Positioning clamping device for workpiece

A positioning clamping and workpiece positioning technology, which is applied in the field of positioning clamping devices and workpiece positioning clamping devices, can solve problems such as clamping deviation, quality defects, and unclamped workpieces, and achieve enlarged retractable radius, simple structure, and clamping strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

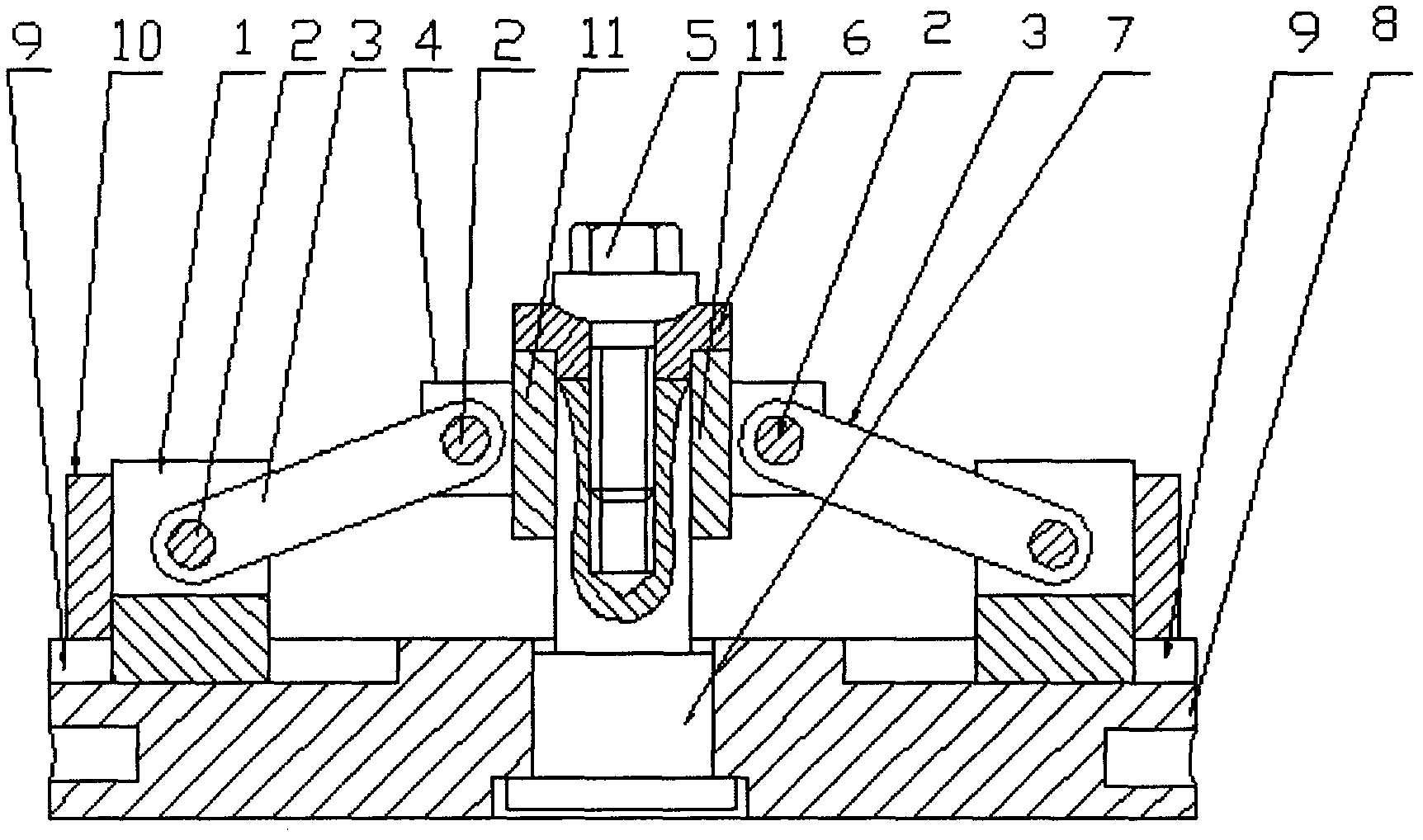

[0011] On the upper plane of the base 8, an appropriate number of guide rail grooves 9 are made along the center radius direction, and a step through hole is made at the center of the base 8 at the same time, and the central axis of the hole is kept vertical to the upper and lower planes of the base 8 at the same time. Install the mandrel 7 and the slider 1 in the center hole of the base 8 and the guide rail groove 9 respectively. When assembling, ensure that the connecting sleeve 4 and the bushing 6 are installed on the mandrel 7 and at the same time in the middle of the mandrel 7 Screw in the booster bolt 5 in the threaded hole, and the slide block 1 and the connecting sleeve 4 are hinged with the pin shaft 2 . Its working principle is: install the mandrel 7 in the center of the base 8, the mandrel 7 is kept perpendicular to the upper and lower planes of the base 8, and several guide rail grooves are made on the upper plane of the base 8 from the center of the base 8 to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com