Debitterized honey pomelo tea and production method thereof

A production method and technology of honey pomelo tea, applied in food preparation, tea substitutes, food science, etc., can solve problems such as bitter taste of pomelo tea, loss of nutritional components, and difficult molding of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

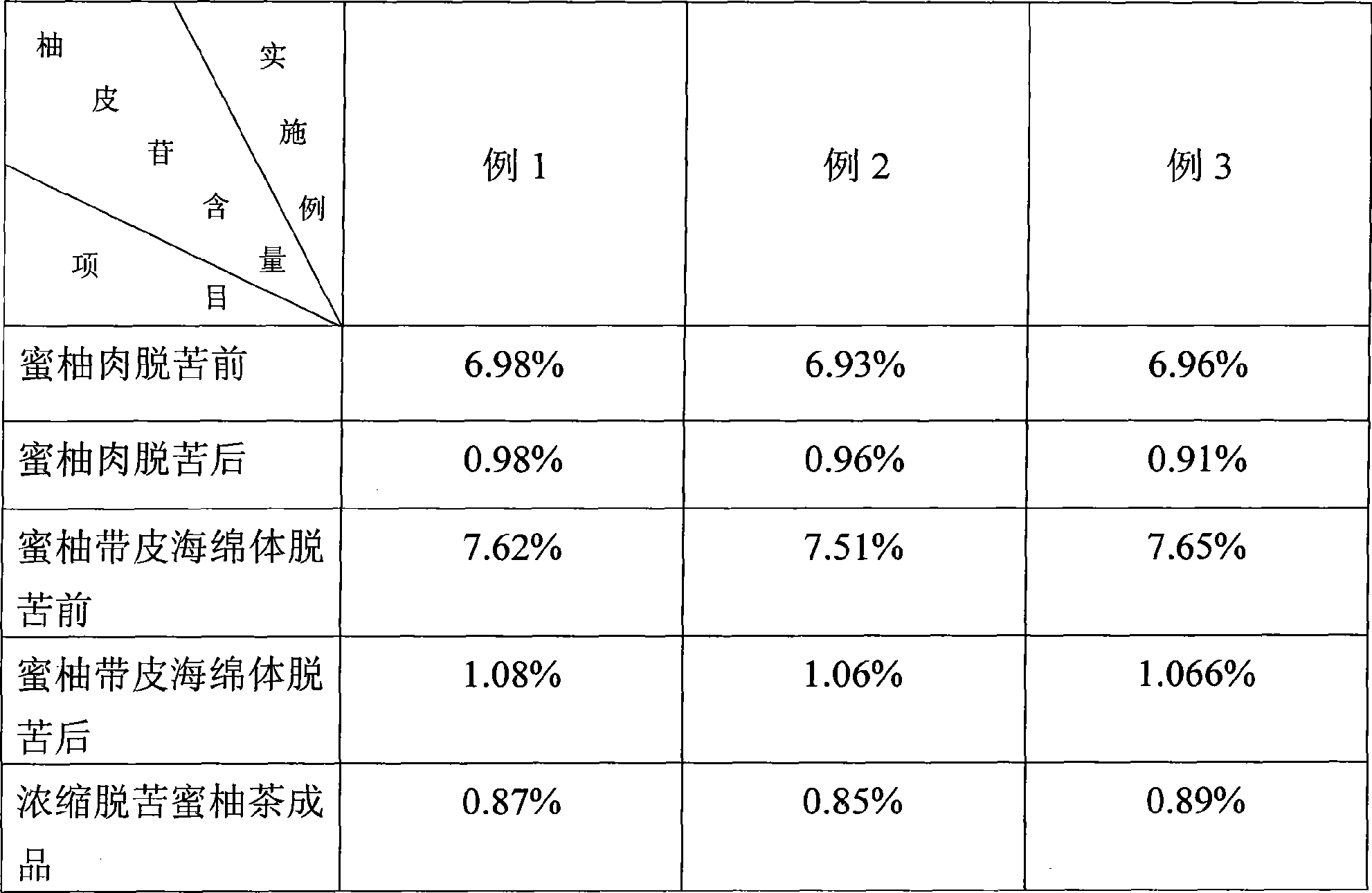

Embodiment 1

[0058]After the pomelo fresh fruit is cleaned, its sponge with skin, pomelo meat, and pomelo meat capsule are separated; weigh 20 kg of pomelo sponge with skin and 60 kg of pomelo meat, and the weighed pomelo sponge with skin Cut into fine grains; cut the weighed honey pomelo meat and the obtained pomelo skin sponge body into fine grains, soak them in 160kg of chlorine dioxide with a concentration of 150ppm for 3 minutes for disinfection, clean and dry them; grind soybeans Finally, the high-pressure homogeneous homogenate becomes soybean milk, and its protein content is measured at 1.5% according to conventional methods; the sterilized honey pomelo skin sponge body fine particles and honey pomelo meat are respectively dropped into 160kg soybean milk, and are incubated at 55°C for 4 hours to remove Bitter, after debittering, the honey pomelo skin sponge fine grains and honey pomelo meat are washed twice with clean water respectively, and dehydrated by a centrifugal dehydrator. A...

Embodiment 2

[0061] After the pomelo fresh fruit is cleaned, separate its sponge body with skin, honey pomelo meat, and pomelo meat sac; weigh 30 kg of honey pomelo sponge with skin and 70 kg of honey pomelo meat, and cut the weighed pomelo skin sponge Fine-grained material; the honey pomelo meat that weighs and the honey pomelo skin sponge that obtains are cut into fine-grained material and use 250kg concentration respectively to be 180ppm chlorine dioxide soak 5 minutes disinfection, clean and dry; , high-pressure homogenization and homogenization to become soybean milk, and its protein content was determined to be 3% according to conventional methods; the sterilized honey pomelo skin sponge fine particles and honey pomelo meat were respectively put into 250kg soybean milk, and kept at 60°C for 3 hours to debitter , after debittering, the honey pomelo skin sponge body fine grain material and honey pomelo meat are washed 3 times with clean water respectively, and dehydrated by a centrifuga...

Embodiment 3

[0064] After the pomelo fresh fruit is cleaned, its spongy body with skin, pomelo meat, and pomelo meat sac are separated. Weigh pomelo skin sponge body 40kg, pomelo meat 80kg, the pomelo skin sponge body weighed is cut into fine grains; the pomelo meat and the pomelo skin sponge body obtained are cut into fine grains The pellets were disinfected by soaking 360kg of chlorine dioxide with a concentration of 200ppm for 6 minutes, cleaned and dried; after the soybeans were refined, they were homogenized under high pressure to become soybean milk with a protein content of 5%, and the sterilized honey pomelo was peeled Spongy body fine particles and pomelo meat were put into 360kg soybean milk respectively, and kept at 66°C for 2 hours to debitterize. After debittering, the sponge body fine particles with skin and pomelo meat were washed with water for 3 times, and dehydrated in a centrifugal dehydrator. At this time, the pomelo meat is also separated into fine-grained materials; d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com