Patents

Literature

49results about How to "Implement gradient distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reliving FCC dead catalyst

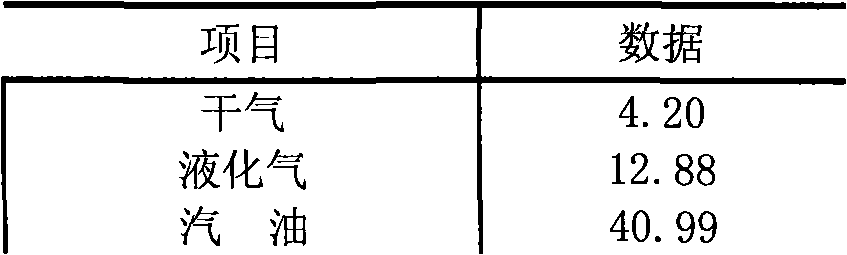

ActiveCN101219396AIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Gel-casting 3D printing preparation method for ceramic gradient material

InactiveCN104493952AImplement gradient distributionImprove work efficiencyCeramic shaping apparatusGradient materialAdditive ingredient

The invention discloses a gel-casting 3D printing preparation method for ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material includes steps that 1) building a computer three-dimensional sketch map of the ceramic gradient material, slicing, and building a scanning route; 2) calculating ingredient proportions of different positions; 3) setting corresponding printing parameters; 4) preparing ceramic ingredient, organic monomer, cross-linking agent, initiator, catalyst and the like; 5) starting printing equipment to perform sol-gel 3D printing, pouring the ceramic ingredient, organic premixed liquid, initiator and catalyst to a printing head, and printing to form according to a set track and a set speed after mixing; 6) sintering the green body to prepare the ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material has advantages that the gradient distribution for the ingredients is really realized through using a computer to control the ingredient proportions at different positions; the 3D printing technology belongs to a material increase preparing method, compared with a traditional technique, raw material is saved.

Owner:HARBIN UNIV OF SCI & TECH

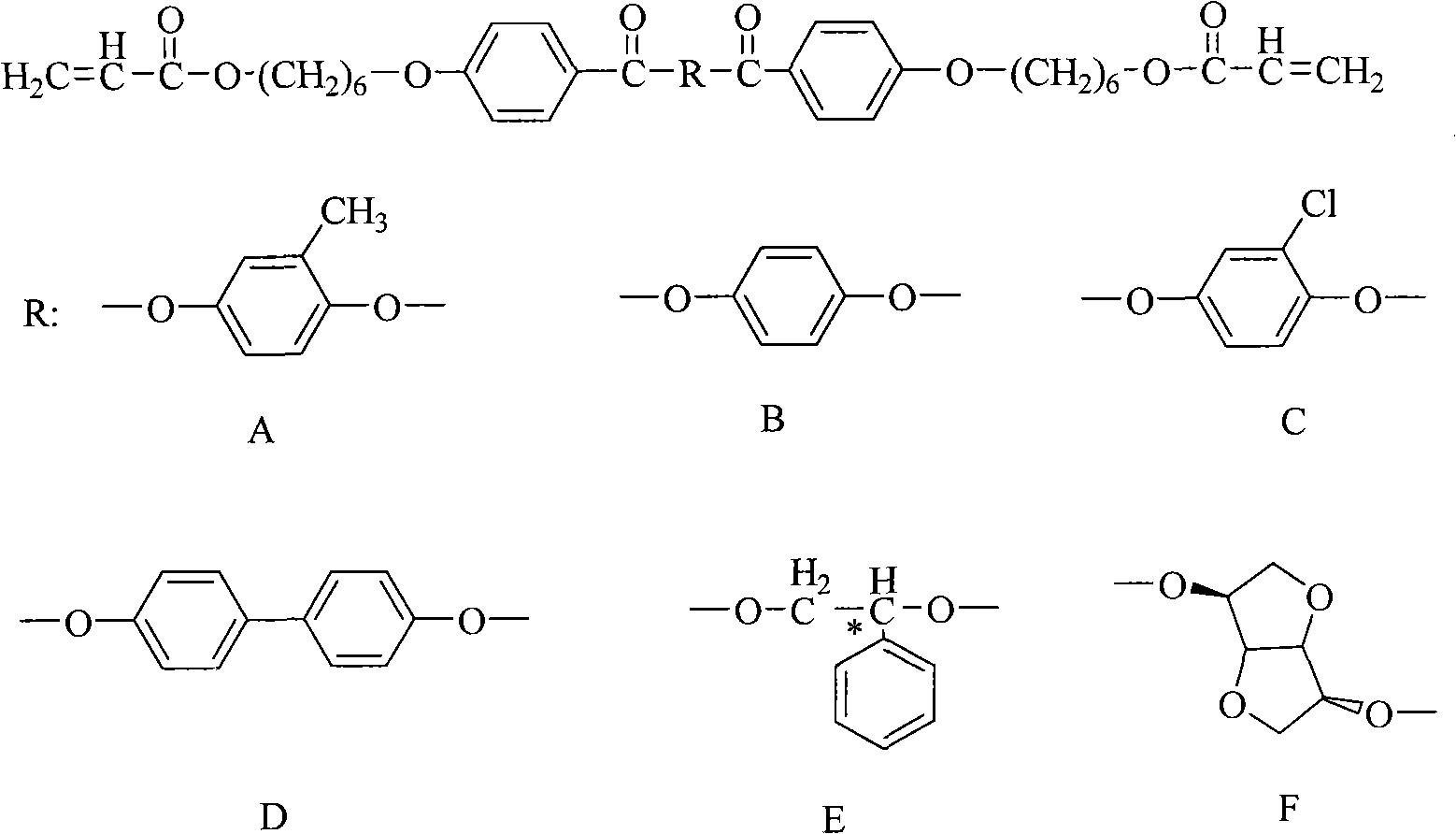

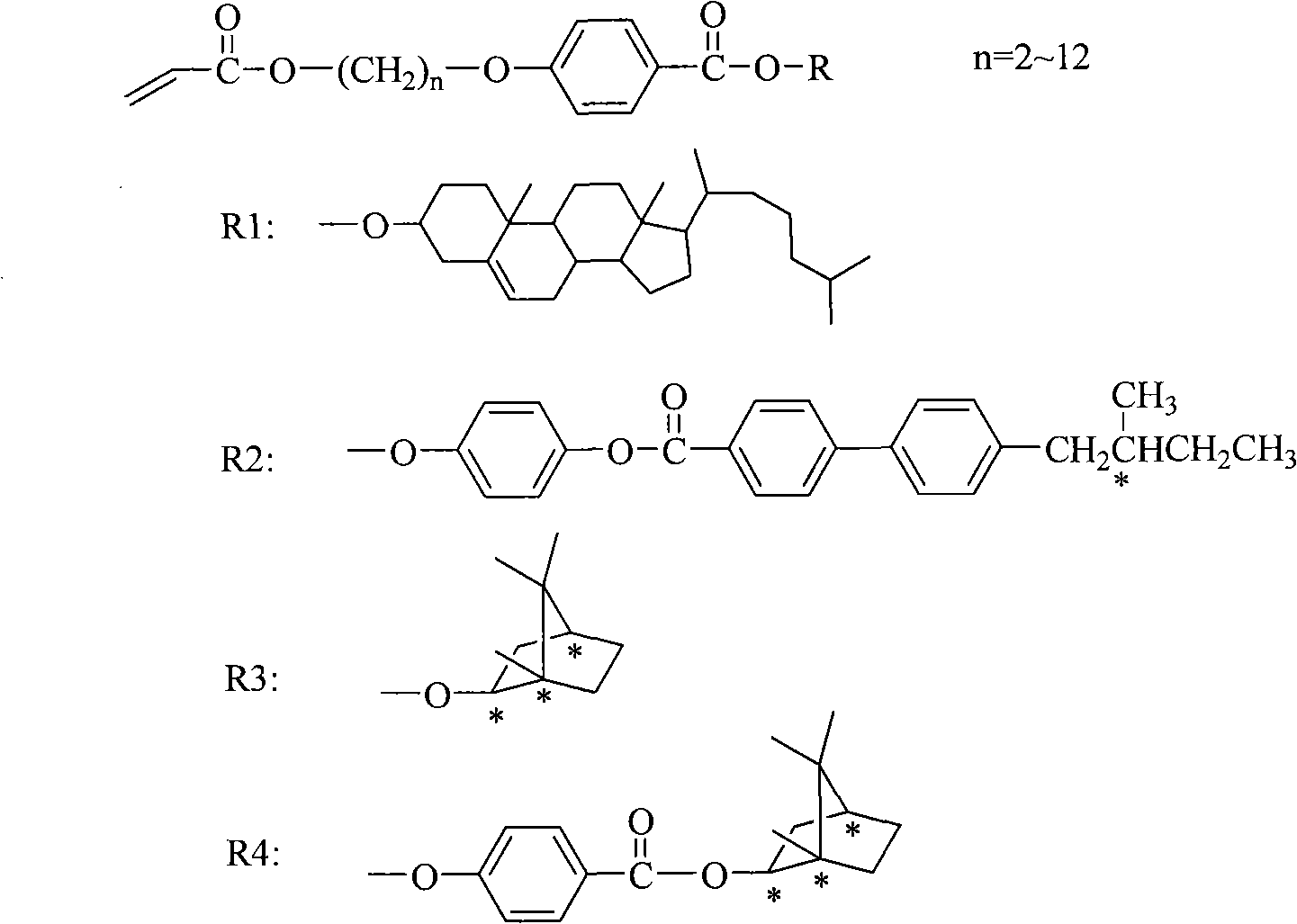

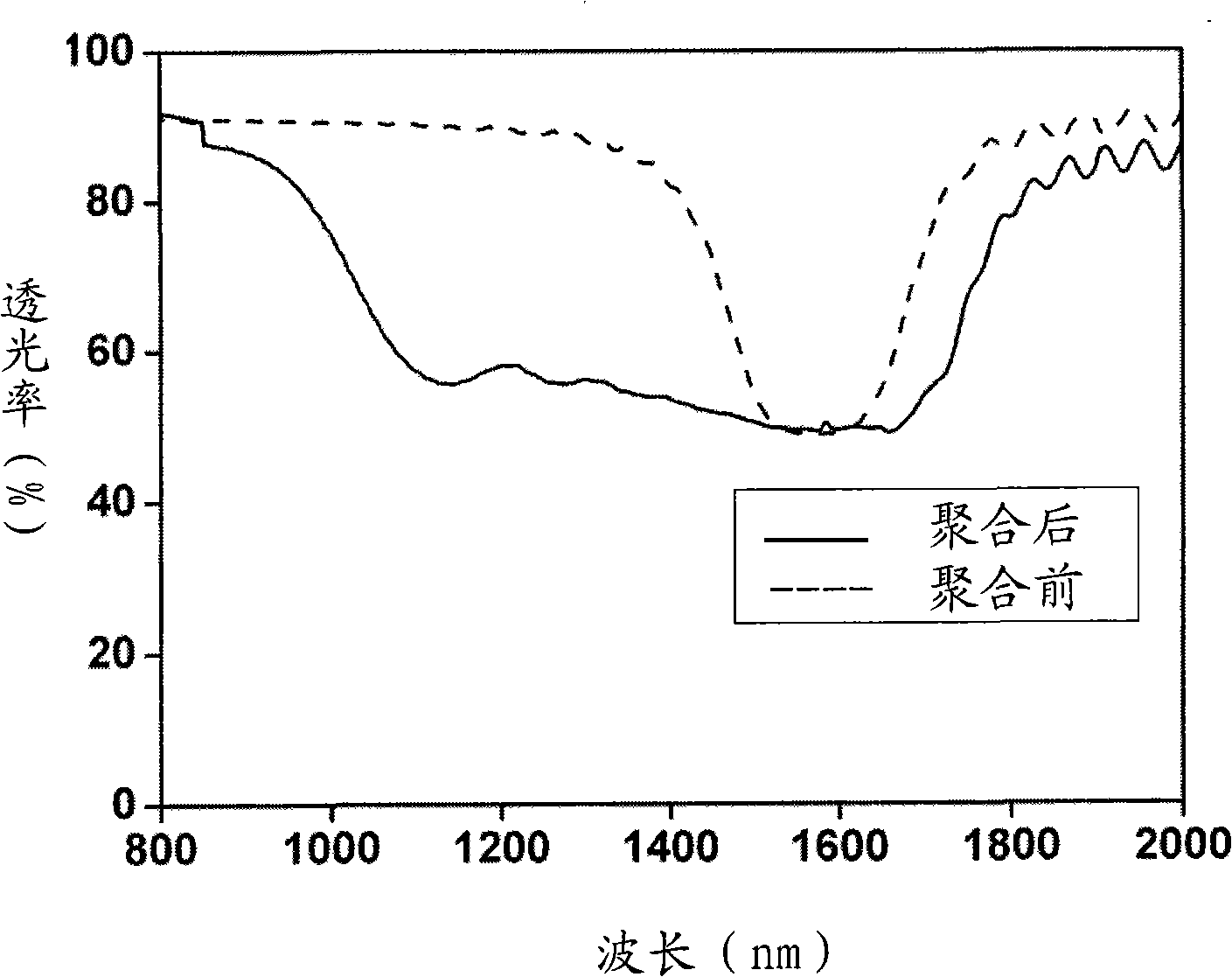

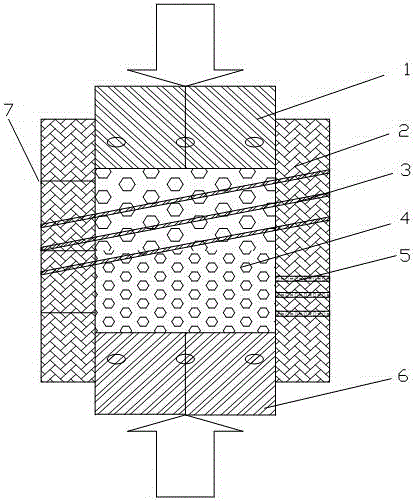

Method for preparing LCD polarized sheet with wide wave reflection characteristic

InactiveCN101281269AStable planar textureWiden reflection widthPolarising elementsCross-linkCrystallography

The present invention provides a preparing method of liquid crystal polarizing sheet with broad wave reflection characteristic, pertaining to the liquid crystal material application and correlation technique field. Small molecule nematic phase liquid crystal, chiral polymerisable simple function group monomer, chiral compound, chiral or non-chiral polymerisable double functional group monomer, photo-initiation agent, polymerization inhibitor, and the like are homogeneously mixed to inject in a liquid crystal box whose interior surface has an inverse parallel orientation process; the liquid crystal is at a cholesteric liquid crystal plane textile state, to execute ultraviolet irradiation, thereby the light polymerisable monomers are cross linked into a polymer network, the screw pitch of the cholesteric liquid crystals are in a gradient distribution, so that the liquid crystal polarizing sheet with broad wave reflection characteristic can be obtained. The present invention can realize the liquid crystal polarizing sheet with broad wave reflection band, and the reflection area can be arbitrarily regulated according to the content of the chiral compound and the chiral polymerisable monomer; the optical quality can be reciprocally changed between the transparent state and the dispersion state with broad wave reflection characteristic; the polarizing sheet has simple preparing technique and low cost.

Owner:UNIV OF SCI & TECH BEIJING

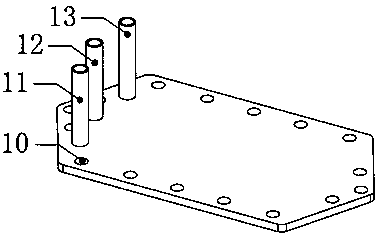

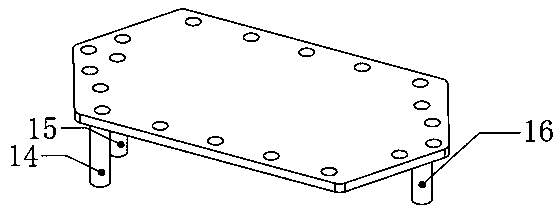

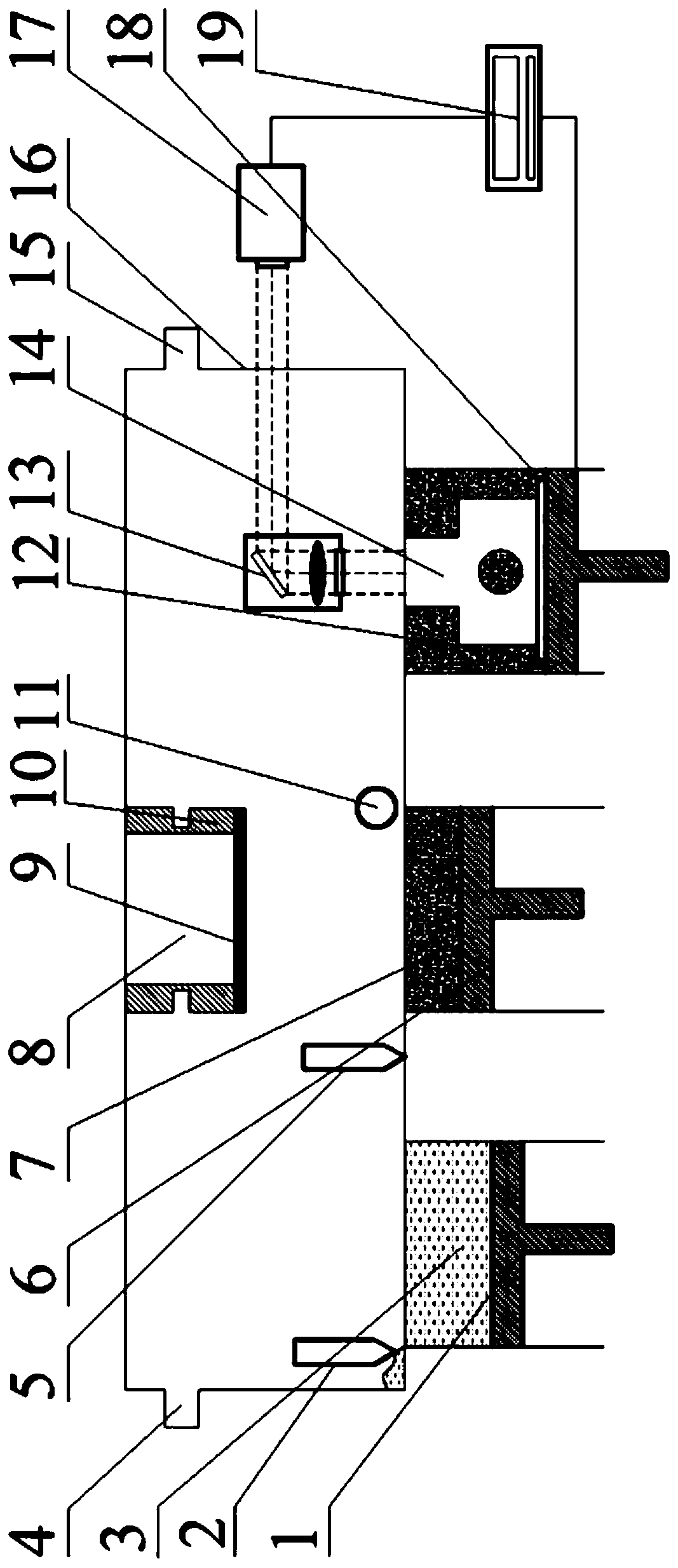

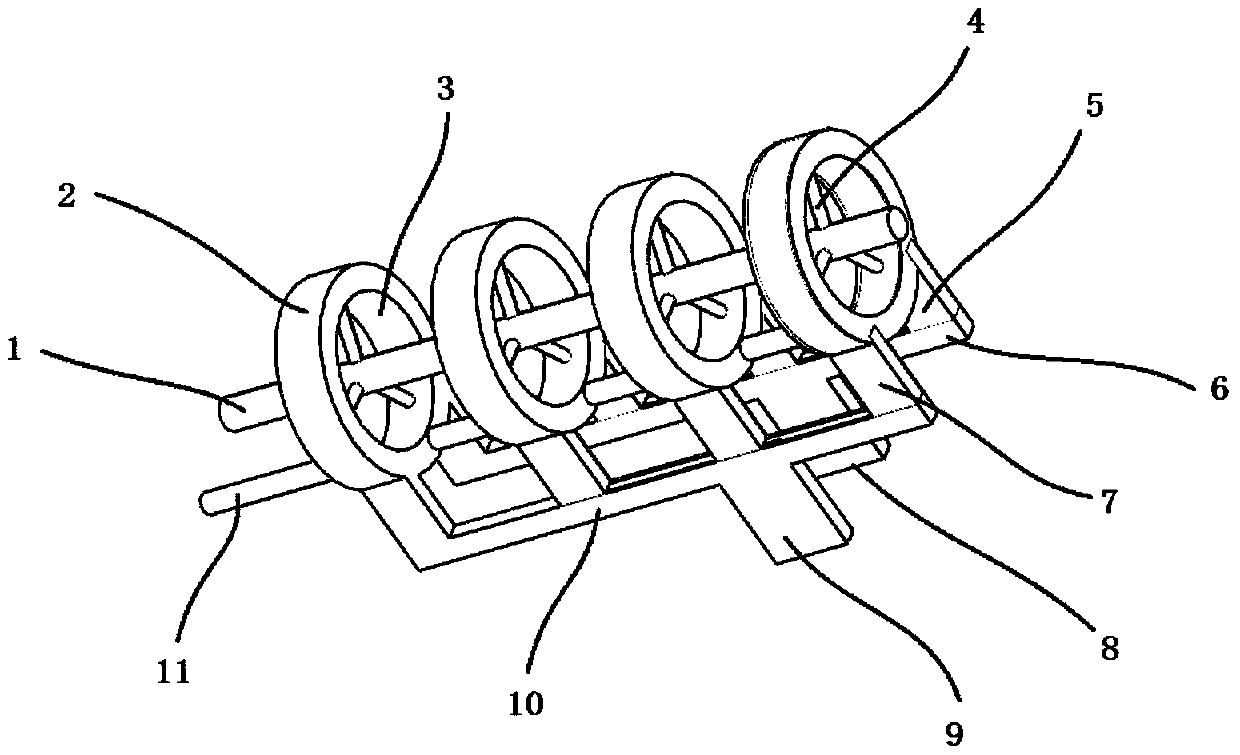

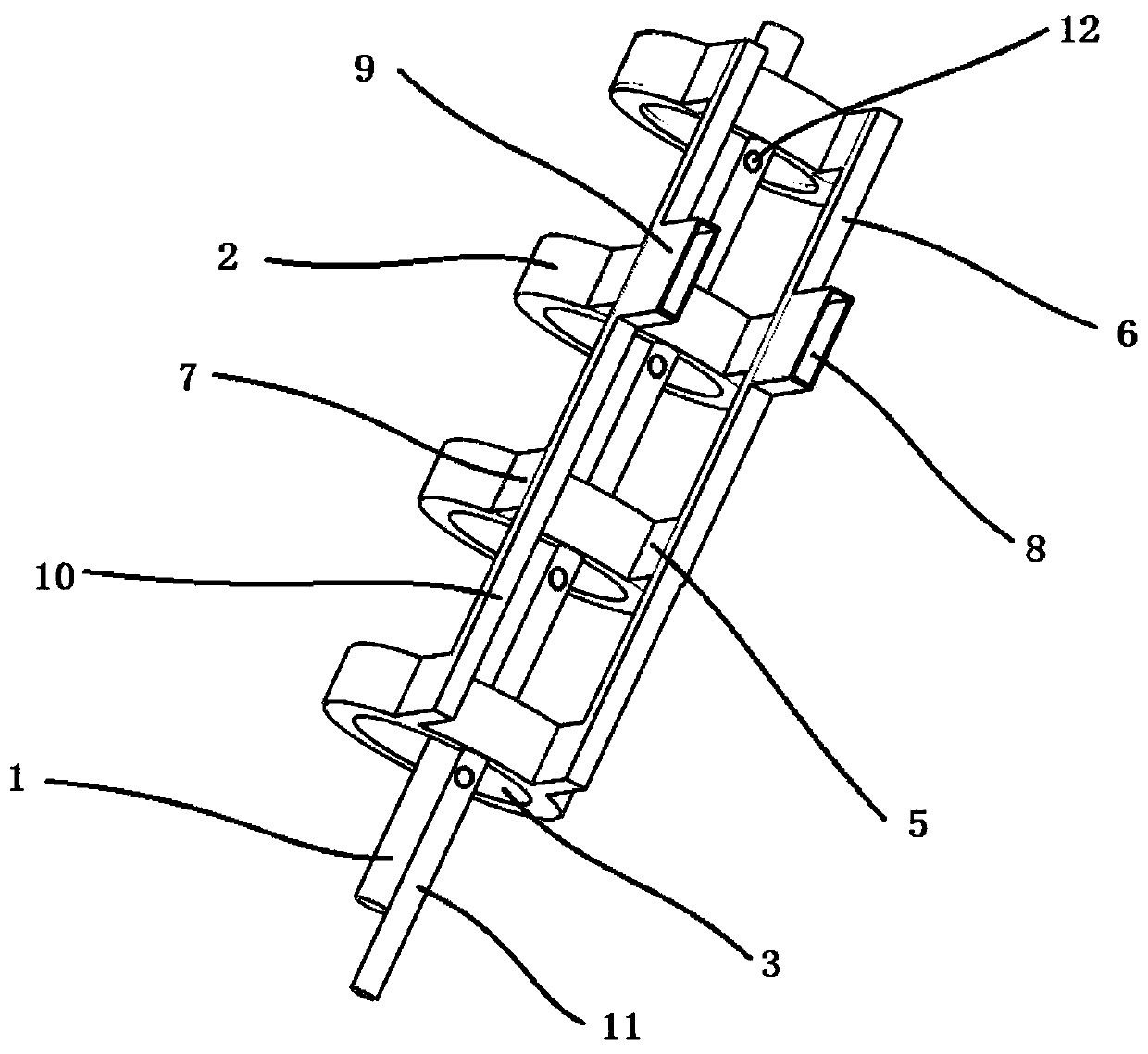

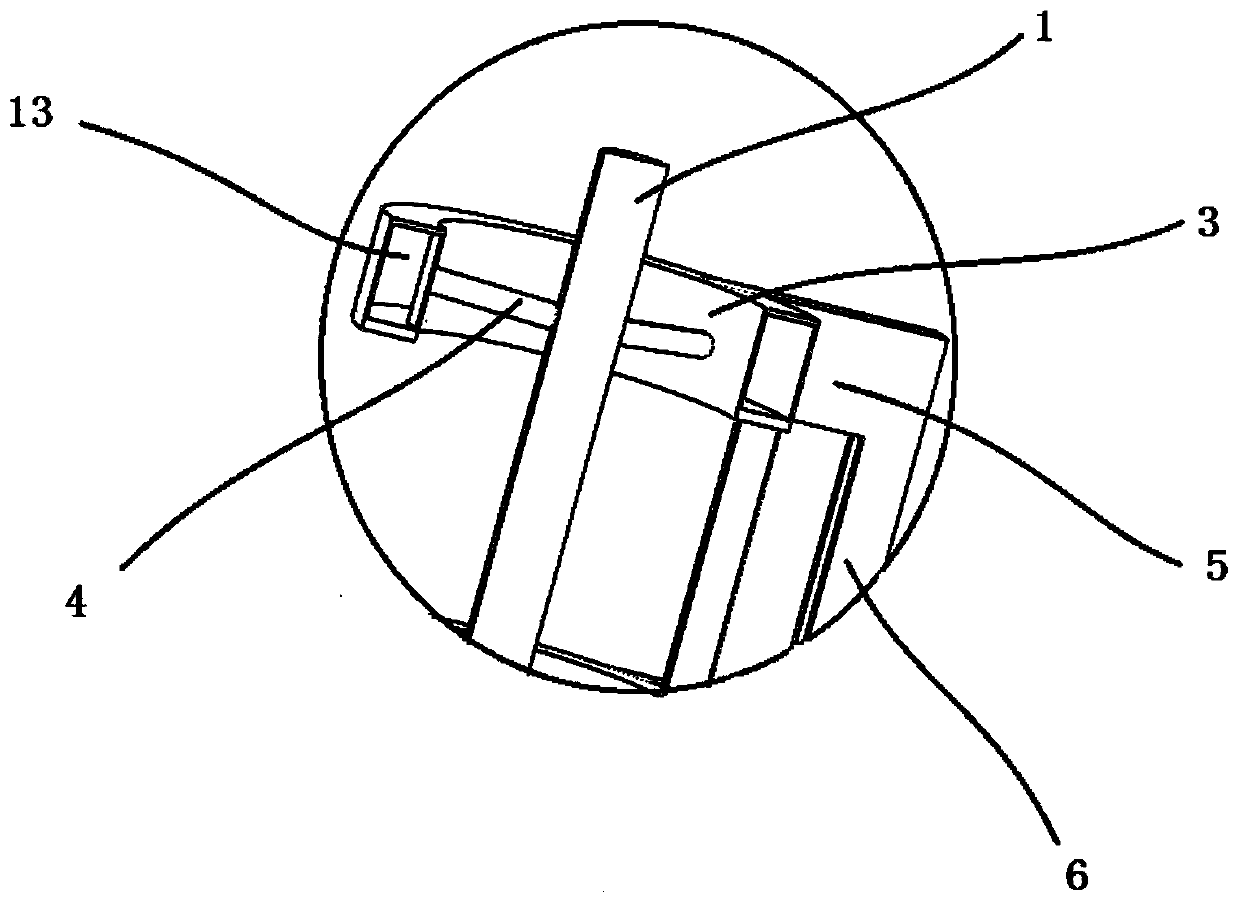

High-throughput preparation device and method for high-silicon aluminum alloy structural gradient material used for packaging

The invention discloses a high-throughput preparation device and method for a high-silicon aluminum alloy structural gradient material used for packaging. The device comprises an upper high-temperature die, outer die moulds, induction coils, a gradient workpiece, cooling water circulating devices, a lower low-temperature die and thermocouples, wherein the upper high-temperature die is used for keeping the inner temperature of the whole die balancing and supplying a certain heat source to atomized powder of the high-silicon aluminum alloy; the outer die moulds are used for positioning two or three kinds of the prepared atomized powder of the gradient high-silicon aluminum alloy; the atomized powder of the high-silicon aluminum alloy is fed based on the sequence that the low-component alloy powder is at the bottom end of each outer die mould, and the high-component aluminum powder is at the top end of each outer die mould; the induction coils can be used as movable induction heating elements for supplying heat to the whole preparation process; the gradient workpiece is used for preparing the gradient material; the cooling water circulating devices can be used for exporting excess heat when the temperature in the preparation process is beyond a set temperature; the temperature of the lower low-temperature die is in contrast to the temperature of the upper high-temperature die, so that temperature gradient can be generated; the thermocouples are used for testing the temperature and controlling the induction heating time, so as to generate the temperature gradient. The alloy prepared by the device and the method is high in density, and the structure is refined, so that the alloy is outstanding in comprehensive performances.

Owner:SUZHOU XINHUILIAN SEMICON TECH CO LTD

3D printing preparation method for gel injection mold of ceramic gradient materials

InactiveCN106965291AImplement gradient distributionImprove work efficiencyAdditive manufacturing apparatusCeramic shaping apparatusModeling softwareGradient material

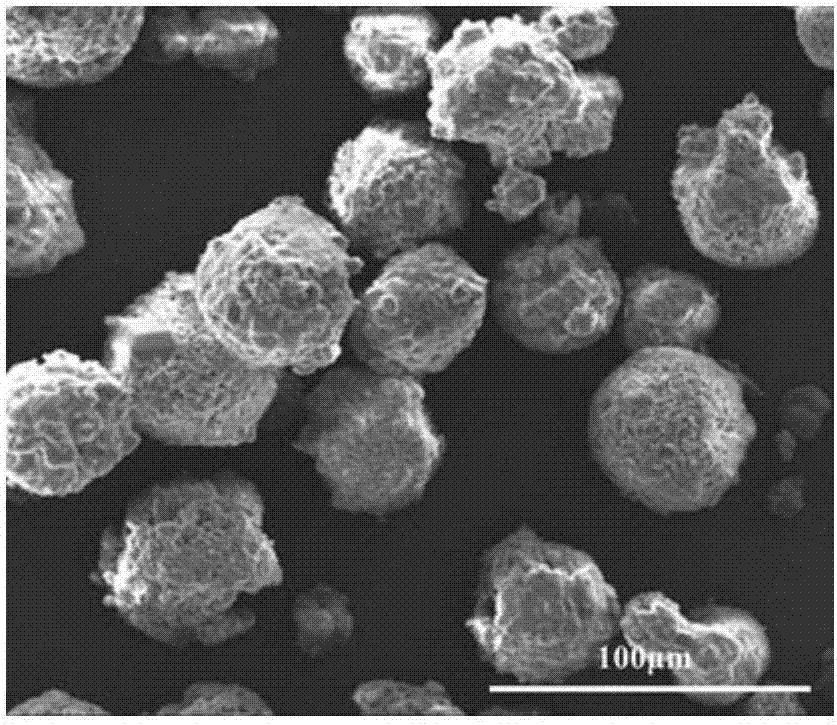

The invention discloses a preparation method for gel injection molding 3D printing of ceramic gradient materials. The specific method includes the following steps: the establishment of a three-dimensional model is firstly modeled by computer modeling software, and then the built three-dimensional model is "partitioned" into thicknesses It is a section of 50-120 μm, that is, a slice, so as to guide the printer to print layer by layer; the raw material ratio of the ceramic gradient material is calculated according to the composition design requirements of the ceramic gradient material, and the component distribution ratio of different positions of the ceramic gradient structure is calculated as a variable Input the computer to control the powder feeding ratio at different positions during printing; set the printing parameters, set the printing speed to 0.2~0.5m / s, print resolution 60~100μm, and the powder feeding amount to 0.1~5mm 3 / s. The present invention adopts 3D printing technology as an additive preparation method, which saves raw materials and avoids waste compared with traditional techniques.

Owner:南京先临三维科技有限公司

Aluminum-based density gradient material and preparation method and application thereof

The invention relates to an aluminum-based density gradient material and a preparation method and application thereof. A region with density in gradient change and (or) a region with density in continuous change exist in the aluminum-based density gradient material, and the materials of all the regions in the aluminum-based density gradient material are consistent. The preparation method comprises the following steps: water-soluble pole-forming agent powder and aluminum alloy powder are proportioned according to the volume ratio of the water-soluble pole-forming agent powder to the aluminum alloy powder being X to (100-X), and then are mixed uniformly to obtain mixed powder containing different amounts of pole-forming agents; die forming is carried out on laminated spread powder, and a prefabricated blank is sintered in a vacuum environment at 575-675 DEG c to obtain a sintered body; and water soaking treatment is carried out to obtain the aluminum-based density gradient material. The aluminum-based density gradient material prepared by the method has no obvious deformation, and the density from 1.1 g / cm<3>-2.7g / cm<3> in gradient distribution is achieved through adjusting porosity; and the aluminum-based density gradient material is excellent in performance and is suitable for being used as an aerospace material.

Owner:CENT SOUTH UNIV

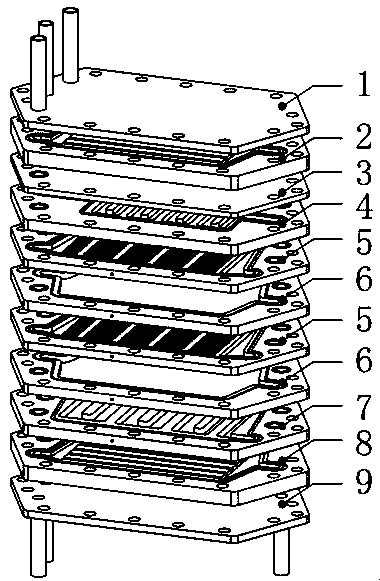

Self-heating methanol reforming hydrogen production reactor integrating CO selective methanation

ActiveCN110155945AAchieve removalSave the water vapor inverse conversion processHydrogen separation using solid contactHydrogen separation using liquid contactMethanol waterMethanation

The invention discloses a self-heating methanol reforming hydrogen production reactor integrating CO selective methanation. The reactor comprises an upper cover plate, an upper heat exchange plate, aheat exchange plate separation layer, an evaporation plate, a first methanol catalytic combustion plate, a first methanol water vapor reforming plate, a second methanol catalytic combustion plate, a second methanol water vapor reforming plate, a CO selective methanation reaction plate, a lower heat exchange plate and a lower cover plate from top to bottom. A CO selective methanation reaction is integrated in the reactor, and the CO selective methanation reaction is completed by directly using hydrogen in reformed gas; after the reformed gas which is reformed and prepared by a methanol water vapor reaction is subjected to CO selective methanation treatment, the CO content is reduced; in a CO removal process of the reactor, other reactants are not introduced, and the content of hydrogen in final product gas is 70% or above. Gradient distribution of the temperature in the reactor is realized through the laminating sequence and connecting gas paths of all the reaction plates, so that eachof two different catalysts is located in an optimum working temperature; and the heat exchange plates are respectively designed at the upper end and the lower end of the reactor for preheating and recycling, so that the energy utilization rate is improved.

Owner:ZHEJIANG UNIV

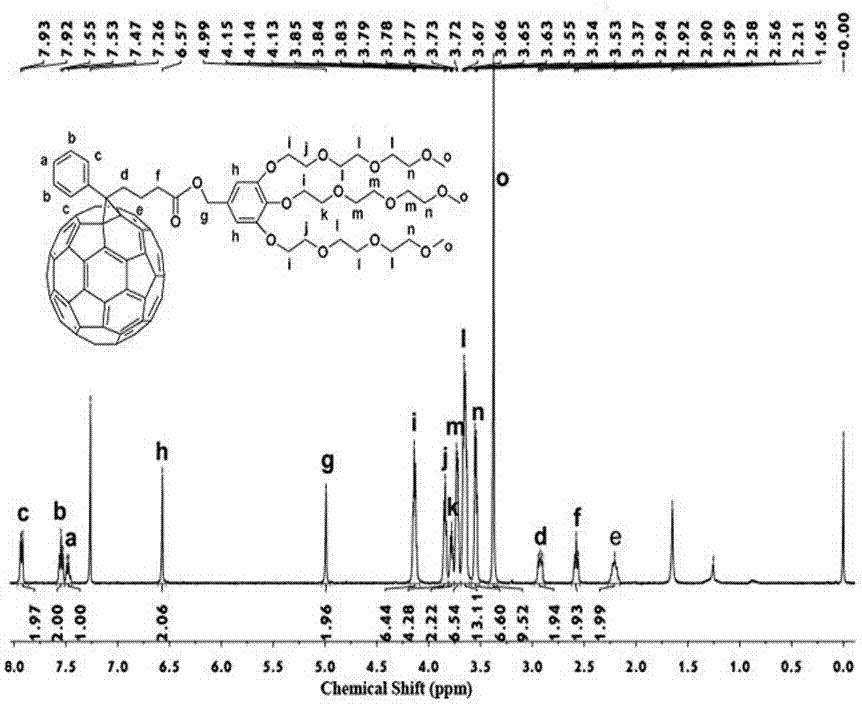

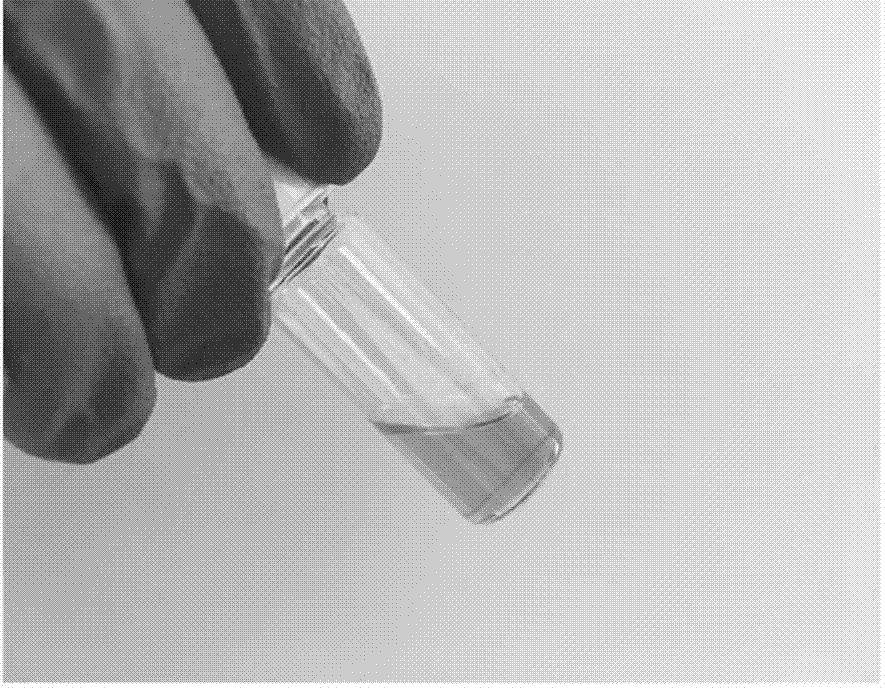

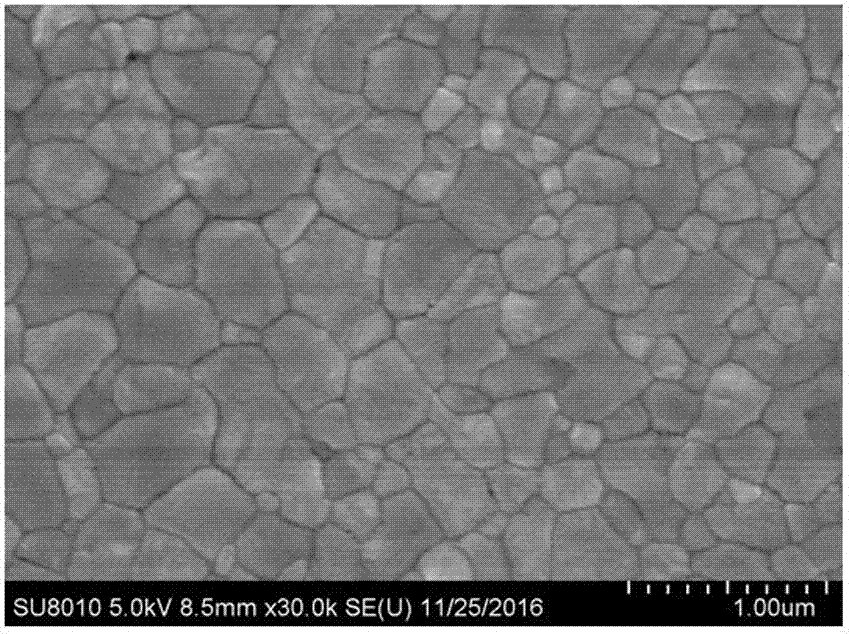

Application of alcohol soluble fullerene derivative in perovskite solar cell

ActiveCN107394047ALarge grainDense grainOrganic compound preparationOrganic chemistry methodsHole transport layerSpin coating

The invention discloses an application of an alcohol soluble fullerene derivative in a perovskite solar cell. The preparation process of a cell includes the following steps: preparing a cavity transmission layer on a piece of clean electro-conductive glass; spin-coating the cavity transmission layer with DMF solution of PbI2, spin-coating methyl ammonium iodide (MAI) isopropanol solution doped with the alcohol soluble fullerene derivative, and then obtaining a perovskite layer through annealing; and preparing an electronic modification layer and electrodes on the perovskite layer, and obtaining a perovskite solar cell. The application of an alcohol soluble fullerene derivative in a perovskite solar cell enables the fullerene to be distributed in a perovskite film from top to bottom in a graded manner by means of a simple doping method, thus maximally improving the electron mobility so as to improve the current and fill factors of devices. Therefore, the application of an alcohol soluble fullerene derivative in a perovskite solar cell can obtain a perovskite solar cell with high performance and simplify the process of device preparation, and can obtain better device performance at the same time.

Owner:SUZHOU UNIV +1

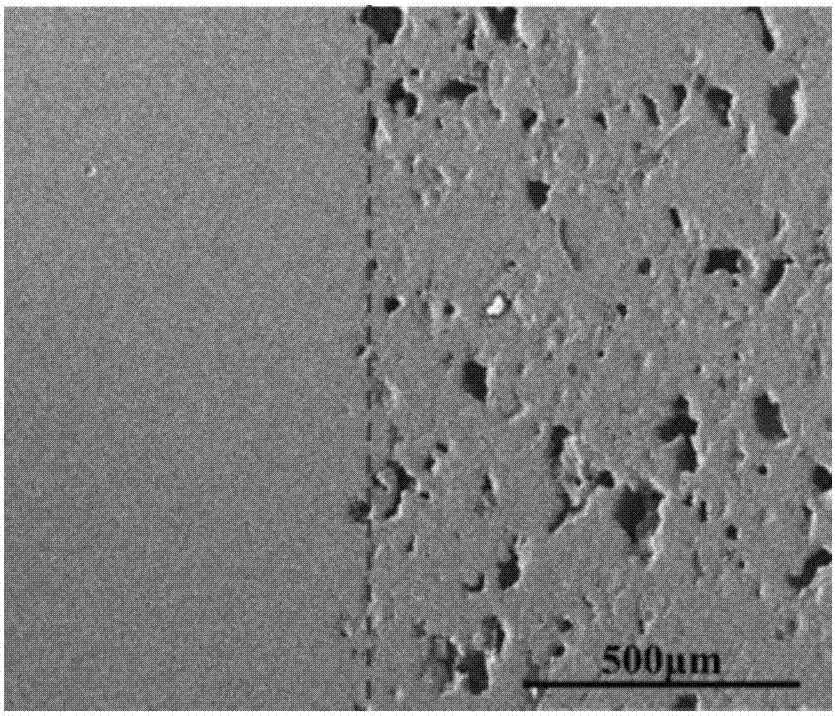

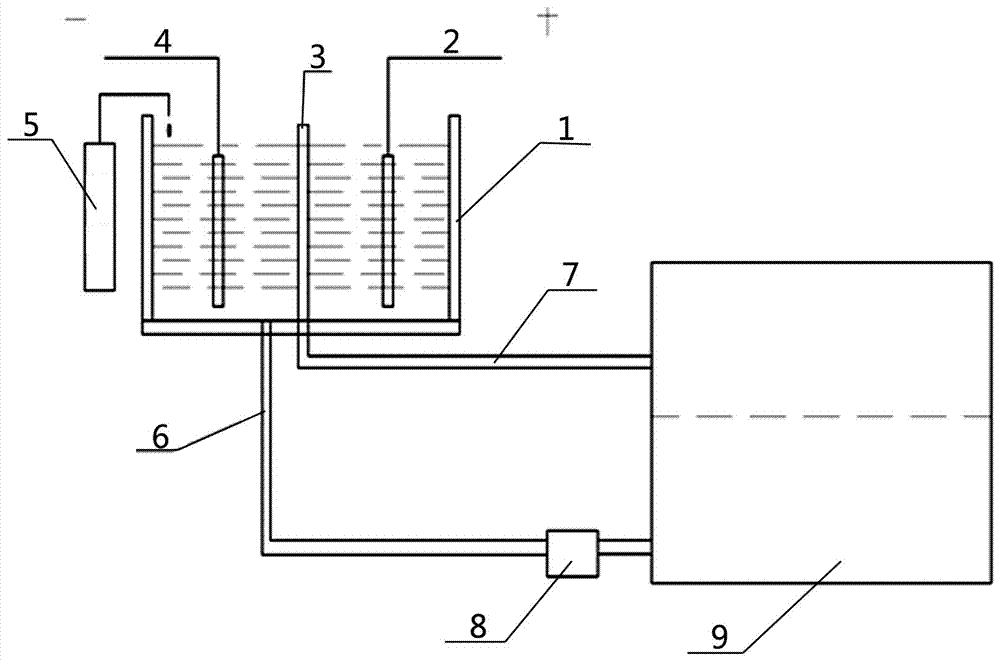

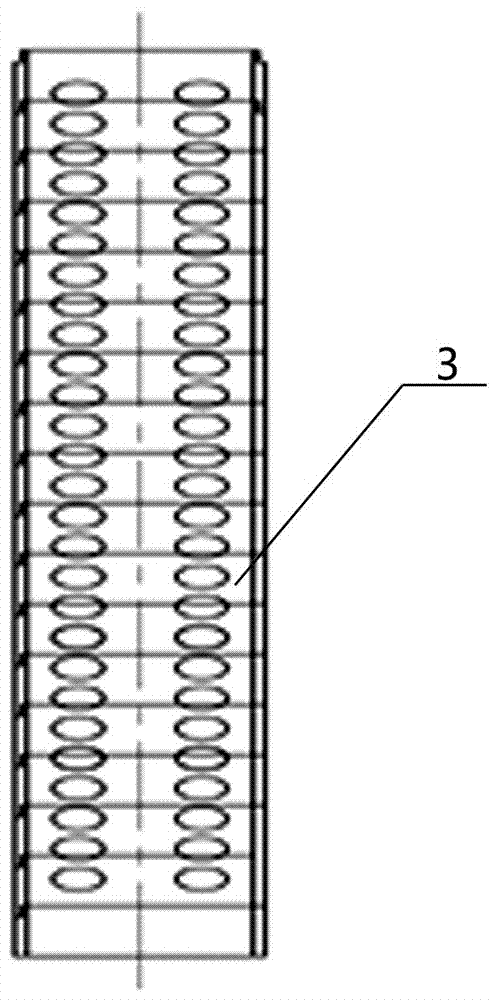

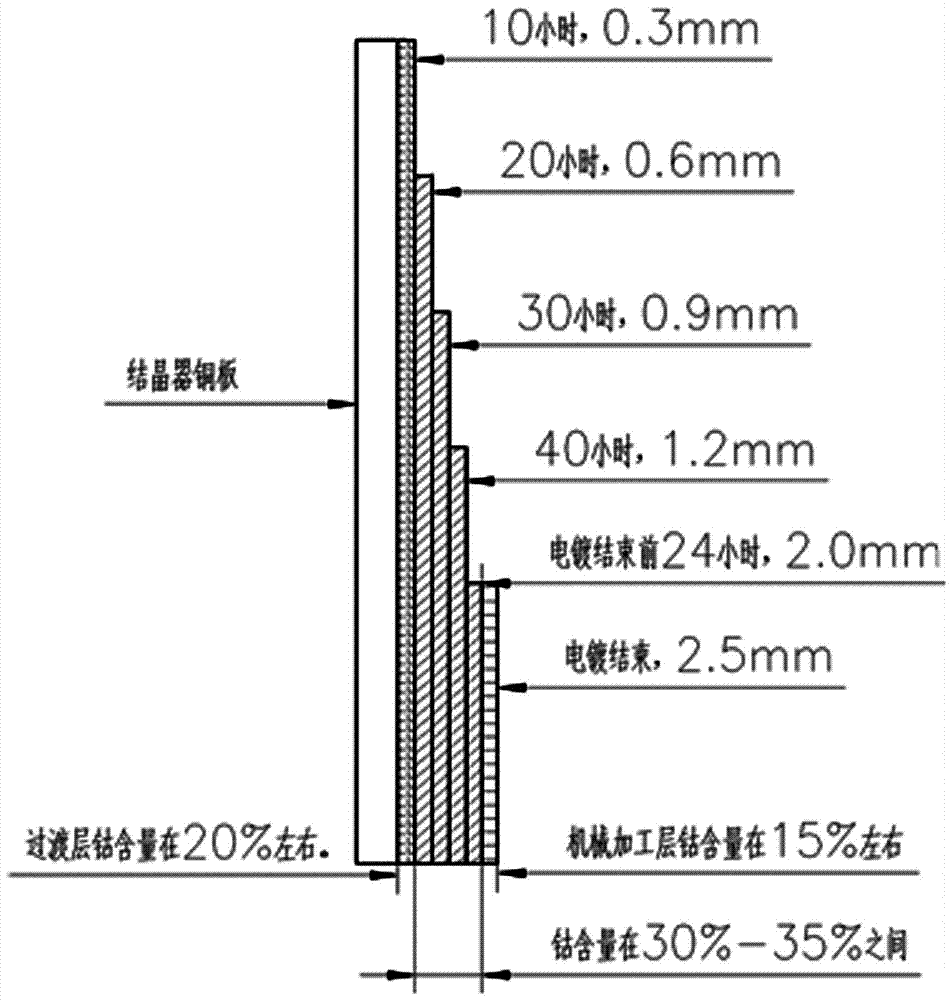

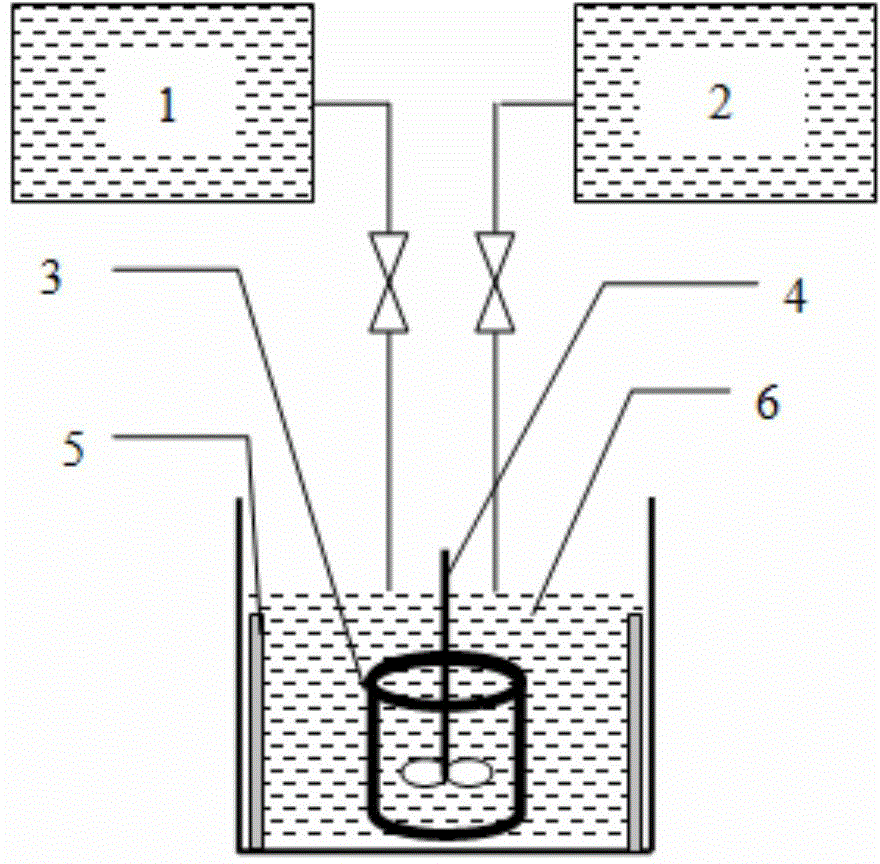

Gradient distribution technique for cobalt in nickel-cobalt alloy plating layer of crystallizer copper plate and electroplating equipment

The invention discloses a gradient distribution technique for cobalt in a nickel-cobalt alloy plating layer of a crystallizer copper plate. According to the technique, before plating, the cobalt content and other plating liquid components are analyzed, and plating liquid is prepared in primary and secondary tanks; electroplating begins to be conducted, and first-time liquid falling is conducted after electroplating is conducted for 10 h; second-time liquid falling is conducted after electroplating is conducted for 20 h; third-time liquid falling is conducted after electroplating is conducted for 30 h; fourth-time liquid falling is conducted after electroplating is conducted for 40 h; when the electroplating time before the thickness of the plating layer is achieved is 24 h, adding of the cobalt is stopped; after liquid falling is conducted for 10 h, at the moment, the cobalt content in electroplating liquid maintains 6 g / L and over, and the cobalt content in the plating layer is 30-35%; during the last 24 h, the cobalt is continuously consumed; after electroplating is conducted for 24 h, the cobalt content in a machining layer is 15%; and after electroplating is finished, a liquid feeding pump is closed, a liquid return pipe is pulled out to enable the plating liquid to completely flow back into the primary tank, and then the crystallizer copper plate provided with the plating layer with the gradient-distribution cobalt content is obtained. The problems that the traditional processing volume on a cobalt content plating layer is very large, a great number of materials are wasted, and the product cost is increased are solved.

Owner:QINHUANGDAO SHOUGANG CHANGBAI MOLD

Method for reliving FCC dead catalyst

ActiveCN101219396BIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

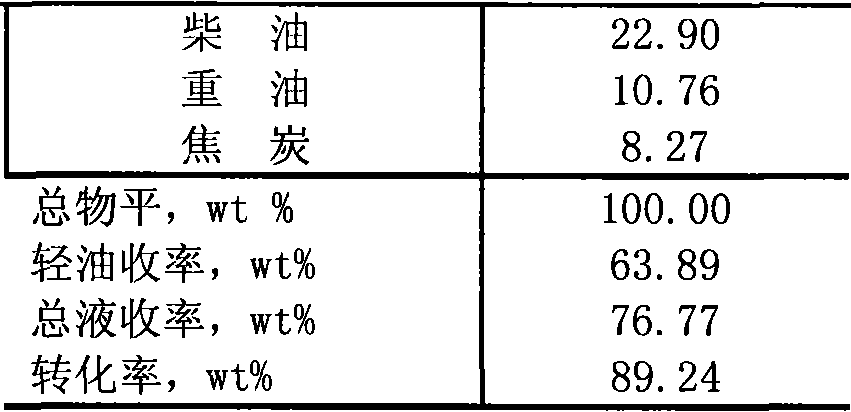

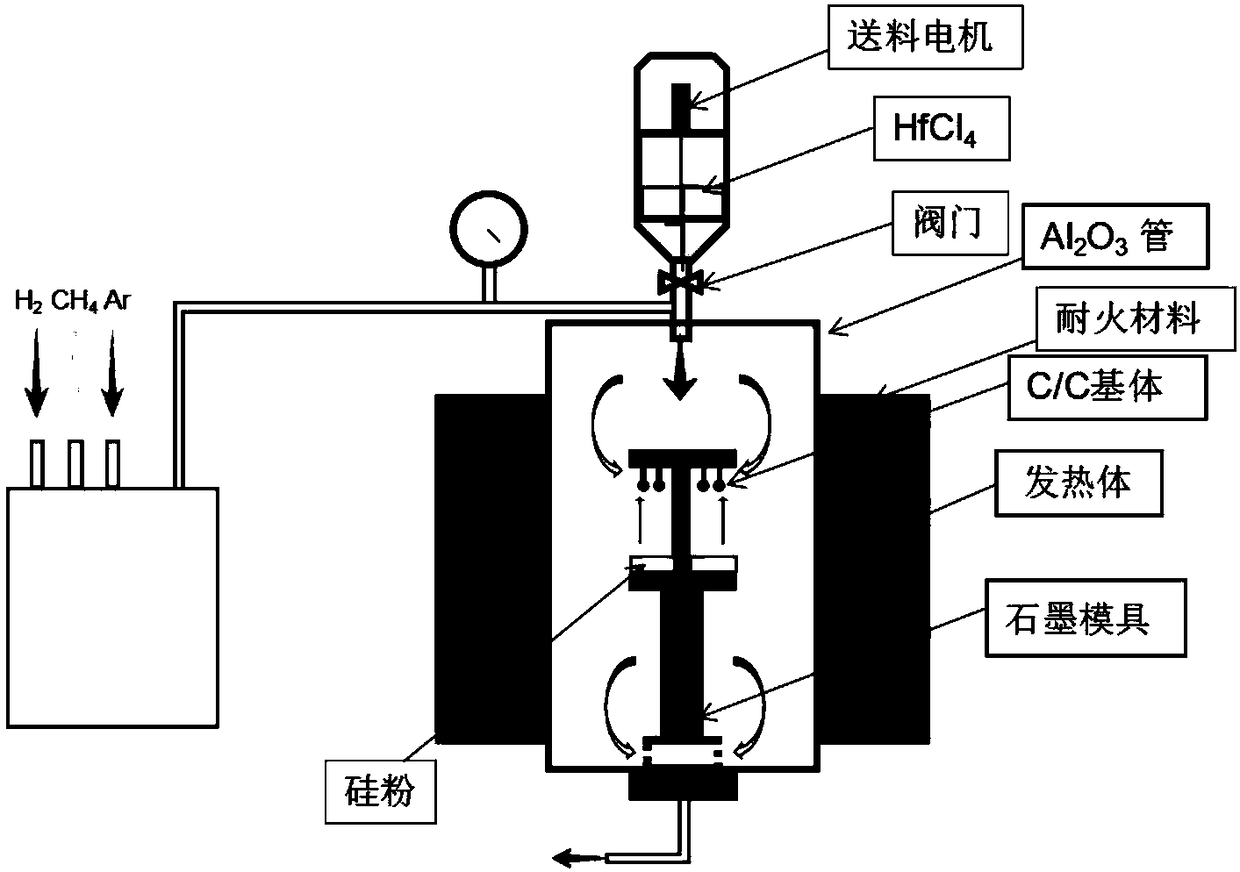

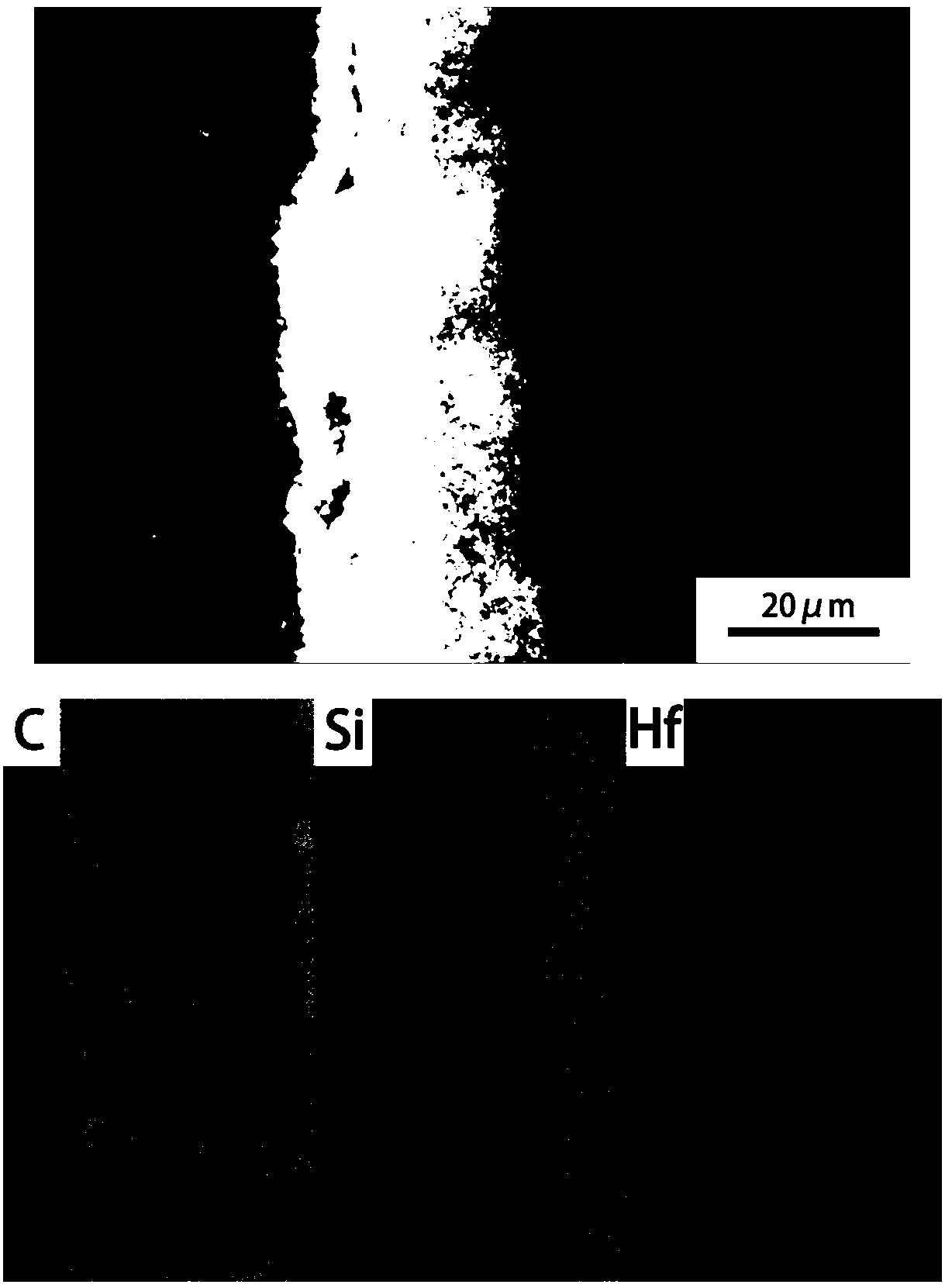

Method for producing HfC-SiC multiphase gradient coating layer by chemical vapor co-deposition technology

The invention relates to a method for producing a HfC-SiC multiphase gradient coating layer by a chemical vapor co-deposition technology. The HfC-SiC multiphase gradient coating layer is deposited onthe surface of a C / C composite material by the chemical vapor co-deposition technology. The HfC-SiC multiphase gradient coating layer produced by the method realizes the gradient distribution of thermal expansion coefficients by controlling the structural constituent of the coating layer in order to fundamentally solves the mismatch of the thermal expansion coefficients between the coating layer and a substrate. The produced coating is well combined to the substrate, and can realize the control of the structural constituent, and the method using the chemical vapor phase co-deposition technology has the advantages of short production period, simple process and low cost. The surface of the HfC-SiC multi-phase gradient coating layer produced on the surface of the C / C composite material in theinvention has no cracks, and the bonding strength between the coating layer and the substrate is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

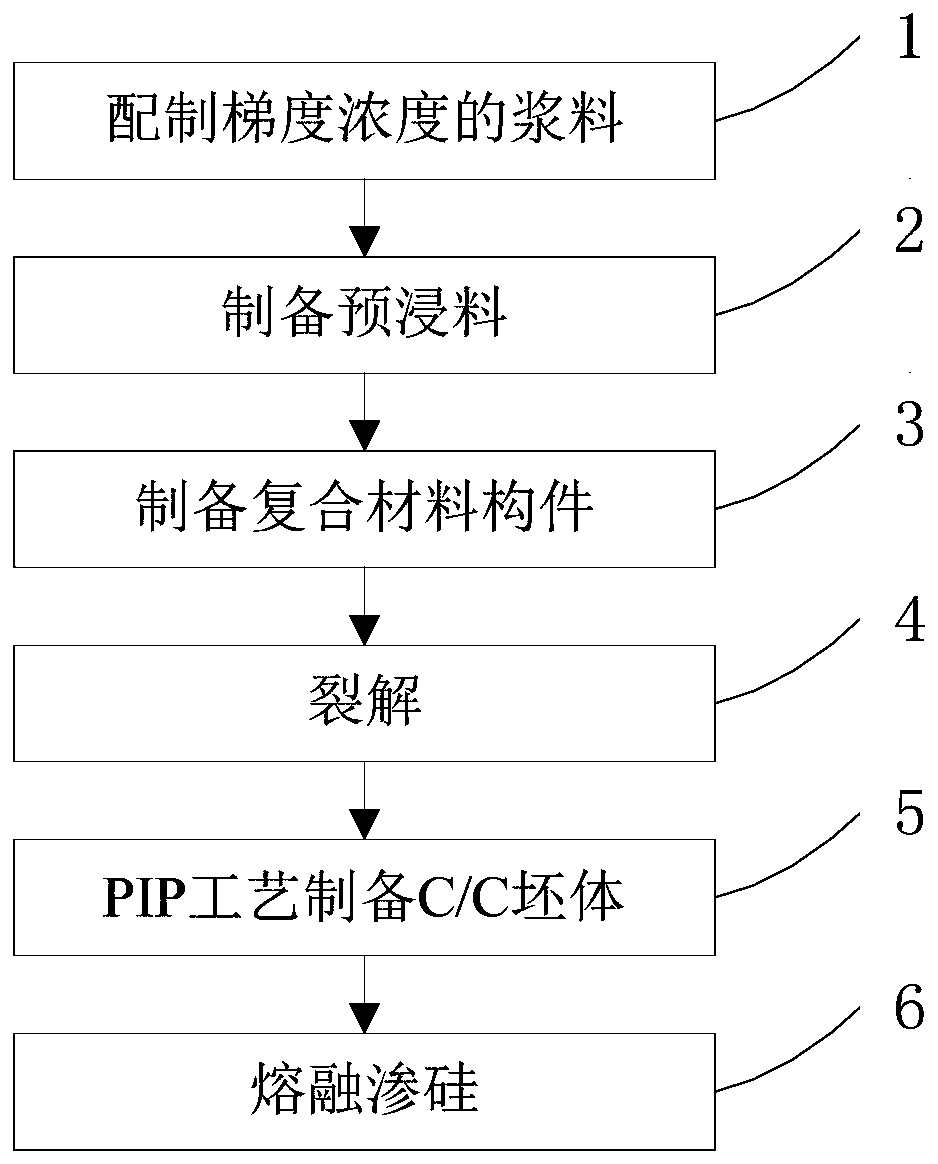

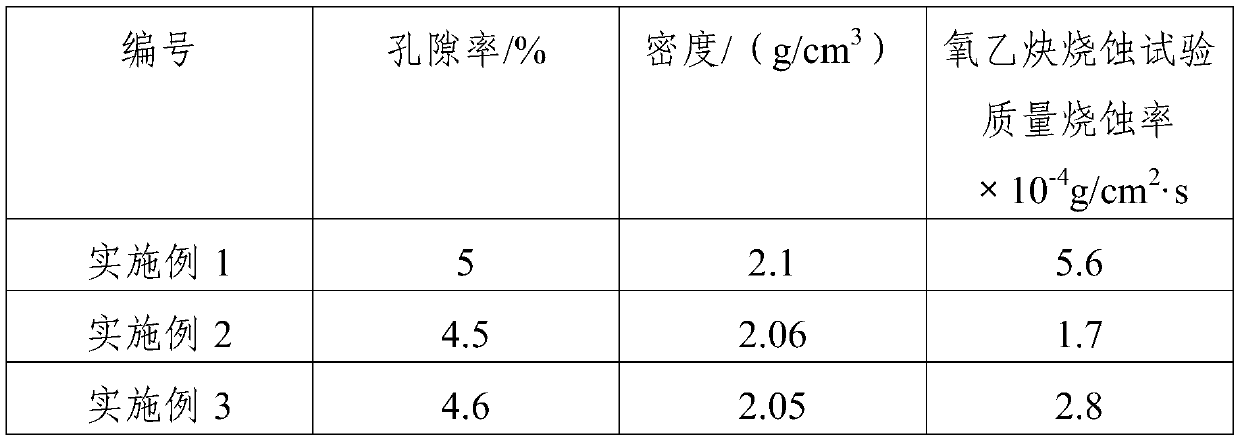

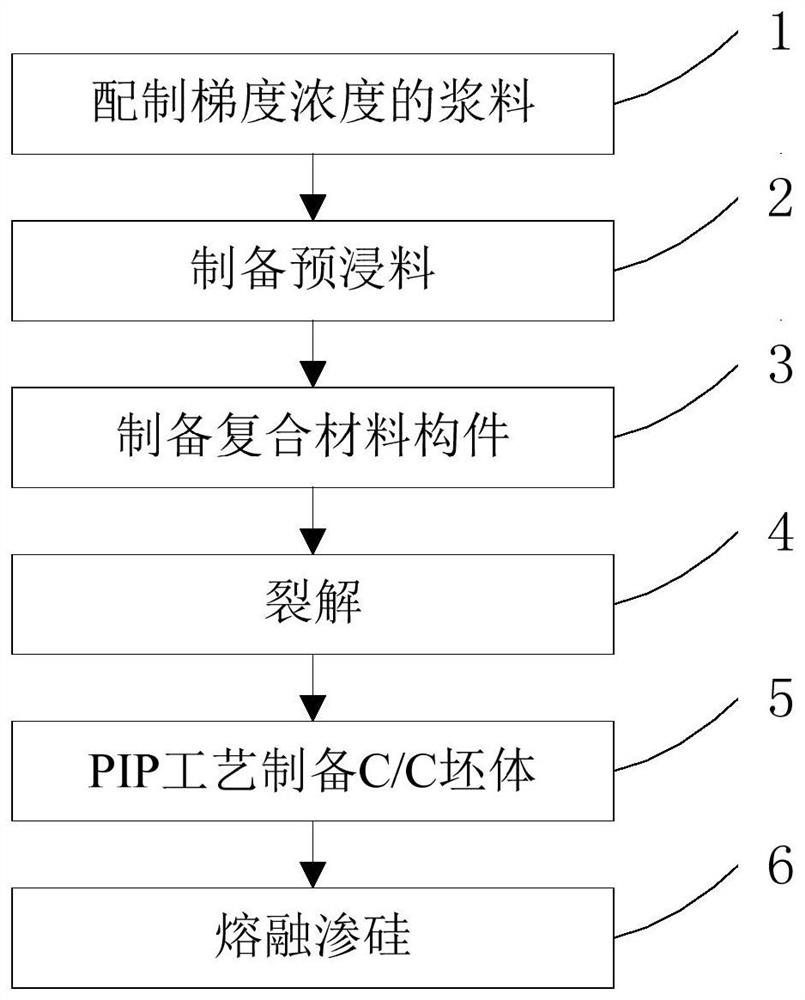

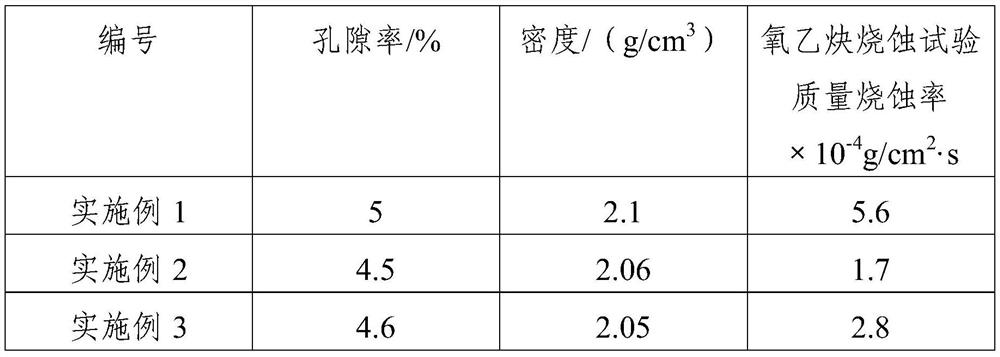

Gradient ultrahigh-temperature ceramic-based composite material and preparation method thereof

The invention relates to a gradient ultrahigh-temperature ceramic-based composite material and a preparation method thereof. The method comprises the following steps: (1) preparing slurry of gradientconcentrations, namely, by taking zirconium carbide powder as a solid component, and thermoset phenolic resin as a liquid component, mixing the solid component with the liquid component, and performing preparation so as to obtain slurry of n gradient concentrations, wherein n is greater than or equal to 2; (2) preparing prepregs, namely, respectively compounding the slurry of n gradient concentrations with n pieces of carbon cloth so as to obtain multiple prepregs; (3) preparing a composite material component, namely, laying and overlapping the multiple prepregs obtained in the step (2), and curing the prefabricated body obtained after laying so as to obtain the composite material component, wherein the content of the powder changes in a gradient manner along a thickness direction; (4) performing pyrolysis; (5) preparing a C / C blank by using a PIP (pyrolysis process); and (6) performing melting siliconing. By adopting the preparation method provided by the invention, the gradient ultrahigh-temperature ceramic-based composite material which is low in density and excellent in high-temperature ablation resistance can be prepared, and has substantive benefits in fields of space flightand aviation.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Surface anticorrosion wear-resistant composite coating for cylinder sleeve of automobile engine applying bio-oil

ActiveCN104313554AReduce concentrationRealize the effect of degreasing and derustingLiquid/solution decomposition chemical coatingChemical platingWear resistant

A surface anticorrosion wear-resistant composite coating for a cylinder sleeve of an automobile engine applying bio-oil is disclosed. The coating comprises a Ni-Cu-Ce-La-P-Graphene composite material, and can be prepared by adopting a gradient chemical plating coating process. The coating is characterized in that: Ni, Cu, Ce, La and P in a special ratio, and Graphene are simultaneously deposited on the surface of the cylinder sleeve, and the composite coating with good anticorrosion and wear-resistant functions is prepared. The coating is advantageous in that: the binding force of the coating and a substrate is strong, compactness of the coating is high, the coating has excellent anticorrosion and wear-resistant effects especially for the bio-oil, a preparing method of the coating is simple, convenient, and prone to industrial production, and the coating can be widely used in the fields of metal material protection, mechanical surface treatment, energy-saving and environmental friendly automobiles, and the like.

Owner:黄山市开发投资集团有限公司

Cartilage-bone repair support with bionic gradient and preparation method thereof

ActiveCN109481736ARealize the structureRealize the biomimetic process of compositionTissue regenerationProsthesisApatiteTarsal Joint

The invention discloses a cartilage-bone repair support with bionic gradient and a preparation method thereof. For the cartilage-bone repair support, a cartilage layer of an interwoven porous structure is prepared from sodium hyaluronate and chitosan, a subchondral bone layer of a porous structure is prepared from graphene oxide, chitosan and nano-hydroxyapatite, and structure, composition and function bionics of natural articular cartilage is realized by combining a coprecipitation method and a gradient refrigeration technology by referring to an in-situ bionic thorough. The obtained supporthas an upper layer of structure and a lower layer of structure, nano-hydroxyapatite presents change of bionic gradient distribution which is gradually increased from the cartilage layer to the subchondral bone layer; meanwhile, the cartilage layer in the upper layer is of a mutually penetrating interwoven hierarchical pore structure, the subchondral bone layer is of an array microtube structure which is axially arranged and is vertically through, the support material is excellent in mechanical performance, strong in interface bonding property and good in biological performance, and is expectedto become a novel composite material for treating cartilage-bone defect.

Owner:FUZHOU UNIV

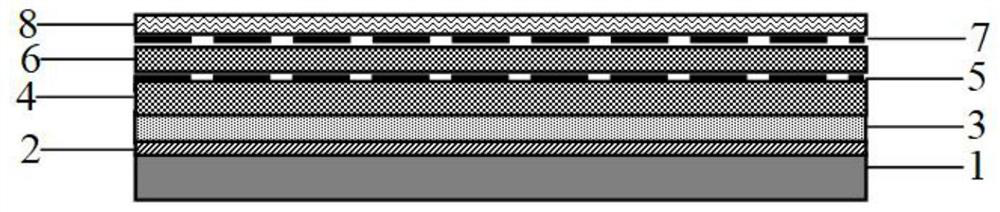

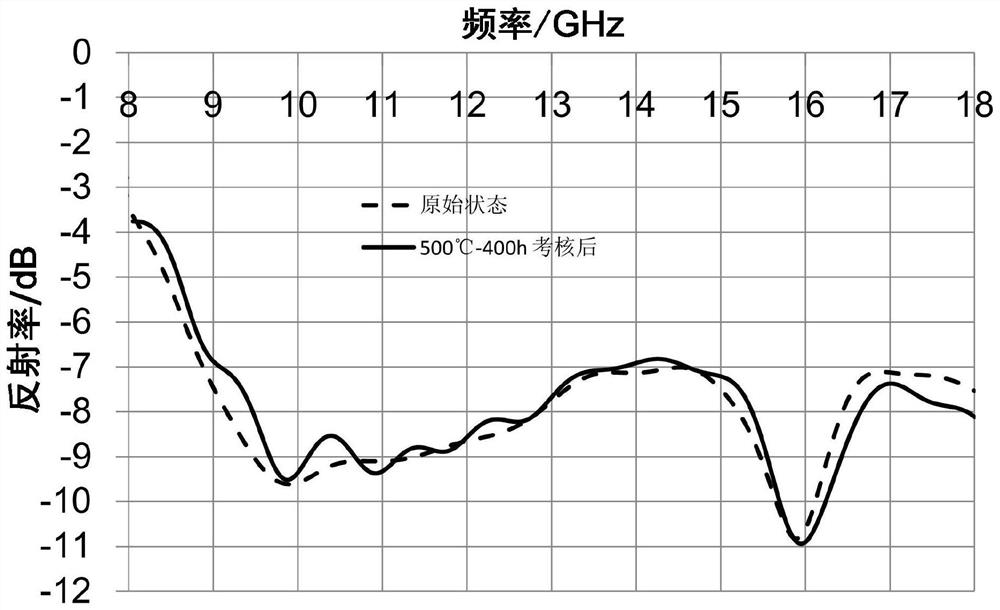

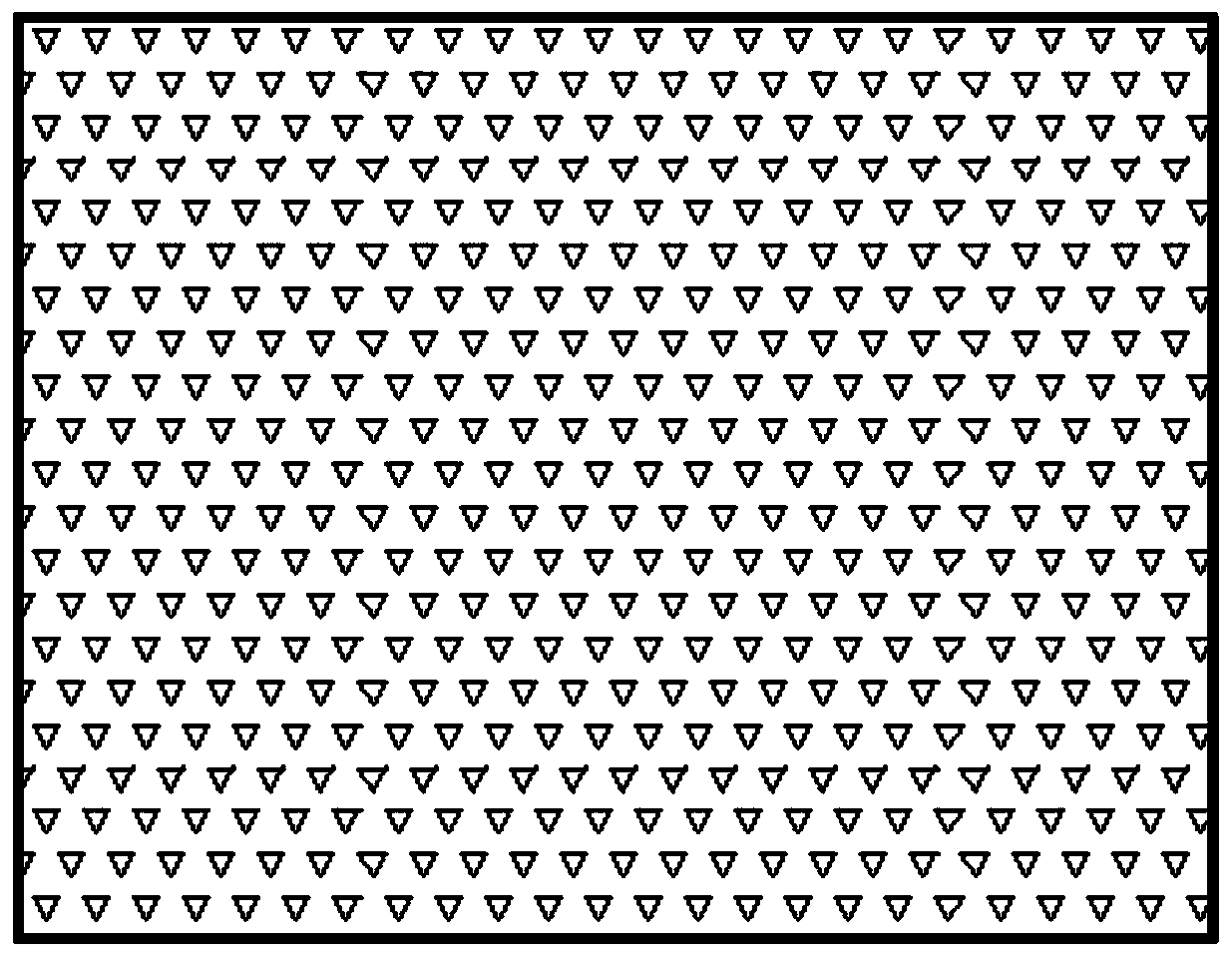

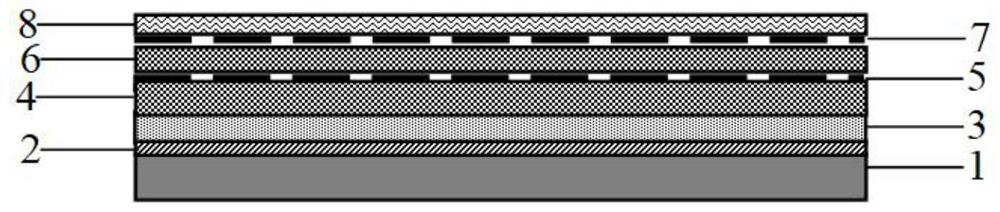

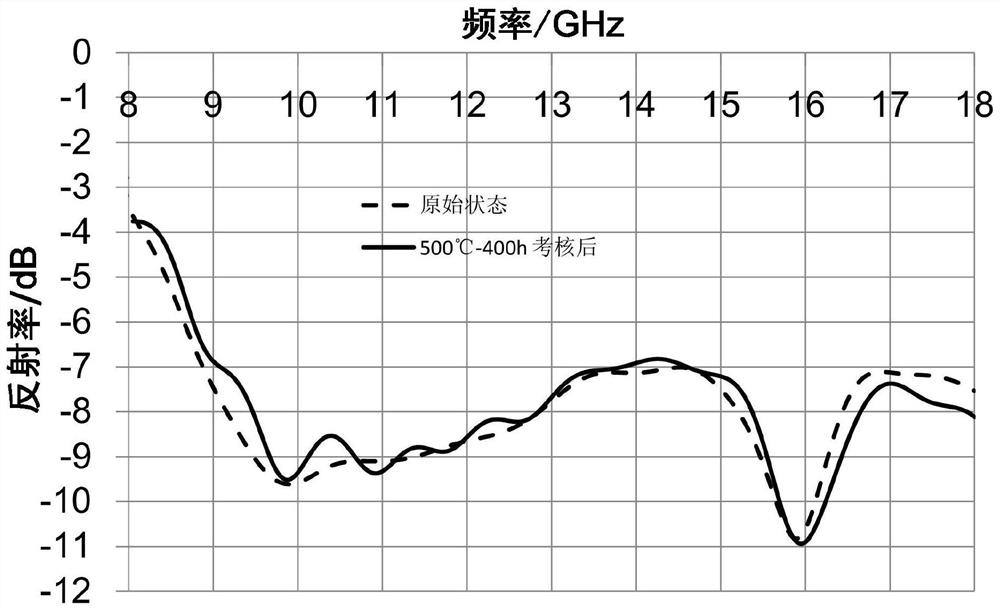

Functional gradient distribution high-temperature radar and infrared compatible stealth coating and preparation method thereof

ActiveCN112961531AImprove absorbing performanceHigh resistivityPowdery paintsSpecial surfacesThermal dilatationRadar

The invention relates to the technical field of high-temperature stealth coatings, and particularly discloses a functional gradient distribution high-temperature radar and infrared compatible stealth coating and a preparation method thereof. The surface of a metal base material is coated with the high-temperature radar and infrared compatible stealth coating, and from the surface of the metal base material, the coating sequentially comprises a metal bonding layer, a thermal matching ceramic layer, a dielectric ceramic layer, a first high-temperature electromagnetic periodic structure layer, a dielectric isolation layer, a second high-temperature electromagnetic periodic structure layer and an infrared stealth layer from bottom to top. The high-temperature radar and infrared compatible stealth coating disclosed by the invention has radar and infrared compatible stealth functions, adopts a multifunctional layer structure, realizes gradient distribution of thermal expansion coefficients of the coating, can realize better thermal matching with a metal substrate, and is good in thermal shock resistance; and the softening point temperature of the selected glass phase does not exceed 600 DEG C, so the coating has the advantages of low sintering temperature and short sintering time, and can reduce the influence of oxidation, damage, deformation and the like on the metal substrate.

Owner:NAT UNIV OF DEFENSE TECH

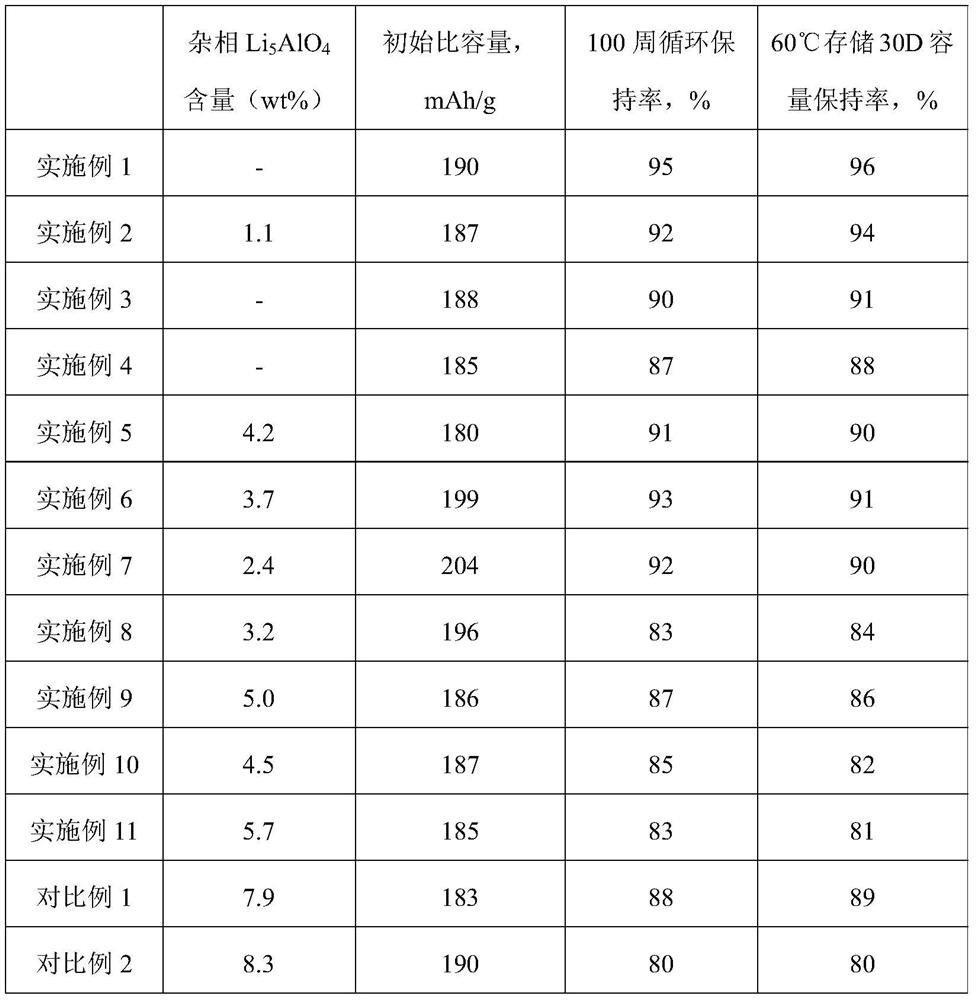

Preparation method of single-crystal high-nickel positive electrode material, product and application thereof

PendingCN112520791AImplement gradient distributionImprove cycle performanceSecondary cellsPositive electrodesLithiumSingle crystal

The invention relates to a preparation method of a single-crystal high-nickel positive electrode material, a product and application thereof. The preparation method comprises two steps of calcining. According to the first step of calcining, a nickel-cobalt precursor and / or a nickel-cobalt-manganese precursor are / is mixed with a lithium salt, and the obtained mixture is calcined, so that a single-crystal lithium nickel cobalt oxide material and / or a single-crystal lithium nickel cobalt manganese oxide material can be obtained. According to the second step of calcining, the product calcined in the step step is mixed with an aluminum source, and the mixture is calcined, so that the single-crystal high-nickel positive electrode material can be obtained. The temperature of the first-step calcining is higher than that of the second-step calcining. According to the method, a specific mixing sequence and a calcining method are combined, so that the generation of an impurity phase in the preparation process of the single-crystal high-nickel positive electrode material is reduced, the pure-phase single-crystal high-nickel positive electrode material is obtained, the performance of the single-crystal high-nickel positive electrode material is improved; and with the method adopted, the content distribution of an aluminum element in the single-crystal high-nickel positive electrode materialis easy to regulate and control, and the formation of an Al gradient material is facilitated, so that the capacity performance of the single-crystal high-nickel positive electrode material is improved.

Owner:EVE ENERGY CO LTD

Method and device for preparing gradient functional material of flexible additional material

ActiveCN110496965AImprove service qualityImplement element gradient distributionAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingAdditive layer manufacturing

The invention relates to the field of laser additive manufacturing, in particular to a method and a device for preparing a gradient functional material of a flexible additional material. The proportion of mixed powder in each layer is changed in an additive manufacturing process, so that element gradient distribution of an additional material member is achieved. Dissimilar metal powder is fully and uniformly mixed, so that the uniformity and compactness of the additional material member are guaranteed. Meanwhile, residual powder in the mixed powder is achieved, so that the cost is saved to a great extent, and the quality of the additional material member is improved.

Owner:JIANGSU UNIV

Zeolite roller capable of intensively treating exhaust gas

ActiveCN109529538ATo achieve intensive processingImprove efficiencyGas treatmentDispersed particle separationPulp and paper industryZeolite

The invention relates to a zeolite roller capable of intensively treating exhaust gas. The zeolite roller comprises a rotating shaft, inner shells, outer shells, an air inlet duct, an air outlet ductand rollers; the multiple inner shells are arranged on the outer side of the rotating shaft at intervals and can be driven by the rotating shaft to rotate; the rollers are arranged between the inner shells and the outer shells; the surfaces of the rollers are coated with nano-scale zeolite materials, and thus volatile organic chemcials (VOCs) in the exhaust gas can be adsorbed; the adjacent outershells are connected through hot air pipes, hot air is introduced into the hot air pipes, and when the rollers rotate to the hot air pipes, the VOCs are desorbed through the hot air; and temperature controllers are arranged on the sides, about to enter the rollers, on the hot air pipes correspondingly, by adjusting the temperature controllers, the temperatures of the air in the hot air pipes are in gradient distribution, and then the VOCs desorbed from the different zeolite rollers can be classified and recycled.

Owner:无锡康纳利环保科技有限公司

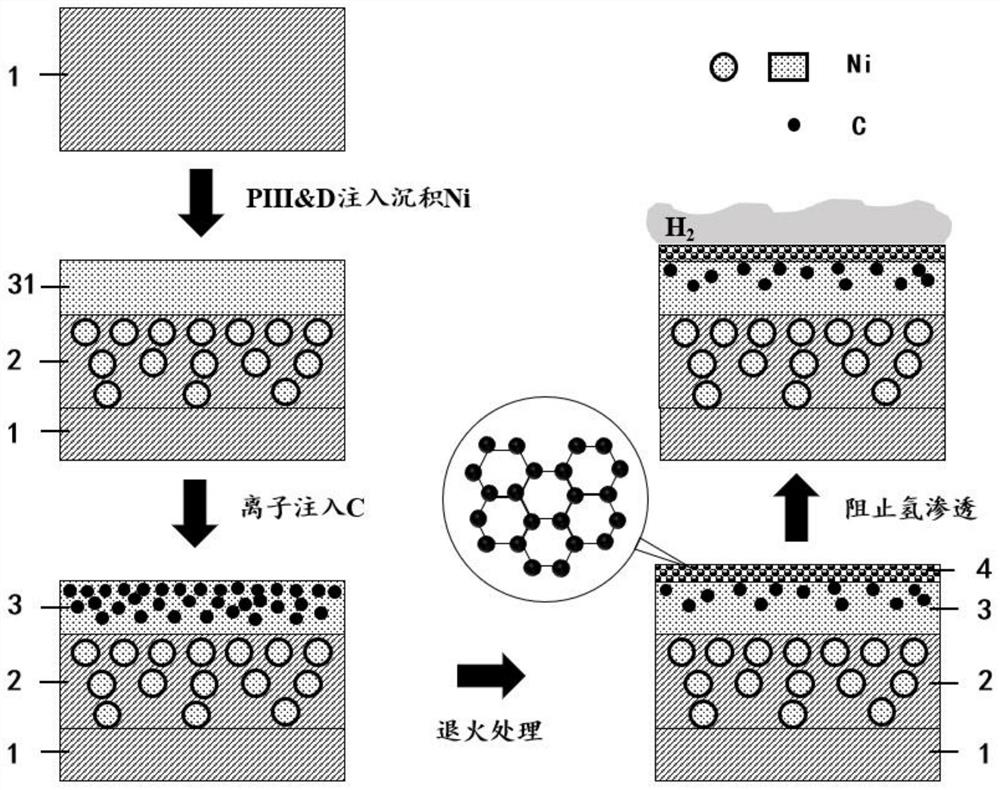

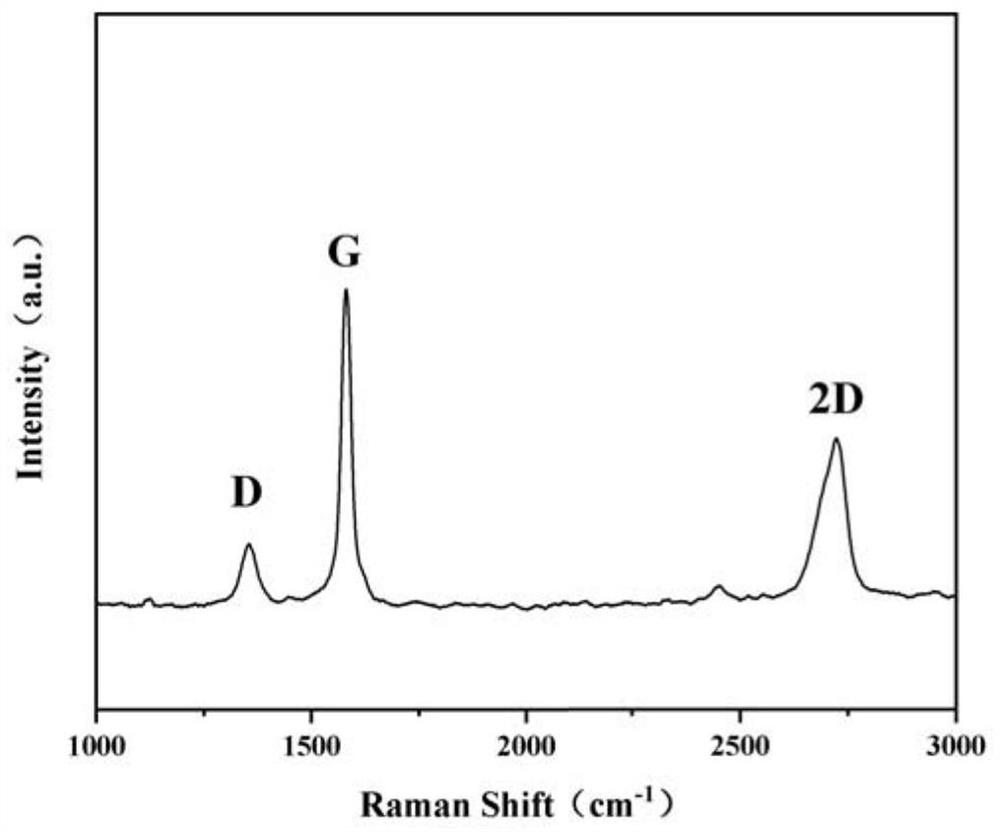

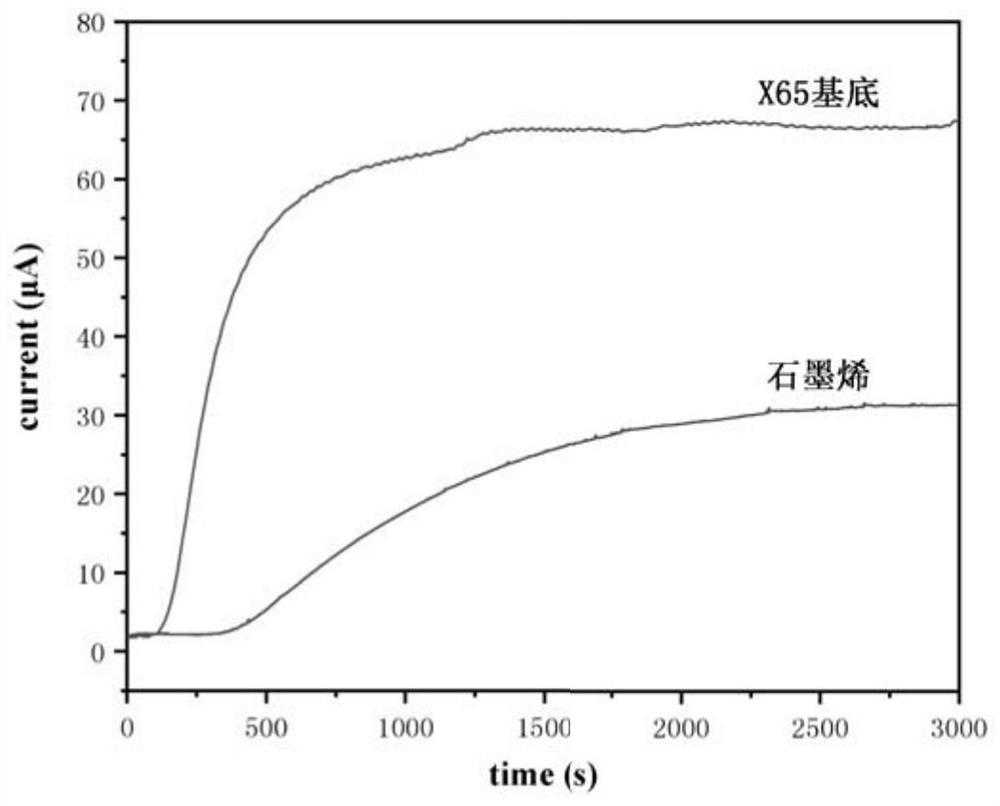

Hydrogen-preventing coating based on inner surface of hydrogen storage device and preparation method

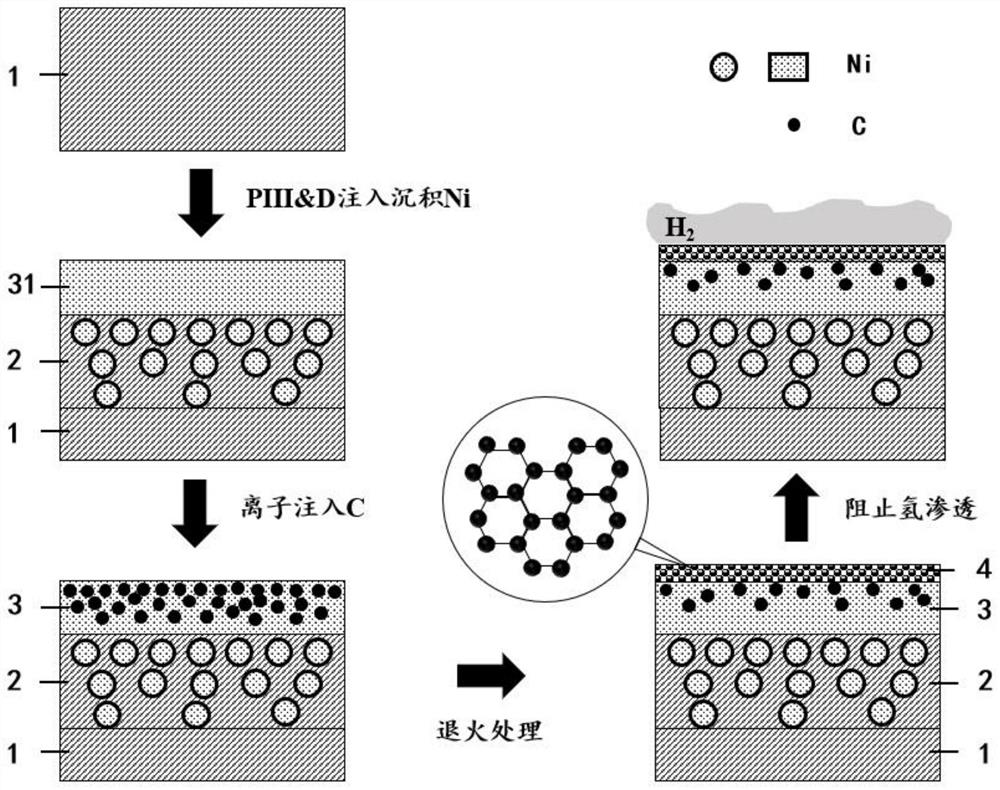

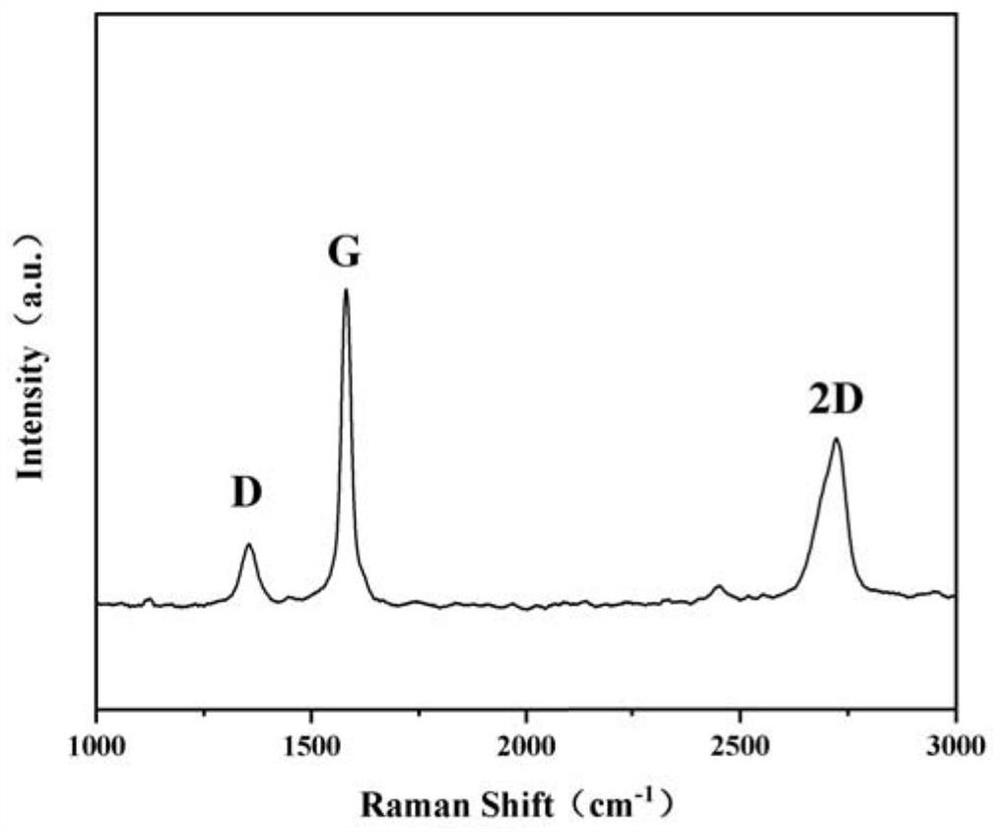

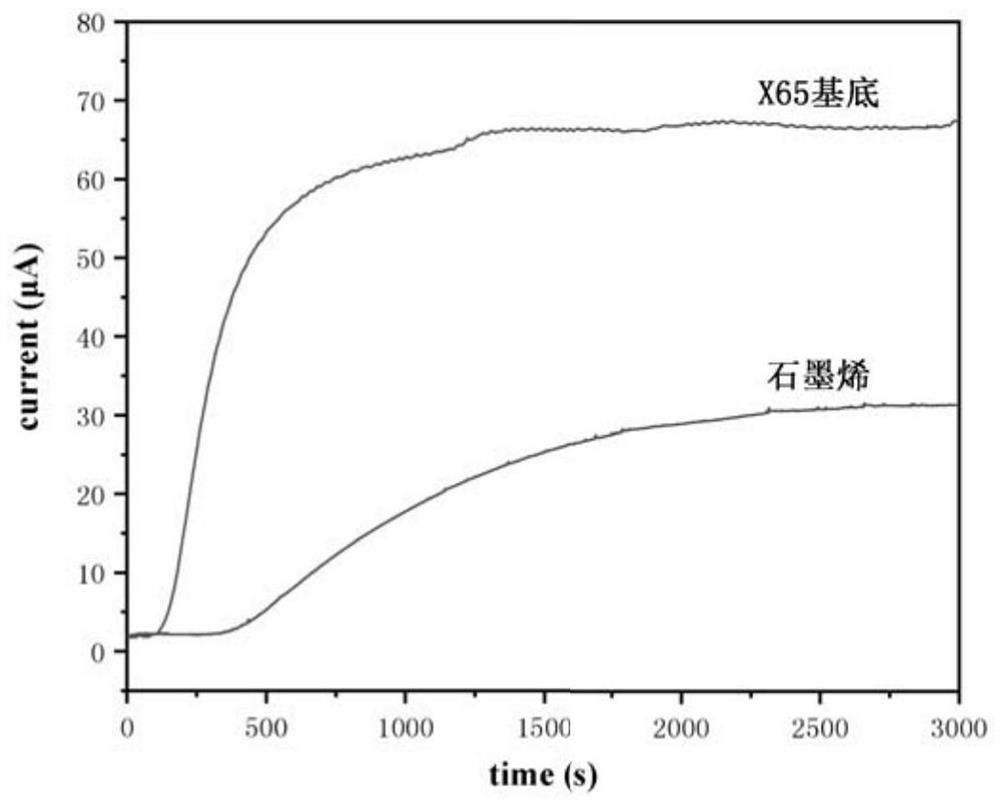

ActiveCN111826612AStructural impactNo pollution in the processVacuum evaporation coatingSputtering coatingGraphene coatingGraphite

The invention relates to a hydrogen-preventing coating based on the inner surface of a hydrogen storage device and a preparation method. The preparation method comprises the following steps of S10, after grinding and polishing the surface of a matrix step by step and cleaning and air-drying the surface of the matrix, injecting depositing Ni ions to the surface of the matrix by a PIII and D deposition technology to obtain a depositing Ni layer and an injection layer which are successively laminated from bottom to top; S11, injecting C ions uniformly to the surface of the injection layer to obtain an injecting C layer rich in C ions; and S12, annealing a sample forming the injecting C layer, wherein the surface of the injecting C layer is segregated to grow a graphene coating. The technicalscheme provided by the invention is high in operability and good in controllability. The bonding strength between the graphene coating and the matrix prepared by the method is high, and the graphene coating is good in hydrogen-preventing performance. By controlling the injection amount of C ions, the thickness of the graphene coating can be controlled. The hydrogen-preventing coating is high in technical realizability and is suitable for a structural material where graphene cannot grow on the surface directly.

Owner:SOUTH CHINA UNIV OF TECH

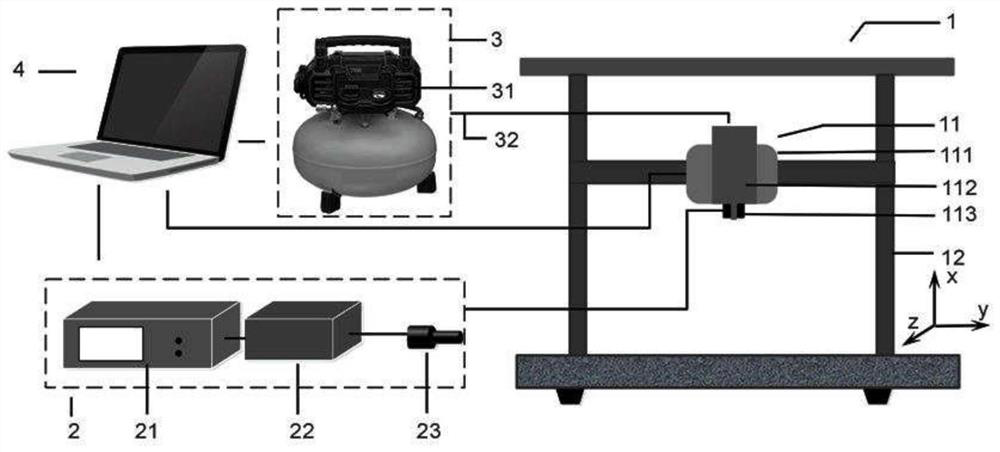

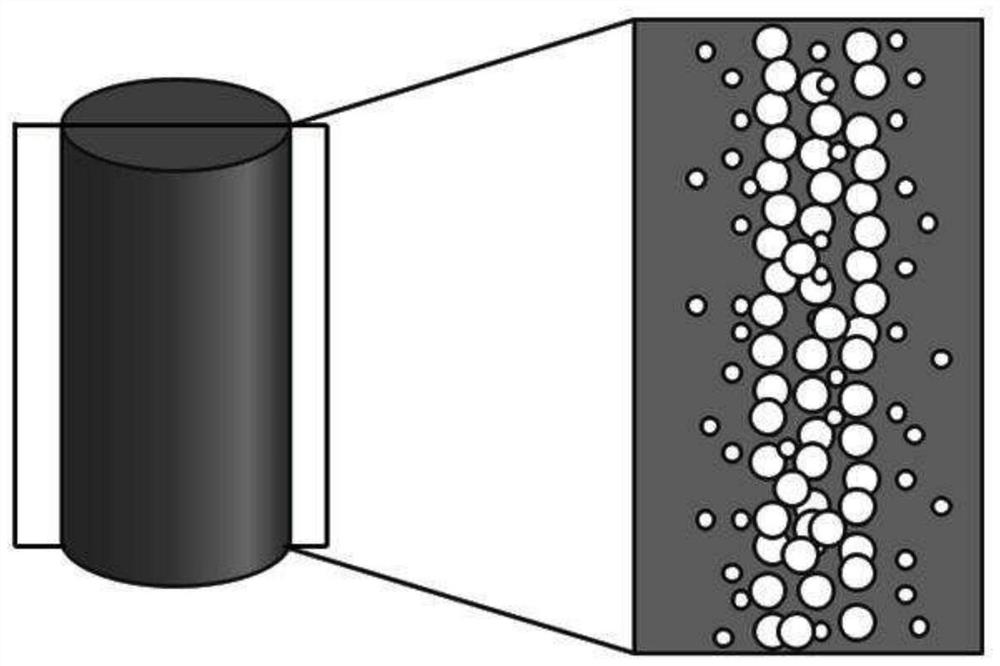

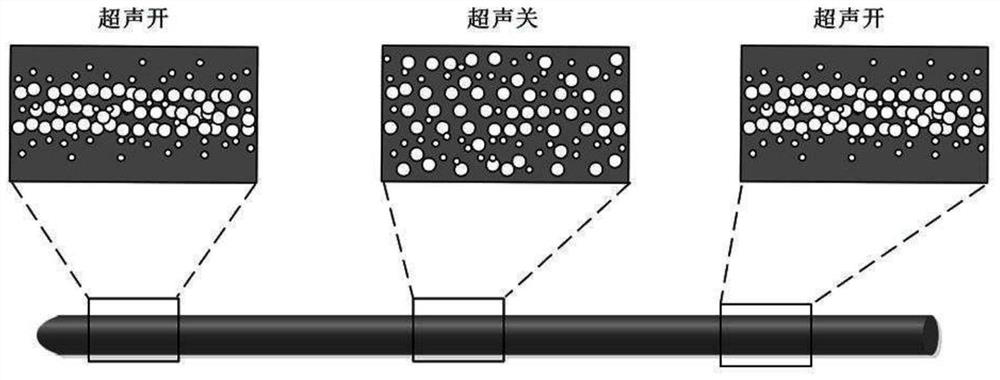

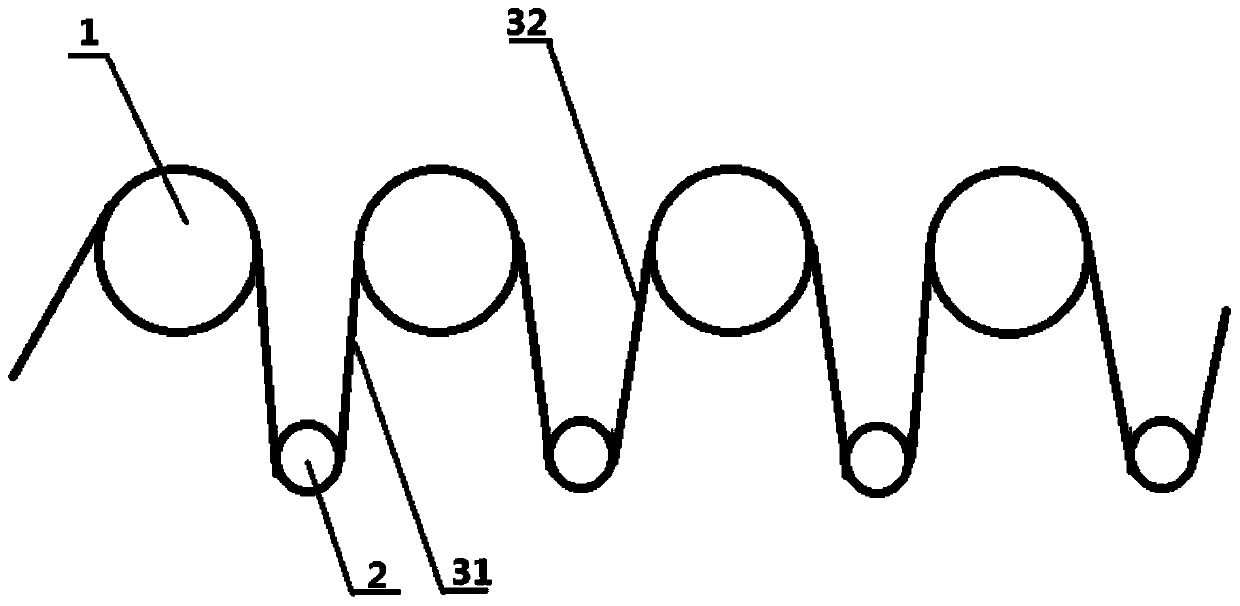

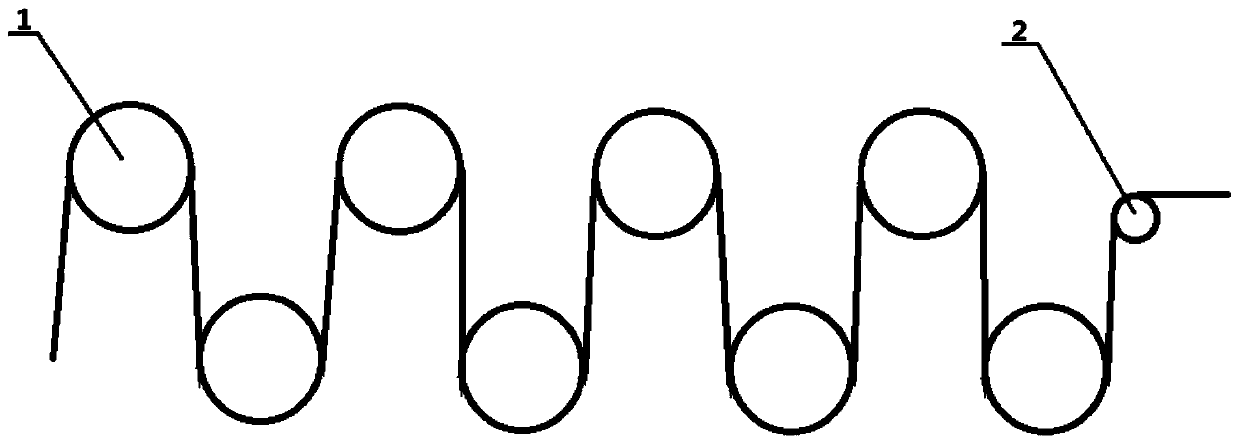

3D printing system and method for ordered gradient porous material

ActiveCN113103576AImplement gradient distributionAperture adjustableAdditive manufacturing apparatus3D object support structuresComputer control systemEngineering

The invention relates to the technical field of additive manufacturing, in particular to a 3D printing system and method for an ordered gradient porous material, and aims to solve the printing problem that a anisotropic gradient porous material in a single channel cannot be extruded through traditional 3D printing. The system specifically comprises a three-dimensional forming motion module, a digital ultrasonic auxiliary manufacturing system, a controllable pneumatic conveying module and a computer control system. The method comprises the steps of preparation of a printing material containing sacrificial template particles, ultrasonic-assisted additive manufacturing and aftertreatment. The gradient distribution of a directional pore structure in a single extruded filament from inside to outside during 3D printing can be realized, and the unique mechanical properties and physical properties of the filament have great application potential in the fields of tissue engineering and machinery.

Owner:JILIN UNIV

Production process of high-dust-holding-capacity filter paper

ActiveCN110952369AEffective control of thermal migration processControlling the Thermal Migration ProcessNon-fibrous pulp additionDryer sectionProcess engineeringFilter paper

The invention relates to the technical field of filter material manufacturing, and particularly discloses a production process of high-dust-holding-capacity filter paper. According to the production process, filter paper base paper is dipped and glued and then is subjected to drying treatment, in the drying treatment process, a drying cylinder is adopted for drying, and the temperature and the drying time of the drying cylinder are adjusted, so that the accurate control on the thermal migration process of a resin glue solution is realized, gradient distribution is formed in a filter paper interface, and the filter material dust holding capacity is improved.

Owner:石家庄辰泰滤纸有限公司

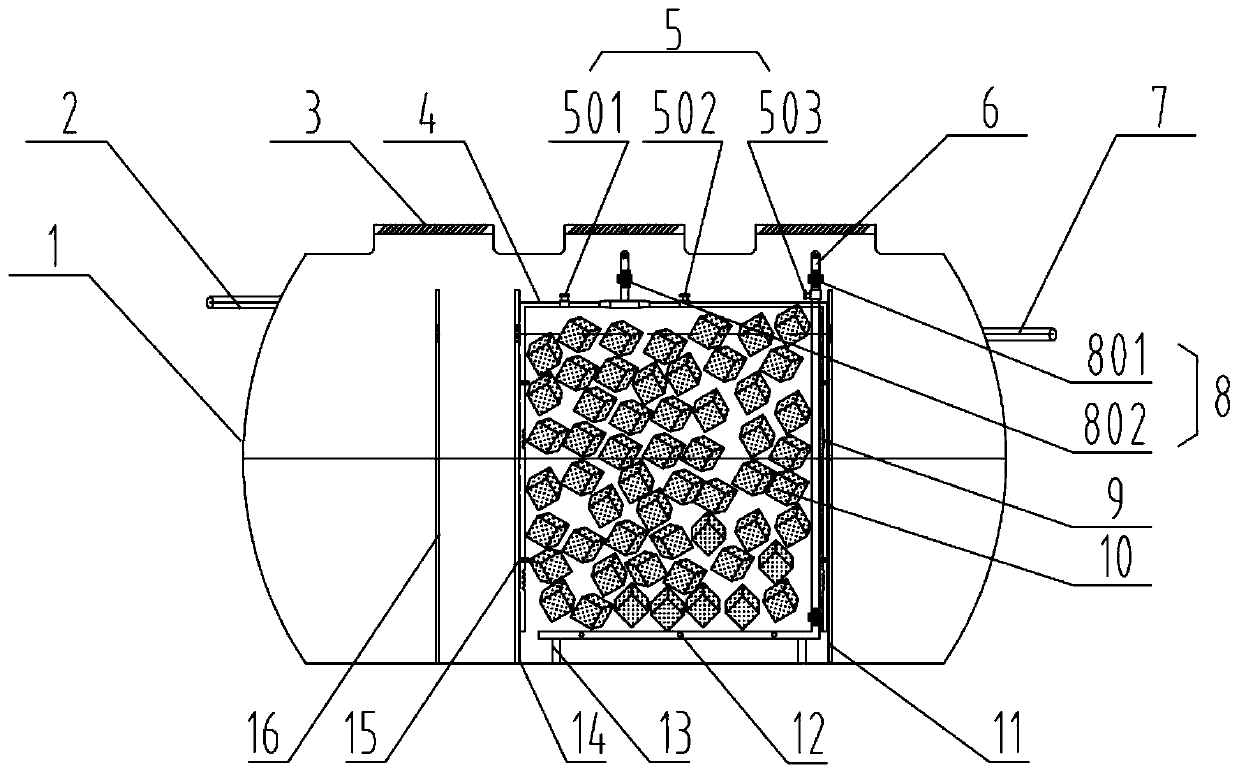

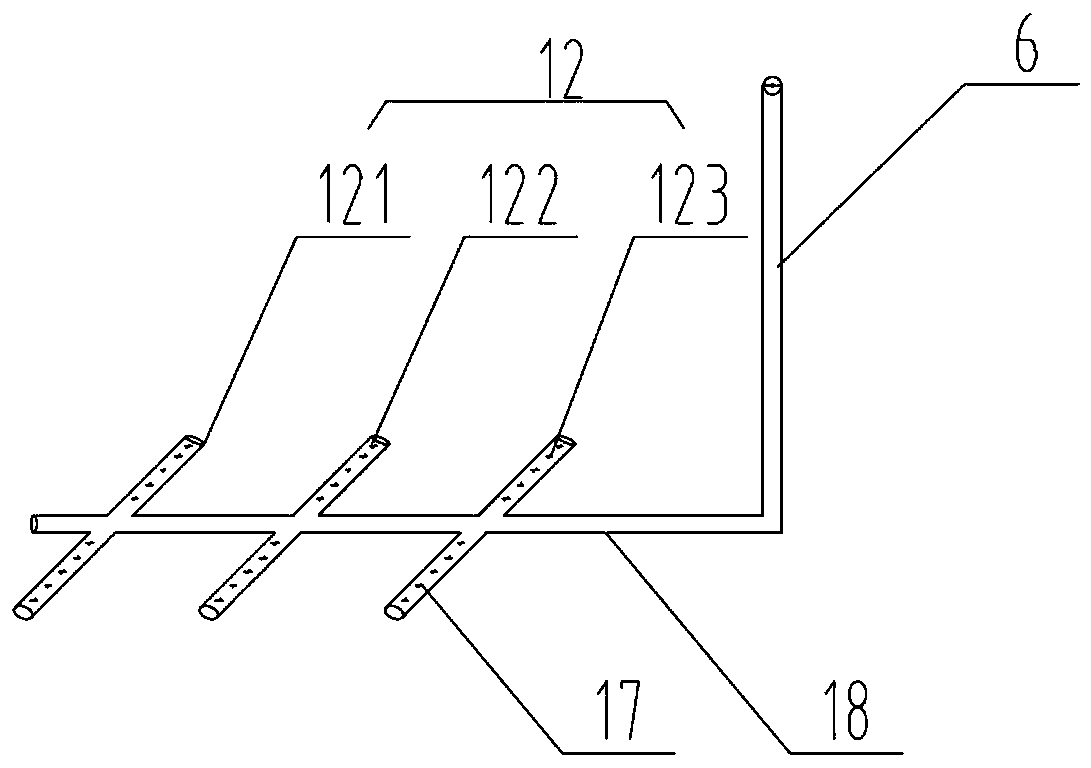

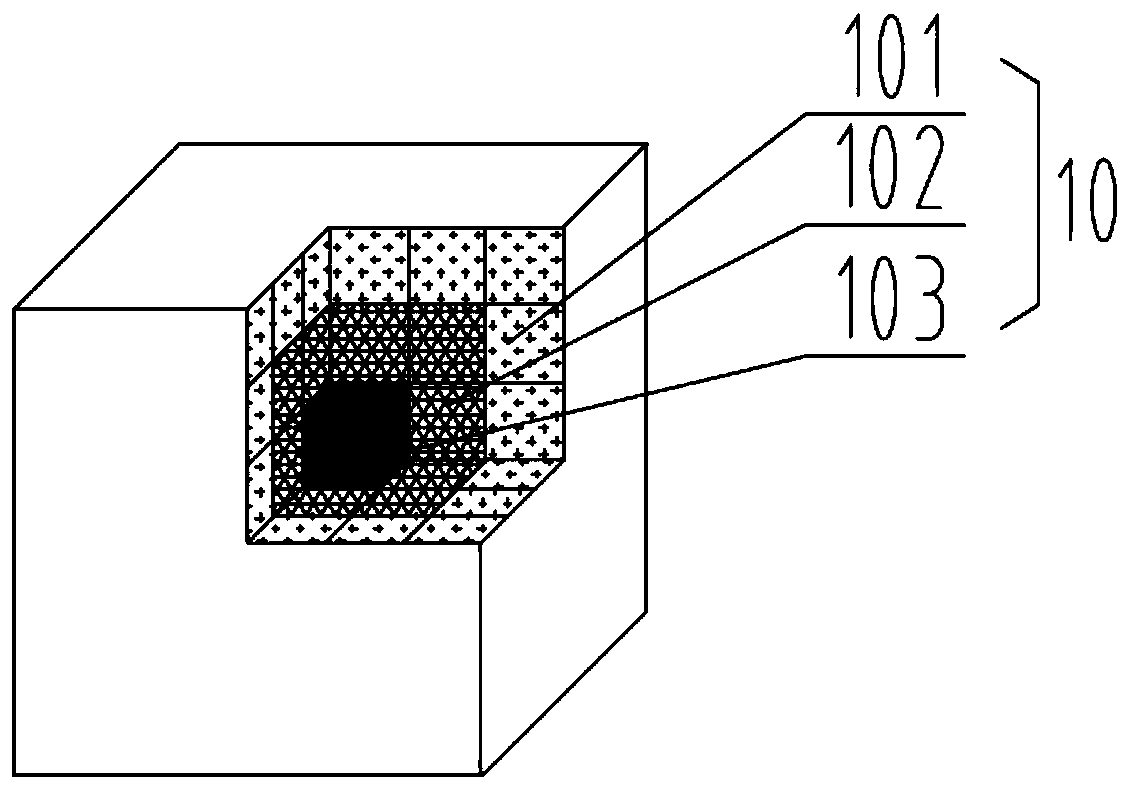

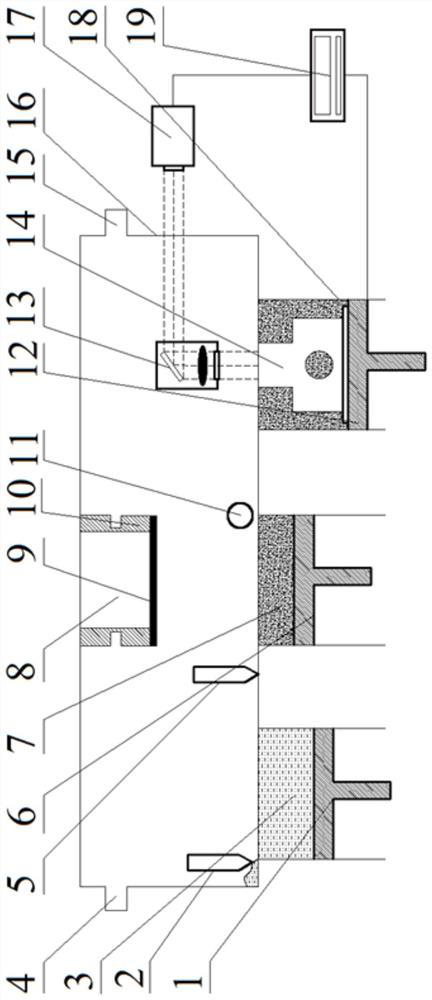

Compound aeration device for controlling gradient dissolved oxygen distribution

PendingCN110776117AImplement gradient distributionFlexible aeration adjustment methodWater aerationTreatment with aerobic and anaerobic processesSewage treatmentOxygen distribution

The invention discloses a compound aeration device for controlling gradient dissolved oxygen distribution, and belongs to the technical field of sewage treatment. The compound aeration device comprises a sewage treatment device body, wherein access holes are formed in the top of the sewage treatment device body; a water inlet pipe is arranged at one end of the sewage treatment device body; a wateroutlet pipe is arranged at the other end of the sewage treatment device body; through the arrangement of a first separation plate, a second separation plate and a third separation plate inside the sewage treatment device body, the inside of the sewage treatment device body is separated into an anoxic region, an anaerobic region and an aeration region; the aeration region is filled with nanometermodified flexible fillers; and a micropore aeration air inlet pipe and a perforated air inlet pipe are arranged on the side edge of the aeration region. By using a compound aeration method of combining a perforated pipe and a micropore aeration pipe, sufficient mass transfer, high oxygen charging efficiency and good denitrification effects can be ensured; the nanometer modified flexible fillers have developed pore structures, so that the dissolved oxygen gradient is gradually formed from the surface to the inside; short-cut simultaneous nitration and denitrification is realized; the denitrifying efficiency of a system is improved; and outlet water is enabled to stably reach standards.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

A method and device for preparing a flexible additive graded functional material

ActiveCN110496965BGuaranteed uniformityGuaranteed compactnessAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser additive manufacturing

The present invention relates to the field of laser additive manufacturing, in particular to a method and device for preparing a flexible additive gradient functional material. During the additive process, the proportion of mixed powder in each layer is changed, so as to realize the element gradient distribution of the additive component and make the The dissimilar metal powders are fully and uniformly mixed to ensure the uniformity and compactness of the additive components; at the same time, the recovery of excess powder in the mixed powder is realized, which saves costs to a large extent and improves the quality of the additive components.

Owner:JIANGSU UNIV

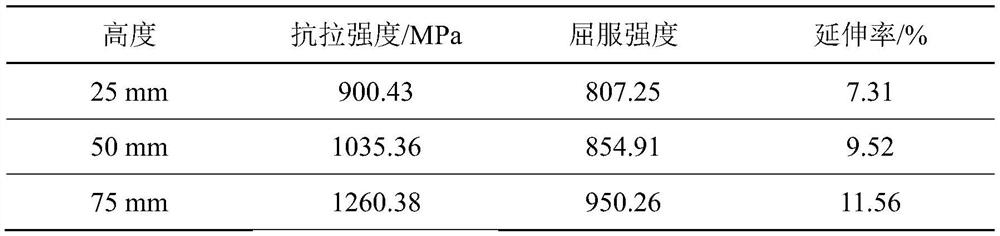

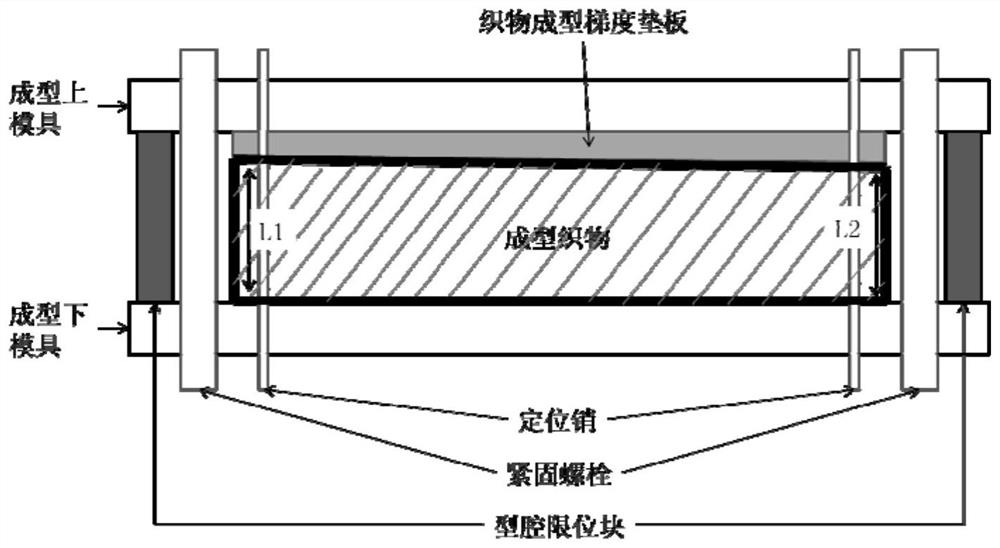

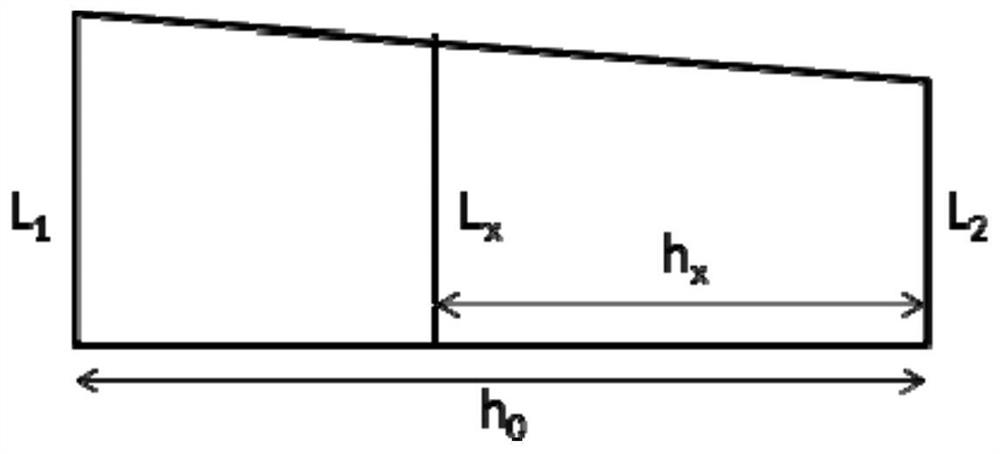

High-throughput continuous gradient fiber volume content preparation method of ceramic matrix composites

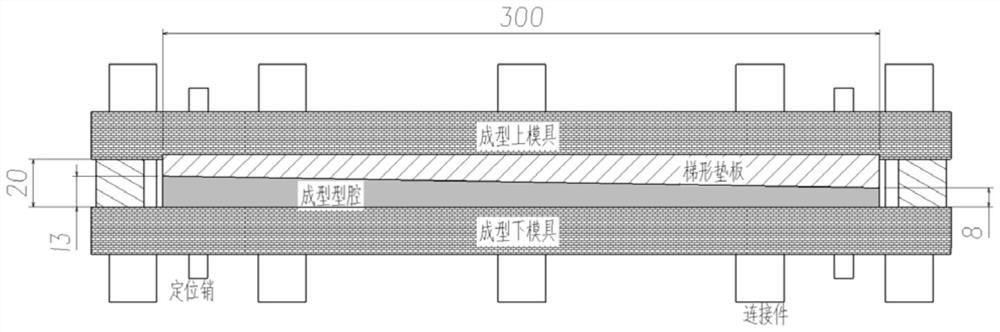

ActiveCN112405831BShorten the development cycleReduce R&D costsLamination ancillary operationsLaminationFibrous bodyCeramic matrix composite

The invention relates to a method for preparing a ceramic matrix composite material with a high-throughput continuous gradient fiber volume content. Through the gradient design of the blank forming tooling, the fabric with a uniform fabric structure and uniform thickness is pressed and formed in a gradient cavity, and the subsequent cycle is dense. In the process of using gradient tooling to repeatedly strengthen the size of the blank, a ceramic matrix composite material with a continuous gradient change in fiber volume content can be obtained, and through the method of the present invention, the influence of any fiber volume content within a certain range on the performance of the composite material can be quickly obtained Data, establish a data-rich influence law curve, greatly shorten the development cycle and reduce R&D costs.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Hydrogen barrier coating and preparation method based on inner surface of hydrogen storage and transportation equipment

ActiveCN111826612BStructural impactNo pollution in the processVacuum evaporation coatingSputtering coatingGraphene coatingGraphite

A hydrogen-resistant coating based on the inner surface of hydrogen storage and transportation equipment and its preparation method, the preparation method comprising the following steps: Step S10, after the surface of the substrate is gradually polished and cleaned and air-dried, the surface of the substrate is deposited on the surface of the substrate by PIII&D deposition technology Implanting and depositing Ni ions on top to obtain a deposited Ni layer and an implanted layer sequentially stacked from bottom to top; Step S11, uniformly implanting C ions on the surface of the implanted layer to obtain an implanted C layer rich in C ions; Step S12 , annealing the sample formed with the implanted C layer, so that the surface of the implanted C layer segregates and grows a graphene coating. The technical solution provided by the invention has strong operability and good controllability. The graphene coating prepared by this method has high bonding strength and good hydrogen resistance, and the graphene coating can be controlled by controlling the amount of C ion implantation. The thickness of the layer, the technical feasibility is strong, and it is suitable for structural materials whose surface cannot directly grow graphene.

Owner:SOUTH CHINA UNIV OF TECH

A gradient ultra-high temperature ceramic matrix composite material and its preparation method

The invention relates to a gradient ultra-high temperature ceramic matrix composite material and a preparation method thereof. The method comprises the following steps: (1) preparing slurry with a gradient concentration: the solid component is zirconium carbide powder, the liquid component is thermosetting phenolic resin, Mix the solid component and the liquid component to prepare n slurries with gradient concentrations, where n≥2; (2) Preparation of prepreg: compound n slurries with gradient concentrations with n parts of carbon cloth respectively to obtain Multiple prepregs; (3) Preparation of composite material components: stacking multiple prepregs prepared in step (2), when stacking, along the thickness direction, the powder content changes in a gradient; the layup The final prefabricated body is solidified to obtain a composite material component; (4) cracking; (5) PIP process to prepare a C / C green body; (6) molten silicon infiltration. The gradient ultra-high temperature ceramic matrix composite material with low density and excellent high temperature ablation resistance can be prepared by using the preparation method provided by the invention, which has substantial benefits in the field of aerospace.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-temperature radar infrared compatible stealth coating with functional gradient distribution and preparation method thereof

ActiveCN112961531BImprove absorbing performanceHigh resistivityPowdery paintsSpecial surfacesThermal dilatationRadar

The invention relates to the technical field of high-temperature stealth coatings, and specifically discloses a high-temperature radar infrared-compatible stealth coating with functional gradient distribution and a preparation method thereof. The high-temperature radar infrared-compatible stealth coating is coated on the surface of a metal substrate, Starting from the surface of the substrate, it includes a metal bonding layer, a heat matching ceramic layer, a dielectric ceramic layer, a first high-temperature electromagnetic periodic structure layer, a dielectric isolation layer, a second high-temperature electromagnetic periodic structure layer, and an infrared stealth layer from bottom to top. The high-temperature radar infrared compatible stealth coating of the present invention has radar and infrared compatible stealth functions. The coating adopts a multi-functional layer structure, which realizes the gradient distribution of the thermal expansion coefficient of the coating, and can achieve better thermal matching with the metal substrate, and is heat resistant. Good vibration performance; the temperature of the softening point of the glass phase selected in the present invention does not exceed 600°C, which has the advantages of low sintering temperature and short time, and can reduce the effects of oxidation, damage and deformation on the metal substrate.

Owner:NAT UNIV OF DEFENSE TECH

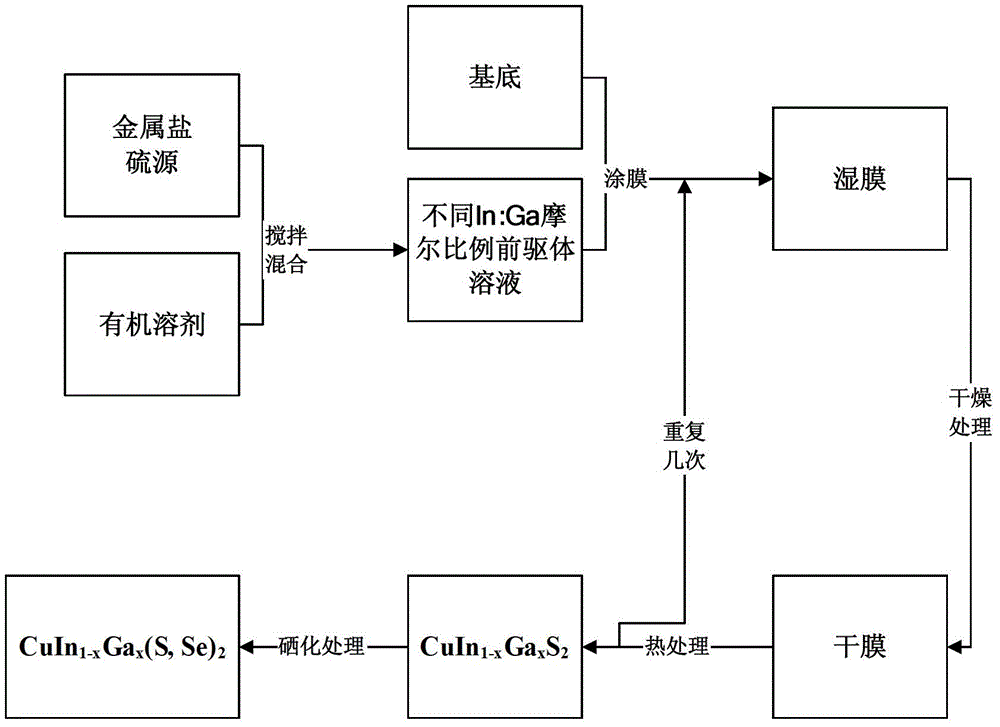

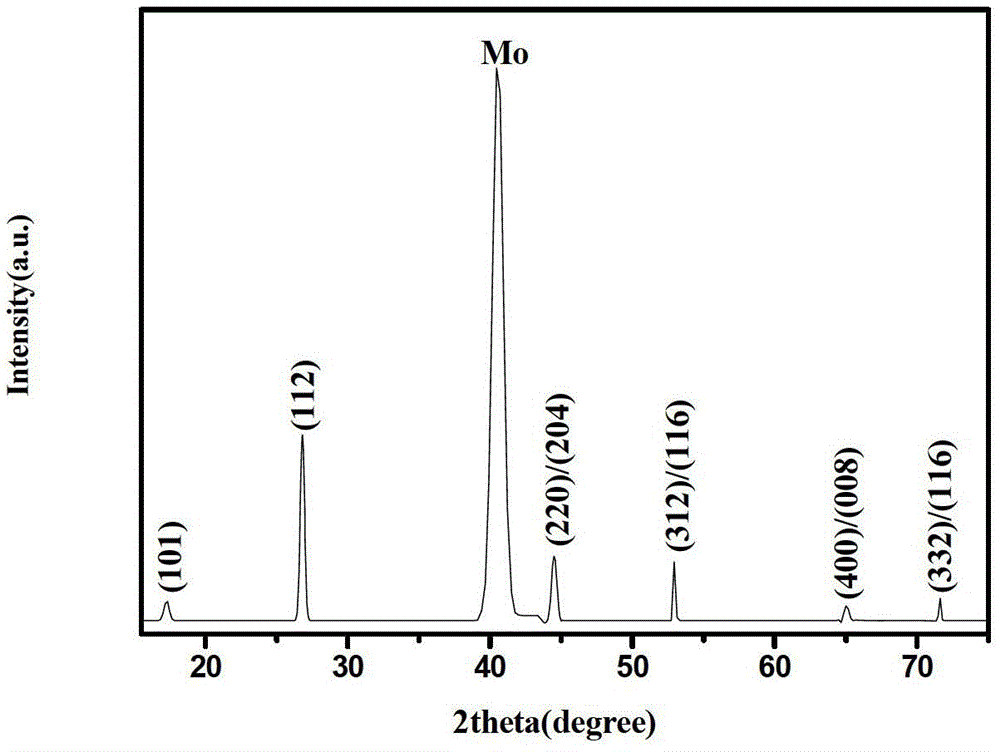

Copper indium gallium sulfide selenide solar cell, thin film absorber layer and preparation method thereof

ActiveCN103318851BImplement gradient distributionBandgap width can be adjustedSelenium/tellurium compundsFinal product manufactureIndiumSulfur

The invention discloses a preparation method of a copper-indium-gallium-sulfur-selenium film absorbing layer. The preparation method comprises the following steps of preparing a precursor solution, preparing a precursor film, carrying out a heat treatment to the precursor film, preparing a CuIn1-xGaxS2 film with Ga in gradient distribution, and carrying out selenization processing to the CuIn1-xGaxS2 film with Ga in gradient distribution in a selenization furnace; and a CuIn1-xGax(S,Se)2 film absorbing layer is obtained. The invention also discloses a copper-indium-gallium-sulfur-selenium film absorbing layer and a cell comprising the same. Because components of the precursor solution are adjustable, Ga can be in gradient distribution in the absorbing layer by means of adjusting the molar ratio of In to Ga in the solution; and at the same time, by means of a volume expansion effect of Se atoms replacing part of S atoms in the selenization process, the structure densification of the copper-indium-gallium-sulfur-selenium film is achieved, and the forbidden band width of the absorbing layer can be adjusted by replacing S atoms by Se atoms.

Owner:徐东

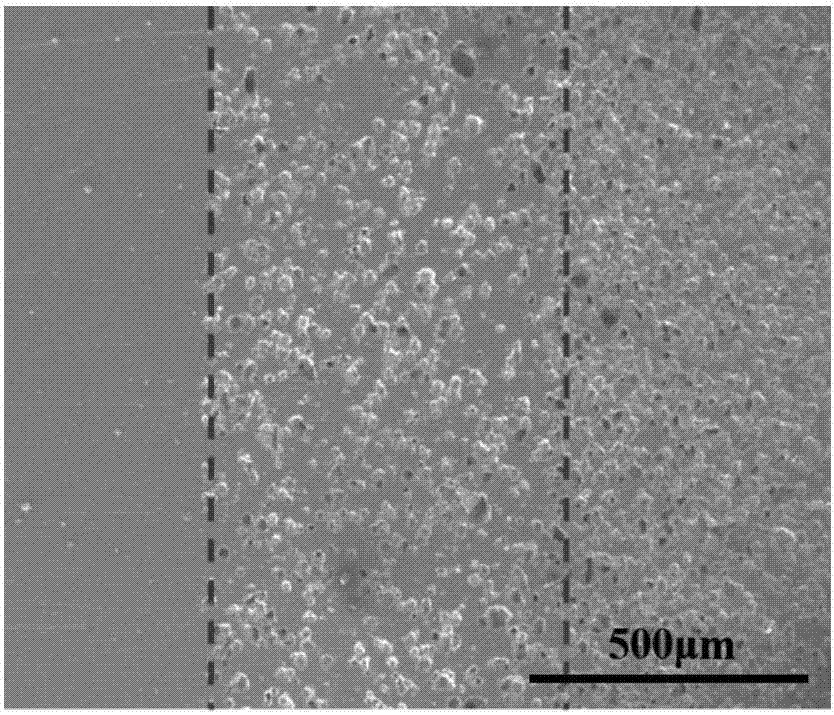

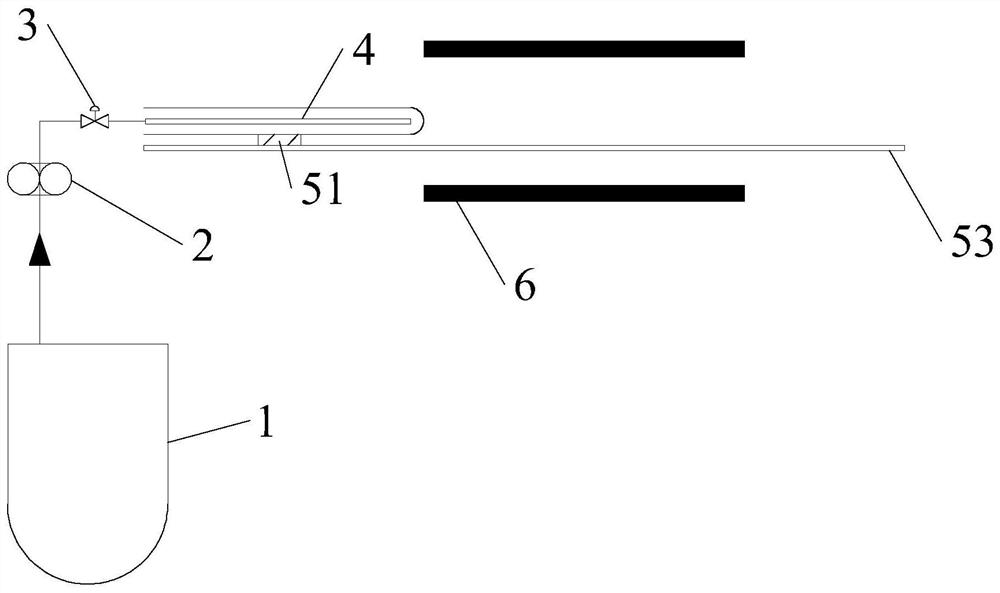

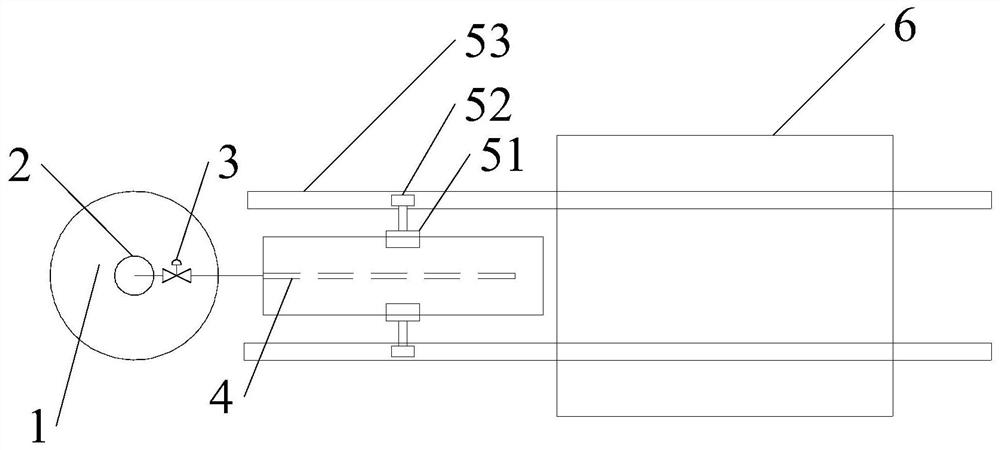

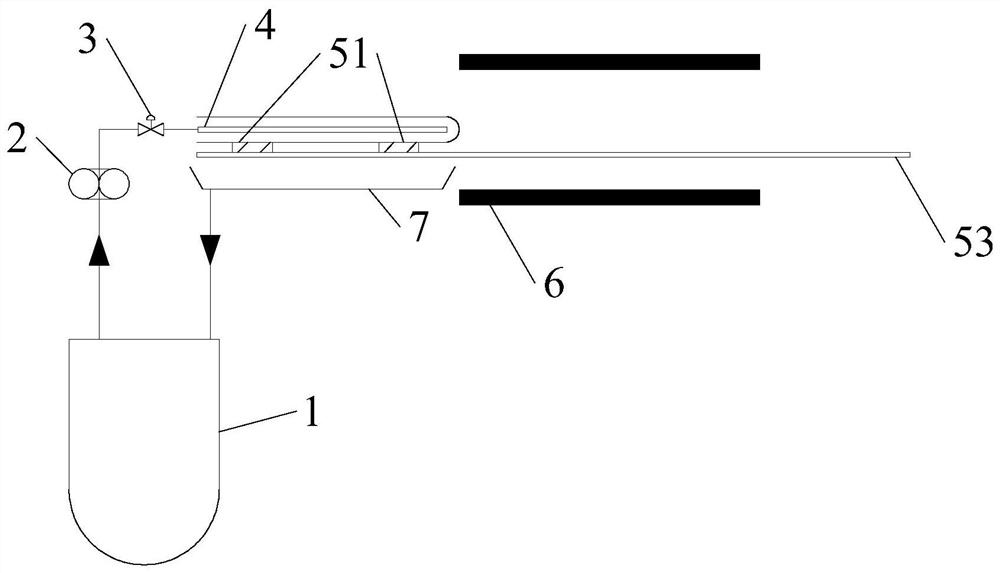

A catalytic filter element and its preparation method and device and application of the device

ActiveCN110384980BImplement gradient distributionAvoid cloggingDispersed particle filtrationMembrane filtersNano catalystFiber

The invention relates to a catalytic filter element, a preparation method and a device thereof and application of the device. The preparation method comprises the following steps that nanometer catalyst slurry is inserted in the inner part of a blank ceramic fiber filter element through an ejecting method, and the catalytic filter element is obtained through heating curing; the device comprises aslurry storage unit, a slurry ejecting unit, a filter element fixing unit and a heating unit, the slurry storage unit is connected with the slurry ejecting unit, a slurry transporting unit is arrangedbetween the slurry storage unit and the slurry ejecting unit, the filter element fixing unit comprises a round roller, a moving sliding wheel and a support bracket which are arranged from top to bottom, and the heating unit is a baking tunnel. According to the catalytic filter element, under the filtering wind speed of 1 m / min, the pressure drop is below 600 Pa, the dust load of filtered gas is below 1 mg / m<3>, and denitration activity can reach above 98% at 250-400 DEG C.

Owner:NANJING WEIHENG EXPERIMENTAL EQUIP CO LTD

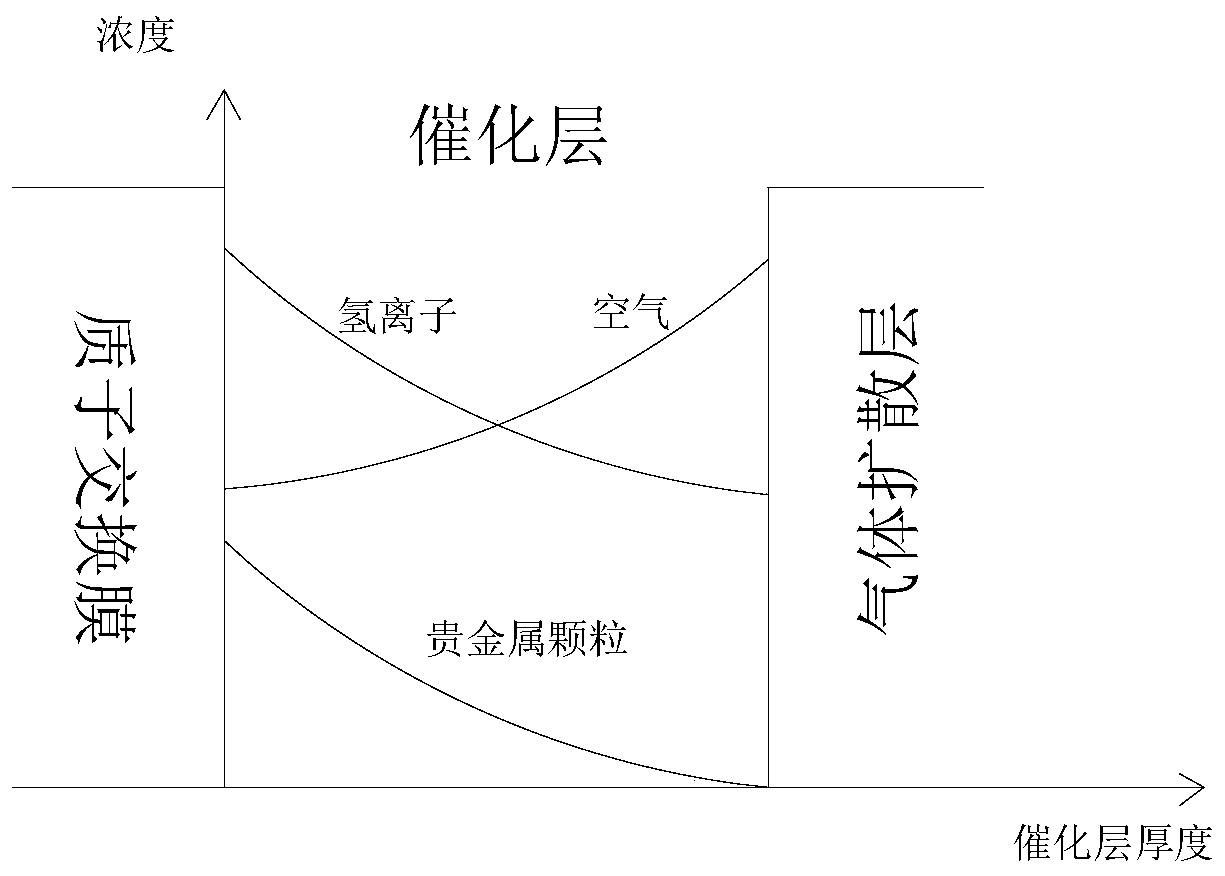

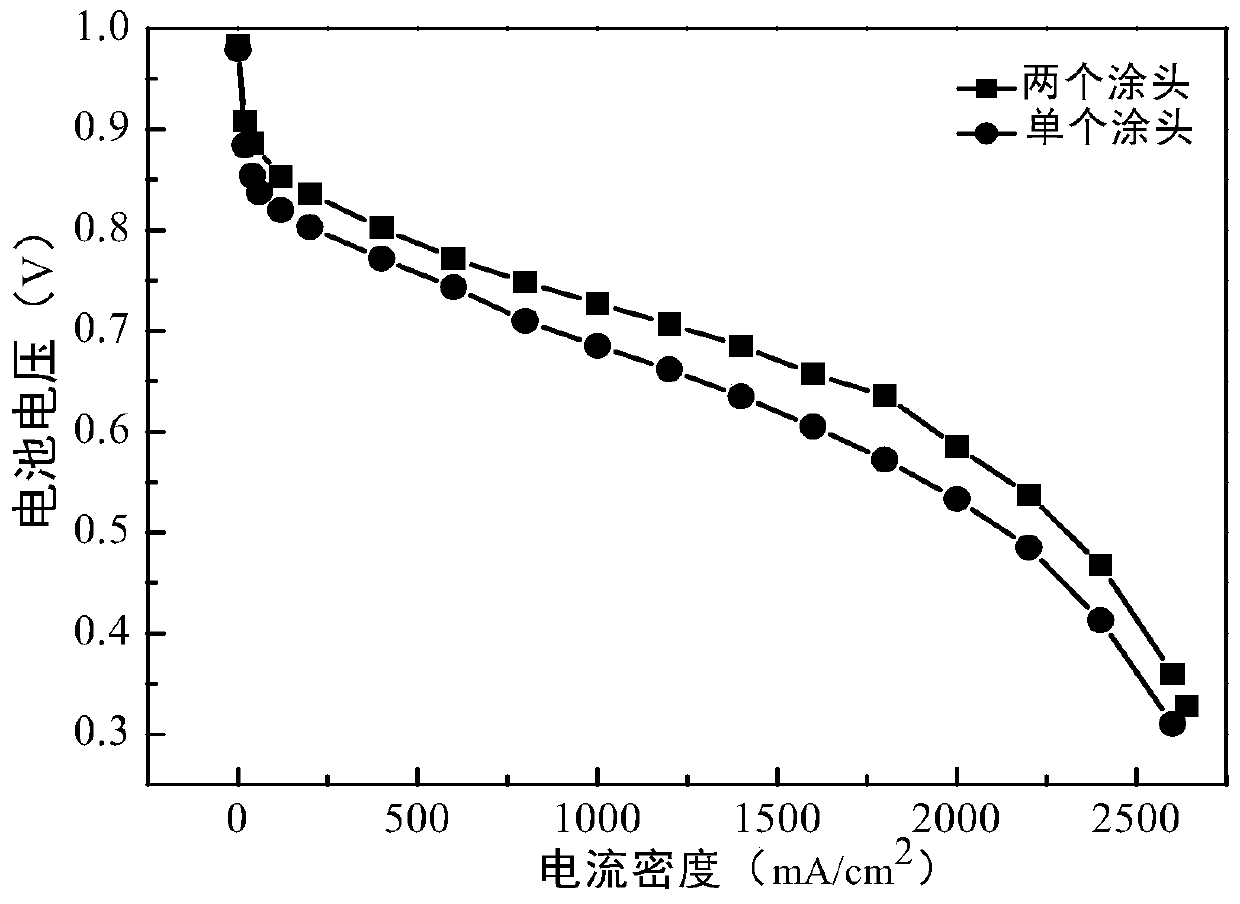

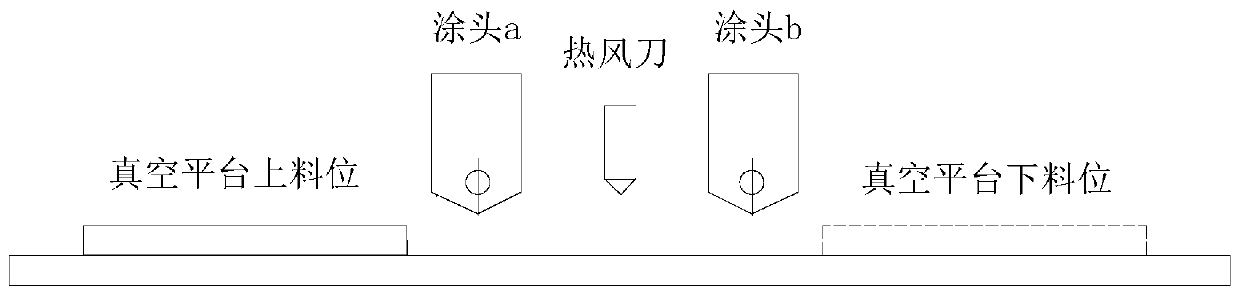

A kind of mea preparation method that noble metal catalyst particles are distributed in gradient

ActiveCN107146891BImplement gradient distributionAvoid wastingCell electrodesElectrochemical responsePtru catalyst

The invention relates to an MEA preparation method for realizing gradient distribution of noble metal catalyst granules. The preparation method specifically comprises the following steps of cutting a proton exchange membrane or carbon paper according to needs; preparing noble metal catalyst granular slurry of different concentrations and fully stirring; and coating the proton exchange membrane or carbon paper with the noble metal catalyst granular slurry of different concentrations layer by layer to realize gradient distribution of the noble metal catalyst granules in a thickness direction. Compared with the prior art, the carrying capacity of the noble metal can be lowered, and improvement of the catalyst utilization rate can be facilitated; according to the oxygen concentration gradient distribution characteristic, a gradient distribution active metal catalytic layer is established, so that the usage amount of the noble metal is reduced; less noble metal is adopted in a place with high oxygen concentration while a high-content noble metal is adopted in a place with insufficient oxygen concentration for enabling the oxygen to be fully reacted in a reduction reaction so as to promote an electrochemical reaction; and compared with a spray method, the preparation method provided by the invention can effectively avoid waste and lower cost.

Owner:河南豫氢动力有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com