Marine riser vibration characteristic simulation test device under deepwater well drilling working condition and test method

A technology of deepwater drilling and vibration characteristics, applied in the field of deepwater drilling, can solve the problems of the deepwater drilling riser model making, incomplete test methods, no consideration of drilling displacement drilling fluid viscosity, poor versatility of test devices, etc., and achieve stable test results. Reliable, wide application range, and firm fixation

Active Publication Date: 2013-09-11

SOUTHWEST PETROLEUM UNIV

View PDF9 Cites 43 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, relevant test devices at home and abroad do not consider factors such as drilling displacement, drilling speed, drilling fluid density, and drilling fluid viscosity during deepwater drilling. To s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

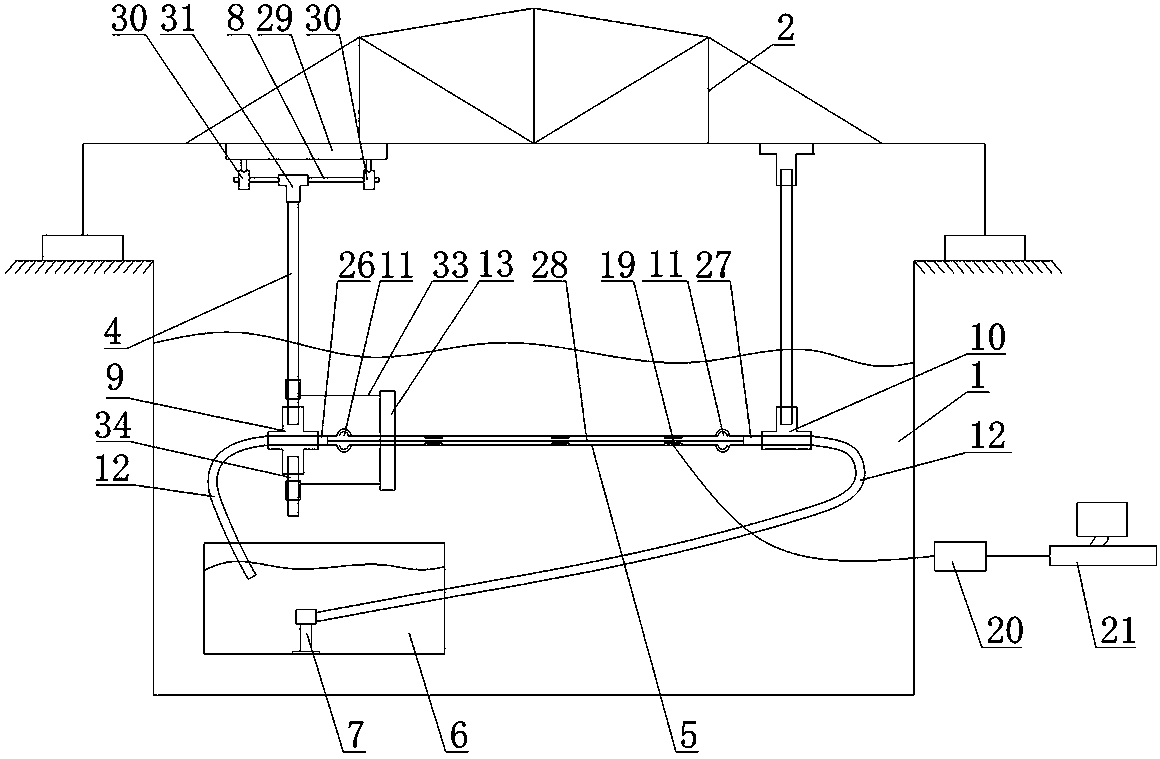

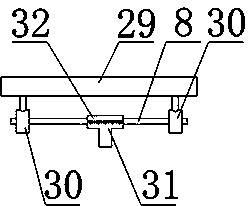

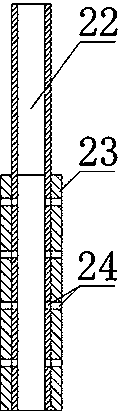

The invention discloses a marine riser vibration characteristic simulation test device under a deepwater well drilling working condition. The marine riser vibration characteristic simulation test device comprises a pool (1) and a trailer (2), wherein a lifting device A (3) is arranged on a horizontal sliding rail (8) of the trailer (2), a marine riser model (5) is connected with a connector A (9) at the bottom of the lifting device A (3) and a connector B (10) at the bottom of a lifting device B (4), the connector A (9) is communicated with a container (6), the connector B (10) is communicated with a liquid pump (7), and a tension adjusting device (33) is further arranged on the marine riser model (5). The invention further discloses a test method of the device. The marine riser vibration characteristic simulation test device has the advantages of being capable of simulating vibration performance of a marine riser of deepwater well drilling under different working conditions, suitable for marine riser models with different lengths, capable of simulating influence of different types of tensile force, different well drilling fluid density, different drilling fluid viscosity, different well drilling discharge capacity and different well drilling rotating speeds on vibration characteristics of the marine riser models, and capable of accurately obtaining real-time data in the test process.

Description

technical field [0001] The invention relates to the technical field of deepwater drilling, in particular to a simulation test device and a test method for the vibration characteristics of a riser under deepwater drilling conditions. Background technique [0002] Offshore oil and gas resources have now become an important part of the global energy strategy, and deep waters will become the main battlefield for the exploration and development of oil and gas resources in the future. However, the mining environment in deep-water areas is harsh, which puts forward higher requirements for deep-sea drilling equipment. The riser system is a bridge connecting the surface platform and the subsea oil well. It is one of the most critical equipment in deepwater drilling operations. When the natural frequency of the riser vibration is close to the frequency of the vortex shedding generated by the ocean current, the phenomenon of vortex-induced vibration occurs. Vortex-induced vibration no...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M7/02G01M10/00

Inventor 刘清友毛良杰伊海洋邓猛王国荣

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com