Patents

Literature

1335 results about "Vibration measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

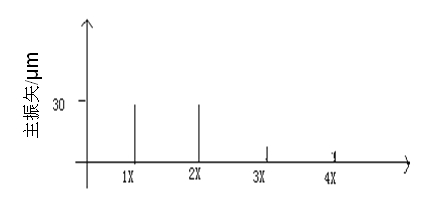

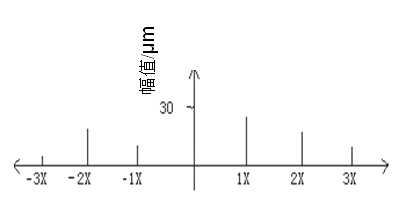

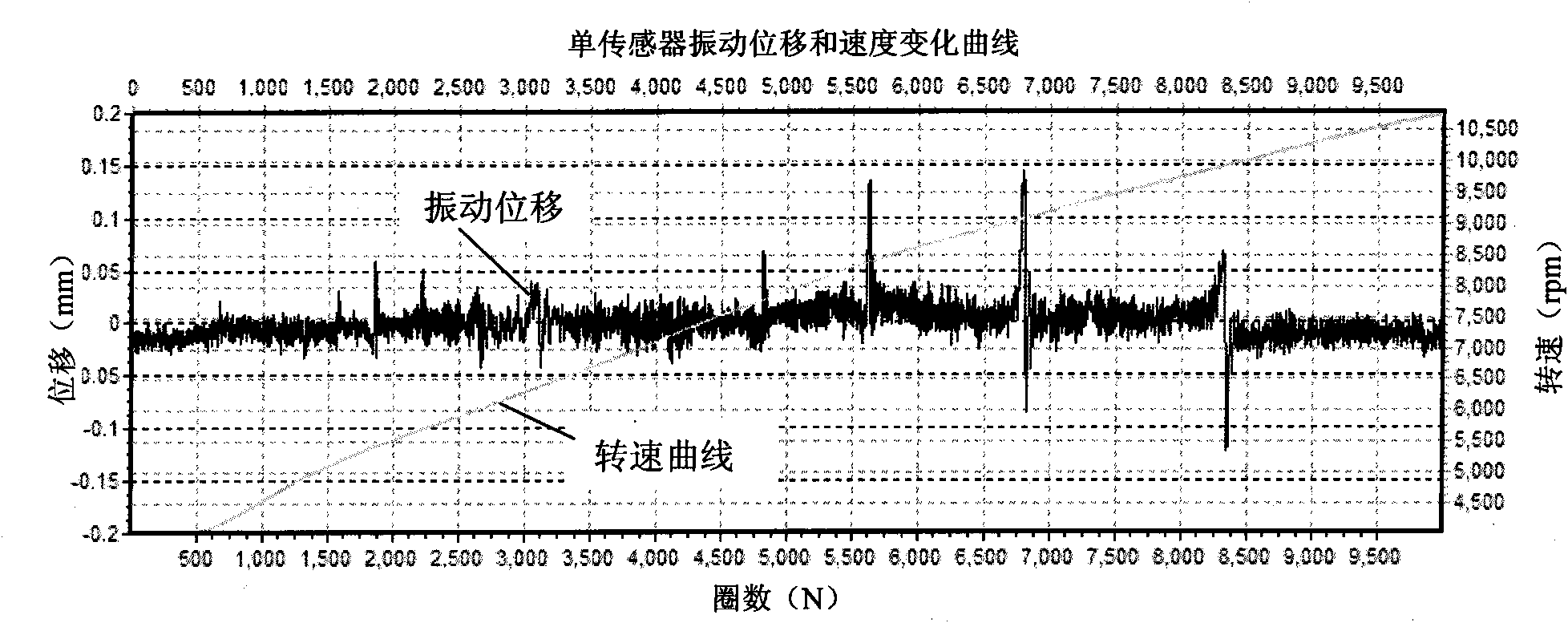

Vibration is measured either in terms of displacement, velocity or acceleration. Vibration displacement is always measured as Peak to Peak, a measure of the total excursion of the rotor or machine casing in MILS or MICROMETERS. Vibration velocity and Acceleration are measured as Zero to Peak or RMS.

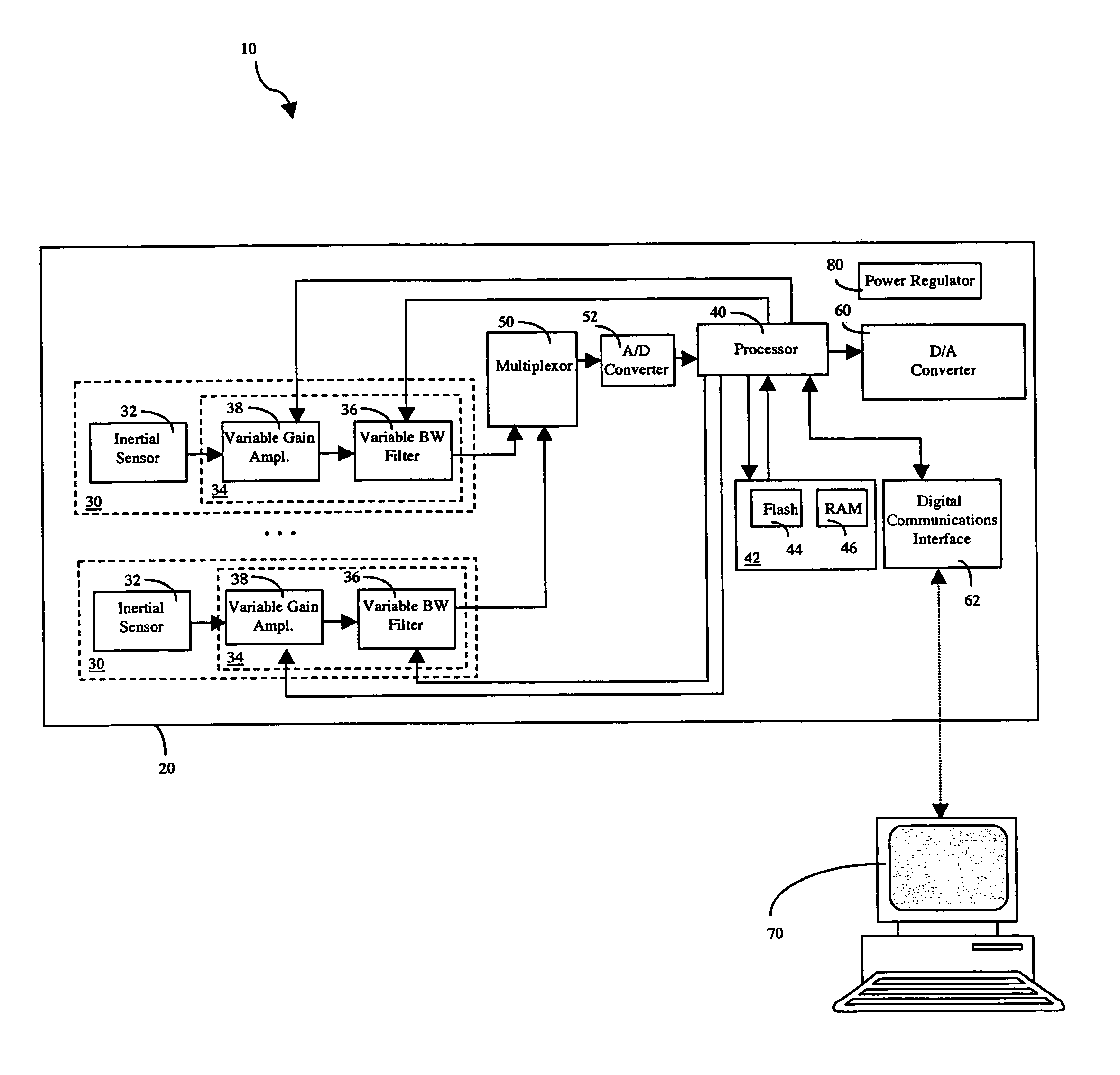

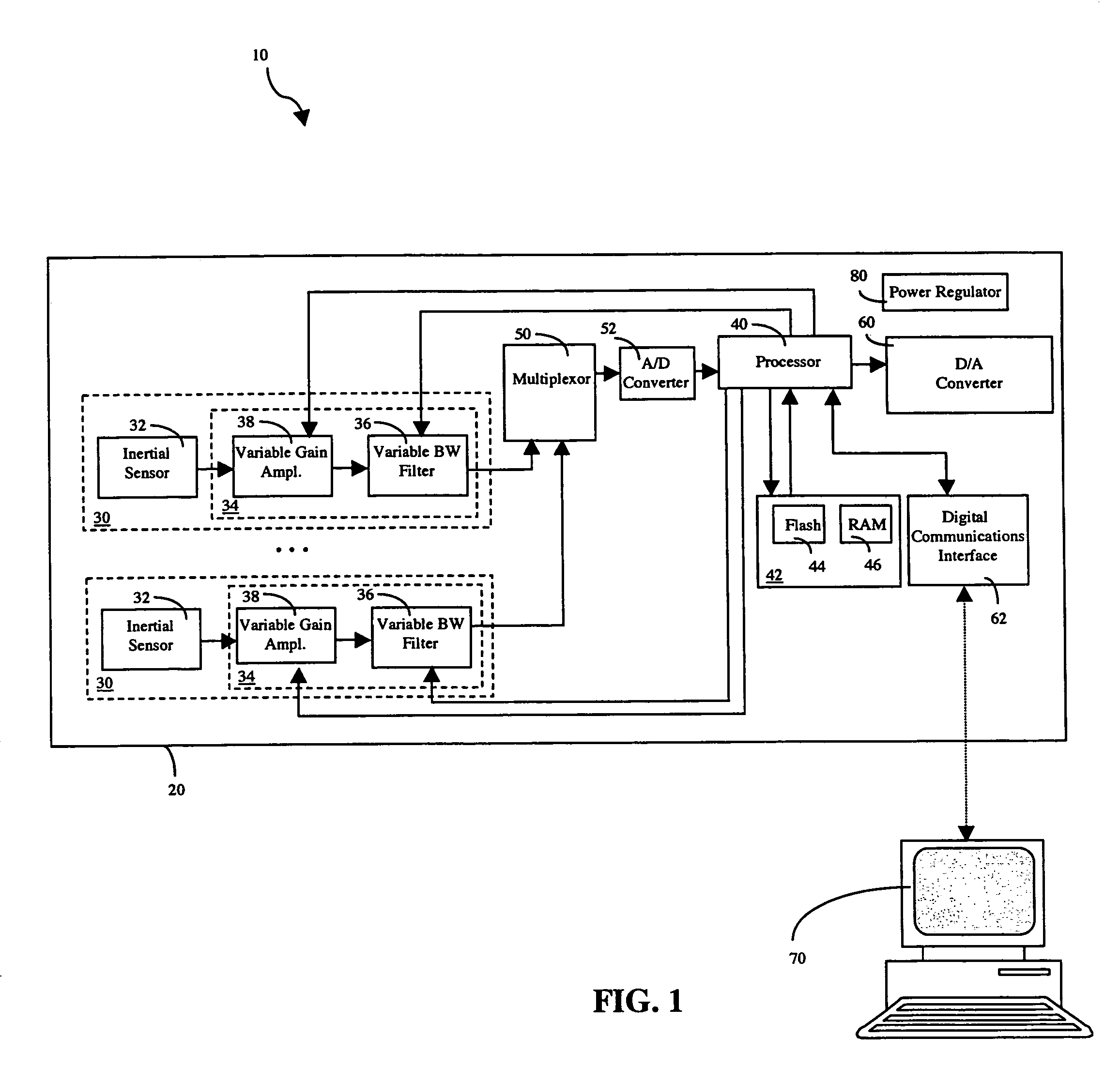

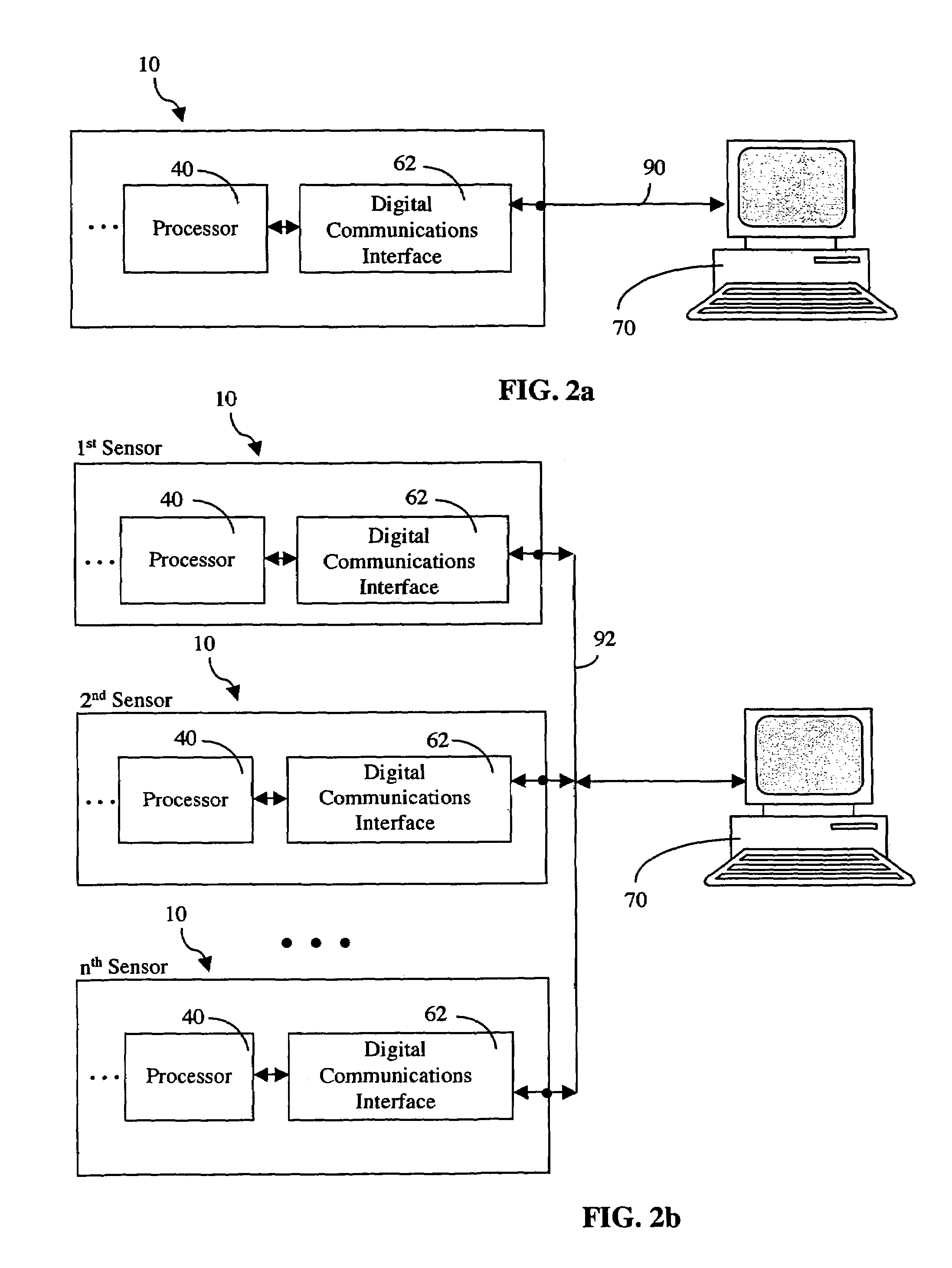

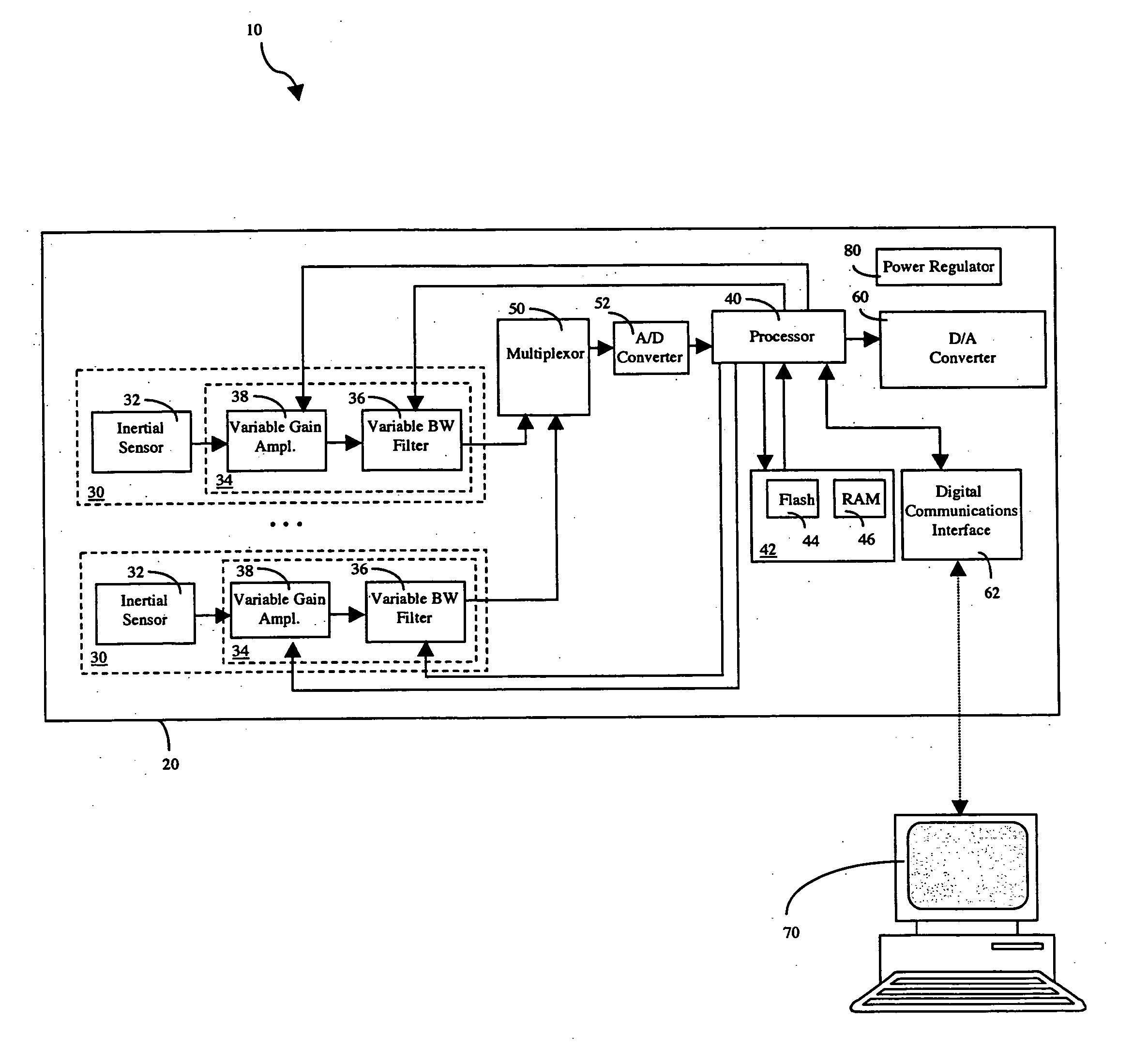

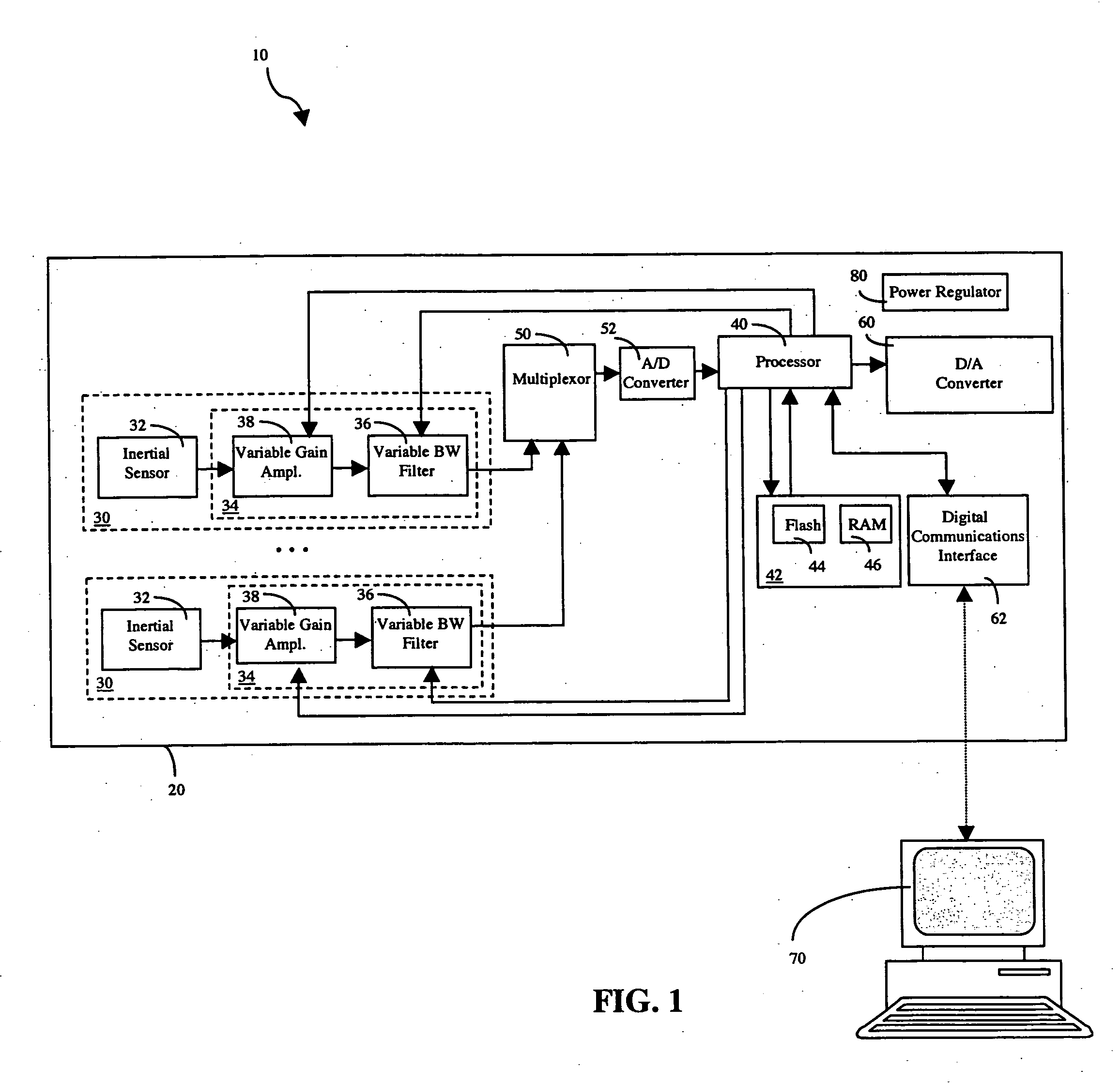

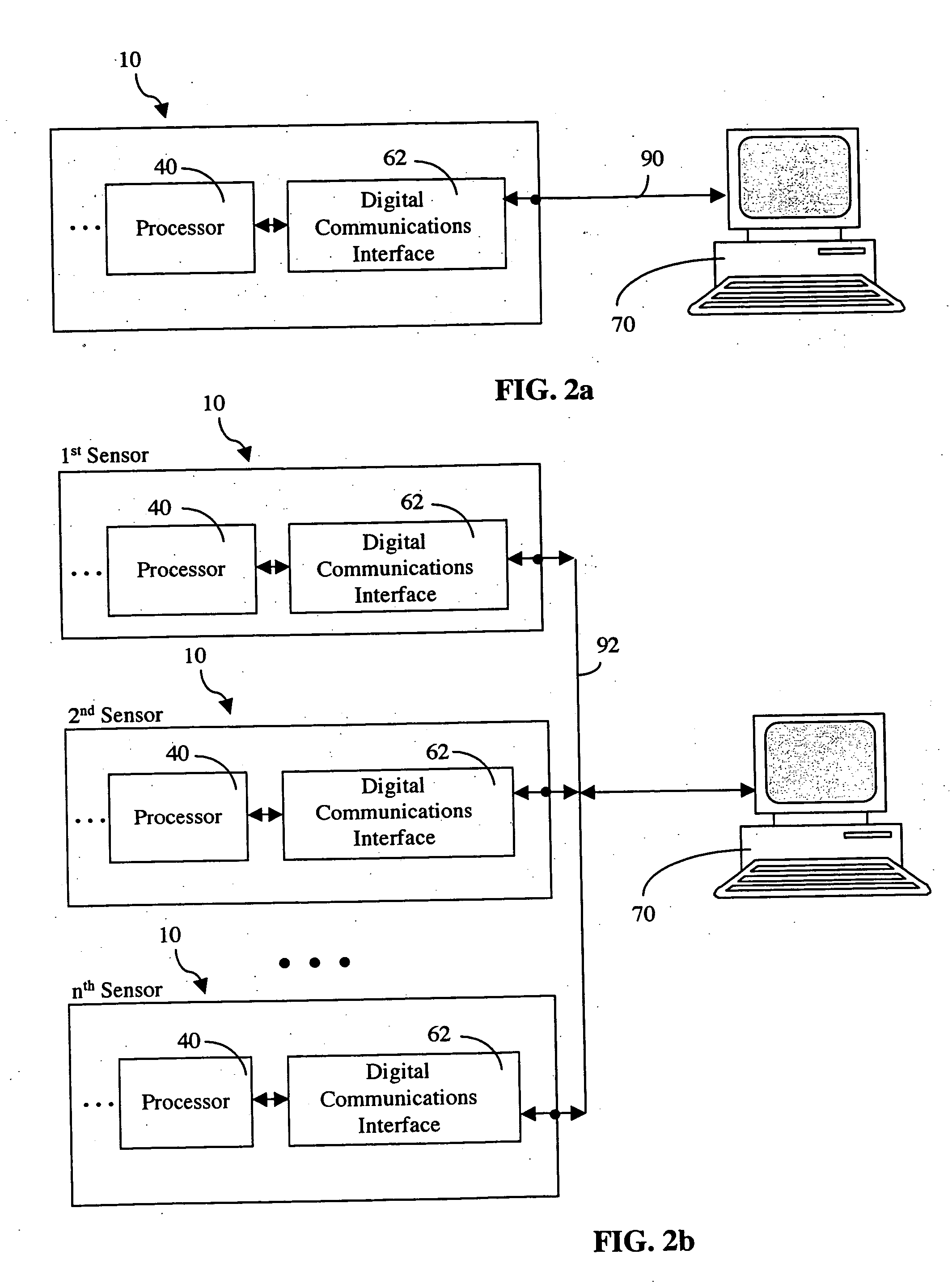

Configurable vibration sensor

InactiveUS7093492B2Vibration measurement in solidsMachine part testingVibration measurementVariable-gain amplifier

A configurable vibration sensor having a sensor circuit, an analog-to-digital converter and a processor is provided. The sensor circuit employs a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

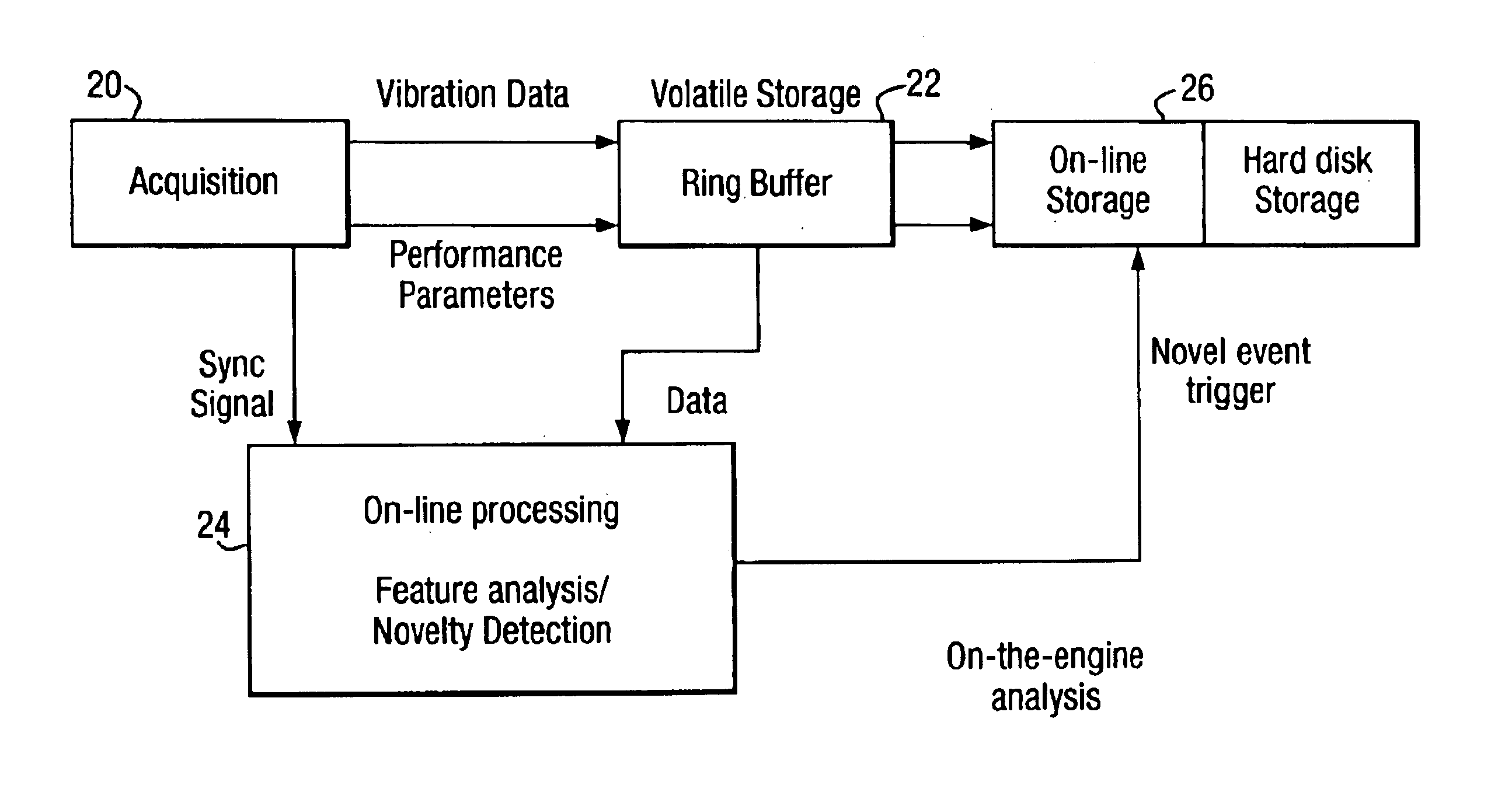

Health monitoring

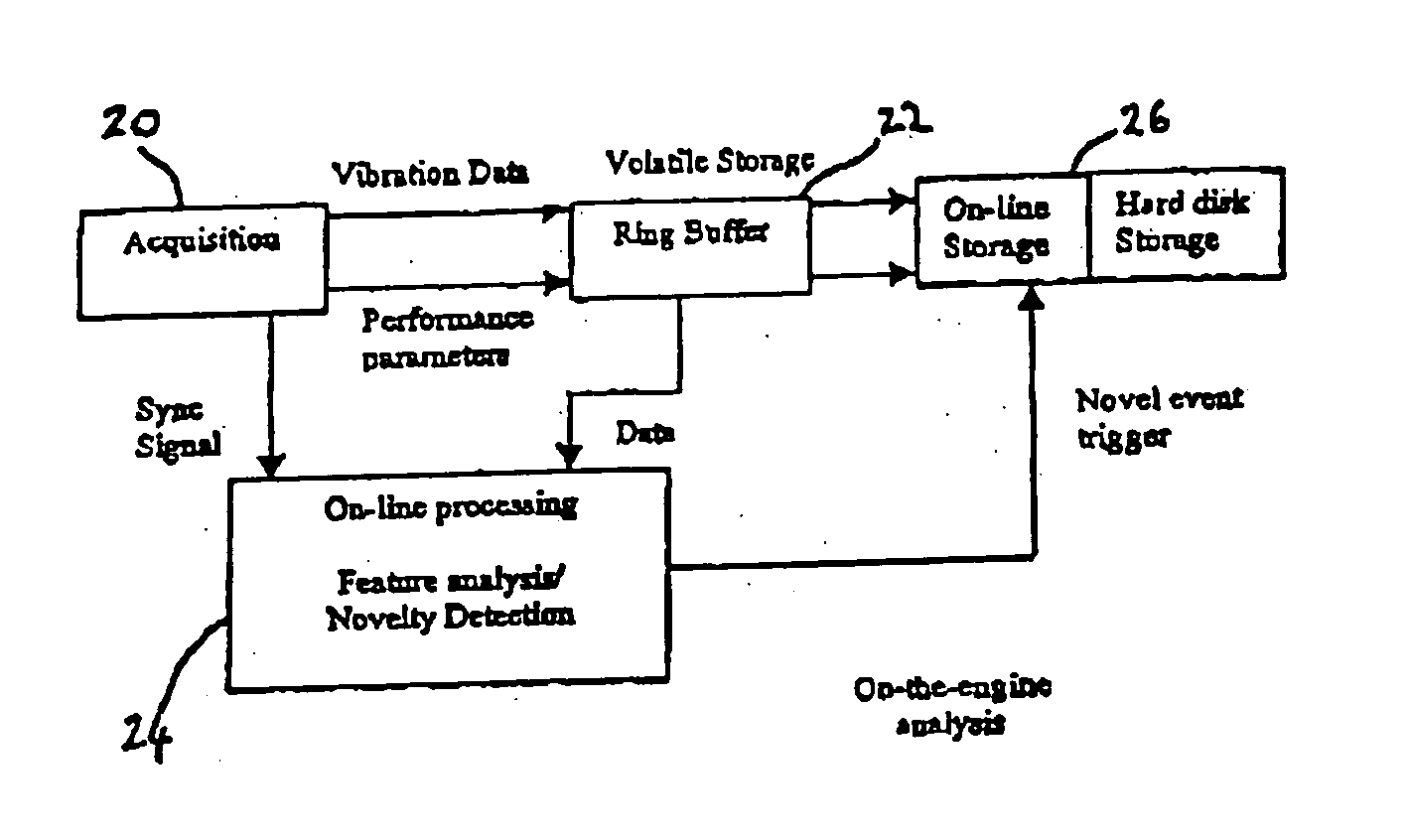

InactiveUS6928370B2Facilitate acquisitionEasy to analyzeVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurementMonitoring system

A method for monitoring the health of a system comprises performing at each of a plurality of times the steps of:constructing a condition signature from a plurality of condition indicators including (a) a plurality of vibration measurements acquired from the system or (b) one or more vibration measurements and one or more performance parameter measurements acquired from the system;predicting a normal signature from a model defining one or more inter-dependencies between said condition indicators, the normal signature corresponding to the condition signature for a healthy system;comparing the condition signature with the normal signature; andregistering an event if the condition signature differs from the normal signature by more than a predetermined threshold.

Owner:ROLLS ROYCE PLC

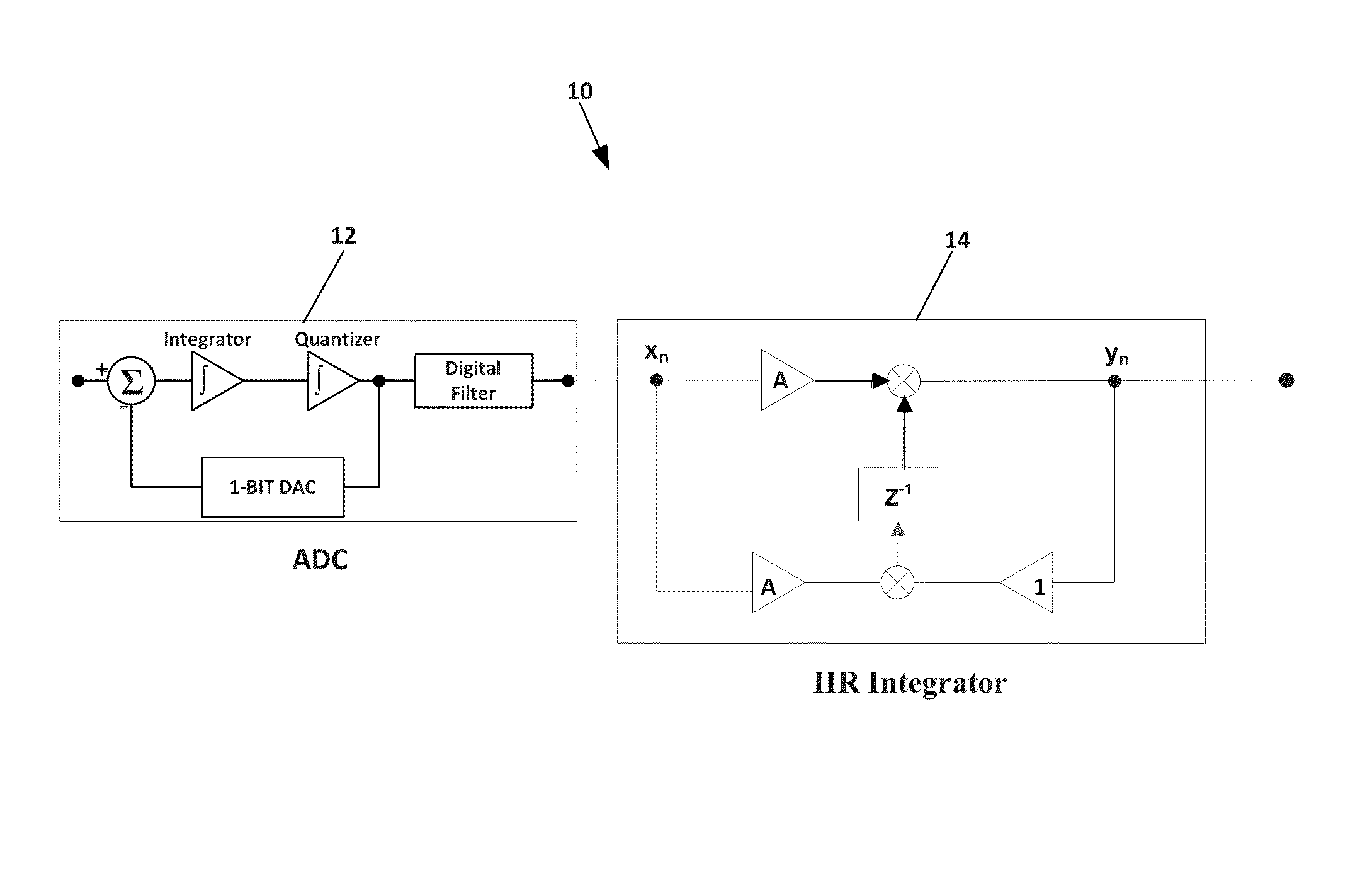

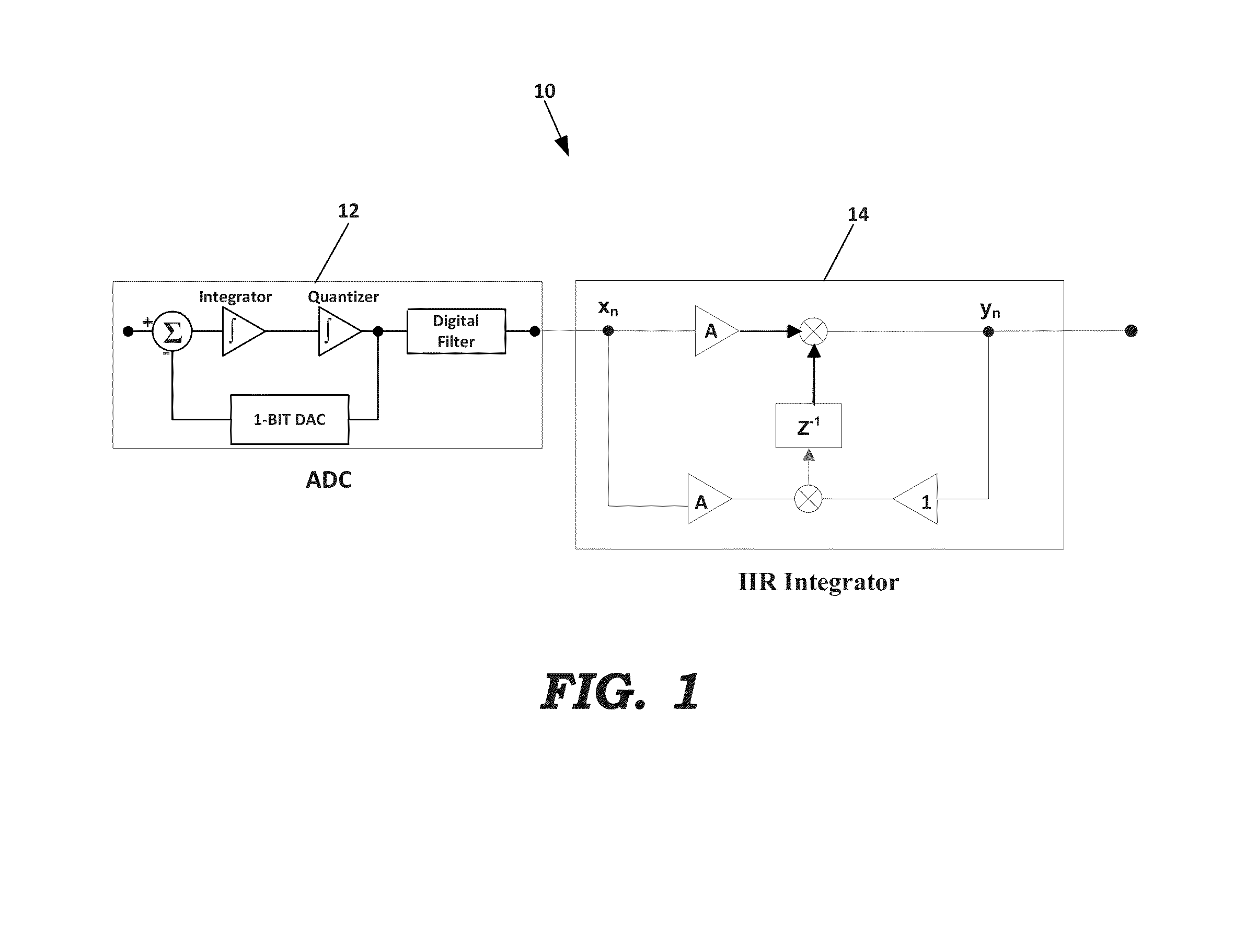

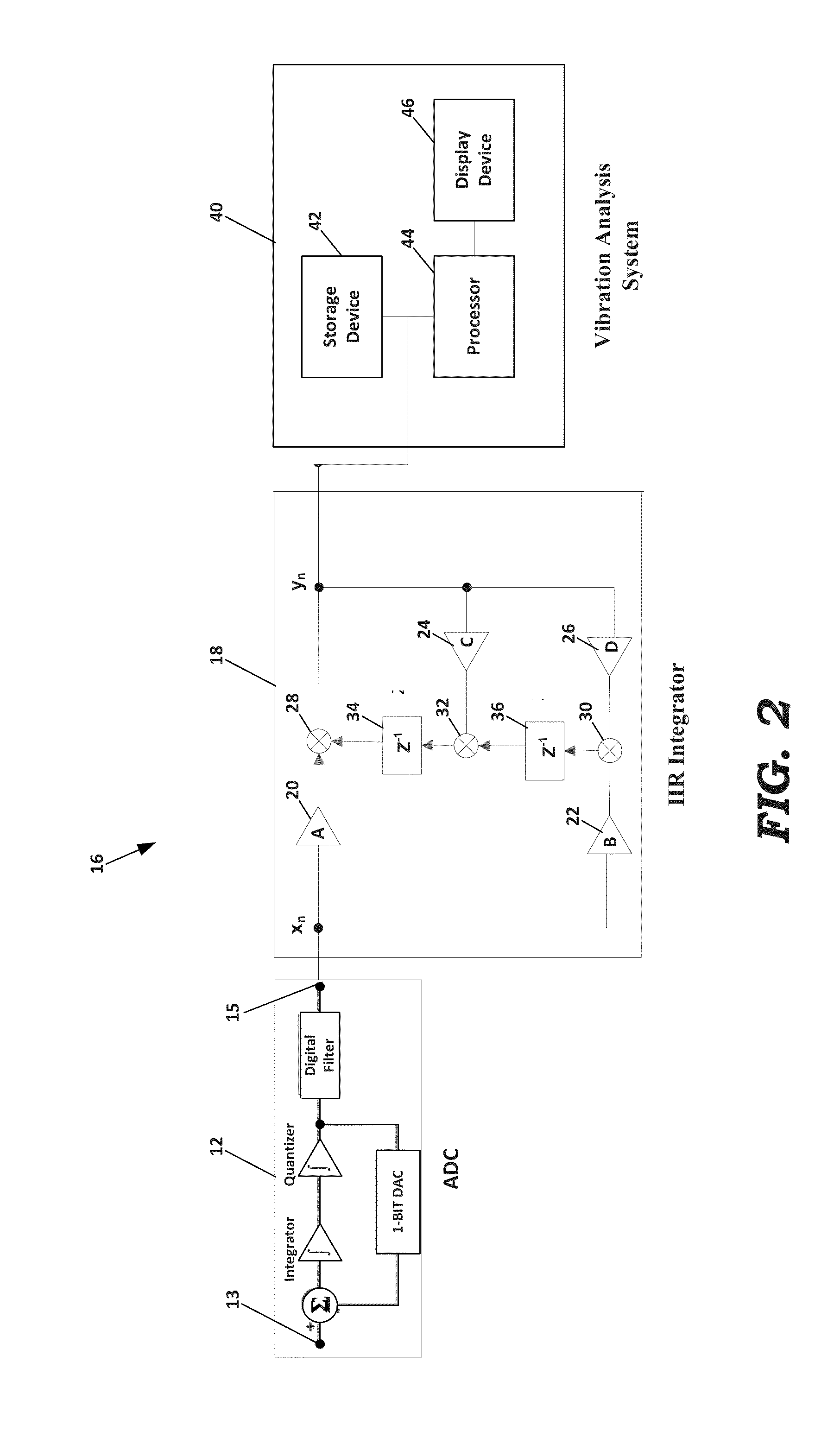

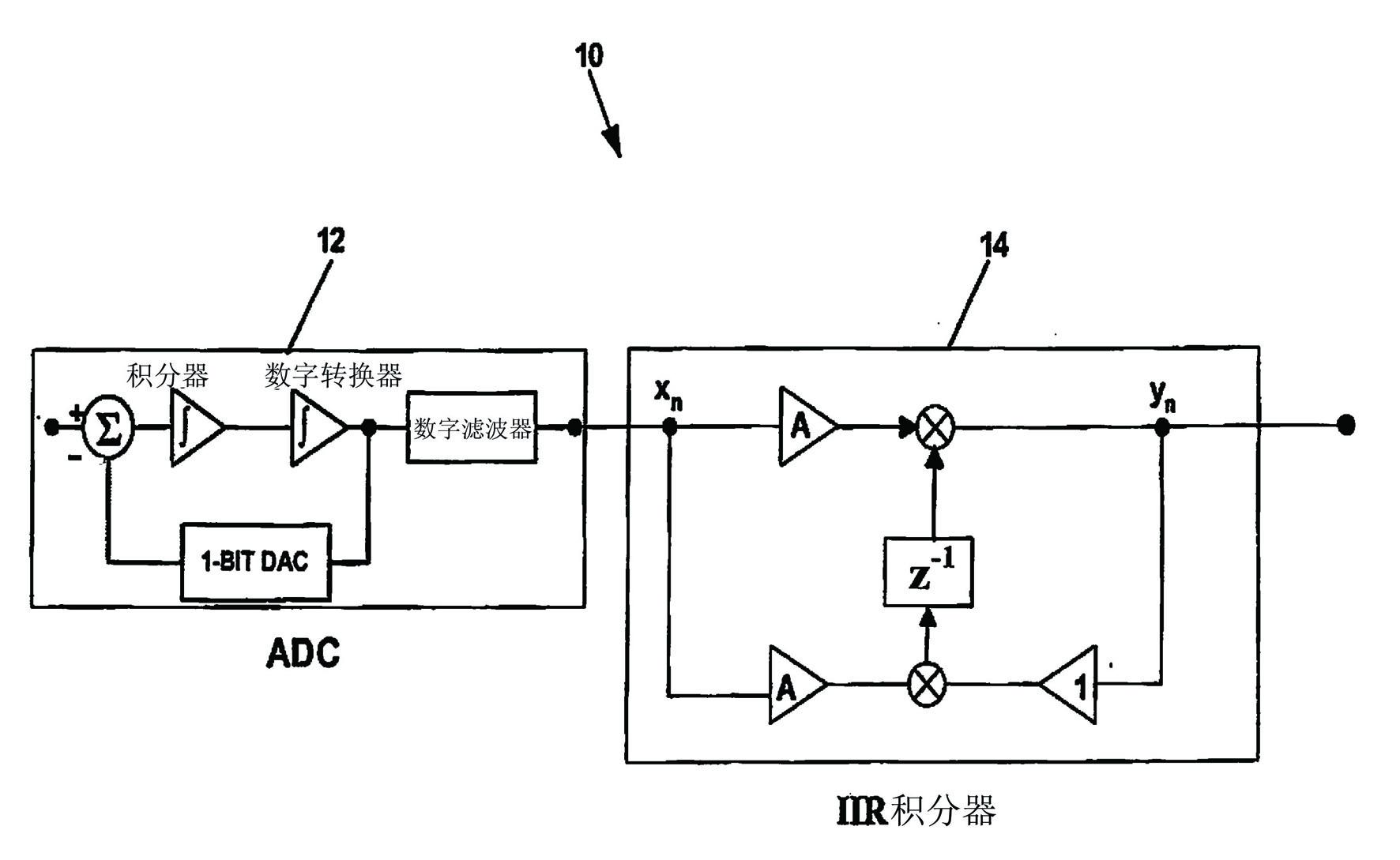

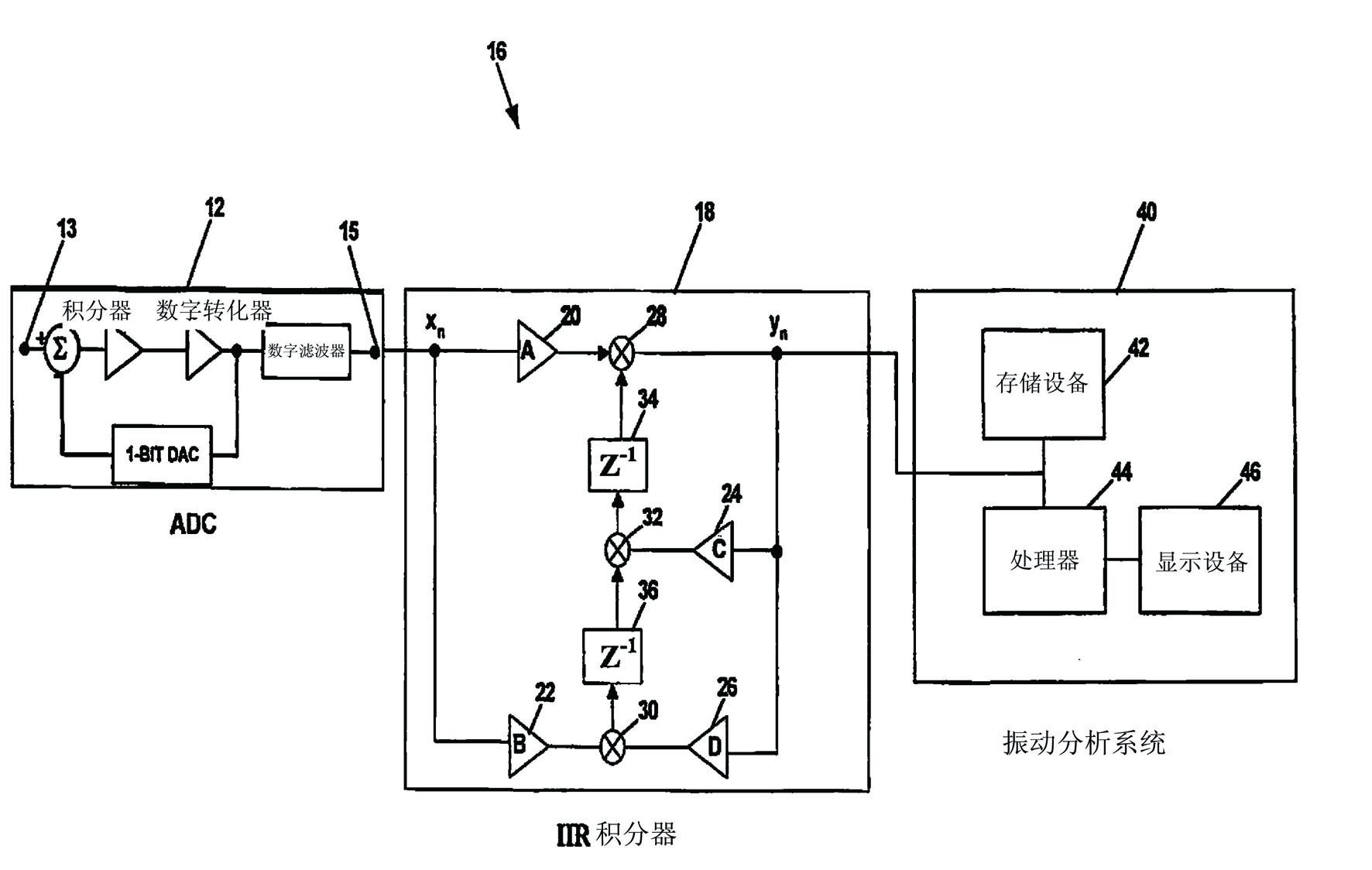

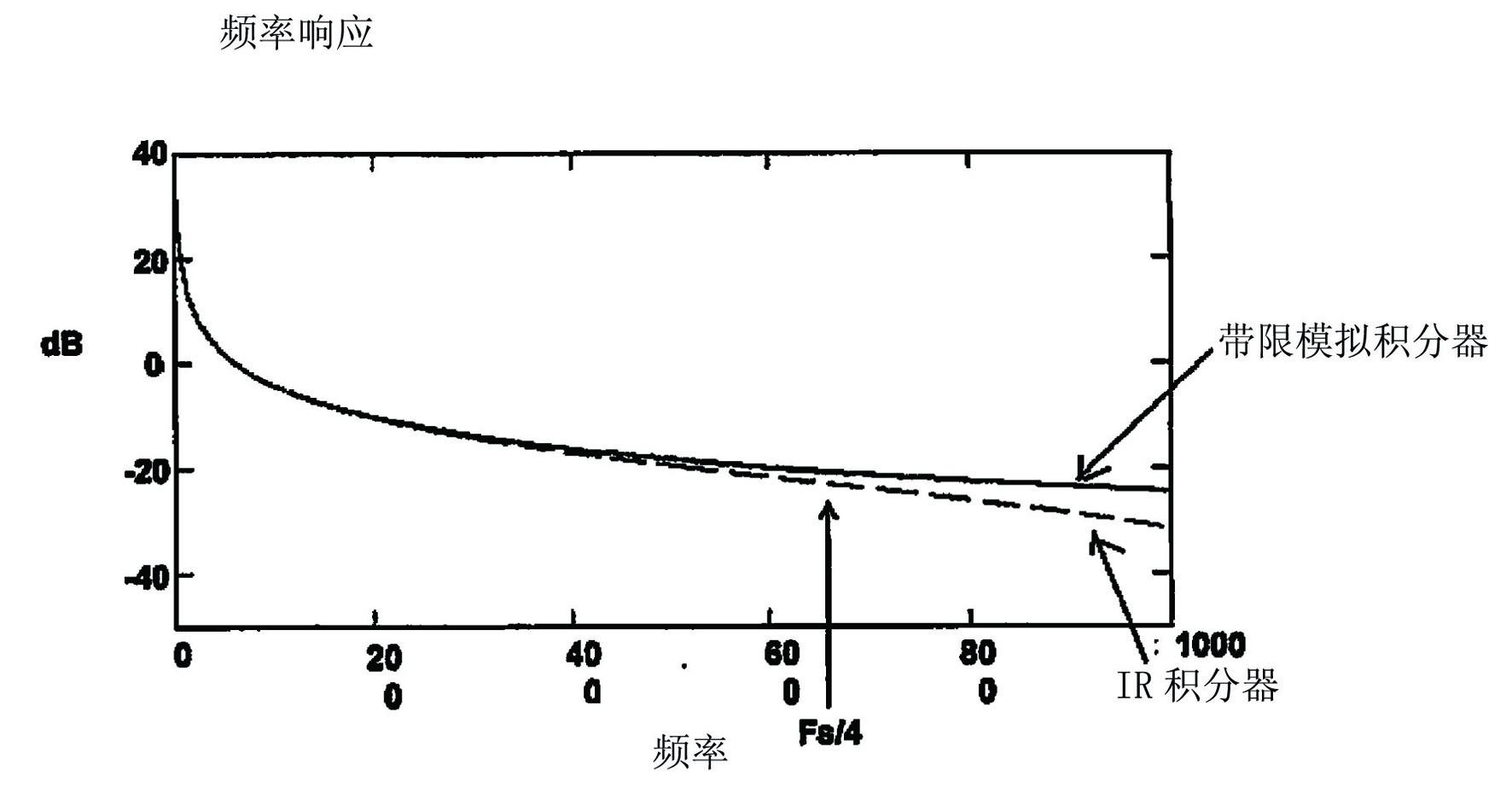

Integrated vibration measurement and analysis system

ActiveUS20140067289A1Reduce hardware complexityReduces data storage requirementVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurementData rate

A vibration data collection system performs an integration or differentiation process on incoming digitized vibration data in real time. The system uses a digital Infinite Impulse Response (IIR) filter running at the input data rate to provide the integration or differentiation function. With this approach, the system reduces hardware complexity and data storage requirements. Also, the system provides the ability to directly integrate or differentiate stored time waveforms without resorting to FFT processing methods.

Owner:COMPUTATIONAL SYST

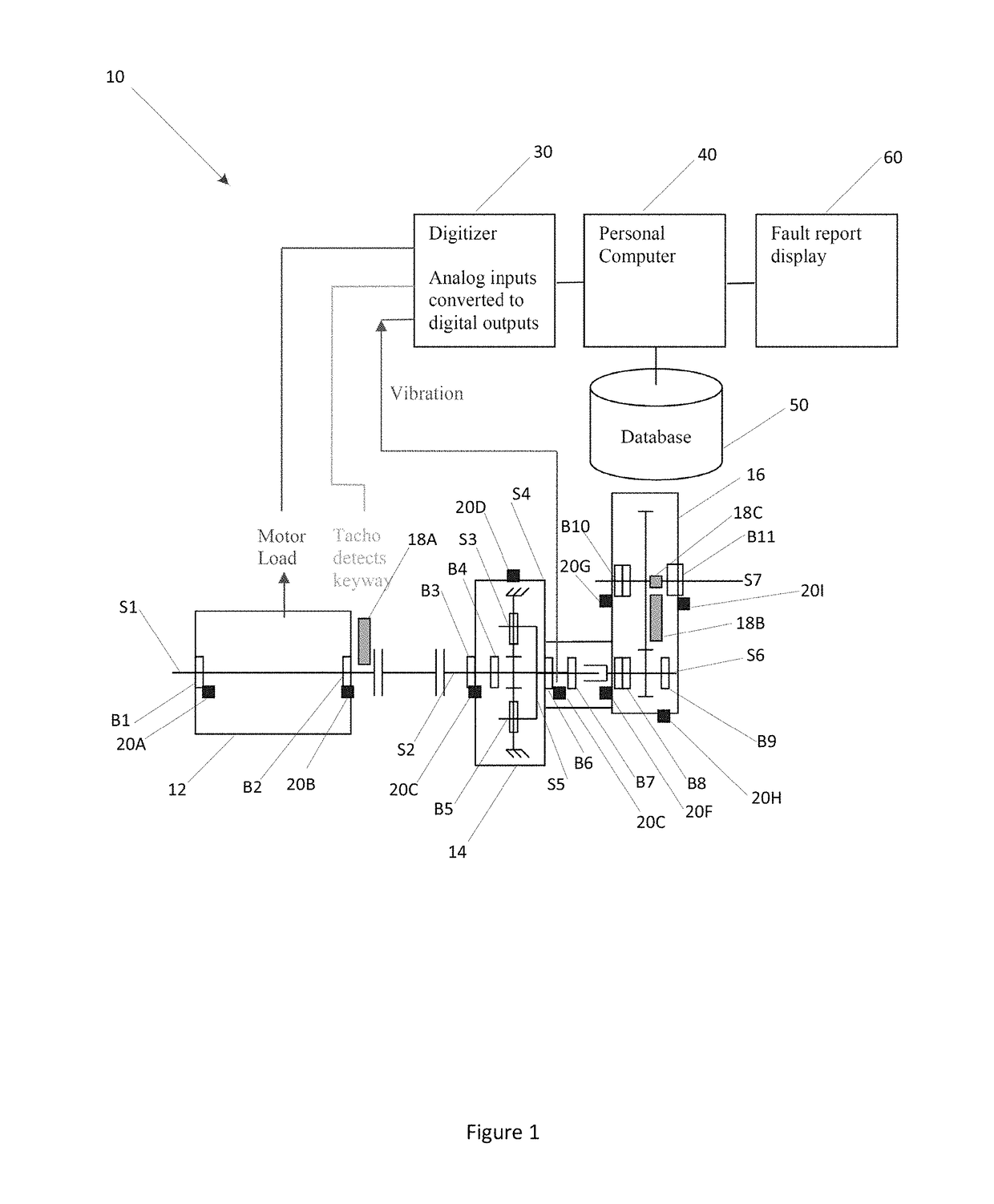

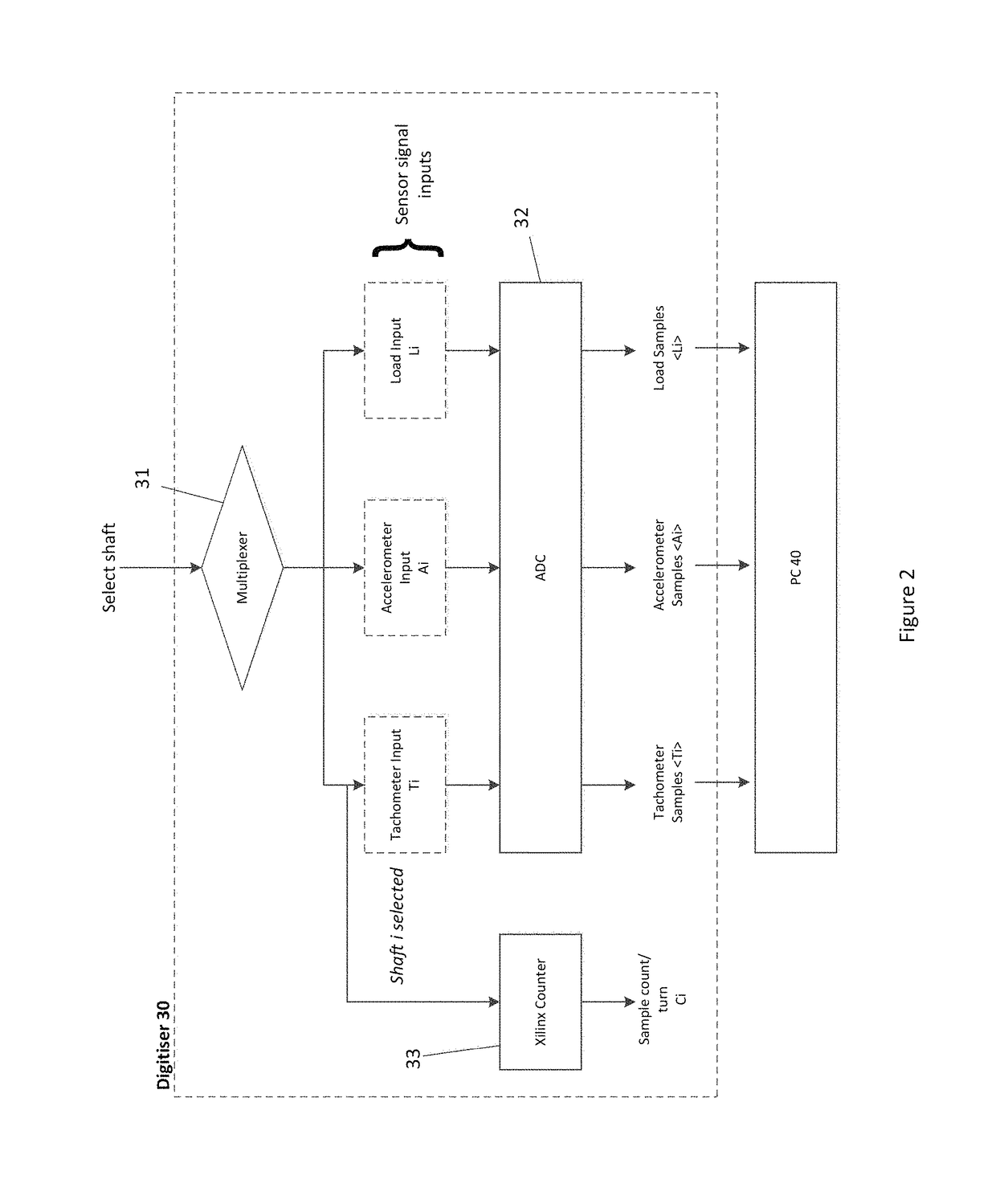

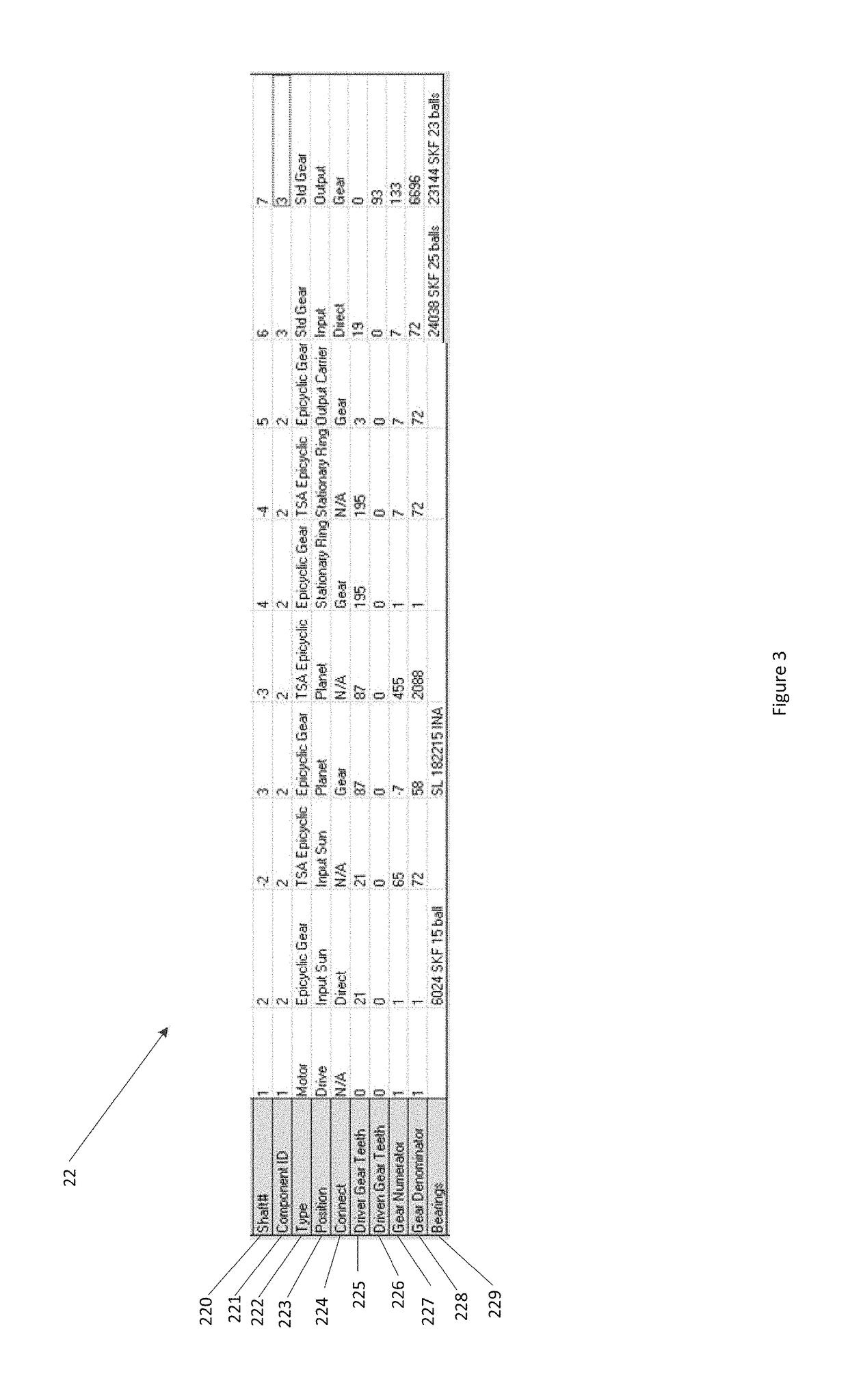

Vibration measurement and analysis

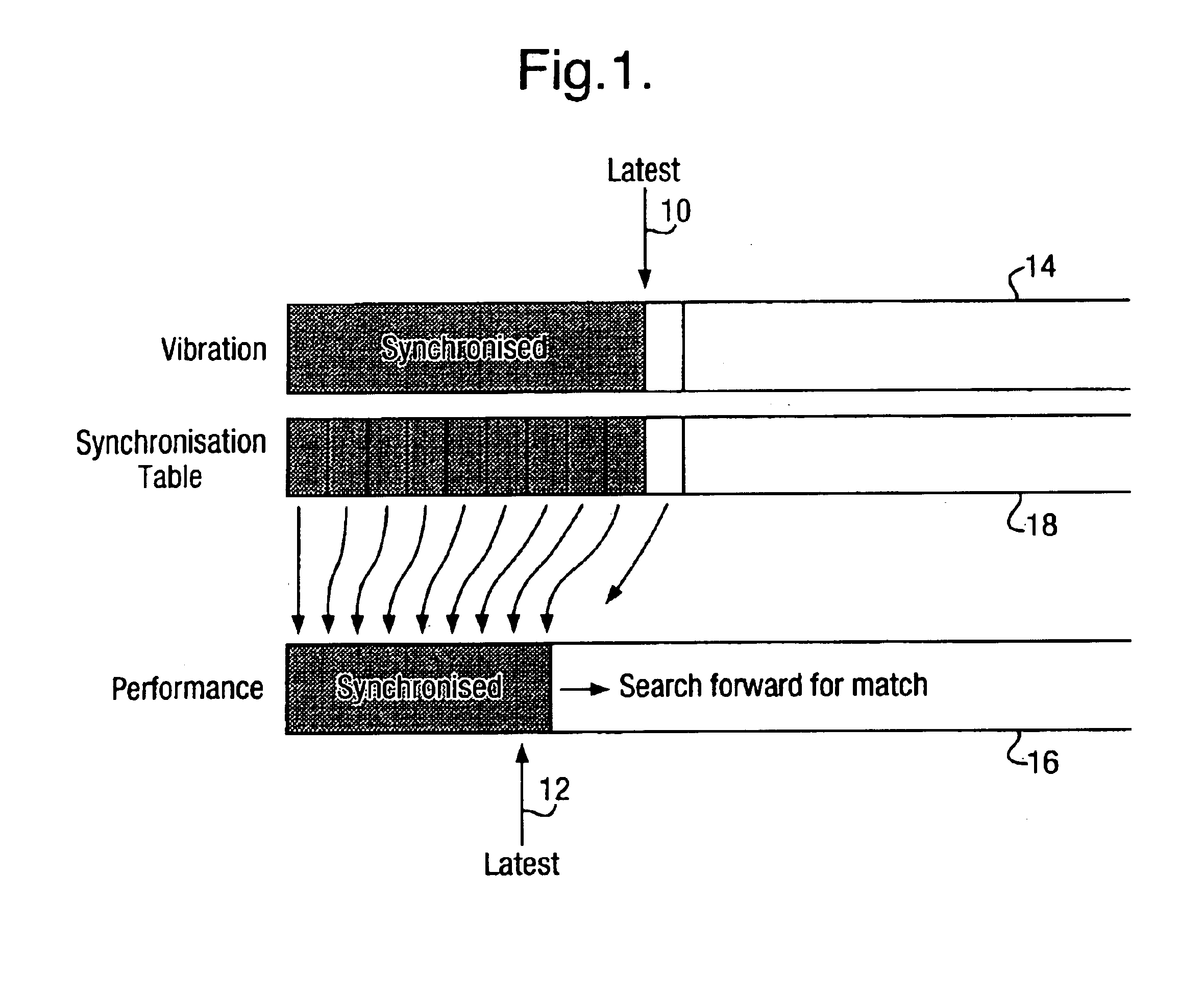

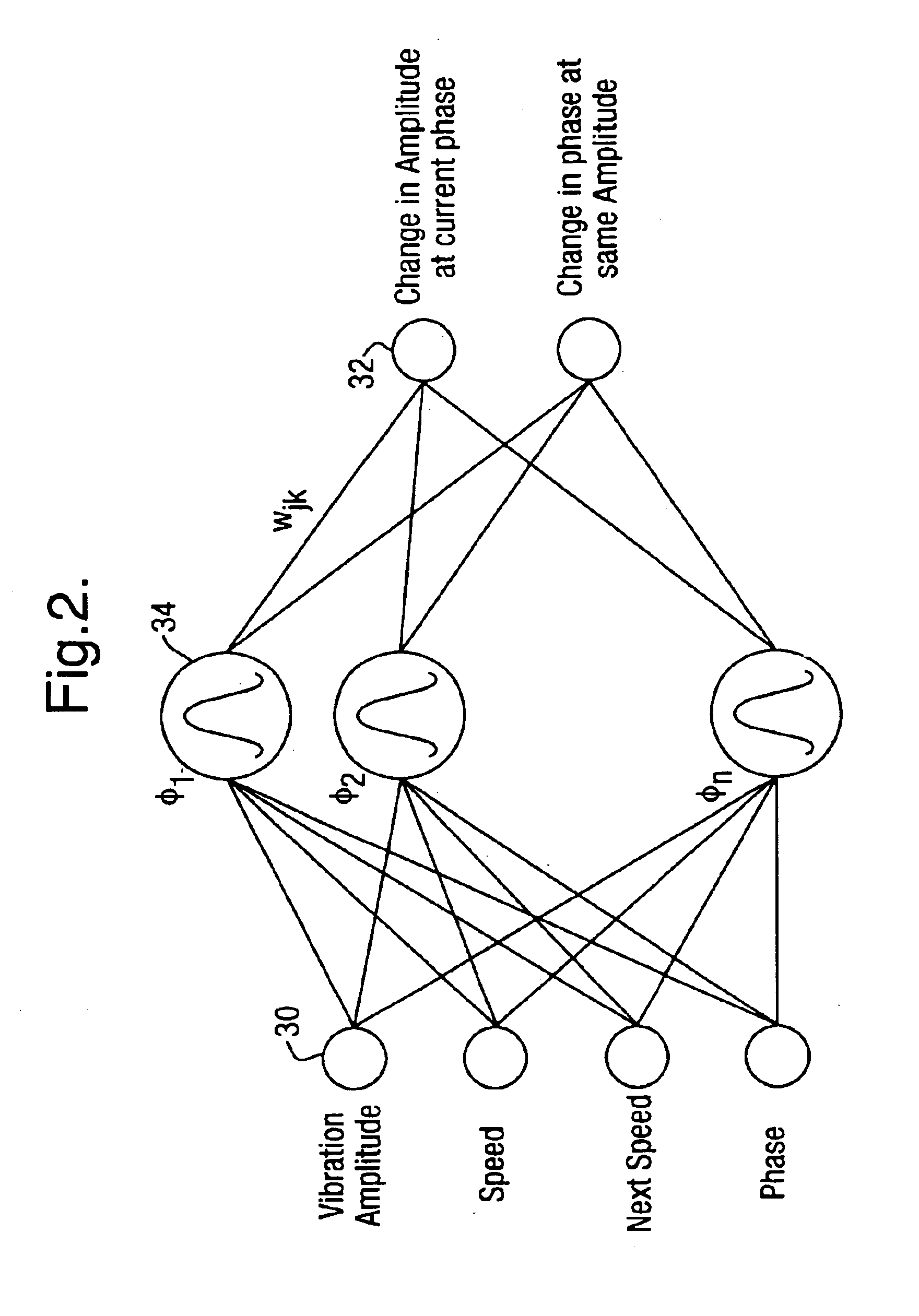

ActiveUS10168248B1Machine gearing/transmission testingMachine bearings testingVibration measurementEngineering

A method of measuring and analyzing vibrations of a mechanical system, e.g., for performing gear and bearing fault detection within a system having a reference shaft and a plurality of rotating components. The method may include the steps of tabulating gear ratios of the plurality of rotating components relative to the reference shaft in integer form, establishing a measurement specification and communicating the measurement specification to a digitizer, recording vibration data from the mechanical system during operation, and resampling the recorded vibration data using the tabulated gear ratios to obtain vibration data corresponding to the rotating components and a vibration signature for a component of interest at predetermined angular increments.

Owner:TENSOR SYST PTY LTD

Configurable vibration sensor

InactiveUS20050204820A1Vibration measurement in solidsMachine part testingVibration measurementAudio power amplifier

A configurable vibration sensor comprising a sensor circuit, an analog-to-digital converter and a processor, where each sensor circuit comprises a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

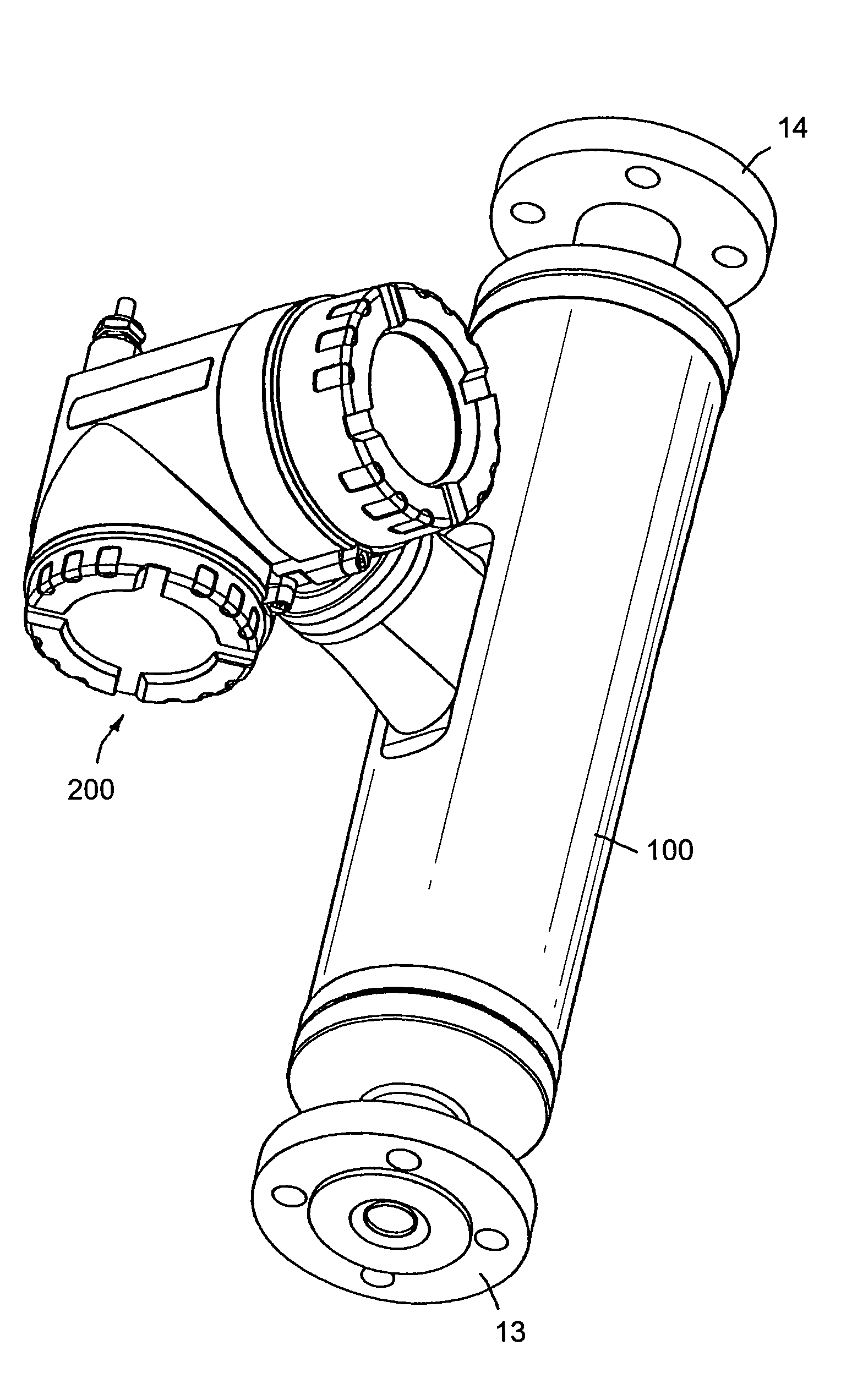

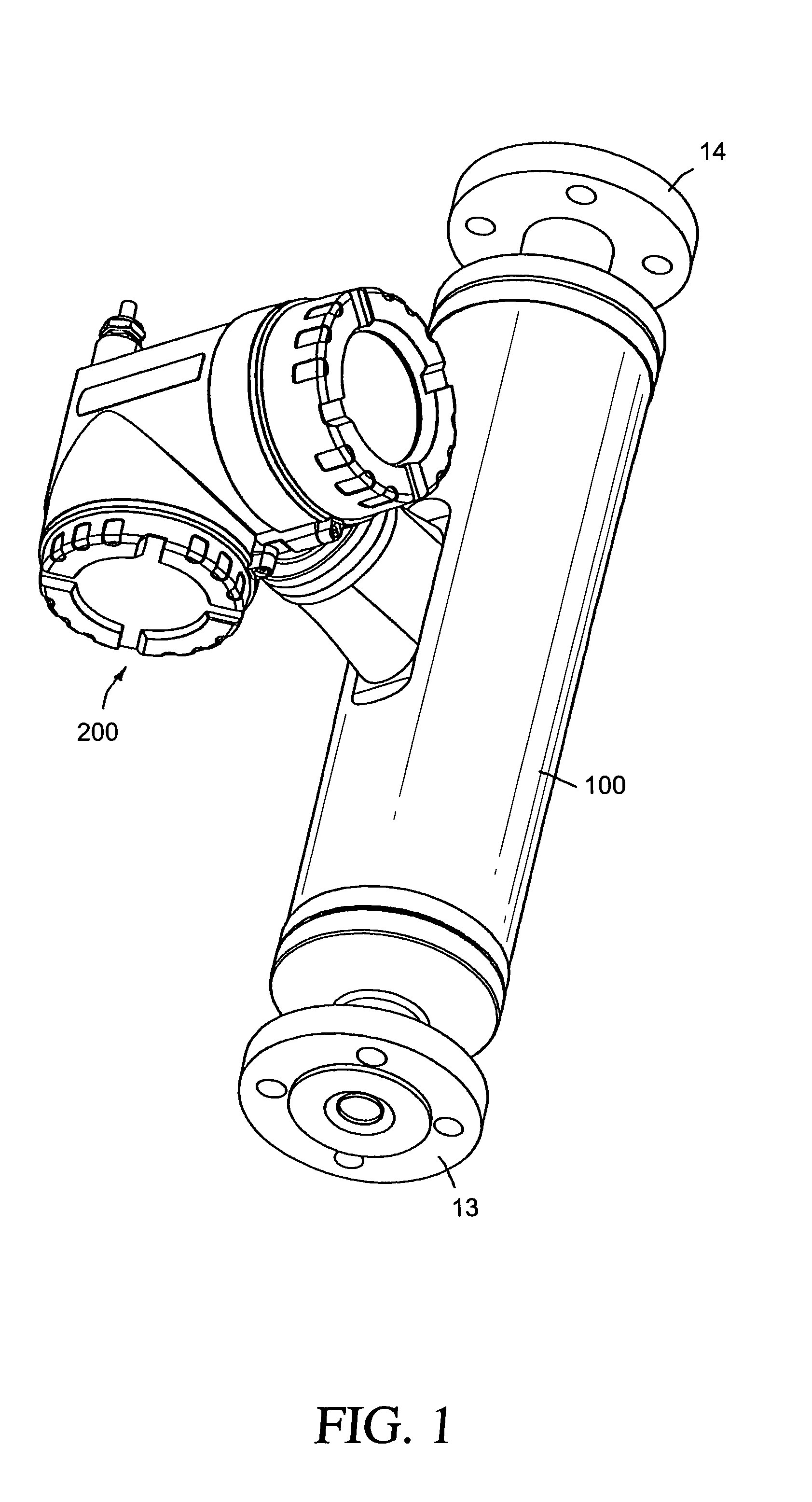

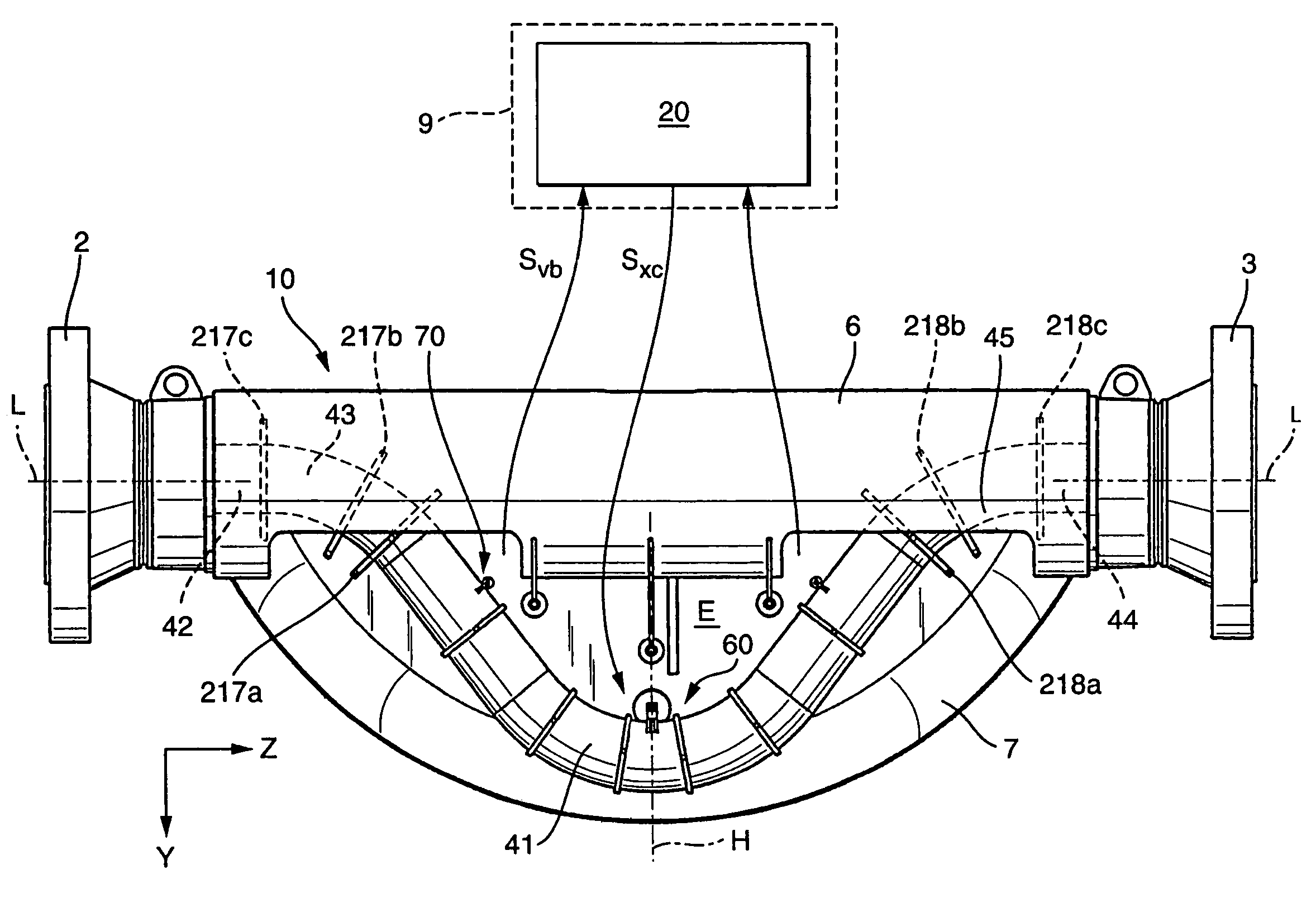

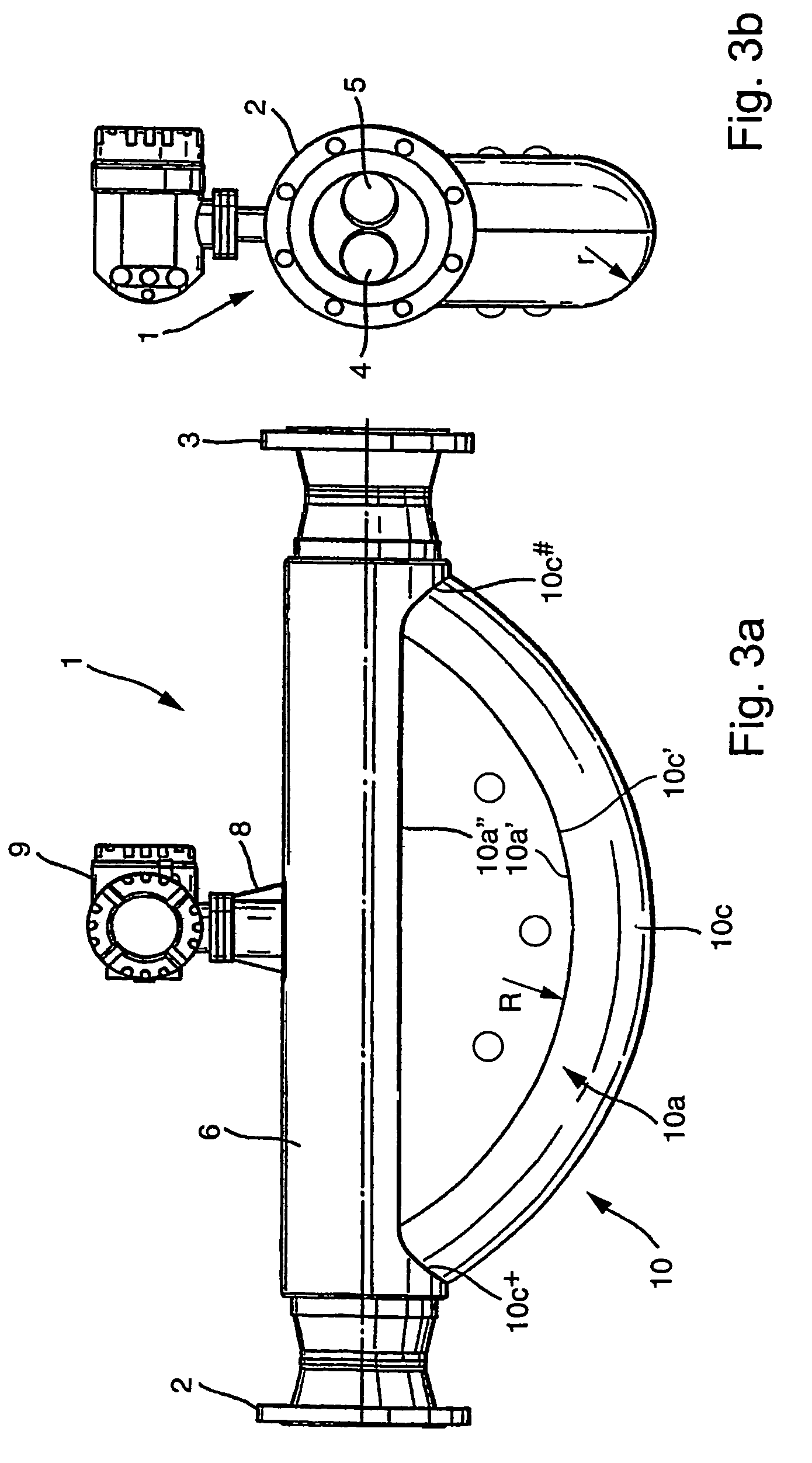

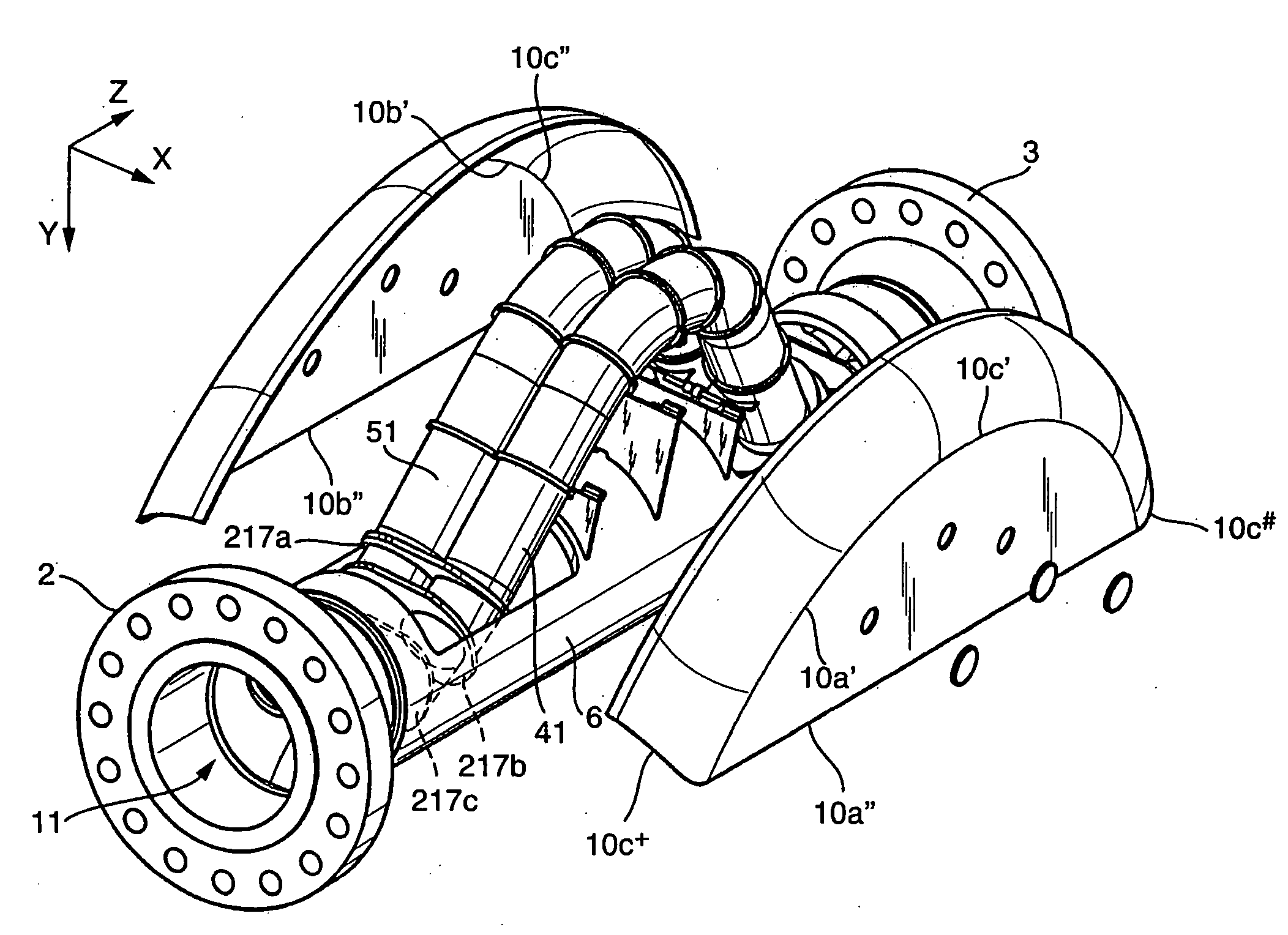

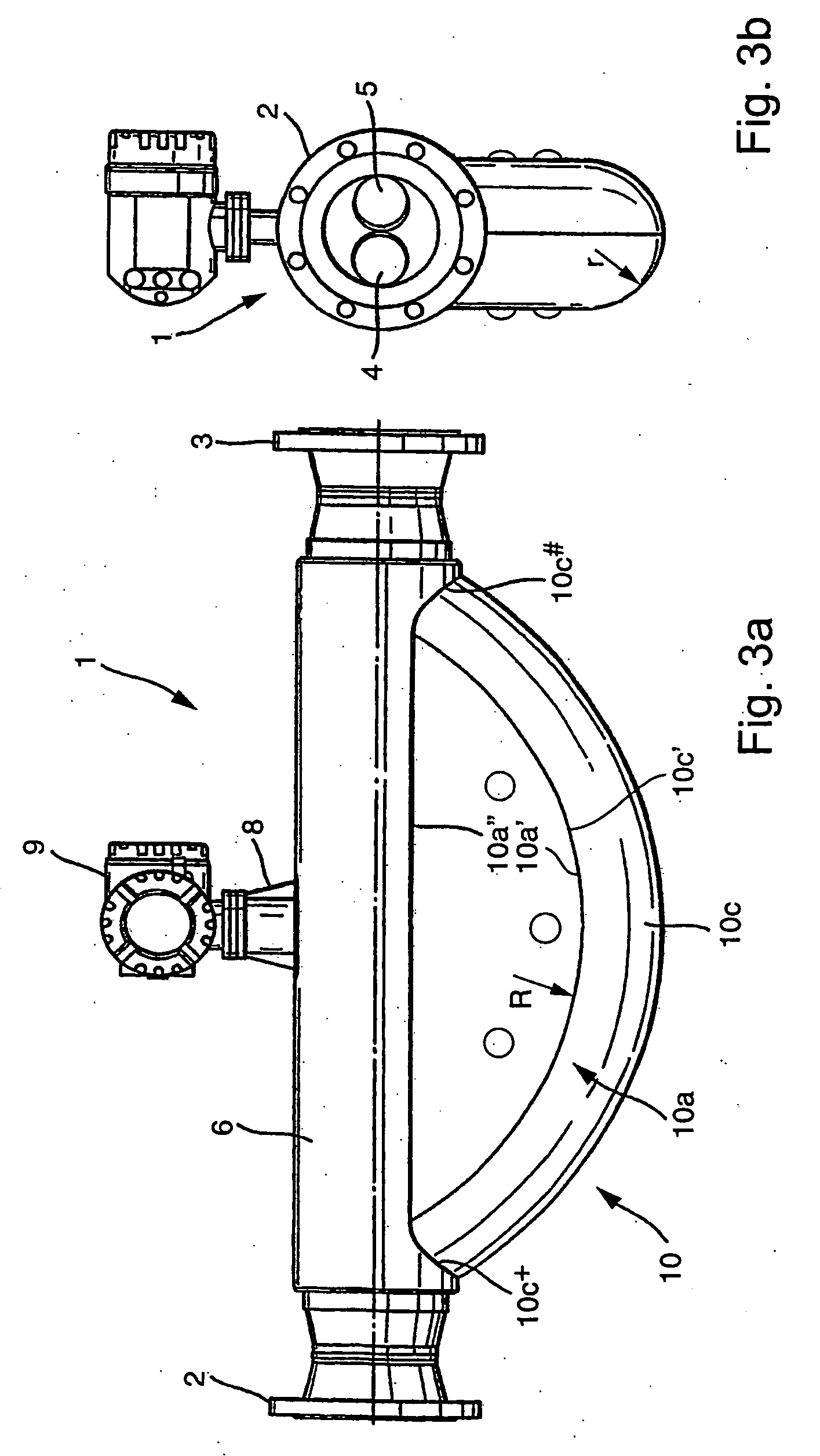

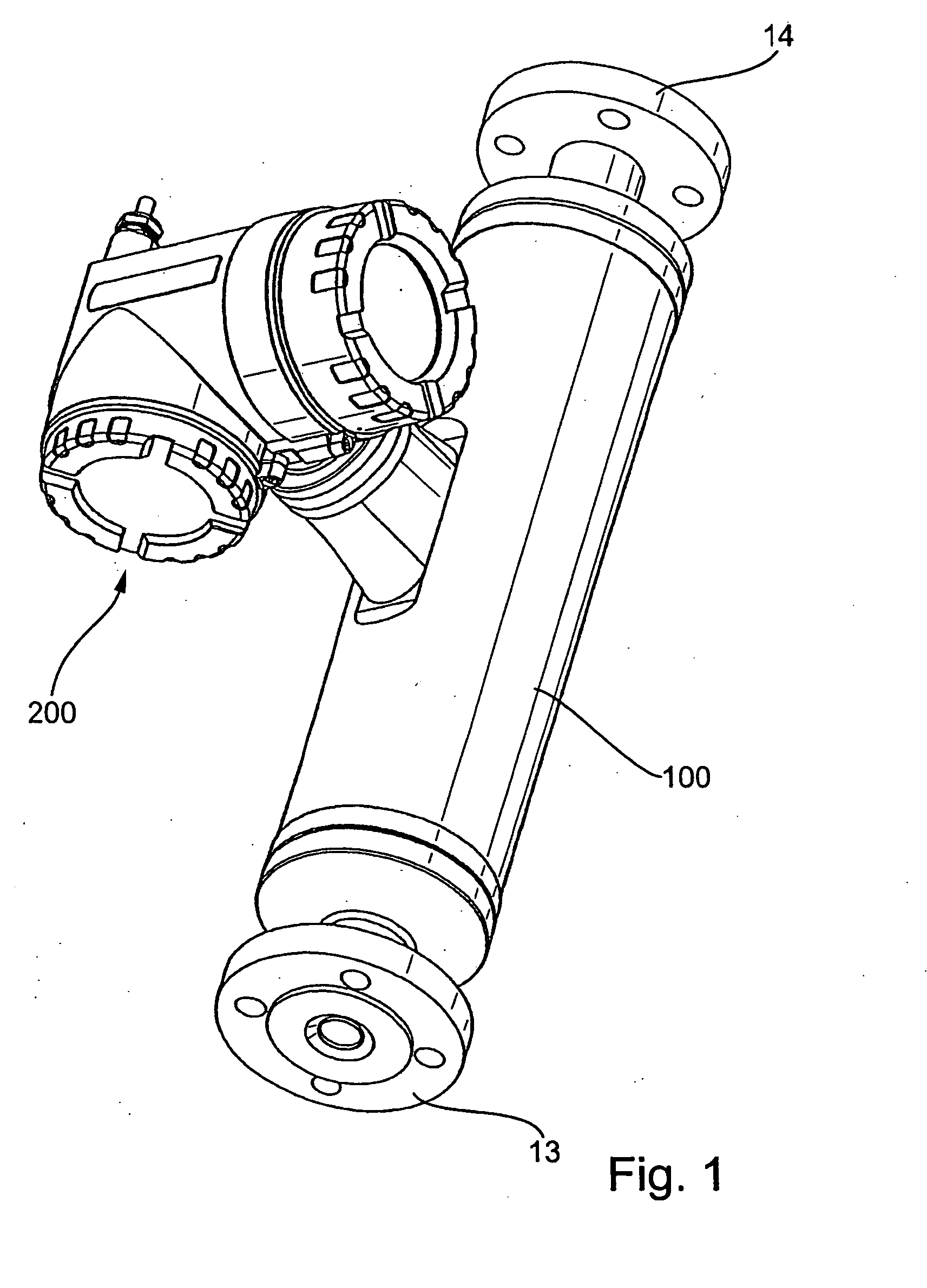

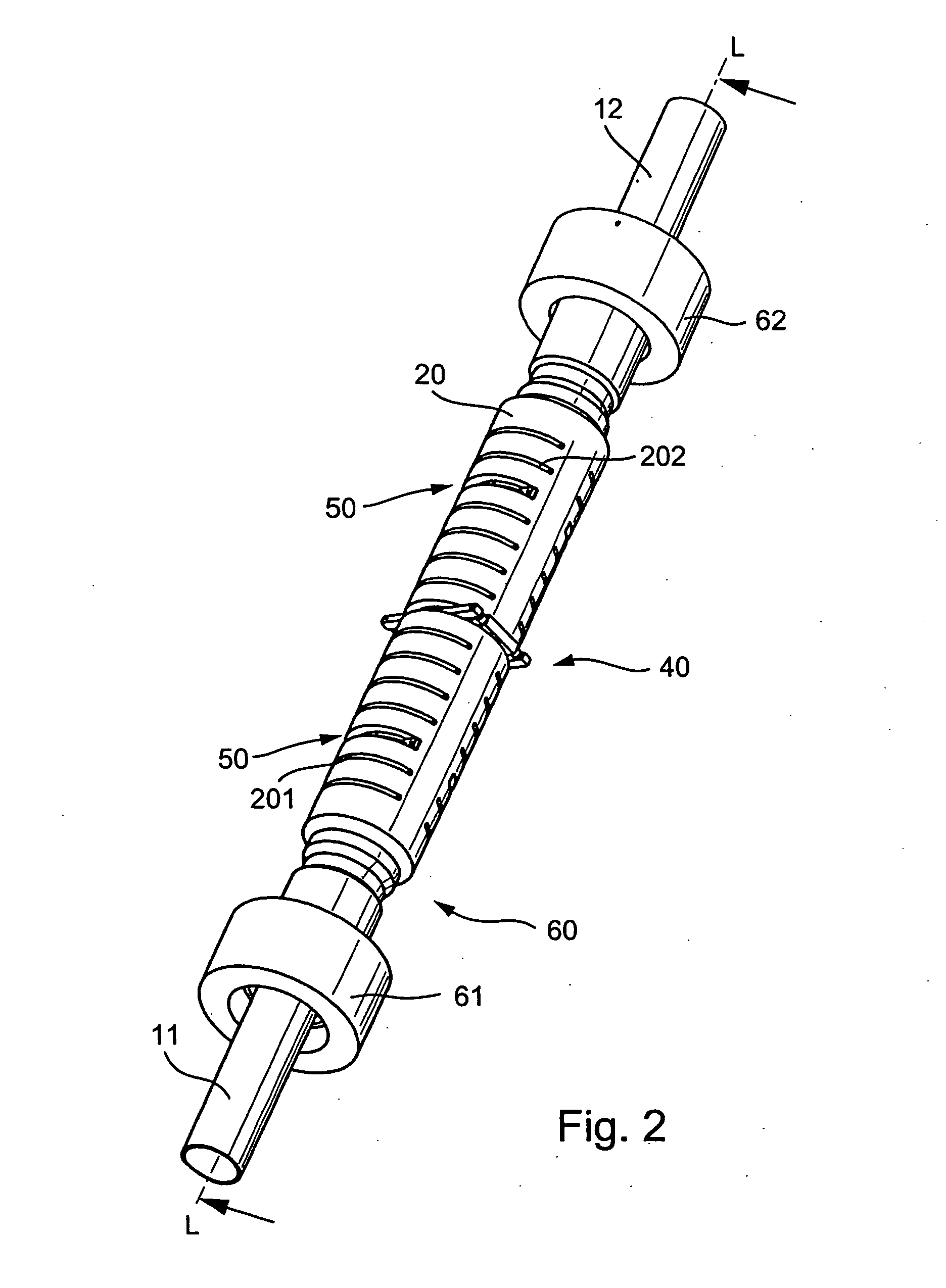

Vibration-type measuring transducer

For conveying a fluid, the measuring transducer is equipped with a measuring tube, which is held oscillatably in a support element and vibrates during operation. The measuring tube executes, during operation, at least over part of its length, driven by an exciter arrangement, bending oscillations about an oscillation axis. These bending oscillations predominantly assume an oscillation form having at least three bending oscillation antinodes. Inlet-end and outlet-end oscillations are registered by means of a sensor arrangement. Additionally provided in the measuring transducer is a coupler arrangement connected with measuring tube and with support element and having at least one coupling element interacting mechanically, especially resiliently, with the vibrating measuring tube and the support element. By suitable choice of the effective spring constant, c60, of the coupler arrangement, this can cancel transverse forces produced, during operation, on the part of the vibrating measuring tube, for example due to fluctuating fluid density.

Owner:ENDRESS HAUSER FLOWTEC AG

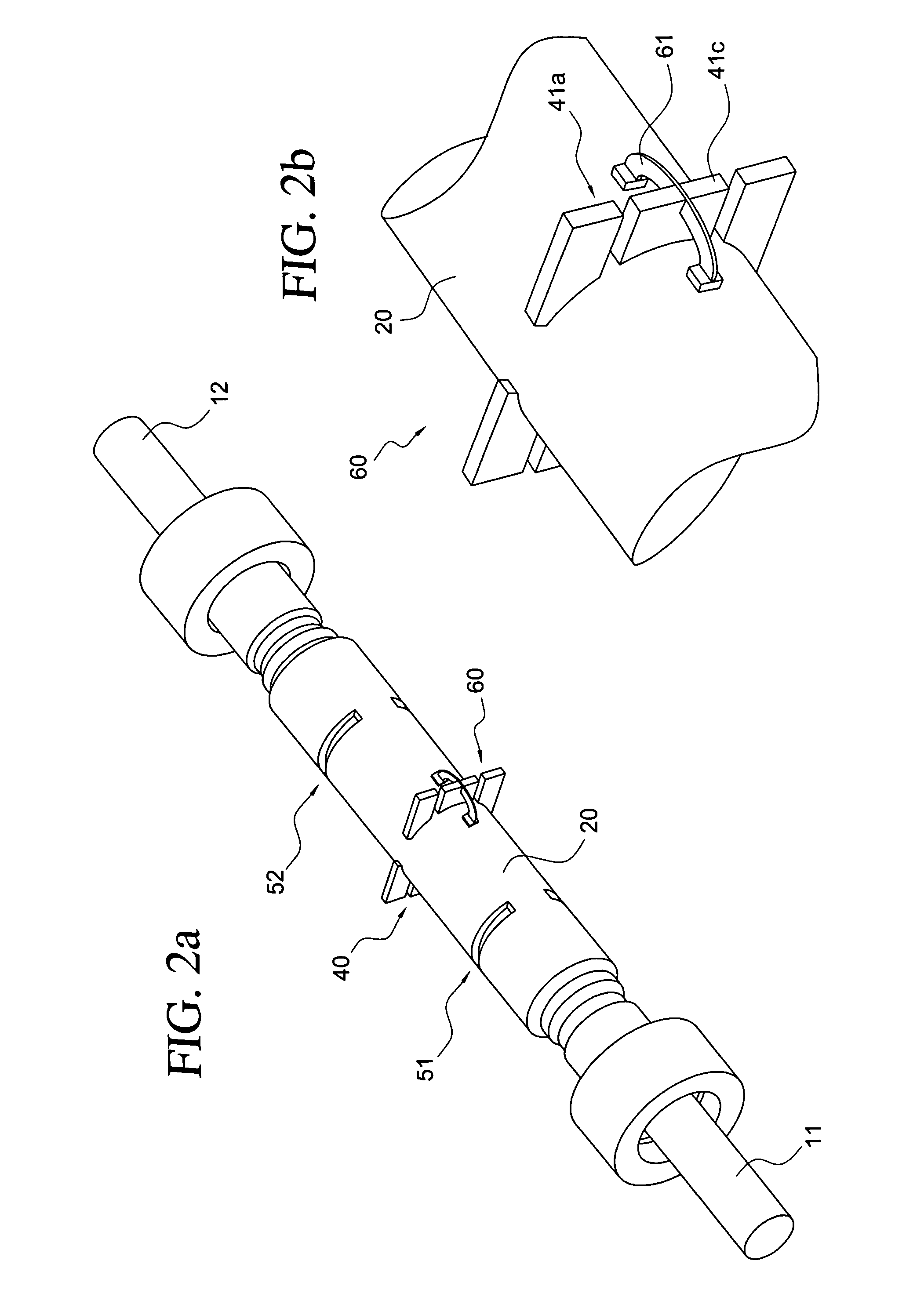

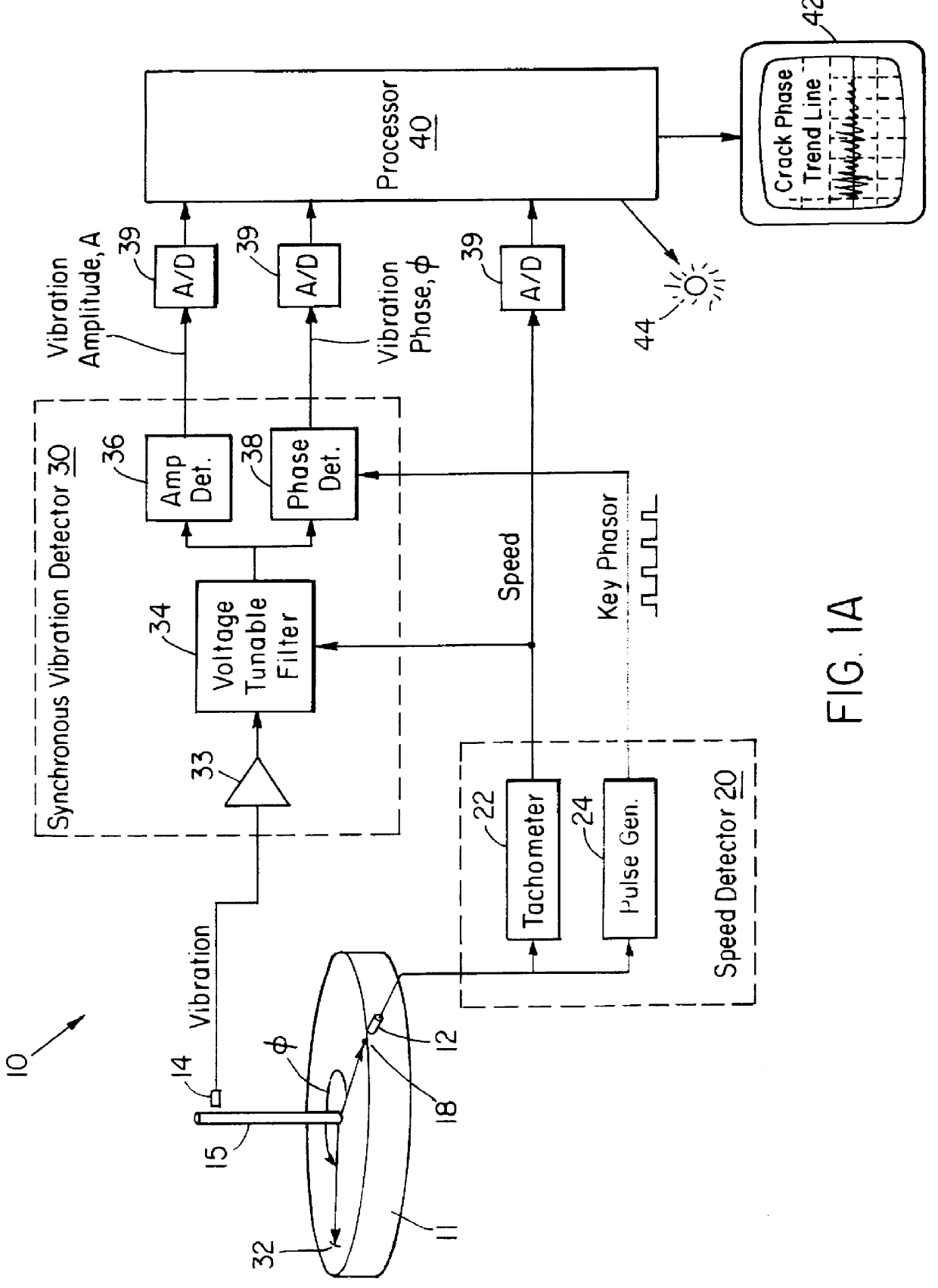

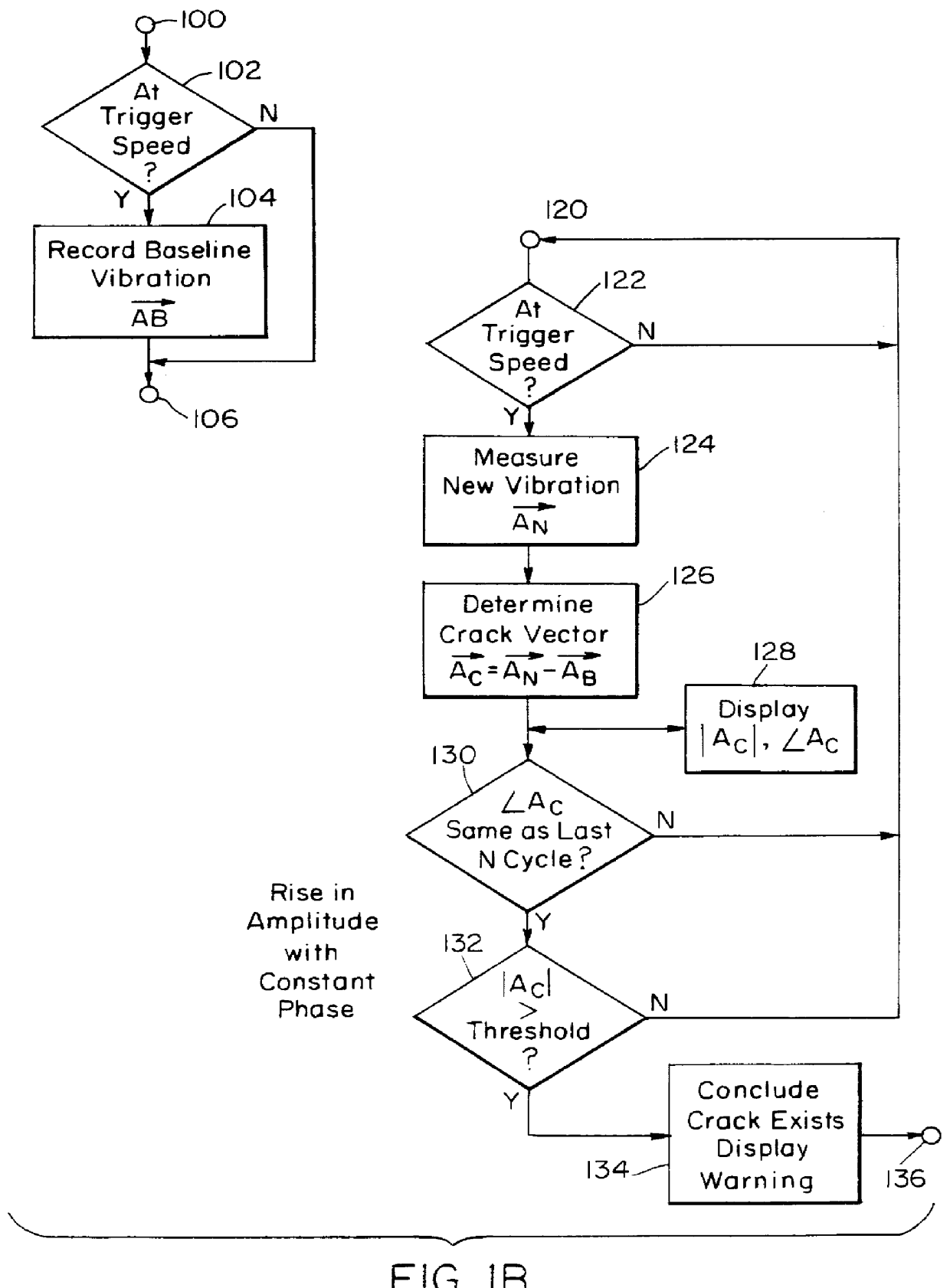

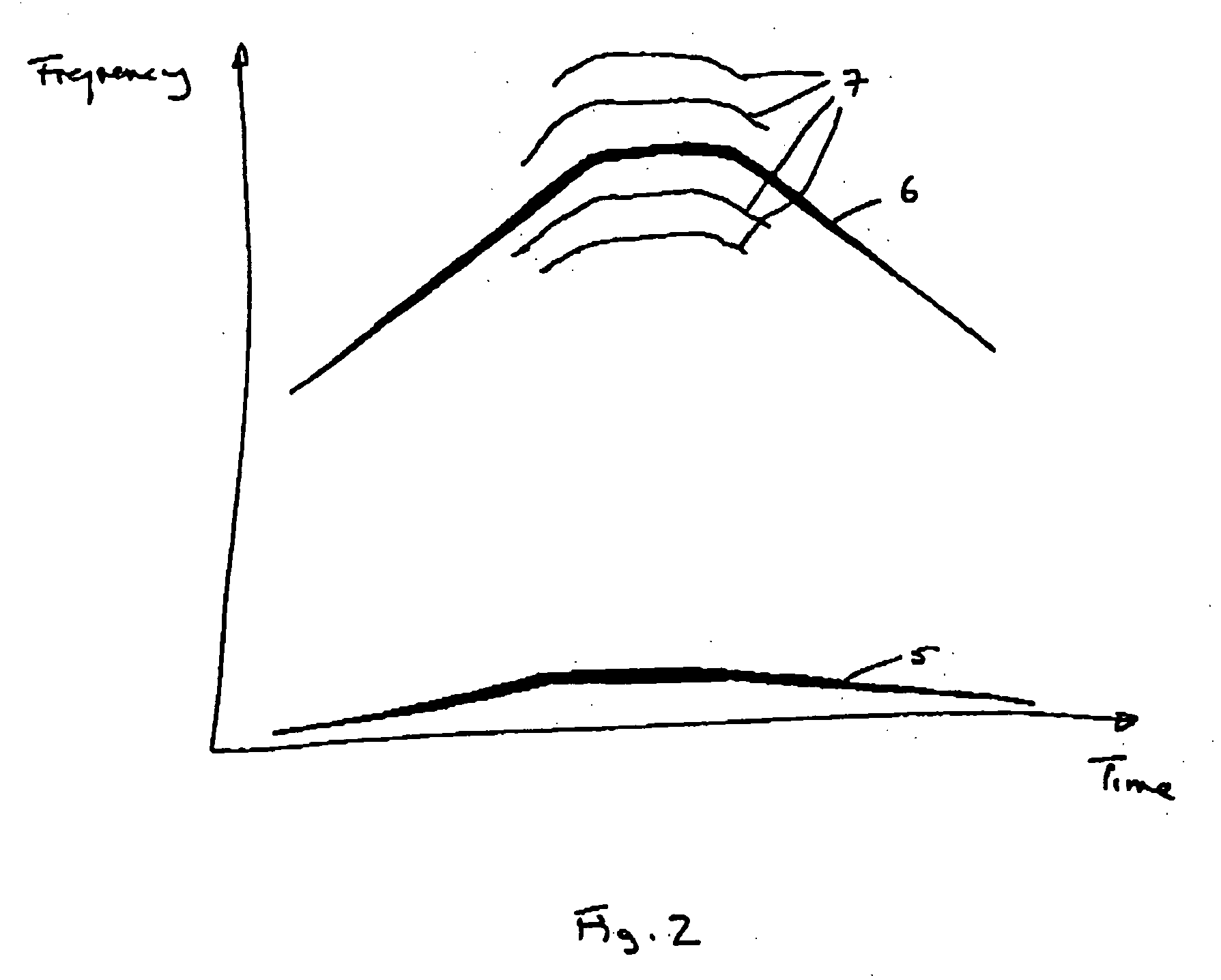

Detecting anomalies in rotating components

InactiveUS6098022AImprove accuracyHigh sensitivityMachine gearing/transmission testingFlow propertiesVibration measurementAcoustics

A method for detecting an anomaly, such as a crack, in a rotor includes measuring the rotational speed and vibration of the rotor. A vibration signal synchronous with the frequency of rotation is filtered from the vibration measurement. A background vibration vector is then subtracted from the synchronous vibration signal to produce a vibration difference signal. The phase and amplitude of the vibration difference signal are measured and evaluated to determine whether an anomaly has developed. An apparatus for performing this method includes vibration and speed sensors coupled to a filter for extracting a signal from the vibration measurement having a frequency synchronous with the rotation of the rotor. A processor is coupled to the filter and the speed sensor and is programmed to perform the processing steps, described above.

Owner:TEST DEVICES

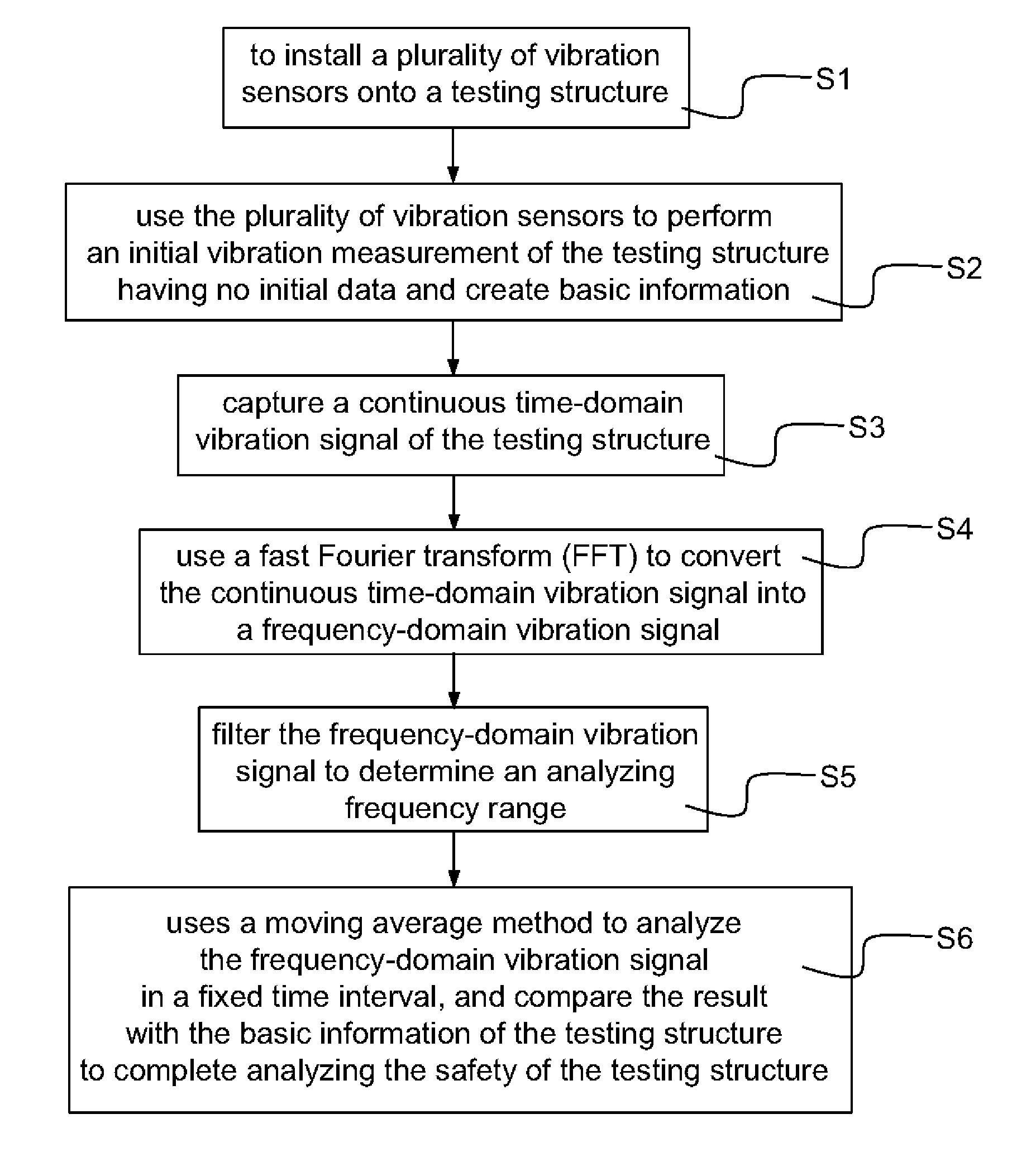

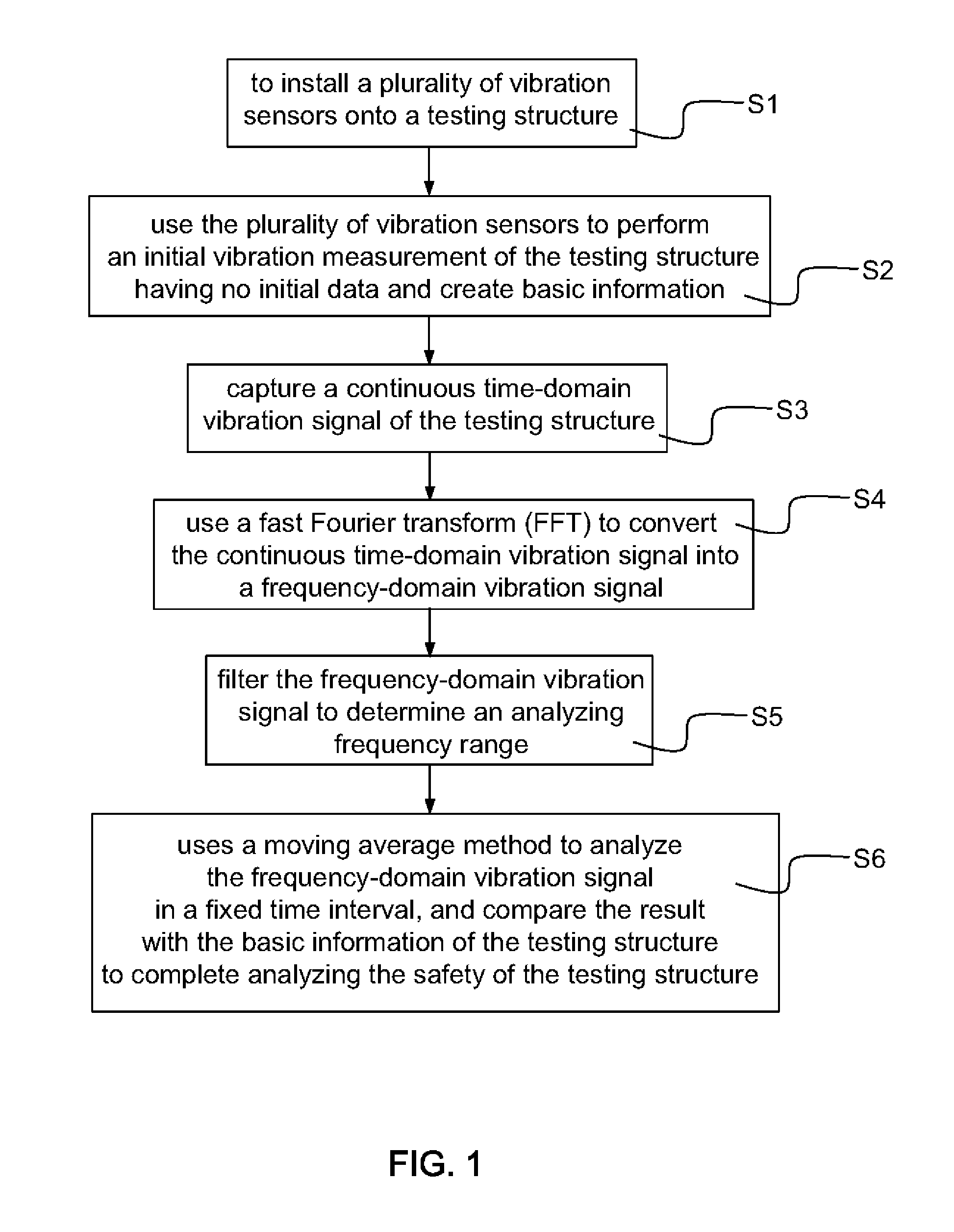

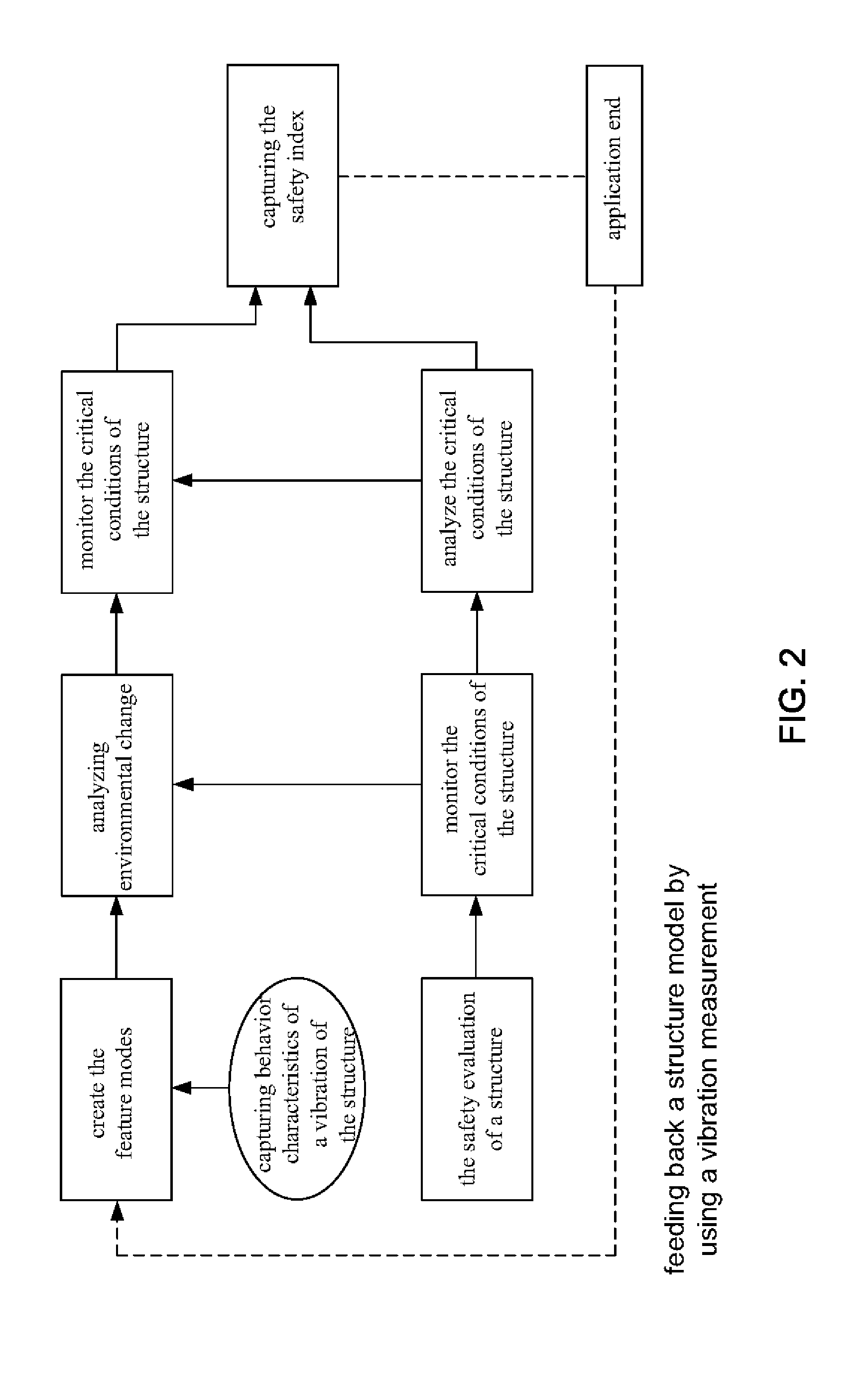

Method for analyzing structure safety

InactiveUS20120204646A1Guarantee structureMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial strength using single impulsive forceVibration measurementStability index

The present invention discloses a method for analyzing structure safety, and the method uses valid vibration measurement signals to obtain mutual feedbacks for a structural model analysis and a calibrated structural model to simulate a disaster situation to obtain the critical force exertion and deformation scale of a structure. The method is applied to capture the stability index of the structure to analyze the structure safety or applied for a structure safety evaluation or a health monitoring, or even for a structure multi-hazards safety determination.

Owner:NAT TAIWAN UNIV OF SCI & TECH

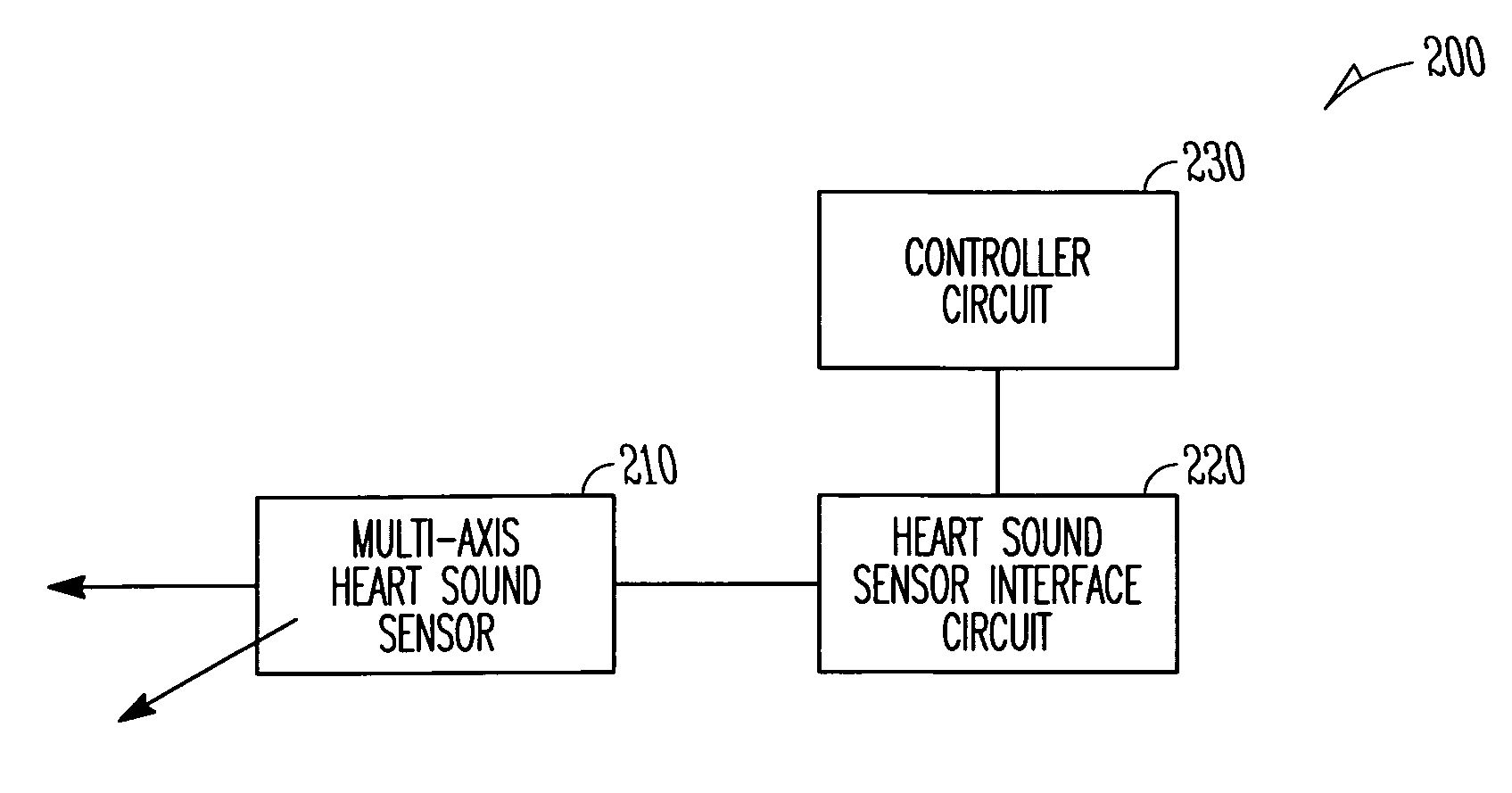

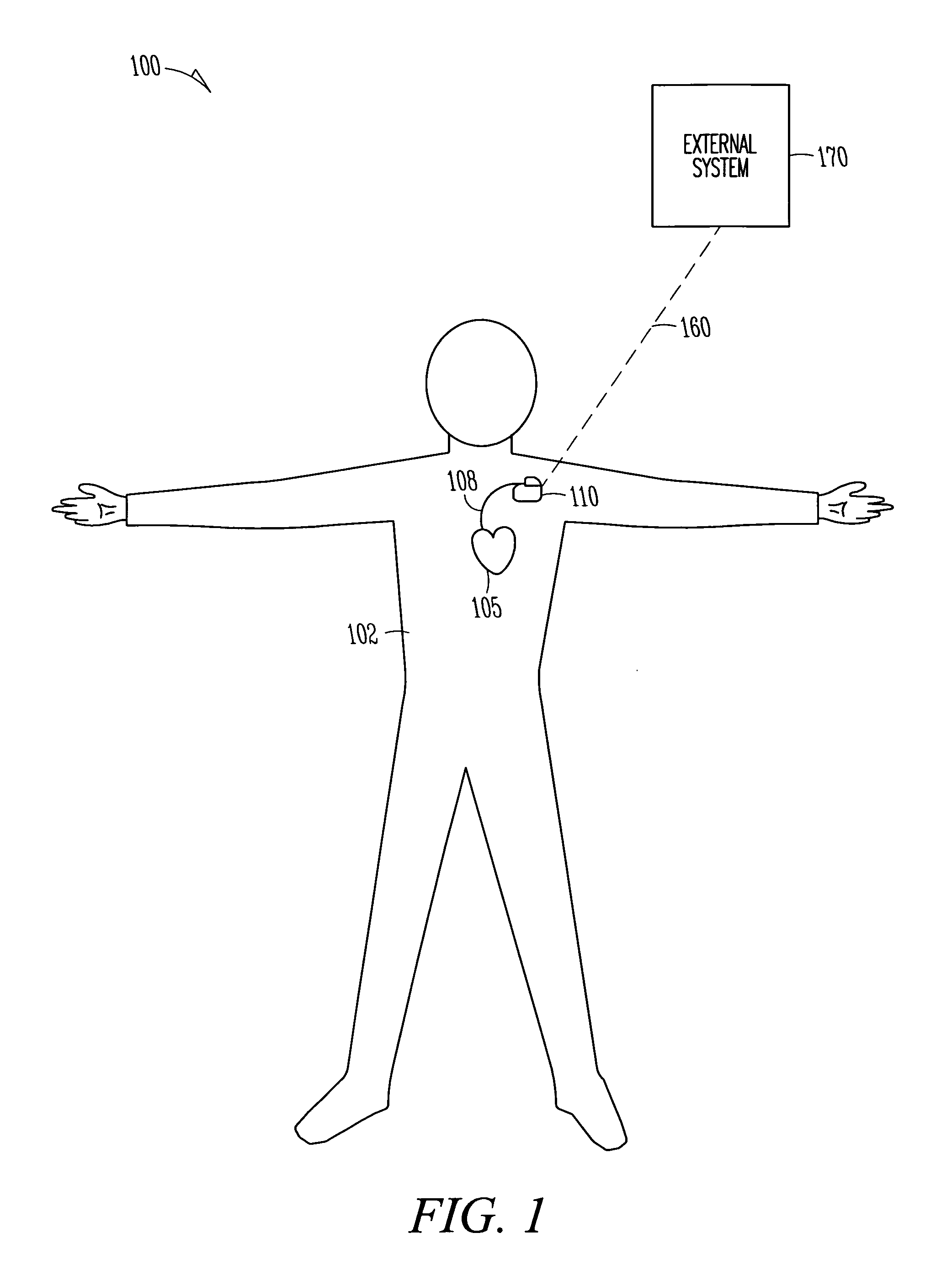

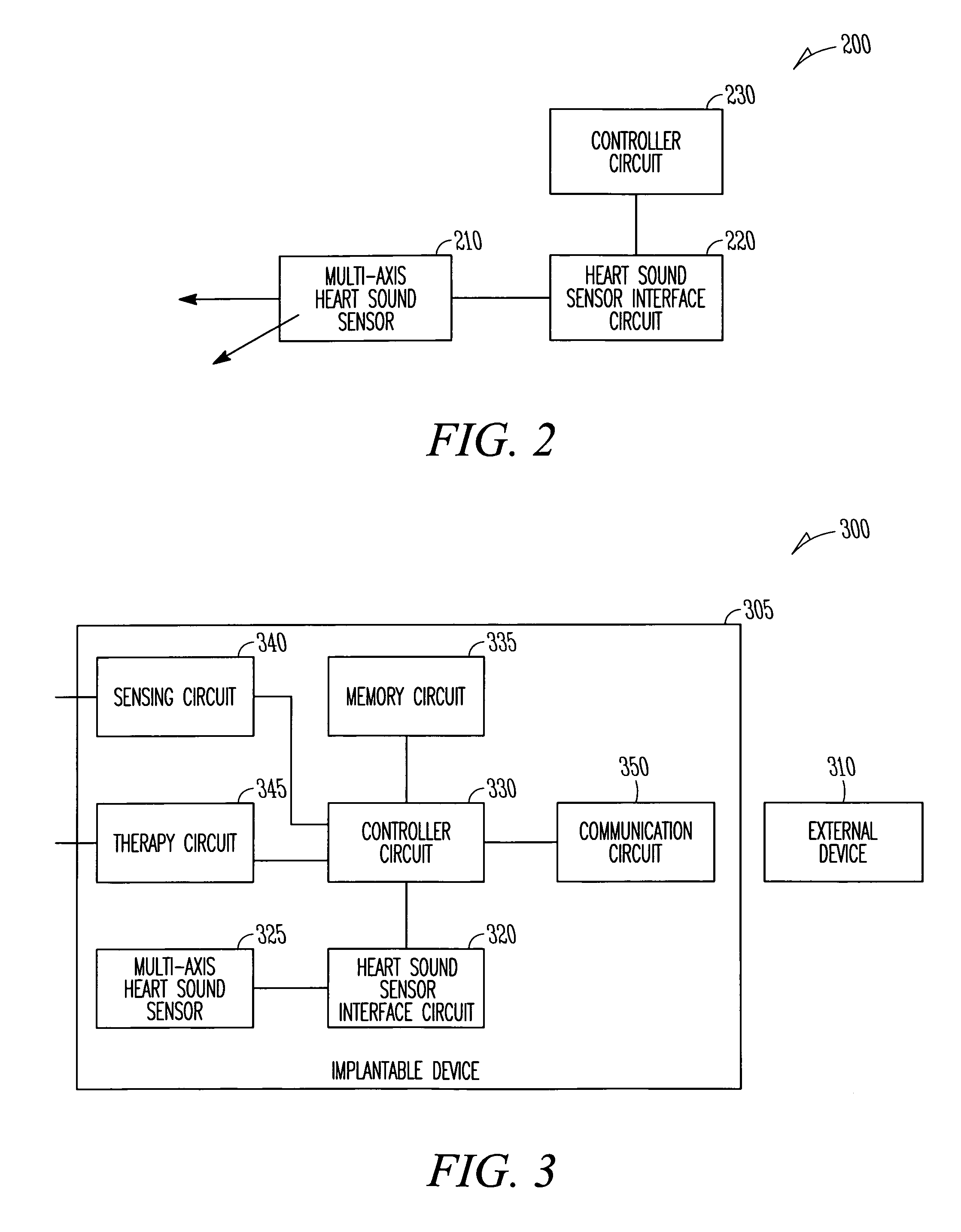

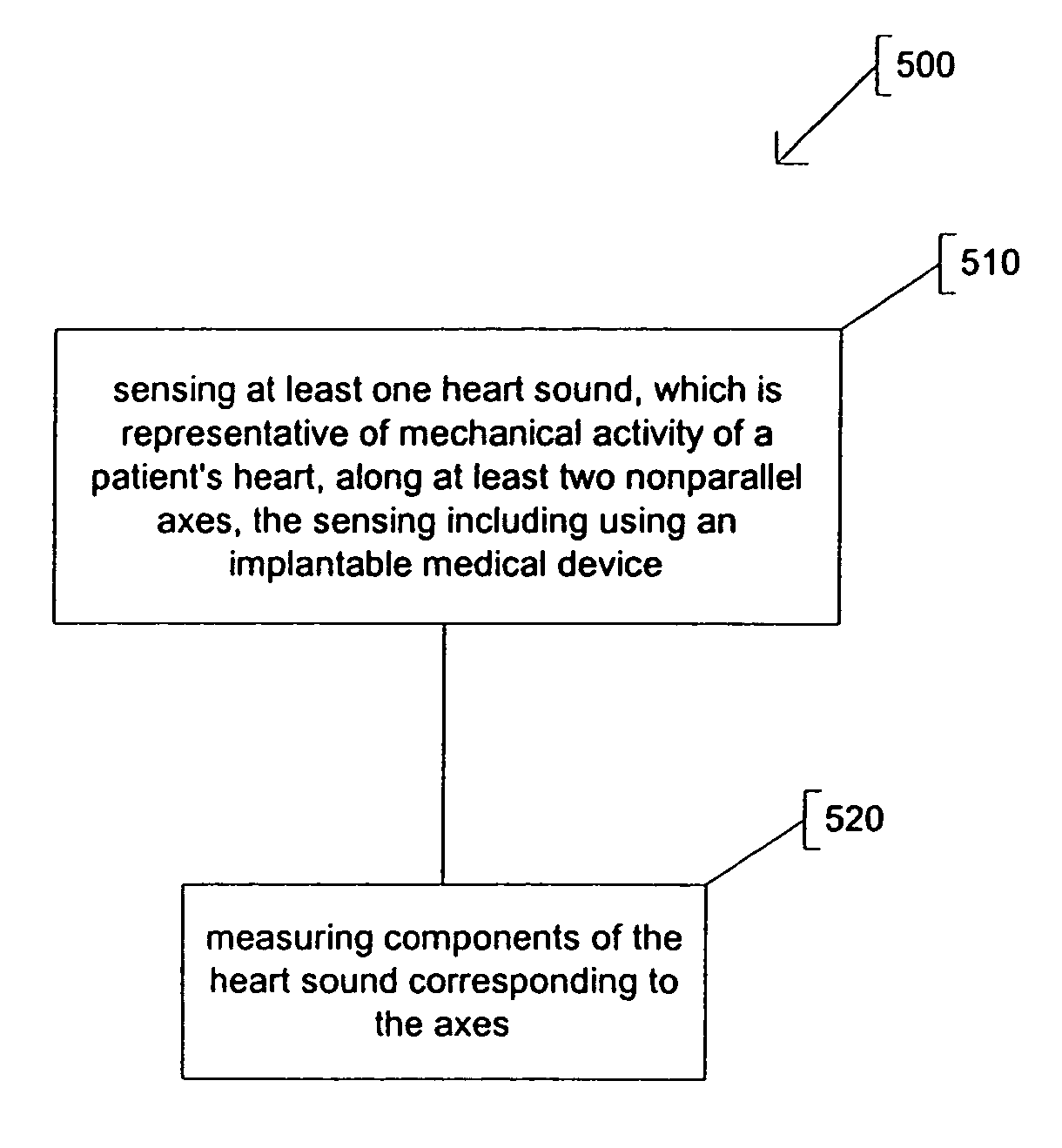

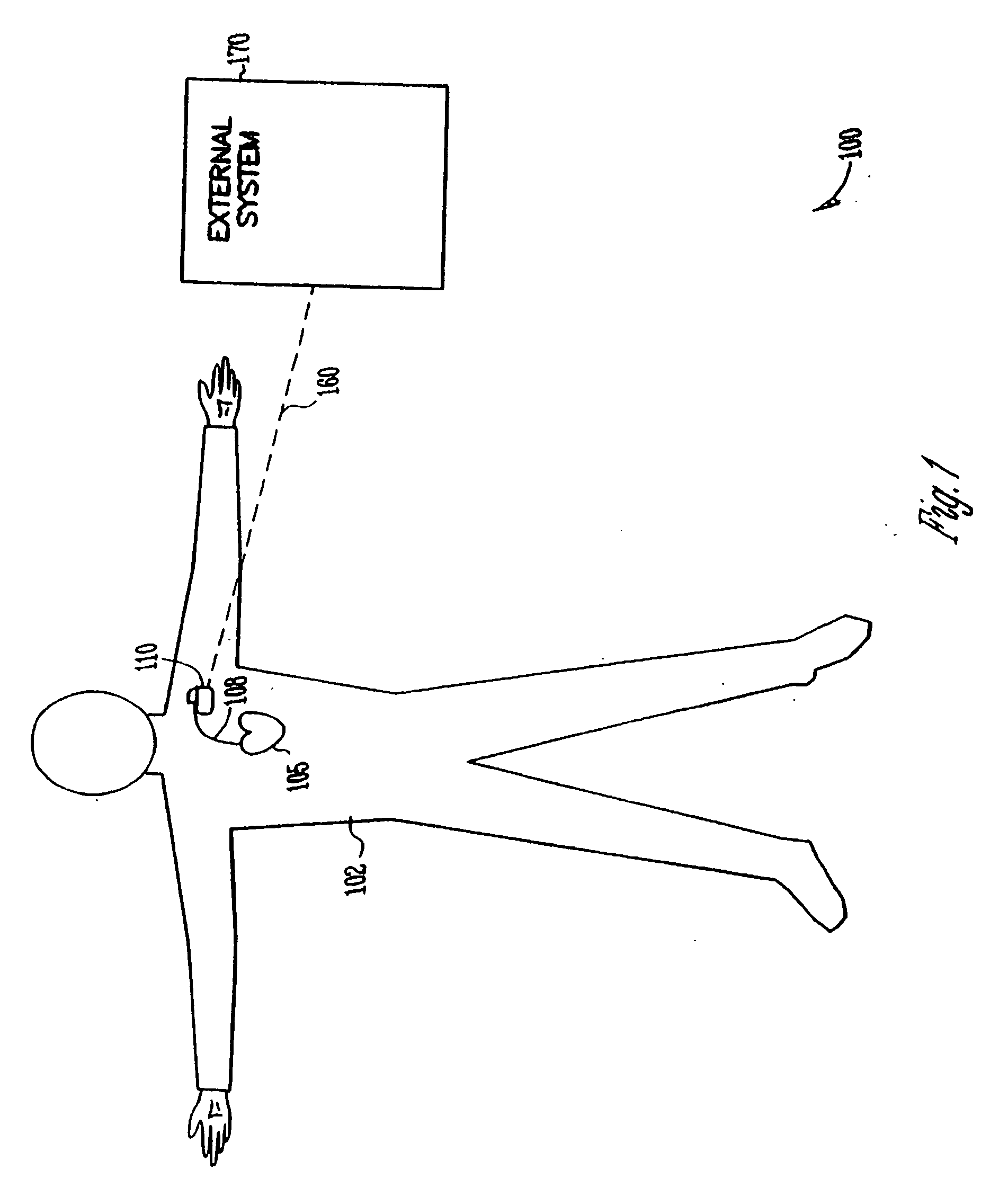

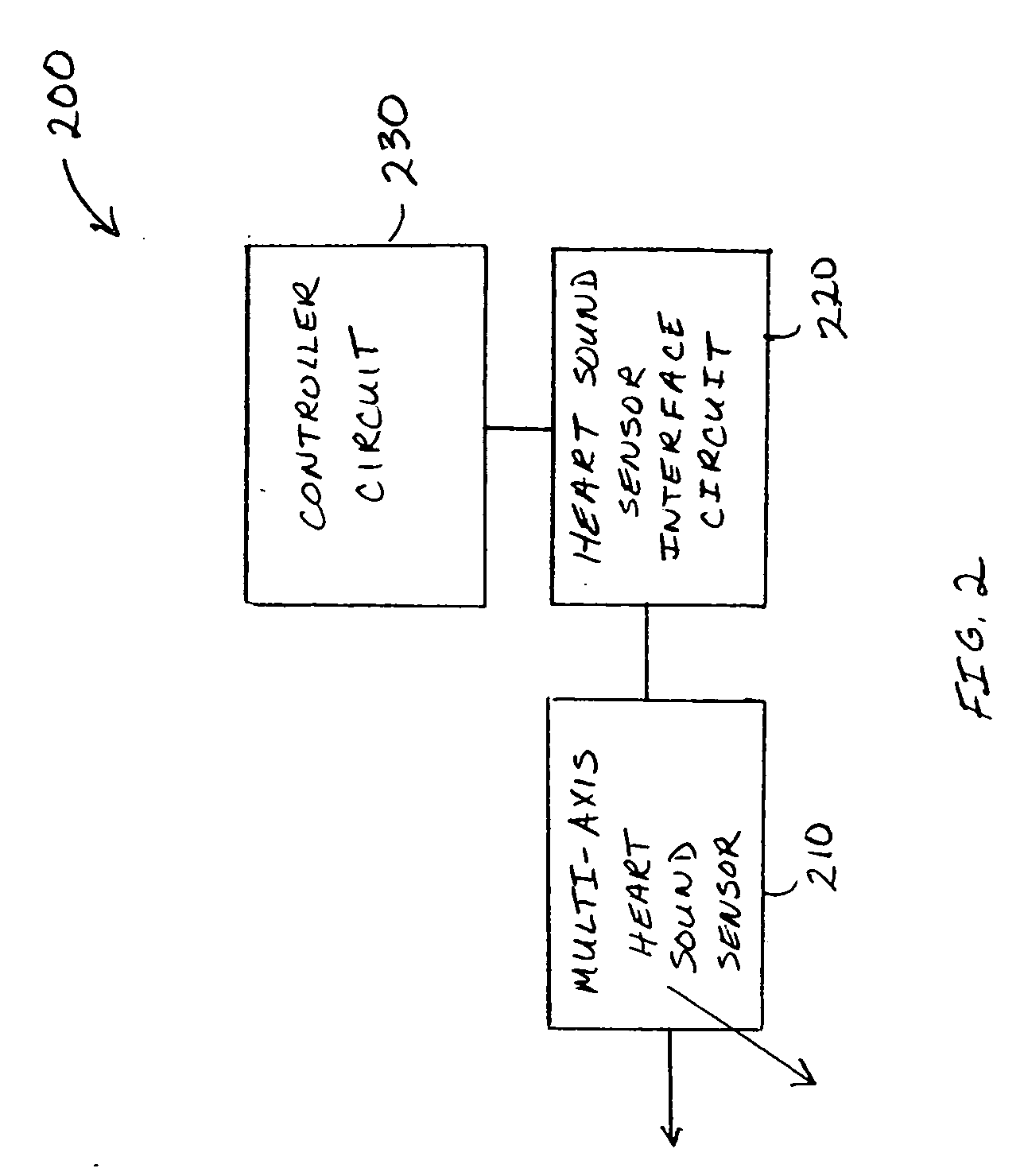

Systems and methods for multi-axis cardiac vibration measurements

A system to monitor heart sounds, such as to detect a worsening condition of heart failure decompensation. The system comprises a medical device that includes an implantable multi-axis heart sound sensor, operable to produce, for each of at least two nonparallel axes, an electrical signal representative of at least one heart sound, the heart sound associated with mechanical activity of a patient's heart. The device further includes a controller circuit coupled to the heart sound sensor. The controller circuit measures components of the heart sound that respectively correspond to each of the axes.

Owner:CARDIAC PACEMAKERS INC

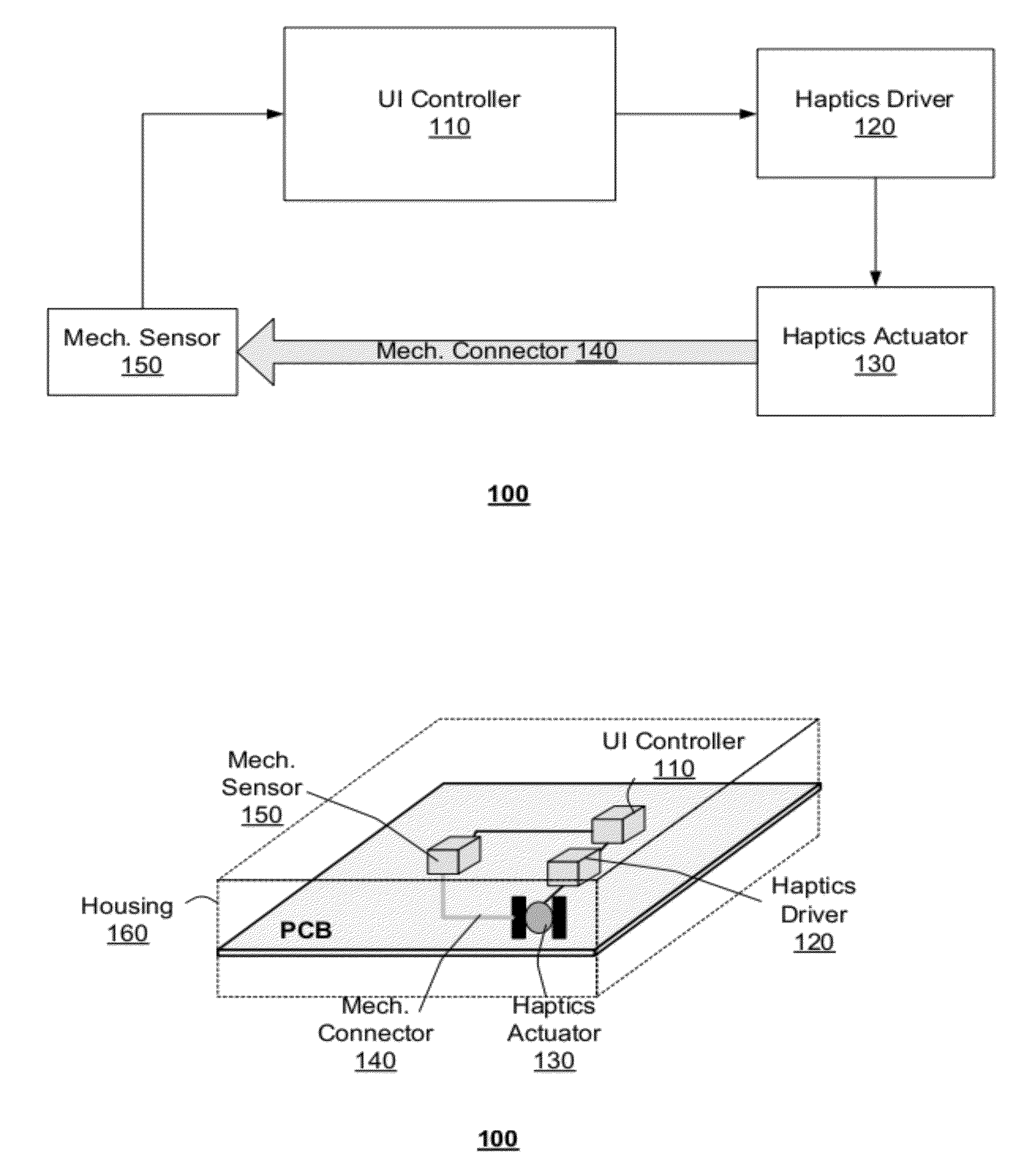

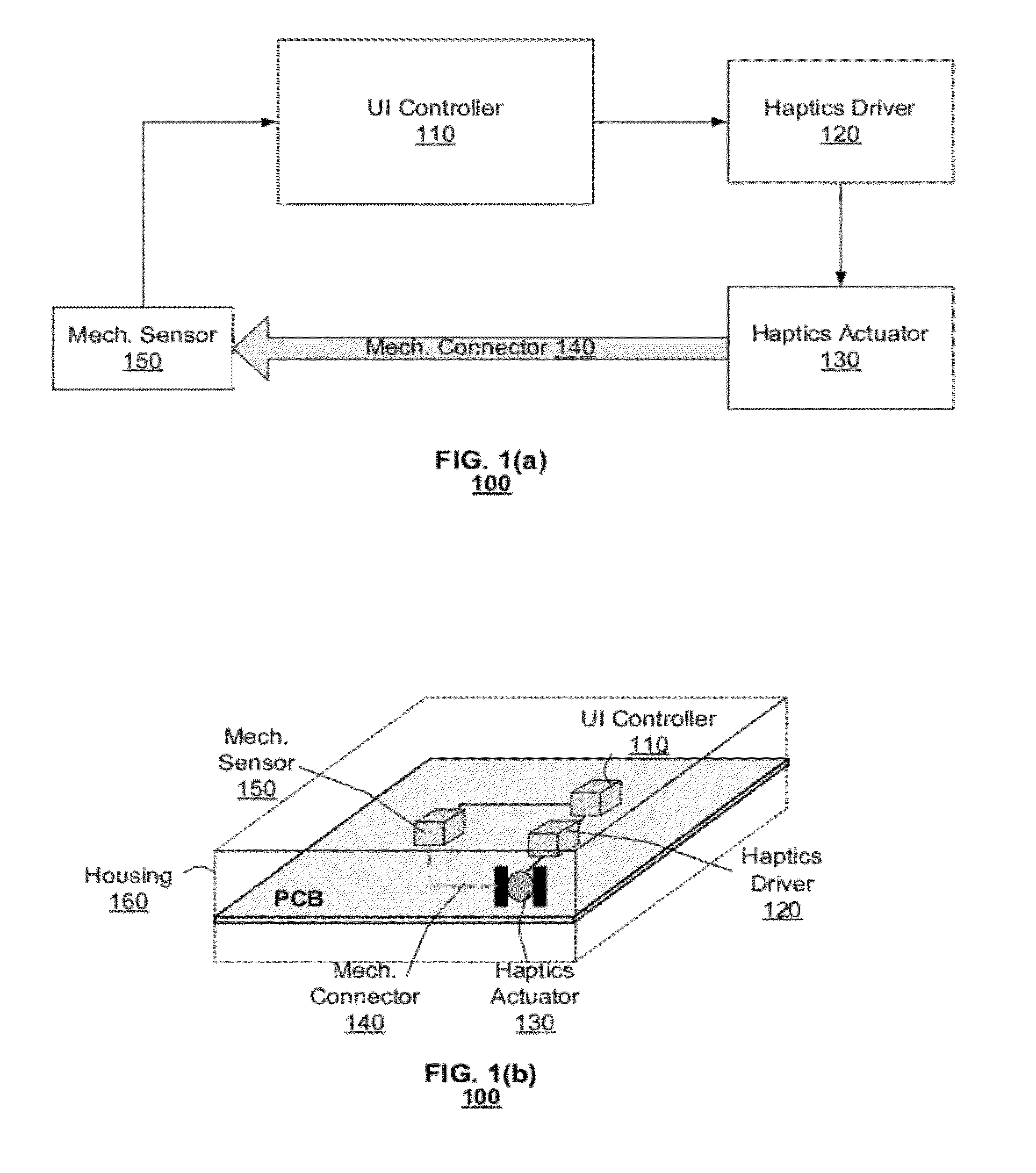

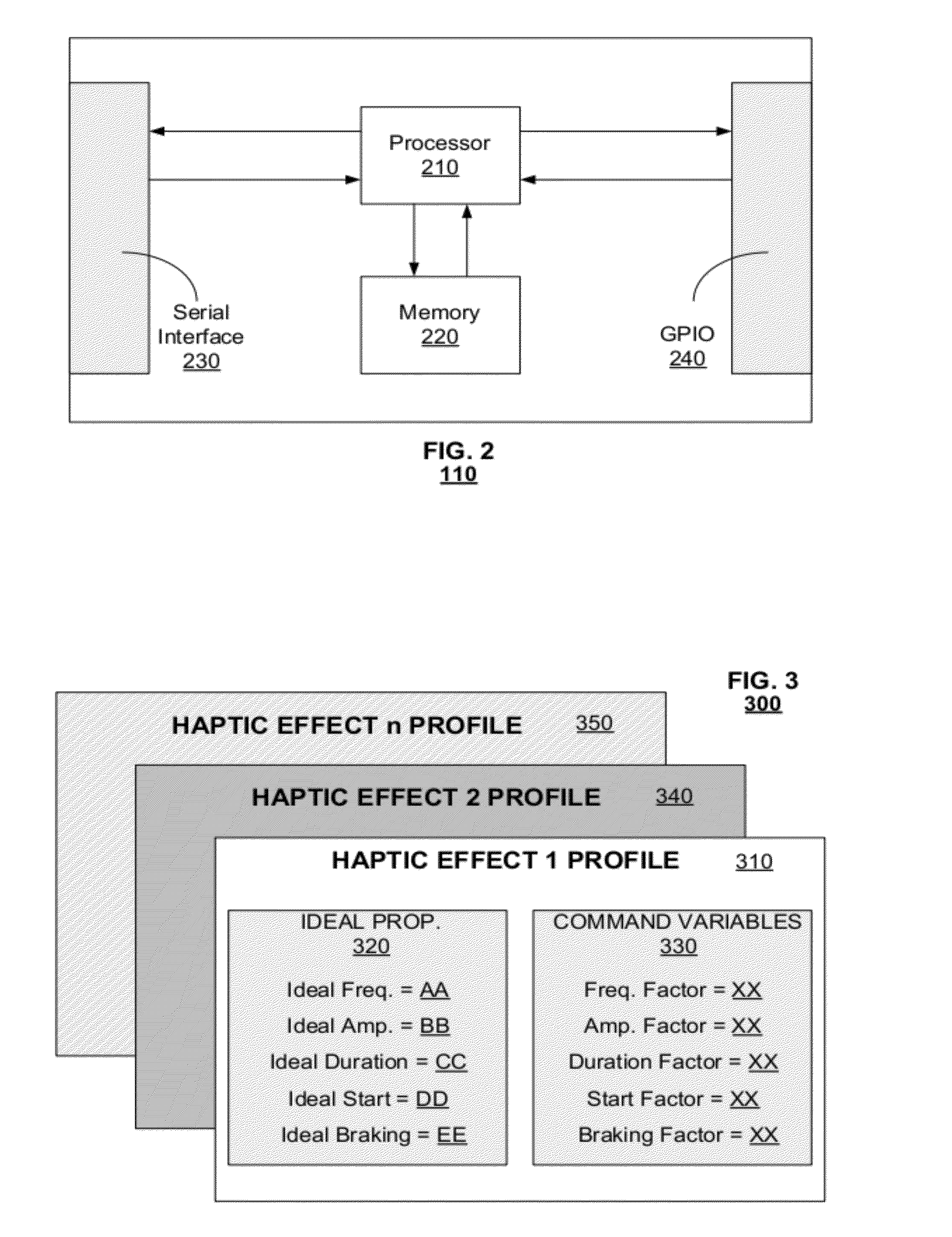

Method and apparatus for haptic vibration response profiling and feedback

ActiveUS20120249462A1Digital data processing detailsRepeater circuitsVibration measurementEngineering

Embodiments of the present invention may provide a device to adaptively generate a haptic effect. The device may include a controller to generate a haptic command associated with a haptic profile and a haptic driver to generate a drive signal based on the haptic command, wherein the drive signal causes an actuator to produce vibrations corresponding to a haptic effect. Further, the device may include a sensor, coupled mechanically to the actuator, to measure at least one property of the vibrations. The controller may adjust the haptic command according to the measured at least one property. Therefore, the device may continuously tune haptic effect generation according to vibration measurements.

Owner:ANALOG DEVICES INC

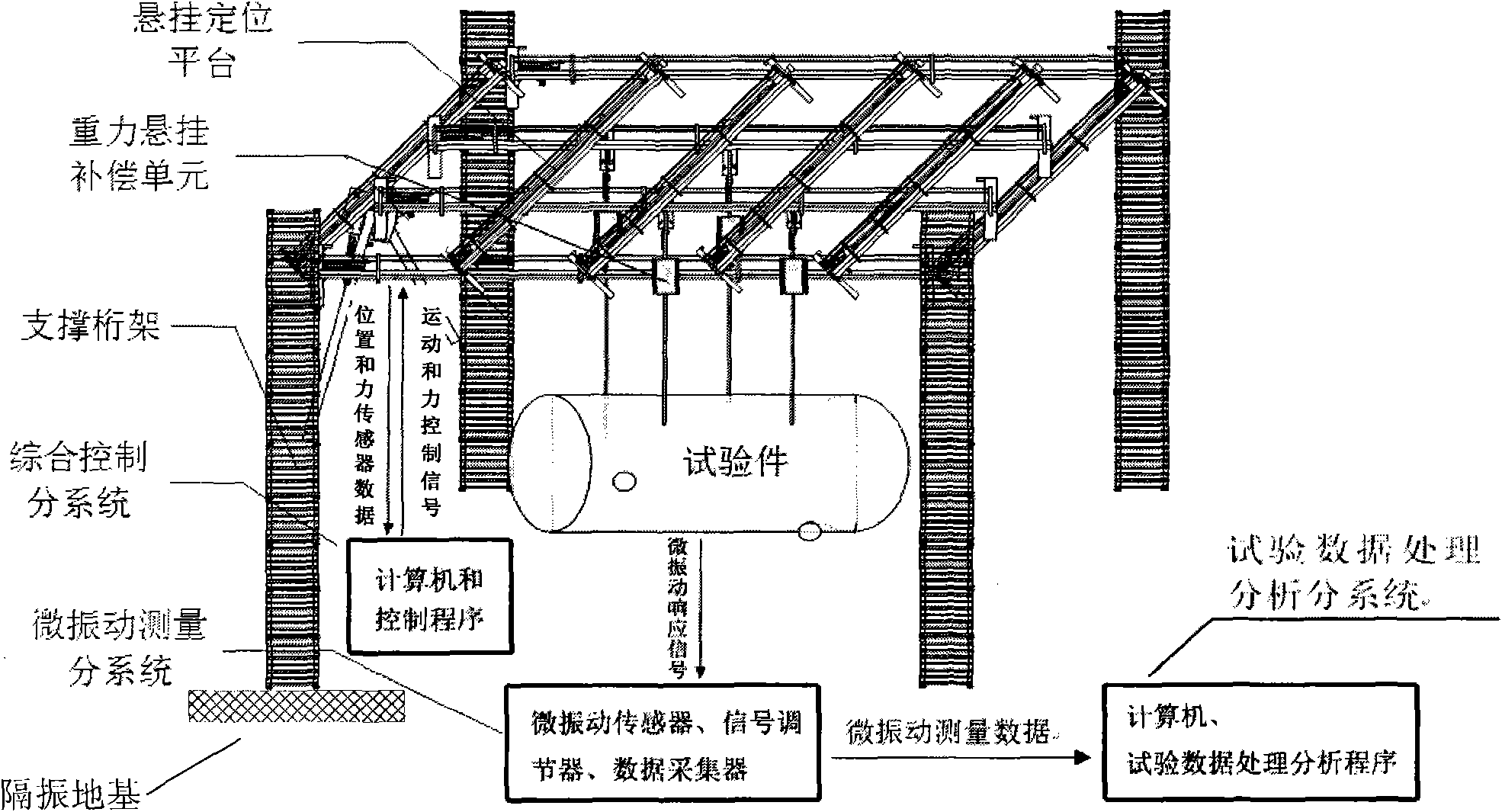

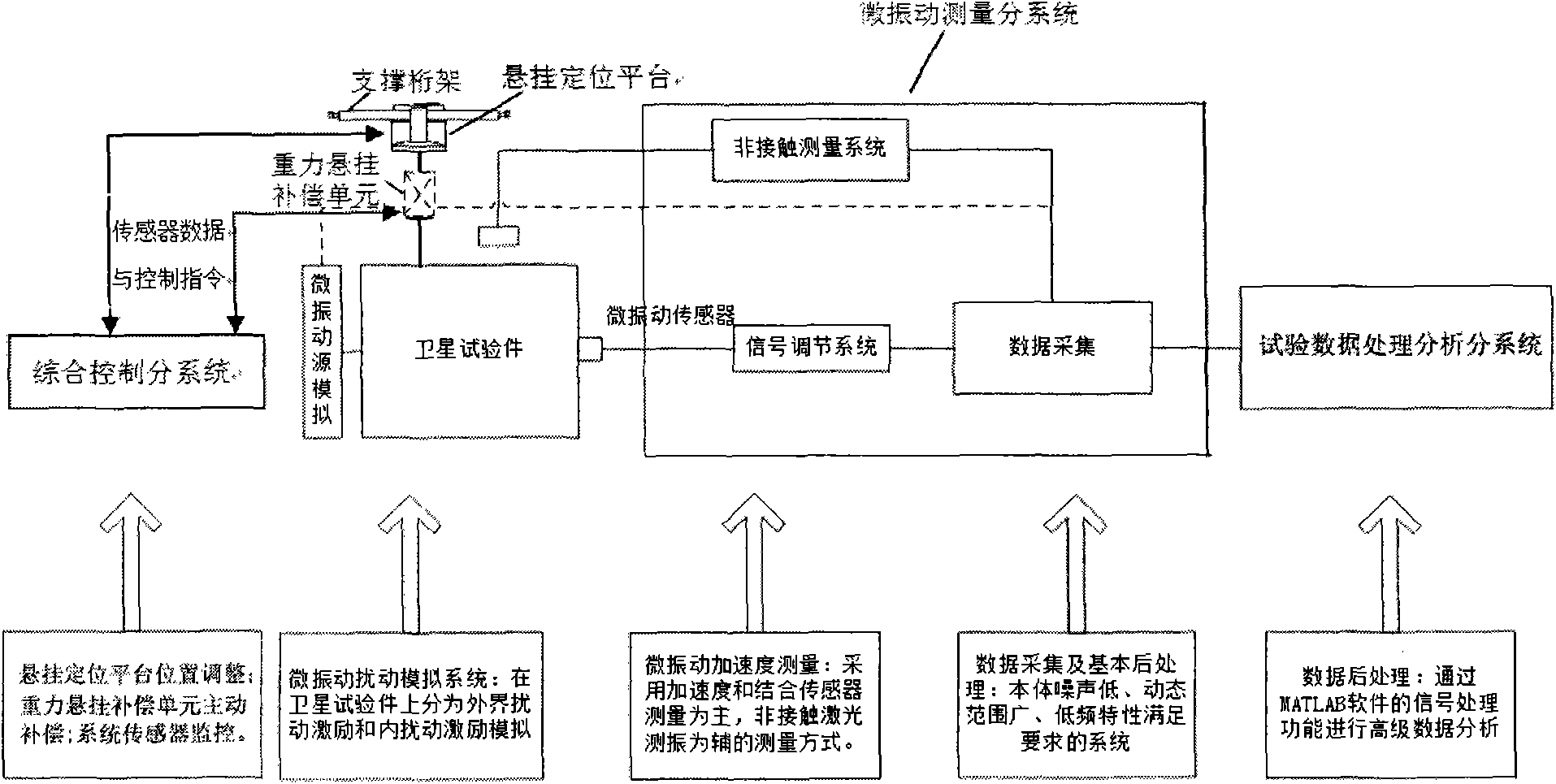

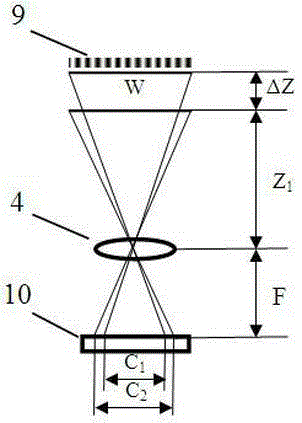

Ground testing system for on-track micro vibration of spacecraft

ActiveCN102650563AImprove the technical level of micro-vibration testMeet test verification requirementsVibration testingVibration measurementEngineering

The invention discloses a ground testing system for on-track micro vibration of a spacecraft, which comprises a vibration isolating foundation, a supporting truss with a framework structure, a suspended positioning platform, a gravity suspended compensation unit, an integrated control subsystem, a micro vibration measurement subsystem and a test data processing and analyzing subsystem, wherein the vibration isolating foundation is connected with the ground, the supporting truss with the framework structure is fixedly supported on the vibration isolating foundation, the suspended positioning platform is supported on the supporting truss, the gravity suspended compensation unit is hung on the suspended positioning platform, and the integrated control subsystem is used for controlling the positioning and the fixation of the suspended positioning platform via coordination of sensors in various positions and performing the overall integrated control on the state of the system. By adopting the system, the ground simulation of the on-track micro vibration environment, the measurement of micro vibration and the data processing can be realized for the spacecraft at the system level and the component level, the technical level of testing the micro vibration of the spacecraft can be improved, and the demands for testing and verification of the on-track micro vibration environment in research on the spacecraft, particularly the high-precision satellite, can be satisfied.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Vibratory measurement transducer

The measurement transducer includes a transducer housing, which exhibits a plurality of natural oscillation modes, as well as at least one first flow tube held oscillatably in the transducer housing, vibrating at least at times, and conveying at least a portion of the medium to be measured. Additionally, the measurement transducer includes an electromechanical, especially electrodynamic, exciter arrangement acting on the at least one flow tube for producing and / or maintaining mechanical oscillations of the at least one flow tube, and a sensor arrangement reacting to movements of the flow tube, especially bending oscillations, for producing at least one oscillation measurement signal representing oscillations of the flow tube. Additionally, for improving the oscillation properties and, consequently, also the measurement accuracy of the measurement transducer, at least three coupling elements are provided for connecting the first and second flow tubes together at the inlet end, as well as at least three coupling elements for connecting the first and second flow tubes together at the outlet end. By using at least six coupling elements, it is possible to produce vibration-type measurement transducers of high measuring accuracy even at large nominal diameters of more than 150 mm, especially also while largely maintaining already established and proven forms of construction.

Owner:ENDRESS HAUSER FLOWTEC AG

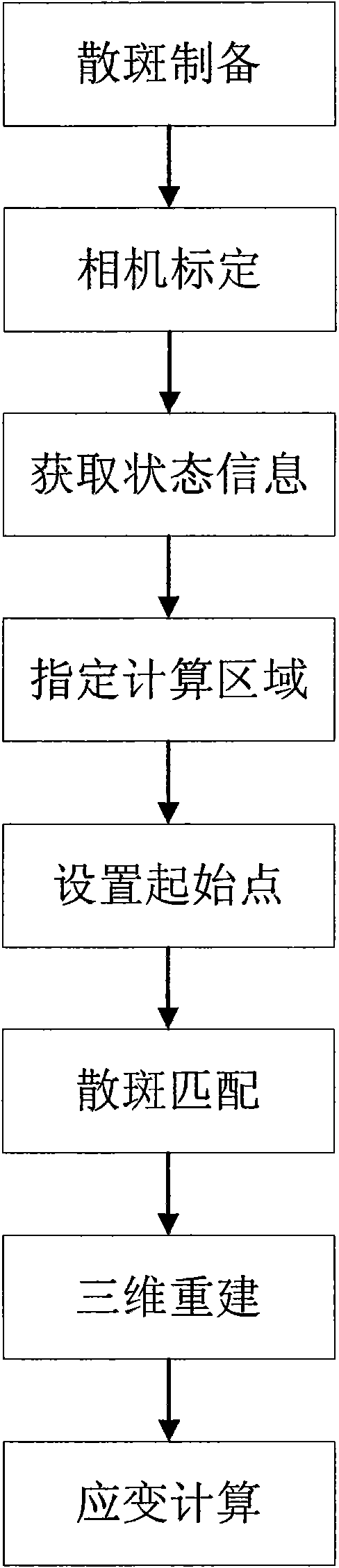

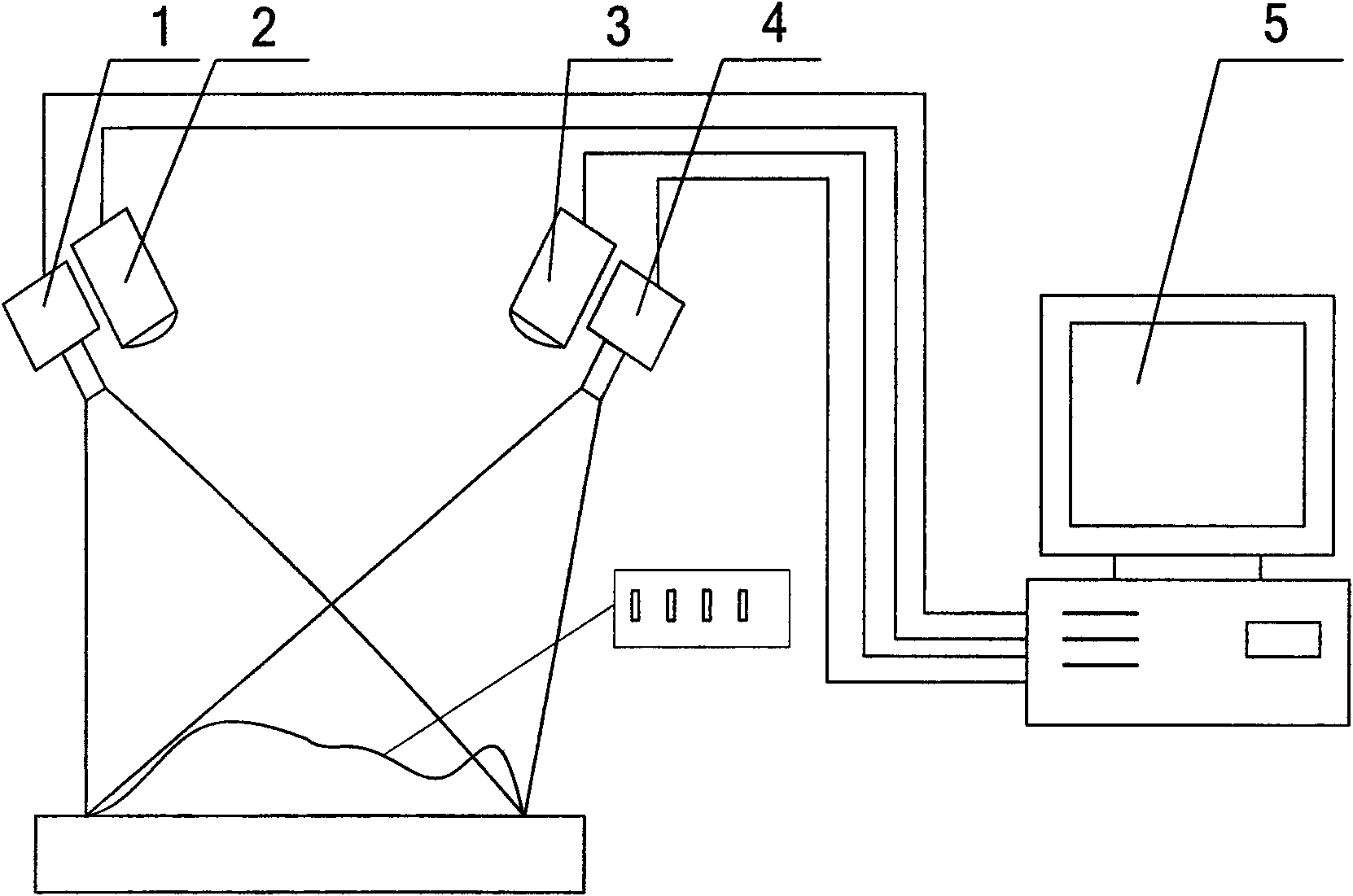

Three-dimensional speckle strain measurement device and measurement method thereof

ActiveCN101655352AHigh measurement accuracySimplify requirementsUsing optical meansVibration measurementFracture mechanics

The invention discloses a three-dimensional speckle strain measurement method, comprising: (1) speckle preparation; (2) camera calibration; (3) state information acquisition; (4) computational domaindesignation; (5) initial point setting; (6) speckle matching; (7) three-dimensional reconstruction; and (8) strain computation. By the above operation steps, the invention provides a three-dimensionalspeckle strain measurement method, which can effectively obtain high preciseness measurement results in measurements of material characteristic parameters such as full-field vibration measurement, dynamic strain measurement, high speed deformation measurement, fracture mechanics, impact excitation and dynamic material experiments. The invention has the characteristics of convenient measurement operation, high automation degree, exact and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

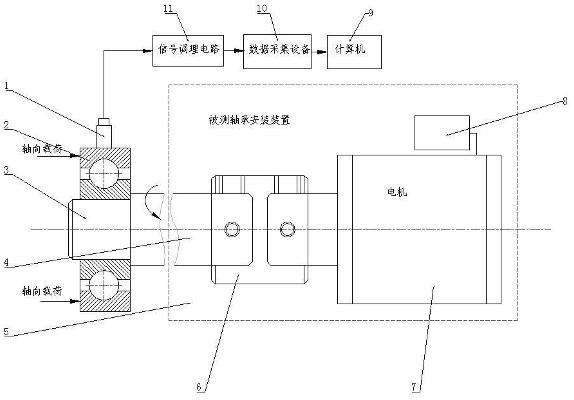

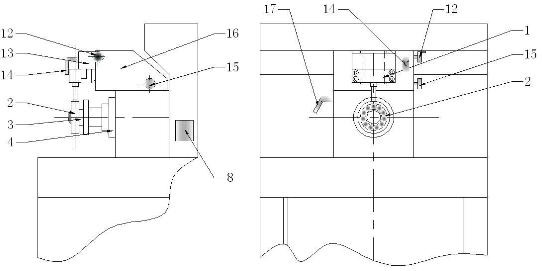

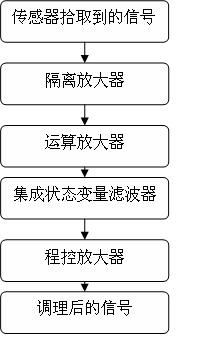

Device and method for vibration measurement and failure analysis of rolling bearing

InactiveCN102183366AAccurate measurementImprove anti-interference abilityVibration measurement in solidsMachine bearings testingVibration measurementSignal conditioning circuits

The invention relates to a device and method for vibration measurement and failure analysis of a rolling bearing. The device comprises a detected bearing mounting device, a speed sensor, a signal conditioning circuit, a data collection device and a computer, wherein a detected bearing is mounted on a mandrel of the detected bearing mounting device; a vibration rod of the speed sensor is arranged on a middle plane of an outer cylindrical surface of an outer ring of the detected bearing with prescribed pressure, the measurement direction is along the radial direction of the bearing and vertical to the axis of the bearing, and the signal conditioning circuit and the data collection device are connected to the computer; the speed sensor measures radial vibration speed signals of the outer ring of the bearing, the picked bearing radial vibration speed signals are converted into corresponding electric signals which are processed by the signal conditioning circuit and then transferred to the data collection device which carries out A / D conversion of the conditioned signals to convert the conditioned signals into digital signals capable of being processed by the computer, and finally the computer carries out analysis and processing of the digital signal. The device and the method are applicable to production test and user acceptance of finished bearings by laboratories and bearing manufacture factories.

Owner:SHANGHAI UNIV

Bearing anomaly detection and location

ActiveUS20050119840A1Easy to detectEasy to analyzeVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurementAnomaly detection

A method for monitoring the health of a system comprises performing at each of a plurality of times the steps of: constructing a condition signature (30) from a plurality of condition indicators including (a) a plurality of vibration measurements acquired from the system or (b) one or more vibration measurements and one or more performance parameter measurements acquired from the system; predicting a normal signature (32) from a model defining one or more inter-dependencies between said condition indicators, the normal signature corresponding to the condition signature for a healthy system; comparing the condition signature with the normal signature; and registering an event if the condition signature differs from the normal signature by more than a predetermined threshold.

Owner:ROLLS ROYCE PLC

Systems and methods for multi-axis cardiac vibration measurements

A system to monitor heart sounds, such as to detect a worsening condition of heart failure decompensation. The system comprises a medical device that includes an implantable multi-axis heart sound sensor, operable to produce, for each of at least two nonparallel axes, an electrical signal representative of at least one heart sound, the heart sound associated with mechanical activity of a patient's heart. The device further includes a controller circuit coupled to the heart sound sensor. The controller circuit measures components of the heart sound that respectively correspond to each of the axes.

Owner:CARDIAC PACEMAKERS INC

Vibratory measurement transducer

ActiveUS20060150750A1Large clamping forceSuitable for measuringDirect mass flowmetersVibration measurementCoupling

The measurement transducer includes a transducer housing, which exhibits a plurality of natural oscillation modes, as well as at least one first flow tube held oscillatably in the transducer housing, vibrating at least at times, and conveying at least a portion of the medium to be measured. Additionally, the measurement transducer includes an electromechanical, especially electrodynamic, exciter arrangement acting on the at least one flow tube for producing and / or maintaining mechanical oscillations of the at least one flow tube, and a sensor arrangement reacting to movements of the flow tube, especially bending oscillations, for producing at least one oscillation measurement signal representing oscillations of the flow tube. Additionally, for improving the oscillation properties and, consequently, also the measurement accuracy of the measurement transducer, at least three coupling elements are provided for connecting the first and second flow tubes together at the inlet end, as well as at least three coupling elements for connecting the first and second flow tubes together at the outlet end. By using at least six coupling elements, it is possible to produce vibration-type measurement transducers of high measuring accuracy even at large nominal diameters of more than 150 mm, especially also while largely maintaining already established and proven forms of construction.

Owner:ENDRESS HAUSER FLOWTEC AG

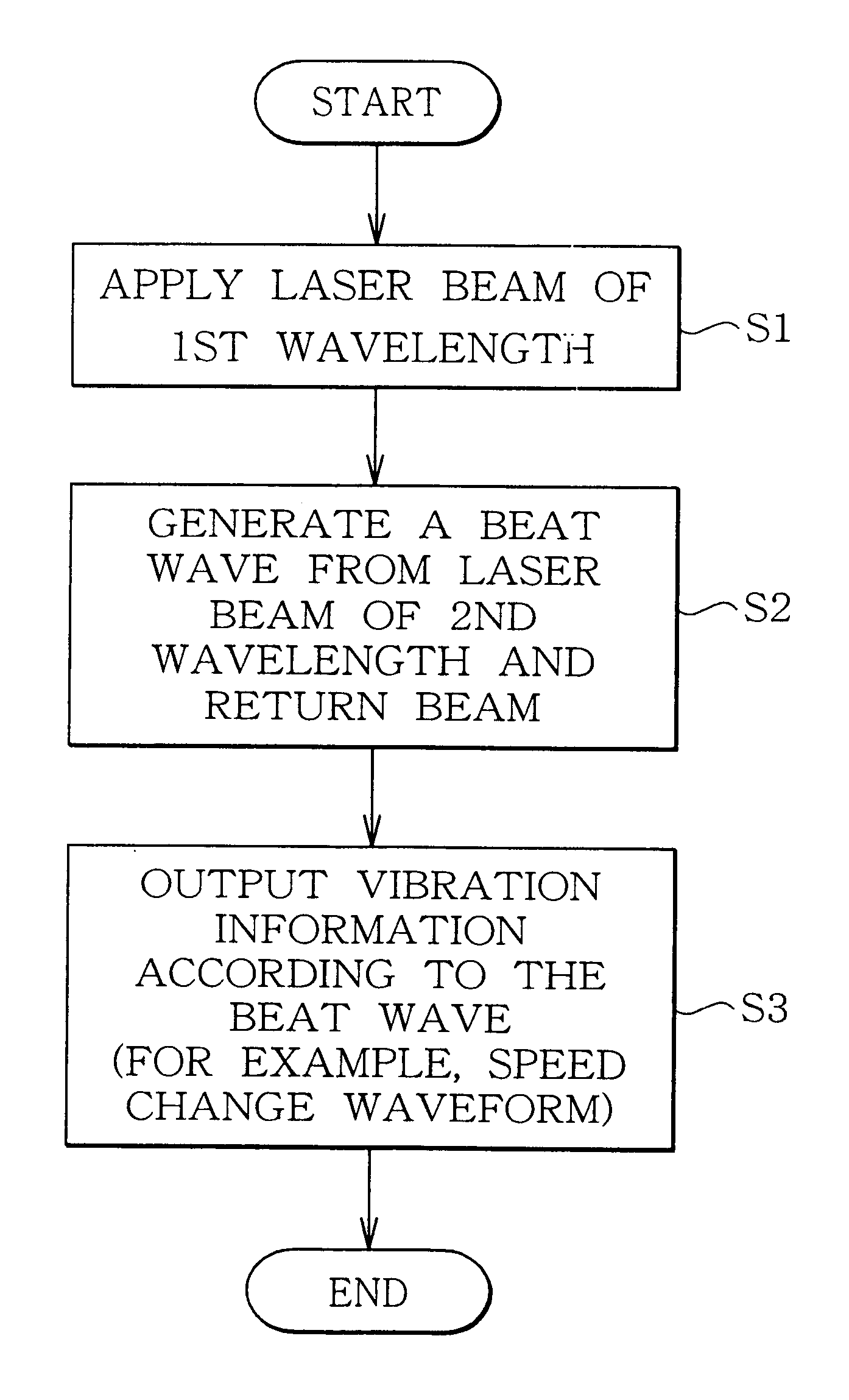

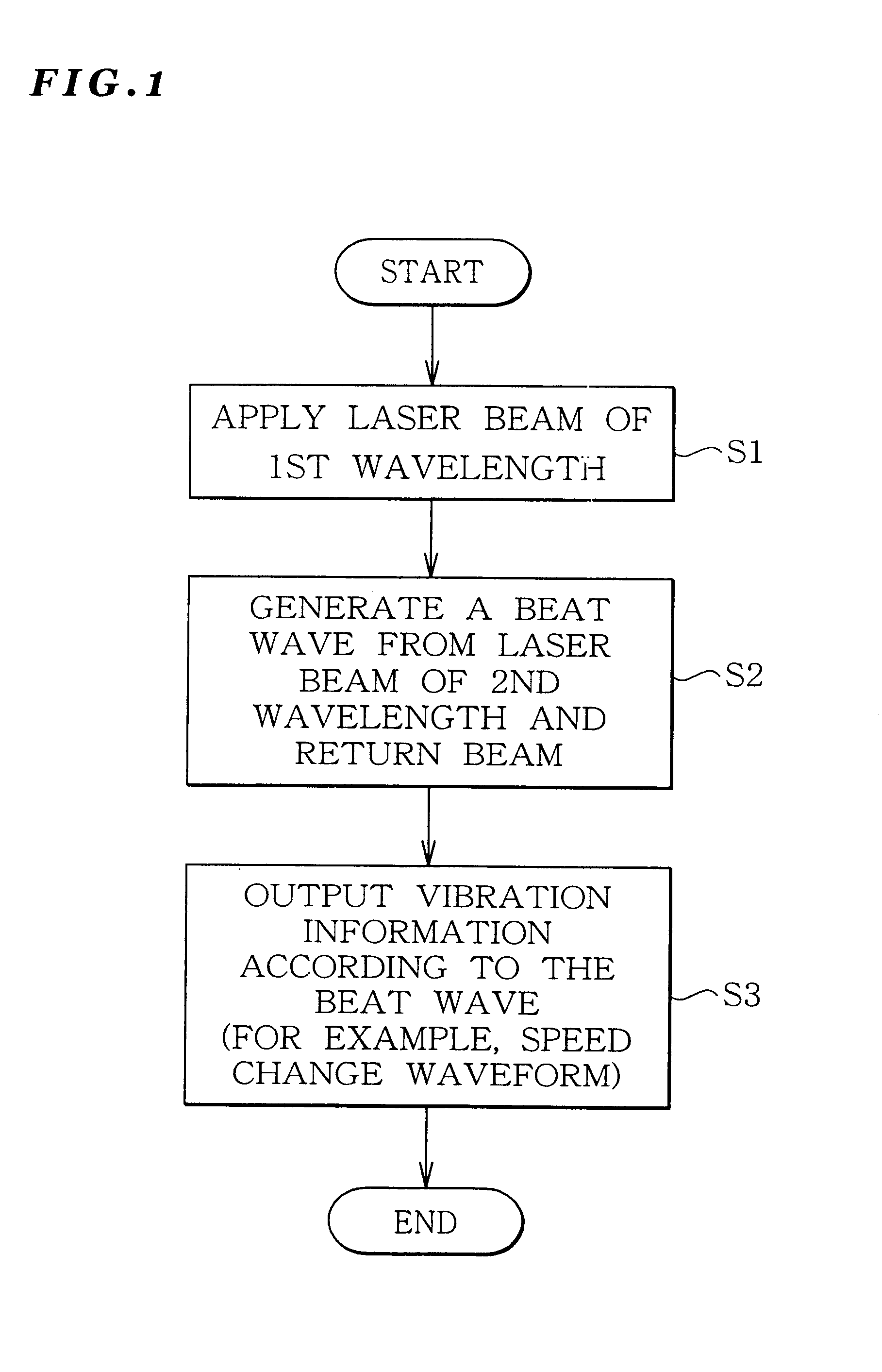

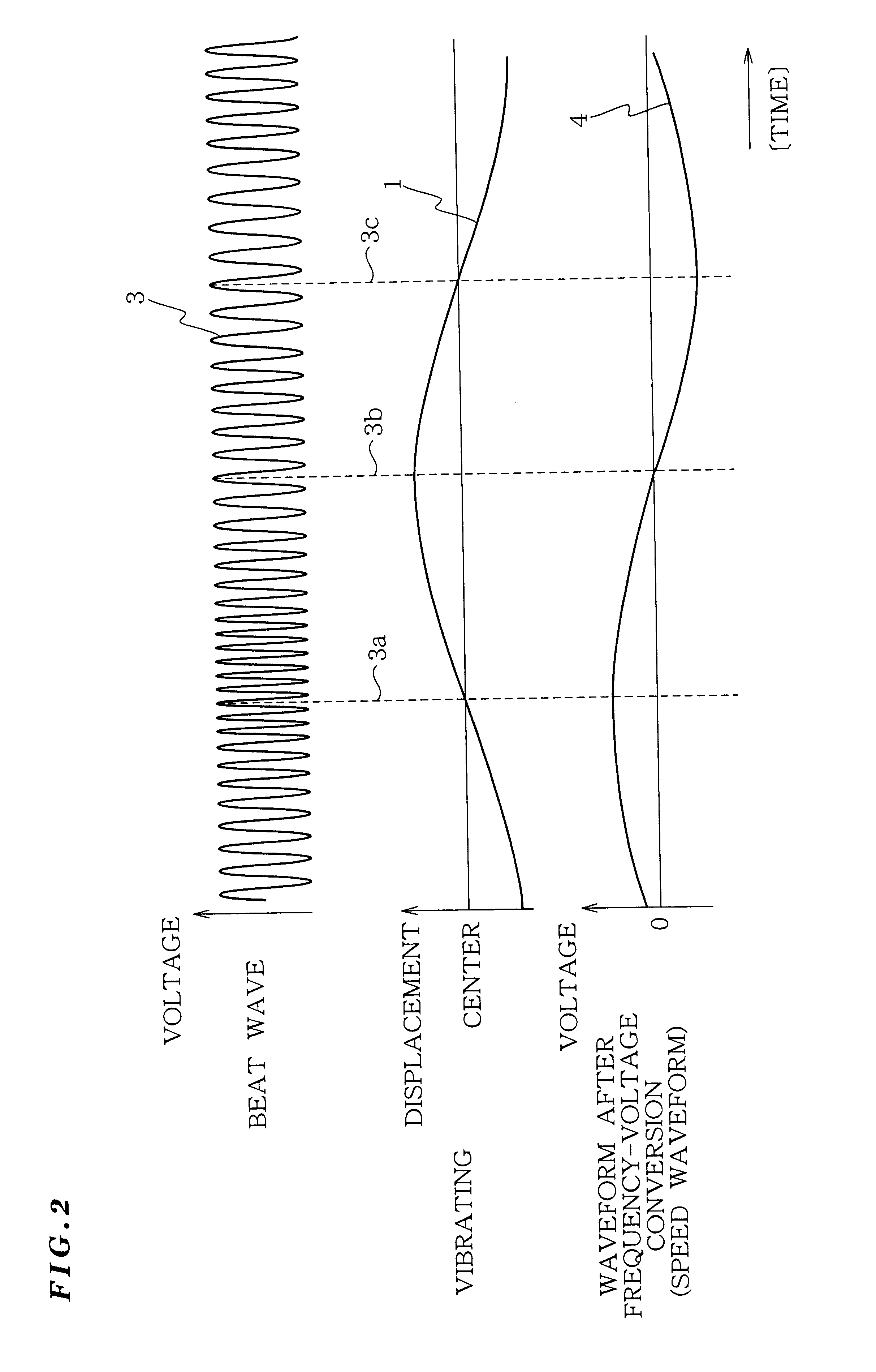

Vibration measurement method and apparatus

InactiveUS6301968B1Analysing solids using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementVibration measurementLight beam

The present invention provides a vibration measurement method and apparatus capable of accurately measuring displacement even if the displacement is very small. The vibration measurement method according to the present invention comprises: a laser beam application step (step S1) for applying a laser beam of a first wavelength to an object to be measured; a beat wave generation step (step S2) for mixing a laser beam of a second wavelength which is different from the first wavelength and the return beam reflected from the object to be measured; and a vibration information output step (step S3) for outputting the beat wave thus generated as a vibration information of the object to be measured.

Owner:SUZUKI MOTOR CORP

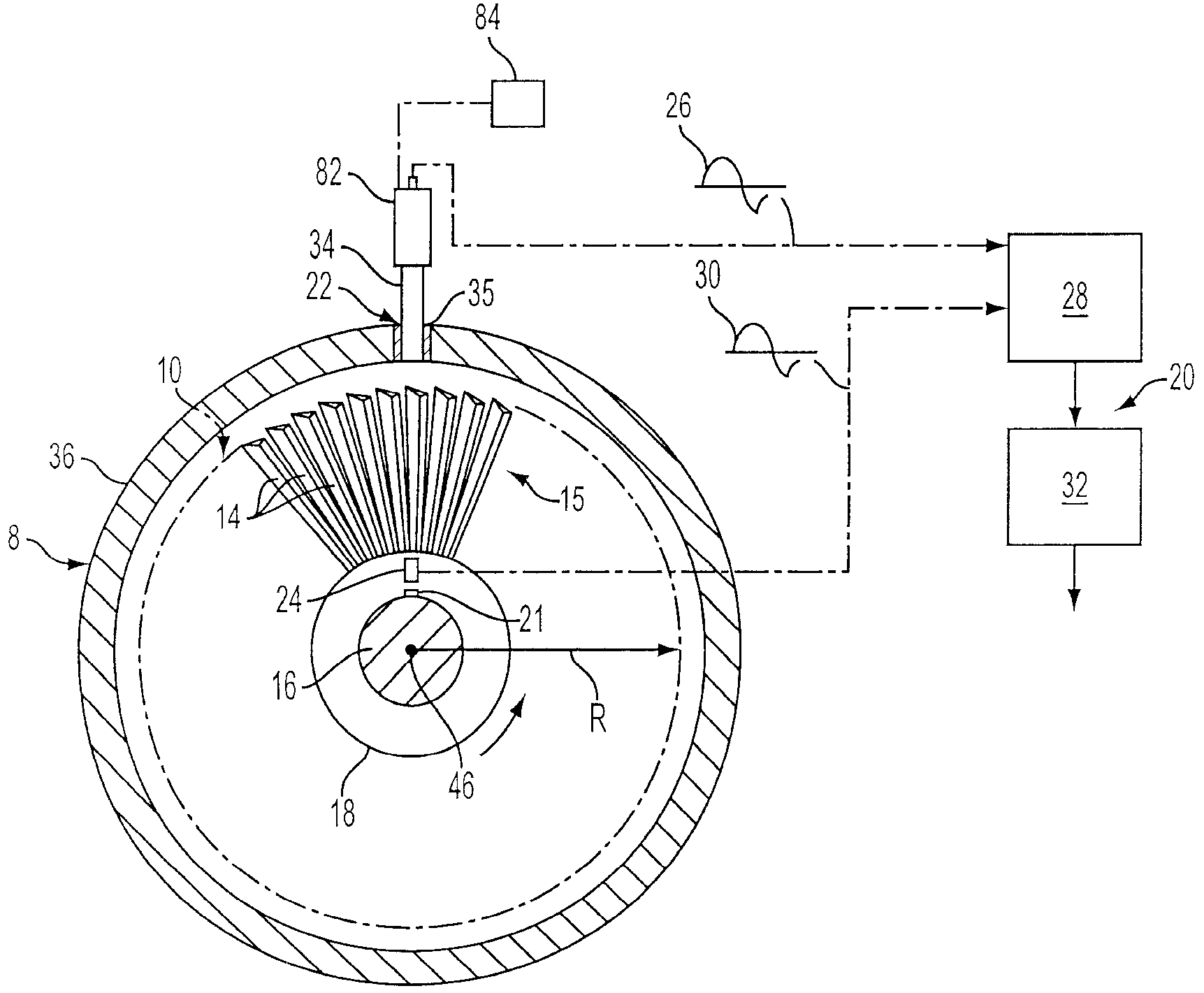

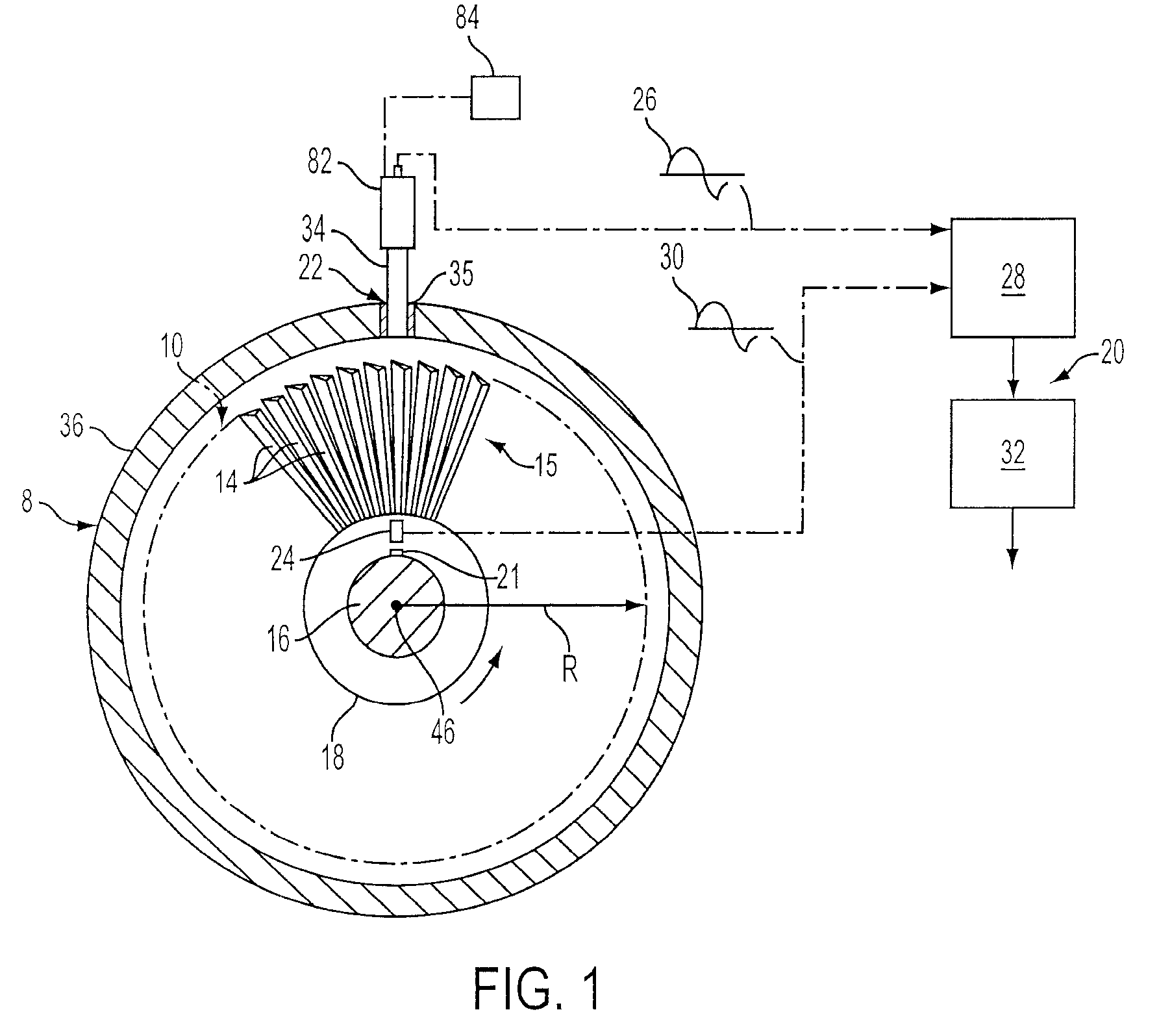

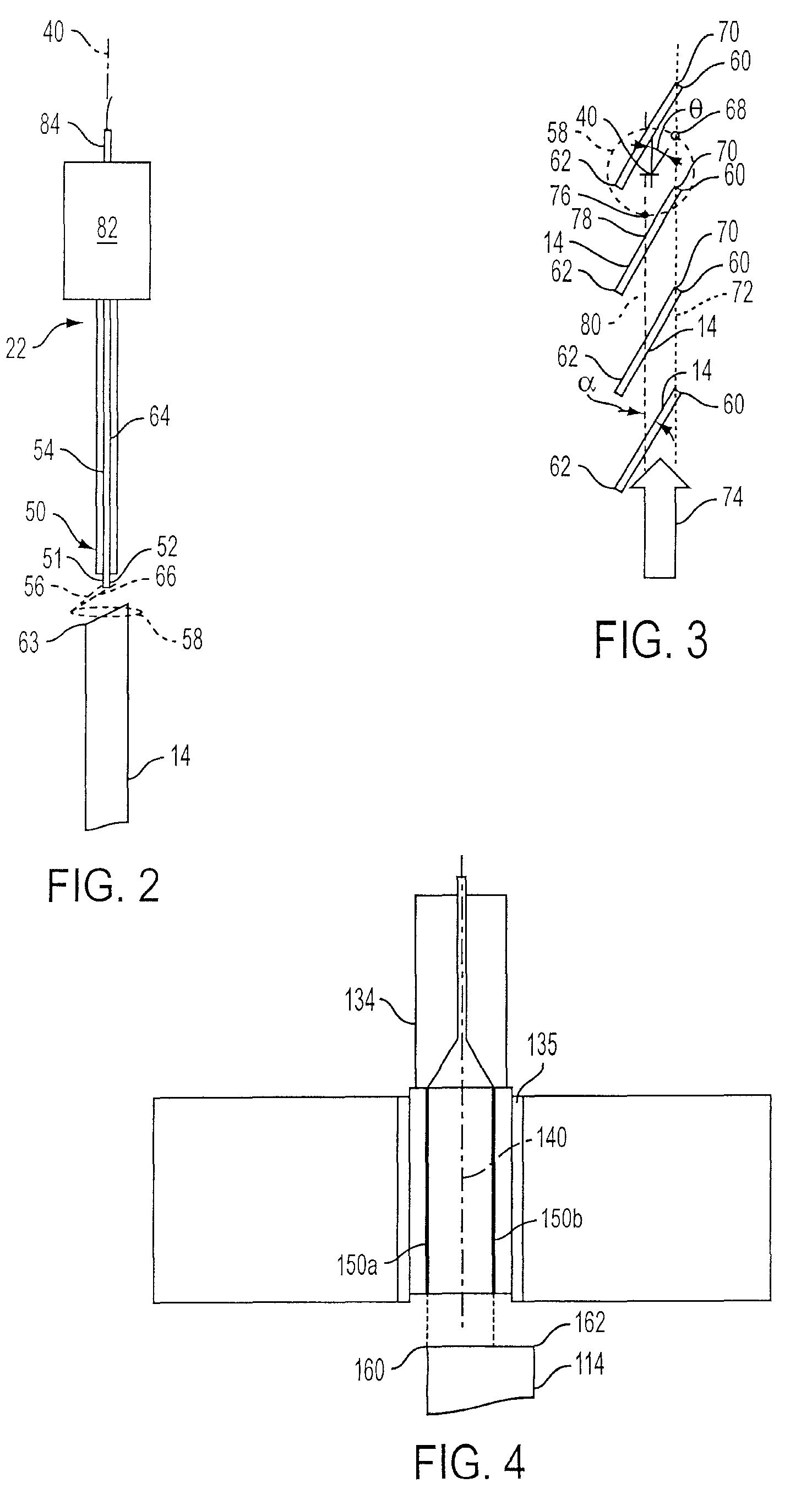

Method and Apparatus for Tracking a Rotating Blade Tip for Blade Vibration Monitor Measurements

InactiveUS20090078053A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurementLeading edge

A method and apparatus for monitoring vibrations in a blade structure of a turbine including generating signals from a probe located adjacent to a radial outer edge of the blade structure to provide signals corresponding to vibrations at predetermined locations along the tips of the blades. A leading edge of a blade tip is detected during a blade tracking operation, and a known location along the length of the blade tips is monitored during a vibration measurement operation. The measurement operation may be performed simultaneously with the tracking operation to provide measurements as the axial location of the blades change during transitional modes of operation of the turbine.

Owner:SIEMENS ENERGY INC

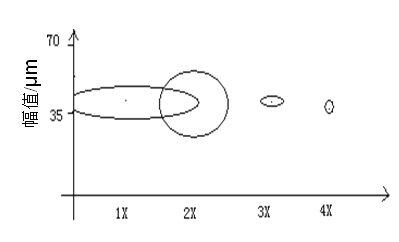

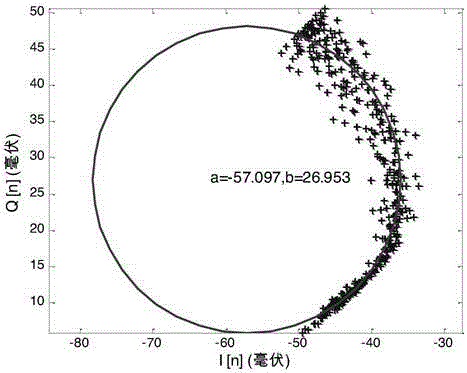

Fault diagnosis method for rotary machine

InactiveCN101929917AVibration signatures can be distinguishedAvoid misjudgmentMachine part testingVibration testingVibration measurementAnti-aliasing

The invention relates to a fault diagnosis method for a rotary machine, comprising the following steps: acquiring original vibration signals of two perpendicular channels on a vibration measurement section, and carrying out anti-aliasing filtering, low pass filtering and the like on collected signals; removing unnecessary interference noise signals, adopting complex FFT conversion to calculate a primary vibration vector a and a secondary vibration vector b; further calculating relevant numerical values of a vector area and a vector vibration ratio and obtaining graphs of the vector area and the vector vibration ratio relative to various variables; and utilizing the vector area to express the vibration strength and direction of a measuring point under single frequency, and utilizing the vector vibration ratio to express eccentricity size, flat degree and forward and reverse precessional motion of a vector ellipse. The method has the advantage of good effect in diagnosing the steady-state faults and instantaneous faults of the rotary machine; and the vector area graph and the vector vibration ratio are combined to diagnose the faults, thus the erroneous judgment generated by only utilizing the vector area is avoided, the diagnosis accuracy is enhanced, and the diagnosis efficiency and precision are improved.

Owner:陈先利 +1

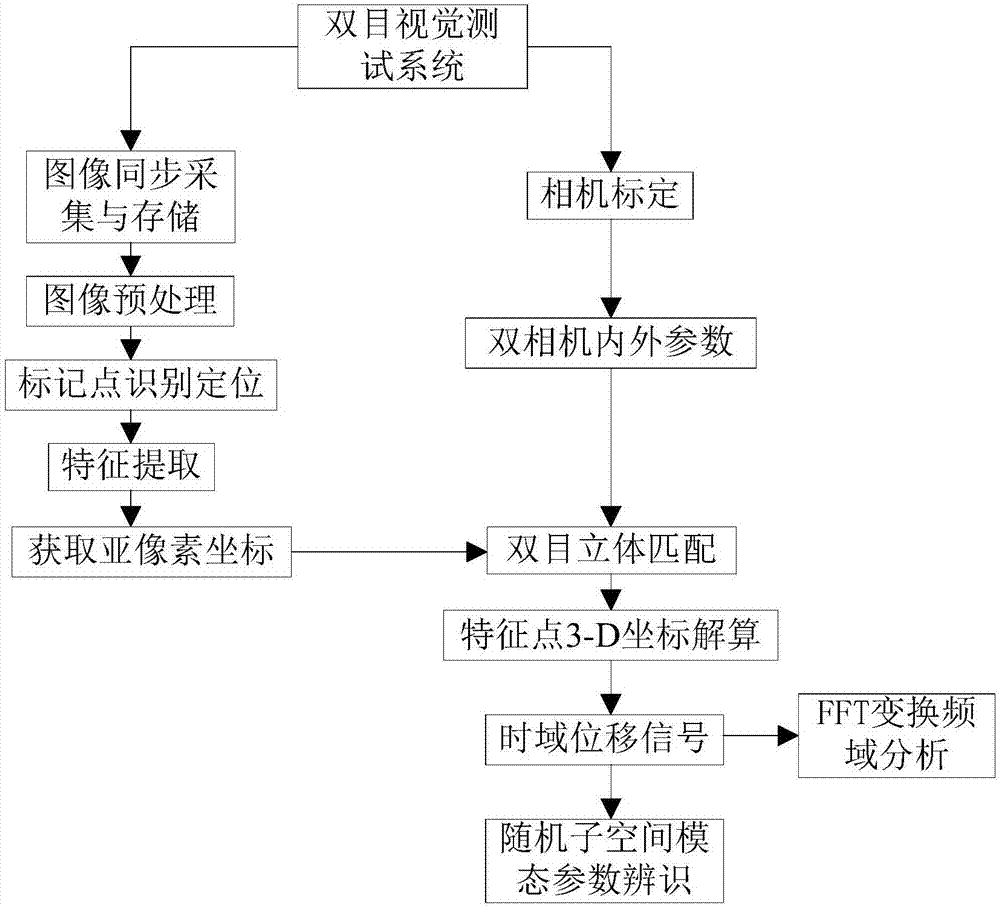

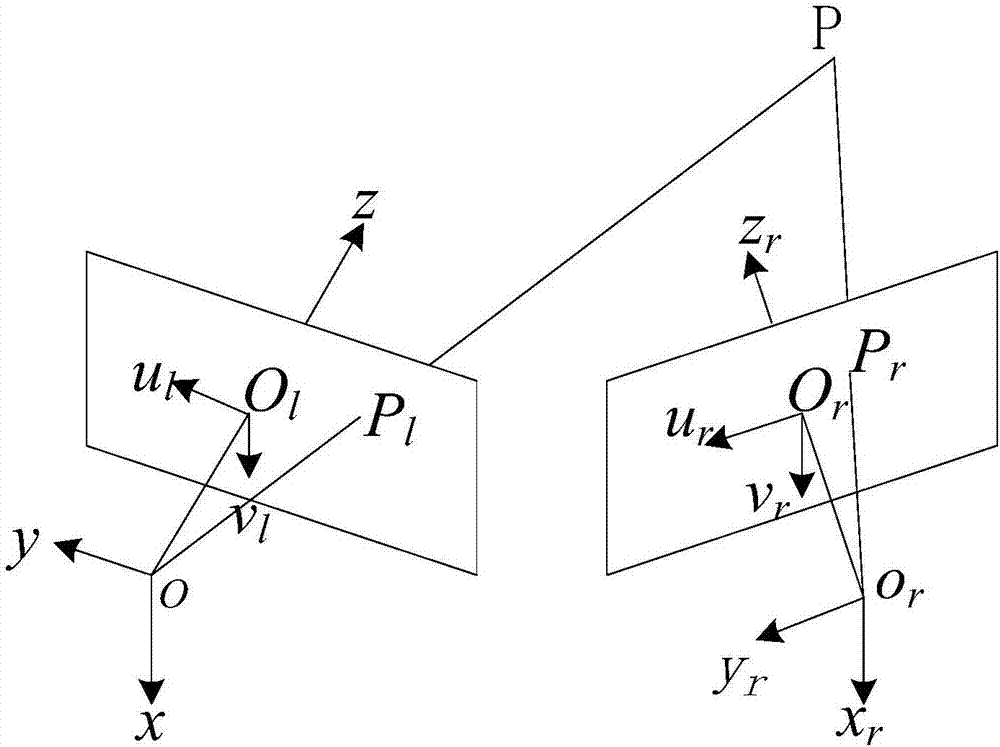

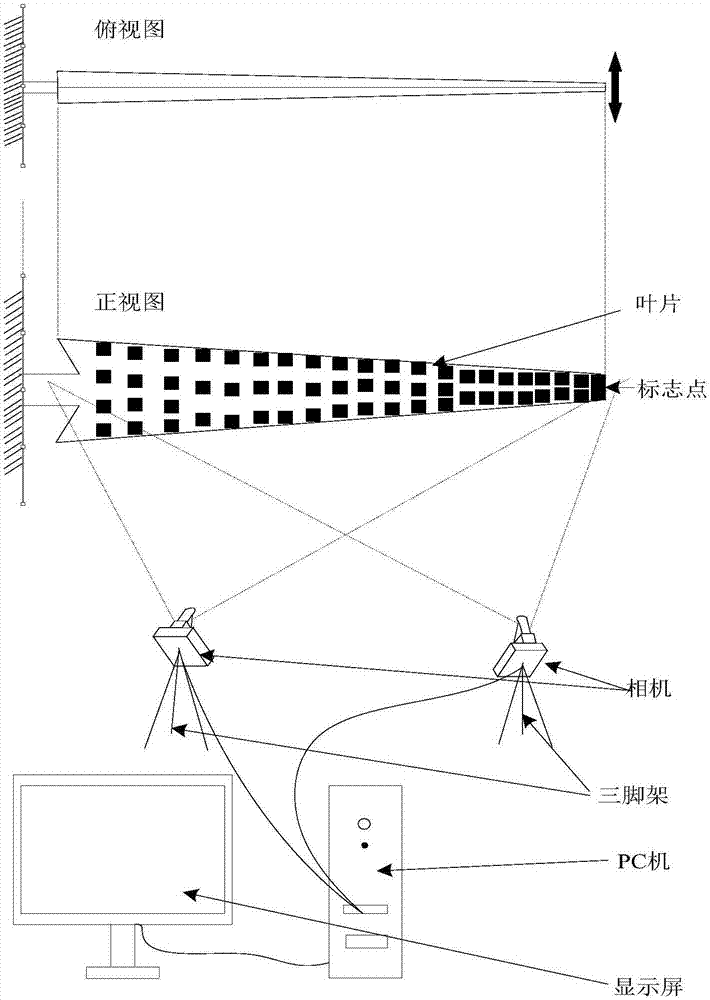

Modal test method of large draught fan blade based on photography measurement technology

ActiveCN106989812AThe influence of dynamic characteristicsRealize non-contact measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement pointFourier transform on finite groups

The invention discloses a modal test method of a large draught fan blade based on the photography measurement technology. The method comprises steps of using a pair of CMOS / CCD industrial cameras to carry out synchronous shooting on surface images of the draught fan blade under random excitation vibration; identifying and positioning multiple marking points in the images; extracting central sub-pixel level coordinates of the marking points and carrying out stereo matching of the double cameras; calculating three-dimensional coordinates of each measurement point through the three-dimensional reconstruction technology; carrying out micro-division processing on displacement data to obtain required vibration response (speed and accelerated speed) signals; through the Fourier transform, converting time domain signals into observation peak values in frequency domains to find corresponding modal frequencies; by combining analyzed frequency values, further using the stochastic subspace identification method (SSI) to precise calculate modal parameters of the blade; and acquiring the fixed frequency, the vibration mode and the damping ratio of the blade. According to the invention, by use of non-contact type multi-point synchronous vibration measurement, rapid high-precision model test on the draught fan blade can be achieved.

Owner:HUNAN UNIV OF SCI & TECH

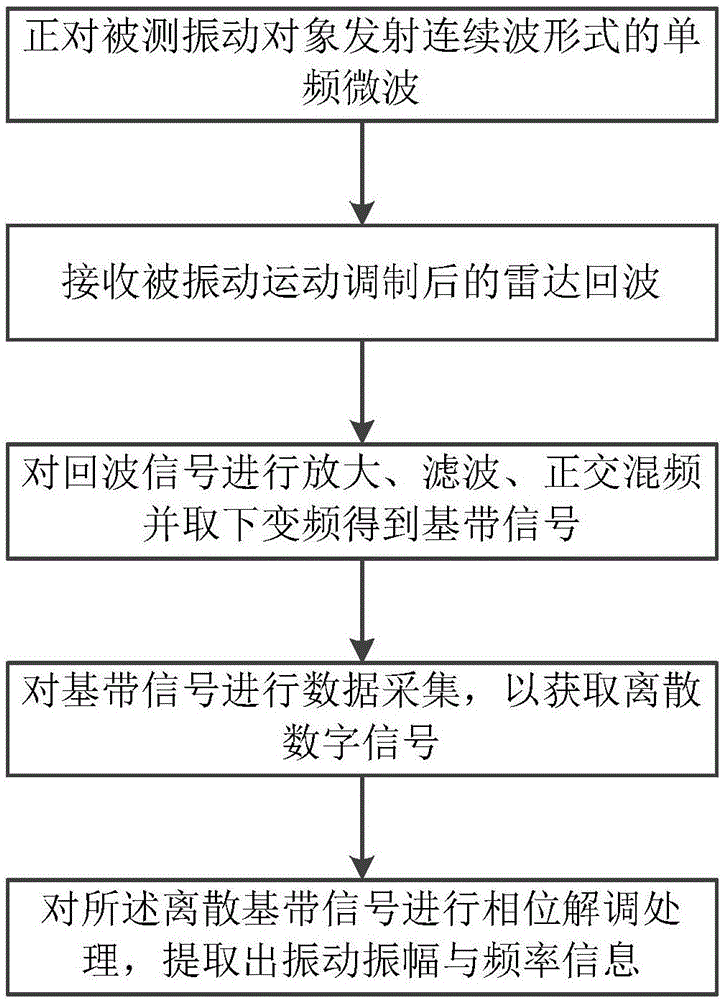

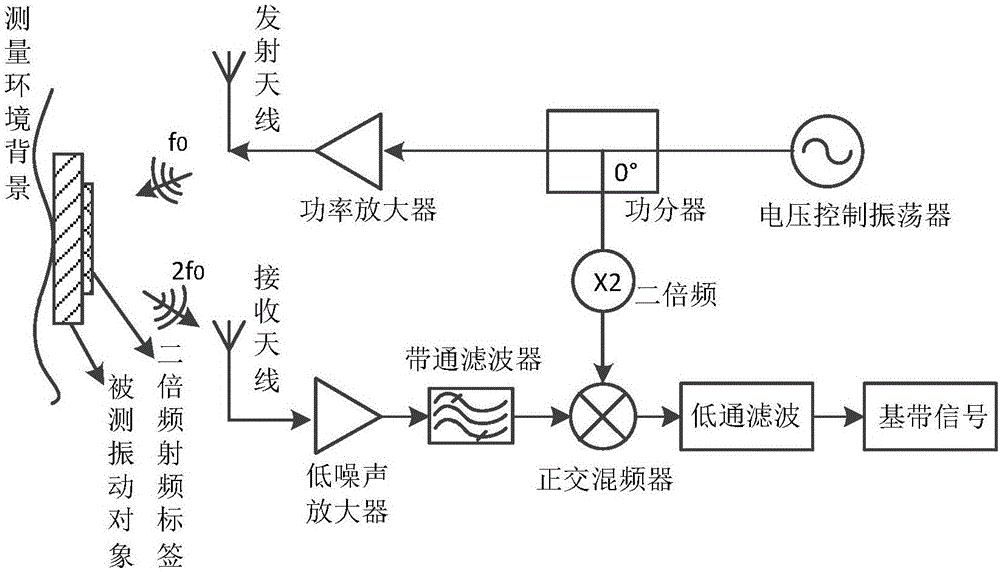

Doppler radar-based non-contact type vibration measuring method

ActiveCN106644030AReduce power consumptionCompact structureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration amplitudeData acquisition

The invention discloses a Doppler radar-based non-contact type vibration measuring method. The method includes the following steps: S1. directly facing a measured vibration object to emit single-frequency microwaves in the form of continuous waves, and receiving radar echoes after modulation by vibration motion; S2. performing amplifying, filtering and quadrature mixing on echo signals and taking down conversion signals to obtain two paths of baseband signals I(t) and Q(t); S3. performing data collection on the baseband signals to obtain discrete digital signals; and S4. performing phase demodulation processing on the discrete baseband signal I[n] and Q[n], and extracting vibration amplitude and frequency information. The Doppler radar-based non-contact type vibration measuring method provided by the invention uses a microwave radar to perform non-contact type vibration measurement based on a Doppler effect, has good low frequency measurement sensitivity, is high in environmental adaptation, and can perform accurate vibration measurement under the condition of containing a barrier. The microwave radar used by the method is compact in structure and low in cost and has relatively low power consumption, thereby providing a solution to integration of a large-scale vibration measuring system.

Owner:SHANGHAI JIAO TONG UNIV

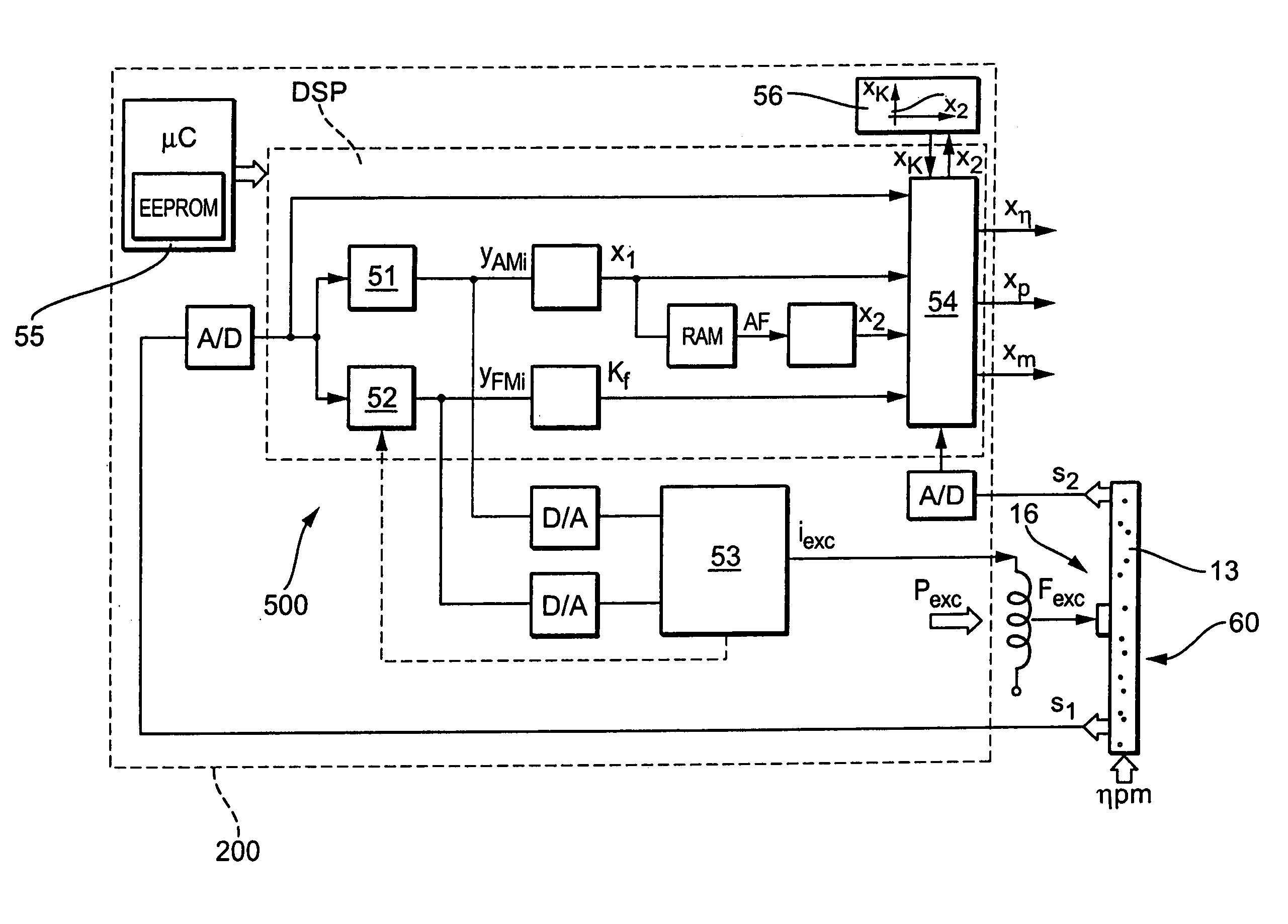

In-Line measuring devices and method for compensation measurement errors in in-line measuring devices

ActiveUS20070186686A1Little effortVolume meteringDirect mass flowmetersElectricityMeasurement device

The measuring device comprises, for measuring multi phase mixture, a vibratory-type transducer and a measuring device electronics electrically coupled with the vibratory-type transducer. The transducer includes at least one measuring tube inserted into the course of the pipeline. An exciter arrangement acts on the measuring tube for causing the at least one measuring tube to vibrate. A sensor arrangement senses vibrations of the at least one measuring tube and delivers at least one oscillation measurement signal representing oscillations of the measuring tube. Further, the measuring device electronics delivers an excitation current driving the exciter arrangement. The measuring device is adapted to compensating measurement errors, induced due to the presence of multi phase mixture, based on a movin resonator model (MRM).

Owner:ENDRESS HAUSER FLOWTEC AG

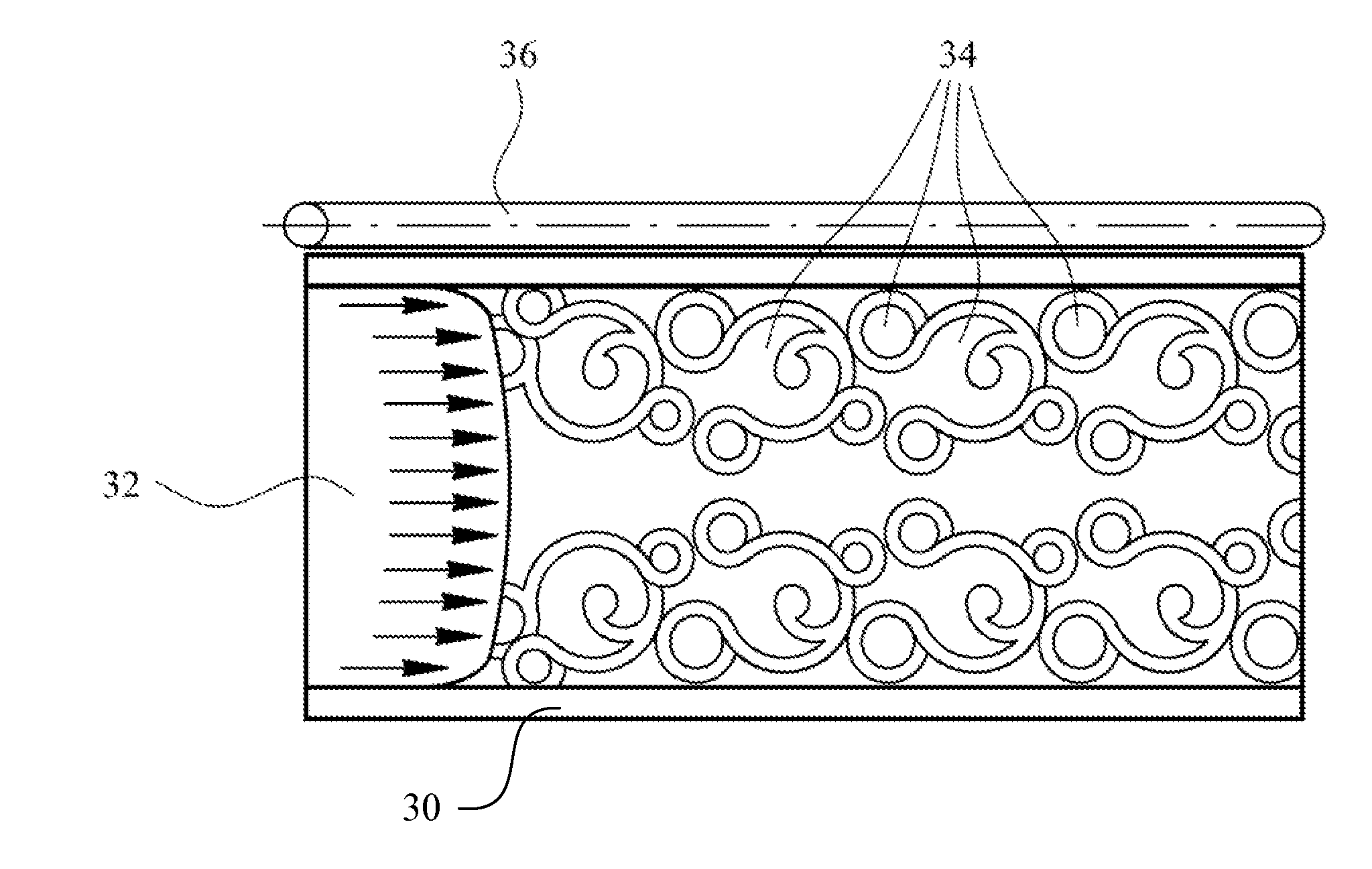

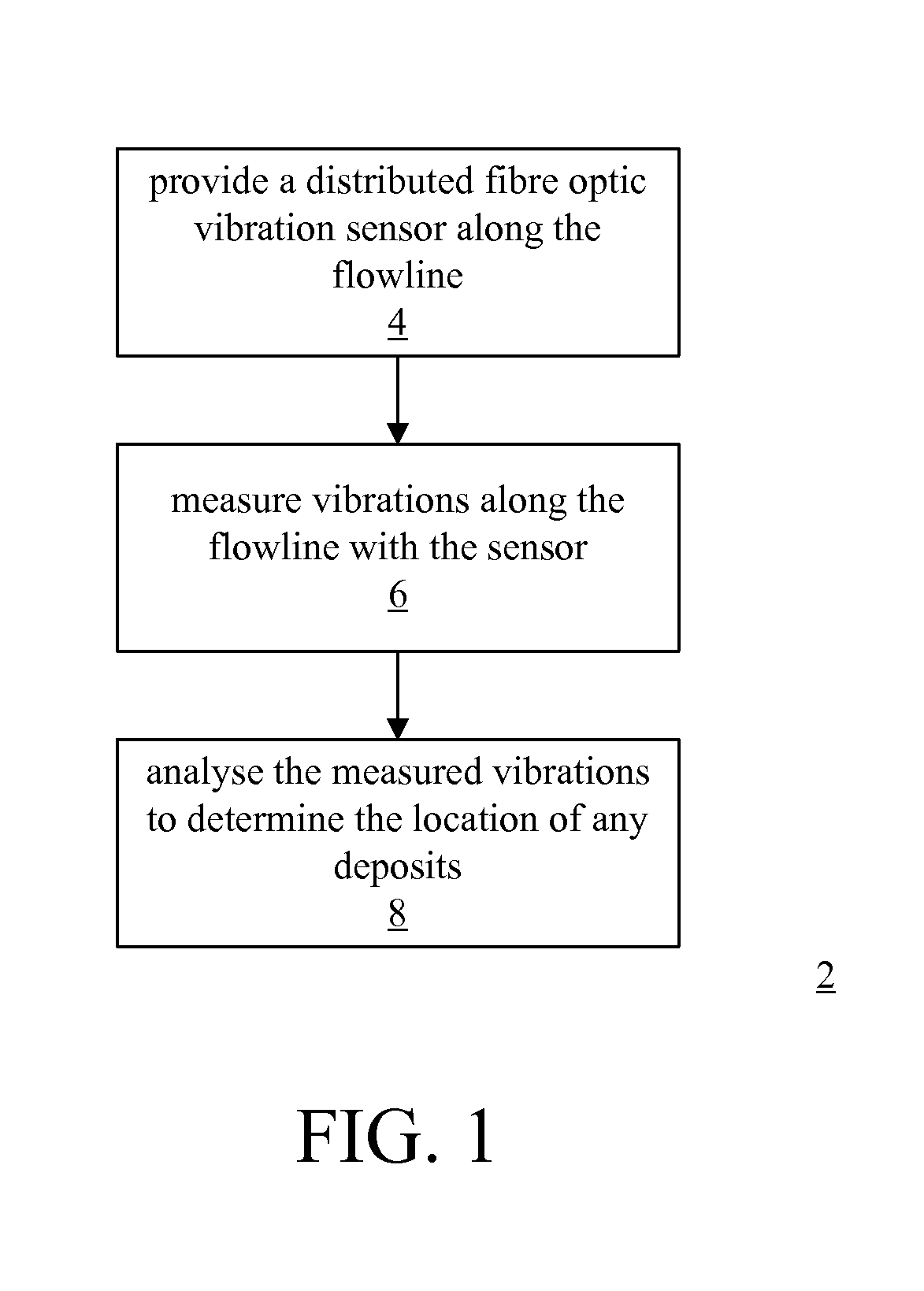

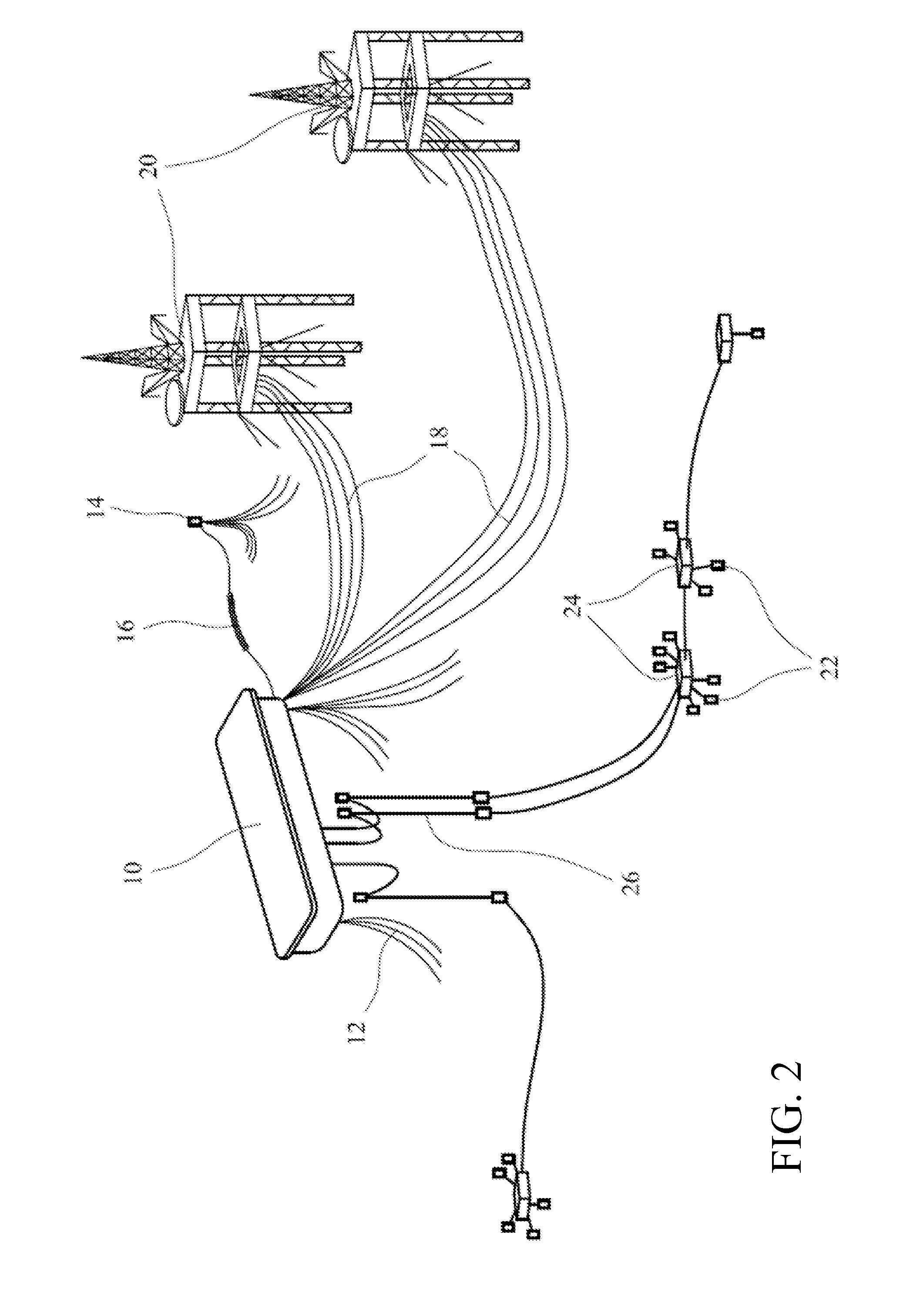

Detection of deposits in flowlines

ActiveUS20110185815A1Simple methodVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurementSediment

A method 2 of determining the location of deposits in a flowline comprises providing 4 a distributed vibration sensor along the flowline, measuring 6 vibrations along the flowline with the sensor and analysing 8 the measured vibrations to determine the location of any deposits. The vibration measurements are made using a distributed fibre optic sensor provided on the flowline. The measurements are analysed in real time to identify deposit formation and location within the flowline.

Owner:SCHLUMBERGER TECH CORP

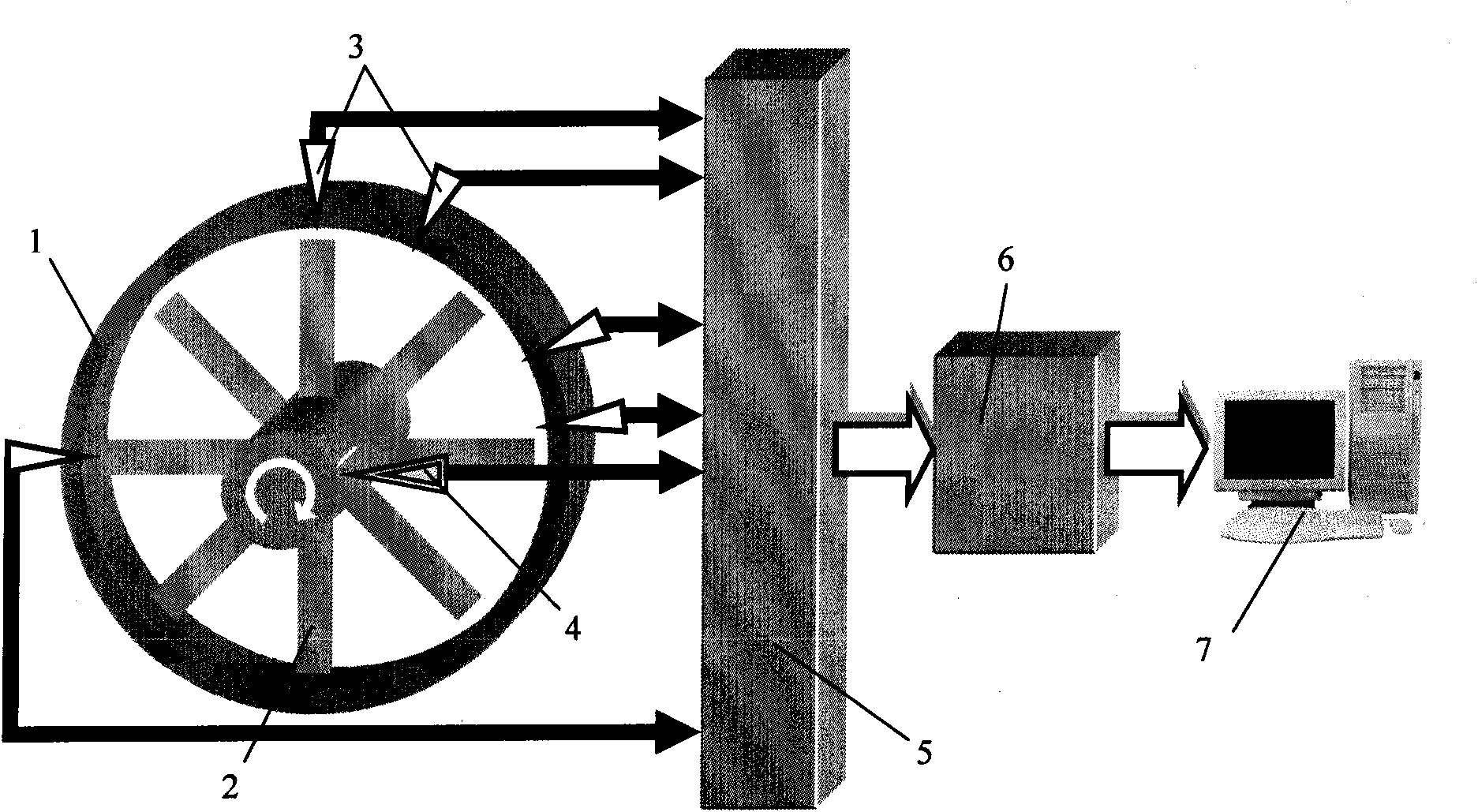

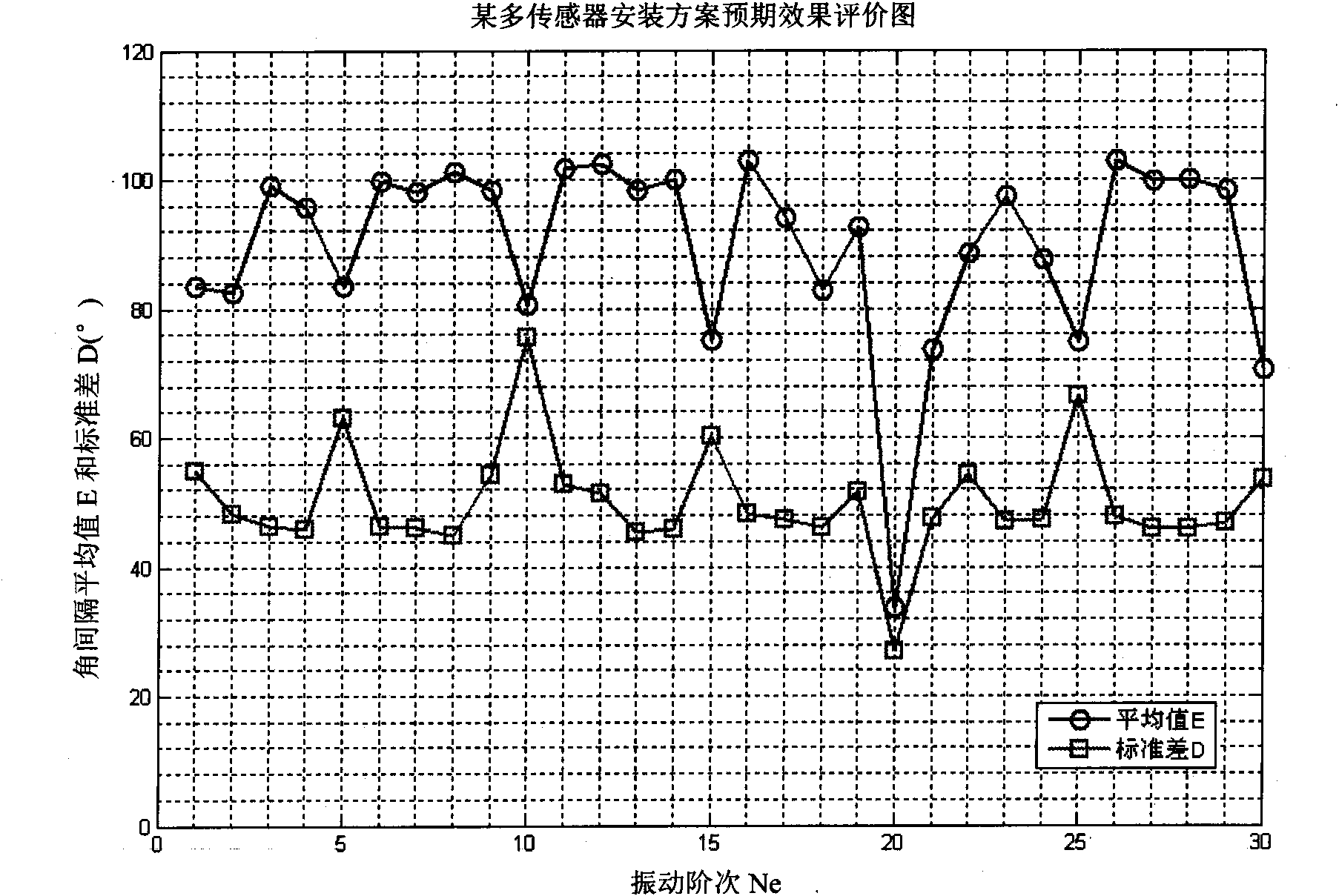

Method for detecting high speed rotating blade synchronous vibration parameters under speed change

ActiveCN101625260AAdaptableAccurate and reliable measurement resultsVibration measurement in solidsResonant frequencyVibration measurementResonance

The invention relates to a method for detecting rotating mechanical blade vibration, in particular to a method for detecting high speed rotating blade synchronous vibration parameters under speed change, aiming at providing a method for detecting high speed rotating blade synchronous vibration parameters under speed change with high resolution preciseness and strong adaptability. The technical proposal of the invention comprises the following steps: step 1, determining a multi-sensor distribution scheme of blade tip timed vibration measurement: firstly pre-estimating the synchronous vibration frequency multiplication Ne possible to occur to the blade to be detected according to the actual detected rotating mechanical performance, and secondly determining the number and distribution condition of the mountable blade tip timed sensors and determining the mounting angles among the sensors according to the actual requirement of the rotating machinery; step 2, carrying out synchronous vibration measurement according to the above determined scheme; and step 3, adopting the traversal method to precisely obtain blade resonance frequency multiplication Ne, natural frequency fn and other parameters. The invention is mainly used for detecting rotating mechanical blade vibration.

Owner:ZHEJIANG ZHONGXIN POWER MEASUREMENT & CONTROL TECH

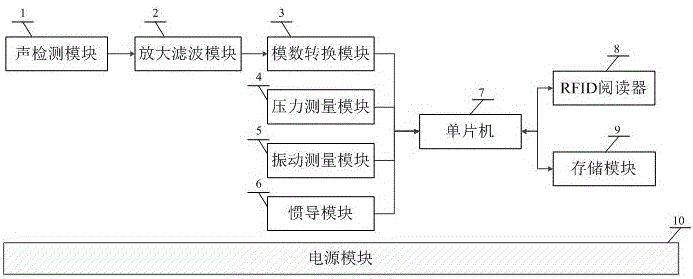

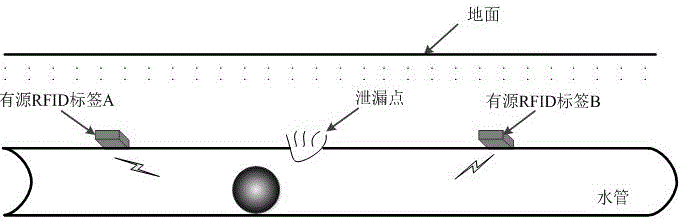

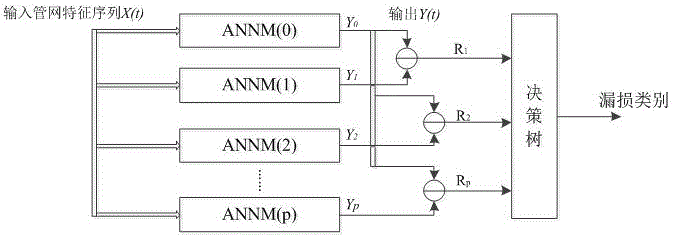

Intelligent in-pipe detection ball device for leakage locating of urban water supply network and method

The invention discloses an intelligent in-pipe detection ball device for leakage locating of an urban water supply network and a method. The device comprises a sound detection module, an amplifying and filtering module, an analog-digital conversion module, a pressure measurement module, a vibration measurement module, an inertial navigation module, a single-chip microcomputer, an RFID reader, a storage module and a power module. The detection ball device is put into a water supply pipeline and rolls along the inner wall of the pipeline under pushing of water flow; by means of a sound sensor, a pressure sensor and a vibration sensor in the device, whether leakage happens to the water supply pipeline or not is detected based on a multisensor fusion method; and a leakage point is precisely located through the inertial navigation and RFID combination locating manner, and detected leakage information is transmitted to an upper computer through the RFID technology in a wireless manner to be further analyzed and processed. According to the intelligent in-pipe detection ball device and the method, leakage detection and locating can be carried out in the water supply pipeline, and the reliability and accuracy of leakage detection of the water supply network are effectively improved.

Owner:ZHEJIANG UNIV

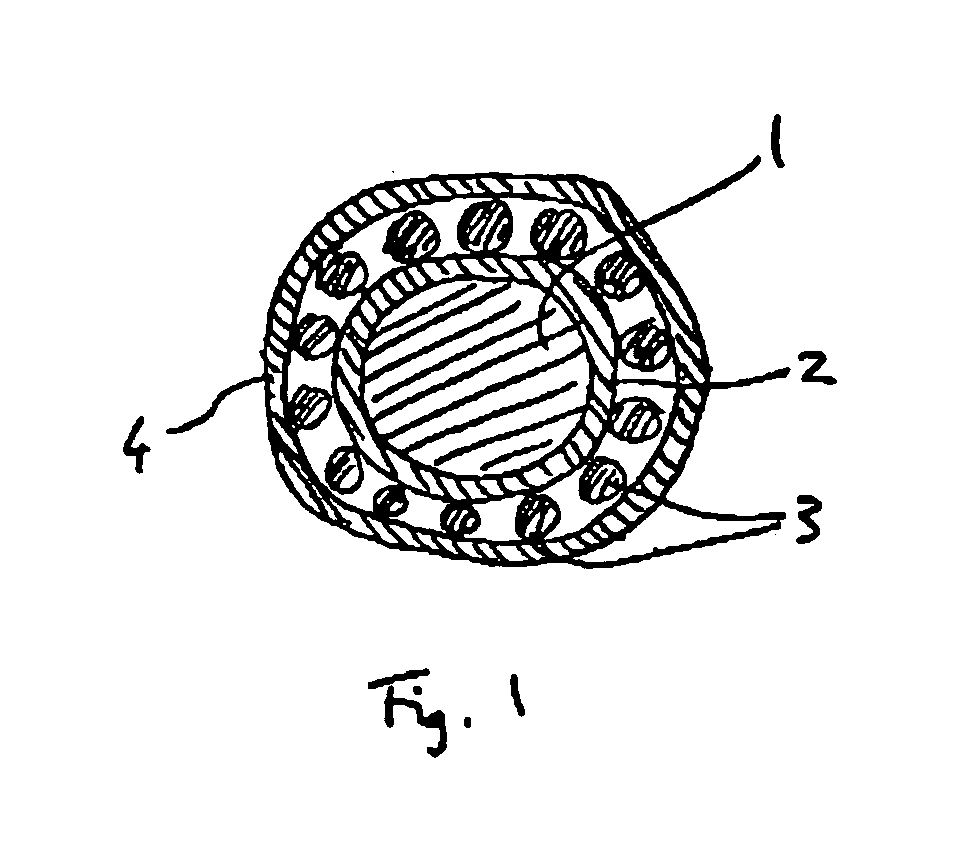

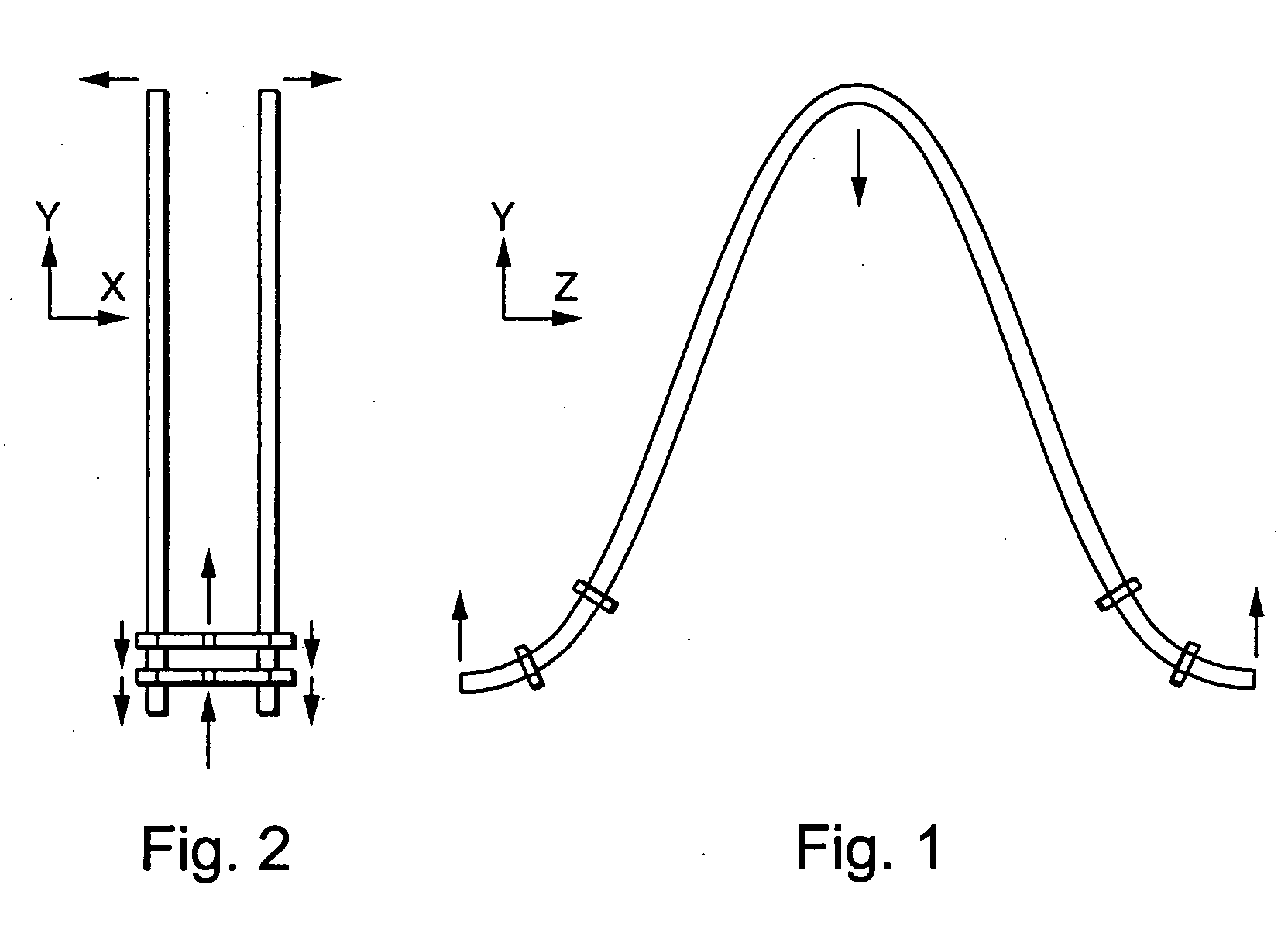

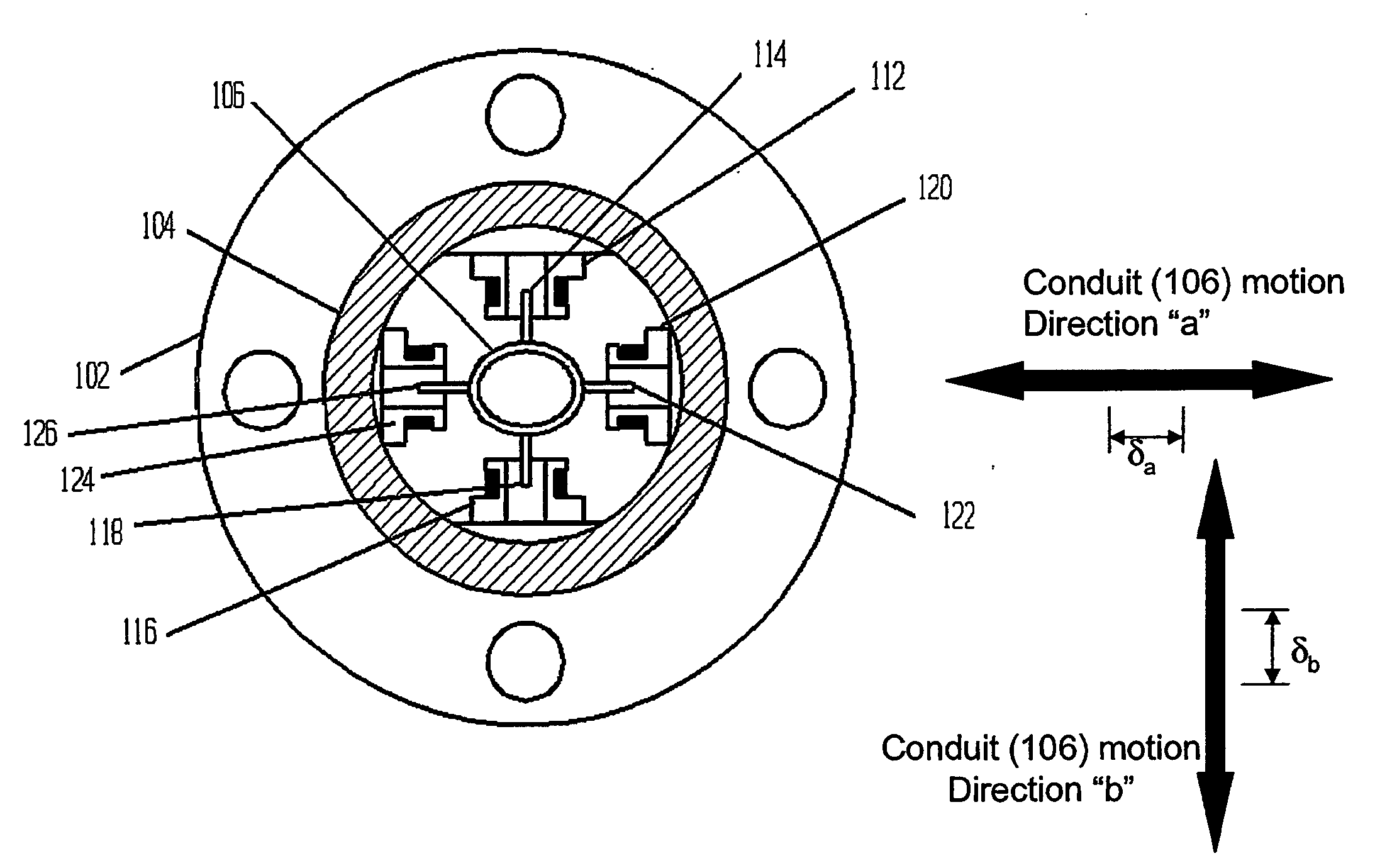

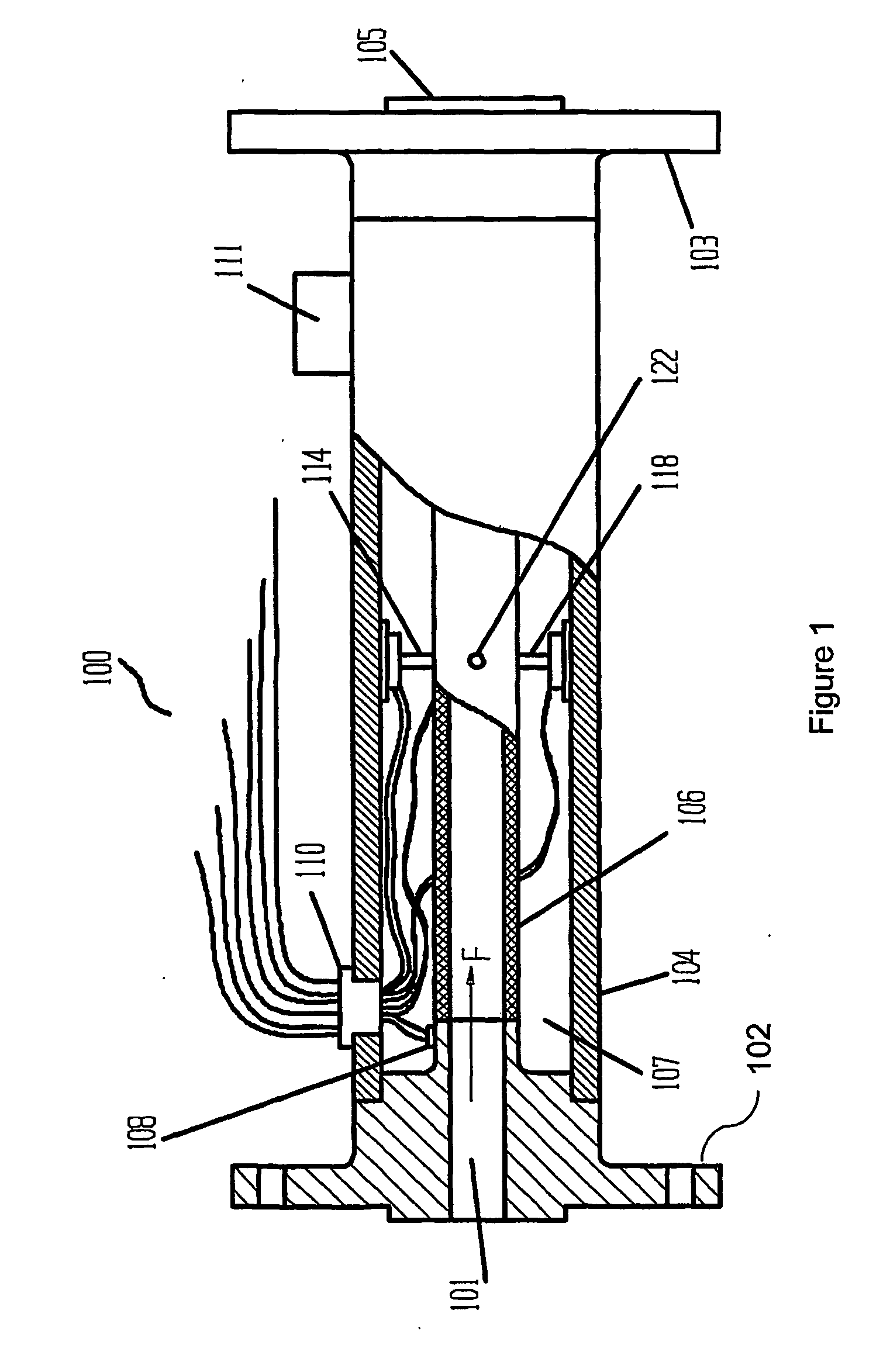

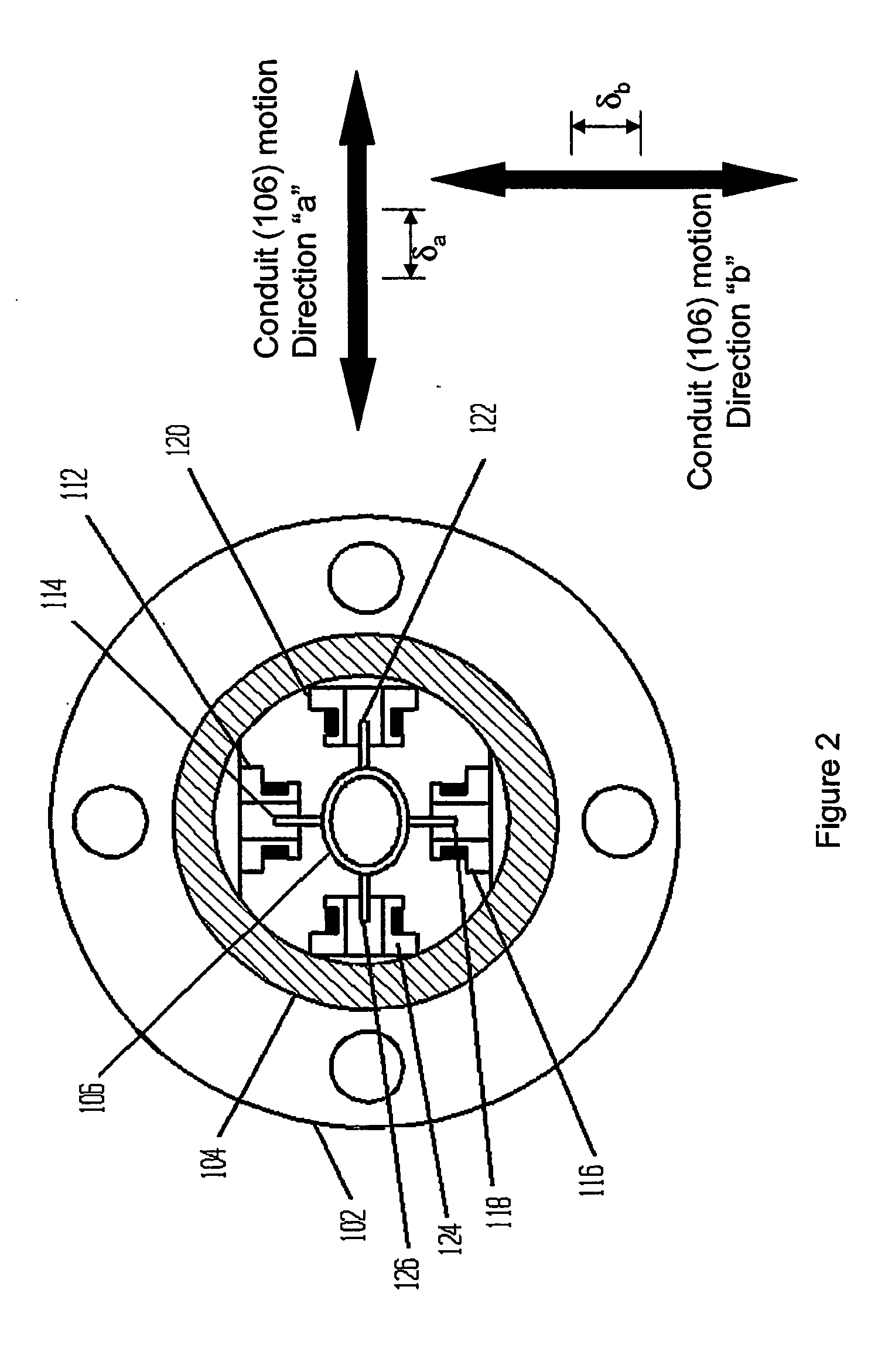

Precise pressure measurement by vibrating an oval conduit along different cross-sectional axes

A conduit (106), with geometry designed to enhance pressure sensitivity, is vibrated at resonance in two modes along different cross-sectional axes (a, b). Measuring the change in the frequency ratio squared of the modes yields a substantially linear relationship to pressure that is substantially immune to other material properties and other environmental factors. Moments of inertia in different cross-sectional axes are related to pressure as a result of the elliptical or oral cross section of the conduit (106).

Owner:CARPENTER BRENT L

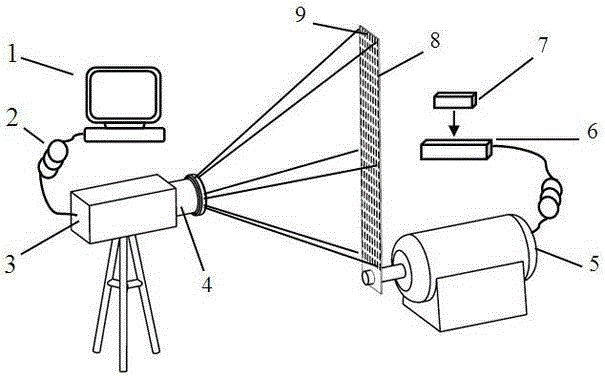

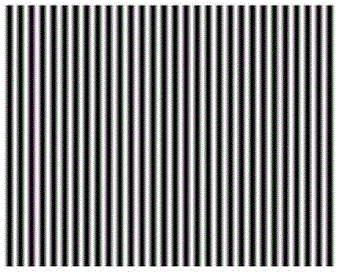

High speed multi-dimensional vibration measuring device and method based on stripe target

ActiveCN104614064AQuick measurementWith displacementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement deviceFourier transform on finite groups

The invention relates to a high speed multi-dimensional vibration measuring device and method based on a stripe target. The device comprises a stripe target, an imaging module, a signal control and processing module and a display module. The method includes the following steps: arranging the stripe target on a vibration structure to be measured; adopting an image module to conduct continuous imaging and recording on the stripe target; utilizing the imaging module to transmit the image of the stripe target to the signal control and processing module; utilizing the signal control and processing module to conduct Fourier transform on the stripes at the same position of the same stripe target in each frame of the image, adopting a certain peak value frequency correction method to accurate correct the peak value frequency, and then utilizing the imaging mathematical relation and the corrected peak value frequency to obtain a time domain curve with stripe target structure vibration, namely acquiring structure vibration signals through reduction; displaying an image processing result through a display module or conducting further data processing through vibration signals. By means of the device and method, vibration measurement of points, lines and faces in certain range is achieved, the measurement speed is high, and the accuracy is high.

Owner:FUZHOU UNIV

Integrated vibration measurement and analysis system

ActiveCN102374876AVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurementRound complexity

A vibration data collection system performs an integration or differentiation process on incoming digitized vibration data in real time. The system uses a digital Infinite Impulse Response (IIR) filter running at the input data rate to provide the integration or differentiation function. With this approach, the system reduces hardware complexity and data storage requirements. Also, the system provides the ability to directly integrate or differentiate stored time waveforms without resorting to FFT processing methods.

Owner:CSI TECH

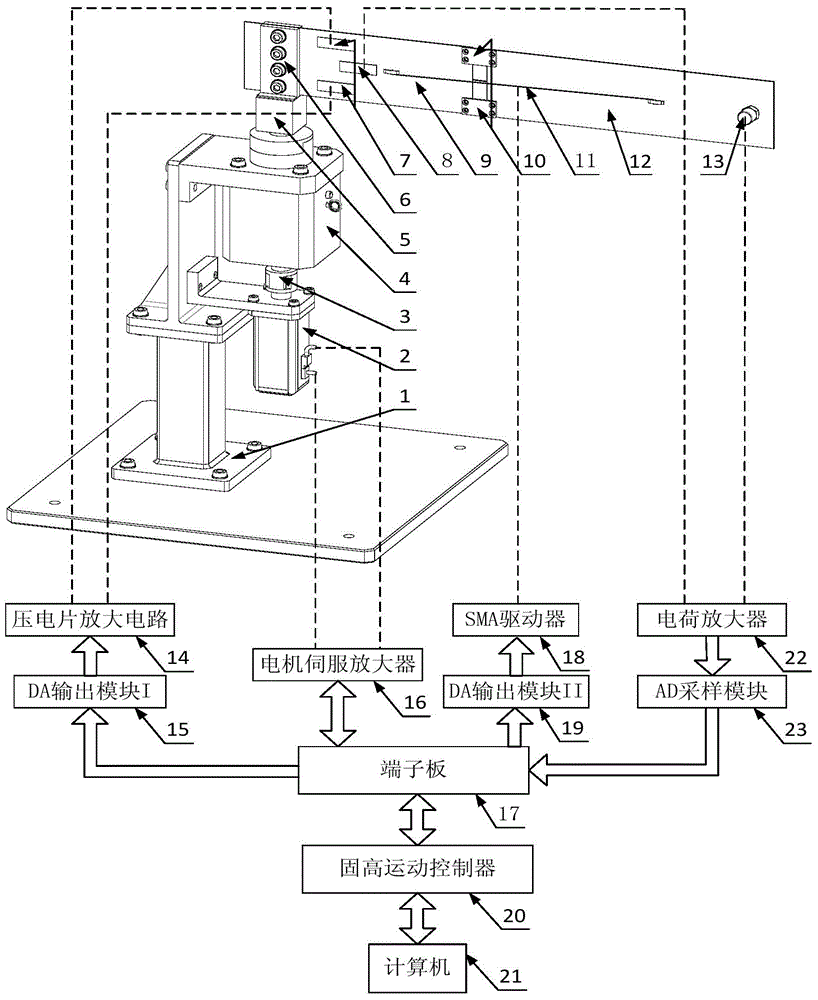

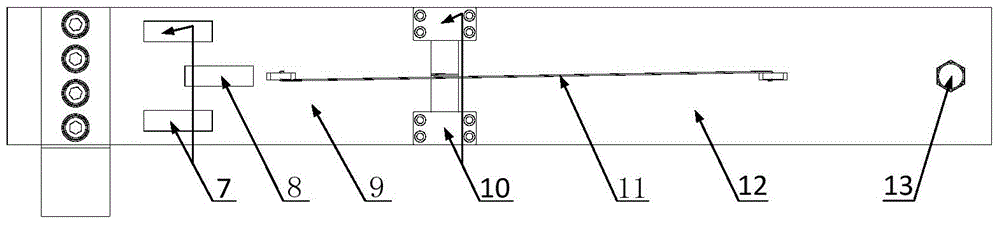

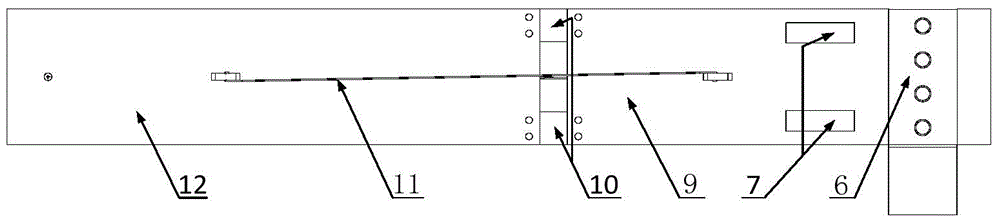

Vibration measurement and control device and method of rotary flexible hinge beam

InactiveCN104006110AGood for studying vibrationsAccurate Experimental PlatformNon-rotating vibration suppressionElectricityVibration measurement

The invention discloses a vibration measurement and control device and method of a rotary flexible hinge beam. The vibration measurement and control device comprises a flexible hinge beam body portion, a vibration signal detecting portion and a driving control portion. The flexible hinge beam is formed by connecting two beams through a hinge, and a prestretching shape memory alloy wire is arranged between the two beams, and is used for restraining low-frequency large-amplitude bending vibration of the connecting position. A piezoelectric ceramic piece sensor and a piezoelectric ceramic piece driver are pasted on to the front face and the rear face, close to a mechanical tightening device, of the flexible hinge beam respectively, and are used for detecting and restraining the bending vibration of the hinge beam. An acceleration sensor used for detecting vibration is arranged at the tail end of the hinge beam. The device is used for simulating vibration measurement and control over a space flexible joint and a flexible mechanical arm, the sensors and the composite control drivers are adopted, the corresponding control algorithm is operated, and active control over the bending vibration of the rotary hinge flexile beam is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com