Process for manufacturing injection moulding seal edge of wooden floor or furniture board and edger thereof

A manufacturing process and technology of furniture boards, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of incomplete sealing, failure to achieve moisture resistance, complex shape of tenon and groove joints, etc., to prevent wet expansion and dry shrinkage deformation, prevent Effect of cracking and deformation, external dimension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A manufacturing process for injection-molded edge sealing of wooden floor or furniture boards has the following steps:

[0037]1. Process wooden floor or furniture panel according to the design size;

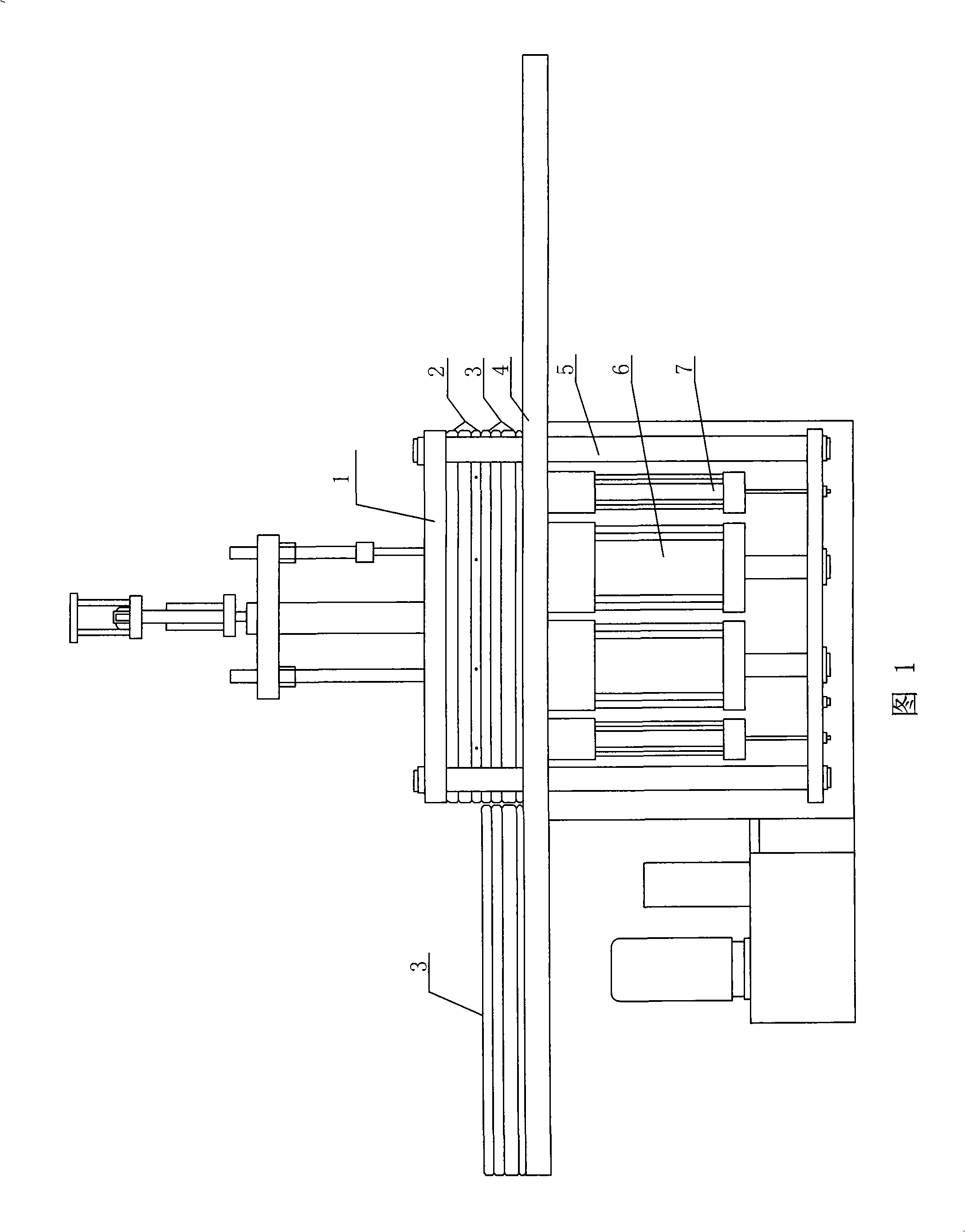

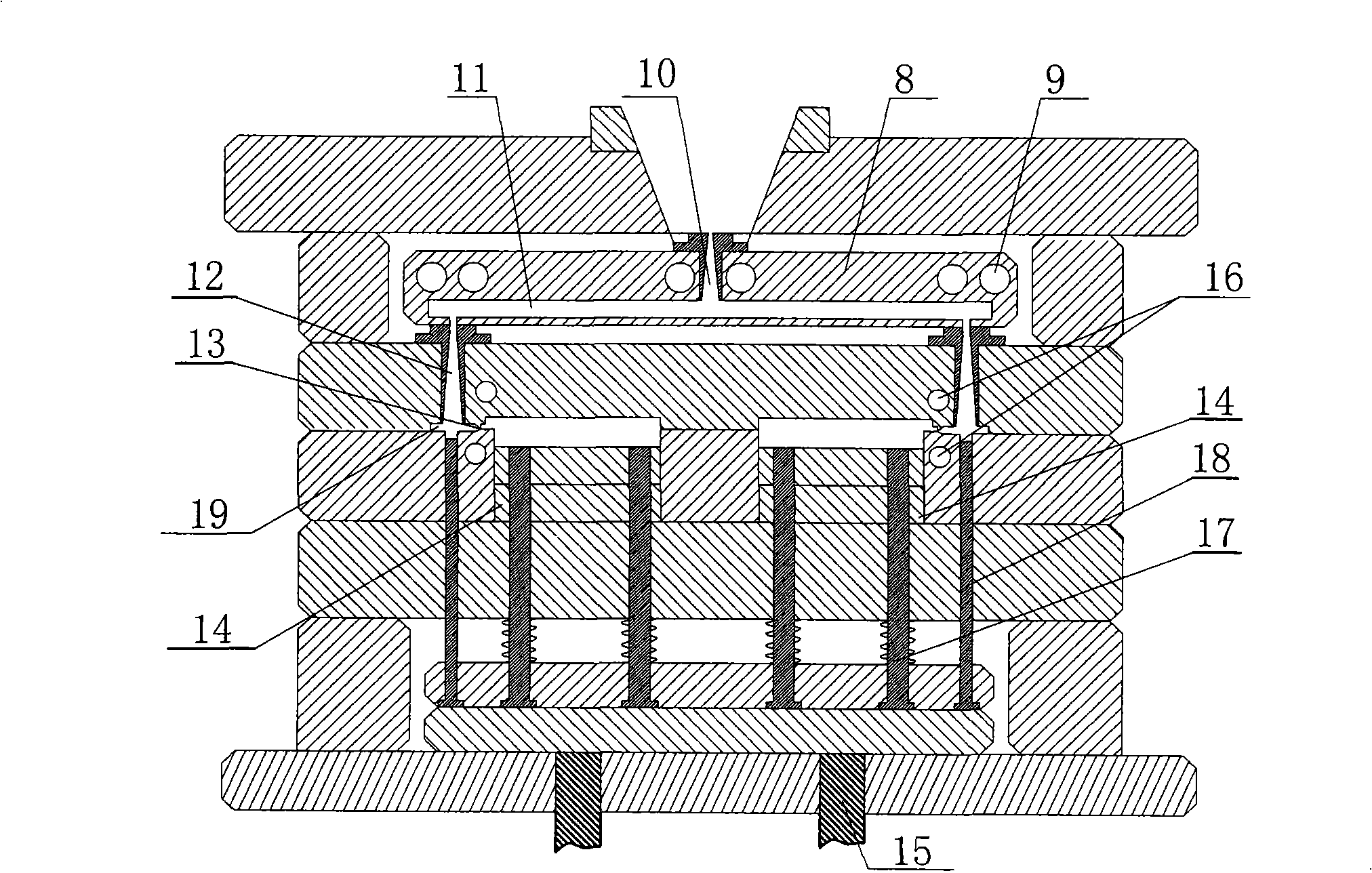

[0038] 2. Open the injection molding edge banding forming mold on the injection molding edge banding machine, put the processed wooden floor or furniture board into the corresponding cavity of the forming mold, and first manipulate the auxiliary cylinder 7 of the hydraulic system to perform film lamination. Then operate the clamping oil cylinder 6 to lock the mold;

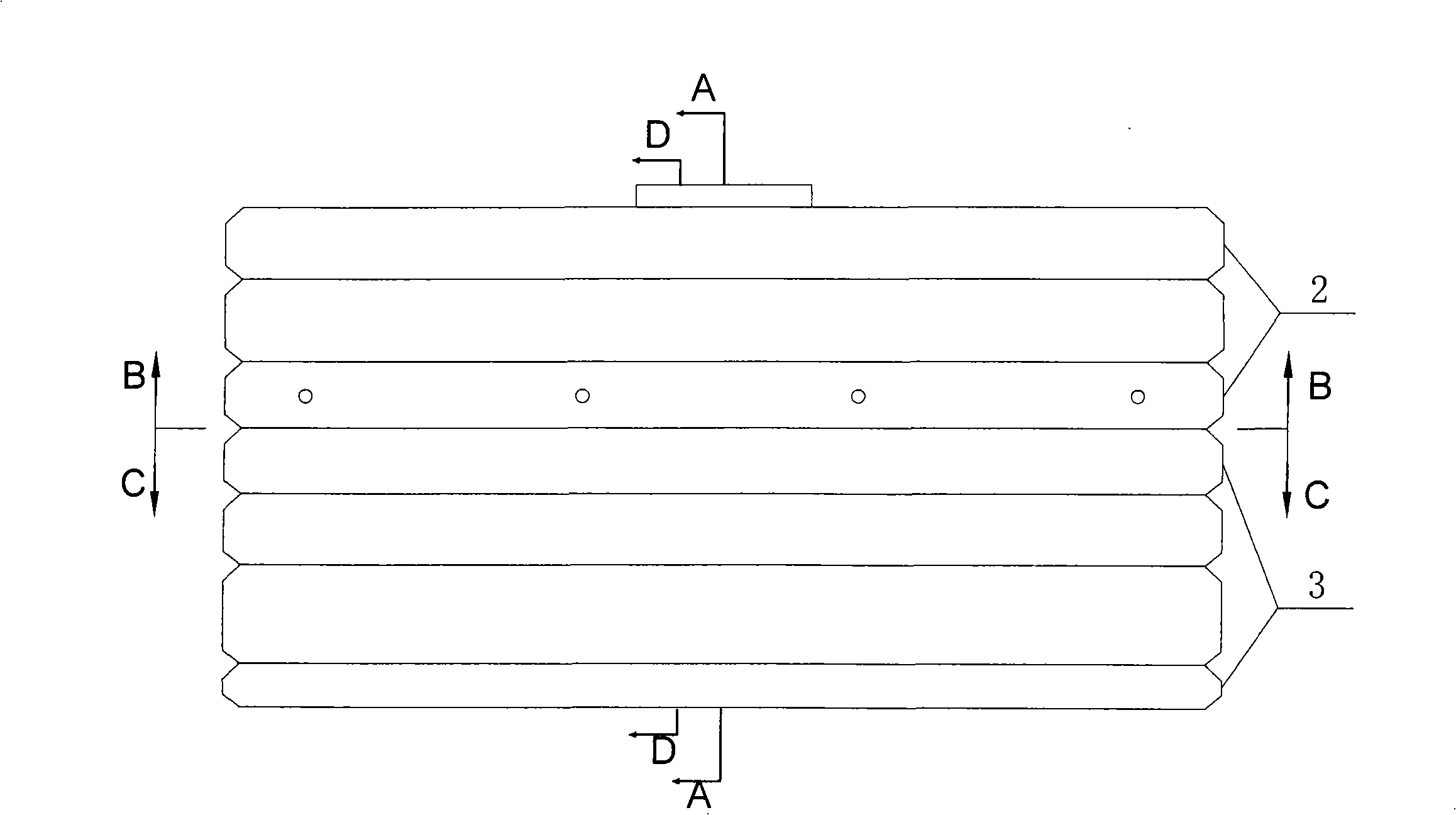

[0039] 3. Start the injection molding system, and put the high-temperature molten plastic from the main material port 10 into the uniformly distributed hot runner 11 in the heating plate, and then pass through the gate of the tapered nozzle 12 with cold material level evenly distributed along the periphery of the molding mold Inject into the gap between the cavity of the molding mold and the periphery of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com