Preparation method of pore-controllable porous nickel-titanium shape memory alloy

A memory alloy, nickel-titanium alloy technology, applied in medical science, prosthesis, etc., can solve the problems of uneven pore distribution, low porosity, and difficult to control the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

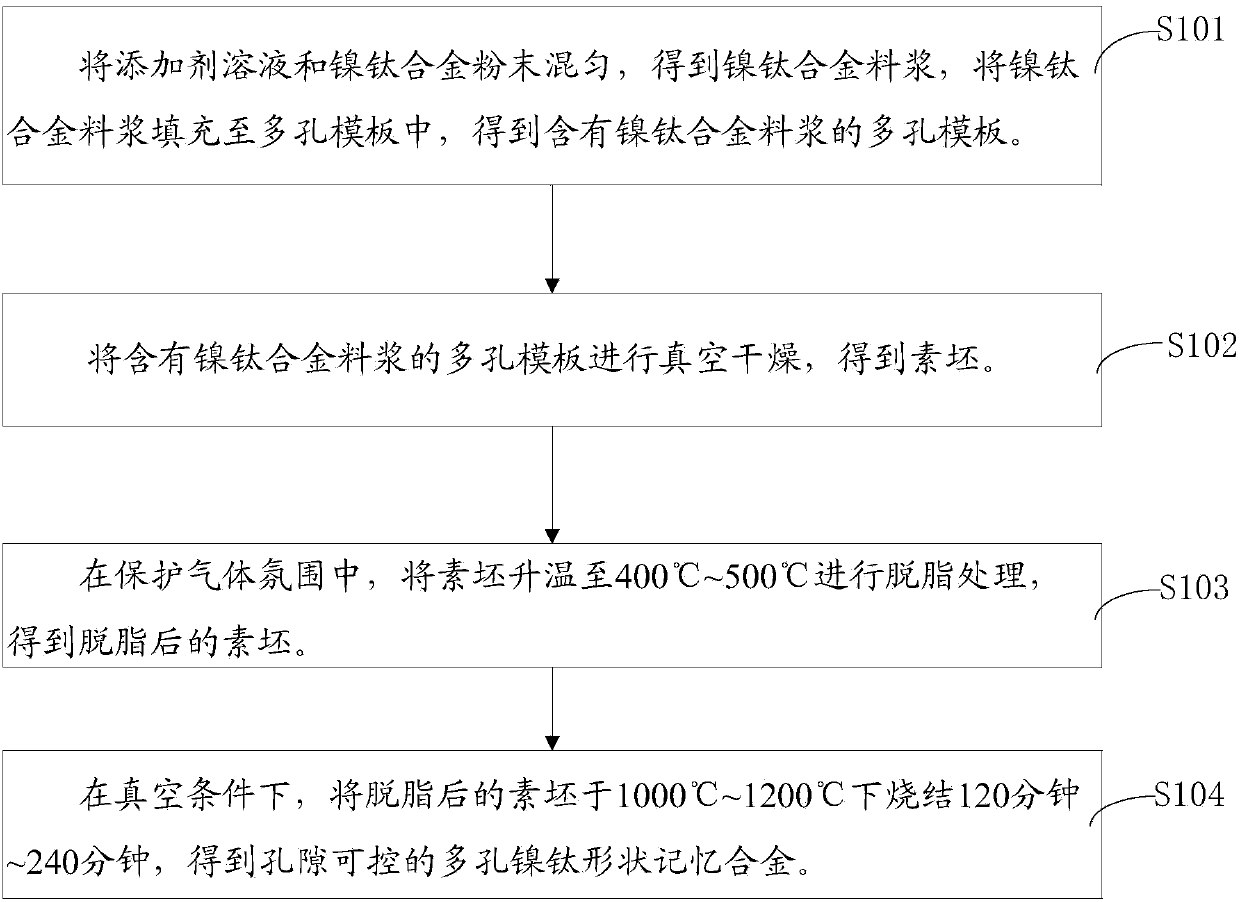

[0030] see figure 1 A method for preparing a porous nickel-titanium shape memory alloy with controllable pores in one embodiment, comprising the following steps:

[0031] Step S101: mixing the additive solution and the nickel-titanium alloy powder to obtain a nickel-titanium alloy slurry, filling the nickel-titanium alloy slurry into a porous template to obtain a porous template containing the nickel-titanium alloy slurry.

[0032] The additive is configured into an additive solution with water or ethanol as a solvent, and the cooled additive solution is added into the nickel-titanium alloy powder and stirred evenly to form a stable suspension to obtain a nickel-titanium alloy slurry. The porous template is immersed in the nickel-titanium alloy slurry until the pores of the porous template are completely filled, and any inclusions are avoided during dipping.

[0033] The porous template is used as a carrier to make the pores of the nickel-titanium alloy uniformly distributed,...

Embodiment 1

[0051] 1. Weigh 3g of methylcellulose, put it into a glass, add enough distilled water, heat it on an electric stove and stir evenly to prepare 100mL of methylcellulose aqueous solution. Weigh 40g of nickel-titanium alloy powder, the atomic ratio of Ni atoms to Ti atoms in the nickel-titanium alloy powder is 1:1, and the particle size is 15 μm. Add the nickel-titanium alloy powder to 10 g of methyl cellulose aqueous solution, and mix evenly by hand. To make it into a nickel-titanium alloy slurry, select a polymer bracket with a pore size of 0.8mm and a size of φ12×25mm and dip it in it until the polyurethane foam no longer absorbs the nickel-titanium alloy slurry, scrape off the excess nickel-titanium alloy material on the surface slurry to obtain polyurethane foam containing the nickel-titanium alloy slurry, and clamp the polyurethane foam containing the nickel-titanium alloy slurry into a porcelain plate.

[0052] 2. Place the porcelain plate containing the polyurethane foam...

Embodiment 2

[0061] 1. Weigh 5g of methyl cellulose, put it into a glass, add enough distilled water, heat it on an electric stove and stir evenly to prepare 100mL of methyl cellulose aqueous solution. Weigh 30g of nickel-titanium alloy powder, the atomic ratio of Ni atoms to Ti atoms in the nickel-titanium alloy powder is 1:1, and the particle size is 25μm, add 10g of methyl cellulose aqueous solution, stir and mix evenly by hand to make it into nickel For the titanium alloy slurry, polyurethane foam with a pore size of 1.0mm and a size of 15×15×35mm was used to impregnate it until the polyurethane foam no longer absorbed the nickel-titanium alloy slurry, and the excess nickel-titanium alloy slurry was scraped off the surface to obtain For the polyurethane foam of the nickel-titanium alloy slurry, the polyurethane foam containing the nickel-titanium alloy slurry is taken out with a clip and put into a porcelain plate.

[0062] 2. Place the porcelain plate containing the polyurethane foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com