Patents

Literature

92 results about "Post-Procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The time period after a diagnostic or therapeutic procedure.

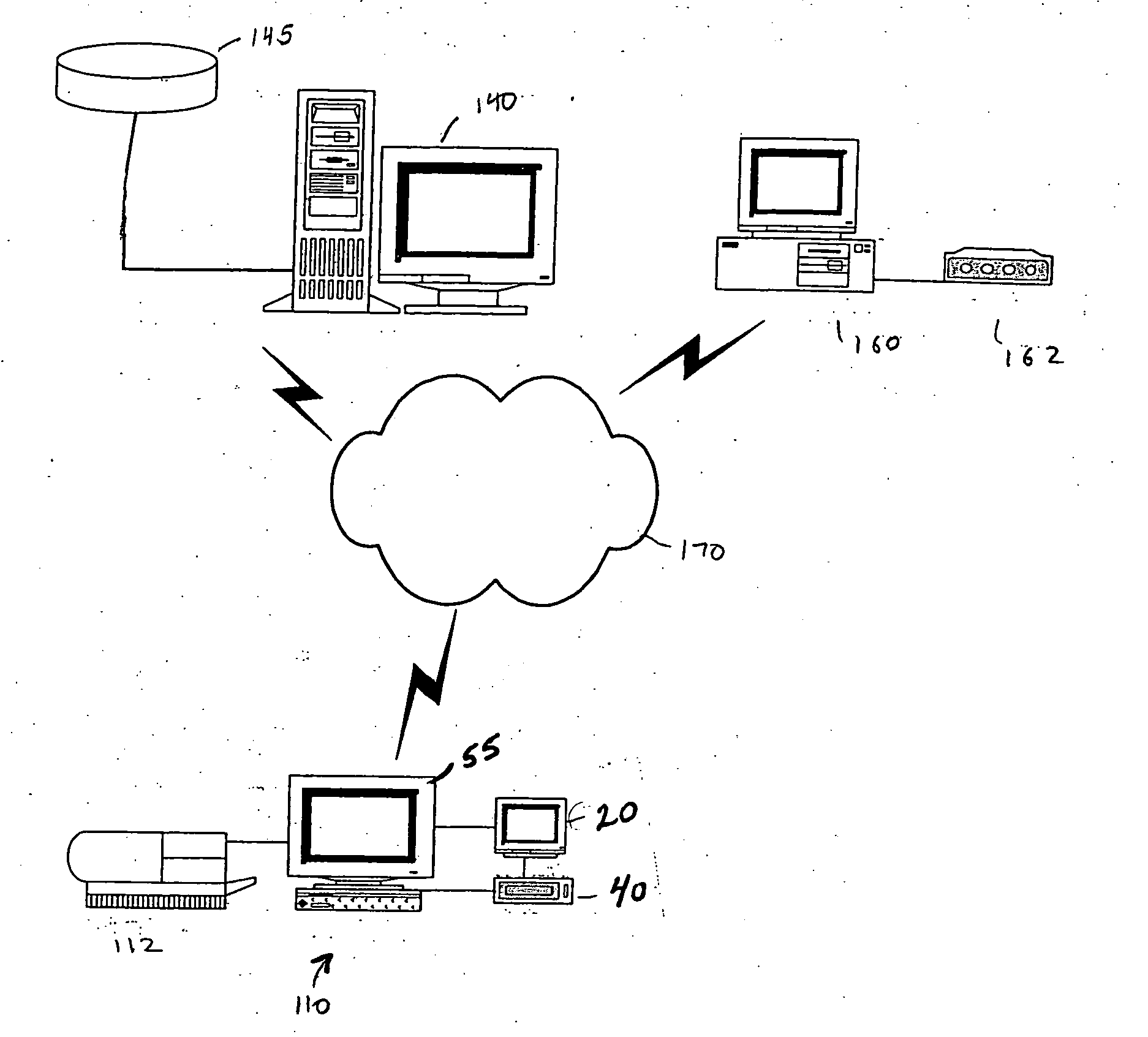

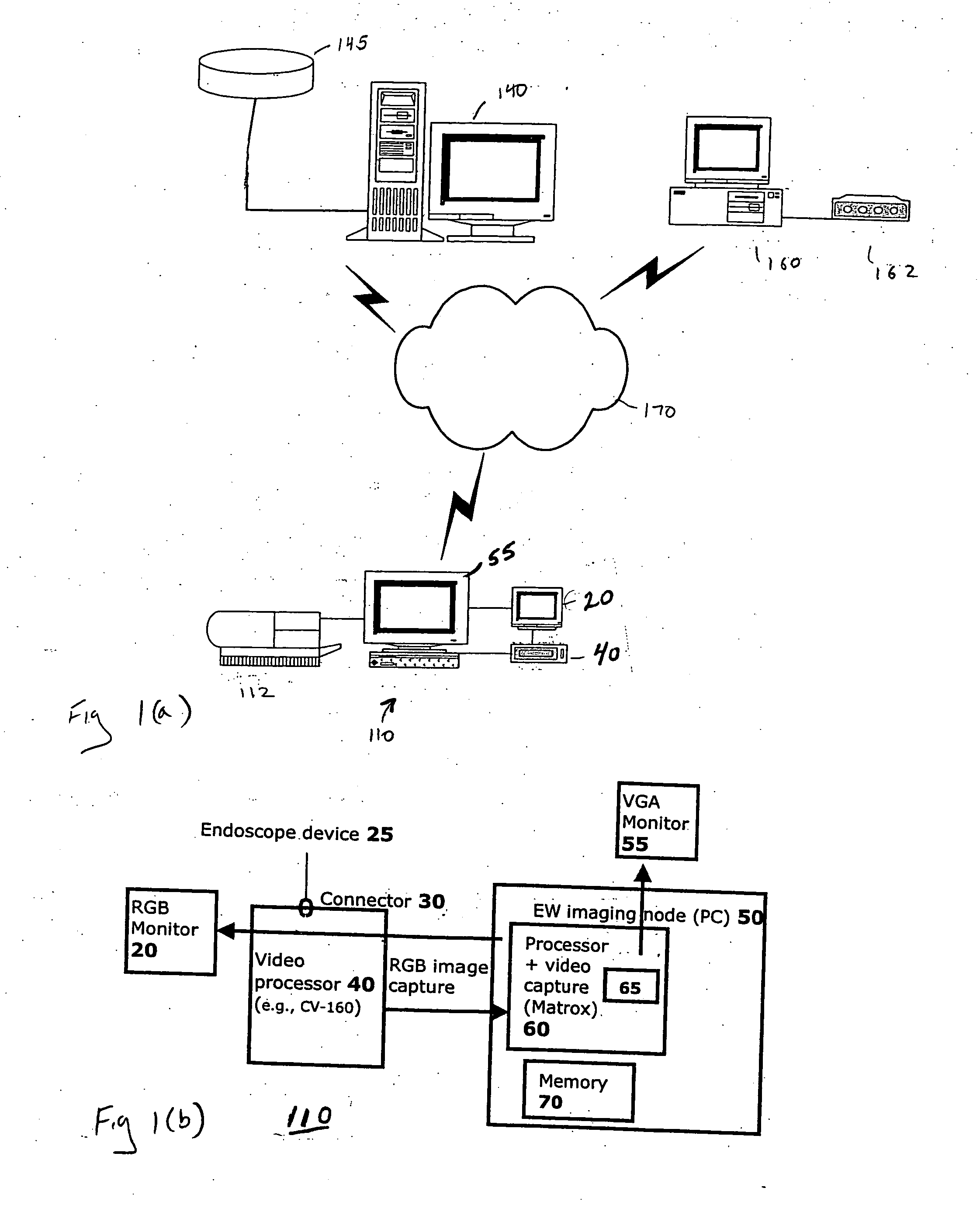

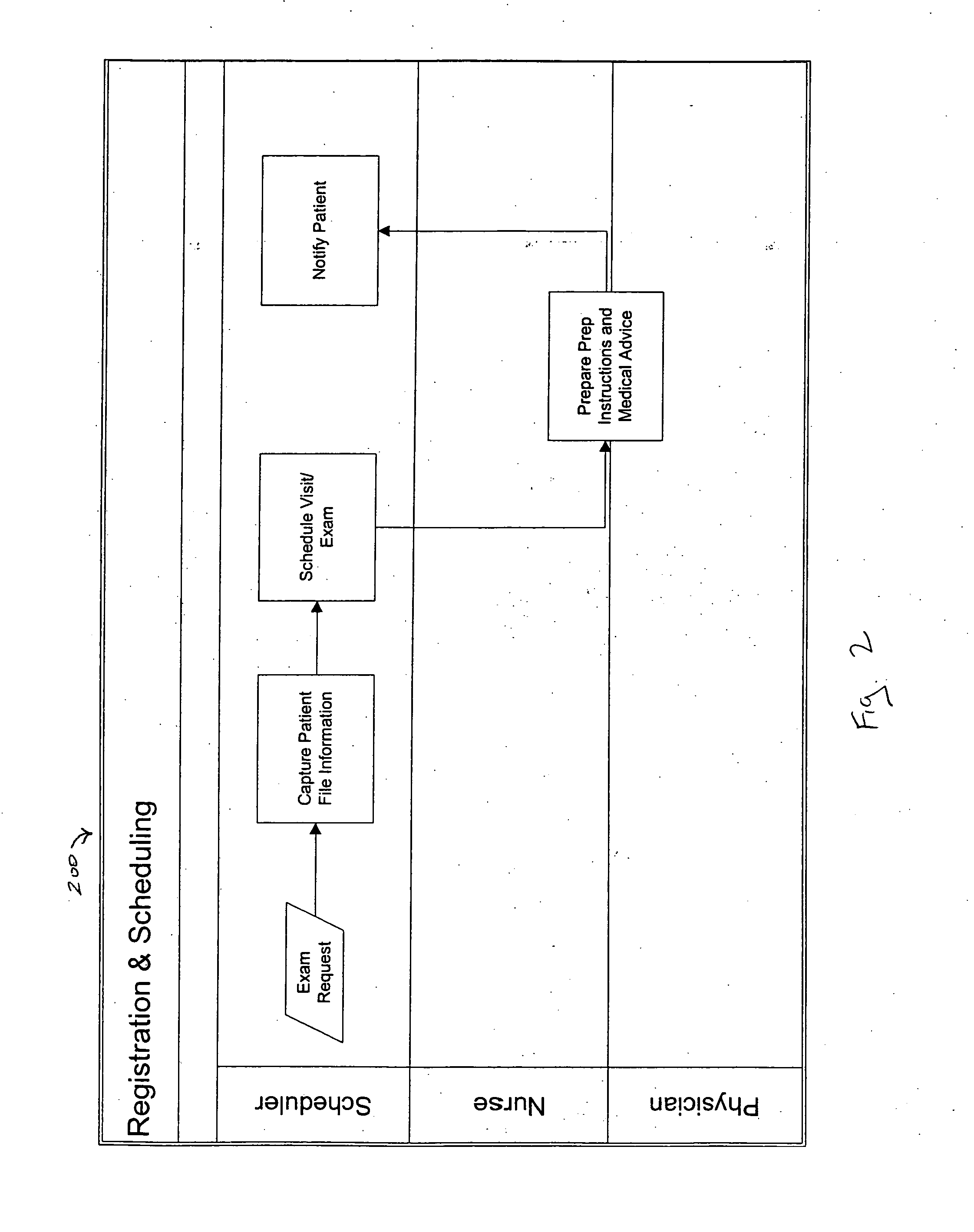

System and method for managing an endoscopic lab

A system designed to support and manage the workflow for all user roles pertaining to an endoscopic laboratory, from registration and scheduling of patient information through pre-procedure, procedure and post-procedure phases of an endoscopic examination, including support for the entry, by various users associated with an endoscopic laboratory, of information and data including the processing and storage of endoscopic images captured during an endoscopic exam of a patient, for association with a patient record stored in a database, and including the entry of procedure notes and generation of reports that include the stored images, all via an integrated user interface.

Owner:OLYMPUS AMERICA +1

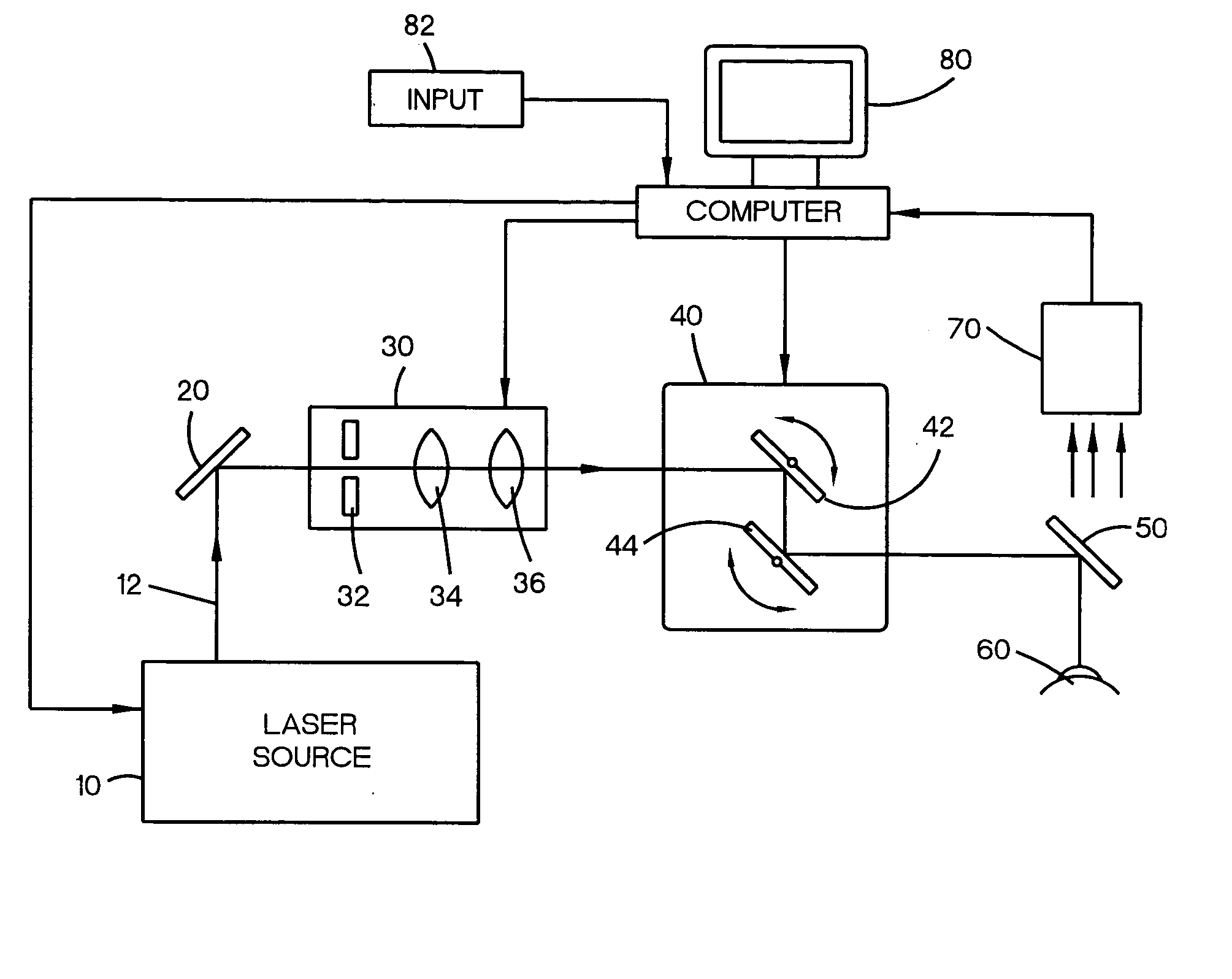

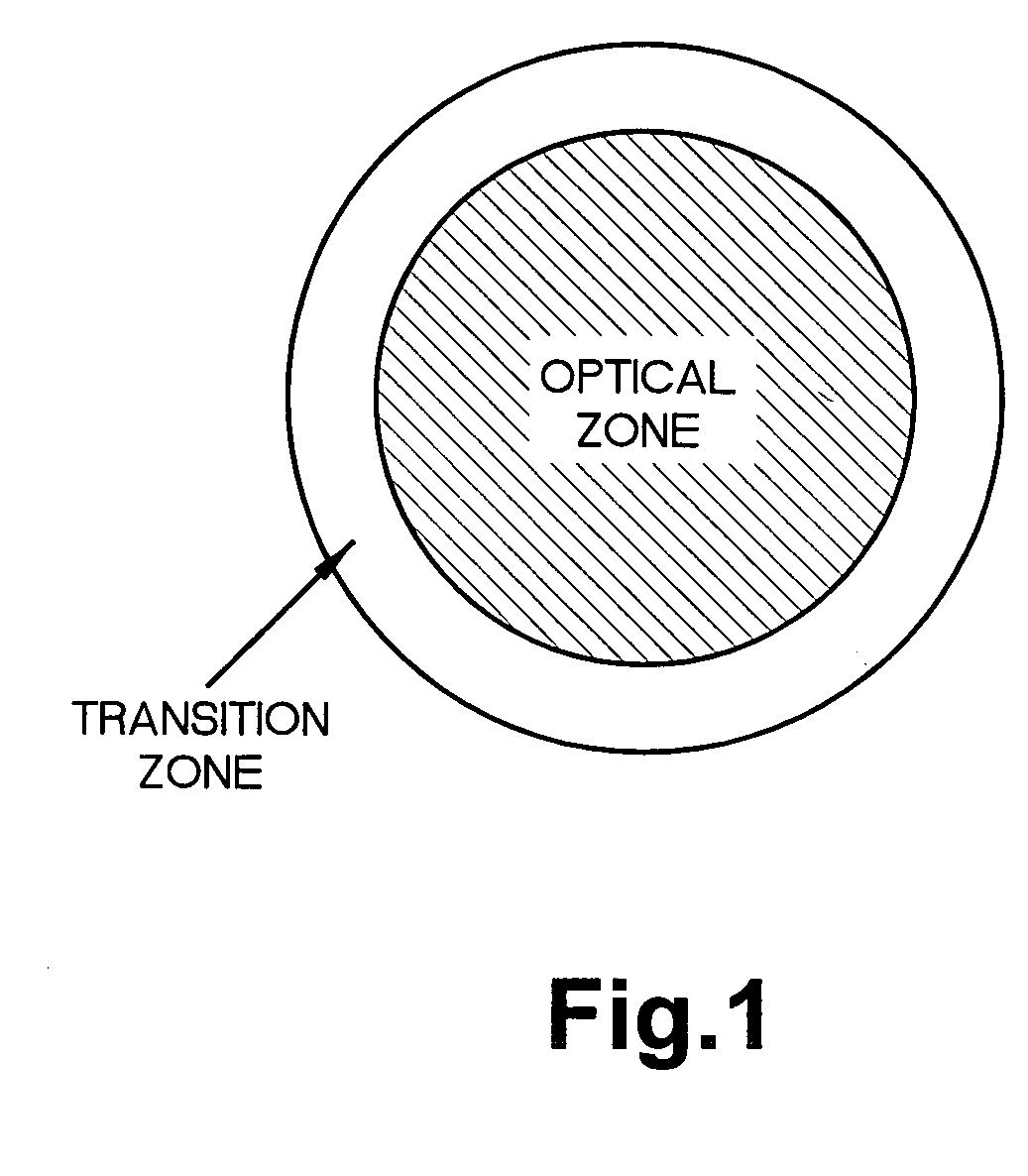

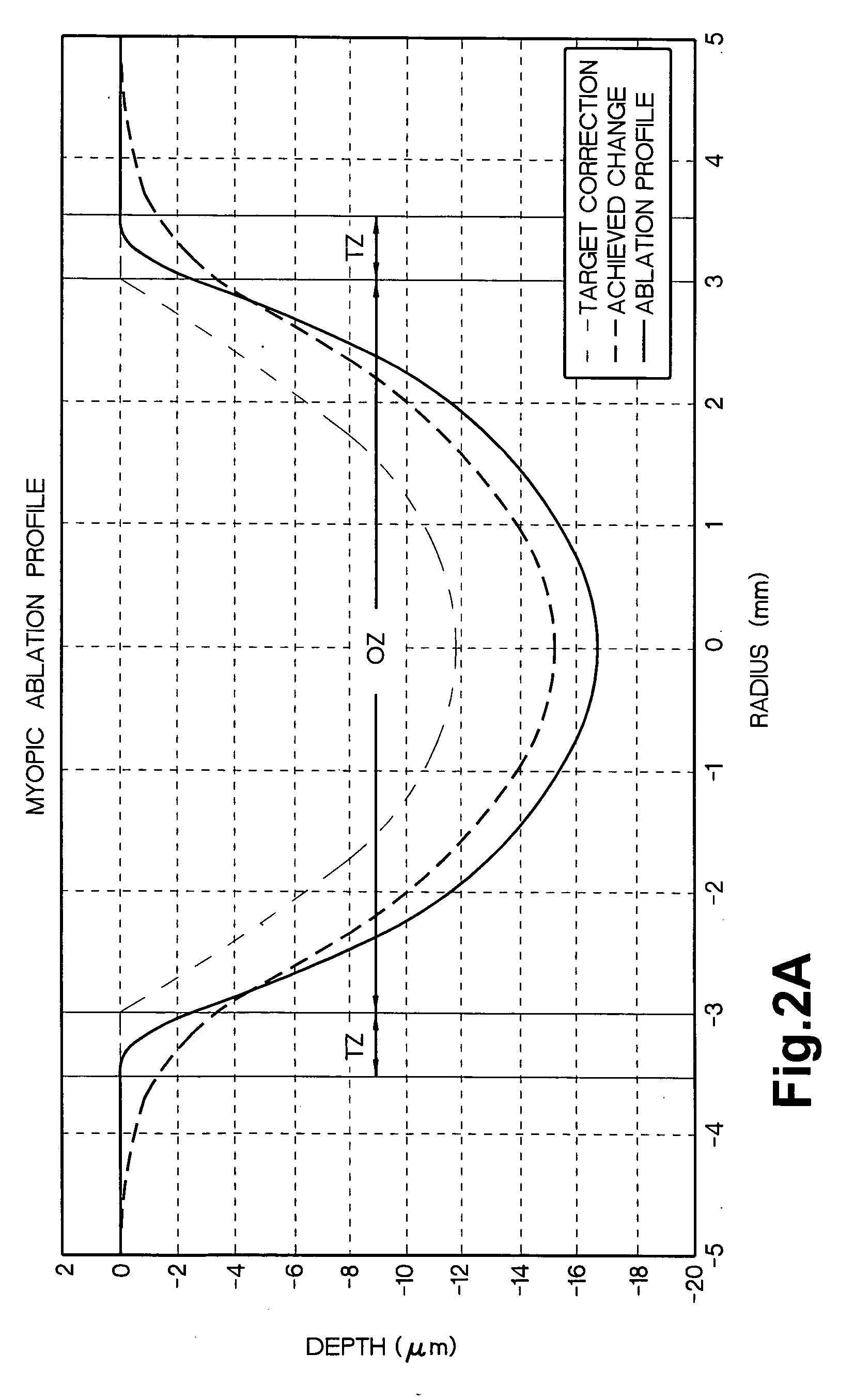

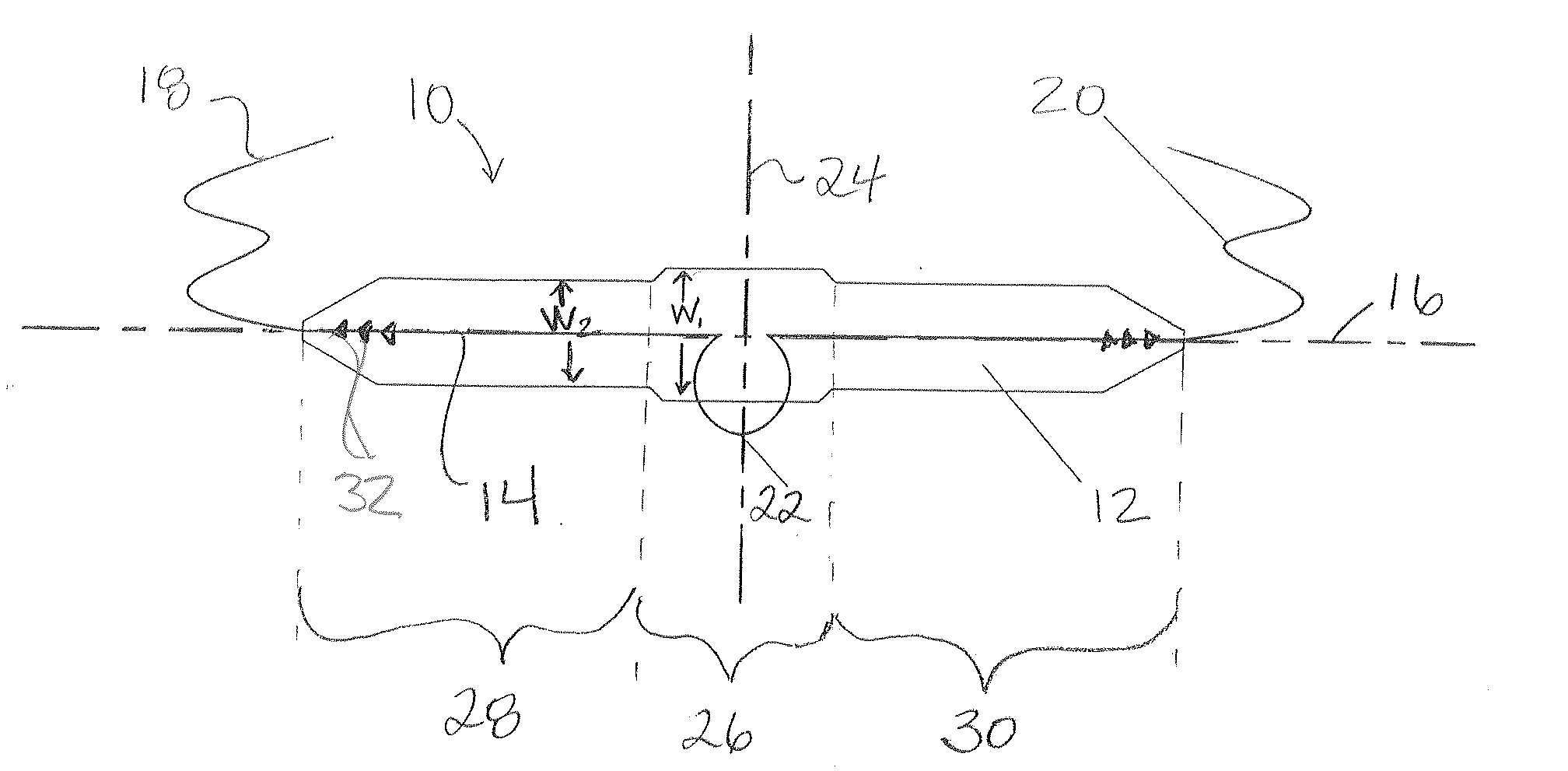

Method and apparatus for controlling ablation in refractive surgery

InactiveUS20050107775A1Minimize spatial overlapThe result is accurateLaser surgerySurgical instrument detailsRefractive errorFarsightedness

The present invention relates to laser ablation patterns to correct refractive errors of the eye (60) such as nearsightedness, farsightedness, astigmatism, and higher order aberrations of the eye (60). The laser ablation patterns used to control the laser (10) prevent induced aberrations by compensating for post-procedure epithelial smoothing. The position of laser pulses (12) is also controlled to optimize the achievement of the intended ablation pattern.

Owner:THE CLEVELAND CLINIC FOUND

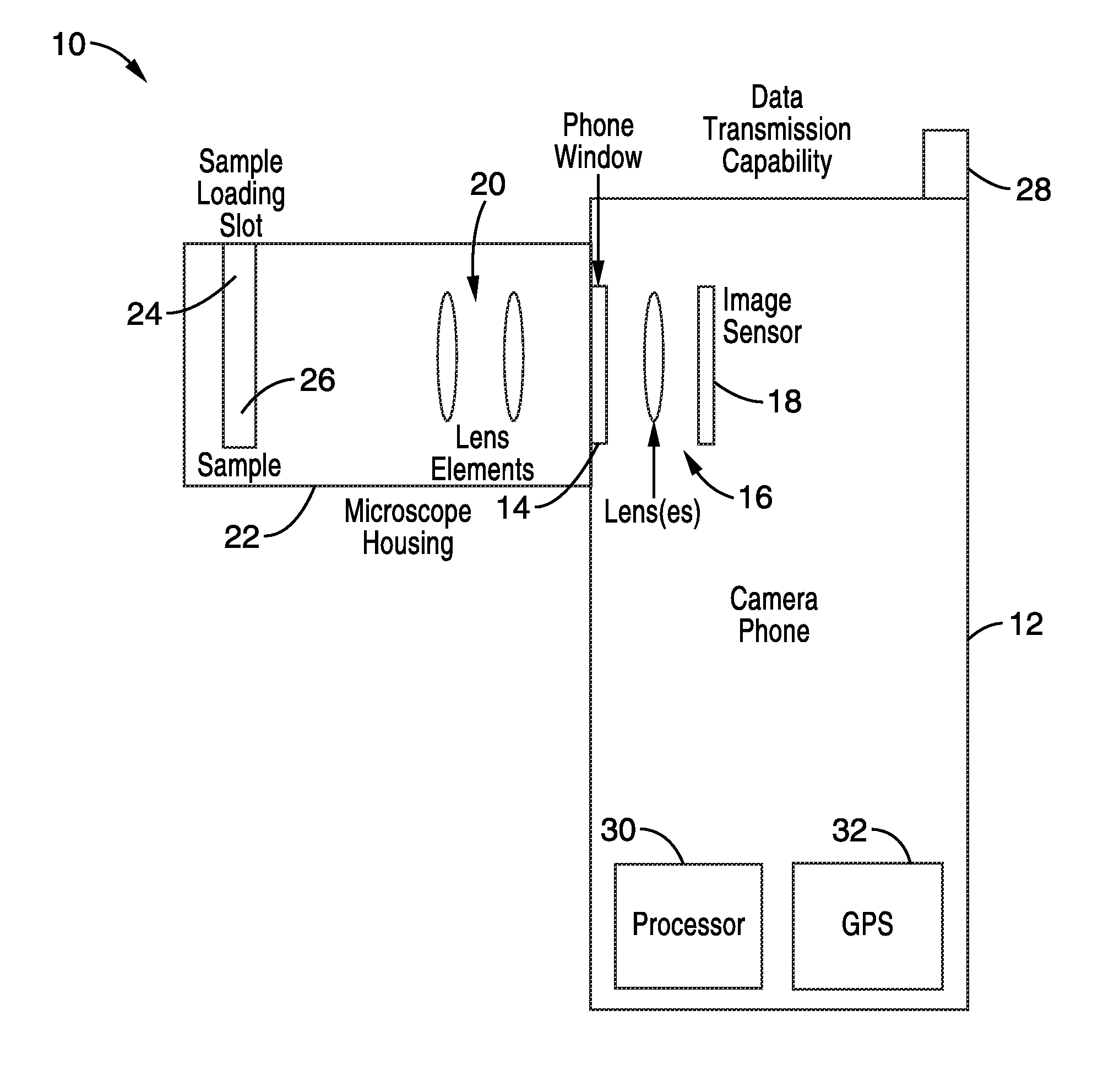

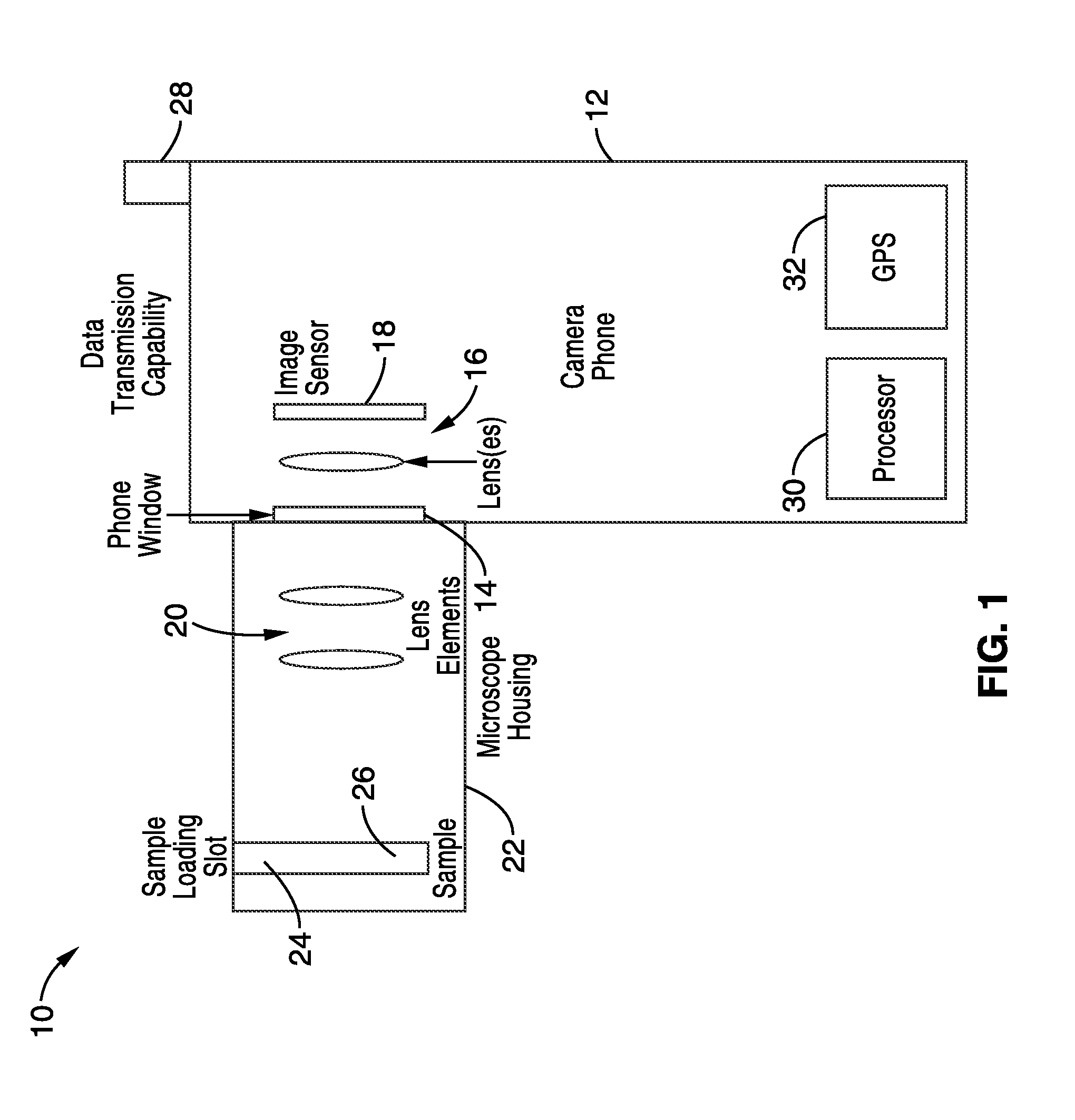

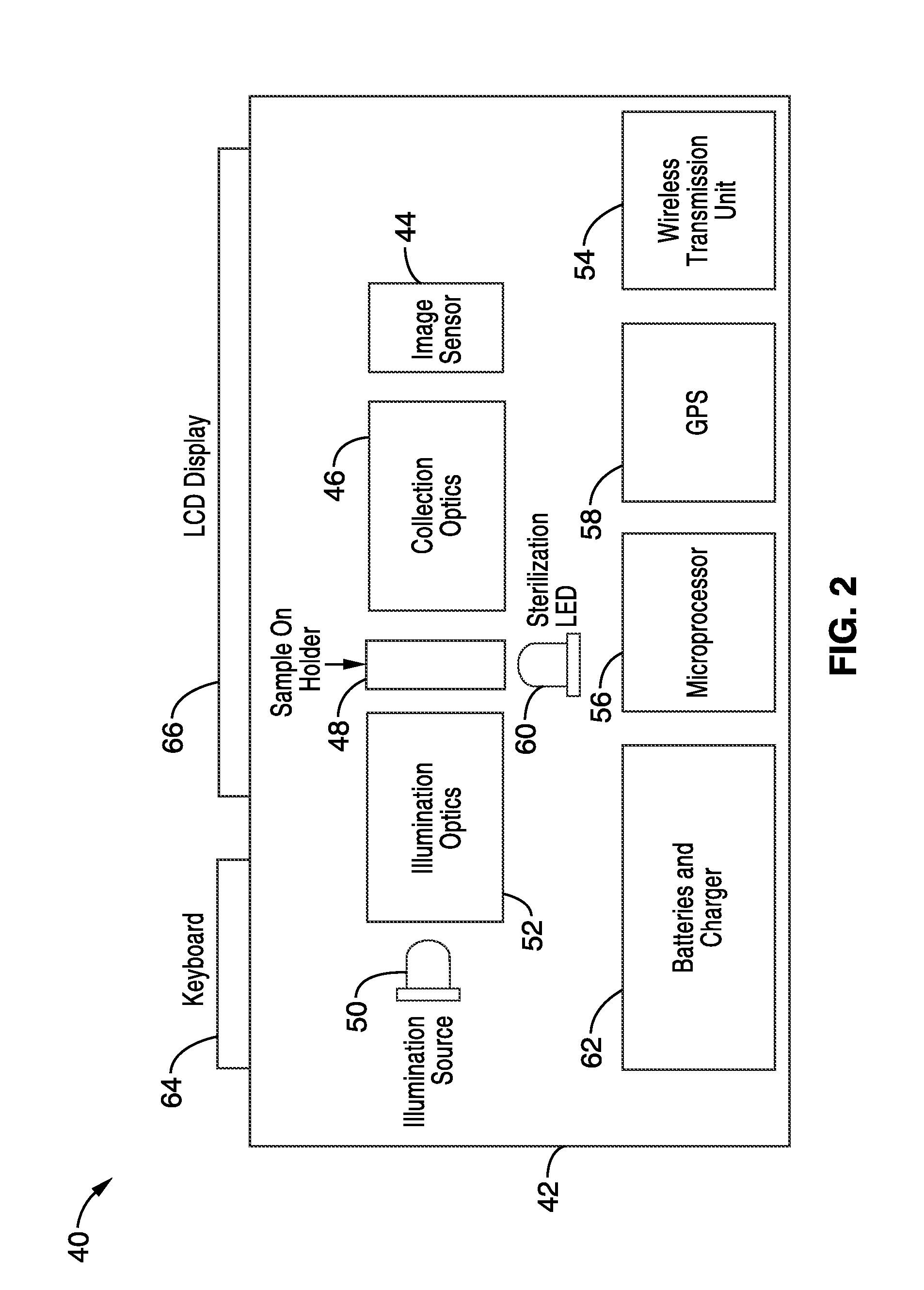

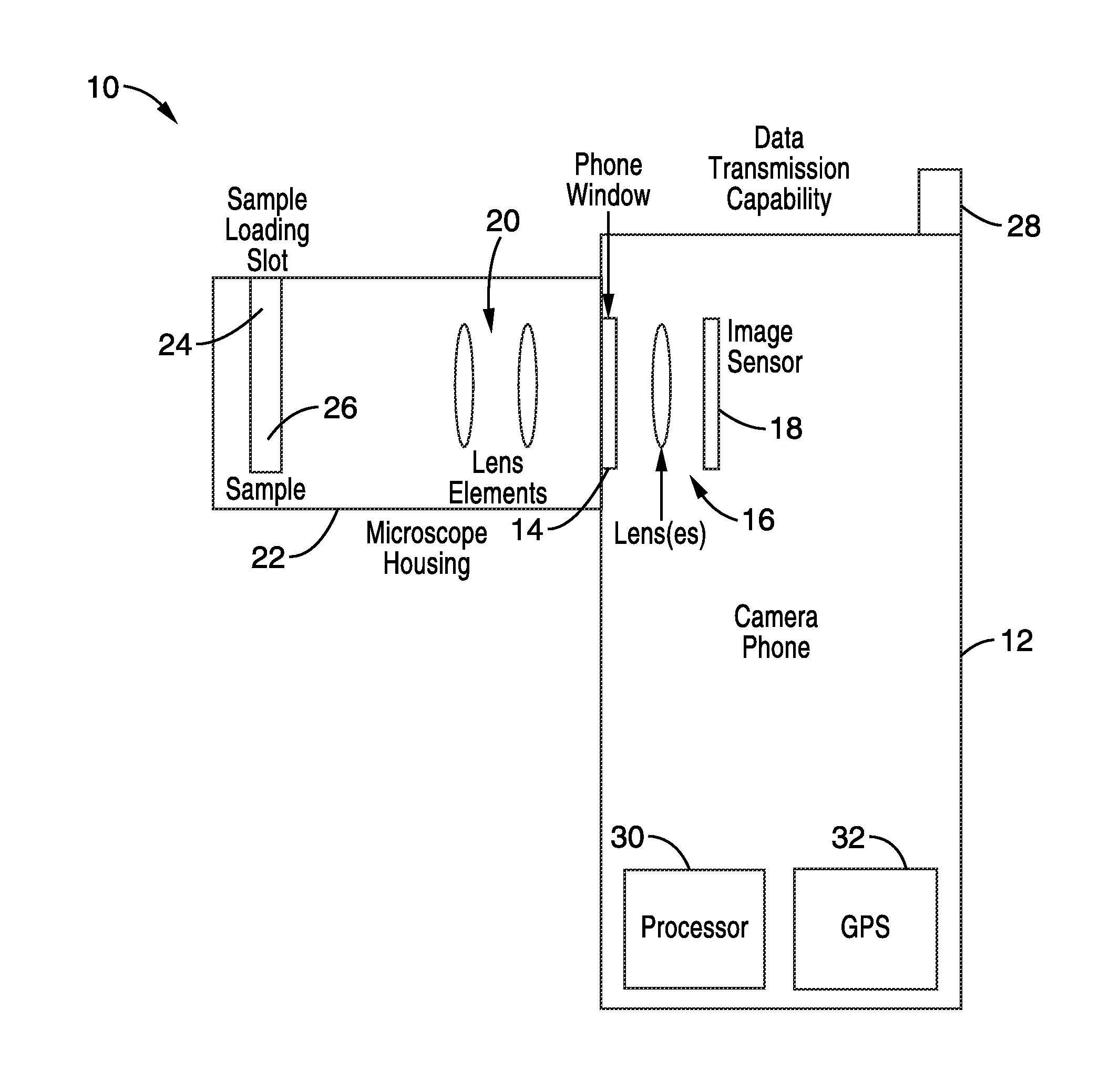

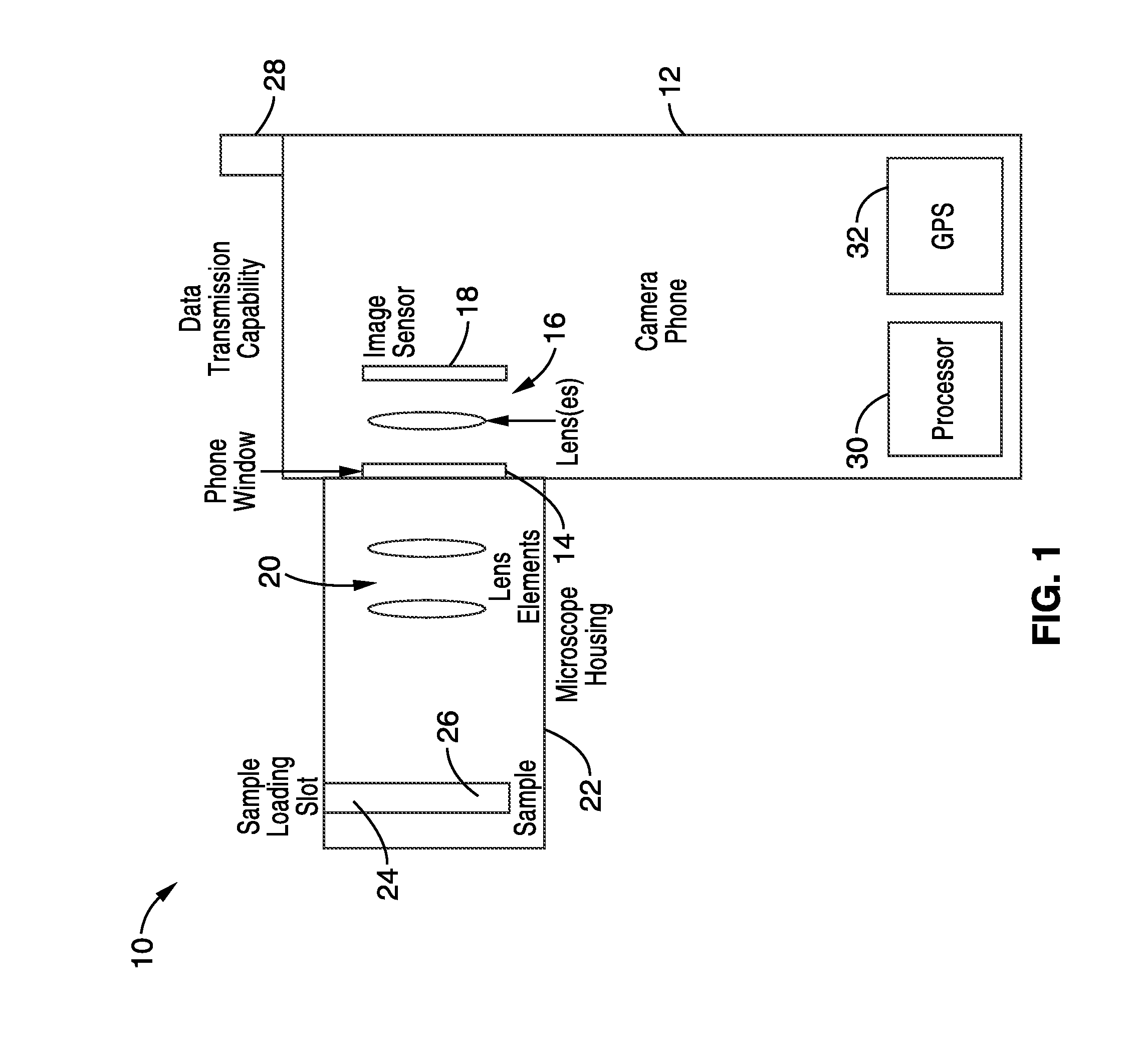

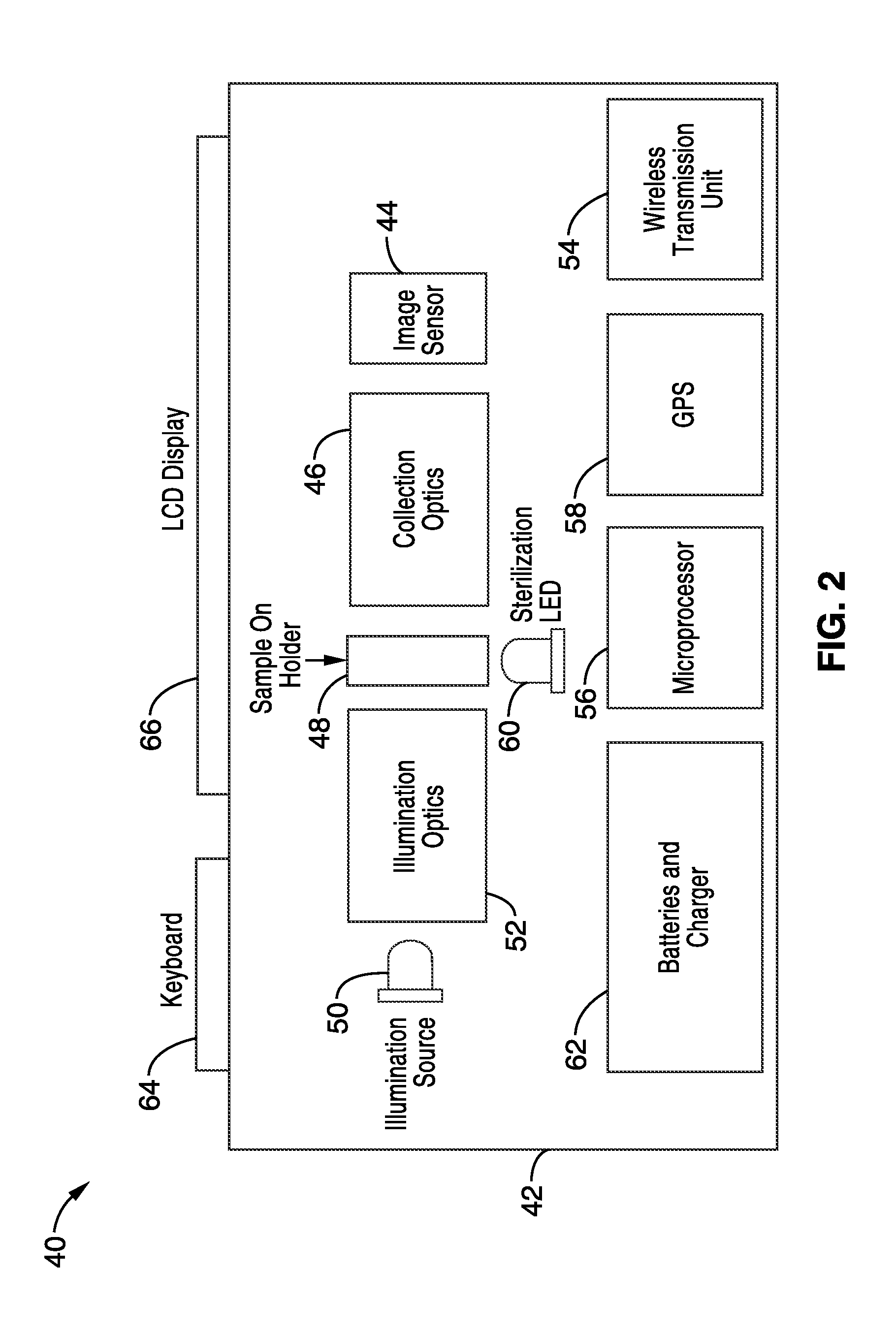

High numerical aperture telemicroscopy apparatus

ActiveUS20110009163A1High numerical aperture opticIncrease the number ofTelevision system detailsMaterial analysis by optical meansDiseaseHigh numerical aperture

An imaging system consisting of a cell-phone with camera as the detection part of an optical train which includes other components. Optionally, an illumination system to create controlled contrast in the sample. Uses include but are not limited to disease diagnosis, symptom analysis, and post-procedure monitoring, and other applications to humans, animals, and plants.

Owner:RGT UNIV OF CALIFORNIA

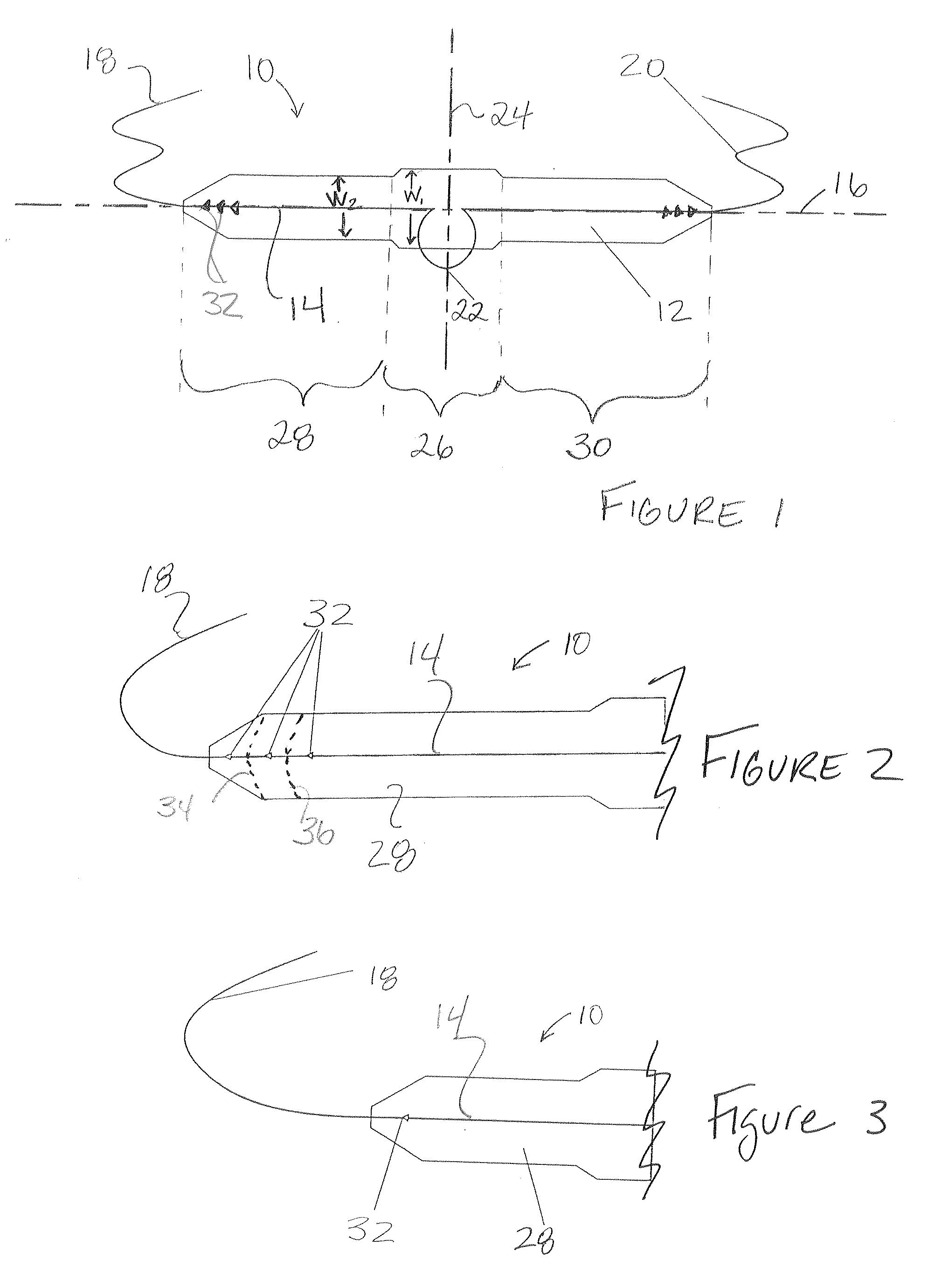

Apparatus and method for the treatment of stress urinary incontinence

An apparatus and method for the treatment of stress urinary incontinence. The apparatus includes a suburethral sling having an adjustment member for adjusting the tension of the sling both during the procedure and post-procedure. The method includes using a needle to simultaneously implant the sling and to deliver a local anesthetic in the groin area while implanting the sling.

Owner:BOSTON SCI SCIMED INC

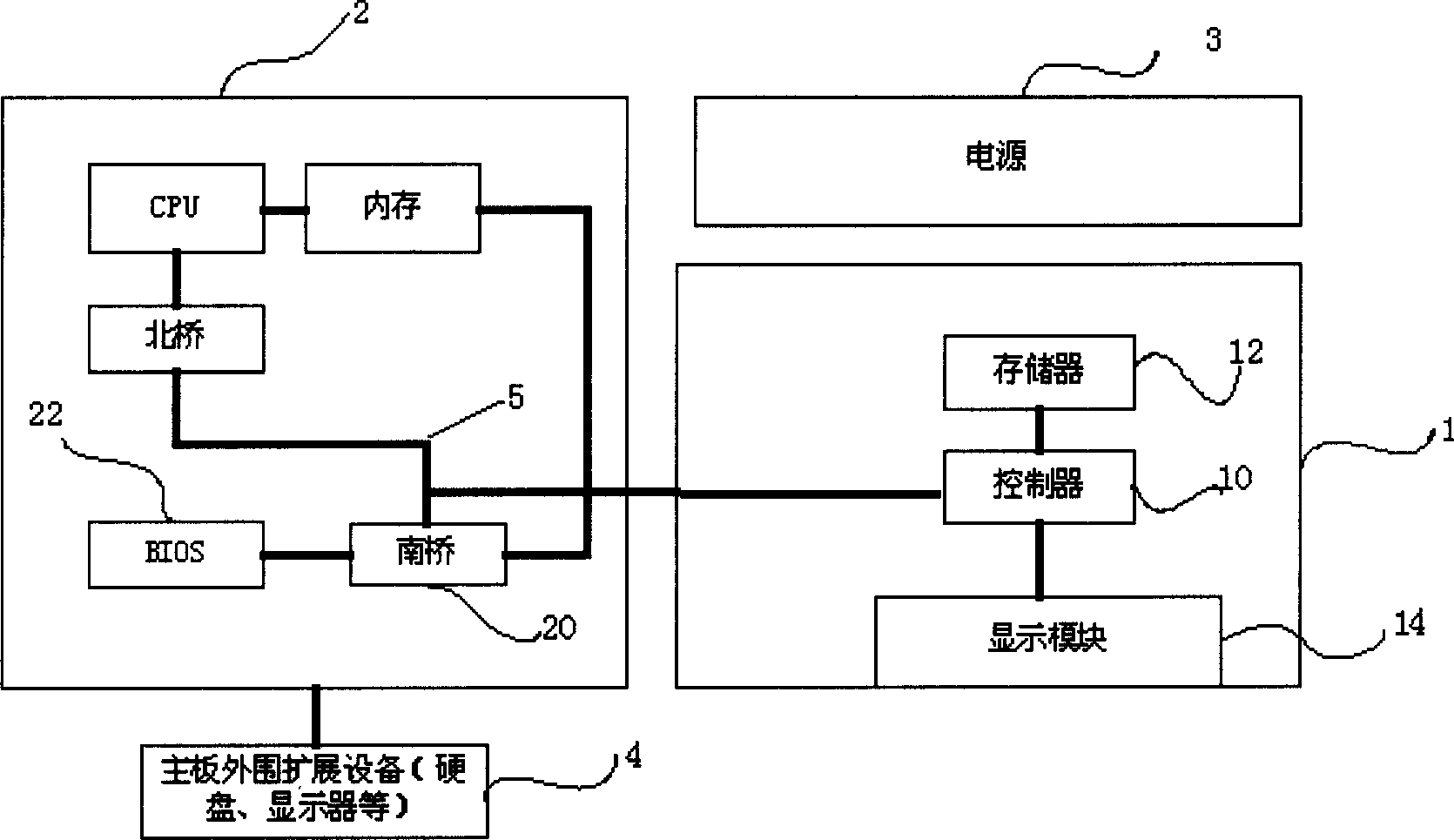

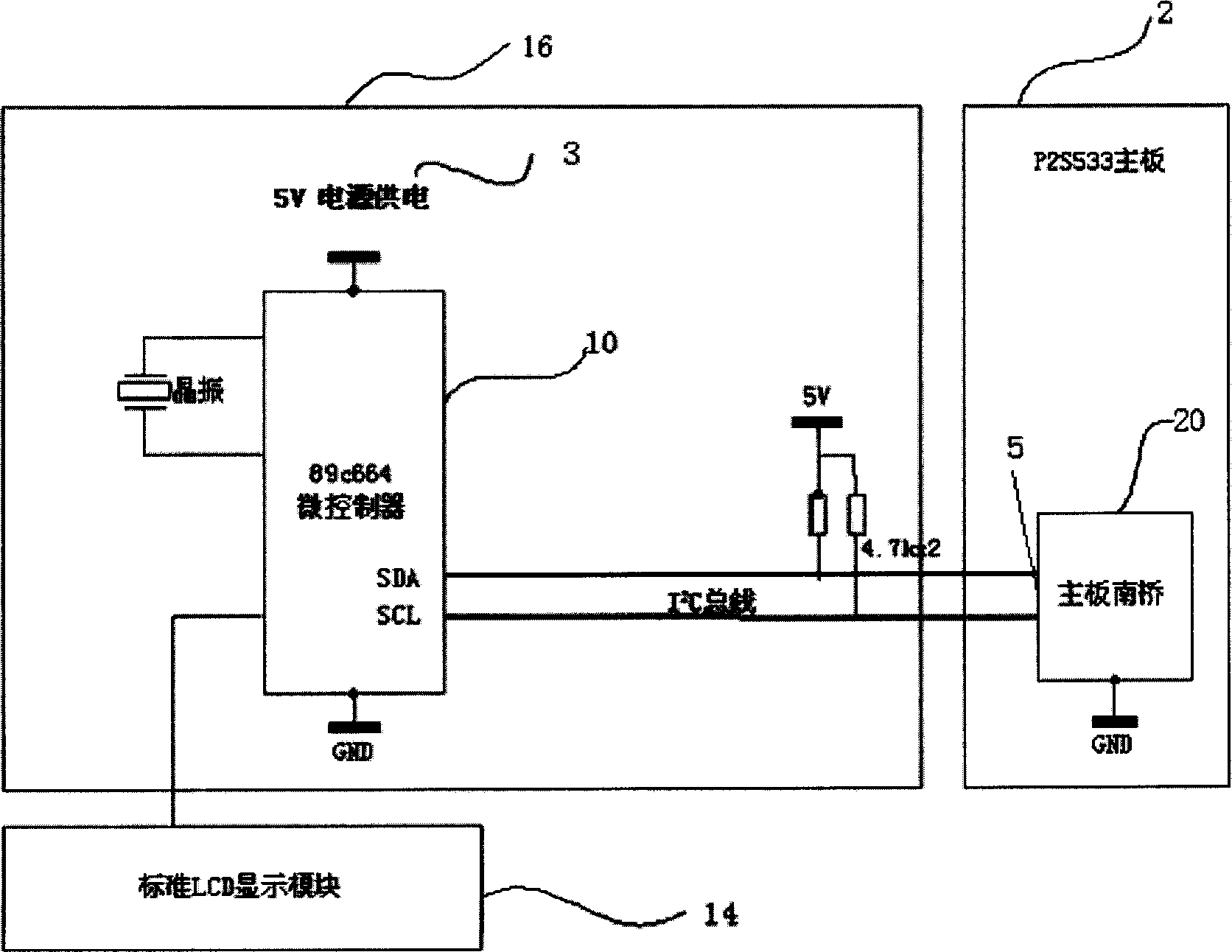

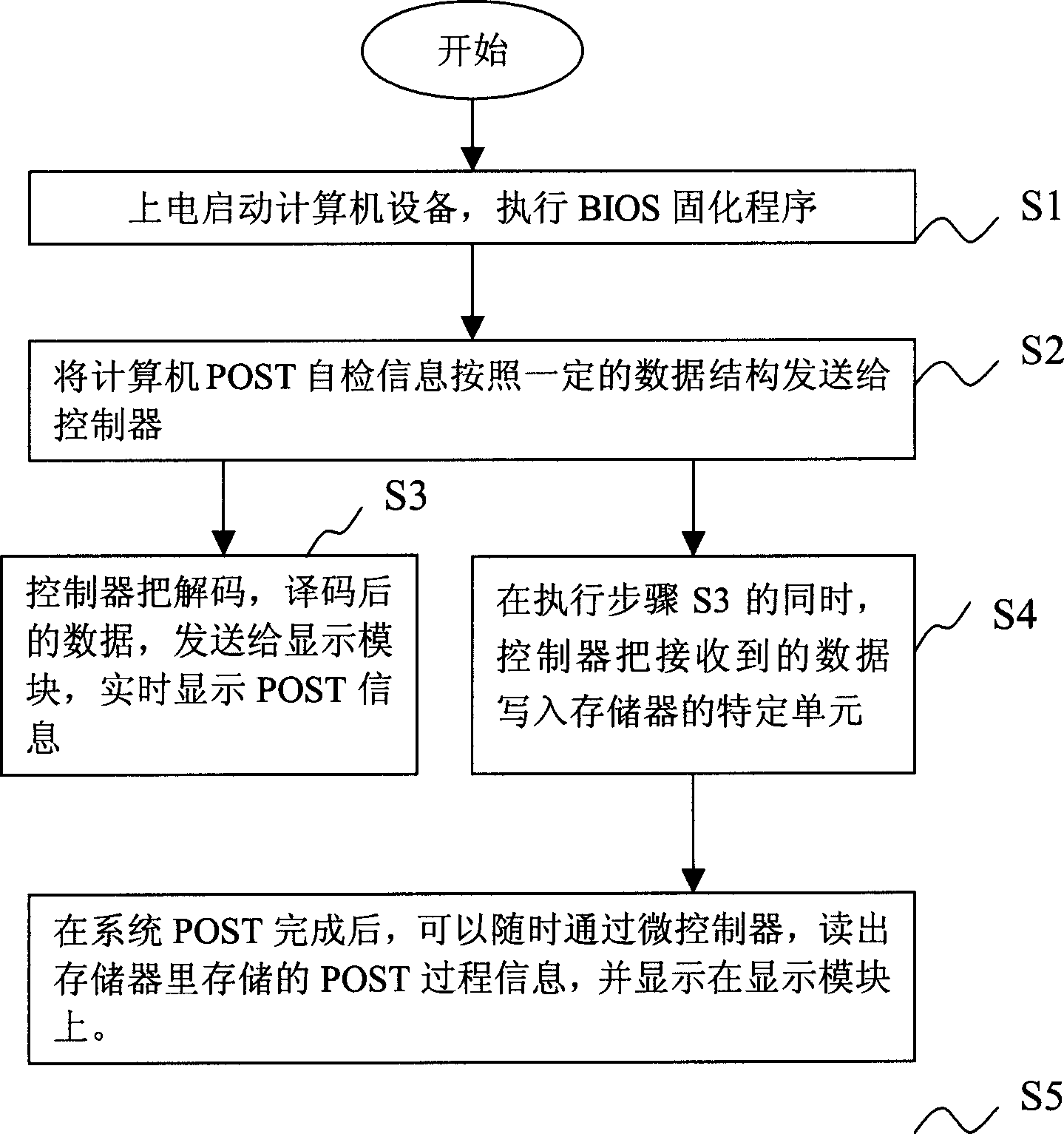

Detection and display method and device for computer self-test information

InactiveCN1506821AEasy to installIntuitive and convenient displayHardware monitoringPost-ProcedureReal time display

The present invention is detection and display method and device for computer self-test information. The method includes in the power-on self test (POST) state executing curing program in the BIOS in the POST stage of computer system to send POST information in certain data structure to controller chip and transmit the information to the display module timely so as to display the POST procedure and information in characters and sentences; and displaying fault information, if any, in the display module. The device for the detection and display includes a controller connected to the system control bus of the computer mainboard to obtain POST information; and a display module connected to the controller to display real-time POST information. The present invention makes it possible to display POST information conveniently and intuitively.

Owner:LENOVO (BEIJING) CO LTD

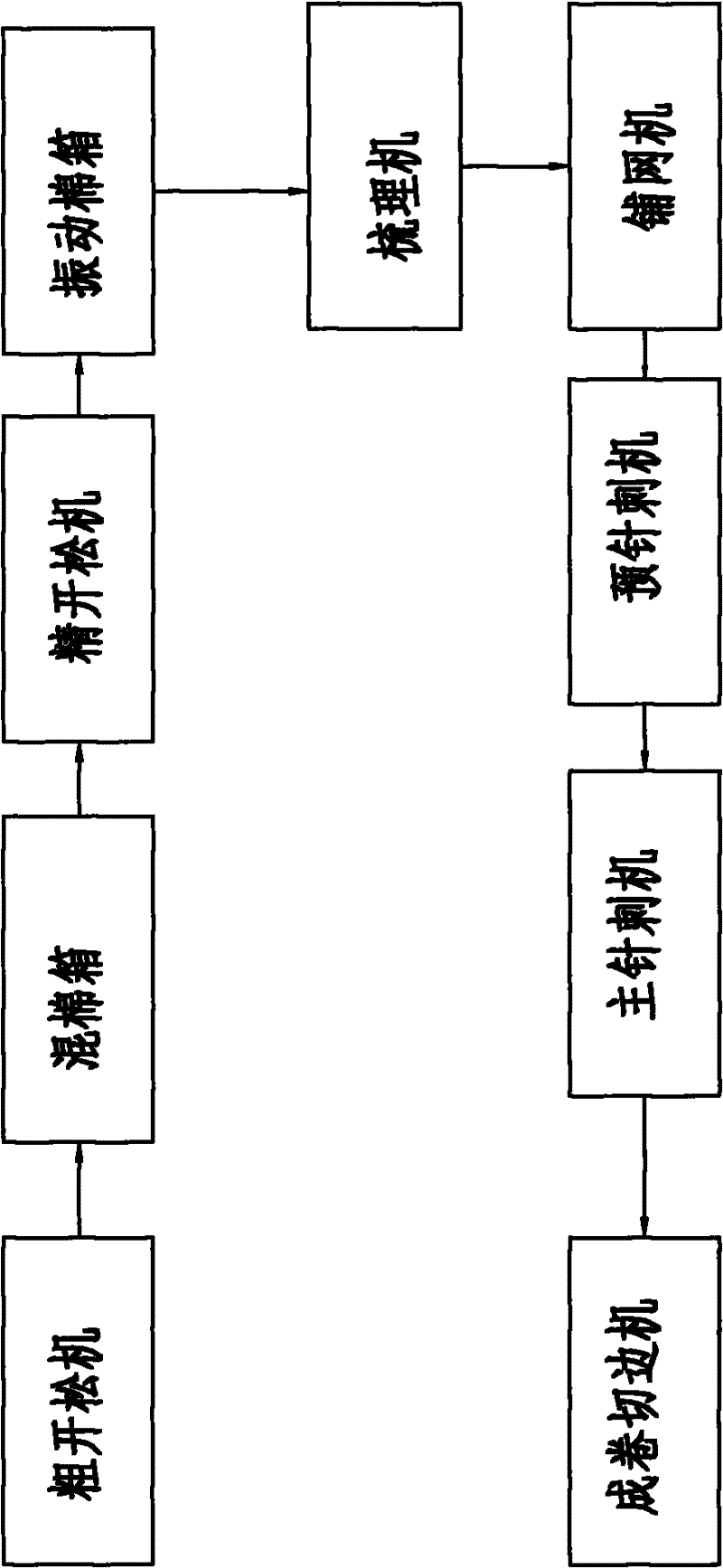

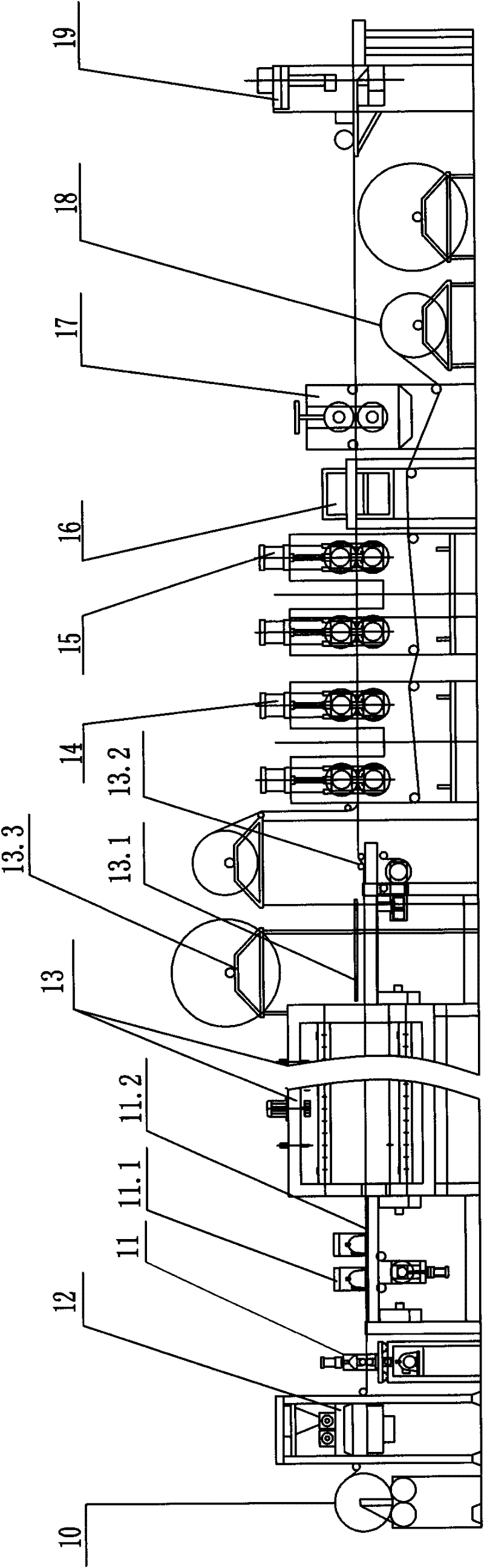

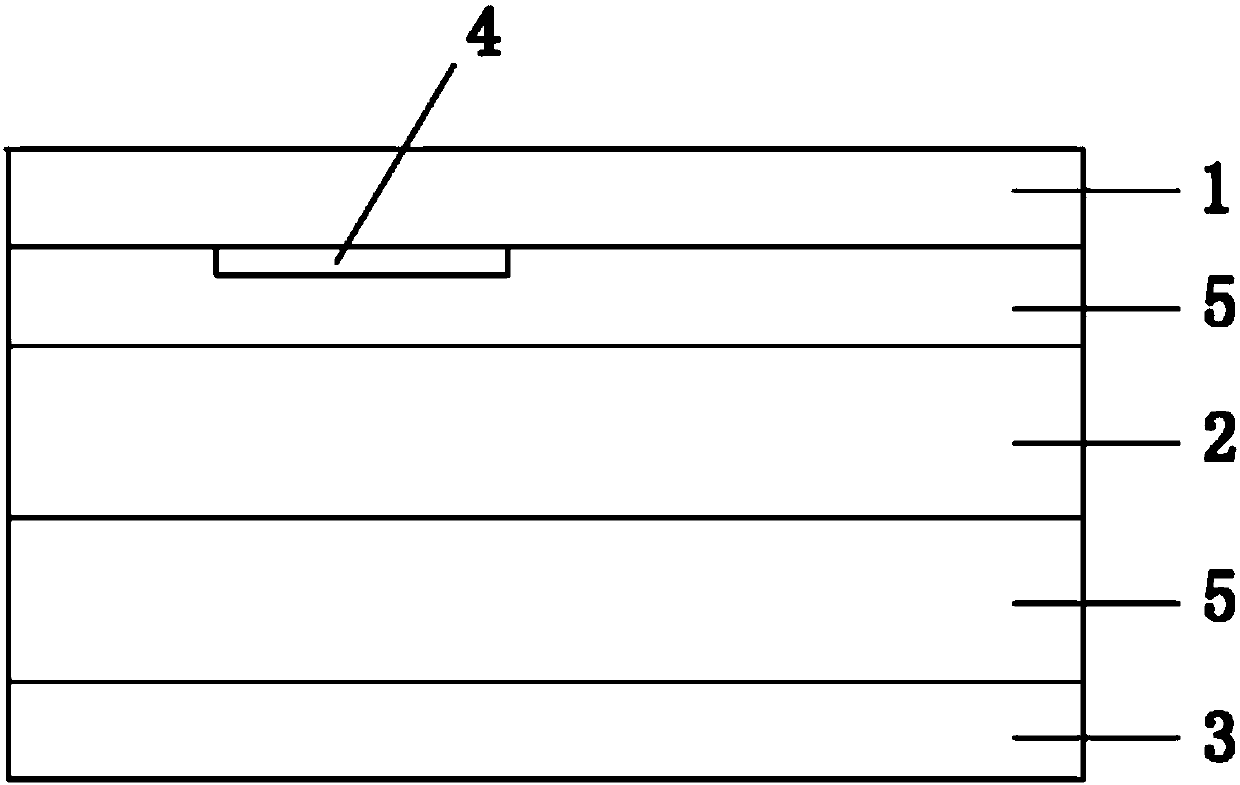

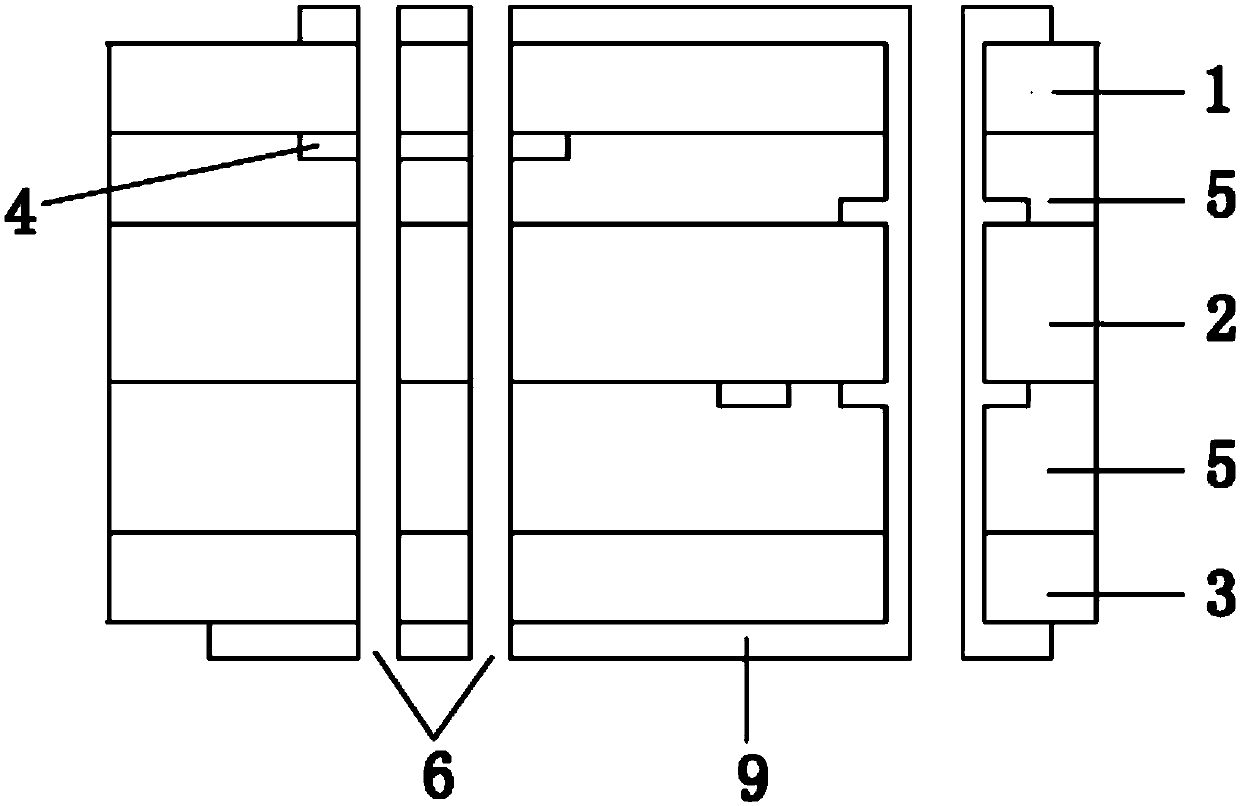

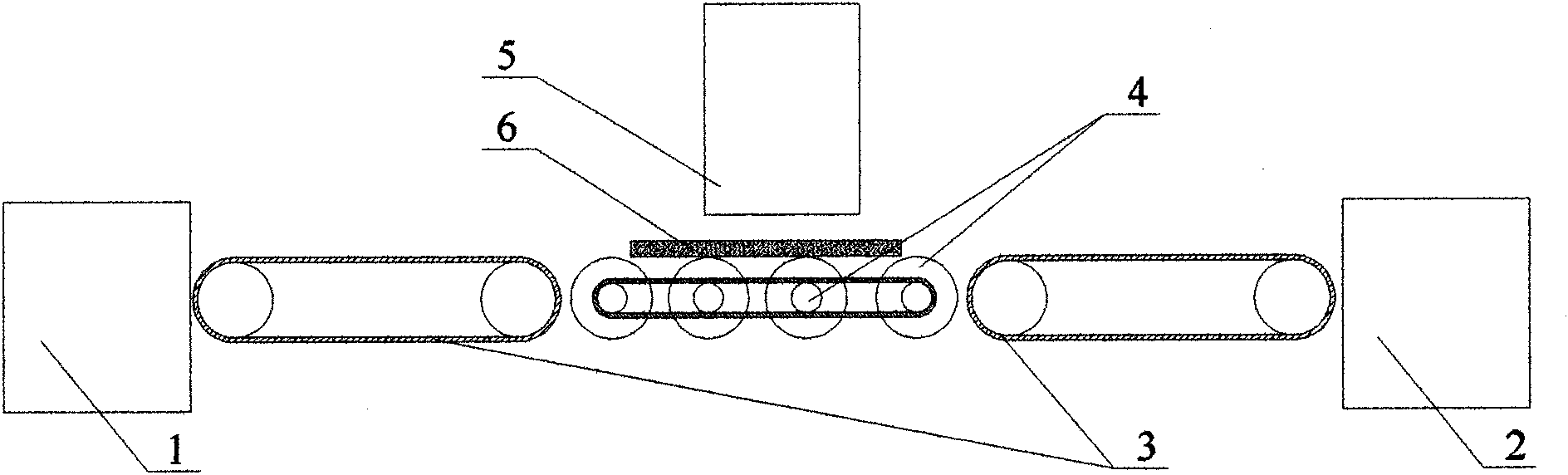

Method for preparing glass fiber and reinforced polypropylene fiber composite material

ActiveCN102303430AAchieving reinforcementHigh tensile strengthSynthetic resin layered productsLaminationGlass fiberPost-Procedure

The invention relates to a method for preparing a glass fiber and reinforced polypropylene fiber composite material. The method comprises a non-weaving process in pre-procedure and a thermal pressing and molding process in post-procedure; the non-weaving process in pre-procedure comprises the following steps of: weighing polypropylene fibers and glass fibers in proportion, loosening the fibers by a coarse opener, then conveying to a blending box by a cotton conveying blower, conveying to a fine opener, a vibrating cotton box and a big cotton bin, sufficiently mixing the fibers by means of a conveying curtain, an inclined curtain and a picker roller beater, outputting to a carding machine by a cotton pressing roller and an output curtain, lapping by a lapping machine, conveying the fiber mesh by a feeder to a pre-needling machine for pre-needling operation, and setting and needling into a felt material by using a main needling machine; and the thermal pressing and molding process in post-procedure comprises the following steps of aligning and unreeling, powdering, deviation correction, open-width feeding, heating of a drying room, thermal pressing and compounding, rolling and cooling, and air-cooling. The method for preparing the glass fiber and reinforced polypropylene fiber composite material has the advantages of stronger tensile strength and impact resistance performance, capability of satisfying the usage requirements in the high-load defending parts of automobiles and ships and the like, and wide application range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

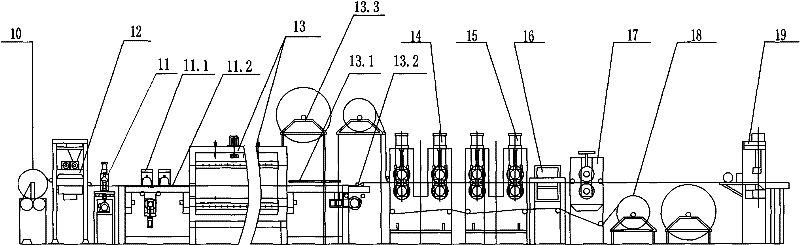

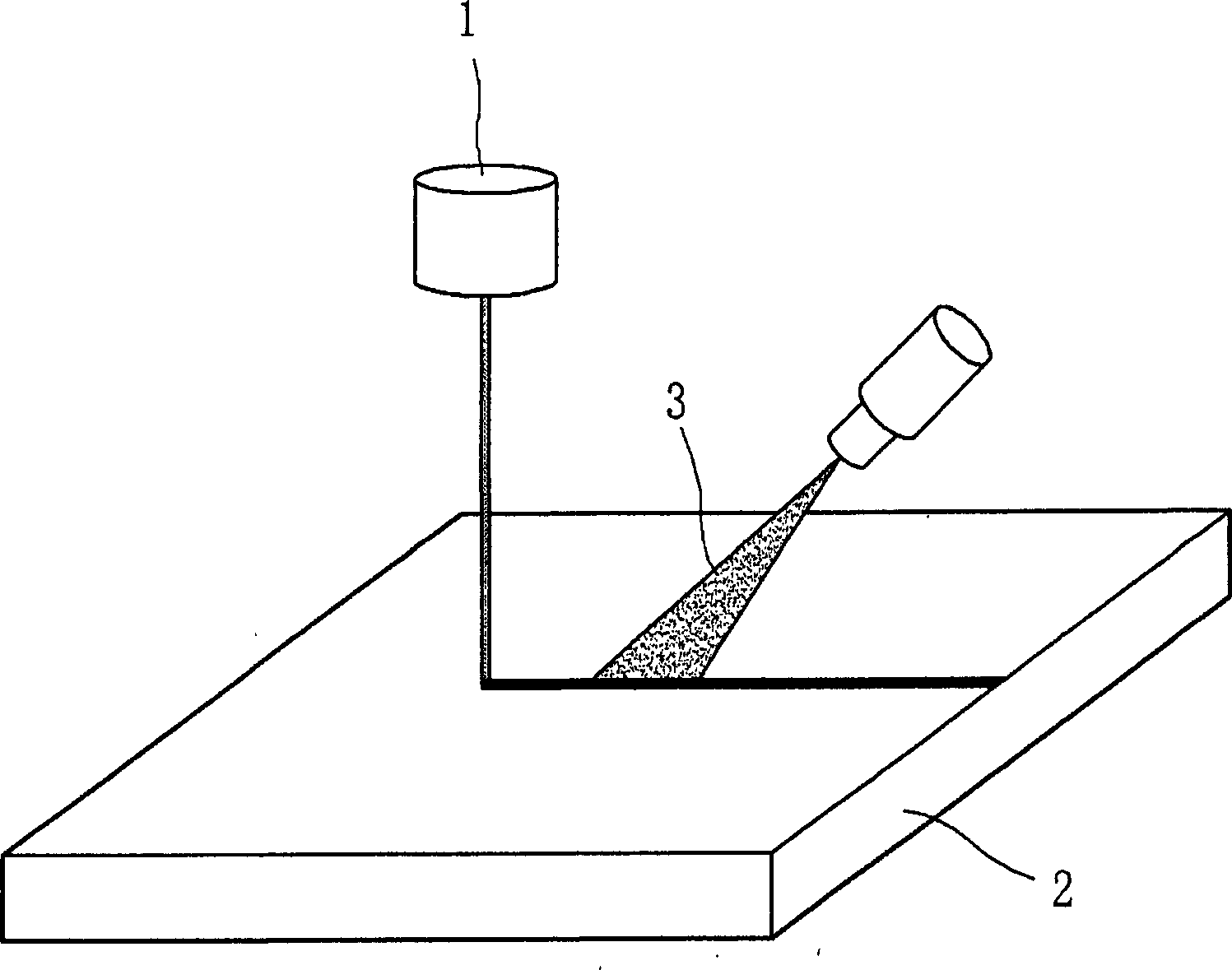

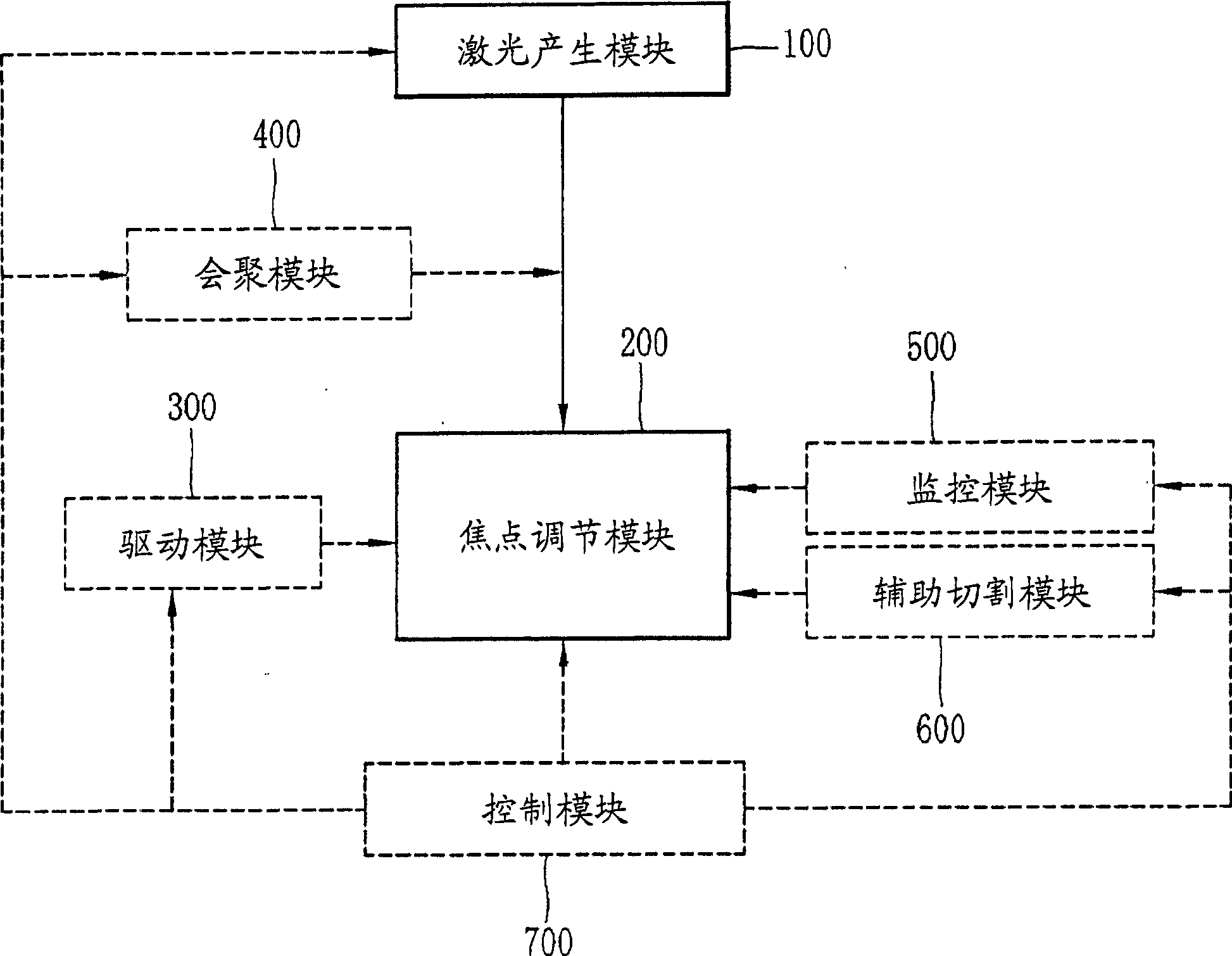

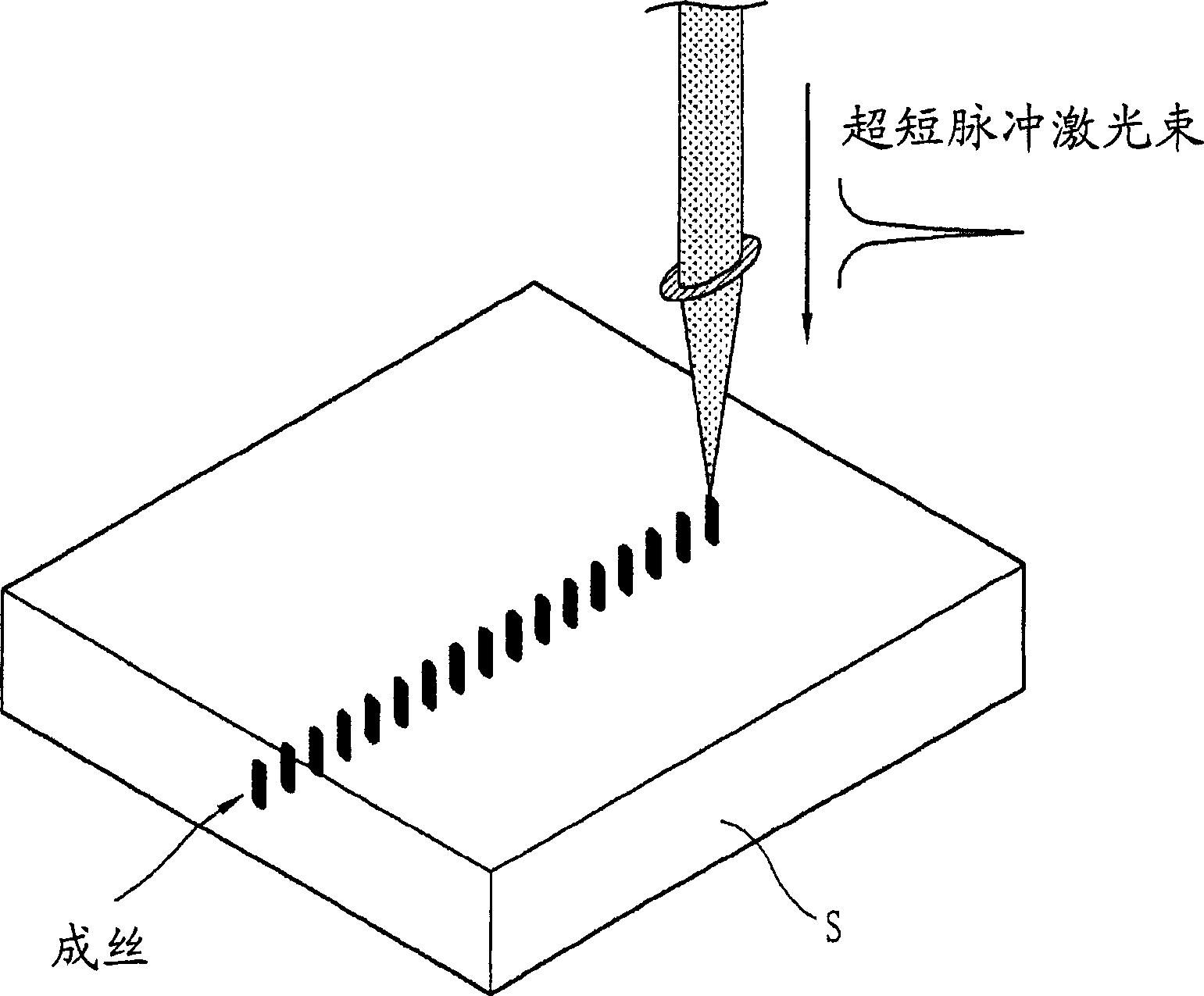

A cutter for substrate using microwaves laser beam and method thereof

InactiveCN101391860AHigh precisionAvoid heat damageSemiconductor/solid-state device manufacturingGlass severing apparatusMicrowaveDisplay device

The invention relates to a substrate cutting device by using ultrashort pulse laser bean and a cutting method thereof. Ultrashort pulse laser from FS to PS is used, complex per / post procedures are simplified as far as possible unrelated to substrate characteristic of glass or transparent material, wherein the substrate characteristic of glass or transparent material is a little different according to use and property of displays, thereby preventing unwanted cutting, gaps or damage, and minimizing defect rate. The substrate cutting device by using ultrashort pulse laser bean comprises a laser generating unit which generates ultrasonic pulse laser bean; a focus adjusting unit for adjustment to focus the ultrashort pulse laser bean on the internal of the substrate to be cut, which guides internal filament forming phenomenon to form a cutting groove in the substrate by focusing the ultrashort pulse laser bean on the internal of the substrate and radiating along the desired cutting path. Substrates of diversified displays can be quickly cut with high precision by simple procedure without generation of damage and gaps.

Owner:RAINBOW SUN

High numerical aperture telemicroscopy apparatus

ActiveUS20140120982A1High numerical aperture opticIncrease the number ofTelevision system detailsMaterial analysis by optical meansDiseaseHigh numerical aperture

An imaging system consisting of a cell-phone with camera as the detection part of an optical train which includes other components. Optionally, an illumination system to create controlled contrast in the sample. Uses include but are not limited to disease diagnosis, symptom analysis, and post-procedure monitoring, and other applications to humans, animals, and plants.

Owner:RGT UNIV OF CALIFORNIA

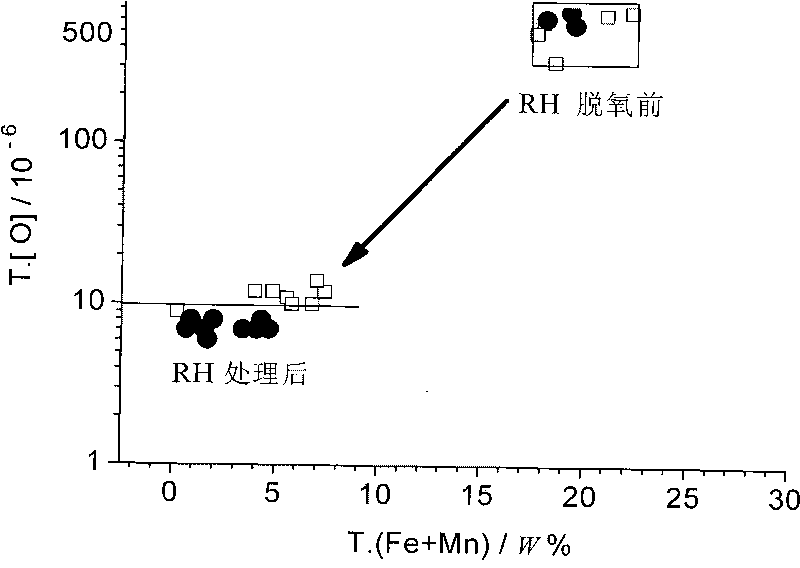

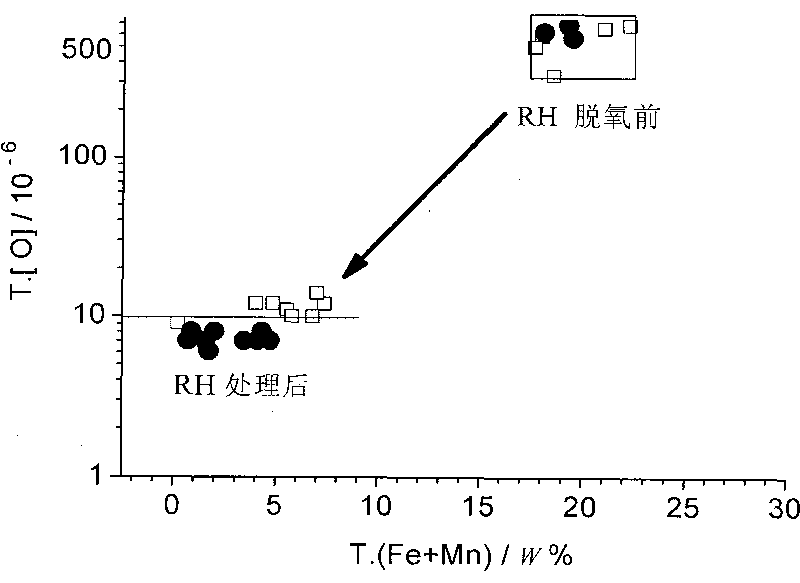

Method for removing total oxygen in molten steel

The invention relates to a method for removing total oxygen in low-carbon molten steel. The method of the invention solves the shortcomings that in the prior art, the content of dissolved oxygen of molten steel is increased, the inclusion is increased after deoxygenation, and the total oxygen content is higher and the like. The method has the following steps: tapping by a slag dam method; adding lime with 2.6-3.0kg of each ton of steel into steel ladle liquid level when tapping amount reaches 1 / 2-2 / 3; transmitting steel ladle to an RH work station after tapping, controlling the content of carbon in molten steel to be 0.03-0.04% in weight ratio, the content of dissolved oxygen to be 0.055-0.07% in weight ratio, and the slag thickness to be 50-70 mm; carrying out RH vacuum processing: firstly carrying out vacuum decarbonizing, deoxidizing and alloying; adding blending agent composed of lime and fluorite to the molten steel, wherein, the adding amount is 3-5 kg of each ton of steel; and driving molten steel circulation by argon during the time. In the invention, the equipment does not need to change, the operation is flexible, the total oxygen content in the molten steel and the sulphur content are obviously lowered after processing, and the performance and quality of post-procedure products are improved.

Owner:WUHAN IRON & STEEL (GROUP) CORP

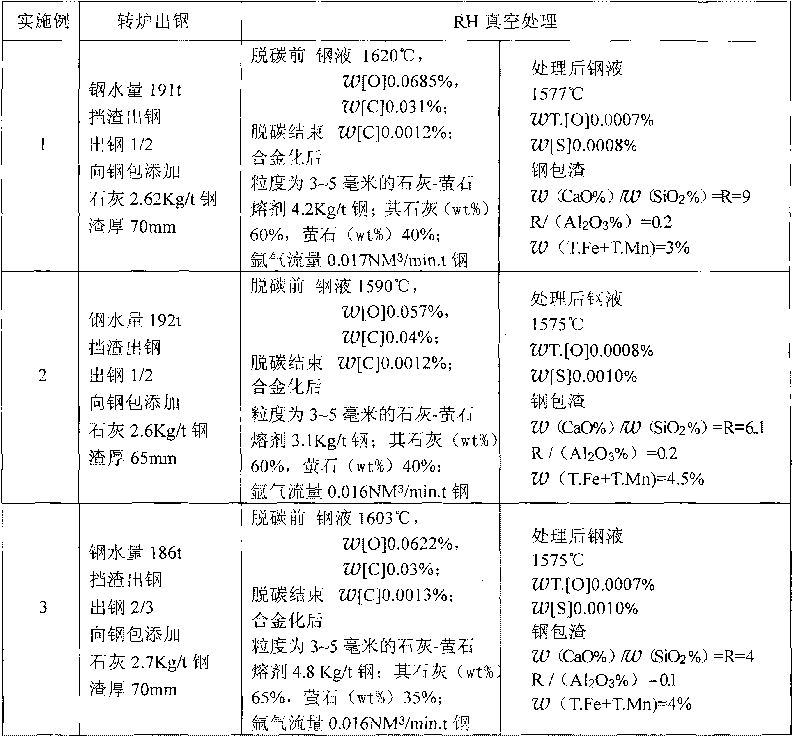

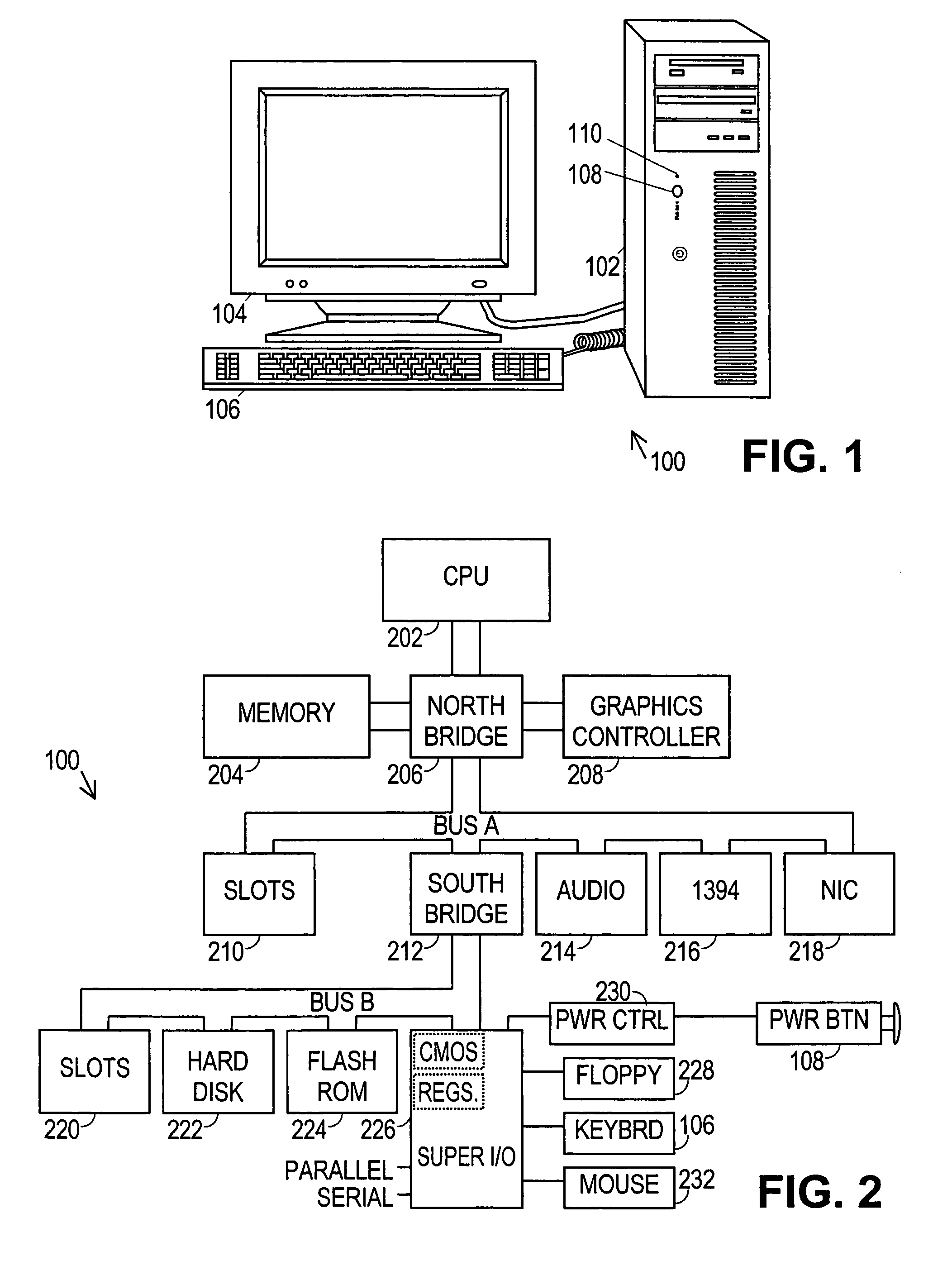

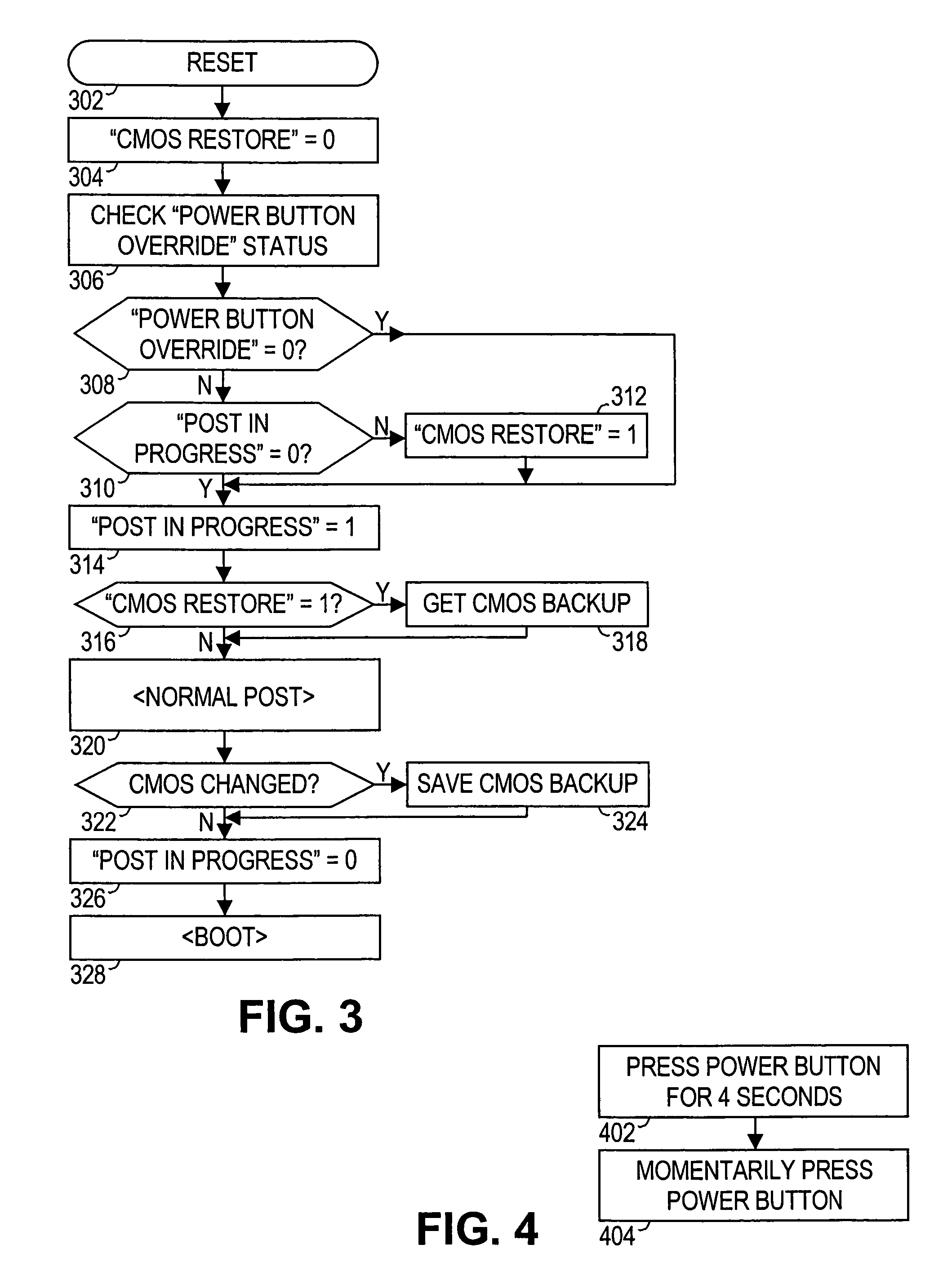

Method for restoring CMOS in a jumperless system

A method for easily restoring CMOS parameters in a computer having a multi-function power button is provided. In one embodiment, the method for restoring CMOS parameter values in a computer includes (a) pressing the power button for a predetermined time delay while the computer is performing a power-on self test (“POST”), thereby placing the computer in an OFF state; and (b) momentarily pressing the power button to turn on the computer. Pressing the power button for four seconds preferably invokes a power button override function. The power button override function unconditionally forces the computer to a “soft-off” state. The BIOS is preferably configured to determine if the power-override function was invoked during the POST in the previous boot-up, and if so, to replace the CMOS parameter values with backup parameter values before proceeding with the current boot-up. The CMOS parameter values are preferably backed up only if they have changed and the BIOS has successfully completed the POST procedure with the changed values. This ensures that the backup values will allow the computer to boot when CMOS parameter restoration is needed.

Owner:HEWLETT PACKARD DEV CO LP

Manufacturing process of high-fall stepped circuit board

InactiveCN107949190AGuaranteed smoothGuaranteed to dentMultilayer circuit manufactureEngineeringPost-Procedure

The invention discloses a manufacturing process of a high-fall stepped circuit board. The manufacturing process comprises the steppeds of: manufacturing inner-layer circuits on a plurality of core boards separately, and manufacturing an auxiliary copper skin at a position corresponding to a stepped platform when the inner-layer circuit is manufactured on one of the core board; laminating the plurality of core boards into a multi-layer board; performing intermediate processing on the multi-layer board sequentially; performing depth-control groove milling inwardly at a position corresponding tothe stepped platform on the multi-layer board to a position 0.1 mm + / - 0.075 mm away from the auxiliary copper skin beform outer layer etching during the manufacturing process of an outer layer circuit, and forming the stepped platform after removing a cover; performing ablation on a residual dielectric layer at the bottom part at the stepped platform by means of laser; manufacturing the outer layer circuit through etching and removing the auxiliary copper skin at the stepped platform at the same time; and performing post-procedure processing on the multi-layer board to manufacture the high-fall stepped circuit board. According to the manufacturing process, the core board thickness is adopted to make a residual thickness step, the residual thickness tolerance of the stepped platform aftermolding and milling is ensured to meet requirements, the high-precision residual thickness tolerance is ensured to be realized, and the production efficiency can be improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH +1

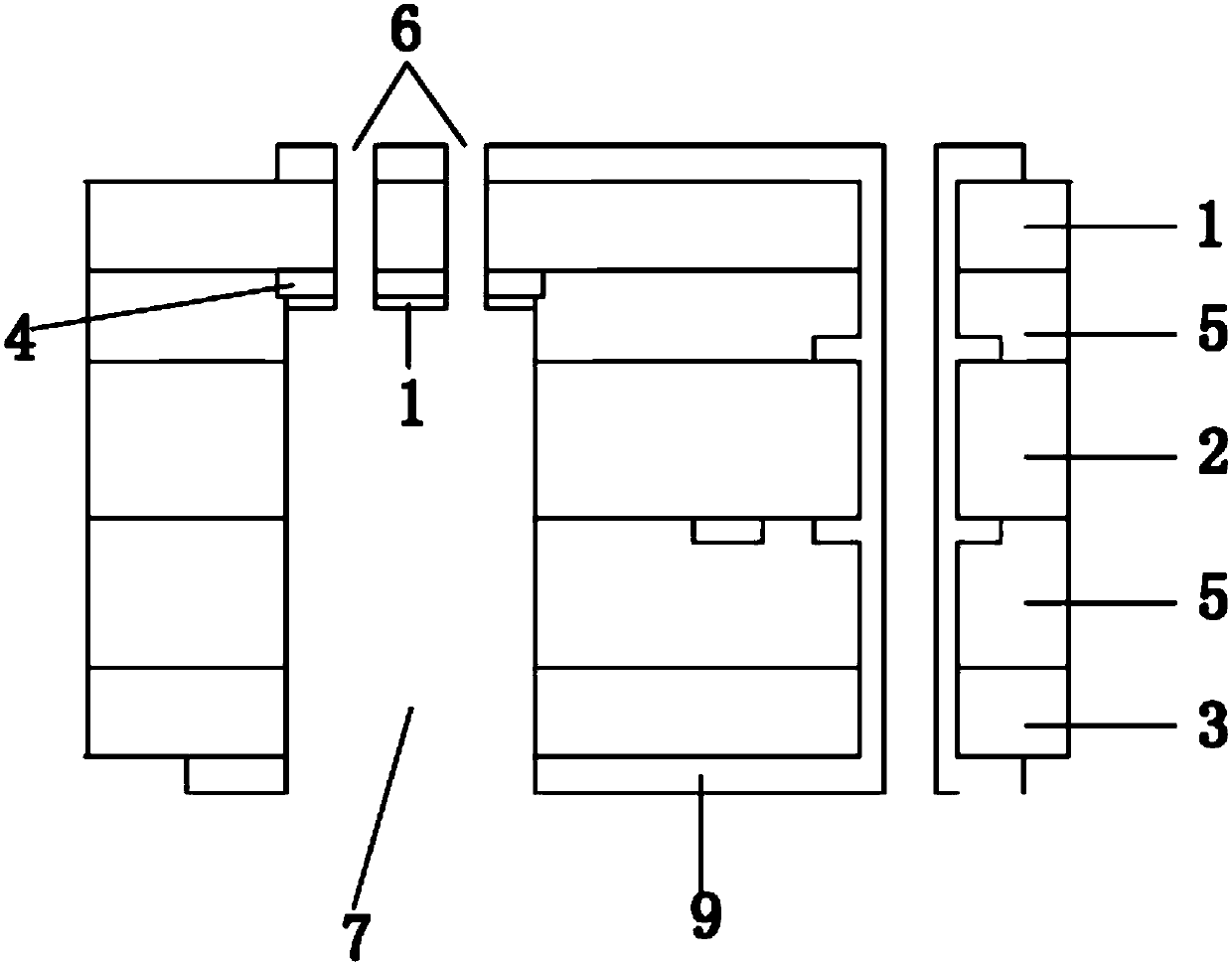

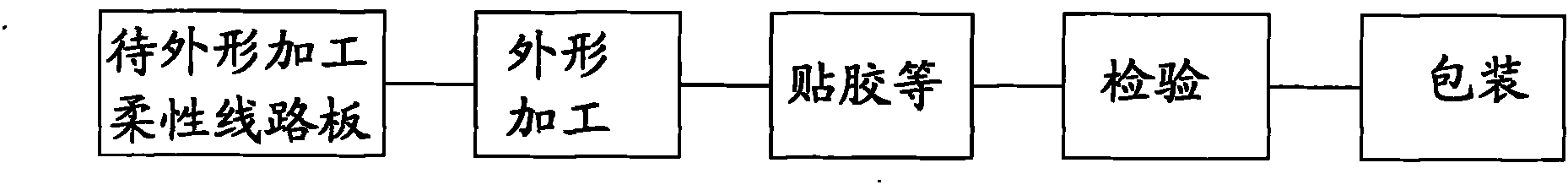

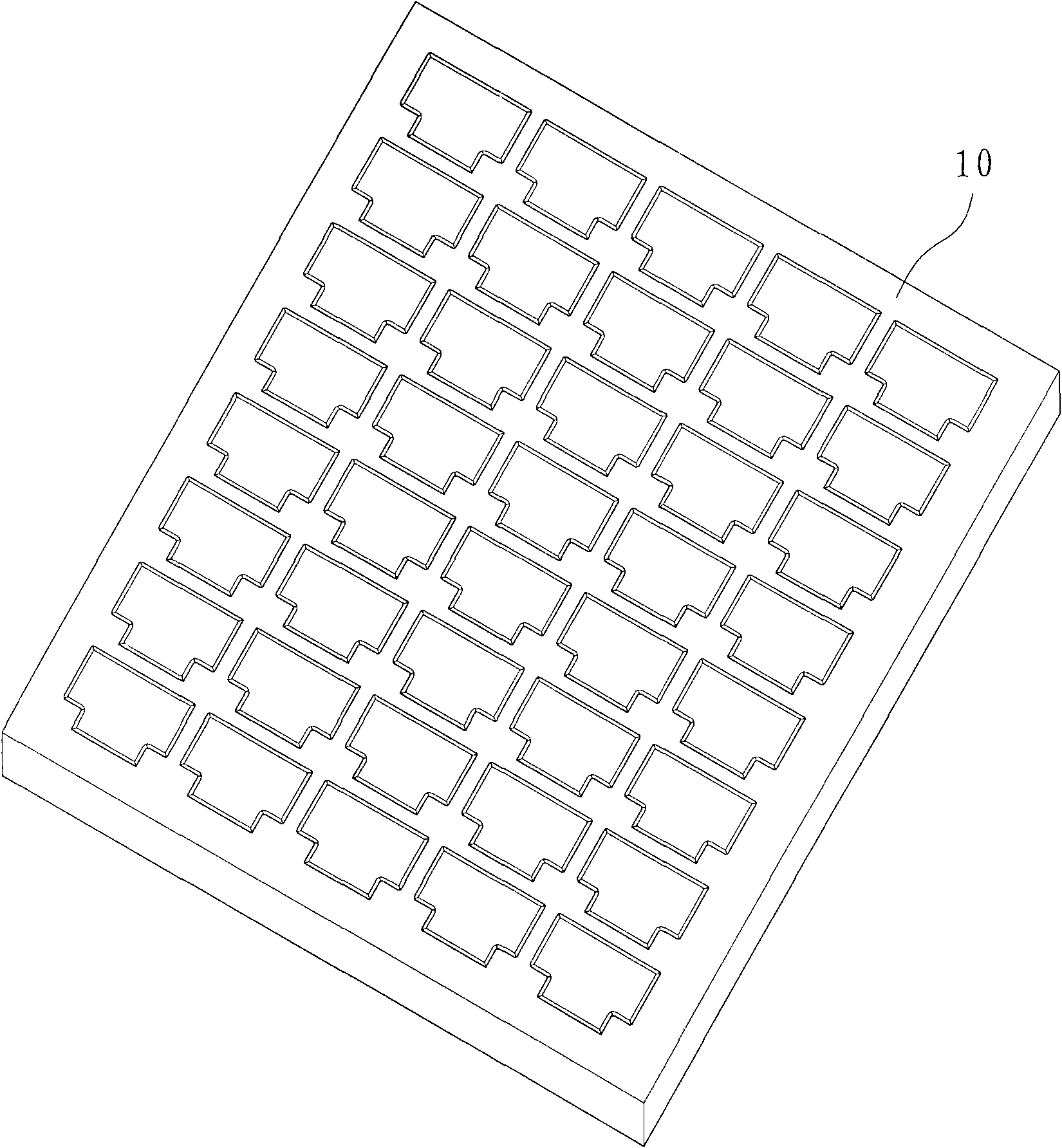

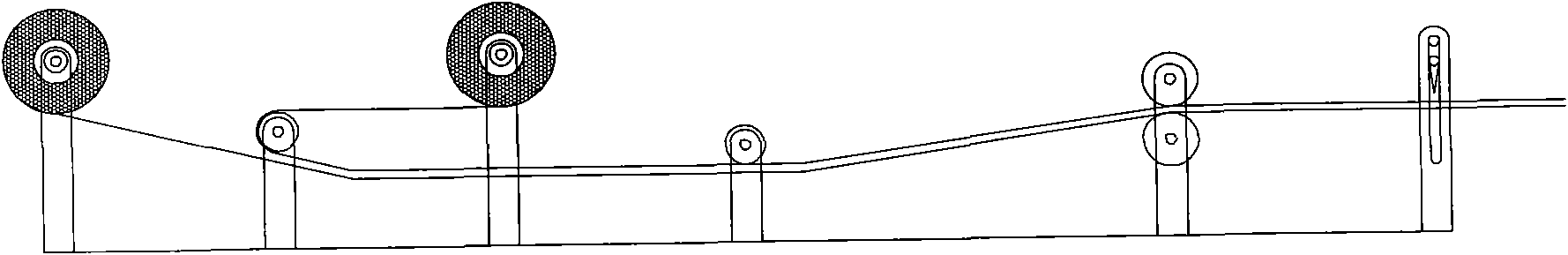

Manufacturing method of flexible printed circuit board post-procedures

The invention provides a manufacturing method of flexible printed circuit board post-procedures, comprising the following steps: cropping and blanking low-viscosity protective films according to the specification of flexible printed circuit boards to be subject to outline machining; carrying out outline machining on the front sections of the flexible printed circuit boards to be subject to outline machining; attaching the low-viscosity protective film 1 on one surface of each flexible printed circuit board, and carrying out outline machining on the rear sections of the flexible printed circuit boards; attaching the low-viscosity protective film 2 on the other surface of each flexible printed circuit board; removing the low-viscosity protective film 1 and waste on board surfaces, and keeping the single-piece boards stuck on the low-viscosity protective film 2; attaching steel sheets, film switches, gummed paper and other auxiliary materials; and finally attaching the low-viscosity protective film 3, and carrying out conventional finished product inspection to complete the manufacturing of the flexible printed circuit board post-procedures. In the invention, during the double outline machining period, the products are not lost, thus avoiding unnecessary loss; and the products are packaged with the low-viscosity protective films and are arranged regularly, thus facilitating statistics, lowering cost, reducing defects such as product friction and the like during the transfer process, and lowering transportation cost.

Owner:厦门弘信智能科技有限公司

Cache device for glass substrate production line and control method thereof

ActiveCN101935157AShorten the lengthSave production spaceGlass transportation apparatusGlass productionProduction linePost-Procedure

The invention relates to a cache device for a glass substrate production line and a control method thereof, solving the problems of large occupation of a conveyor belt and high production cost. The technical scheme is as follows: the control method is realized by using a horizontal conveyor belt between a preceding procedure and a post procedure and a control unit with a CPU (Central Processing unit) and a mating software program in the process of continuously delivering a glass substrate; a group of convey roll-type intermediate conveyor belts and a cache device consisting of a servo motor, an inversion mechanism and a storage mechanism for temporarily storing the glass substrate are additionally arranged between the horizontal conveyor belts in the preceding procedure and the post procedure; in the preceding procedure, the glass substrate is conveyed to the intermediate conveyor belt through the horizontal conveyor belt; based on the working state of the preceding procedure and the post procedure, a management circuit controls the cache device to perform cache processing on the glass substrate. The invention has the advantages that the length of the horizontal conveyor belt is shortened and the production space is saved by adding the cache device for storing the glass substrate on the horizontal conveyor belt in the vertical direction.

Owner:北京东旭天泽科技有限公司

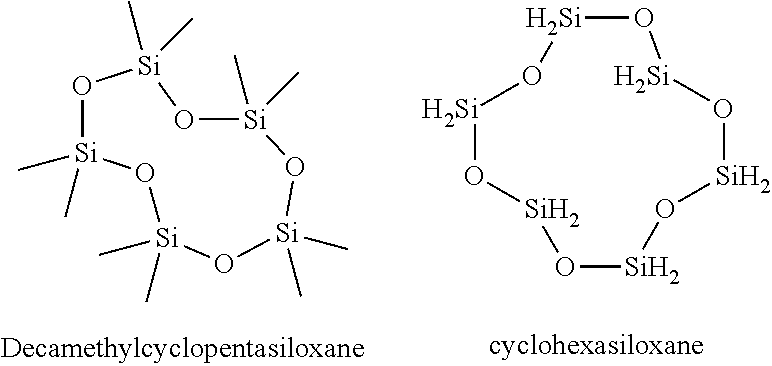

Post procedure skin care gel and methods of use thereof

ActiveUS20140228291A1Shorten the length of timeCosmetic preparationsPeptide/protein ingredientsDermabrasionPost-Procedure

Compositions and methods are provided for a post-procedure care following the treatment of skin with cosmetic skin resurfacing treatments, which include without limitation a variety of laser treatments, chemical peeling and dermabrasion, by applying a silicone-based gel formulation in combination with therapeutic peptides. Peptides of interest include one or more of transforming growth factor, epidermal growth factor, and basic fibroblast growth factor. The formulation may further comprise an effective dose of one or more acylated peptides, which peptides are active in remodeling of the skin.

Owner:JAN MARINI SKIN RES

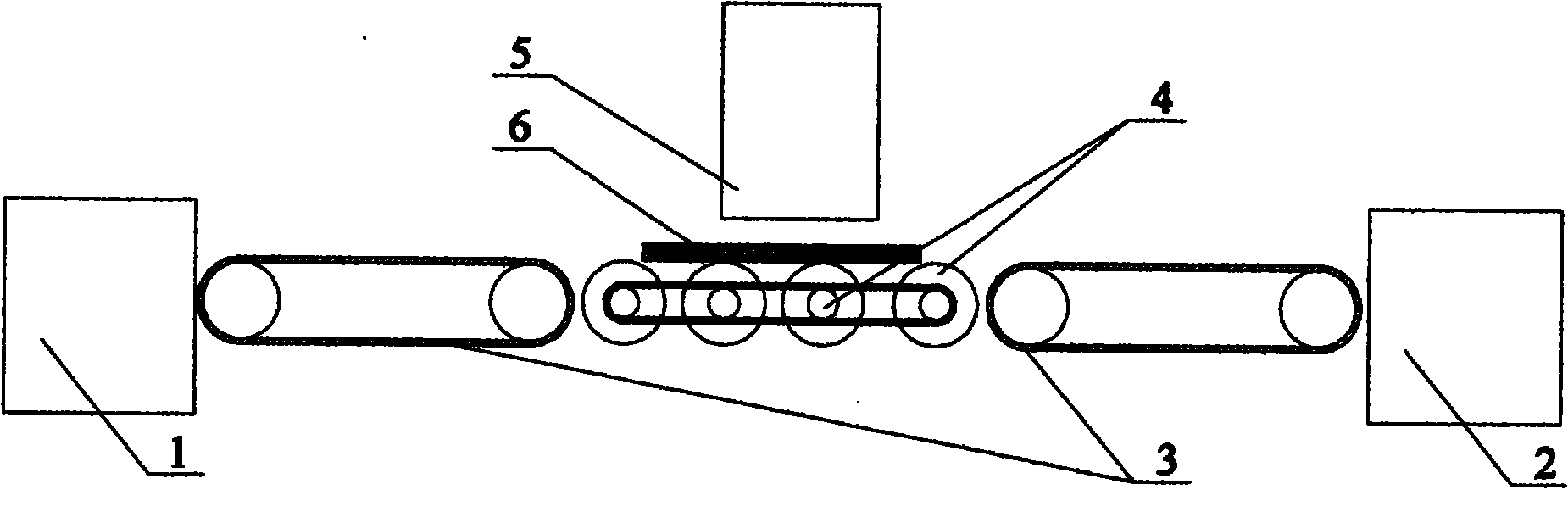

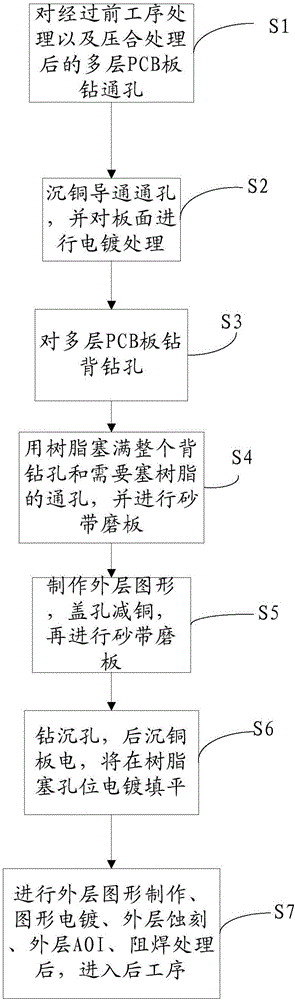

Resin-filled back drilling hole processing method of PCB (Printed Circuit Board)

InactiveCN106535482AQuality assuranceImprove realismPrinted element electric connection formationResistPost-Procedure

The invention relates to a resin-filled back drilling hole processing method of a PCB (Printed Circuit Board). The processing method comprises the steps of drilling through holes in a multi-layer PCB after previous procedure processing and lamination processing; plating copper to conduct the through holes, and electroplating a board surface; drilling a back drilling hole in the multi-layer PCB; filling the whole back drilling hole and the through holes which are needed to be filled with resin with the resin, grinding the board with an abrasive belt; fabricating an outer-layer pattern, covering the holes, reducing the copper, and grinding the board with the abrasive belt again; drilling a counter hole, depositing a copper plate, filling the holes with the resin for electroplating and filling; and entering a post procedure after fabricating the outer-layer pattern, electroplating the pattern, etching the outer layer, performing outer-layer AOI and performing soldering resist processing. By the processing method, the back drilling hole is an NPTH (Non Plating Through Hole) and is filled with the resin, the circuit quality is ensured, a PTH (Plating Through Hole) and the NPTH back drilling hole are both filled with the resin, and the signal reality is improved to a relatively high extent.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

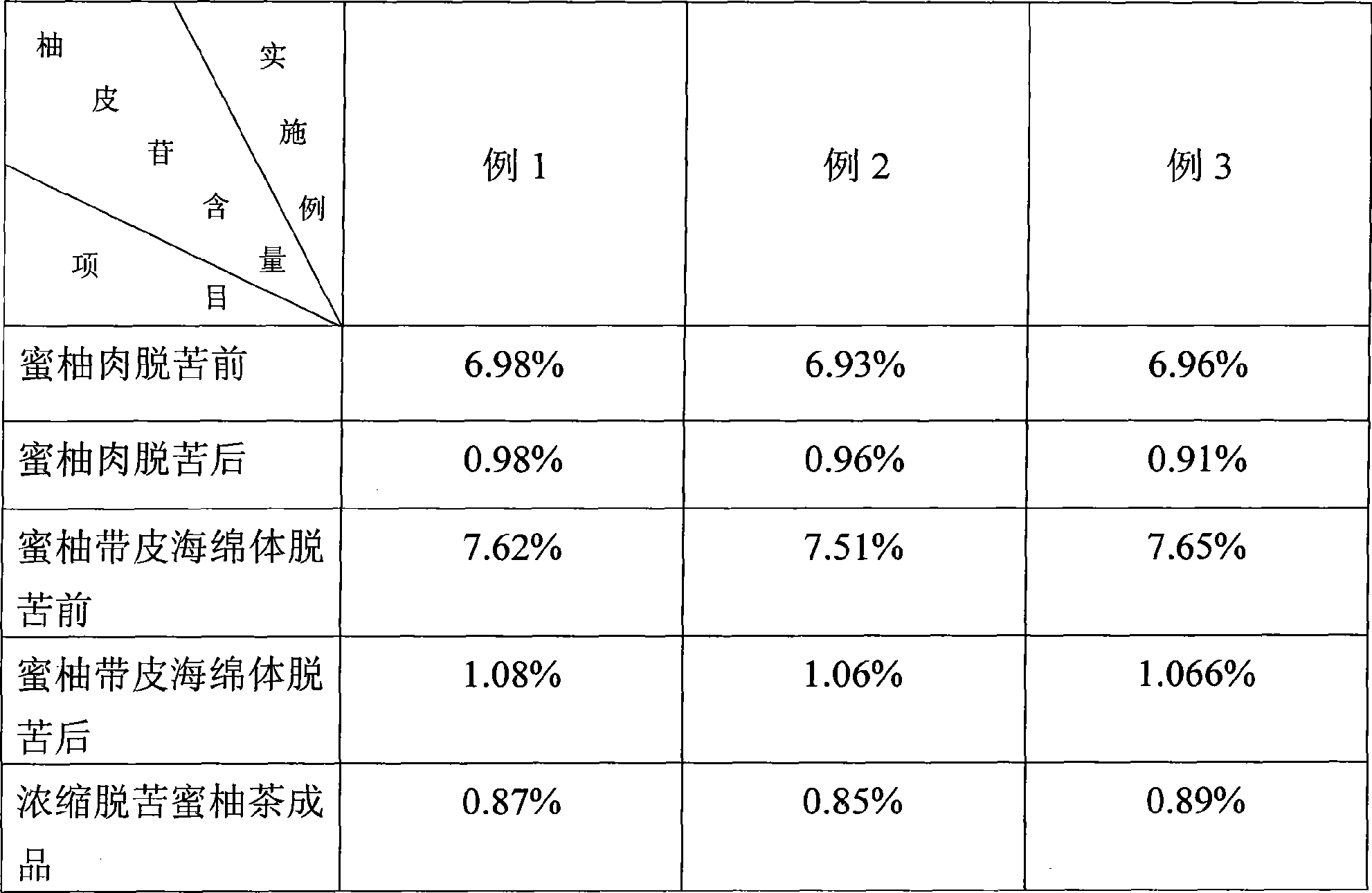

Debitterized honey pomelo tea and production method thereof

InactiveCN101390553AReduce contentSignificant debitterness effectTea substituesFood preparationNaringinPost-Procedure

Disclosed are a debittered honey pomelo tea and a production method; the skinned honey pomelo cavernous body and honey pomelo flesh peeled from the honey pomelo are taken as raw material; the raw material is put into the soy milk at a weight ratio of 1:2-3, insulated at a temperature of 55-66 DEG C for 2-4 hours and debittered; the plant enzyme in the soy milk is used to effectively reduce the content of the bitter principle naringin in the raw material; the debittered and molded material of the honey pomelo flesh is mixed with the debittered and molded material of the skinned honey pomelo cavernous body; upplementary materials and water are added into the mixture to obtain the debittered honey pomelo tea proportioning material; and after post-procedure homogenization, degassing and sterilization process, the debittered honey pomelo tea is prepared. In the preparation process of the invention, the raw material composed of skinned honey pomelo cavernous body and honey pomelo flesh is put into heated soy milk and debittered; upon tests, the debittered raw material and the debittered honey pomelo tea prepared thereof have low content of bitter principle naringin, so as to achieve significant debittering effect.

Owner:FUJIAN NANHAI FOOD

Method and special bacteria-adding equipment for adding bacteria after preparing bio-organic fertilizer

ActiveCN101538174AImprove fertilityEfficient decompositionOrganic fertilisersBiological material testing proceduresPost-ProcedureHigh pressure

The invention discloses a method and a special bacteria-adding equipment for adding bacteria after preparing bio-organic fertilizer. When the bio-organic fertilizer is being produced, the water content is 25-30% during the granulation process; after the granulation, the high-temperature quick drying is adopted in a drying cylinder and the water content is not more than 5%; after drying and cooling by a cooling cylinder, a microbial inoculum is added before packaging; furthermore, the special bacteria adding device is adopted to carry out high-pressure haze spraying so as to carry out computation adding; subsequently, the post-procedure of bacteria adding is carried out and the special bacteria adding equipment is selected; the bacterial liquid is added so that the active bacteria number is kept at 2 billion / gram; and before the product is packaged, the humidity needs to be kept at 12% of the water content by mass percentage, thus leading the selected bio-organic fertilizer grains to keep uniform and leading moisture to keep in an environment needed by the added microorganism bacteria. The method effectively avoids the loss of the active bacteria number of the beneficial bacteria in the bio-organic fertilizer, ensures the active bacteria number of the beneficial bacteria during adding the bio-organic fertilizer, and leads the beneficial bacteria to bring beneficial functions tothe bio-organic fertilizers.

Owner:新疆惠森生物技术有限公司

Process for mixing tire tread with high white carbon black content

InactiveCN104985710AGood dispersionImprove wear resistanceRolling resistance optimizationRolling resistancePost-Procedure

The invention discloses a process for mixing tire tread with high white carbon black content. The characteristics of a rubber mixing system based on a one-step method are combined, aspects of internal mixing process optimization (medicine input sequence optimization, as well as 'silanization reaction' condition optimization of an internal mixer), mixing process optimization of an open mixer, and the like are adopted, and the aspect of a formula of the tire tread filled with high content white carbon black and the means of silane coupling agent and white carbon black coordination proportion optimization and the like are combined, so as to achieve the following technical effect: the dispersivity of white carbon black is improved, the abrasion resistance is improved, the high sizing material calorigenesis is reduced, and the rolling resistance is reduced; through the means of combining high temperature silanization reaction of the internal mixer and low temperature section silanization reaction of the open mixer, the silanization reaction degree is improved, and the dynamic performance and processing safety of a sizing material are optimized; the flowability of the sizing material is improved, the post-procedure processability is improved, and the processing energy consumption is reduced; the mixing section number is reduced, and the production efficiency is improved.

Owner:特拓(青岛)轮胎技术有限公司

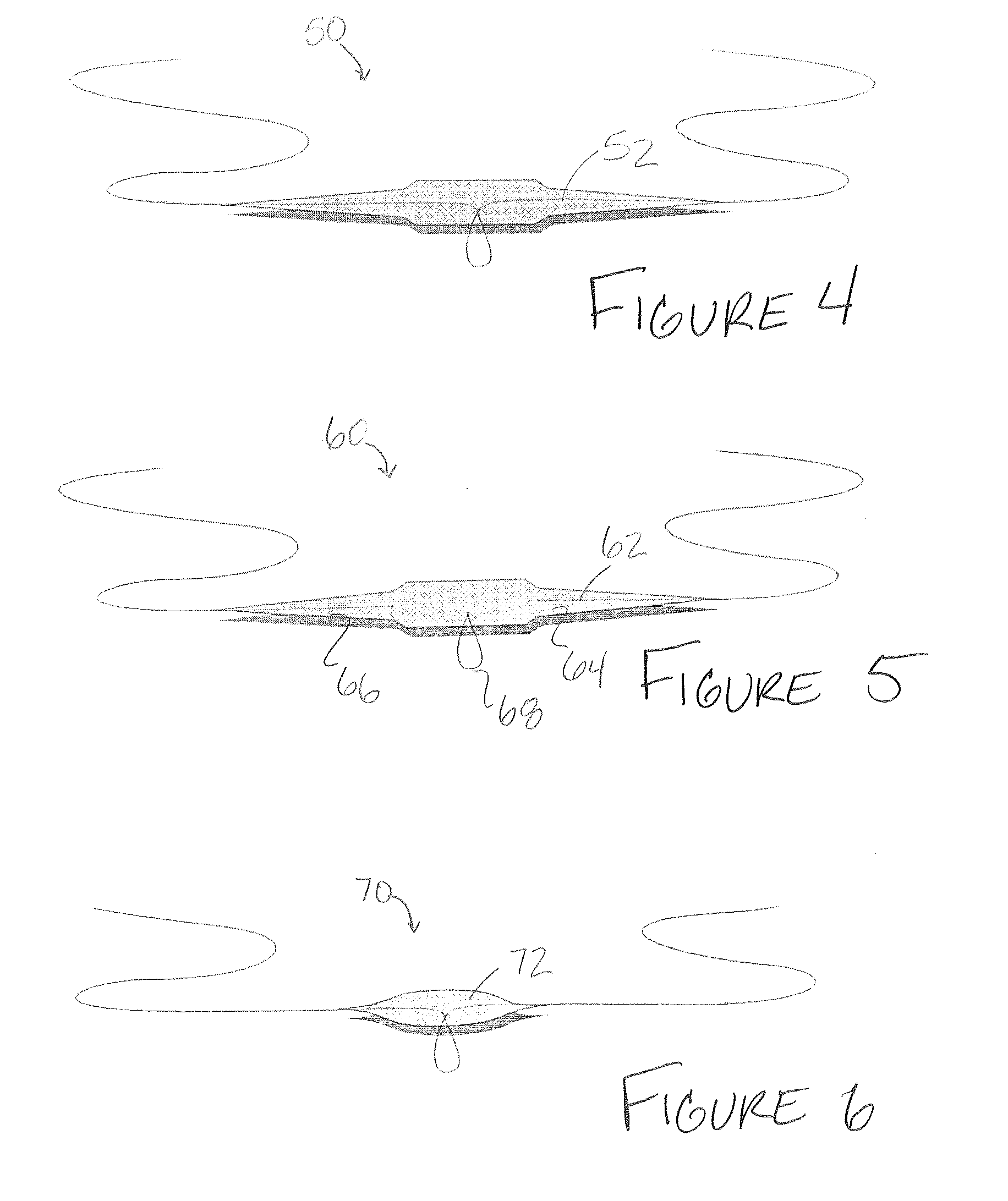

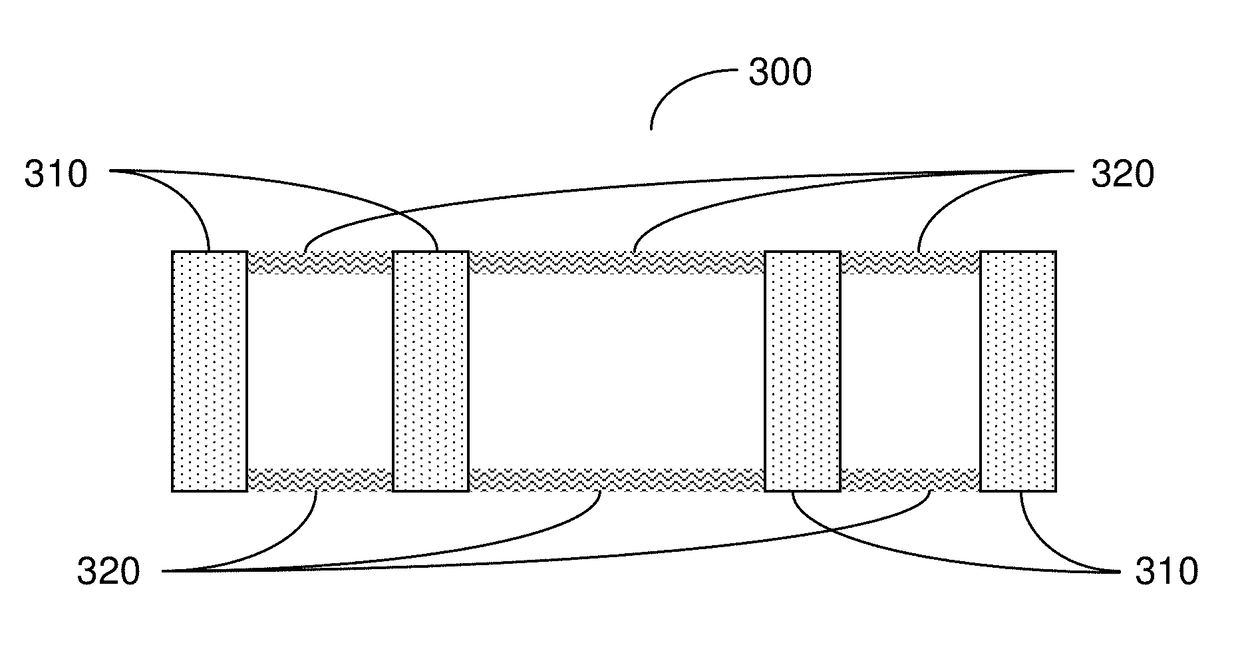

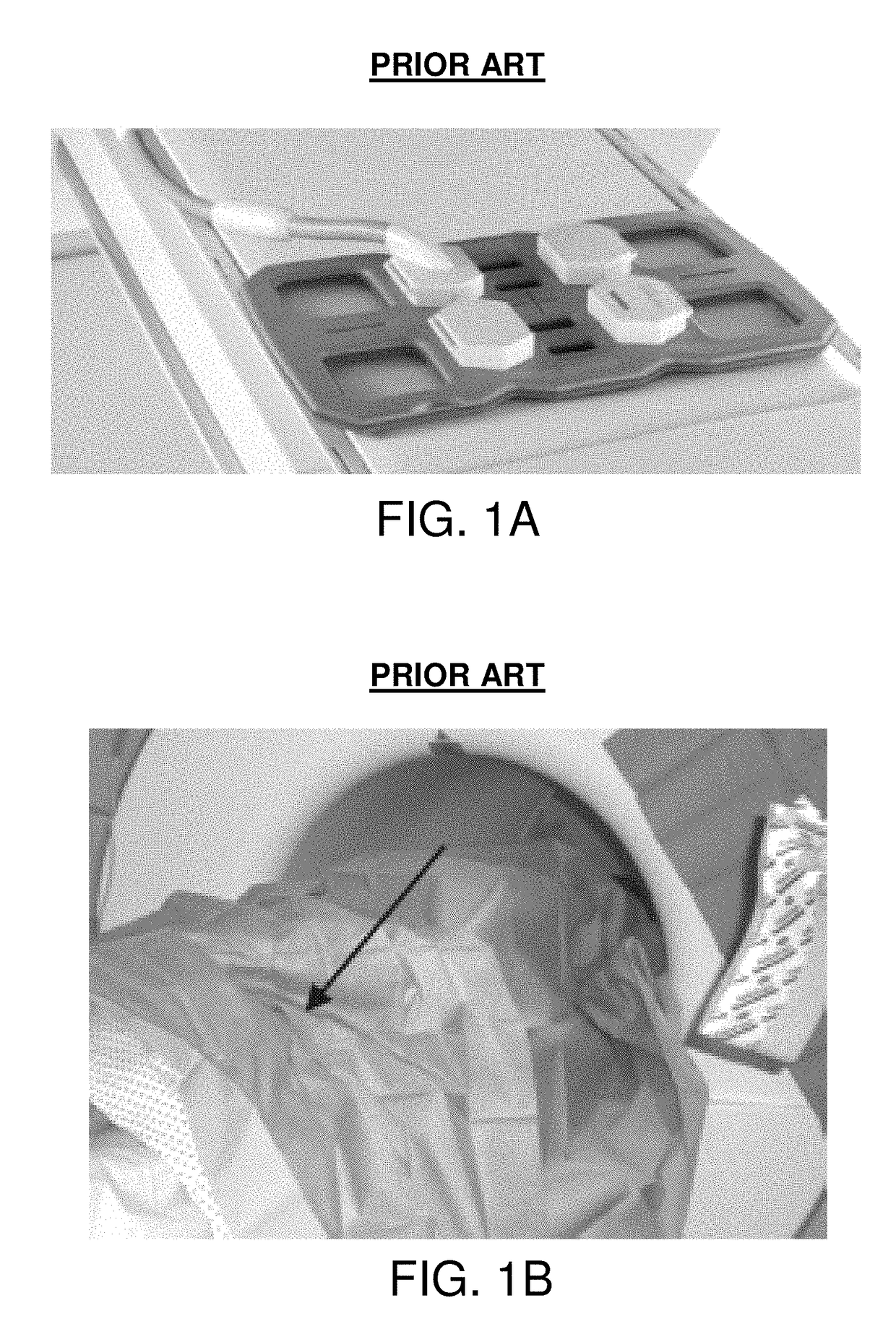

Magnetic Resonance Imaging Coil With Adjustable Opening

ActiveUS20170248666A1Improve image qualityAdequate accessDiagnostic recording/measuringSensorsMri guidedImaging quality

A configurable coil arrangement for use with MRI-guided procedures is provided that facilitates optimal imaging for both pre-procedure planning and imaging of the target sites during the procedure. The coil arrangement includes a plurality of connected coil elements. Spacers connecting the coil elements can be adjustable and / or deformable to provide one or more openings in the coil arrangement of optimal size for accessing the subject within the imaged region. Individual coil elements can also be removed to provide access openings during such procedures, or left in the array for improved pre- and post-procedure image quality. The MRI system can be configured to detect configurations of the coil arrangement and modify imaging parameters to optimize image quality.

Owner:SIEMENS HEALTHCARE GMBH +1

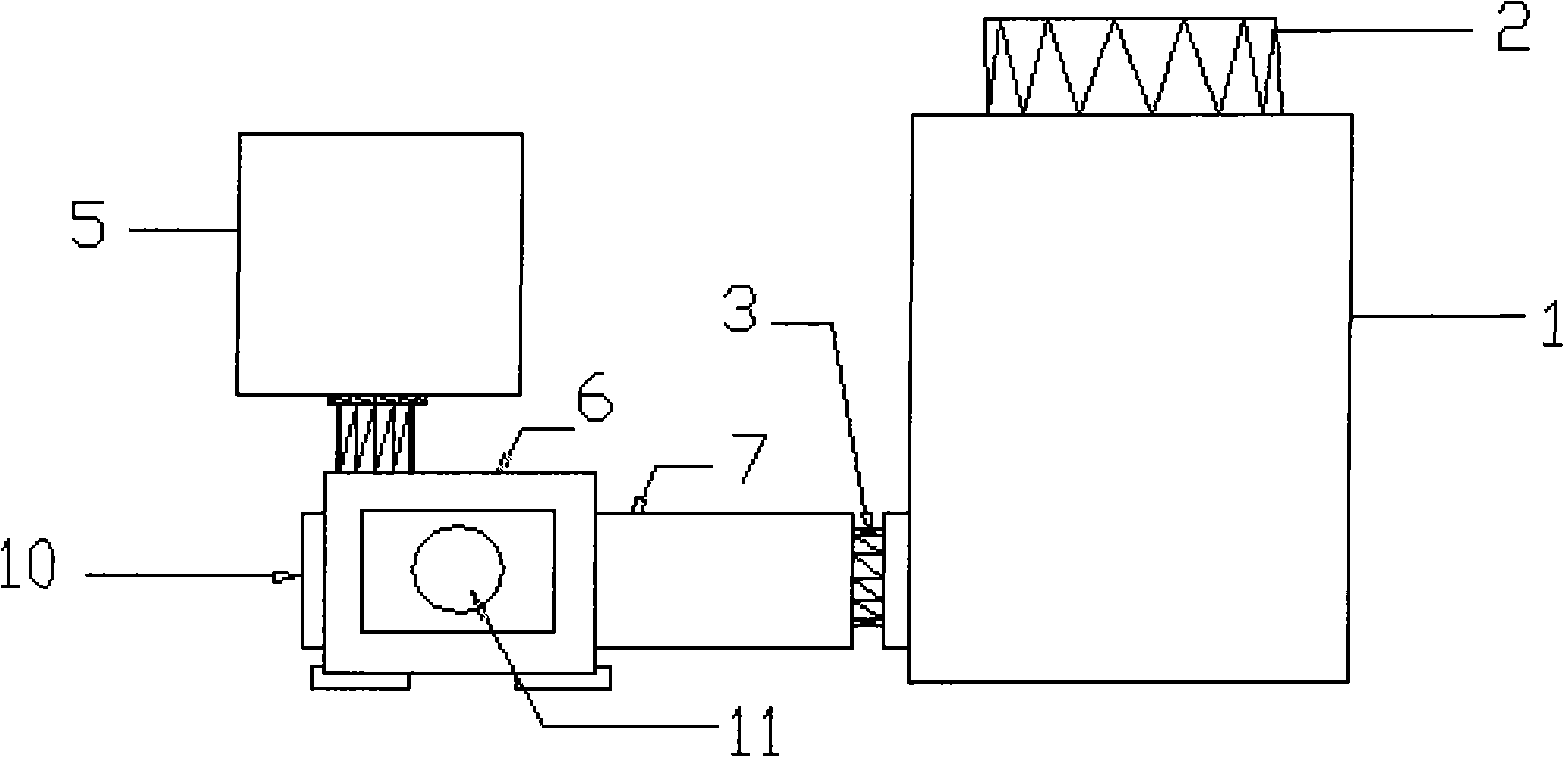

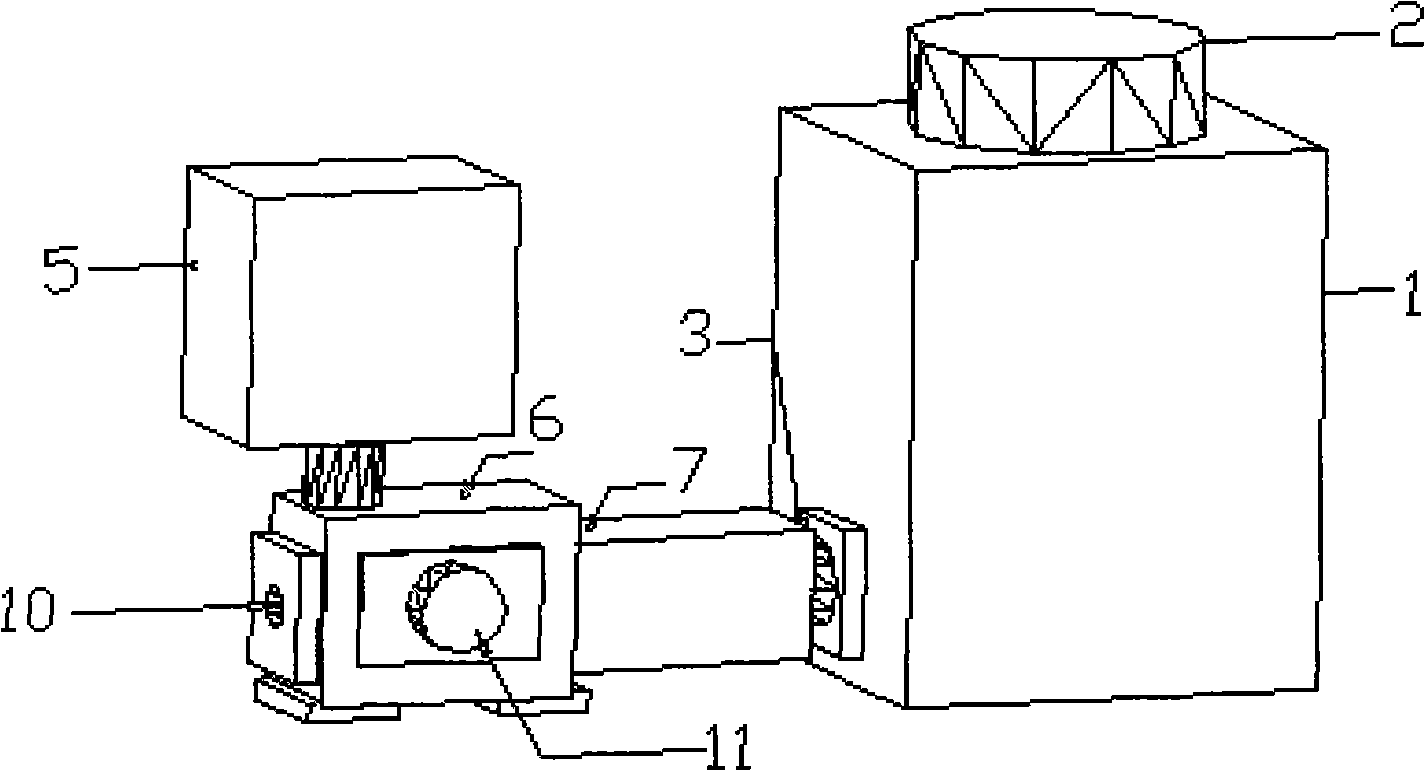

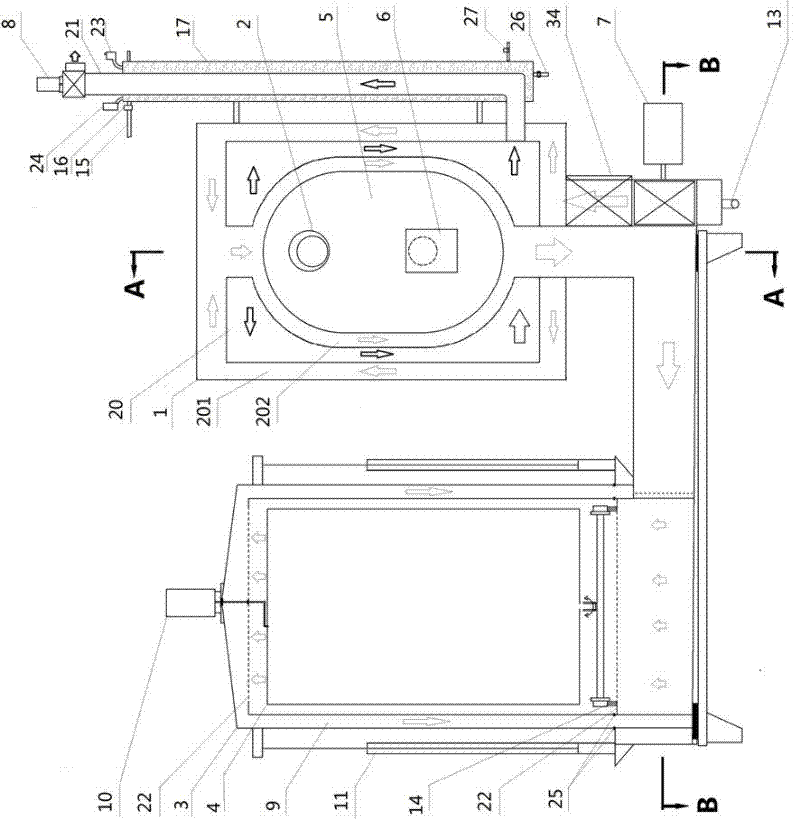

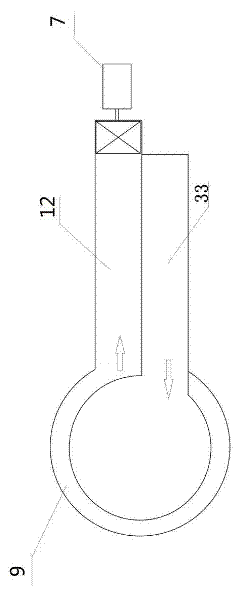

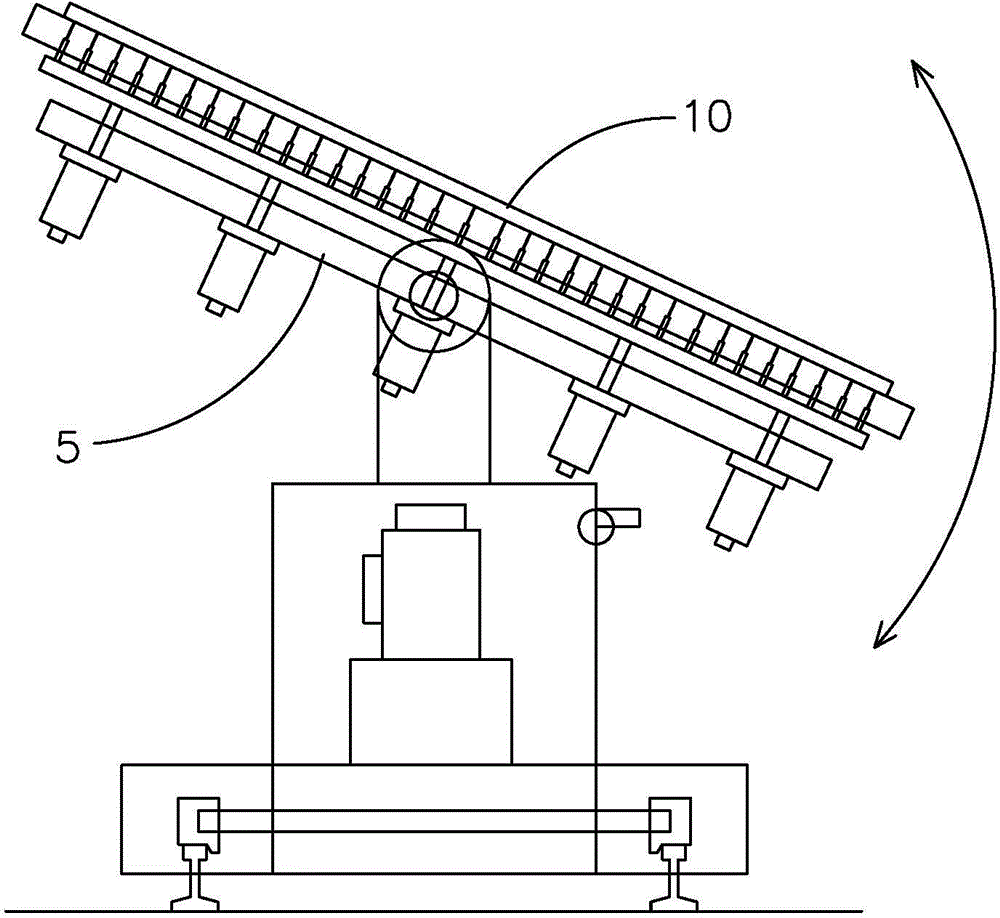

Sock steam shaping machine

InactiveCN102230263AFlat shapeImprove appearance qualityShaping/stretching tubular fabricsCombustion chamberEngineering

The invention discloses a sock steam shaping machine belonging to the field of knit goods finishing equipment. The sock steam shaping machine comprises a heating device, a shaping drying device, a sock car and a connection device, wherein the heating device consists of a combustion chamber and a circular fan; the shaping drying device consists of a shaping working chamber and a base; the sock car consists of a sock rack and a sock car base for fixing the sock rack; and the connection device consists of a wind feeding channel and a wind returning channel, wherein the sock rack can rotate horizontally. Knit goods heated and shaped by the invention are shaped evenly, so that the appearance quality of the products is largely improved; and the post-procedure matching difficulty is reduced; an individual steam generator is used for avoiding damage of hearth walls and pollution on machines and products by scale caused by spraying water on the walls of the high temperature combustion chamber in the same technology at present, thus the service life of the equipment is prolonged.

Owner:吴肆雄

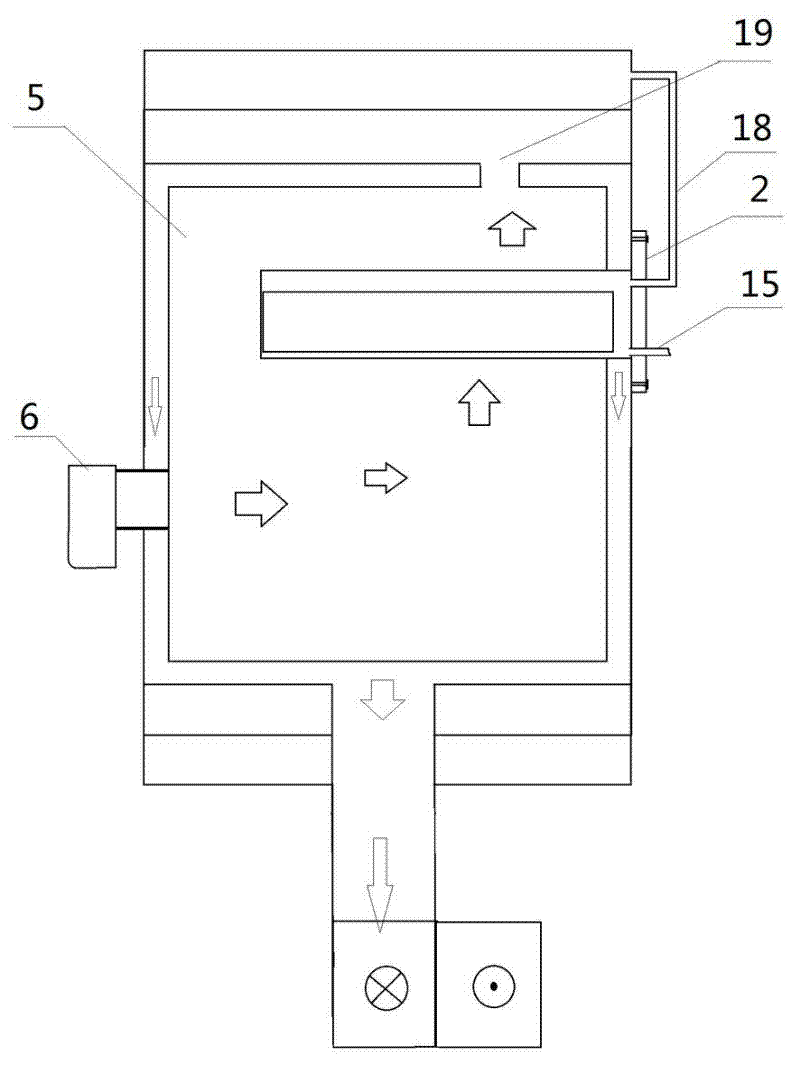

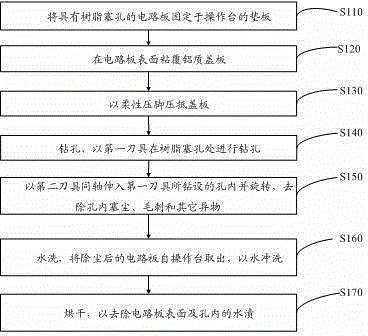

Drilling method of resin plugging circuit boards

InactiveCN104582315AEfficient removalReduce scrap ratioPrinted element electric connection formationForeign matterCyclone

The invention discloses a drilling method of resin plugging circuit boards. The drilling method comprises the following steps: fixing a circuit board on a backing board; sticking an aluminum covering board on the surface of the circuit board; pressing the covering board with a flexible pressure foot, and tightly pressing and fixing the covering board, the circuit board and the backing board on an operation desk; drilling a resin plugging hole with a first tool, wherein the diameter of the first tool is R1; coaxially stretching a second tool into a hole drilled by the first tool and rotating to remove plug dust, burrs and other foreign matters in the hole, wherein the diameter of the second tool is R2, and R2 is 0.02-0.1mm less than R1; after drilling, using the second tool slightly smaller than the first tool to drill in the hole again, removing resin residues and burrs in the hole by the rotation of the second tool, and adsorbing and discharging the dust in the hole by the negative pressure cyclone formed in gaps of hole walls when the second tool rotates in the hole at a high speed, so that the residues in the hole are removed effectively, the scrap rate of post-procedures is reduced, and the operation is simple.

Owner:TEXIN MICROELECTRONICS DONGGUAN

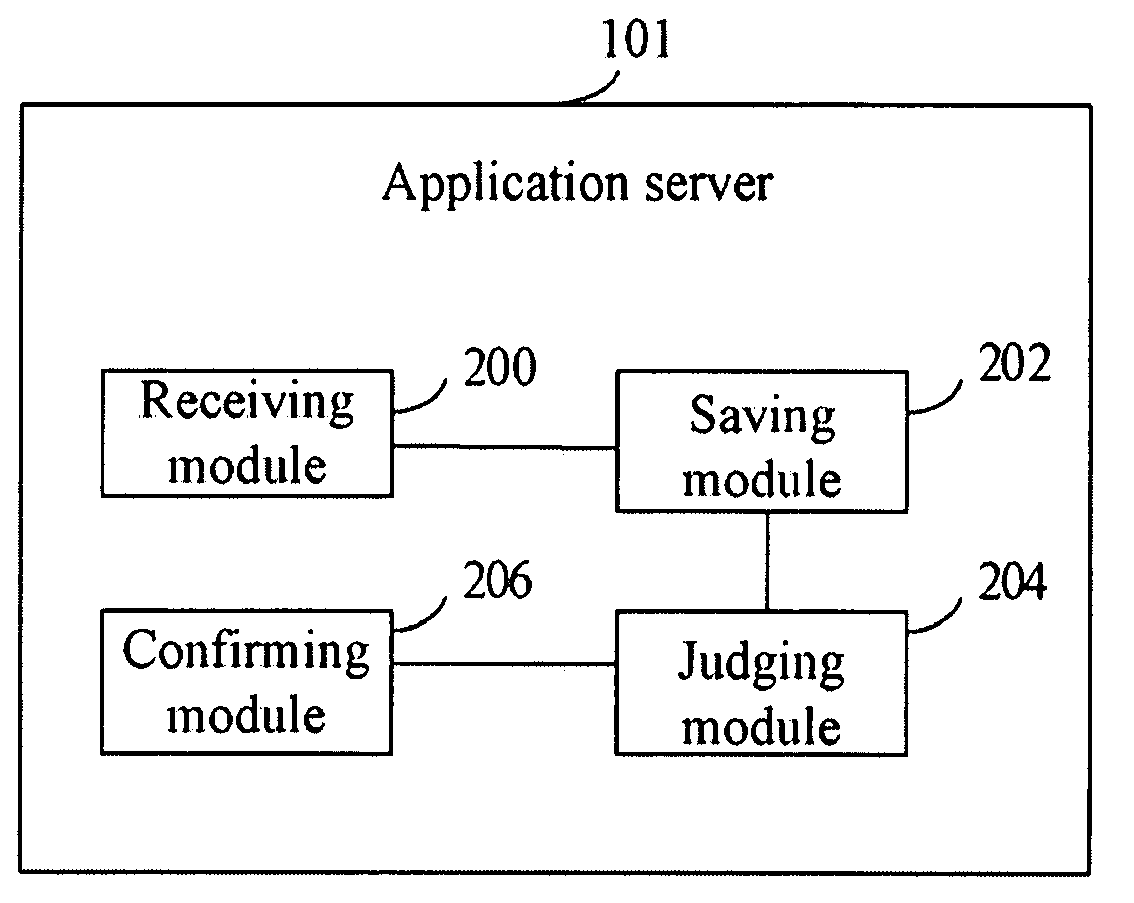

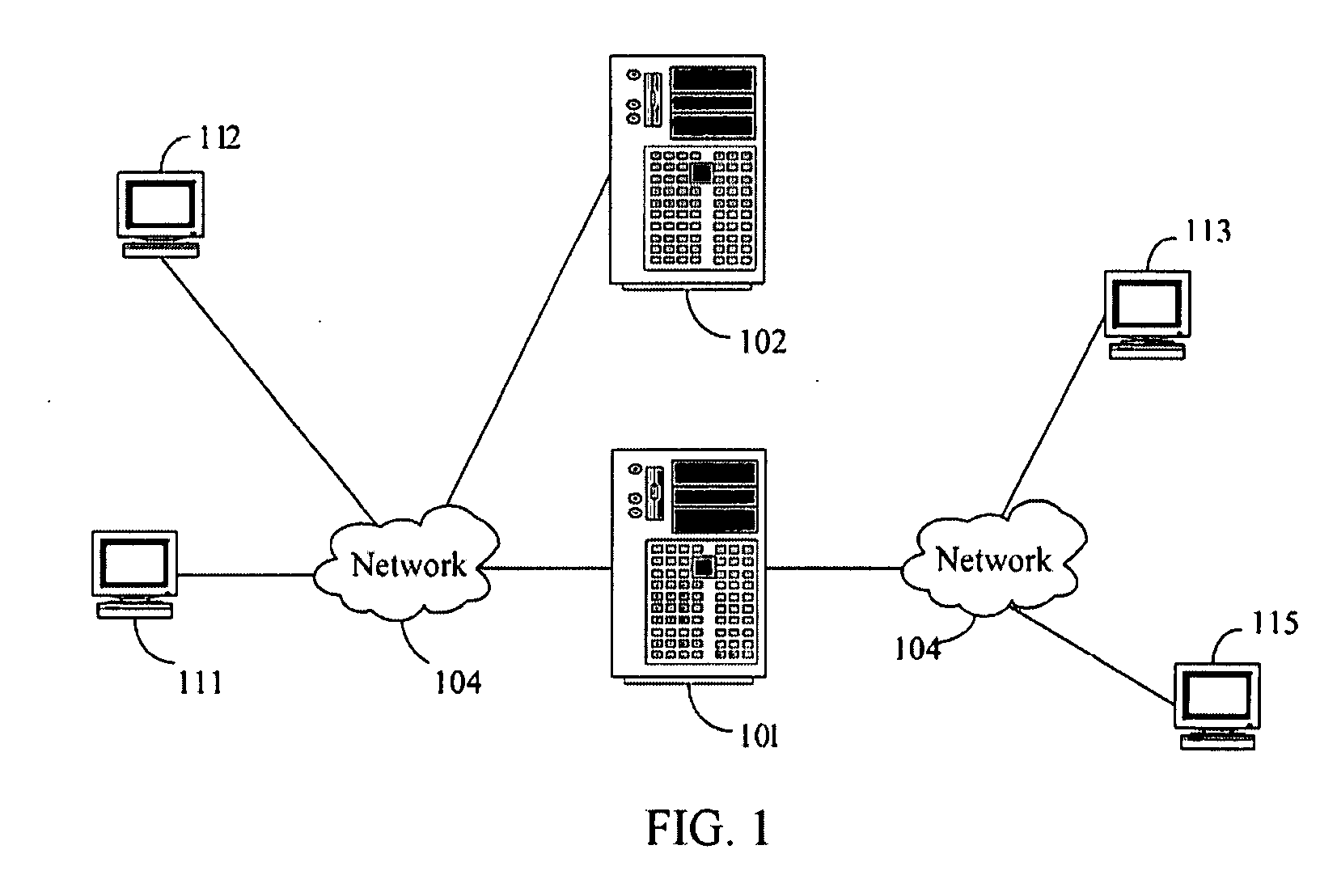

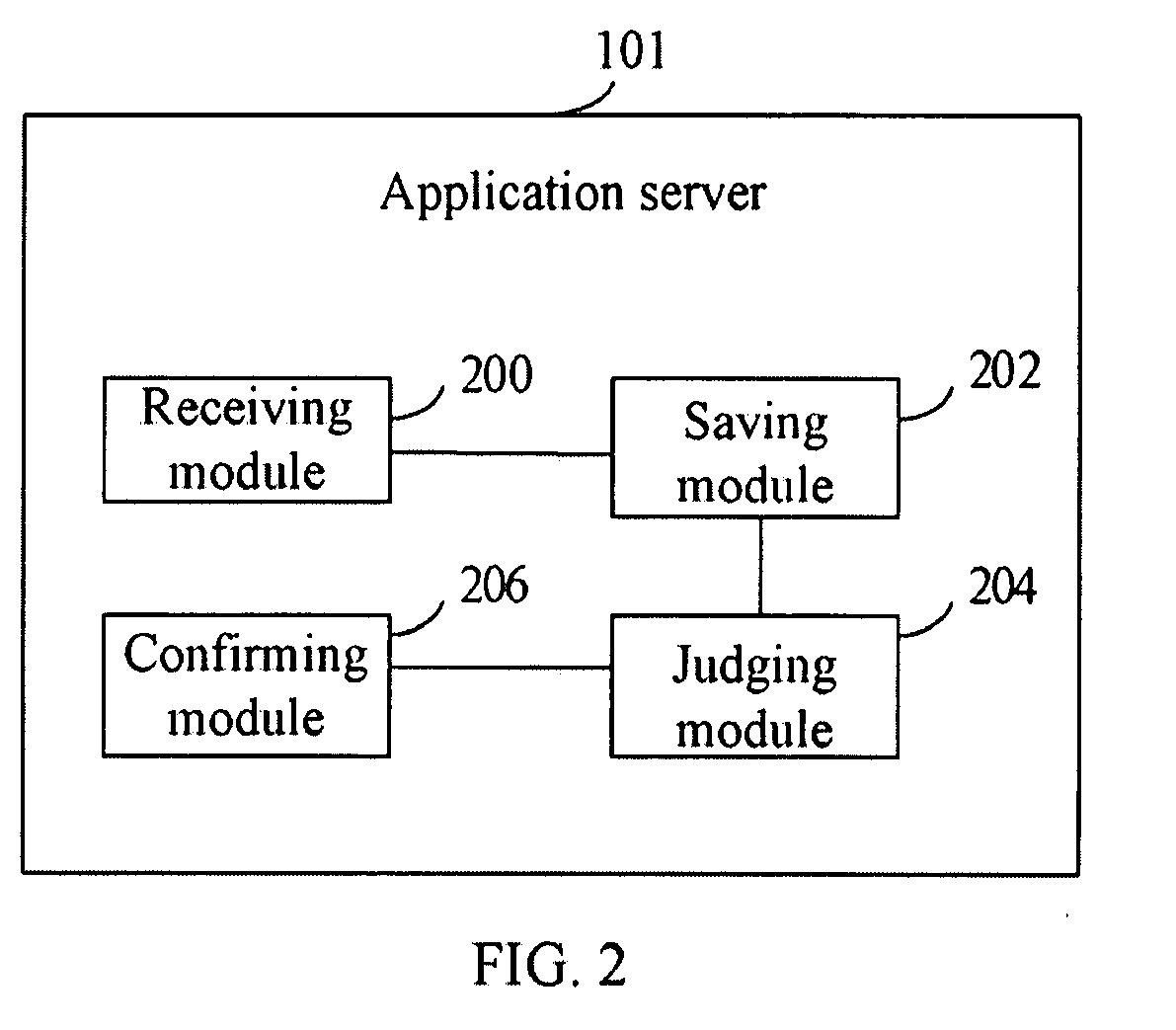

System and method for controlling product quality

InactiveUS20080228305A1Hand manipulated computer devicesAnimal feeding devicesPost-ProcedureComputer science

A computer-based method for controlling product quality is disclosed. The method includes the steps of: detecting whether a quality of raw materials bought from at least one supplier are acceptable; detecting whether a quality of using materials used at a processing procedure are acceptable; detecting whether a quality of products being manufactured at the processing procedure are acceptable; receiving and storing a post-procedure report obtained by sampling the products after the processing procedure; repeating steps of detecting materials used at a processing procedure, detecting products being manufactured at the processing procedure, detecting the sampling products after the processing procedure, and completing the manufacturing if all the products are finished. A related system is also disclosed.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

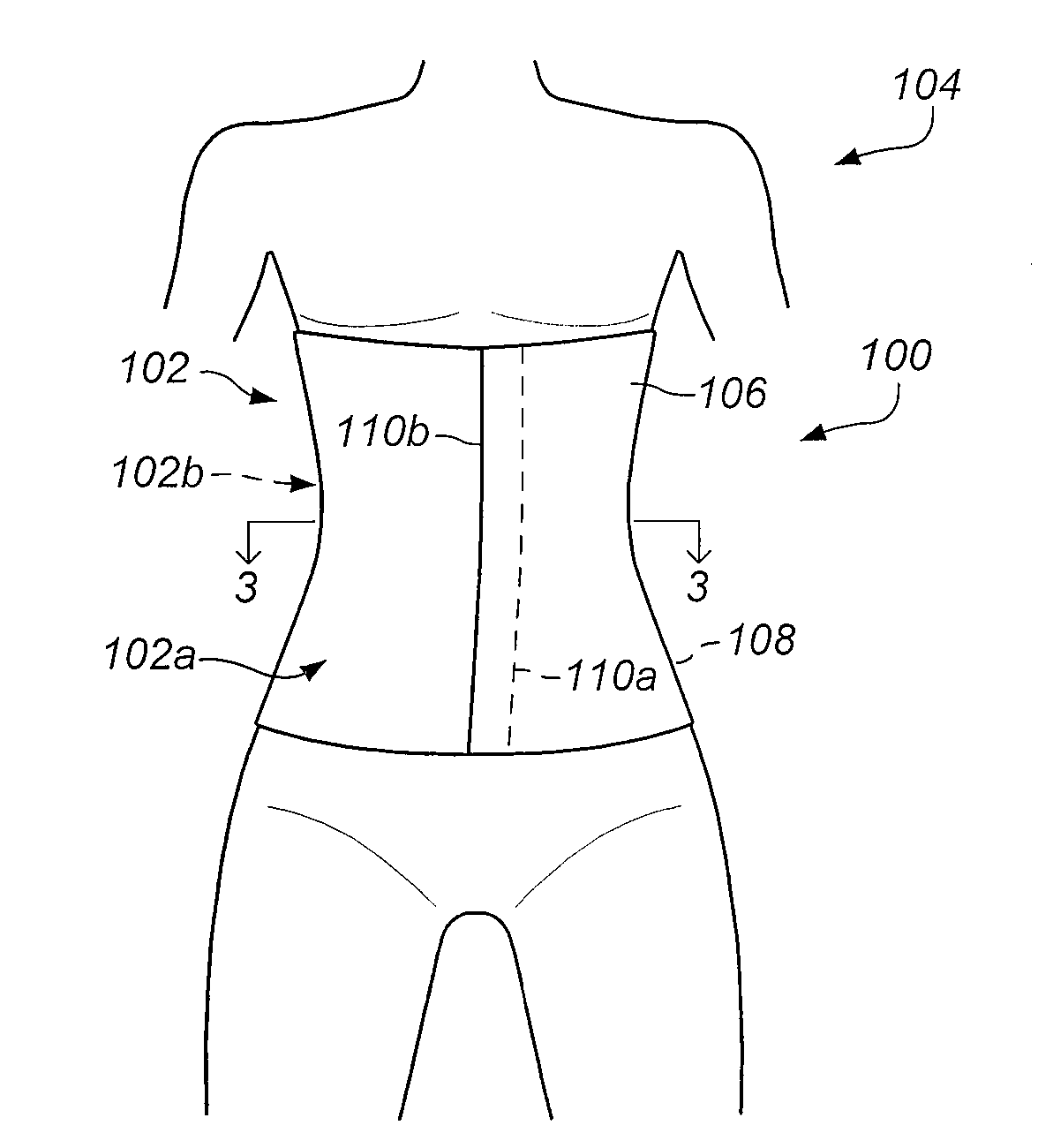

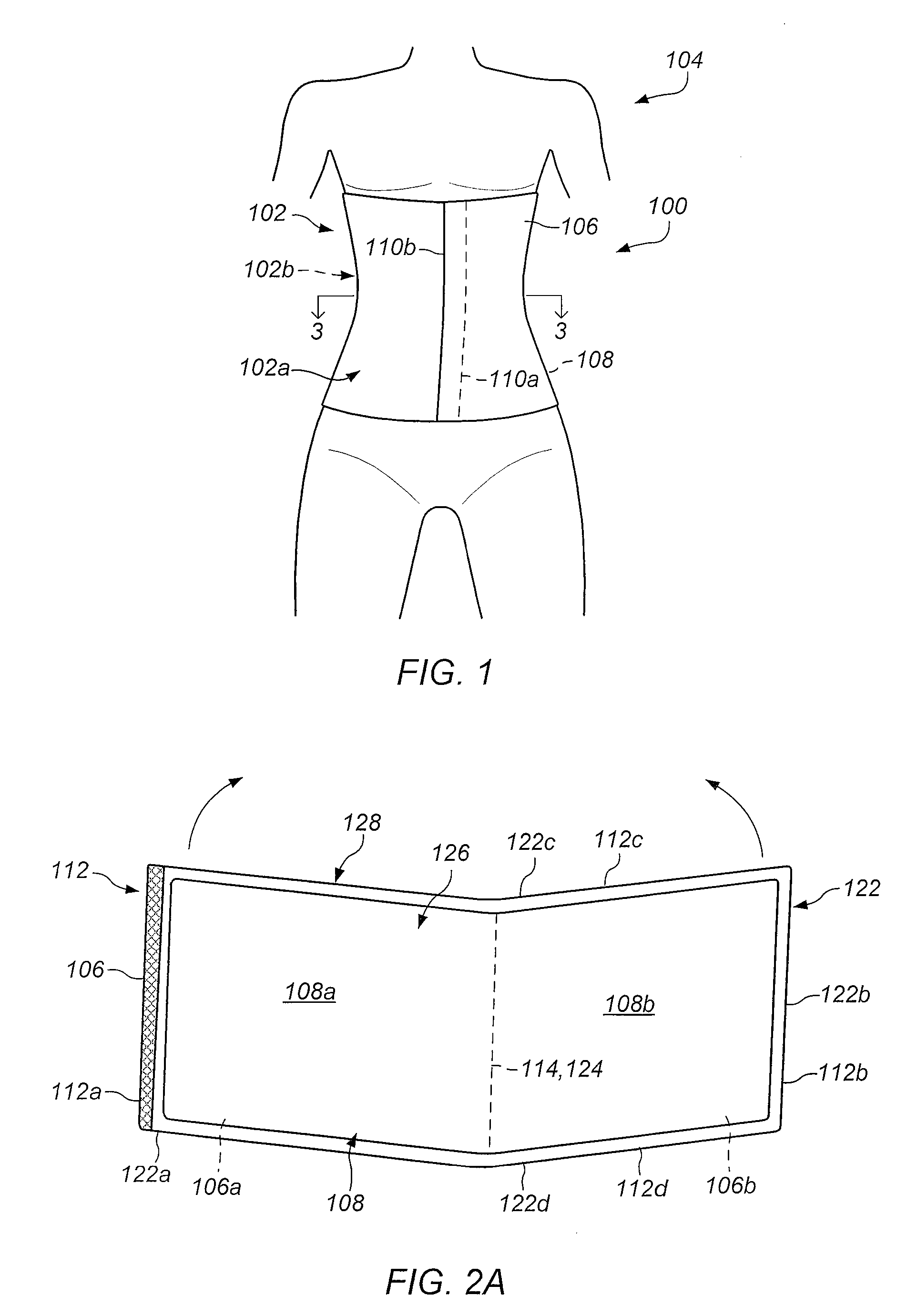

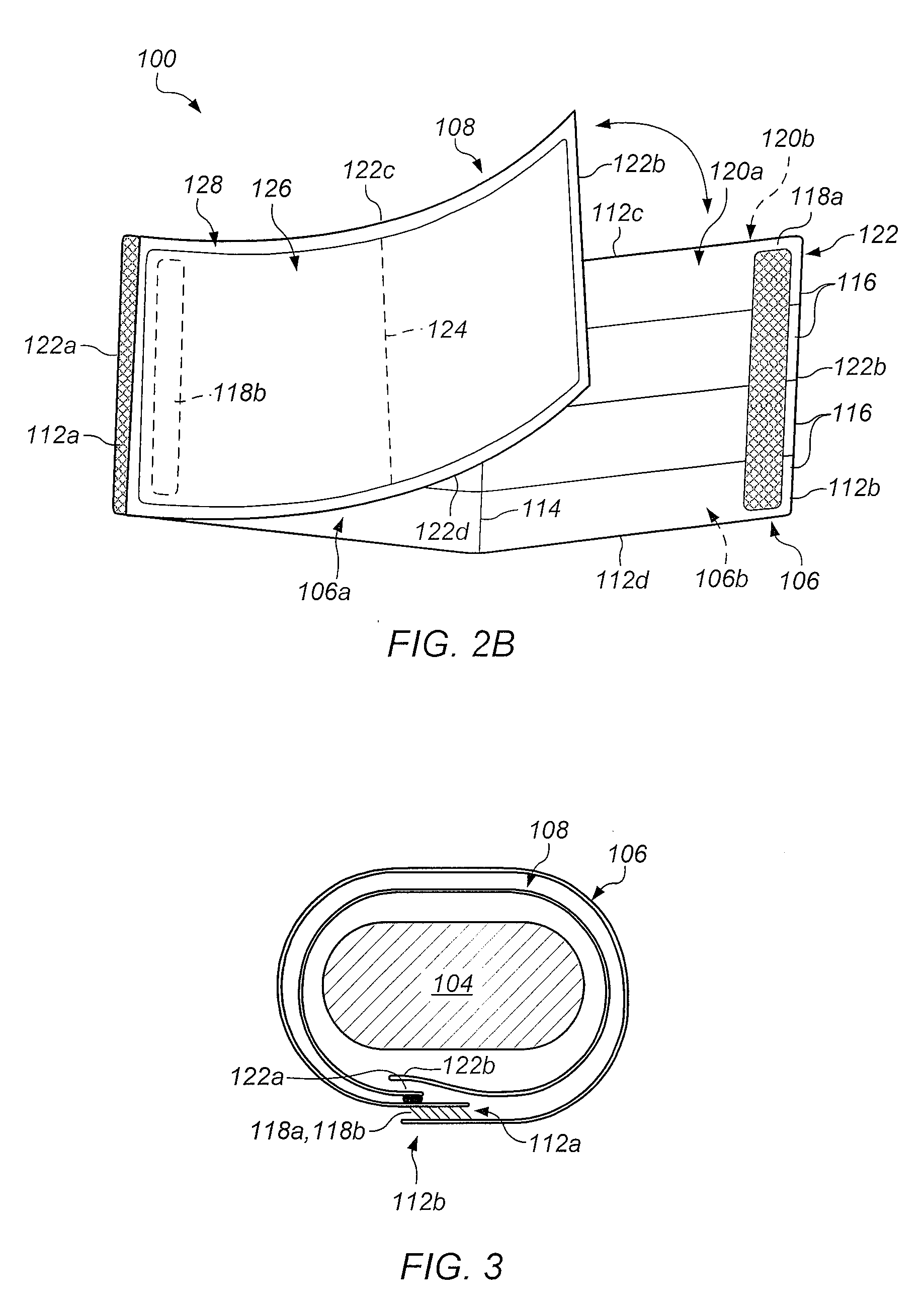

Absorbing medical binder system and method

Provided is a method and system for bandaging an abdominal region of a patient. A method includes providing an abdominal binder and securing the abdominal binder about the abdominal region of a patient. The abdominal binder has an inner layer including an absorbent pad configured to contact and extend about at least a majority of the circumference of the abdominal region of a patient, and configured to absorb post-procedure fluids during use, and an outer layer including an elastic sheet of material for surrounding at least a portion of the inner layer and providing a compressive force to retain at least a majority of the inner layer against the abdominal region of the patient during use. The outer layer is about 70 to 130% of the size of the inner layer when the outer layer is provided in an unbiased state. The inner layer and the outer layer are coupled to one another at or near a first end of the inner layer and a first end of the outer layer, and a second end of the inner layer and a second end of the outer layer are configured to allow movement relative to one another.

Owner:CORE COMPRESSIONS +1

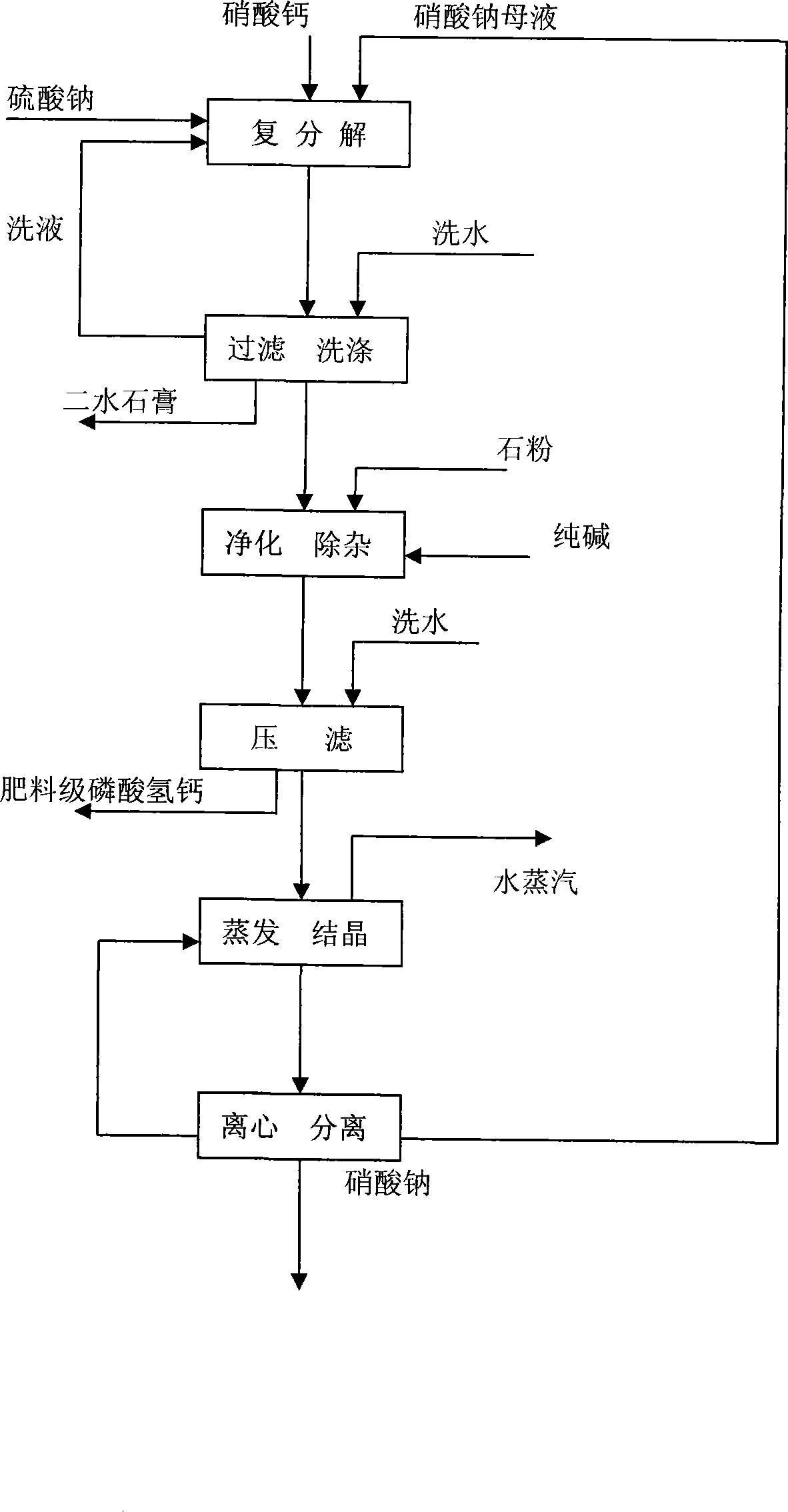

Method for preparing sodium nitrate by using nitric acid to decompose phosphorus ore byproduct calcium nitrate

InactiveCN101186318ADi-calcium phosphate fertilisersAlkali metal nitrate preparationMagmaDecomposition

The invention discloses a sodium nitrate preparation method by calcium nitrate that discomposes byproduct of phosphate rock by using nitric acid. The sodium nitrate preparation method comprises that: (1) double decomposition: namely, calcium nitrate, washing liquid of gypsum filter residue in post procedure and returned mother liquor of calcium nitrate are mixed and stirringly added with sodium sulfate to double discompose, and then the generated dihydrate gypsum is filtered and washed by clean water, the lotion is recycled; the generated calcium nitrate is left in the filtrate; (2) removing calcium through purification: namely, limestone powder and soda are added to the filtrate in the last step to neutralize and heated to boil and then the mixture is filtered to remove calcium carbonate which is dried to obtain fertilizer-grade calcium hydrogen phosphate; (3) evaporation, crystallization and separation: namely, the neutralized filtrate in the last step is put into a double evaporator to condense and cooled to crystallize, thus obtaining sodium nitrite magma. The sodium nitrite magma is put into a centrifugal separator to separate to obtain sodium nitrite product. The preparation method of the invention can transform the waste residue calcium nitrate that is discharged from a nitric phosphate device by freezing method into sodium nitrite product, which has good economic and environmental benefit.

Owner:GUIZHOU RES INST OF CHEM IND

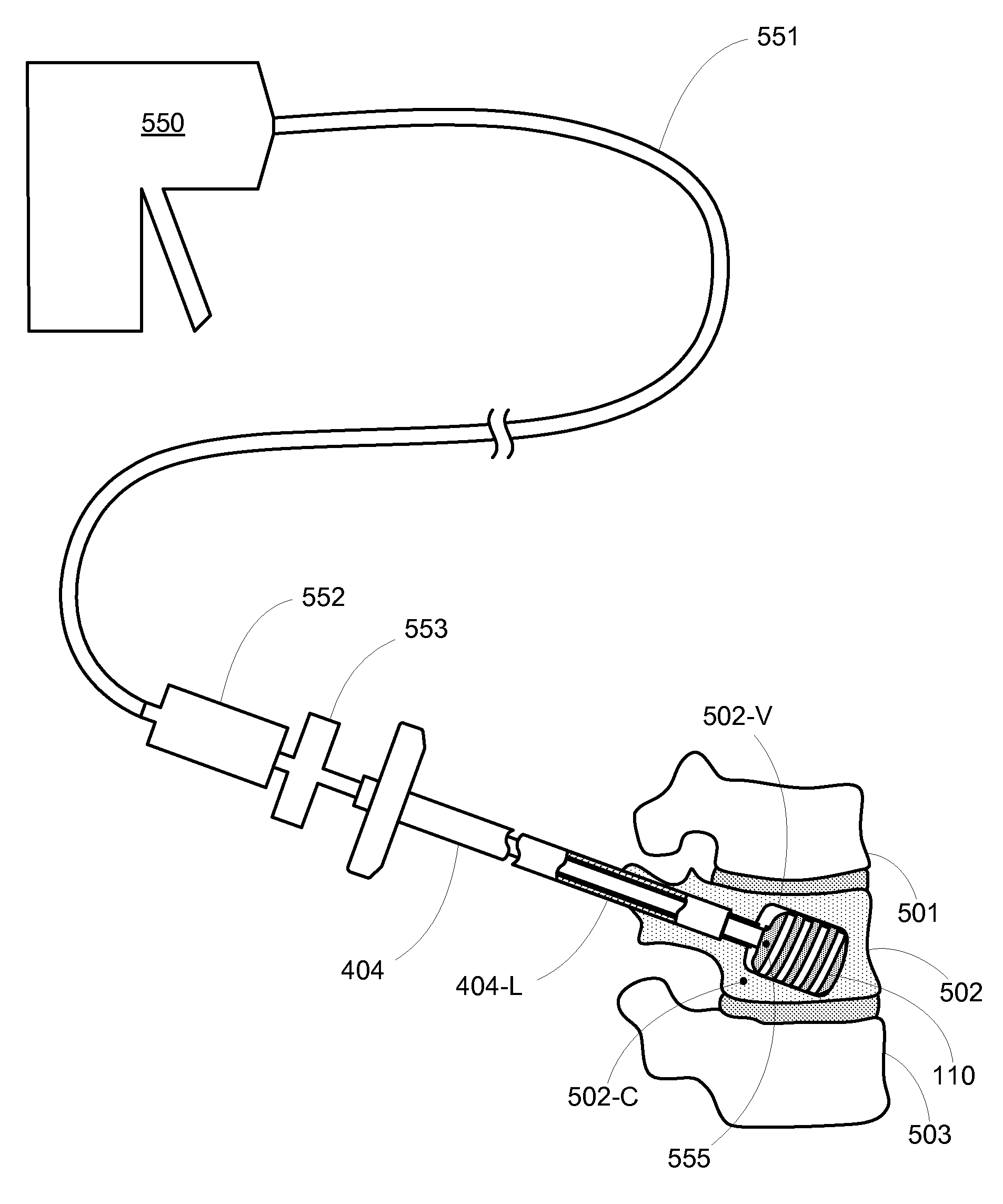

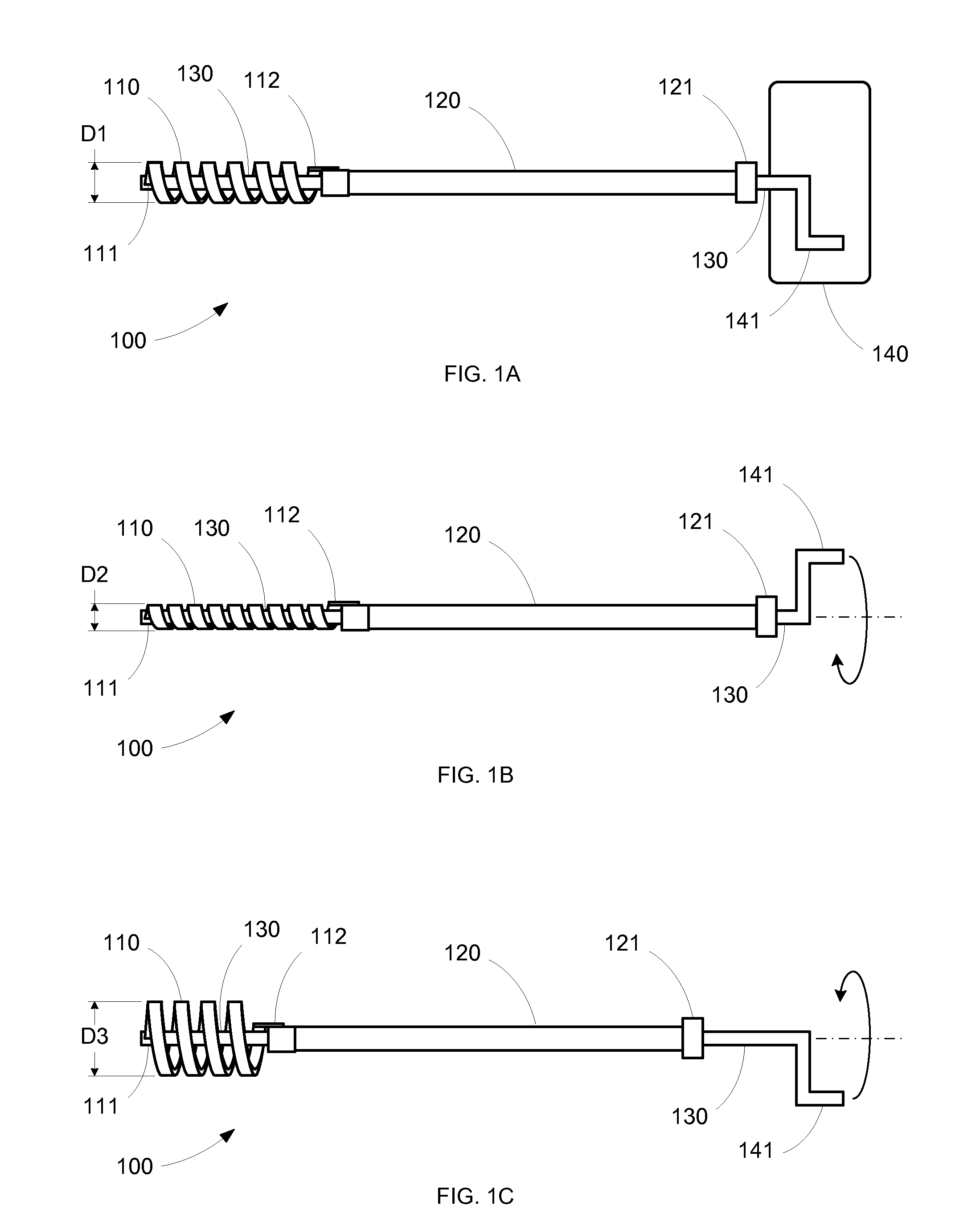

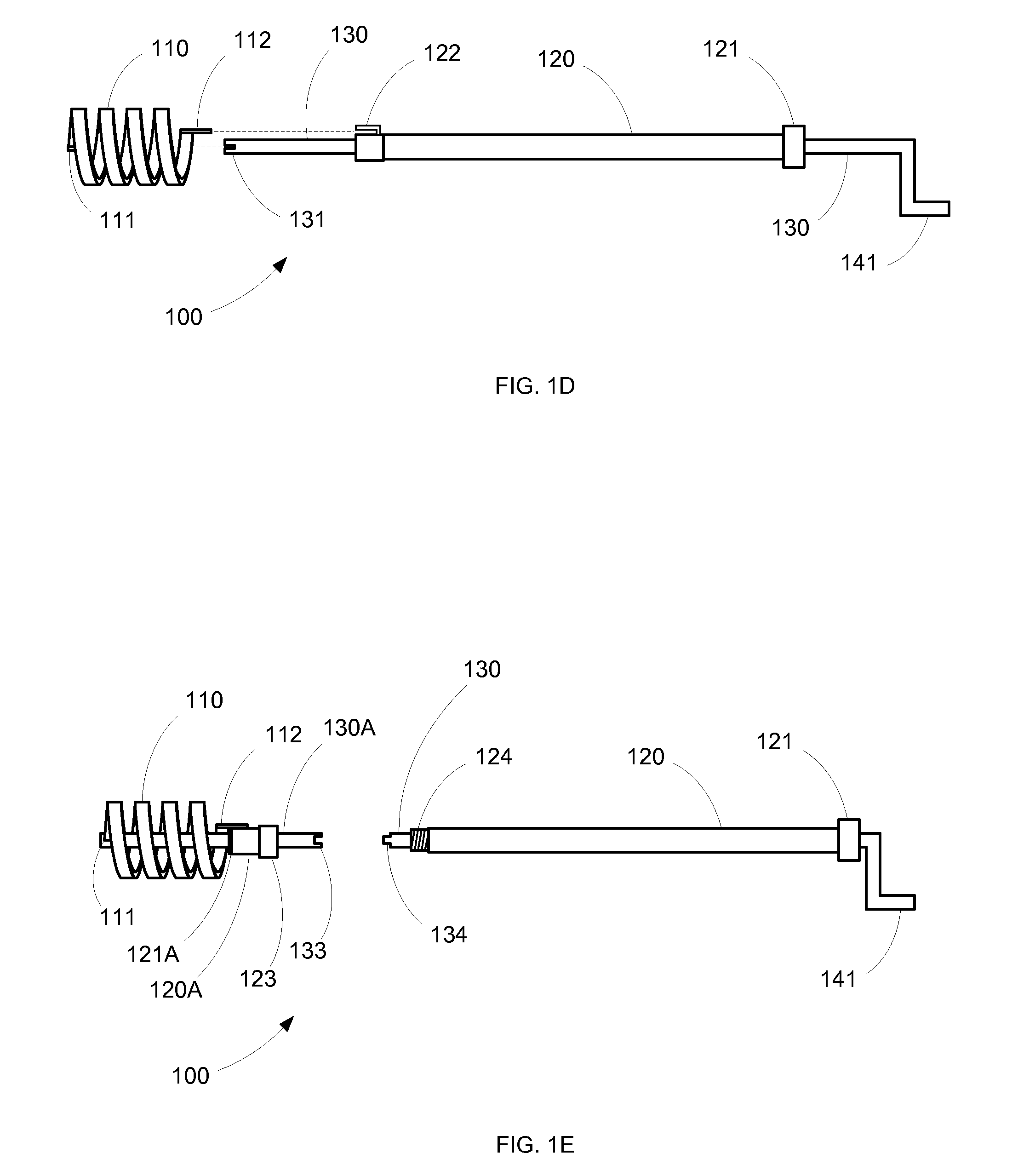

Expandable device for bone manipulation

InactiveUS20110098759A1Raise the possibilityInternal osteosythesisJoint implantsEngineeringPost-Procedure

An expandable bone tamp for performing a minimally invasive surgical procedure includes a coil connected between an inner shaft and an outer shaft. Rotating the inner shaft relative to the outer shaft can then cause the coil to expand or collapse around the inner shaft. The coil allows large expansion forces to be generated by a structure Thant can pass through a small cannula. The rotation of the inner shaft relative to the outer shaft can be performed manually (e.g., via a crank handle) for good tactile control, or can be performed using a motor or other assist mechanism to increase the expansion force output. The coil can either be withdrawn after use, or can be left in the patient to provide additional post-procedure support.

Owner:KYPHON

Manufacturing process of PCB (Printed Circuit Board)

InactiveCN102244988AAvoiding the Problem of Expansion BurstsImprove yieldNon-metallic protective coating applicationPrinted element electric connection formationLight irradiationUltraviolet lights

The invention relates to a manufacturing process of a PCB (Printed Circuit Board), in particular to a soldmask hole-plugging procedure of the PCB. The manufacturing process comprises the steps of: (1) soldmask pretreatment; (2) ink hole plugging of a PCB; (3) prebaking; (4) exposure; (5) development; (6) appearance inspection (7) UV (ultraviolet light irradiation) of the PCB for curing ink for hole plugging; and (8) postcuring of the PCB. According to the manufacturing process, the step of UV light irradiation is added to the soldmask hole plugging procedure of the PCB, thereby not only achieving a strong light curing effect on the ink in the plugging hole of the PCB, but also better curing the soldmask ink on the surface of the board; and the problem of popping in the post procedure can be effectively avoided, the falling of the soldmask ink on the surface of the board in the post procedure is prevented, the product quality of the finished PCB can be guaranteed, and the production efficiency is improved.

Owner:惠州中京电子科技股份有限公司

Post-procedure skin care systems, compositions, and methods of use thereof

Provided are topical biocompatible compositions including a topical wound healing composition, a topical soothing composition and epidermal / dermal wound healing / repair composition. Also provided are methods of using the biocompatible compositions for treating and / or preventing comprimised, and methods for producing the biocompatible compositions.

Owner:ZO SKIN HEALTH

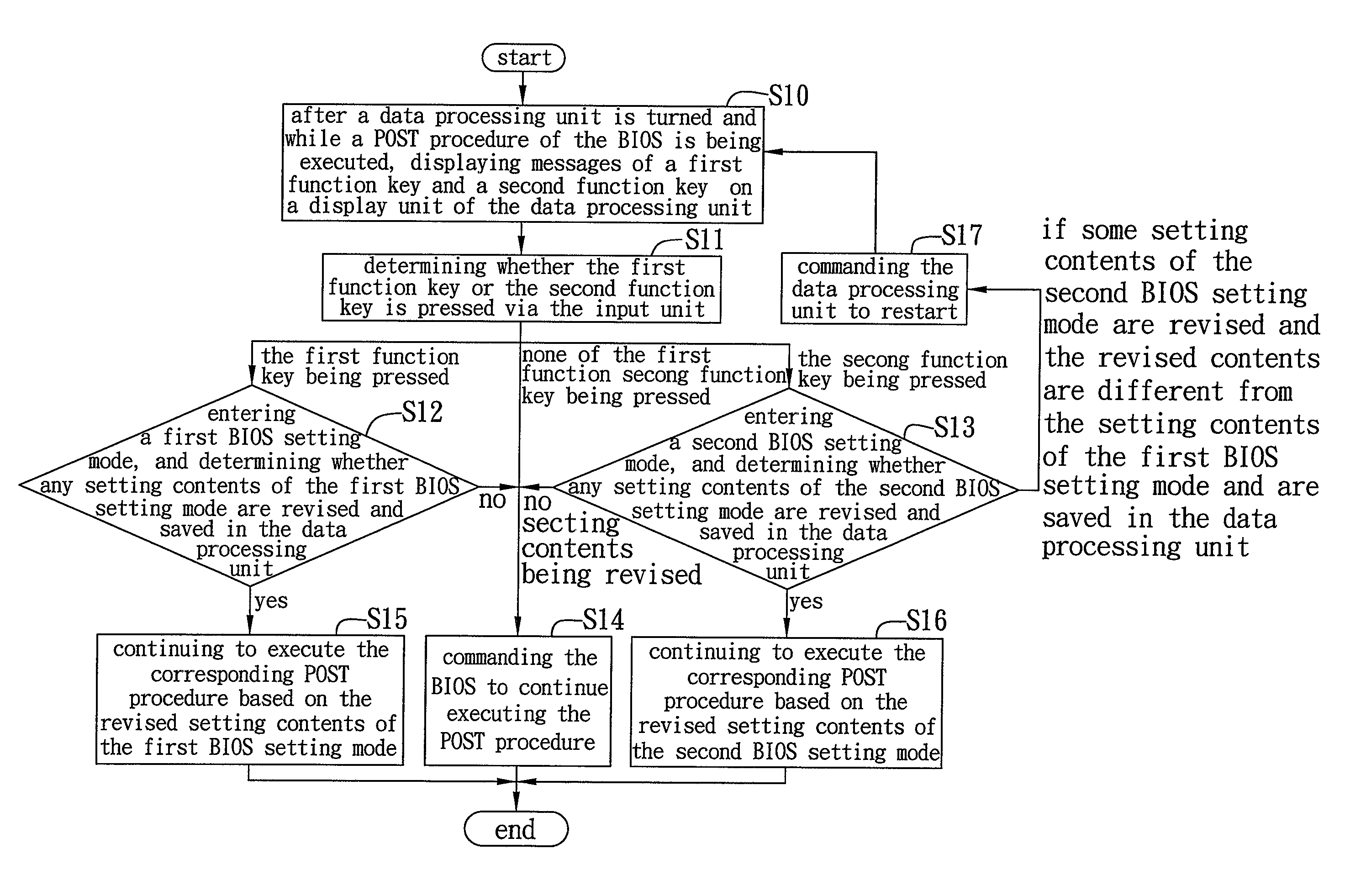

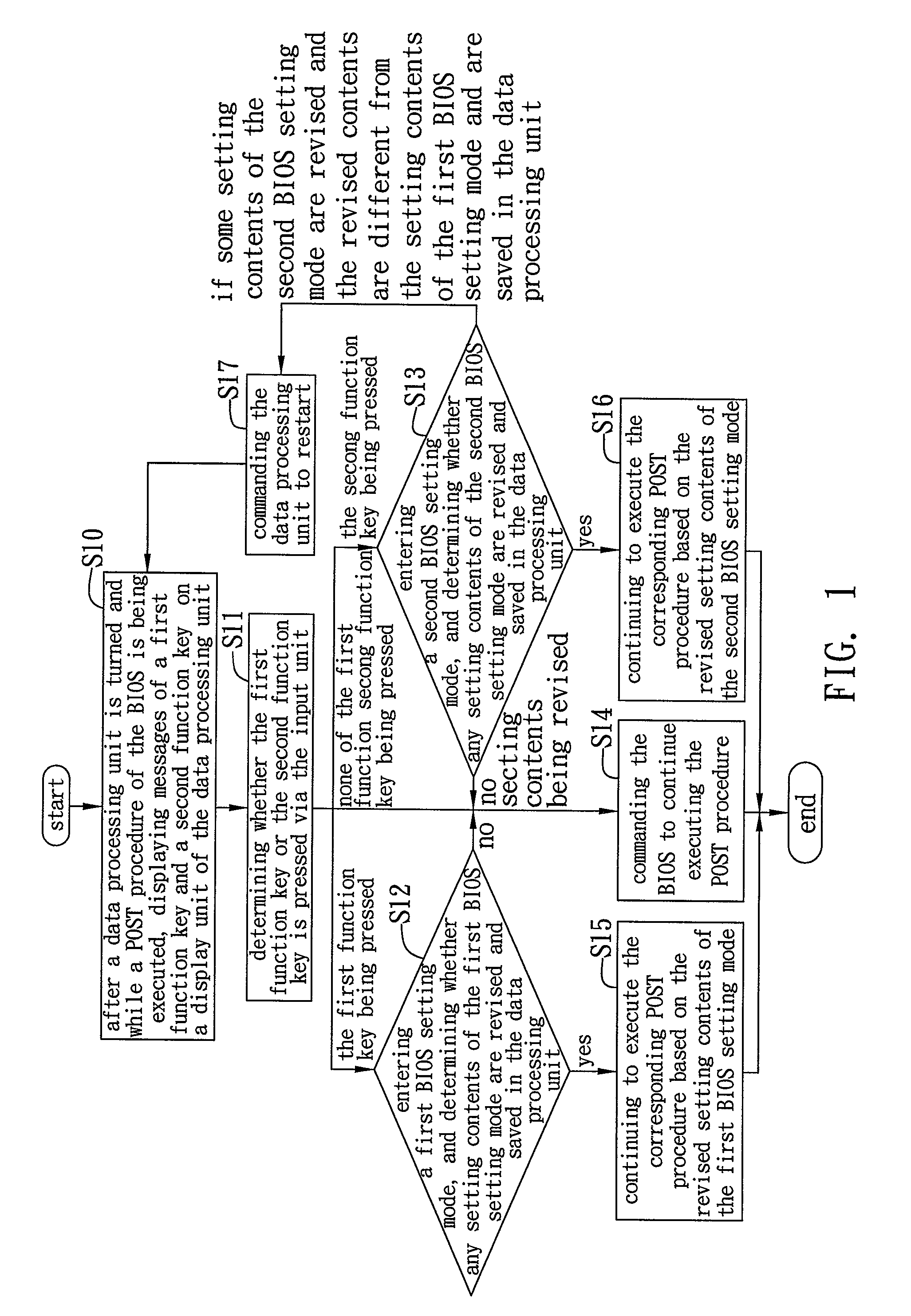

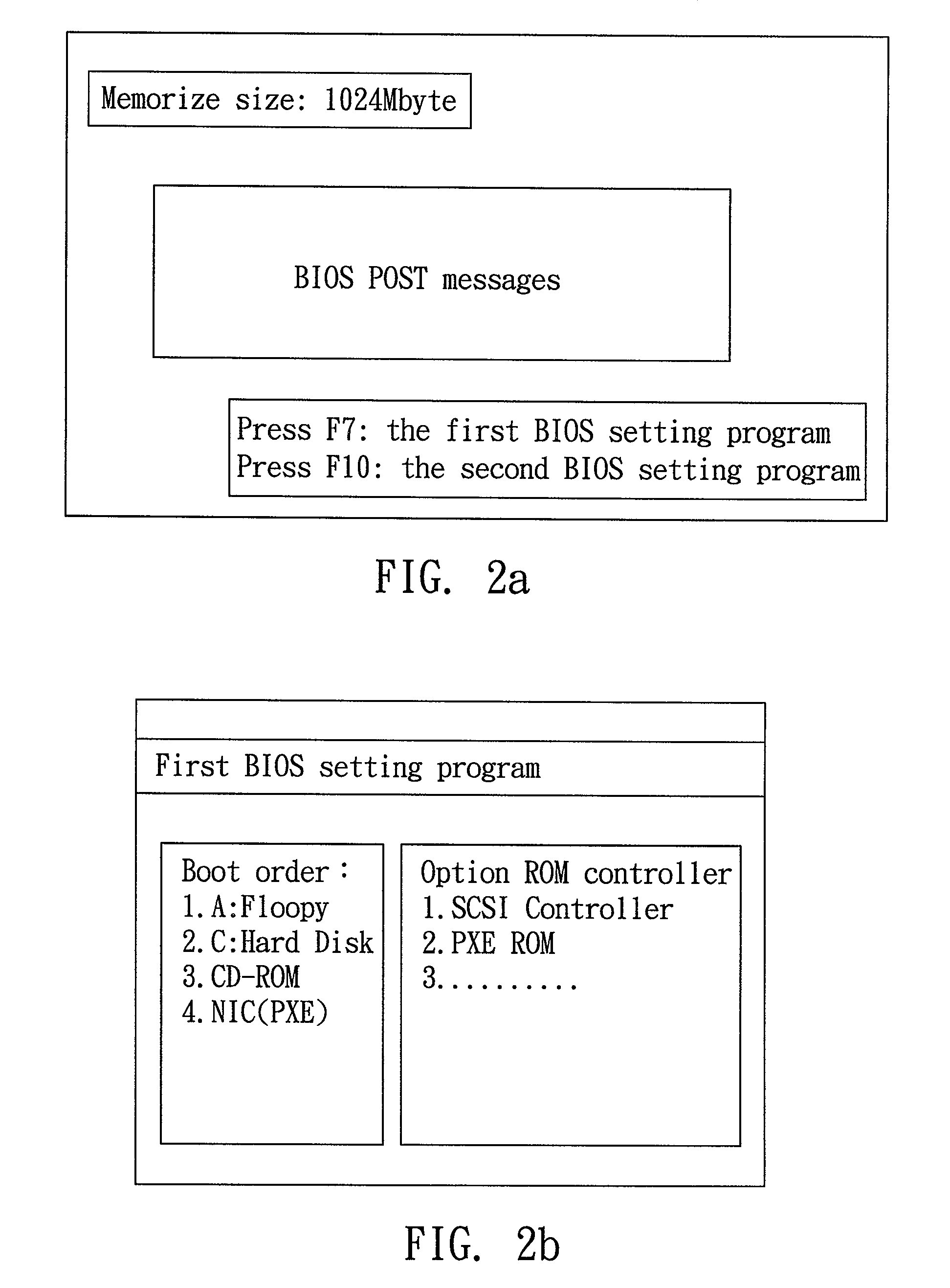

Bios setting method

ActiveUS7725705B2Improve efficiencyDigital computer detailsData resettingMain processing unitPost-Procedure

A basic input output system (BIOS) setting method is applicable to a BIOS setting procedure of a data processing unit having a display unit and an input unit. After the data processing unit is turned on and a power on self test (POST) procedure of the BIOS is being executed, messages of a first function key and a second function key are displayed on the display unit. If the first function key is pressed, a first BIOS setting mode is entered. After the first BIOS setting mode is entered, whether any setting contents of the first BIOS setting mode are revised and saved in the data processing unit is determined, and the corresponding POST is executed based on the revised setting contents of the first BIOS setting mode, or the first BIOS setting mode is skipped and the continuing POST procedure continues to be executed.

Owner:INVENTEC CORP

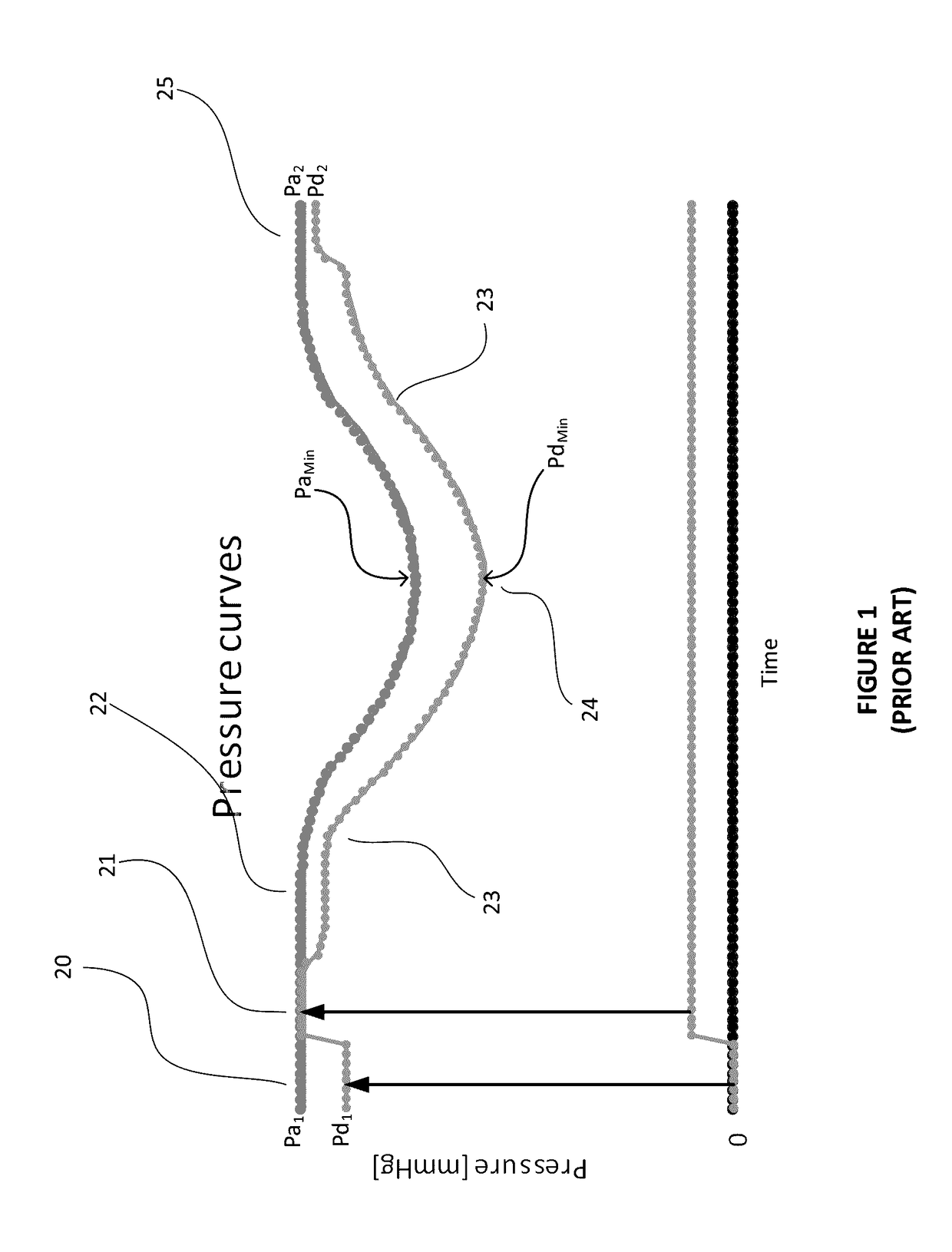

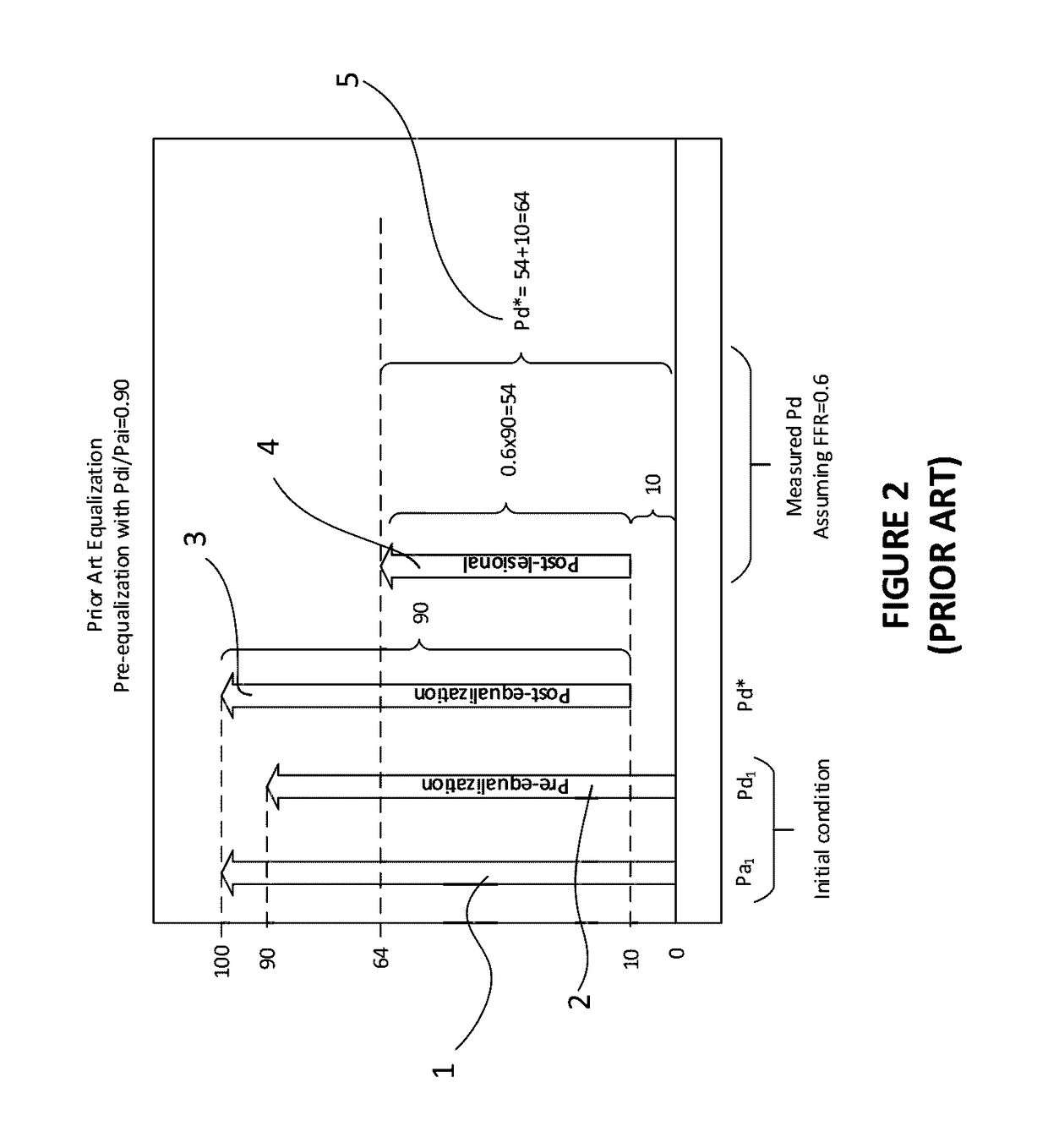

Method for pressure guidewire equalization

The present document describes a system for equalizing the pressure of a pressure guidewire against the pressure of an aortic pressure device: the system comprising two methods of equalizing the pressure against each other, one method that involves a gain adjustment and another method that involves the addition of an offset; the method further comprising a method for detecting which method should be applied to the situation, the detecting methods including: the contribution of the operator; an algorithm detecting the first equalization from subsequent post procedure equalizations, the algorithm including various factors such as incrementing the equalization requests, measuring the elapsed time and others.

Owner:OPSENS

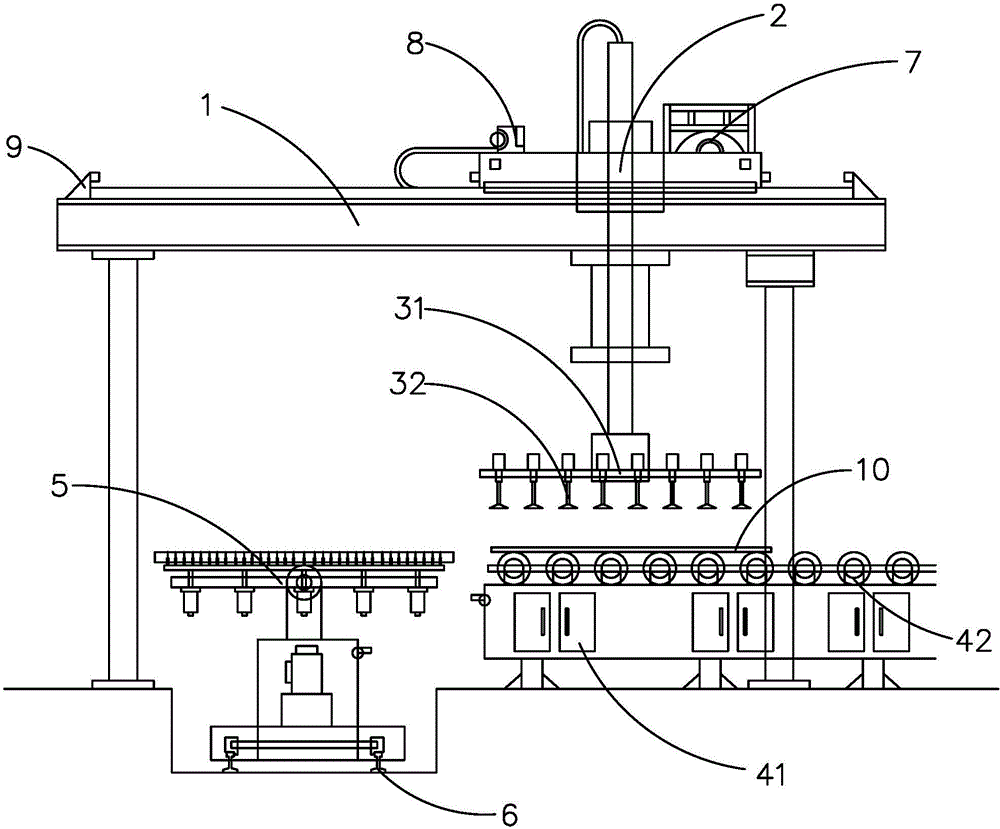

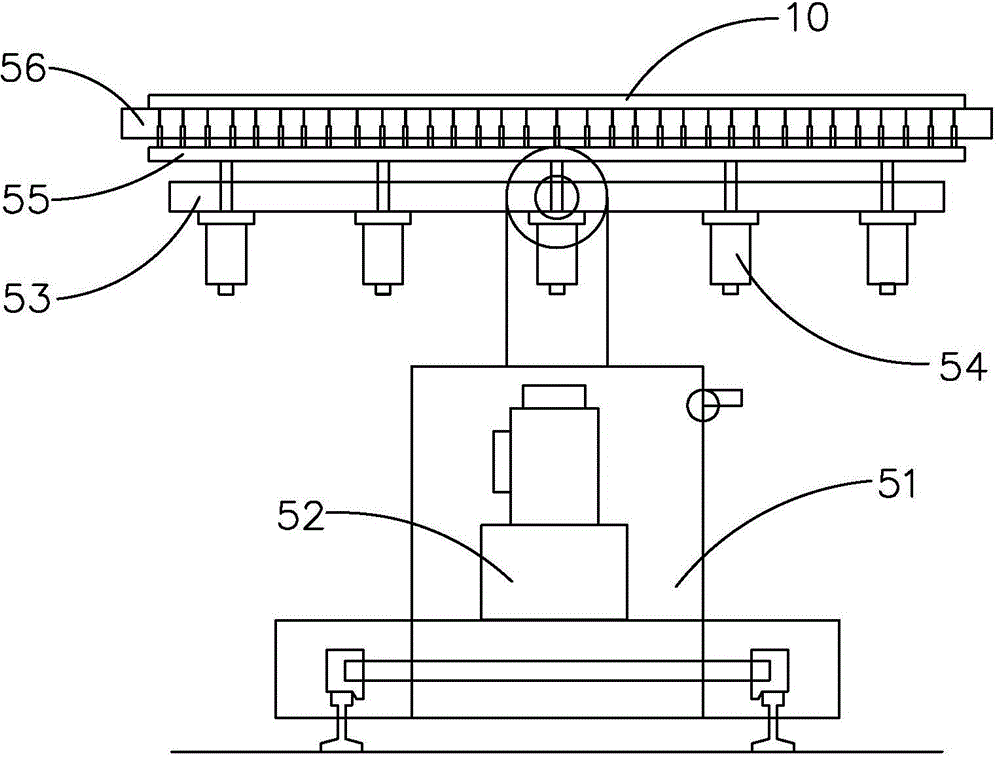

High-definition OLED line post-procedure automatic distribution system

InactiveCN104609180AImprove manufacturing speedIncrease productivityConveyor partsDistribution systemEngineering

The invention discloses a high-definition OLED line post-procedure automatic distribution system which comprises a manipulator truss. A manipulator truss beam is provided with a manipulator capable of moving in the X-axis direction, in the Y-axis direction and in the Z-axis direction, the lower end of the manipulator is provided with an attraction device used for attracting an OLED substrate, and a load drive device capable of moving according to a technical route is arranged below the manipulator truss beam. The distribution system can greatly improve the manufacturing speed and production efficiency of OLEDs, and reduces product loss caused by manual operation. Drive requirements are different in different sub-procedures or working areas, different drive signals can be connected by operators after the load drive device reaches a current station to achieve the aim of quick signal switching, and the OLED substrate does not need to be assembled and disassembled again. A load drive unit can rotate to meet detection requirements of different detection and control stations or requirements of operation habits of different people, and the system is more user-friendly.

Owner:SICHUAN CCO DISPLAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com