Method for preparing porous nickel-based amorphous alloy material

A technology of amorphous alloy and porous nickel, which is applied in the field of preparation of porous nickel-based amorphous alloy materials, can solve the problem that the amorphous alloy material must be loaded on the carrier, the uniform dispersion is difficult to achieve, and the catalytic performance cannot be satisfied. and other problems, to achieve the effect of simple and easy method, controllable porosity ratio and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

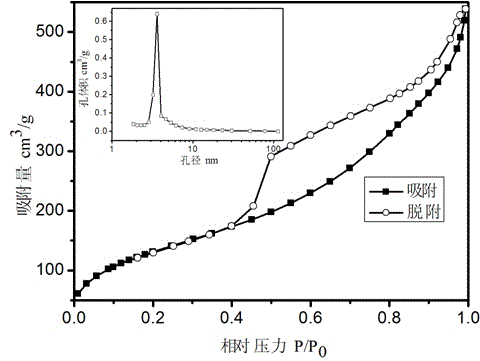

Image

Examples

Embodiment 1

[0027] Weigh 0.02mol NiSO 4 ·6H 2 O and 0.005mol CaCl 2 Dissolve in 25mL distilled water successively, stir well to obtain solution A; then weigh 0.006mol Na 2 CO 3 and 0.05mol KBH 4 Dissolve in 40mL distilled water successively, then weigh 0.008mol NaOH to adjust the pH value of the solution to be higher than 12, stir evenly to obtain solution B; place solution A in an ice-water bath, and start rapid stirring, slowly add solution B dropwise to solution A During the reaction, the reaction proceeds immediately and a large number of bubbles are generated. After the dropwise addition is completed, the reaction is continued for 5 to 10 minutes. When almost no gas is generated, the suspension obtained from the reaction is quickly filtered under reduced pressure under suction conditions, and the filter cake is washed with distilled water. to neutral, then wash the filter cake 6 times with 50mL HCl solution with a concentration of 0.05mol / L, basically no bubbles are generated, th...

Embodiment 2

[0029] Weigh 0.02mol NiSO 4 ·6H 2 O and 0.008mol CaCl 2 Dissolve in 25mL distilled water successively, stir well to obtain solution A; then weigh 0.01mol Na 2 CO 3 and 0.05mol KBH 4 Dissolve in 40mL distilled water successively, then weigh 0.008mol NaOH to adjust the pH value of the solution to be higher than 12, stir evenly to obtain solution B; place solution A in an ice-water bath, and start rapid stirring, slowly add solution B dropwise to solution A , the reaction proceeds immediately and a large number of bubbles are generated at the same time. After the dropwise addition is completed, the reaction is continued for 5 to 10 minutes. When almost no gas is generated, the suspension obtained from the reaction is quickly filtered under reduced pressure under suction conditions, and the filter cake is washed with distilled water until Neutral, then wash the filter cake with 80mL of 0.05mol / L HCl solution for 6 times, basically no bubbles, then wash with distilled water unt...

Embodiment 3

[0031] Weigh 0.02mol NiSO 4 ·6H 2 O and 0.002mol CaCl 2 Dissolve in 25mL distilled water successively, stir well to obtain solution A; then weigh 0.002mol Na 2 CO 3 and 0.05mol KBH 4Dissolve in 40mL distilled water successively, then weigh 0.008mol NaOH to adjust the pH value of the solution to be higher than 12, stir evenly to obtain solution B; place solution A in an ice-water bath, and start rapid stirring, slowly add solution B dropwise to solution A , the reaction proceeds immediately and a large number of bubbles are generated at the same time. After the dropwise addition is completed, the reaction is continued for 5 to 10 minutes. When almost no gas is generated, the suspension obtained from the reaction is quickly filtered under reduced pressure under suction conditions, and the filter cake is washed with distilled water until Neutral, then wash the filter cake with 25mL of 0.05mol / L HCl solution for 6 times, almost no bubbles, then wash with distilled water until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com