Patents

Literature

34results about How to "Bursting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Balloon catheter device

InactiveUS6923827B2Bursting strengthAid in insertion and withdrawalStentsBalloon catheterAngioplasty balloonBursting strength

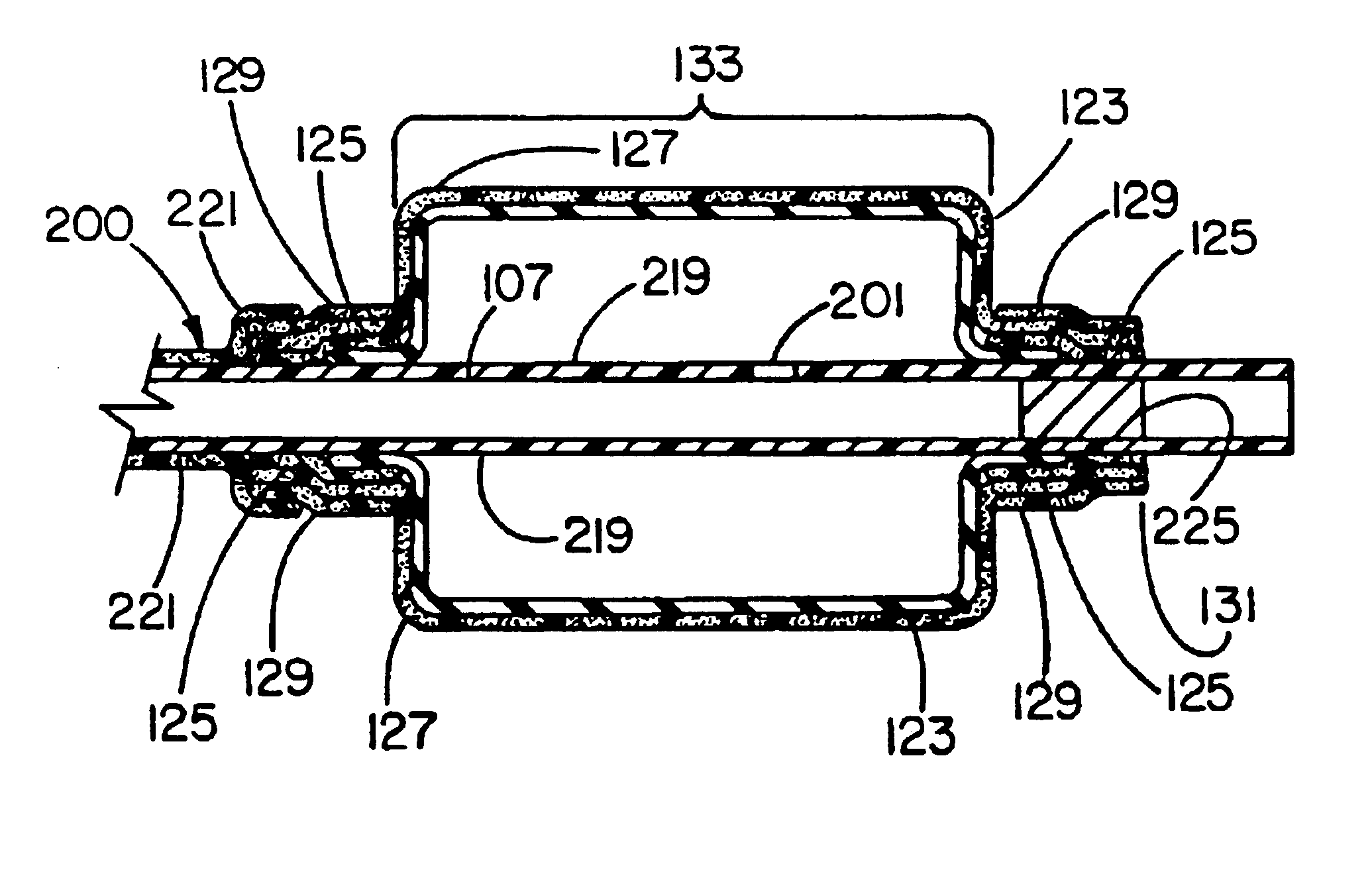

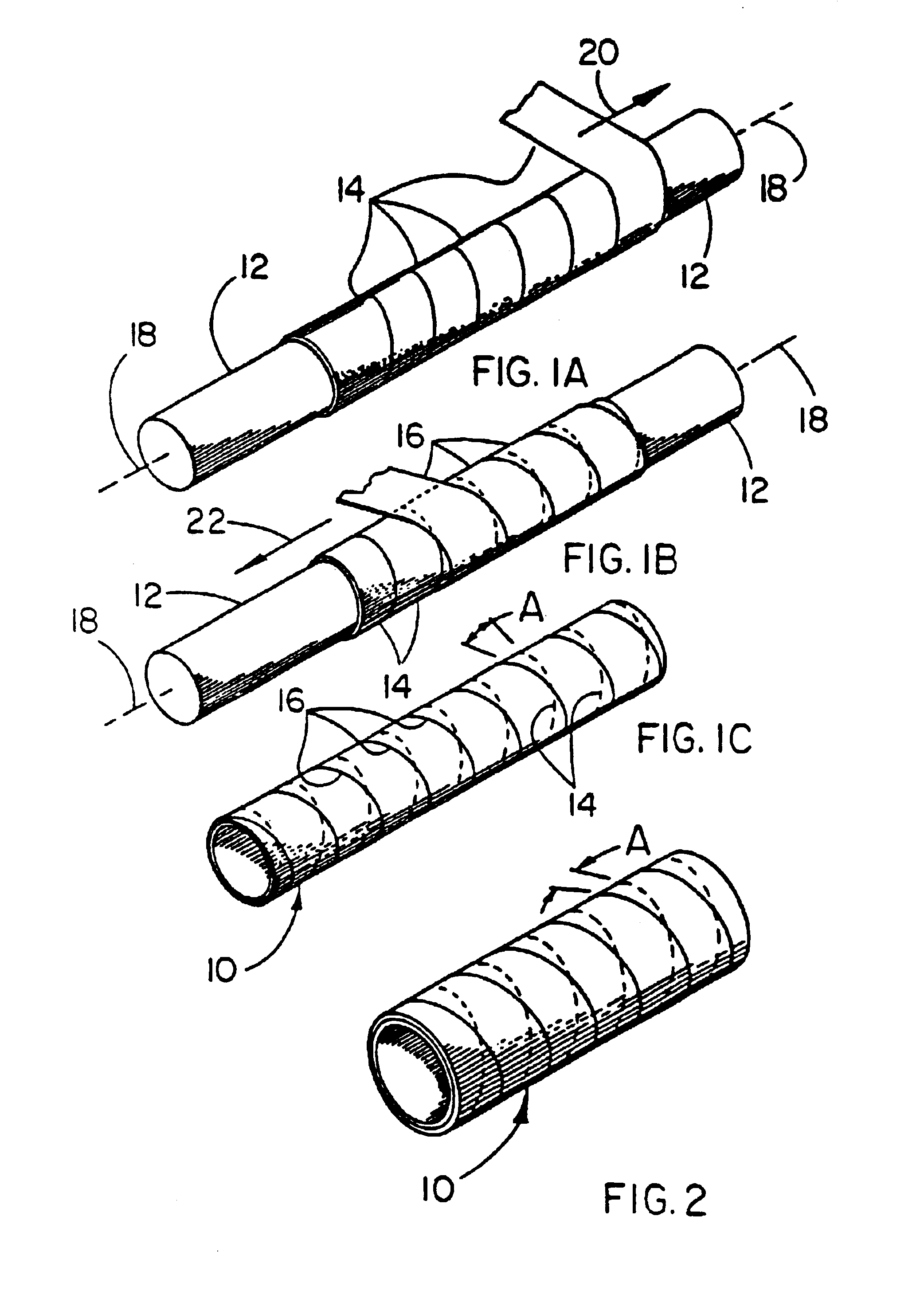

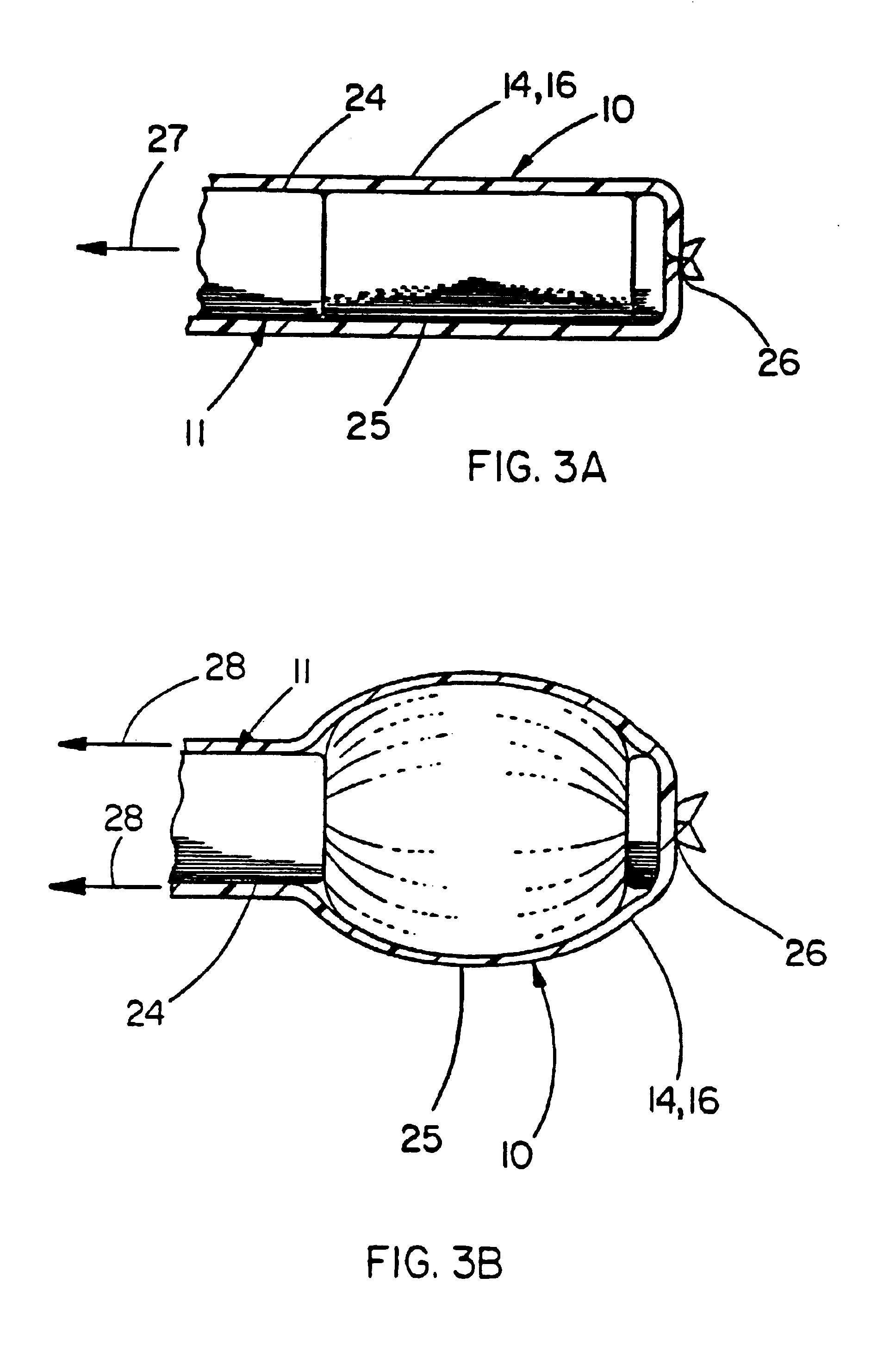

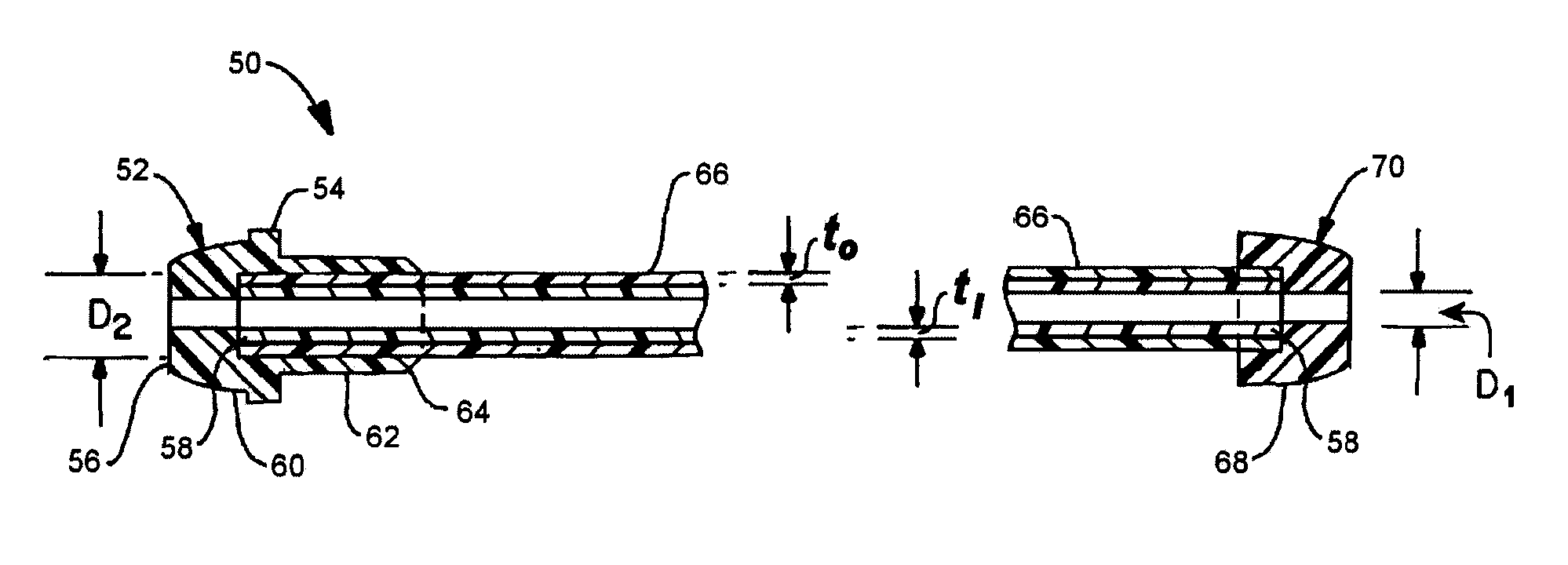

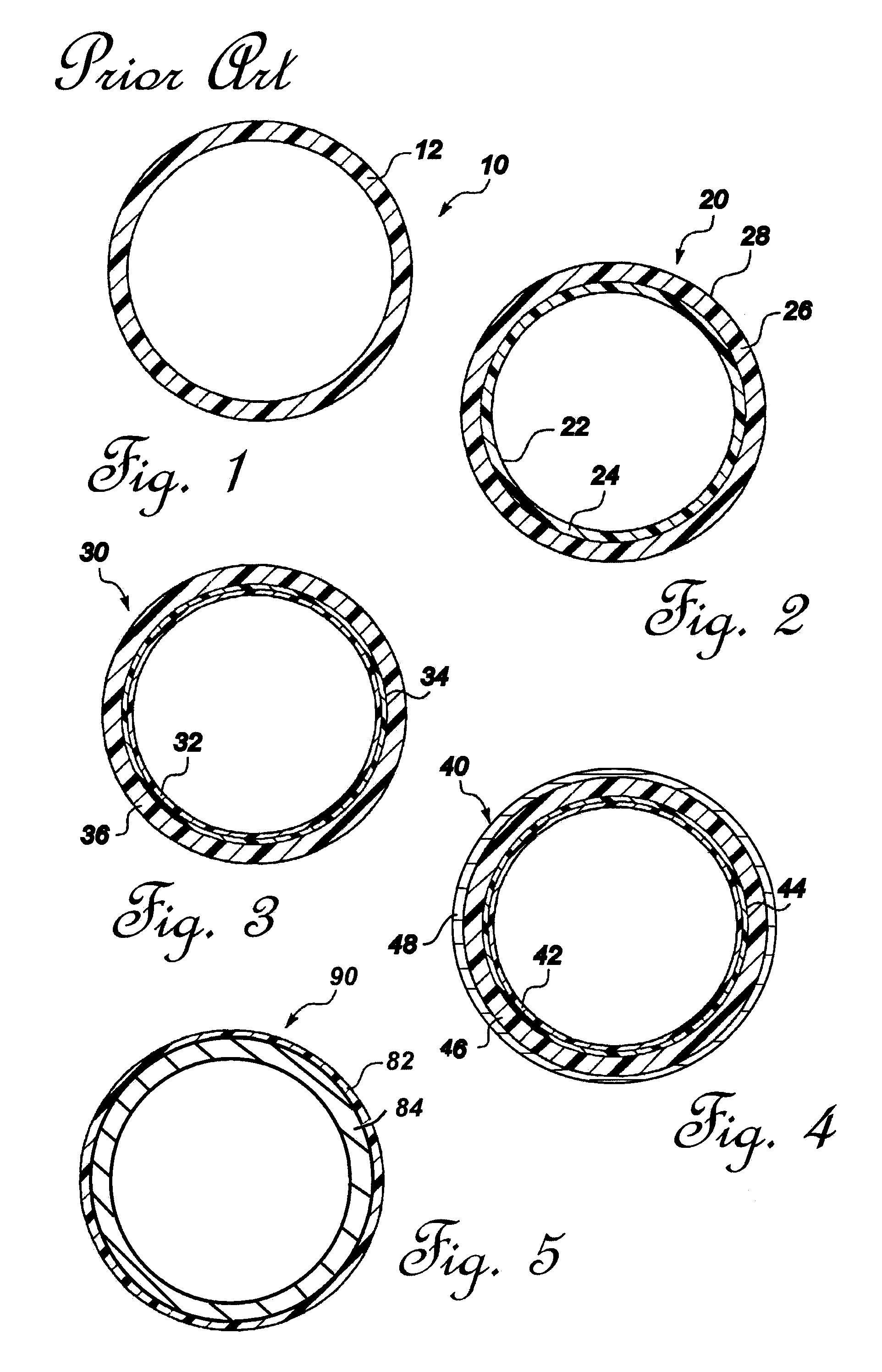

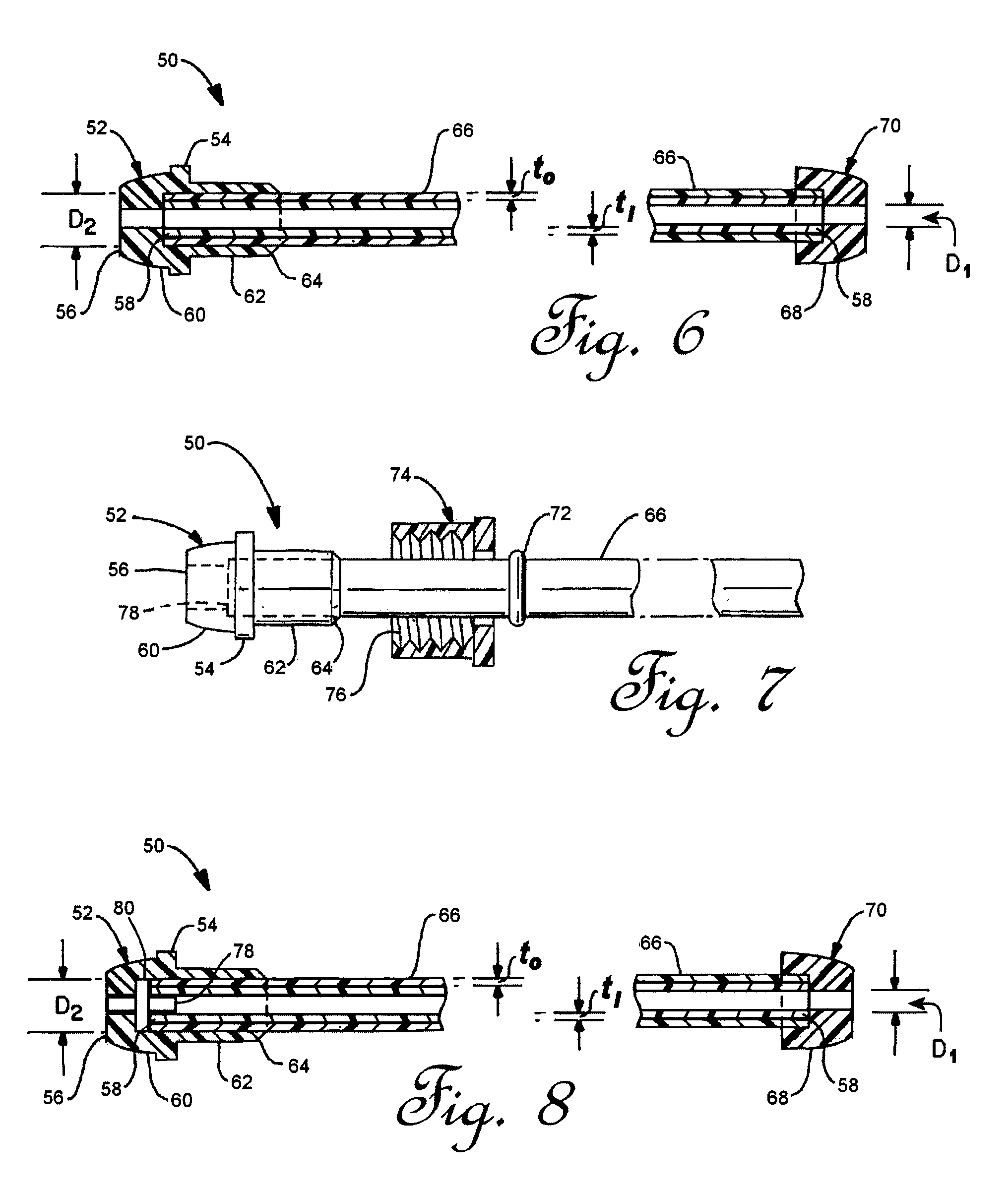

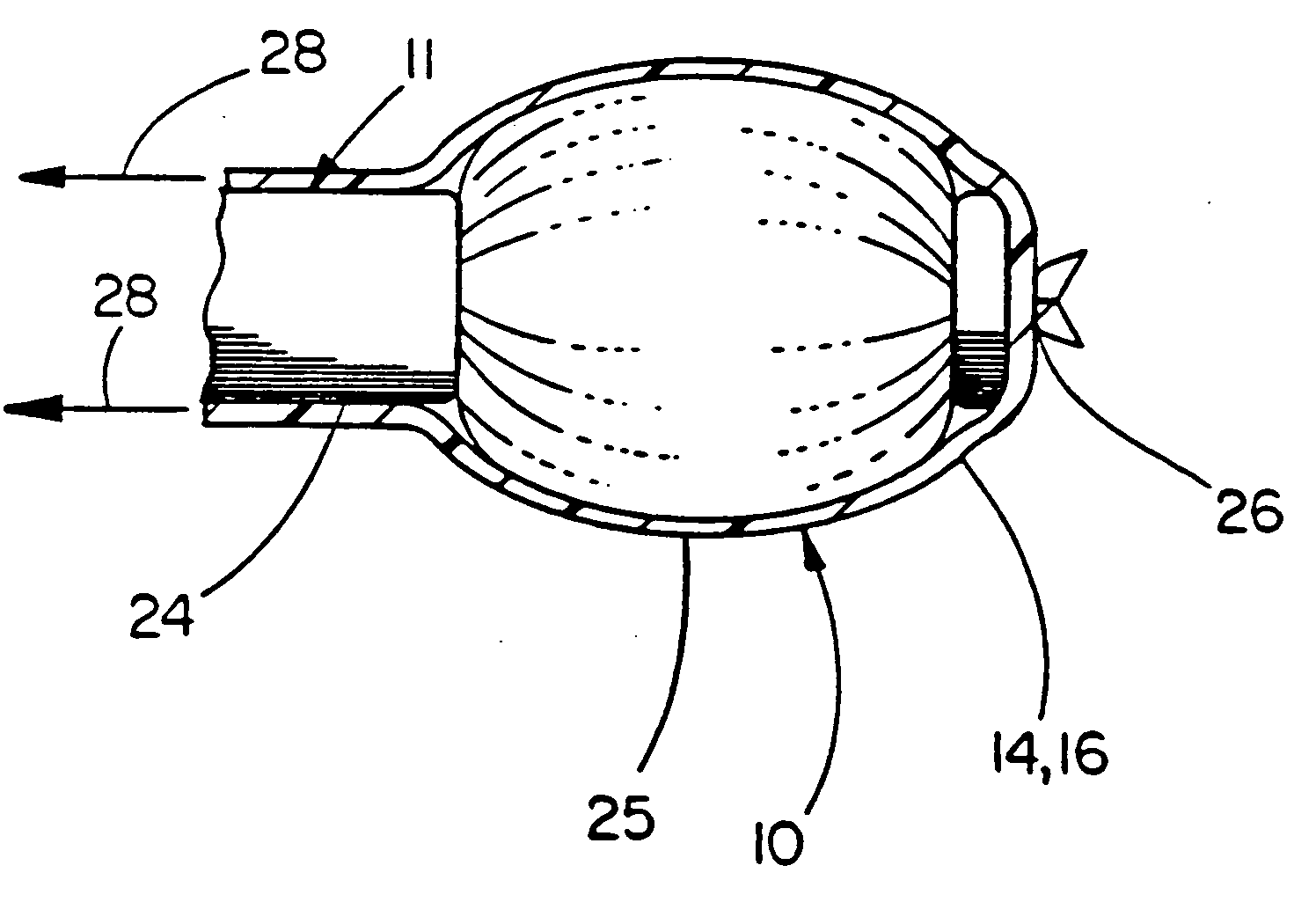

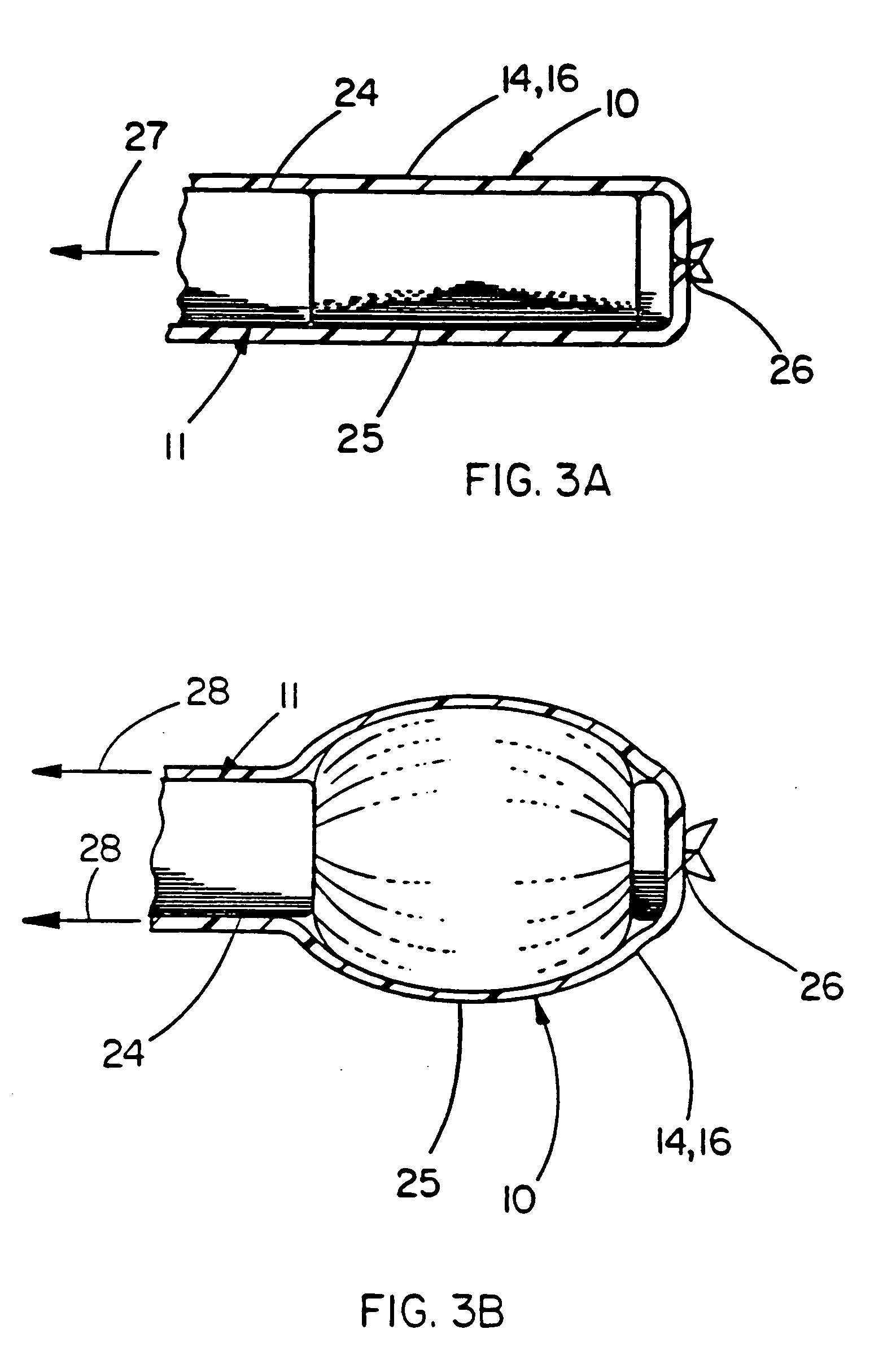

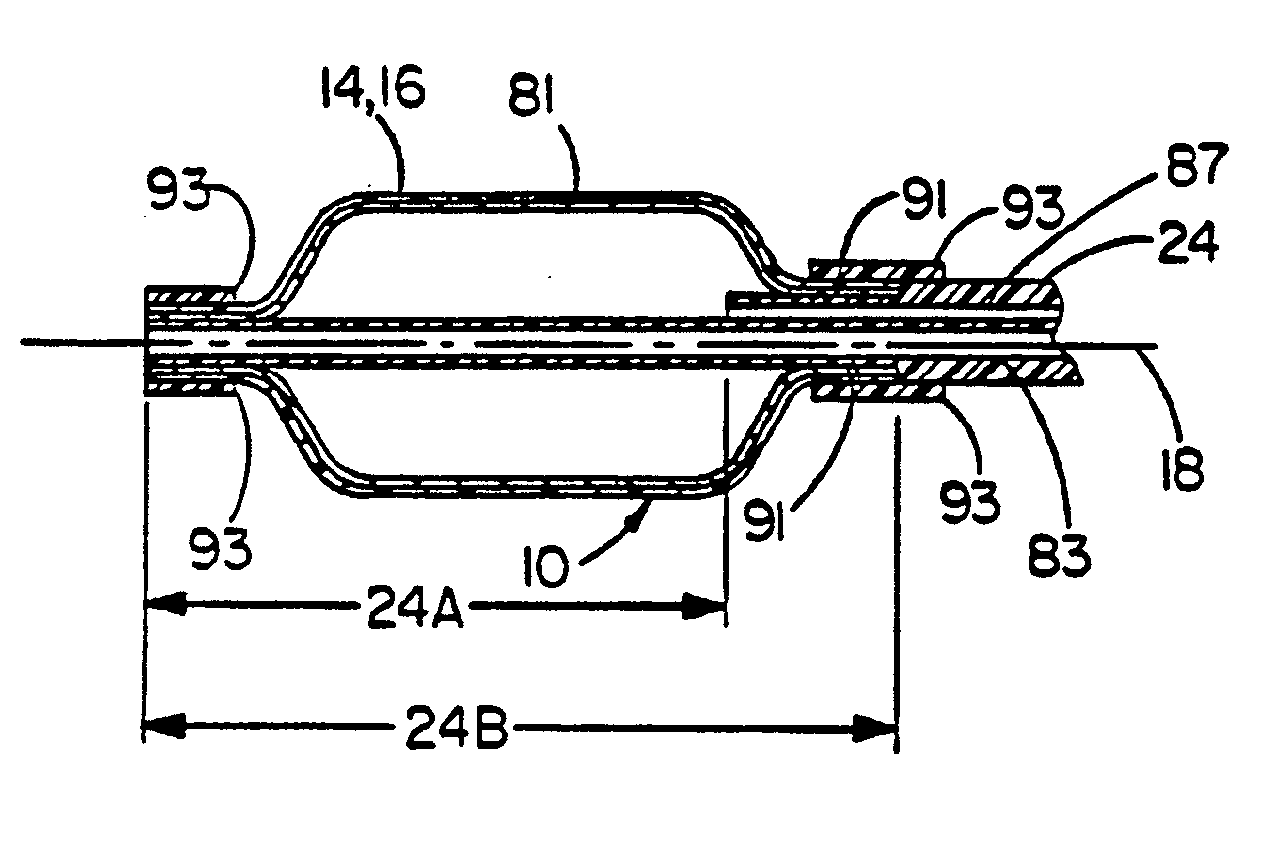

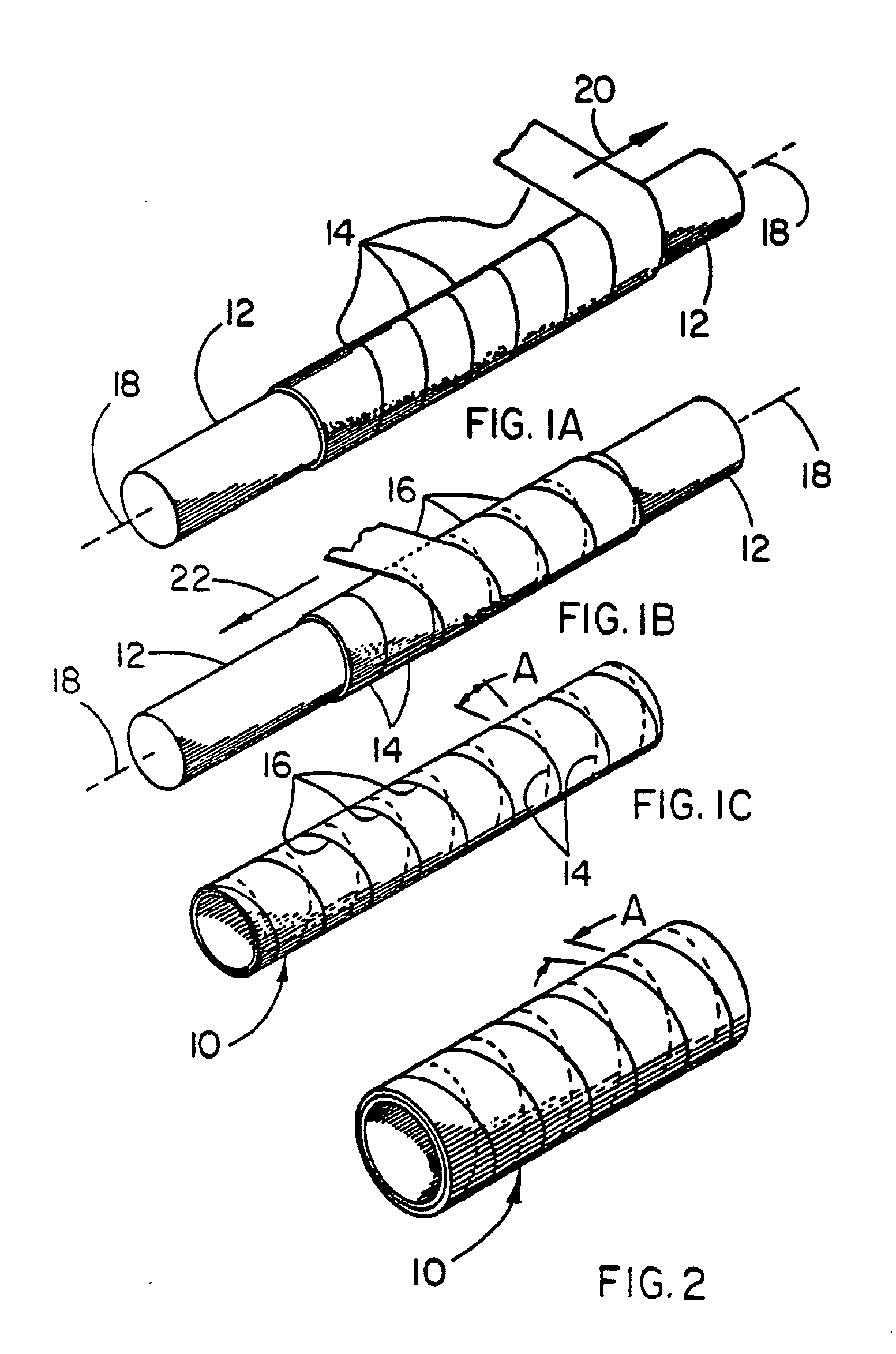

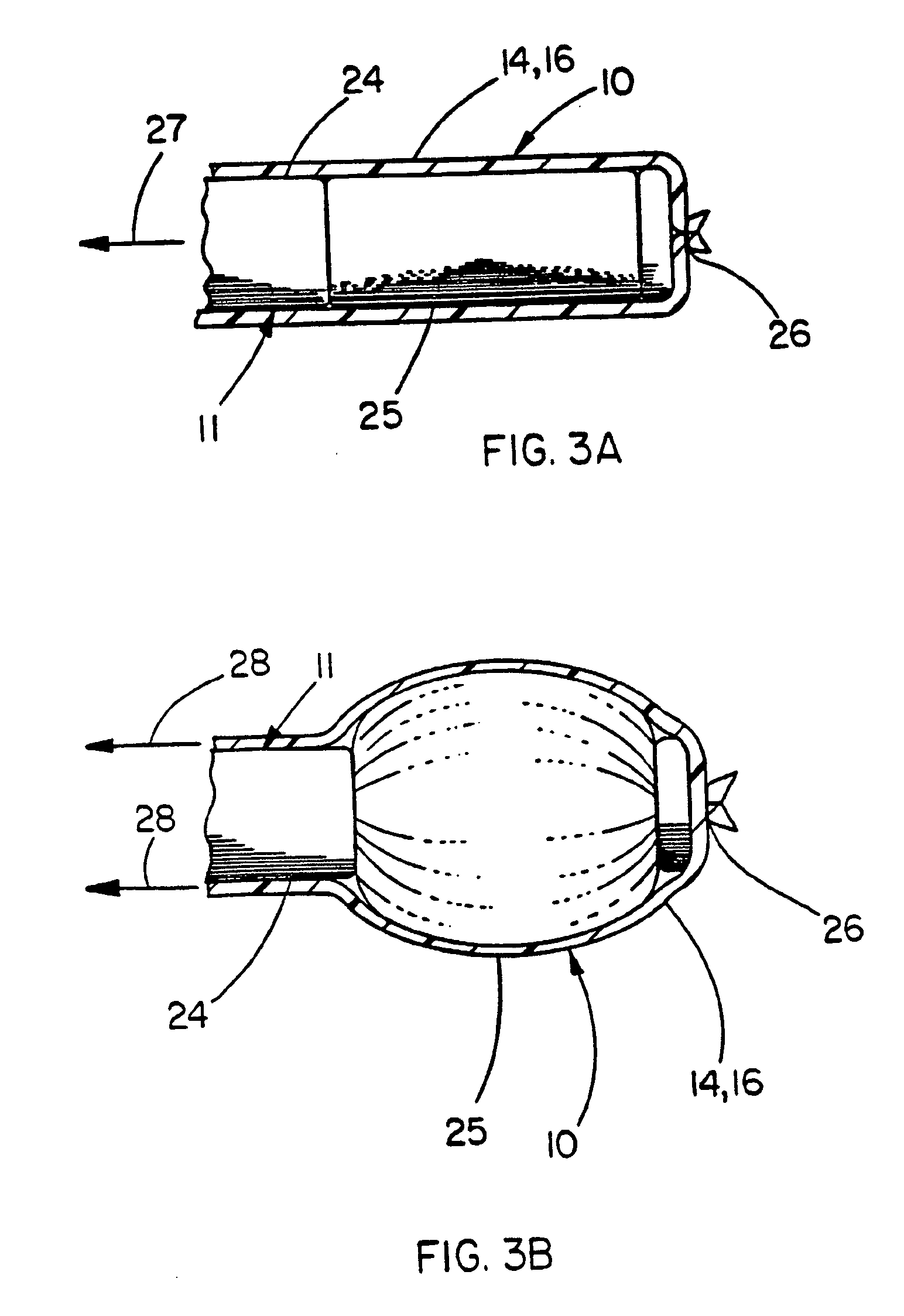

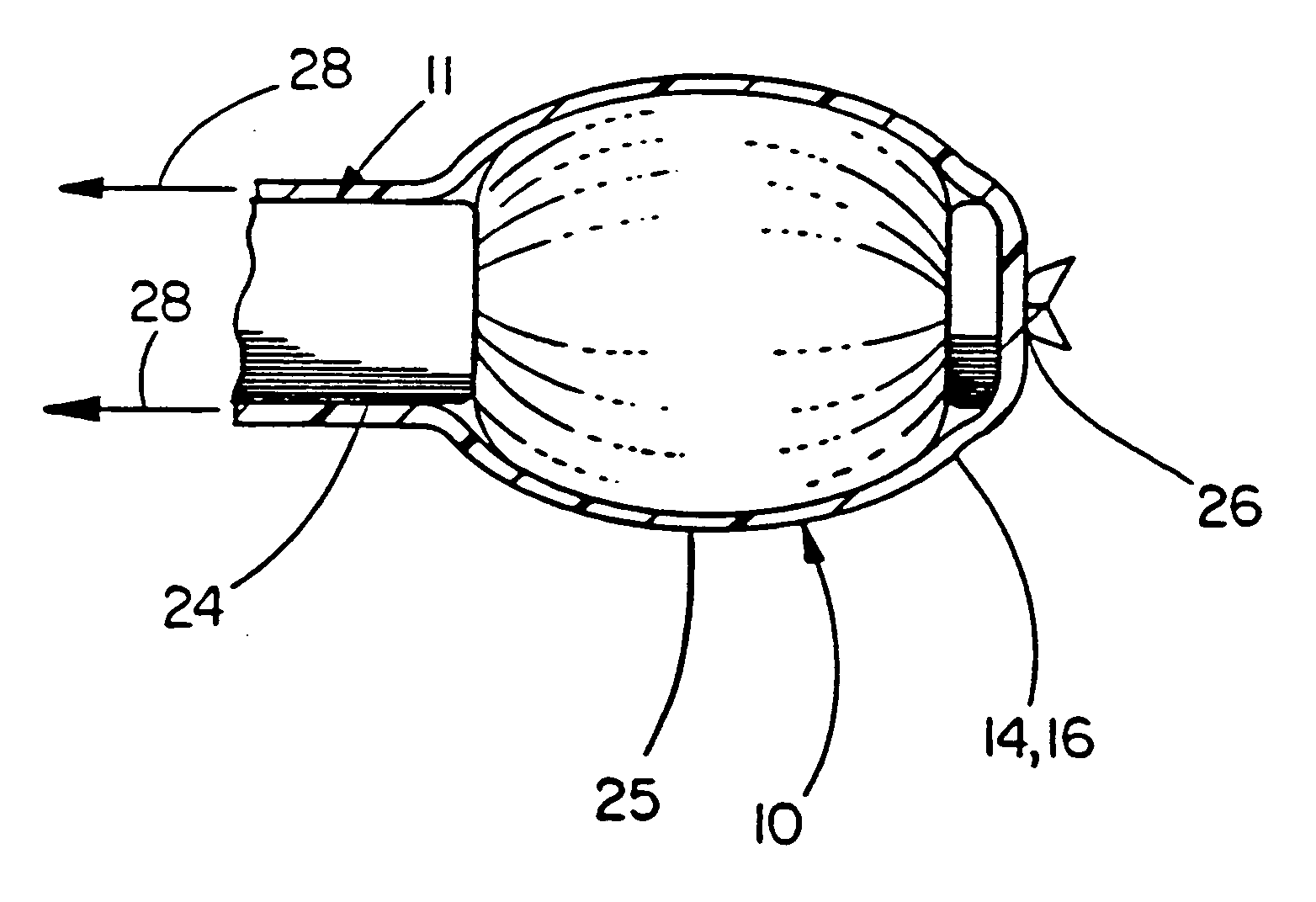

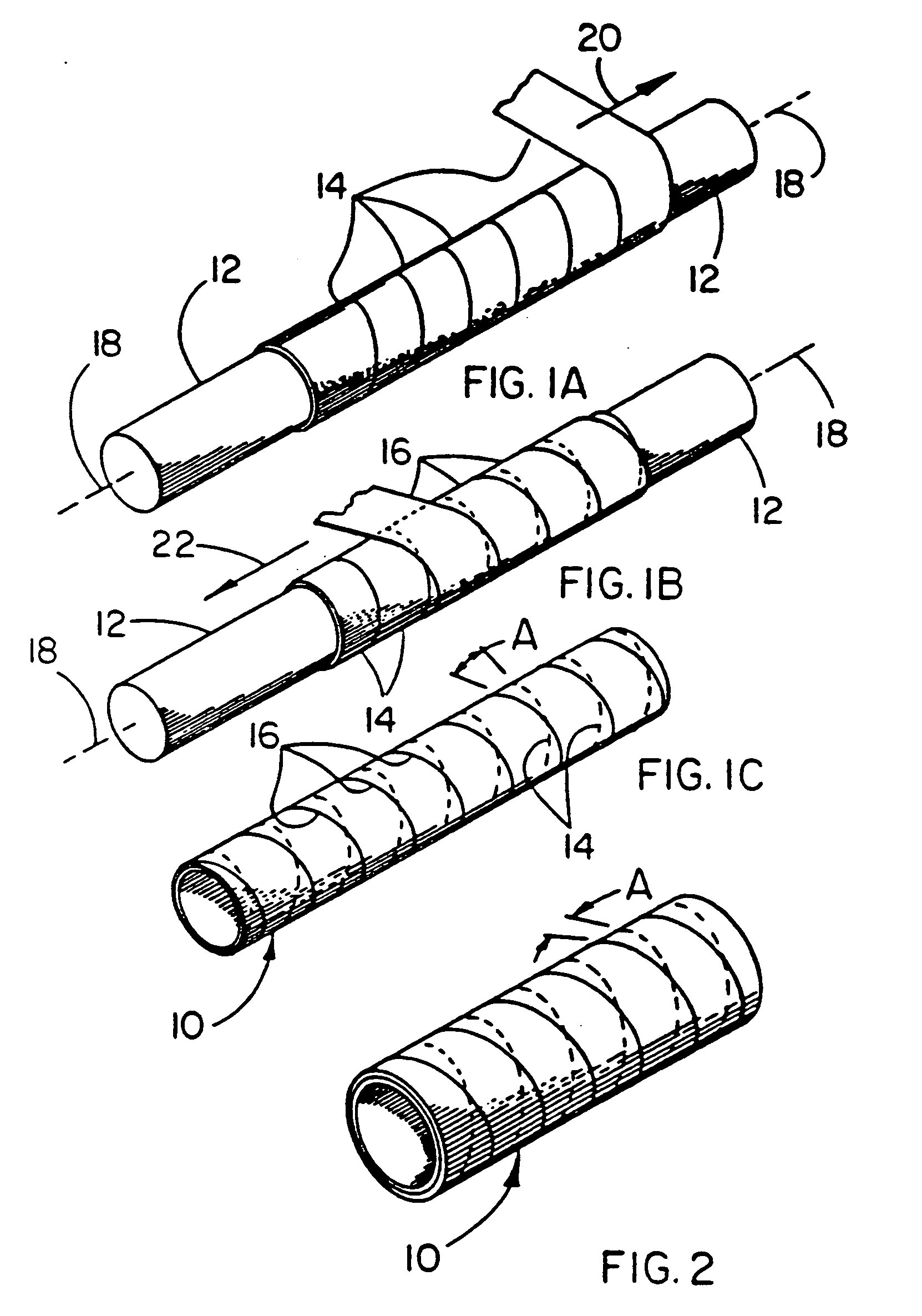

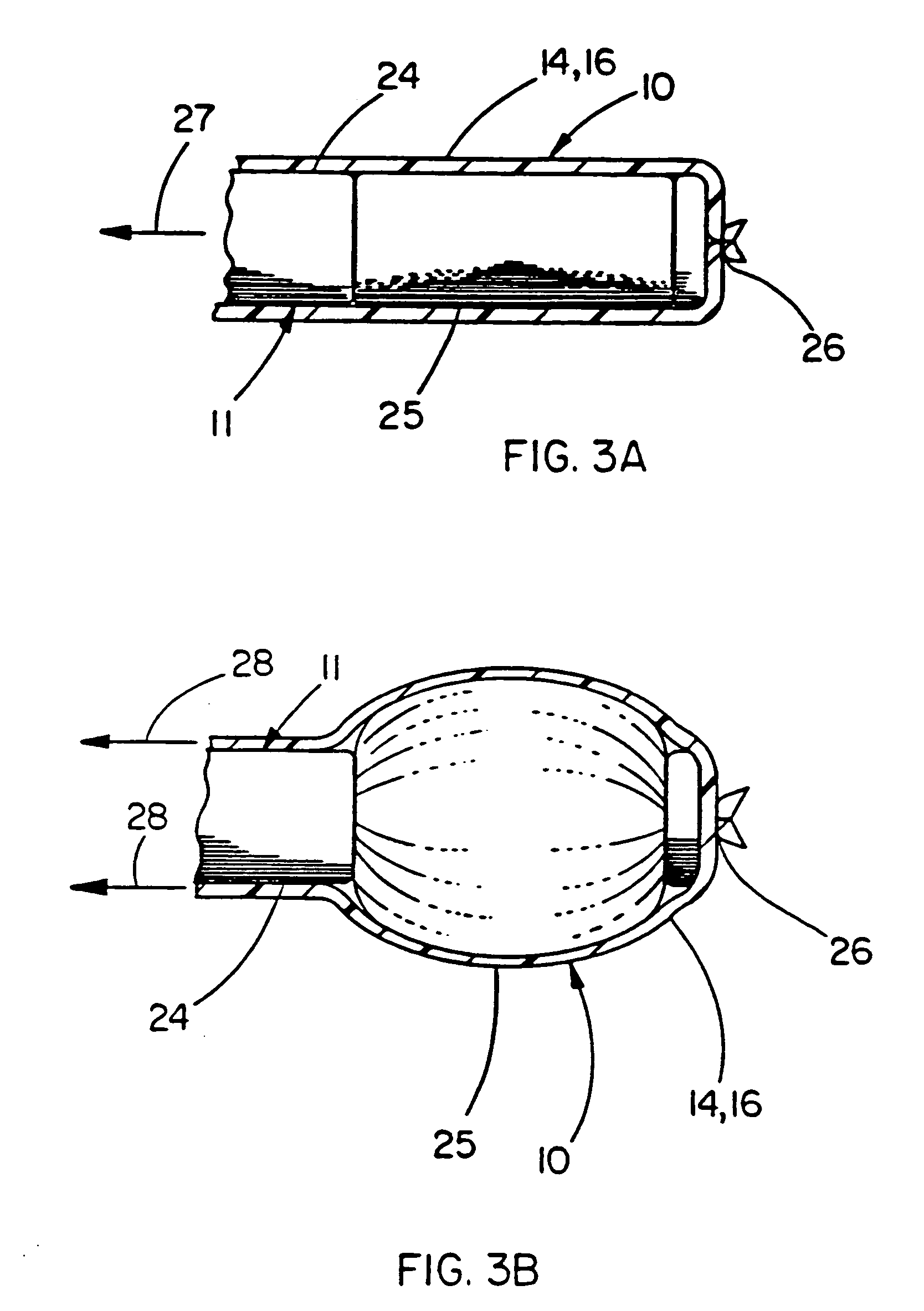

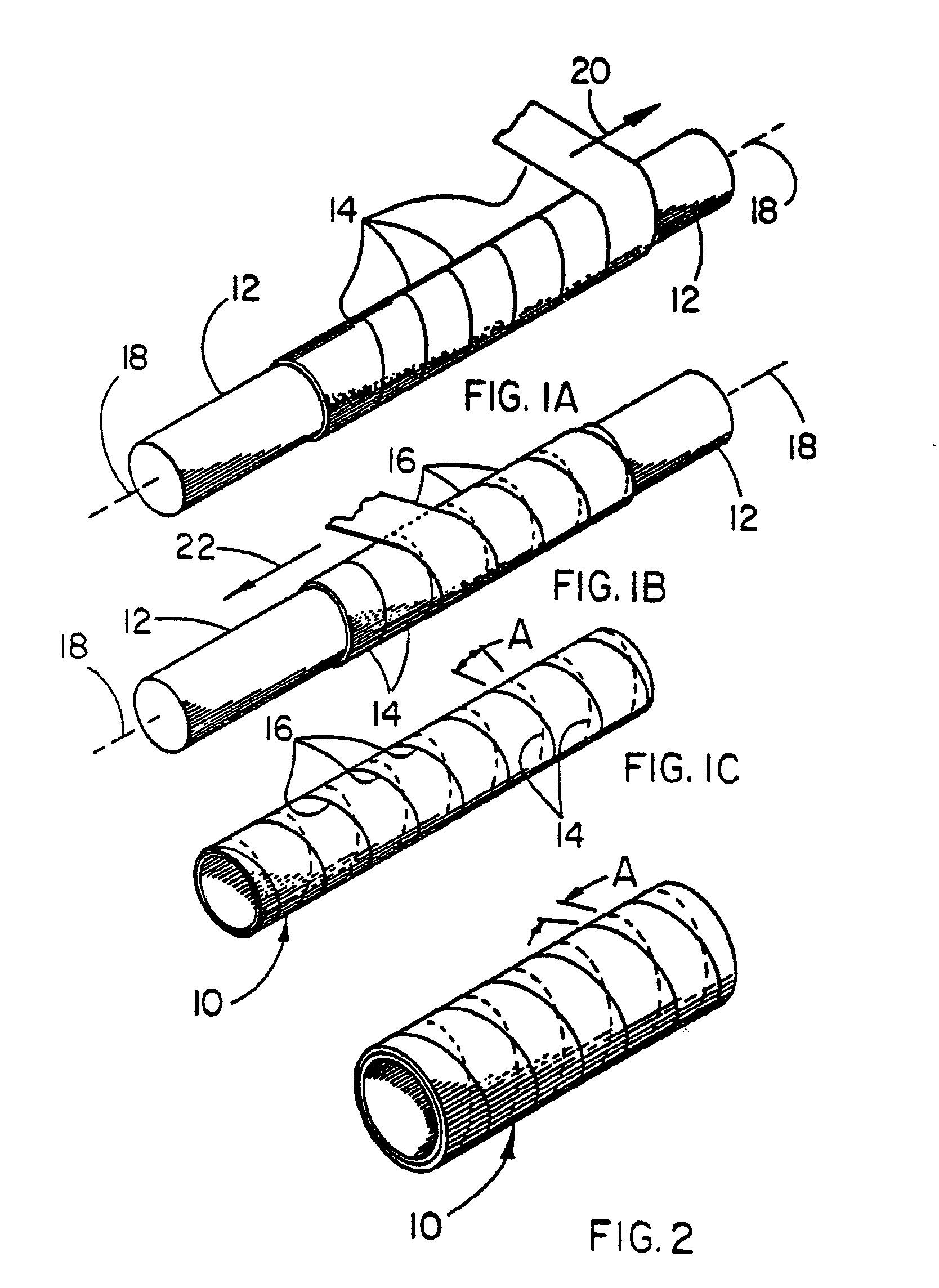

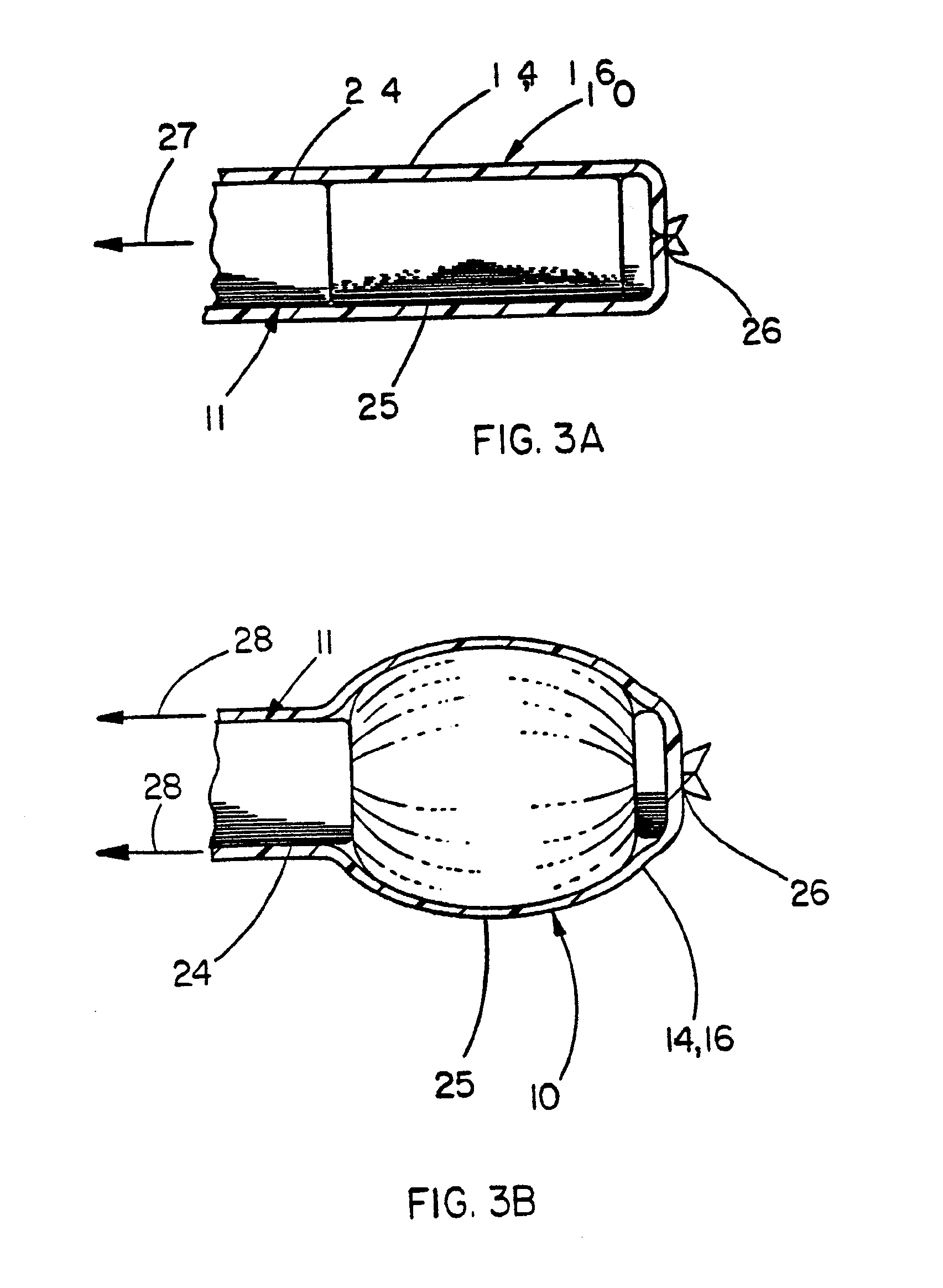

Balloon catheters having the strength and maximum inflated diameter characteristics of an angioplasty balloon and having the recovery characteristics during deflation of an elastic embolectomy balloon. The balloon catheter can be made in very small sizes and has a lubricious and chemically inert outer surface. The balloon catheter is easy to navigate through tortuous passageways, is capable of rapid inflation and deflation and has high burst strengths. Balloon covers having these same characteristics are also described for use with conventional embolectomy balloons or angioplasty balloons.

Owner:WL GORE & ASSOC INC

Multilayer tubes

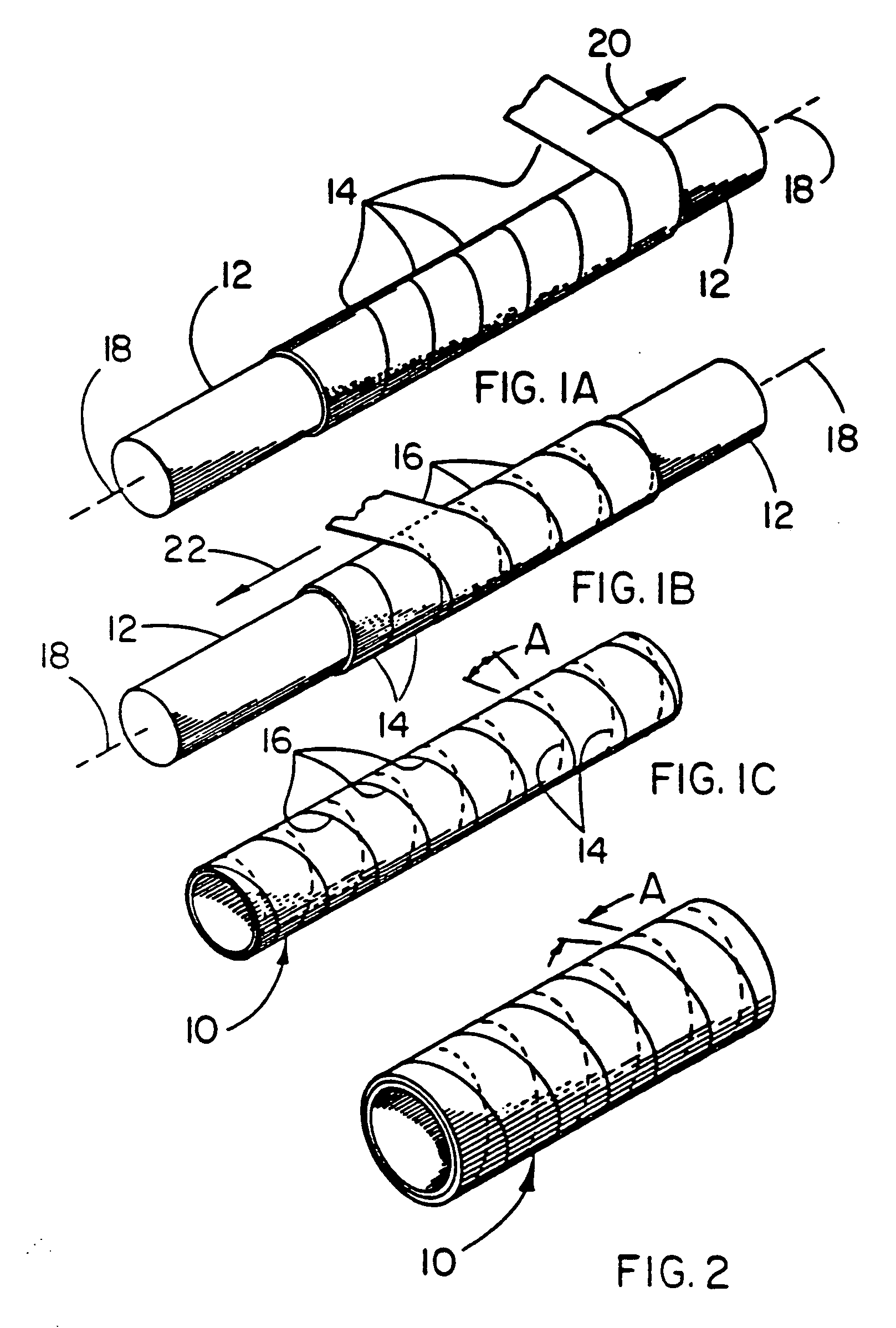

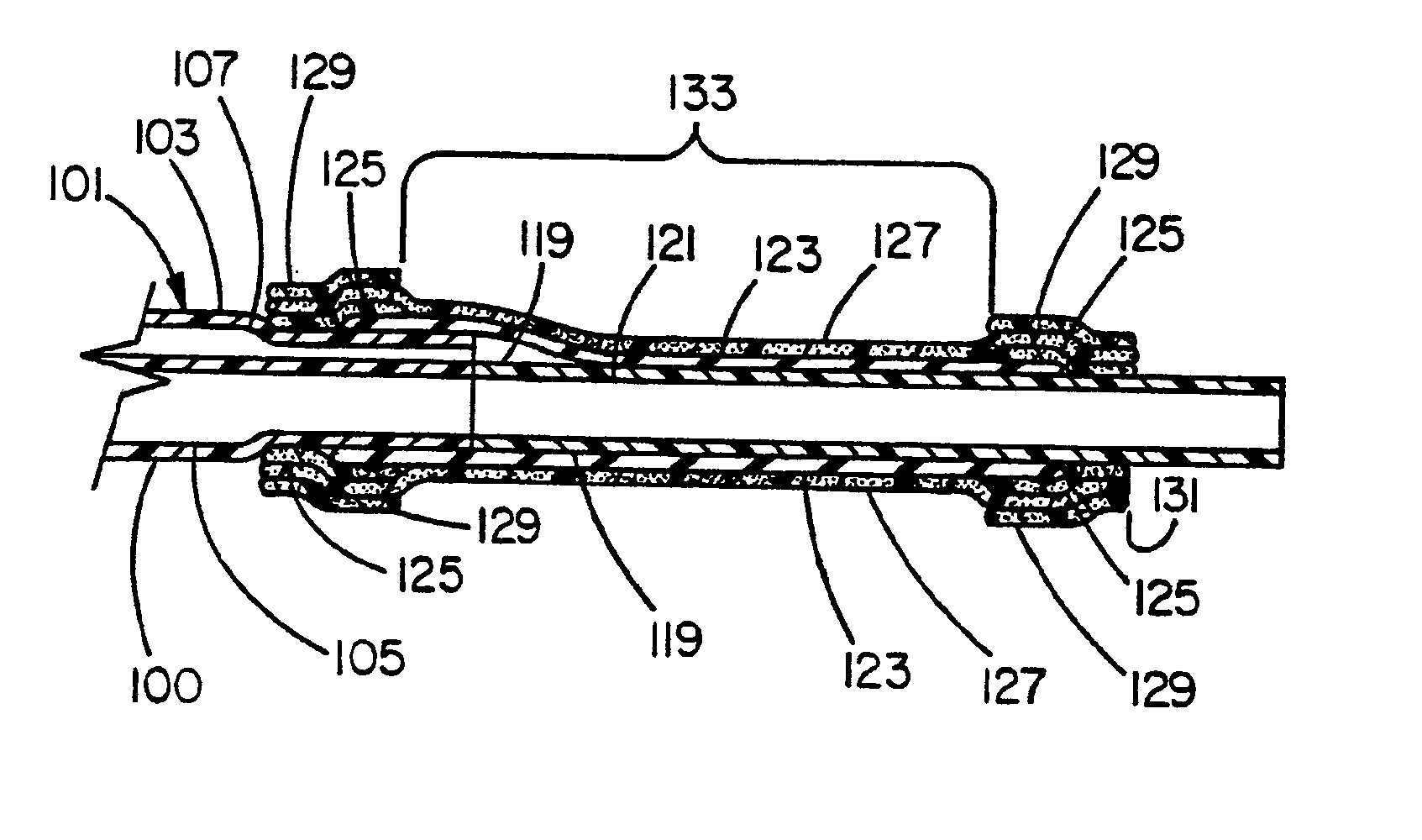

InactiveUS20070051418A1Reduced flexibilityReduce wall thicknessFlexible pipesRigid pipesThermoplastic elastomerEngineering

The invention described relates to a composition for a multilayer tube having an inner and an outer layer. Preferably the inner layer of the tube has at least one at least partially crosslinked, preferably polyethylene, which is less flexible than the adjacent more flexible outer layer, which is preferably a thermoplastic elastomer. The inner and outer layers are typically coextruded during manufacture, with at least one overmolded end, preferably crosslinked, which generally has an internal diameter which is essentially the same as the internal diameter of the multilayer tube. The multilayer tube is typically crosslinked, preferably by electron beam.

Owner:ROWLES BRIAN A +1

Balloon catheter device

InactiveUS20060271091A1Increase profitBursting strengthStentsBalloon catheterMedicineBalloon catheter

Balloon catheters are provided having the balloon length is substantially surrounded by an elastic cover. The balloon and the cover maintain a substantially and circular cross-section along the balloon length during inflation. The cross section is able to maintain a uniform size down the length of the balloon during inflation.

Owner:WL GORE & ASSOC INC

Balloon catheter device

InactiveUS20050273152A1Bursting strengthAid in insertion and withdrawalStentsBalloon catheterBursting strengthAngioplasty balloon

Balloon catheters having the strength and maximum inflated diameter characteristics of an angioplasty balloon and having the recovery characteristics during deflation of an elastic embolectomy balloon. The balloon catheter can be made in very small sizes and has a lubricious and chemically inert outer surface. The balloon catheter is easy to navigate through tortuous passageways, is capable of rapid inflation and deflation and has high burst strengths. Balloon covers having these same characteristics are also described for use with conventional embolectomy balloons or angioplasty balloons.

Owner:WL GORE & ASSOC INC

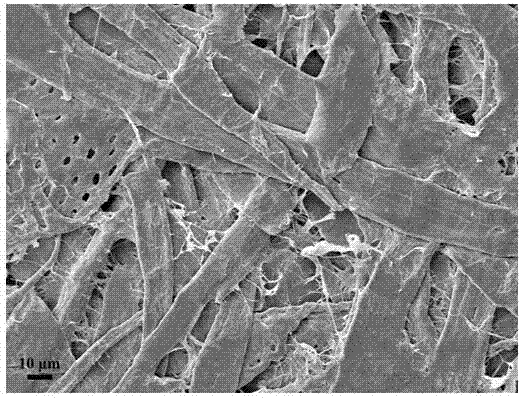

High temperature resistant flame retardant filter paper used for diesel filter and preparation method thereof

ActiveCN102877368AHigh temperature resistant and flame retardantBursting strengthPaper/cardboardFiltration separationBursting strengthCellulose

The invention discloses a high temperature resistant flame retardant filter paper used for a diesel filter and a preparation method thereof. The high temperature resistant flame retardant filter paper comprises the following raw materials in parts by weight: 60-70 parts of wood pulp celluloses, 30-40 parts of vinylon fibers, 10-15 parts of glass fibers, 2-5 parts of dolomite dust, 1-3 parts of nanometer titanium dioxide, 2-4 parts of light calcium carbonate, 1-2 parts of modified nano-carbon, 1-2 parts of nanometer titanium oxide, 0.5-0.8 part of ammonium dihydrogen phosphate, 3-4 parts of modified water-soluble phenolic resin emulsion, 2-5 parts of styrene-acrylic emulsion, 0.5-1 part of diethanolamide, 0.5-1 part of silane coupling agent KH550, 0.4-0.8 part of sodium laurylsulfate and 4-6 parts of a wet strength agent. The filter paper, prepared by the invention, has the advantages of good water permeability, large filtering area, small maximum aperture, high filtering precision, strong bursting strength, high temperature resistance and flame resistance, the filtering efficiency is 99.999%, the filter paper has stable performance index at normal temperature and high temperature, and better temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

Balloon catheter device

InactiveUS20070055301A1Bursting strengthAid in insertion and withdrawalStentsBalloon catheterBalloon catheterUniform size

Owner:WL GORE & ASSOC INC

Zirconium oxide-loaded silicone air filtration paper and preparation method thereof

ActiveCN102888785AImprove adsorption capacityImprove filtering effectFiltration separationInorganic compound additionAir filtrationFiber

The invention discloses zirconium oxide-loaded silicone air filtration paper and a preparation method thereof. The air filtration paper comprises the following raw materials in part by weight: 70 to 80 parts of wood pulp, 20 to 30 parts of jute pulp, 10 to 20 parts of ceramic fiber, 2 to 5 parts of modified silicone, 1 to 3 parts of nano calcium carbonate, 2 to 4 parts of activated carbon, 1 to 2 parts of nano aluminium oxide, 0.5 to 0.8 part of ammonium polyphosphate, 2 to 3 parts of acrylic latex, 1 to 2 parts of polyethylene glycol, 0.5 to 1 part of tricresyl phosphate, 0.5 to 1 part of anilmomethyl triethoxy silane, 0.4 to 0.8 part of sodium lauryl sulfate and 2 to 5 parts of modified polyethyleneimine. The prepared filtration paper has the advantages of high water permeability, filtration accuracy, bursting strength and tensile strength, large filtration area, high temperature resistance and the like, the maximum aperture is small, and the filtration efficiency reaches 99.98 percent; and the filtration paper has a stable performance index under the working conditions of normal temperature and high temperature and has relatively good heat resistance and filtration effects.

Owner:ANHUI PHOENIX INT CO LTD

Balloon catheter device

InactiveUS20070061000A1Bursting strengthAid in insertion and withdrawalStentsBalloon catheterBursting strengthAngioplasty balloon

Owner:WL GORE & ASSOC INC

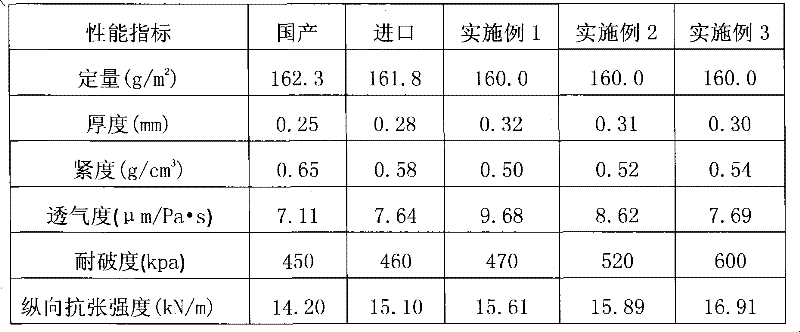

Hot-pressing tympan paper and manufacturing method thereof

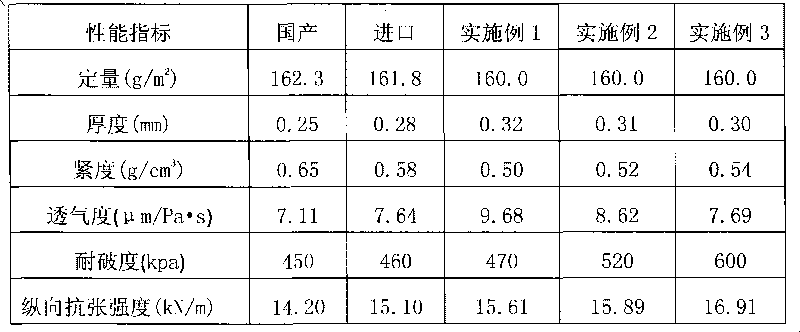

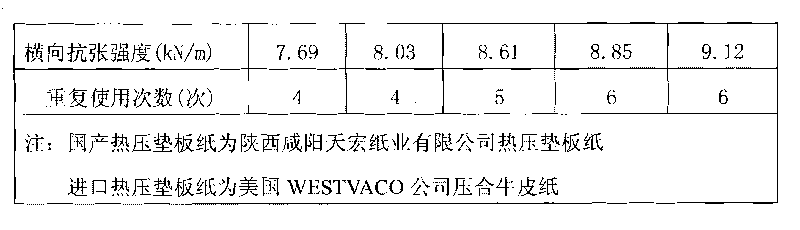

ActiveCN101736629ABursting strengthGood surface smoothnessSpecial paperPaper/cardboardFiberBursting strength

The invention provides hot-pressing tympan paper and a manufacturing method thereof. The hot-pressing tympan paper is composed of a surface layer, a core layer and a bottom layer, wherein, the oven dry stock weight of the surface layer accounts for 20-30% of the total oven dry stock weight, the oven dry stock weight of unbleached pulp used by the bottom layer is the same as the oven dry stock weight of batter, the oven dry stock weight of unbleached pulp and coal ash fiber slurry used in a core layer accounts for 40-60% of the total oven dry stock weight, and the oven dry weight ratio of unbleached pulp to coal ash fiber slurry is 25-40:60-75. The method is characterized in that a multi-layer manufacturing technique of the core layer containing coal ash fiber is adopted to generate hot-pressing tympan paper, compared with a manufacturing technique adopted by current hot-pressing tympan paper, the produced hot-pressing tympan paper has the advantages of level surface, large bursting strength, strong buffering capacity, good temperature tolerance, good temperature conductivity and the like.

Owner:CHINA HAISUM ENG

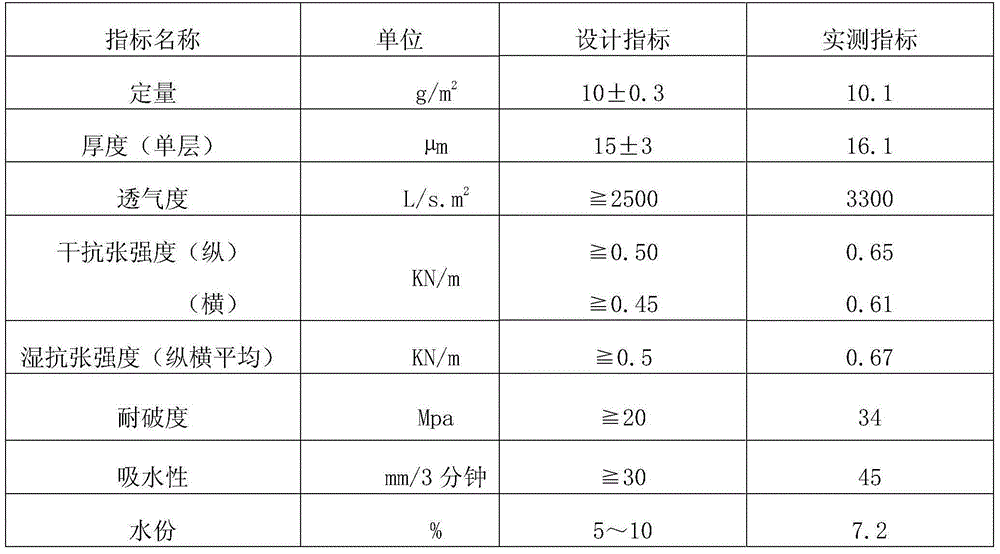

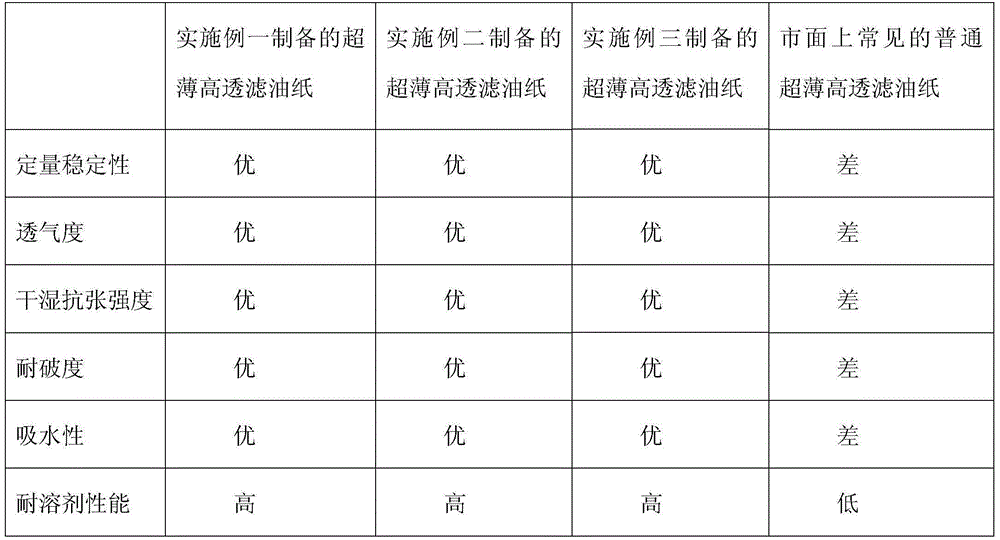

Ultrathin high-permeability oil filter paper and production method thereof

ActiveCN105220573AQuantitative lowQuantitatively stableReinforcing agents additionPaper/cardboardPapermakingFilter paper

The invention relates to an ultrathin high-permeability oil filter paper and a preparation method thereof. The filter paper is prepared with the raw materials of hemp pulp, chemical fiber, a wet strength agent and bamboo charcoal powder. Through the steps of pulp beating treatment, auxiliary agent addition, bamboo charcoal powder addition, papermaking and cutting, the ultrathin high-permeability oil filter paper is obtained. The filter paper and the production method have the following advantages: the produced ultrathin high-permeability oil filter paper is ultrathin and has low basis weight; the produced paper has stable basis weight, high air permeability, good filtering and absorption performance, good dry and wet strength, good bursting strength, good high-temperature resistance, good folding endurance, good acid and alkali resistances, good solvent resistance, and good application effect. The filter paper and the production method are suitable for popularization.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

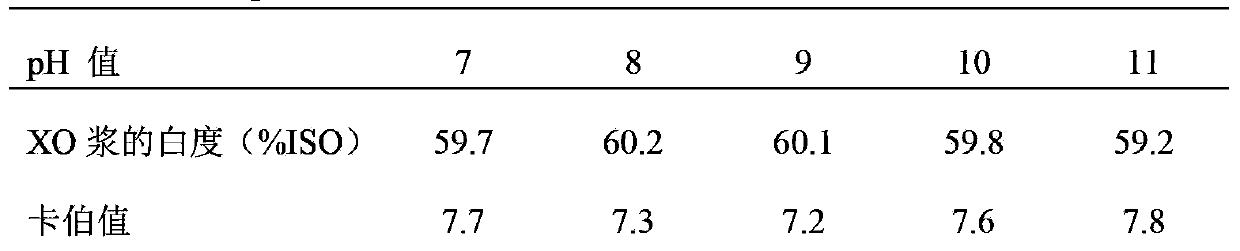

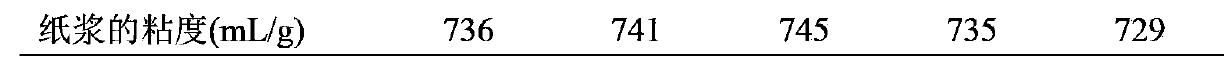

Rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process

ActiveCN103362009AHigh viscosityHigh folding resistancePulp bleachingCellulose material pulpingXylanasePre treatment

The invention discloses a rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process. The process is characterized in that the process comprises the steps that: (1) steaming is carried out, wherein rapid-growth poplar wood sheets are steamed in a steaming pot, such that an original pulp is obtained; washing and screening are carried out, such that paper pulp is obtained; (2) xylanase pretreatment is carried out; (3) TCF bleaching is carried out, wherein the treated paper pulp is bleached with one of the bleaching sequence selected from OP-Q-P, O1-O2P-Q-P and O1P-O2P-Q-P. According to the invention, paper pulp is pretreated by using xylanase, and bleaching is carried out with one of the three bleaching sequences of XOPQP, XO1O2PQP and XO1PO2PQP, such that paper pulp with higher whiteness and viscosity are obtained. Compared with paper pulp obtained by direct bleaching without xylanase pretreatment, the paper pulp provided by the invention has lower beating whiteness loss. A folding resistance is higher by 30-49 times, a burst index is higher by 0.3-0.6N.m.g<-1>, a breaking length is higher by 0.15-0.36KM, and a tearing index is not significantly changed. When a same or similar beating degree is reached, needed beating revolutions are less, and beating energy consumption can be saved by approximately 17.8%.

Owner:QILU UNIV OF TECH

Production method of waterproof wear-resistant homogeneous dual-layer corrugated enhanced paperboard

InactiveCN108115990AGood waterproof and wear-resistant effectImprove toughnessMechanical working/deformationLamination ancillary operationsFiberCardboard

The invention discloses a production method of a waterproof wear-resistant homogeneous dual-layer corrugated enhanced paperboard. Silanization modification is conducted in emulsified asphalt modifiedby neoprene latex, the elasticity and wear resistance of silica sol and the water resistance of the emulsified asphalt are effectively combined, and waterproof wear-resistant glue excellent in waterproof and wear-resistant performance is obtained; the glue is used for coating modification of the inner surface and the outer surface of a corrugated paperboard, the glue is pressed into fiber pits andpores of the corrugated paperboard through a high-temperature and high-pressure processing technology, and the glue is combined with fiber to form a compact and firm waterproof wear-resistant layer;in the dynamic transporting process, the coating scratching phenomenon can be effectively reduced, and meanwhile waterproofing is effectively achieved. Two corrugated paper cores coated with the waterproof wear-resistant glue are combined through a corrugated paper core coinciding technology, homogeneous dual-layer real-time combining and corrugating are achieved, processing time can be saved andproduction cost can be reduced compared with an ordinary corrugated paperboard technology, and meanwhile the toughness, strength and waterproof performance of the corrugated paperboard are further enhanced.

Owner:ANHUI HONGSHI OPTOELECTRONICS HIGH TECH CO LTD

Impregnation liquid and transparent paper sheets prepared from impregnation liquid as well as method for rapidly preparing transparent paper sheets

ActiveCN107022924ASimple ingredientsRich sourcesSurfactants additionNon-macromolecular organic additionBursting strengthPulp and paper industry

The invention discloses impregnation liquid and transparent paper sheets prepared from the impregnation liquid as well as a method for rapidly preparing the transparent paper sheets. The impregnation liquid disclosed by the invention is prepared from a transparent agent, a surfactant, a water-resisting agent and a lubricant. The method for rapidly preparing the transparent paper sheets comprises the following steps: putting raw paper into the impregnation liquid and impregnating; taking out the raw paper and fitting the impregnated paper sheets between two pieces of thin film materials; extruding extra surplus impregnation liquid by utilizing an extruding device; then separating the impregnated paper sheets from the thin film materials; after drying the impregnated paper sheets, carrying out calendering treatment to obtain the transparent paper sheets. The impregnation liquid disclosed by the invention has the advantages of simple raw materials, abundant sources and easy preparation; the preparation method disclosed by the invention has the advantages of simple and convenient operation process and easy industrialized production; the paper sheets prepared by the method have good transparency and also has excellent tensile strength, bursting strength, barrier property and water-resisting property.

Owner:广东华顺材料科技有限公司

TCE bleaching technology for sulfate pulp of growing poplar by biological chemical method

The invention discloses a TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method. The technology comprises the following steps: (1), cooking: getting fast-growing polar pieces; putting the fast-growing polar pieces into a distilling pan for cooking, so as to obtain primary pulp, and then washing and screening the primary pulp to obtain paper pulp; (2), pre-treating the paper pulp with xylanase; (3), TCE bleaching: bleaching the paper pulp pre-treated with the xylanase, wherein the bleaching process is one of OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P. According to the TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method, the xylanase is adopted to pre-treat the paper pulp, then one of the bleaching processes OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P is adopted for bleaching, so that the paper pulp with higher whiteness and viscosity is obtained; compared with the paper pulp obtained through directly bleaching without xylanase pre-treatment, the paper pulp provided by the invention has the advantages that the loss value of whiteness is lesser, the folding strength is higher 45 times averagely, the bursting index is higher 0.45 N*m*g <-1> averagely, the breaking length is higher 0.35 KM, and the tearing index is quite. The beating revolution number is lesser when the paper pulp reaches the same or similar beating degree, and the 20% of beating energy consumption can be saved approximately.

Owner:QILU UNIV OF TECH

Papery food packaging bag and preparing method

InactiveCN1600649ABursting strengthImprove protectionWater-repelling agents additionDryer sectionFiberPulp and paper industry

Owner:蔡明哲

Starch-based fully-degradable nano antibacterial material and preparation method thereof

The invention discloses a starch-based fully-degradable nano antibacterial material and a preparation method thereof. The starch-based fully-degradable nano antibacterial material is prepared from thefollowing substances in parts by weight: 80 to 100 parts of starch, 5 to 50 parts of plant fibers, 0.1 to 3 parts of nano chitosan, 0.01 to 0.1 part of carbon nanotubes, 0.001 to 0.1 part of cellulose nanocrystals, 0.1 to 1 part of a surfactant and 65 to 200 parts of water. According to the invention, a plurality of methods such as starch modification, nano chitosan, carbon nanotubes, cellulose nanocrystalline, plant fiber modification, injection molding, micro-explosion foaming and the like are combined to obtain the light-weight, antibacterial and fully-degradable nano material; meanwhile,the material has stronger pressure resistance and bursting strength than common starch products; the whole production process is free of wastewater, waste gas and waste residues, safe and environment-friendly.

Owner:上海麟定生物科技有限公司

High-temperature resistant fuel oil filter paper and preparation method thereof

ActiveCN102912683AHigh filtration precisionHigh tensile strengthNon-macromolecular organic additionPaper/cardboardFiberPolyvinyl alcohol

The invention discloses high-temperature resistant fuel oil filter paper and a preparation method thereof. The high-temperature resistant fuel oil filter paper comprises, by weight, 70-80 parts of hardwood pulp, 20-30 parts of polybenzimidazole fiber, 10-20 parts of modified activated carbon fiber, 2-5 parts of modified kaoline, 1-3 parts of nano calcium carbonate, 2-4 parts of silica gel, 1-2 parts of nano titania, 0.5-0.8 part of decabromodiphenyl ethane, 2-3 parts of polyvinyl acetate emulsion, 1-2 parts of polyvinyl alcohol, 0.5-1 part of n-butyl methacrylate, 0.5-1 part of phenyl-triethoxysilane, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of polyethyleneimine. The high-temperature resistant fuel oil filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and tensile strength and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, filtering efficiency of the high-temperature resistant fuel oil filter paper can reach 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

Papery food packaging bag

InactiveCN100377972CBursting strengthImprove protectionWater-repelling agents additionDryer sectionFiberPulp and paper industry

Owner:蔡明哲

Preparation method of heat-resistant latex abrasive paper raw paper

InactiveCN108951265AEasy accessBursting strengthNon-macromolecular organic additionPaper/cardboardBursting strengthDiacetone alcohol

The invention discloses heat-resistant latex abrasive paper raw paper. The heat-resistant latex abrasive paper raw paper contains the following raw materials in parts by weight: 14 parts of a hydroxypolyacrylate emulsion, 5 parts of a cellulose acetate butyrate solution, 30 parts of bleached sulfate softwood pulp, 26 parts of broad-leaf blenched chemical wood pulp, 5 parts of a PVM / MA copolymer,6 parts of diacetone alcohol, 2.5 parts of an aqueous polyisocyanate solidifying agent, 5 parts of polyacrylamide, 14 parts of a 900-mesh environment-friendly pigment, 6 parts of talcum powder, 5 parts of an aid and 7 parts of a flame retardant. The invention further discloses a manufacturing method of the heat-resistant latex abrasive paper raw paper. The required materials are easily available,and the prepared heat-resistant latex abrasive paper raw paper has good bursting strength, folding strength, water absorption value and heat resistance.

Owner:枣庄市天龙纸业有限公司

High temperature resistant flame retardant filter paper for diesel filter and preparation method thereof

ActiveCN102877368BHigh temperature resistant and flame retardantBursting strengthPaper/cardboardFiltration separationFiberCellulose

The invention discloses a high temperature resistant flame retardant filter paper used for a diesel filter and a preparation method thereof. The high temperature resistant flame retardant filter paper comprises the following raw materials in parts by weight: 60-70 parts of wood pulp celluloses, 30-40 parts of vinylon fibers, 10-15 parts of glass fibers, 2-5 parts of dolomite dust, 1-3 parts of nanometer titanium dioxide, 2-4 parts of light calcium carbonate, 1-2 parts of modified nano-carbon, 1-2 parts of nanometer titanium oxide, 0.5-0.8 part of ammonium dihydrogen phosphate, 3-4 parts of modified water-soluble phenolic resin emulsion, 2-5 parts of styrene-acrylic emulsion, 0.5-1 part of diethanolamide, 0.5-1 part of silane coupling agent KH550, 0.4-0.8 part of sodium laurylsulfate and 4-6 parts of a wet strength agent. The filter paper, prepared by the invention, has the advantages of good water permeability, large filtering area, small maximum aperture, high filtering precision, strong bursting strength, high temperature resistance and flame resistance, the filtering efficiency is 99.999%, the filter paper has stable performance index at normal temperature and high temperature, and better temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

Fruit-protecting bag and its making method

InactiveCN1141013CImprove shadingWeatherproofPaper/cardboardPlant protective coveringsFiberEngineering

A fruit-protecting bag for protecting growth of fruits is made up from paper pulp through digestion, bleaching, filtering, mixing it with durable non-toxic or low-toxin antibacterial chemical, stirring, making paper, baking and making the fruit-protecting bags. Its advantages include no need of spraying agricultural chemical, and high light shielding, wind and rain resistance, hydrophobicity and air permeability.

Owner:蔡秒水 +1

A kind of dipping liquid and the transparent paper prepared by it and the method for rapidly preparing transparent paper

ActiveCN107022924BSimple ingredientsRich sourcesSurfactants additionNon-macromolecular organic additionBursting strengthPulp and paper industry

The invention discloses impregnation liquid and transparent paper sheets prepared from the impregnation liquid as well as a method for rapidly preparing the transparent paper sheets. The impregnation liquid disclosed by the invention is prepared from a transparent agent, a surfactant, a water-resisting agent and a lubricant. The method for rapidly preparing the transparent paper sheets comprises the following steps: putting raw paper into the impregnation liquid and impregnating; taking out the raw paper and fitting the impregnated paper sheets between two pieces of thin film materials; extruding extra surplus impregnation liquid by utilizing an extruding device; then separating the impregnated paper sheets from the thin film materials; after drying the impregnated paper sheets, carrying out calendering treatment to obtain the transparent paper sheets. The impregnation liquid disclosed by the invention has the advantages of simple raw materials, abundant sources and easy preparation; the preparation method disclosed by the invention has the advantages of simple and convenient operation process and easy industrialized production; the paper sheets prepared by the method have good transparency and also has excellent tensile strength, bursting strength, barrier property and water-resisting property.

Owner:广东华顺材料科技有限公司

A kind of silica gel loaded zirconia air filter paper and preparation method thereof

ActiveCN102888785BImprove adsorption capacityImprove filtering effectFiltration separationInorganic compound additionAir filtrationFiber

The invention discloses zirconium oxide-loaded silicone air filtration paper and a preparation method thereof. The air filtration paper comprises the following raw materials in part by weight: 70 to 80 parts of wood pulp, 20 to 30 parts of jute pulp, 10 to 20 parts of ceramic fiber, 2 to 5 parts of modified silicone, 1 to 3 parts of nano calcium carbonate, 2 to 4 parts of activated carbon, 1 to 2 parts of nano aluminium oxide, 0.5 to 0.8 part of ammonium polyphosphate, 2 to 3 parts of acrylic latex, 1 to 2 parts of polyethylene glycol, 0.5 to 1 part of tricresyl phosphate, 0.5 to 1 part of anilmomethyl triethoxy silane, 0.4 to 0.8 part of sodium lauryl sulfate and 2 to 5 parts of modified polyethyleneimine. The prepared filtration paper has the advantages of high water permeability, filtration accuracy, bursting strength and tensile strength, large filtration area, high temperature resistance and the like, the maximum aperture is small, and the filtration efficiency reaches 99.98 percent; and the filtration paper has a stable performance index under the working conditions of normal temperature and high temperature and has relatively good heat resistance and filtration effects.

Owner:ANHUI PHOENIX INT CO LTD

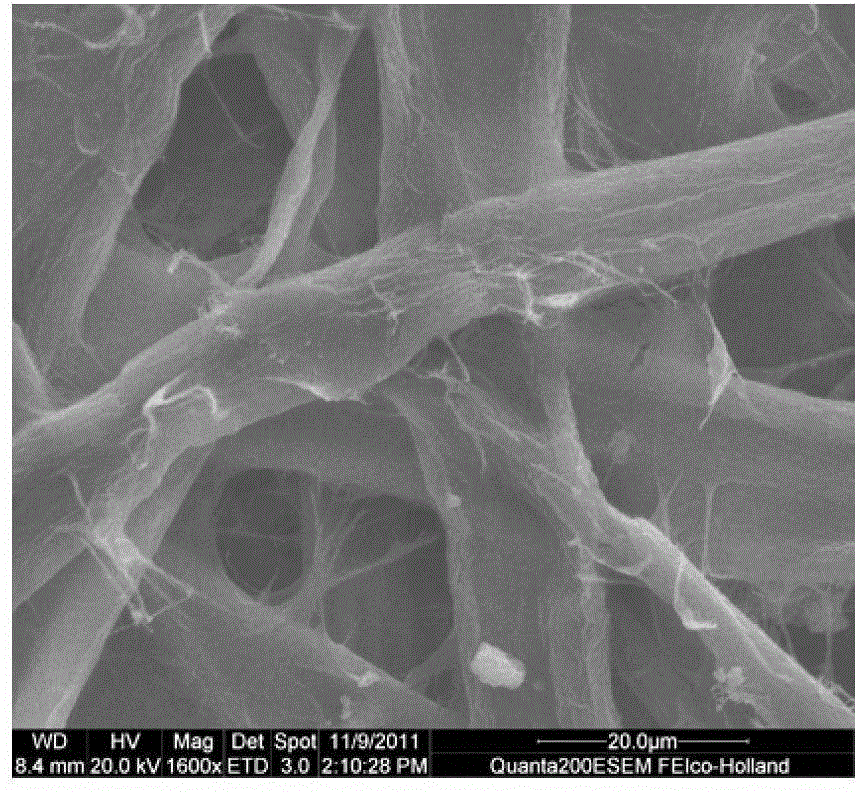

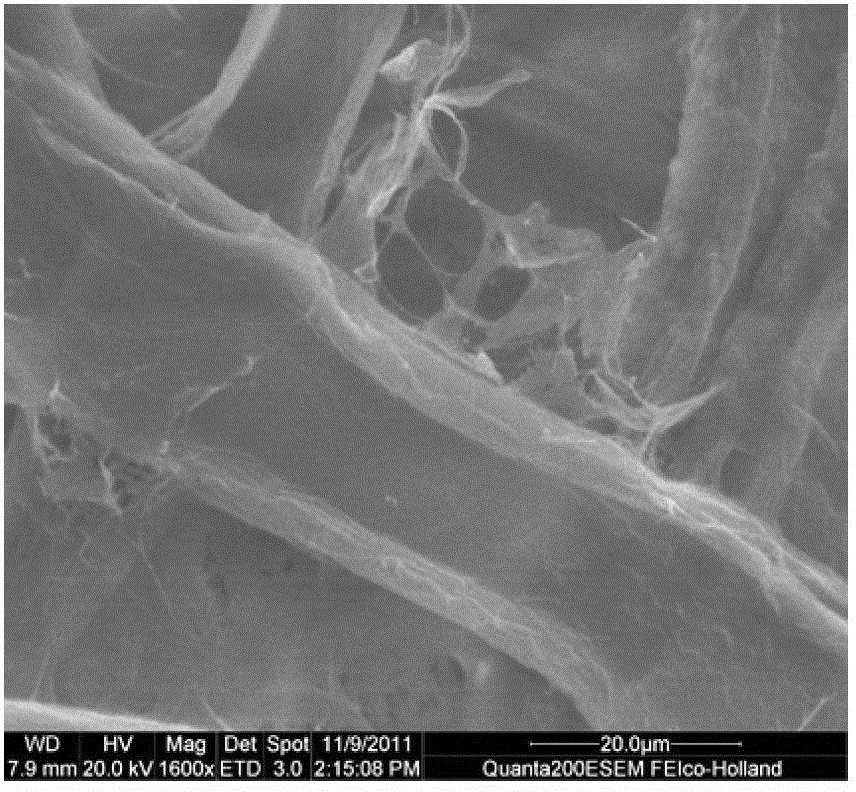

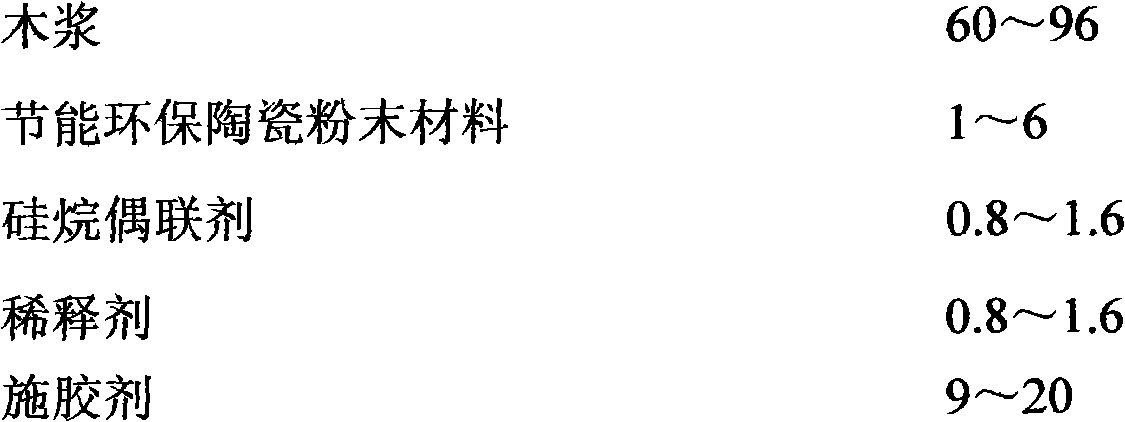

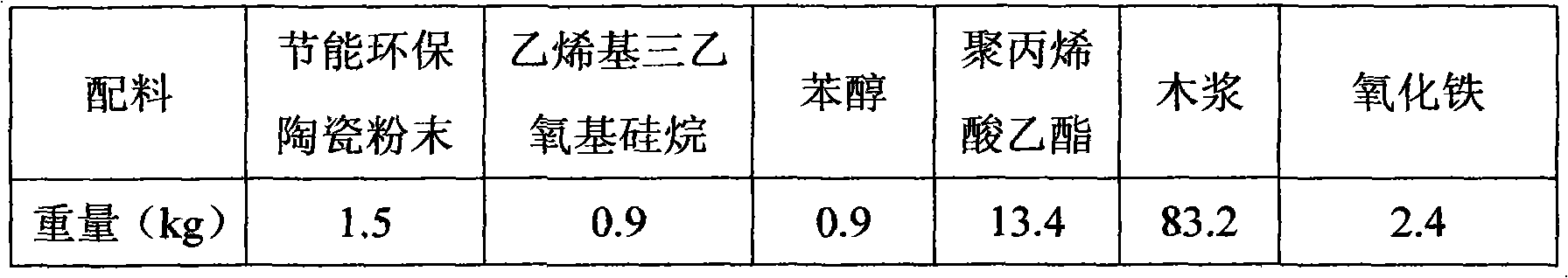

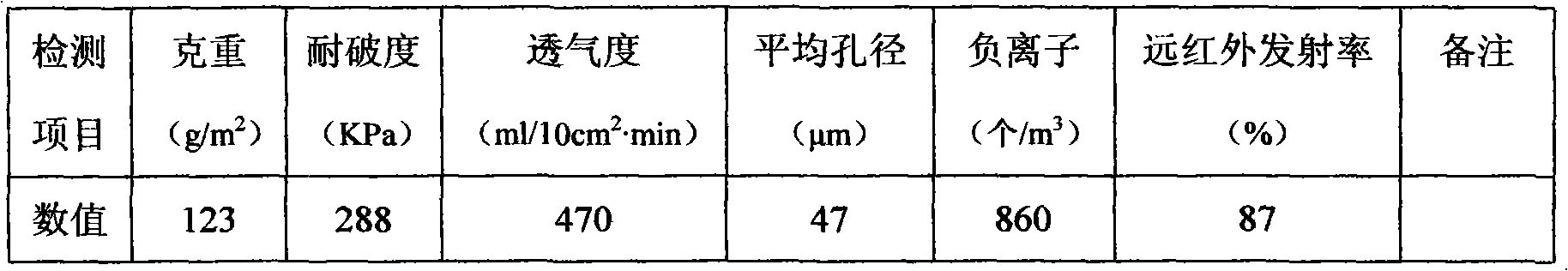

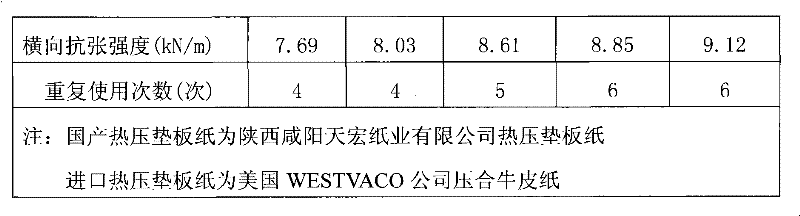

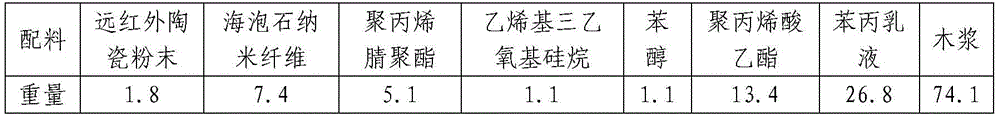

Filter paper of energy-saving and environment-friendly filter and making method thereof

ActiveCN102199903BIt has the function of radiation related frequency far infrared raySimple preparation processFiltration separationFilter paperFuel conservationAir filter

The invention relates to filter paper of an energy-saving and environment-friendly filter and a making method thereof. The filter paper is made from an energy-saving and environment-friendly ceramic powder material, a silane coupling agent, a dilute, a sizing agent and wood pulp. The filter paper can be made into an air filter and a fuel filter so as to improve the power performance by 6-12%, save the fuel by 2-5% and reduce pollutants in discharged tail gas by 16-47%.

Owner:北京联飞翔科技股份有限公司

TCE bleaching technology for sulfate pulp of growing poplar by biological chemical method

The invention discloses a TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method. The technology comprises the following steps: (1), cooking: getting fast-growing polar pieces; putting the fast-growing polar pieces into a distilling pan for cooking, so as to obtain primary pulp, and then washing and screening the primary pulp to obtain paper pulp; (2), pre-treating the paper pulp with xylanase; (3), TCE bleaching: bleaching the paper pulp pre-treated with the xylanase, wherein the bleaching process is one of OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P. According to the TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method, the xylanase is adopted to pre-treat the paper pulp, then one of the bleaching processes OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P is adopted for bleaching, so that the paper pulp with higher whiteness and viscosity is obtained; compared with the paper pulp obtained through directly bleaching without xylanase pre-treatment, the paper pulp provided by the invention has the advantages that the loss value of whiteness is lesser, the folding strength is higher 45 times averagely, the bursting index is higher 0.45 N*m*g <-1> averagely, the breaking length is higher 0.35 KM, and the tearing index is quite. The beating revolution number is lesser when the paper pulp reaches the same or similar beating degree, and the 20% of beating energy consumption can be saved approximately.

Owner:QILU UNIV OF TECH

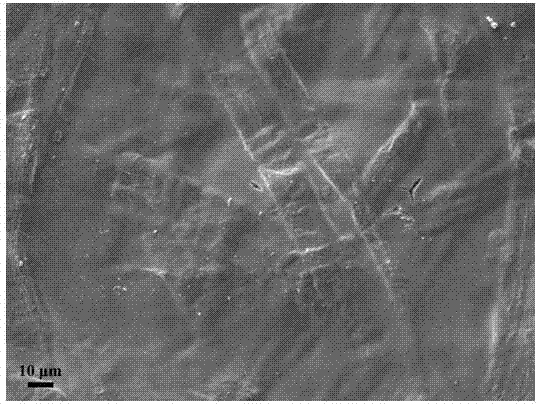

Water-resistant transparent paper as well as preparation method and application thereof

ActiveCN113123158AImprove wet strengthAchieve water resistance and transparencyNon-macromolecular organic additionPulping with halogen compoundsPaper sheetPaper manufacturing

The invention relates to the field of special paper manufacturing, in particular to water-resistant transparent paper as well as a preparation method and application thereof. The cellulose water-resistant transparent paper with the fiber diameter of 5-999 nm is provided, the fibers are mutually entangled and do not depend on the maintenance of hydrogen bonds, and the cellulose water-resistant transparent paper still has high wet strength in water. The cellulose molecular structure is not modified, a hydrophobic additive difficult to degrade is not introduced, the influence on a cellulose crystal structure is reduced as far as possible, and the performance of a cellulose-based material is maintained, so that control on cellulose fibers with the diameter as low as 5nm is realized, excessive influence on the transparency of paper is avoided, the transparency can reach 92%, and the balance of water resistance and transparency of the cellulose paper is well realized. The water-resistant paper prepared by the invention is easy to degrade and environment-friendly, has excellent performance and wide application scene, and has good commercial prospect.

Owner:NANJING UNIV

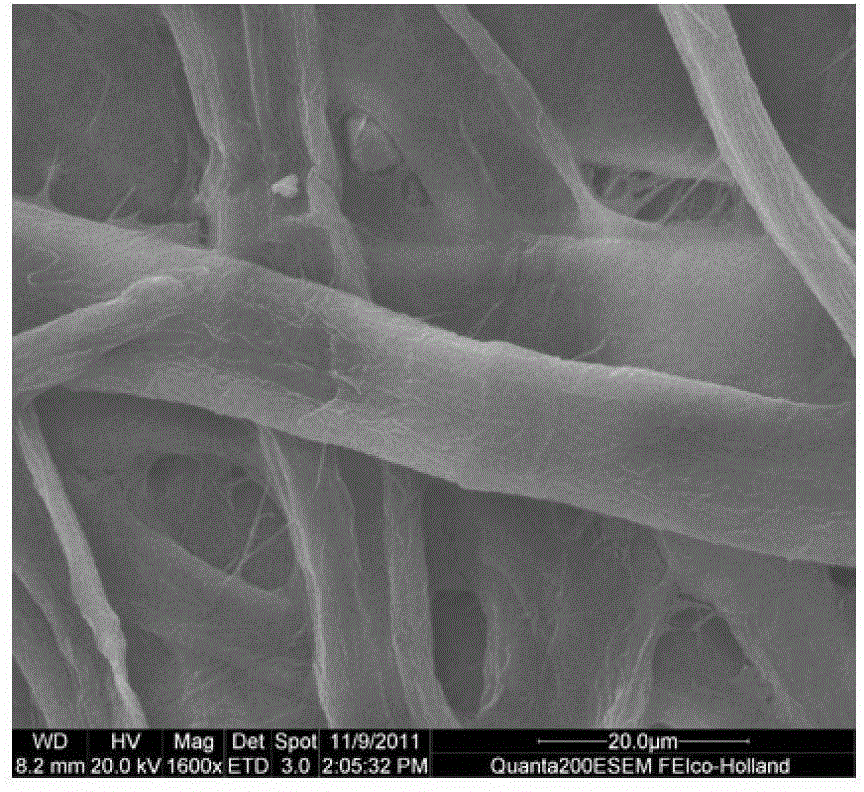

Bamboo load-bearing chitosan industrial filter paper for automobiles and preparation method of bamboo load-bearing chitosan industrial filter paper

ActiveCN102877369BImprove adsorption capacityImprove filtering effectFiltration separationInorganic compound additionFiberNano al2o3

The invention discloses bamboo load-bearing chitosan industrial filter paper for automobiles, which comprises the following raw materials by weight: 50 to 60 parts of bamboo pulp, 40 to 50 parts of polytetrafluoroethylene fiber, 10 to 20 parts of glassfiber, 2 to 5 parts of modified bamboo, 1 to 3 parts of carbon molecular sieve, 2 to 4 parts of light calcium carbonate, 1 to 2 parts of nano alumina, 2 to 3 parts of modified water-soluble nano silica sol, 1 to 2 parts of styrene-acrylic emulsion, 0.5 to 0.8 part of antimony trioxide powder, 3 to 4 parts of dibutyl phthalate, 0.5 to 1 part of fatty alcohol-polyoxyethylene ether, 0.5 to 1 part of silane coupling agent KH792, 0.4 to 0.8 part of sodium laurylsulfate, 0.5 to 1 part of antioxidant 1010 and 4 to 6 parts of wet strength agent PAE. The filter paper prepared according to the invention has the advantages of good water permeability, large filtering area, small maximum pore size, high filtering precision, high temperature resistance, high water resistance and the like; the filtering efficiency reaches 99.96%, the performance index is stable under normal-temperature and high-temperature conditions, and the filter paper has better temperature resistance and a good filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

Hot-pressing tympan paper and manufacturing method thereof

ActiveCN101736629BBursting strengthGood surface smoothnessSpecial paperPaper/cardboardFiberIndustrial engineering

The invention provides hot-pressing tympan paper and a manufacturing method thereof. The hot-pressing tympan paper is composed of a surface layer, a core layer and a bottom layer, wherein, the oven dry stock weight of the surface layer accounts for 20-30% of the total oven dry stock weight, the oven dry stock weight of unbleached pulp used by the bottom layer is the same as the oven dry stock weight of batter, the oven dry stock weight of unbleached pulp and coal ash fiber slurry used in a core layer accounts for 40-60% of the total oven dry stock weight, and the oven dry weight ratio of unbleached pulp to coal ash fiber slurry is 25-40:60-75. The method is characterized in that a multi-layer manufacturing technique of the core layer containing coal ash fiber is adopted to generate hot-pressing tympan paper, compared with a manufacturing technique adopted by current hot-pressing tympan paper, the produced hot-pressing tympan paper has the advantages of level surface, large bursting strength, strong buffering capacity, good temperature tolerance, good temperature conductivity and the like.

Owner:CHINA HAISUM ENG

A kind of automobile filter filter paper coating material and preparation method thereof

ActiveCN103774492BSimple processHigh filtration precisionCoatings with pigmentsWater-repelling agents additionEmission standardFar infrared

Owner:北京联飞翔科技股份有限公司

Water-resistant transparent paper and its preparation method and application

ActiveCN113123158BEasy to degradeEasy to controlNon-macromolecular organic additionPulping with halogen compoundsPolymer sciencePaper manufacturing

The invention relates to the field of special paper manufacturing, in particular to a water-resistant transparent paper and its preparation method and application. The invention provides a cellulose water-resistant transparent paper with a fiber diameter of 5nm to 999nm. The fibers are entangled with each other without relying on the maintenance of hydrogen bonds, and still have high wet strength in water. And without modifying the molecular structure of cellulose, without introducing refractory hydrophobic additives, the impact on the crystal structure of cellulose is minimized, and the performance of the cellulose-based material itself is maintained, thus achieving the goal of reducing the diameter of the cellulose to 5nm. The control of cellulose fibers will not affect the transparency of the paper too much, and the transparency can be as high as 92%, which has achieved a good balance between water resistance and transparency of cellulose paper. The water-resistant paper prepared by the invention is easy to degrade, environmentally friendly, has both superior performance and broad application scenarios, and has good commercial prospects.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com