Patents

Literature

448 results about "Fluid density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The relative density of any fluid is defined as the ratio of the density of that fluid to the density of the standard fluid. For liquids we take water as a standard fluid with density ρ=1000 kg/m 3.

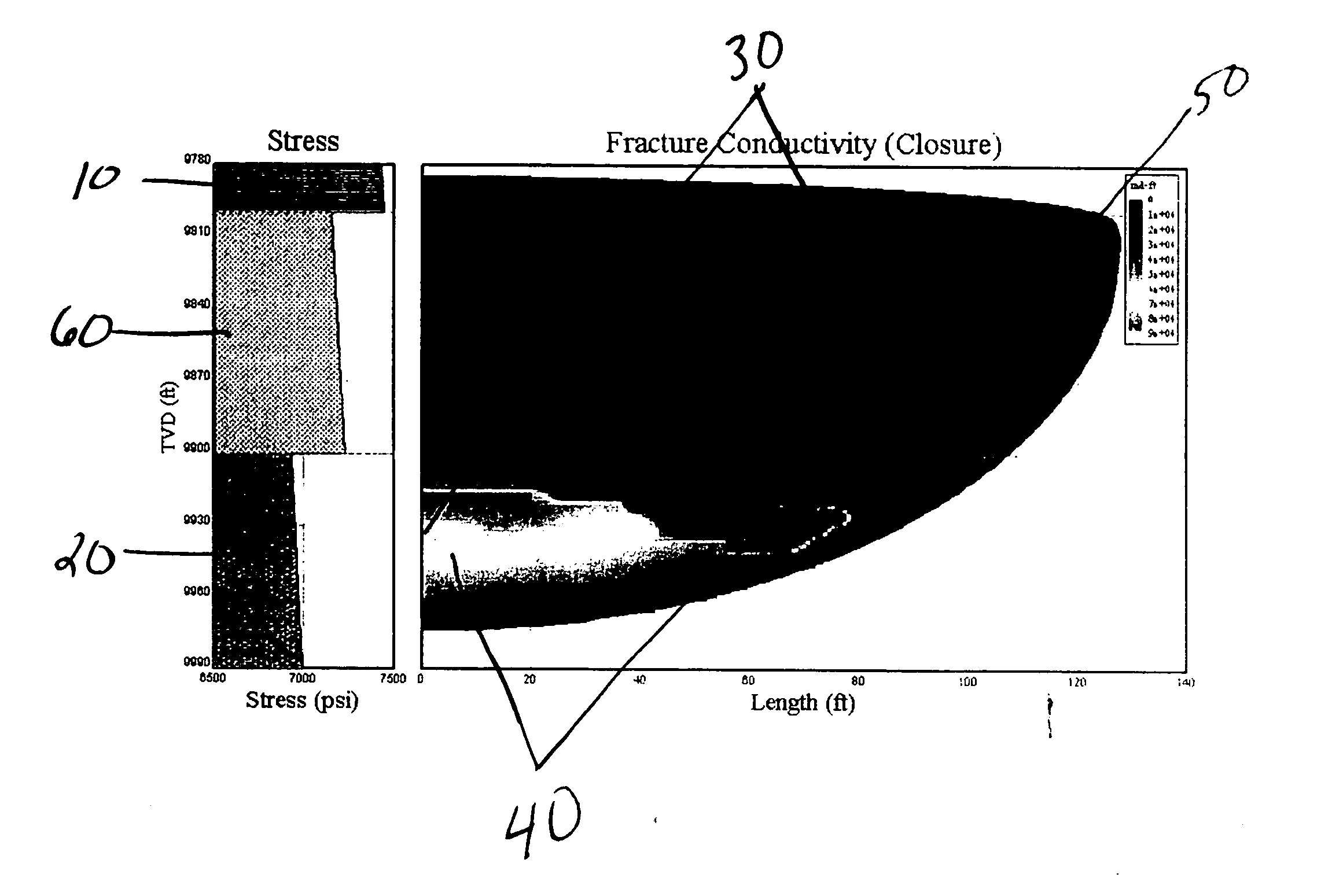

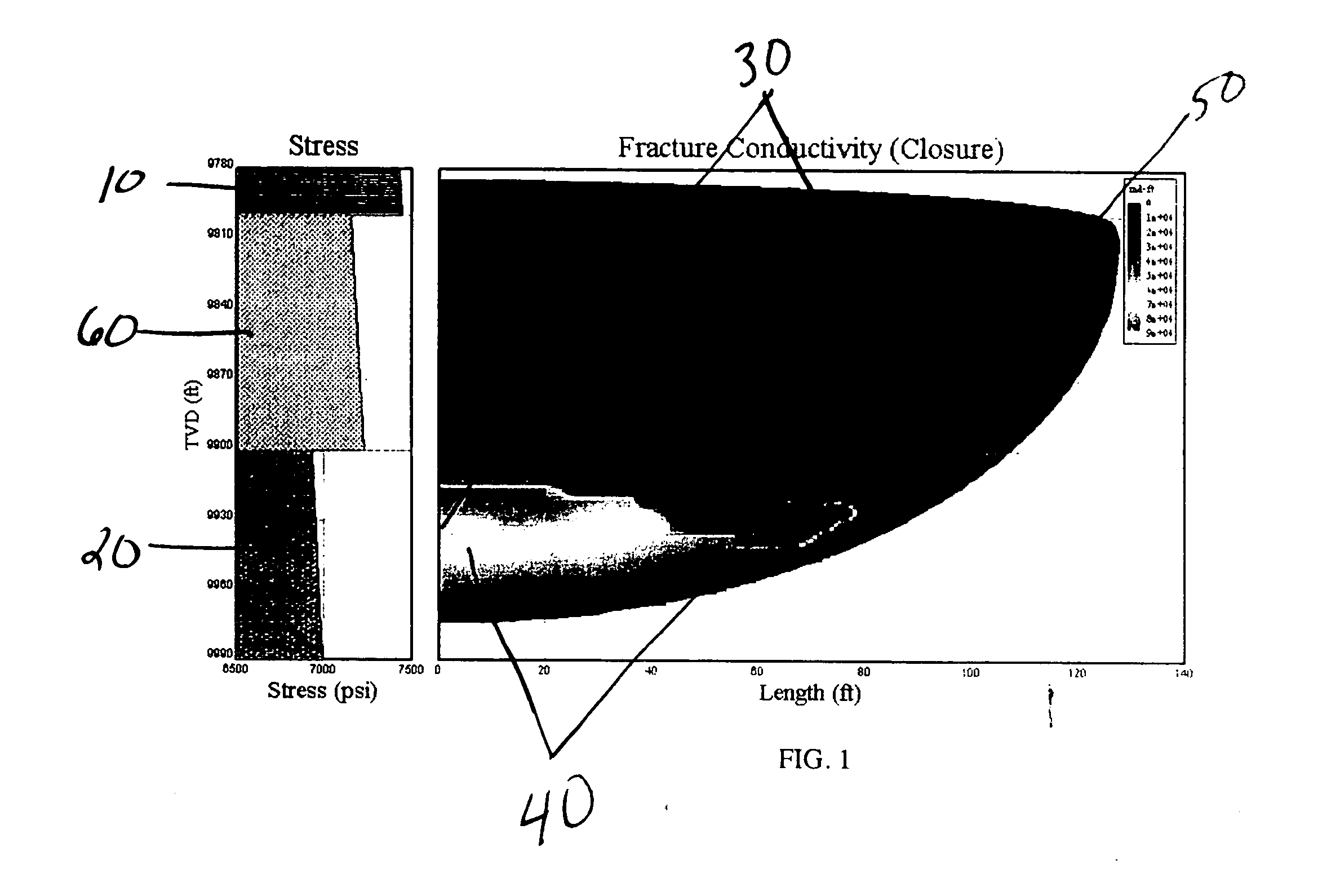

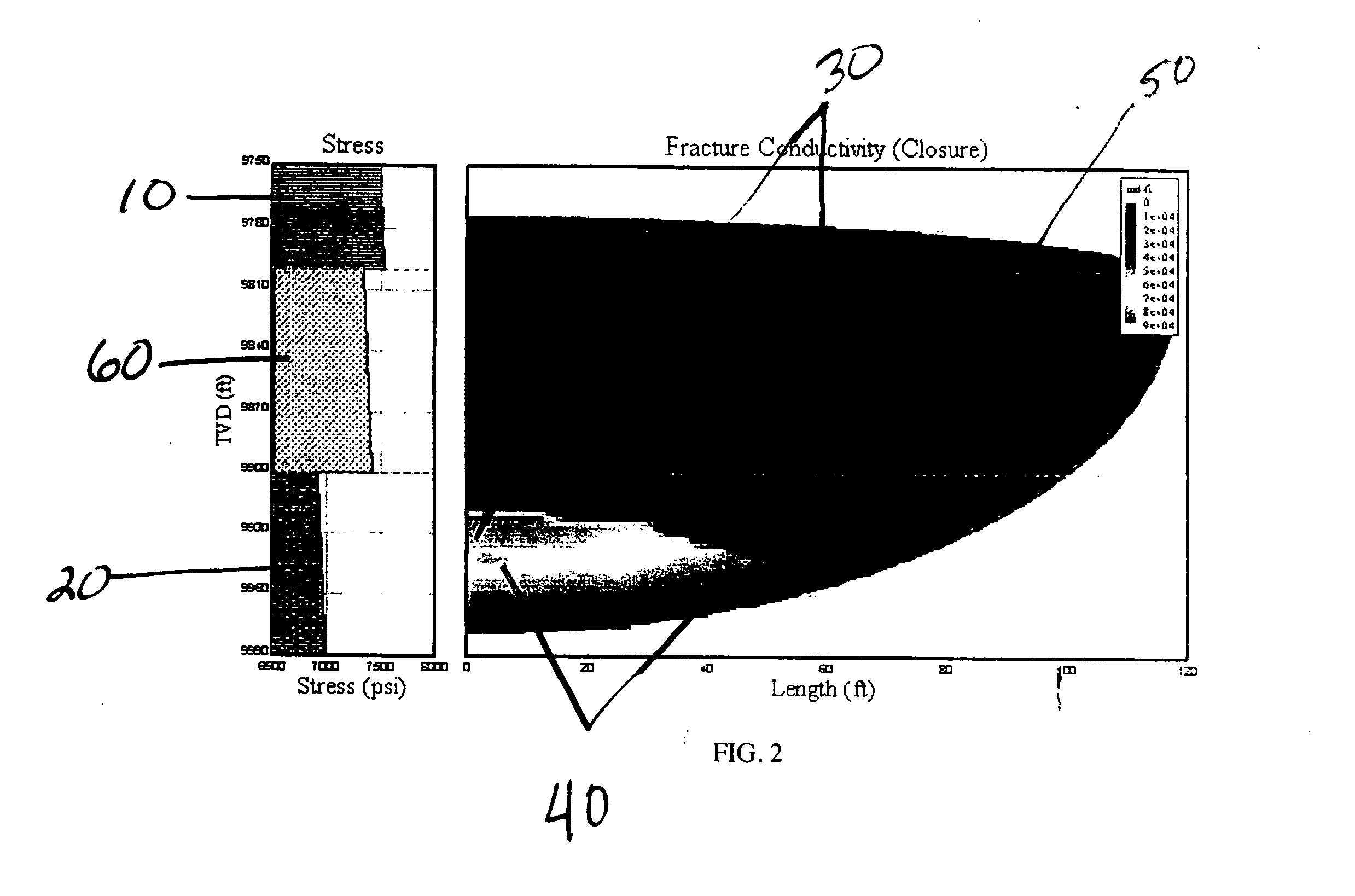

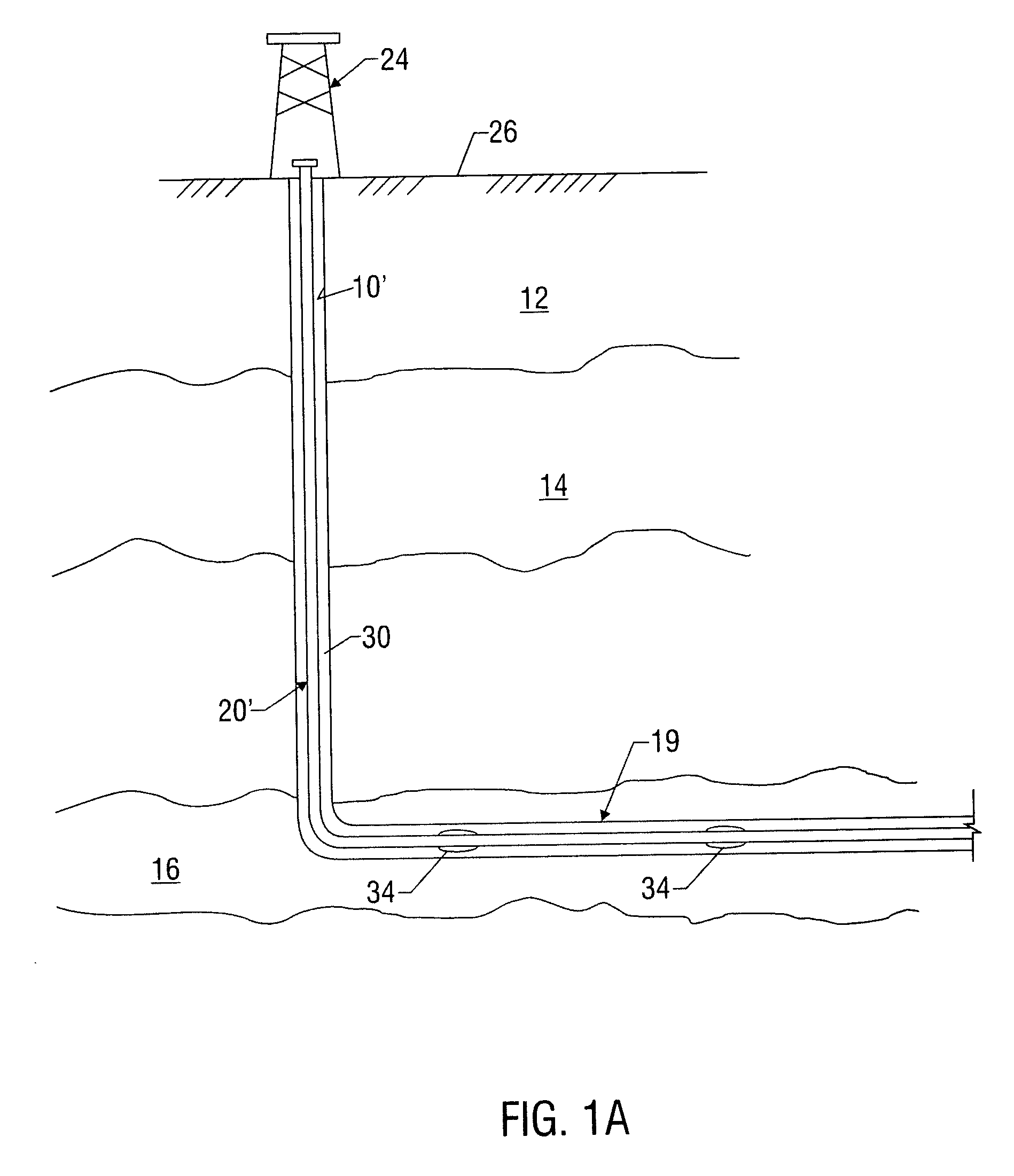

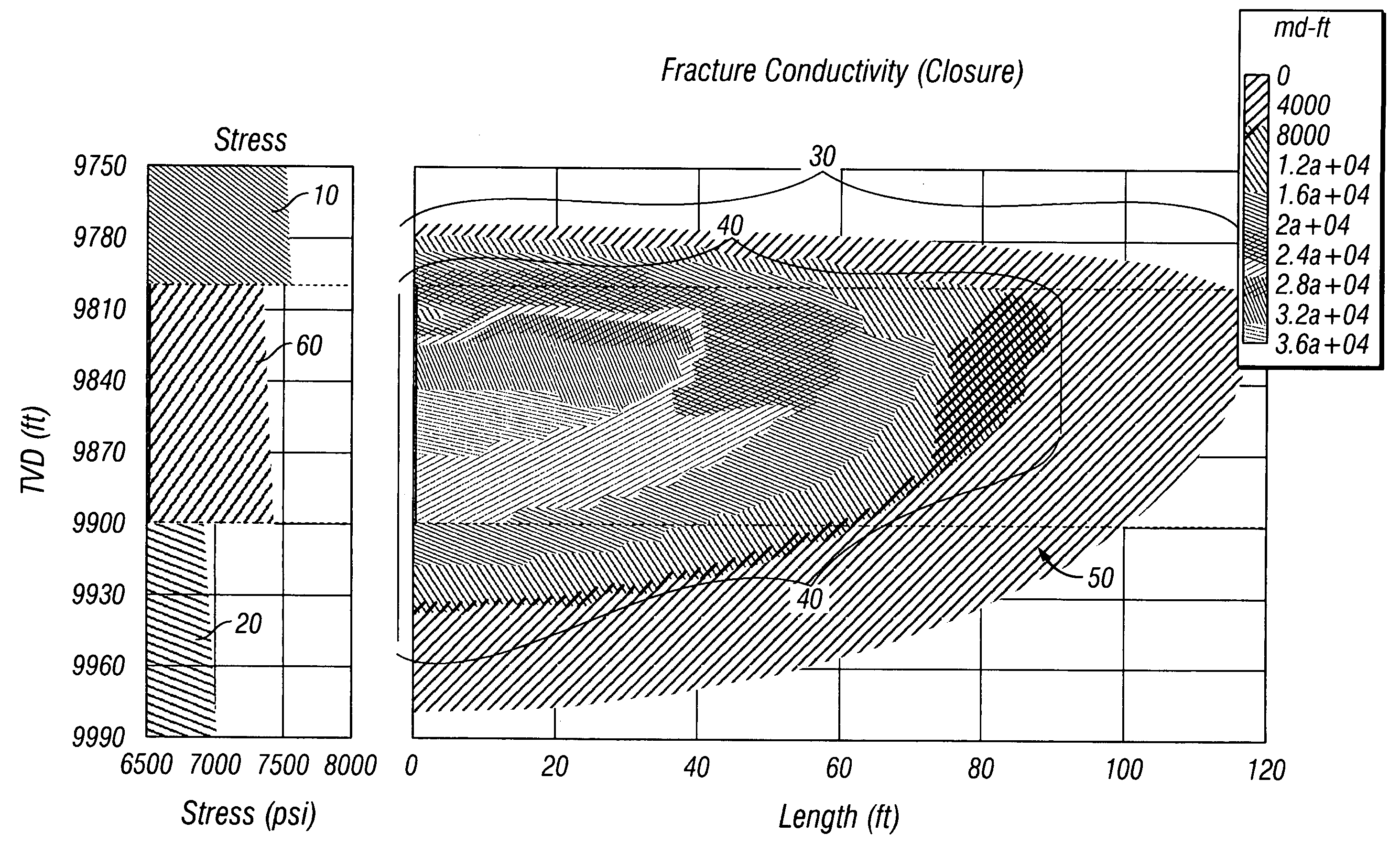

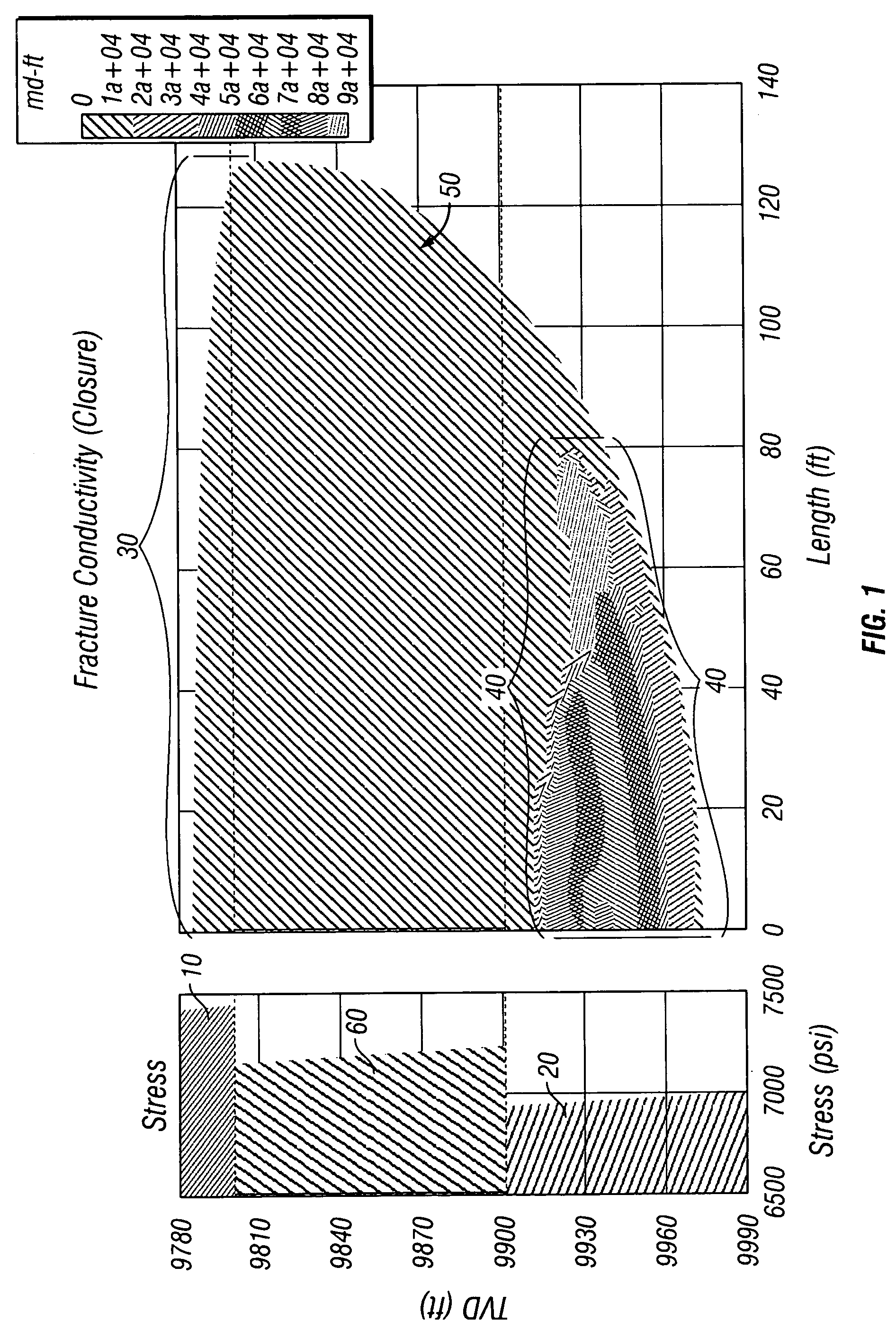

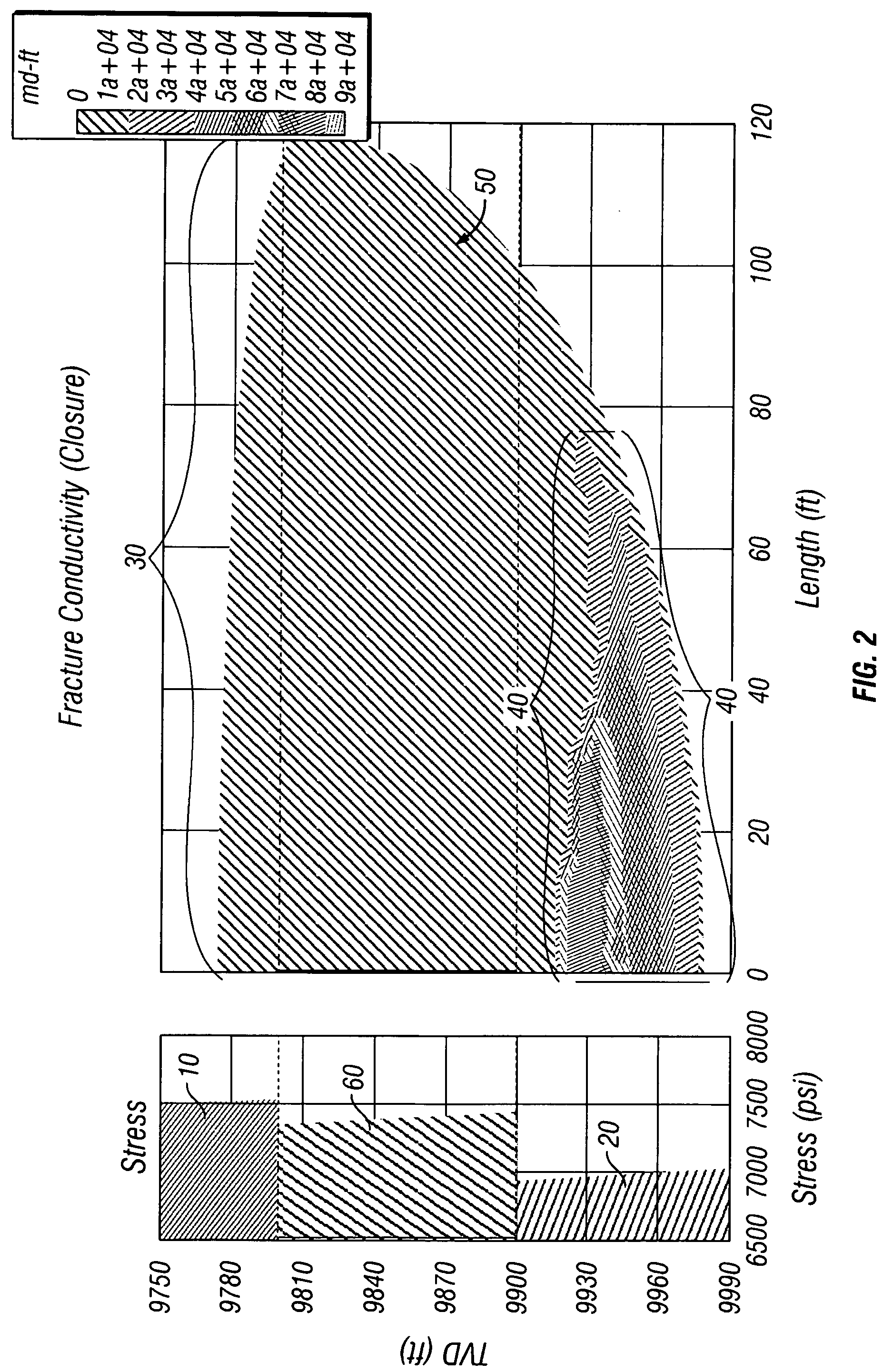

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS20050016732A1Reduce conductivityFluid removalDrilling compositionGeomorphologyWater production

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES INC

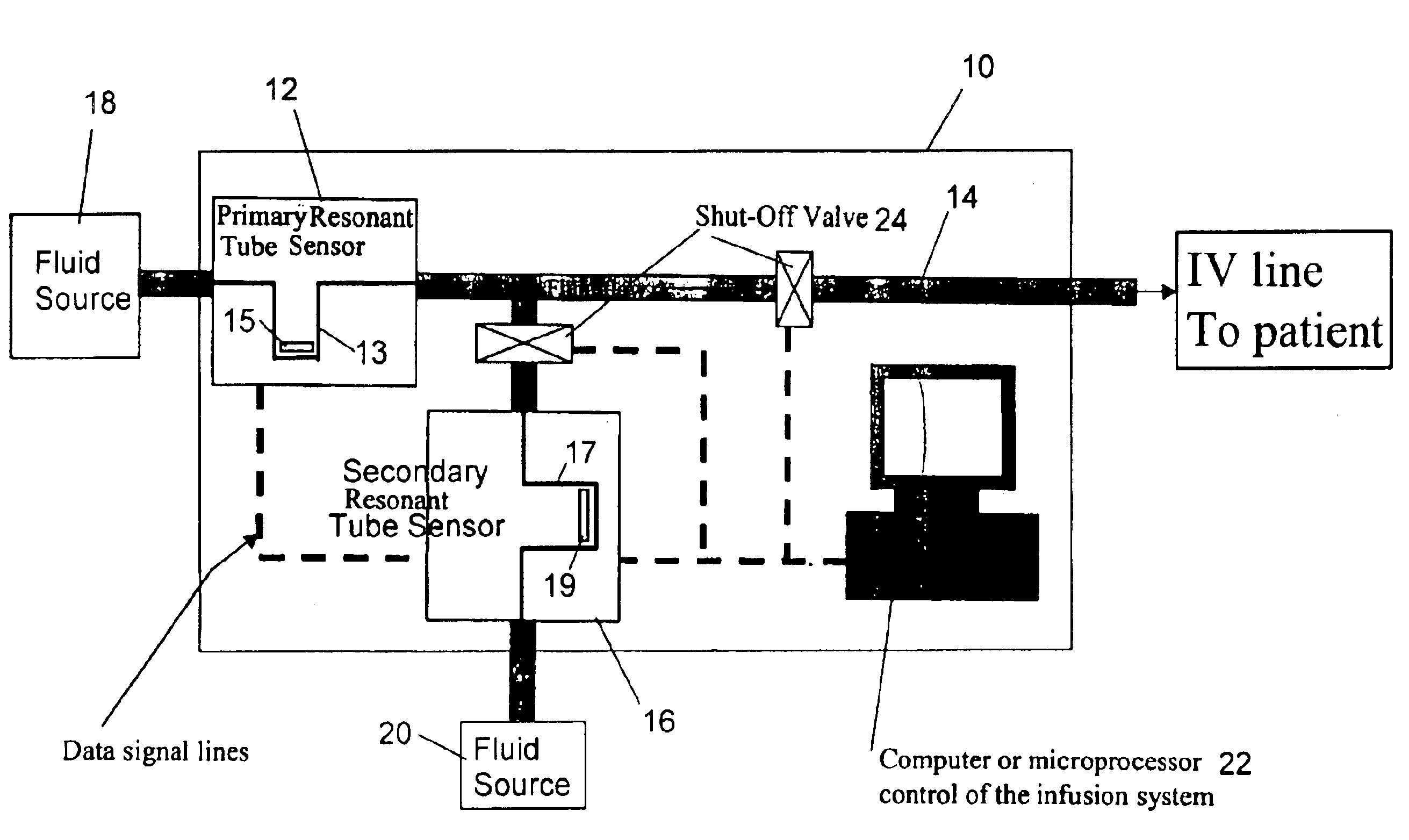

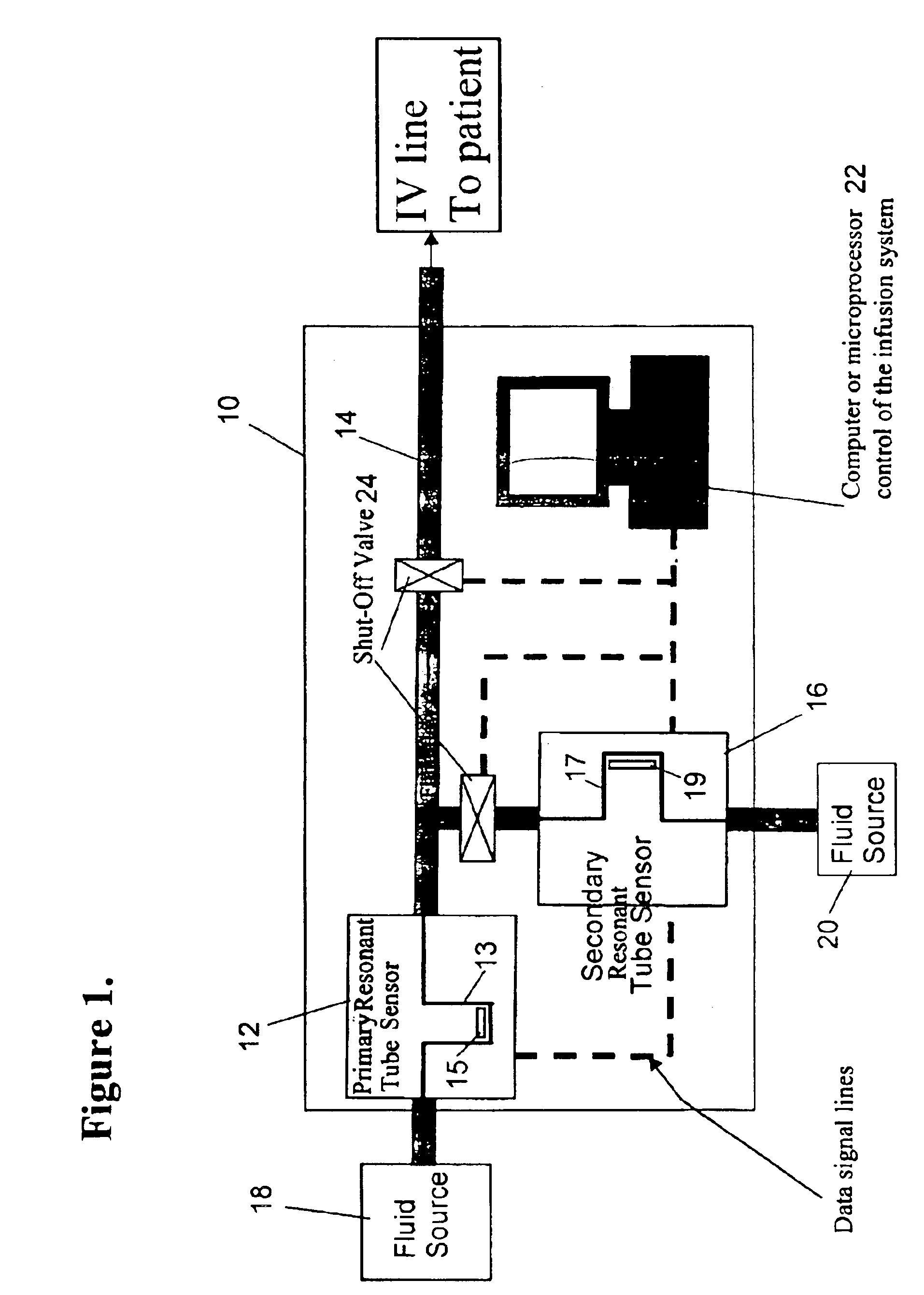

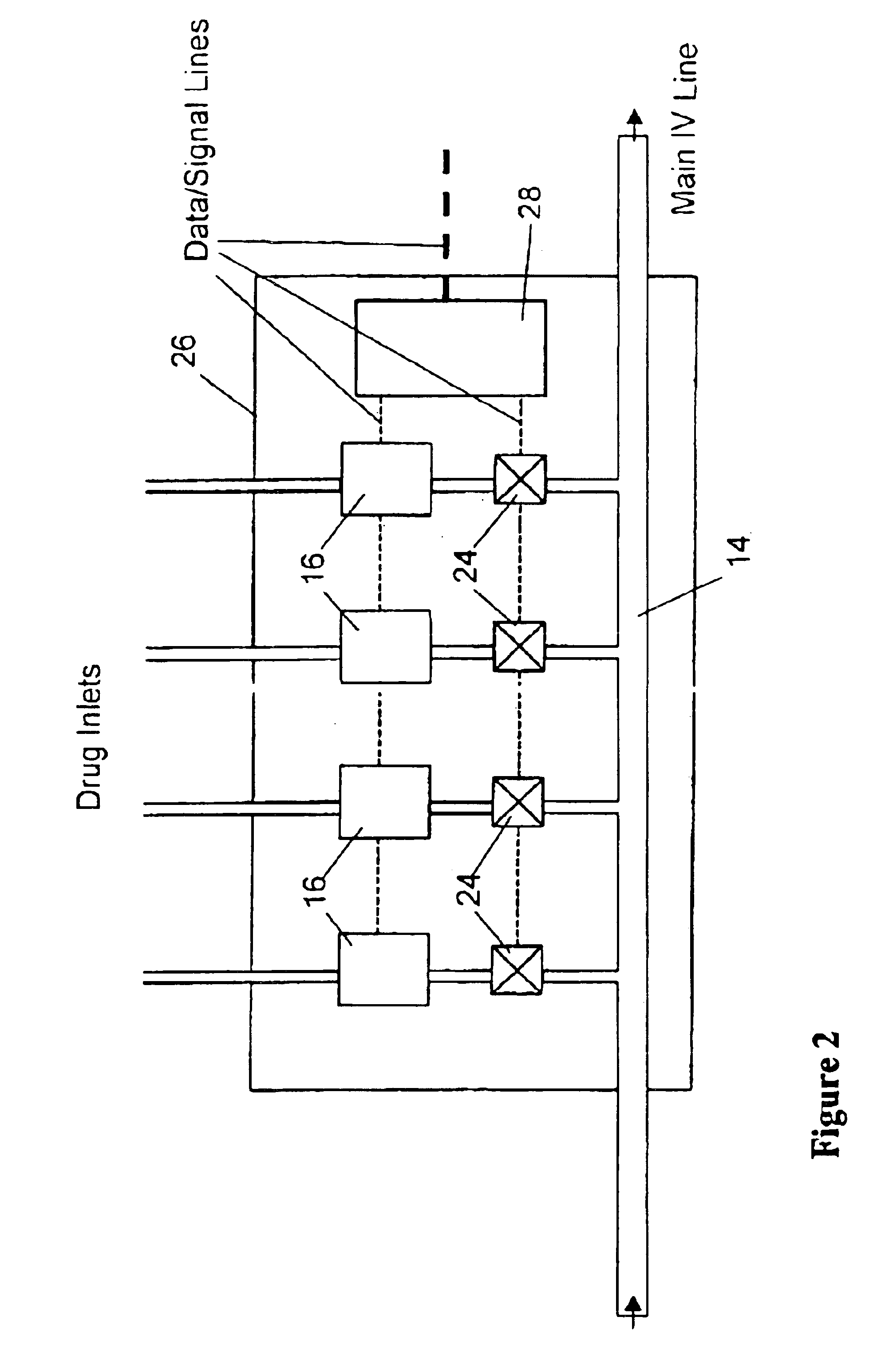

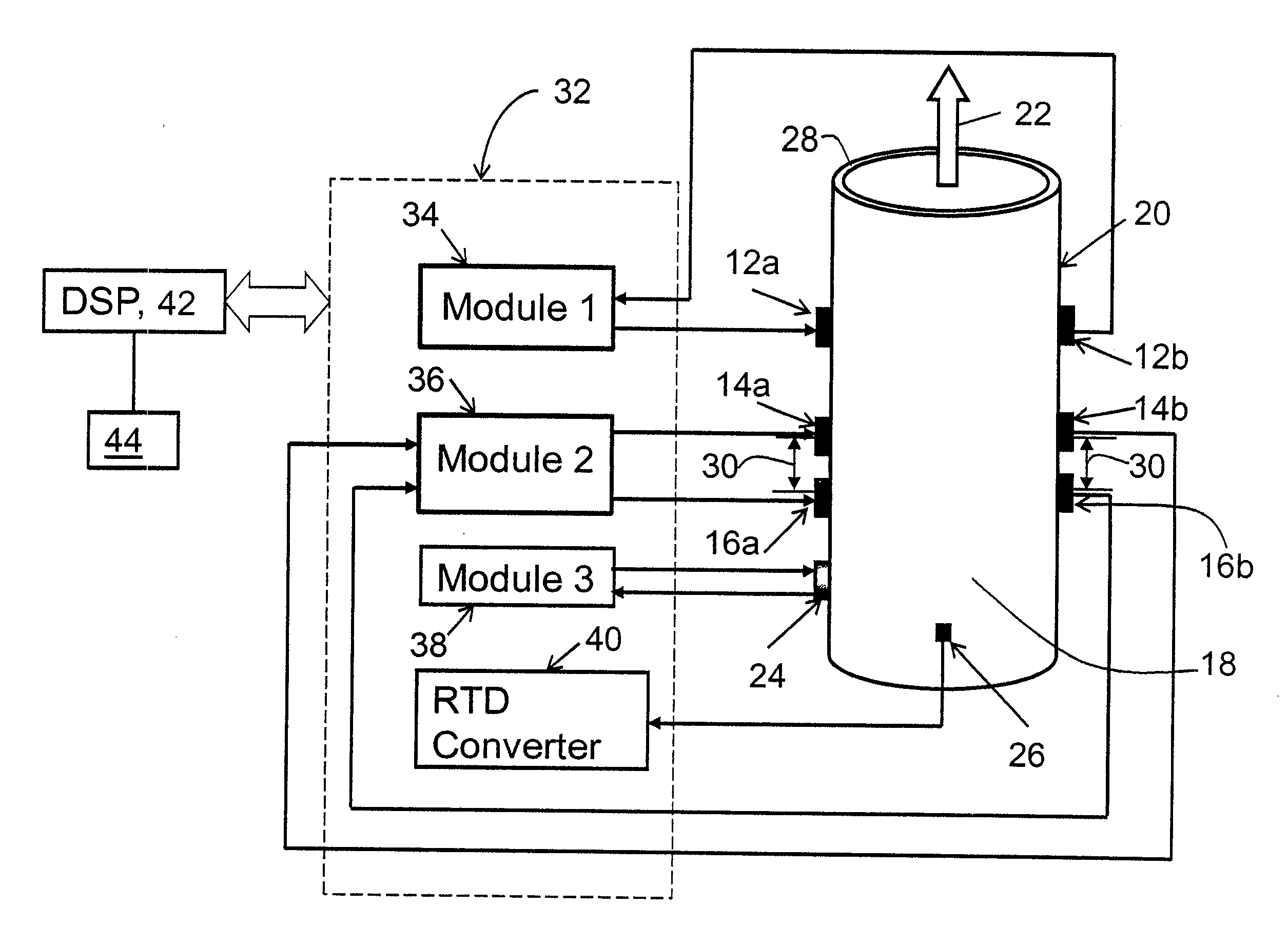

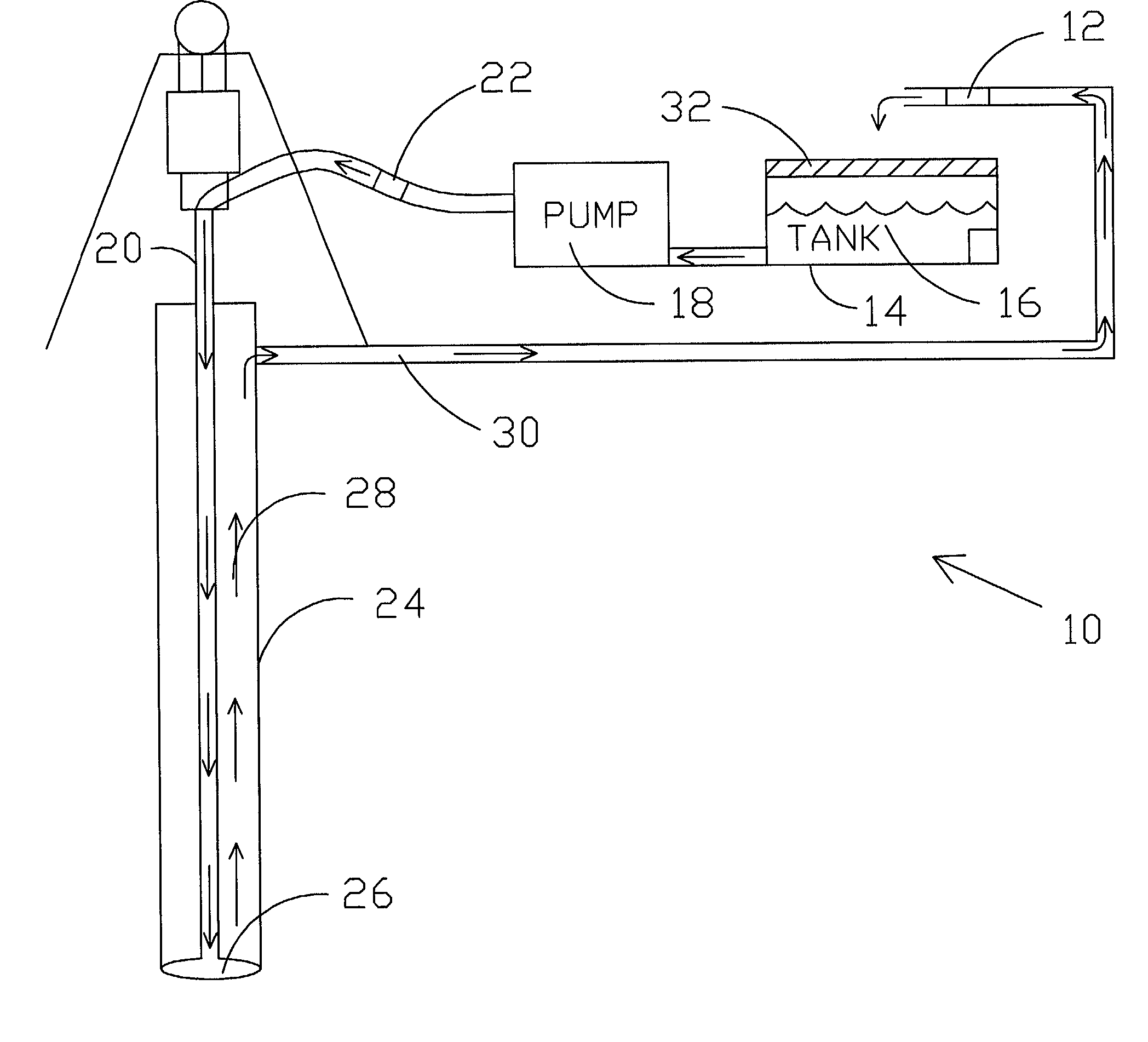

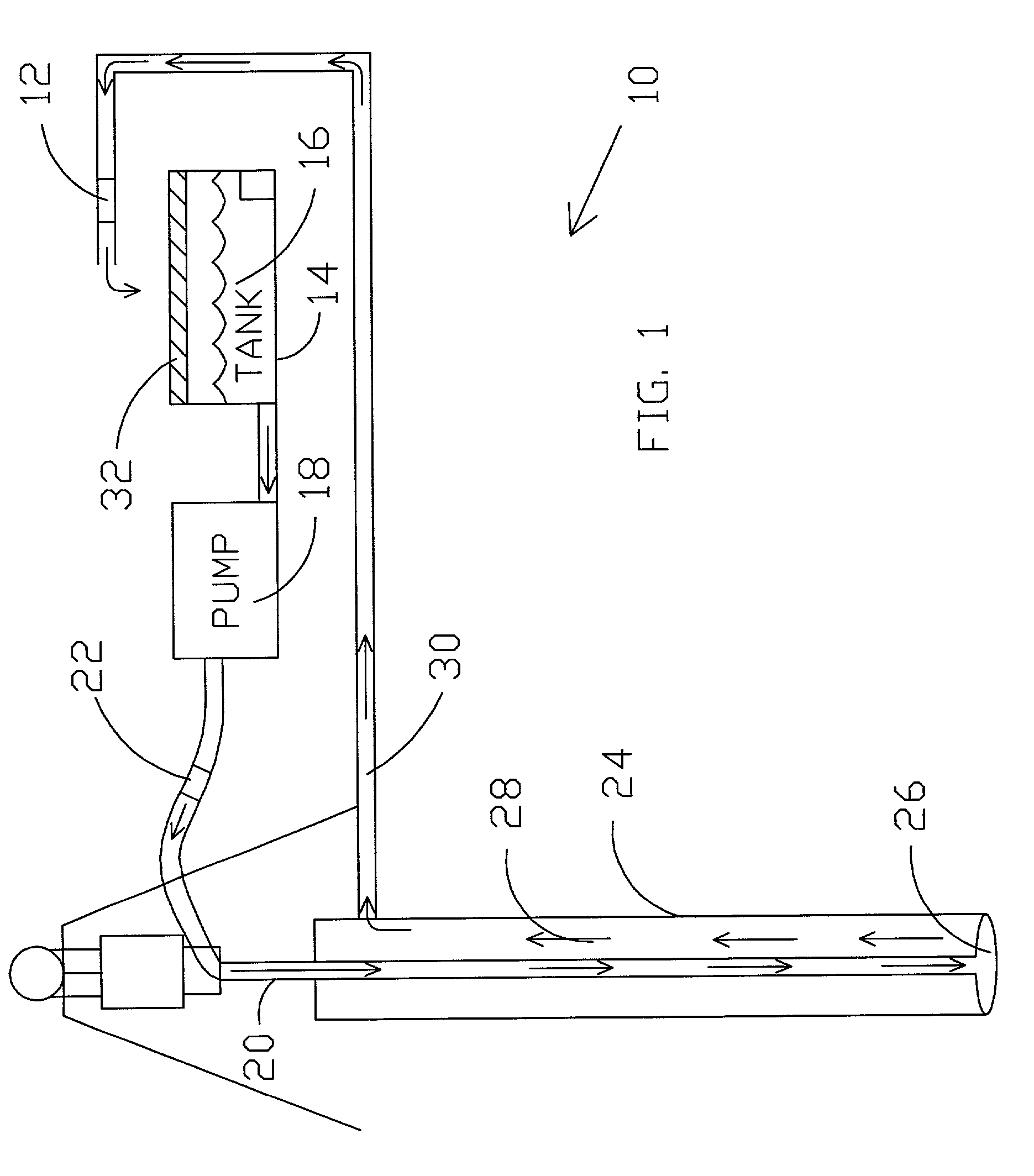

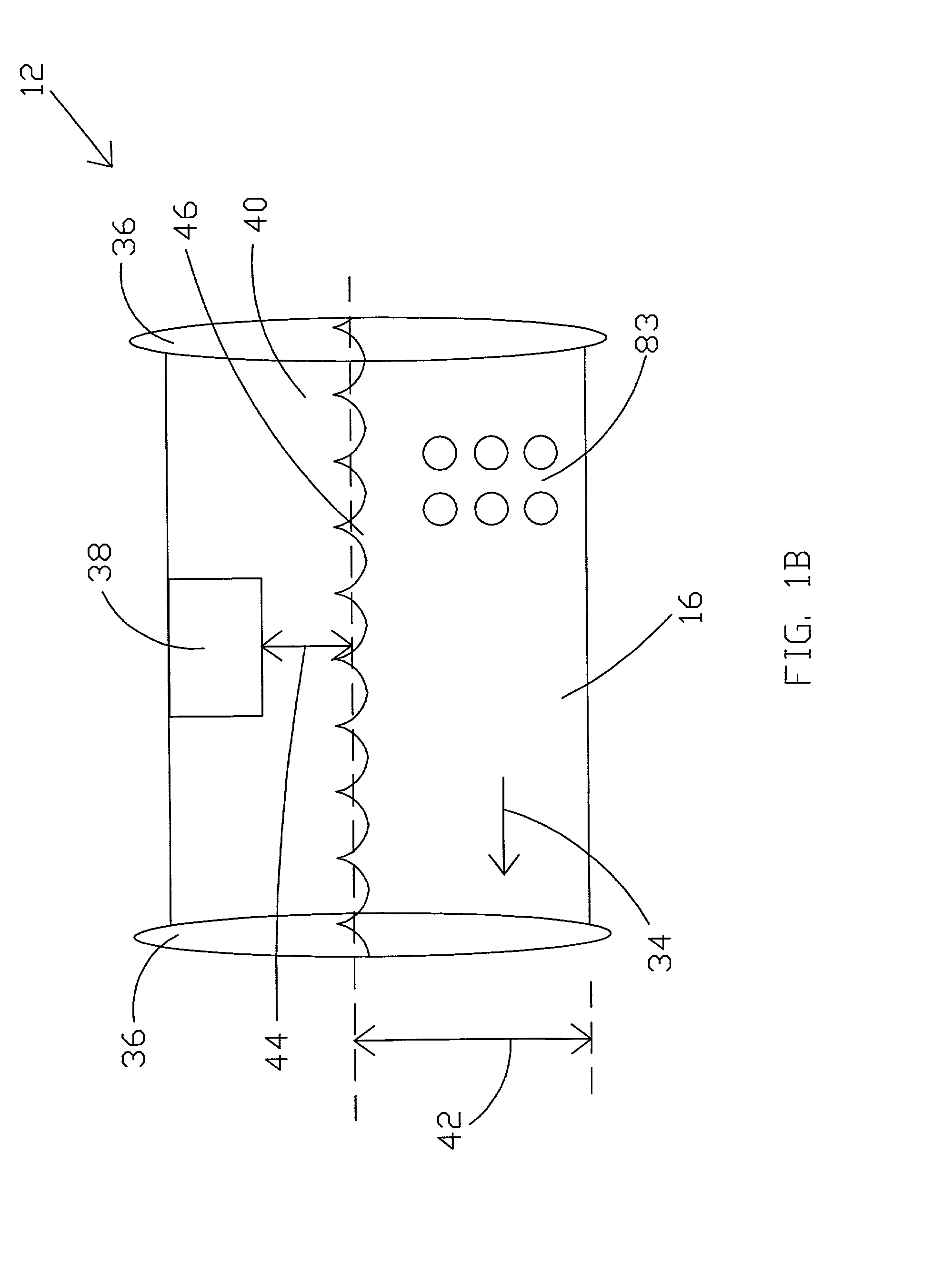

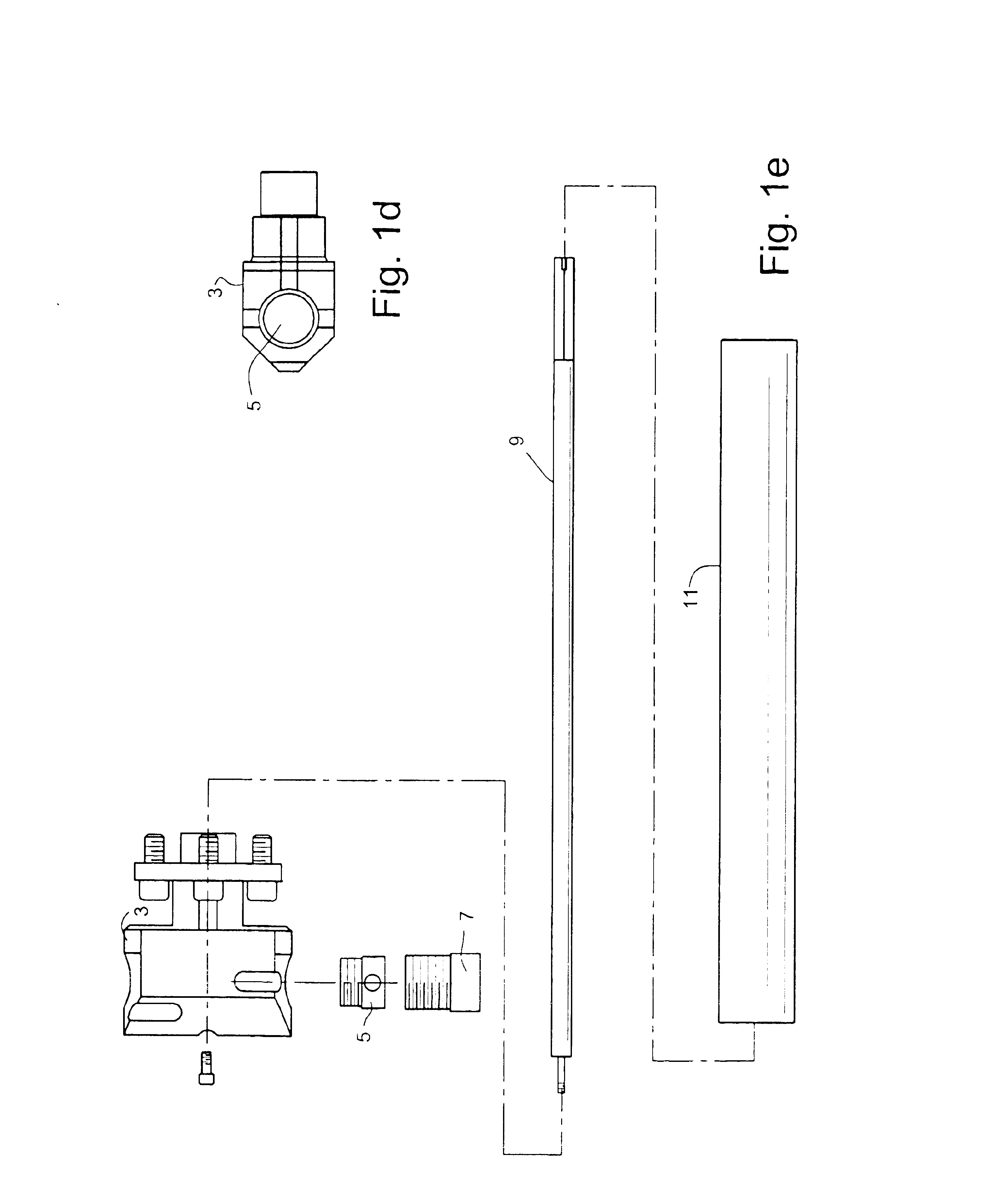

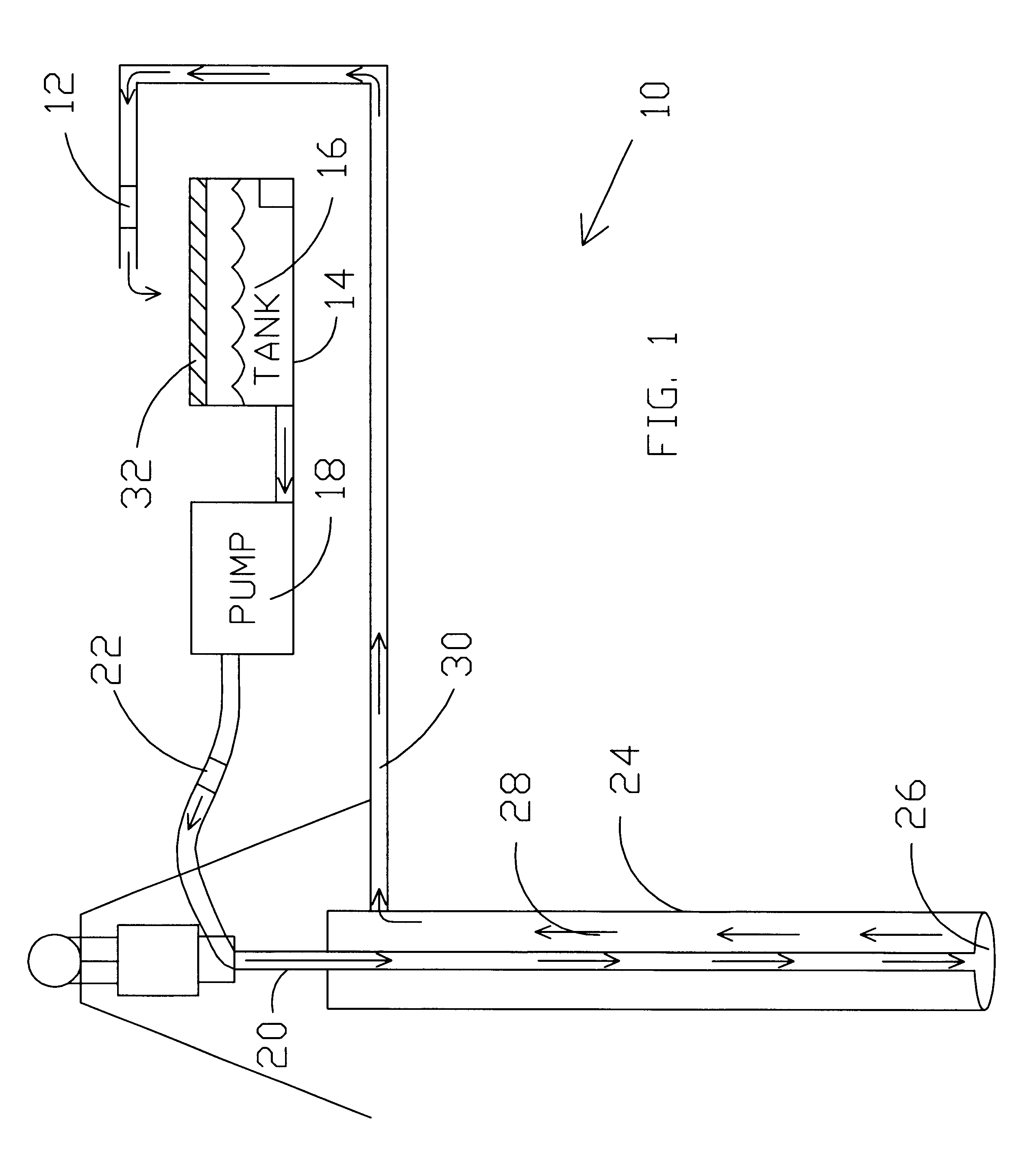

Fluid delivery system and method

InactiveUS6932114B2The right amountSafe deliveryCircuit elementsVolume measurement and fluid deliveryEngineeringDelivery system

A fluid delivery system capable of delivering a precise amount of fluid and monitor certain properties of the fluid so that the correct fluid is safely delivered to its intended destination. The system makes use of a flow sensor comprising a freestanding tube portion vibrated at a resonant frequency, wherein the resonant frequency corresponds to the density of the fluid flowing through the tube portion and the tube portion exhibits a degree of twist that varies with the mass flow rate of the fluid flowing therethrough. Movement of the tube portion is then sensed to produce a first output signal corresponding to the fluid density and a second output signal corresponding to the mass flow rate. The system is also equipped to measure elapsed time and to stop fluid flow in response to either of the first and second output signals.

Owner:INTEGRATED SENSING SYST INC

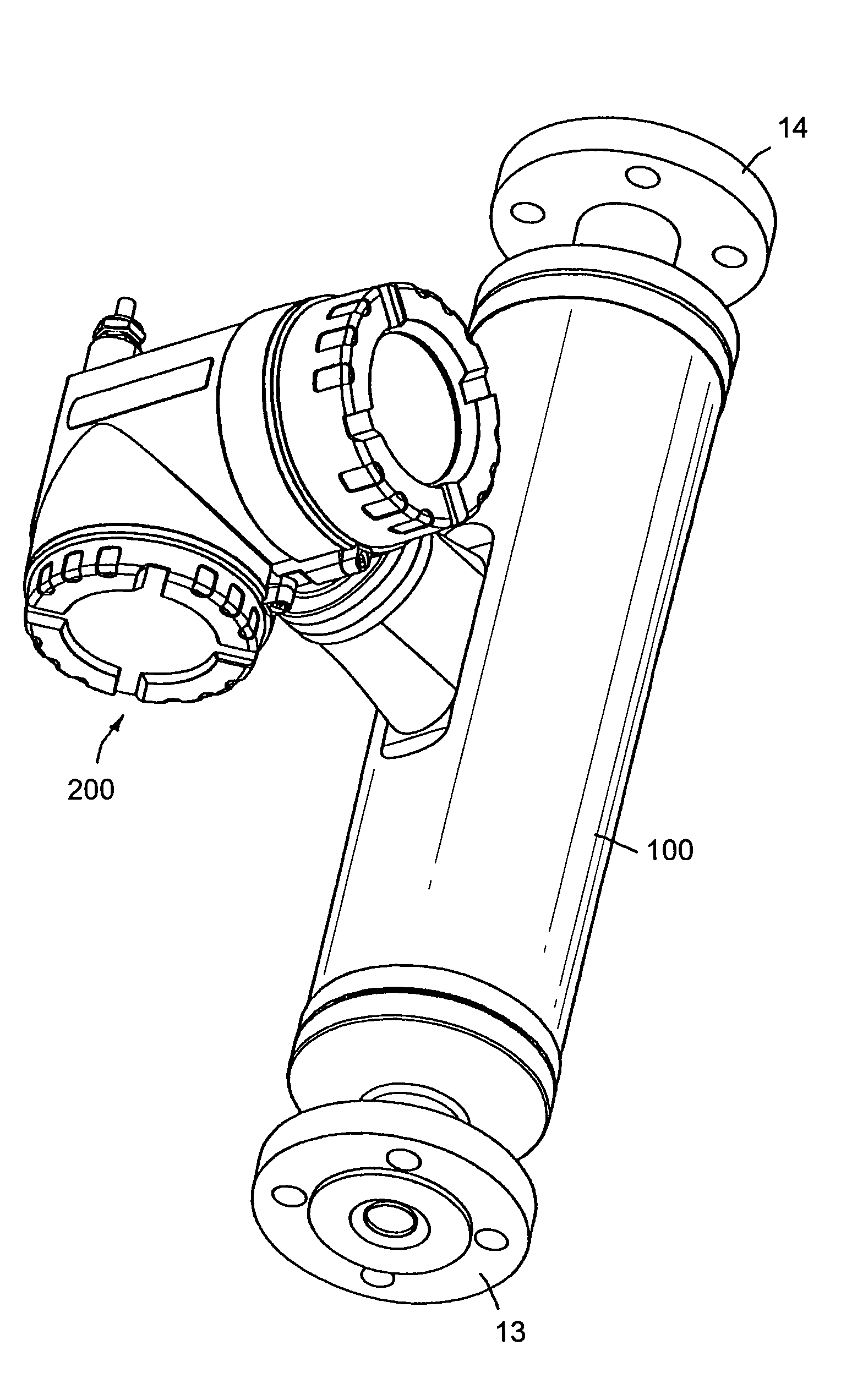

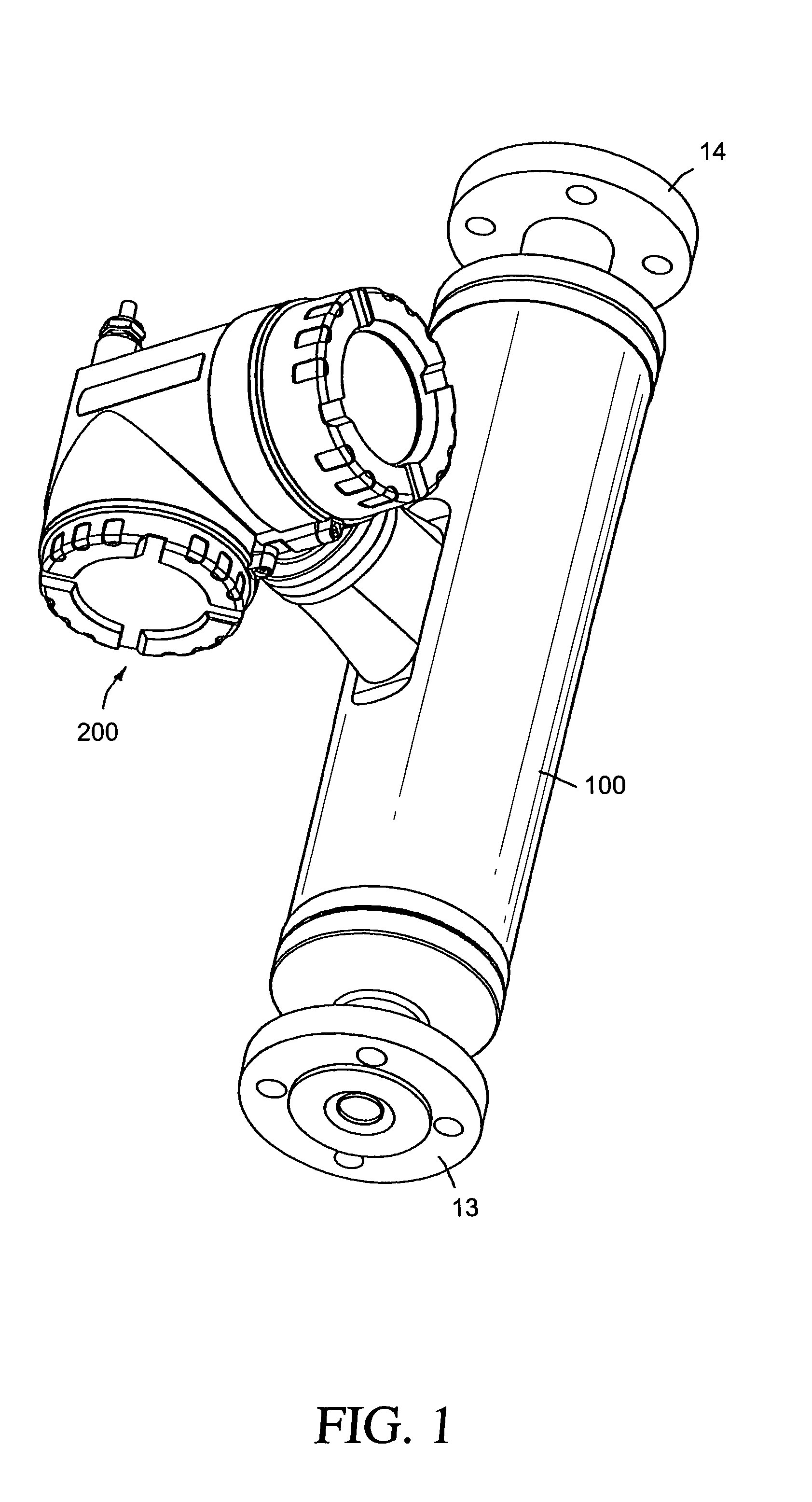

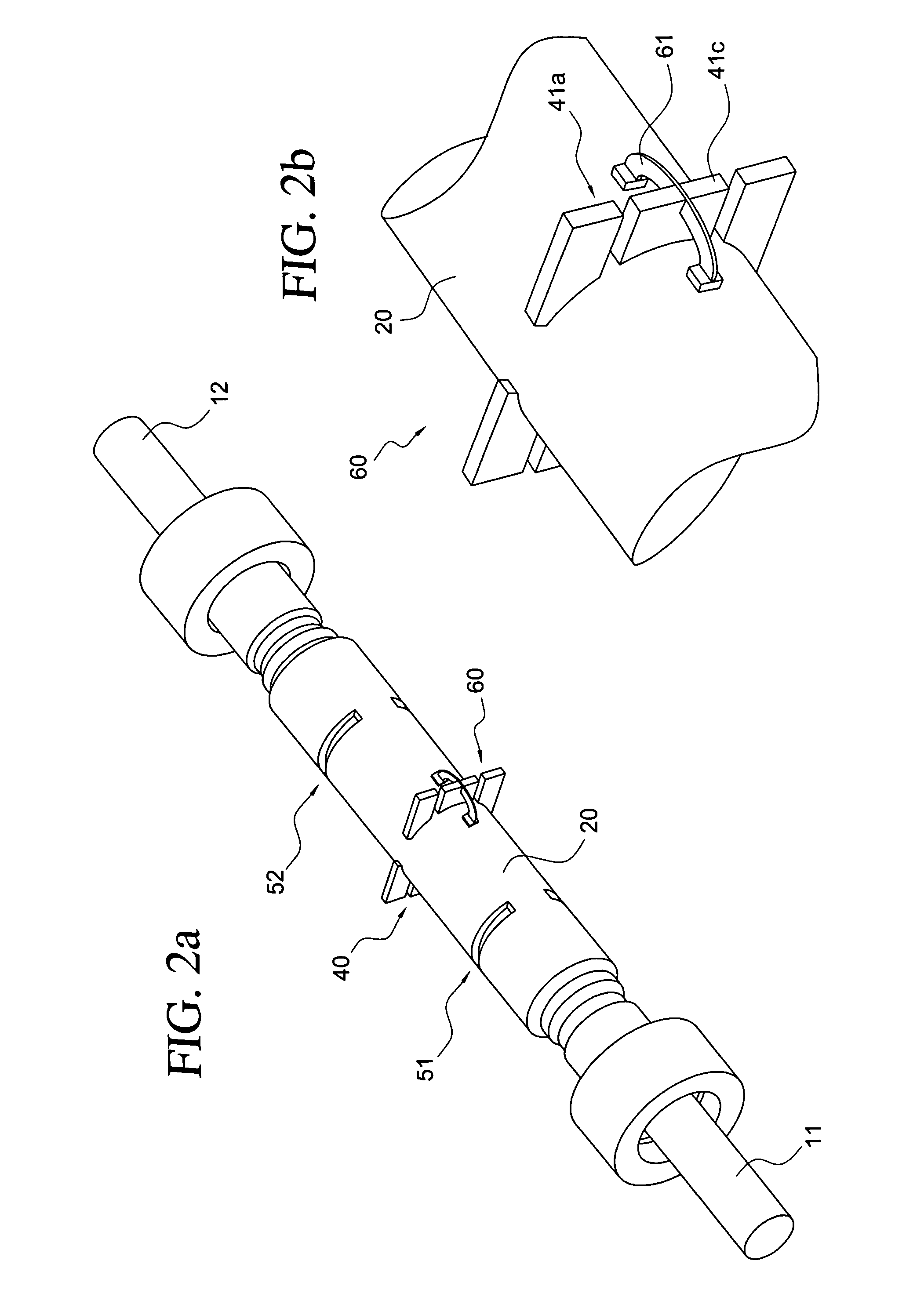

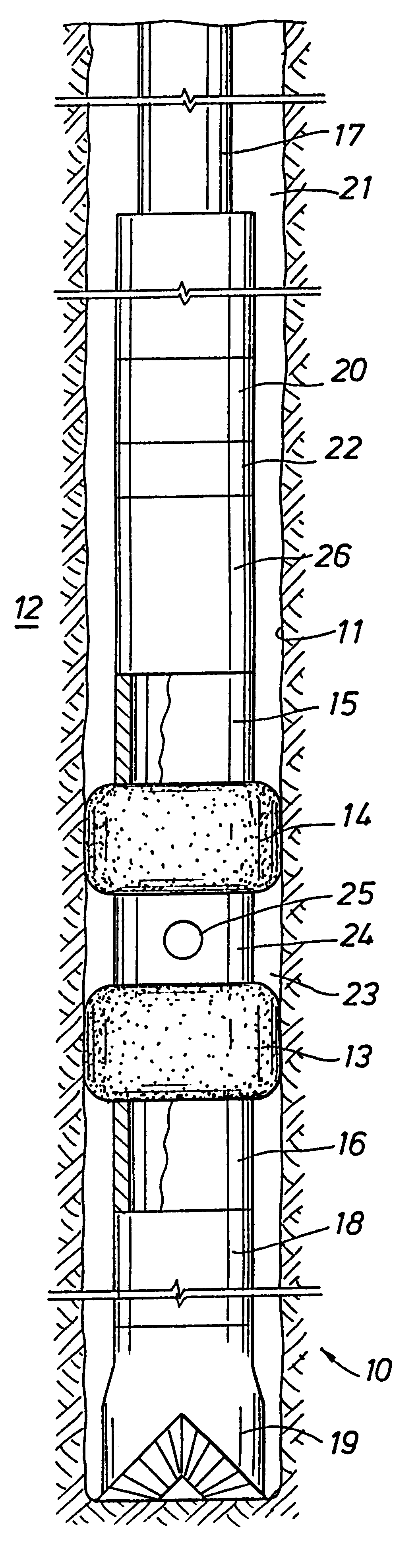

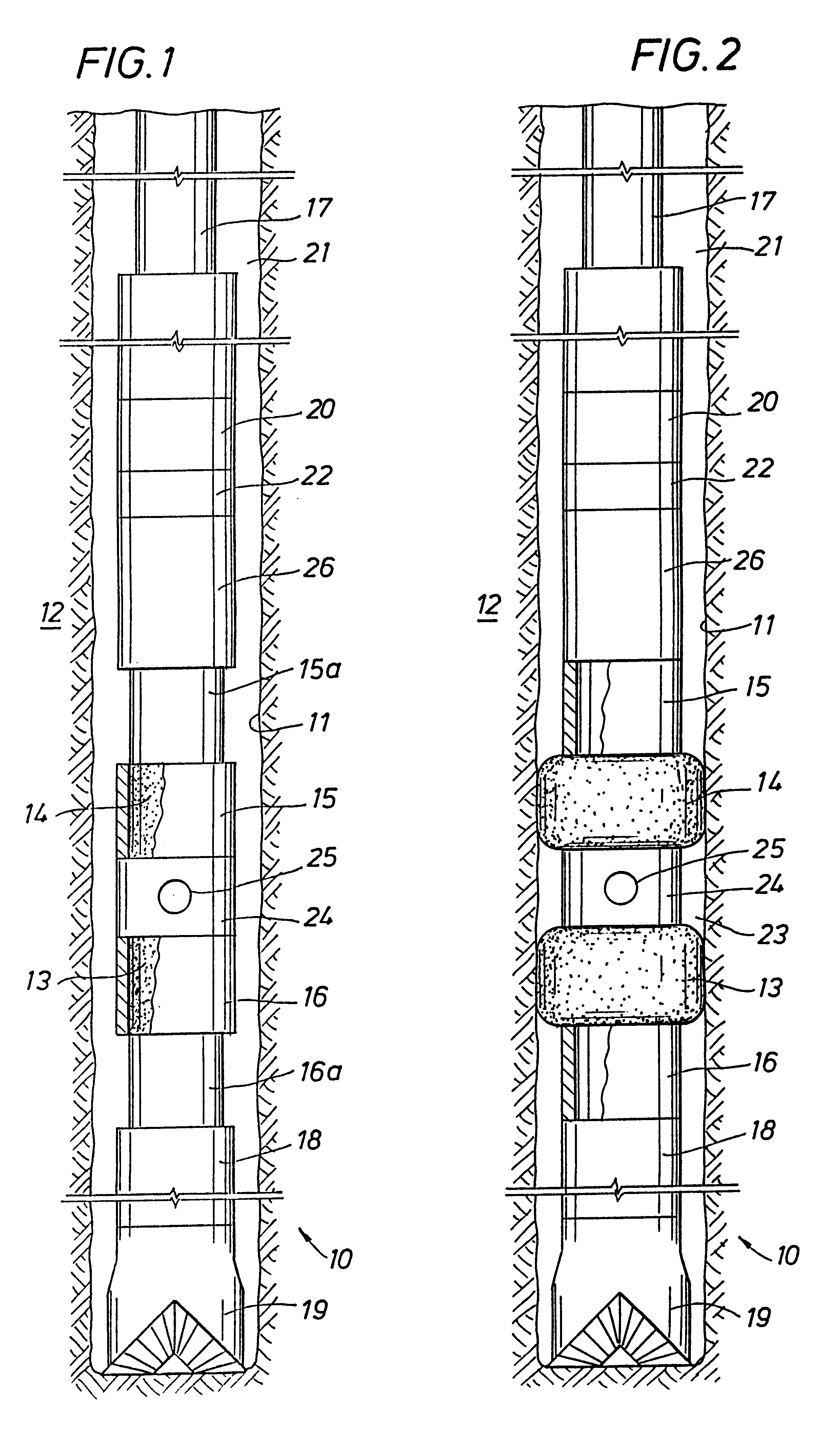

Downhole inflow control device with shut-off feature

InactiveUS20060113089A1Fluid removalWell/borehole valve arrangementsControl flowChemical composition

A system and method for controlling inflow of fluid into a production string. In aspects, the invention provides a downhole sand screen and inflow control device with a gas or water shut-off feature that can be operated mechanically or hydraulically from the surface of the well. The device also preferably includes a bypass feature that allows the inflow control device to be closed or bypassed via shifting of a sleeve. In embodiments, the flow control device can be adaptive to changes in wellbore conditions such as chemical make-up, fluid density and temperature. Exemplary adaptive inflow control devices include devices configured to control flow in response to changes in gas / oil ratio, water / oil ratio, fluid density and / or the operating temperature of the inflow control device. In other aspects of the present invention, inflow control devices are utilized to control the flow of commingled fluids drained via two or more wellbores.

Owner:BAKER HUGHES INC

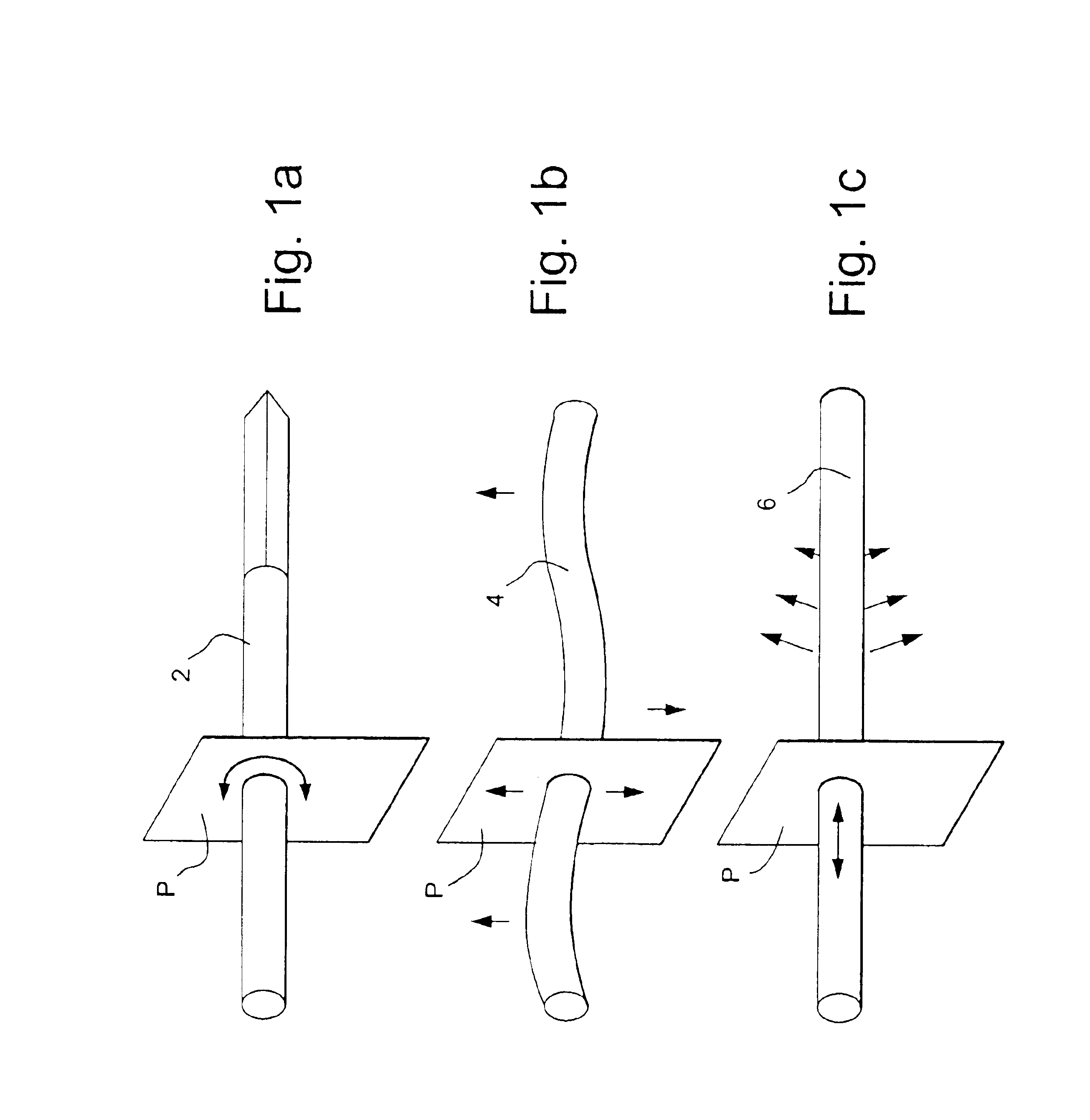

Vibration-type measuring transducer

For conveying a fluid, the measuring transducer is equipped with a measuring tube, which is held oscillatably in a support element and vibrates during operation. The measuring tube executes, during operation, at least over part of its length, driven by an exciter arrangement, bending oscillations about an oscillation axis. These bending oscillations predominantly assume an oscillation form having at least three bending oscillation antinodes. Inlet-end and outlet-end oscillations are registered by means of a sensor arrangement. Additionally provided in the measuring transducer is a coupler arrangement connected with measuring tube and with support element and having at least one coupling element interacting mechanically, especially resiliently, with the vibrating measuring tube and the support element. By suitable choice of the effective spring constant, c60, of the coupler arrangement, this can cancel transverse forces produced, during operation, on the part of the vibrating measuring tube, for example due to fluctuating fluid density.

Owner:ENDRESS HAUSER FLOWTEC AG

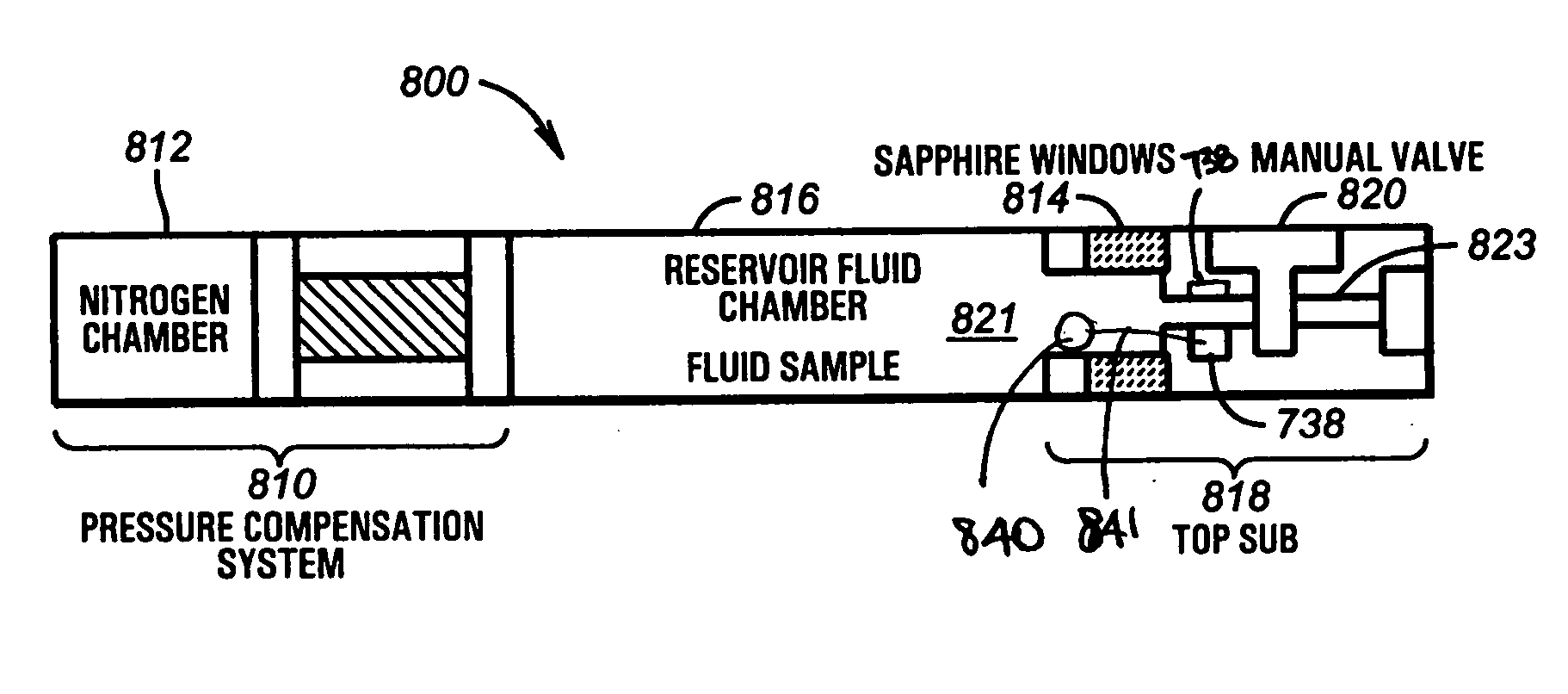

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

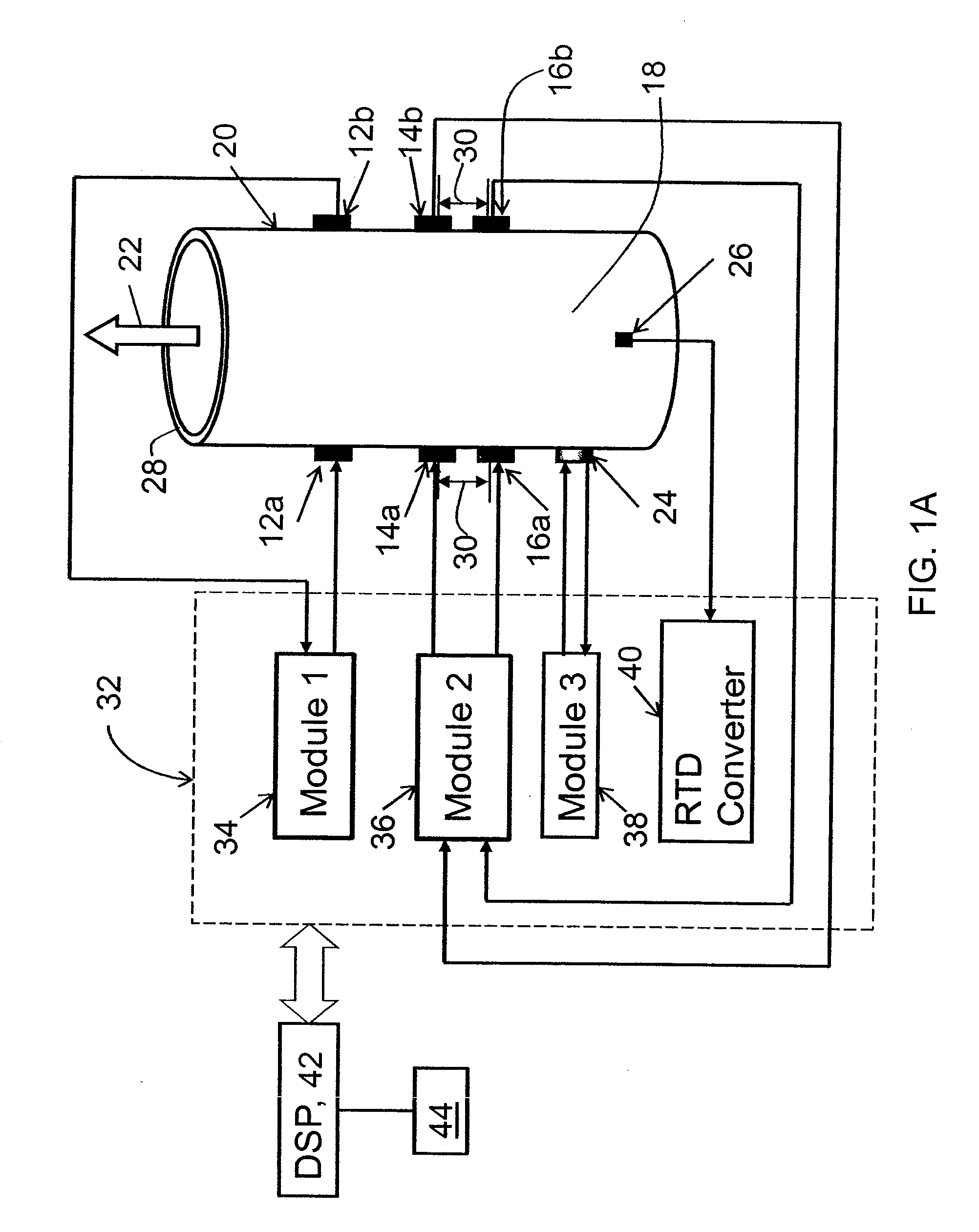

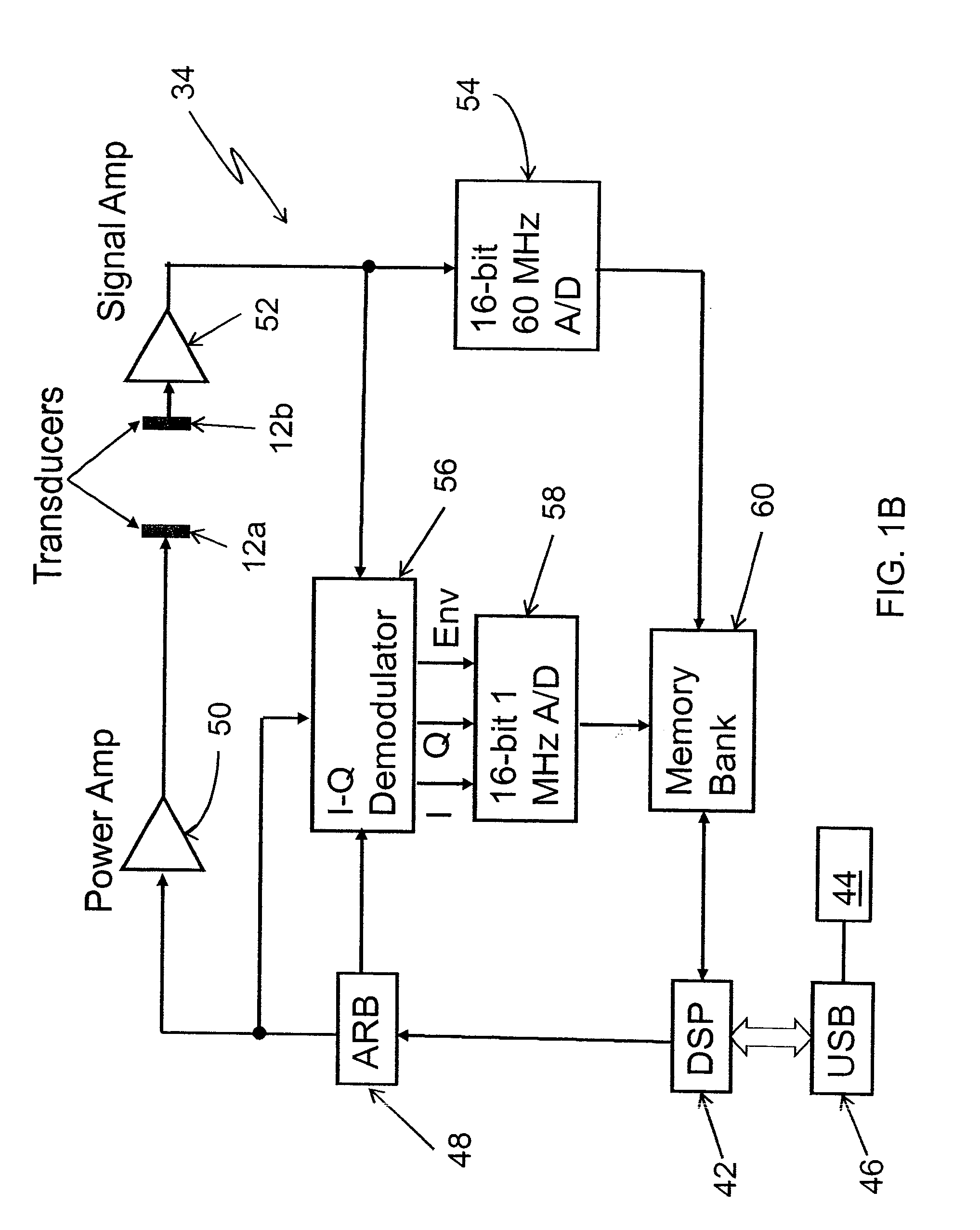

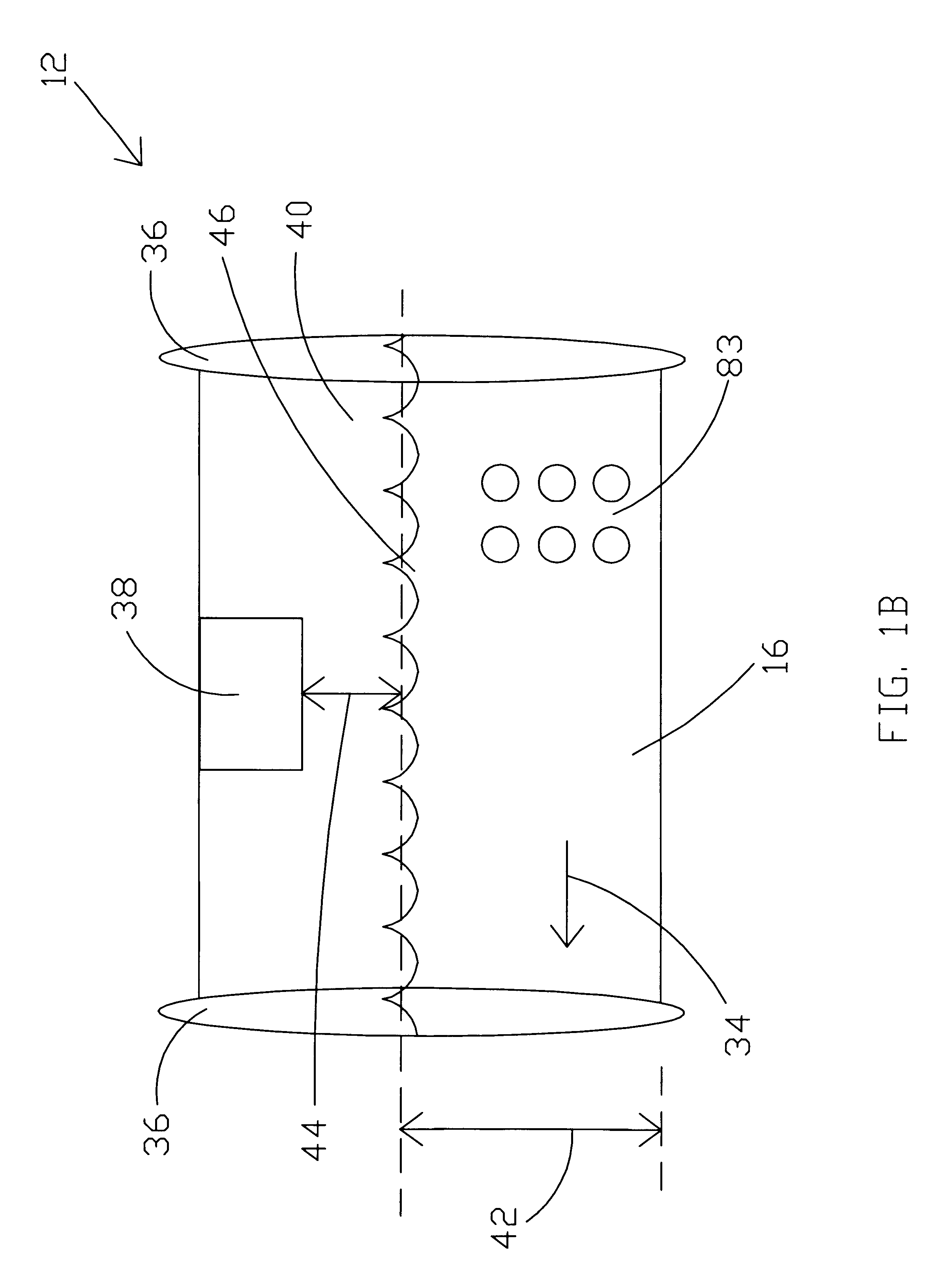

Noninvasive method for determining the liquid level and density inside of a container

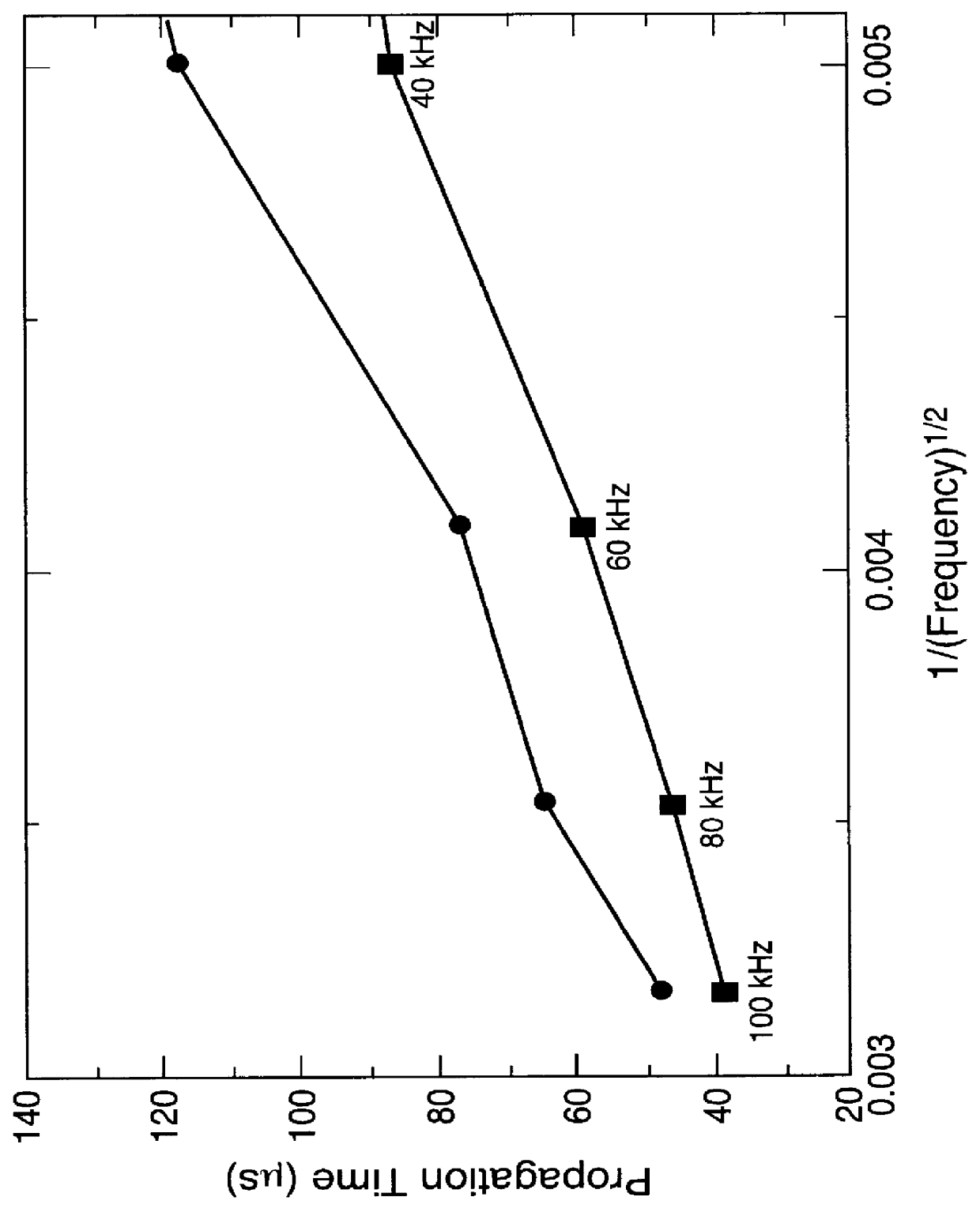

InactiveUS6053041AHigh resolutionMaterial analysis using sonic/ultrasonic/infrasonic wavesMachines/enginesPhase differenceWave detection

Noninvasive method for determining the liquid level and density inside of a container having arbitrary dimension and shape. By generating a flexural acoustic wave in the container shell and measuring the phase difference of the detected flexural wave from that of the originally generated wave a small distance from the generated wave, while moving the generation and detection means through the liquid / vapor interface, this interface can be detected. Both the wave generation and wave detection may be achieved by transducers on the surface of the container. A change in the phase difference over the outer surface of the vessel signifies that a liquid / vapor interface has been crossed, while the magnitude of the phase difference can be related to fluid density immediately opposite the measurement position on the surface of the vessel.

Owner:LOS ALAMOS NATIONAL SECURITY

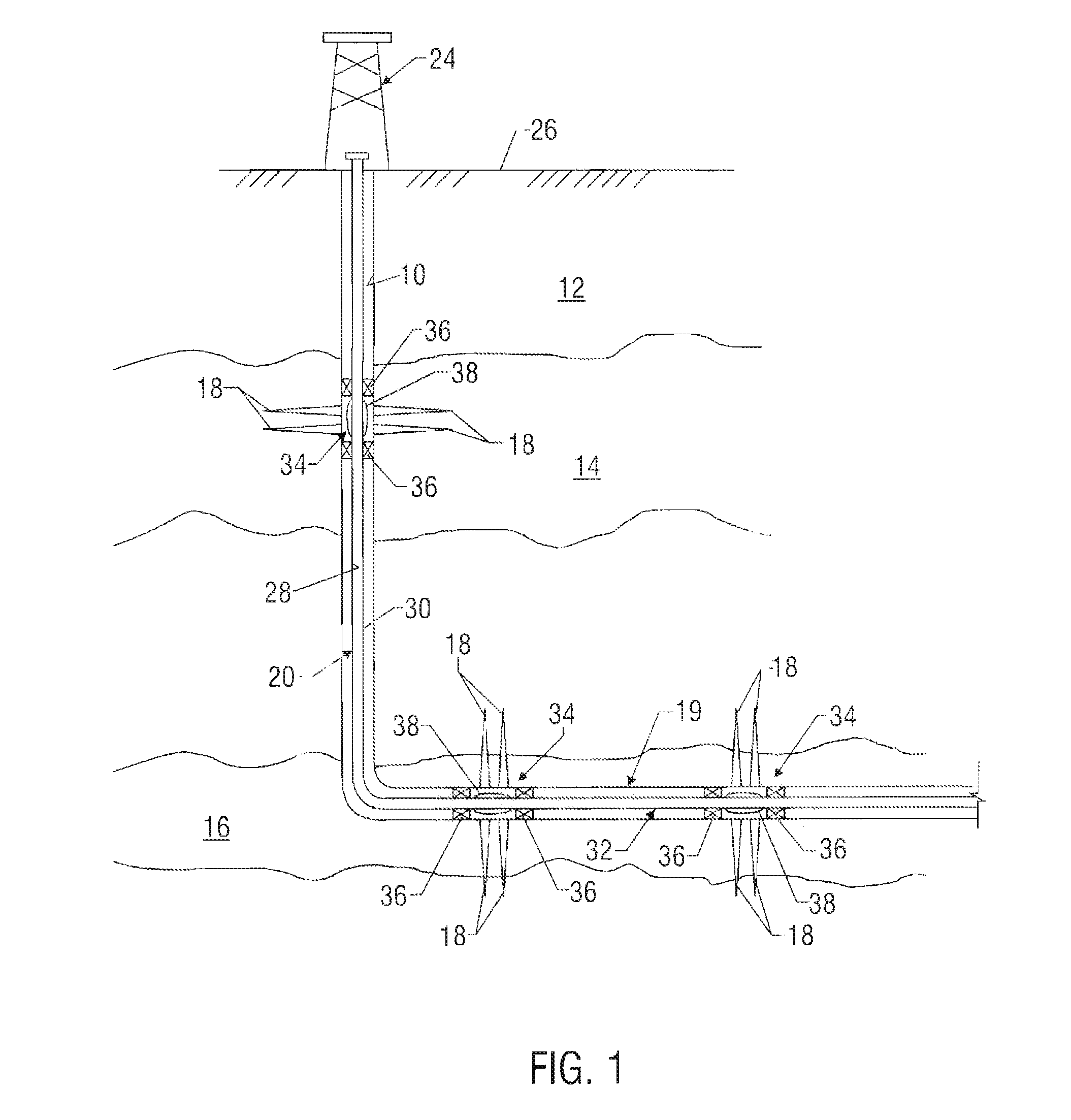

Downhole Inflow Control Device with Shut-Off Feature

A system and method for controlling inflow of fluid into a production string. In aspects, the invention provides a downhole sand screen and inflow control device with a gas or water shut-off feature that can be operated mechanically or hydraulically from the surface of the well. The device also preferably includes a bypass feature that allows the inflow control device to be closed or bypassed via shifting of a sleeve. In embodiments, the flow control device can be adaptive to changes in wellbore conditions such as chemical make-up, fluid density and temperature. Exemplary adaptive inflow control devices include devices configured to control flow in response to changes in gas / oil ratio, water / oil ratio, fluid density and / or the operating temperature of the inflow control device. In other aspects of the present invention, inflow control devices are utilized to control the flow of commingled fluids drained via two or more wellbores.

Owner:BAKER HUGHES INC

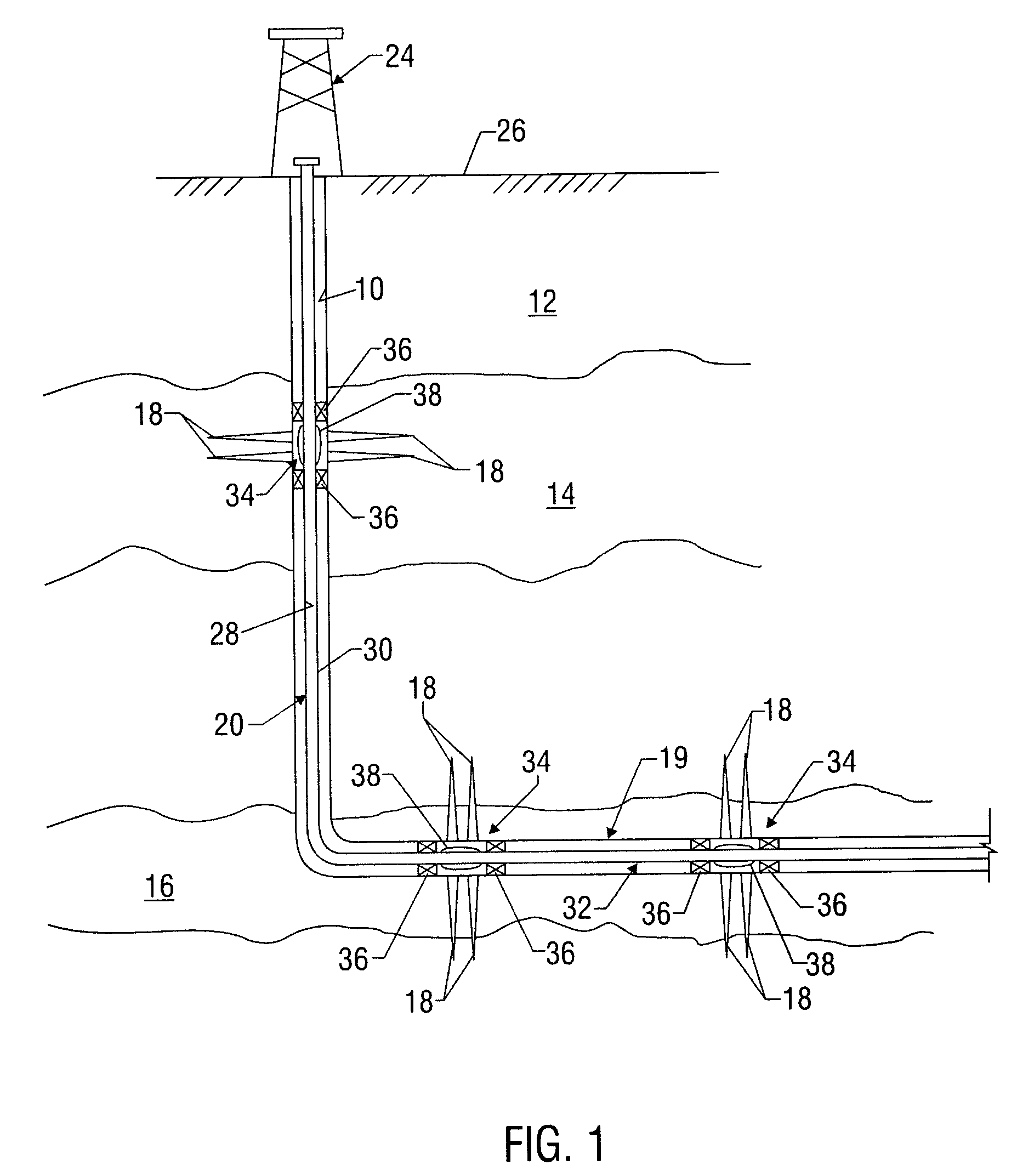

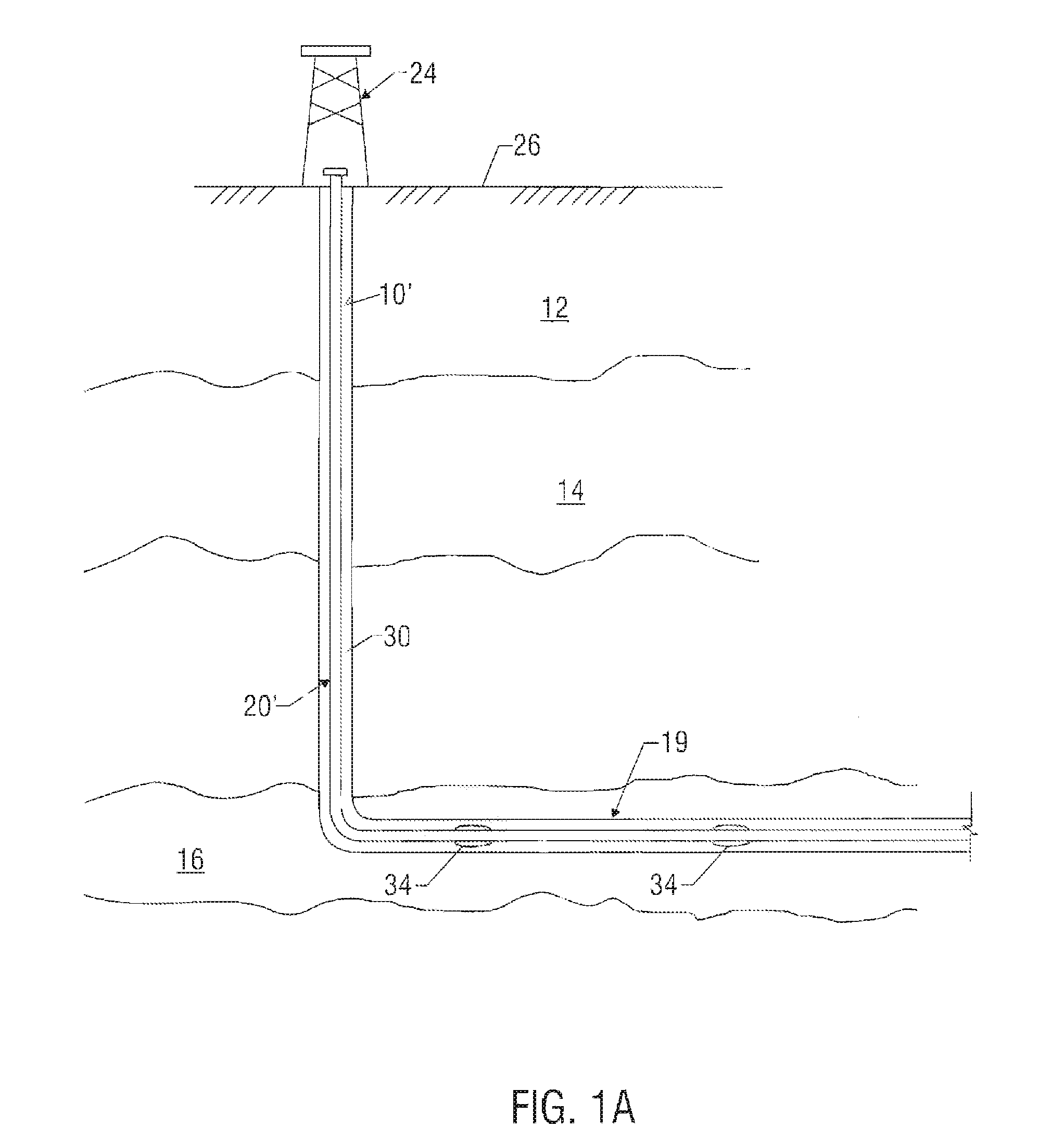

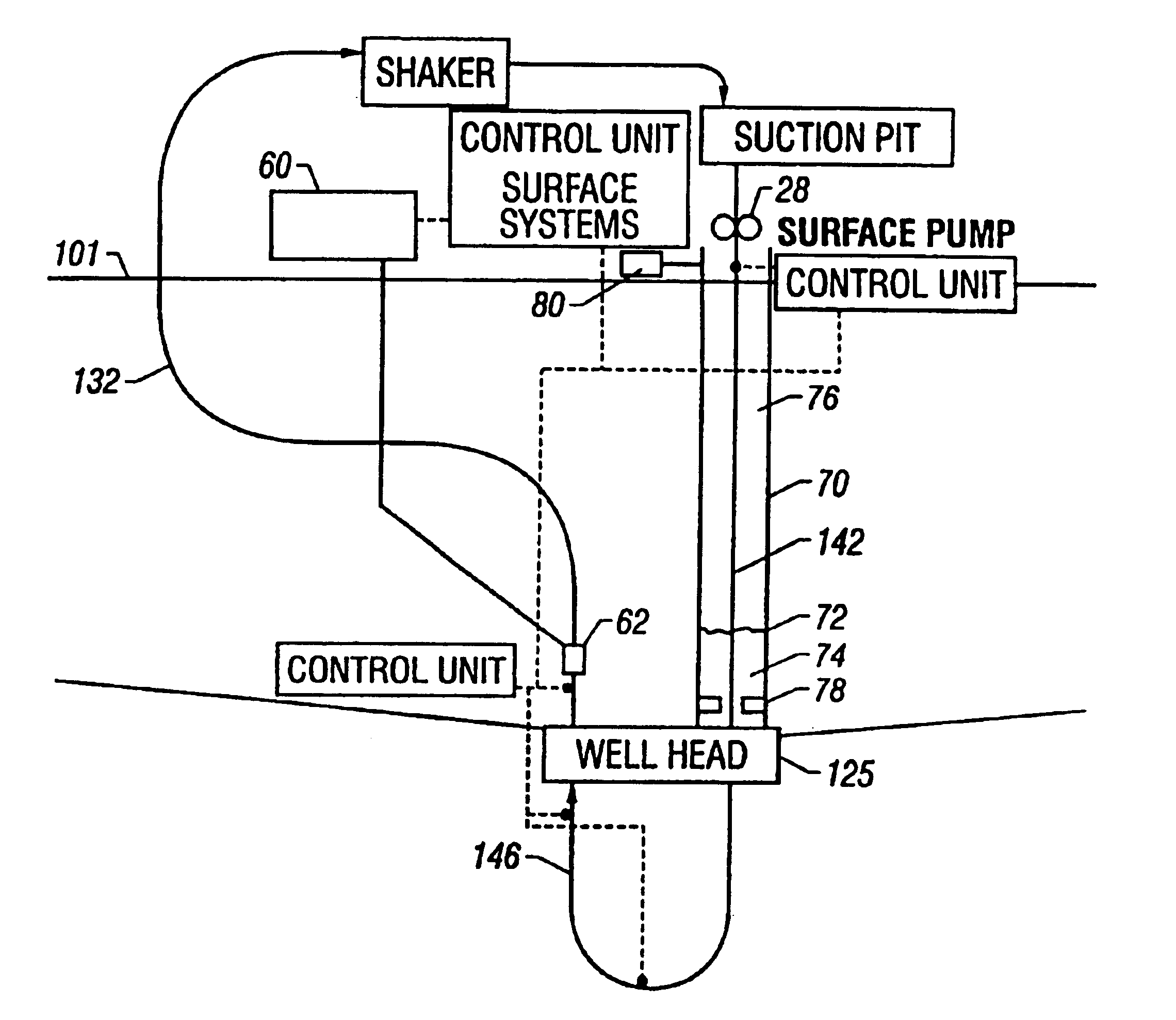

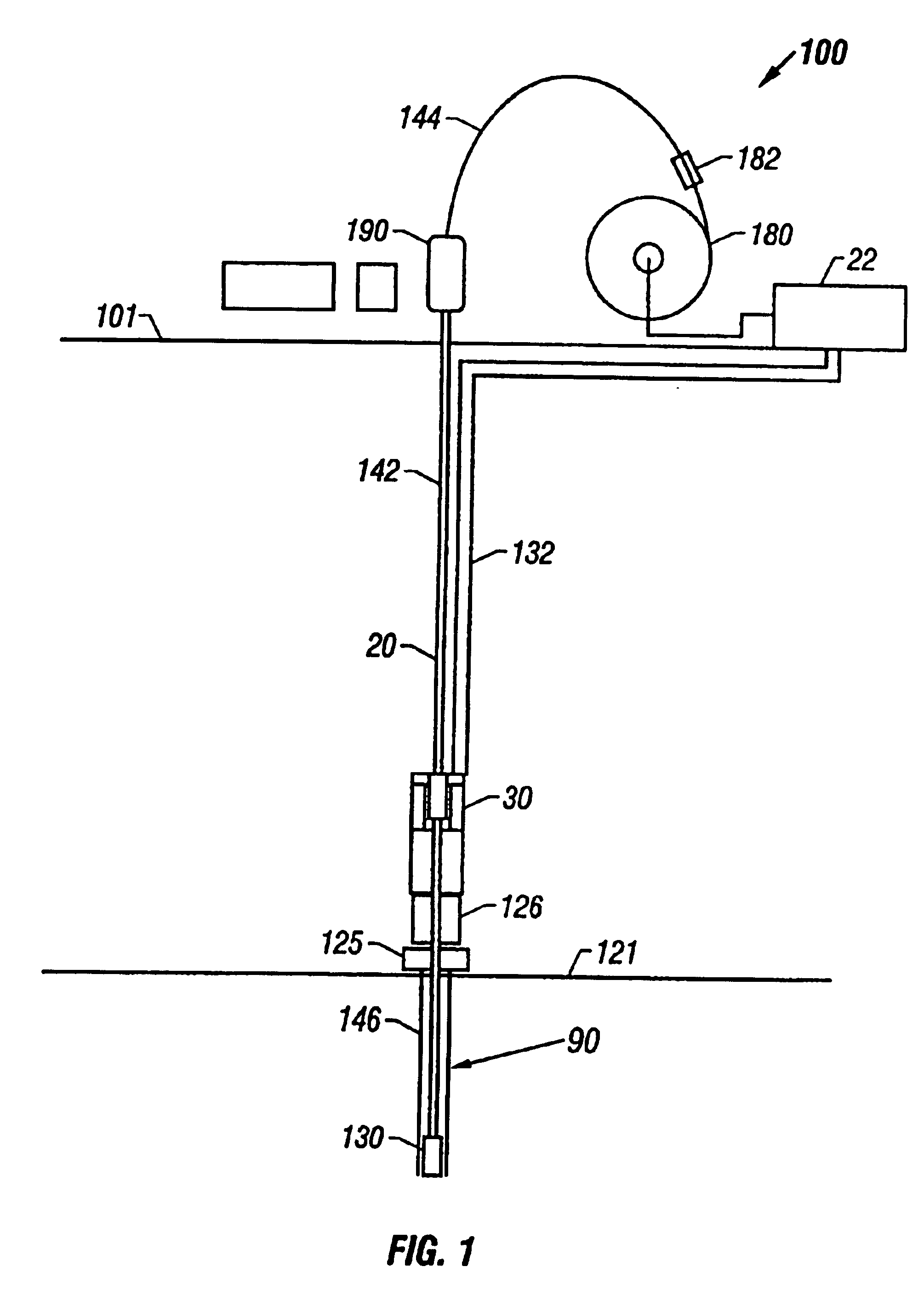

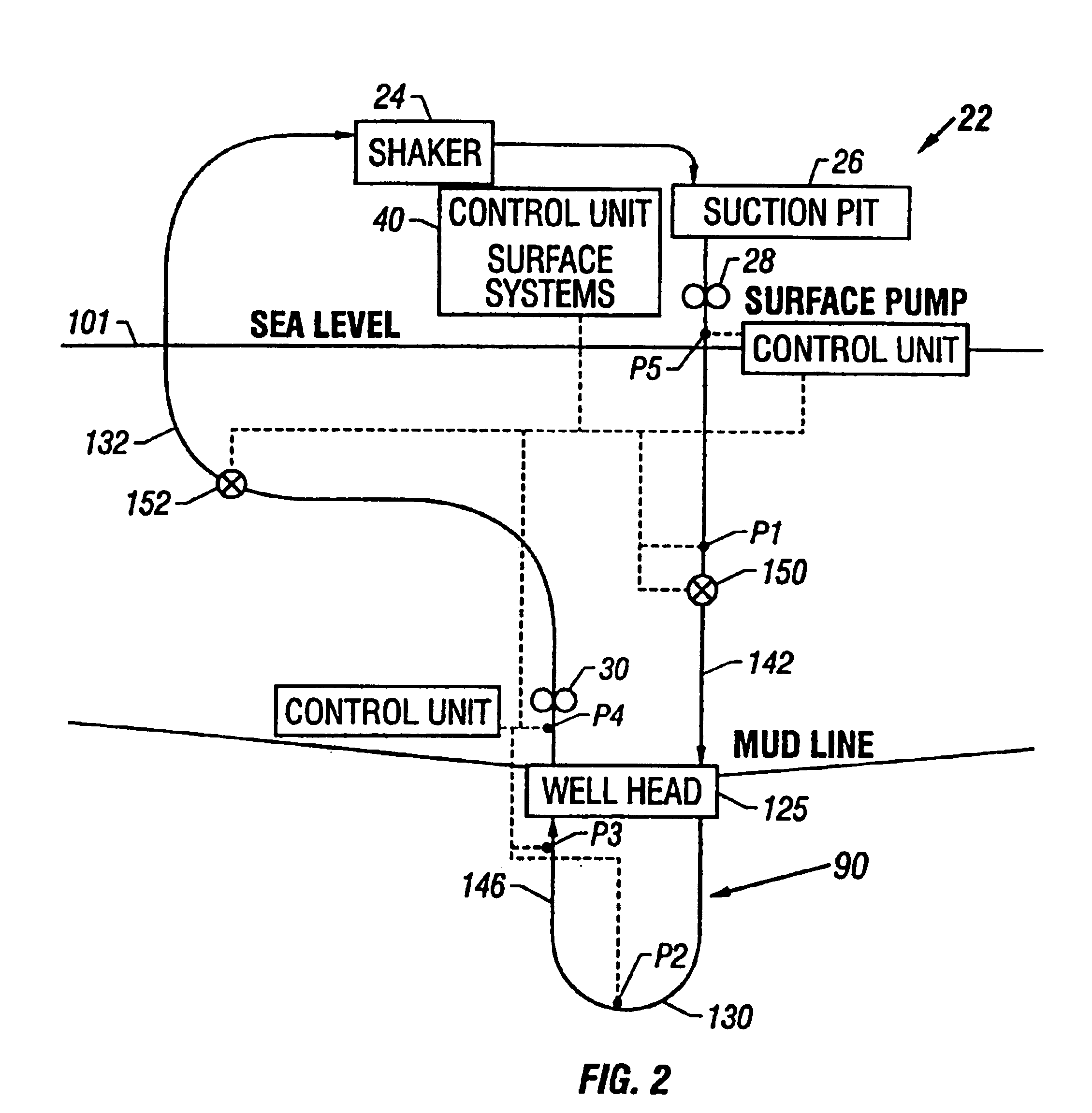

Subsea wellbore drilling system for reducing bottom hole pressure

InactiveUS6854532B2Easy to deployFaster and effective subsea downhole operationDrilling rodsConstructionsDelivery systemBottom hole assembly

The present invention provides drilling systems for drilling subsea wellbores. The drilling system includes a tubing that passes through a sea bottom wellhead and carries a drill bit. A drilling fluid system continuously supplies drilling fluid into the tubing, which discharges at the drill bit bottom and returns to the wellhead through an annulus between the tubing and the wellbore carrying the drill cuttings. A fluid return line extending from the wellhead equipment to the drilling vessel transports the returning fluid to the surface. In a riserless arrangement, the return fluid line is separate and spaced apart from the tubing. In a system using a riser, the return fluid line may be the riser or a separate line carried by the riser. The tubing may be coiled tubing with a drilling motor in the bottom hole assembly driving the drill bit. A suction pump coupled to the annulus is used to control the bottom hole pressure during drilling operations, making it possible to use heavier drilling muds and drill to greater depths than would be possible without the suction pump. An optional delivery system continuously injects a flowable material, whose fluid density is less than the density of the drilling fluid, into the returning fluid at one or more suitable locations the rate of such lighter material can be controlled to provide supplementary regulation of the pressure. Various pressure, temperature, flow rate and kick sensors included in the drilling system provide signals to a controller that controls the suction pump, the surface mud pump, a number of flow control devices, and the optional delivery system.

Owner:BAKER HUGHES INC

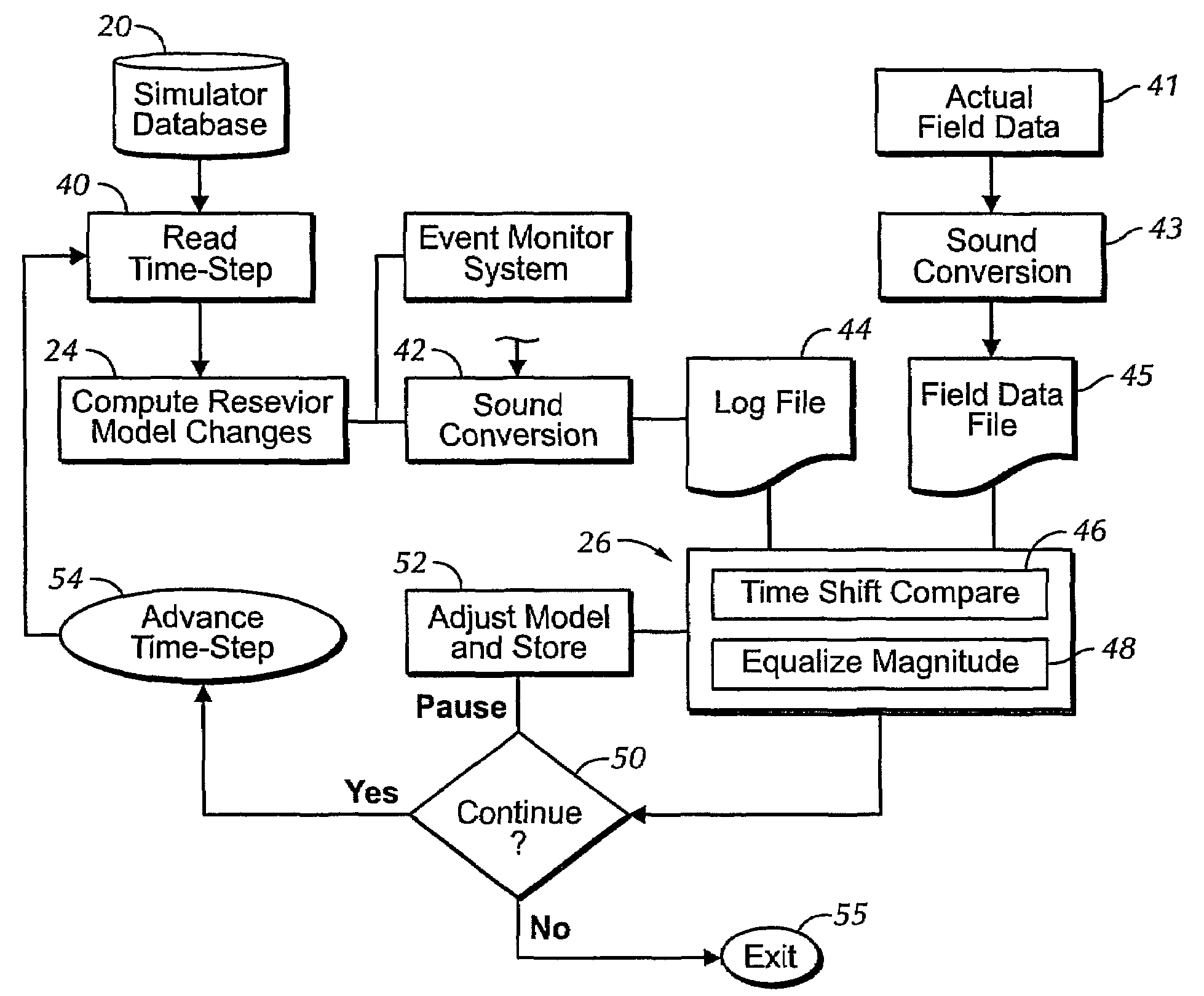

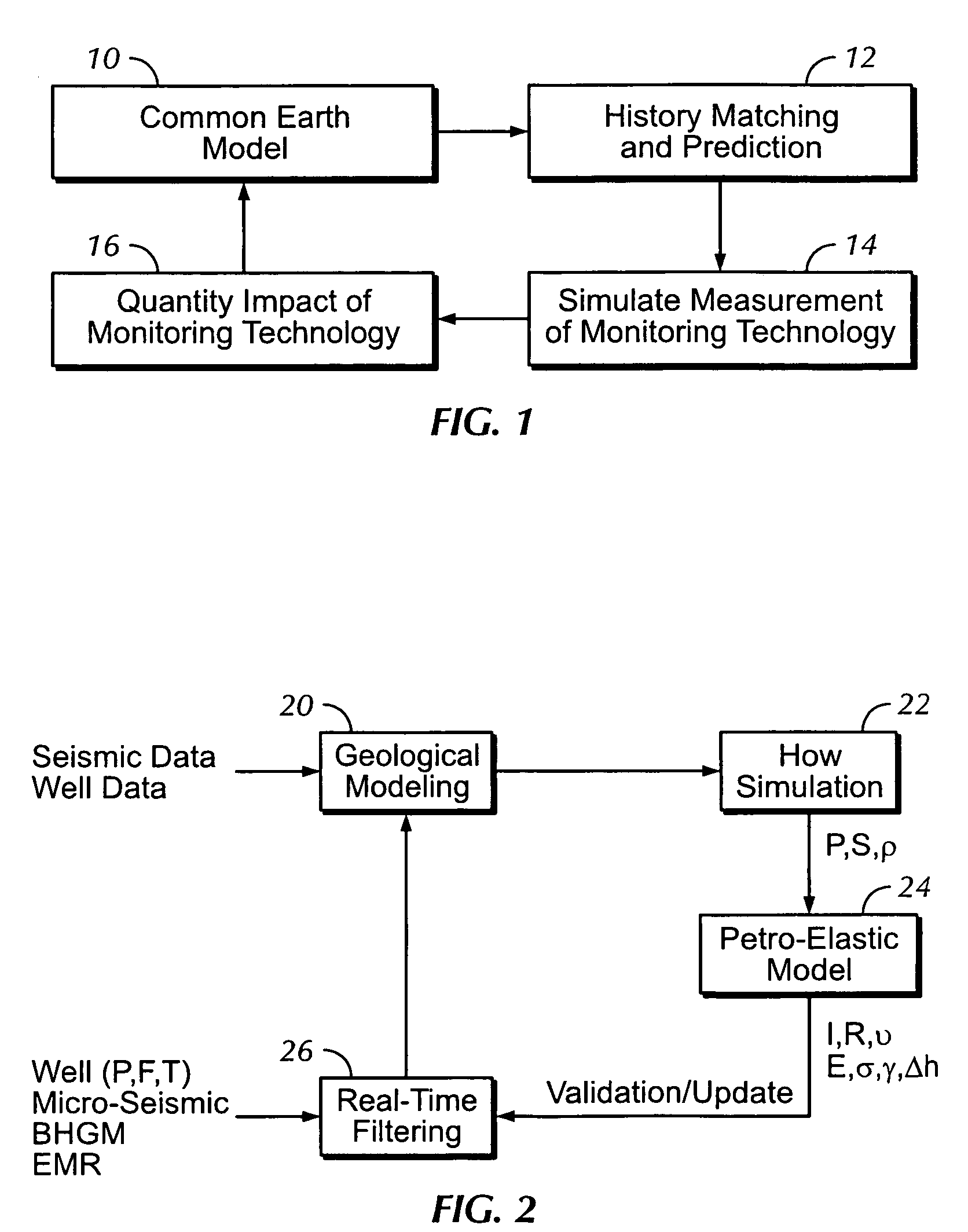

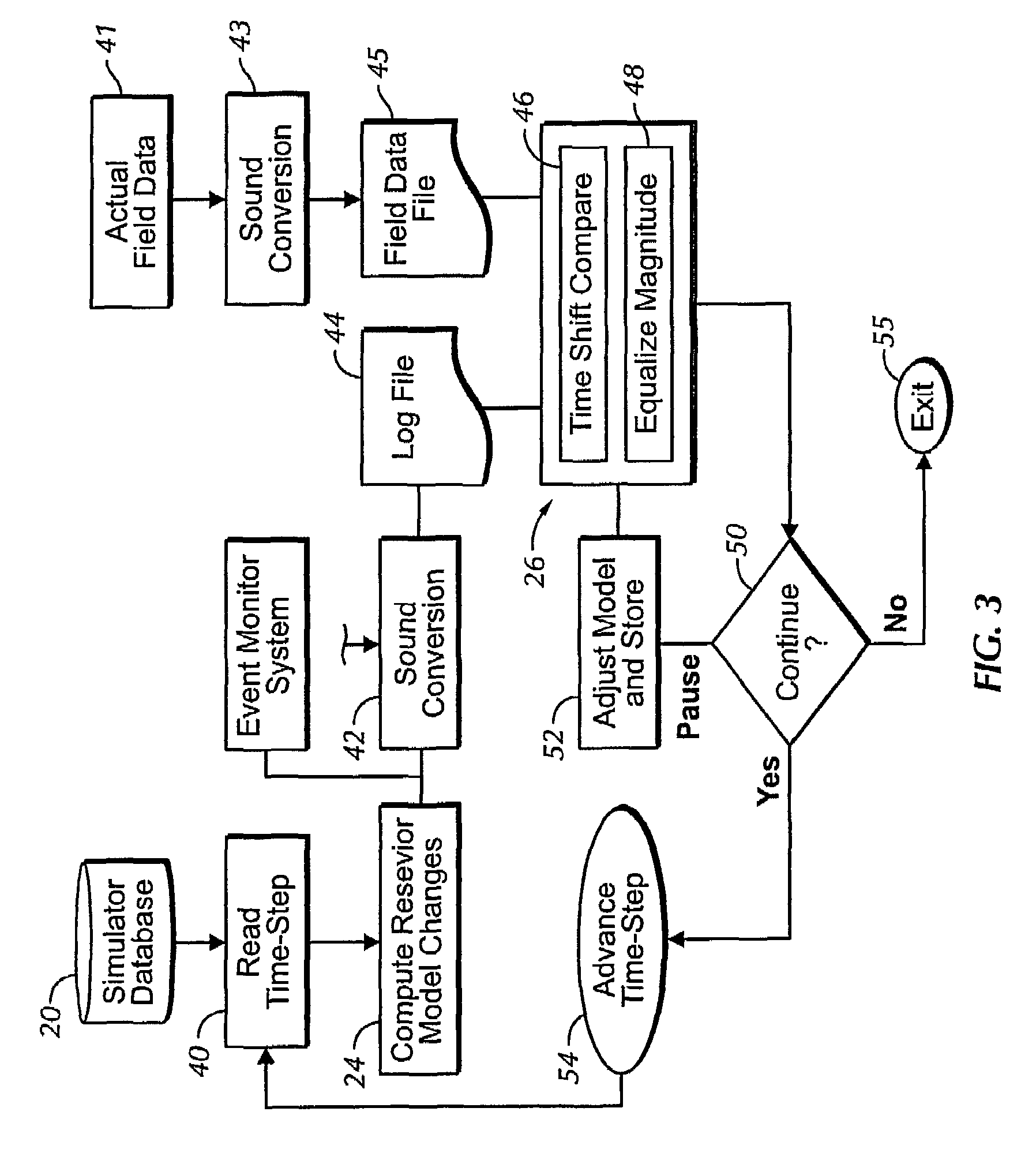

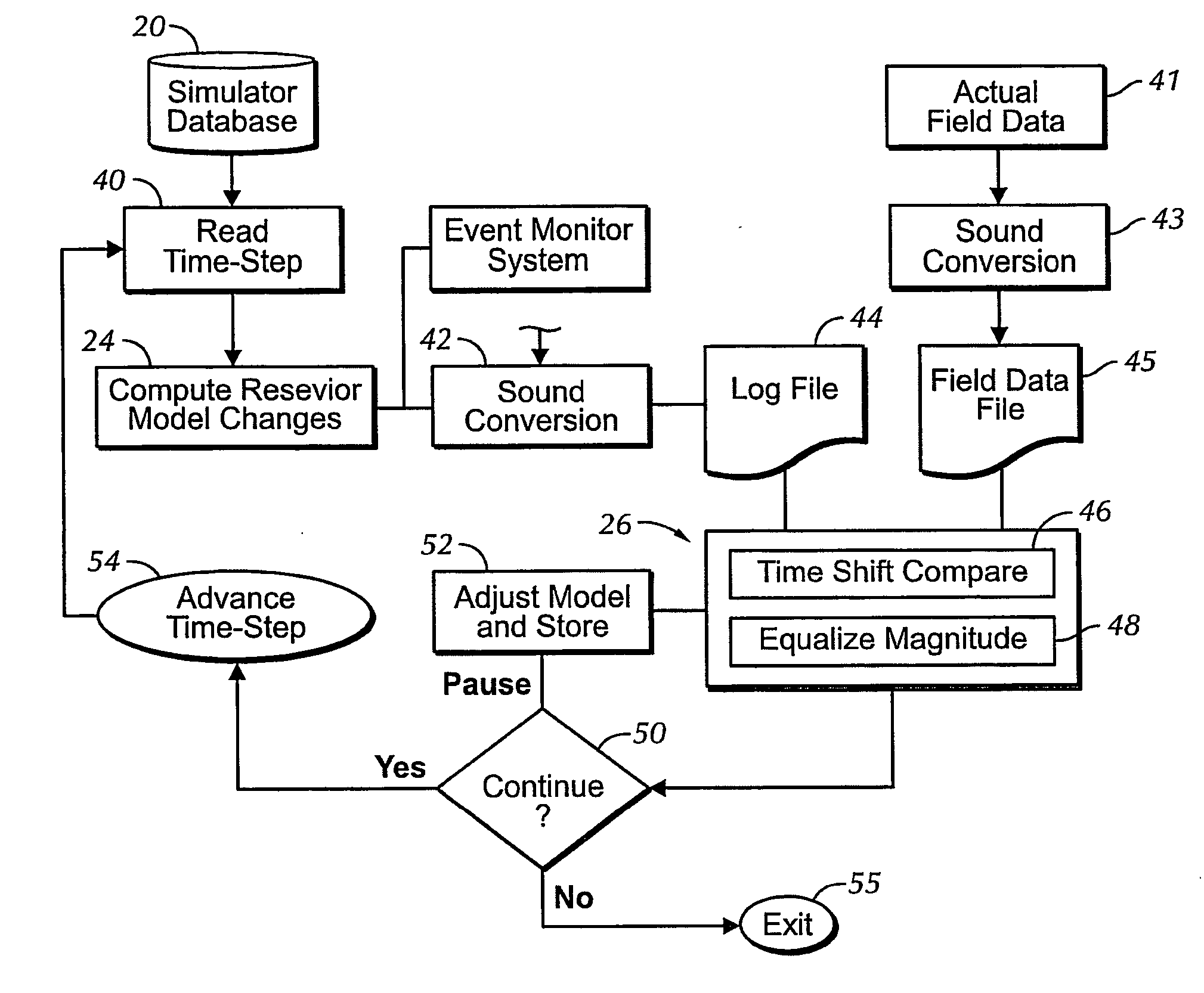

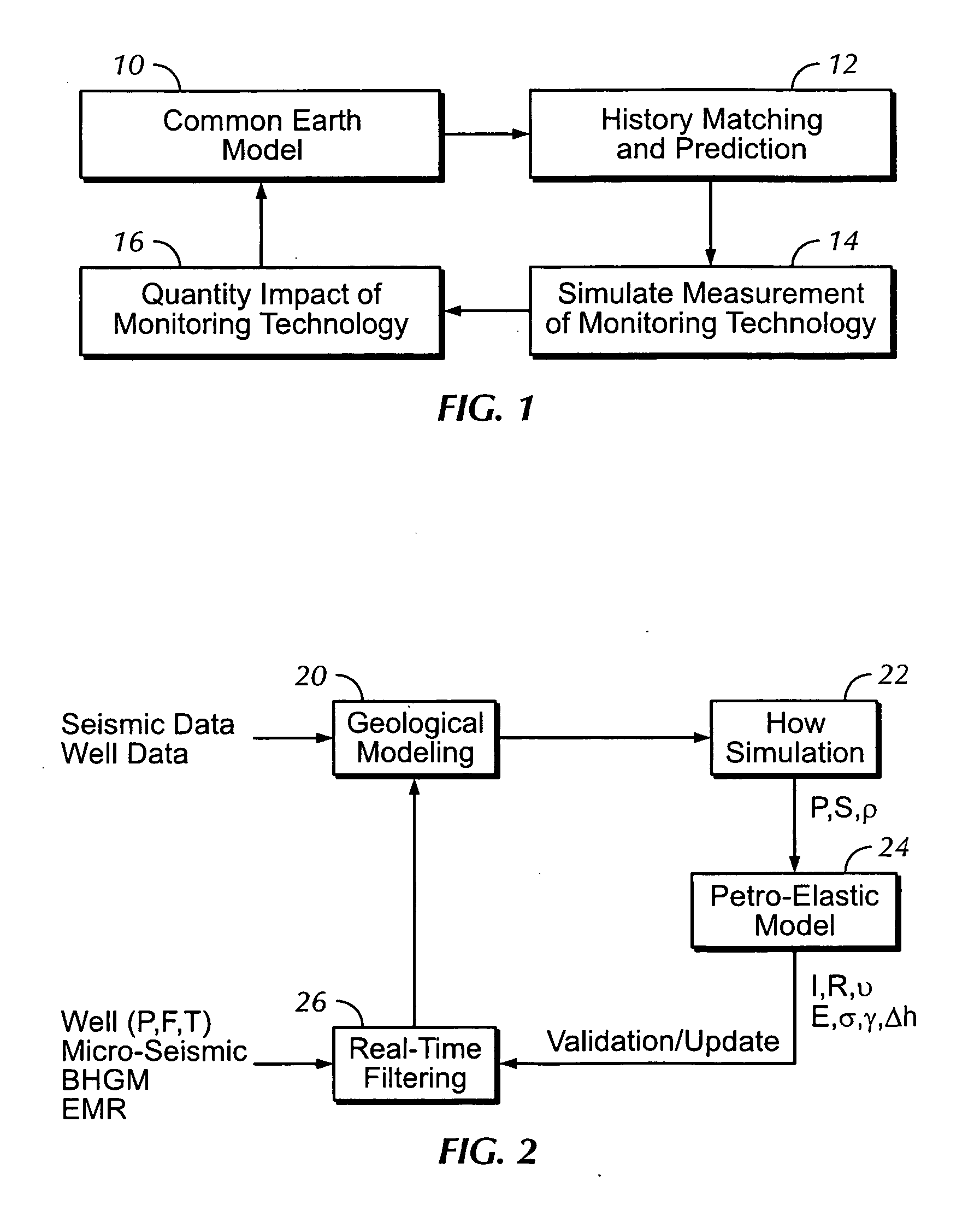

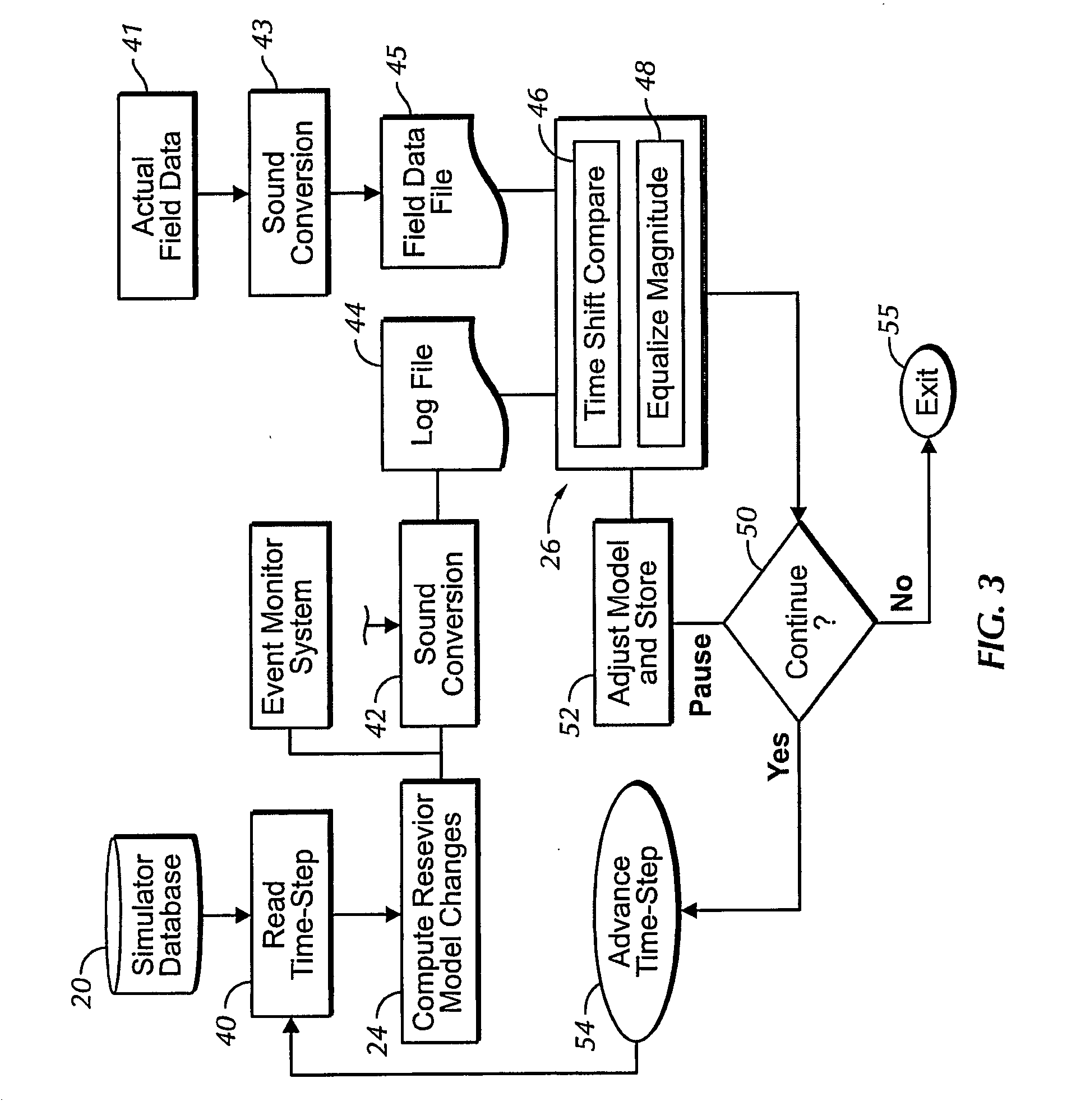

Sound enabling computerized system for real time reservoir model calibration using field surveillance data

ActiveUS7620534B2Digital data processing detailsVolume/mass flow measurementHydrocotyle bowlesioidesComputerized system

A computer-based system generates digital and audio responses to changes in fluid and rock properties of a producing hydrocarbon reservoir for surveillance analysis. The system calibrates observed changes against directly-measured field data in order to optimize the reservoir model. The changes may include, for example, stress changes in rock, impedance changes in rock, and fluid density changes.

Owner:ARAMCO SAUDI

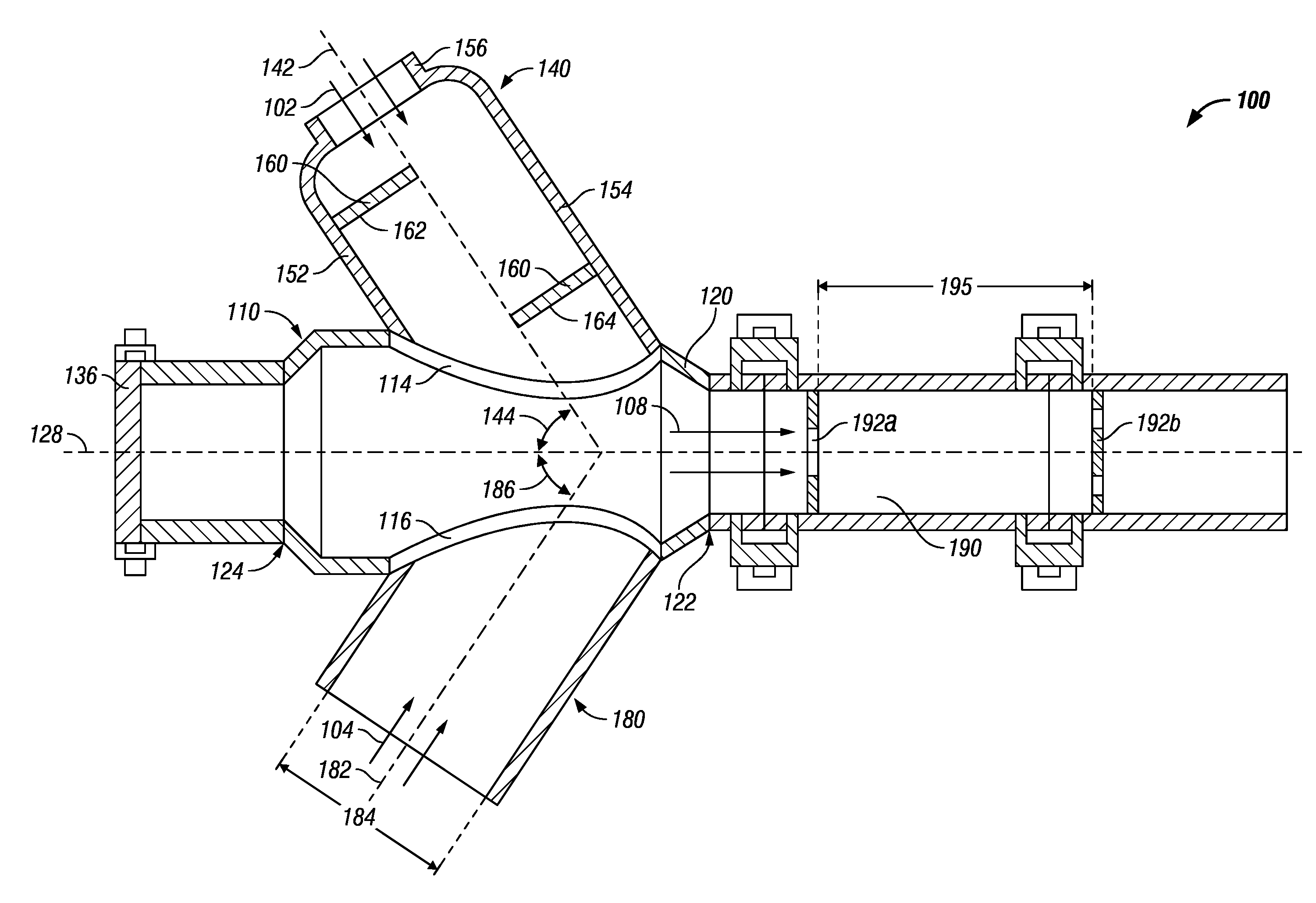

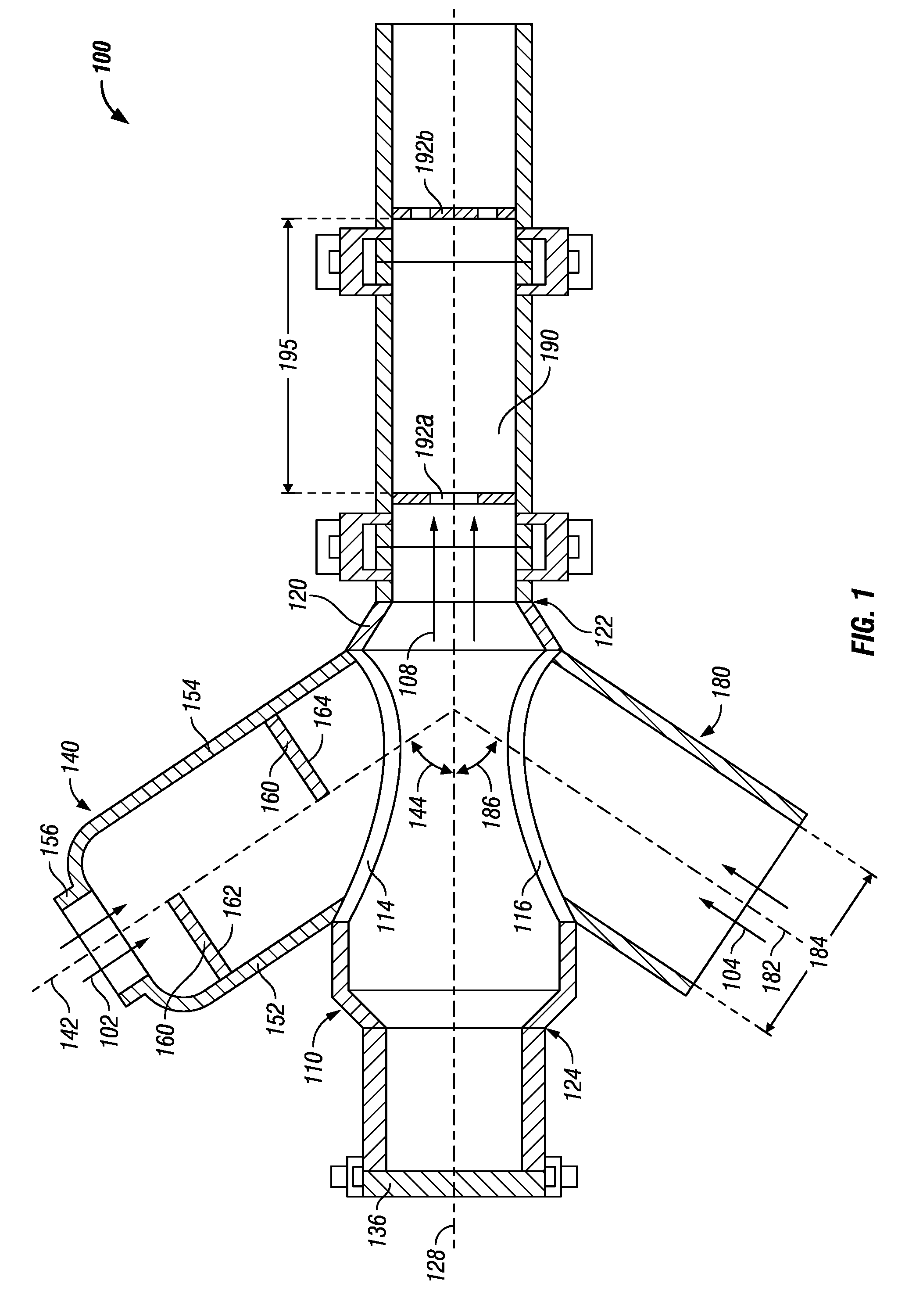

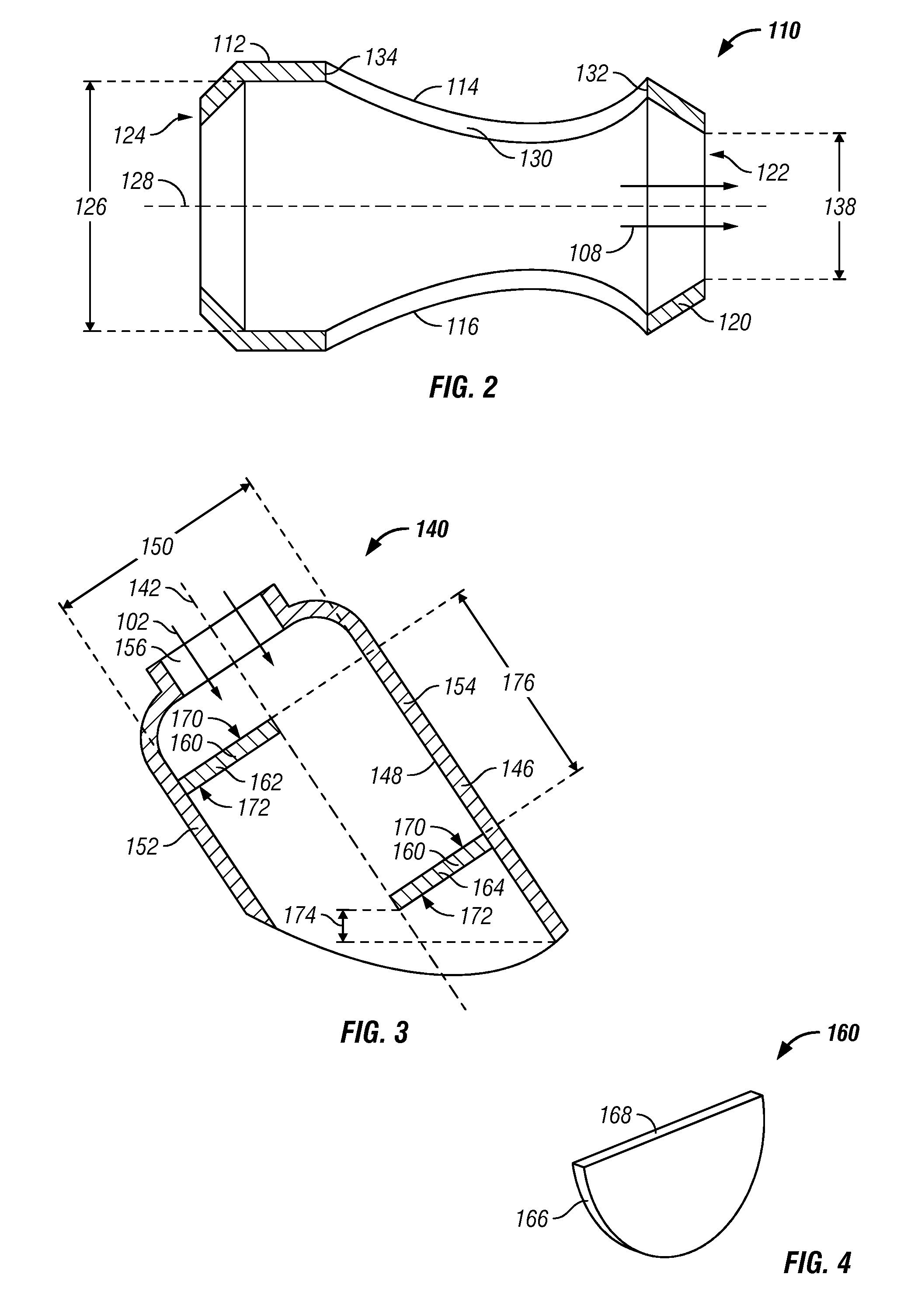

Apparatus for homogenizing two or more fluids of different densities

ActiveUS8079751B2Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingVolumetric Mass DensityEngineering

A blending apparatus for blending a first fluid stream having a first density and a second fluid stream having a second fluid density, the first density being greater than said second density, is discussed. The apparatus includes a first fluid director including a plurality of baffles affixed therein to create turbulence and shear in the first fluid, a cylindrical second fluid director, a primary mixing chamber receiving the first sheared fluid from the first fluid director and receiving the second fluid from the second fluid director, wherein the first fluid and second fluid are mixed in the primary mixing chamber to form a mixed primary fluid stream, and a secondary blending chamber comprising at least one static mixer and coaxially aligned with and receiving the mixed primary fluid stream from the primary mixing chamber.

Owner:MI

Sound enabling computerized system for real time reservoir model calibration using field surveillance data

ActiveUS20070255500A1Digital data processing detailsVolume/mass flow measurementReliable computingComputerized system

A computer-based system generates digital and audio responses to changes in fluid and rock properties of a producing hydrocarbon reservoir for surveillance analysis. The system calibrates observed changes against directly-measured field data in order to optimize the reservoir model. The changes may include, for example, stress changes in rock, impedance changes in rock, and fluid density changes.

Owner:ARAMCO SAUDI

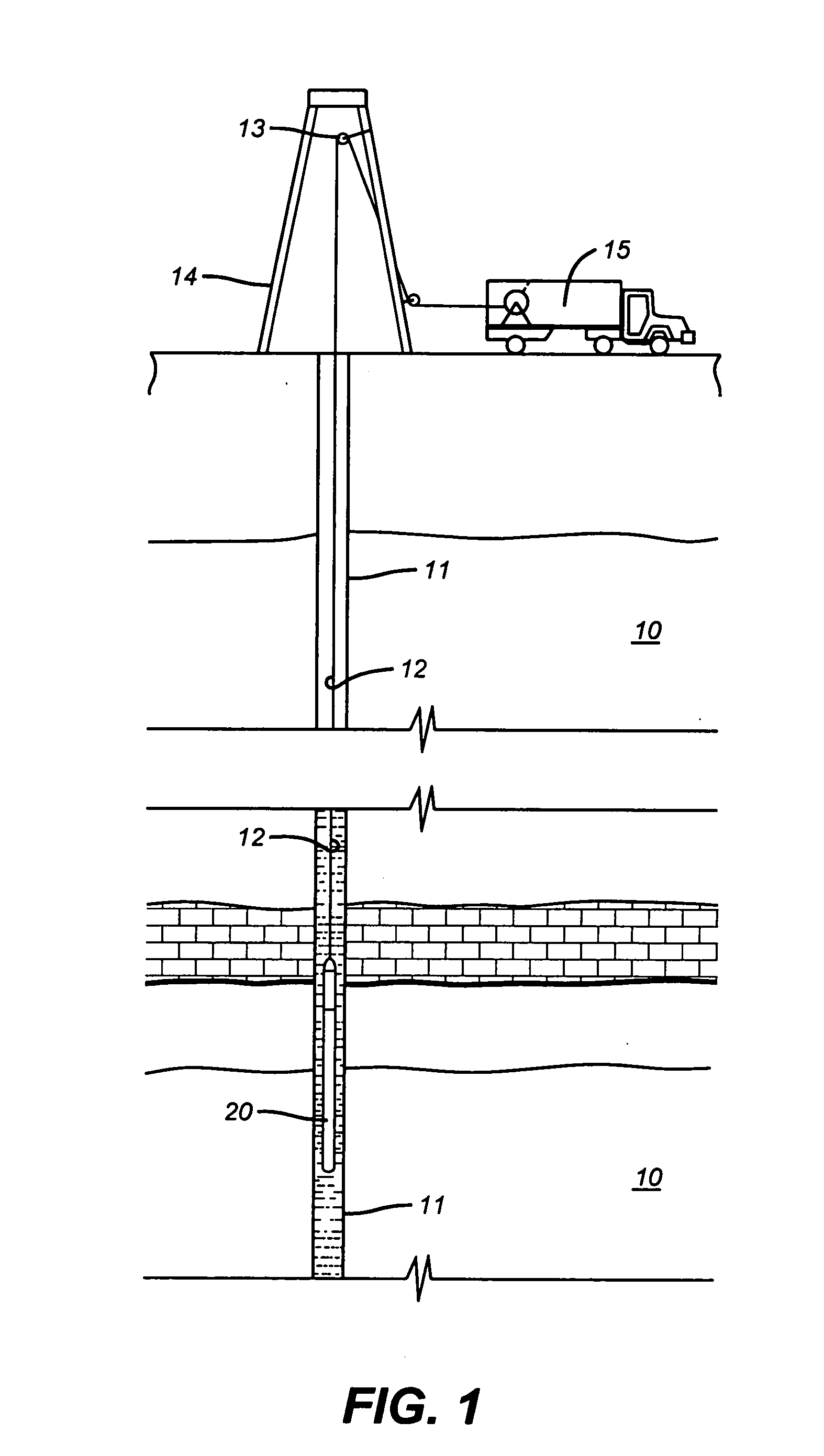

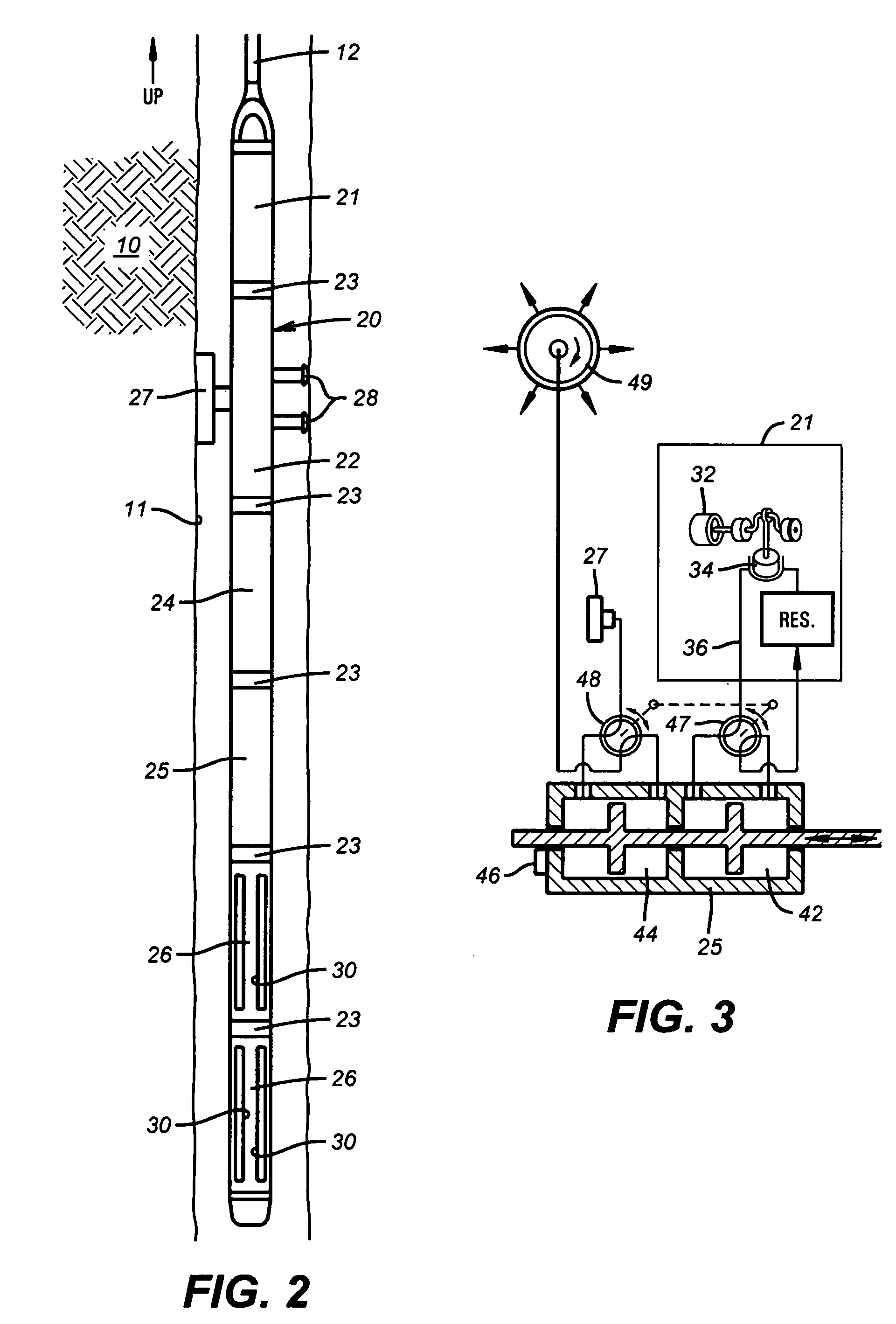

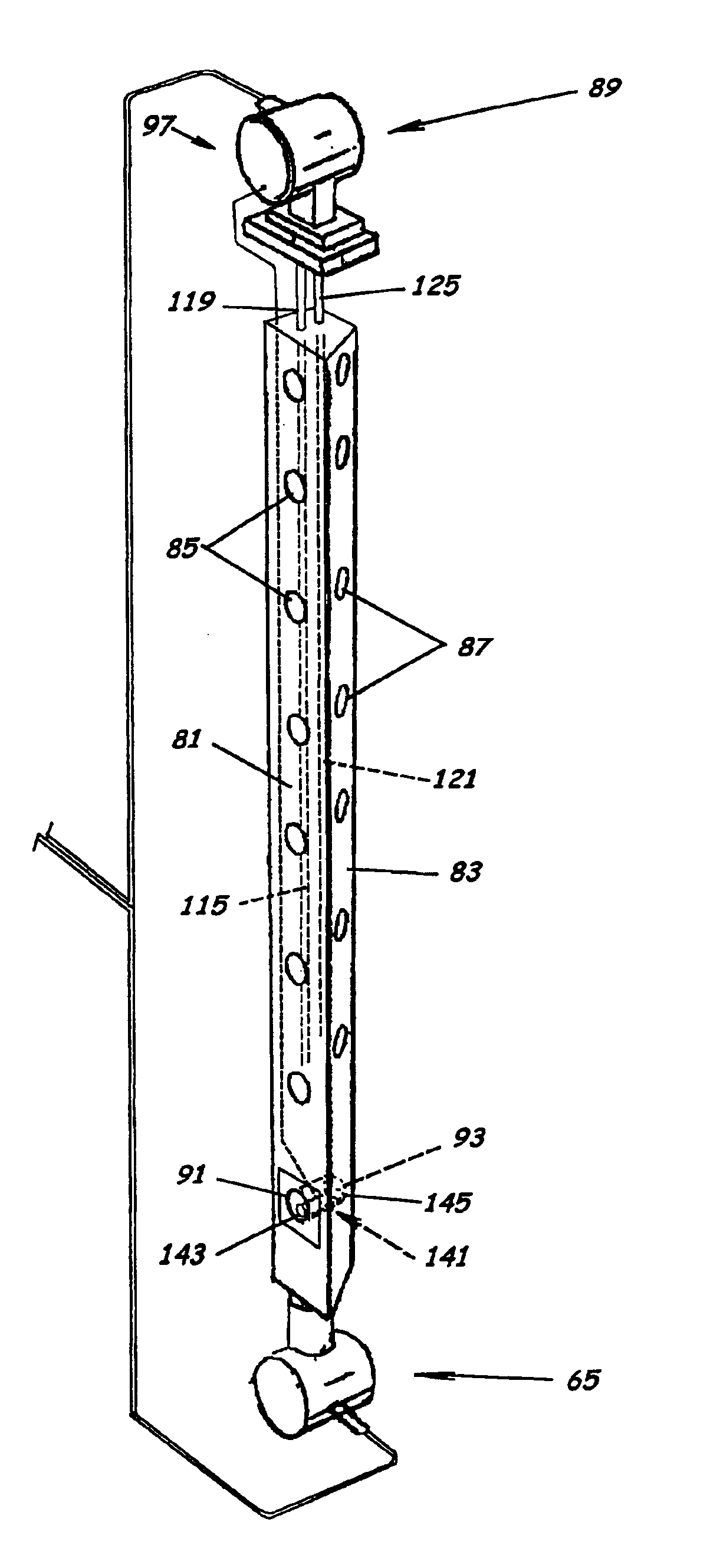

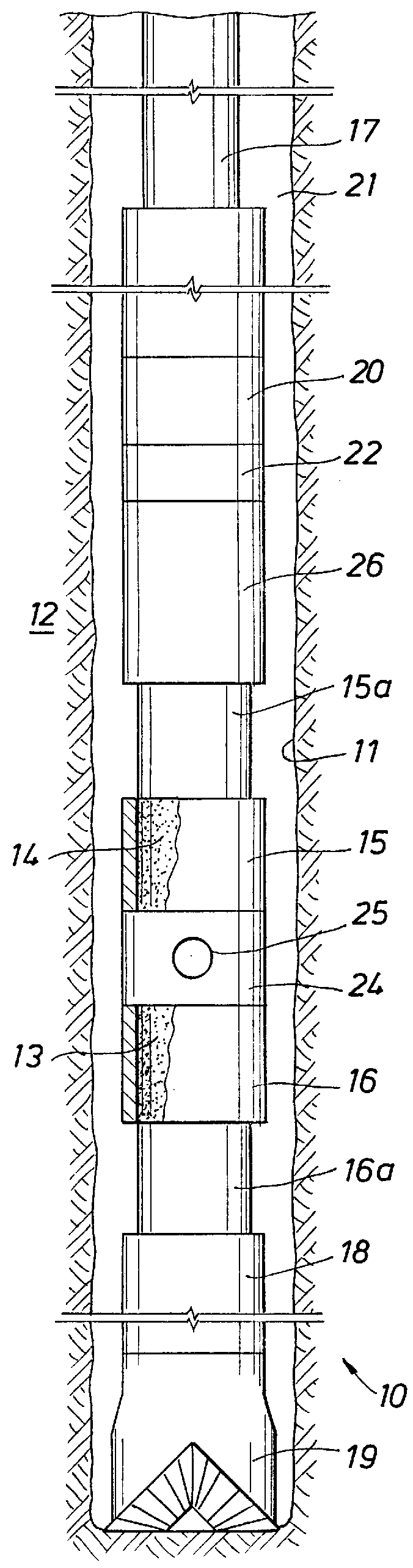

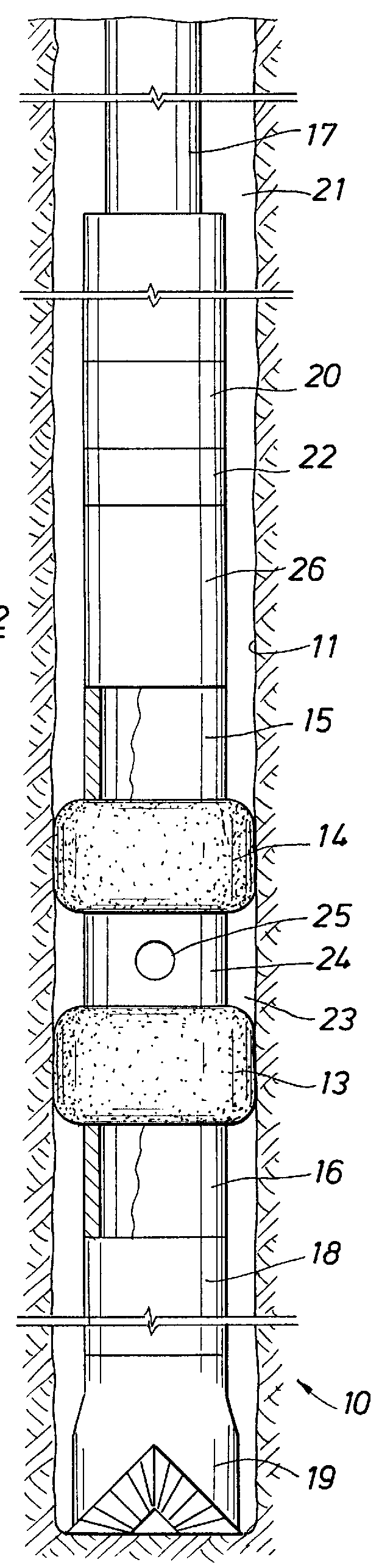

Subsurface measurement apparatus, system, and process for improved well drilling, control, and production

Subsurface wellbore conditions are measured directly in the wellbore while the fluid circulation system is not pumping. The measured values are recorded at the subsurface location and subsequently transmitted to the well surface when circulation is resumed using fluid pulse telemetry (FPT). Real-time measurements made when the fluids are circulating are transmitted real time using FPT. Axially spaced measurements are used to obtain differential values. The apparatus of the invention comprises an assembly carried by a drill string that is used to selectively isolate the area within the well that is to be evaluated. The apparatus includes an assembly having axially spaced inflatable well packers that are used to isolate an uncased section of the wellbore. The apparatus is equipped with self-contained measuring and recording equipment, a fluid receiving reservoir, circulation valving, measurement while drilling equipment, and automated controls. Measurements are made while the circulation is terminated or while the well packers are being used to isolate an area of the wellbore from the circulating fluid. The method is used to directly measure and evaluate conditions caused by pumping and drill string movement, such as swab and surge pressures. Other conditions such as the formation strength, formation pressure, the fluid density, and other subsurface conditions related to the well are also measured.

Owner:HALLIBURTON ENERGY SERVICES INC

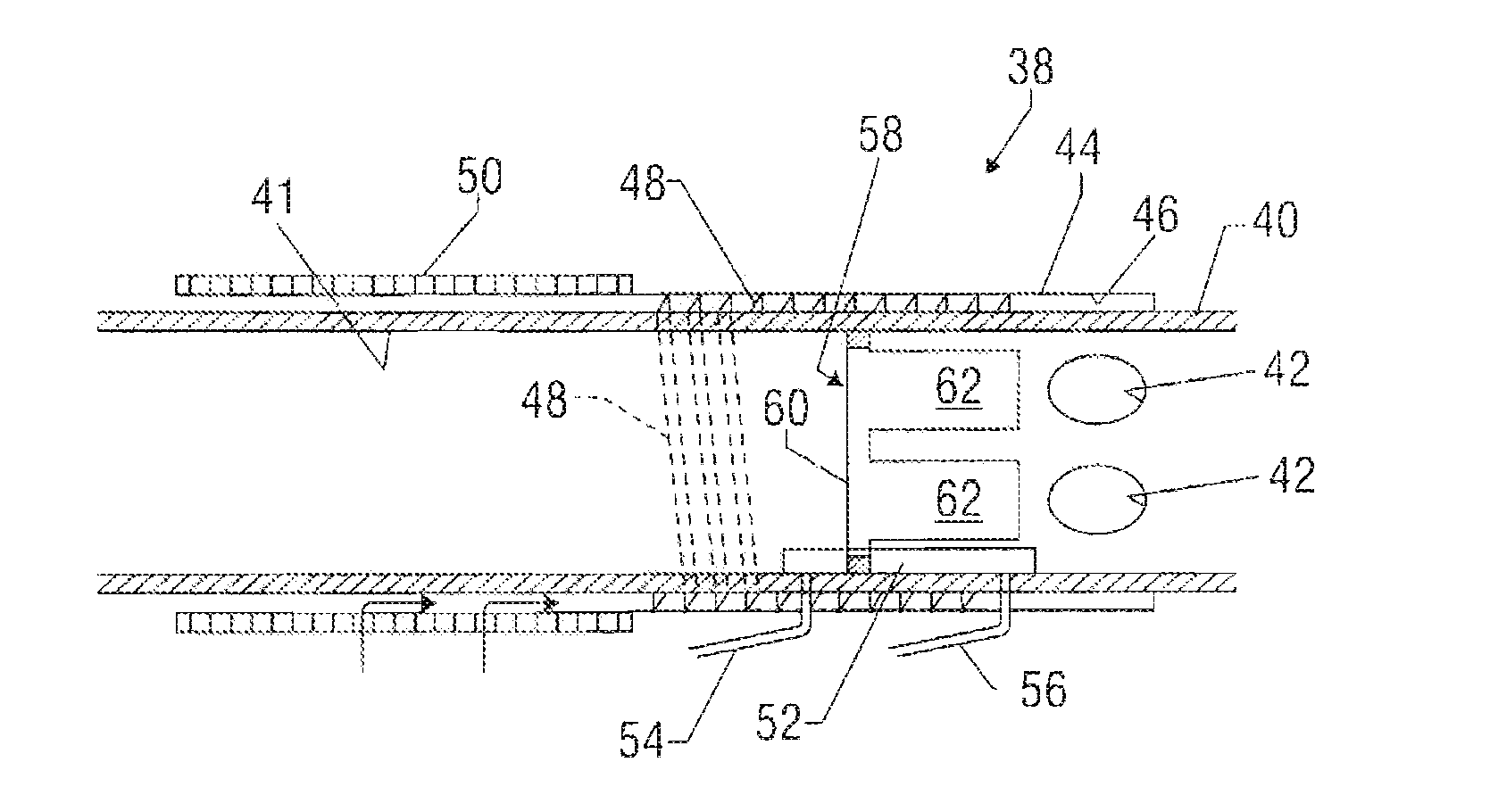

Multiphase fluid characterization system

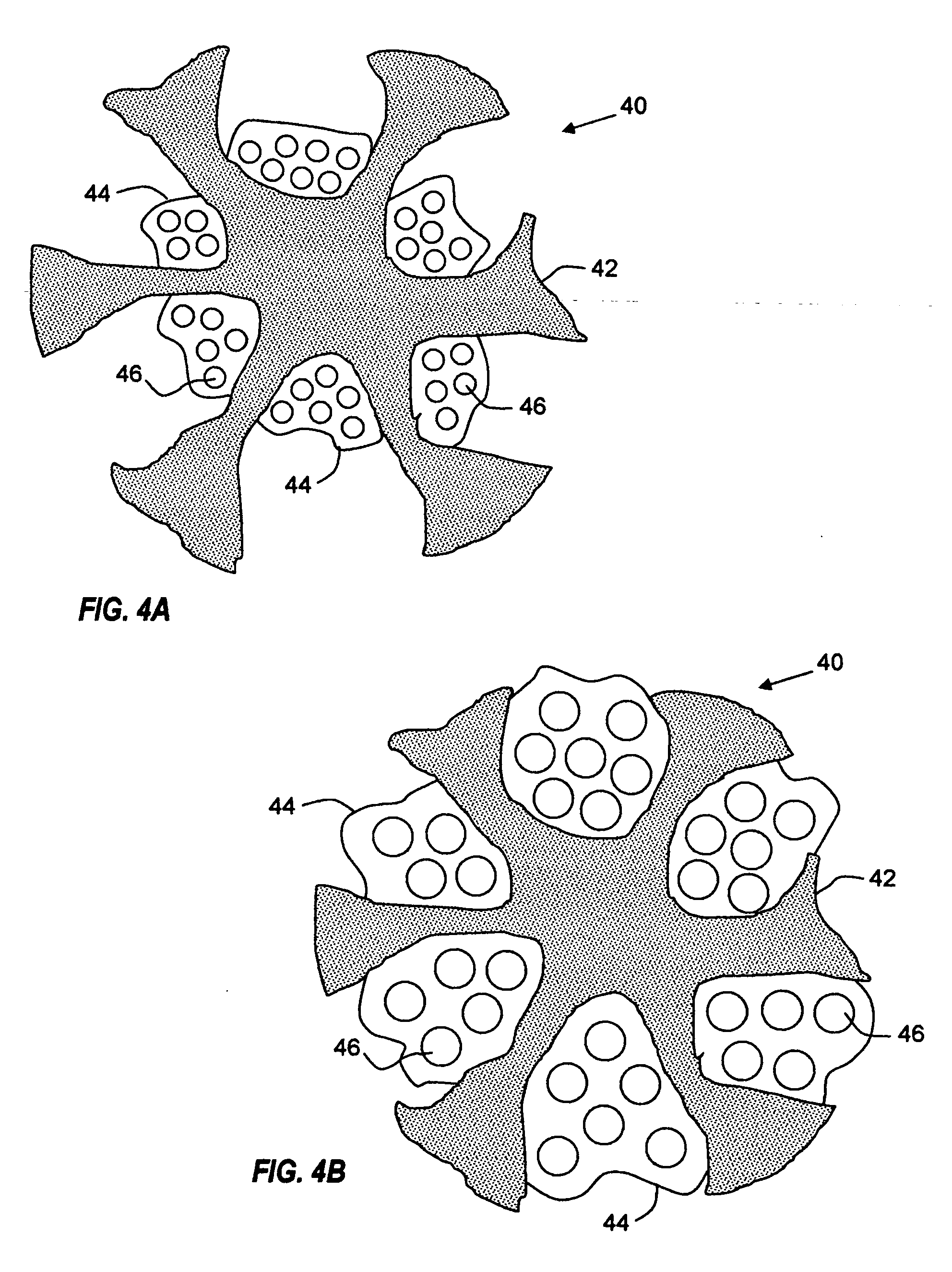

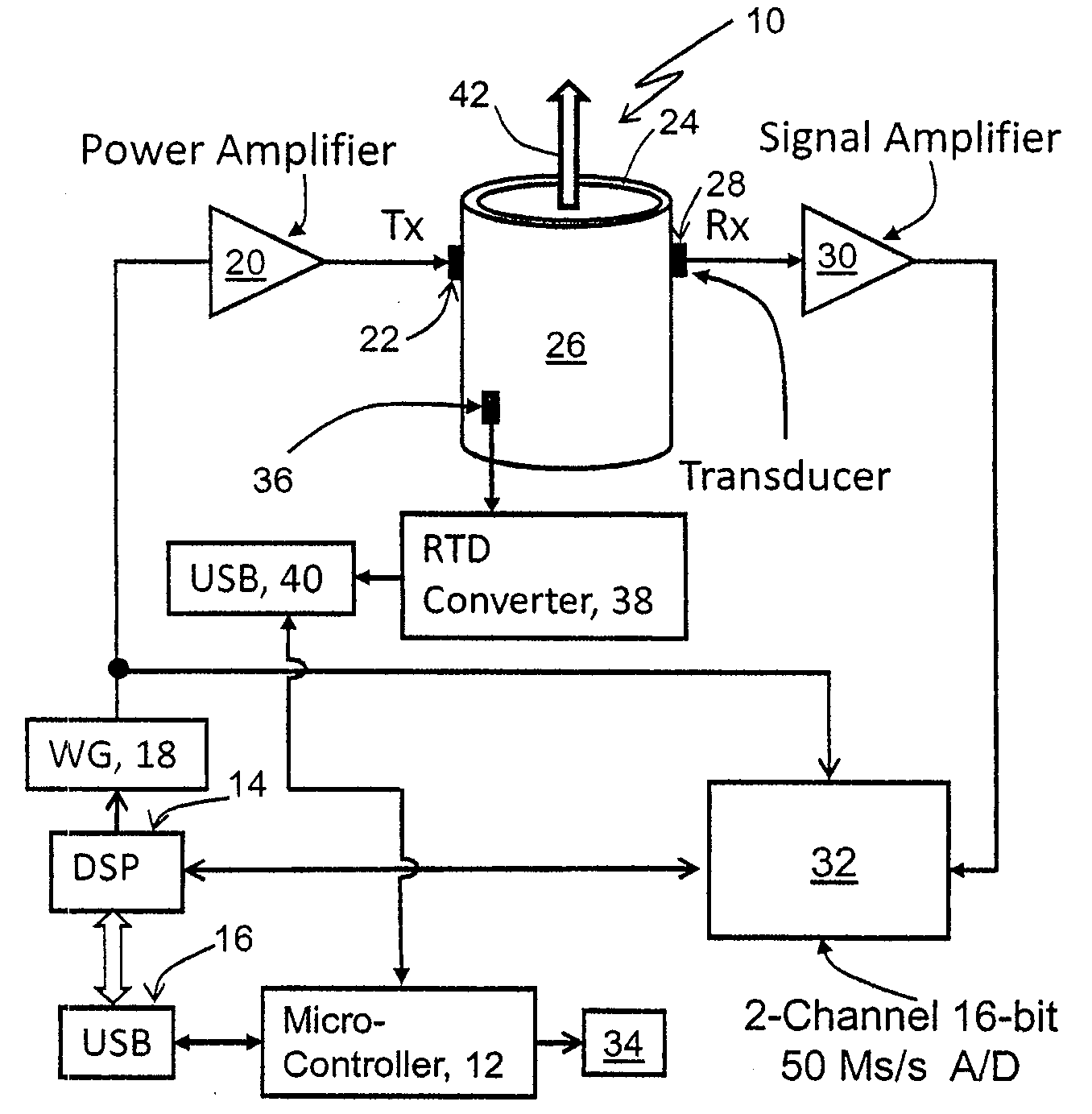

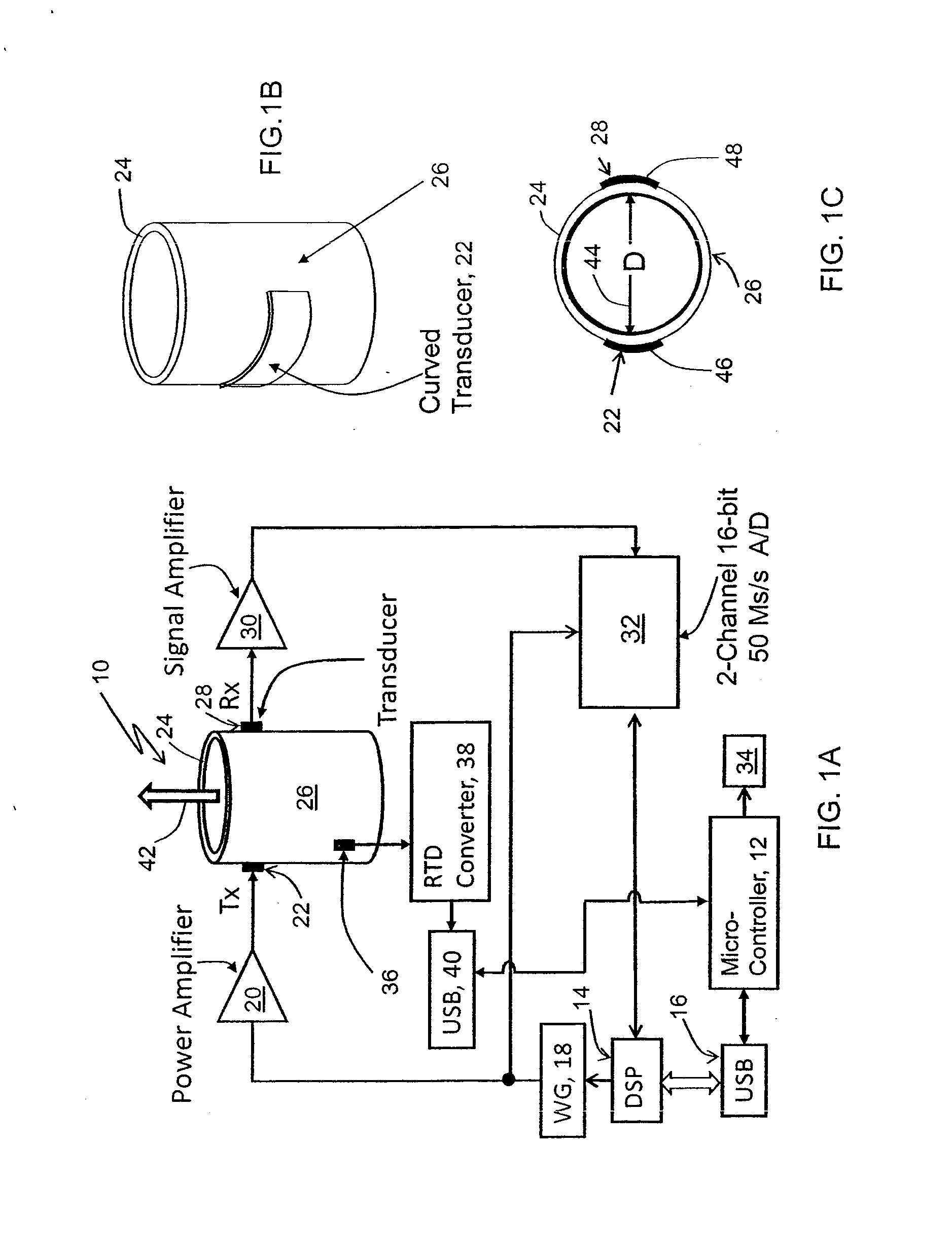

ActiveUS20120055239A1Analysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration for volume flowUltrasound attenuationResonance

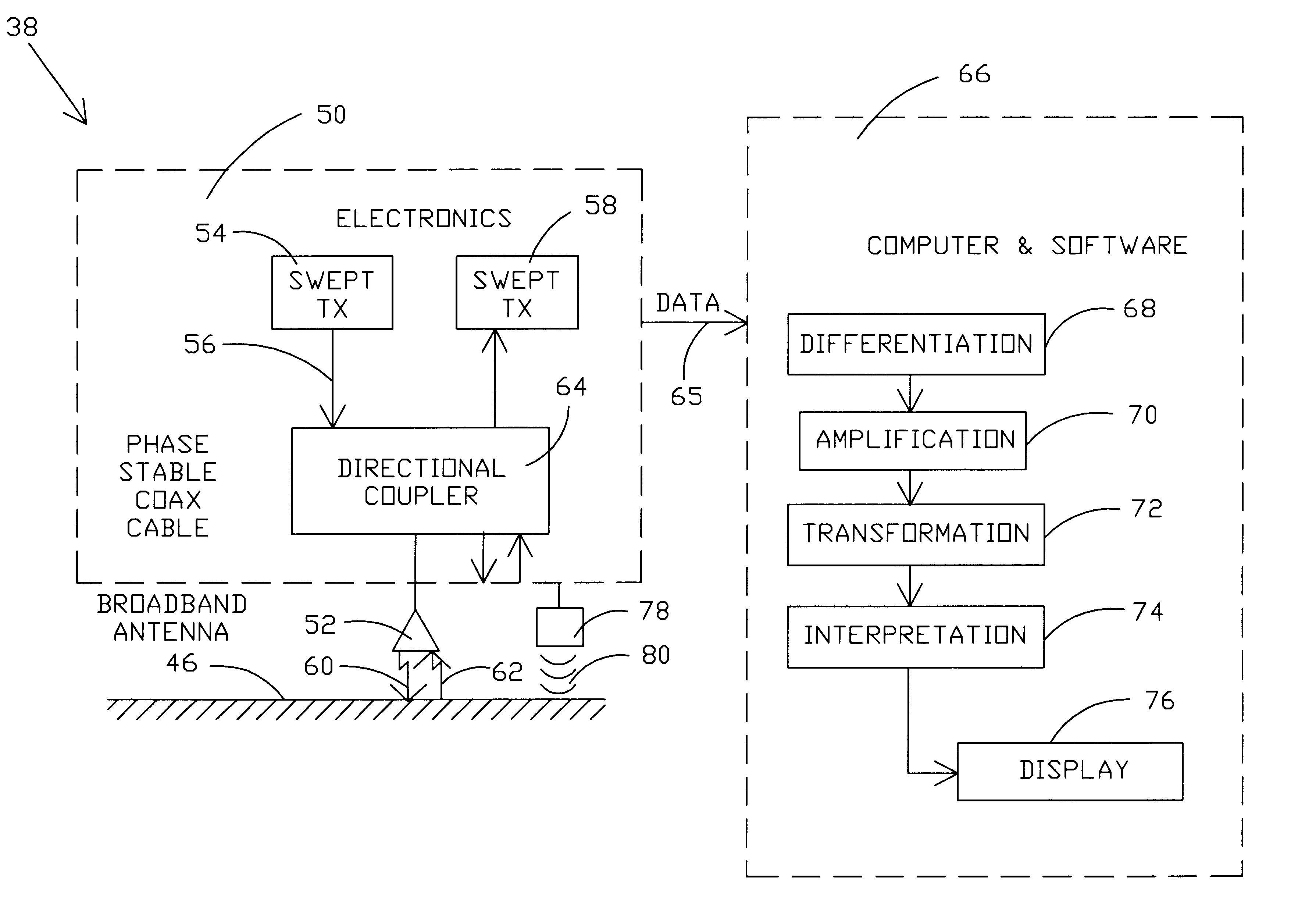

A measurement system and method for permitting multiple independent measurements of several physical parameters of multiphase fluids flowing through pipes are described. Multiple acoustic transducers are placed in acoustic communication with or attached to the outside surface of a section of existing spool (metal pipe), typically less than 3 feet in length, for noninvasive measurements. Sound speed, sound attenuation, fluid density, fluid flow, container wall resonance characteristics, and Doppler measurements for gas volume fraction may be measured simultaneously by the system. Temperature measurements are made using a temperature sensor for oil-cut correction.

Owner:TRIAD NAT SECURITY LLC

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS7207386B2Limit undesirable height growthFluid removalDrilling compositionSaline waterGeomorphology

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES HLDG LLC

Measurment system and method

System and methods are disclosed for fluid measurements which may be utilized to determine mass flow rates such as instantaneous mass flow of a fluid stream. In a preferred embodiment, the present invention may be utilized to compare an input mass flow to an output mass flow of a drilling fluid circulation stream. In one embodiment, a fluid flow rate is determined by utilizing a microwave detector in combination with an acoustic sensor. The acoustic signal is utilized to eliminate 2 pi phase ambiguities in a reflected microwave signal. In another embodiment, a fluid flow rate may be determined by detecting a phase shift of an acoustic signal across two different predetermined transmission paths. A fluid density may be determined by detecting a calibrated phase shift of an acoustic signal through the fluid. In another embodiment, a second acoustic signal may be transmitted through the fluid to define a particular 2pi phase range which defines the phase shift. The present invention may comprise multiple transmitters / receivers operating at different frequencies to measure instantaneous fuel levels of cryogenic fuels within containers positioned in zero or near zero gravity environments. In one embodiment, a moveable flexible collar of transmitter / receivers may be utilized to determine inhomogenuities within solid rocket fuel tubes.

Owner:NASA

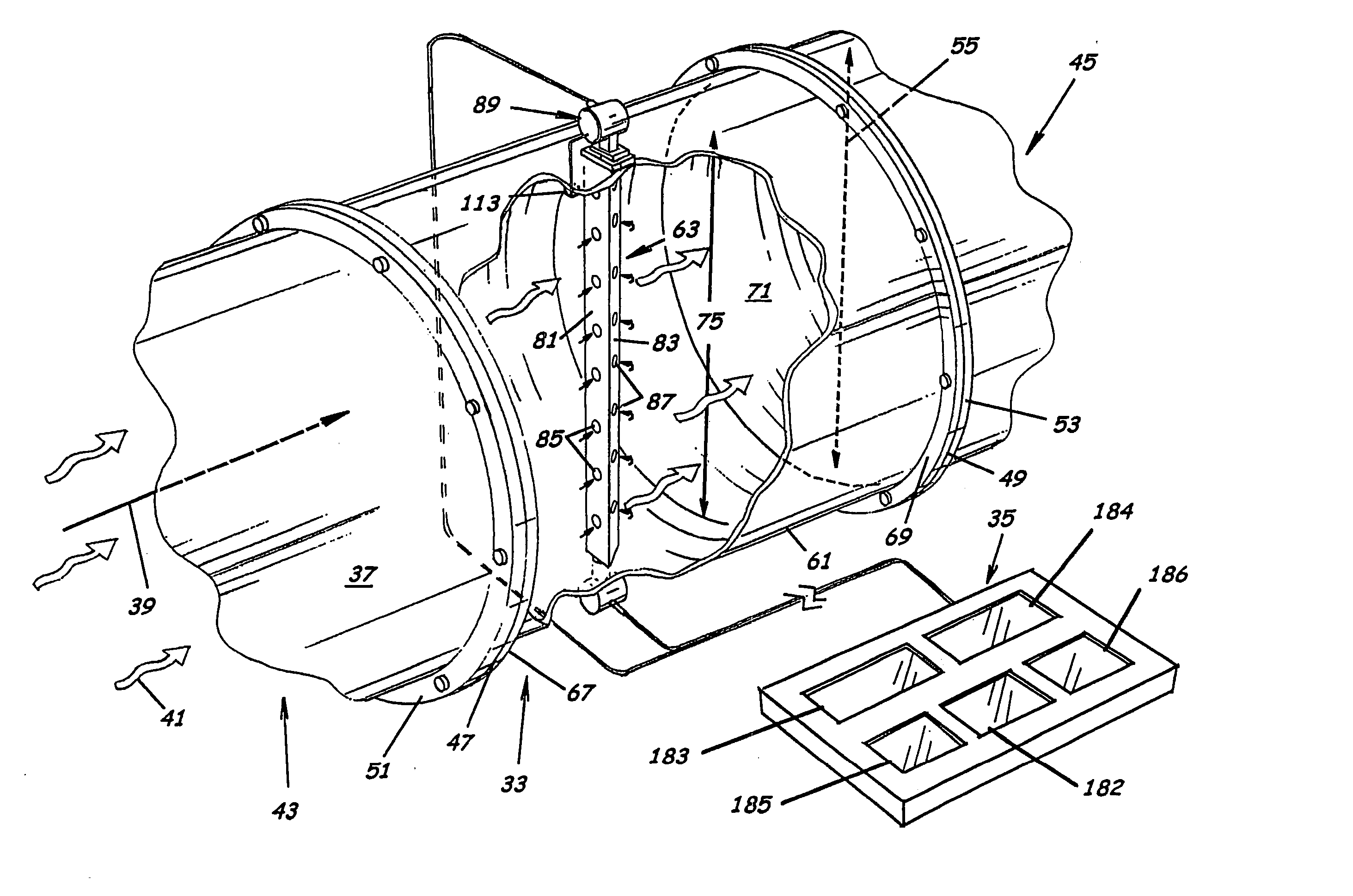

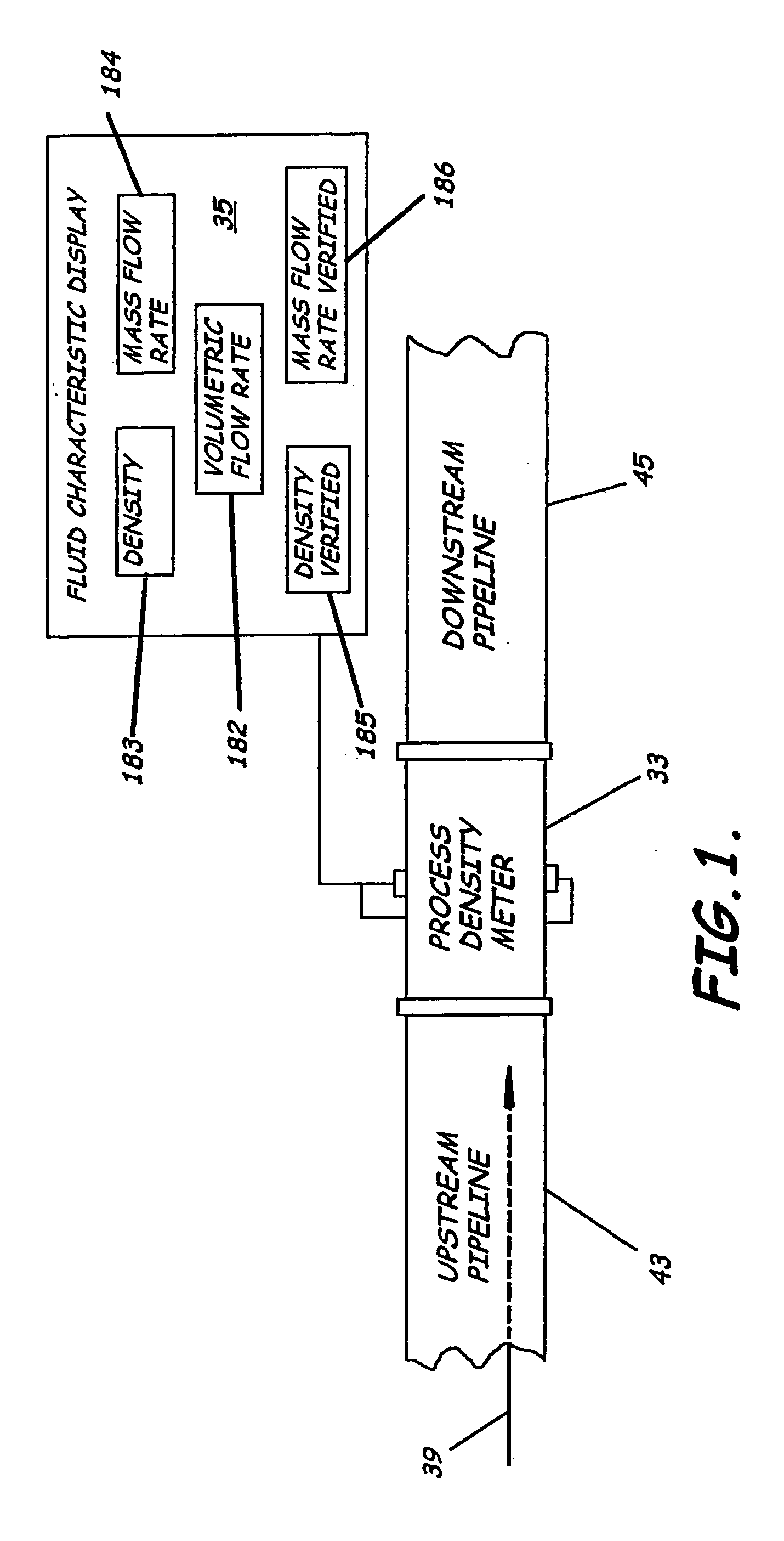

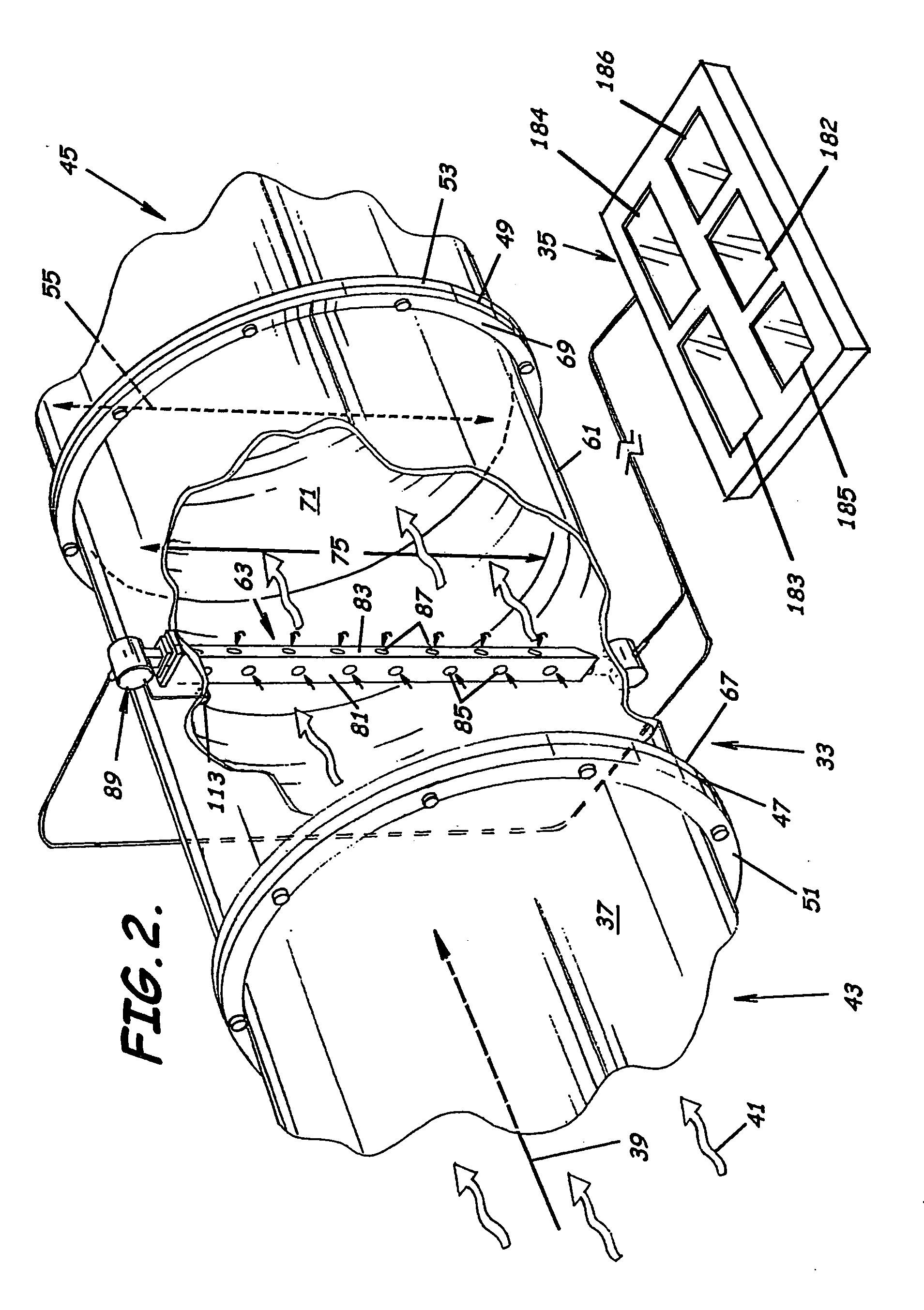

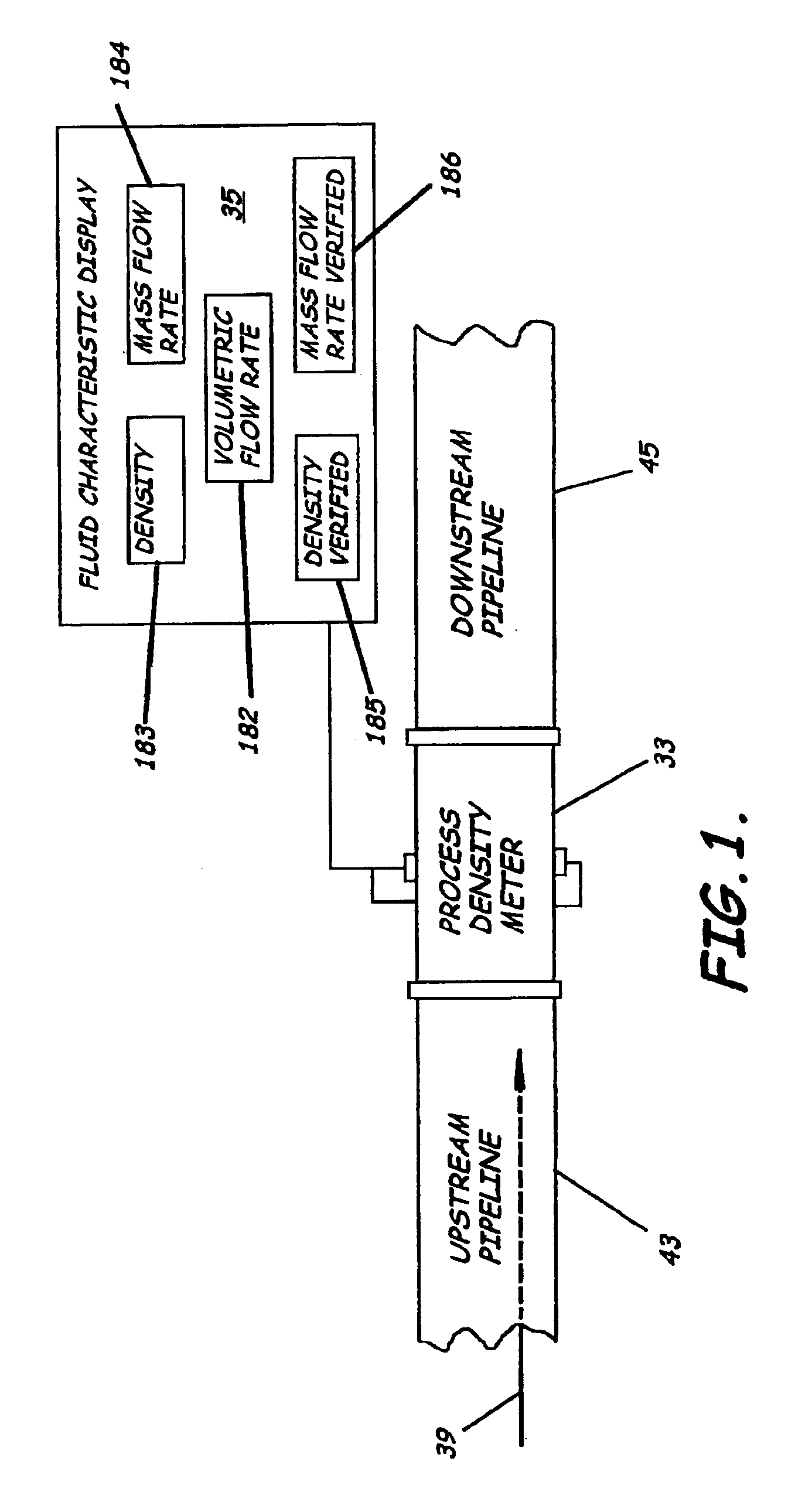

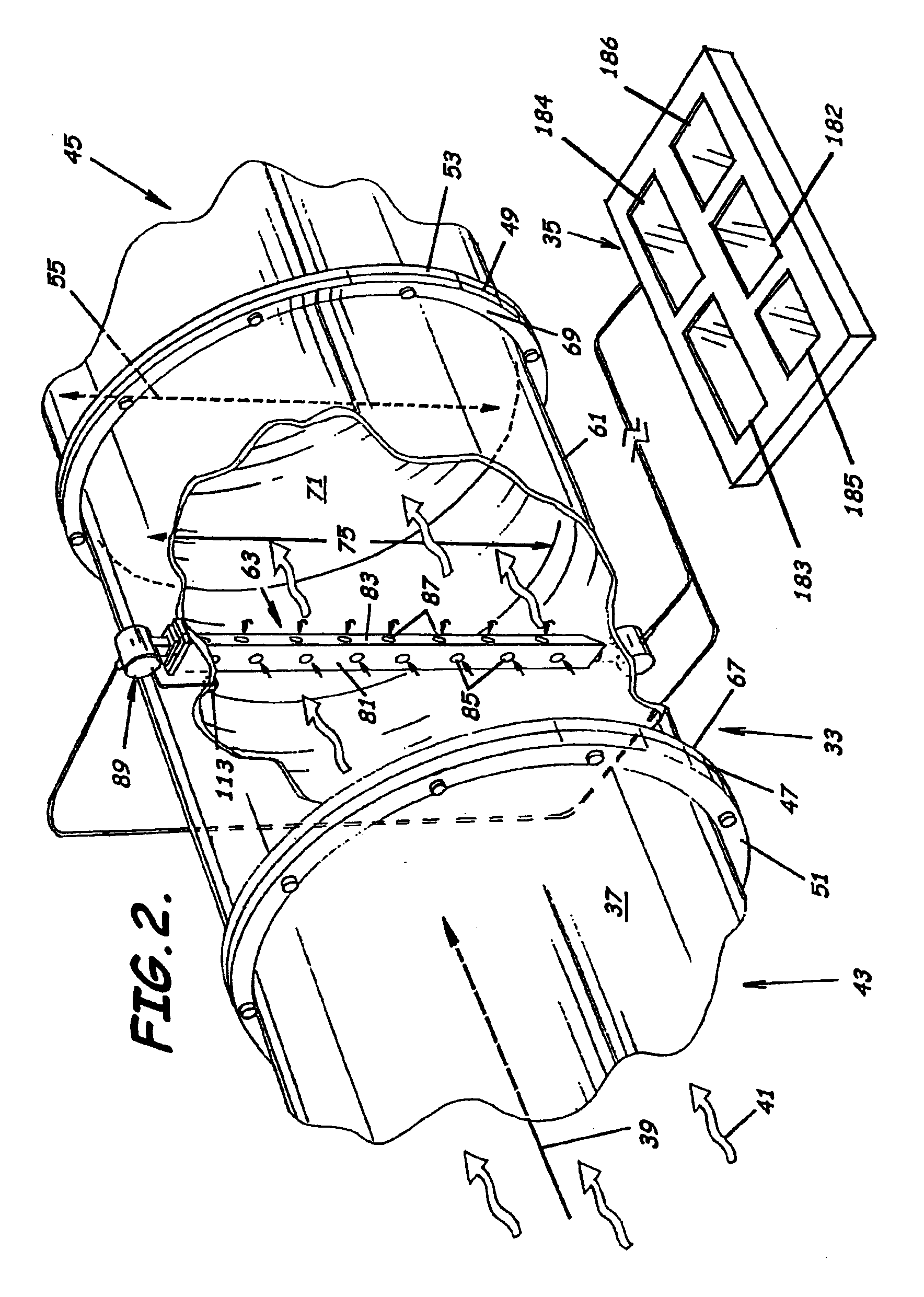

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS20050034535A1Little maintenanceMinimization needsVolume/mass flow by thermal effectsVolume/mass flow by dynamic fluid flow effectDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

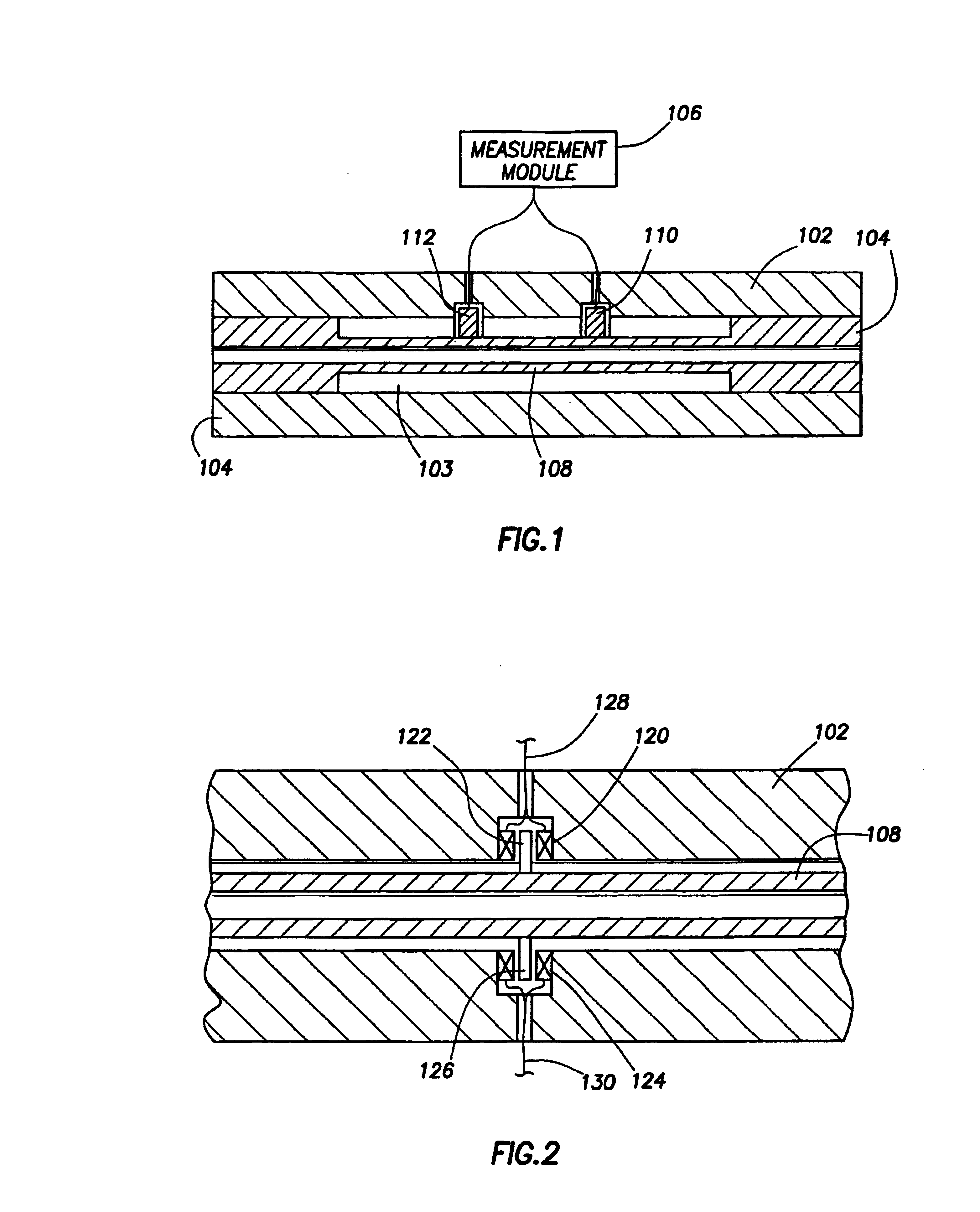

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

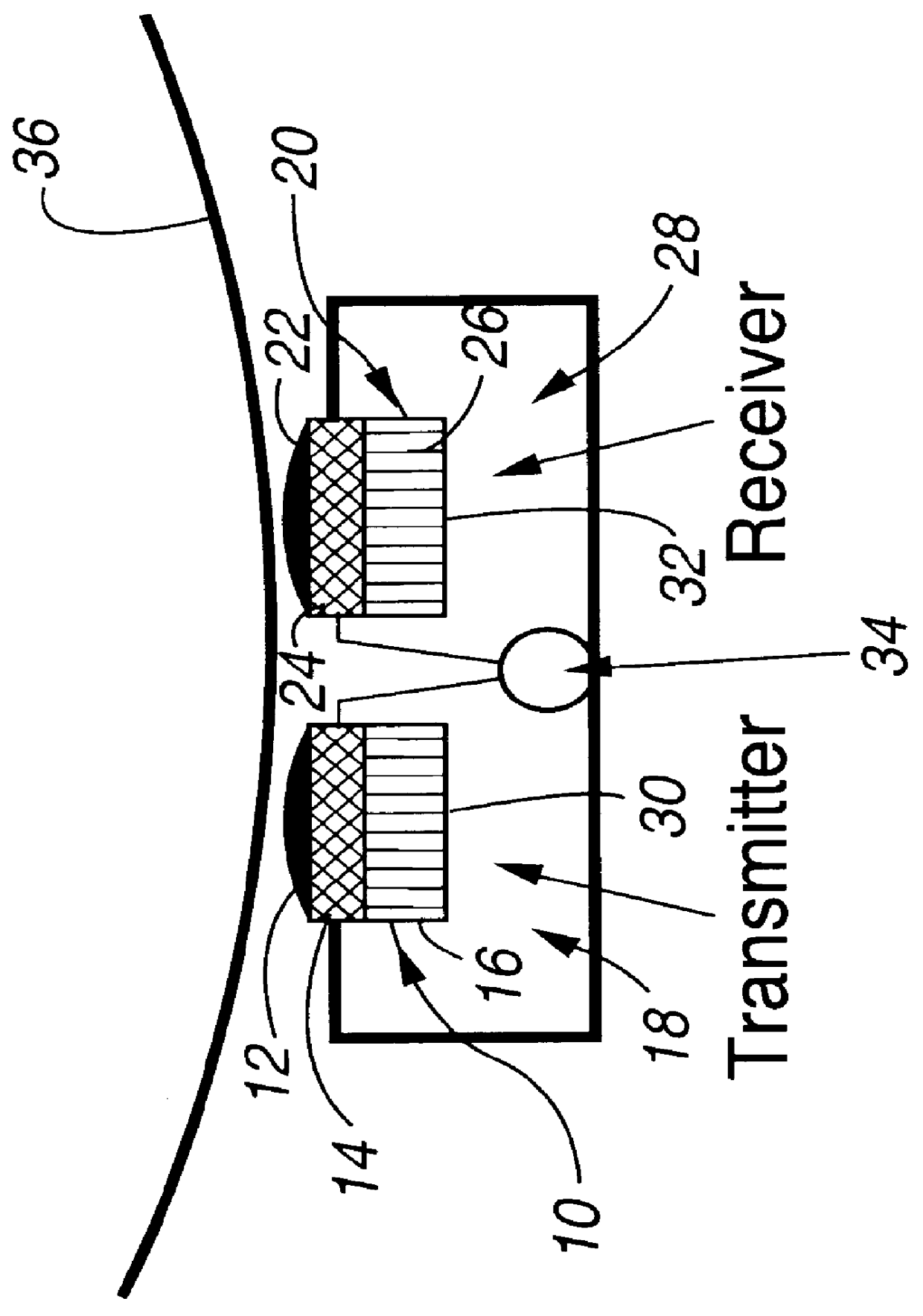

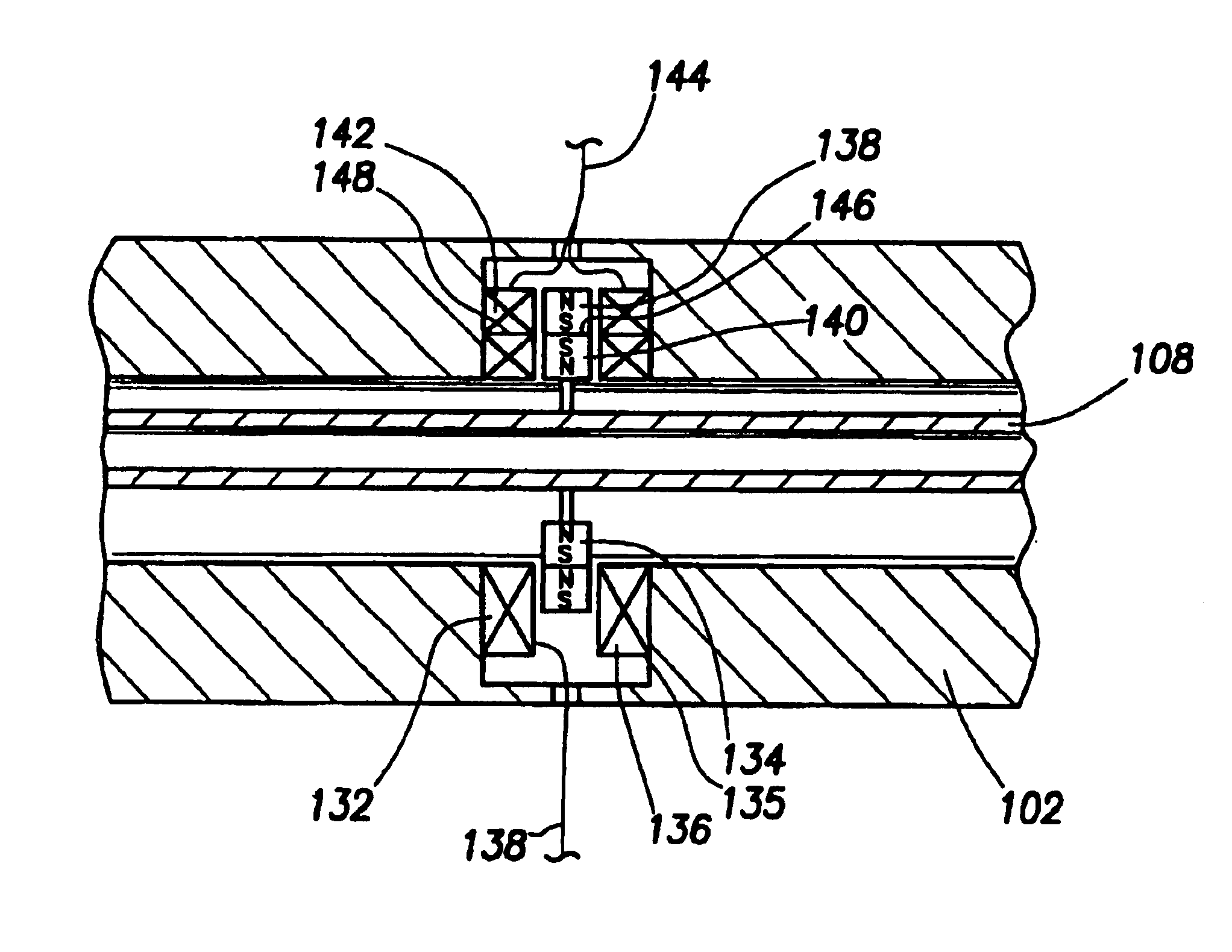

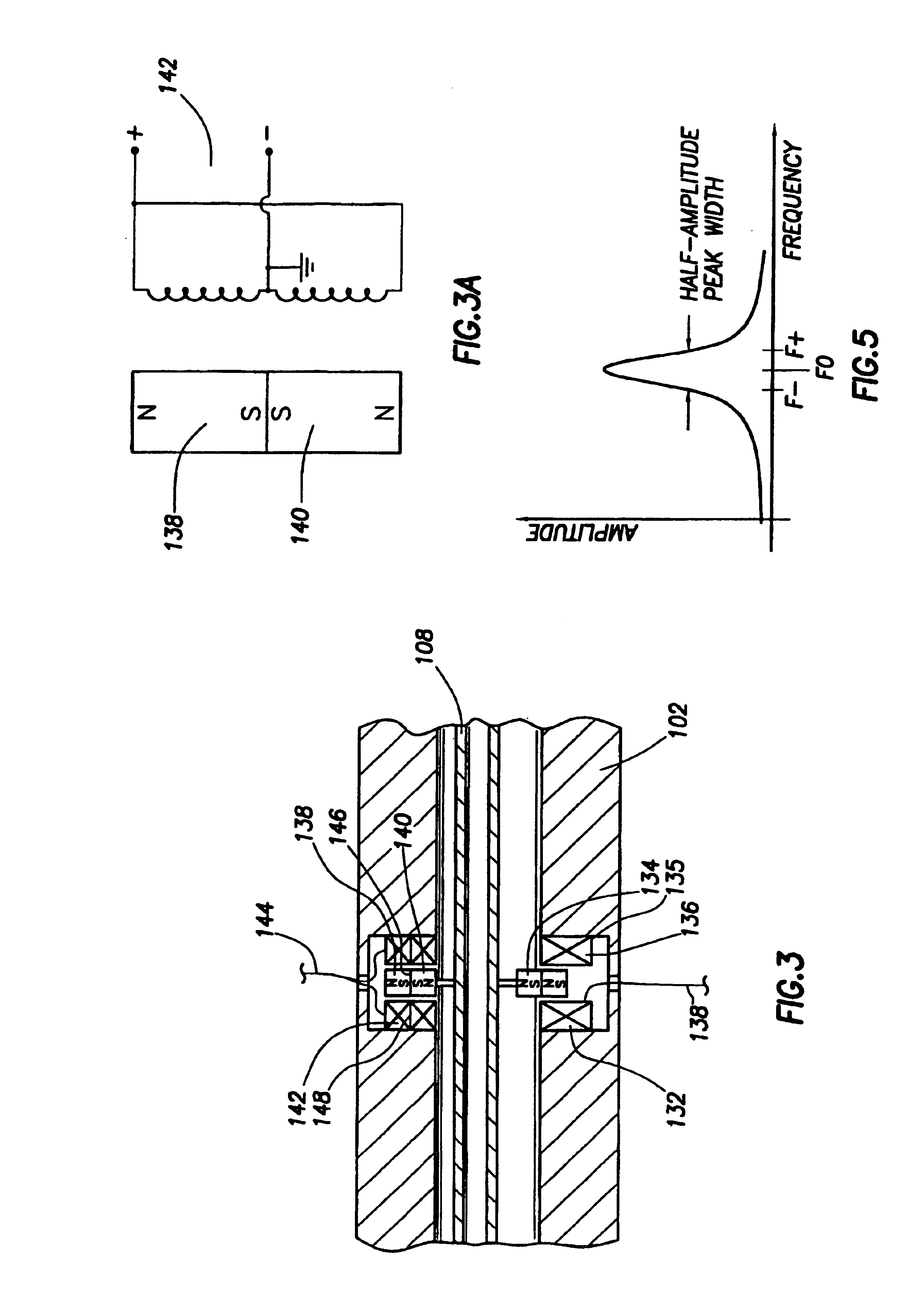

Mass flow sensor and methods of determining mass flow of a fluid

ActiveUS6912918B1Prevent leakageAvoid radiationVolume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonificationUltrasonic beam

The mass flow rate sensor includes a waveguide disposed in a flow passage having a bluff body facing in an upstream direction. Waves are pulsed along the waveguide for interaction with the fluid. A receiver is coupled to the waveguide to detect a propagated wave and provides a first output signal proportional to the transit time of the propagated wave for determining fluid density. The receiver also provides a second output signal proportional to the shedding frequency of vortices from the waveguide to determine velocity. An electronics module calculates mass flow rate from the velocity times density times area of the flow passage and a constant. In other forms, the velocity is ascertained by transmitting an ultrasonic beam through the shedding vortices to determine vortex frequency which is proportional to velocity.

Owner:BAKER HUGHES INC

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS6957586B2Little maintenanceMinimization needsVolume/mass flow by thermal effectsSpecific gravity using flow propertiesDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

Subsurface measurement apparatus, system, and process for improved well drilling control and production

Subsurface wellbore conditions are measured directly in the wellbore while the fluid circulation system is not pumping. The measured values are recorded at the subsurface location and subsequently transmitted to the well surface when circulation is resumed using fluid pulse telemetry (FPT). Real-time measurements made when the fluids are circulating are transmitted real time using FPT. Axially spaced measurements are used to obtain differential values. The apparatus of the invention comprises an assembly carried by a drill string that is used to selectively isolate the area within the well that is to be evaluated. The apparatus includes an assembly having axially spaced inflatable well packers that are used to isolate an uncased section of the wellbore. The apparatus is equipped with self-contained measuring and recording equipment, a fluid receiving reservoir, circulation valving, measurement while drilling equipment, and automated controls. Measurements are made while the circulation is terminated or while the well packers are being used to isolate an area of the wellbore from the circulating fluid. The method is used to directly measure and evaluate conditions caused by pumping and drill string movement, such as swab and surge pressures. Other conditions such as the formation strength, formation pressure, the fluid density, and other subsurface conditions related to the well are also measured.

Owner:HALLIBURTON ENERGY SERVICES INC

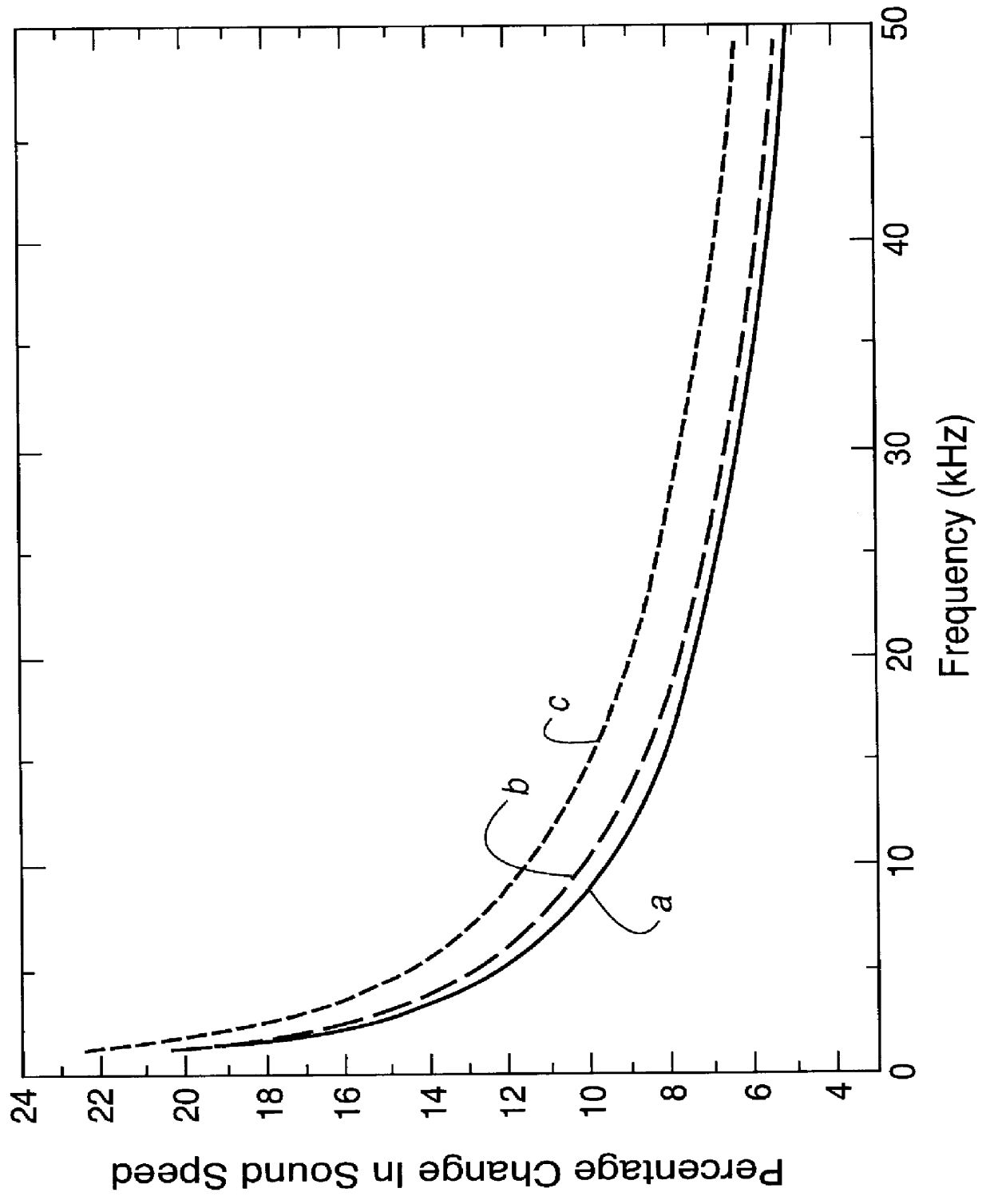

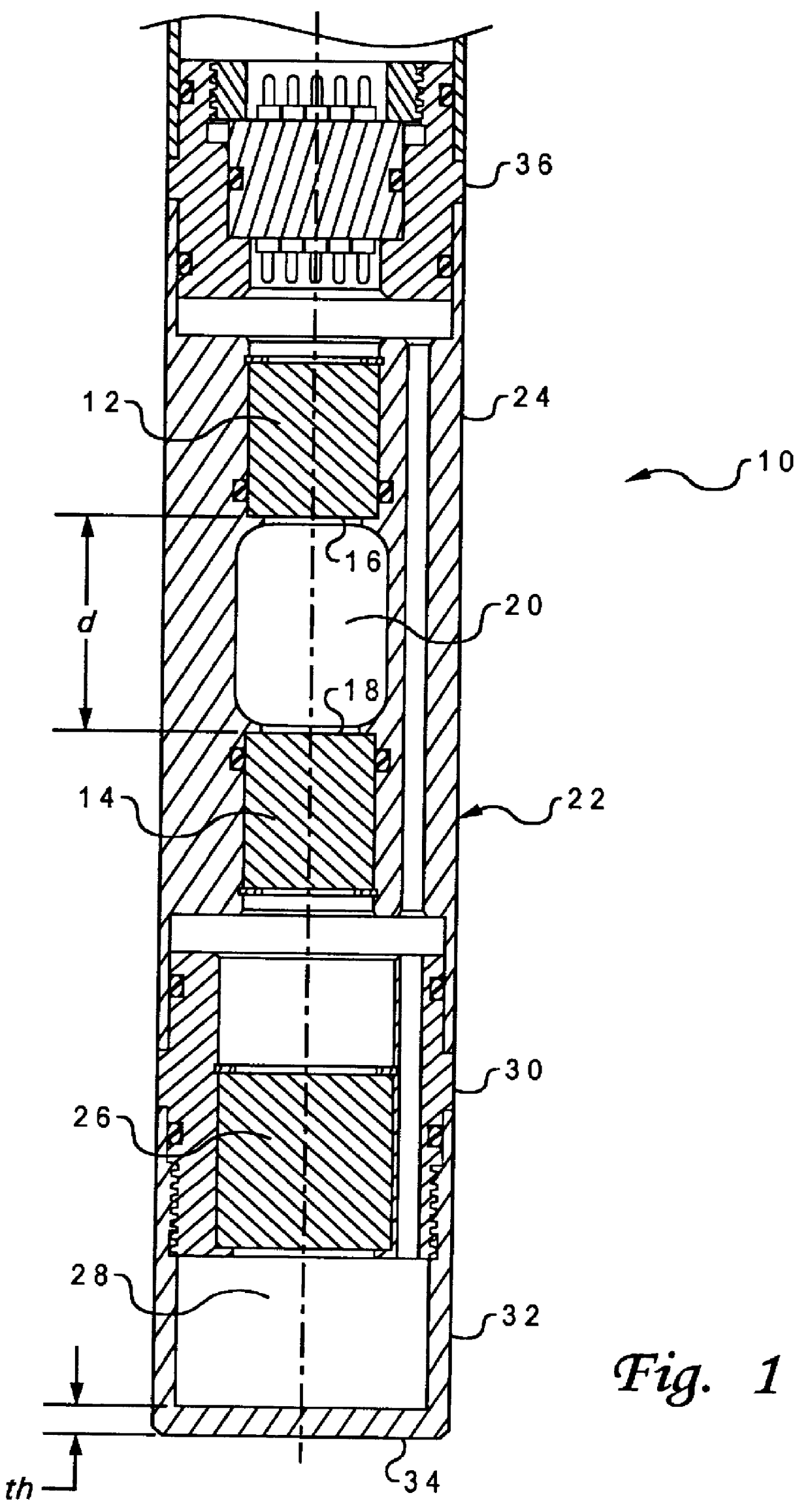

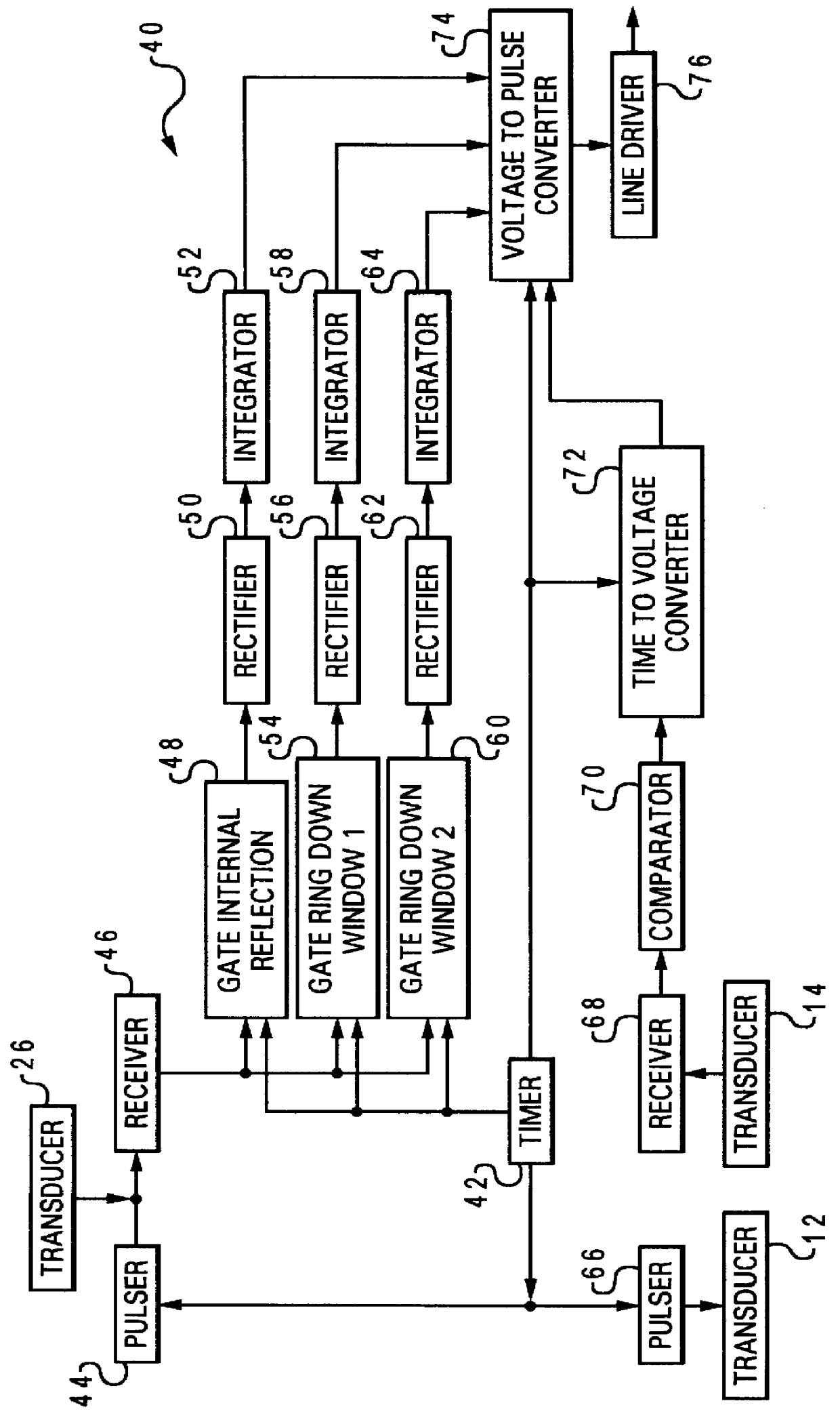

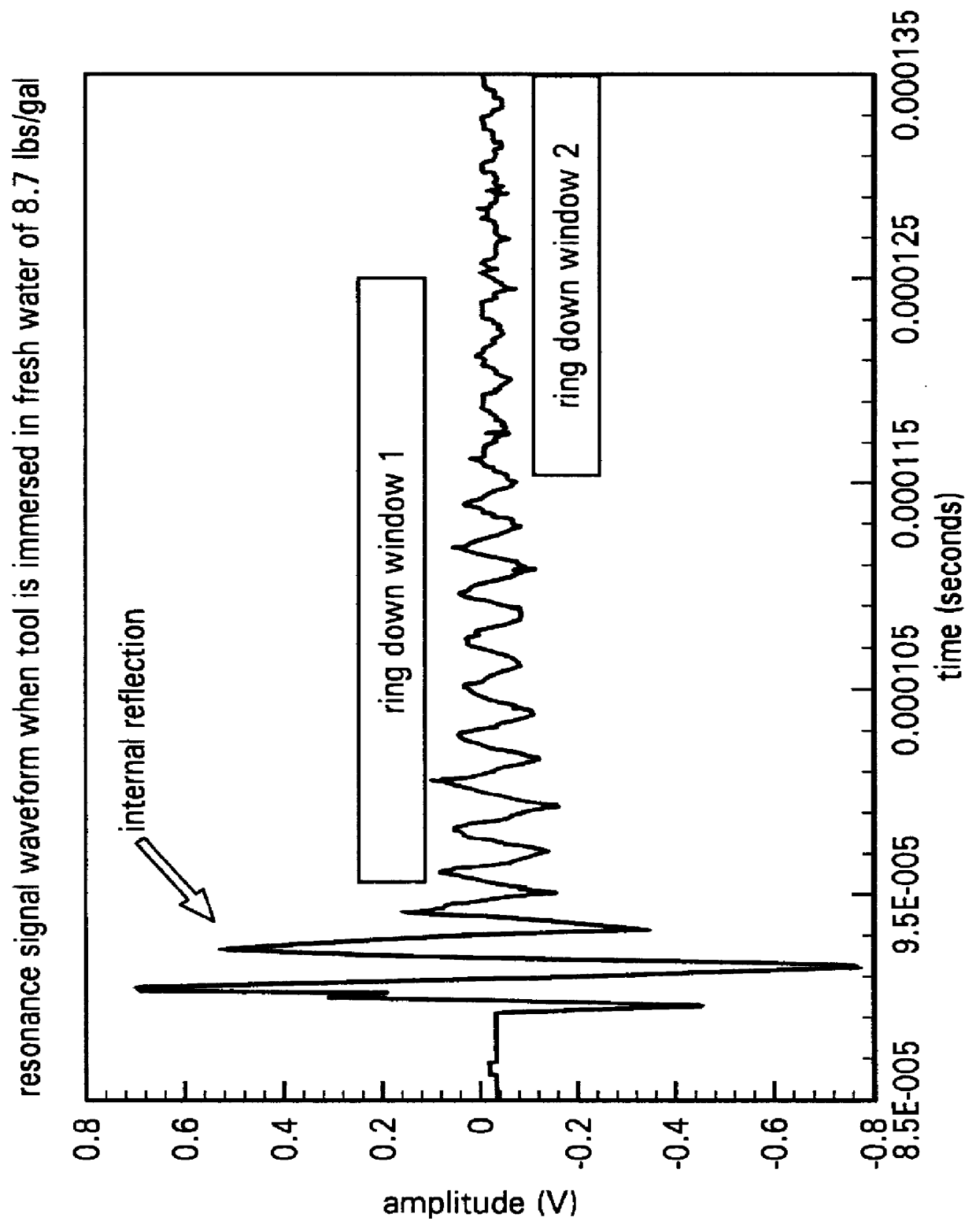

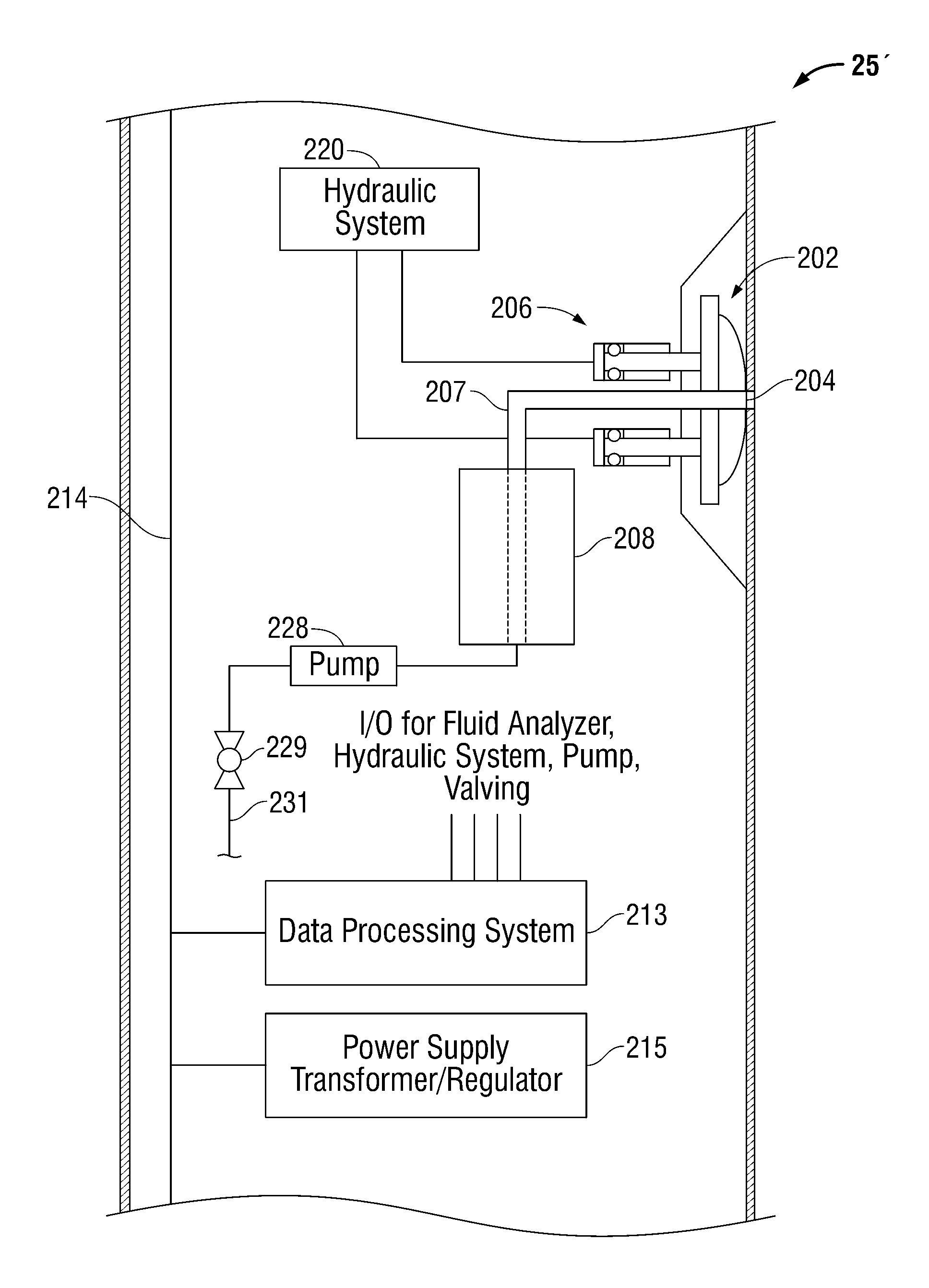

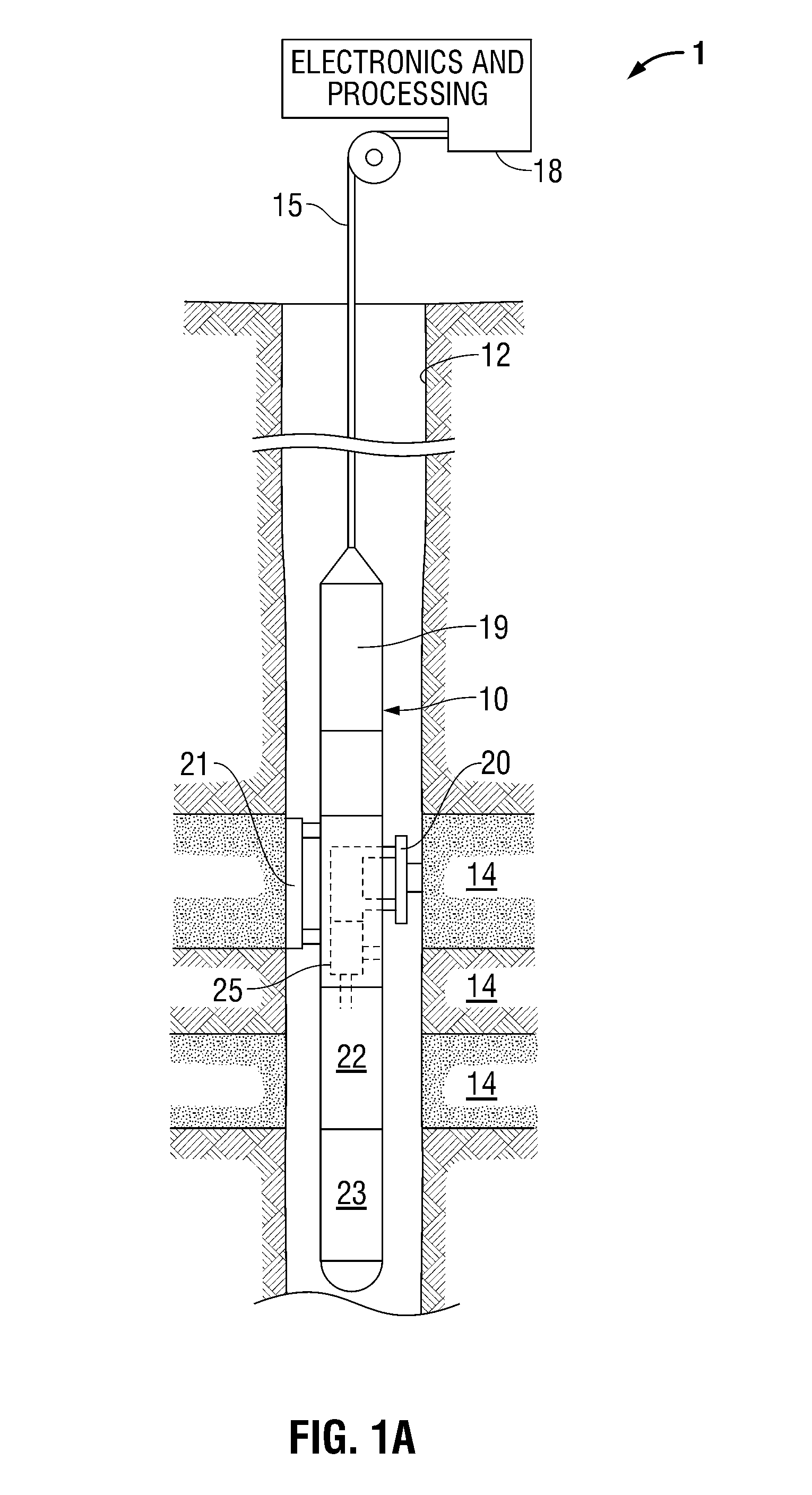

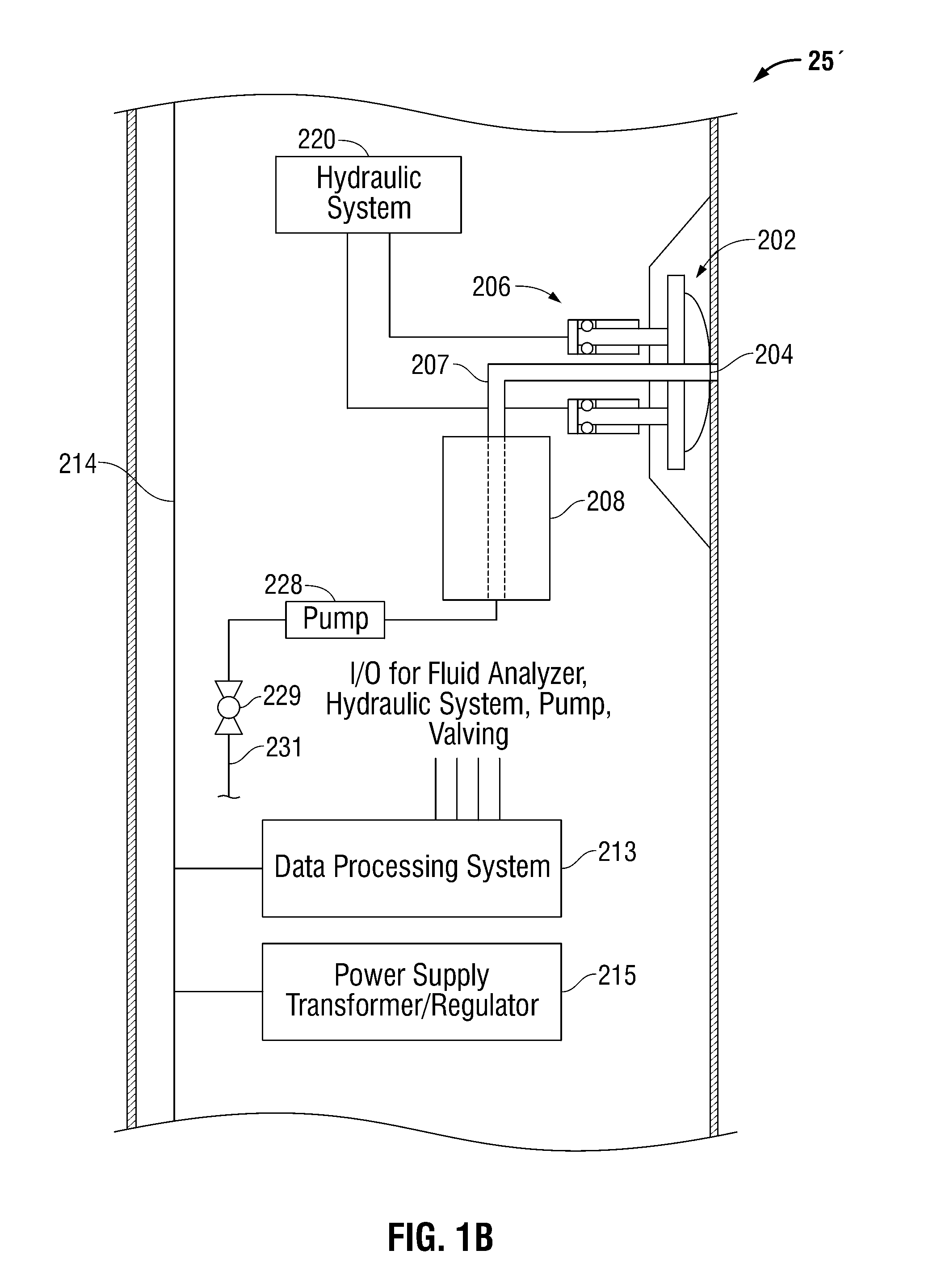

Method and apparatus for acoustic logging of fluid density and wet cement plugs in boreholes

A method of determining the acoustic impedance of a fluid in a borehole, by gating a reflected acoustic signal into a plurality of time slots, and comparing received energies of the signal for the time slots to obtain a value indicative of the acoustic impedance of the fluid. The value may be normalized to yield the acoustic impedance of the fluid using the acoustic impedance of, e.g., water as a calibration point. The comparison is performed by comparing a ratio of an integration of a first ring down time slot and a second ring down time slot, to an integration of an internal reflection time slot. The acoustic pulse may be generated using a transducer immersed in an intermediate fluid contained within a chamber defined in part by a plate in contact with the borehole fluid and having a thickness such that a mechanical resonance frequency of the plate in a thickness mode is substantially equal to a resonance frequency of the transducer. The sonic velocity of the fluid is also measured and, when combined with the acoustic impedance, is used to determine the fluid density.

Owner:WEATHERFORD CANADA PARTNERSHIP +1

Methods and Apparatus for Characterization of Petroleum Fluids Contaminated with Drilling Mud

ActiveUS20110088949A1Avoids computational delayCompensation differenceElectric/magnetic detection for well-loggingFlushingGas oil ratioWell drilling

A method and system for characterizing formation fluids contaminated with drilling mud that compensates for the presence of such drilling mud. The operations that characterize formation fluids contaminated with drilling mud can be carried out in real-time. The operations also characterize a wide array of fluid properties of petroleum samples contaminated with drilling mud in a manner that compensates for the presence of drilling mud. The operations characterize the viscosity and density of petroleum samples contaminated with drilling mud at formation conditions in a manner that compensates for differences between formation conditions and flowline measurement conditions. The operations also derive live fluid density unaffected by contamination of mud filtrate based on a scaling coefficient dependent on measured gas-oil ratio of the formation fluid. This scale factor accounts for excess volume created during mixing processes, which increases the accuracy of characterizations for high gas-oil ratio samples, especially gas condensate.

Owner:SCHLUMBERGER TECH CORP

Measurement system and method

InactiveUS6650280B2Highly accurate real timeAccurate density measurementSurveyTesting/calibration apparatusAmbiguityEngineering

System and methods are disclosed for fluid measurements which may be utilized to determine mass flow rates such as instantaneous mass flow of a fluid stream. In a preferred embodiment, the present invention may be utilized to compare an input mass flow to an output mass flow of a drilling fluid circulation stream. In one embodiment, a fluid flow rate is determined by utilizing a microwave detector in combination with an acoustic sensor. The acoustic signal is utilized to eliminate 2pi phase ambiguities in a reflected microwave signal. In another embodiment, a fluid flow rate may be determined by detecting a phase shift of an acoustic signal across two different predetermined transmission paths. A fluid density may be determined by detecting a calibrated phase shift of an acoustic signal through the fluid. In another embodiment, a second acoustic signal may be transmitted through the fluid to define a particular 2pi phase range which defines the phase shift. The present invention may comprise multiple transmitters / receivers operating at different frequencies to measure instantaneous fuel levels of cryogenic fuels within containers positioned in zero or near zero gravity environments. In one embodiment, a moveable flexible collar of transmitter / receivers may be utilized to determine inhomogenuities within solid rocket fuel tubes.

Owner:NASA

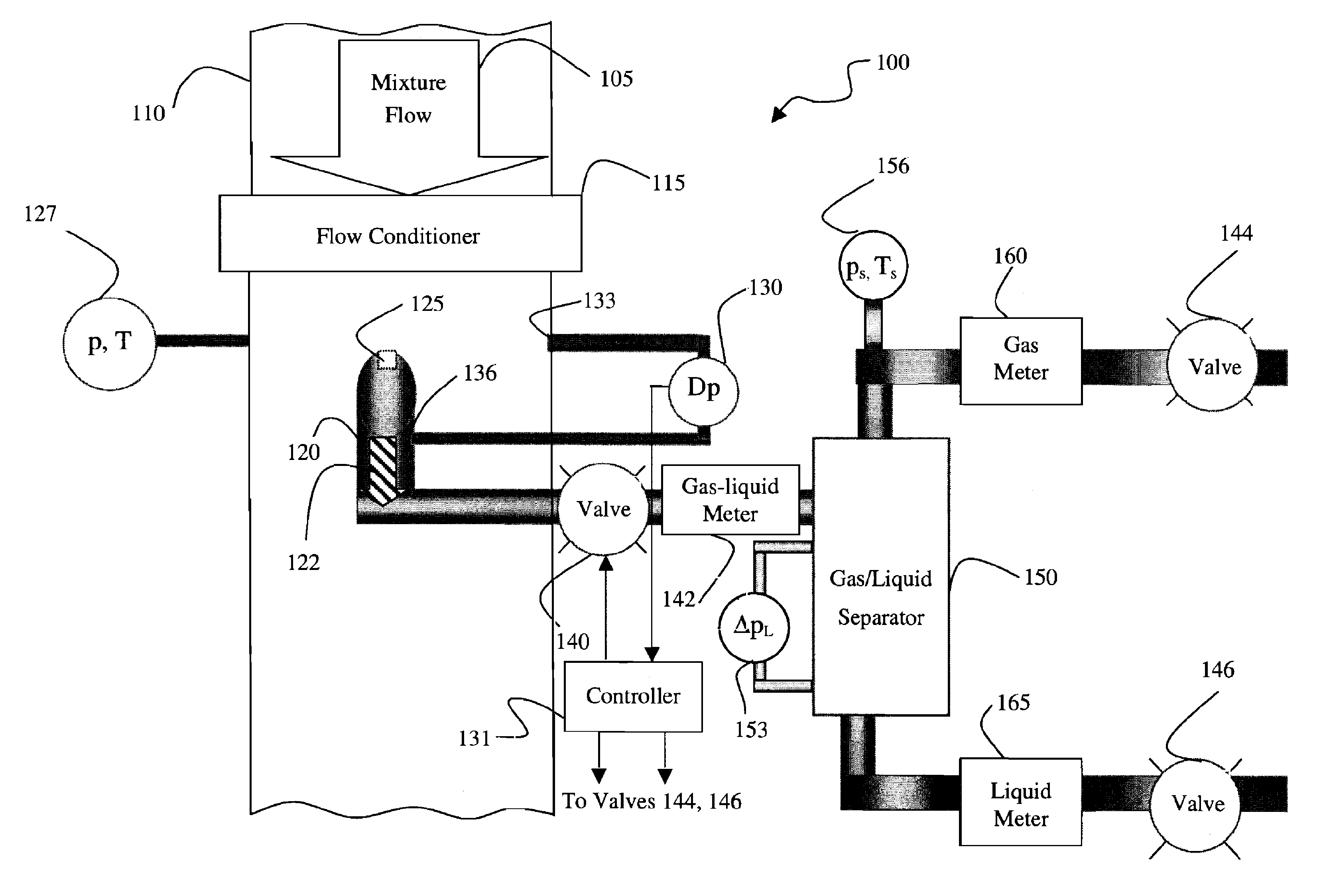

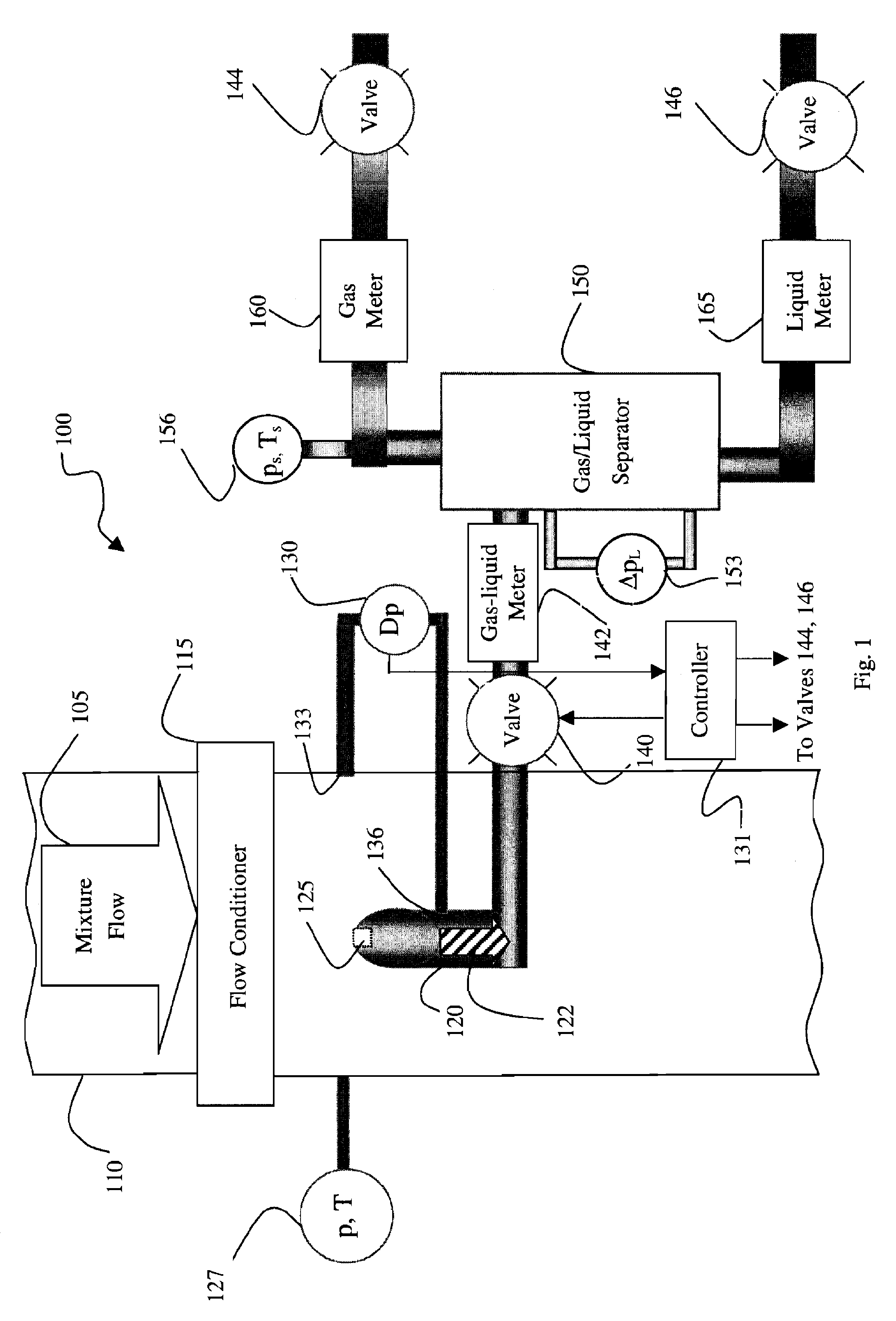

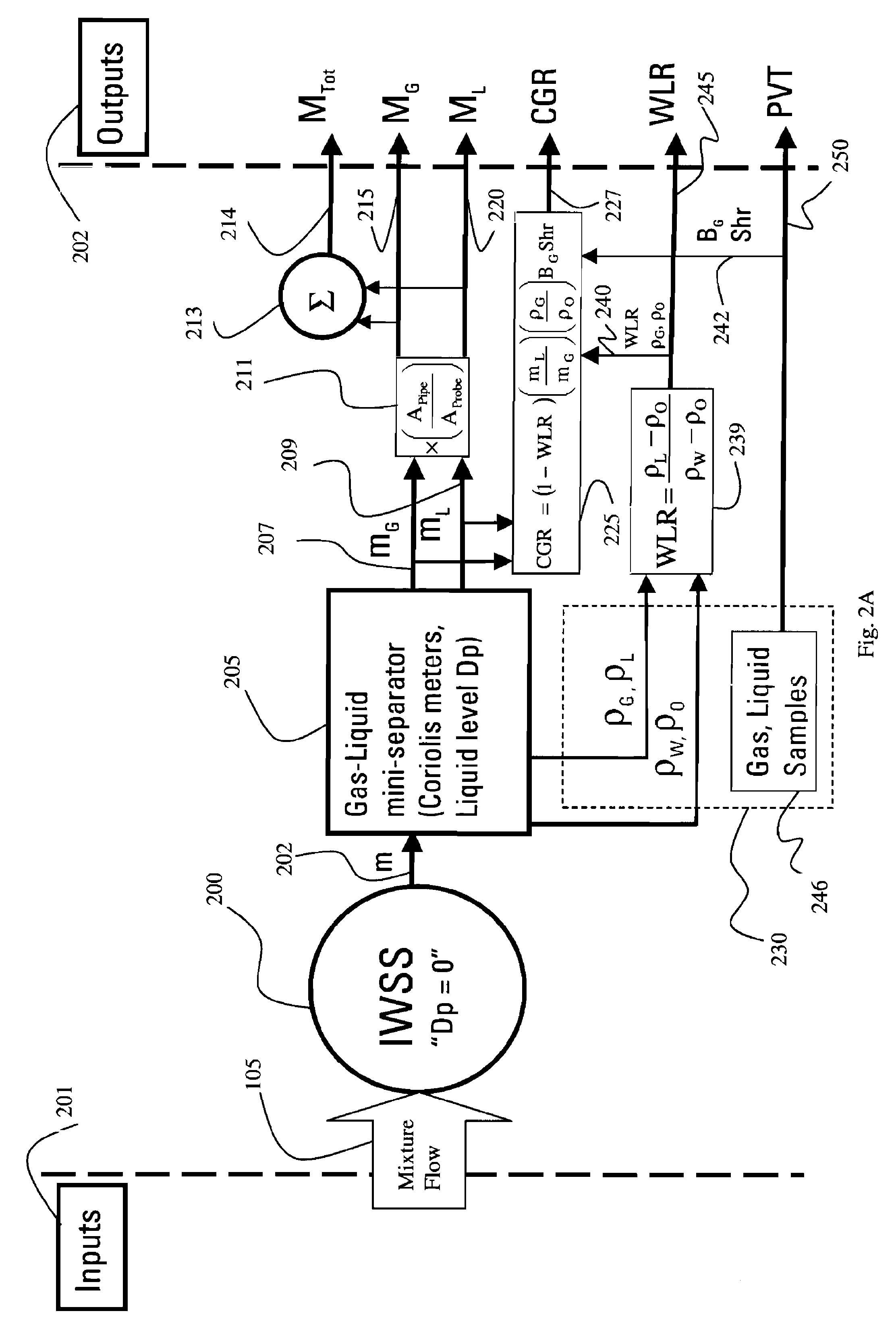

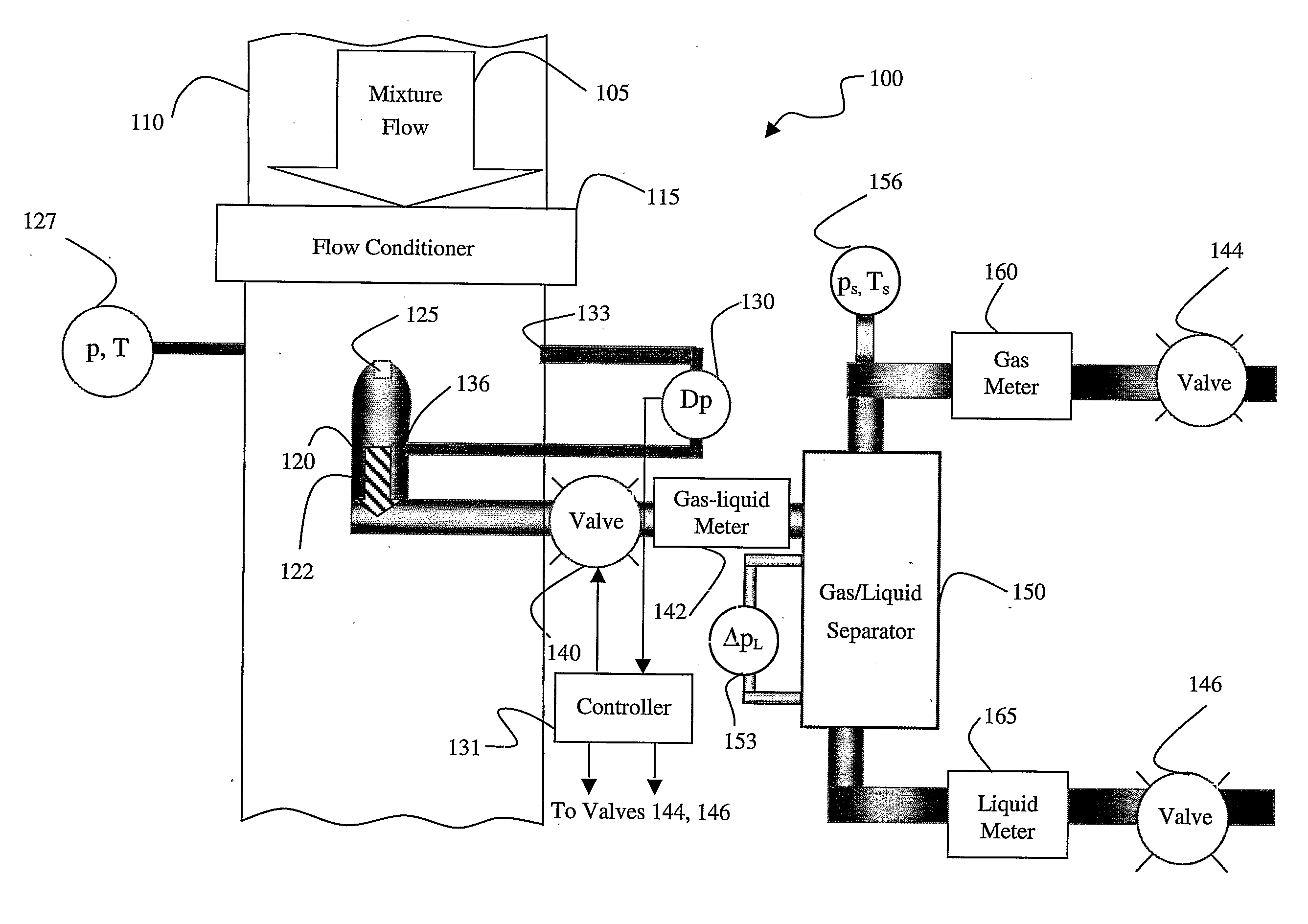

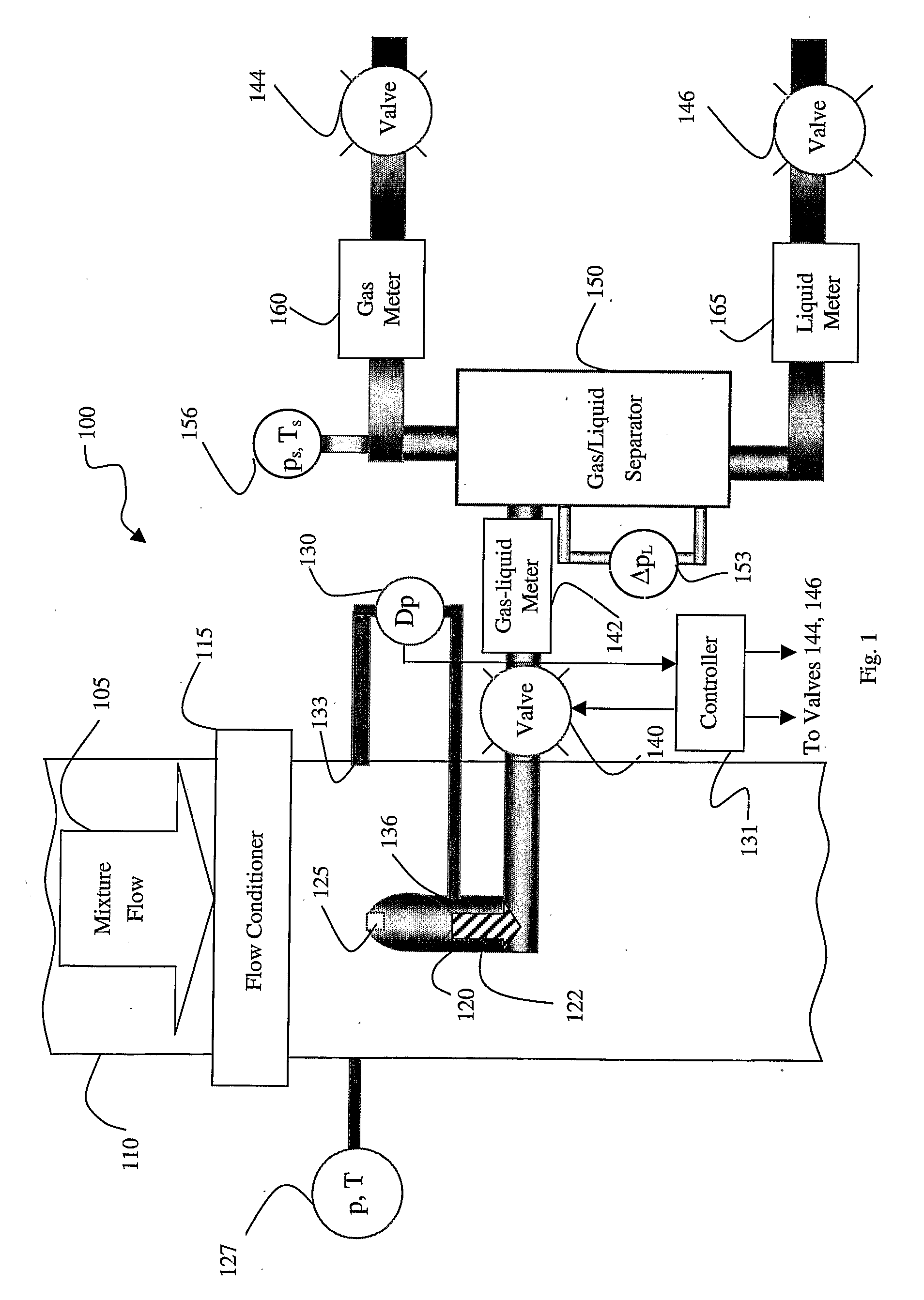

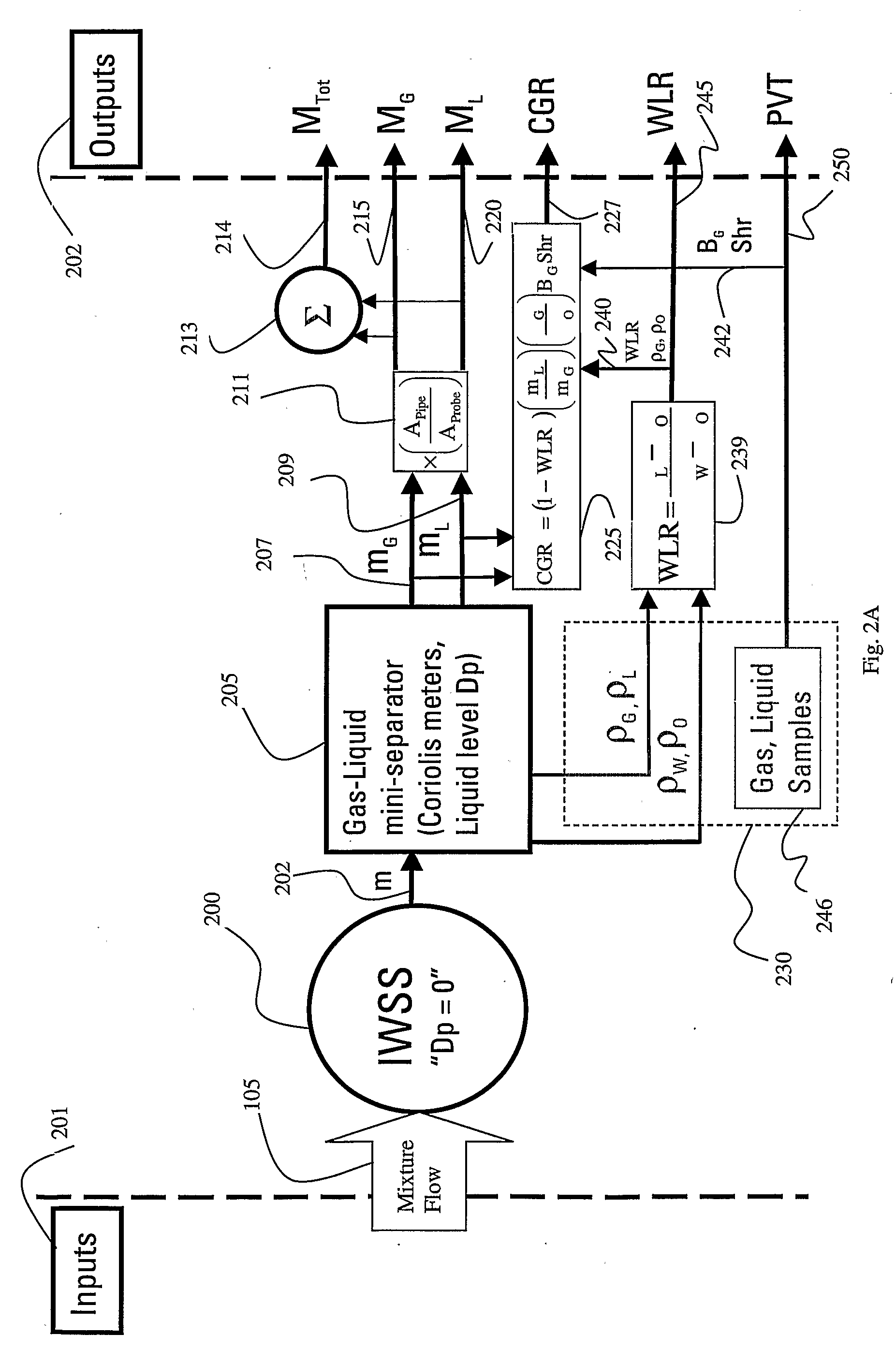

Isokinetic sampling method and system for multiphase flow from subterranean wells

InactiveUS7942065B2Withdrawing sample devicesVolume/mass flow measurementNuclear radiationControl flow

The invention relates in a one aspect to a method or apparatus for measuring flow properties of a multiphase fluid stream flowing in a pipeline comprising means for sampling, with a sampling probe, a portion of the fluid stream; for measuring a differential pressure between a first pressure of the fluid stream in the pipeline and a second pressure of the portion of the fluid stream in the sampling probe; for controlling flow rate of the sampled portion, wherein the flow rate of the sampled portion is controlled to provide for nullification of the differential pressure in order to obtain substantially isokinetic sampling of the fluid stream; for measuring properties of the portion of the fluid stream; and for processing the measured properties to determine the flow properties of the multiphase fluid stream flowing in the pipeline, wherein the above elements do not require- or are performed without the determination of the density of fluid in the fluid stream through nuclear radiation methods.

Owner:SCHLUMBERGER TECH CORP

Isokinetic sampling method and system for multiphase flow from subterranean wells

InactiveUS20090139345A1Volume/mass flow measurementVolume variation compensation/correction apparatusNuclear radiationControl flow

The invention relates in a one aspect to a method or apparatus for measuring flow properties of a multiphase fluid stream flowing in a pipeline comprising means for sampling, with a sampling probe, a portion of the fluid stream; for measuring a differential pressure between a first pressure of the fluid stream in the pipeline and a second pressure of the portion of the fluid stream in the sampling probe; for controlling flow rate of the sampled portion, wherein the flow rate of the sampled portion is controlled to provide for nullification of the differential pressure in order to obtain substantially isokinetic sampling of the fluid stream; for measuring properties of the portion of the fluid stream; and for processing the measured properties to determine the flow properties of the multiphase fluid stream flowing in the pipeline, wherein the above elements do not require- or are performed without the determination of the density of fluid in the fluid stream through nuclear radiation methods.

Owner:SCHLUMBERGER TECH CORP

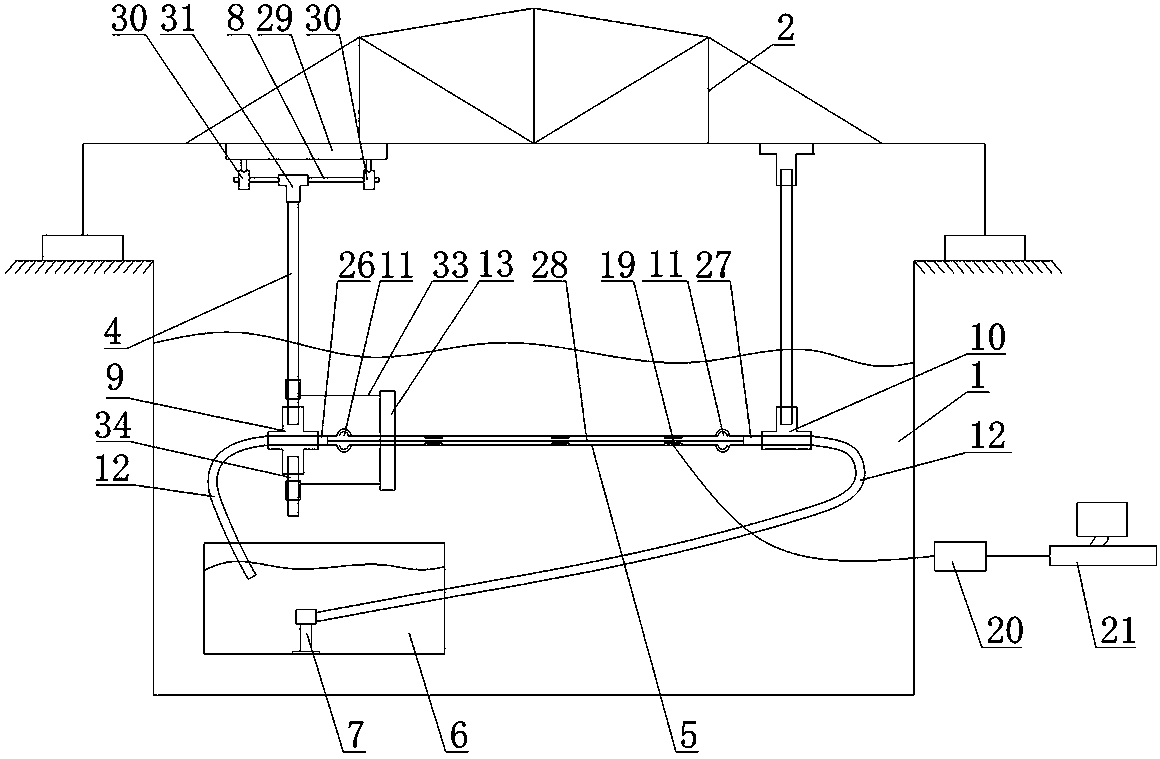

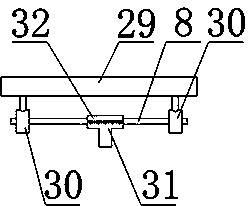

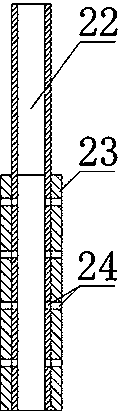

Marine riser vibration characteristic simulation test device under deepwater well drilling working condition and test method

ActiveCN103292970ASimulate vibration characteristicsThe vibration characteristics are real and effectiveHydrodynamic testingVibration testingReal-time dataWell drilling

Owner:SOUTHWEST PETROLEUM UNIV

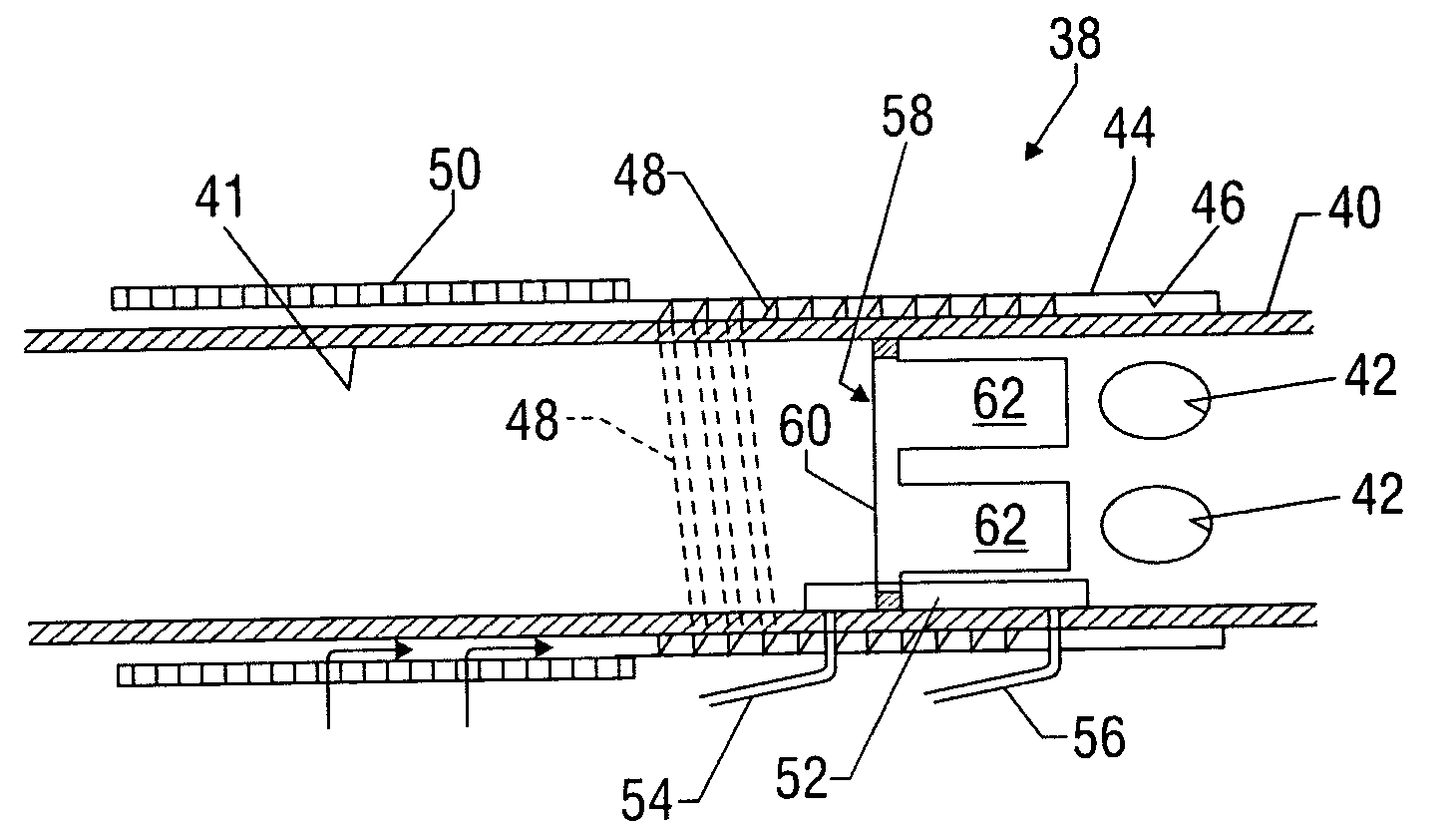

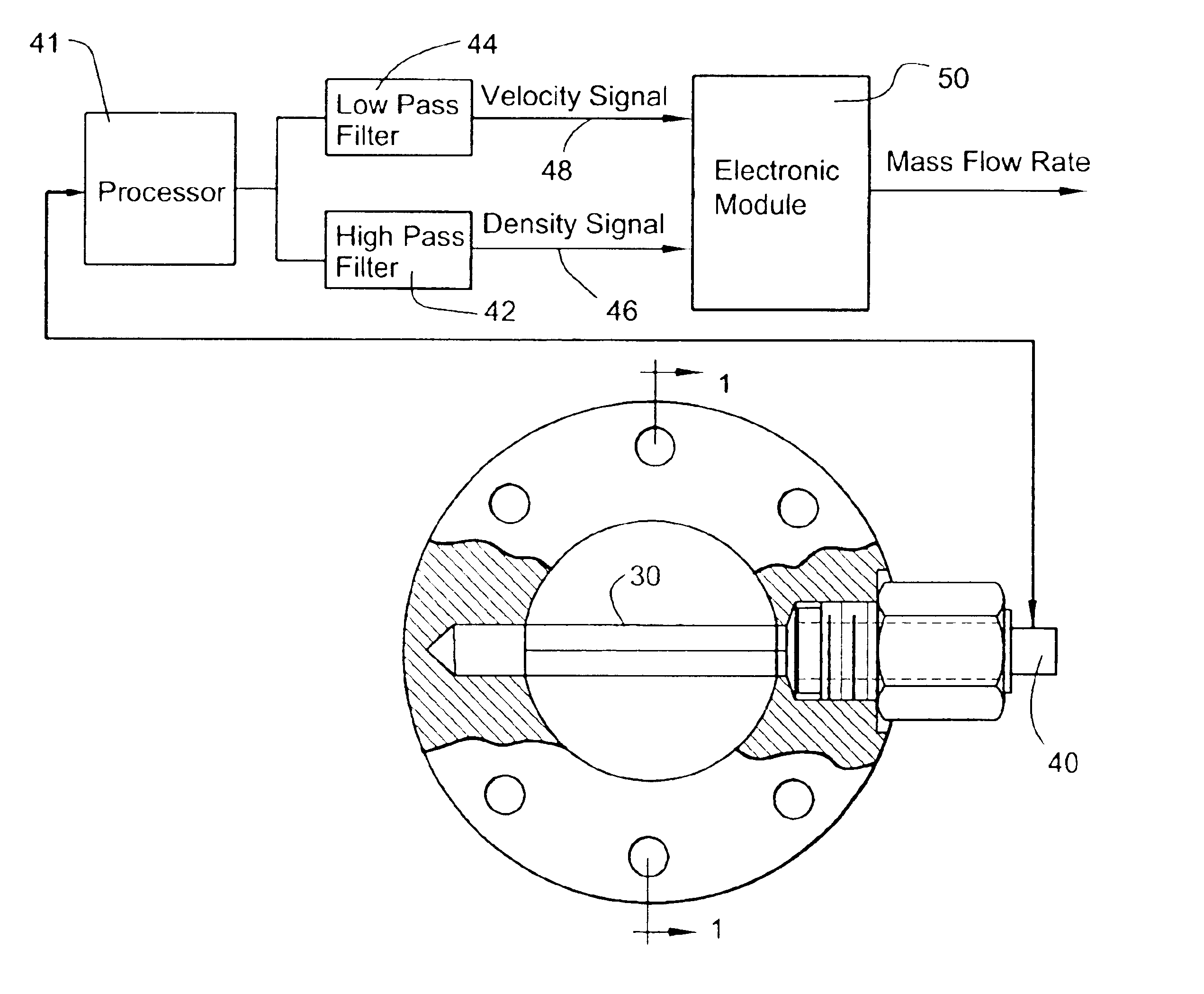

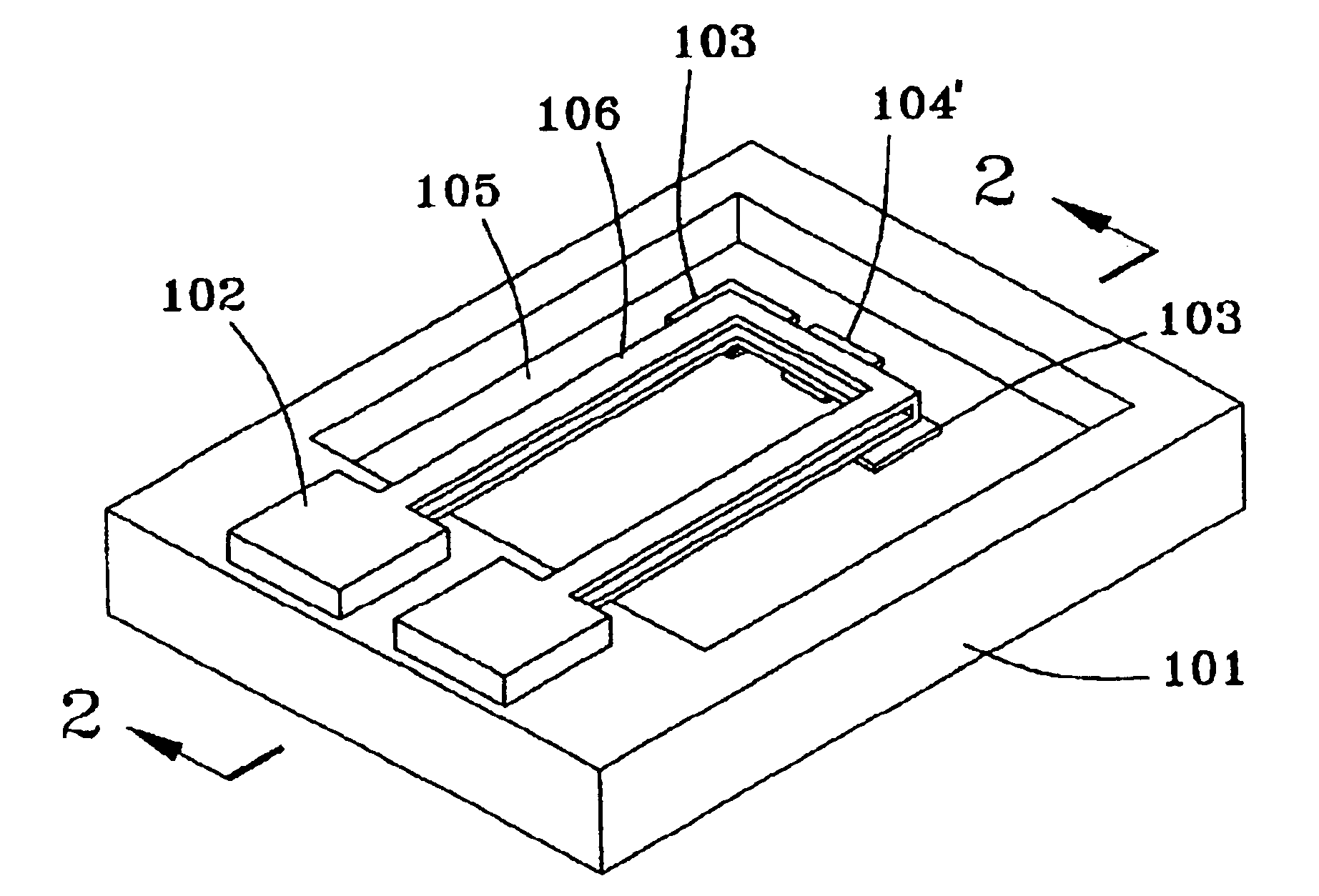

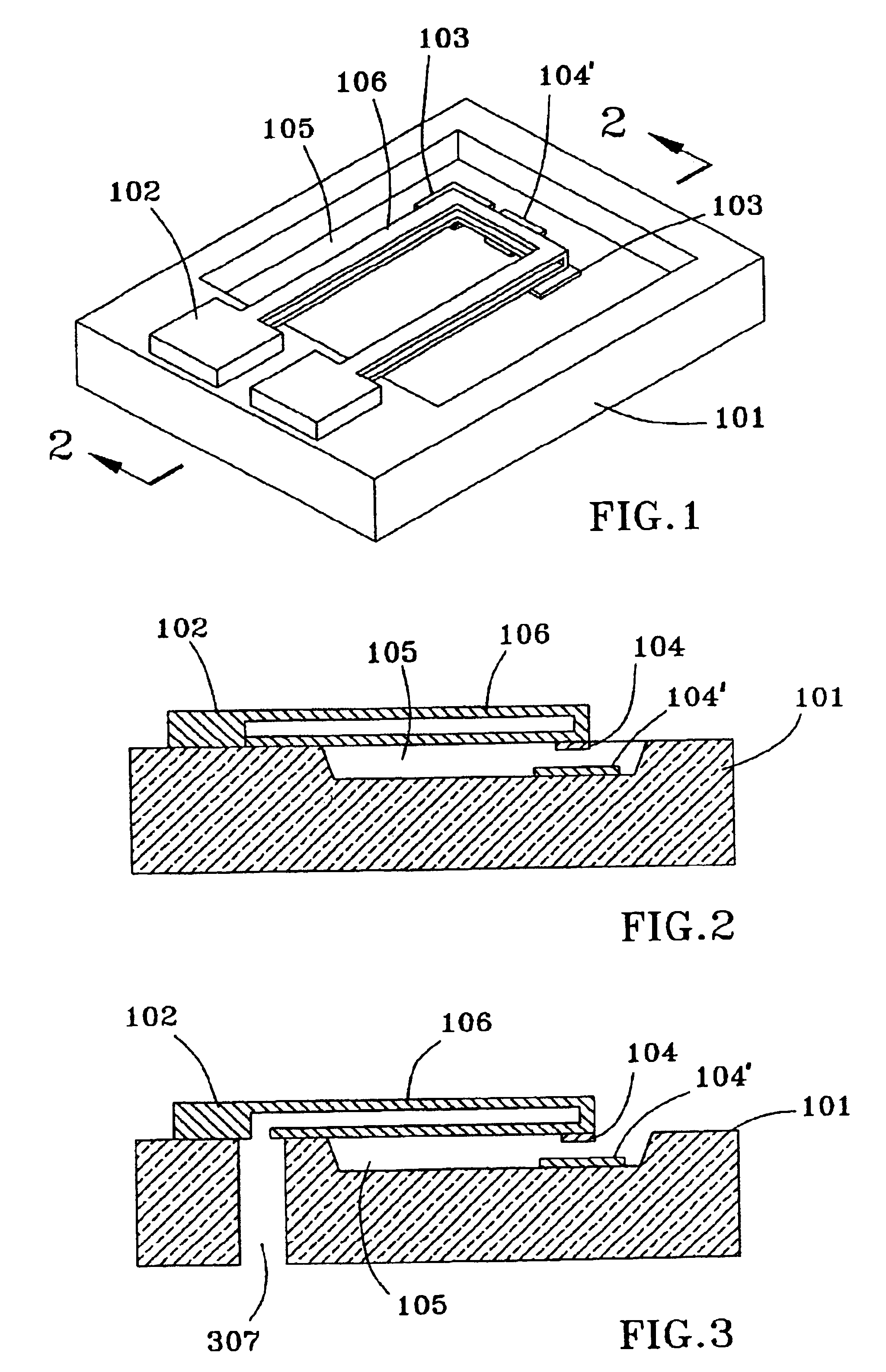

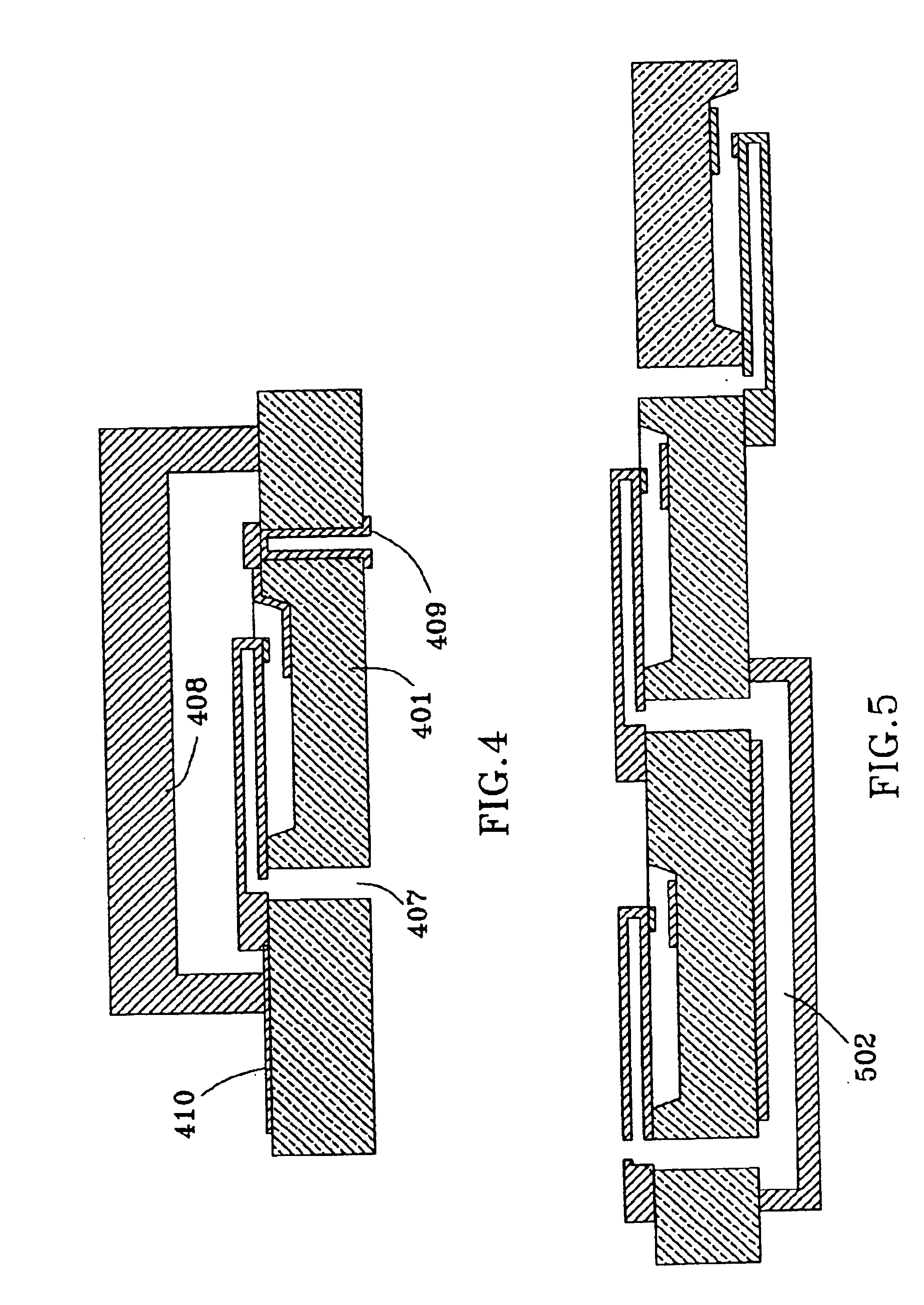

Method of fabricating a micromachined tube for fluid flow

InactiveUS6935010B2Advanced technologyWave amplification devicesFlow propertiesCapacitanceFluid transport

Micromachine fluidic apparatus incorporates a free-standing tube section and electrodes to actuate or control the movement of the tube section, or to sense the movement of the tube section, or both. Electronic circuitry, which may be disposed on the same substrate as the fluidic portion of the apparatus, is used in conjunction with the tube and electrodes in conjunction with a variety of different applications, including fluid flow measurement, fluid density measurement, fluid viscosity measurement, fluid transport, separation and / or mixing. According to a particular embodiment, the free-standing section of the tube is resonated for fluid flow and density measurements according to the Coriolis effect. Capacitive / electrostatic actuation techniques are used to control or resonate the free-standing section of the tube, and to detect variations in tube movement. Different methods of fabricating micromachine fluidic apparatus are also disclosed, including the use of fusion bonding of non-conducting substrates, high-aspect ratio etching techniques, and anisotropic etching and refill techniques, preferably utilizing chevron-shaped slit openings to fabricate microtube sections.

Owner:INTEGRATED SENSING SYST INC

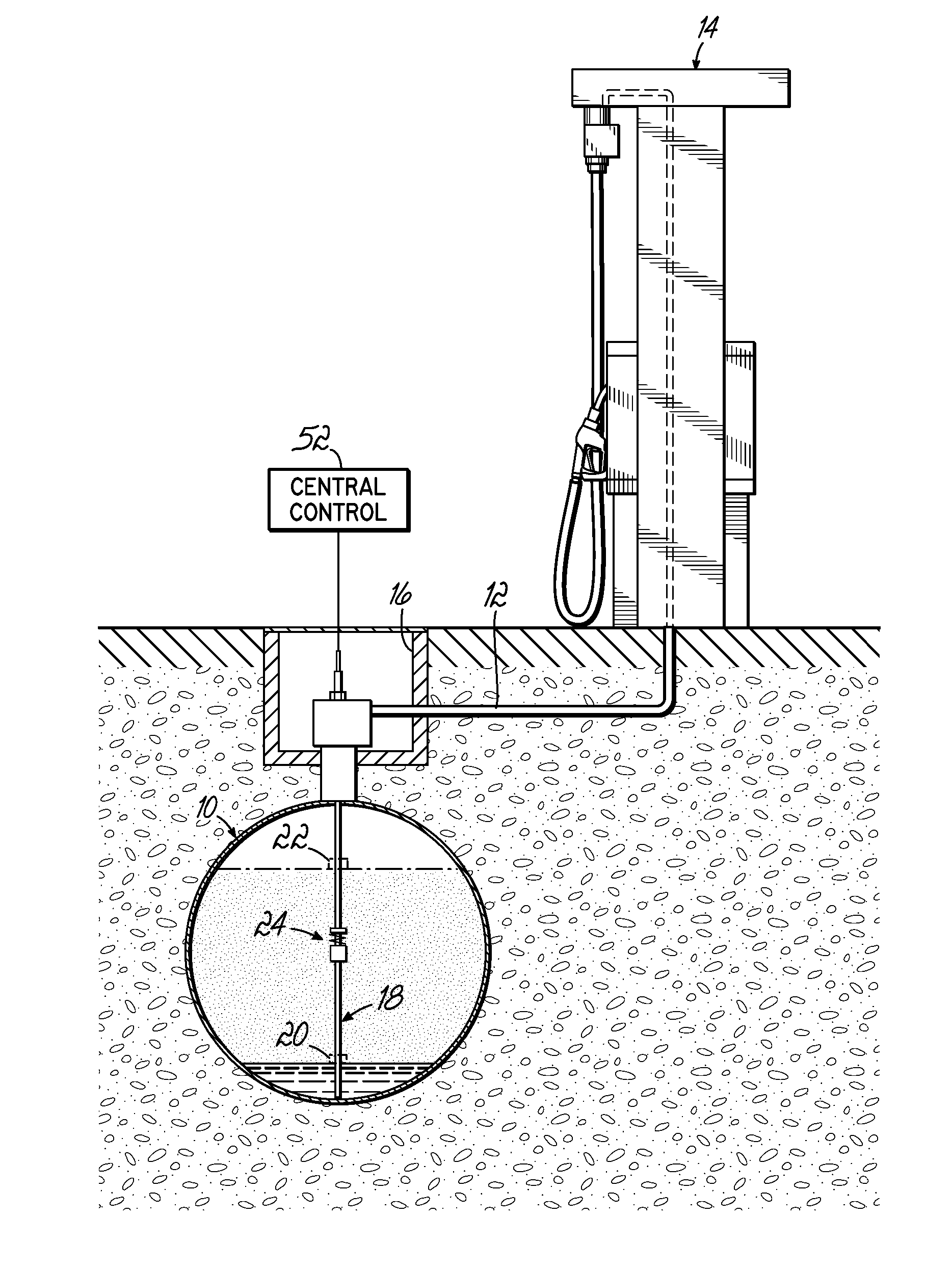

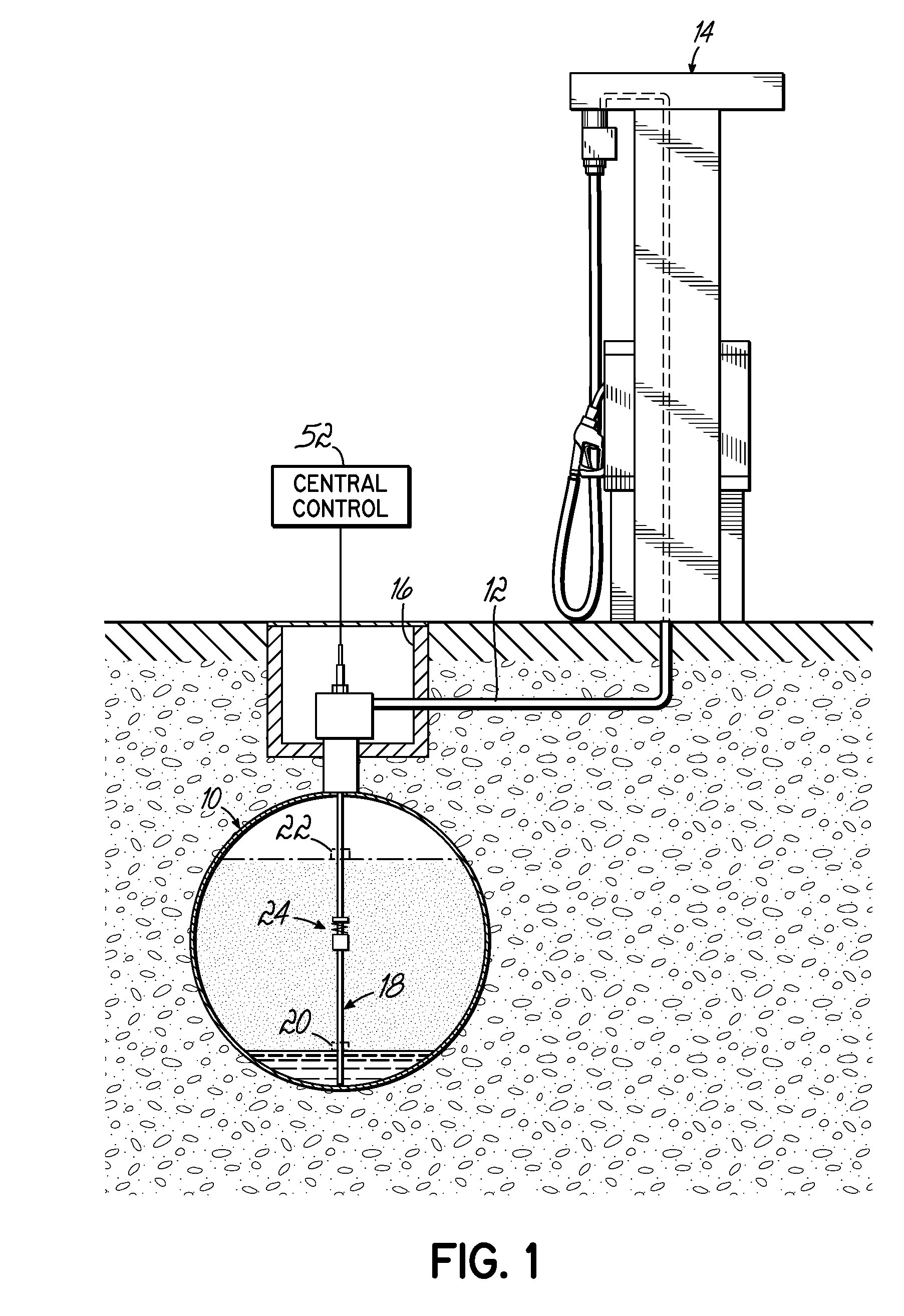

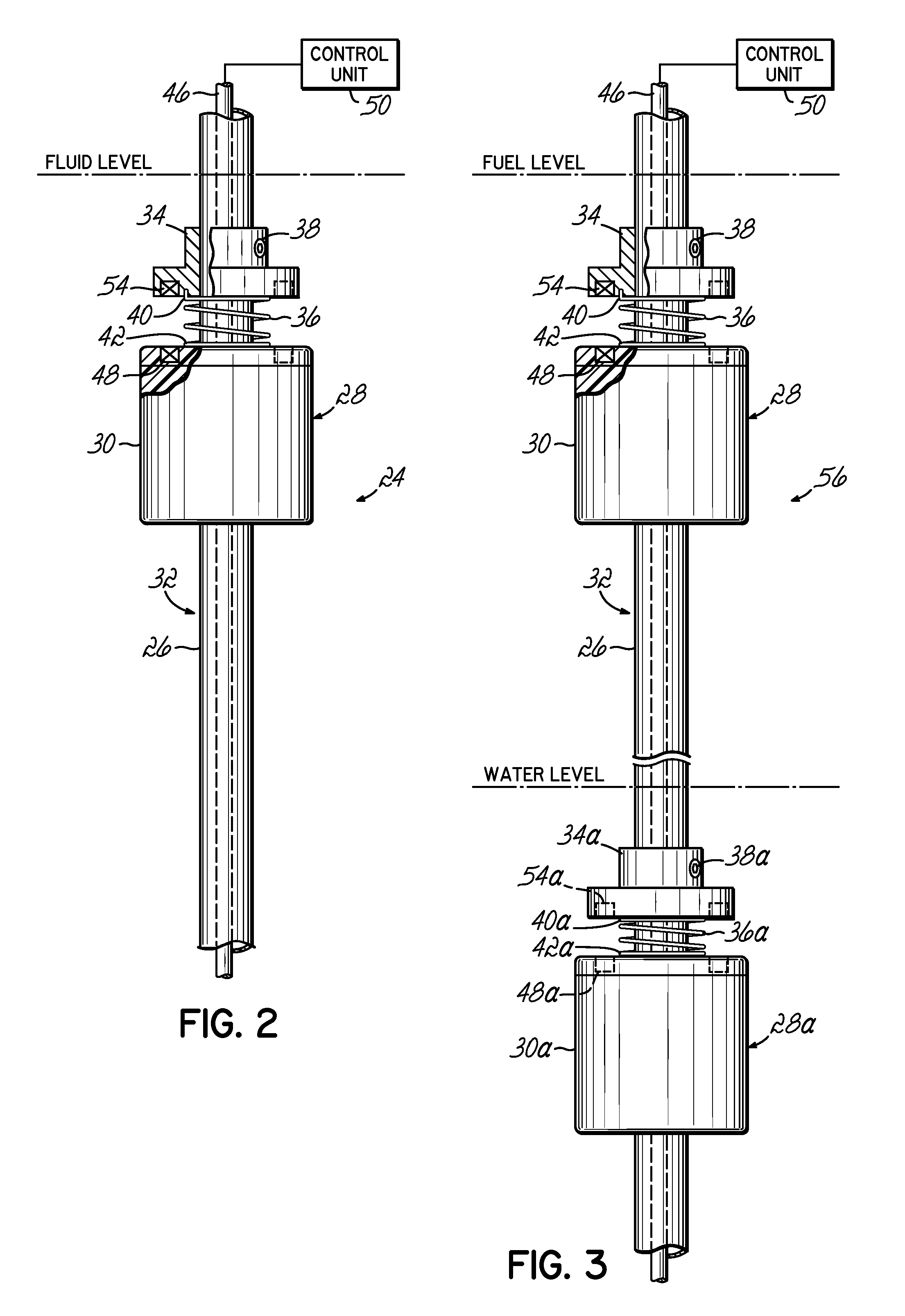

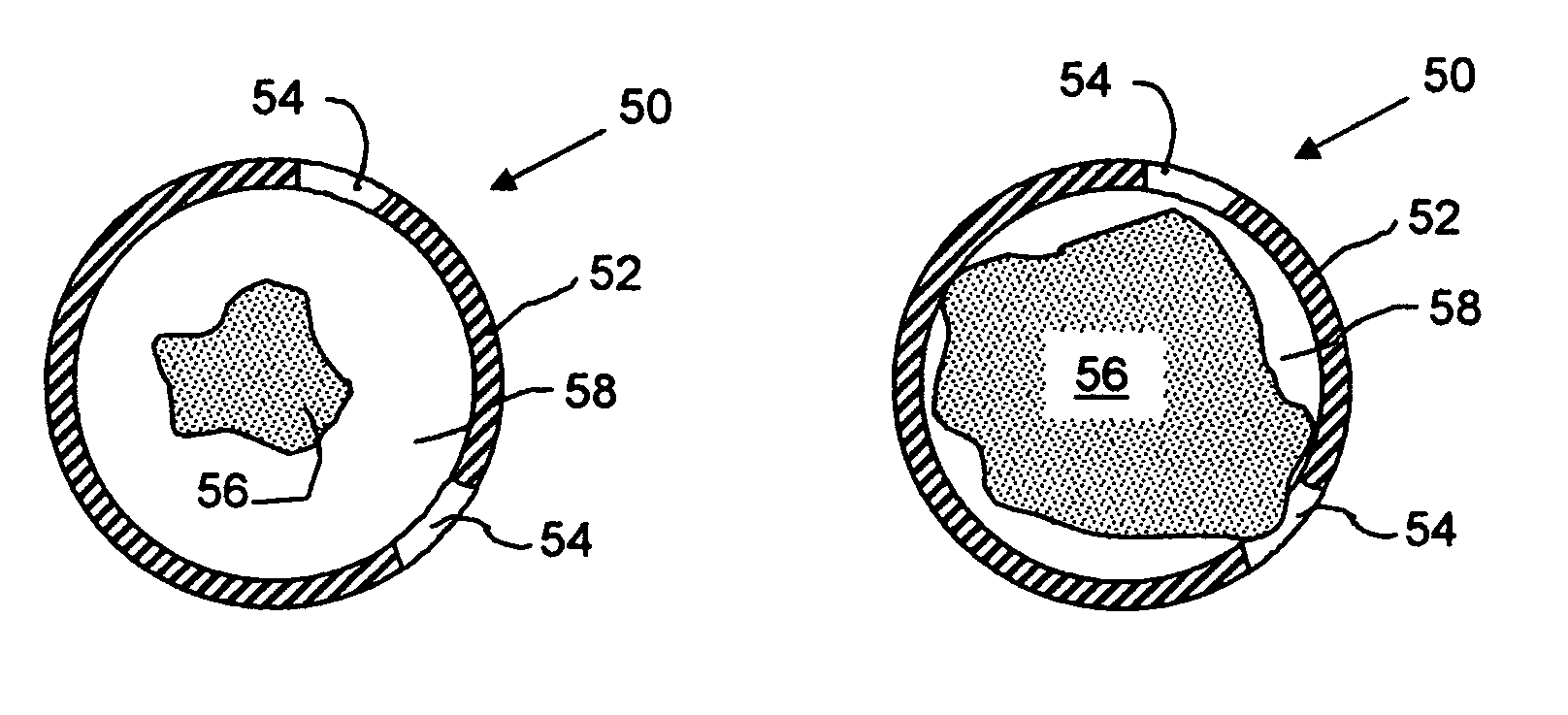

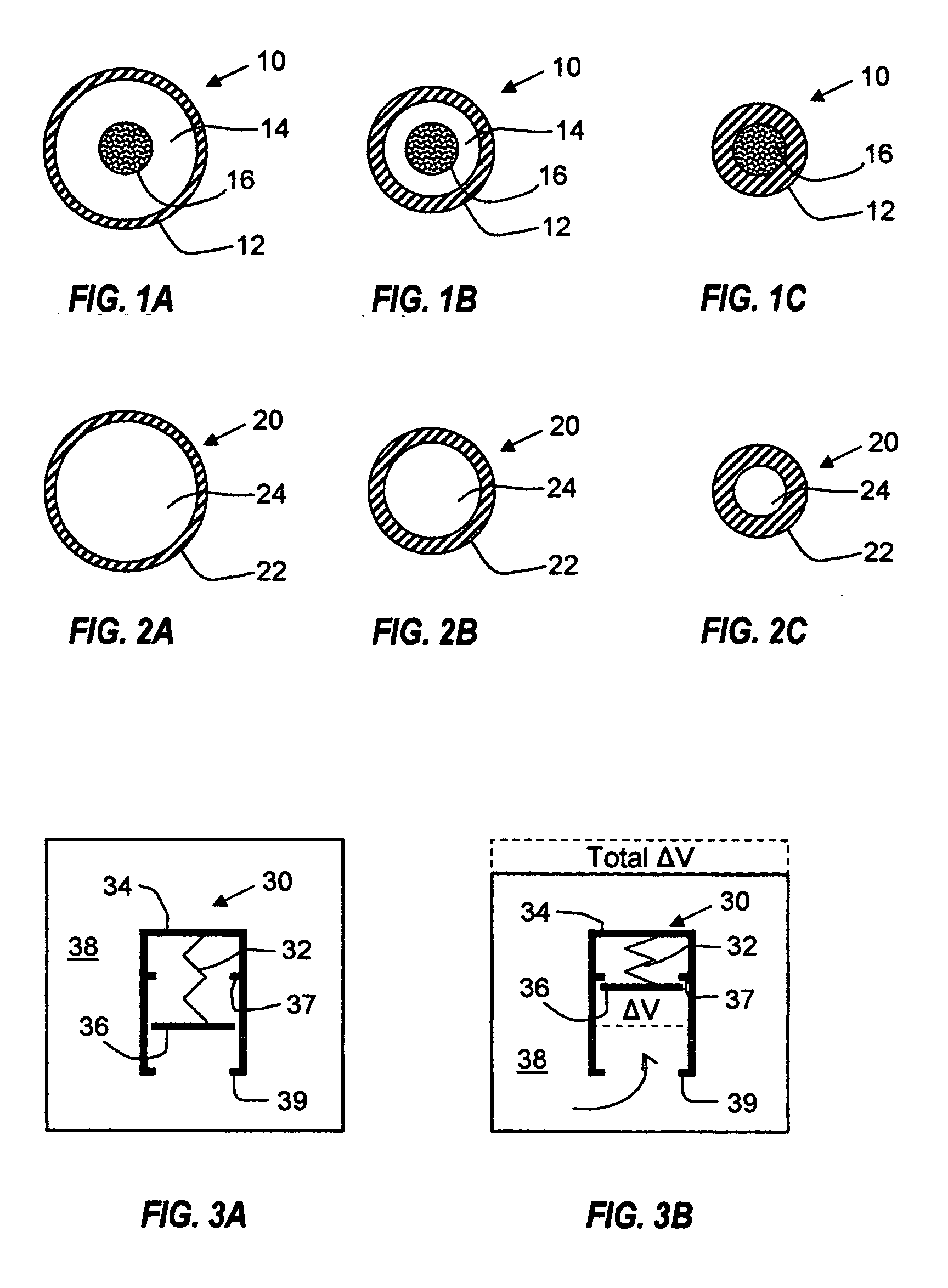

A method and apparatus for fluid density sensing

InactiveUS20060248952A1Level indicator with buoyant probesMaterial analysis by observing immersed bodiesEngineeringFluid density

Owner:OPW FUELING COMPONENTS

Controlled variable density fluid for wellbore operations

Fluid systems may contain elements to provide changes in bulk fluid density in response to various environmental conditions. One environmental driver to the variable density is pressure; other environmental drivers include, but are not limited to, temperature or changes in chemistry. The variable density of the fluid is beneficial for controlling sub-surface pressures within desirable pore pressure and fracture gradient envelopes. The variability of fluid density permits construction and operation of a wellbore with much longer hole sections than when using conventional single gradient fluids.

Owner:BAKER HUGHES INC

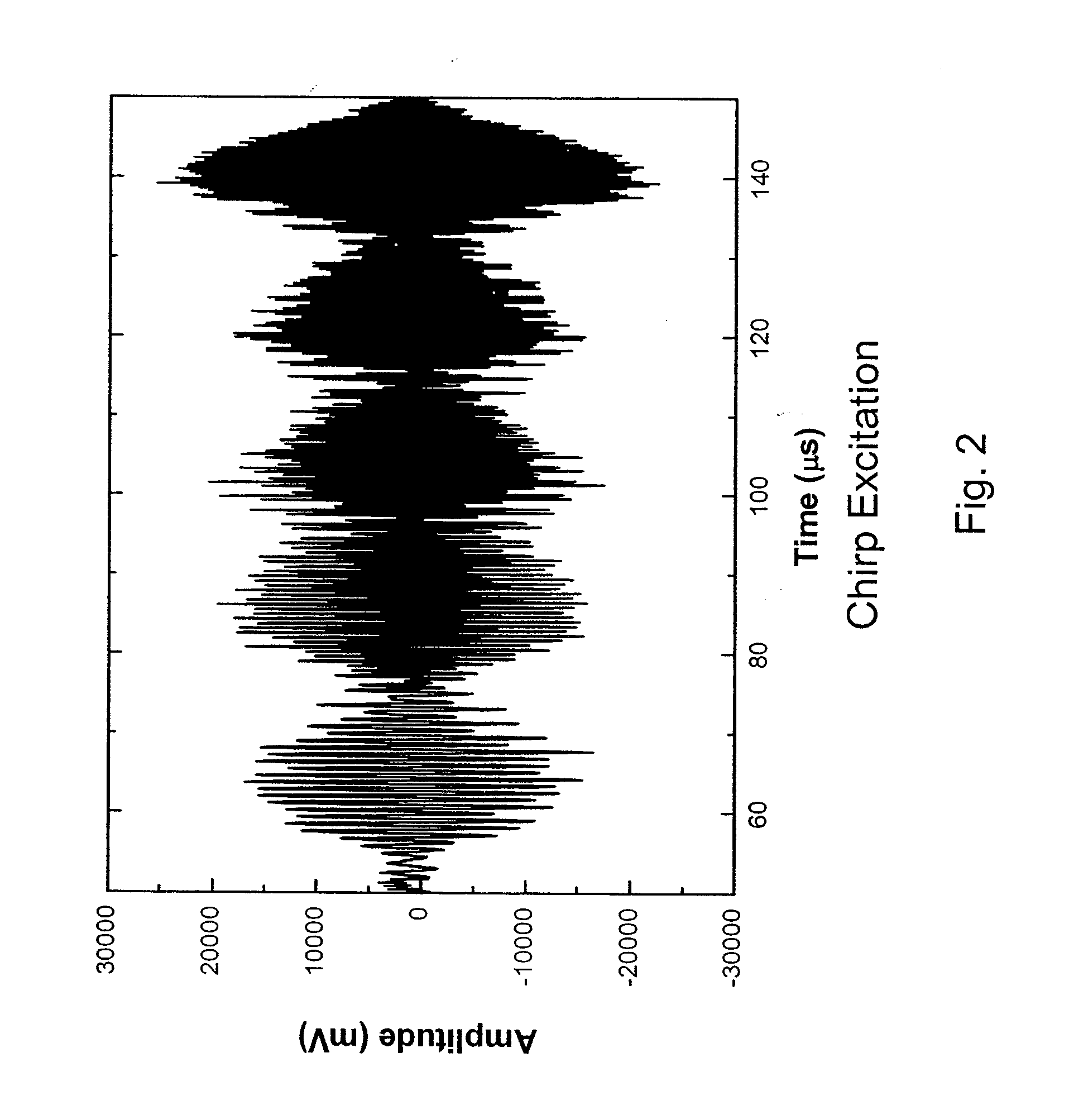

Method for noninvasive determination of acoustic properties of fluids inside pipes

ActiveUS20120055253A1Simplifies wave generationPower consumption electronicsAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationSonification

A method for determining the composition of fluids flowing through pipes from noninvasive measurements of acoustic properties of the fluid is described. The method includes exciting a first transducer located on the external surface of the pipe through which the fluid under investigation is flowing, to generate an ultrasound chirp signal, as opposed to conventional pulses. The chirp signal is received by a second transducer disposed on the external surface of the pipe opposing the location of the first transducer, from which the transit time through the fluid is determined and the sound speed of the ultrasound in the fluid is calculated. The composition of a fluid is calculated from the sound speed therein. The fluid density may also be derived from measurements of sound attenuation. Several signal processing approaches are described for extracting the transit time information from the data with the effects of the pipe wall having been subtracted.

Owner:TRIAD NAT SECURITY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com