Patents

Literature

116results about How to "Aperture size controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

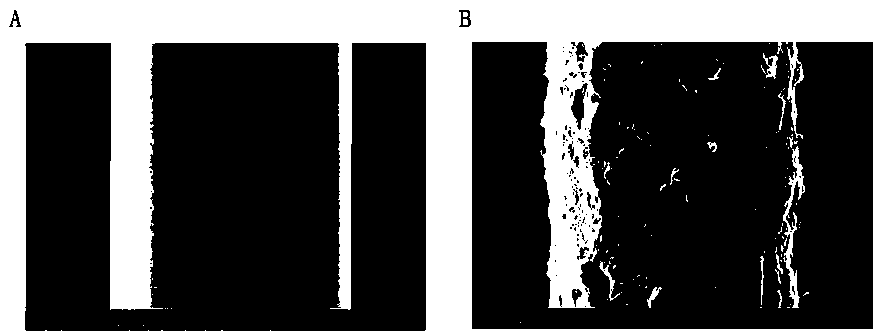

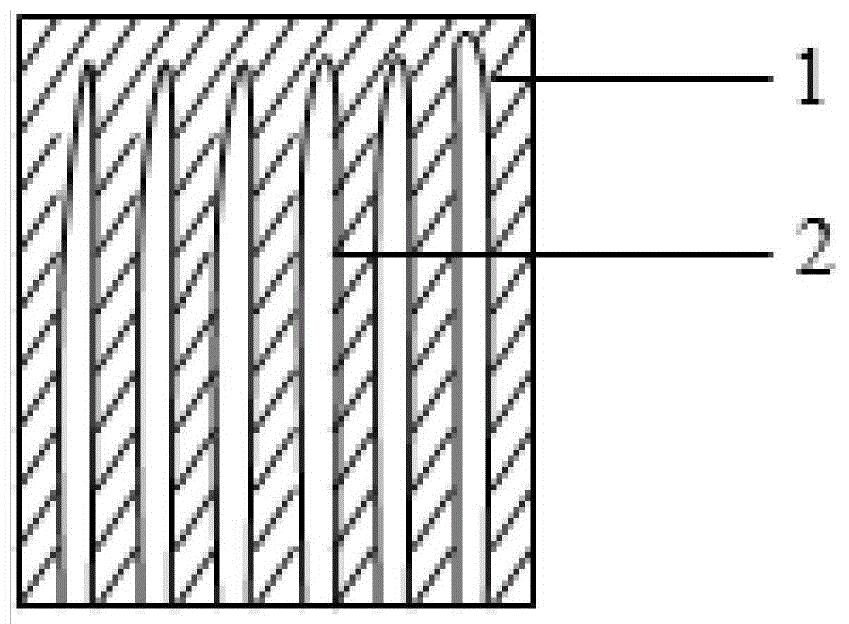

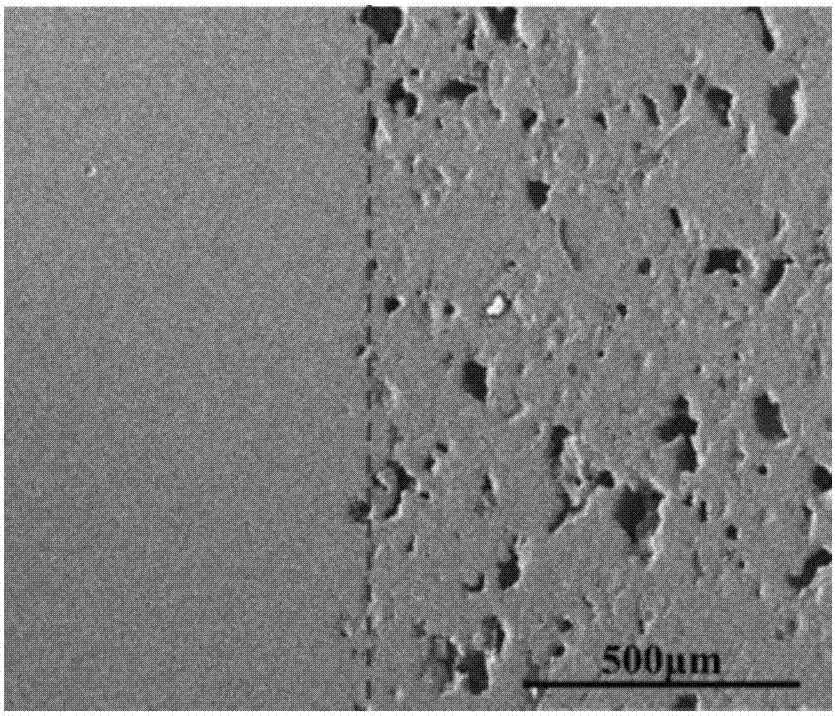

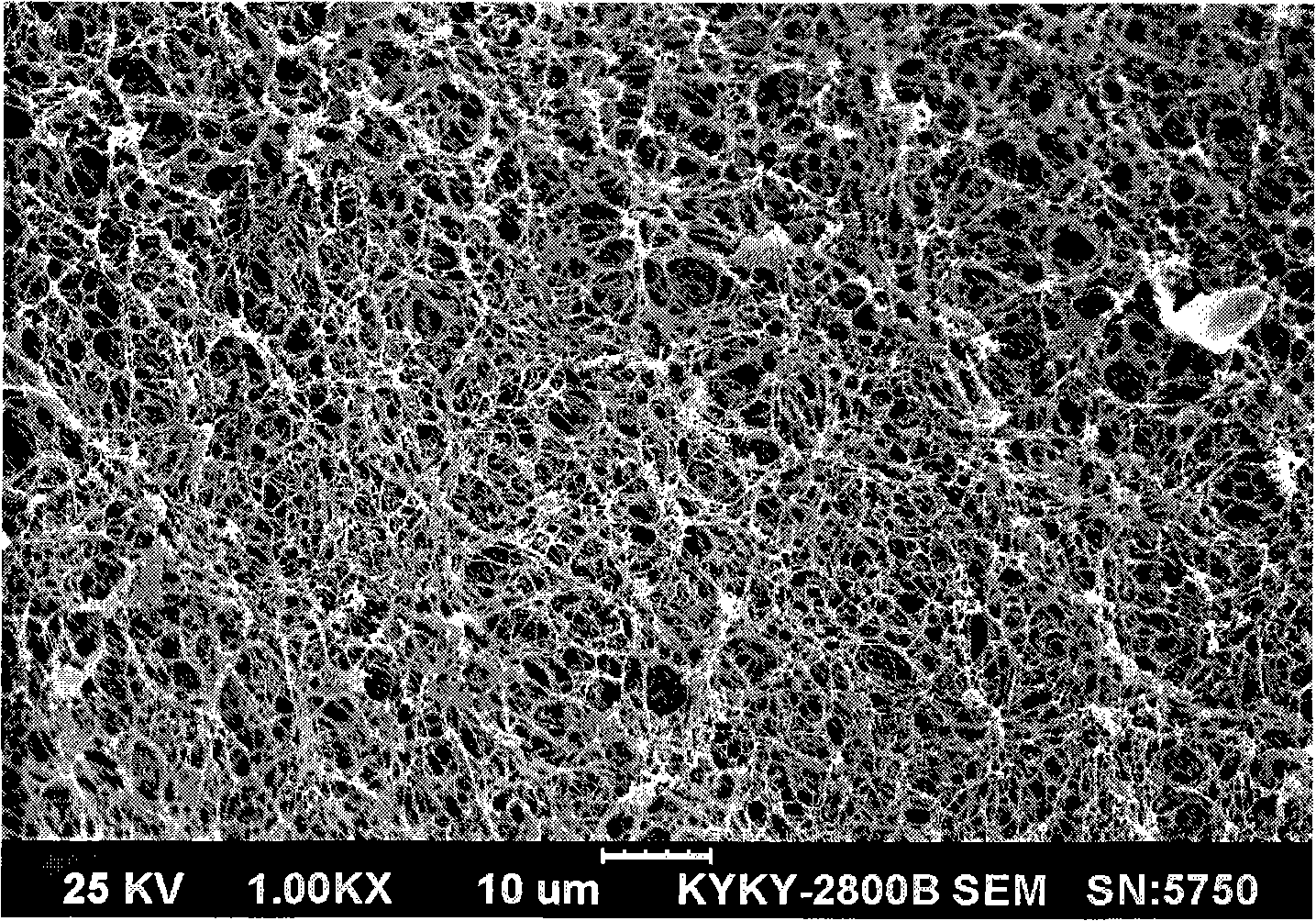

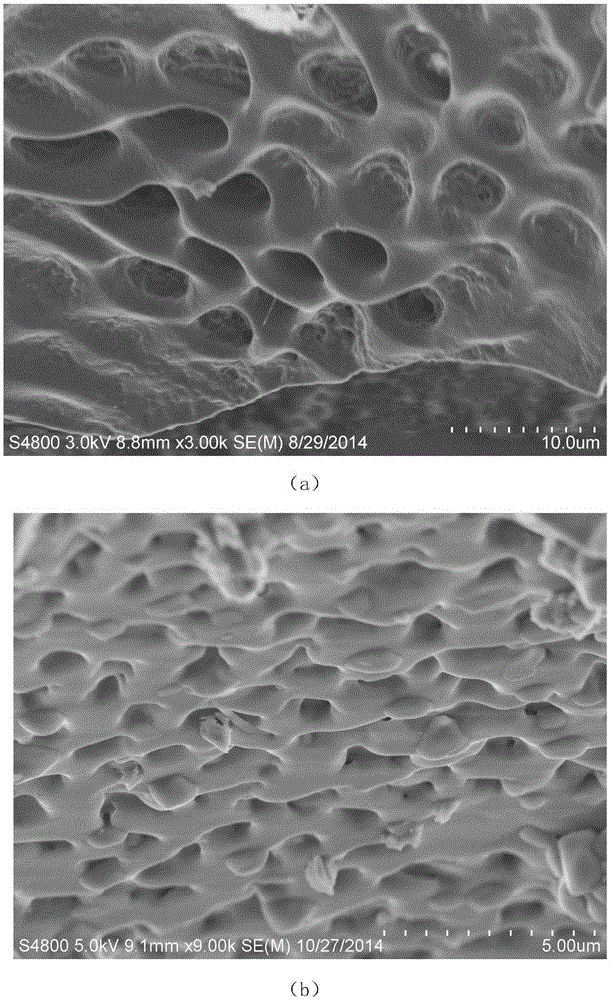

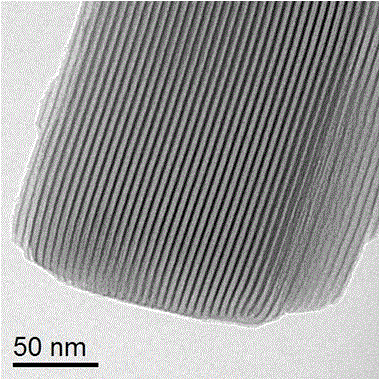

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN1864828AAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

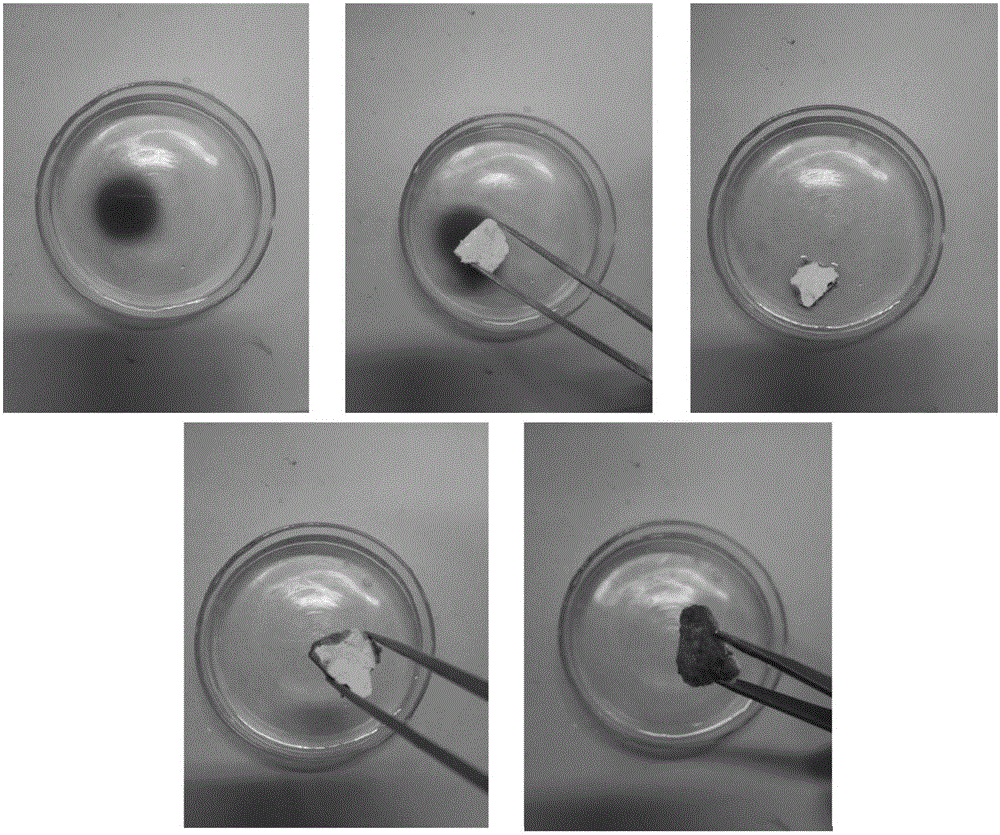

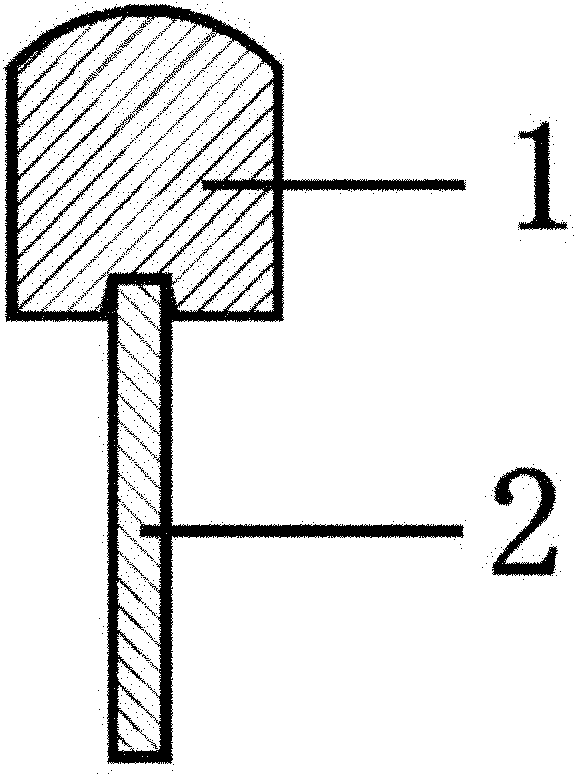

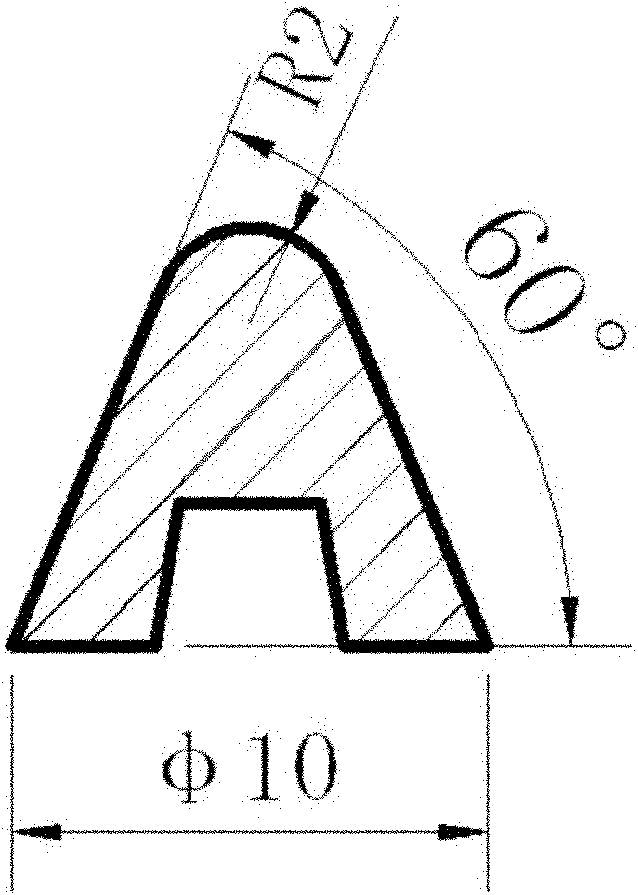

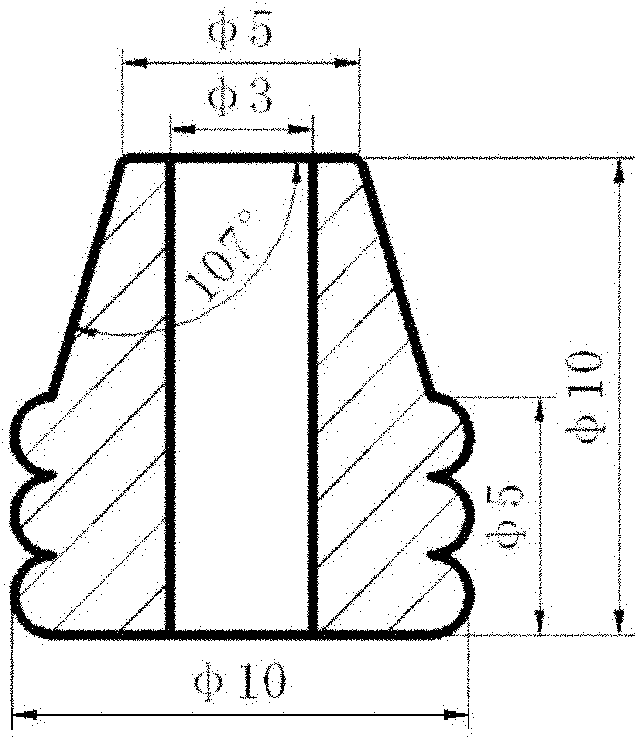

The invention discloses a method for preparing intensified netted hollow fiber membrane, belonging to technology for preparing hollow fiber membrane. The process comprises: taking polyvinylidene fluoride as membrane material, N,N-dimethyl formamide as disslovant, polyvinyl pyrrolidon as additive, preparing membrane liquid according to a certain proportion among them; textiling hollow fiber membrane under certain temperature, pressure and dragging speed; braiding net with synthetic fiber out of hollow fiber membrane, putting intensified hollow fiber membrane sequentially through membrane producing liquid and coagulating bath; coating and congealing under certain temperature, pressure and dragging speed, and getting final product. The invention is characterized in that there is no clogging, the flow resistance is small, stretching intensity amounts to 10-50 MPa, bursting strength is 0.5-1 MPa, and the process is continous and easy for industrialization.

Owner:TIANJIN UNIV

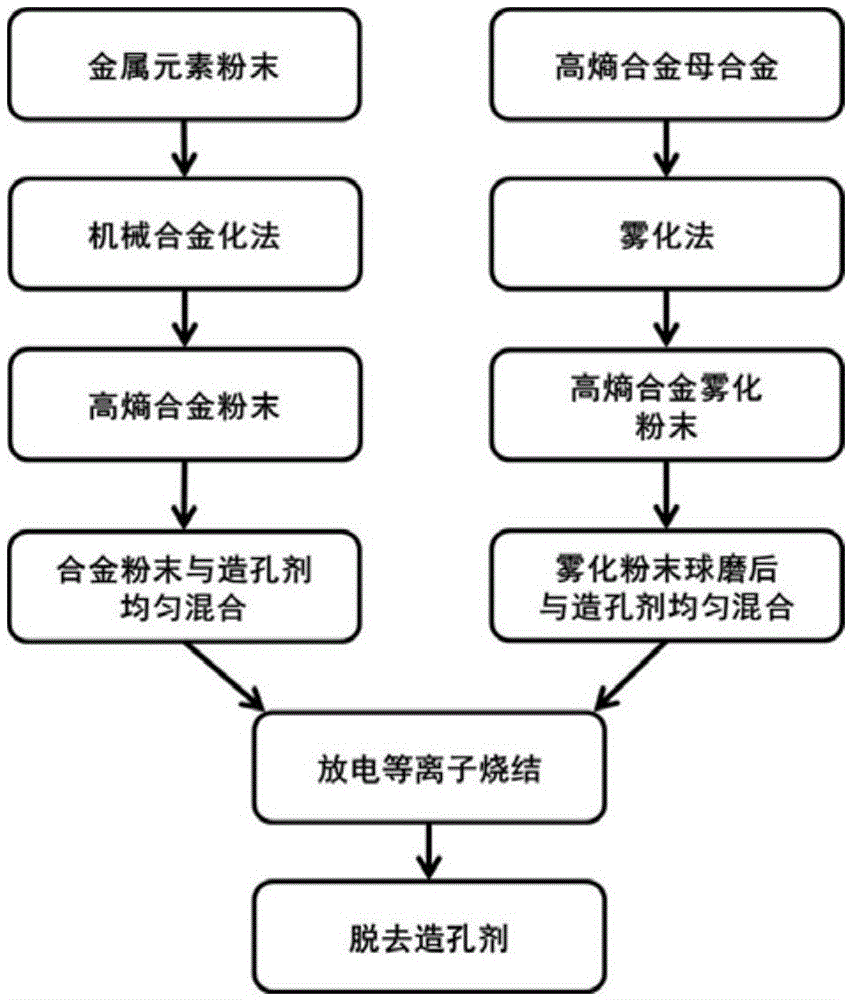

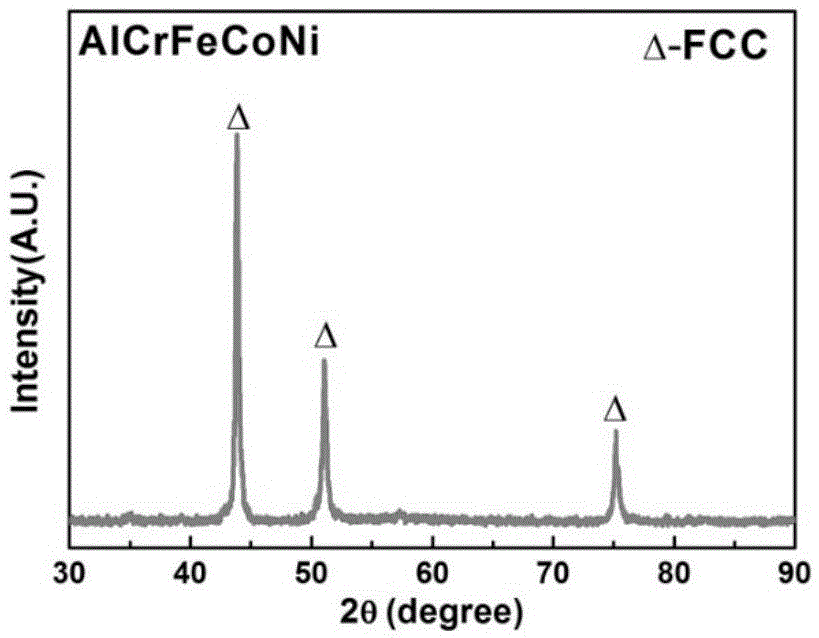

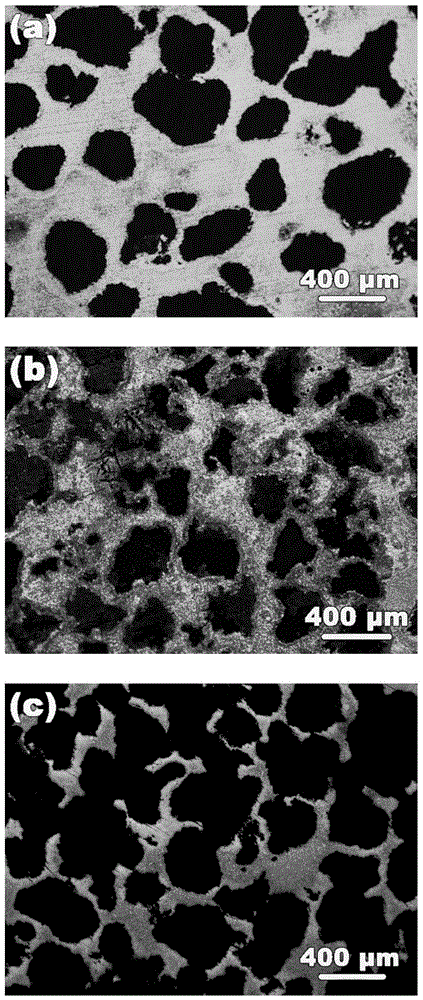

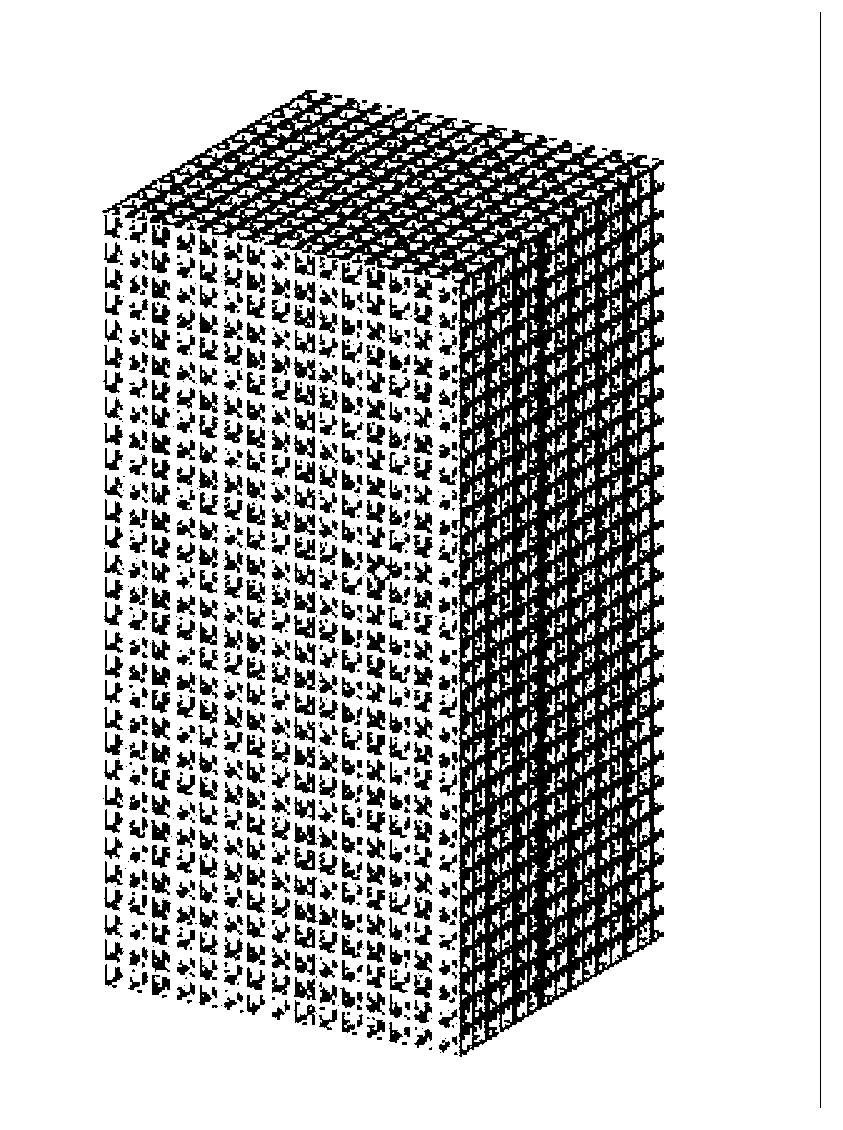

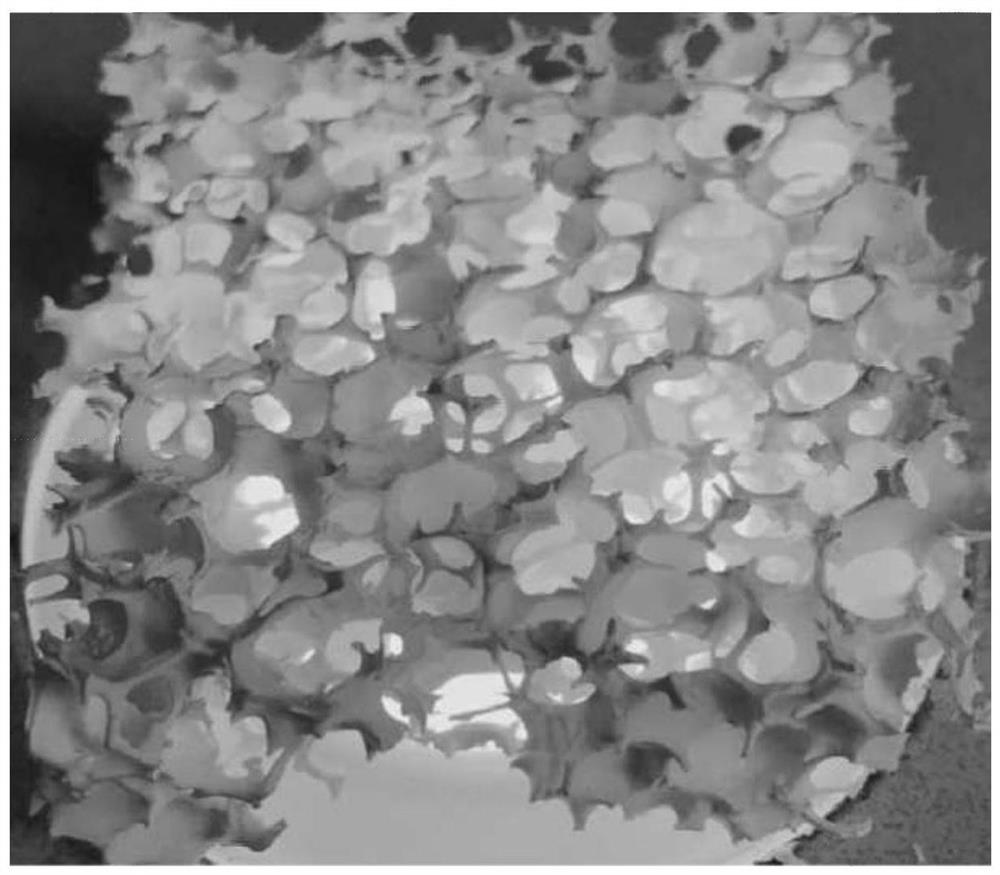

Porous high-entropy alloy and preparation method thereof

The invention discloses porous high-entropy alloy and a preparation method thereof and belongs to the field of porous foam metal. The preparation method of the porous high-entropy alloy specifically comprises the steps that high-entropy alloy powder and screened pore-forming agents are mixed proportionally according to the requirements for the porosity and the pore size, and the high-entropy alloy powder and the screened pore-forming agents are sintered through spark plasma sintering (SPS) directly after being uniformly mixed by a blender mixer; after sintering is completed, a sintered sample is put into deionized water to be subjected to ultrasonic cleaning, and particles of the pore-forming agents are removed by using the characteristic that the pore-forming agents are soluble in water; and finally the porous high-entropy alloy is obtained. The preparation method is simple in process, particularly, the preparation time is shortened greatly through the SPS method, and the efficiency is improved. The prepared porous high-entropy alloy has the characteristics of being high in porosity, uniform in pore size distribution, controllable in porosity and pore size and the like and has potential application prospects in the fields of biology, petroleum, metallurgy, chemical industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

Polyvinyl formal sponge material with uniform abscesses and rapid imbibition and preparation method thereof

ActiveCN102020816ASolution can not be reusedSolve the shortcomings of high closed cell rate and slow water absorption rate of the productPharmaceutical non-active ingredientsAbsorbent padsCross-linkLiquid waste

The invention discloses a polyvinyl formal sponge material with uniform abscesses and rapid imbibition and a preparation method thereof. The material comprises polyvinyl alcohol, a cross-linking agent, a catalyst and a pore-forming agent, wherein the cross-linking agent is formaldehyde or paraformaldehyde or formaldehyde solution. The preparation method comprises the following steps of: stirring 2-9 parts of polyvinyl alcohol in 100-200 parts of water of which the temperature is 60-98 DEG C to obtain solution, and adding 0.05-8 parts of pore-forming agent to the solution; fully emulsifying the pore-forming agent to form evenly dispersed continuous solution phase; then adding 1-26 parts of catalyst and 1-15 parts of cross-linking agent or 5-50 parts of recovered liquid waste, 1-8 parts of catalyst and 1-15 parts of cross-linking agent, and mixing; pouring the mixture into a mould after 1-60 min for cross-linking reaction for 0.1-2 hours to form the abscesses under the action of the pore-forming agent; and continuing to heat and cure for 2-18 hours to prepare the polyvinyl formal sponge material. The invention has the advantages of good hydrophily, high compression strength, high dry wetting rate, high imbibition ratio and the like.

Owner:克林纳奇(荆州)高分子科技有限公司

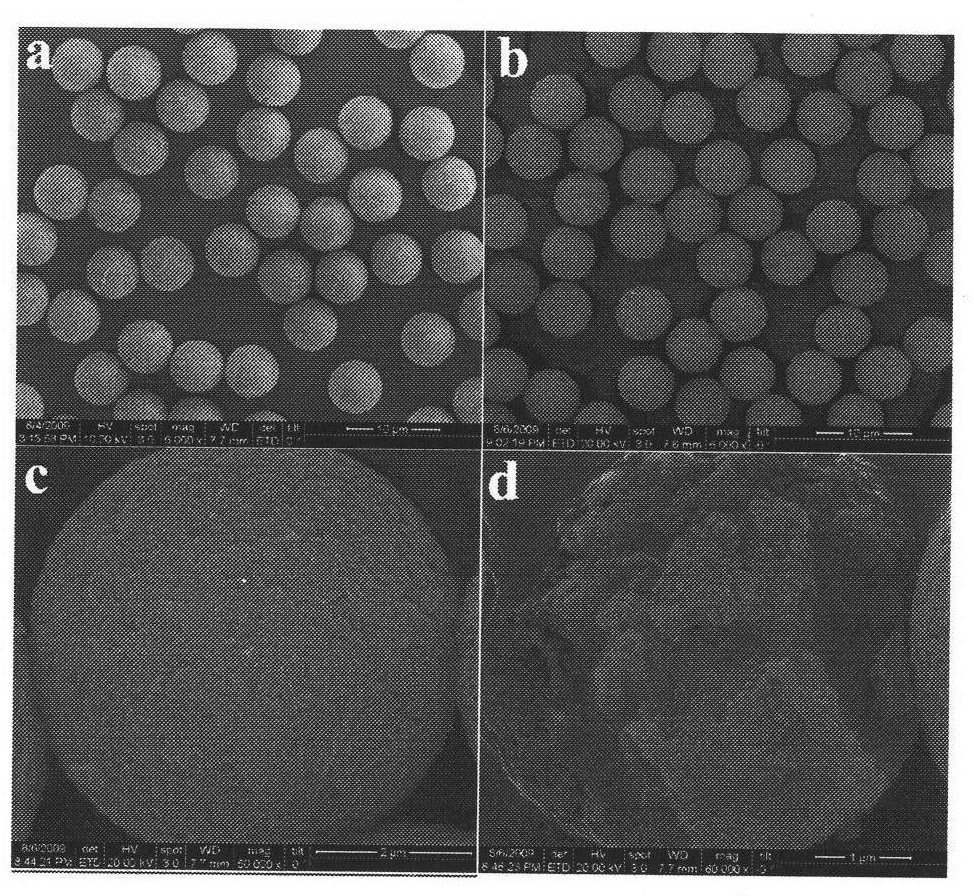

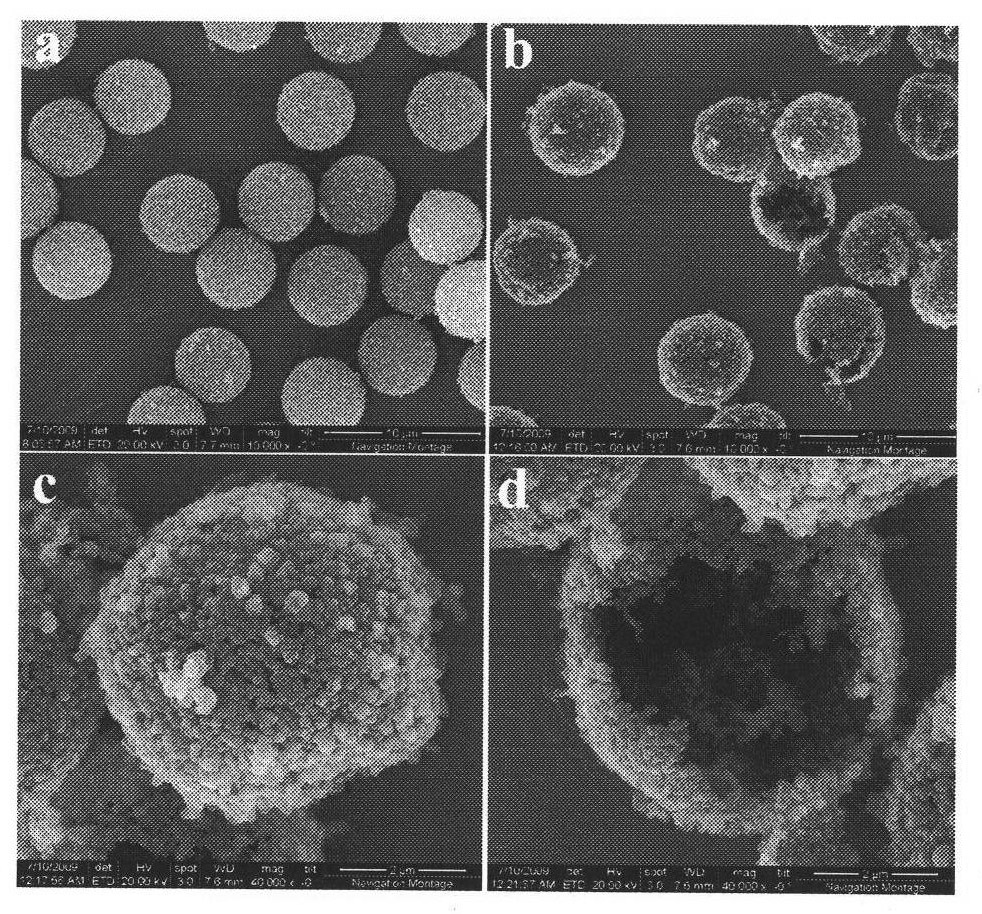

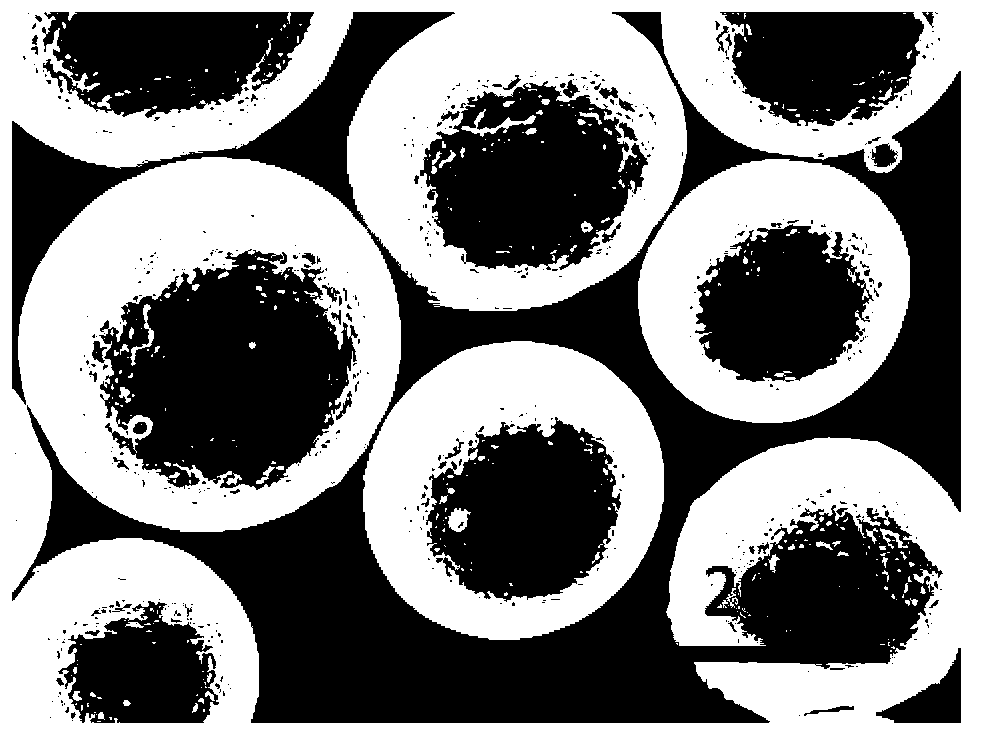

Preparation method of monodisperse porous inorganic microsphere

InactiveCN102133513AUniform sizeAperture size controllableMicroballoon preparationMicrocapsule preparationMicrosphereWastewater

The invention provides a preparation method of a monodisperse porous inorganic microsphere. Functionalized porous polymer microspheres are used as templates; the hydrolysis condensation reaction of an inorganic precursor is controlled to perform in the pores of the microspheres so as to prepare polymer / inorganic substance composite microspheres; and the templates are removed to obtain porous inorganic microspheres. The porous inorganic microspheres provided by the invention has the same size as the templates with no size reduction phenomenon, and the yield is up to above 98%; the inorganic microspheres have stable chemical properties and high mechanical strength, and have potential application value to the fields of chromatography, bioseparation, wastewater treatment, catalyst carrier, immobilized enzyme, etc.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

High-strength pore-closed mullite material and preparation method thereof

The invention relates to a high-strength pore-closed mullite material and a preparation method thereof. The material comprises, by weight, 30-84wt% of alumina raw material, 1-55wt% of alumina-silica raw material, 15-60% of silica raw material and 2-10wt% of additive. The preparation method includes: mixing the raw materials according to the above proportion, adding the additive, stirring well, and pouring into a die; performing mechanical pressing under 80-150MPa to obtain a blank, and drying the blank at 60-140 DEG C for 3-16h; putting the blank in a high-temperature kiln for calcining to obtain the high-strength pore-closed mullite material. Sintering in-situ pore forming technology is adopted, so that the high-strength pore-closed mullite material prepared by the method has the advantages of high closed porosity, high pressure-resistant strength and high refractoriness under load and can be used for a long time at high temperature of 1550-1700 DEG C.

Owner:ZHENGZHOU UNIV

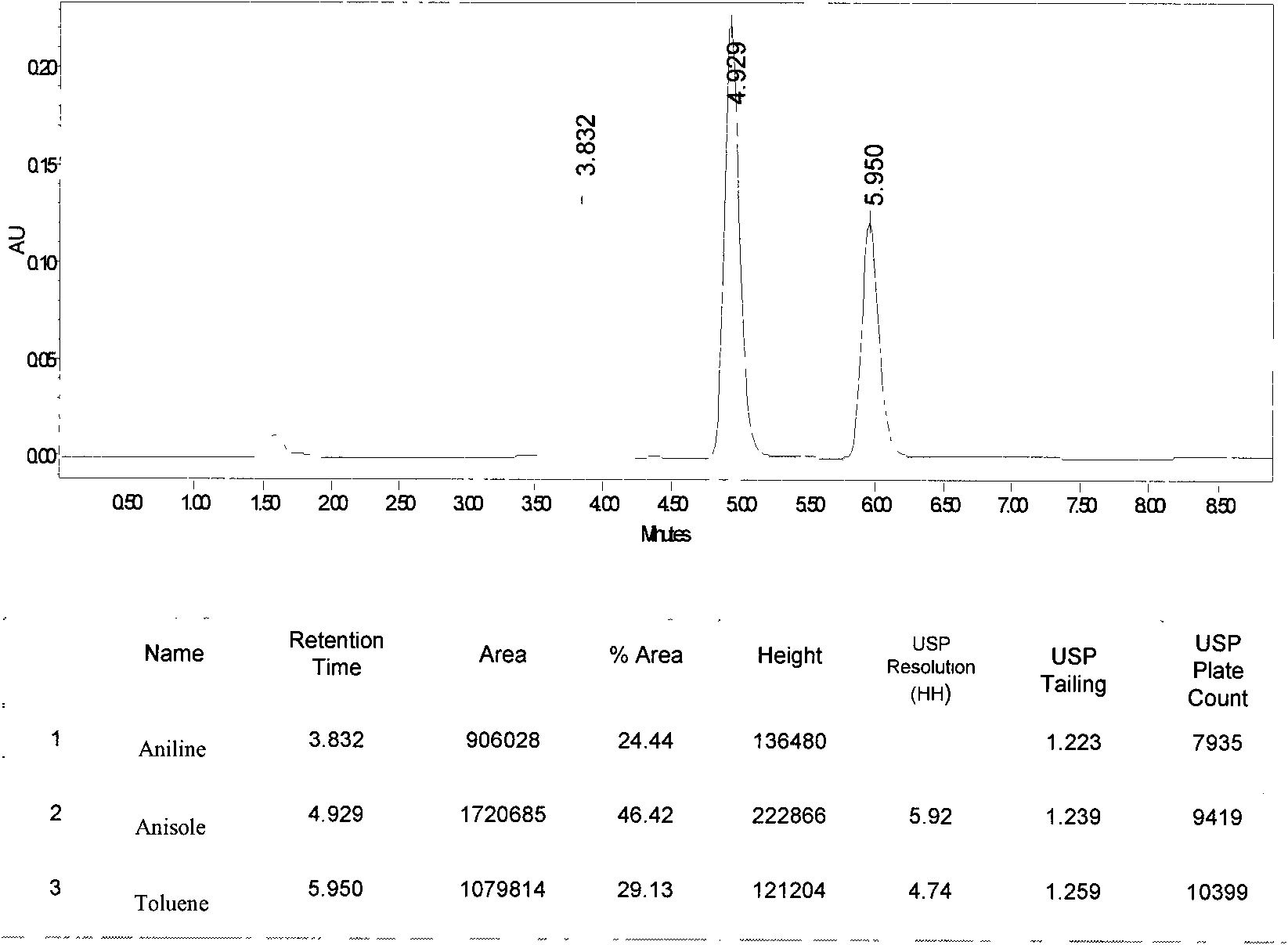

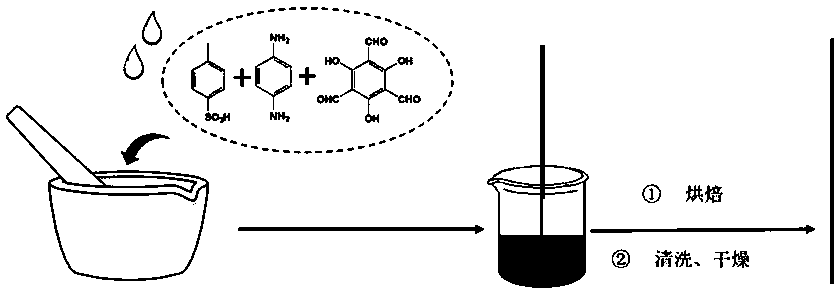

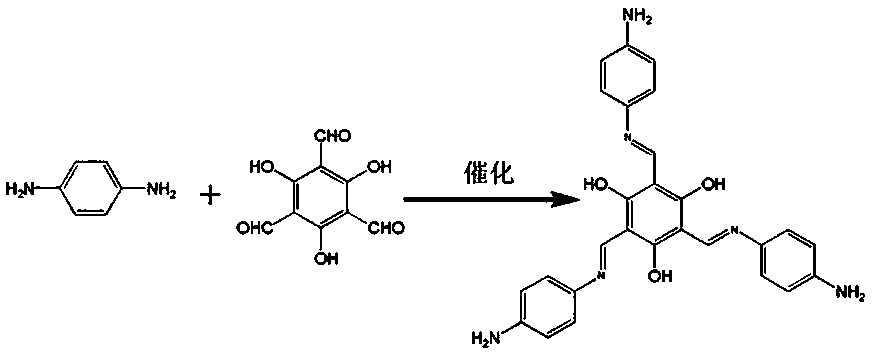

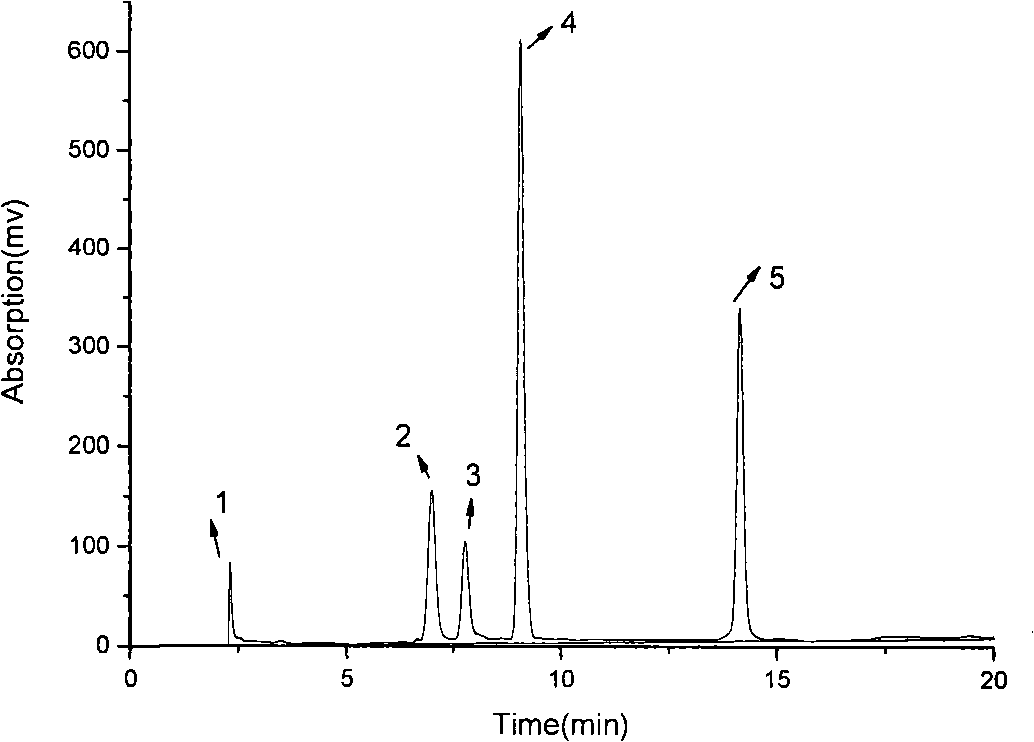

Simple and rapid preparation method and application of covalent-organic framework compound solid-phase microextraction coating

ActiveCN108543519AThickness is easy to controlShorten the timeComponent separationOther chemical processesOrganic solventSolid-phase microextraction

The invention provides a simple and rapid preparation method and application of a covalent-organic framework compound solid-phase microextraction coating. According to the preparation method, the covalent-organic framework compound coating is quickly formed on quartz fiber, a device needed for the entire synthesizing process is extremely easy, and the method comprises the steps of performing amino-functionalization on the quartz fiber, impregnating surface amino-functionalized quartz fiber in a ground material precursor, repeating performing impregnating for several times, performing simple baking and cleaning the coating, so that the covalent-organic framework compound solid-phase microextraction coating can be obtained. The synthesizing method of the invention is easy to operate, requires few devices, and does not need an organic solvent, and by using the method, the covalent-organic framework compound solid-phase microextraction coating with high-temperature resistance, solvent resistance, acid and alkali resistance, high specific surface area, controllable pore size, and controllable thickness can be quickly prepared. Then the extraction coating is used to enrich environmentalpollutants polychlorinated biphenyls in water and it is detected that the coating has good enriching effects by using gas chromatography-mass spectrometry, thereby showing that the coating has good application prospect in the environment and other fields.

Owner:FUZHOU UNIV

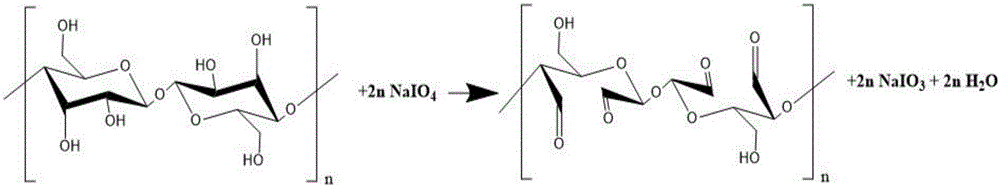

Self-crosslinked hydroformylated bacterial cellulose functional porous nano-material and preparation method thereof

ActiveCN106084302AGood moisture absorptionImprove water holding capacityPharmaceutical delivery mechanismAbsorbent padsWound dressingFoaming agent

The invention relates to a self-crosslinked hydroformylated bacterial cellulose porous nano-material and a preparation method thereof. The material comprises bacterial cellulose, polysaccharides or polypeptides, an antibacterial agent and a foaming agent. The preparation method comprises the following steps: dissolving the polysaccharides or polypeptides, stirring the polysaccharides or polypeptides to form a solution, adding a certain amount of dispersed hydroformylated bacterial cellulose, a certain amount of the antibacterial agent (or antibacterial sol) and a certain amount of the foaming agent to the solution, stirring all above materials to make bubbles uniformly exist in the obtained mixed solution, pouring the mixed solution to a die, quenching the above sample, placing the quenched sample in a vacuum lyophilizer, and carrying out vacuum drying to prepare the self-crosslinked degradable polysaccharide or polypeptide composite hydroformylated bacterial cellulose functional porous nano-material. The material has the inherent good mechanical performances of a porous material, also as the advantages of good biocompatibility, fast dry state wetting rate, good attachment to skins, and good antibacterial function, and can be used as various medical wound repairing materials, multifunctional wound dressings and novel tissue engineering scaffolds.

Owner:UNIV OF SCI & TECH BEIJING

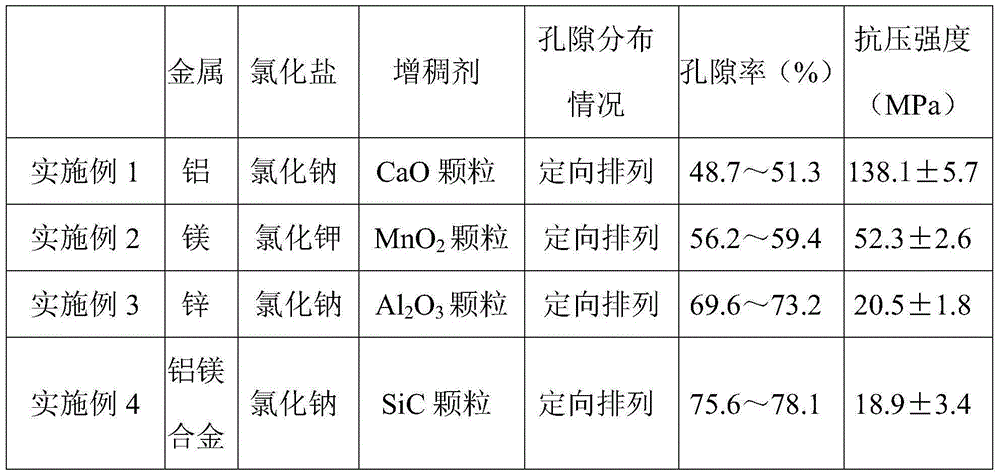

Method for utilizing directional solidification technique to prepare porous metal materials

The invention provides a method for utilizing a directional solidification technique to prepare porous metal materials. The method comprises the following concrete steps of melting and mixing metal powder added with a thickening agent and chlorizated salts powder to form metal slurry; directionally solidifying and quickly cooling the metal slurry in a mould to obtain a mixture of solidified metal and solidified chlorizated salts; removing the chlorizated salts in the mixture; drying to obtain the porous metal materials. According to the method provided by the invention, through the combination of the directional solidification technique and casting forming, the porous metal materials with directionally aligned pores and a porous structure with a certain pore size are obtained, the pore size can be controlled and are uniform, and the mechanical strength of the porous metals is improved through the directional porous structure; due to the phase change forming of the metal from a liquid state to a solid state, a hole wall is more dense, and the porous metal is endowed with more excellent mechanical property; meanwhile, the preparation process is simple, the production efficiency is high, and the method has wide application prospect in the fields such as aerospace, filtering materials, catalyst carriers, porous electrodes, heat exchangers and flame-proof devices.

Owner:XIAN UNIV OF TECH

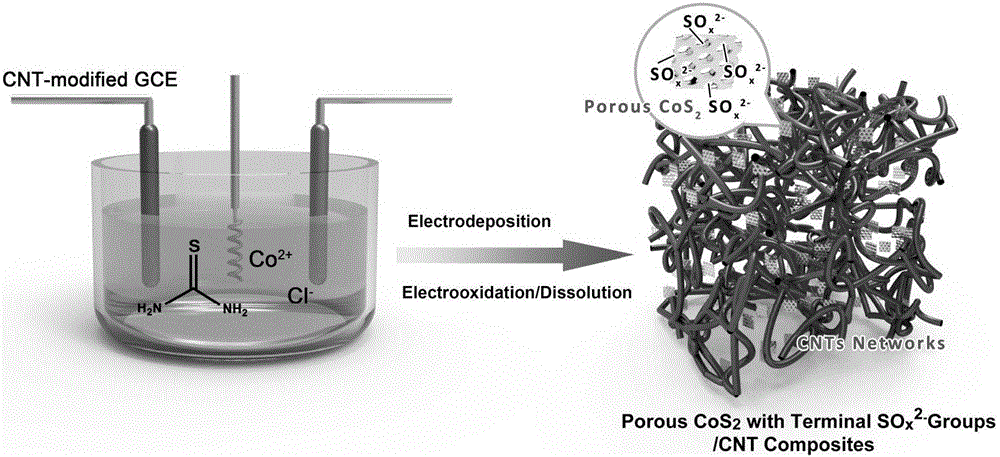

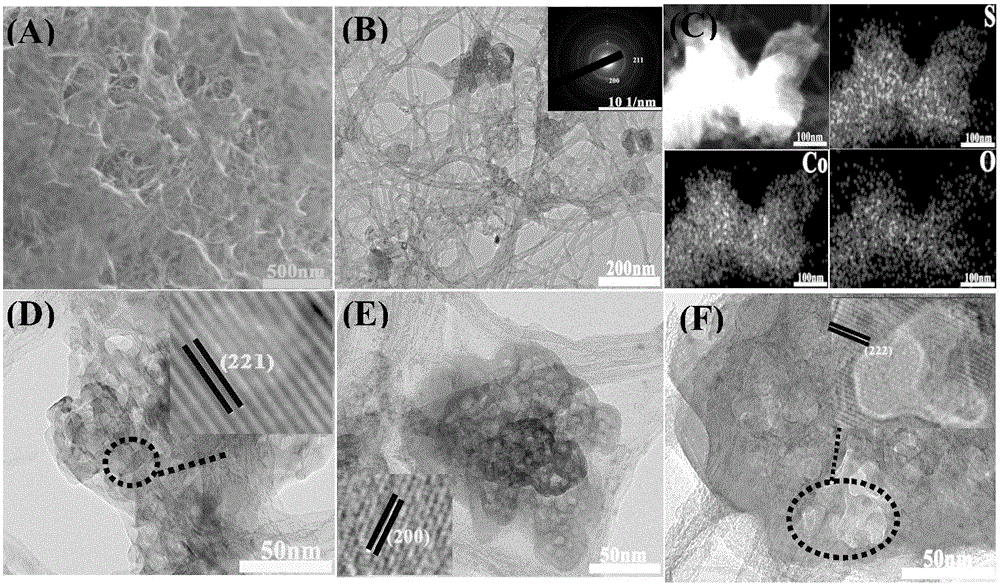

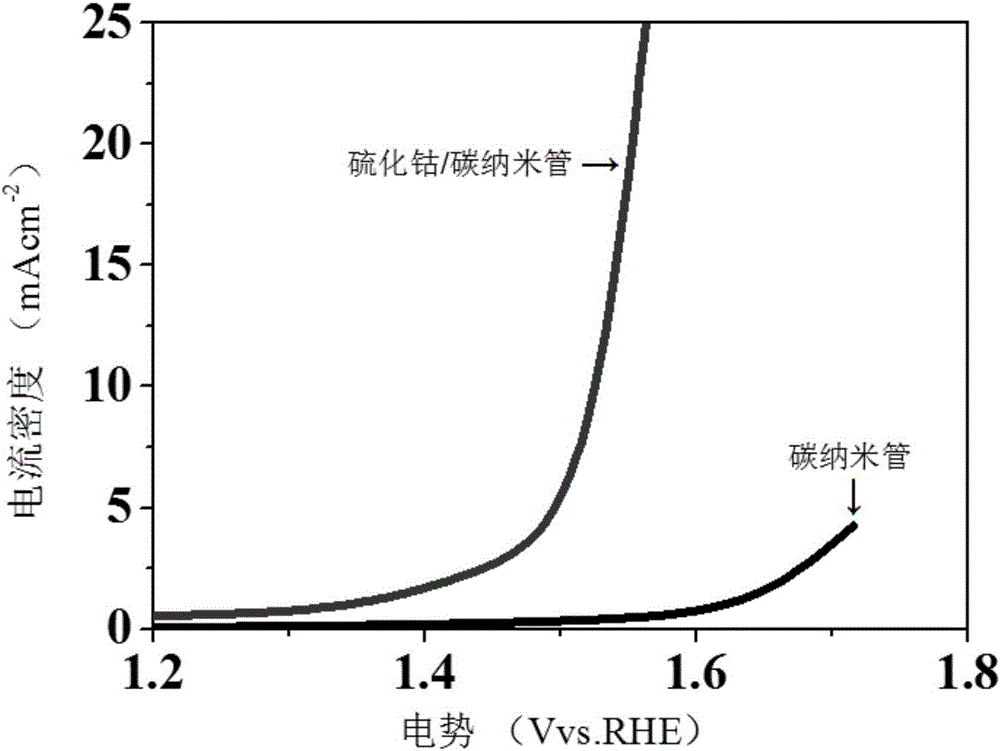

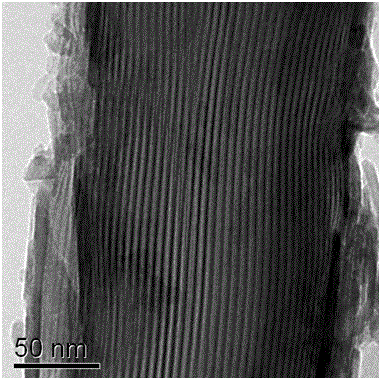

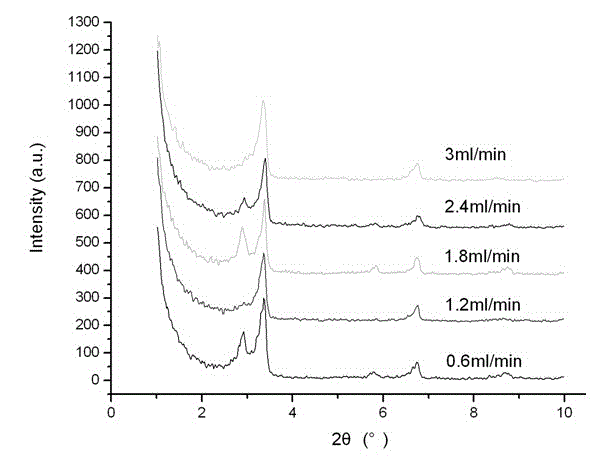

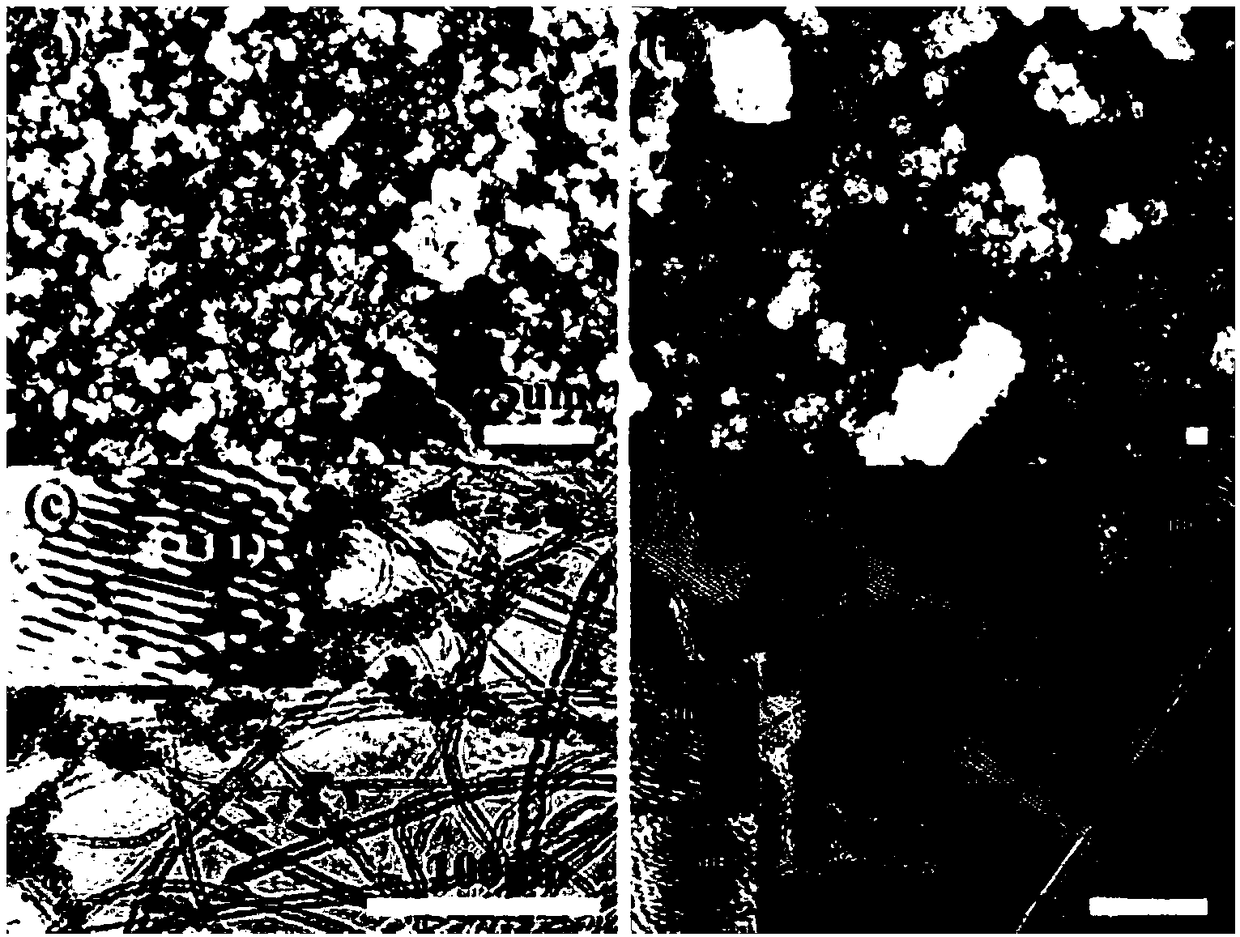

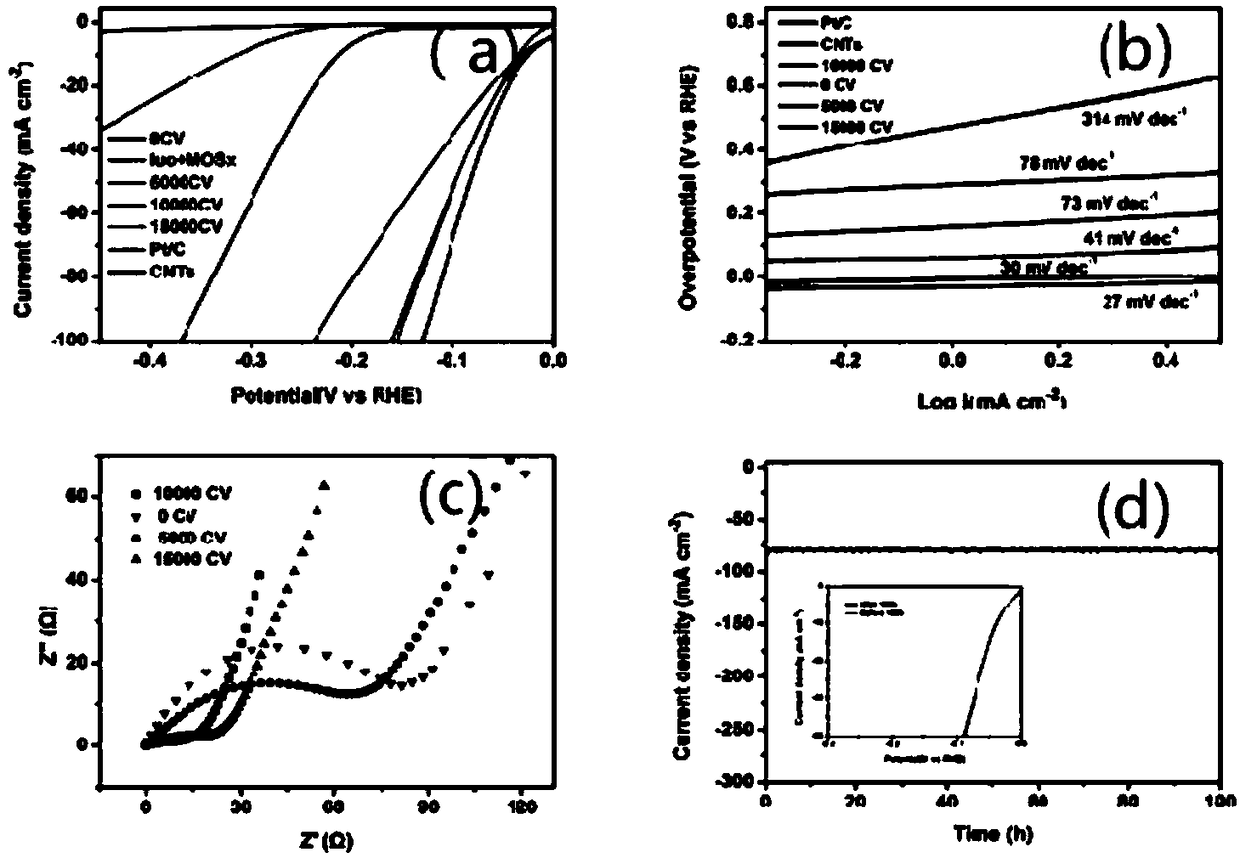

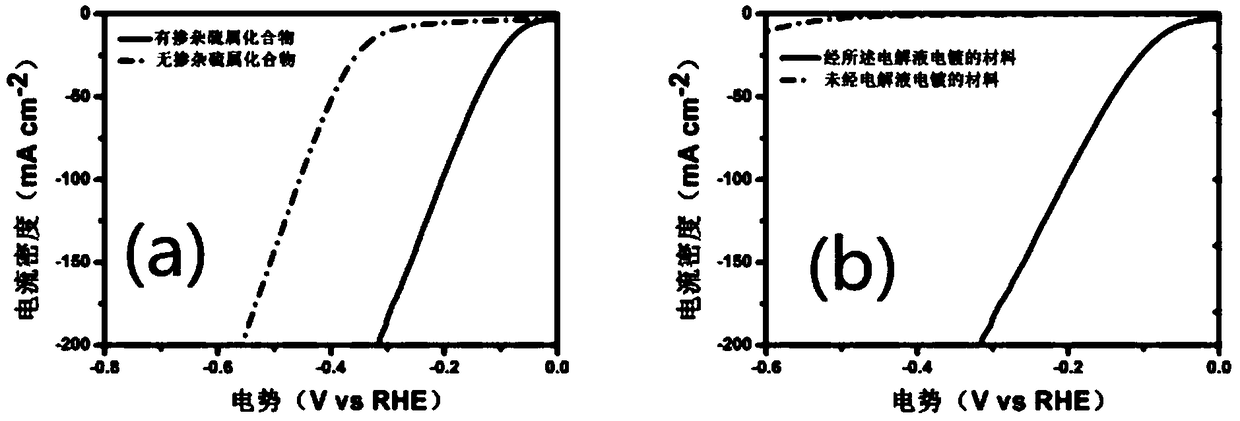

Transition metal sulfide/carbon nanotube composite material as well as preparation method and application thereof

InactiveCN106669739AAperture size controllableMore edge active sitesElectrolytic inorganic material coatingCatalyst activation/preparationThioureaCarbon nanotube

The invention provides a transition metal sulfide / carbon nanotube composite material. A preparation method of the transition metal sulfide / carbon nanotube composite material comprises the following steps: adding carbon nanotubes to a solvent, forming a suspension by ultrasonic treatment; dropping the suspension on the surface of a pretreated glassy carbon electrode; naturally airing to form a uniform thin layer of carbon nanotubes, to obtain a carbon nanotube-modified glassy carbon electrode; adding thiourea and transition metal salt to deionized water; adjusting pH to 0-13 to obtain an electroplating solution; placing the carbon nanotube-modified glassy carbon electrode in the electroplating solution for electroplating to obtain the glassy carbon electrode covered with a transition metal sulfide / carbon nanotube composite material; washing with water and drying naturally; scraping the transition metal sulfide / carbon nanotube composite material from the surface of the glassy carbon electrode. The preparation method provided by the invention is simple in operation and easy in mass production; the prepared composite material has great advantages in catalytic oxygen evolution and energy conversion, and can be used as a catalyst for photo and electro-catalytic oxygen evolution reaction.

Owner:WENZHOU UNIVERSITY

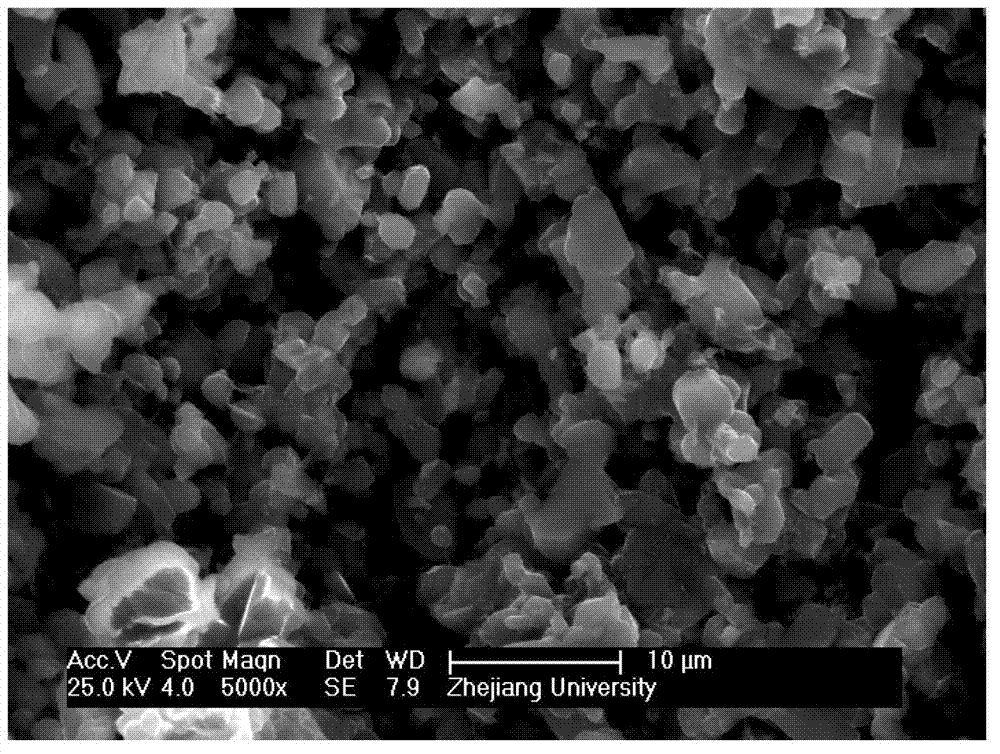

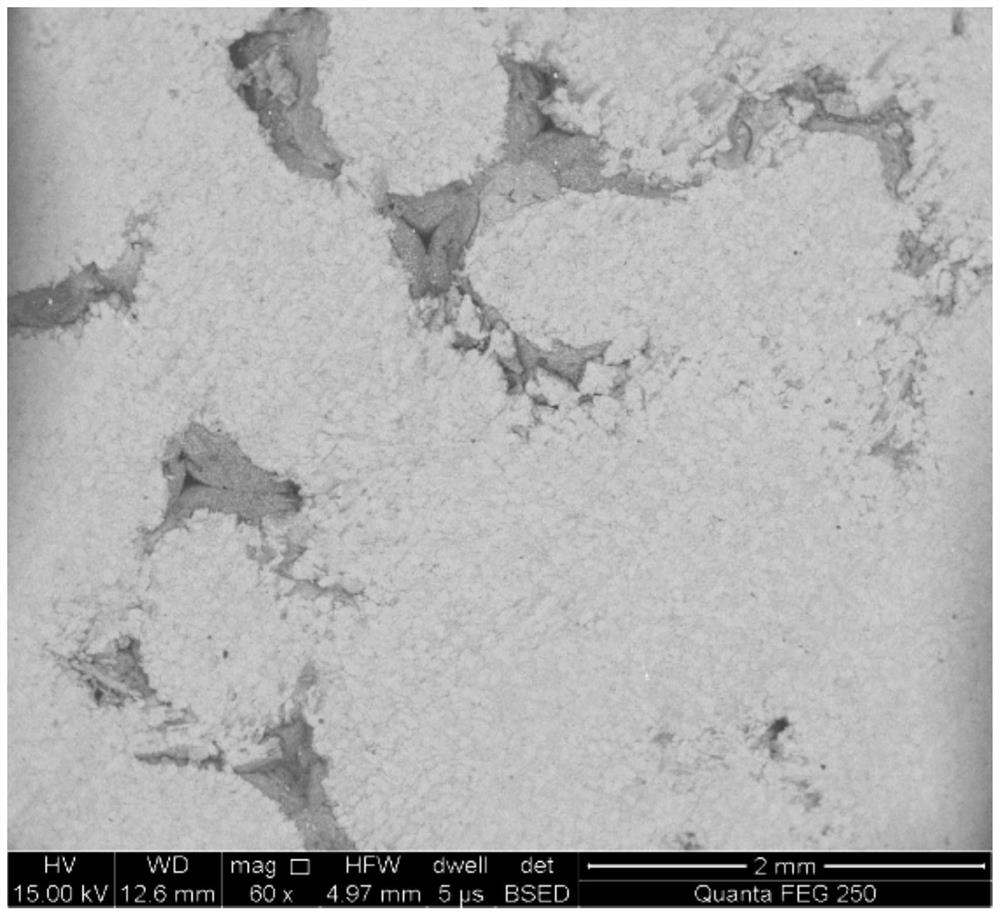

Preparation method of high-porosity silicon-carbide porous ceramics

ActiveCN102807384ALow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

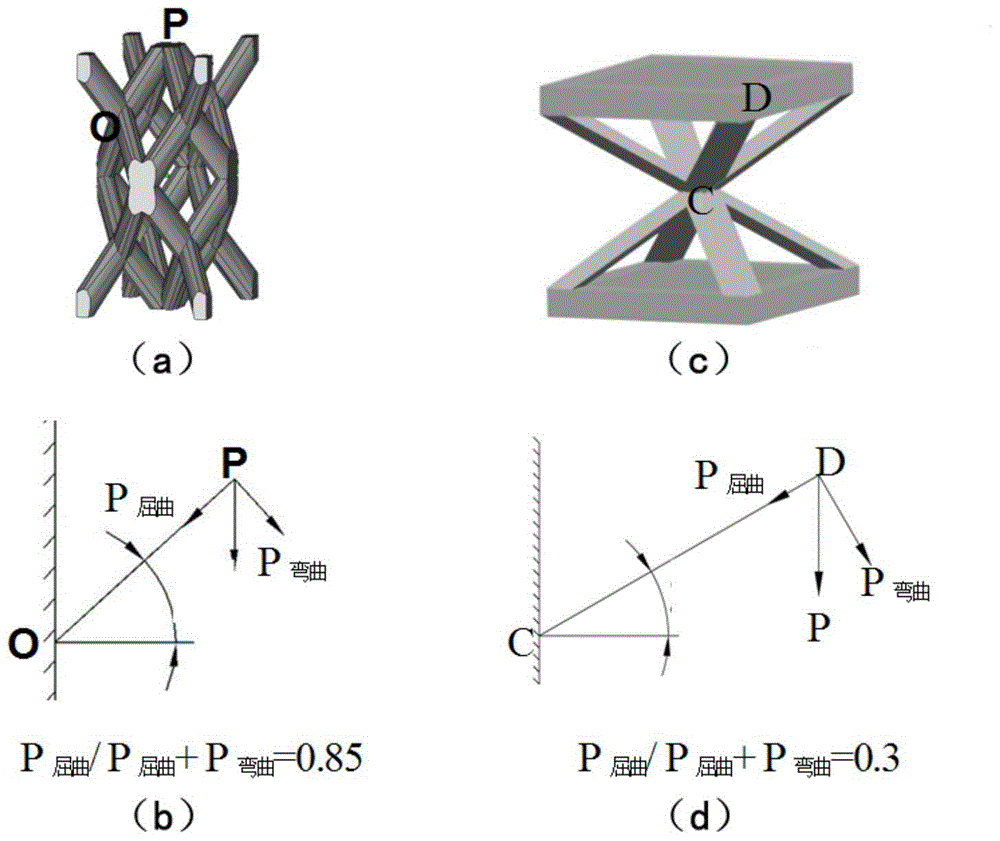

Method for preparing high fatigue property porous Ti-6Al-4V bulk material

The invention relates to porous material preparation, in particular relates to a method for preparing a high fatigue property porous Ti-6Al-4V bulk material, which is used for solving the problem of low fatigue property of the porous Ti-6Al-4V bulk material of the prior art. The method is that an 'electron beam molten metal molding technology' is utilized to prepare the large Ti-6Al-4V bulk material with the porosity of 50%-95% at first, the porous material is then subjected to two steps of thermal treatment of annealing and aging at 400 DEG C and 1000 DEG C, and the Ti-6Al-4V porous material with high fatigue strength, low elasticity modulus of (0.1-20 GPa) and 'the ratio of fatigue strength / compressive strength' of 0.7 is obtained finally. According to the method, the mechanical performance of the porous Ti-6Al-4V pore wall material is controlled through a thermal treatment technology, and thus, a large titanium alloy porous material with excellent fatigue property is obtained and can be widely applied to the fields of aerospace, medical treatment and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

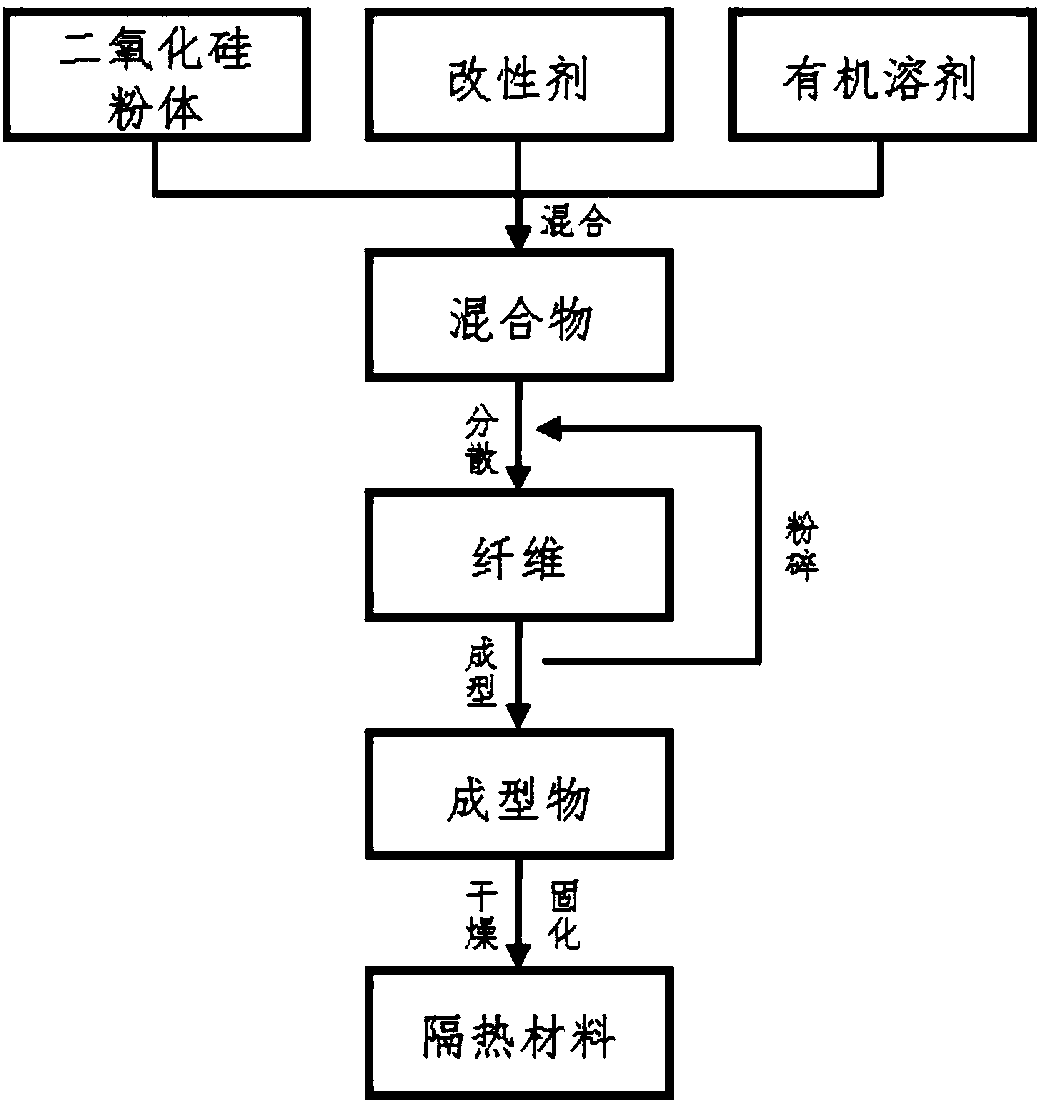

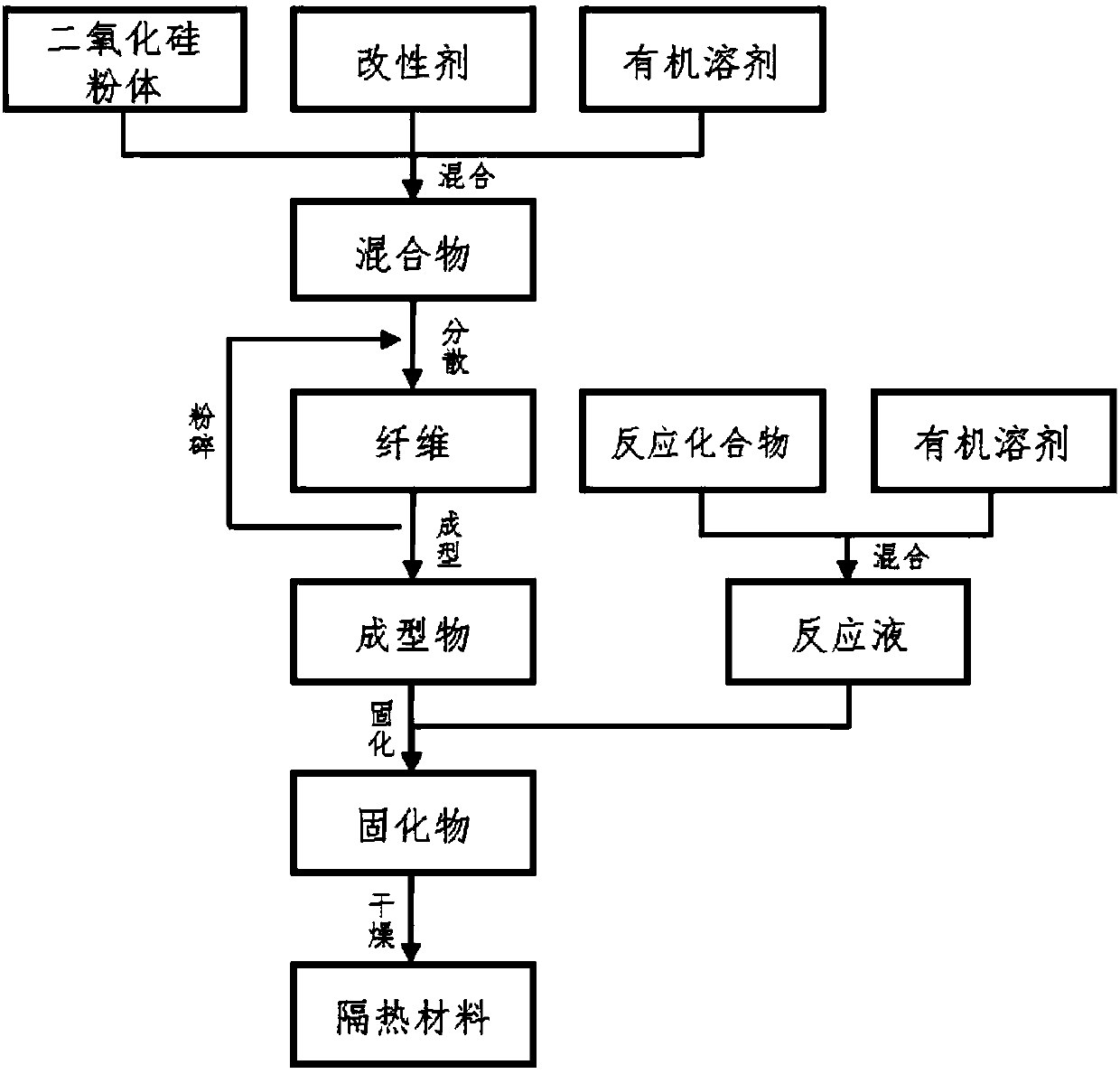

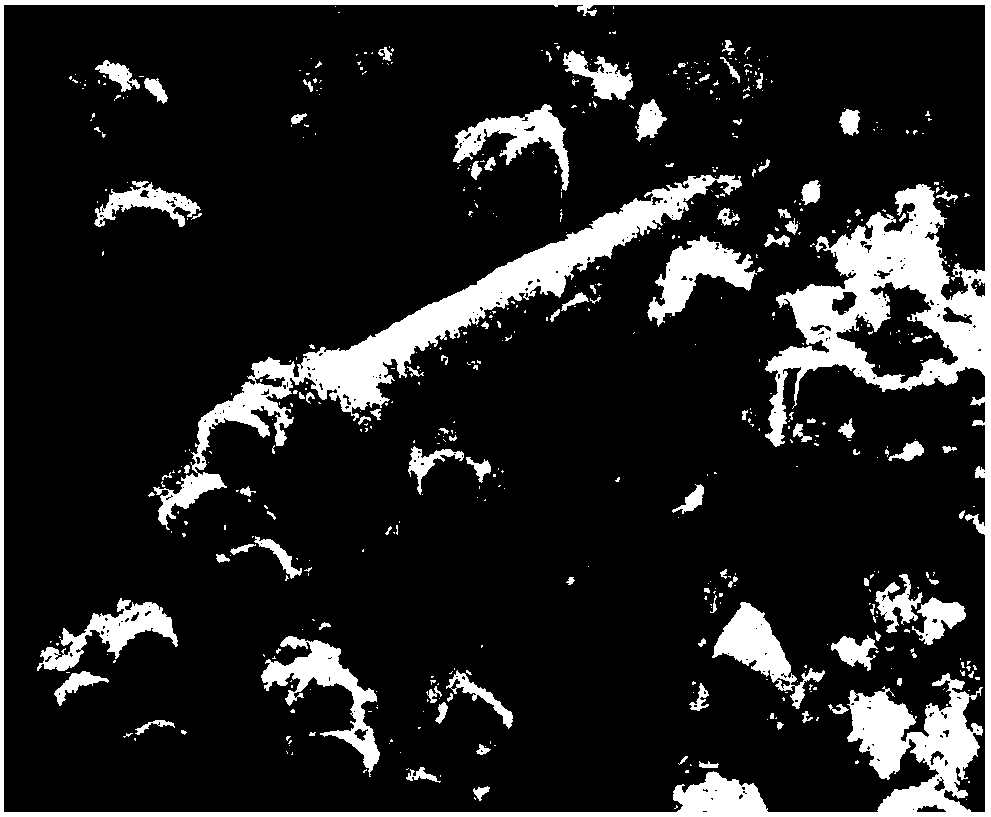

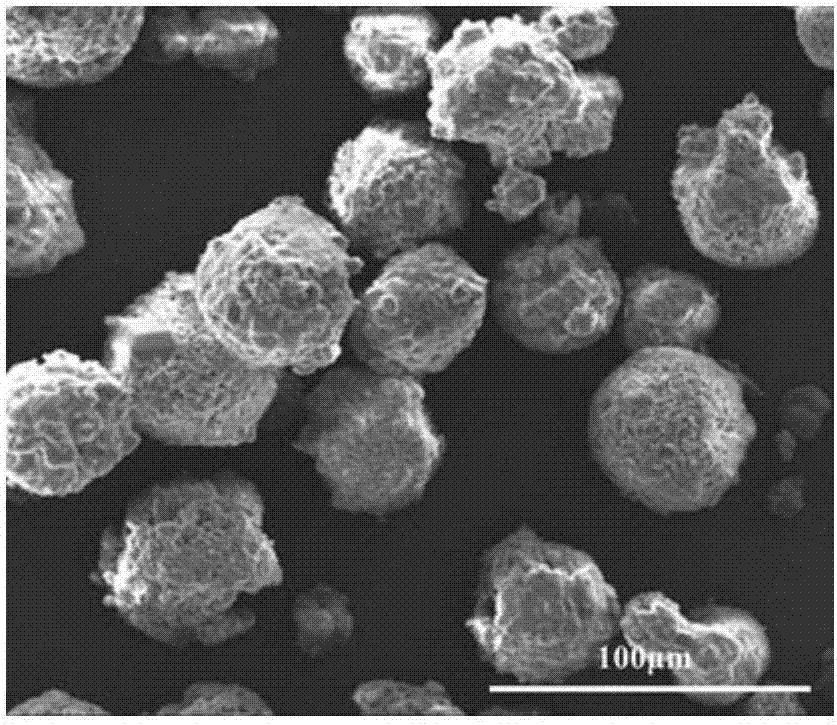

Silica heat-insulation composite material and preparation method thereof

The invention provides a silica heat-insulation composite material and a preparation method thereof. The silica heat-insulation composite material is prepared from the following raw materials: 100wt%of silica powder, 0.5mol% to 20mol% of modifier, 50wt% to 400wt% of organic solvent, 5wt% to 200wt% of reinforcing fiber, 0wt% to 20wt% of opacifier, 0mol% to 10mol% of cross-linking agent and 0wt% to3wt% of thickener. The invention also provides the preparation method of the heat-insulation composite material. An organic-solvent solution of the modifier is added into the silica powder; the reinforcing fiber is added; the agitation and the setting are carried out; the organic solvent is volatilized; curing is carried out, so as to obtain the composite material. The silica heat-insulation composite material is obtained by using the silica powder as a raw material, modifying the silica powder with the modifier, adding the reinforcing fiber, then directly setting, volatilizing the solvent and curing; the preparation method is simple; the procedure is short; problems that the raw material is expensive, a product is fragile and powder falls, and the like, are solved and the silica heat-insulation composite material is suitable for industrialized production.

Owner:金光虎

Aluminum-based density gradient material and preparation method and application thereof

The invention relates to an aluminum-based density gradient material and a preparation method and application thereof. A region with density in gradient change and (or) a region with density in continuous change exist in the aluminum-based density gradient material, and the materials of all the regions in the aluminum-based density gradient material are consistent. The preparation method comprises the following steps: water-soluble pole-forming agent powder and aluminum alloy powder are proportioned according to the volume ratio of the water-soluble pole-forming agent powder to the aluminum alloy powder being X to (100-X), and then are mixed uniformly to obtain mixed powder containing different amounts of pole-forming agents; die forming is carried out on laminated spread powder, and a prefabricated blank is sintered in a vacuum environment at 575-675 DEG c to obtain a sintered body; and water soaking treatment is carried out to obtain the aluminum-based density gradient material. The aluminum-based density gradient material prepared by the method has no obvious deformation, and the density from 1.1 g / cm<3>-2.7g / cm<3> in gradient distribution is achieved through adjusting porosity; and the aluminum-based density gradient material is excellent in performance and is suitable for being used as an aerospace material.

Owner:CENT SOUTH UNIV

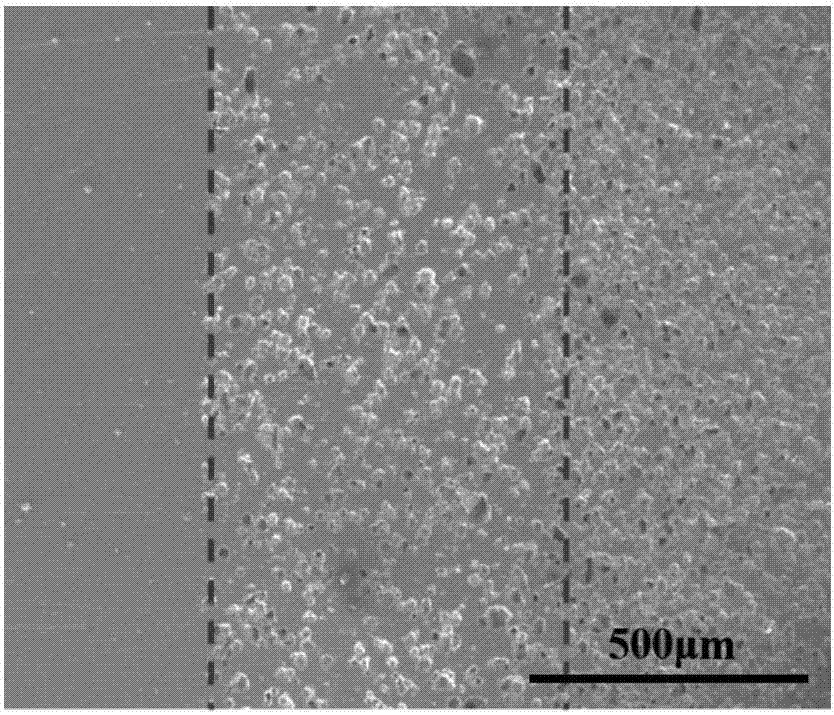

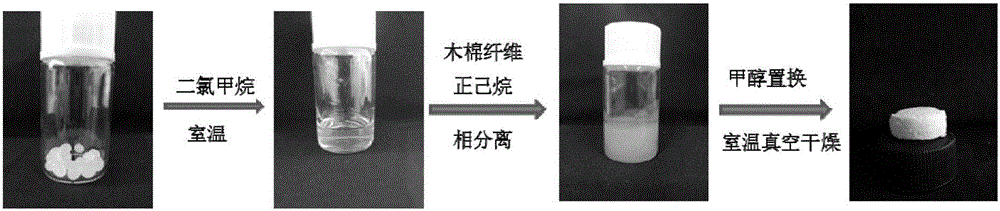

Method for preparing three-dimensional porous oil absorption material

InactiveCN106334543ASimple processHigh porosityOther chemical processesAlkali metal oxides/hydroxidesRoom temperatureSolvent

The invention relates to a method for preparing a three-dimensional porous oil absorption material. The method comprises the steps that polylactic acid is dissolved in a solvent and stirred to be dissolved, and a polylactic acid solution is obtained; under the stirring condition, a poor solvent is dropwise added into the polylactic acid solution till the solution turns turbid from clear, still standing is carried out at room temperature, replacement and vacuum drying are carried out, and the three-dimensional porous oil absorption material is obtained; or under the stirring condition, natural fibers are added into the polylactic acid solution, then the poor solvent is dropwise added till the solution phase is separated, still standing is carried out at room temperature, replacement is carried out, and the three-dimensional porous oil absorption material is obtained. The novel oil absorption material is controllable in aperture size and shape and can be suitable for different application occasions.

Owner:DONGHUA UNIV

Method for producing cathode component for flashlight

InactiveCN102157319AUniform densityAperture size controllableCathode heaters manufactureFlash-lampThermoplastic

The invention provides a new method for producing a cathode component for a flashlight. The method comprises the following steps of: carrying out calcining, ball milling and sieving on powdered raw materials, uniformly mixing the powdered raw materials with a thermoplastic or thermoset organic matter under the heating state, preparing the mixture into a green body having a certain shape by adopting the metal injection molding process, removing the organic matter in the green body through a chemical or heating method, obtaining a cathode basal body with certain porosity through high-temperature sintering, immersing an electron emission substance in a gap on the cathode basal body, and finally obtaining the cathode component for the flashlight through surface cleaning, washing and high-temperature treatment. The method has the advantage of preparing the cathode basal body material with considerably uniform density, controllable porosity and pore diameters, uniform pore diameters and narrow pore diameter distribution, simplifying the process for preparing the cathode component for the flashlight, reducing the production cost, and achieving volume production, low cost and considerablycomplex production shapes.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

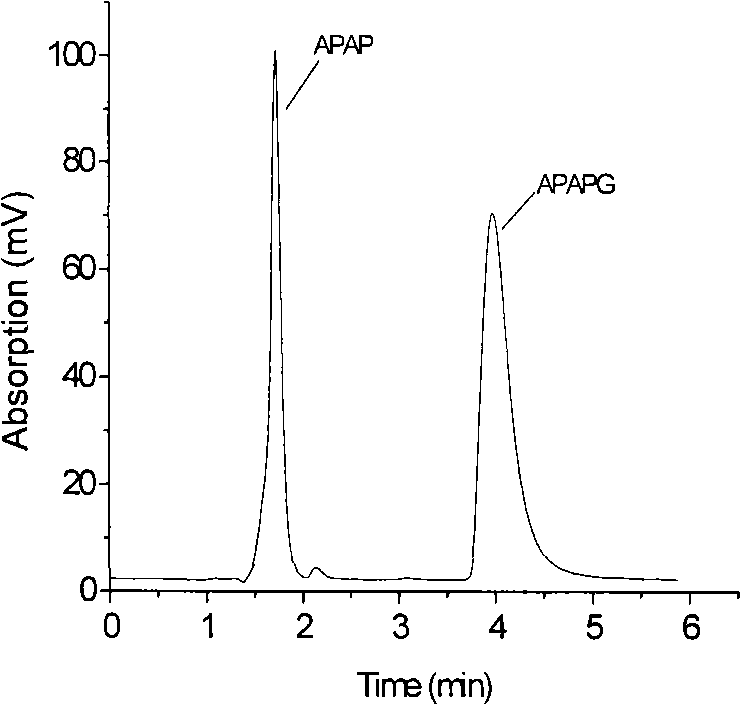

Porous integral medium, preparation and use thereof

InactiveCN101348577AMedium specific surface areaImprove permeabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityNanowire

The invention discloses a porous integral medium and a preparation method and application thereof. The invention provides the porous integral medium with a nanometer line cage construction, wherein the porous integral medium consists of a nanometer line network framework and micron-order through holes, the size of the network framework is between 50 and 500nm, and the aperture of each micron-order through hole is between 1 and 100mu m. The porosity of the porous integral medium is between 60 and 95 percent. The porous integral medium which has the very regular nanometer line network framework and internal pores arranged orderly has excellent properties of high porosity, larger specific surface area, controllable aperture size, etc. The excellent properties enable the medium to be characterized by low resistance, high efficiency, high flux, etc. while the characteristics of excellent biocompatibility, wide pH accommodation range, etc. brought by the draw material enlarge the application range of the medium.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heat-insulating and fire-resistant calcium alumino-titanate material and preparation method thereof

The invention relates to a heat-insulating and fire-resistant calcium alumino-titanate material and a preparation method thereof. According to the technical scheme, the method comprises the steps thatfine calcium alumino-titanate powder and coke powder are pre-mixed in a mass ratio of (8-9):1, and then placed in a tube furnace, heat preservation is conducted at the temperature of 1600-1700 DEG Cin the nitrogen atmosphere, and cooling, crushing and magnetic separation are conducted in sequence; heat preservation is conducted at the temperature of 1400-1450 DEG C, cooling and crushing are conducted, grinding is conducted until the particle size is smaller than or equal to 0.088 mm, and a mixture is obtained; sodium dodecyl benzene sulfonate accounting for 2-3 wt% of the mixture, dextrin accounting for 3-8 wt% of the mixture, sodium polyacrylate accounting for 0.2-0.5 wt% of the mixture and water accounting for 35-40 wt% of the mixture are added into the mixture, stirring, forming, maintaining and drying are conducted in sequence, heat preservation is conducted at the temperature of 1400-1500 DEG C, and the heat-insulating and fire-resistant calcium alumino-titanate material is obtained. The preparation method has the advantages of being low in cost, simple in process and high in yield. The heat-insulating and fire-resistant calcium alumino-titanate material has the advantages of being small in bulk density, high in compression strength, high in high-temperature breaking strength, small in heat conductivity coefficient and high in thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH +1

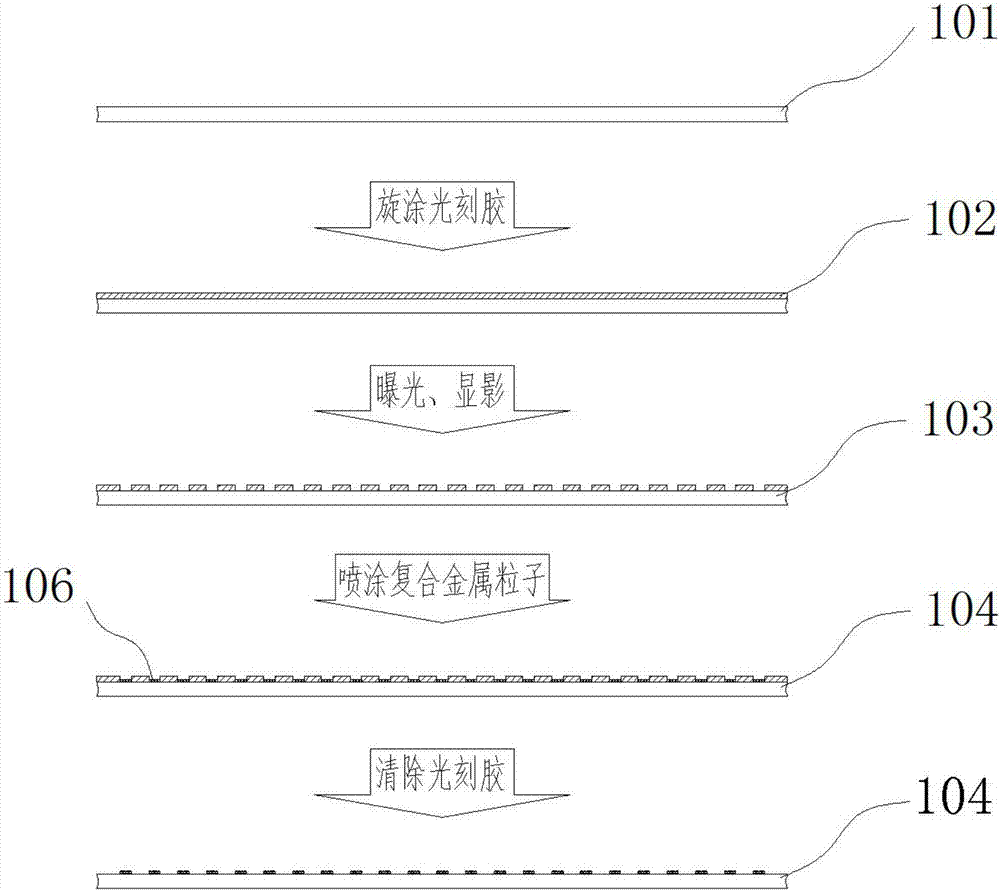

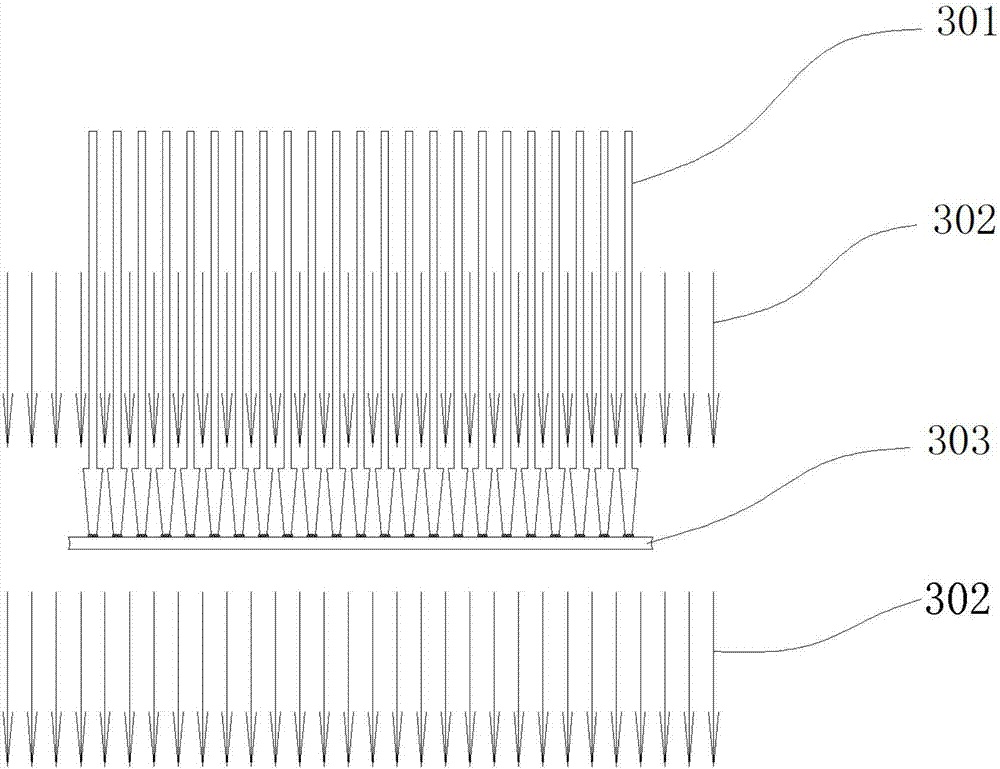

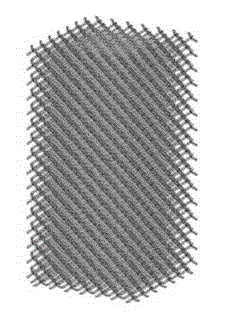

Processing method of nanometer-sized and micron-sized holes

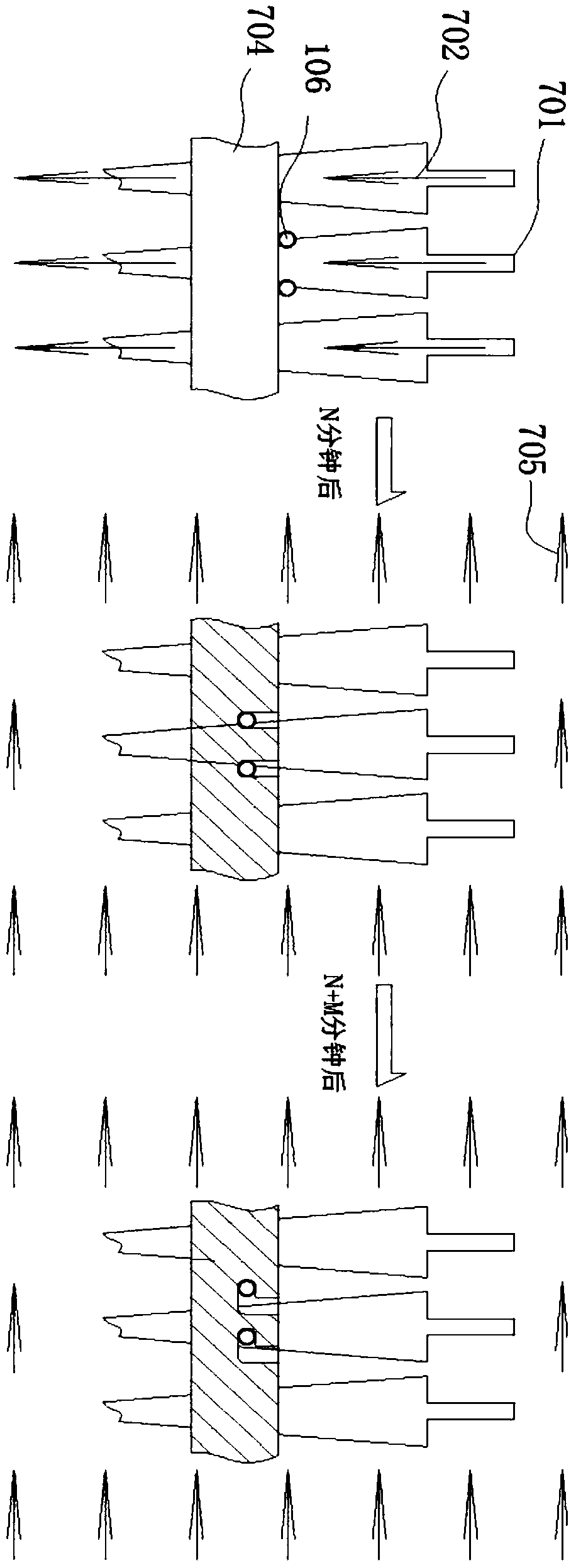

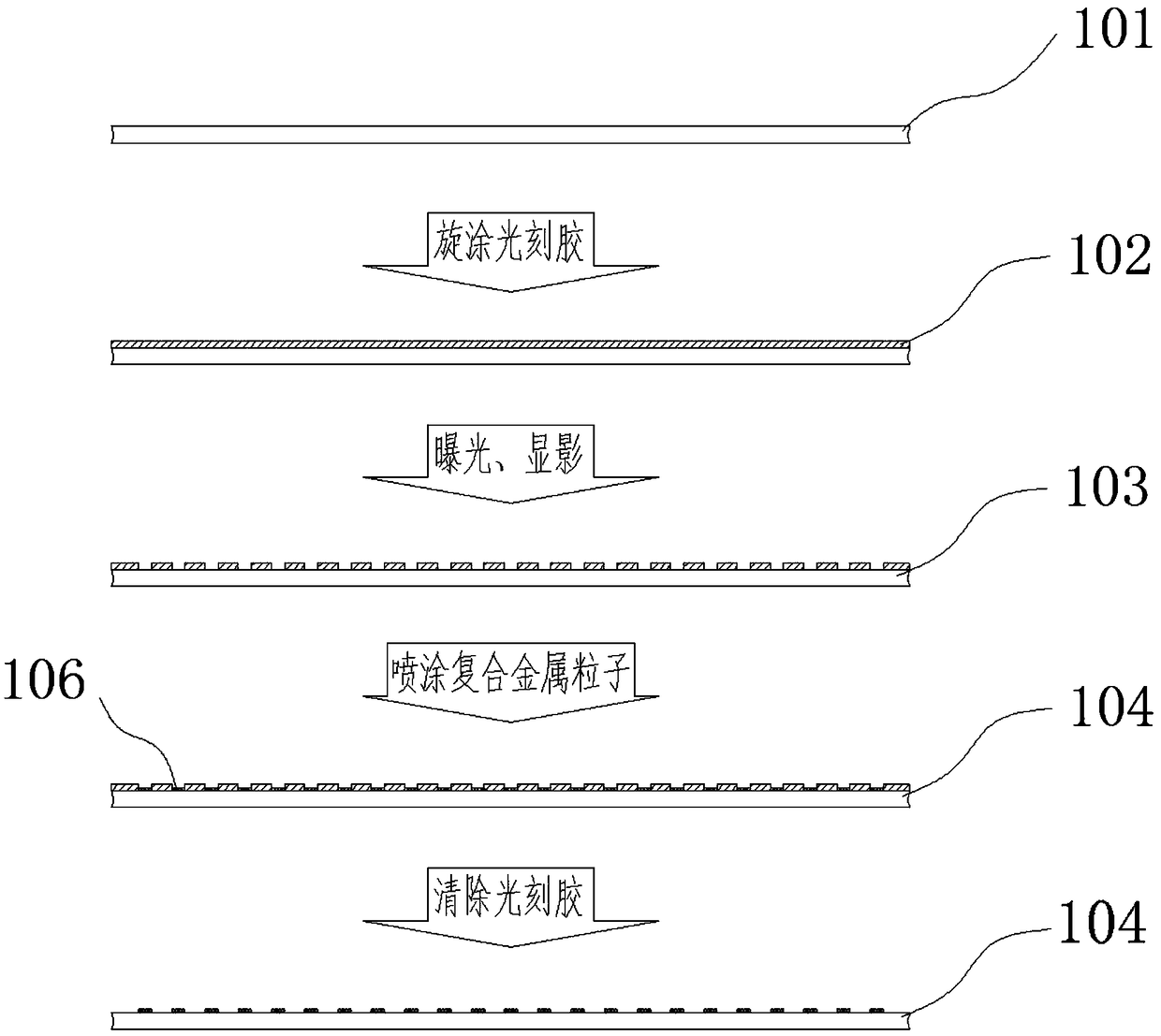

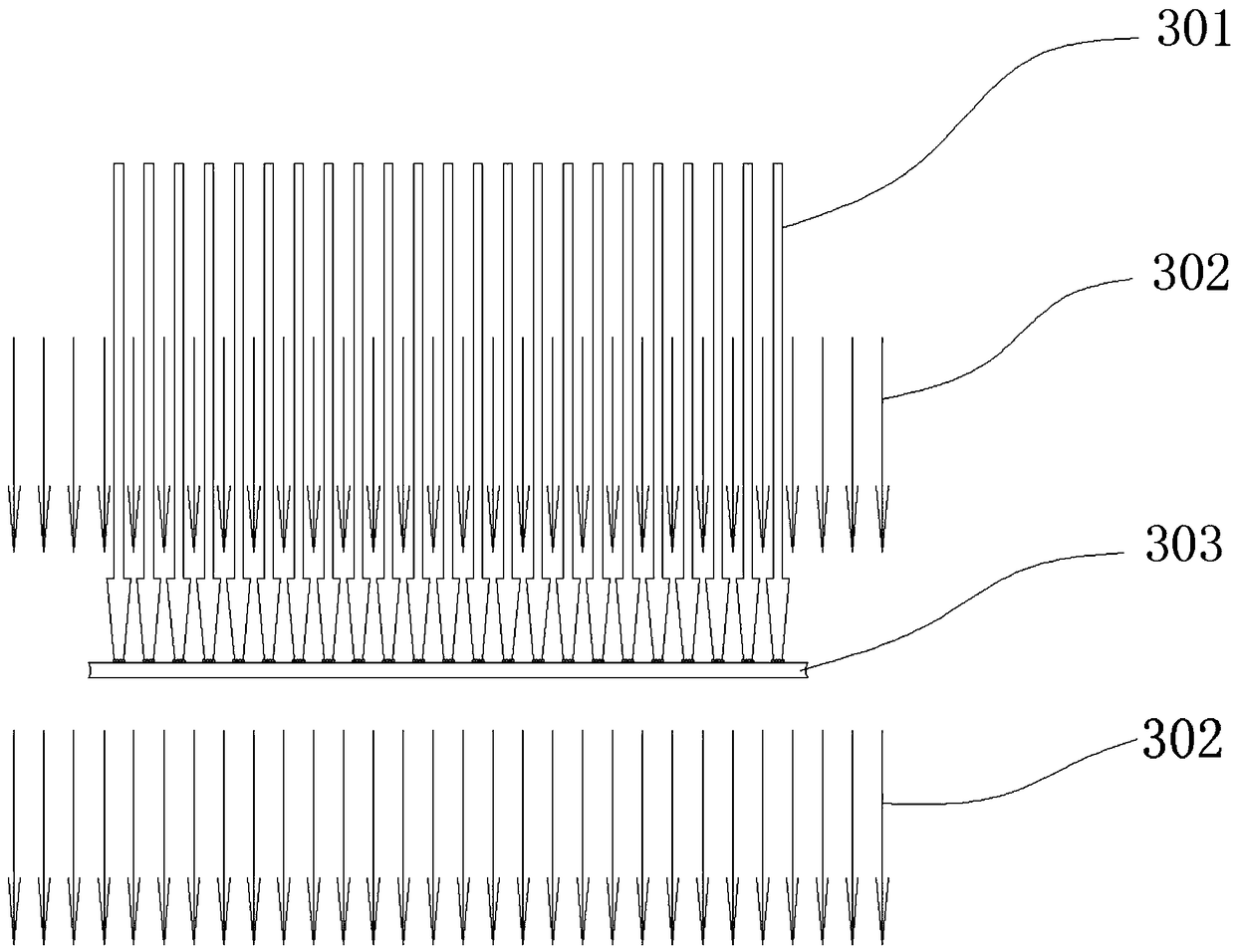

ActiveCN107973268AEasy to operateAperture size controllableDecorative surface effectsSemiconductor/solid-state device manufacturingMicro nanoMetal particle

The invention relates to a processing method of nanometer-sized and micron-sized holes, which comprises the following steps: (1) a base material is cleaned, and dirt on the surface is removed; (2) photoresist is spin-coated, and after exposure and development, a substrate is formed; (3) micro-nano composite structure metal particles are deposited on the surface of the substrate; and with a magnetic core as a center, the surface of the micro-nano composite structure metal particle is plated with a metal nanoparticle plating composed of a plurality of nano-gold, -silver or -aluminium particles;(4) the photoresist is removed with only a micro-nano composite structure metal particle dot array left; (5) laser is adopted to irradiate the substrate while a uniform strong magnetic field is applied, so that processed holes are formed by processing; (6) after nanometer-sized holes or micron-sized holes with a target hole diameter, shape and depth are achieved, laser irradiation is stopped and the uniform magnetic field is removed, and thereby a finished product is obtained. The processing method proposed by the invention can process blind holes or through holes with a hole diameter being 100nm or more and any nanometer-sized shape, is environmentally friendly, and is easy to operate, and the processed hole diameter, shape and depth can all achieve a controllable effect.

Owner:GUANGDONG UNIV OF TECH +1

Gradient porous Ti-6Al-4V block material concurrently having high strength and high absorption energy, and preparation method thereof

ActiveCN106148749APorosity is easy to controlEasy to control appearanceAdditive manufacturing apparatusPorosityHigh absorption

The invention discloses a gradient porous Ti-6Al-4V block material concurrently having high strength and high absorption energy, and a preparation method thereof, and belongs to the technical field of porous materials. According to the present invention, the large size Ti-6Al-4V gradient porous material with an effectively density of 0.2-2.0 g / cm<3> is prepared through an electron beam melting metal forming technology, and by adjusting the porosity distribution and the unit structure and optimizing the process parameters, the lightweight Ti-6Al-4V porous material concurrently having high strength (~200 MPa) and high absorption energy (~90 MJ / m<3>) and having low elastic modulus (0.1-20 GPa) is obtained; and the preparation method has characteristics of simple process and low cost, and is suitable for industrial scale production, and the porous Ti-6Al-4V block material can be widely used in the fields of aerospace, medical treatment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

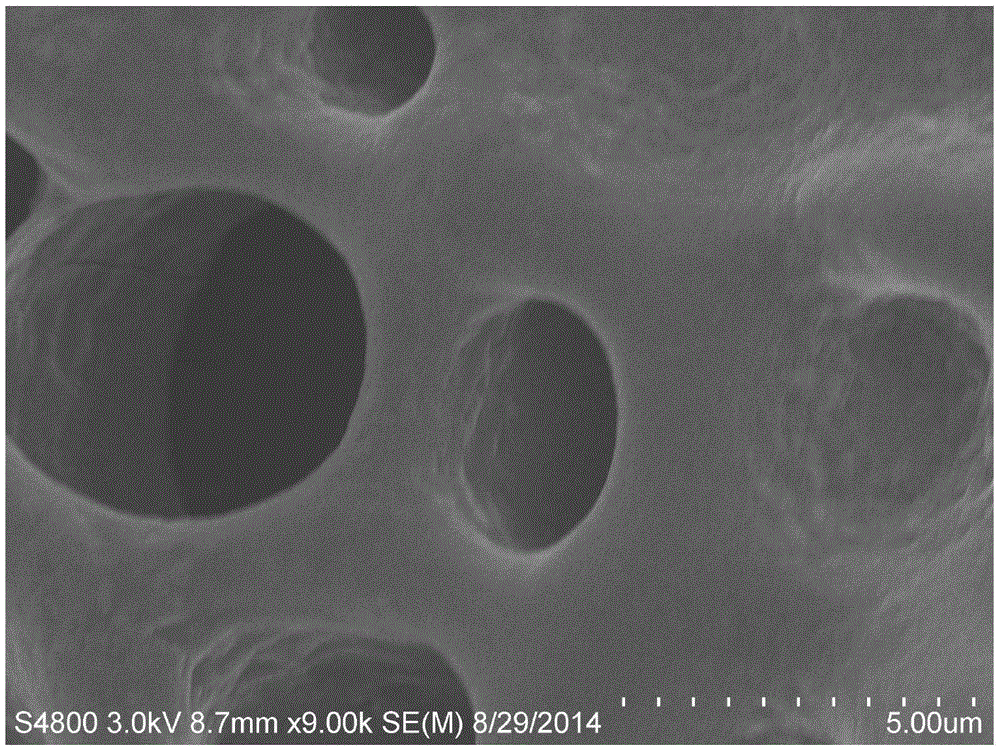

Porous graphene preparation method

The present invention belongs to the technical field of nanometer materials, and discloses a novel porous graphene preparation method, which specifically comprises: (1) respectively weighing a proper amount of a carbon-hydrogen-oxygen-containing organic matter and an inorganic salt; (2) uniformly mixing the carbon-hydrogen-oxygen-containing organic matter and the inorganic salt to obtain a mixture; and (3) heating the mixture under an inert gas atmosphere to achieve a temperature of 900-1600 DEG C so as to finally prepare the porous graphene. According to the present invention, the obtained graphene material having the porous structure has characteristics of uniform pore size distribution and controllable pore size, and is widely used in the fields of catalysis, adsorption, ultracapacitors and the like; the carbon-hydrogen-oxygen-containing organic matter and the inorganic salt are adopted as the raw materials to prepare the graphene, such that the variety of the raw materials is rich, the sources are wide, the cost is low, and the method is suitable for mass production; and the high temperature firing process is used, the process is simple and is easy to operate, no substance harm on the environment is introduced or generated, and the advantages of safety and environmental protection are provided.

Owner:NANJING UNIV OF POSTS & TELECOMM

Preparation method of laminar nanometer hydroxylapatite with controllable pore diameter

ActiveCN102862966ANarrow pore size distributionStrong periodicityNanotechnologyPhosphorus compoundsPhosphatePore diameter

The invention discloses a preparation method of laminar nanometer hydroxylapatite with a controllable pore diameter. The laminar nanometer hydroxylapatite with ordered pore canals, narrow distribution range of pore diameter, high periodicity, high dispersity and controllable pore diameter is prepared by performing a hydro-thermal reaction on a soluble calcium salt and soluble phosphate or phosphoric acid, which serve as major raw materials, and monododecyl phosphate serving as a template agent. The preparation method disclosed by the invention is simple, is low in raw material cost, has a wide source, and is easy to popularize.

Owner:FUZHOU UNIVERSITY

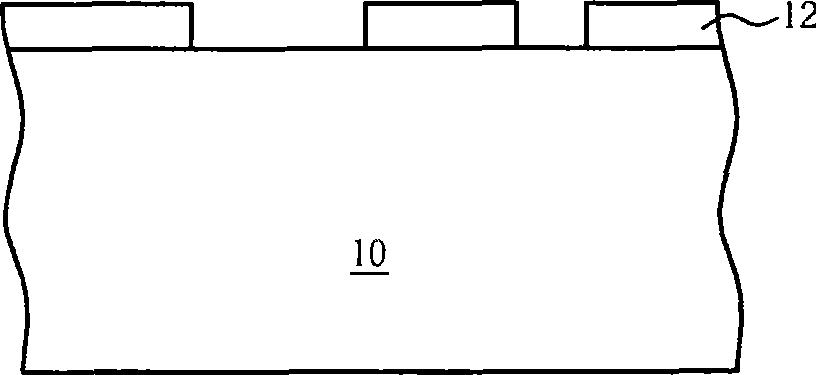

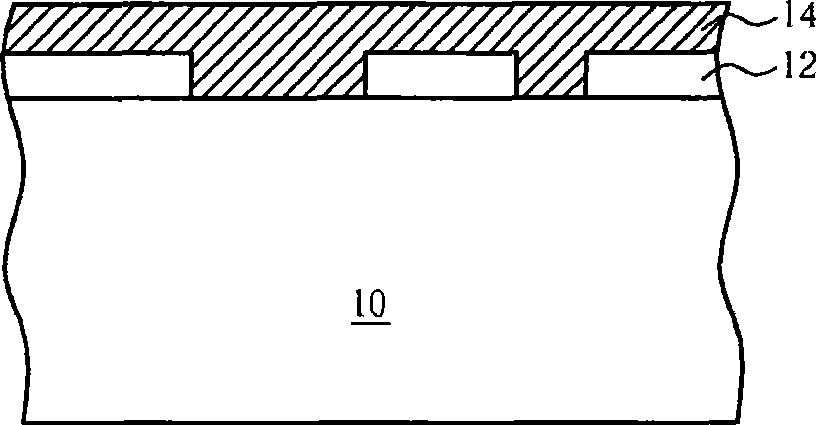

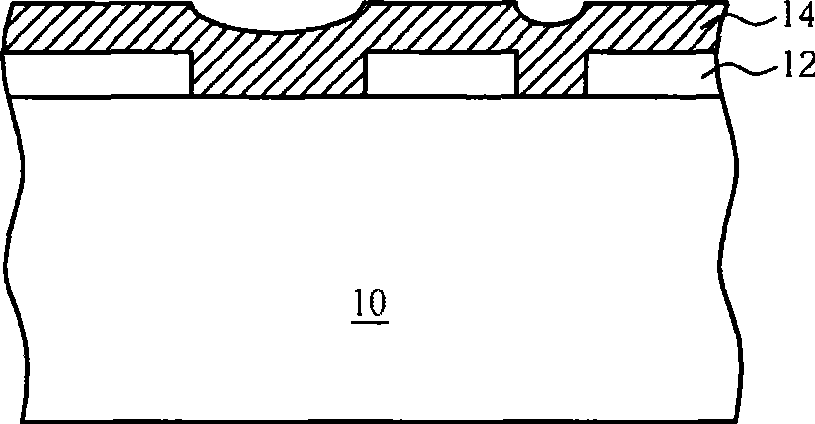

Circuit board producing method

InactiveCN101389189AAperture size controllableEasy to control roughness uniformityMultilayer circuit manufactureNon-metallic protective coating applicationFine lineInsulation layer

The invention provides a manufacturing method for circuit board, which is characterized in that when manufacturing additional layered insulation layer of circuit board, a fist dielectric layer is firstly formed, and a second dielectric layer is formed subsequently after the curing process, that is the same layer of additional layered insulation layer is formed by two times of forming and curing steps. Therefore, problem of surface unevenness of the additional layered insulation layer is avoided, and yield of the fine line is improved. Moreover, because of using the same dielectric material by the first dielectric layer and the second dielectric layer, operation condition of the subsequent blind hole machining and coursing process of the additional layered insulation layer is easy to control.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

Spherical active carbon and preparation method thereof

The invention relates to the field of active carbon preparation, and discloses spherical active carbon and a preparation method thereof. The method comprises the following steps: (1) mixing sulfonatedasphalt and an activating agent, and carrying out spray granulation on the obtained mixed solution to obtain mixed microspheres; (2) carrying out microwave activation on the mixed microspheres to obtain active microspheres; and (3) removing impurities from the active microspheres to obtain spherical active carbon, wherein the activating agent is potassium hydroxide, and the temperature of spray granulation is 600-1000 DEG C. The preparation method is simple and rapid, and the prepared spherical active carbon has the advantages of good sphericity, large specific surface area, uniform and controllable pore diameter, uniform particle size distribution and excellent adsorption performance.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

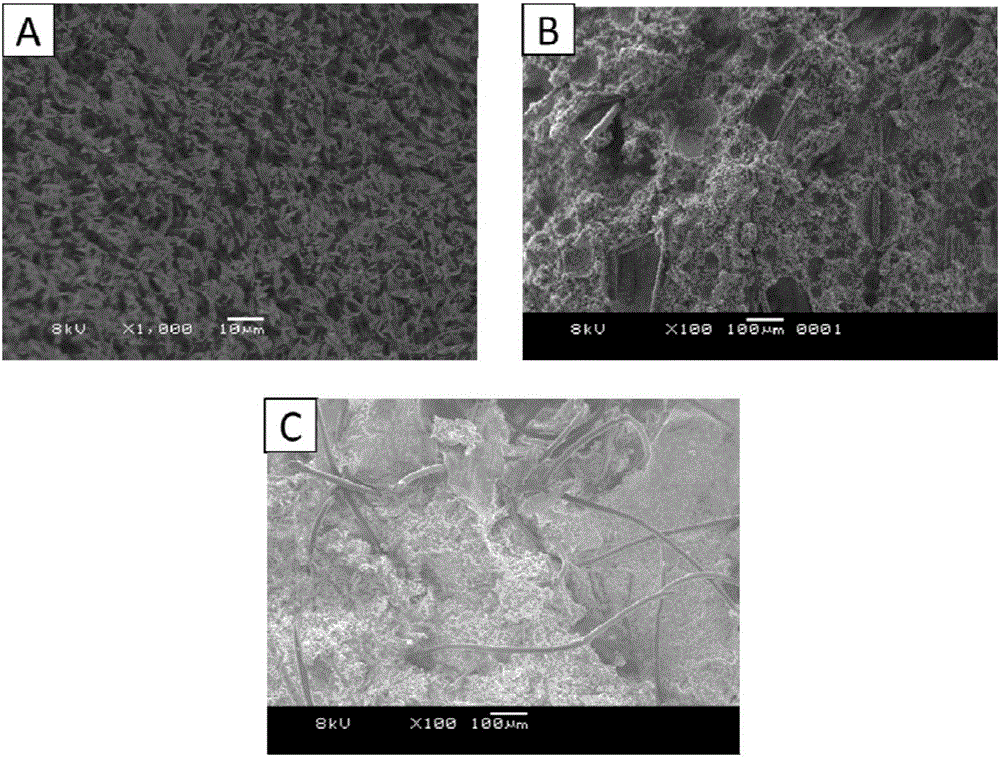

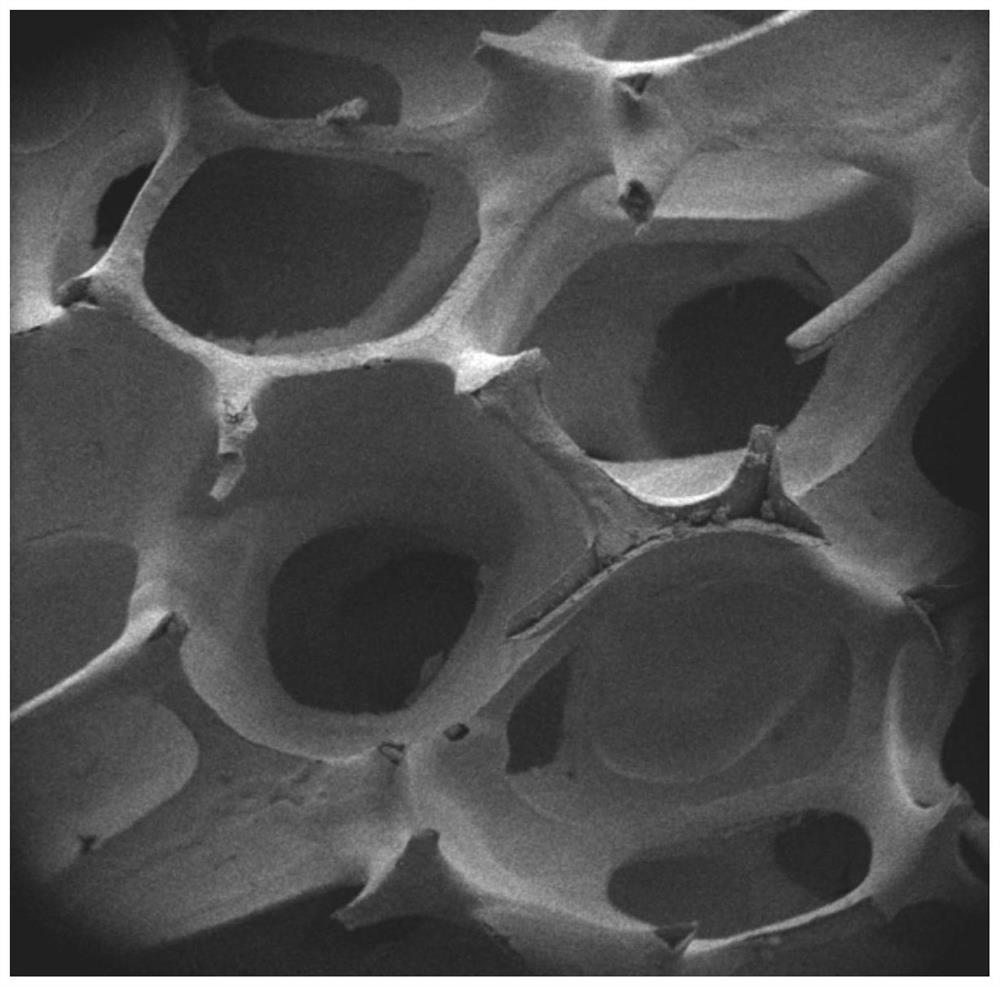

Preparation method of high-performance ceramic reinforced iron-based composite material

ActiveCN112481541AGood wear resistanceGood impact resistanceLiquid/solution decomposition chemical coatingCeramicwareOxide ceramicAluminium oxide

The invention relates to a high-performance ceramic reinforced iron-based composite material and a preparation method thereof, and belongs to the technical field of composite materials. The compositematerial comprises an iron matrix and a three-dimensional network-shaped ZTA ceramic. The three-dimensional network-shaped ZTA ceramic is a three-dimensional network-shaped ZTA ceramic with a macroscopic size, and the iron matrix penetrates through the three-dimensional network-shaped ZTA ceramic and coats the surface of the three-dimensional network-shaped ZTA ceramic. The preparation method comprises the following steps of sintering zirconium oxide and aluminum oxide ceramic mixed powder slurry through a template replication method to obtain the three-dimensional network-shaped ZTA ceramic;casting and infiltrating molten iron into the three-dimensional network-shaped ZTA ceramic to obtain the three-dimensional network-shaped ZTA ceramic reinforced iron-based composite material. The composite material has the advantages of excellent shock resistance, impact resistance and wear resistance under various severe working conditions.

Owner:CENT SOUTH UNIV

Molybdenum platinum porous composite material as well as preparation method and application thereof

InactiveCN108220996ASmall particle sizeMany active sitesElectrolytic coatingsElectrodesNew energyCarbon nanotube

The invention provides a molybdenum platinum porous composite material as well as a preparation method and application thereof. The preparation method comprises the following steps that a carbon nanotube is added into a solvent; turbid liquid is formed through ultrasound, and is then dripped on the surface of a pretreated glassy carbon electrode; a carbon nanotube thin layer is formed; a glassy carbon electrode is obtained; the glassy carbon electrode modified by the carbon nanotube is put into electroplating liquid to implement the electroplating; cleaning and natural drying are performed; then, the glassy carbon electrode containing a molybdenum sulfide carbon nanotube composite material is put into a sulfuric acid solution; pt is used as a counter electrode; a saturated calomel electrode is used as a reference electrode; under the certain condition, the glassy carbon electrode coated with a molybdenum platinum / carbon nanotube composite material is obtained; the glassy carbon electrode is cleaned by water and is naturally dried at normal temperature; the composite material is scrapped from the surface of the glassy carbon electrode to obtain a final product. The operation of themethod is simple; the prepared composite material has great advantages in the aspects of electrocatalysis hydrogen production, electrocatalysis oxygen evolution, electrocatalysis oxygen reduction andenergy conversion; the composite material can be applied to the fields of fuel battery and new energy source conversion.

Owner:WENZHOU UNIVERSITY

Preparation method of light-weight high-strength calcium hexaluminate fire resistant material

ActiveCN108558418AHigh porosityAperture size controllableCeramicwareCompression moldingSpray Granulation

The invention provides a preparation method of a light-weight high-strength calcium hexaluminate fire resistant material. The method is characterized by comprising the following steps that (1) 38-60%of calcarea carbonica raw material and 40-62% of aluminium hydroxide are mixed by weight and mixed with, by weight, 80-120% of water, 0.02-0.05% of dispersing agent and 1-4% of binding agent, and ball-milling is carried out for 3-5 hours to obtain a mixed slurry; (2) spray granulation is carried out on the mixed slurry to obtain spherical fine particles; (3) the spherical fine particles are calcined at 1000-1200 DEG C to obtain light-weight porous beads; (4) 15-30% of light-weight porous beads and 70-85% of aluminium oxide raw material are mixed by weight and mixed with 2-6% of binding agent by weight, after stirring is uniform, compression molding is carried out under 10-30 MPa, and calcination is carried out for 6-8 hours at 1600-1700 DEG C to obtain the light-weight high-strength calcium hexaluminate fire resistant material.

Owner:遵义润辉实业有限公司

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN100393397CAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

Owner:TIANJIN UNIV

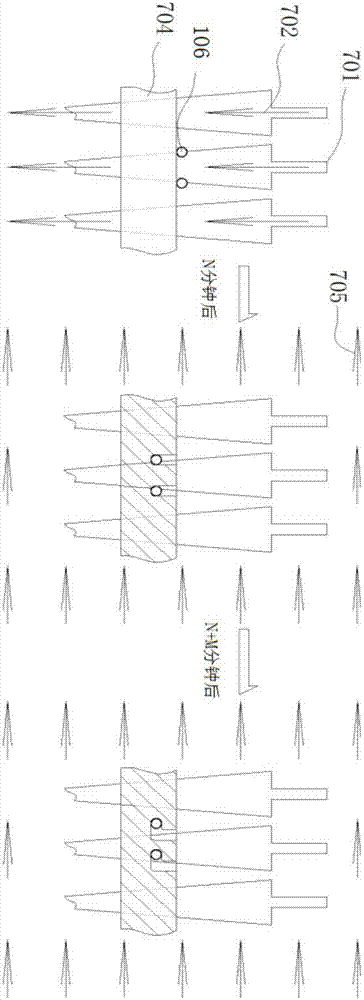

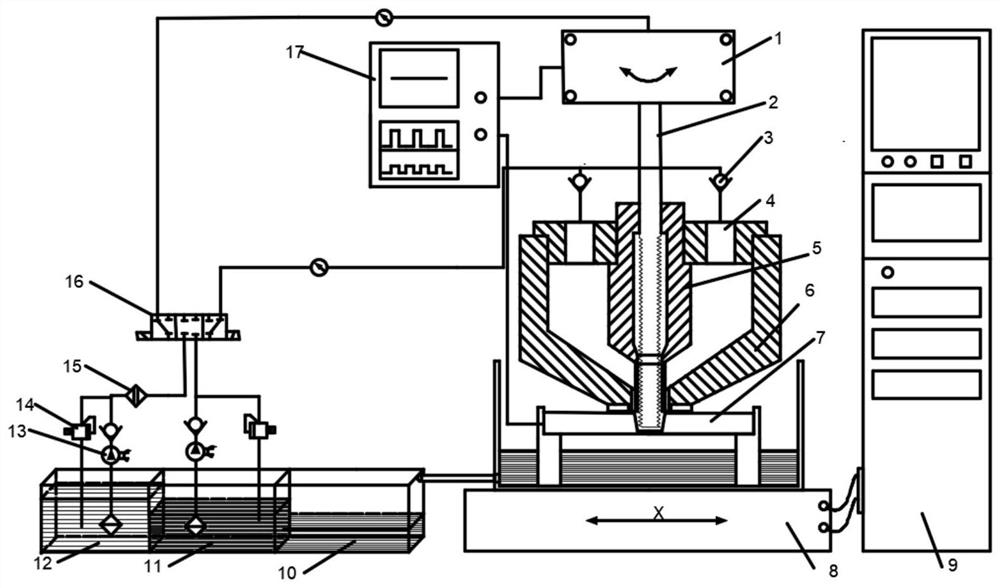

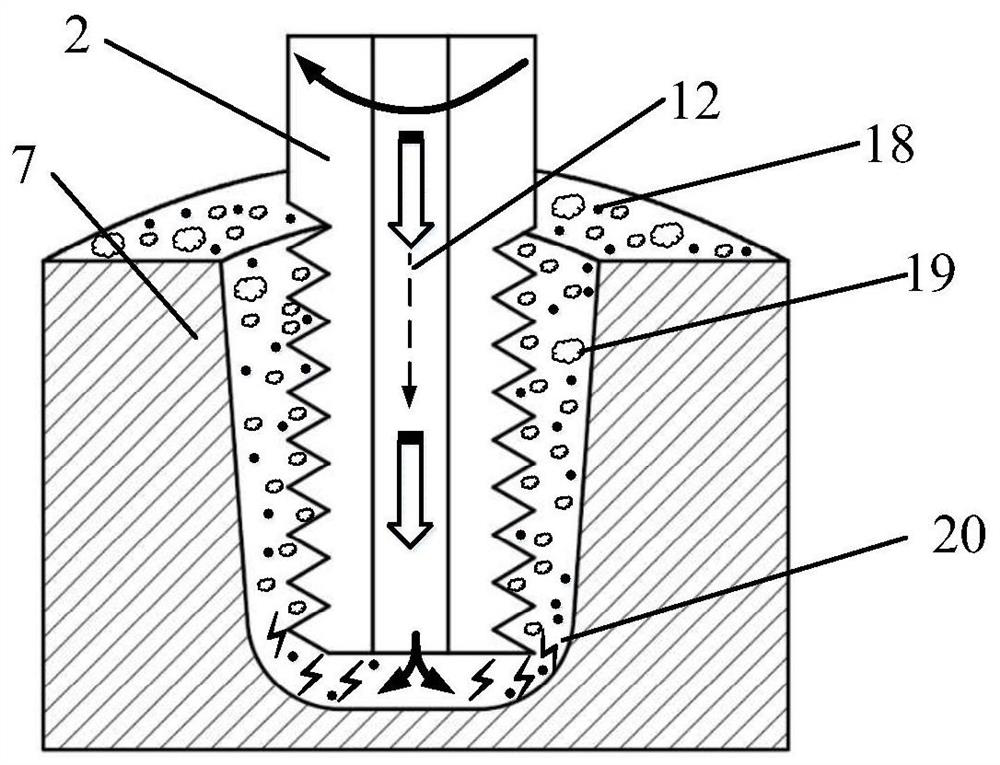

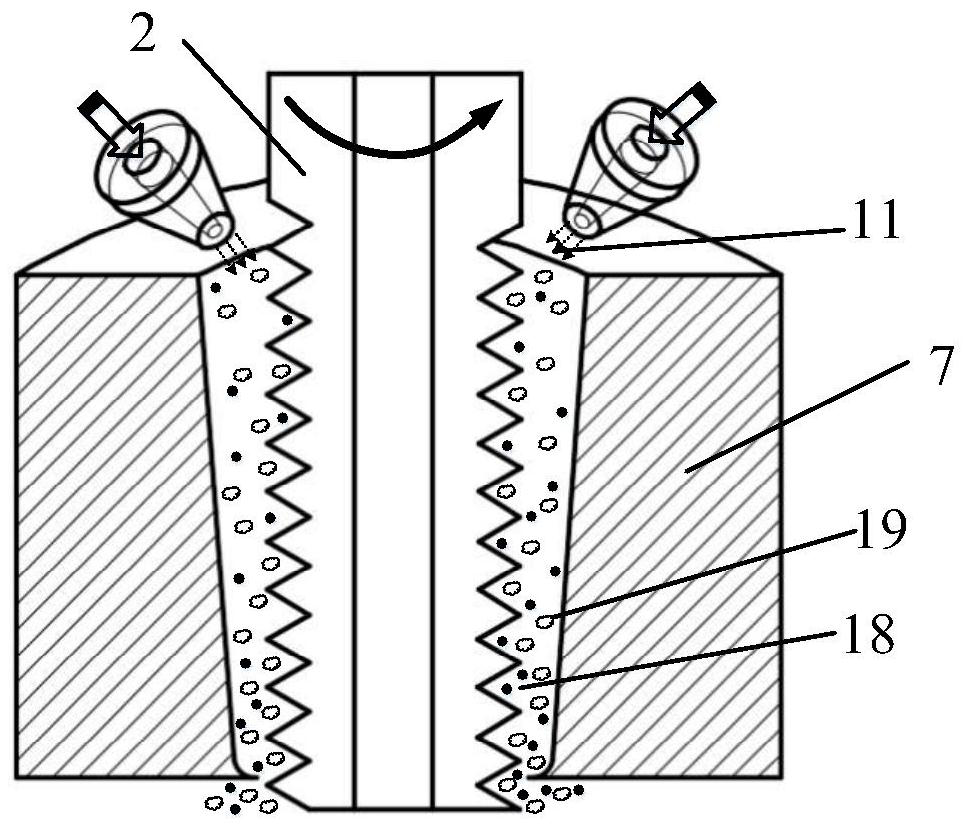

Method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing

The invention provides a method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing. At the electric spark high-speed hole making machining stage, an electric spark pulse power source is connected, the inner liquid flushing manner is adopted for leading in of deionized water, in cooperation with rotation of thethread pipe electrode, meanwhile, downward feeding is carried out, when the interpolar distance is up to the electric spark discharge gap, a pulse electric spark is generated, a workpiece material issubjected to corrosion removing, through thread rotation disturbance and upward action force of a thread groove on electric corrosion solid small particles, the electric corrosion solid small particles can be rapidly and upwards discharged, when a workpiece is subjected to breakdown, the electrode station is kept unchangeable, an electrolysis power source is connected, outer liquid flushing is replaced, an outer nozzle is aligned with the gap to spray an electrolyte, in cooperation with reverse rotation of the thread pipe electrode, the thread groove can contain more electrolyte to enter thenarrow and small gap, the workpiece has the anodic dissolution reaction, electrolytic flocs can be rapidly and downwards discharged under extrusion of the thread groove, micro hole manufacturing highprecision and high efficiency can be ensured, and the hole wall non-micro-crack and non-recast-layer machining needs can be achieved.

Owner:NANJING UNIV OF TECH

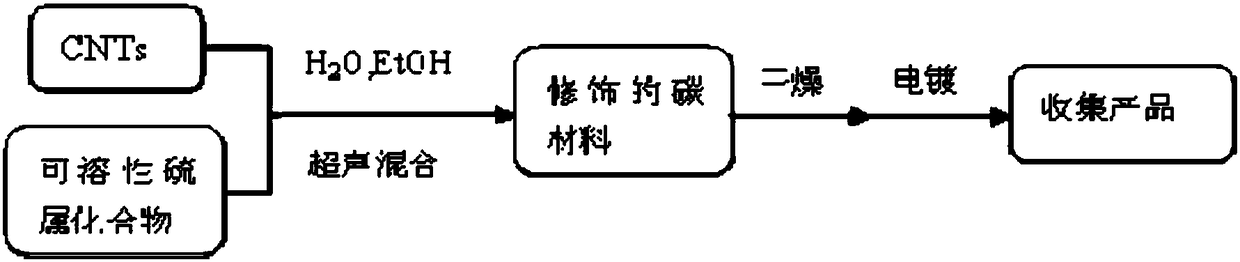

Carbon composite material modified by chalcogen compound and transition metal as well as preparation method and application of carbon composite material

ActiveCN108273524AUniform shapeThe size is easy to controlCell electrodesCatalyst activation/preparationSupporting electrolyteCarbon composites

The invention provides a carbon composite material modified by a chalcogen compound and a transition metal as well as a preparation method and application of the carbon composite material. The preparation method comprises the following steps: adding a mixture of carbon nanotubes and the soluble chalcogen compound into a solvent, performing ultrasonic treatment to form a suspension liquid, adding the suspension liquid dropwise to the surface of a pretreated glassy carbon electrode, and performing natural drying to form a uniform carbon nanotube thin layer, so as to obtain a glassy carbon electrode modified by a mixture of the carbon nanotubes and the chalcogen compound; adding a transition metal salt and a supporting electrolyte into deionized water, and adjusting the pH to 0-13 by using sulfuric acid to obtain an electroplating solution; and placing the glassy carbon electrode modified with the mixture of the carbon nanotubes and the chalcogen compound into the electroplating solution,performing electroplating, performing washing by using water, and performing natural drying at normal temperature to obtain the final product. The method provided by the invention is simple in operation, and the obtained composite material has great advantages in catalysis of hydrogen evolution and energy conversion, and can be applied to the fields of electro-catalyzing water decomposition for hydrogen production and photoelectric conversion.

Owner:WENZHOU UNIVERSITY

A kind of processing method of nanometer and micrometer hole

ActiveCN107973268BEasy to operateAperture size controllableDecorative surface effectsSemiconductor/solid-state device manufacturingMetal particlePhotoresist

A method for processing nano and micro holes, comprising the following steps: 1. Cleaning a base material and removing dirt on its surface; 2. Spin-coating photoresist, exposing and developing to form a substrate; 3. Depositing micro-nano holes on the surface of the substrate. Composite structure metal particles; the micro-nano composite structure metal particles are centered on the magnetic core, and the surface is coated with nano-metal particle coatings composed of multiple nano-gold, silver or aluminum particles; 4. Remove the photoresist and only retain the micro-nano composite structure Metal particle dot array; 5. Use laser to irradiate the substrate, and apply a uniform strong magnetic field at the same time to process and form processing holes; 6. After reaching the target aperture size, shape, and depth of nano-holes or micro-holes, stop laser irradiation and remove the uniform strong magnetic field , to obtain finished products; the processing method proposed by the present invention can process blind holes or through holes of any shape with a diameter above 100nm and a micron level, which is environmentally friendly and easy to operate, and the processed aperture size, shape and depth can all achieve controllable effects .

Owner:GUANGDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com