Porous tantalum-niobium alloy and preparation method thereof

A niobium alloy and porous tantalum technology, applied in medical science, prosthesis, etc., can solve the problems of large elastic modulus, stress shielding, high density, etc., and achieve the effect of easy porosity, lower raw material cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

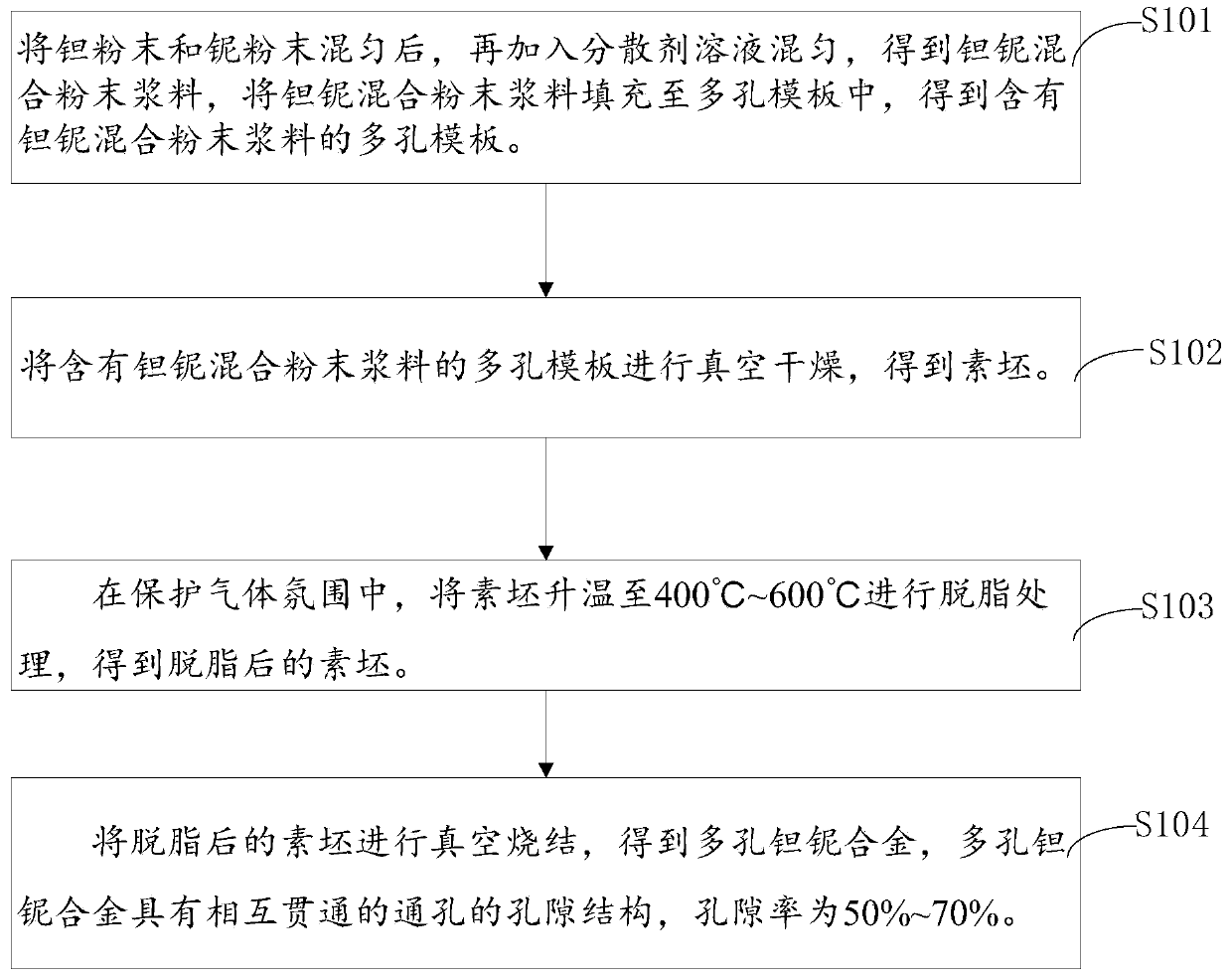

[0034] see figure 1 , the preparation method of the porous tantalum-niobium alloy of an embodiment, comprises the following steps:

[0035] Step S101: After mixing the tantalum powder and the niobium powder, adding a dispersant solution and mixing to obtain a tantalum-niobium mixed powder slurry, filling the tantalum-niobium mixed powder slurry into a porous template to obtain a tantalum-niobium mixed powder slurry porous template.

[0036] After mixing the tantalum powder and niobium powder, add the dispersant solution and mix evenly to keep the tantalum powder and niobium powder mixed evenly, which will help the subsequently formed tantalum-niobium mixed powder slurry to be smoothly filled into the porous template. Using water as a solvent to prepare the dispersant into a dispersant solution, adding the cooled dispersant solution into the tantalum-niobium alloy powder and stirring evenly to form a stable suspension to obtain a tantalum-niobium mixed powder slurry. Put the ...

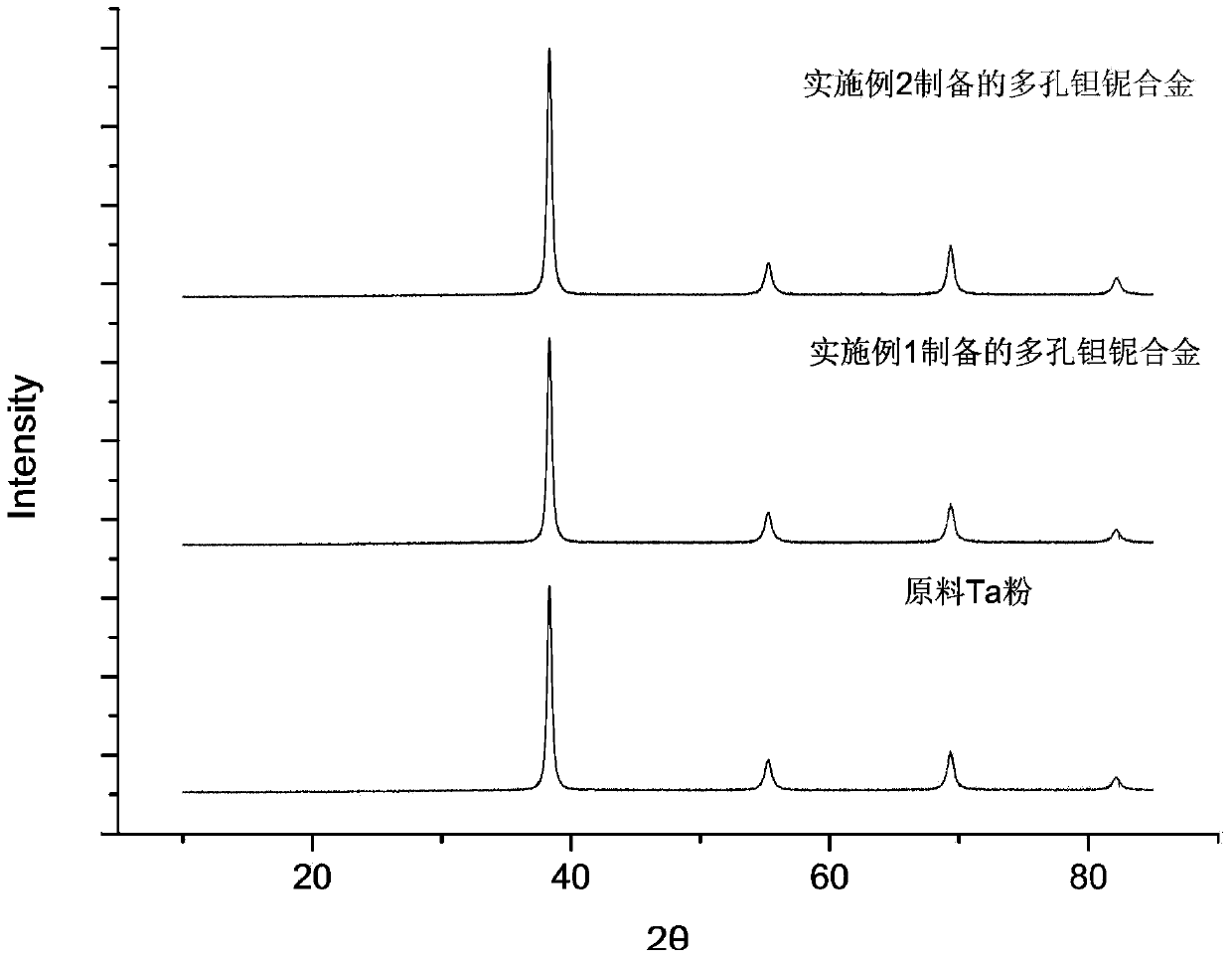

Embodiment 1

[0059] 1. Weigh 6g of polyvinyl alcohol, put it into a beaker with 100ml of deionized water, add an appropriate amount of distilled water to the mark, put the beaker into a water bath, heat it in a water bath and stir evenly to make it an aqueous solution of polyvinyl alcohol. According to the weight ratio of tantalum powder and niobium powder of 9:1, use a balance to weigh 45g of tantalum powder and 5g of niobium powder respectively. The particle size of tantalum powder and niobium powder is 10μm, the oxygen content is less than 0.1%, and the carbon content is less than 0.02%. . Add the uniformly mixed tantalum powder and niobium powder into an aqueous solution of 7 g of polyvinyl alcohol, stir and mix uniformly to obtain a tantalum-niobium mixed powder slurry. select A 10×25mm porous polyurethane foam is put into it for dipping until the pores of the polyurethane foam are filled with the tantalum-niobium mixed powder slurry, and the polyurethane foam filled with the tantal...

Embodiment 2

[0066] 1. Weigh 5g of polyvinyl alcohol, put it into a beaker with 100ml of deionized water, add an appropriate amount of distilled water to the mark, put the beaker into a water bath, heat it in a water bath and stir evenly to make it an aqueous solution of polyvinyl alcohol. According to the weight ratio of tantalum powder and niobium powder of 3:1, weigh 60g of tantalum powder and 20g of niobium powder respectively with a balance. The particle size of tantalum powder and niobium powder is 30μm, the oxygen content is less than 0.1%, and the carbon content is less than 0.02%. Add the uniformly mixed tantalum powder and niobium powder into an aqueous solution of 10 g of polyvinyl alcohol, stir and mix uniformly to obtain a tantalum-niobium mixed powder slurry. Select a porous polyurethane foam of 10×10×30mm and put it into it for dipping until the pores of the polyurethane foam are filled with the tantalum-niobium mixed powder slurry, and put the polyurethane foam filled with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com