Production process of high-dust-holding-capacity filter paper

A production process and technology of dust holding capacity, applied in the field of filter material manufacturing, can solve problems such as affecting the filtration efficiency and reducing the air permeability of filter paper, and achieve the effect of improving dust holding capacity, prolonging service life and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of production technology of filter paper with high dust holding capacity, concrete steps are as follows:

[0029] Pulping: Feed hardwood pulp and softwood pulp into a pulper according to a certain ratio, and after pulping, the wood pulp raw materials are evenly dispersed in water to obtain pulp;

[0030] Wet forming: the slurry is evenly distributed on the forming net through the headbox, and vacuum suction is used to remove a large amount of water to form a wet paper sheet;

[0031] Base paper drying: dry the wet paper sheets to obtain base paper without moisture, which is convenient for absorbing glue and applying glue; after drying, the base paper has a weight of 95 grams, a thickness of 0.35 mm, and an air permeability of 160 L / m 2 / s, the bursting strength is 90kpa.

[0032] Dipping and gluing: dip the dried base paper in acrylic latex (viscosity 250cp) for 1.5s, so that the latex fully penetrates the base paper.

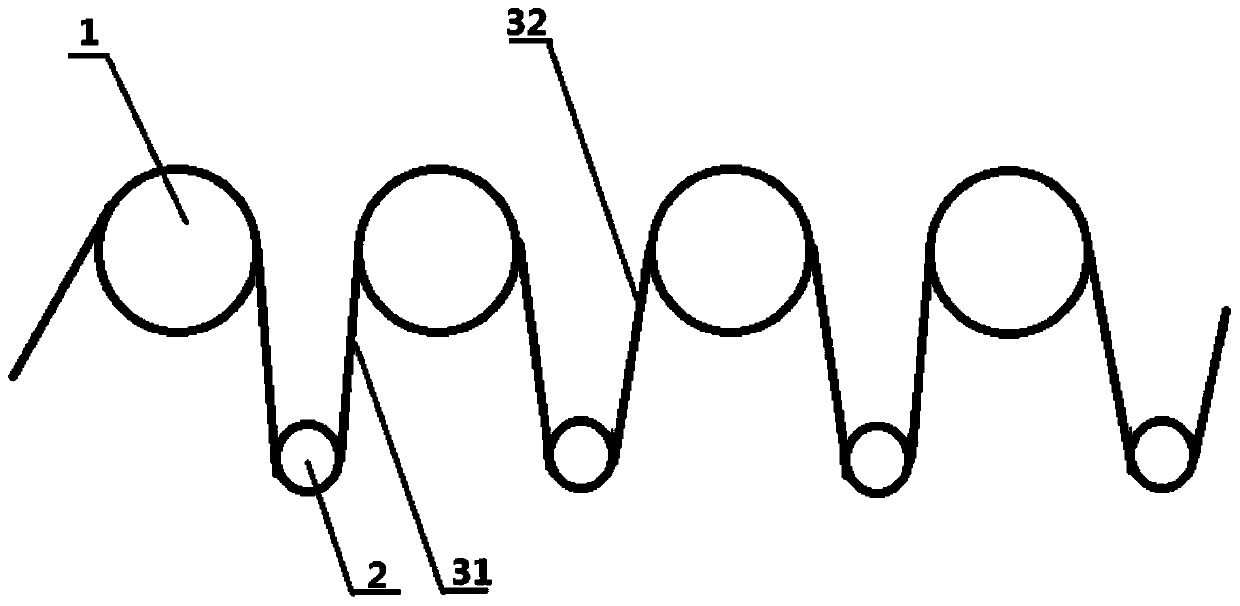

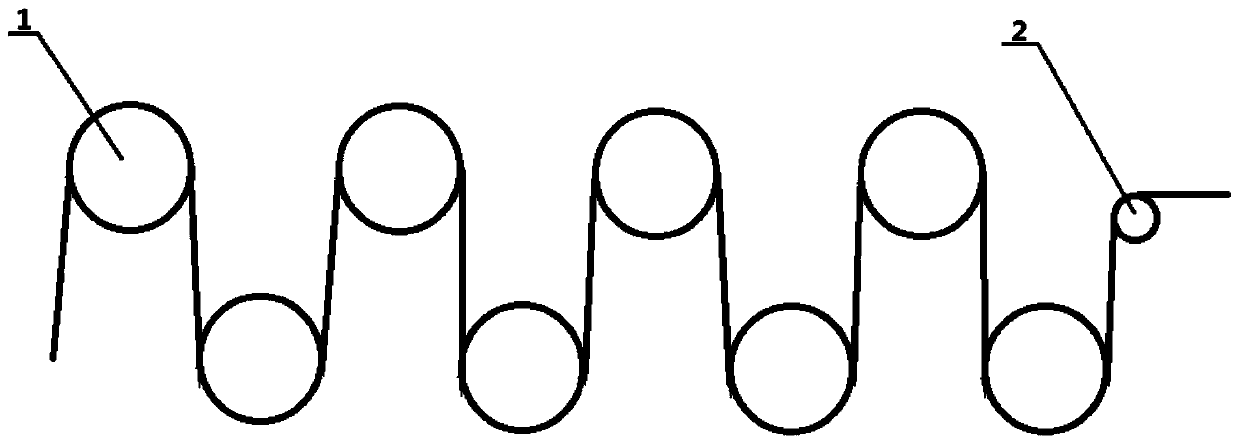

[0033] Drying: four sets of drying cylind...

Embodiment 2

[0041] A kind of production technology of filter paper with high dust holding capacity, concrete steps are as follows:

[0042] Pulping: Feed hardwood pulp and softwood pulp into a pulper according to a certain ratio, and after pulping, the wood pulp raw materials are evenly dispersed in water to obtain pulp;

[0043] Wet forming: the slurry is evenly distributed on the forming net through the headbox, and vacuum suction is used to remove a large amount of water to form a wet paper sheet;

[0044] Base paper drying: dry the wet paper sheets to obtain base paper with a moisture content of 3wt%, which is convenient for absorbing glue and applying glue; after drying, the base paper has a weight of 115 grams, a thickness of 0.45 mm, and an air permeability of 500 L / m 2 / s, the bursting strength is 60kpa.

[0045] Dipping and gluing: dip the dried base paper in acrylic latex (viscosity 800cp) for 1.5s, so that the latex fully penetrates the base paper.

[0046] Drying: four sets ...

Embodiment 3

[0054] The base paper obtained in Example 2 was dipped and coated with the same conditions and then dried with the same four sets of drying cylinders, the difference being the temperature of each group of drying cylinders, the time passing through each drying cylinder and the total drying of each step The time is as follows:

[0055] (1) 180°C, 5s, 1min;

[0056] (2) 150°C, 5s, 0.5min;

[0057] (3) 150°C, 5s, 0.5min;

[0058] (4) 140°C, 5s, 40s.

[0059] The grammage, thickness, air permeability and bursting strength of the filter paper sheets after drying in this embodiment are equivalent to those in embodiment 2, and the dust holding capacity is 69g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com