Statistical modeling and on-line monitoring method based on multimodality collaboration time frame automatic division

An automatic division, multi-modal technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems that have not yet been seen, and achieve the effects of deepening understanding, improving efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

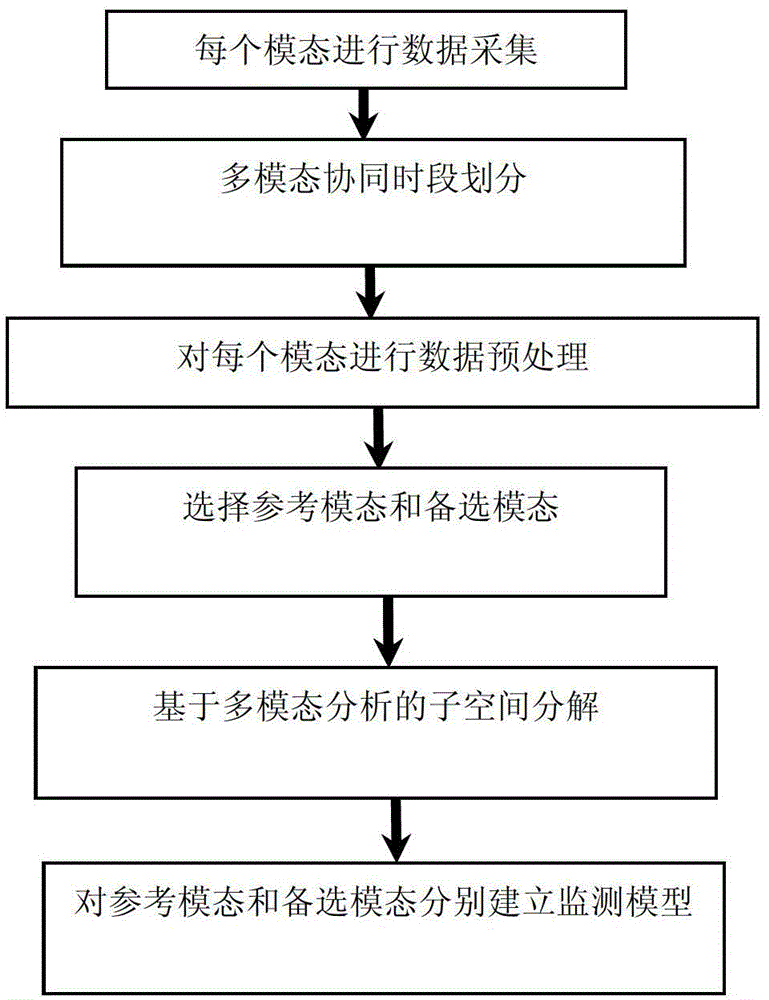

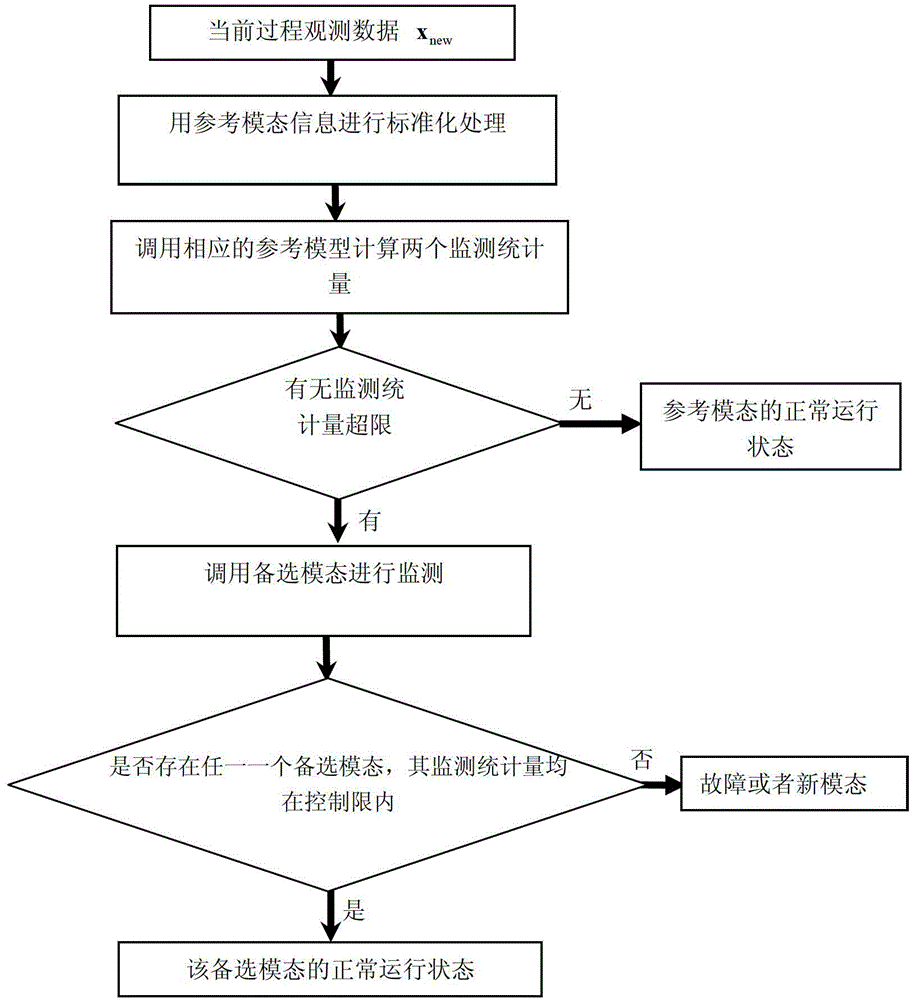

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

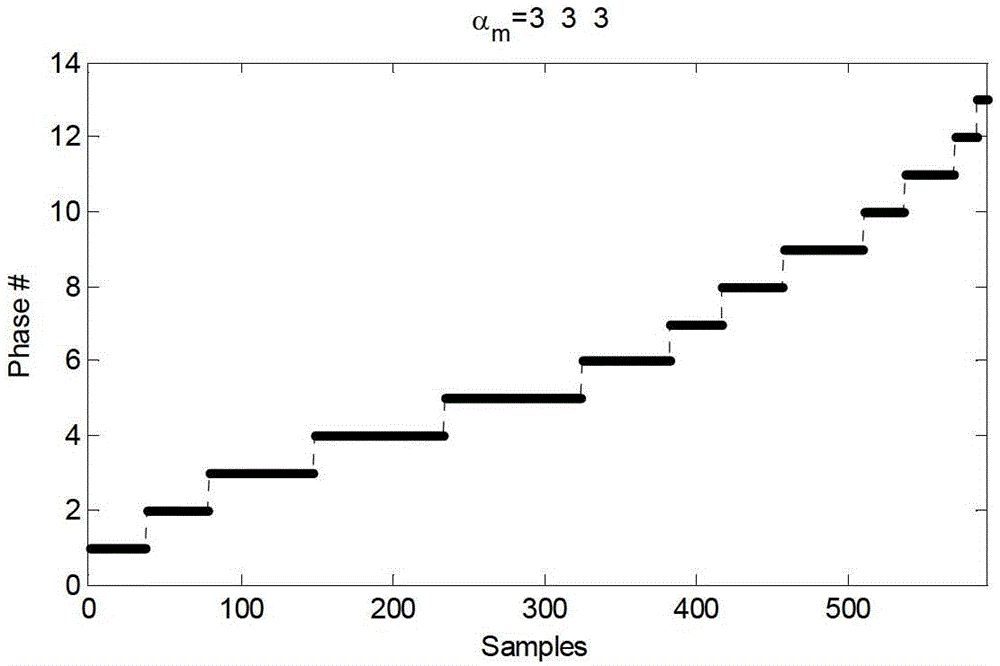

[0048] The injection molding process is a typical multi-period intermittent production process, generally consisting of three stages: injection, pressure holding, and cooling. In addition, the plasticizing process is completed at the initial stage of cooling. Specifically, in the injection stage, the hydraulic system pushes the screw to inject the plastic viscous fluid into the cavity until the cavity is filled with fluid. When the process is in the pressure-holding stage, a small amount of viscous fluid is still squeezed into the mold cavity under high pressure to compensate for the volume shrinkage of the plastic viscous fluid during cooling and plasticizing. The hold phase continues until the gate of the cavity freezes and the process enters the cooling section. When the melt at the head of the screw gradually increases and reaches a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com