Patents

Literature

383results about How to "Reduce cutting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

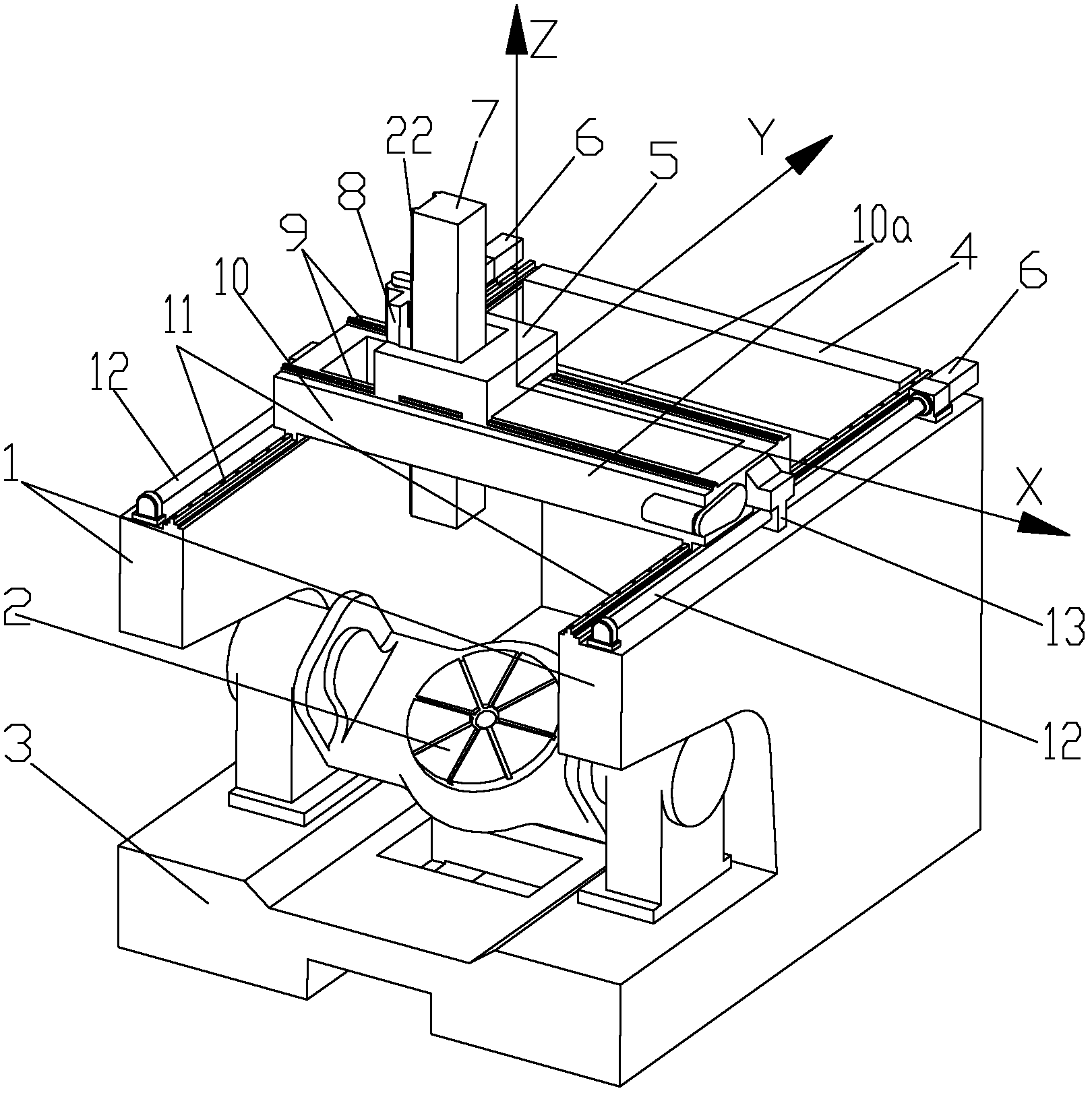

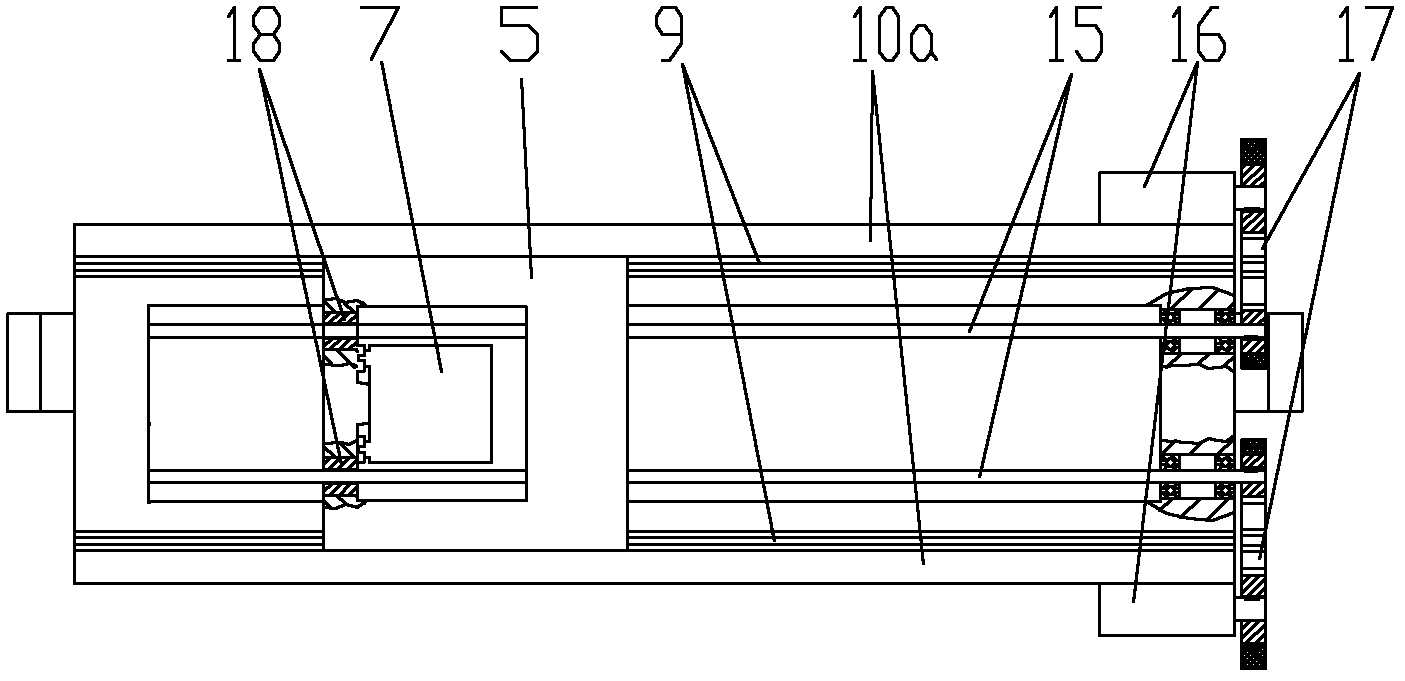

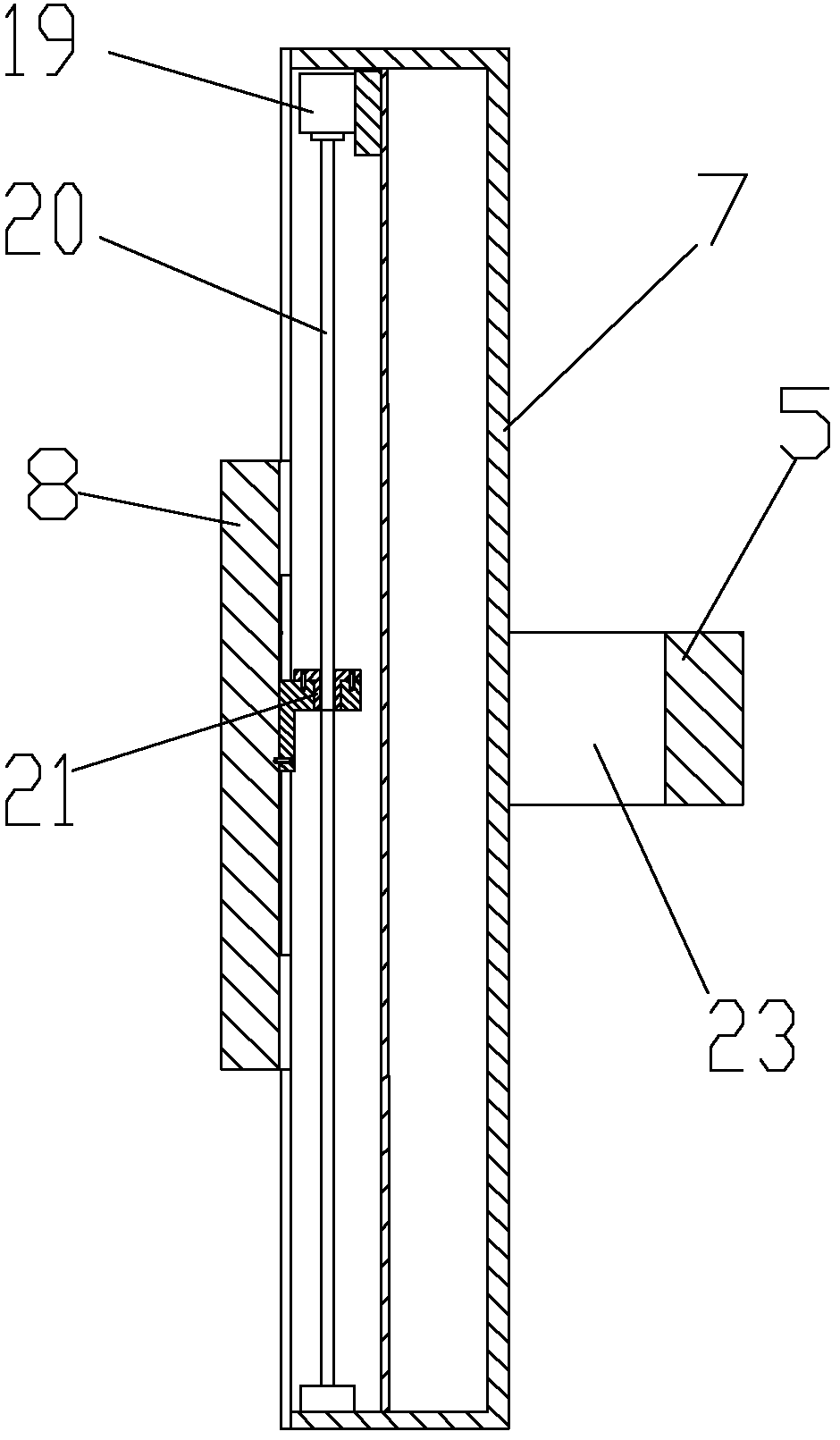

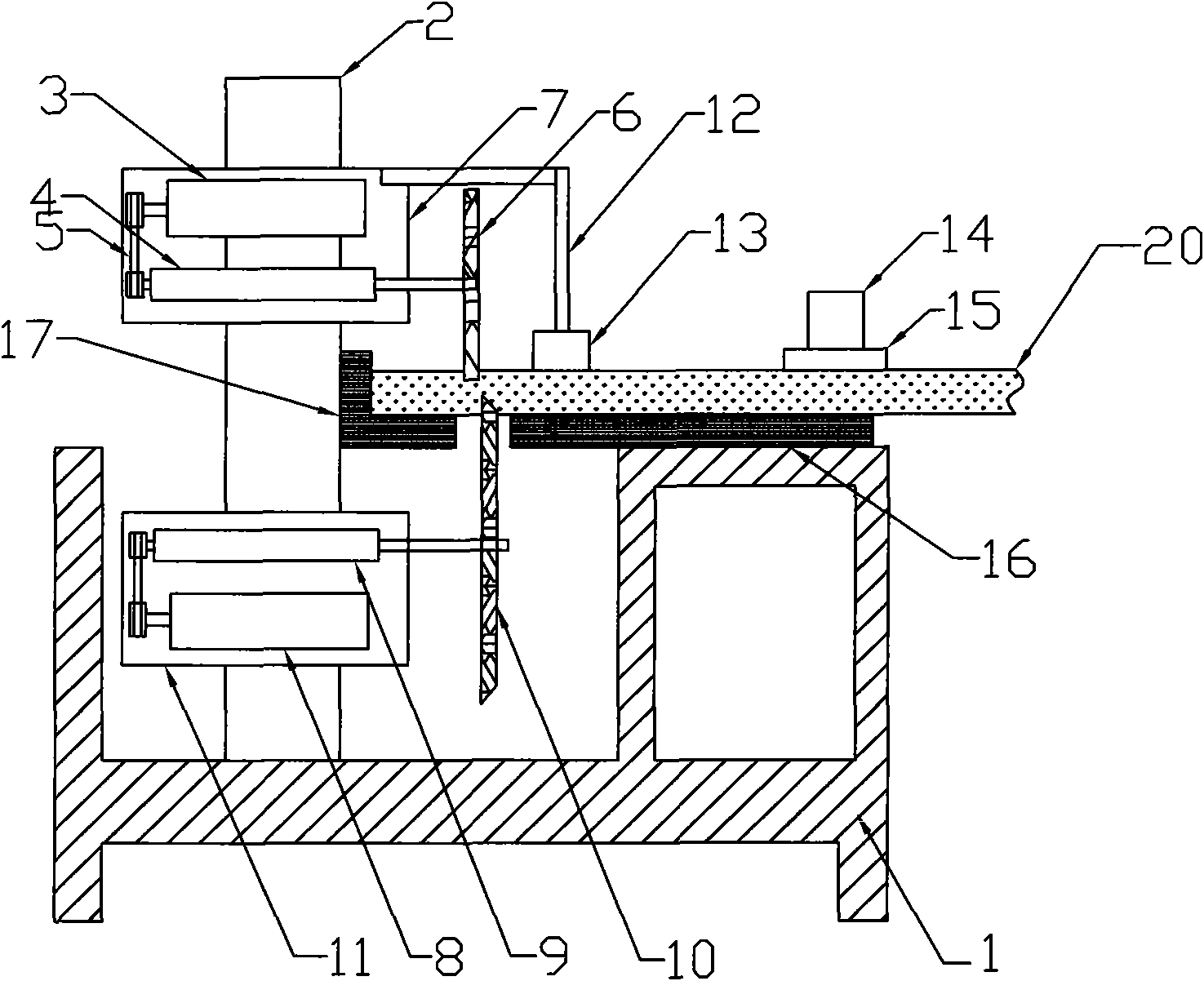

Small high-speed five-axis linkage machine tool

InactiveCN102632422AGuaranteed stabilitySmall sizeMachine tool componentsFeeding apparatusBridge typeEngineering

The invention discloses a small high-speed five-axis linkage machine tool, which comprises a foundation structure, a spindle box component and a cradle type worktable. The spindle box component is supported on the foundation structure, and a crossbeam with a frame-shaped structure is arranged on two upright columns to form a bridge-type portal structure. The torque bearing capacity of the crossbeam is improved, the small high-speed five-axis linkage machine tool has all advantages of a five-axis linkage machine tool in the prior art, and carries identical machining reacting force, the volume of a structural part is reduced, and the weight of the structural part is greatly lightened; a spindle box is positioned between two transverse rods of the frame-shaped crossbeam, overturning moment is eliminated, and the stability of the machine tool can be guaranteed; in addition, sizes of various components are greatly reduced on the premise of identical machining capacity, and the stroke of the machine tool can be large in the design; and by the aid of the structure, the machining precision is greatly improved, the machining range is greatly expanded, better dynamic characteristics and higher feeding speed and higher cutting speed can be realized, cutting and machining time is greatly shortened, better surface machining quality is obtained, and machining efficiency is enhanced.

Owner:CHONGQING UNIV

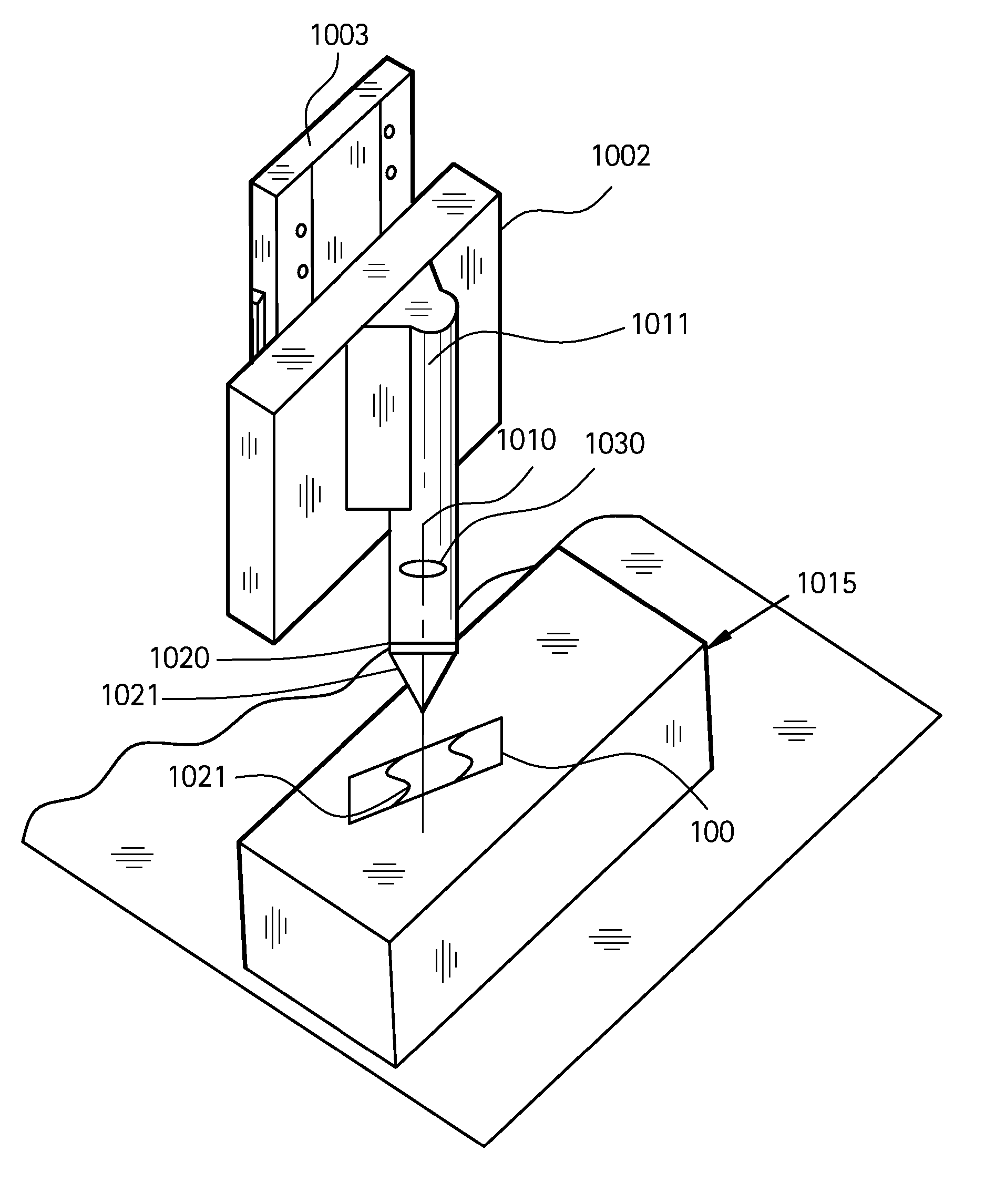

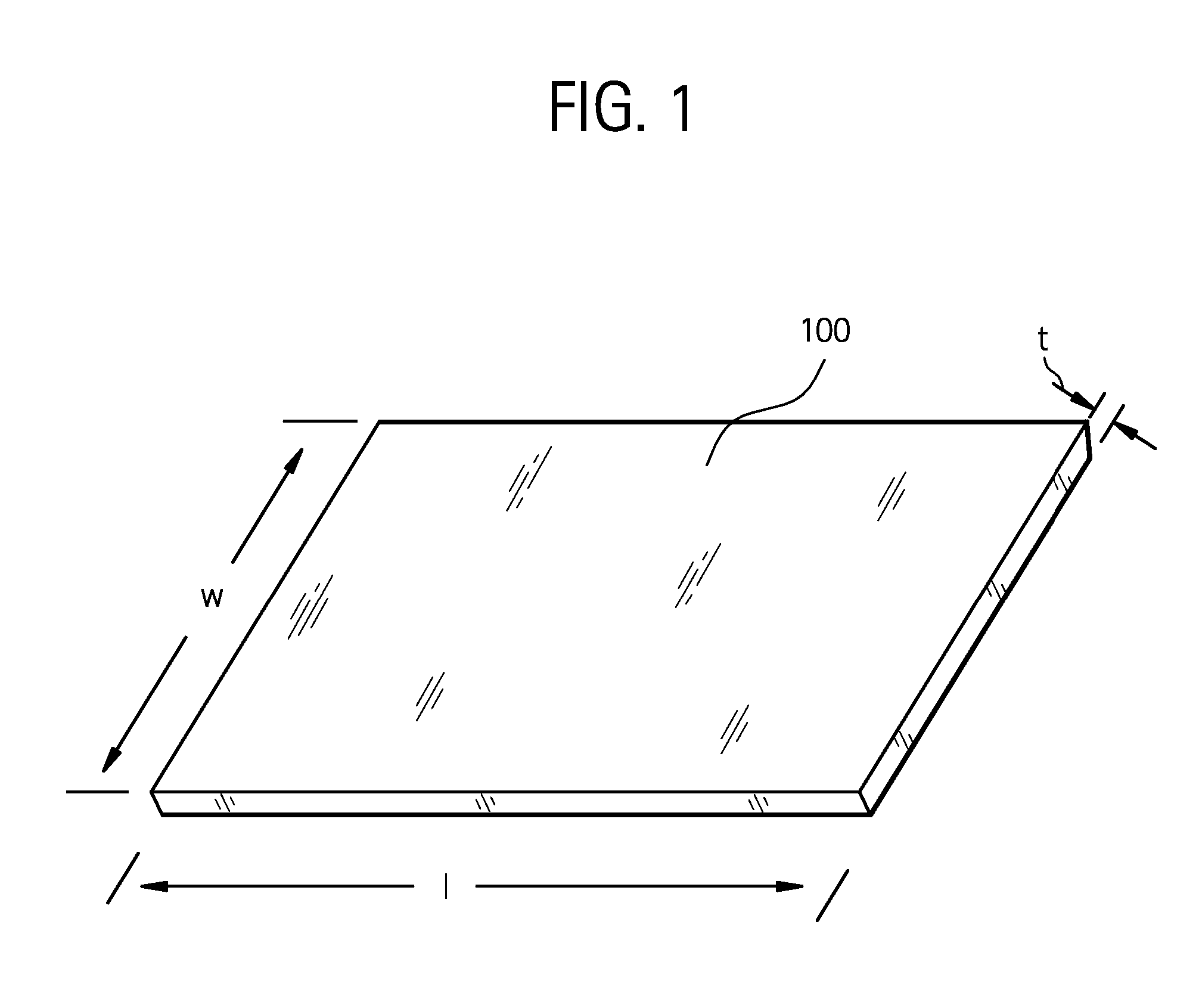

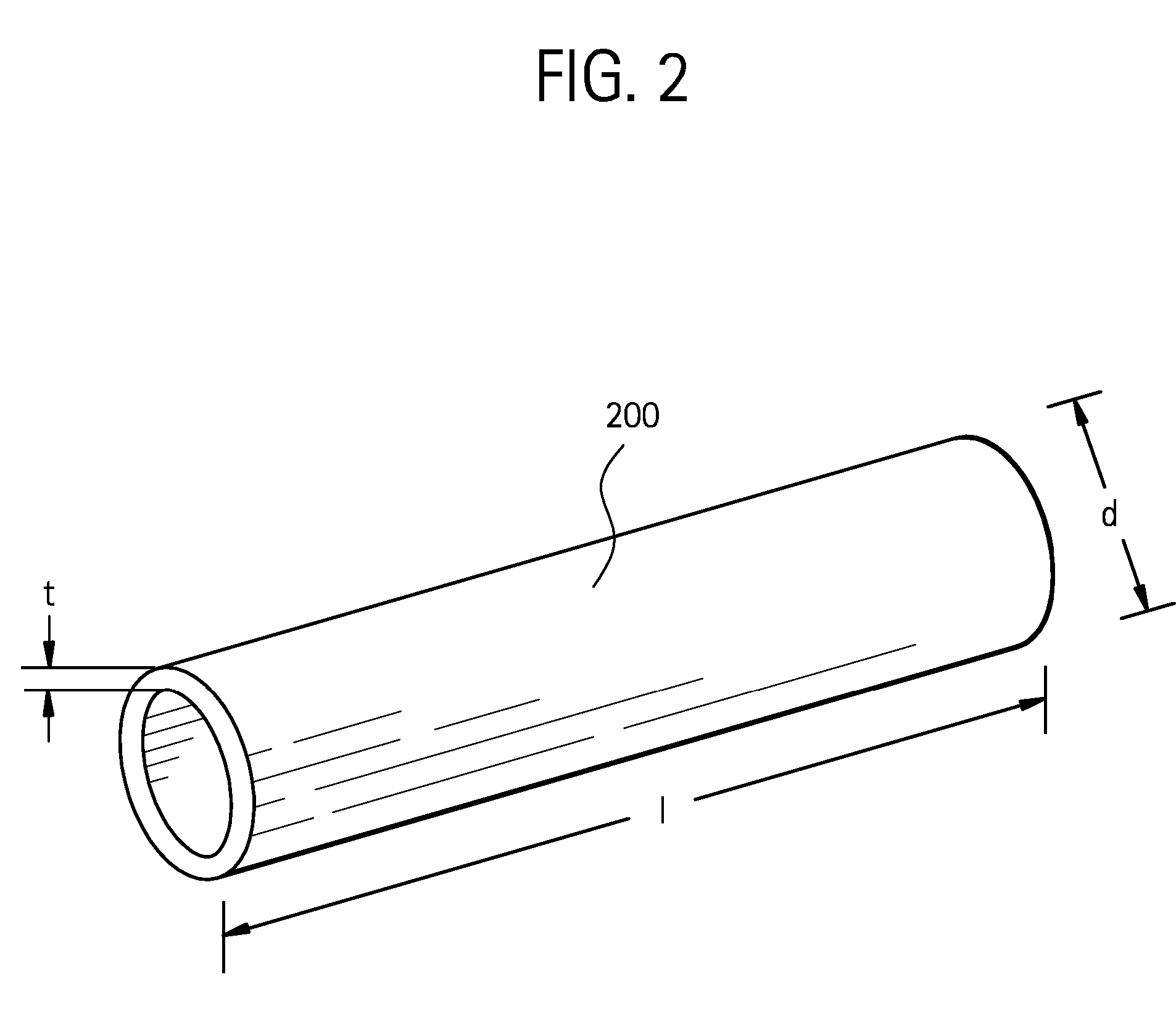

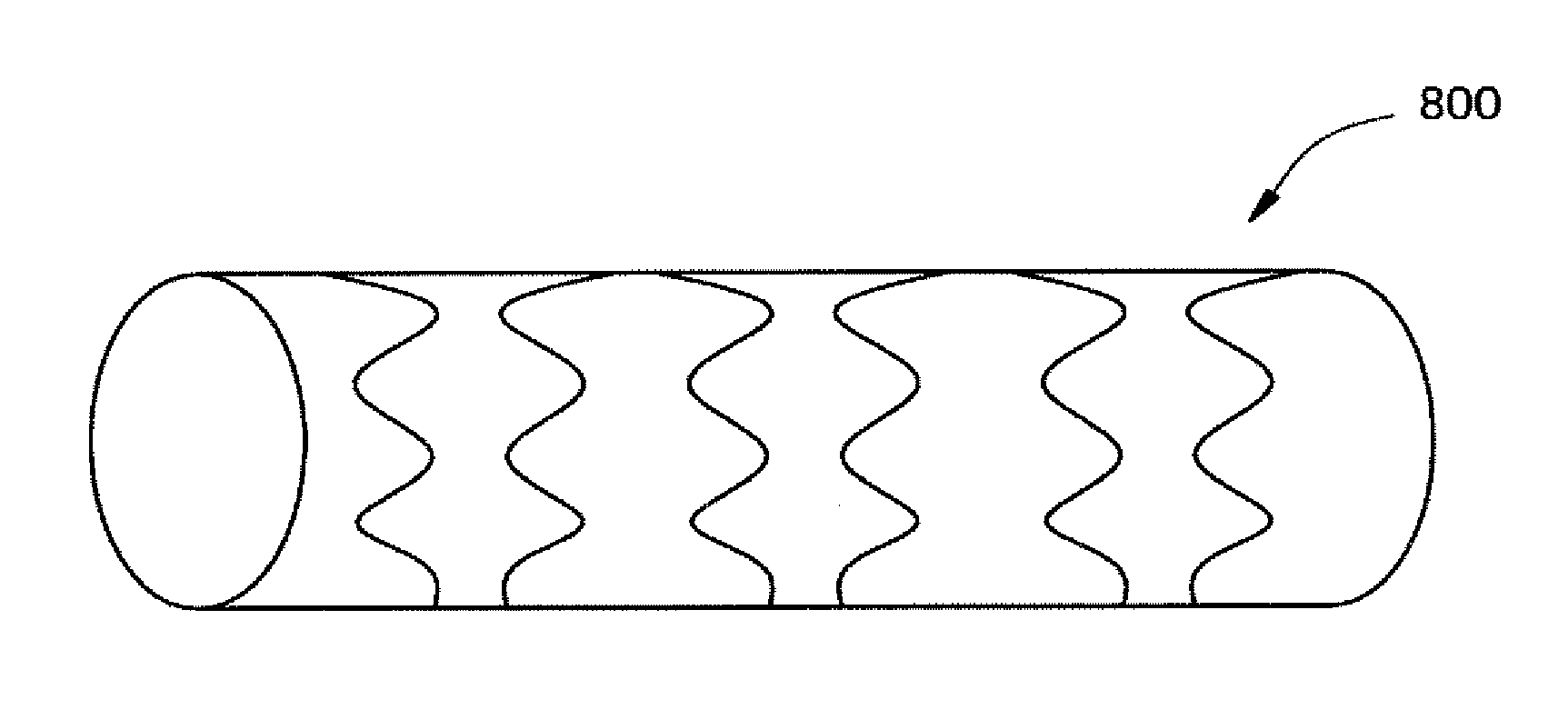

Laser cut intraluminal medical devices

InactiveUS20070142903A1Eliminate the effects ofSimply and readily achievedStentsBlood vesselsMedicineActive agent

Laser cut bioabsorbable intraluminal devices or stents and methods for forming such an intraluminal device or stent. A precursor sheet or tube of bioabsorbable material is laser cut in the presence of an inert gas to form an intraluminal medical device or stent having a desired geometry or pattern. The device or stent may comprise a helical, or other shape, having the laser cut geometry or pattern imparted thereon. The device or stent may further comprise drugs or bio-active agents incorporated into or onto the device or stent in greater percentages than conventional devices or stents. Radiopaque materials may be incorporated into, or coated onto, the intraluminal device or stent. Precise geometries or patterns are simply and readily achievable using the laser cutting methods in the presence of an inert gas while minimizing damage to the precursor materials.

Owner:CORDIS CORP

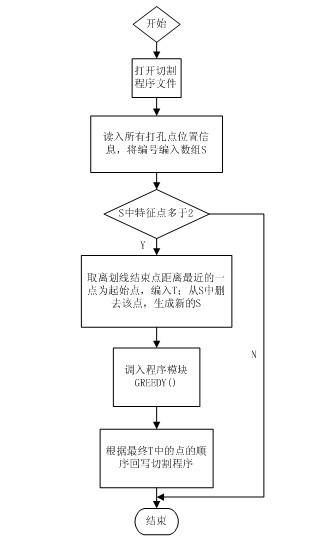

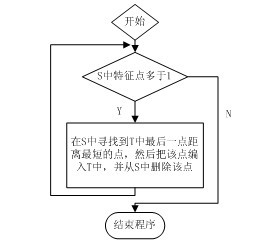

Seeking route plan optimizing method of laser cutting machine

InactiveCN102023611AHigh degree of automationPrecise positioningLaser beam welding apparatusNumerical controlPunchingArray data structure

The invention provides a seeking route plan optimizing method of a laser cutting machine. The method comprises the following steps that: 1, a program writes the information of all the 'punching points' into an array S according to sequence; 2, the points in S are judged and optimally sequenced, if the points are less than 2, the program is terminated, and if the points are more than 2, the program is continued; 3, the point closest to a ruling end point is taken as a start point, is written into an array T and is then deleted from the array S to generate a new array S; 4, a greedy program module GREEDY () is called until all the points are processed by the greedy method to generate a new route point array T; and 5, a cutting program is written back according to the sequence of the punching point optimized in the array T to acquire the optimized cutting program. By the method provided by the invention, the automation degree of the laser cutting machine can be improved; the positioning is accurate; the idle stroke is shortened to the largest extent; the cutting time is shortened; and the working efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

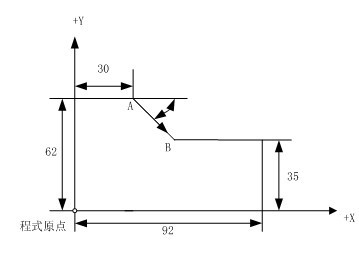

Numerical control processing parameter optimizing method

InactiveCN102331749AOptimize cutting parametersReduce cutting timeProgramme controlComputer controlSwarfTool path

The invention provides a numerical control processing parameter optimizing method. The numerical control processing parameter optimizing method is used for optimizing a feeding speed, and comprises the following steps of: reading a path file of a numerical control tool, and dividing a motion path of the tool into a plurality of small segments, wherein the dimension of each segment is 0.25-0.5 folds of the diameter of the tool; and distributing an optimal feeding rate as for respective cutting conditions (cut-in, pick-up arc, cut-out and empty cutting) according to the quantity (cutting depth X cutting width X length of the segment) of cut material in each small segment so as to generate a new tool path, wherein the new path is the same as the original path with increased feeding rate. Compared with the prior art, cutting parameters are optimized; and other cutting performances are also obviously enhanced at the same time as cutting time is greatly saved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Laser cut intraluminal medical devices

InactiveUS20080033532A1Eliminate the effects ofSimply and readily achievedBlood vesselsWelding/soldering/cutting articlesActive agentLaser cutting

Laser cut bioabsorbable intraluminal devices or stents and methods for forming such an intraluminal device or stent. A precursor sheet or tube of bioabsorbable material is laser cut in the presence of an inert gas to form an intraluminal medical device or stent having a desired geometry or pattern. The device or stent may comprise a helical, or other shape, having the laser cut geometry or pattern imparted thereon. The device or stent may further comprise drugs or bio-active agents incorporated into or onto the device or stent in greater percentages than conventional devices or stents. Radiopaque materials may be incorporated into, or coated onto, the intraluminal device or stent. Precise geometries or patterns are simply and readily achievable using the laser cutting methods in the presence of an inert gas while minimizing damage to the precursor materials.

Owner:DAVE VIPUL BHUPENDRA

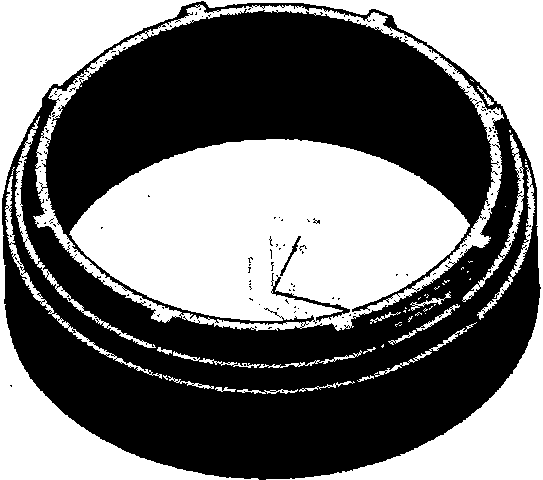

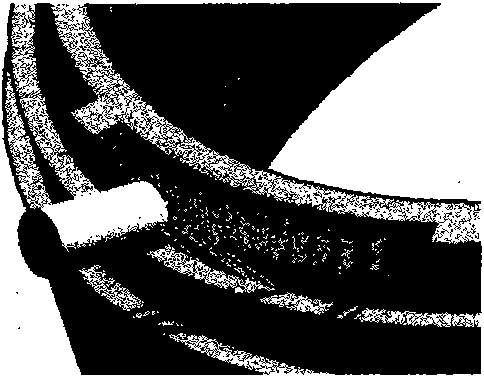

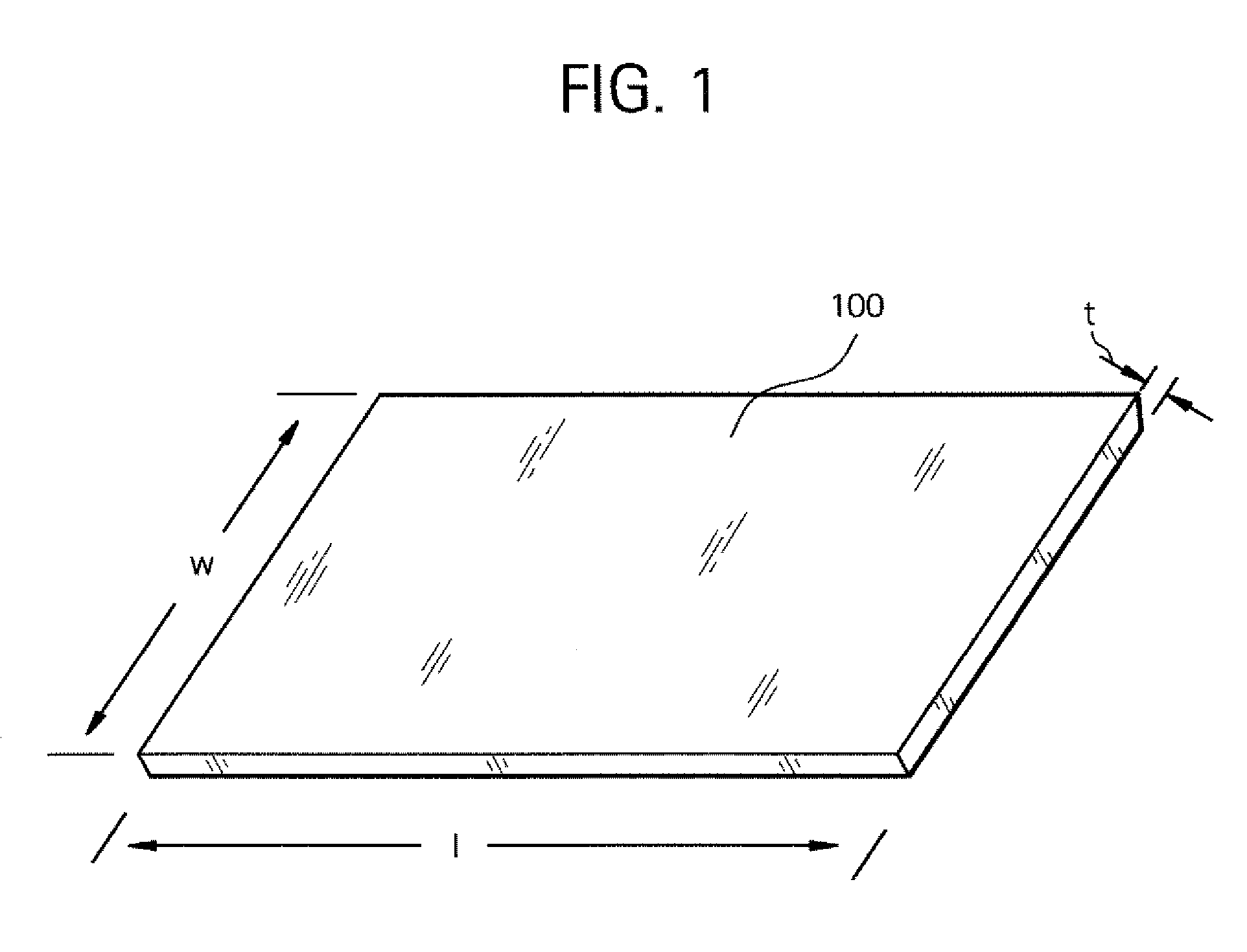

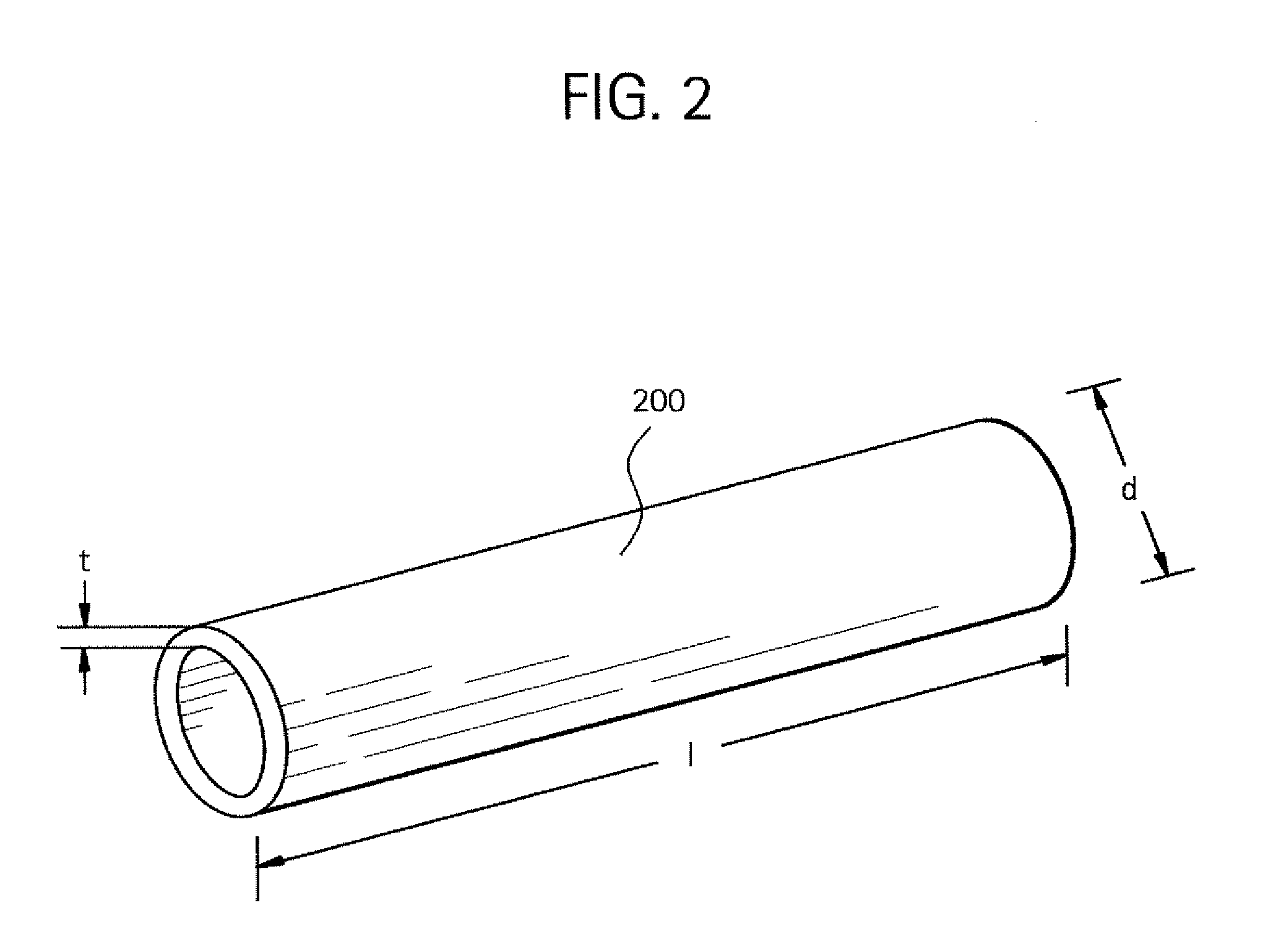

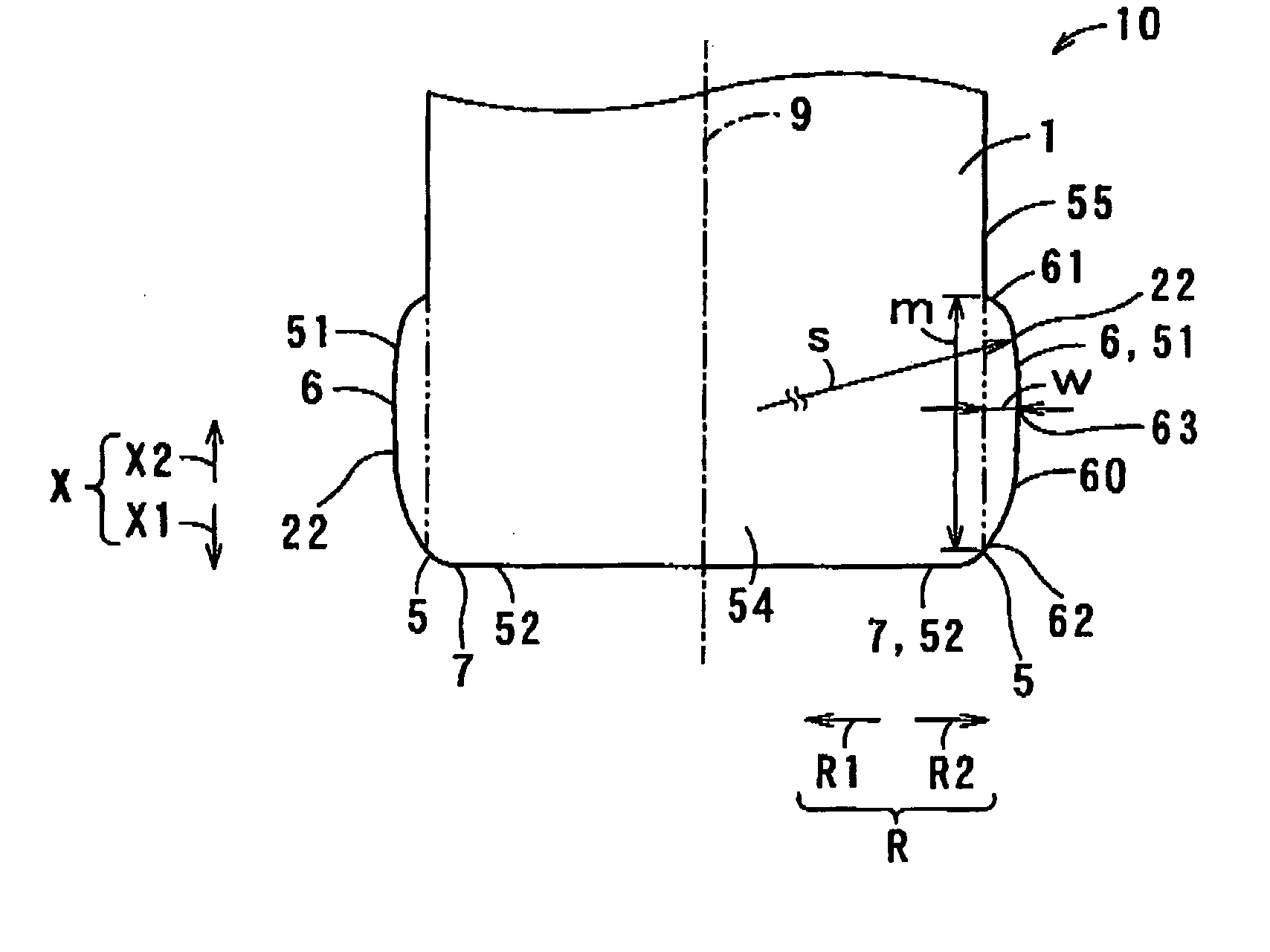

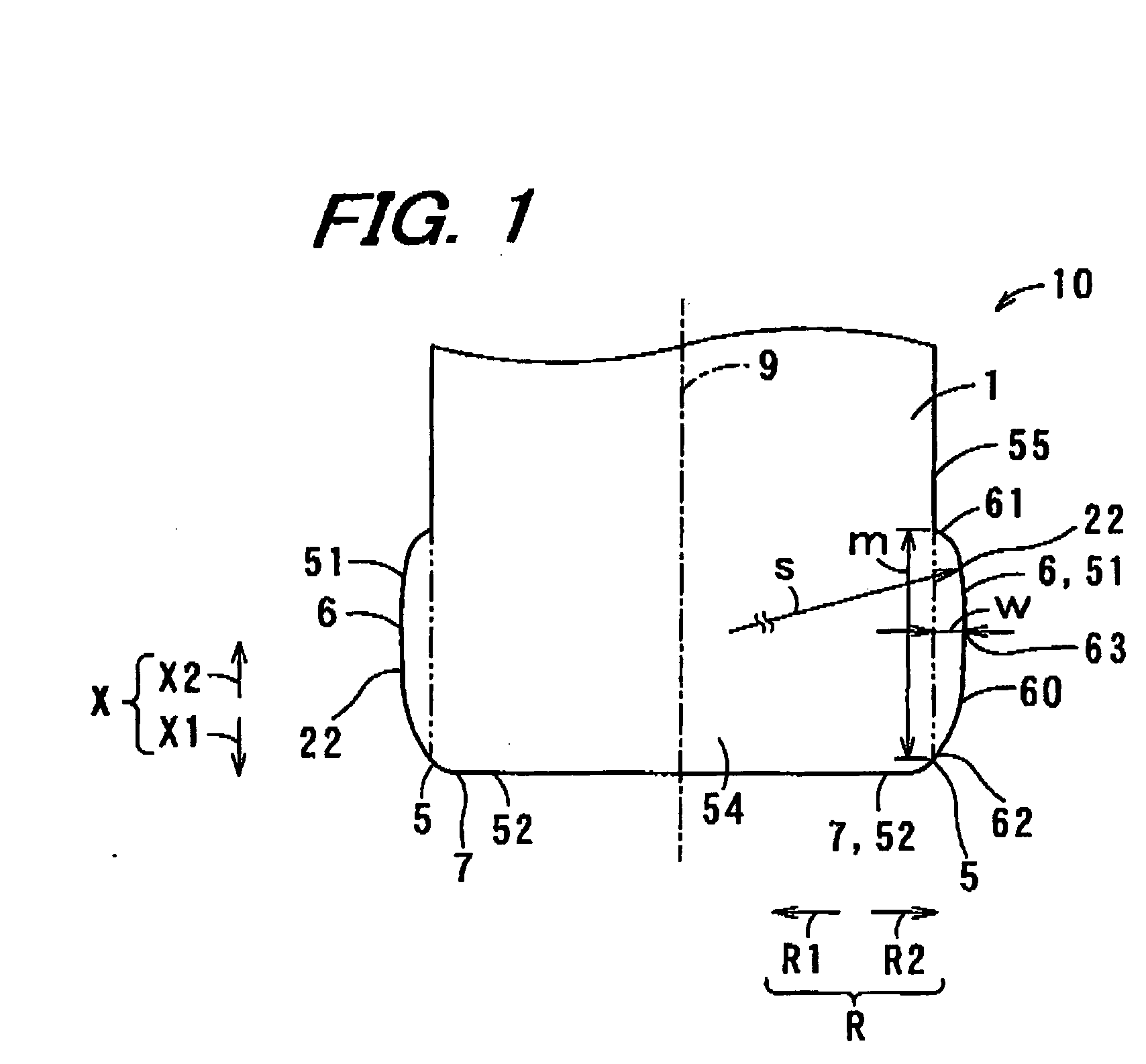

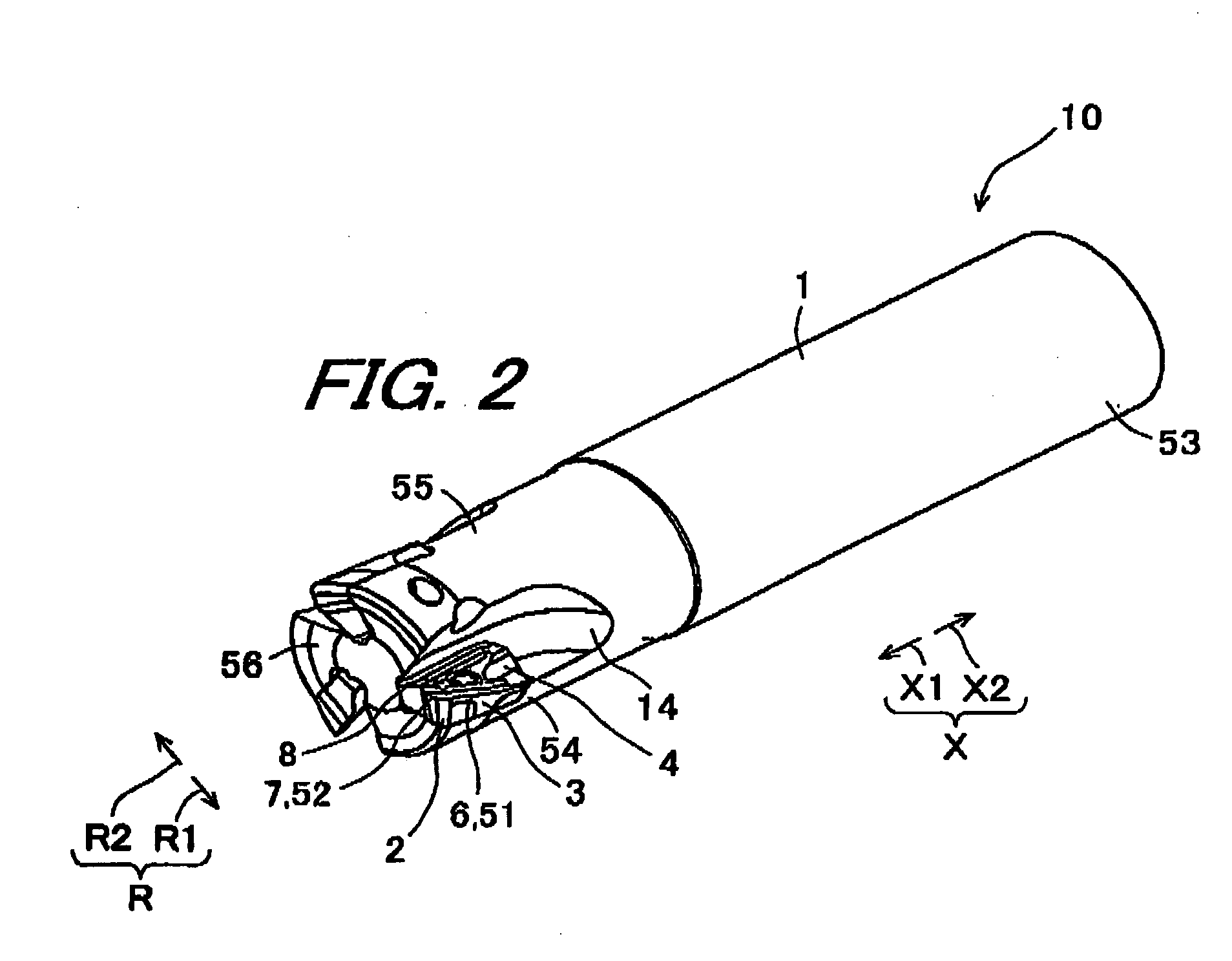

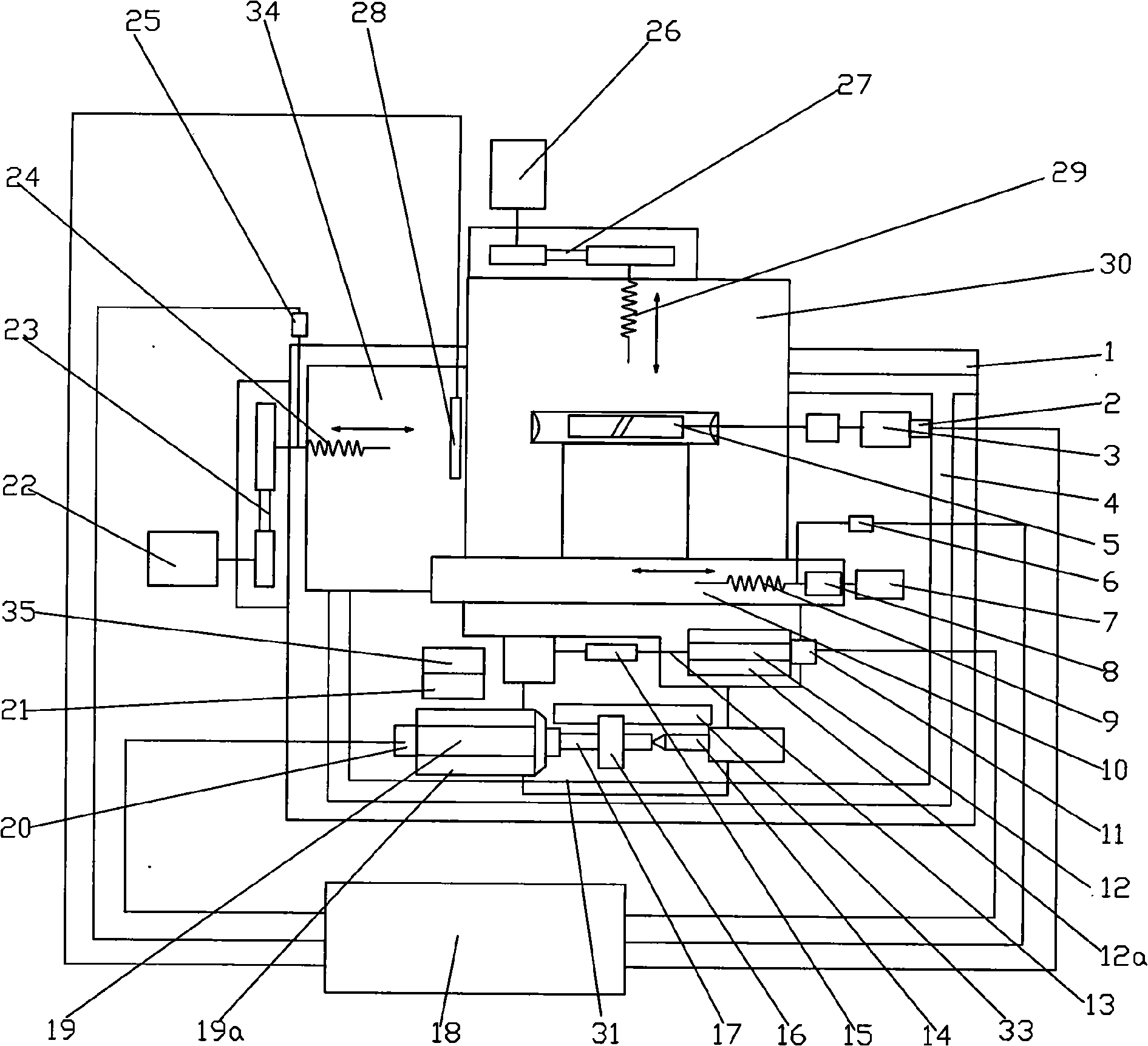

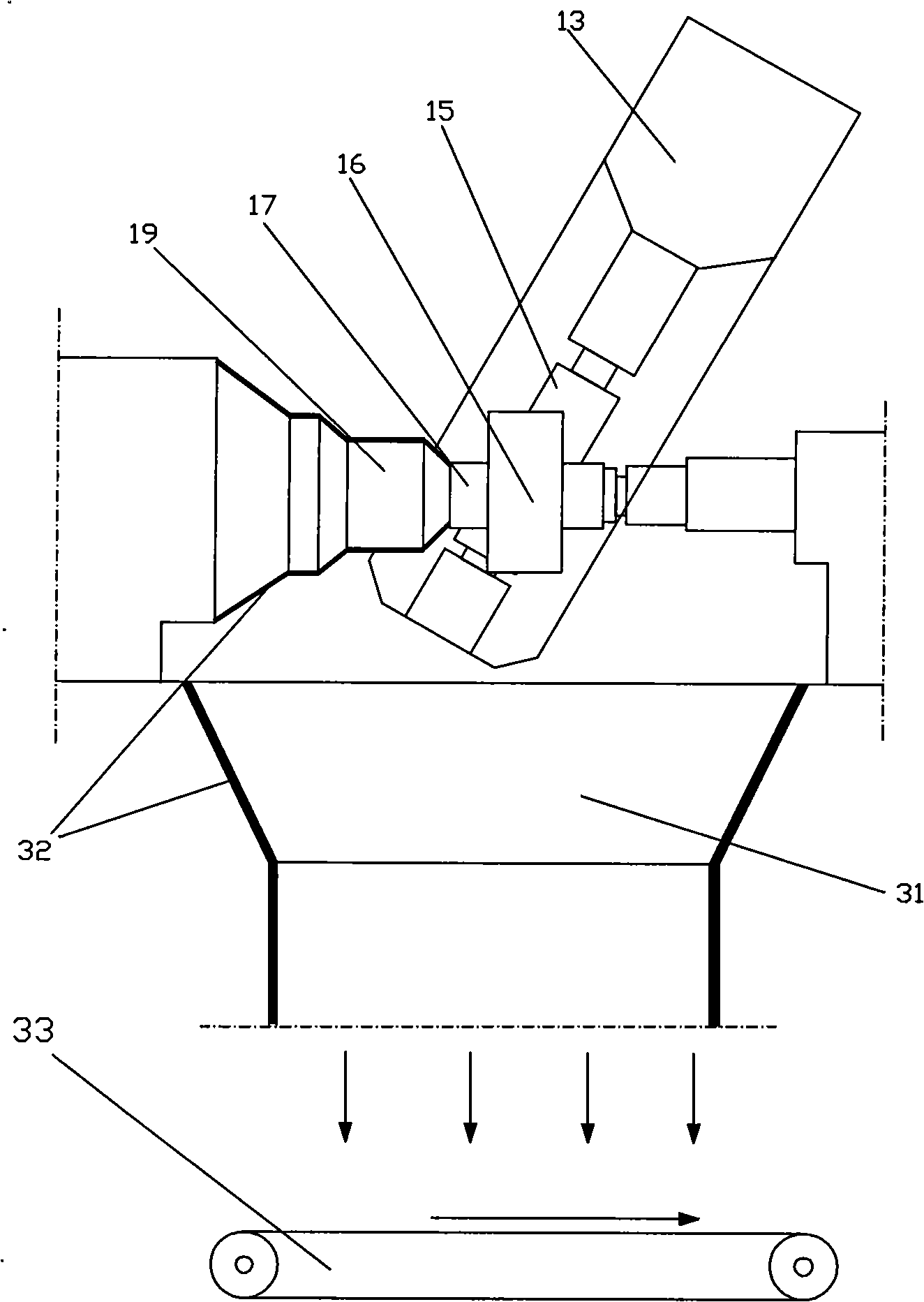

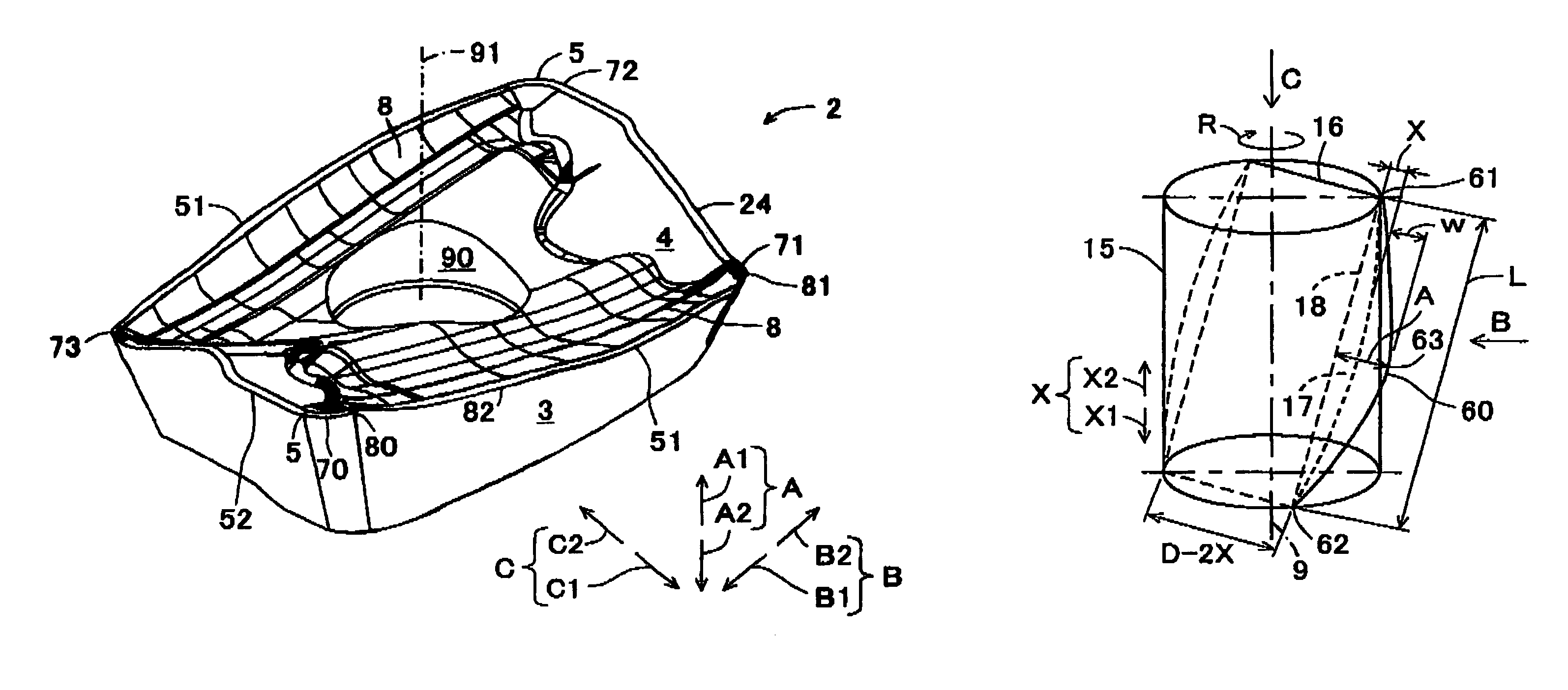

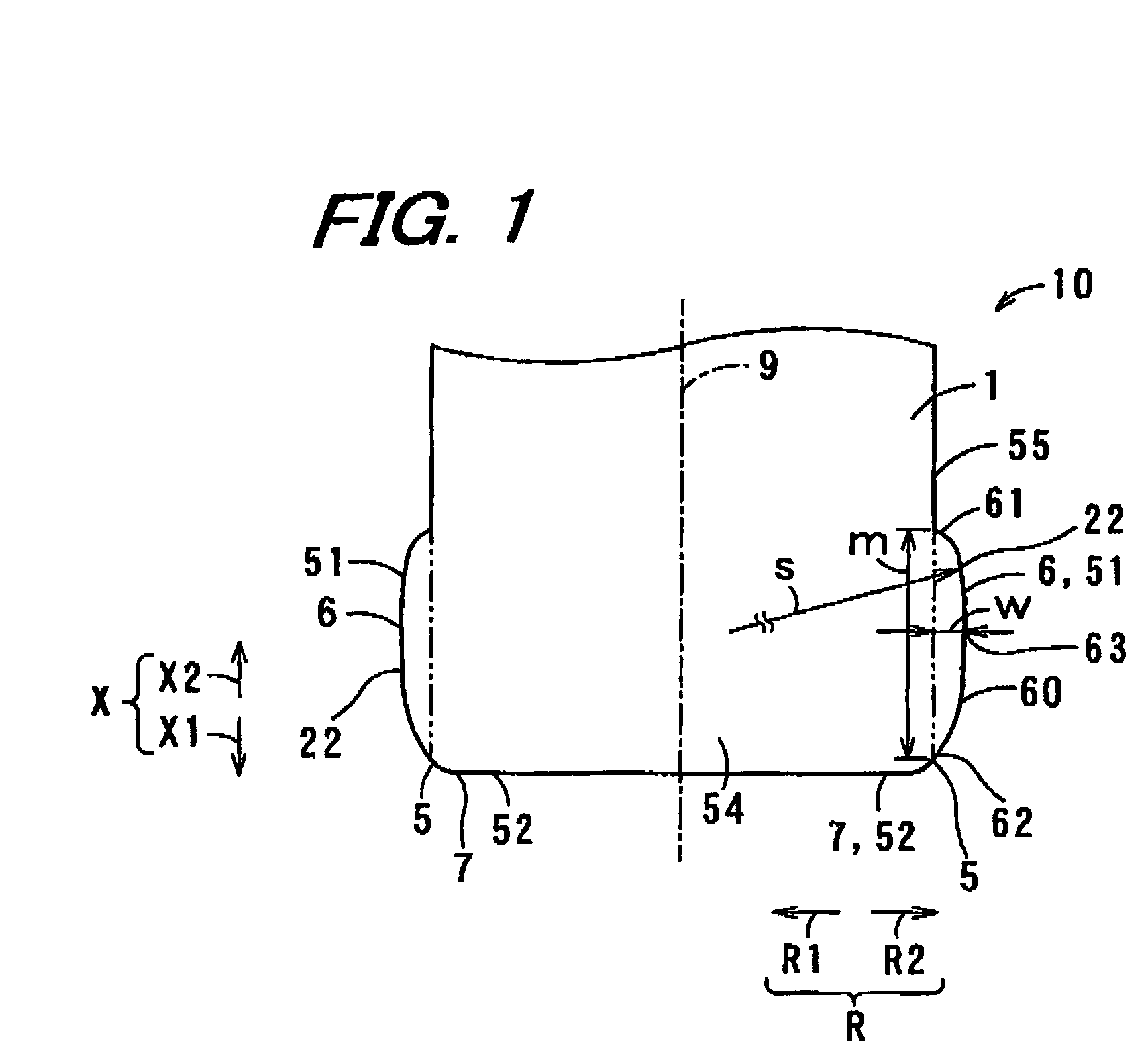

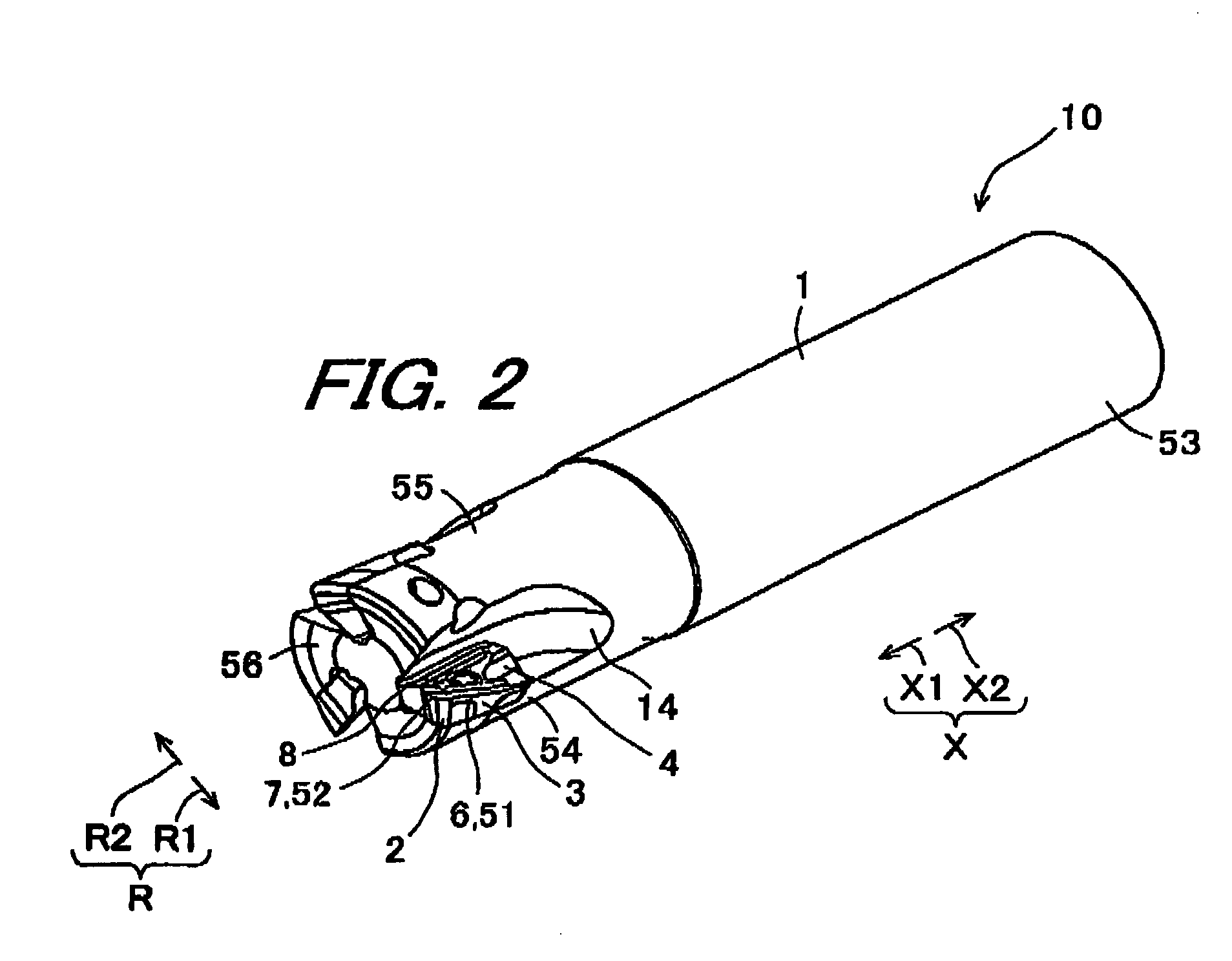

Cutting insert and milling tool

ActiveUS20060115340A1Improve surface roughnessReduce cutting timeMilling cuttersMilling machinesRotational axisEngineering

A milling tool includes a cutting tool insert, roughly plate-shaped and having a rake face on an upper face and a flank on a side face and a main cutting edge at an intersection ridge line part at the intersection of the rake face and the flank, fitted in the periphery of a substantially cylindrical holder removably and so that an axial rake angle of the cutting edge ridge line of the main cutting edge is positive. When the cutting tool insert is rotated about the axis of rotation of the holder, the shape of the locus of rotation of the main cutting edge in a section parallel to the axis of rotation is made an approximate circular arc shape swelling outward with progress from the ends to the center.

Owner:KYOCERA CORP

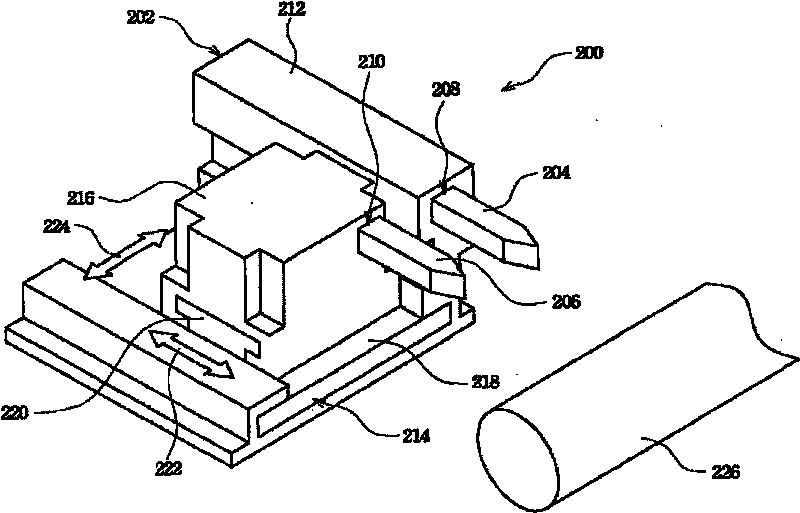

Rotary floating cutting numerical control machine tool for silicon rod

InactiveCN102862239AControl BrokenReduce vibrationWorking accessoriesFine working devicesNumerical controlEngineering

The invention discloses a rotary floating cutting numerical control machine tool for a silicon rod, and relates to a numerical control machine tool, in particular to a numerical control cutting machine for cutting the silicon rod. The rotary floating cutting numerical control machine tool comprises a numerical control box, a machine tool body, a transmission mechanism, and a cutting mechanism and a silicon rod clamping mechanism which are arranged on the machine tool body, and is characterized in that the silicon rod clamping mechanism comprises a driving rotation support wheel which clamps the silicon rod in a matching manner in the vertical direction, and a floating rotary pressing wheel; the floating rotary pressing wheel is connected with an elastic pressing device which drives the floating rotary pressing wheel to tightly press the silicon rod; and the transmission mechanism is connected with a shaft of the driving rotation support wheel. The rotary floating cutting numerical control machine tool can realize the non-concentric axial rotation floating radius cutting of polycrystalline silicon rods which have the characteristics that the material texture density is sparse, workpieces are bent in the axial direction, ovality exists in the diameter direction, the diameters are different, the appearances are not irregular, the breaking phenomenon is easy to generate, and the like in the floating rotation state, and is novel and capable of realizing the automatic radius cutting.

Owner:刘鸿彬

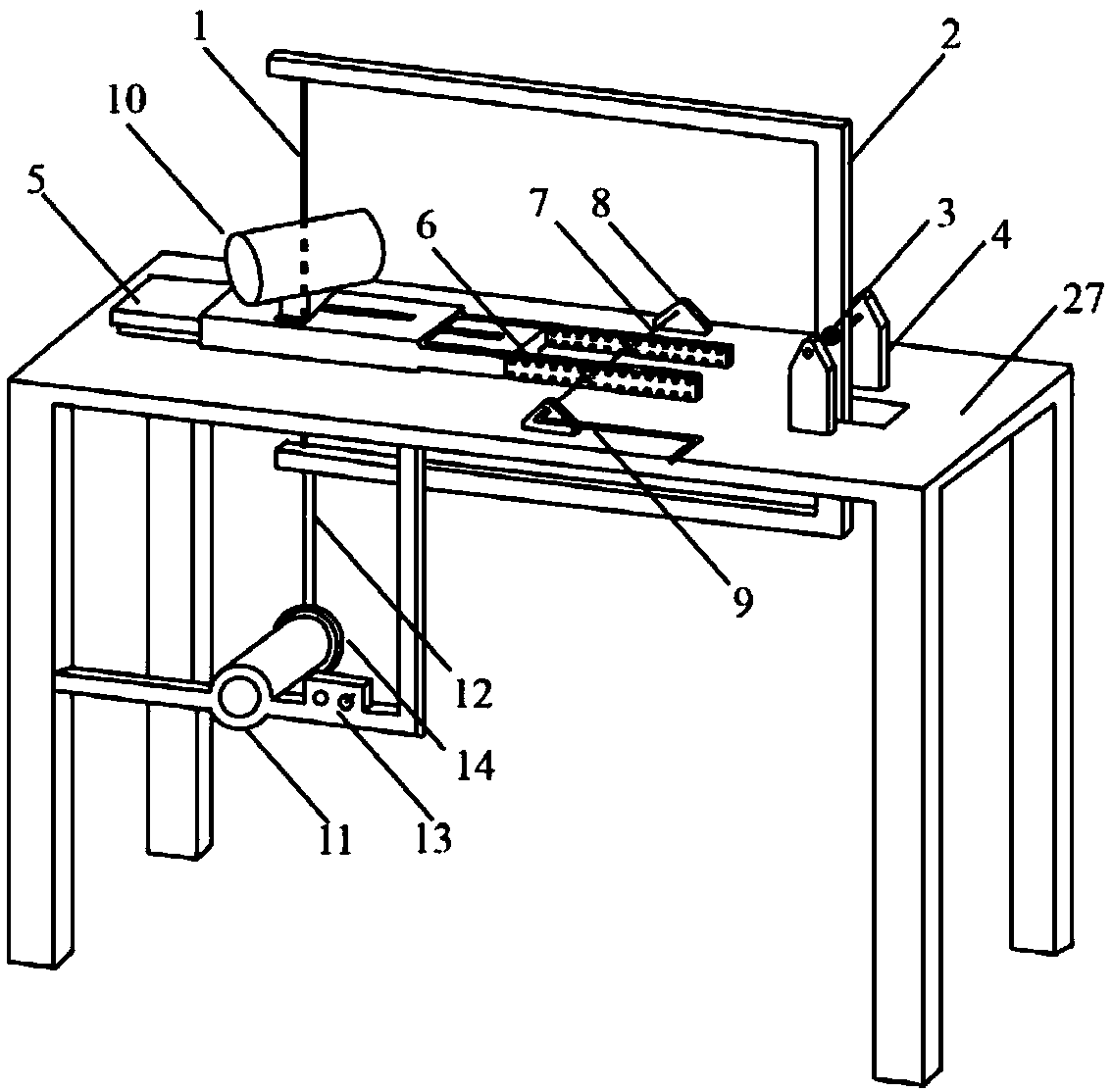

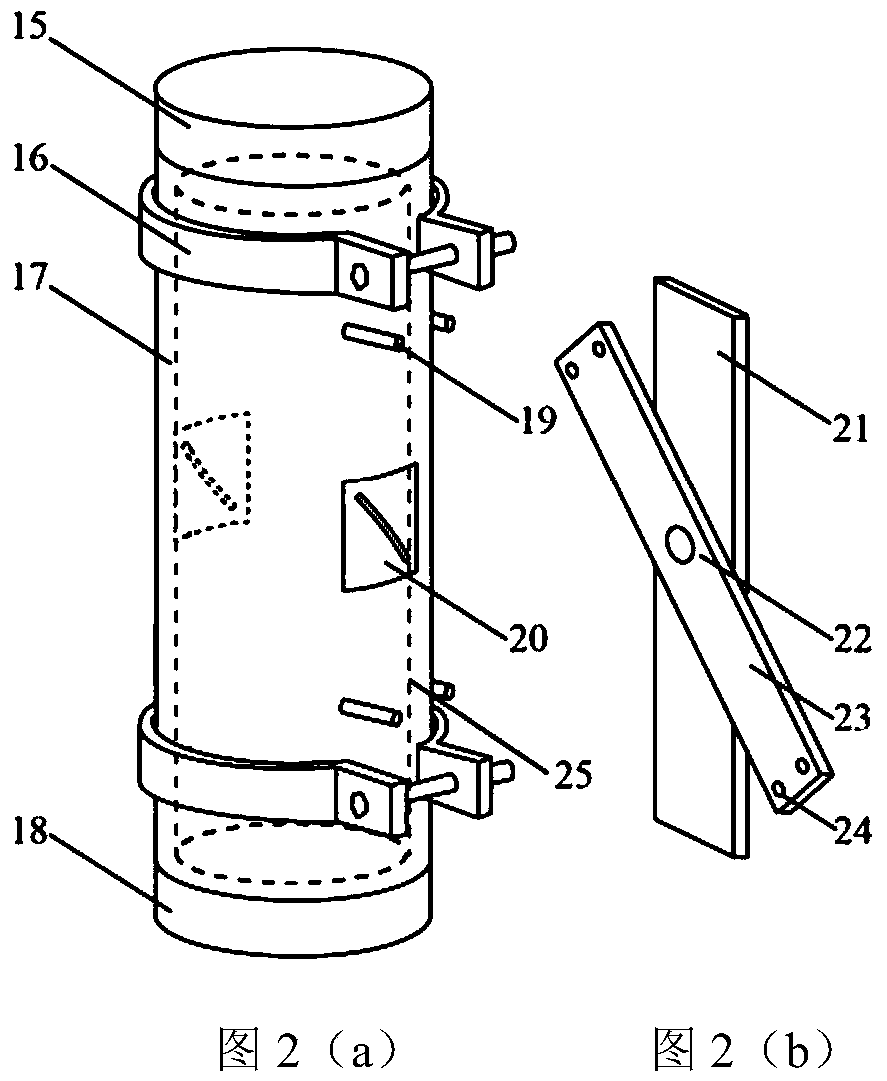

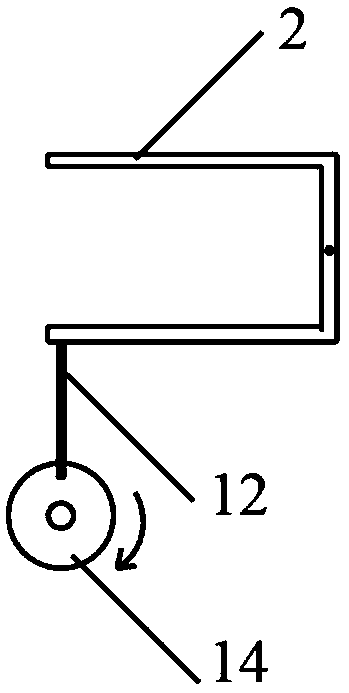

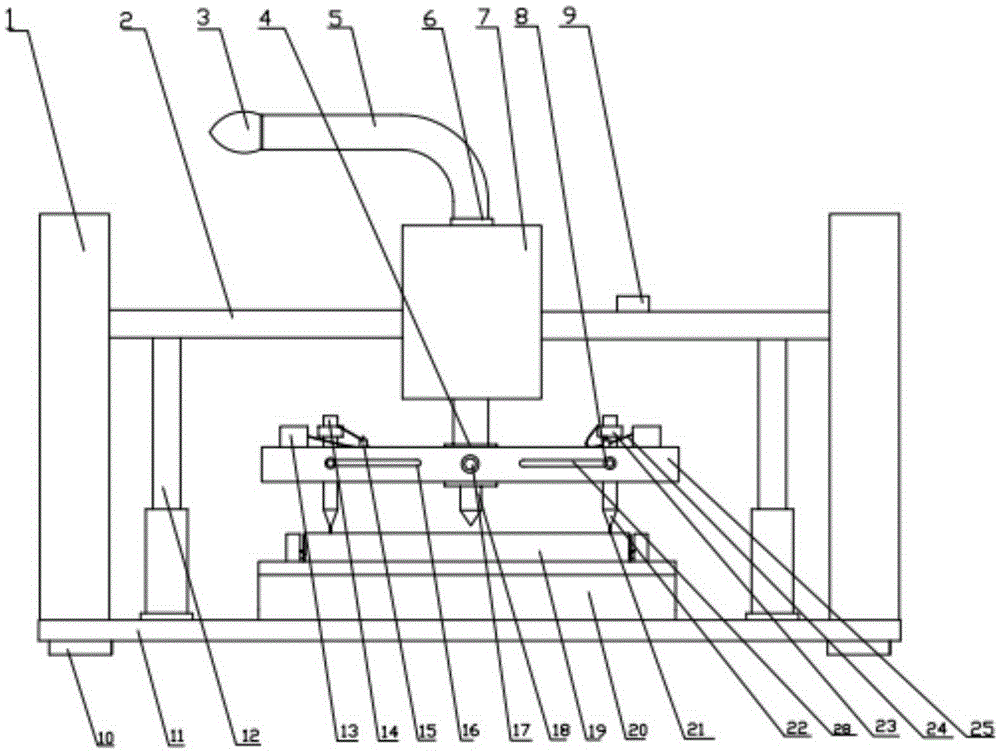

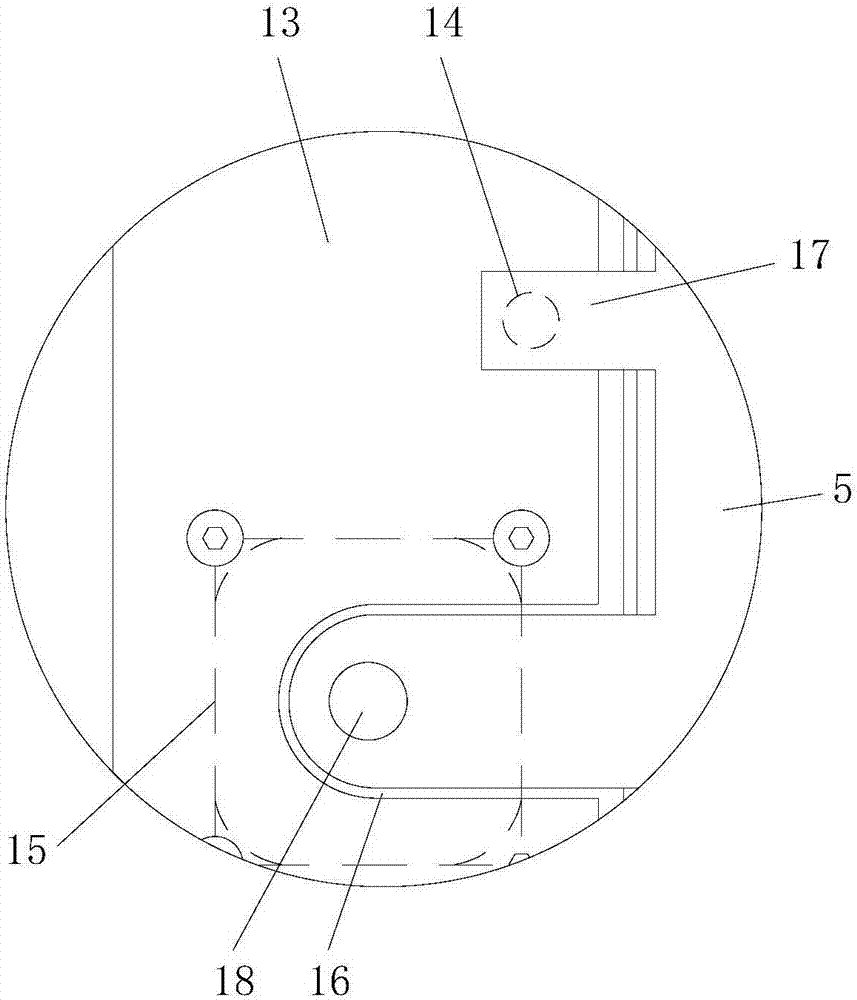

Prefabricated crack preparation device and method for standard rock test piece

The invention relates to a prefabricated crack preparation device and method for a standard rock test piece. The preparation device mainly comprises a cutting system, a driving system and a tabletop system. The standard rock test piece is arranged in the test piece cutter of the tabletop system and the test piece cutter comprises a crack positioning semi-open steel mold and a cutting angle adjuster. The cutting system is used for crack cutting of rock pieces. The driving system provides driving force for the cutting system. The cutting system and the driving system are arranged on the tabletopsystem. According to the prefabricated crack preparation device and method for standard rock test piece, the preparation of the inclined crack and the through crack of the standard rock test piece surface can be realized, the geometrical dimension and the cutting speed of the crack can be adjusted, the structure is simple, the manufacturing process is simple, the degree of mechanization is high,and the crack is prepared accurately, and can be widely applied to joint fracture rock mechanics tests in the field of hydroelectric, transportation, energy and mine engineering.

Owner:SHANDONG UNIV

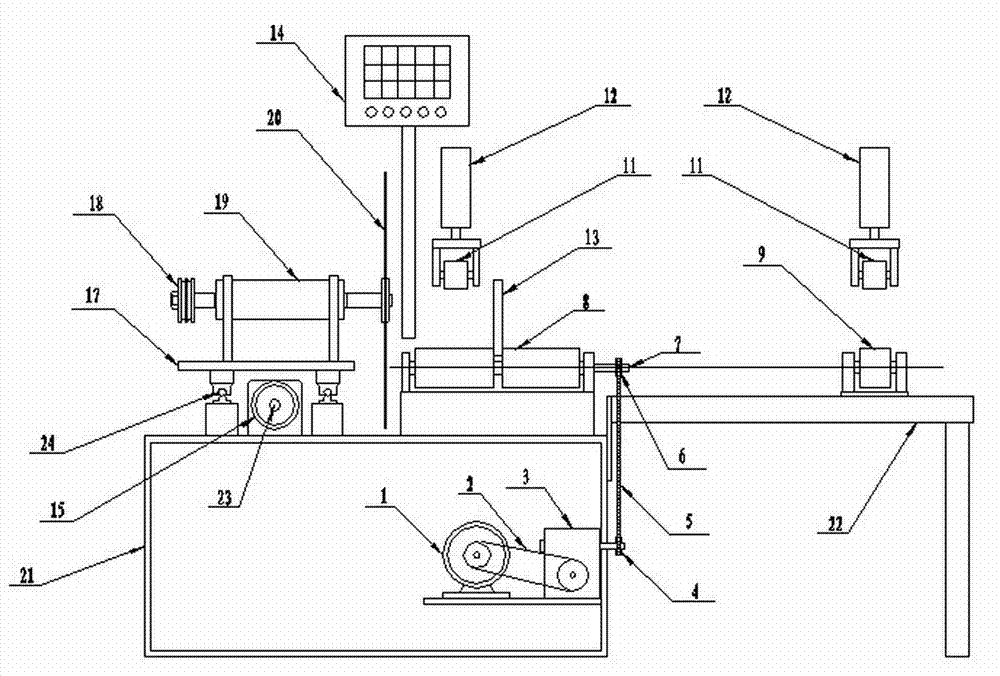

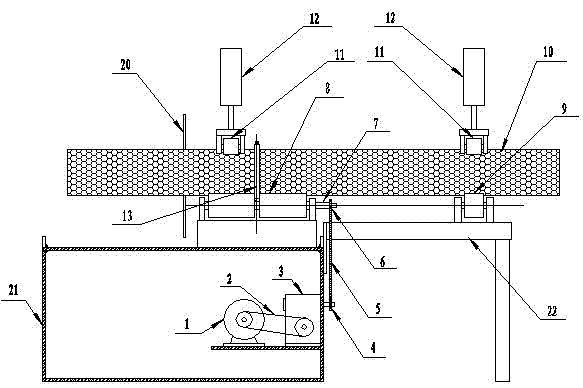

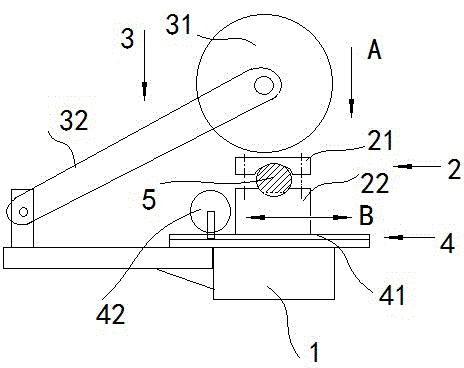

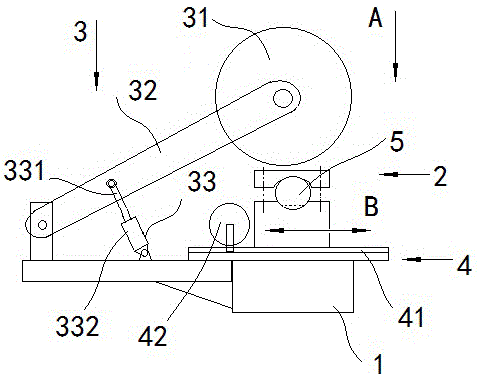

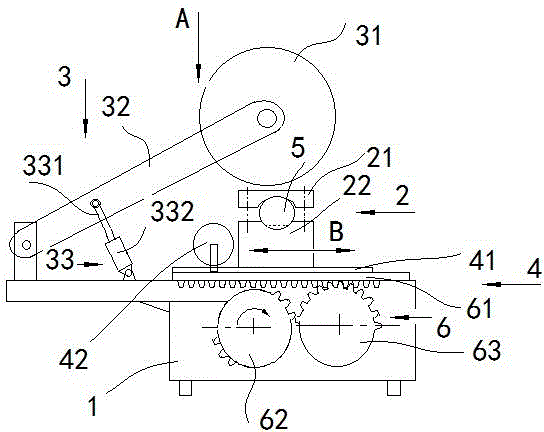

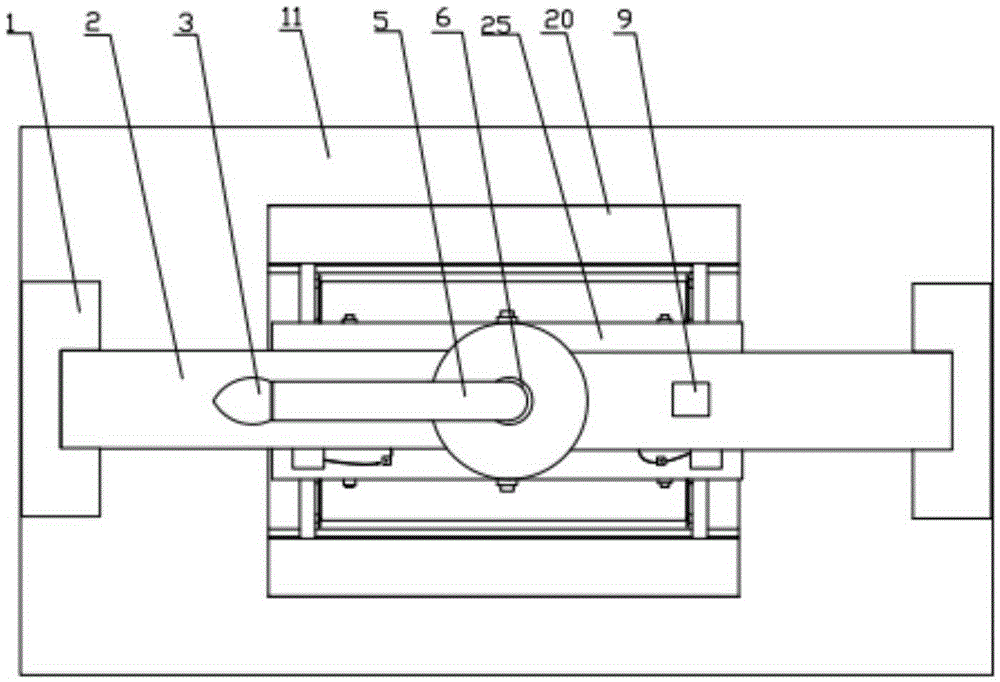

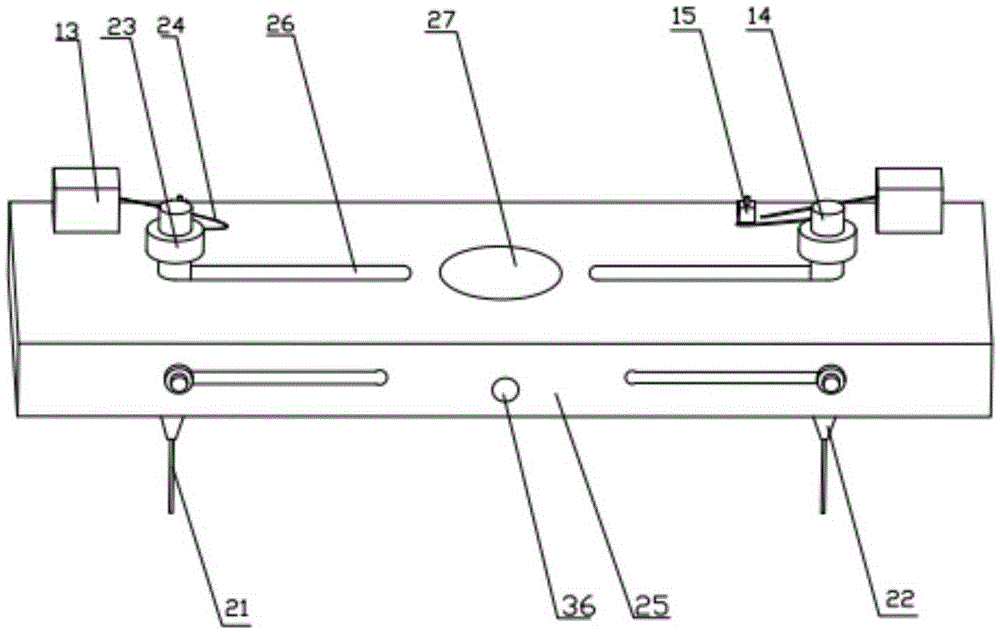

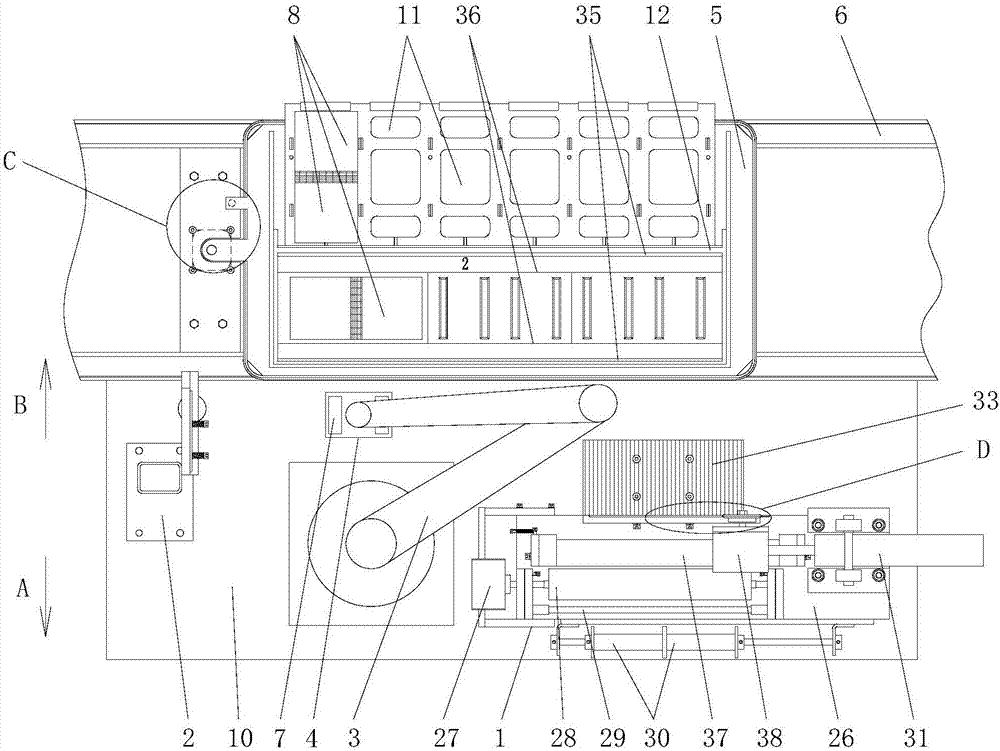

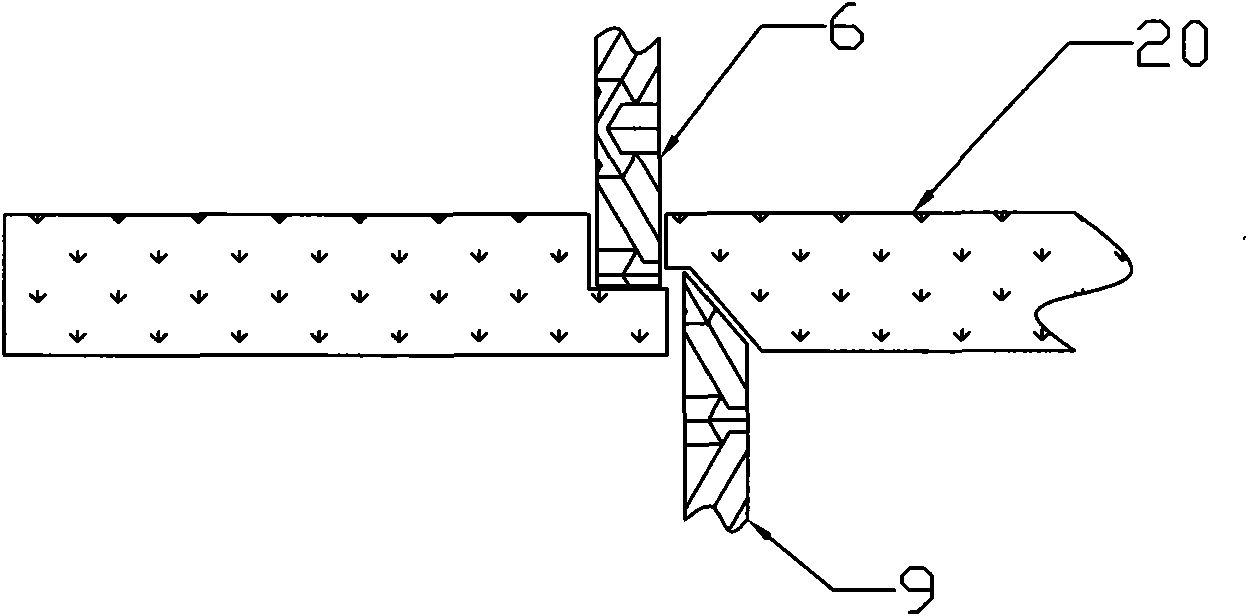

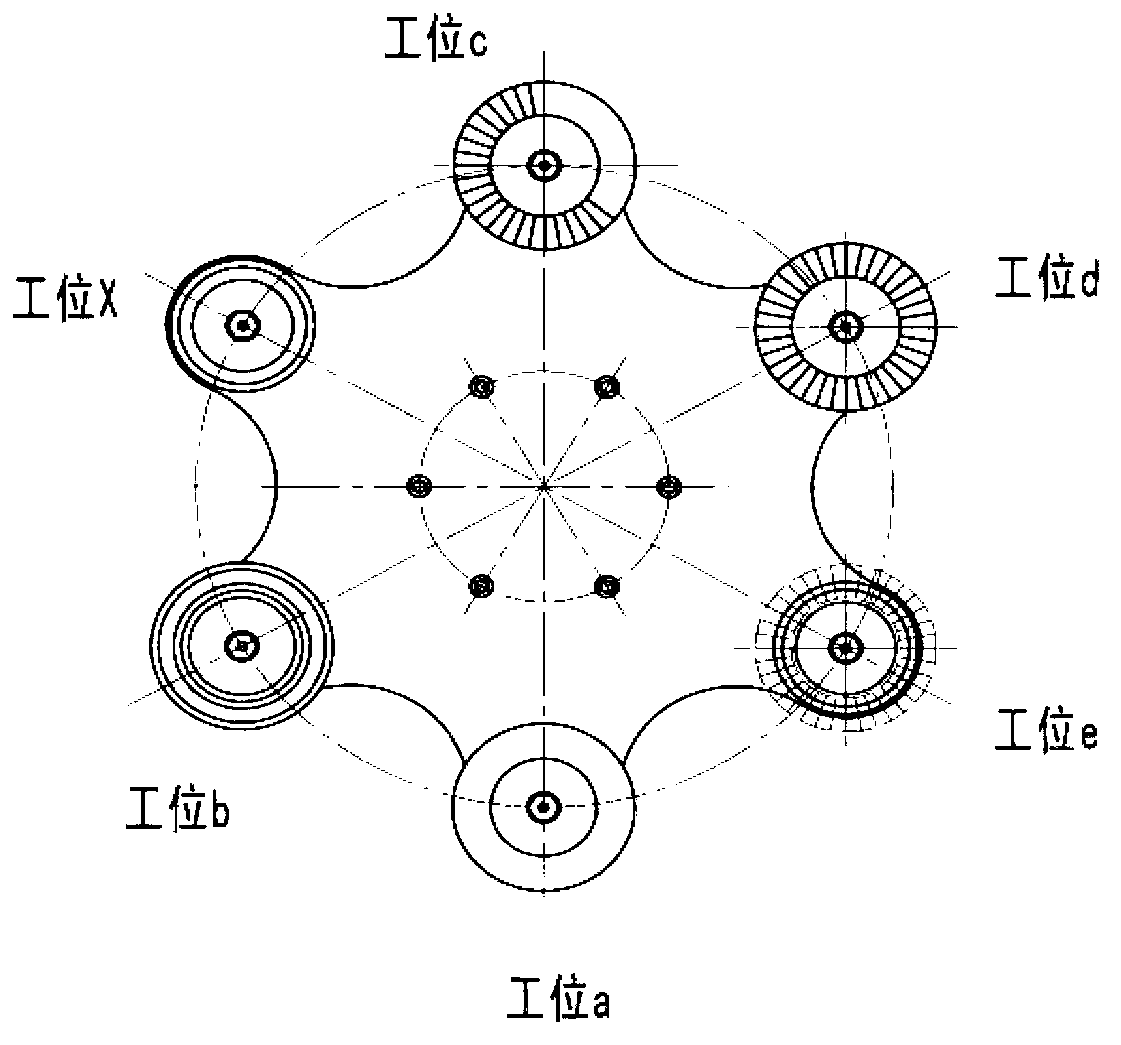

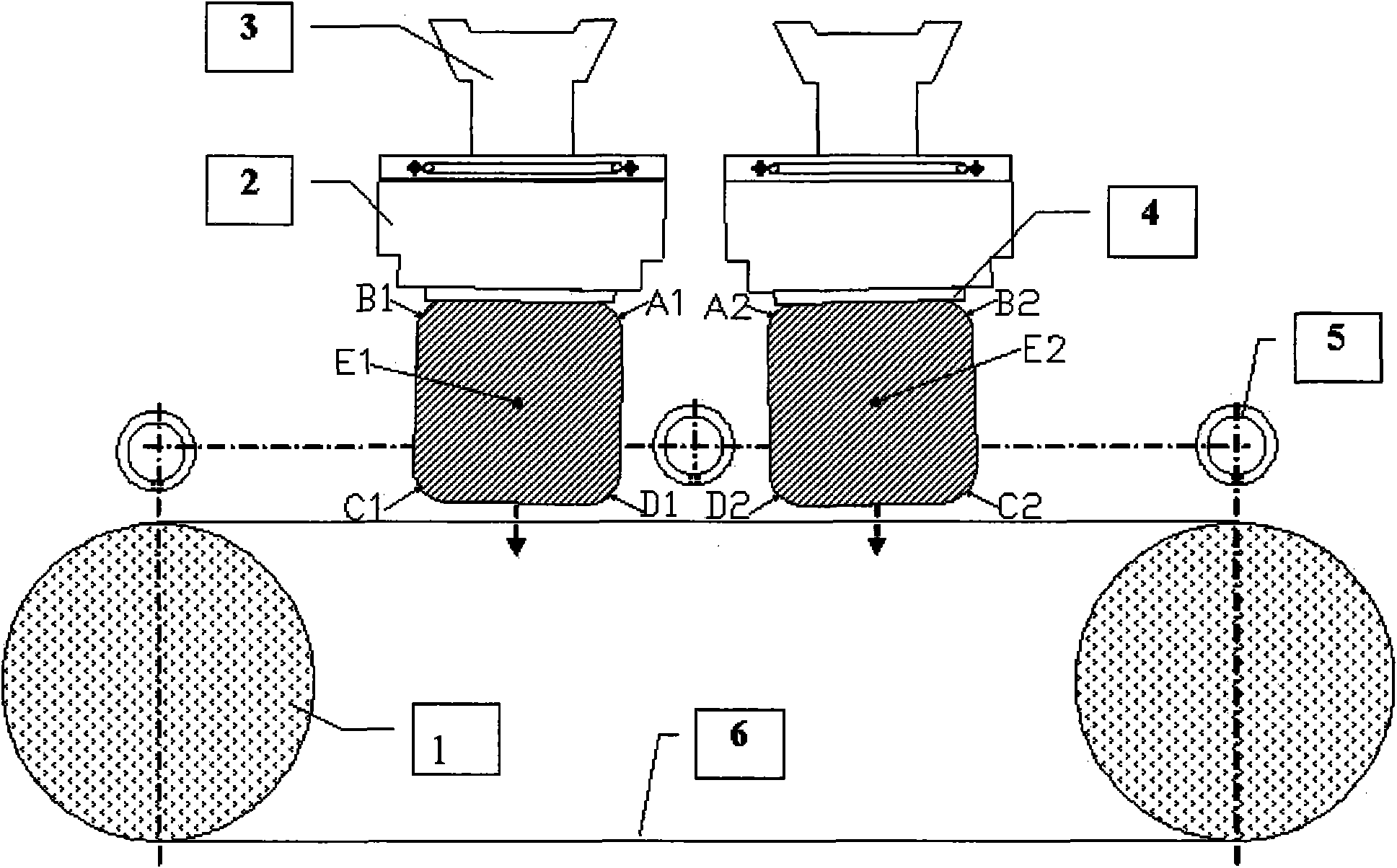

Horizontal and vertical feed burr-free bar cutting device

ActiveCN103600126AReduce cutting timeGood product qualityFeeding apparatusPositioning apparatusAutomatic controlEngineering

The invention discloses a horizontal and vertical feed burr-free bar cutting device, and provides a double-cutter horizontal and vertical bar cutting device to overcome the defect that a workpiece directly cut by a single cutter of a bar cutting machine in the prior art always has burrs. The horizontal and vertical feed burr-free bar cutting device comprises a base, an upper cutter mechanism and a bar clamping mechanism, the upper cutter mechanism is connected onto the base, the bar clamping mechanism is vertically arranged along the base, the upper cutter mechanism comprises an upper cutter frame hinged to the base, a main motor and an upper cutter are mounted on the upper cutter frame, a lower cutter mechanism positioned below the upper cutter mechanism is arranged on the base and comprises a guide rail horizontally arranged along the base, a lower cutter frame is slidably connected onto the guide rail, a lower cutter motor and a lower cutter are mounted on the lower cutter frame, and the lower cutter frame is driven by a transmission mechanism connected on the base. The burr-free bar cutting device has the advantages that the device is provided with a vertical cutting mechanism and a horizontal cutting mechanism, the burrs are avoided, automatic control can be realized, bars are rapidly cut and are fine in quality, and labor and time are saved.

Owner:浙江安统汽车部件有限公司

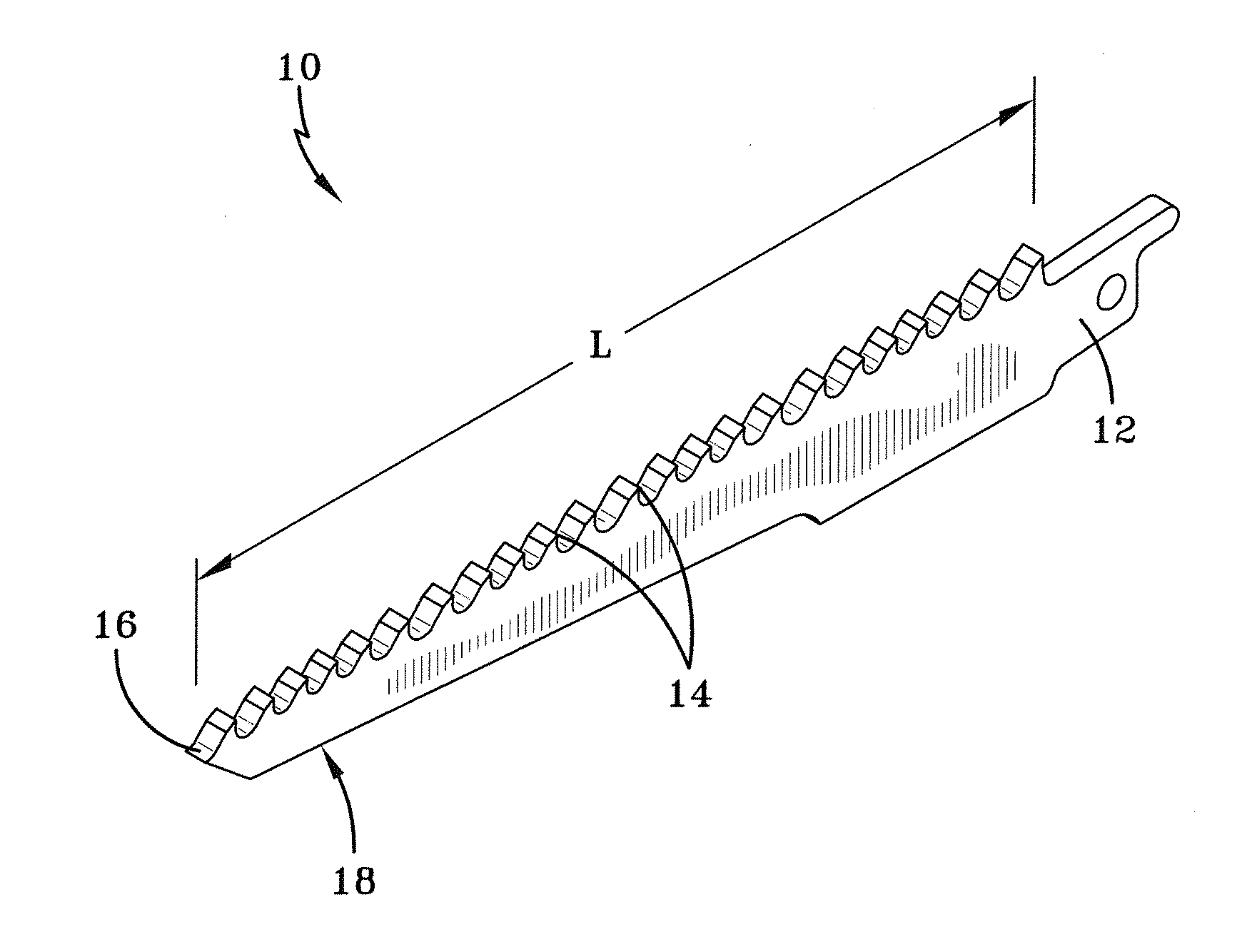

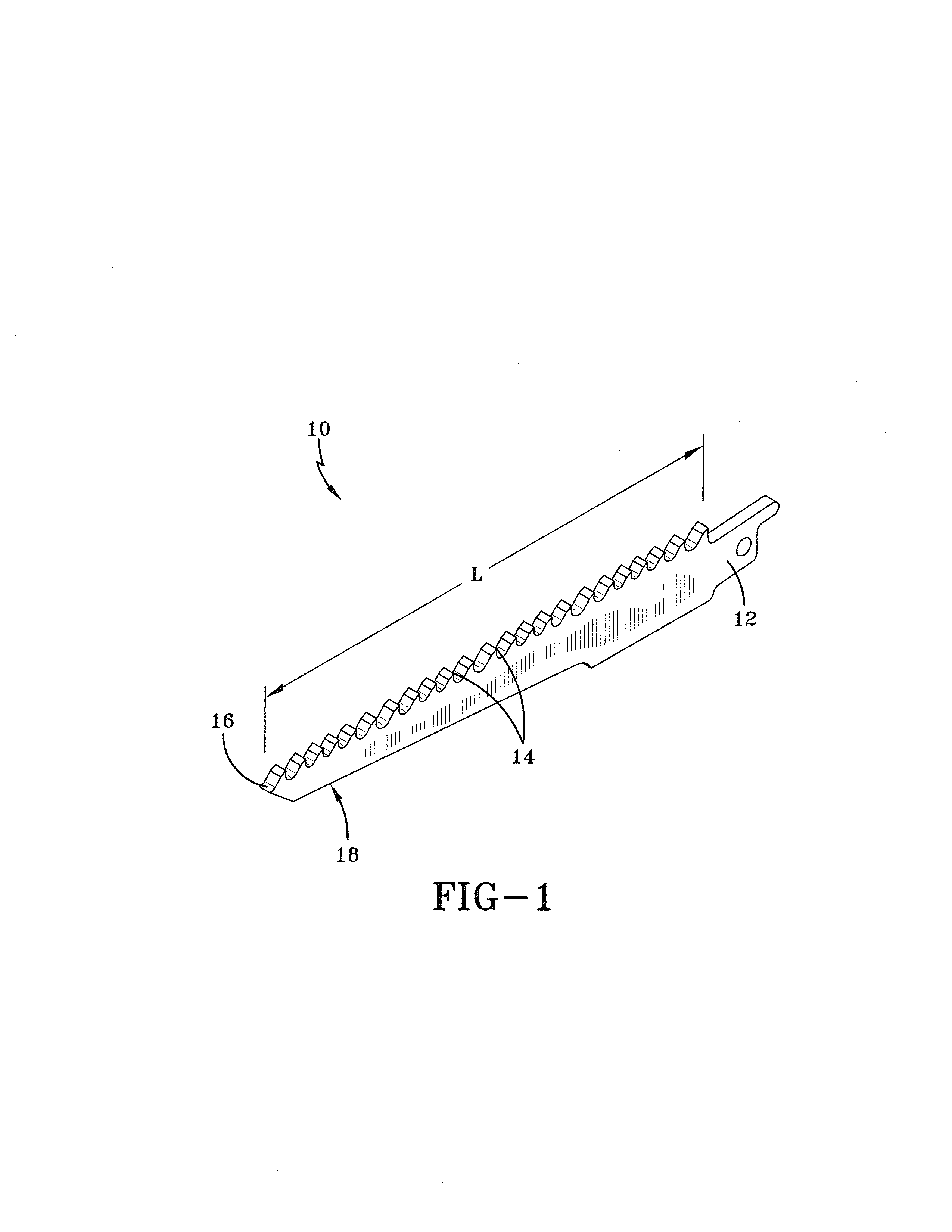

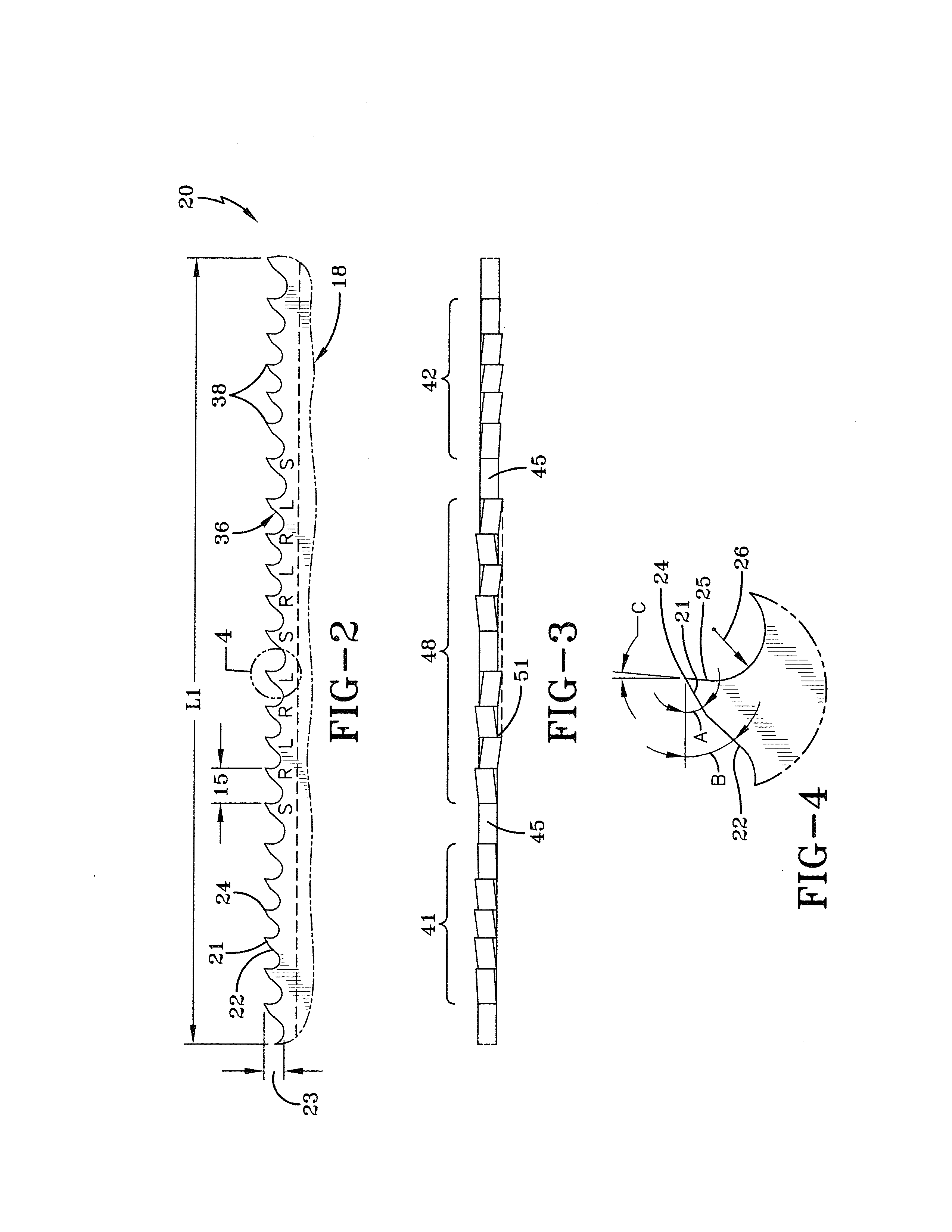

Reciprocating saw blade

InactiveUS20130180375A1Reduce cutting timeIncreased durabilityMetal sawing devicesMetal sawing toolsEngineering

A reciprocating saw blade includes a body, and the body includes a connecting portion for connecting the blade to the saw, and a cutting edge. The cutting edge includes a plurality of teeth organized in an overall tooth set pattern. The overall tooth set pattern approximately corresponds to the stroke length of the reciprocating saw. By the overall tooth set pattern corresponding to the stroke length of the reciprocating saw, the cut time is decreased, the life of the blade is increased, the vibration is minimized and / or a smoother finishing cut is enabled.

Owner:THE M K MORSE CO

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

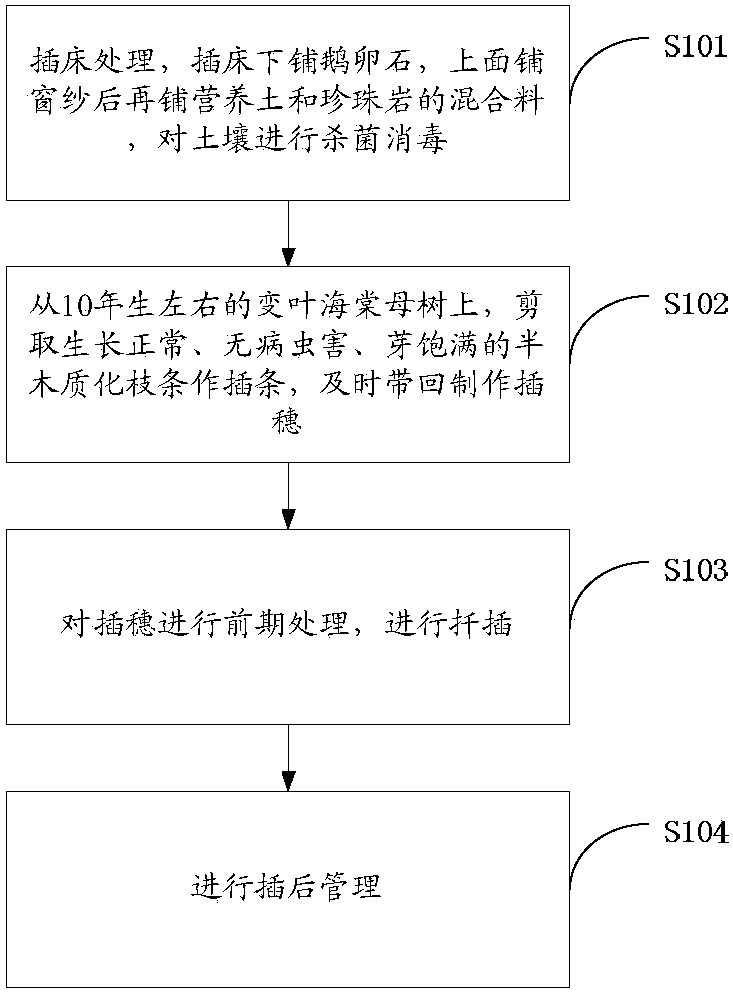

Cutting seedling method for malus toringoides

The invention discloses a cutting seedling method for malus toringoides. The cutting seedling method for the malus toringoides comprises the following steps of treating a cutting bed; laying cobblestones under the cutting bed; laying a window gauze on the cutting bed; laying mixing materials comprising nutrient soil and perlite on the window gauze; sterilizing soil; shearing semi-lignified branches, which grow normally, are not affected by plant diseases and insect pests and have plump buds, from a malus toringoides seed tree with the age about 10 years; timely bringing back the branches and manufacturing cutting slips; performing earlier-stage treatment on the cutting slips and performing cutting; and performing management after cutting. By using the cutting seedling method, the operation is simple, the yield is high, requirements on production of nursery-grown plants of the malus toringoides can be met, and the nutrient soil 3 and the perlite 1 serve as a cutting medium which is loose and breathable, has rich nutrition and can provide nutrition for the nursery-grown plants during earlier-stage growth. After the cutting slips are rapidly dipped in 1200mg / L of naphthaleneacetic acid liquor, cutting can be directly performed on the cutting slips, the cutting time is shortened, and the work efficiency is improved; the cutting yield is higher than 90%; the nursery-grown plants grow healthily and strongly; and the excellent performance of the maternal malus toringoides is kept. Compared with a seed raising method, the cutting seedling method has the advantages that cutting propagation is not limited by seasons, branches can be treated by cutting immediately after being shearing from the tree, and the operation is simple and feasible.

Owner:SICHUAN AGRI UNIV

Acoustic material cutting device

InactiveCN105415445AImprove efficiencySmooth edgesWithdrawing sample devicesMetal working apparatusEngineeringElectric heating

The invention relates to a material cutting device, in particular to an acoustic material cutting device which comprises a manual rotating device, a cutting device part, a material clamping device, a supporting device and two hydraulic jack devices, wherein the manual rotating device is fixed to the cutting device part; the material clamping device is fixed to the middle position of the supporting device; the hydraulic jack devices are arranged at the two ends of the material clamping device and are fixed to the supporting device; the cutting device part is arranged at the lower end of the manual rotating device; a cutting head in the cutting device part is in contact with the upper surface of an acoustic material clamped by the material clamping device, and can move up and down along with the movement of the hydraulic jack devices. The acoustic material cutting device adopts an electric heating method to cut a material, so that the material cutting efficiency is high, height and cutting speed of the cutting speed can be manually controlled, cutting flexibility is guaranteed, and the material cutting time can be greatly reduced.

Owner:JILIN UNIV

Cutting and assembling device used for carbon fiber battery polar plates

ActiveCN107994272AReduce in quantityEasy to operateFinal product manufactureLead-acid accumulators constructionFiberCarbon fibers

The present invention discloses a cutting and assembling device used for carbon fiber battery polar plates. The device comprises a membrane cutting mechanism, a grid cutting mechanism, a mechanical arm, a grabbing plate, an assembling frame and a guiding rail. The membrane cutting mechanism, the grid cutting mechanism and the mechanical arm are all arranged on the fixing table near the guiding rail. The assembling frame is slidably connected to the guiding rail, and the assembling frame is provided with a pallet used for placing polar plates and shells. The installing end of the mechanical armis fixed on the fixing table, and the output end of the mechanical arm is connected with the grabbing plate in a detachable connection mode. The device can lower the manpower consumption, shorten theprocessing time, improve the production efficiency, avoid the artificial error and reduce the probability of the occurrence of inferior products.

Owner:肇庆中特能科技投资有限公司

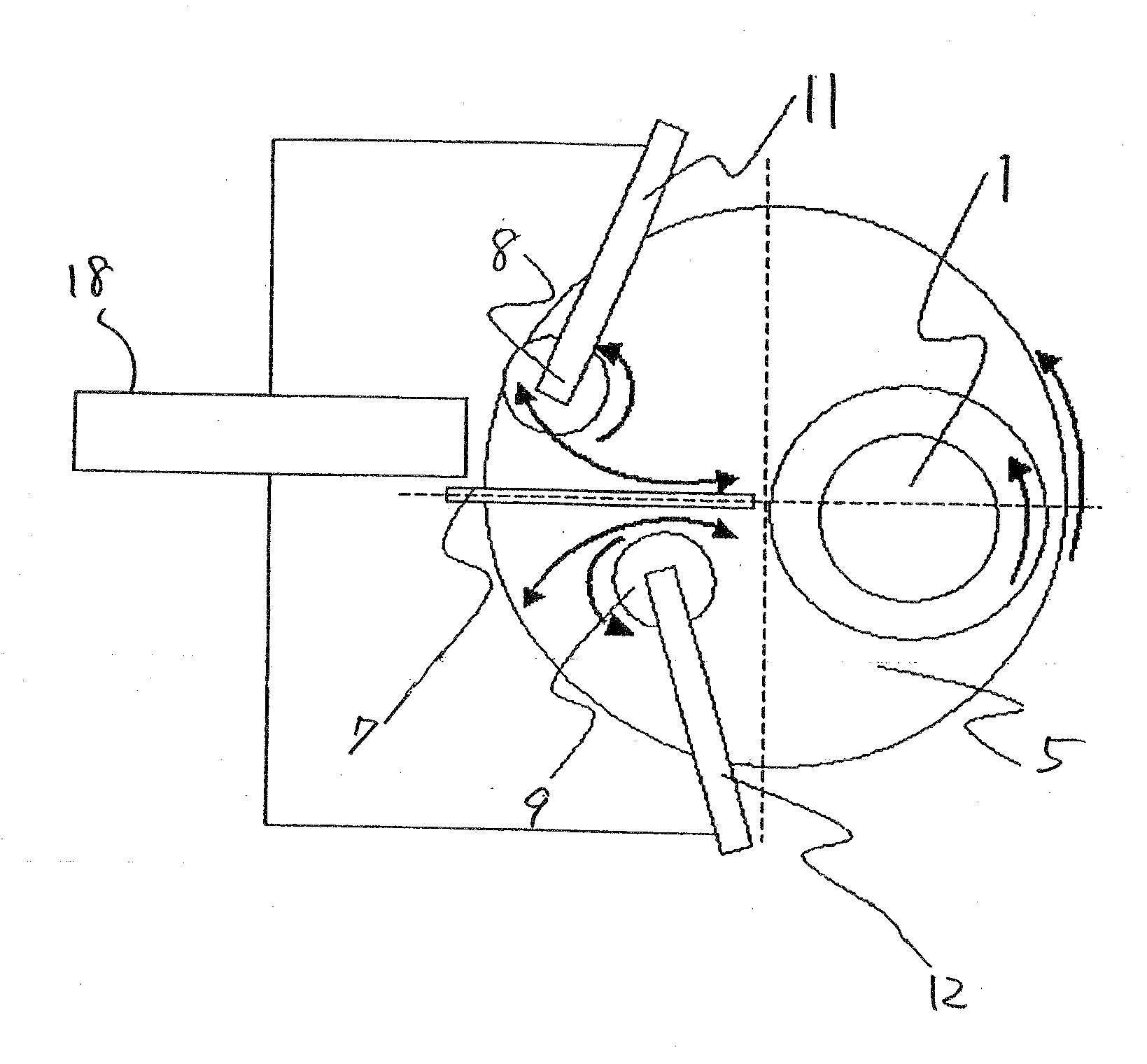

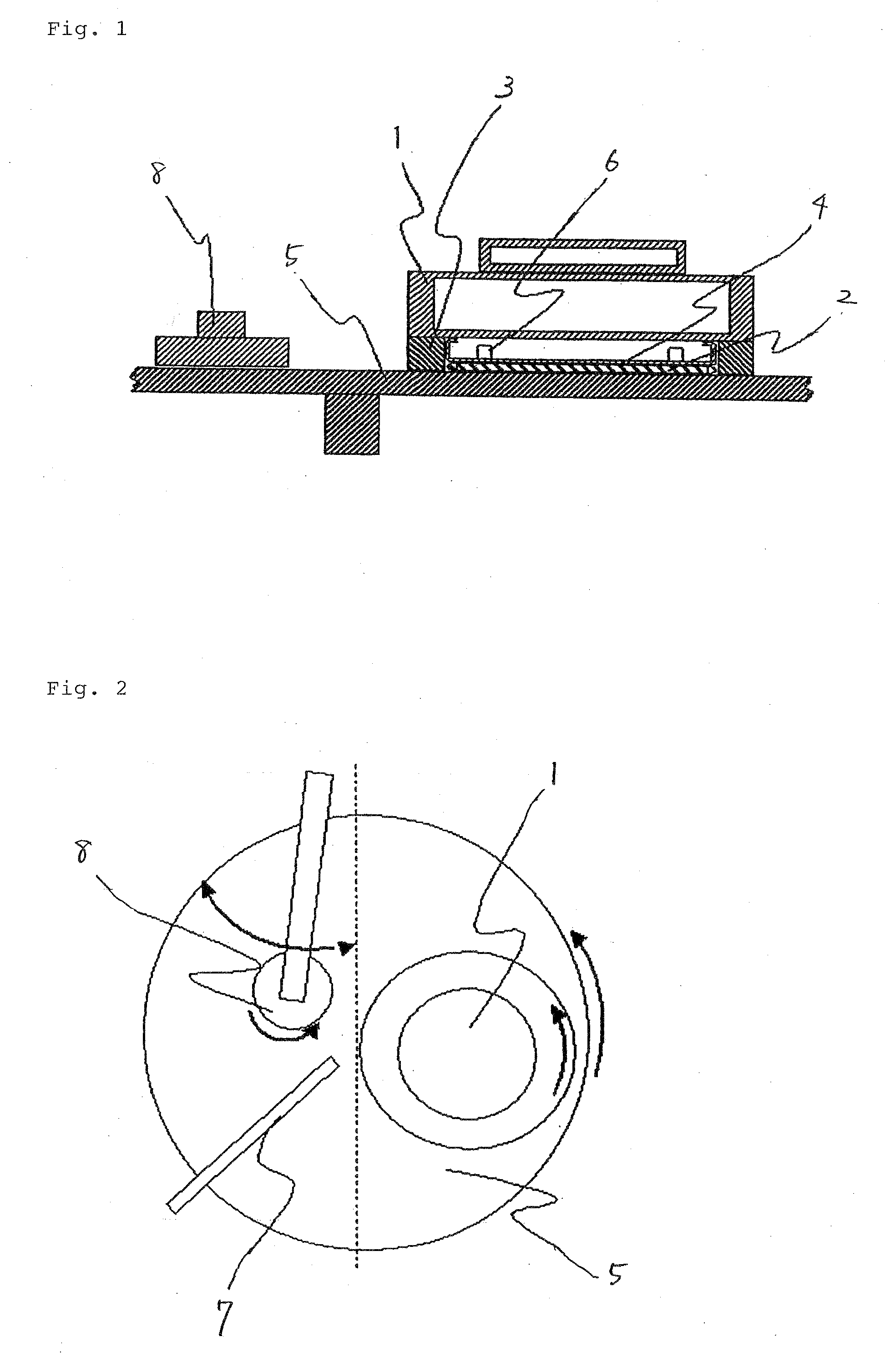

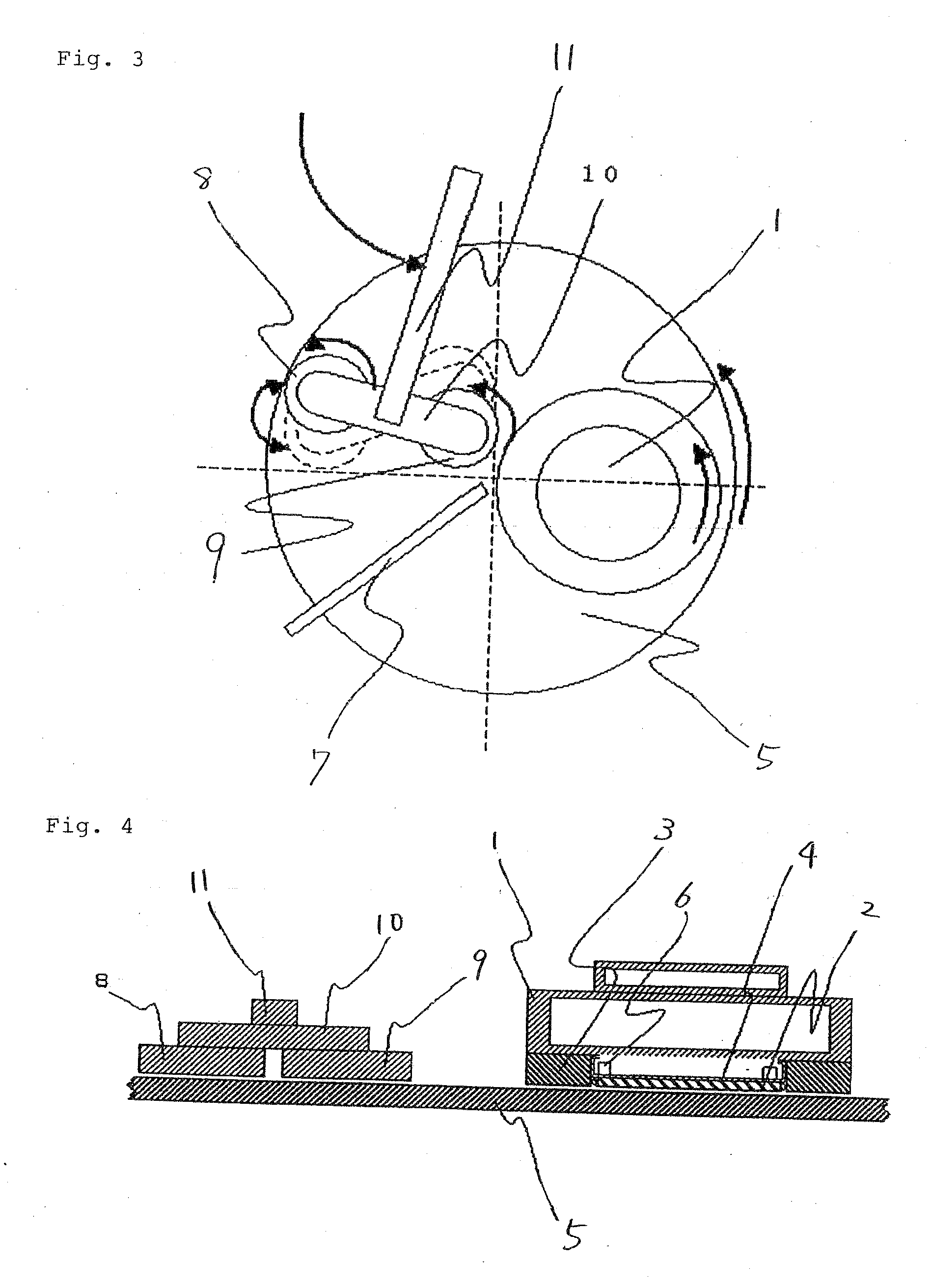

Sheet-processing lathe

InactiveCN101623878AReduce cutting timeReduce labor intensityFeeding devicesCircular sawsAutomatic controlEngineering

The invention relates to a sheet-processing lathe, in particular to an automatic sheet-cutting lathe with double knife saws. The invention provides a sheet-cutting lathe with double knife saws for overcoming the defect that sheets in a knife saw width are wasted when the prior wood knife saws are used for cutting sheet. An upper knife saw and a lower knife saw are utilized to simultaneously cut the upper side and the lower side of the sheet which is cut off at a tangency point of the upper knife saw and the lower knife saw. The method not only saves the sheet in the knife saw width, but also can directly cut the sheet into various shapes and simplifies the post procedure of slot production of the sheet. The invention also utilizes an automatic control system to achieve the automatic cutting of the sheet, lessens the manual interference and improves the working efficiency.

Owner:朱君山 +1

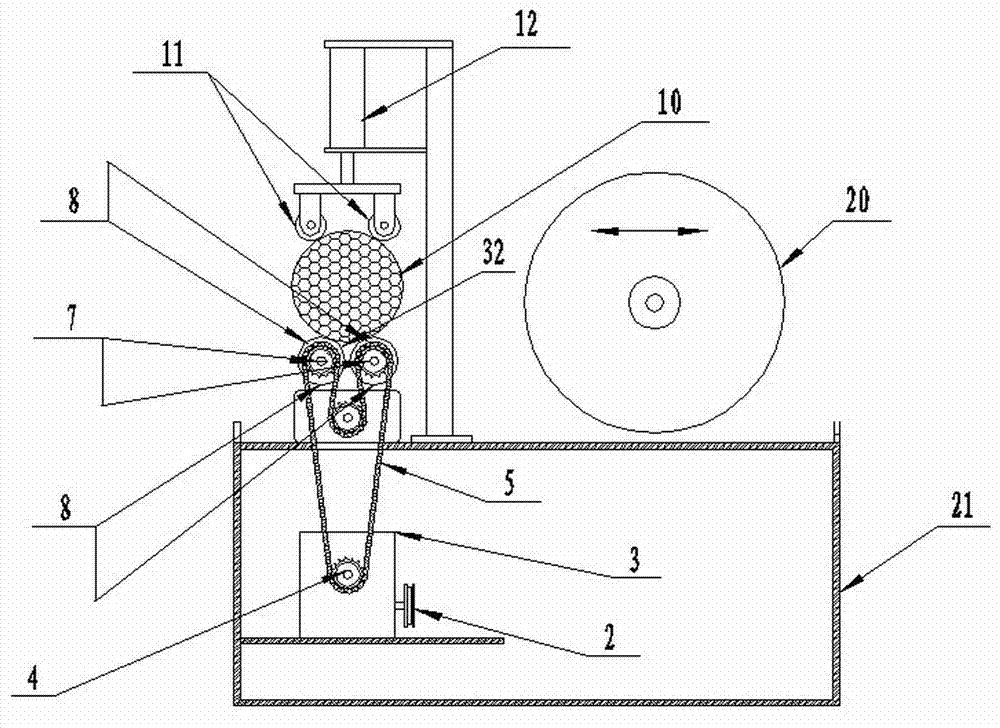

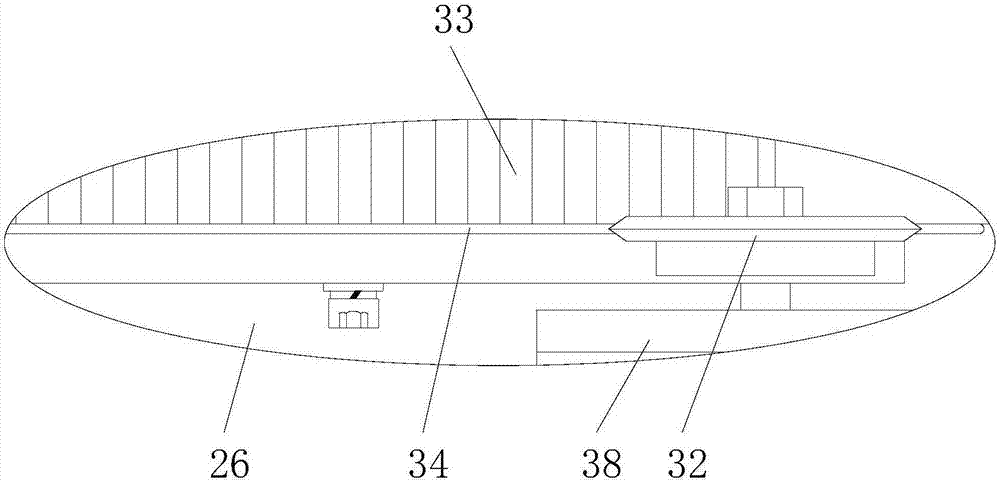

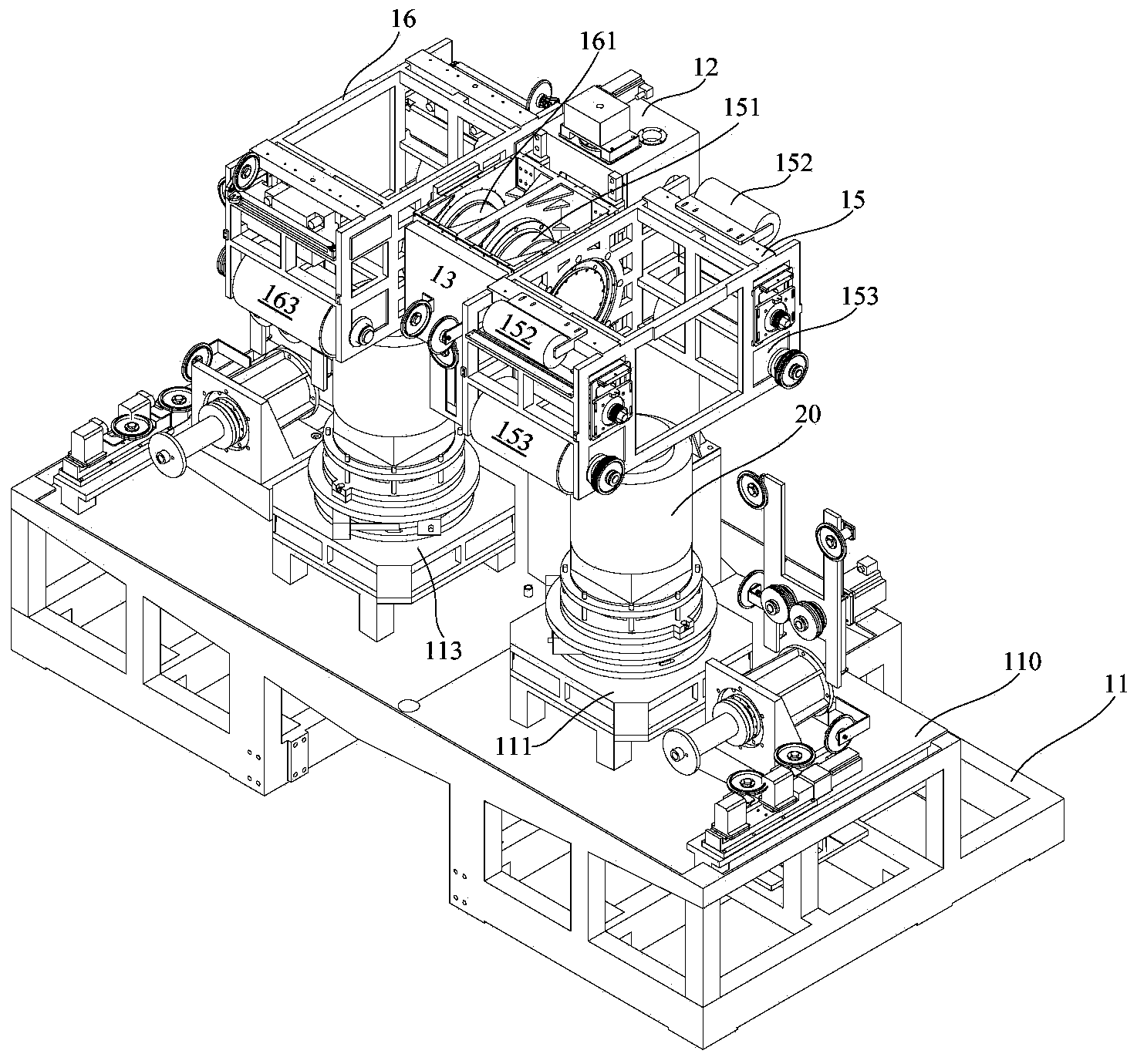

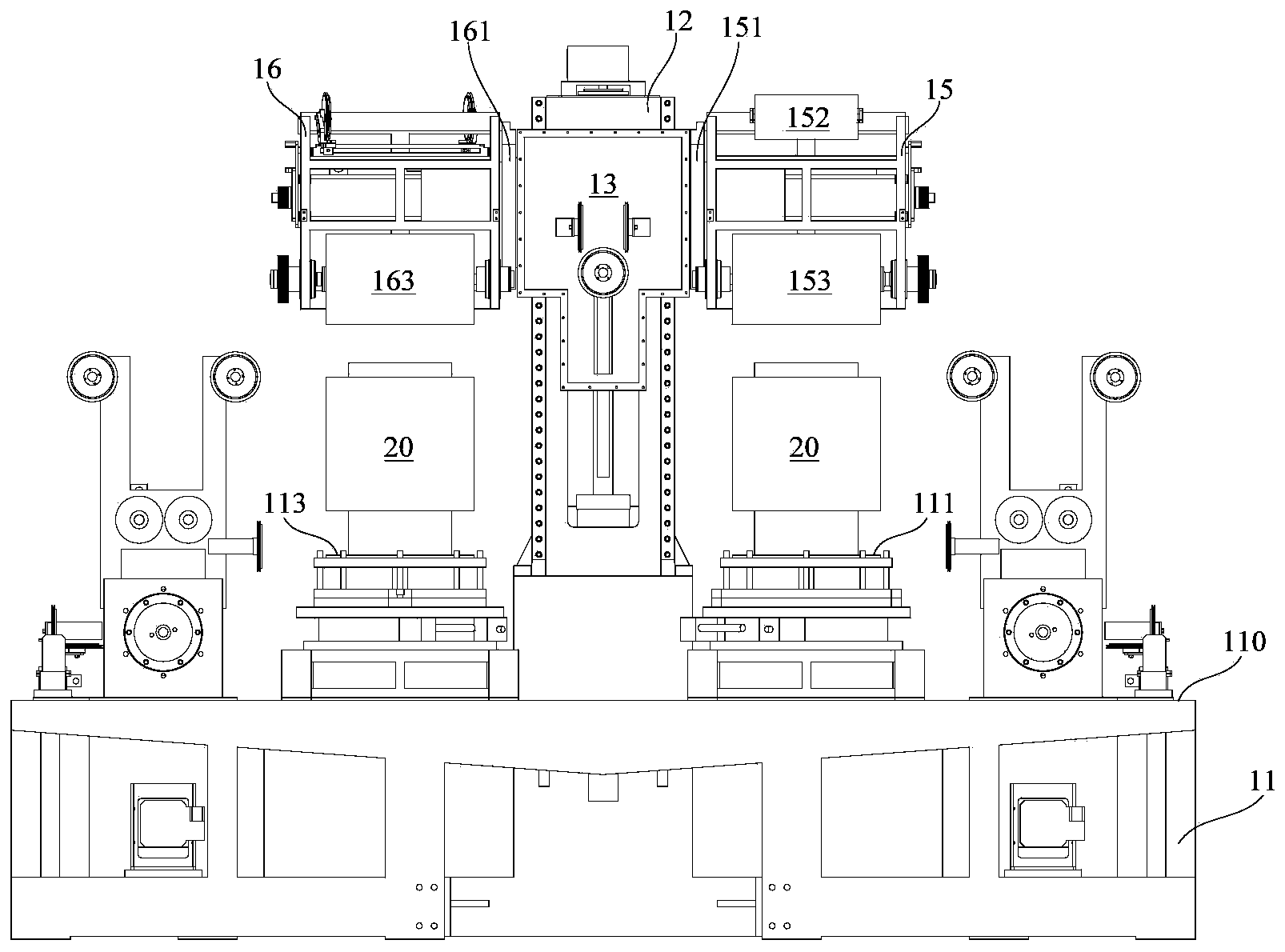

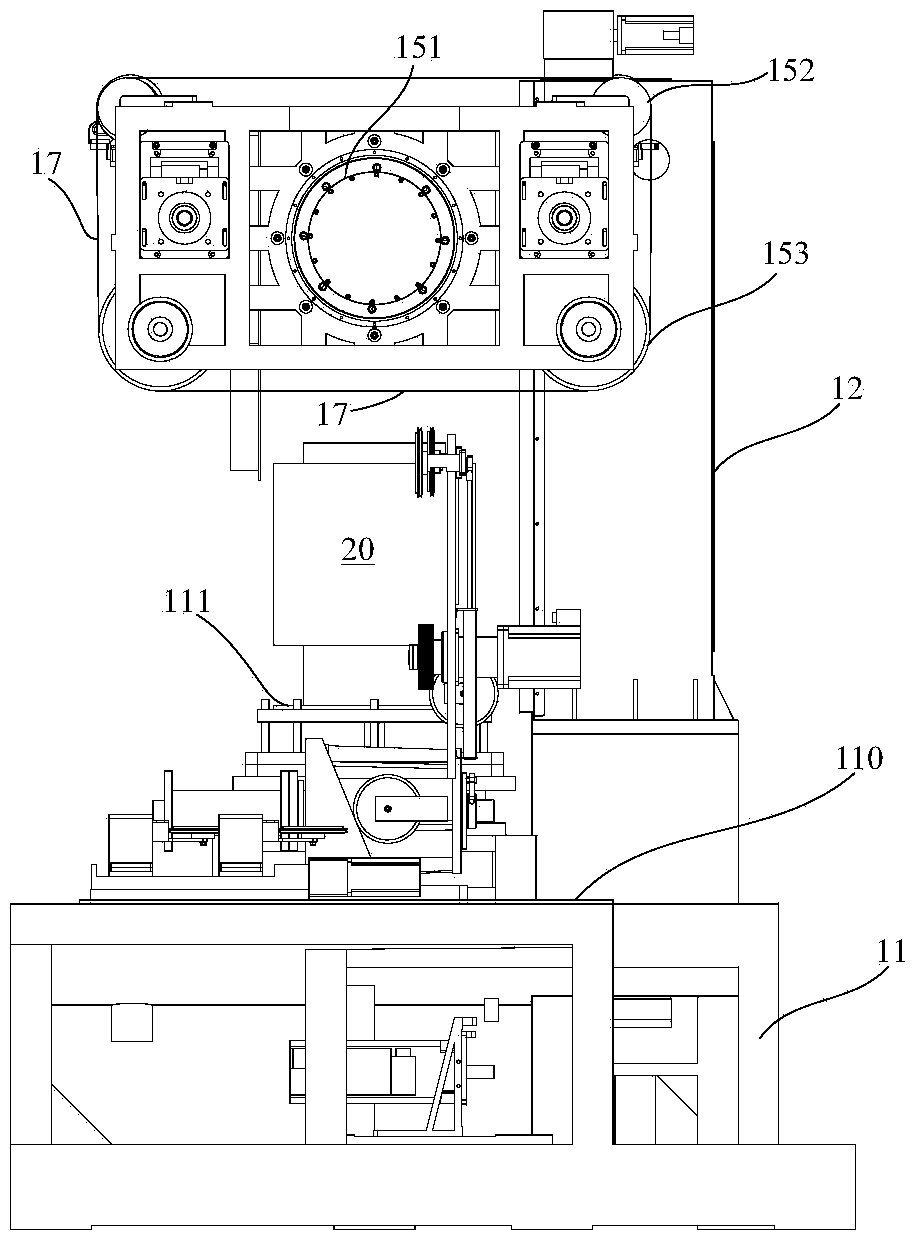

Diamond wire squaring machine

ActiveCN103921360AResolve resistanceSolve cutting difficultiesFine working devicesCouplingEngineering

The invention provides a diamond wire squaring machine which comprises a rack. The rack is provided with a rack platform, two workbenches, a supporting stand column, a turning-connection support and two wire stands, wherein the two workbenches and the supporting stand column are arranged on the rack platform, the turning-connection support is arranged on the supporting stand column in a lifting mode, and the two wire stands are connected to the two sides of the turning-connection support in a coupling and rotating mode. Each wire stand is provided with a cutting roller, a server motor and a diamond wire which is wound on the cutting roller. Any wire stand rotates relative to the turning-connection support in a coupling mode to drive the diamond wire to alternatively and obliquely cut machined parts on the workbenches relative to the horizontal line, the entire cutting process is smooth, control is easy, the cutting time is greatly shortened, and the cutting precision and the cutting efficiency are improved.

Owner:海宁市日进科技有限公司

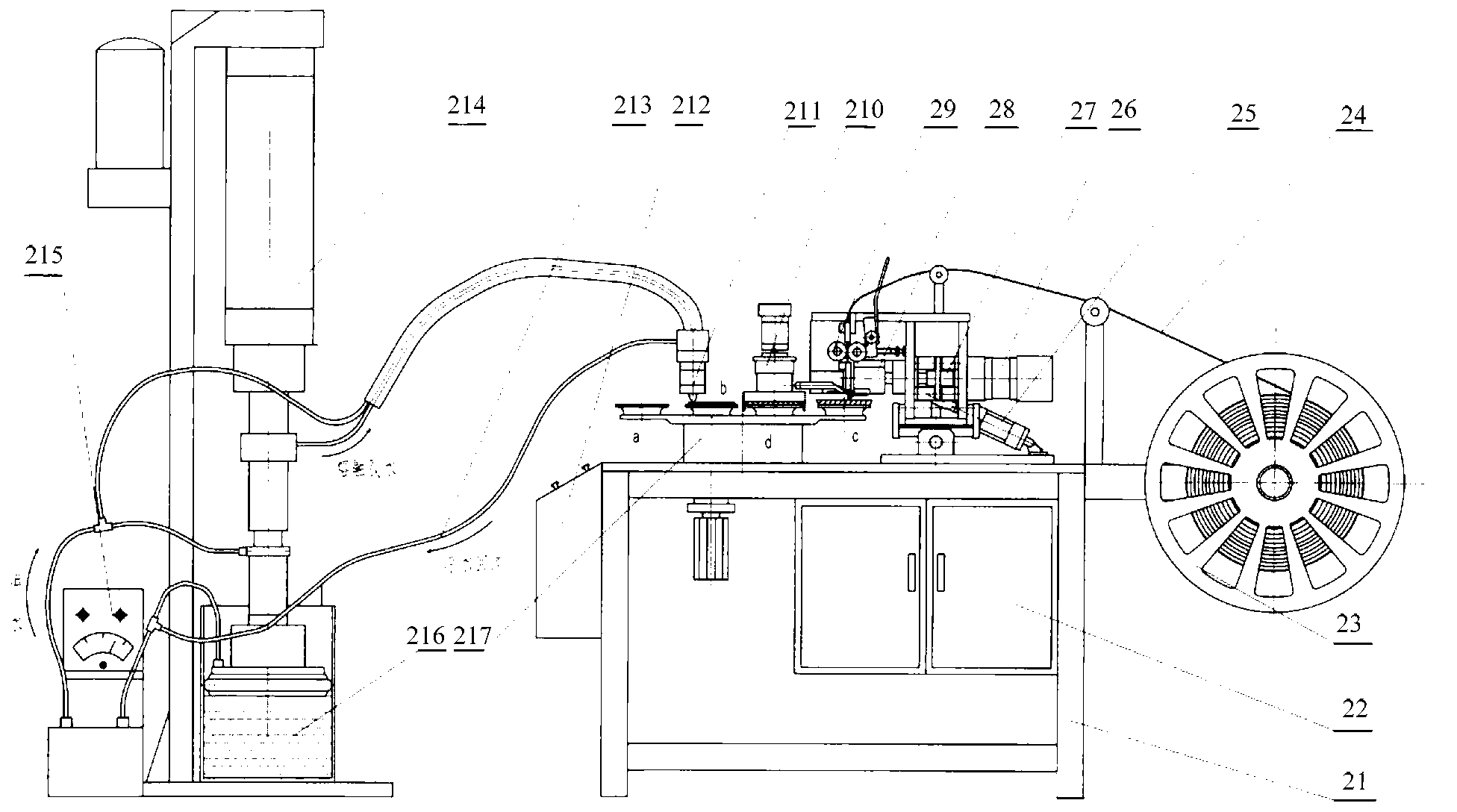

Flap wheel production device and production method

InactiveCN102794720AIncrease productivityMeet the use requirementsGrinding devicesEngineeringMachine tool

The invention provides a flap wheel production device which is used for cutting strips through a strip cutting mechanism. The strip cutting mechanism comprises a first compression roller and a second compression roller which are parallelly arranged, and the first and second compression rollers are in roll-in fit so as to convey strips, namely that a strip passing through a space between the two compression rollers is conveyed by using a drawing force generated by the mutual extrusion of the two compression rollers in the process of reverse rotation; and the conveyed strip is conveyed to a movable tool head, and then the strip is cut through the shearing fit of a main tool and an accessory tool. Through controlling the conveying speed of the first compression roller and the second compression roller and cooperating with the cutting interval of the movable tool head, strips in different sizes can be cut; the manual cutting of strips is converted into the automatic cutting of a strip cutting device, so that the cutting time of strips is reduced; and the strip subjected to cutting is conveyed to a swing mechanism for gluing and rotated on a chassis of a flap wheel so as to carry out circumferential arrangement and shaping on the strips subjected to cutting, thereby improving the production efficiency of flap wheels. The invention also provides a method for producing flap wheels.

Owner:上海青浦良明工贸有限公司

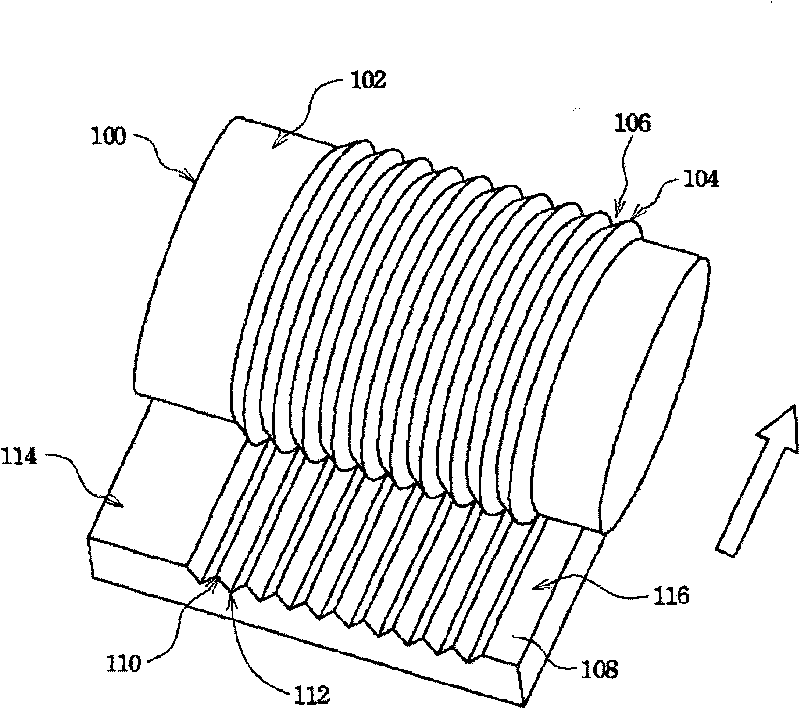

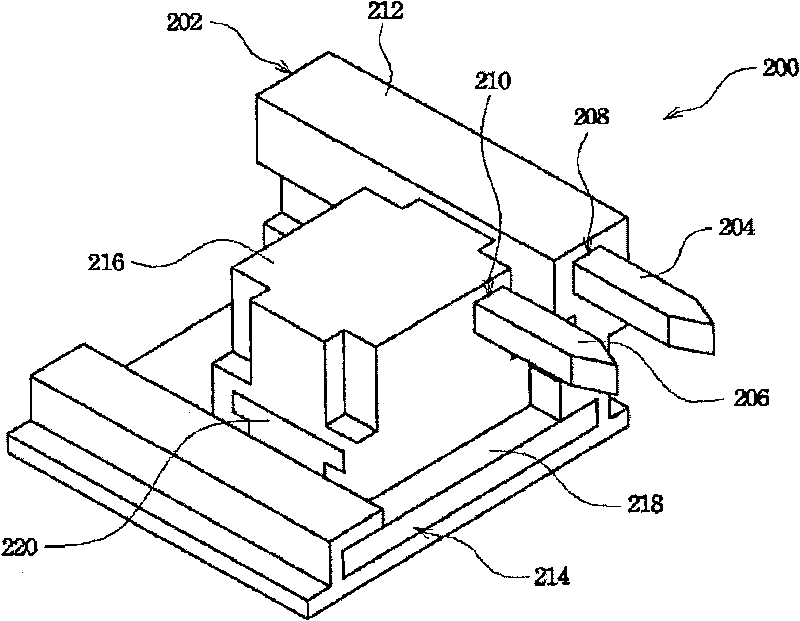

Cutting insert and milling tool

ActiveUS7452167B2Add depthImprove surface roughnessMilling cuttersMilling equipment detailsMechanical engineeringRake angle

A milling tool includes a cutting tool insert, roughly plate-shaped and having a rake face on an upper face and a flank on a side face and a main cutting edge at an intersection ridge line part at the intersection of the rake face and the flank, fitted in the periphery of a substantially cylindrical holder removably and so that an axial rake angle of the cutting edge ridge line of the main cutting edge is positive. When the cutting tool insert is rotated about the axis of rotation of the holder, the shape of the locus of rotation of the main cutting edge in a section parallel to the axis of rotation is made an approximate circular arc shape swelling outward with progress from the ends to the center.

Owner:KYOCERA CORP

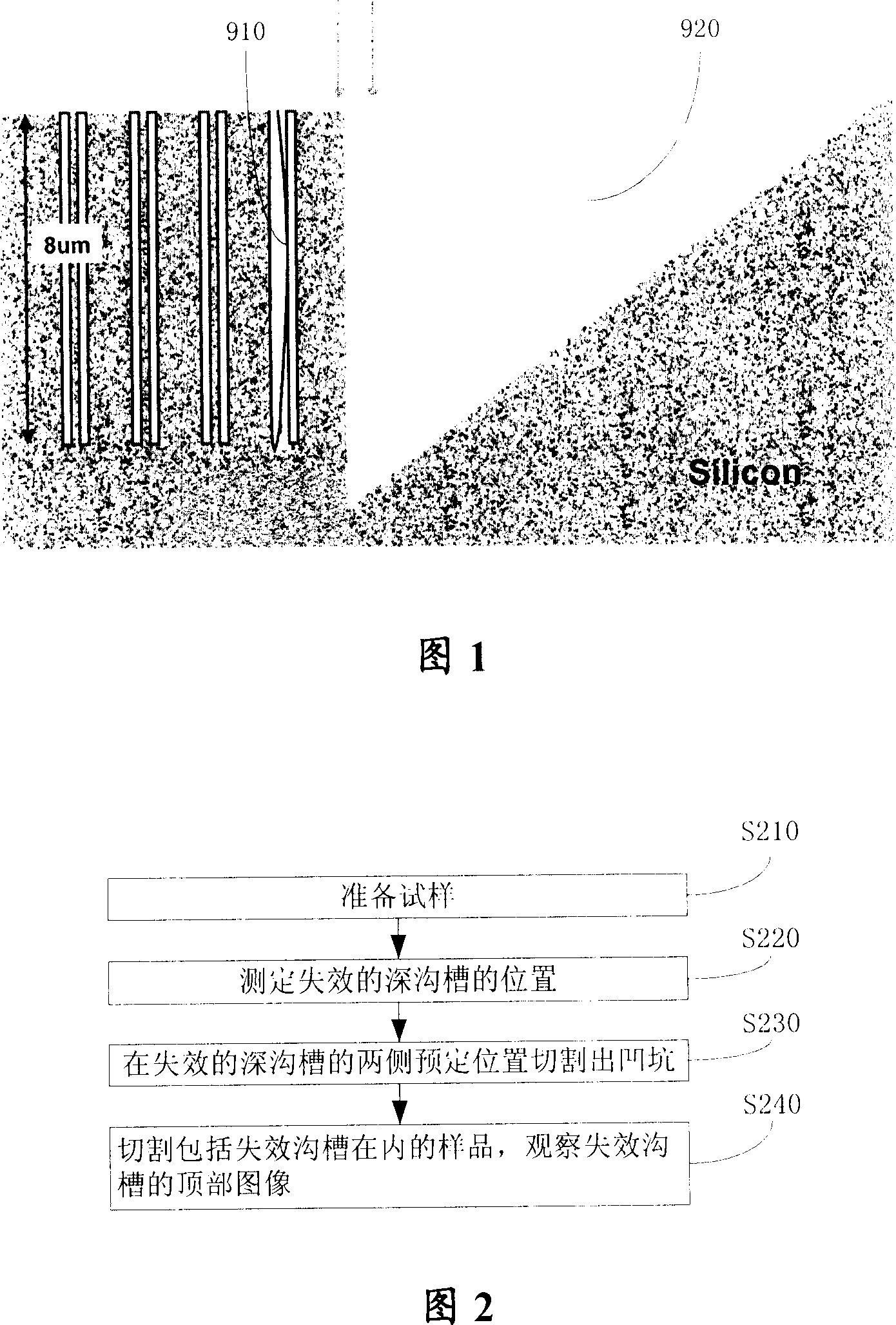

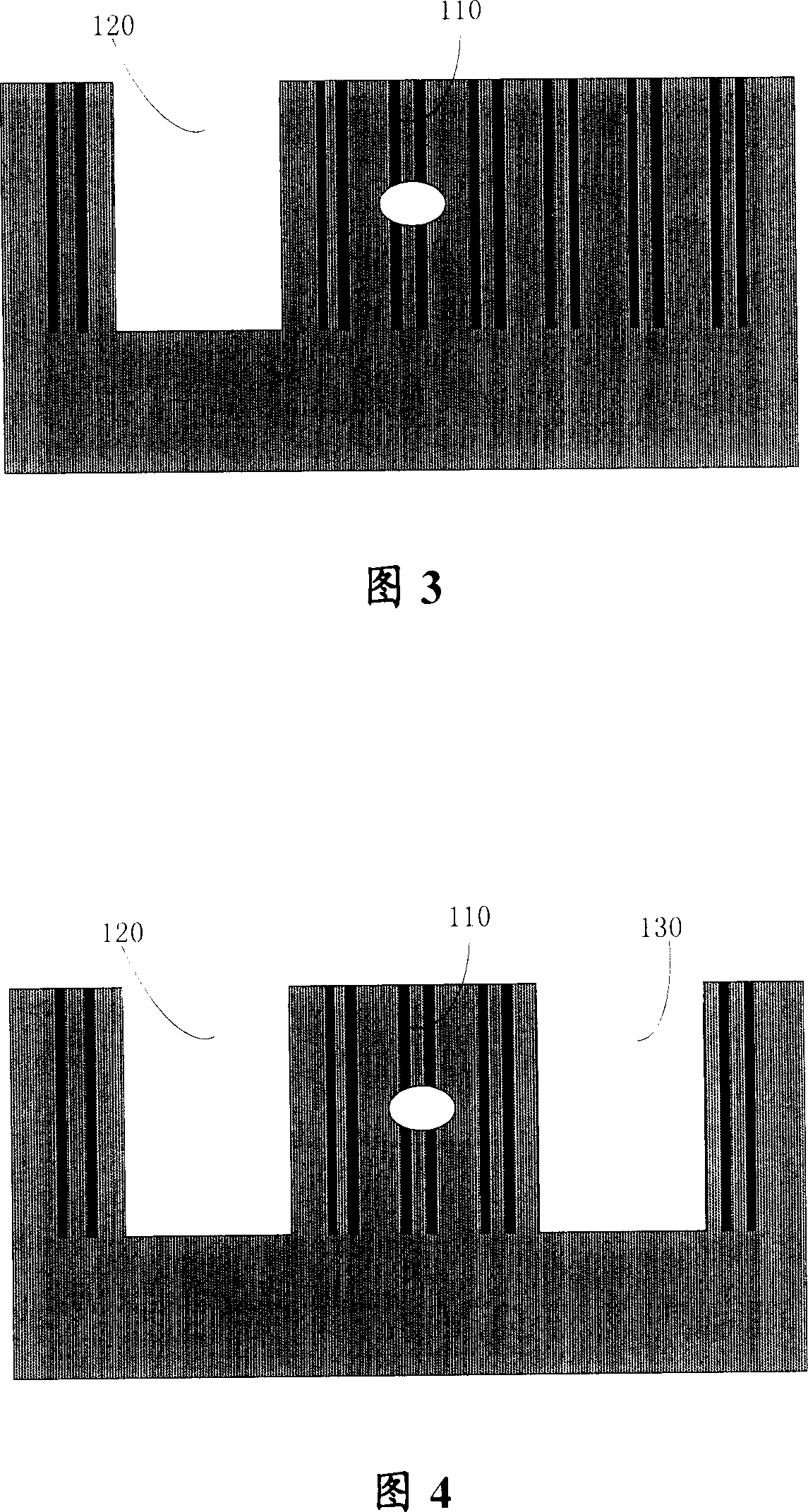

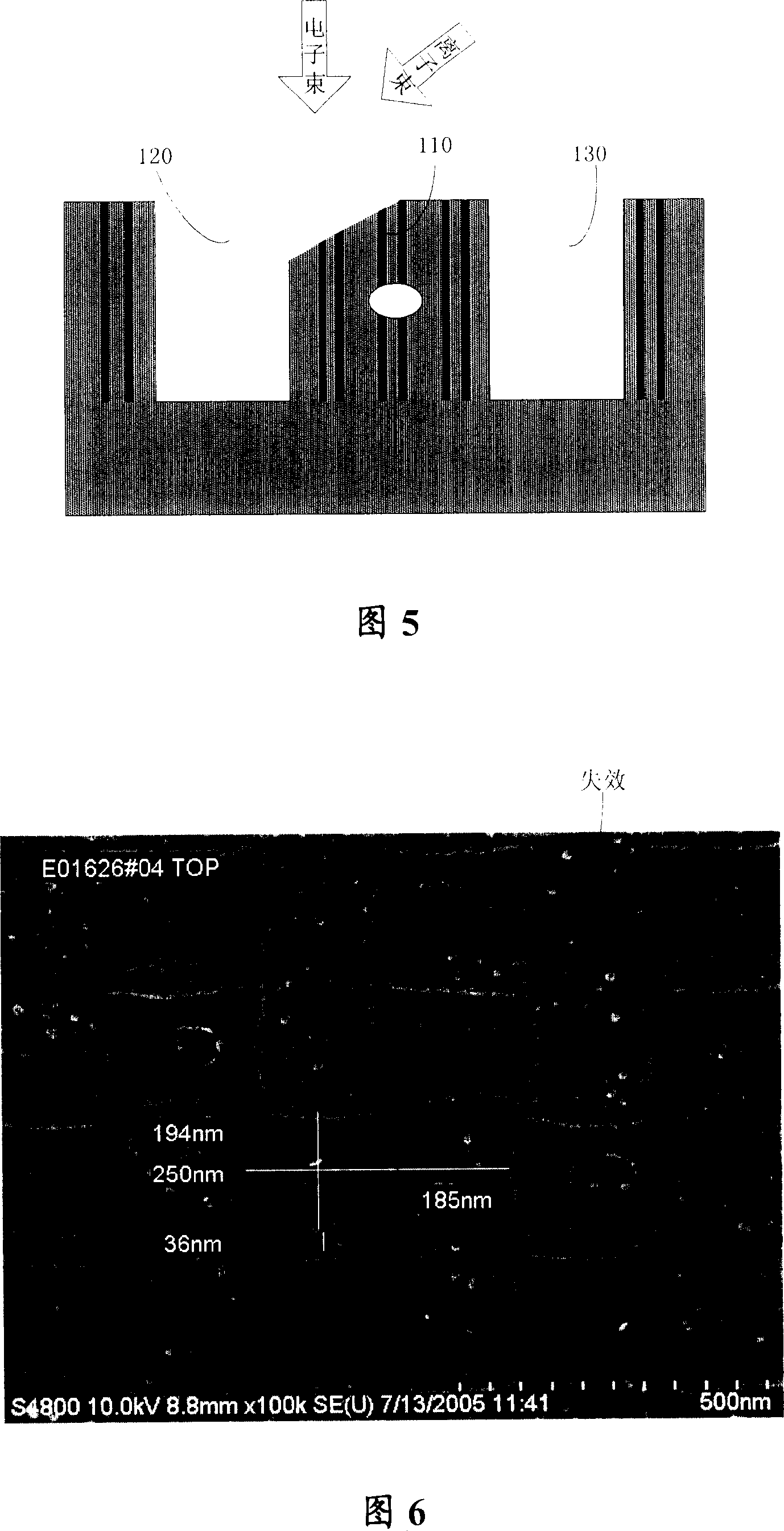

Method for detecting failure dapth of deep channel

InactiveCN1979791AImprove accuracyIncrease success rateSemiconductor/solid-state device testing/measurementIon beamElectron

The method includes steps: preparing specimen, and obtaining position of ineffective deep groove in the sample; when rotating specimen stage for focusing ion beam to prearranged angle; the method uses ion beam perpendicular to surface of specimen to cut out drop pit at prearranged distance on one side of the deep groove; rotating specimen stage for focusing ion beam, the method uses ion beam inclined a prearranged angle with surface of the specimen to cut specimen including specimen with ineffective deep groove; and using electron beam inclined a prearranged angle with surface of the specimen to observing image at top of the ineffective deep groove. The invention saves time for analyzing ineffective depth of deep groove; raises analytical accuracy, and success ratio.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

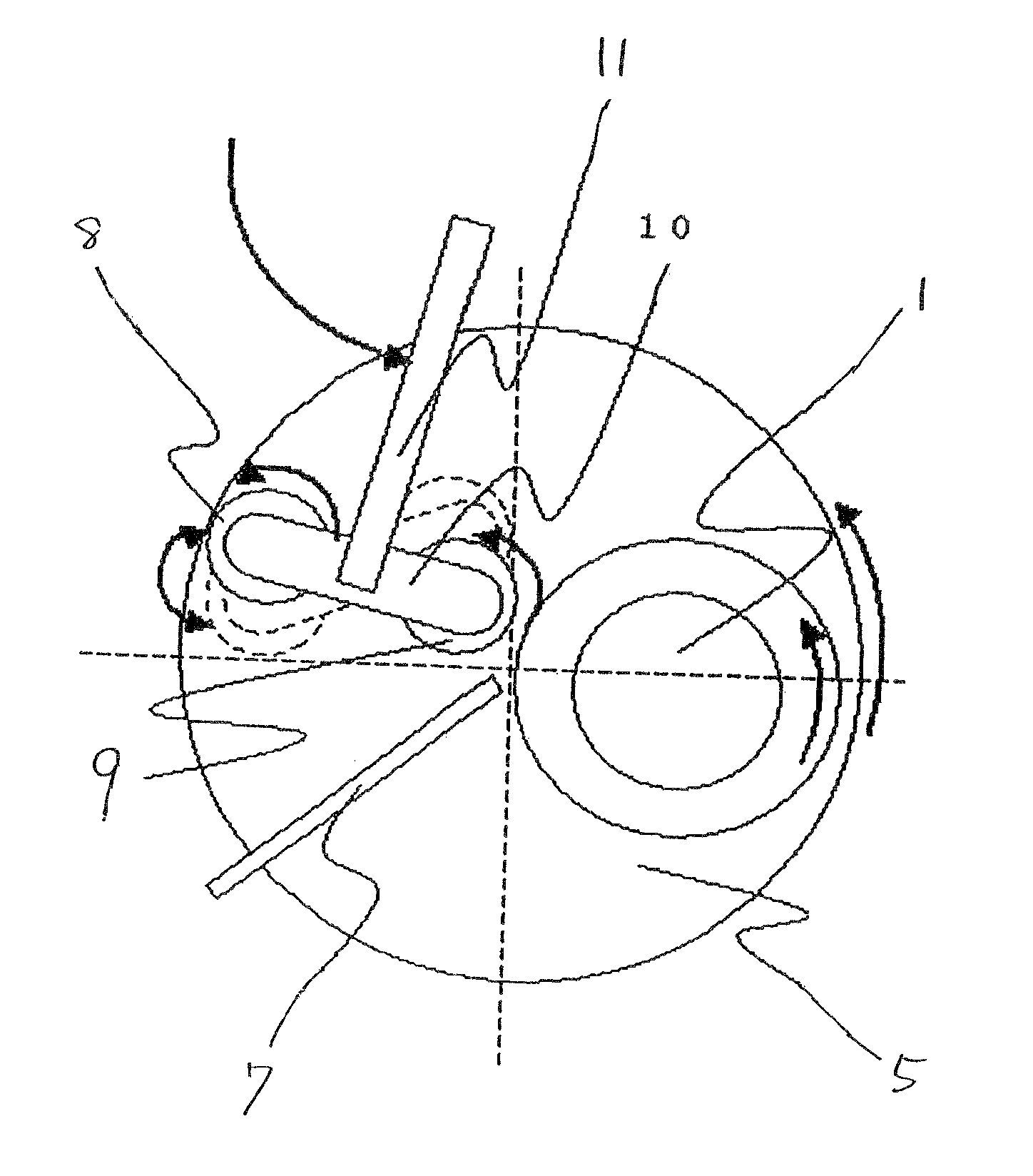

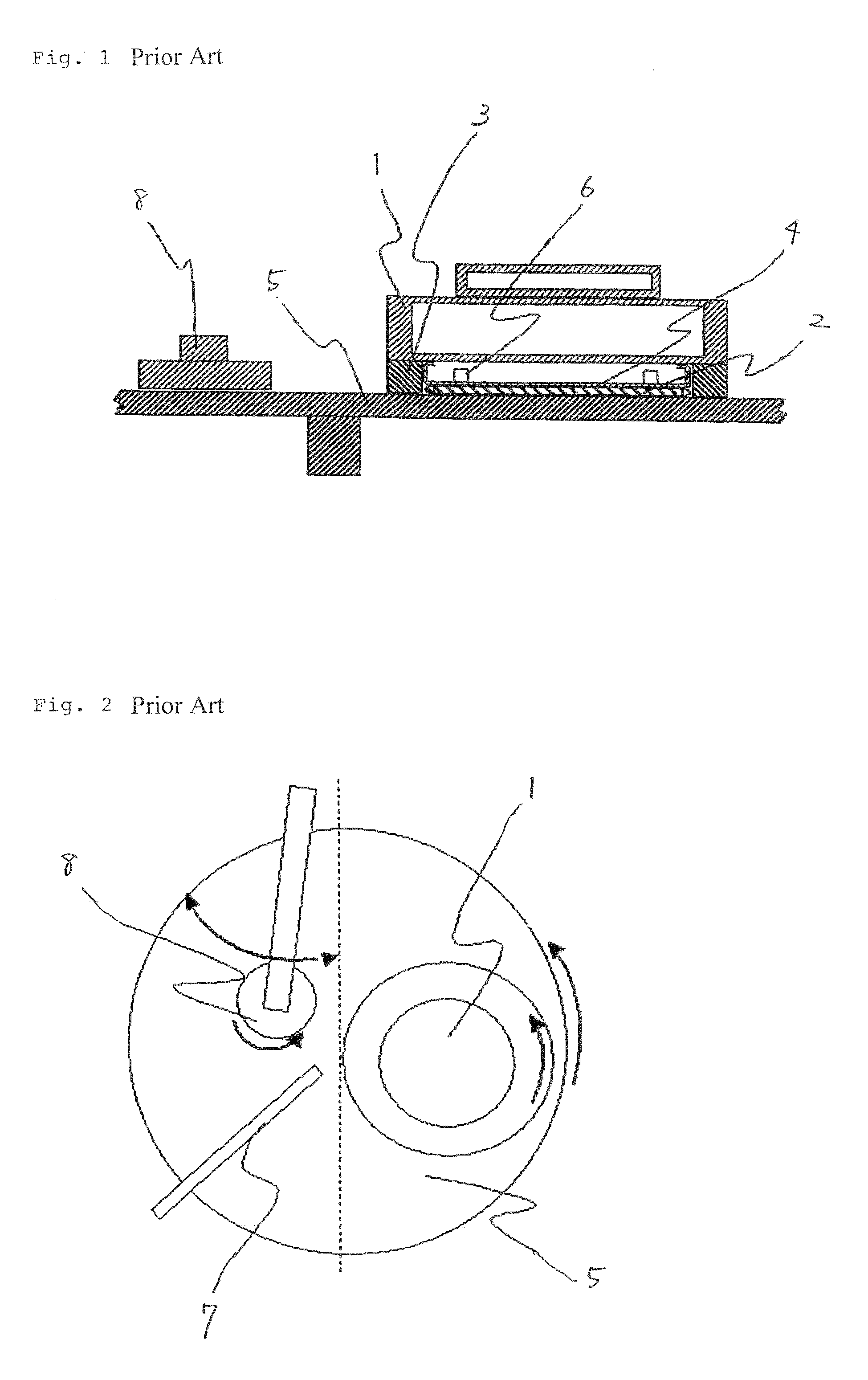

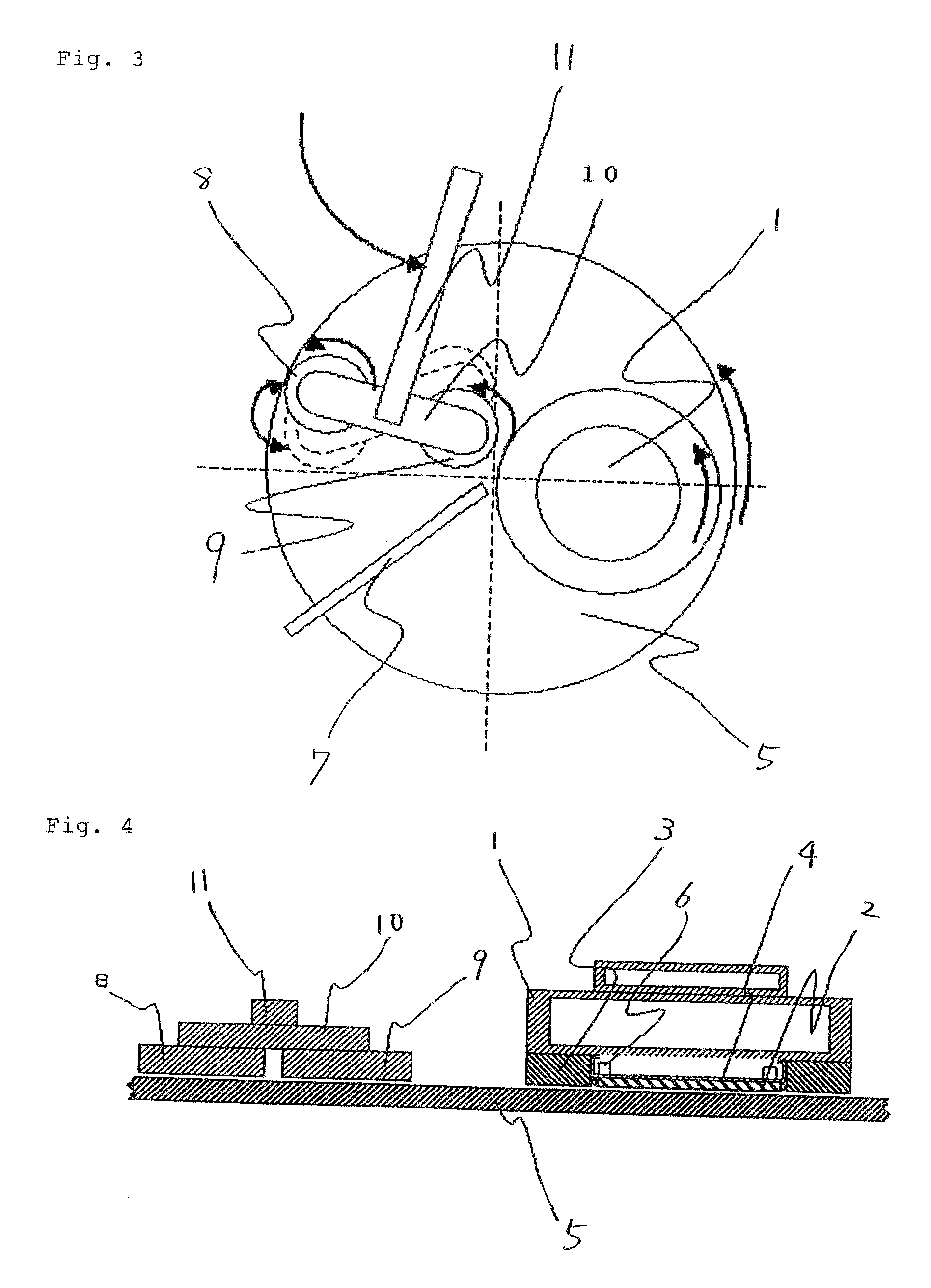

Polishing apparatus and method of reconditioning polishing pad

ActiveUS7708621B2Improve throughputDowntime of the CMP apparatus to be reducedPolishing machinesRevolution surface grinding machinesSemiconductor

This polishing apparatus includes a head that holds a semiconductor wafer, a polishing pad that polishes a surface to be polished of the semiconductor wafer held by the head, and a dresser that reconditions the polishing pad by cutting the polishing pad. The polishing apparatus polishes a surface to be polished of the semiconductor wafer while causing the head and the polishing pad to rotate and reconditions the polishing pad by use of the dresser before and after polishing the surface to be polished. The polishing apparatus of the present invention supports at least two dressers so that the dressers can rotate on their own axes and further includes a dresser oscillator that causes the dressers to oscillate simultaneously on the polishing pad.

Owner:HEFEI RELIANCE MEMORY LTD

Polishing apparatus and method of reconditioning polishing pad

ActiveUS20080242199A1Improve throughputReduce downtimePolishing machinesRevolution surface grinding machinesSemiconductor

This polishing apparatus includes a head that holds a semiconductor wafer, a polishing pad that polishes a surface to be polished of the semiconductor wafer held by the head, and a dresser that reconditions the polishing pad by cutting the polishing pad. The polishing apparatus polishes a surface to be polished of the semiconductor wafer while causing the head and the polishing pad to rotate and reconditions the polishing pad by use of the dresser before and after polishing the surface to be polished. The polishing apparatus of the present invention supports at least two said dressers so that the dressers can rotate on their own axes and further includes a dresser oscillator that causes the dressers to oscillate simultaneously on the polishing pad.

Owner:HEFEI RELIANCE MEMORY LTD

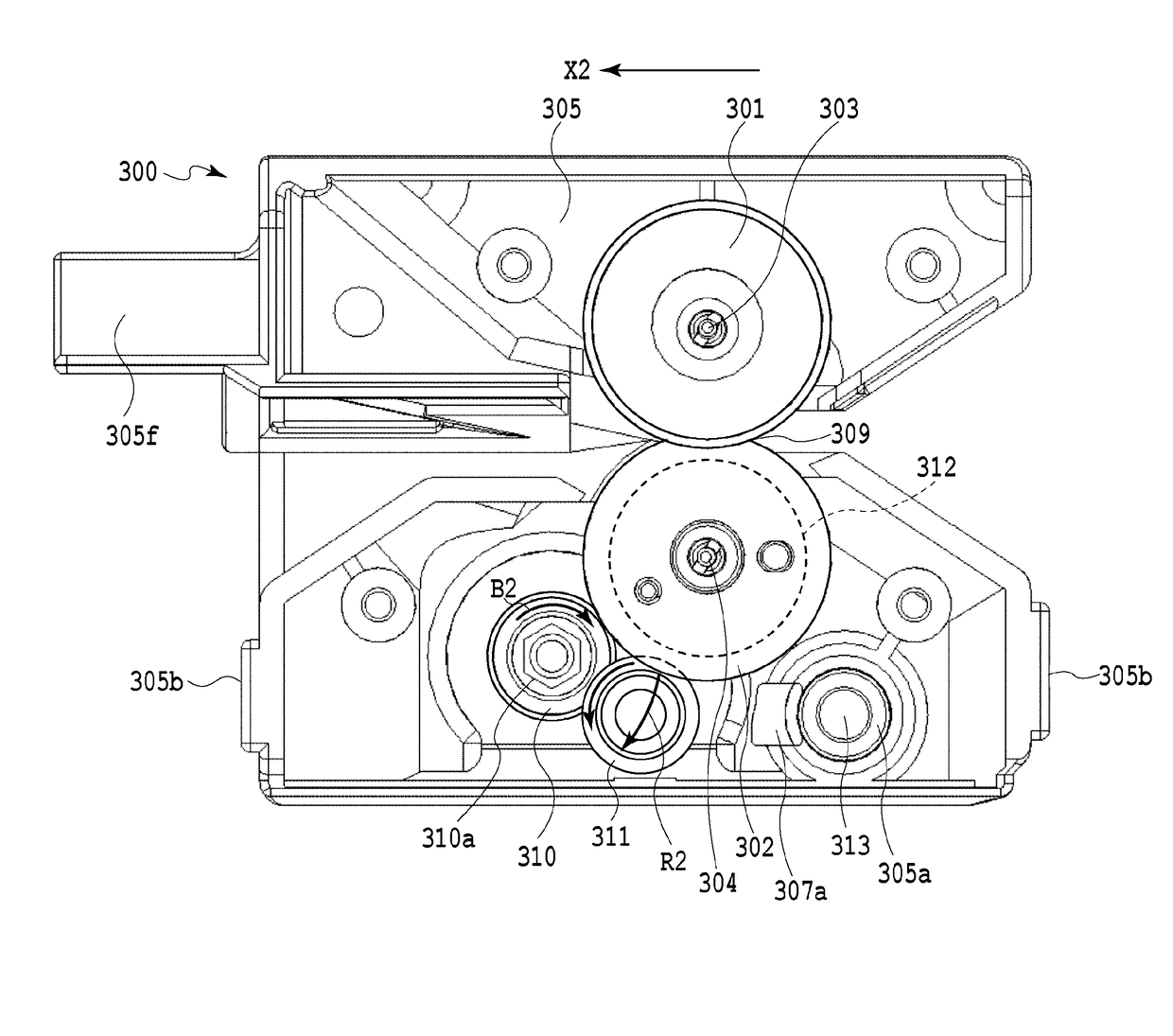

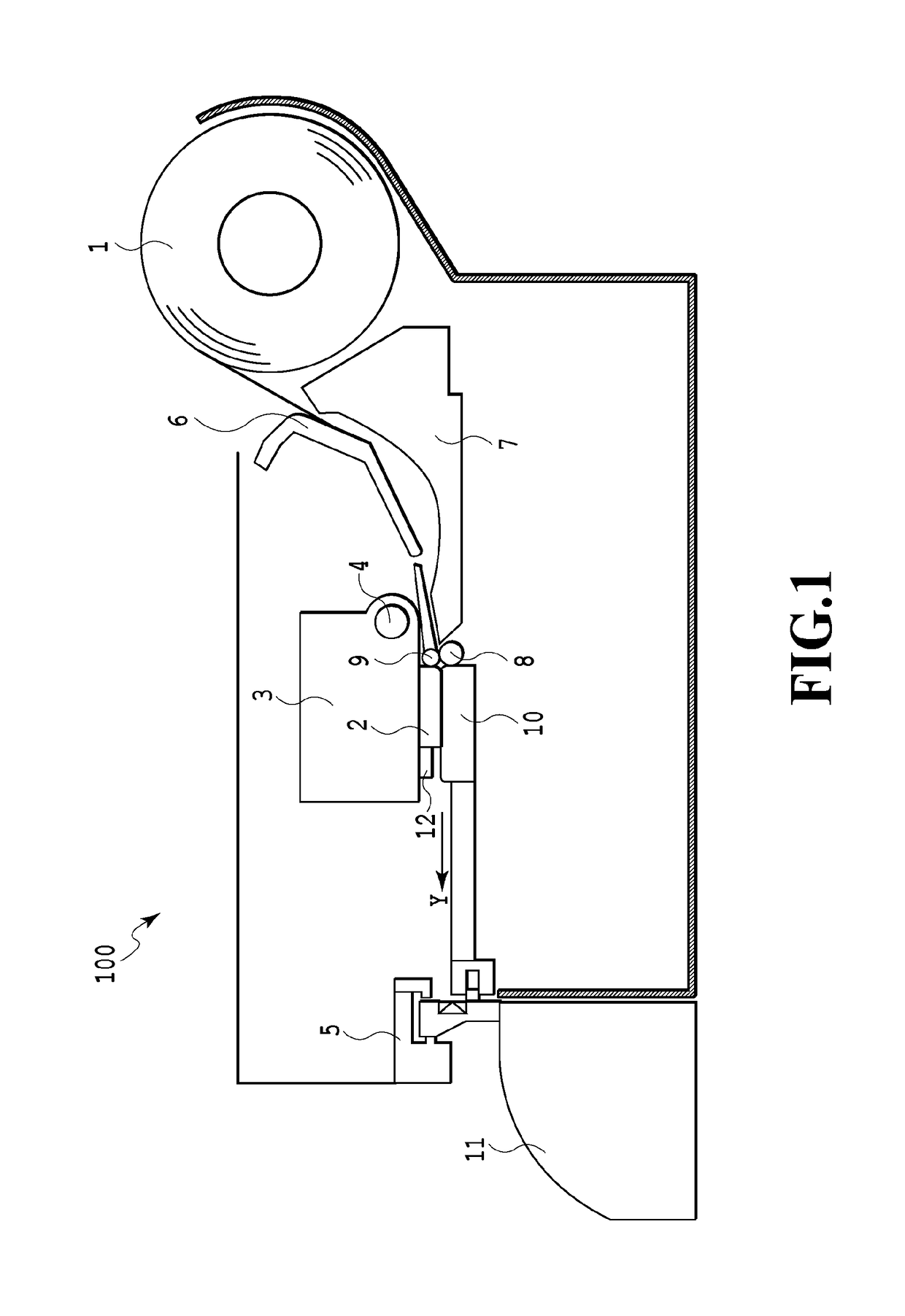

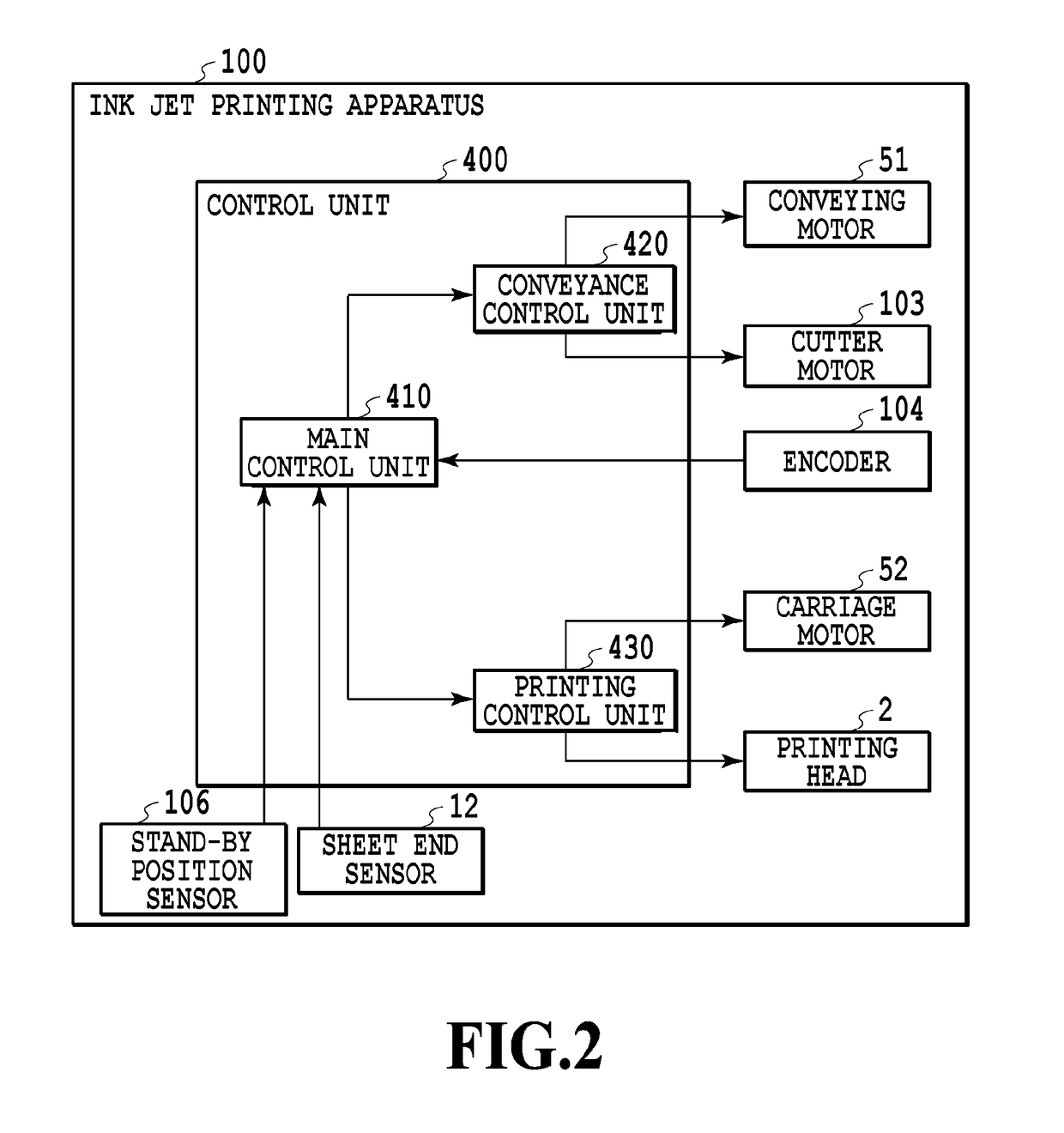

Cutting apparatus and printing apparatus

ActiveUS20170087889A1Reliably cut a sheetReduce cutting timeOther printing apparatusMetal working apparatusEngineeringMechanical engineering

Owner:CANON KK

Device and method for processing roller micro groove

InactiveCN101722316AReduce lossReduce processing costsTool holdersTurning machinesEngineeringTool holder

The invention discloses a device and a method for processing a roller micro groove. The device for processing the roller micro groove at least comprises: a cutter holder, wherein one side of the tool holder is at least provided with a plurality of cutter fixing openings; and a plurality of cutters which are fixedly arranged in the cutter fixing openings in a corresponding manner, wherein each cutter is provided with a knifing and a nose radius, the knifings are different from each other and the same goes for the nose radii, and these cutters can cut the surface of a roller simultaneously.

Owner:INNOLUX CORP

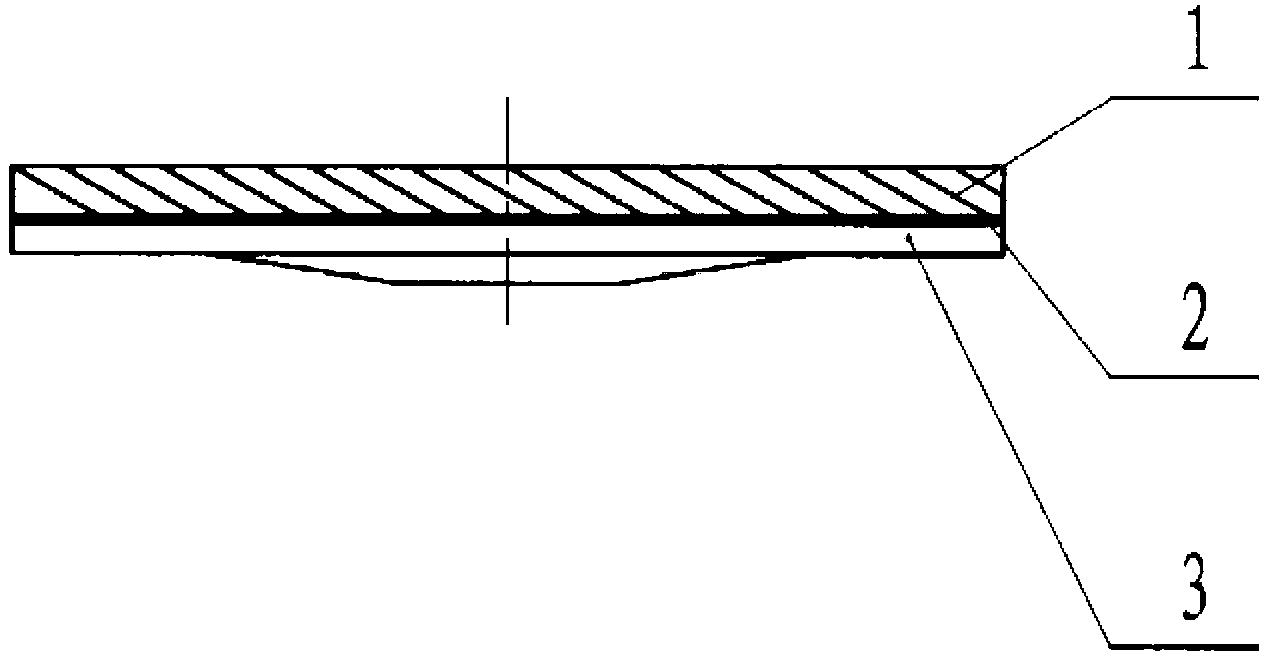

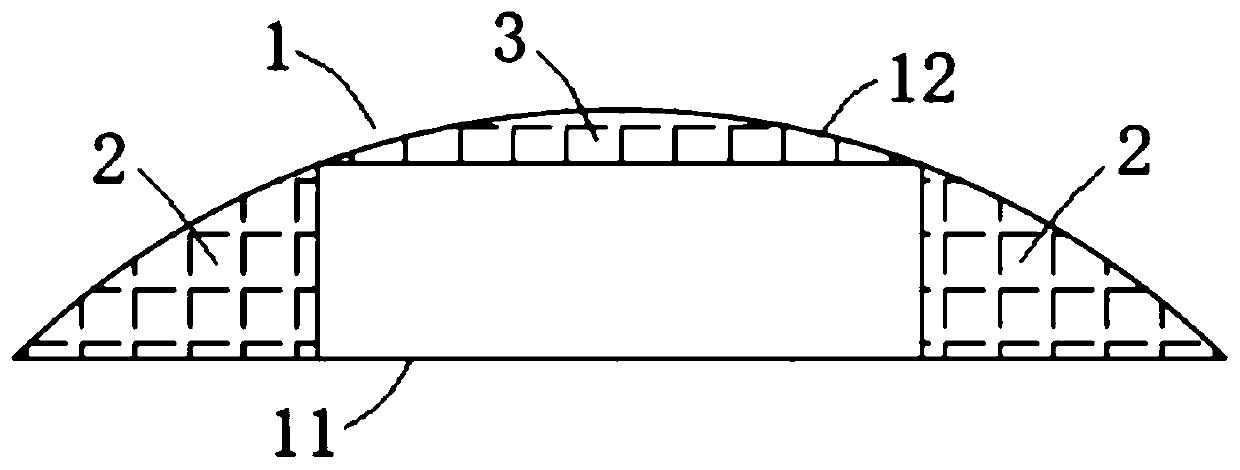

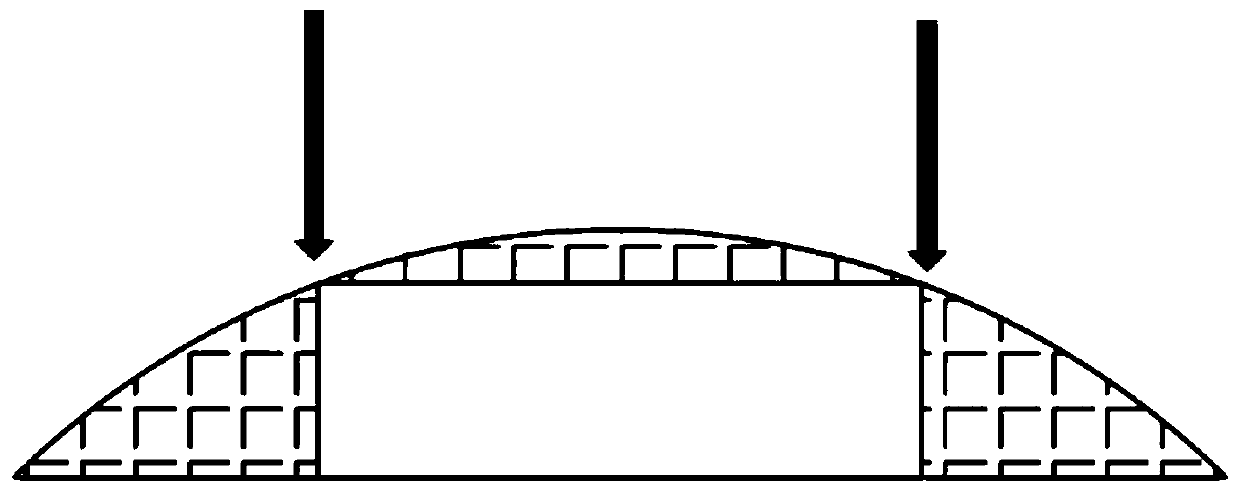

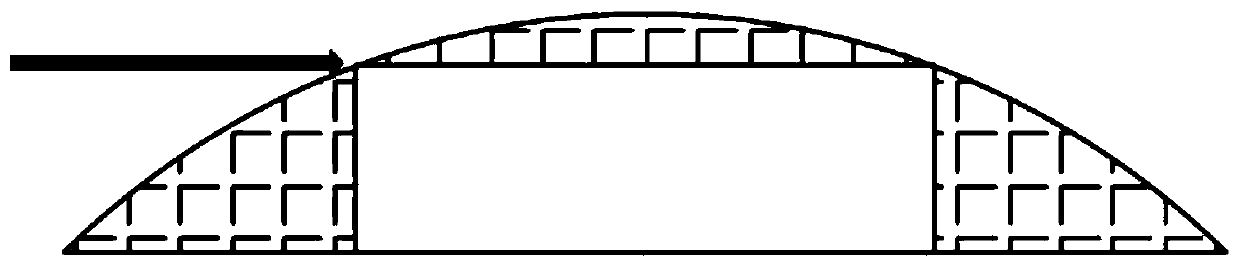

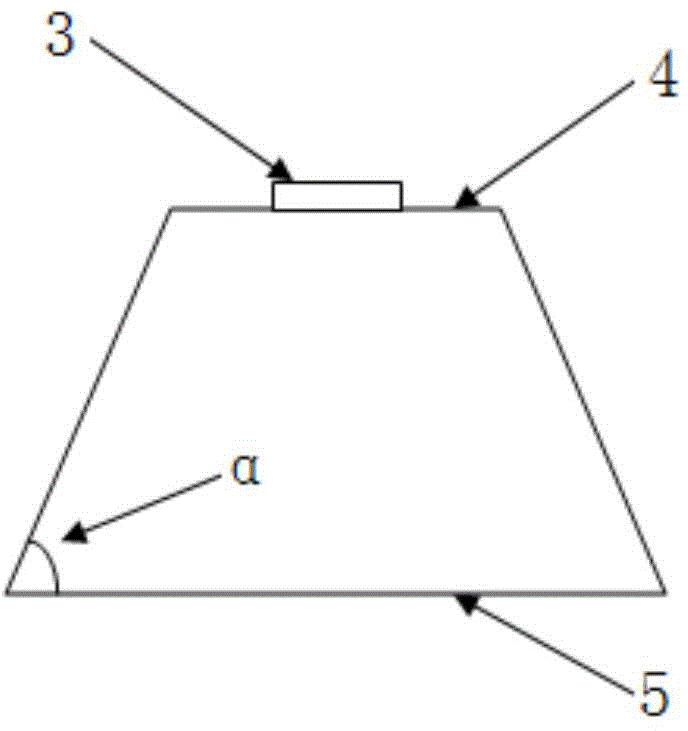

Cutting method of side leather material

PendingCN110712308AReduce cutting timeImprove cutting efficiencyFine working devicesStructural engineeringSingle crystal

The invention discloses a cutting method of a side leather material. The side leather material is generated through silicon single crystal rod squaring. The side leather material comprises a rectangular bottom face, an arc face reverse to the bottom face, and a pair of end faces arranged on the two ends, in the length direction, of the bottom face; combination parts of the bottom face and the arcface are sharp corner portions; and the portion, between the sharp corner portions on the two sides of the side leather material, of the arc face is an arc protruding portion. The cutting method comprises the steps that the sharp corner portions on the two sides are cut off, and the arc protruding portion is cut off; and in the thickness direction of the side leather material, the sharp corner portions on the two sides are cut off, and the arc protruding portion is cut off in the width direction of the bottom face of the side leather material. The cutting time of the sharp corner portions andthe arc protruding portion can be reduced, the cutting efficiency of the sharp corner portions and the arc protruding portion can be improved, slicing time is shortened, and the slicing efficiency isimproved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

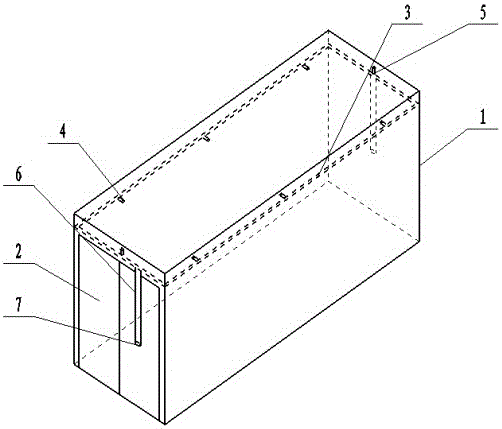

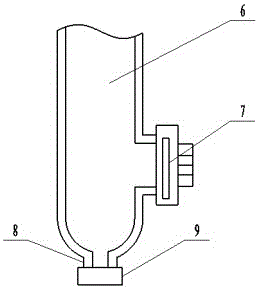

Container integrating fire extinguishing device and using method

The invention discloses a container integrating a fire extinguishing device and a using method. A container main body is of a cuboid structure. A movable door is arranged on the outer side of the container. A circle of fire extinguishing pipeline is arranged at the top end of the side wall of an inner cavity of the container. A plurality of unidirectional nozzles are arranged on the fire extinguishing pipeline. Unidirectional external connectors are fixedly arranged at the two ends in the length direction of the outer side of the container and connected with the fire extinguishing pipeline on the inner cavity side. Two connecting hose perpendicular to the bottom of the container can be arranged temporarily when needed, so that introduction of external fire extinguishing media is facilitated; and the connecting hoses can be taken out and stored in a safe place when not needed. The fixed fire extinguishing pipeline and nozzle devices are arranged in the container, when the interior of the container catches a fire, the fire extinguishing media, such as water or CO2, are conveyed to the container internal pipeline and the nozzles through the external connectors, and the purpose of rapid fire extinguishing is achieved; and the fire extinguishing requirement can be met when a ship is provided with fire fighting water or CO2, and meanwhile the cutting time can be shortened, so that the fire extinguishing efficiency is greatly improved.

Owner:NANTONG COSCO KHI SHIP ENG

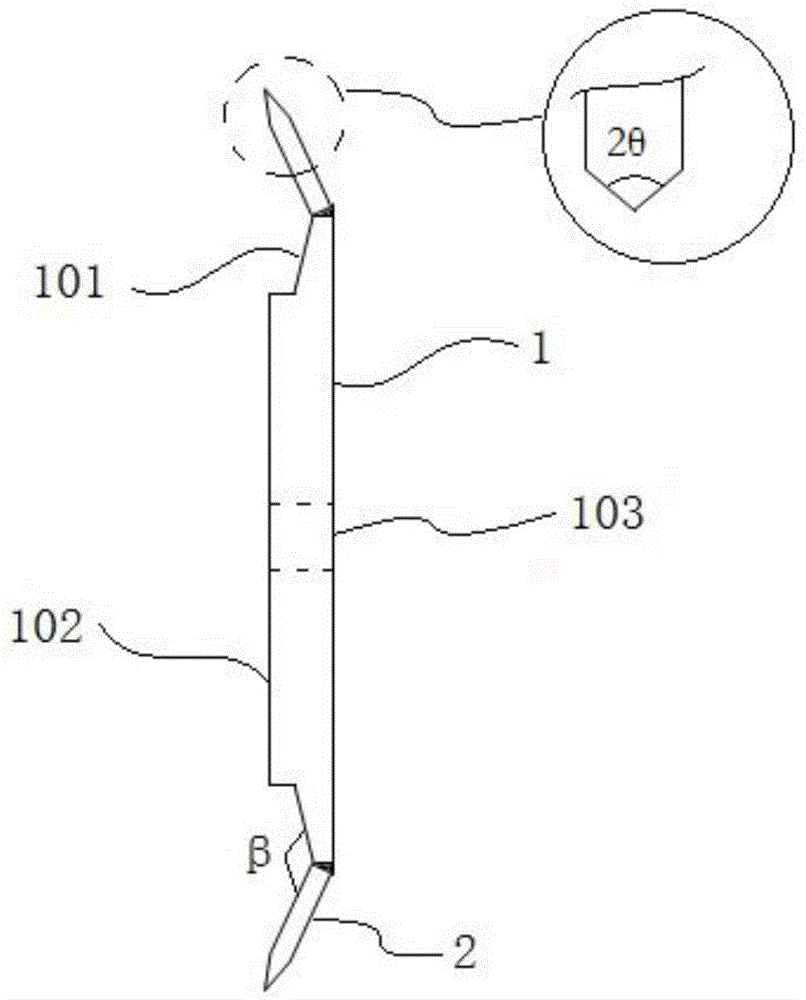

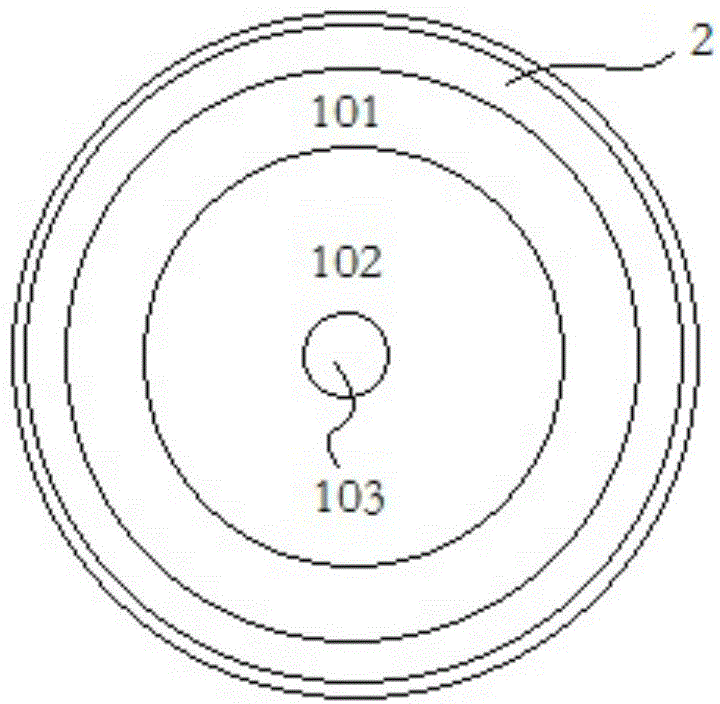

LED (light-emitting diode) chip cutting cutter with novel structure and LED chip cutting method

ActiveCN104476684AReduce cutting timeImprove cutting efficiencyFine working devicesSemiconductor devicesEngineeringSemiconductor

The invention discloses an LED (light-emitting diode) chip cutting cutter with a novel structure and an LED chip cutting method, which belong to the field of semiconductor device processing. The LED chip cutting cutter comprises a flange plate and a blade, wherein the flange plate is shaped like a disk, the center of the flange plate is provided with a flange bulge, the edge is provided with a flange transition, and the center of the flange bulge is provided with a mounting hole; the blade is shaped like a ring, and is fixed at the outer edge of the flange transition. The LED chip cutting cutter is highly stable under the condition of high-speed rotation, and is convenient to mount and dismount. By taking the cutting cutter as a cutting tool, the cutting method can be adopted to directly cut out chips with a trapeziform structure, cutting time is shortened, cutting efficiency is increased, and the cut chips are not damaged, and are high in luminous efficiency.

Owner:马鞍山太时芯光科技有限公司

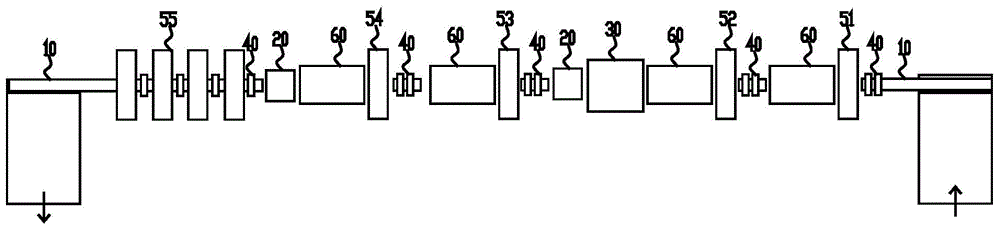

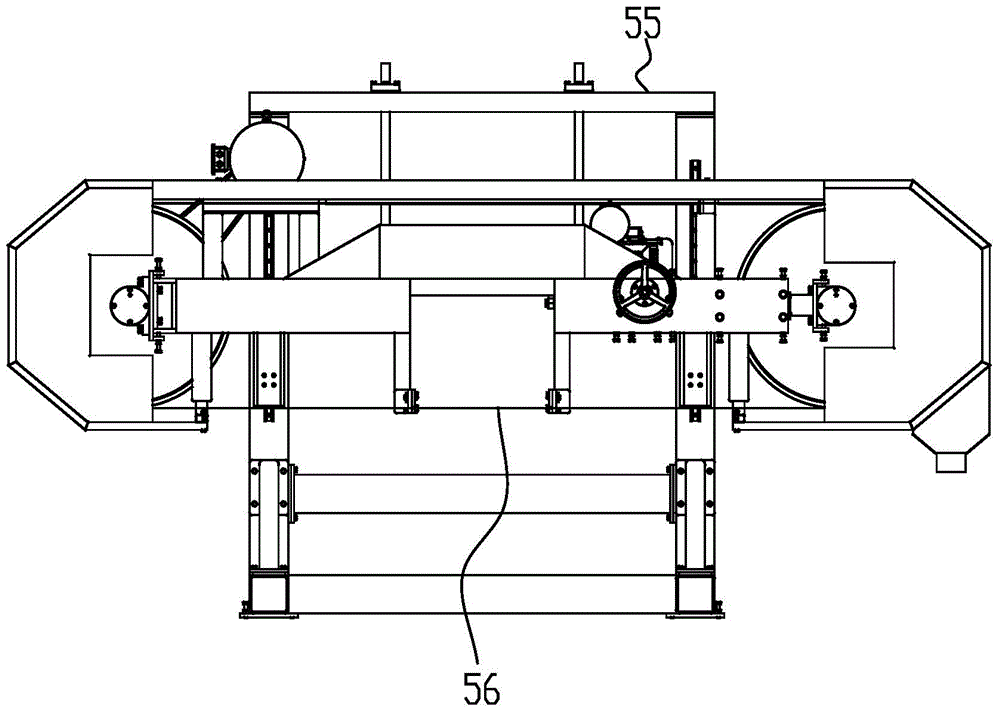

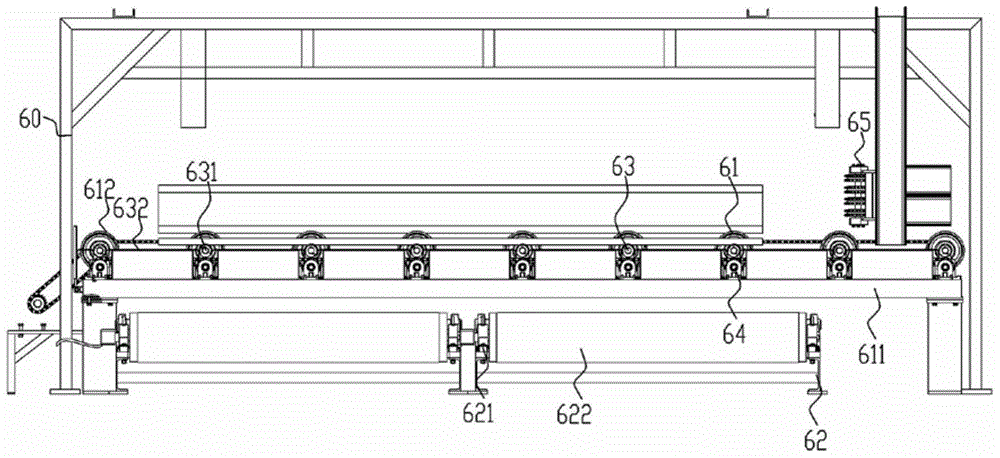

Automatic log treatment system

ActiveCN104308903AFully automated processingImprove processing efficiencyFeeding devicesAdjusting equipmentAutomatic controlPrimary treatment

The invention provides an automatic log treatment system, which comprises a conveyer belt for conveying logs among devices, a primary treatment device for removing peripheral round edges of the logs, and a joint cutting device for cutting the logs in a centralized way. According to the automatic log treatment system, multiple horizontal type saws are combined and are used for accurately cutting the side edges of the logs; under the circumstance of removing edge materials, available log base materials are kept maximally, the primary log treatment accuracy is improved, and full-automatic control is realized. The logs subjected to primary processing are automatically cut in sequence by the joint cutting device via the multiple horizontal type saws, and are cut into multiple needed plates in one step, the log treatment efficiency is improved, and plate cutting and quick and automatic treatment are realized. The automatic log treatment system can be used for improving the log treatment efficiency, reducing the waste and lowering the labor intensity of workers.

Owner:HEBEI RUIFUXIANG MACHINERY MFG

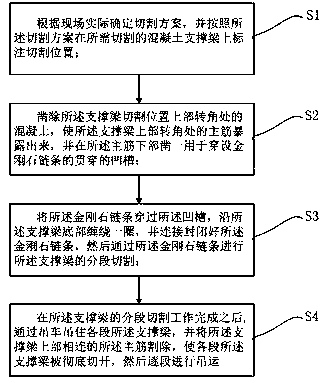

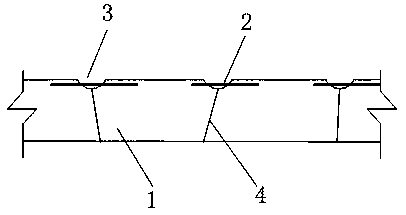

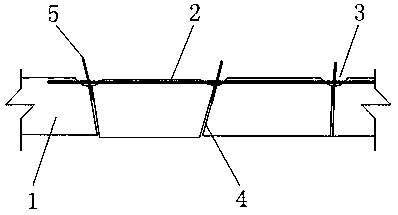

Concrete support beam no-support disassembly method

ActiveCN108612109AReduce construction proceduresReduce construction costsExcavationsStructural engineeringEngineering

The invention provides a concrete support beam no-support disassembly method. The method comprises the following steps: (a) a cutting scheme is actually determined according to the scene; and a cutting position is marked on a concrete support beam needing to be cut according to the cutting scheme; (b) concrete at the upper corner of the cutting position of the support beam is drilled off, so thata main rib at the upper corner of the support beam is exposed; and a through groove for enabling a diamond chain to penetrate through is drilled in the lower part of the main rib; (c) the diamond chain penetrates through the groove to wind the bottom of the support beam by one lap; the closed diamond chain is connected; and then, the segmented cutting is performed on the support beam through the diamond chain; and (d) after the segmented cutting work of the support beam is finished, each section of the support beam is lifted through a crane; and the main rib connected to the upper part of thesupport beam is cut off, so that each section of the support beam is thoroughly cut off, and is lifted for transportation one by one.

Owner:CHINA MCC20 GRP CORP

Drilling method for PCB

ActiveCN105611732AImprove usage accuracyEliminate in timePrinted circuit manufactureEngineeringIndustrial engineering

The invention relates to a drilling method for a PCB. According to the drilling method, a tool is taken from a cutter tray to begin to drill according to a drilling process and cutter data, wherein the drilling process is generated on the basis of drilling data; the drilling data comprise a hole site, a hole number, a plated-through hole or a non-metal through hole, a blind hole or a buried hole layer; the use frequencies of all tools in the cutter tray are recorded in the drilling process; and when the use frequency of one tool reaches the upper limit, the steps are executed as follows: the tool is moved to a preset region from a current position of the cutter tray, and a standby tool in a standby area of the cutter tray is moved to the current position. The drilling data and the cutter data are pre-stored in a computer which is connected with a PCB drilling machine; and the drilling machine can directly take the tool from the cutter tray according to the cutter data in the drilling process, therefore, a worker can carry out gang tool operation without referring to the drilling process in the gang tool operation process; one cutter gang tool mode can be adopted by an entire factory; and the gang tool time is greatly shortened.

Owner:奥士康精密电路(惠州)有限公司

Deflection angle multi-line cutting method and cutting device thereof

The invention relates to a deflection angle multi-line cutting method and a cutting device thereof. In a method for cutting silicon ingots into a plurality of chips in the traditional process, the first silicon ingot and the second silicon ingot are totally parallel to the horizontal plane during fixing, and the cut lines are parallel to the bottoms of the silicon ingots, so no deflection angle is formed. The deflection angle multi-line cutting method of the invention cuts the two silicon ingots subjected to chamfering treatment in a multi-line mode at the same time. By adopting the method of the invention, the reduction of cutting time by 10 to 20 minutes from the traditional 430 minutes has great significance, for a certain working time needs to be consumed during detaching the cut silicon chips and replacing new cut lines; if the detachment and replacement consume over-long time and the time is converted into the cutting time of about 7 hours, the total working period exceeds 8 hours, and the working mode of three shifts made every 8 hours each day can be converted into a mode of two shifts in the effective working period; thus, enough time is left for preparing a next cutting operation.

Owner:JINKO SOLAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com