiation from natural solar or artificial illumination sources by differential absorption spectroscopy. A multispectral sensor is scanned to envelop an area of interest, detect the presence and location of a leak, and raster scan the area around the leak to create an image of the leak. The resulting absorption image related to differential spectral optical depth is color mapped to render the degree of gas absorption across the scene. Analysis of this optical depth image, with factors including known inline pressures and / or surface wind speed measurements, enable estimation of the leak rate, i.e., emission mass flux of gas.

Owner:MULTISENSOR SCI INC

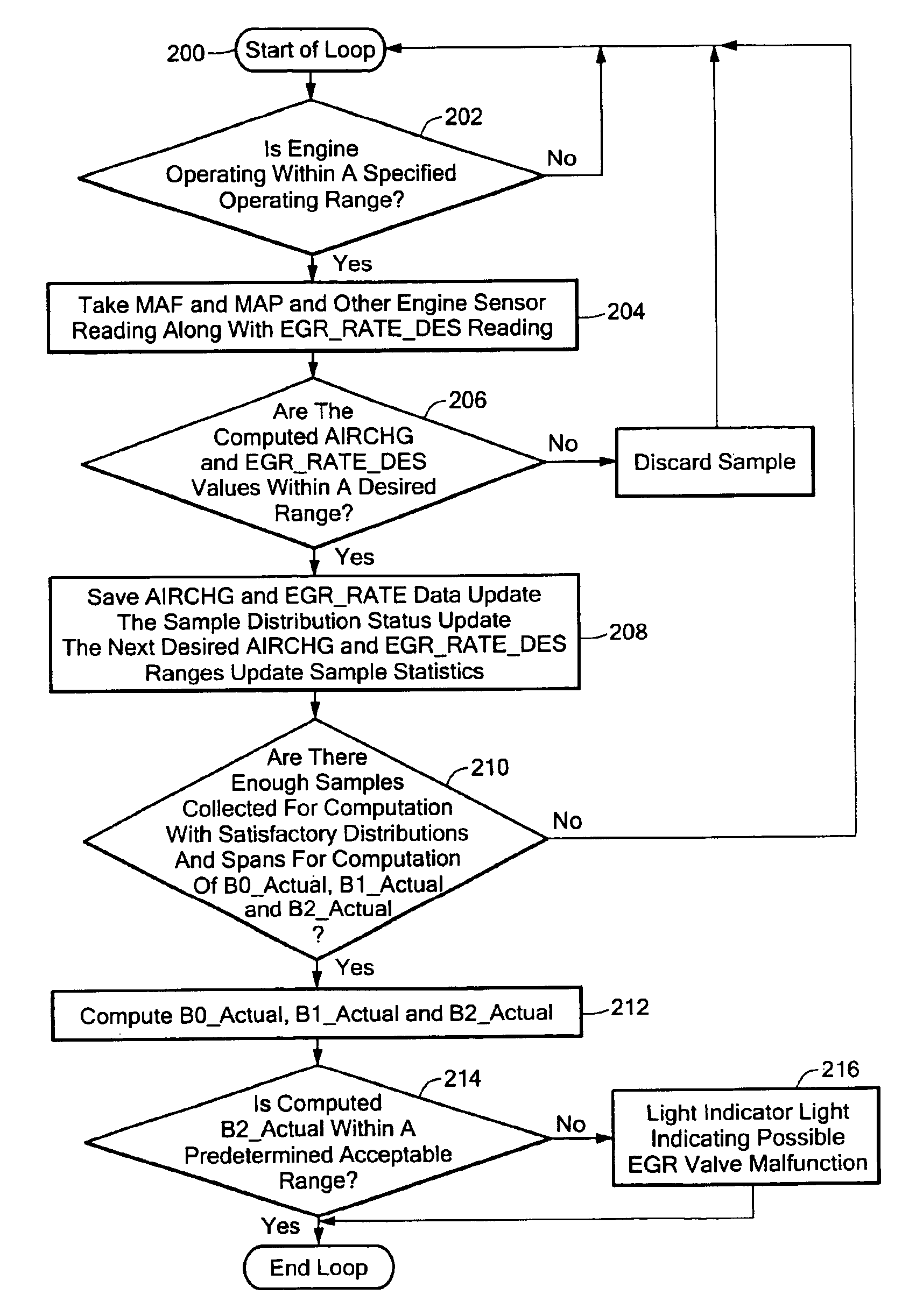

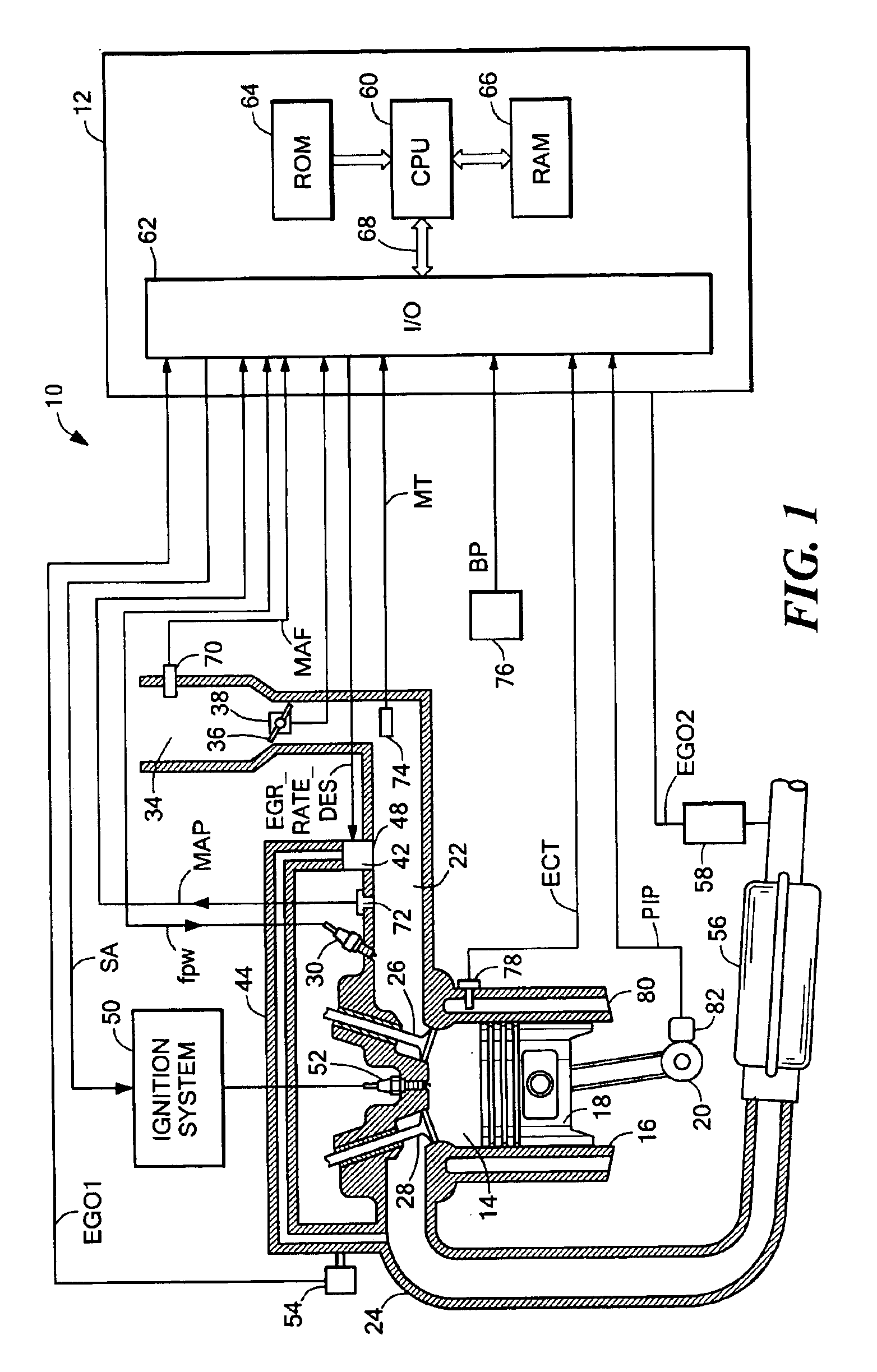

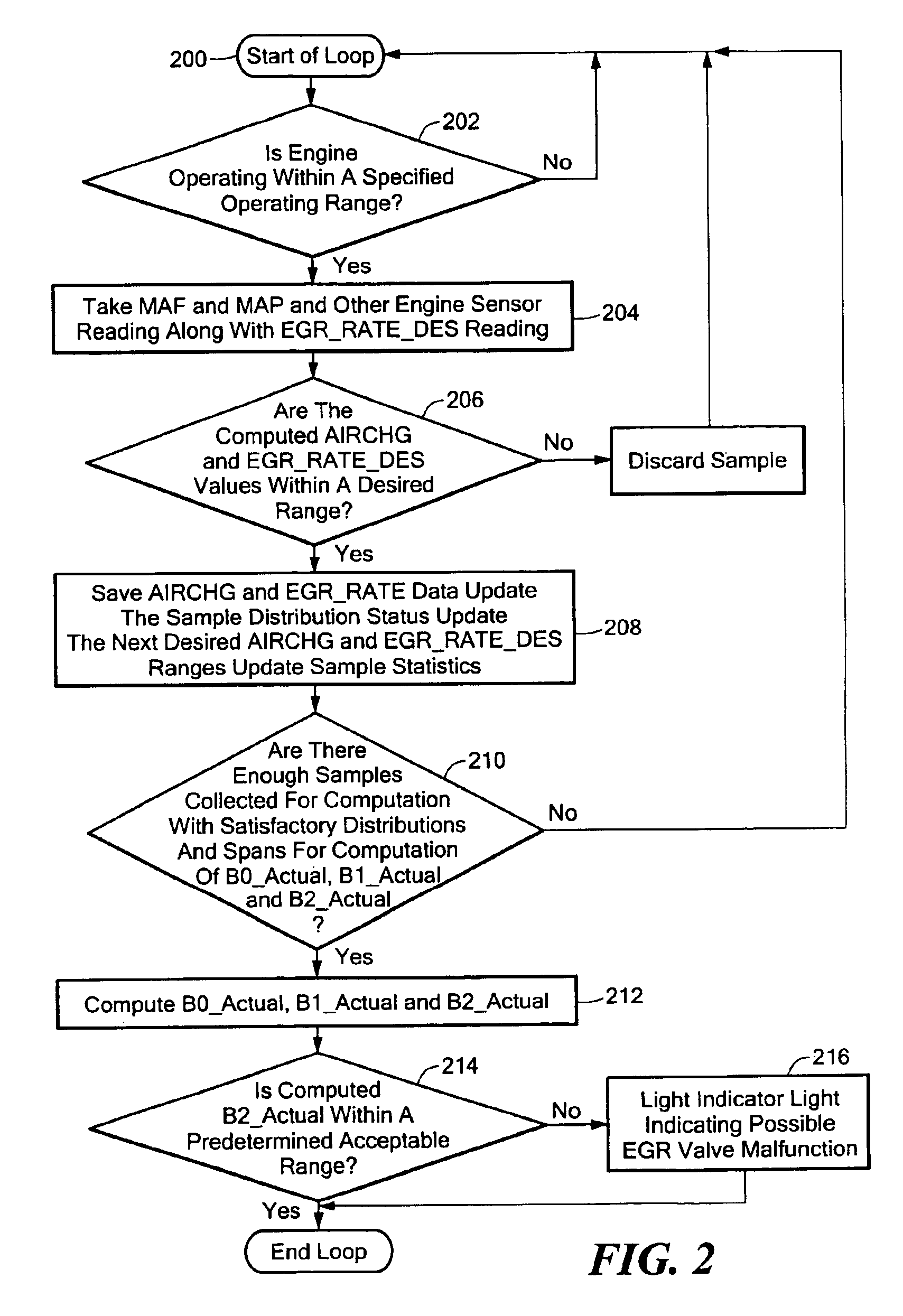

Method and system for detecting degradation of EGR flow delivery

ActiveUS6850834B1Reduce engine emissionsImprove fuel economyMass flow measurement devicesElectrical controlExhaust fumesForce sensor

A method for determining EGR flow in an internal combustion engine, such flow being from an exhaust manifold of the engine to an intake manifold of the engine through an EGR valve. The method includes using information provided by a mass air flow sensor disposed upstream of an exhaust gas inlet to the intake manifold and information provided by an manifold absolute pressure sensor disposed downstream of such exhaust gas inlet to provide an indication of the flow of exhaust gas into the intake manifold through such inlet. The method compares such estimated exhaust gas flow into the intake manifold with a commanded exhaust gas flow to the EGR valve. With such method, a determination may be made as to whether the EGR valve is operating properly.

Owner:FORD GLOBAL TECH LLC

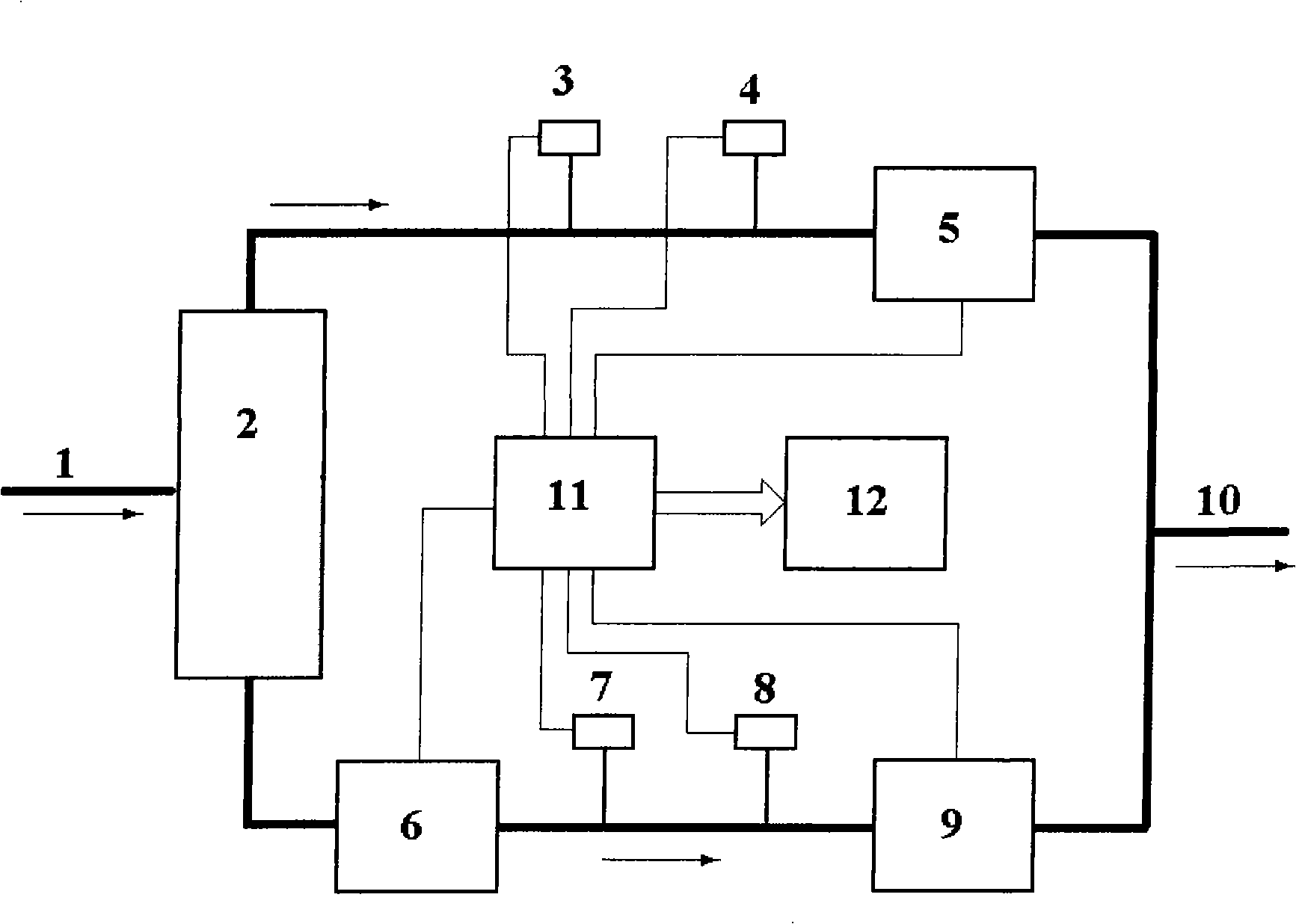

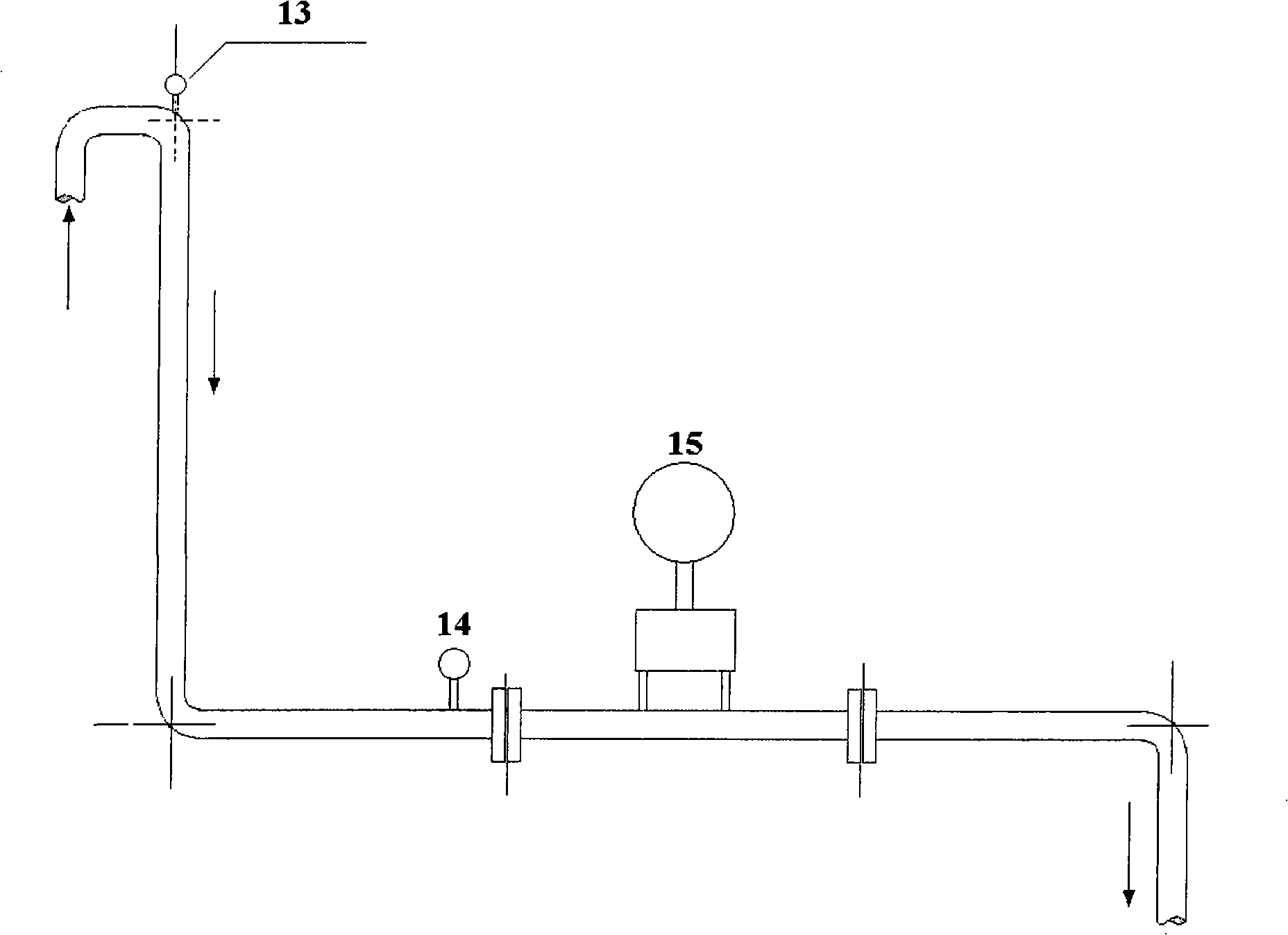

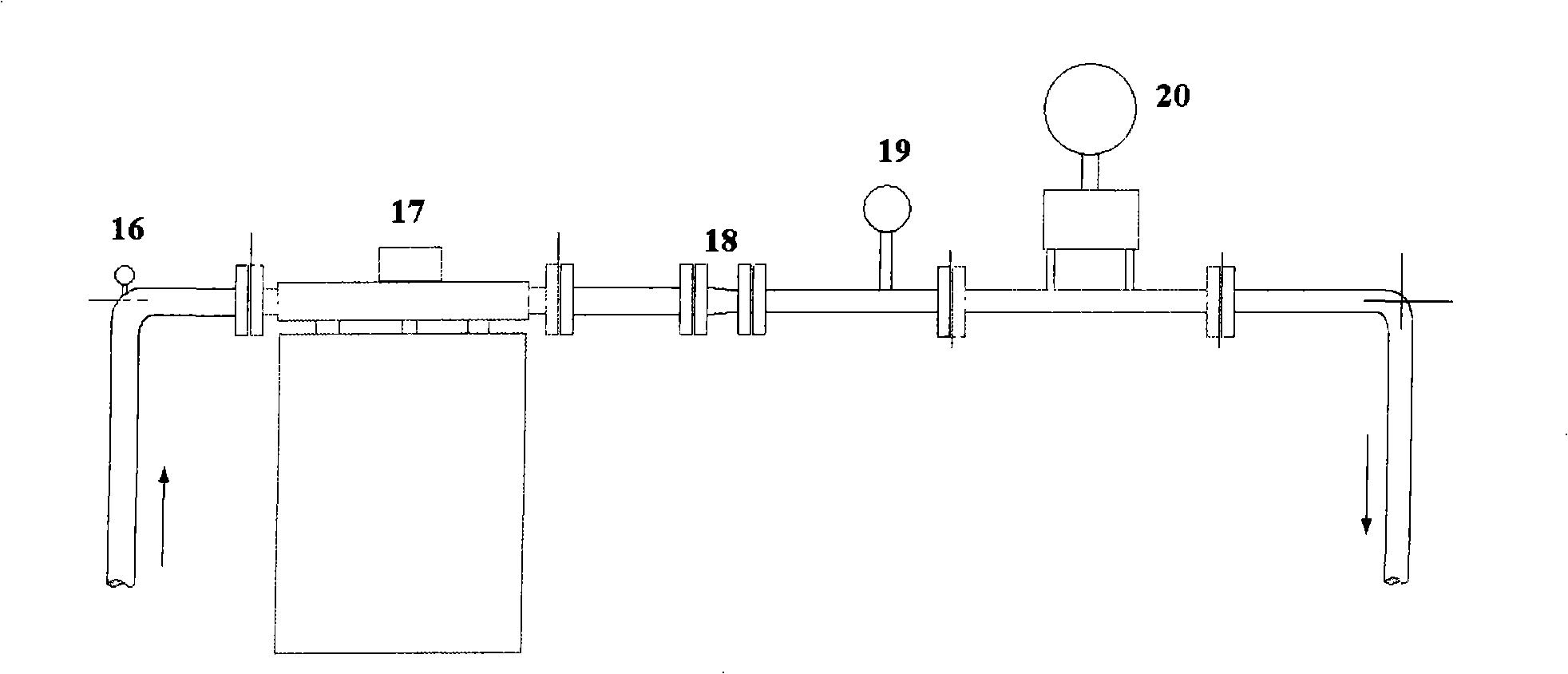

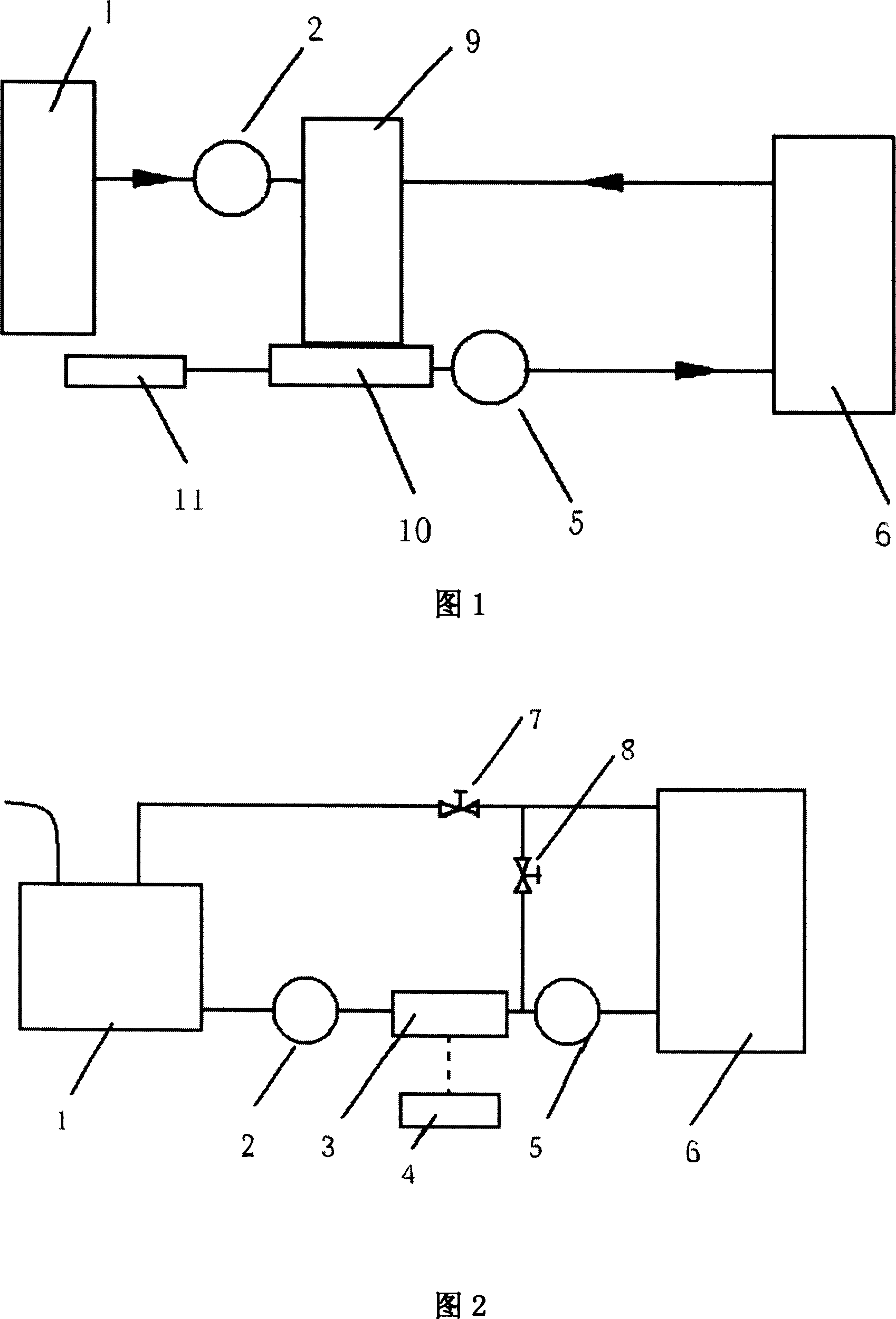

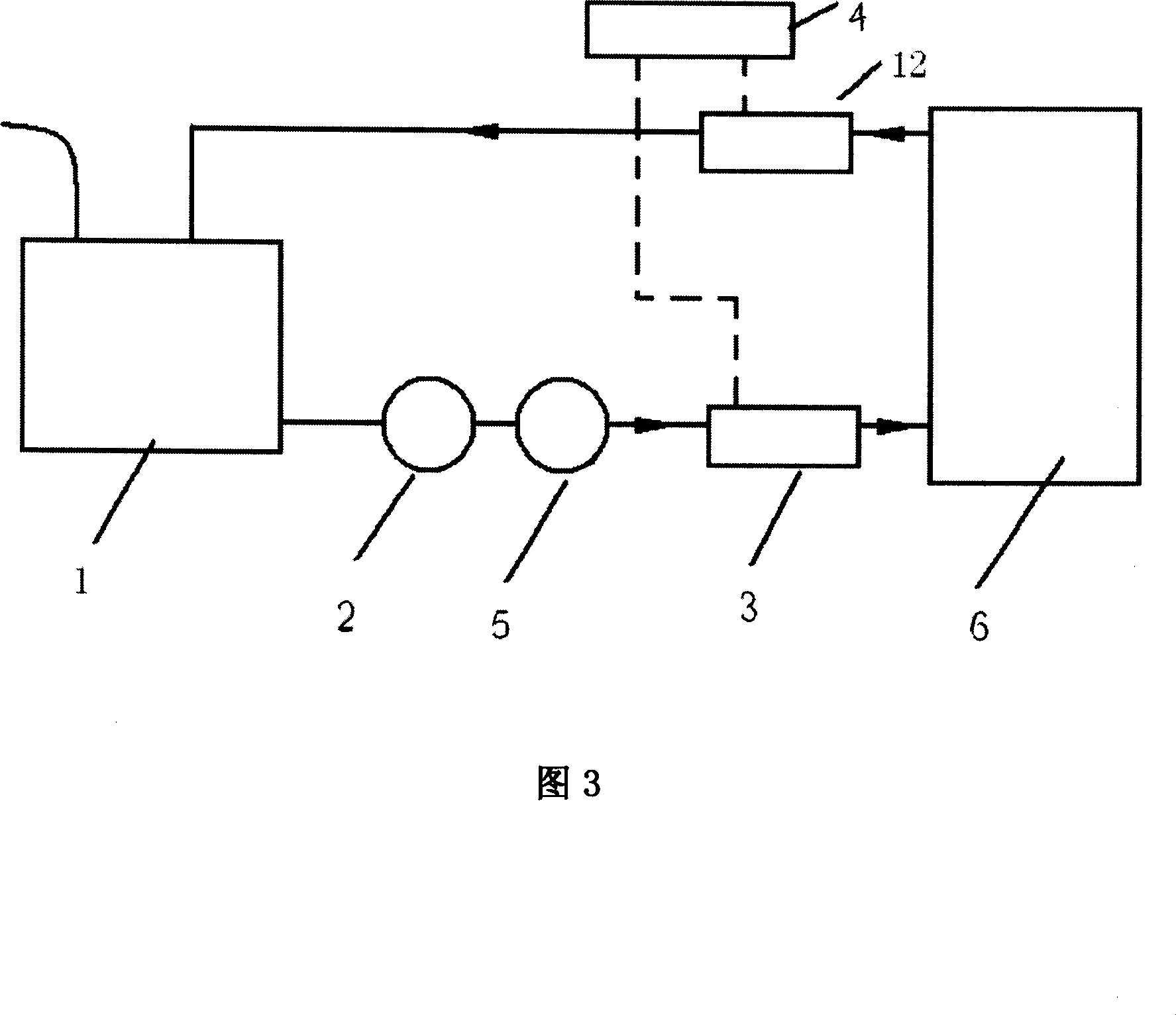

Oil, gas and water three phase oil well continuous metering device and its measurement method

InactiveCN101260802AReliable measurementSolve the two major technical problems of measurementMass flow measurement devicesSurveyVapor–liquid separatorOil well

The invention belongs to the fluid measuring technical field and relates to an oil, gas and water three-phase oil well continuous gauging device, which comprises a high-efficient gas-liquid separator; the high-efficient gas-liquid separator is connected with an oil, gas and water three-phase inflowing port; a gas phase outlet of the oil, gas and water three-phase inflowing port is connected with a gas phase measuring pipeline; a gas path temperature sensor, a gas path pressure sensor and a gas path endocone flowmeter with high-frequency differential pressure transmitter are arranged on the gas phase measuring pipeline; a liquid phase outlet of the high-efficient gas-liquid separator is connected with a liquid phase measuring pipeline; a liquid path Coriolis mass flowmeter and a liquid path endocone flowmeter are arranged on the liquid phase measuring pipeline; and the cross section of the pipeline for mounting the liquid path Coriolis mass flowmeter is more than the cross section of the pipeline for mounting the liquid path endocone flowmeter. The invention also provides a measuring method which is adopted by the device. The oil, gas and water three-phase oil well continuous gauging device has the advantages of a simple structure, no movable parts in the measuring sensor, convenient, reliable and accurate signal acquisition, and easy realization.

Owner:TIANJIN UNIV

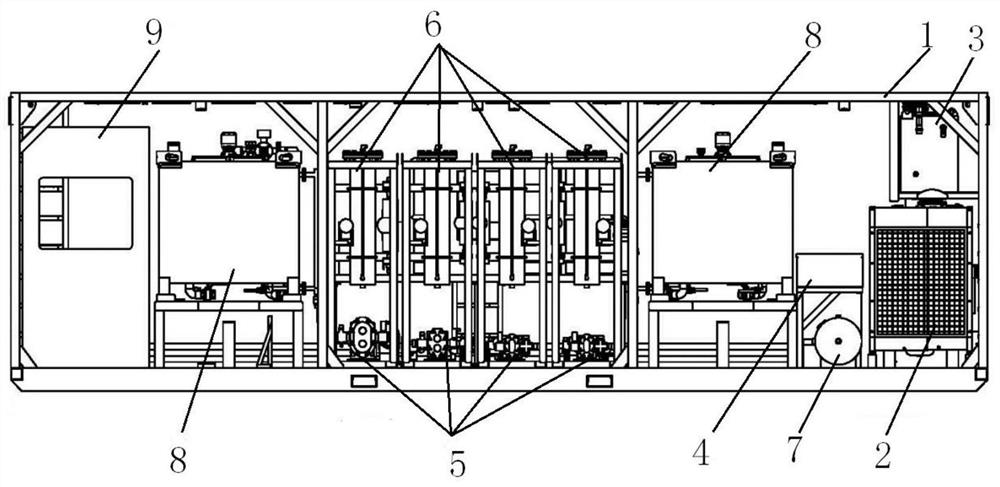

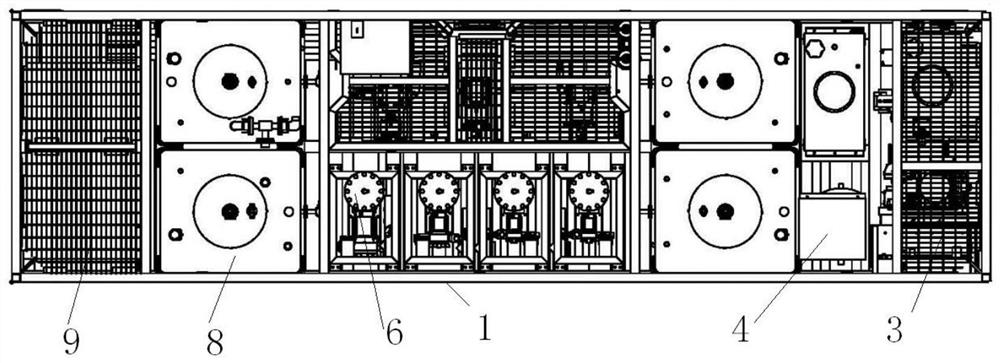

Full-automatic liquid adding device for fracturing construction and adding calibration method

PendingCN112196508AStable structureStructure, stable installationMass flow measurement devicesTransportation and packagingTransfer caseControl engineering

The invention belongs to the technical field of fracturing construction mechanization, and particularly provides a full-automatic liquid adding device for fracturing construction and an adding calibration method. The full-automatic liquid adding device comprises a prying frame, an engine, a transfer case, a hydraulic device, a liquid adding pump, a metering calibration tank, a liquid additive tank, a liquid supply pump and a control unit, wherein the input ends of the engine, the transfer case and the hydraulic device are sequentially connected; the output end of the hydraulic device is connected with the liquid supply pump and the liquid adding pump; the liquid supply pump is connected with an inlet of the liquid additive tank; an outlet of the liquid additive tank is sequentially connected with inlets of the metering calibration tank, the liquid adding pump and the liquid additive tank; the control unit is electrically connected with the engine, the transfer case, the hydraulic device, the liquid adding pump, the metering calibration tank, the liquid supply pump and the liquid additive tank; and the current situation that in the fracturing construction process, the liquid additive adding precision is large in adding difficulty and discontinuous is avoided, the mechanization and automation degree of fracturing construction is improved, meanwhile, the construction quality and potential safety hazards are effectively eliminated, and the construction success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

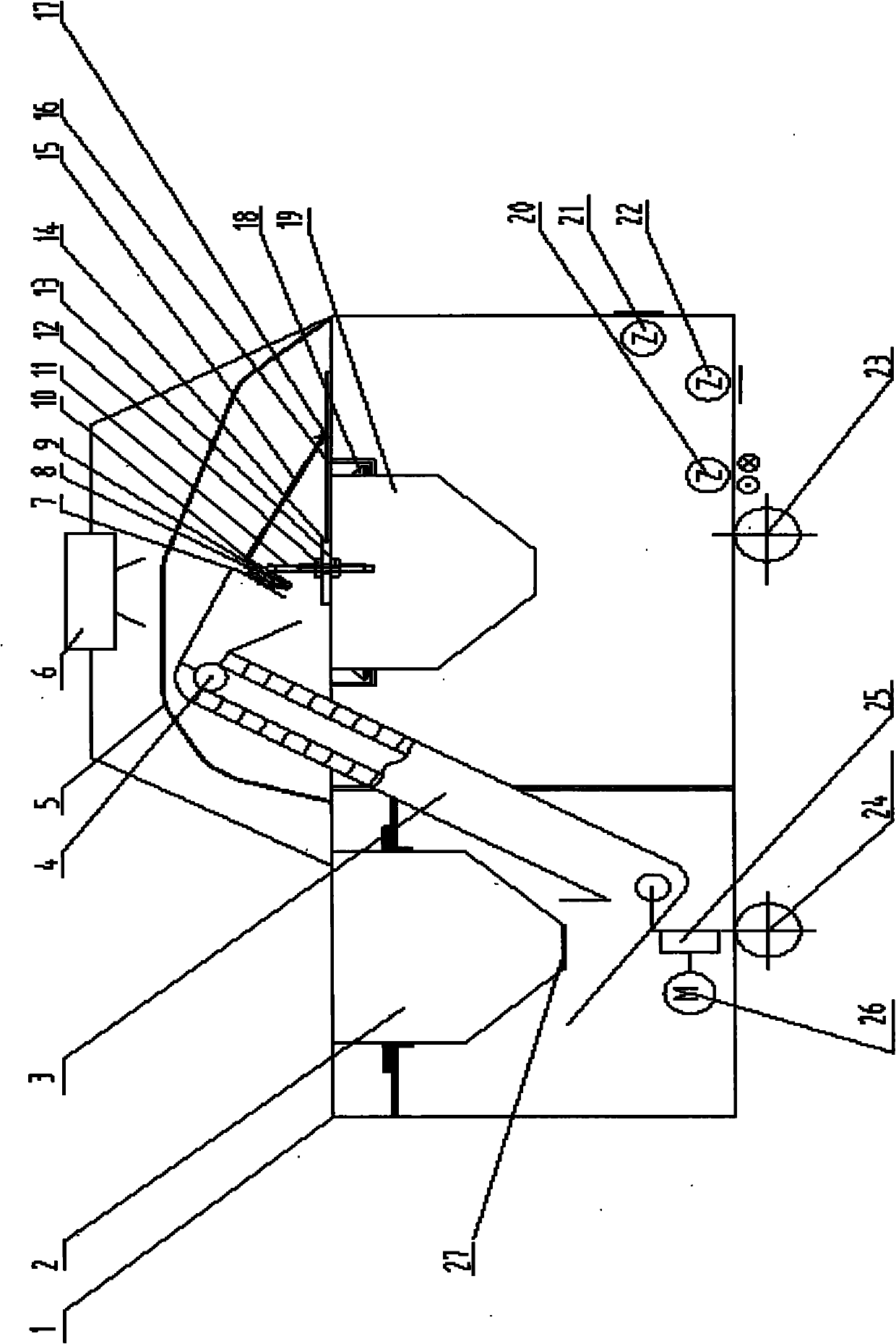

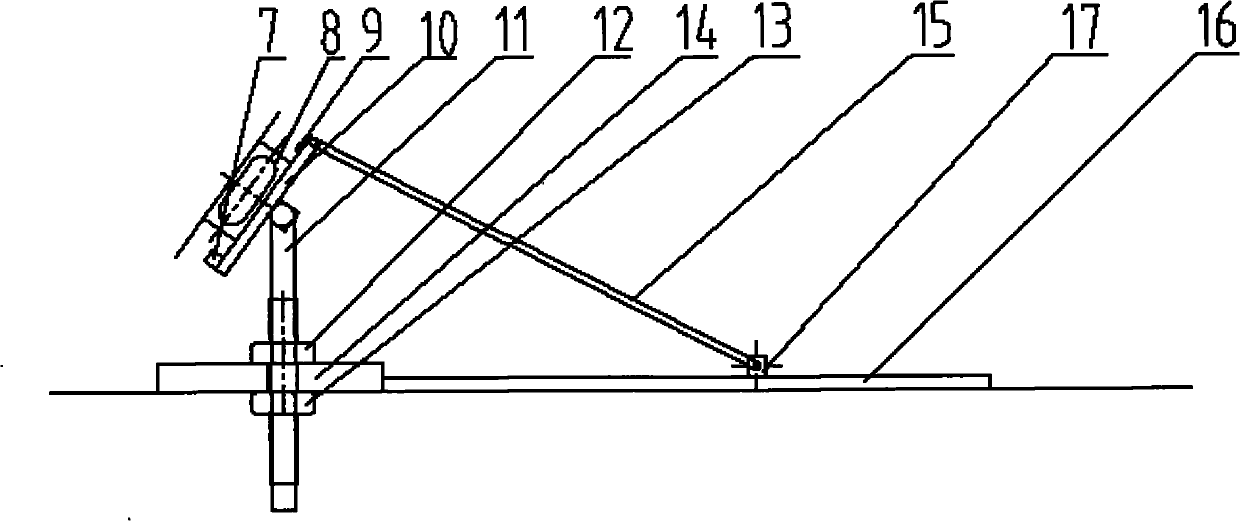

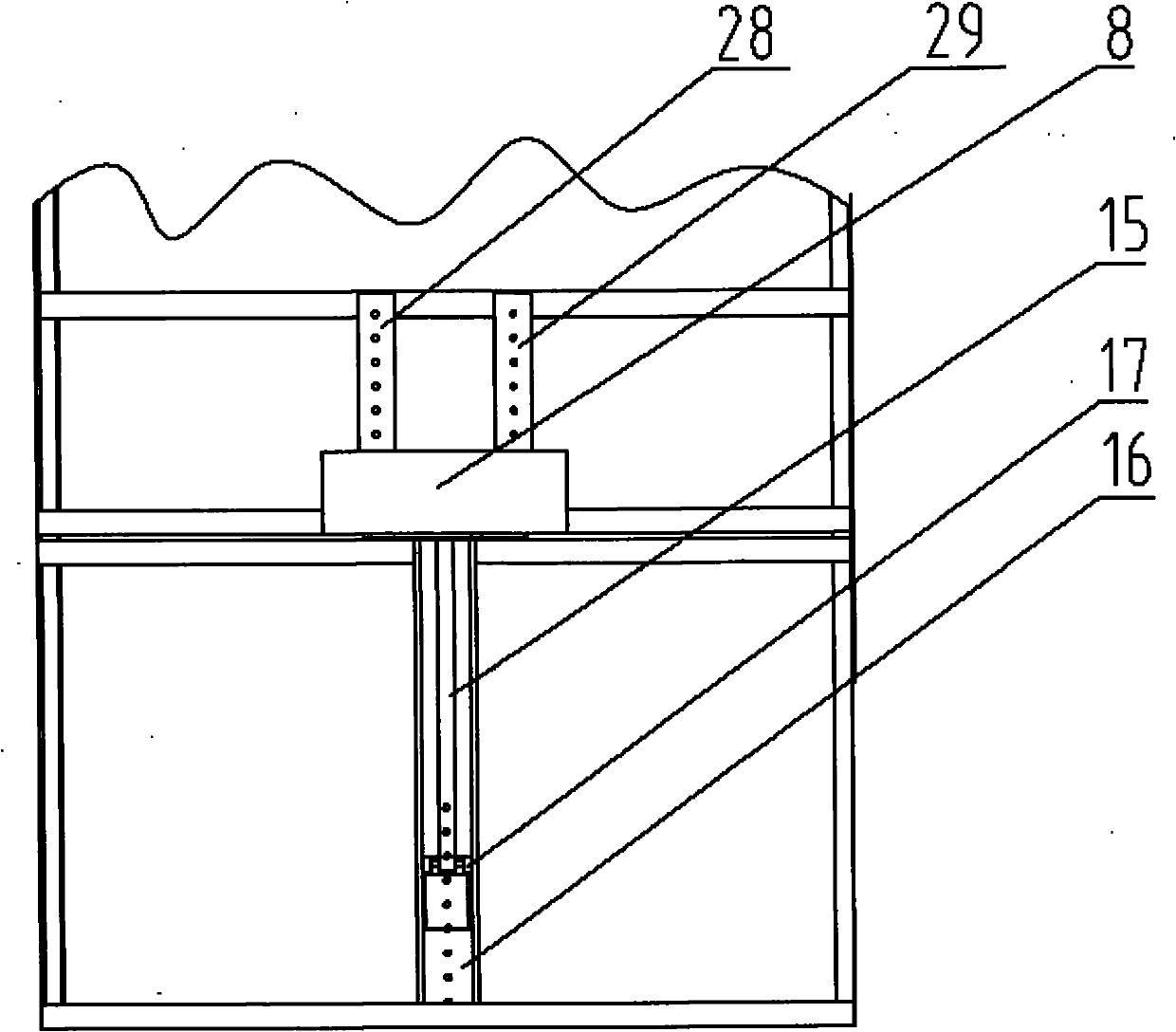

Impulse type grain mass flow sensor calibrating and testing device

InactiveCN101995284ARealize automated detectionEasy to installMass flow measurement devicesTesting/calibration apparatusFrequency changerElectric machine

The invention discloses an impulse type grain mass flow sensor calibrating and testing device, which relates to the field of grain mass flow sensor calibrating and test machines. The impulse type grain mass flow sensor calibrating and testing device comprises a machine frame (1), a net rice elevator (3), a hopper A (2), a hopper B (19), a rotating speed sensor (4), a vibration sensor (7), a tilt angle sensor (9), a hopper scale (18), a grain flow sensor mounting position adjusting device, a grain mass sensor mounting position adjusting device, three vibration motors, a three-phase asynchronous motor (26), four frequency converters, a high-speed camera acquisition system (6), a monitoring storage system and four wheels. The impulse type grain mass flow sensor calibrating and testing device is simple in mounting and is convenient to detach and move. After an impulse type grain flow sensor is calibrated on the testing device, the impulse type grain flow sensor can be directly arranged on a combine harvester to operate.

Owner:JIANGSU UNIV

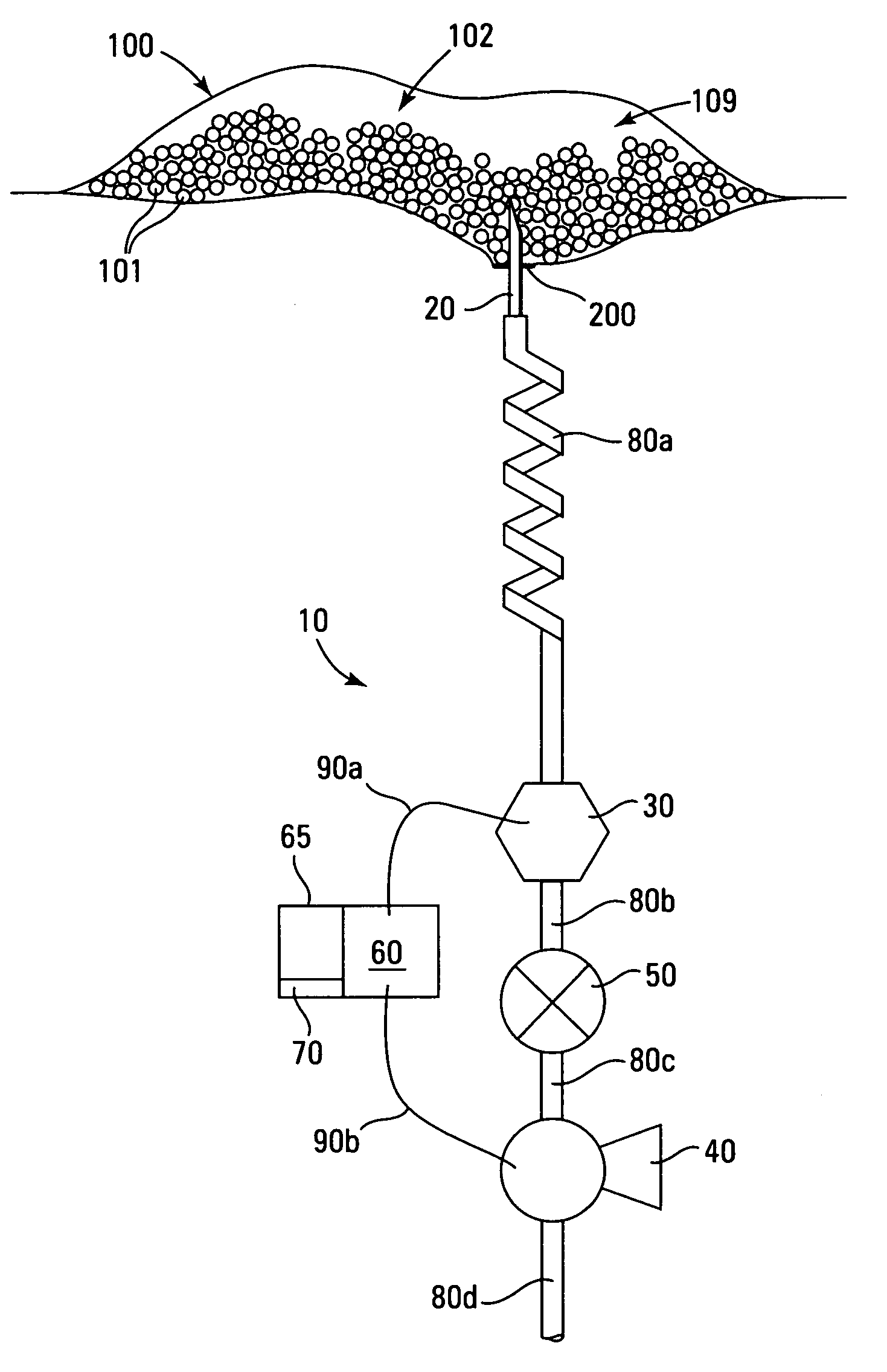

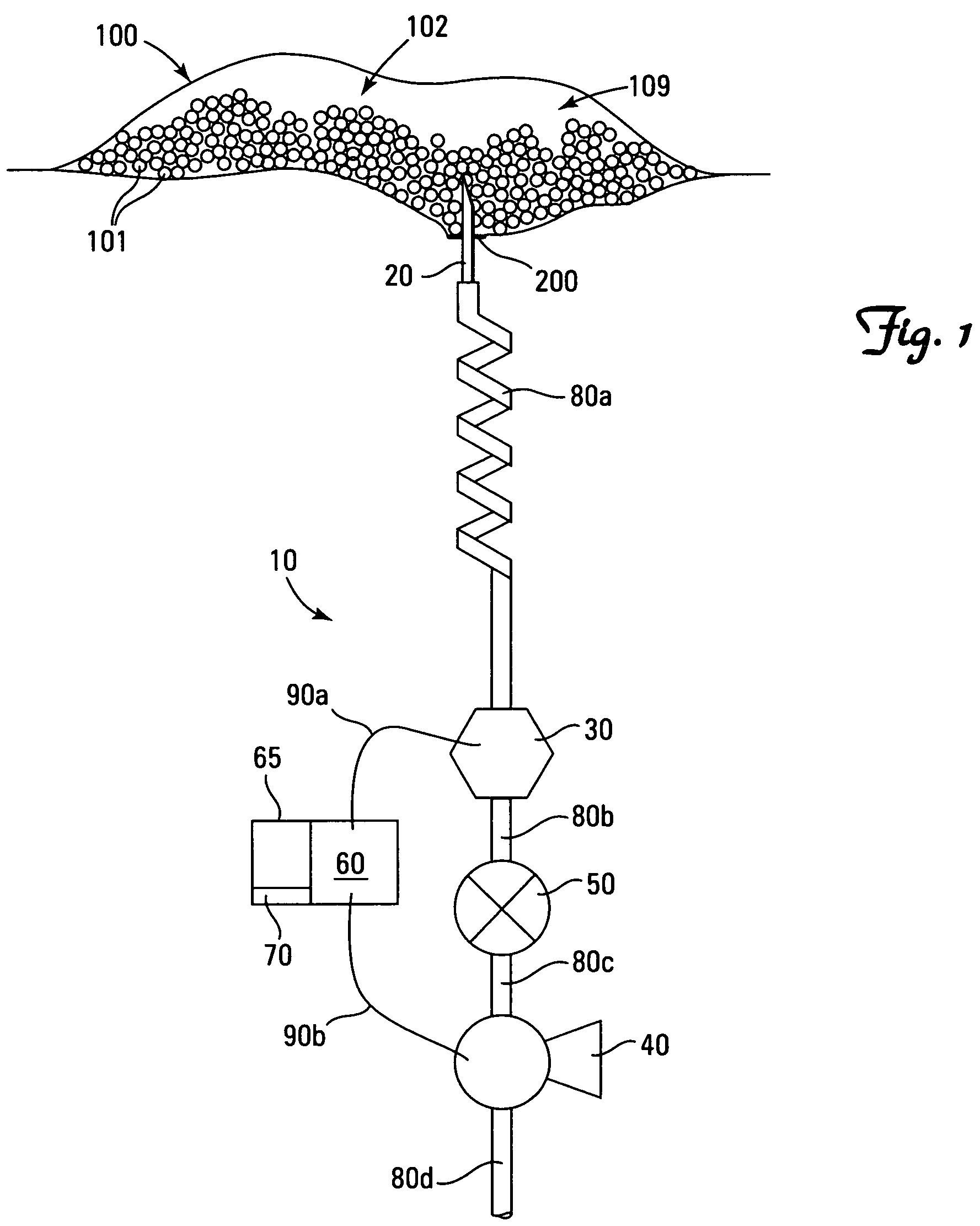

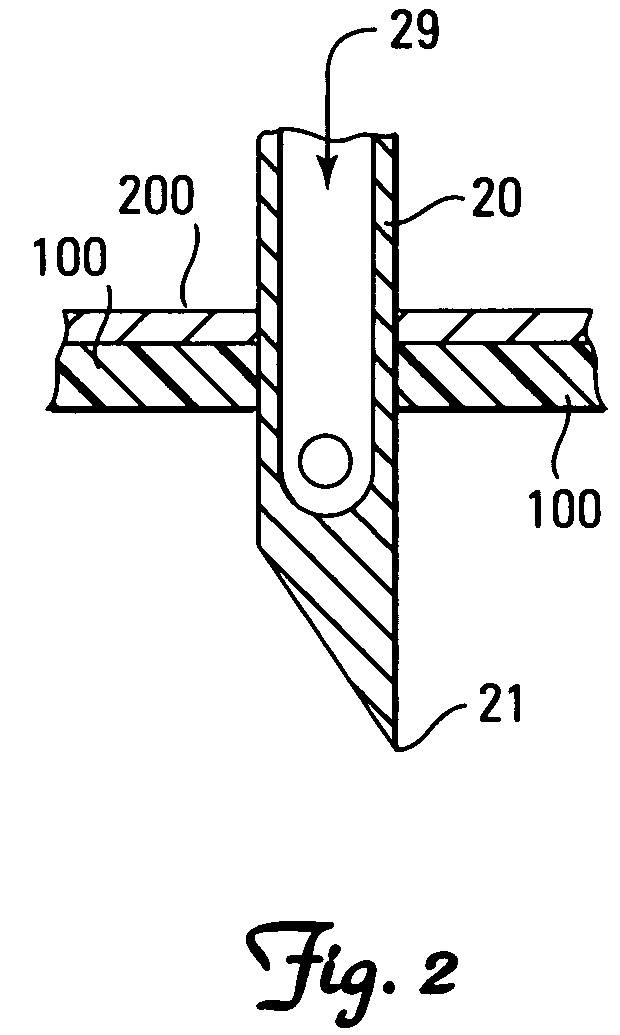

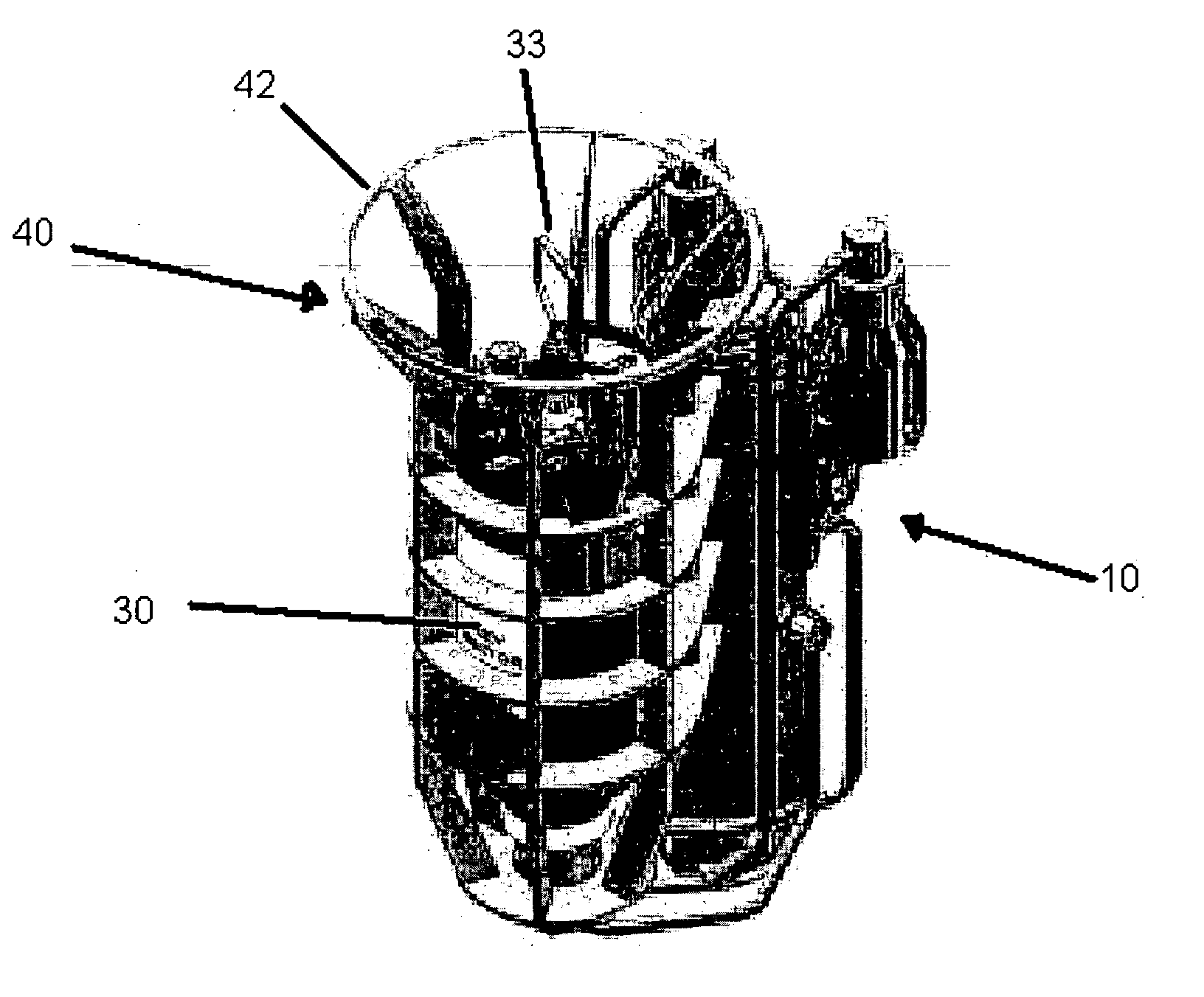

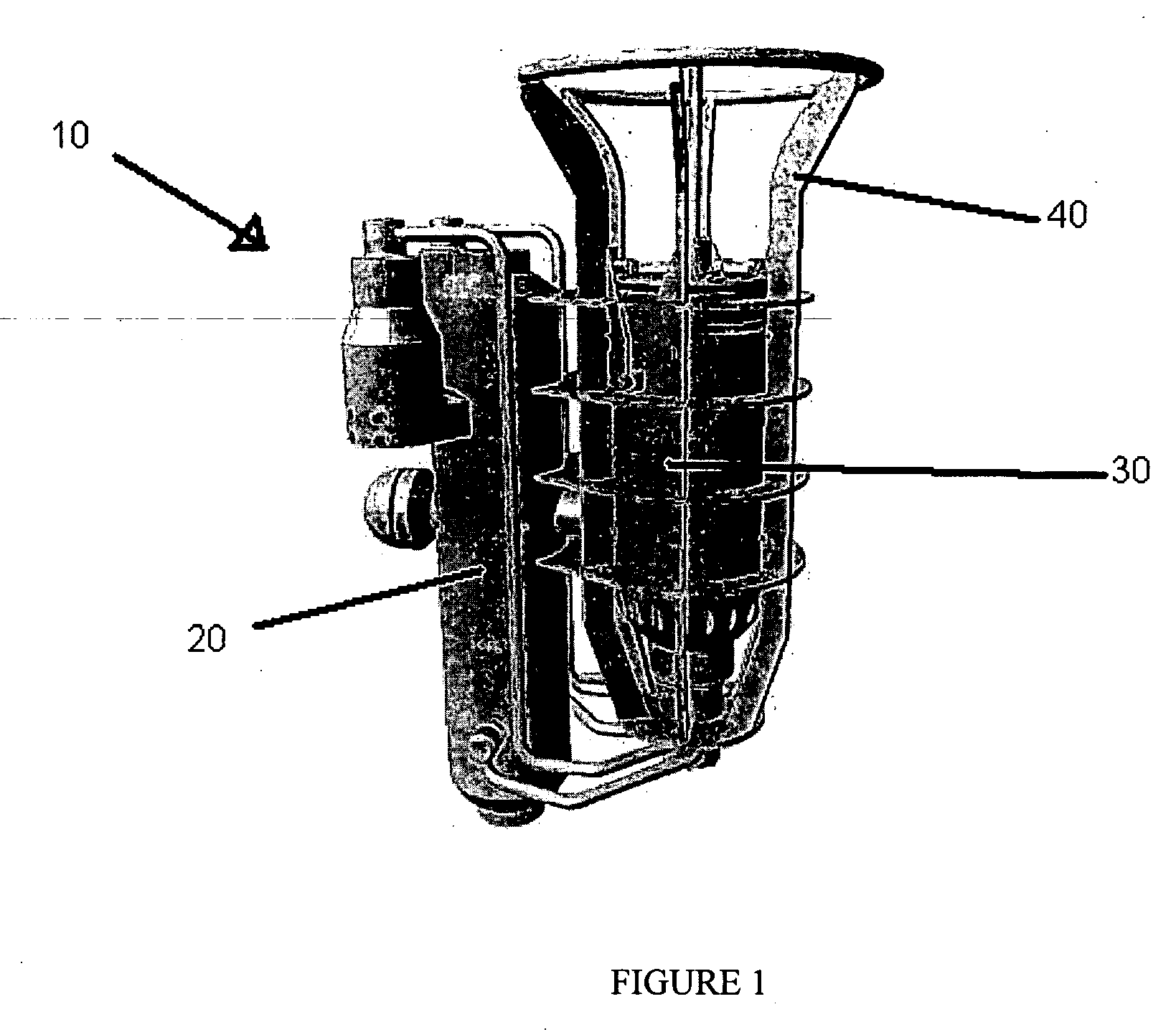

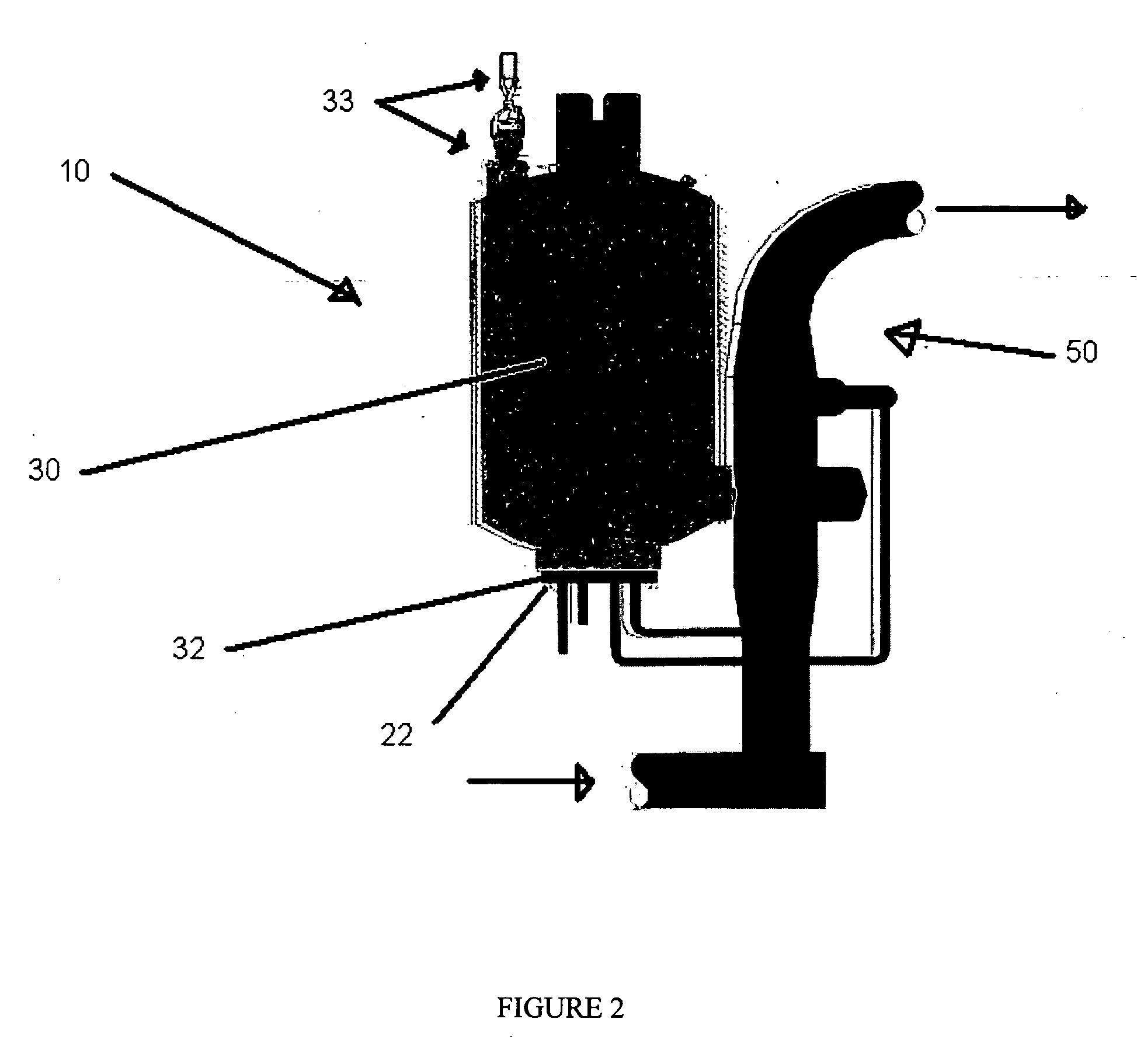

Method of measuring flow rate of flowable material under continuous flow conditions, and an in-line continuous flow meter

A method of determining the rate of flow of a flowable material, particulate or liquid, through a flowable material passageway, comprising causing the material passing through the passageway to move downwardly by gravity slowing the downward movement of material as compared to free falling gravitational movement measuring the weight of material passing slowly downwardly with respect to the passageway; causing an electronic signal to be generated in response to the magnitude of the weight measuring; and connecting the electronic signal to a read out display to reflect the flow rate of material with respect to units of weight with respect to units of time.

Owner:IOWA STATE UNIV RES FOUND

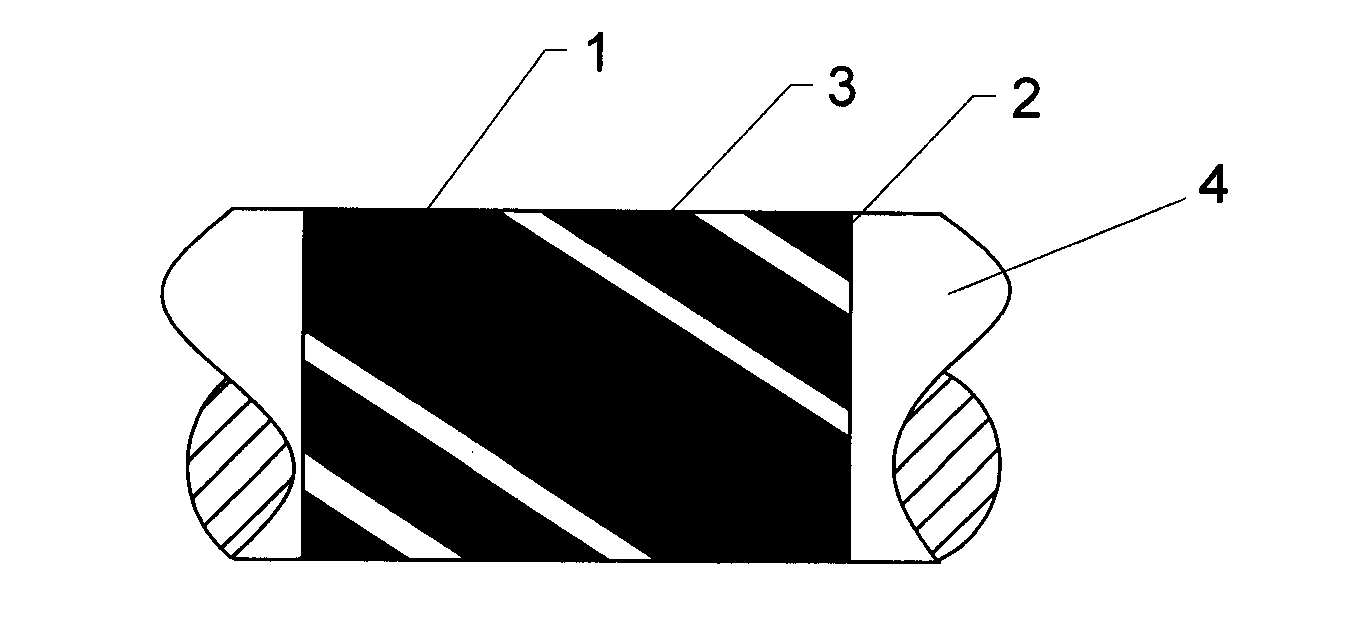

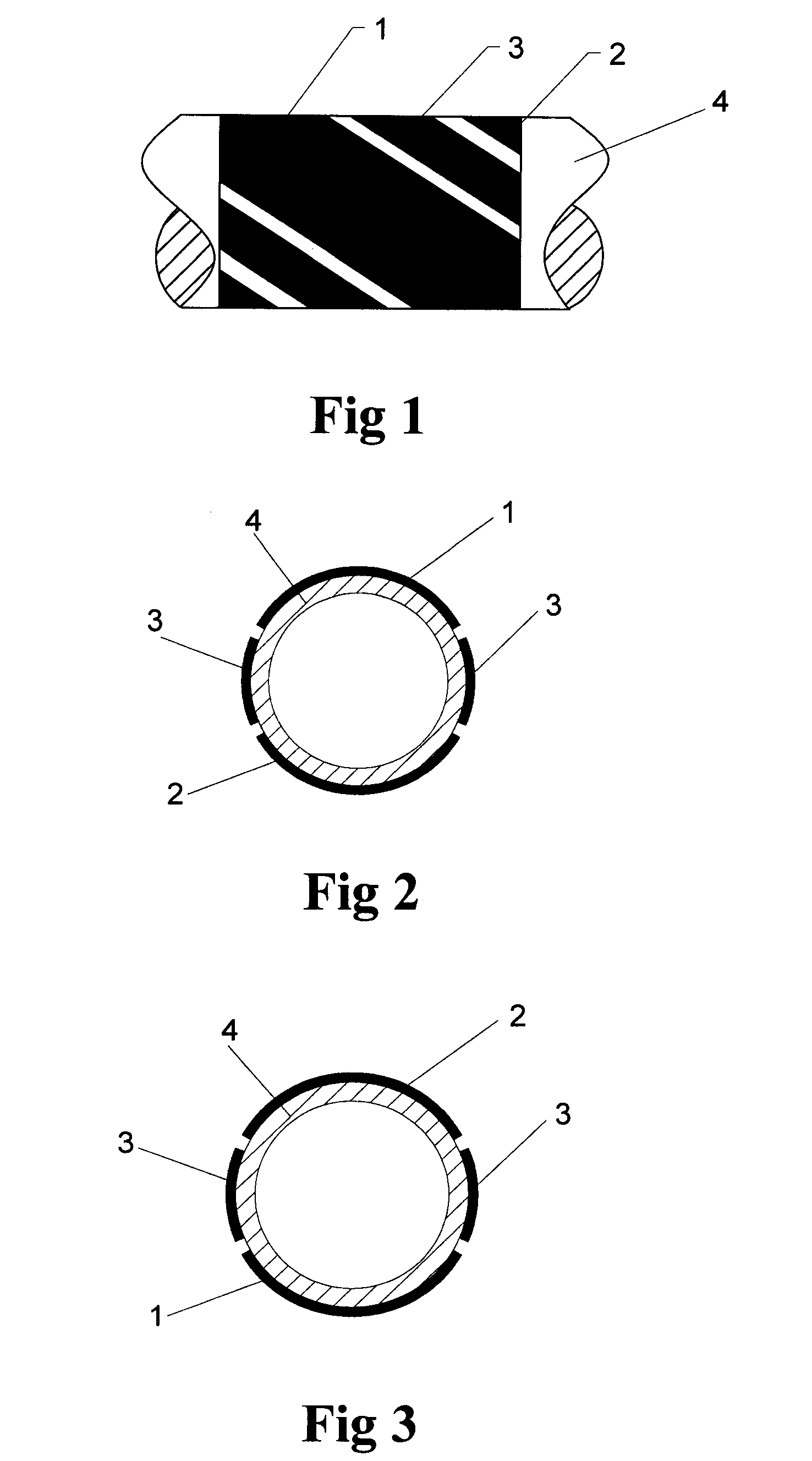

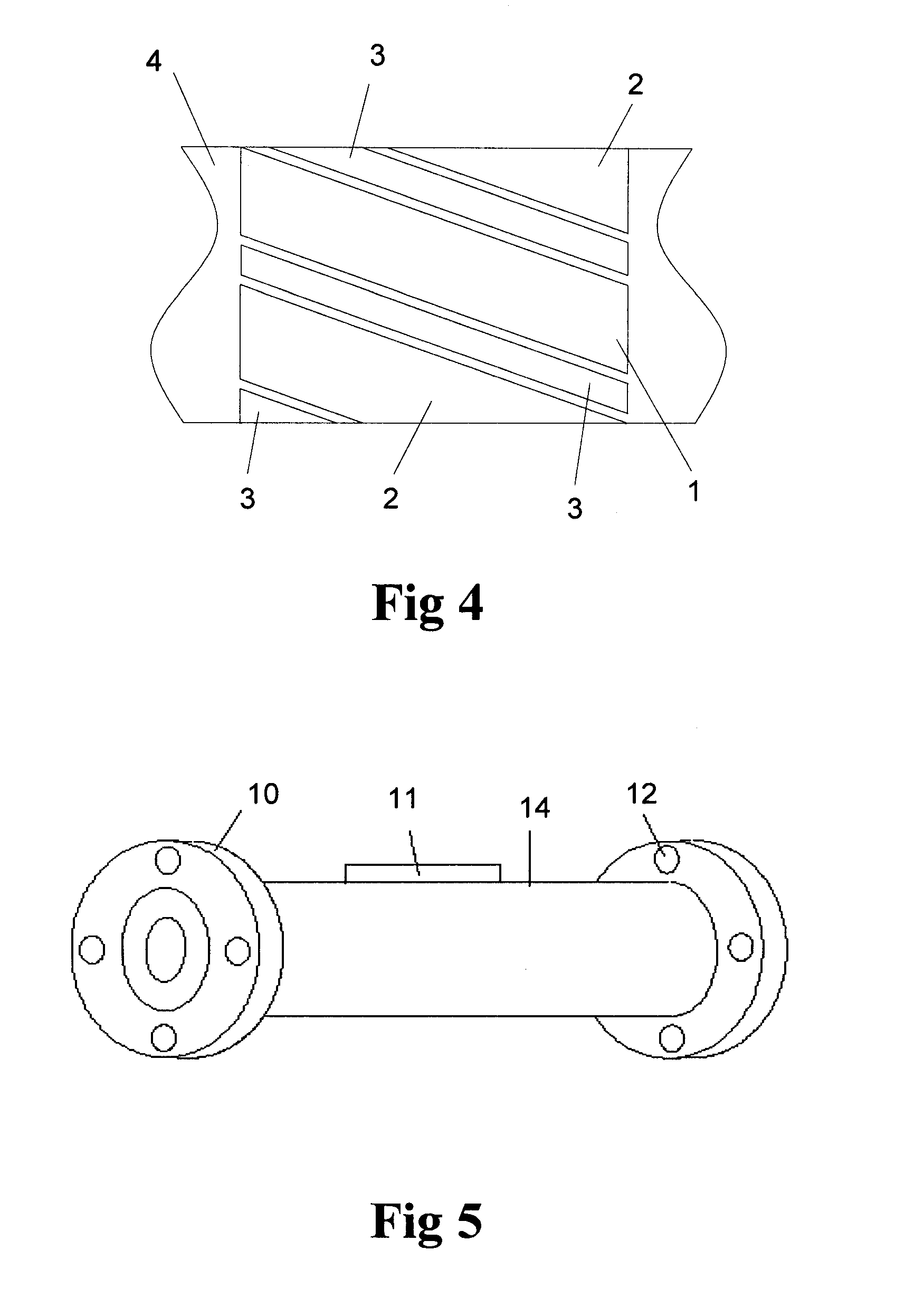

System, Method, And Device For Measuring Parameters Of A Two-Phase Flow

InactiveUS20100107775A1Accurate measurementMass flow measurement devicesVolume/mass flow by electric/magnetic effectsRemote controlComputerized system

A capacitive sensor for measuring flow parameters of a two-phase flow, a device for measuring phase concentration of a two-phase flow, and a system and method for measuring flow parameters of a two-phase flow is disclosed. In the capacitive sensor, at least one pair of electrodes is twisted by 180° in a common direction into a spiral shape. Edge guard electrodes are twisted in the common direction and are formed between adjacent electrode edges. Problems of non-homogeneous sensitivity distribution of a measuring field and soft field effect can be effectively addressed, thereby allowing reliable and accurate measurement of phase concentration of a two-phase flow. The system for measuring flow parameters of the two-phase flow can output signals with a current of 4˜20 mA to a PLC system or communicate with an industrial process control computer or with a remote control computer system in a operating room.

Owner:NORTHEASTERN UNIV

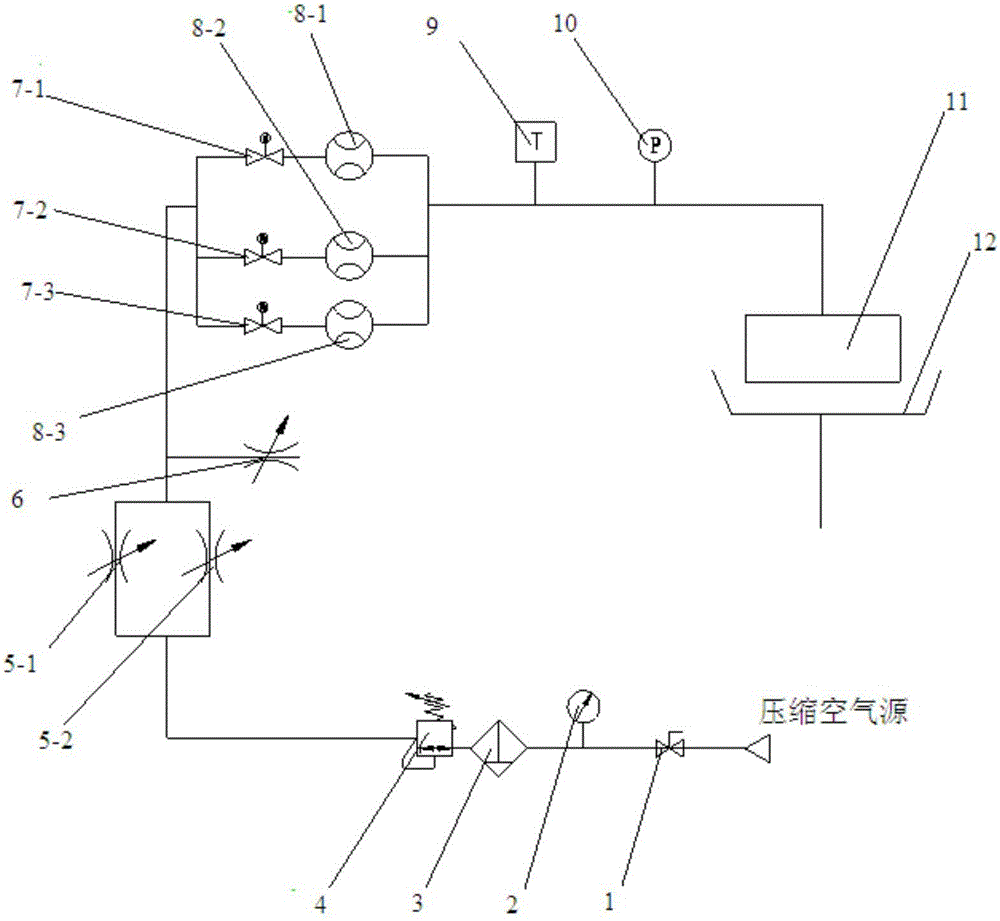

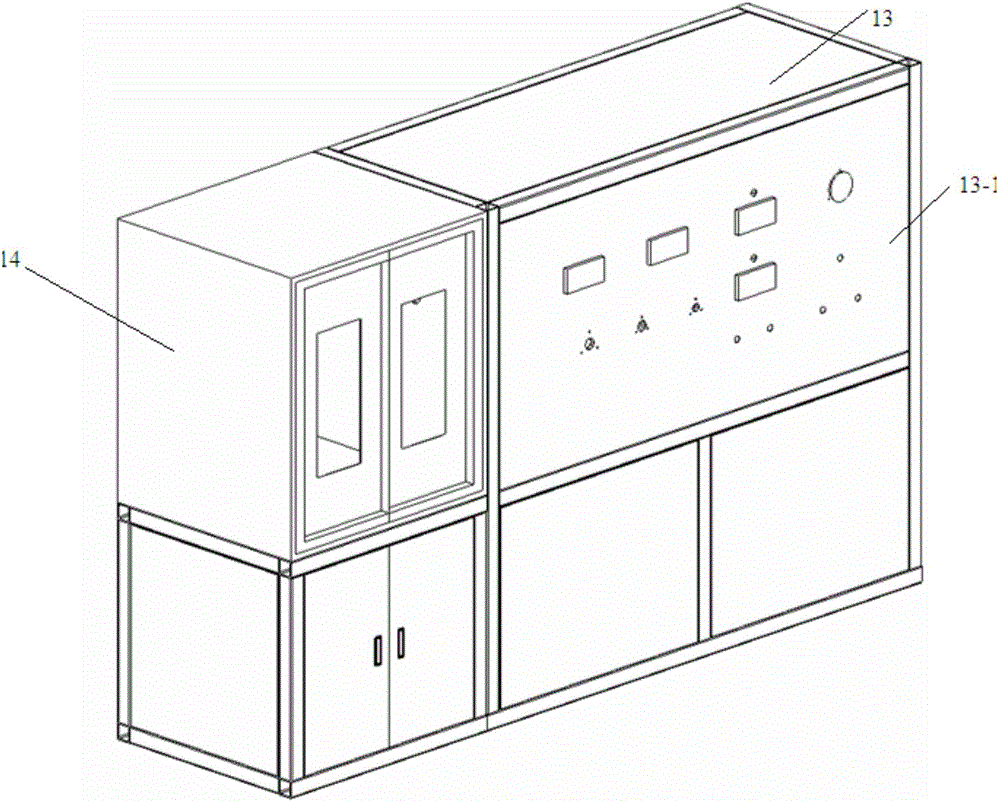

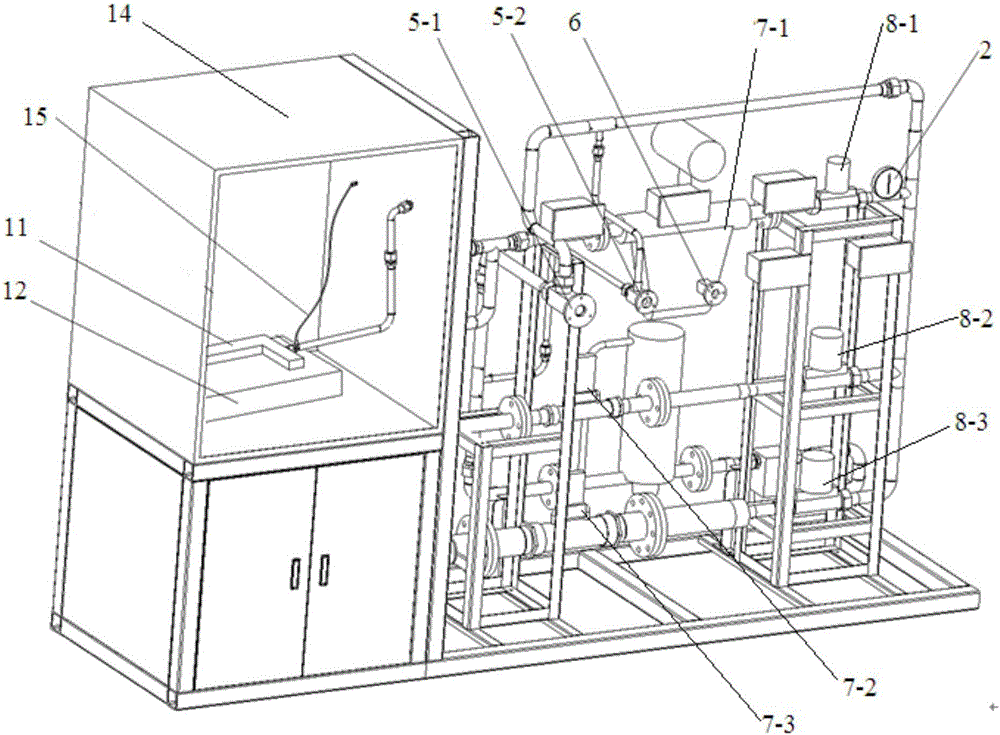

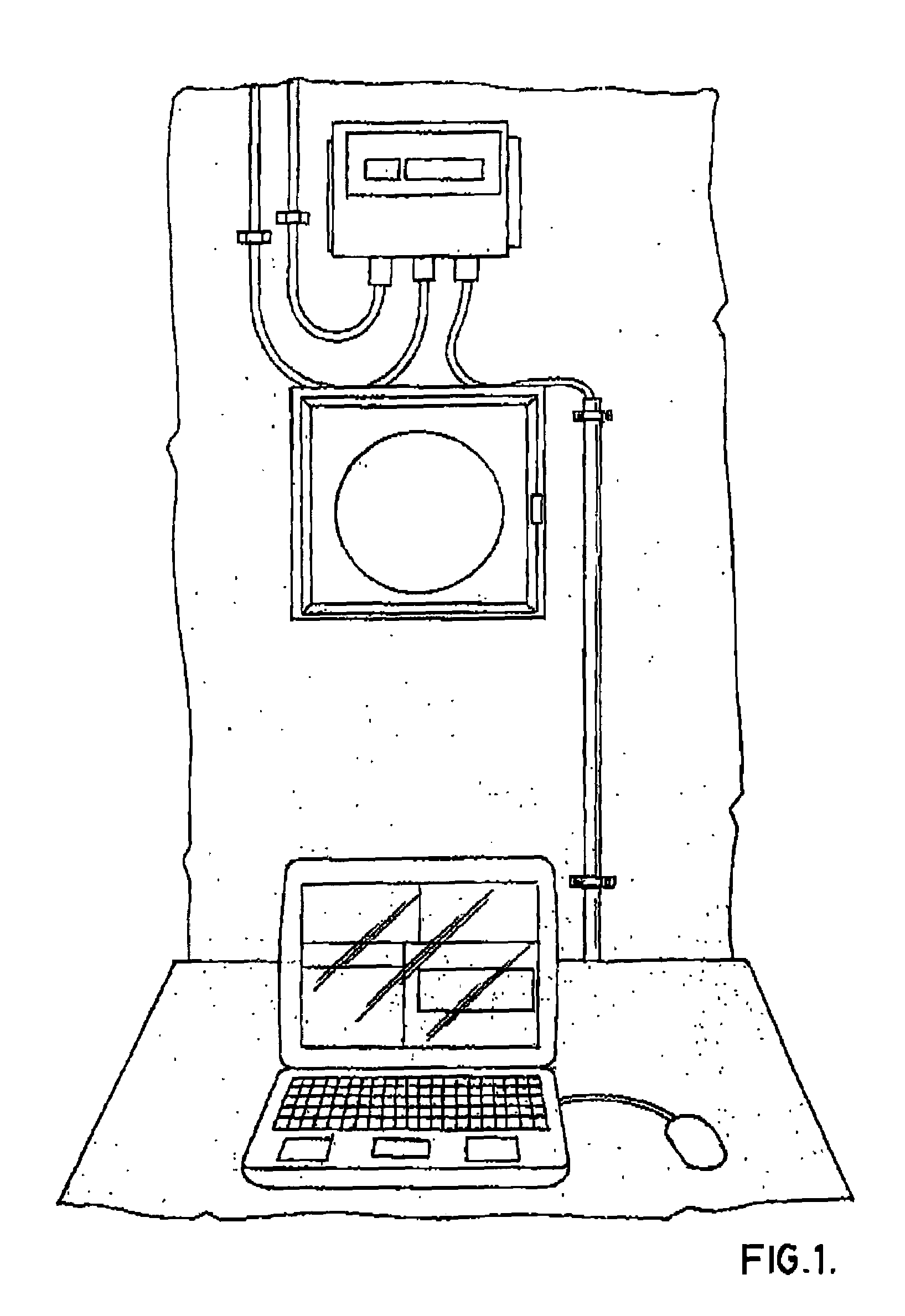

Aero-engine turbine blade air mass flow testing device

InactiveCN106643942AAir flow test facilitatedHigh measurement accuracyMass flow measurement devicesAviationTurbine blade

The invention provides an aero-engine turbine blade air mass flow testing device. The testing device comprises an inlet valve, a pressure gauge, a filter, a self-operated pressure maintaining valve, a main path adjustment valve, a bypass fluid passage provided with a bypass adjustment valve, at least two multipled measuring by-paths, a temperature sensor, a pressure sensor, a blade clamp and a worktable. Each measuring by-path is provided with a stop valve and a flowmeter from an inlet end to an outlet end in sequence, and the flowmeter of each measuring by-path has different measuring ranges. The provided aero-engine turbine blade air mass flow testing device is used for making testing the conditions of film holes of turbine blades and internal fluid passage processing convenient, and provides reference for choosing installed blades.

Owner:四川成发普睿玛机械工业制造有限责任公司

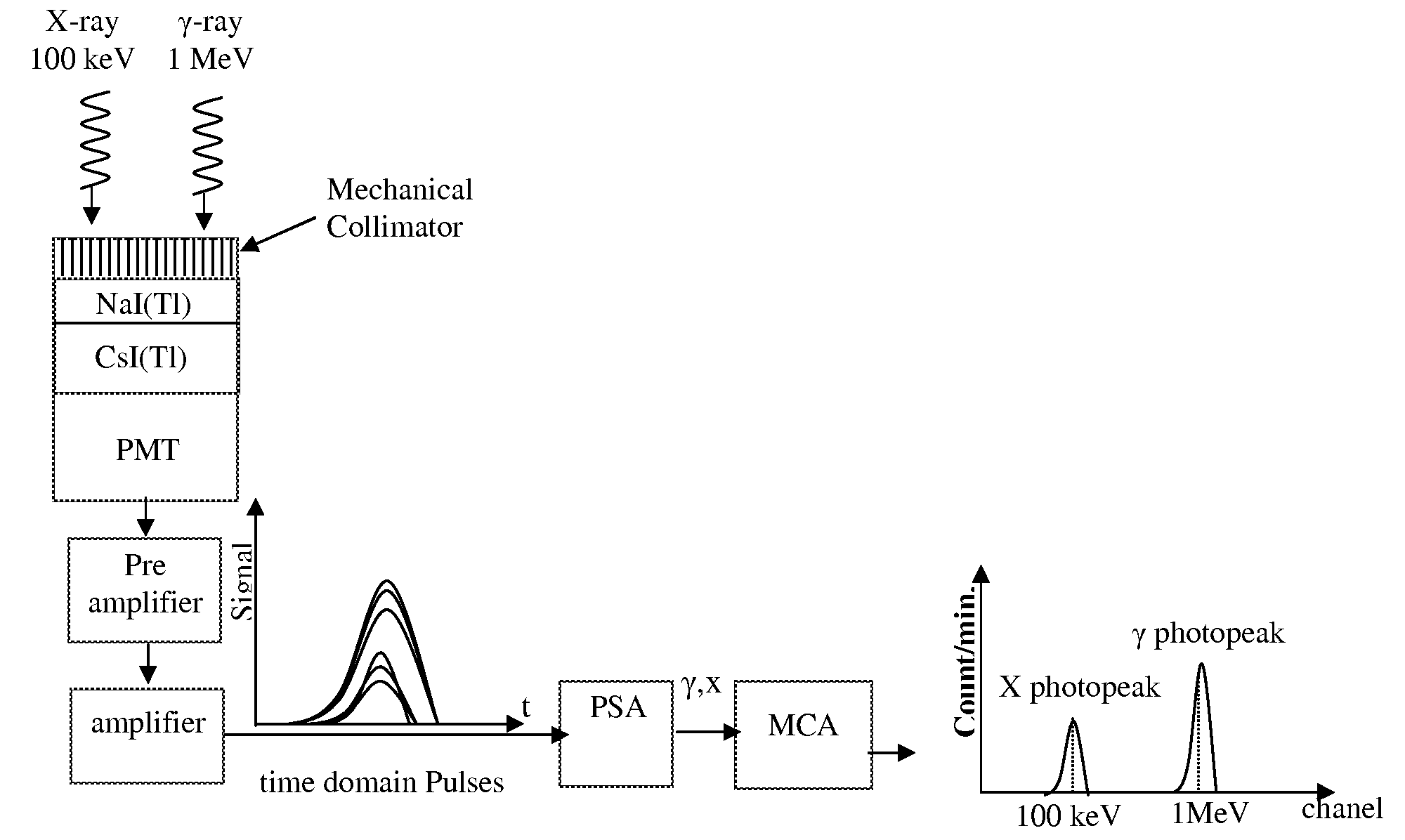

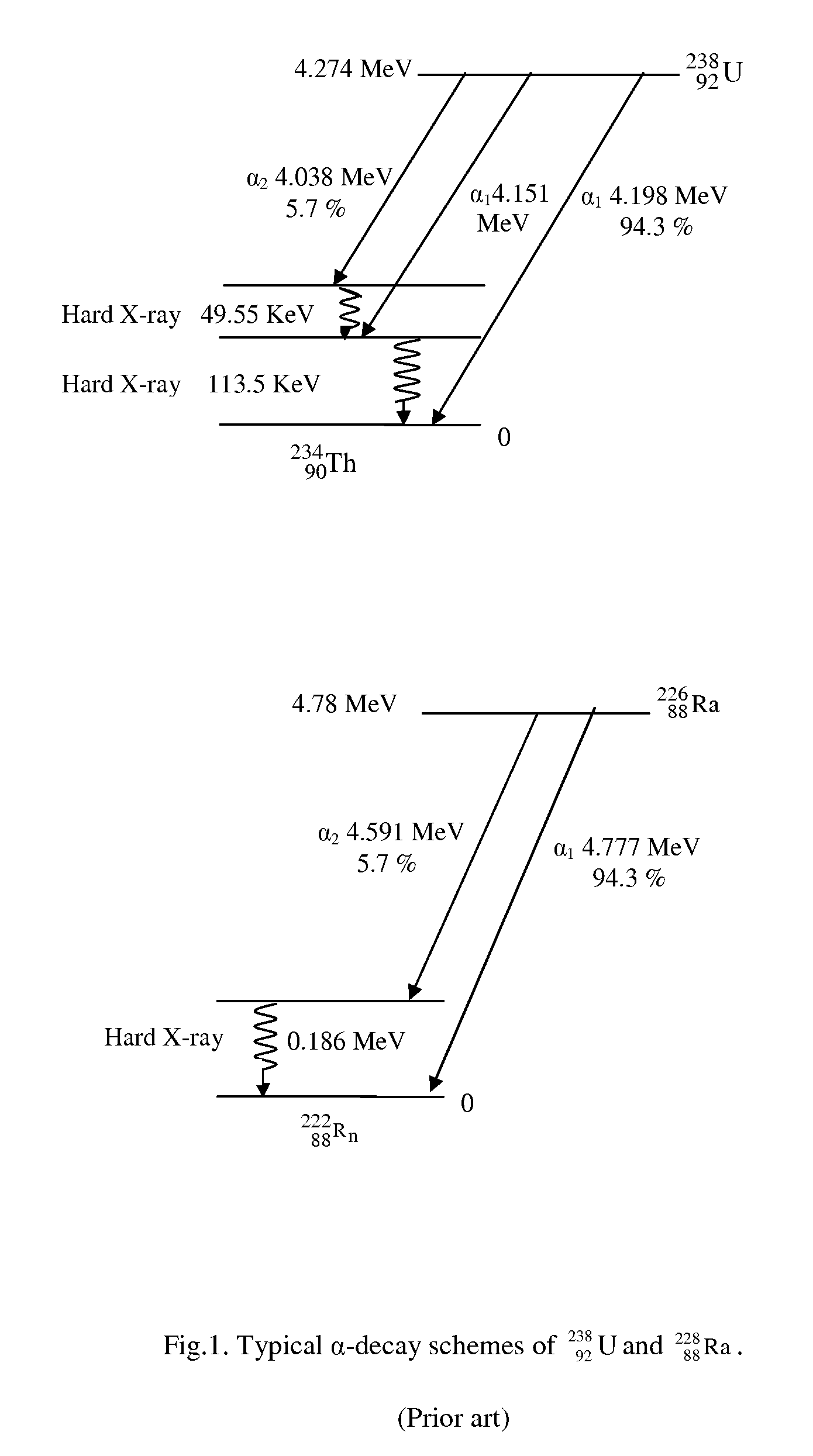

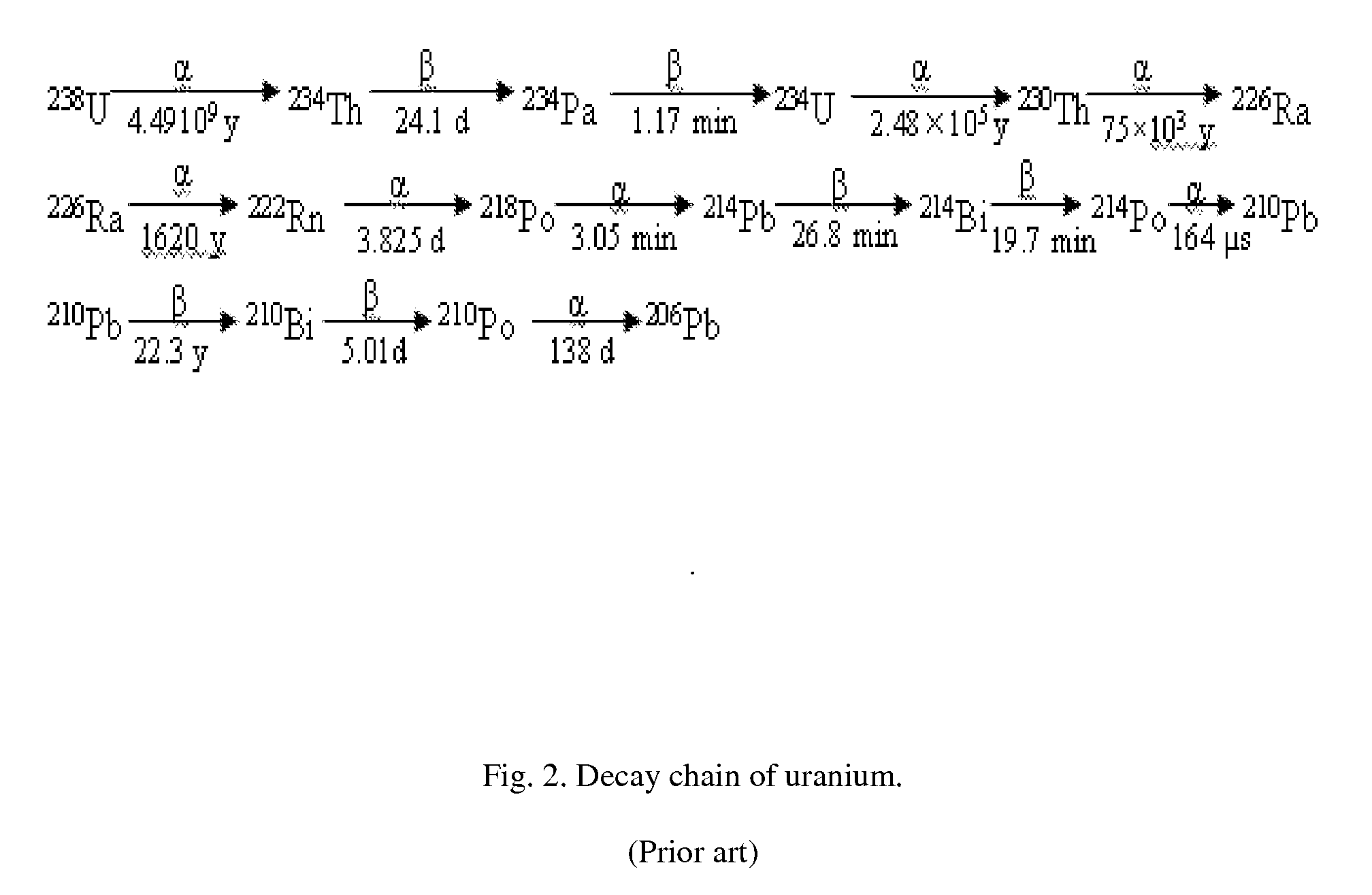

DIAL-Phoswich hybrid system for remote sensing of radioactive plumes in order to evaluate external dose rate

InactiveUS20080149838A1Rapid responseHigh gainMass flow measurement devicesMaterial analysis by optical meansDose rateNuclear power

An interactive combination of Phoswich detector array (PDA) and differential absorption lidar (DIAL) is proposed to trace the unknown radioactive plumes released into the atmosphere from a reactor stack, containment of the nuclear power plants, radioisotope separation laboratories, reprocessing plants or the uranium conversion facilities. The hybrid system represents a powerful technique for the prompt identification and quantification of the effluents with various radionuclide contents to determine the corresponding external dose rate accordingly.

Owner:SHAHI LAILA

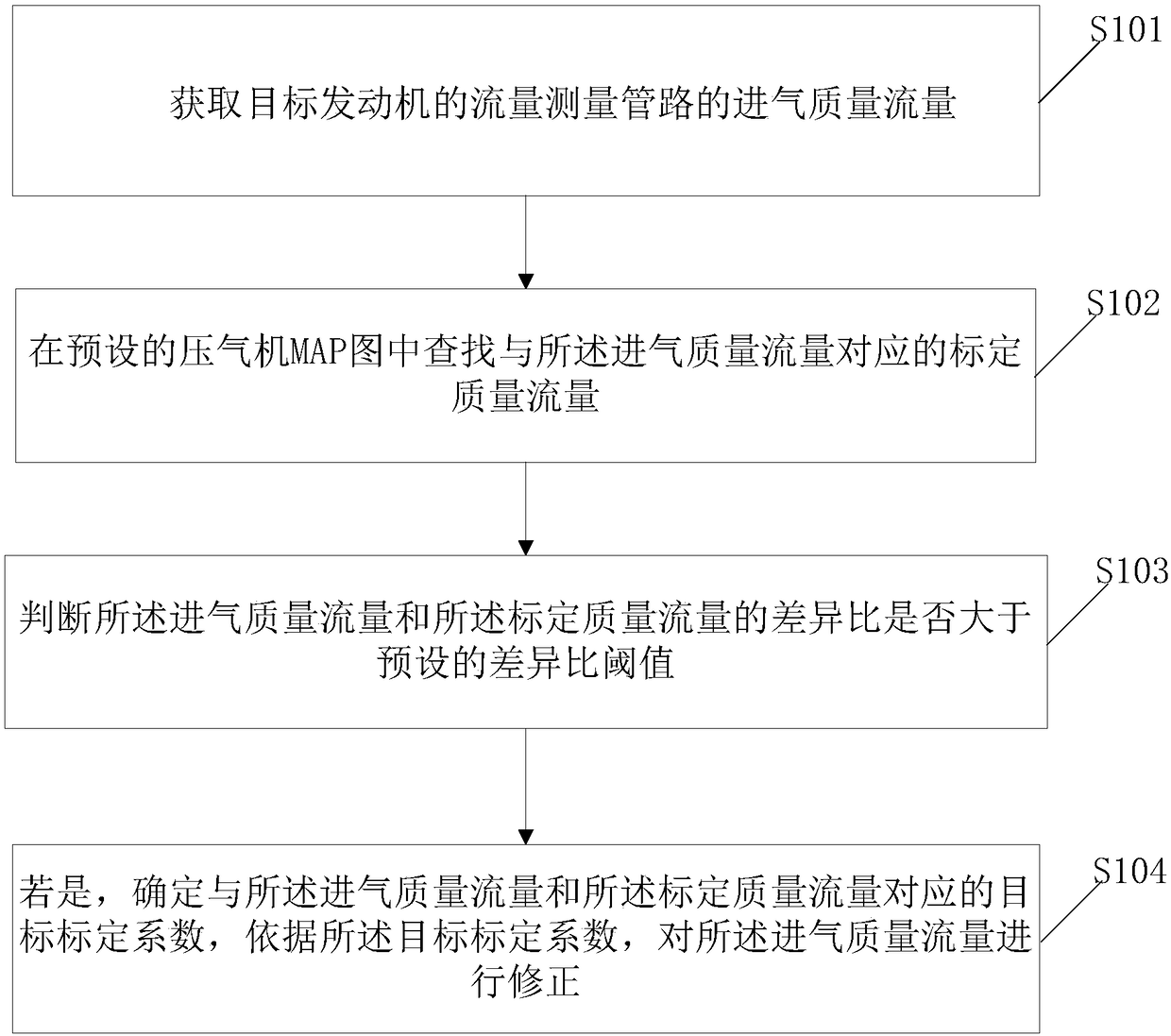

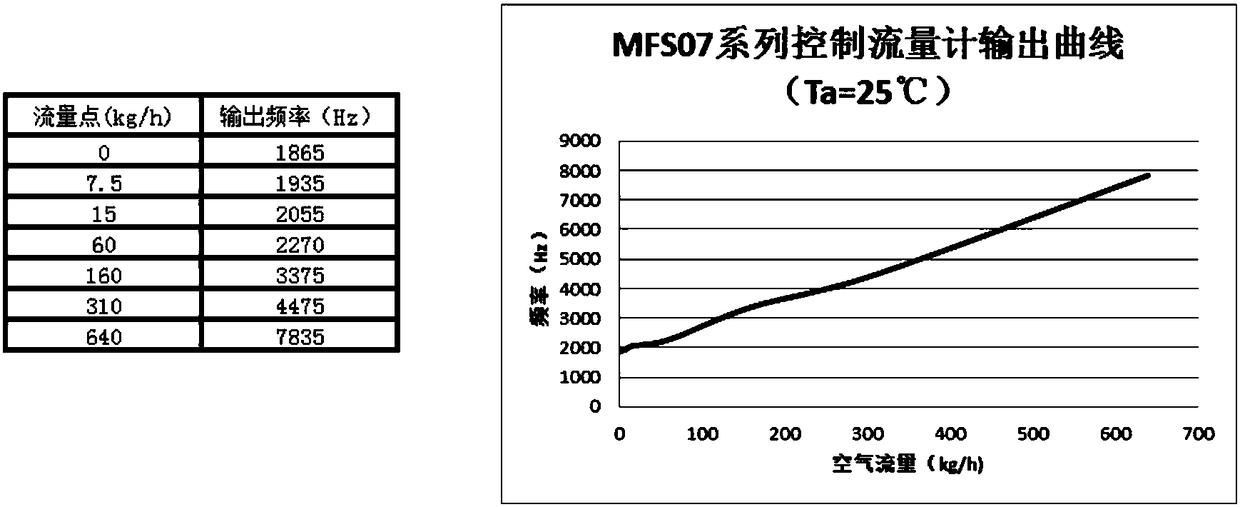

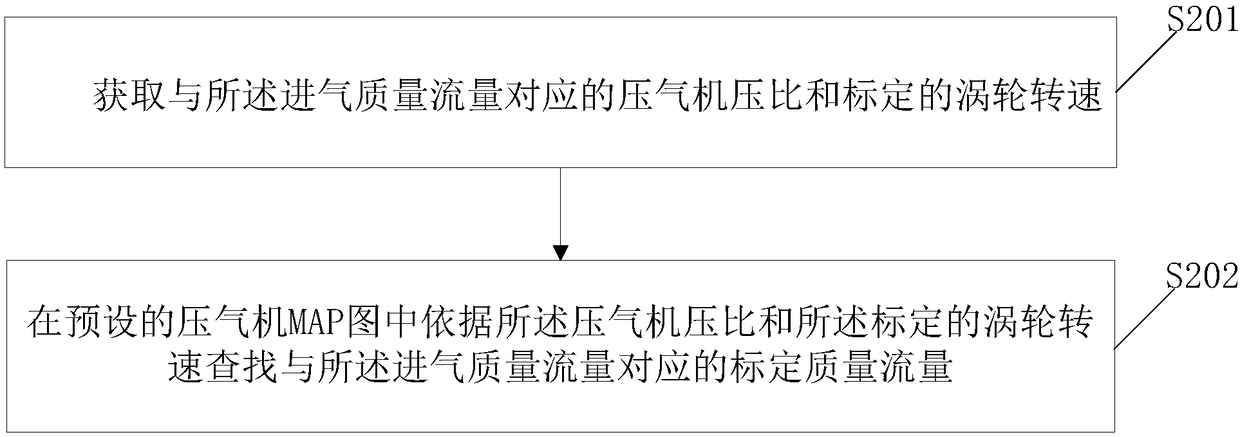

Method and system for correcting air mass flow

ActiveCN108195591AAvoid inaccurate measurementsMass flow measurement devicesInternal-combustion engine testingOriginal equipment manufacturerDischarge measurements

The invention discloses a method for correcting air mass flow. The method includes: acquiring the air mass flow of the flow measuring pipeline of a target engine; searching for calibration mass flow,corresponding to the air mass flow, in a preset air compressor MAP; judging whether the difference ratio between the air mass flow and the calibration mass flow is larger than a preset different ratiothreshold or not; if so, determining a target calibration coefficient corresponding to the air mass flow and the calibration mass flow, and correcting the air mass flow according to the target calibration coefficient. When the method is used to perform correction at a certain time interval, the acquired air mass flow is corrected according to the preset air compressor MAP, and the problem that anexisting air mass flow measuring method is inaccurate in measuring due to the fact that a flow sensor is sensitive to pipelines and environments and the arrangement and use of the air inlet pipelinesin an automotive original equipment manufacturer generate measuring drifting.

Owner:WEICHAI POWER CO LTD +1

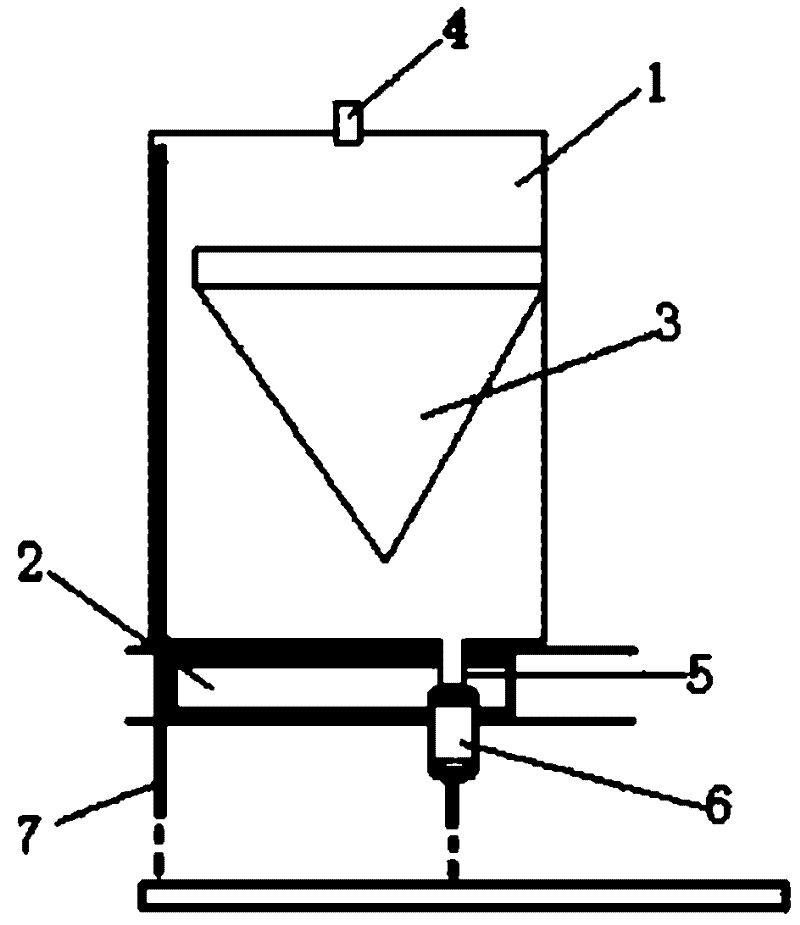

Mass flow meter based on weighing method

InactiveCN102252720AReduce measurement errorSolve the blockageMass flow measurement devicesWater flowWater circulation

The invention discloses a mass flow meter based on a weighing method. The mass flow meter comprises a container; the upper part of the container is provided with a water inlet, the lower part of the container is provided with a water outlet, and the bottom of the container is provided with a weighing sensor; and a flow guide and impact resistance device is arranged below the water inlet in the container. The mass flow meter can reduce the measurement error of the weighing sensor which is caused by liquid compact force during dynamic measurement of flow, and filter large impurity of water to solve the problem of blockage of pipelines and a water circulation system.

Owner:NAT INST OF NATURAL HAZARDS MINISTRY OF EMERGENCY MANAGEMENT OF CHINA

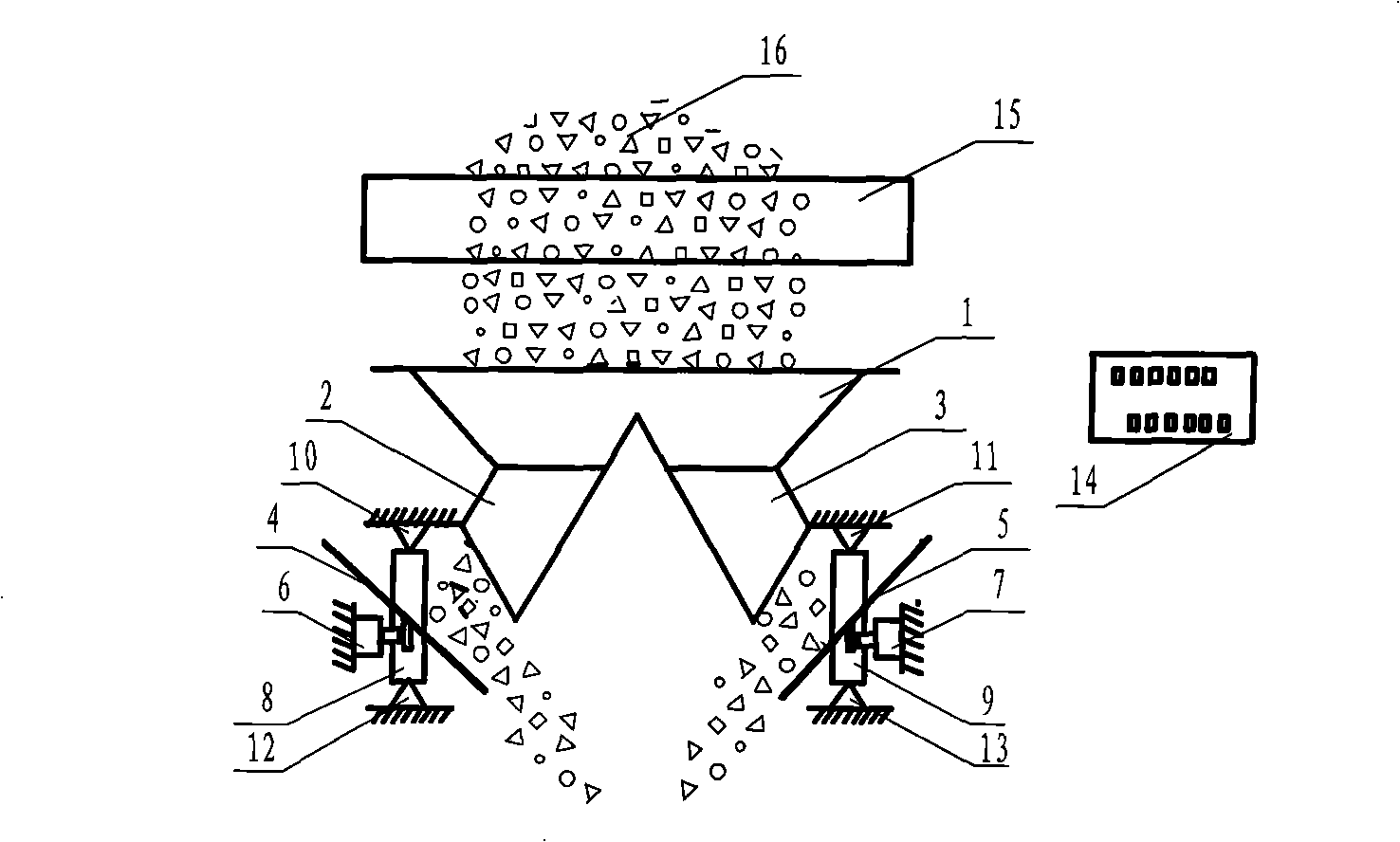

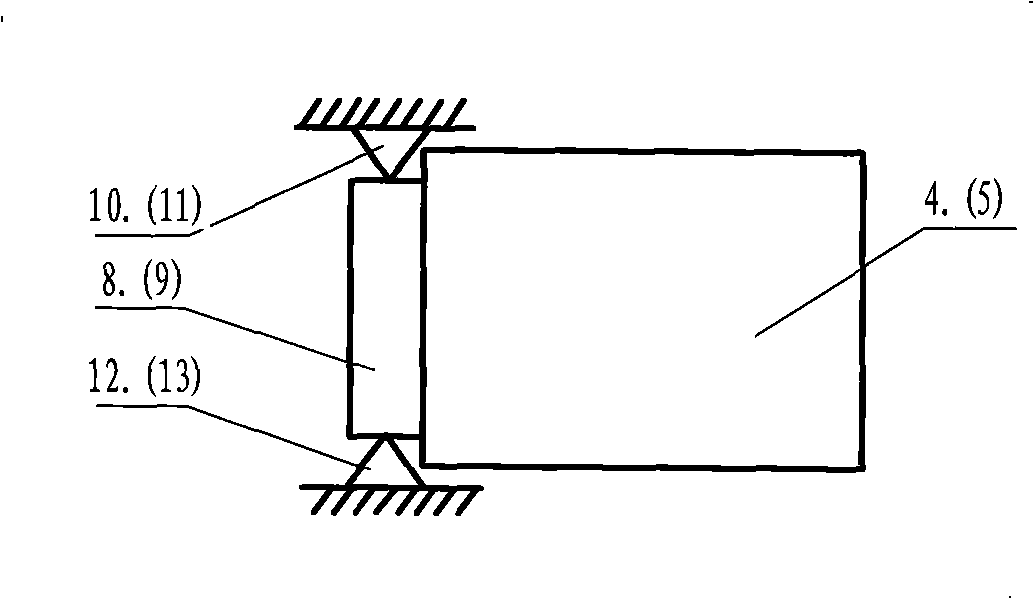

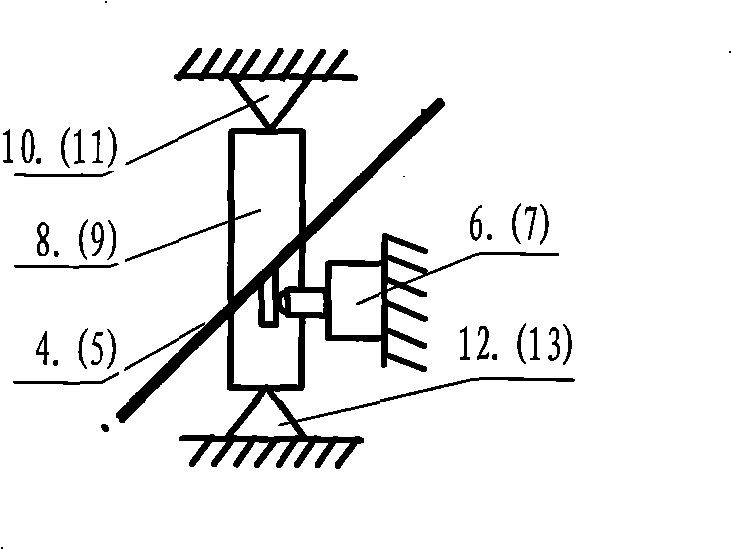

Continuous dynamic intelligent metering mechanism

InactiveCN101266160AHigh precisionReasonable structureMass flow measurement devicesWeighing apparatus for materials with special property/formElectricityPunching

A scattered solid material intelligent metering device belongs to the automation detection metering technology field, which can be applied widely to industries using a belt transporter for example coal, metallurgy, power generation, characterized in that the device is composed of a funnel 1, downspoutings 2, 3, punchings 4, 5, weighing sensors 6, 7 and an intelligent measuring and control instrument 14. The funnel 1 and the punching 4, 5 form weighing frame structure; the weighing sensor 6, 7 and the intelligent measuring and control instrument 14 form the measuring system; the invention not only has high precision, wide measuring range, reasonable structure, strong overload capacity but also does not change original on site devices. The invention is applied to continuously dynamic scattered solid material metering for example the coal, the dock, the electricity power plant, which replaces traditional electronic belt weigh meter and nuclear scale. The metering device can be used even under condition that the belt weigh meter can not be used, for example, various material transporter and storage material feeding opening of chain board, scrapping board, screw and so on.

Owner:TAIYUAN UNIV OF TECH

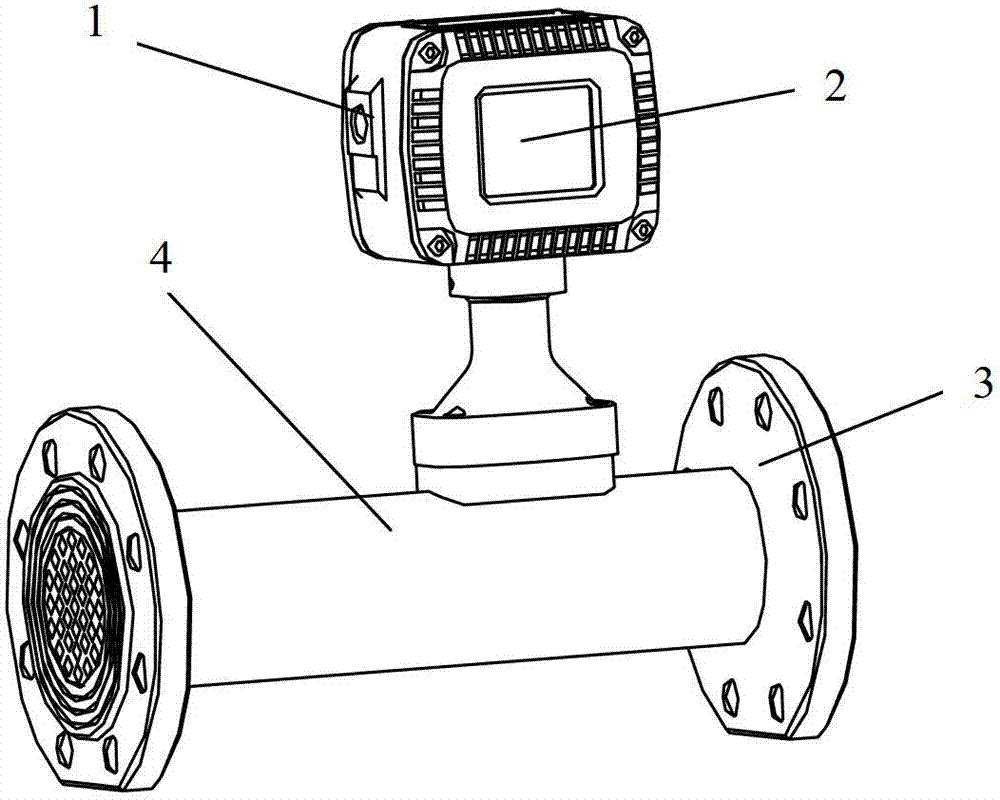

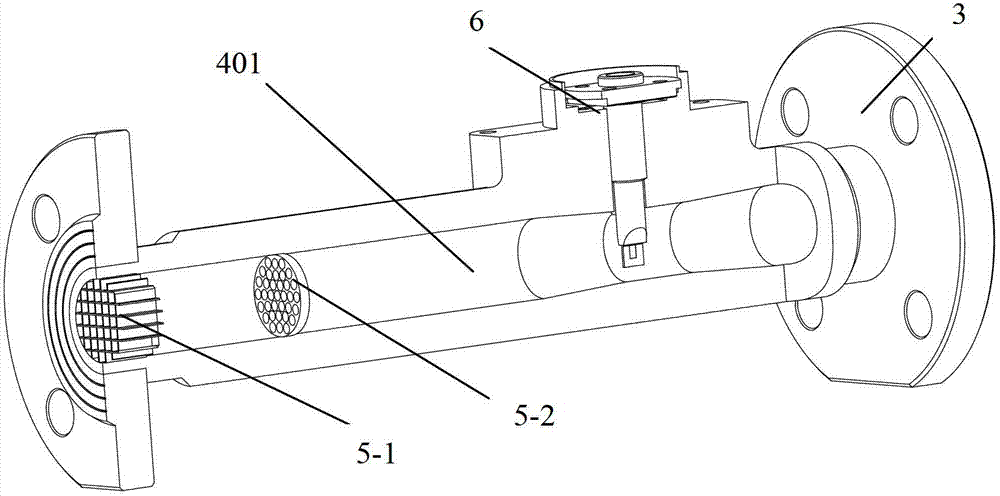

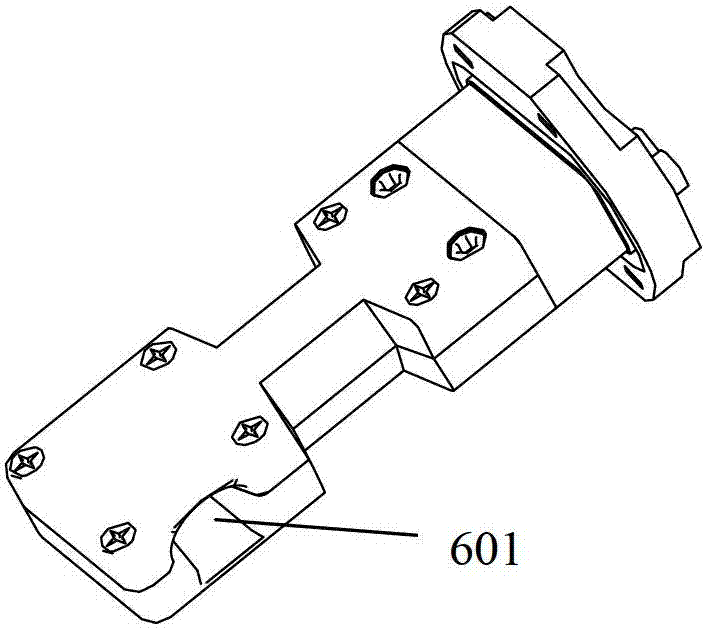

Gas flowmeter and gas flow rate measuring method

ActiveCN102735300AHigh measurement accuracyMass flow measurement devicesVolume indication and recording devicesProcess engineeringStreamflow

The invention relates to the field of gas metering, particularly a gas flowmeter and a gas flow rate measuring method which can provide a wide metering range. The gas flowmeter comprises a gas pipeline and a sensor module, wherein the sensor module is installed on the gas pipeline, and comprises a gas sensing flow channel; the gas sensing flow channel is positioned inside the gas pipeline; the gas has the same flow direction in the gas pipeline and the gas sensing flow channel; the sensor module comprises a calorimetric sensing element, a heat dissipation sensing element and a data processing chip; the calorimetric sensing element and the heat dissipation sensing element are positioned inside the gas sensing flow channel, and used for transmitting a detected temperature change signal to the data processing chip; and the data processing chip carries out data storage and data computation according to the temperature change signal.

Owner:卓度仪表(控股)有限公司

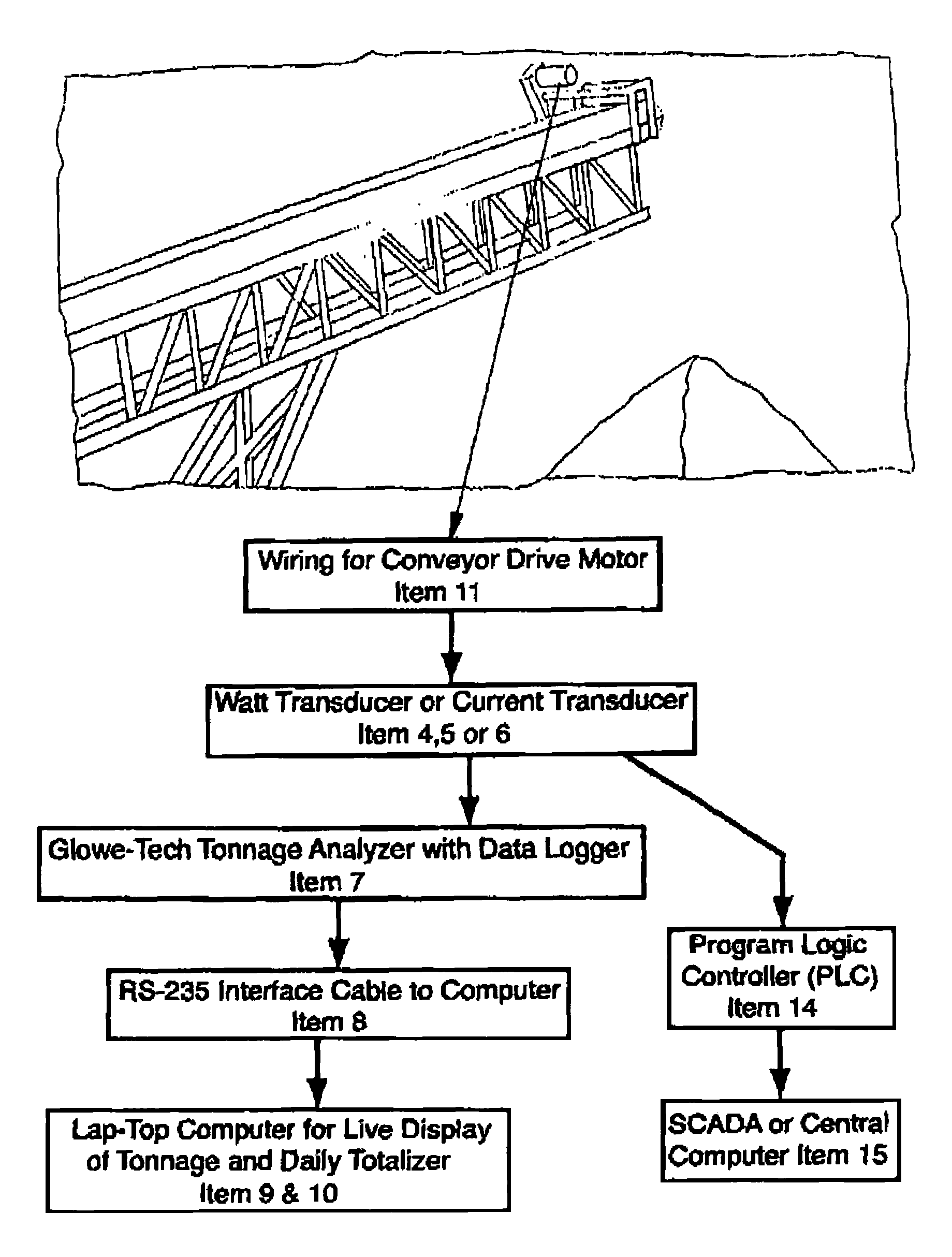

Method for assessing the operation of a conveying apparatus

ActiveUS7193162B2Mass flow measurement devicesDigital computer detailsEngineeringProcess engineering

The present invention is directed to an apparatus and method for measuring the weight of material such as rock, earth, wood, pulp, grain, gravel, sand, ore, cement etc. being processed or moved by an apparatus such as a conveyor, apron conveyor or bucket elevator driven by an electrical motor. The apparatus measures the electrical energy consumed by the motor powering the apparatus during operation of the apparatus and uses a calibration formula derived from an average of no-load readings plus up to 2.0 standard deviations for converting the power consumption of the motor to tonnage per hour of raw material processed by the apparatus. A continual record is kept of all “No-load” and “start-up load” time during the recording process and these figures are totalized along with tonnage for the recording period.

Owner:GLOWE CONSULTING SERVICES

Diesel engine fuel consumption measuring apparatus

ActiveCN101013064AEasy to measureHigh precisionMass flow measurement devicesInternal-combustion engine testingMeasurement deviceFuel oil

The invention relates to a diesel engine fuel consumption measurement device, and the device installs mass flow meter on the original fuel system, and transmits the signals of the mass flow meter output and the signals of the original diesel engine output power to the fuel oil consumption device to conduct operations, and outputs the diesel engine output power, fuel consumption volume and fuel consumption rate. The diesel engine fuel consumption measurement device of the invention greatly enhances the measurement precision, and it can real-time monitor the diesel fuel consumption status, applied to the diesel on the land or water.

Owner:HUDONG HEAVY MACHINERY

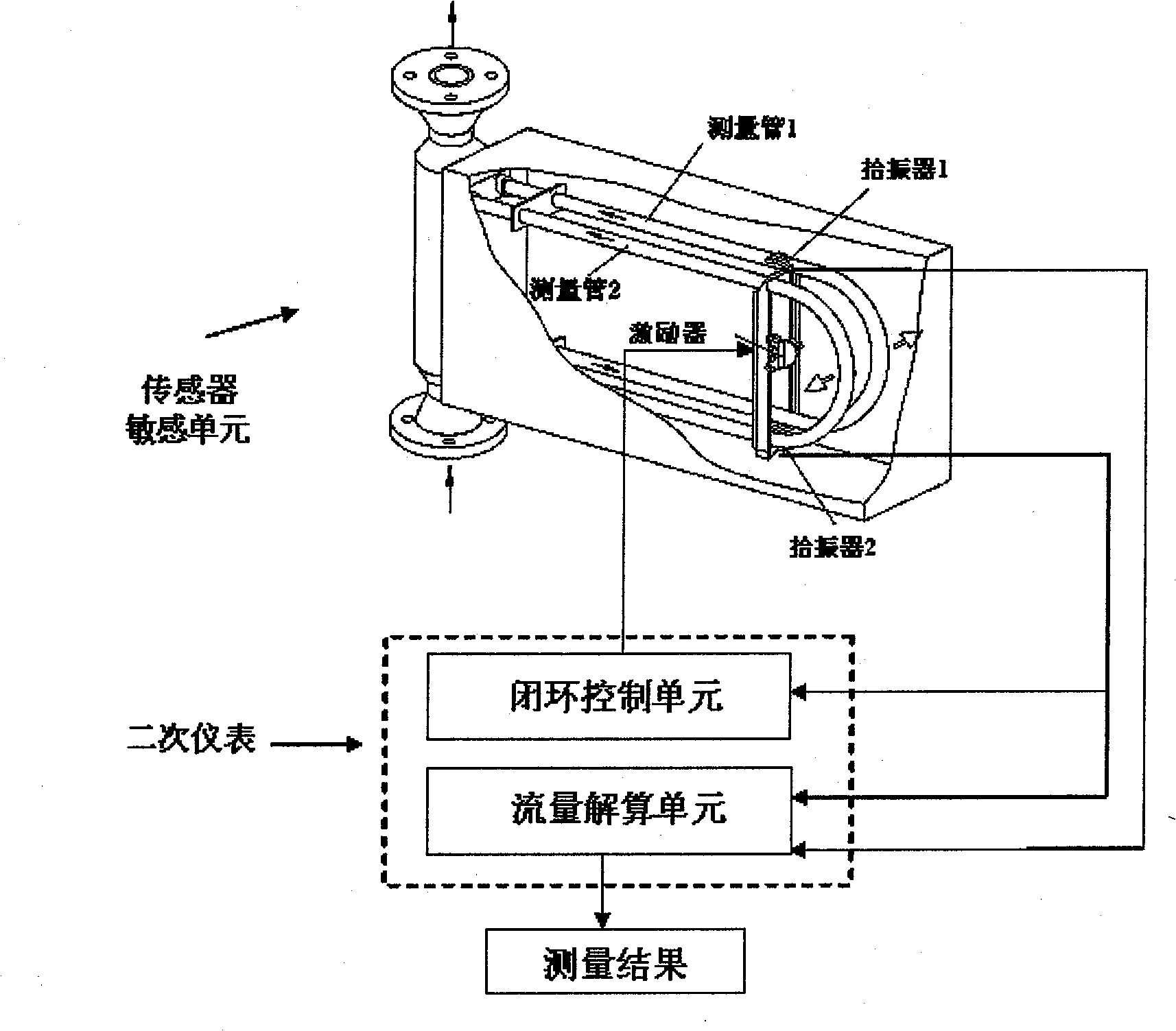

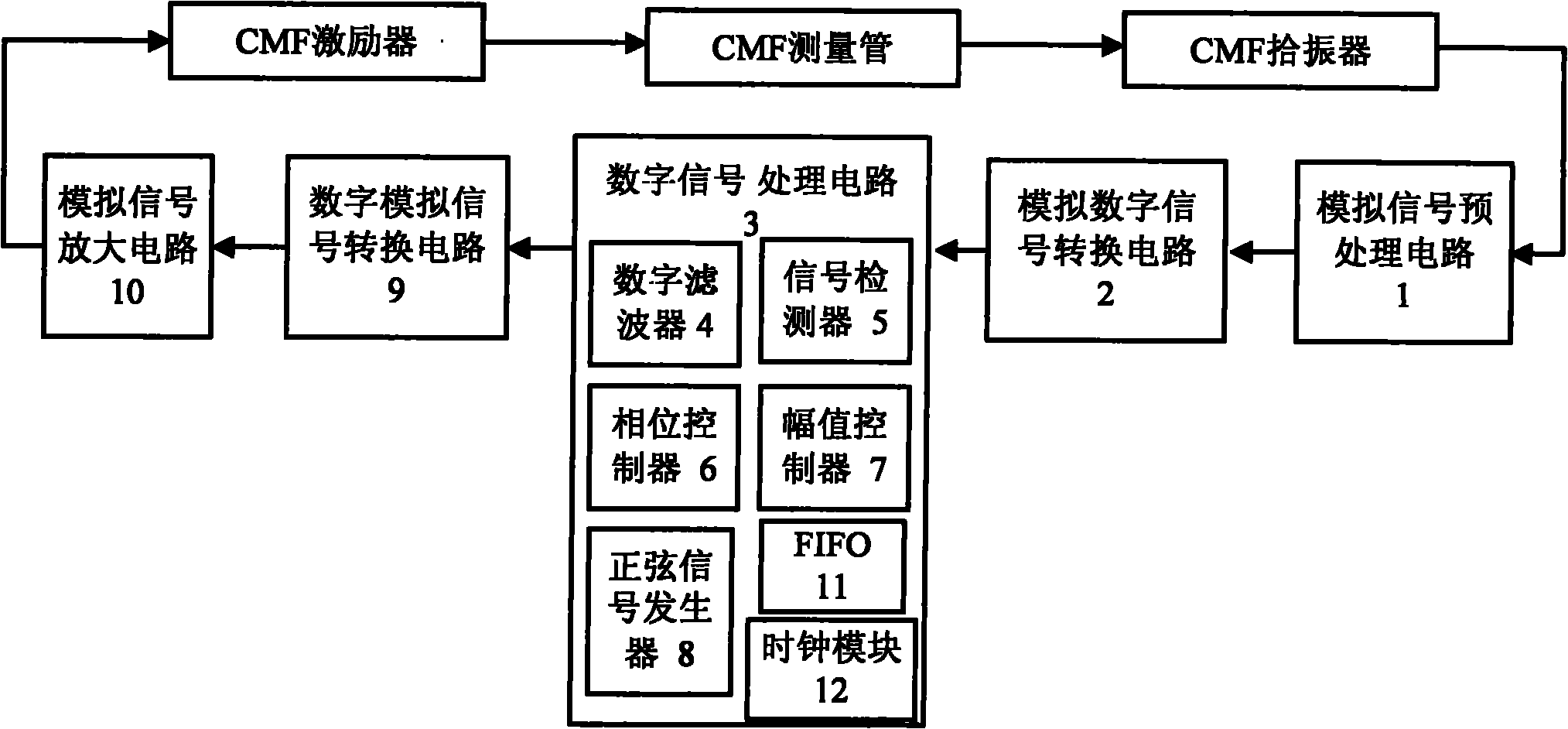

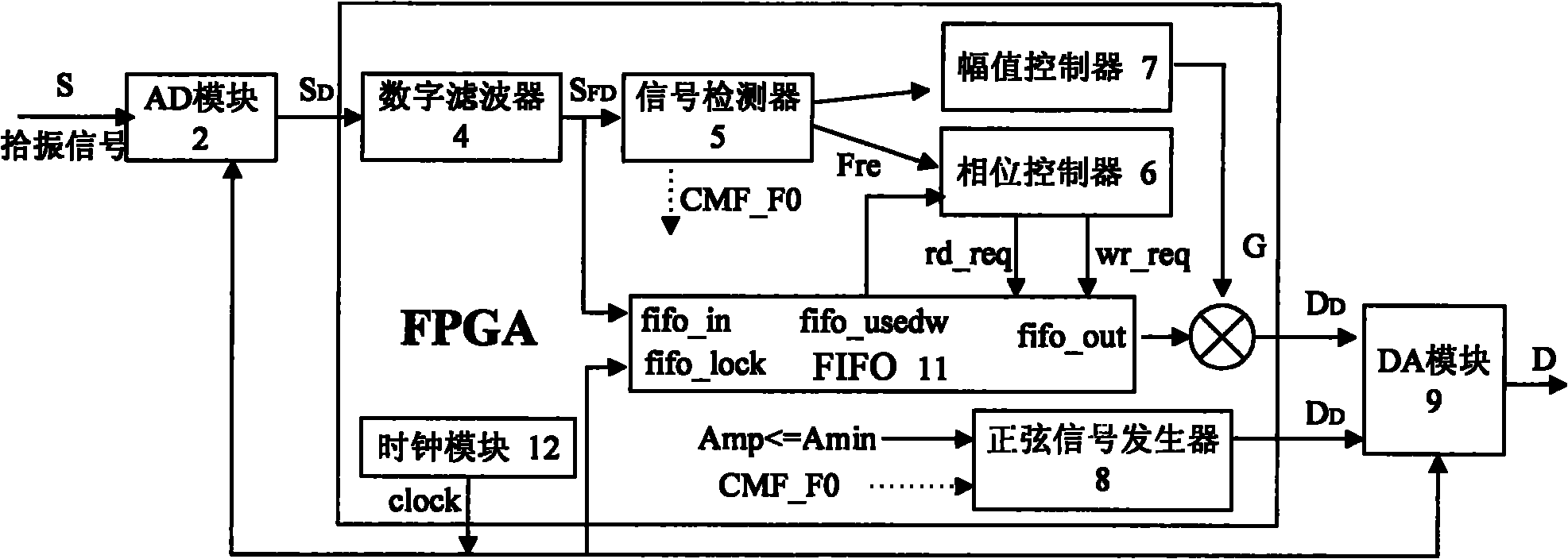

All-digital closed-loop system of Coriolis mass flowmeter

ActiveCN101881947AAvoid vibration stopGuaranteed measurementMass flow measurement devicesProgramme control in sequence/logic controllersDigital signal processingSignal processing circuits

The invention provides an all-digital closed-loop system of a Coriolis mass flowmeter (CMF). A hardware circuit is based on digital components to achieve the stable closed-loop control of the CMF, particularly, the digital signal processing circuit is mainly based on a field programmable gate array (FPGA), and a digital signal processing method is used in the FPGA to achieve the digital closed-loop control algorithm for the CMF and track the frequency on a real-time basis; by using the non-linear amplitude control method and introducing FIFO (first in, first out) components to the phase control, stable and accurate control can be achieved on the amplitude and phase; by better tracking the changes in the vibration of the measuring tube of the CMF to obtain vibration pickup signals reflecting the information of fluid more accurately and further output the vibration pickup signals at a stable amplitude, the invention is favorable for resolving a secondary meter, further improving the accuracy and stability in the measurement of the CMF and ensuring that the resource consumption and operation load are lower; and the invention further solves the problem of two-phase flow, particularly, when the CMF undergoes the problem of two-phase flow, the sinusoidal signal at the controllable amplitude and at the same frequency as the natural frequency of the measuring tubes of the CMF can be actively outputted to force the measuring tubes of the CMF to continue vibrating, thus ensuring the non-stop vibration and non-interrupted measurement when the CMF undergoes the problem of two-phase flow and enabling the CMF to carry out the flow measurement when undergoing the problem of the two-phase flow.

Owner:BEIHANG UNIV

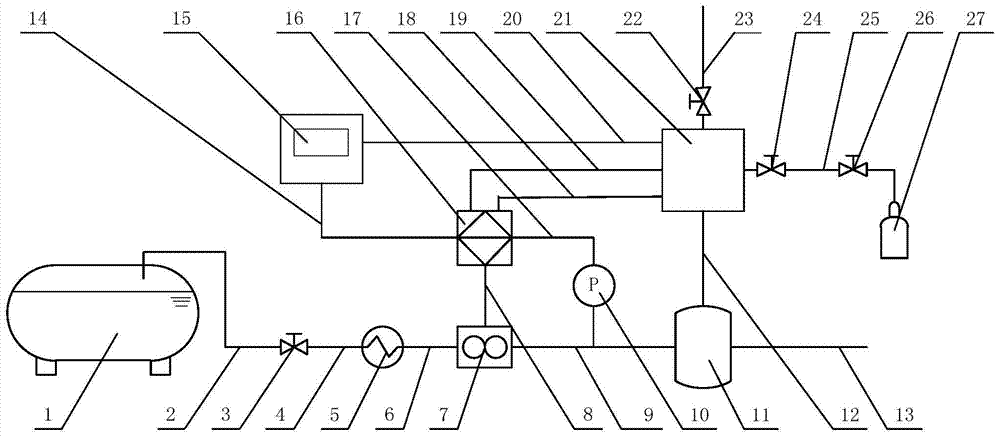

System for measuring evaporation rate of cryogenic vessel with stable back pressure

InactiveCN103697956AStable pressureReduce the effects of evaporationMass flow measurement devicesBuffer tankControl system

The invention discloses a system for measuring evaporation rate of a cryogenic vessel with stable back pressure. The system comprises a gas emission pipeline. An emptying valve and a gas mass flow meter are arranged on the gas emission pipeline. The outlet of the gas mass flow meter is provided with a buffer tank; the buffer tank is connected with a discharge pipe. The system also comprises a back pressure control system. The back pressure control system comprises a pressure sensor, a programmable controller, a computer, a pressure controller, a rapid exhaust line and a rapid gas supply system. The pressure controller is used for controlling pressure in the buffer tank; the input end of the pressure controller is connected with the computer and the programmable controller; the pressure controller is also connected with three gas control connectors of the rapid exhaust line, the rapid gas supply system and the buffer tank; the input end of the programmable controller is connected with the gas mass flow meter and the pressure sensor. The system can be used for effectively reducing influences of environment pressure changes on the evaporation rate of the cryogenic vessel, and has the characteristics that the structure is simple, and the measuring accuracy is high.

Owner:SHANGHAI MICROPOWERS

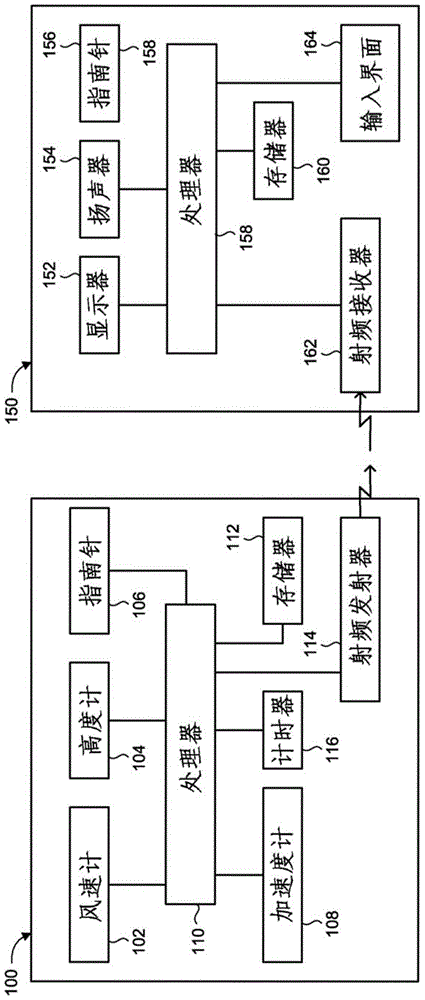

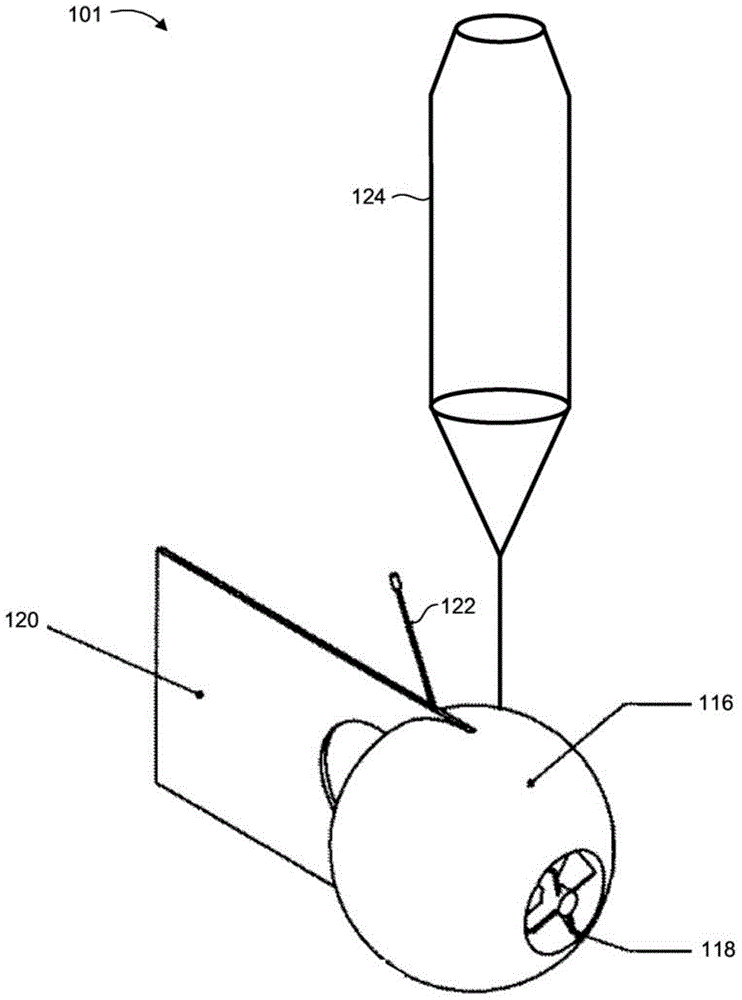

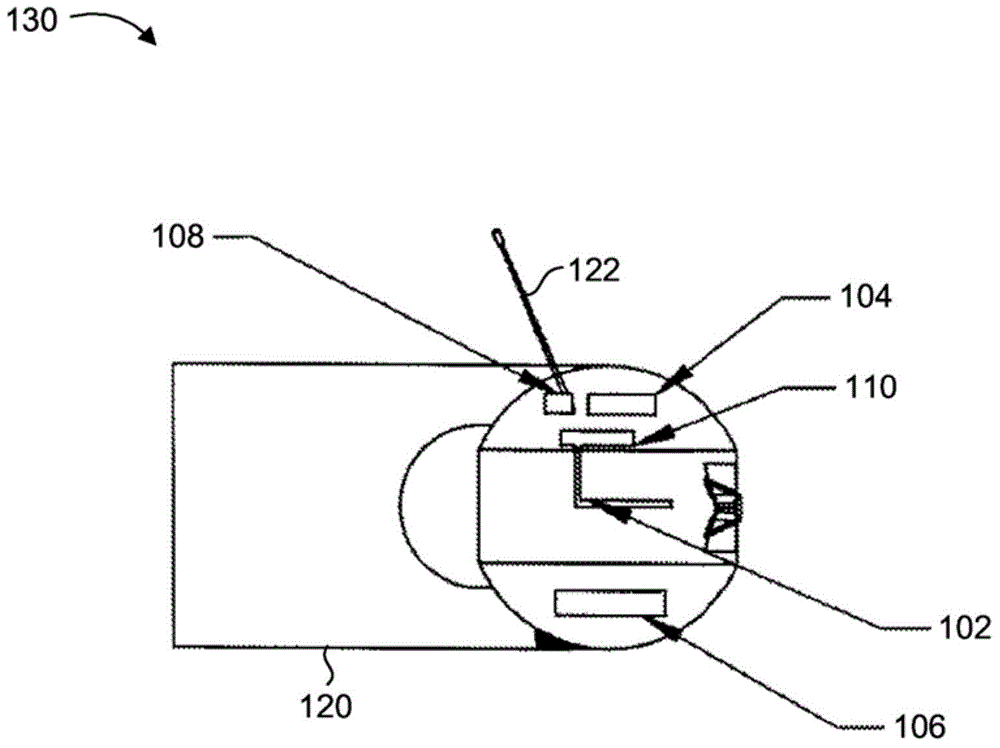

Wind parameter indication

Wind parameter indication device and method for providing an indication of wind speed and wind direction. The device is deployed along an aerial trajectory toward a ground surface, such as after being ejected from an aircraft in flight. The device includes an anemometer, an altimeter, a compass, a processor and a transmitter. The anemometer obtains local wind speed and local wind direction measurements along the trajectory. The altimeter obtains altitude measurements along the trajectory. The compass obtains direction measurements along the trajectory. The device may further include an accelerometer, for obtaining acceleration measurements along the trajectory. The processor determines a wind speed value and a wind direction value associated with a predetermined altitude of the device. The transmitter transmits the determined wind speed value and wind direction value to a remotely located receiver. The device may further include a stabilizing decelerator to stabilize and decelerate the device along the trajectory.

Owner:VENTUS PROD DEV & CONSULTING

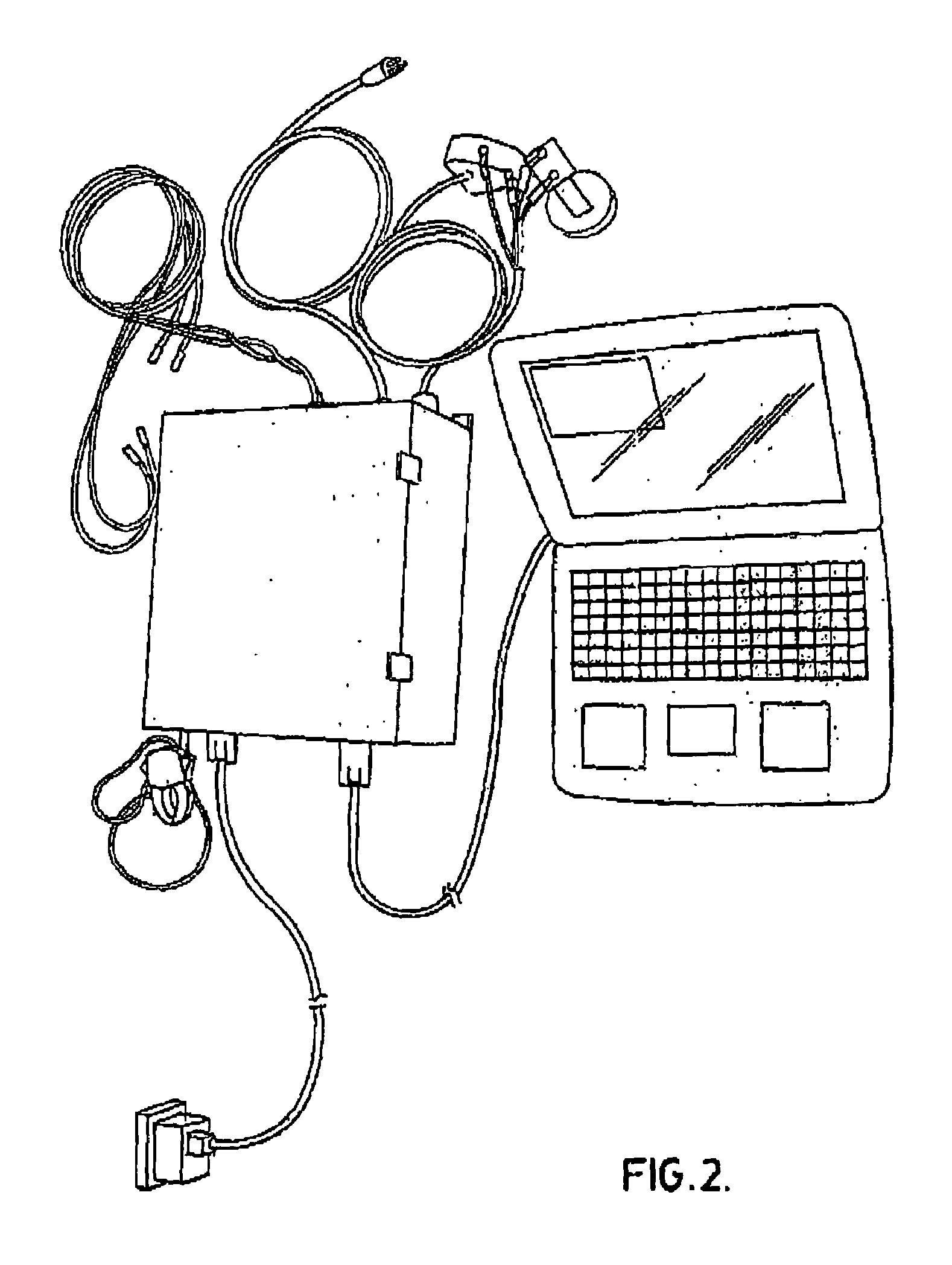

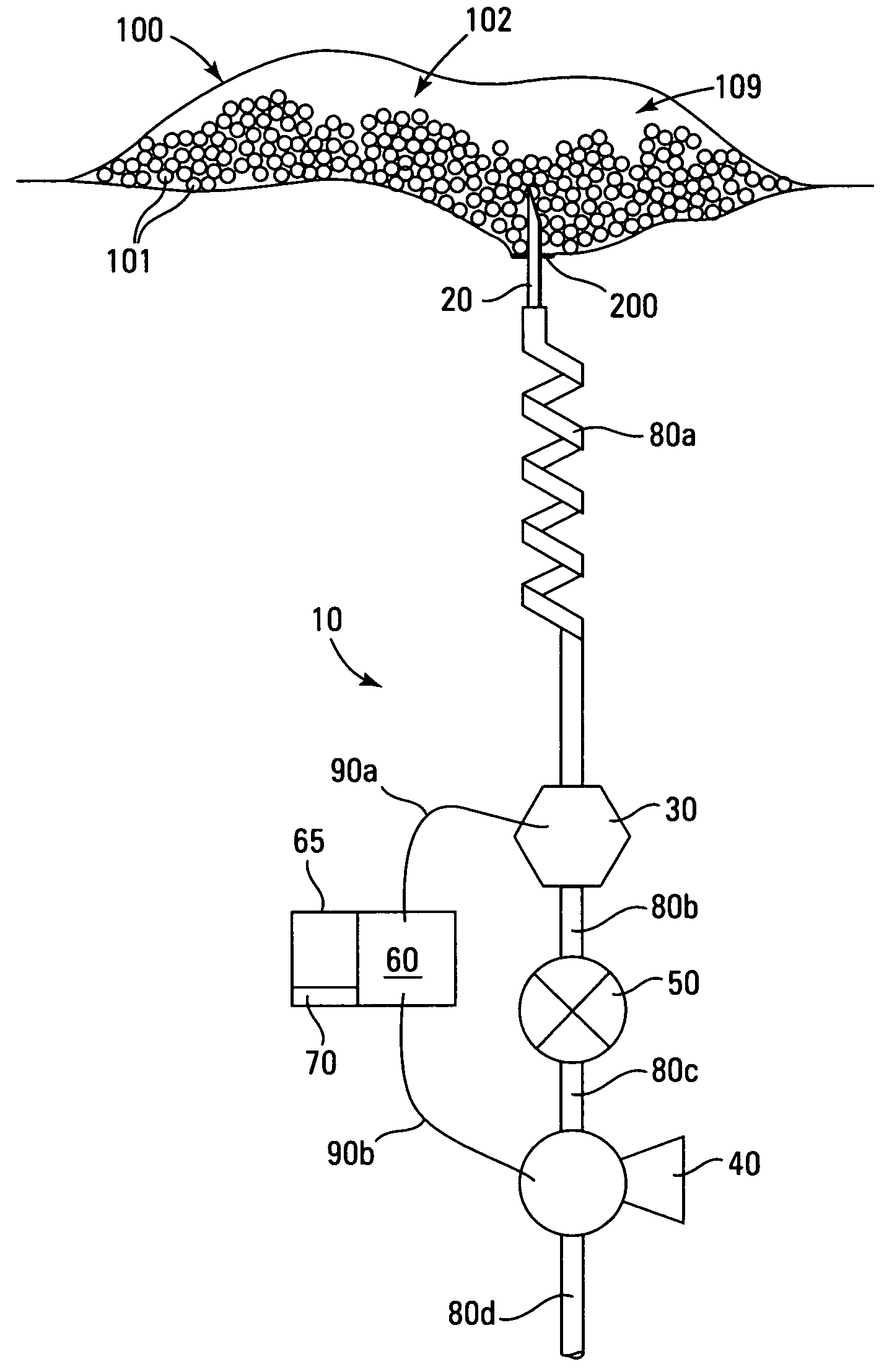

Instrument for accurately measuring mass flow rate of a fluid pumped from a hermetically sealed container

ActiveUS20070289390A1Accurate measurementPrevented being sensedMass flow measurement devicesDetection of fluid at leakage pointCheck valveVacuum pump

An instrument for accurately measuring mass flow rate of a fluid pumped from a hermetically sealed container, through attainment of a steady state mass flow rate, having a check valve positioned between a vacuum pump and a mass flow rate sensor.

Owner:MODERN CONTROLS

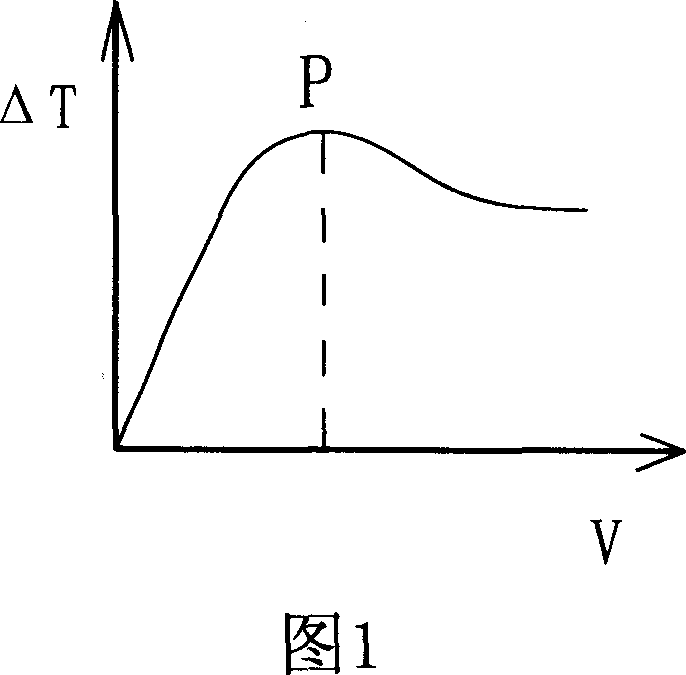

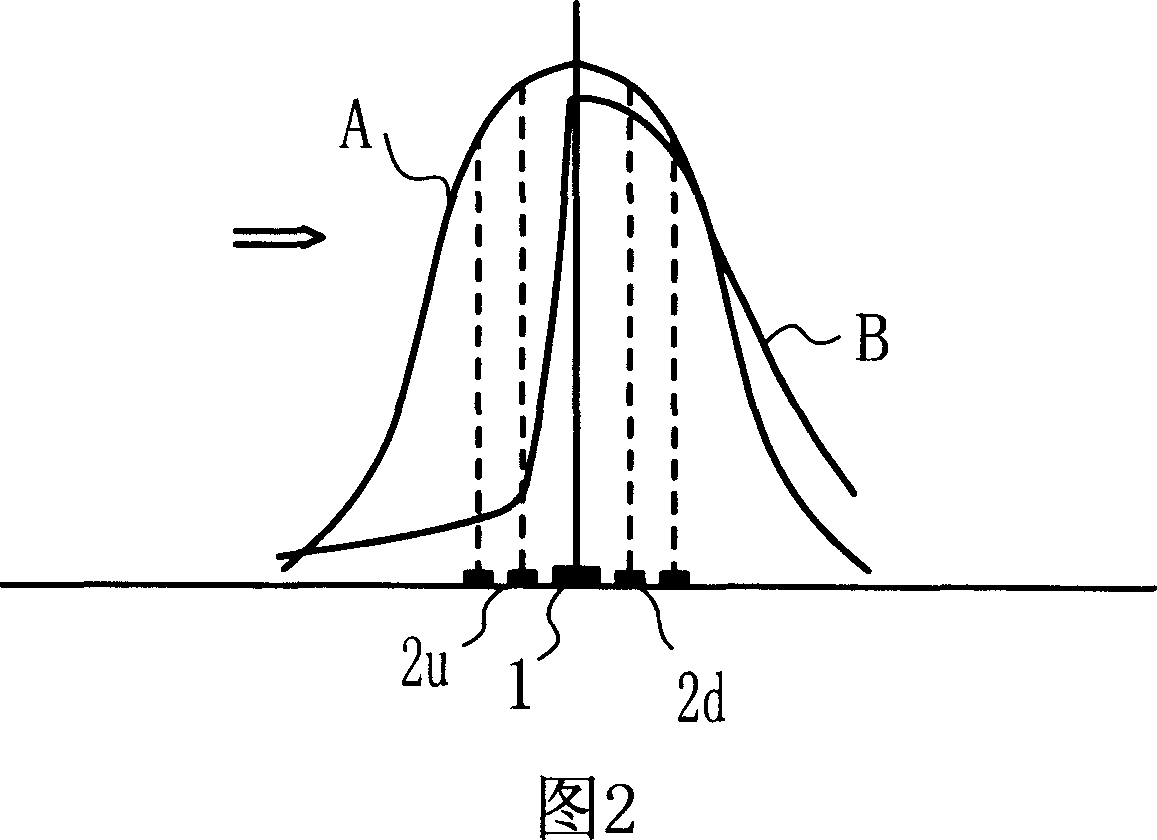

Measuring method and sensor for secondary differential flow of up-stream and down-stream temperature distribution and use

InactiveCN101050974AExpand the scope of testingSmall declineMass flow measurement devicesConstant powerTransducer

A measurement transducer of secondary differential flow rate based on up-down stream temperature distribution is prepared for connecting heating element to constant power source excitation, connecting up-stream temperature detection element and down-stream temperature detection element separately to two signal input ends of differential operation circuit and connecting output end of said differential operation circuit to central processing unit.

Owner:MEMSIC SEMICON WUXI

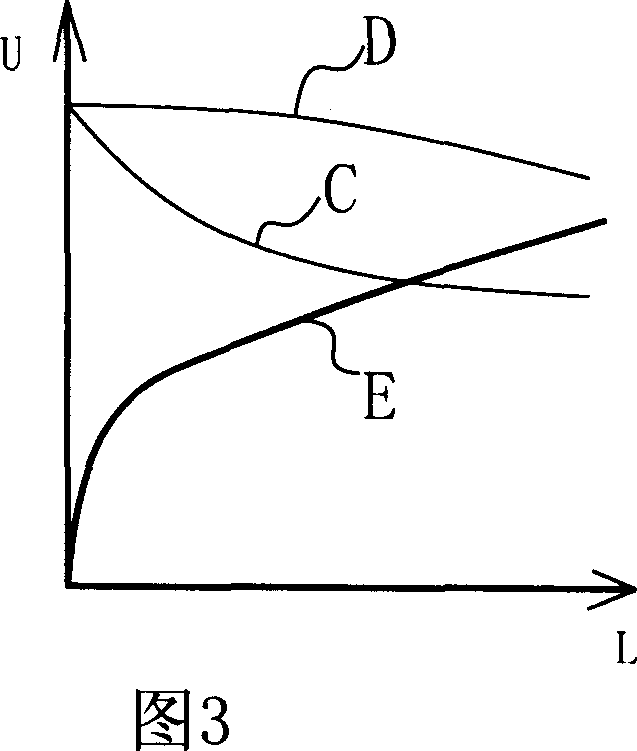

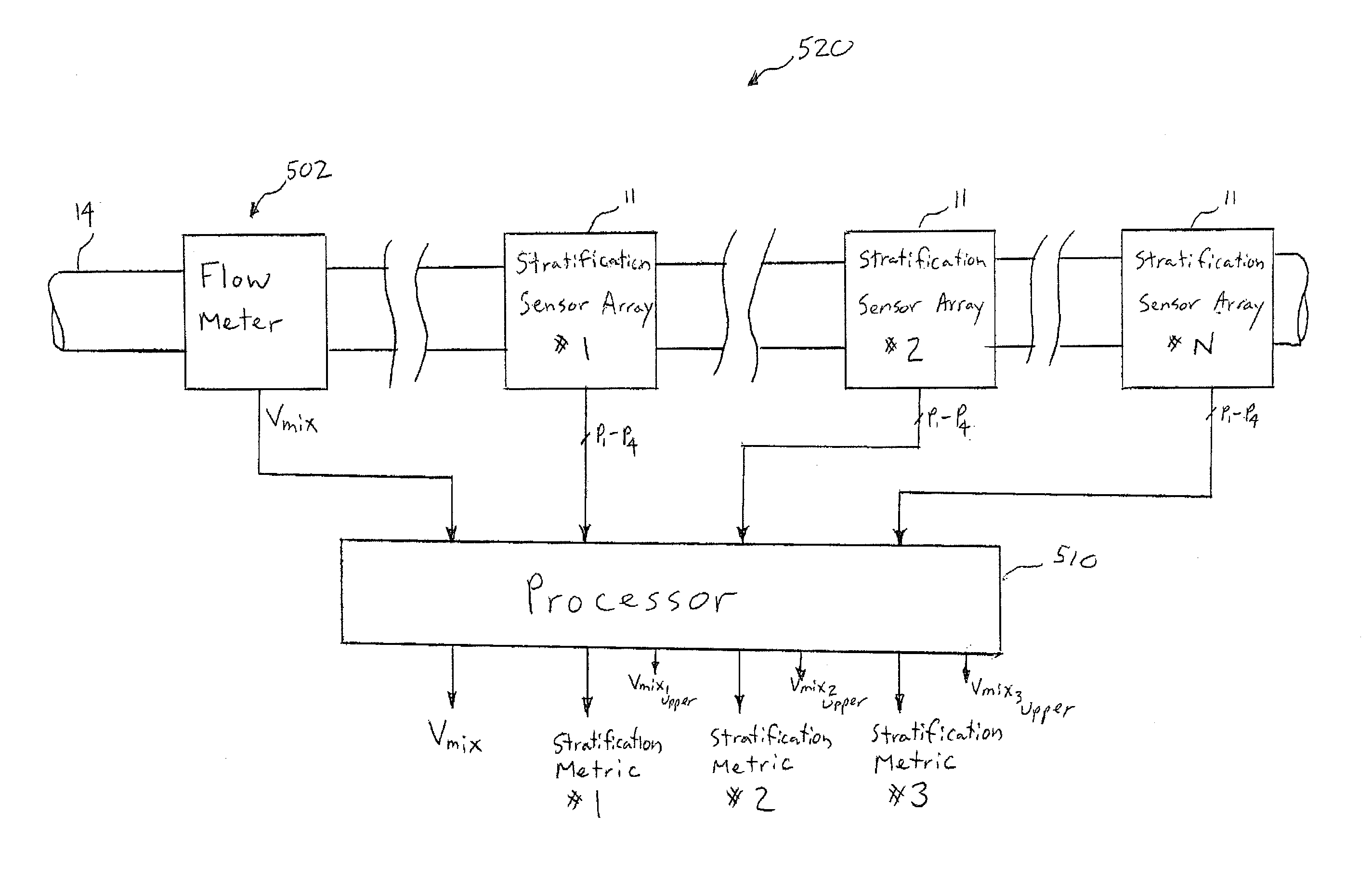

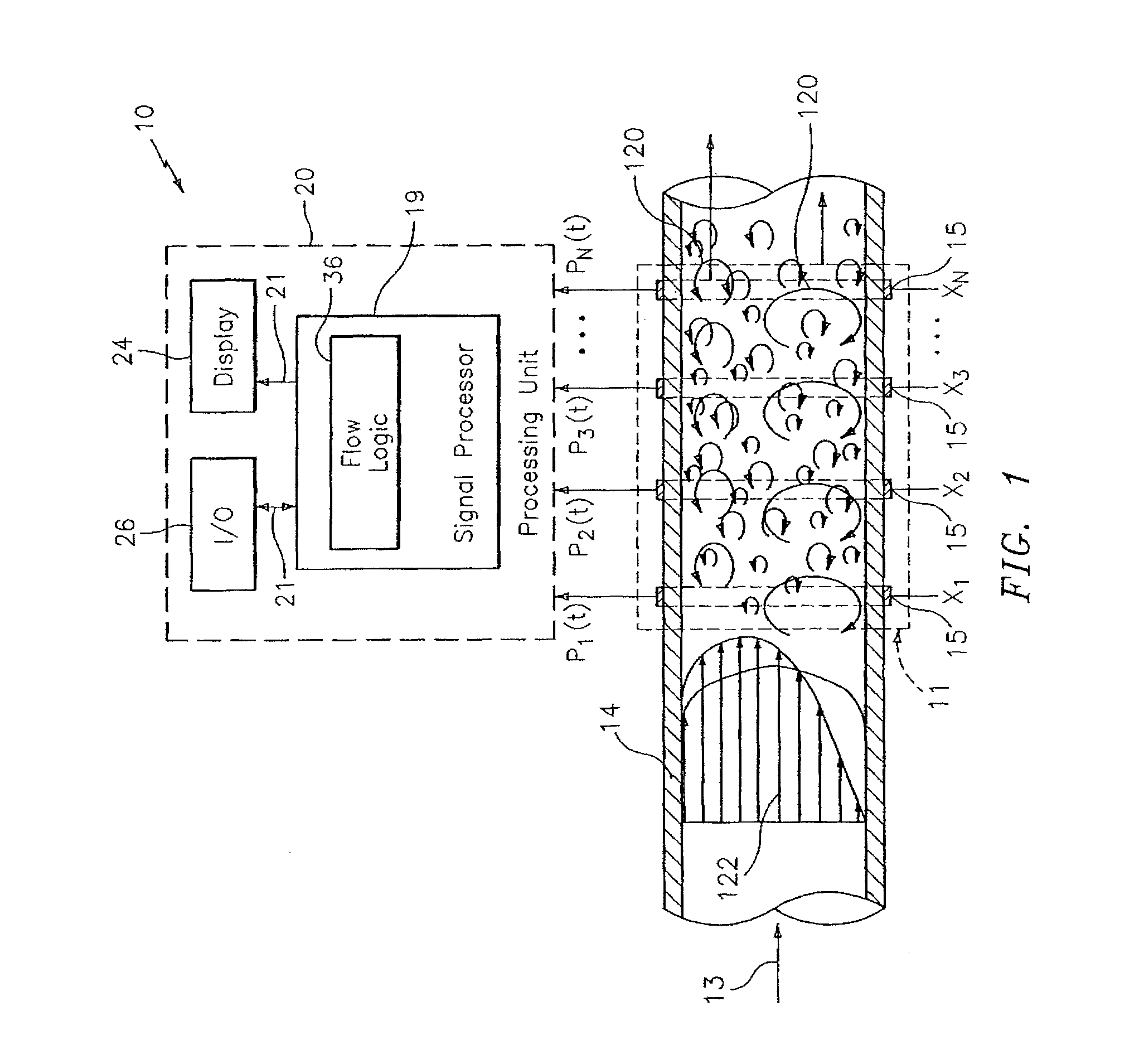

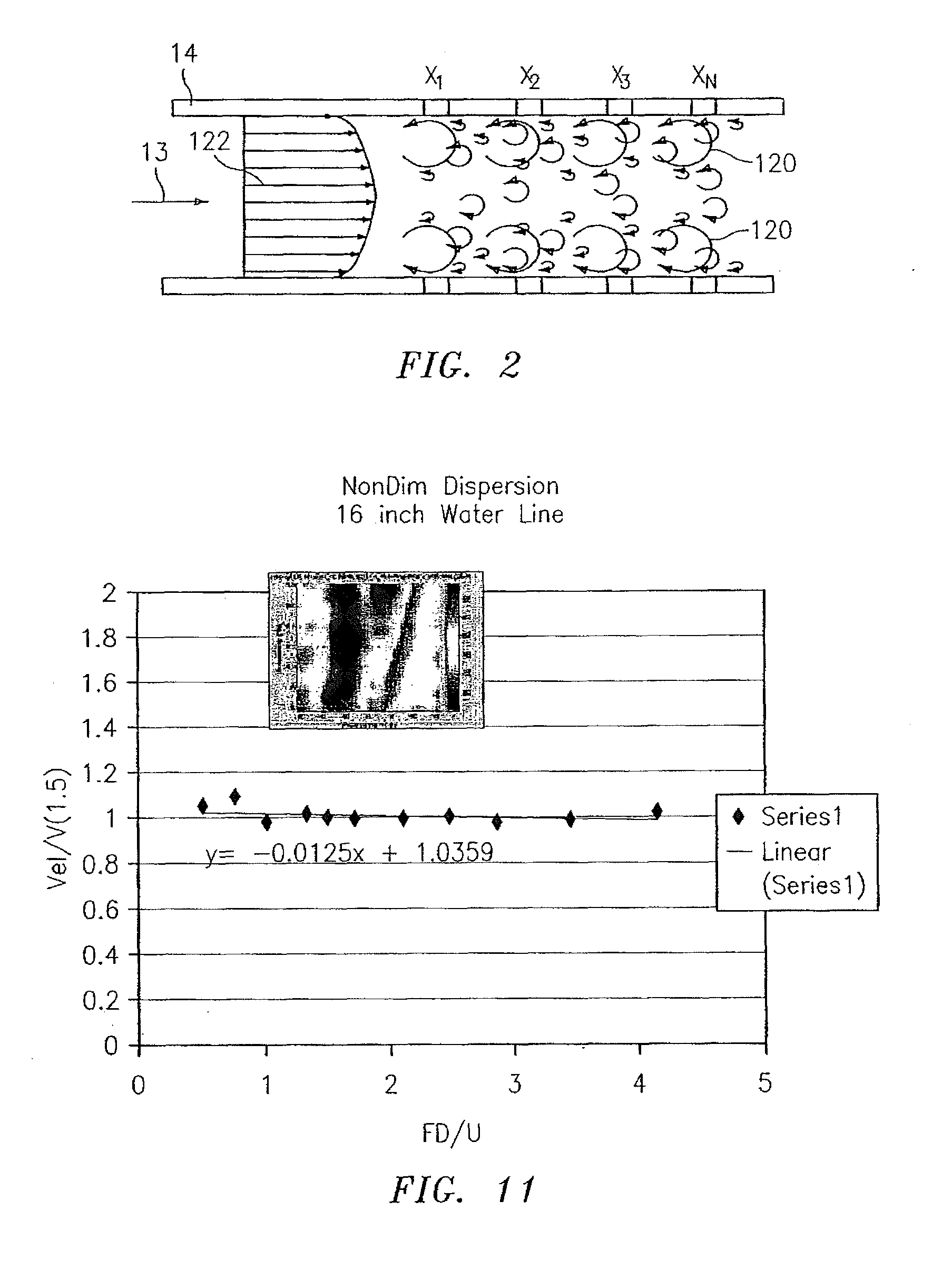

Apparatus and method for providing a stratification metric of a multiphase fluid flowing within a pipe

ActiveUS7962293B2Mass flow measurement devicesVolume measurement apparatus/methodsEnvironmental geology

Owner:EXPRO METERS

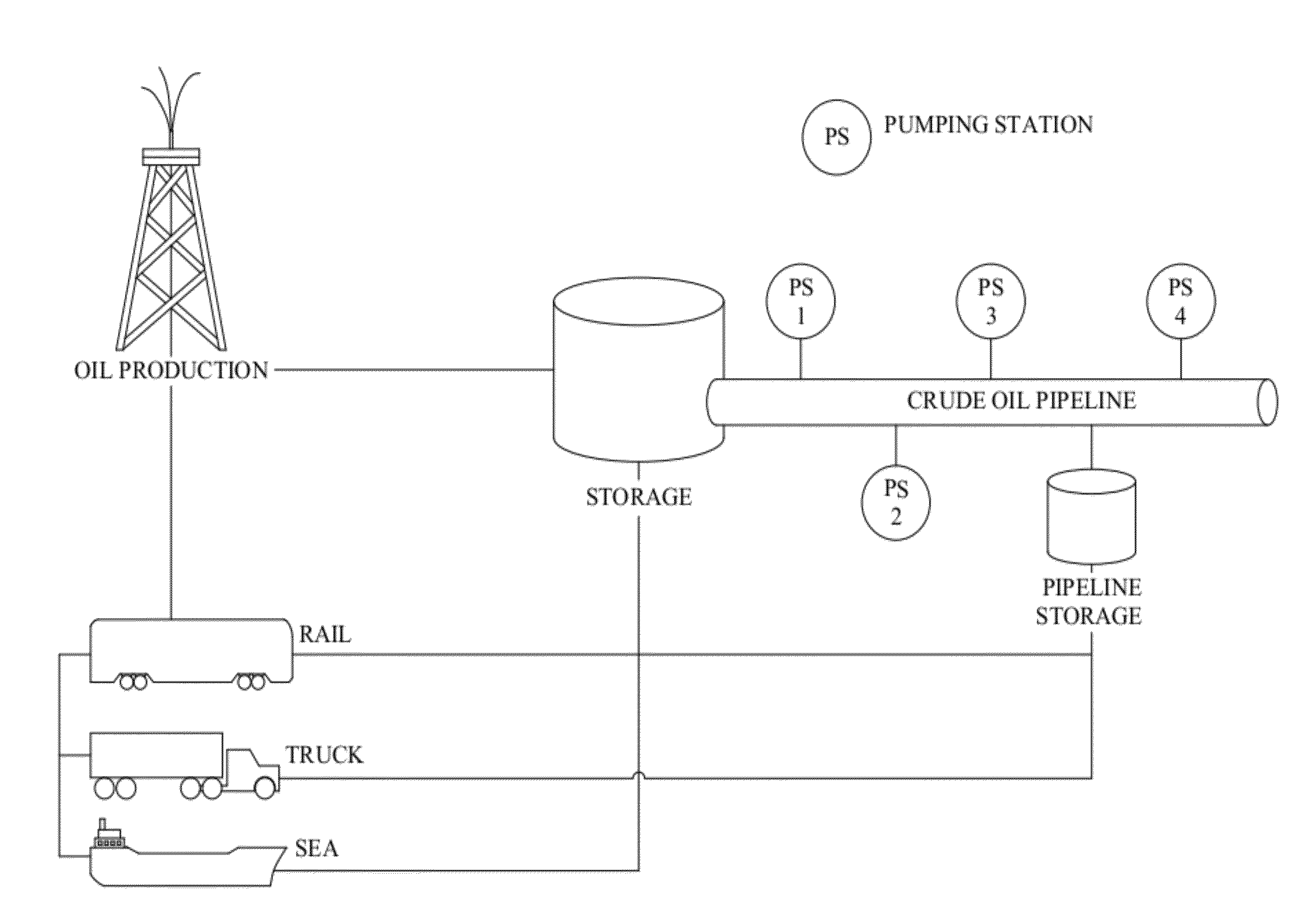

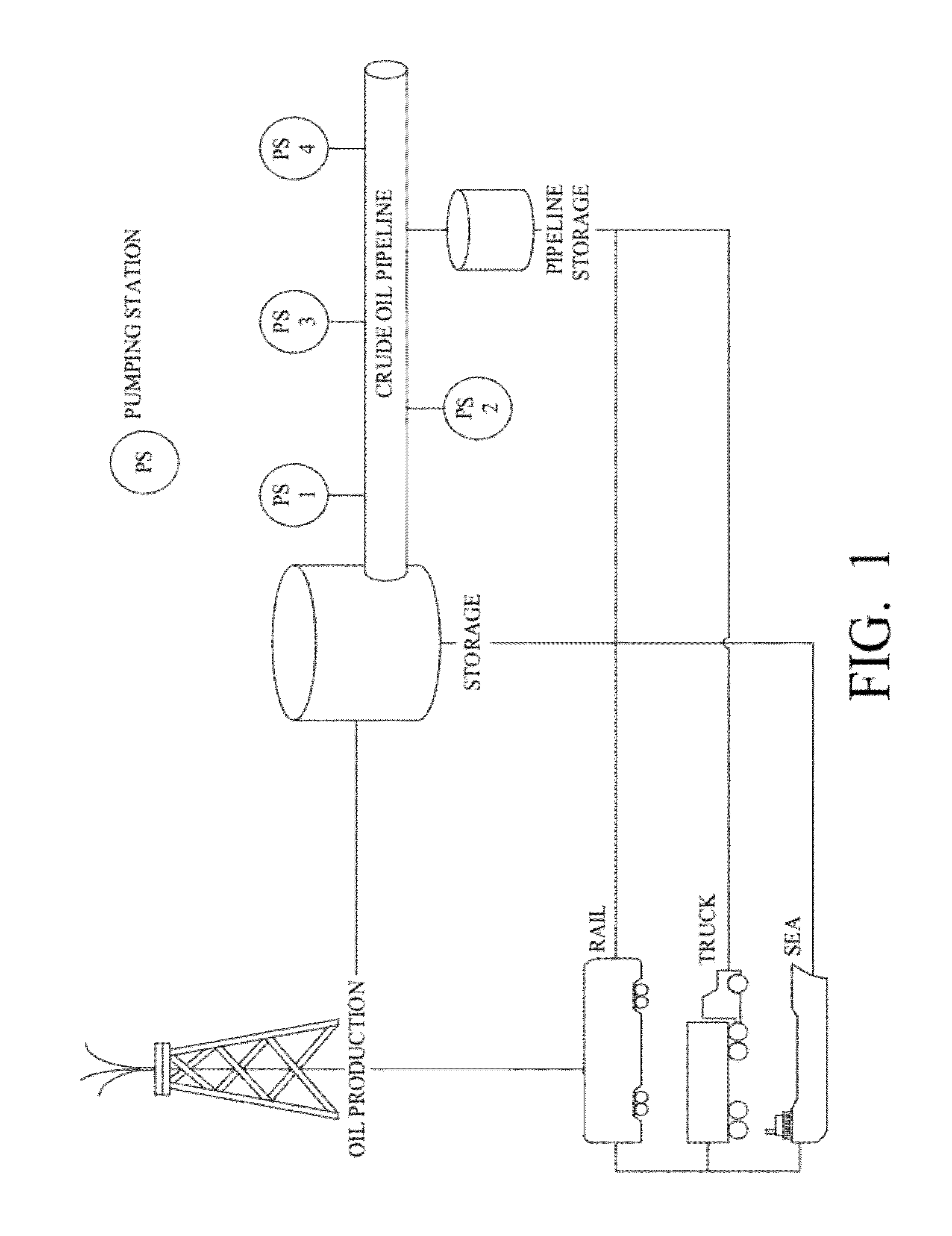

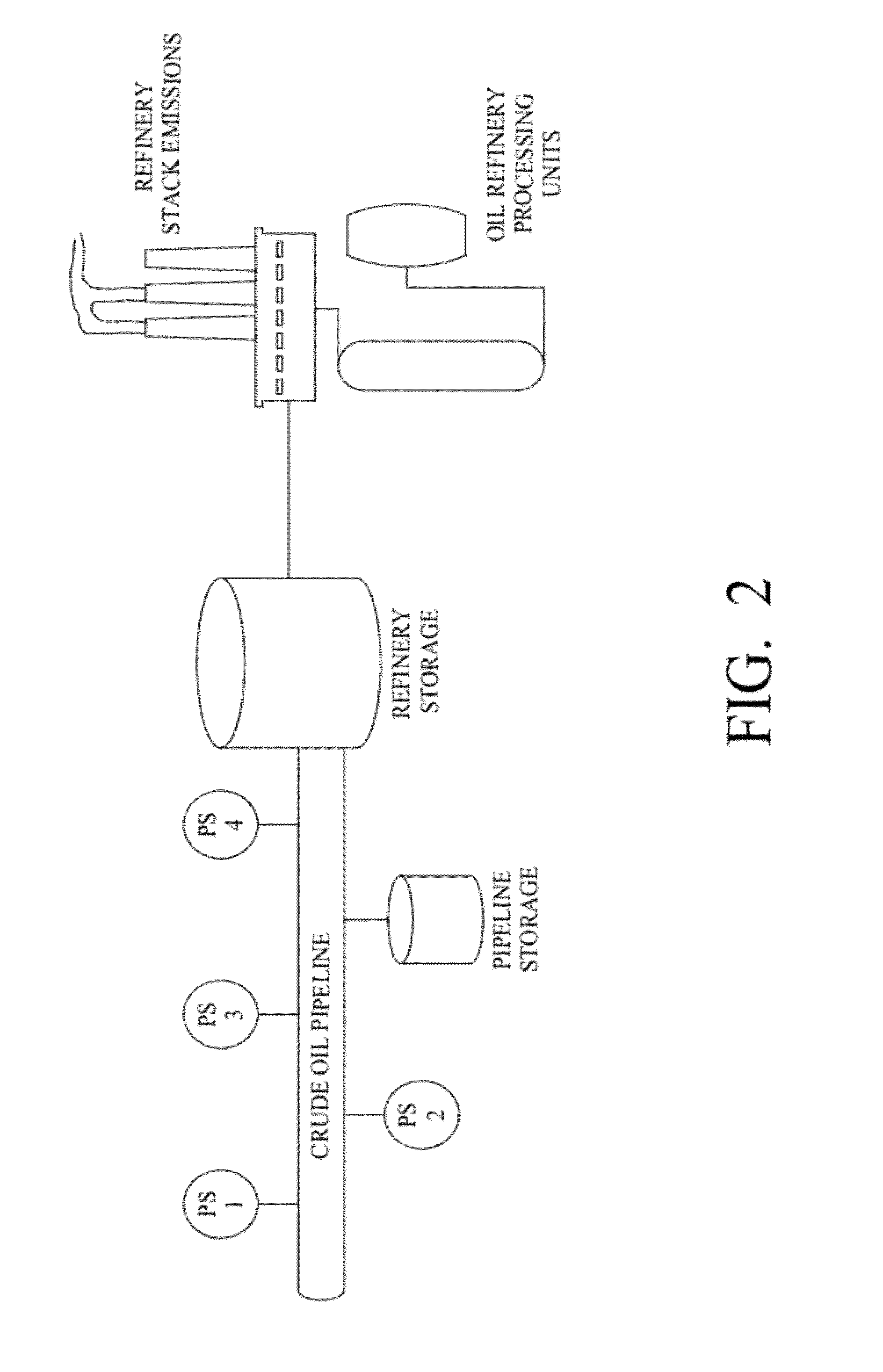

Method and system for collecting and analyzing operational information from a network of components associated with a liquid energy commodity

ActiveUS20120206595A1Keep the pressureTelevision system detailsMass flow measurement devicesTraffic capacityThird party

A method for collecting and analyzing operational information from a network of components associated with a liquid energy commodity comprises the steps of: (a) measuring an amount of the liquid energy commodity in storage at one or more storage facilities in the network, and storing that measurement data; (b) determining a flow rate of the liquid energy commodity in one or more selected pipelines in the network, and storing that flow rate data; (c) ascertaining an operational status of one or more processing facilities in the network, and storing that operational status information; (d) analyzing the measurement data, the flow rate data, and the operational status information to determine a balance of the liquid energy commodity in the network or a selected portion thereof at a given time; and (e) communicating information about the balance of the liquid energy commodity to a third-party market participant.

Owner:GENSCAPE

Instrument for accurately measuring mass flow rate of a fluid pumped from a hermetically sealed container

ActiveUS7654131B2Mass flow measurement devicesDetection of fluid at leakage pointEngineeringCheck valve

An instrument for accurately measuring mass flow rate of a fluid pumped from a hermetically sealed container, through attainment of a steady state mass flow rate, having a check valve positioned between a vacuum pump and a mass flow rate sensor.

Owner:MODERN CONTROLS

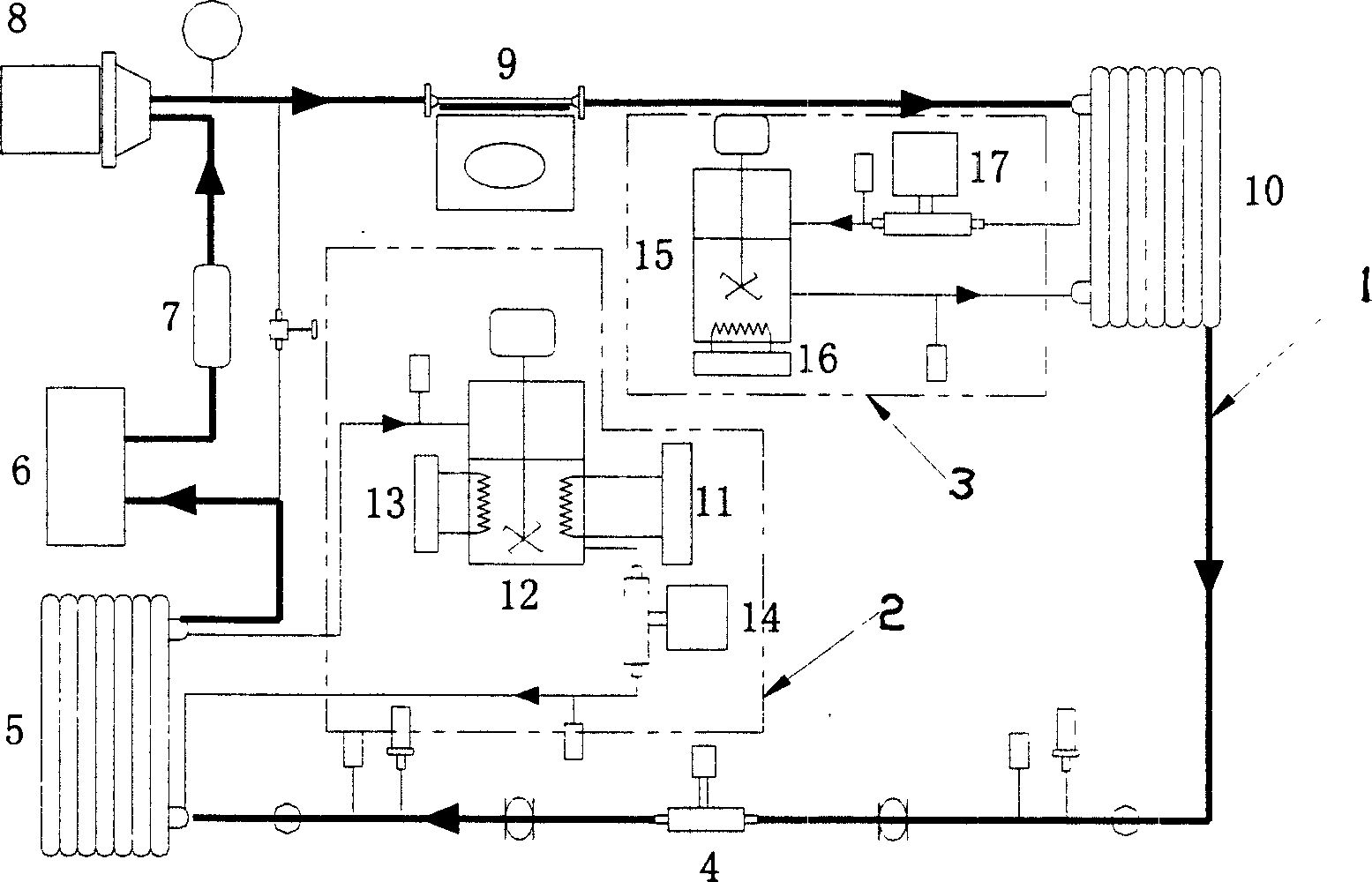

Electronic expansion valve flowing character test table control system by liquid ring method

InactiveCN1587920ASolve Lubricant ProblemsReduce energy consumptionMass flow measurement devicesStructural/machines measurementMagnetic tension forceTest flow

A liquid ring electric expansion valve flow characteristic test bed control system is used for air conditioning refrigeration technical field, comprising test loop, cold source loop, hot source loop, its test loop consists of magnetic drive pump, mass flow meter, high pressure heat exchanger, electric expansion valve, low pressure heat exchanger, liquid storage and dry filter. Magnetic drive pump outlet is linked to mass flow meter inlet, mass flow meter outlet is linked to high pressure heat exchanger inlet high pressure heat exchanger outlet is linked to electric expansion valve inlet, electric expansion valve outlet is linked to copper pipe between low pressure heat exchanger then to liquid storage upper inlet, liquid storage under outlet is linked to dry filter inlet by copper pipe, liquid storage outlet is linked to magnetic drive pump inlet, cold source loop is linked to test loop through low pressure heat exchanger and hot source loop is linked to test loop through low pressure heat exchanger. The invention has solved cold producing medium lubricating oil problem, and can test flow characteristic of electric expansion valve several cold producing medium.

Owner:SHANGHAI JUNLE REFRIGERATION CONTROL +1

Screening device and apparatus including same

A screening device including a screen having a first side for presentation to material to be screened and a second side, a plurality of screen openings in the screen extending between the first and second side thereof, a plurality of tines mounted on a support device disposed on the second side of the screen, each tine being moveable in a first direction along a path at least part of which includes one of the screen openings whereby the tine is receivable in and moveable along the screen opening, the tine extending beyond the first side of the screen for at least part of the movement thereof along the screen opening, the tines being moveably mounted on the support device for deflection away from said first direction while continuing to move in said first direction upon encountering an obstruction.

Owner:SORD TECH

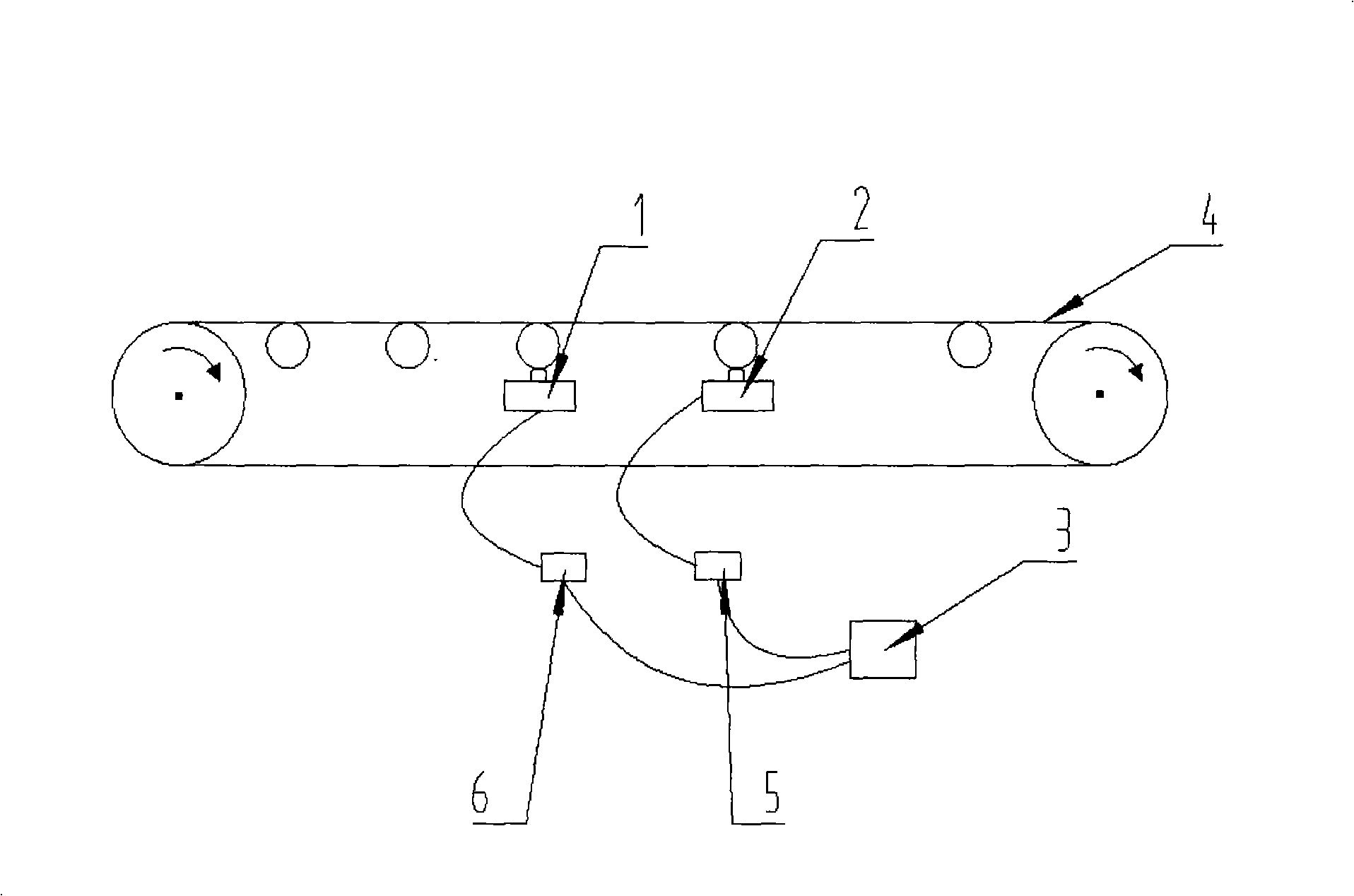

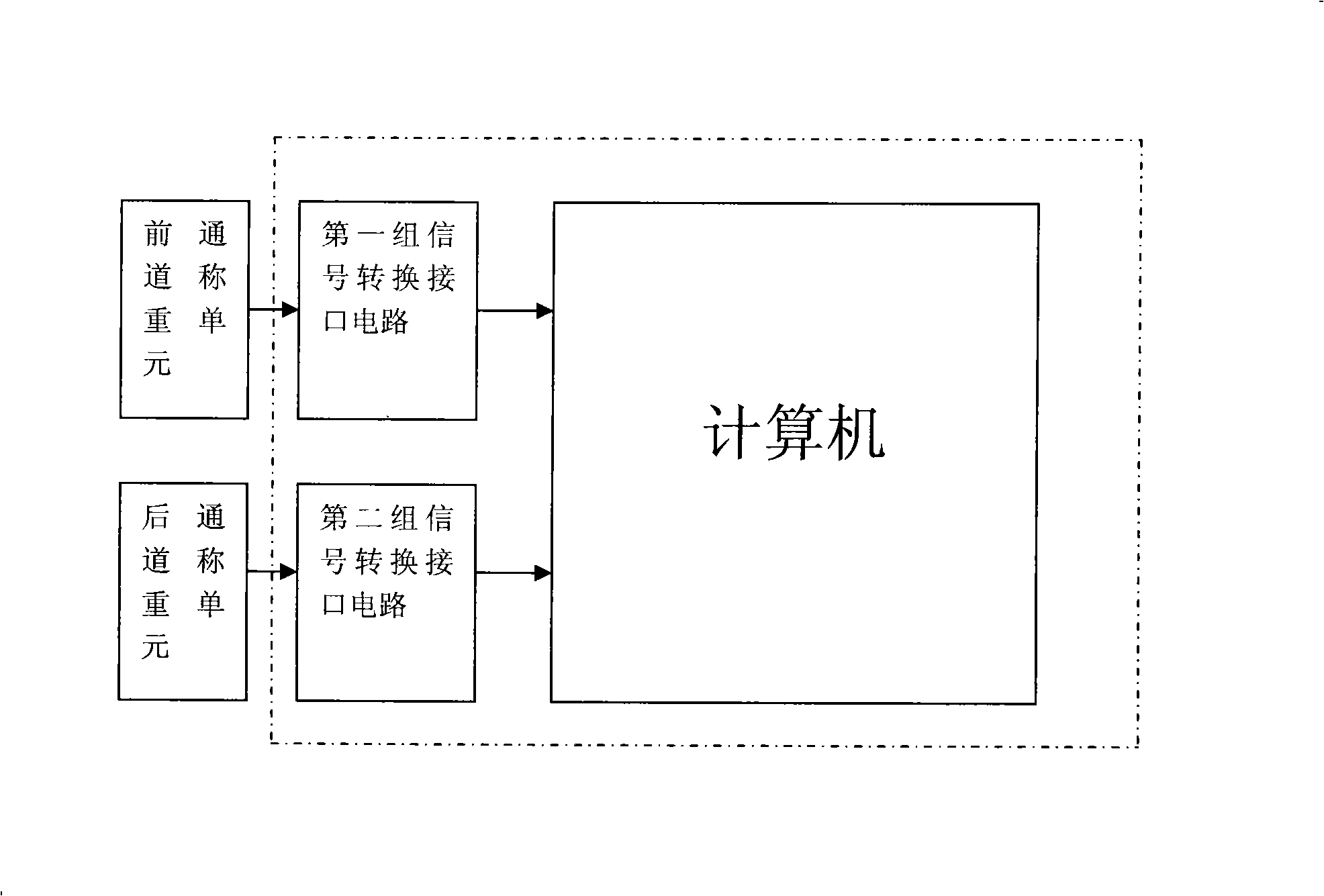

Method for metering travelling belt material and its device

InactiveCN101285697ASave costSave maintenance troubleMass flow measurement devicesWeighing apparatus for continuous material flowEngineeringLoad cell

The invention discloses a method and a device for metering materials on conveying belts, which belongs to the electronic belt scale field and solves the technical problem that inaccurate signal transmission of speed sensors of belt scales causes the metering distortion of the belt scales. The method is based on a scale frame structure of an electronic belt scale with double weighing channels, uses no speed measurement sensor and only sets a weighing sensor in a weighing unit, and has a computer use some algorithm to process signals by comparing the weighing sampling values of two weighing channels, so as to obtain the running speed of the belt scale. The method can avoid using speed sensors, thereby reducing the loss of sensors and the probability of artificial cheating. The invention simultaneously provides a method of metering the flow rate and weight of materials conveyed on conveying belts under the condition with no speed measurement sensor and a device for realizing the method.

Owner:SHANXI XINYUAN AUTOMATIC INSTR

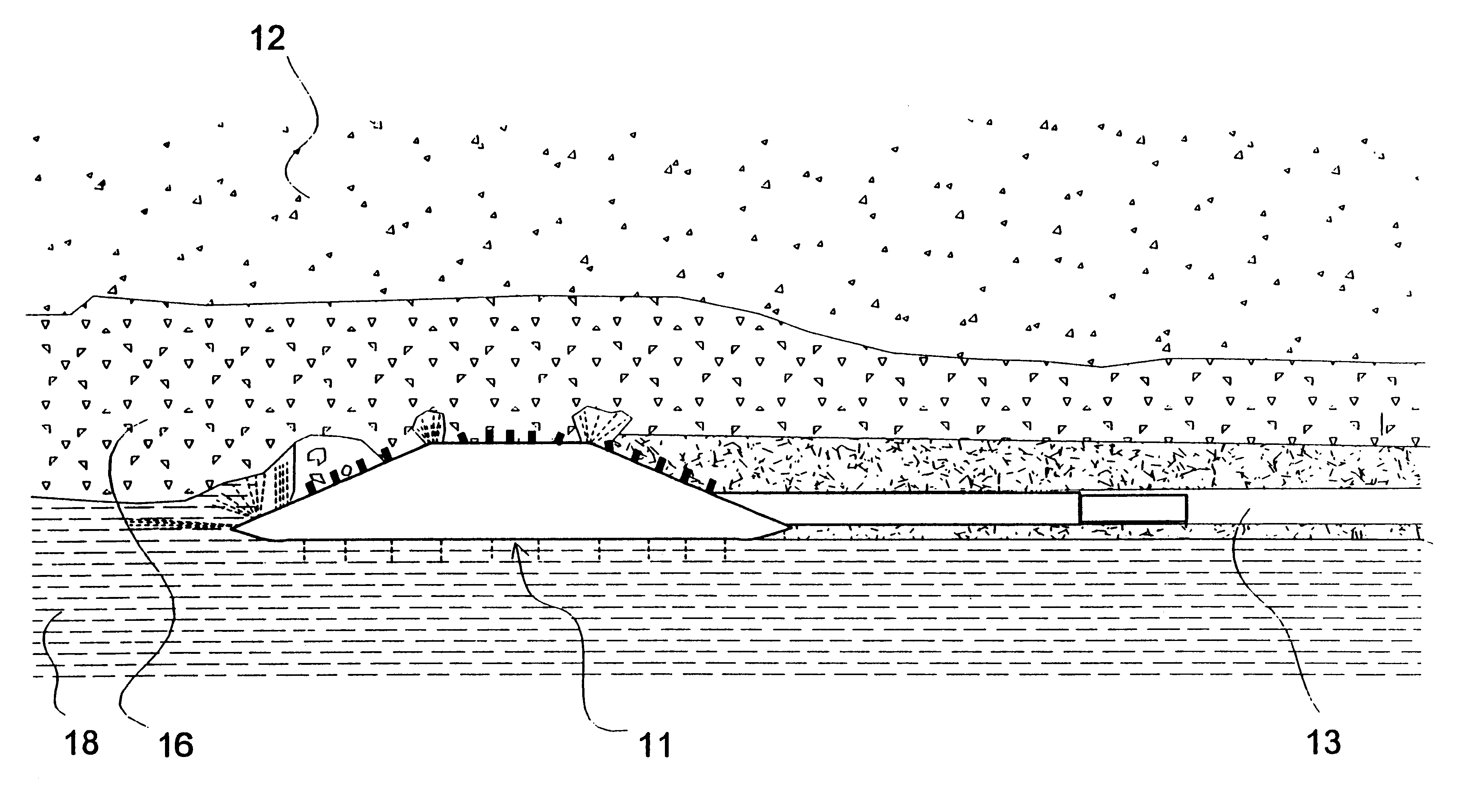

Subsea multiphase flow meter detector retrievable electronics

InactiveUS20050241410A1Precise positioningImprove componentMass flow measurement devicesVolume meteringSubject matterEngineering

An apparatus and a method for its use allow selective installation and removal of a canister such as one containing interface electronics to a mating connector on a housing, such as one containing a subsea multiphase flow meter sensor. The separately retrievable canister may contain multiphase flow meter detector electronics and is sealed, waterproof, and preferably light-weight. Installation and retrieval may be via use of an ROV and an alignment guide which acts as a guide to aid in correct positioning of the canister. The canister may be cooled by surrounding sea water and / or by insulation. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:ROXAR FLOW MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com