Patents

Literature

179results about How to "Good product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

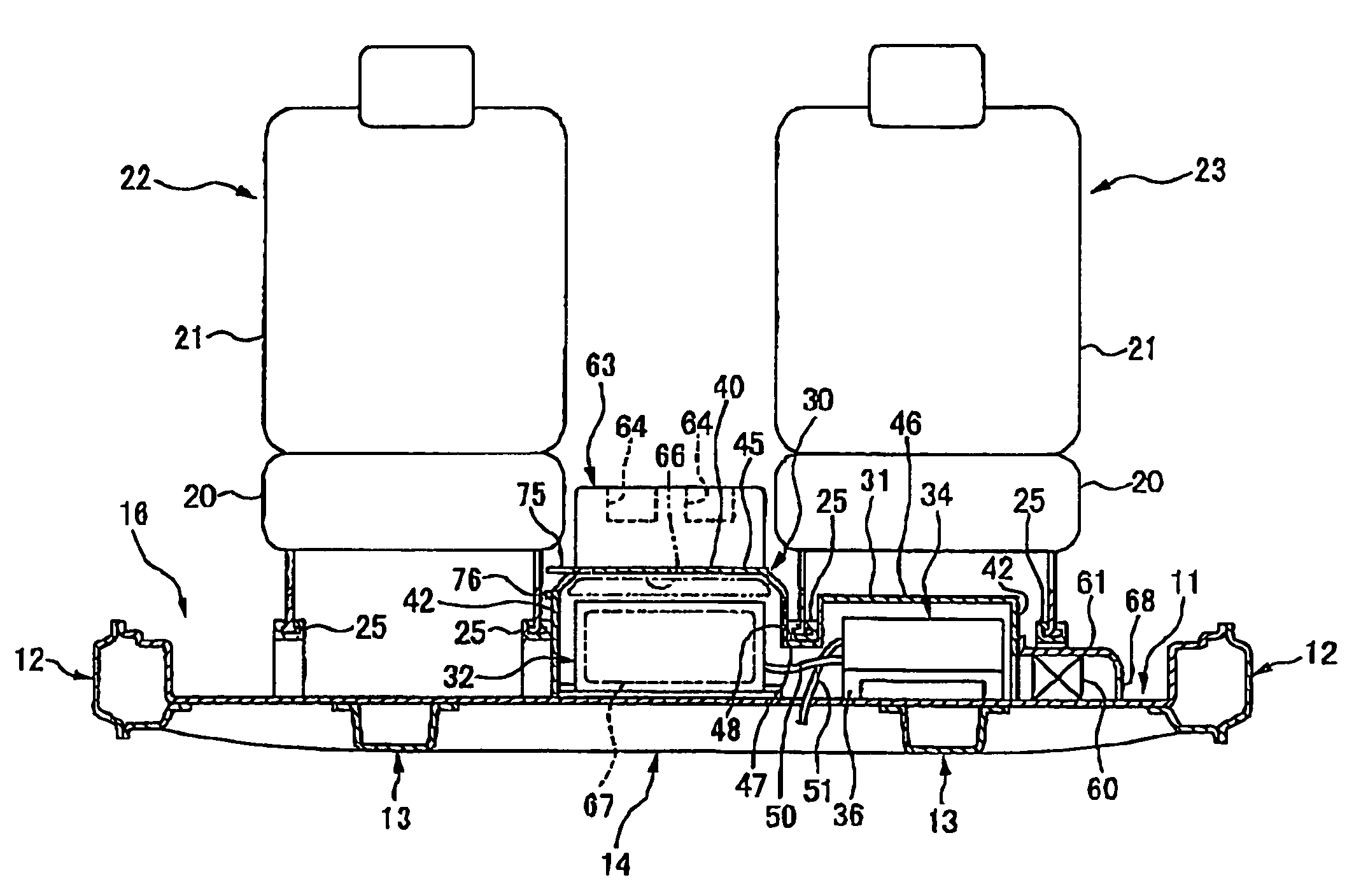

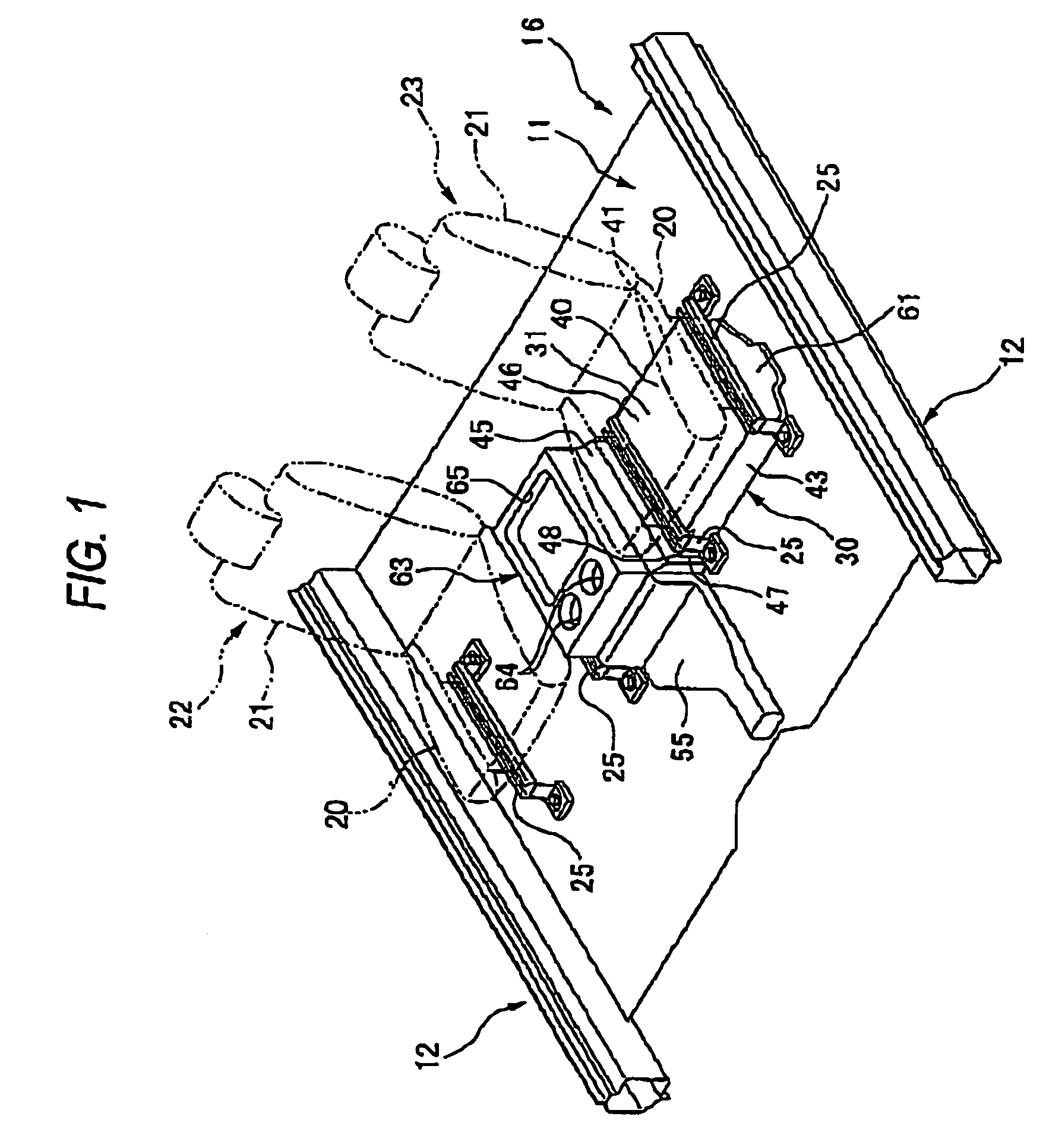

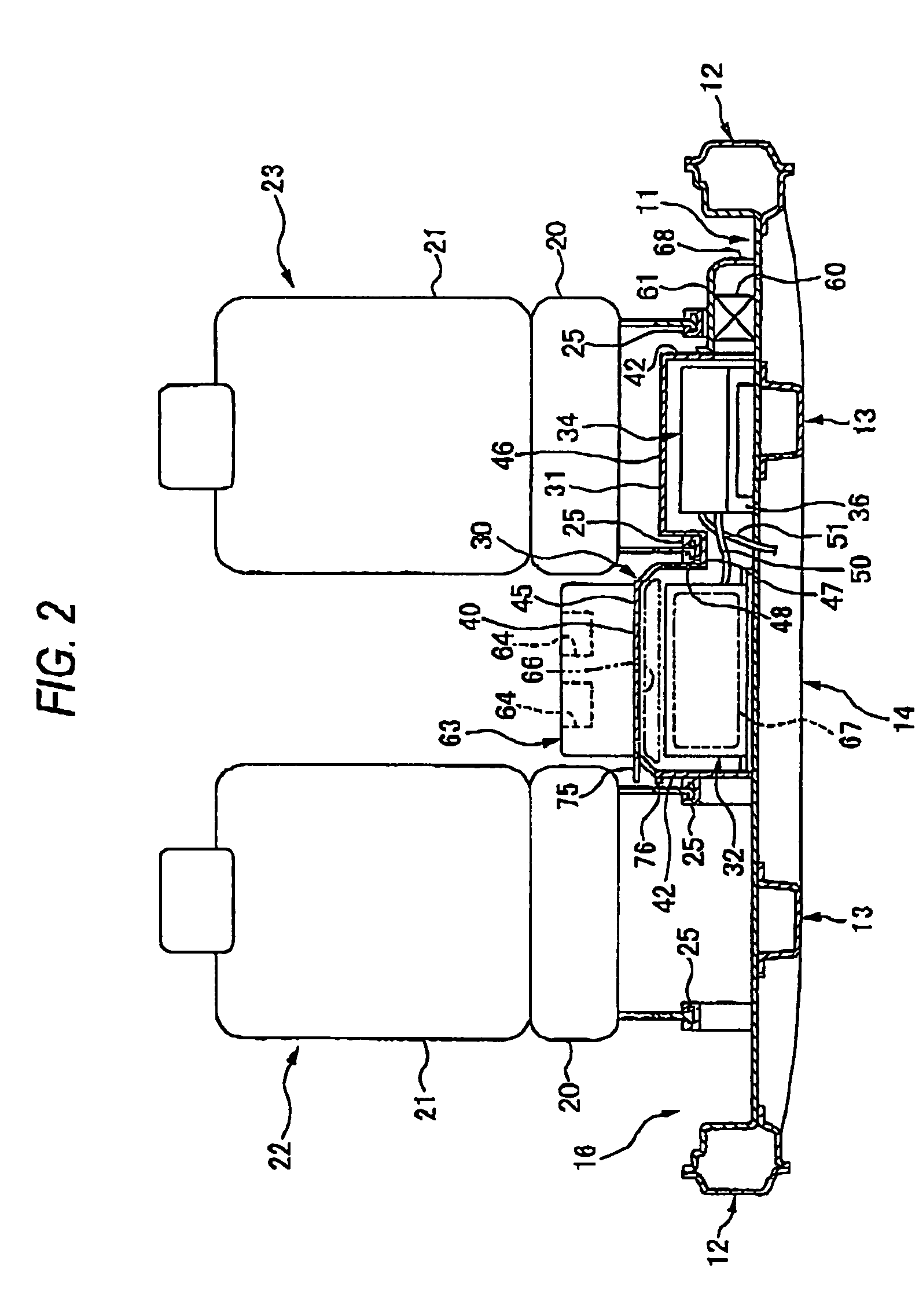

High-voltage electrical equipment case arranging structure

InactiveUS7048321B2Good distributionGood product qualityPassenger spacePedestrian/occupant safety arrangementElectrical batteryEngineering

A high-voltage electrical equipment case is arranged between a driver's seat and a front passenger's seat which are placed in parallel in a transverse direction, whereby in the event that the battery which is a heavy article is accommodated in this high-voltage electrical equipment case, a necessity is obviated of disposing the battery underneath a rear seat. Moreover, the high-voltage electrical equipment case can be disposed near an air conditioner that is installed in a front part of a vehicle.

Owner:HONDA MOTOR CO LTD

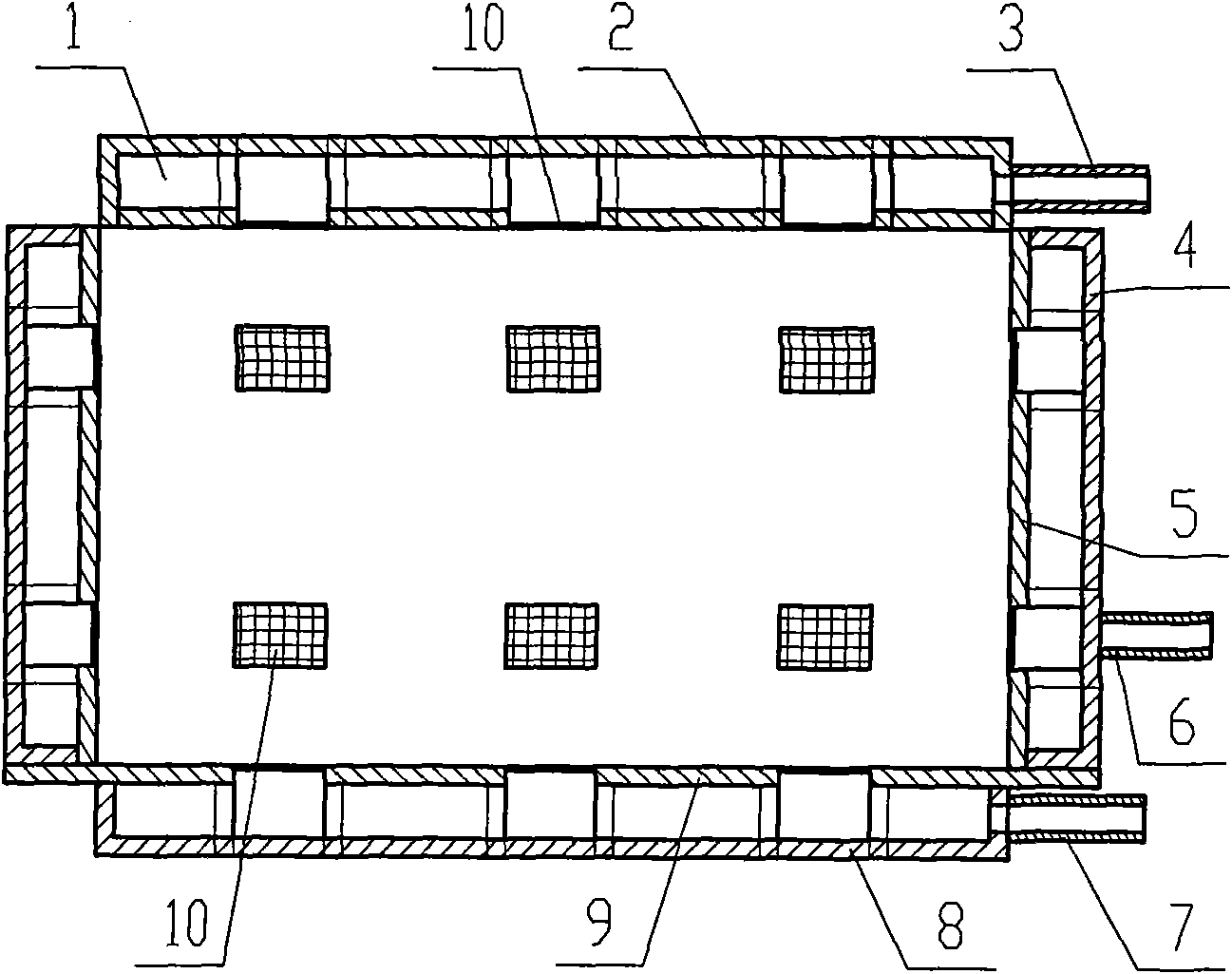

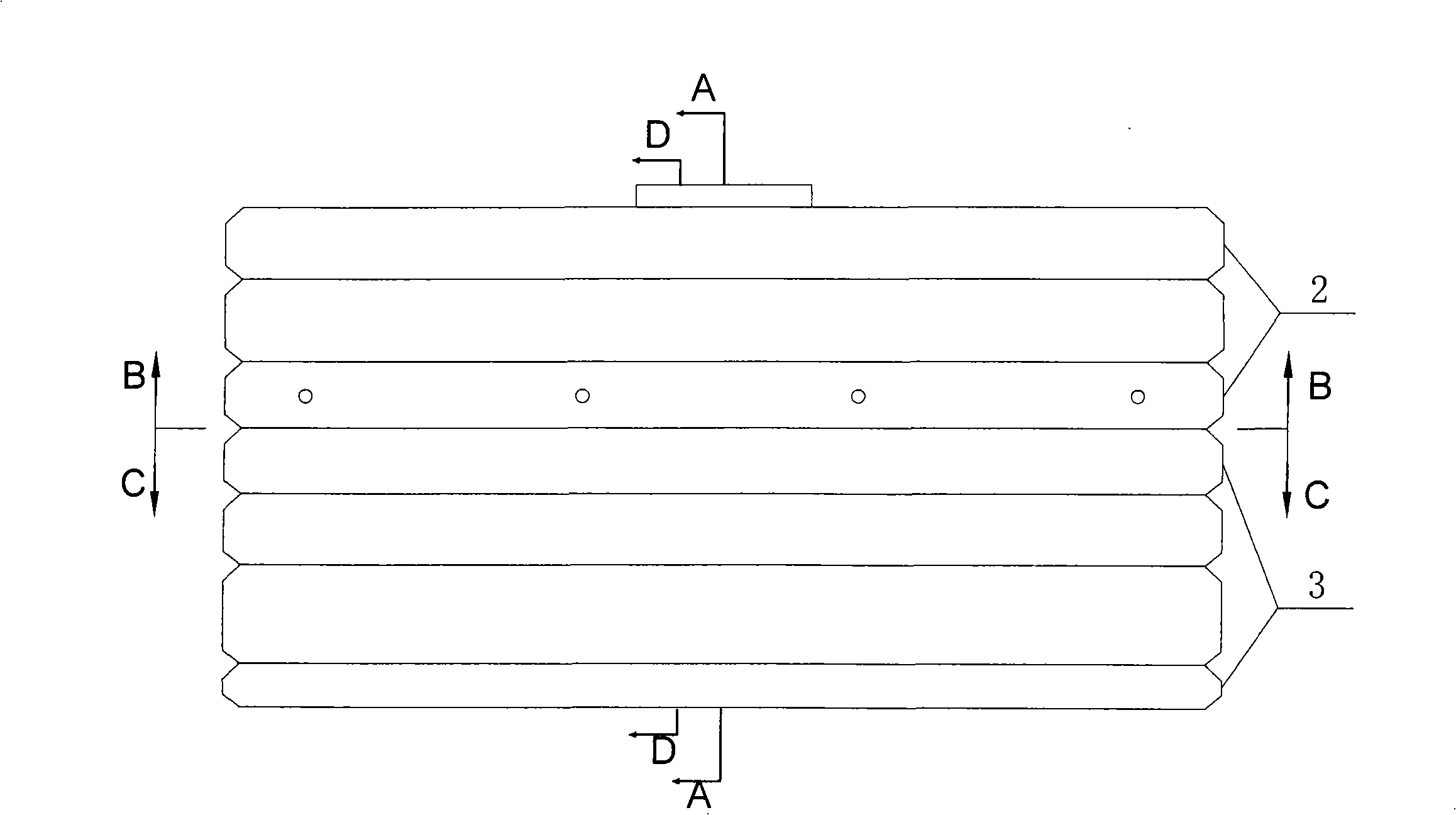

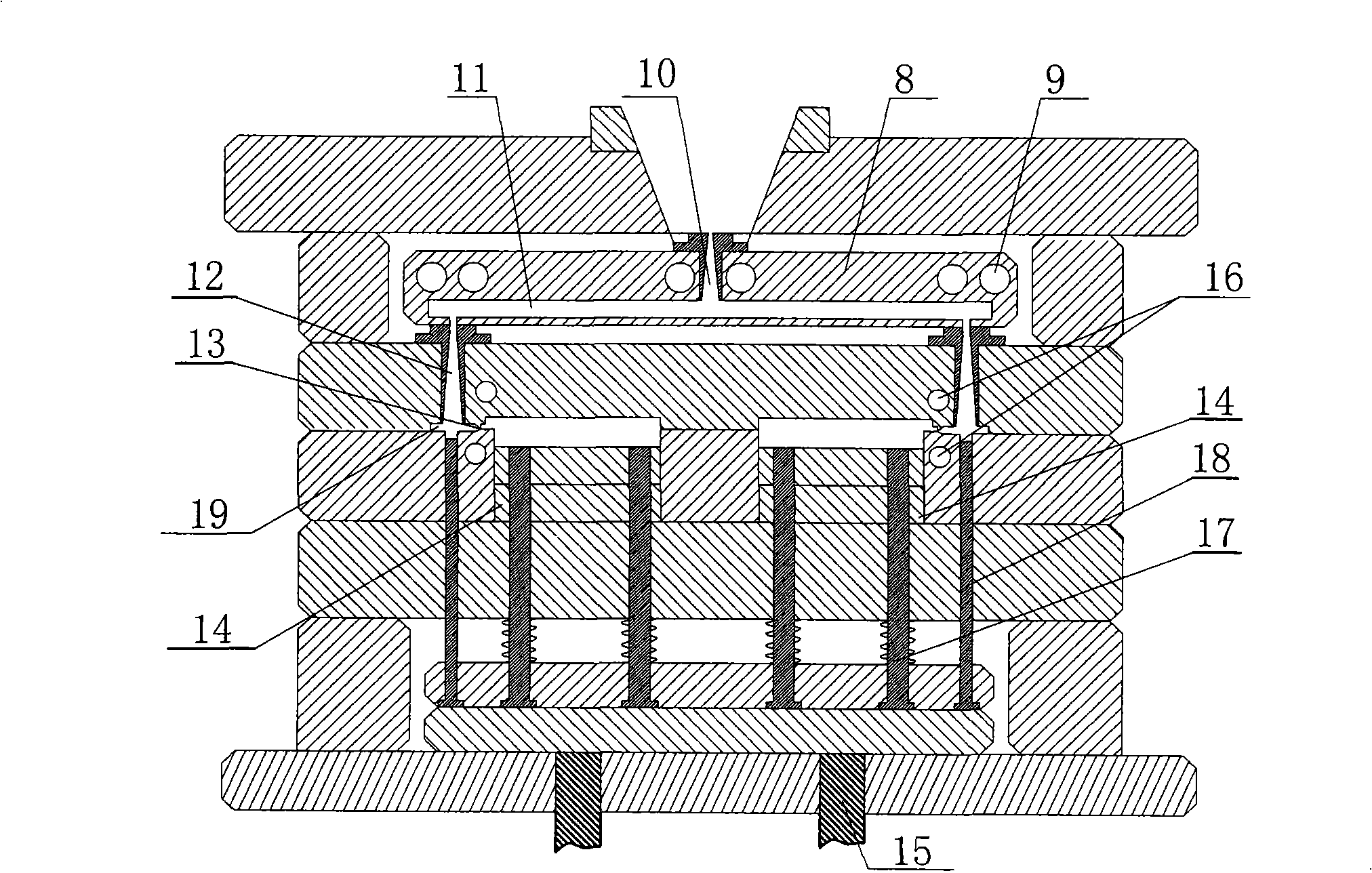

Vacuum expendable pattern casting (V-EPC) molding method of large complex castings

ActiveCN101607299AGood product qualityAvoid driftingFoundry mouldsFoundry coresLost-foam castingMolding sand

The invention discloses a vacuum expendable pattern casting (V-EPC) molding method of large complex castings. A flask for molding comprises three parts including flask bottom, a flask body and an up draught pneumatic hoist press bar; each part is provided with an independent vacuum air duct. The molding procedures comprise the following steps: filling sand and carrying out vibrating molding on the bottom of the expendable pattern, turning over the flask, removing a supporting plate and a tire plate rack and placing the up draught pneumatic hoist press bar, filling the sand, exerting pressure for vibrating molding, sealing the flask and carrying out pouring after vacuumizing. The parts with blind holes and grooves are filled with resin sand and core irons and a floating crane is employed to fix the core irons; local compaction is carried out on loose parts. Being adopted, the method of the invention ensures compact and uniform molding sand, solves the difficult problems frequently appearing in the process of V-EPC of large castings, including sand crushing, sand drop, sand inclusion and deformation, can ensure the accuracy of the blind holes, deep grooves and entire castings, can enable the pattern to be almost free from floating and deformation in the process of vibration and can produce high quality large complex castings.

Owner:BOTOU QINGFENG MACHINERY

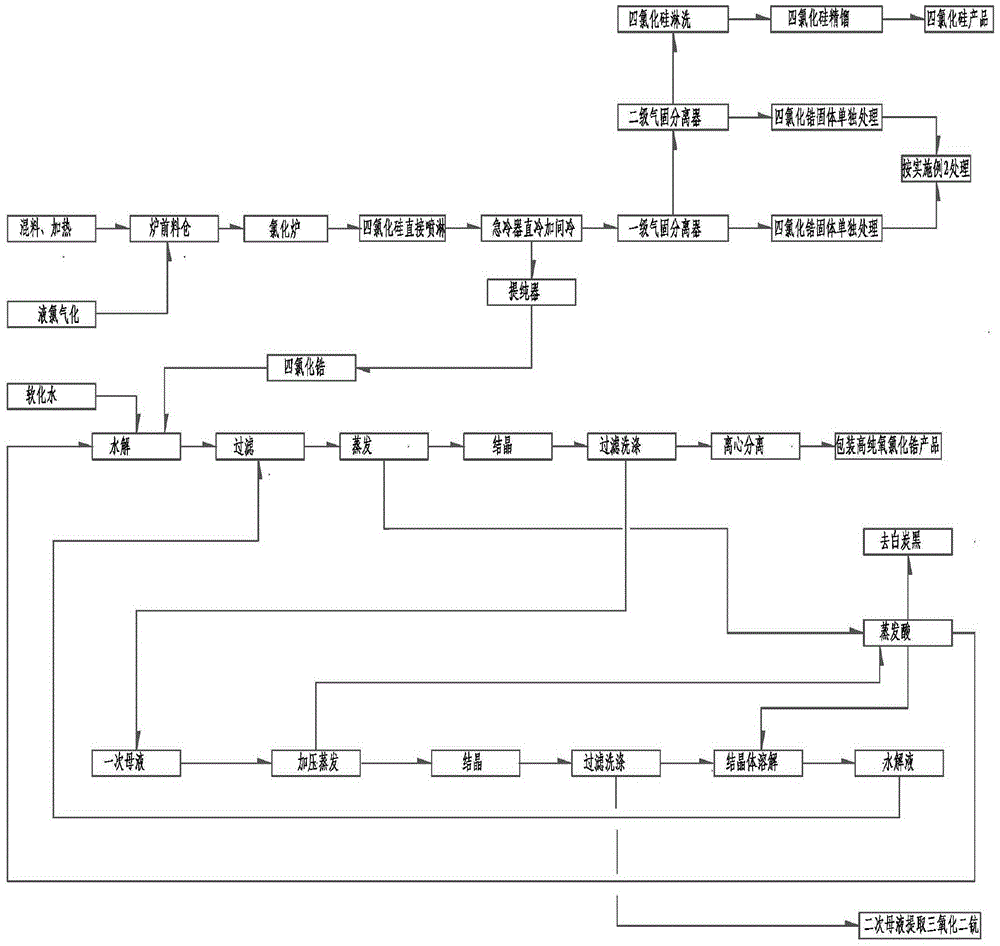

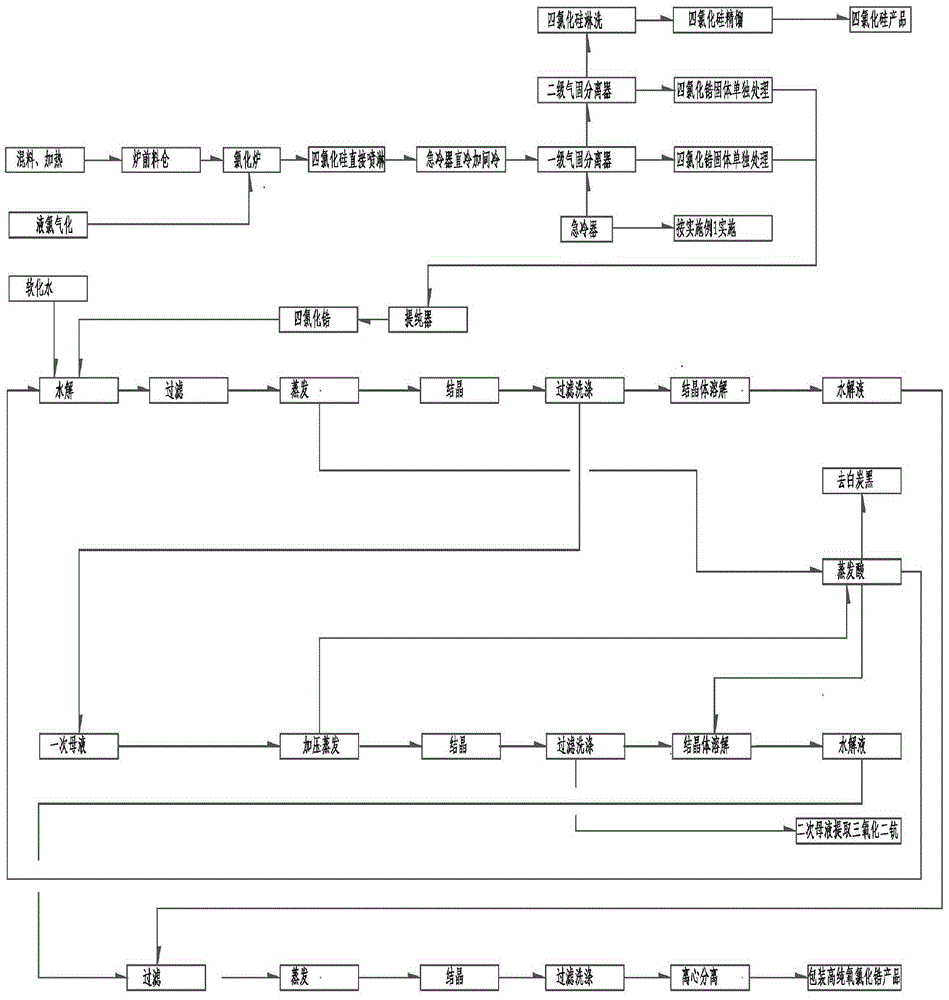

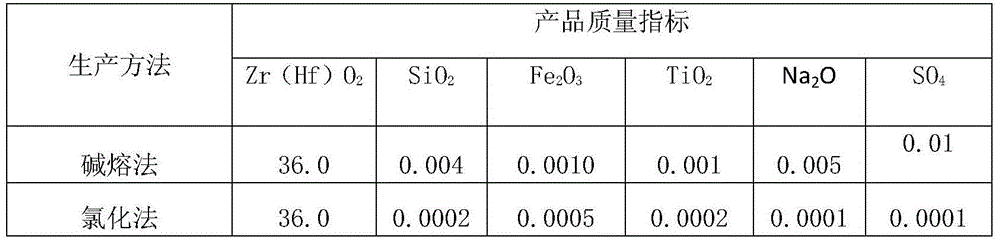

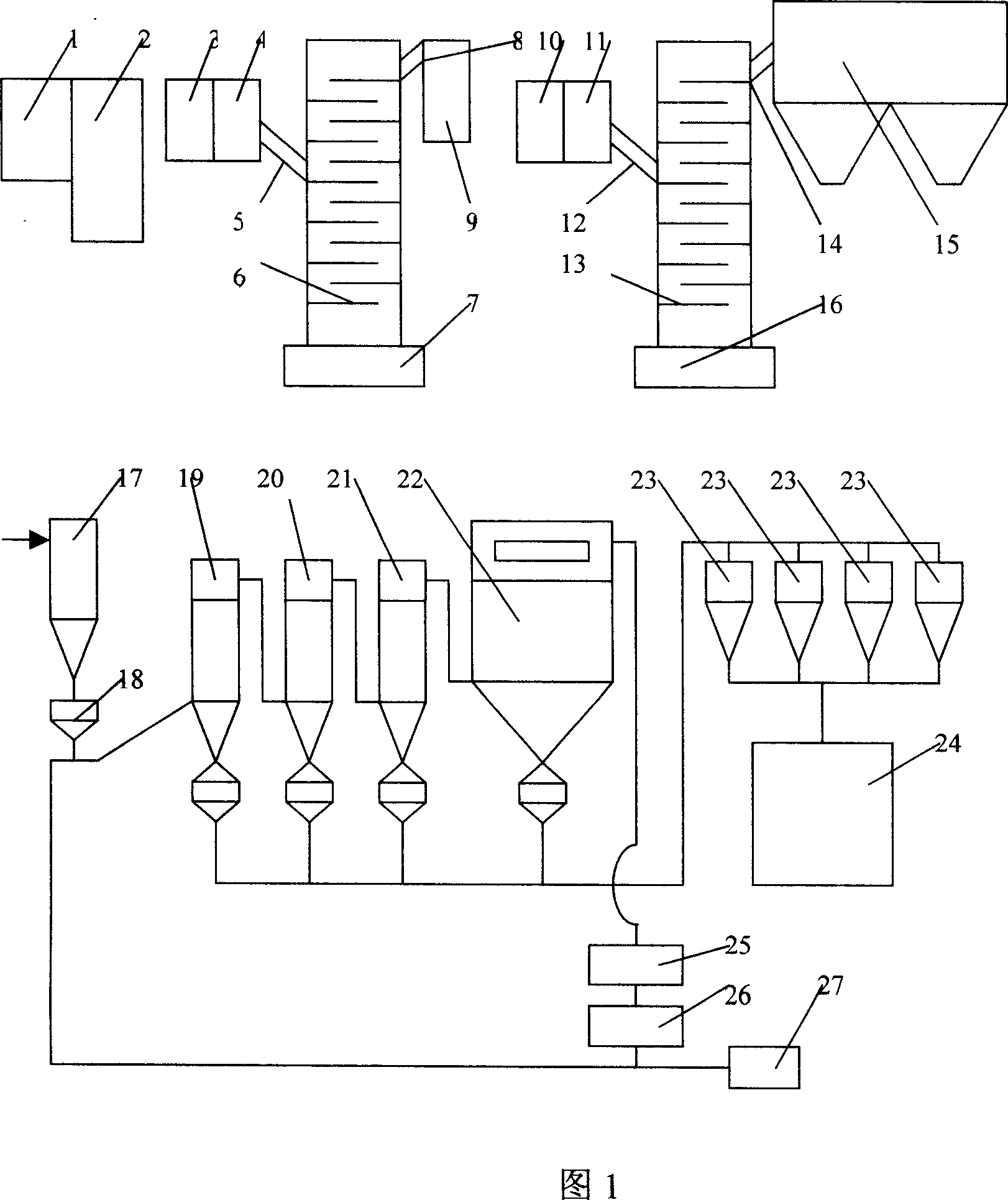

Method for producing high-purity zirconium oxychloride and co-producing silicon tetrachloride through zircon sand boiling chlorination method

ActiveCN104817110AGood product qualityReduce manufacturing costHalogenated silanesZirconium halidesZirconium oxychlorideSilicon tetrachloride

The present invention relates to a high-purity zirconium oxychloride production method, specifically to a method for producing high-purity zirconium oxychloride and co-producing silicon tetrachloride through a zircon sand boiling chlorination method. The method comprises: adopting zircon sand, a reducing agent and a stabilizer, introducing chlorine gas into a chlorination furnace at a gas velocity of 0.07-0.12 m / s, carrying out a boiling chlorination reaction at a temperature of 1150-1200 DEG C to generate zirconium tetrachloride and silicon tetrachloride, carrying out gas-solid separation, and carrying out hydrolysis and purification on the separated solid and carrying out evaporation, crystallization and separation on the zirconium oxychloride solution so as to obtain the high-purity zirconium oxychloride and the co-produced product silicon tetrachloride, wherein a mass ratio of the zircon sand to the reducing agent to the stabilizer to the chlorine gas is 0.9-1.1:0.2-0.3:0.3-0.4:2.7-2.8. The product produced through the method of the present invention has characteristics of good quality, low production cost, and no polluting.

Owner:赤峰盛森硅业科技发展有限公司

Hydroxyl carthamus tinctorius yellow colour A, preparation method and application thereof

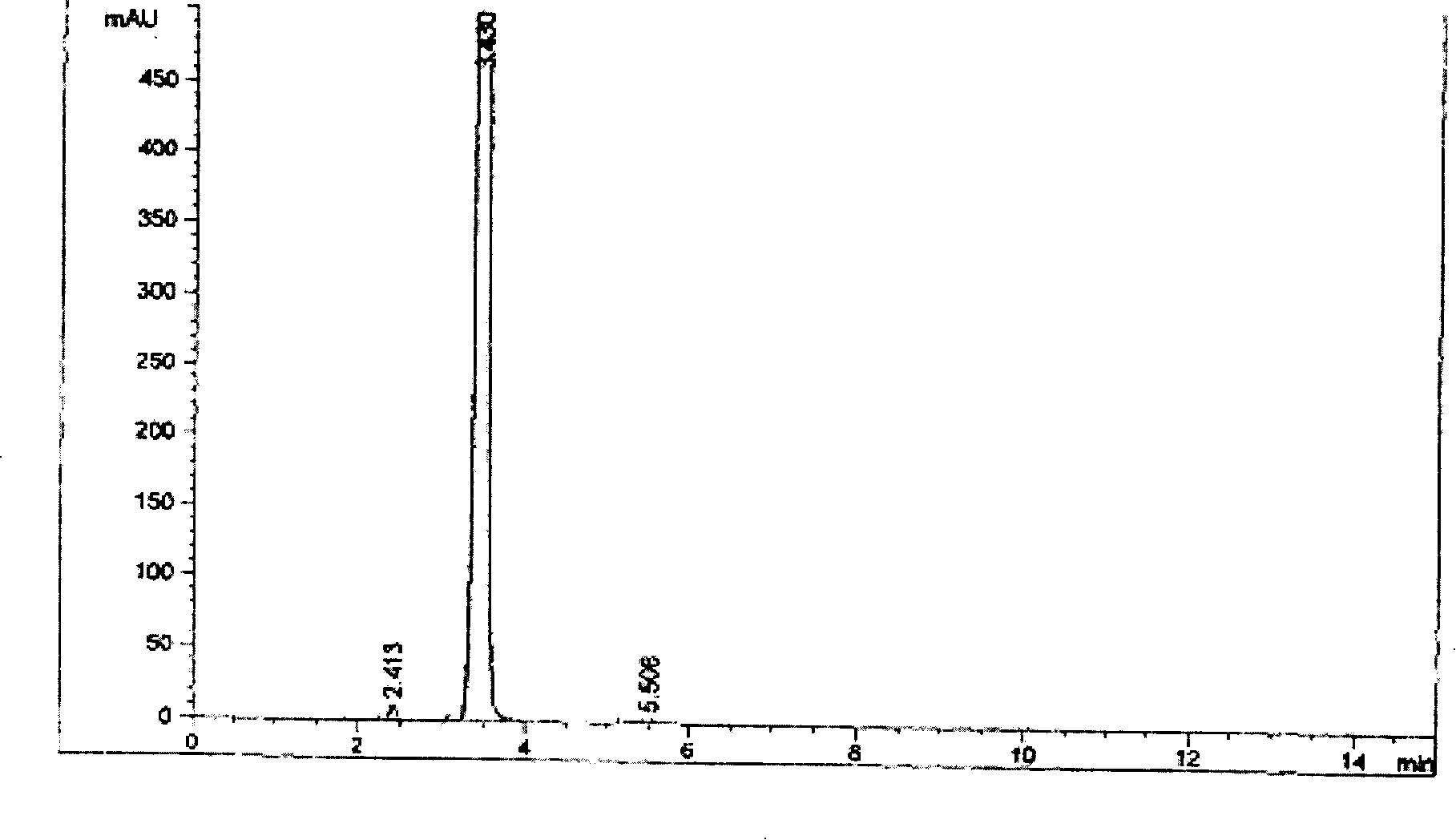

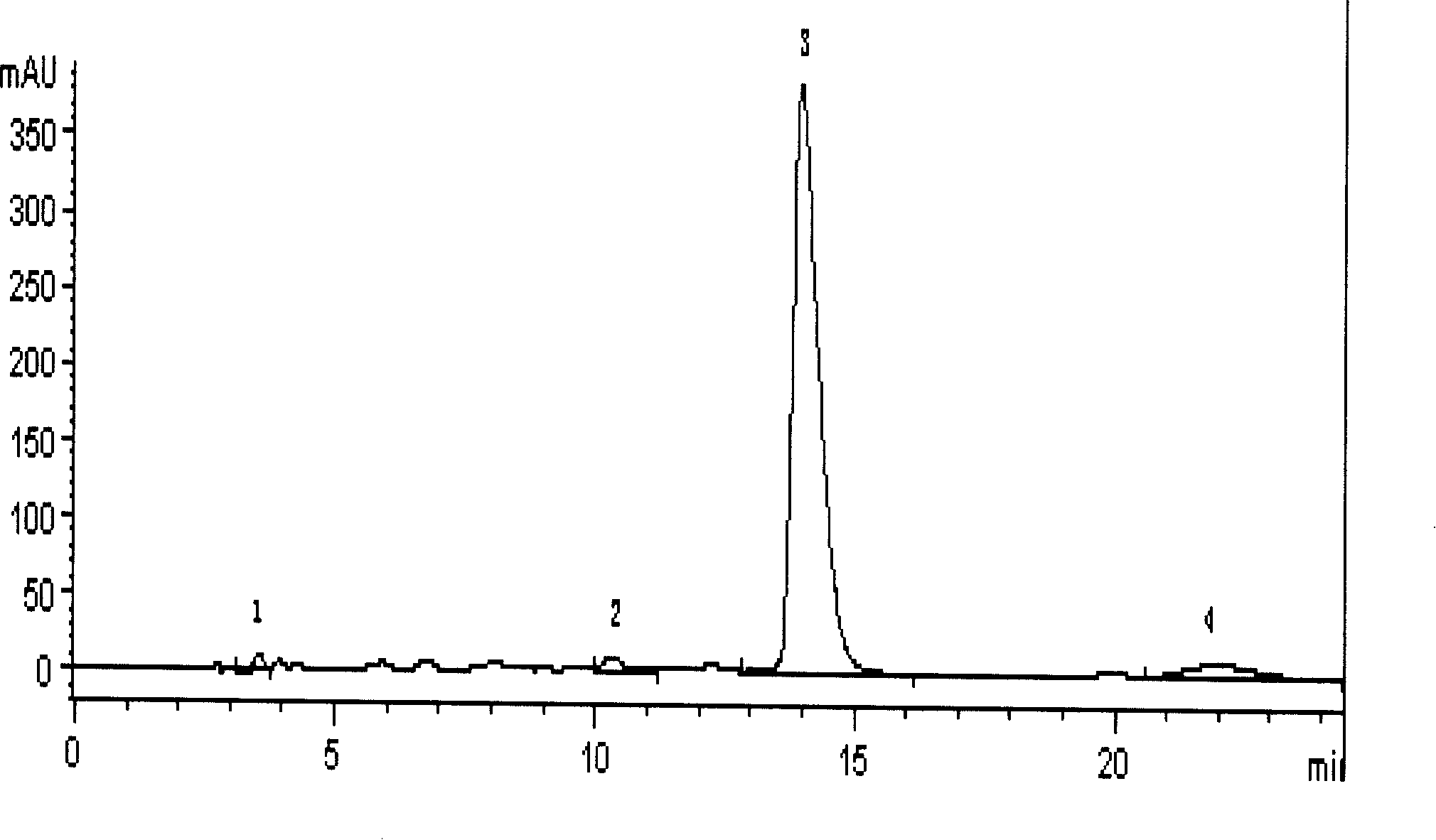

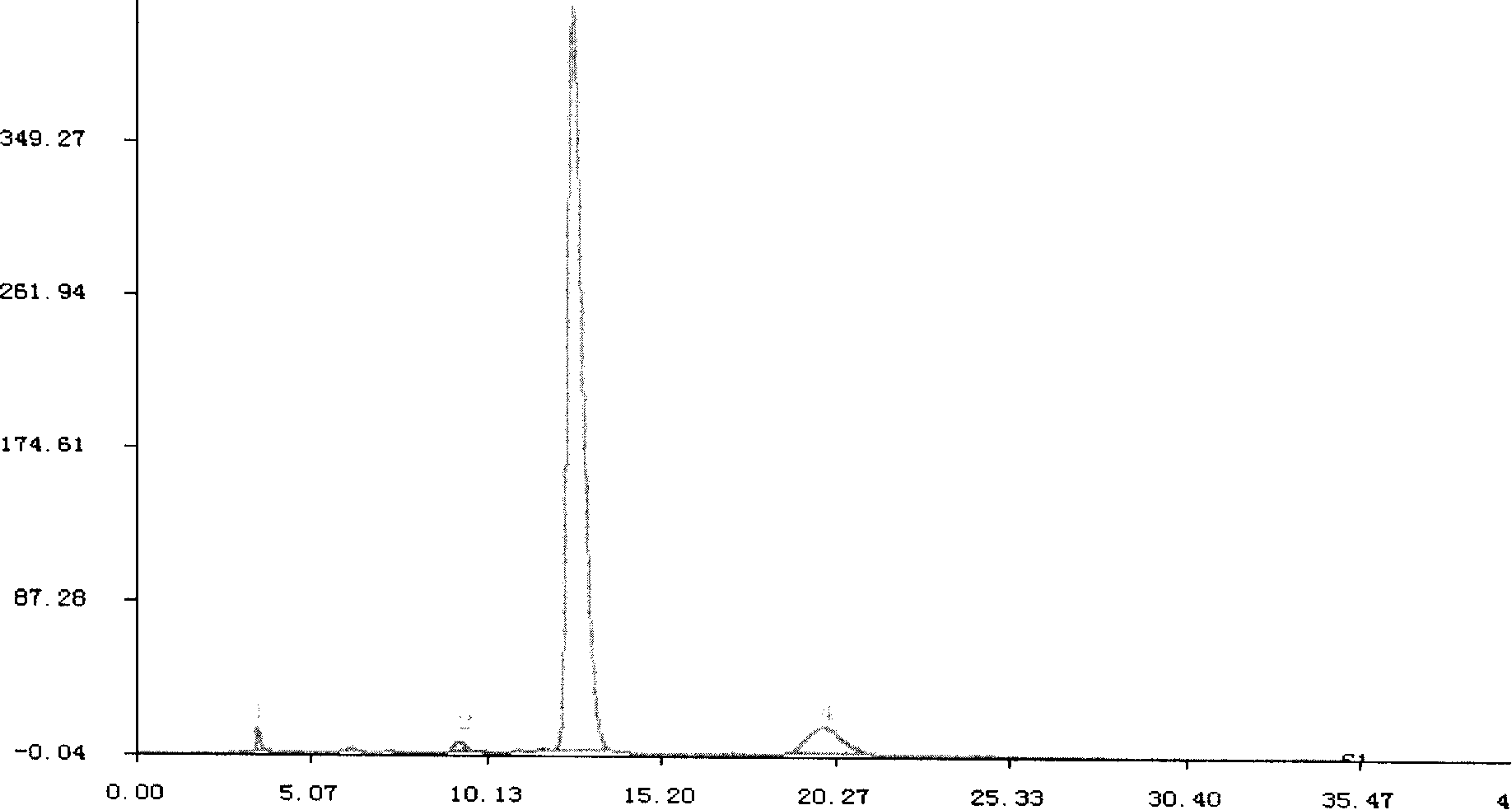

ActiveCN101195647AGood product qualityFine particleOrganic active ingredientsSugar derivativesCarthamusChemistry

The invention relates to a hydroxysaffloryellow A extracted from Chinese medicinal material safflower, a relative preparation method and application thereof. The inventive extraction method of hydroxysaffloryellow A is stuffed into chromatography column according to different diameter-height ratios, the invention uses the upper sample to process column chromatography according to different ratios between upper sample volumes and bed volumes, to separate and purify safflower extract. The invention has simple process, few steps, low cost, high yield, no environment pollution and suitability for industrialized and large-scale production. The yield of extracted hydroxysaffloryellow A is higher than 50%, while the hydroxysaffloryellow A content tested by high-effect liquid hydroxysaffloryellow A reaches 99.5%. The drug prepared from the hydroxysaffloryellow A can effectively prevent and treat cerebrovascular diseases as cerebral infraction and hypertensive cerebral hemorrhage or the like.

Owner:山西德元堂药业有限公司

Zanthoxylum oil production process

The invention relates to a process for preparing zanthoxylum oil, which comprises the steps of choosing materials, preparing fresh pricklyash extract, and making the final zanthoxylum oil product. In the making process, no heating step is needed.

Owner:重庆市树上鲜食品(集团)有限公司

Process for manufacturing injection moulding seal edge of wooden floor or furniture board and edger thereof

ActiveCN101407069ALarge clamping forceGood product qualityWood working apparatusHot runnerEngineering

The invention discloses an edge bander for bonding edges of wooden floor board or furniture board by injecting plastic and a production process thereof. The process comprises the following steps: using the edge bander and the method to place a pre-processed wooden floor board or furniture board into a corresponding mold cavity of an opened forming mold for mold spotting and locking mold, injecting high-temperature melt plastic into hot runners uniformly arranged in heating boards from a main feeding opening, injecting the plastic into the clearance between a forming mold cavity and the periphery of the wooden floor board or the furniture board from taper-shaped feeding ports which are uniformly arranged along the periphery of the forming mold and are provided with cold feeding positions respectively so as to melt and cast the plastic and the wood fiber into a whole, then cool the whole body, and make an edge banding product demould from a front mold and a back mold respectively through pneumatic and mechanical demolding. The edge bander and the process not only ensure the good quality of banding wooden floor board or the furniture board by using plastic, high strengthen of adhesion, long service and uneasy falling, but also realize mechanized one-time forming, rapid edge banding and enable the edge banding plastic and a plate material for edge banding to form a whole body with stable and reliable quality.

Owner:罗生权

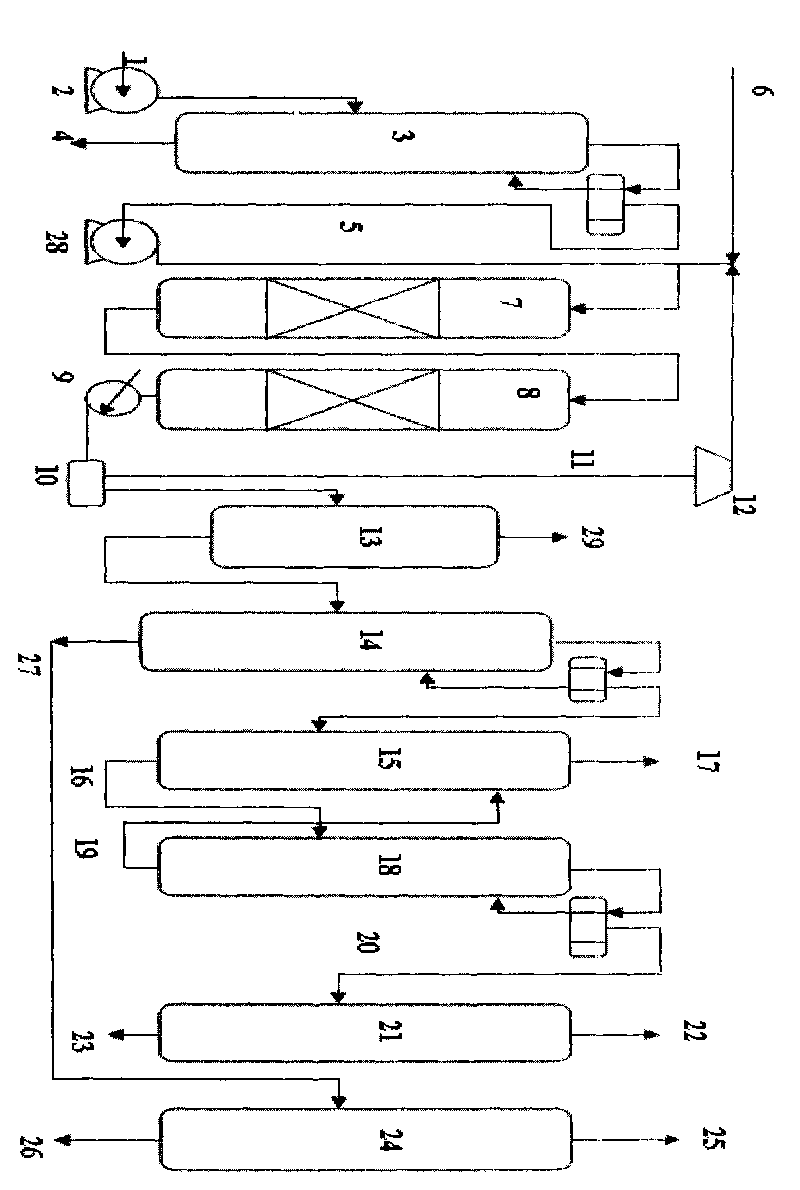

Production equipment of high-purity superfine active zinc powder and method for preparing same

The invention relates to a device used to produce high-purity ultra-fine active zinc powder and relative production, wherein via the element weights, in the fusion process, separating some foreign elements as lead and iron with high weight, from the zinc; in the distillation, via the boiling point difference of elements, from low temperature to high temperature, removing cadmium with low boiling point and lead iron with high boiling point, to obtain high-purity zinc steam; via quick condensation theory, condensing the zinc steam into micro particles to obtain the zinc powder; since different diameter zinc powder will bear different forces in eddy flow, controlling the parameters of classifier, to obtain 2-120 mum product, to classify the zinc powder.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH

Edible mushroom original ecology cultivating method

InactiveCN101147450AExcellent growing environmentGood product qualityHorticultureFungal myceliumSecondary forest

The present invention relates to an edible fungus cultivation method, in the concrete, it relates to a plesiomorphy cultivation method of edible fungus. The plesiomorphy is the ecological environment of wild edible fungus growth and propagation in the nature. Said cultivation method includes the following steps: culturing fungus seed, mycelia culture, culture matrix is nuisance-free agricultural and forestry by-products, selecting plesiomorphy environment to make cultivation, the plesiomorphy environment includes primeval forest, secondary forest, artificial forest and grassland, excavating pit on the forest land or grassland, placing fungus rod into the pit, covering said fungus rod with soil, when the mushroom cap is not spread and the spore is not ejected, the mushroom can be picked.

Owner:李程才

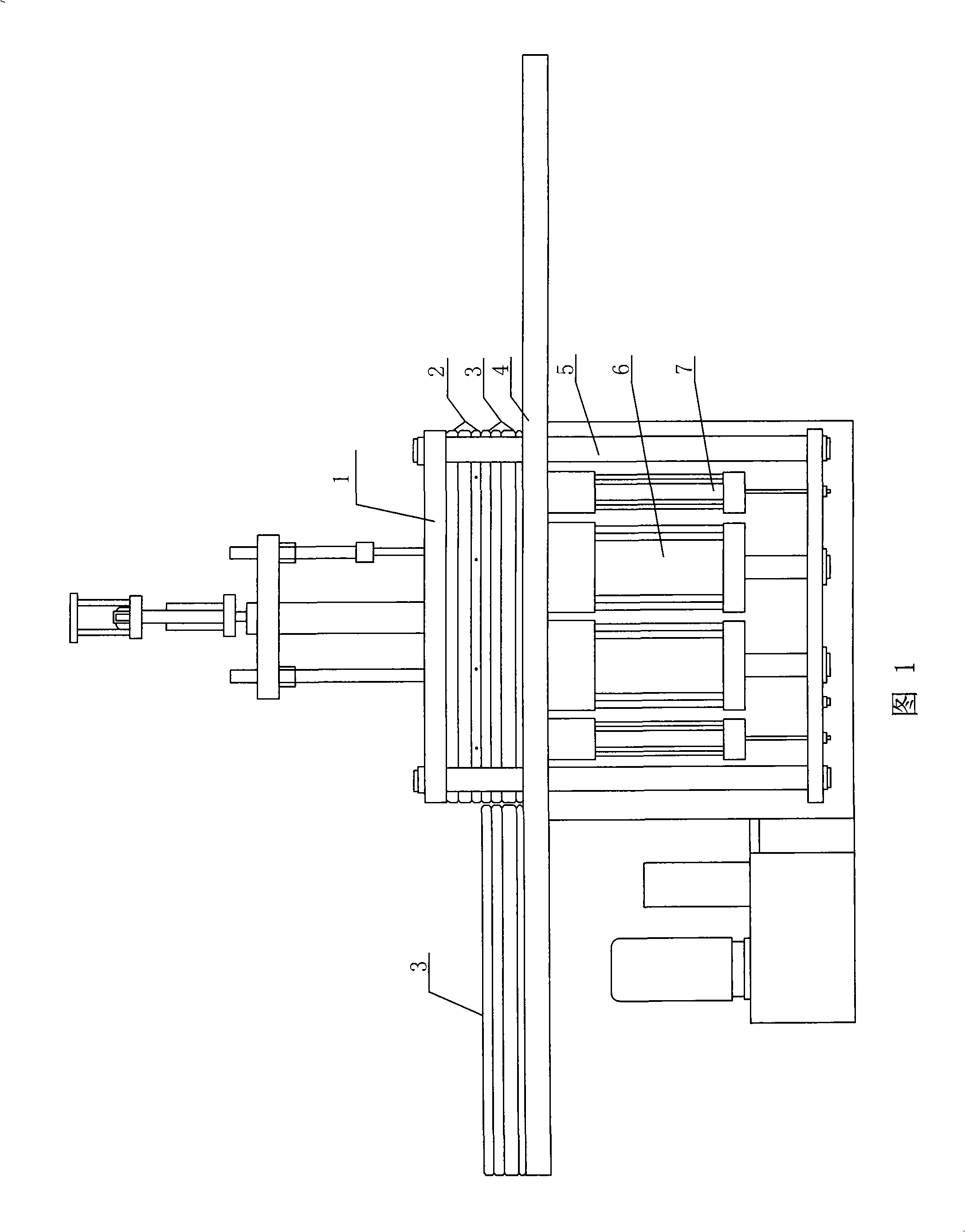

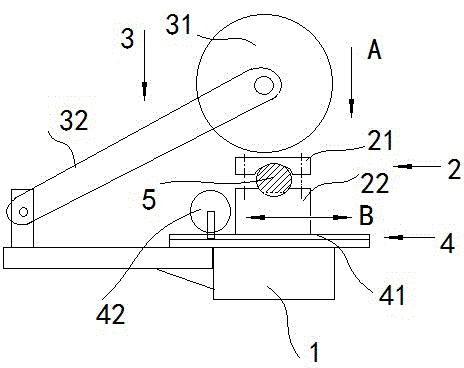

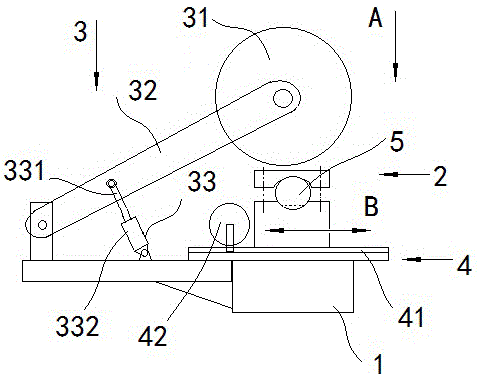

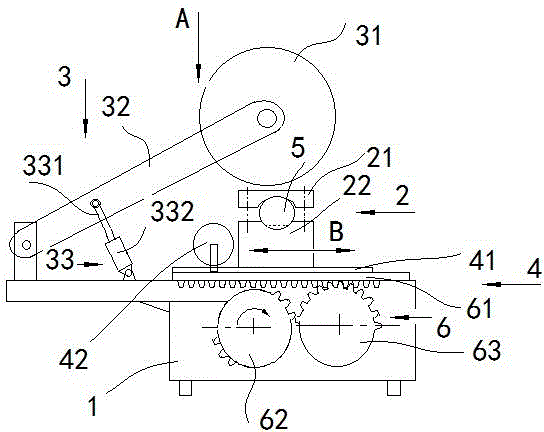

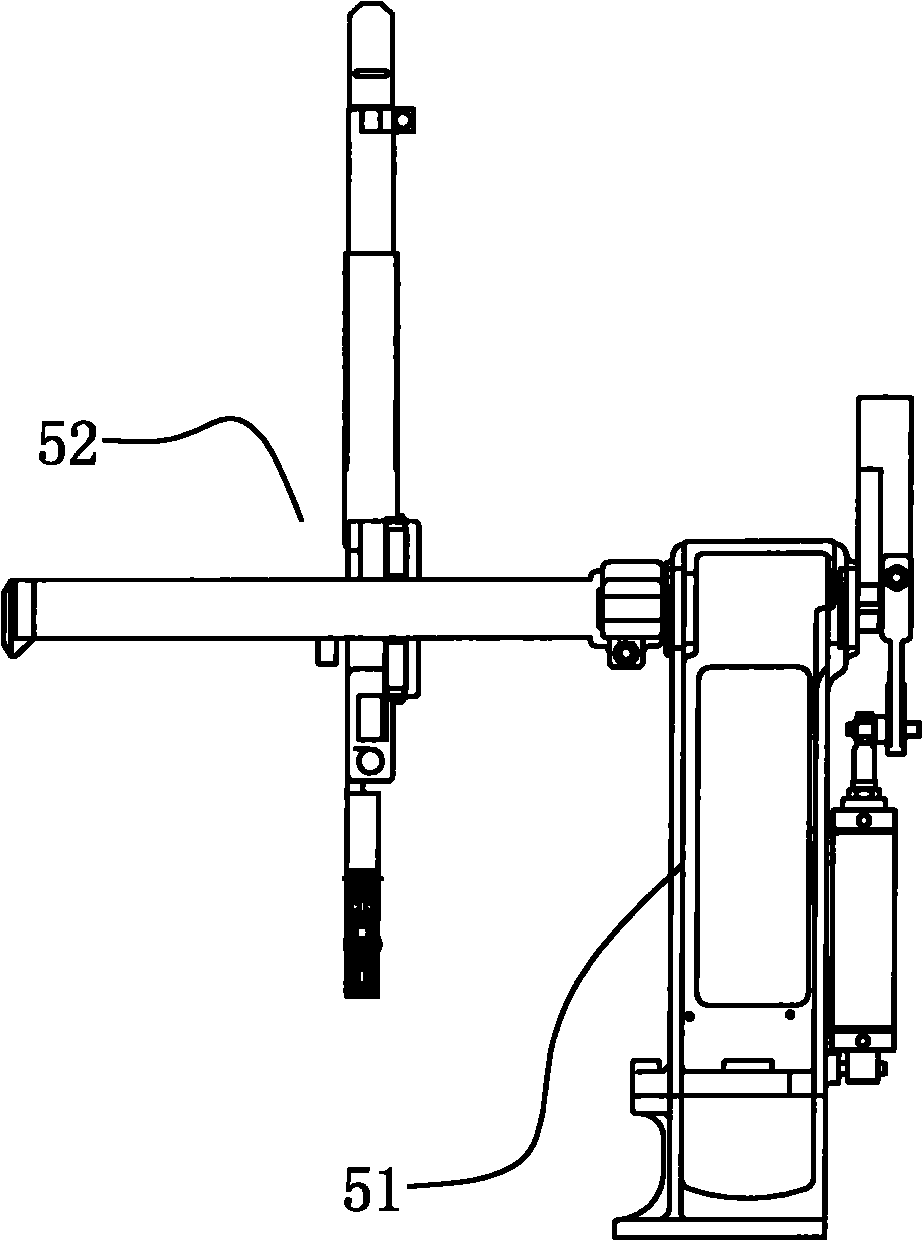

Horizontal and vertical feed burr-free bar cutting device

ActiveCN103600126AReduce cutting timeGood product qualityFeeding apparatusPositioning apparatusAutomatic controlEngineering

The invention discloses a horizontal and vertical feed burr-free bar cutting device, and provides a double-cutter horizontal and vertical bar cutting device to overcome the defect that a workpiece directly cut by a single cutter of a bar cutting machine in the prior art always has burrs. The horizontal and vertical feed burr-free bar cutting device comprises a base, an upper cutter mechanism and a bar clamping mechanism, the upper cutter mechanism is connected onto the base, the bar clamping mechanism is vertically arranged along the base, the upper cutter mechanism comprises an upper cutter frame hinged to the base, a main motor and an upper cutter are mounted on the upper cutter frame, a lower cutter mechanism positioned below the upper cutter mechanism is arranged on the base and comprises a guide rail horizontally arranged along the base, a lower cutter frame is slidably connected onto the guide rail, a lower cutter motor and a lower cutter are mounted on the lower cutter frame, and the lower cutter frame is driven by a transmission mechanism connected on the base. The burr-free bar cutting device has the advantages that the device is provided with a vertical cutting mechanism and a horizontal cutting mechanism, the burrs are avoided, automatic control can be realized, bars are rapidly cut and are fine in quality, and labor and time are saved.

Owner:浙江安统汽车部件有限公司

Method for producing organic clay

ActiveCN1821075AGood product qualityReduce manufacturing costSilicon compoundsClaywaresSolventAqueous solution

The present invention discloses organic clay producing process, which includes the steps of: pulping clay mineral, deposition and centrifuging purification to obtain clay suspension; preparing quaternary ammonium salt aqua of 10-30 wt% concentration with tertiary amine as material, water as solvent and introduced chloromethane; adding quaternary ammonium salt aqua into clay suspension for modification; and dewatering the modified solution, drying and crushing to obtain organic clay product. Thus produced organic clay product has high quality and the production process has low waste water CODCr index, and is one clean low-cost production process.

Owner:浙江华特新材料有限公司

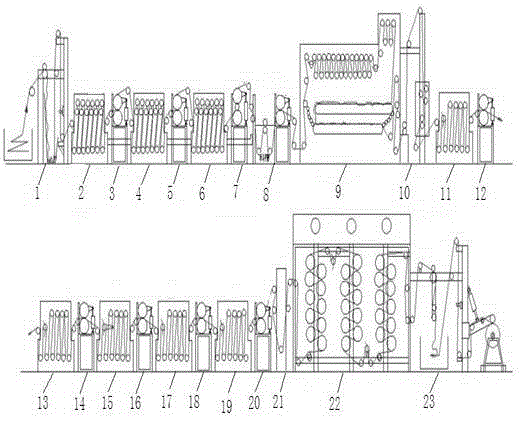

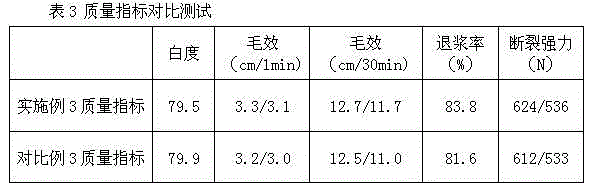

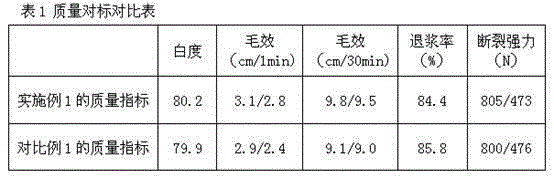

Printing and dyeing pretreatment process

ActiveCN102978894ASave steam energy consumptionGood product qualitySucessive textile treatmentsDry-cleaning apparatus for textilesWoven fabricPolymer chemistry

The invention relates to a printing and dyeing pretreatment process, which comprises the steps of cloth turning, sewing, singeing and low-temperature annealing, scouring and bleaching, and is characterized by comprising the following steps: washing to remove attachments on the cloth surface after the woven fabric is subjected to cloth turning, sewing and singeing treatment, padding the operating fluid after padder squeezing, and padding through a high liquid feeding padder; and piling at the temperature of 40-45 DEG C for 40-60 minutes, finishing annealing, scouring and bleaching pretreatment, and washing the reaction residues through hot water, wherein the process flow of the low-temperature annealing, scouring and bleaching comprises hot-water washing, cold-water washing, padding, soaking operating fluid, padding through the high liquid feeding padder, room temperature piling and hot-water washing. The printing and dyeing pretreatment process has the characteristics of high efficiency and good pretreatment effect, is low in fiber damage, high in quality of the treated fabric and soft in handfeel, and the pretreatment energy consumption can be greatly reduced, and the production period can be shortened; and moreover, the woven fabric is subjected to annealing, scouring and bleaching by piling at the low temperature of 40-45 DEG C for 40-60 minutes.

Owner:YUYUE HOME TEXTILE

Method for producing salt-free compound amino acid powder from combination of sesame seed meal and soybean meal

InactiveCN101974576AHigh purityGood product qualityMicroorganism based processesFermentationAmino acid compositionActivated carbon

The invention discloses a method for producing salt-free compound amino acid powder from the combination of sesame seed meal and soybean meal as raw materials, which relates to a production method of compound amino acid powder. The method comprises the following steps of: (1) crushing the mixture of the sesame seed meal and the soybean meal, adding water into the powder, adding amylase, alpha-amylase, cellulase and compound protease into the powder respectively, and adding high-temperature resistant brewing high-activity dried yeast into the mixture to perform enzymolysis and fermentation at the same time; (2) after 4 to 7 days of heat-preservation enzymolysis and fermentation, performing filtration for the first time, and adding active carbon of which the weight is 1 to 4 percent of thatof filtrate into the filtrate to perform decolorization for 2 to 4 hours in a boiling state; and (3) performing spray drying on concentrated solution. Compared with an acid hydrolysis method and an alkaline hydrolysis method, the method causes no environmental pollution, and the produced leftovers can also be processed into feeds; the amino acid composition of the product is more reasonable, which can greatly improve the amino acid score of the product; and the soybean meal has a beany flavor, and the sesame seed meal has a sesame flavor, so the sensory score of the amino acid product obtained by compounding the soybean meal and the sesame seed meal is improved.

Owner:JIANGSU UNIV

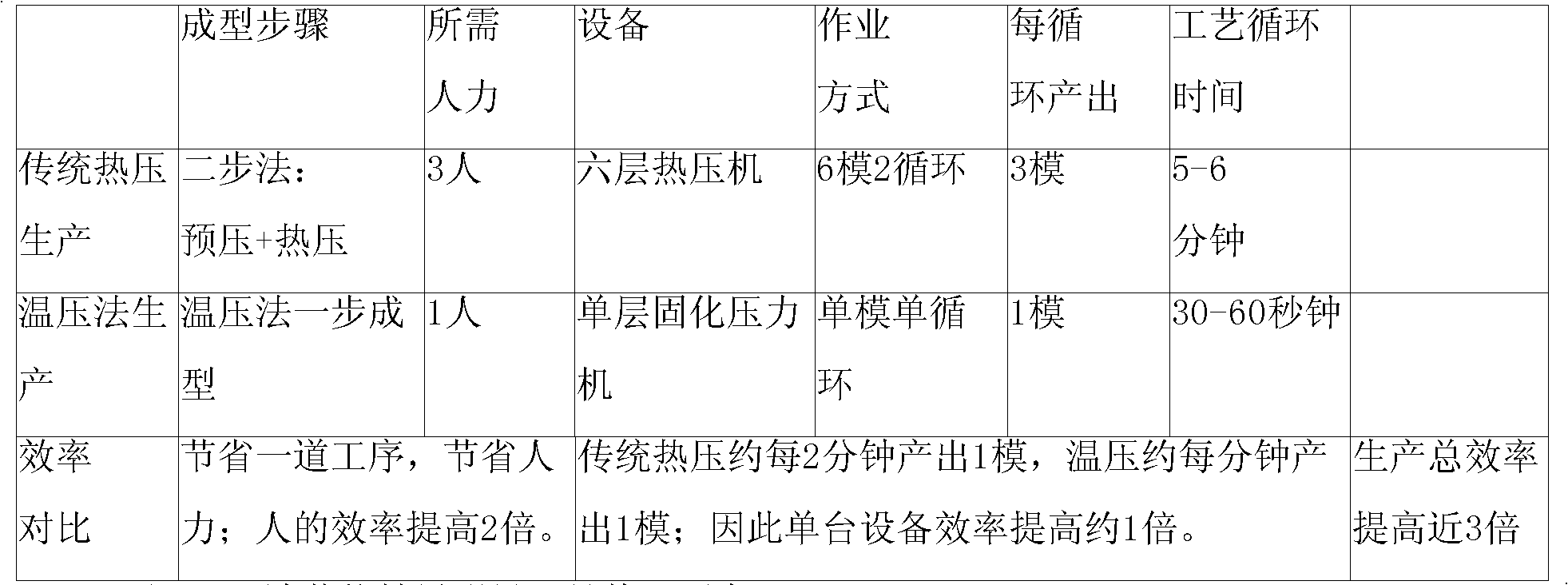

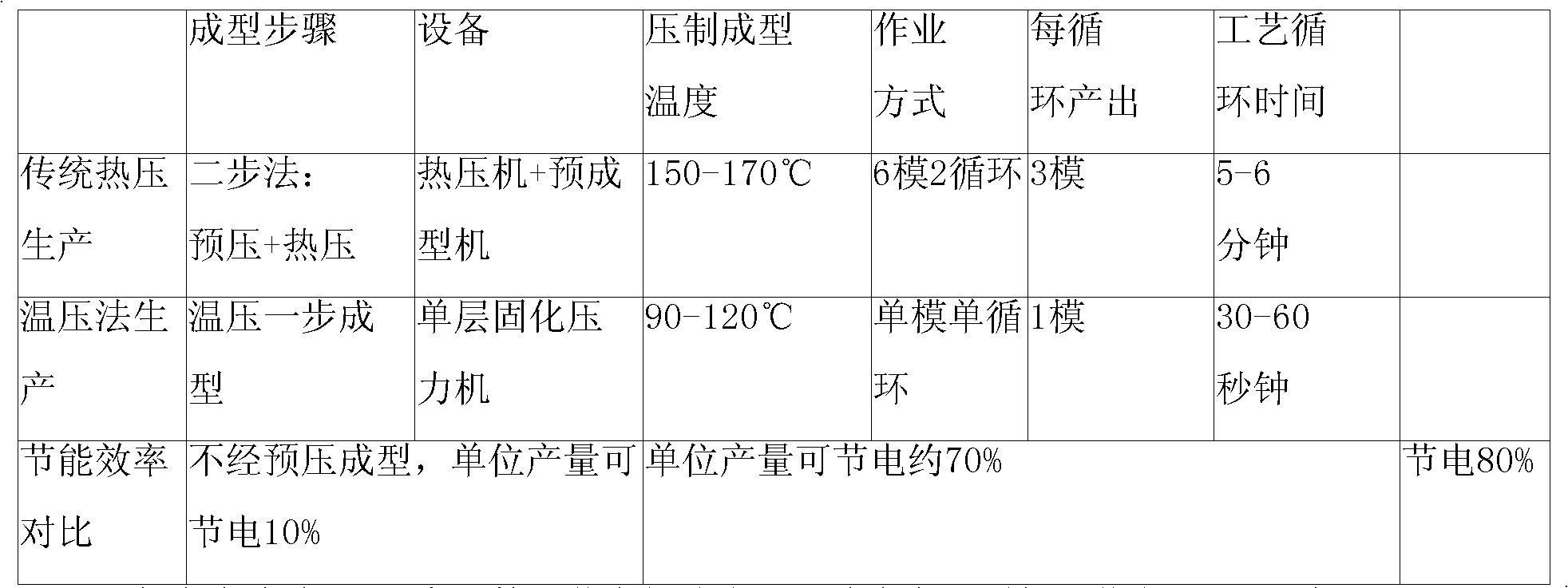

Preparation method of friction material

ActiveCN101664979AReduce equipment investmentGood product qualityOther chemical processesSolventThermal radiation

The invention relates to the technical field of braking of vehicles, in particular to a preparation method of a friction material. The preparation method is characterized by comprising the following steps: using a water-based solvent to mix raw materials and preparing the mixture into prefabricated particles; carrying out temperature-pressure forming of the prefabricated particles and preparing the prefabricated particles into a blank; and carrying out heat treatment to the blank. The preparation method overcomes the defects that in the traditional method, the hot pressing temperature is high,the time is long, the resin can generate a certain gas with irritant smell in the process of solidification reaction, and an operator needs to operate in high-temperature environment for long time; the adopted temperature-pressure method has low temperature, short time, incomplete solidification reaction, has no obvious smell generated in the process and obviously reduces the thermal radiation effect to the operator.

Owner:SHANDONG DOUBLE LINK BRAKE MATERIAL

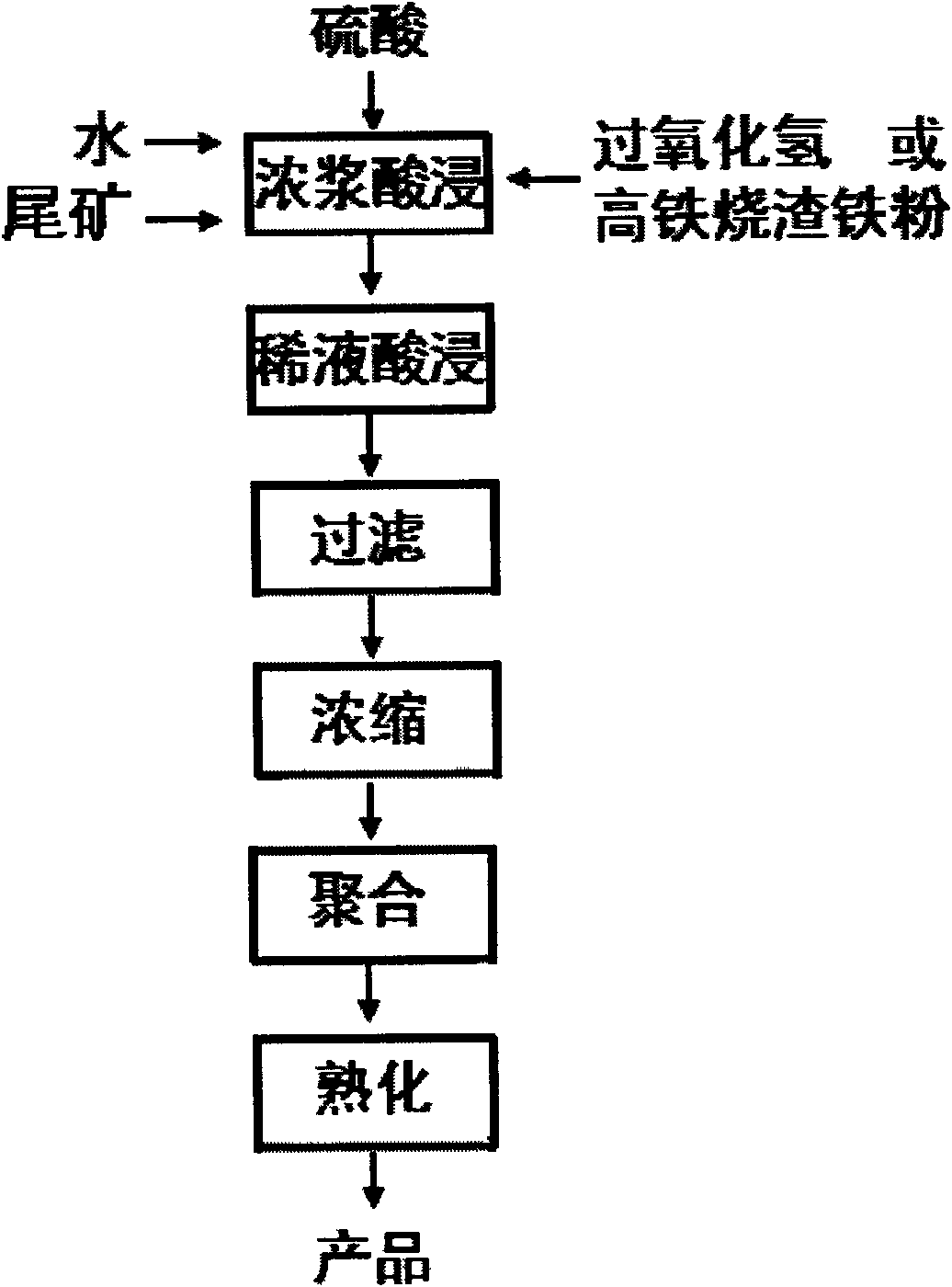

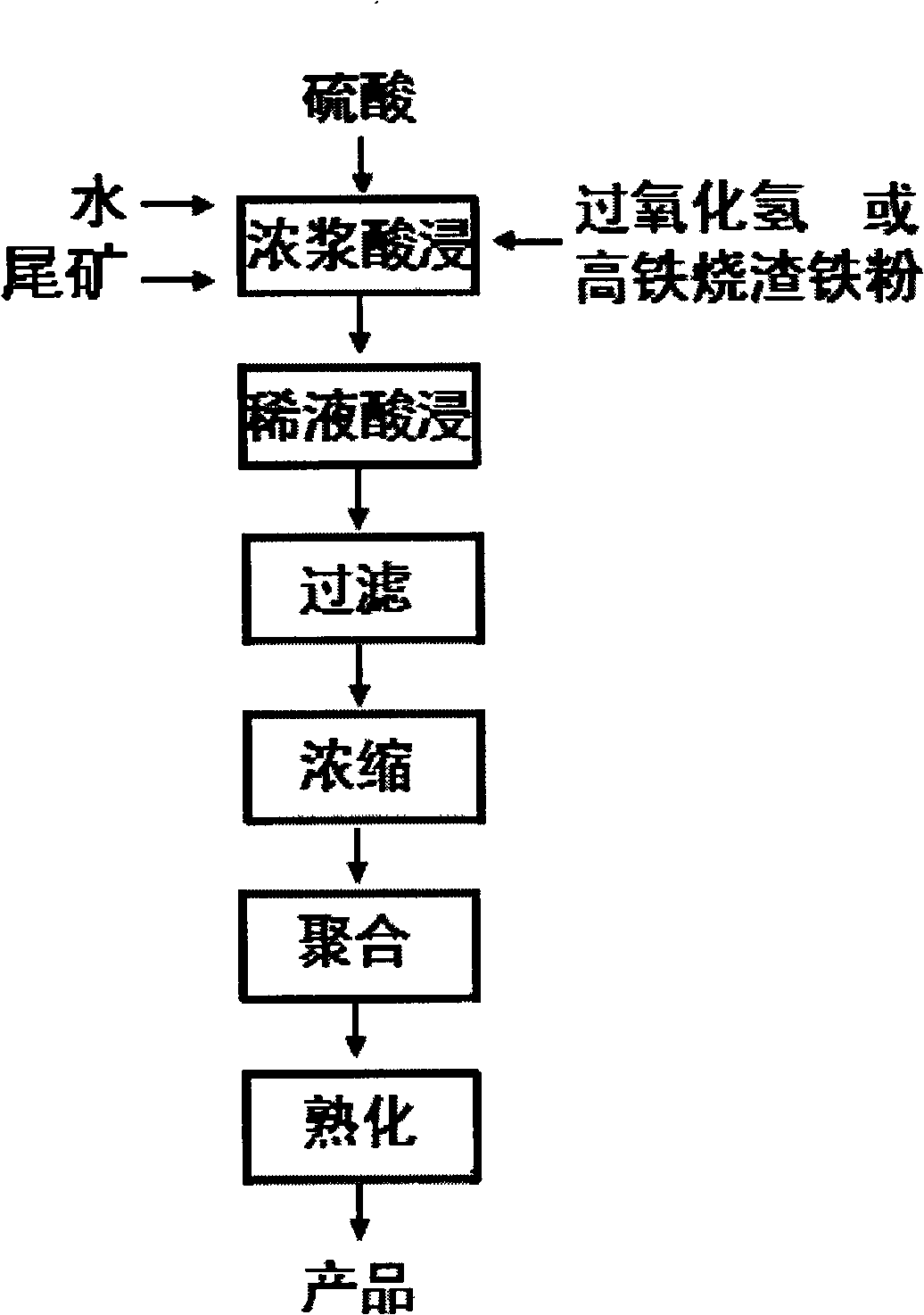

Method for preparing polymeric aluminum ferric sulfate by using aluminium ore washing gangue

InactiveCN101973586AIncrease reaction rateGood product qualityIron sulfatesWater/sewage treatment by flocculation/precipitationAluminium saltsBrass

The invention discloses a method for preparing polymeric aluminum ferric sulfate by using aluminium ore washing gangue, which is characterized in that washing gangue or / and brasses of a karst accumulated aluminium ore or other aluminium ores is or are used for preparing high-iron pyritic residue iron powder which reacts with sulfuric acid to generate aluminum sulfate and ferric sulfate water solutions, and then an alkalizer is added for polymerizing to produce the polymeric aluminum ferric sulfate. Meanwhile, the gangue has thinnest granularity, wherein the content of fine silt with the granularity of -10 micrometers accounts for 80 percent, and the fine silt is the optimal raw material for producing the polymeric aluminum ferric sulfate, and has the advantages of high reaction ratio and good product quality. The invention has the advantages of being capable of reasonably and effectively utilizing aluminium ore resources, effectively controlling the aluminium ore washing gangue from a pollution source, protecting the environment, realizing the harmony of human beings and the environment, lowering the production cost of the polymeric aluminum ferric sulfate and realizing high-efficiency recycling economy.

Owner:广西天工冶金科技有限公司

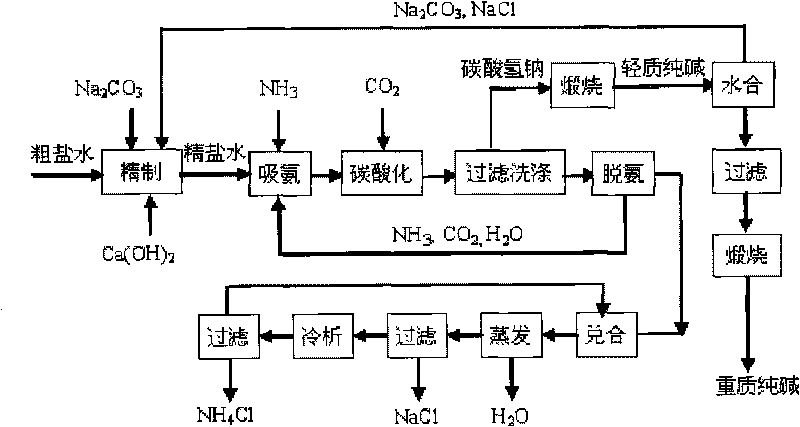

Method for producing low-salt high-quality dense soda ash

ActiveCN101708858AGood product qualityBroad development prospectsCarbonate preparationSea saltSolid phases

The invention provides an improved method for producing low-salt high-quality dense soda ash by using light soda ash produced by a hot method alkali combination process as a raw material. The method comprises the following steps: firstly, producing the light soda ash containing 0.5 to 0.9 percent of NaCl in mass fraction through hot method alkali combination; and secondly, producing the low-salt high-quality dense soda ash containing less than 0.3 percent of the NaCl in mass fraction by adopting a liquid-phase hydration method or a modified solid-phase hydration method, wherein in order to ensure the salinity in the product, a certain amount of saliferous mother liquor of 40 to 80 g / L is needed to be discharged from a hydration system continuously or discontinuously and the saliferous soda mother liquor is sent back into a brine refining system, a Na2CO3 component in the mother liquor serves as a calcium remover, and a NaCl component serves as a raw material component. The method overcomes the defects that an ammonia soda process for producing the low-salt dense soda ash has a large sewage discharge and a combination soda production method cannot normally produce the low-salt dense soda ash; the raw materials can be coarse sea salts and mine salts, or bitterns obtained through solution mining of salt mines can be used directly; and the method has the advantages of no sewage discharge, good product quality and extensive development prospect.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

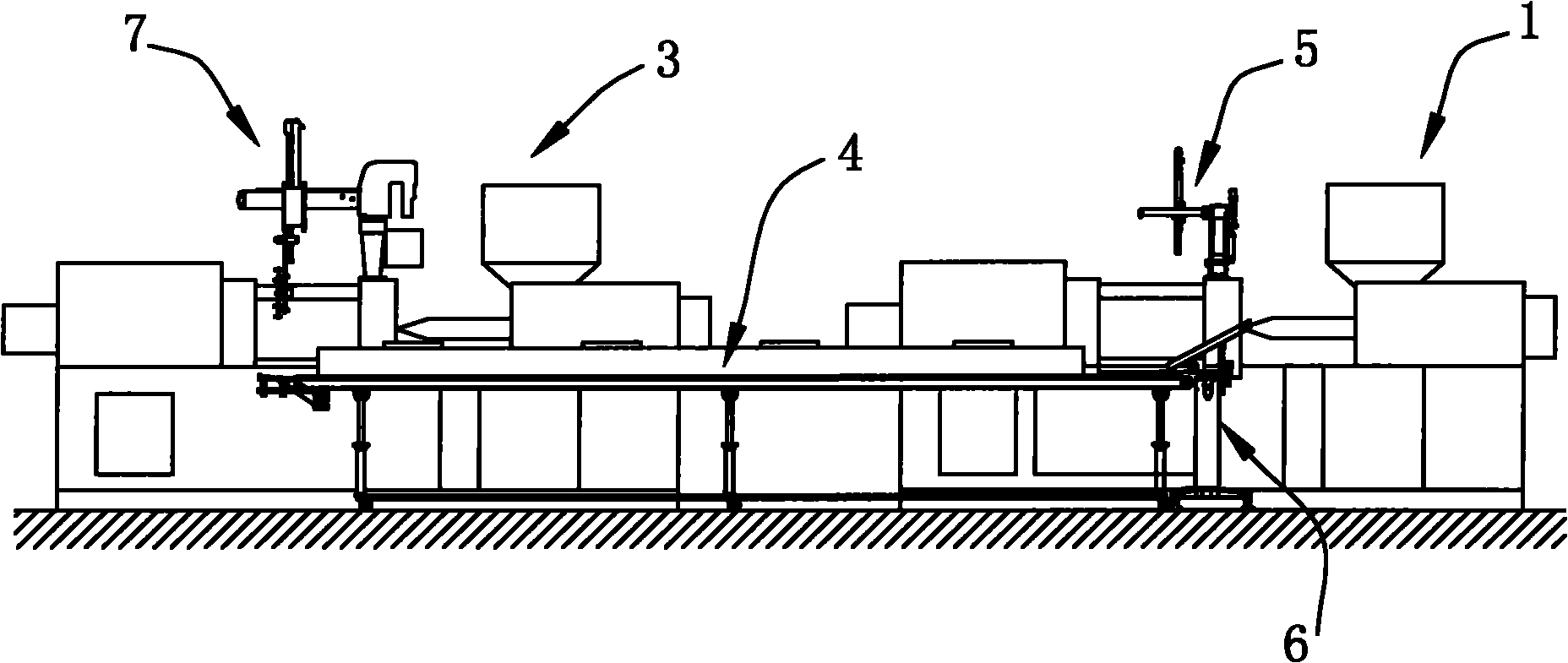

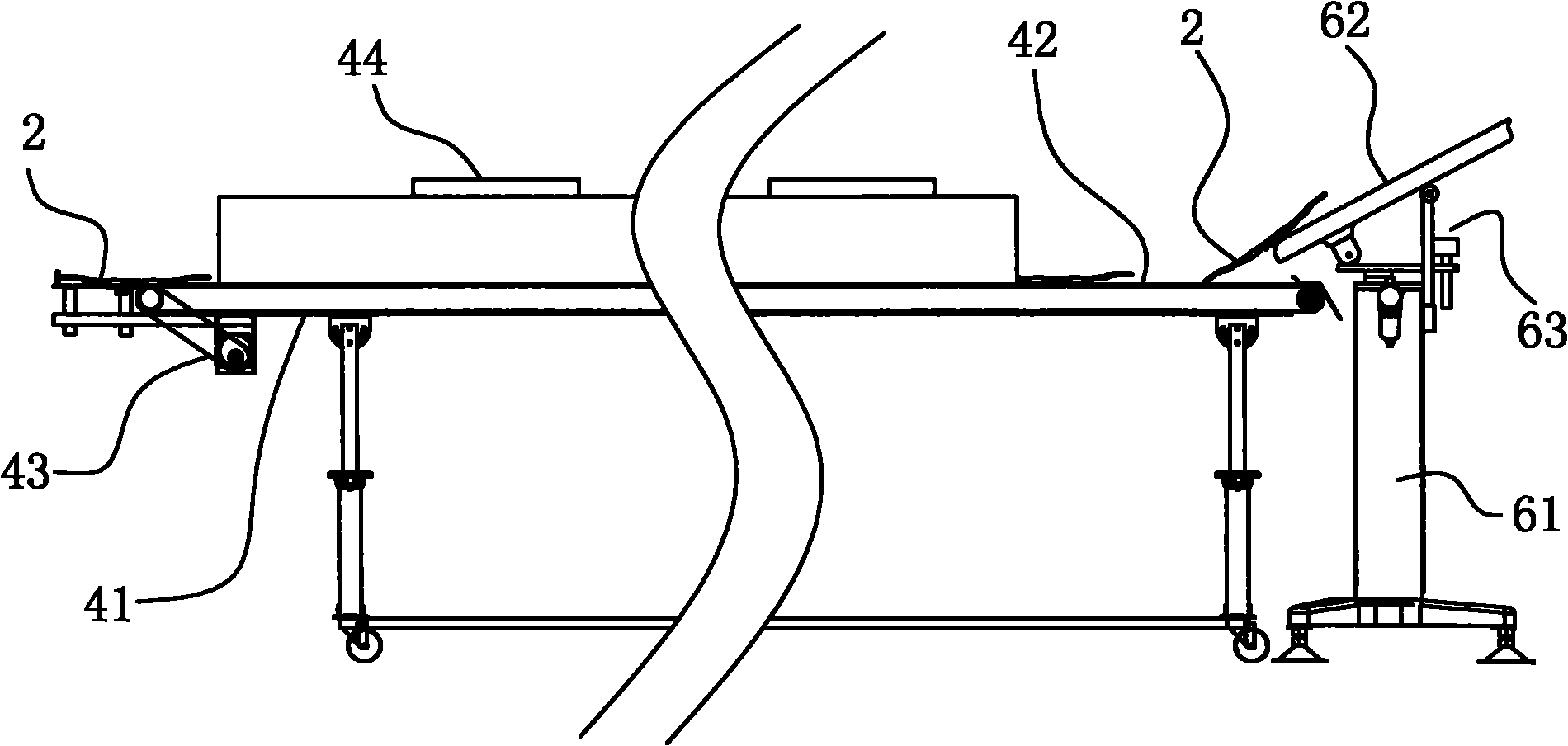

Secondary injection molding method for toothbrush handles and system for implementing same

InactiveCN102166807AReduce manufacturing costGood product qualityDomestic articlesEngineeringInjection moulding

The invention discloses a secondary injection molding method for toothbrush handles, comprising the following steps of: (1) arranging a molding injection machine for performing injection molding of a toothbrush body; (2) arranging an encapsulating injection machine for performing secondary encapsulating injection on the toothbrush body to obtain the finished product; and (3) arranging a control system which is respectively connected with the molding injection machine and the encapsulating injection machine for controlling the operating modes thereof. The invention also discloses a system for implementing the method. The method provided by the invention can realize secondary injection molding on the basis of not changing the existing structure of the mold, so that the production cost is effectively reduced and the product quality is good. The system provided by the invention has a simple and reasonable structure, combines the molding injection machine and the encapsulating injection machine, realizes secondary injection molding, has high efficiency and quick speed, greatly improves the production efficiency and the product percent of pass, has high degree of automation, and greatly reduces the labor intensity.

Owner:东莞艾尔发自动化机械有限公司

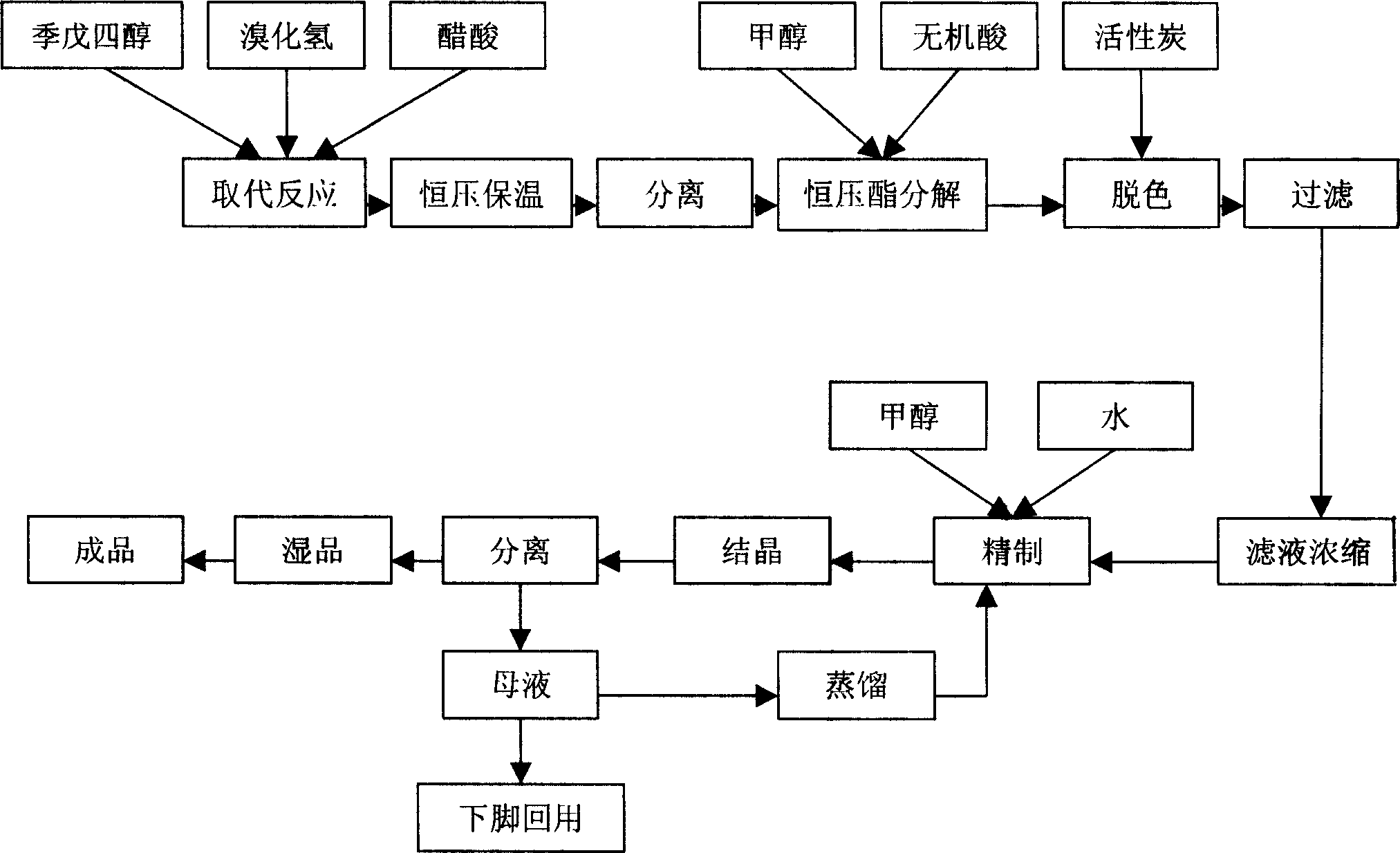

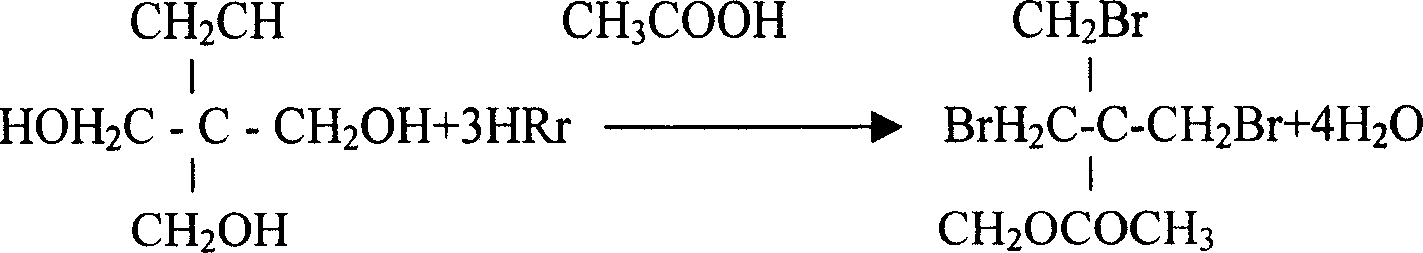

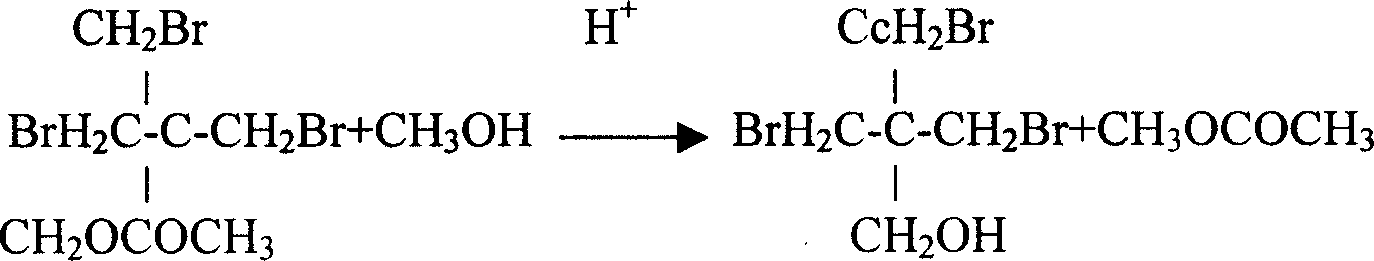

Synthetic method and refining for tribromoneoamyl alcohol

InactiveCN101016227AFull responseGood product qualityPreparation by halogen introductionDecompositionPentaerythritol

The invention discloses a synthesizing method of tribromo-neoamyl alcohol, which comprises the following steps: aerating hydrogen bromide into pentaerythrite to substitute; insulating; separating tribromo-neoamyl alcohol ester; adding carbinol and inorganic acid into tribromo-neoamyl alcohol to do ester decomposition under 0.4-0.6Mpa; insulating under 0.6-0.8Mpa after substituting; making the mass react completely; improving product property obviously.

Owner:宜兴市中正化工有限公司

Method for preparing light aromatics from coal tar

ActiveCN101712889AGood product qualityReduce manufacturing costTreatment with hydrotreatment processesTar working-up by distillationSolventCoal tar

The invention discloses a method for preparing light aromatics from coal tar. The method is characterized by comprising the following steps of: cutting the coal tar into light oil fraction lower than 200 DEG C and heavy oil fraction higher than 200 DEG C; sequentially enabling the light oil fraction lower than 200 DEG C to enter two fixed-bed hydrogenation reactors for selective hydrogenation refining; stripping and pre-distilling the obtained hydrogenated generating oil; and extracting, distilling and finely distilling the solvent to obtain light aromatic products, such as benzene, toluene, xylene, and the like and byproducts, such as non-aromatics and solvent oil. The invention has wide raw material resources, low production cost, long device-running period and good aromatic product quality.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

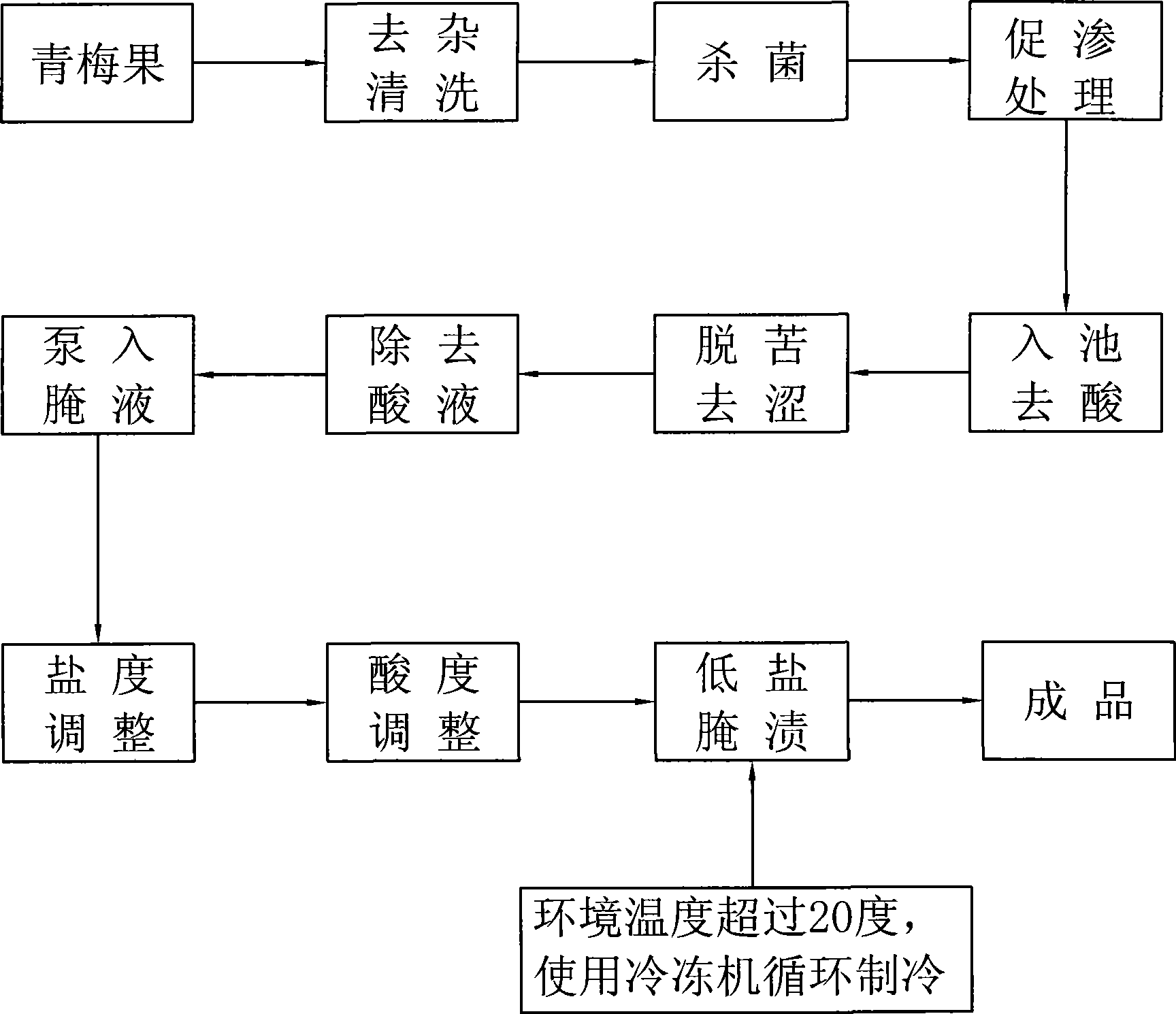

Method for pickling green plum fruits

InactiveCN101411357AEasy processingGood product qualityFruits/vegetable preservation using acidsOrganic acidSalt content

The invention provides a method for pickling green plum fruits, which comprises the following steps: a. picking up green plum fruits; b. removing impurities and cleaning; c. desulfurization; d. deacidification; e. preparing low-salt pickling liquid; f. controlling the temperature of the pickling liquid; and g. pickling the green plum fruits in a pickling pond for 25 to 30 days. The method has the advantages that: the green plum fruits are pickled under a condition of less than 6 percent salt concentration; and the high acidity and the high osmotic pressure are utilized to restrain the growth and breeding of microbes, so that the pickled green plum fruit keeps the original light-scent taste, and the shelf life reaches nearly 30 months; and, the following processing steps are simple, the desalting step is unnecessary, the processed product has good quality, the organic acid and nutritive materials are insusceptible to loss, the green plum fruit can also be processed into various products, thereby facilitating the mass production of all varieties. Once the pickled liquid is prepared, common salt does not need to be added, the pickled liquid can be repeatedly used, so that the method can reduce sewage discharge, salt content in the sewage, thereby facilitating the sewage treatment and environmental protection, saving cost and improving economic benefits.

Owner:俞关权

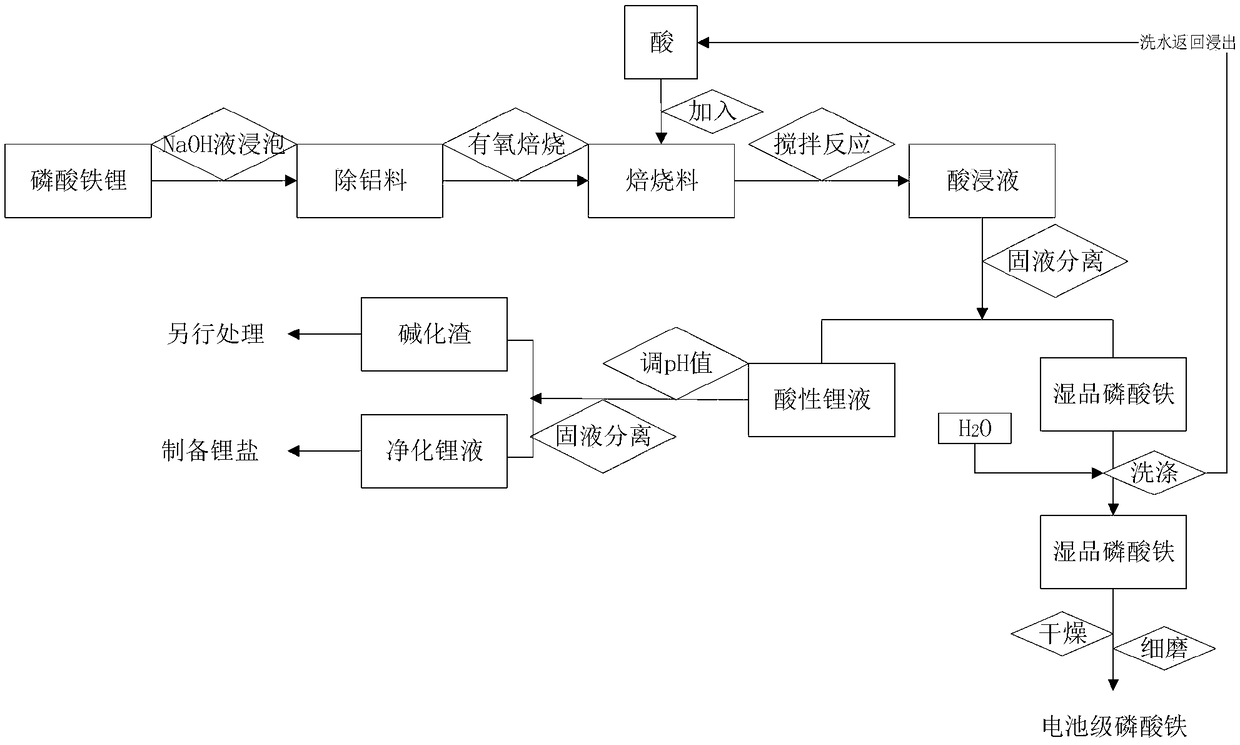

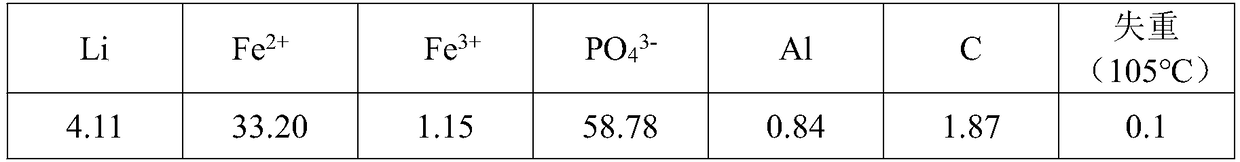

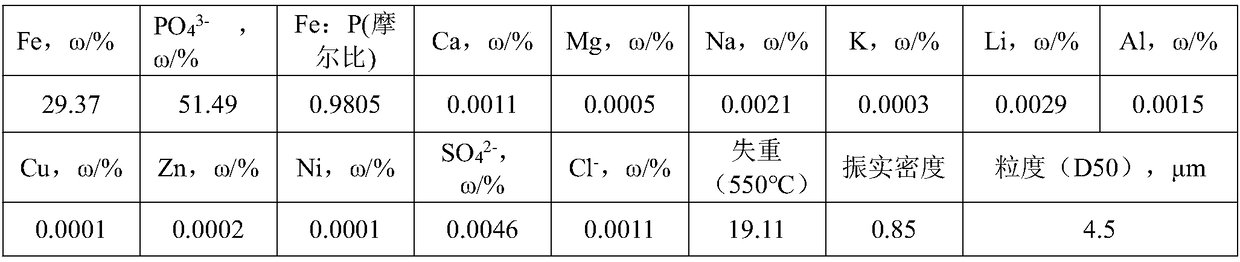

Method for extracting lithium and iron phosphate from lithium iron phosphate waste

InactiveCN109179359AImprove material utilizationGood product qualityLithium halidesLithium oxides/hydroxidesPhosphoric acidScrap

The invention provides a method for extracting lithium and iron phosphate from lithium iron phosphate waste, comprising the following steps: (1) immersing lithium iron phosphate powder with NaOH to obtain an aluminum removal material; (2) performing an aerobic calcination reaction on the aluminum removal material to obtain a calcined material; (3) cooling the calcined material, and adding acid tocarry out a leaching reaction to obtain pickle liquor and iron phosphate; (4) performing solid-liquid separation on the pickle liquor to obtain an iron phosphate solid and an acidic lithium liquid; (5) washing the iron phosphate and drying to obtain battery-grade iron phosphate; and (6) regulating pH value of the acidic lithium liquid to alkaline level and filtering to obtain a purified lithium liquid. The method of the invention has simple process and no requirement for raw materials; the consumption of acid and alkali in the extraction process is low, and the by-products are few; the qualityof the obtained product iron phosphate is stable, and index requirements of the battery-grade product are met; and the elements such as lithium, iron and phosphorus are effectively recovered and theyield is high, and the method is easy to achieve industrial production.

Owner:CHENGDU LV LI ENVIRONMENTAL PROTECTION TECH CO LTD

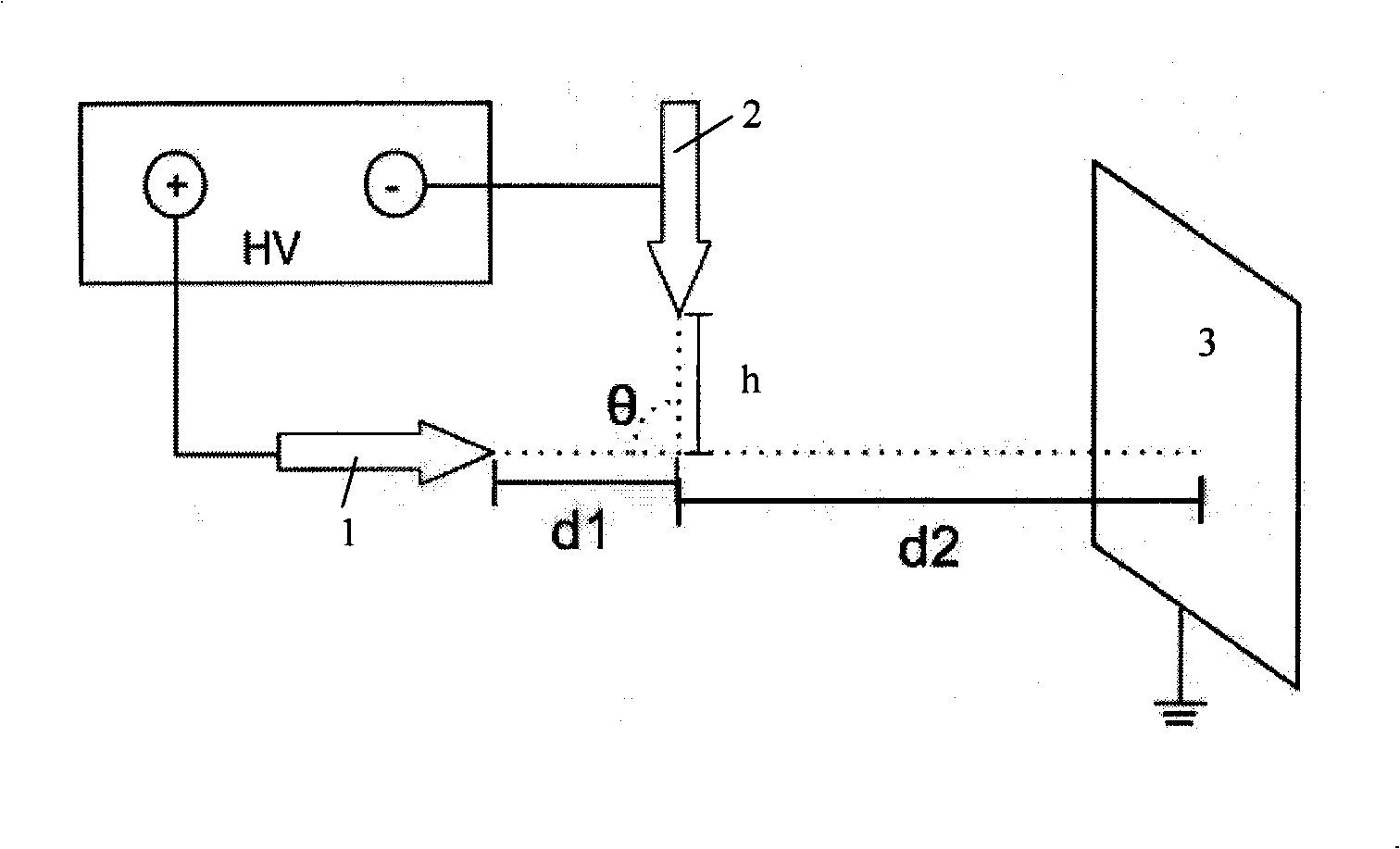

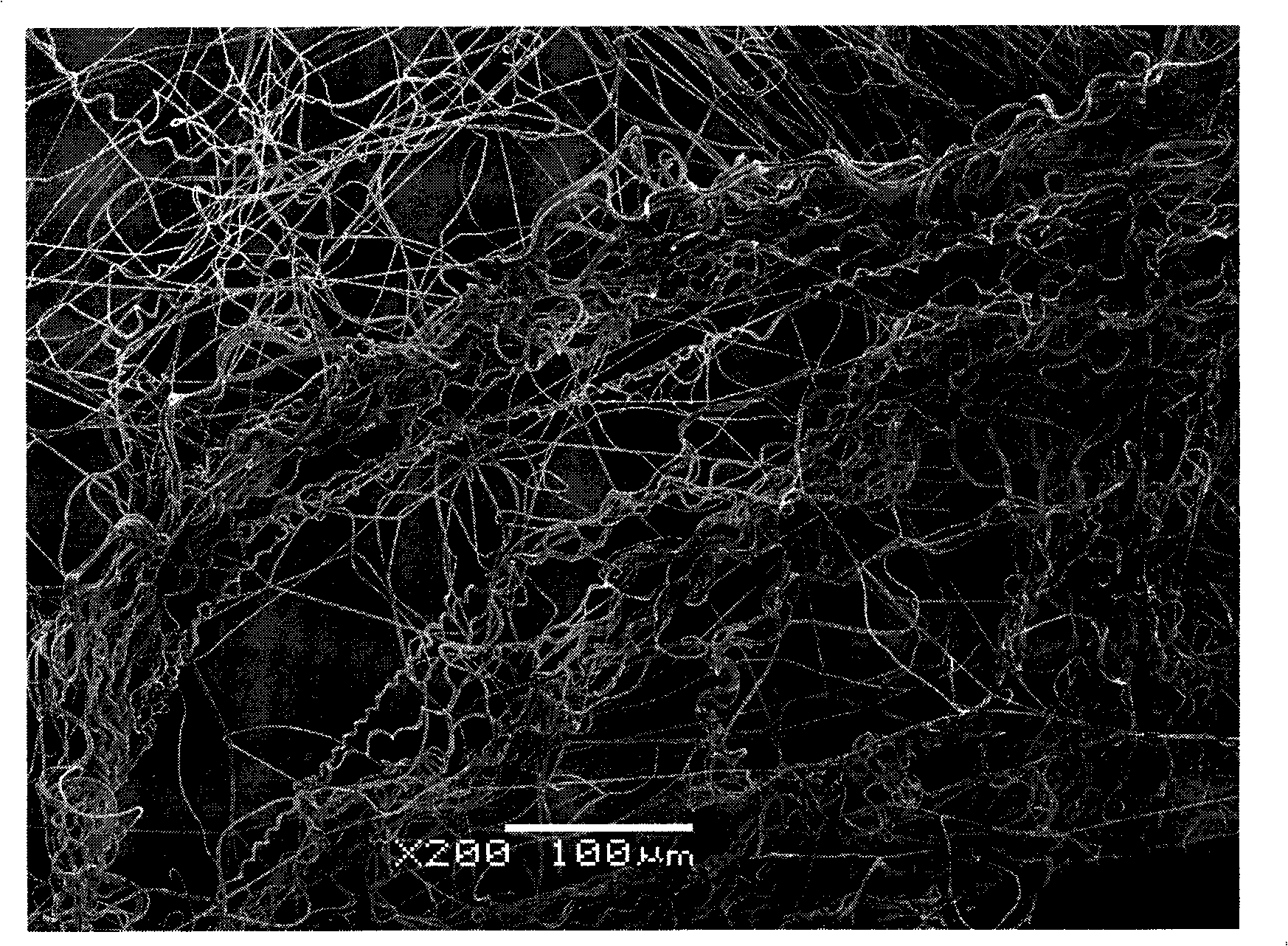

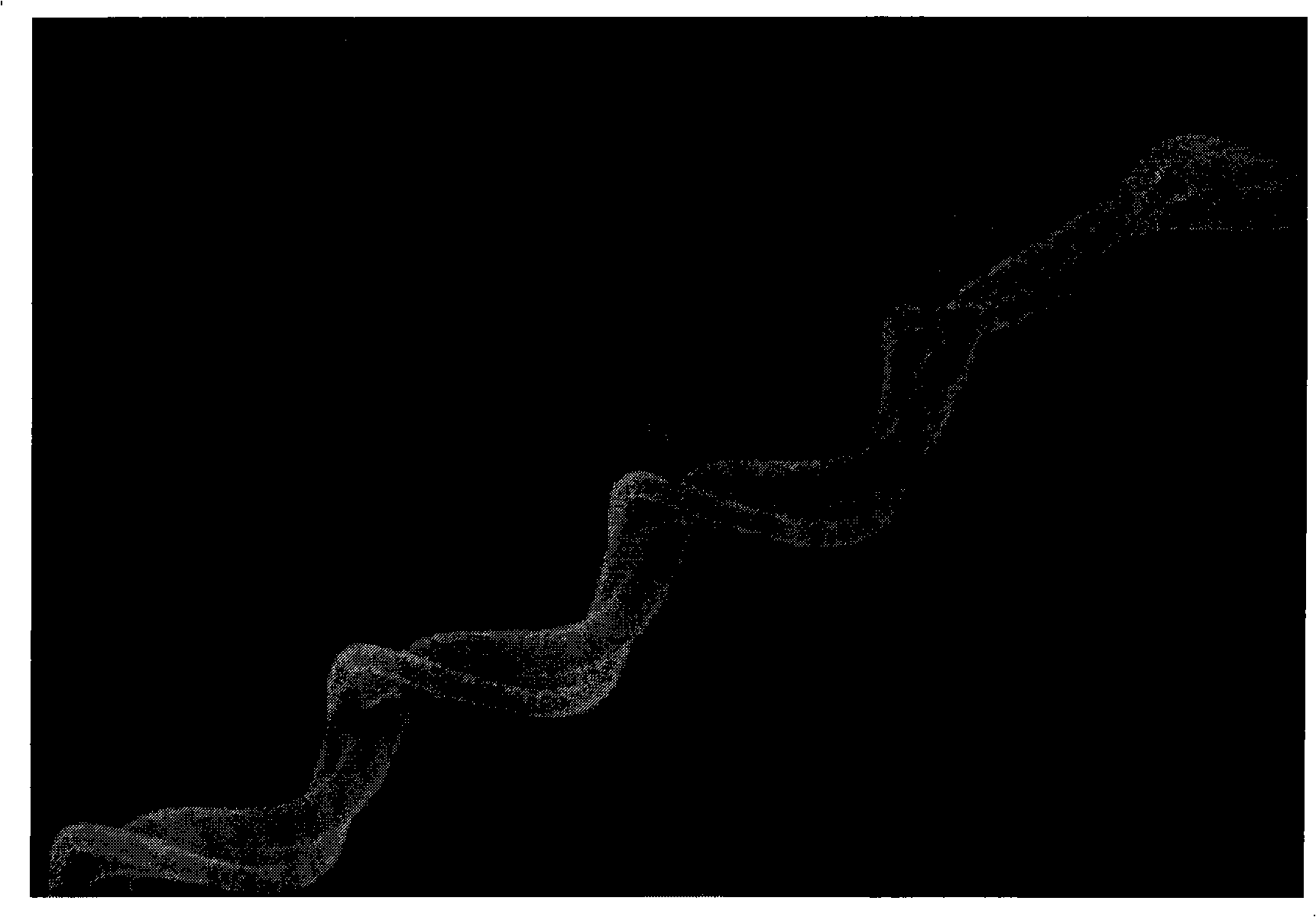

Device for preparing distorted-structure polymer micron/nano composite fiber and method thereof

InactiveCN101525771ASimple methodGood product qualityFilament/thread formingConjugated synthetic polymer artificial filamentsSolventElectric field

The invention discloses a device for preparing distorted-structure polymer micron / nano composite fiber and a method thereof. The device provided by the invention consists of at least a spinneret set and a receiving device. Two spinnerets in the spinneret group are respectively imposed with positive and negative voltage of different magnitudes and added with components of different shrinkage rates; after being ejected out under the effect of positive and negative voltage and agglutinated, the two components continue to extend under the effect of electric field, then form the composite fiber with the solvent volatilization and finally are received by the receiving device. The composite fiber on the receiving device shrinks due to the resilience caused by charge transfer and then forms distorted fiber due to different shrinkage rates of the two components. According to differences of component properties, voltage and relative positions of the two spinnerets of the receiving device, distorted fibers with different morphologies can be prepared. The invention solves the control problem of the distorted structure and is applicable to large-scale production with simple method and low cost.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Method for producing natural brown pigment of chestnut case

The invention relates to the technique of natural edible pigment in the food additives, which in detail a method for producing natural chestnut shell brown pigment, breaking the chestnut shell, extracting with base solvent after removing the flocculus, filtering the extracting fluid, condensing the filtering fluid, depositing, separating, drying and getting the natural chestnut brown pigment. The invention is characterized by the high productivity, good product quality, strong stability, simple process, low cost, changing the disposal to useful things, which opens a new way of producing natural brown pigment for food industry and at the same the industrialized production of the pigment contributes a lot for protecting ecological environment and increasing social benefit.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

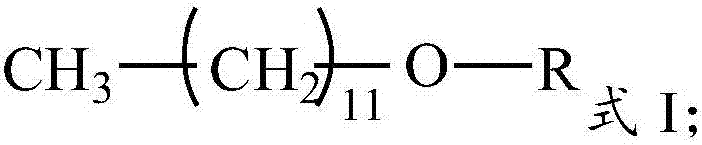

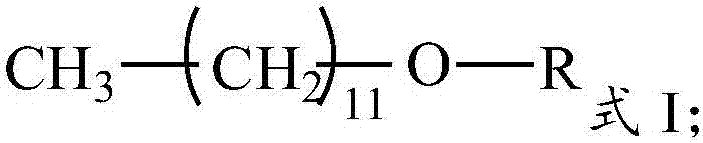

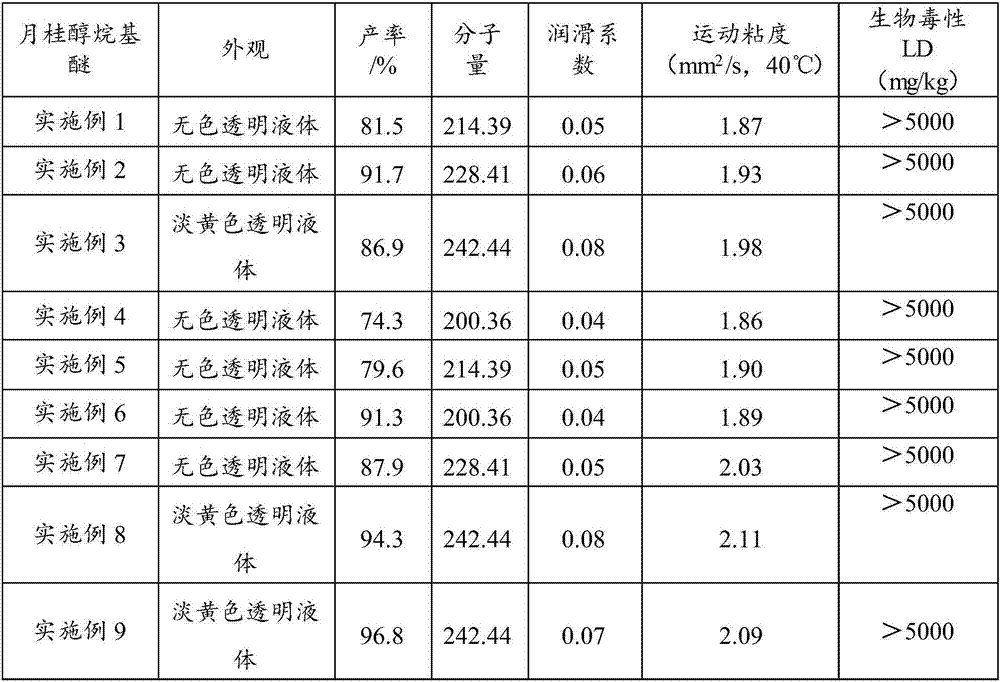

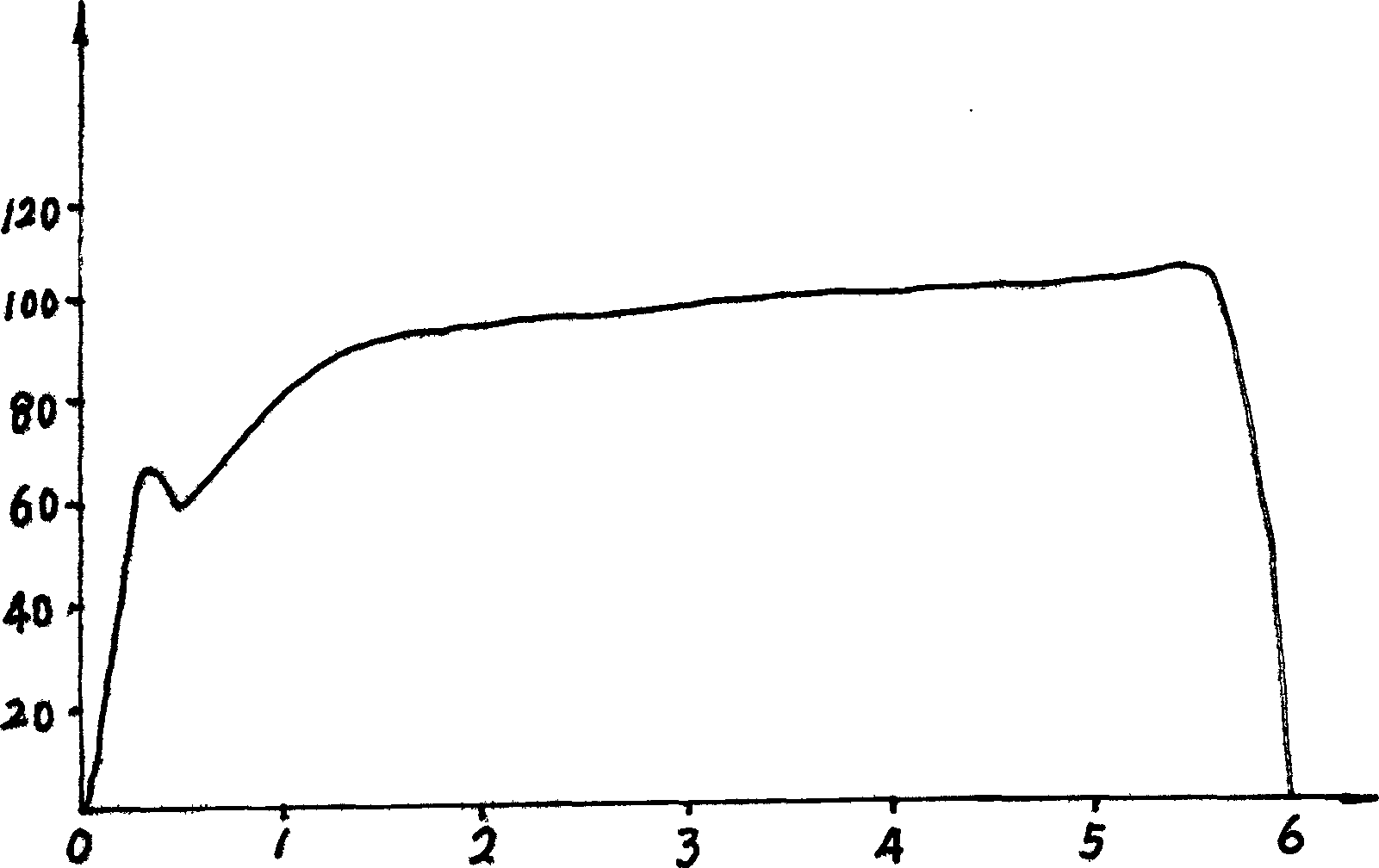

Laurinol alkyl ether, as well as preparation method and drilling fluid thereof

InactiveCN107304161AHigh reaction yieldGood product qualityDrilling compositionEther preparationTemperature resistanceDrilling fluid

The invention provides laurinol alkyl ether, which has a structure as shown in a formula I, wherein R is alkyl having the number of carbon atoms of 1-10. The invention further provides a method for preparing laurinol alkyl ether, which comprises the following steps: enabling laurinol, alkyl reagent and alkaline compound to react in the presence of a catalyst to obtain the laurinol alkyl ether. A drilling fluid is prepared from the laurinol alkyl ether by adopting the technical scheme. The laurinol alkyl ether has excellent inhibition, low viscosity, strong temperature resistance, hydrolytic stability and biodegradability, and can be used as a basic fluid for synthetic base drilling fluid. The preparation method has high reaction yield and good product quality, is simple in process and mild in condition, has a non-toxic, efficient and environment-friendly preparation process, and can be popularized and applied to catalytic esterification reactions.

Owner:SINOPEC SSC +1

Process for preparing polyvinyl chloride in 70.5 mcube polymeri reactor

A process for preparing polyvinyl chloride in 70.5 cu.m polymer reactor includes such steps as isolating oxygen, flushing inner surface of reactor by water, spraying detackifier by steam, flushing with water, sequentially adding buffering agent, vinyl chloride, hot water, disperser, composite trigger and chain transferring agent, polymerizing for 10 min, adding low-temp water to make reaction temp to be 49-64 deg.C, reacting until the conversion rate reaches 80%, adding stopping agent, terminating reaction, discharging slurry, recovering excessive vniyl chloride, steam stripping, dewatering and drying.

Owner:航锦锦西氯碱化工有限公司

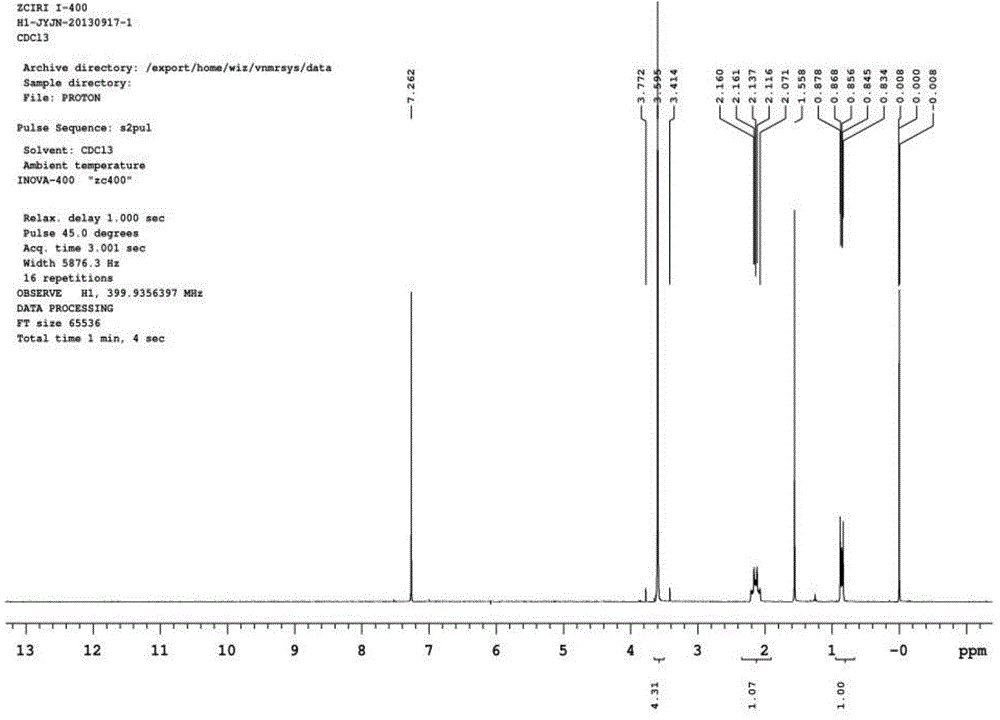

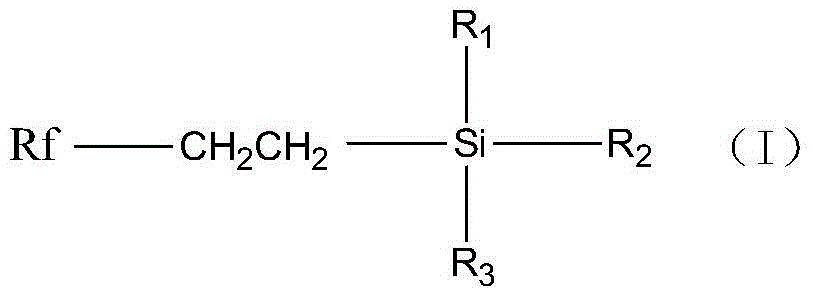

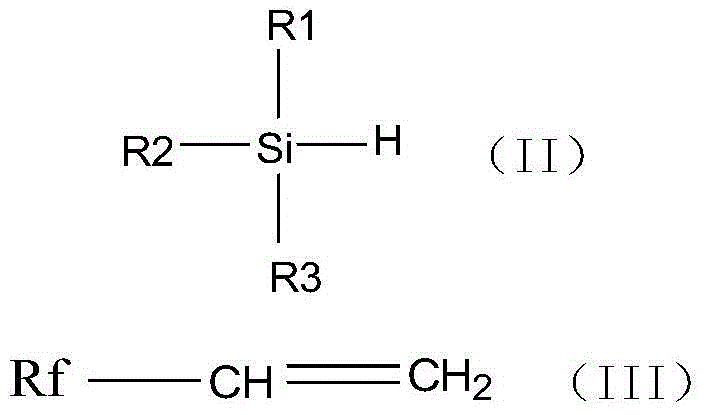

Fluoroalkyl alkoxy silane and preparation method thereof

InactiveCN104628759ALess corrosiveGood product qualityGroup 4/14 element organic compoundsSilanesStructural formula

The invention provides fluoroalkyl alkoxy silane and a preparation method thereof. The fluoroalkyl alkoxy silane has a structural formula (I) as shown in the specification, wherein substituents are defined in the specification. The fluoroalkyl alkoxy silane prepared by the invention has the advantages of good quality, strong stability, high yield of the preparation method, safety and environmental protection.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

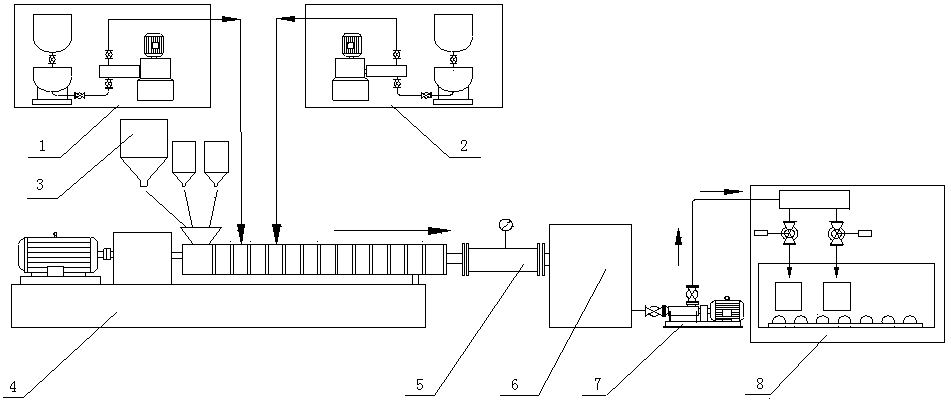

Bagged high-viscosity asphalt as well as production method and device thereof

InactiveCN103408958AEasy to transportGood product qualityRoads maintainenceBuilding insulationsPOLYETHYLENE WAXPressure regulator

The invention belongs to the technical field of pavement materials, and in particular relates to bagged high-viscosity asphalt as well as a production method and device thereof. The bagged high-viscosity asphalt comprises the components including road asphalt, polymer, petroleum resin, aromatic oil (or rubber oil), polyethylene wax, an antioxidant, an initiator and a grafting agent. The production method comprises the following steps of weighing the components by using a weighing system; adding the components into a screw extruder; mixing, shearing and extruding at a certain temperature; preparing a high-viscosity asphalt product through a temperature regulator and a pressure regulator; and treating the high-viscosity asphalt product in a finished product tank, and finally filling the product into packaging bags. When in use, the bagged high-viscosity asphalt is put into an asphalt melting pot of which the temperature is 160 DEG C and is driven into a stirring cylinder in an asphalt concrete stirring plant connected with the asphalt melting pot through an asphalt pump after being completely melted, and a graded stone material is added into the stirring cylinder to prepare a high-viscosity asphalt mixture. The preparation process of the bagged high-viscosity asphalt is advanced and simple to operate, the product is excellent in performance and convenient to use and transport, and the performance index of the prepared high-viscosity asphalt mixture can completely meet the technical requirements for paving drainage asphalt pavements and steel bridge surface asphalt pavements.

Owner:李振华

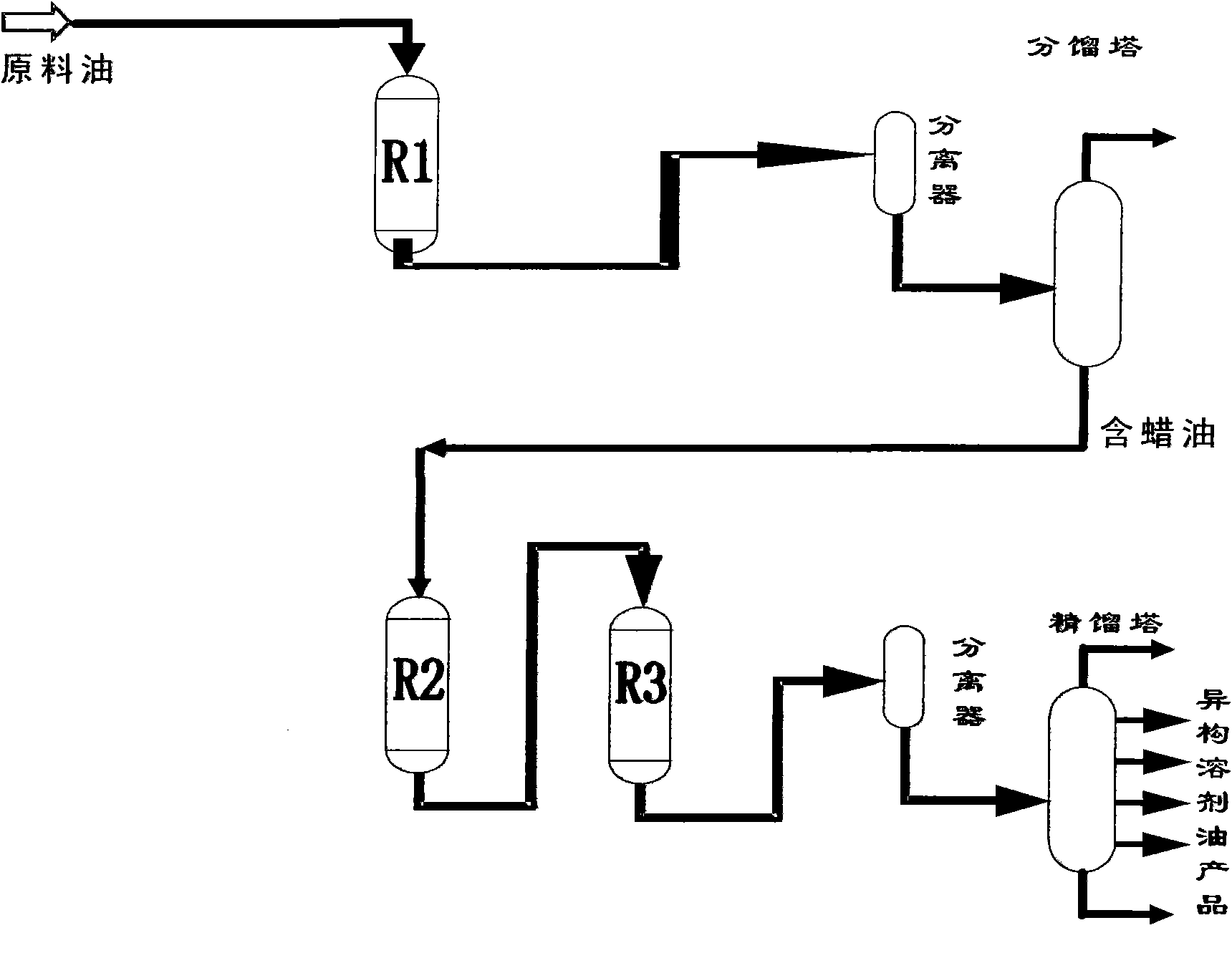

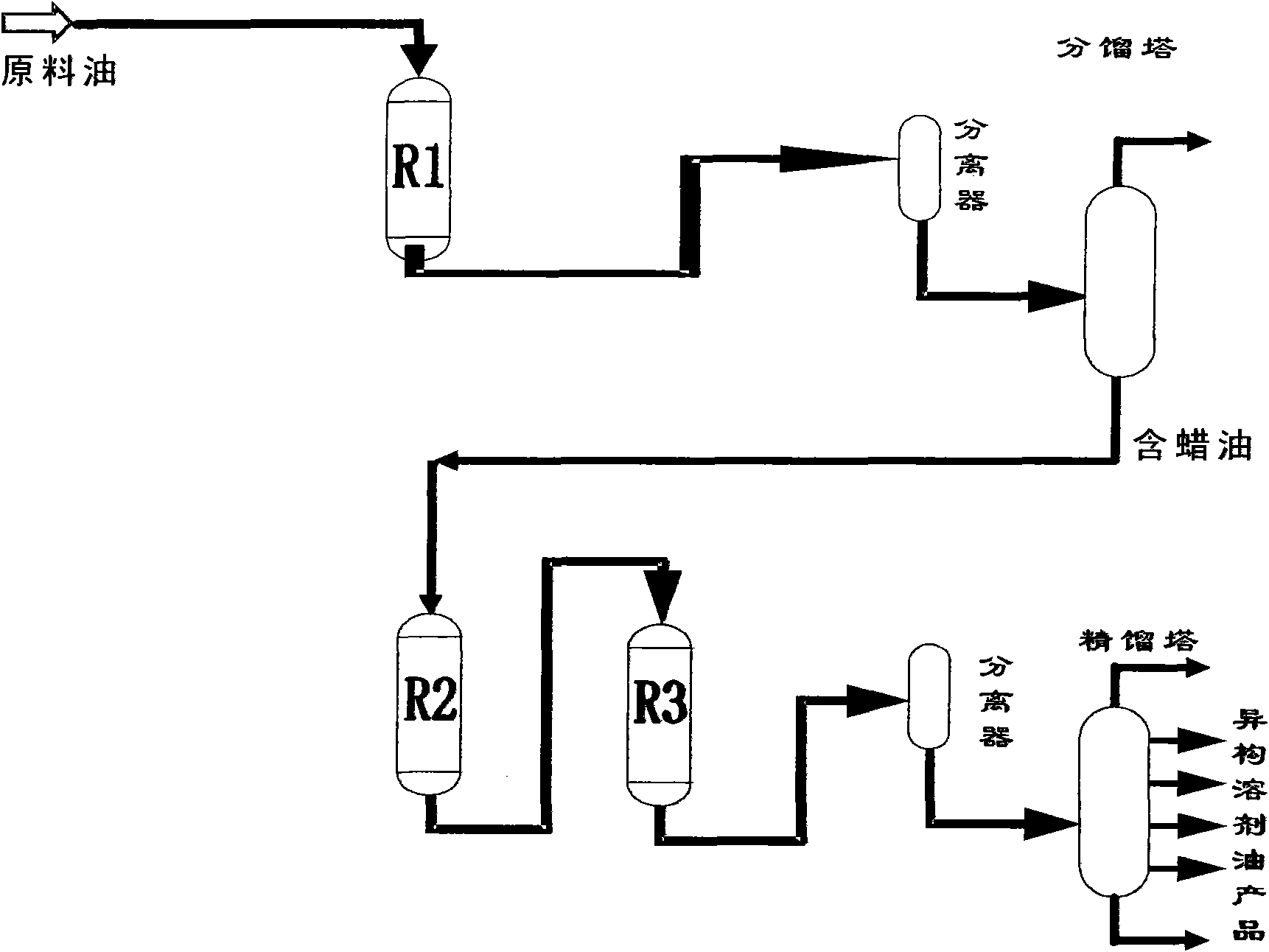

Method for manufacturing isoparaffin solvent oil

ActiveCN101921621AStrong raw material adaptabilityGood product qualityRefining to change hydrocarbon structural skeletonTreatment with hydrotreatment processesSolventChemistry

The invention discloses a method for manufacturing an isoparaffin solvent oil. By utilizing distillate or light deasphalted oil and the like as a raw material, the isoparaffin solvent oil is manufactured by the integrated process of hydroprocessing-hydrogenation isomerization-hydrofinishing. With the method of the invention, high-quality isoparaffin solvent oil products of various fractions can be manufactured with ordinary raw oil. The method has the characteristics of good raw material adaptability, good quality of products, flexible manufacturing and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment

InactiveCN102190737AGood product qualitySimplify the production processFood preparationFunctional foodChemistry

The invention discloses a method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment, which comprises the following steps of: regulating the pH value of 30 to 45 weight percent starch milk at the temperature of between 25 and 50DEG C to be 10.5-12.5, adding sodium trimetaphosphate / sodium tripolyphosphate in an amount which is 0.2 to 12 percent based on the weight of the dry basis of starch, keeping for 30 to 240 minutes, drying until the weight percent of water is 15-45 percent, and performing heat moisture reaction at the temperature of between 100 and 140DEG C for 1 to 72 hours in a heat moisture reactor; and washing, drying, crushing and sieving to obtain a product. In the method, starch is taken as a raw material, the content of resistant starch is greatly improved by a physiochemical means, a process of preparing the resistant starch is simplified, the efficiency is effectively improved, waste liquor and pollution are avoided in the production process, and the energy consumption is reduced. The prepared resistant starch can serve as a functional food material and biochemical medicine carrier.

Owner:SOUTH CHINA UNIV OF TECH

Method for making high intensity non-magnetic non-corrodible steel tauten screw rod

InactiveCN101113749AGood product qualityLow costMagnetic circuit stationary partsScrewsCorrosion resistantNickel

The invention relates to metallurgy field, in particular to a manufacturing method of a corrosion resistant, high strength non-magnetic stainless pulling bolt. The manufacturing method is that: original waste steel with a weight ratio accounted for 70 to 80 percent of the whole material, and nitride with a weight ratio accounted for 20 to 30 percent of the whole material are added during the melting process of steel rods and steel ingots. The original waste steel refers to the first stage waste steel with less impurities that is cut after the ore is smelt into steel, and has the advantages of high manganese and high nitrogen instead of nickel, good quality, lowering cost by 30 to 50 percent, and the intensity of manufactured pulling screws Sigma b is more than or equal to 1000Mpa, magnetic permeability Mu is less than or equal to 1.005, roughness Ra is equal to or less than 0.8Mum, the invention can meet the technical requirements of large turbine generators with a power of 600Mkw or 1000Mkw.

Owner:上海加宁新技术研究所

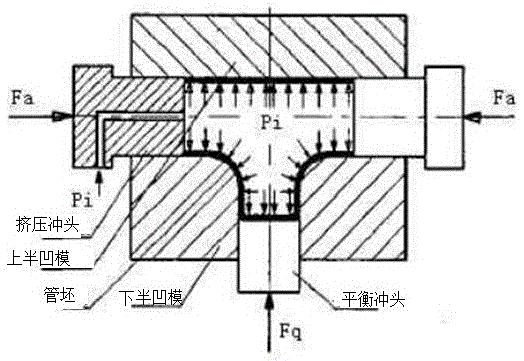

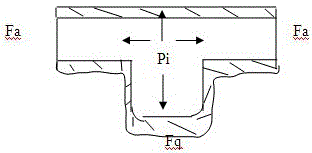

Preparation method for bi-metal composite t-branch pipe

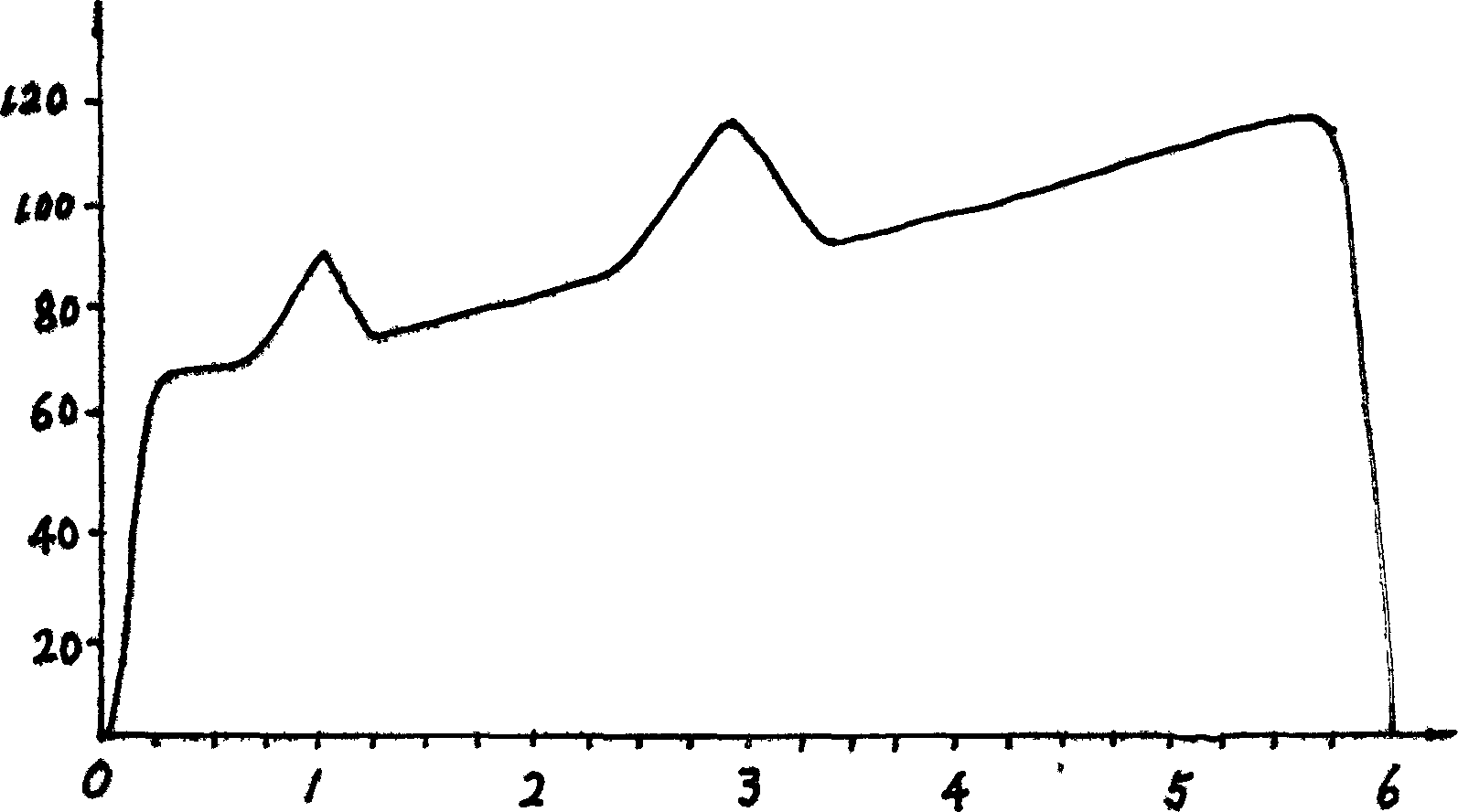

InactiveCN105537364AUniform distribution of bulging pressureGood product qualityLiquid pressureEngineering

The invention relates to a preparation method for a bi-metal composite t-branch pipe. The preparation method comprises the following steps that 1, an inner metal pipe and an outer metal pipe which are made of different materials are prepared and assembled together in a sleeving mode; 2, the metal pipes which are assembled together in the sleeving mode are placed in a tee machine mold; 3, liquid which is purified water is injected into the inner metal pipe; and 4, a pressurization system for equipment is started, and internal pressure Pi is provided through the pressurization system for the equipment; meanwhile, two horizontal side cylinders of a hydraulic machine carry out centering movement synchronously for squeezing a pipe blank, pressure Fa is provided by a left oil cylinder and a right oil cylinder, and balance force Fq of the end of a branch pipe is provided by an upper oil cylinder; the size of the pipe blank is decreased after the pipe blank is squeezed, the pressure of the liquid in the pipe blank is increased as the size of the pipe blank is decreased, and (meanwhile, the pressurization system can be determined whether to conduct pressurization or not according to the recombination and deformation conditions of the pipe blank); as the pressure in the pipes is increased, the elastic deformation state of the inner pipe is converted to a plastic deformation state, the inner pipe is attached to the outer pipe tightly, and the inner pipe and the outer pipe are attached together tightly; when the pressure in the pipes is further increased and reaches the pressure which is required when the t-branch pipe is expanded out, a metal material flows along an inner cavity of the mold and is expanded out of the branch pipe under the dual action of the side cylinders and the liquid pressure in the pipe blank.

Owner:LIANYUNGANG ZHENZHUHE PETROCHEM PIPE FITTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com