Patents

Literature

1562results about How to "Large clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

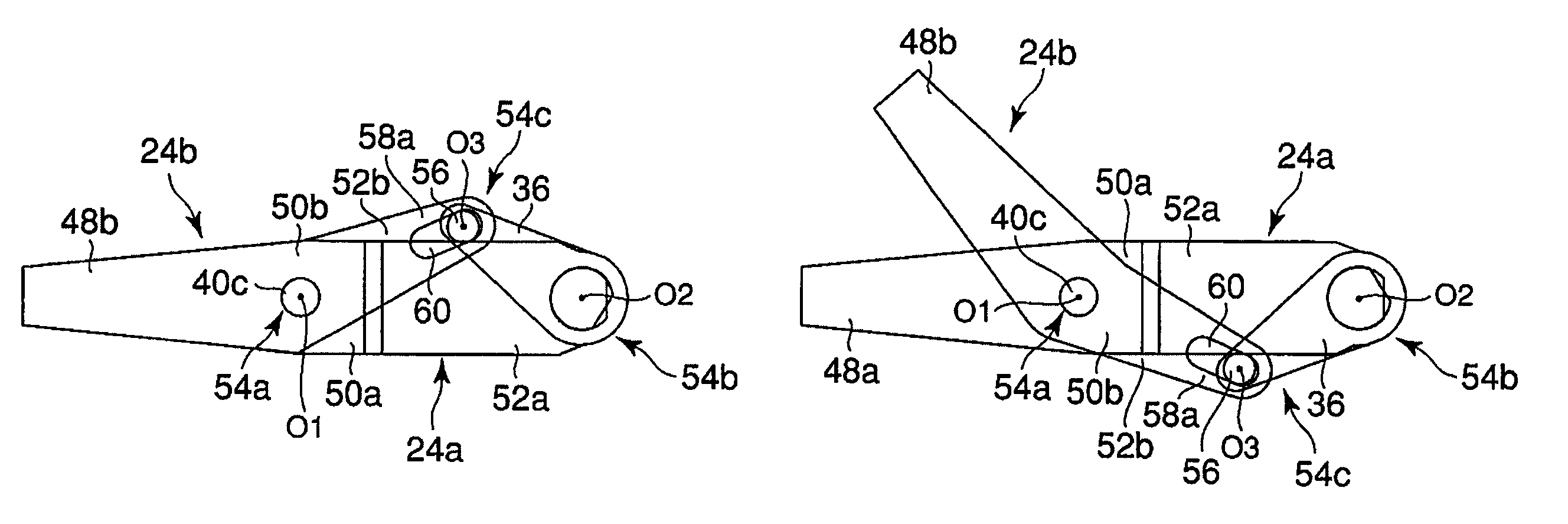

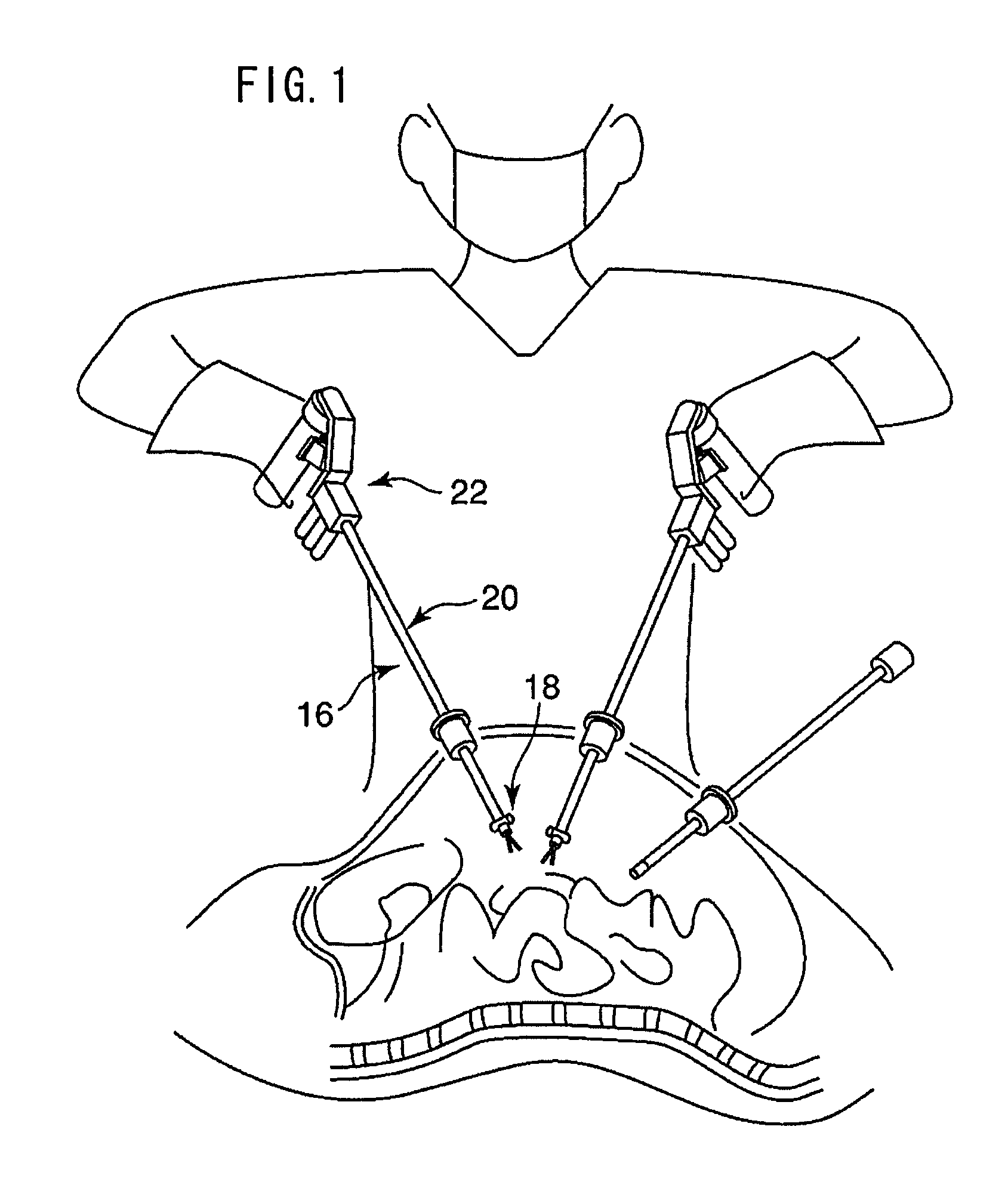

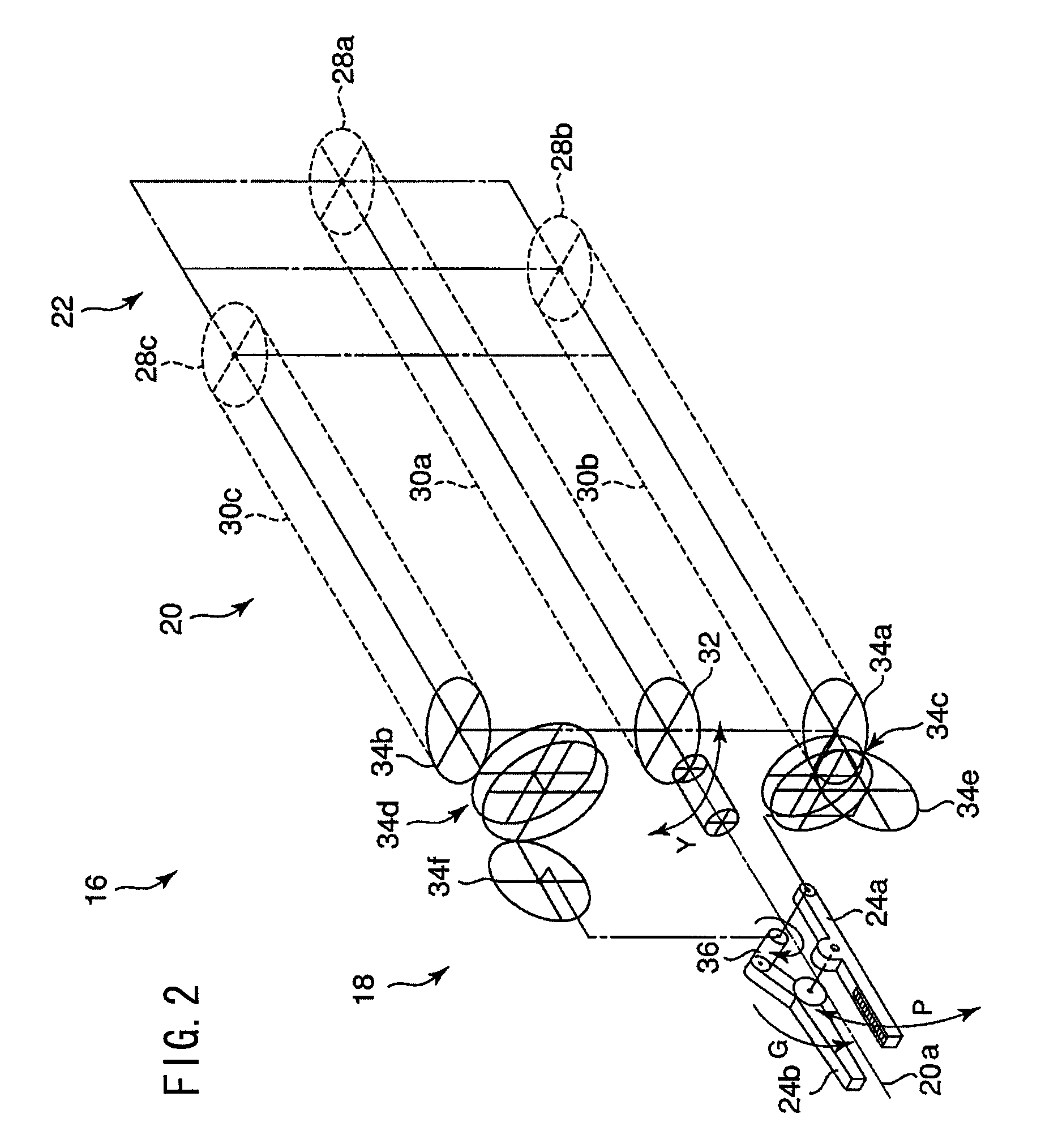

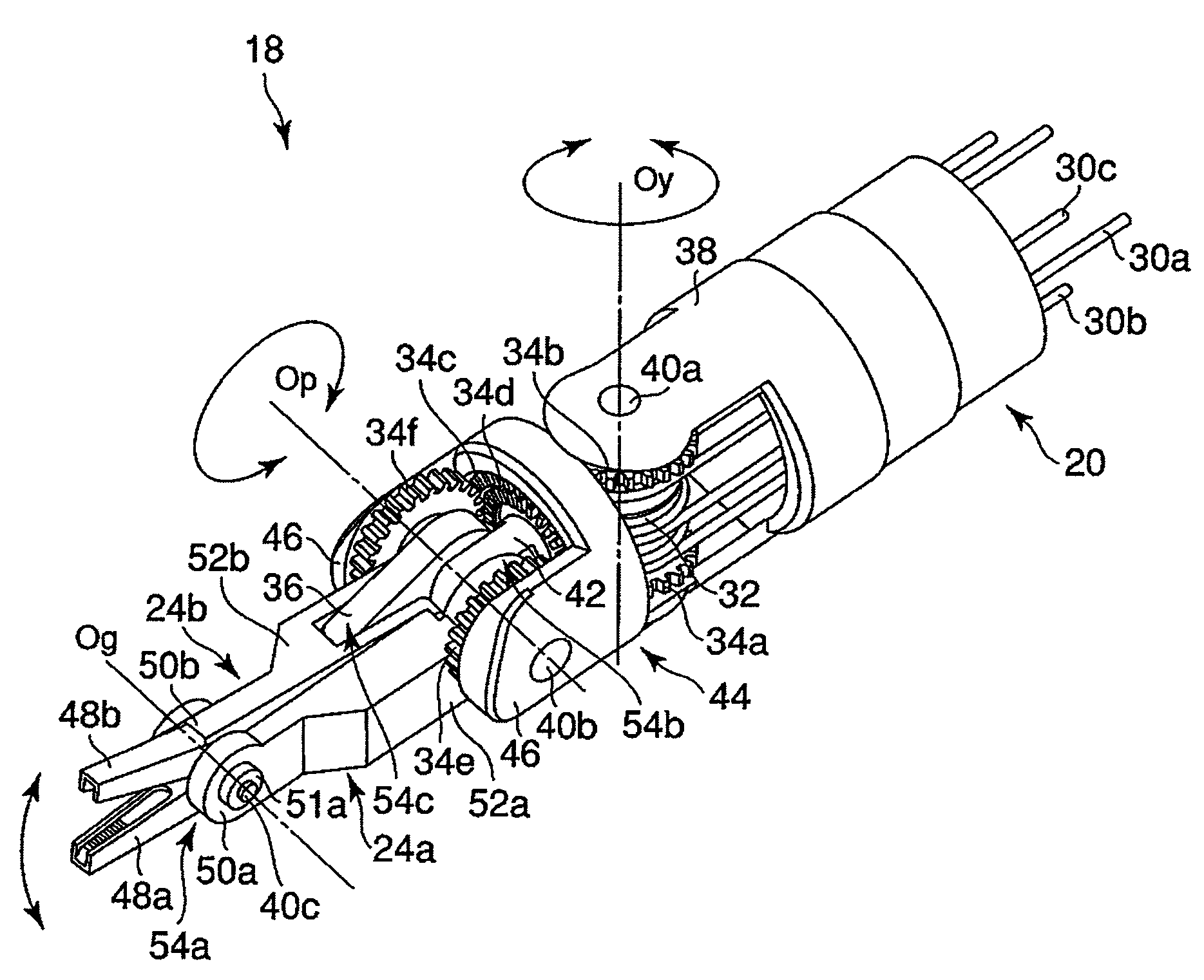

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

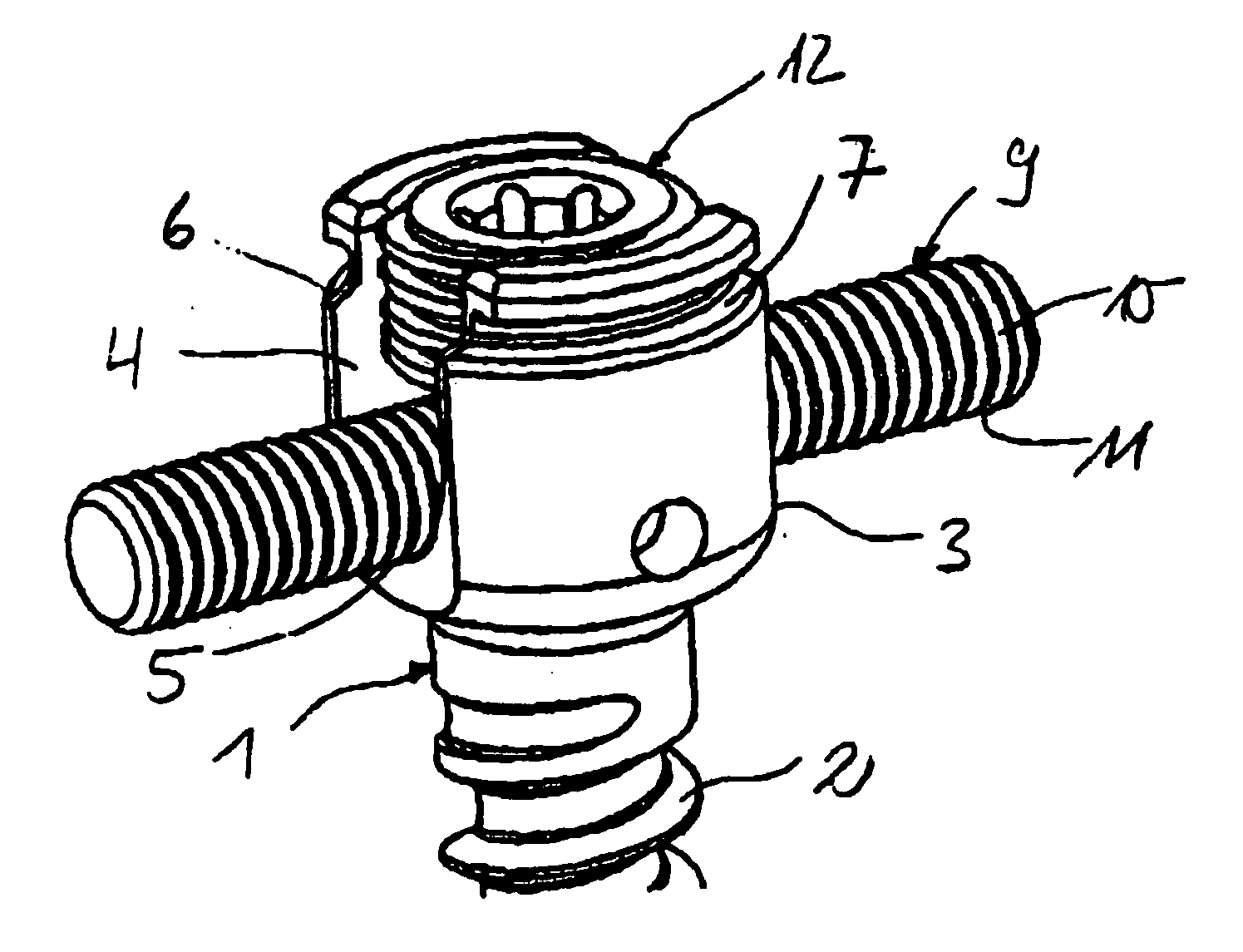

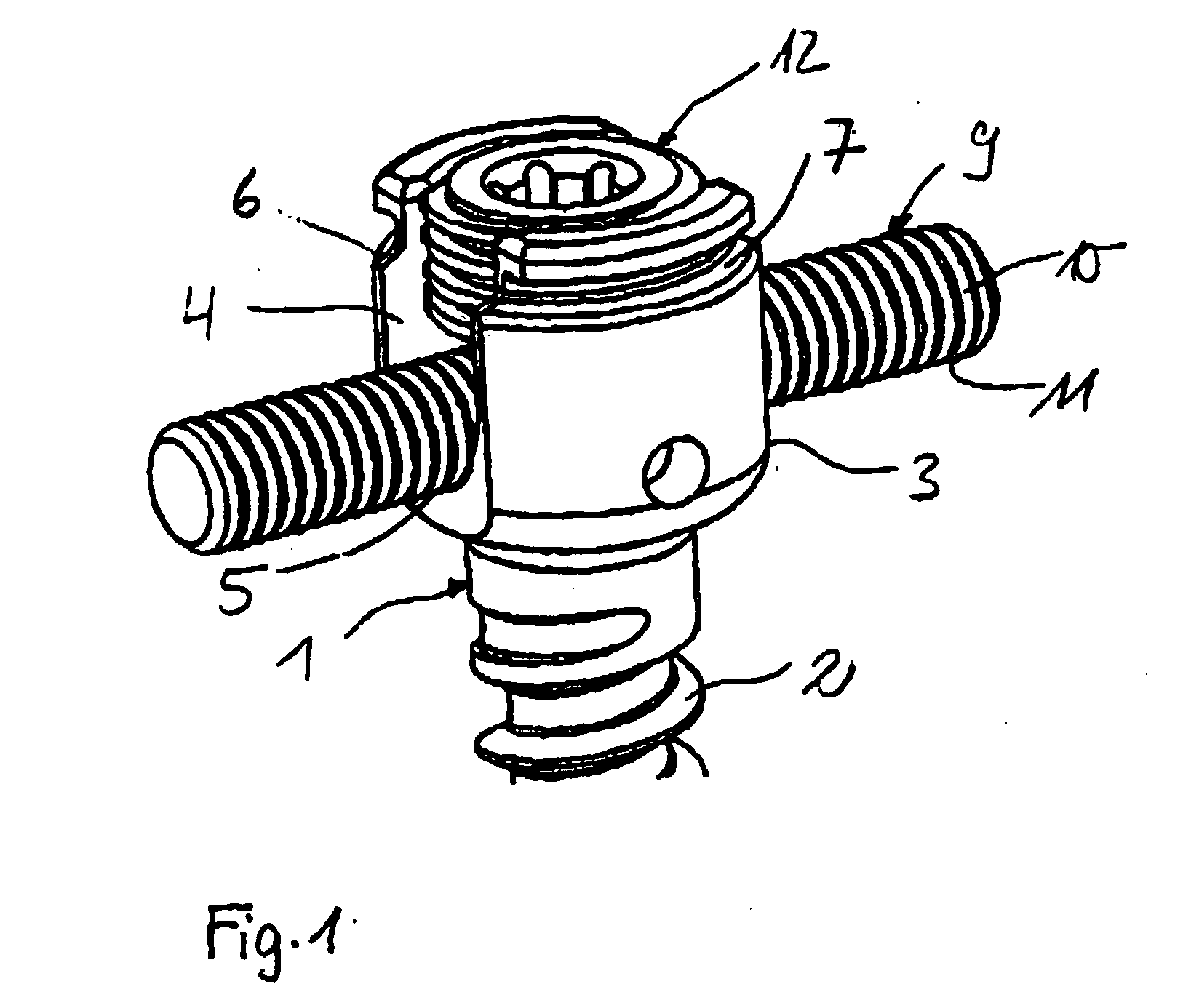

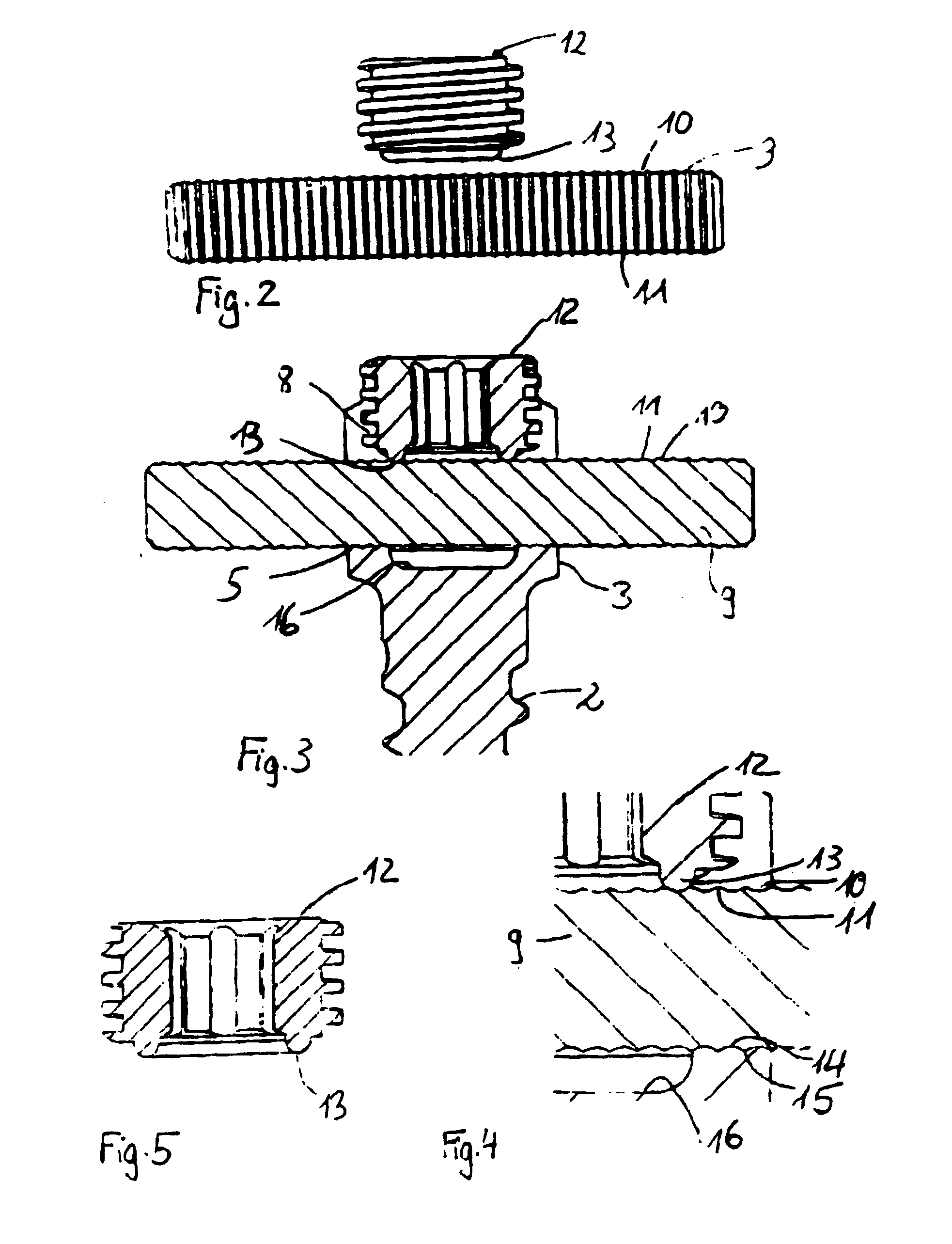

Bone anchoring assembly

InactiveUS20070233086A1Easy to fixHigh strengthInternal osteosythesisJoint implantsTrauma surgeryEngineering

A bone anchoring assembly for use in spinal surgery or trauma surgery includes an anchoring element having a shaft and a receiving part having a substantially U-shaped cross-section with a base connected to said shaft and two free legs forming a channel for receiving a rod having an at least partially structured surface. The bone anchoring assembly further includes a locking member cooperating with the receiving part for locking said rod in the channel. At least on the locking member or in the receiving part an engagement portion for engaging said structured surface of the rod is provided. The locking member, the rod and the receiving part cooperate in such a manner that as soon as the engagement portion comes into engagement with the structured surface the rod is held in the receiving part in a form-locking manner preventing movement of the rod.

Owner:BIEDERMANN TECH GMBH & CO KG

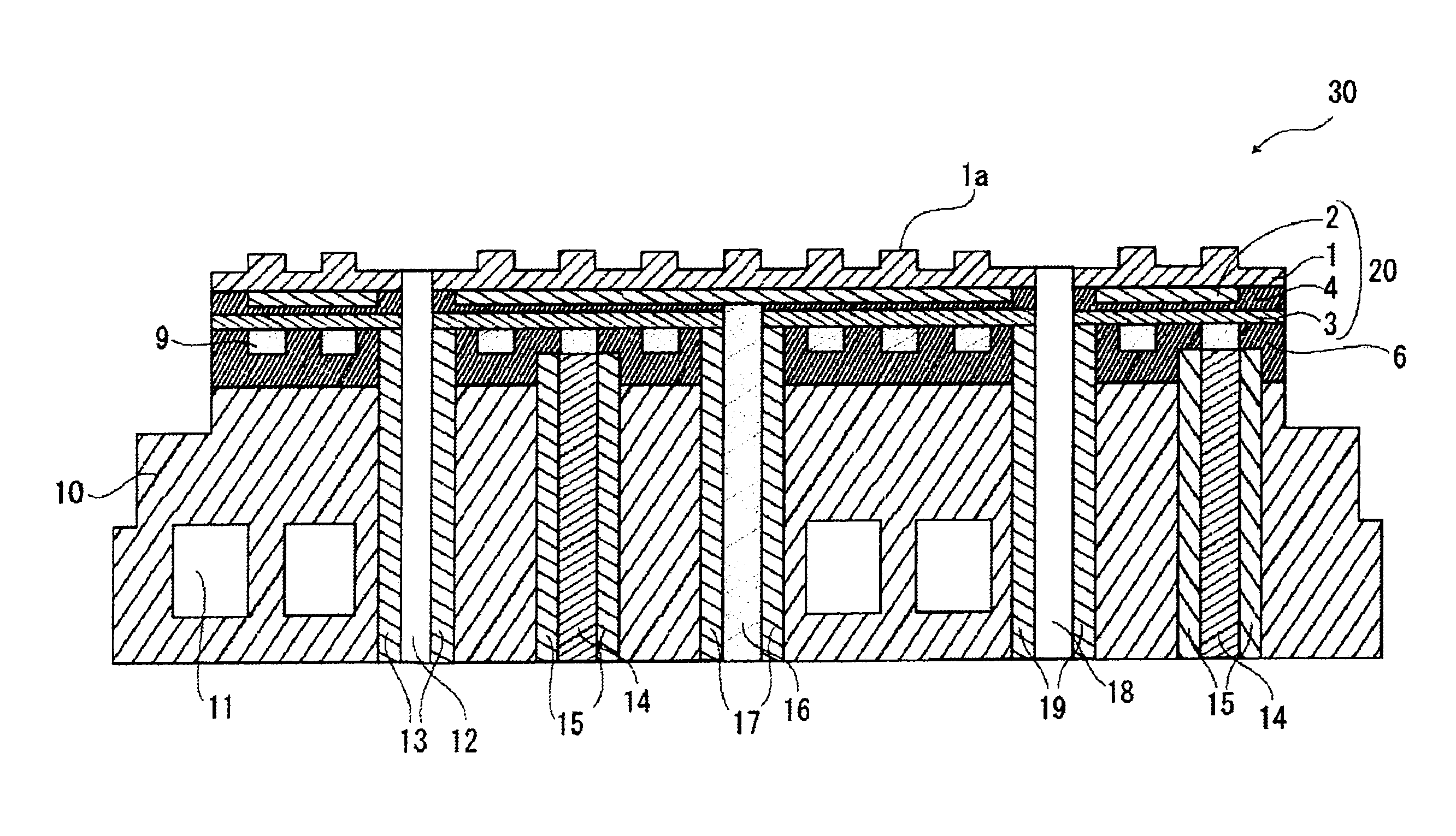

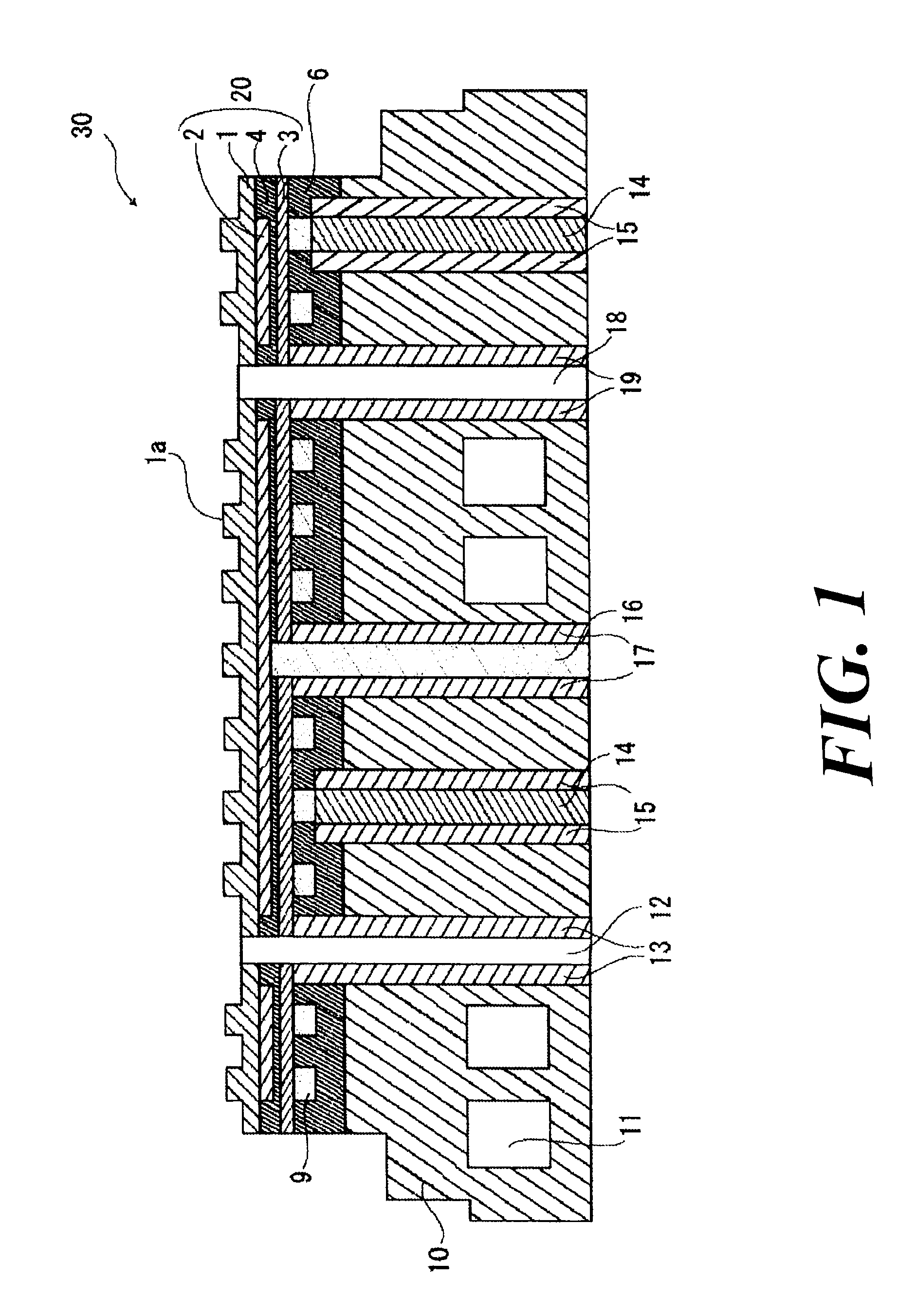

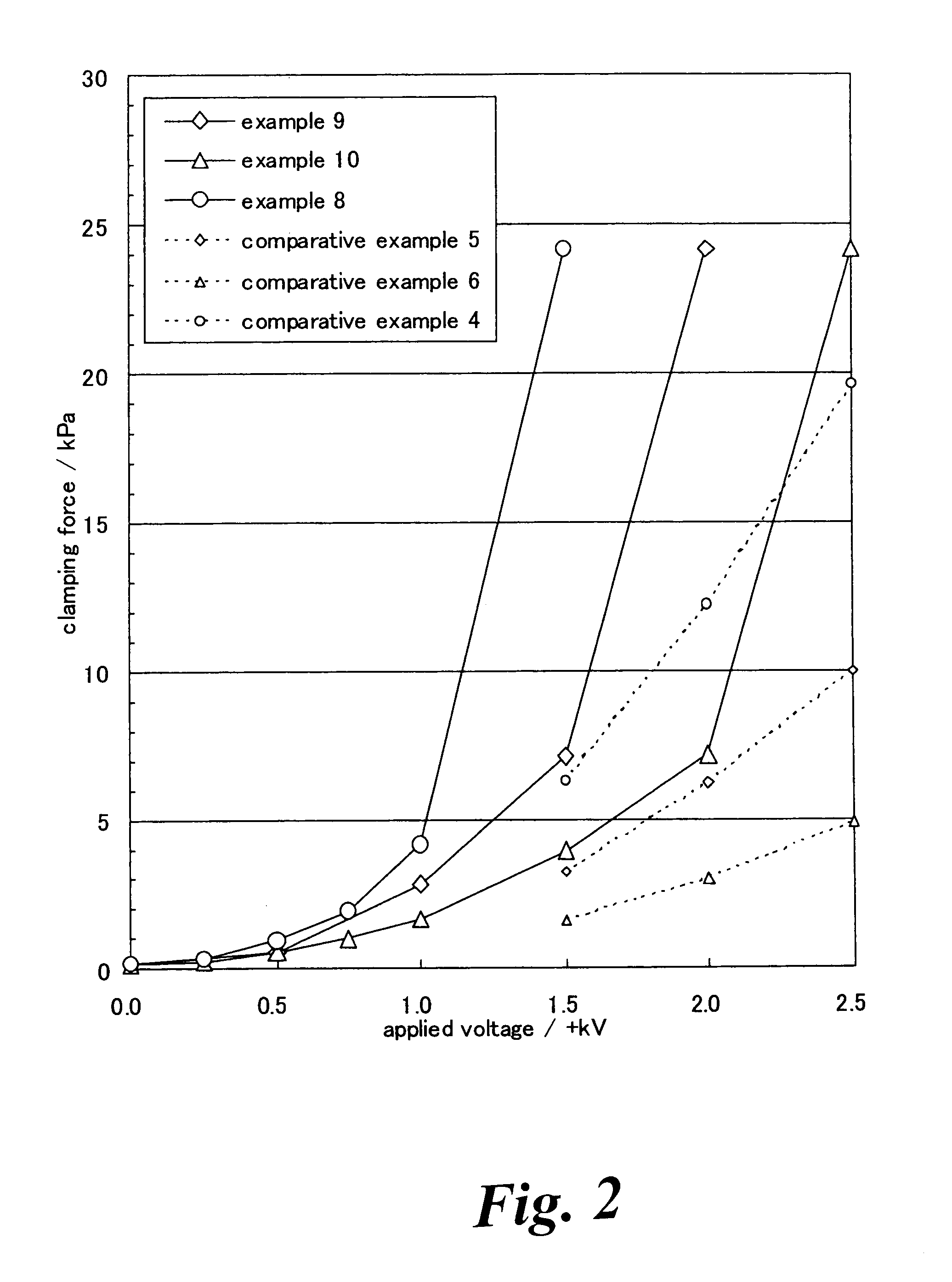

Electrostatic chuck, production method of electrostatic chuck and electrostatic chuck device

ActiveUS20110149462A1Large clamping forceReduce voltageConductive materialSemiconductor/solid-state device manufacturingInsulation layerComposite oxide

The present invention relates to an electrostatic chuck comprising a specific composite oxide sintered body, wherein in the sintered body, an L* value of a reflected color tone measured by a C light source on a 2° angle visual field condition is 10 or more and 50 or less in a CIEL*a*b* color system prescribed in JIS Z 8729-1994 and an electrostatic chuck device comprising an electrostatic chuck member (A) having a tabular body provided with a clamping surface for clamping a sample by the electrostatic force, an internal electrode layer for clamping a sample by electrostatic force which is provided on the back face of the tabular body and an insulation layer, wherein at least the sample clamping surface of the tabular body in the electrostatic chuck member (A) comprises the composite oxide sintered body constituting the electrostatic chuck described above.

Owner:SUMITOMO OSAKA CEMENT CO LTD

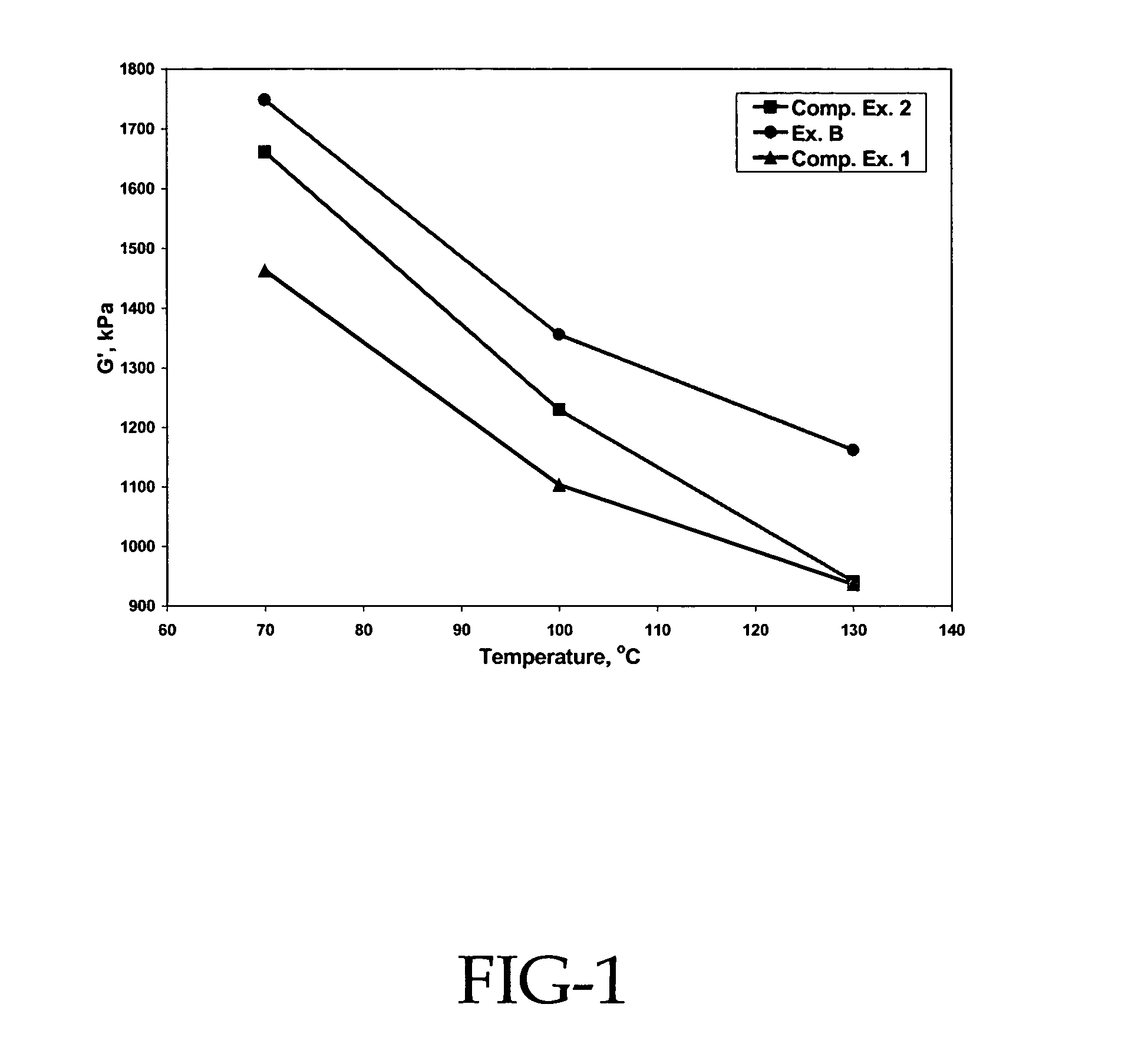

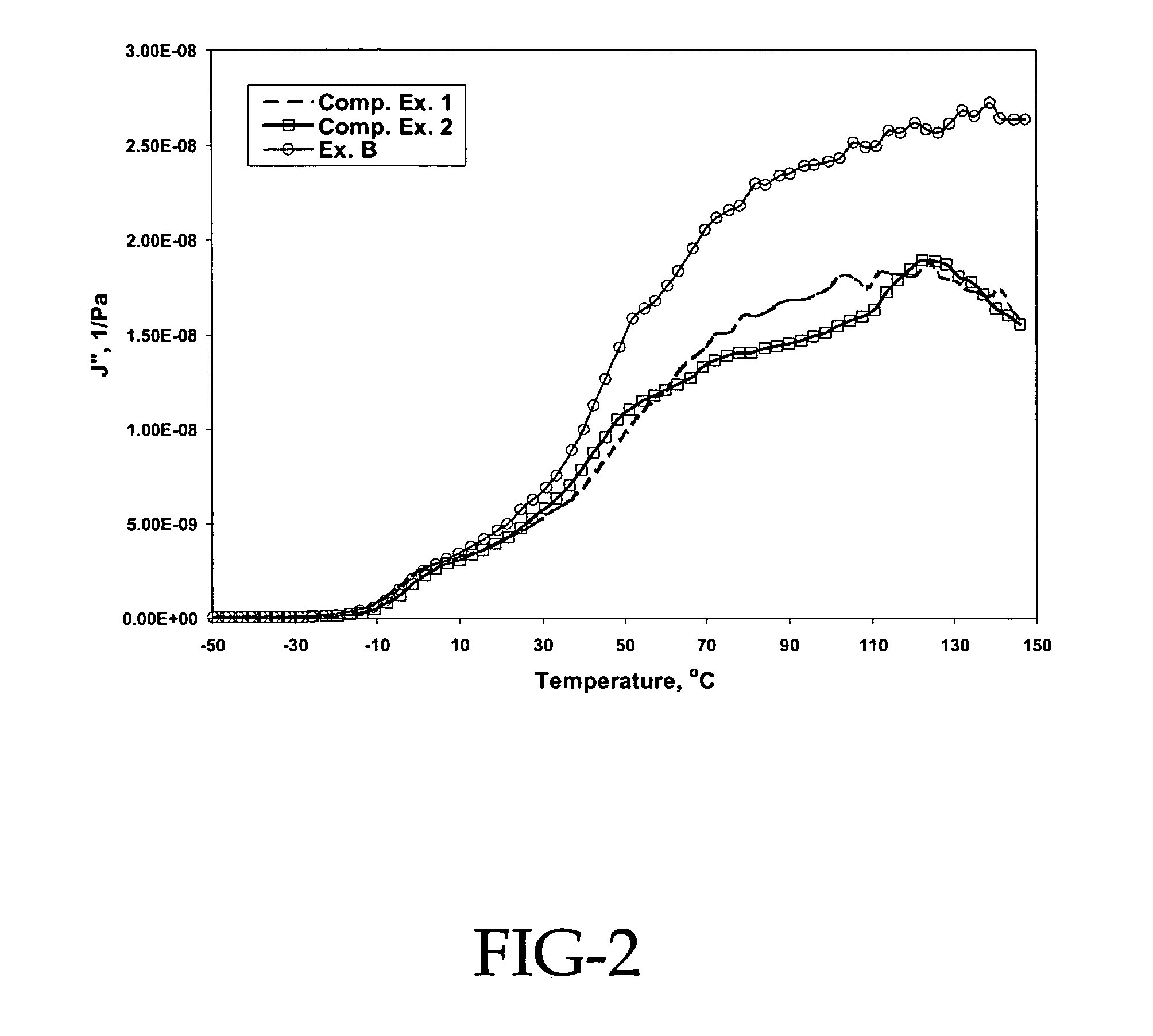

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

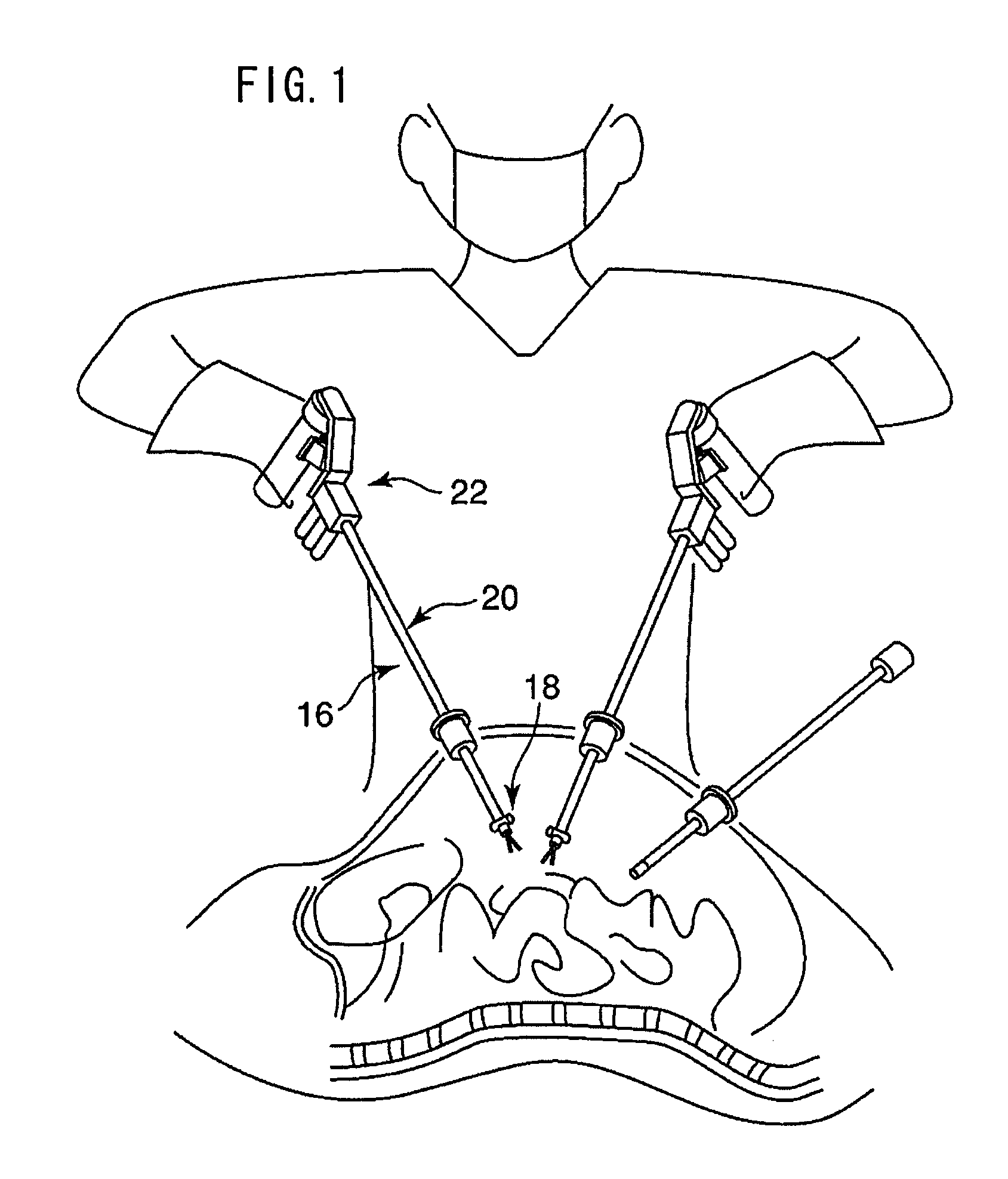

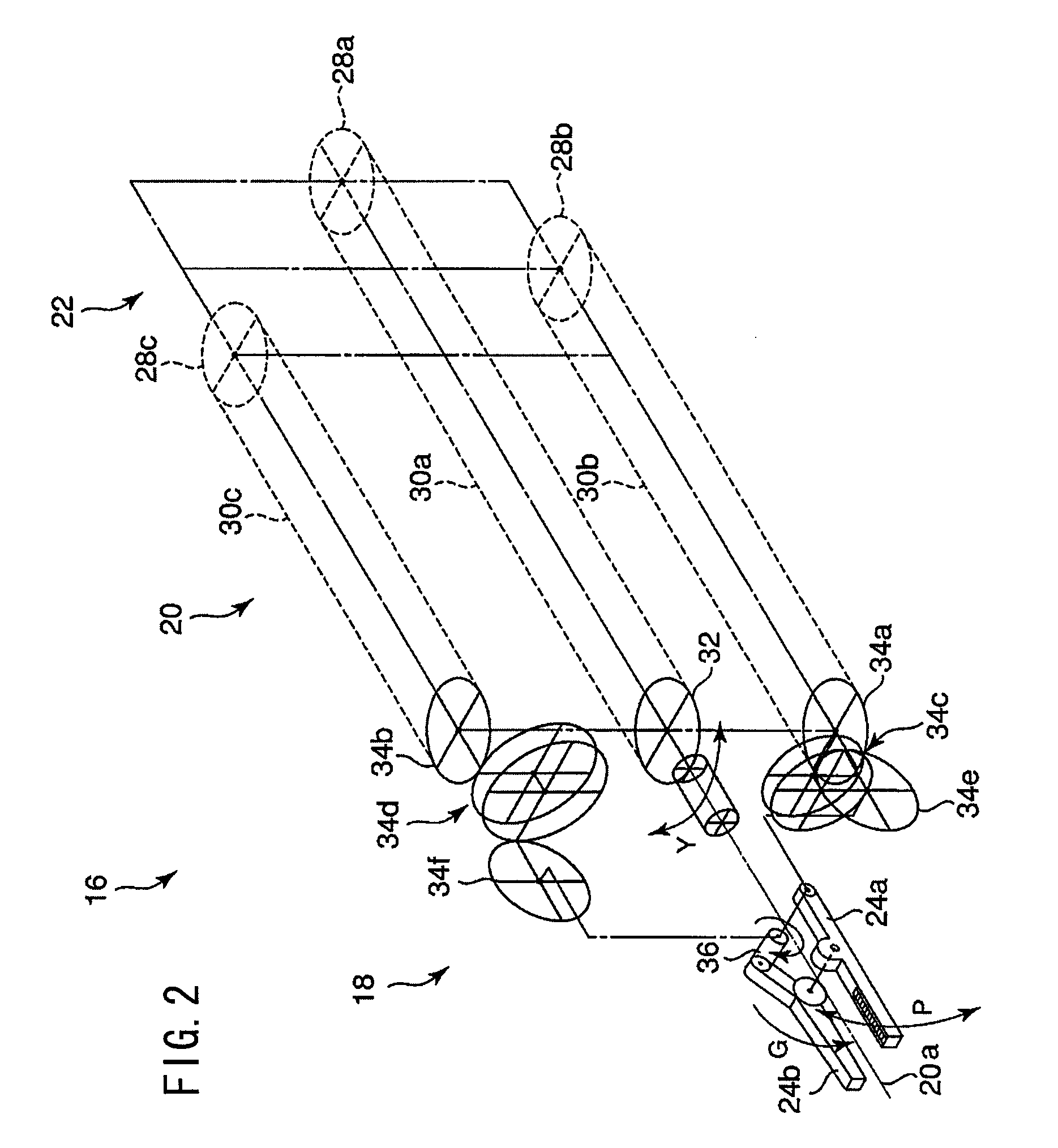

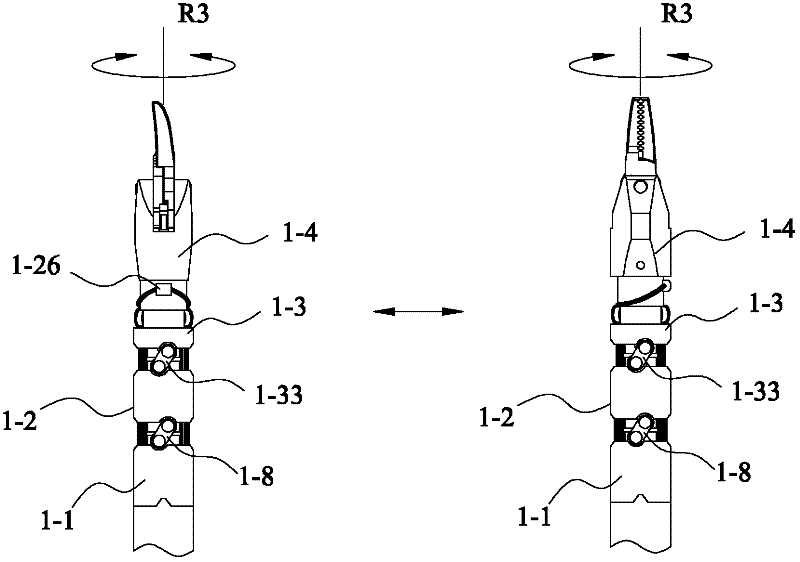

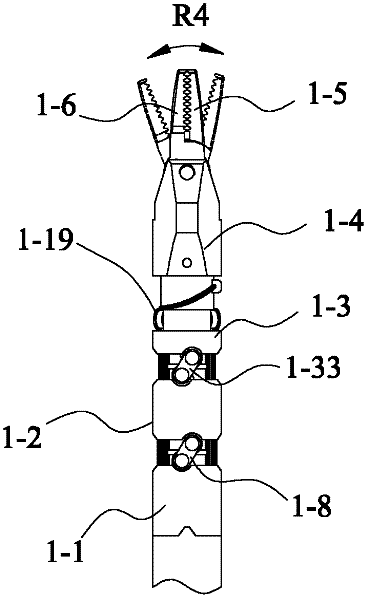

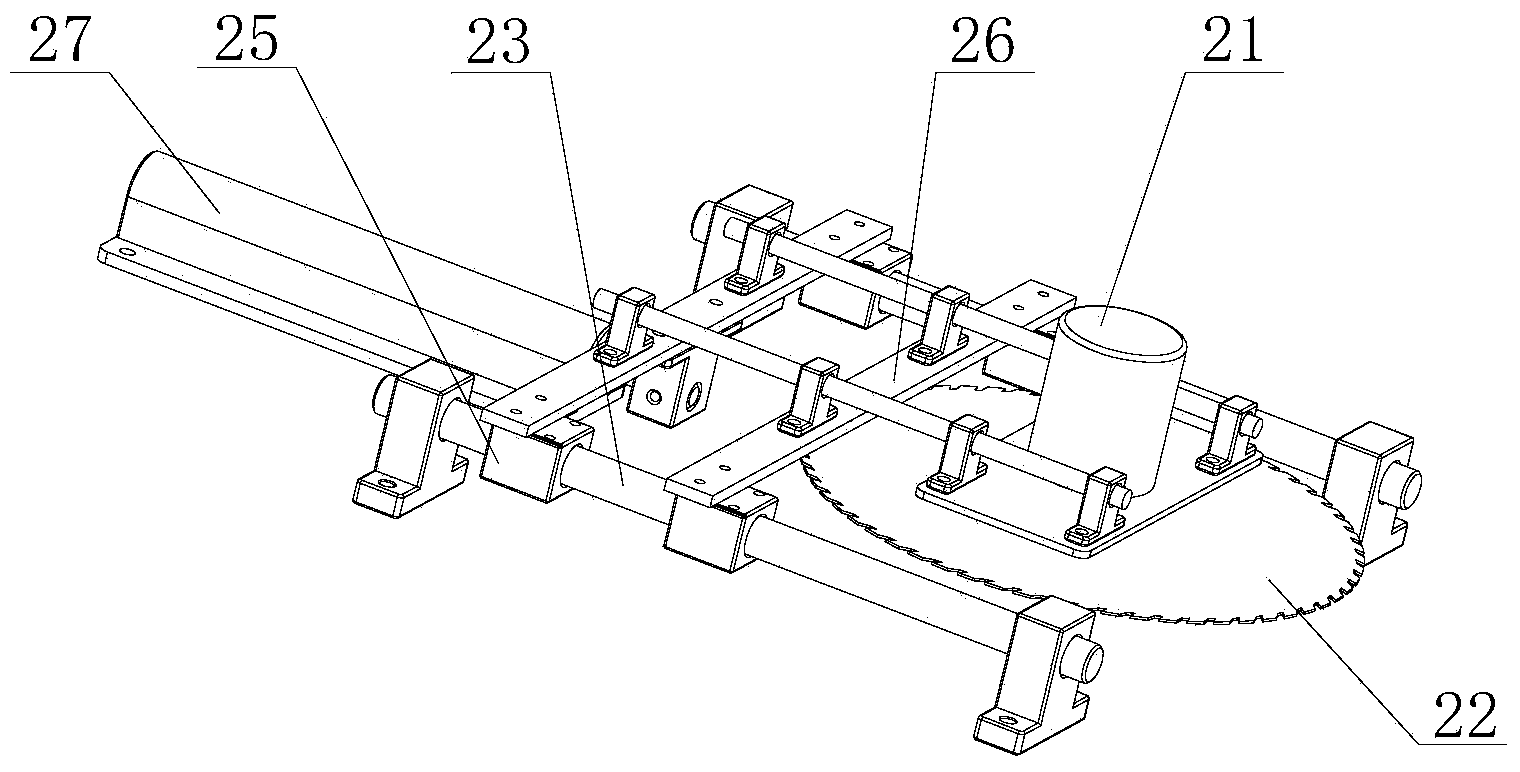

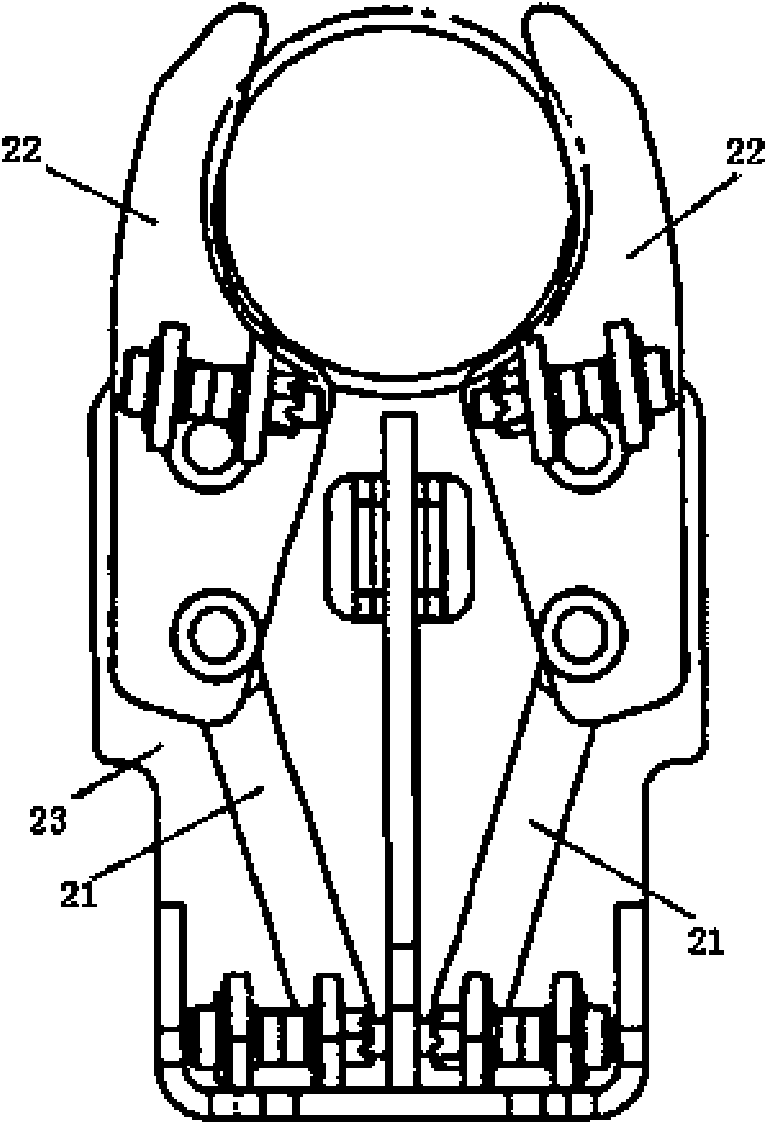

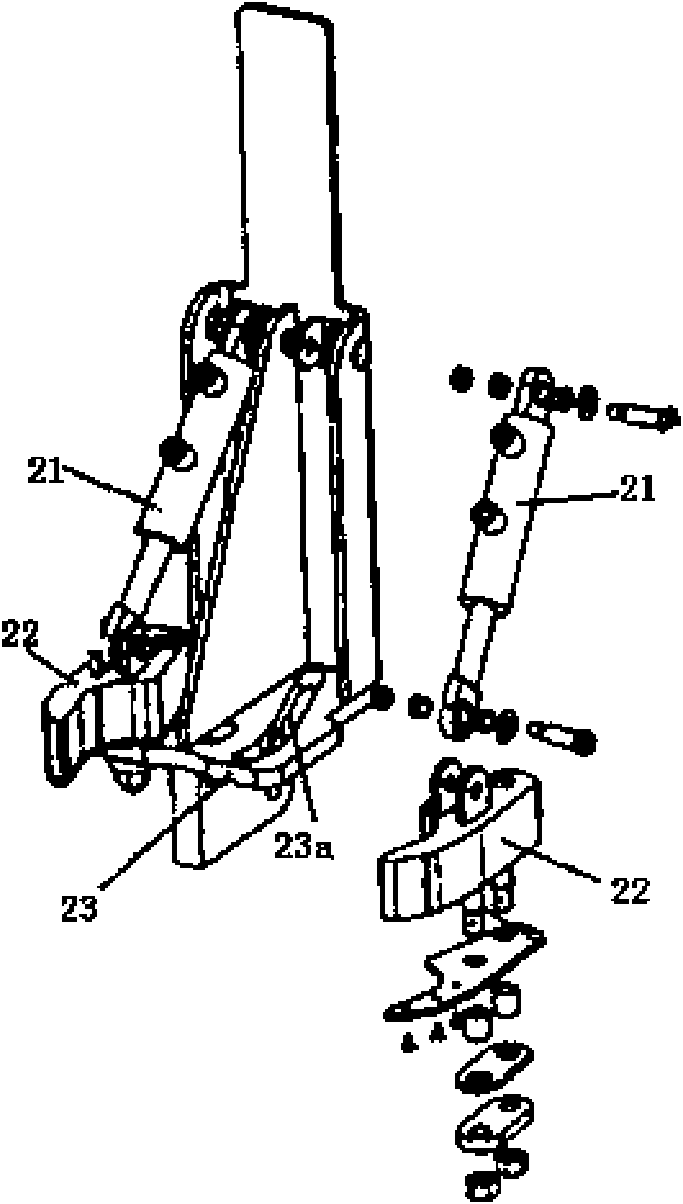

Micro instrument terminal based on module joint and used for minimally invasive surgery robot

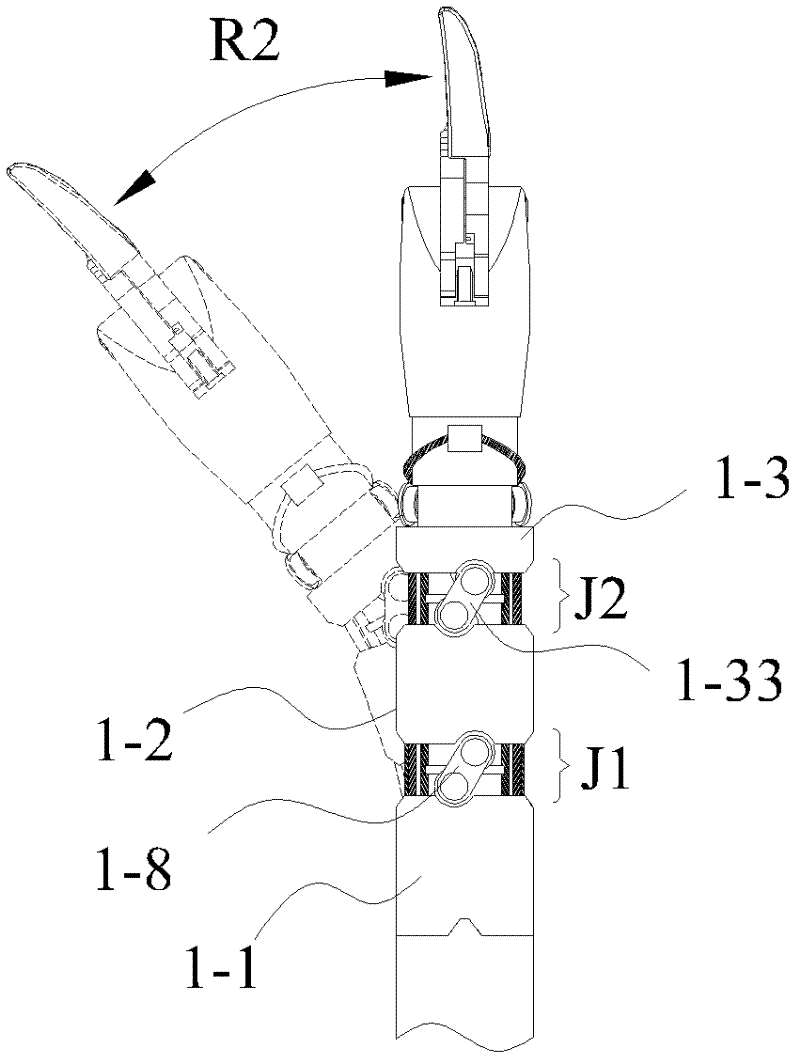

ActiveCN102488554AFlexible to completeThe total length of the closed-loop transmission remains unchangedDiagnosticsSurgical robotsSurgical departmentTarsal Joint

The invention discloses a micro instrument terminal based on module joints and used for a minimally invasive surgery robot. The micro instrument terminal comprises a rotary module of a first four-bar mechanism consisting of a module top end part, a module bottom end part, a lower support and first left and right connection pieces, and a rotary module of a second four-bar mechanism consisting of amodule top end part, a rotary connection shaft, an upper support and second left and right connection pieces; two ends of a first steel wire rope are connected with the top surfaces of the module topend parts, and the other two ends of the first steel wire rope are sequentially connected with a first rotary actuating device through the module bottom end part; two ends of a second steel wire ropeare connected with a rotary connecting shaft, and the other two ends of the second steel wire rope are sequentially connected with the first rotary actuating device through the module top end parts and the module bottom end part; and the upper part of the rotary connecting shaft is inserted into the central hole of a rotary rod and is in clearance and running fit with the rotary rod, and the rotary rod is connected with a surgery apparatus. Complex surgery can be more flexibly completed by adopting the device.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

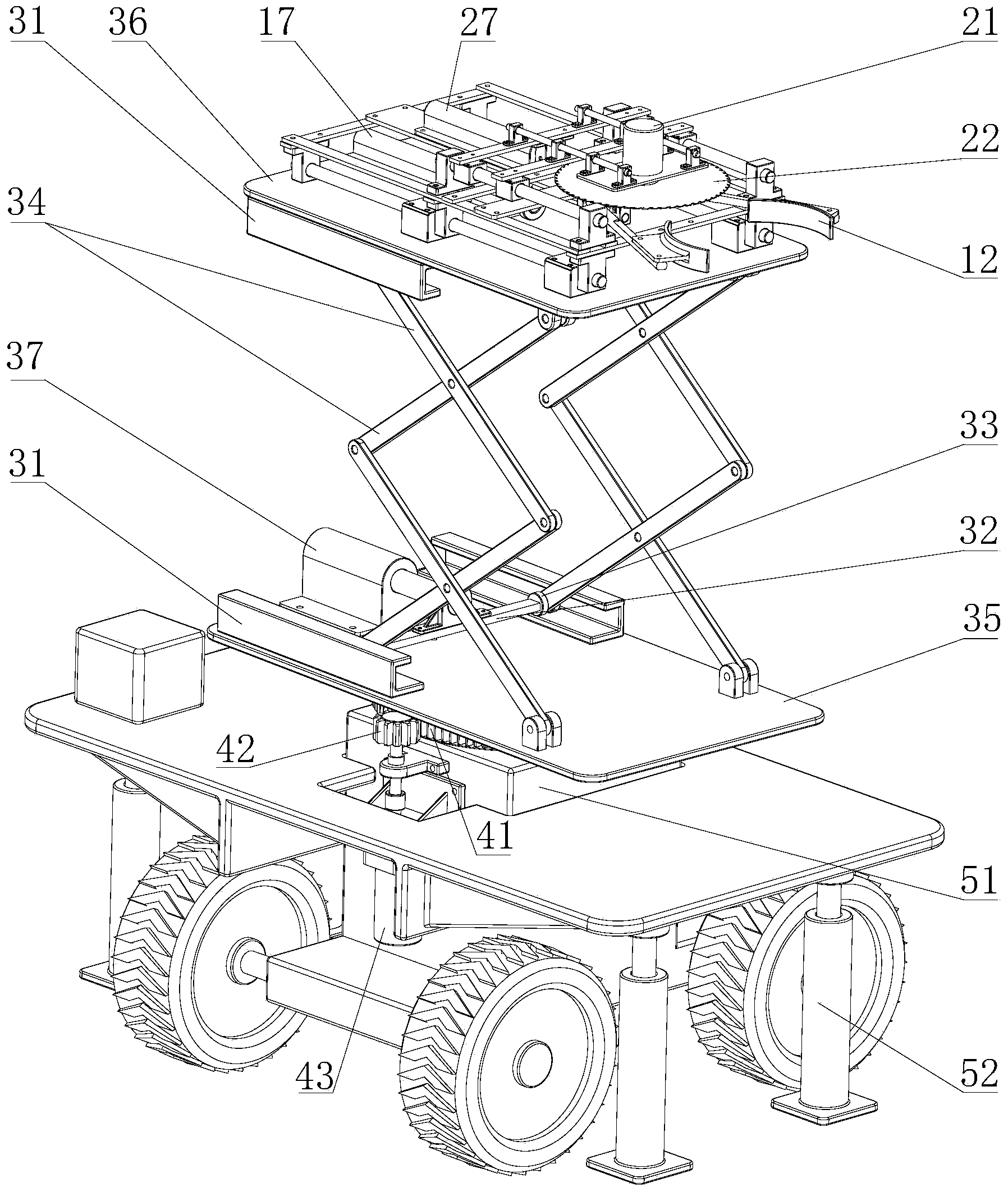

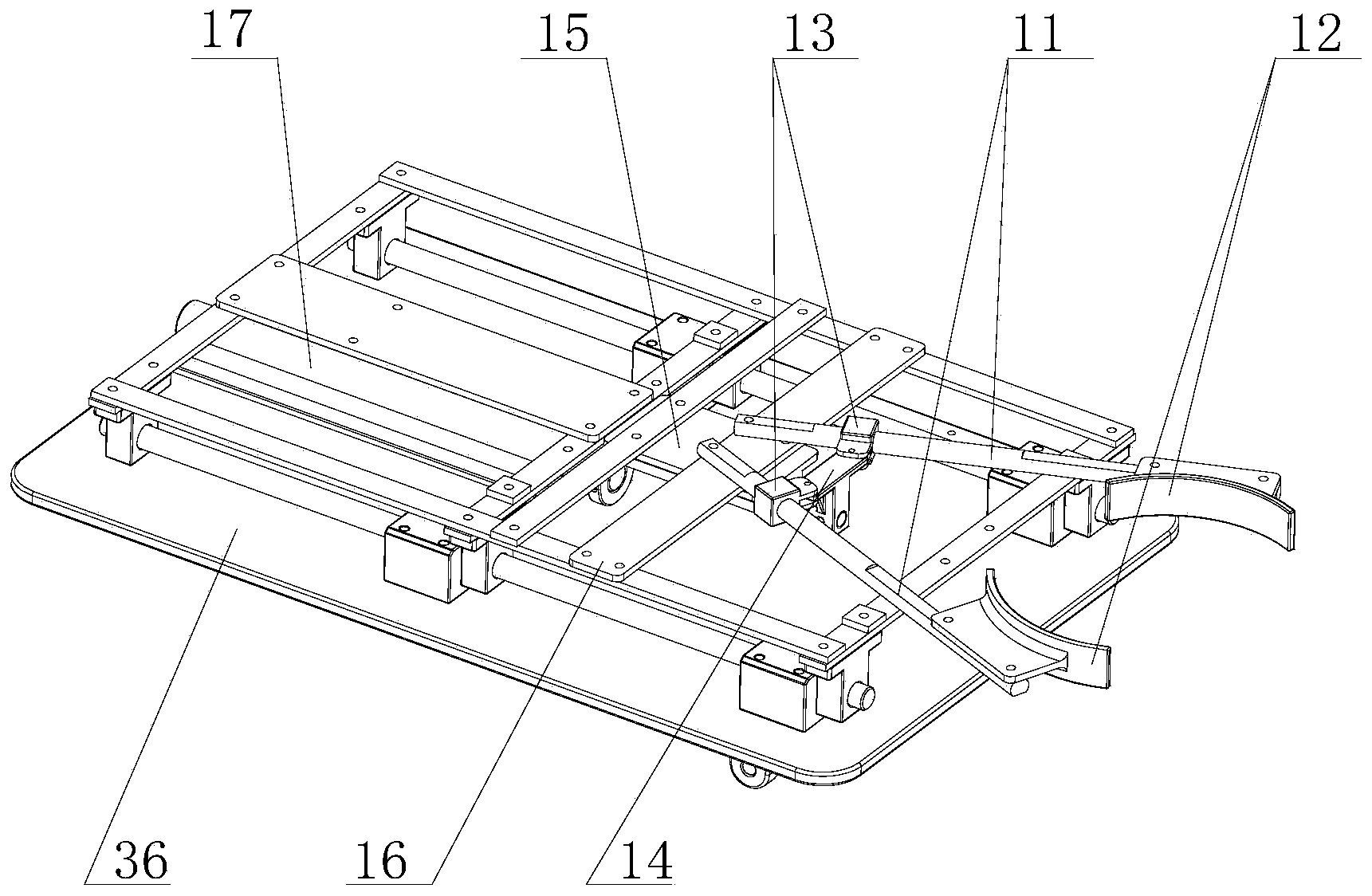

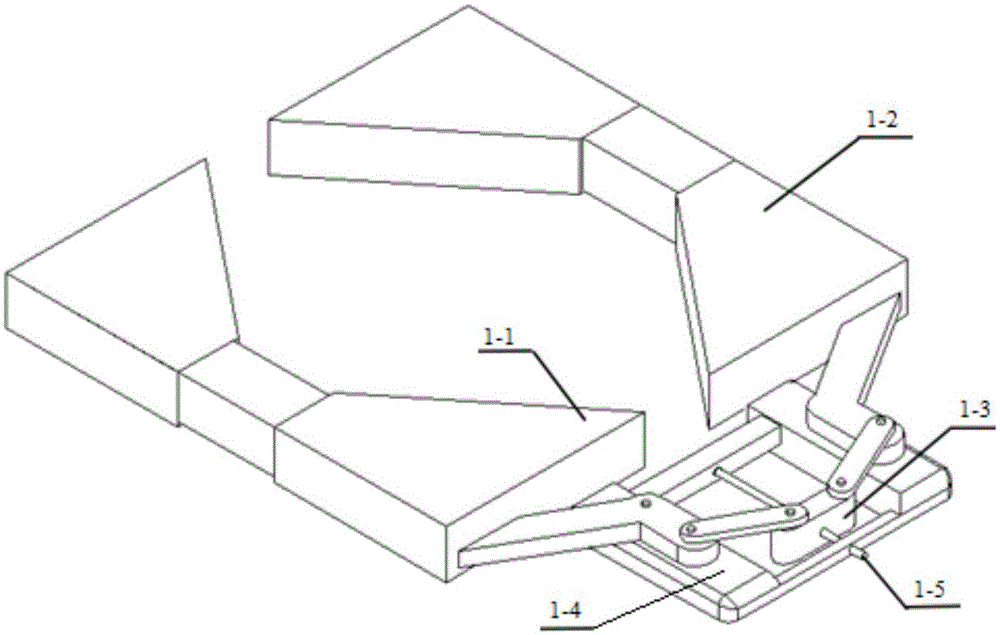

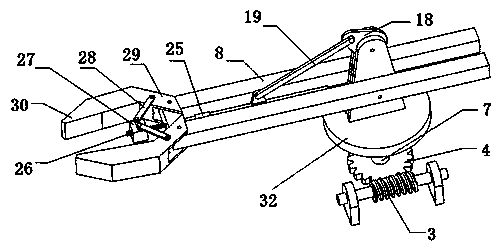

Banana picking device and picking method

The invention discloses a banana picking device, which comprises a rack, a cutter, clamping manipulator sliding blocks and a clamping manipulator opening and closing driving mechanism. A clamping manipulator comprises clamping rods. One ends of the clamping rods are hinged on the rack. The sliding blocks are slideably connected onto the clamping rods. The clamping manipulator opening and closing mechanism drives the clamping manipulator to open or close. The clamping manipulator opening and closing driving mechanism is hinged with the sliding blocks. The invention additionally discloses a banana picking method, which comprises the steps of propelling a walking trolley to a position under a banana tree; horizontally supporting the walking trolley through hydraulic supporting legs; lifting a scissor-type lifting mechanism to a position beside a banana fruit string; stretching the clamping manipulator to clamp a fruit stem; cutting off the fruit stem by using the cutter; after the fruit stem is cut off, lowering the scissor-type lifting mechanism; and after the scissor-type lifting mechanism is lowered down, restoring the clamping manipulator, taking down bananas and restoring the hydraulic supporting legs to complete the picking. The banana picking device and the banana picking method have the advantages that the problem that the clamping manipulator is difficult to open is solved, the clamping force lasts long, the clamping stability and reliability are high, the clamping manipulator can be opened and closed smoothly and sensitively, and the working efficiency is improved.

Owner:SOUTH CHINA AGRI UNIV

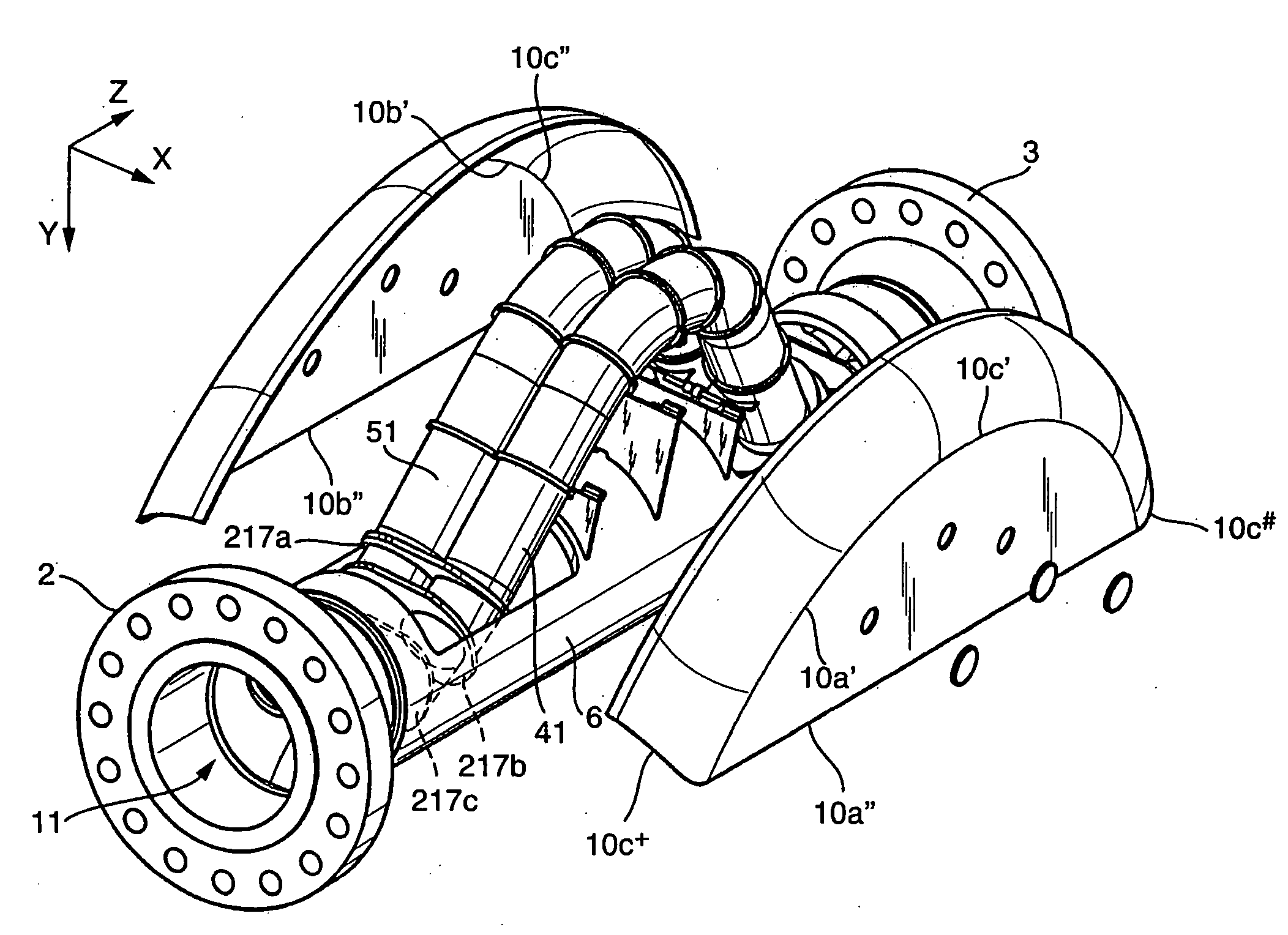

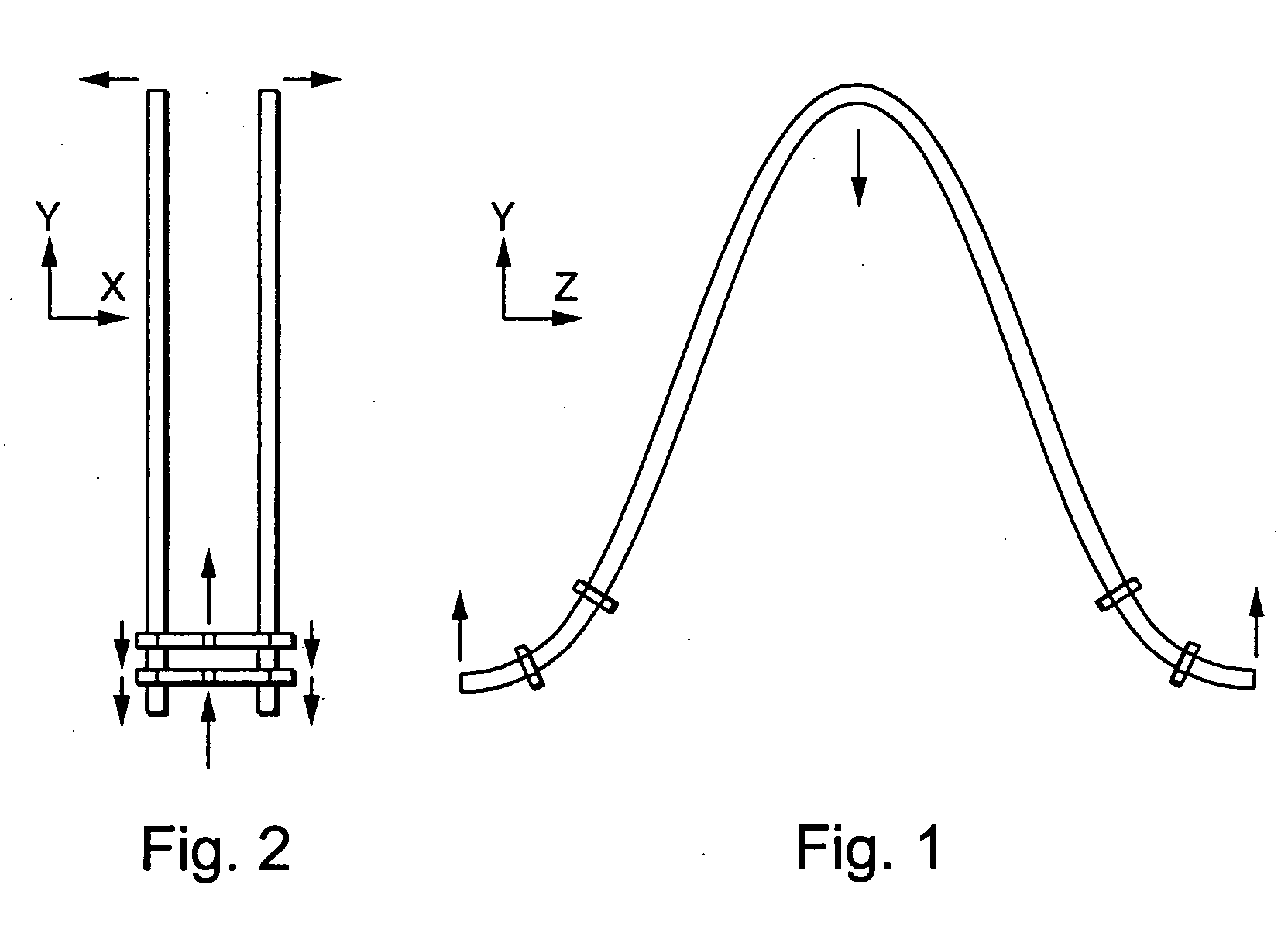

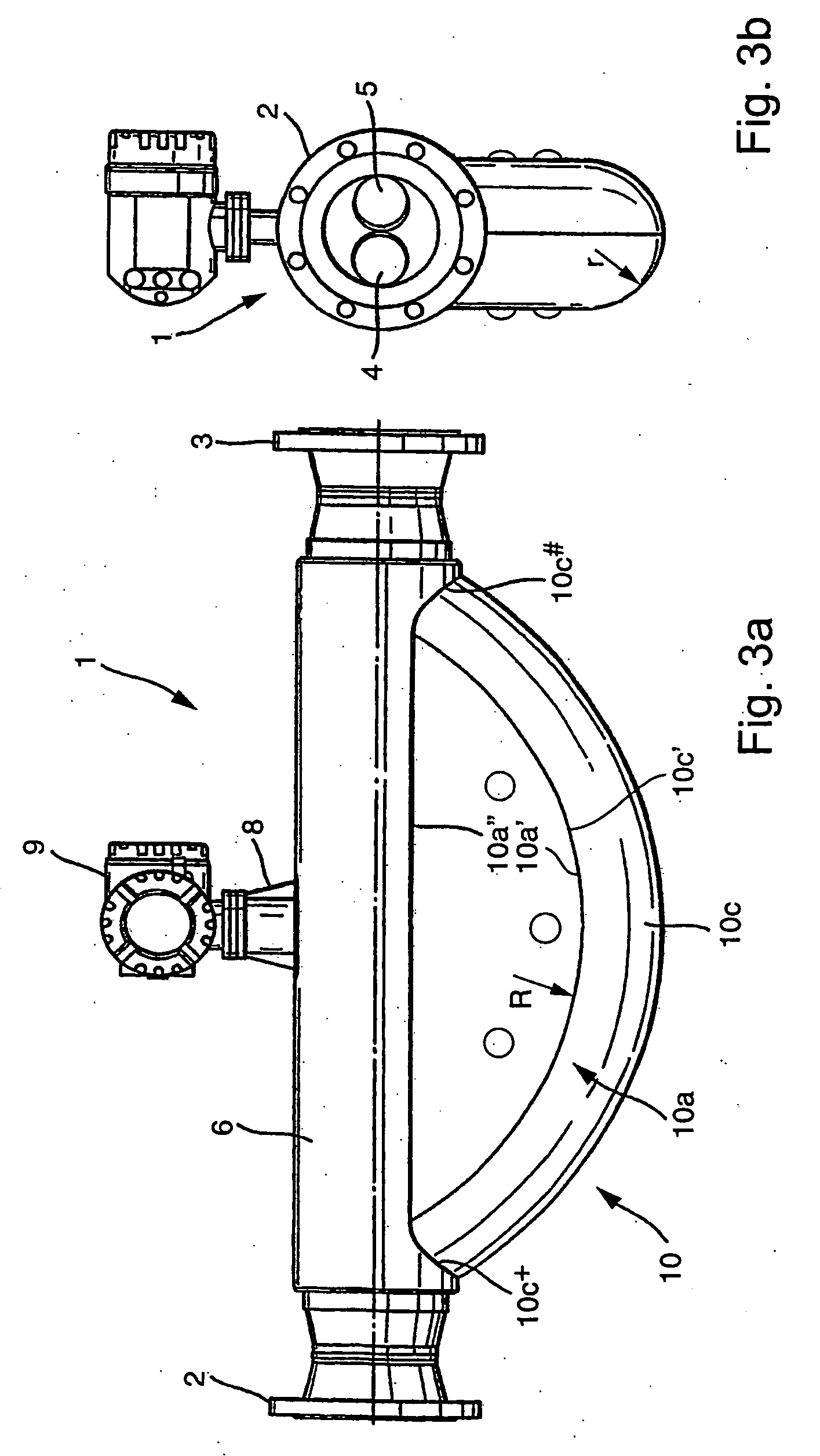

Vibratory measurement transducer

ActiveUS20060150750A1Large clamping forceSuitable for measuringDirect mass flowmetersVibration measurementCoupling

The measurement transducer includes a transducer housing, which exhibits a plurality of natural oscillation modes, as well as at least one first flow tube held oscillatably in the transducer housing, vibrating at least at times, and conveying at least a portion of the medium to be measured. Additionally, the measurement transducer includes an electromechanical, especially electrodynamic, exciter arrangement acting on the at least one flow tube for producing and / or maintaining mechanical oscillations of the at least one flow tube, and a sensor arrangement reacting to movements of the flow tube, especially bending oscillations, for producing at least one oscillation measurement signal representing oscillations of the flow tube. Additionally, for improving the oscillation properties and, consequently, also the measurement accuracy of the measurement transducer, at least three coupling elements are provided for connecting the first and second flow tubes together at the inlet end, as well as at least three coupling elements for connecting the first and second flow tubes together at the outlet end. By using at least six coupling elements, it is possible to produce vibration-type measurement transducers of high measuring accuracy even at large nominal diameters of more than 150 mm, especially also while largely maintaining already established and proven forms of construction.

Owner:ENDRESS HAUSER FLOWTEC AG

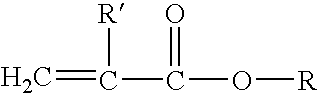

Rubber composition containing resinous nanopractice

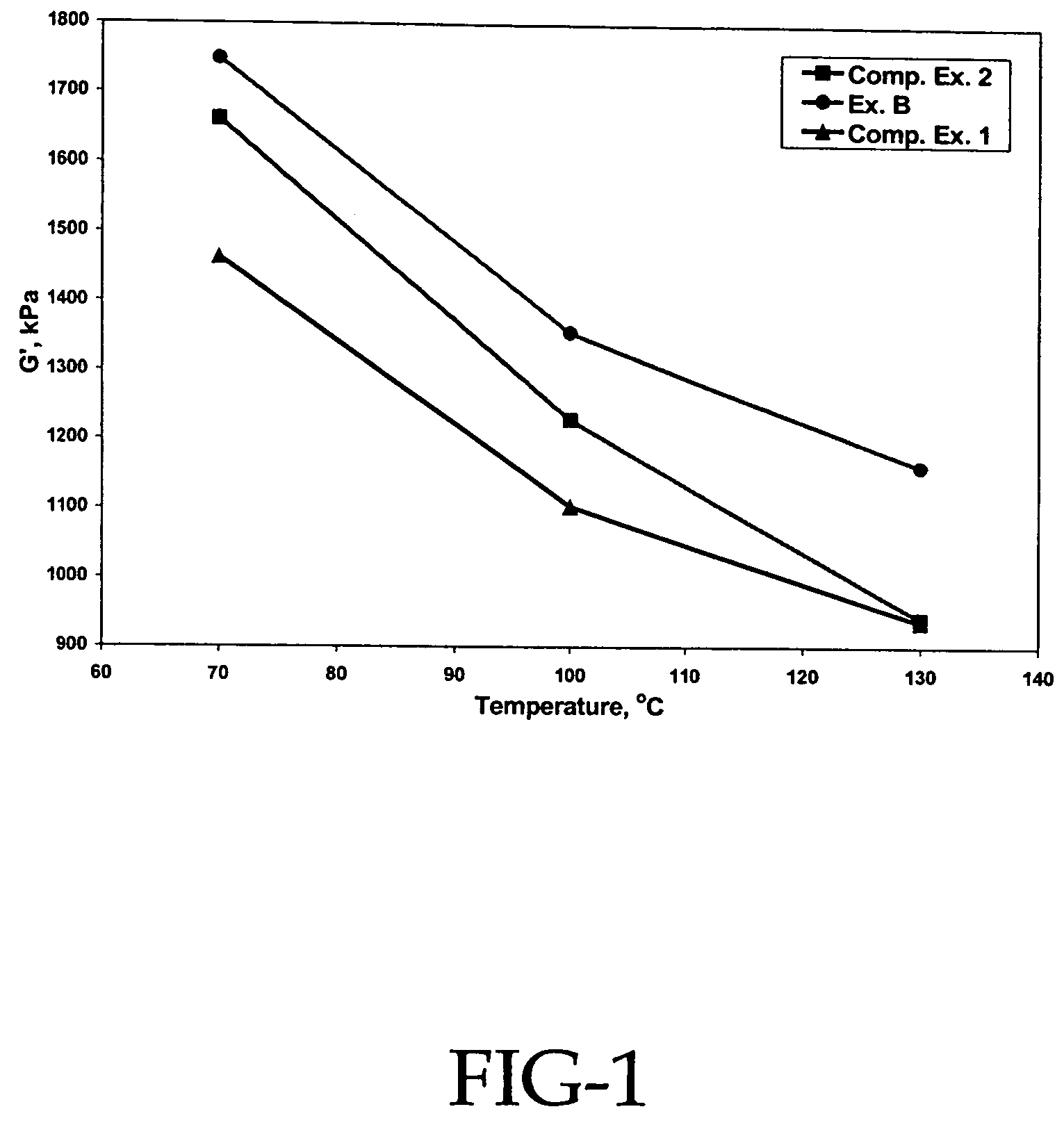

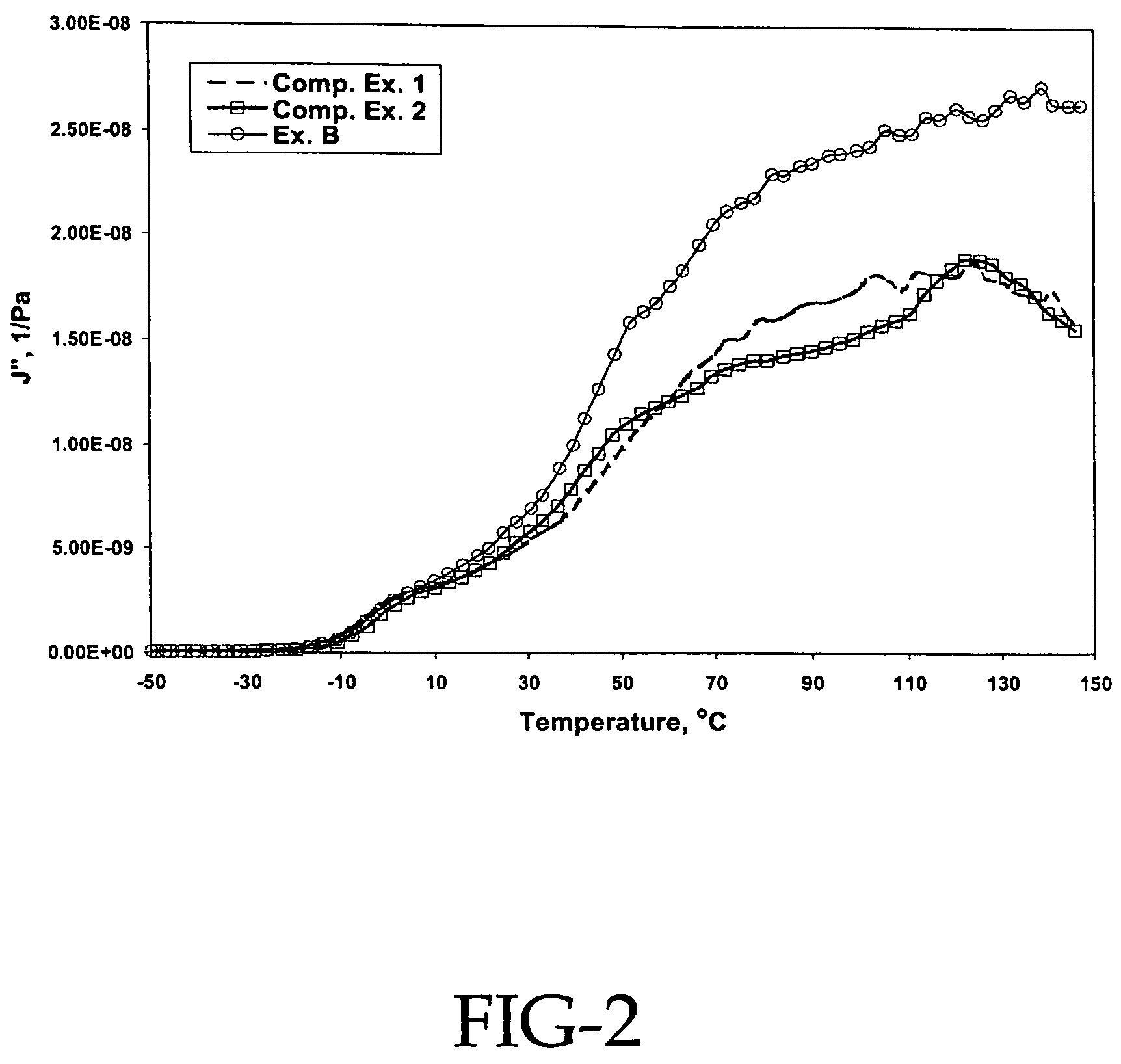

InactiveUS7071246B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

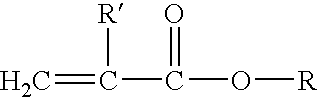

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 to 30 parts per hundred parts of rubber by weight (phr) of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

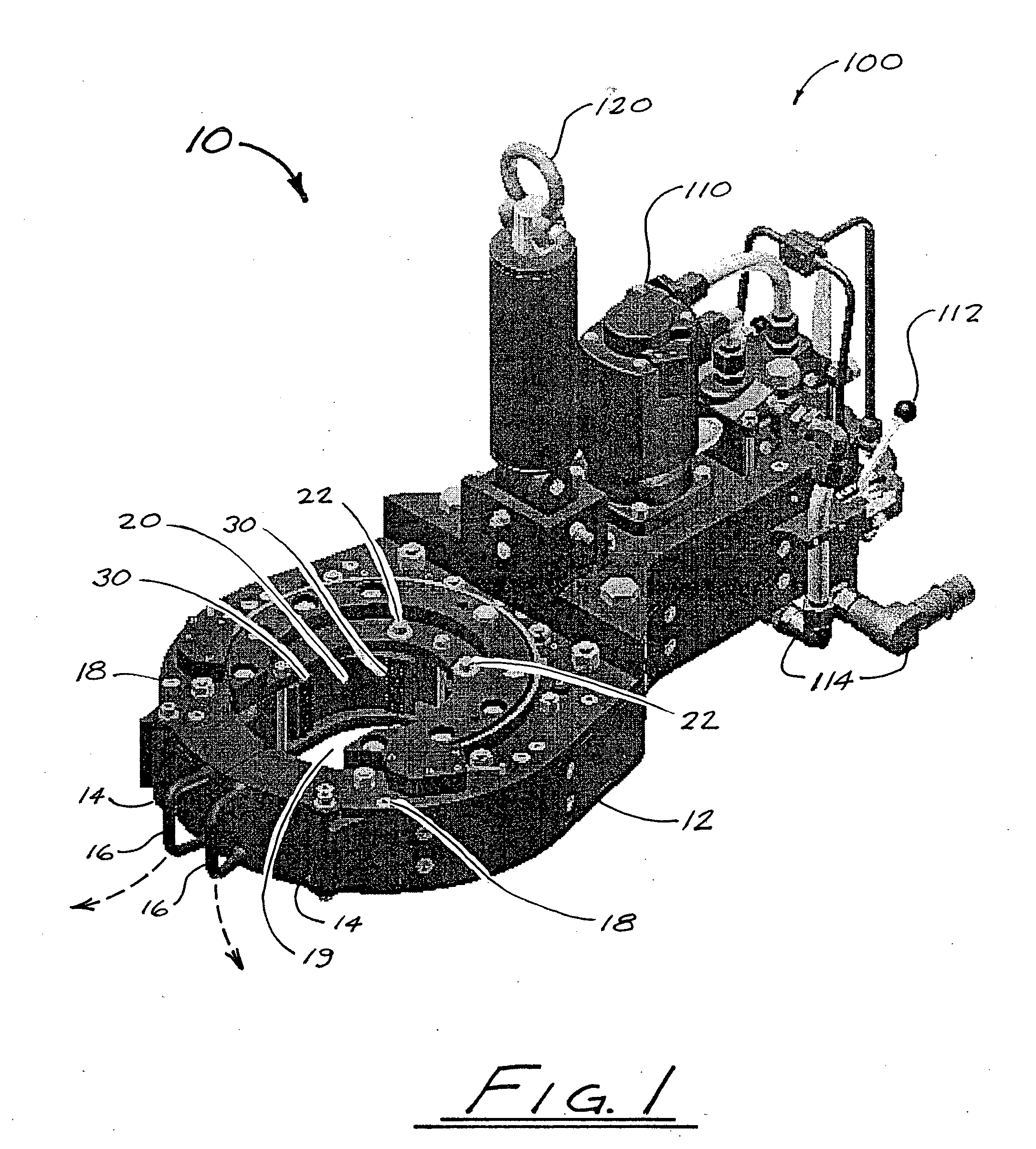

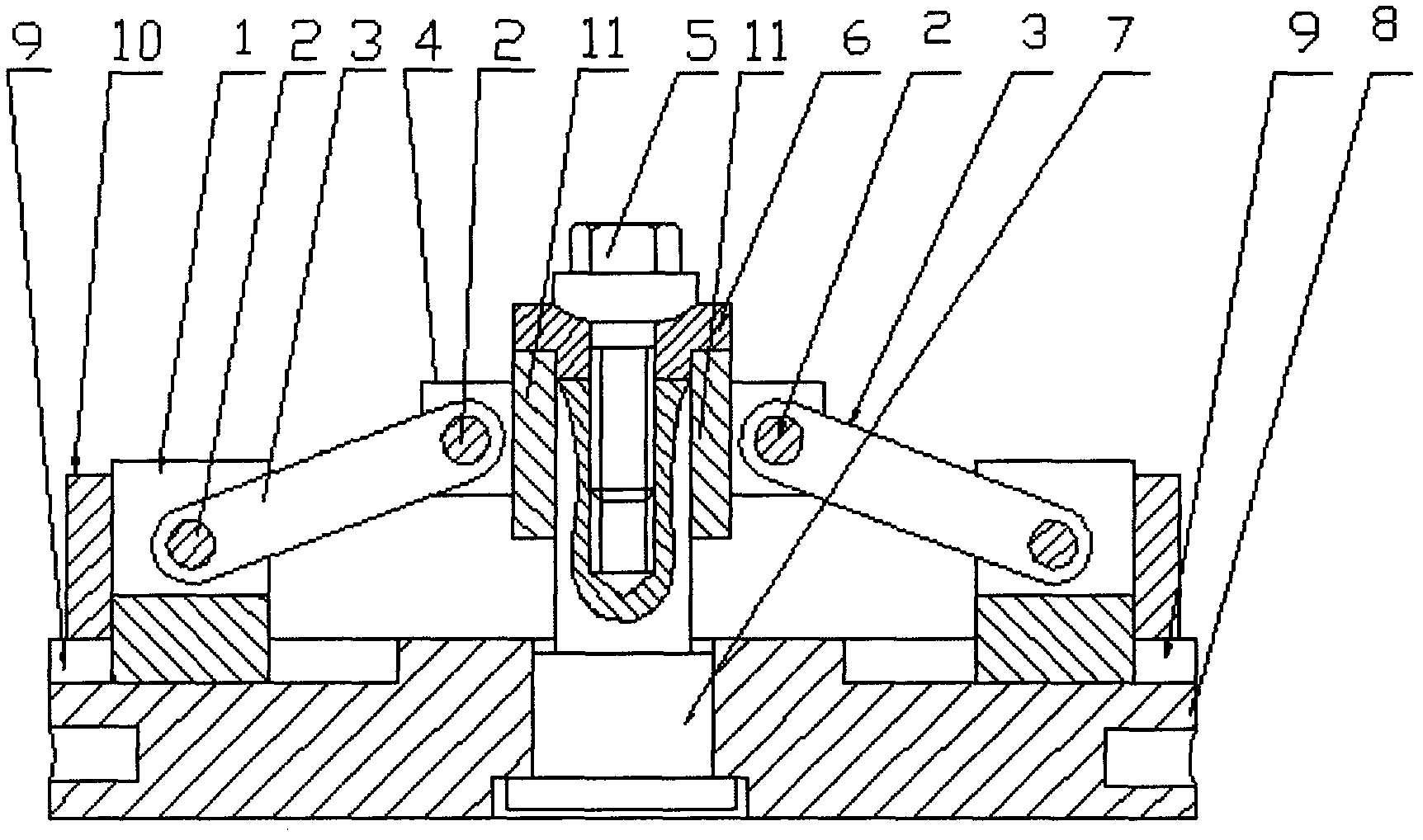

Clamping mechanism

ActiveCN101637909ARealize the clamping actionSimple structureDrilling rodsGripping headsBilateral symmetryPiston rod

The invention discloses a clamping mechanism which comprises a shell and an oil cylinder installed in the shell, wherein clamping blocks are distributed in the front part of the shell in bilateral symmetry; and the inner side surfaces of the front half parts of the clamping blocks are inner concave surfaces. The clamping mechanism is characterized in that a cylinder barrel of the oil cylinder is centered at the rear part of the shell; the front end of a piston rod of the oil cylinder is articulated with a connecting plate; the left part and the right part of the connecting plate are respectively articulated with the rear ends of the clamping blocks; the front part of at least one cover plate of the shell is symmetrically provided with guide grooves left and right; guide pins are arranged in the middle parts of the two clamping blocks and inserted into the guide grooves; fixed blocks are clamped and fixed in the middle parts of the front ends of the two cover plates, and the normal lineof the surfaces of the front parts of the inner concave surfaces of the two clamping blocks are inclined to the directions of the fixed blocks. The invention has simple structure, high strength and large clamping force and can be suitable for different pipe columns with the external diameter range of 3.5-9.75 inches without replacing the clamping mechanism, and the clamping mechanism can not interfere with the adjacent pipe column during working.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

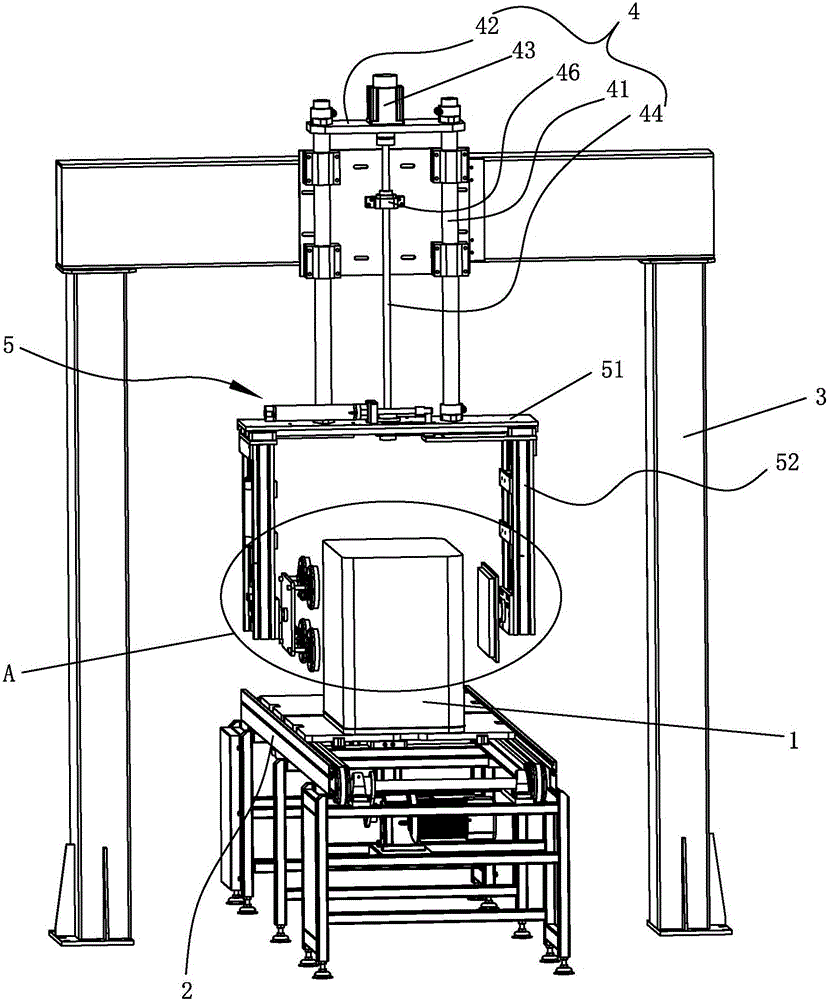

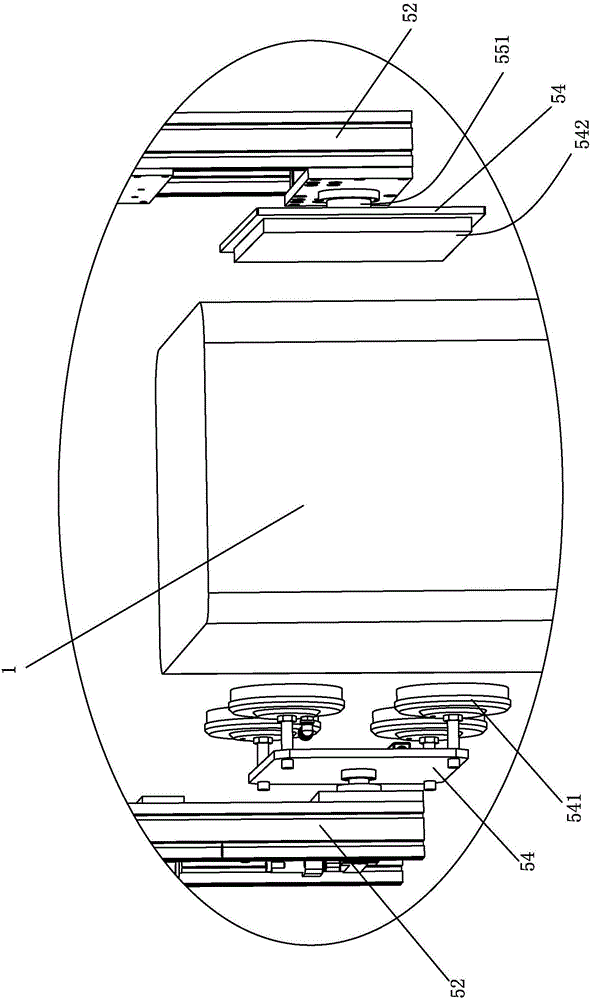

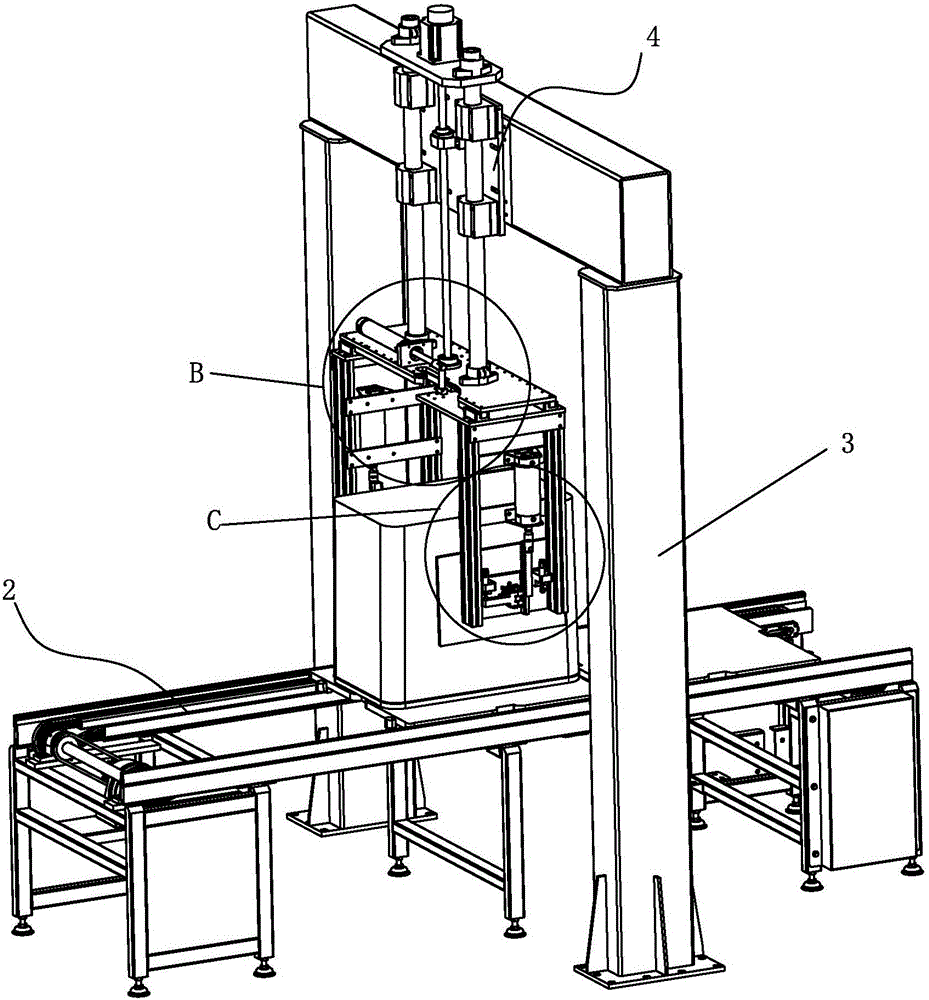

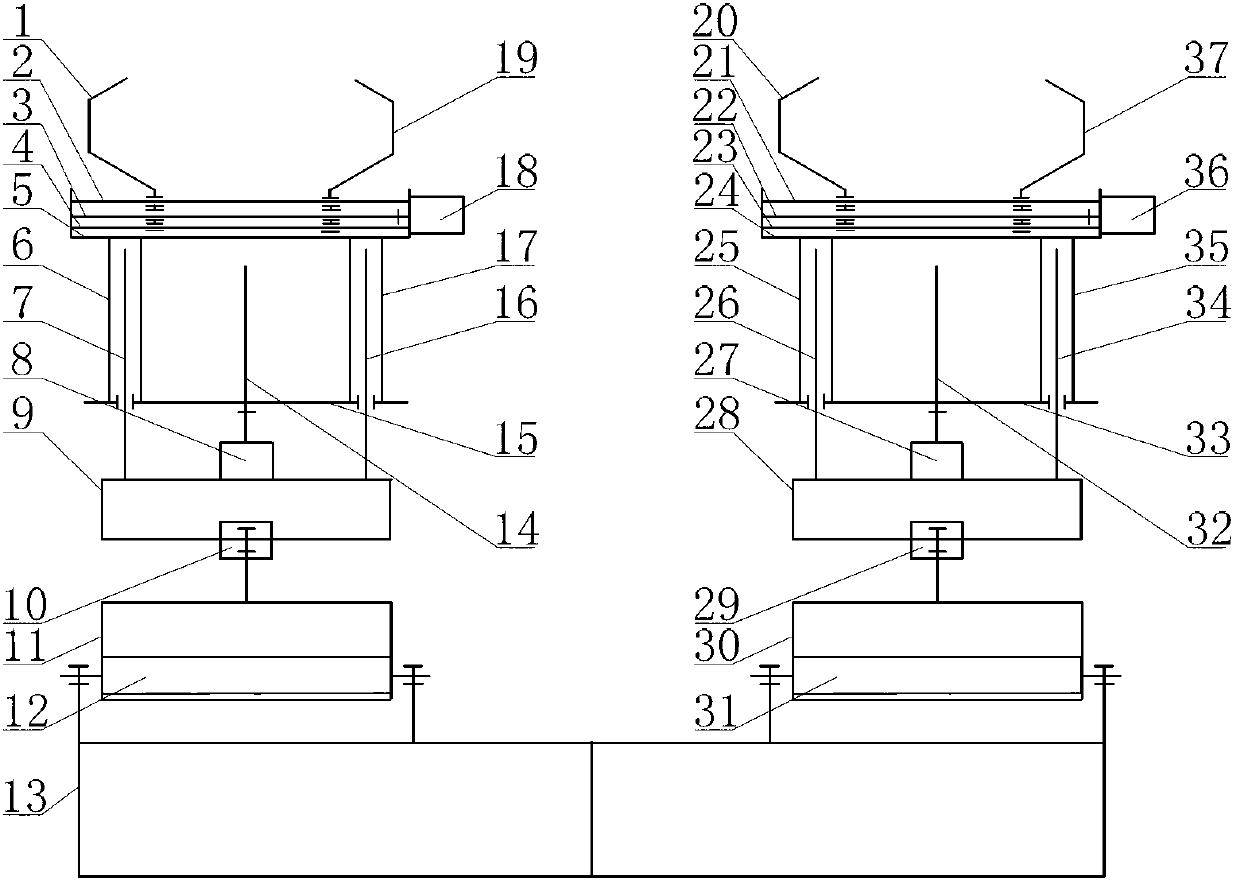

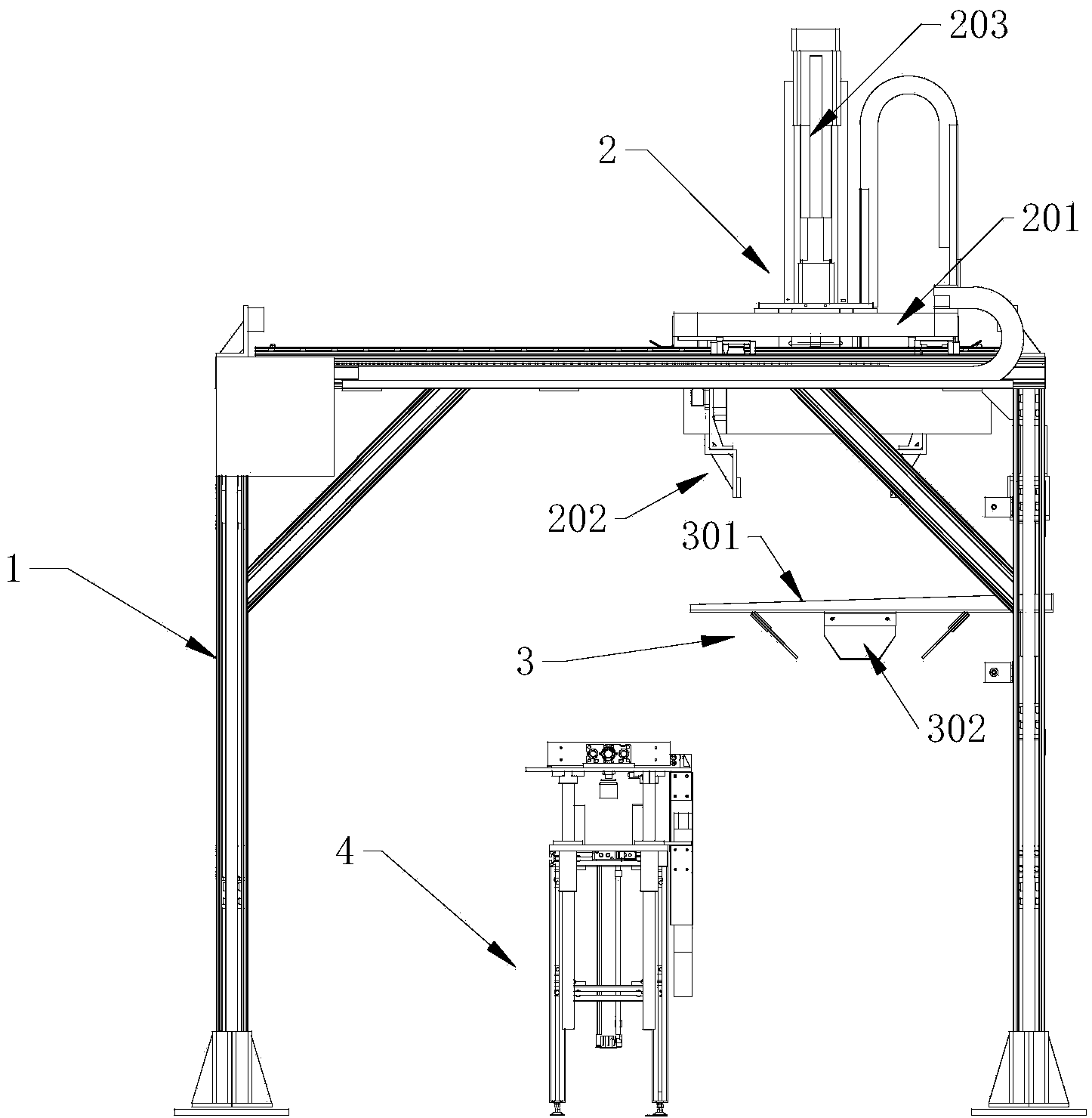

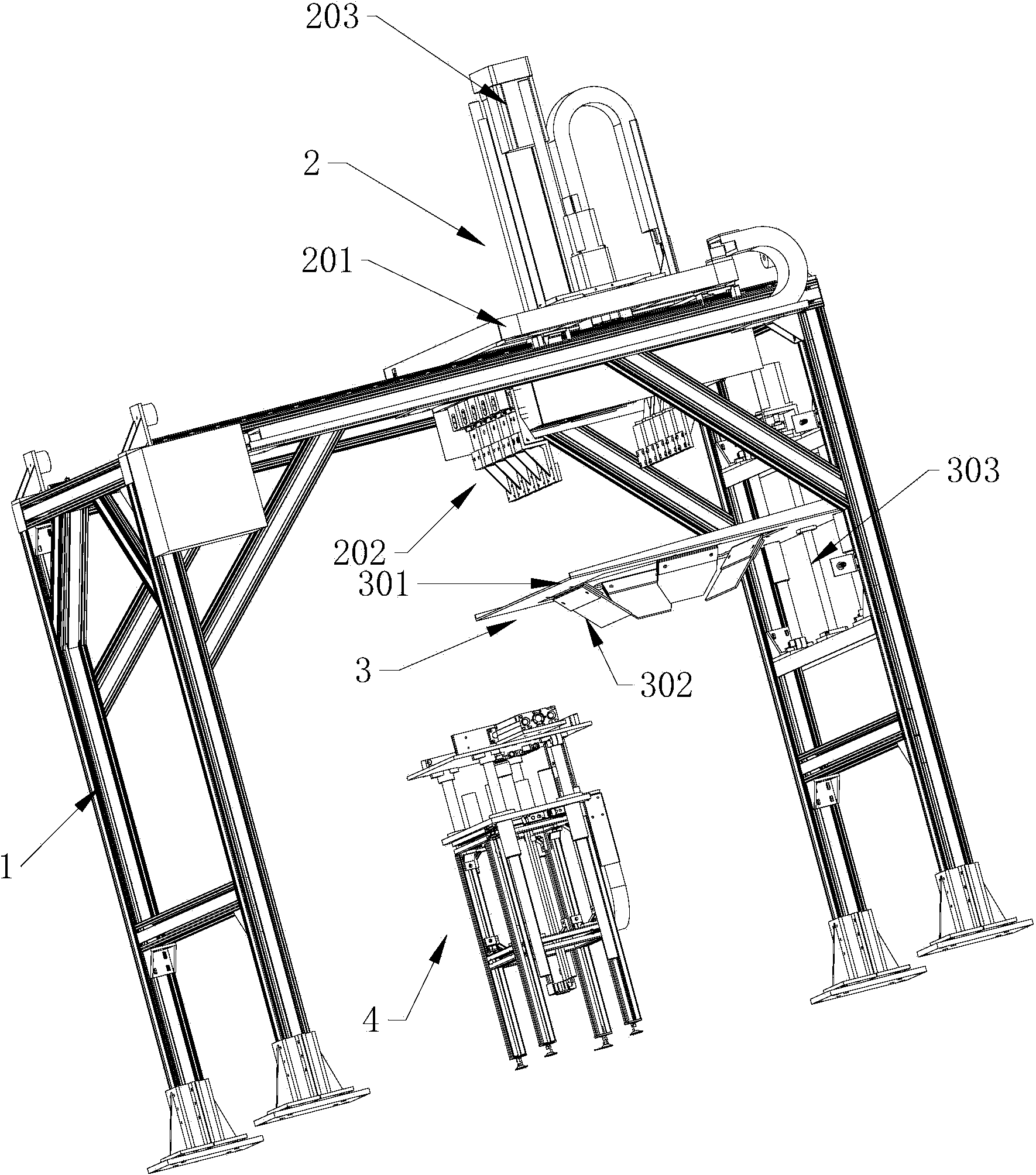

On-line automatic overturning equipment

InactiveCN106044140AReduce labor intensityImprove work efficiencyConveyorsConveyor partsEngineeringPortal frame

The invention discloses on-line automatic overturning equipment. The on-line automatic overturning equipment comprises a conveying line for conveying boxes and a portal frame arranged on the conveying line in a straddling manner; a lifting mechanism is arranged on the portal frame; the lower end of the lifting mechanism is connected with a clamping overturning mechanism; the clamping overturning mechanism comprises a clamping seat and two clamping arms; the clamping seat is connected to the lower end of the lifting mechanism; the two clamping arms are slidably connected onto the clamping seat; the clamping seat is provided with a clamping driving assembly which drives the two clamping arms to carry out clamping or releasing action; the lower ends of the two clamping arms are rotatably connected with clamping blocks for clamping the boxes respectively; an overturning driving assembly which is used for driving the corresponding clamping block to overturn so as to overturn the boxes is arranged between each clamping arm and the corresponding clamping block. Under collaborative operation of the lifting mechanism and the clamping overturning mechanism, the boxes from the conveying line are automatically overturned at an angle, by the clamping overturning mechanism, the boxes can be quickly and efficiently overturned at an angle, work efficiency is improved, labor intensity of workers is reduced, and production cost is reduced.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

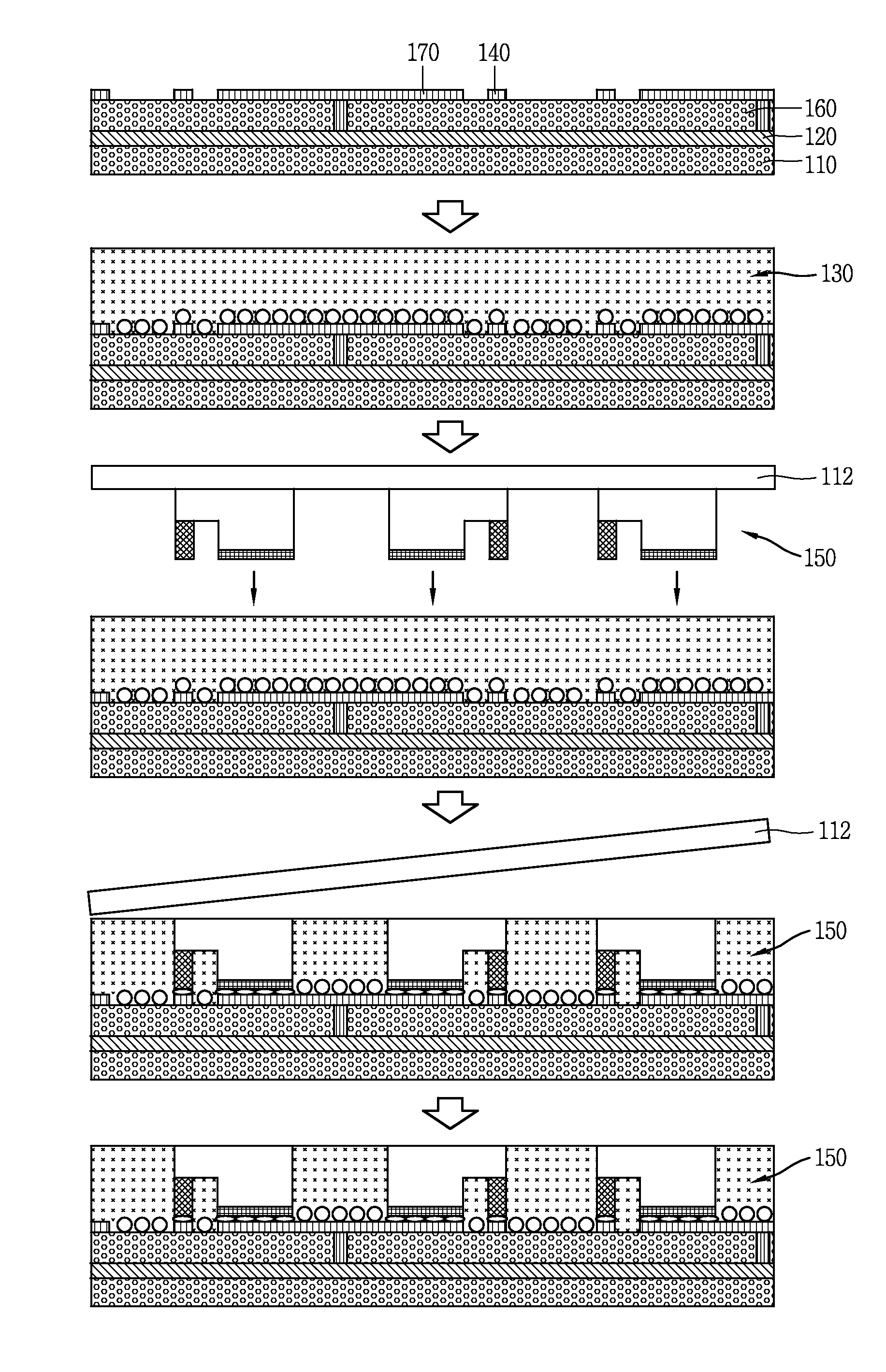

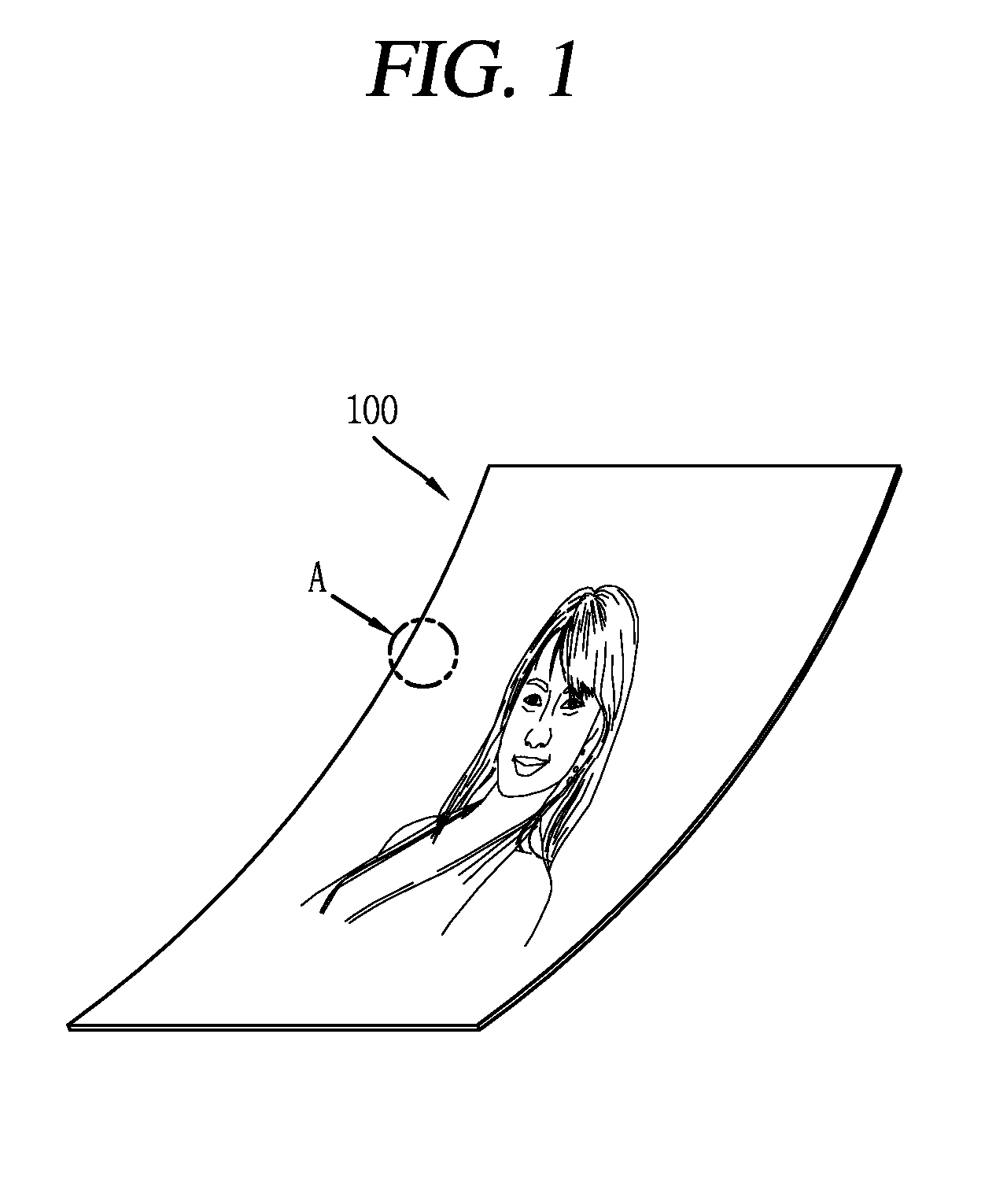

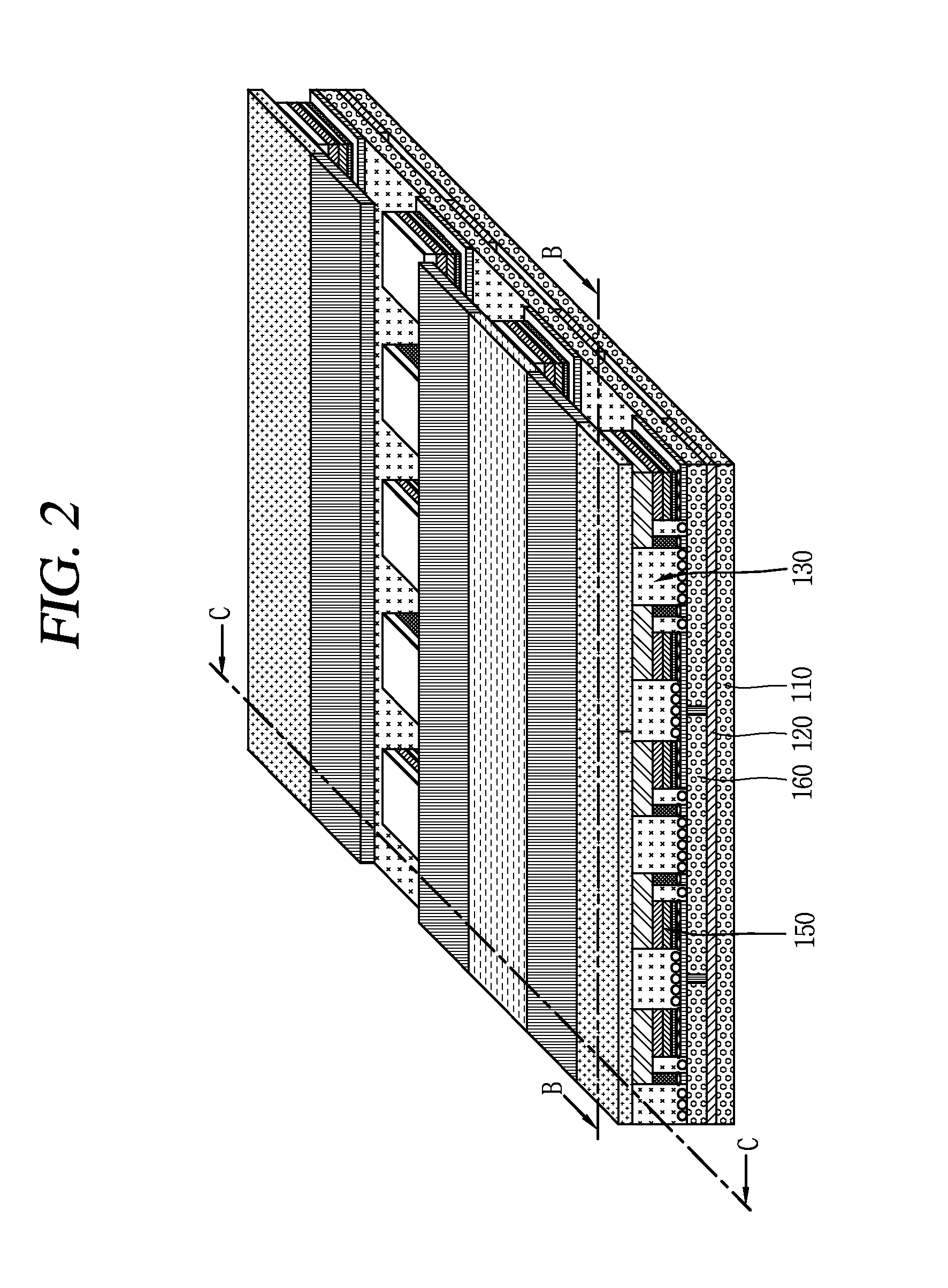

Semiconductor light emitting device, transfer head of semiconductor light emitting device, and method of transferring semiconductor light emitting device

ActiveUS20160300745A1Improve reliabilityLarge clamping forceSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceSemiconductor

A method of transferring a semiconductor light emitting device, and which includes positioning a transfer head having a head electrode facing a semiconductor light emitting device having an undoped semiconductor layer, the semiconductor light emitting device arranged on a carrier substrate; moving the head electrode of the transfer head close to the undoped semiconductor layer of the semiconductor light emitting device; applying a voltage to the head electrode to provide an attachment force to the undoped semiconductor layer by an electrostatic force; and picking-up the semiconductor light emitting device and transferring the semiconductor light emitting device to base substrate.

Owner:LG ELECTRONICS INC

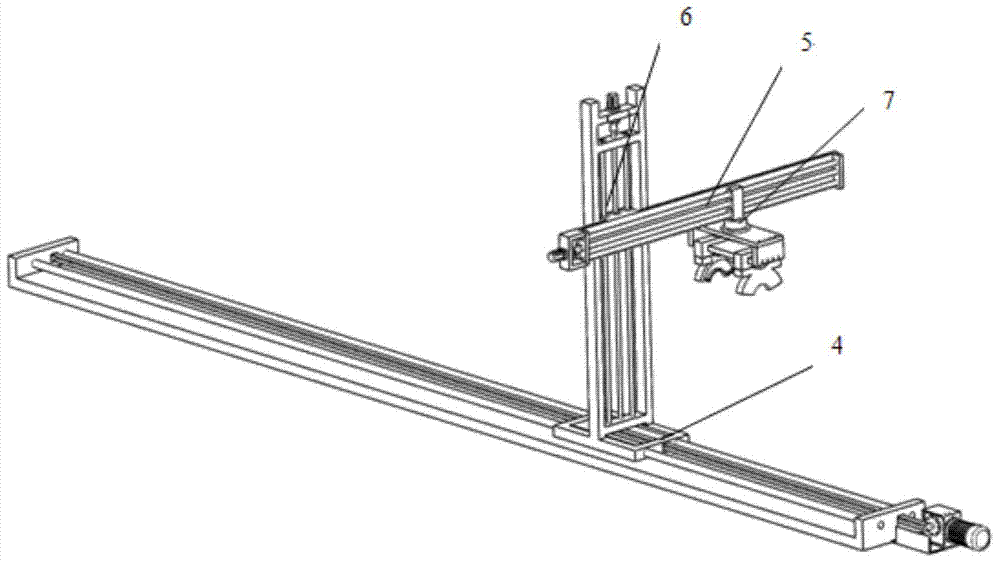

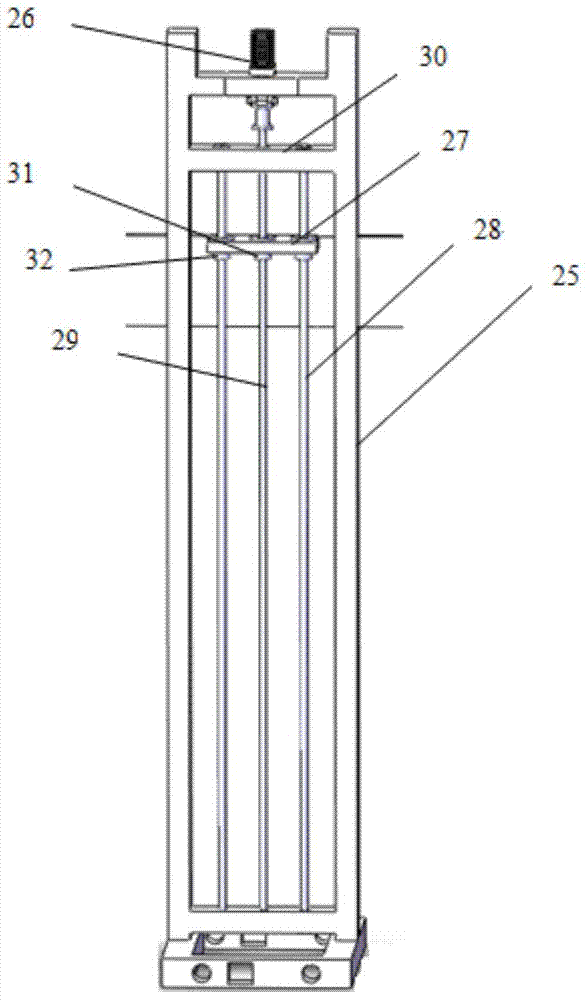

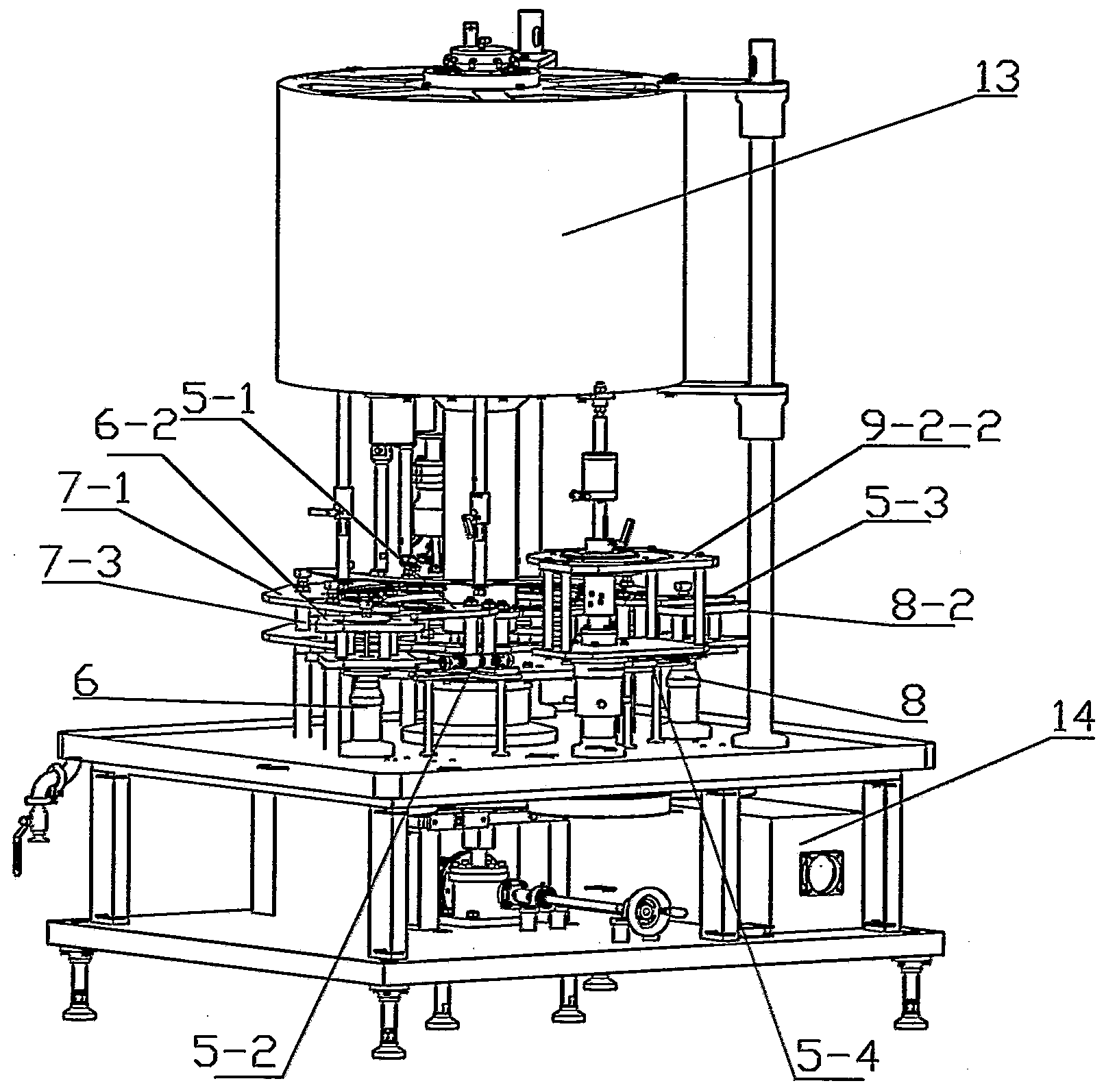

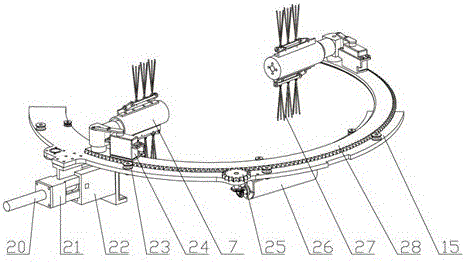

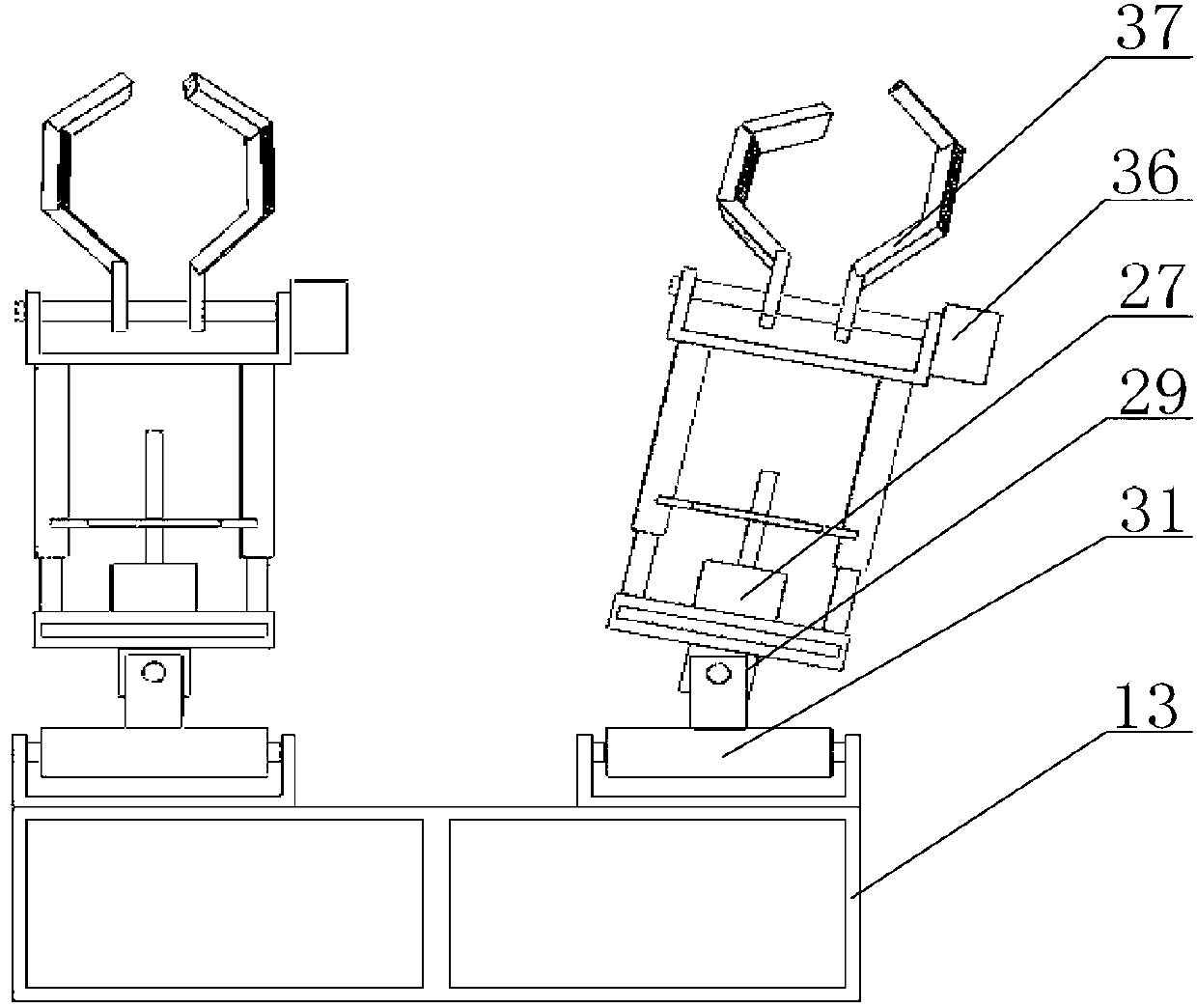

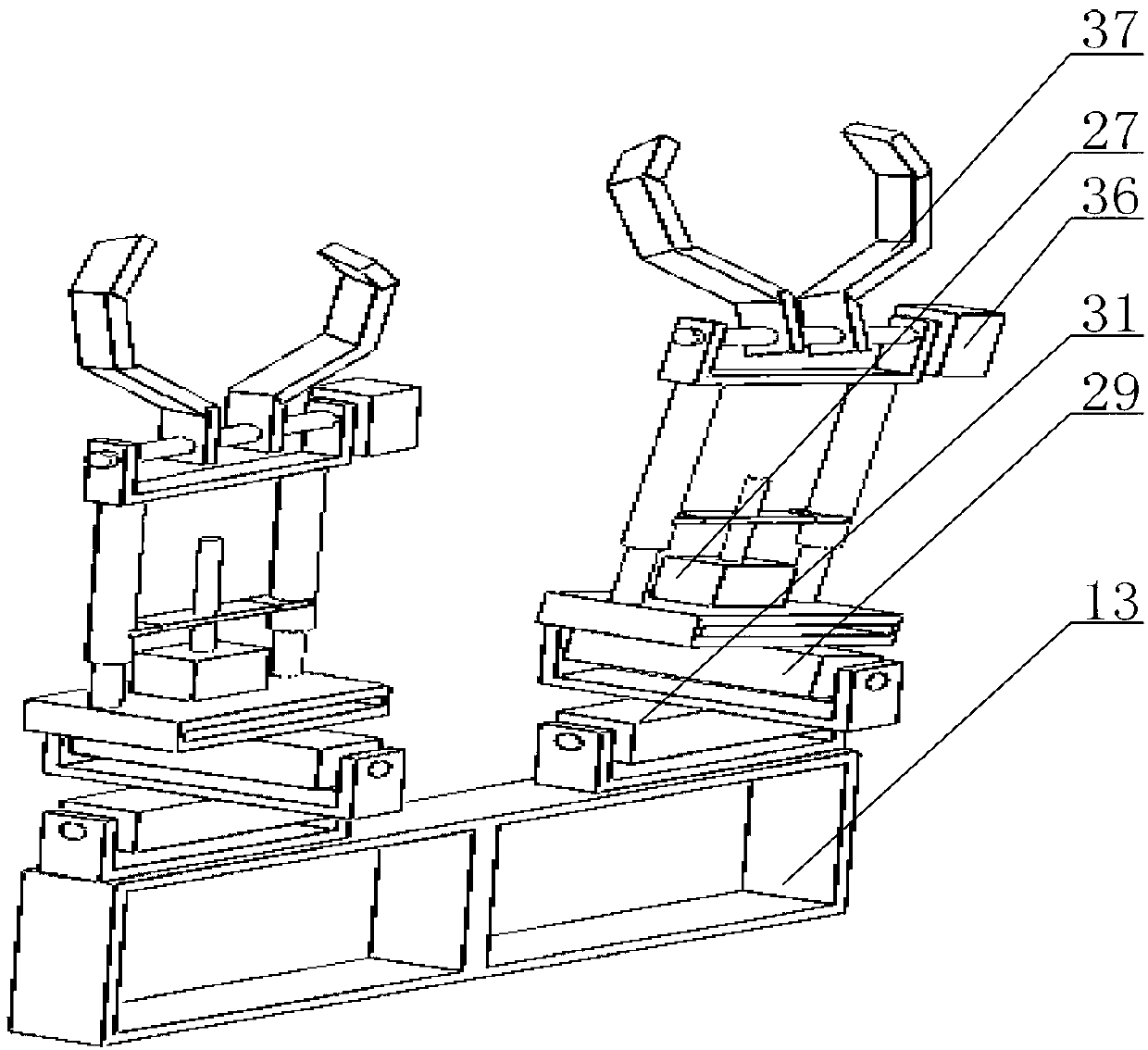

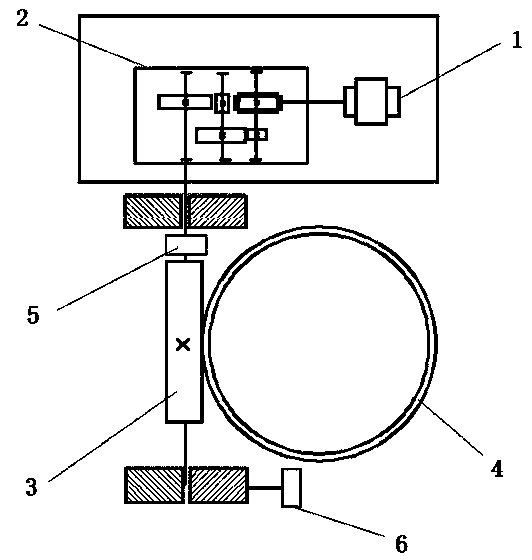

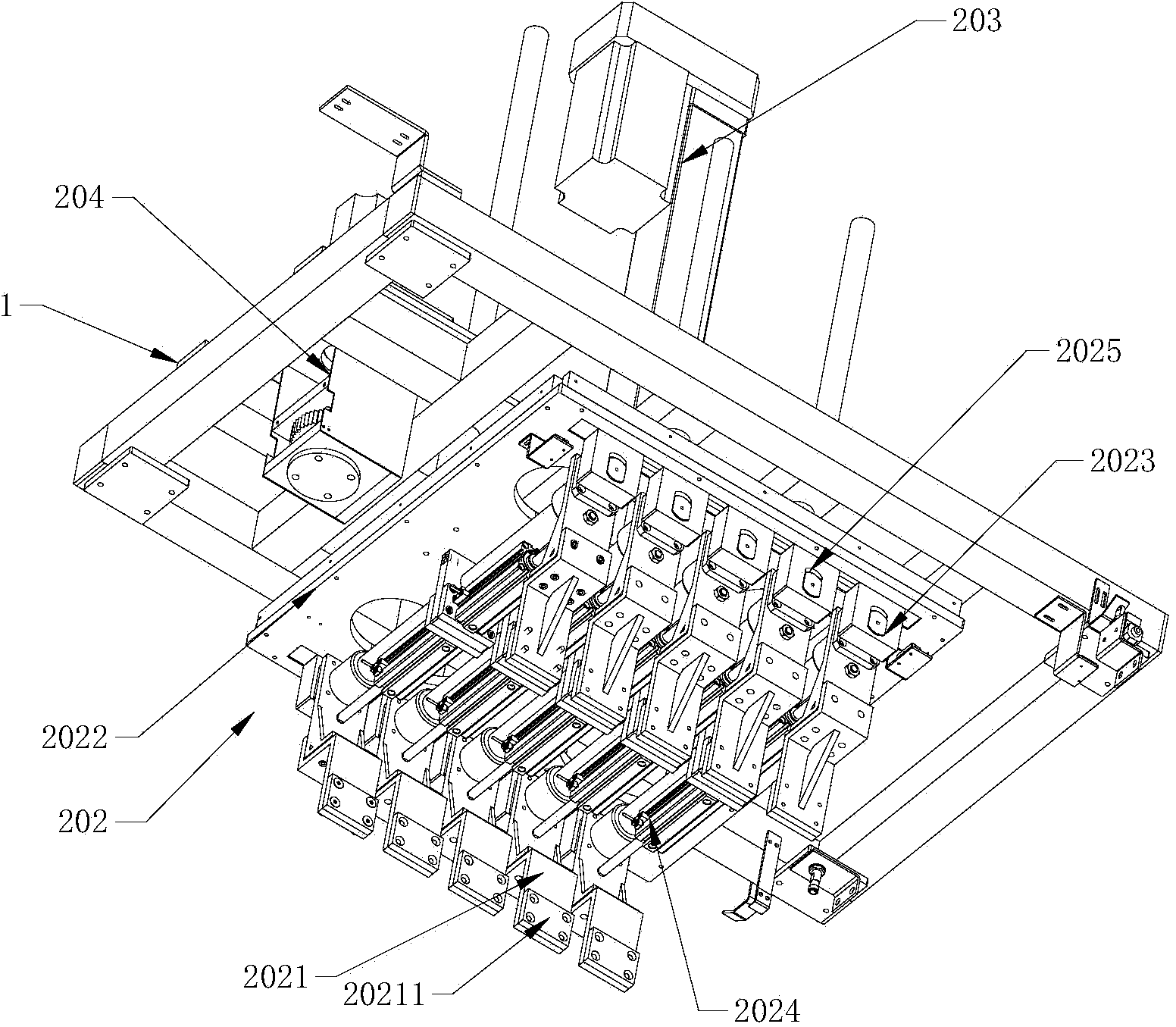

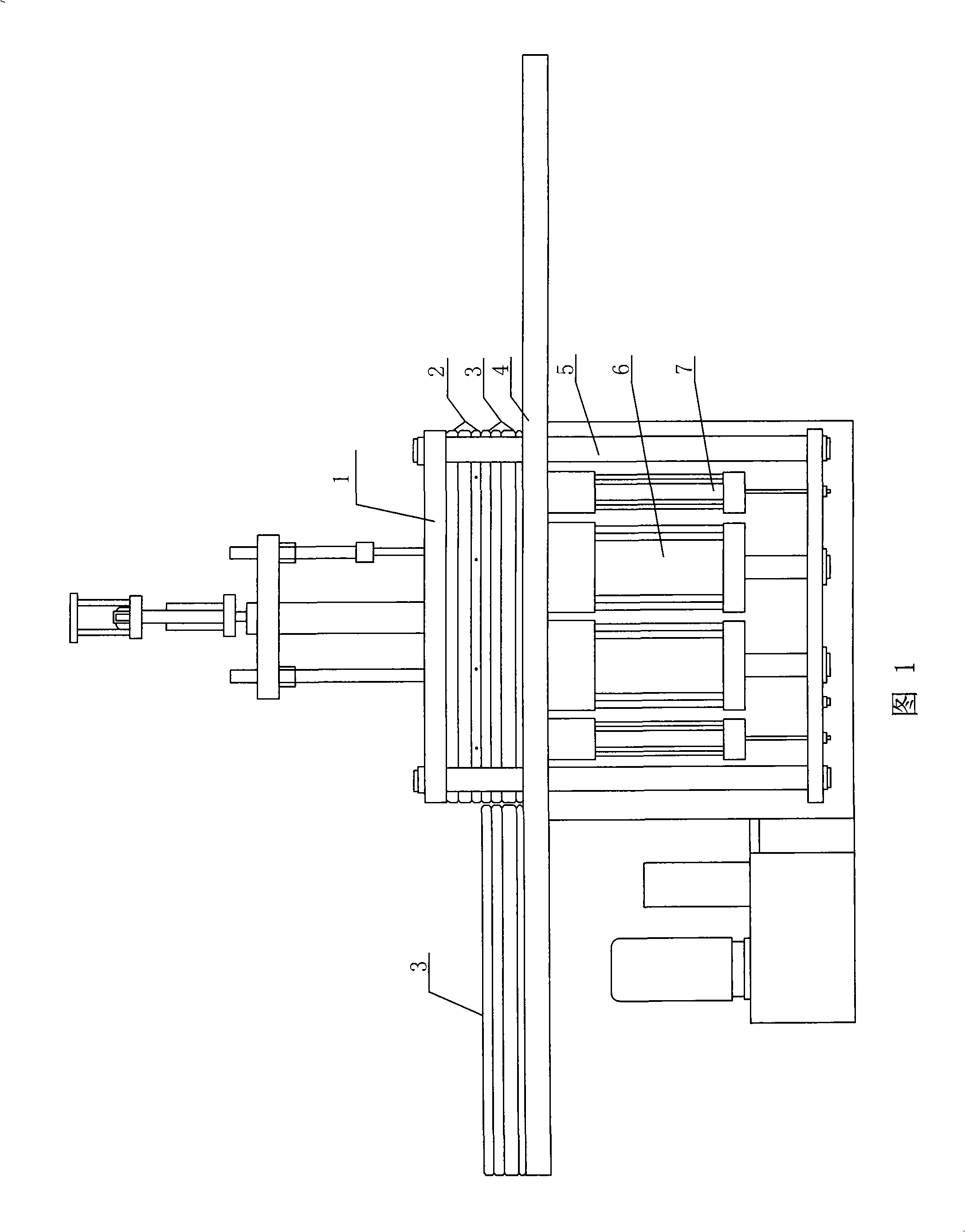

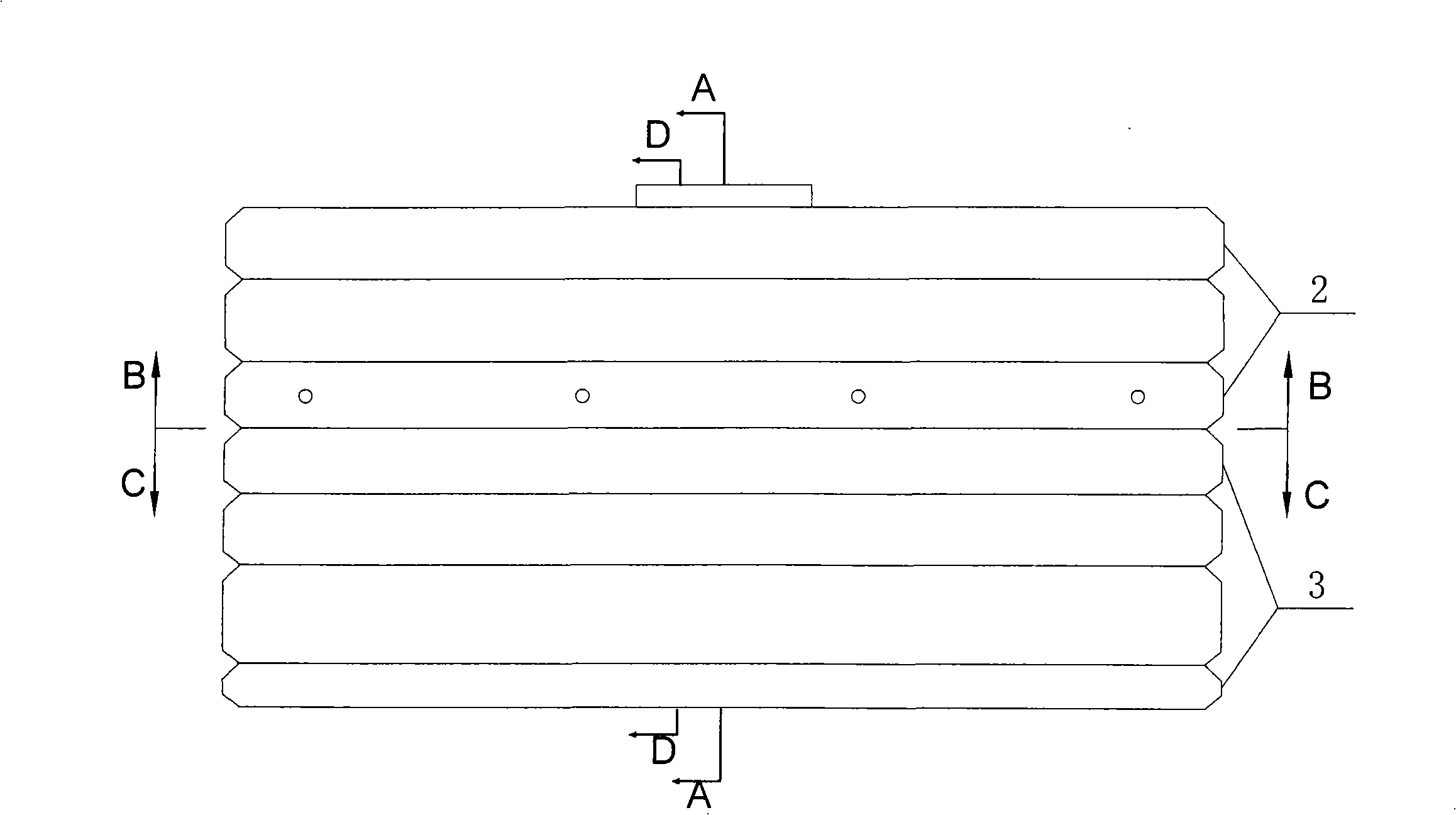

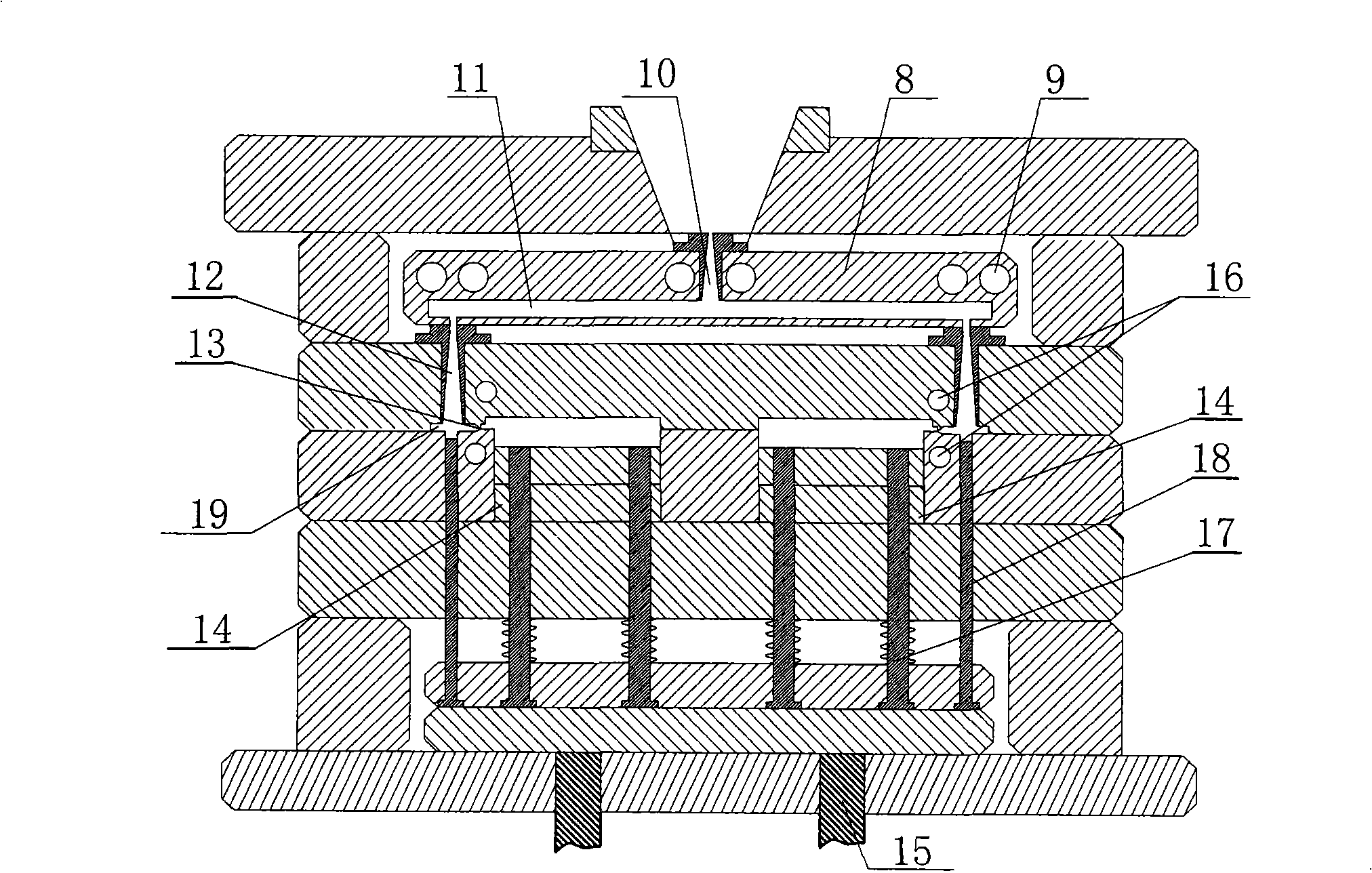

Automatic carrying device of spool of stranding machine

ActiveCN103879777ARealize fully automatic loading and unloading processing operationsImprove processing efficiencyConveyor partsHuman–machine interfaceDegrees of freedom

The invention discloses an automatic carrying device of a spool of a stranding machine. The automatic carrying device is characterized by comprising a carrying robot and a spool grip, wherein the carrying robot comprises a longitudinal moving mechanism, a vertical moving mechanism, a transverse moving mechanism and a rotary mechanism, the vertical moving mechanism is arranged on a longitudinal sliding block of the longitudinal moving mechanism in a sliding mode, the transverse moving mechanism is arranged on a vertical sliding block of the vertical moving mechanism in a sliding mode, the rotary mechanism is arranged at the lower end of a transverse sliding block, the lower end of the rotary mechanism is provided with the spool grip, and the longitudinal moving mechanism, the transverse moving mechanism, the vertical moving mechanism and the rotary mechanism achieve movement of the tail end executor spool grip of four degrees of freedom in longitudinal, transverse, vertical and rotary directions. According to the automatic carrying device, a servo system is adopted, actions are accurate and stable, a human-computer interface is adopted for operation, and operation is flexible.

Owner:重庆市隆泰稀土新材料有限责任公司

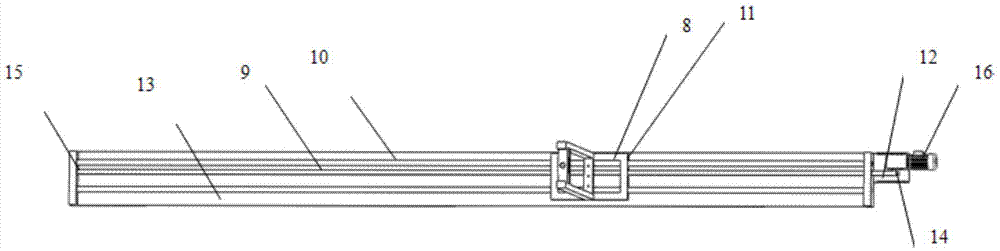

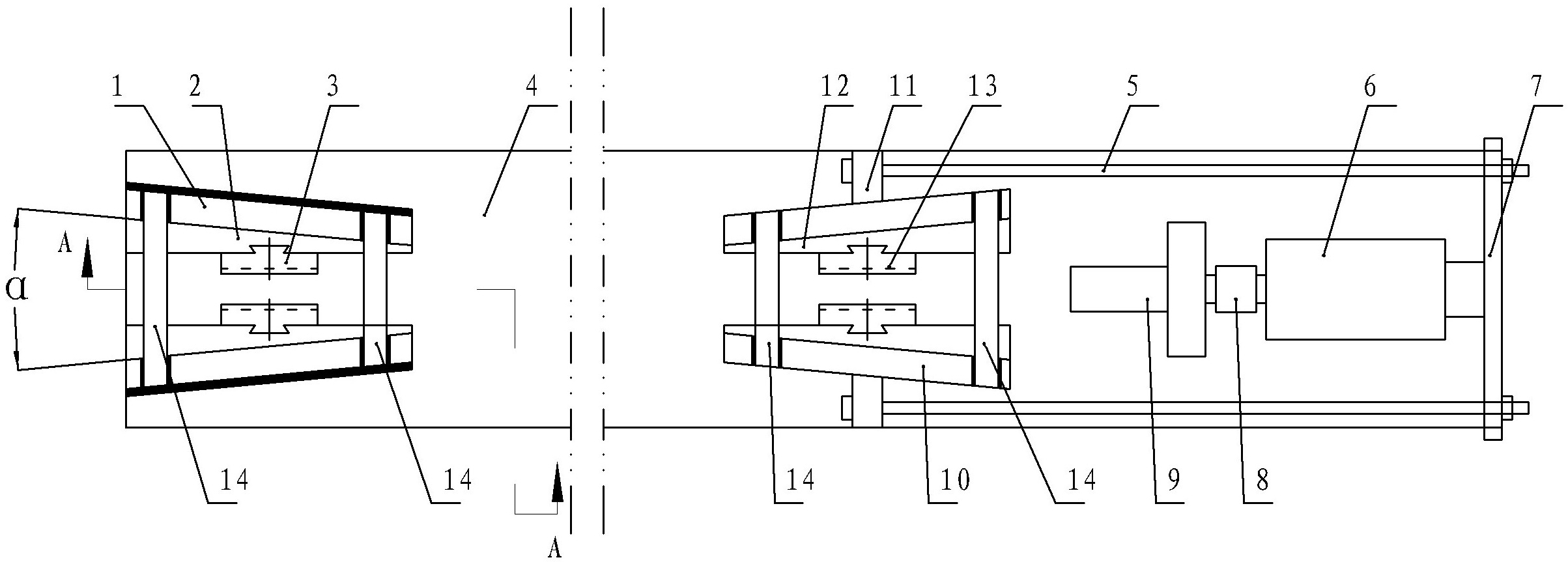

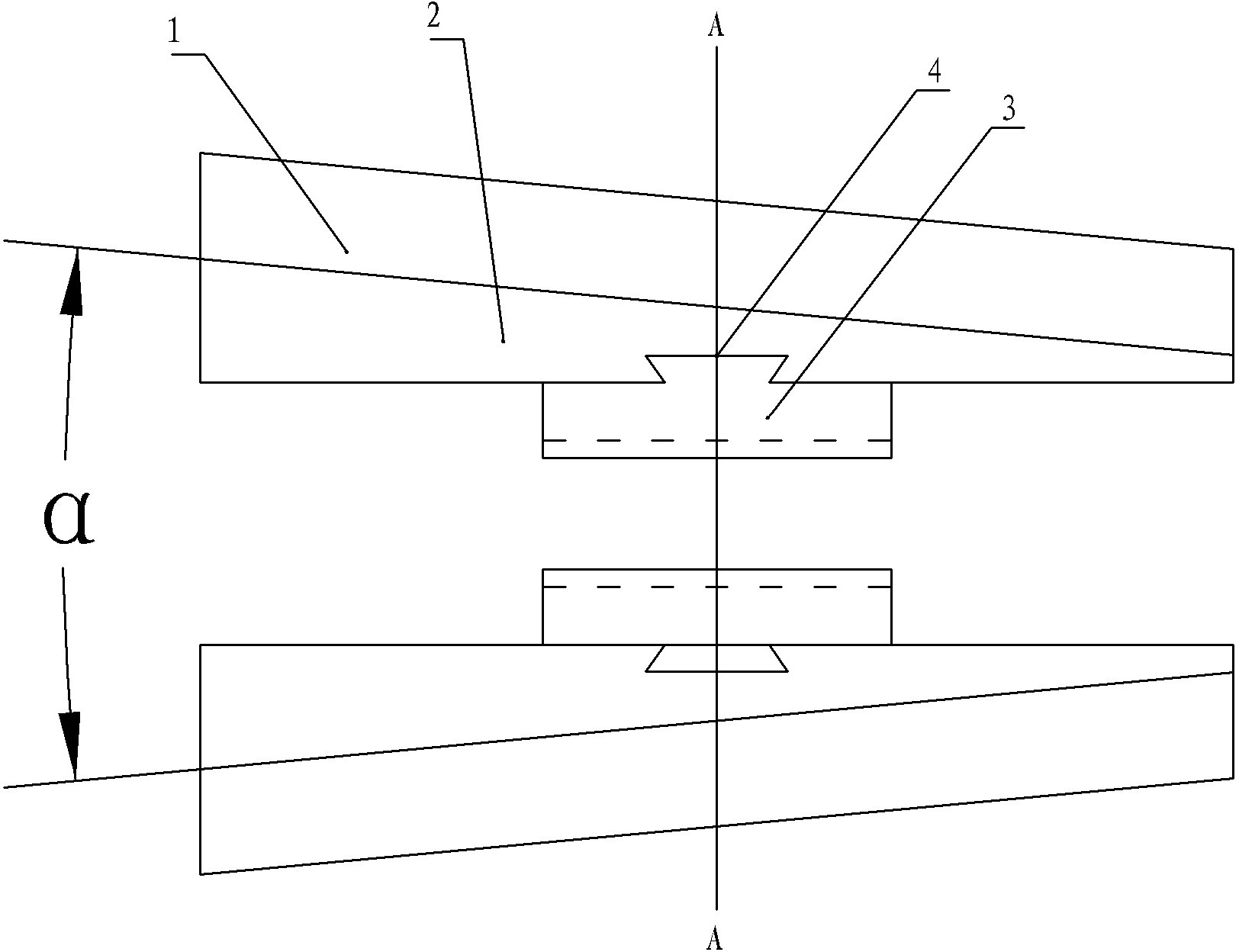

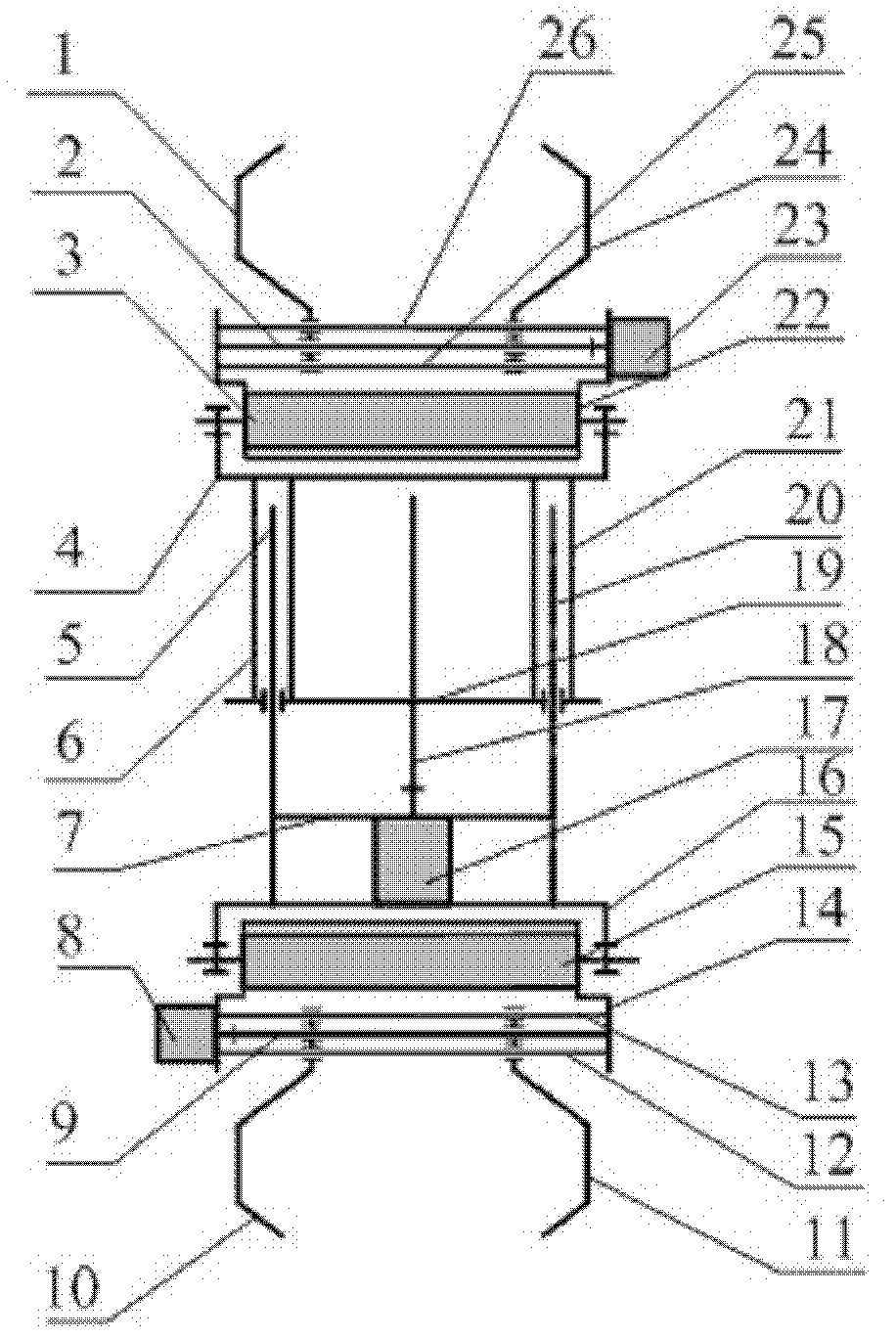

Steel wire rope tensile fixture and horizontal steel wire rope tensile testing machine thereof

ActiveCN102323144ARealize breaking testLarge clamping forceMaterial strength using tensile/compressive forcesEngineeringSlide plate

The invention discloses a steel wire rope tensile fixture and a horizontal steel wire rope tensile testing machine thereof. The steel wire rope tensile fixture comprises frame bodies, wedged sliding plates and friction blocks which are arranged symmetrically, wherein each frame body comprises two vertical plates of which the inner surfaces are arranged by forming an included angle alpha; the inclination angle of each wedged sliding plate is matched with the included angle alpha; the inner surface of each wedge sliding plate is connected with each friction block through a vertical dovetail groove structure; the included angle alpha is more than or equal to 13 degrees and less than or equal to 23 degrees; and the width L of each friction block is 190-340 millimeters. The horizontal steel wire rope tensile testing machine comprises a pressure sensor, a power device, a fixed steel wire rope tensile fixture and a movable steel wire rope tensile fixture, wherein the pressure sensor is arranged horizontally; the fixed steel wire rope tensile fixture comprises an upper fixture; and the power device is connected with the movable steel wire rope tensile fixture through a pull rod. The horizontal steel wire rope tensile testing machine has a simple structure, and is convenient to operate; the horizontal steel wire rope tensile testing machine is only required to be fixed on the ground, and the operation of the entire test process can be completed by one person, so that the labor intensity of detection test can be reduced greatly; and compared with the conventional testing machine, the horizontal steel wire rope tensile testing machine has the advantages of energy-saving test process, safety, environmental friendliness, mobility, low manufacturing cost and low test cost.

Owner:河南省煤科院检测技术有限公司

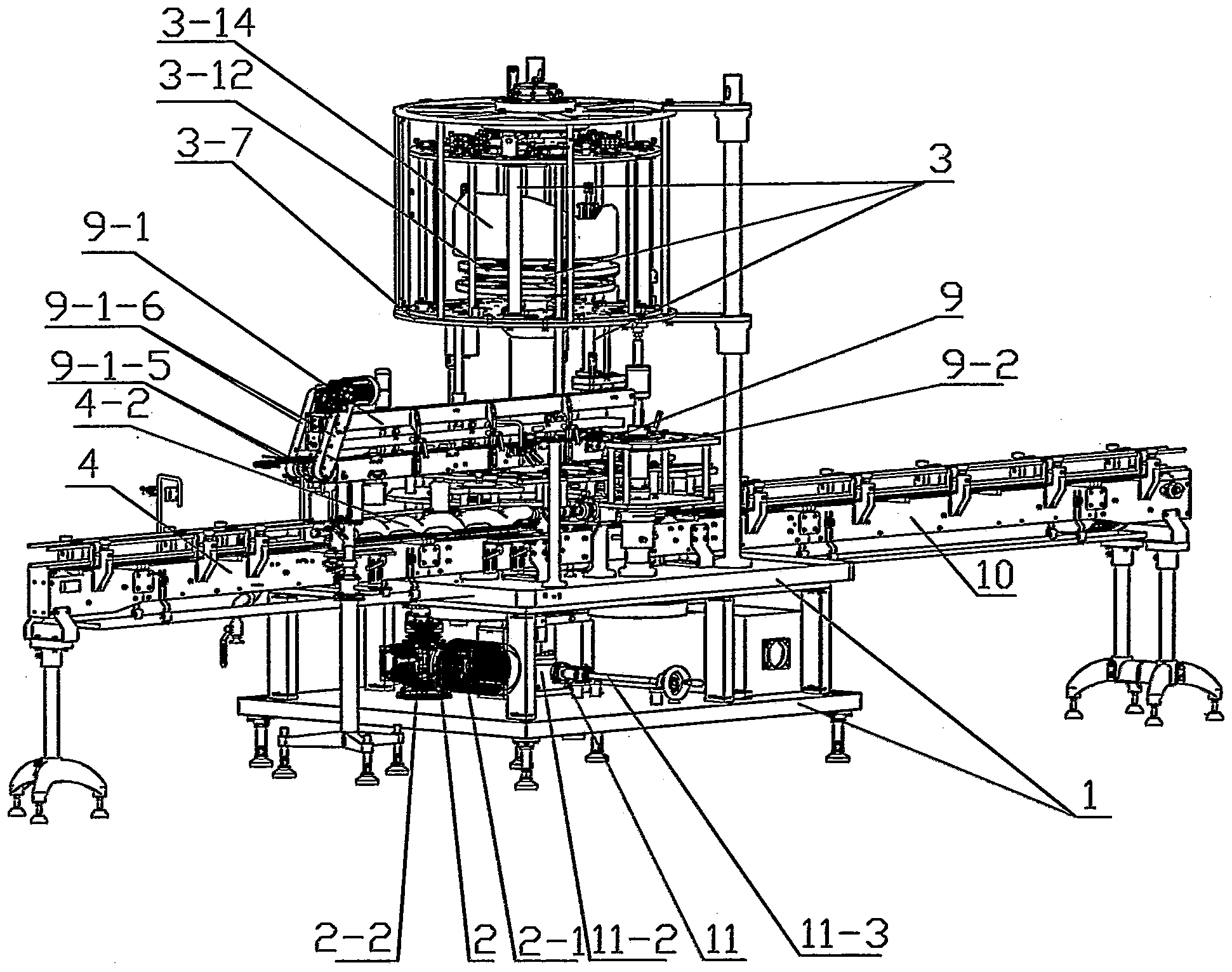

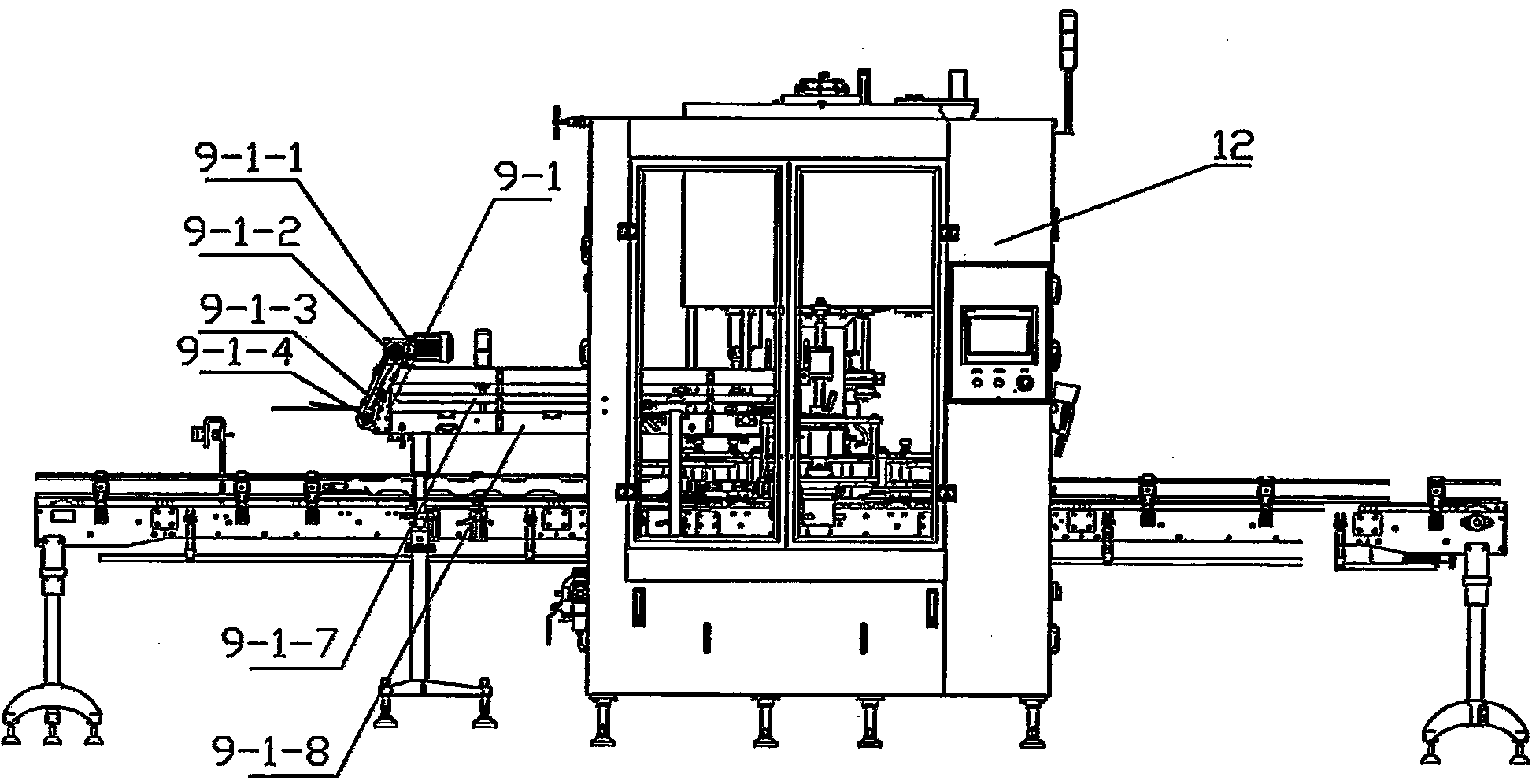

Pump cap screwing machine

ActiveCN103466523AAdjustable cap tightening forceEasy to connectThreaded caps applicationStops devicePower transmission

The invention discloses a pump cap screwing machine, which comprises a rack, a power transmission device, a cap screwing assembly, a bottle body supply device, a first bottle guide device, a second bottle guide device, a bottle feed star wheel device, a bottle stopping device, a bottle discharge star wheel device, a cap supply device, a rotating air path distribution device and a bottle output device, wherein the first bottle guide device is arranged at the tail of a screw rod and is matched with the bottle feed star wheel device, and a bottle feed inlet is formed between the first bottle guide device and the bottle feed star wheel device; the bottle feed star wheel device comprises a bottle feed turntable and a bottle feed rotating shaft which is movably connected with the power transmission device, the bottle feed turntable is provided with bottle feed clamping mounts and the bottle feed turntable is sheathed on the bottle feed rotating shaft; the second bottle guide device is matched with the bottle discharge star wheel device, a bottle discharge outlet is formed between the second bottle guide device and the bottle discharge star wheel device and the bottle stopping device is connected with the bottle discharge outlet. The pump cap screwing machine has the advantages that the structure is simple, the production efficiency is high, the processes of cap conveying, cap grabbing and cap screwing can be finished in one step, the effect of multiple products on one production line can be realized and the cap screwing effect is good.

Owner:CHANGZHOU HUITUO TECH

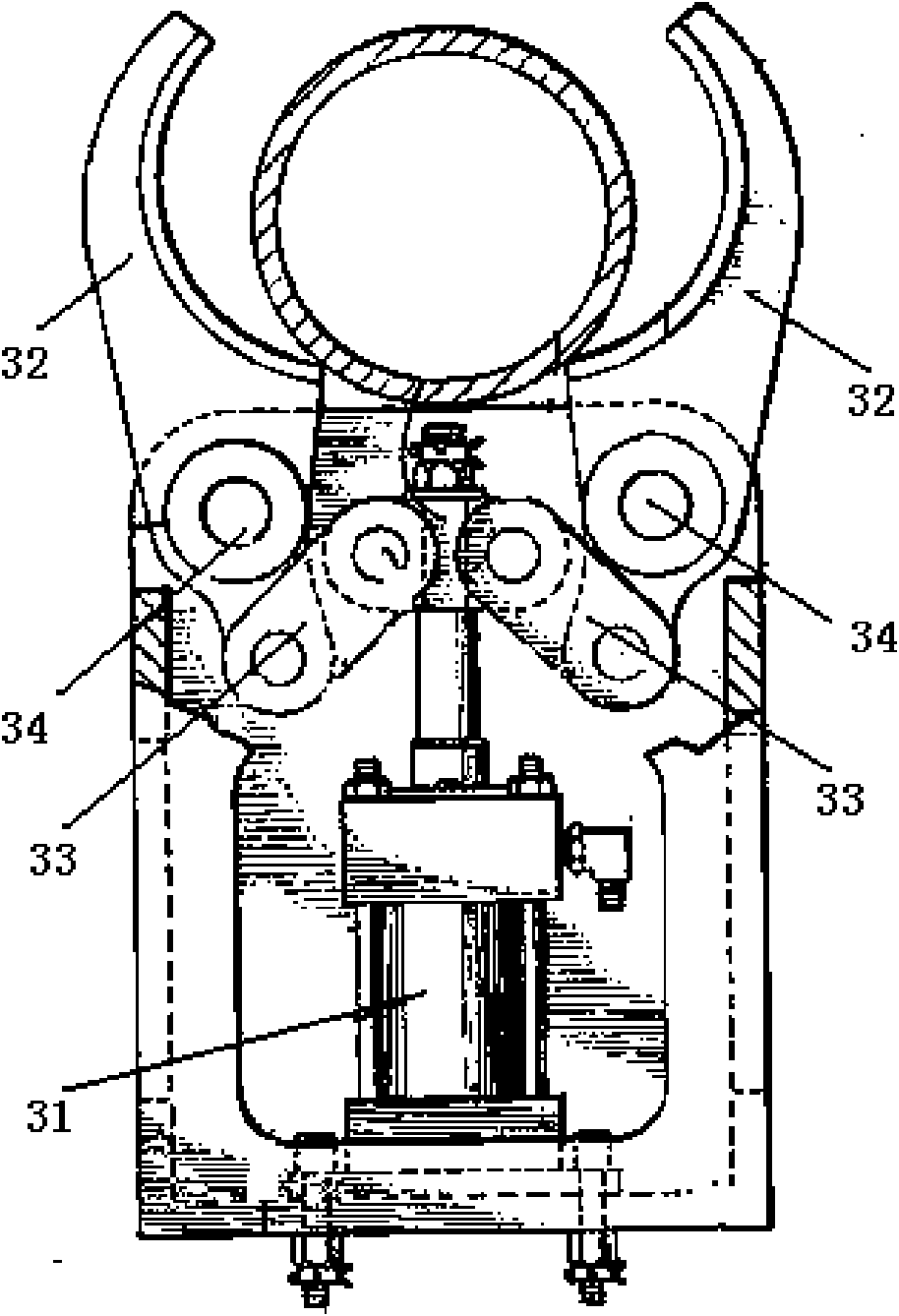

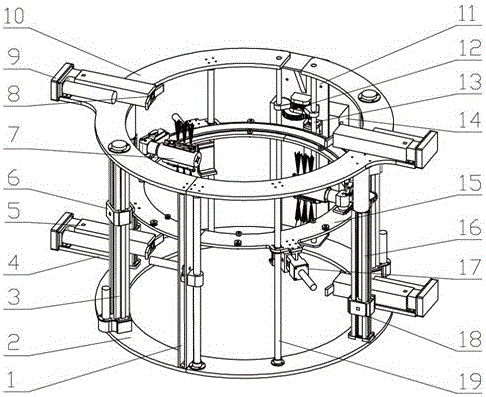

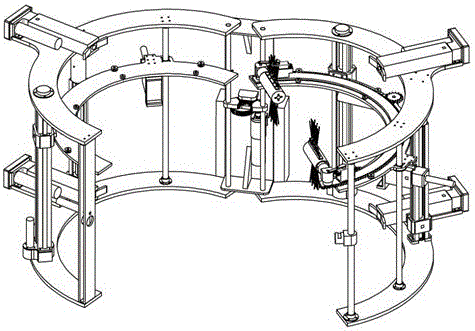

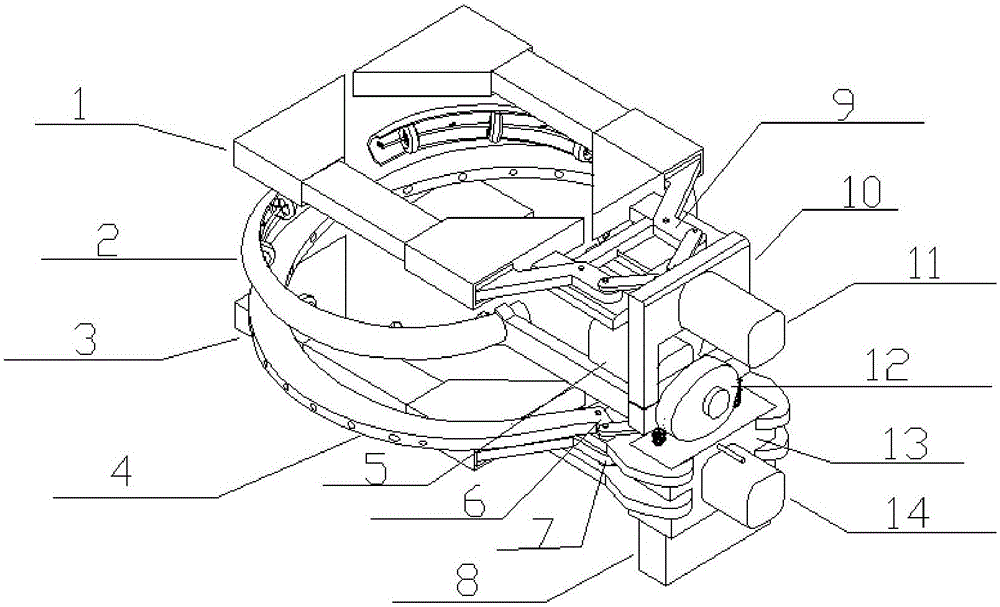

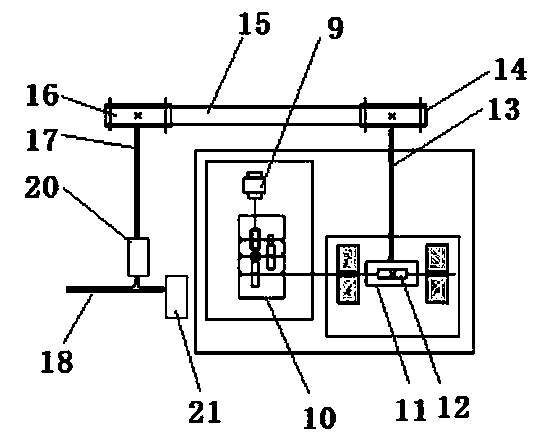

Insulator sweeping and detecting robot for high-voltage power transmission line

ActiveCN105855200AImprove practicalityCompact structureCleaning using toolsApparatus for overhead lines/cablesLocking mechanismElectric machine

The invention discloses an insulator sweeping and detecting robot for a high-voltage power transmission line. The robot comprises an annular frame and a control box; the annular frame is capable of being opened towards the two sides around a rotating shaft and comprises an upper layer bracket, a lower layer bracket and a middle layer bracket, wherein the upper layer bracket and the lower layer bracket are fixedly connected through a plurality of auxiliary brackets; the middle layer bracket is capable of moving up and down through a sweeping layer elevating mechanism; the upper layer bracket is provided with an upper clamping jaw for clamping an insulator; a detecting device is arranged on the upper clamping jaw; the middle layer bracket is provided with a sweeping device and an auxiliary clamping jaw which is used for clamping the skirt section of the insulator; a lower clamping jaw capable of moving up and down through a clamping jaw layer elevating mechanism is also arranged between the upper layer bracket and the lower layer bracket; the annular frame opposite to the rotating shaft is provided with a locking mechanism for locking the closed state of the annular frame; a power supply and a controller which is used for controlling the running and action sequence of a rotating mechanism and a servo motor are arranged inside the control box. The insulator sweeping and detecting robot disclosed by the invention is compact in structure, good in adaptablity, complete in sweeping, high in load capacity and applicable to hot-line sweeping and detection of horizontal and suspension insulator strings.

Owner:WUHAN UNIV

Pole-climbing robot with stabilizing device

The invention relates to a pole-climbing robot, in particular to a pole-climbing robot with a stabilizing device. The problem that an existing small pole-climbing robot is poor in stability is solved. A storage battery is installed at the lower end of a linear telescoping mechanism. A second mechanical hand is installed on the lower portion of the linear telescoping mechanism through a second crank-link mechanism. A third motor is installed on the lower portion of the linear telescoping mechanism. A working mechanical hand is installed on the lower portion of the linear telescoping mechanism through a first crank-link mechanism. The stabilizing device and the linear telescoping mechanism are connected above the second mechanical hand and located above the working mechanical hand. A first mechanical hand is installed on the upper portion of the linear telescoping mechanism through a third crank-link mechanism. A second motor is connected with the third crank-link mechanism. The second motor drives the third crank-link mechanism to move to open or close the first mechanical hand. The pole-climbing robot with the stabilizing device is used for pole-climbing cleaning of an electric pole.

Owner:HARBIN INST OF TECH

Clamping type integral shrinking and overturning climbing robot

InactiveCN102632505AFast straight climbImprove terrain adaptabilityGripping headsEngineeringClimbing robots

The invention aims at providing a clamping type integral shrinking and overturning climbing robot comprising two clamping parts, an internal extension tube, an external extension tube, a shrinking motor, an extension tube connecting frame, an overturning frame and an overturning motor, wherein each clamping part comprises a clamping paw, a clamping motor, a clamping motor rack, a guide shaft and a paw lead screw, and the two clamping parts are respectively located on the two ends of a main body of the clamping type integral shrinking and overturning climbing robot and are connected with the corresponding overturning motors through the respective clamping motor racks. According to the invention, a shrinking mechanism is designed according to the helical lead screw transmission principle to enable the robot to quickly and linearly climb in a shrinking manner; the integral shrinking and overturning design mode entitles better terrain adaptability to the robot; and the shrinking part utilizes an internal and external extension tube structure so as not to bear radial force.

Owner:HARBIN ENG UNIV

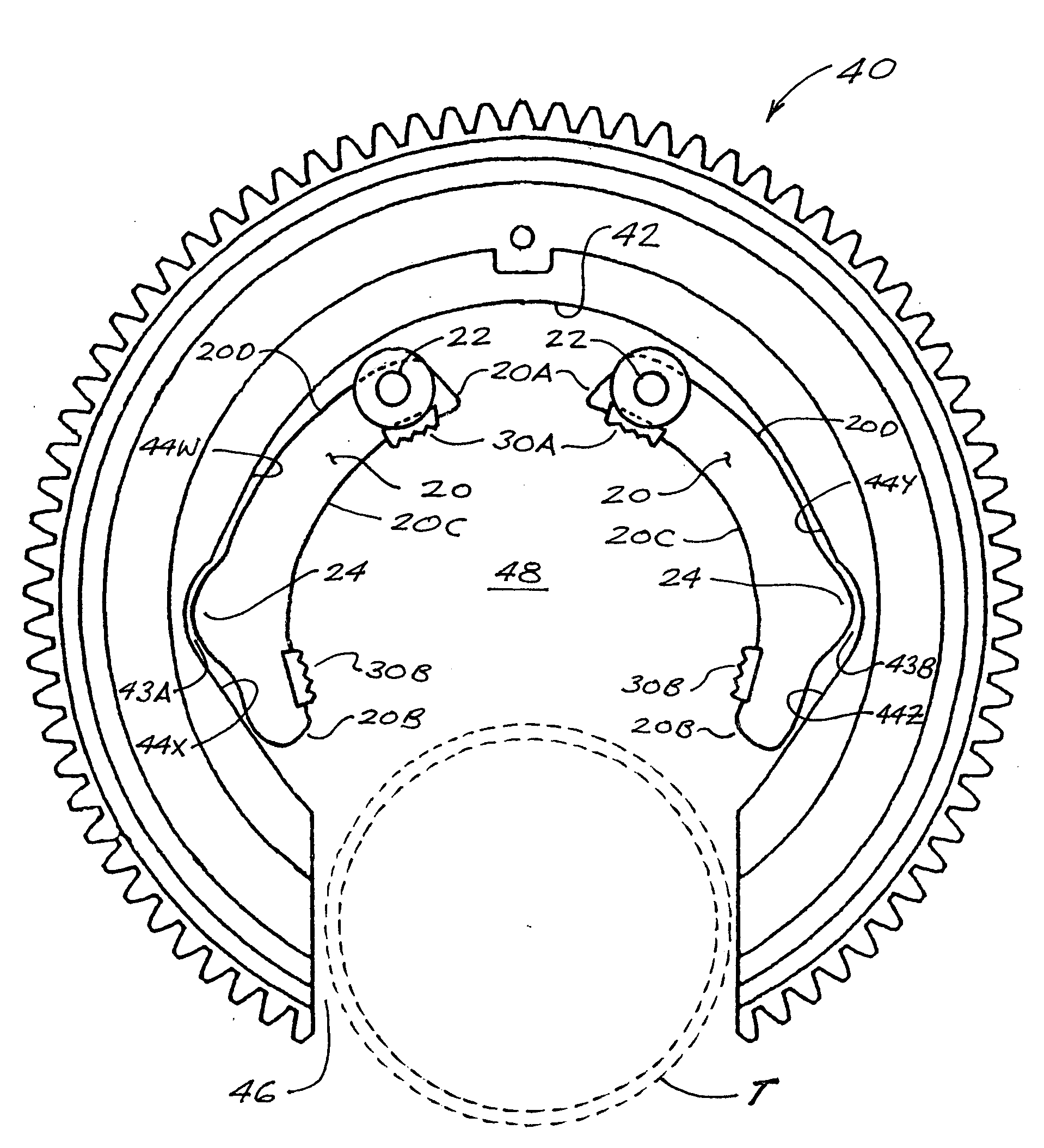

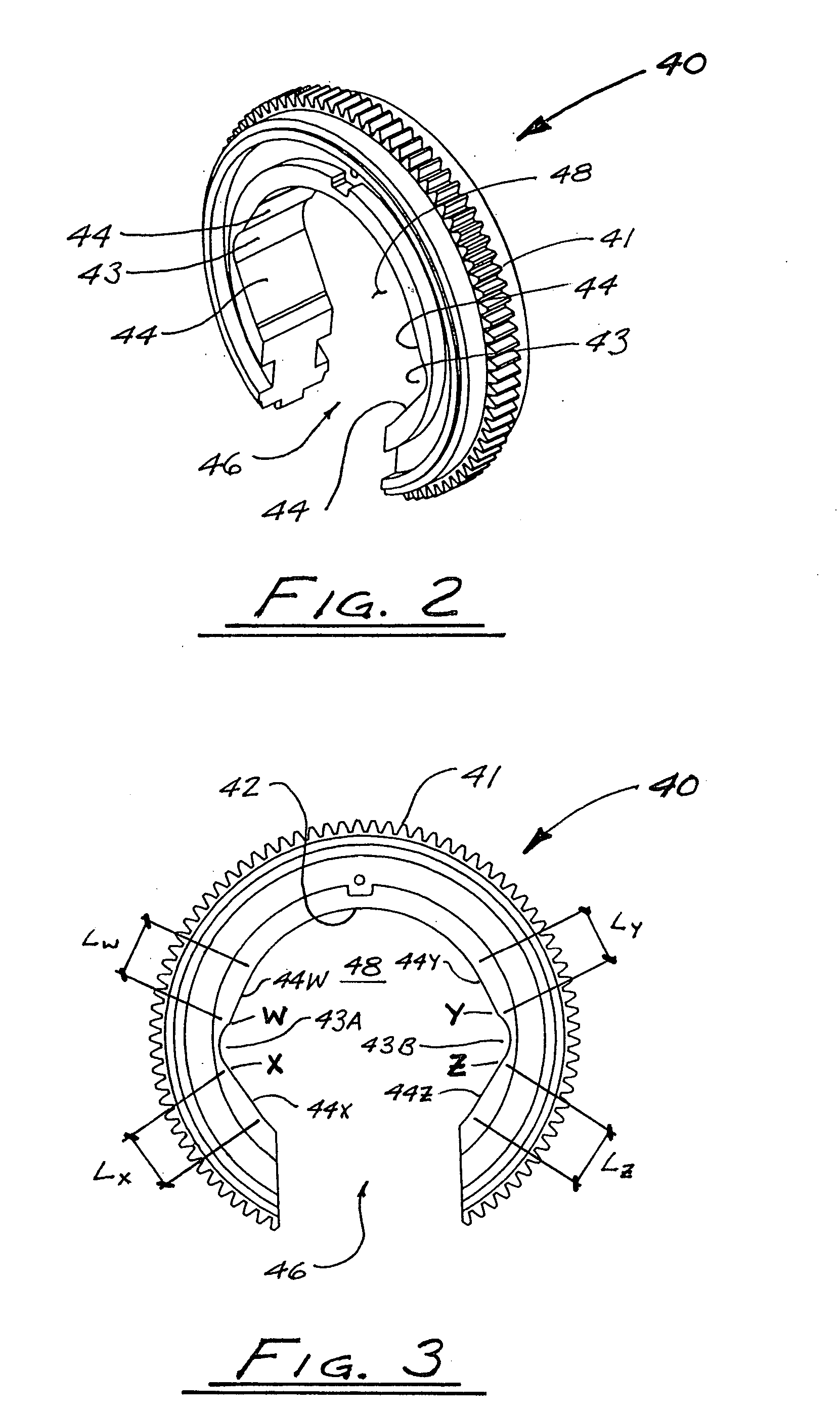

Power tong with linear camming surfaces

InactiveUS20060011017A1High strengthRadial distance to a pointDrilling rodsSpannersGrip forceAcute angle

In a pivoting-jaw power tong, each primary camming surface of the rotary gear has a substantially linear rather than curved configuration. Each primary camming surface forms an acute angle with a radial line extending from the rotary gear centerline to the point where the primary camming surface transitions to its associated neutral recess. Accordingly, the radial distance to a point on any of the primary camming surfaces reduces linearly with increased distance from the neutral recess. Rotation of the rotary gear in either direction away from the neutral position thus results in a linearly progressive reduction in the distance from the center of rotation to the points where the pivoting jaws' cam followers contact the camming surfaces, thus increasing the force exerted by the dies of the jaws upon a tubular disposed within the jaws. This camming surface geometry allows the power tong to automatically adjust for wear in the mechanism such that the contact force between the rollers and the camming surfaces, and the gripping force applied by the dies, will be substantially uniform.

Owner:KATHAN MURRAY

Overturning and climbing robot with two telescopic arms

ActiveCN103273500AIncrease flexibilityIncreased range of mobile workGripping headsArmsControl modeClimbing robots

Provided is an overturning and climbing robot with two telescopic arms on different sides. A body is driven to climb in the modes of grabbing through two hands, stretch outing or drawing back of the arms and spatial overturning. The opening and closing of each hand is realized through horizontal movement of a screw rod along two guiding shafts, wherein the screw rod is driven by a motor and provided with a forward buckle and a reverse buckle in a machined mode. The stretch and contraction of the arms are realized through vertical movement of a single-buckle screw rod along two telescopic pipes, wherein the single-buckle screw rod is also driven by the motor. The spatial overturning is realized through a cross-shaped motor installation structure. A unit formed by the two hands, a unit formed by the arms and a spatial overturning unit are connected in sequence and then fixedly mounted on the body (namely a vehicle body) through a support, and therefore the body is driven in a grabbing type climb mode. The overturning and climbing robot with the two telescopic arms on different sides is simple in structure and high in mobility. Corresponding technology application demands for carrying out field tasks can be met in different control modes by means of carrying different sensors.

Owner:HARBIN ENG UNIV

Three-freedom degree manipulator

InactiveCN103878763AStrong wear resistanceFlexible liftingProgramme-controlled manipulatorGripping headsDegrees of freedomEngineering

The invention relates to the technical field of mechanical automation, in particular to a three-freedom degree manipulator which is formed by a base assembly, an arm assembly and a gripper assembly. The arm assembly is arranged on the base assembly, and the gripper assembly is arranged at the end of the arm assembly. The three-freedom degree manipulator has the advantages that a three-freedom degree manipulator work station can be applied to automatic meal delivery of the catering industry and mechanical principle and designed experiment practical teaching of colleges and universities, and the automation degree reaches the international advanced level; the base assembly, the arm assembly and the gripper assembly are installed as a set, a mechanical structure is high in abrasion resistance, and the manipulator is safer and more reliable in operation.

Owner:JIANGSU UNIV

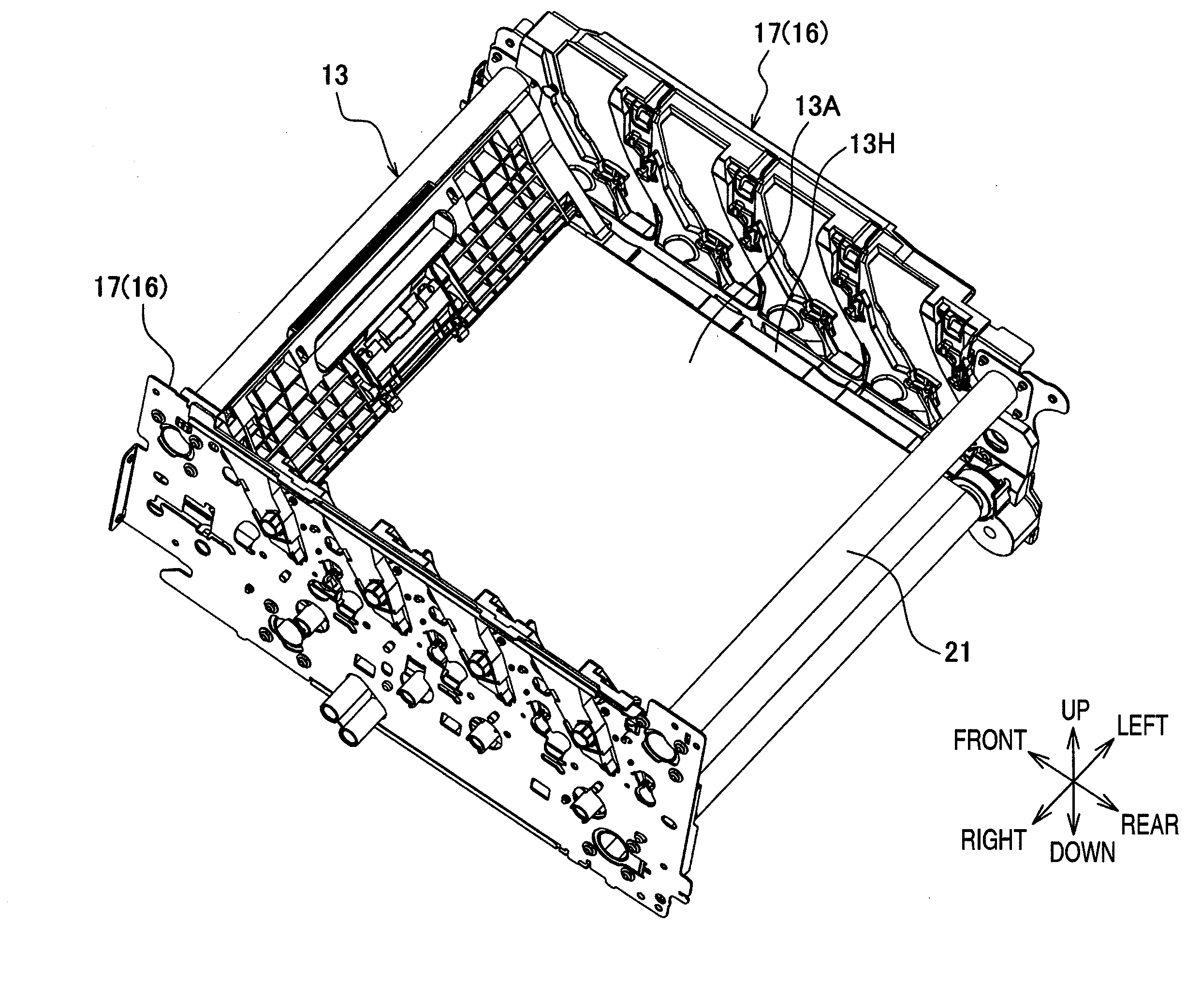

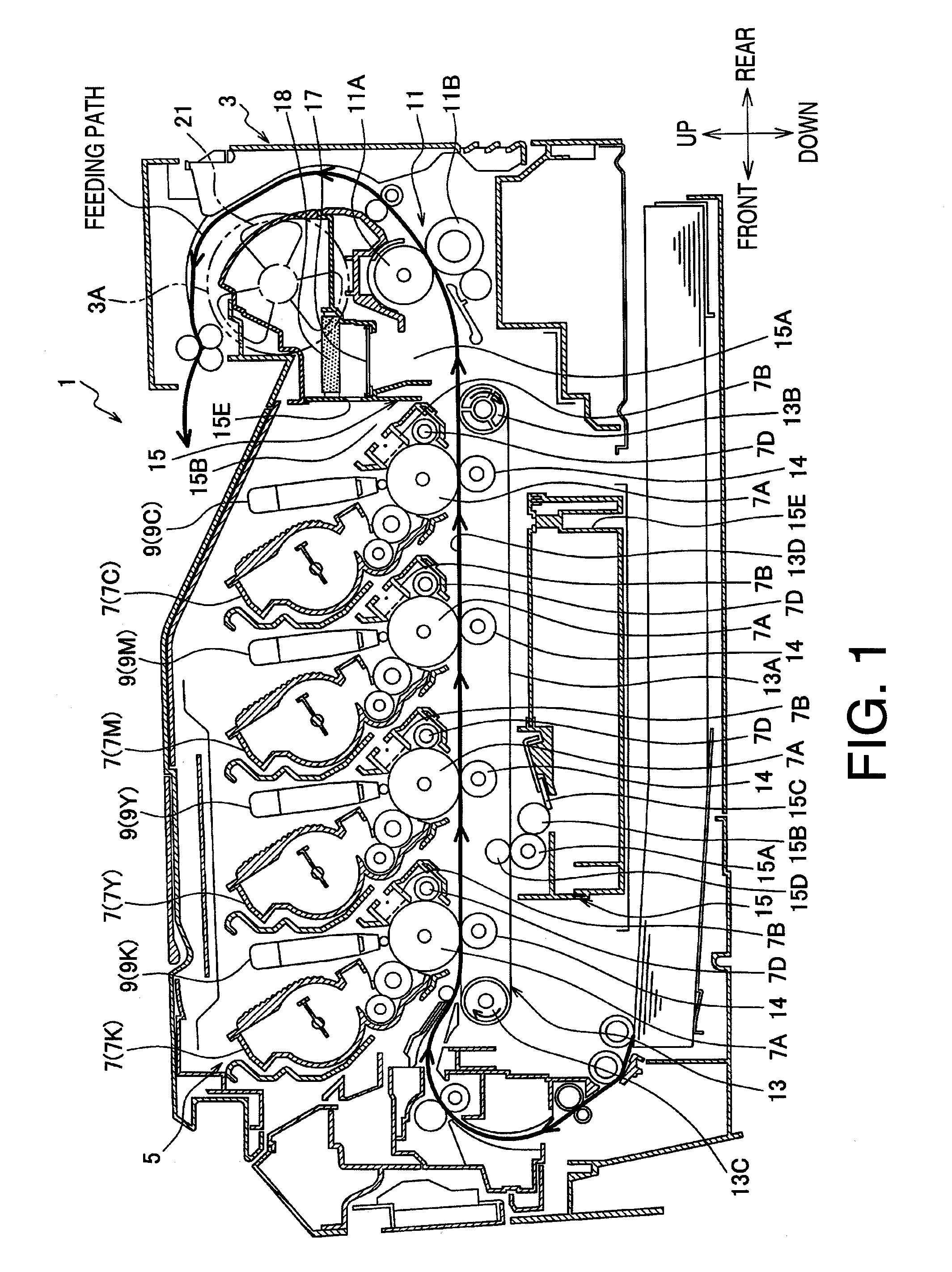

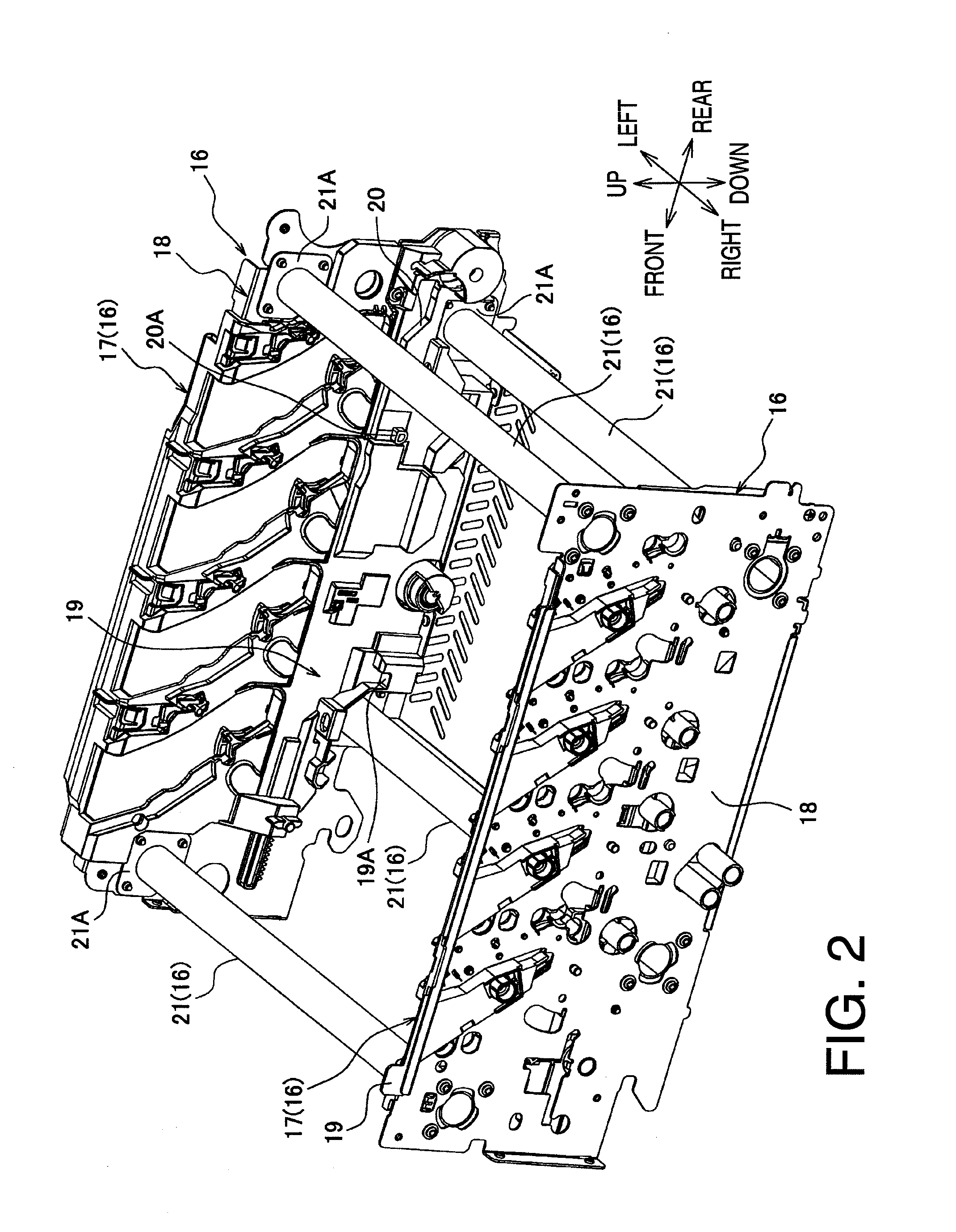

Image forming apparatus

ActiveUS20100080612A1Large clamping forceReduce the amount requiredElectrographic process apparatusImage formationEngineering

An image forming apparatus is provided. The image forming apparatus includes a plurality of detachable unit components and a frame assembly to hold the detachable unit components in predetermined positions in the image forming apparatus. The frame assembly includes a pair of metal frames and a pair of resin frames, each of which is attached to one of the metal frames. Each of the metal frames includes a first positioning structure, which corresponds to an original point of the metal frame, a first fixing structure, a second positioning structure, wherein each of the resin frames includes, a first positioning structure, which corresponds to an original point of the resin frame, a fixing structure, a second positioning structure, and a plurality of pressing pieces, by which the resin frame is pressed against one of the metal frame.

Owner:BROTHER KOGYO KK

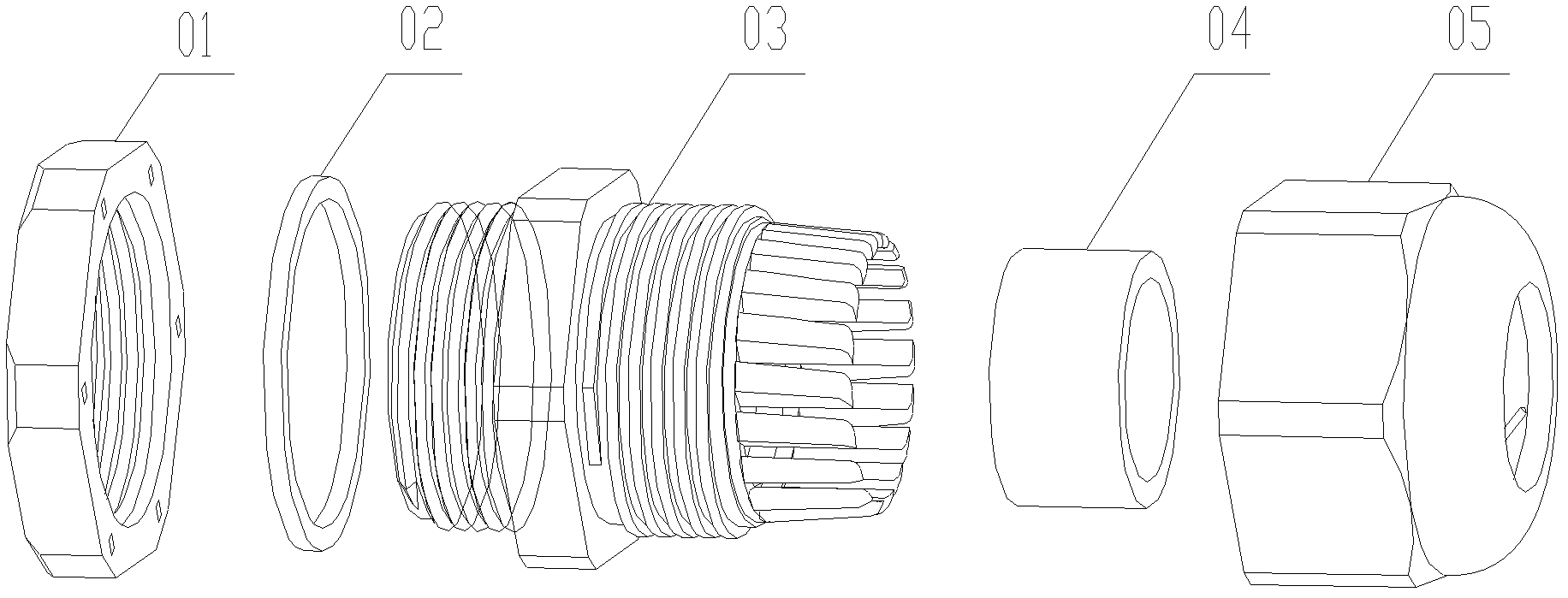

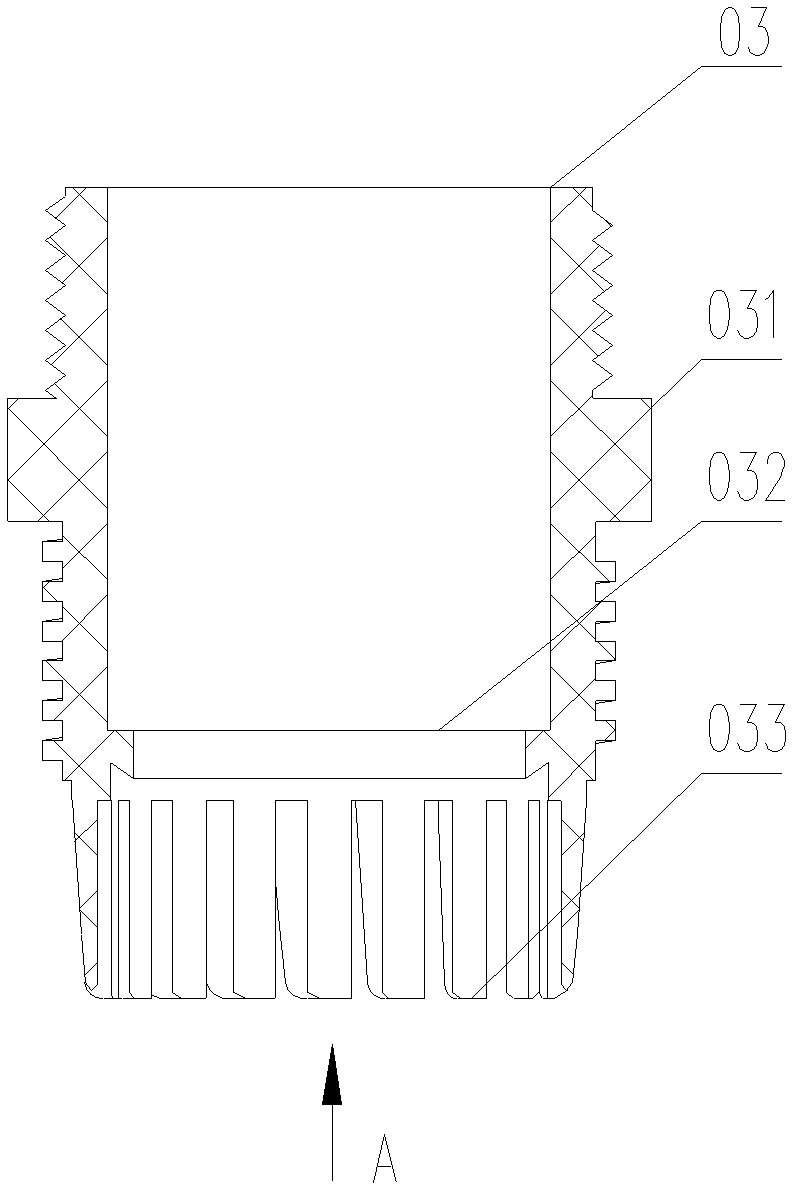

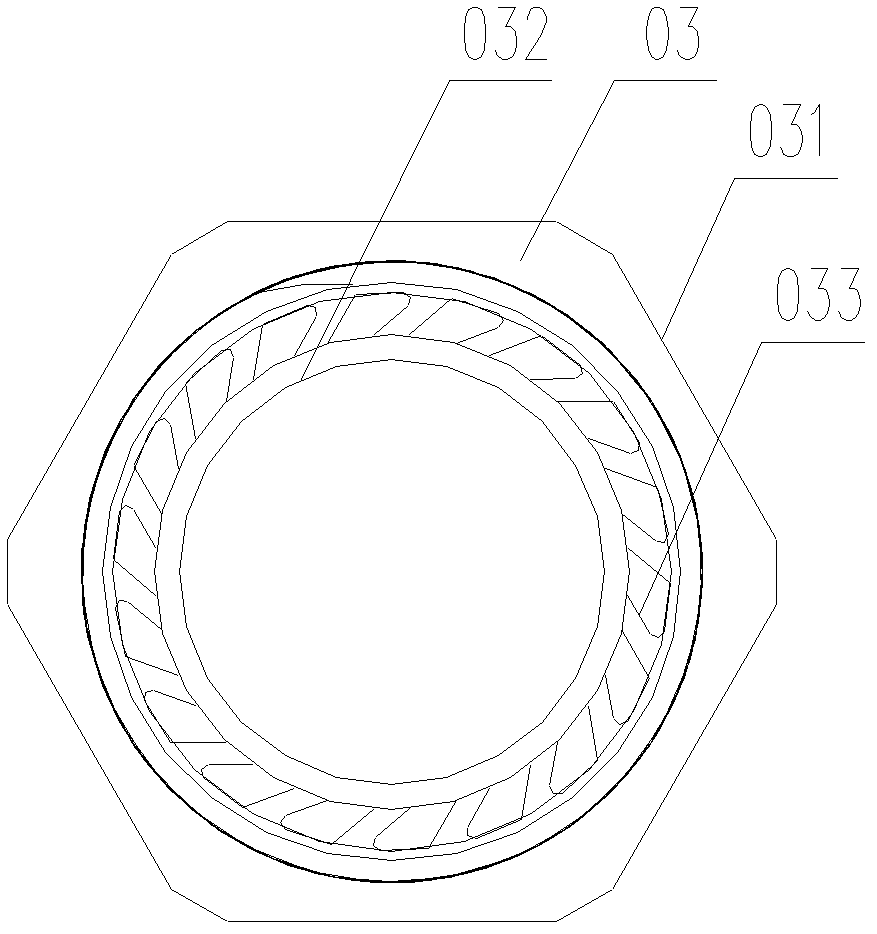

Cable fixing head

ActiveCN102856857AImprove the ability to resist external pullPrevent ejectionElectrical apparatusPipesCable glandPush out

The invention relates to the field of electric equipment, in particular to a cable fixing head. The cable fixing head comprises a nut, a waterproof ring, a tightening nut and a tubular body with outer threads. A clamping claw with gaps, which extends along the axial direction of the body, is disposed at a clamp end of the body. A fixed protrusion extending outwards is disposed on the outer periphery of the body. The nut is matched with a fixed end of the body. Positioning protrusions are disposed on the inner side of the clamping claw. A limit groove which opens towards the positioning protrusions is arranged on the inner wall of the body. Positioning grooves which are matched with the positioning protrusions are arranged at one end of the waterproof ring. The other end of the waterproof ring is inserted into the limit groove. The tightening nut is tightened at the clamp end of the body. The waterproof ring can be prevented from being pushed out by a cable, the water ring is less prone to deformation, and accordingly spacing between the waterproof ring and the body is avoided so as to improve airtightness between the waterproof ring and the body, dust, moisture and the like are prevented from entering a box, and stability of electric equipment elements in the box is improved.

Owner:BEISIT ELECTRIC TECH HANGZHOU CO LTD

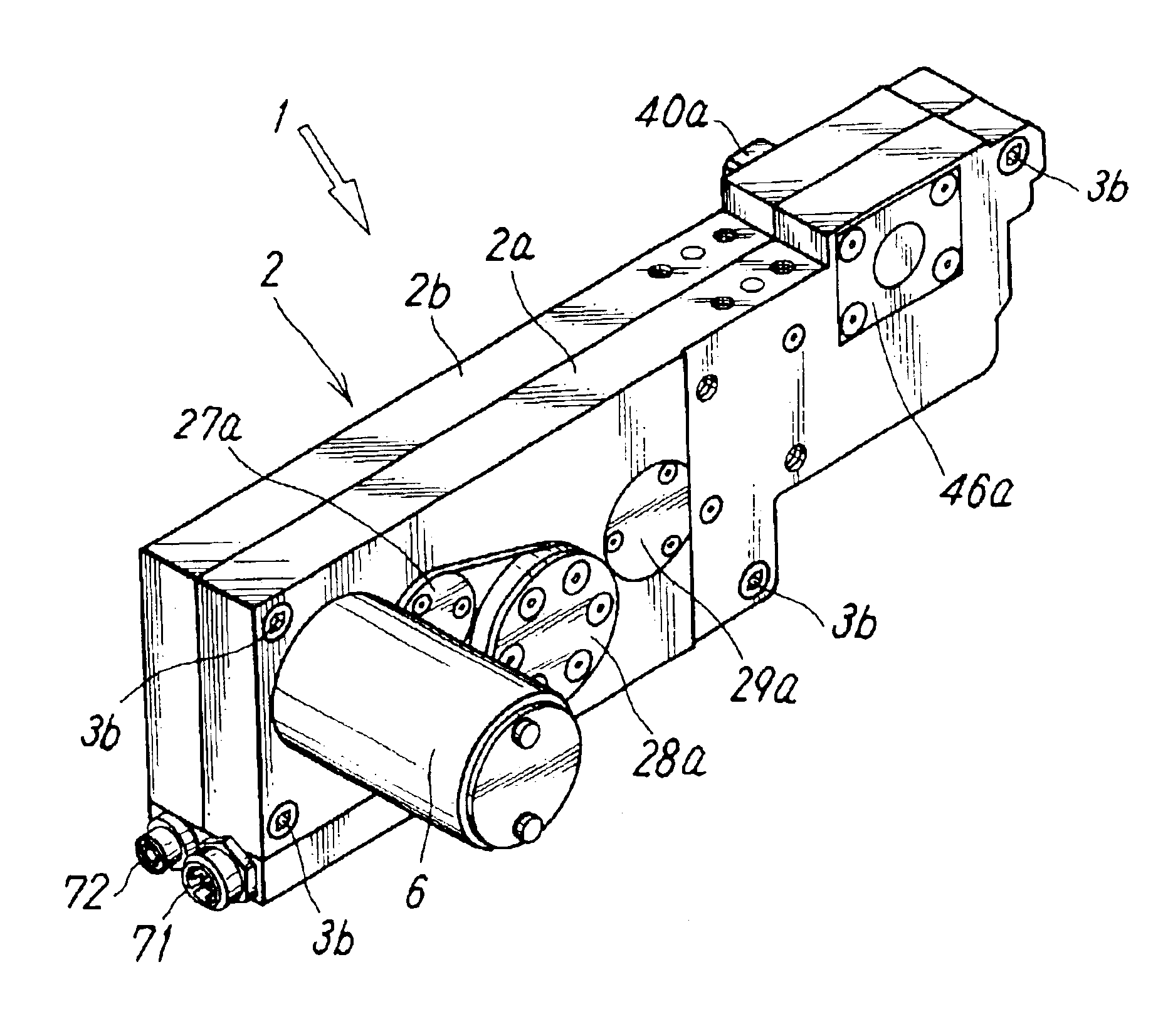

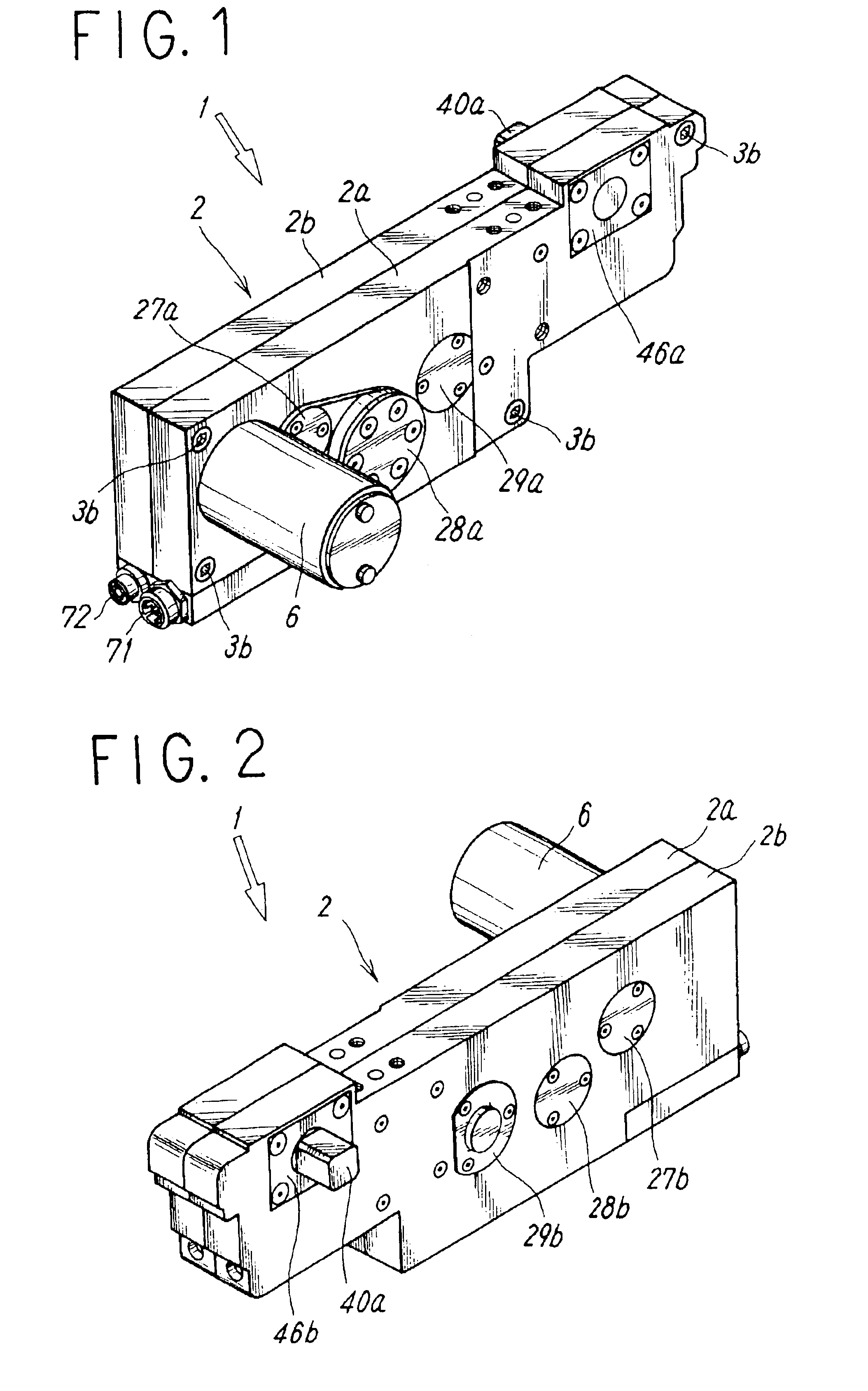

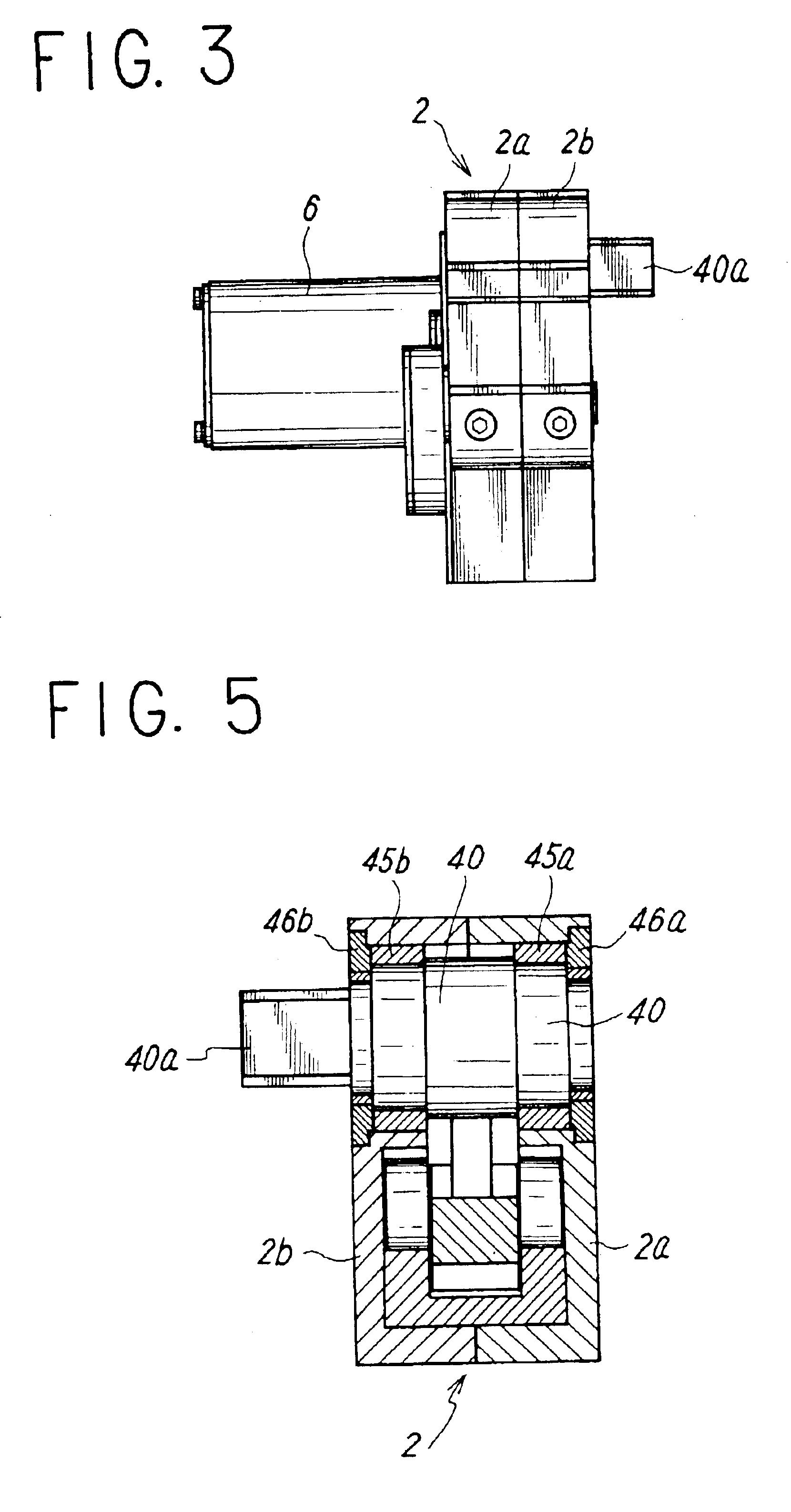

Electric clamping device

The present invention provides a low-cost electric clamping device in which a toggle linkage can be actuated by a small low-torque electric motor. The device includes a gear speed reducing mechanism connected to the electric motor, a linkage connected to the speed reducing mechanism, a clamp arm shaft connected to the linkage, and a body 2 for housing them. The linkage includes a crank link connected to a last-stage spur gear of the speed reducing mechanism, a cam follower link which is connected at one end thereof to the crank link and to which a cam follower moving on cam rail faces is rotatably mounted, and a driving lever to which the other end of the cam follower link is connected and which projects from the clamp arm shaft.

Owner:SMC CORP

Positioning clamping device for workpiece

InactiveCN102806481ASimple in structureLarge clamping forcePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:鹿丙稳

Packing device of battery packaging line

ActiveCN103895900APrevent fallingSmooth movementIndividual articlesEngineeringMechanical engineering

The invention discloses a packing device of a battery packaging line. The packing device comprises a frame, a packing container conveying device, a container press device, a battery clamping handling device and a sorting platform. The container press device comprises a press frame, a packing opening is formed in the middle of the press frame, press plates are arranged on the edge of the packing opening, and the press frame is driven through a press frame lifting device; the sorting platform is used for temporarily storing and sorting a well arrayed battery pack; the battery clamping handling device comprises a sliding base which is driven through a driving device; a clamping base is vertically slidably mounted on the sliding base is driven through a clamping component and the lifting device; a plurality of mounting blocks are horizontally and slidably mounted at the bottom of the clamping seat, and each mounting block is provided with a detachable clamping jaw; the mounting blocks are driven to be connected through clamping jaw driving device. By the arrangement, the well arrayed batteries can be sorted through the packing device, then the sorted batteries are clamped to be packed accurately, and stable and normal operation of a battery packing line can be guaranteed.

Owner:蚌埠航宇知识产权服务有限公司

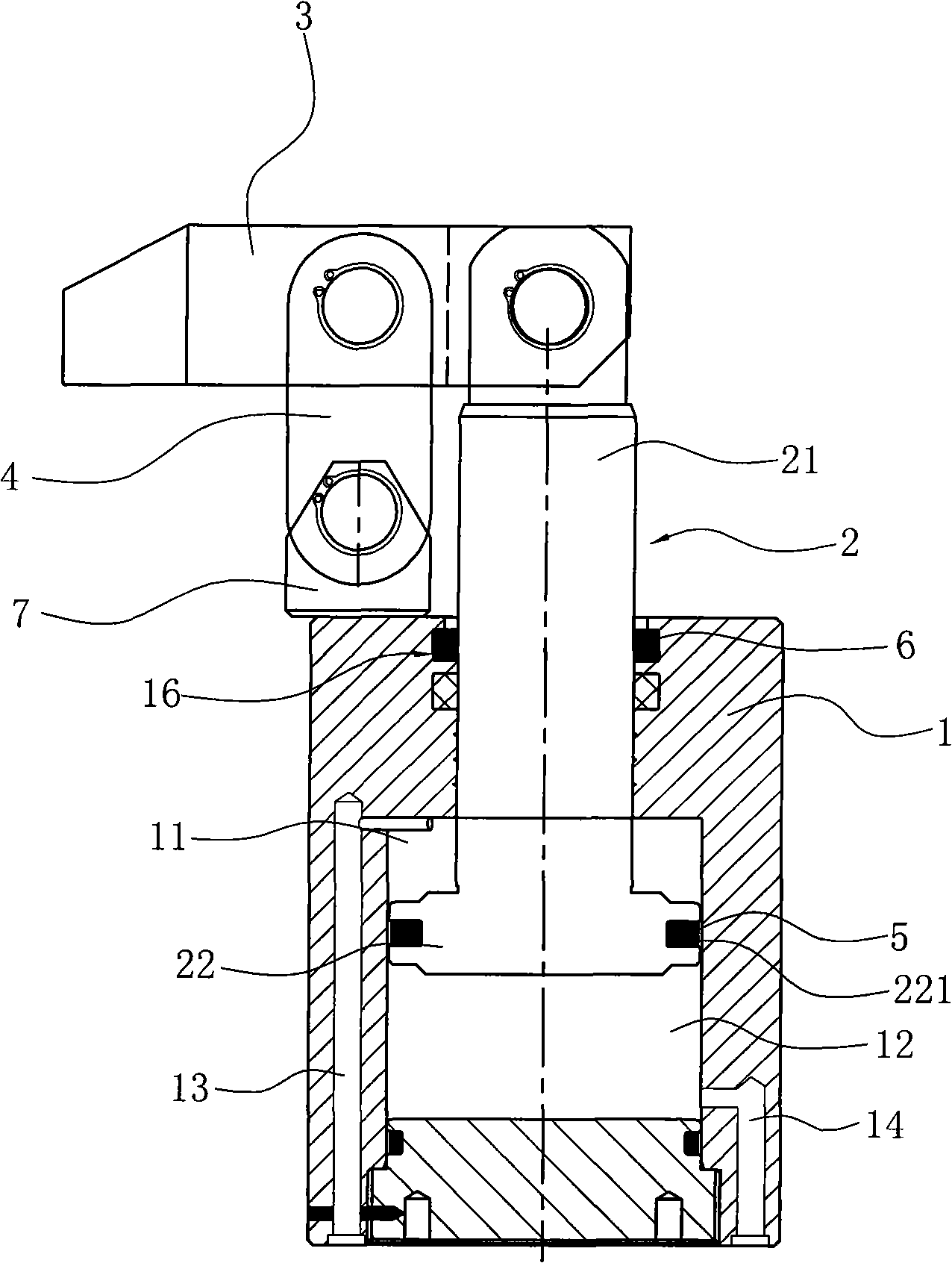

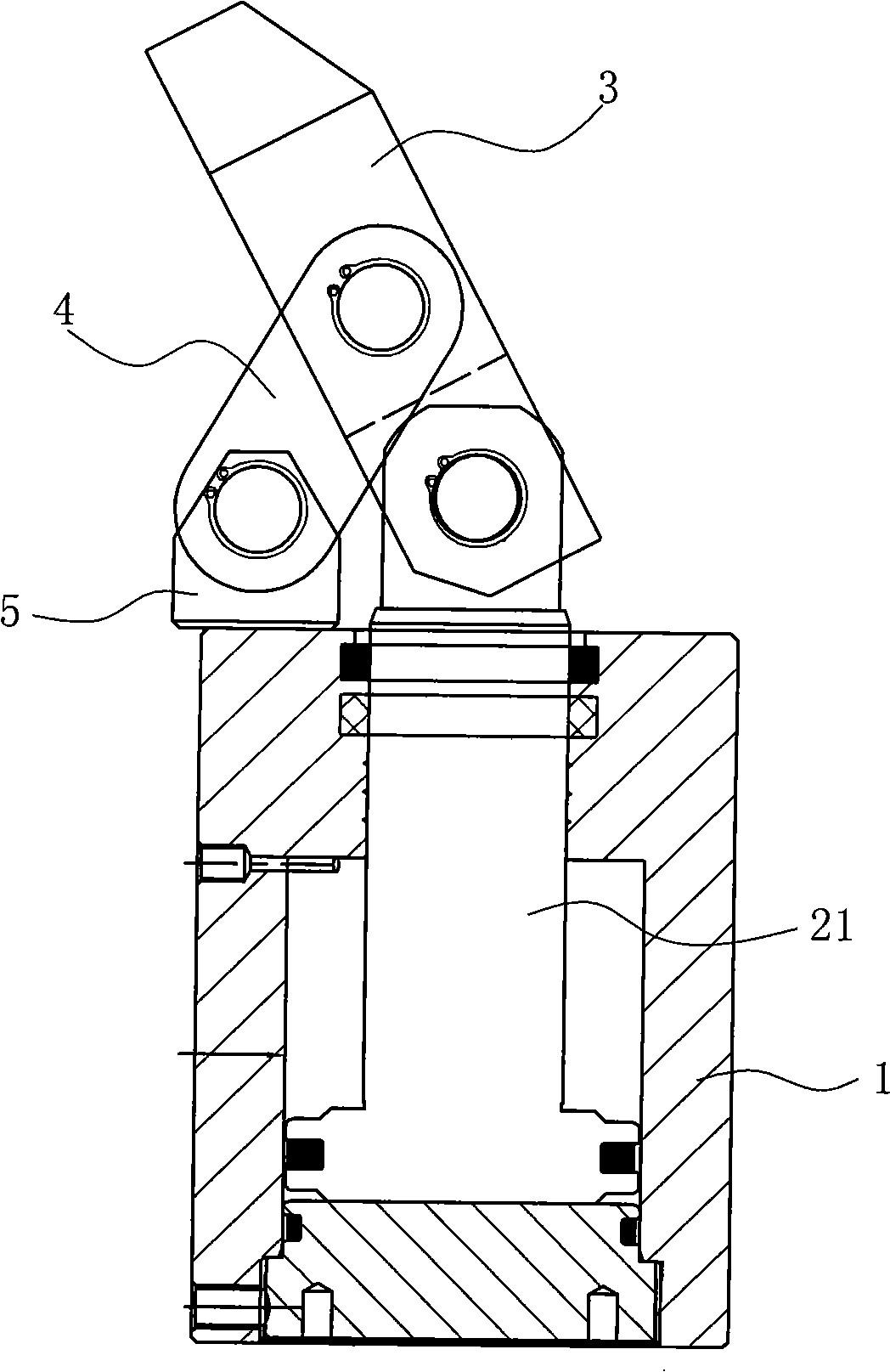

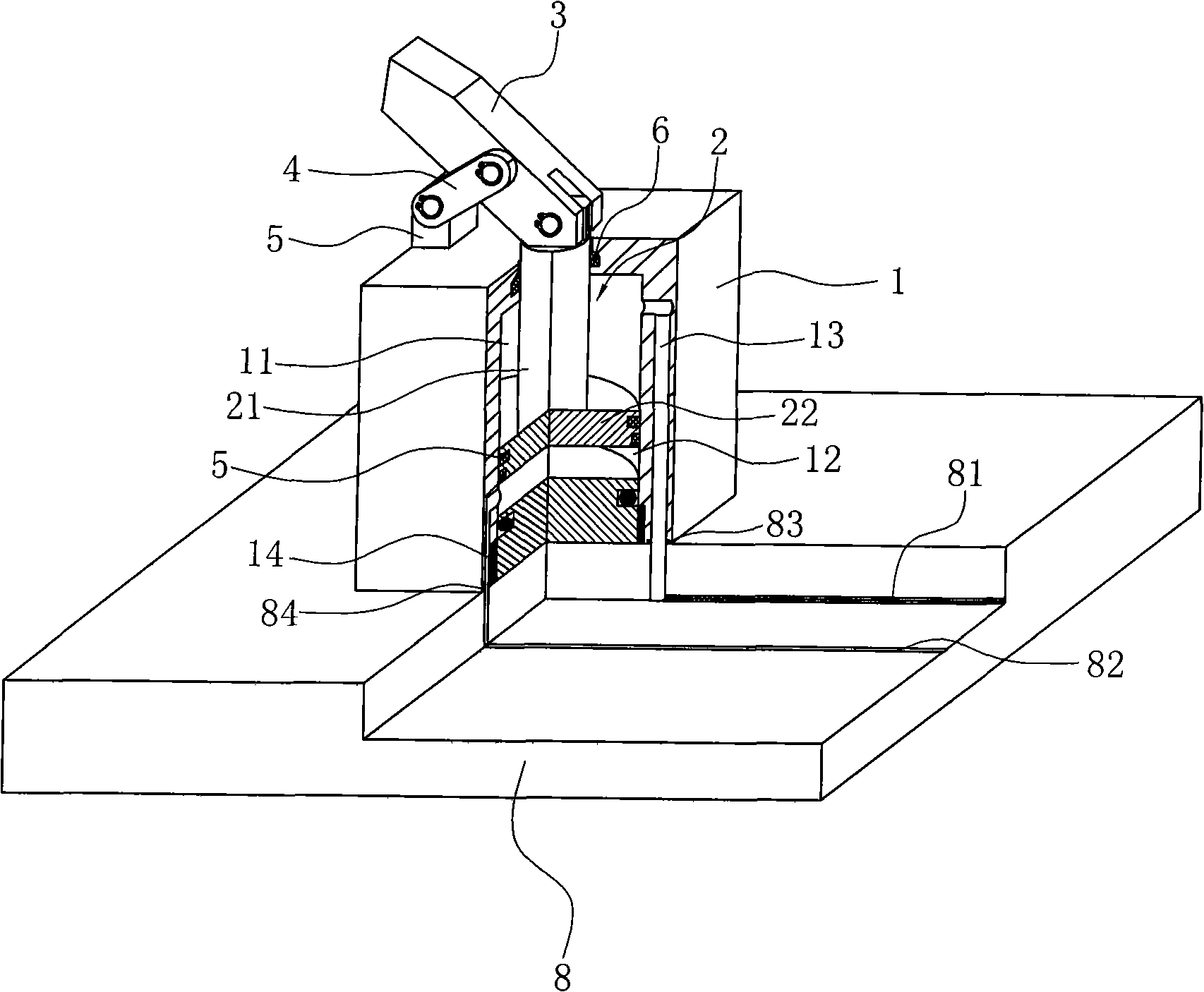

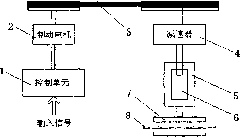

Lever cylinder for fixture

InactiveCN101303034ALarge clamping forceFluid-pressure actuatorsPositioning apparatusEngineeringCylinder block

The invention discloses a lever cylinder used for fixtures, which comprises a cylinder body (1) and a piston rod (2) arranged in the cylinder body (1), wherein, the upper end of the piston rod (2) extends out of the cylinder body (1) and the piston rod (2) is matched with the inner wall of the cylinder body (1) by liquid seal and divides the inner space of the cylinder body (1) into two seal cavities, an upper seal cavity (11) and a lower seal cavity (12). The cylinder body (1) is provided with a first channel (13) communicated with the upper seal cavity (11) and a second channel (14) communicated with the lower seal cavity (12). The lever cylinder of the invention is characterized in that the upper part of the piston rod (2), extending out of the cylinder body (1), is articulated with a pressure plate (3) and a pulling plate (4), the upper end of pulling plate (4) is articulated with the middle part of the pressure plate (3) while the lower end thereof is articulated with the upper part of the cylinder body (1). The up-down movement of the piston rod drives one end of the pressure plate to move down, and the pressing force of the outer end of the pressure plate is more than the upward pushing force of the piston rod according to the lever principle, thus realizing the output of more clamping force on the basis of limitations of cylinder diameter and space.

Owner:NINGBO FENGZHOU MACHINERY

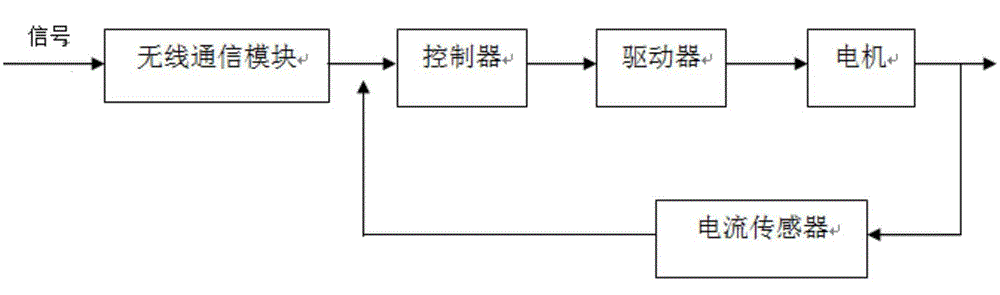

Electronic parking brake system and control method thereof

ActiveCN101823481APrevent slippingAchieve brakingBraking action transmissionCurrent transducerDriver/operator

The invention aims to provide an electronic parking brake system which can be controlled simply and reliably and has a control method of an assistant hill starting function. The electronic parking brake system comprises a control unit and a brake motor which is controlled by the control unit and the signal input end of the control unit is connected with a throttle opening sensor, a clutch sensor, an engine rotating speed sensor, a current sensor of the brake motor, a hand brake switch and a hill start switch; the brake motor drives a turbine worm to rotate through a driving mechanism; the turbine worm is sleeved with a screw rod, and the end part of the screw rod is fixed with a friction plate. The electronic parking brake system has the advantages of greatly reducing the operational difficulty of a driver and improving the driving and operating comfort and convenience, along with low cost, simple structure, reliable control method, basic function of the traditional hand brake and assistant hill start function.

Owner:CHERY AUTOMOBILE CO LTD

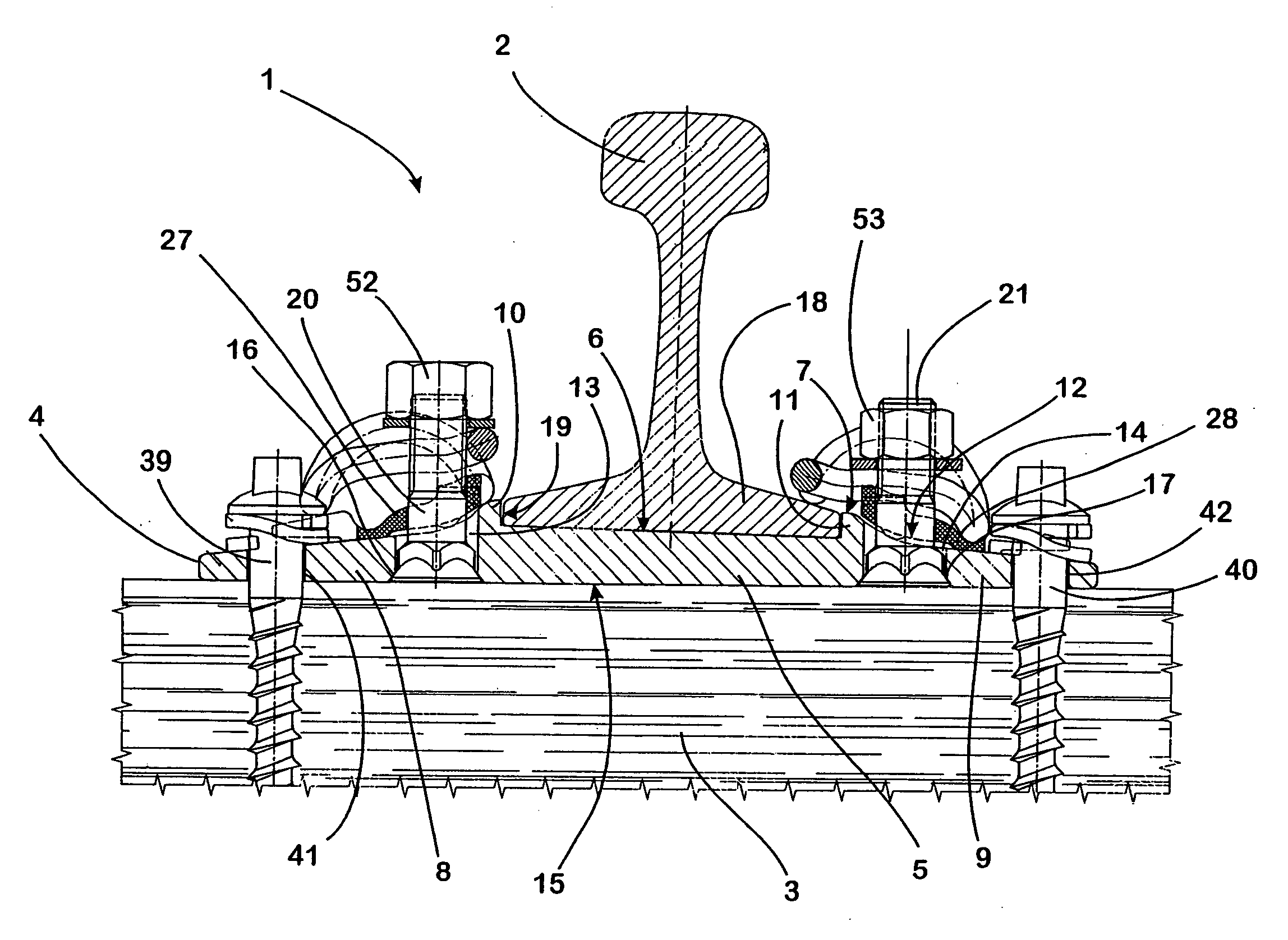

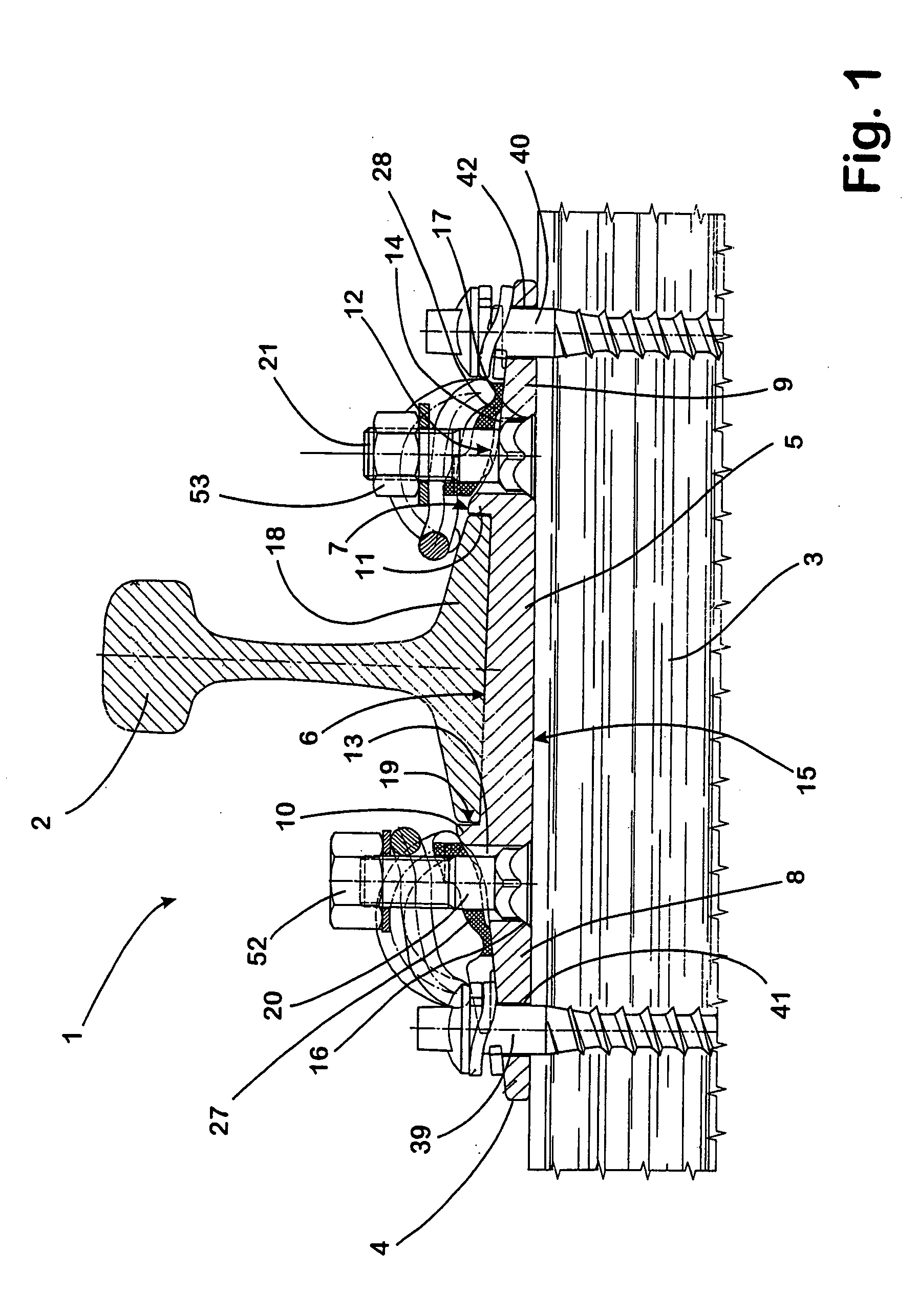

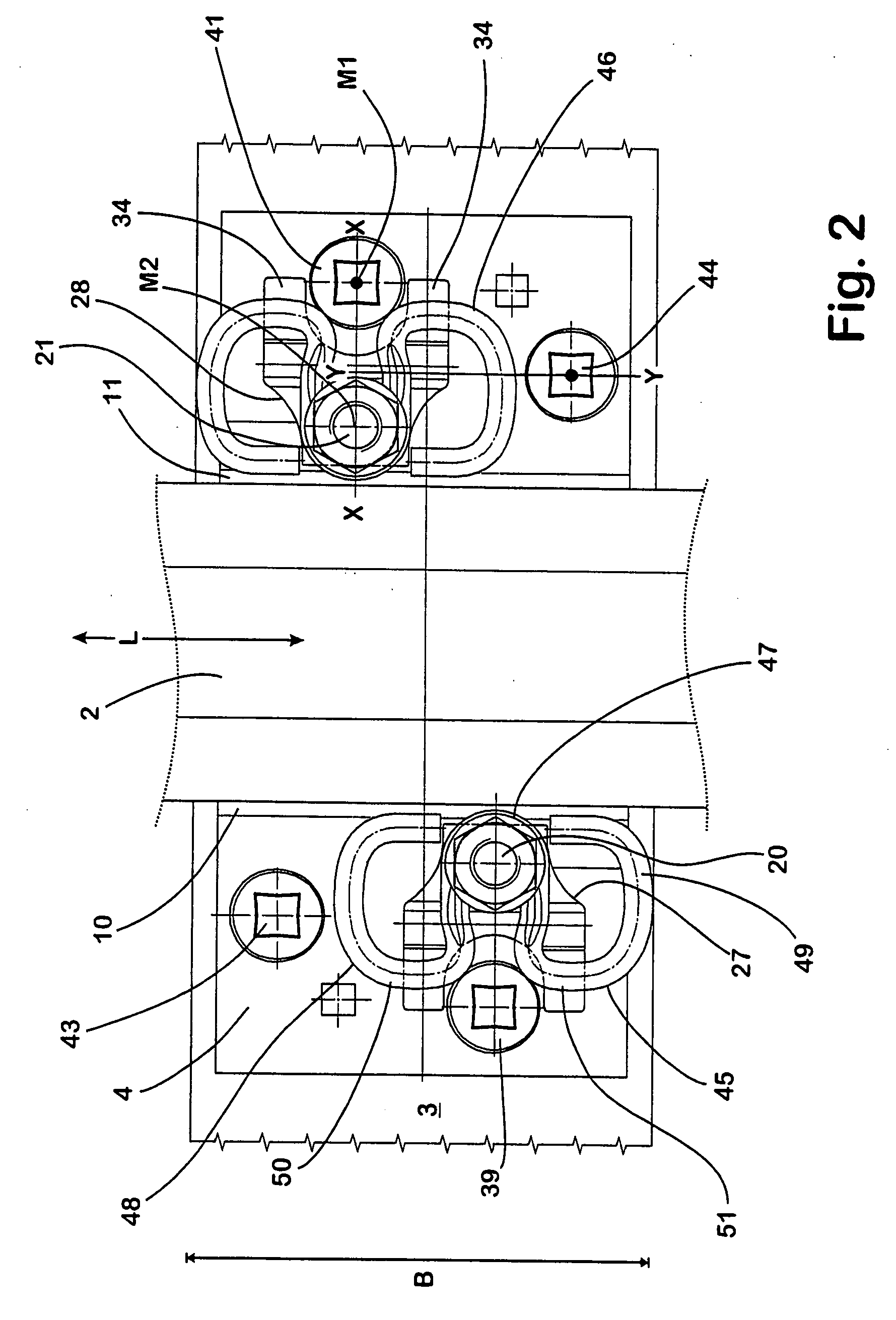

System for fastening a rail

ActiveUS20090084864A1Beneficial production costSimple assemblyRail fastenersTrack superstructureEngineeringMechanical engineering

Owner:VOSSLOH WERKE GMBH

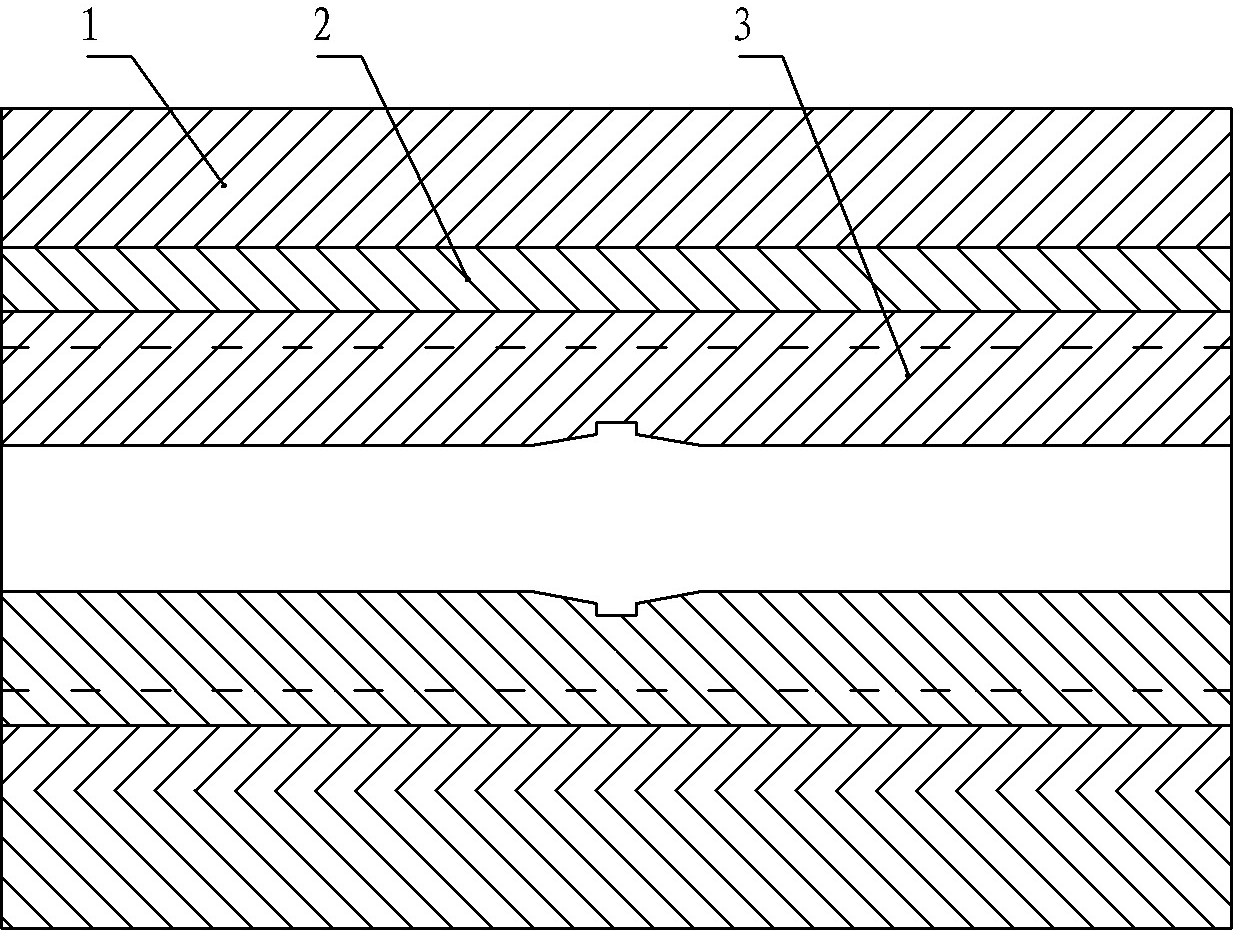

Process for manufacturing injection moulding seal edge of wooden floor or furniture board and edger thereof

ActiveCN101407069ALarge clamping forceGood product qualityWood working apparatusHot runnerEngineering

The invention discloses an edge bander for bonding edges of wooden floor board or furniture board by injecting plastic and a production process thereof. The process comprises the following steps: using the edge bander and the method to place a pre-processed wooden floor board or furniture board into a corresponding mold cavity of an opened forming mold for mold spotting and locking mold, injecting high-temperature melt plastic into hot runners uniformly arranged in heating boards from a main feeding opening, injecting the plastic into the clearance between a forming mold cavity and the periphery of the wooden floor board or the furniture board from taper-shaped feeding ports which are uniformly arranged along the periphery of the forming mold and are provided with cold feeding positions respectively so as to melt and cast the plastic and the wood fiber into a whole, then cool the whole body, and make an edge banding product demould from a front mold and a back mold respectively through pneumatic and mechanical demolding. The edge bander and the process not only ensure the good quality of banding wooden floor board or the furniture board by using plastic, high strengthen of adhesion, long service and uneasy falling, but also realize mechanized one-time forming, rapid edge banding and enable the edge banding plastic and a plate material for edge banding to form a whole body with stable and reliable quality.

Owner:罗生权

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com