Patents

Literature

830results about "Filter paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet type nonwoven fabric and filter

ActiveUS20100133173A1Suitable for collectionLayered productsSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceSingle fiber

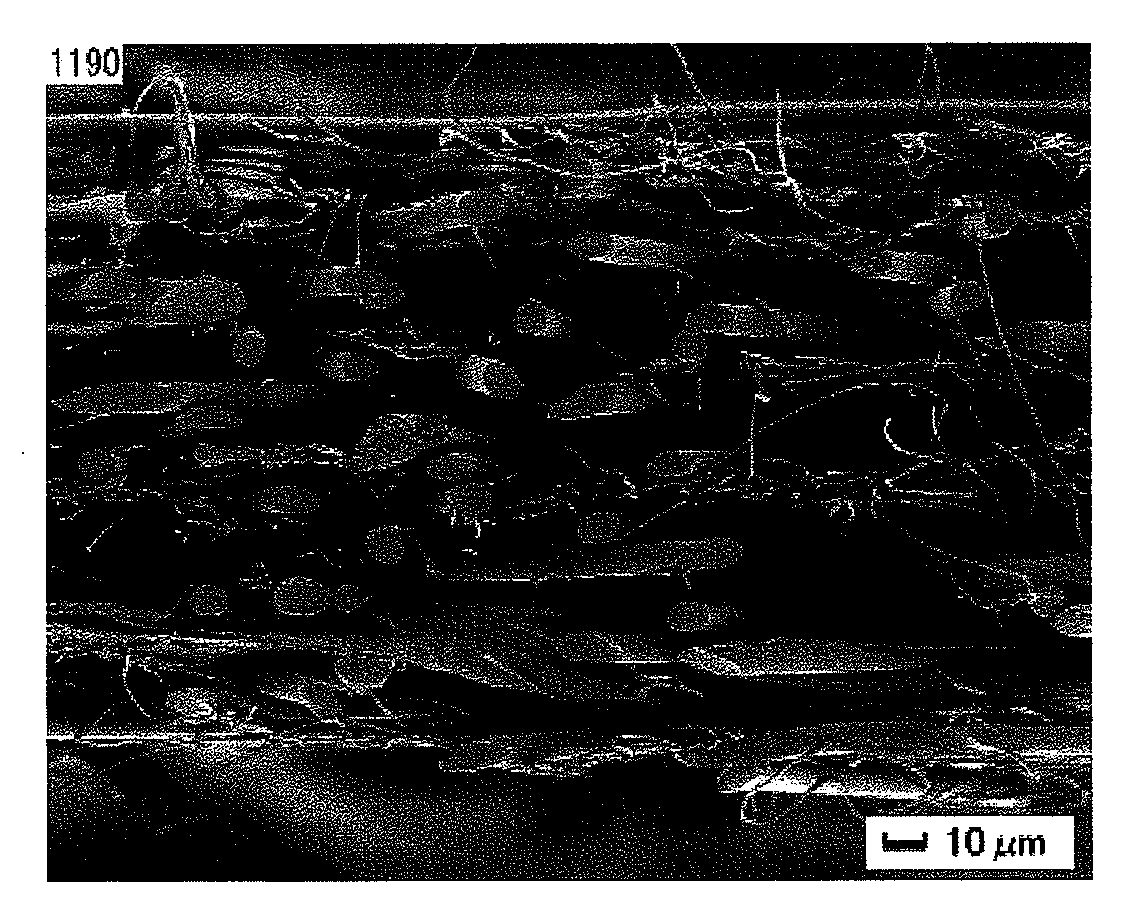

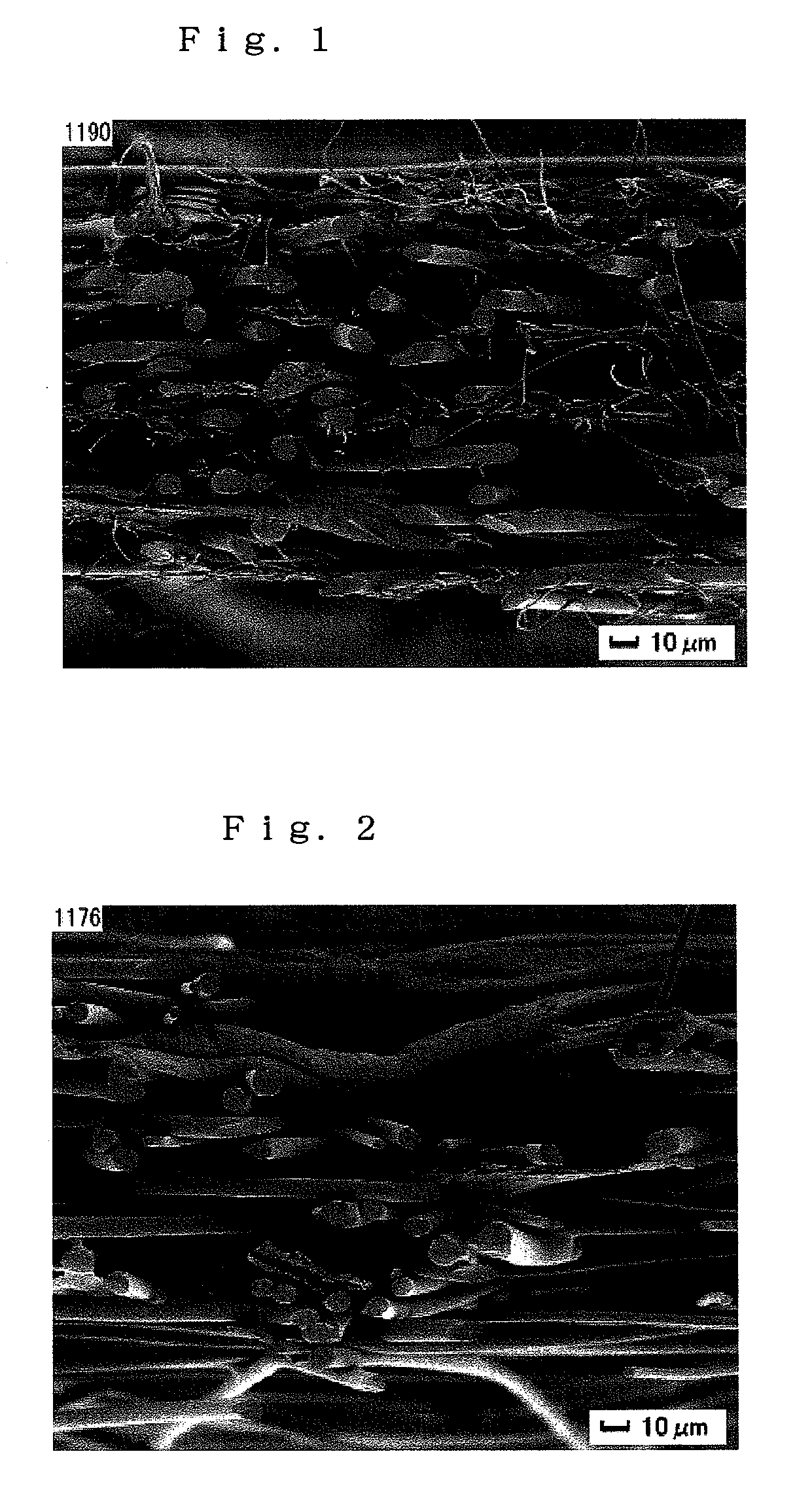

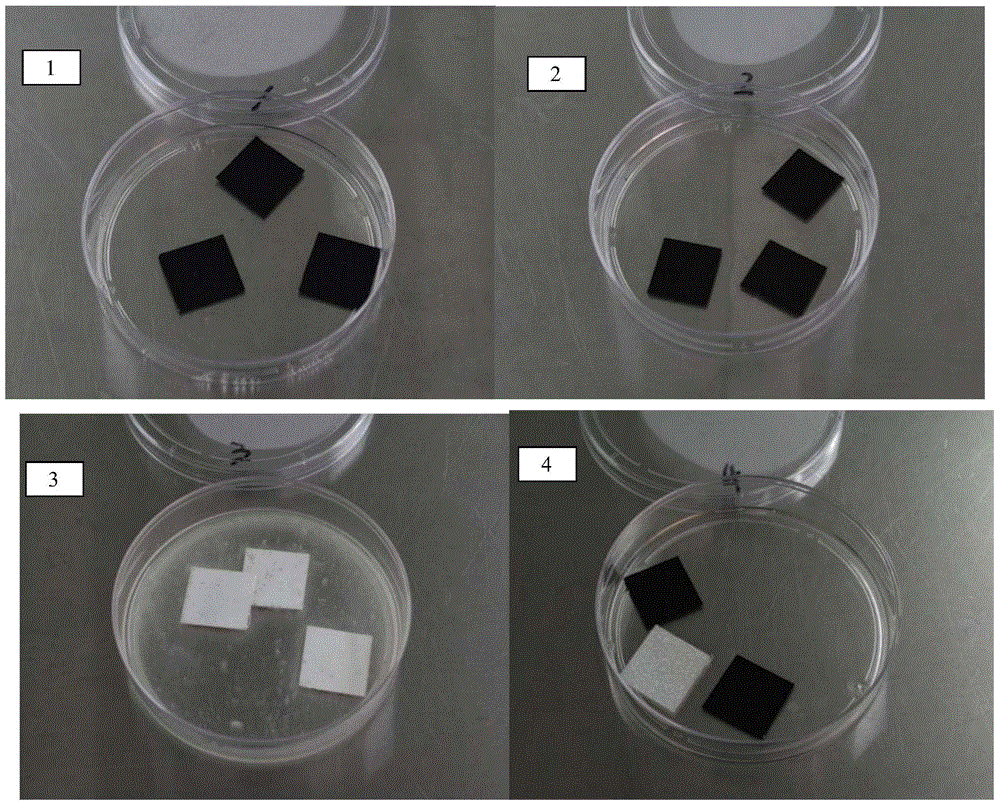

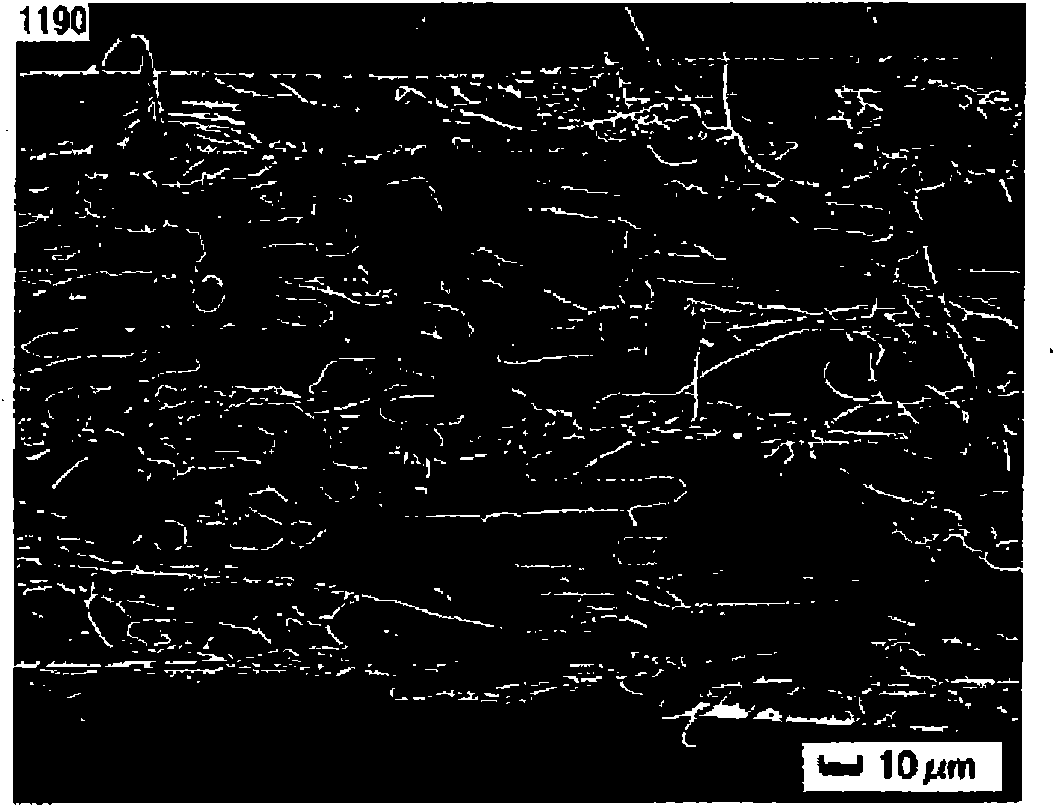

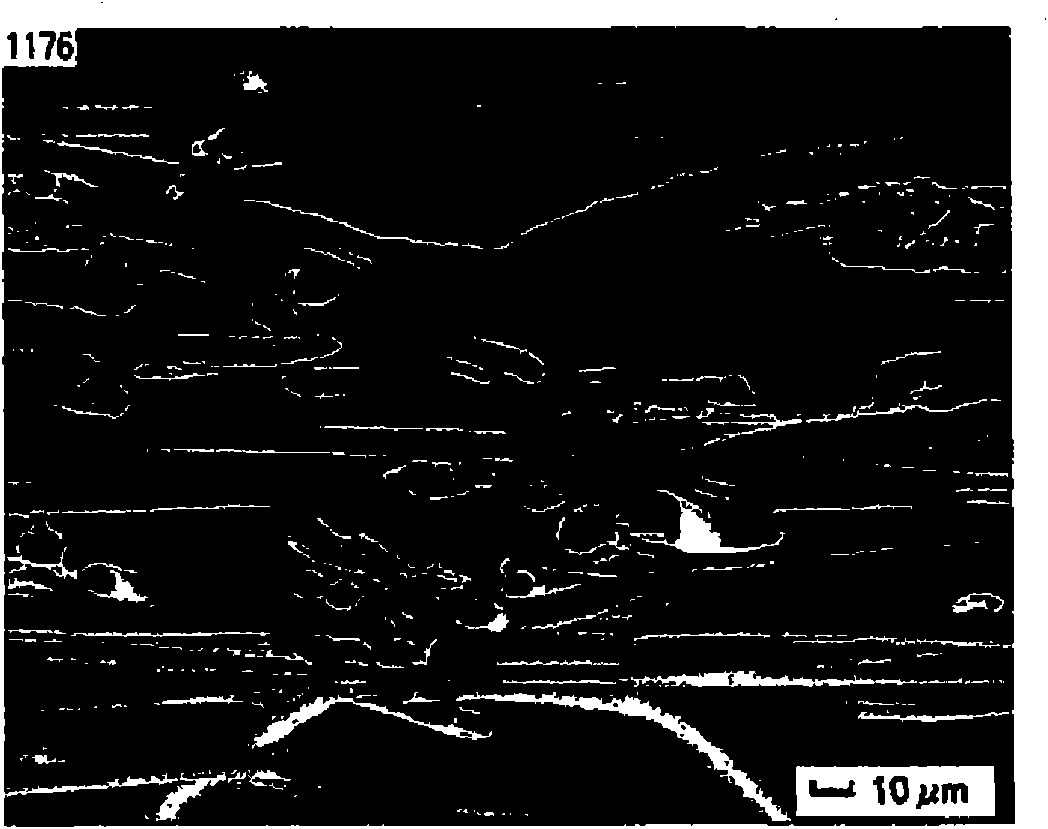

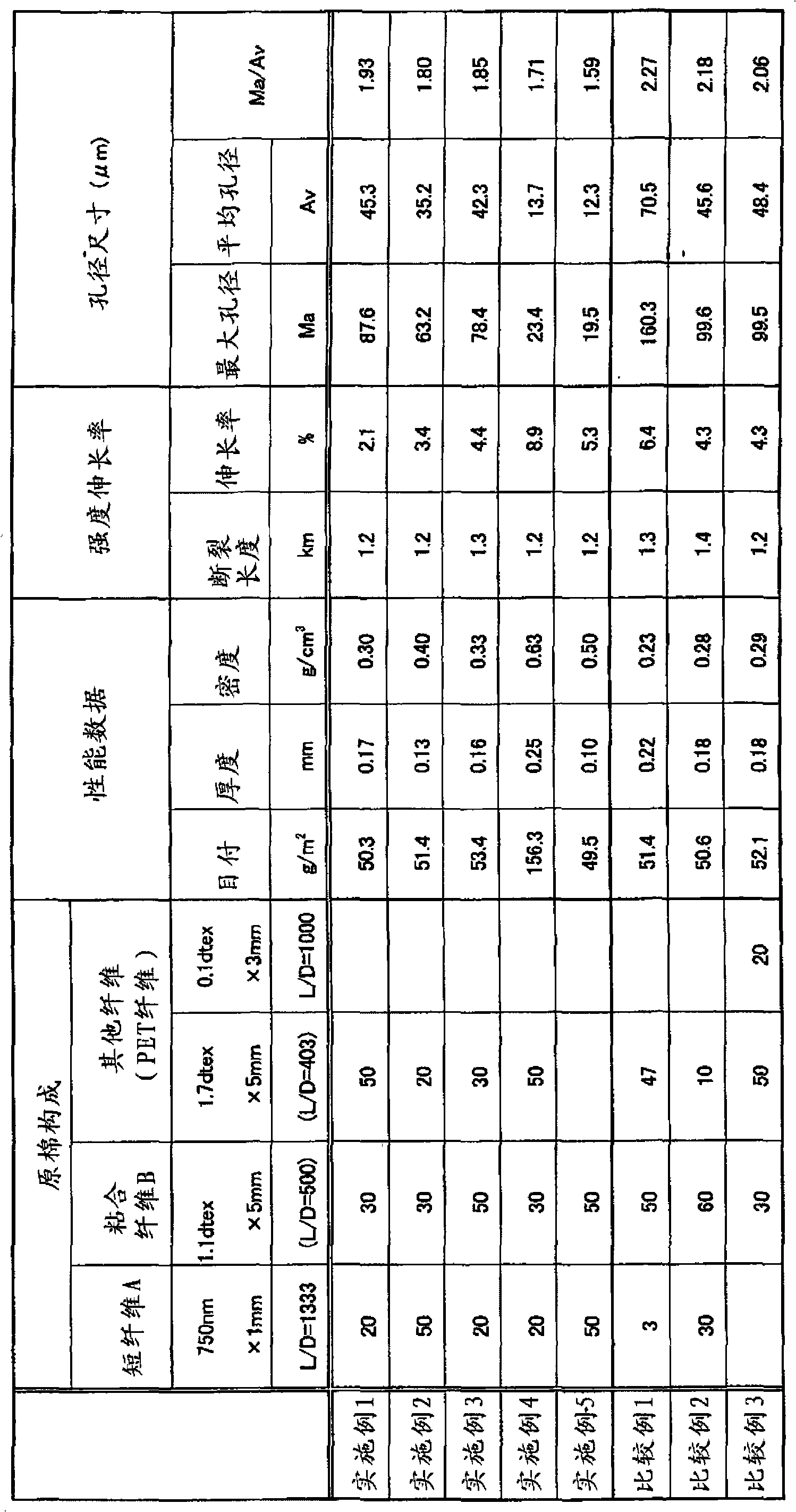

The present invention is a wet type nonwoven fabric that includes two or more kinds of fibers, wherein the wet type nonwoven fabric includes a short fiber A that is constituted of a fiber-forming thermoplastic polymer and has a fiber diameter D of from 100 to 1000 nm and the ratio of a fiber length L to the fiber diameter D, L / D, in the range of from 100 to 2500 in from 4 to 50% by weight relative to the total weight of the nonwoven fabric, and a binder fiber B that has a single fiber fineness of 0.1 dtex or less in from 10 to 50% by weight relative to the total weight of the nonwoven fabric.

Owner:TEIJIN FRONTIER CO LTD

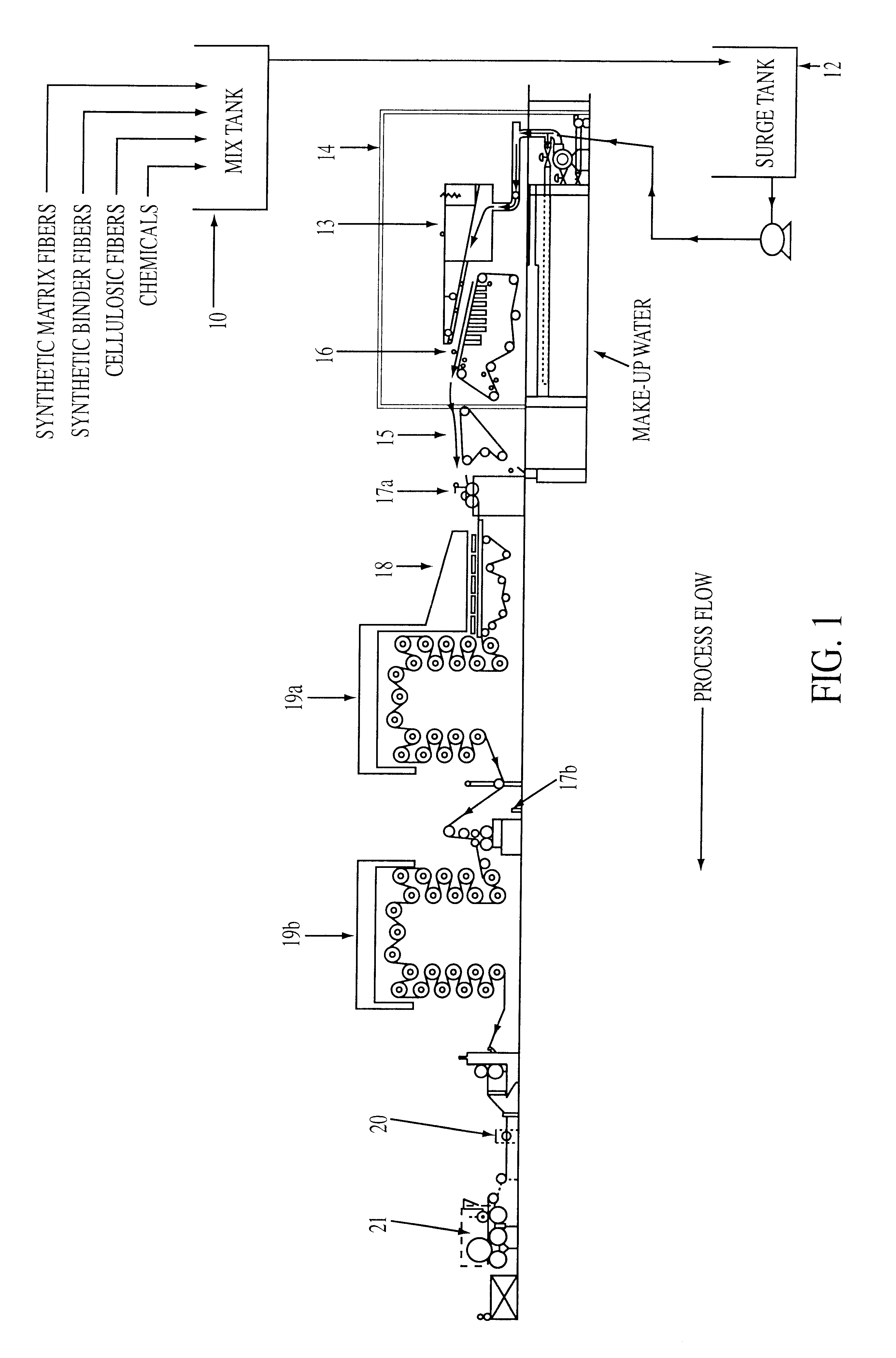

High efficiency thermally bonded wet laid milk filter

InactiveUS6352947B1Increase flow rateImprove filtering effectSynthetic resin layered productsPaper/cardboardFiberBursting strength

A filtration fabric which is composed of 15.0 to 100.0% binder fiber, 0.0 to 85.0% pulp portion, 0.0% to 15.0% latex binder or other stiffening agent. A filter media made of the fabric has an improved flow rate averaging no more than 21 seconds, while maintaining an average sediment retention of 70% and minimum wet burst strength of about 40 psi to about 50 psi, preferably about 50 psi.

Owner:AHLSTROM MOUNT HOLLY SPRINGS

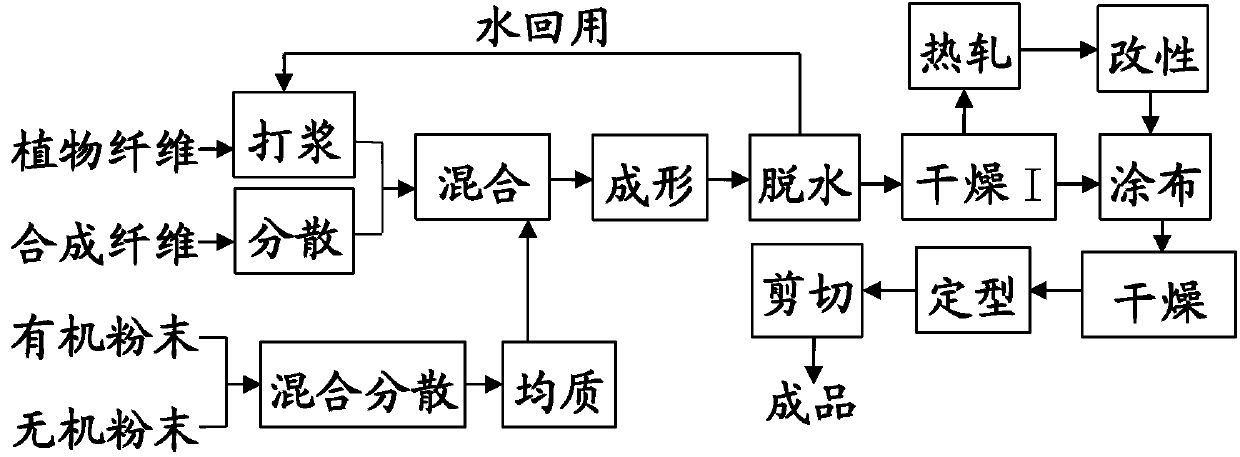

Battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and preparation method of filter material

InactiveCN103100264AImprove uniformityHigh strengthCoatings with pigmentsElectrolytic capacitorsSocial benefitsHigh diaphragm

The invention discloses a battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and a preparation method of the filter material. The fiber materials are as follows in percentage by weight: 0.1%-2.5% of plant fibers and 80%-99.9% of synthetic fibers, inorganic powder being 45%-1000% of the weight of the fiber, organic powder being 0-50% of the weight of the fibers, and strengthening binder being 0.5%-15% of the weight of the fibers. The preparation method of the filter material comprises the following steps of: pulping the plant fiber and the synthetic fibers, respectively; homogenizing and mixing the inorganic powder with the organic powder under high pressure, and forming the mixture into a single layer or a plurality of layers by a mixer; coating, thermally rolling and modifying the mixture, so that various physical and chemical indexes of the diagram are improved, the pore diameter size can be effectively controlled and the uniformity of the pore diameter is improved; moreover, treelike crystals can be prevented from being generated by maze type bent holes; the filtering precision and the efficiency are high; the inner resistance of the diagram is high; the liquid retaining rate and the high temperature resistance of the diagram are improved; the over-temperature closed-cell protection is improved; the dimension deformation is small; the service life is long; and the economic benefits and the social benefits are better.

Owner:吕凯

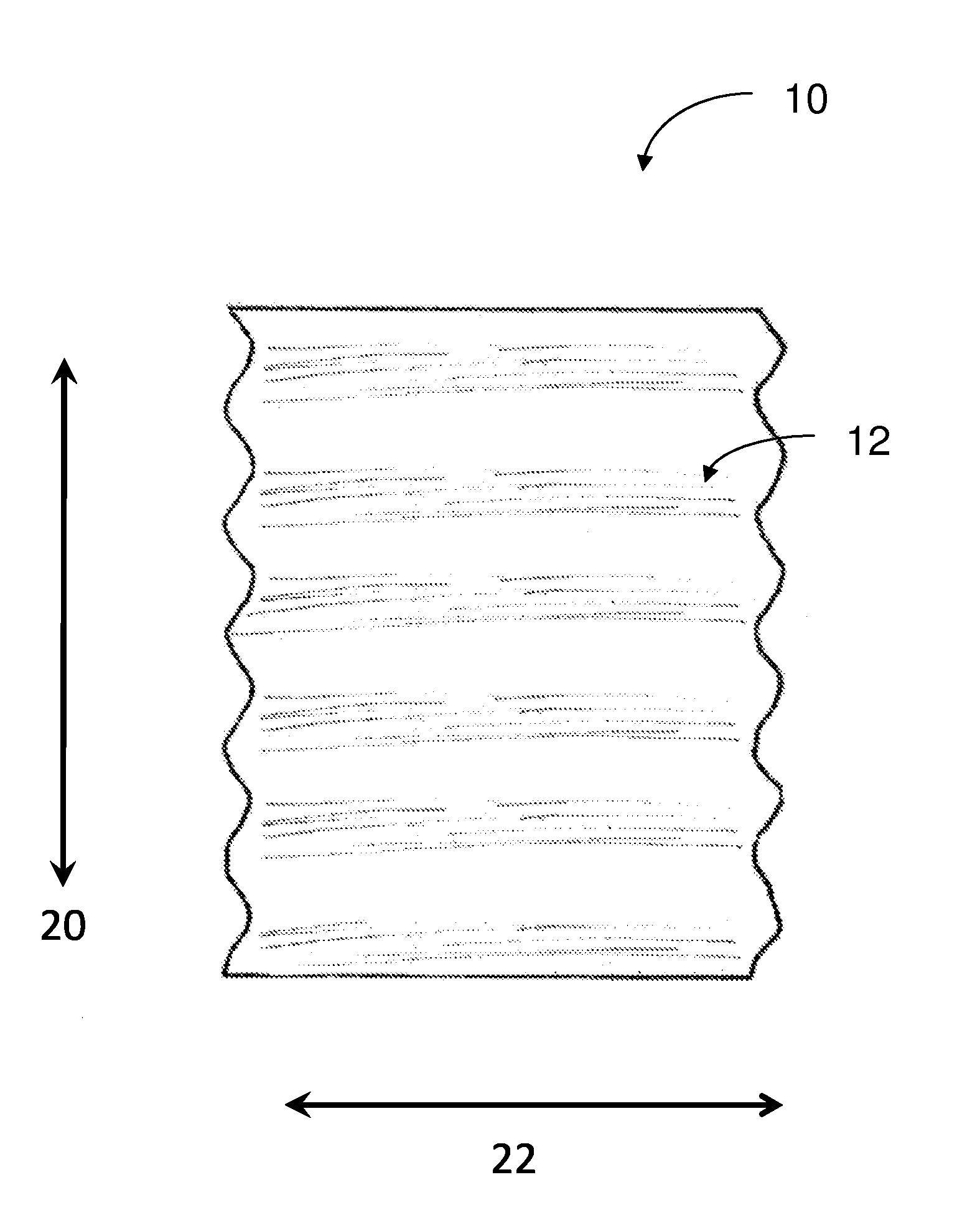

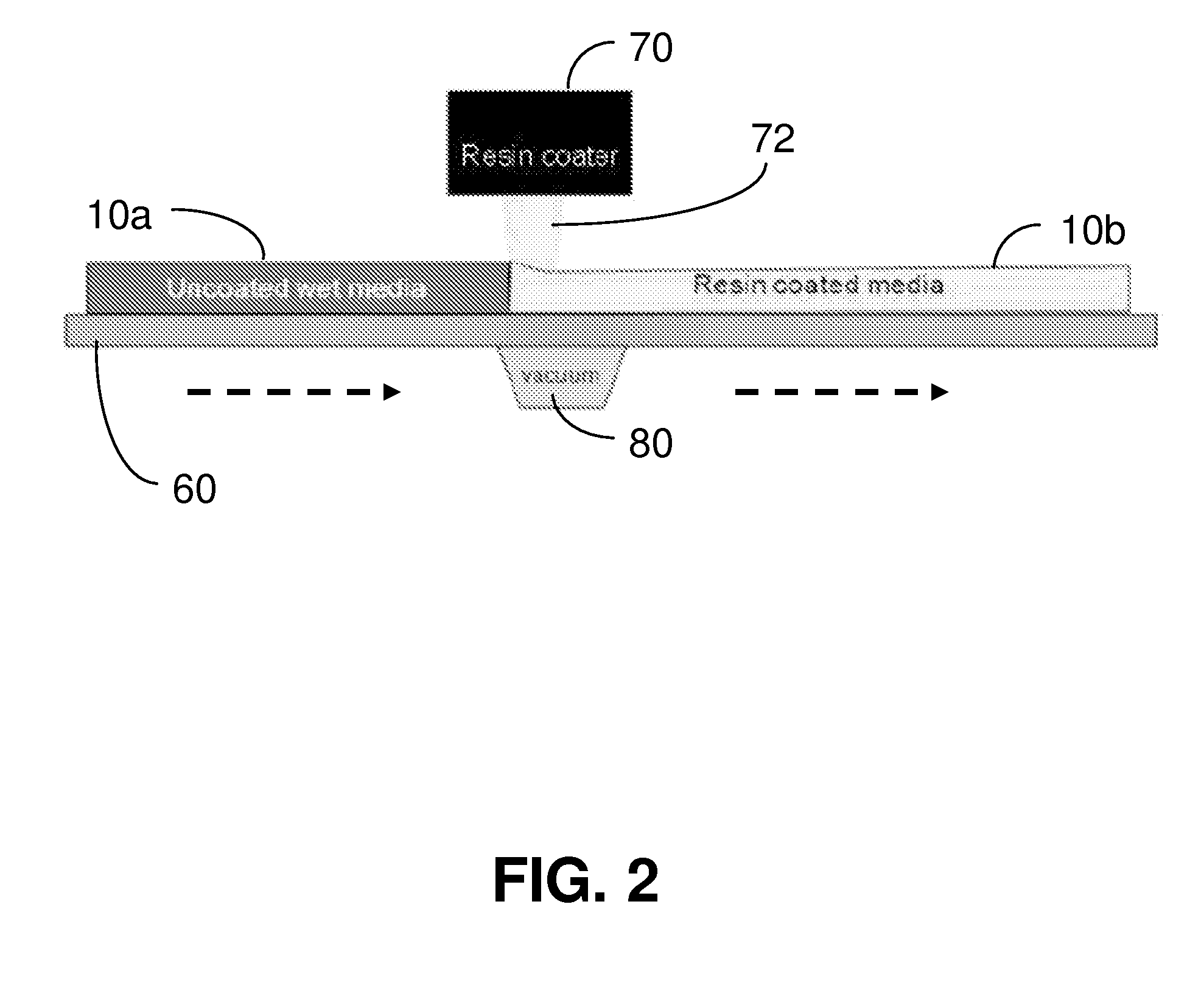

Flutable fiber webs with high dust holding capacity

The fiber webs described herein may be incorporated into filter media and filter elements. The fiber webs may exhibit a high dust holding capacity. The fiber webs may also exhibit a low thickness. The fiber webs may be sufficiently flexible and / or deformable so that they may be processed to include a series of waves (also known as flutes) that extend along the cross-machine direction.

Owner:HOLLINGSWORTH VOSE

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

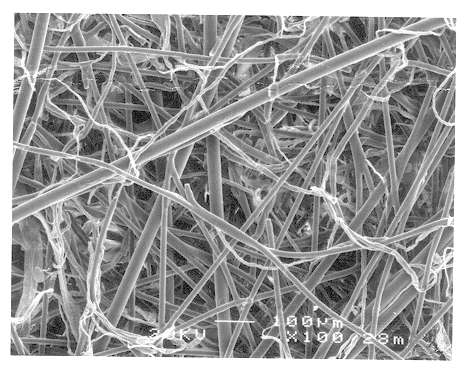

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

Multiple layer composite micropore filtration separation material and preparation method and use thereof

ActiveCN101380535AImprove uniformityUniform pore size distributionSemi-permeable membranesCell component detailsMicropore FilterElectrical battery

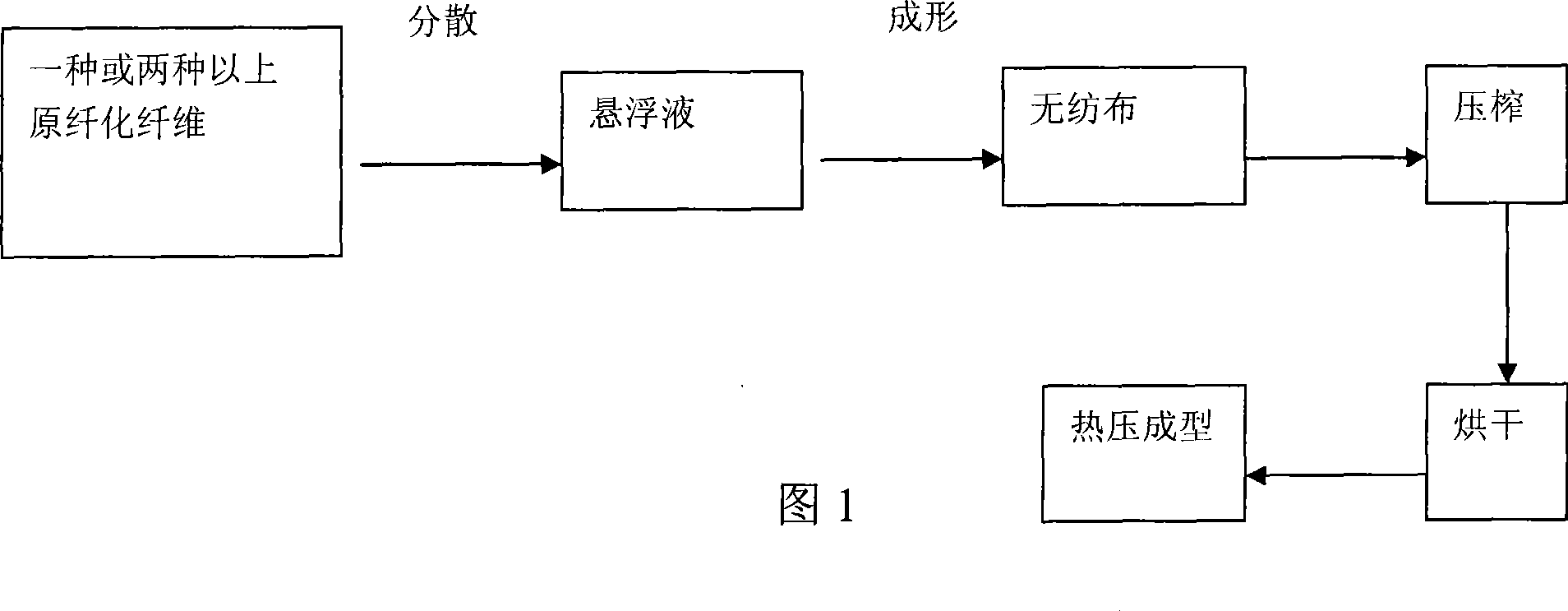

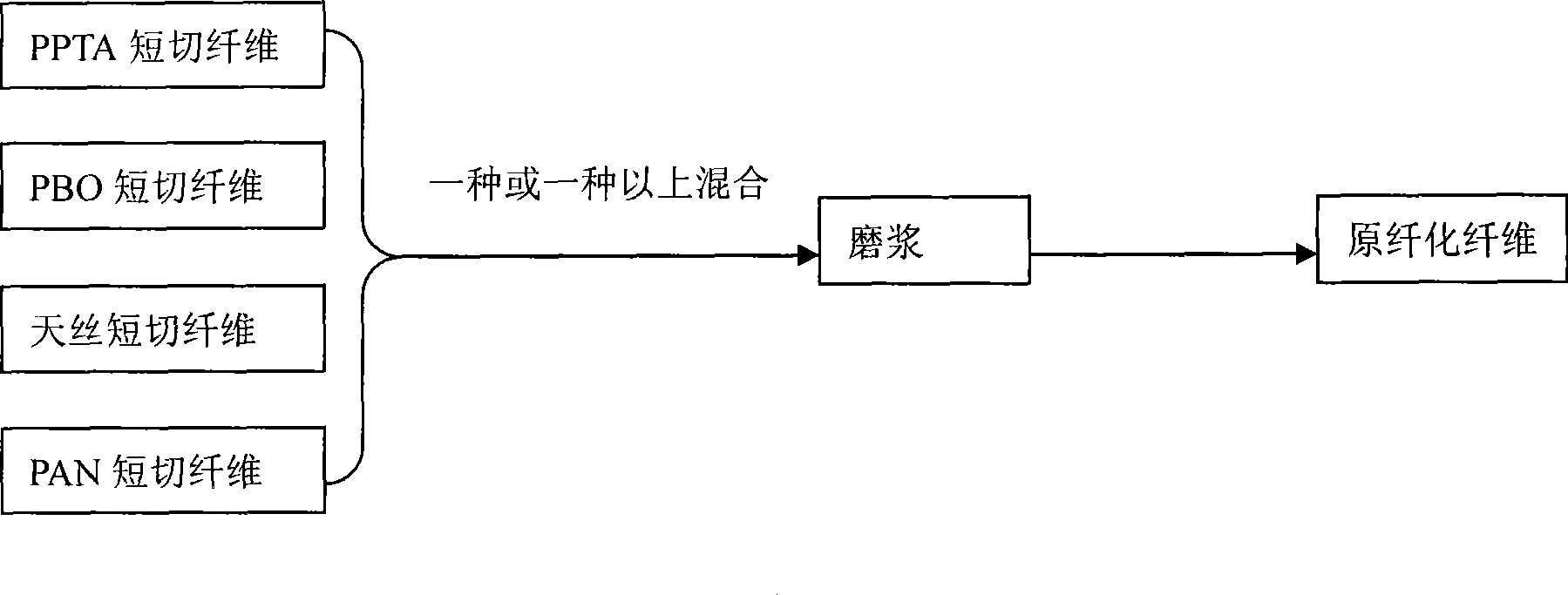

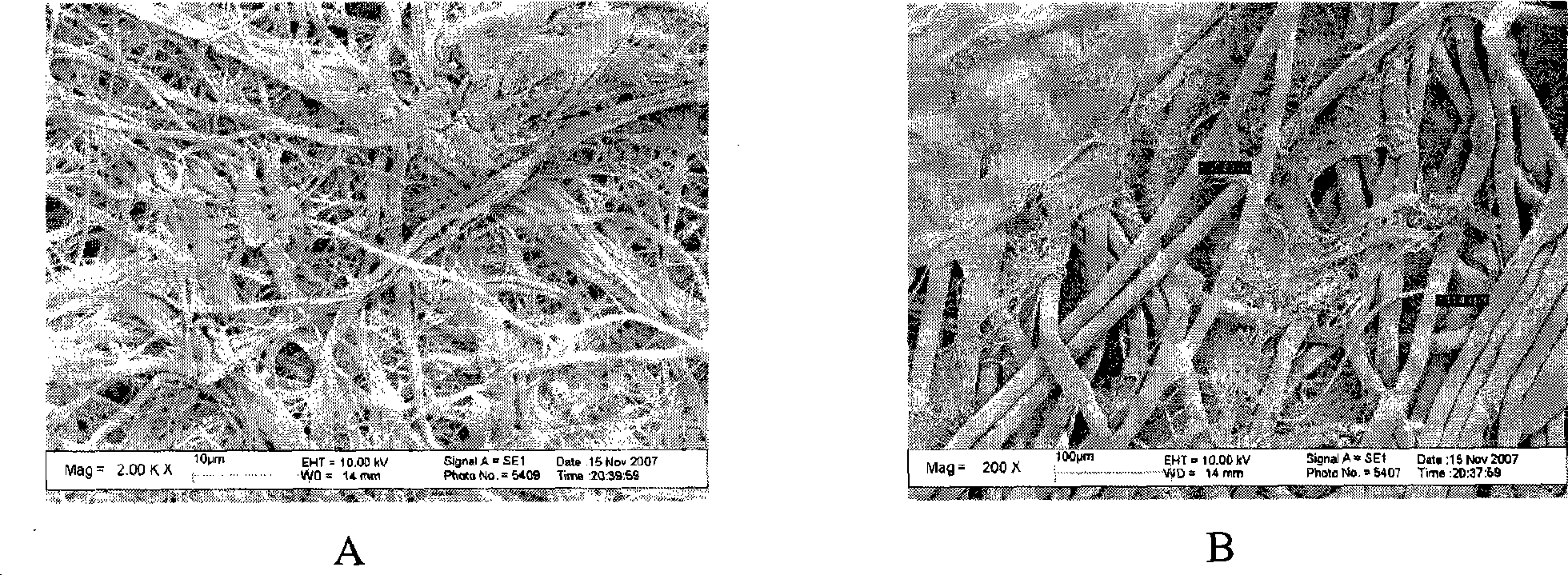

The invention relates to a multi-layer composite micropore filter separation material, a method for preparing the material and the application thereof, wherein, the preparation method comprises the following steps: (1) the fiber which can be fibrillated is prepared into fully fibrillated fiber material by pulping process; (2) the slurry is obtained after the fully fibrillated fiber material is dispersed in water; (3) advancing to the net and shaping are carried out, a layer of nonwoven fabric is placed on a shaping net, the above slurry is dehydrated on the nonwoven fabric directly for compound molding; (4) drying is carried out for obtaining the product. The product can also be processed by hot press molding. The method can be operated easily, is applicable for application of large scale, the obtained multi-layer composite high temperature resistance micropore filter separation material has the outstanding performance of high temperature resistance, meanwhile the uniformity of the holes is excellent, the average aperture can reach 10nm-1mum, and the method can be used in such fields as preparing filter material, battery septum material, electrolytic capacitor paper and double electric layers capacitor septum, etc.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

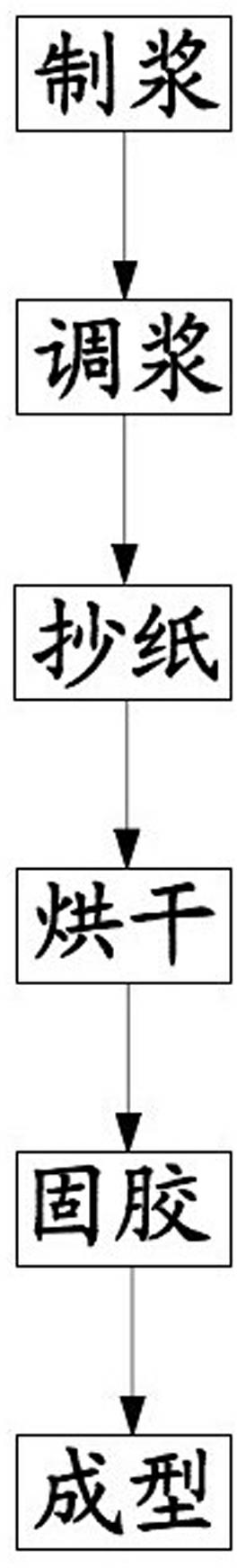

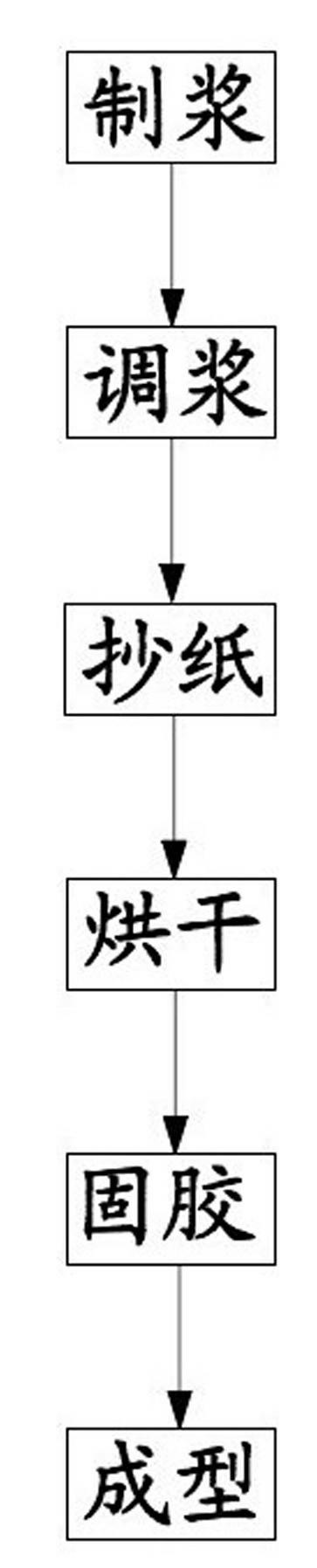

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

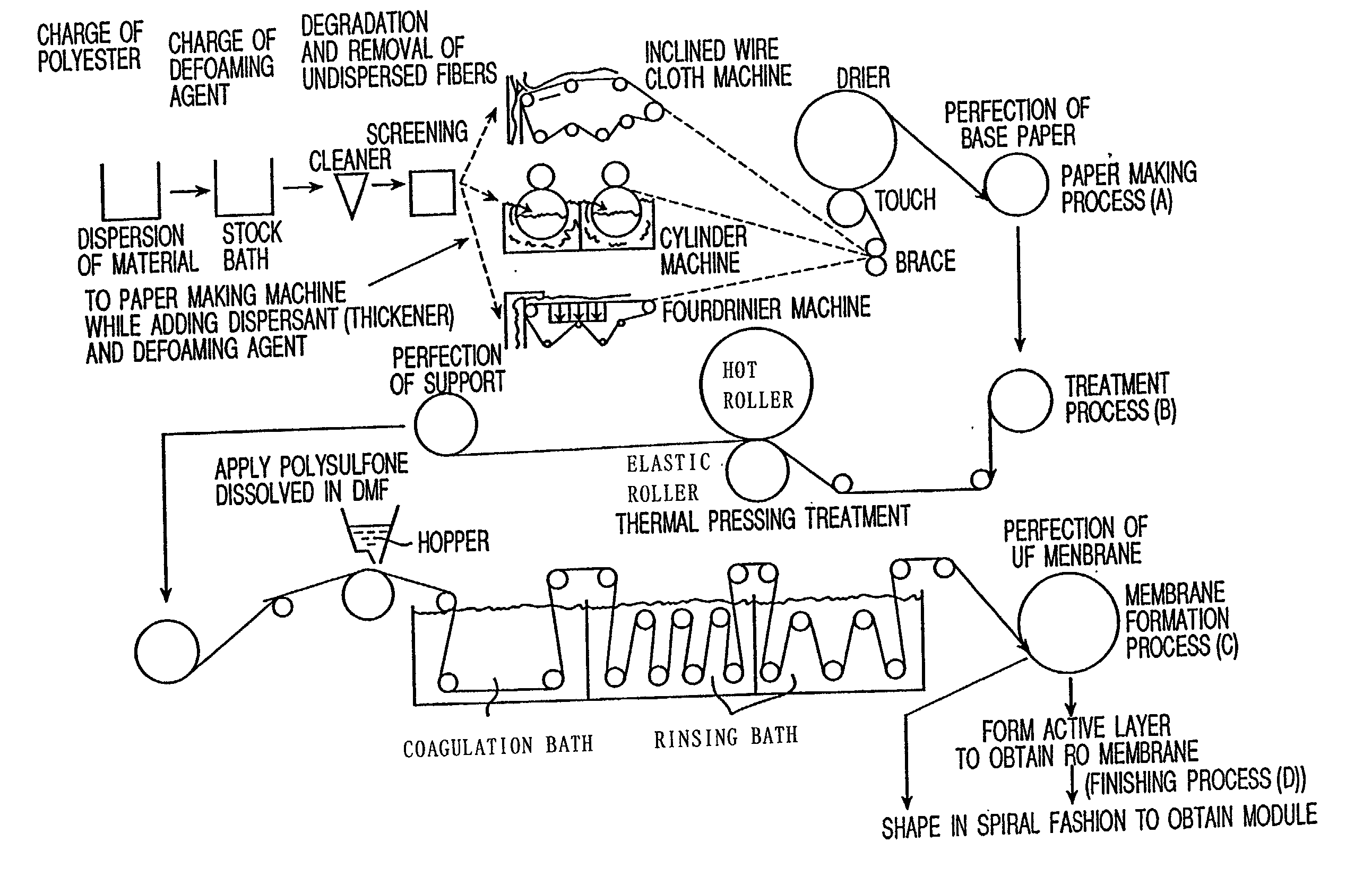

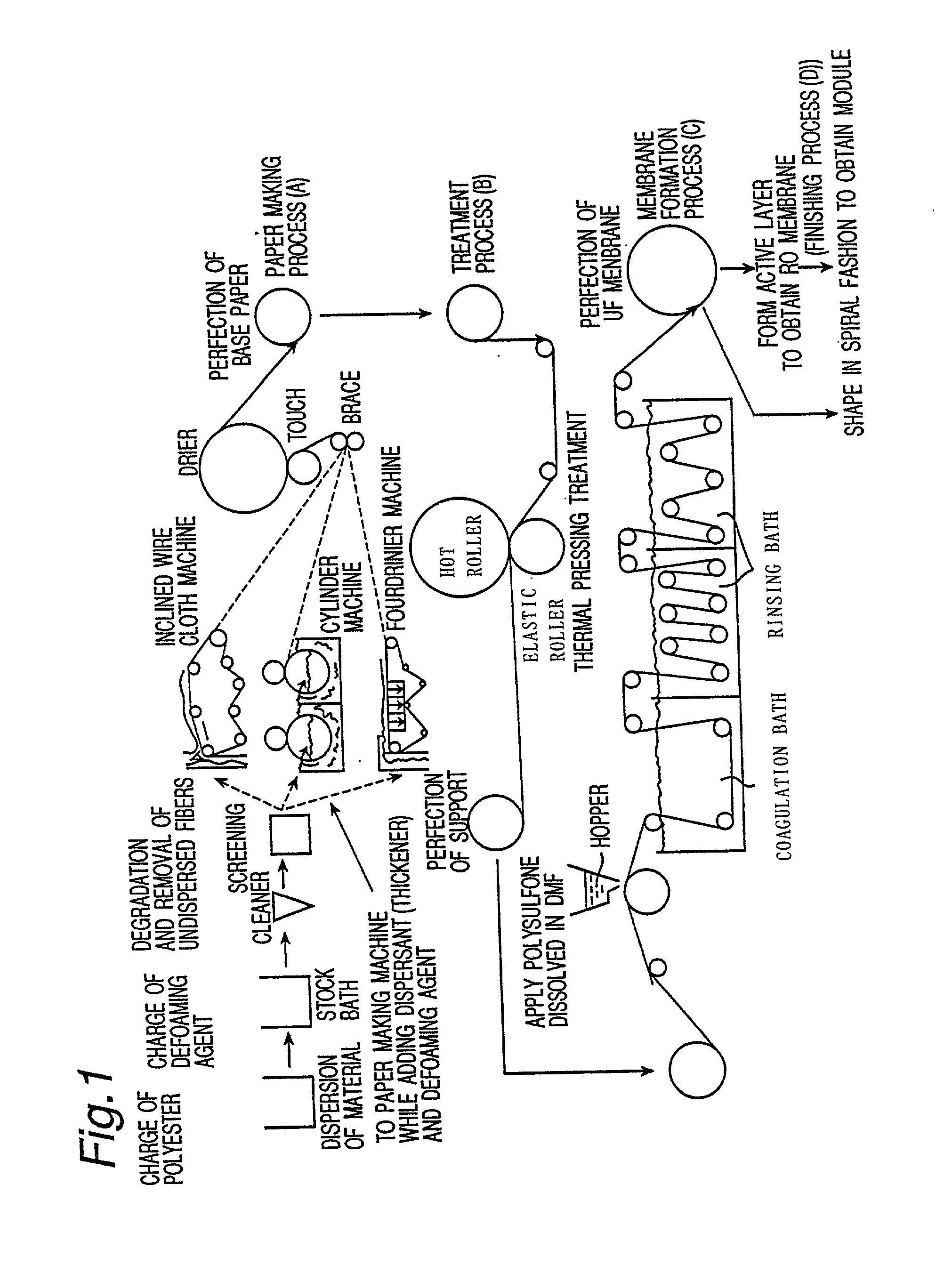

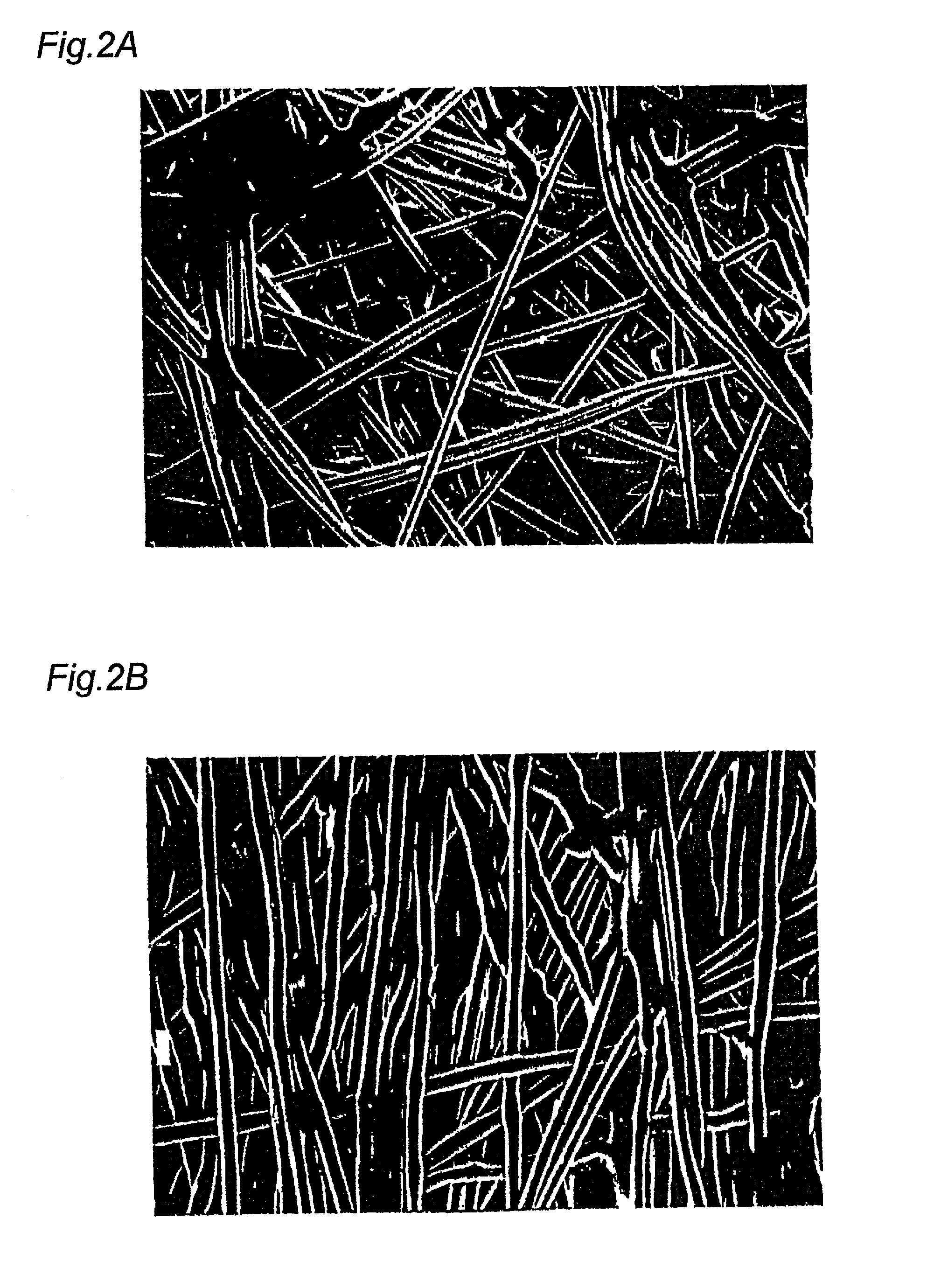

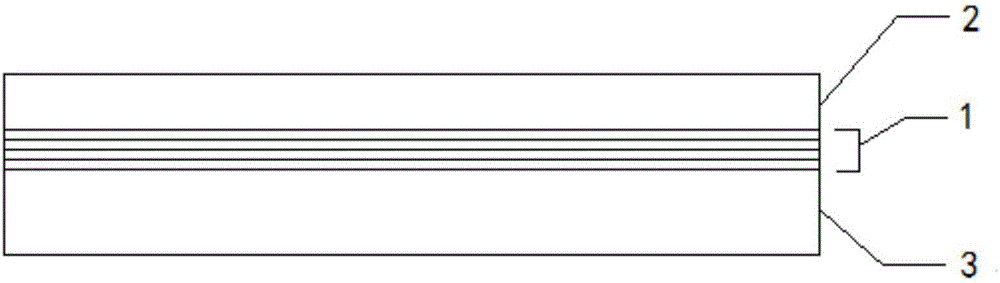

Semipermeable membrane support and process of preparation thereof

InactiveUS20020056535A1Avoid bendingQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperFiberSemipermeable membrane

Owner:AWA PAPER MFG +1

High-temperature resistant fiber filter paper for engine oil filter and preparation method of high-temperature resistant fiber filter paper

ActiveCN102912680AImprove high temperature resistanceImprove toughnessNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses high-temperature resistant fiber filter paper for an engine oil filter and a preparation method of the high-temperature resistant fiber filter paper. The high-temperature resistant fiber filter paper comprises, by weight, 60-70 parts of coniferous wood pulp, 20-30 parts of cotton pulp, 20-30 parts of modified polyimide fiber, 2-5 parts of kaoline, 1-3 parts of lithopone, 2-4 parts of silica gel, 1-2 parts of nanometer titania, 0.5-0.8 part of ammonium polyphosphate, 1-2 parts of modified acrylic emulsion, 2-4 parts of acetic styrene-acrylic emulsion, 0.5-1 part of stearic acid monoglyceride, 0.5-1 part of silane coupling agent KH590, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of urea resin. The high-temperature resistant fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the high-temperature resistant fiber filter paper can reach 99.97%.

Owner:ANHUI PHOENIX INT CO LTD

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

Super-hydrophobic coating, super-hydrophobic coating layer, and preparation method thereof

InactiveCN106366907AImprove environmental adaptabilityImprove friction resistanceCoatings with pigmentsFiltration separationFiberSolvent

The invention provides a preparation method of a super-hydrophobic coating layer. The preparation method includes the steps of: 1) according to mass percentage of a final solution, dissolving 0.5-10% of hydrophobic nano particles and 1-15% of hydrophobic resin in a solvent, performing ultrasonic dispersion for 15-60 min to obtain a mixed solution; 2) forming the mixed solution on the surface of a substrate material and in internal microstructures of the substrate material; 3) naturally air-drying the substrate material to form the super-hydrophobic coating layer. According to the method, the preparation process of the coating layer is free of assistance of external equipment, such as heating and the like, so that the method is simple and low-cost. The method can achieve preparation of the super-hydrophobic coating layer on various fiber surfaces and porous material surfaces, has excellent universality and is easy to achieve in industrial large-area preparation.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

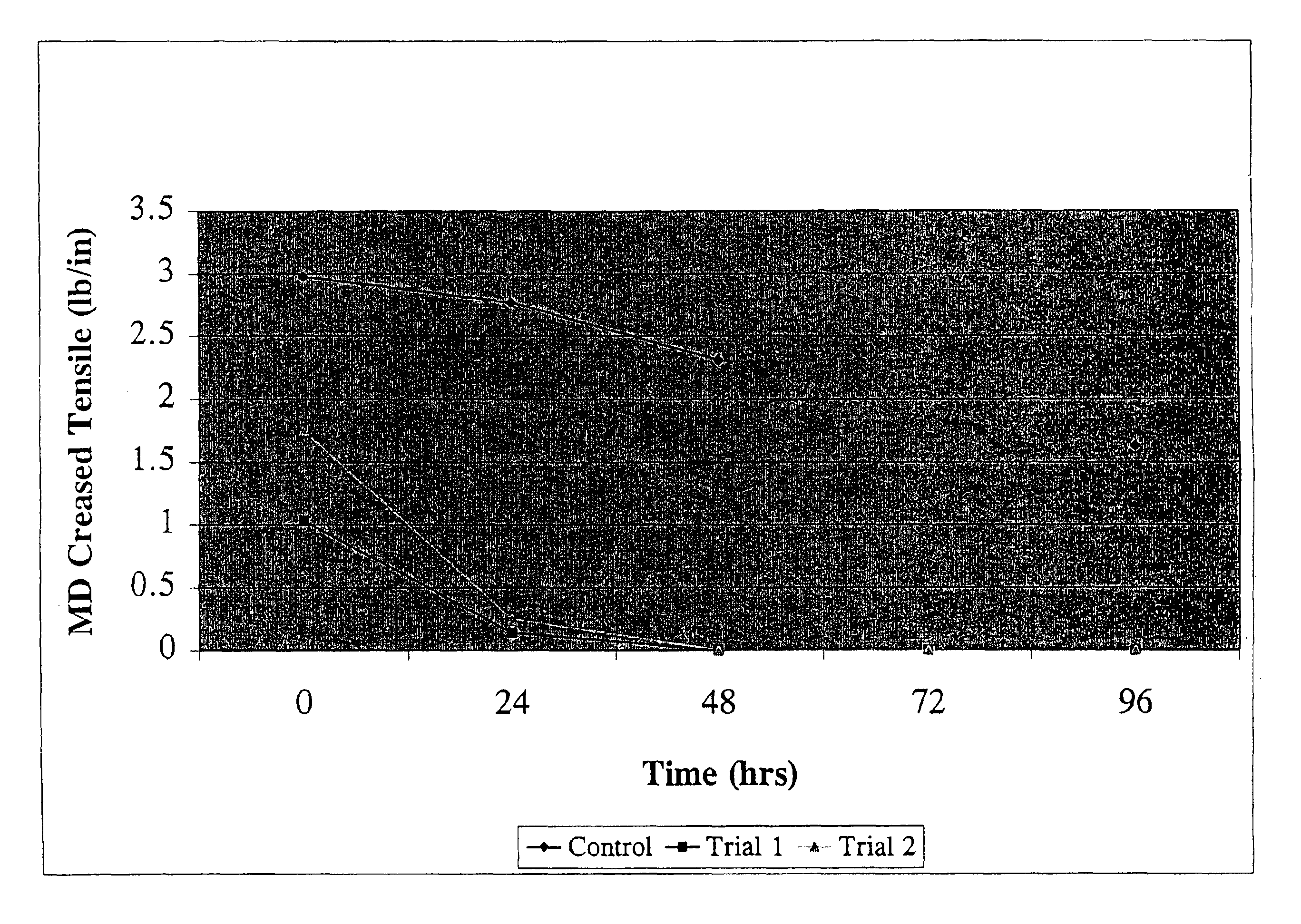

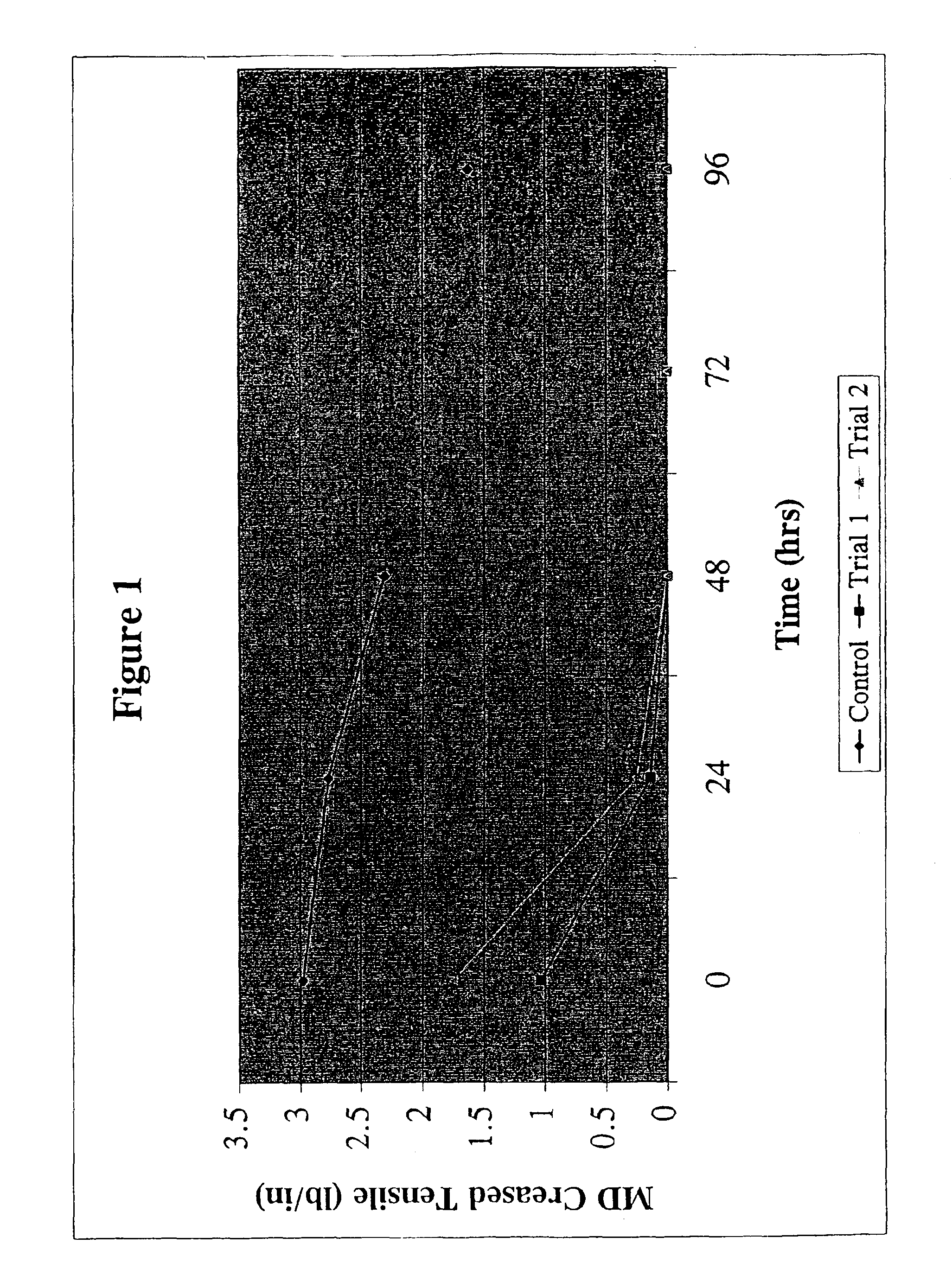

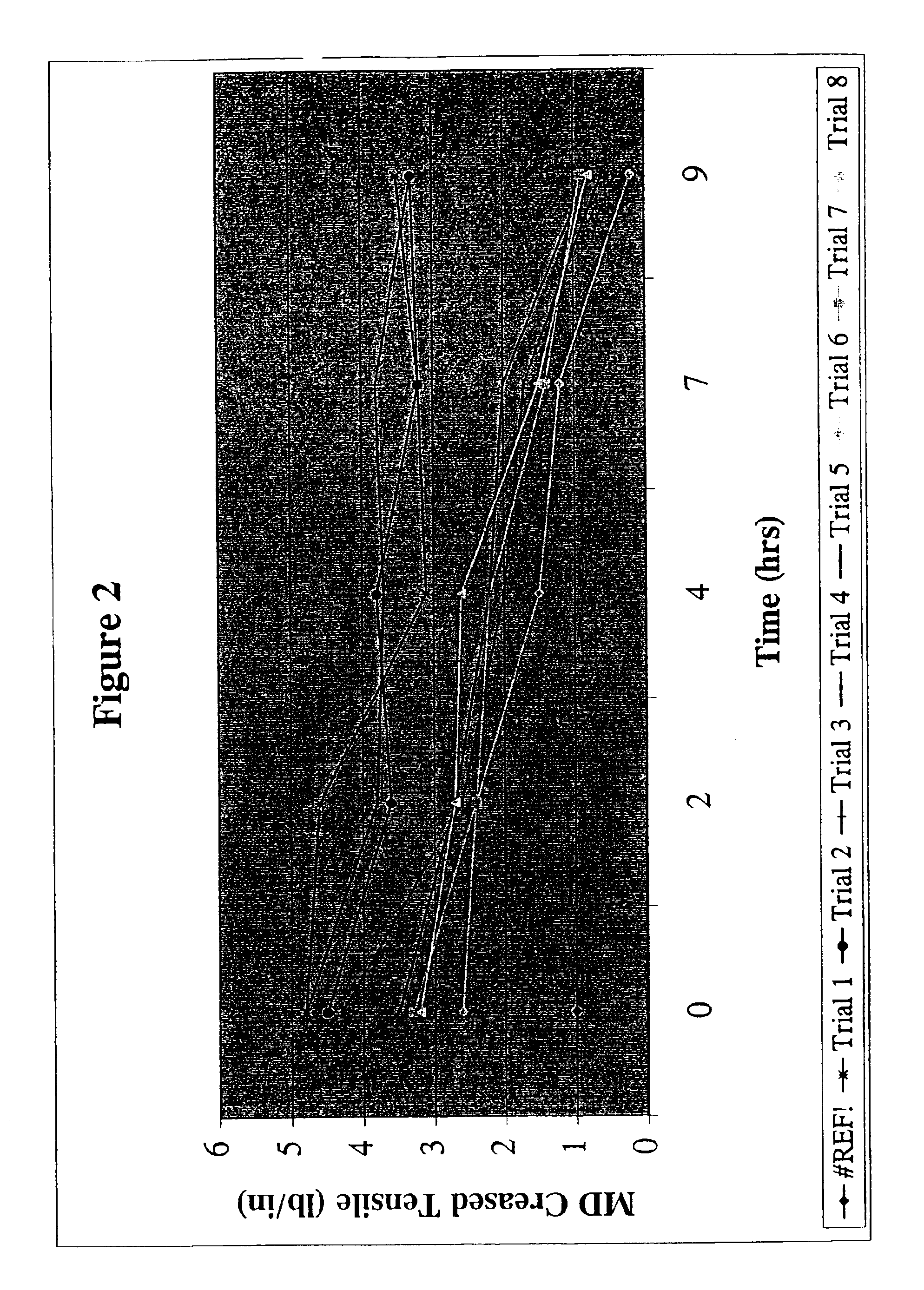

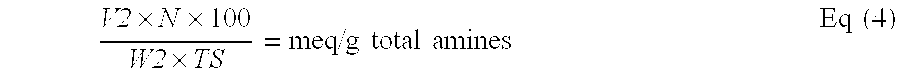

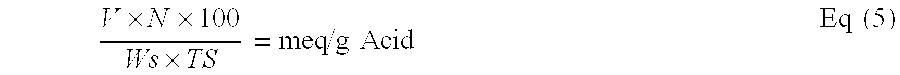

Reduced by product polyamine-epihalohydrin resins

Processes for rendering a polyamine-epihalohydrin resin storage stable, including processes that prepare a storage stable resin and / or processes that treat resins. A composition containing a polyamine-epihalohydrin resin which includes CPD-forming species can be treated with at least one agent under conditions to at least one of inhibit, reduce and remove the CPD-forming species to obtain a reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin when stored for 2 weeks at 50° C., and a pH of about 2.5 to 3.5 contains less than about 250 ppm dry basis of CPD. The invention is also directed to a gelation storage stable reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin, when stored at pH 1 for 24 hours at 50° C. and measured at 24 hours, produces less than about 1000 ppm dry basis of CPD. A paper product containing the storage stable polyaminopolyamide-epihalohydrin resin, when corrected for adding at about a 1 wt % addition level of the polyaminopolyamide-epihalohydrin resin, contains less than about 250 ppb of CPD. Moreover, a resin can be prepared starting from a prepolymer having a low acid number or low concentration of acid end groups. The invention is also directed to papers containing the resins.

Owner:SOLENIS TECH CAYMAN

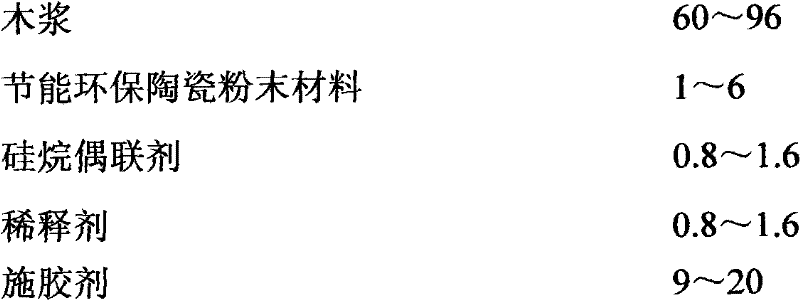

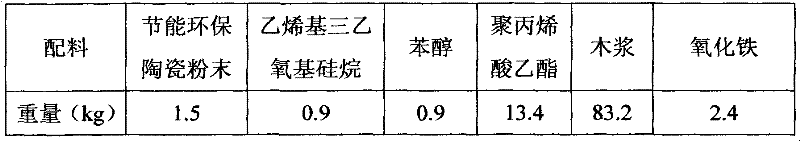

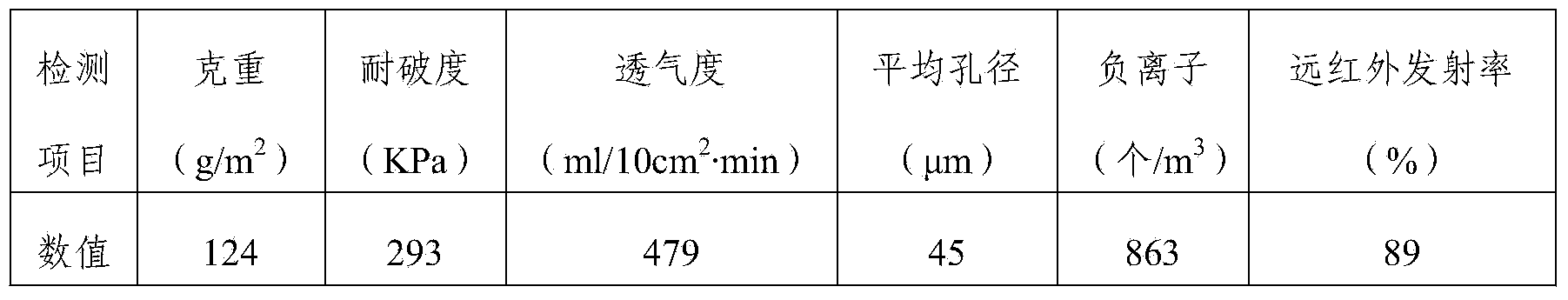

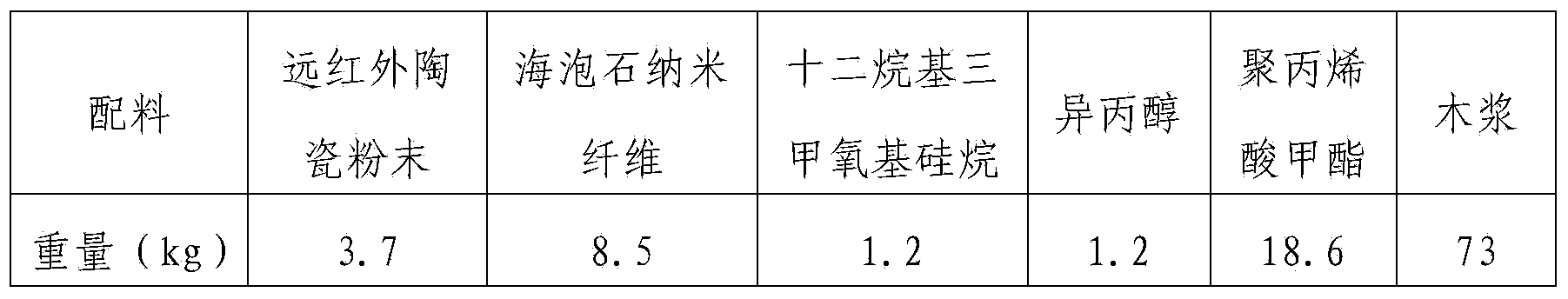

Filter paper of energy-saving and environment-friendly filter and making method thereof

ActiveCN102199903AHigh filtration precisionHigh burst resistanceInorganic fibres/flakesFiltration separationAir filterFuel filter

The invention relates to filter paper of an energy-saving and environment-friendly filter and a making method thereof. The filter paper is made from an energy-saving and environment-friendly ceramic powder material, a silane coupling agent, a dilute, a sizing agent and wood pulp. The filter paper can be made into an air filter and a fuel filter so as to improve the power performance by 6-12%, save the fuel by 2-5% and reduce pollutants in discharged tail gas by 16-47%.

Owner:北京联飞翔科技股份有限公司

Fibrous substrate containing fibers and nanofibrillar polysaccharide

A single-layer fibrous substrate comprising, by dry weight compared with the weight of the substrate:between 39.9 and 87.9% natural fibers refined to above 50° SR;between 12 and 60% nanofibrillar polysaccharide; andbetween 0.1 and 4% of at least one retention agent.

Owner:AHLSTROM MUNKSJO OYJ

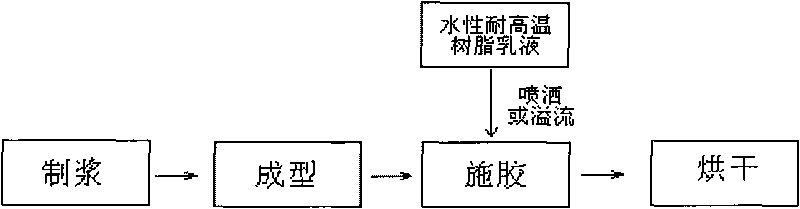

High-temperature resistant air filter paper and preparation method thereof

InactiveCN101725086AHigh tensile strengthImprove stiffnessNon-fibrous pulp additionPaper/cardboardGlass fiberFiber

The invention aims to provide high-temperature resistant air filter paper and a preparation method thereof. The high-temperature resistant air filter paper comprises glass fiber air filter paper and a resin layer formed on the surface of the glass fiber air filter paper, wherein the mass of the resin layer is 3 to 15 percent of that of the glass fiber air filter paper. Preferably, the main raw material of the glass fiber air filter paper is alkali-free superfine glass fibers. The alkali-free superfine glass fibers are mixed with alkali-free continuous glass fiber chopped strands and a small amount of organic fiber to be pulped and formed; then a high-temperature resistant water-soluble resin diluted by 5 to 20 folds is sprayed or overflowed onto a base layer; drying the base layer to obtain the air filter paper of which the filtration efficiency can reach more than 99.995 percent. The high-temperature resistant air filter paper has high tensile strength and deflection, can be continuously used in an environment of a temperature of 220 to 350 DEG C and can be used in an ultra-clean oven or high temperature air purification equipment and systems.

Owner:SINOMA SCI & TECH

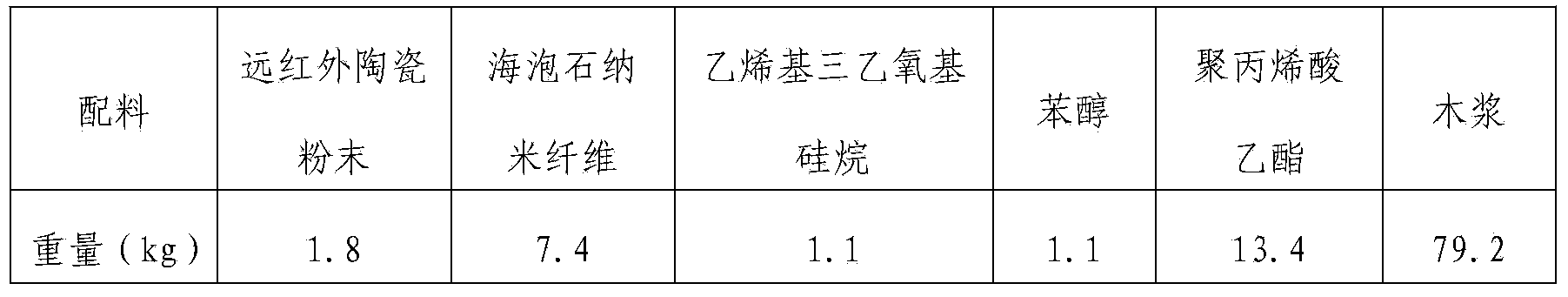

Filter paper for environmental-friendly automobile filter and preparation method of filter paper

InactiveCN103774503ASimple processHigh filtration precisionInorganic fibres/flakesWater-repelling agents additionExhaust gas emissionsEmission standard

The invention relates to filter paper for an environmental-friendly automobile filter. The filter paper for the environmental-friendly automobile filter is prepared from the following components in parts by weight: 1-5 parts of far infrared ceramic powder, 2-20 parts of sepiolite nanofibers, 0.8-1.6 parts of a silane coupling agent, 0.8-1.6 parts of a diluent, 9-20 parts of a sizing agent and 60-96 parts of wood pulp. Air, fuel oil and engine oil filters made of the filter paper are obvious in comprehensive effect; pollutants generated by exhaust gas emission of an automobile are reduced by 16-47%; the dynamic performance is improved by 6-12%; fuel oil can be saved by 2-5%; the emission standard reaches the European IV standard.

Owner:北京联飞翔科技股份有限公司

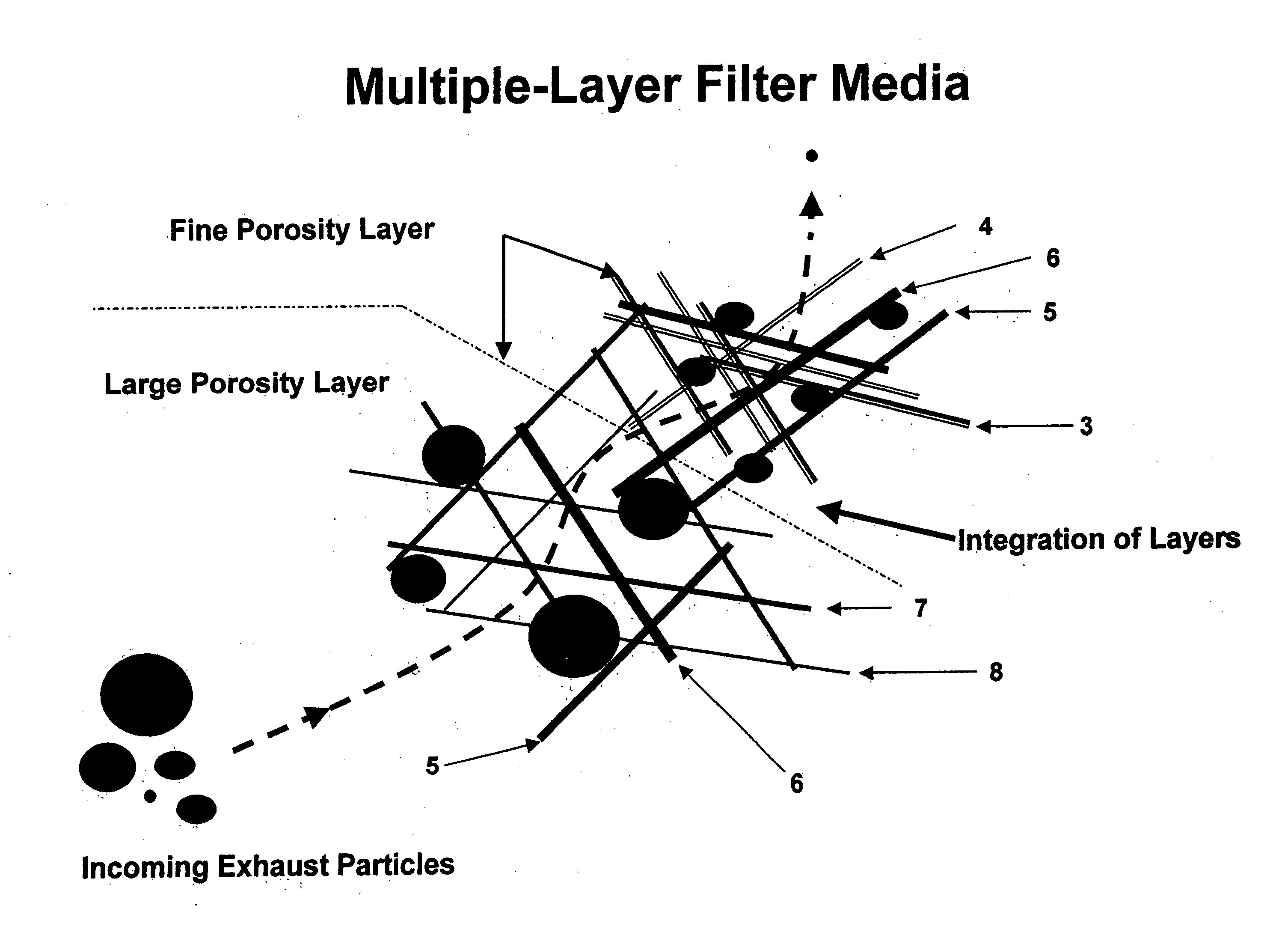

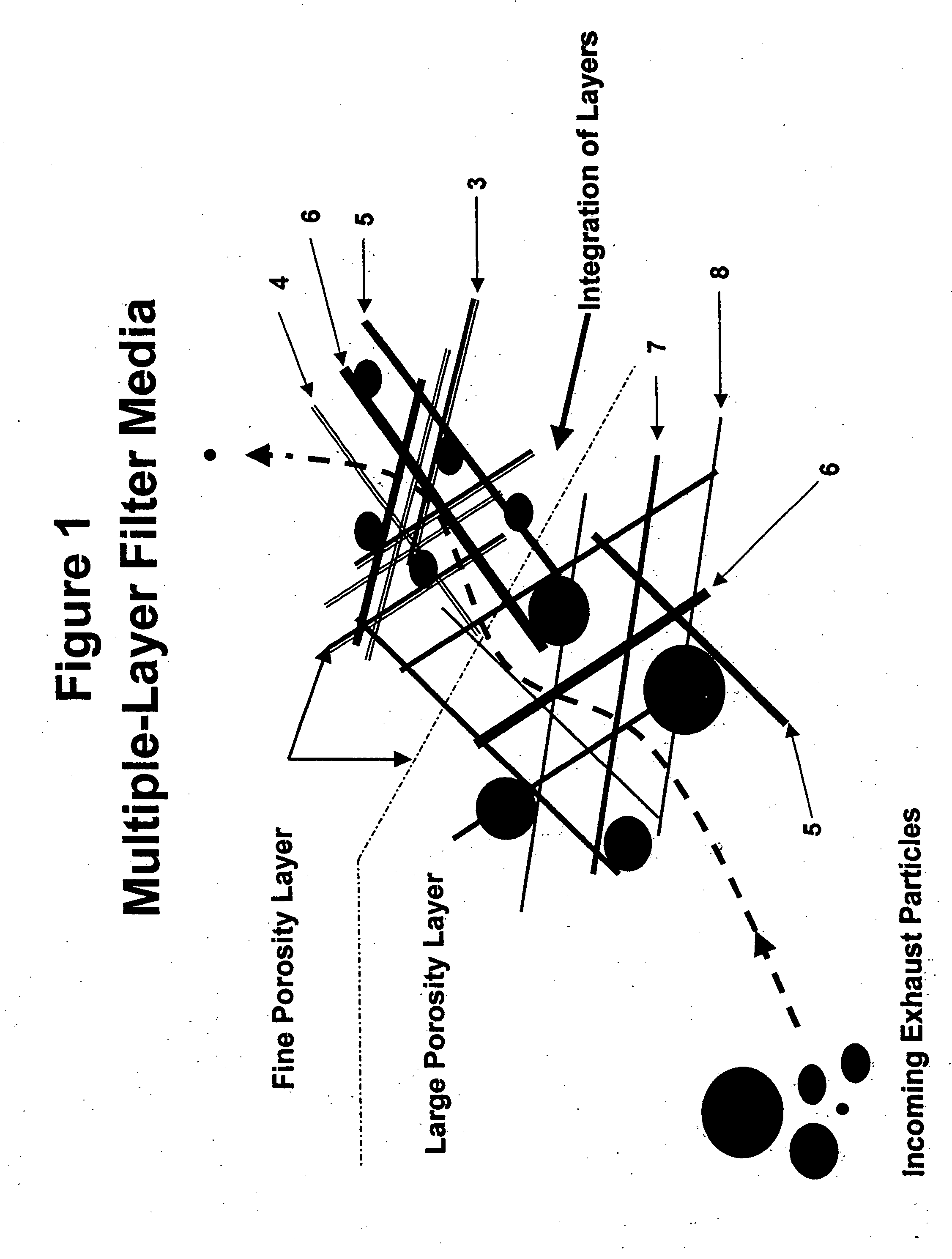

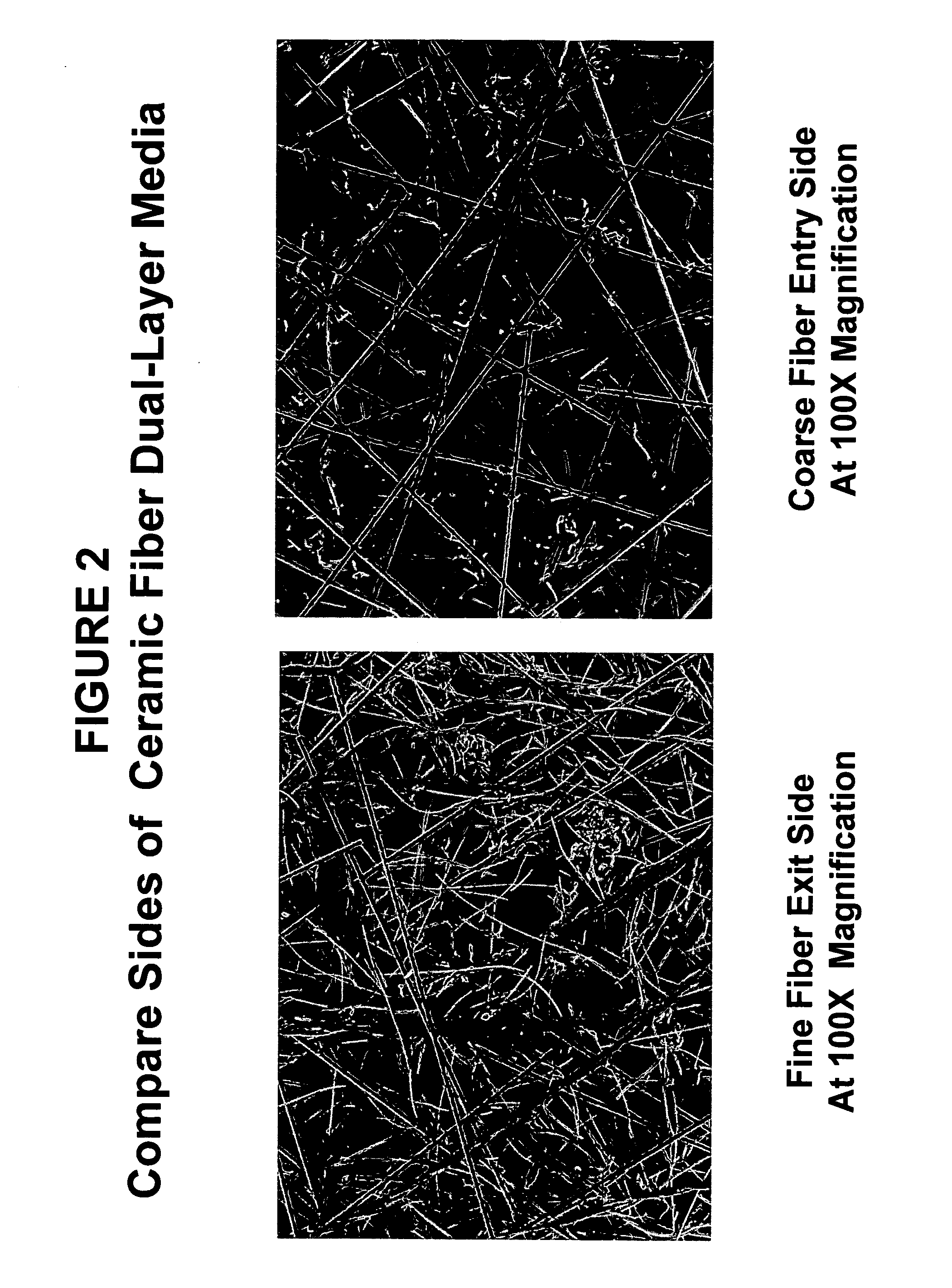

Multiple integrated-layer ceramic fiber filter paper and method

A composition of a multiple-layered ceramic fiber filter paper and method for manufacturing for use in a filter apparatus removes particulate from high temperature gas streams. In this application, ceramic fibers of varying diameters and lengths are combined in such a manner to yield different specific average pore sizes in segregated locations in the filter paper. The fiber combinations are formed into a paper sheet using a method that produces two or three porosity zones with different average pore sizes in each layer or porosity zone. The porosity gradient from large at gas stream entry to fine at gas stream exit increases particle-holding capacity while reducing the filtered gas backpressure experienced in single sized porosity layer media.

Owner:INDAL CERAMIC SOLUTIONS

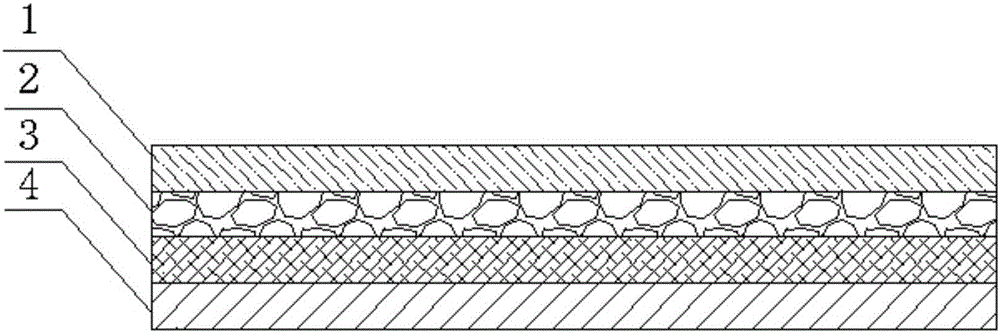

Composite air purifying filter paper material and filter element using same

InactiveCN106334373AImprove fast purification adsorption performanceImprove removal rateGas treatmentDispersed particle filtrationFiberEnvironmental engineering

The invention relates to a composite air purifying filter paper material and a filter element using the same. The composite air purifying filter paper material comprises an active carbon fiber pre-filtering layer, an adsorption catalytic particle layer, a particulate matter filtering layer and a sterilizing supporting layer which are superposed according to any sequence. Compared with the existing filter paper material, the composite air purifying filter paper material is provided with the active carbon fiber pre-filtering layer; an air purifying filter element prepared from the composite air purifying filter paper material can significantly improve quick purification and adsorption performance on pollutant molecules, such as peculiar smell and the like, in the environment, and the removal rate of the whole filter element on gas-state pollutant molecules is increased.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Air filter paper and preparation method thereof

ActiveCN104611995AEvenly dispersedGood adhesionNon-fibrous pulp additionSynthetic resin layered productsParticulatesFiber

The invention discloses air filter paper and a preparation method thereof. The preparation method includes the following steps: (1), preparing a piece of bottom paper; (2), preparing carbon nanomaterial dispersion mixed liquid; (3), arranging the bottom paper on a former, conveying the carbon nanomaterial dispersion mixed liquid to the former, enabling the carbon nanomaterial dispersion mixed liquid to be filtered and formed on the bottom paper, then sizing and drying to obtain the air filter paper. According to the invention, a simple filtering method is adopted to directly load the carbon nanomaterial on the inner fiber of a filtering medium, the preparation technology is simple, the cost is low, the pollution is avoided, and the large-scale production and application of the carbon nanomaterial in the air filtering field can be realized; the prepared air filter paper is high in filtering efficiency, low in filtering resistance, not only can filter particulate pollutants, but also can remove chemical pollutants and virus in the air.

Owner:KUNMING NATAI TECH CO LTD

Wet-laid non-woven fabric and filter

Disclosed is a wet-laid non-woven fabric comprising two or more types of fibers. Specifically disclosed is a wet-laid non-woven fabric comprising a short fiber A in an amount of 4 to 50 wt% and a binder fiber B in an amount of 10 to 50 wt% both relative to the total weight of the non-woven fabric, wherein the short fiber A comprises a fiber-forming thermoplastic polymer, has a fiber diameter (D) of 100 to 1000 nm and has a ratio of the fiber length (L) to the fiber diameter (D) (i.e., a L / D ratio) of 100 to 2500, and wherein the binder fiber B has a single fiber fineness of 0.1 dtex or less.

Owner:TEIJIN FRONTIER CO LTD

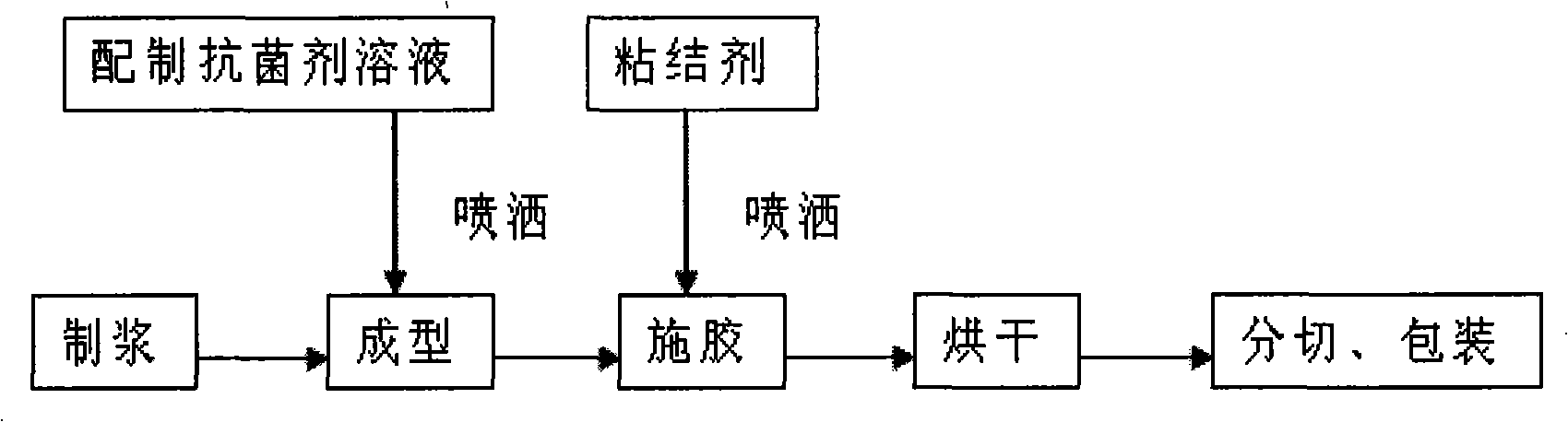

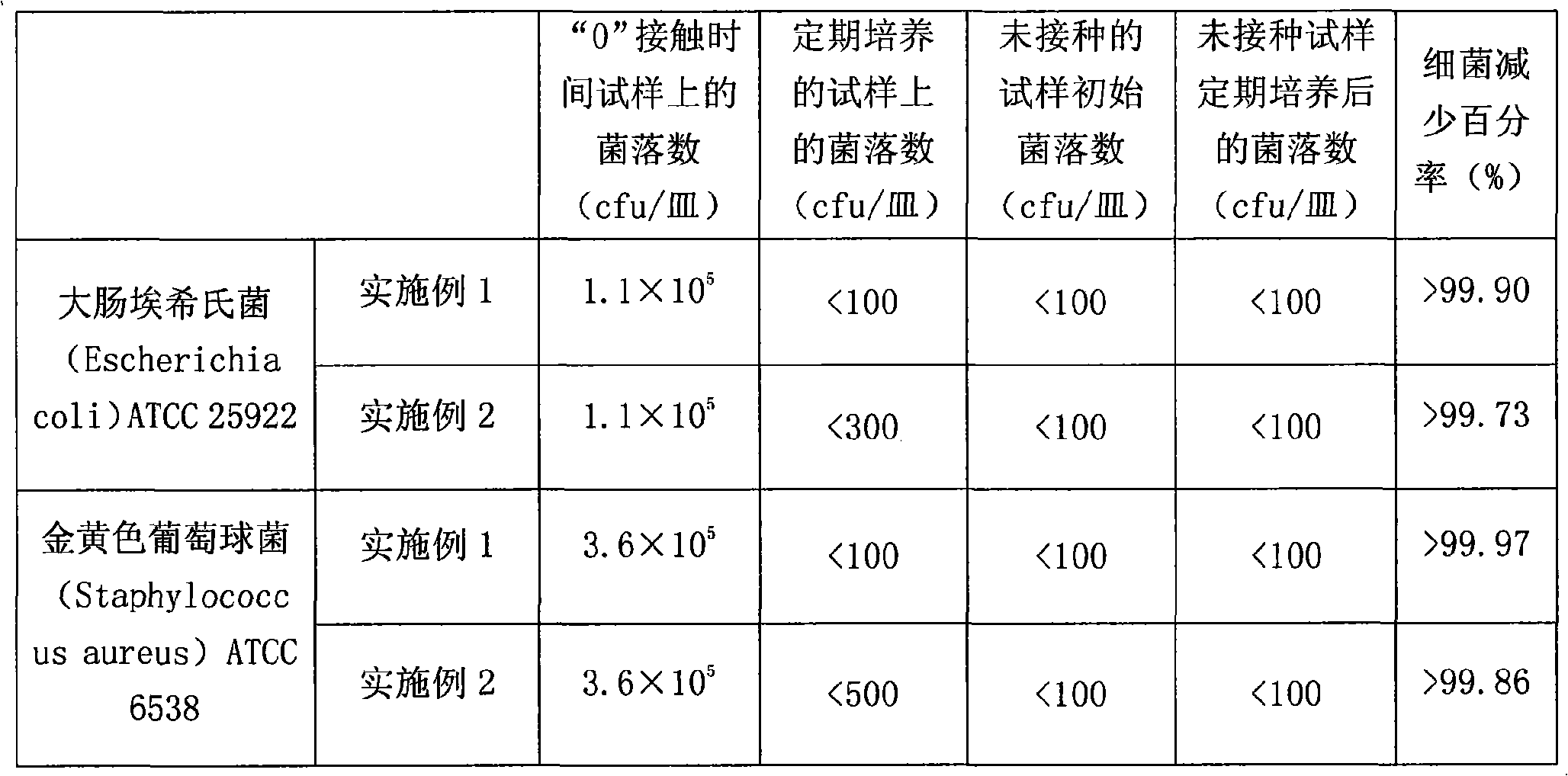

Antibiotic air filter paper and preparation method thereof

ActiveCN101349031ASimple structureEfficient bactericidalPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberAir filter

The invention provides air filter paper which is effective in anti-bacterial performance and has a simple structure and a preparation method thereof. The anti-bacterial air filter paper comprises a filter paper substrate and an antibacterial agent covered on the surface of the filter paper substrate, and the mass of the antibacterial agent is 0.05 to 1 percent against that of the filter paper substrate. The filter paper substrate is preferably glass microfiber air filter paper, in particular air filter paper produced by glass microfibers, non-alkali continuous glass fiber chopped strands and organic fibers or plant fibers. The antibacterial agent is preferably a nano-silver ion antibacterial agent. As the improvement of the invention, adhesive can be used for the adhesion of the antibacterial agent and the filter paper substrate. The preparation method for the air filter paper has the following steps that: the surface of the filter paper substrate is sprayed with a diluent of the antibacterial agent and then is dried. The adhesive can also be sprayed after the diluent of the antibacterial agent is sprayed. The air filter paper has a simple structure, simple and convenient process, low cost, and high-efficiency sterilization and bacteria-inhibiting performances due to the fact that the antibacterial agent covers the surface of the air filter paper and partially permeates the air filter paper.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Filter paper for laden liquids

InactiveUS6224768B1Increase capacityReduce capacityNon-fibrous pulp additionNatural cellulose pulp/paperAbsorption capacitySubject matter

The subject-matter of the present invention is a filter paper for laden liquids, with a high adsorption and absorption capacity. This paper, based on cellulose fibers, is filled with organic and / or inorganic pulverulent matter. The powder filling is adapted in quantity and quality to the liquid to be filtered. It finds its application in petrochemical, agri-foodstuffs and papermaking industries.

Owner:ELF FRANCE +1

High-temperature edible oil filter paper and manufacturing method thereof

ActiveCN102041751AHigh wet and dry strengthUniform paperFiltration separationFilter paperState of artFiber

The invention relates to a high-temperature edible oil filter paper and a manufacturing method thereof, belonging to the technical field of paper making. The manufacturing method comprises the following steps: adding a fibrous adhesive to enhance chemical fibers acting as main raw materials, pulping to defiber the chemical fibers and the fibrous adhesive, adding a certain amount of dispersant, molding with an inclined sieve or a lateral flow type cylinder sieve, applying a liquid adhesive to the surface for enhancement, drying, and cutting to obtain the filter paper capable of being used continuously. The manufacturing method can also comprise the following steps: adding a certain number of plant fibers to the chemical fiber materials, and drying without previously applying a liquid adhesive to the surface for enhancement, thus obtaining the filter paper capable of being used intermittently. Compared with the prior art, the high-temperature edible oil filter paper manufactured by the invention can be continuously or intermittently used, has favorable dry / wet strength, can resist high oil temperature of 180-200 DEG C and has the advantages of high paper uniformity and the like, thereby having fine application prospects.

Owner:龙游鹏辰新材料科技有限公司

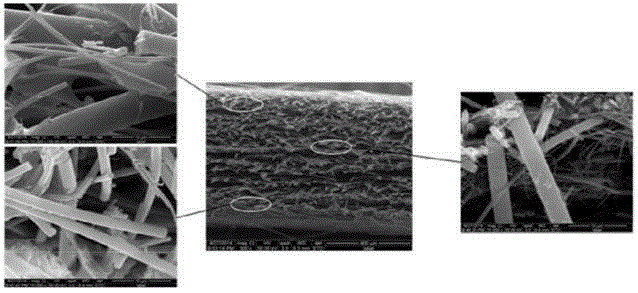

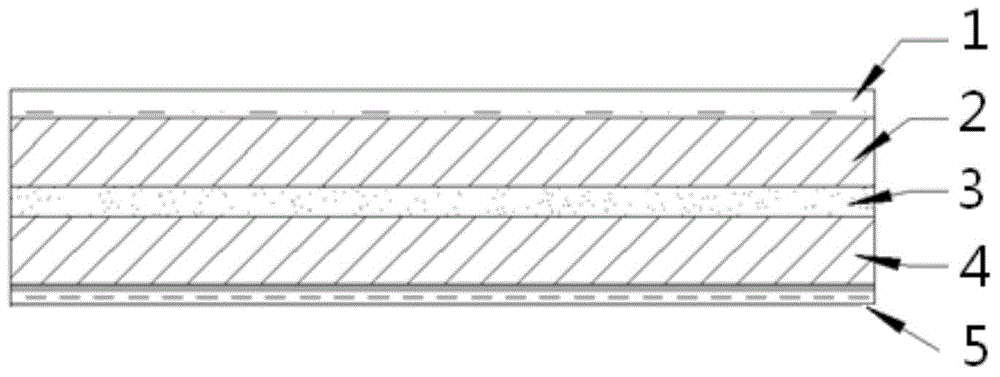

Antibacterial mildewproof glass fiber composite air filter paper and preparation method of antibacterial mildewproof glass fiber composite air filter paper

ActiveCN104532683ALarge specific surface areaReduce resistancePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberGlass fiber

The invention discloses antibacterial mildewproof glass fiber composite air filter paper which comprises an upper glass fiber layer (2) and a lower glass fiber layer (4), wherein an antibacterial layer (3) is arranged between the upper and lower glass fiber layers; a glue spraying layer (1) is compounded on the upper surface of the upper glass fiber layer (2) and an impregnation layer (5) is compounded on the lower surface of the lower glass fiber layer (4); the upper glass fiber layer (2) and the lower glass fiber layer (4) are prepared from glass fiber cotton with the diameter of 0.35-6.5 microns. The invention further discloses a method for moulding and preparing the glass fiber filter paper by a wet process. The glass fiber air filter paper disclosed by the invention is in a multilayered composite structure, and the antibacterial and moistureproof capacity of the paper is enhanced while the filter efficiency of the paper is not affected.

Owner:CHONGQING ZAISHENG TECH CORP

Compostable wet-laid articles comprising cellulose and cellulose esters

InactiveUS20200063365A1Reduce consistencyLow variabilityFlexible coversWrappersPolymer scienceCellulose fiber

Wet laid products including packaging is obtained from co-refined cellulose fibers and synthetic fibers are made biodegradable, and can also be compostable and soil biodegradable. The synthetic fibers include staple cellulose ester fibers. Desirably, such staple cellulose ester fibers have a denier per filament of 3 or less, a cut length of 6 mm or less, are crimped, or are non-round and crimped, and have a degree of substitution of 2.5 or less.

Owner:EASTMAN CHEM CO

Air-filtration paper for automobile engine filter and preparation method of air-filtration paper

ActiveCN102912677AImprove adsorption capacityImprove filtering effectNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses air-filtration paper for an automobile engine filter and a preparation method of the air-filtration paper. The air-filtration paper for the automobile engine filter is prepared from the following materials in parts by weight: 60-70 parts of hardwood pulp, 30-40 parts of cotton pulp, 10-15 parts of modified polyester fiber, 2-5 parts of nanocarbon, 1-3 parts of kaolin, 1-2 parts of lime milk, 2-4 parts of modified zealite sieve, 0.5-0.8 parts of water talcum powder, 3-4 parts of polyacrylic emulsion, 2-5 parts of polyvinyl acetate emulsion, 0.5-1 part of sodium laurylsulfate, 0.5-1 part of silane coupling agent DL171, 0.4-0.8 parts of sodium laurylsulfate and 4-6 parts of dialdehyde starch. The filtration paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, high water tolerance, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

High temperature resistant flame retardant filter paper used for diesel filter and preparation method thereof

ActiveCN102877368AHigh temperature resistant and flame retardantBursting strengthPaper/cardboardFiltration separationBursting strengthCellulose

The invention discloses a high temperature resistant flame retardant filter paper used for a diesel filter and a preparation method thereof. The high temperature resistant flame retardant filter paper comprises the following raw materials in parts by weight: 60-70 parts of wood pulp celluloses, 30-40 parts of vinylon fibers, 10-15 parts of glass fibers, 2-5 parts of dolomite dust, 1-3 parts of nanometer titanium dioxide, 2-4 parts of light calcium carbonate, 1-2 parts of modified nano-carbon, 1-2 parts of nanometer titanium oxide, 0.5-0.8 part of ammonium dihydrogen phosphate, 3-4 parts of modified water-soluble phenolic resin emulsion, 2-5 parts of styrene-acrylic emulsion, 0.5-1 part of diethanolamide, 0.5-1 part of silane coupling agent KH550, 0.4-0.8 part of sodium laurylsulfate and 4-6 parts of a wet strength agent. The filter paper, prepared by the invention, has the advantages of good water permeability, large filtering area, small maximum aperture, high filtering precision, strong bursting strength, high temperature resistance and flame resistance, the filtering efficiency is 99.999%, the filter paper has stable performance index at normal temperature and high temperature, and better temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

Preparation and application of cigarette paper filter material containing Chinese herbal components

ActiveCN101736654ALess irritatingReduce mistTobacco smoke filtersFiltration separationMedicineLicorice roots

The invention discloses preparation and application of cigarette paper filter material containing Chinese herbal components, which belongs to the technical field of cigarette preparation. The preparation and the application comprise: crushing one or more of common coltsfoot flowers, aster, fineleaf schizonepeta herbs, ballonflower, reed rhizome, Japanese ardisia herbs, sessile stemona roots, cynanchum stauntoni, mint, licorice roots and the like and then performing beating and papermaking on the obtained product together with wood pulp, cotton pulp or bamboo pulp for papermaking; or extracting raw materials through water or ethanol and then smearing or spraying extract on cigarette paper filter material; embossing and cutting the cigarette paper filter material; molding the obtained product to be cigarette filter rods; and preparing cigarettes from the filter rods separately or preparing the filter rods into composite filter rod rolls and then preparing the cigarettes. The method has the advantages of significantly reducing the irritation and mixed smell of the cigarettes with paper filter tips, improving the smoking odor of the cigarettes and improving the applicability of paper filter material in the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Air filtration articles

ActiveUS20200063354A1Improve breathabilityReduce consistencyPaper/cardboardMembrane filtersAir filtrationPolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The present invention also relates to a filter media for air filtration comprising cellulose fiber and a staple fiber; wherein said staple filter comprises cellulose ester; wherein said air permeability is higher for a given mean pore size as compared to a filtration that comprises 100% cellulose.

Owner:EASTMAN CHEM CO

Air purification filter and process for producing the same

InactiveUS20060117958A1Improves the bactericidal/sterilizing or antimicrobial means propertiesHigh tensile strengthCombination devicesAuxillary pretreatmentFiberGas phase

It is intended to provide an air purification filter which has a high dry tensile strength, a high wet tensile strength in association with a high water resistance and a high water repellency and exhibits a bactericidal effect due to a gas phase reaction in a gas phase. Namely, an air purification filter having a high dry tensile strength, a high wet tensile strength (a high water resistance) and a high water repellency as well as a bactericidal effect which is obtained by blending a filter fiber having a functional group with a mixture of a modification enzyme which has an ionic polarity opposite to the ionic polarity of the whole filter fiber as described above and a bactericidal effect with an ionic synthetic resin binder having the opposite ionic polarity similar to the modification enzyme.

Owner:NIKKI UNIVERSAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com