Horizontal and vertical feed burr-free bar cutting device

A cutting device, burr-free technology, used in positioning devices, feeding devices, clamping and other directions, can solve the problem of inability to cut with solid bars, and achieve the effect of saving cutting time, uniform cutting and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

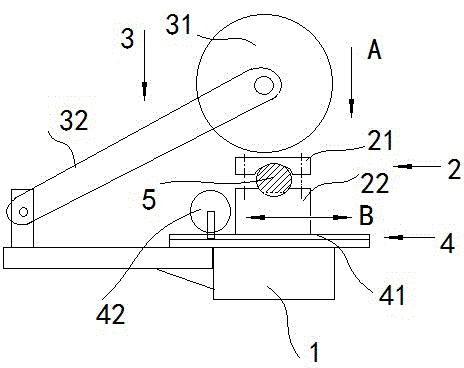

[0029] Embodiment 1: as figure 1 As shown, a burr-free bar cutting device with vertical and horizontal feeds includes a machine base 1, an upper cutter mechanism connected to the machine base 1, and a bar clamping mechanism 2 arranged longitudinally along the machine base 1. The upper cutter The mechanism includes an upper cutter frame 3 hinged with the machine base 1, the upper cutter frame 3 is equipped with a main motor and an upper cutter 31, and a joystick is connected to the movable end of the upper cutter frame 3; The following cutter mechanism is arranged below the knife mechanism, and the lower cutter mechanism includes a guide rail 41 arranged laterally along the machine base 1, and the lower cutter frame 4 is slidably connected on the guide rail 41, and the lower cutter motor is installed on the lower cutter frame 4. And following cutter 42, following cutter rest 4 is driven by the transmission mechanism that is connected on the support 1.

[0030] figure 1 Th...

Embodiment 2

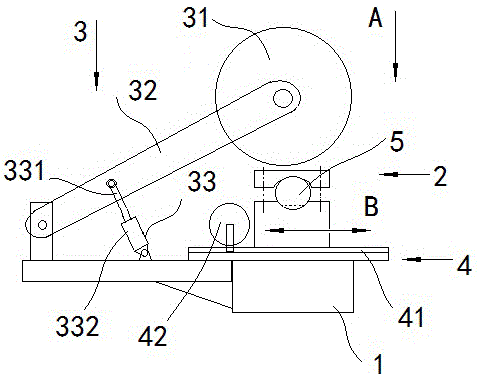

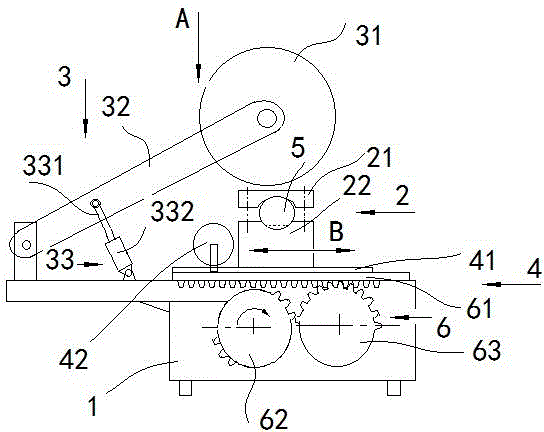

[0032] Embodiment 2: The upper cutter frame 3 is hinged with the machine base 1 through the swing arm 32, the middle part of the swing arm 32 is pinned to the piston rod 331 of the swing arm oil cylinder 33, and the cylinder body 332 of the swing arm oil cylinder 33 is hinged with the machine base 1. The piston rod of the swing arm oil cylinder 33 drives the swing arm of the upper cutter holder, so that the upper cutter is pressed to the bar material 5, and the feed force of the upper cutter 31 is provided, as figure 2 shown.

Embodiment 3

[0033]Embodiment 3: The transmission mechanism that drives the lower cutter frame to move is composed of a rack and pinion transmission mechanism, the rack is fixedly connected to the lower side of the lower cutter frame, the gear shaft is connected to the frame through a bearing, and the motor is connected to the gear shaft through a speed change mechanism For the control of the motor, the conventional method is used, and the motor can be rotated forward or reversely with a changeover switch, and the cutter head is moved forward or reversed in the corresponding direction, and the rest of the structure is the same as that of embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com