Method for preparing medical porous tantalum implant material

A technology of porous tantalum and tantalum powder, applied in medical science, prosthesis, etc., can solve problems affecting the processing of porous tantalum materials, mechanical properties such as insufficient ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

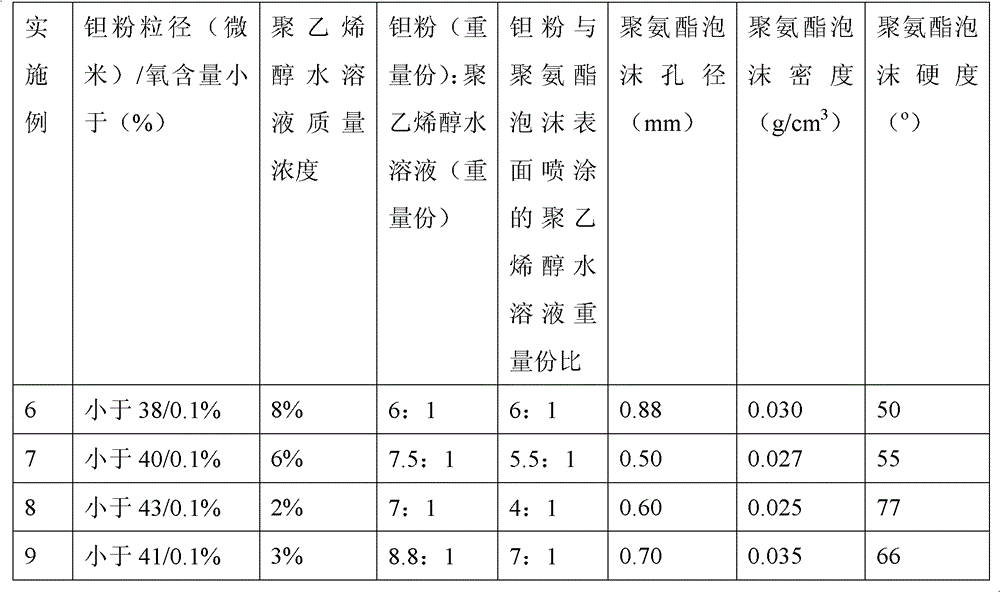

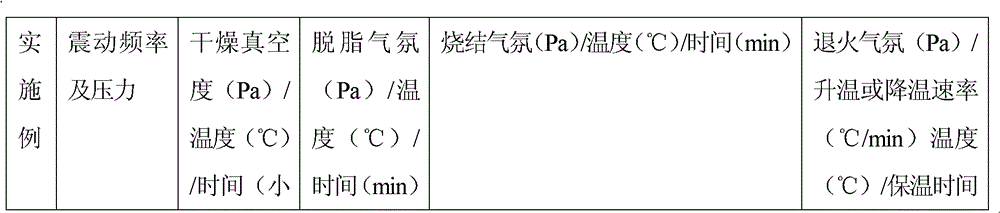

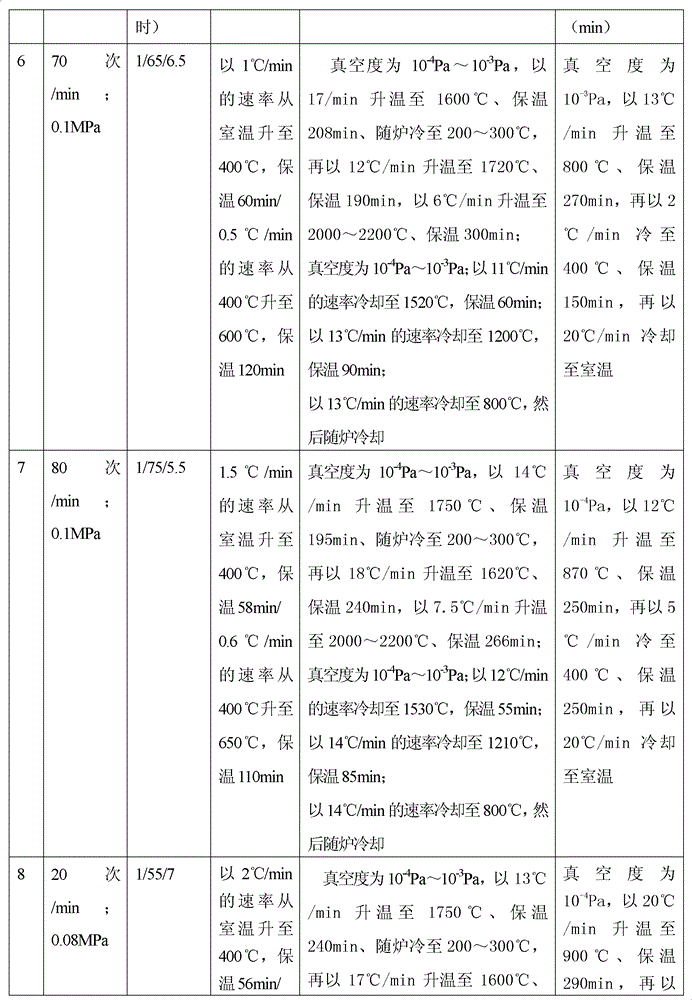

[0023] Example 1: Weigh 12.2 g of polyvinyl alcohol and put it into a container with 240 ml of distilled water; place it on an electric stove to heat and stir to make it into an aqueous solution of polyvinyl alcohol. Use a 200g balance to weigh 60g of tantalum powder with an average particle size of less than 43 microns and an oxygen content of less than 0.1%, add 50ml of cooled polyvinyl alcohol aqueous solution, stir and mix evenly, and make it into a tantalum powder slurry. Use 10×10×30mm porous polyurethane foam (average pore diameter is 0.48mm, density 0.025g / cm 3 , hardness 50°), the tantalum powder slurry was poured into it by vibrating pressure at 55 times / min and 0.1Mpa. Dry in a vacuum drying oven at a drying temperature of 60° C., a drying time of 8 hours, and a vacuum degree of 1 Pa. Degreasing treatment: the vacuum degree is lower than 10 -4 Pa, temperature 600°C, holding time 120 minutes. Vacuum sintering: vacuum degree is 10 -3 Pa, heat up to 1800°C at 13°C / ...

Embodiment 2

[0025] Example 2: Weigh 10 g of polyvinyl alcohol and put it into a container with 200 ml of distilled water; place it on an electric stove to heat and stir to make it into an aqueous solution of polyvinyl alcohol. Use a 200g balance to weigh 40g of tantalum powder with an average particle size of less than 43 microns and an oxygen content of less than 0.1%, add 32ml of polyvinyl alcohol aqueous solution, stir and mix evenly, and make it into a tantalum powder slurry. Use 10×10×25mm porous polyurethane foam (average pore diameter is 0.56mm, density 0.030g / cm 3 , hardness 60°), the tantalum powder slurry was poured into it by vibrating pressure at 60 times / min and 0.08Mpa. Dry in a vacuum drying oven at a drying temperature of 100°C for a drying time of 4 hours and maintain a vacuum of 10 -2 Pa. Degreasing treatment: vacuum degree 10 -4 Pa, temperature 800°C, holding time 120 minutes. Vacuum sintering: vacuum degree is 10 -4 Pa, heat up to 1600°C at 10°C / min, hold for 180m...

Embodiment 3

[0027] Example 3: Weigh 11 g of polyvinyl alcohol and put it into a container with 220 ml of distilled water; place it on an electric stove to heat and stir to make it into an aqueous solution of polyvinyl alcohol. Use a 200g balance to weigh 45g of tantalum powder with an average particle size of less than 43 microns and an oxygen content of less than 0.1%, add 36ml of polyvinyl alcohol aqueous solution, stir and mix evenly, and make it into a tantalum powder slurry. Use 8×8×25mm porous polyurethane foam (average pore diameter is 0.70mm, density 0.035g / cm 3 , hardness 70°), the tantalum powder slurry was poured into it by vibrating pressure method at 80 times / min and 0.2Mpa. Dry in a vacuum drying oven at a drying temperature of 80°C for a drying time of 6 hours and maintain a vacuum of 10 -1 Pa. Degreasing treatment: vacuum degree 10 -3 Pa, temperature 700°C, holding time 90 minutes. Vacuum sintering: vacuum degree is 10 -3 Pa, heat up to 1700°C at 20°C / min, hold for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com