Patents

Literature

212 results about "Porous tantalum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

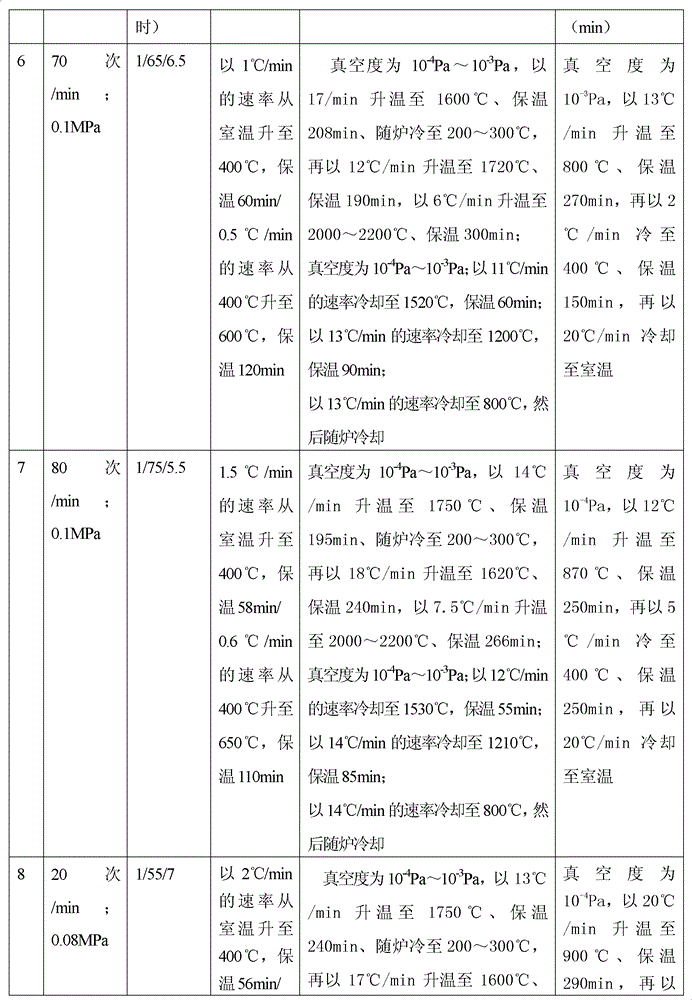

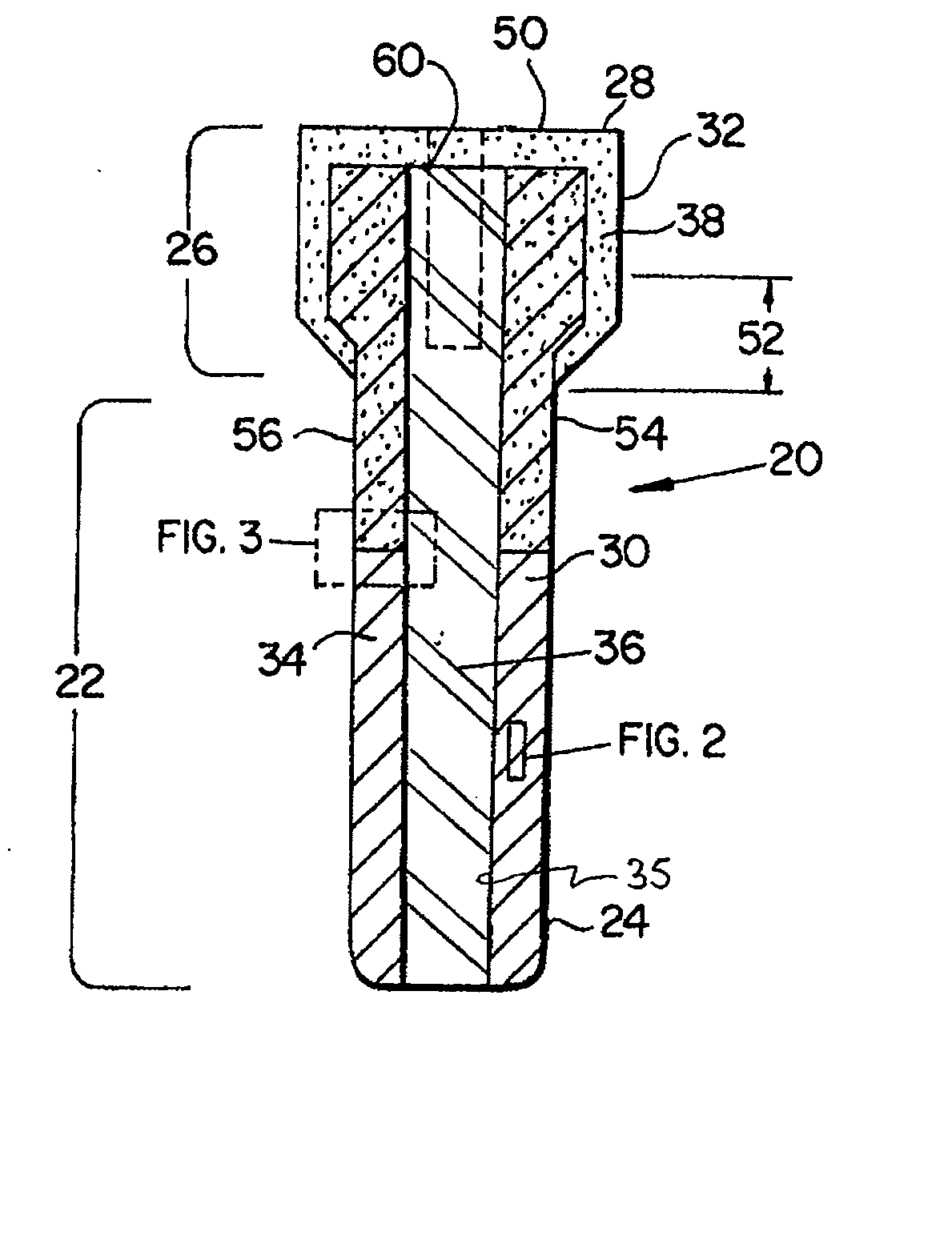

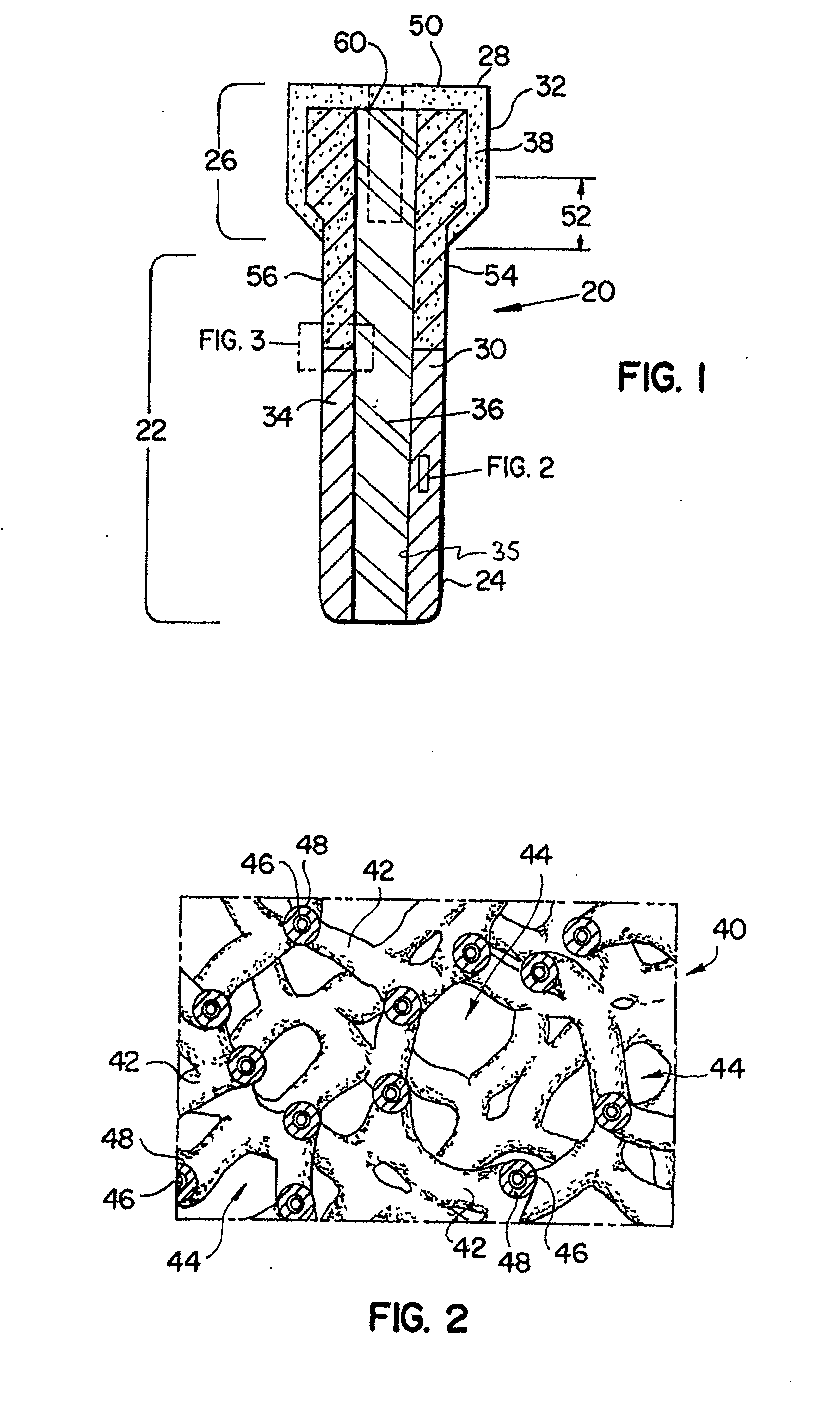

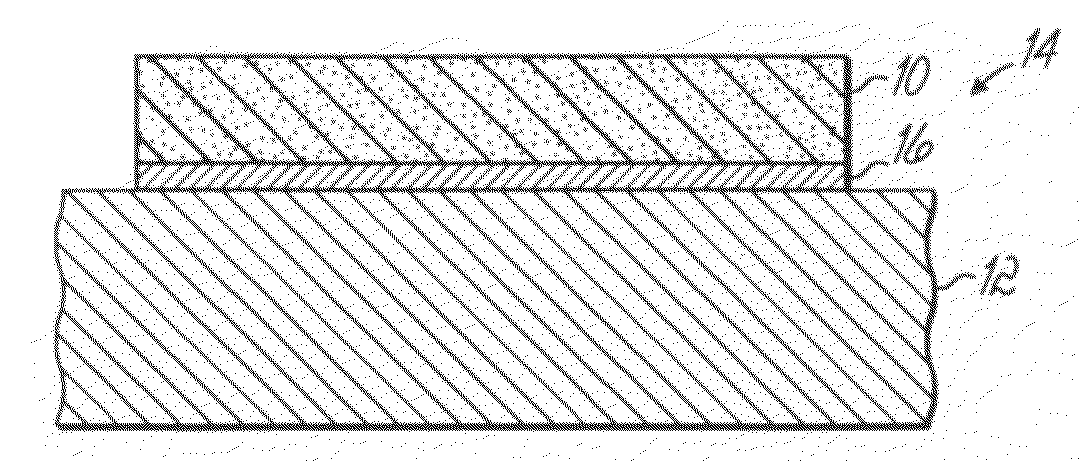

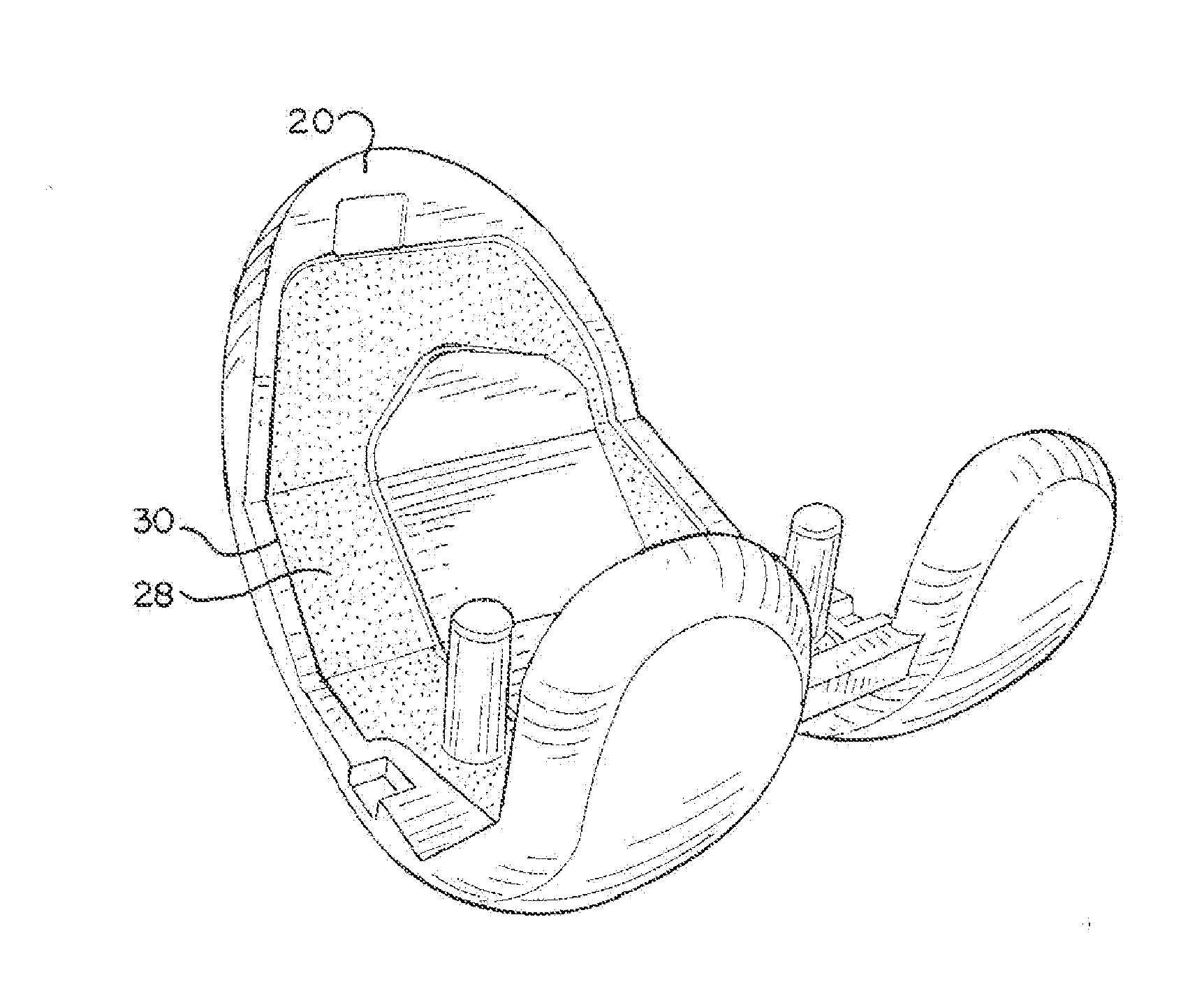

Interbody fusion device and method for restoration of normal spinal anatomy

InactiveUS7238186B2Maintain patency and stabilityRapid and stable arthrodesisInternal osteosythesisBone implantSpinal columnPorous tantalum

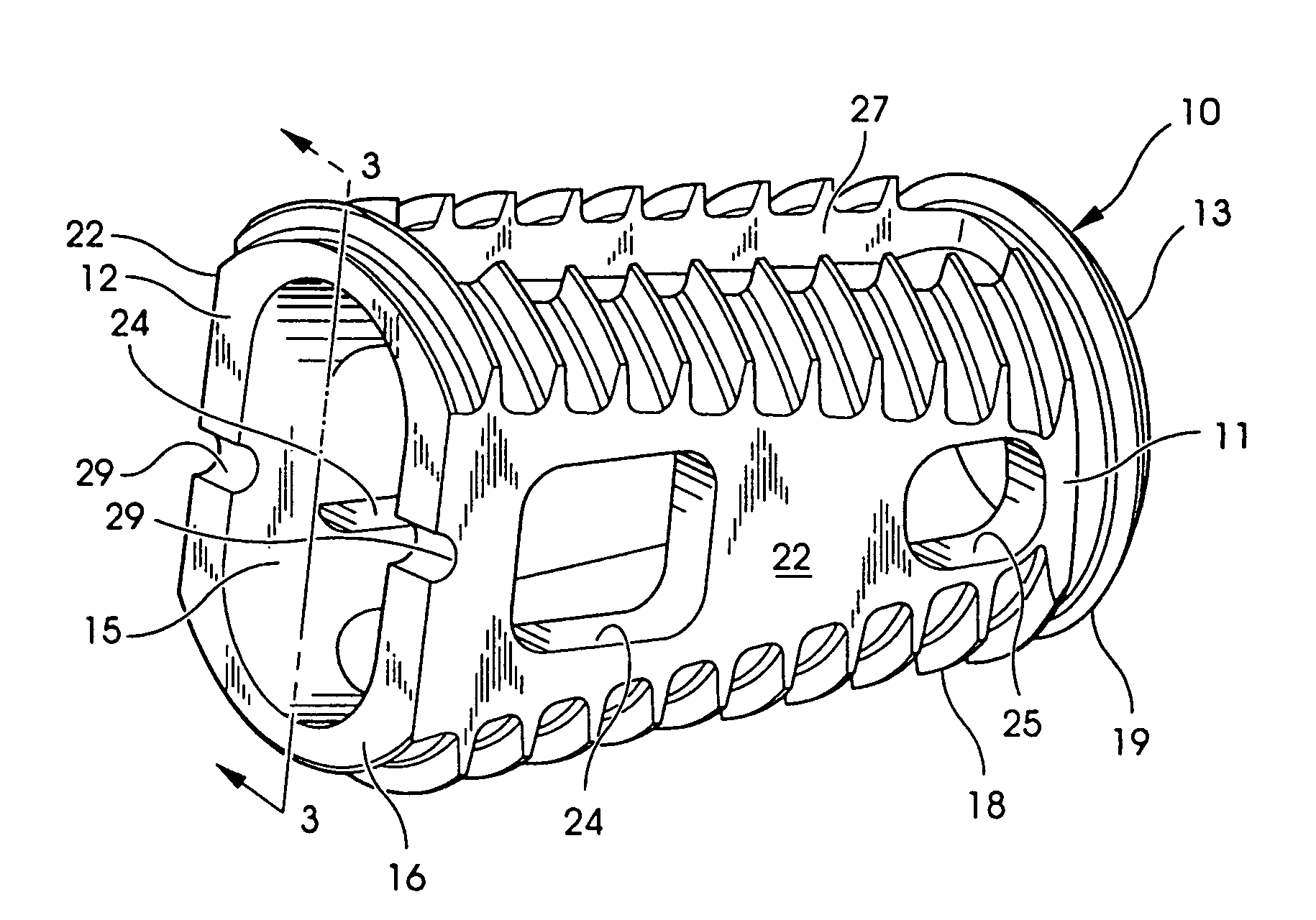

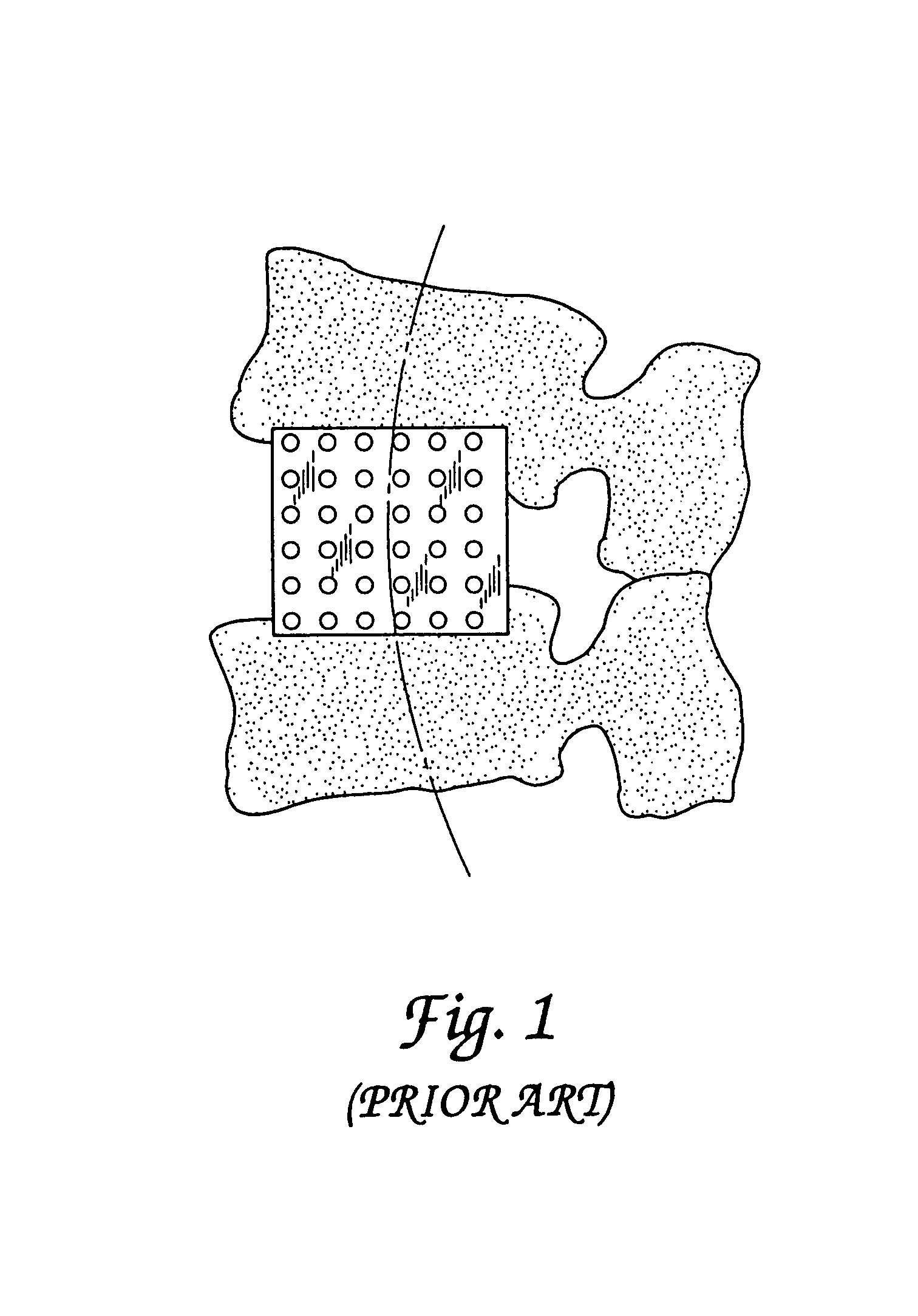

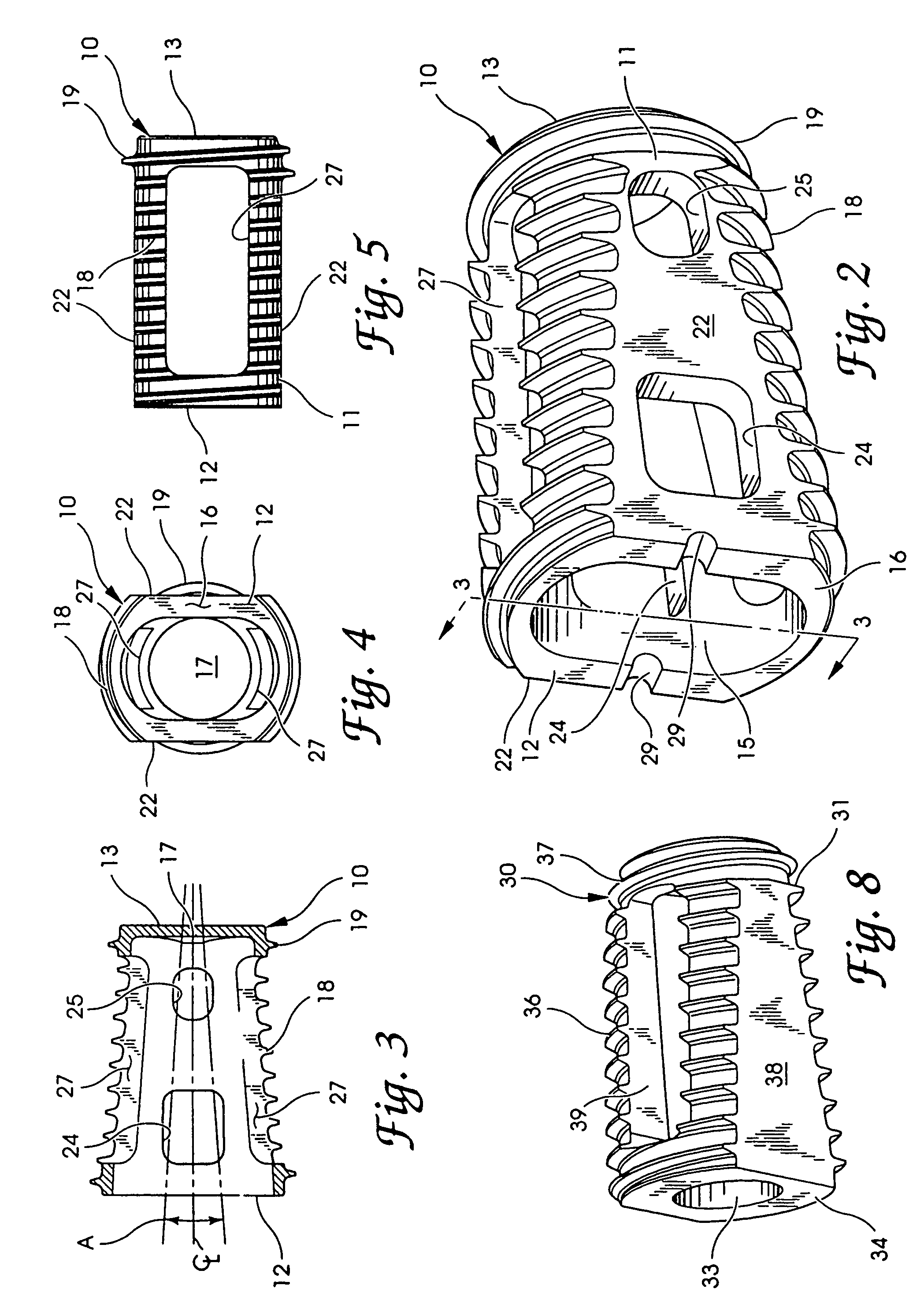

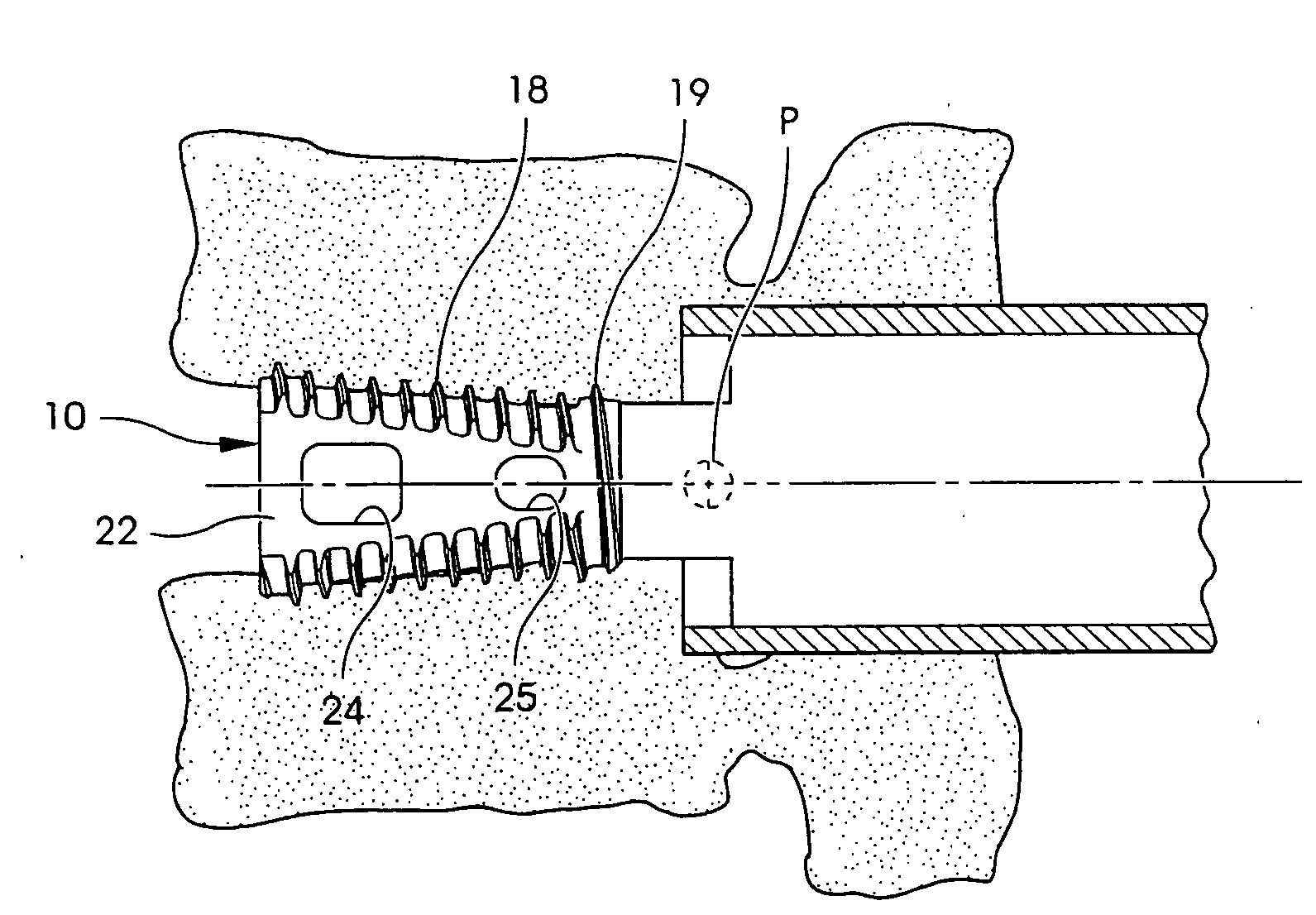

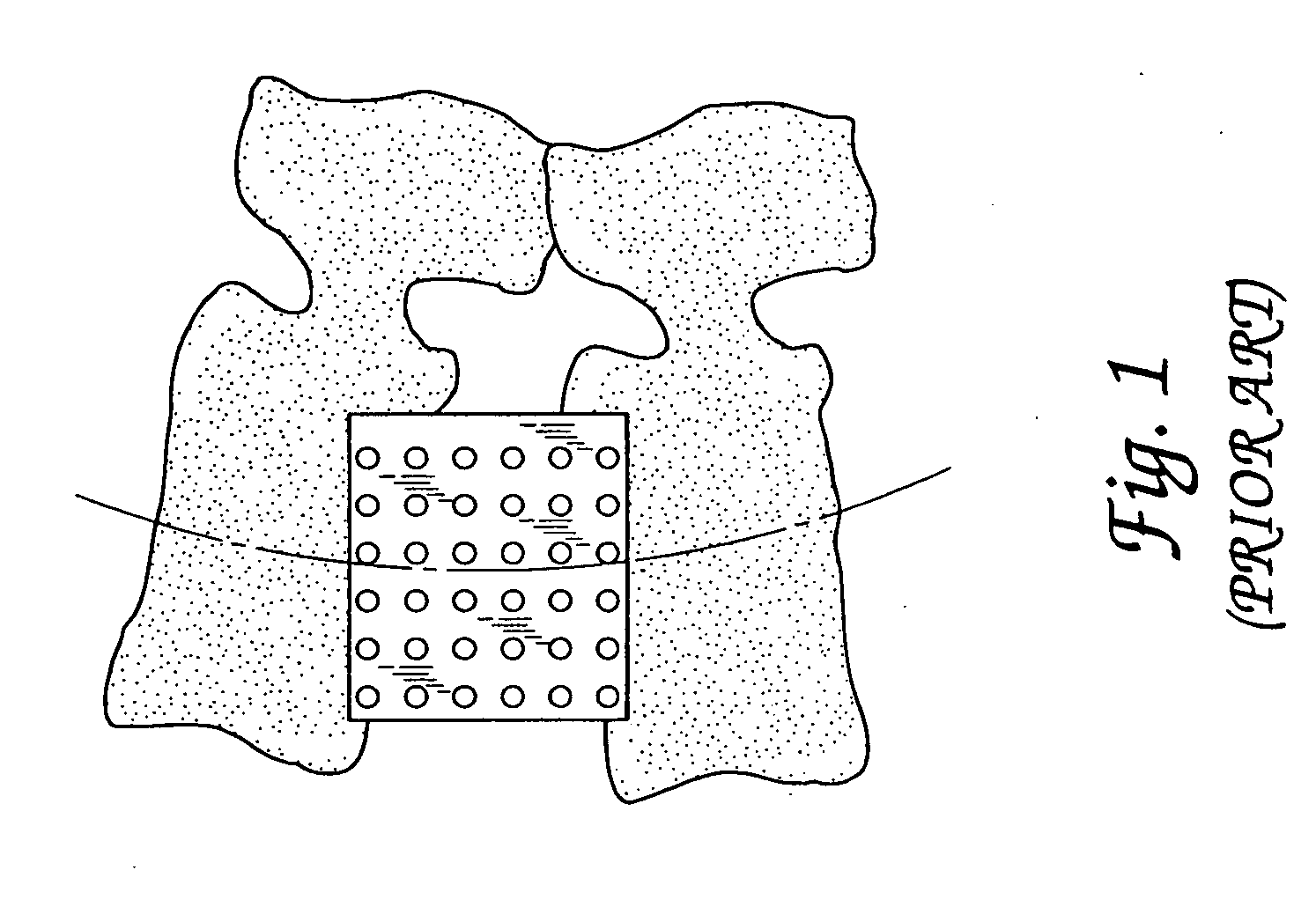

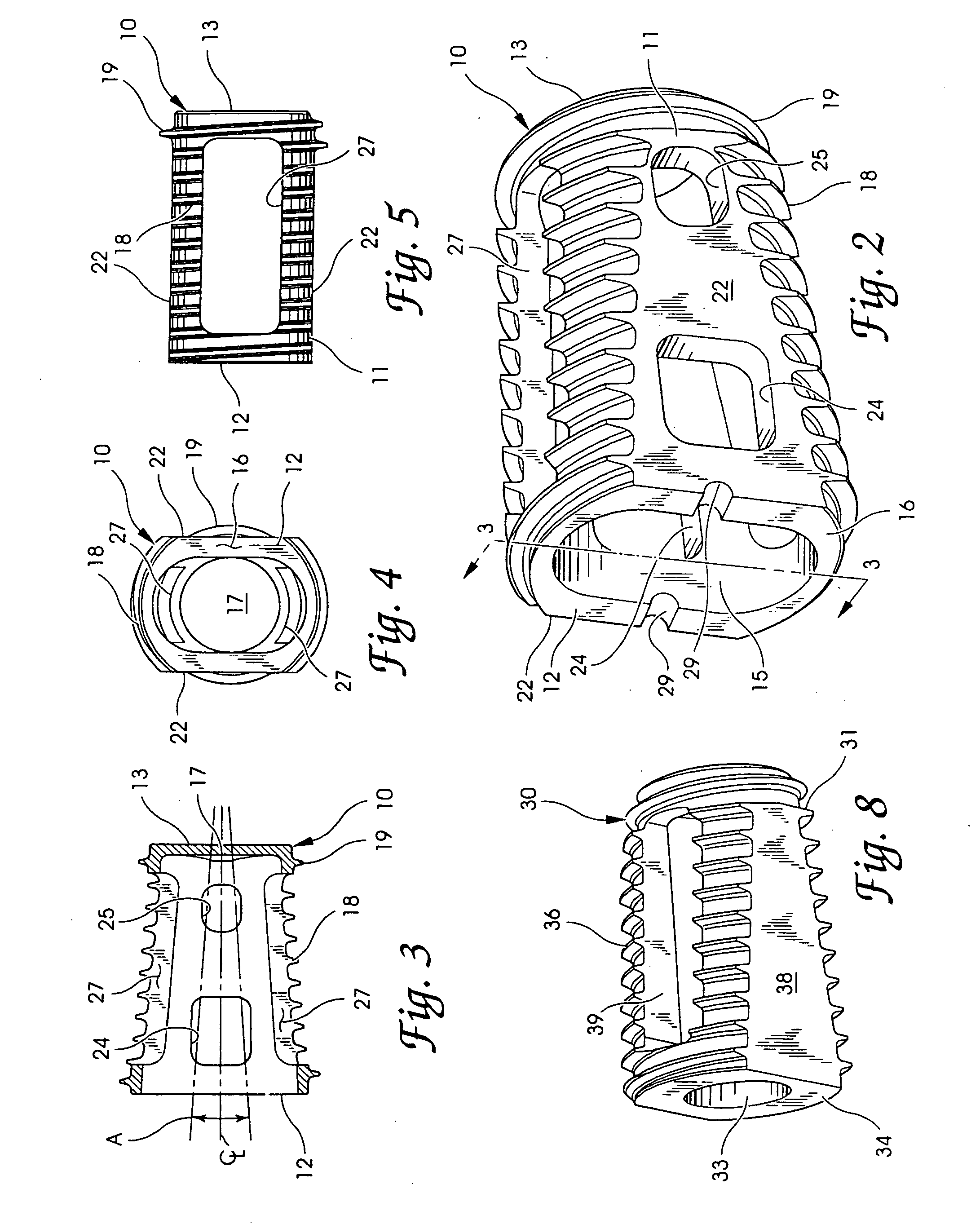

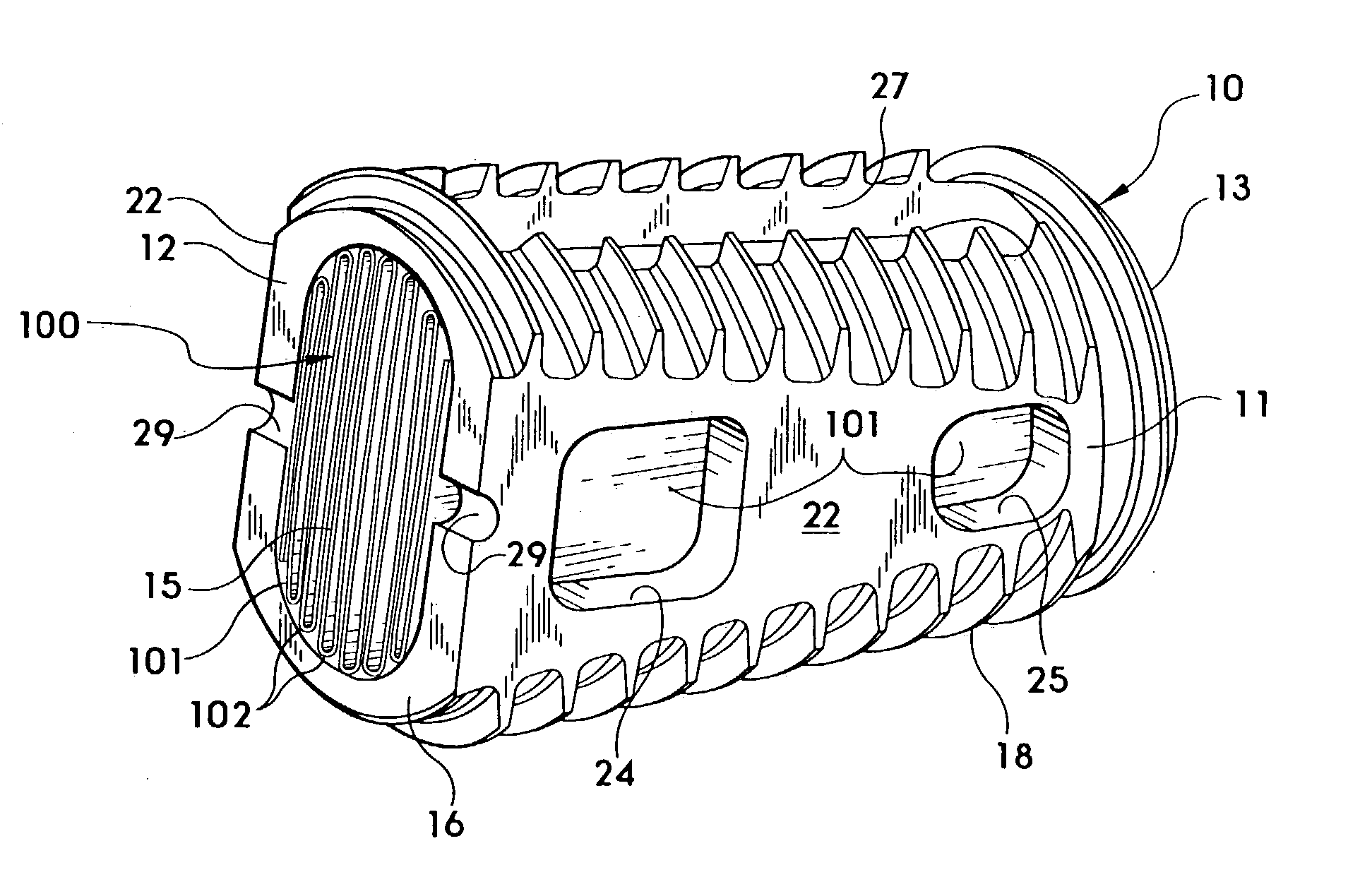

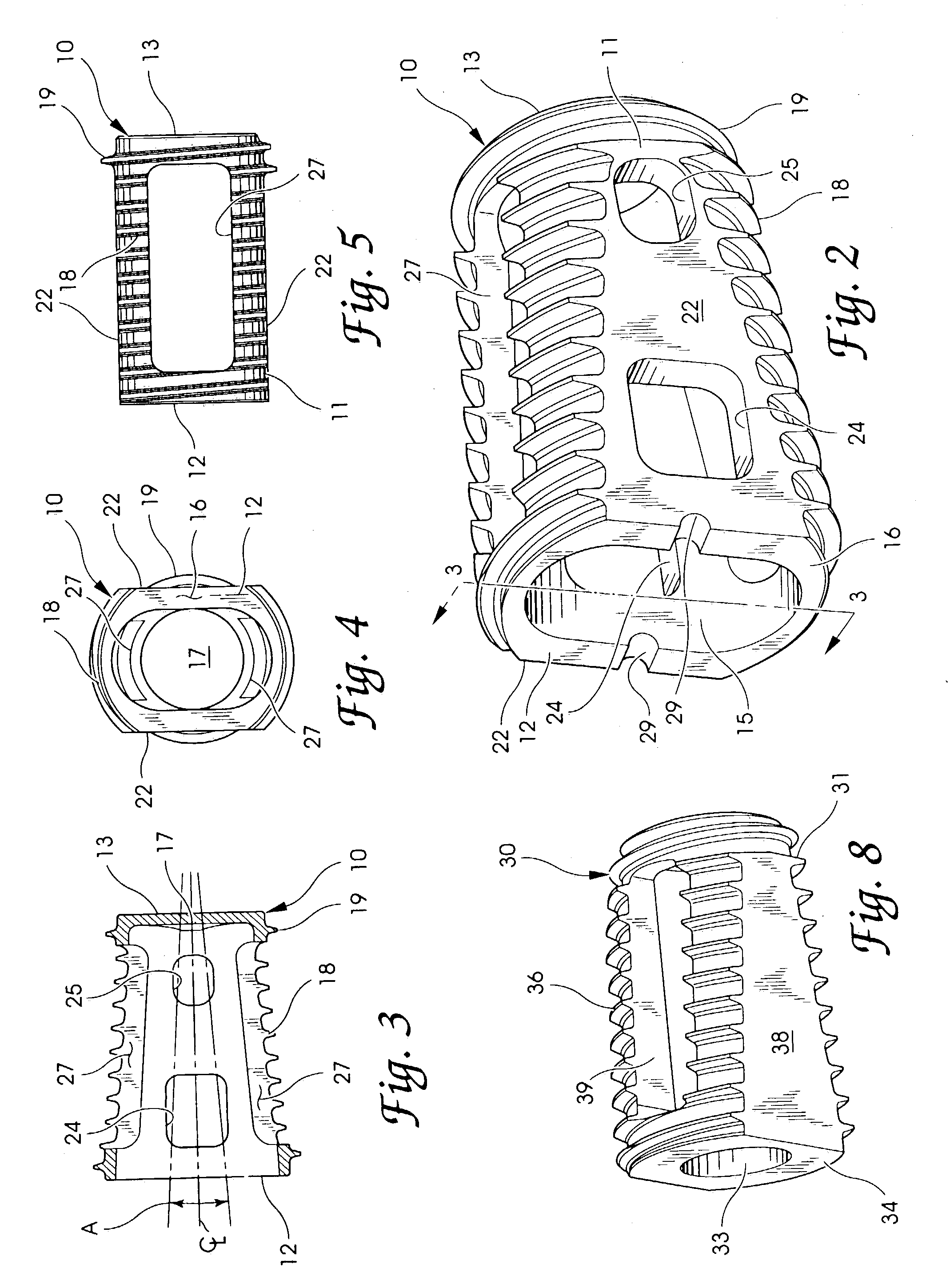

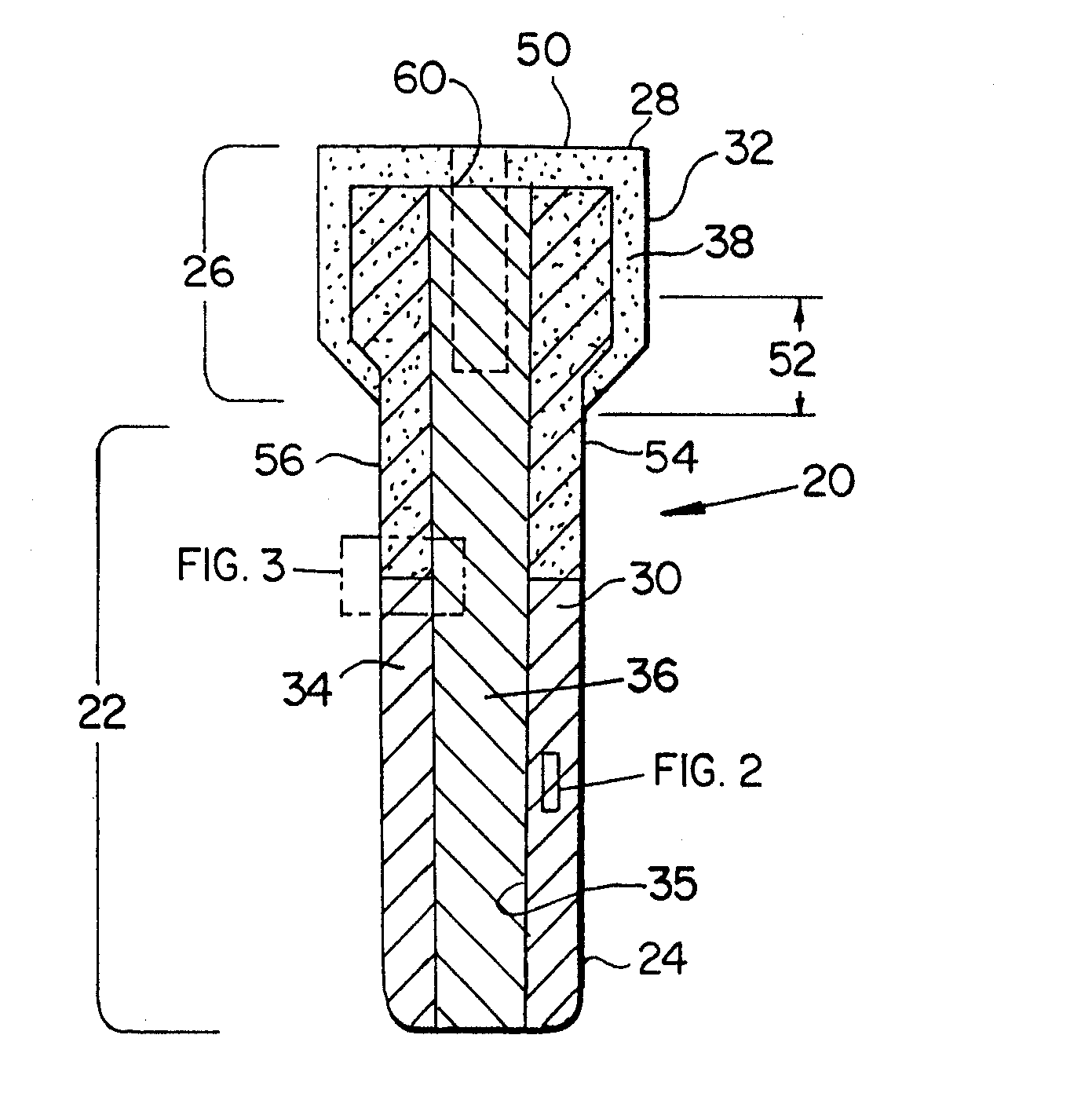

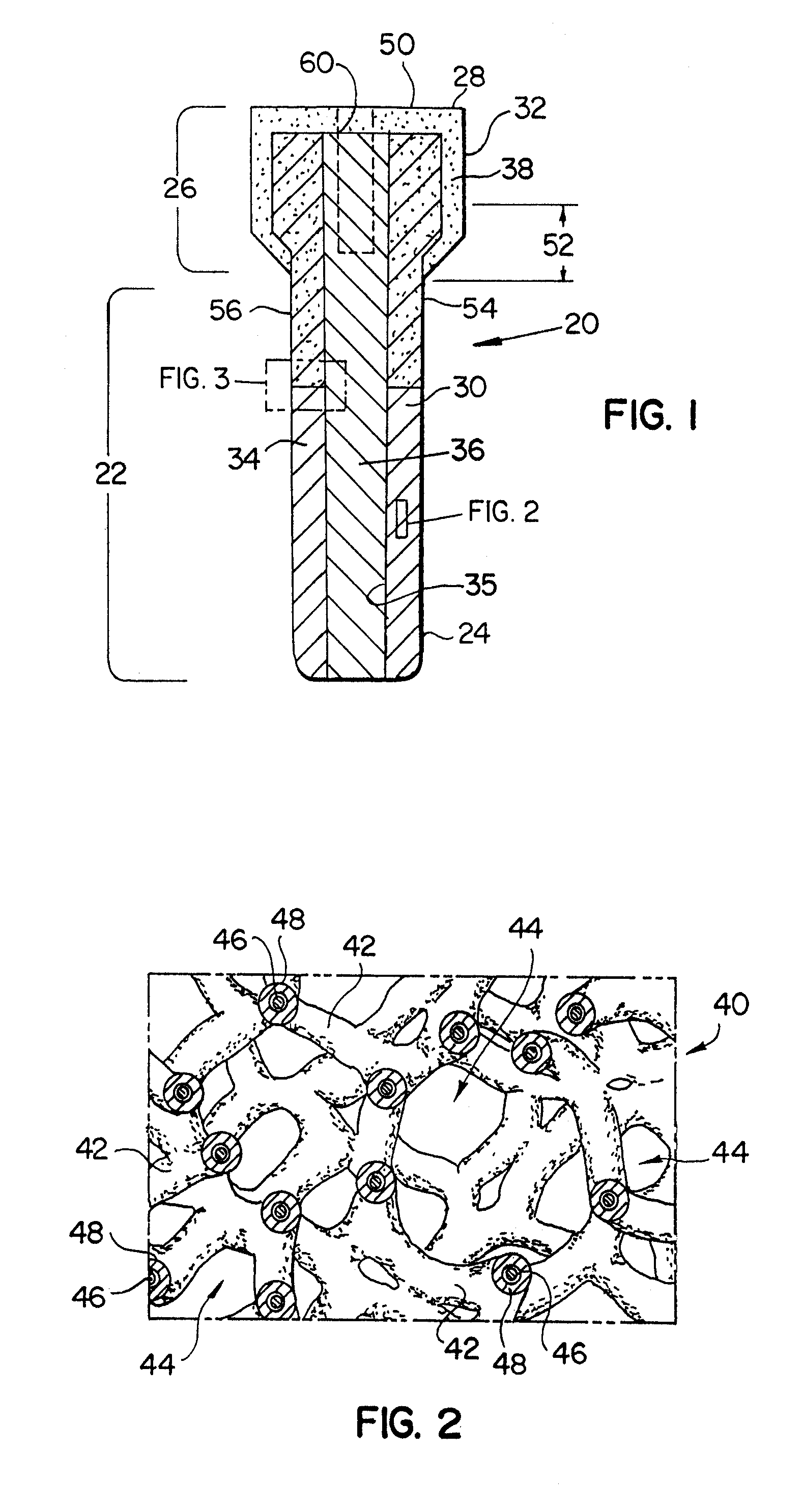

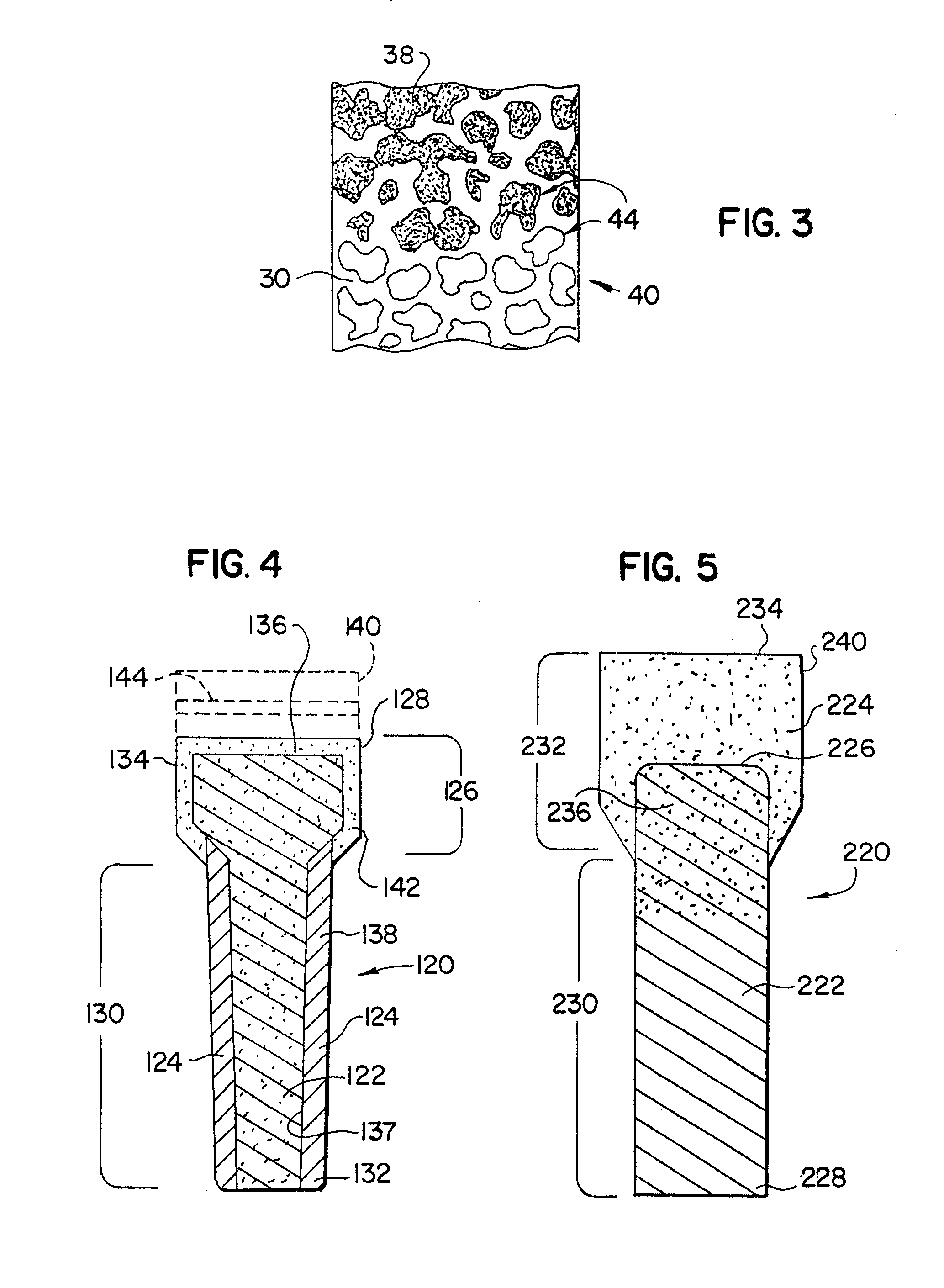

An interbody fusion device in one embodiment includes a tapered body defining a hollow interior for receiving bone graft or bone substitute material. The body defines exterior threads which are interrupted over portions of the outer surface of the device. The fusion device defines truncated side walls so that on end view the body takes on a cylindrical form. The side walls are provided with vascularization openings, and the body wall device includes opposite bone ingrowth slots extending through the interrupted thread portion of the body. In another embodiment, the tapered body is solid and formed of a porous biocompatible material having sufficient structural integrity to maintain the intradiscal space and normal curvature. The material is preferably a porous tantalum having fully interconnected pores to facilitate complete bone tissue ingrowth into the implant. An implant driver is provided which engages the truncated side walls to complete the cylindrical form of the implant at the root diameter of the interrupted threads, to thereby facilitate threaded insertion of the implant to the intra-discal space between adjacent vertebrae. Methods for posterior and anterior insertion of the fusion device are also disclosed.

Owner:WARSAW ORTHOPEDIC INC

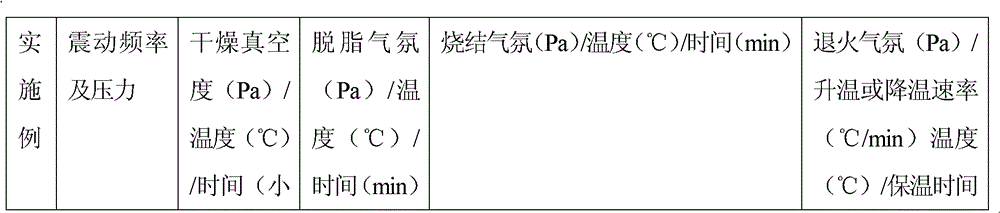

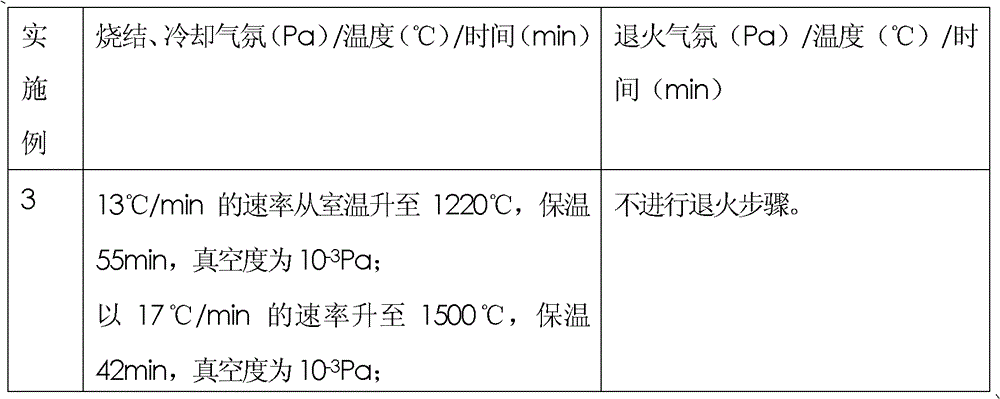

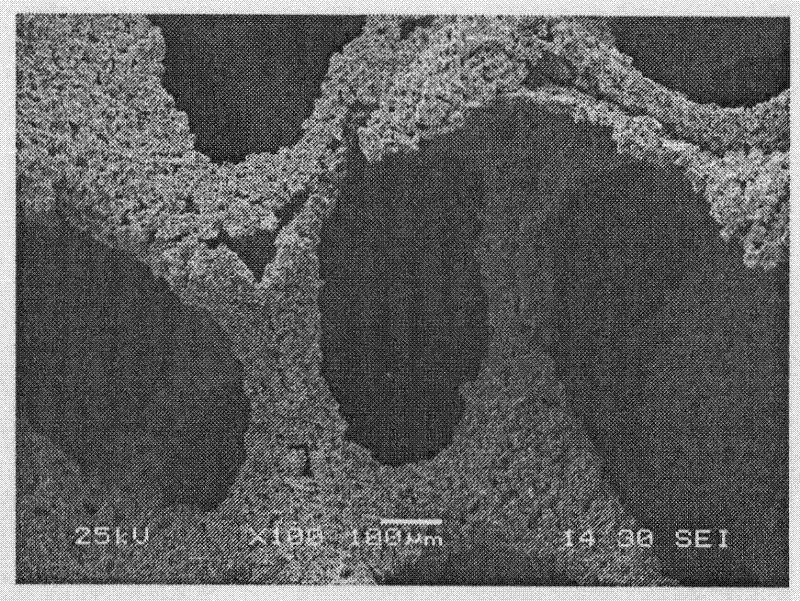

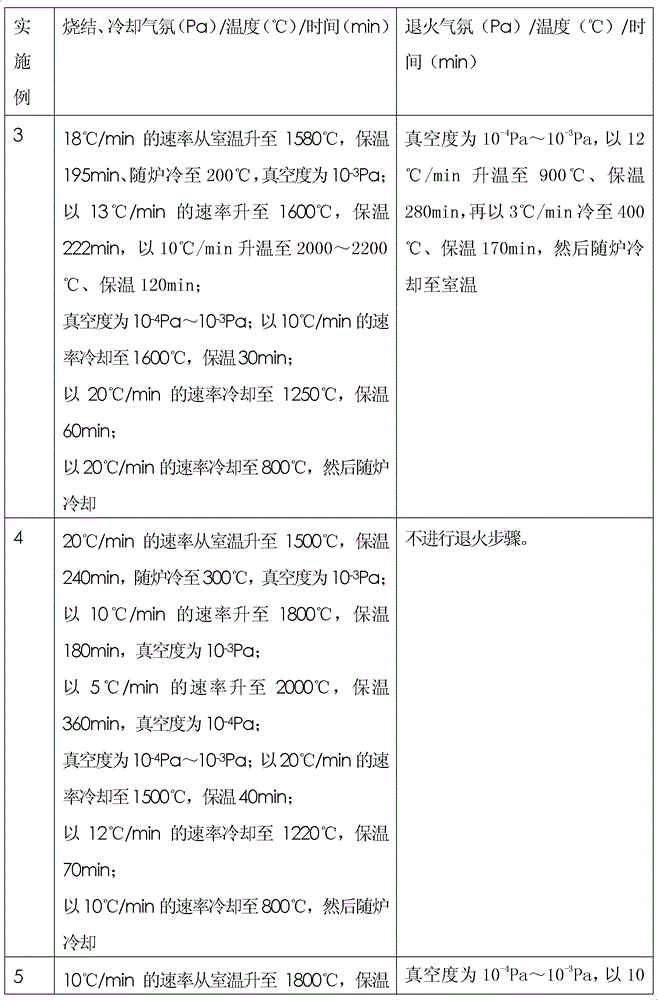

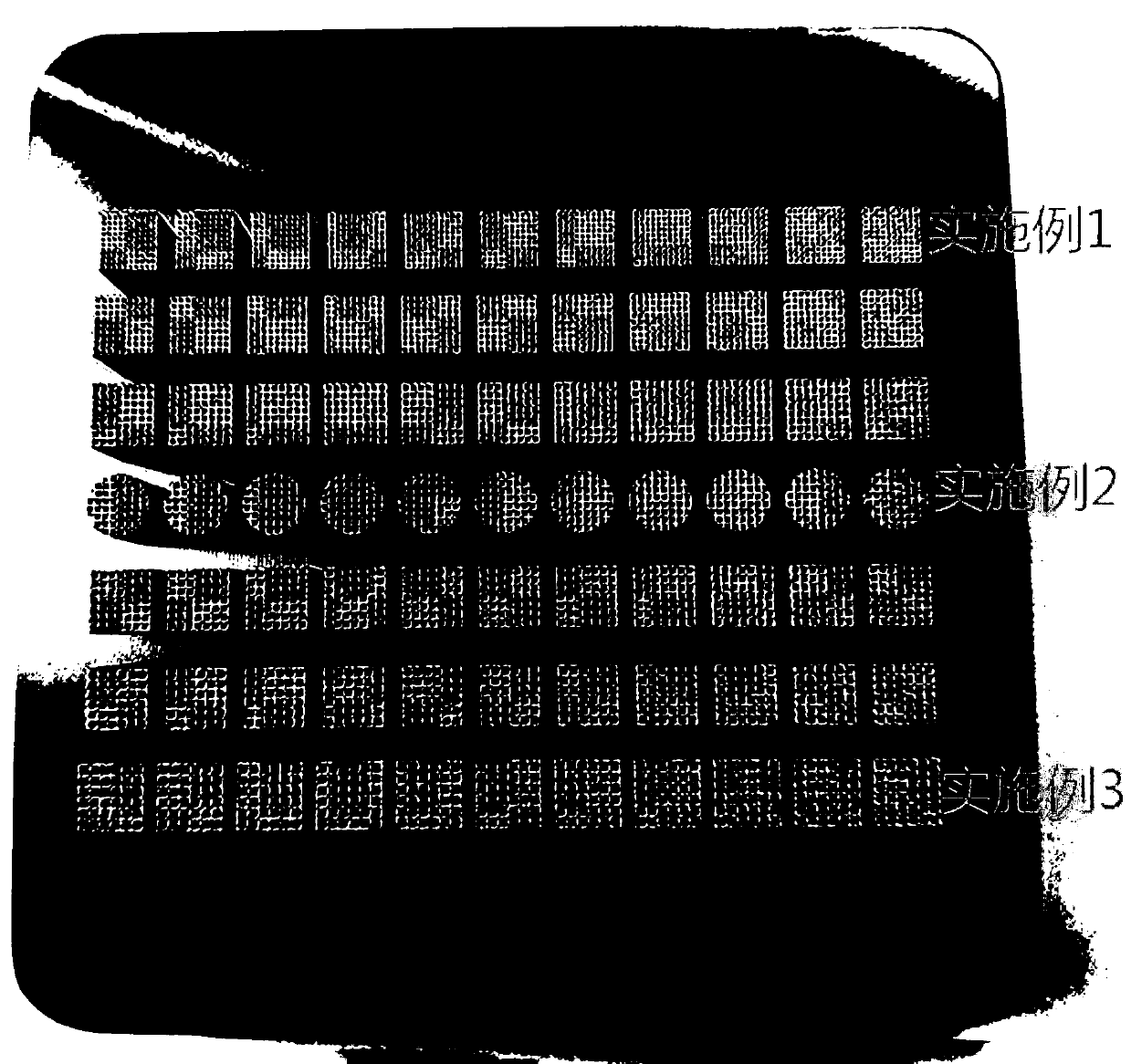

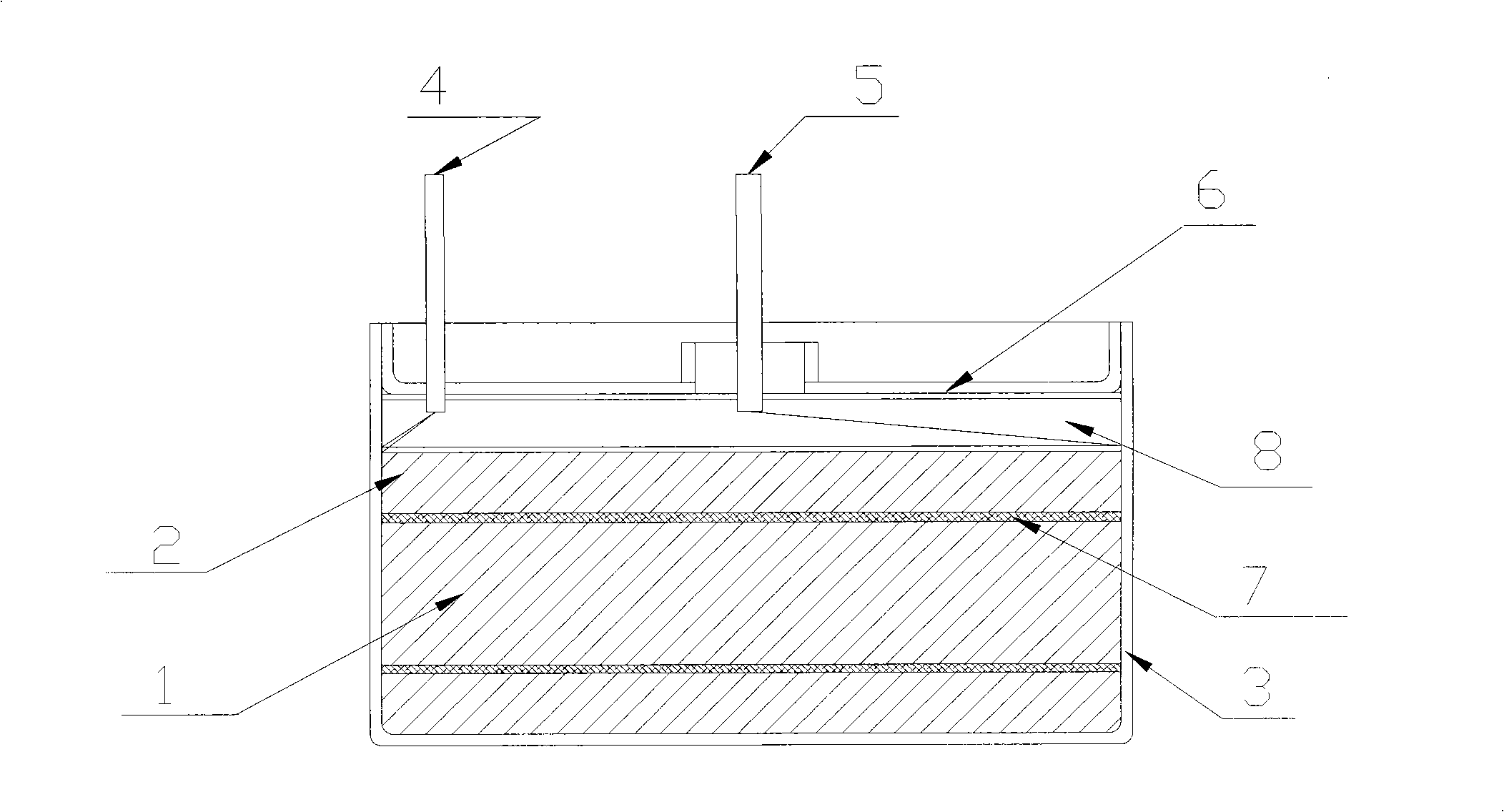

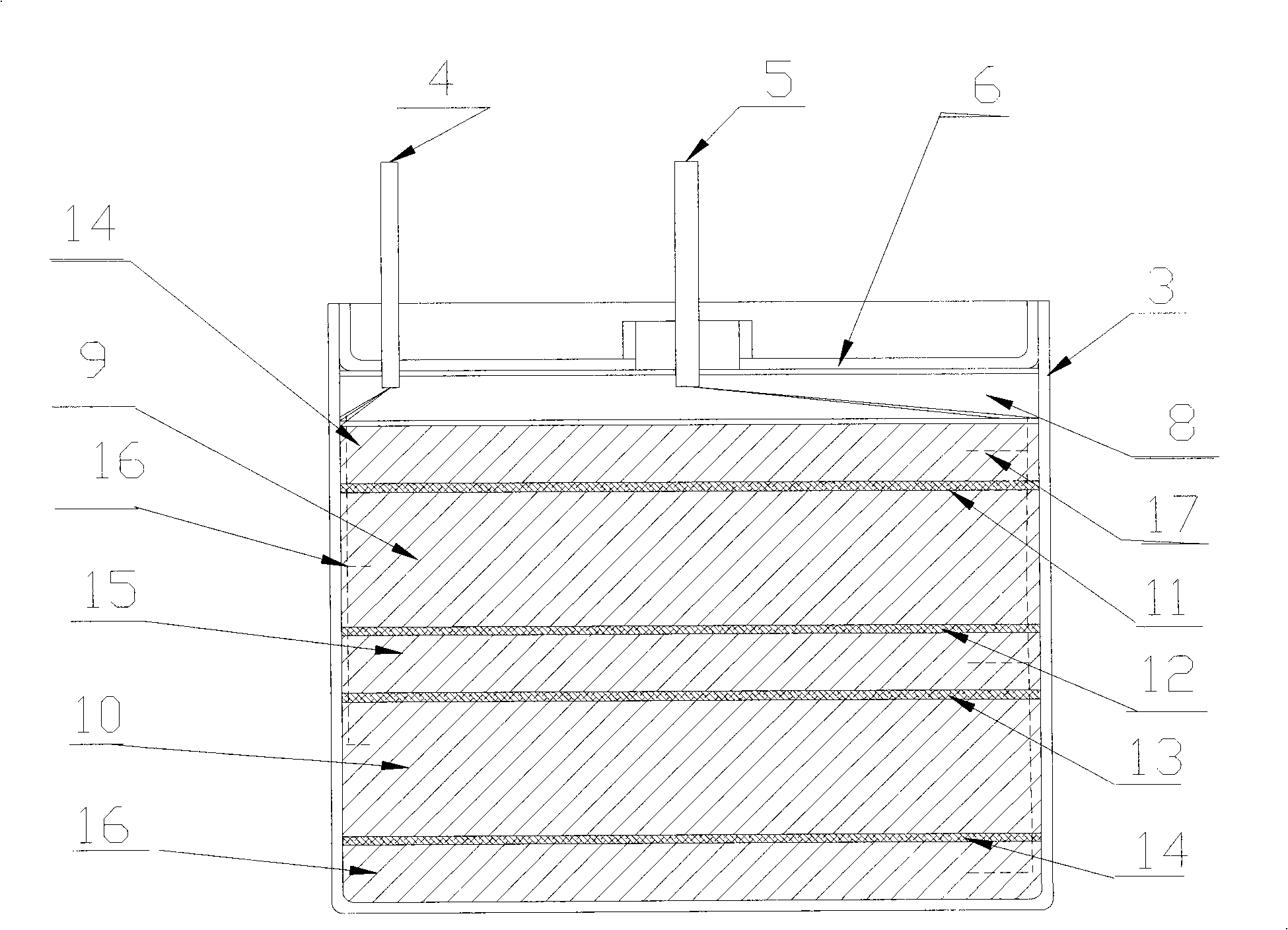

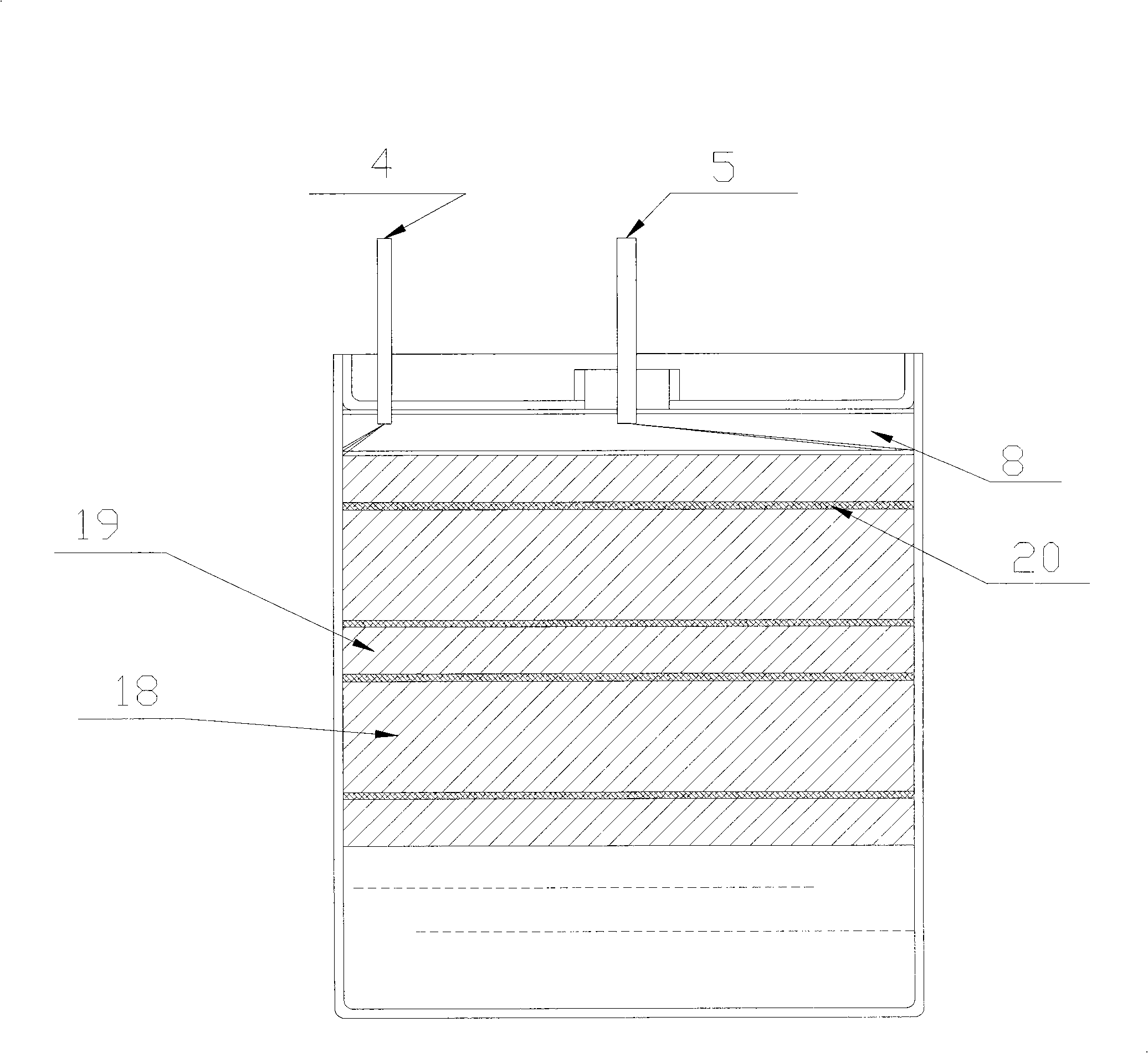

Method for preparing medical porous tantalum implant material

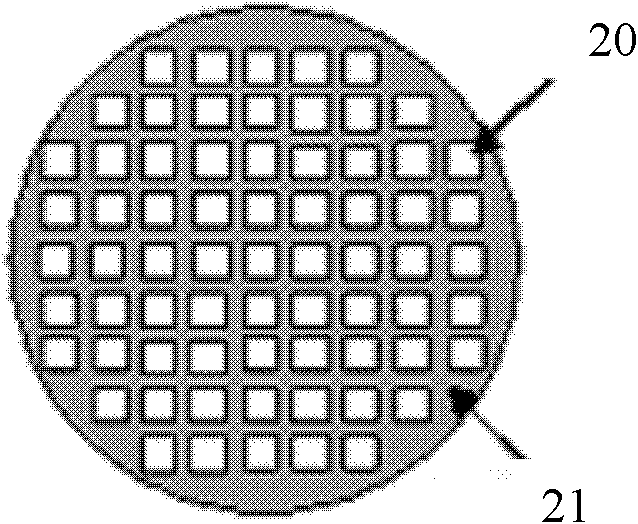

ActiveCN102796894AReduce contentImprove mechanical propertiesProsthesisPolyvinyl alcoholBiocompatibility Testing

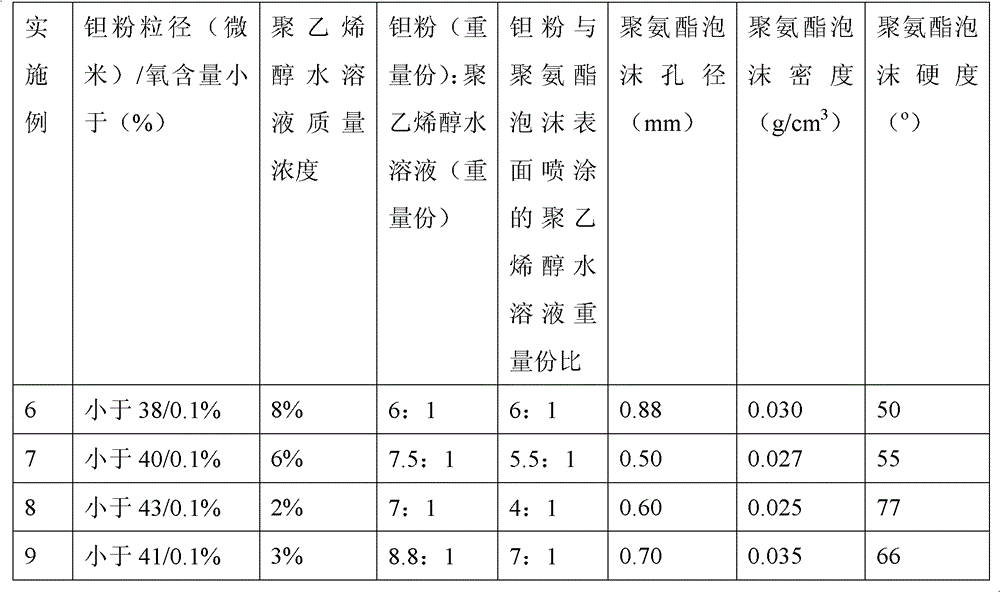

The invention discloses a method for preparing a medical porous tantalum material. The method comprises the following steps of: mixing a poly ethanol aqueous solution and tantalum powder to obtain slurry, wherein the mass concentration of the poly ethanol aqueous solution is 2 to 8 percent; injecting the slurry into an organic foam by vibrating and pressurizing, wherein the vibrating frequency is 20 to 80 times / min; drying; degreasing; sintering, namely raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3>Pa, preserving heat for 120 to 240 minutes, cooling to 200 to 300 DEG C along with a furnace, raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min again, preserving heat for 180 to 240 minutes, raising temperature to 2,000 to 2,200 DEG C at the speed of 5 to 10 DEG C / min, and preserving heat for 120 to 360 minutes; cooling; and performing thermal treatment, namely raising temperature to 800 to 900 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DGE C at the speed of 2 to 5 DGE C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with the furnace. The porous tantalum prepared by the method is very suitable to be used for the medical implant material for replacing bearing bone tissues, and biocompatibility and the mechanical property can be guaranteed simultaneously.

Owner:CHONGQING RUNZE PHARM CO LTD

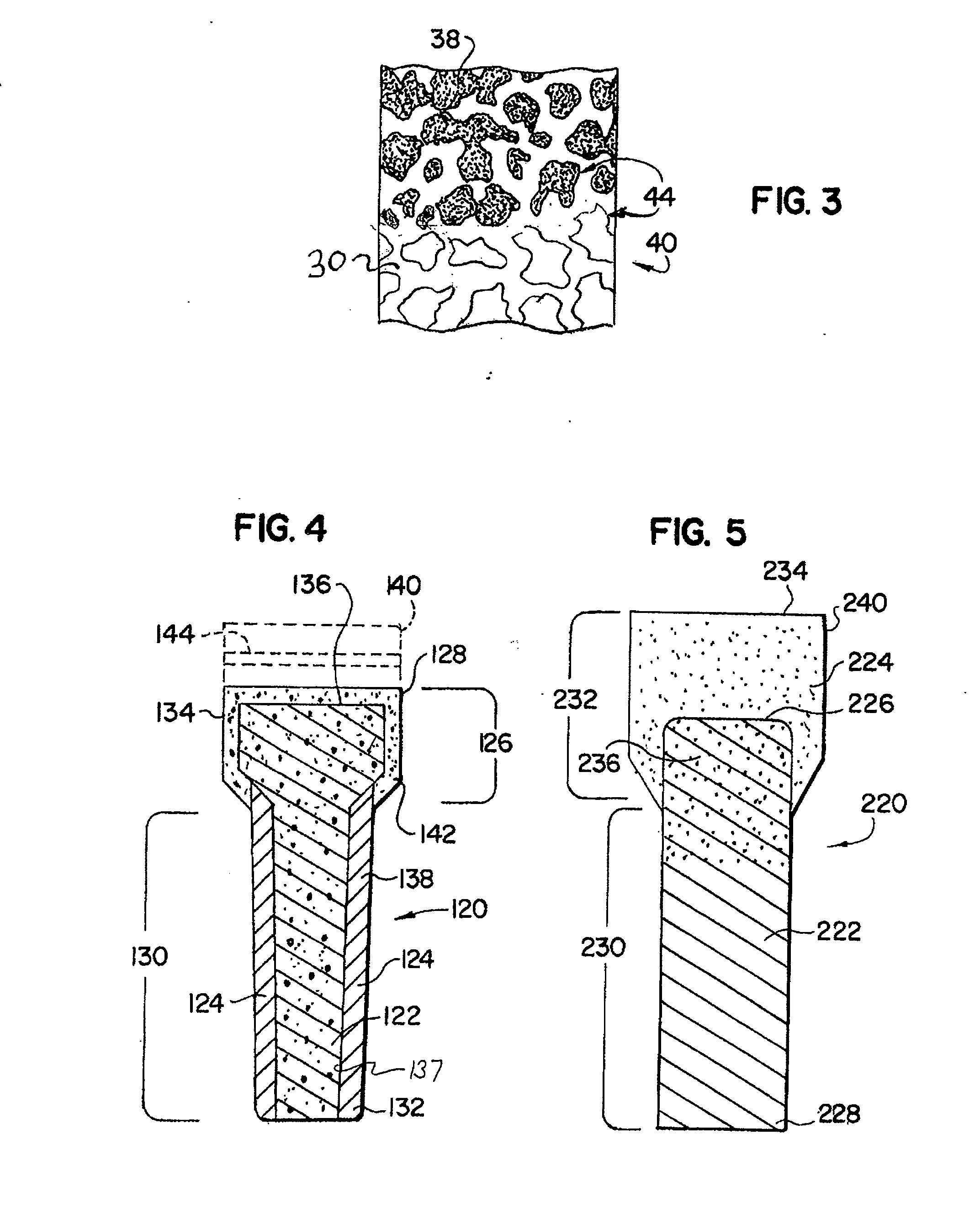

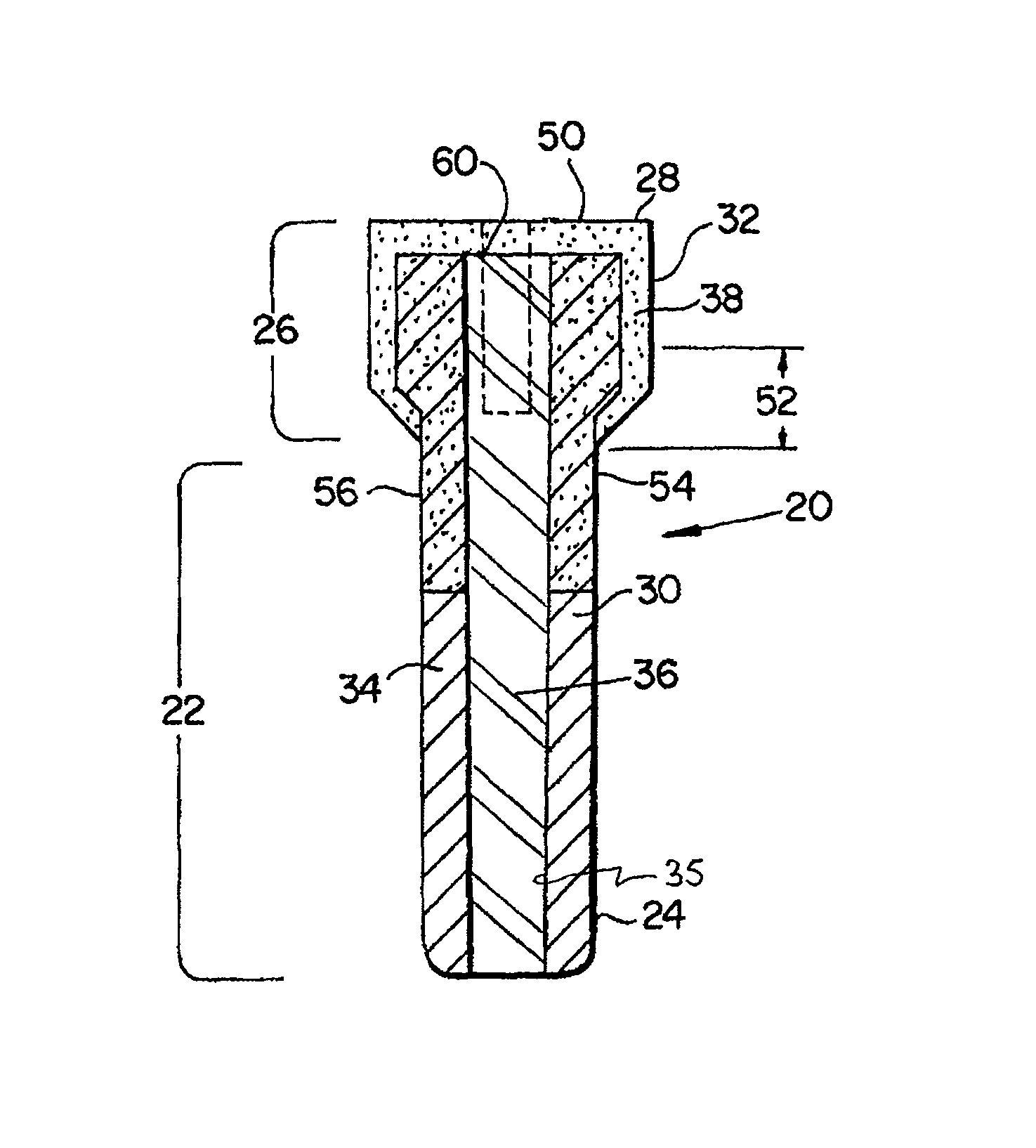

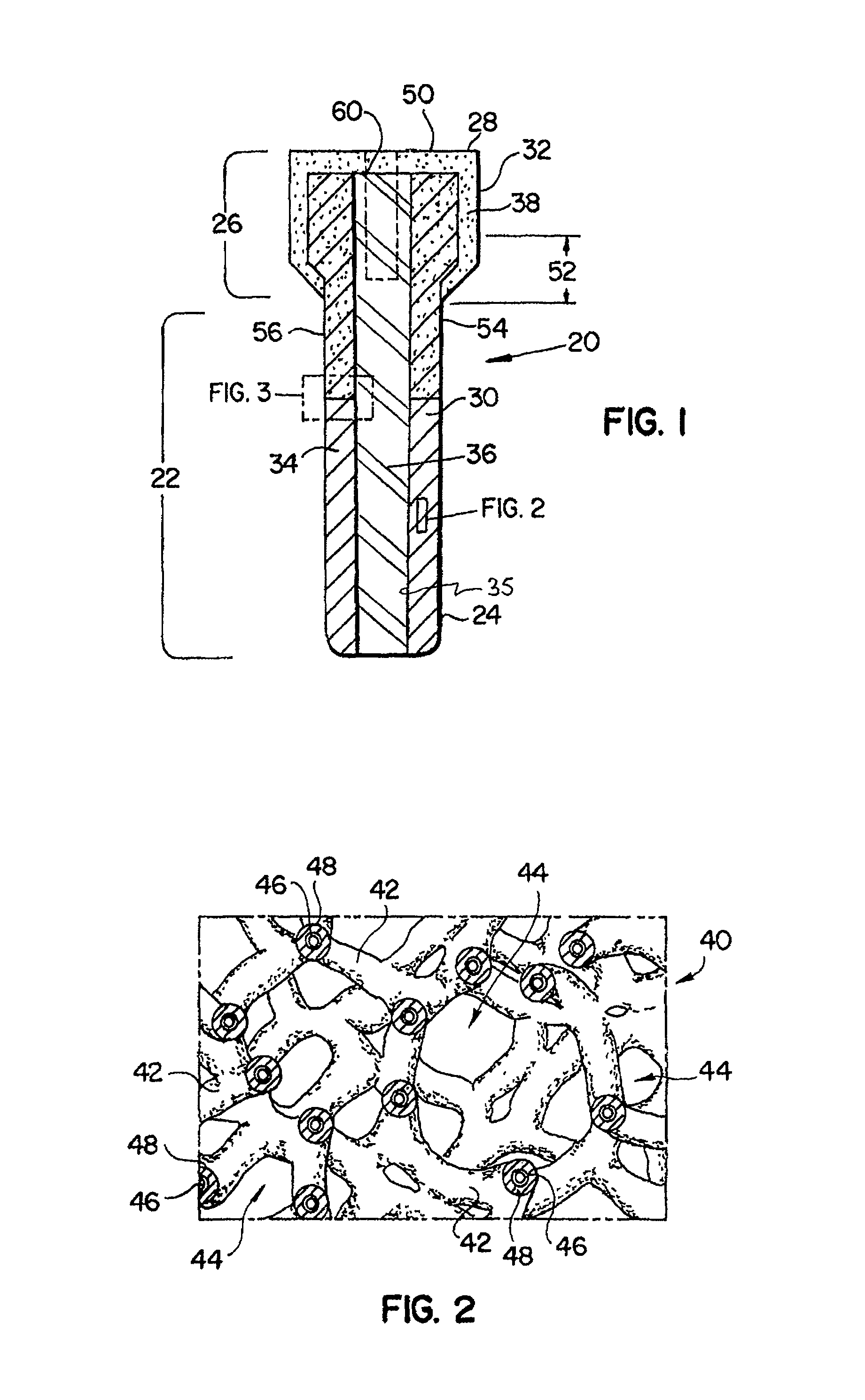

Dental implant prosthetic device with improved osseointegration and esthetic features

Dental implants made at least in part of a porous tantalum material for enhancing the osseointegration of the dental implant into surrounding bone. For example, there is provided a dental implant which includes a porous tantalum portion and an outer portion having a color generally replicating the color of natural teeth. The dental implant further comprises a core portion and the porous tantalum portion at least partially surrounds the core portion. An esthetic portion is disposed at least the outer portion and the porous tantalum portion is disposed for at least partially reinforcing the esthetic portion. After implantation of the implant, bone tissue may osseointegrate into the porous tantalum portion to anchor the implant in position within the surrounding bone. Other embodiments of implants are provided, each implant including at least a portion thereof formed of porous tantalum for improved osseointegration.

Owner:ZIMMER DENTAL INC

Spinal fusion implants and tools for insertion and revision

InactiveUS20090043394A1Avoid expulsionInternal osteosythesisBone implantSpinal columnPorous tantalum

An interbody fusion device in one embodiment includes a tapered body defining a hollow interior or chamber for receiving bone graft or bone substitute material. The body defines exterior threads which are interrupted over portions of the outer surface of the device. The fusion device includes truncated side walls so that on end view the body takes on a cylindrical form. In another embodiment, the tapered body is solid and formed of a porous biocompatible material having sufficient structural integrity to maintain the intradiscal space and normal curvature. The material is preferably a porous tantalum composite having fully interconnected pores to facilitate complete bone tissue ingrowth into the implant. In further embodiments, the fusion devices are provided with osteogenic material to facilitate bone ingrowth. A cap is also provided to block the opening of hollow fusion devices. The cap includes an occlusion body and an elongated anchor. In some embodiments the anchor includes a lip which is engageable to openings in the body wall. Tools are also provided for manipulating caps for interbody fusion devices. In one embodiment the tool includes a pair of prongs each having facing engagement surfaces for engaging the fusion device, and a shaft slidably disposed between the prongs. The shaft has a first end defining a cap-engaging tip for engaging a tool hole in the cap. In one embodiment the cap engaging tip defines threads. In another embodiment the prongs include a pair of releasing members on each of the facing engagement surfaces. The releasing members have a height and a width for being insertable into apertures in a body wall in the fusion device to disengage the elongate anchors from the apertures.

Owner:WARSAW ORTHOPEDIC INC

Spinal fusion implants and tools for insertion and revision

InactiveUS20050192669A1Avoid expulsionInternal osteosythesisBone implantSpinal columnPorous tantalum

An interbody fusion device in one embodiment includes a tapered body defining a hollow interior or chamber for receiving bone graft or bone substitute material. The body defines exterior threads which are interrupted over portions of the outer surface of the device. The fusion device includes truncated side walls so that on end view the body takes on a cylindrical form. In another embodiment, the tapered body is solid and formed of a porous biocompatible material having sufficient structural integrity to maintain the intradiscal space and normal curvature. The material is preferably a porous tantalum composite having fully interconnected pores to facilitate complete bone tissue ingrowth into the implant. In further embodiments, the fusion devices are provided with osteogenic material to facilitate bone ingrowth. A cap is also provided to block the opening of hollow fusion devices. The cap includes an occlusion body and an elongated anchor. In some embodiments the anchor includes a lip which is engageable to openings in the body wall. Tools are also provided for manipulating caps for interbody fusion devices. In one embodiment the tool includes a pair of prongs each having facing engagement surfaces for engaging the fusion device, and a shaft slidably disposed between the prongs. The shaft has a first end defining a cap-engaging tip for engaging a tool hole in the cap. In one embodiment the cap engaging tip defines threads. In another embodiment the prongs include a pair of releasing members on each of the facing engagement surfaces. The releasing members have a height and a width for being insertable into apertures in a body wall in the fusion device to disengage the elongate anchors from the apertures.

Owner:ZDEBLICK THOMAS +4

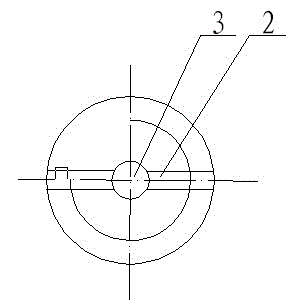

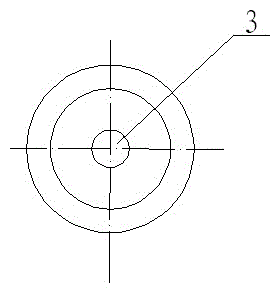

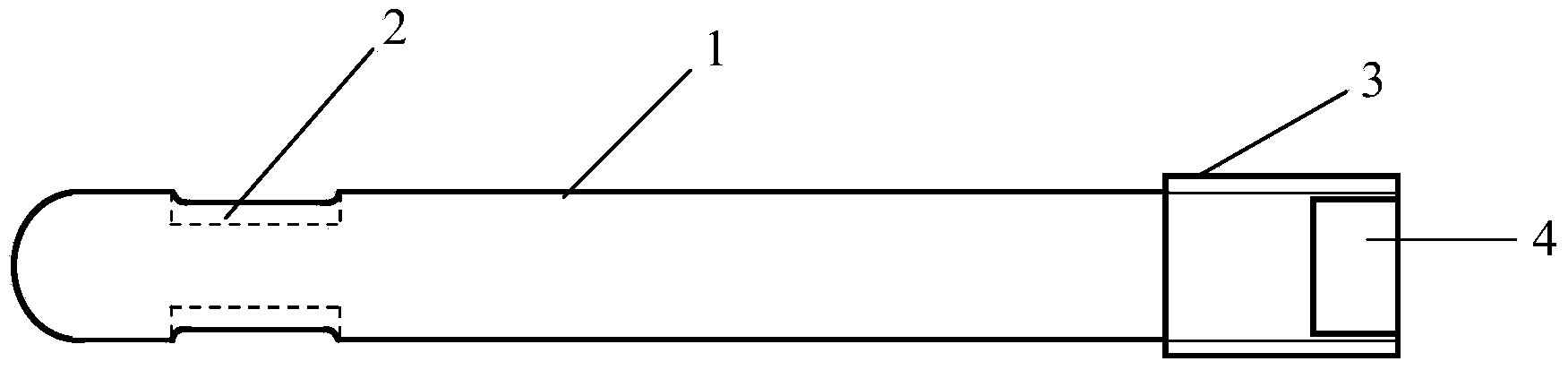

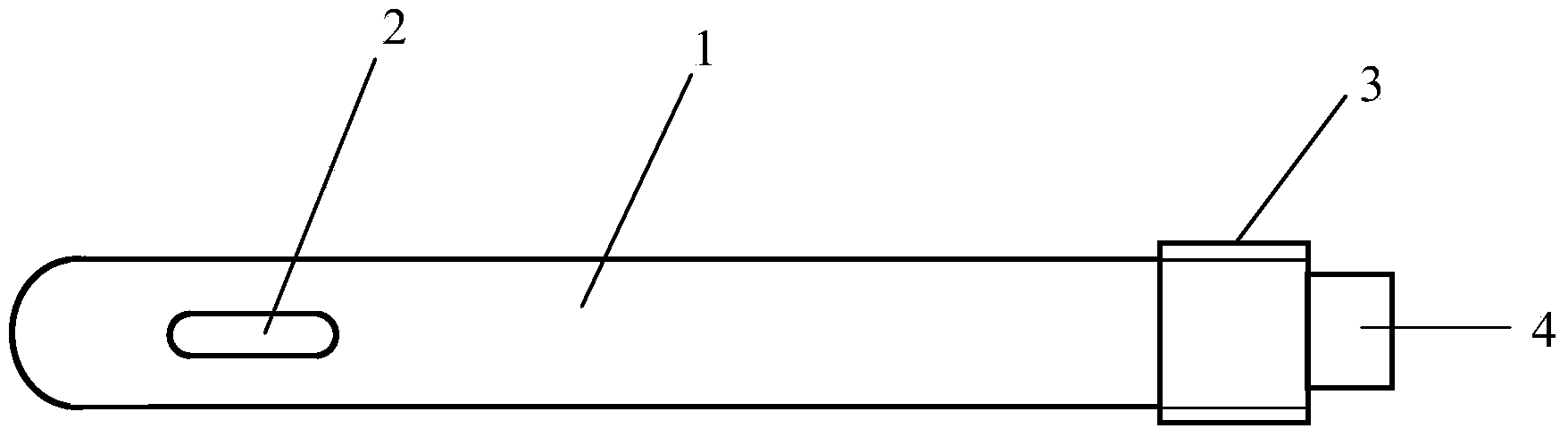

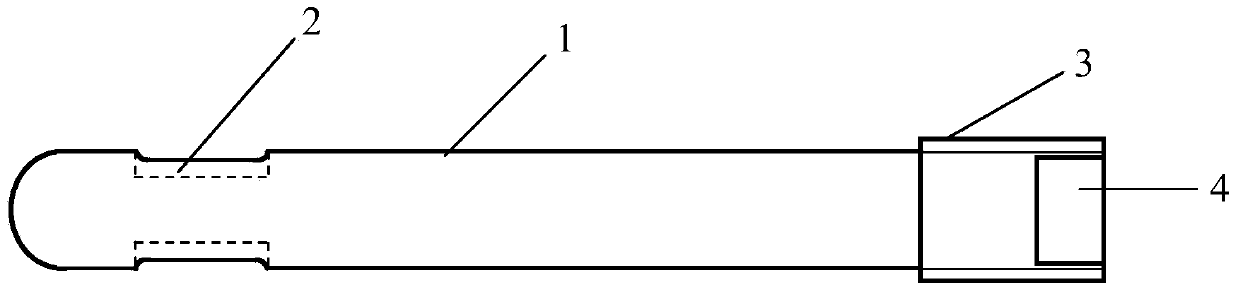

Porous tantalum rod

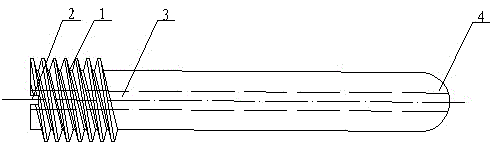

ActiveCN102743218AEasy to fixIncrease success rateInternal osteosythesisFastenersNeck structureRight femoral head

The invention relates to a medical implant part for femoral head joint surface depression or I-stage or II-stage femoral head necrosis, namely a porous tantalum rod. One end of the implant part is provided with a connection fastening structure connected with a bone tissue, and a through hole is formed in the center of the tantalum rod; the porous tantalum rod is made of a porous tantalum material with a foam structure of pore three-dimensional communicated distribution, and is sintered by adopting a foam impregnation method; and tantalum powder particles have a sinter neck structure on a foam frame formed by accumulating the sintered pure tantalum powder. The through hole in the porous tantalum rod facilitates accurate positioning in an operation; and a related object can be picked out and injected conveniently through the through hole, so that the effect of constant pressure reduction can be achieved.

Owner:CHONGQING RUNZE PHARM CO LTD

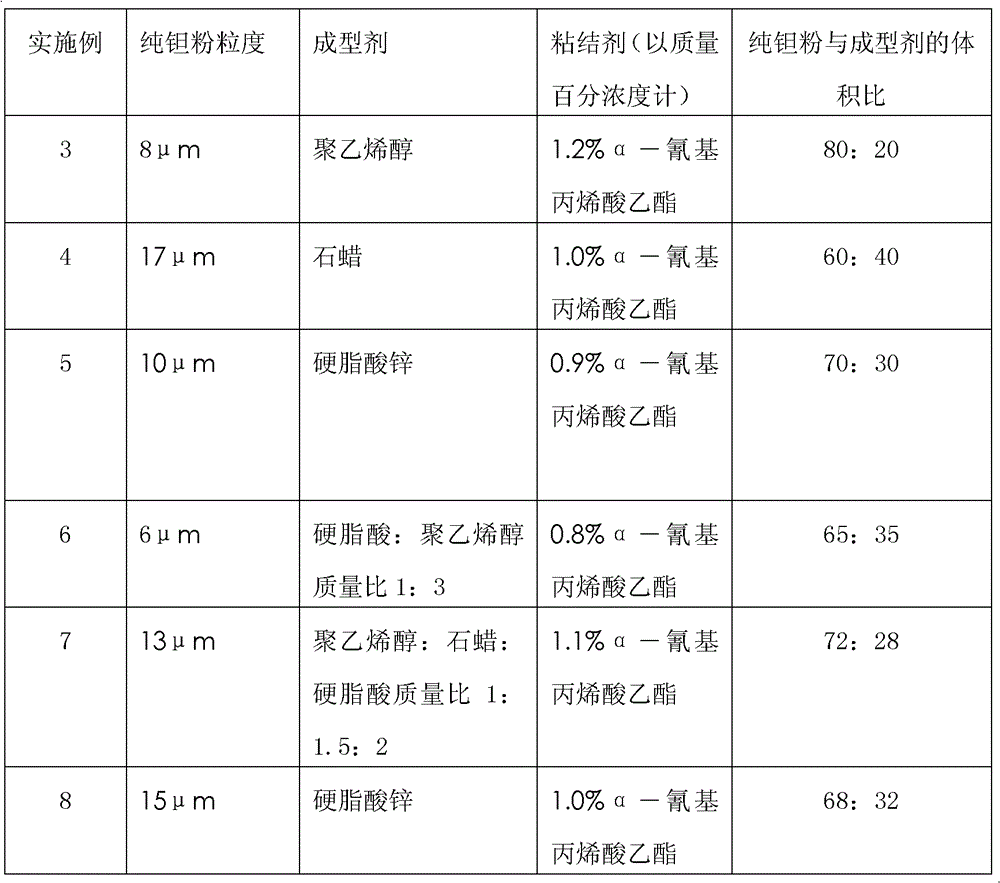

Method for preparing porous tantalum medical implant material through three-dimensional printing forming

ActiveCN102796909AFast molding speedHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyPorous tantalumBone tissue

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps of: feeding mixed tantalum power formed by mixing pure tantalum powder and a forming agent into a printing platform of a three-dimensional printer, and rolling and paving; spraying an adhesion agent by a printing head of the three-dimensional printer to adhere the mixed tantalum powder so as to form a two-dimensional plane; descending a working table 80 to 100 mu m, and processing the next layer; accumulating and forming layer by layer; removing the tantalum powder particles which are not adhered to obtain an initially formed sample; and performing aftertreatment such as degreasing, vacuum sintering, cooling and the like to obtain the porous tantalum medical implant material, wherein the volume ratio of the pure tantalum powder to the forming agent is (60-80):(20-40), and the adhesion agent is 1 mass percent alpha-cyanoacrylate adhesive. The pores of the porous tantalum medical implant material prepared by the method are completely communicated in a three-dimensional mode; the porous tantalum medical implant material prepared by the method is high in biocompatibility; and meanwhile, the mechanical property of the porous tantalum medical implant material prepared by the method is consistent with that of loading bone tissues of a human body.

Owner:CHONGQING RUNZE PHARM CO LTD

Multiple root implant

A dental implant has a body and a plurality of distinct roots that extend outwardly from the main portion that generally define a coronal-apical axis. A porous tantalum metal portion is disposed at the body for engaging bone and the plurality of distinct roots are configured to resist a torsional force that is applied to the dental implant and around the coronal-apical axis.

Owner:ZIMMER DENTAL INC

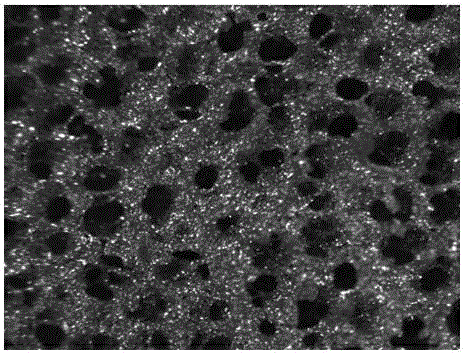

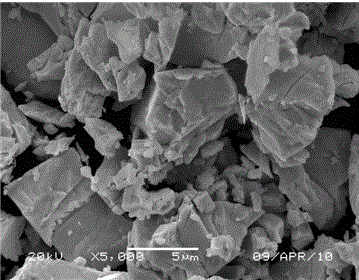

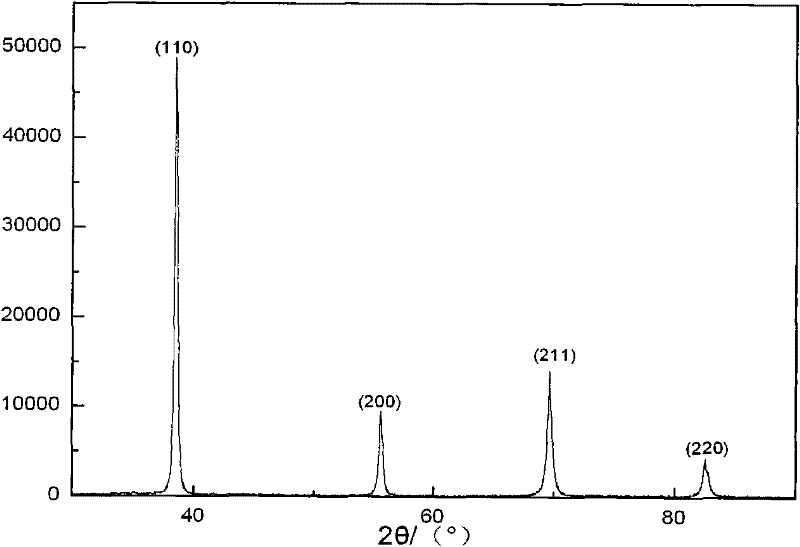

Porous tantalum serving as medical metal implanted material and preparation method thereof

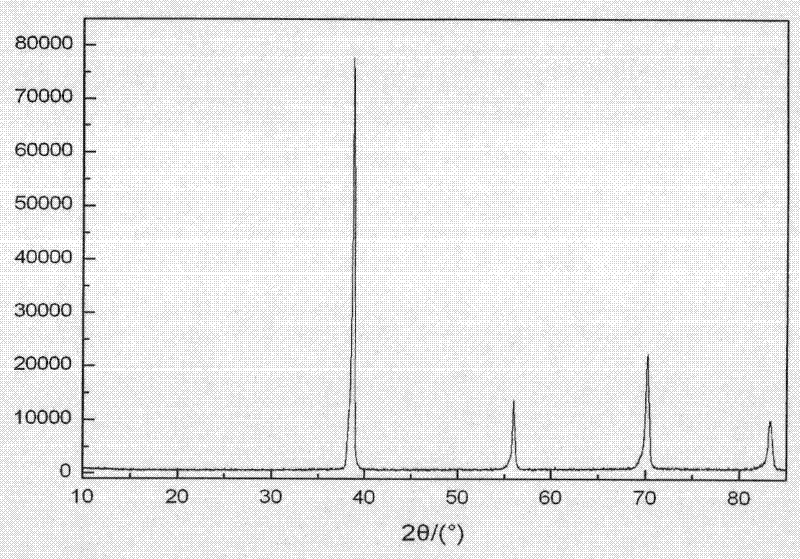

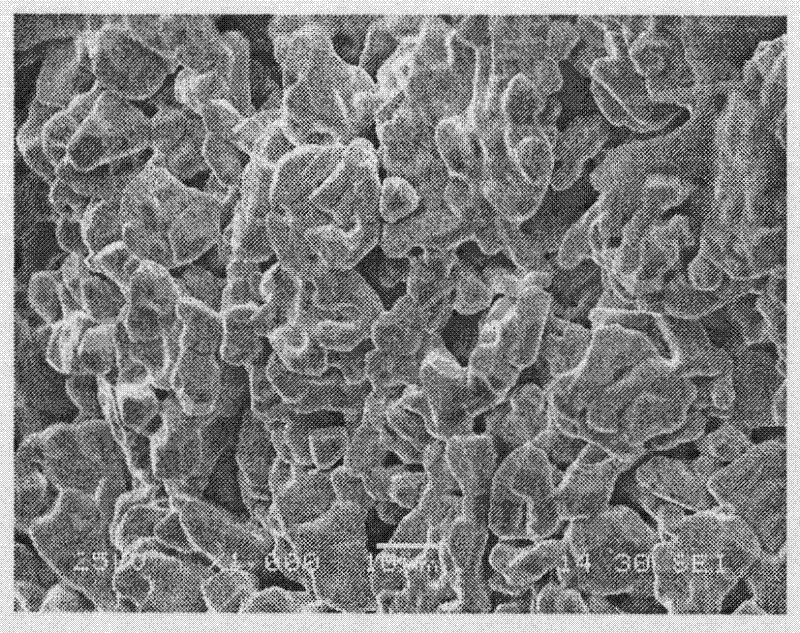

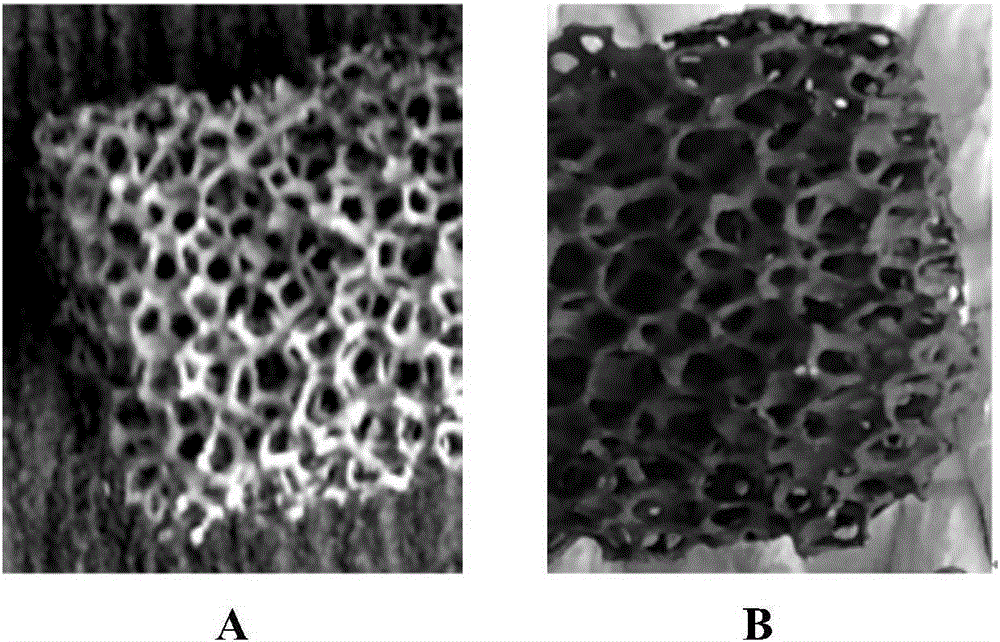

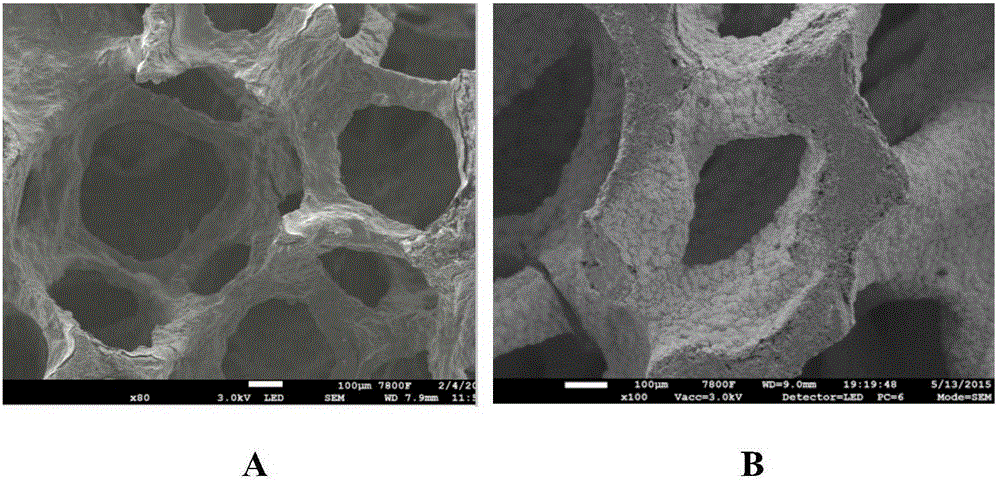

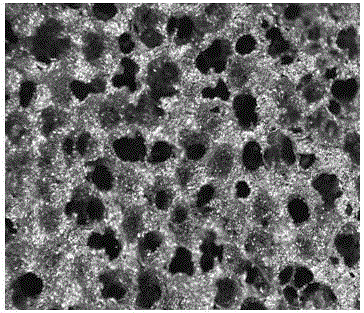

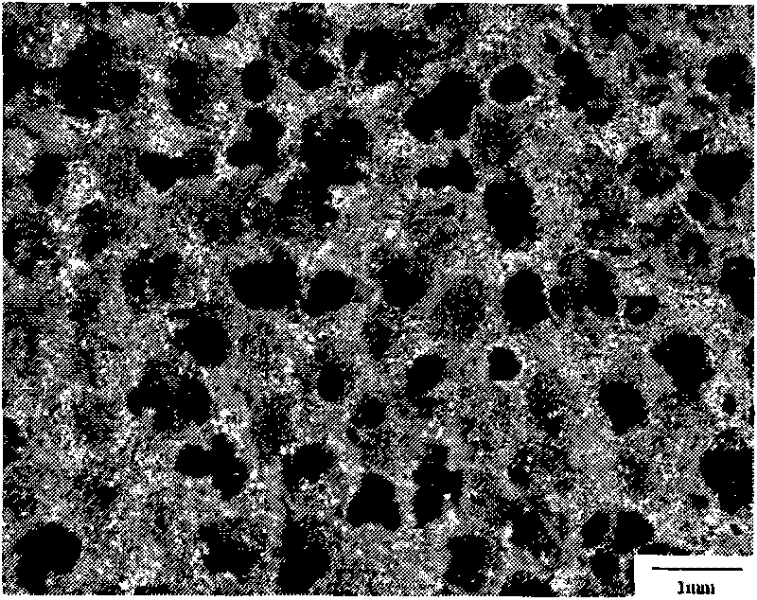

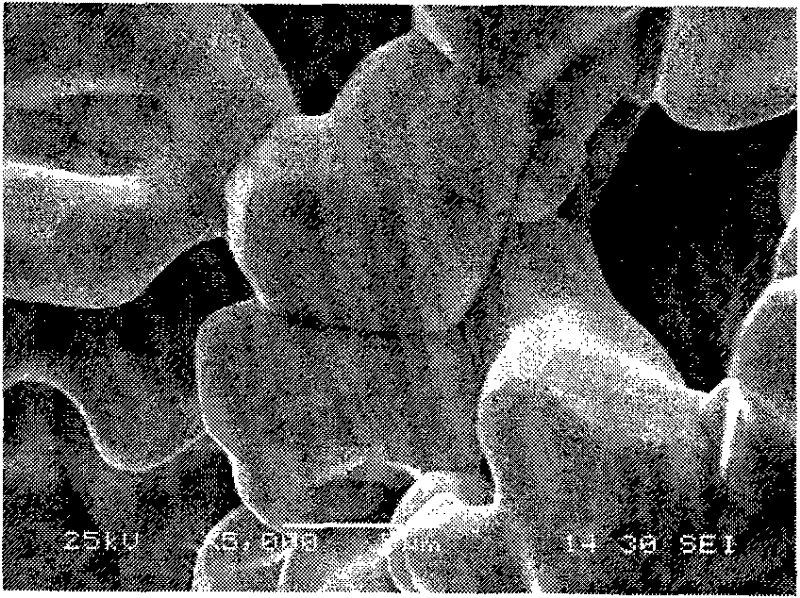

ActiveCN102205144AReduce contentImprove mechanical propertiesMetal-working apparatusPharmaceutical delivery mechanismPorosityNeck structure

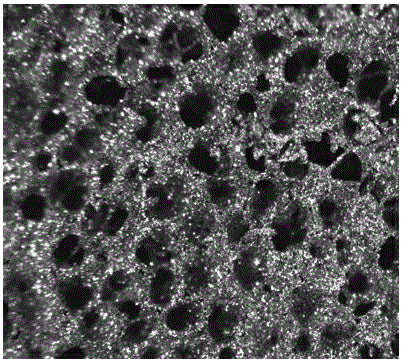

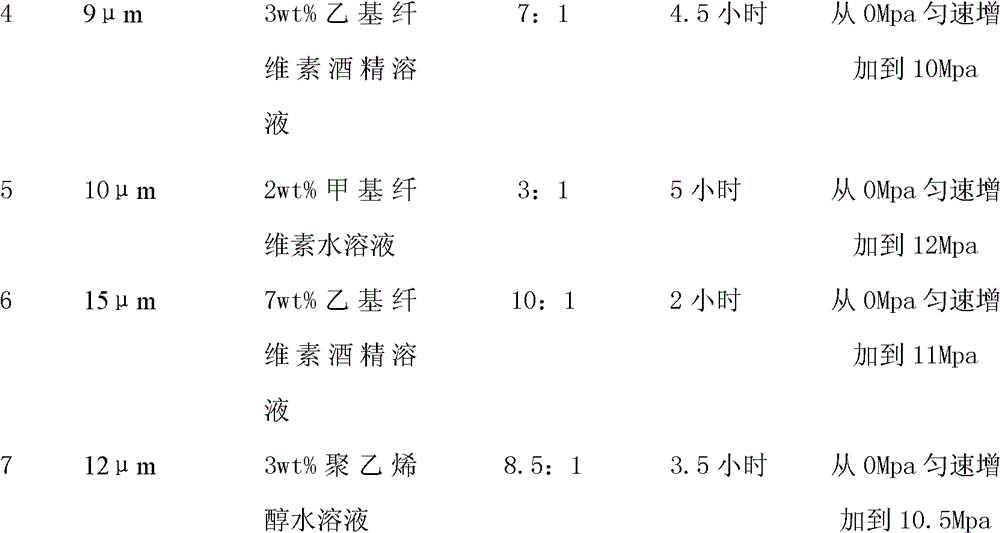

The invention relates to porous tantalum serving as a medical metal implanted material and a preparation method thereof. The porous tantalum has a pore three-dimensional communicating distribution foam structure, wherein a solution which is prepared from an organic adhesive and a dispersant and tantalum powder are adopted to prepare a tantalum powder slurry; the tantalum powder slurry is poured into an organic foam body and soaked until the tantalum powder slurry is filled in the pores of the organic foam body, drying is carried out so as to remove the dispersant in the organic foam body which is poured with the tantalum powder slurry, and ungreased treatment is carried out in the presence of inert gas so as to remove the organic adhesive and the organic foam body, and vacuum sintering is carried out so as to prepare the porous sintered body; on a foam framework which is formed by accumulated sintered pure tantalum powder, and a sintering neck structure exists among tantalum powder particles; and the tantalum powder is annealed in vacuum and subjected to conventional post-treatment. The porous tantalum has the advantages of high porosity, uniform and communicated porous distribution, uniform sintered microstructure particles, remarkable sintering neck, ensured excellent chemical performance and especially excellent ductibility.

Owner:CHONGQING RUNZE PHARM CO LTD

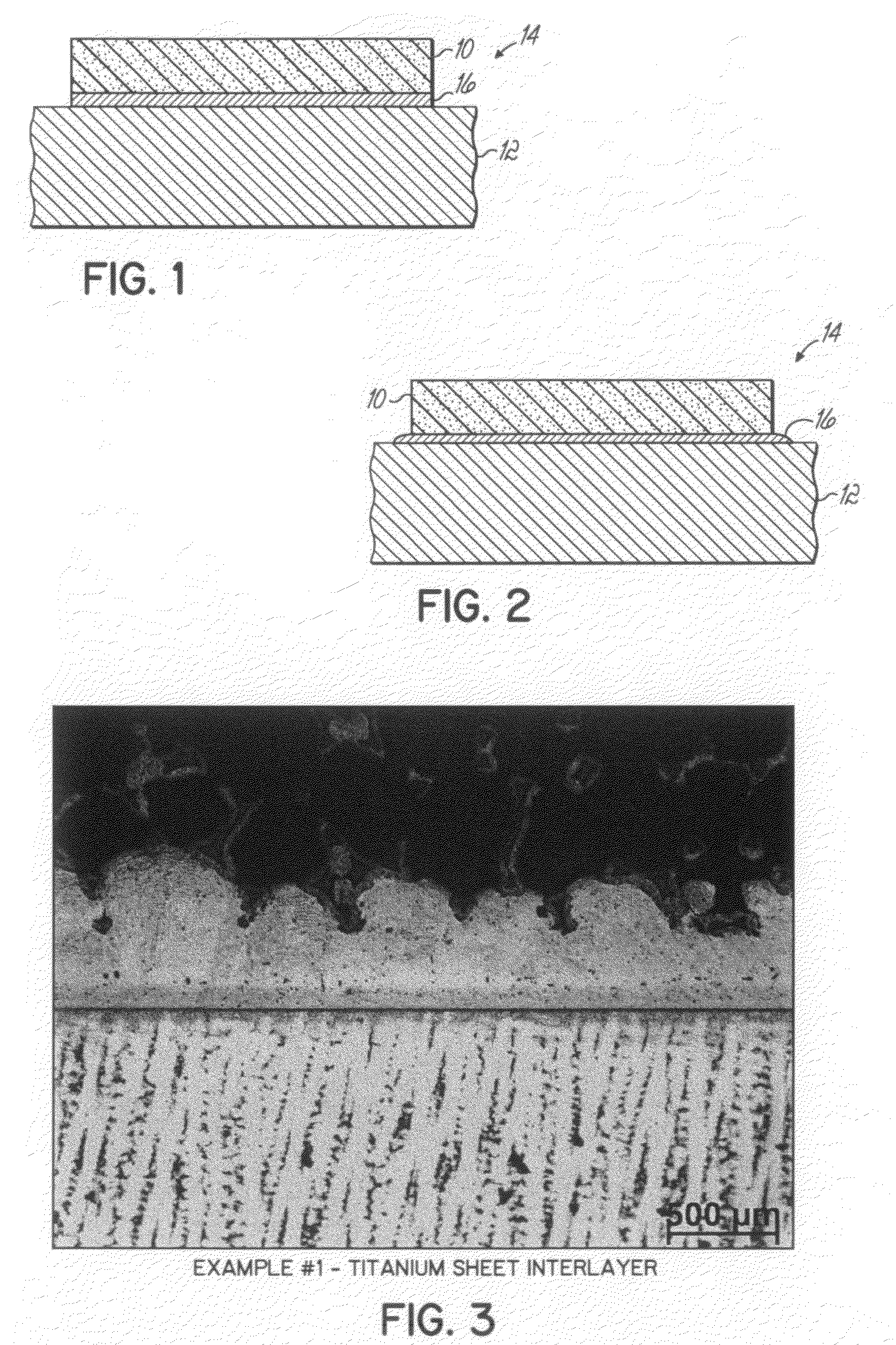

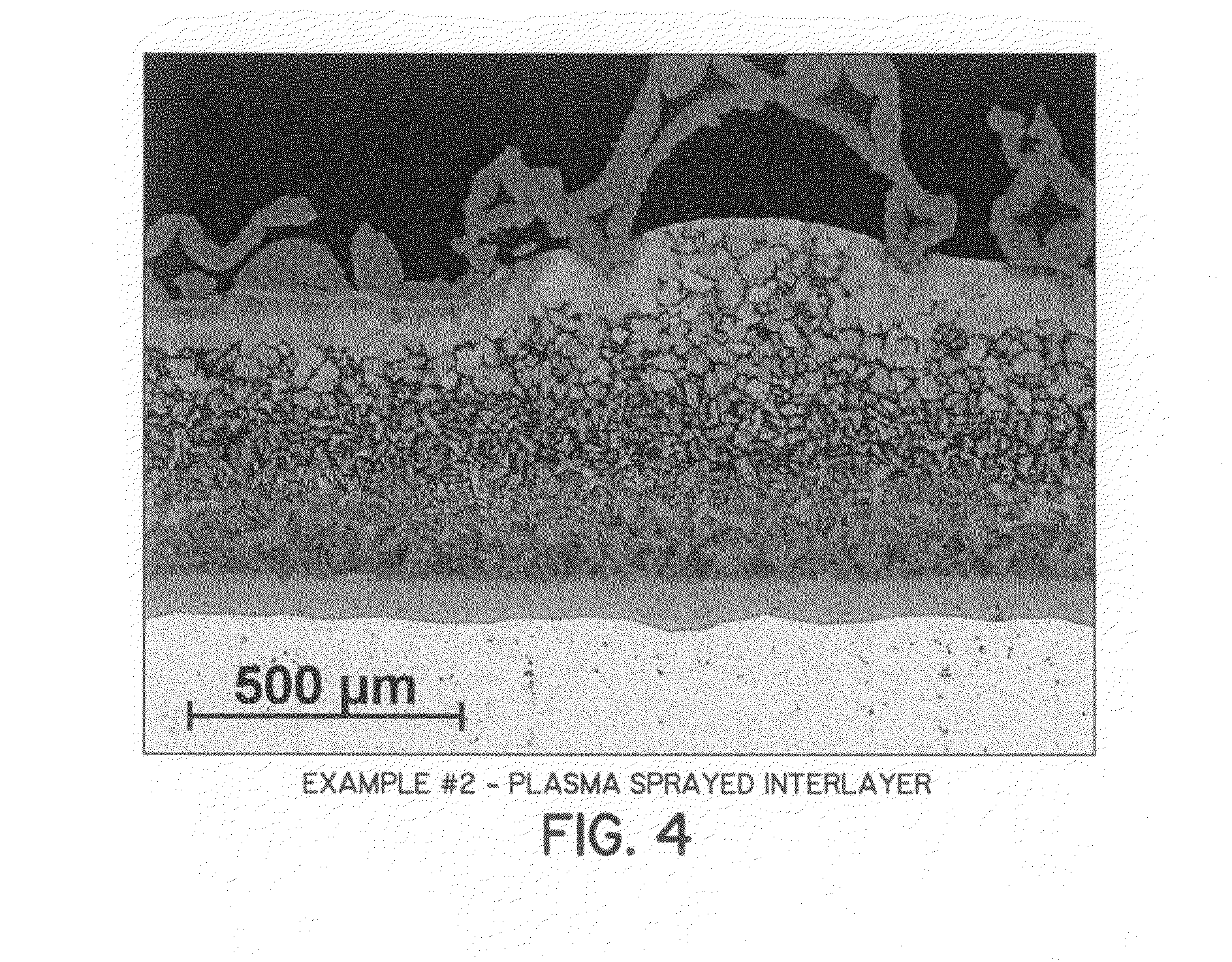

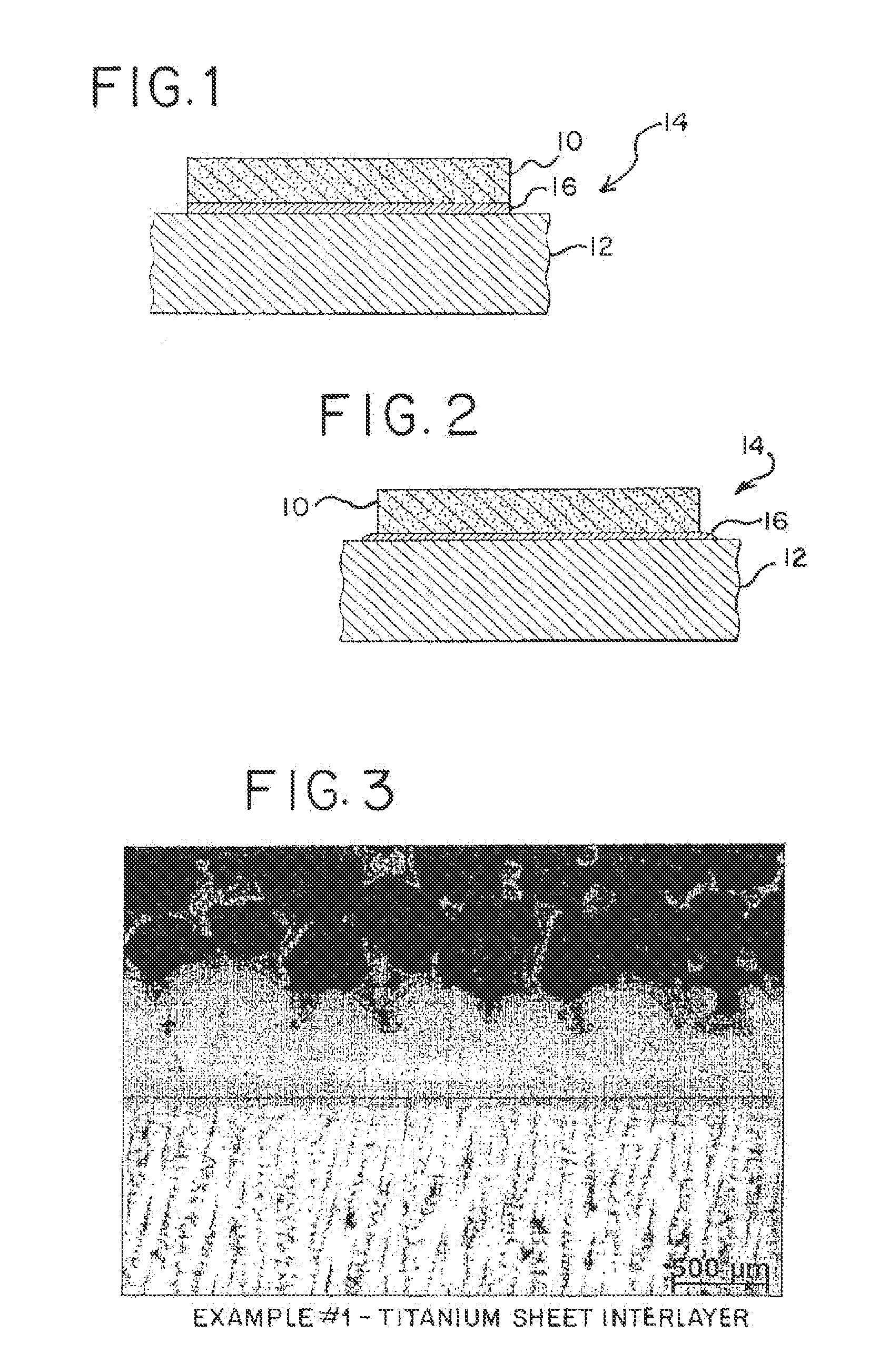

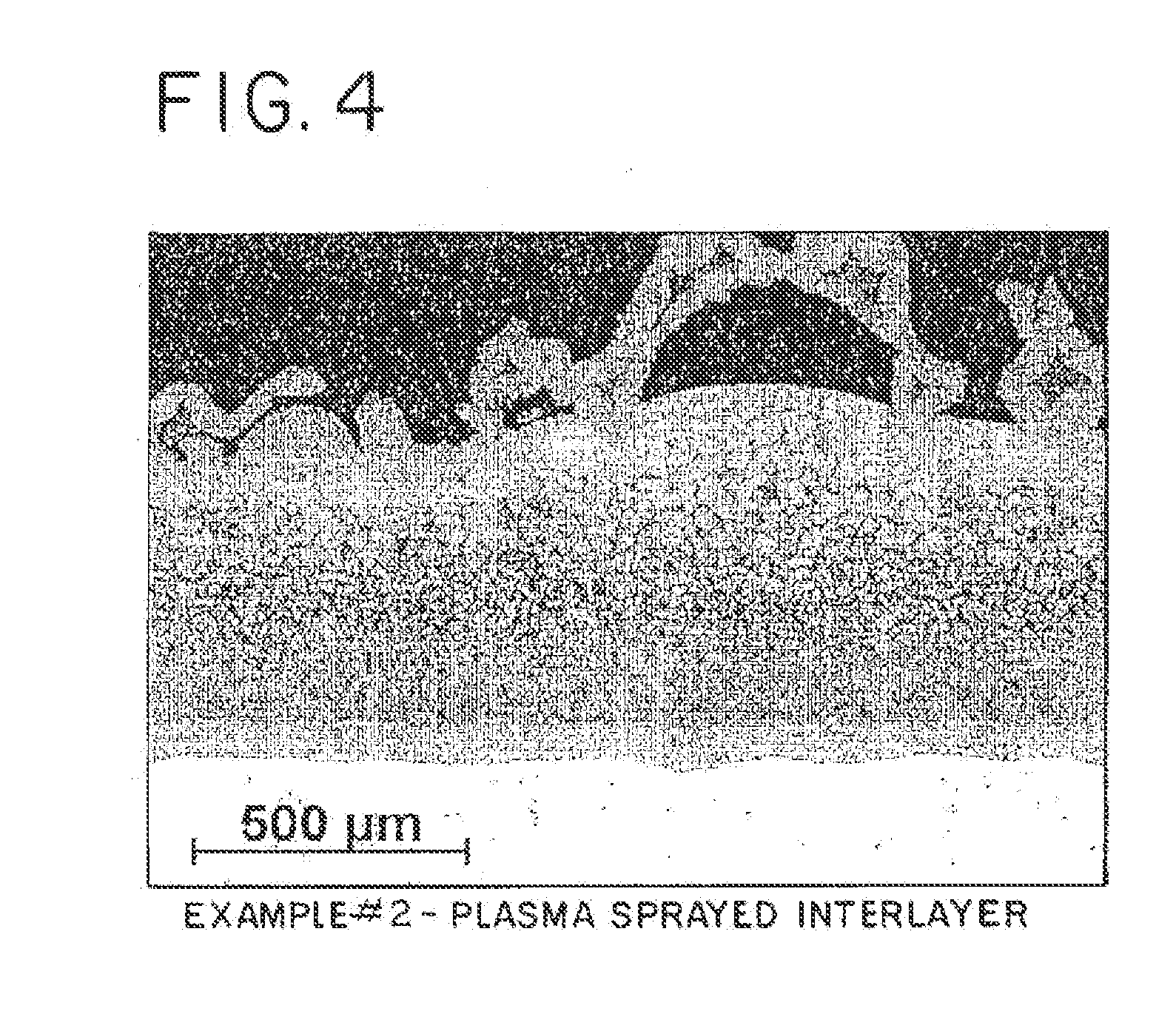

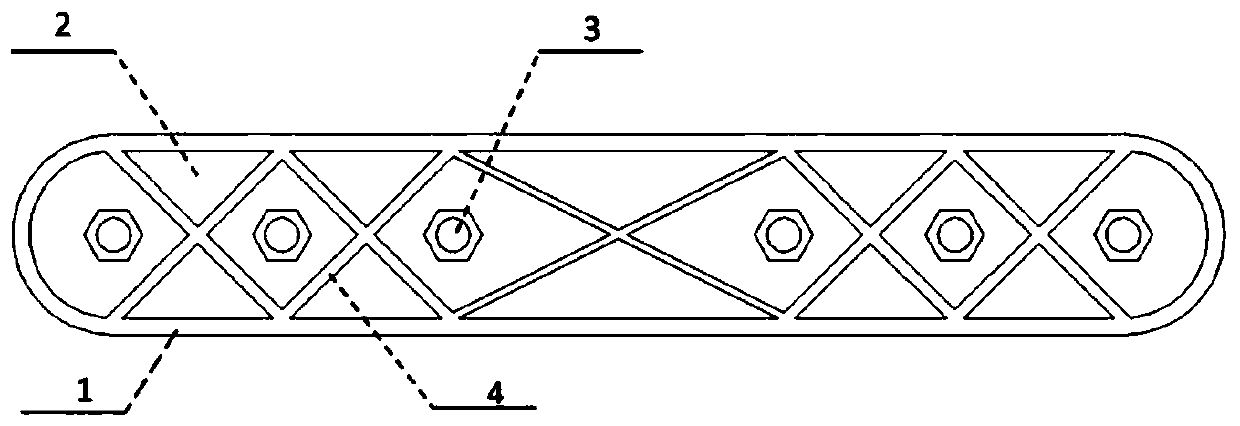

Method for bonding a tantalum structure to a cobalt-alloy substrate

A method for bonding a porous tantalum structure to a substrate is provided. The method comprises providing a substrate comprising cobalt or a cobalt-chromium alloy; an interlayer consisting essentially of at least one of hafnium, manganese, niobium, palladium, zirconium, titanium, or alloys or combinations thereof; and a porous tantalum structure. Heat and pressure are applied to the substrate, the interlayer, and the porous tantalum structure to achieve solid-state diffusion between the substrate and the interlayer and between the interlayer and the porous tantalum structure.

Owner:ZIMMER INC

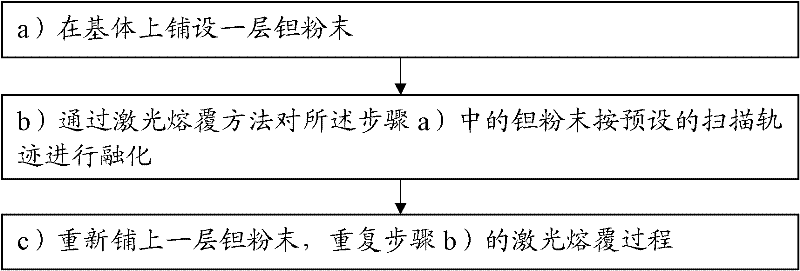

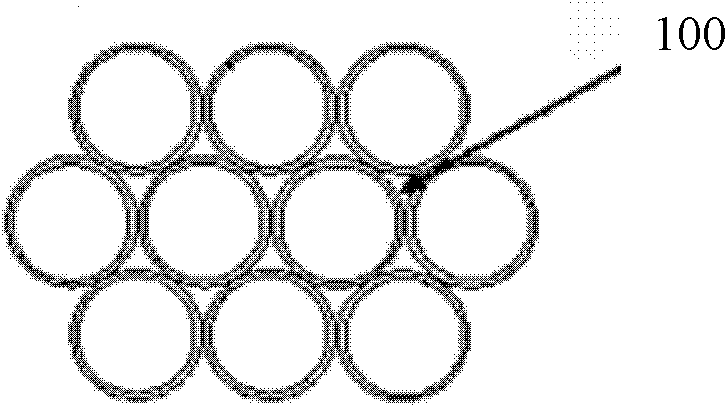

Preparation method of porous tantalum and device applied to same

The invention discloses a preparation method of porous tantalum. The preparation method comprises the following steps of: a), laying a layer of tantalum powder on a substrate; b), melting the tantalum powder in the step a) through a laser cladding method according to a preset scanning track; and c), laying a layer of powder again, repeating the laser cladding process in the step b), wherein the step c) is performed at least once, so as to prepare multiple layers of porous tantalum. The invention also discloses a device applied to the preparation method of porous tantalum. According to the invention, the laser cladding method is applied to the preparation of porous tantalum; and porous tantalum prepared by the preparation method and the device can be directly formed in no need of subsequent processing, and at the same time, any toxic substances are not introduced in the preparation process, and any substances can not be remained.

Owner:SUZHOU UNIV

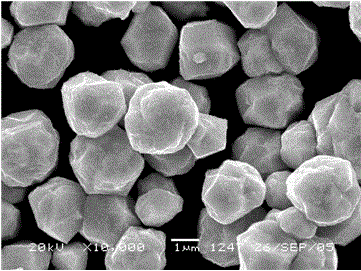

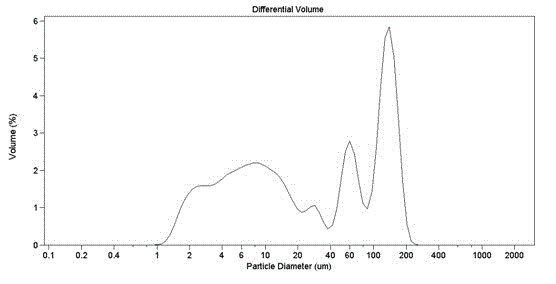

Medical tantalum powder and preparation method thereof

Disclosed is medical tantalum powder. The oxygen content of the tantalum powder is smaller than or equal to 1000ppm, the granularity of 95% of the tantalum powder is 1.0-50.0 micrometers, and the particle shape of the tantalum powder is spherical or sphere-like. The preparation method of the medical tantalum powder includes that hydrogenation, breaking, classification and impurity removal, wherein breaking includes that coarse breaking is performed, the particle size of tantalum powder subjected to coarse breaking is controlled below 3mm, then the tantalum powder is delivered into a cyclonic breaking classifier to be broken and classified, the power of a classifying wheel is controlled below 50KW / hour, and the impact gas flow is 0.3-0.8 MPa. The medical tantalum powder is applied to preparation of medical porous tantalum implant materials and has high sintering strength, and prepared porous tantalum is even in pore size, stable in mechanical property, high in purity and good in biocompatibility, accordingly is an ideal material for human skeleton production. The preparation method of the medical tantalum powder is simple, the product percent of pass is high, the rate of finished products can reach 99.0%-99.5%, and the production cost is low. Besides, compared with cost of the current tantalum powder technique, the cost of the medical tantalum powder is reduced by 40-50%.

Owner:CHONGQING RUNZE PHARM CO LTD

Medical porous tantalum metal material and preparation method thereof

ActiveCN105177523AHigh porosityUniform porosityBone implantTissue regenerationPorous tantalumGas phase

The invention discloses a medical porous tantalum metal material and a preparation method thereof. The medical porous tantalum metal material is prepared through the steps that through a chemical vapor deposition method, tantalum metal compounds are reduced to tantalum metal powder, the tantalum metal powder is evenly deposited on the surface of a porous silicon support to form a tantalum coating, and then the medical porous tantalum metal material is prepared, wherein one of tantalum pentachloride and fluoride tantalum is adopted as the tantalum metal compounds, the porosity of the porous silicon support is larger than 70 percent, the pore diameter of the porous silicon support is 100-600 micrometers, and the thickness of the tantalum coating is 10-50 micrometers. According to the medical porous tantalum metal material and the preparation method thereof, the porous tantalum metal material is of a communicated porous structure, is high in porosity, uniform in pore, few in pore dead space and similar to the cancellous bones of a human body and can promote bone ingrowth and be applied to bone defect repair after bone trauma and osteonecrosis of multiple portions in the human body occur.

Owner:伟坦(大连)生物材料有限公司

Porous tantalum rod and application of porous tantalum rod

The invention relates to a medical permanent implantation object, in particular to a medical implantation porous tantalum rod used for treating early-mid femoral head necrosis. The porous tantalum rod comprises a body, wherein one end of the body is provided with a groove, the other end of the body is provided with a threaded structure, and a notch is formed in the end surface of the tail end of the threaded structure. One end of the body of the porous tantalum rod is provided with the notch, bone marrow stromal cells or bone marrow stromal cell united biological membrane complexes and the like can be loaded, the generation of a new bone is favorably realized, a better clinical effect is particularly realized in the early femoral head necrosis treatment, and the defects of poor clinical treatment effect and the like of the existing entity type porous tantalum rod are overcome. The porous tantalum rod has the advantages that the preparation method is simple, the cost is low, the implementation and the clinical application are favorably realized, and the porous tantalum rod is suitable for the need of wide patients.

Owner:赵德伟

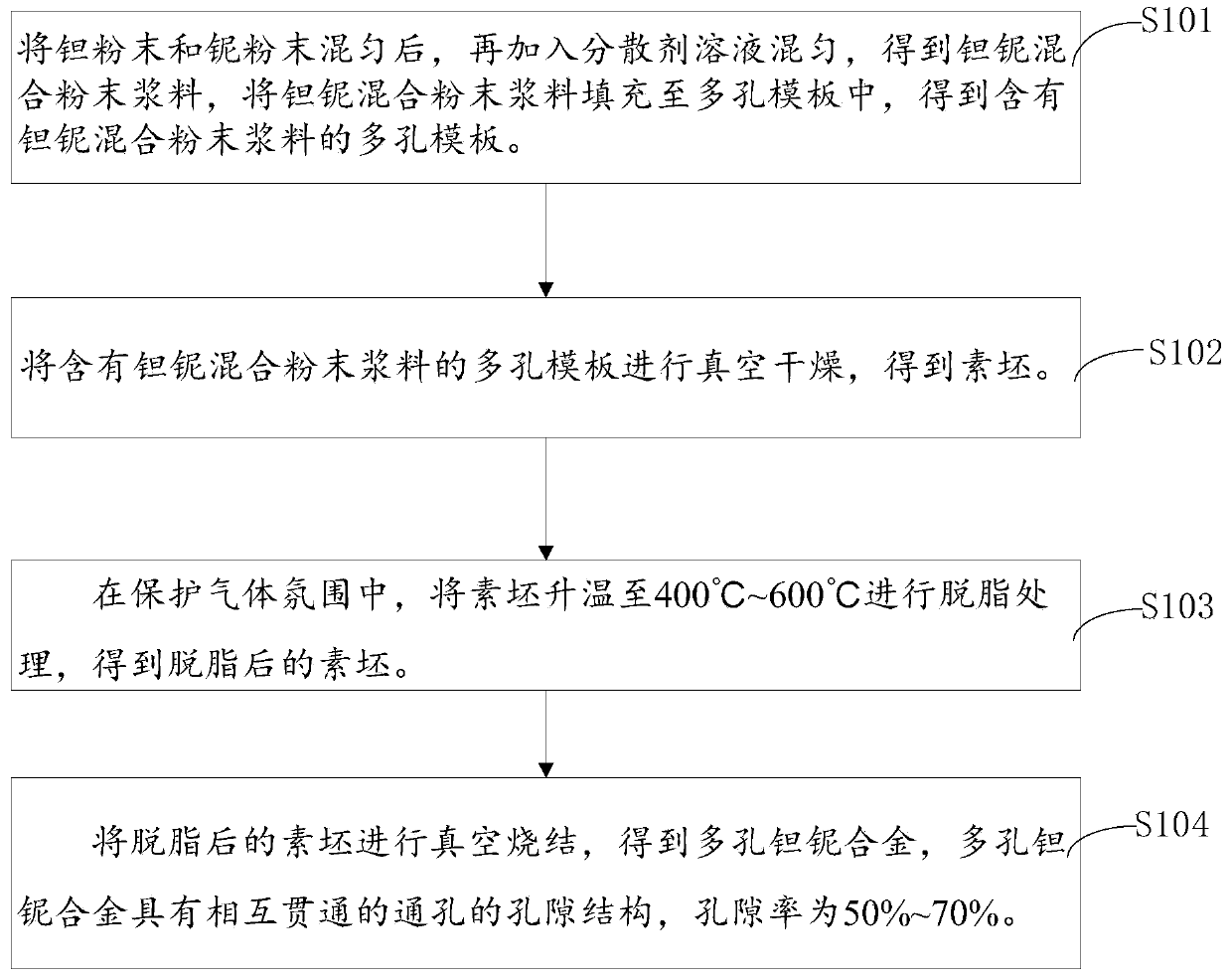

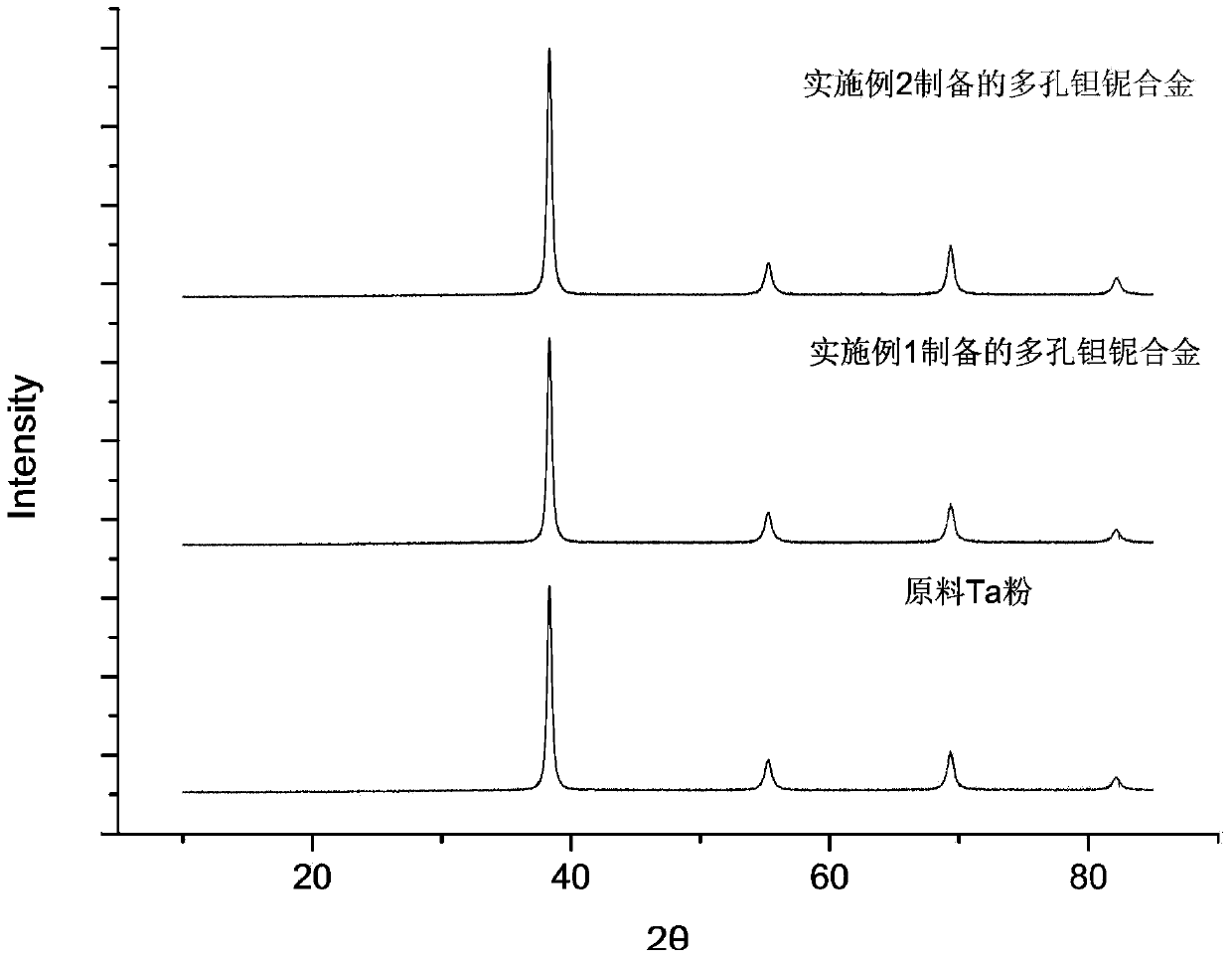

Porous tantalum-niobium alloy and preparation method thereof

The invention provides a porous tantalum-niobium alloy. The porous tantalum-niobium alloy has a pore structure with interconnected through holes. The porosity of the porous tantalum-niobium alloy is 50%-70%. A preparation method of the porous tantalum-niobium alloy comprises the following steps: uniformly mixing tantalum powder and niobium powder, then adding a dispersing agent solution, uniformly mixing so as to obtain tantalum-niobium mixed powder slurry, and filling the tantalum-niobium mixed powder slurry into a porous template, thus obtaining the porous template containing the tantalum-niobium mixed powder slurry; drying the porous template containing the tantalum-niobium mixed powder slurry in vacuum so as to obtain a biscuit; heating the biscuit to 400 DEG C-600 DEG C in a protective gas atmosphere, and carrying out degreasing treatment, thus obtaining the degreased biscuit; and sintering the degreased biscuit in vacuum so as to obtain the porous tantalum-niobium alloy. The porous tantalum-niobium alloy has a three-dimensional connected structure and appropriate porosity, and the elasticity modulus of the material is reduced while the proper strength and porosity are ensured, so that the elasticity modulus is appropriate to that of human bones. The preparation method of the porous tantalum-niobium alloy is simple in process and equipment and low in cost; the porosity of the porous tantalum-niobium alloy is easy to adjust.

Owner:CENT SOUTH UNIV

Method for preparing biological medical porous implant material

ActiveCN102796907AReduce sintering deformationStrong mechanical propertiesTransportation and packagingMetal-working apparatusBiocompatibility TestingSlurry

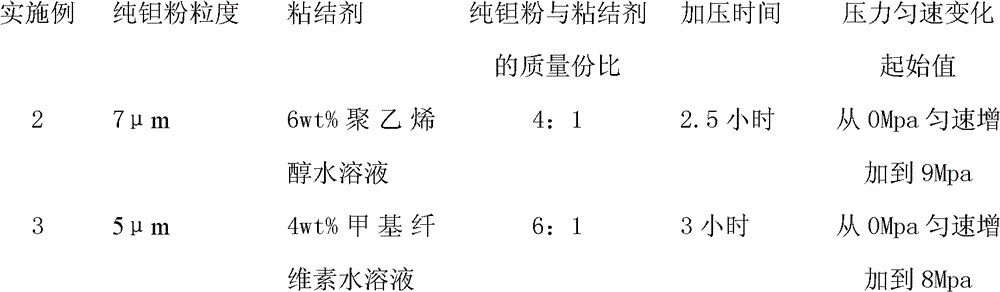

The invention discloses a method for preparing a porous tantalum biological medical implant material. The method comprises the following steps of: uniformly mixing pure tantalum powder and a binding agent to obtain tantalum powder slurry; placing a high polymer resin template support which has the porosity of 20 to 50 percent and of which pores are completely communicated in a three-dimensional way in a steel die; pouring the prepared tantalum powder into the steel die until the high polymer resin template support is immersed; slowly and uniformly applying pressure to the periphery of the steel die to ensure that the tantalum powder can be fully and completely filled into the high polymer resin template support, wherein the applied pressure is increased from 0 Mpa to10 Mpa at constant speed, and the time required by the pressure application process is 2 to 5 hours; performing chemical dissolution to remove the high polymer resin template support to obtain a green body framework of porous tantalum; and performing aftertreatment such as degreasing, sintering and the like to obtain the biological medical porous tantalum implant material. A product prepared by the method is a green body of the porous metal material of which pores are completely communicated in the three-dimensional way, and the green body is sintered to form the porous metal implant material of which the pores are completely communicated in the three-dimensional way, so that the porous metal implant material is high in biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

Porous tantalum used for medical implantation and method for preparing the same

InactiveUS20130011691A1Reduce the presence of impuritiesImprove mechanical propertiesLayered productsMetal-working apparatusNeck structurePorous tantalum

A porous tantalum used for medical implantation is provided, which includes a foam structure with three-dimensional interconnecting pores and produced by: mixing a solution made by organic binder and dispersant and tantalum powder to form tantalum slurry, casting the tantalum slurry into a organic foam body through impregnation until the pores of the organic foam body are filled, drying the impregnated organic foam body with the tantalum slurry to remove the dispersant, degreasing the dried organic foam body to separate the organic binder and the organic foam body from the dried tantalum slurry in a protective environment of inert gas, vacuum sintering the dried tantalum slurry to obtain a porous sintered body, and vacuum annealing then treating the porous sintered body with normal post-treatments to obtain the porous tantalum. Accordingly, the porous tantalum has well-distributed interconnecting pores and sintering neck structures resulting in good mechanical properties, and especially good ductility.

Owner:CHONGQING RUNZE PHARM CO LTD

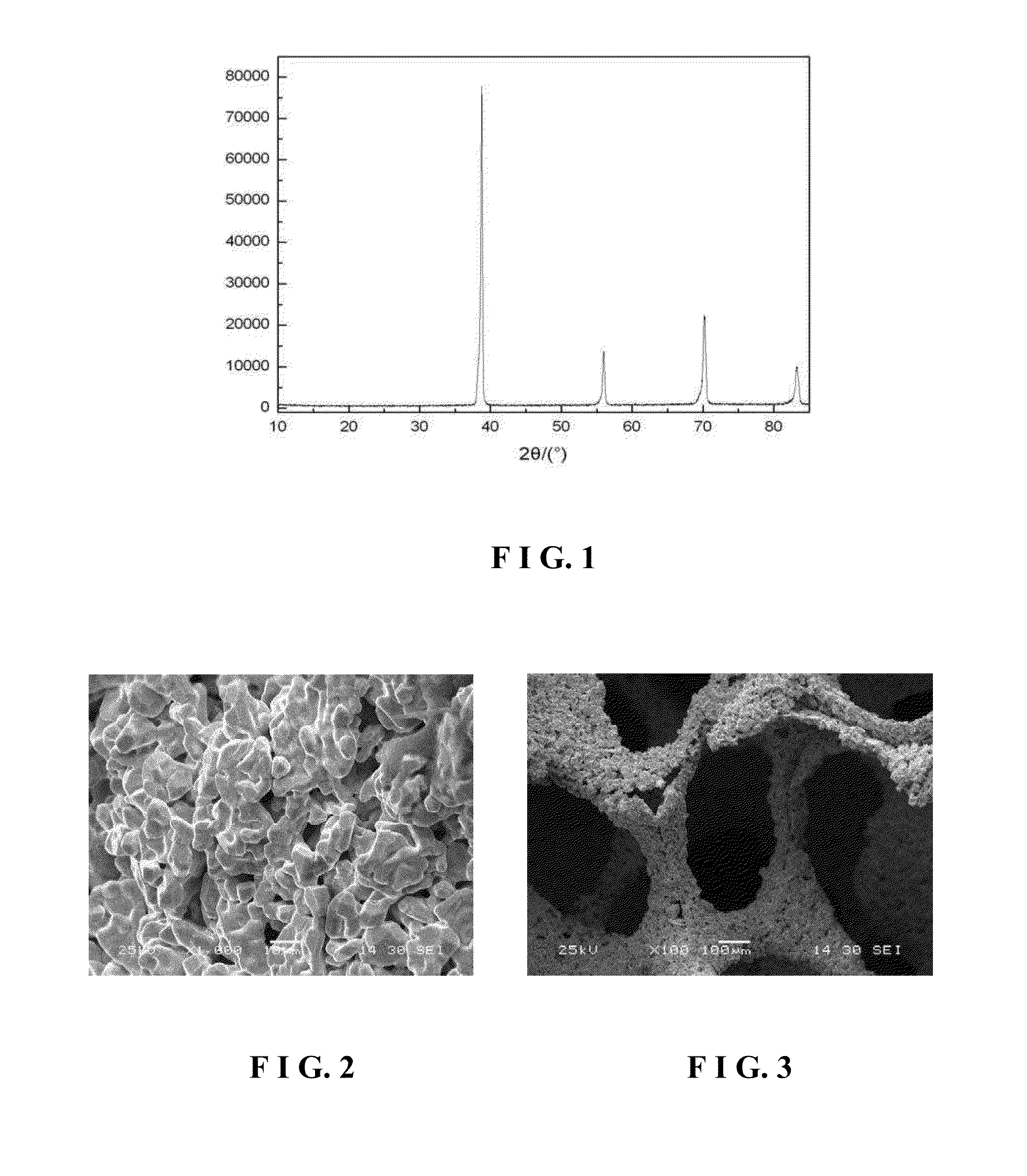

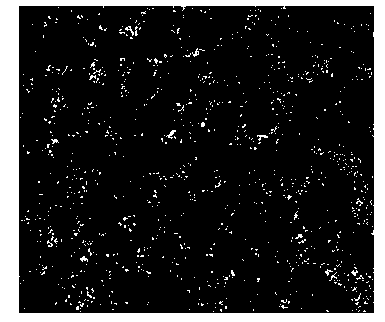

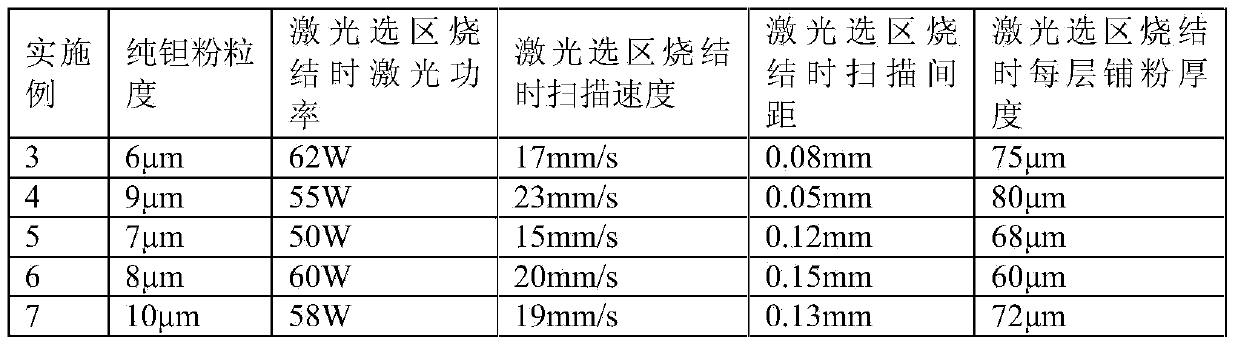

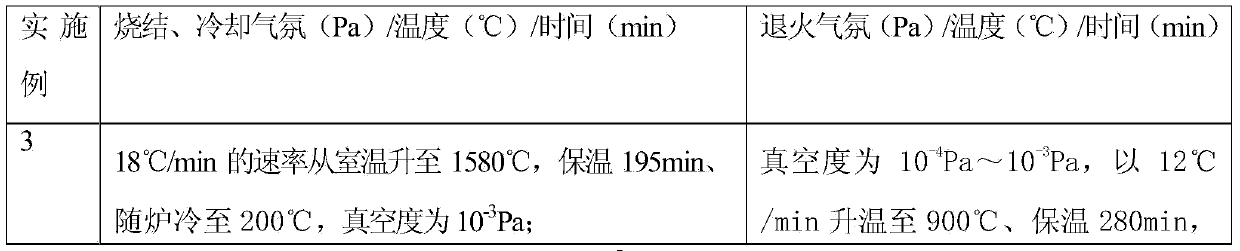

Method for preparing porous tantalum medical implant material by selective laser sintering formation

ActiveCN103740963AGood biocompatibilityHigh biosecurityProsthesisHuman bodySelective laser sintering

The invention relates to a preparation method of a porous tantalum medical implant material. The preparation method comprises the following steps: by adopting pure tantalum powder with the particle size of not more than 10mu m as a raw material, directly performing selective laser sintering formation to form a human bone metal biomimetic material, wherein the thickness of powder spread in each layer during selective laser sintering is 60-80mu m; further sintering and cooling the formed human bone metal biomimetic material to obtain the porous tantalum medical implant material. The porous tantalum medical implant material with complete three-dimensional communication is obtained by sintering and cooling treatment of a formed blank prepared by selective laser sintering, and has a consistent microstructure with a bone tissue of a human body, so that the porous metal implant material has good biocompatibility and biological safety. The method provided by the invention further has the advantages of simple process equipment, low operation cost, no pollution in the whole preparation process, no side effect on a human body, capacity of ensuring the biological safety of the implant material and high forming speed, and is very conductive to industrial production and application.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing porous tantalum medical implant material through selective laser sintering forming

ActiveCN102796910AGood biocompatibilityHigh biosecurityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringSide effect

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps of: directly performing selective laser sintering on pure tantalum powder of which the particle size is less than or equal to 10 mu m and which is used as a raw material to form a human bone metal biomimetic material, wherein the thickness of powder paved on each layer during selective laser sintering is 60 to 80 mu m; and sintering and cooling the human bone metal biomimetic material to obtain the porous tantalum medical implant material. Forming blank prepared by selective laser sintering is sintered and cooled so as to obtain the porous tantalum medical implant material of which pores are completely communicated in a three-dimensional way and the structure is consistent with a microstructure of a bone tissue of a human body; the porous medical implant material is high in biocompatibility and biosecurity; and the method also has the advantages that process equipment is simple, operation cost is low, pollution is avoided in the whole preparation process, the toxic and side effects on the human body can be avoided, the biosecurity of the implant material can be guaranteed, the forming speed is high, and the porous tantalum medical implant material can be industrially produced and applied.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous tantalum parts based on selective laser melting technology

InactiveCN110421172AAdditive manufacturing apparatusIncreasing energy efficiencyPorositySelective laser melting

The invention belongs to the technical field of laser additive manufacturing, and relates to a method for preparing medical porous tantalum parts based on a selective laser melting technology. The preparation method comprises the following steps that spherical tantalum powder prepared through an ultra-high-speed plasma rotating electrode method is selected as a raw material; three-dimensional software is adopted for constructing a to-be-prepared cubic porous structure model, in order to reach the specific porosity, the proper pore size and pore edge size are designed, supports are added, and the model is subjected to two-dimensional slicing and then guided into laser melting molding equipment; and proper laser printing process parameters are selected, the molding process is carried out under an argon protection atmosphere, after the parts are printed, the parts are subjected to vacuum heat treatment together with a substrate, then cutting, cleaning and sand blasting are conducted, andfinally the porous tantalum parts are obtained. Compared with the prior art, according to the method for preparing the porous tantalum parts, by optimizing the porous structure model and the laser printing process parameters, the prepared porous tantalum has good mechanical properties and is better matched with human sclerotin.

Owner:XIAN CONTINENTAL BIOMATERIALS CO LTD

Method for bonding a tantalum structure to a cobalt-alloy substrate

Methods for bonding a porous tantalum structure to a substrate are provided. The method includes placing a compressible or porous interlayer between a porous tantalum structure and a cobalt or cobalt-chromium substrate to form an assembly. The interlayer comprising a metal or metal alloy that has solid state solubility with both the substrate and the porous tantalum structure. Heat and pressure are applied to the assembly to achieve solid state diffusion between the substrate and the interlayer and the between the porous tantalum structure and the interlayer.

Owner:ZIMMER INC

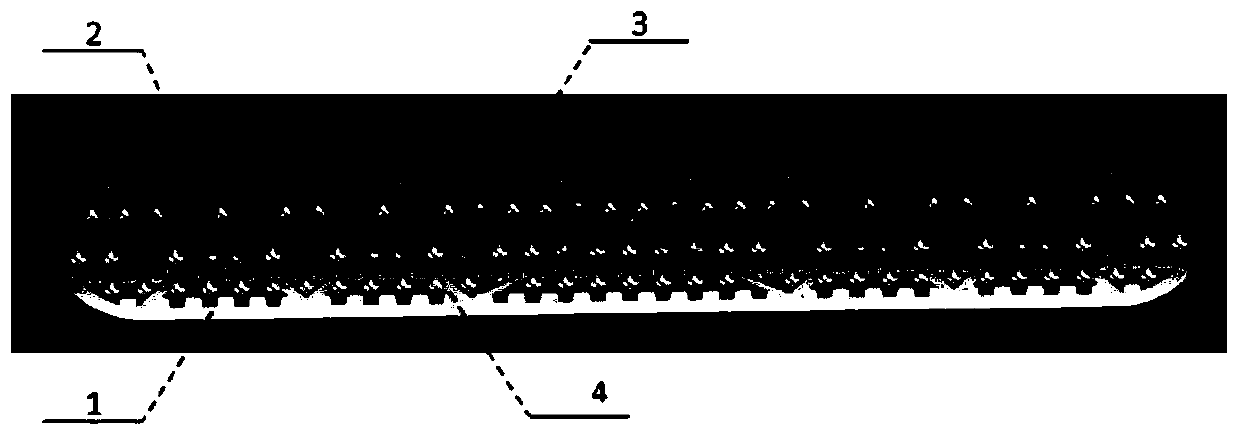

3D-printed porous tantalum metal bone plate

ActiveCN109793565AAids in healingAvoid stress shieldingAdditive manufacturing apparatusBone platesOsseointegrationBone growth

The invention relates to a 3D-printed porous tantalum metal bone plate. The 3D-printed porous tantalum metal bone plate is characterized in that tantalum metal powder is taken as a base material, andthe bone-imitating trabecular bone plate having bone induction property and produced by 3D printing has an interconnecting-pore structure fit for bone growth. The production method includes: under argon production, using medical grade spherical tantalum powder as a raw material to produce the porous bone plate by 3D printing; removing excess metal powder adhering to the surface of the bone plate through sandblasting; removing residual stress through heat treatment to make the surface of the bone plate smooth. By the arrangement, the porous bone plate with the bone induction property can form excellent bone integration with bone tissue so as to achieve permanent fixation in biology.

Owner:赵德伟 +2

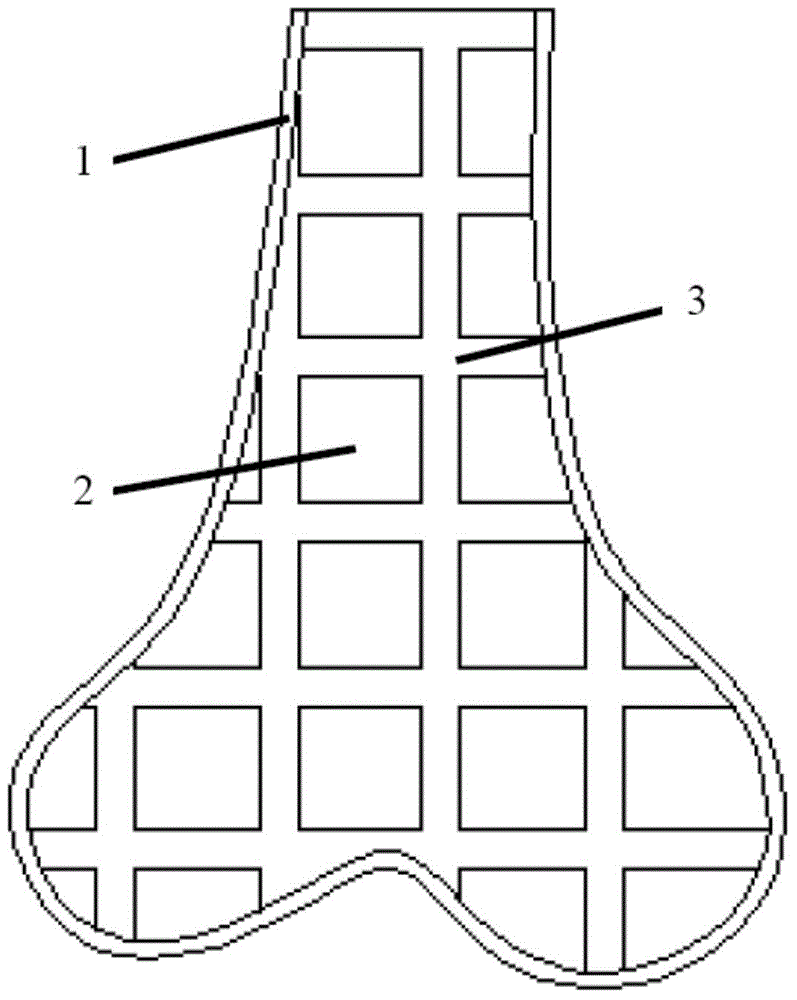

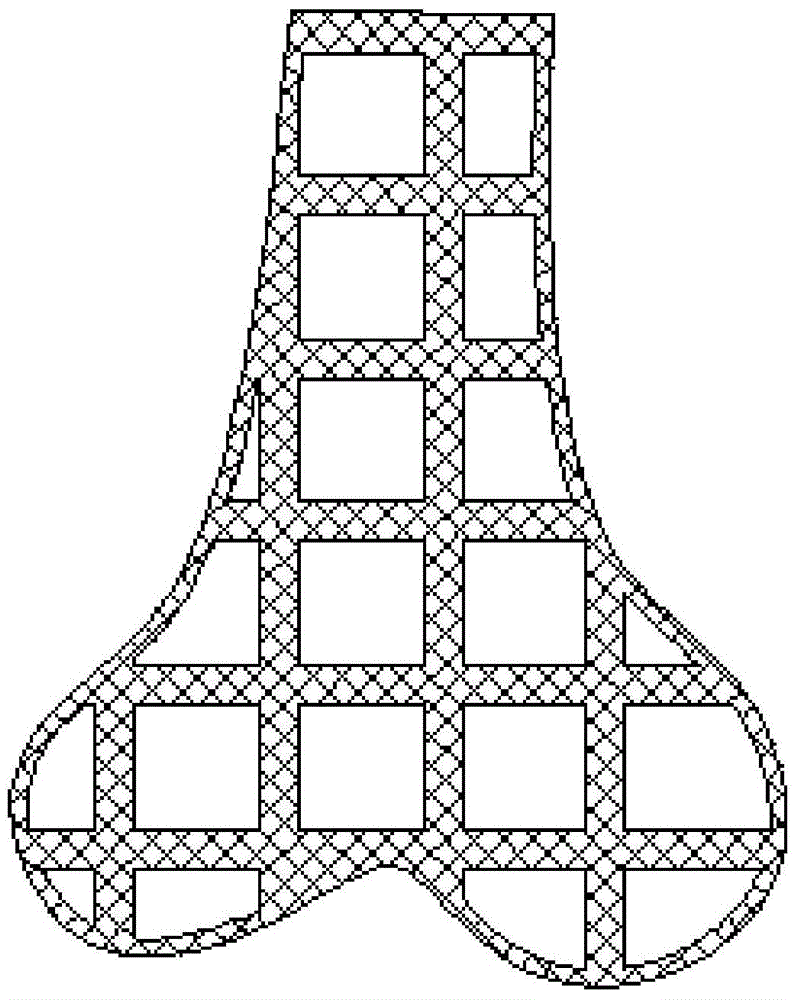

Customized porous tantalum implant and preparation method thereof

The invention discloses a customized porous tantalum implant and a preparation method thereof. The preparation method comprises the following steps: firstly, adopting CT or MRI scanning to obtain a multiplanar reconstruction image of a natural bone, designing the appearance of a customized implant, shelling the customized implant, and designing net racks in a shell; manufacturing prototypes of the thin shell and the net racks by a rapid prototyping machine; uniformly mixing tantalum powder and pellets capable of burning loss to obtain a mixture, adding the mixture in a dispersant to prepare mixed slurry of the powder and the pellets, filling a prototype stent with the mixed slurry, performing vacuum drying to obtain a green body, carrying out low-temperature sintering and skimming in protecting gas at the temperature of 1,000-1,200 DEG C to obtain low-strength porous tantalum body, and performing low-temperature sintering and skimming in the protecting gas at the temperature of 1,800-2,500 DEG C to obtain the final customized porous tantalum implant. The net racks and the pellets can form communicated main pipelines and communicated spherical holes, and the main pipelines can prevent passages from blockage, so that nutriment conveying is facilitated, the spherical holes are beneficial to bone cell adhesion and growth, and the elasticity modulus of the implant is equivalent to that of that of the human bone.

Owner:宁波创导三维医疗科技有限公司 +1

Medical metal implant material porous niobium and preparation method thereof

A porous niobium used as medical implant material is of a foam structure with three dimensional interconnecting pores. There is a sintering neck structure between the niobium particles. The method for preparing the porous niobium comprises the steps of using the niobium powder and the solution prepared by mixing an organic binder and a dispersant to obtain the niobium slurry, casting the niobium slurry into an organic foam body to immerse until the pores of the organic foam body are full of the niobium slurry, drying to remove the dispersant in the organic foam body in which the niobium slurry is cast, degreasing to remove the organic binder and the organic foam body in the protective environment of inert gas, and then vacuum sintering to obtain the porous sintered body. The porous niobium is of high porosity and good ductility.

Owner:CHONGQING RUNZE PHARM CO LTD

Porous tantalum rod and application of porous tantalum rod

The invention relates to a medical permanent implantation object, in particular to a medical implantation porous tantalum rod used for treating early-mid femoral head necrosis. The porous tantalum rod comprises a body, wherein one end of the body is provided with a groove, the other end of the body is provided with a threaded structure, and a notch is formed in the end surface of the tail end of the threaded structure. One end of the body of the porous tantalum rod is provided with the notch, bone marrow stromal cells or bone marrow stromal cell united biological membrane complexes and the like can be loaded, the generation of a new bone is favorably realized, a better clinical effect is particularly realized in the early femoral head necrosis treatment, and the defects of poor clinical treatment effect and the like of the existing entity type porous tantalum rod are overcome. The porous tantalum rod has the advantages that the preparation method is simple, the cost is low, the implementation and the clinical application are favorably realized, and the porous tantalum rod is suitable for the need of wide patients.

Owner:伟坦(大连)生物材料有限公司

Dental implant prosthetic device with improved osseointegration and esthetic features

Dental implants made at least in part of a porous tantalum material for enhancing the osseointegration of the dental implant into surrounding bone. For example, there is provided a dental implant which includes a porous tantalum portion and an outer portion having a color generally replicating the color of natural teeth. The dental implant further comprises a core portion and the porous tantalum portion at least partially surrounds the core portion. An esthetic portion is disposed at least the outer portion and the porous tantalum portion is disposed for at least partially reinforcing the esthetic portion. After implantation of the implant, bone tissue may osseointegrate into the porous tantalum portion to anchor the implant in position within the surrounding bone. Other embodiments of implants are provided, each implant including at least a portion thereof formed of porous tantalum for improved osseointegration.

Owner:ZIMMER DENTAL INC

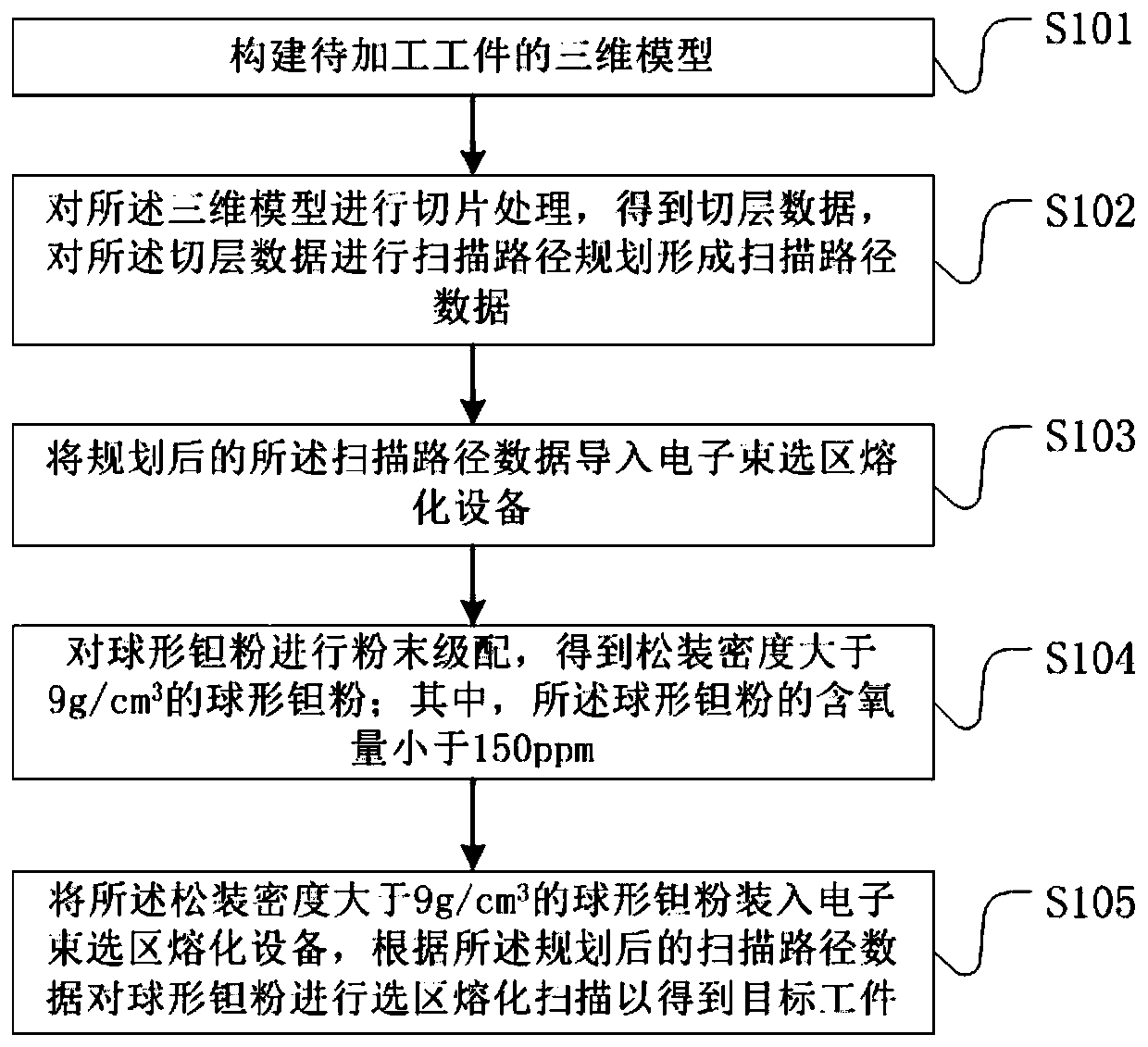

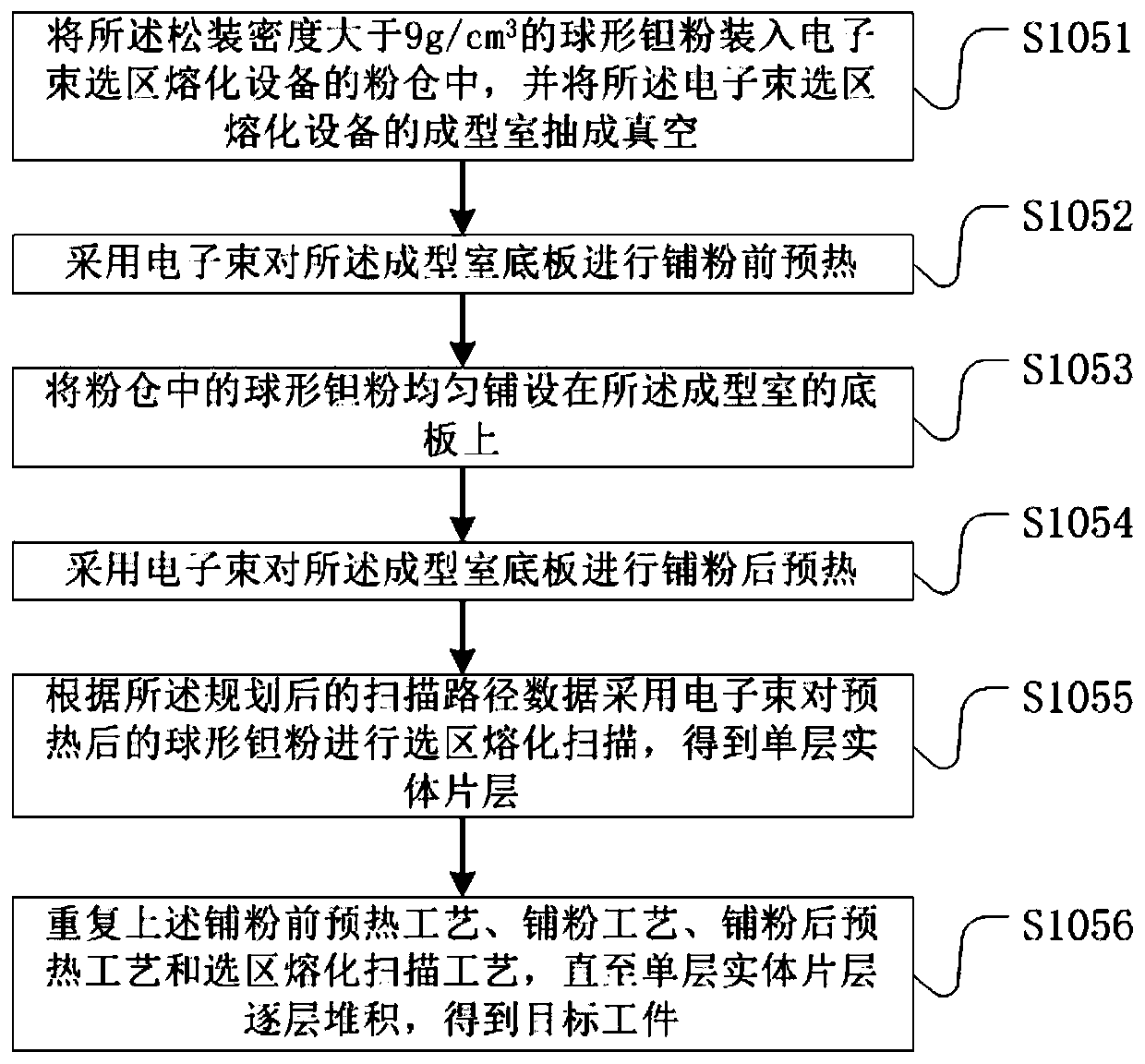

Porous tantalum implant and method for preparing porous tantalum additive

InactiveCN110340359ALow oxygenImprove biostabilityAdditive manufacturing apparatusIncreasing energy efficiencyApparent densityPorous tantalum

The embodiment of invention relates to a method for preparing a porous tantalum additive. The method for preparing the porous tantalum additive comprises the following steps that a three-dimensional model of a to-be-machined workpiece is constructed; slicing treatment is conducted on the three-dimensional model and sliced layer data are acquired, scanning path planning is conducted on the sliced layer data, and scanning path data are formed; the scanning path data are imported into electron beam selective melting equipment; powder grading is conducted on spherical tantalum powder, and spherical tantalum powder with apparent density greater than 9g / cm<3> is acquired; the oxygen content of the spherical tantalum powder is less than 150 ppm; and spherical tantalum powder with apparent densitygreater than 9g / cm<3> is loaded into the electron beam selective melting equipment, selective melting scanning is conducted on spherical tantalum powder according to the scanning path data, and a target workpiece is acquired. According to the method for preparing the porous tantalum additive disclosed by the embodiment of the invention, on the one hand, working procedures are simple, follow-up treatment is not needed, secondary pollution is avoided, and moreover, biological stability of the porous tantalum additive as a human body implant is high in long-term use; and on the other hand, porous tantalum prepared with the method is low in oxygen content, light in weight and high in compression strength and has outstanding plasticity.

Owner:西安赛隆增材技术股份有限公司 +1

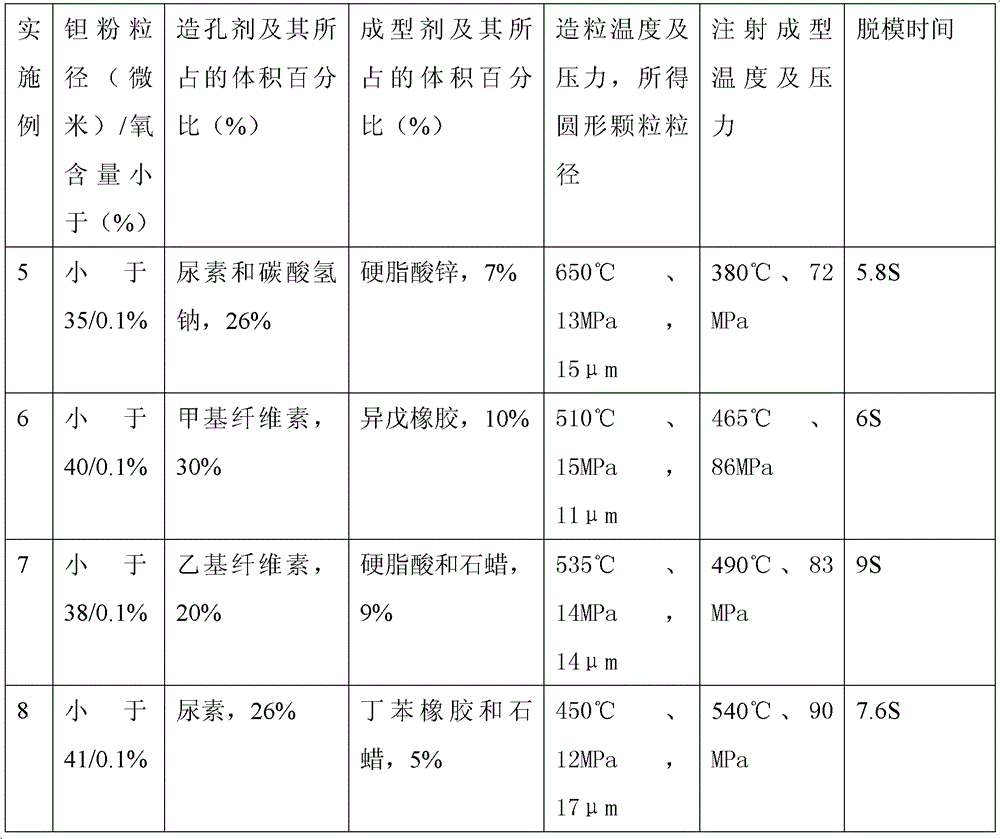

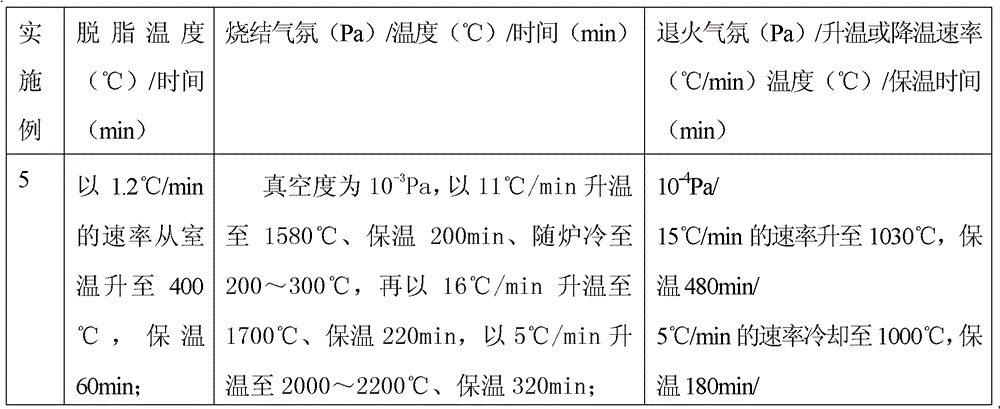

Preparation method of porous tantalum applicable to replacing human dentale tissue

ActiveCN102796893AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePorous tantalum

The invention provides a preparation method of porous tantalum applicable to replacing human dentale tissue. The preparation method comprises the following steps of: mixing tantalum powder, pore-forming agent and forming agent to form into mixed powder, pelleting, injecting into a mould to be formed, demoulding, degreasing, sintering and carrying out thermal treatment, wherein the pore-forming agent is one kind or several kinds of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethocel; the forming agent is one kind or several kinds of poval, stearic acid, zinc stearate, paraffins and synthetic rubber; the degreasing process comprises the following steps of: gradually heating up to 400-800 DEG C at the speed of the 0.5-3DEG C / min, forming the protective atmosphere by charging argon, and keeping the temperature for 60-240min; and the sintering step comprises the following steps of: heating up to 1500-1800 DEG C at the speed of 10-20 DEG C / min under the vacuum degree of 10<-4>-10<-3>Pa, keeping the temperature for 120-240min, cooling to 200-300DEG C along with a furnace, heating up to 1500-1800 DEG C at the speed of 10-20 DEG C / min, keeping the temperature for 180-240min, heating up to 2000-2200 DEG C at the speed of 5-10 DEG C / min, and keeping the temperature for 120-360min. The prepared porous tantalum is very applicable to the medical implant material capable of replacing the human dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

Non solid electrolyte all tantalum capacitor and preparation thereof

ActiveCN101339849AImproved back pressure capabilityIncrease capacityCapacitor electrolytes/absorbentsCapacitor housing/encapsulationTantalum capacitorPorous tantalum

The invention discloses a non-solid electrolyte all-tantalum capacitor and a preparation method thereof. The non-solid electrolyte all-tantalum capacitor comprises an enclosure, a cathode strip, an anode strip, a cathode lead, an anode lead and a gland, wherein, the cathode strip and the anode strip are arranged inside the enclosure; the cathode lead is connected with the cathode strip by penetrating the gland; the anode lead is connected with the anode strip by penetrating the gland; a porous tantalum core cathode strip produced by the pressing and sintering of tantalum metal powder is adopted, the two sides of the anode strip and / or the cathode strip are attached with a metal oxide film medium TaO5 for insulation and back pressure resistance; the cathode strip and the anode strip are of sandwich structure in which two layers of cathode strips clamp one layer of anode strip, an isolating and insulating layer is arranged between the anode strip and the cathode strip; the cathode strip consists of porous tantalum cores and the metal oxide film medium as the insulating layer can also be attached to the cathode strip; and the structures of the enclosure, the gland and the like of the capacitor are composed of tantalum material; The non-solid electrolyte is filled around the anode strip and the cathode strip as well as in the porous tantalum core pores of the anode strip and the cathode strip, thus the non-solid electrolyte all-tantalum capacitor is formed.

Owner:ZHUZHOU HONGDA ELECTRONICS

Method for preparing medical porous tantalum with three-dimensional reticular graphite foam or reticular vitreous carbon

InactiveCN103088310AGood biocompatibilityReduce weightChemical vapor deposition coatingPorous tantalumGas phase

The invention relates to a method for preparing medical porous tantalum with three-dimensional reticular graphite foam or reticular vitreous carbon, which has the advantages of uniform coating, no residual particles, good biocompatibility, and convenience for manufacture in later period. The technical scheme of the method is as follows: the method comprises the following steps of (1) preparing a template and a tantalum source, wherein the template is the three-dimensional reticular graphite foam or the reticular vitreous carbon, and the tantalum source is tantalum pentafluoride, tantalum pentachloride or tantalum ethoxide; and (2) placing the three-dimensional reticular graphite foam or reticular vitreous carbon template in a vapor deposition furnace for reaction by a vapor deposition method, so as to prepare the finish product.

Owner:QINGDAO ADVANCED GRAPHITE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com