Patents

Literature

473 results about "Relative Change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In any quantitative science, the terms relative change and relative difference are used to compare two quantities while taking into account the "sizes" of the things being compared. The comparison is expressed as a ratio and is a unitless number. By multiplying these ratios by 100 they can be expressed as percentages so the terms percentage change, percent(age) difference, or relative percentage difference are also commonly used. The distinction between "change" and "difference" depends on whether or not one of the quantities being compared is considered a standard or reference or starting value. When this occurs, the term relative change (with respect to the reference value) is used and otherwise the term relative difference is preferred. Relative difference is often used as a quantitative indicator of quality assurance and quality control for repeated measurements where the outcomes are expected to be the same. A special case of percent change (relative change expressed as a percentage) called percent error occurs in measuring situations where the reference value is the accepted or actual value (perhaps theoretically determined) and the value being compared to it is experimentally determined (by measurement).

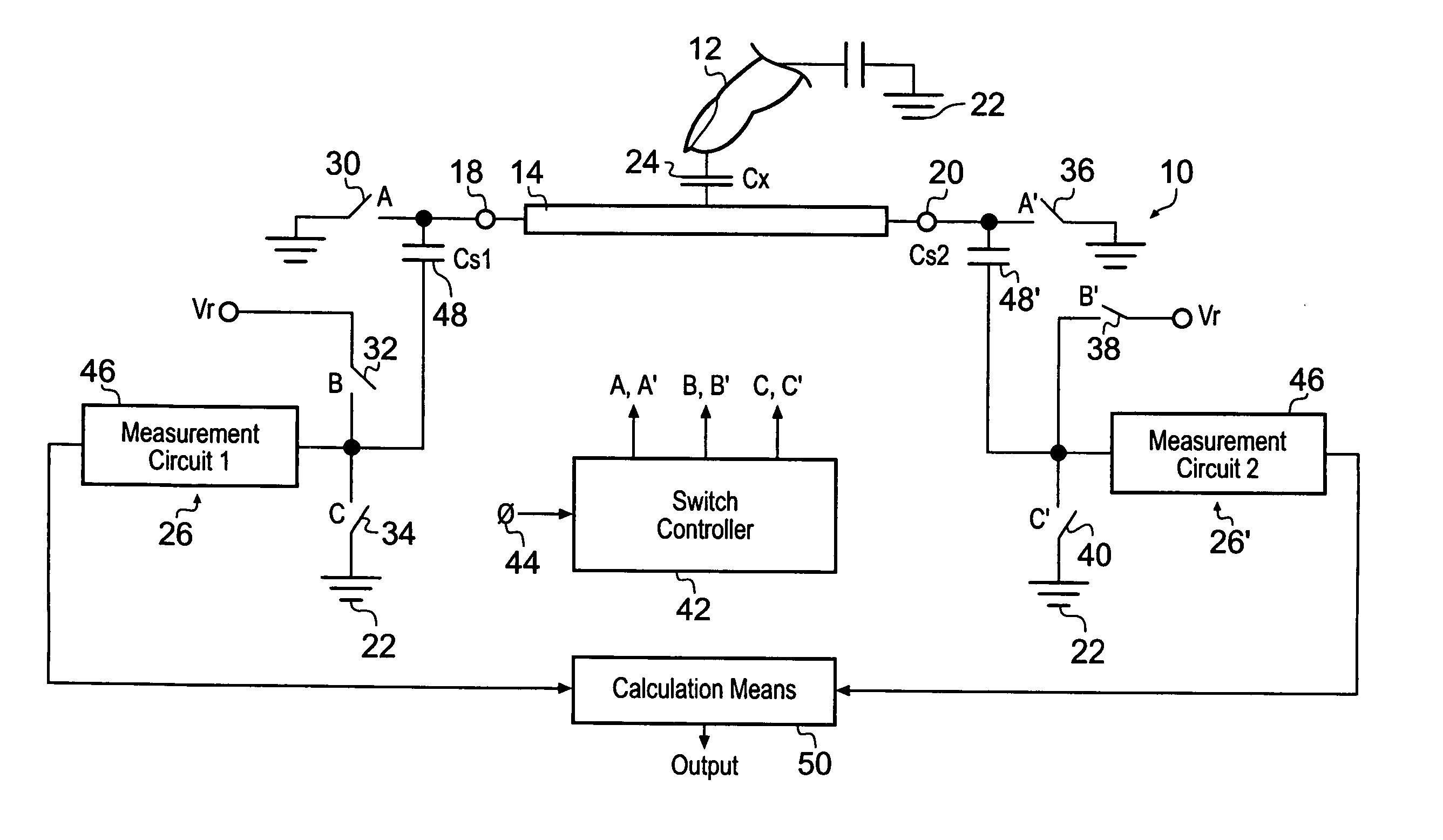

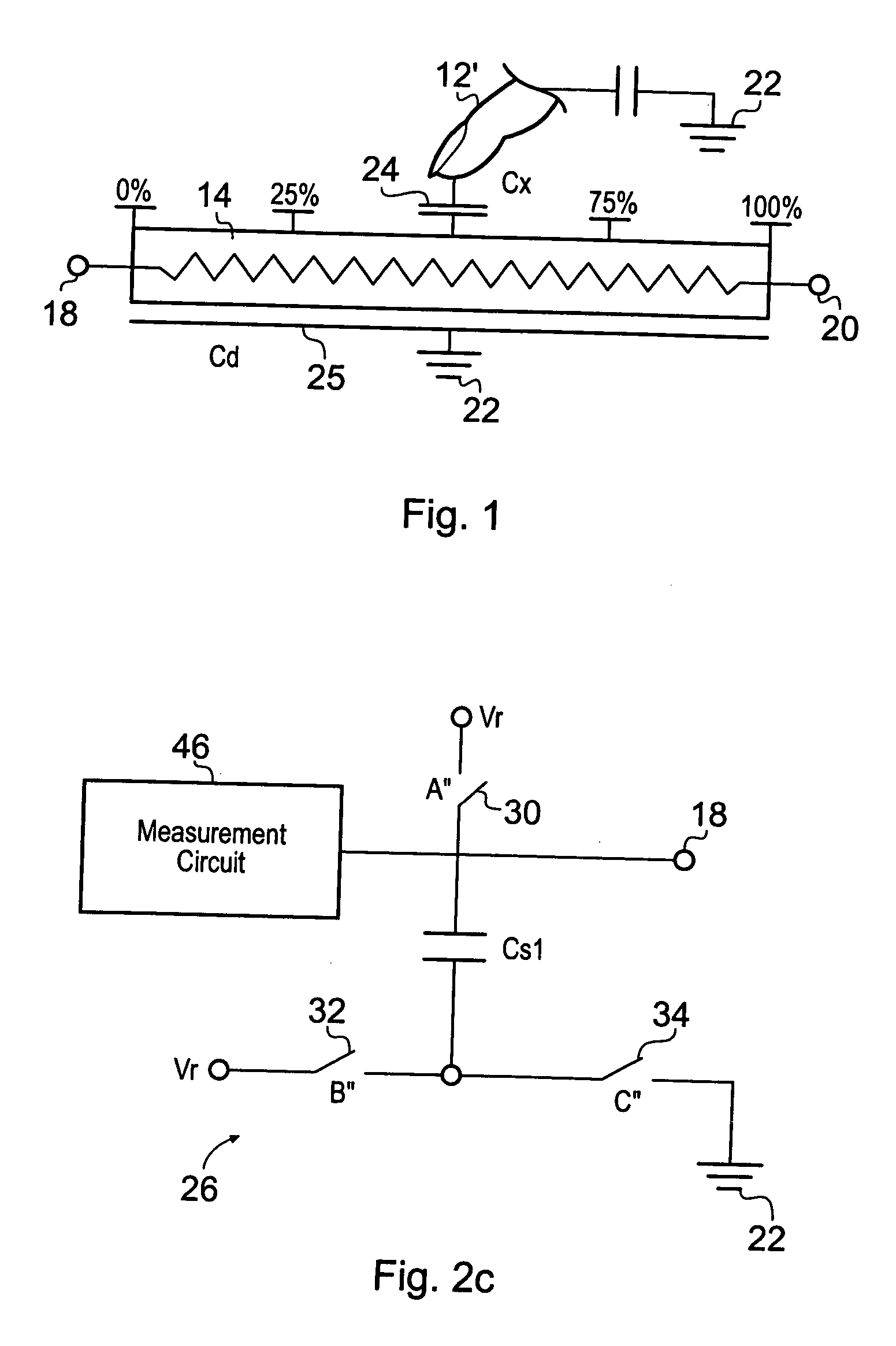

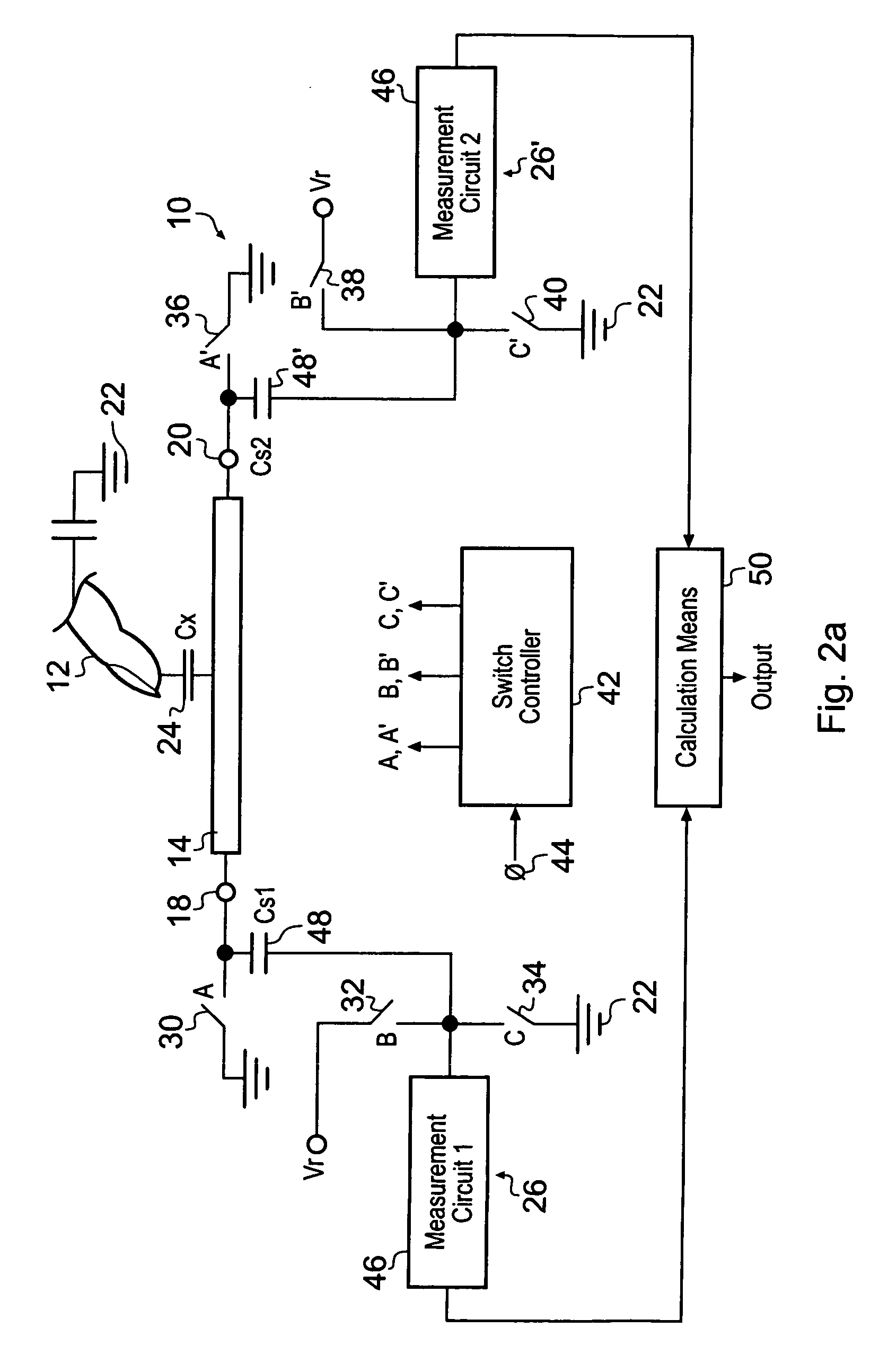

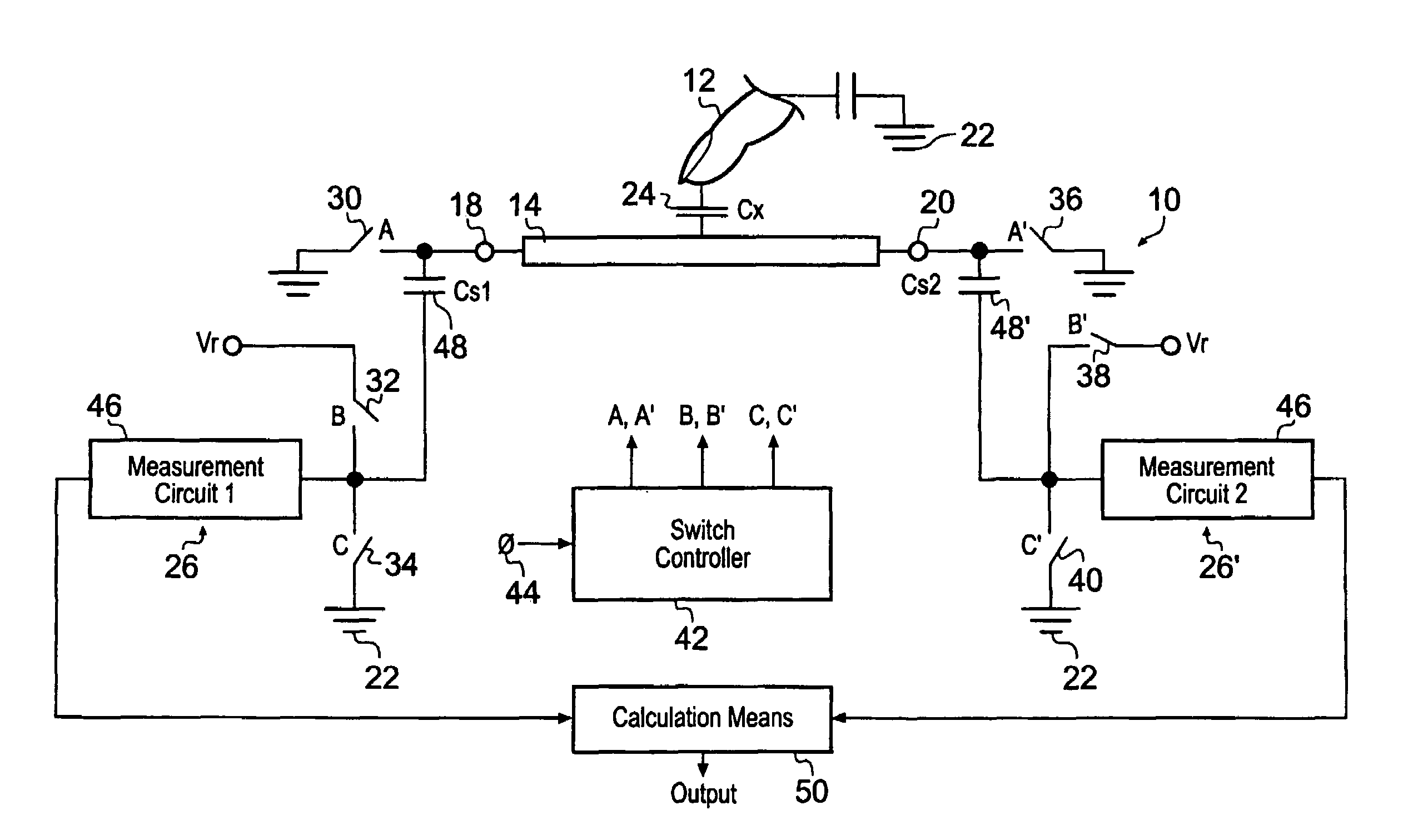

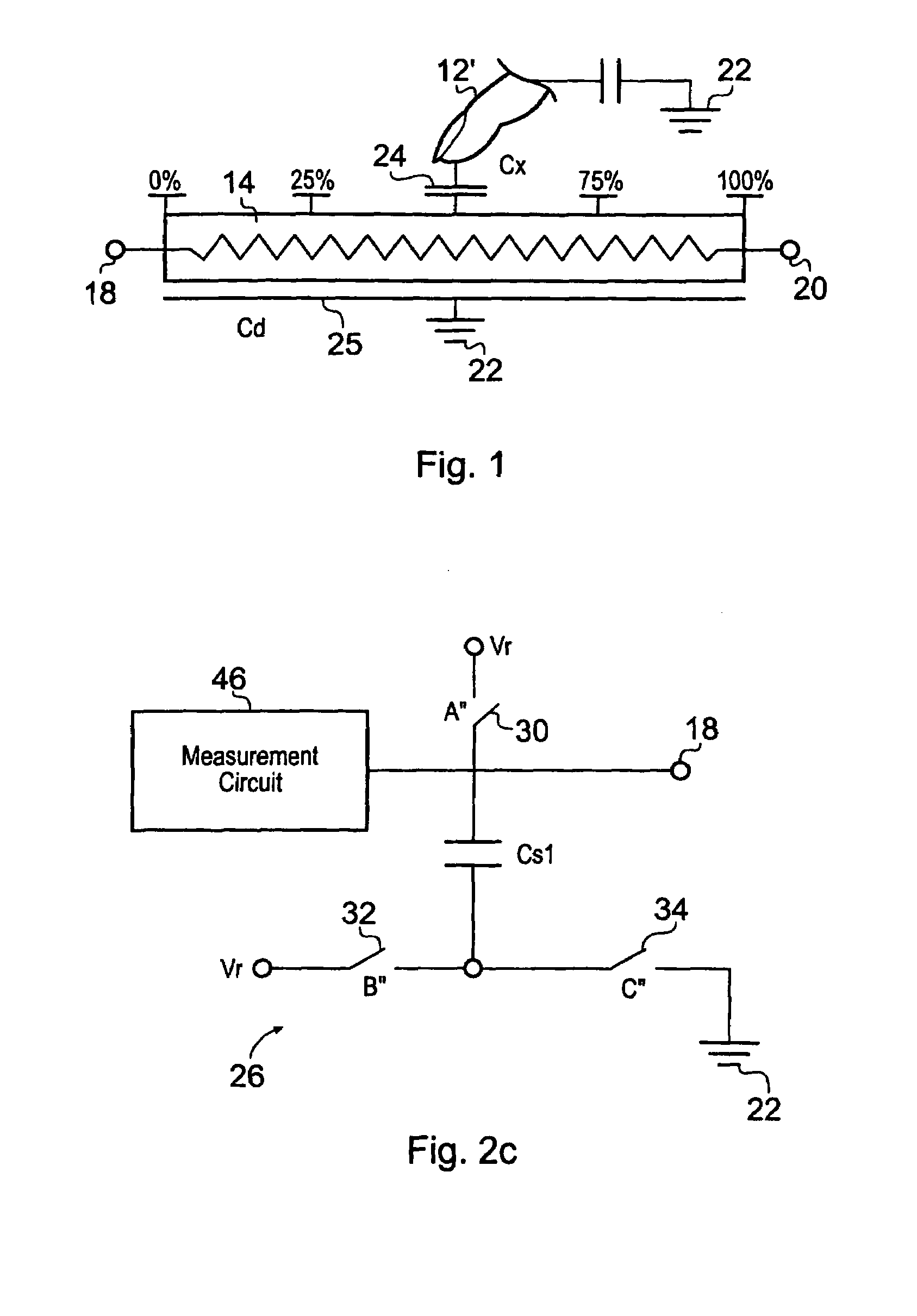

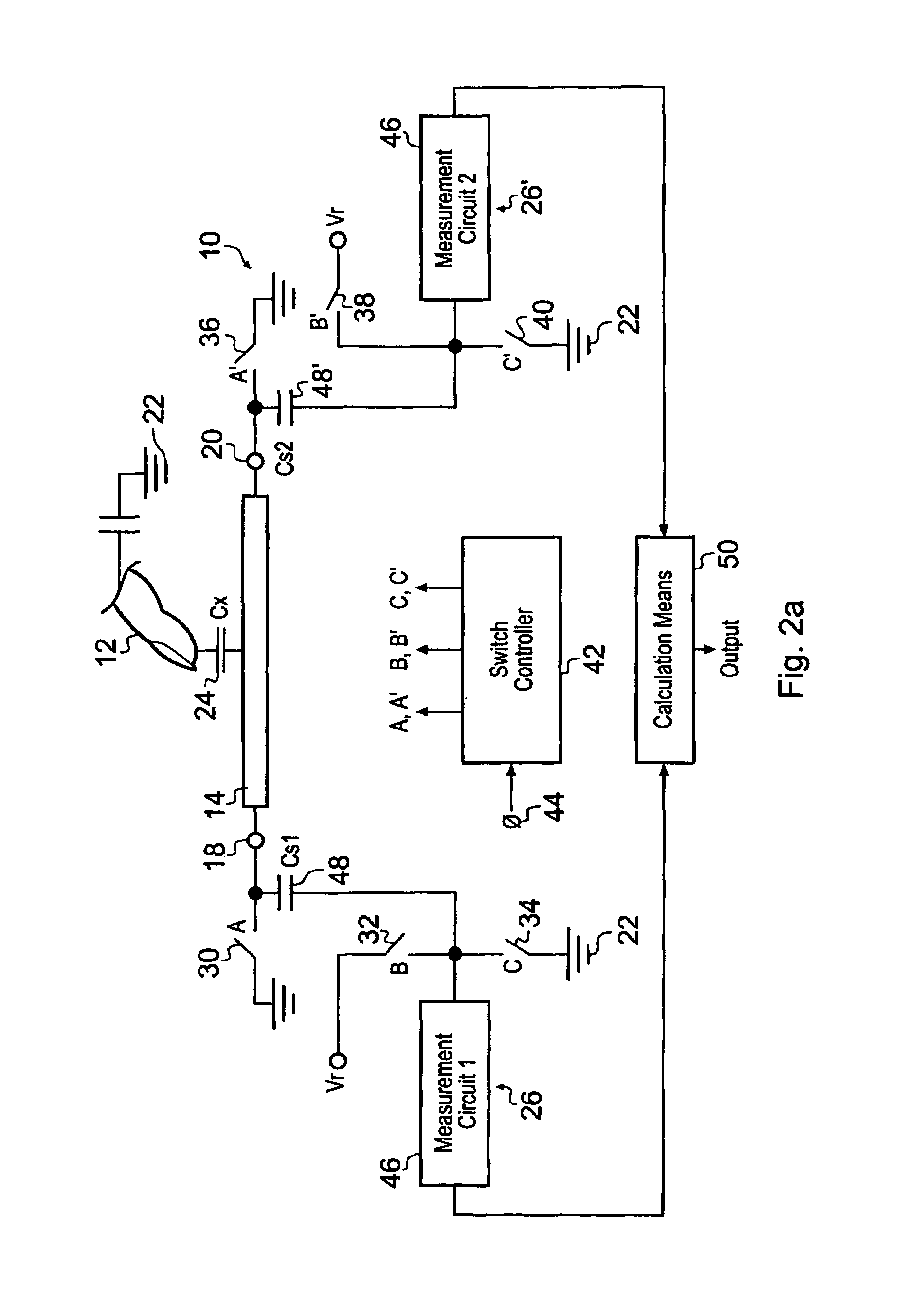

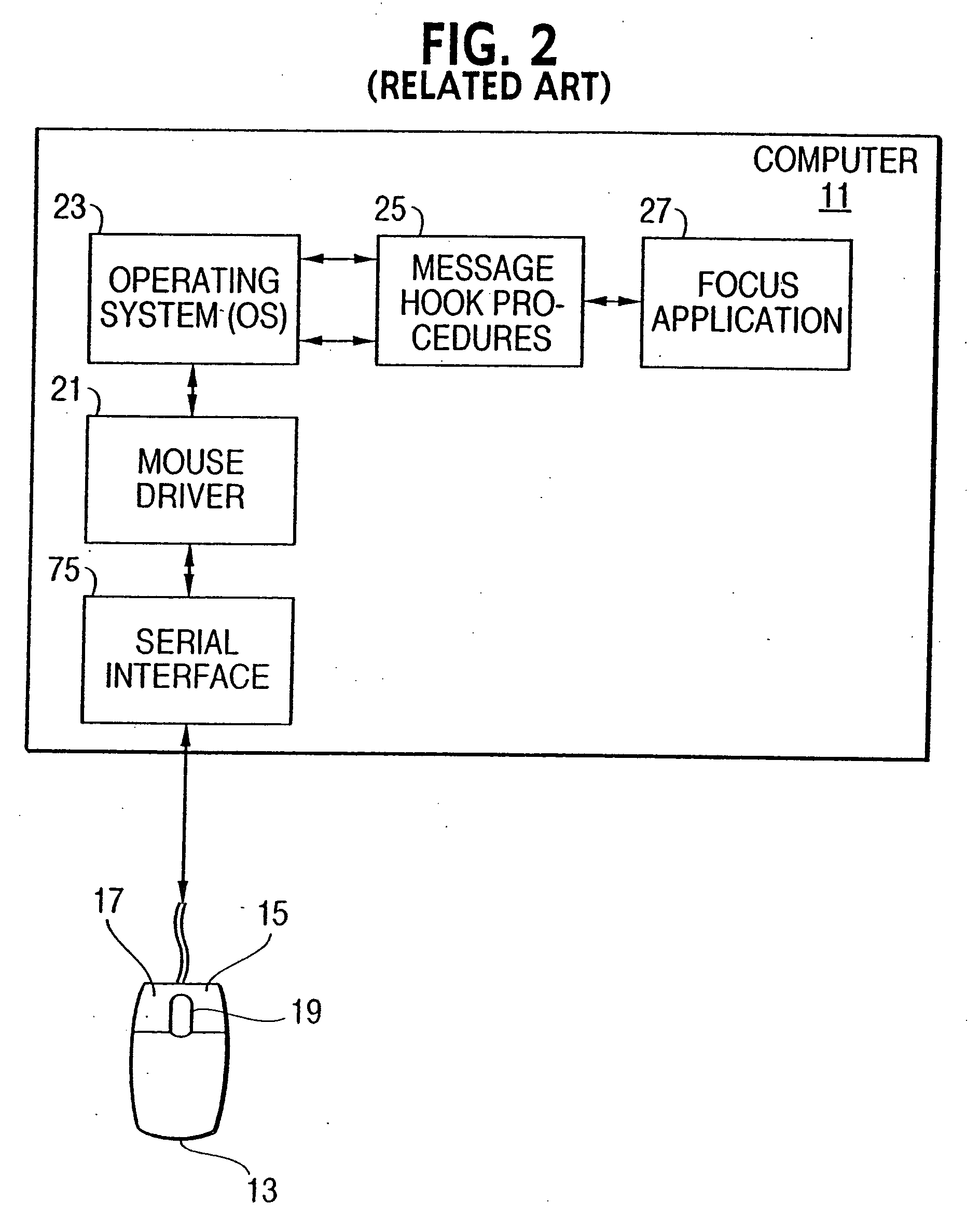

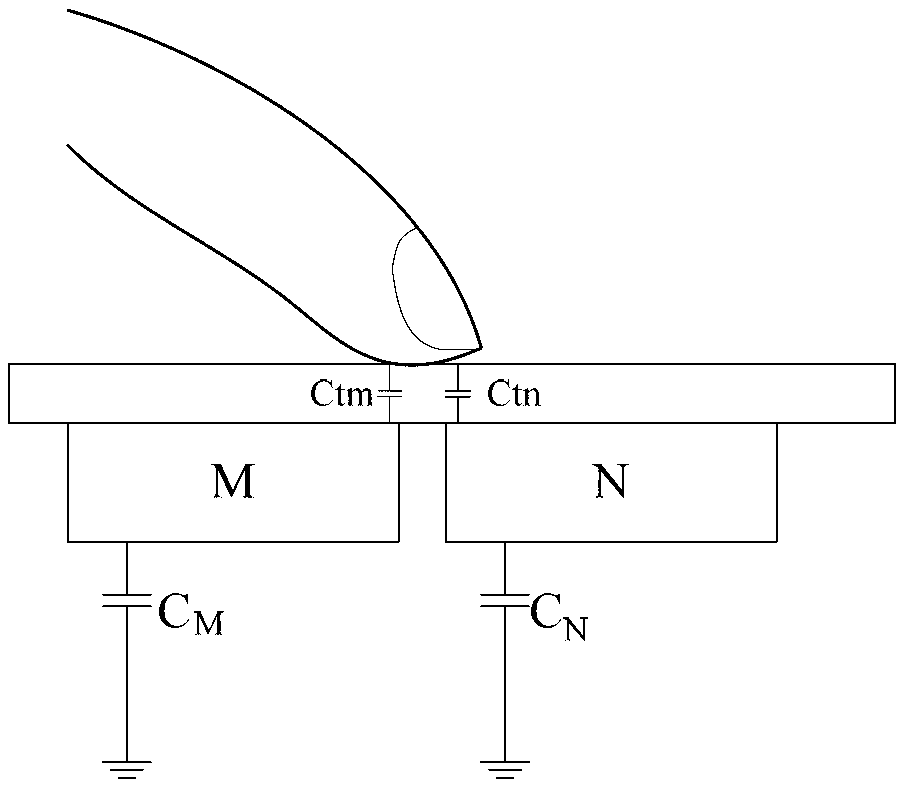

Charge transfer capacitive position sensor

ActiveUS20040104826A1Small sizeDistributed capacitance increasesInput/output for user-computer interactionElectronic switchingCapacitanceEngineering

Owner:ATMEL CORP

Charge transfer capacitive position sensor

InactiveUS7148704B2Small sizePrecise positioningInput/output for user-computer interactionResistance/reactance/impedenceCapacitanceRelative Change

Owner:ATMEL CORP

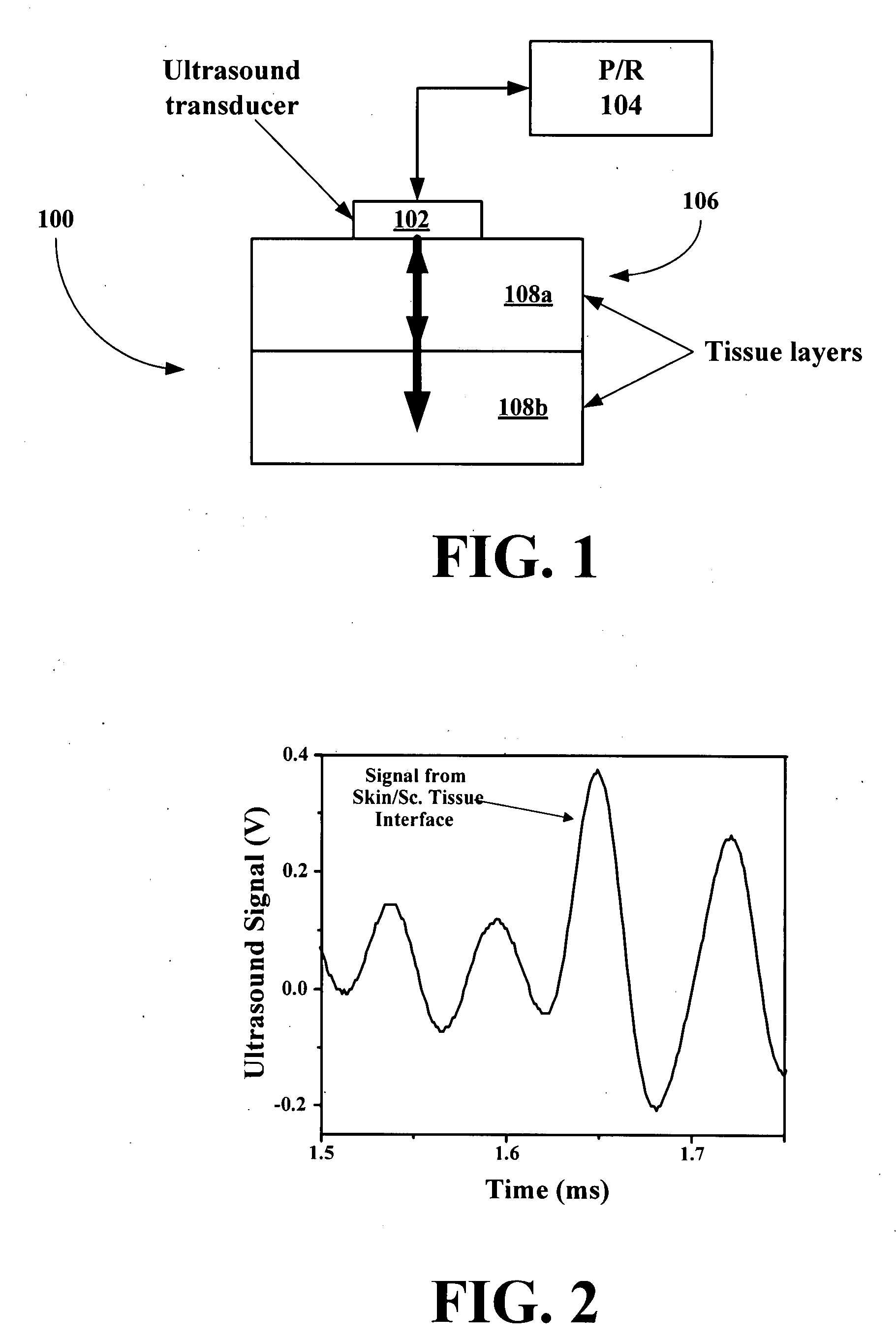

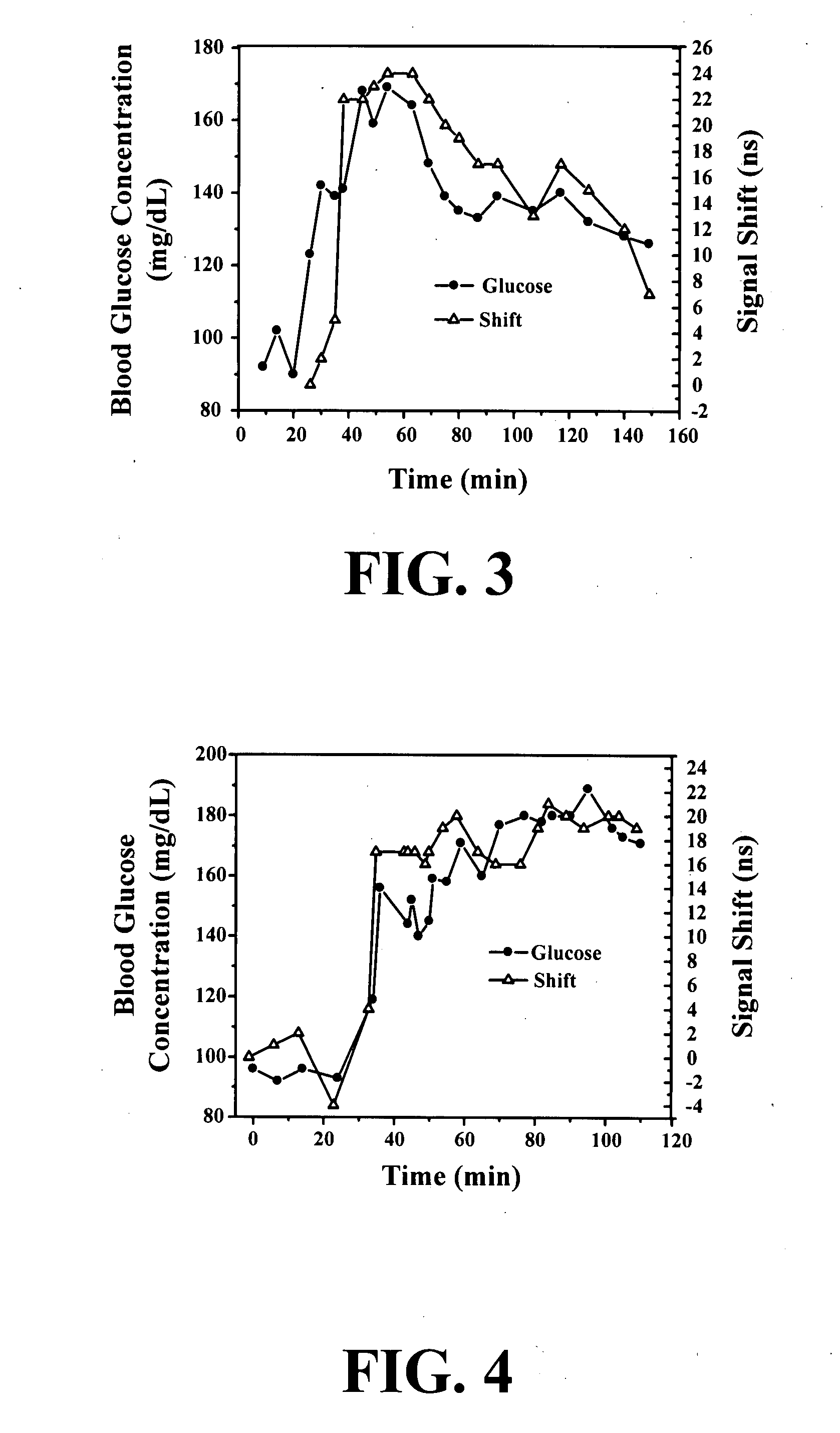

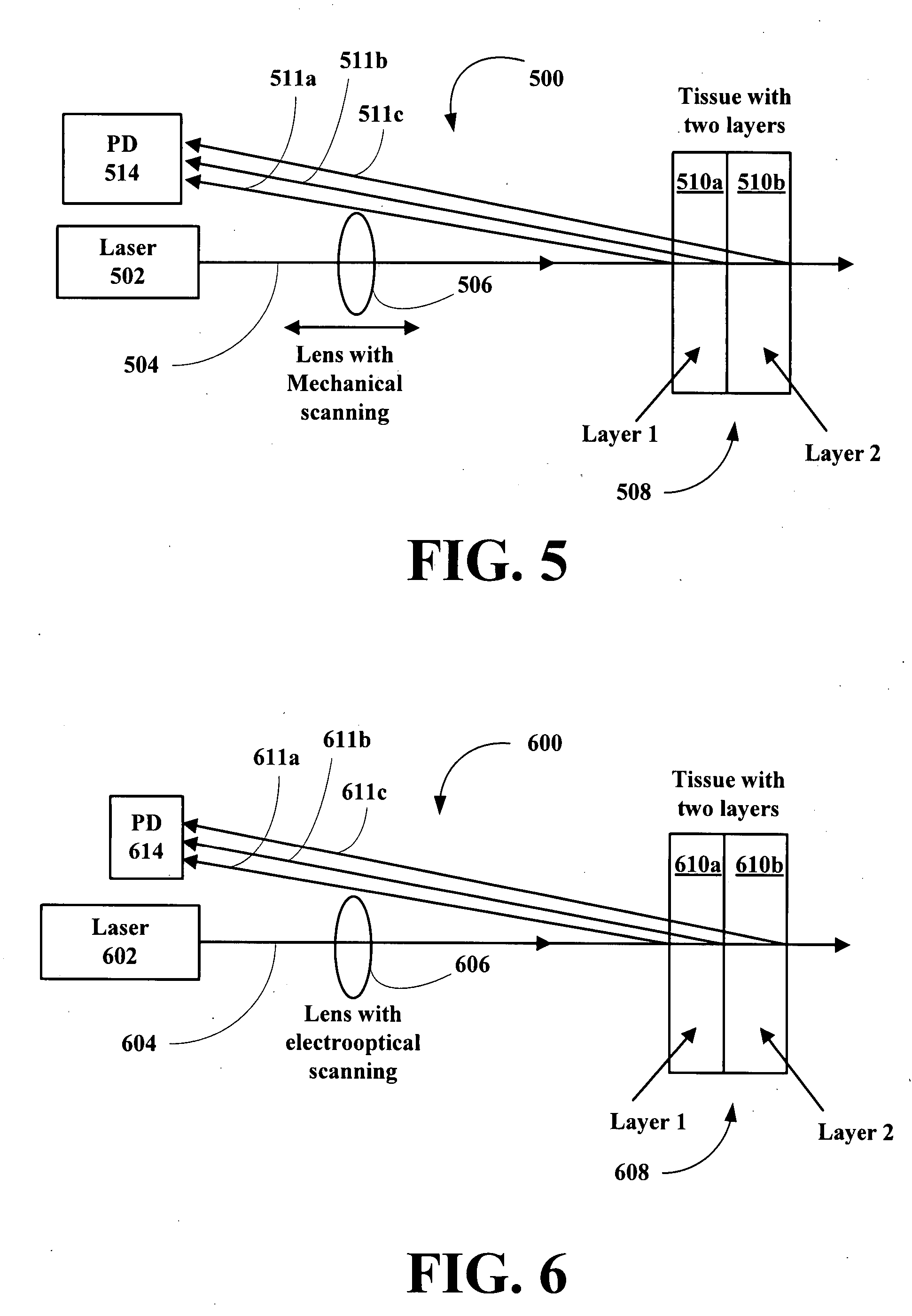

Noninvasive glucose sensing methods and systems

ActiveUS20070255141A1Reduce complicationsReduce mortalityUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsMedicineD-Glucose

New methods and systems for noninvasive glucose monitoring and sensing with electromagnetic waves or ultrasound are disclosed. The methods are based on absolute or relative measurement of tissue dimensions (or changes in the dimensions) including, but not limited to: thickness, length, width, diameter, curvature, roughness as well as time of flight of ultrasound and optical pulses and optical thickness, which change with changing blood glucose concentrations. By measuring noninvasively absolute or relative changes in at least one dimension of at least one tissue or tissue layer or absolute or relative changes in time of flight of ultrasound or optical pulses, one can monitor blood glucose concentration noninvasively.

Owner:ESENALIEV RINAT O +1

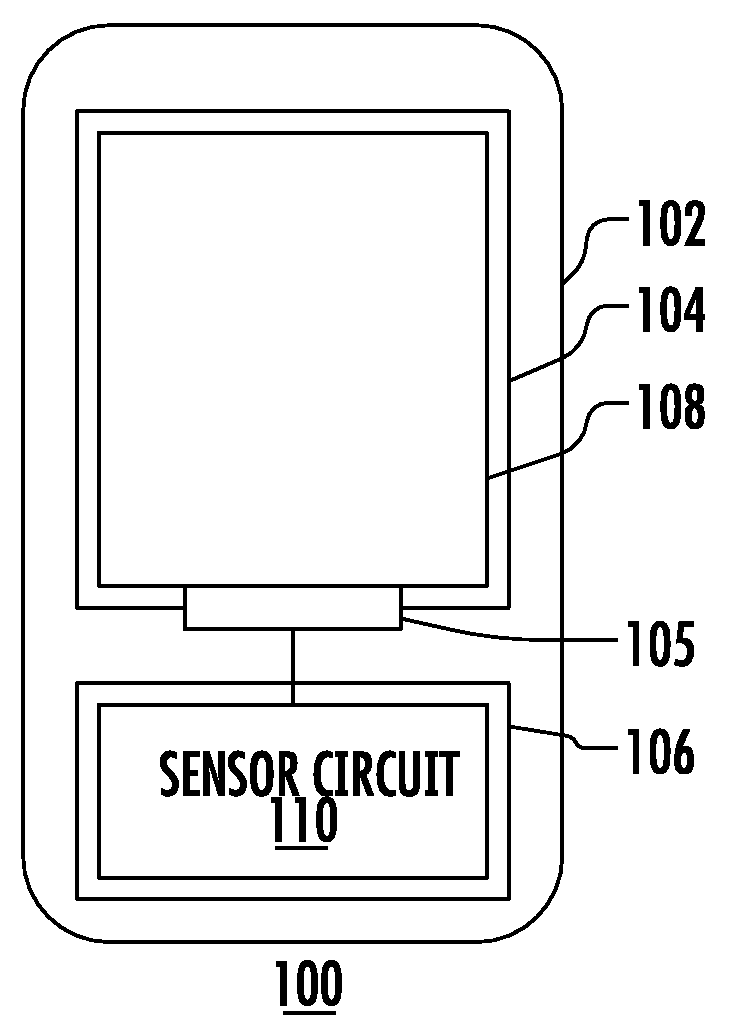

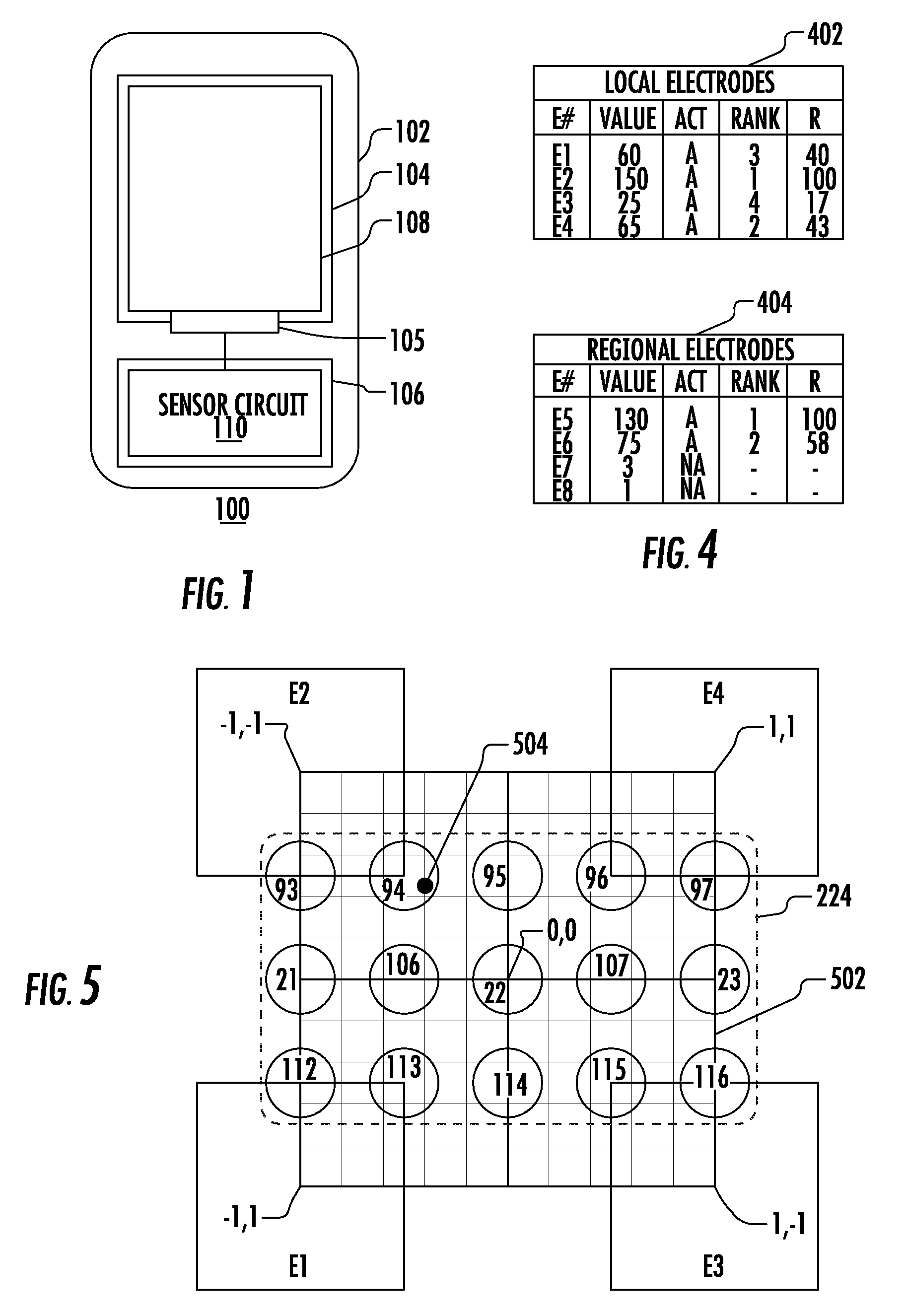

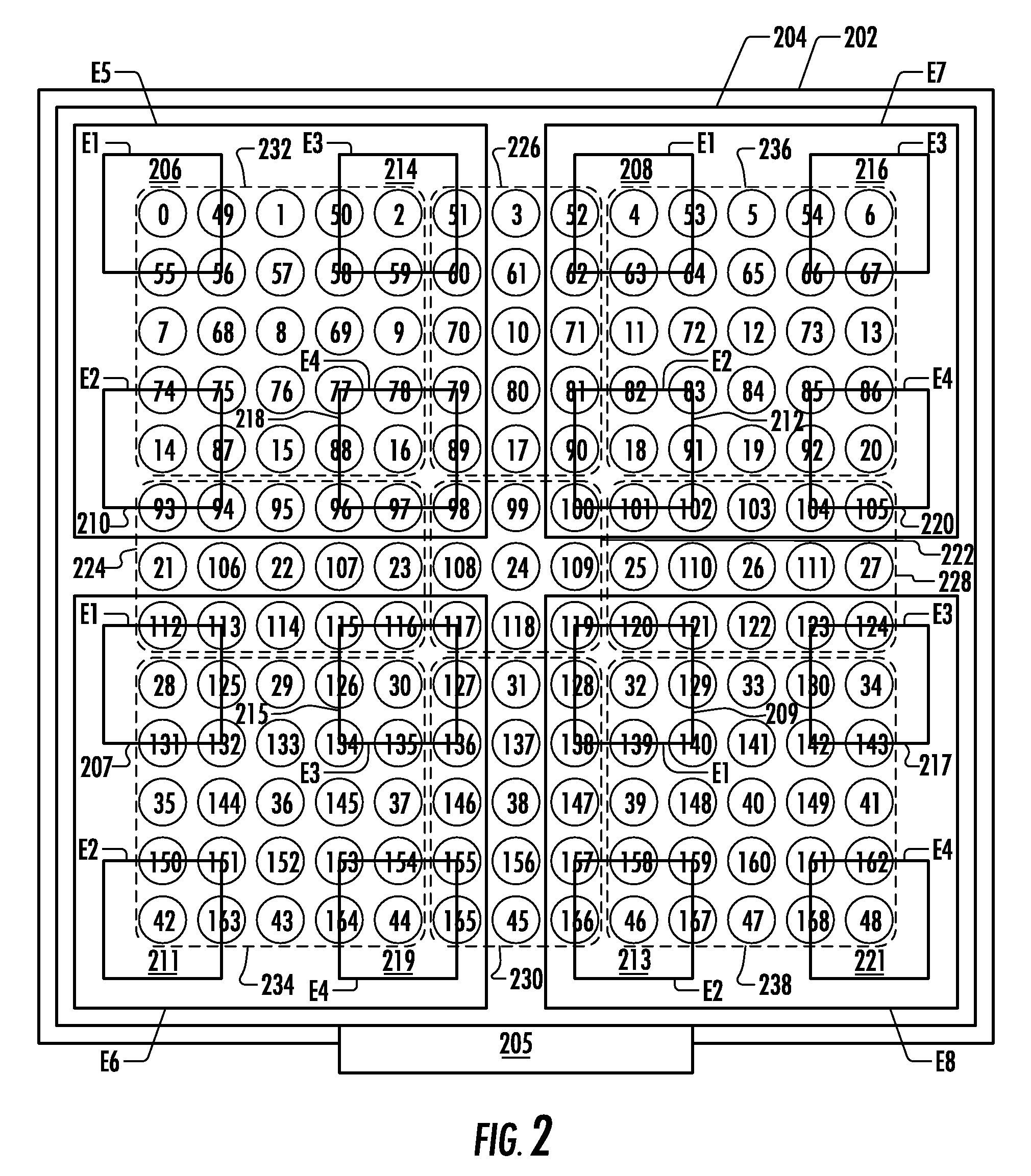

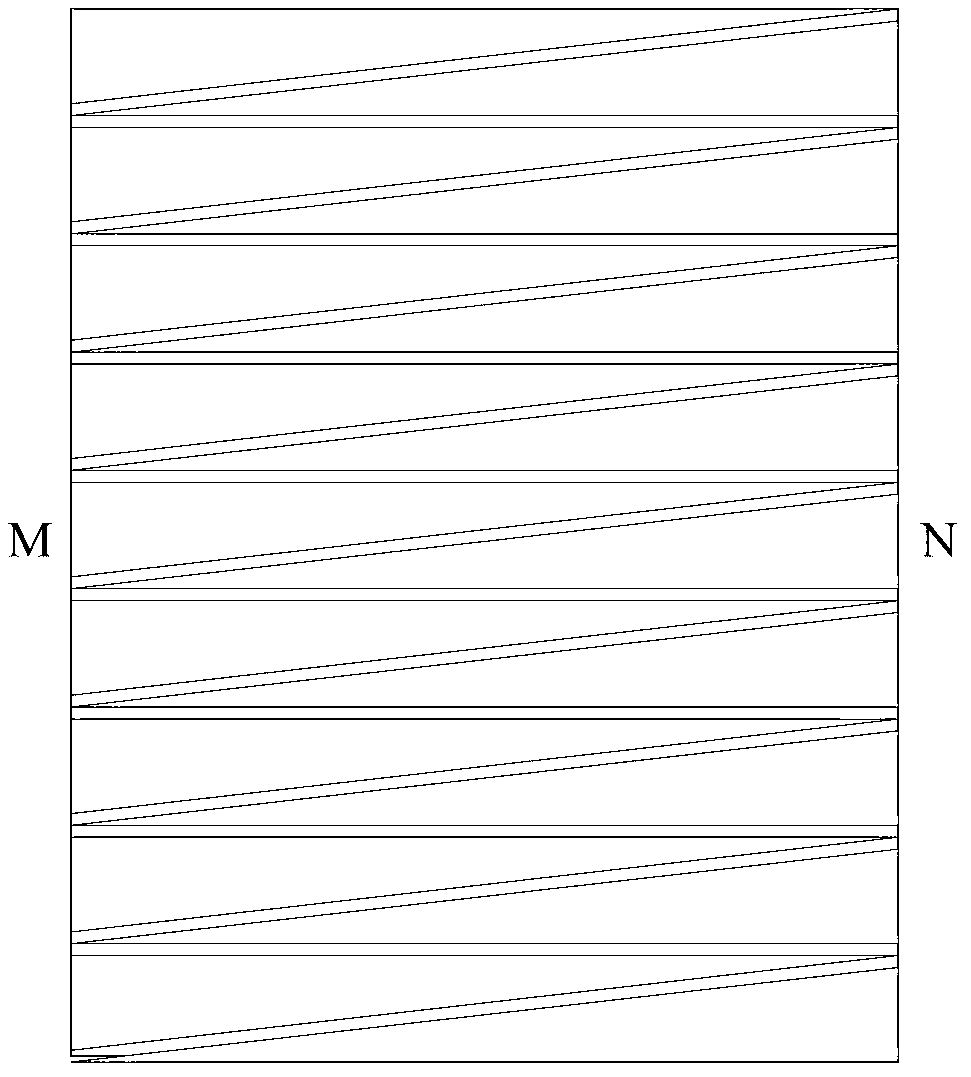

Touch sensor panel using regional and local electrodes to increase number of sense locations

InactiveUS20100134422A1Input/output processes for data processingRelative ChangeElectrical and Electronics engineering

An input sensor for an electronic device which includes a touch sensor panel, multiple electrodes and a sensor circuit. The electrodes include multiple regional electrodes and multiple local electrodes. Each regional electrode covers a corresponding region of the touch sensor panel and each local electrode includes multiple pads including one pad located within each of the regional electrodes. The electrodes are distributed so that a touch anywhere across the touch sensor panel is detected by at least one regional electrode and at least one local electrode. A sensor circuit determines a value for each of the electrodes indicating relative change, and compares relative values of the electrodes to identify a location of a touch of the touch sensor panel. The regional electrodes are used to determine a region of a touch and the local electrodes are used to determine a more specific touch location within the determined region.

Owner:NORTH STAR INNOVATIONS

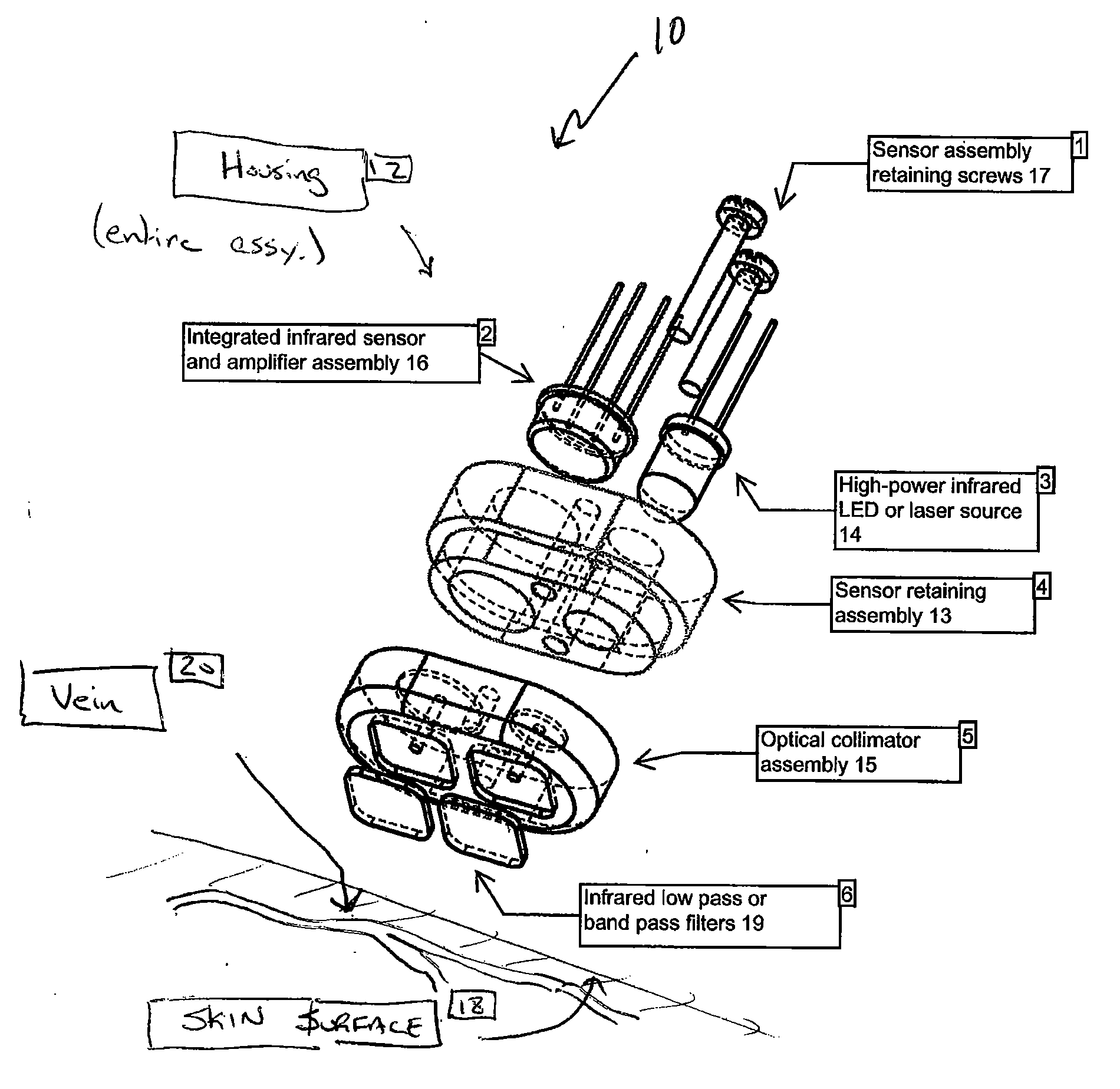

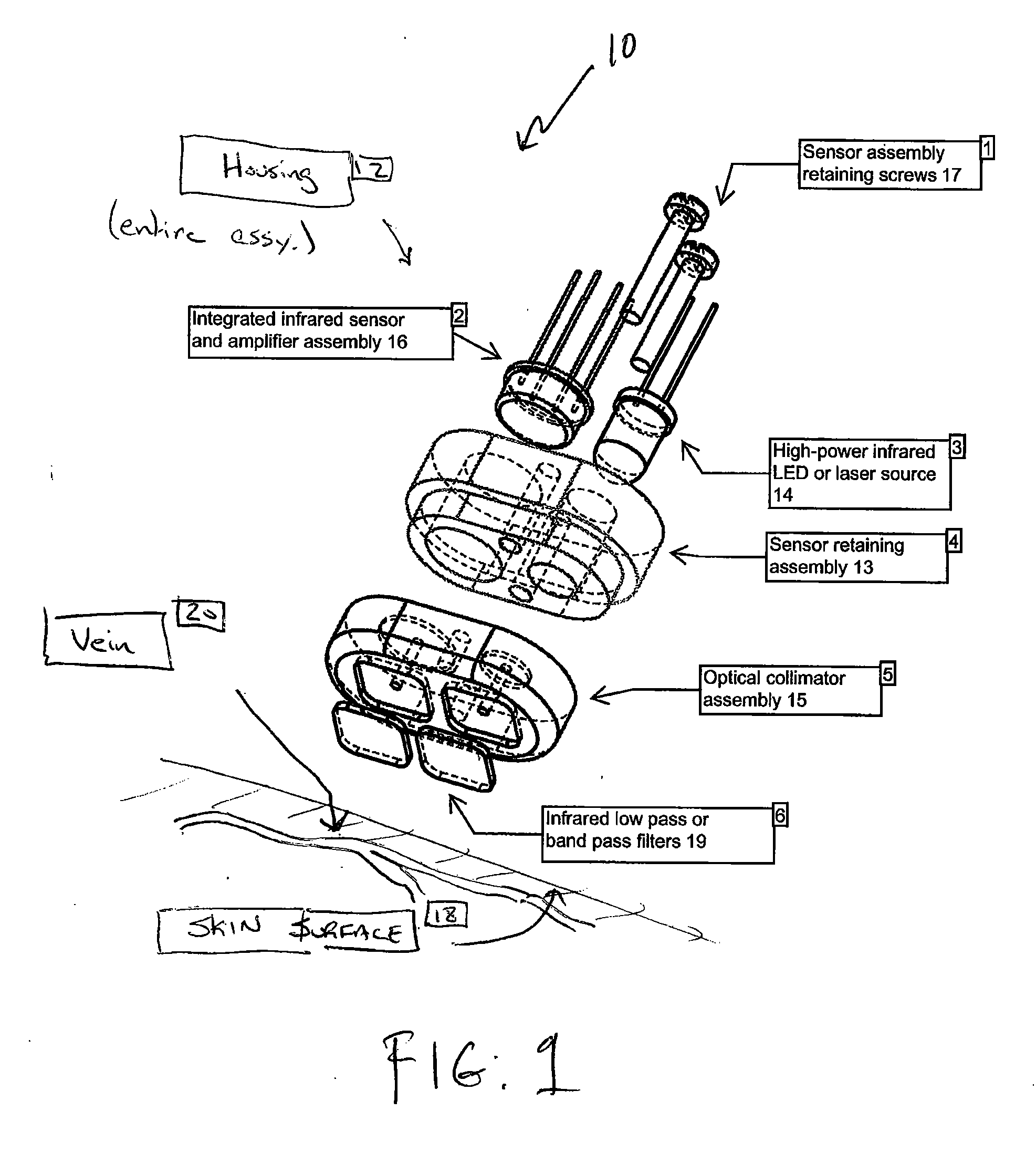

Vein locating device for vascular access procedures

InactiveUS20080147147A1Improve abilitiesLocation can be detectedUltrasonic/sonic/infrasonic diagnosticsDiagnostics using lightMedicineOptical energy

A device for detecting a venous structure or vessels in a patient or animal. The device includes an optical source for transmitting optical energy into the tissue of the patient, an optical detector for detecting at least a portion of the optical energy that is transmitted into and reflected by the tissue, and an indicator operably associated with the optical source and the optical detector. The indicator is adapted to indicate relative changes in the detected reflection or scattering of the optical energy transmitted into the tissue of the patient.

Owner:MEDRAD INC.

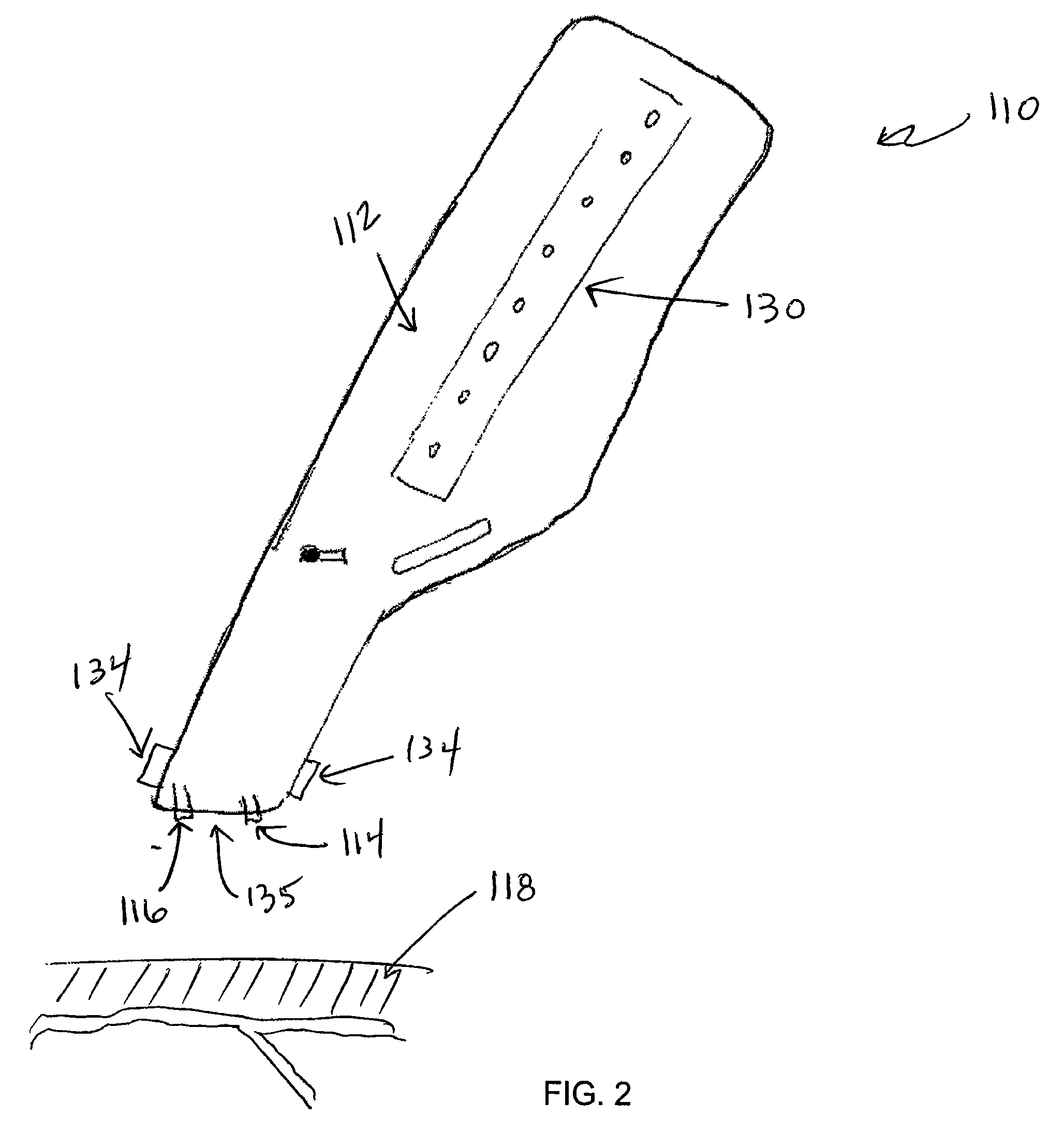

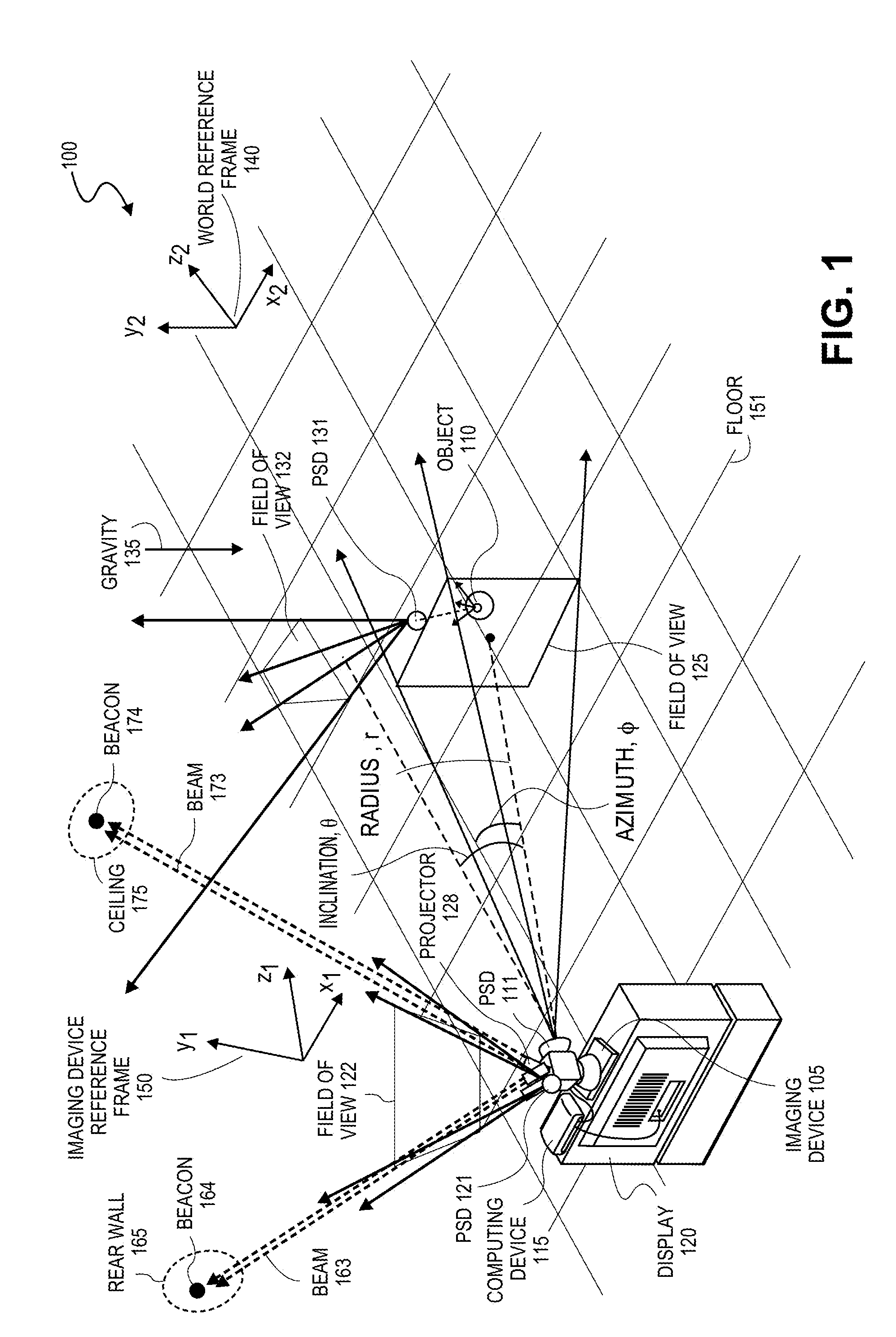

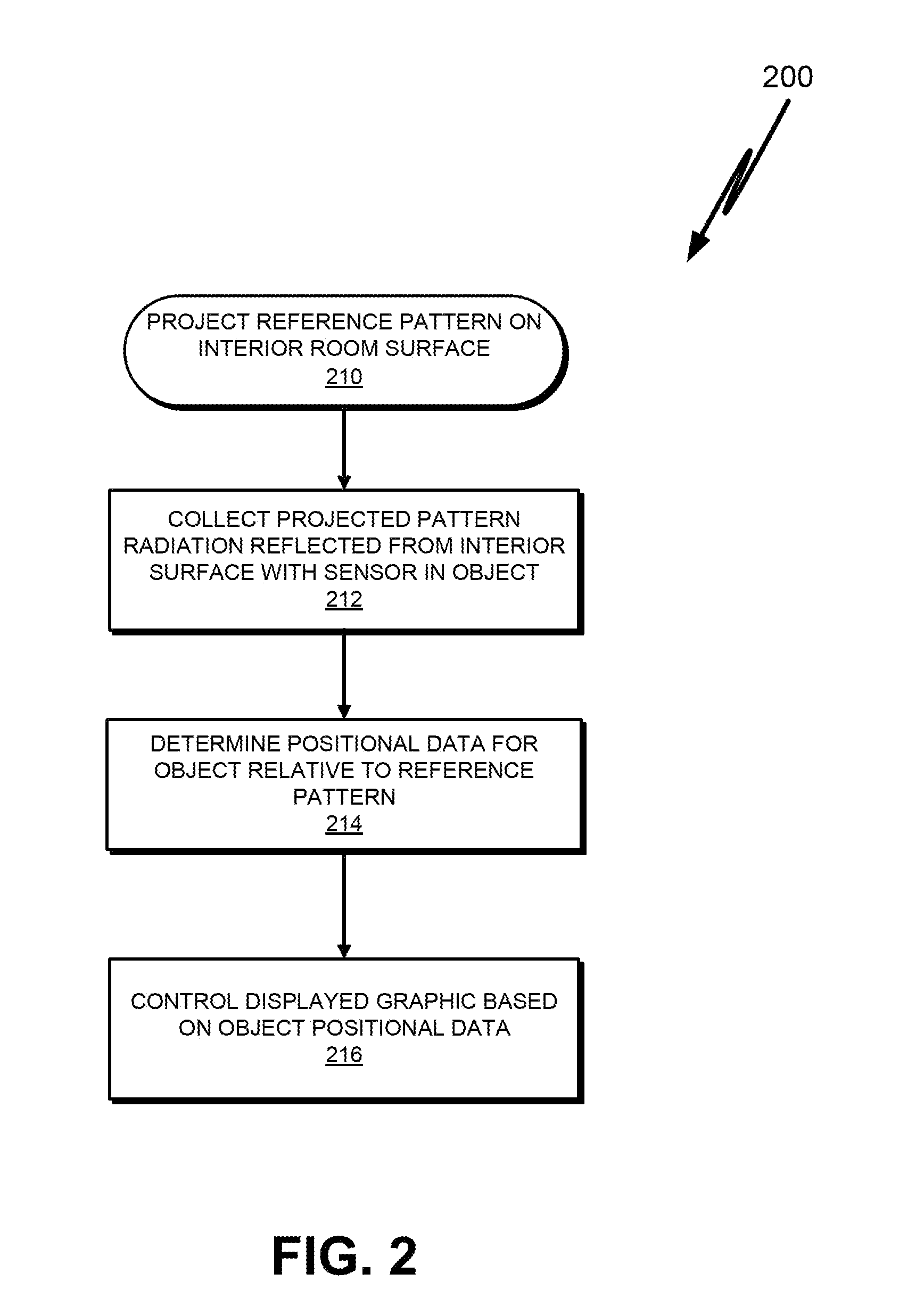

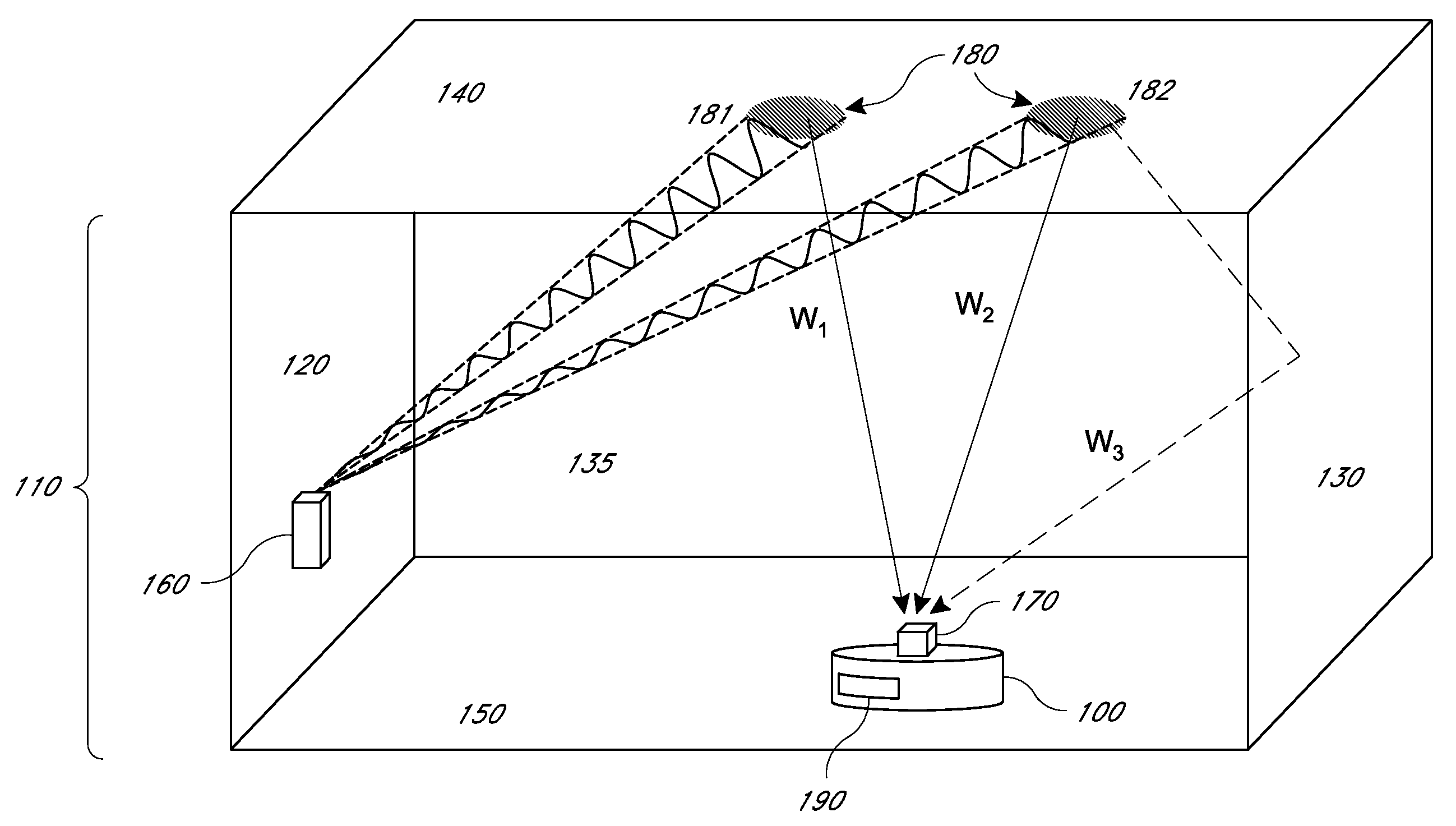

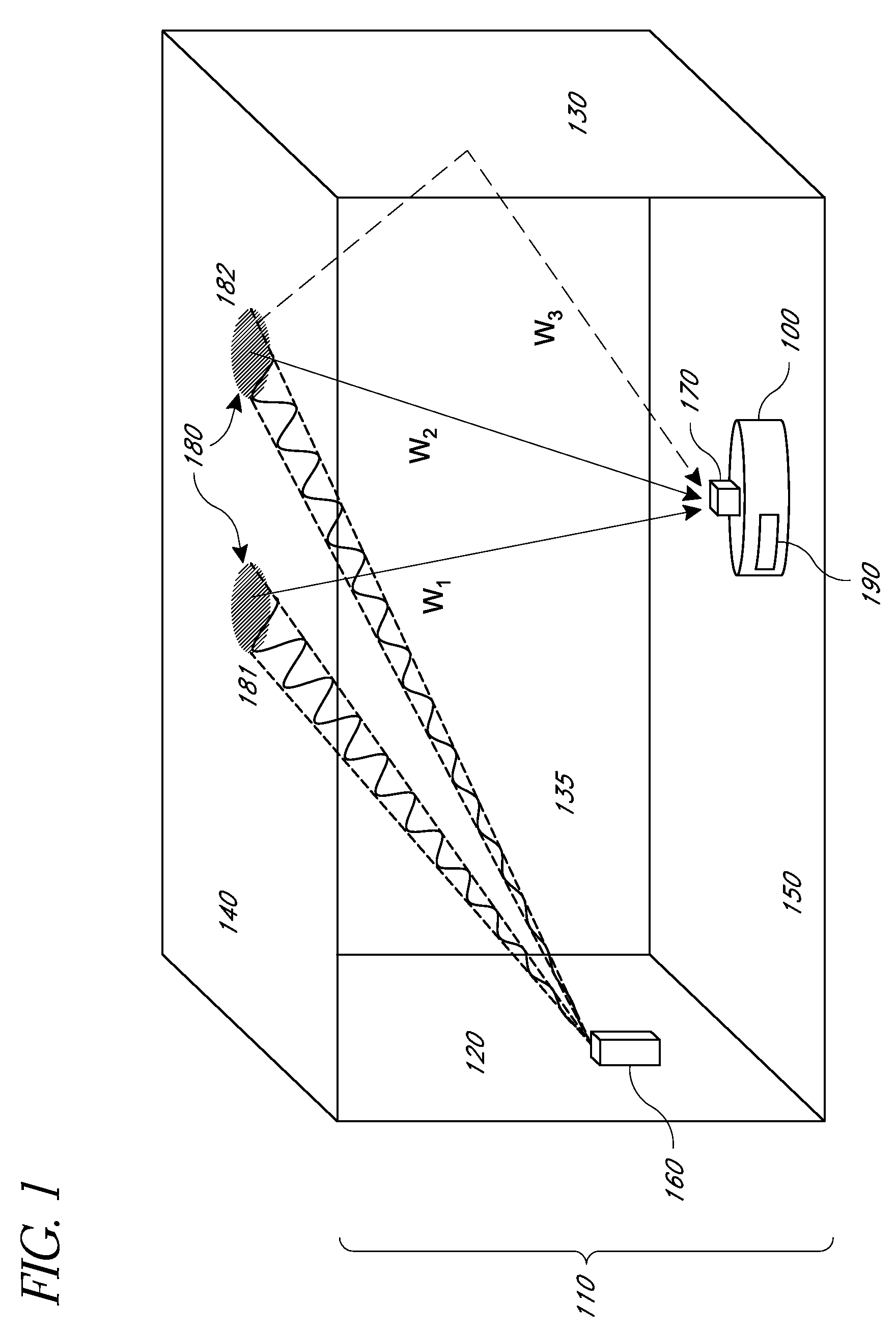

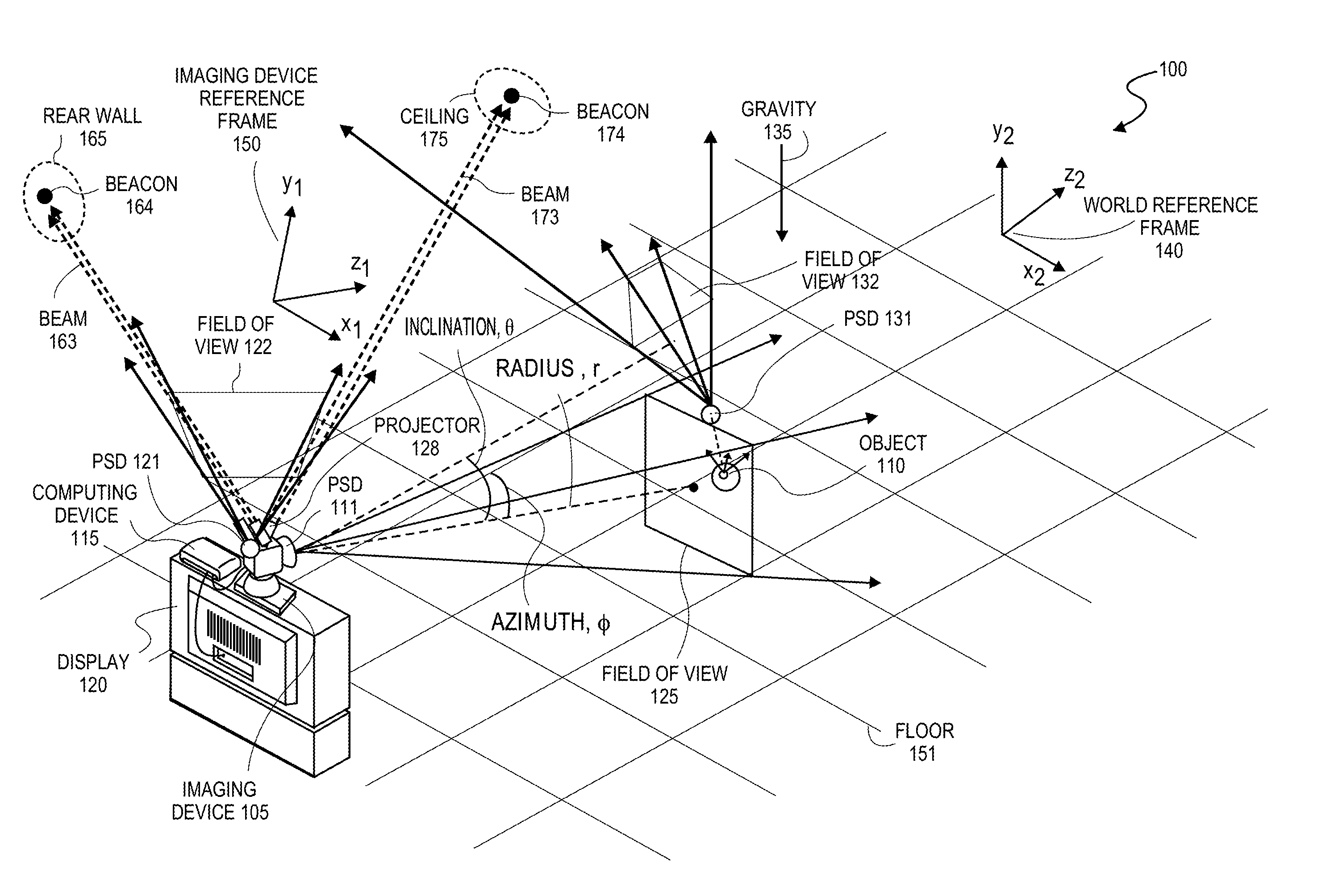

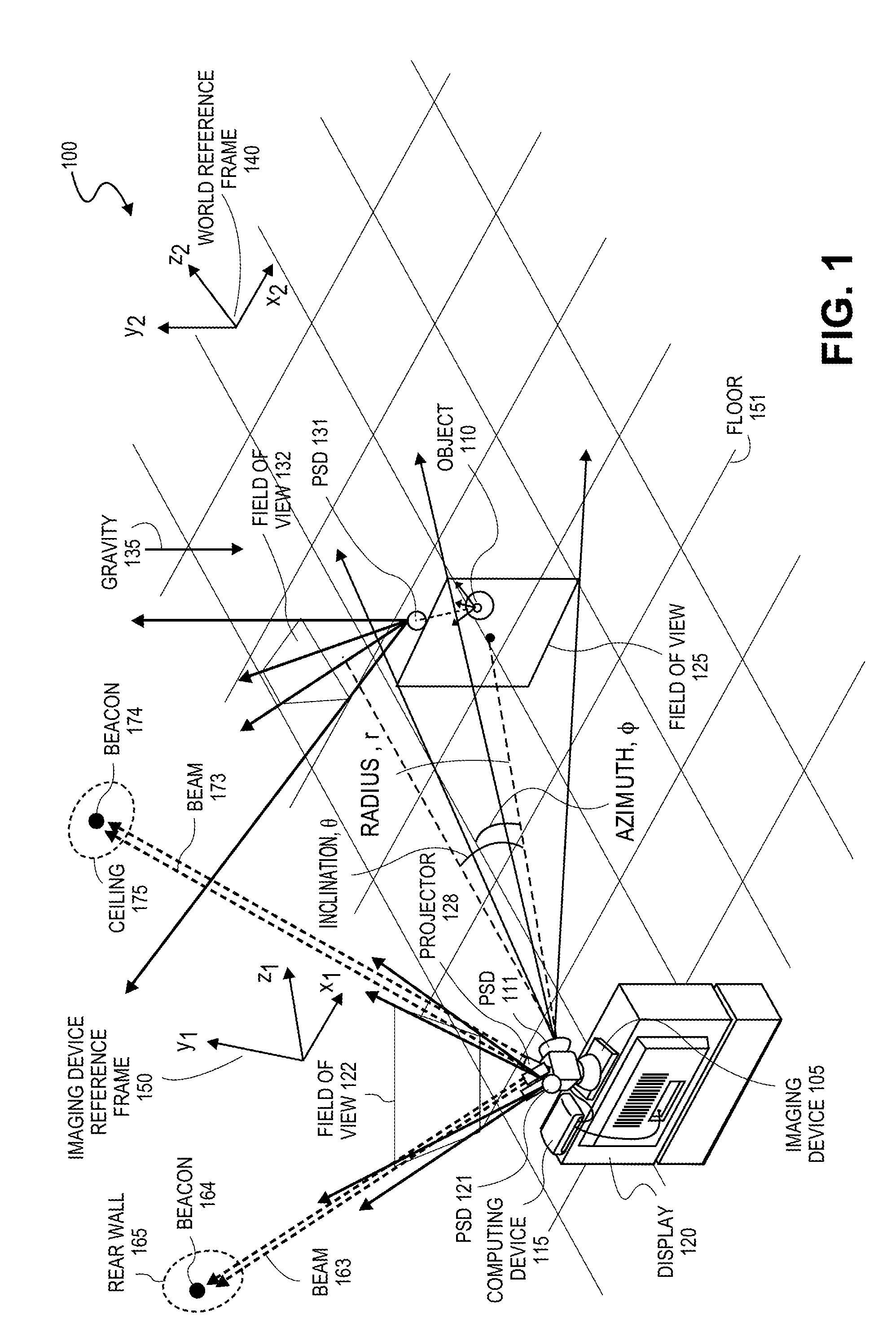

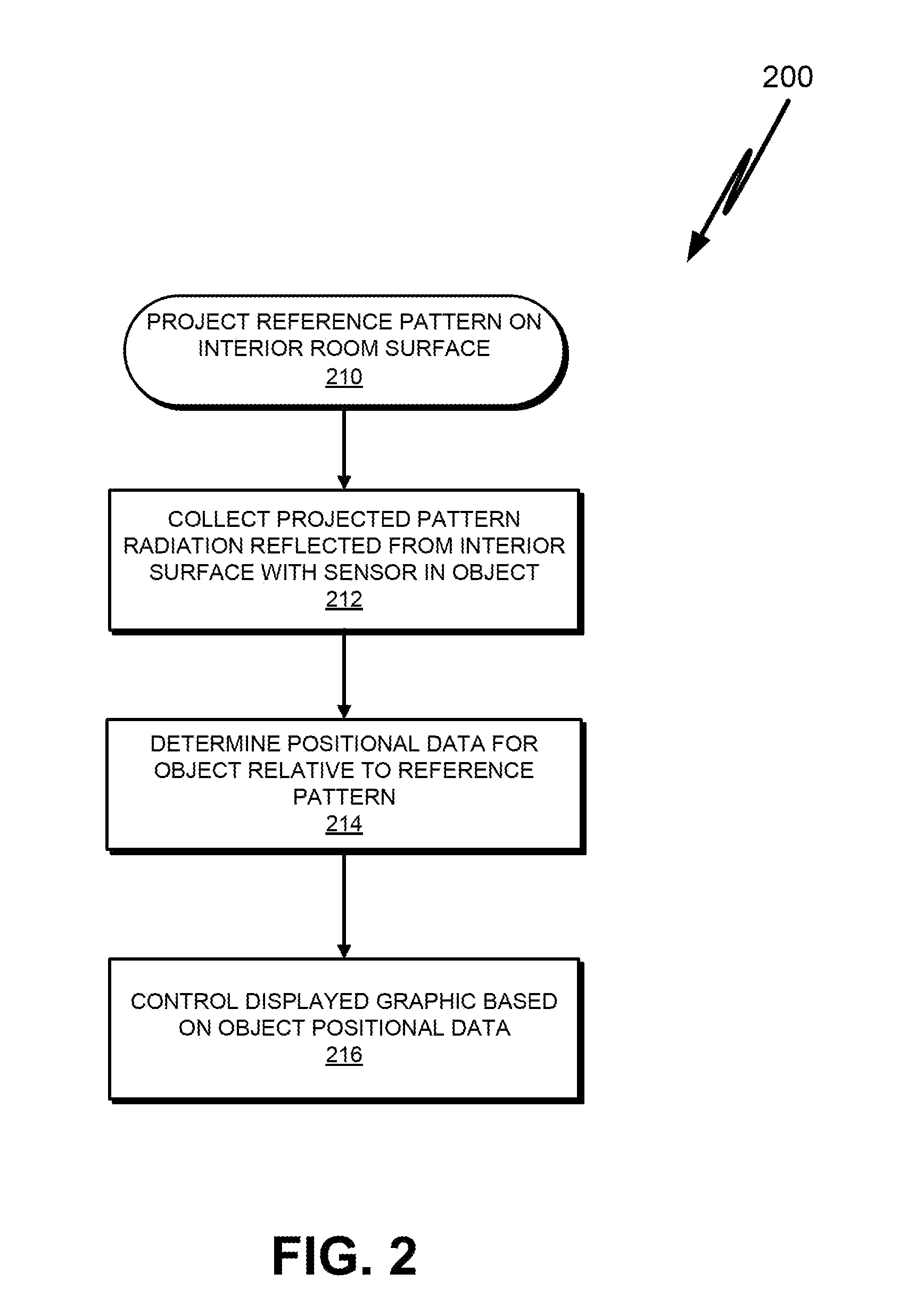

Object tracking with projected reference patterns

ActiveUS20120262365A1Input/output for user-computer interactionCathode-ray tube indicatorsReference patternsComputer vision

Systems and methods for tracking an object's position and orientation within a room using patterns projected onto an interior surface of the room, such as the ceiling. Systems include at least one optical position sensitive device embedded in the object to detect relative changes in the projected pattern as the object's position and / or orientation is changed. In particular systems, the pattern includes a plurality of beacons projected by one or more steerable lasers. Projected beacons may be steered automatically to accommodate a variety of room topologies. Additional optical position sensitive devices may be disposed in known physical positions relative to the projected pattern to view either or both the projected pattern and the object. A subset of object positional data may be derived from a video camera viewing the object while another subset of object positional data is derived from the projected pattern.

Owner:SONY COMPUTER ENTERTAINMENT INC

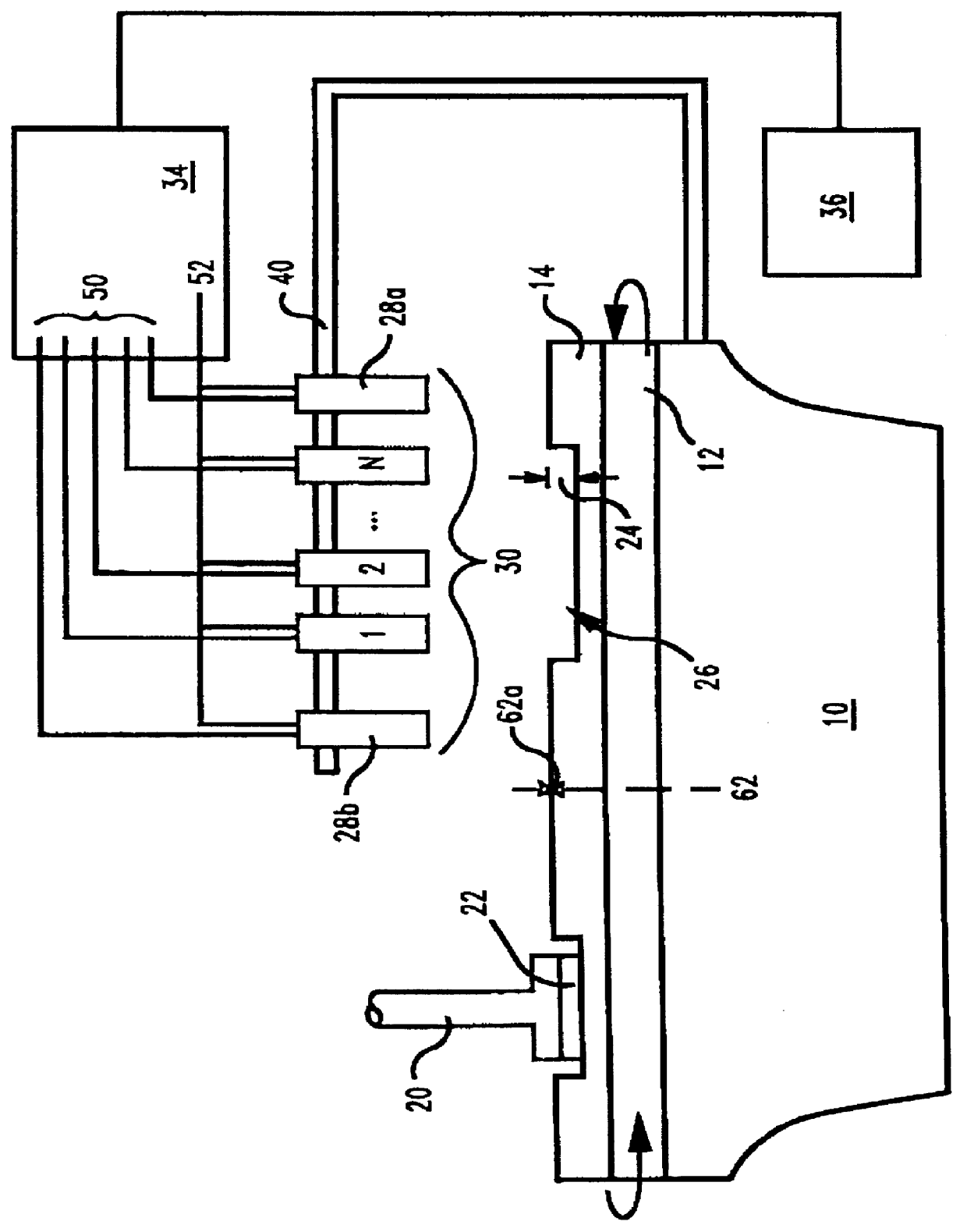

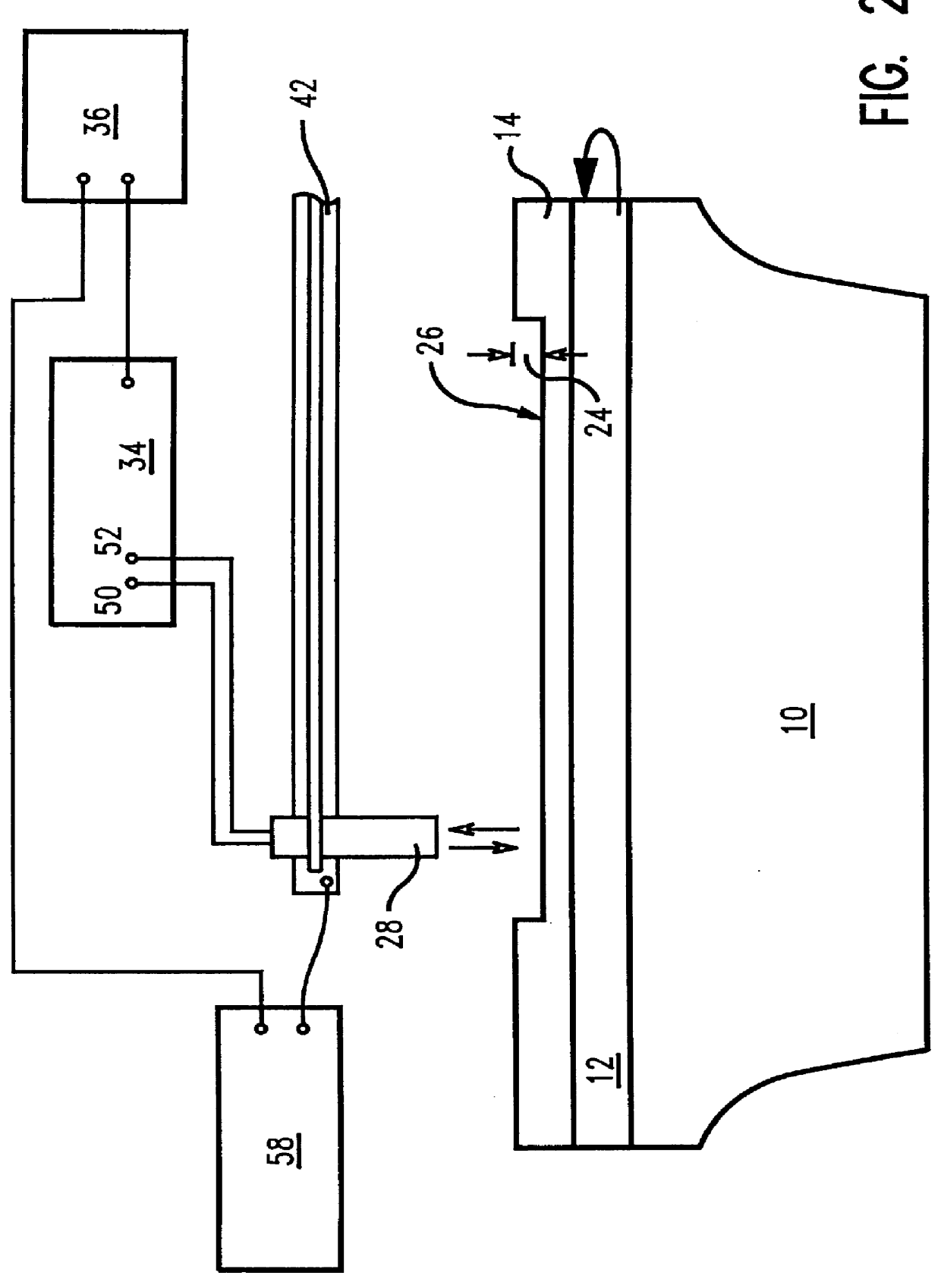

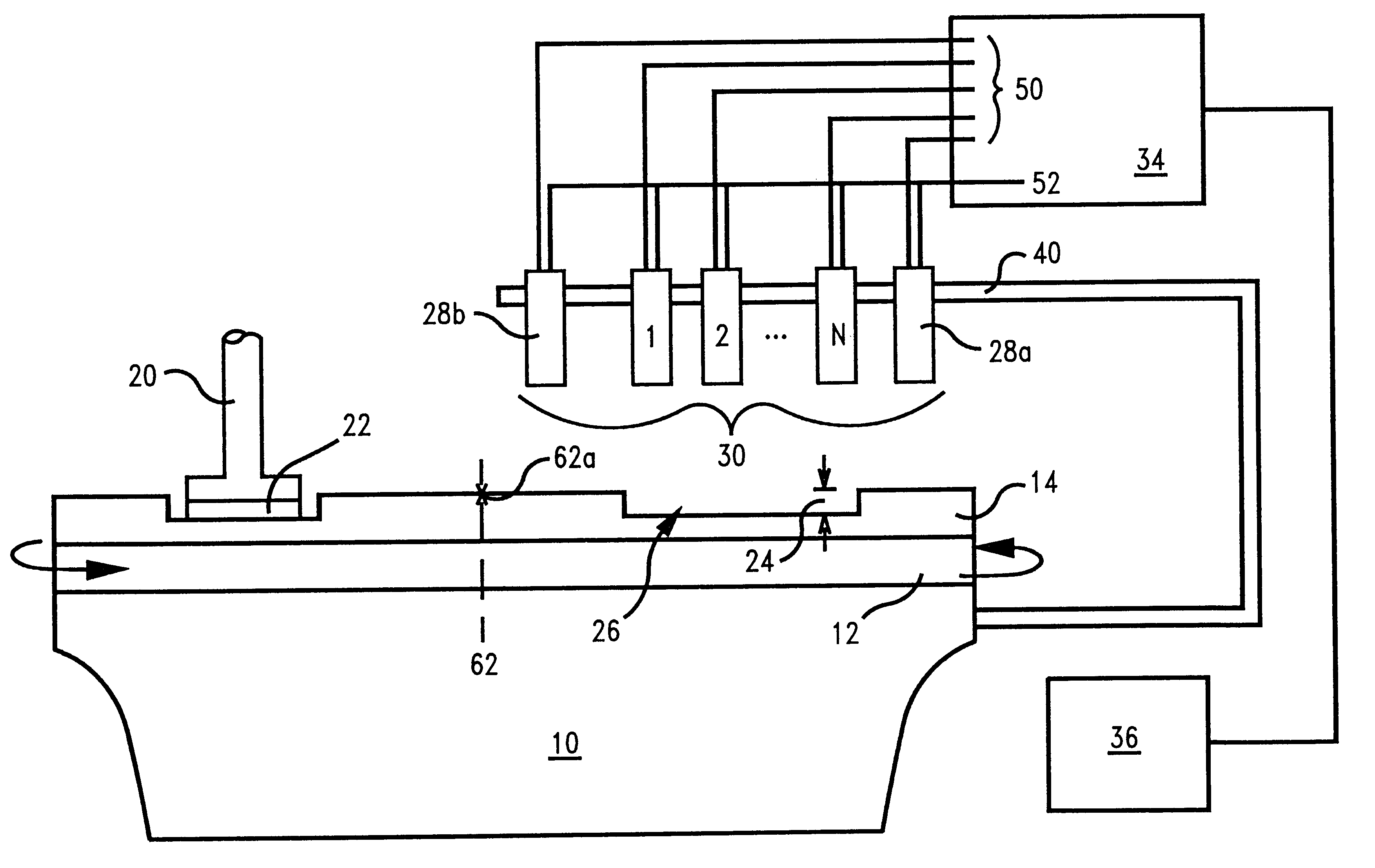

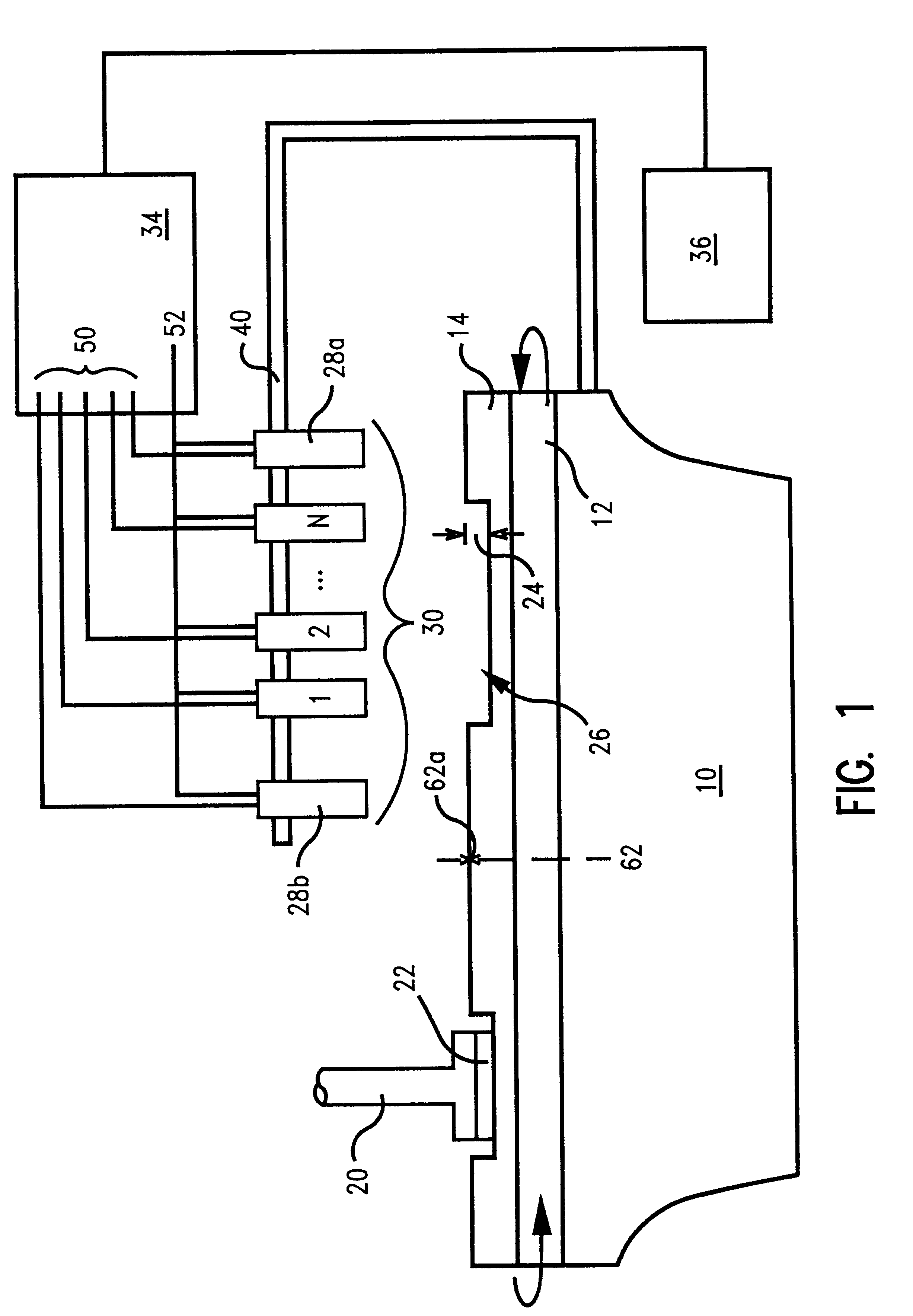

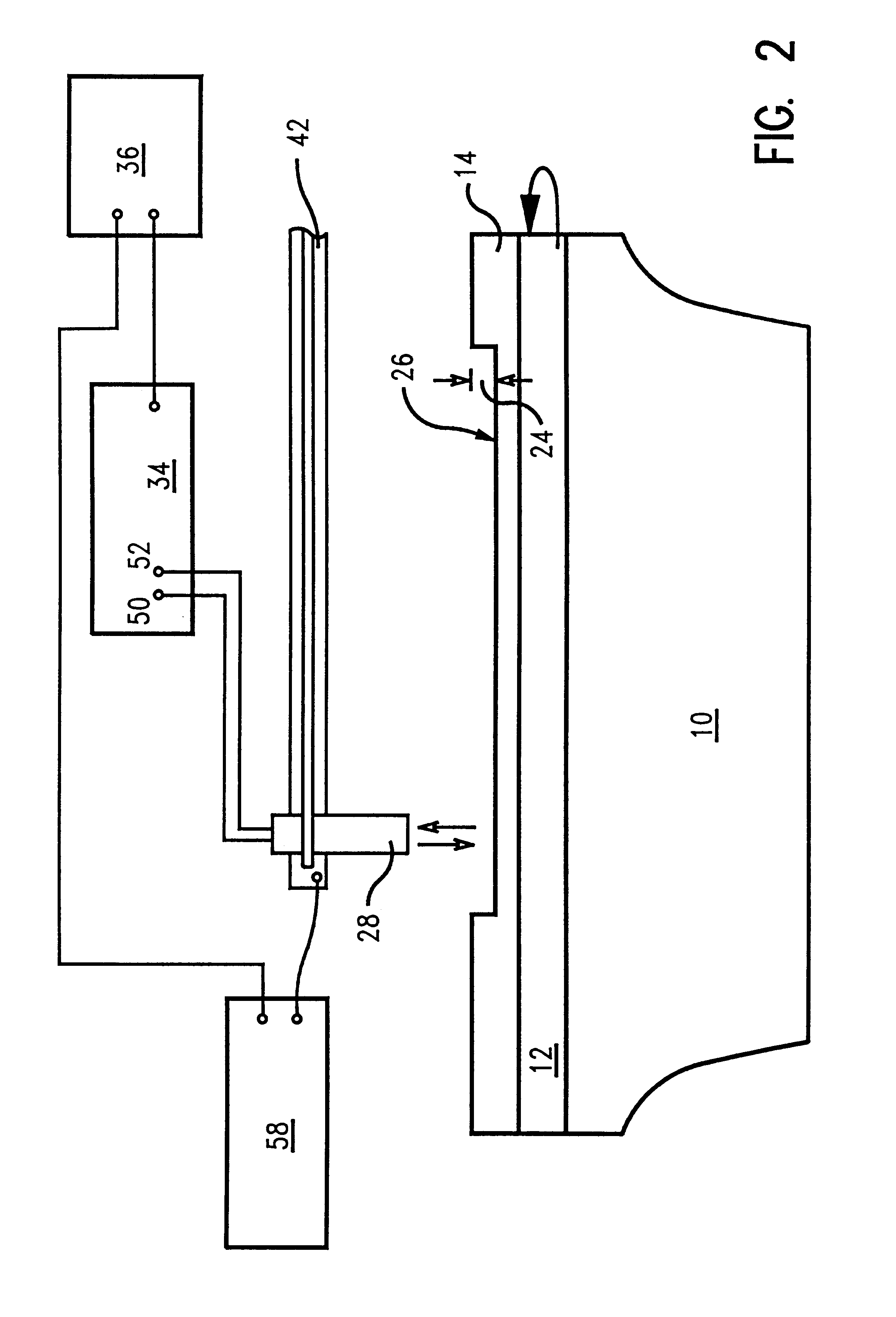

Method and apparatus of monitoring polishing pad wear during processing

InactiveUS6045434AMinimize degradationPolishing machinesRevolution surface grinding machinesClosed loopEngineering

A method and apparatus for monitoring polishing pad wear during processing is developed to extend the pad's useful life, and maintain pad uniformity. This is accomplished in the present invention by measuring and monitoring the diminished pad thickness using a non-intrusive measurement system, and creating a closed-loop system for adjusting the chemical-mechanical polishing tool process parameters. The non-intrusive measurement system consists of an interferometer measurement technique utilizing ultrasound or electromagnetic radiation transmitters and receivers aligned to cover any portion of the radial length of a polishing pad surface. The measurement system is sensitive to relative changes in pad thickness for uniformity, and to abrupt changes such as detecting wafer detachment from the CMP wafer carrier.

Owner:IBM CORP

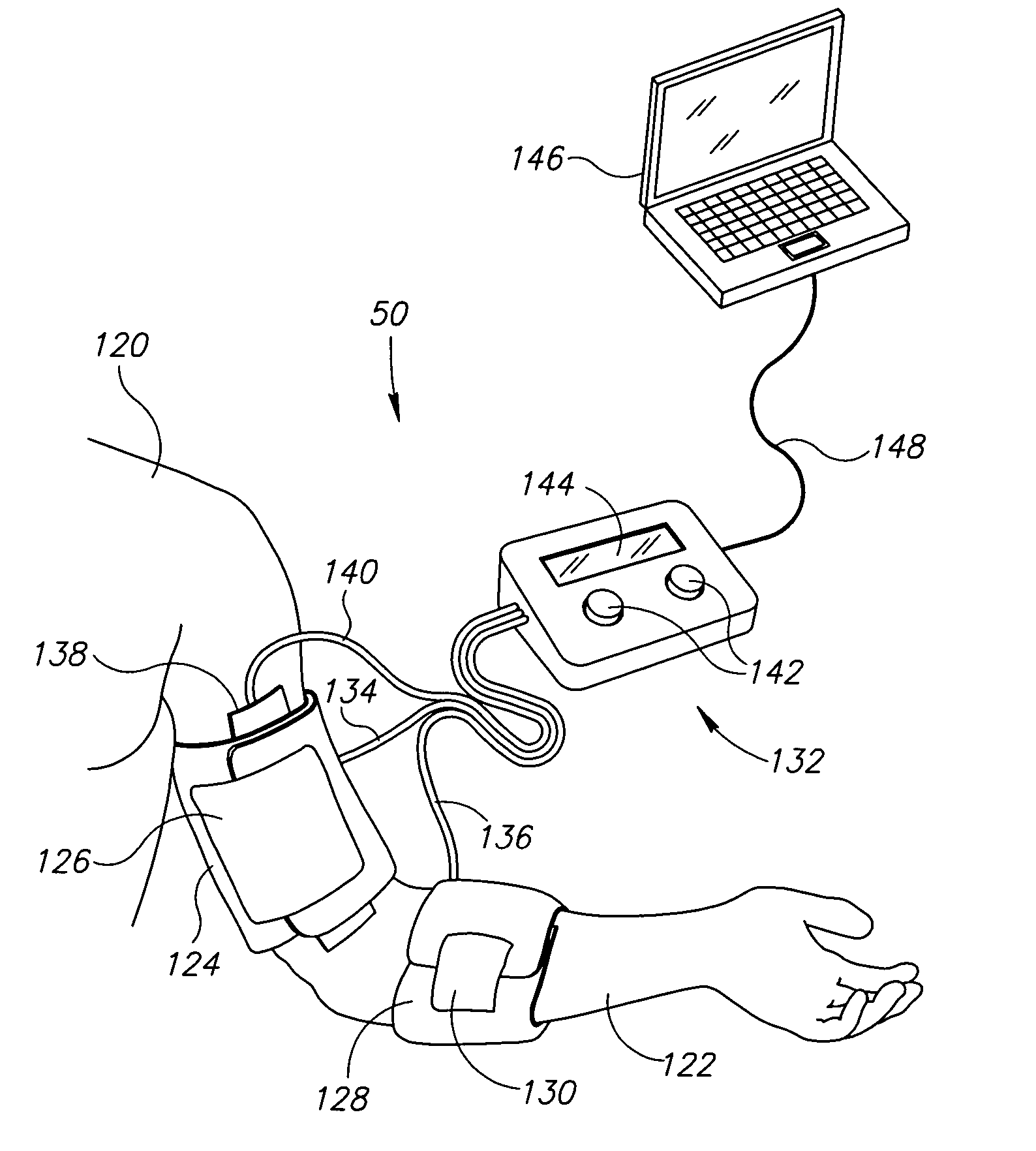

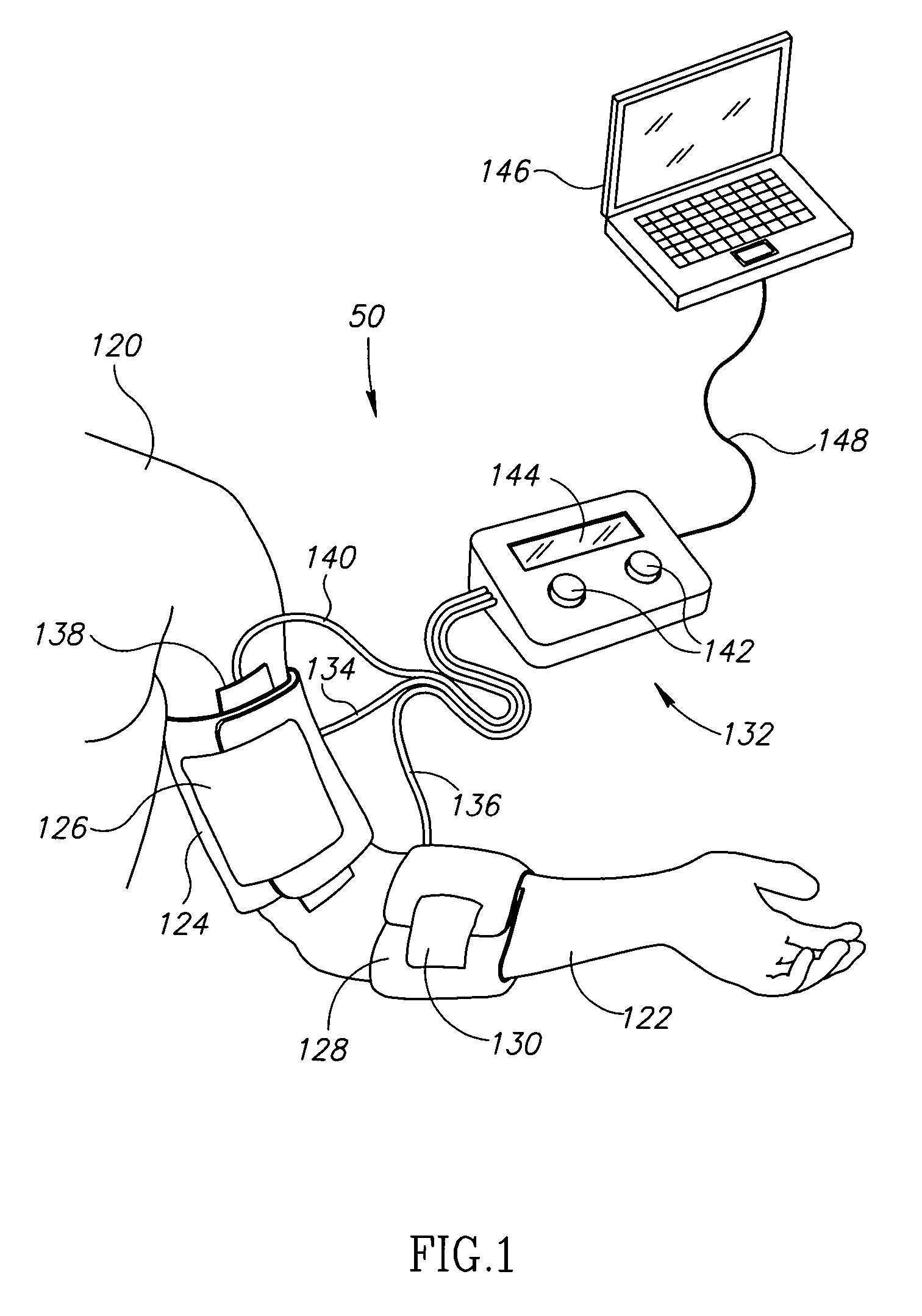

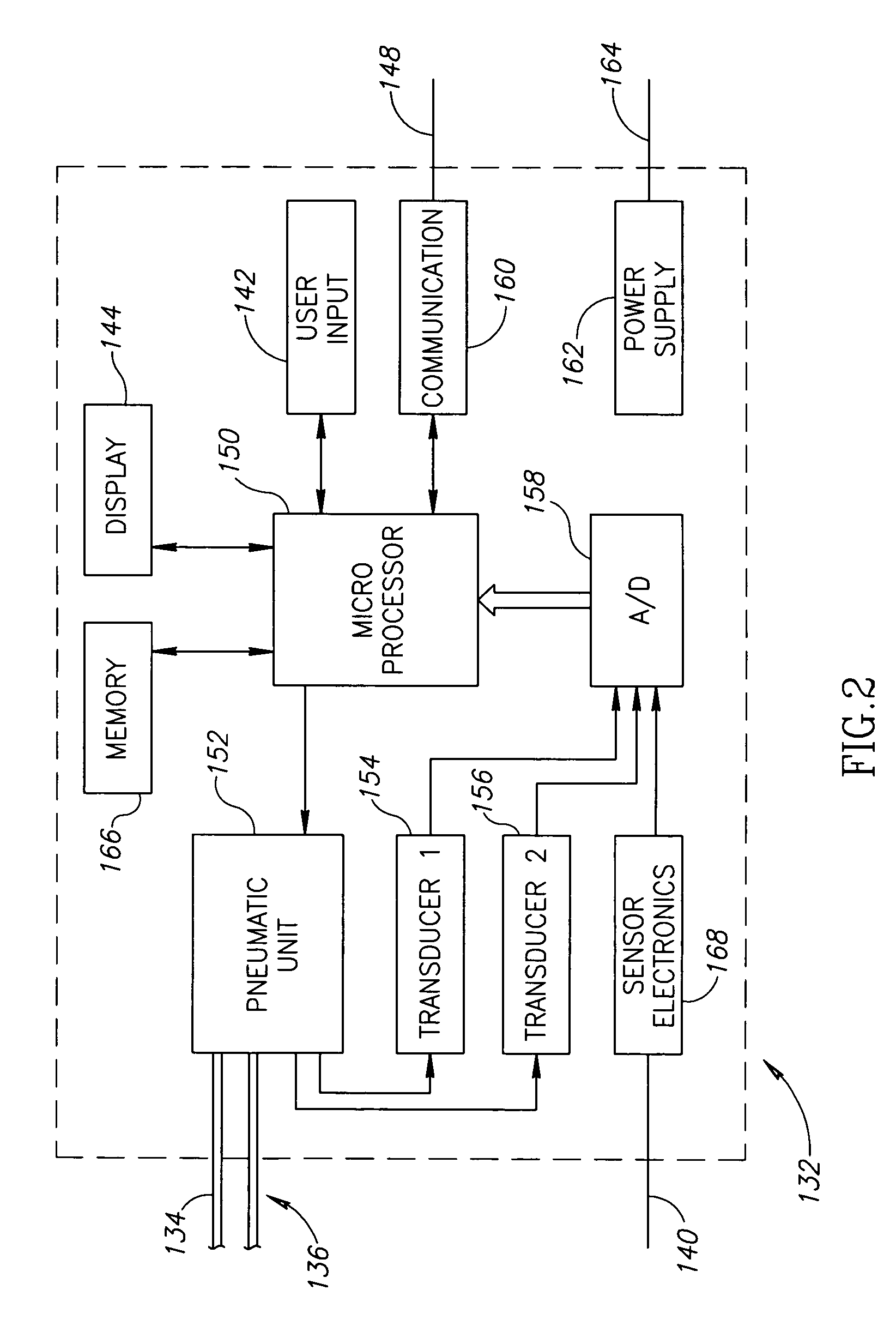

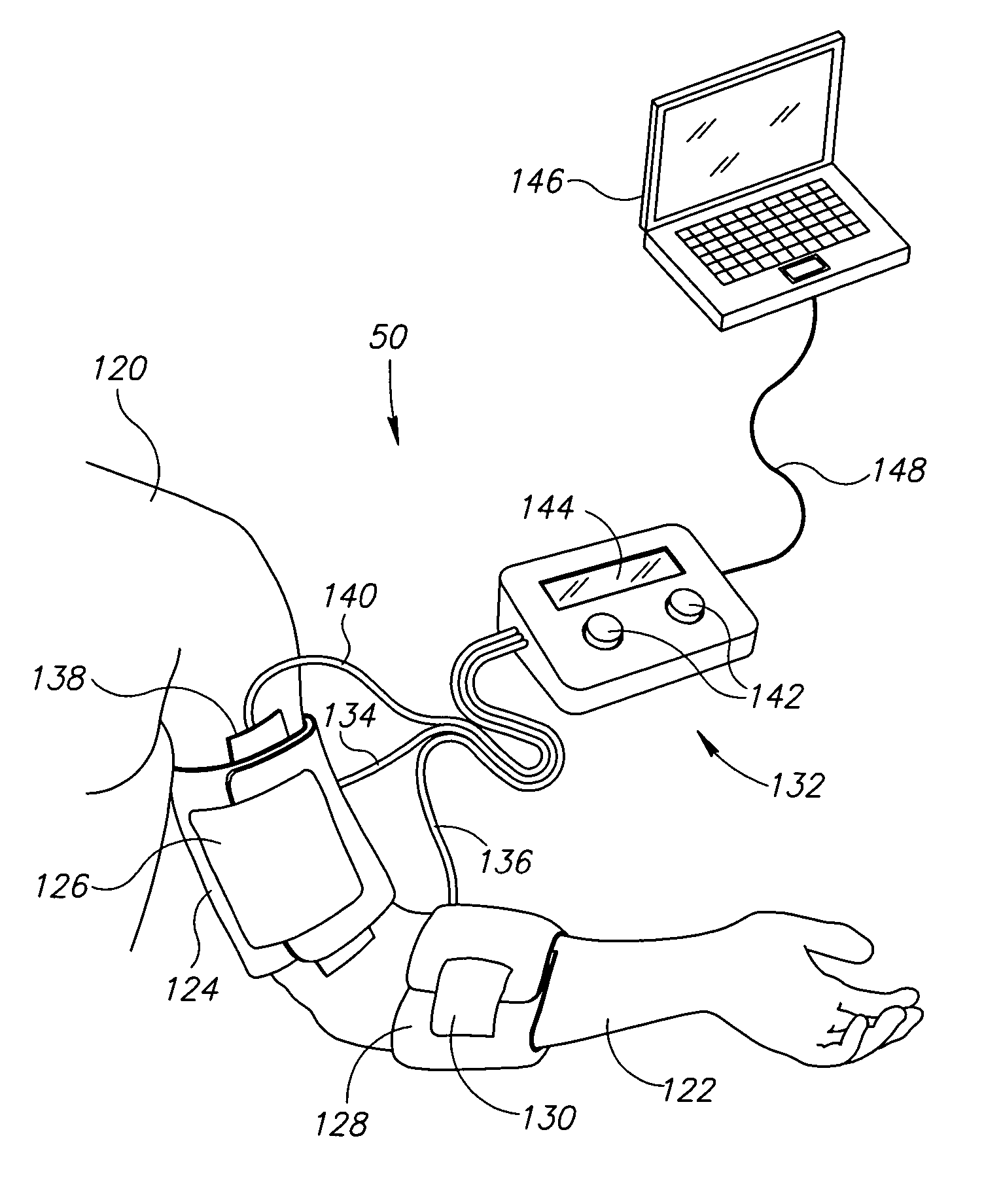

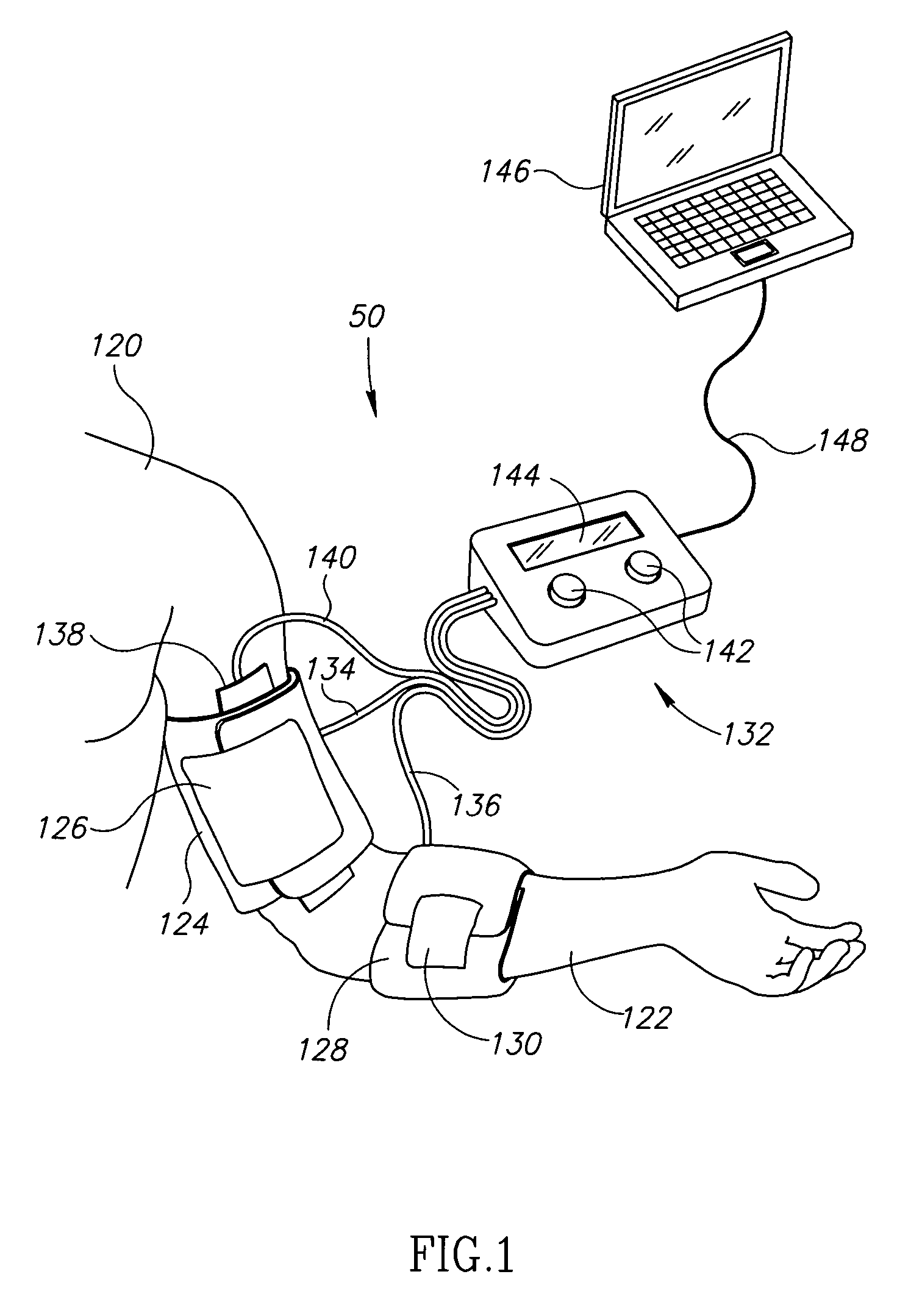

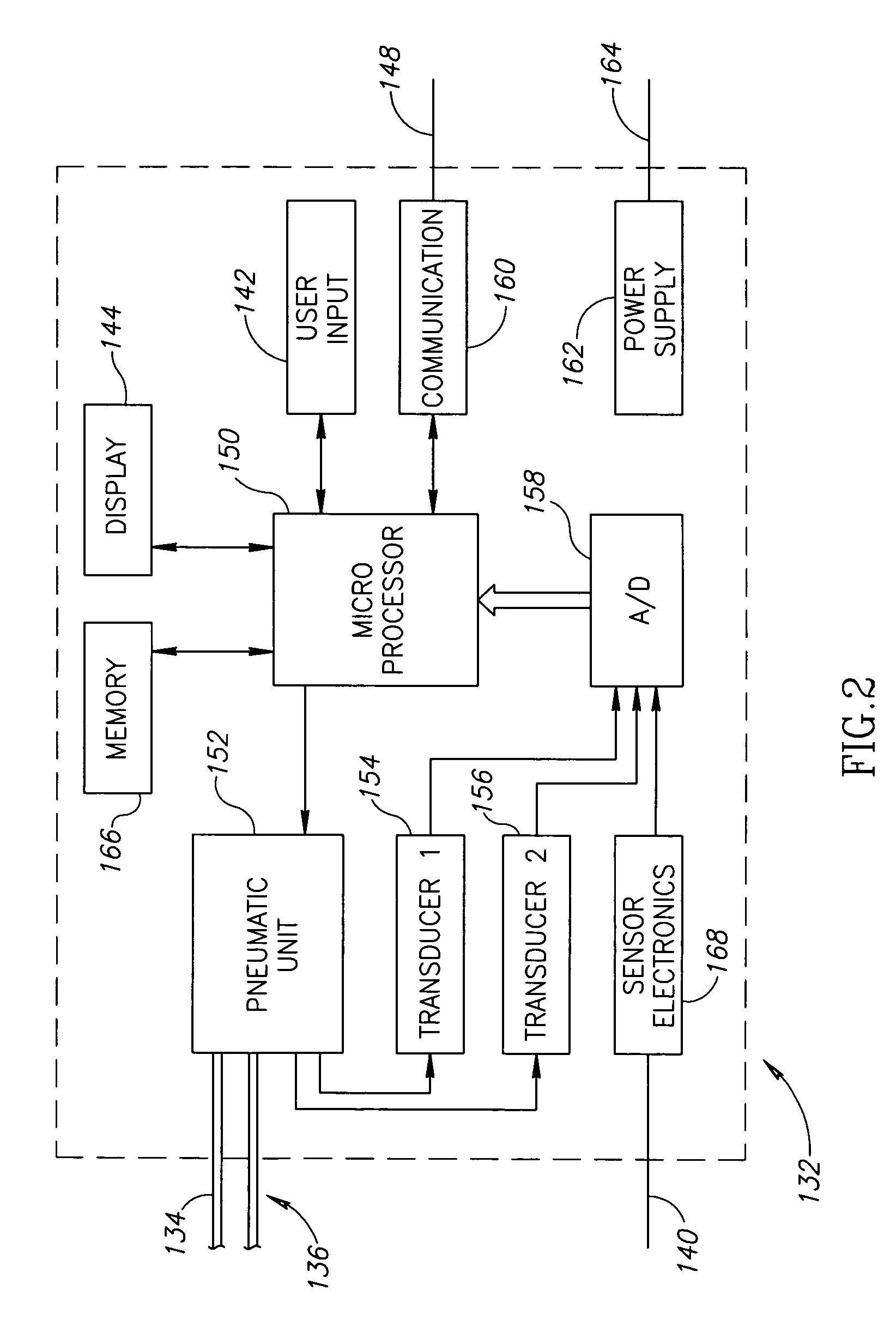

Assessment of vascular dilatation

A method and apparatus of assessment of relative changes in the cross sectional area of a limb artery. The method includes applying to the artery an external pressure, which causes the cross-sectional area of the artery to change between systole and diastole much more than if the pressure is not applied, determining, over one or more cardiac cycles, a baseline value for a parameter related to the cross-sectional area of the artery, while the pressure is applied, applying a stimulus to the artery, determining, over one or more cardiac cycles, a stimulus-affected value for the parameter related to the cross-sectional area of the artery, while the pressure is applied and while the artery is in a dilated state affected by the stimulus and evaluating the artery based on a comparison of the determined stimulus-affected and baseline values, the baseline value is determined while the artery is substantially not affected by the stimulus.

Owner:DAFNI EHUD

Assessment of vascular dilatation

A method and apparatus of assessment of relative changes in the cross sectional area of a limb artery. The method includes applying to the artery an external pressure, which causes the cross-sectional area of the artery to change between systole and diastole much more than if the pressure is not applied, determining, over one or more cardiac cycles, a baseline value for a parameter related to the cross-sectional area of the artery, while the pressure is applied, applying a stimulus to the artery, determining, over one or more cardiac cycles, a stimulus-affected value for the parameter related to the cross-sectional area of the artery, while the pressure is applied and while the artery is in a dilated state affected by the stimulus and evaluating the artery based on a comparison of the determined stimulus-affected and baseline values, the baseline value is determined while the artery is substantially not affected by the stimulus.

Owner:DAFNI EHUD

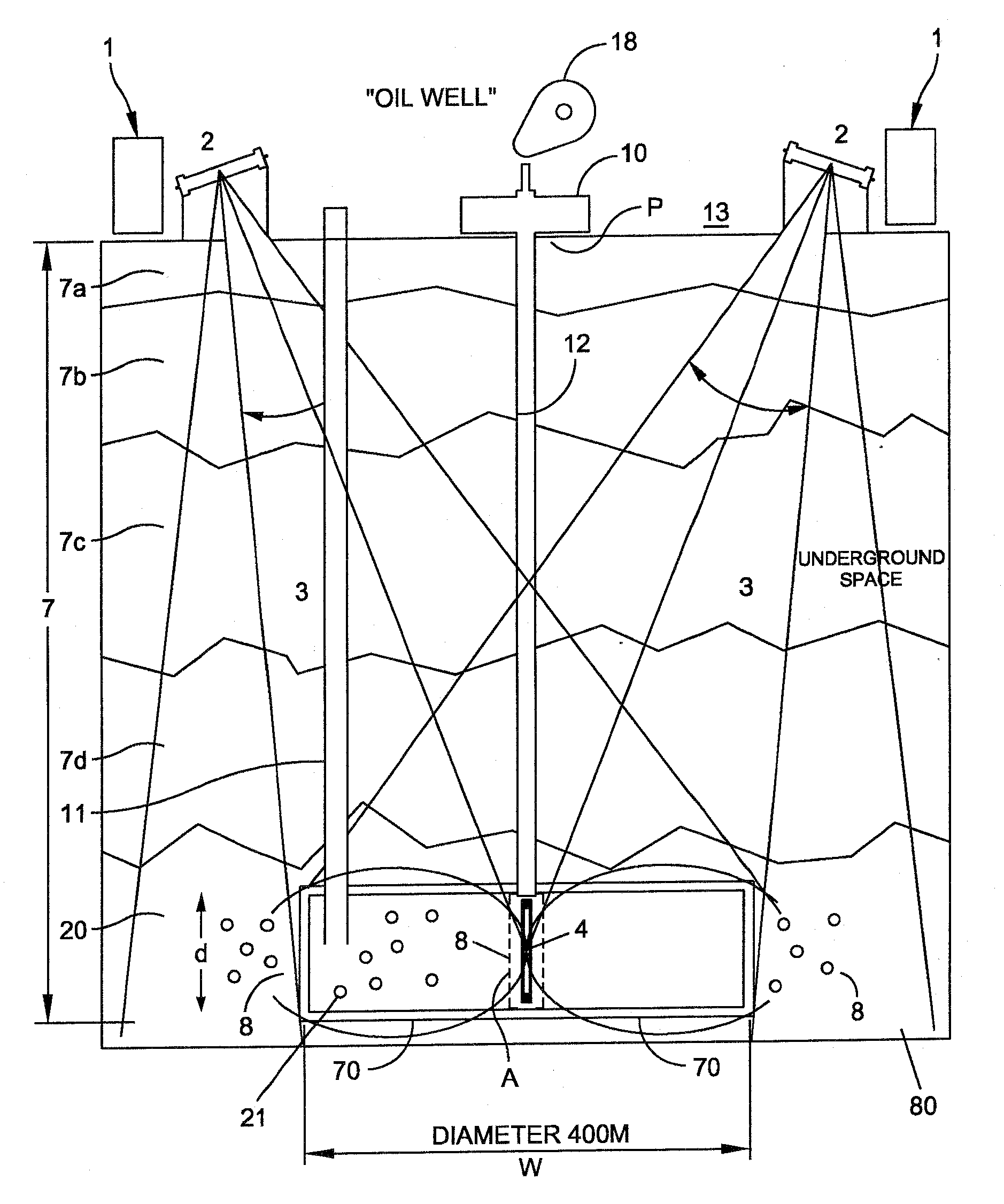

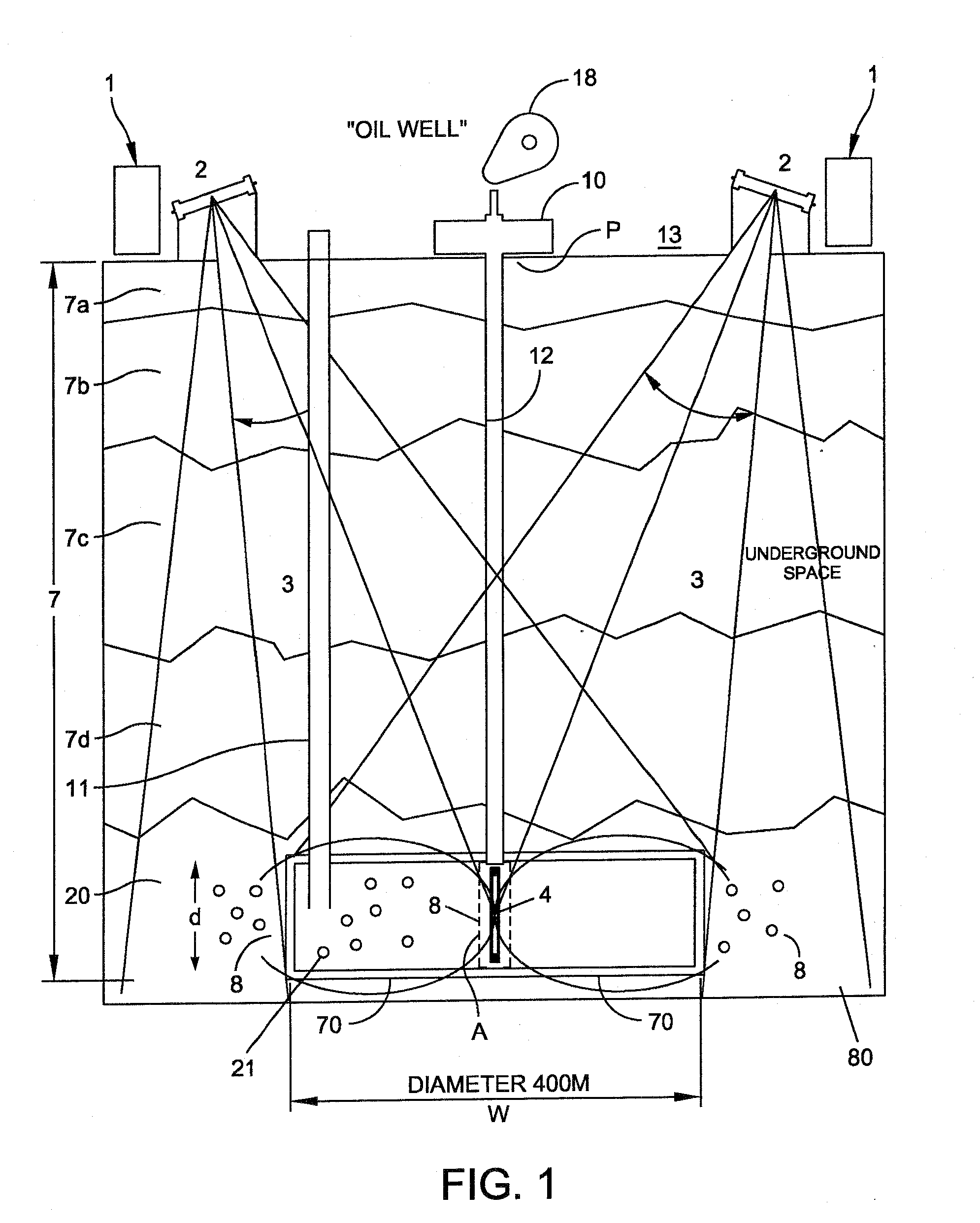

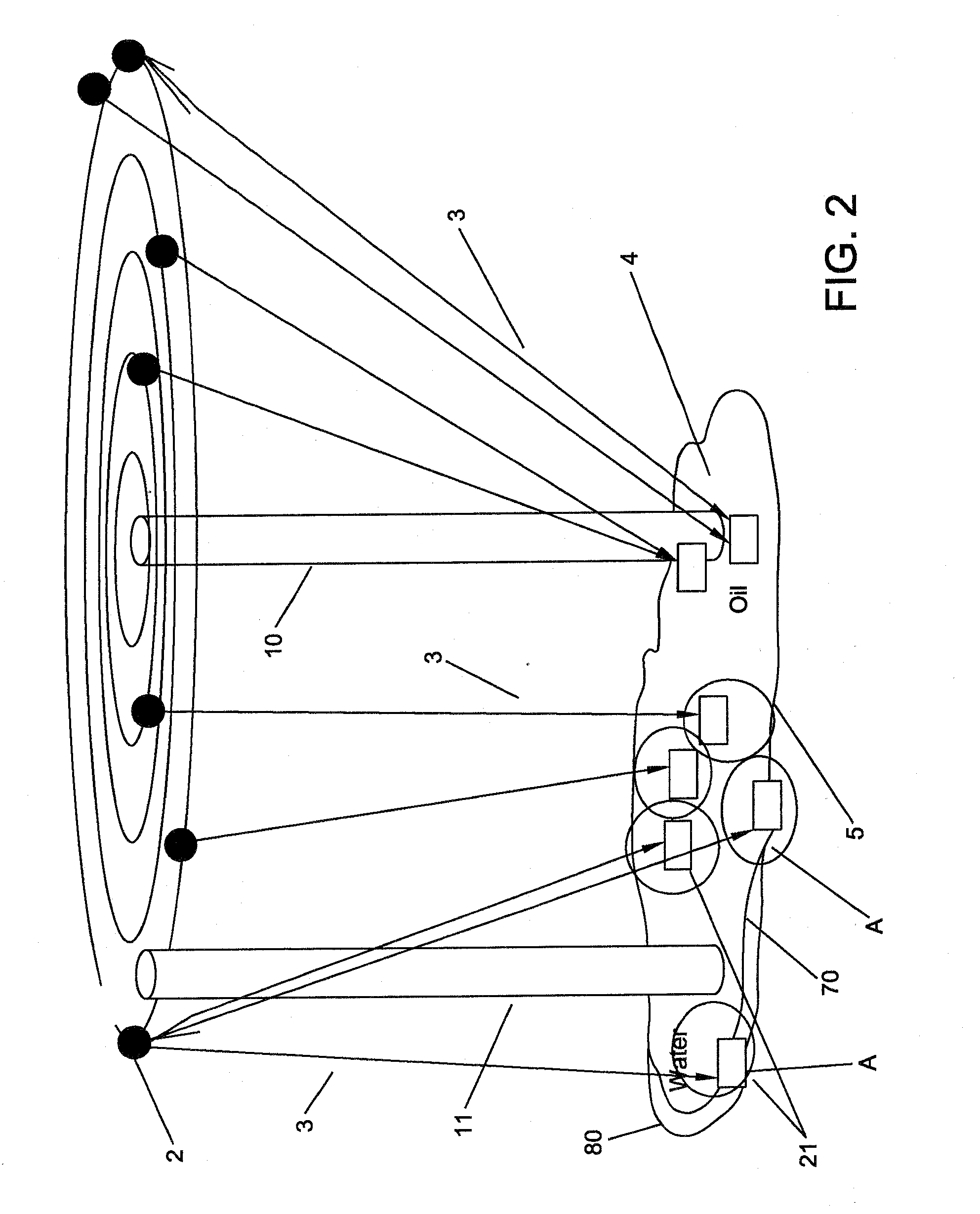

System and method to remotely interact with NANO devices in an oil well and/or water reservoir using electromagnetic transmission

InactiveUS20100102986A1Activation functionConstructionsElectric/magnetic detectionNano-deviceEngineering

The invention provides for electromagnetic transmission and reception used in detecting relative changes associated with nano devices existing within an oil reservoir. The system enables monitoring of the relative movement of the nano devices in the oil and / or water over a given area based on the incremental or relative changes of the intensity of the reflections over time. In one embodiment, a source of electromagnetic energy from an array of antennae transmitting immediately in the far field recharges a power source embedded in the nano devices. In another embodiment, the return signals from the nano devices maps the morphology of ensembles of nano devices. In yet another embodiment the transmission controls the movement of the nano devices and controls the function preformed by the nano devices relative to effecting changes in the well to improve production of oil.

Owner:LOCKHEED MARTIN CORP

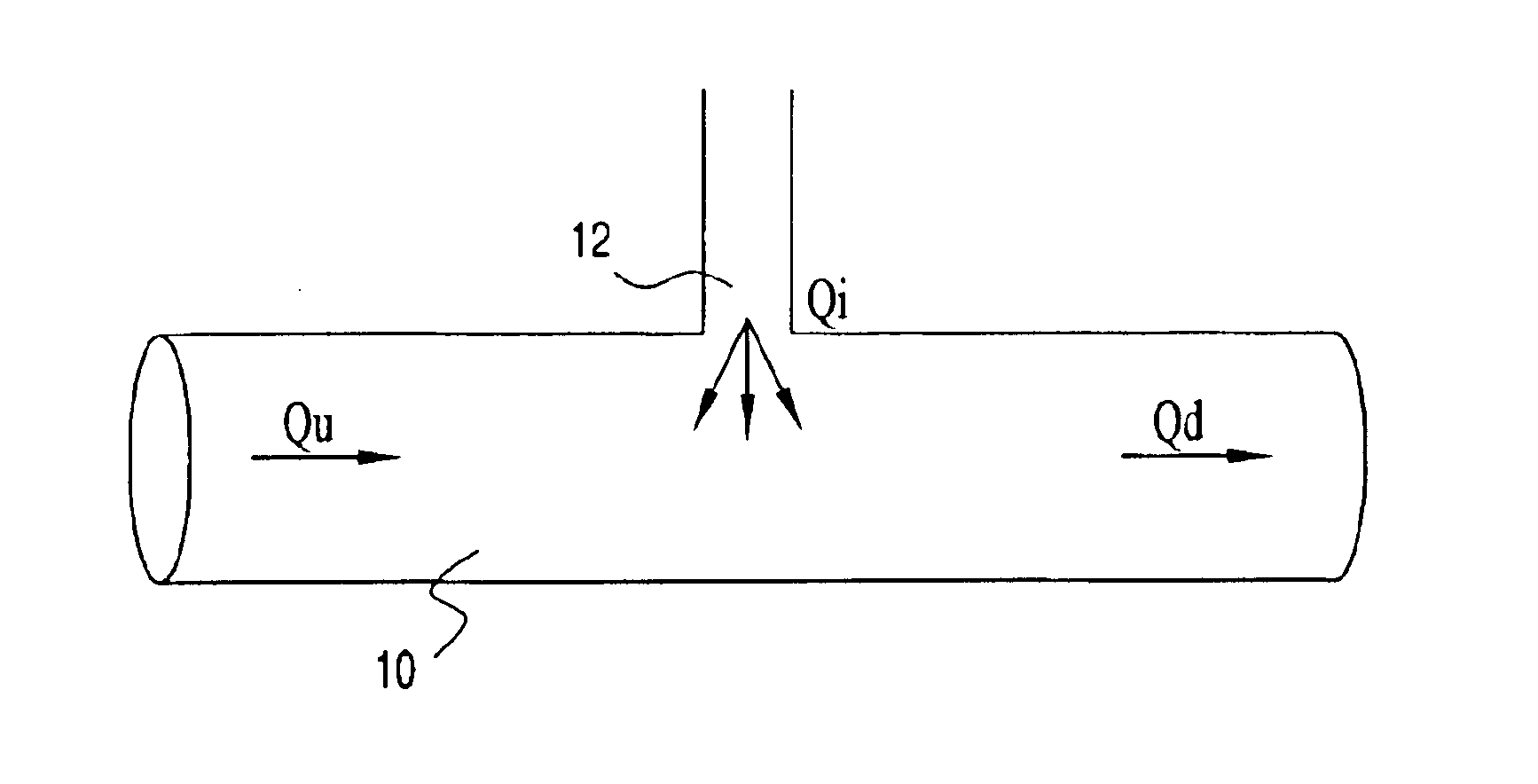

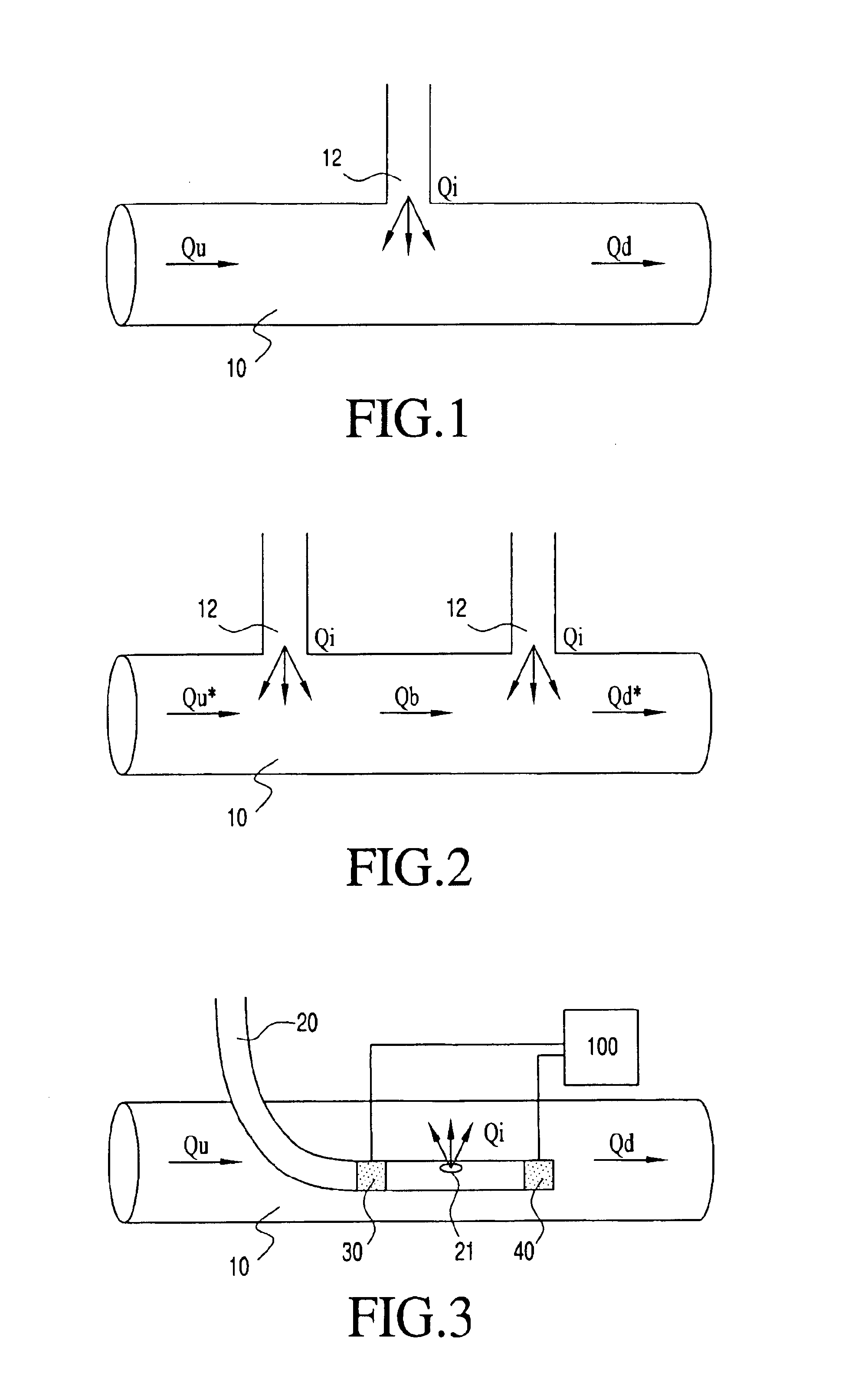

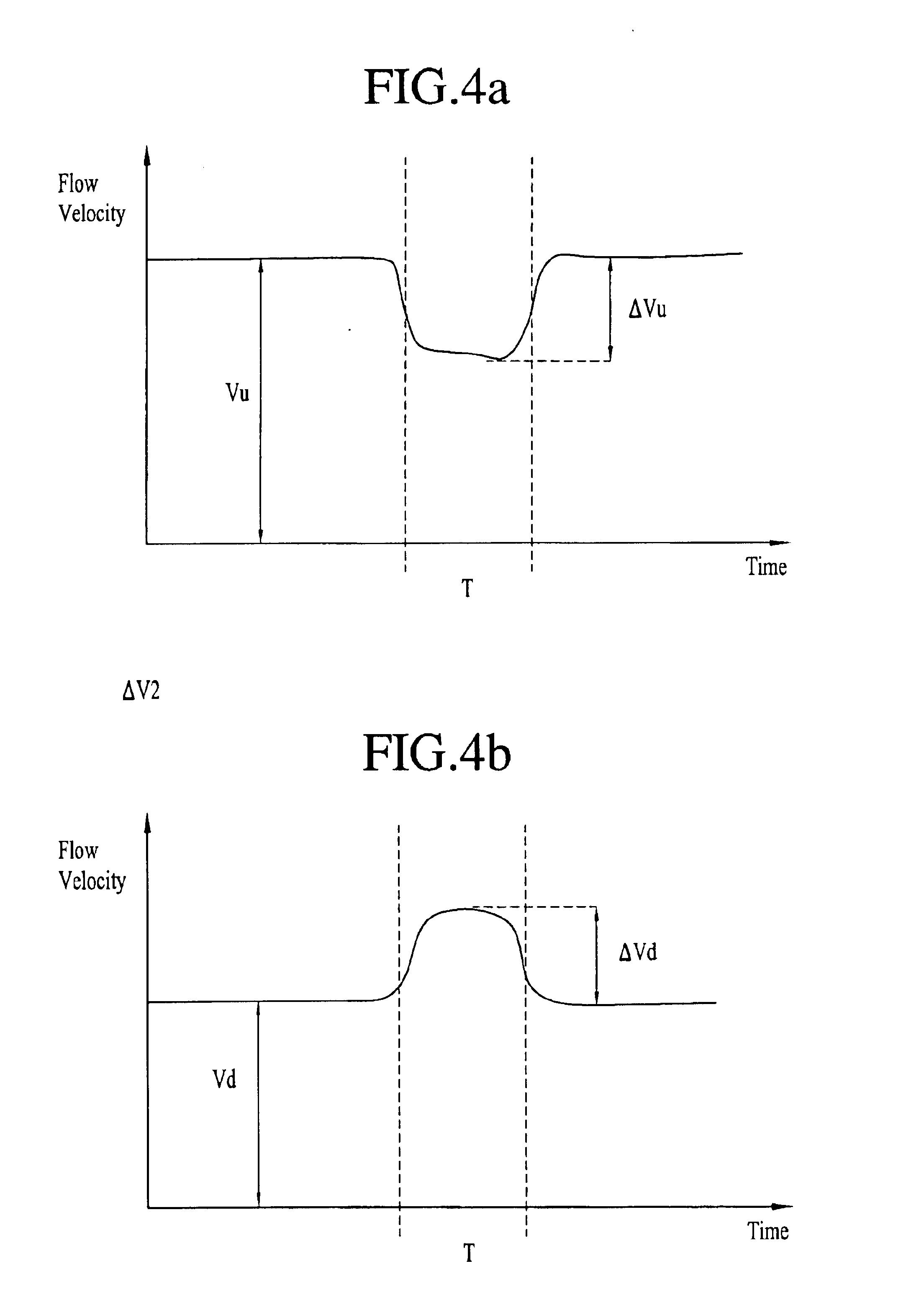

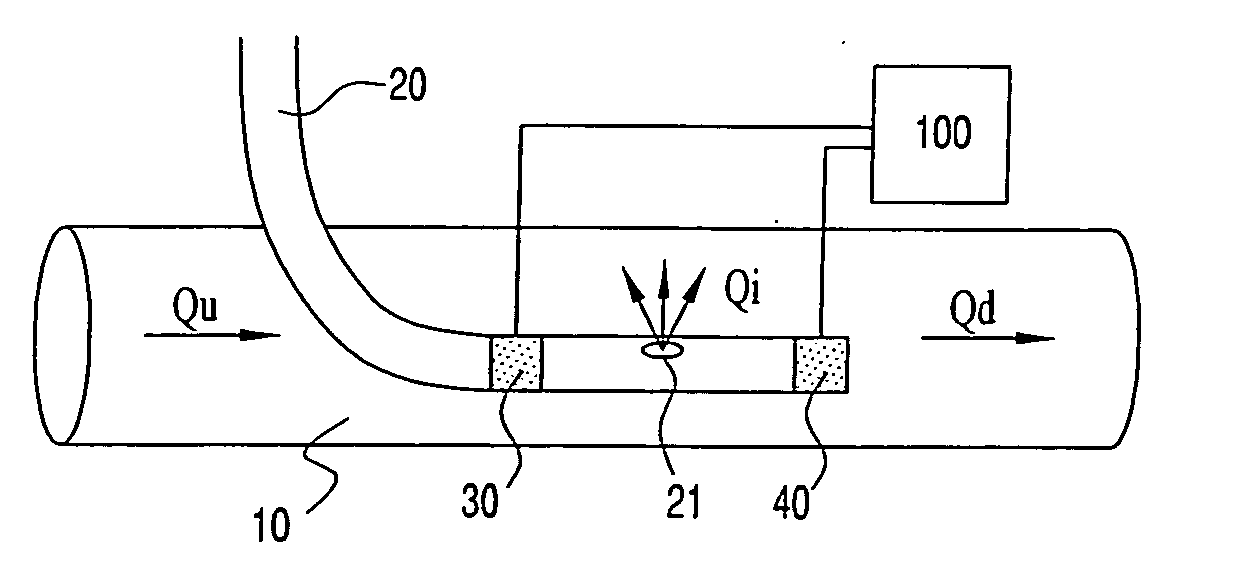

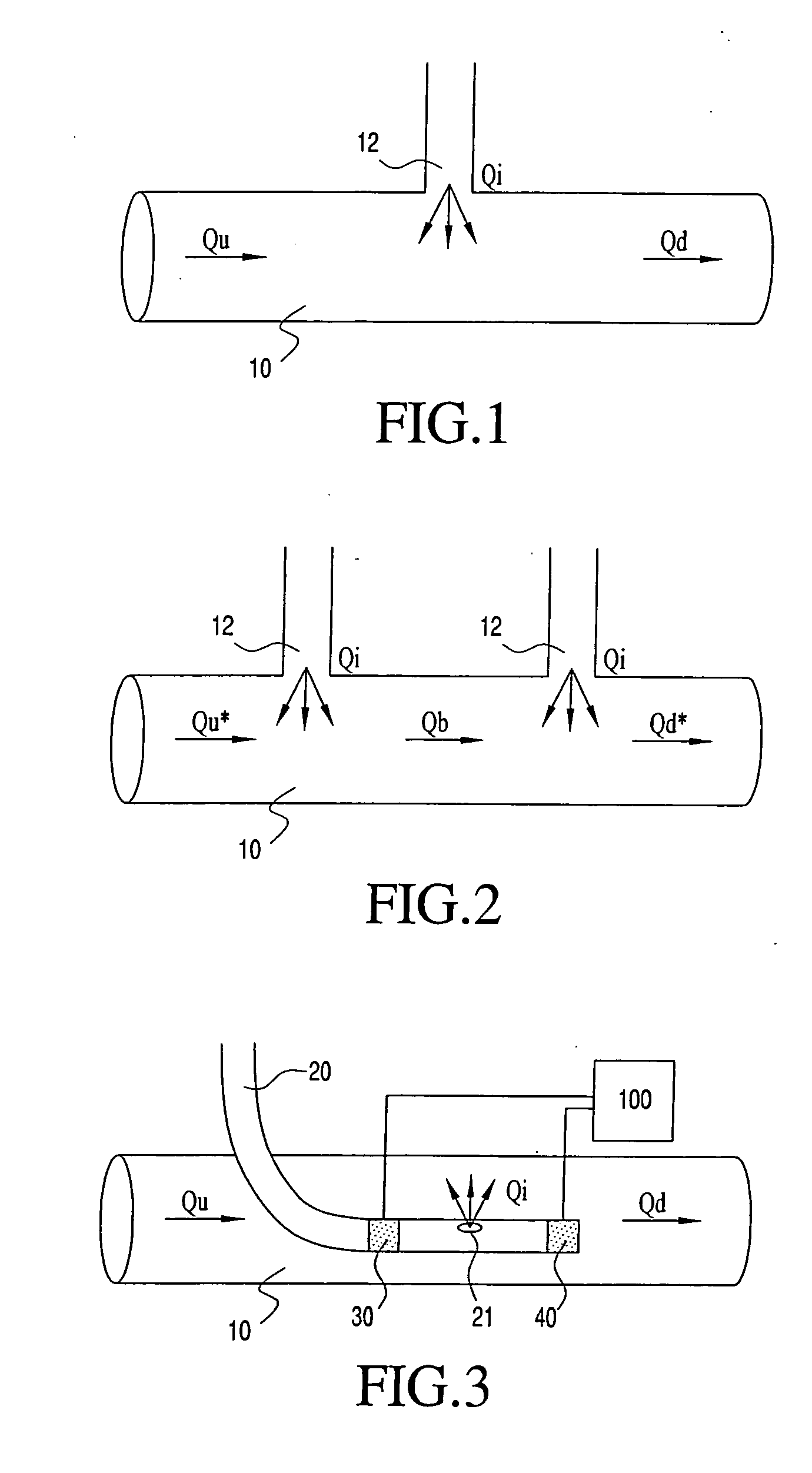

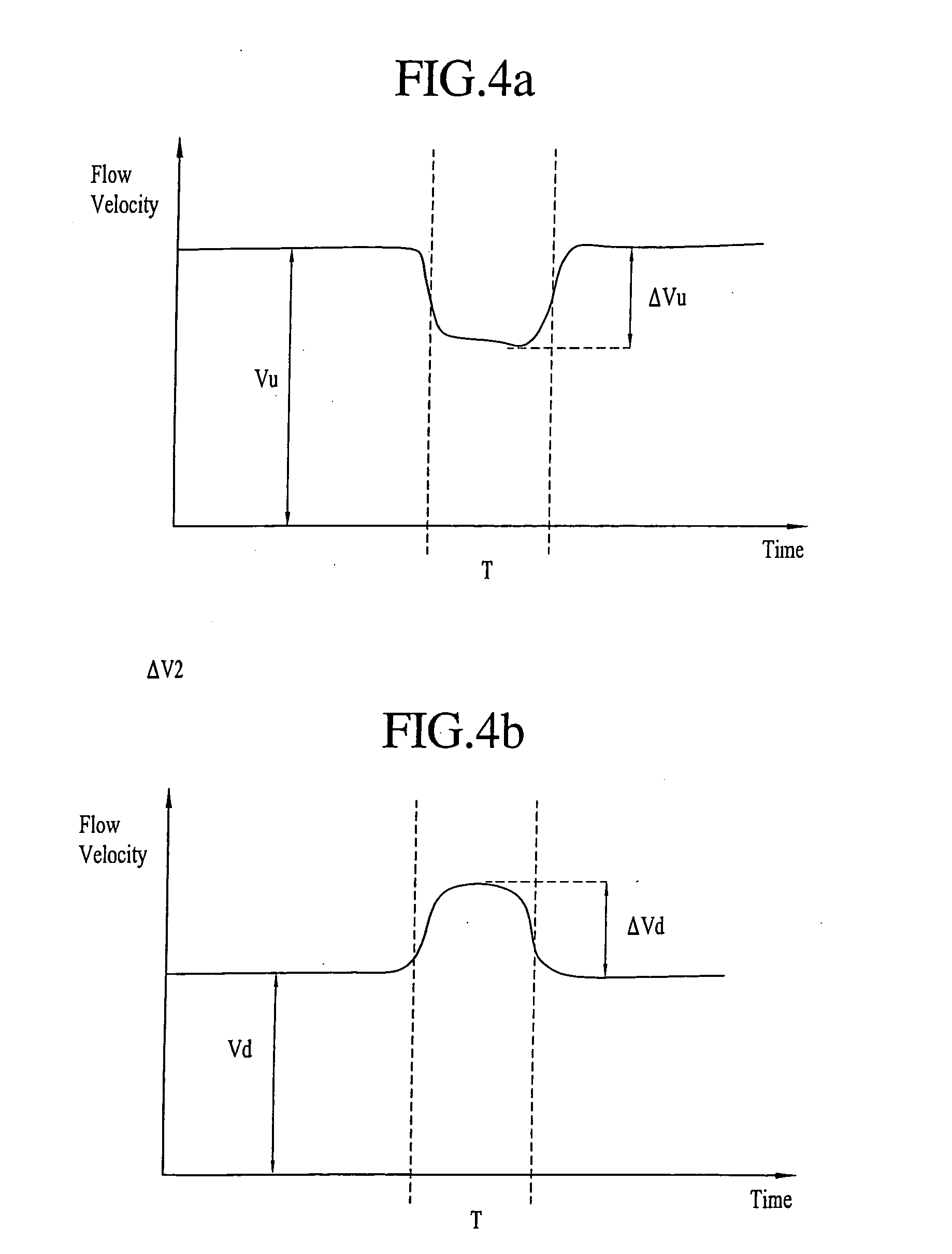

Method and apparatus to measure blood flow by an introduced volume change

A method and apparatus for determining an initial flow rate in a conduit is disclosed. A known change is made to the flow to be measured, resulting changes (or values corresponding to these changes), or relative changes in the flow to be measured are monitored and the initial flow in the conduit is calculated from the value of the known change and monitored changes. Devices to practice the method include catheters having one or two sensors and one or two sites for introducing the volume change.

Owner:TRANSONIC SYST

Method and apparatus for monitoring polishing pad wear during processing

InactiveUS6186864B1Minimize degradationPolishing machinesRevolution surface grinding machinesMaterial removalClosed loop

In a chemical-mechanical polishing (CMP) process, semiconductor substrates are rotated against a polishing pad in order to planarize substrate layers. The condition of the polishing pad directly affects the polishing rate of material removal and uniformity of removal from the semiconductor wafer. Conditioning of the polishing pad surface with an abrasive improves polishing uniformity and rates, however, it has the detrimental affect of removing a quantity of pad material. A method and apparatus for monitoring polishing pad wear during processing is developed to extend the pad's useful life, and maintain pad uniformity. This is accomplished in the present invention by measuring and monitoring the diminished pad thickness using a non-intrusive measurement system, and creating a closed-loop system for adjusting the chemical-mechanical polishing tool process parameters. The non-intrusive measurement system consists of an interferometer measurement technique utilizing ultrasound or electromagnetic radiation transmitters and receivers aligned to cover any portion of the radial length of a polishing pad surface. The measurement system is sensitive to relative changes in pad thickness for uniformity, and to abrupt changes such as detecting wafer detachment from the CMP wafer carrier.

Owner:INT BUSINESS MASCH CORP

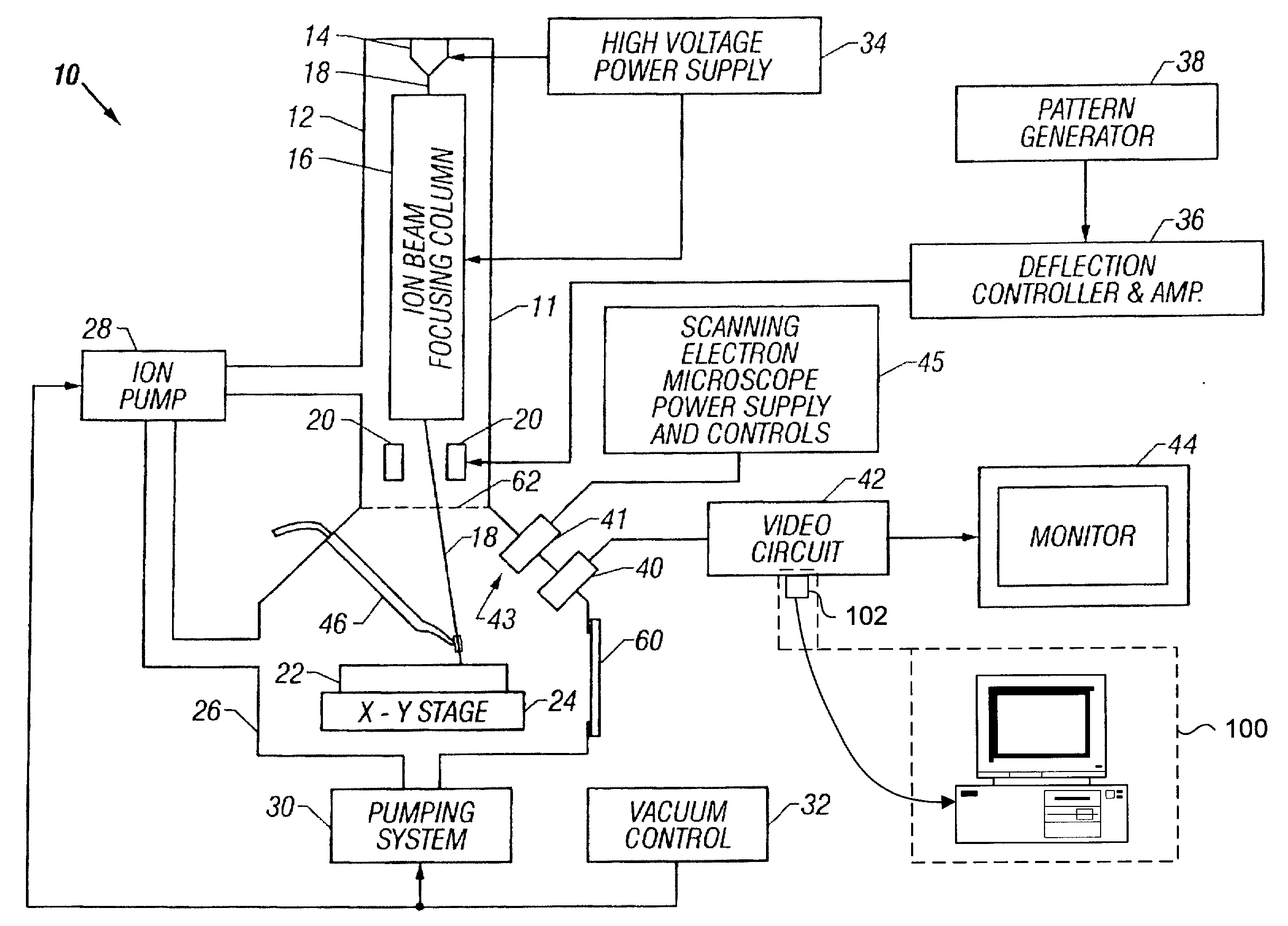

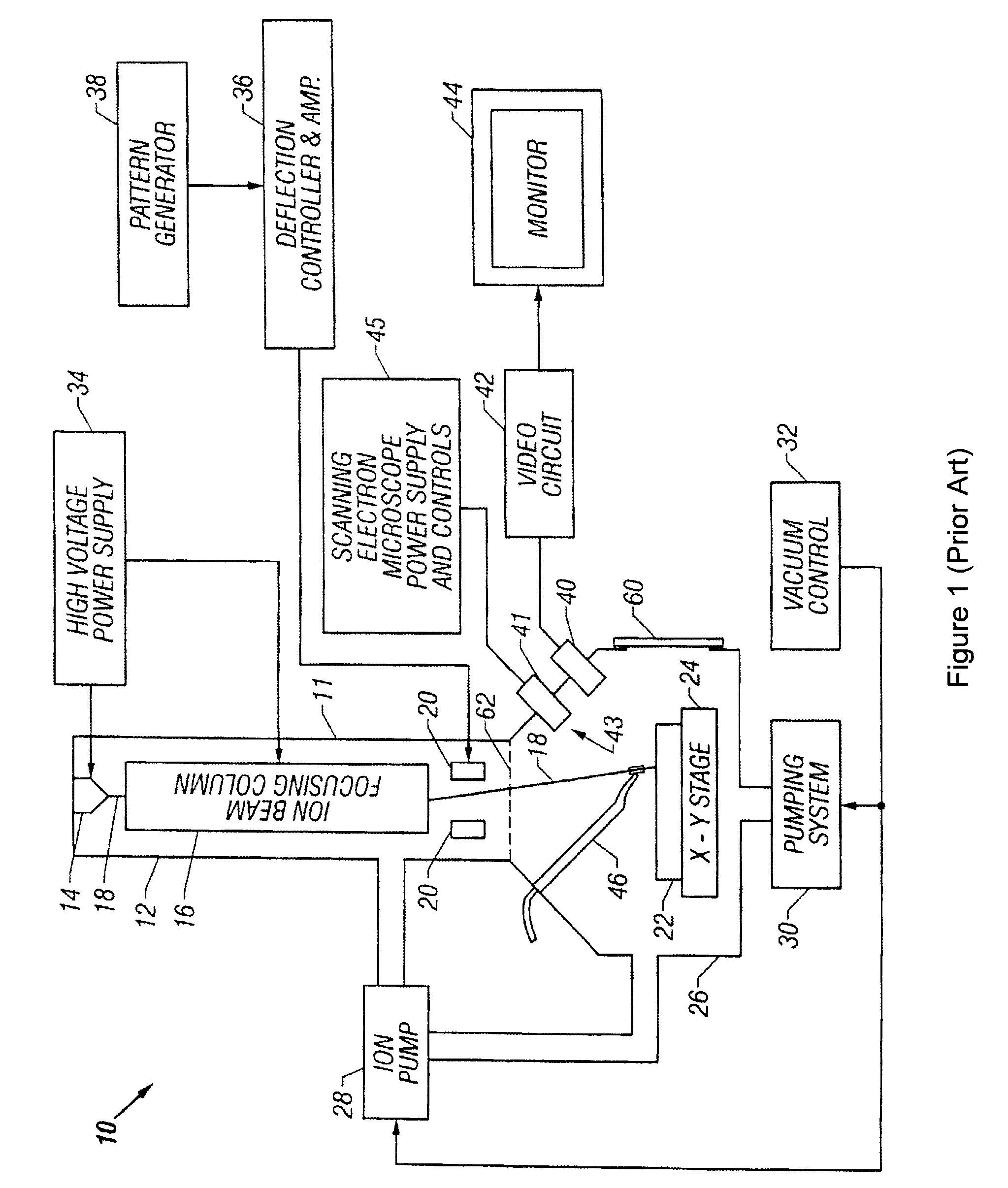

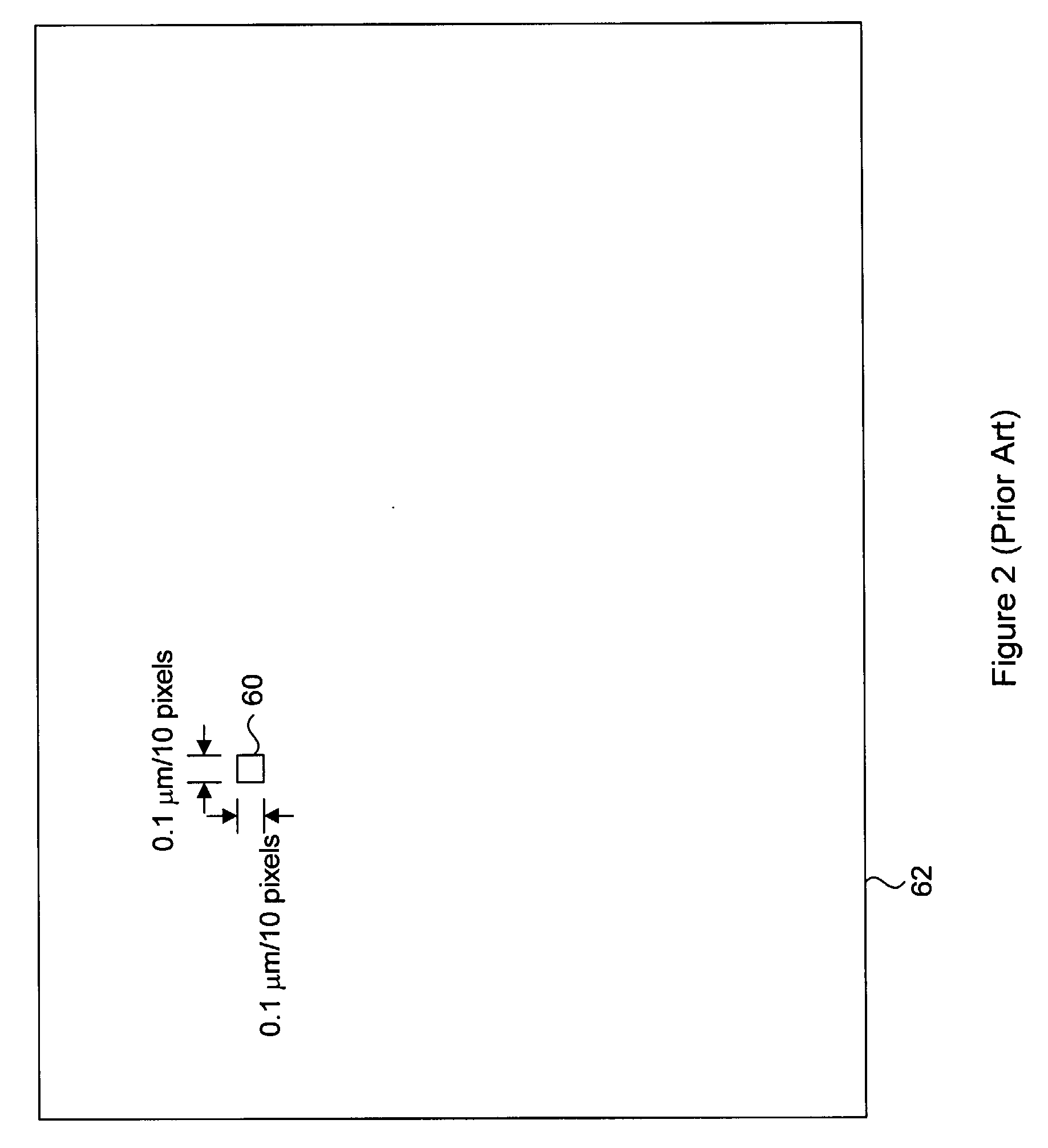

System and Method for Focused Ion Beam Data Analysis

ActiveUS20090135240A1Increase changeFacilitate cognitionMaterial analysis using wave/particle radiationSamplingGraphicsIon beam

A system and method for improving FIB milling endpointing operations. The methods involve generating real-time images of the area being milled and real-time graphical plots of pixel intensities with an increased sensitivity over native FIB system generated images and plots. The images and plots are generated with raw signal data obtained from the native FIB system. More specifically, the raw signal data is processed according to specific algorithms for generating images and corresponding intensity graphs which can be reliably used for accurate endpointing. In particular, the displayed images will display more visual information regarding changes in milled material, while the intensity graphs will plot aggregate pixel intensity data on a dynamically adjusting scale to dramatically highlight relative changes in milled material.

Owner:DCG SYST

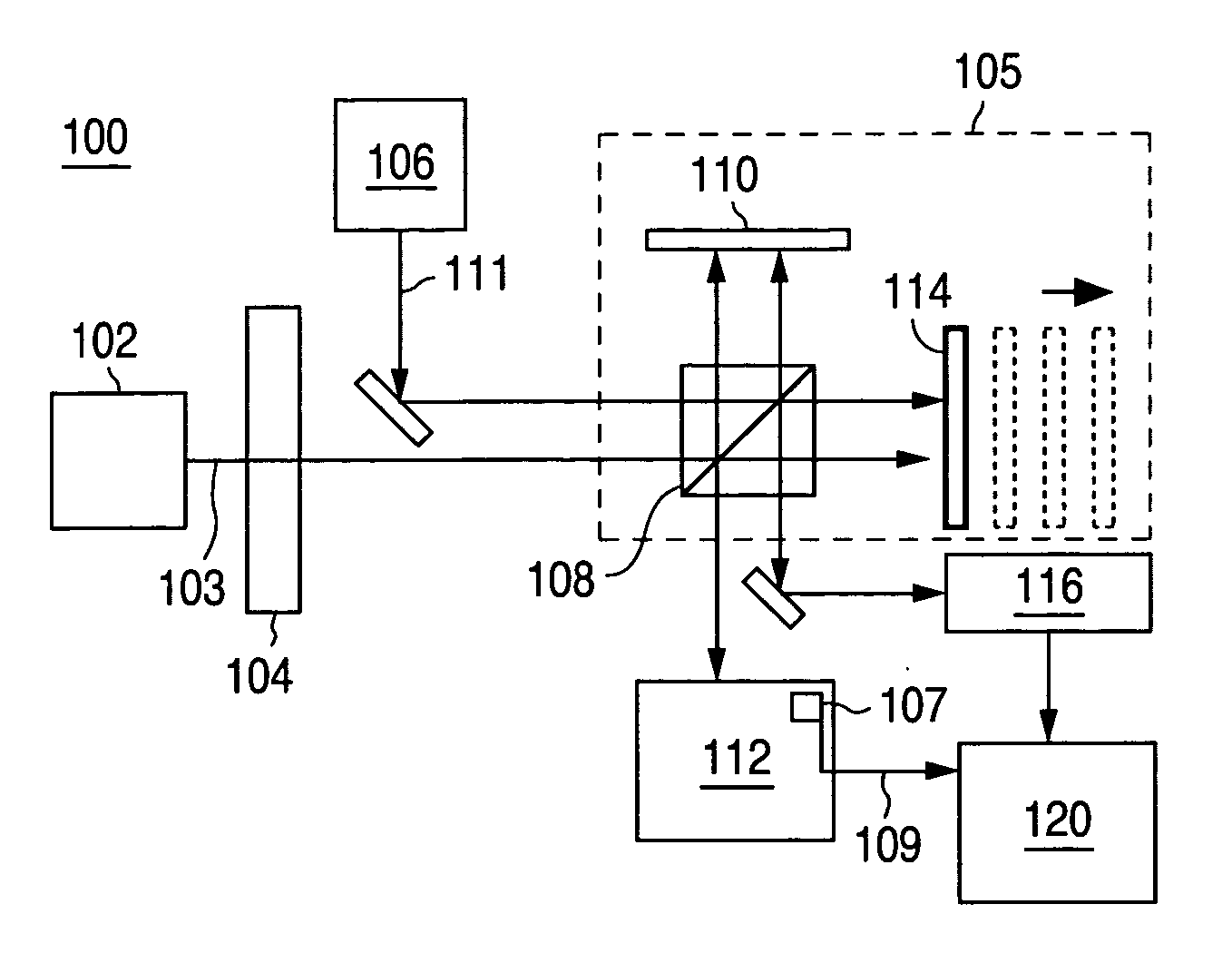

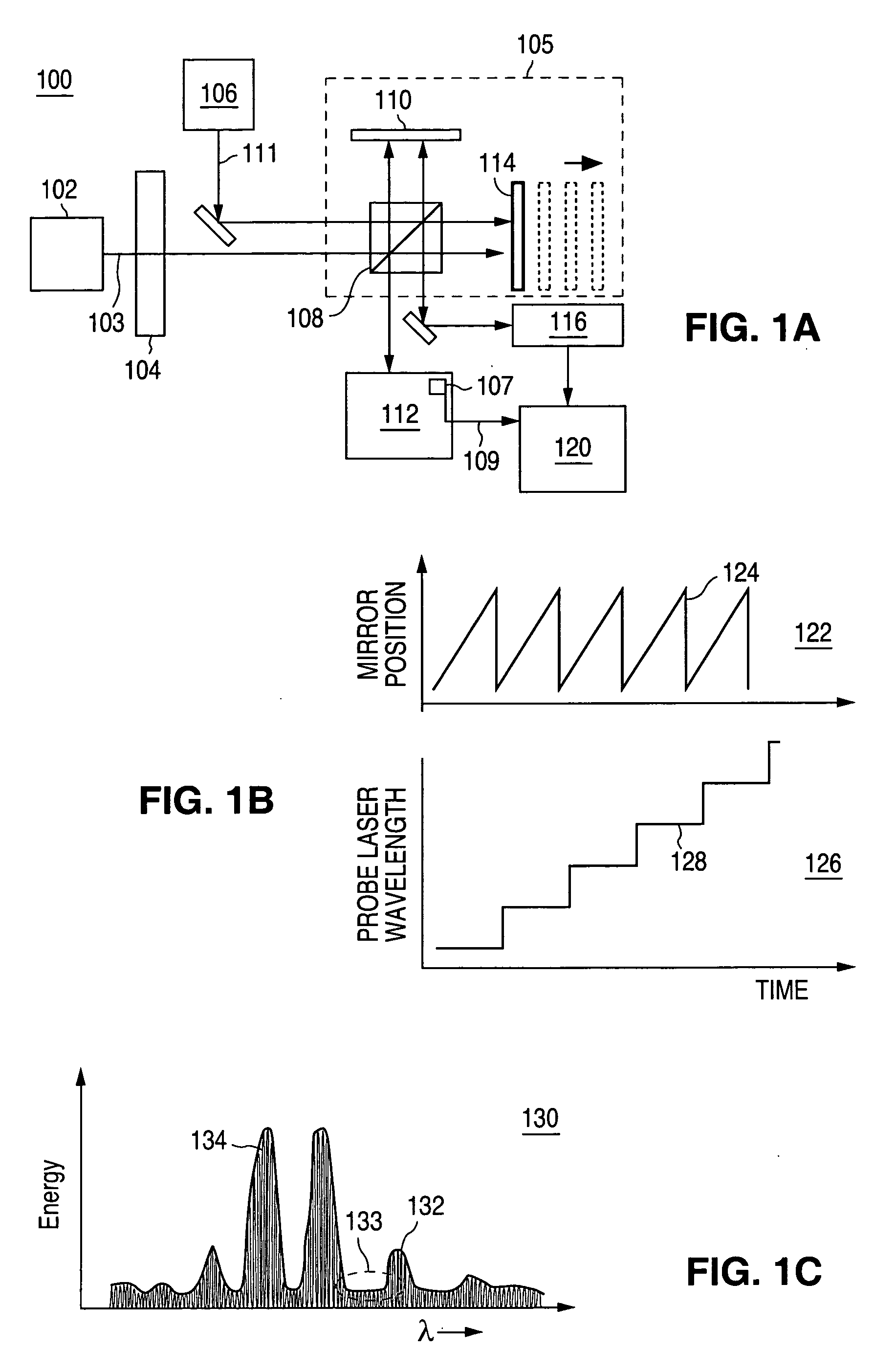

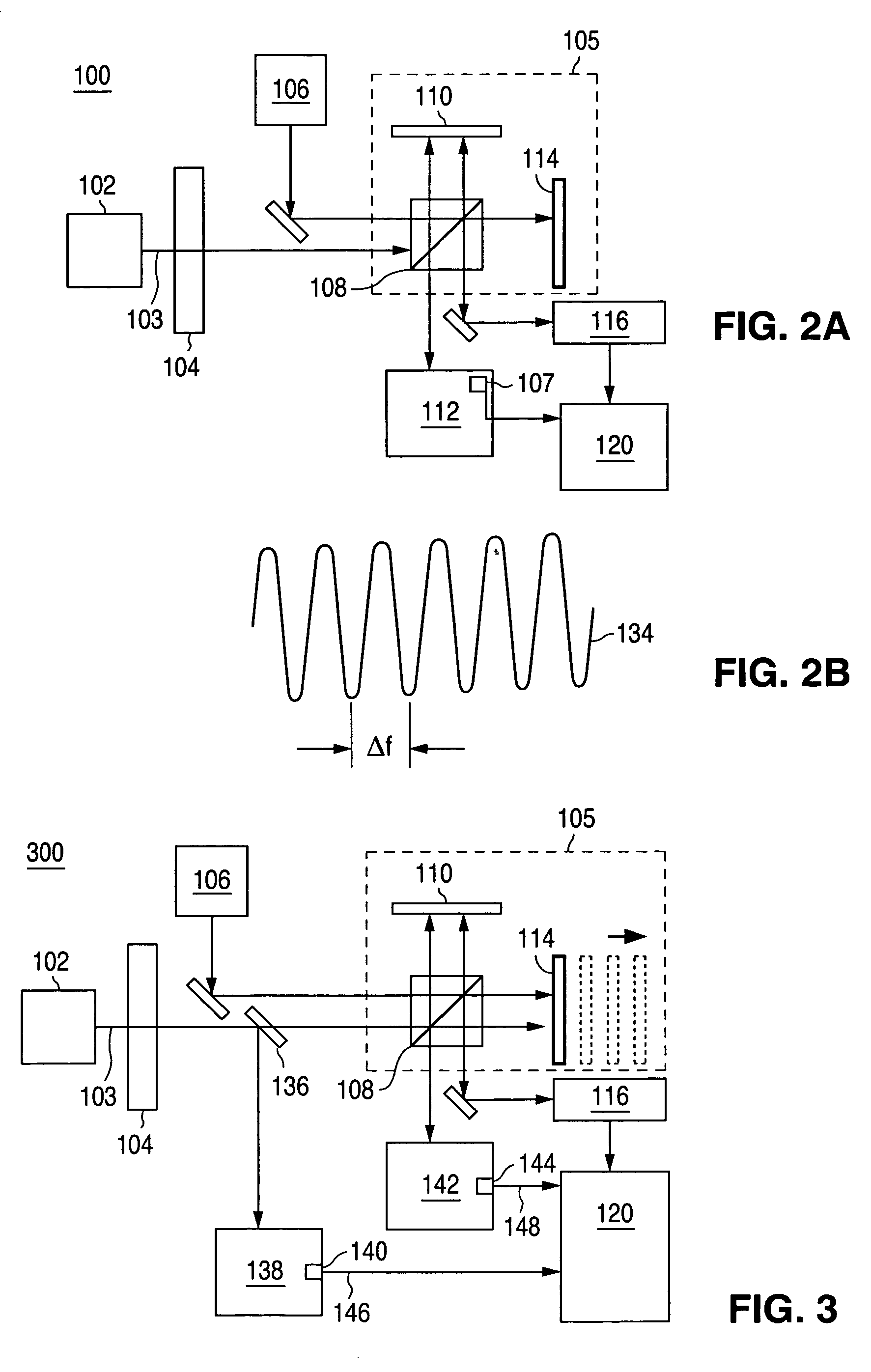

System and method for interferometric laser photoacoustic spectroscopy

InactiveUS20060262316A1Radiation pyrometryInterferometric spectrometryMaterial under testLength wave

A system of using an interferometer, in combination with a laser, and a detector to determine absorptive characteristics of a material under test. The operation of the interferometer allows for determination of the wavelength of the laser beam and for determining relative changes in the wavelength of the laser beam. A method for using a laser source and an interferometer to determine characteristics of a material under test in accordance with the present invention is also provided.

Owner:AGILENT TECH INC

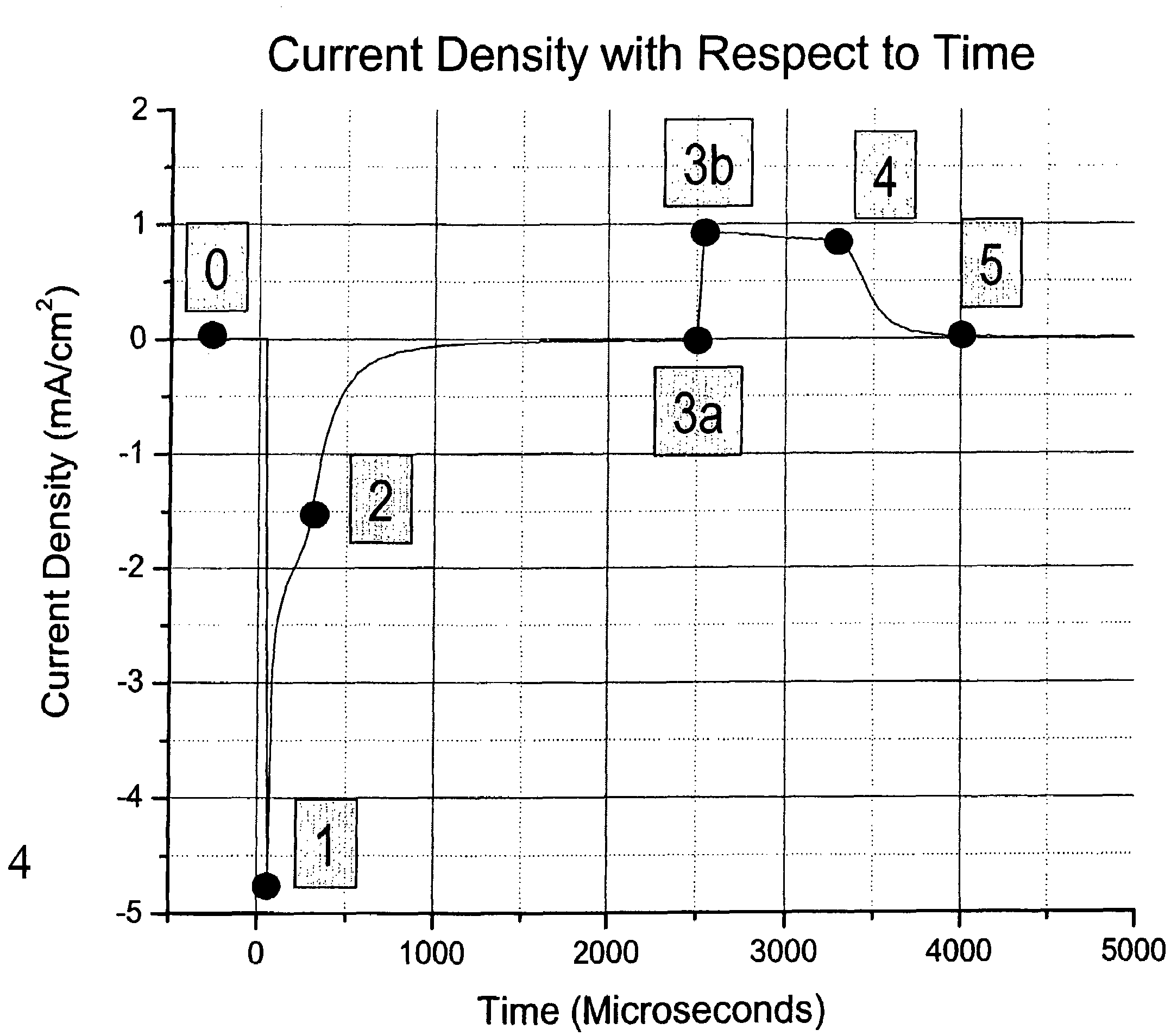

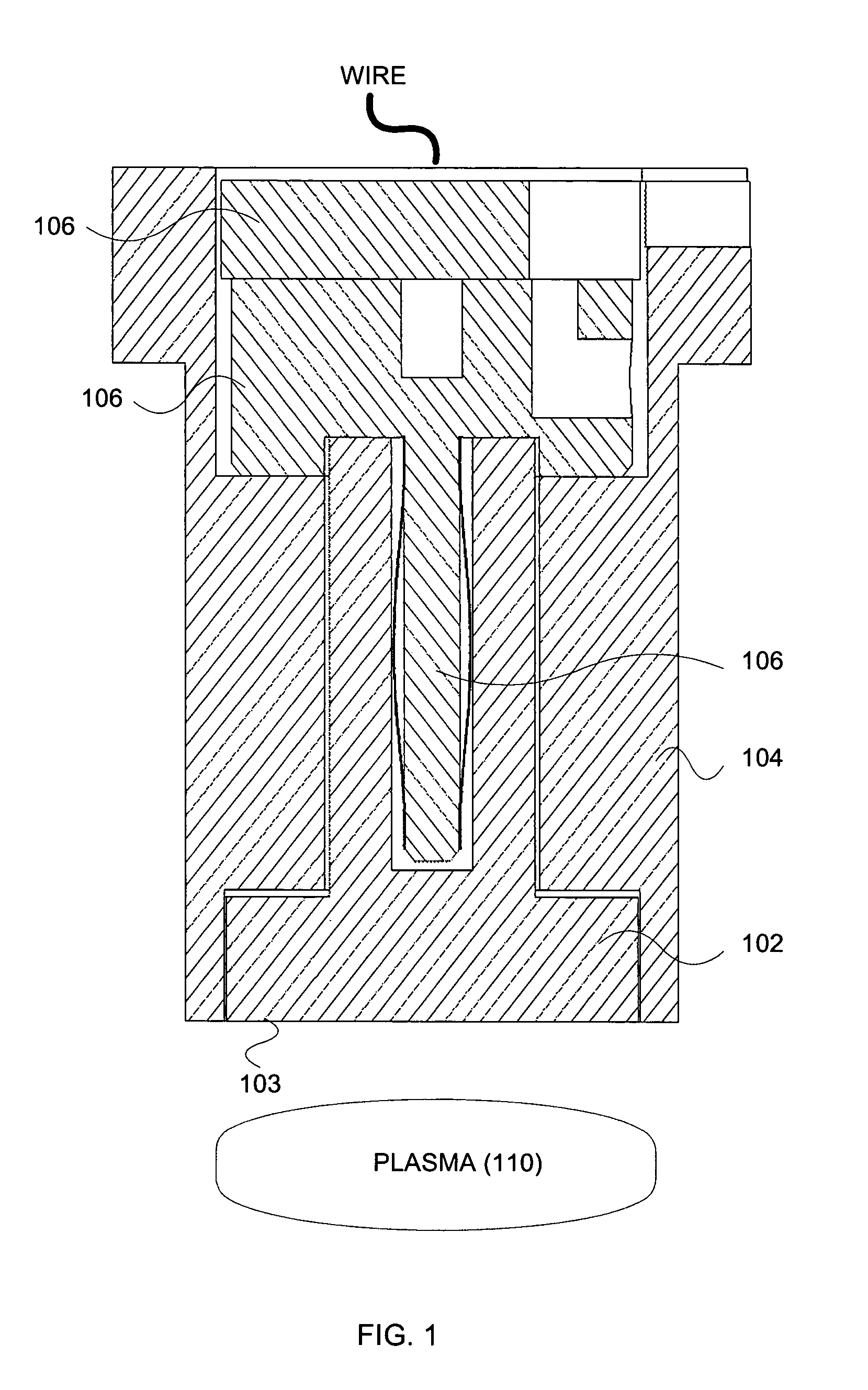

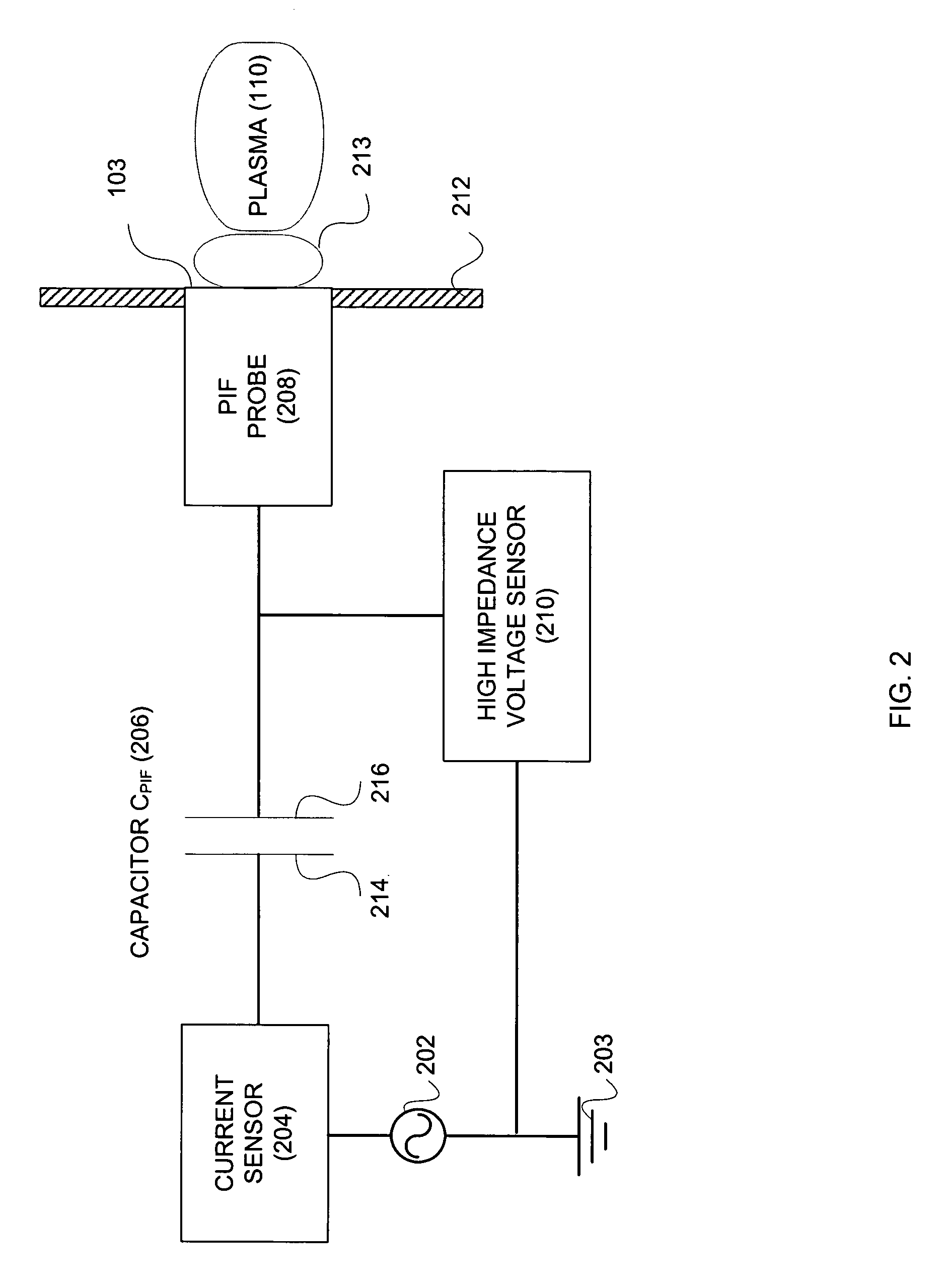

Controlling plasma processing using parameters derived through the use of a planar ion flux probing arrangement

ActiveUS7413672B1Electric discharge tubesCurrent/voltage measurementRelative ChangePlasma processing

Methods and apparatus for detecting and / or deriving the absolute values of and / or the relative changes in parameters such as the plasma potential and the ion flux using a Planar Ion Flux (PIF) probing arrangement are disclosed. The detected and / or derived values are then employed to control plasma processing processes.

Owner:LAM RES CORP

Modified Pulse Oximetry Technique For Measurement Of Oxygen Saturation In Arterial And Venous Blood

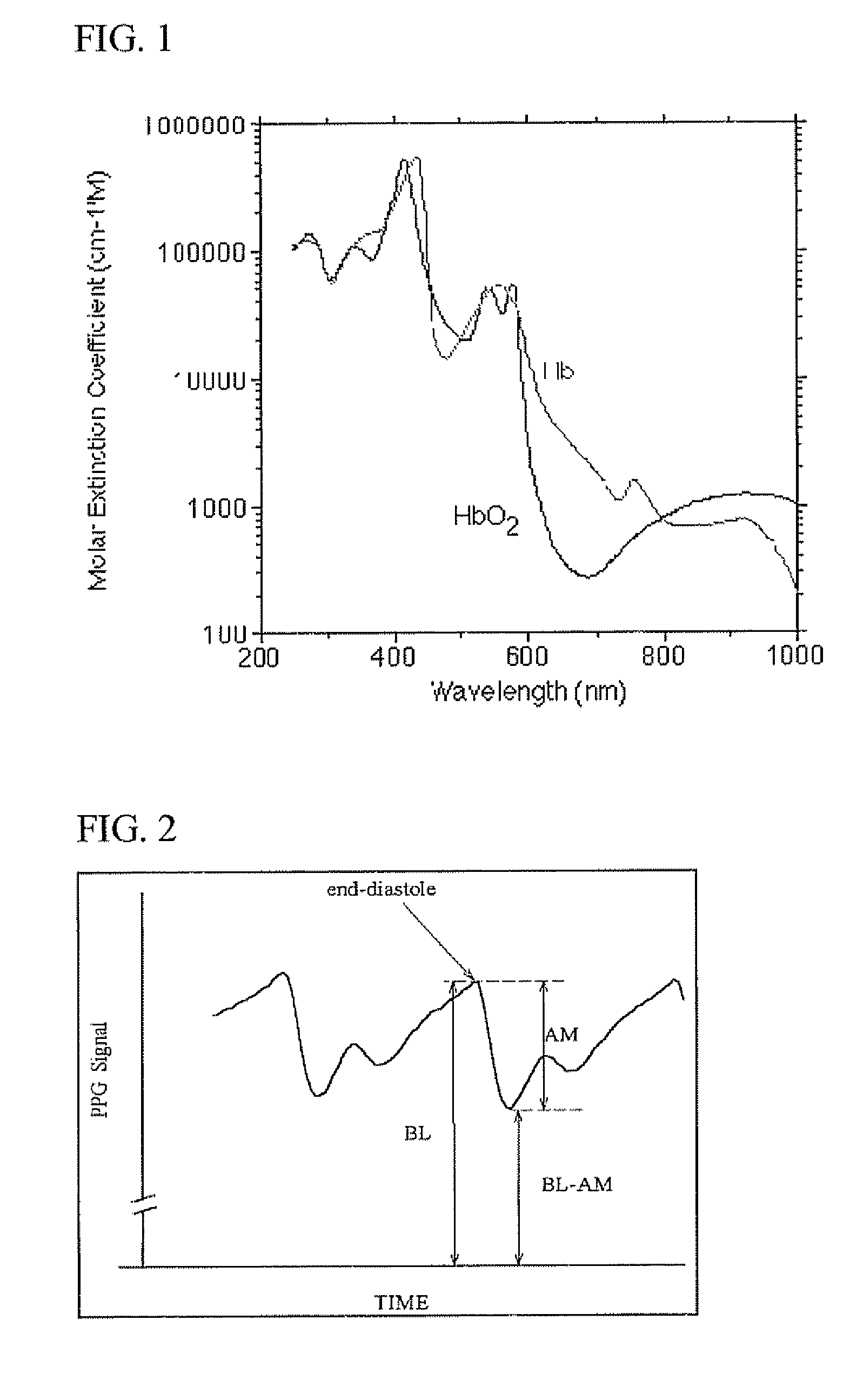

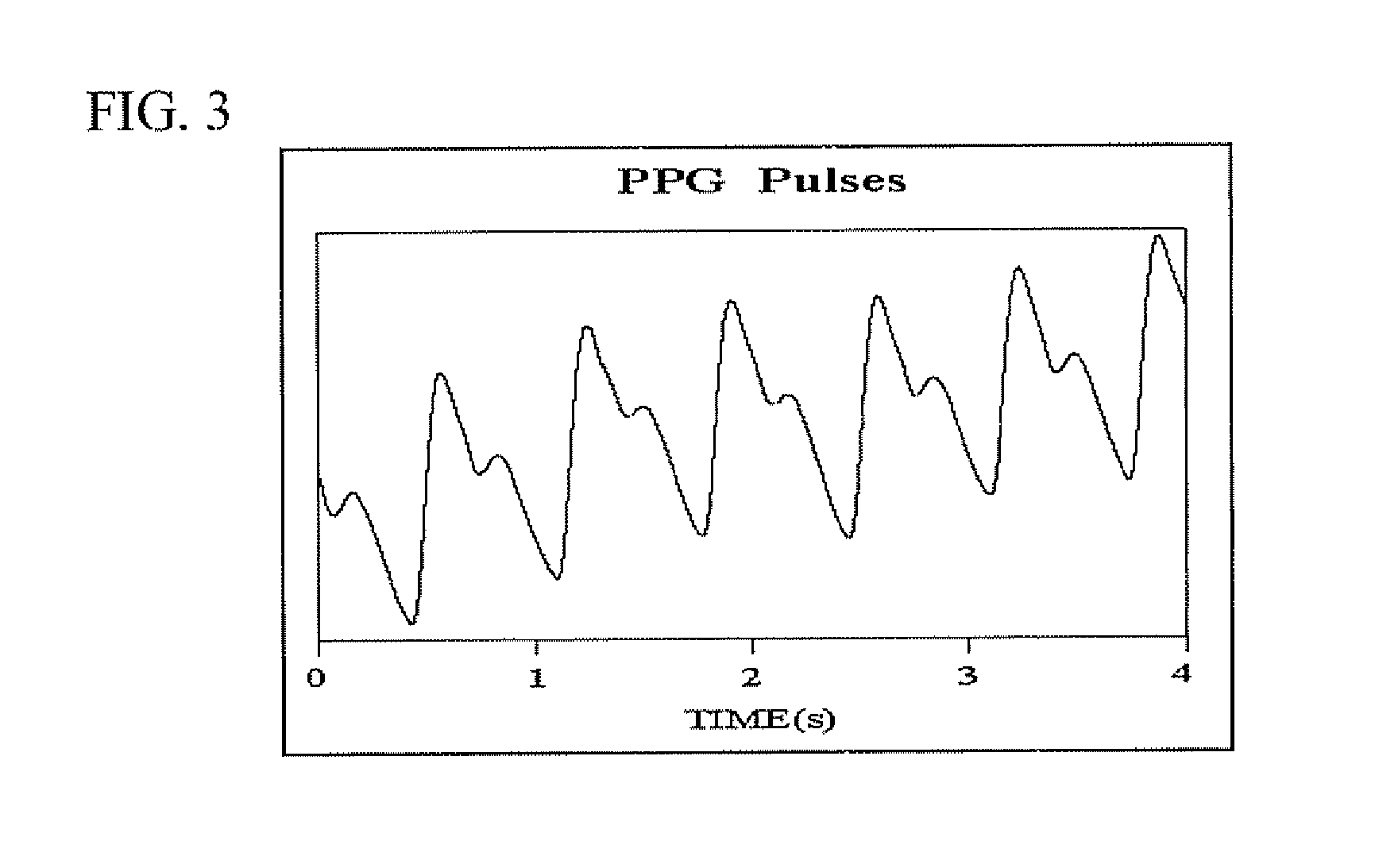

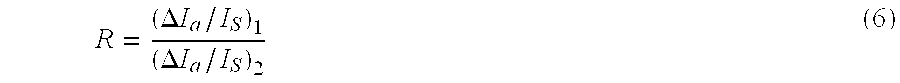

A method for the measurement of oxygen saturation in arterial blood SaO2 by means of pulse oximetry without calibration is described. Photoplethysmography (PPG) is measured in three wavelengths in the infrared and for each PPG curve the relative change in light transmission is obtained. Two equations, each relating SaO2 to the ratio of the relative changes in light transmission for two wavelengths, using the values of the extinction coefficients of oxygenated and deoxygenated hemoglobin for the three wavelengths, enable the determination of SaO2, assuming linear dependence of the optical path-length on the wavelength, for the three wavelengths in the infrared. Similar technique for the determination of oxygen saturation in venous blood from changes in light transmission due to changes in venous blood volume is suggested

Owner:JERUSALEM COLLEGE OF TECHNOLOG

Method and apparatus to determine an initial flow rate in a conduit

A method and apparatus for determining an initial flow rate in a conduit is disclosed. A known change is made to the flow to be measured, resulting changes (or values corresponding to these changes), or relative changes in the flow to be measured are monitored and the initial flow in the conduit is calculated from the value of the known change and monitored changes. Devices to practice the method include catheters having one or two sensors and one or two sites for introducing the volume change.

Owner:TRANSONIC SYST

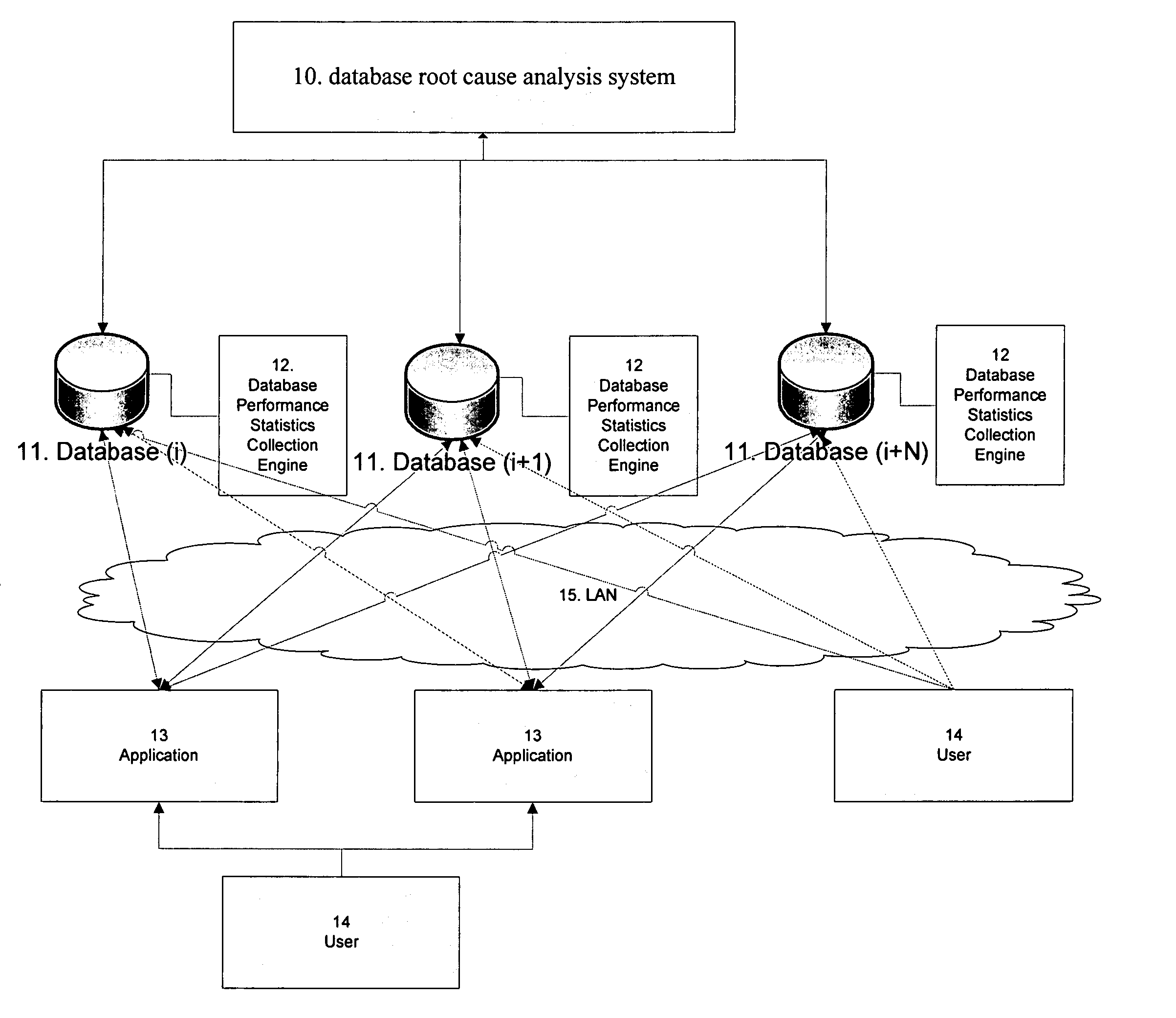

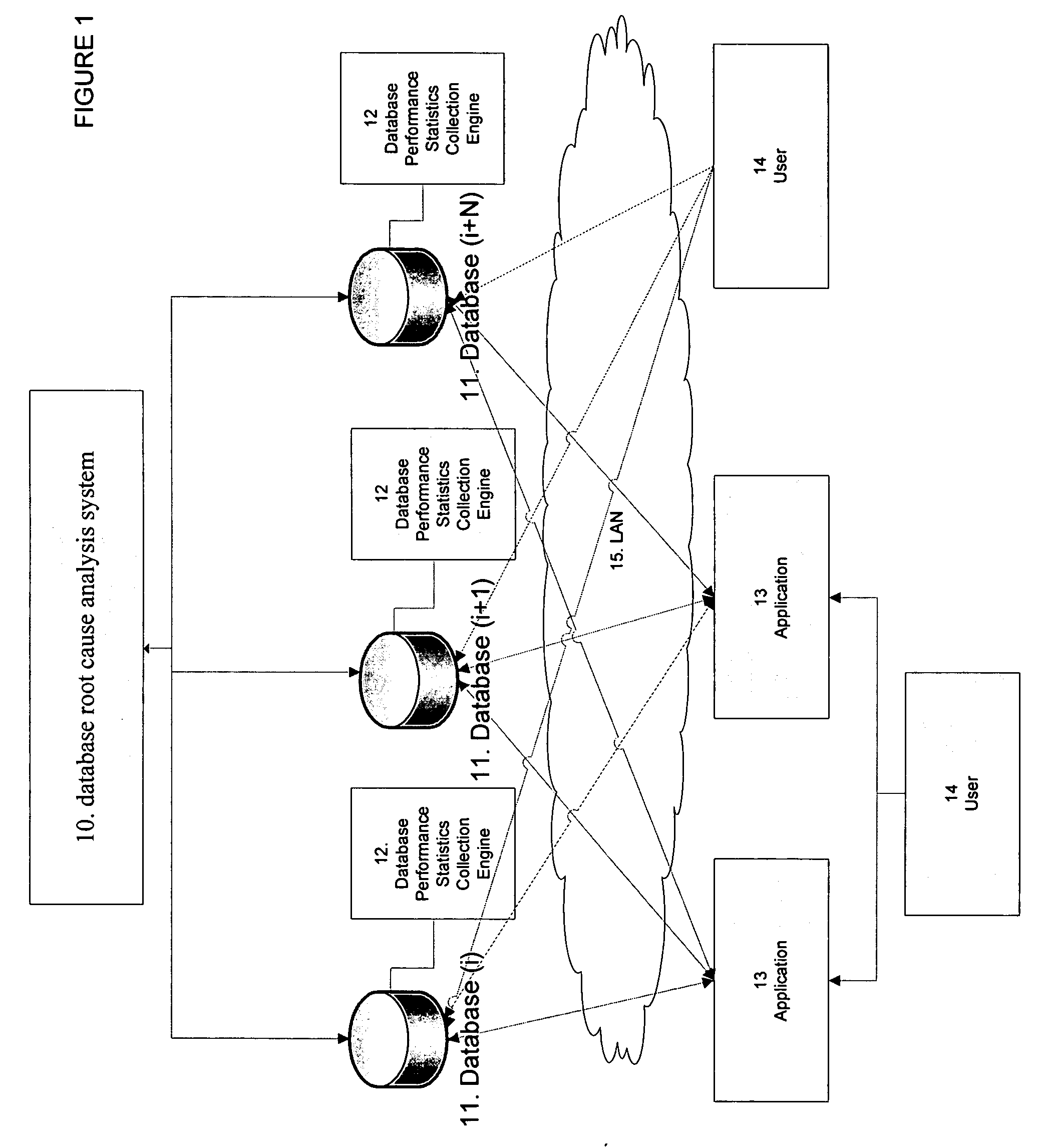

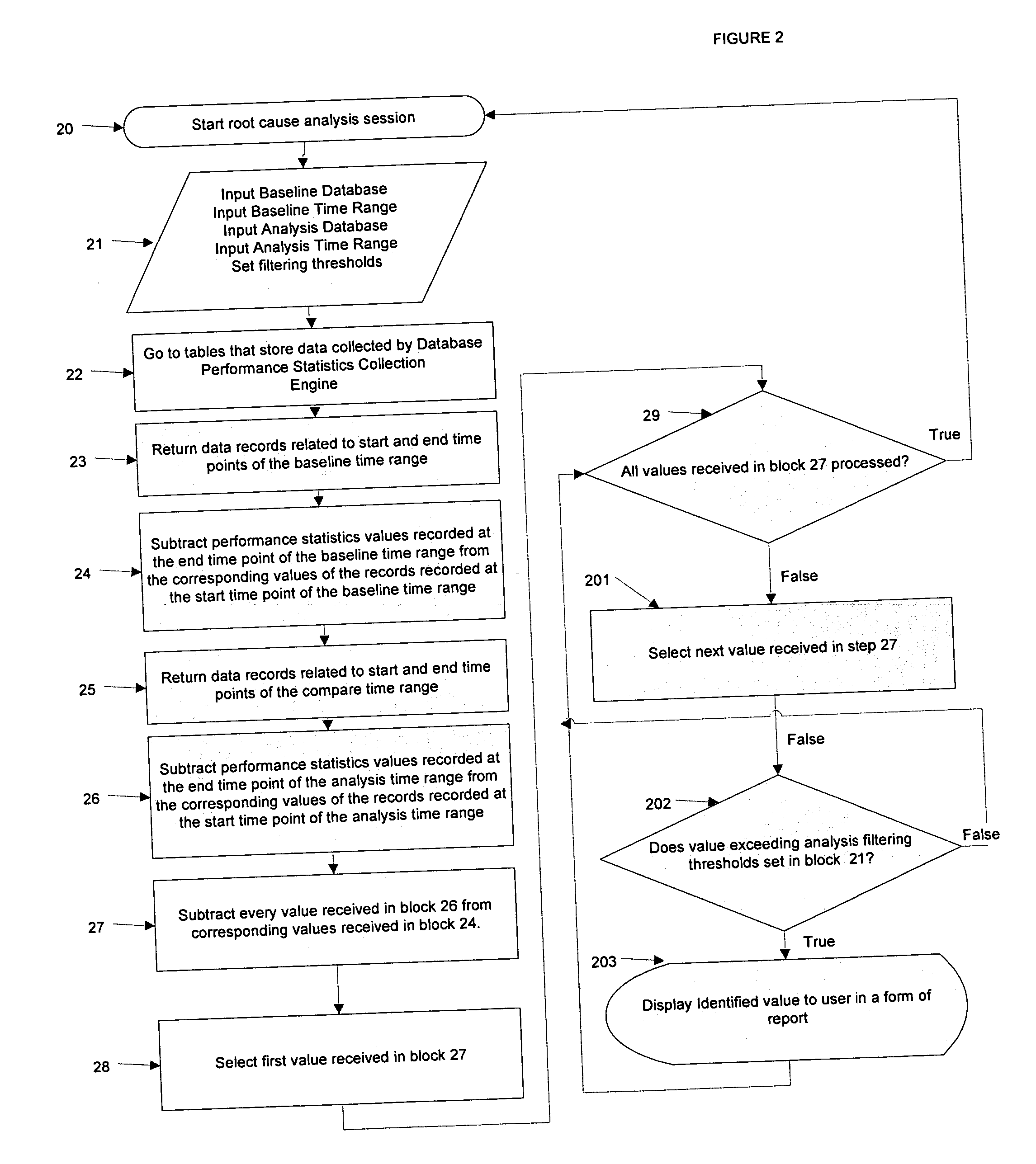

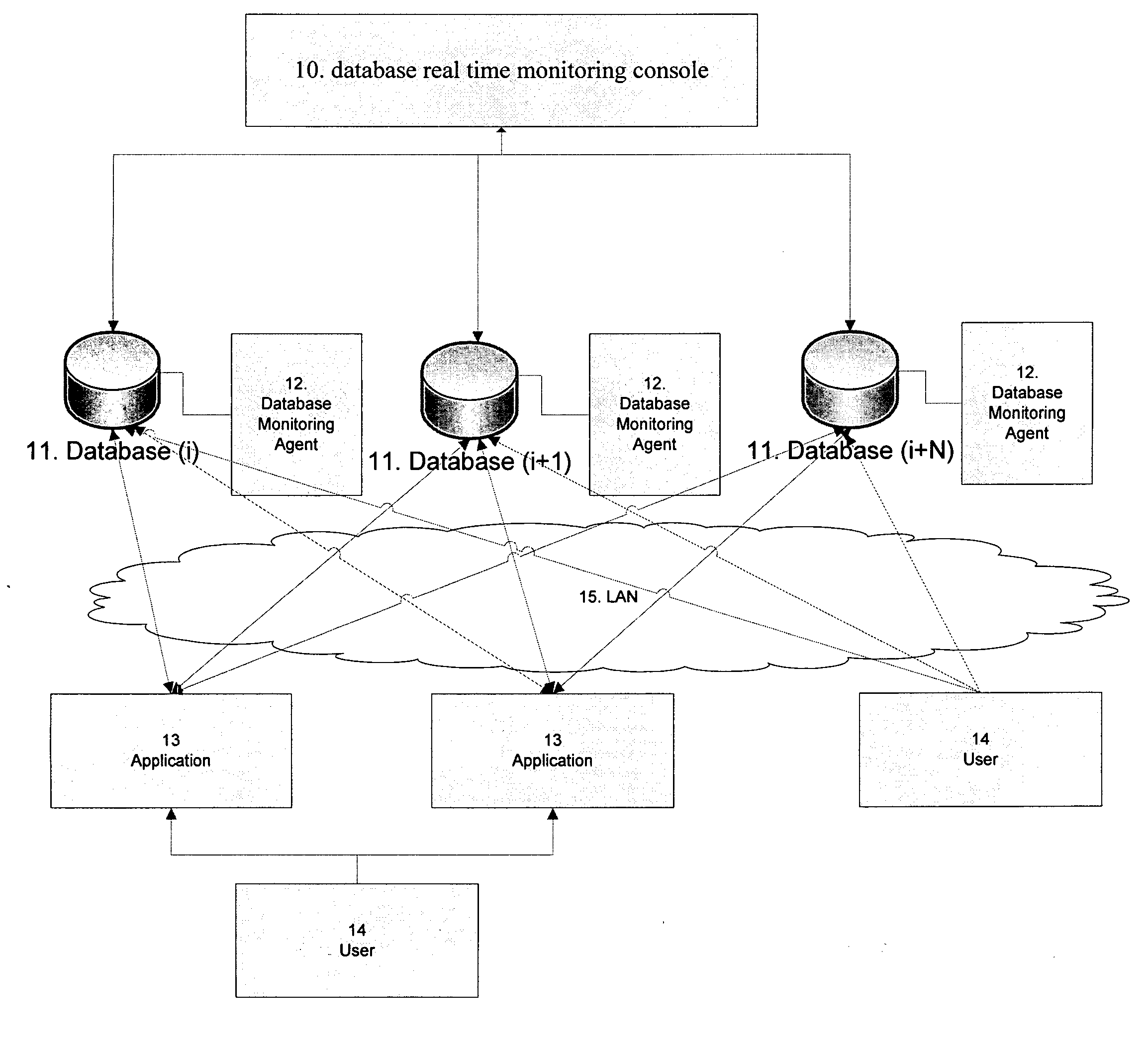

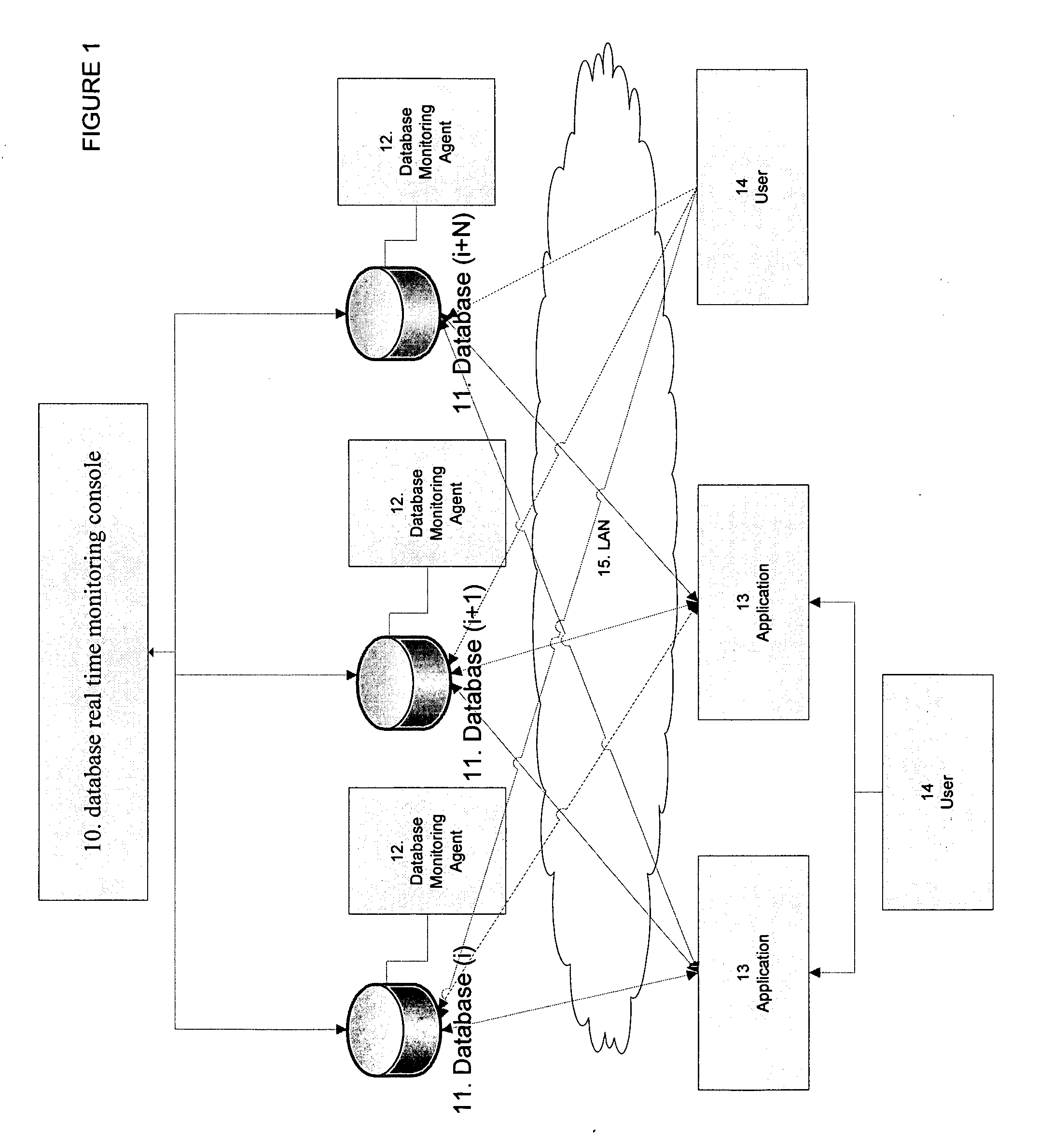

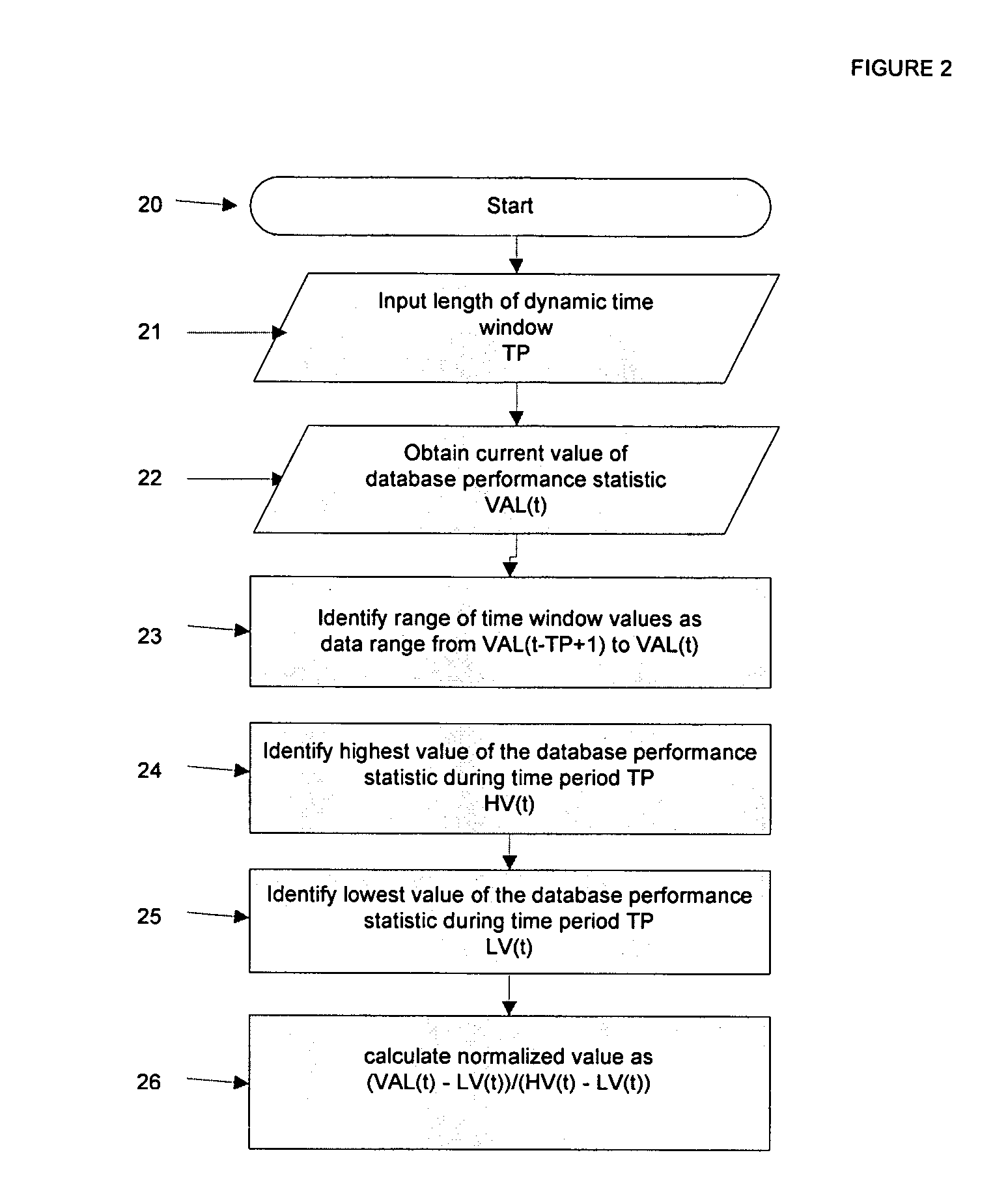

Real-time database performance and availability change root cause analysis method and system

ActiveUS20060112135A1Digital data processing detailsNuclear monitoringVisual comparisonNoise reduction algorithm

Root cause analysis of changes impacting database performance, availability and continuity to the underlying business may be performed. A system for doing so may include analytical and visual comparison root cause analysis engines to identify changed database performance statistical parameters (such as CPU consumption, physical I / O, etc) related to a historical period of time on a single database or across multiple databases. Result data may be displayed through a series of charts and reports that may indicate whether correlations exist between unexpected database performance and relative changes in database performance statistical parameters. A visual root cause analysis system may further apply noise reduction algorithms to clarify trends in changes of database system performance.

Owner:ENTEROS INC

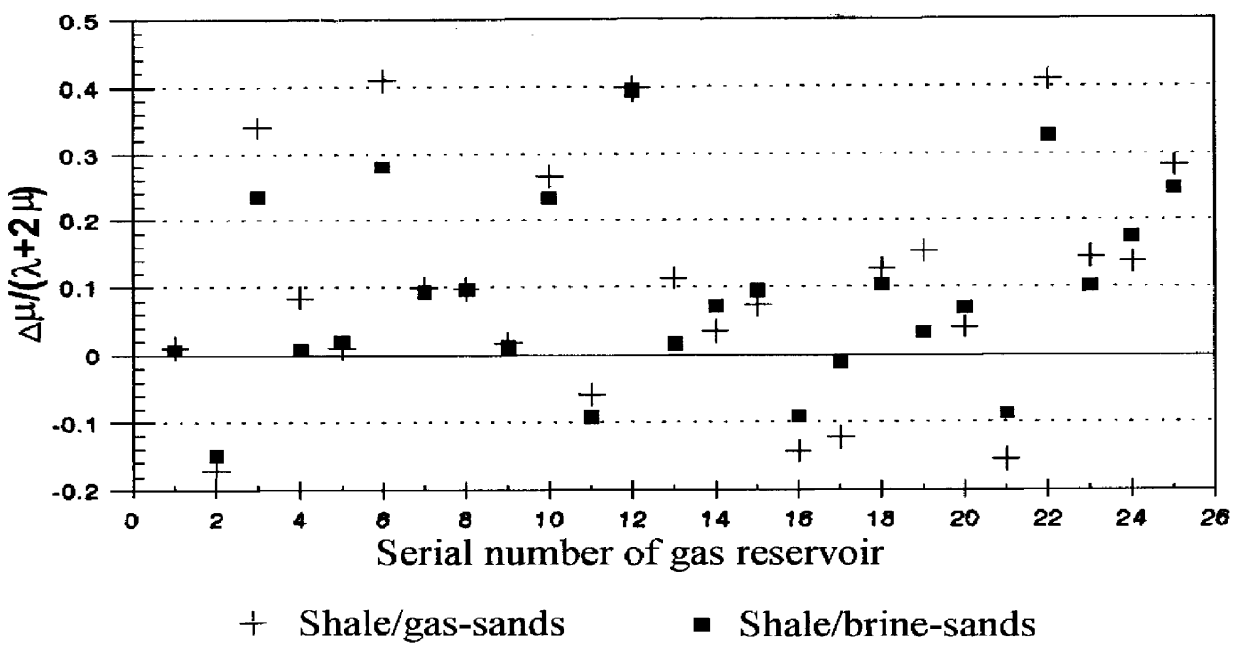

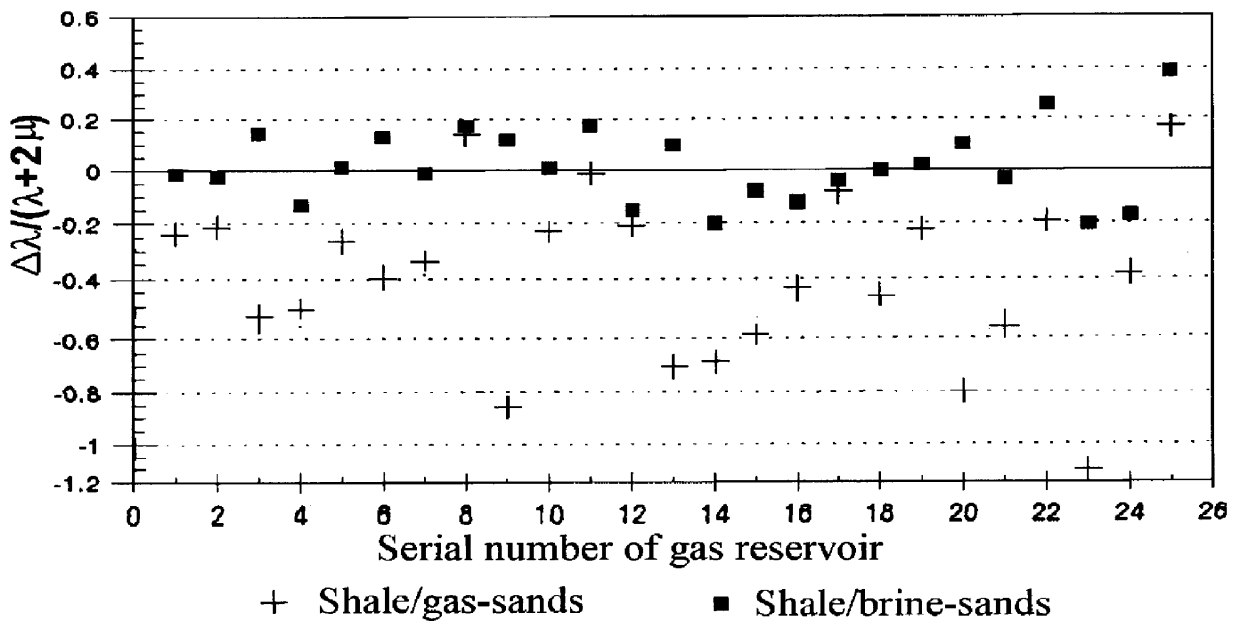

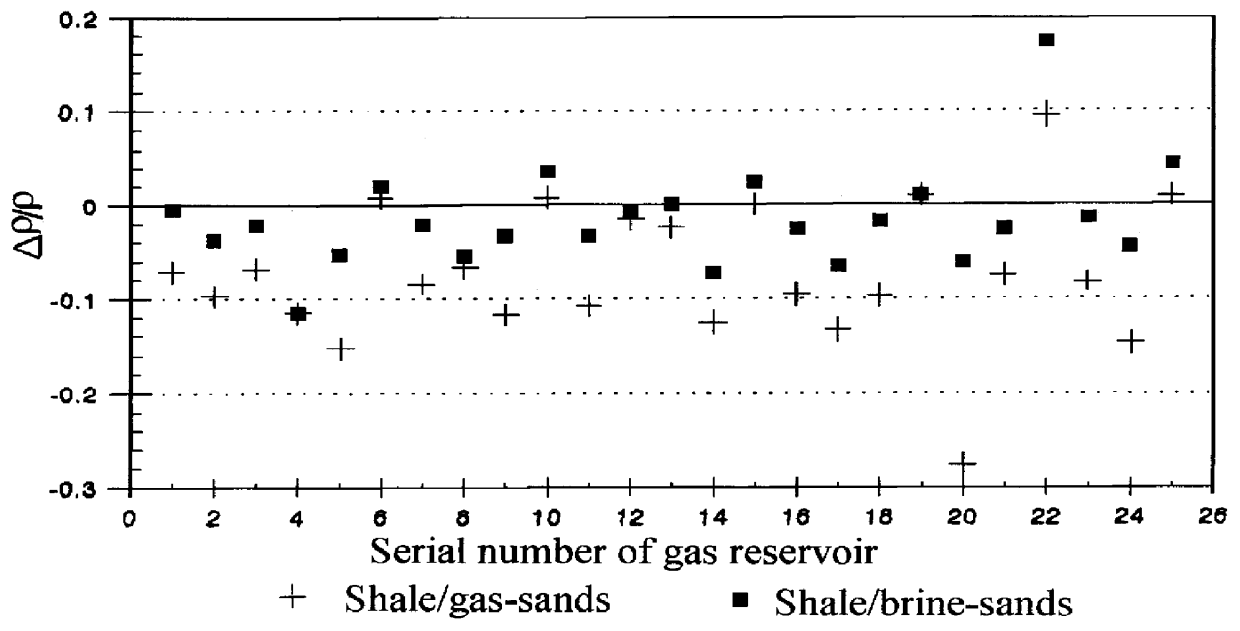

Method of determining, displaying and using the relative changes of elastic modulus and density of underground rock

InactiveUS6091669AReduce riskIncrease the number ofSeismic signal processingShear modulusClassical mechanics

PCT No. PCT / CN96 / 00104 Sec. 371 Date Sep. 29, 1998 Sec. 102(e) Date Sep. 29, 1998 PCT Filed Nov. 20, 1996 PCT Pub. No. WO97 / 19370 PCT Pub. Date May 29, 1997The general object of the present invention is to provide a method for determining and displaying the relative changes of elastic moduli and that of density of geologic formations and for utilizing these relative changes and plottings for gas / oil exploration, especially for direct gas and light oil detection. The said relative changes of elastic moduli are the relative change of Lame constant DELTA lambda / ( lambda +2 mu ), the relative change of shear modulus DELTA mu / ( lambda +2 mu ) and / or DELTA mu / [ kappa +(4 / 3) mu ], the relative change of bulk modulus DELTA kappa / [ kappa +(4 / 3) mu ]; and the relative change of density is DELTA rho / rho .

Owner:CHINA NAT OFFSHORE OIL CORP

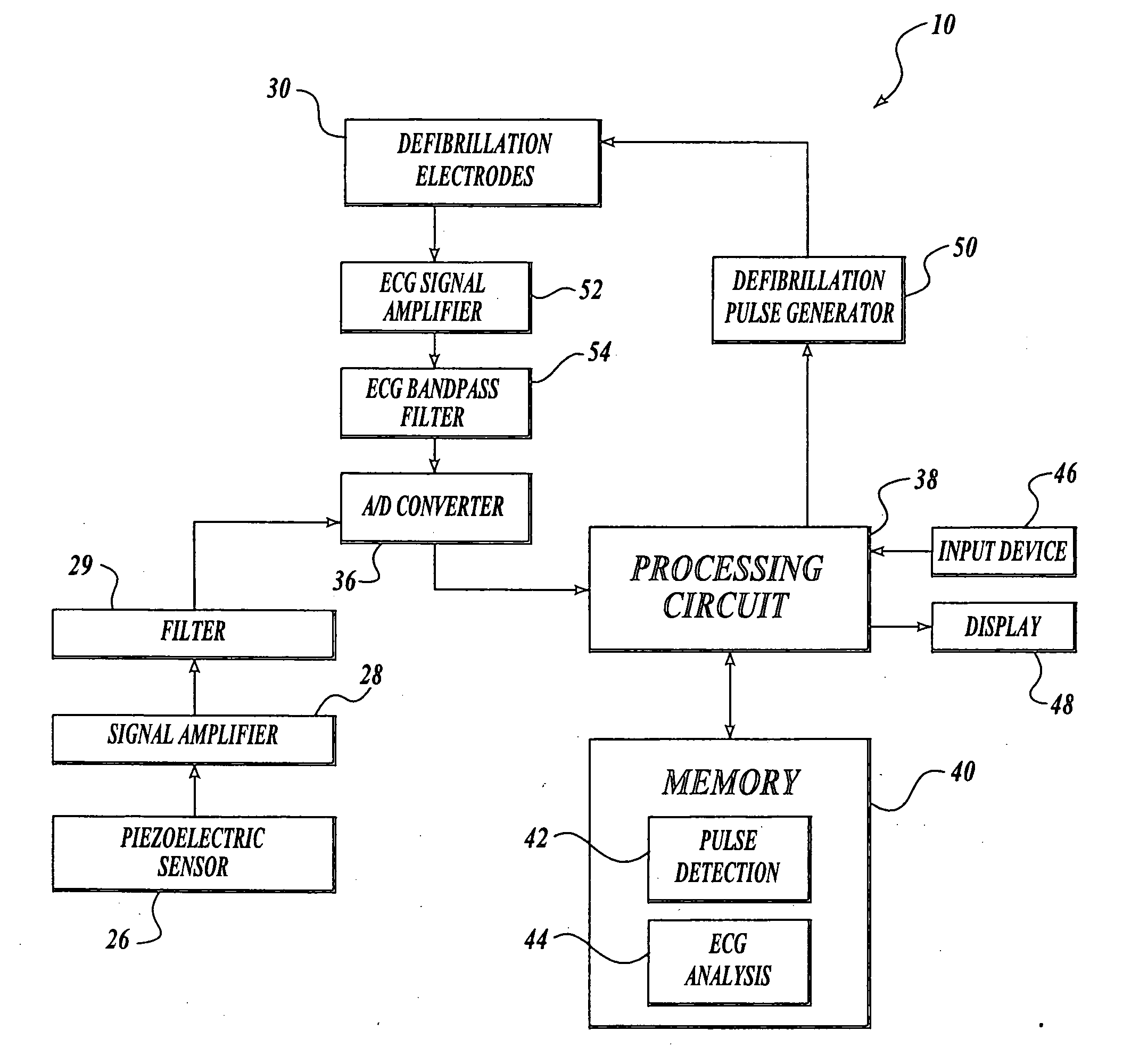

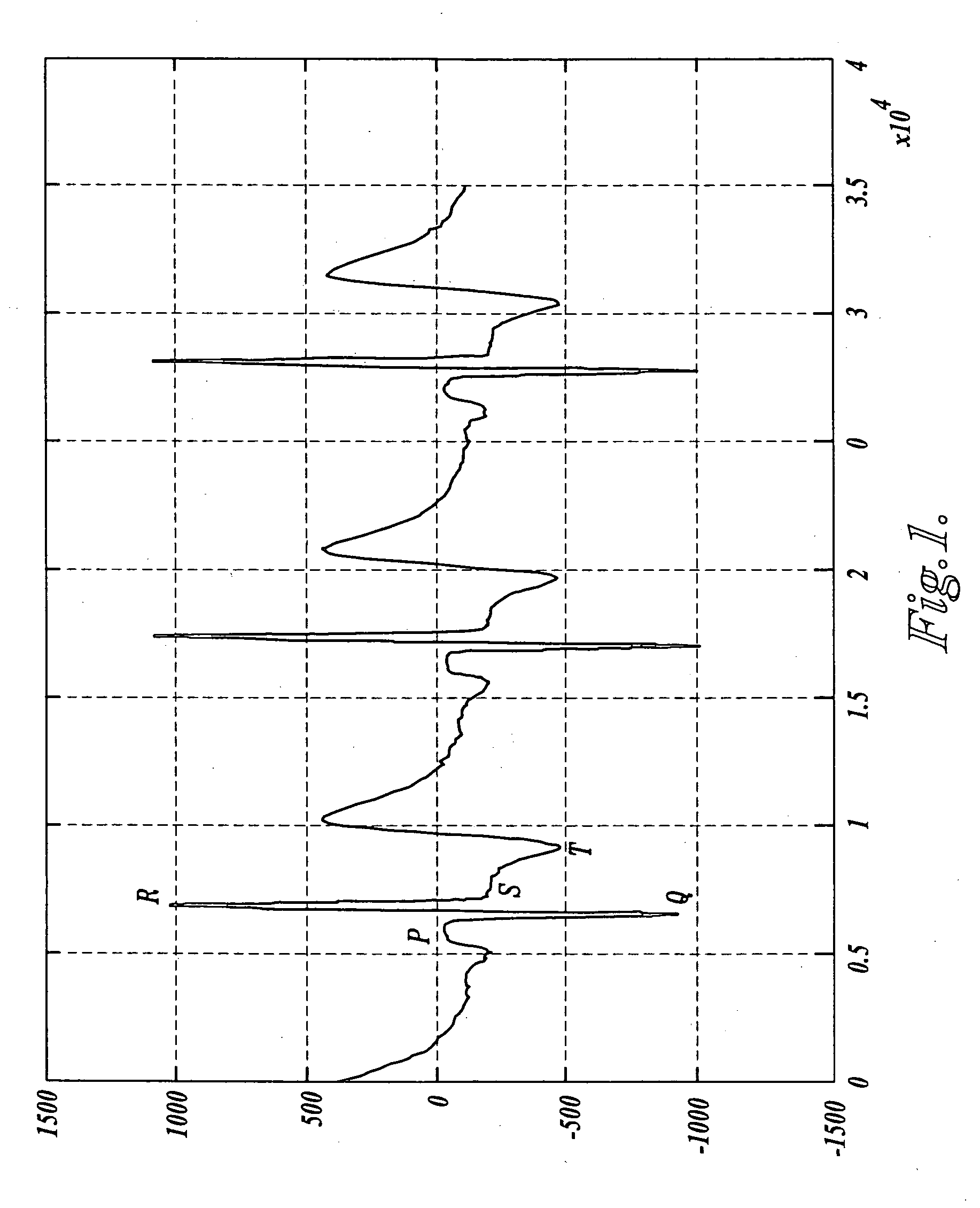

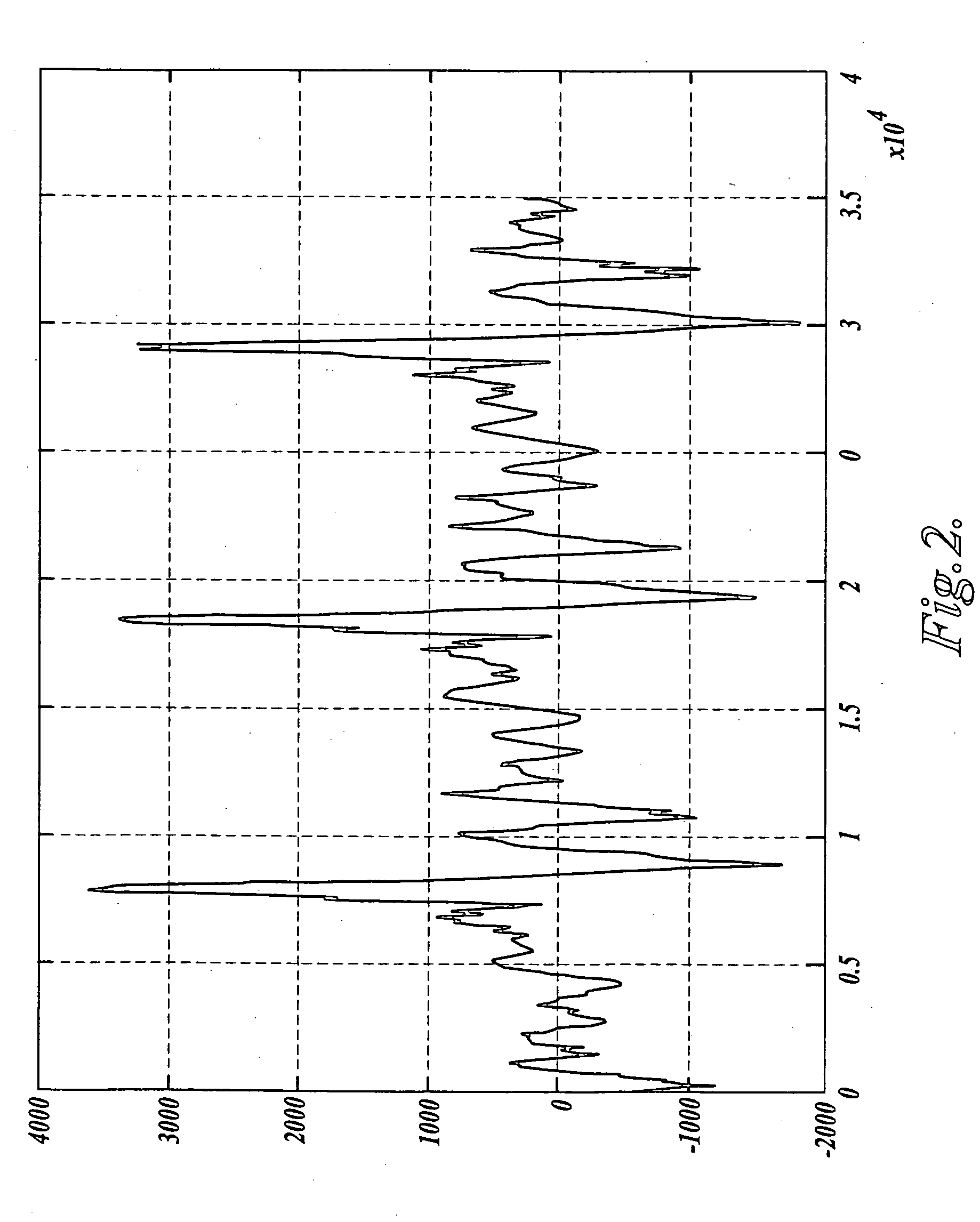

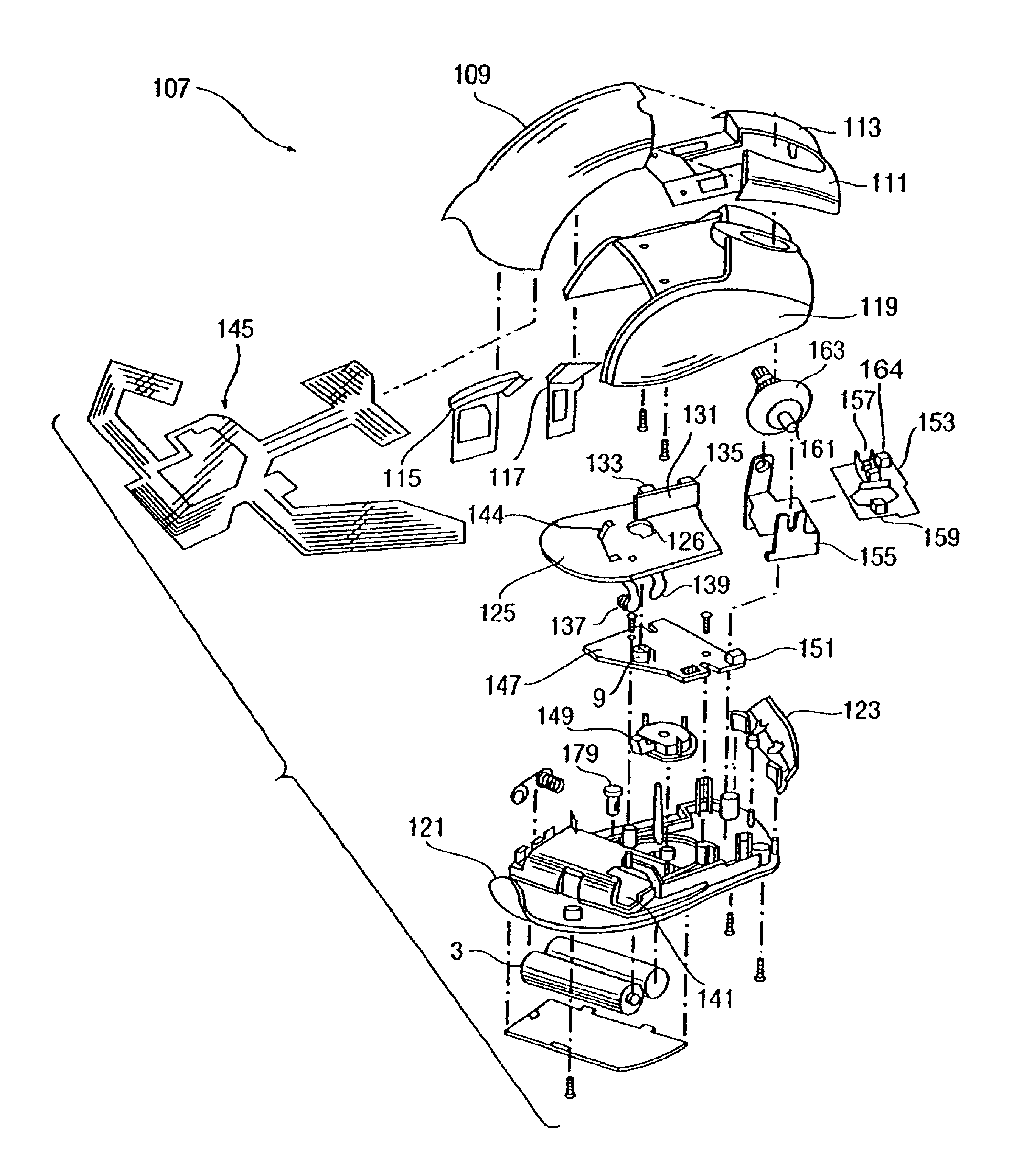

Apparatus, software, and methods for cardiac pulse detection using a piezoelectric sensor

Signal data obtained from a piezoelectric sensor placed on a patient's body is used to detect the presence of a cardiac pulse. The piezoelectric sensor has a transducing element adapted to sense movement due to a cardiac pulse and produce piezoelectric signal data in response thereto. Processing circuitry analyzes the piezoelectric signal data for a feature indicative of a cardiac pulse and determines whether a cardiac pulse is present in the patient based on the feature. In one aspect, the feature may be a temporal feature such as a relative change in energy. In another aspect, the feature may be a spectral feature such as the energy or frequency of a peak in the energy spectrum of the signal. In yet another aspect, the feature may be obtained by comparing the piezoelectric signal data with a previously-identified pattern known to predict the presence of a cardiac pulse. Multiple features may also be obtained from the piezoelectric signal data and classified to determine the presence of a cardiac pulse.

Owner:PHYSIO CONTROL INC

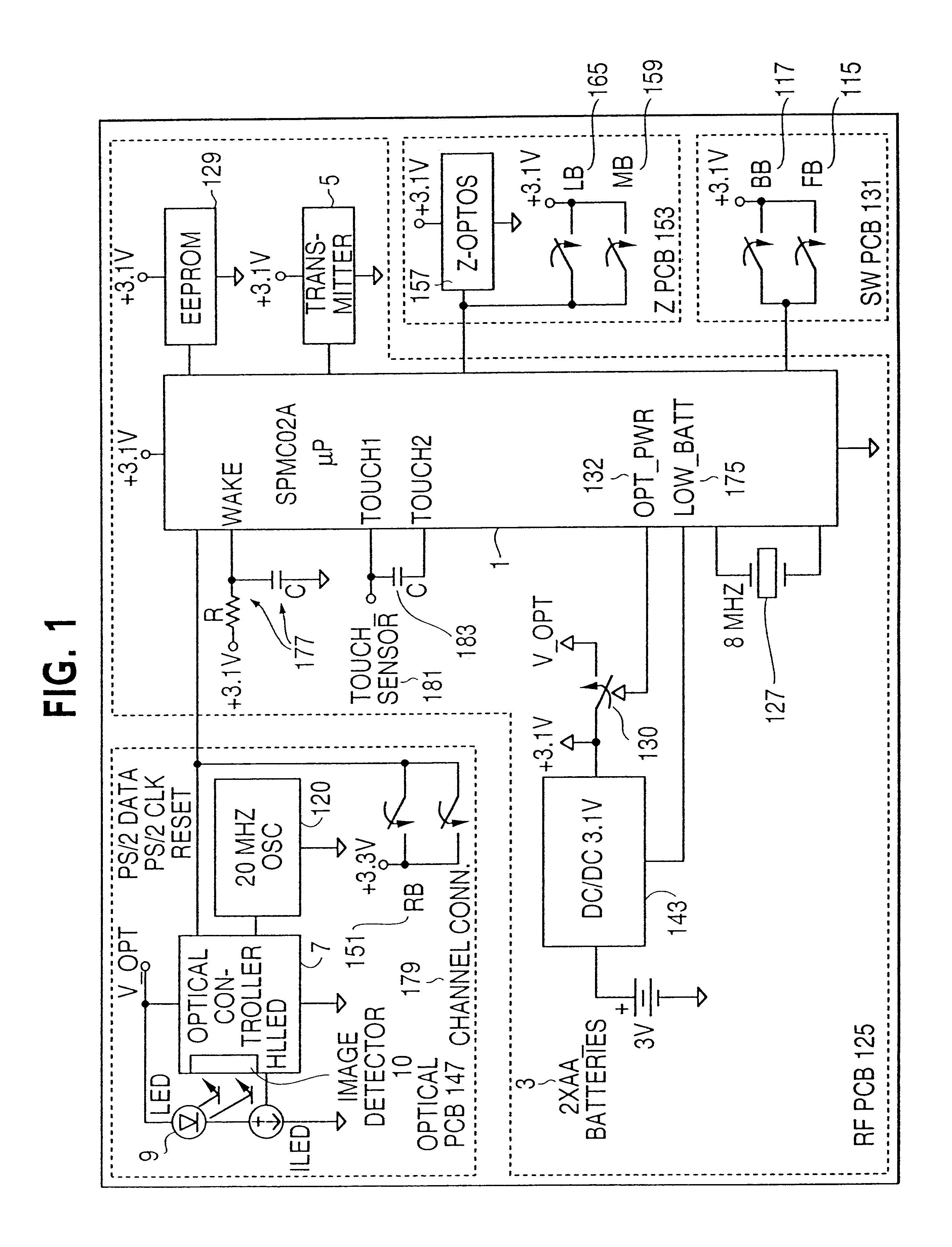

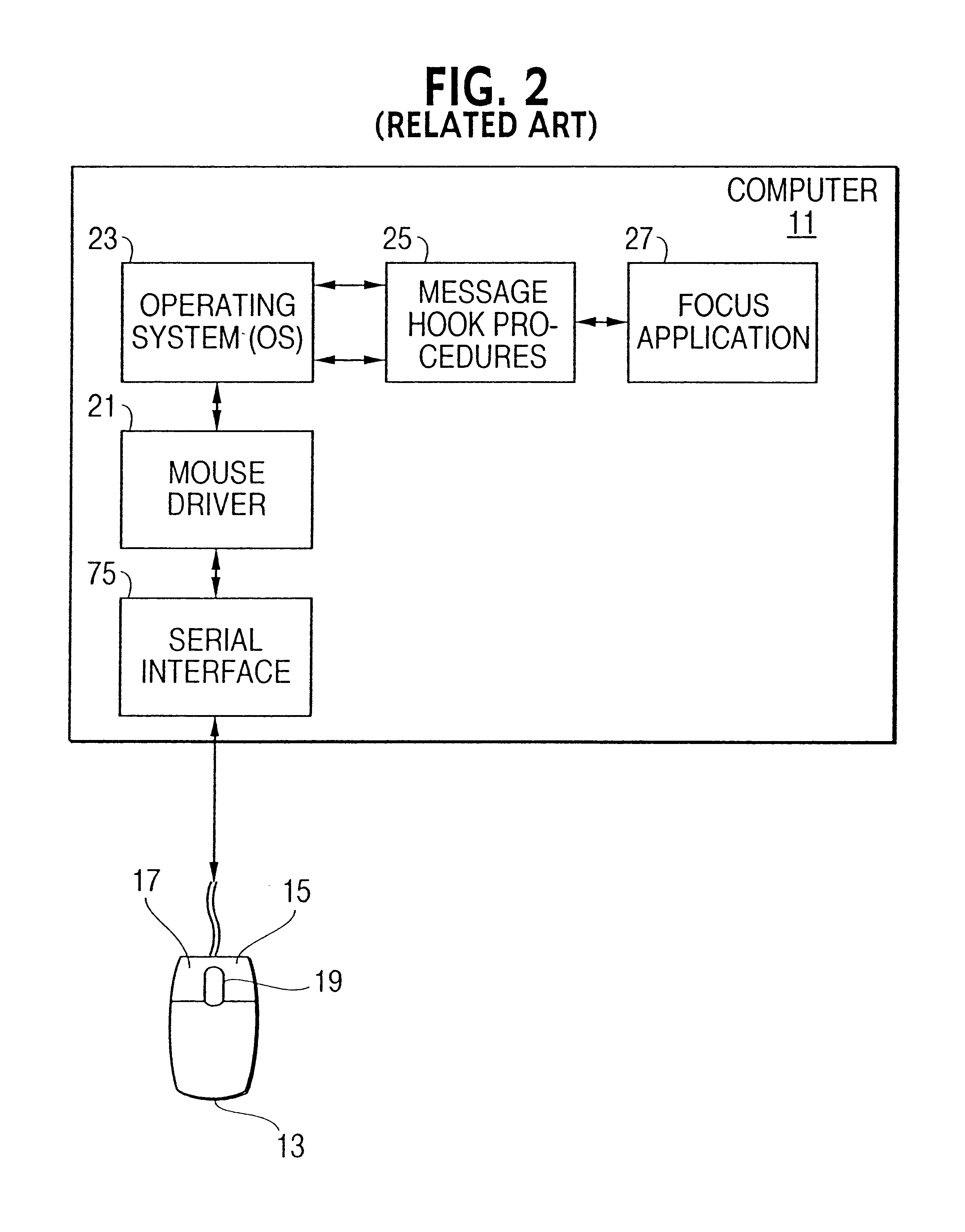

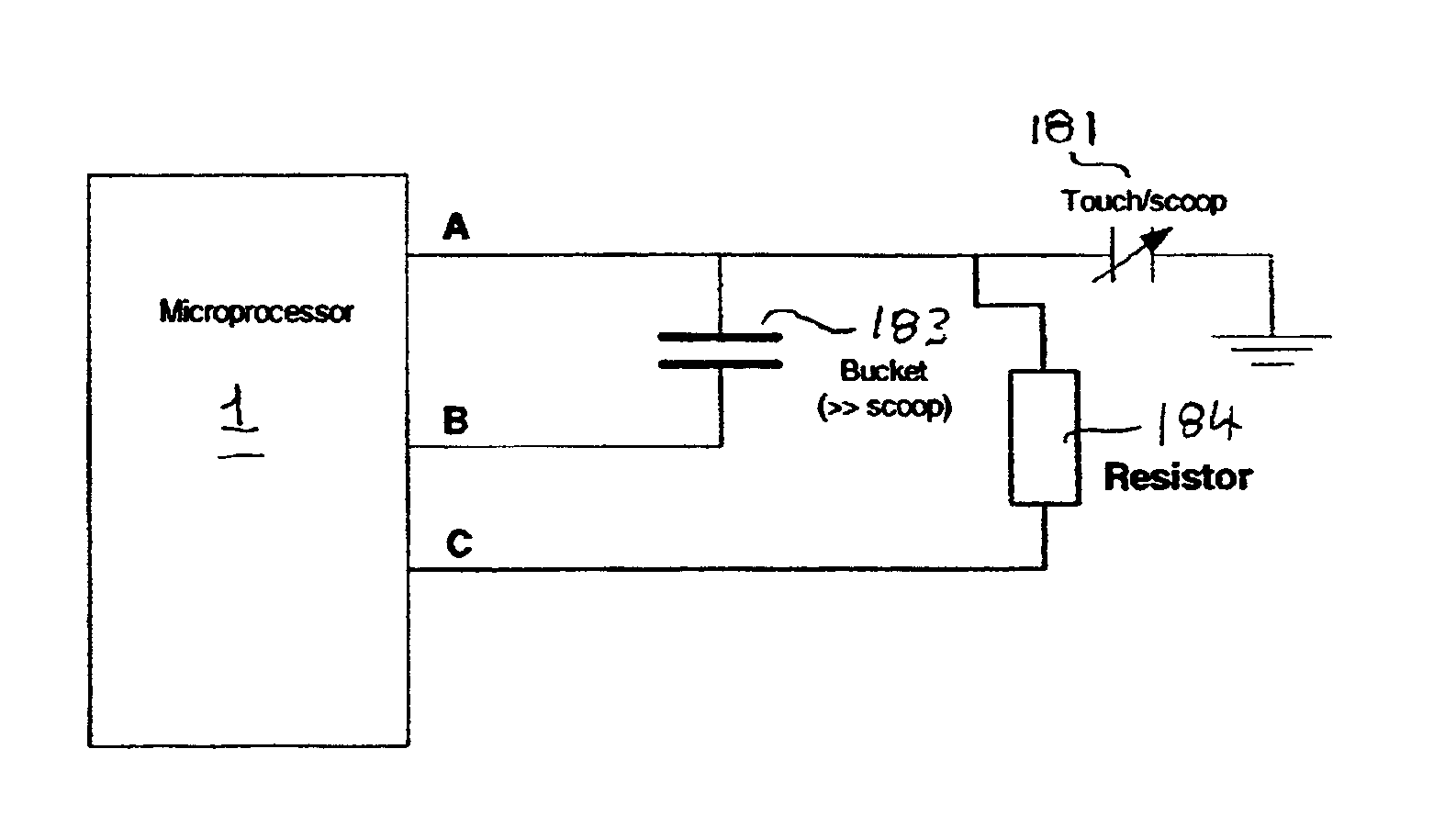

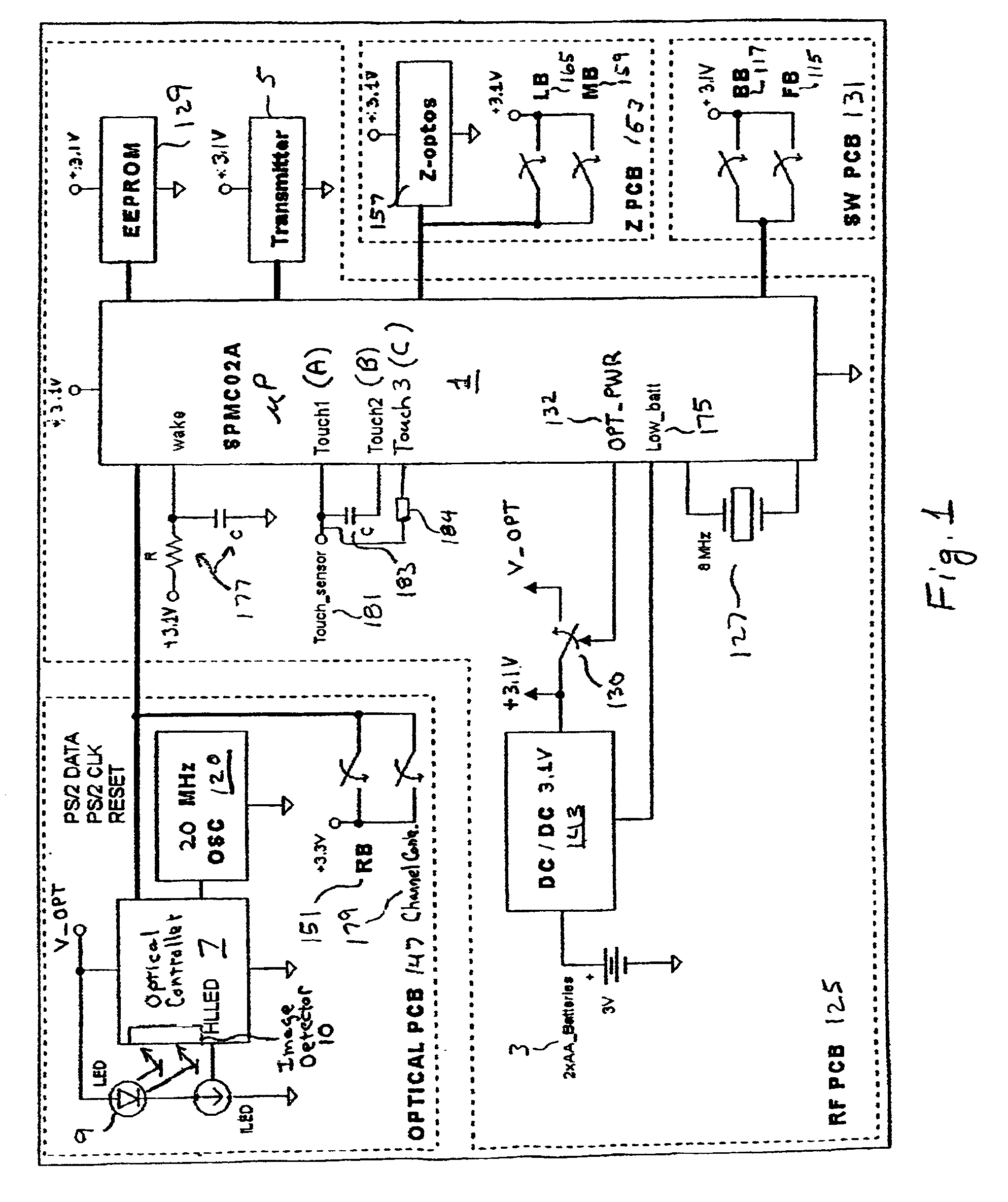

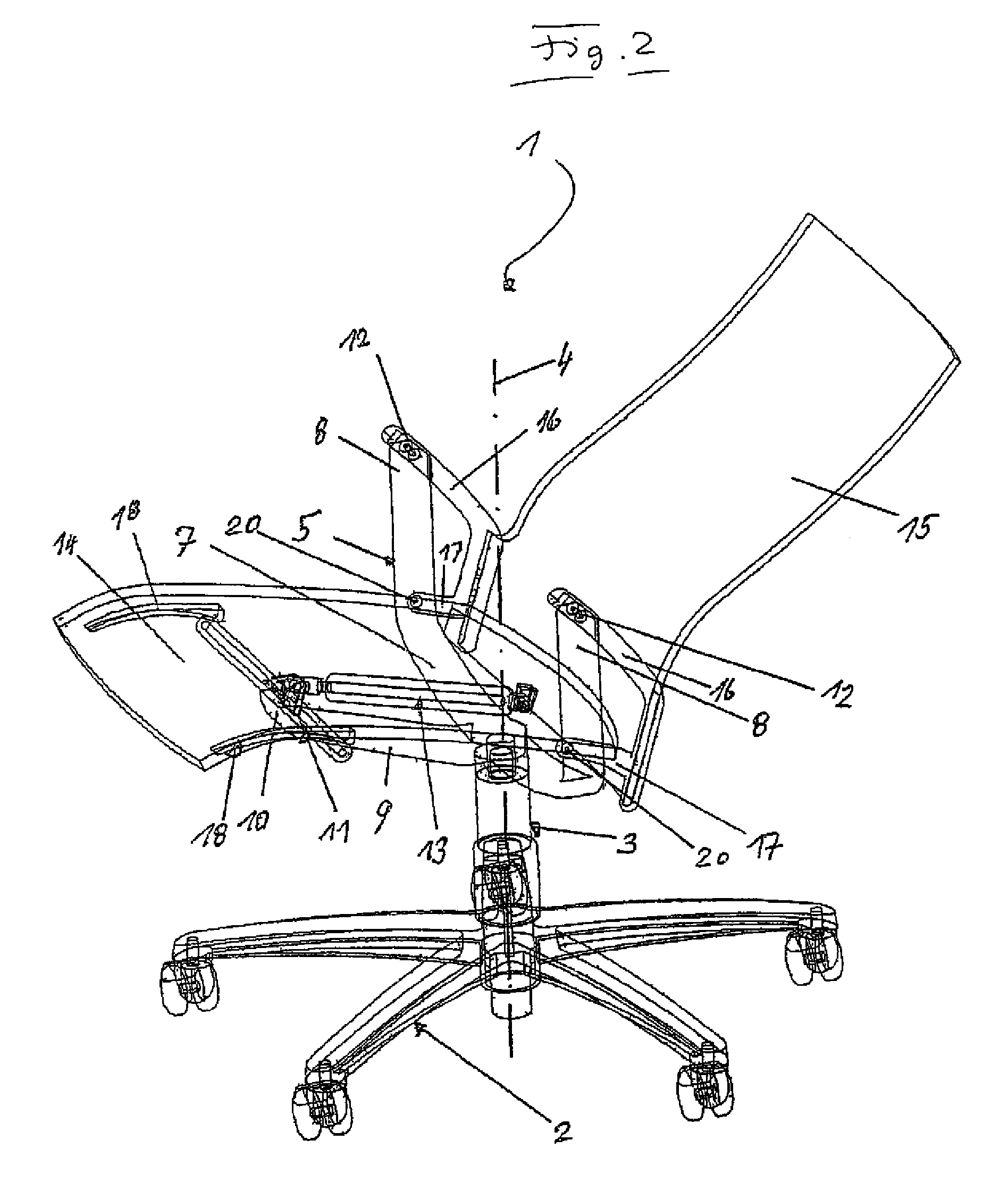

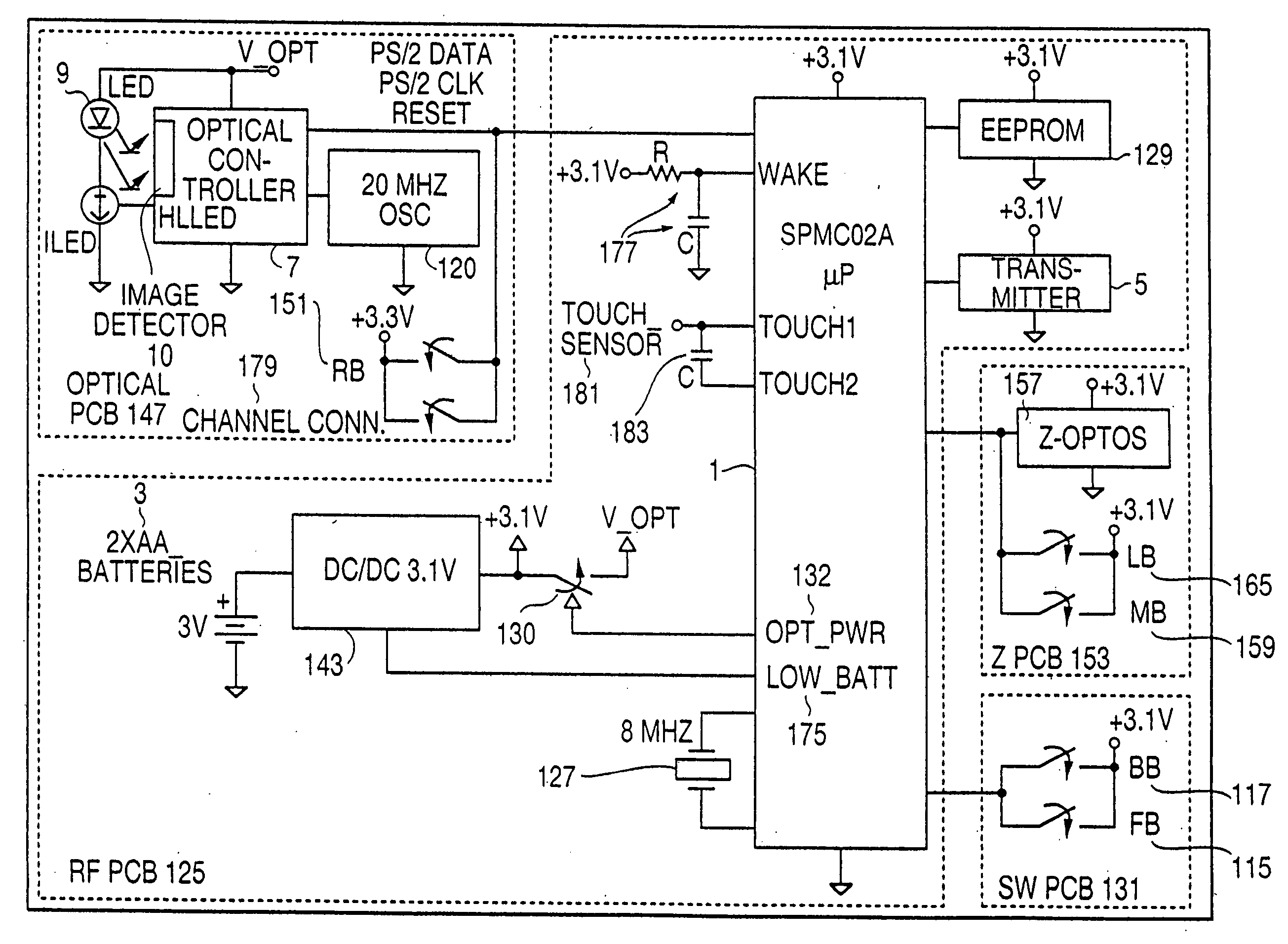

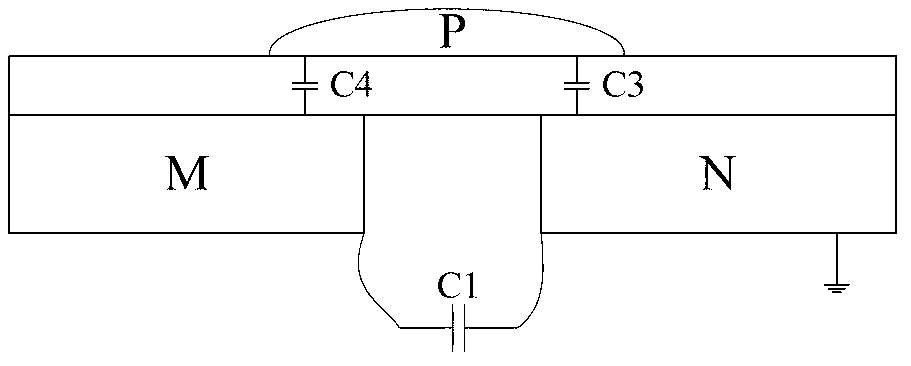

Capacitive sensing and data input device power management

InactiveUS6850229B2Efficient managementExtend battery lifeInput/output for user-computer interactionEnergy efficient ICTCapacitanceRelative Change

Capacitive proximity sensing is carried out by detecting a relative change in the capacitance of a “scoop” capacitor formed by a conductor and a surrounding ground plane. The conductor may be a plate provided in the form of an adhesive label printed with conductive ink. Charge is transferred between the “scoop” capacitor and a relatively large “bucket” capacitor, and a voltage of the bucket capacitor is applied to an input threshold switch. A state transition (e.g., from low to high, or high to low) of the input threshold switch is detected and a value (TouchVal) indicative of a number of cycles of charge transfer required to reach the state transition is determined. The presence or absence of an object or body portion in close proximity to or contact with a device can be determined by comparing TouchVal with a predetermined threshold value (TouchOff). TouchOff can be adjusted to take into account environmentally induced (non-touch related) changes in the capacitance of the scoop capacitor. Power management is provided in a user operated data input device utilizing proximity sensing and switching between three or more power states. Switching between the power states occurs based upon the presence or absence of input activity, and an operation instrumentality (e.g., a hand) in close proximity to or contact with the device. In an optical surface tracking cursor control device embodiment, switching to and from a BEACON state, which provides a reduced flash rate of a surface illuminating light source, is carried out based upon a detected presence or absence of a trackable surface.

Owner:MICROSOFT TECH LICENSING LLC

Capacitive sensing employing a repeatable offset charge

InactiveUS6954867B2Shorten the timeWeaken energyEnergy efficient ICTVolume/mass flow measurementCapacitanceElectrical conductor

Capacitive proximity sensing is carried out by detecting a relative change in the capacitance of a “scoop” capacitor formed by a conductor and a surrounding ground plane. Charge is transferred between the “scoop” capacitor and a relatively large “bucket” capacitor, and a voltage of the bucket capacitor is applied to an input threshold switch. A state transition (e.g., from low to high, or high to low) of the input threshold switch is detected and a value (TouchVal) indicative of a number of cycles of charge transfer required to reach the state transition is determined. The presence or absence of an object or body portion in close proximity to or contact with a device can be determined by comparing TouchVal with a predetermined threshold value (TouchOff). In order to lessen the time required for detection, and / or improve the sensitivity thereof, the bucket capacitor may initially be charged to a repeatable non-zero reference level closer to the charge level that will cause a state transition. TouchOff can be adjusted to take into account environmentally induced (non-touch related) changes in the capacitance of the scoop capacitor. Power management may be provided in a user operated data input device utilizing the inventive proximity sensing.

Owner:MICROSOFT TECH LICENSING LLC

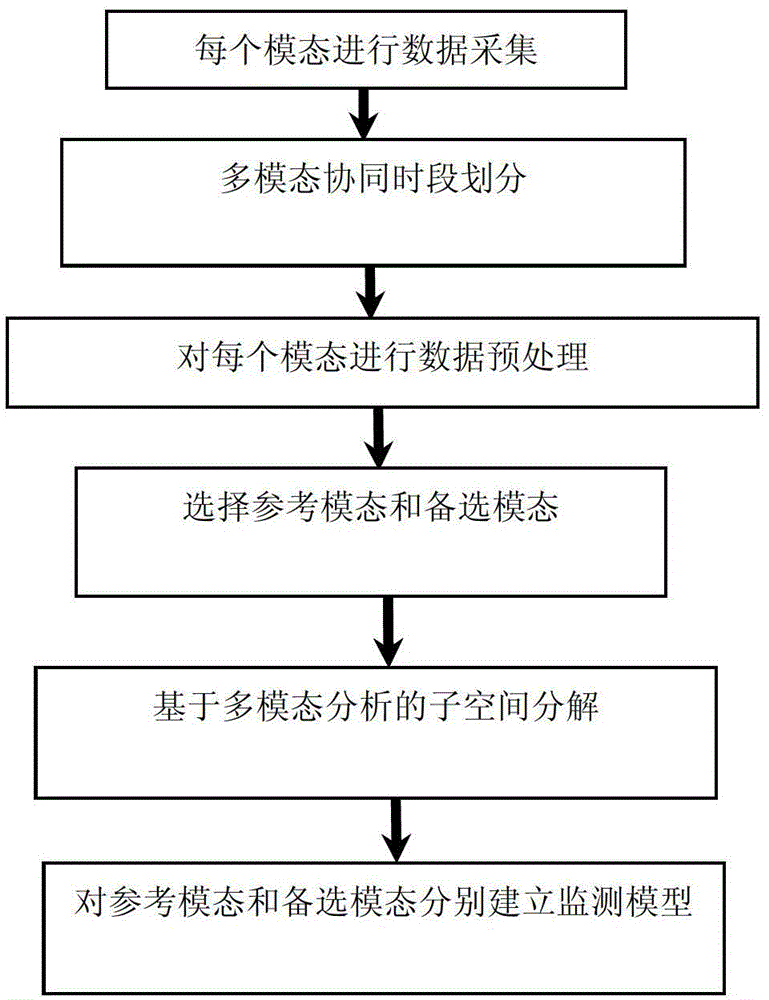

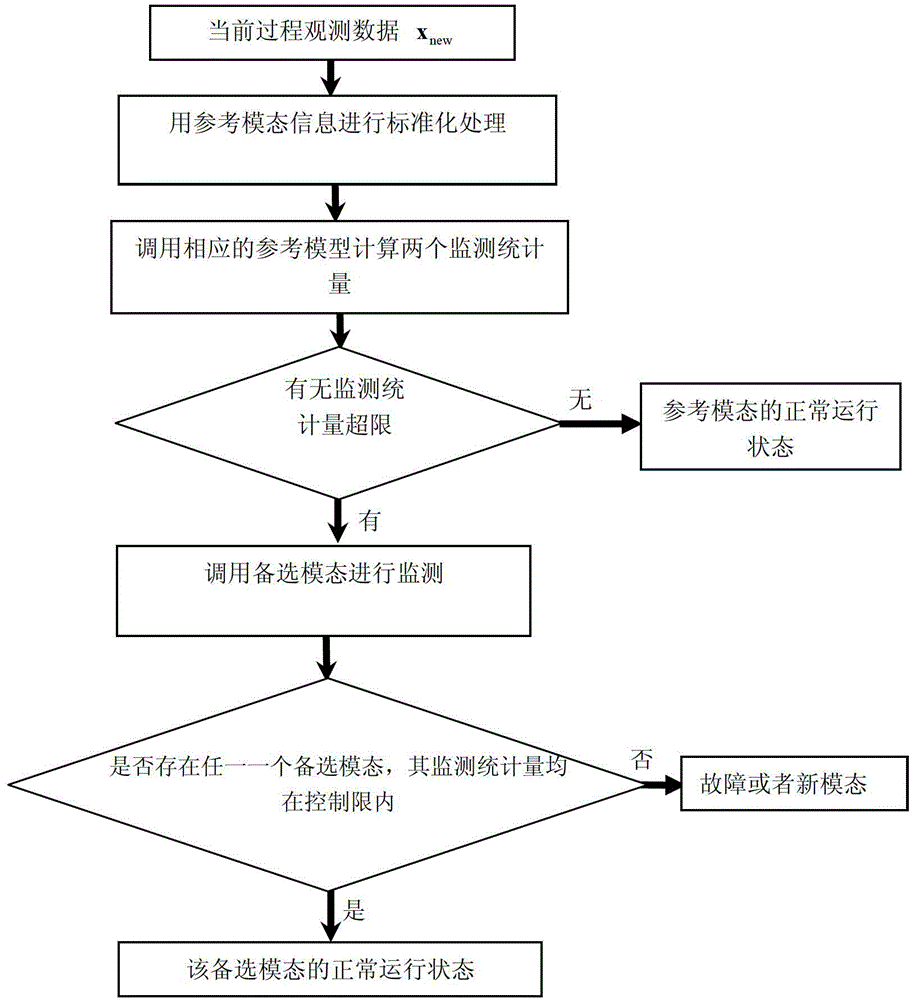

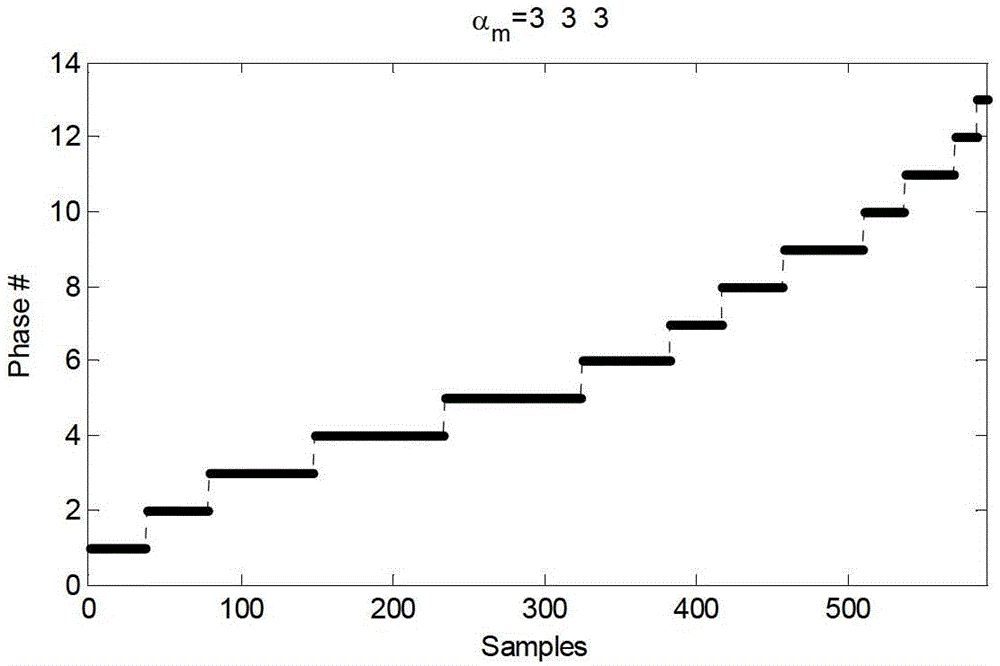

Statistical modeling and on-line monitoring method based on multimodality collaboration time frame automatic division

ActiveCN103336507AHigh precisionImprove efficiencyProgramme total factory controlDiagnostic Radiology ModalityInjection moulding

The invention discloses a modeling and on-line monitoring method based on multimodality collaboration time frame automatic division, which takes variation of process characteristics in batch shaft and time direction as well as time sequence of time frame running into consideration, and includes the steps of diving all the modalities through collaboration time frame, obtaining a unified time frame division result among different modalities, and building a uniform time frame model for similar process characteristics in each modality to simplify the modeling complexity. According to the invention, based on the result of collaboration time frame division, the relative change among all the modalities is analyzed, a multimodality statistic model based on different fluctuation types is built and applied in on-line monitoring, and the on-line monitoring performance is improved; the method is easy to implement, is successfully applied during the injection molding, not only facilitates the understanding of process characteristic, but also enhances the reliability and confidence level of actual on-line process monitoring, facilitates judging the running state of the industrial process, and timely discovers faults, thereby guaranteeing the safe and reliable running of actual production and the pursuit of high-quality products.

Owner:ZHEJIANG UNIV

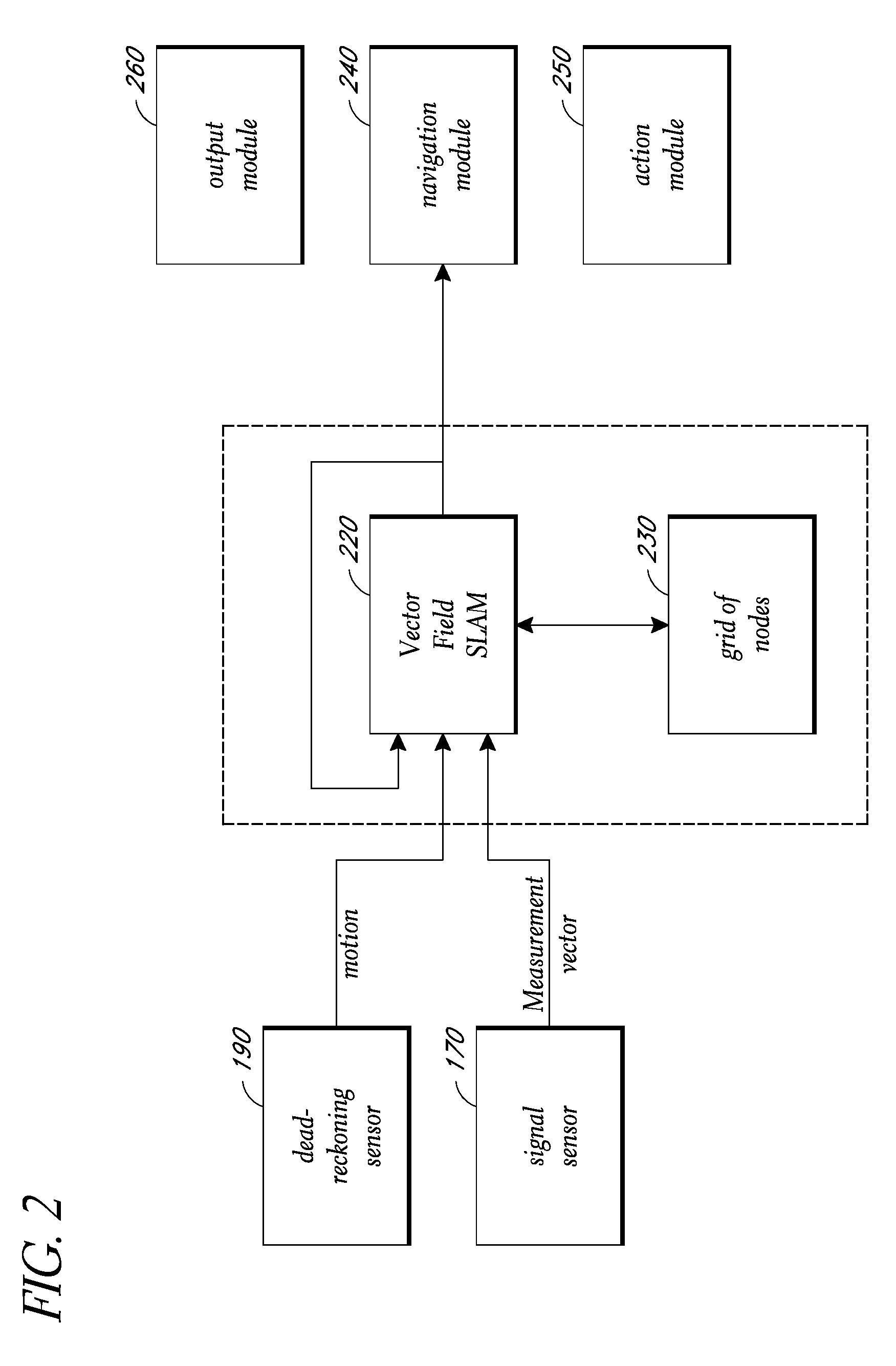

Localization by learning of wave-signal distributions

ActiveUS8930023B2Accurate postureStatistically accurateProgramme controlProgramme-controlled manipulatorEngineeringRelative Change

A robot having a signal sensor configured to measure a signal, a motion sensor configured to measure a relative change in pose, a local correlation component configured to correlate the signal with the position and / or orientation of the robot in a local region including the robot's current position, and a localization component configured to apply a filter to estimate the position and optionally the orientation of the robot based at least on a location reported by the motion sensor, a signal detected by the signal sensor, and the signal predicted by the local correlation component. The local correlation component and / or the localization component may take into account rotational variability of the signal sensor and other parameters related to time and pose dependent variability in how the signal and motion sensor perform. Each estimated pose may be used to formulate new or updated navigational or operational instructions for the robot.

Owner:IROBOT CORP

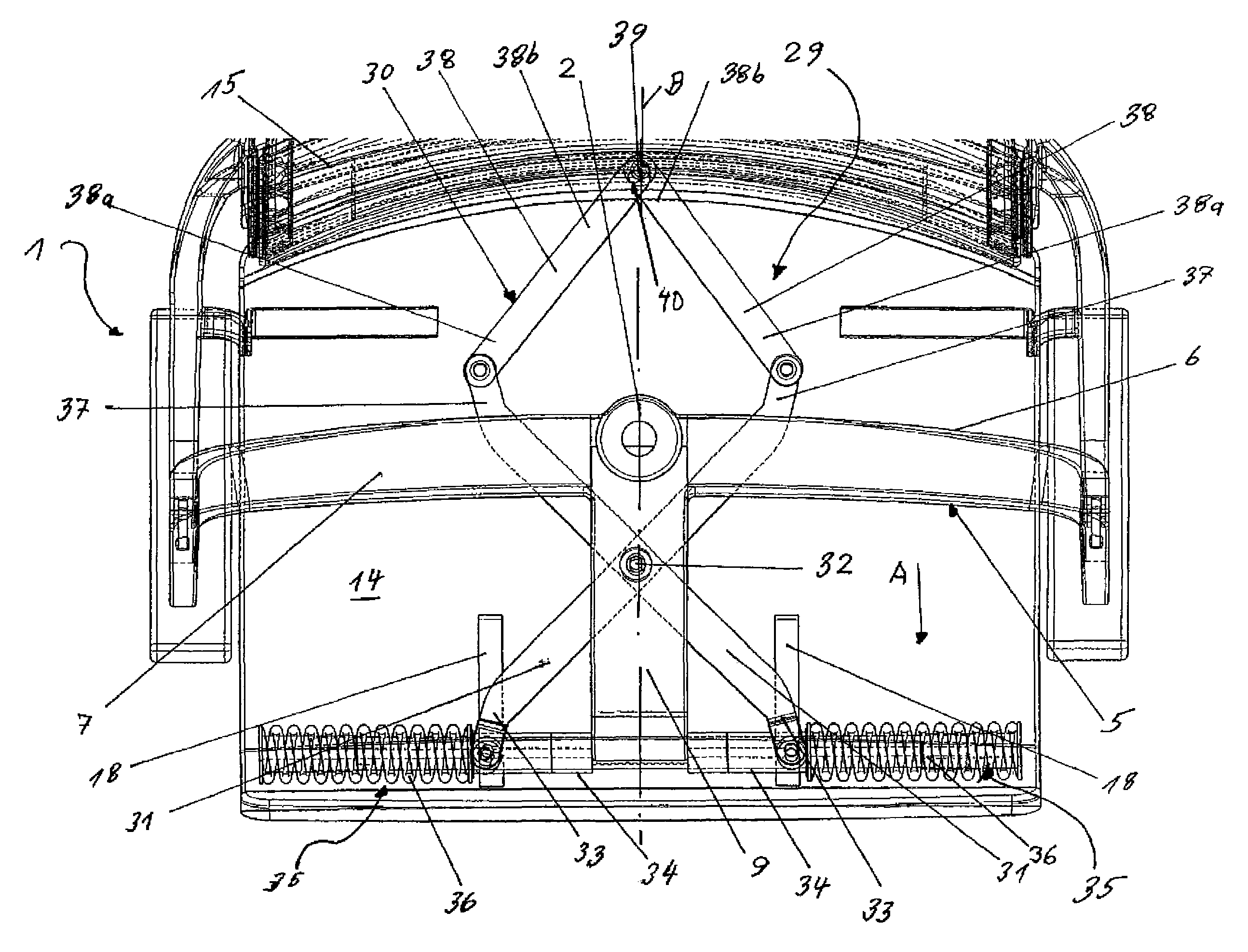

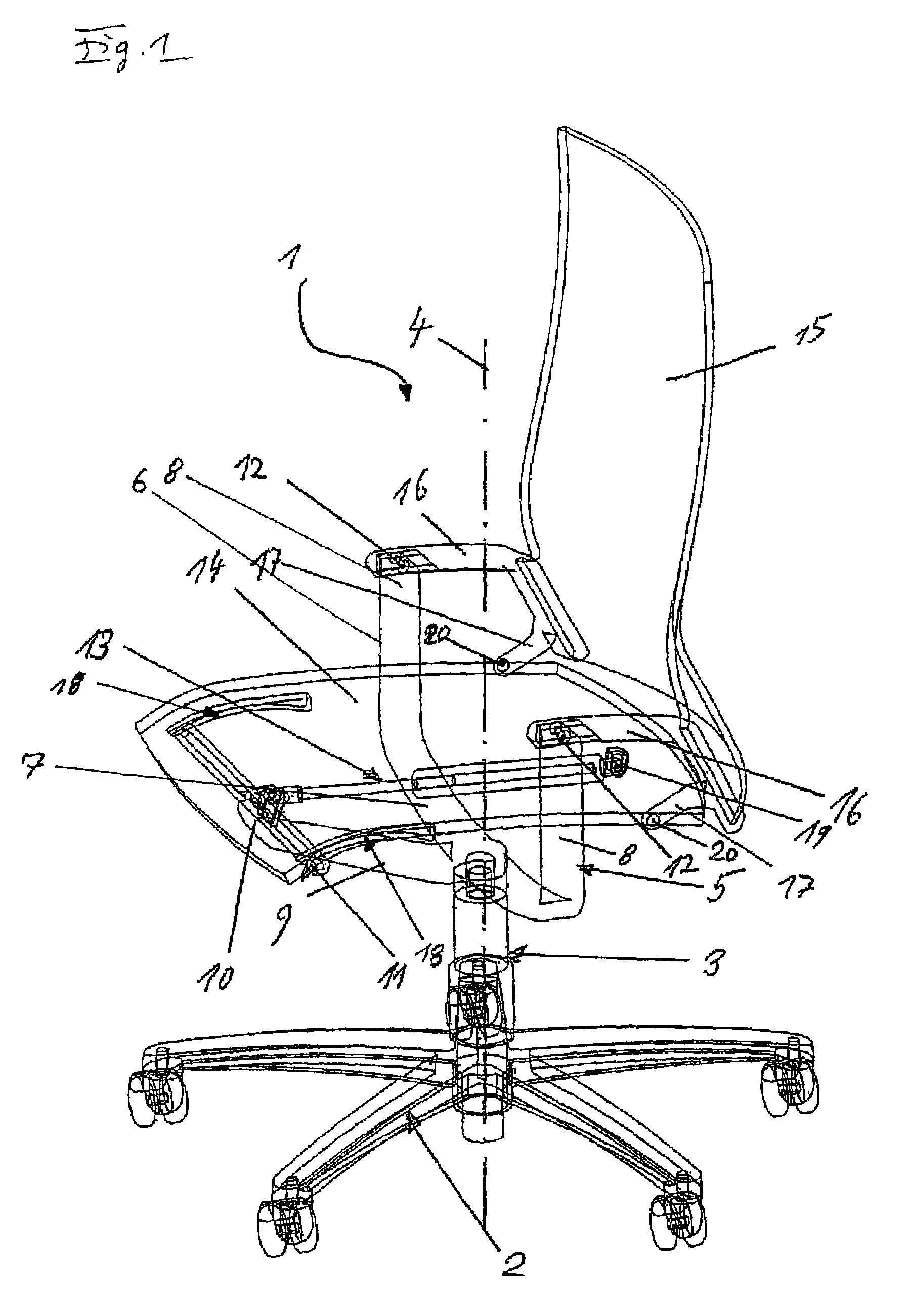

Servo mechanism for a seat part, in particular of a chair

InactiveUS7488040B2Smooth structureEasy to operateOperating chairsDental chairsConstant forceSpring force

A servo mechanism for a seat part arranged on a support frame for travel in a longitudinal direction in synchronism with an adjustment of a back rest part from a normal position to several predetermined reclined positions, includes a scissor-type articulated lever assembly which is connected to the seat part and the support frame. The articulated lever assembly includes several articulated lever elements. A spring assembly progressively applies a spring force upon the scissor-type articulated lever assembly such that a relative change in angular disposition between the lever elements applies a substantially constant force upon the seat part in every position of the seat part, whereby a relatively great longitudinal travel distance of the seat part is accompanied by a short spring travel during the spring force application.

Owner:OMP

Data input device power management including beacon state

InactiveUS20050078085A1Extend battery lifeA large amountInput/output for user-computer interactionEnergy efficient ICTCapacitanceElectrical conductor

Owner:MICROSOFT TECH LICENSING LLC

Method, device and system for detecting self-capacitance touch screen

ActiveCN102799325AHigh detection sensitivityInput/output processes for data processingCapacitanceWater vapor

The embodiment of the invention discloses a method, a device and a system for detecting a self-capacitance touch screen. The method comprises the following steps of: receiving scanning waveform by a current detecting self-capacitance touch screen channel; inputting voltage of the scanning waveform to the input end of a voltage following unit, and at least driving a preset channel adjacent to the current detecting self-capacitance touch screen channel through the output end of the voltage following unit; and calculating self-capacitance touch screen coordinate data when touch happens in the current detecting channel. By the method, touch detecting interference to the current detecting channel of the touch screen due to water vapor or water drops is shielded, the relative change amount caused by the same touch is increased, and the detecting sensitivity of the self-capacitance touch screen is improved.

Owner:FOCALTECH SYST LTD

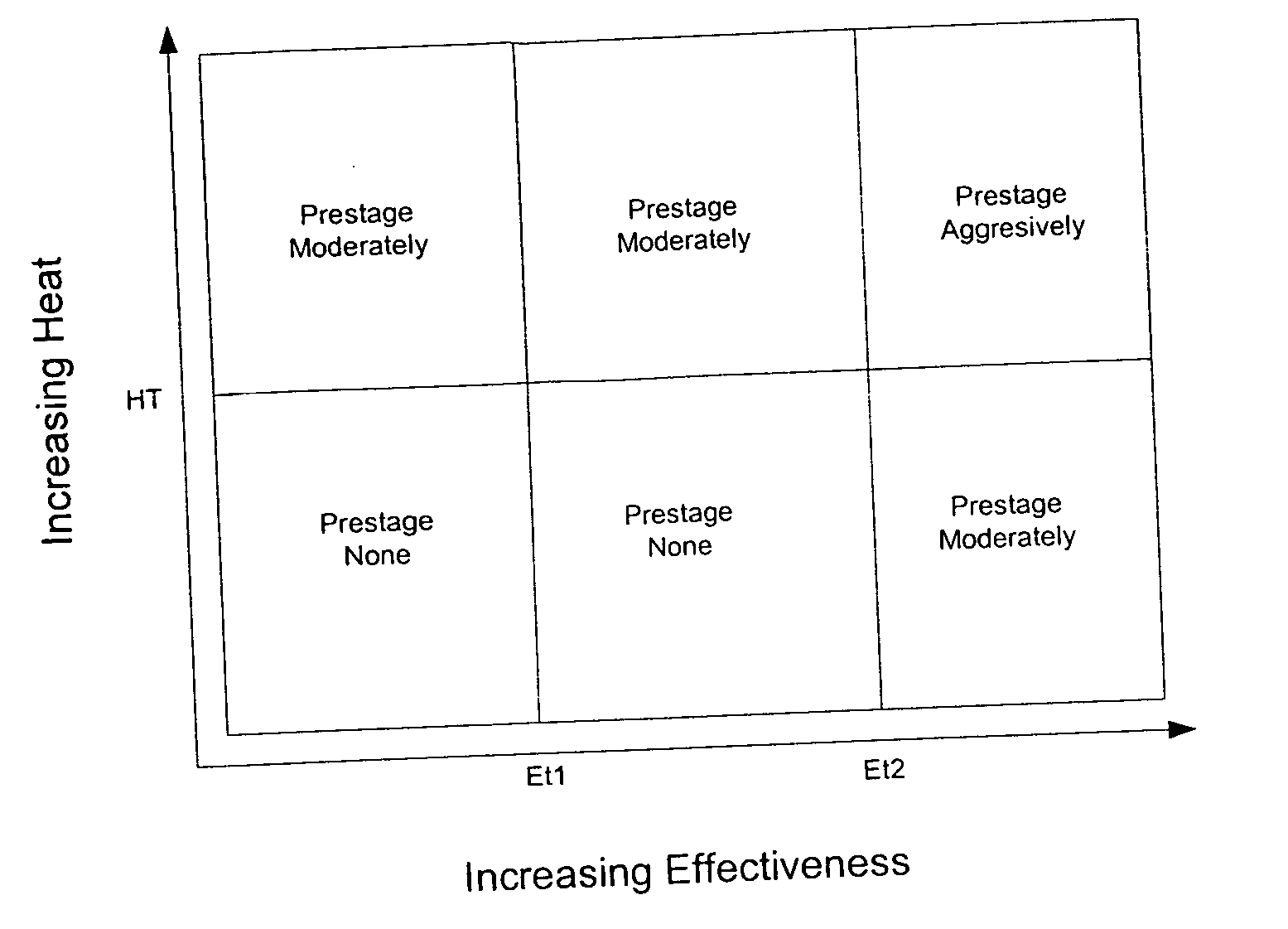

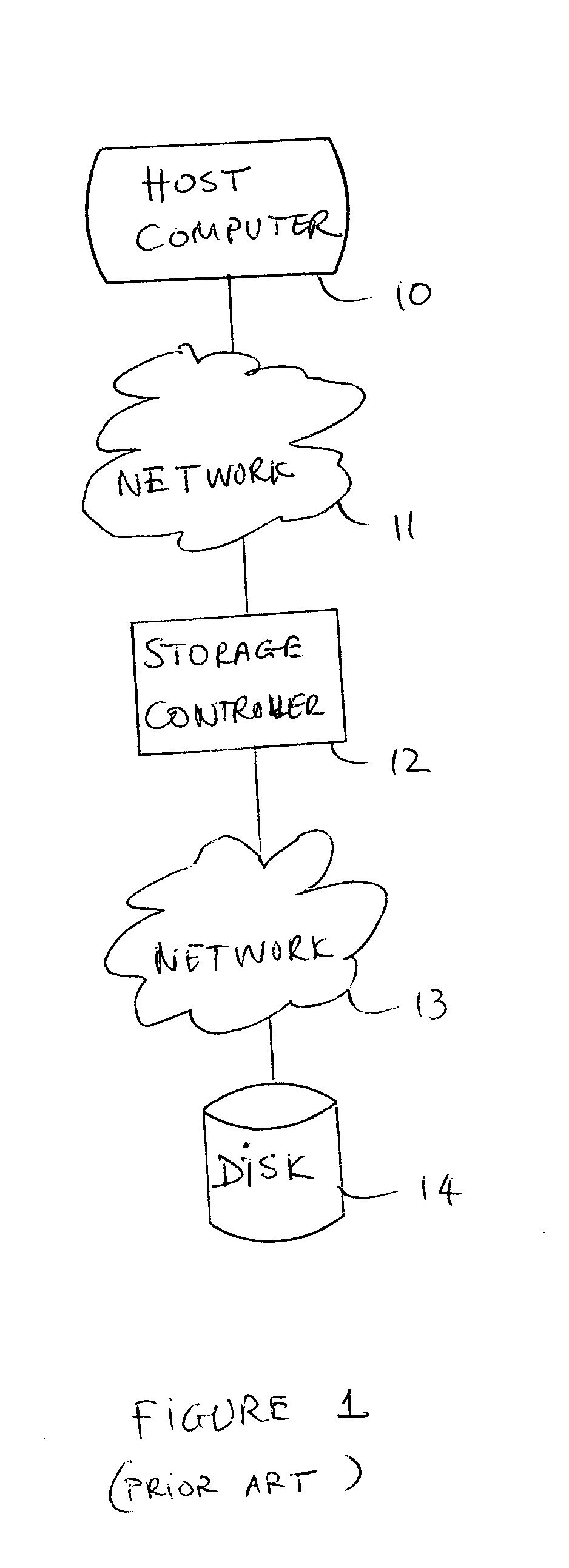

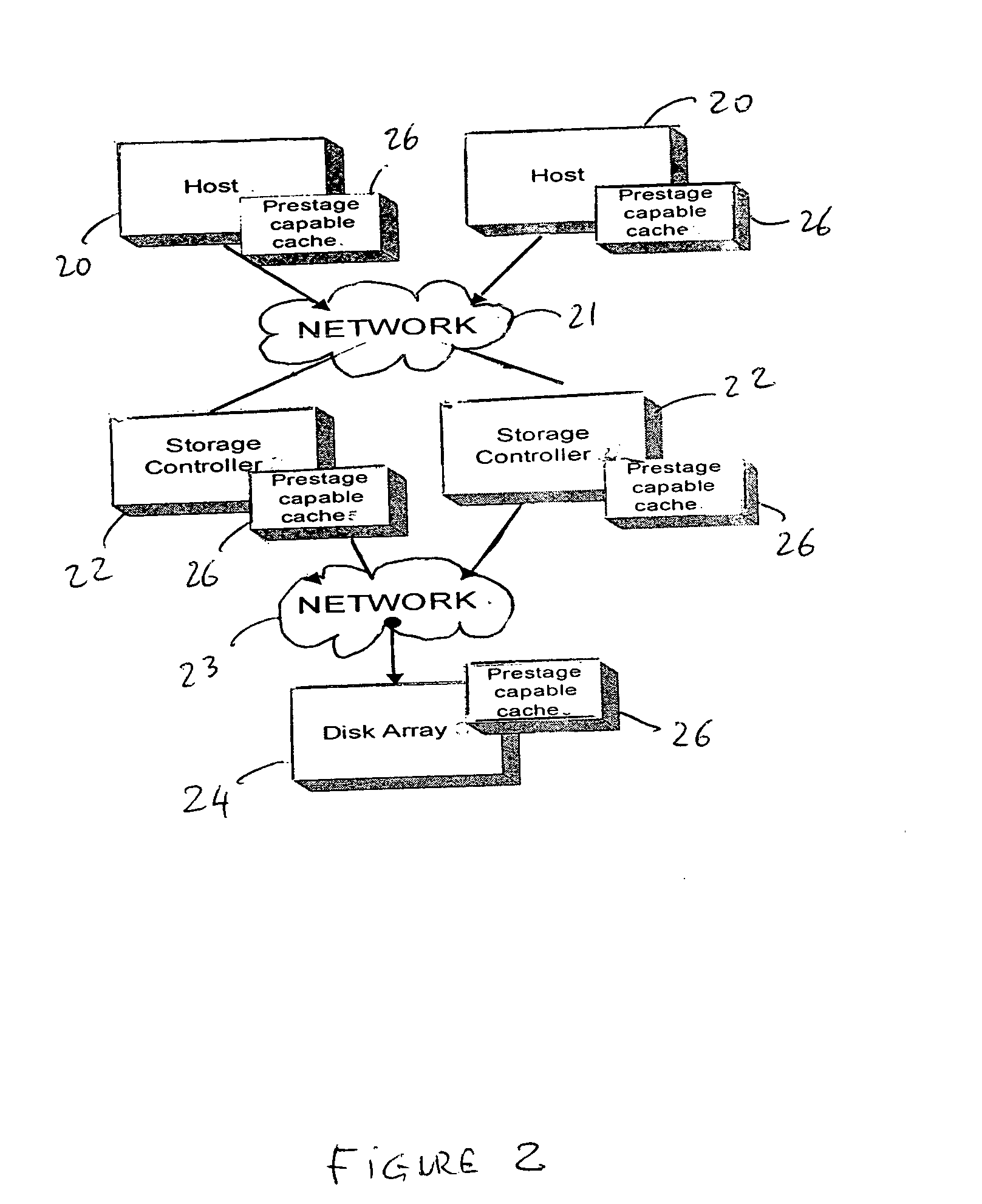

Storage system and method for prestaging data in a cache for improved performance

InactiveUS20050050279A1Memory architecture accessing/allocationMemory adressing/allocation/relocationData accessAccess frequency

A storage system and method for prestaging data in a cache based on relative changes in the frequency of data access and relative changes in the effectiveness of previous prestage operations. The relative changes in the frequency of data access are determined by storing statistics of data access to all regions in the system and comparing recent access statistics to the stored data. Access statistics include data location, I / O size and access frequency. The relative changes in the effectiveness of previous prestage operations are detected by recording the number of previous prestaging operations for a region, recording the number of I / O requests for data that has been prestaged, and dividing the number of I / O requests for previously prestaged data in a region during a time period by the number of previous prestage operations for the region during the same time.

Owner:IBM CORP

Real-time database performance and availability monitoring method and system

ActiveUS20060106851A1Digital data information retrievalDigital data processing detailsReal time analysisRelative Change

Database performance and availability monitoring of changes impacting database performance, availability and continuity to the underlying business may be performed. A method for doing so may include analytical and visual real-time analysis engines to identify and provide alert notifications on changes in database performance statistics (such as CPU consumption, physical I / O, etc.) related to a sample period of time on a single database or across multiple databases. Result data may be displayed through a series of charts and / or summary tables that may indicate whether correlations exist between unexpected database performance and relative changes in database performance statistical parameters.

Owner:ENTEROS INC

Object tracking with projected reference patterns

ActiveUS8791901B2Input/output for user-computer interactionCathode-ray tube indicatorsReference patternsRelative Change

Systems and methods for tracking an object's position and orientation within a room using patterns projected onto an interior surface of the room, such as the ceiling. Systems include at least one optical position sensitive device embedded in the object to detect relative changes in the projected pattern as the object's position and / or orientation is changed. In particular systems, the pattern includes a plurality of beacons projected by one or more steerable lasers. Projected beacons may be steered automatically to accommodate a variety of room topologies. Additional optical position sensitive devices may be disposed in known physical positions relative to the projected pattern to view either or both the projected pattern and the object. A subset of object positional data may be derived from a video camera viewing the object while another subset of object positional data is derived from the projected pattern.

Owner:SONY COMPUTER ENTERTAINMENT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com