Patents

Literature

1895results about "Testing/calibration for volume flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

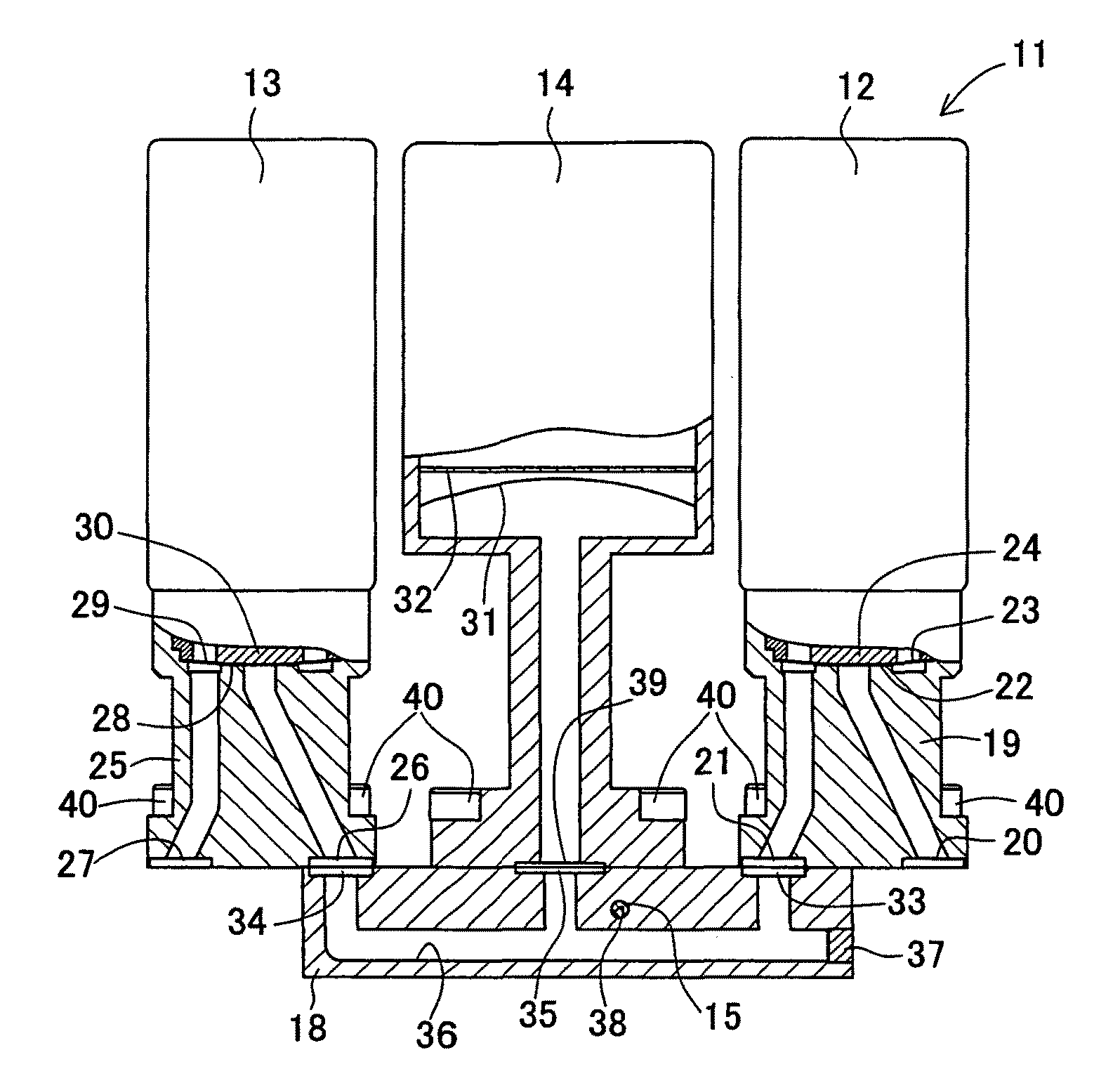

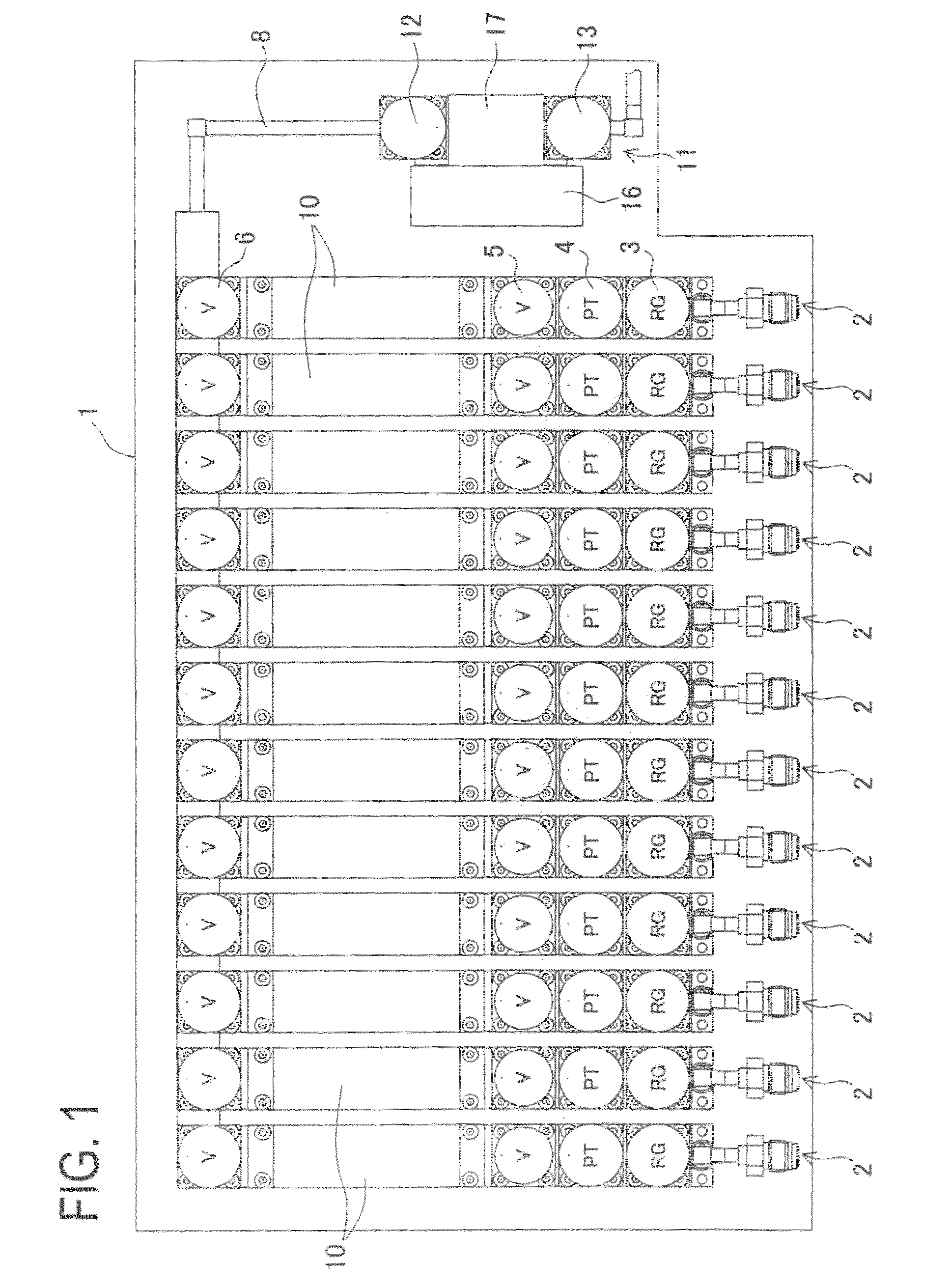

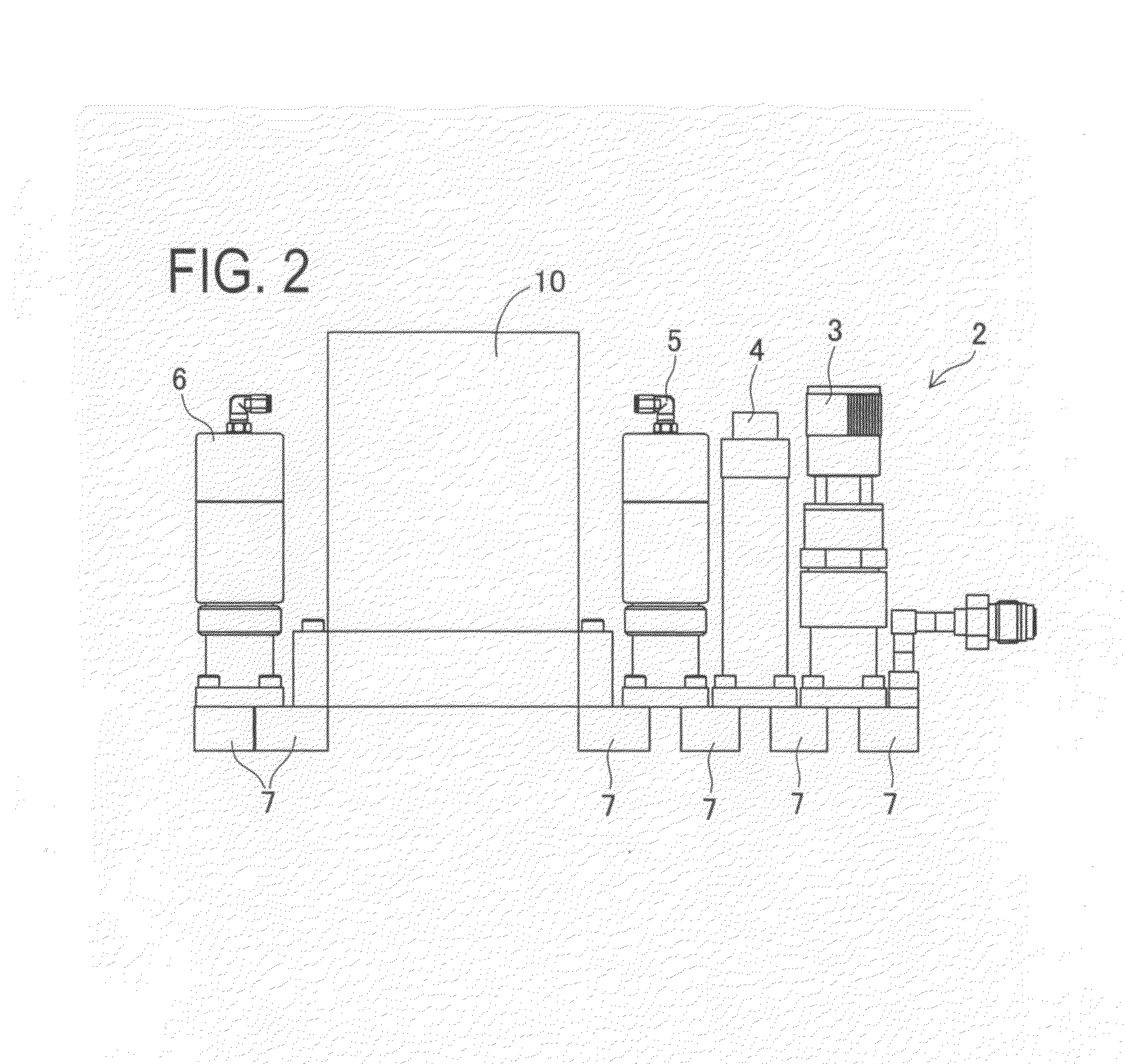

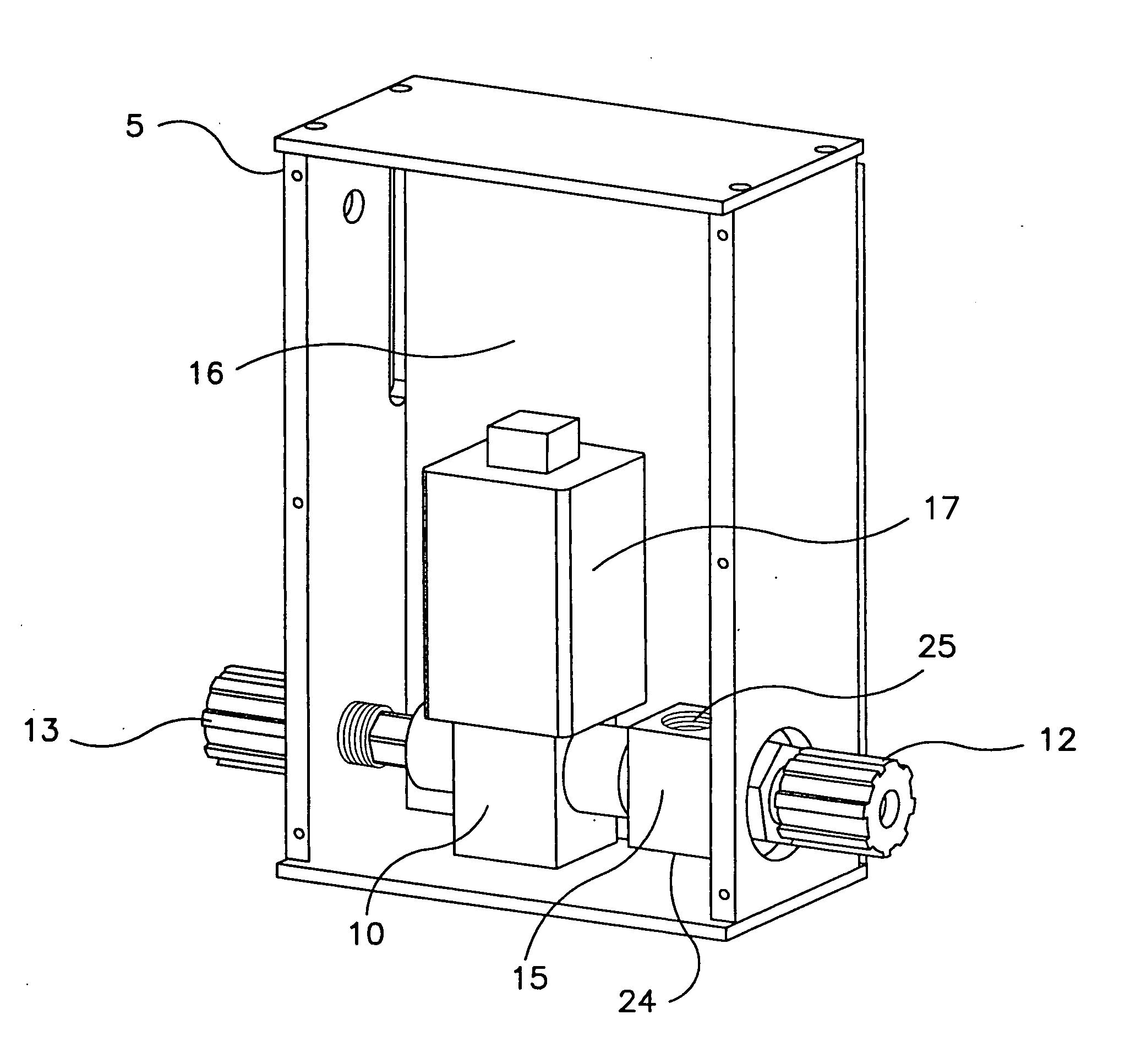

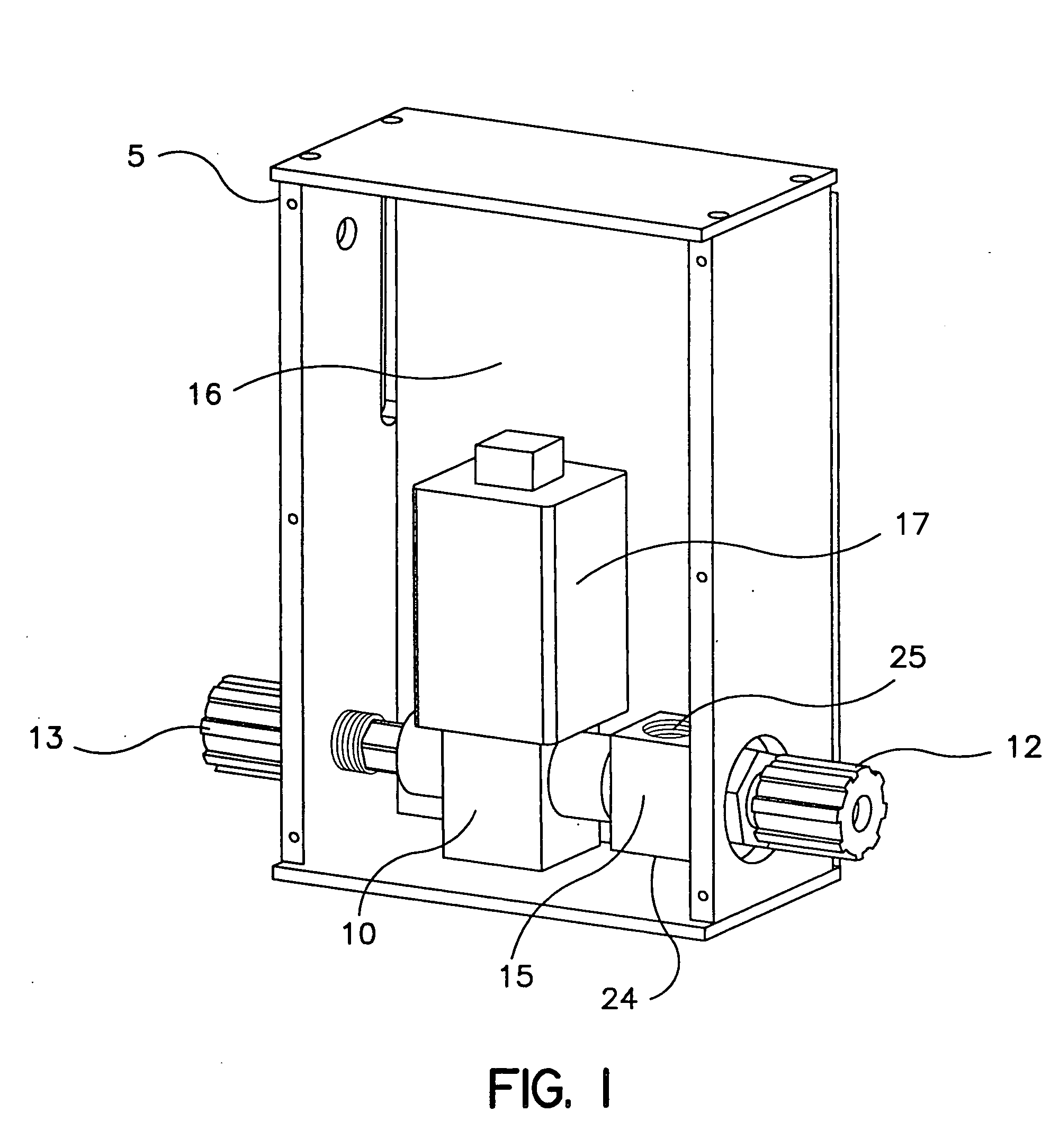

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

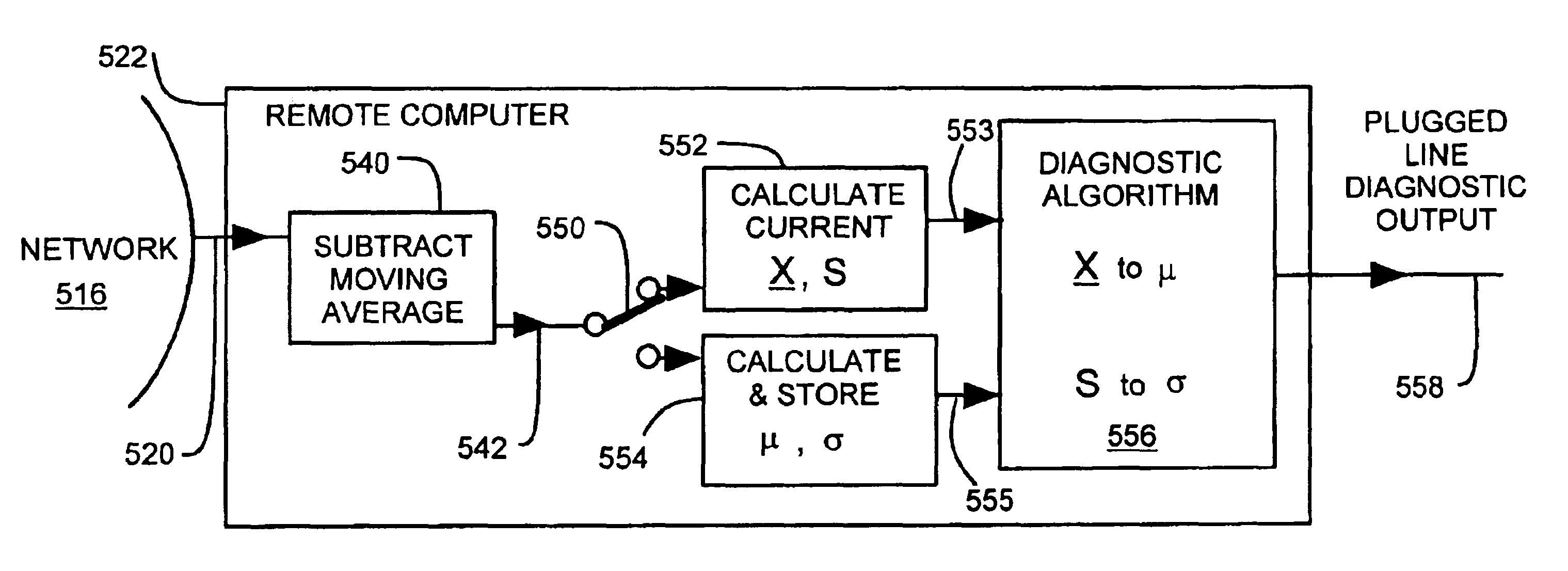

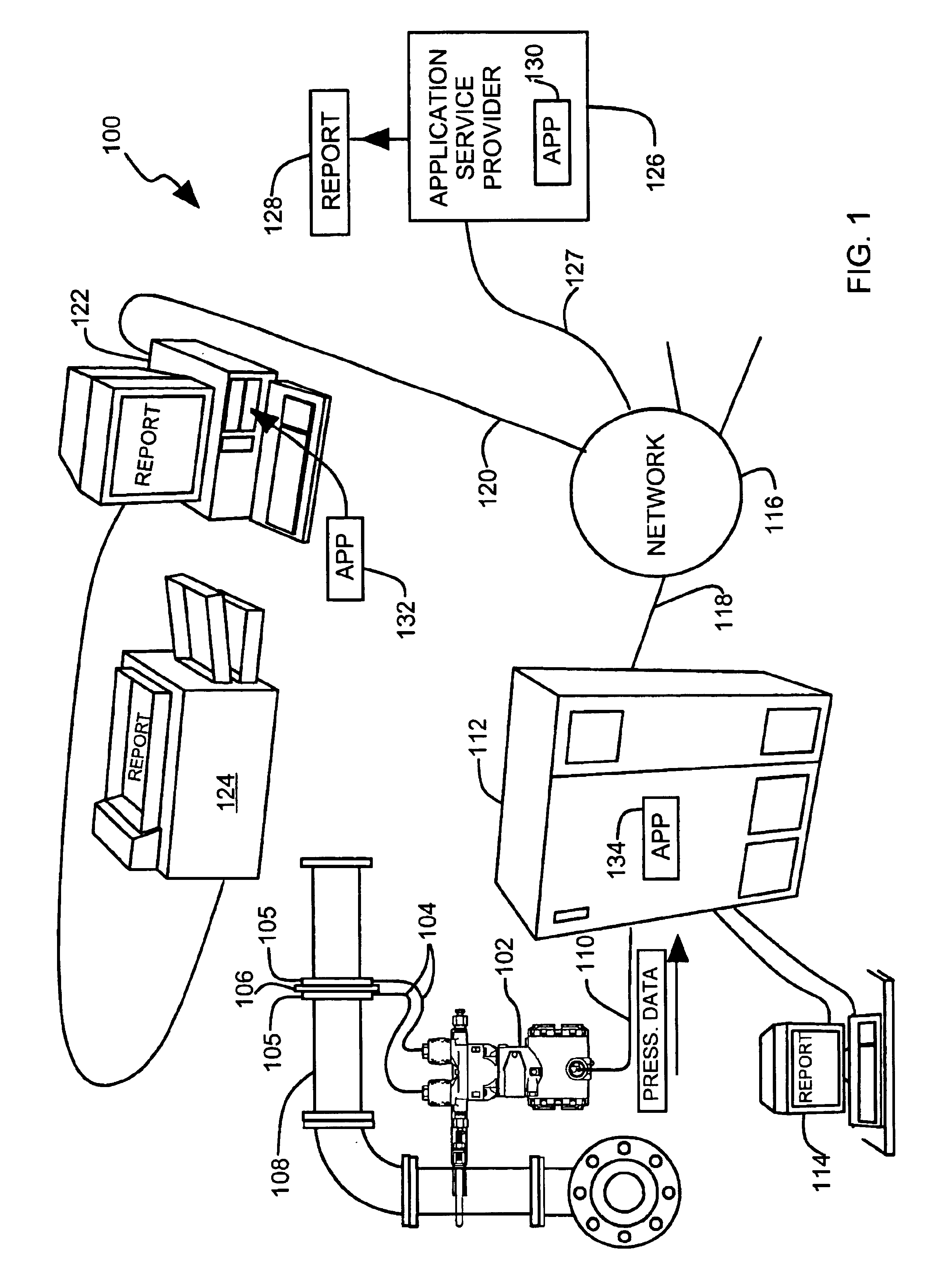

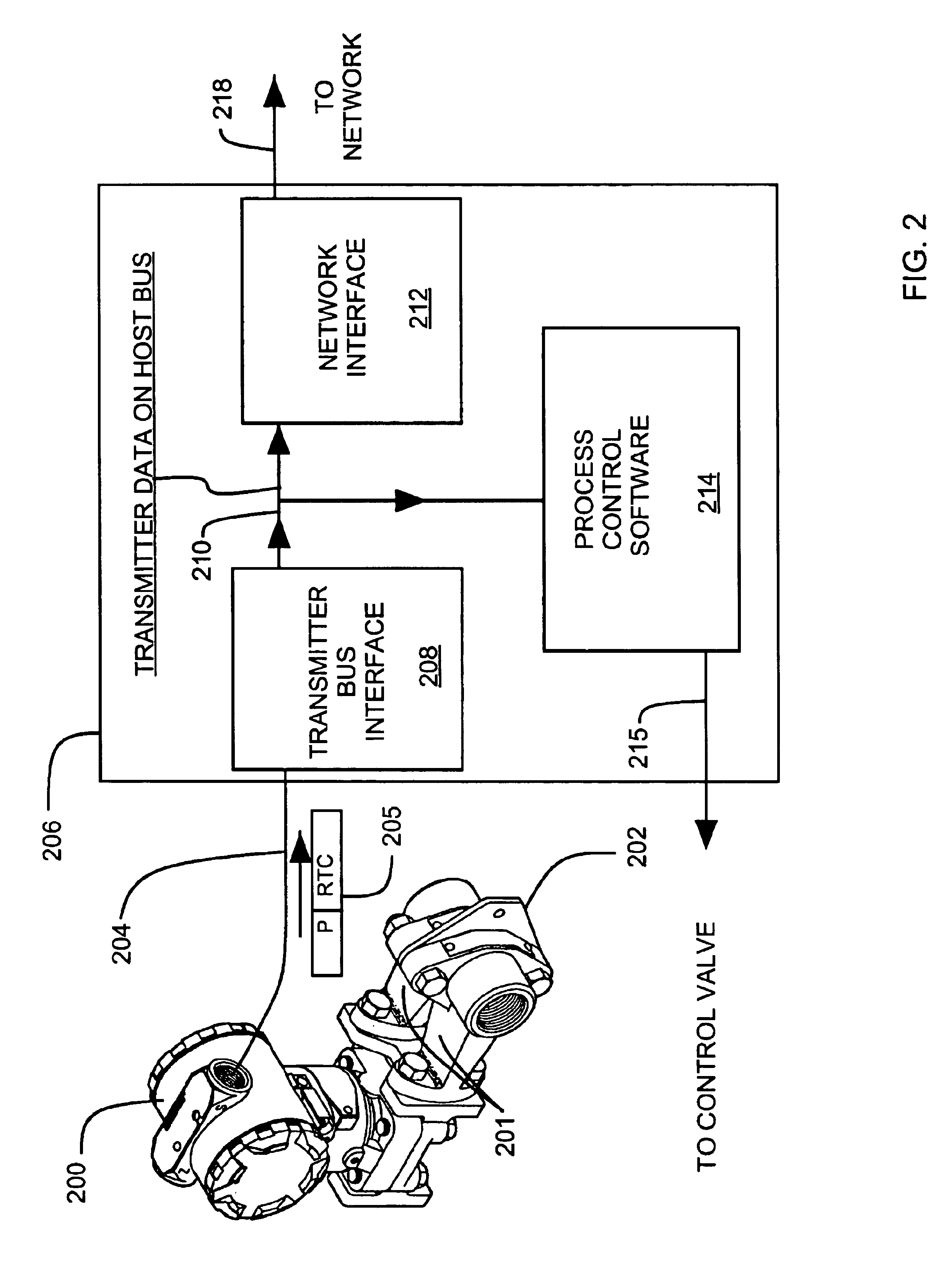

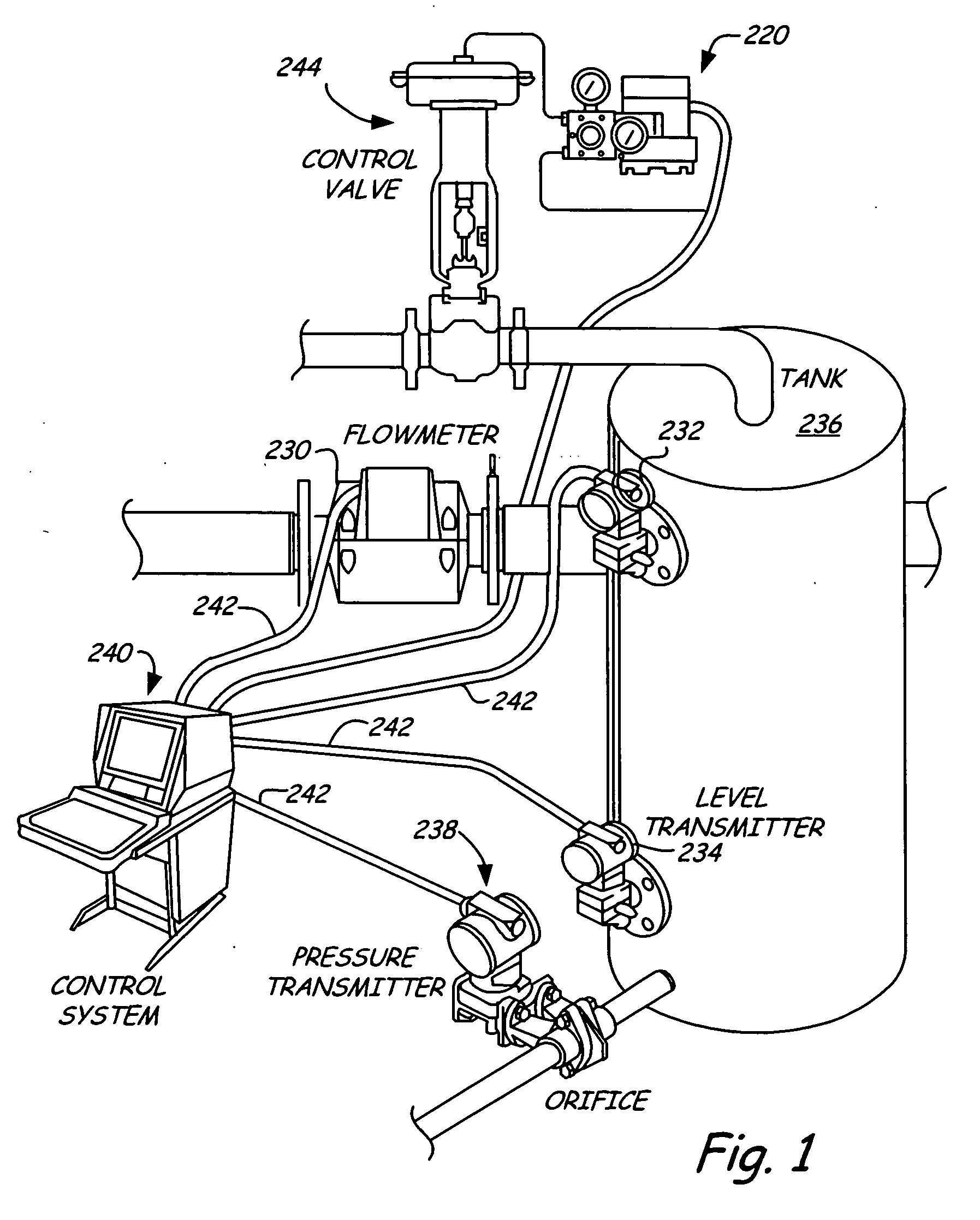

Flow diagnostic system

InactiveUS6907383B2Sampled-variable control systemsFlow control using electric meansMoving averageReal-time clock

A flow diagnostic system for a flow sensing element and impulse lines. A pressure transmitter coupled to the impulse lines provides digital pressure data to a control system. The control system provides the pressure data and real time clock readings to a diagnostic application. The diagnostic application calculates a difference between current pressure data and its moving average. A condition of the primary element or impulse lines is diagnosed from a current pressure data set relative to an historical data set. The diagnostic application is downloadable from an application service provider (ASP). The application can run on the control system, a remote computer or the ASP. A diagnostic report is preferably provided.

Owner:ROSEMOUNT INC

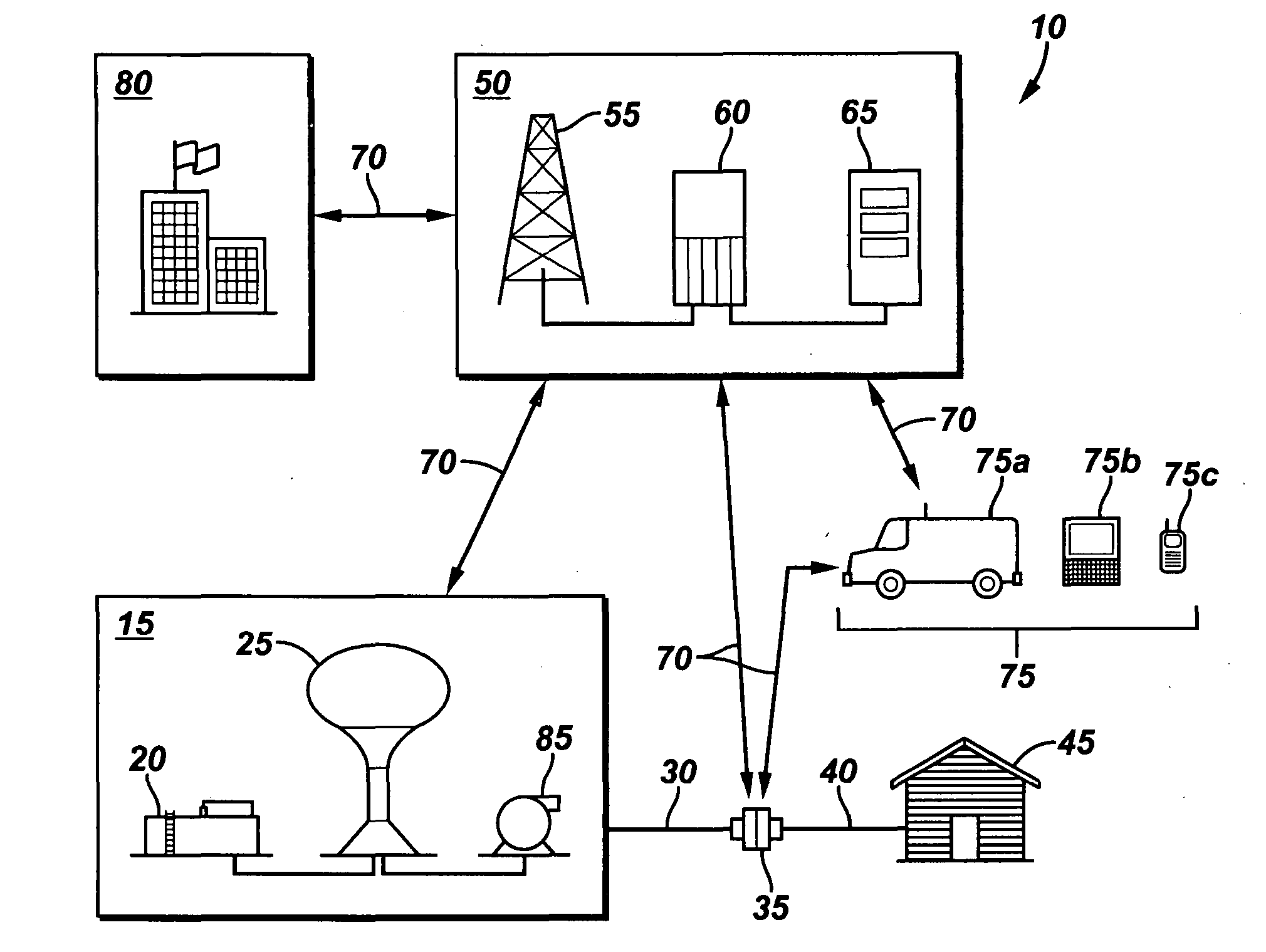

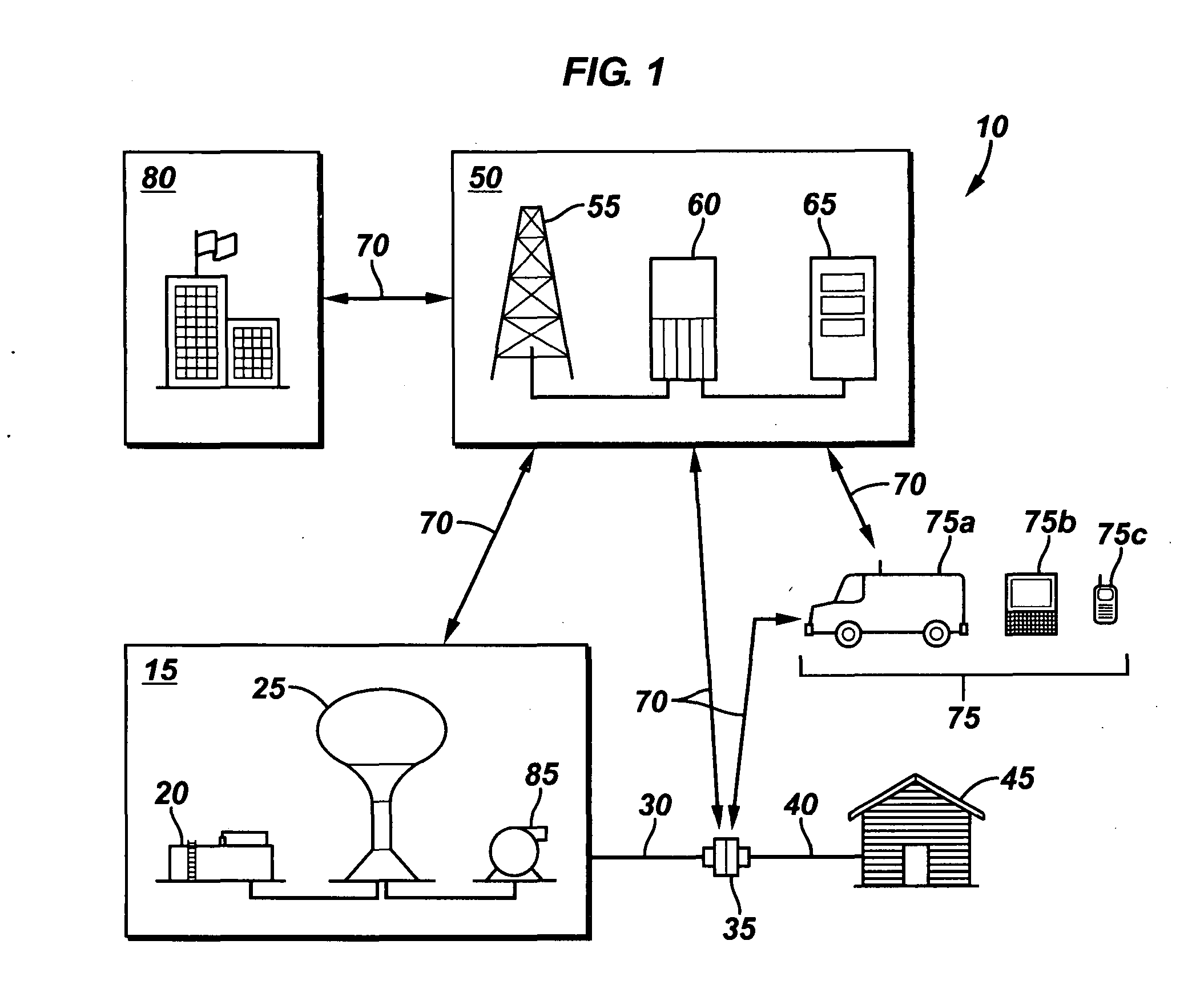

System and method for remotely monitoring and controlling a water meter

ActiveUS20090309755A1Electric signal transmission systemsTariff metering apparatusDistribution systemEngineering

A meter that monitors usage of a water distribution system by a client is provided. The meter includes a wireless communications system operable to communicatively couple the meter to a wireless network to provide two-way communication between the meter and the wireless network; a calibration system operable to calibrate the meter, wherein the calibration system may calibrate the meter in response to an instruction received via the wireless network; and a power system operable to maintain a sufficient level of power for the meter to allow substantially real-time communication between the meter and the wireless network.

Owner:CAPSTONE METERING

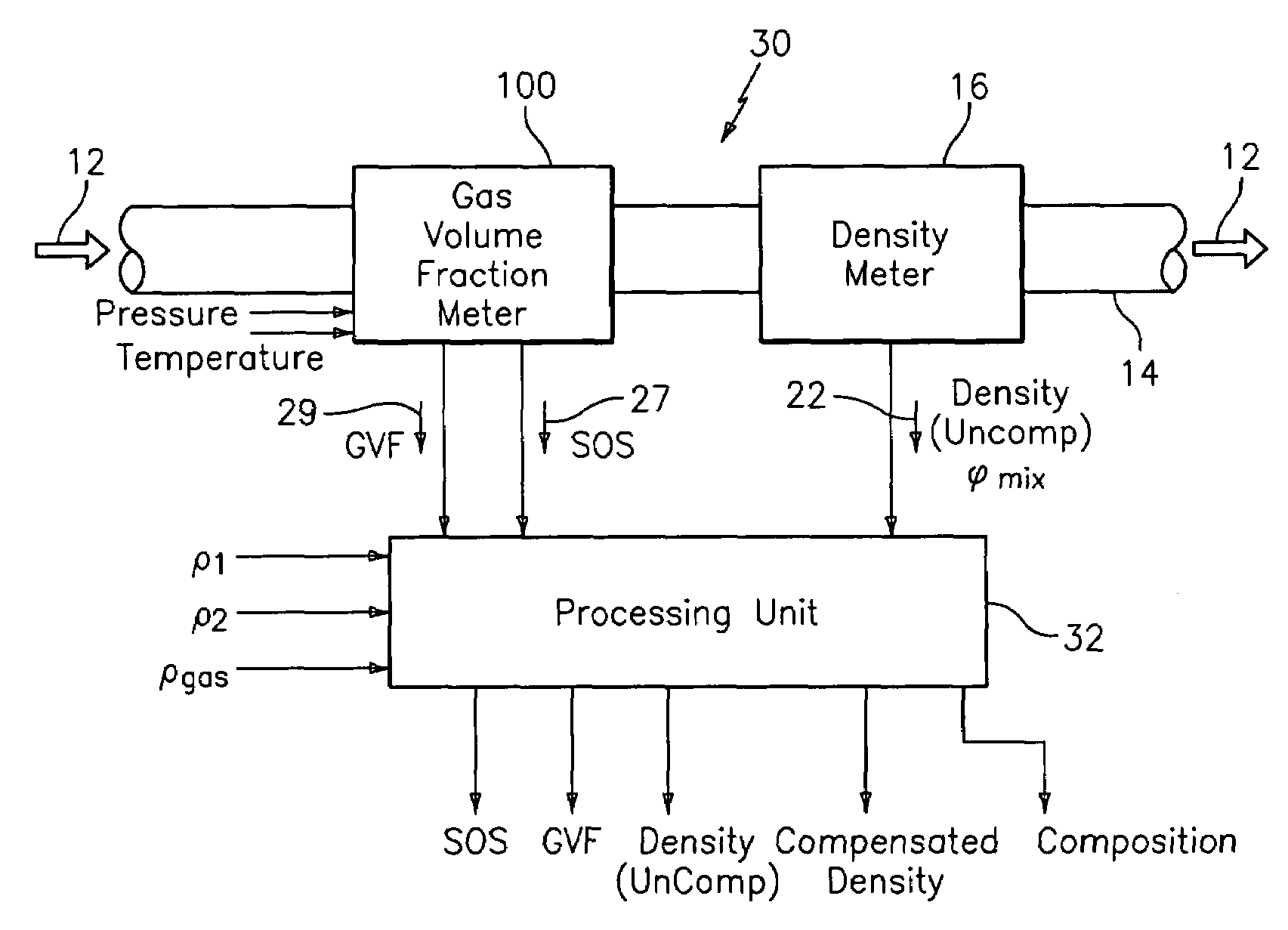

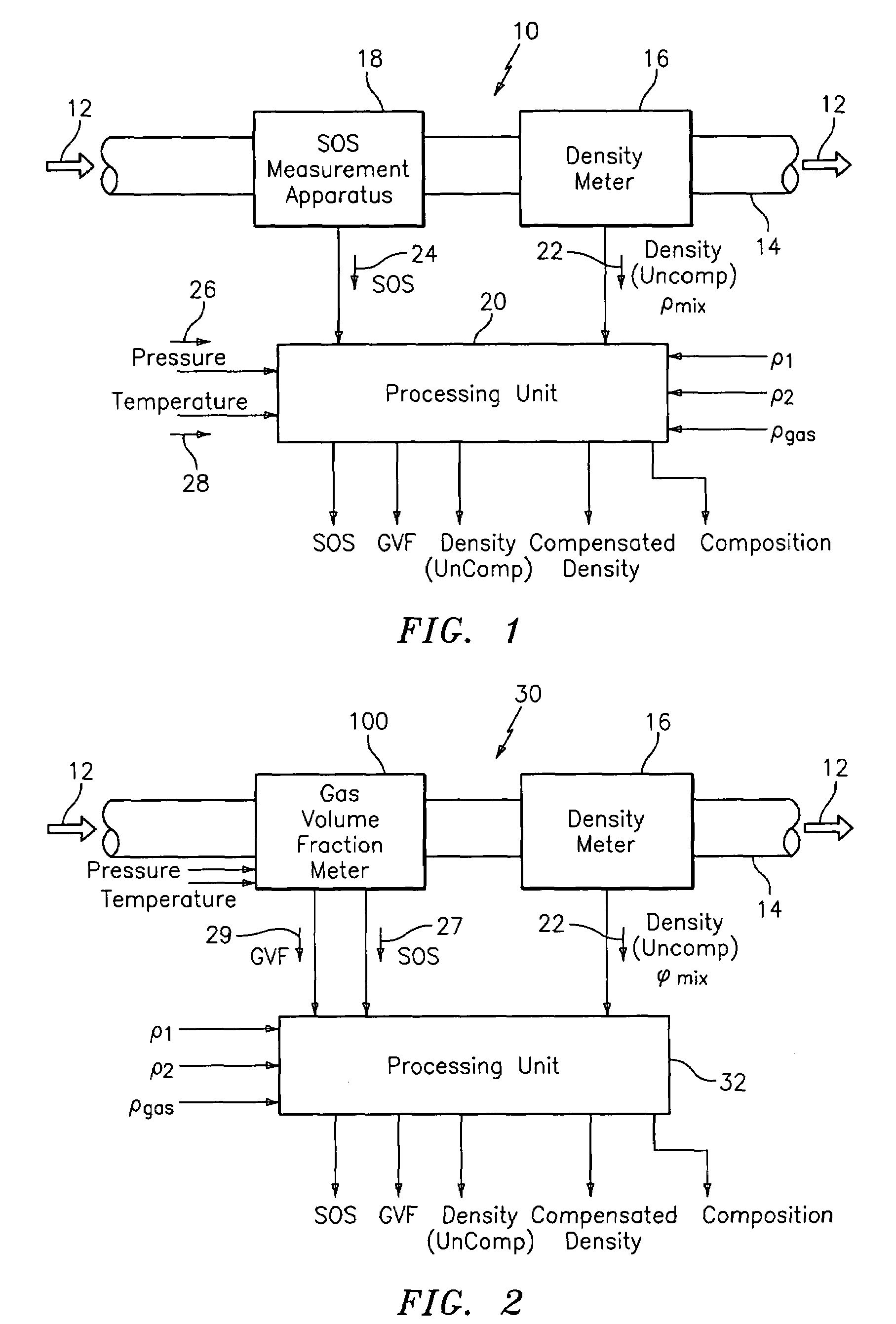

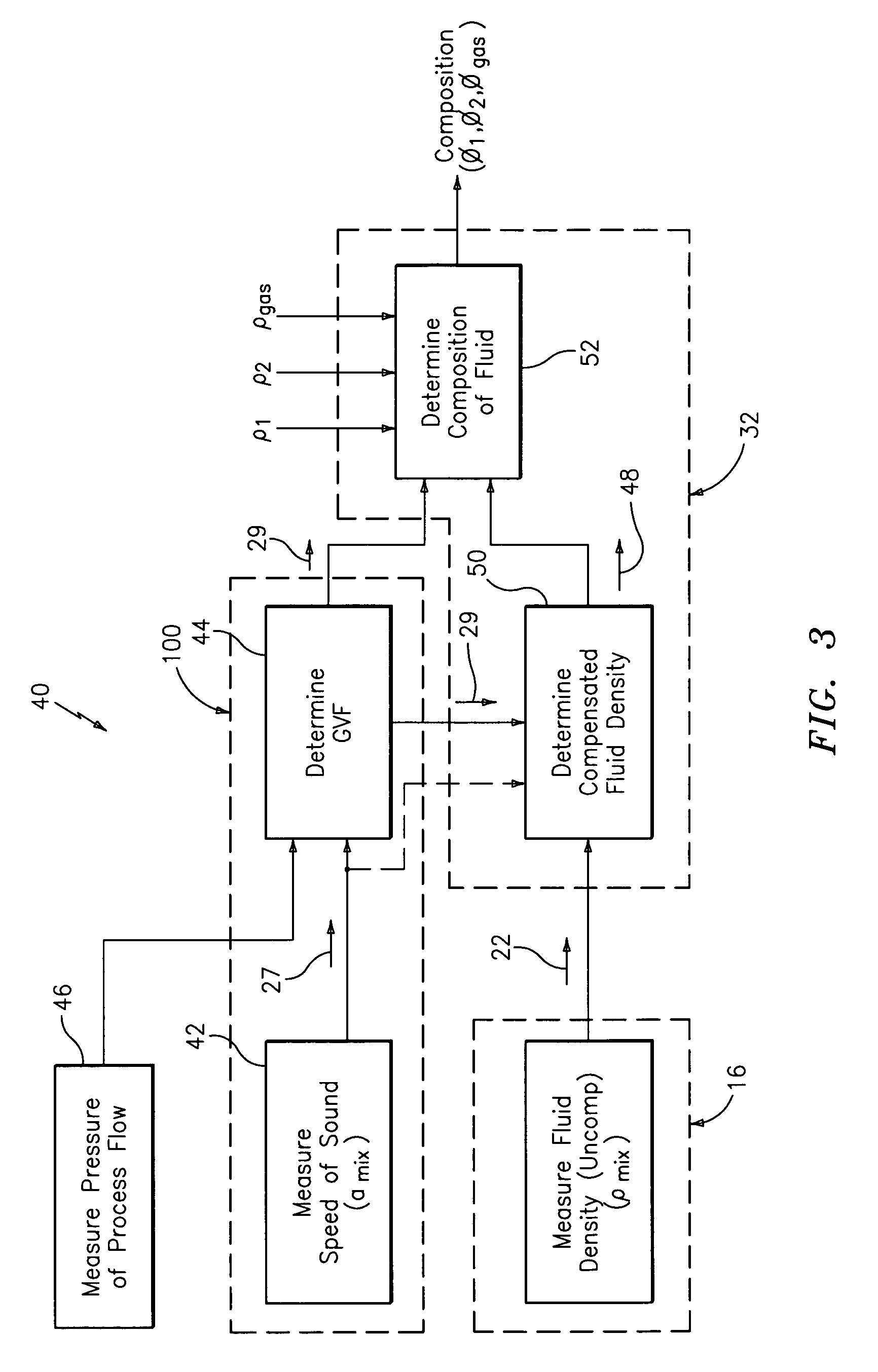

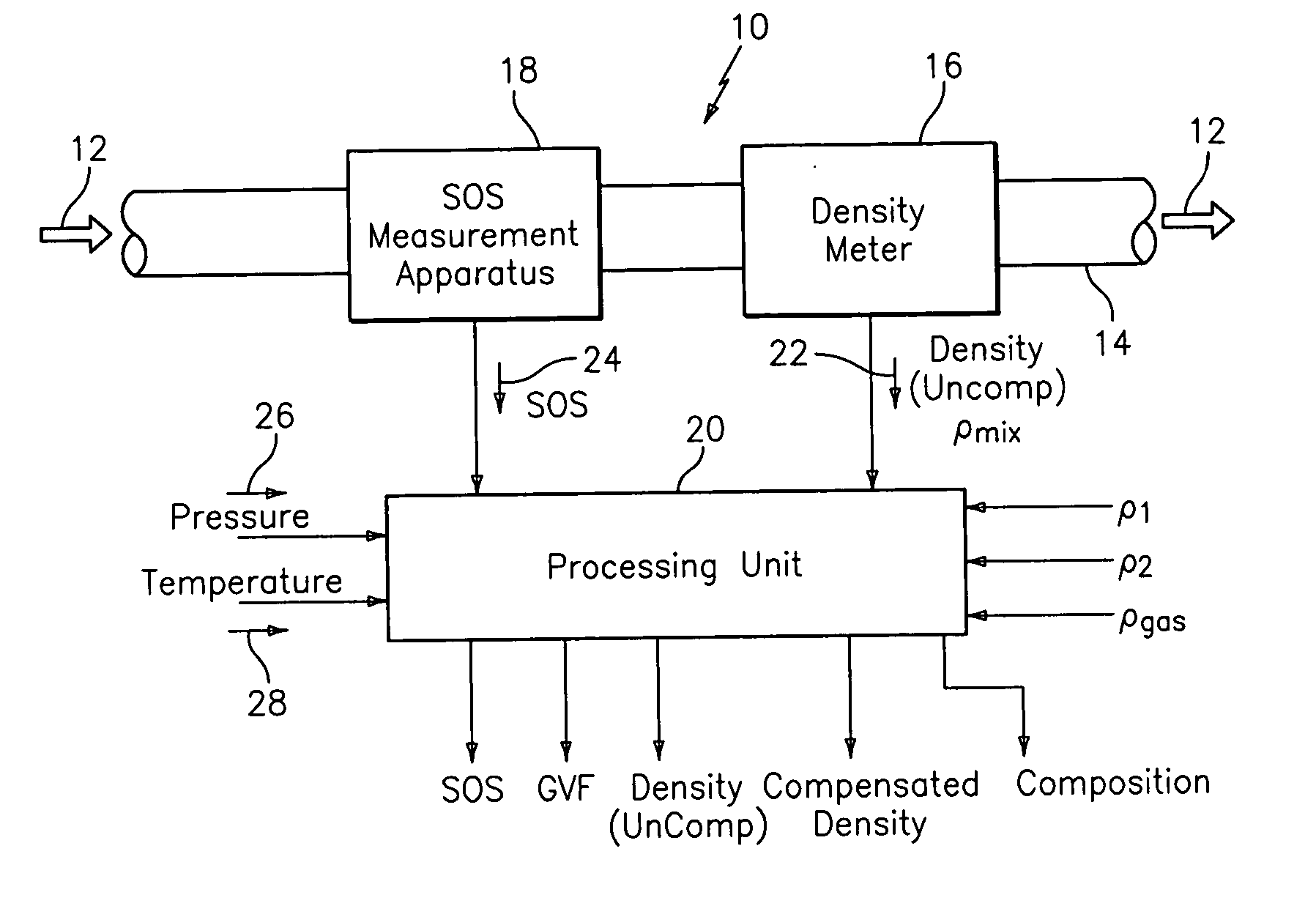

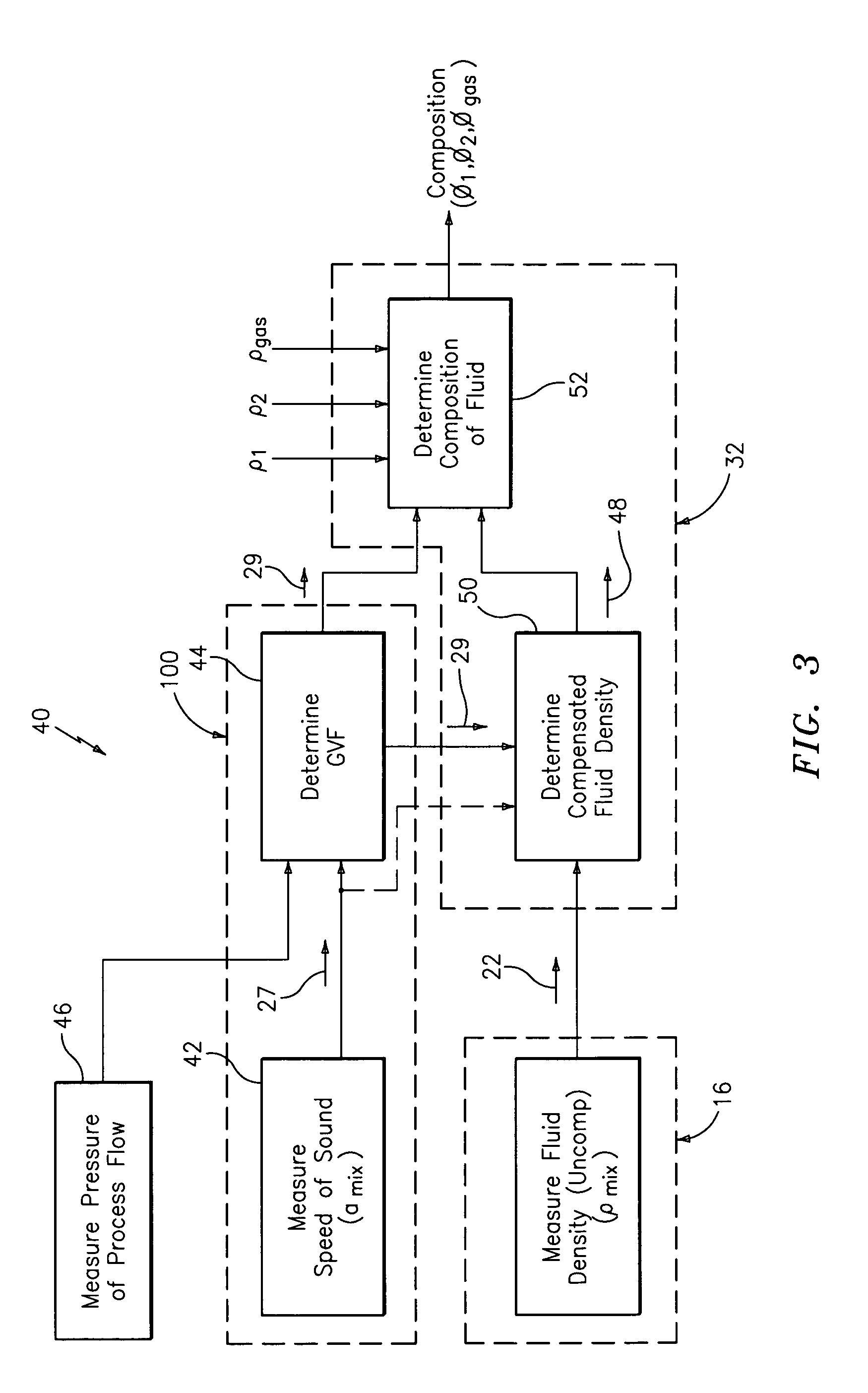

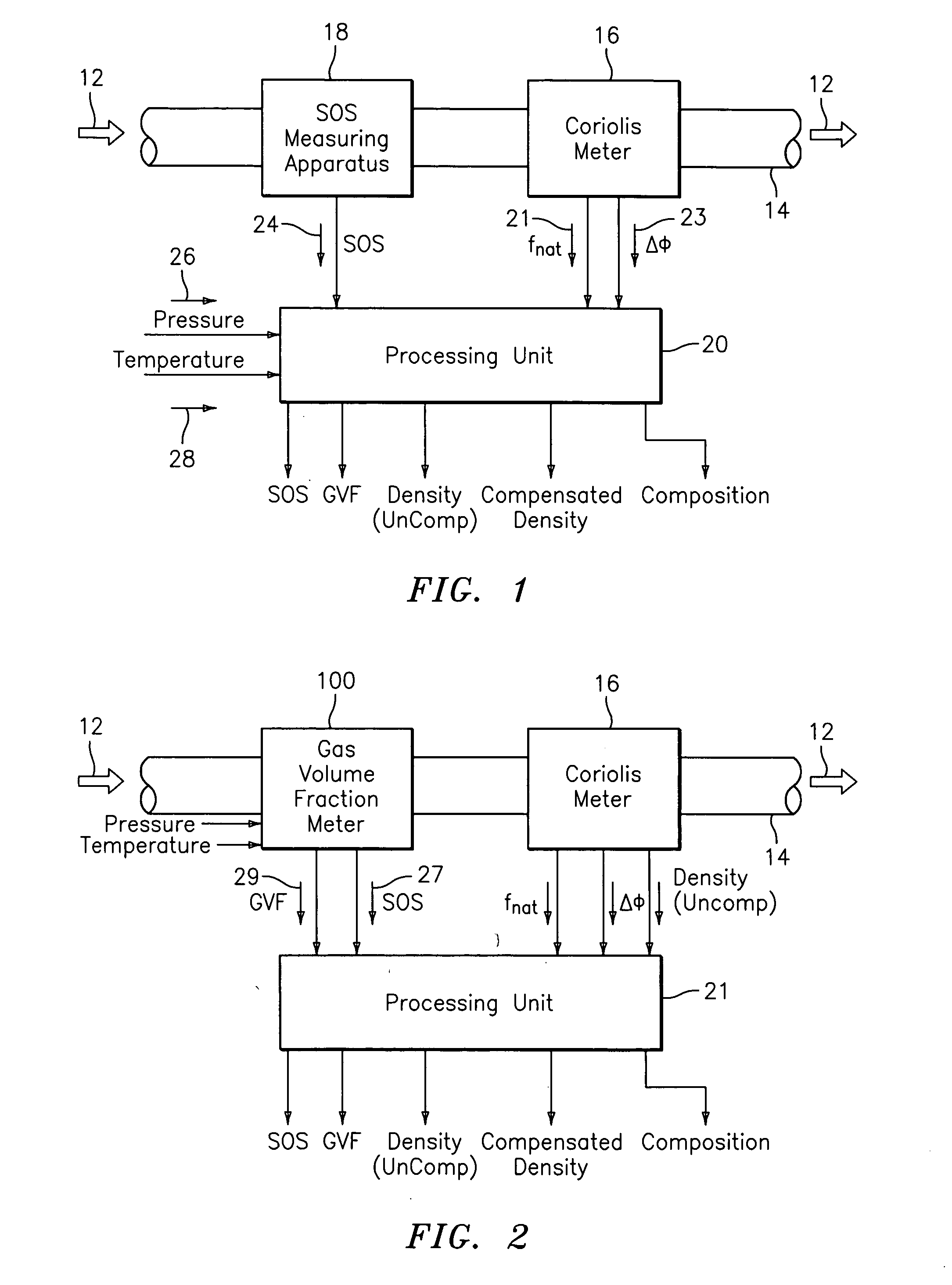

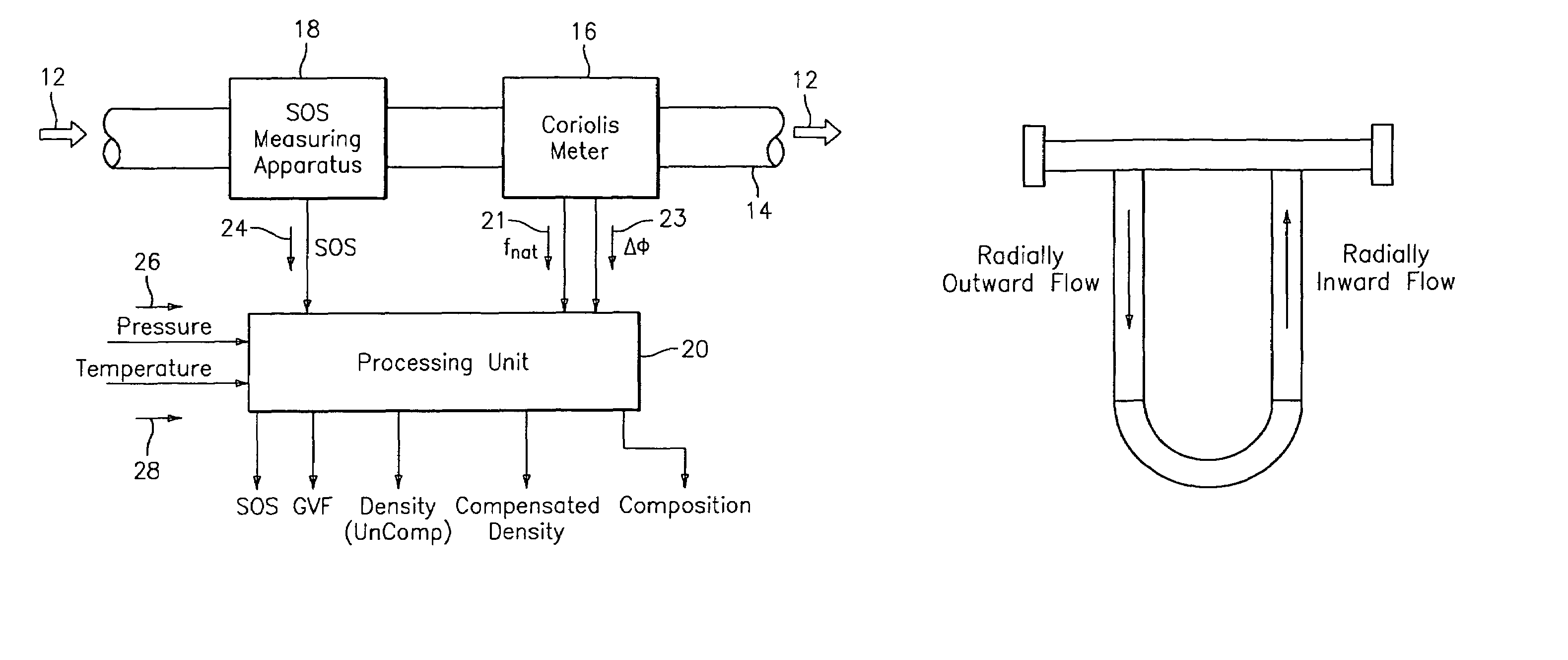

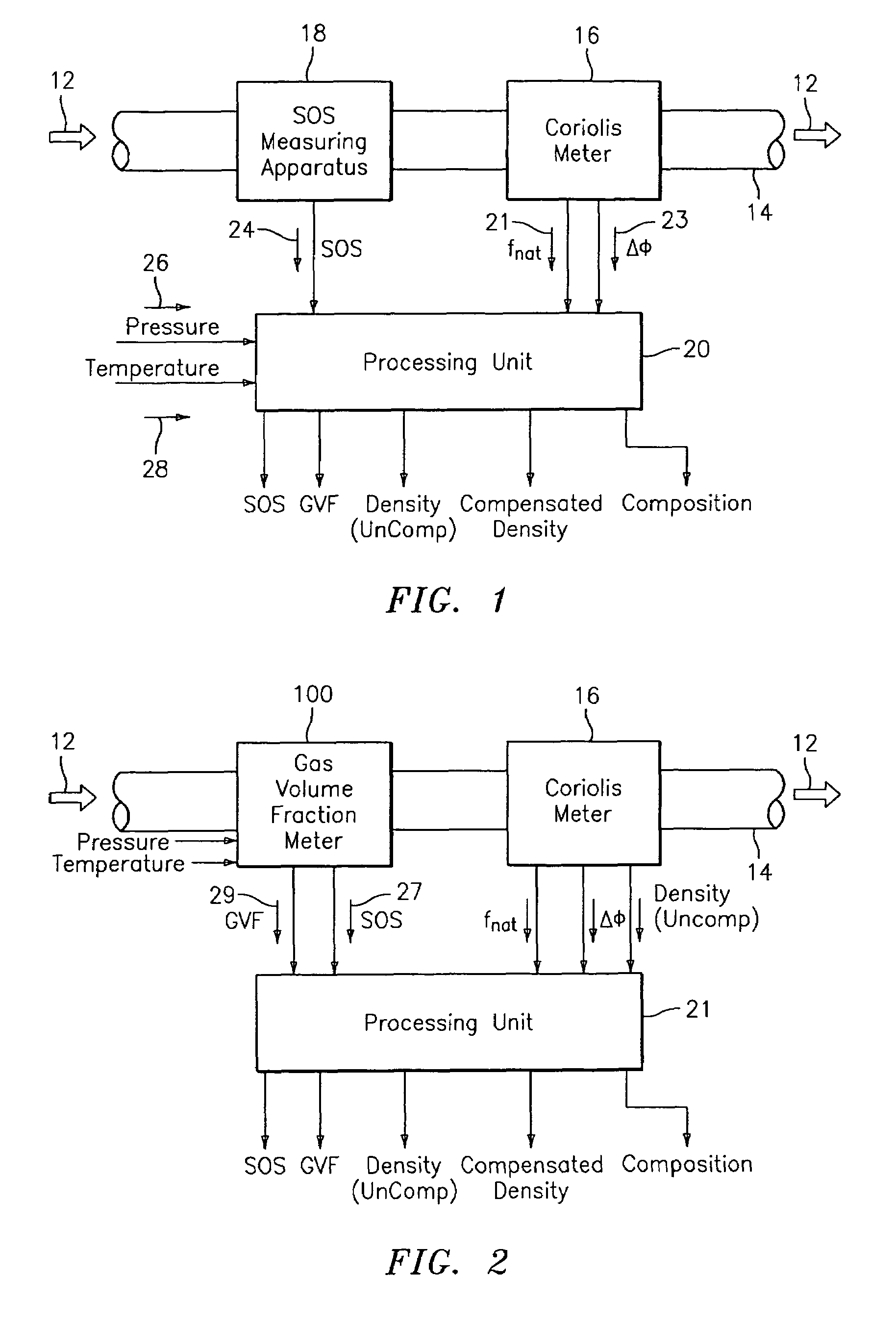

Apparatus and method for providing a density measurement augmented for entrained gas

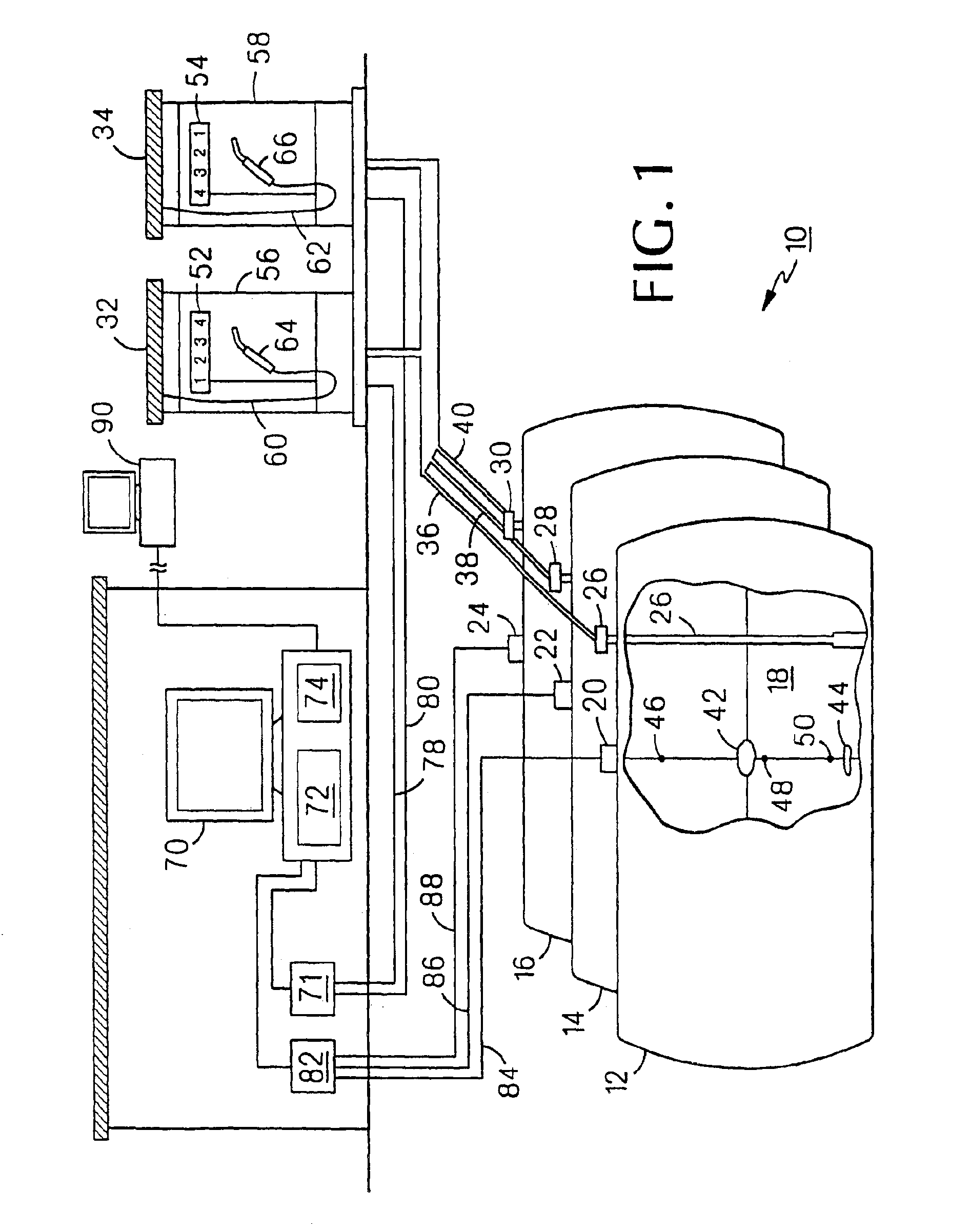

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

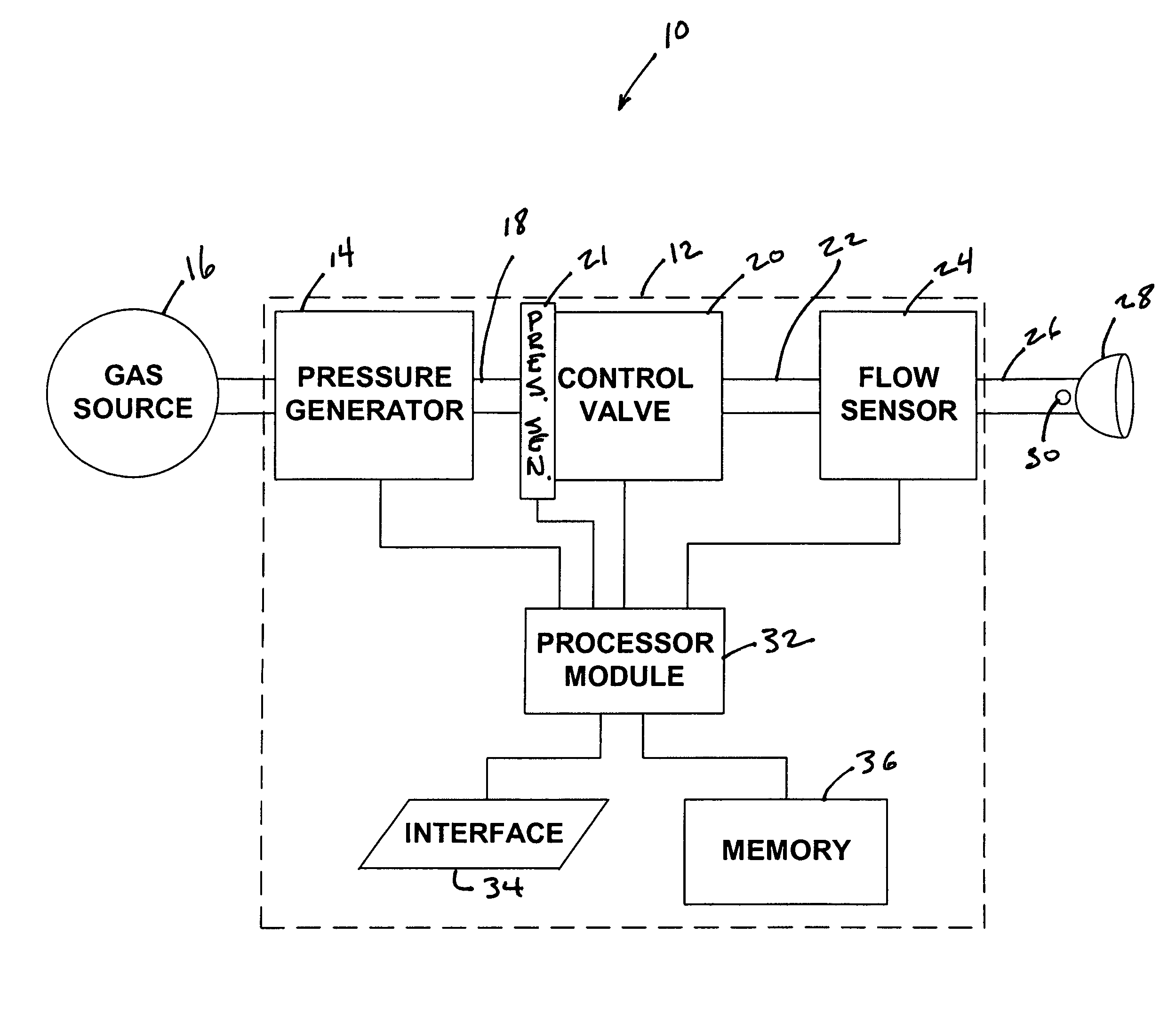

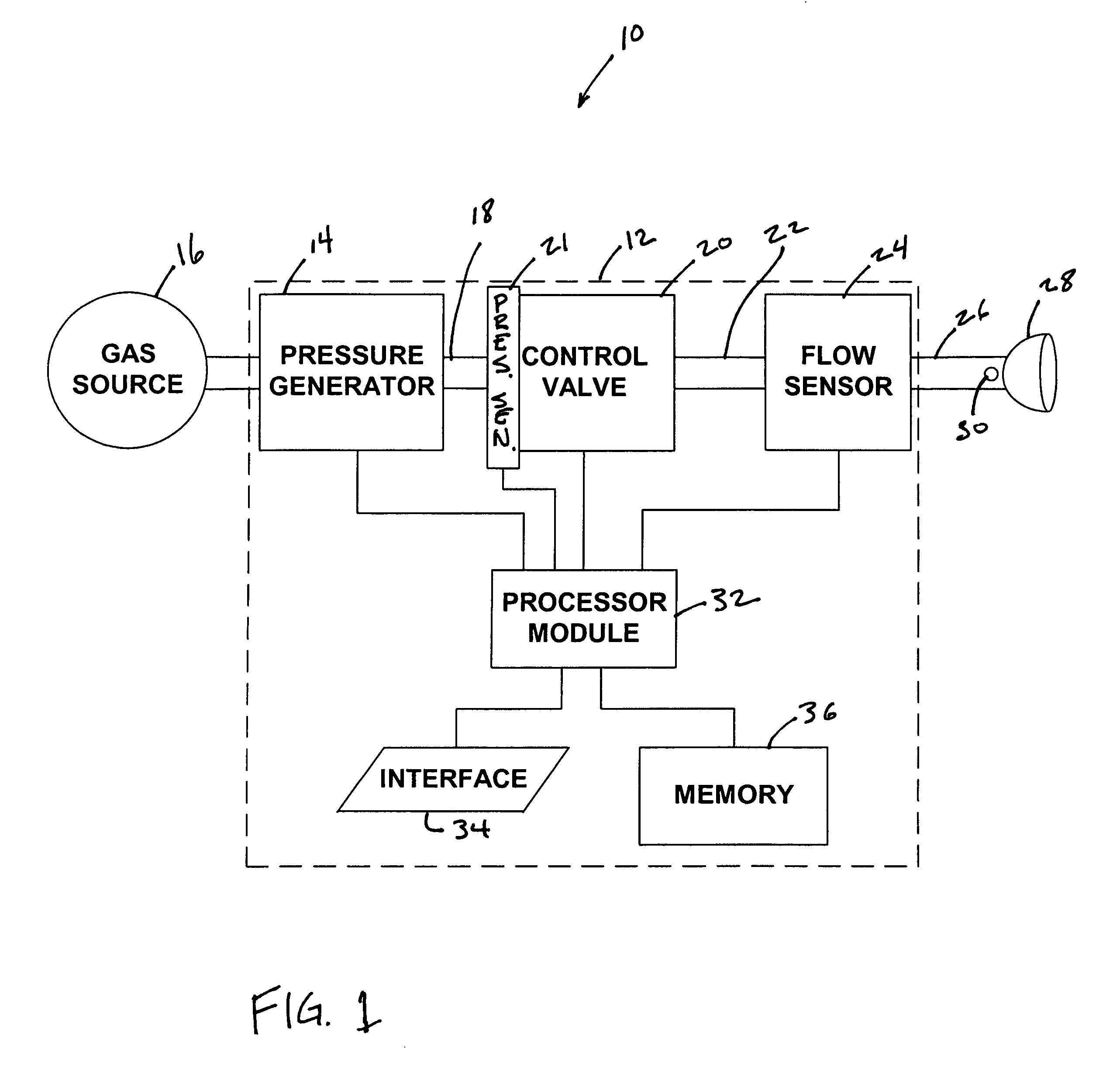

Respiratory device measurement system

ActiveUS20060283450A1RespiratorsOperating means/releasing devices for valvesAtmospheric airBreathing gas

A gas delivery system comprising a pressure generator, a pressure sensor, a control valve, and a processor. The pressure generator pressurizes breathable gas for delivery to a patient. The pressure sensor measures a pressure difference between the pressurized breathable gas and atmospheric pressure. The control valve is disposed downstream from the pressure generator and is constructed and arranged to control a flow rate of the pressurized breathable gas. The processor controls the control valve to bring the flow rate of the pressurized breathable gas to substantially zero while the pressure generator is operating and, when the flow rate is substantially zero, determines at least one of atmospheric pressure, an atmospheric air density, or a density correction factor based at least in part on the pressure difference between the pressurized breathable gas and the atmospheric pressure.

Owner:PHILIPS RS NORTH AMERICA LLC

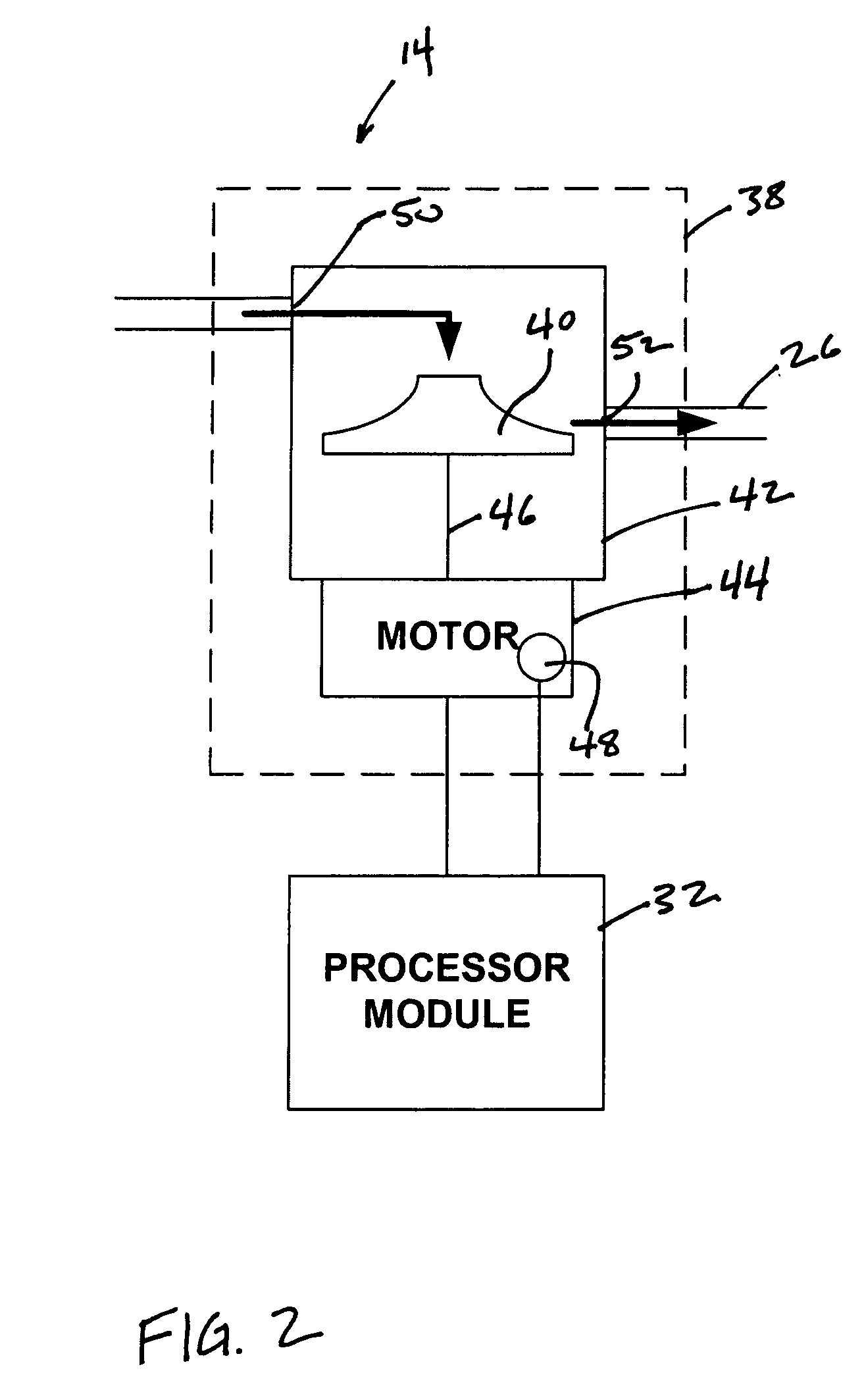

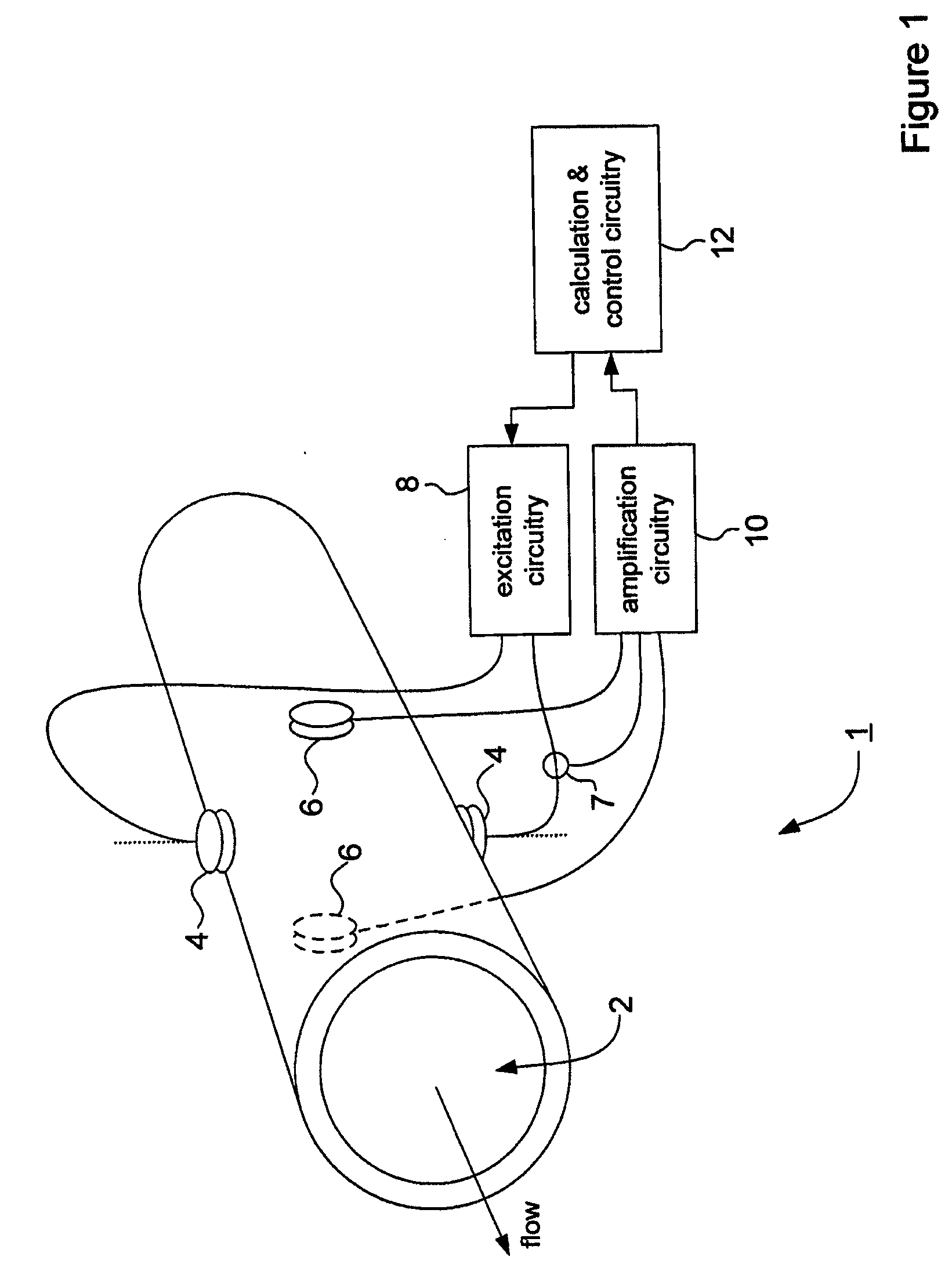

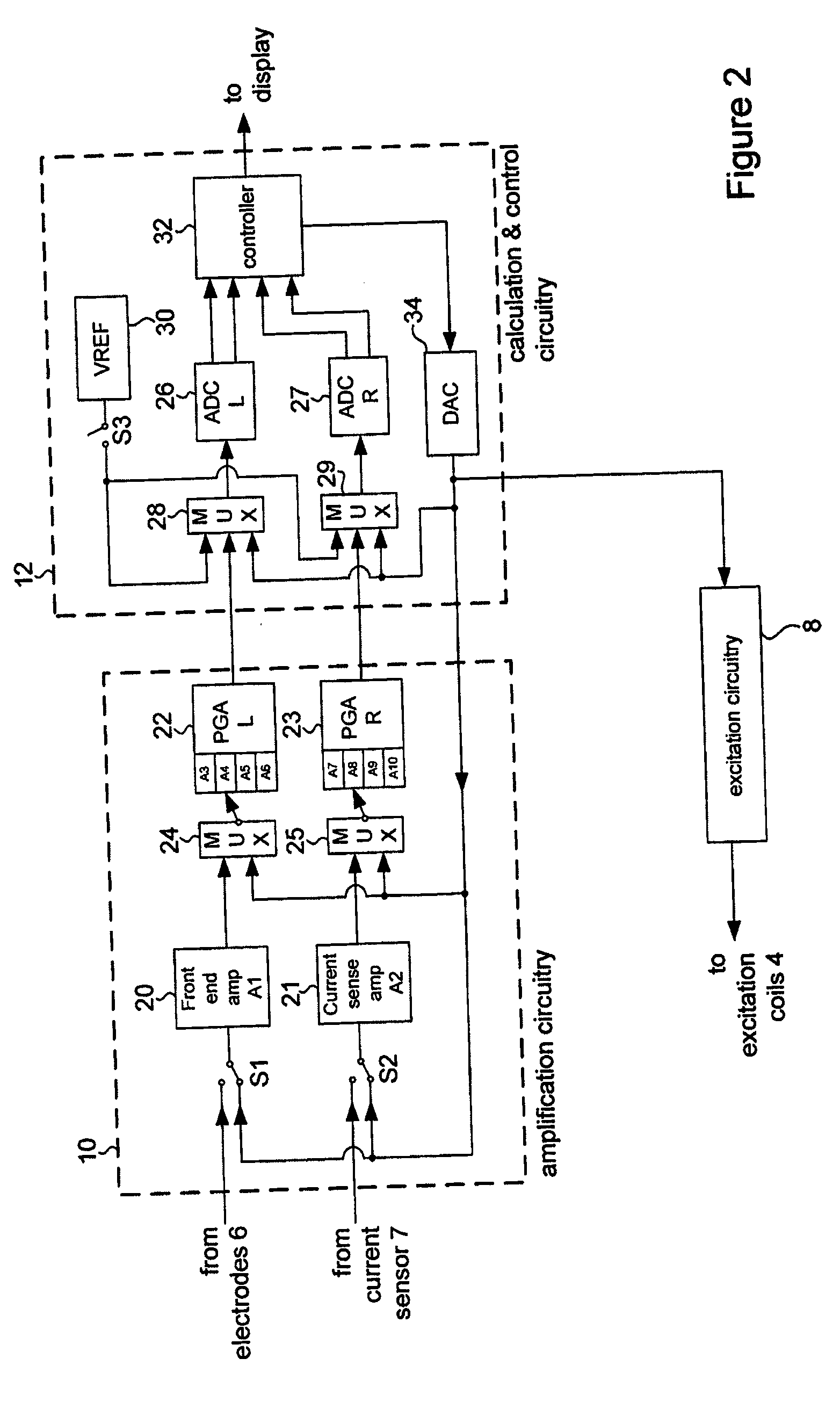

Flowmeter

ActiveUS20090071264A1Interference minimizationReduce the amount requiredFluid pressure measurementTesting/calibration for volume flowElectromagnetic fieldStreamflow

An electromagnetic flowmeter assembly is described in which an excitation field is set up across a flow conduit and electrodes are used to sense the electromagnetic field generated across the flow conduit as a result of interaction between the excitation field and fluid flowing along the flow conduit. The signals obtained from the electrodes are processed, together with stored calibration data, by processing circuitry to determine flow measurements and means is provided for dynamically updating the calibration data.

Owner:ABB LTD

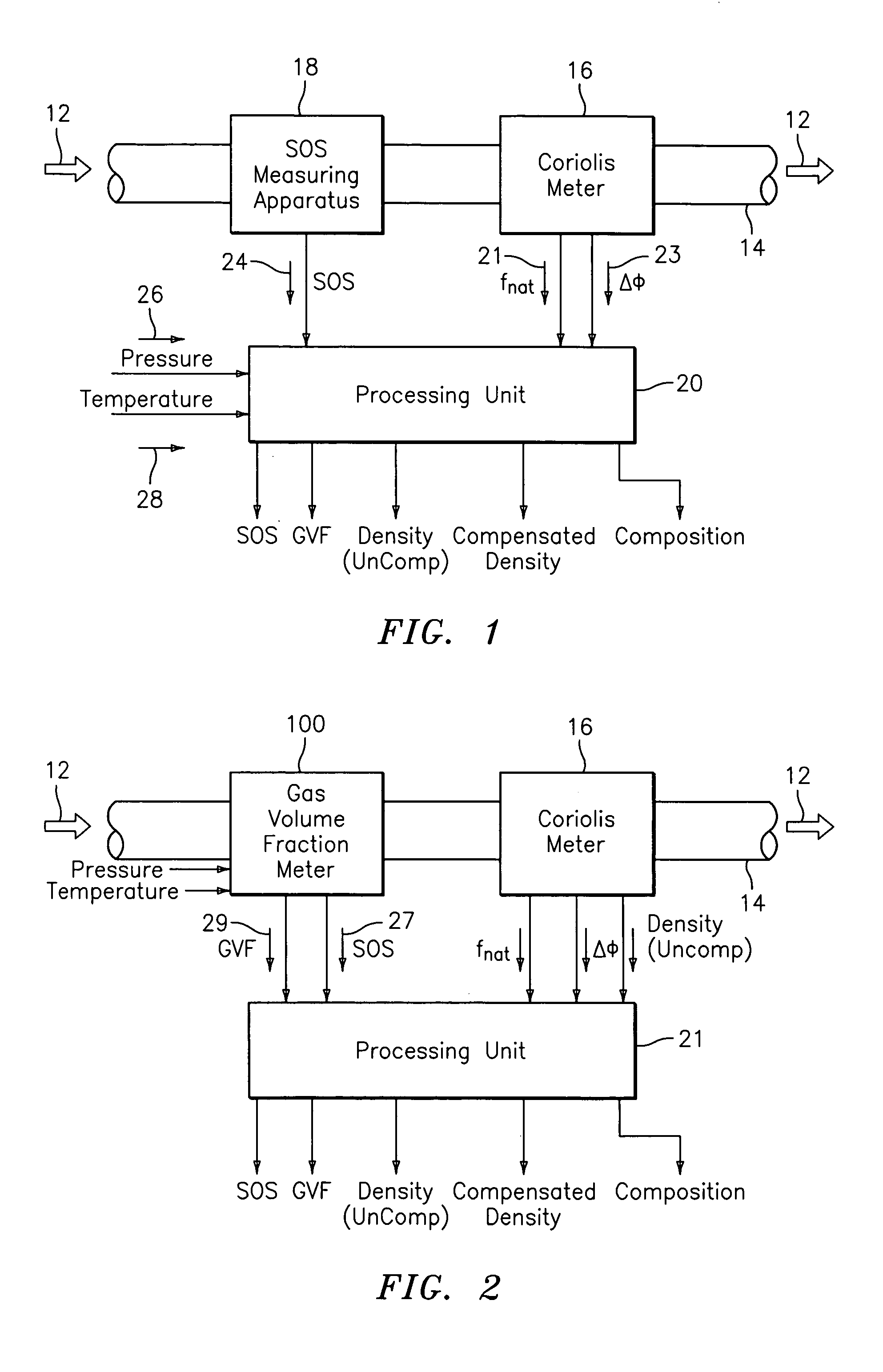

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

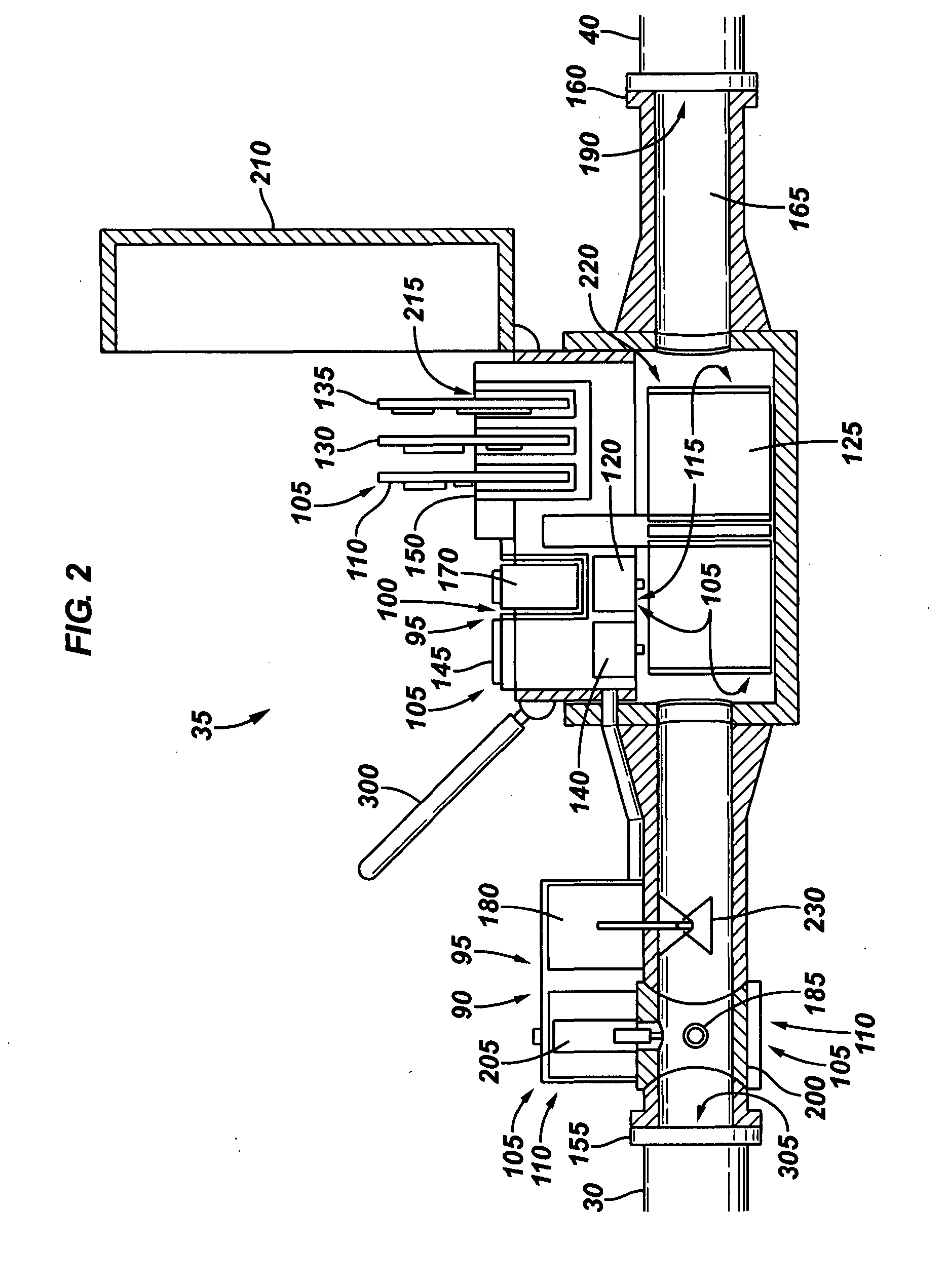

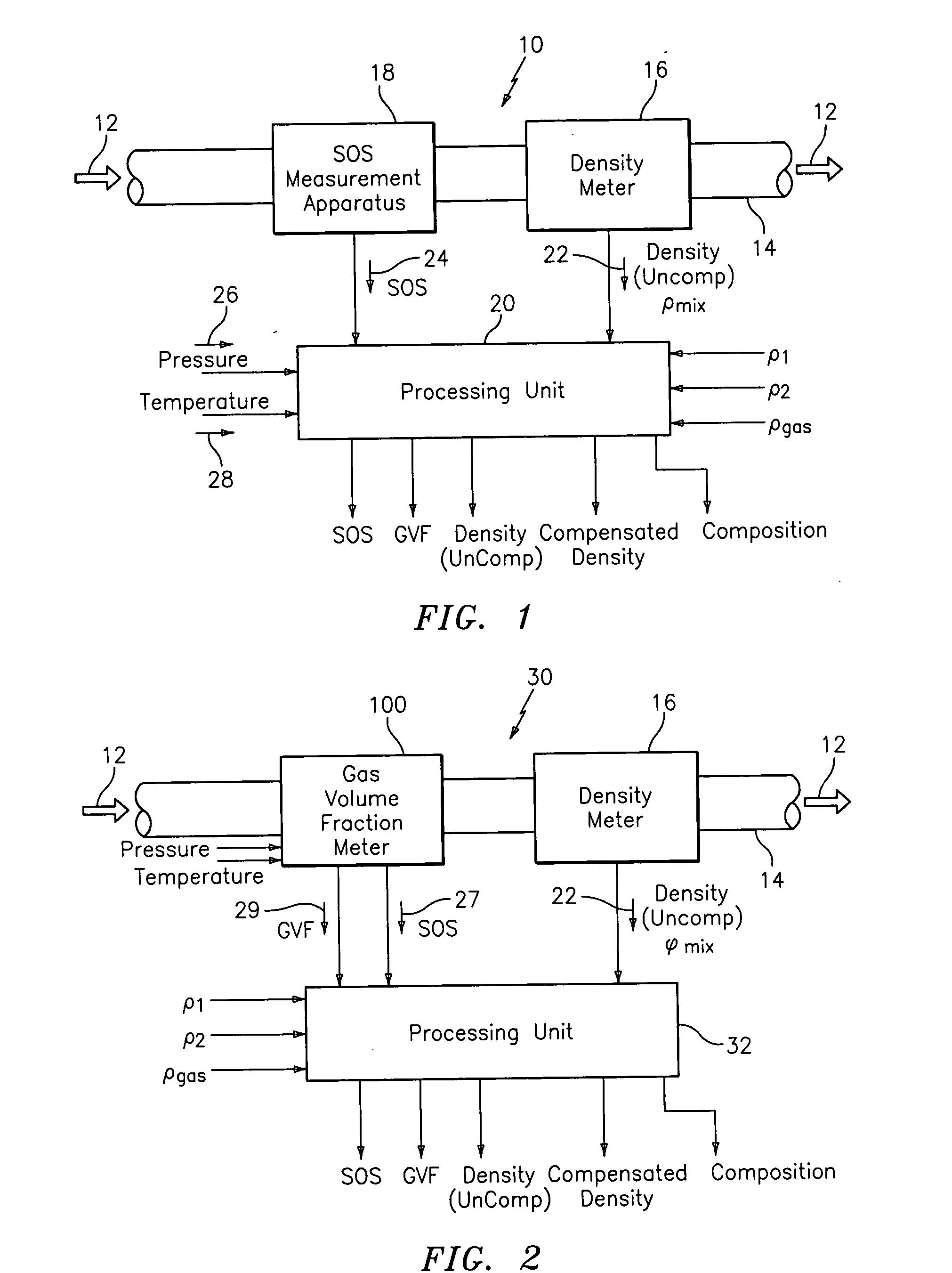

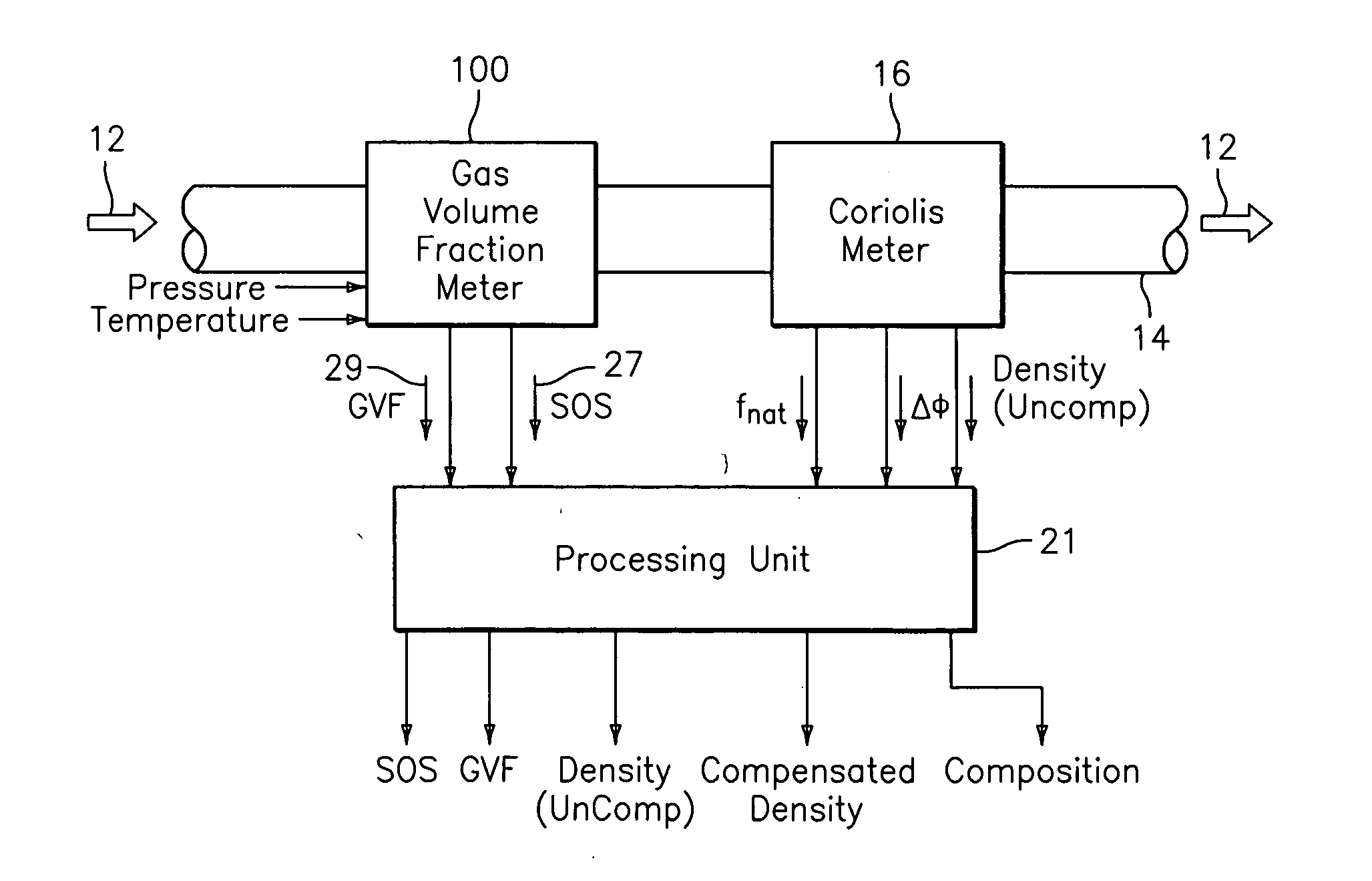

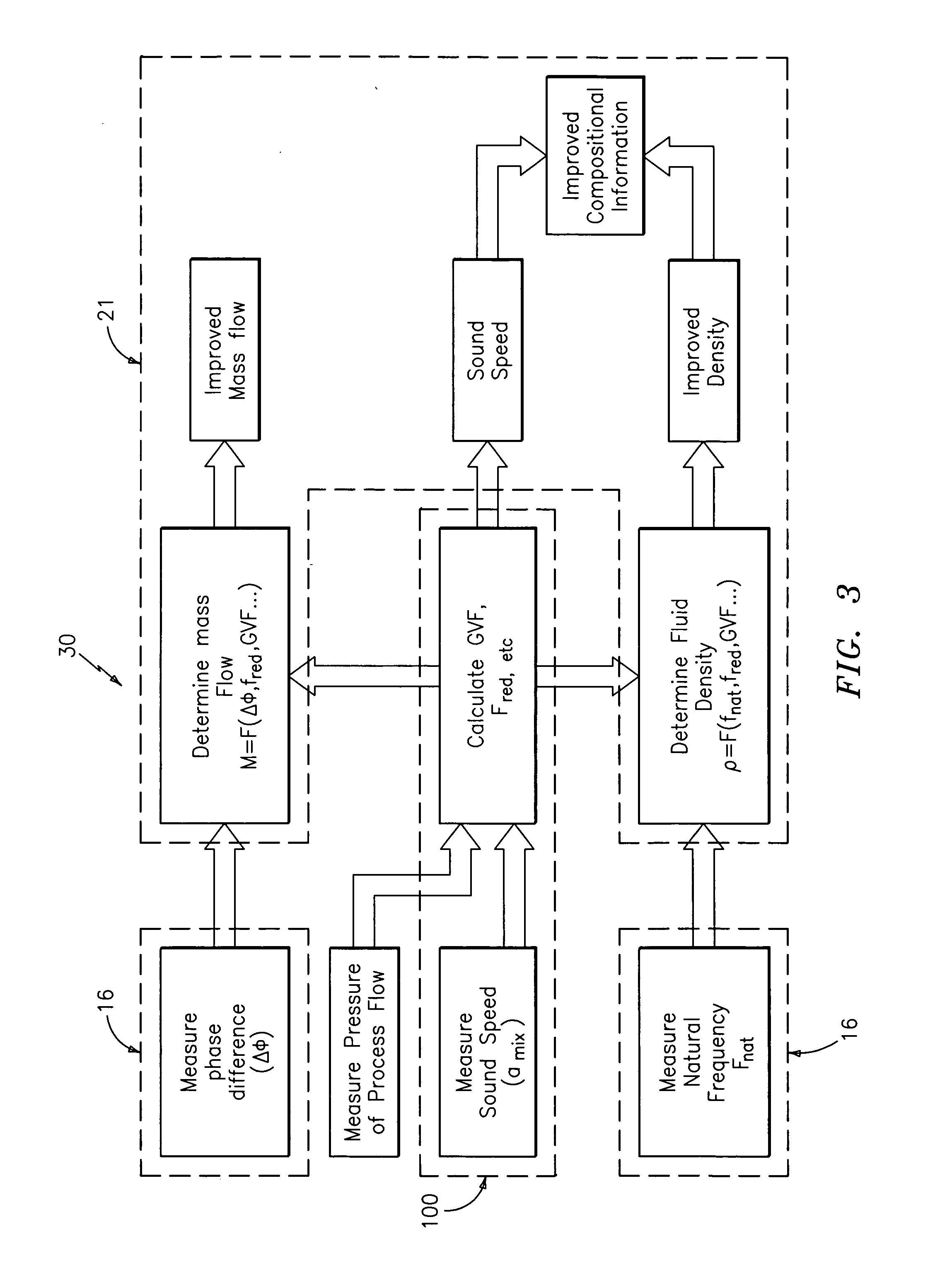

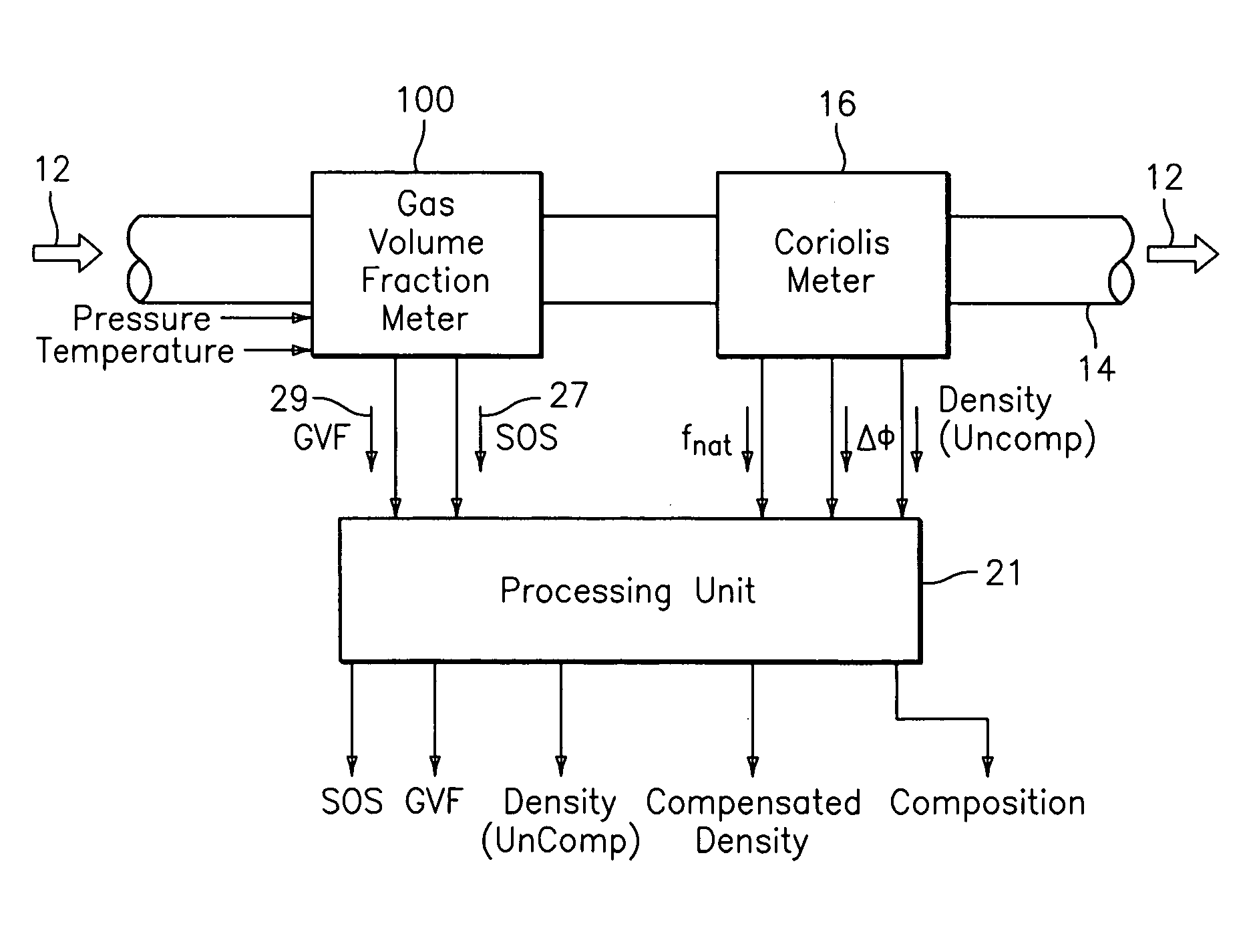

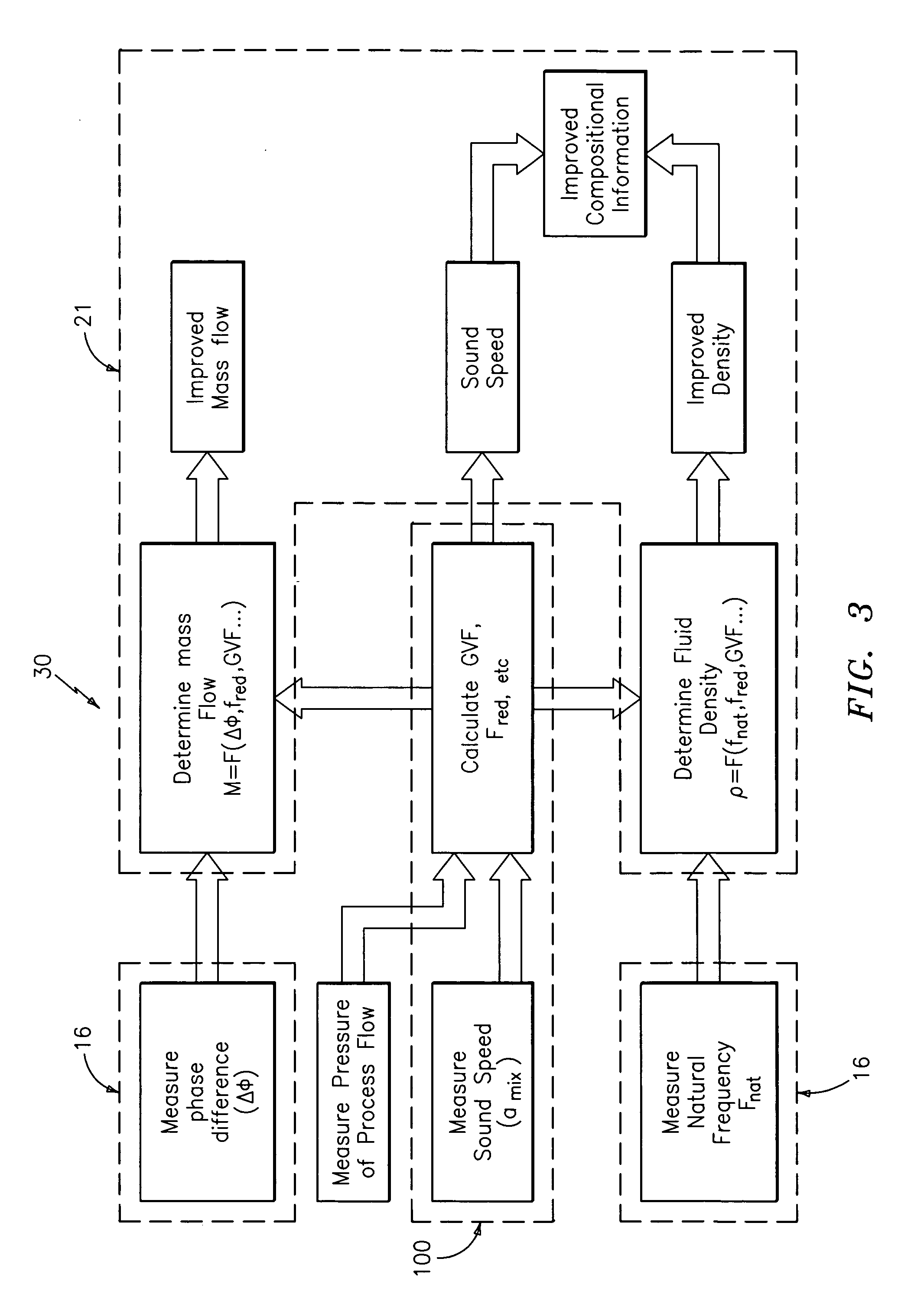

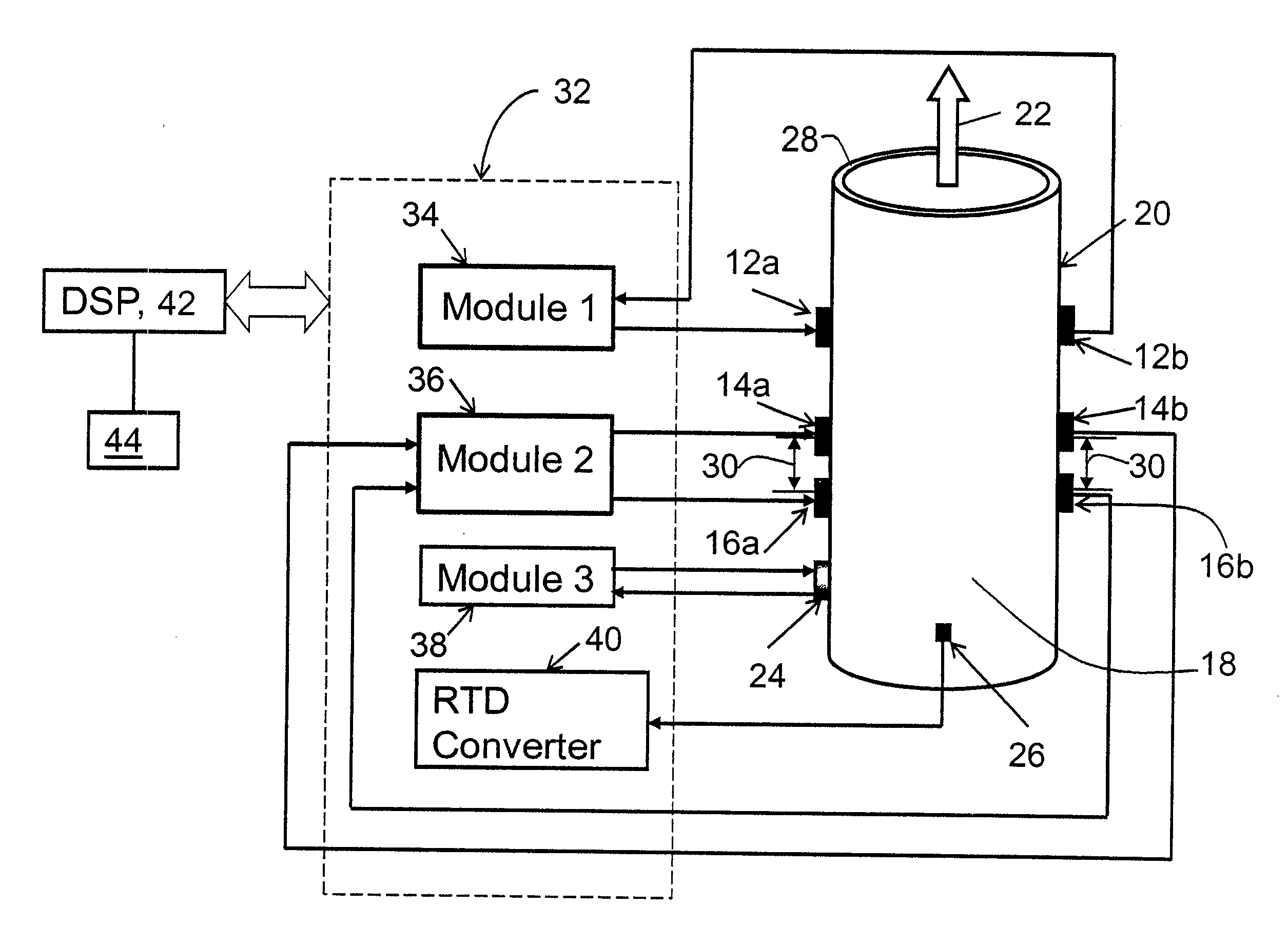

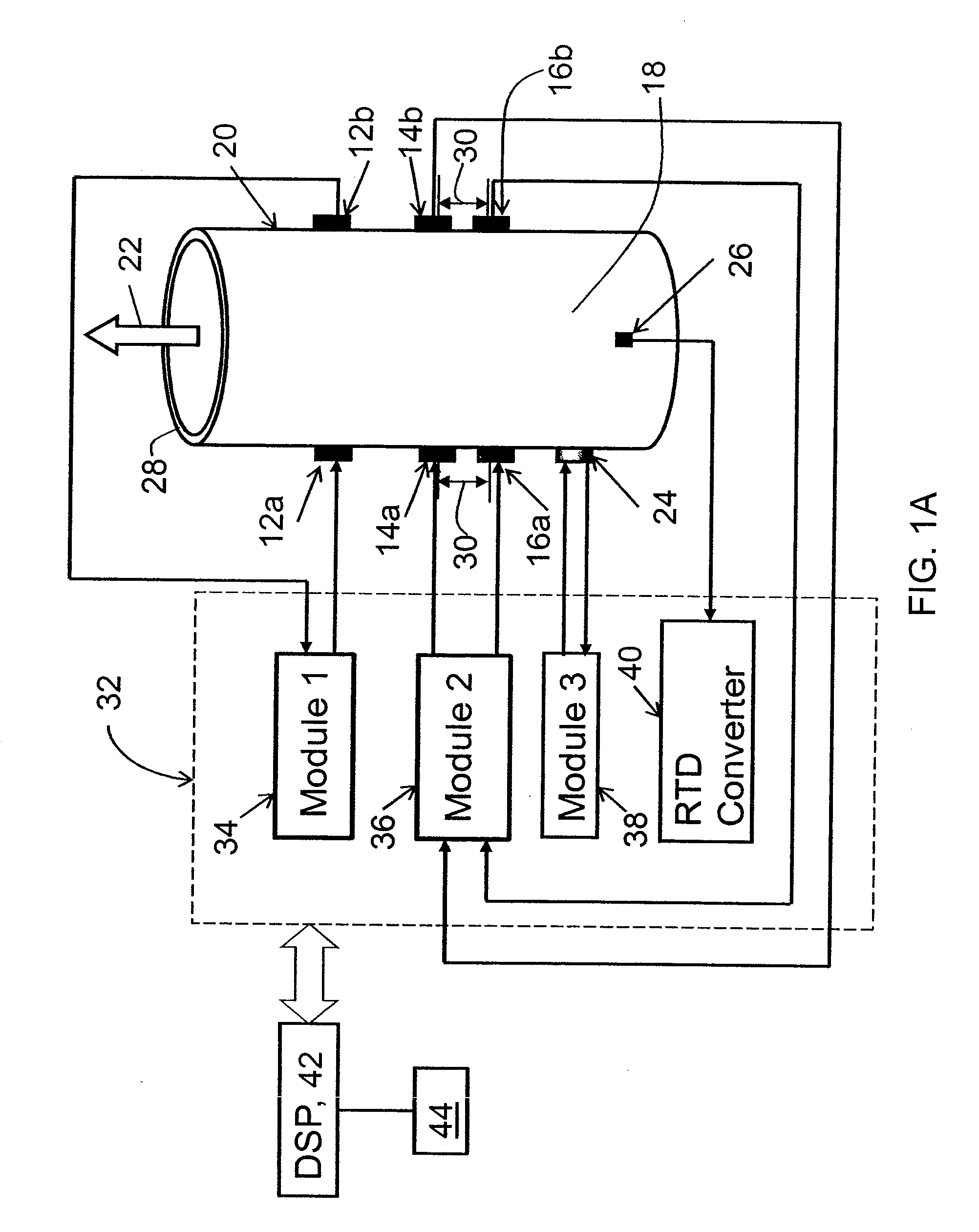

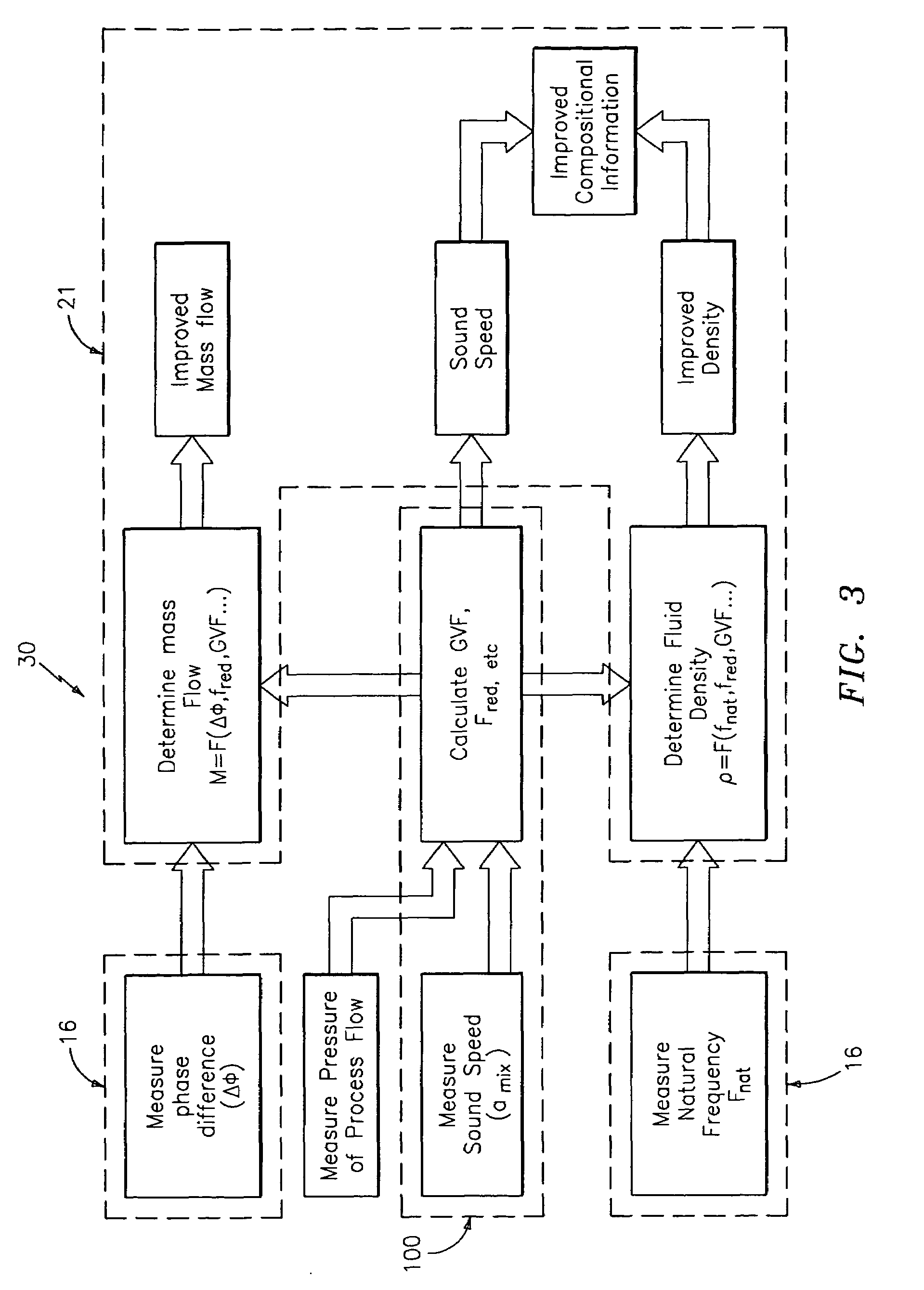

Apparatus and method for compensating a coriolis meter

ActiveUS20050044929A1High densityAdd additional massVolume/mass flow by dynamic fluid flow effectVolume meteringVolumetric Mass DensityDischarge measurements

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

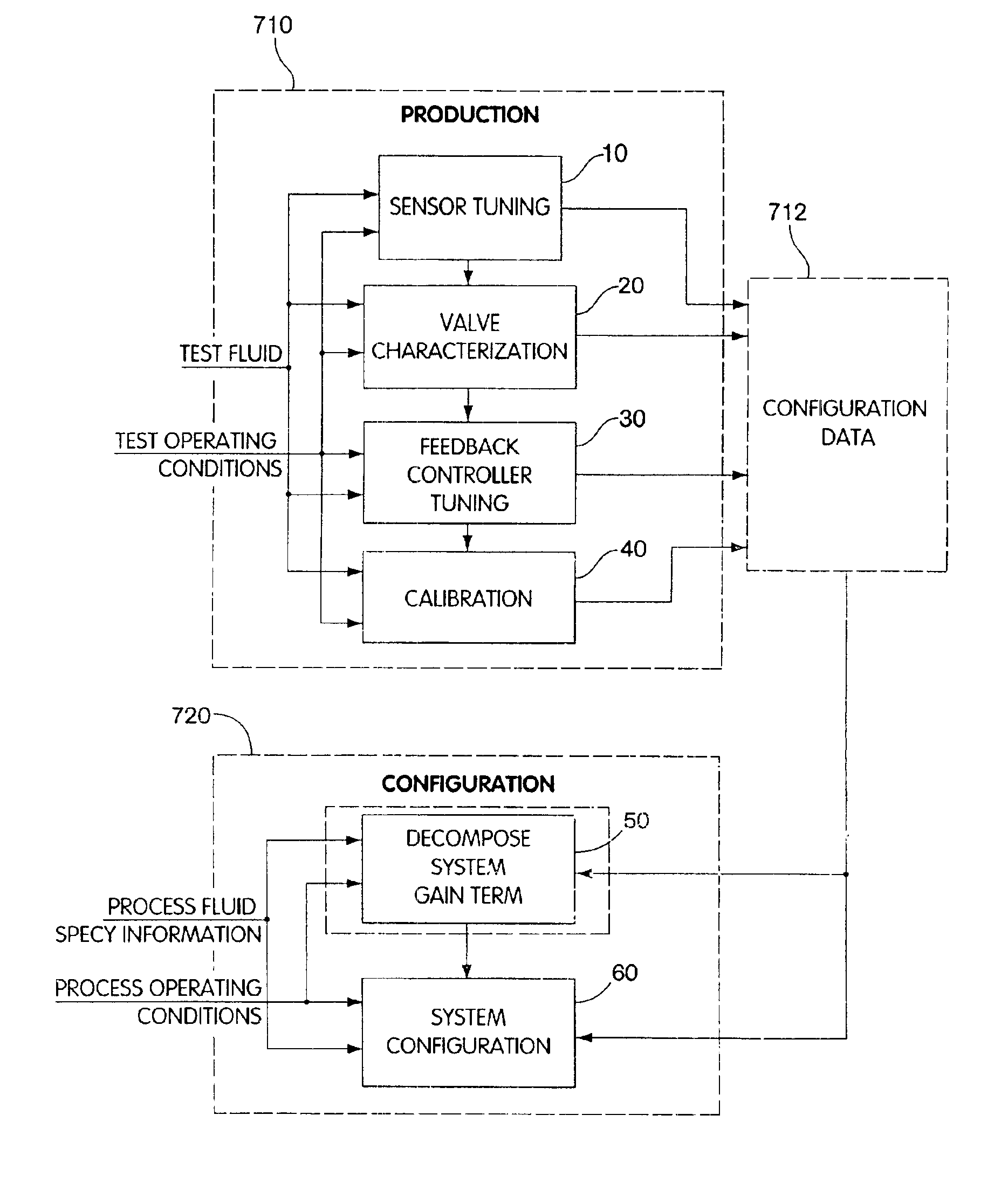

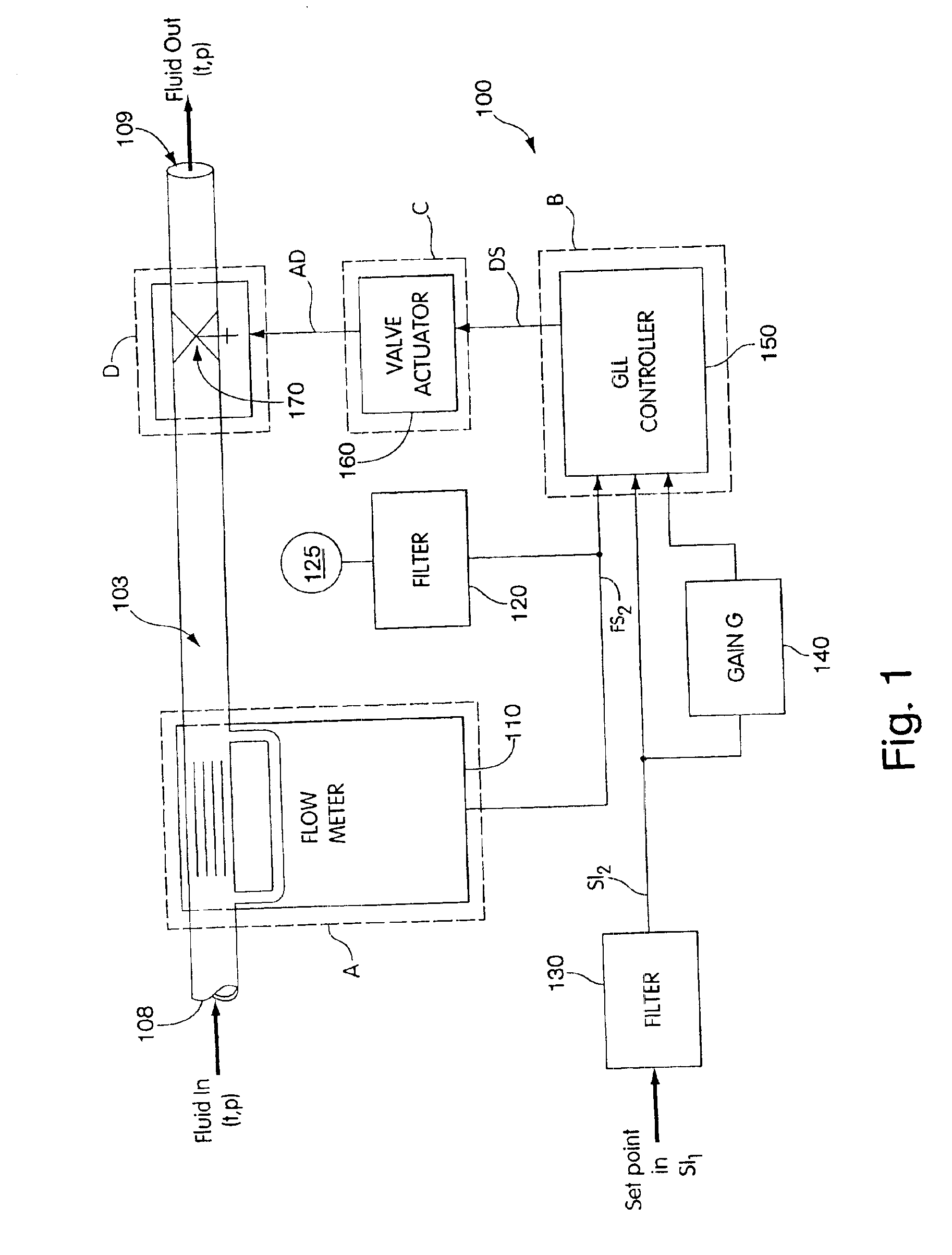

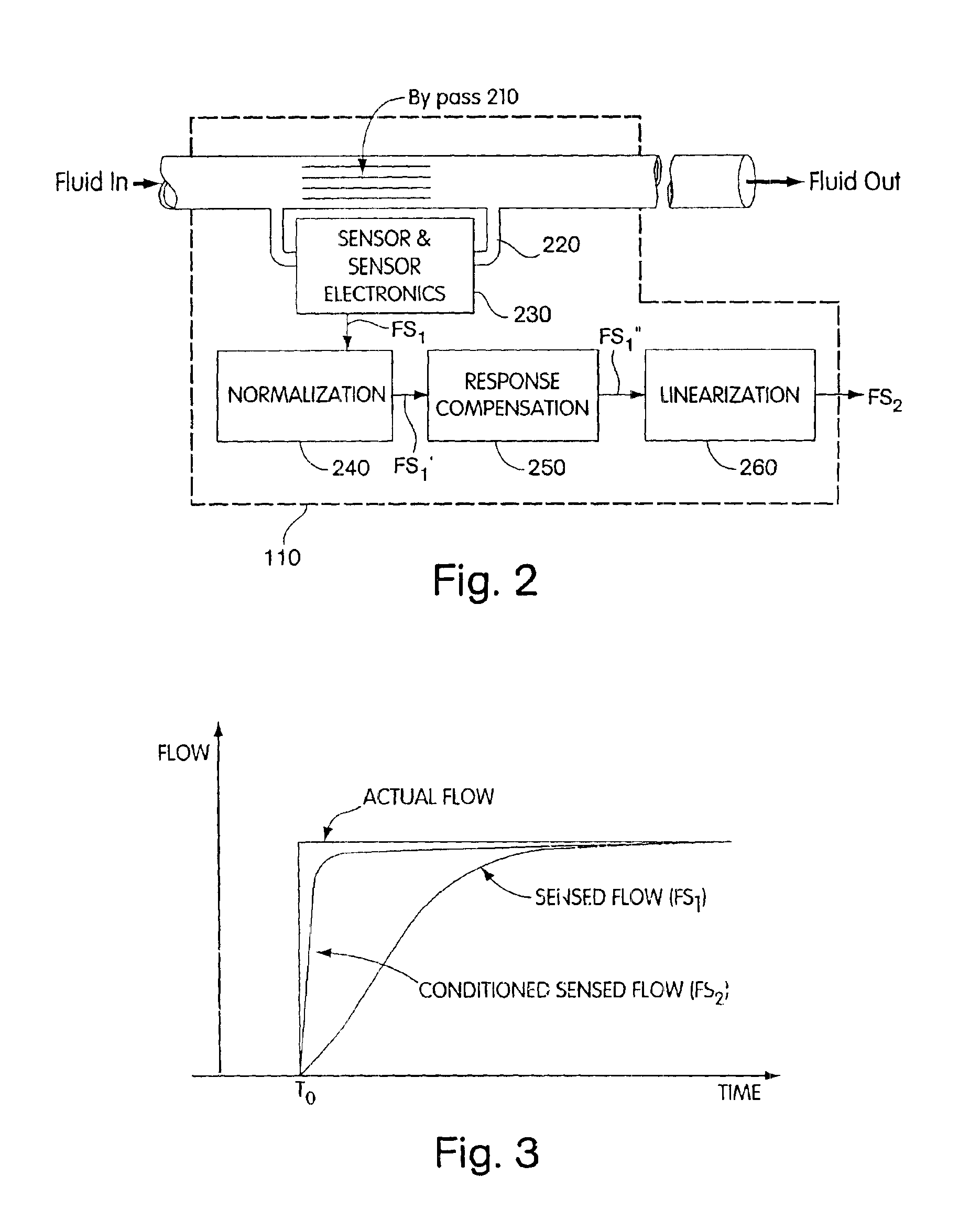

System and method for a mass flow controller

InactiveUS6962164B2Eliminates the effects of hysteresisFluid pressure measurementPipeline systemsHysteresisControl quality

A system and method for controlling a mass flow controller to have a constant control loop gain under a variety of different types of fluids and operating conditions, and for configuring the mass flow controller for operation with a fluid and / or operating conditions different from that used during a production of the mass flow controller. Further, the system and method includes providing control by reducing the effects of hysteresis in solenoid actuated devices by providing a non-operational signal to the solenoid actuated device.

Owner:BROOKS INSTRUMENT

Apparatus and method for compensating a coriolis meter

ActiveUS7152460B2High densityAdd additional massMaterial analysis using microwave meansVolume/mass flow by dynamic fluid flow effectDischarge measurementsVolumetric Mass Density

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

Multiphase fluid characterization system

ActiveUS20120055239A1Analysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration for volume flowUltrasound attenuationResonance

A measurement system and method for permitting multiple independent measurements of several physical parameters of multiphase fluids flowing through pipes are described. Multiple acoustic transducers are placed in acoustic communication with or attached to the outside surface of a section of existing spool (metal pipe), typically less than 3 feet in length, for noninvasive measurements. Sound speed, sound attenuation, fluid density, fluid flow, container wall resonance characteristics, and Doppler measurements for gas volume fraction may be measured simultaneously by the system. Temperature measurements are made using a temperature sensor for oil-cut correction.

Owner:TRIAD NAT SECURITY LLC

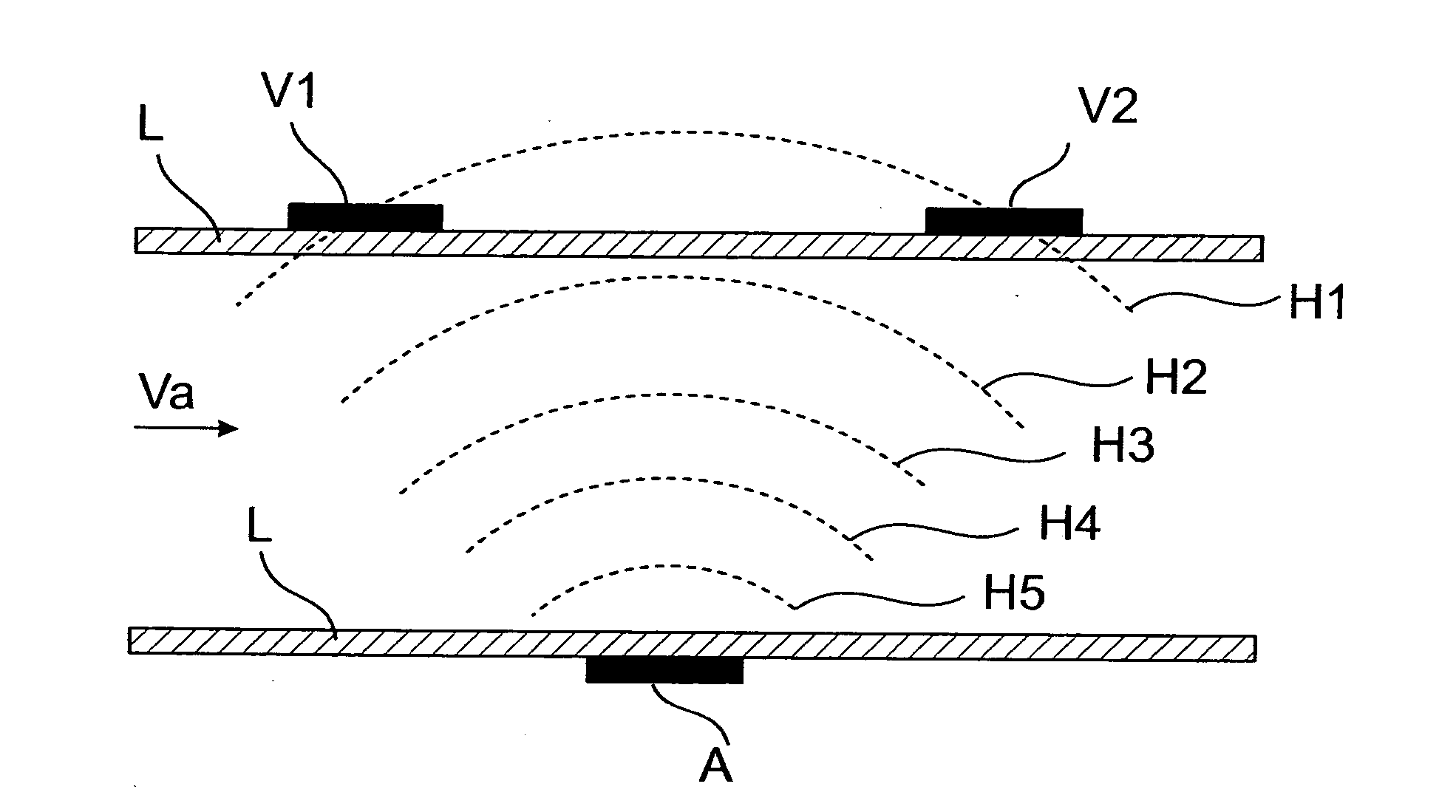

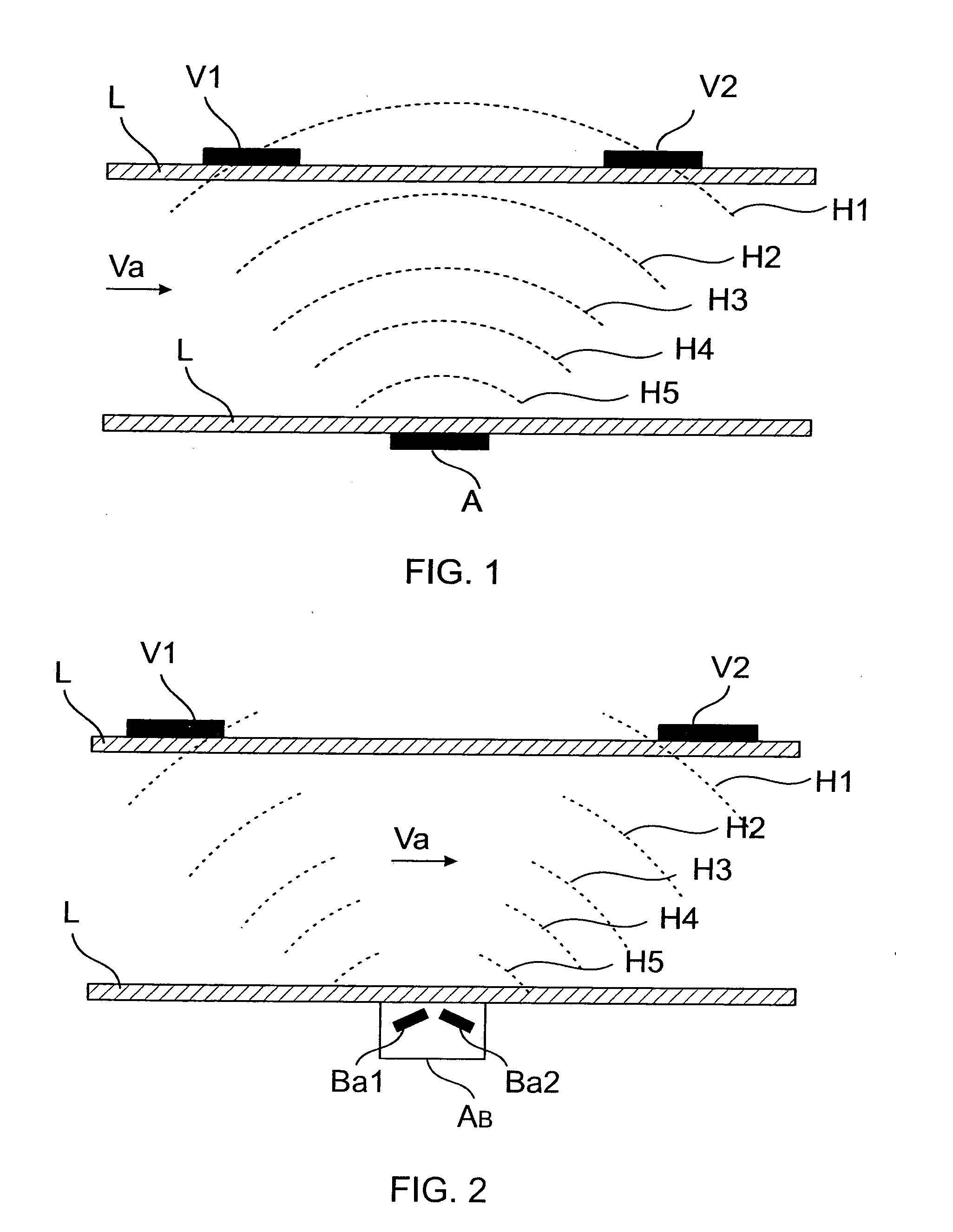

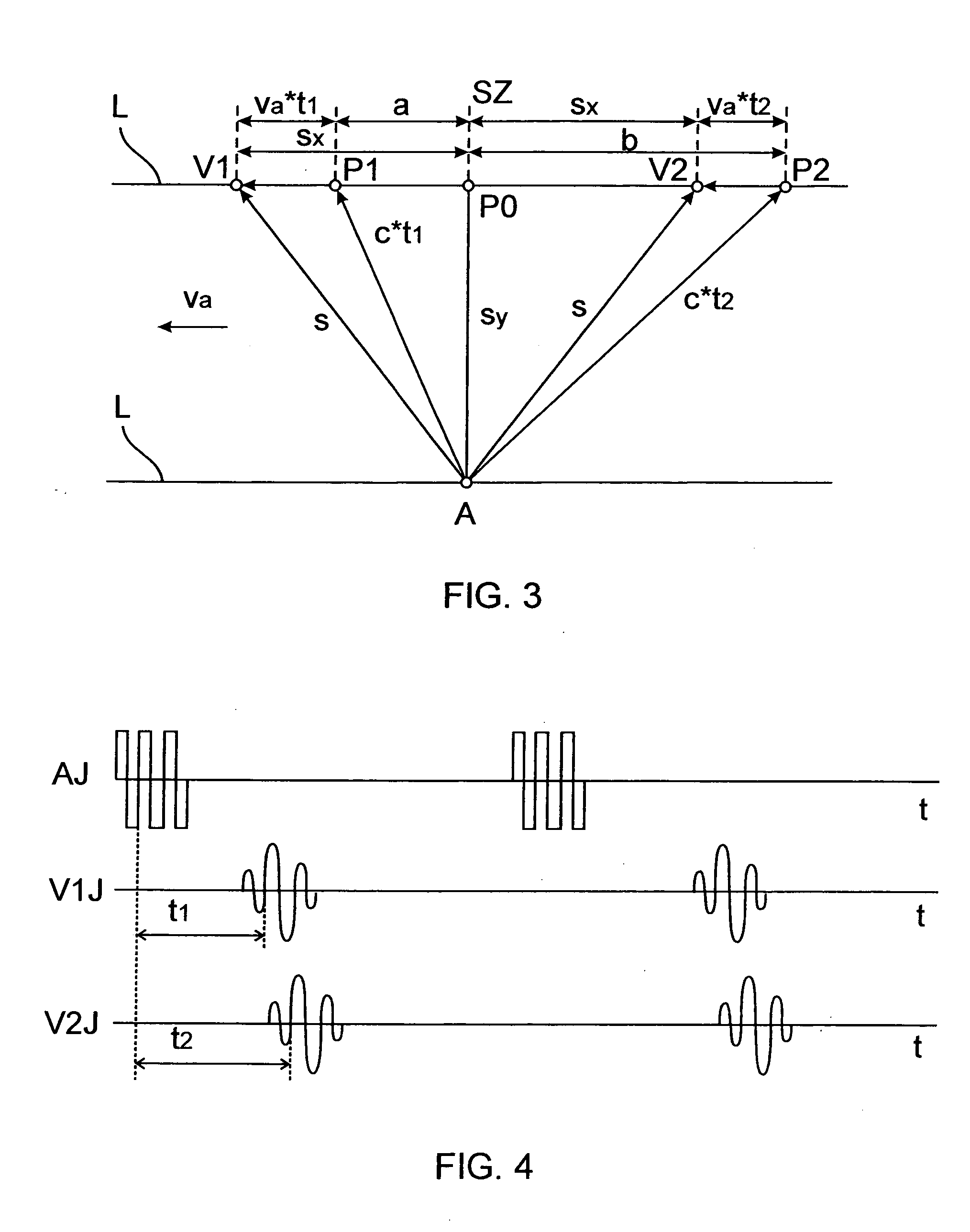

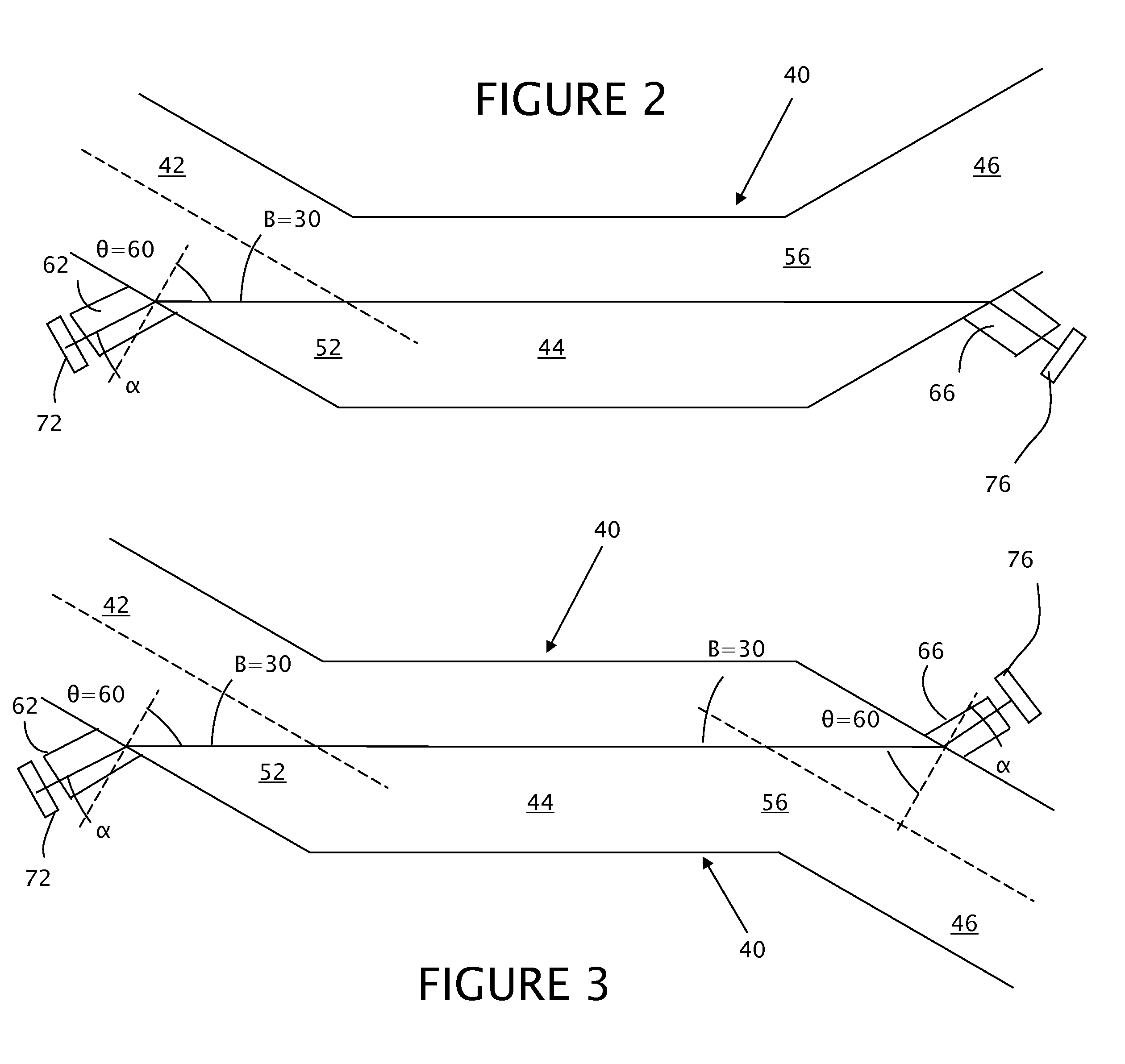

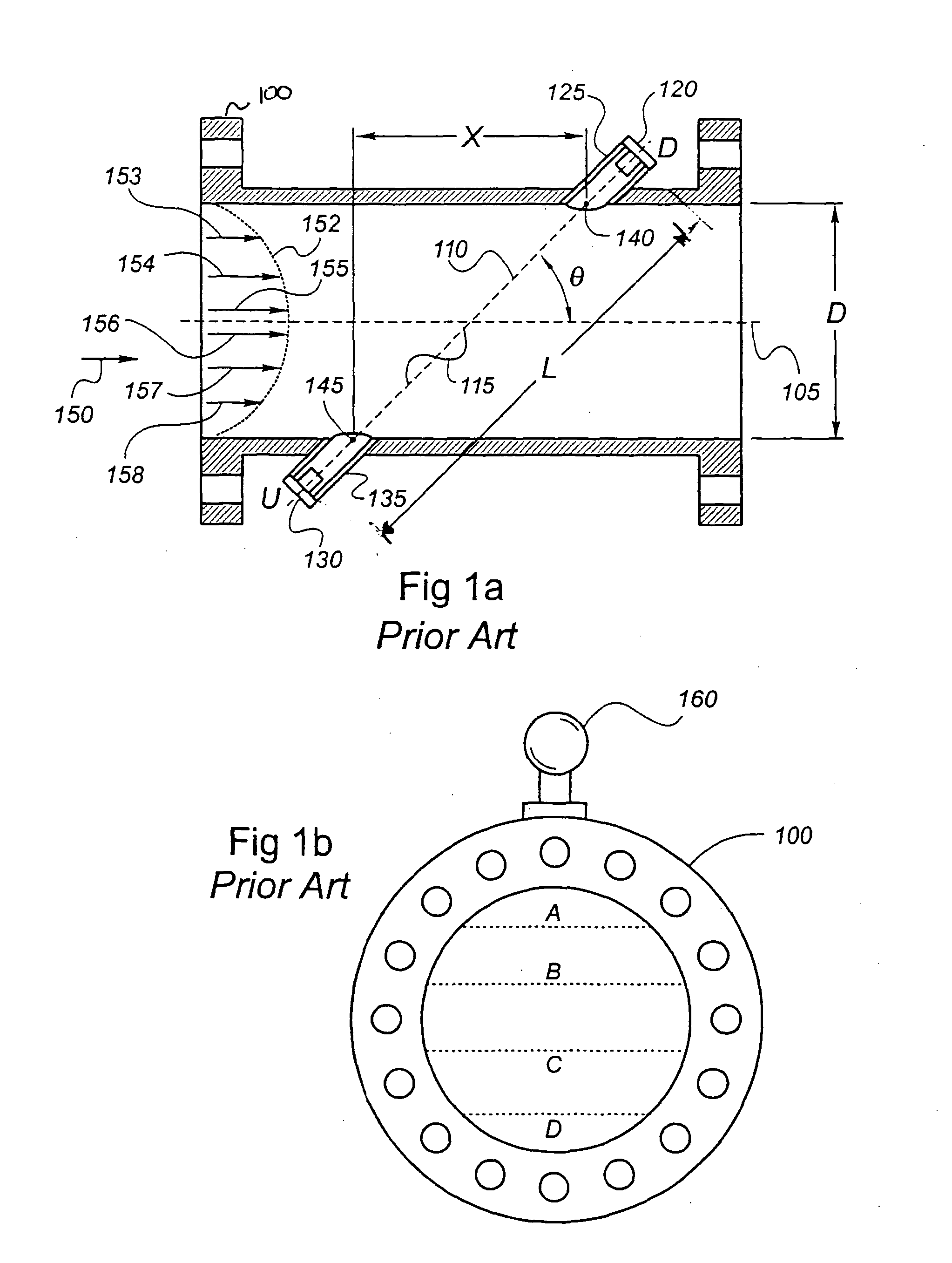

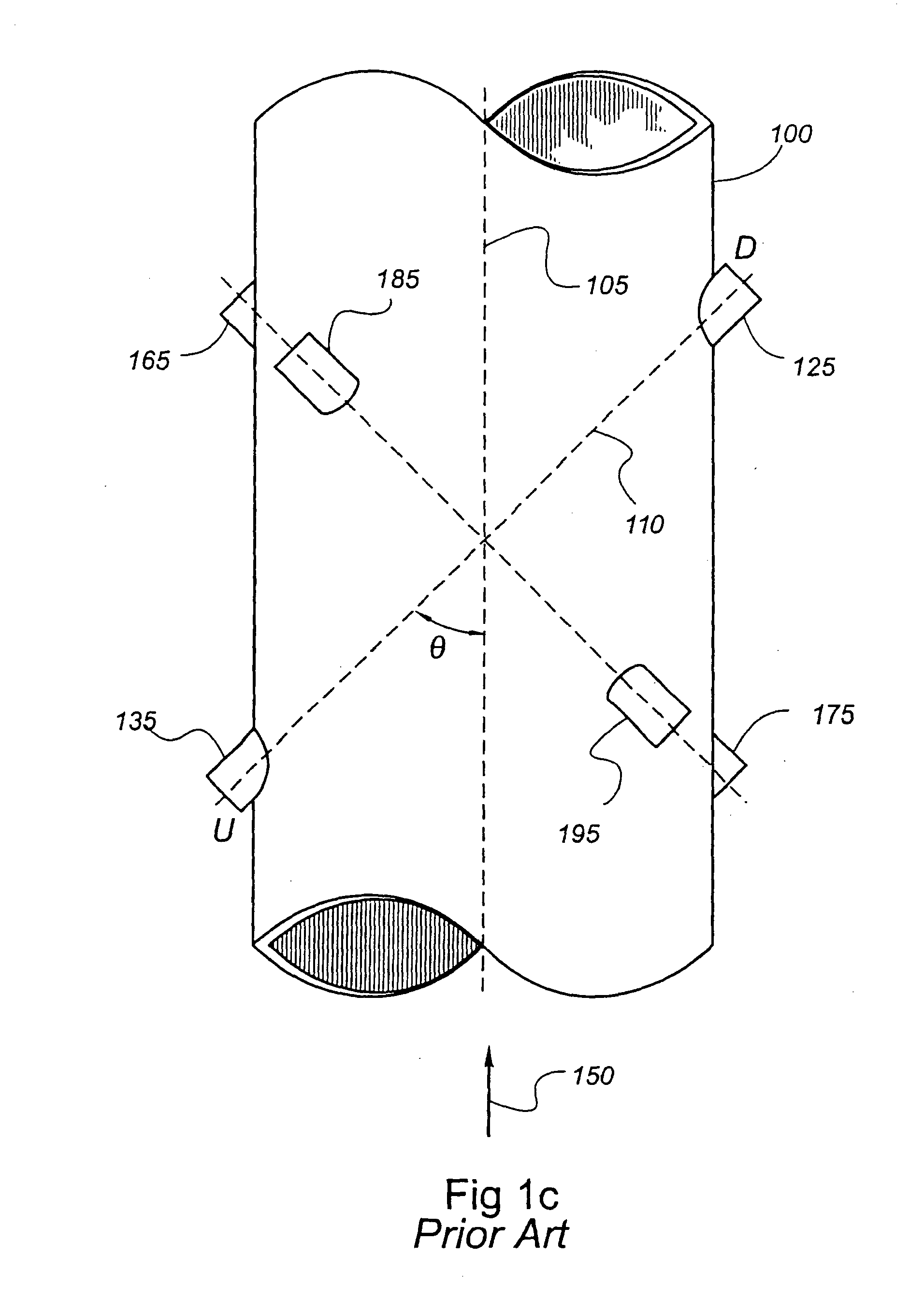

Method and apparatus for determining the flow parameters of a streaming medium

ActiveUS20100095782A1Avoid interferenceHigh measurement accuracyVolume/mass flow measurementVolume meteringLongitudinal waveTransducer

According to the method longitudinal waves are generated in a transducer used only as a transmitter connected from outside to a conduit. These waves are transmitted along two diagonal paths through the streaming medium in an upstream and a downstream direction, and received by two transducers used only as receivers which are located in a diagonal upstream and downstream position and on an opposite side relative to the transducer used as a transmitter, also connected to the conduit. A transit time value of the waves between the transducer used as a transmitter and each of the transducers used as receivers is determined. A difference value on the basis of the determined transit time values is generated and the flow parameters are determined on the basis of said difference value. This measuring method is highly independent of the propagation velocity of the wave in the medium streaming in the conduit therefore also independent of the temperature and humidity of a gaseous medium. An apparatus and a conduit for use in the apparatus for performing the method is also suggested. The conduit used in the apparatus comprises a first location for receiving a transmitter in a middle region of the measuring area and two second locations for receiving receivers in a border region of the measuring area opposite to the first location. The wall of the conduit is dimensioned so that the longitudinal waves can pass through it with minimal loss and maximum efficiency. The inner wall of the conduit forms a uniform and continuos surface for the transmission of the longitudinal waves between the transmitter and the receivers and for blocking the passage of any organic or inorganic material. In medical applications the apparatus and its housing is configured to receive, hold and release a sterile conduit.

Owner:USCOM

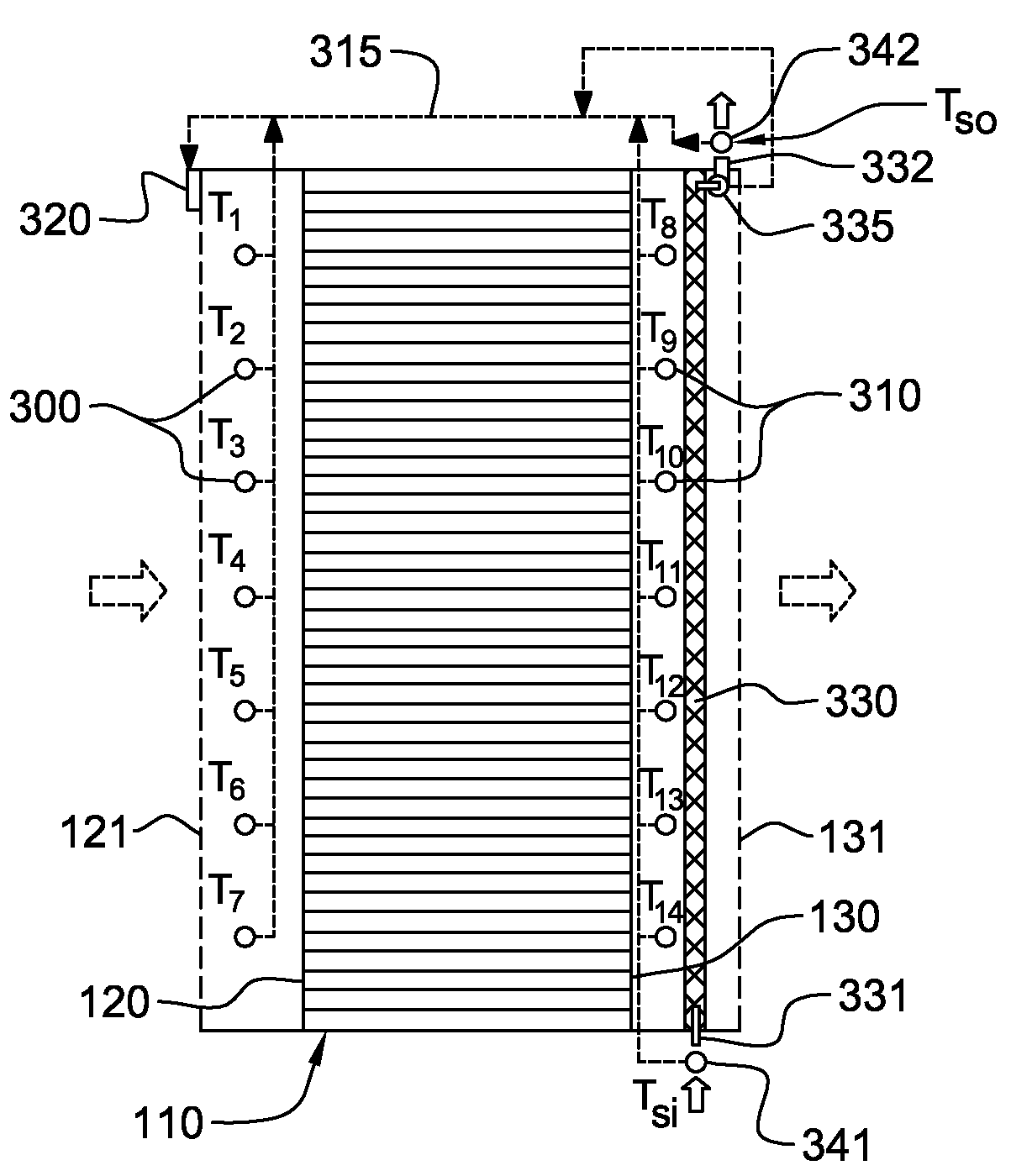

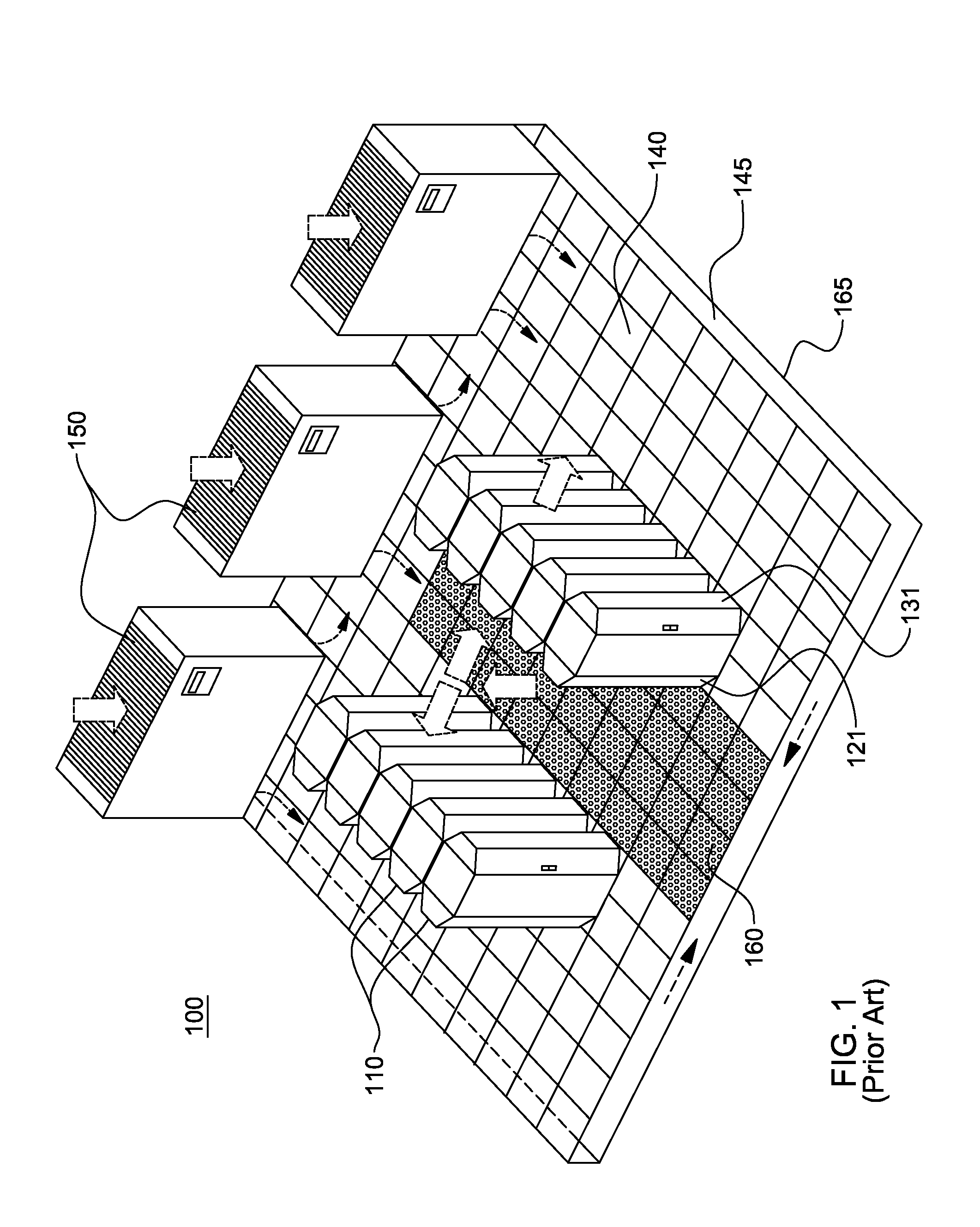

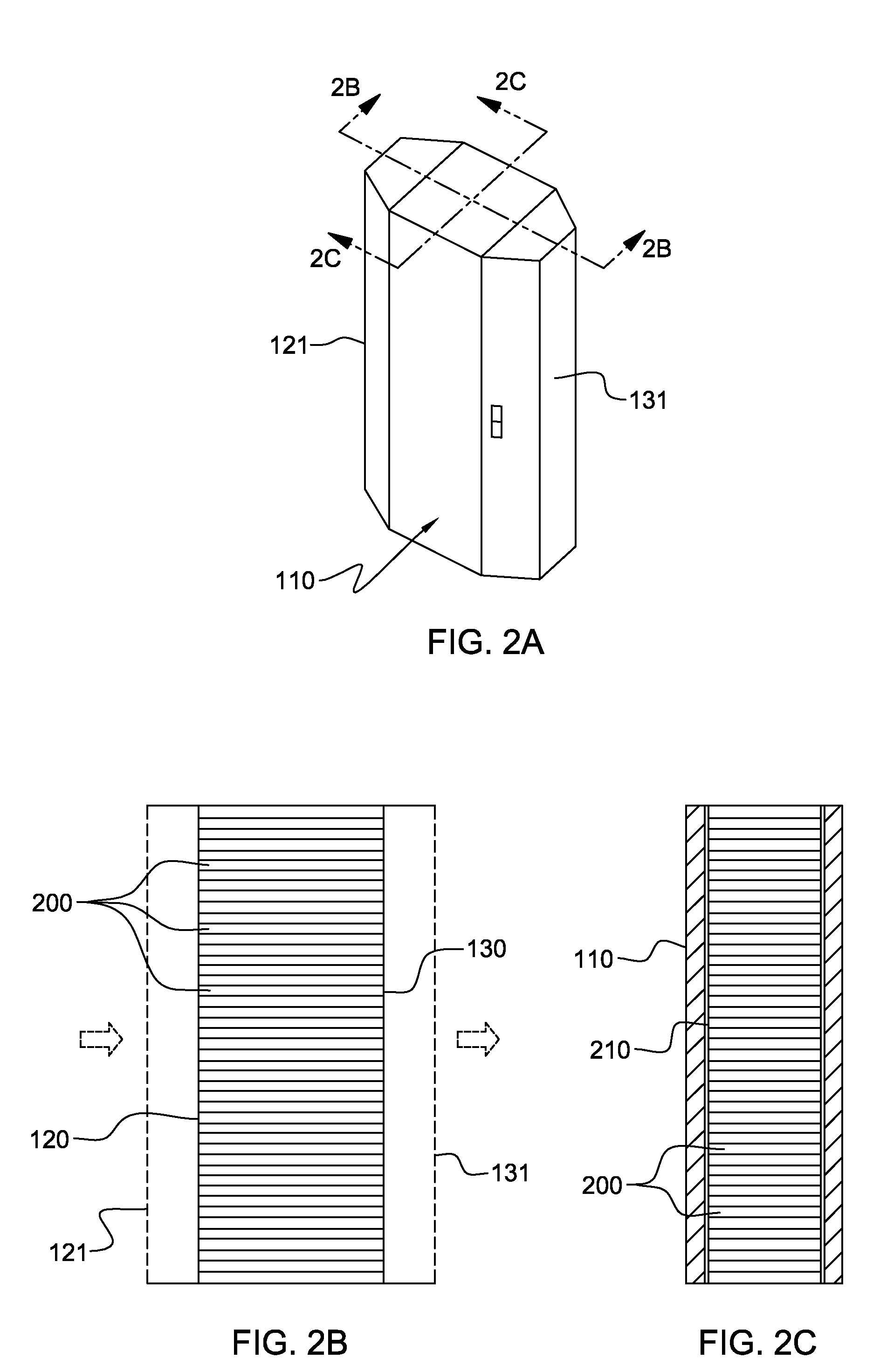

Monitoring method and system for determining rack airflow rate and rack power consumption

ActiveUS20090205416A1Volume/mass flow by thermal effectsVolume flow proportion measurementEngineeringCoolant temperature

Monitoring method and system are provided for dynamically determining rack airflow rate and rack power consumption employing a heat exchanger disposed at an air outlet side of the electronics rack. The method includes: sensing air temperature at the air outlet side of the electronics rack, sensing coolant temperature at a coolant inlet and coolant temperature at a coolant outlet of the heat exchanger, and determining airflow rate through the electronics rack; and outputting the determined airflow rate through the electronics rack. The determining employs the sensed air temperature at the air outlet side of the rack and the sensed coolant temperatures at the coolant inlet and outlet of the heat exchanger. In one embodiment, the heat exchanger is an air-to-air heat exchanger, and in another embodiment, the heat exchanger is an air-to-liquid heat exchanger.

Owner:LENOVO GLOBAL TECH INT LTD

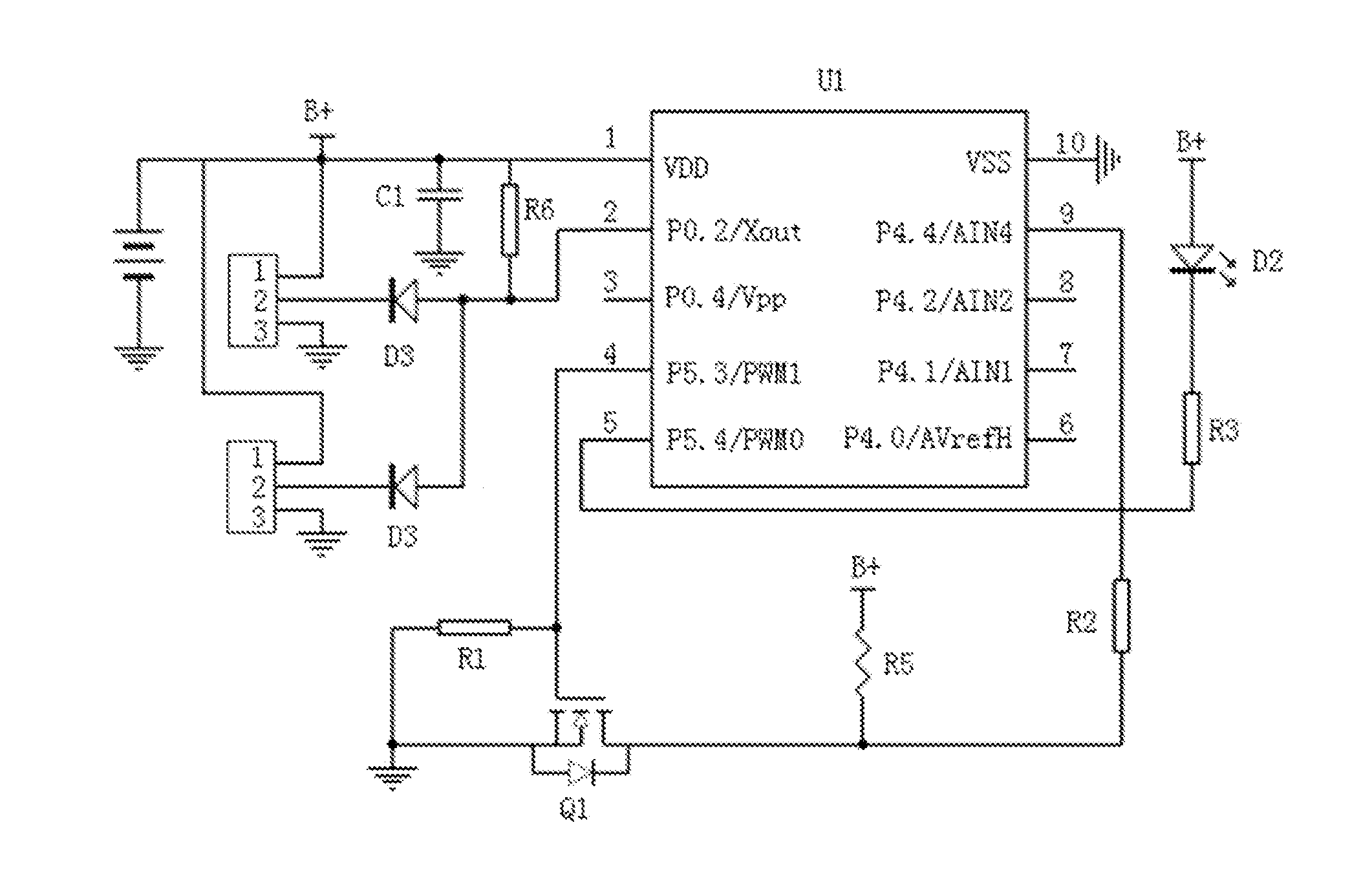

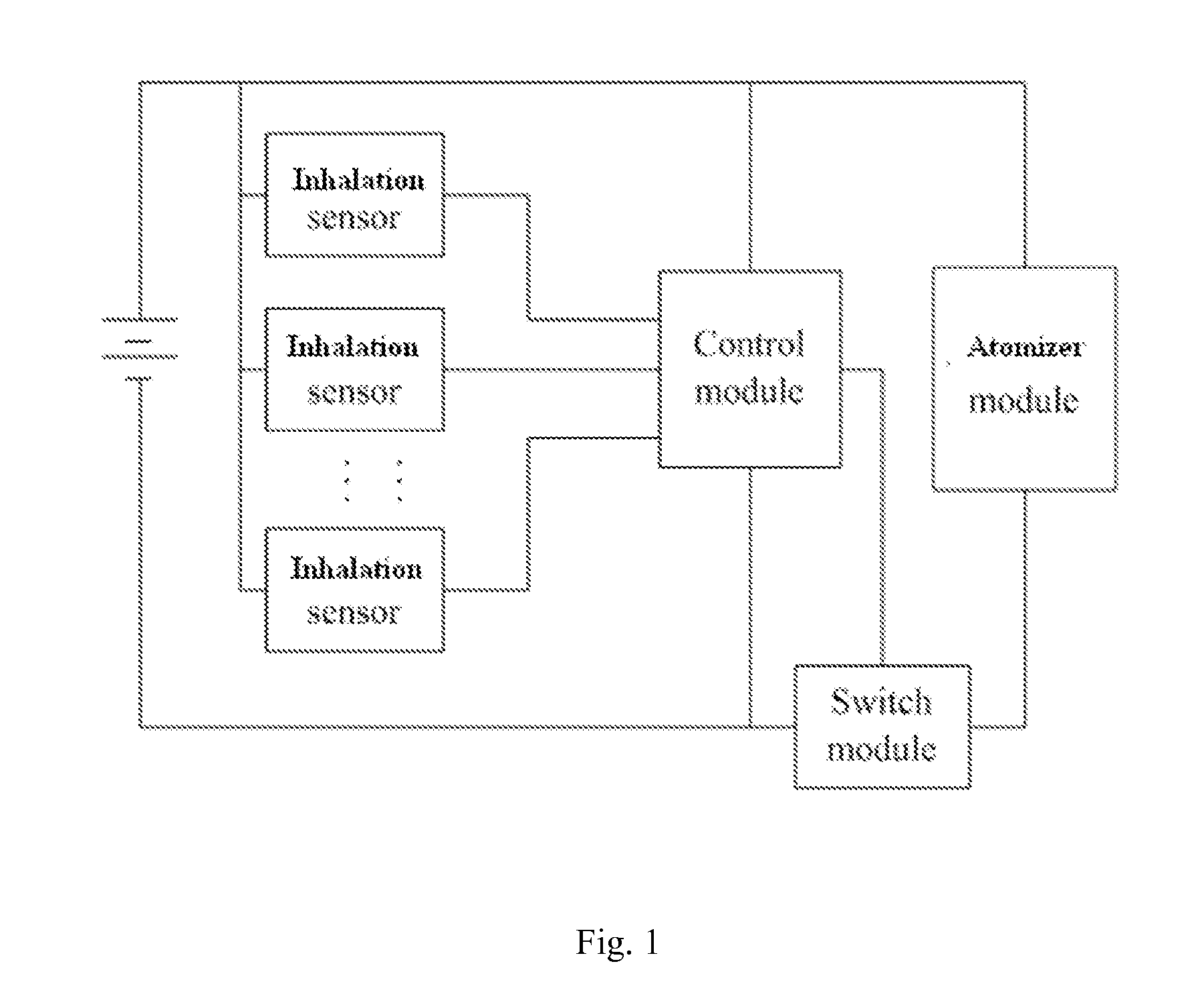

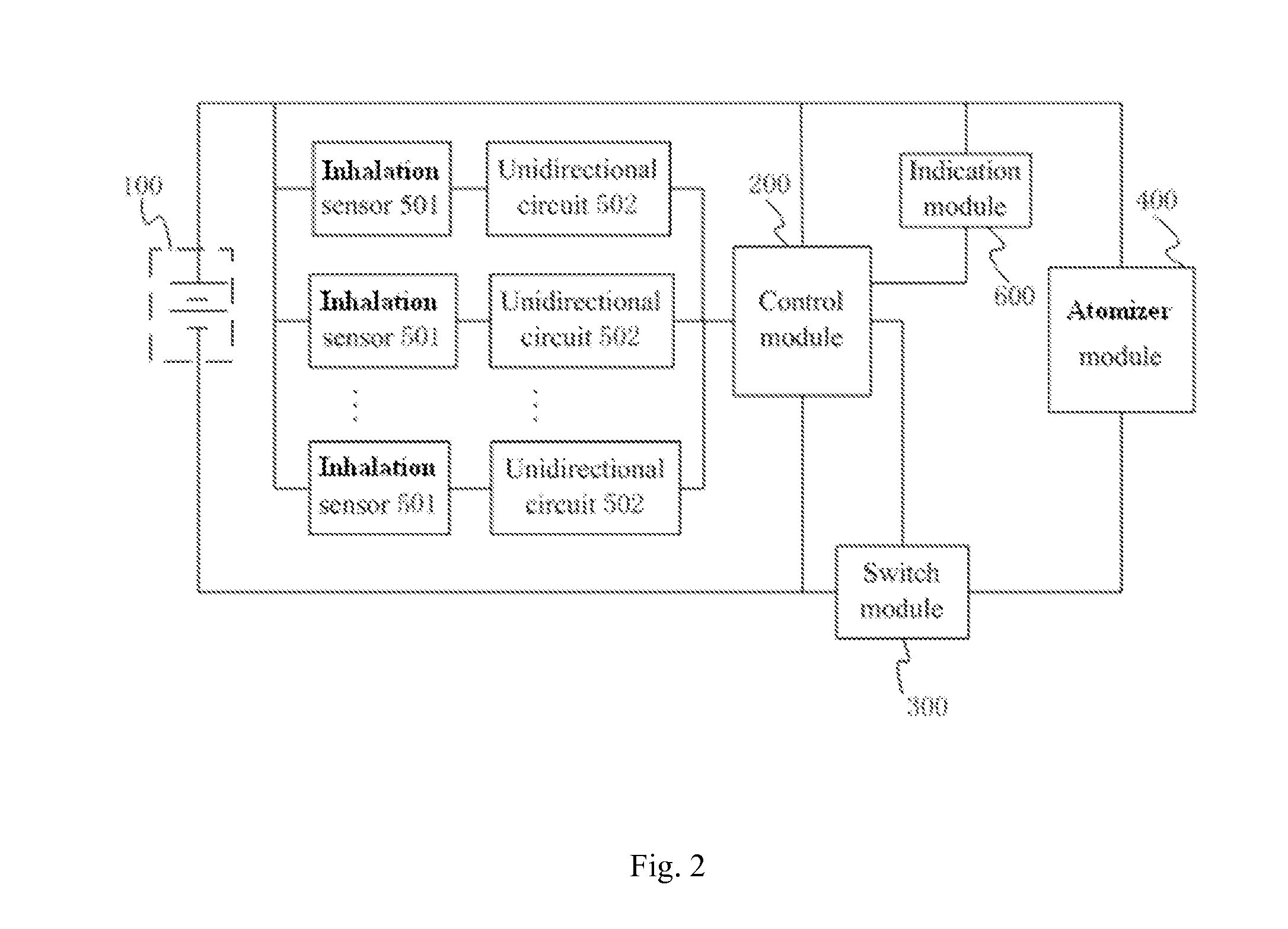

Multi-sensor control circuit and method for using the same

InactiveUS20150082859A1Low failure rateFailure rateVolume/mass flow measurementTobacco devicesControl electronicsComputer module

A multi-sensor control circuit used in an electronic cigarette comprises a control module, at least two inhalation sensors, and at least two unidirectional circuits corresponding to the inhalation sensors. An output terminal of each inhalation sensor is connected to an input terminal of a corresponding unidirectional circuit, and output terminals of the unidirectional circuits are all connected to a same input pin of the control module. Each inhalation sensor outputs a sensing voltage signal to the corresponding one of the unidirectional circuits upon sensing airflow. Each unidirectional circuit filters the sensing voltage signal received from a corresponding inhalation sensor to generate a unidirectional voltage signal, and outputs the unidirectional voltage signal to the input pin of the control module. The control module controls the electronic cigarette to work upon receiving the unidirectional voltage signal outputted from any unidirectional circuit.

Owner:HUIZHOU KIMREE TECH

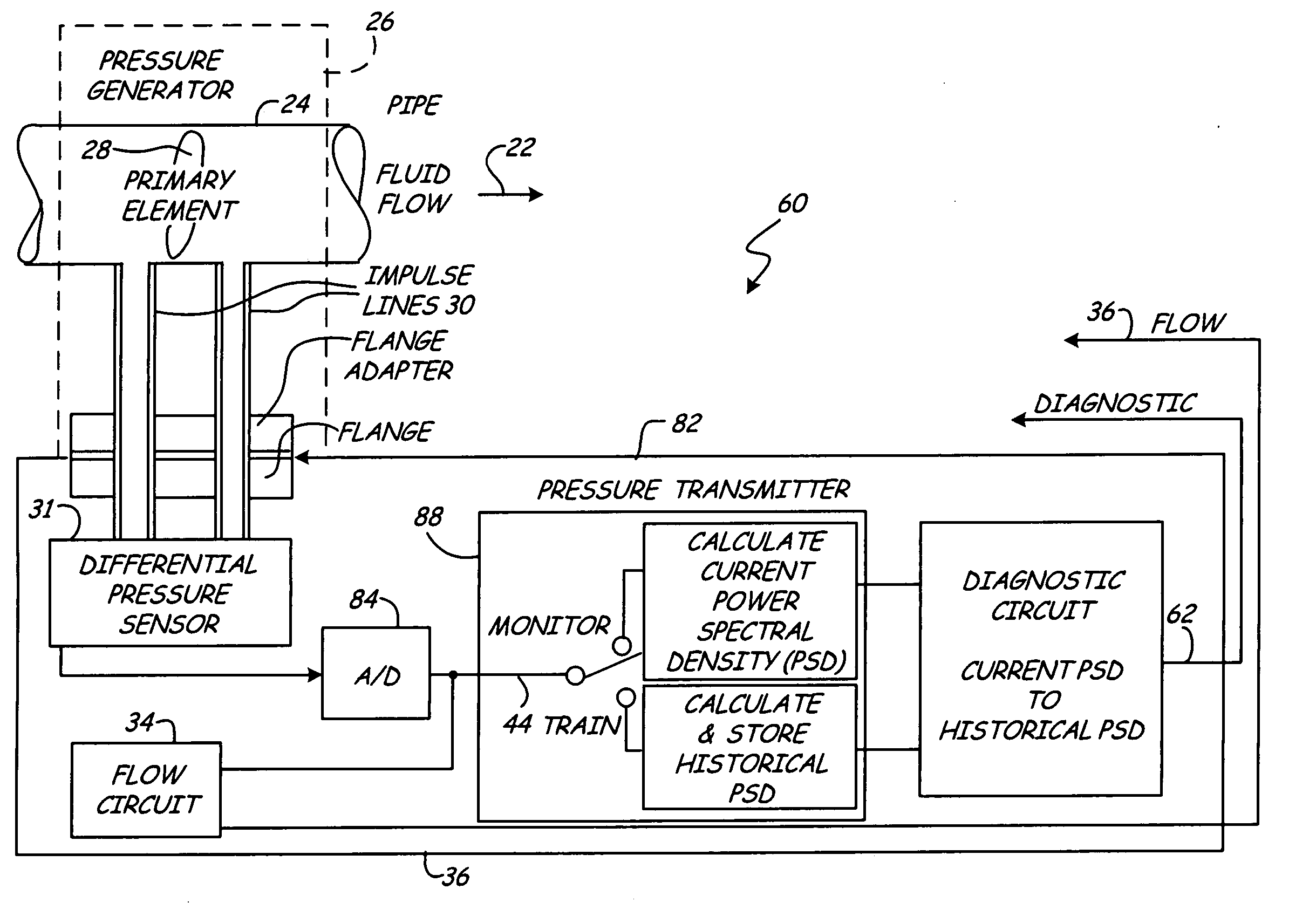

Process variable transmitter with diagnostics

InactiveUS20060036404A1Easy diagnosisSpectral/fourier analysisSampled-variable control systemsDigitizationPrincipal element

A process variable transmitter with diagnostics based on power spectral density (PSD) analysis of a process variable sensor signal is provided. In one embodiment, the process variable transmitter is a pressure transmitter and the diagnostics are used to diagnose impulse line obstruction or impending obstruction. Other diagnostics are also useful such as diagnosing primary element degradation. The sensor signal is digitized and the digitized signal is transferred into the frequency domain. The power of the frequencies on the sensor signal is examined to provide the enhanced diagnostics. In one aspect diagnostics are generated directly with the sensor PSD data. In another aspect, the PSD analysis is used to tune a filter in order to enhance traditional diagnostic algorithms.

Owner:ROSEMOUNT INC

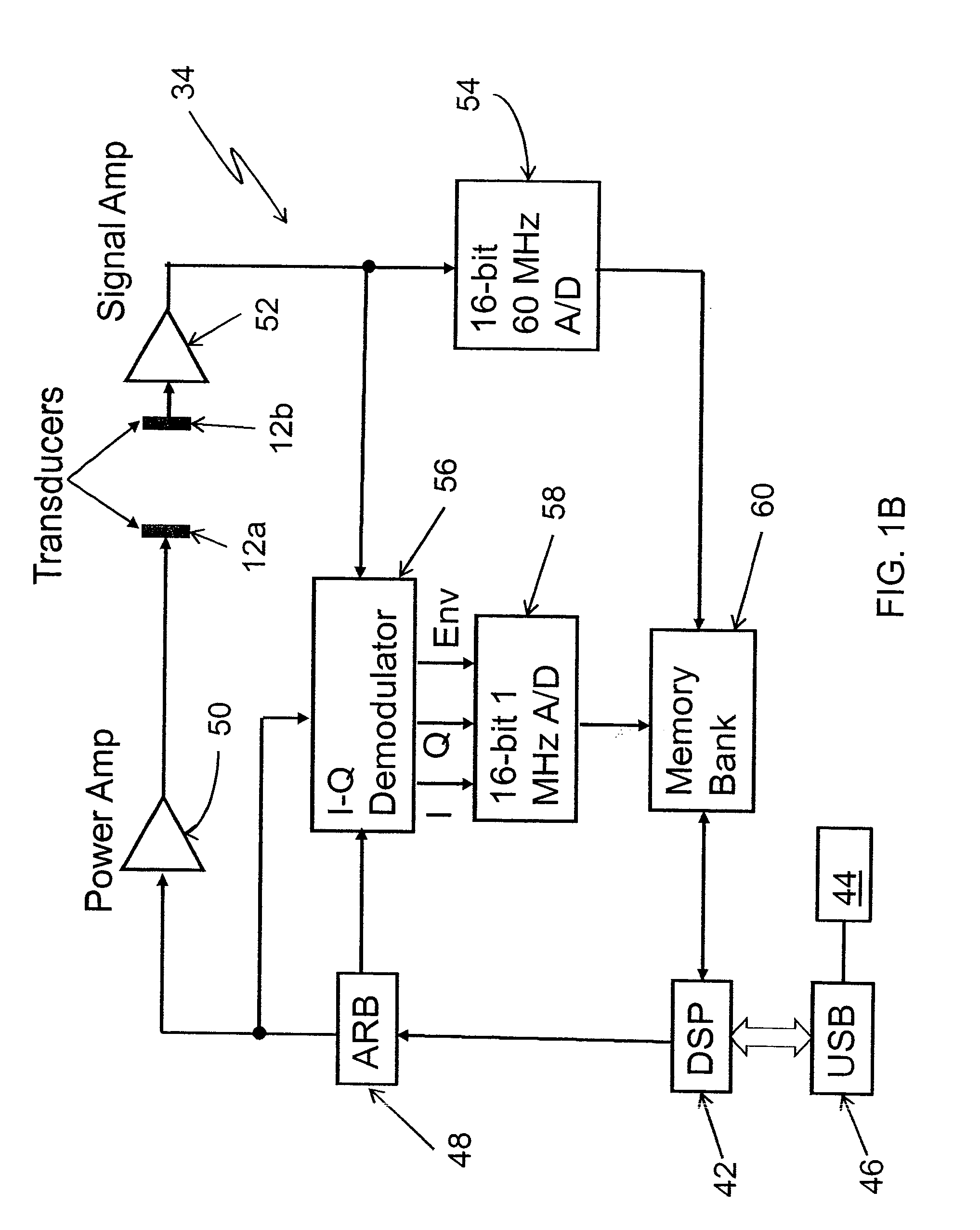

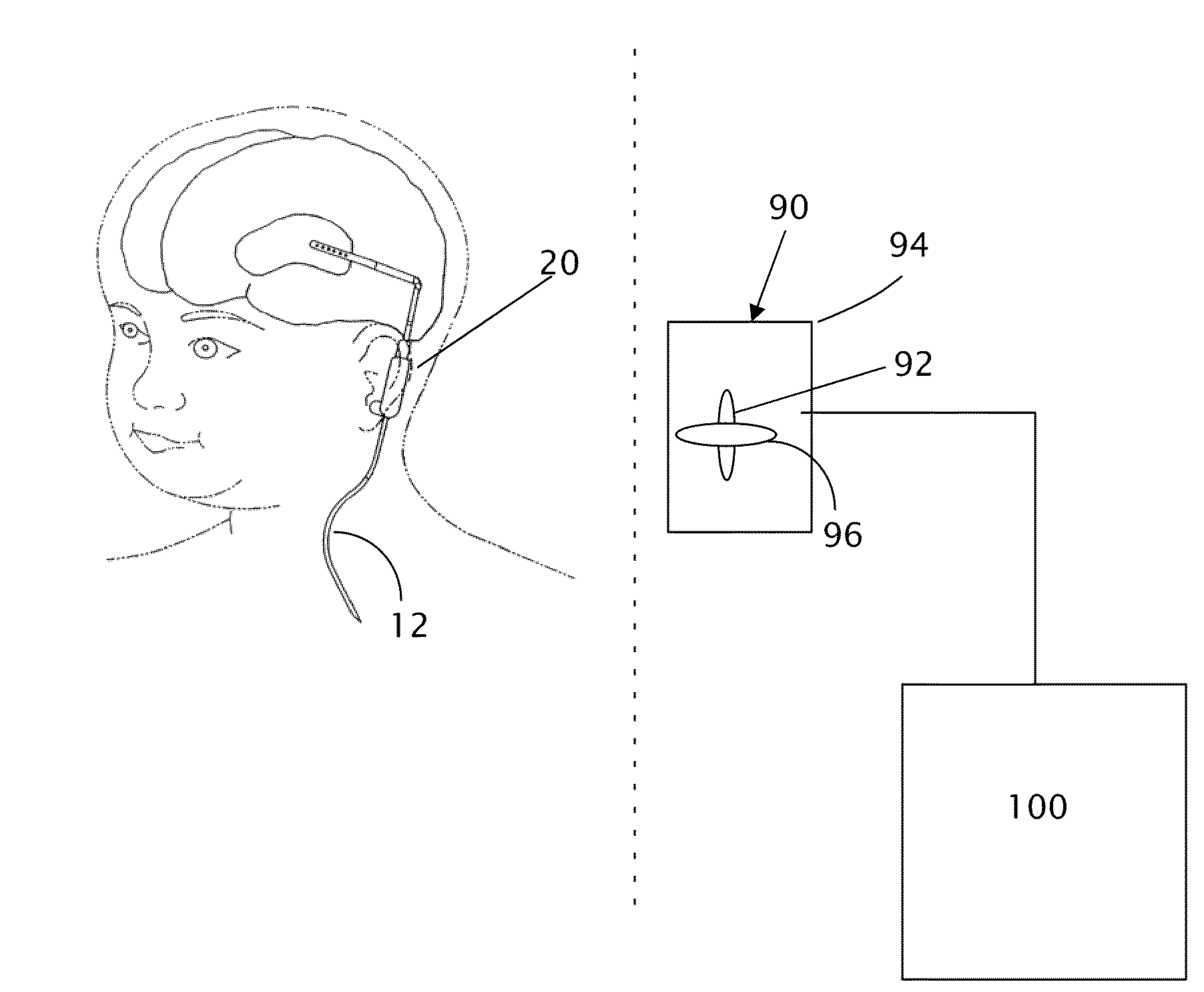

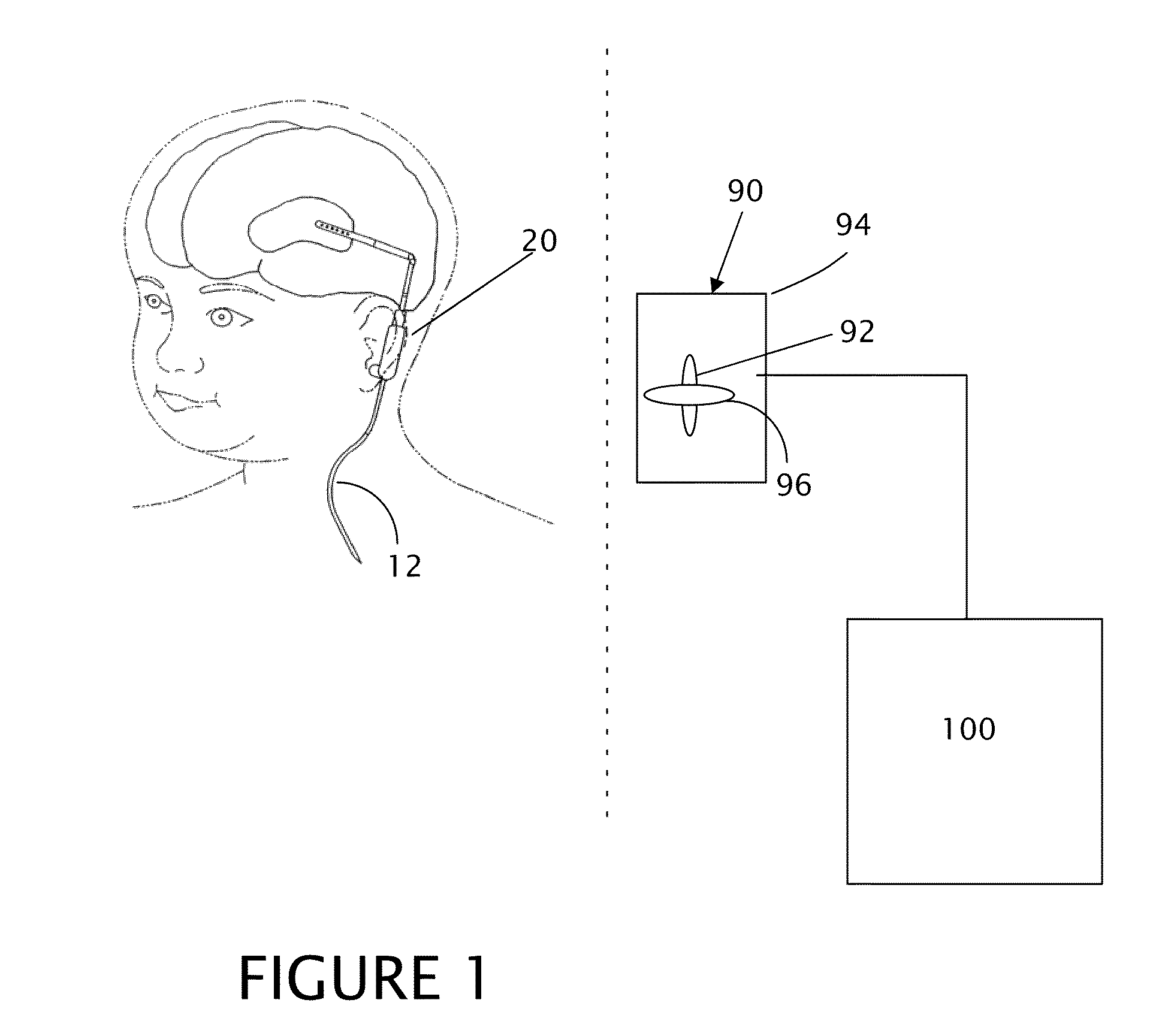

Transit time ultrasonic flow measurement

InactiveUS20090143673A1Ultrasonic/sonic/infrasonic diagnosticsEndoradiosondesTransmitted powerEngineering

A transcutaneous energy transfer system with subcutaneous non coupled coils is used to transmit power and signals to an implanted biological support device or sensor, such as a flow sensor for measuring relatively low flow rates, such as hydrocephalic shunt flow. The flow sensor is configured to convert a shear wave generated by a transducer to a longitudinal wave at the interface of a signal pathway and the flow, wherein the longitudinal wave travels parallel to the flow and exits a flow channel to convert to a shear wave which intersects a second transducer. The transcutaneous energy transfer employs a pair of inductive coupling coils, wherein the coils are disposed in zero coupling orientation which can include a perpendicular orientation of corresponding coil axes.

Owner:TRANSONIC SYST

Method of varying the flow rate of fluid from a medical pump and hybrid sensor system performing the same

ActiveUS20120035535A1Volume/mass flow measurementMedical devicesCapacitanceCapacitive micromachined ultrasonic transducers

A system and method of varying the flow rate of fluid from a medical pump through tubing includes determining an inner diameter of the tubing and fluid flow velocity of fluid in the tubing with a controller based on acoustic signals received by a capacitive micromachined ultrasonic transducer sensor system and then determining and adjusting a fluid flow rate of fluid in the tubing with the controller. In addition, the same sensor system also detects air bubbles in the fluid in the tubing.

Owner:ICU MEDICAL INC

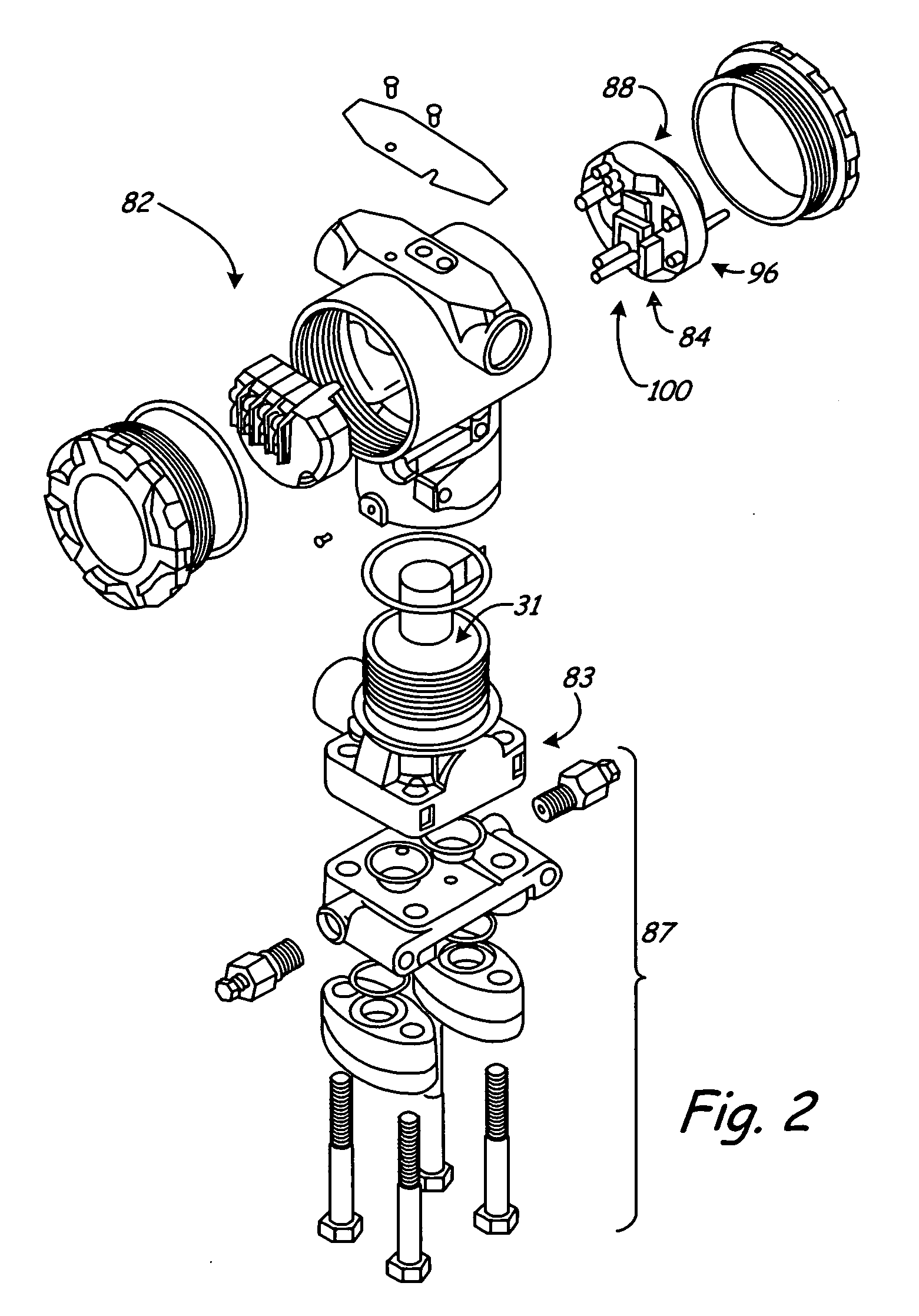

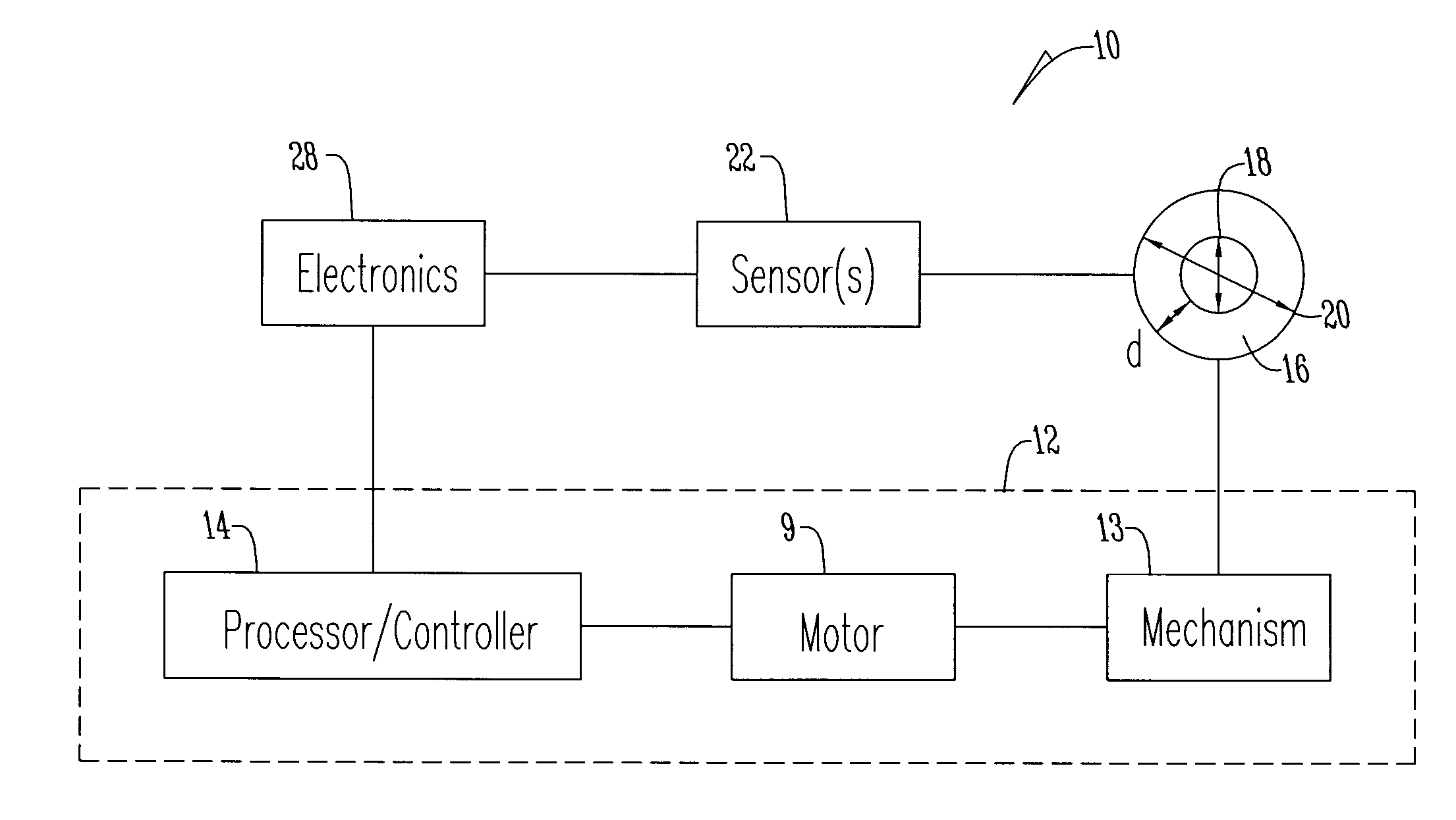

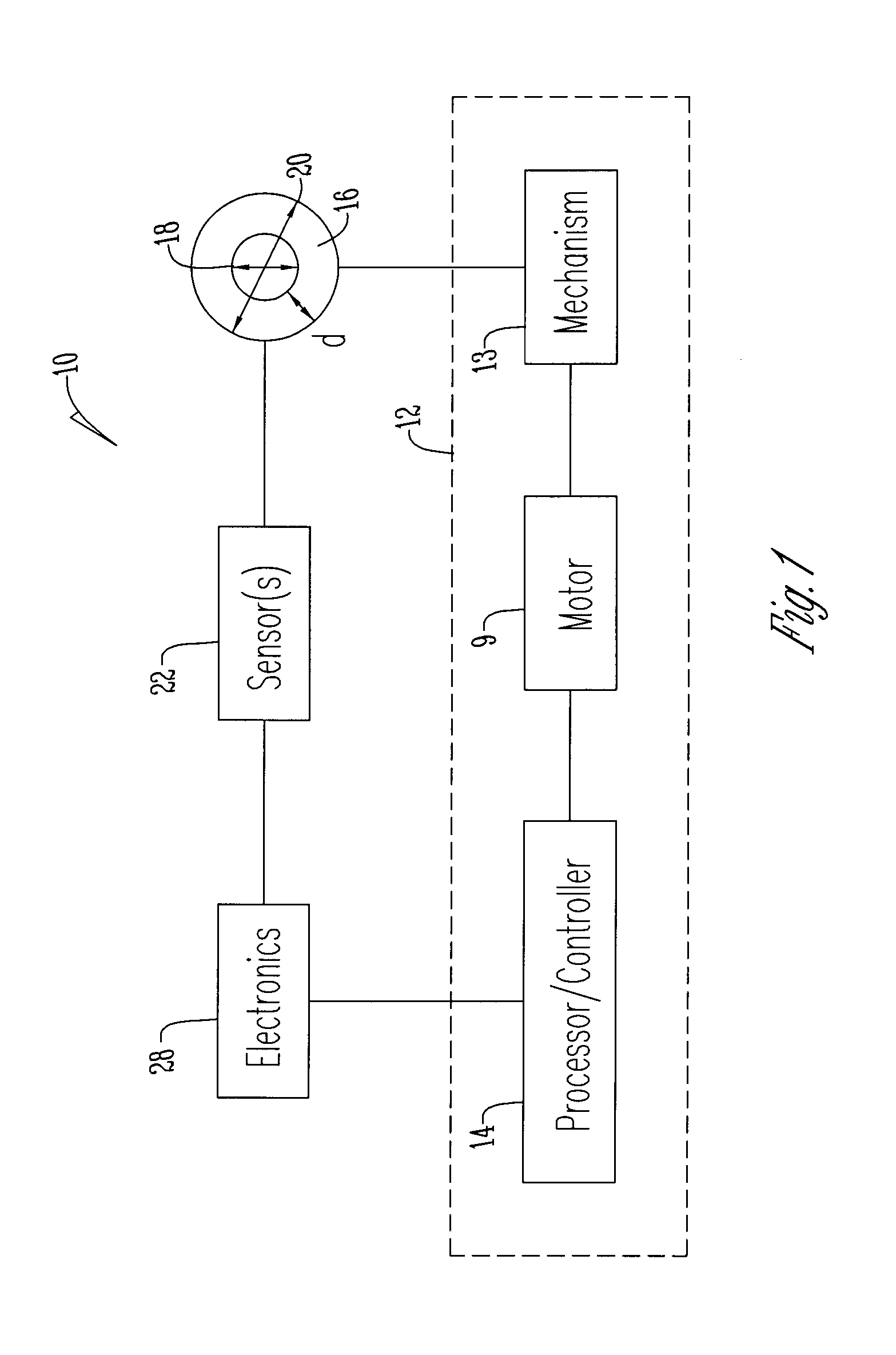

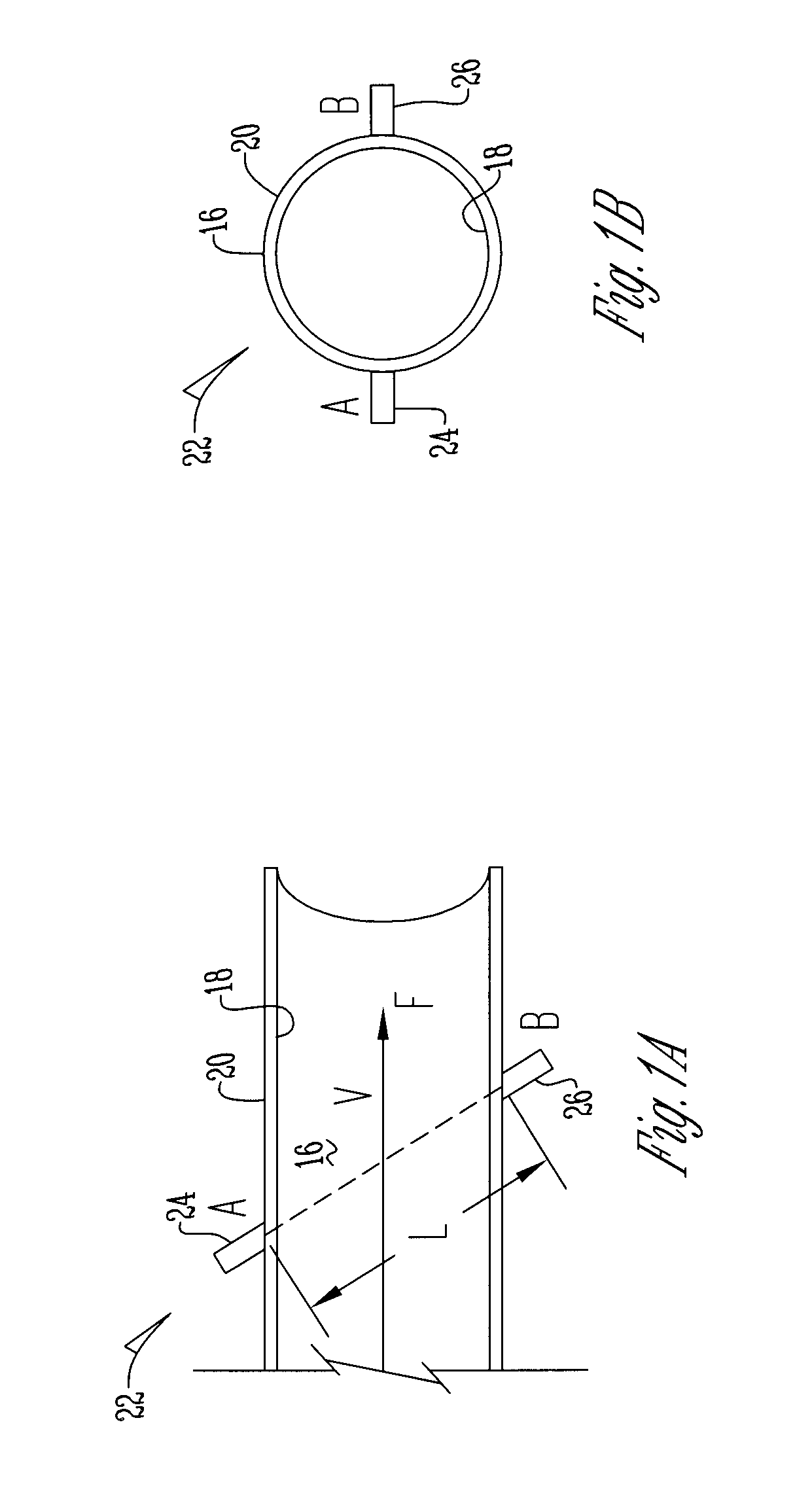

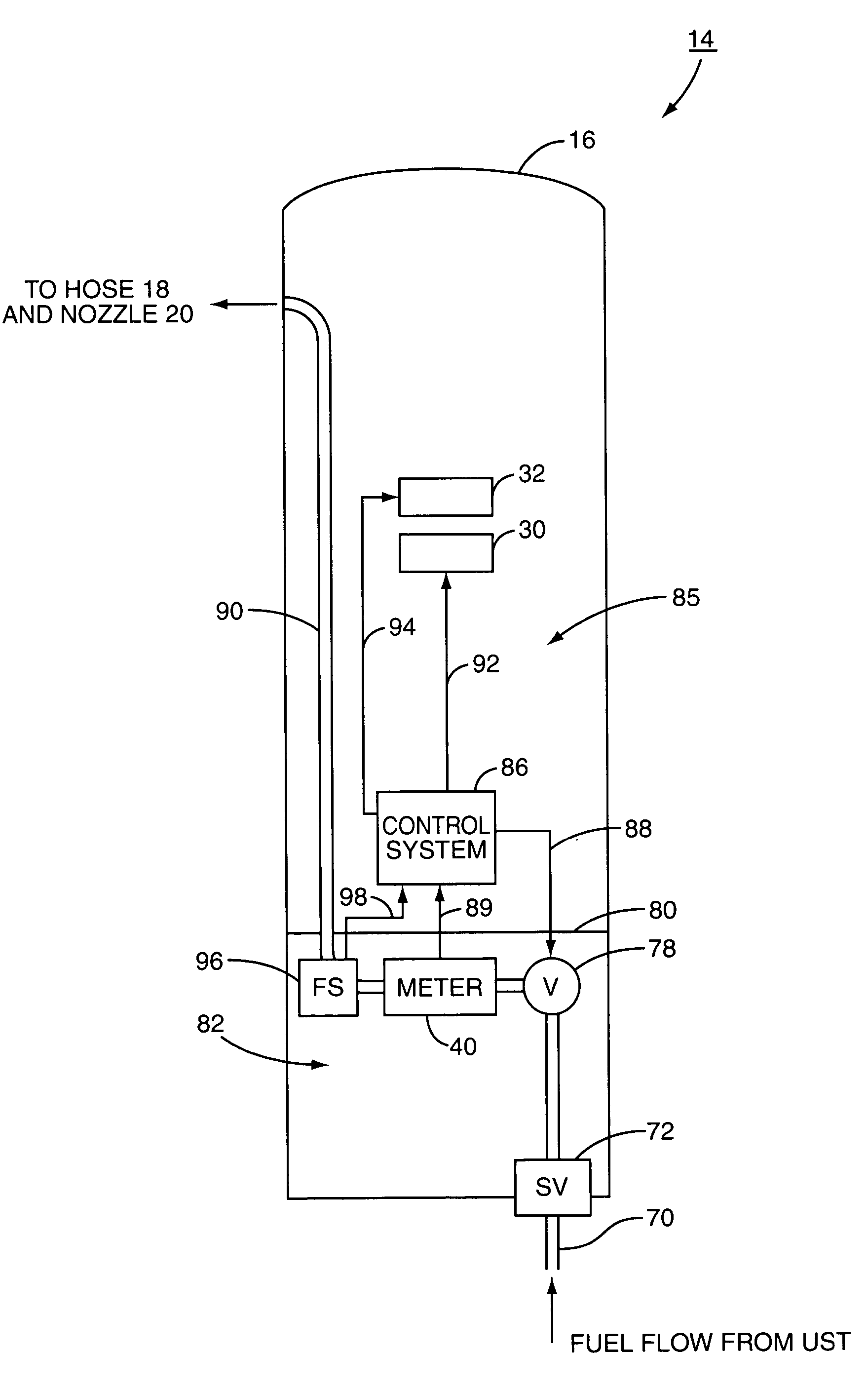

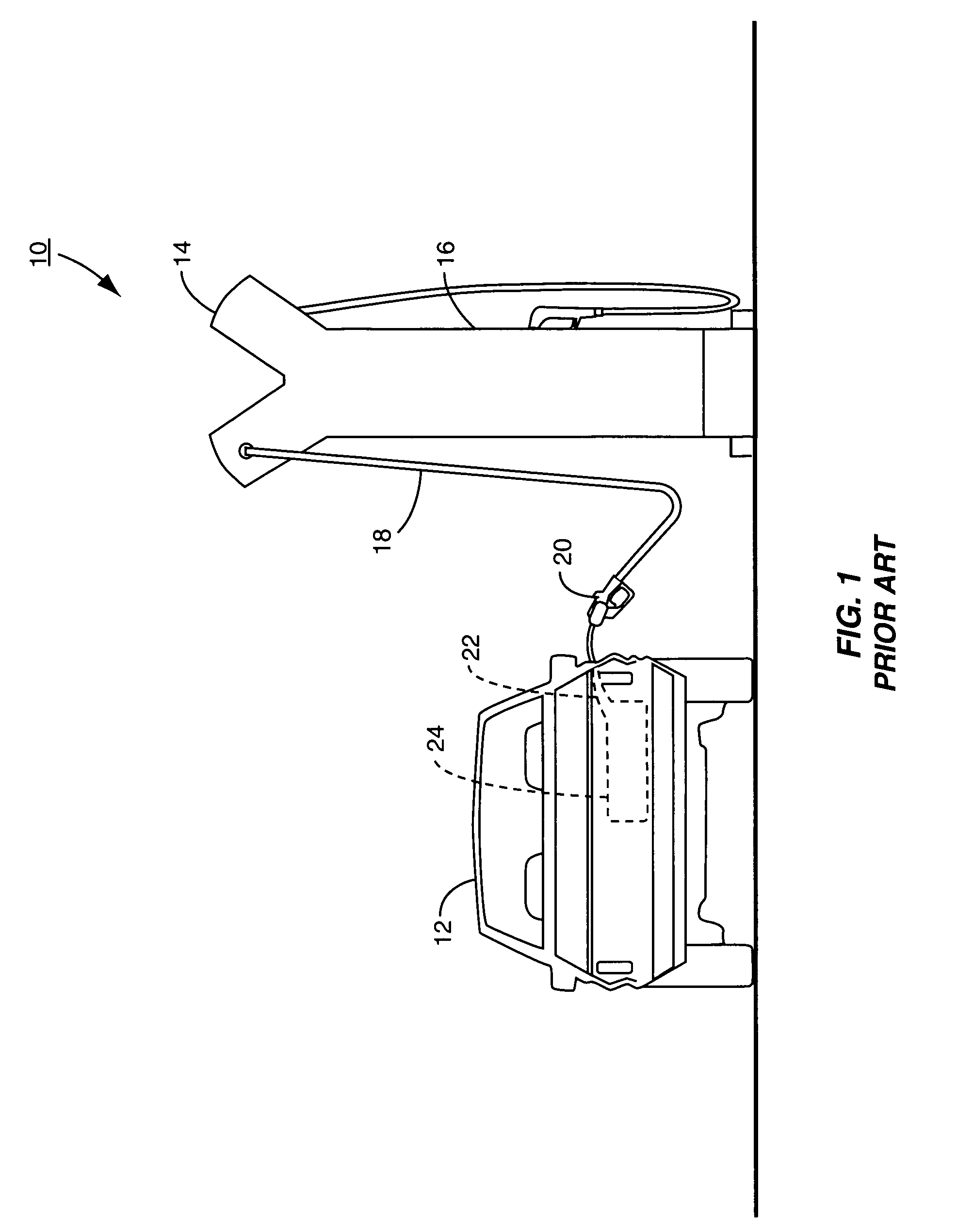

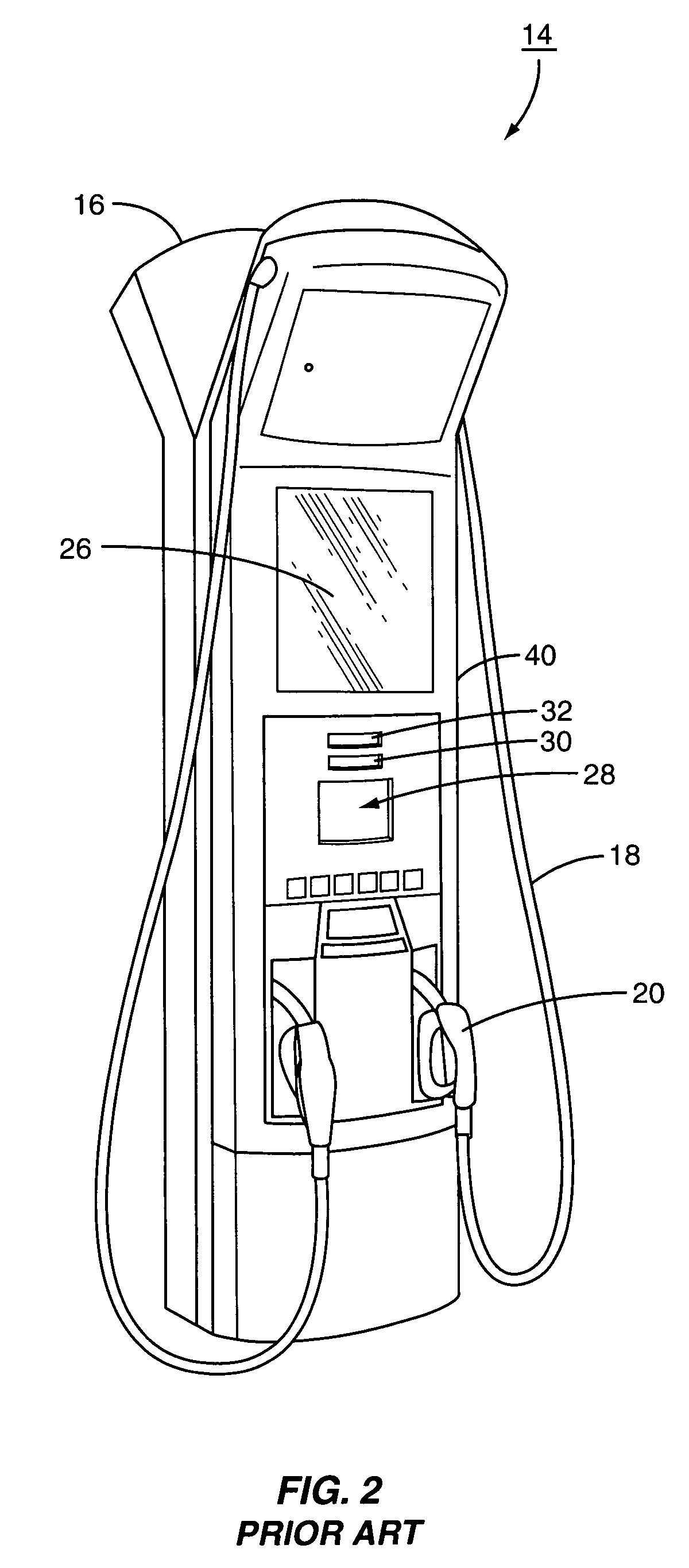

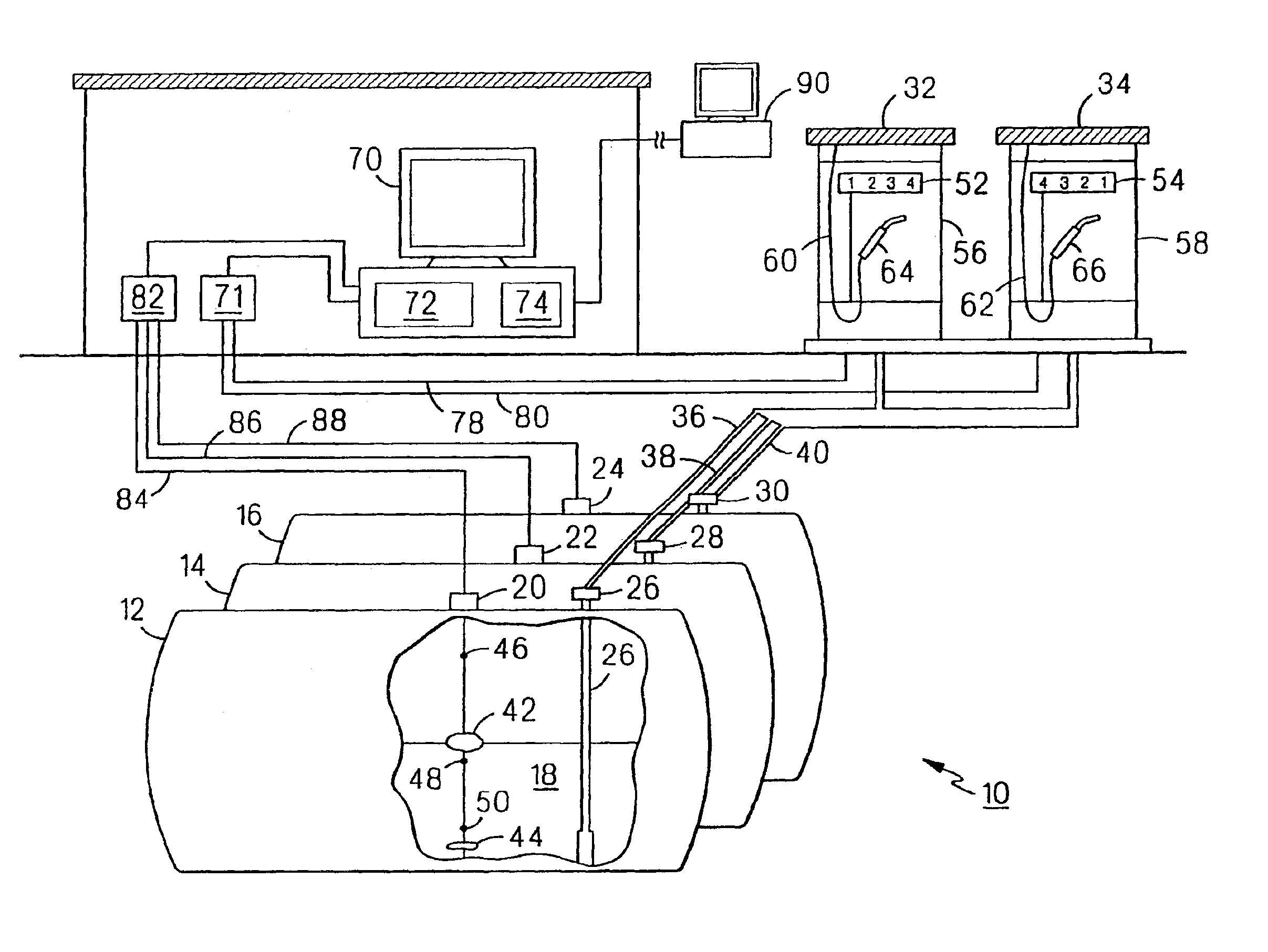

Fuel dispenser fuel meter error detection device, system and method

InactiveUS7028561B2Accurately measuring flow rate and volumePrevent backflowValve arrangementsLiquid transferring devicesCombined useEngineering

A flow switch used in conjunction with a fuel meter in a fuel dispenser to determine when fuel is flowing. A flow switch can only be activated if fuel is flowing through the flow path of the flow switch. If fuel is flowing as indicated by the fuel flow switch, but the meter is not registering fuel flow, there is a meter error, which may be an error internally with components of the meter and / or a pulser that generates pulse signals indicative of fuel flow. If the meter pulser is registering fuel flow, but the flow switch is not registering fuel flow, then an error exists with the flow switch. If fuel is flowing and there are no errors, both the meter and the flow switch should indicate fuel flow.

Owner:GILBARCO

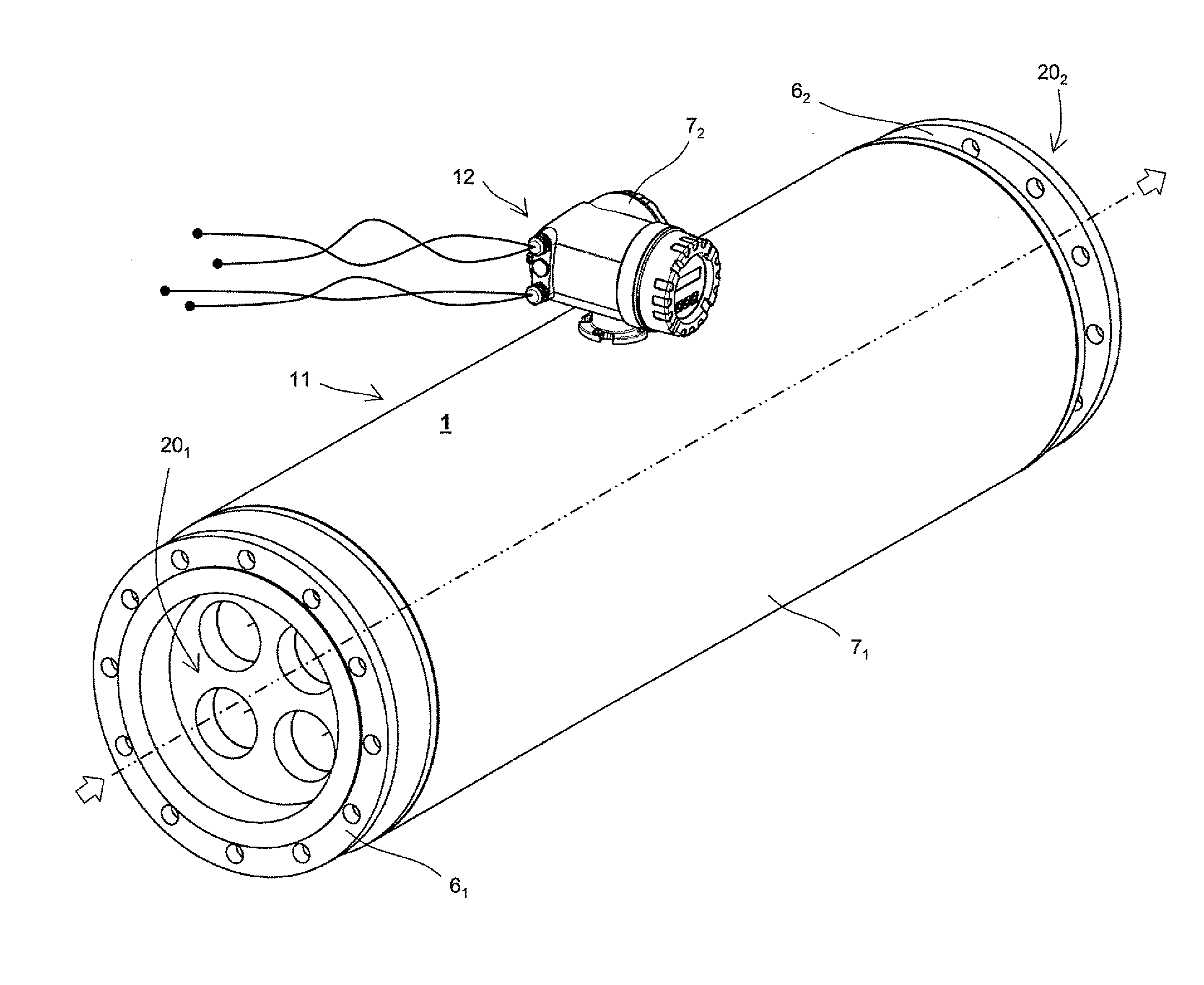

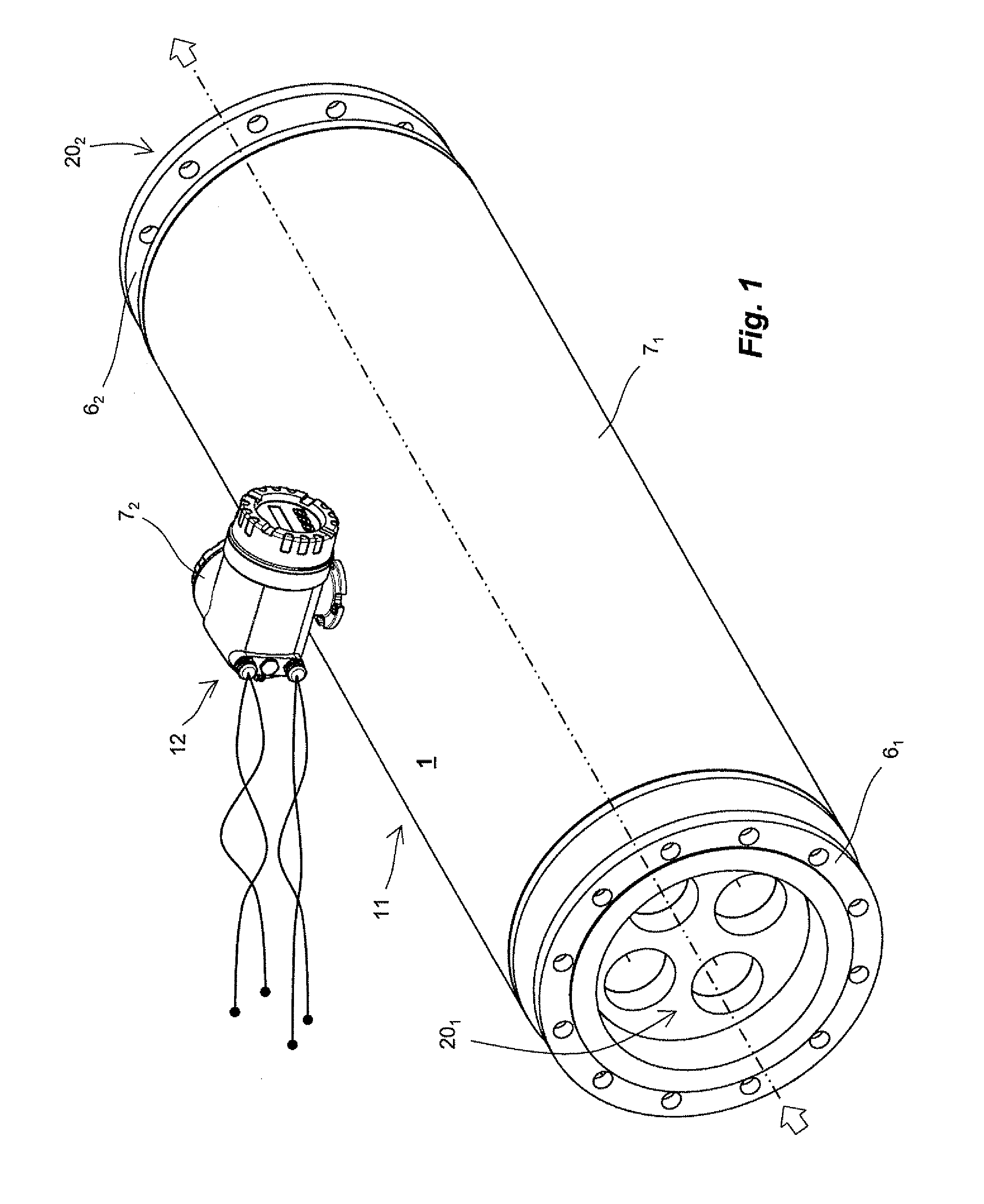

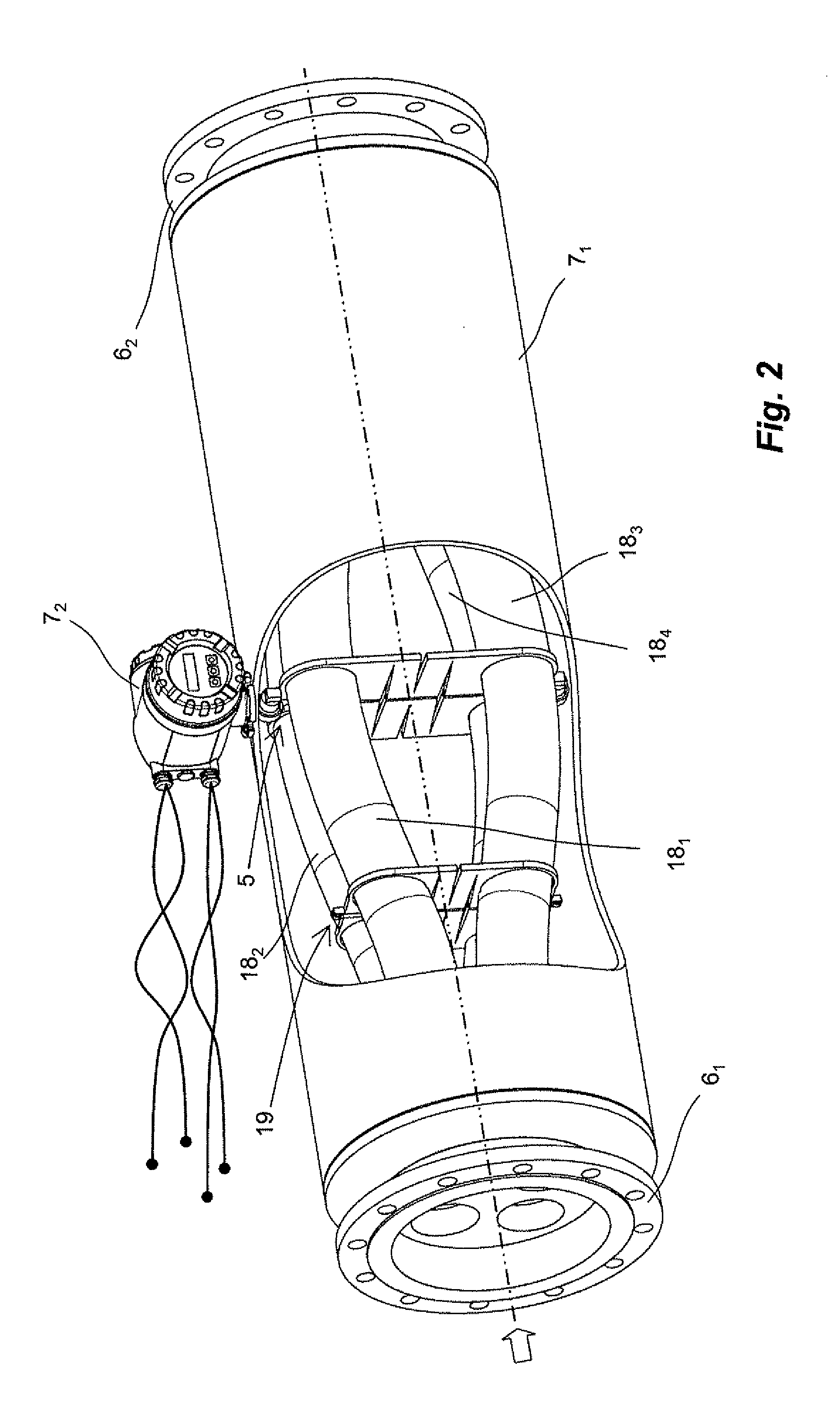

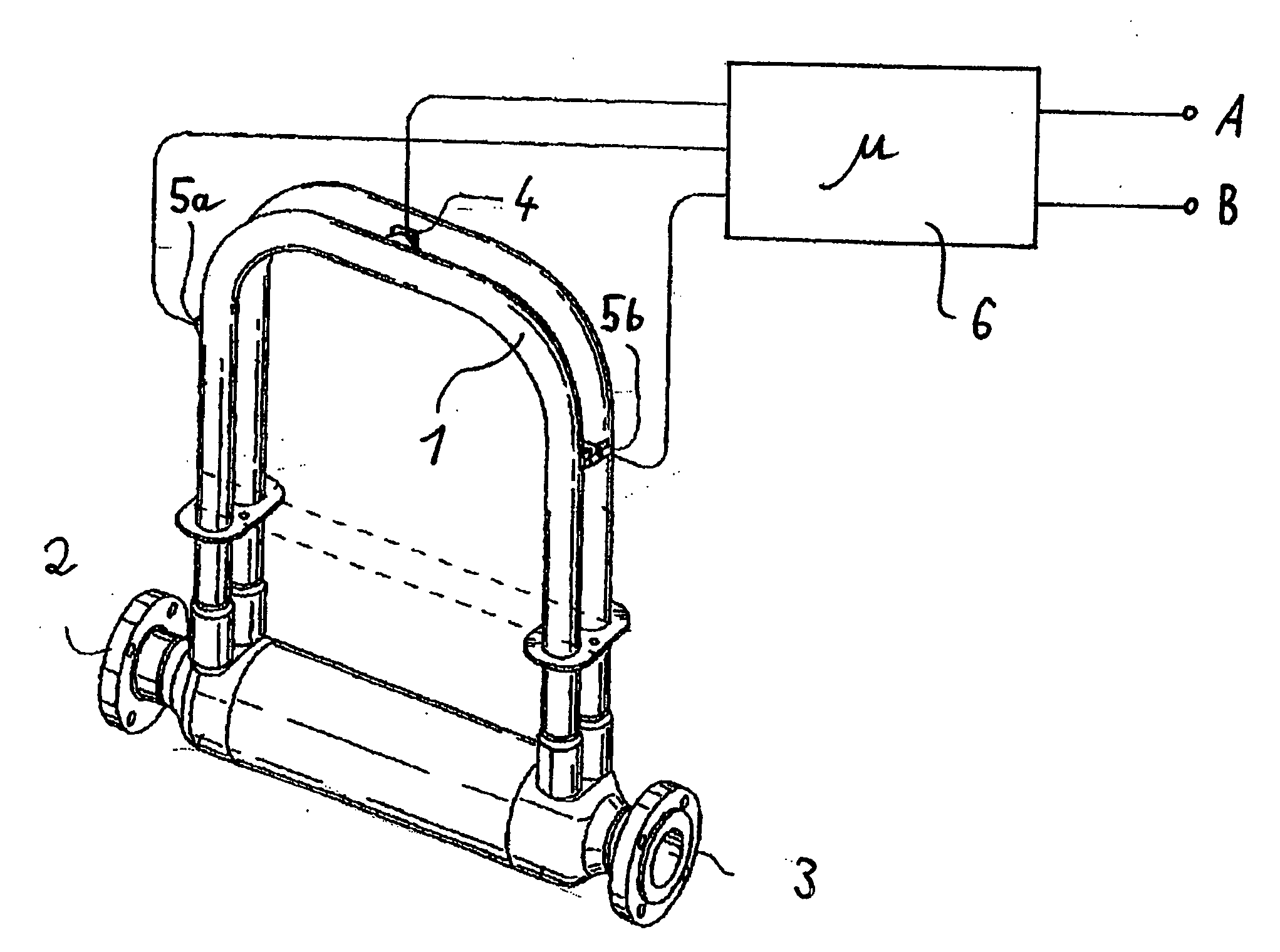

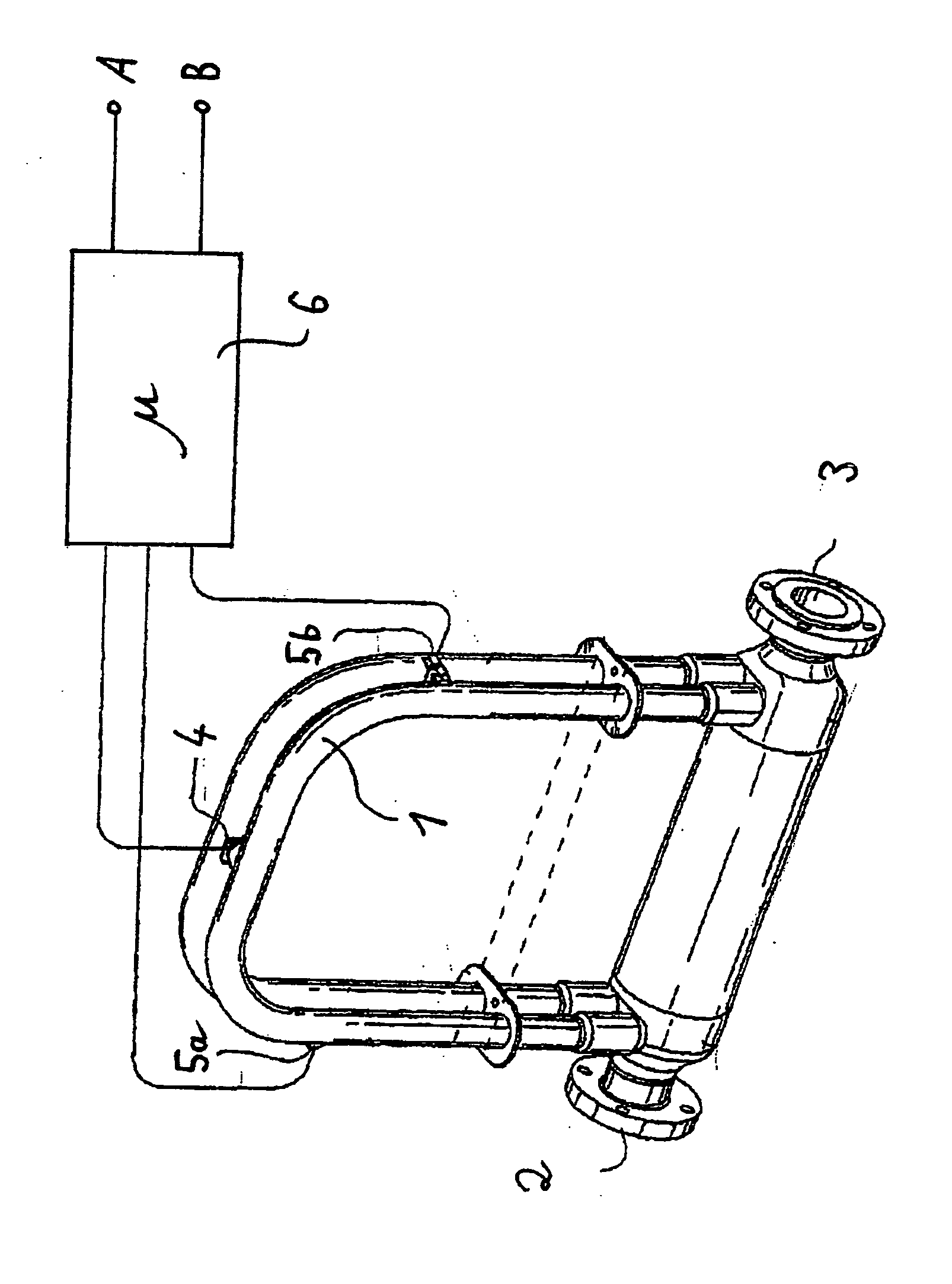

Measuring transducer of vibration-type

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

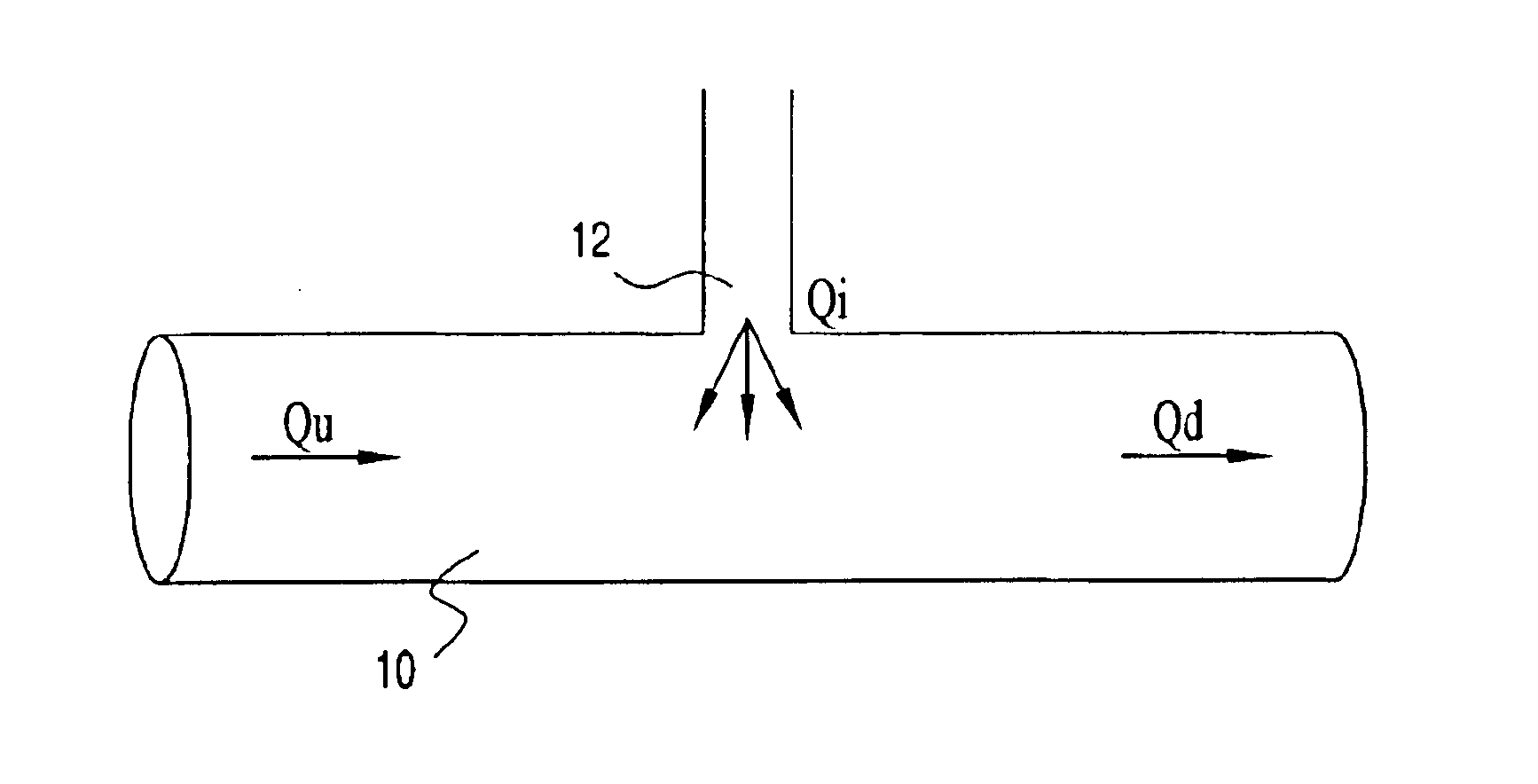

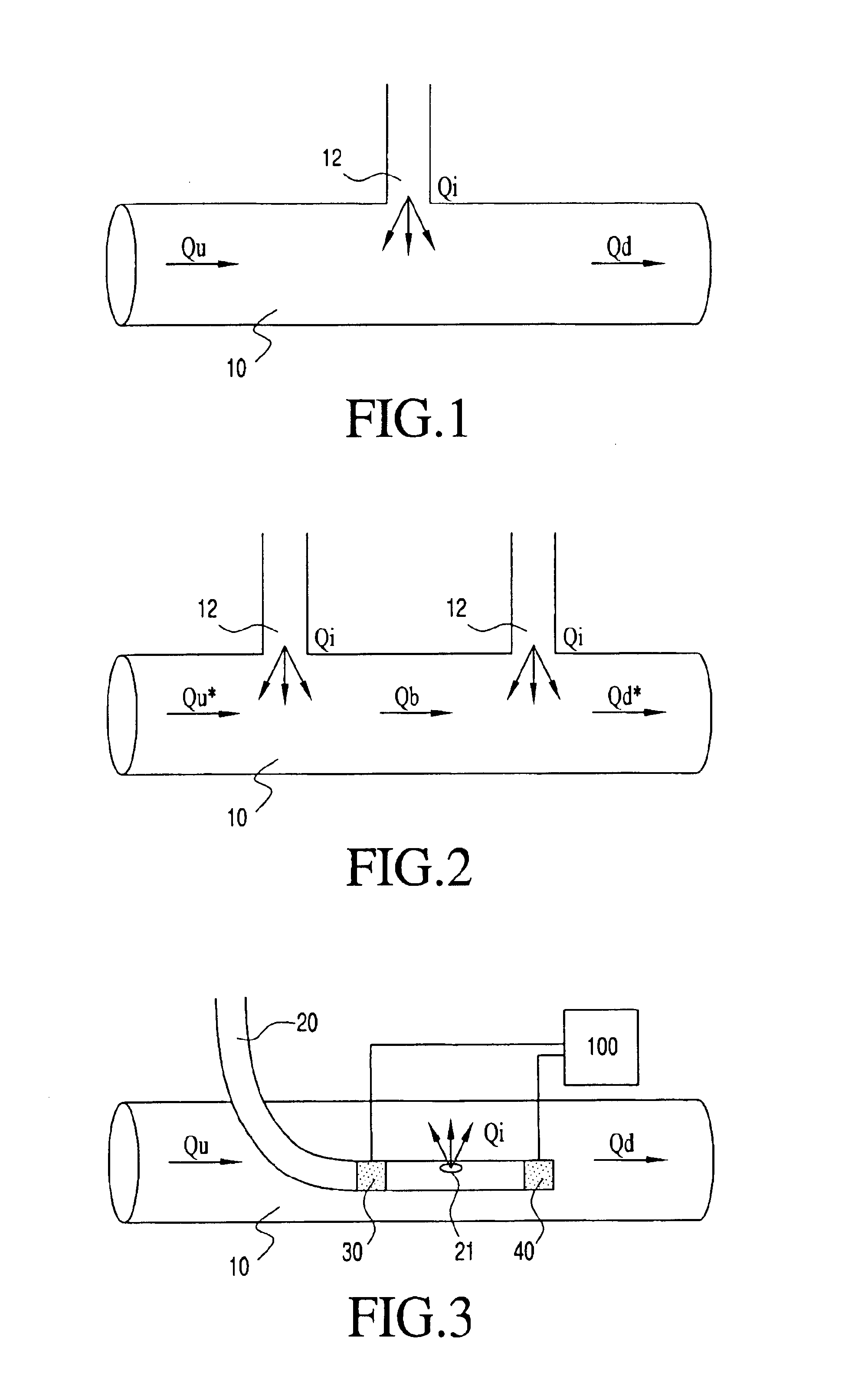

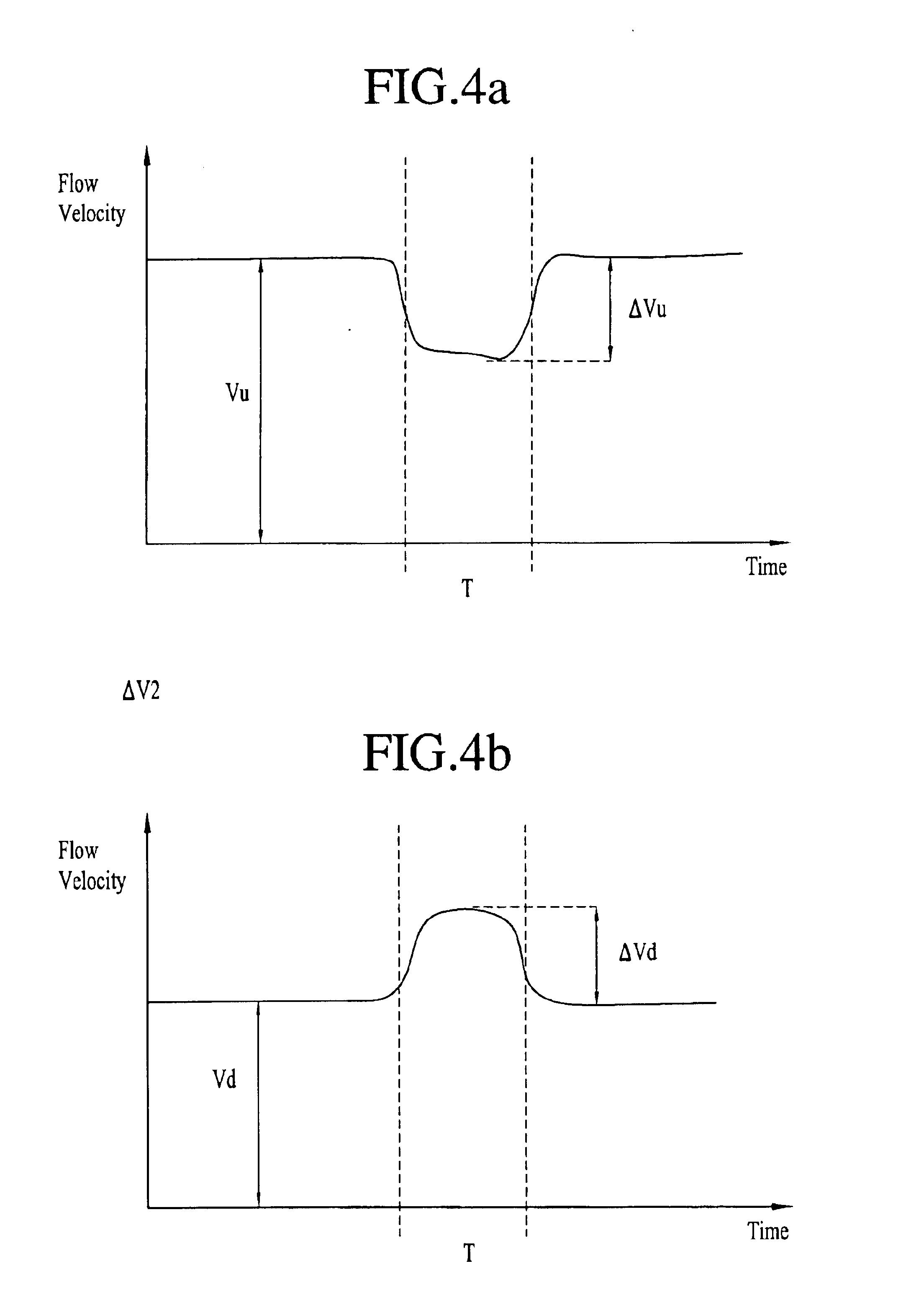

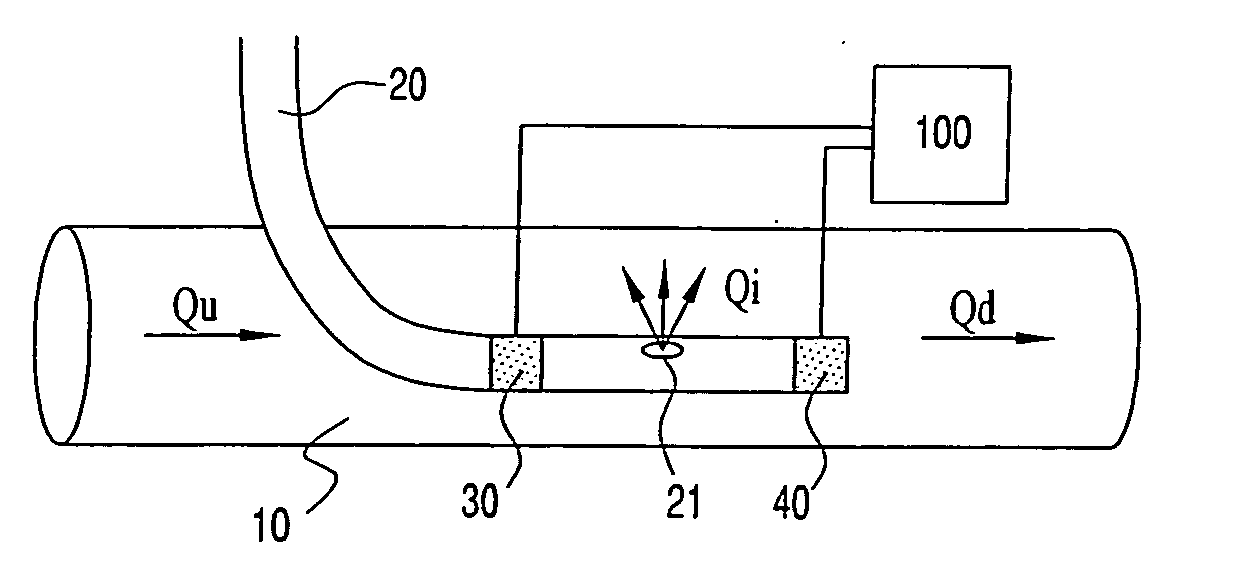

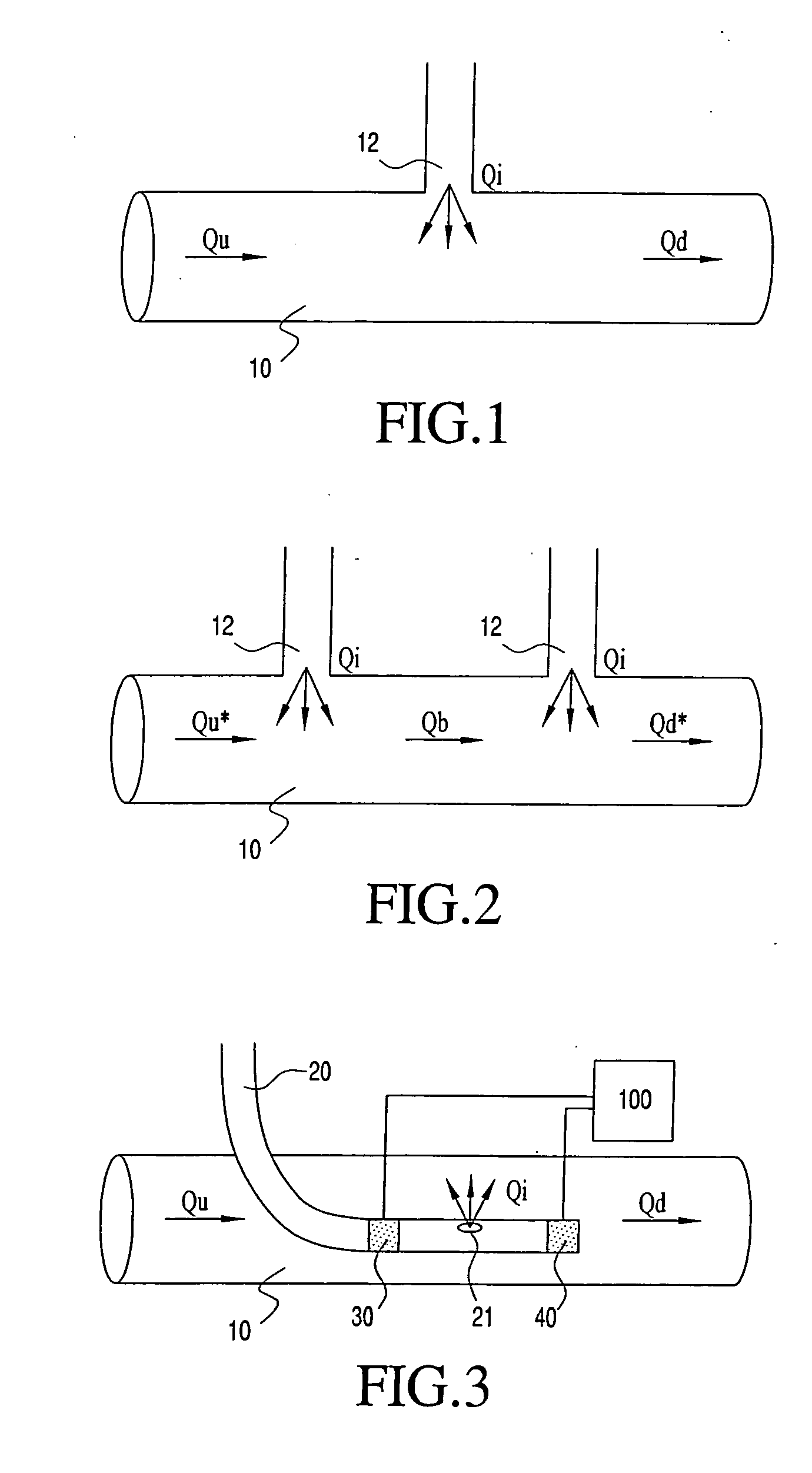

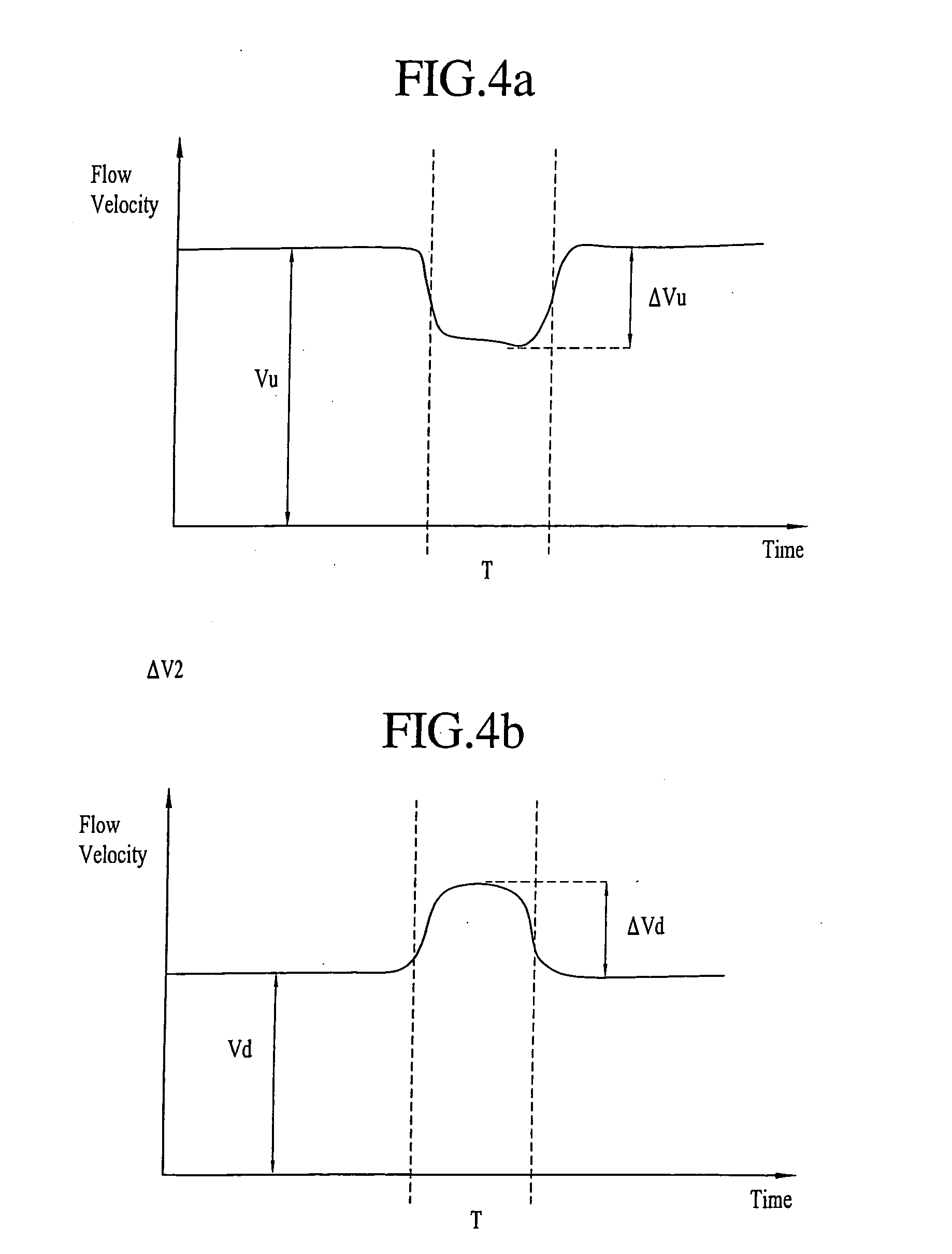

Method and apparatus to measure blood flow by an introduced volume change

A method and apparatus for determining an initial flow rate in a conduit is disclosed. A known change is made to the flow to be measured, resulting changes (or values corresponding to these changes), or relative changes in the flow to be measured are monitored and the initial flow in the conduit is calculated from the value of the known change and monitored changes. Devices to practice the method include catheters having one or two sensors and one or two sites for introducing the volume change.

Owner:TRANSONIC SYST

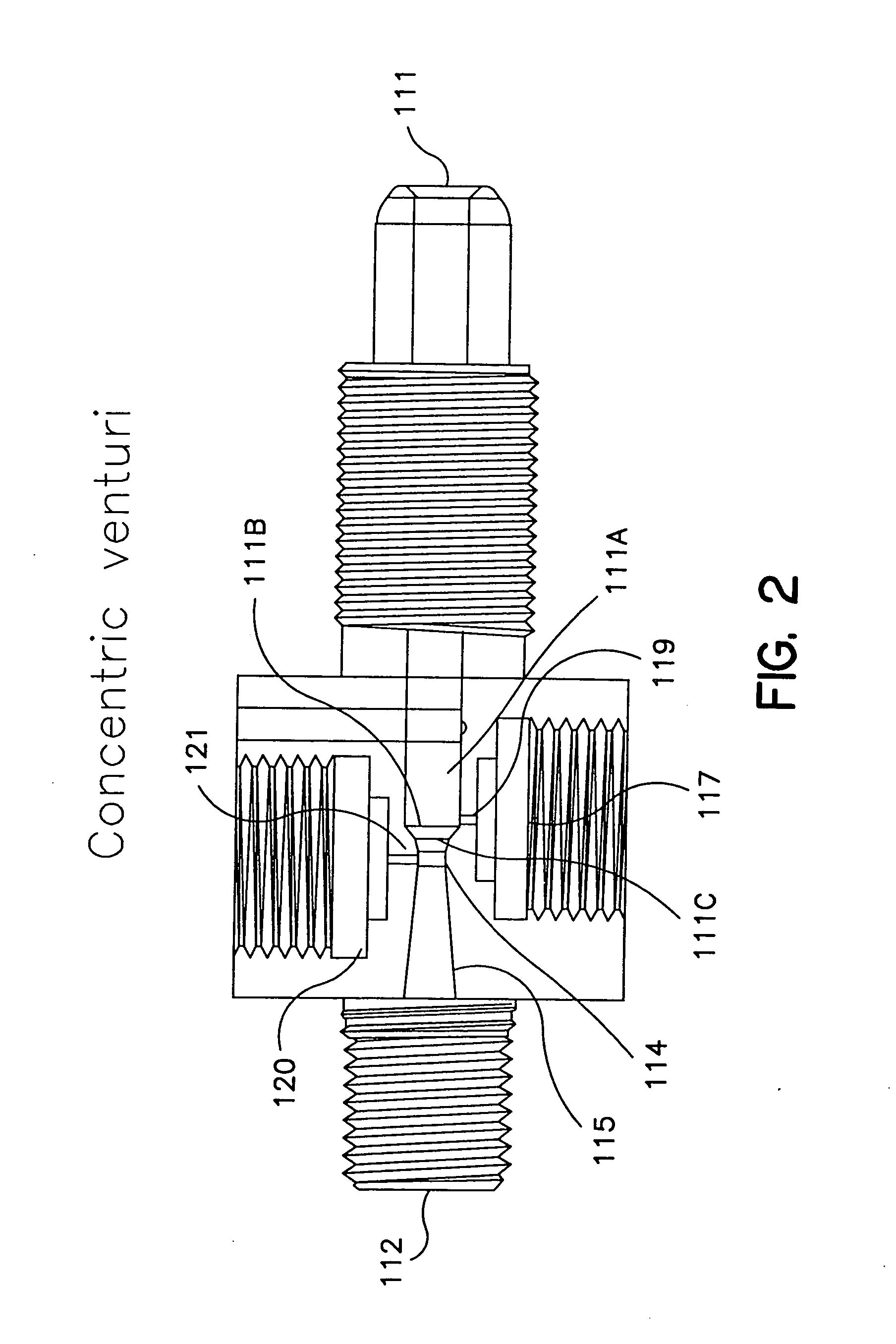

Fluid flow measuring and proportional fluid flow control device

ActiveUS20060162466A1Improve stabilityMinimal operator involvementFlow propertiesFluid speed measurement using pressure differenceMeasurement deviceEngineering

The present invention provides restrictive-flow flow measurement devices, valve improvements and signal control devices and processes that control the flow of liquids, including control processes for single-liquid calibration.

Owner:ENTEGRIS INC

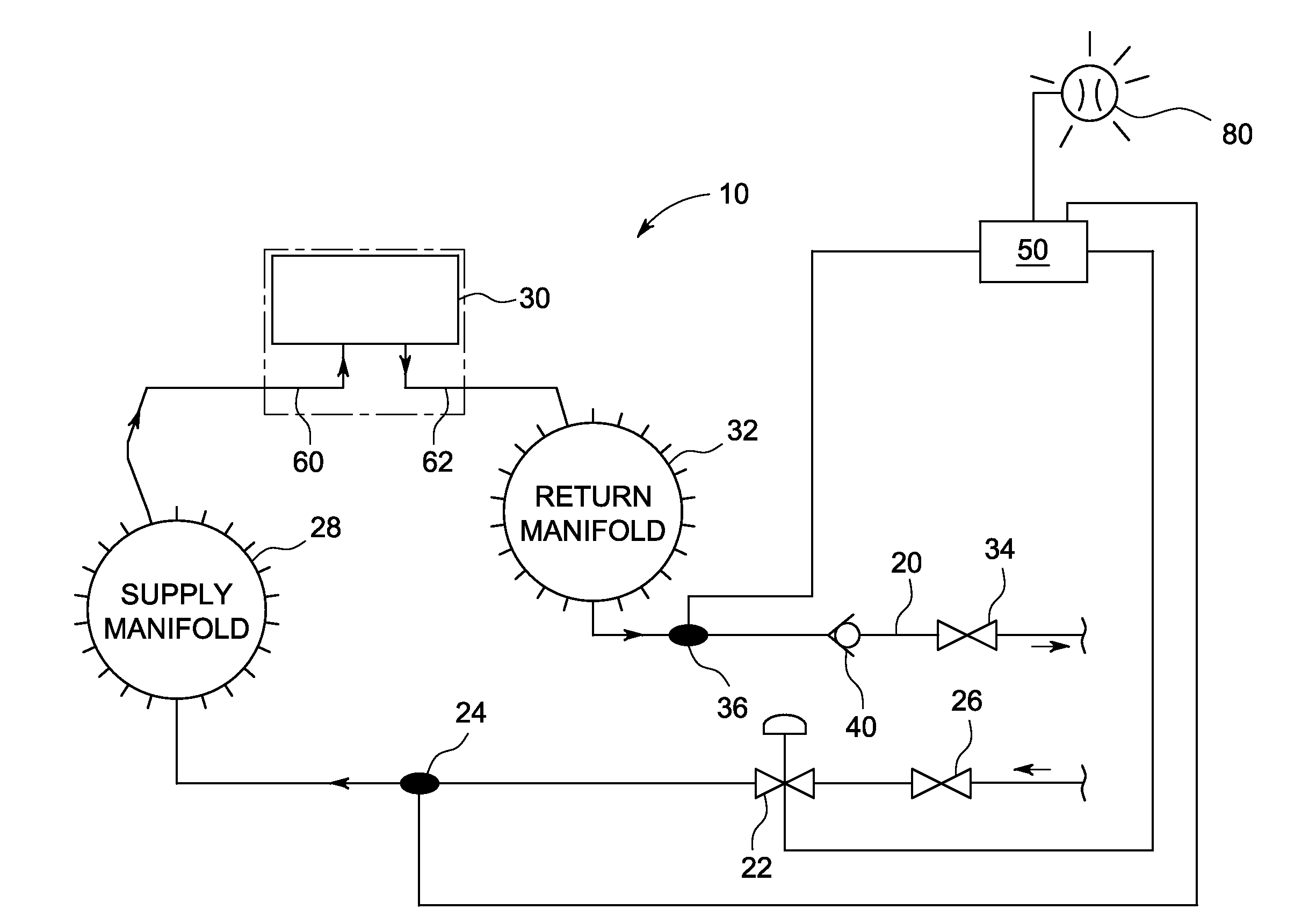

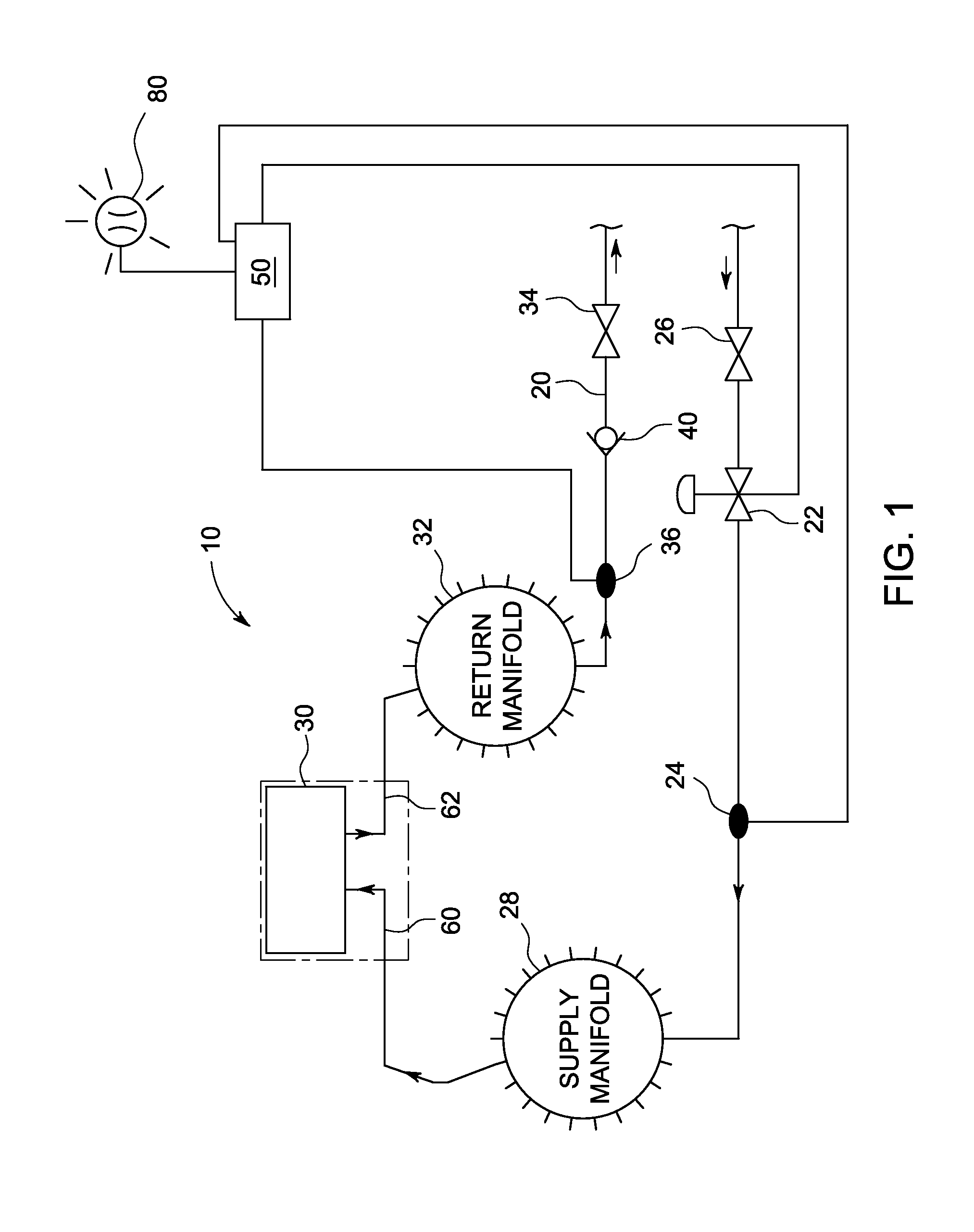

Fluid leak detection system

InactiveUS20120324985A1Measurement of fluid loss/gain rateTesting/calibration for volume flowEngineeringInlet flow

A fluid leak detection system is provided, and includes a fluid conduit, a fluid-cooled device having an inlet and an outlet, an inlet flow meter, an outlet flow meter, and a controller. The inlet flow meter is fluidly connected to the fluid conduit. The inlet flow meter monitors the inlet of the fluid-cooled device for an inlet temperature and an inlet flow rate. The inlet flow meter has an inlet flow meter drift versus process fluid temperature curve. The outlet flow meter is fluidly connected to the fluid conduit. The outlet flow meter monitors the outlet of the fluid-cooled device for an outlet temperature and an outlet flow rate. The outlet flow meter has an outlet flow meter drift versus process fluid temperature curve. The controller is in communication with the inlet flow meter and the outlet flow meter.

Owner:GENERAL ELECTRIC CO

Method for operating a vibratory measuring instrument, and corresponding instrument

InactiveUS20100011882A1Made preciselyAccurate signalVolume variation compensation/correction apparatusTesting/calibration for volume flowMeasuring instrumentClassical mechanics

A method for operation of a vibratory measurement instrument comprises flowing a fluid through at least one measurement tube; causing the measuring tube to oscillate mechanically using an oscillation production unit; detecting an oscillation behavior of the tube using at least one oscillation sensor; determining at least one of a mass flow, a viscosity, and a density in a narrowband frequency range based on the oscillation behavior; evaluating at least one of the mass flow, the viscosity, and the density using signal processing of an electronics unit; and evaluating the oscillation behavior at least at times in a broadband frequency range using the electronics unit.

Owner:ABB PATENT GMBH

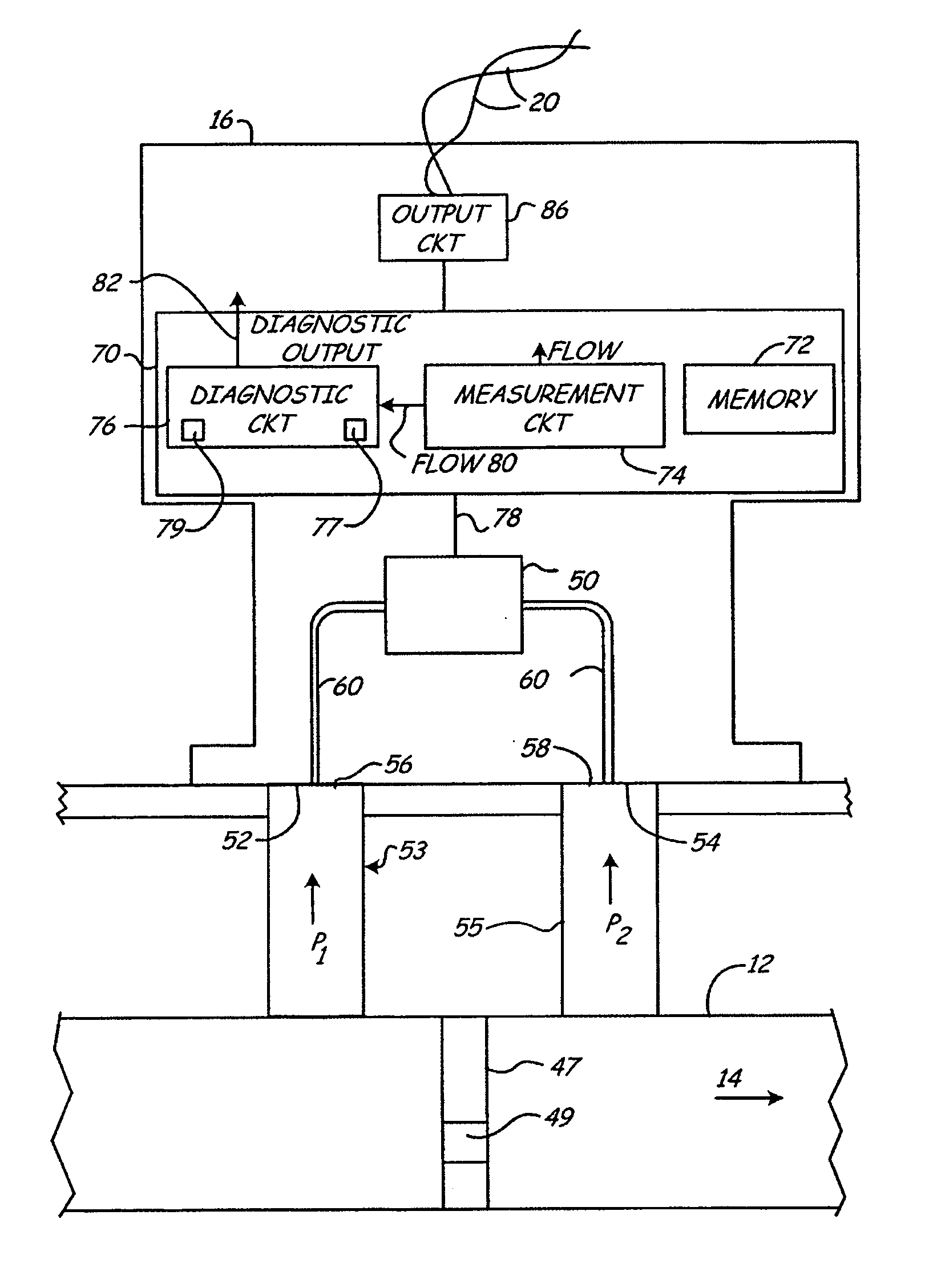

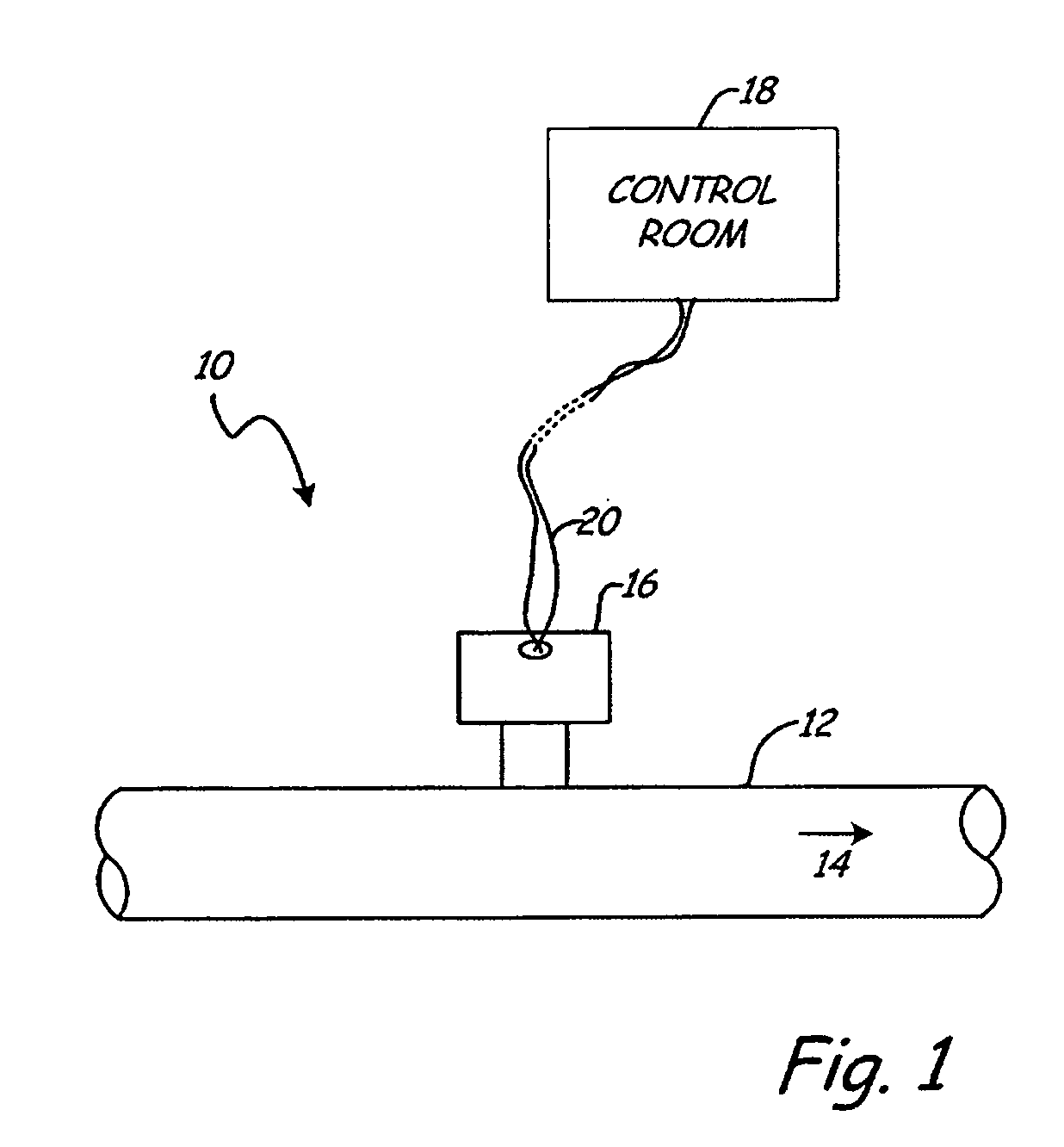

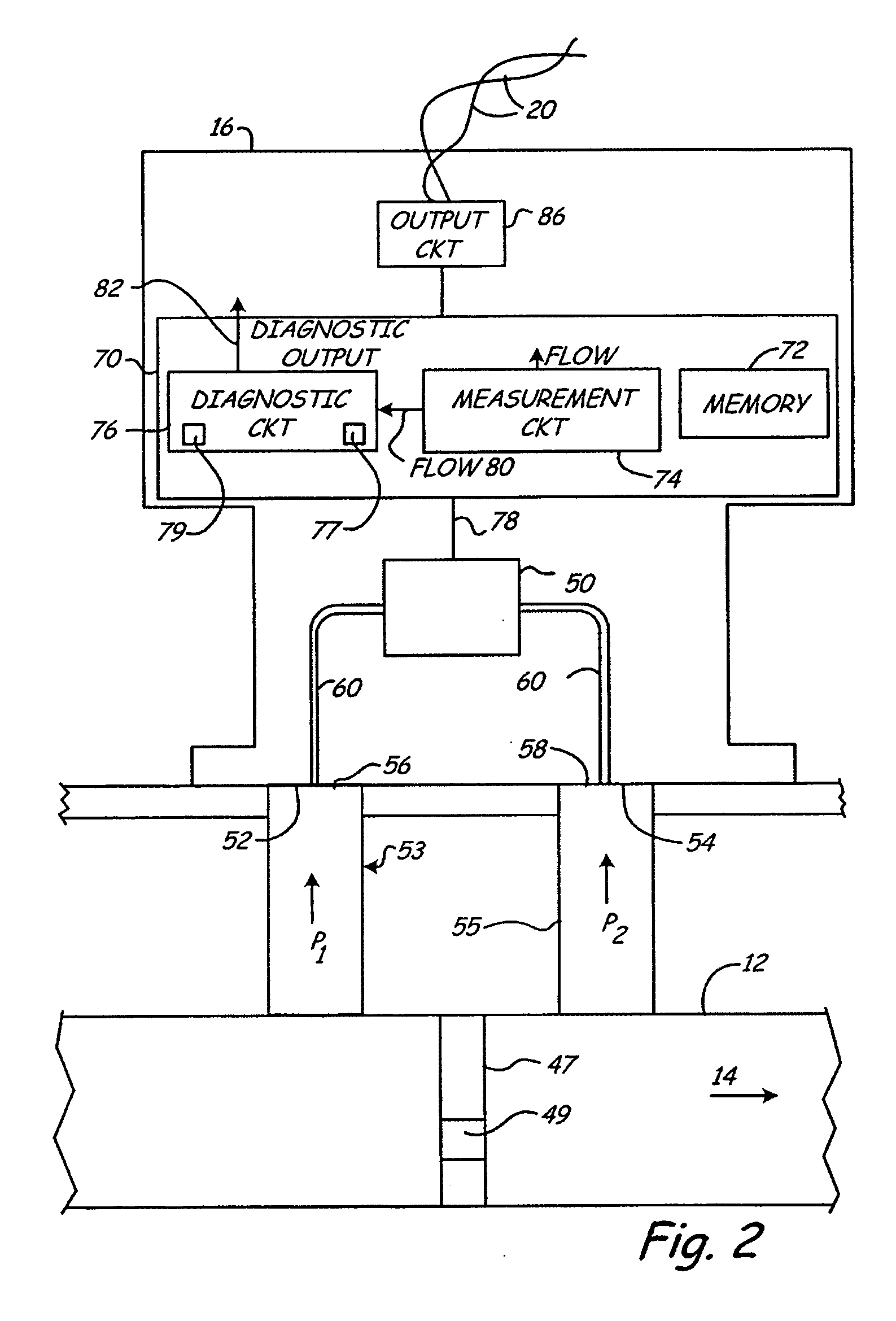

Flow measurement diagnostics

InactiveUS20060277000A1Amplifier modifications to reduce noise influenceVolume/mass flow measurementEngineering

A flow meter for measuring flow of a process fluid includes a sensor configured to provide a sensor output signal. The sensor output signal is related to flow of the process fluid. Circuitry in the flow meter is configured to determine a statistical parameter related to sensor output signal. Diagnostic circuitry provides a diagnostic output based upon the determined statistical parameter and the sensor output signal.

Owner:ROSEMOUNT INC

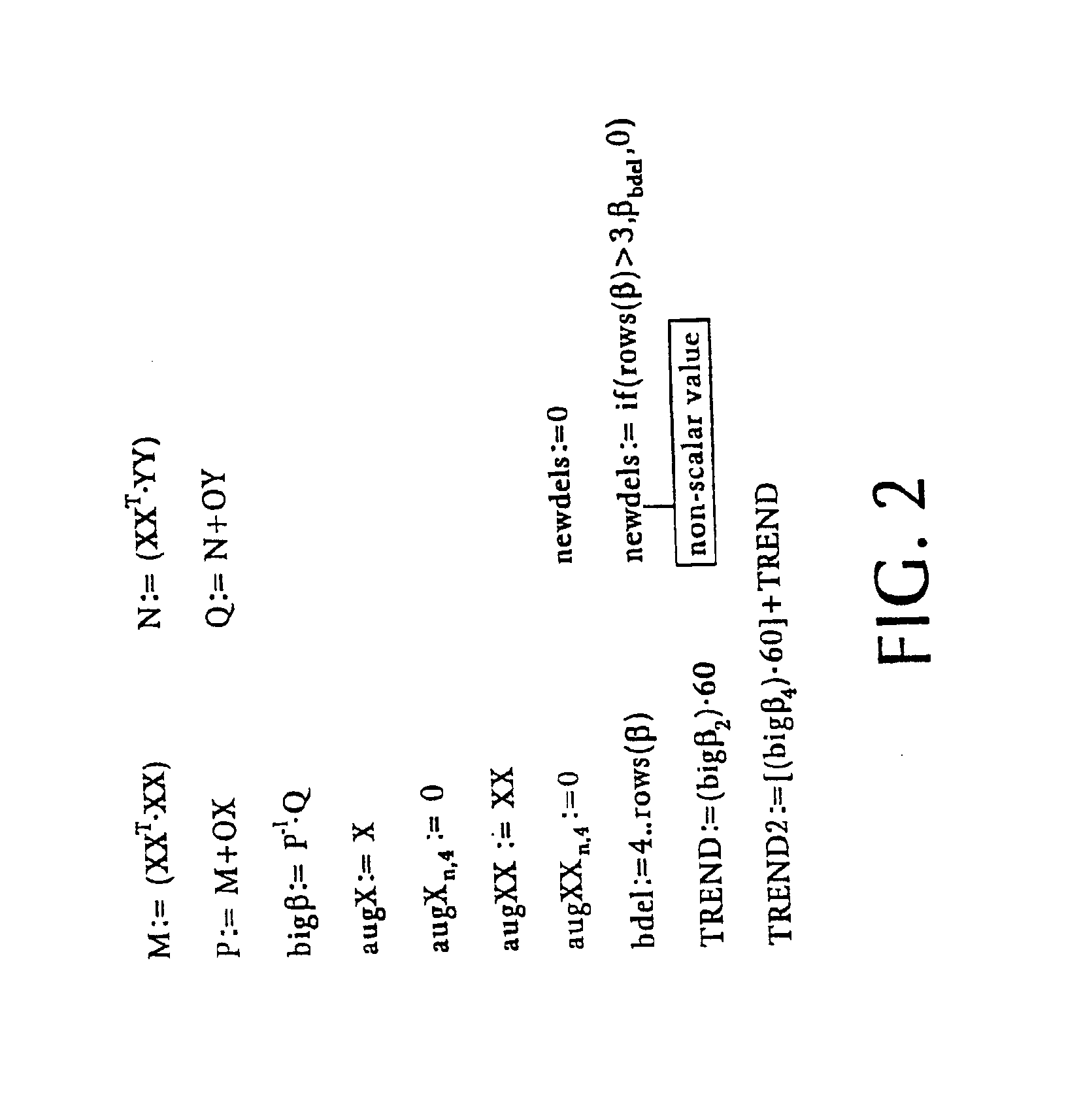

Method and apparatus for monitoring operational performance of fluid storage systems

A method of determining a volume of fluid associated with a fluid storage and dispensing system, the volume of fluid having a height in the system, wherein the system include measurement apparatus for measuring the height. The method includes collecting a plurality of height measurement data from the measurement apparatus in a form readable by a computer; storing the plurality of height measurement data in a compressed matrix format in a computer memory; and performing regression analysis using the compressed matrix format to calculate the volume of fluid associated with the system.

Owner:WARREN ROGERS ASSOC

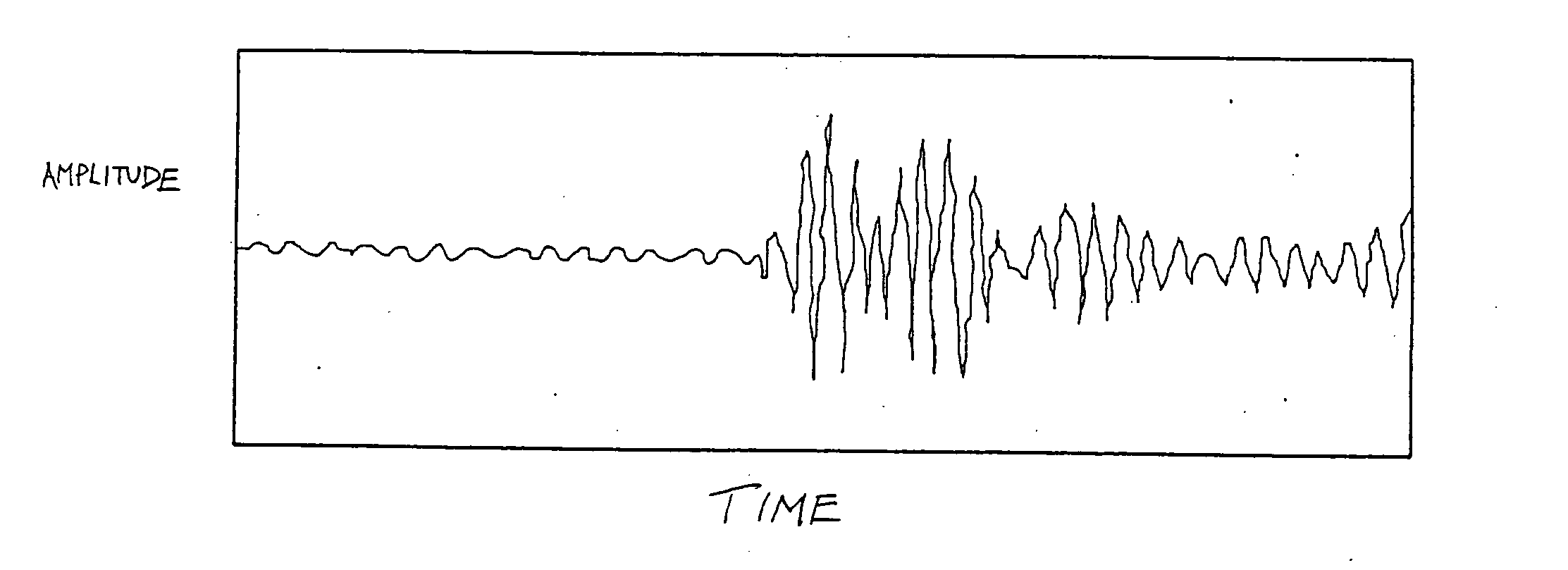

Self-tuning ultrasonic meter

InactiveUS20050055171A1Correction errorWide applicabilityVolume/mass flow measurementElectrical measurementsSelf-tuningTemperature stratification

A method and related ultrasonic meter identify and correct for transit time errors such as peak switch errors. The method includes calculating values for a set of diagnostics from measurements of the fluid flow, including transit time measurements. Based on the values for the diagnostics, and whether and how they fall outside of their respective ranges, the meter can identify a variety of problems with the meter or fluid flow, such as whether there has been an intermittent peak switch, a permanent peak switch, or the presence of noise, velocity pulsation in the fluid flow, temperature stratification, or other problem. In the event there is a problem with the meter, the meter self-tunes in order to minimize the chances of the problem happening again.

Owner:MICRO MOTION INC

Apparatus and method for augmenting a Coriolis meter

ActiveUS7299705B2High densityAdd additional massMaterial analysis using sonic/ultrasonic/infrasonic wavesVolume meteringDischarge measurementsUsage analysis

Owner:EXPRO METERS

Method and apparatus to determine an initial flow rate in a conduit

A method and apparatus for determining an initial flow rate in a conduit is disclosed. A known change is made to the flow to be measured, resulting changes (or values corresponding to these changes), or relative changes in the flow to be measured are monitored and the initial flow in the conduit is calculated from the value of the known change and monitored changes. Devices to practice the method include catheters having one or two sensors and one or two sites for introducing the volume change.

Owner:TRANSONIC SYST

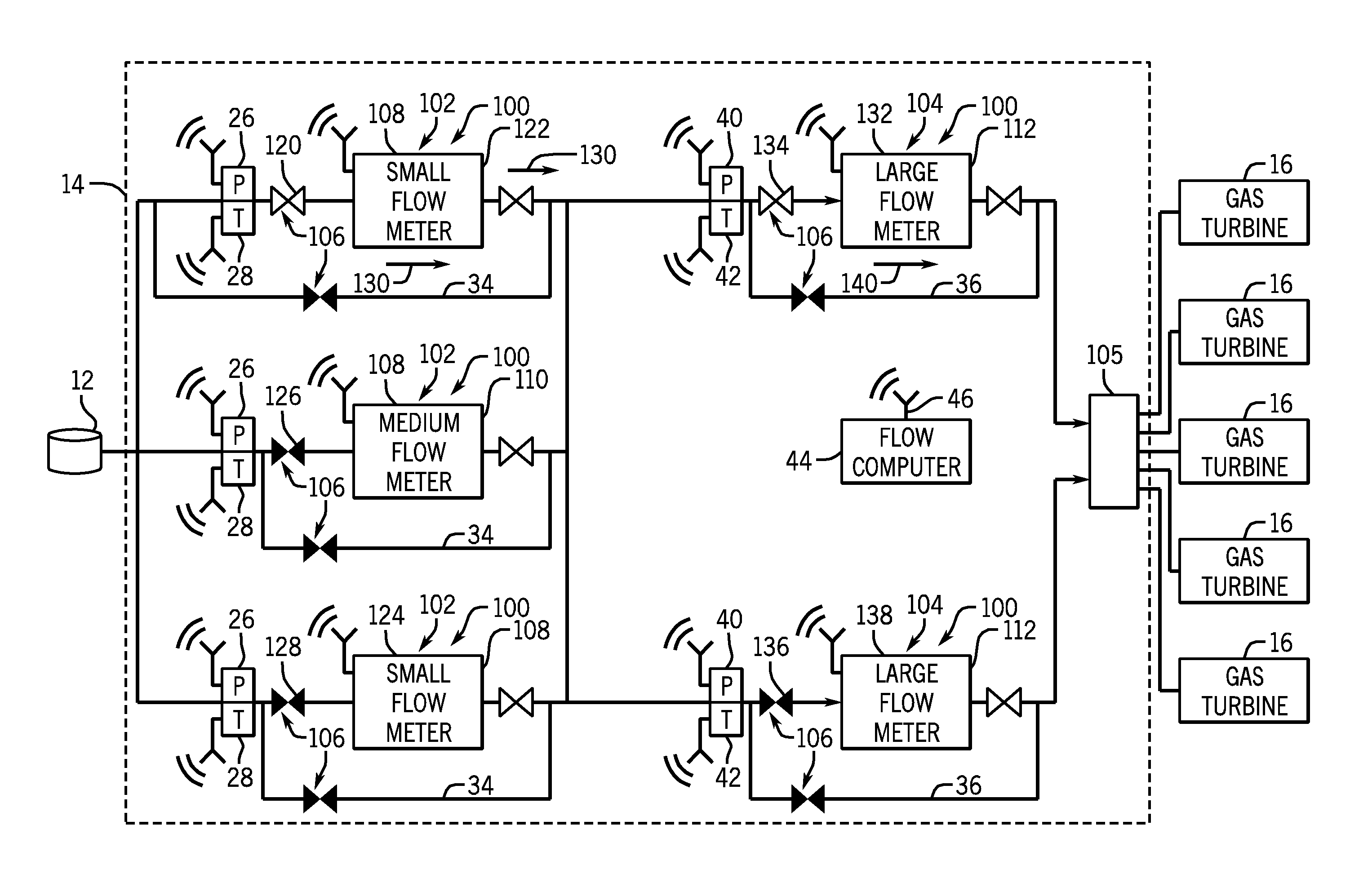

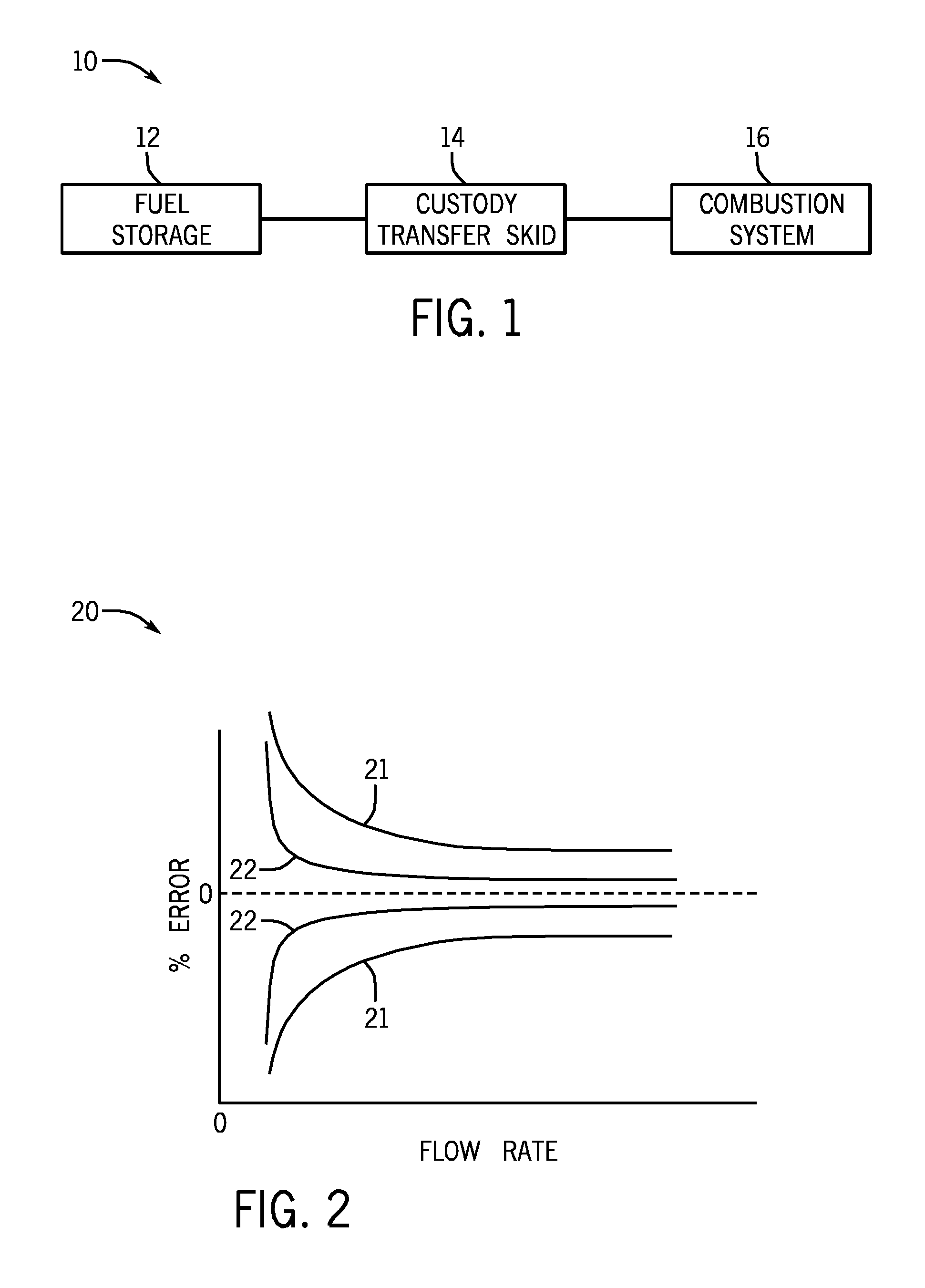

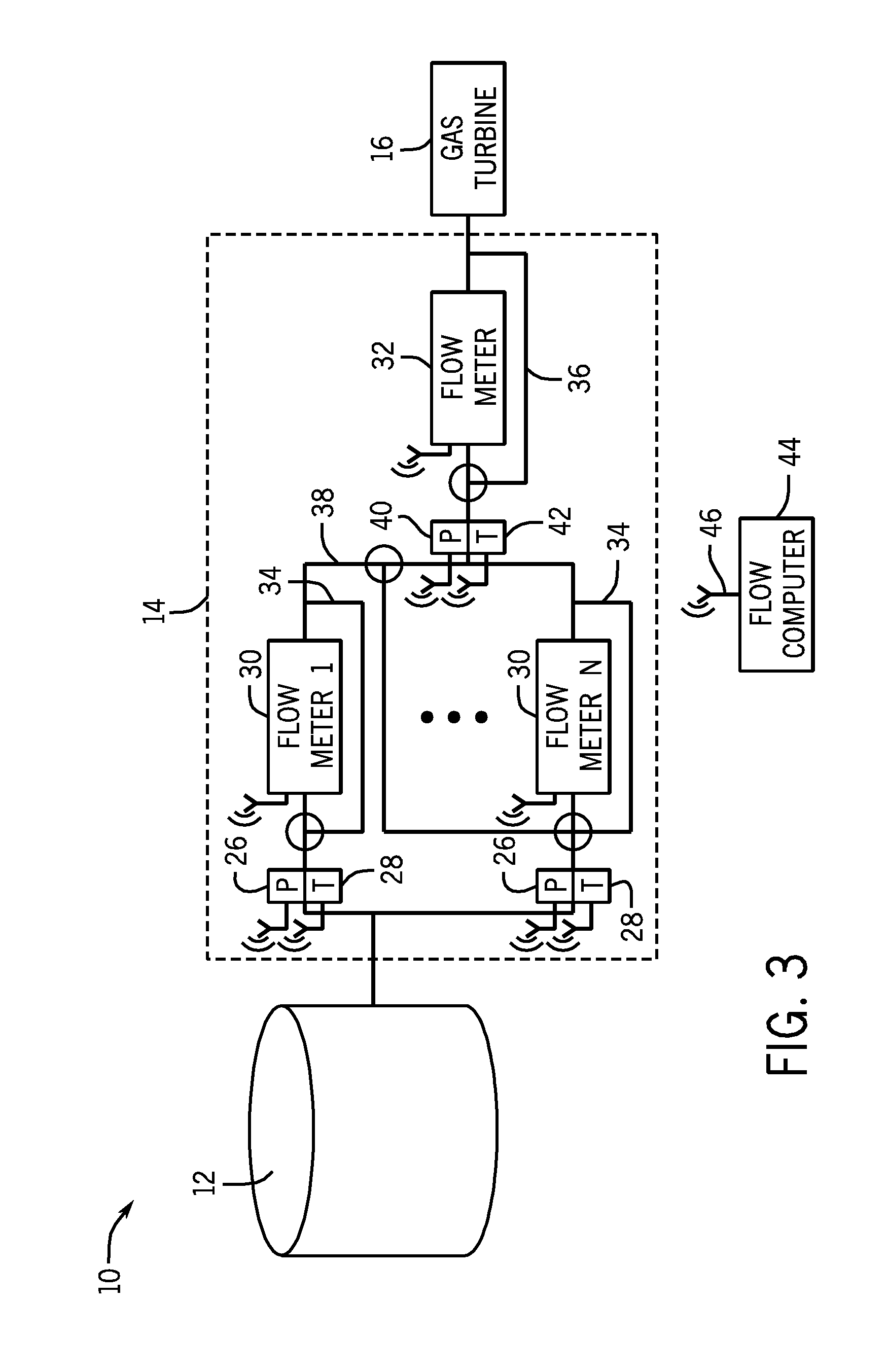

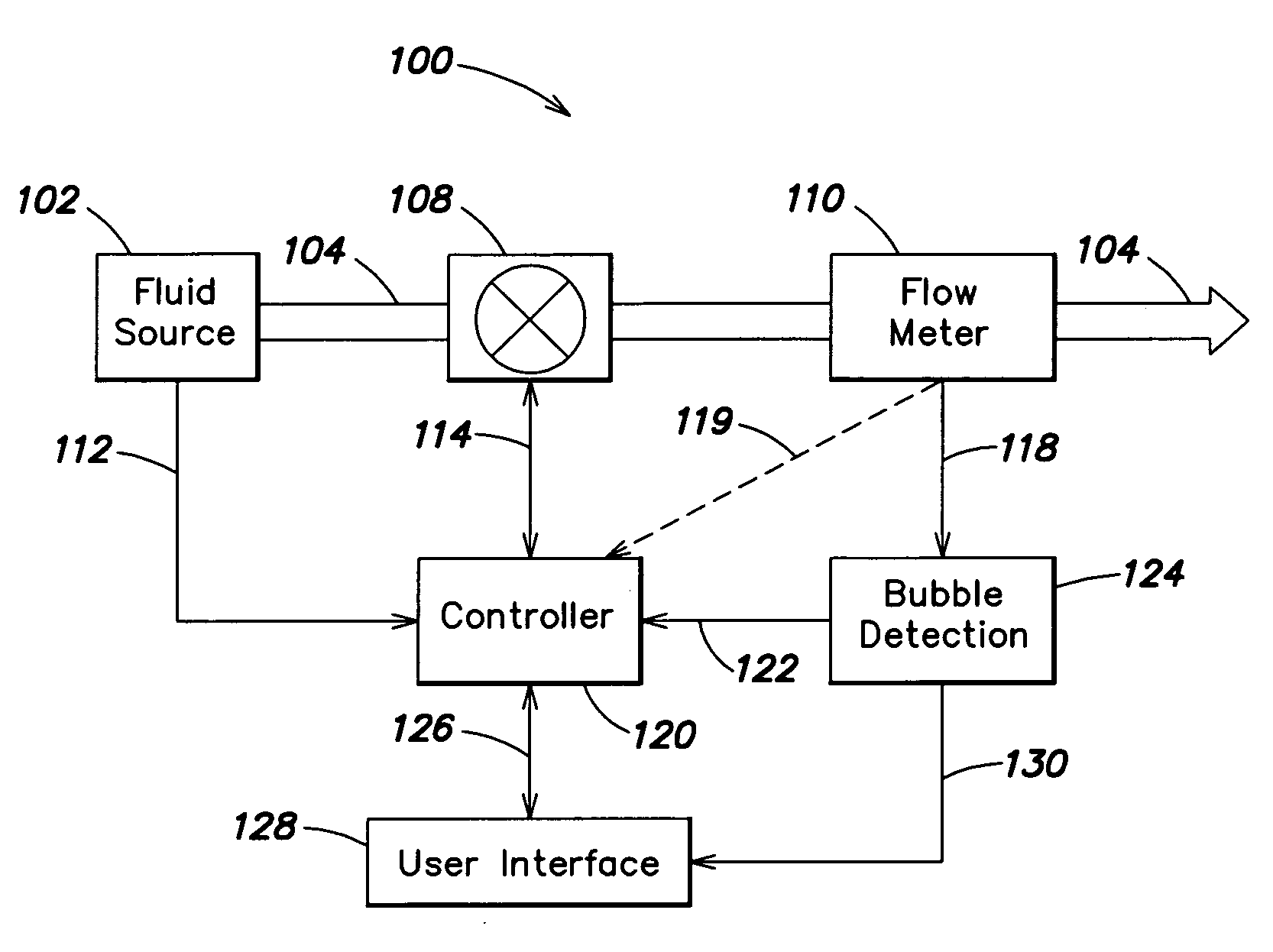

Custody transfer system and method for gas fuel

InactiveUS9175810B2Volume variation compensation/correction apparatusVolume flow proportion measurementTransfer systemProcess engineering

A system includes a custody transfer system configured to transfer a gas fuel from a gas supply to a plurality of gas turbines. The custody transfer system includes a first plurality of flow meters arranged in parallel with each other, wherein each of the first plurality of flow meters is configured to obtain a first measurement of a portion of a flow rate of the gas fuel flowing through the custody transfer system, and a second plurality of flow meters in series with the first plurality of flow meters, wherein each of the second plurality of flow meters is configured to obtain a second measurement of the flow rate of the gas fuel flowing through the custody transfer system, and wherein each of the first and second plurality of flow meters is configured to be blocked or unblocked from receiving the gas fuel based on a number of the plurality of gas turbines in operation.

Owner:GENERAL ELECTRIC CO

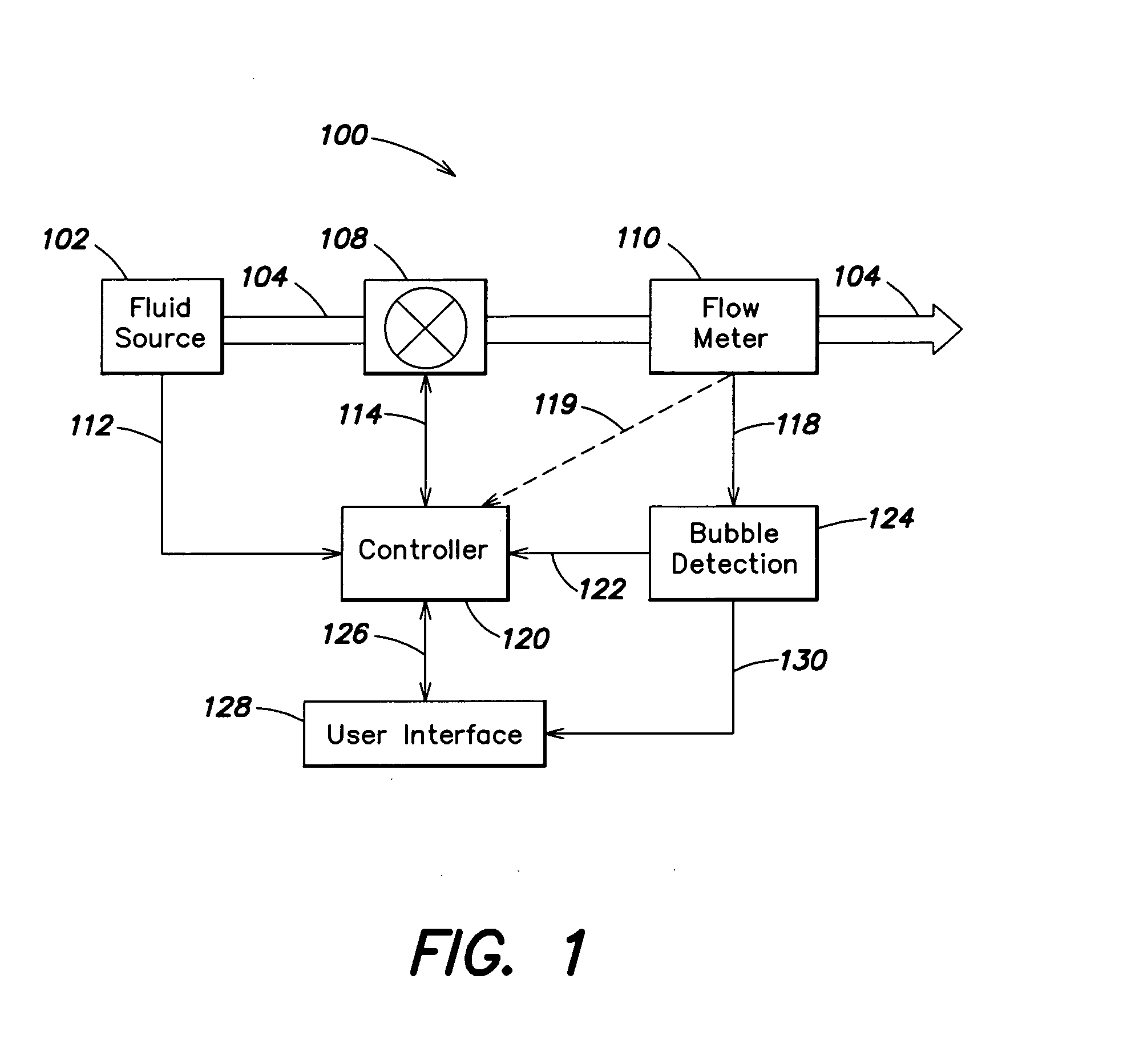

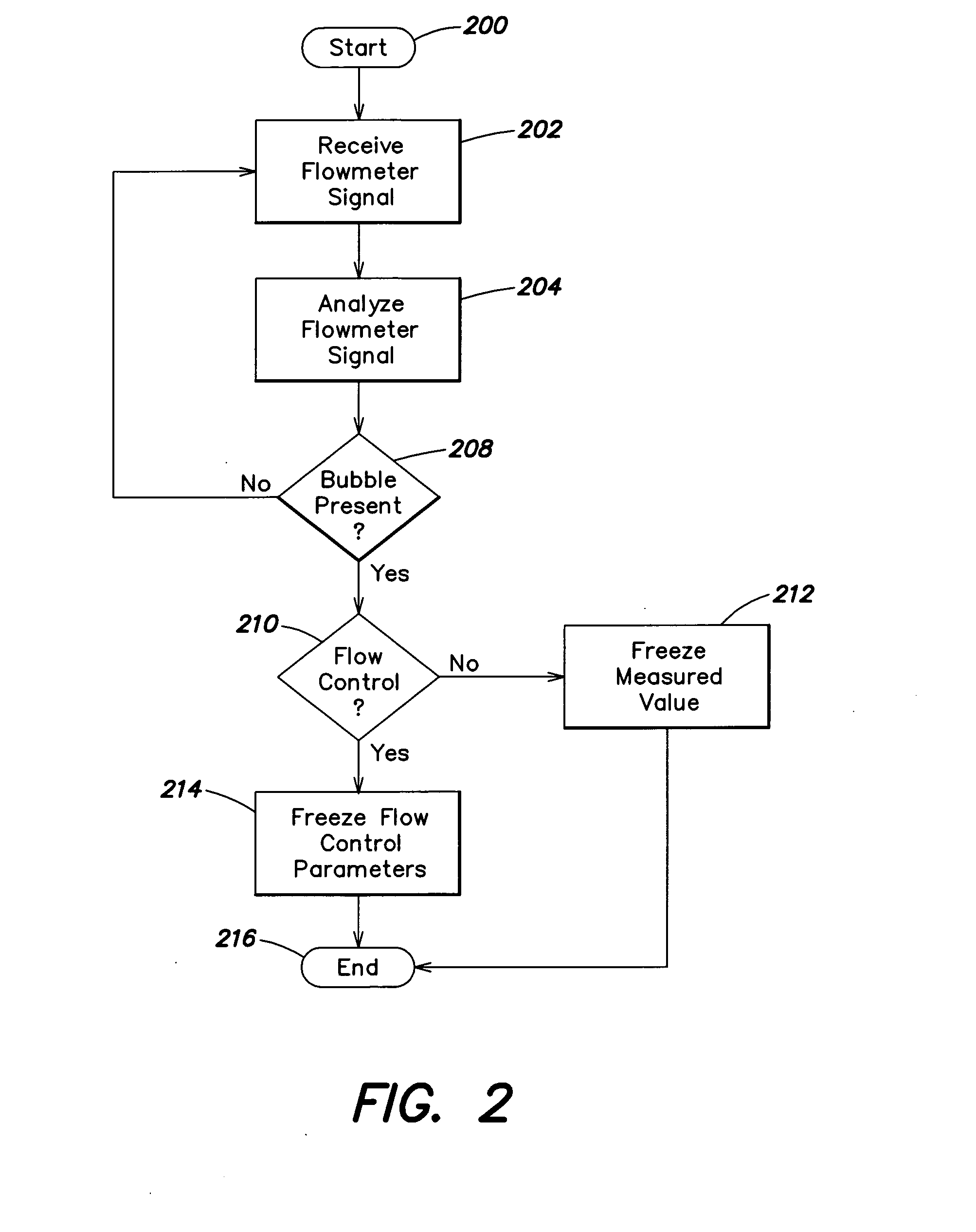

Flow measurement and control with bubble detection

InactiveUS20070191990A1Guaranteed uptimeMinimize impactVolume/mass flow measurementTesting/calibration for volume flowFlow transducerControl system

Systems and methods for liquid flow sensing and control for use with a variety of different types of liquid flow measurement and control systems. The liquid flow sensor system senses a flow signal indicative of the flow rate of the liquid flowing in a sensor conduit and analyzes the flow signal to determine, by detecting characteristic changes in the signal, whether a bubble is present in the sensor conduit. Where the system determines that a bubble is present, it may generate an alarm signal indicative of the presence of the bubble. A flow control system incorporating the flow sensor as a feedback source may respond to the detection of a bubble by temporarily freezing the flow control parameters until the bubble has exited the sensor conduit. The flow control system can implement procedures for clearing a bubble from the sensor conduit where the system detects that the bubble has become stuck.

Owner:CELERITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com