Antibiotic air filter paper and preparation method thereof

A technology of air filter paper and filter paper, applied in the direction of filter paper, separation methods, chemical instruments and methods, etc., can solve the problems of complex structure, high production cost, corrosion of air conditioning system, etc., and achieve the effect of simple process, simple structure and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

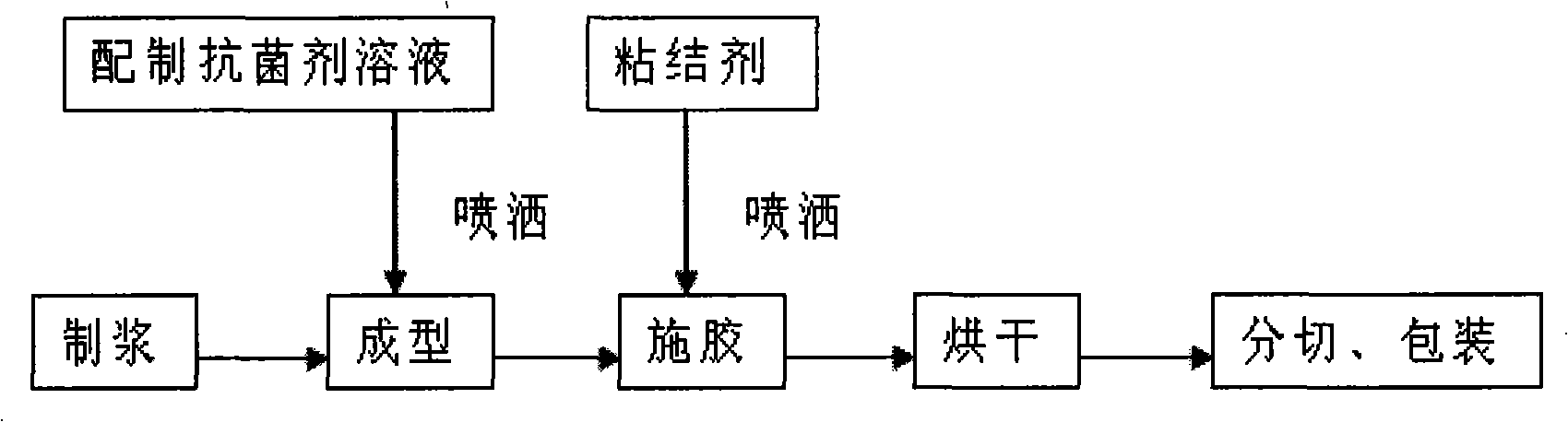

Method used

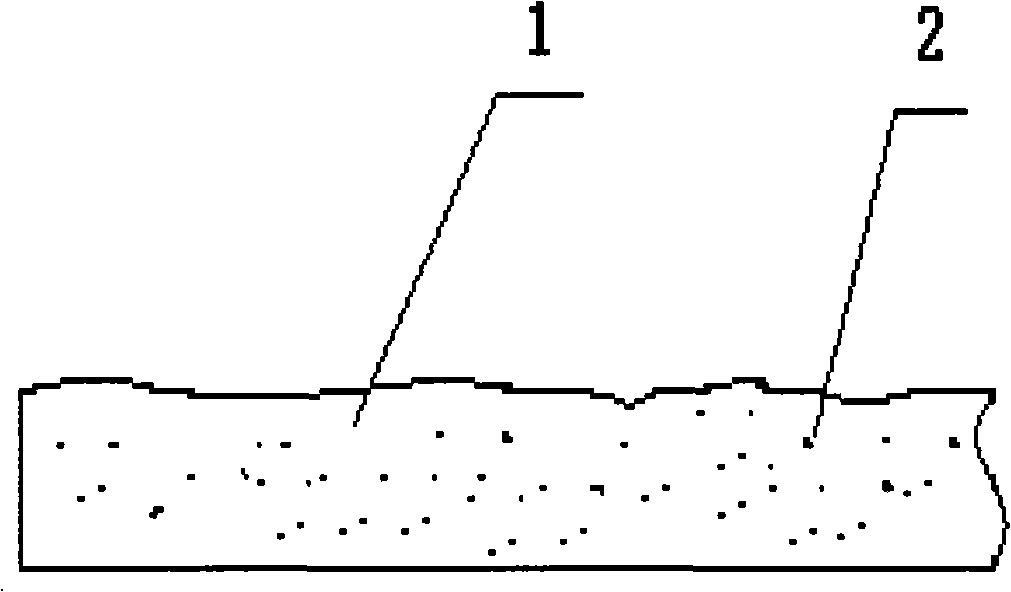

Image

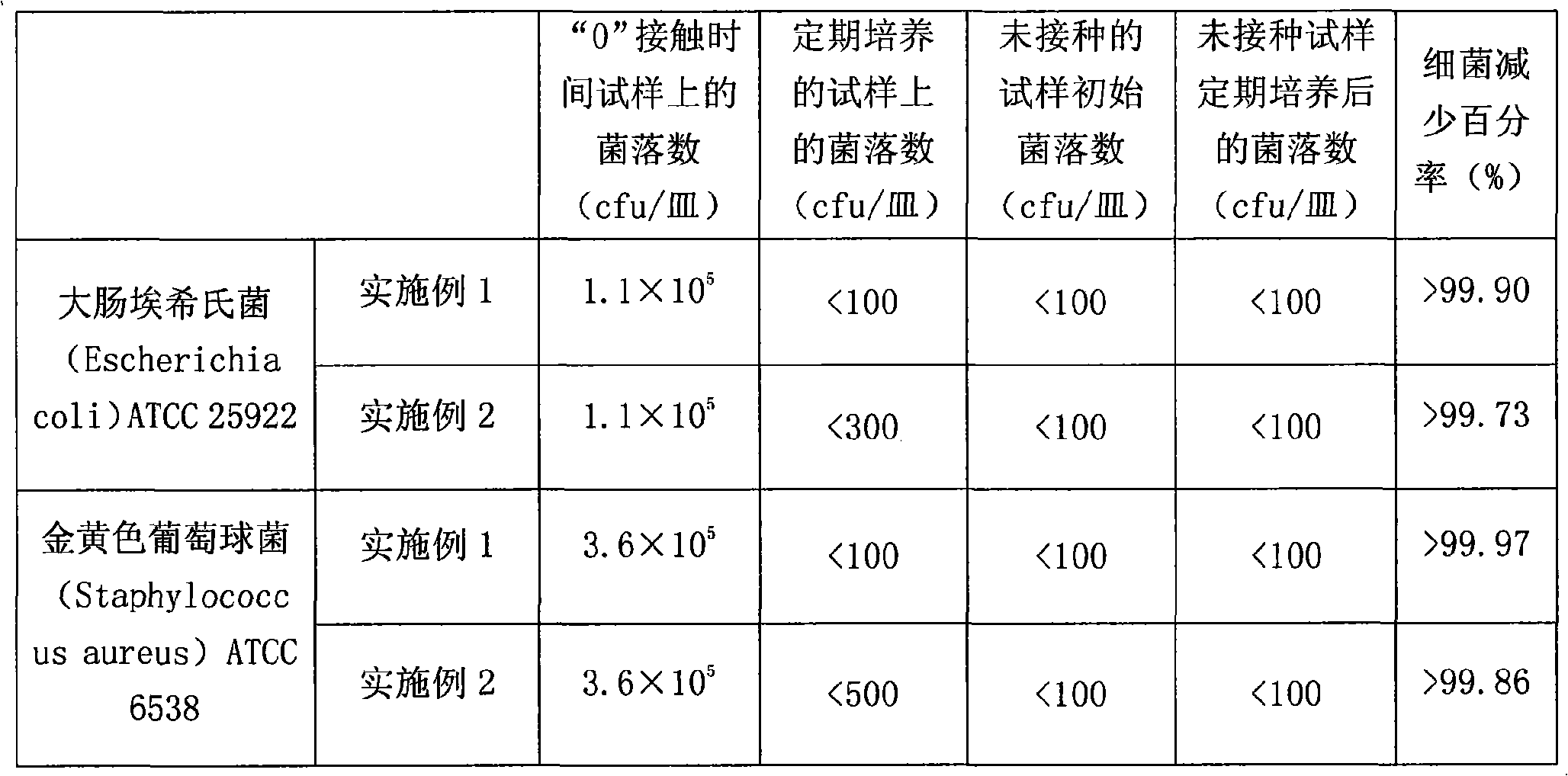

Examples

Embodiment 1

[0028] (1) Disperse the non-alkali glass microfiber and non-alkali continuous glass fiber chopped strands for 10 minutes with a high-frequency deflagging machine, and then dilute it in the slurry mixing tank to make a slurry with a concentration of 0.3% and a pH value of 3.5;

[0029] (2) fully dilute the HTB-038 nanometer silver ion antibacterial agent (produced by Nanjing Haitai Nano Material Co., Ltd.) in the batching device to prepare the dilution;

[0030] (3) In the filter paper forming part, at a forming speed of 16-17m / min, a wet base layer of filter paper is formed, and a sprayer is used to evenly spray the diluent containing antibacterial agent on the surface, then vacuumize, and spray TRC flexible in the sizing part The diluent of acrylic acid emulsion (produced by Jiangsu Sunrise Chemical Co., Ltd.) makes the antibacterial agent and filter paper better bond together;

[0031] (4) After drying in a dryer at 160-180°C, air filter paper with a thickness of 0.32±0.01mm...

Embodiment 2

[0036] (1) Disperse alkali-free glass microfibers, alkali-free continuous glass fiber chopped strands, and PET organic fibers for 8 minutes with a high-frequency disintegrator, and then dilute in the slurry mixing tank to make a slurry with a concentration of 0.3% and a pH value of 3.5;

[0037] (2) HTTi-01 nano TiO 2 The antibacterial agent (produced by Nanjing Haitai Nano Material Co., Ltd.) is fully diluted in the batching device to obtain a diluent;

[0038] (3) In the filter paper forming part, at a forming speed of 15-16m / min, a wet base layer of filter paper is formed, and a sprayer is used to evenly spray the diluent containing antibacterial agent on the surface, then vacuumize, and spray TRC flexible in the sizing part Acrylic acid emulsion (produced by Jiangsu Sunrise Chemical Co., Ltd.) diluent, so that the antibacterial agent and filter paper can be better bonded together;

[0039] (4) After drying at 160-180°C, the thickness is 0.33±0.02mm, the width can be cut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com