Implant porous niobium-titanium alloy material for medical use and preparation method of alloy material

A titanium alloy and porous niobium technology, which is applied to the medical implantation porous niobium-titanium alloy material and its preparation, and the porous niobium-titanium alloy material and its preparation field, can solve the problem of large elastic modulus, high sintering temperature of niobium stent, stress shielding, etc. problem, to achieve the effect of high porosity, moderate hardness and lower elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

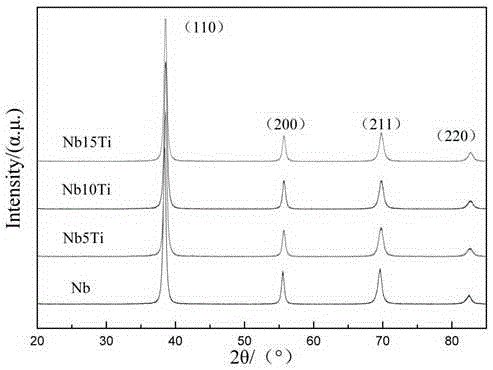

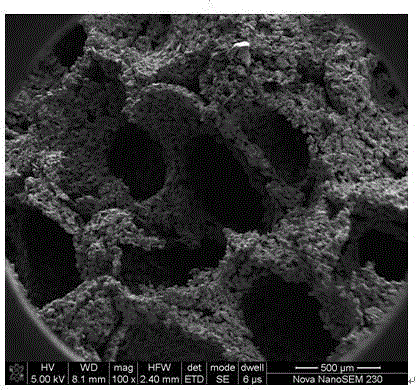

Embodiment 1

[0051] 1. Weigh 6g of polyvinyl alcohol, put it into a beaker with 100ml of deionized water, add an appropriate amount of distilled water to the mark, put the beaker into a water bath, heat it in a water bath and stir evenly to make it an aqueous solution of polyvinyl alcohol. According to the weight ratio of niobium powder and titanium powder of 9:1, weigh 45g of niobium powder and 5g of titanium powder with a balance, the oxygen content is less than 0.1%, and the carbon content is less than 0.02%, and the niobium powder and titanium powder are ball milled to obtain niobium titanium For the composite powder, add the niobium-titanium composite powder into an aqueous solution of 7 g of polyvinyl alcohol, stir and mix evenly to obtain a niobium-titanium mixed powder slurry. select φ A 10×25mm porous polyurethane foam is put into it for dipping until the pores of the polyurethane foam are filled with the niobium-titanium mixed powder slurry, and the polyurethane foam filled with...

Embodiment 2

[0058] 1. Weigh 5g of polyvinyl alcohol, put it into a beaker with 100ml of deionized water, add an appropriate amount of distilled water to the mark, put the beaker into a water bath, heat it in a water bath and stir evenly to make it an aqueous solution of polyvinyl alcohol. According to the proportion of niobium powder and titanium powder weight ratio of 3:1, weigh 60g niobium powder and 20g titanium powder respectively with a balance, the oxygen content is less than 0.1%, and the carbon content is less than 0.02%. After the niobium powder and titanium powder are ball milled, niobium powder is obtained. For the titanium composite powder, add the niobium-titanium composite powder into an aqueous solution of 10 g of polyvinyl alcohol, stir and mix evenly to obtain a niobium-titanium composite powder slurry. Select a porous polyurethane foam of 10×10×30mm and put it into it for impregnation until the pores of the polyurethane foam are filled with the niobium-titanium mixed powd...

Embodiment 3

[0065] 1. Weigh 3g of polyvinyl alcohol, put it into a beaker with 100ml of deionized water, add an appropriate amount of distilled water to the mark, put the beaker into a water bath, heat it in a water bath and stir evenly to make it an aqueous solution of polyvinyl alcohol. According to the weight ratio of niobium powder and titanium powder of 1:1, weigh 50g of niobium powder and 50g of titanium powder with a balance, the oxygen content is less than 0.1%, and the carbon content is less than 0.02%. After the niobium powder and titanium powder are ball milled, niobium powder is obtained. Titanium composite powder, adding the niobium-titanium composite powder into an aqueous solution of 14 g of polyvinyl alcohol, stirring and mixing evenly to obtain a niobium-titanium composite powder slurry. select φ A 10×25mm porous polyurethane foam is put into it for dipping until the pores of the polyurethane foam are filled with the niobium-titanium mixed powder slurry, and the polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com