Full-automatic liquid adding device for fracturing construction and adding calibration method

A technology of liquid addition and liquid additives, which is applied in the direction of measuring devices, chemical instruments and methods, testing/calibration devices, etc., can solve the problems of difficulty in adding liquid additives accurately, personnel falling, vehicle movement, etc. less, stable structure, and compact installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

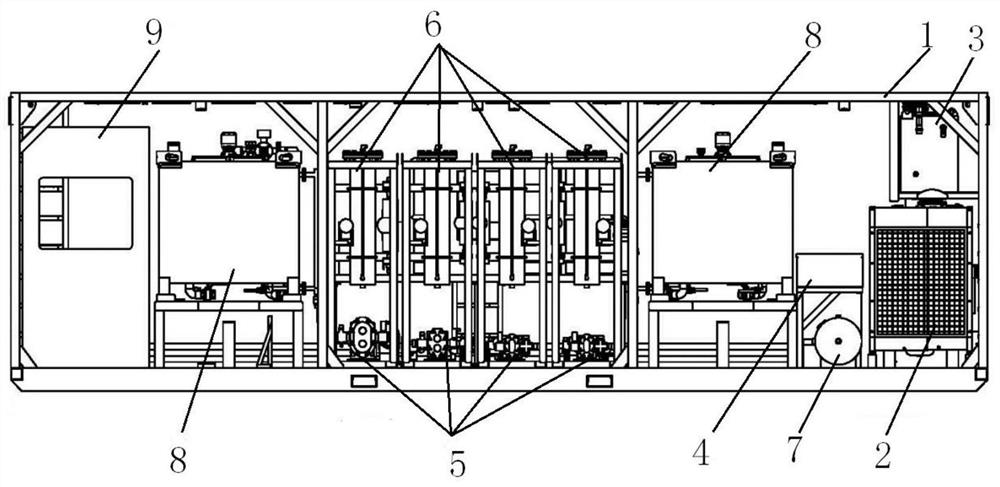

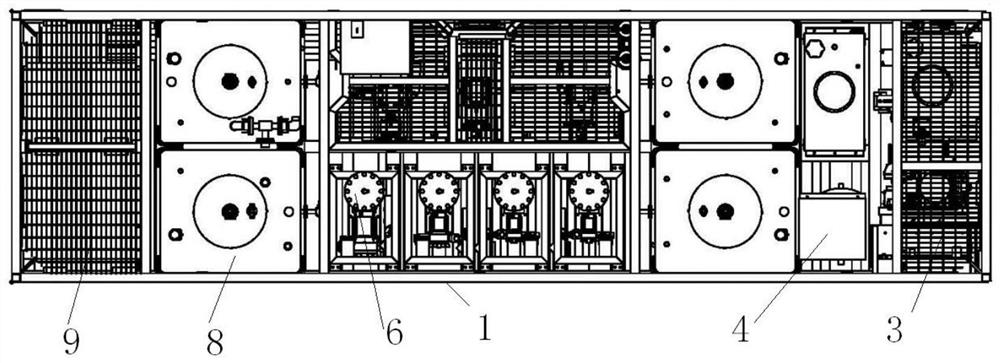

[0025] Such as figure 1 and figure 2 As shown, a full-automatic high-precision liquid addition device for fracturing construction includes a skid frame 1, an engine 2, a transfer case 3, a hydraulic device 4, a liquid addition unit, a liquid supply pump 7 and a control unit 9, and the liquid addition unit The quantity is multiple, and each liquid addition unit includes a liquid addition pump 5, a metering calibration tank 6, a liquid additive tank 8; an engine 2, a transfer case 3, a hydraulic device 4, a liquid addition unit, a liquid supply pump 7 and a control unit 9 are all connected to the skid frame 1; the input ends of the engine 2, the transfer case 3 and the hydraulic device 4 are connected sequentially, and the output ends of the hydraulic device 4 are respectively connected to the liquid supply pump 7 and the liquid addition pump 5 of each liquid addition unit, The liquid supply pump 7 is connected to the inlet of the liquid additive tank 8 of each liquid additive...

Embodiment 2

[0030] On the basis of Embodiment 1, further, the number of the engine 2, the transfer case 3, the hydraulic device 4, and the control unit 9 is 1, the liquid addition pump 5, the metering calibration tank 6, and the liquid additive tank 8 The number of pumps is 4, the number of liquid supply pumps 7 is 3, the engine 2, transfer case 3, hydraulic device 4, liquid addition unit, liquid supply pump 7 and control unit 9 are all connected to the inside of the skid frame 1, and the control The unit 9 is located inside the left part of the skid frame 1, two liquid additive tanks 8 are distributed from front to rear on the right side of the control unit 9, and four metering calibration tanks 6 are distributed from left to right on the upper right side of the two liquid additive tanks 8. Four liquid addition pumps 5 are distributed from left to right on the lower right side of the two liquid supply pumps 7, and another two liquid additive tanks 8 are distributed from front to back on t...

Embodiment 3

[0041] On the basis of Embodiment 2, a fully automatic high-precision liquid addition calibration method for fracturing construction includes the following steps: the engine 2 provides power for the transfer case 3, the transfer case 3 drives the hydraulic device 4, and the hydraulic device 4 provides power for the power supply. The liquid pump 7 and the liquid addition pump 5 provide pressure, and the liquid supply pump 7 supplies the construction liquid for the liquid additive tank 8; when the output displacement of the construction liquid is calibrated, the liquid addition pump 5 sucks the construction liquid from the liquid additive tank 8 Enter the metering calibration tank 6, and calibrate the volume of the construction liquid in the metering calibration tank 6, then the liquid addition pump 5 pumps the construction liquid in the metering calibration tank 6 into the liquid additive tank 8 after being measured by a mass flow meter Then compare the volume of the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com