Patents

Literature

32results about How to "Quantitatively stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diaphragm paper for mercury-free alkaline zinc-manganese dioxide cell, and preparation method of diaphragm paper

ActiveCN104631198AImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingPapermakingManganese

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

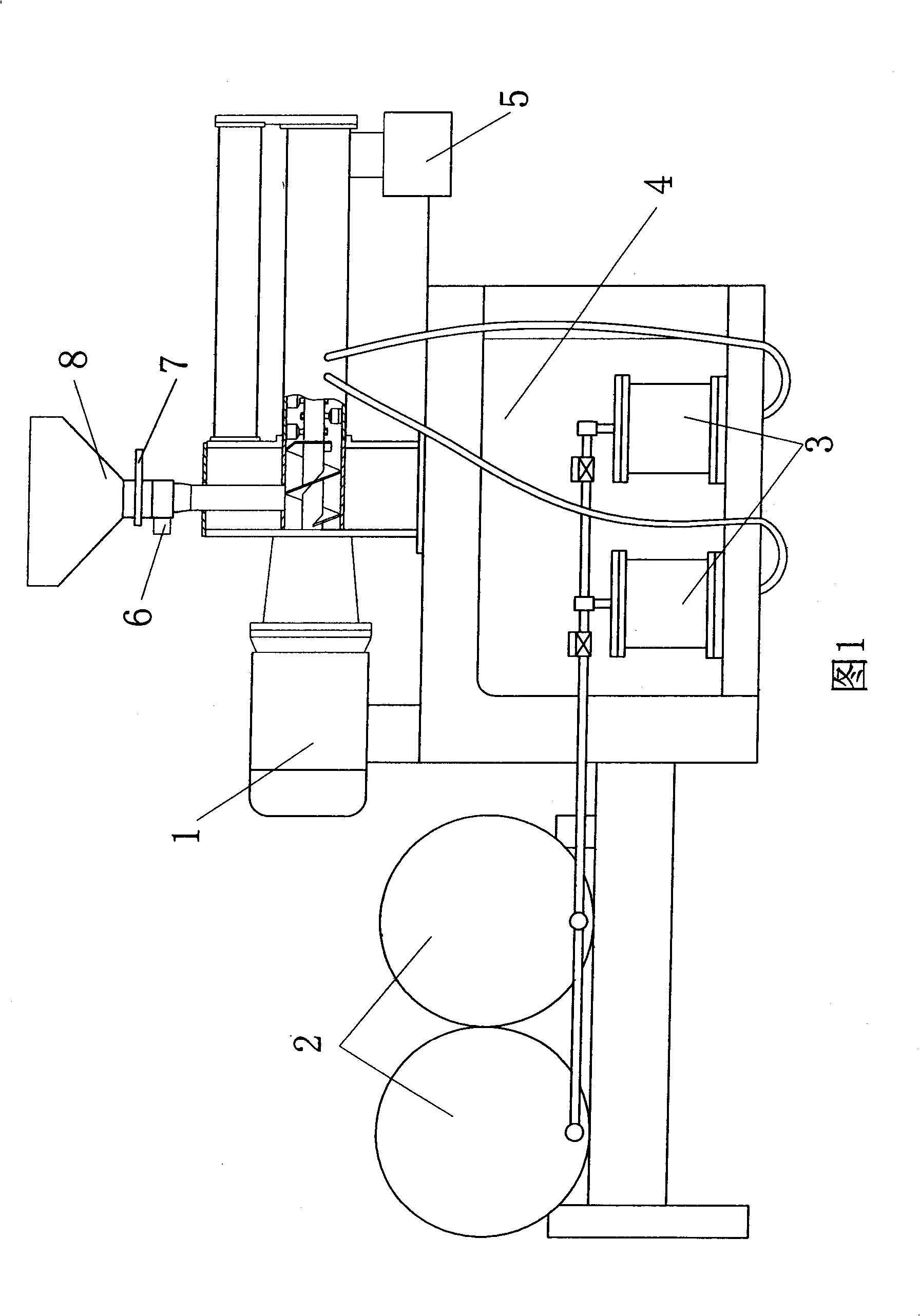

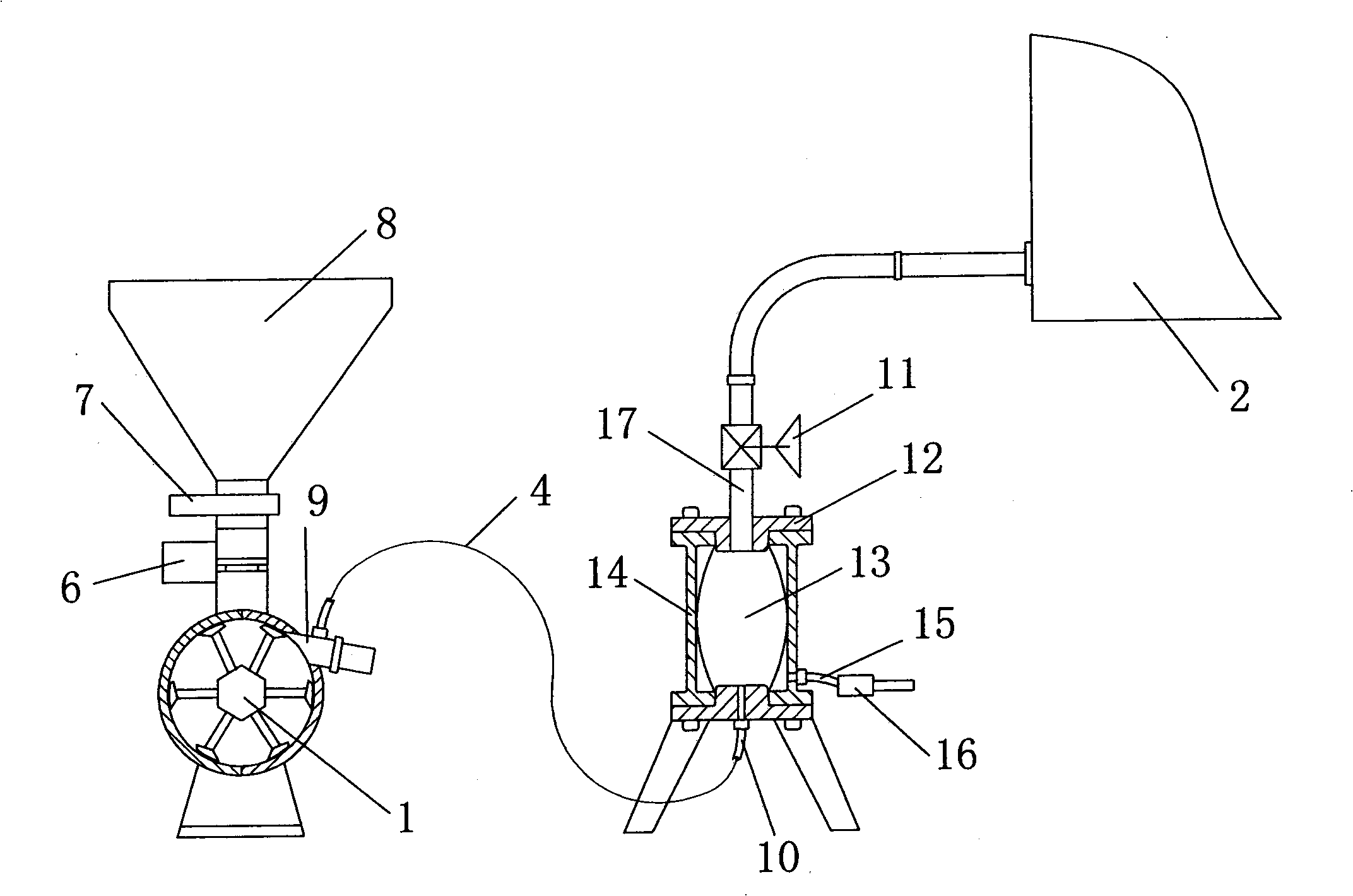

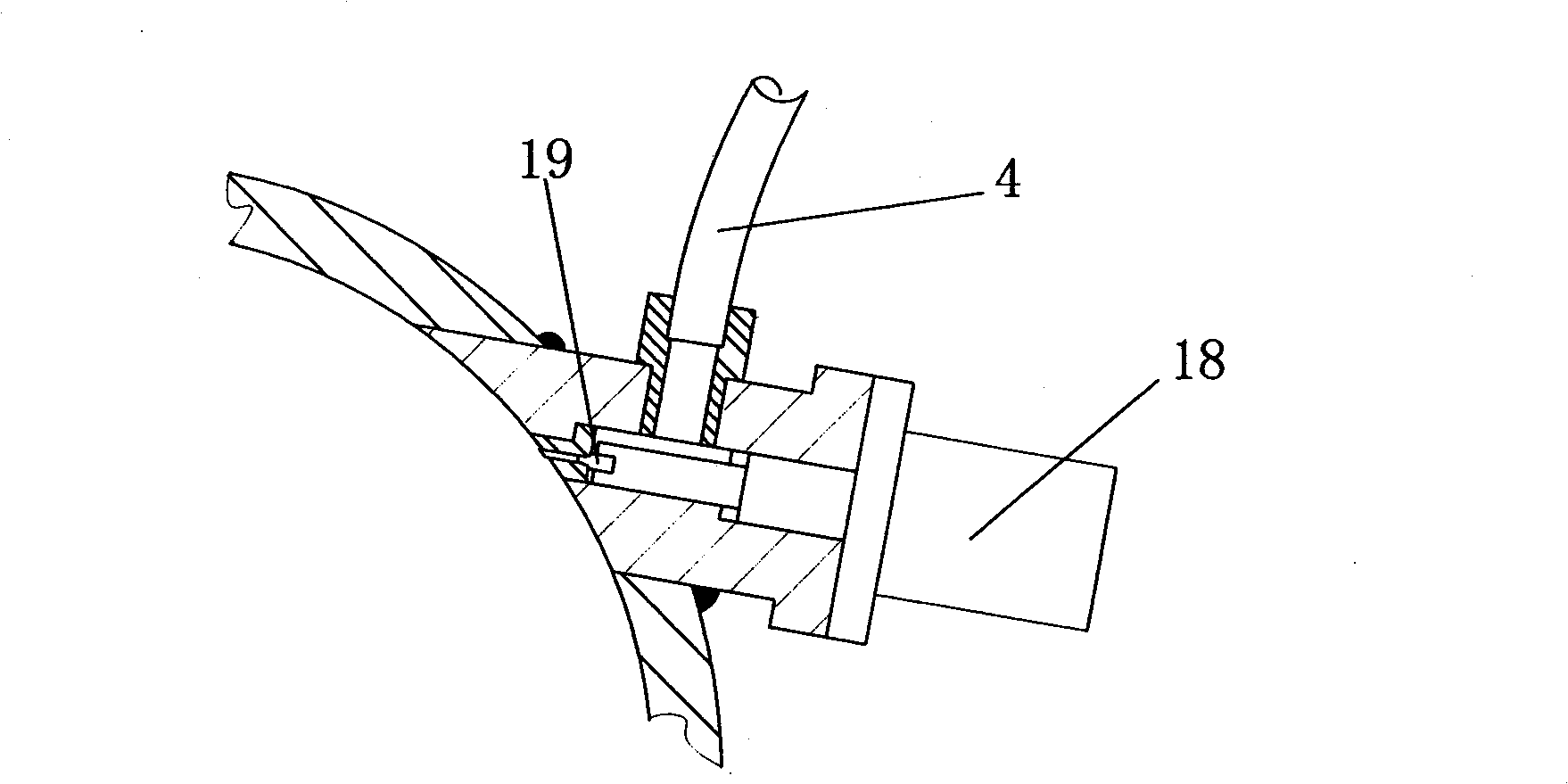

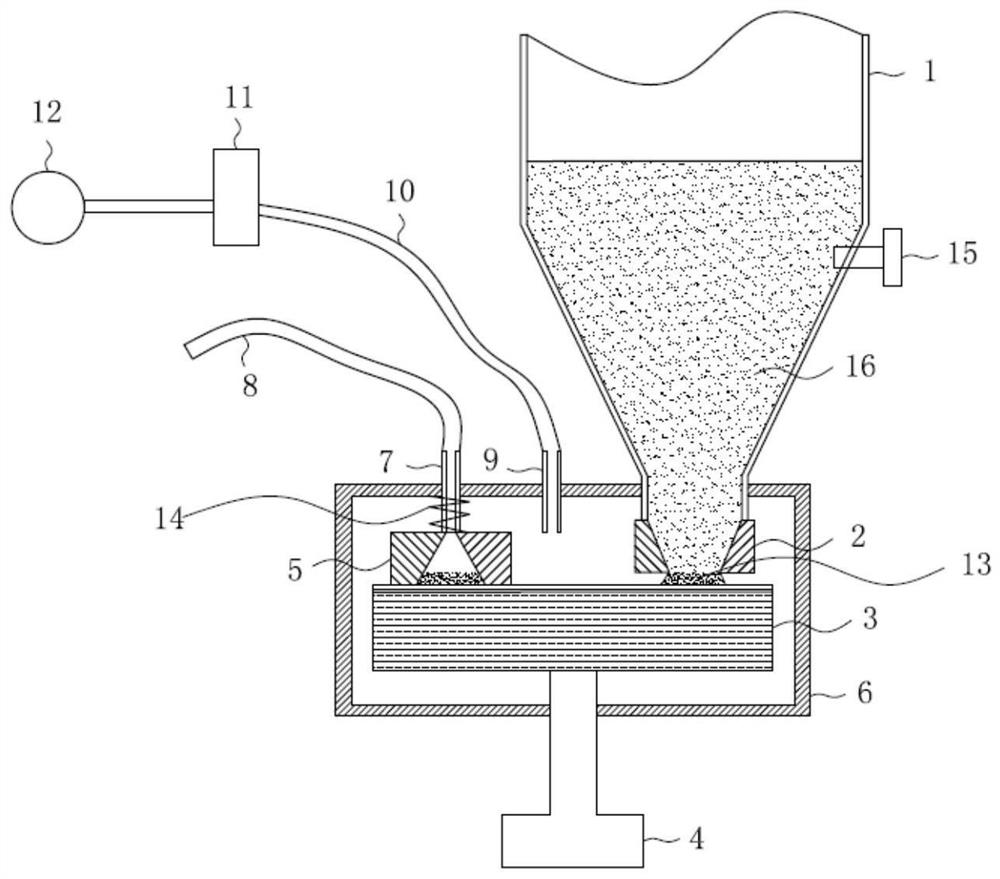

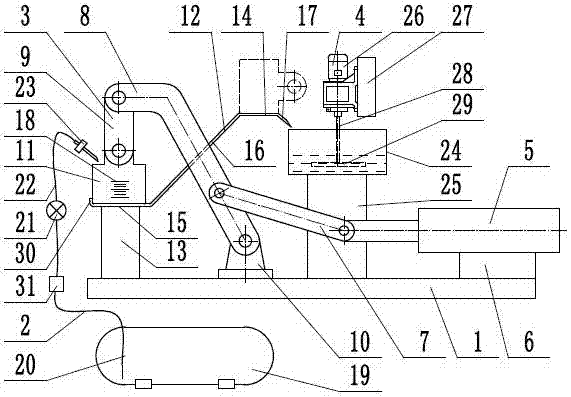

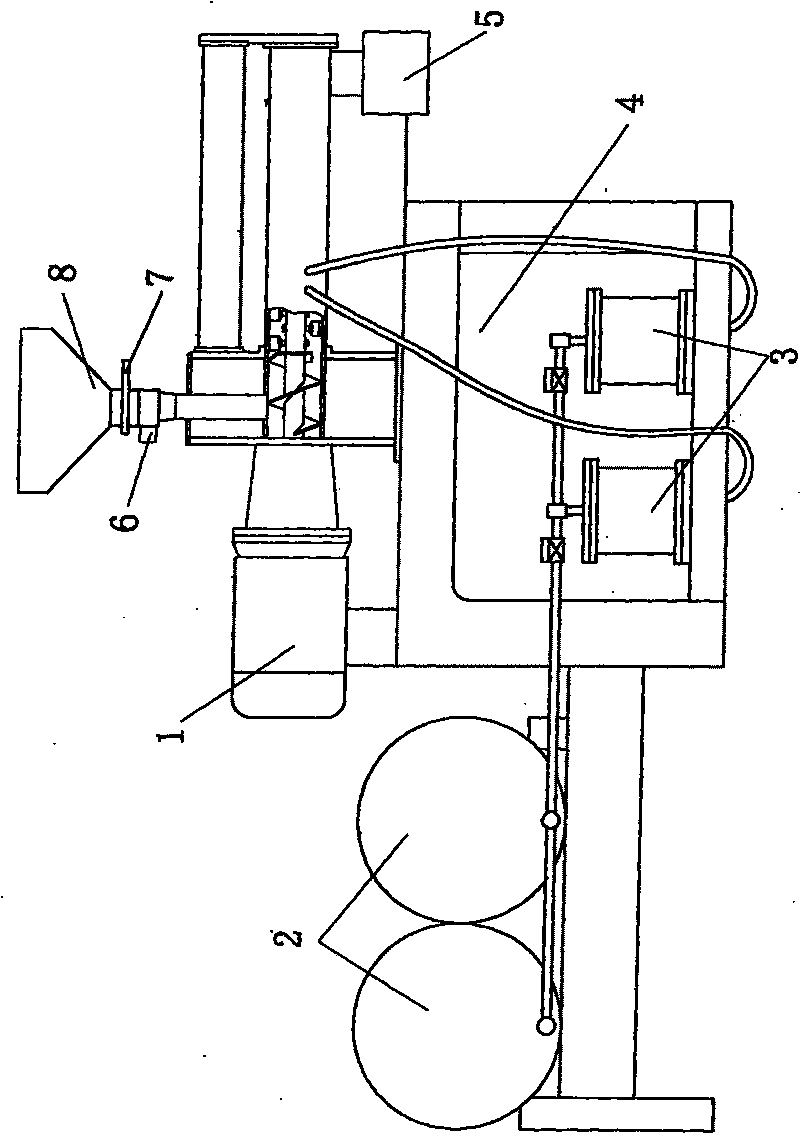

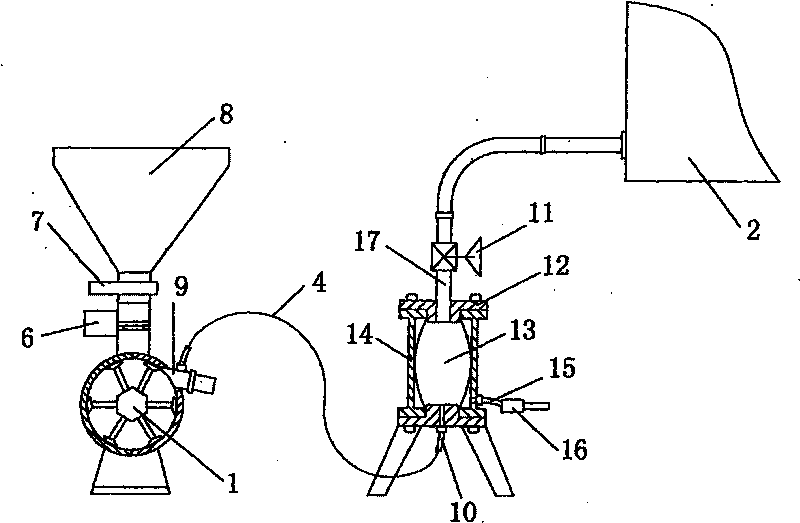

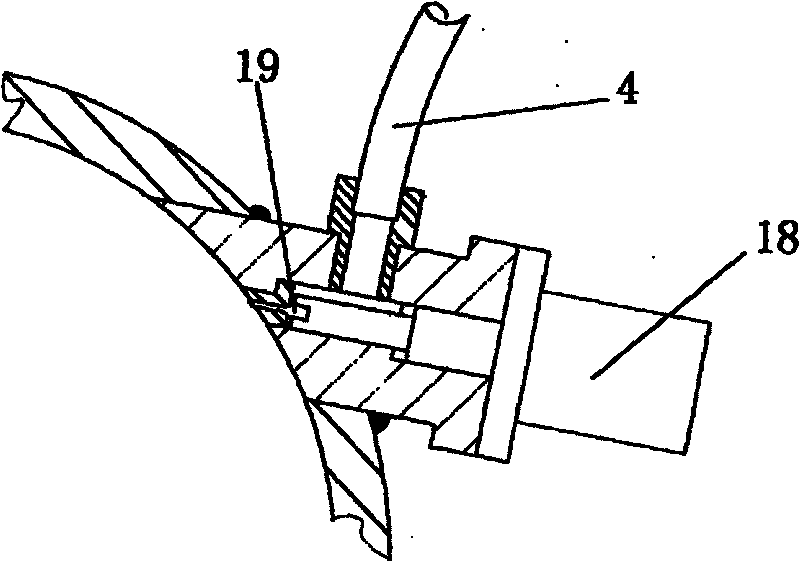

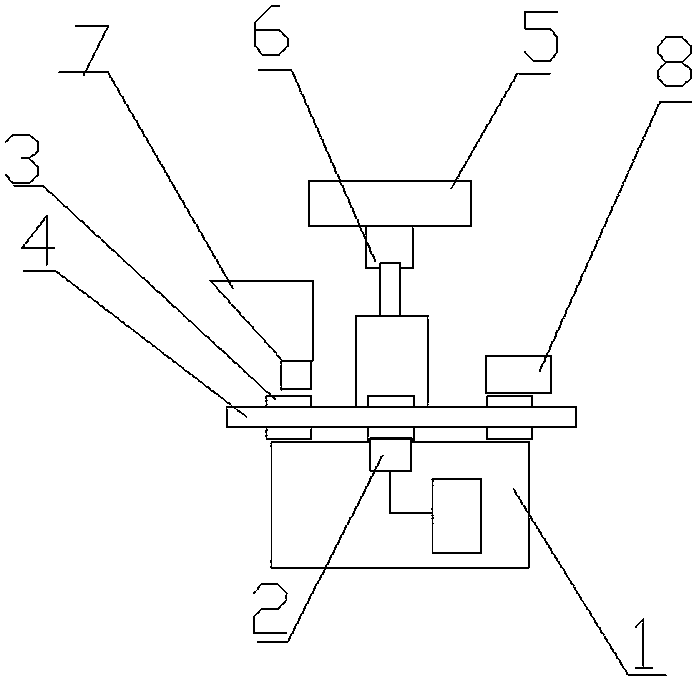

Continuous automatic pug mixer

InactiveCN101347818AHigh viscosityThe amount added is stableMould handling/dressing devicesProportional controlDry sand

The invention provides a continuous automatic sand mixing machine, comprising a sand mixing packing auger, a dry sand bin and an enclosed resin quantitative device; the material inlet of the sand mixing packing auger is connected with the lower mouth of the dry sand bin; the lower mouth of the dry sand bin is provided with a proportion control valve and a sand adding valve; the material outlet of the sand mixing packing auger is provided with a funnel; the shell of the sand mixing packing anger is provided with a resin feeding valve; the enclosed resin quantitative device is connected with the resin feeding valve on the sand mixing packing auger by a delivery pipe; the sand adding valve and the resin feeding valve are connected with the same electromagnetic control valve. The sand adding valve and the resin feeding valve are controlled by the same electromagnetic control valve, thus ensuring the synchronous adding of the dry sand and the resin and ensuring the normal proportion and the strength of sand core. The adopted enclosed resin quantitative device has an anti-oxidation function and can ensure that the resin flux is stable, the quantification is exact and the material inlet of the resin is not blocked.

Owner:济南林青铸造技术有限公司

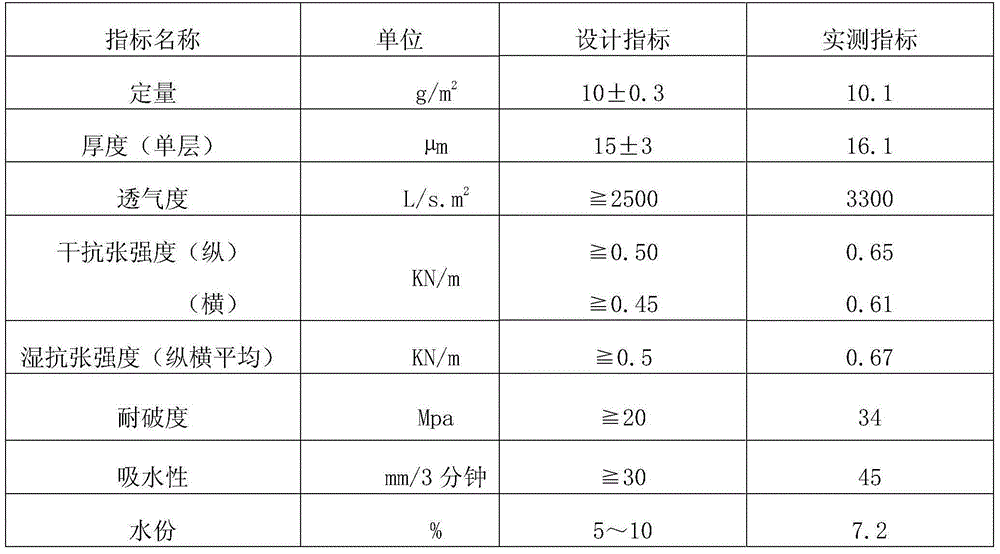

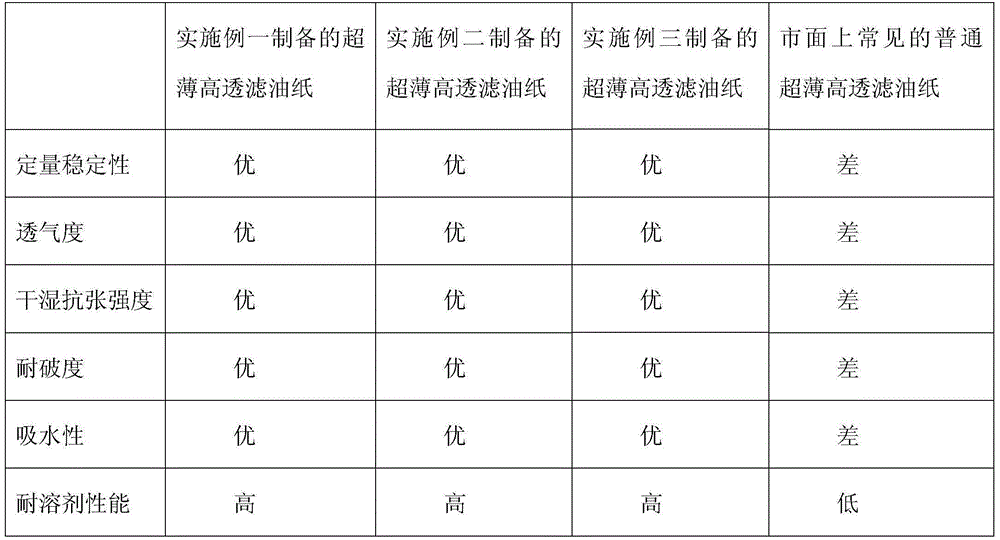

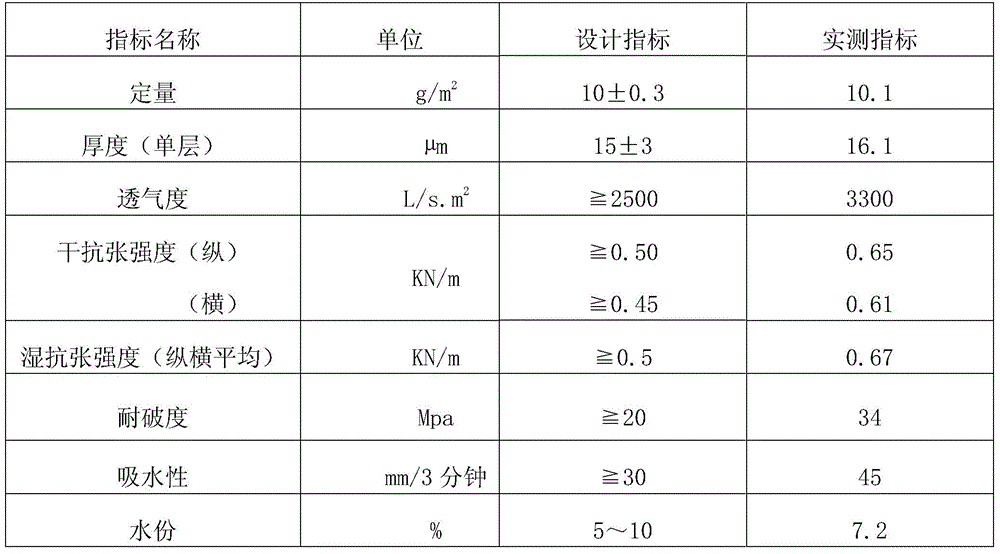

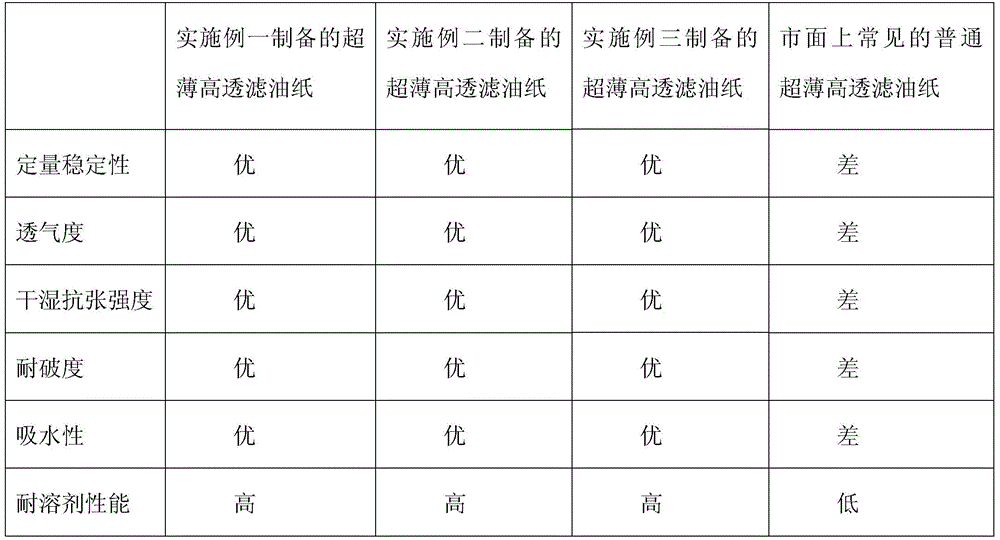

Ultrathin high-permeability oil filter paper and production method thereof

ActiveCN105220573AQuantitative lowQuantitatively stableReinforcing agents additionPaper/cardboardPapermakingFilter paper

The invention relates to an ultrathin high-permeability oil filter paper and a preparation method thereof. The filter paper is prepared with the raw materials of hemp pulp, chemical fiber, a wet strength agent and bamboo charcoal powder. Through the steps of pulp beating treatment, auxiliary agent addition, bamboo charcoal powder addition, papermaking and cutting, the ultrathin high-permeability oil filter paper is obtained. The filter paper and the production method have the following advantages: the produced ultrathin high-permeability oil filter paper is ultrathin and has low basis weight; the produced paper has stable basis weight, high air permeability, good filtering and absorption performance, good dry and wet strength, good bursting strength, good high-temperature resistance, good folding endurance, good acid and alkali resistances, good solvent resistance, and good application effect. The filter paper and the production method are suitable for popularization.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

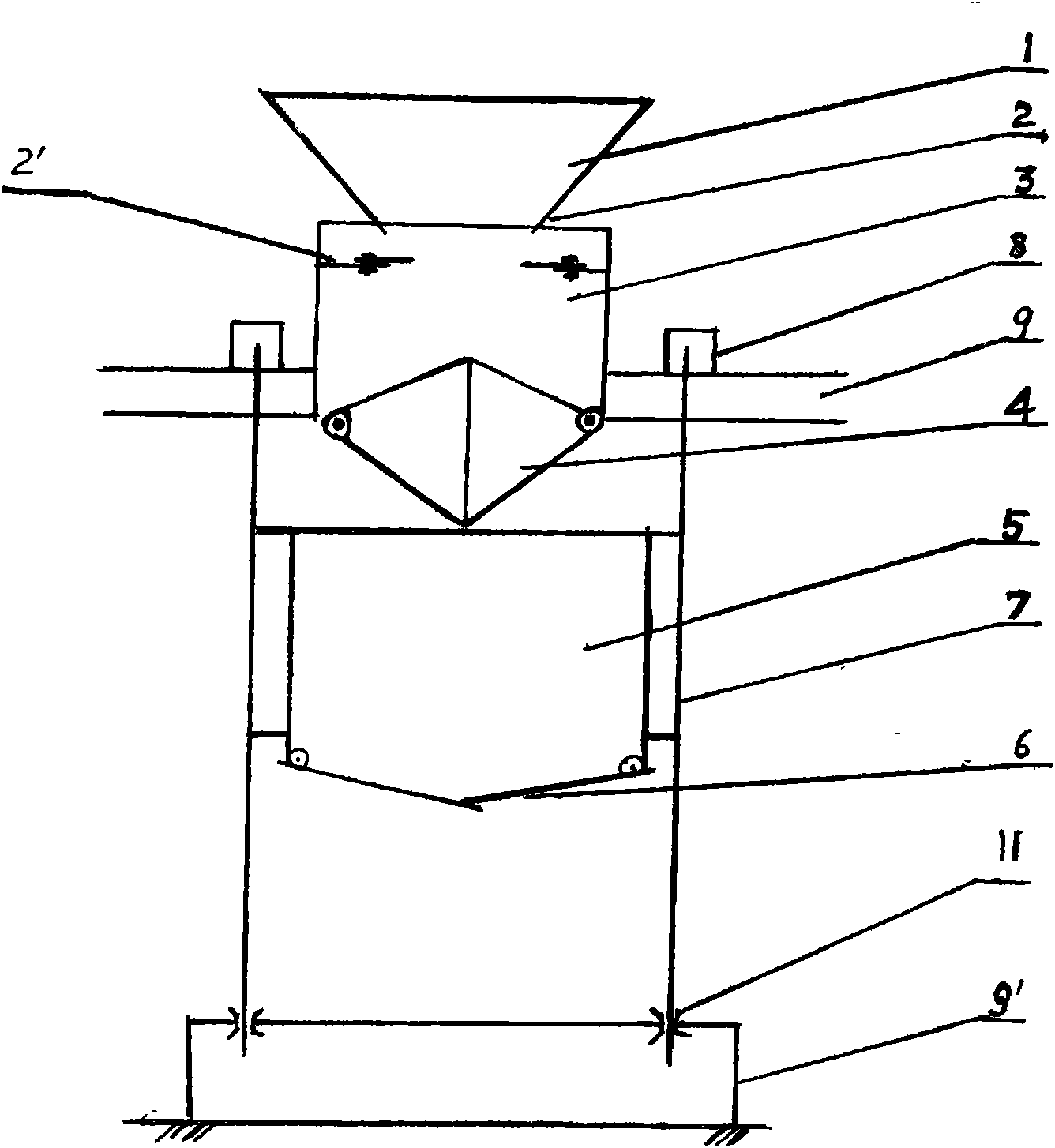

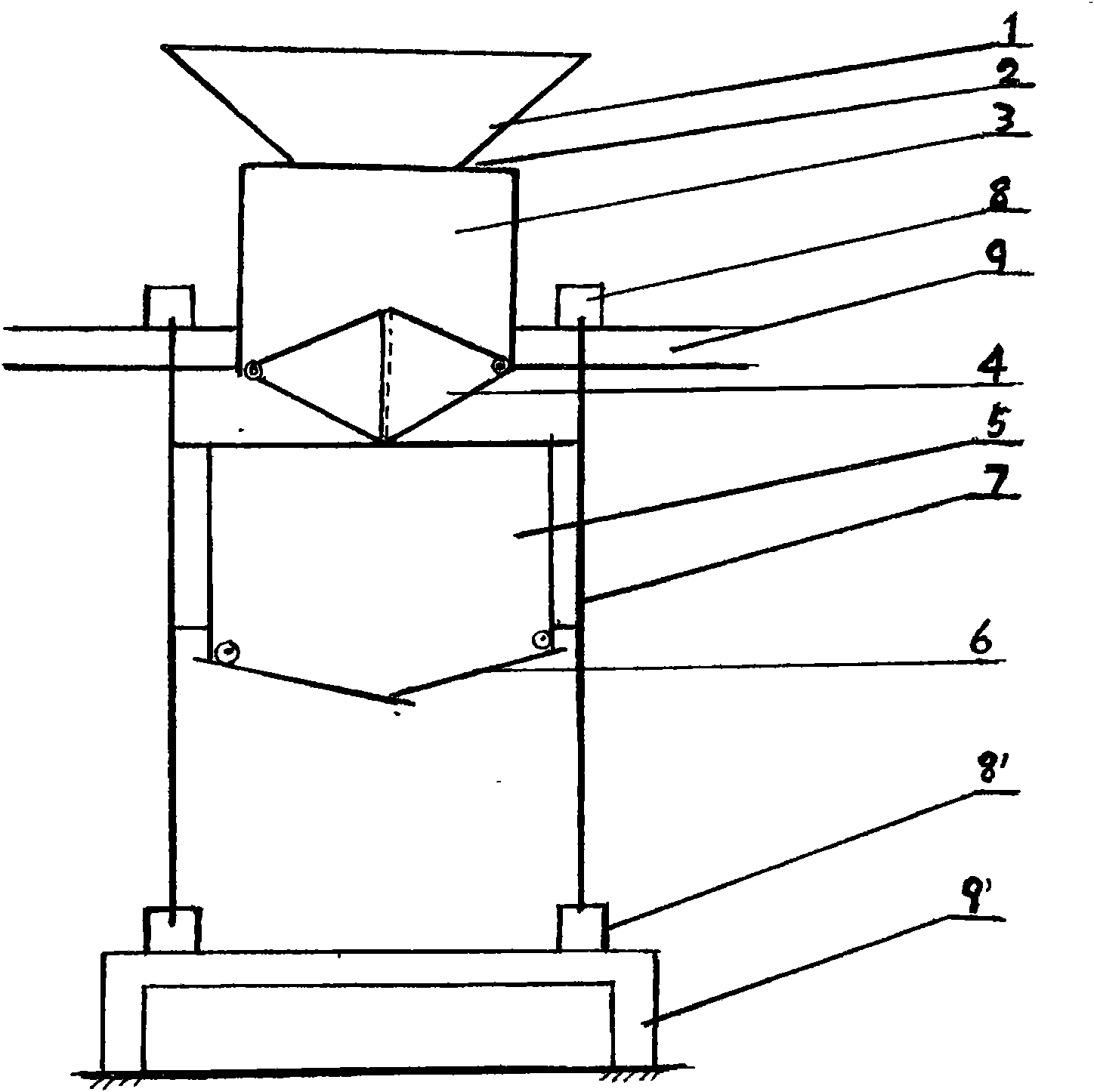

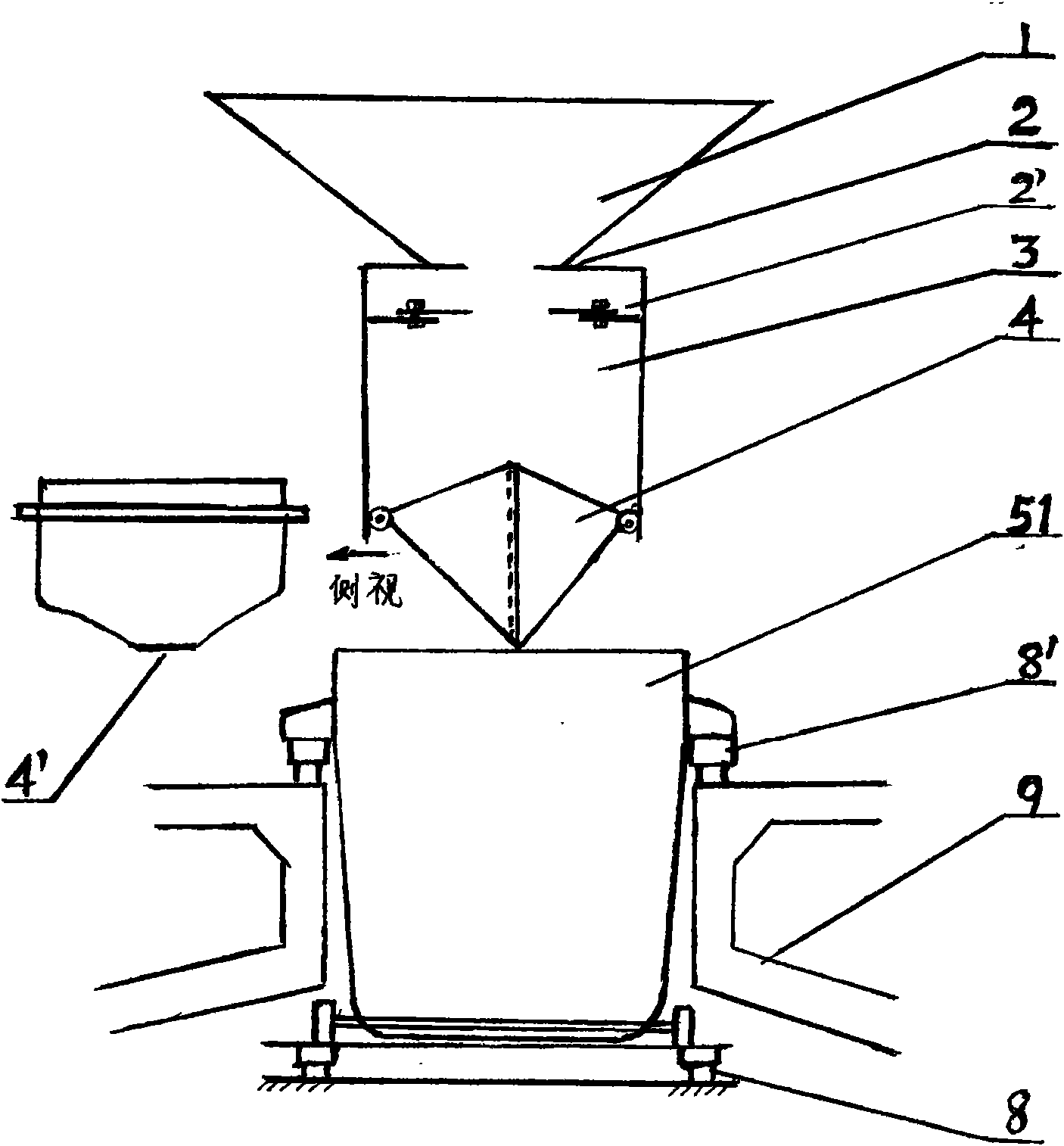

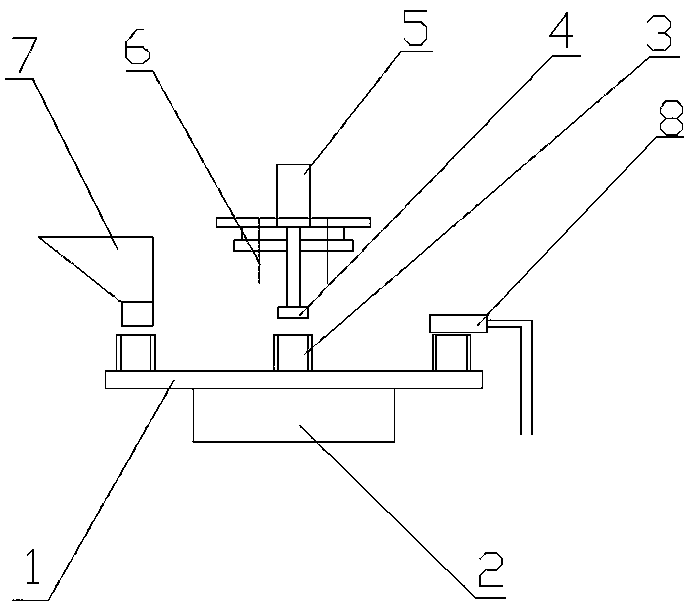

Quantificational packing machine

The invention relates to a quantificational packing machine. The quantificational packing machine mainly comprises a hopper (1), a second feeding door (2), a feeding groove (3), a large feeding control door (4), a small feeding control door (4'), a weighing hopper (5), a discharging door (6) and a sensor (8), wherein the second feeding door (2) is arranged below the hopper (1), and the feeding groove (3) is arranged below the second feeding door (2); the large feeding control door (4) and the small feeding control door (4') are arranged at the bottom of the feeding groove (3), and the weighing hopper (5) is arranged below the large feeding control door (4) and the small feeding control door (4'); the discharging door (6) is arranged at the lower end of the weighing hopper (5); and the sensor (8) is mounted above one side of the discharging door (6), connected with the weighing hopper (5) by a pull rod (7) in a hanging way and mounted on a stand (9). The quantificational packing machine can be a hopper-free quantificational packing machine if the weighing hopper (5) is replaced by a packet-clamping device for direct packing or can be a quantificational package packing machine if the weighing hopper (5) is replaced by a package-strutting support (51). The volumetric feeding amount of the feeding groove (3) is considered as a first feeding amount, and a unit total amount equals to the sum of the first feeding amount and the feeding amounts of the second feeding door (2) and a third-stage small feeding control door (4'). The quantificational packing machine is characterized in that the first feeding amount exceeds 30 percent of the unit total amount within an allowable shortest time. The invention has stable operation, accurate measurement, high efficiency, long service life, strong suitability, wide range and simple operation.

Owner:胡东兵

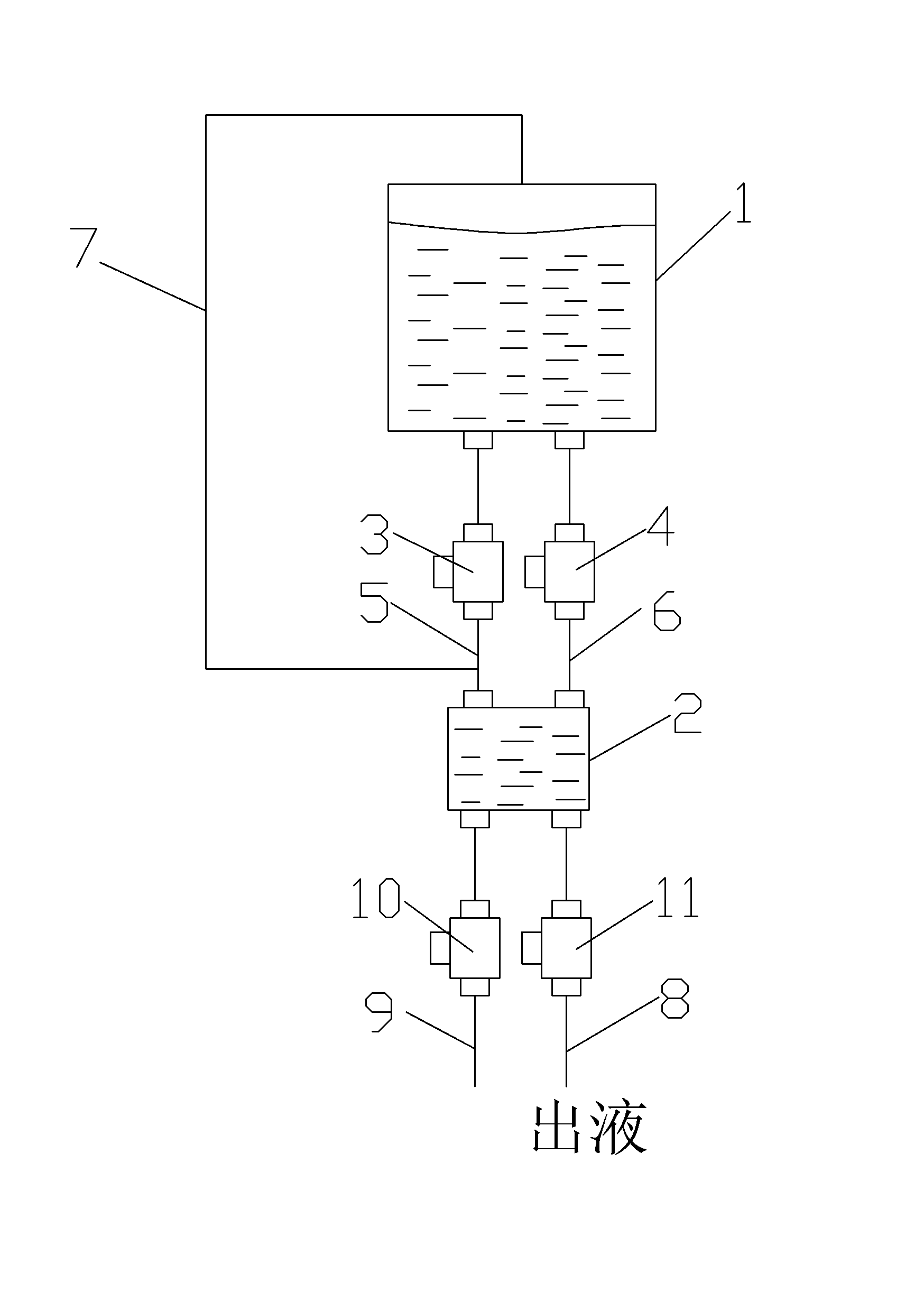

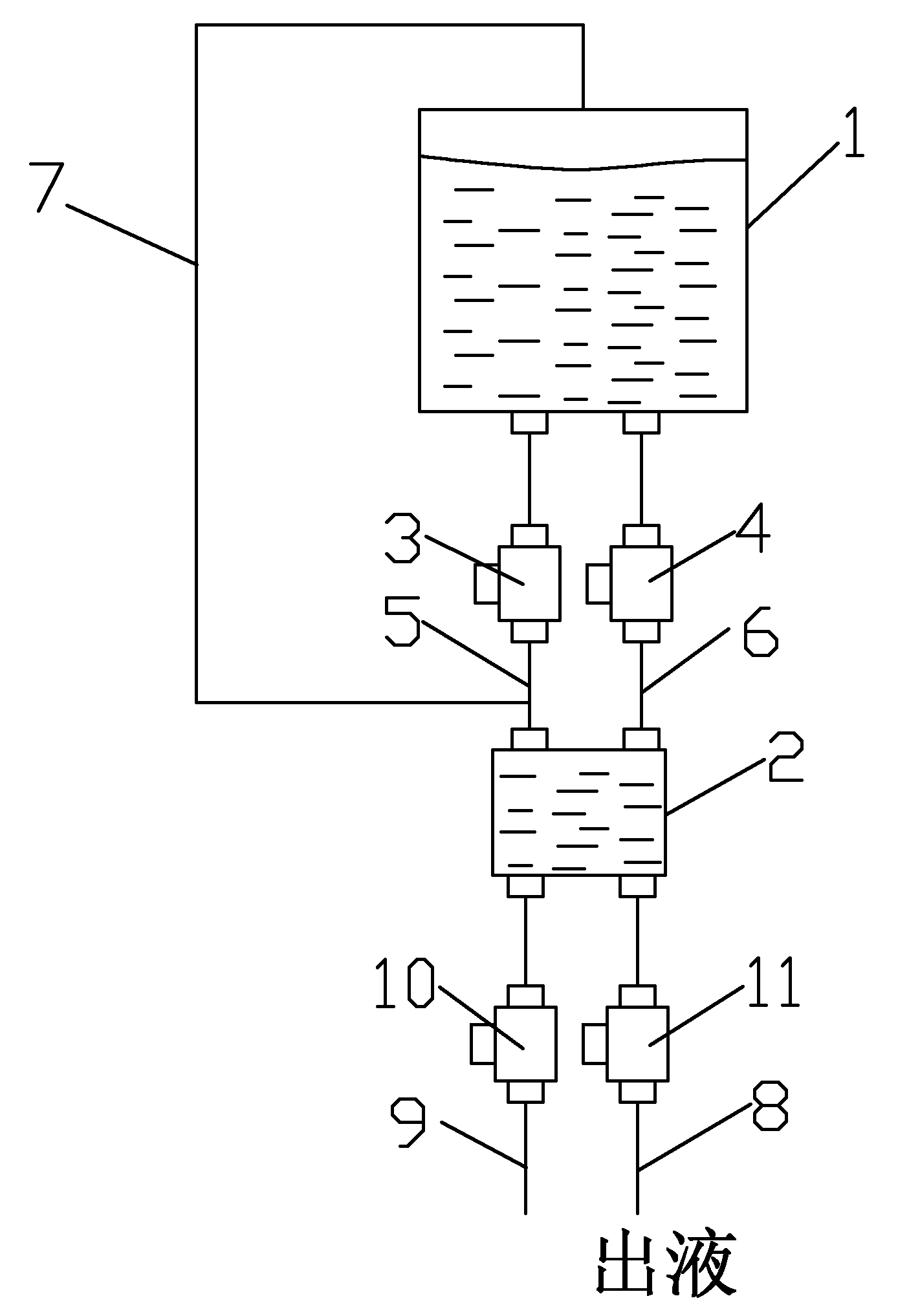

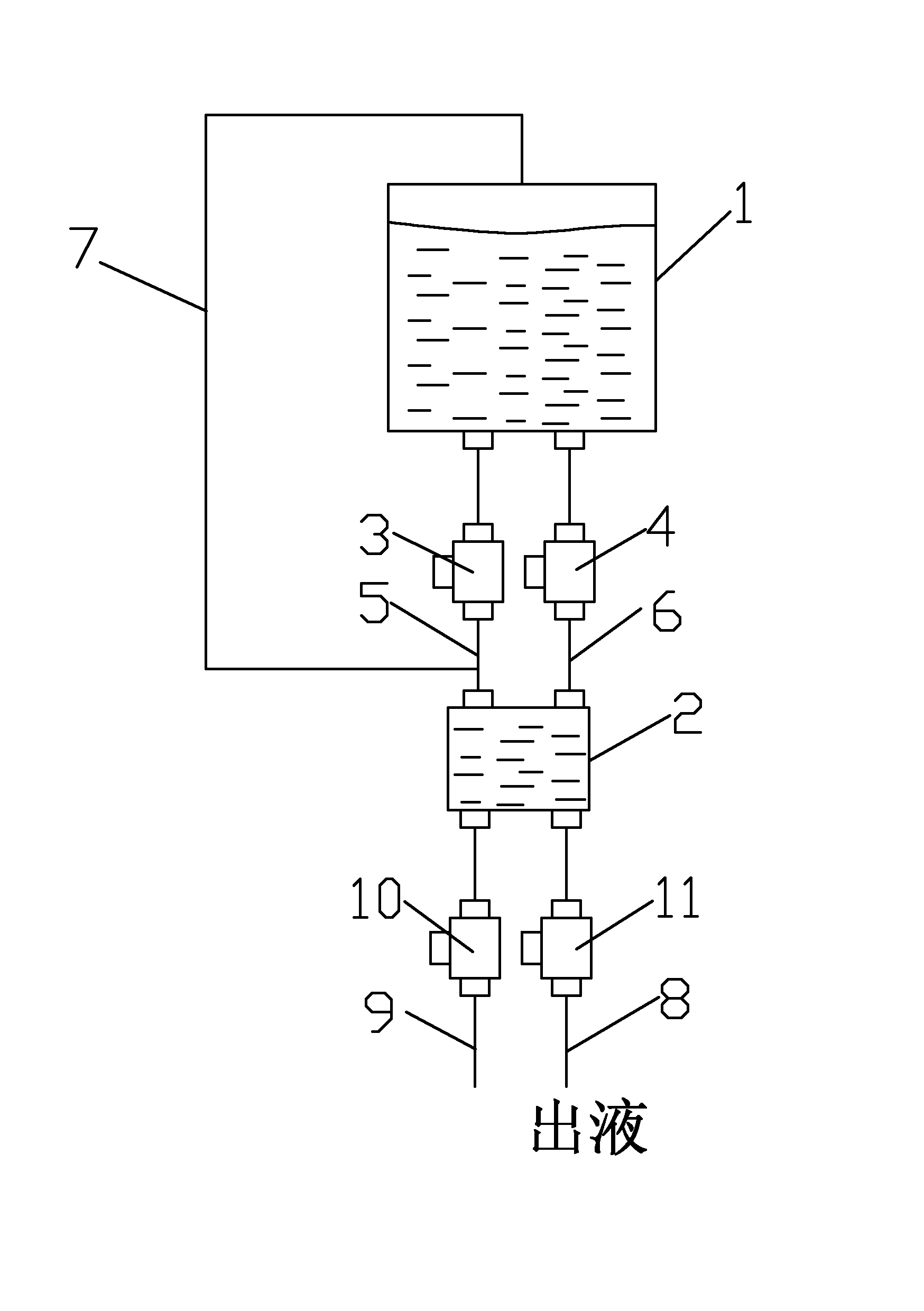

Quantifying liquid-discharging structure with middle exhaust pipe

InactiveCN102211000AGuaranteed stabilityQuantitatively stableStationary measuring chambersFeed devicesExhaust pipeElectromagnetic valve

The invention provides a quantifying liquid-discharging structure with a middle exhaust pipe, which ensures the constant volume of discharging liquid each time, i.e. is capable of stably discharging liquid in a quantifying way. The quantifying liquid-discharging structure comprises a solution tank, a quantifying tank as well as a fluid-discharge pipe and an air inlet pipe below the quantifying tank. The quantifying liquid-discharging structure is characterized in that the bottom of the solution tank is communicated with the top of the quantifying tank below the solution tank through the two middle liquid pipelines, middle electromagnetic valves are respectively installed in the two middle liquid pipelines, the fluid-discharge pipe and the air inlet pipe are respectively installed at the bottom of the quantifying tank, lower electromagnetic valves are respectively installed in the fluid-discharge pipe and the air inlet pipe, one end of the middle exhaust pipe is communicated with one of the two middle liquid pipelines, the other end of the middle exhaust pipe is communicated with the upper part of the solution tank, the middle electromagnetic valves are opened and closed at the same time, the lower electromagnetic valves are opened and closed at the same time, and the middle electromagnetic valves and the lower electromagnetic valves are opened and closed at different times.

Owner:WUXI GREENSTEK

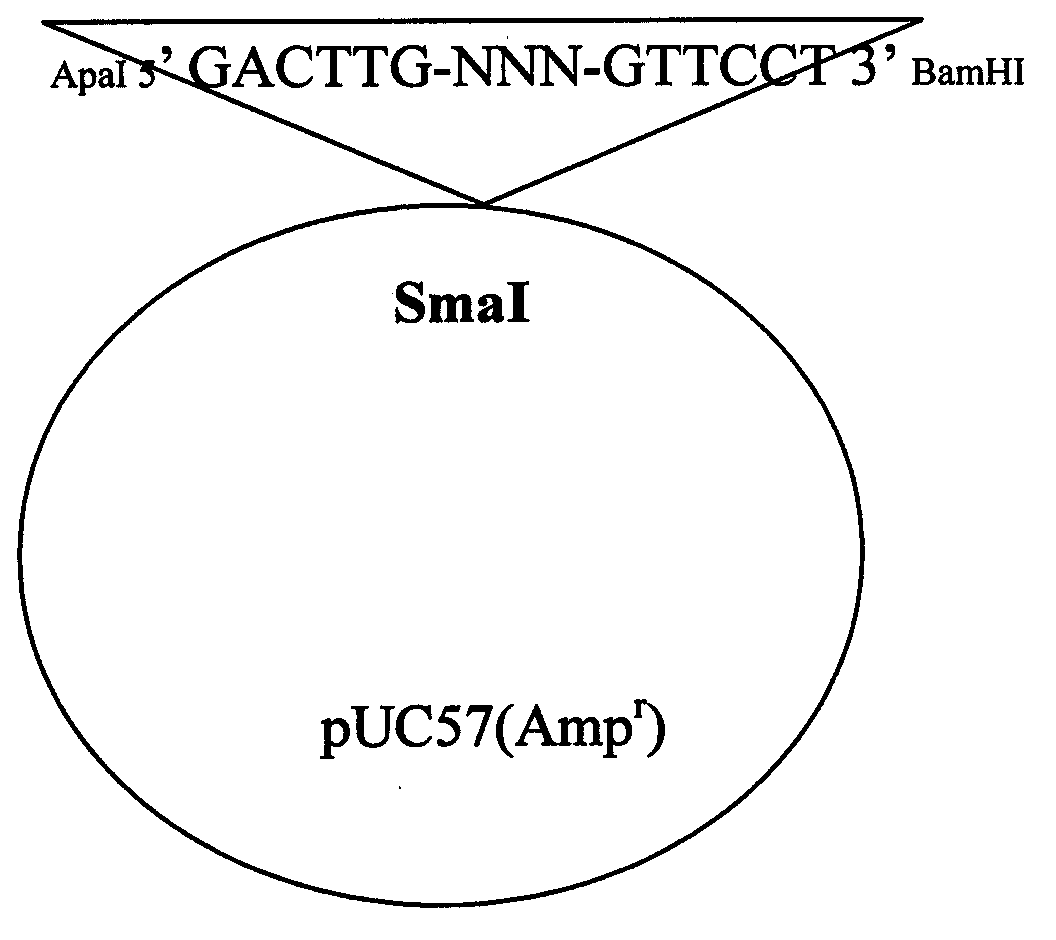

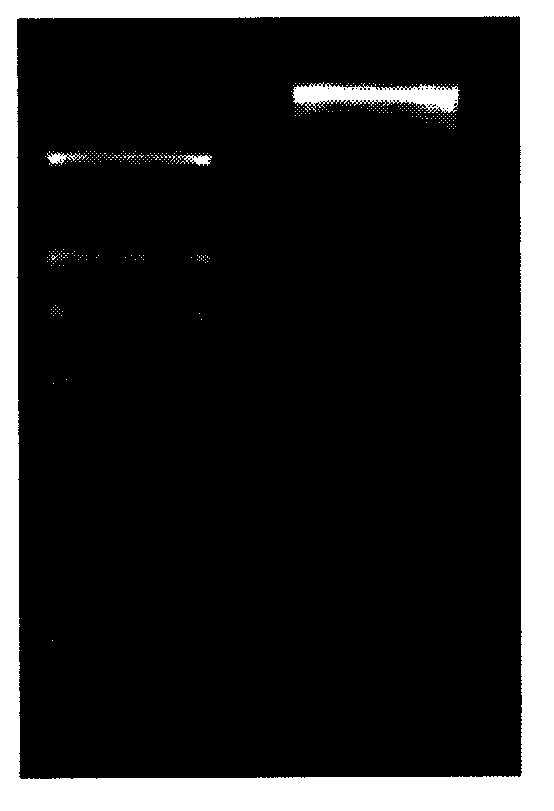

Detection method for dose of ionizing radiation on human peripheral blood lymphocytes

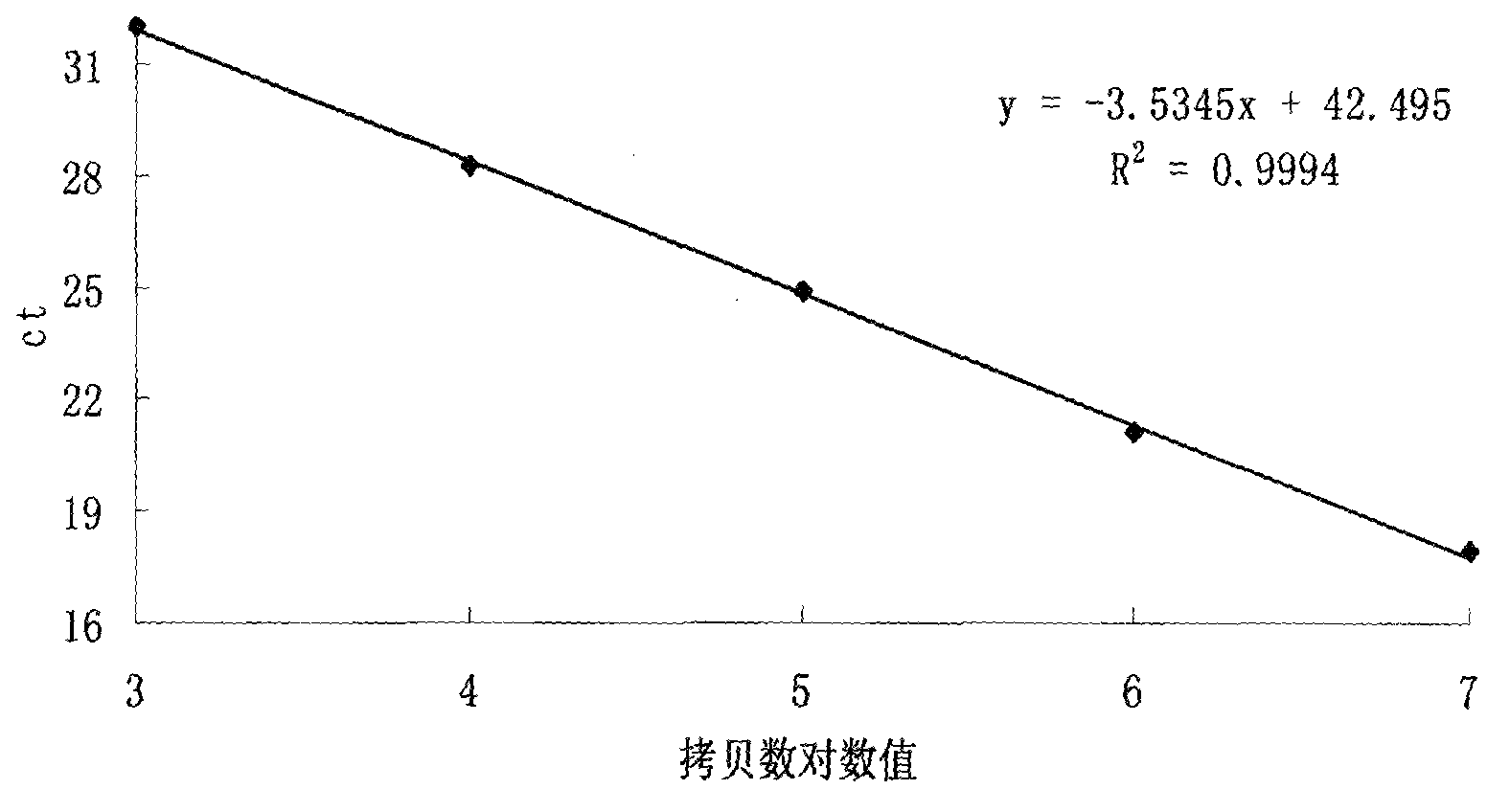

InactiveCN103805683AGood stability and repeatabilityShorten the timeMicrobiological testing/measurementPeripheral blood lymphocyteStandard curve

The present invention relates to a detection method for a dose of ionizing radiation on human peripheral blood lymphocytes. The detection method mainly comprises: designing primers and a Taqman-MGB probe according to a lymphocyte gdf15 gene expression sequence, and constructing a recombinant vector containing the lymphocyte gdf15 gene expression sequence as a standard substance; adopting the 10-fold serial diluted standard substance to carry out real-time fluorescence PCR, and drawing an absolute quantification standard curve; carrying out quantitative determination on the expression levels of the gdf15 gene of lymphocytes with different culture times after ionizing radiations with different doses to obtain a dose-effect fitting curve of the radiation dose and the gdf15 gene expression level; and carrying out quantitative determination on the expression level of the gdf15 gene of lymphocytes with the radiation dose requiring detection, and calculating the dose of the ionizing radiation on the lymphocytes requiring detection. According to the present invention, the dose of ionizing radiation on human peripheral blood lymphocytes can be rapidly and quantitatively detected so as to meet requirements of simpleness, rapid quantitation and high throughput, and the advantages can be provided when the large-scale radiation accident occurs.

Owner:NAT INST FOR RADIOLOGICAL PROTECTION & NUCLEAR SAFETY CHINESE CENT FOR DISEASE CONTROL & PREVENTION

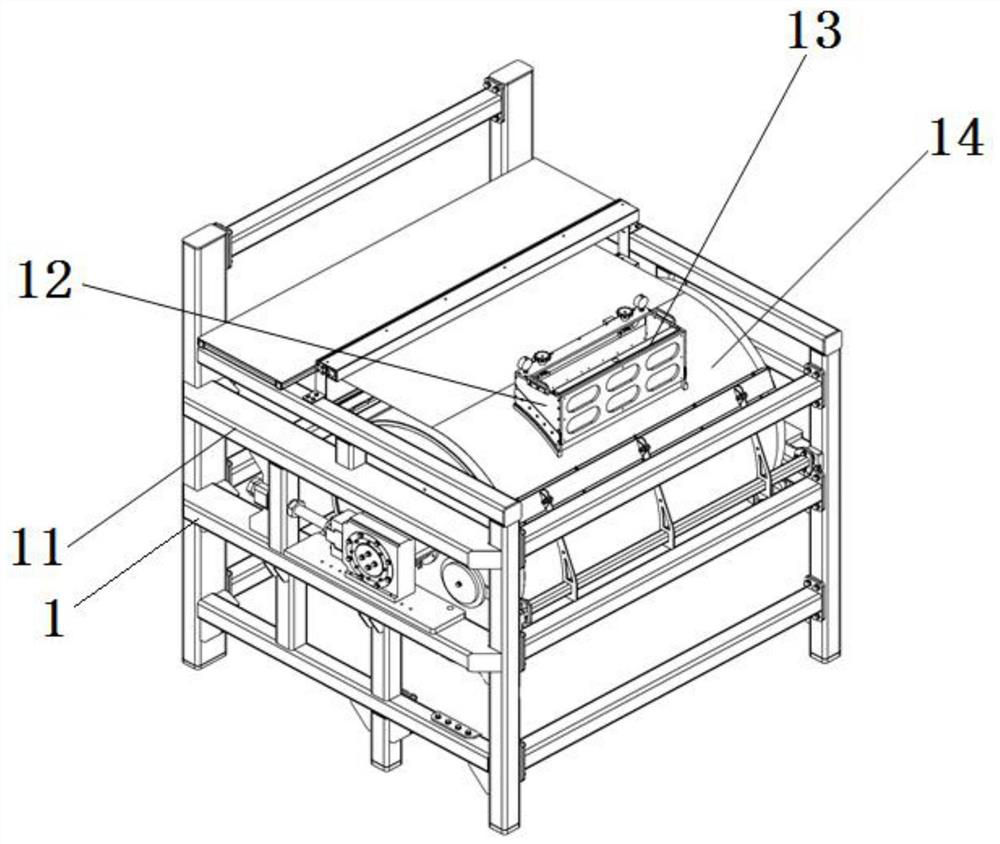

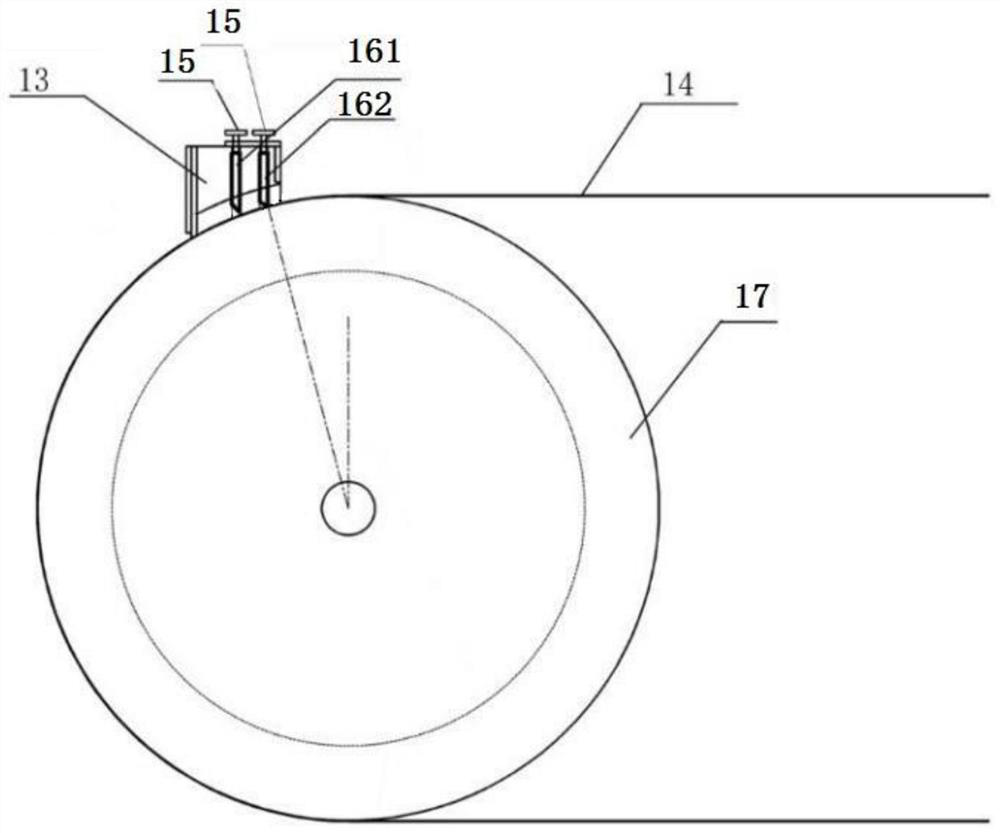

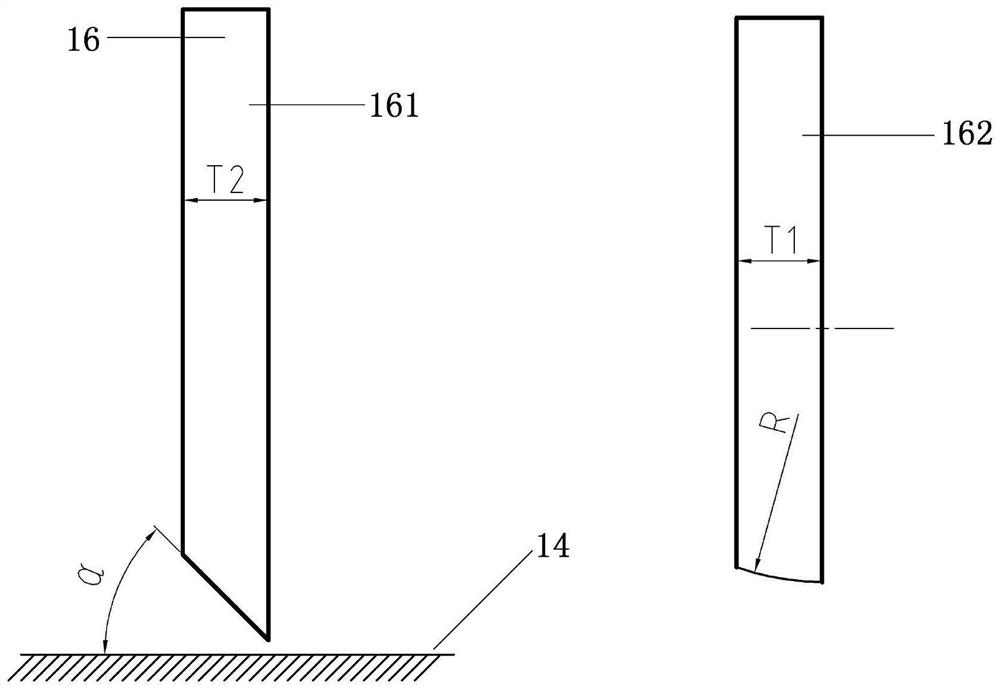

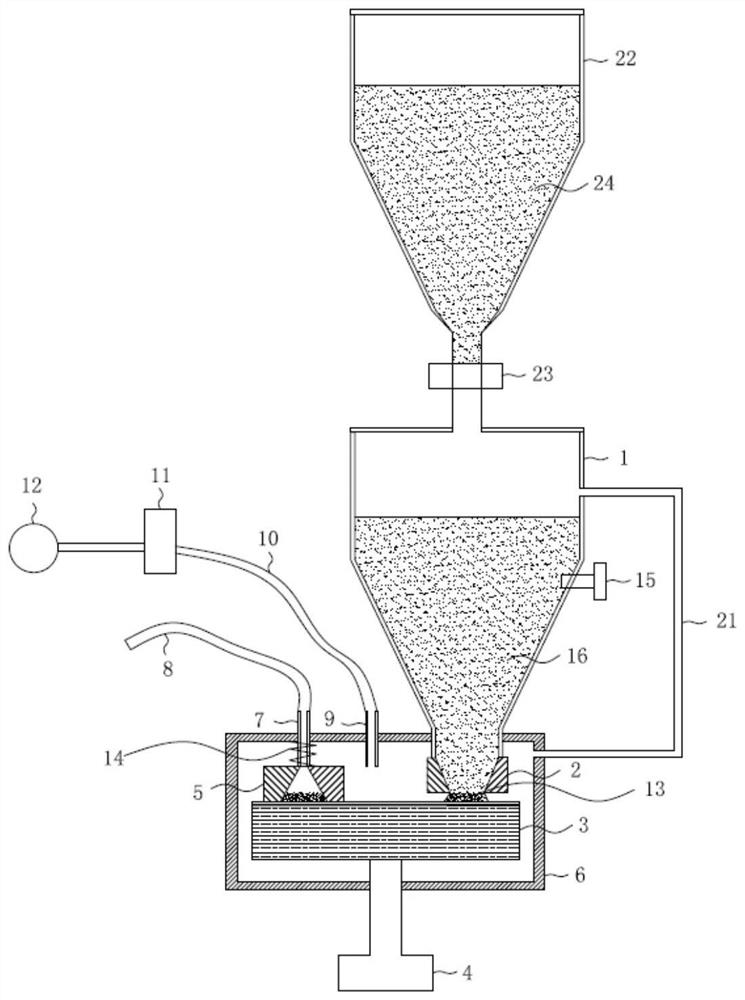

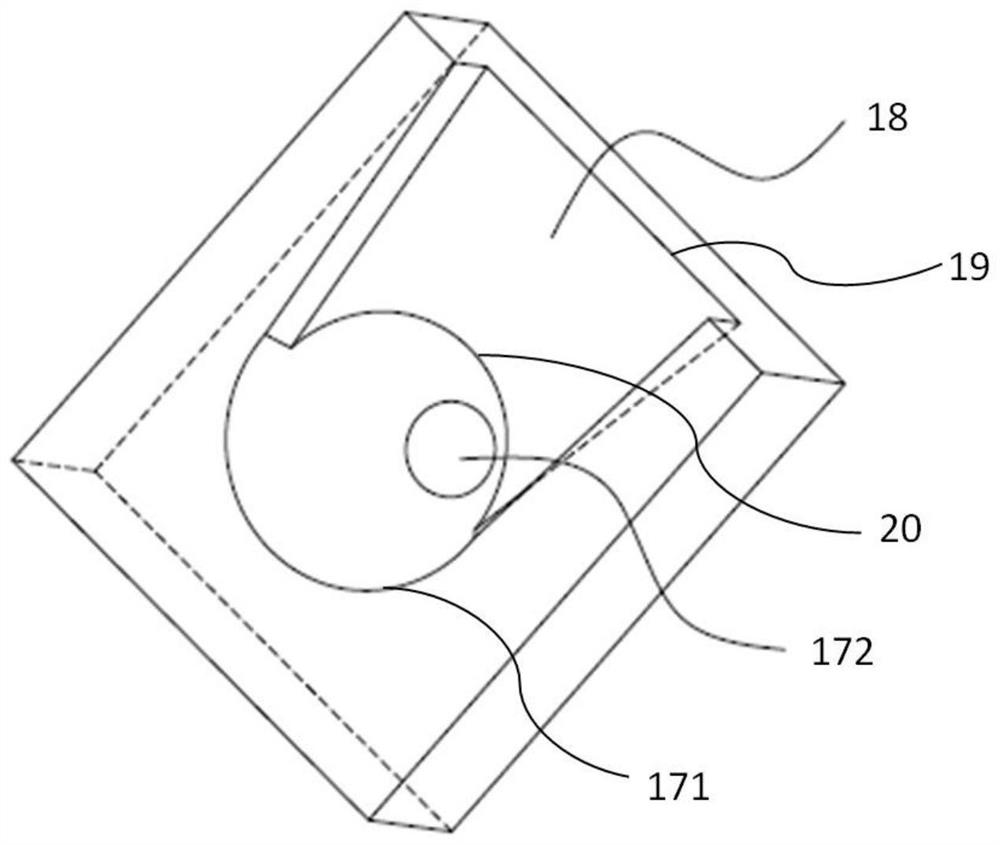

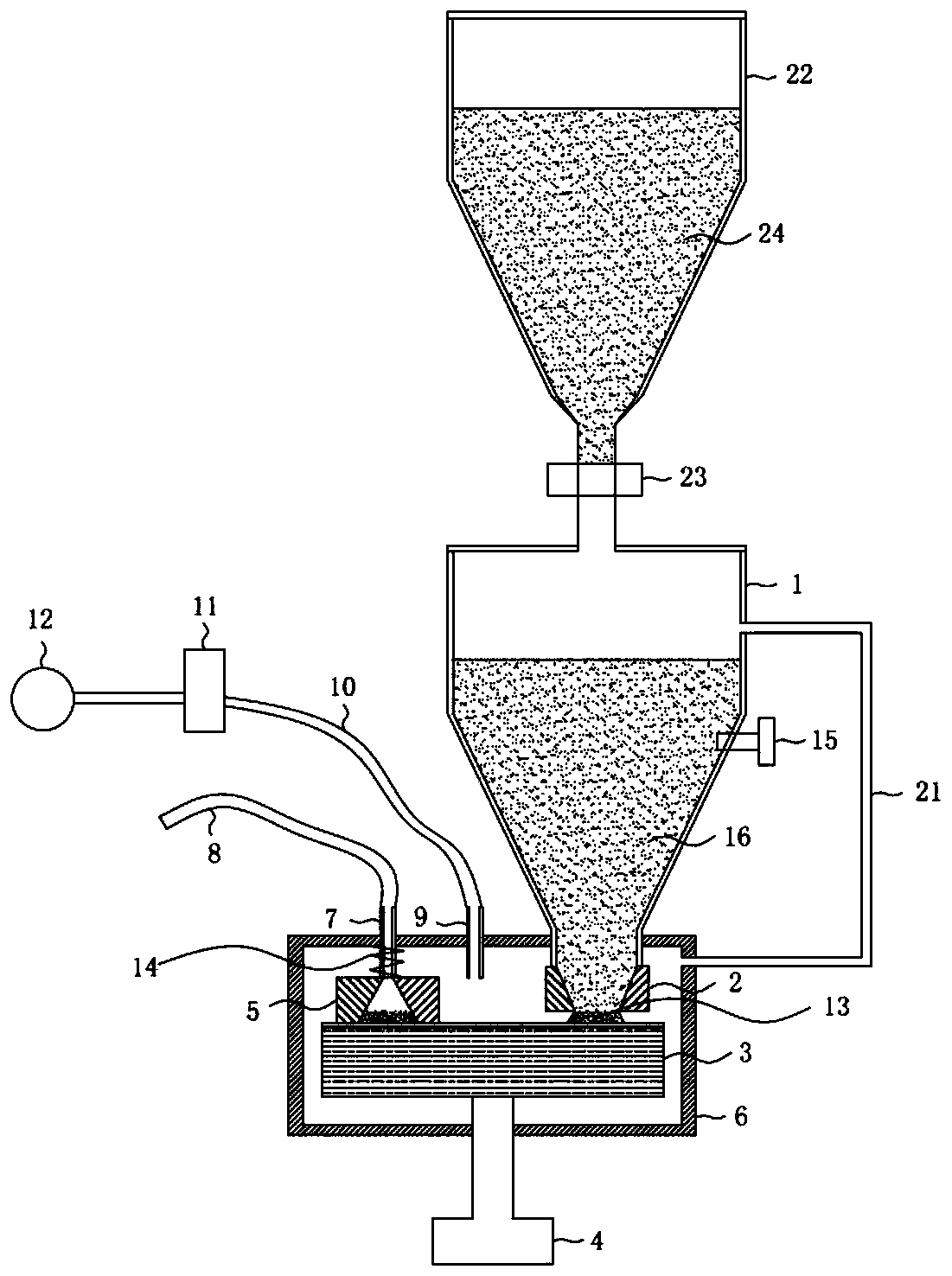

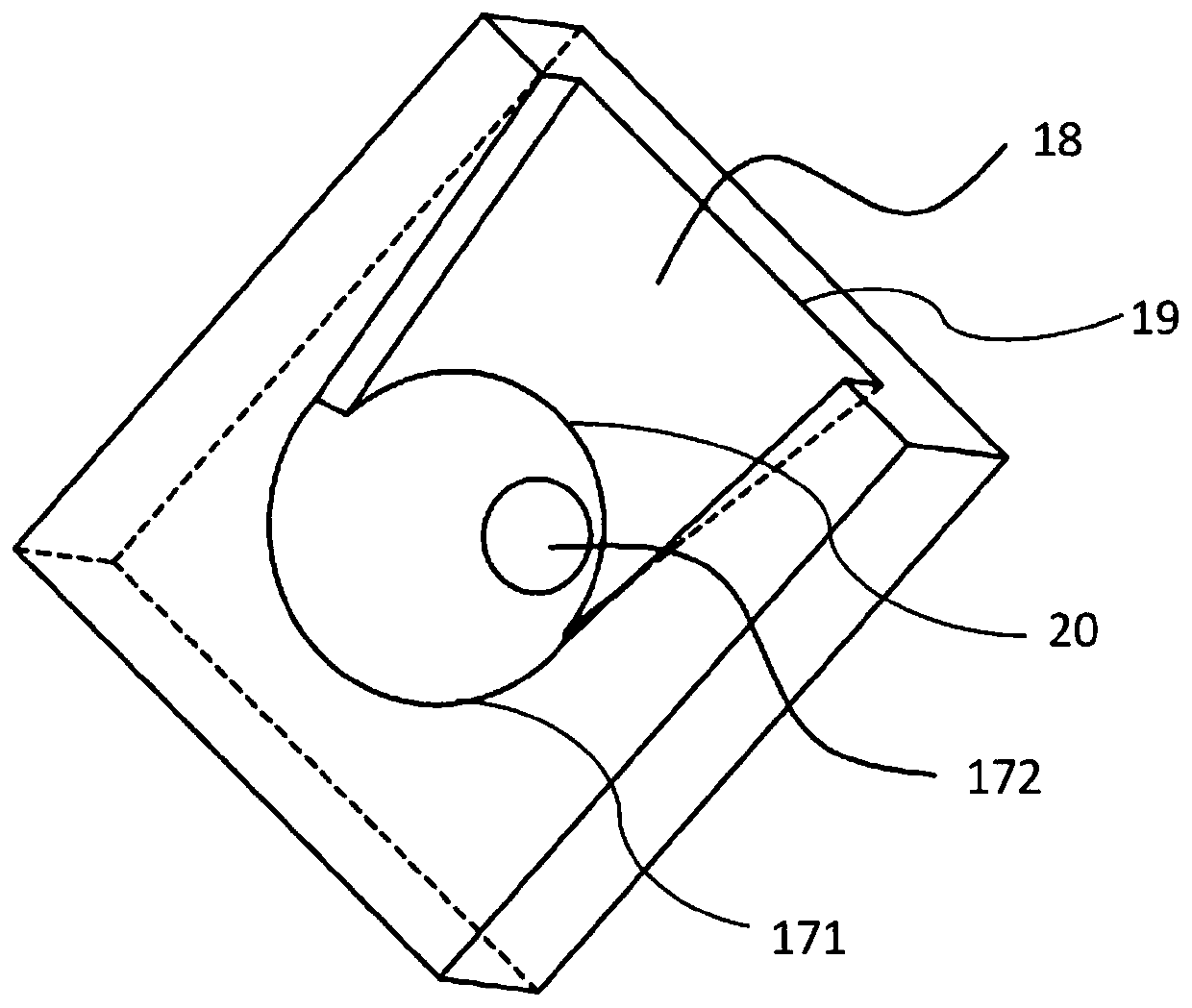

Constant-state pulp distribution forming device of thick-pulp-method reconstituted tobacco special for heating cigarettes

PendingCN112515230AStable casting thicknessImprove stabilityTobacco preparationTobacco treatmentSteel beltTape casting

The invention discloses a constant-state pulp distribution forming device of thick-pulp-method reconstituted tobacco special for heating cigarettes. The constant-state pulp distribution forming devicecomprises a follow-up tape casting unit (1), a curtain type feeding unit (2) and a release agent roller coating unit (3), wherein the follow-up tape casting unit (1) comprises a rack (11), a tape casting box (13), a formed steel belt (14) and a hub (17); the curtain type feeding unit (2) comprises a thick slurry buffer tank (21), a thick slurry discharging pipe (22) and a thick slurry feeding pipe (23); and the release agent coating unit (3) comprises a coating roller (31), a release agent trough (32) and a release agent feeding pipe (33). According to the invention, stable tape casting of thick slurry can be realized, the longitudinal thickness and quantitative stability of the pulp film and thick-slurry-method reconstituted tobacco are improved, holes of the pulp film and thick-slurry-method reconstituted tobacco caused by blockage of the bottom of the scraper by fiber clusters are avoided, and the paper forming rate of the thick-slurry-method reconstituted tobacco is improved; andthe requirements of heating cigarettes on the thickness and quantification stability of the thick-slurry-method reconstituted tobacco are met.

Owner:CHINA TOBACCO YUNNAN IND

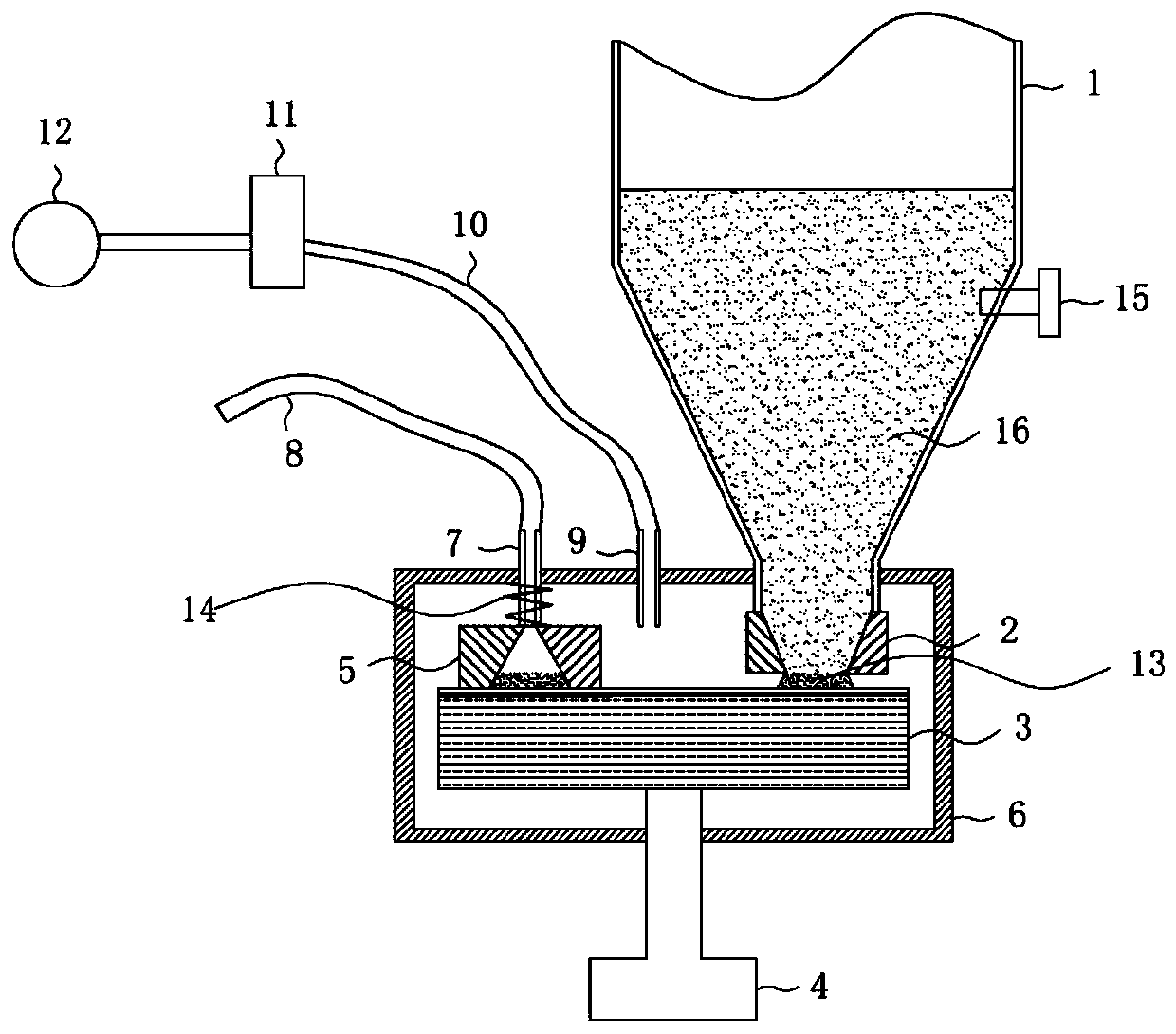

Quartz sand conveying device and method

ActiveCN111204596BPrecise deliveryStable deliveryLoading/unloadingConveyor partsMechanical engineeringQuartz

The main purpose of the present invention is to provide a conveying device and method for quartz sand. The device includes a storage bin, a sealed bin, a transfer plate arranged in the sealed bin, an air source and a blowing block; the method includes the following steps: mechanically transfer the quartz sand to the blowing block in the sealed bin; The blowing block includes a bottom opening and a top opening which communicate with each other; the bottom opening passes through one side of the blowing block through a side opening; the quartz sand passes through the side opening, the blowing block, and The bottom opening and the top opening are transported to the designated position. The technical problem to be solved is the unstable and inaccurate quartz sand flow rate caused by scraper (plate) wear or vibration in the scraper (plate) conveying process in the prior art, and the impact of the scraper (plate) abrasive on the quartz sand. At the same time, the installation position of the conveying device in the prior art is limited by height, which will cause problems such as difficulty in raw material loading and safety risks, so it is more suitable for practical use.

Owner:CHINA BUILDING MATERIALS ACAD

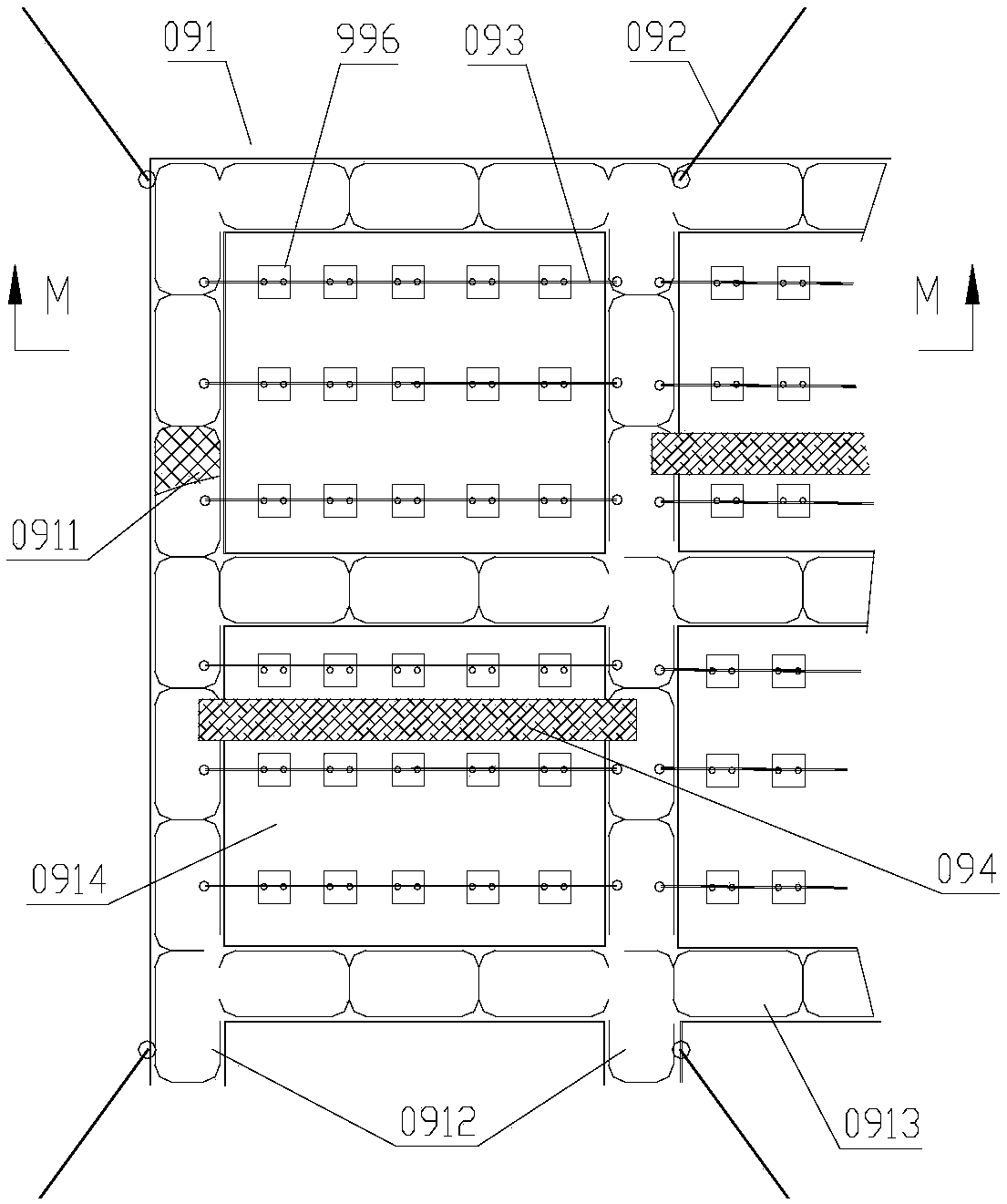

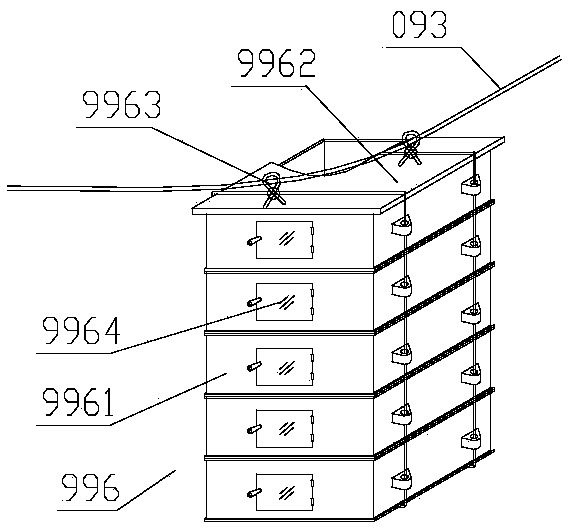

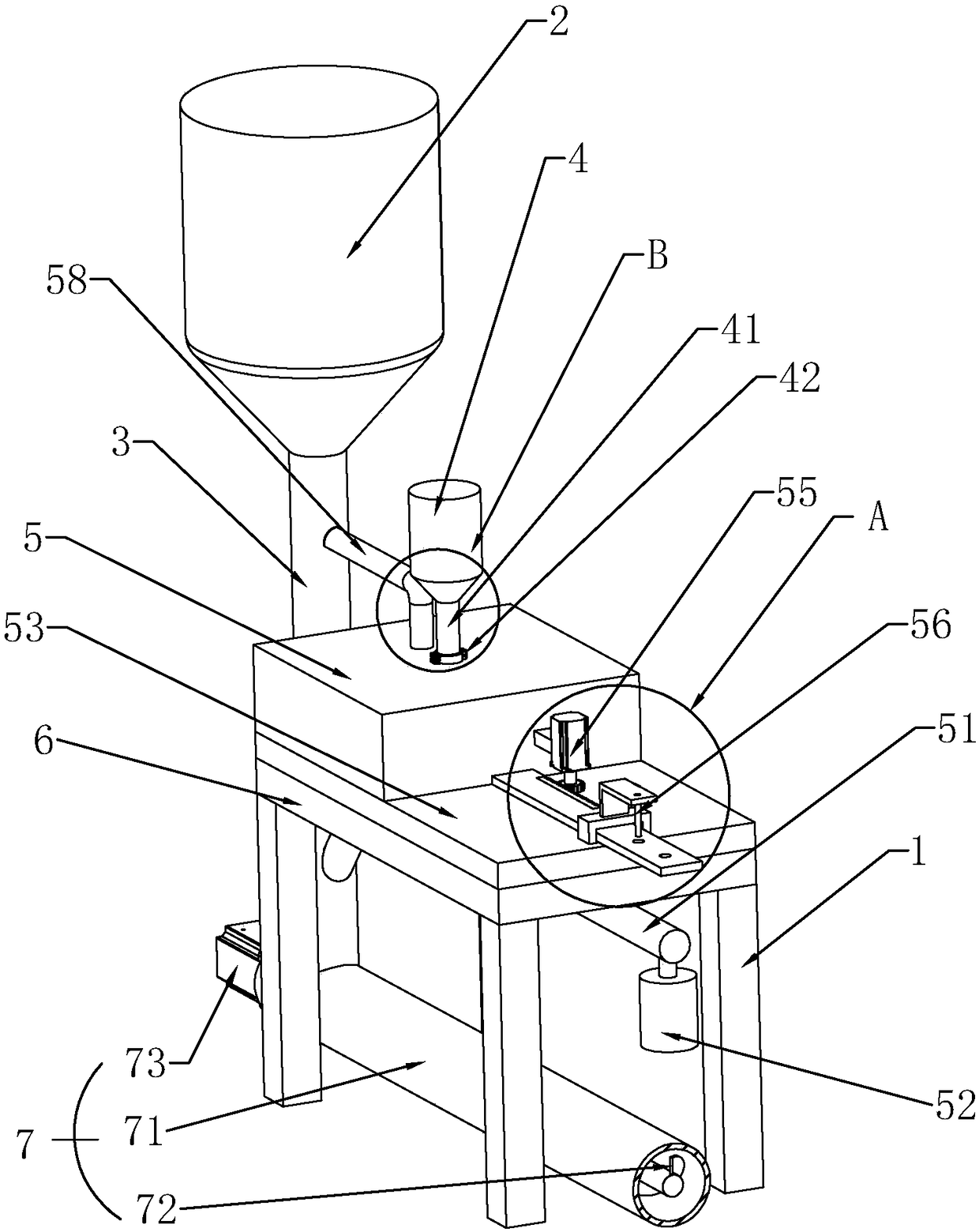

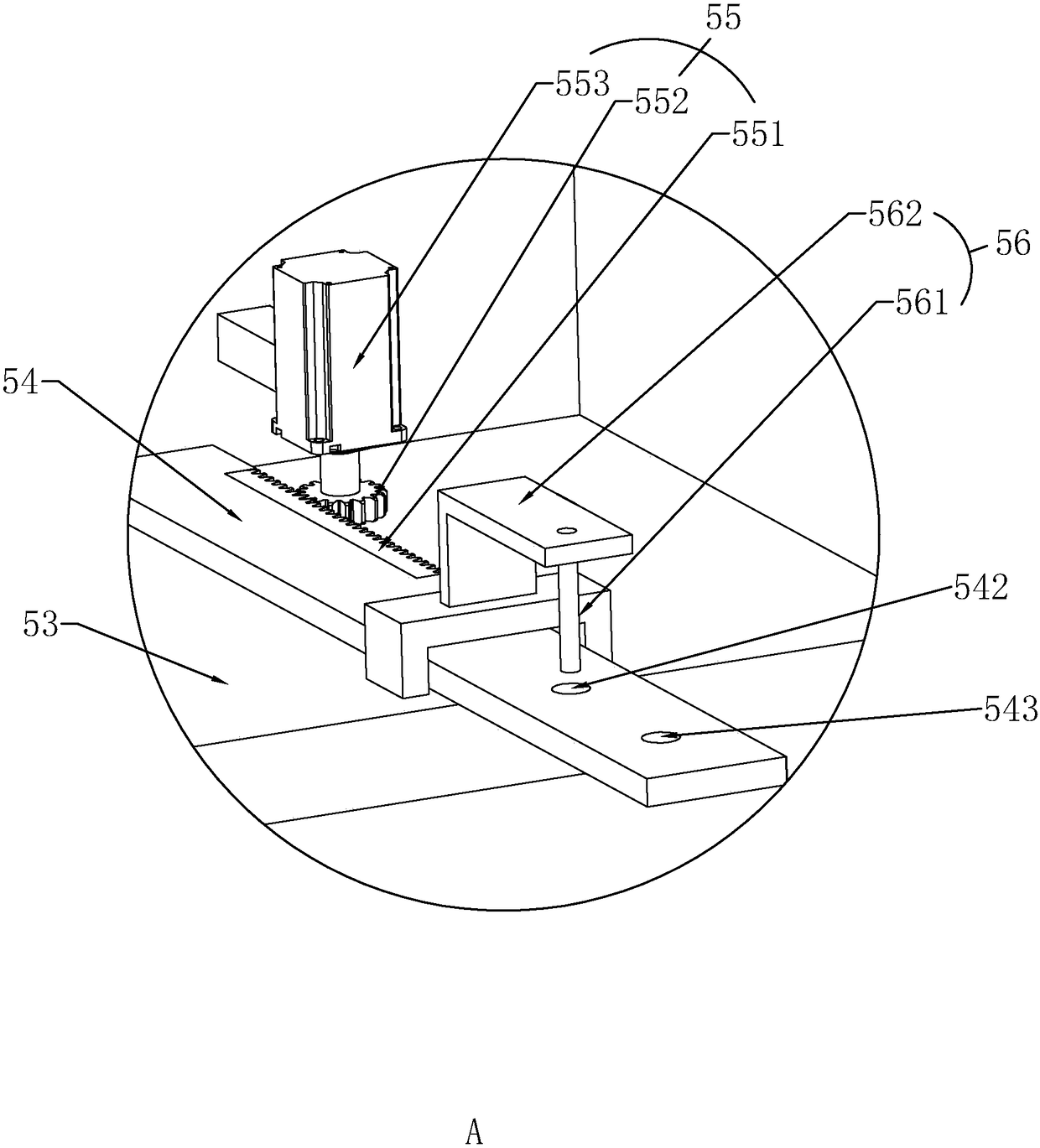

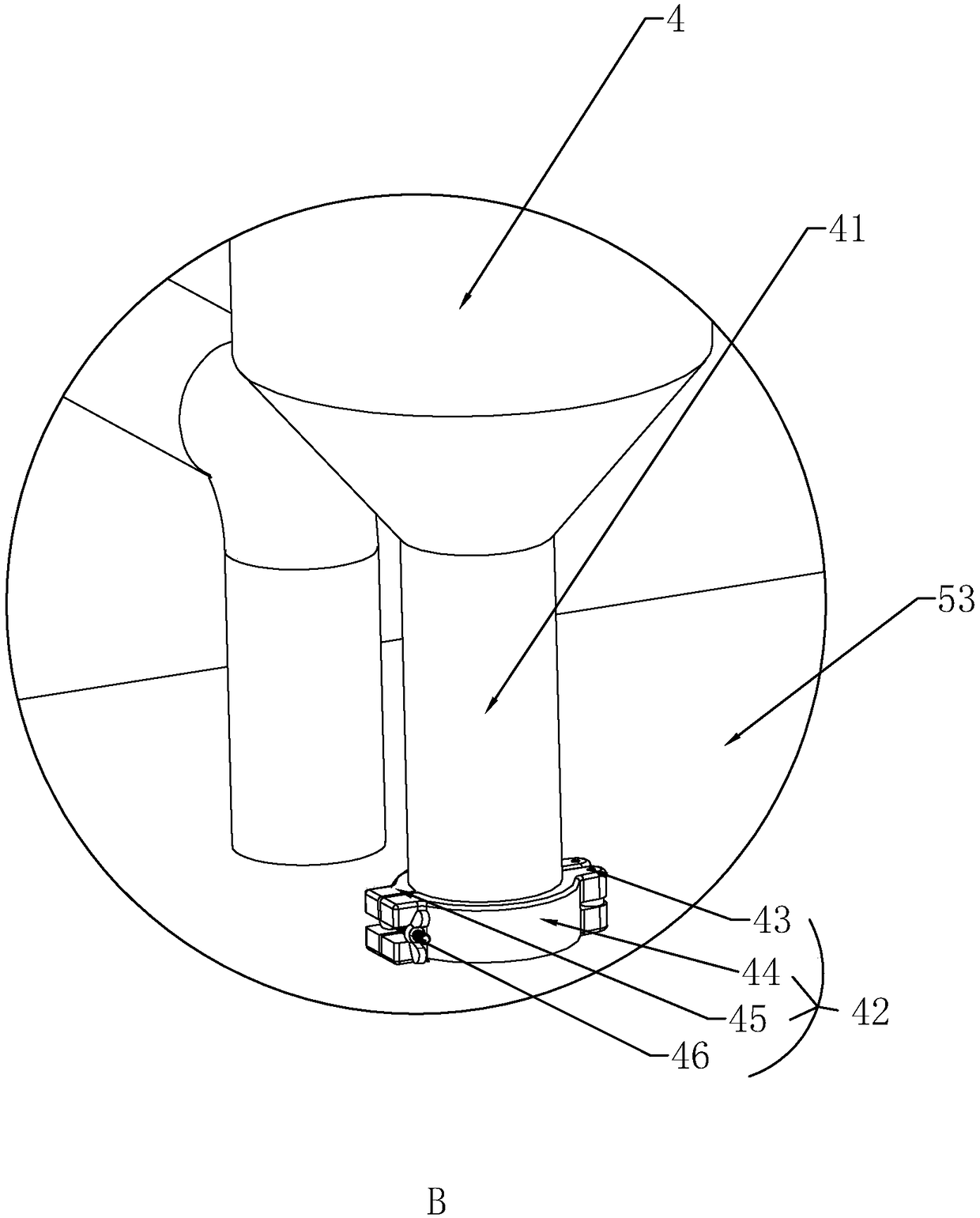

Feeding system used for marine aquaculture and provided with feeders and cranes

InactiveCN109042438AKeep it workingTired and hard workClimate change adaptationPisciculture and aquariaMarine aquacultureEngineering

The invention discloses a feeding system used for marine aquaculture and provided with feeders and cranes. The feeding system includes fishing rafts, aquaculture cabinets, the feeders and the cranes.The fishing rafts are provided with aquaculture ponds, feeding regions and crane tracks, and the aquaculture ponds are provided with hanging cables; the feeding regions are provided with feeding platforms and feeder tracks, and the track surfaces of the feeder tracks are provided with racks; the feeders are connected with the feeder tracks and fixed by braking devices, and the feeders are providedwith pneumatic tanks to store high-pressure seawater; the aquaculture cabinets are connected with the hanging cables through fast-connection hook sets and soaked in the aquaculture ponds; big wheelsand horizontal wheels in big wheel sets of the cranes are embedded in the crane tracks to run; the cranes lift the aquaculture cabinets from the aquaculture ponds to the feeding platforms in the feeding regions or lift the aquaculture cabinets from the feeding platforms into the aquaculture ponds; the feeders are used for quantitative feeding of abalones in the aquaculture cabinets placed on the feeding platforms by using high-pressure water as power.

Owner:张达英

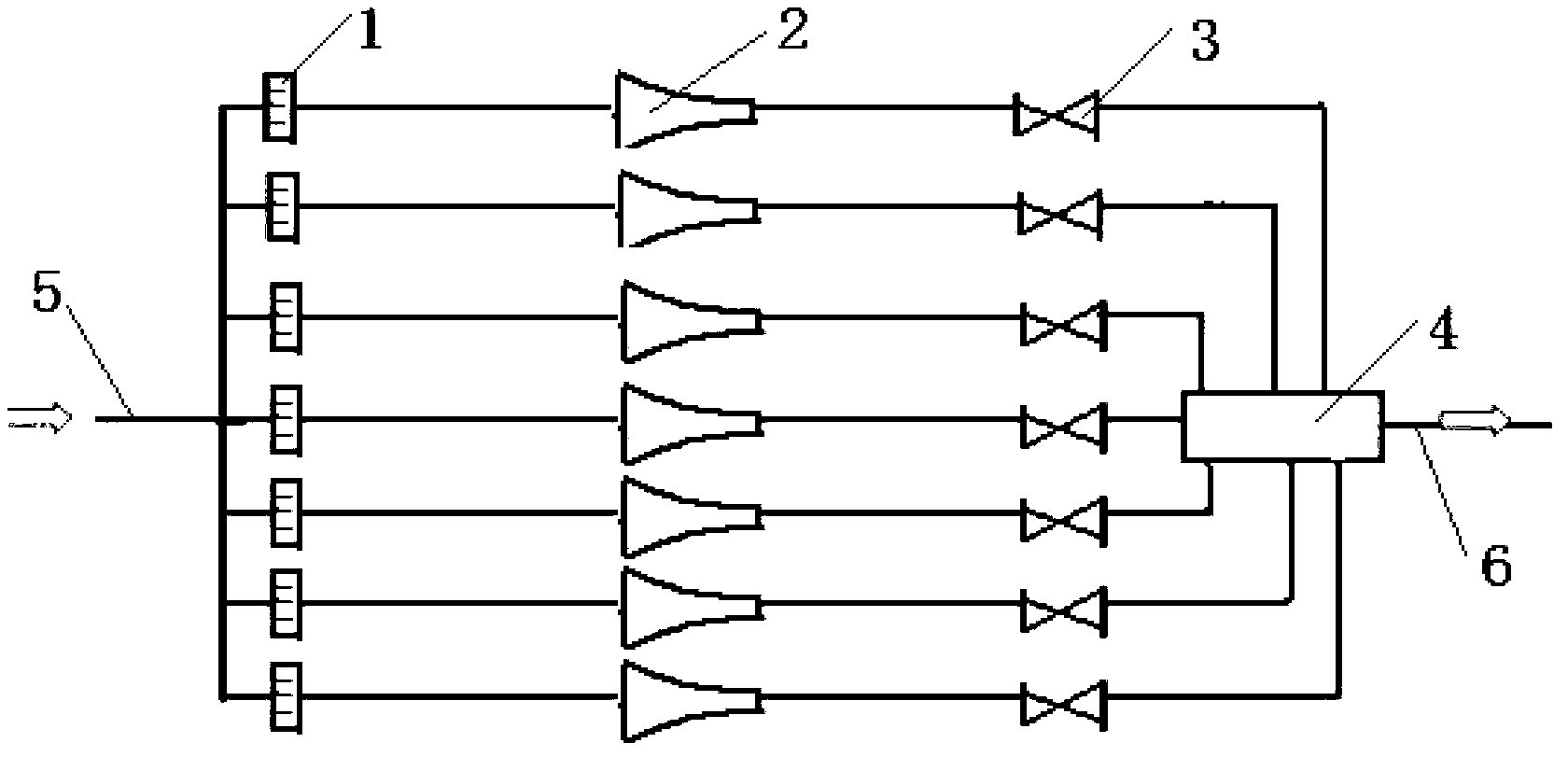

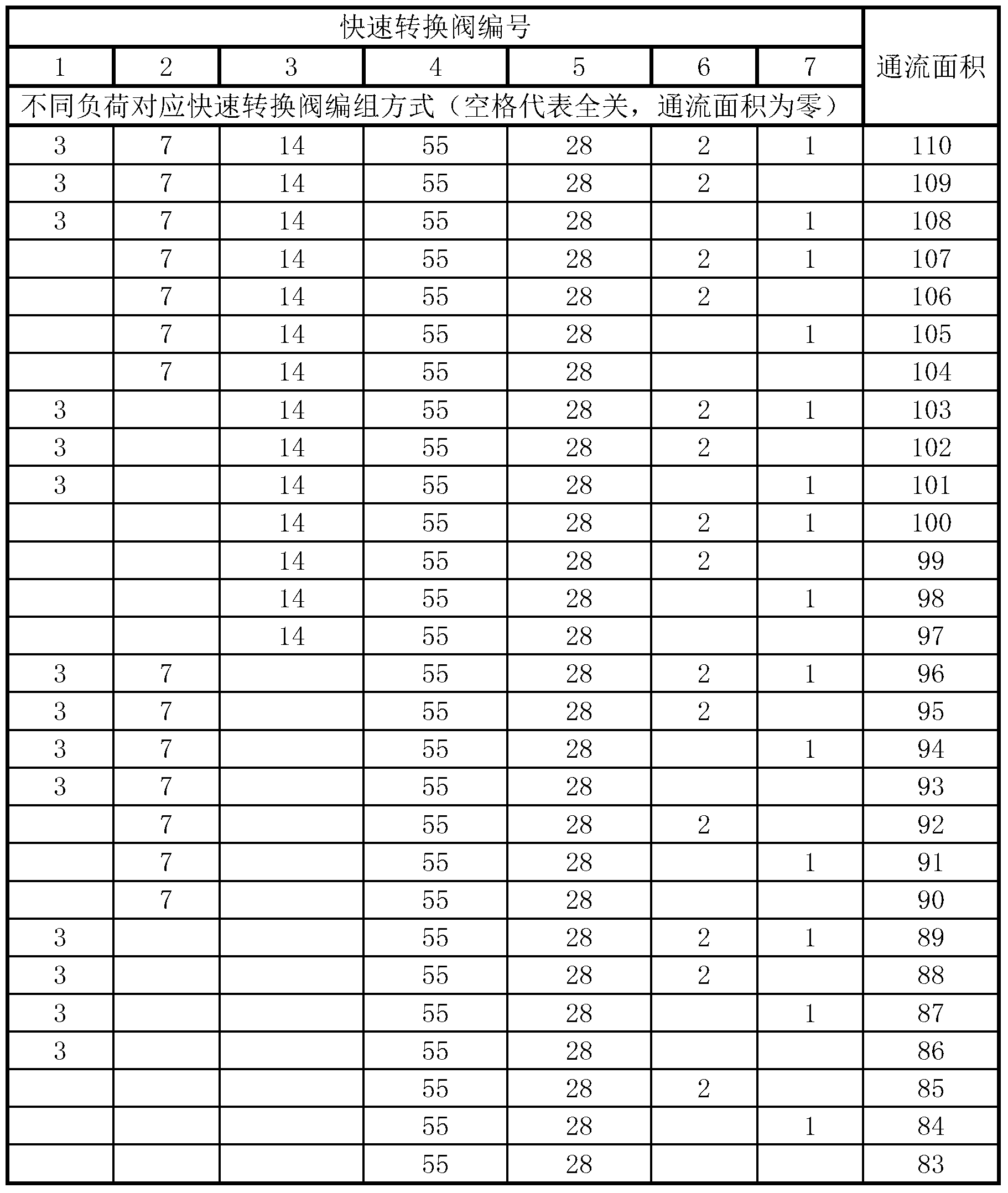

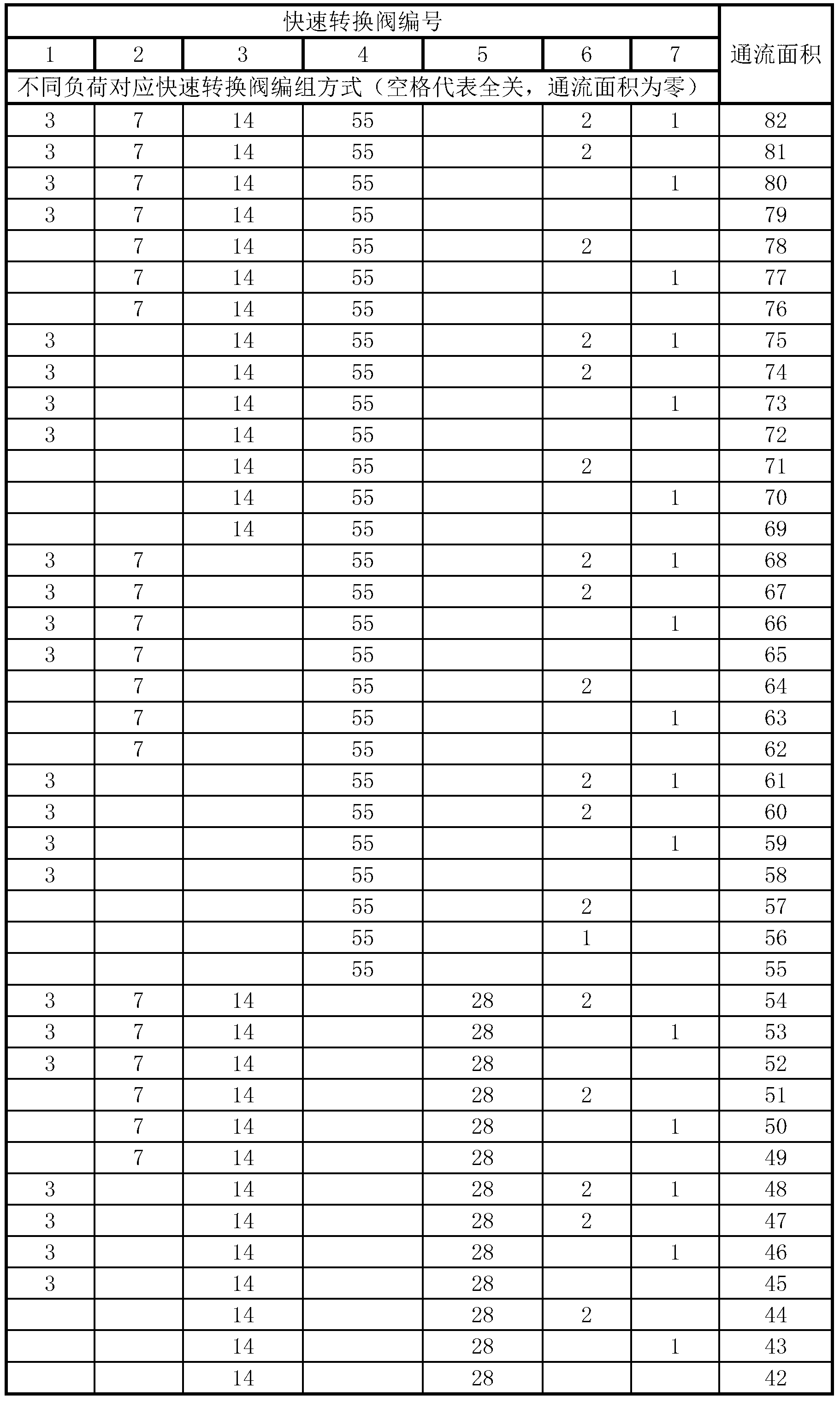

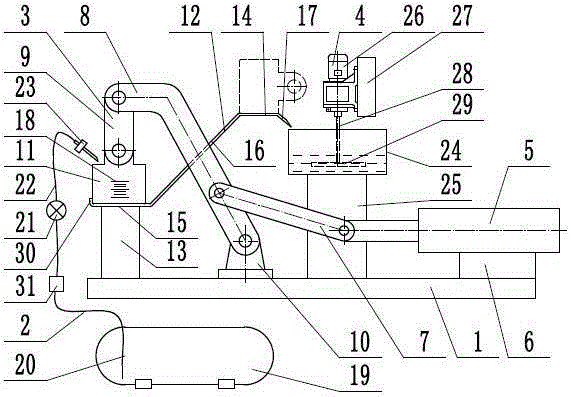

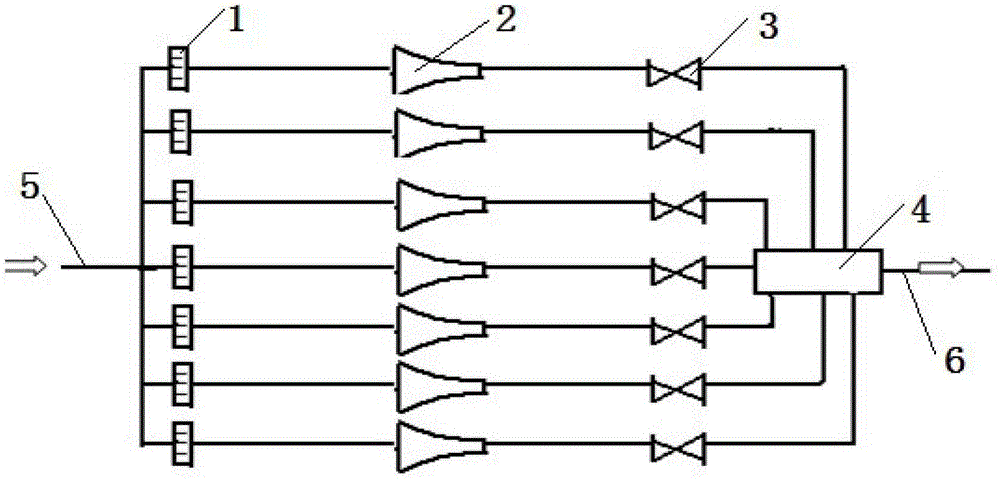

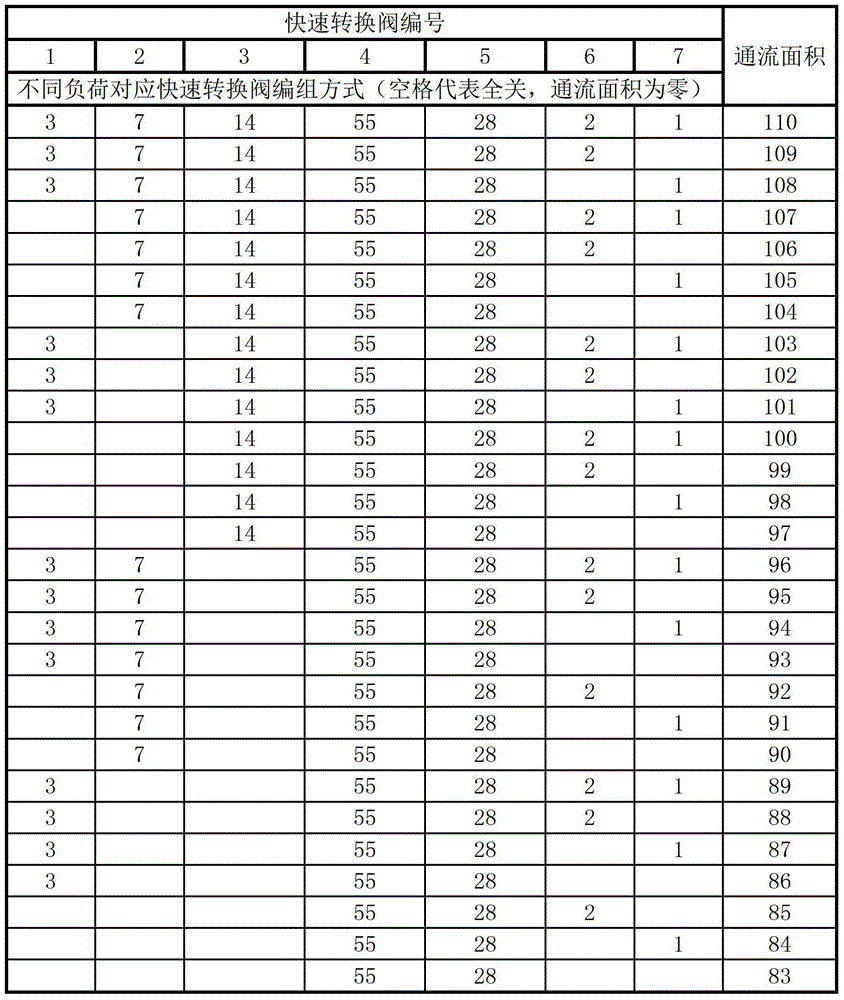

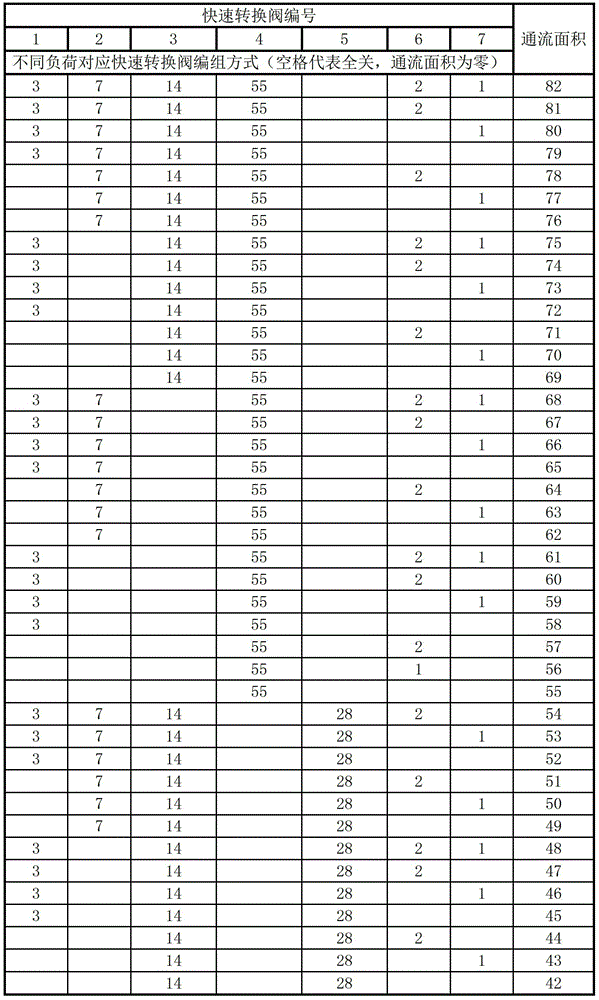

Throttle valve system and working method thereof

ActiveCN103244203AContinuous change of flow areaRegulate fluid flowMachines/enginesEngine componentsSpray nozzleEngineering

The invention discloses a throttle valve system and a working method thereof. The throttle valve system comprises a plurality of channels which are in parallel connection to an upstream straight pipe section; every channel comprises a flow regulator, a flow nozzle and a rapid switching valve which are sequentially connected; every rapid switching valve of every channel is communicated with a downstream straight pipe section through a buffer; and every rapid switching valve has a full open state and a full closed state. The throttle valve system and the working method thereof have the advantages of conforming to the basic theory of engineering thermodynamics, being capable of continuously changing the flow area to adjust the fluid flow, effectively reducing throttling losses and meeting the requirements of energy conservation and emissions reduction to the greatest extent.

Owner:STATE GRID CORP OF CHINA +1

Starch adhesive(SSS-2000)

The starch adhesive SSS-2000 has corn starch and water as main components and contains also stabilizer, oxidant, terminating agent, catalyst, etc. The adhesive is chemically modified neutral grafted starch and is specially for coating pigment. Compared with conventional starch, the present invention has less retrogradation and high compatibility, and is suitable for compounding pigment paint with high solid content and low viscosity. The present invention is suitable for painting various paper products.

Owner:泰州市华光金属制品有限公司

A kind of diaphragm paper for mercury-free alkaline zinc-manganese battery and preparation method thereof

ActiveCN104631198BImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingManganeseZinc

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

Quantitative dye delivery device

ActiveCN105174185AImplement filteringImprove filtering effectLiquid transferring devicesEngineeringPiston rod

The invention provides a quantitative dye delivery device and belongs to the technical field of textile machinery. The quantitative dye delivery device comprises an injection mechanism, a delivery mechanism and a stirring mechanism. An upper platform and a lower platform of a guiding rail of the delivery mechanism are connected through an inclined platform, the front end of a piston rod of a cylinder is hinged to one end of a first connecting rod, and the other end of the first connecting rod is hinged to a rocker. The lower end of the rocker is hinged to a rocker supporting seat, and the upper end of the rocker is hinged to the upper end of a second connecting rod. The lower end of the second connecting rod is hinged to the upper end of a dye container. One end of a pump of the injection mechanism is connected with a dye tank through a first branch pipe, and the other end of the pump is connected with an injection head through a second branch pipe. A stirring box of the stirring mechanism is mounted on a box body support, a stirring motor is located over the stirring box, a stirring bar is coaxially connected to the stirring motor, and stirring blades are arranged at the lower end of the stirring bar. By means of the quantitative dye delivery device, quantitative delivery of dye is automatically achieved, the manual labor intensity is greatly lowered, and efficiency is improved.

Owner:ZHEJIANG HUAYUE PRINTING CO LTD

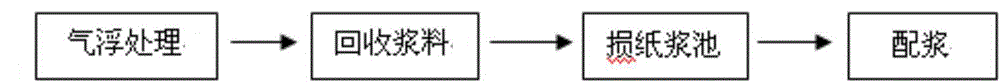

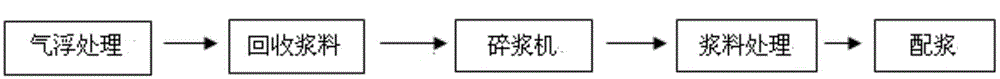

Treatment process of papermaking recovery pulp

ActiveCN105986502AEliminate the effect of concentrationStable concentrationMachine wet endPulp treatmentPaper production

The invention relates to a treatment process of papermaking recovery pulp. The treatment process is characterized by sequentially comprising the following steps that 1, papermaking white water is treated through a gas flotation method, and the recovery pulp is obtained; 2, the recovery pulp obtained in the first step is conveyed to a hardwood pulp pulper for pulping treatment, and the concentration in the pulp is stable; 3, the pulp obtained in the second step is blended into a pulp line for subsequent paper production. Compared with the prior art, the treatment process of the papermaking recovery pulp has the advantages of being high in concentration of the recovery pulp, stable in concentration of the pulp line and the like.

Owner:上海东冠纸业有限公司

A dye quantitative delivery device

ActiveCN105174185BImplement filteringImprove filtering effectLiquid transferring devicesElectric machineryEngineering

The invention provides a quantitative dye delivery device and belongs to the technical field of textile machinery. The quantitative dye delivery device comprises an injection mechanism, a delivery mechanism and a stirring mechanism. An upper platform and a lower platform of a guiding rail of the delivery mechanism are connected through an inclined platform, the front end of a piston rod of a cylinder is hinged to one end of a first connecting rod, and the other end of the first connecting rod is hinged to a rocker. The lower end of the rocker is hinged to a rocker supporting seat, and the upper end of the rocker is hinged to the upper end of a second connecting rod. The lower end of the second connecting rod is hinged to the upper end of a dye container. One end of a pump of the injection mechanism is connected with a dye tank through a first branch pipe, and the other end of the pump is connected with an injection head through a second branch pipe. A stirring box of the stirring mechanism is mounted on a box body support, a stirring motor is located over the stirring box, a stirring bar is coaxially connected to the stirring motor, and stirring blades are arranged at the lower end of the stirring bar. By means of the quantitative dye delivery device, quantitative delivery of dye is automatically achieved, the manual labor intensity is greatly lowered, and efficiency is improved.

Owner:ZHEJIANG HUAYUE PRINTING CO LTD

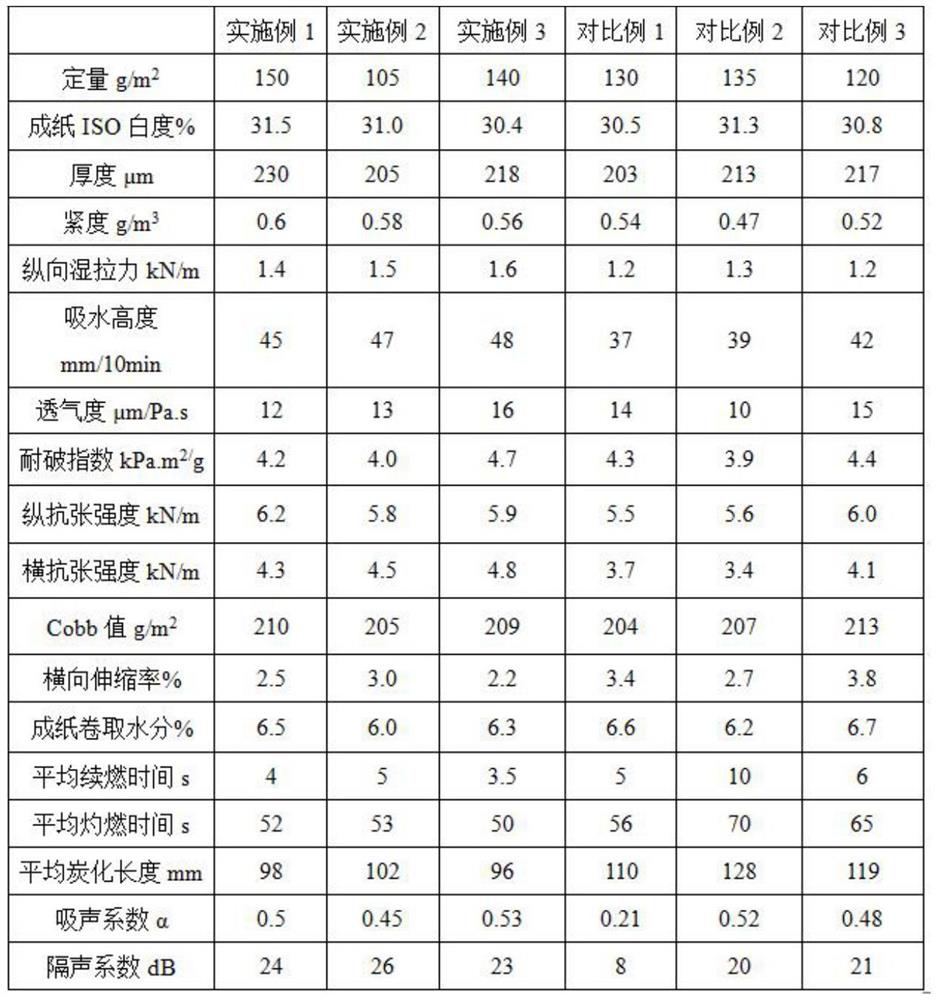

Manufacturing method of fireproof board core paper

InactiveCN111962332AImprove uniformityQuantitatively stableDefoamers additionSpecial paperFiberPapermaking

The invention discloses a manufacturing method of a fireproof board core paper. The invention belongs to the technical field of papermaking, needle-leaved wood, broad-leaved wood and camphorwood are used as fiber raw materials, the preparation method comprises the following steps: cooking, extracting, performing oxygen delignification, performing hydrogen peroxide micro-bleaching, washing, pulping, preparing pulp, slushing, screening and purifying, sizing, dehydrating and forming a net part, squeezing, performing pre-drying, performing surface sizing, performing post-drying, coiling, rewindingand packaging, wherein the ratio of the needle-leaved wood to the broad-leaved wood to the camphorwood is (4.5-5): (3-4): 1. The fireproof board core paper manufactured through the method is good inuniformity, stable in quantification, consistent in tightness, smooth in paper surface, good in laminating performance, free of impurities on the appearance of the paper surface and free of lint on the end face, and the flame retardant property and the sound insulation property of the core paper are improved simultaneously.

Owner:YUEYANG FOREST & PAPER CO LTD

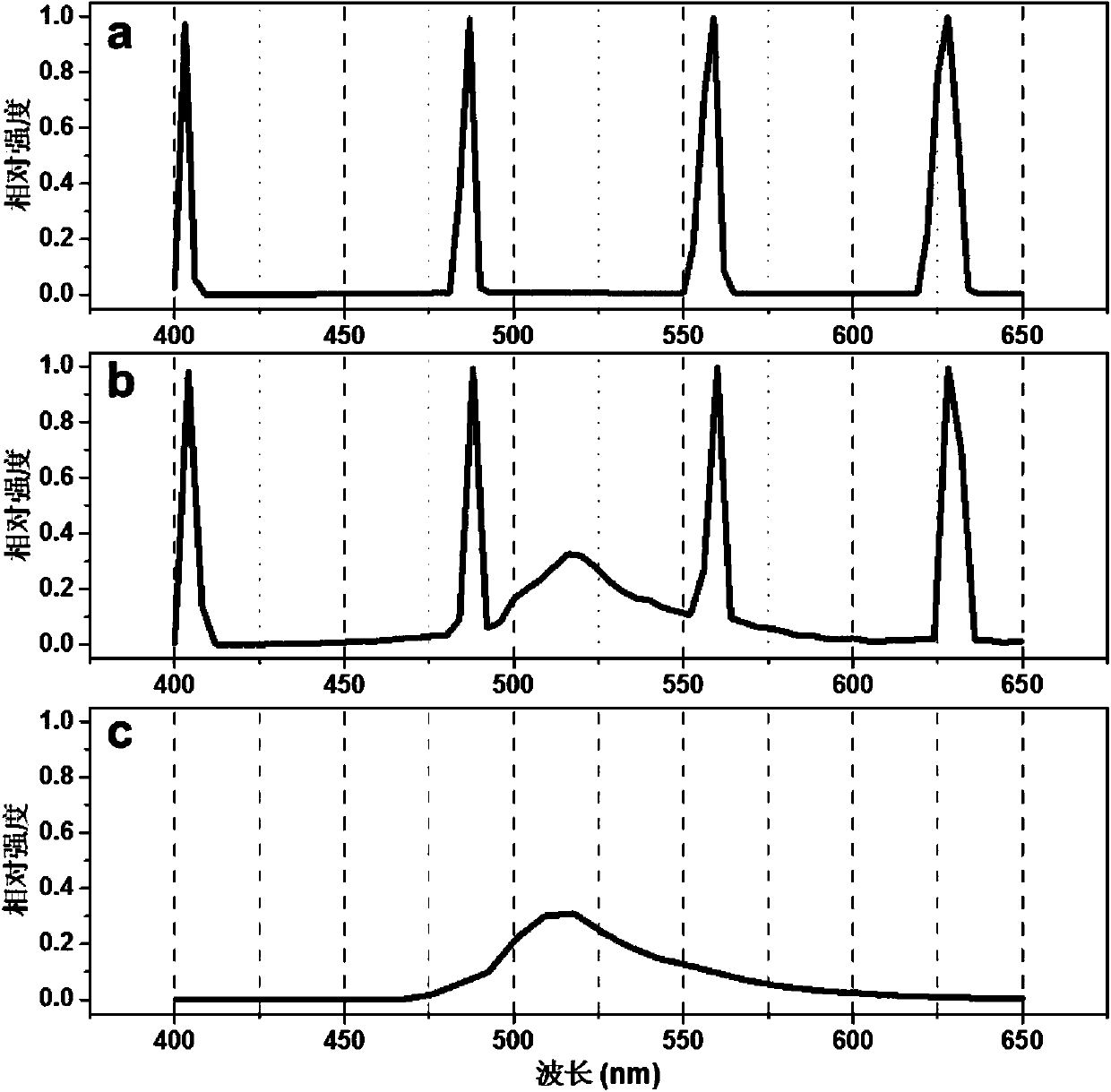

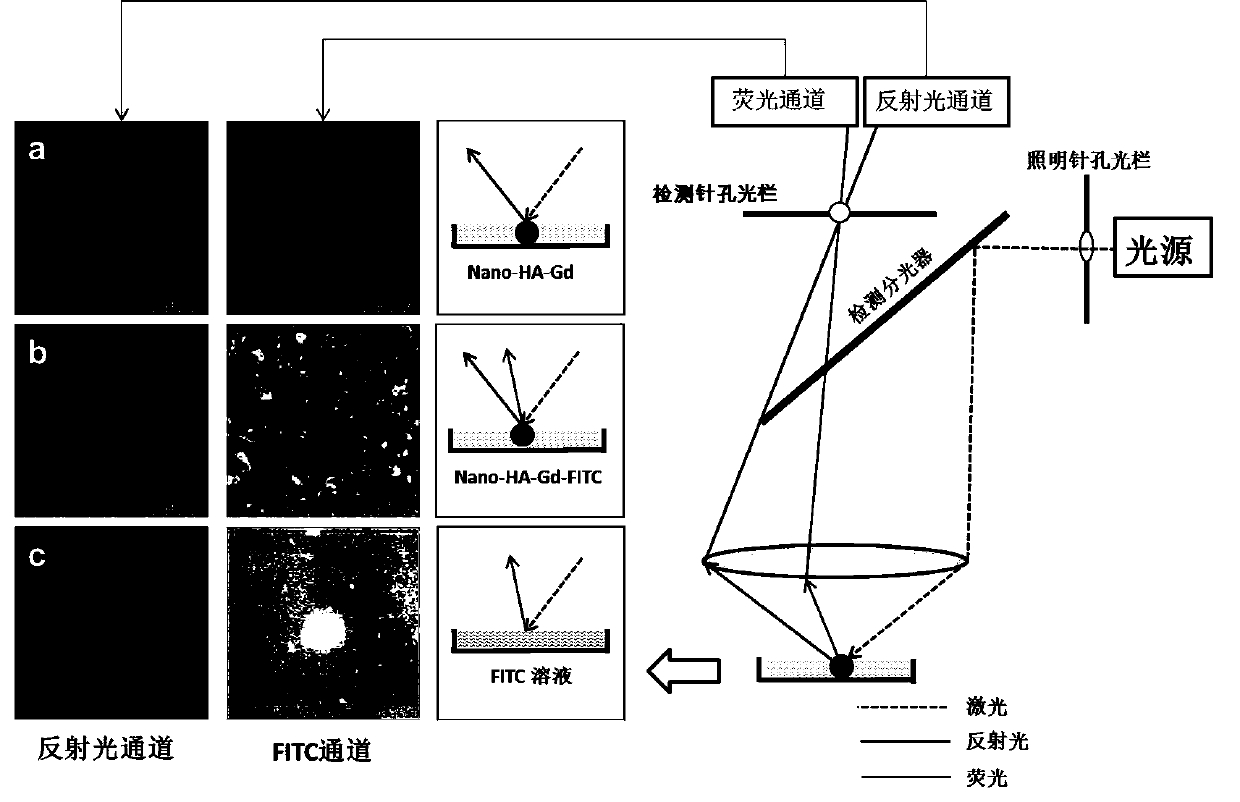

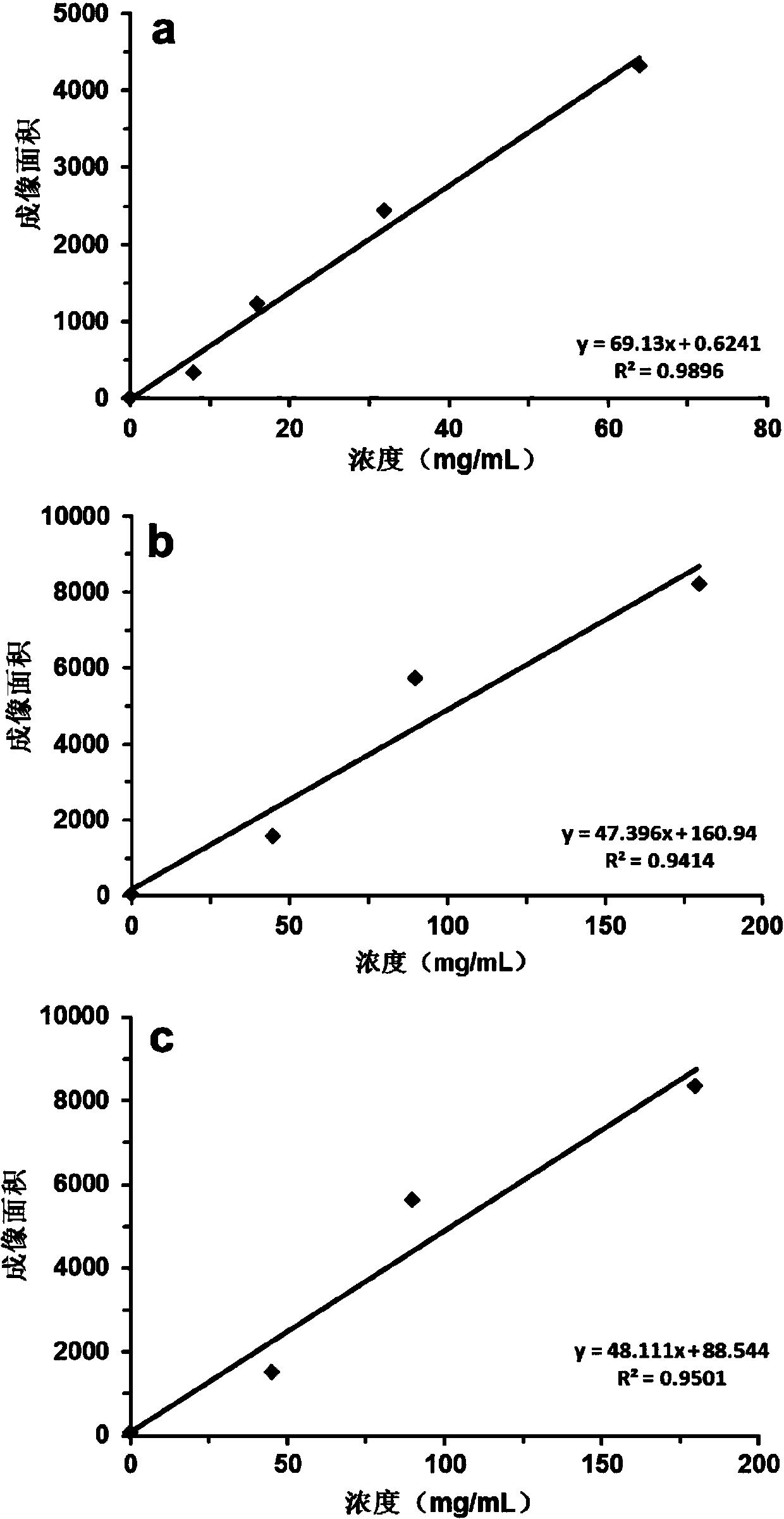

A detection method for gadolinium-containing hydroxyapatite nanoparticles

ActiveCN106153506BImprove detection accuracyImprove linearityMaterial analysisSpectral curvePhysical chemistry

Owner:PEKING UNIV

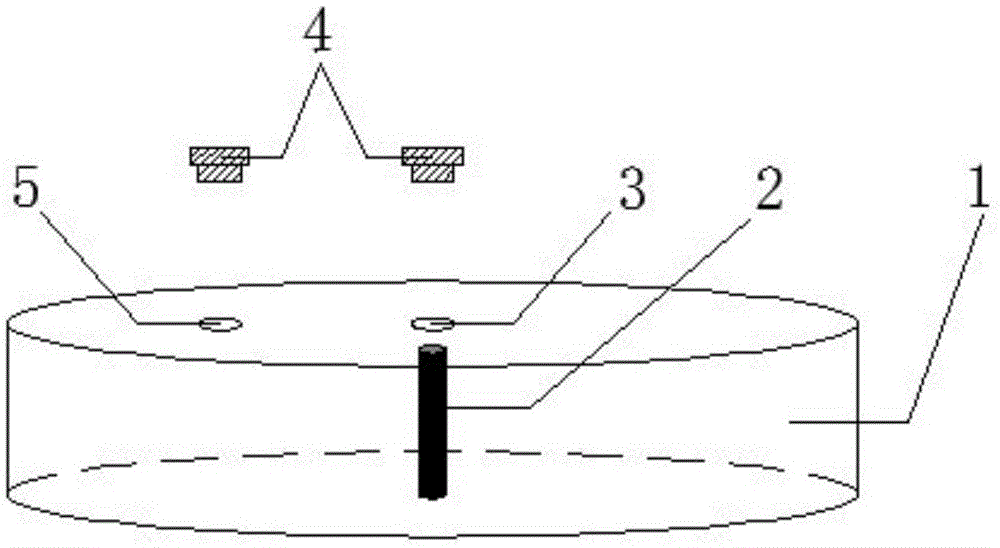

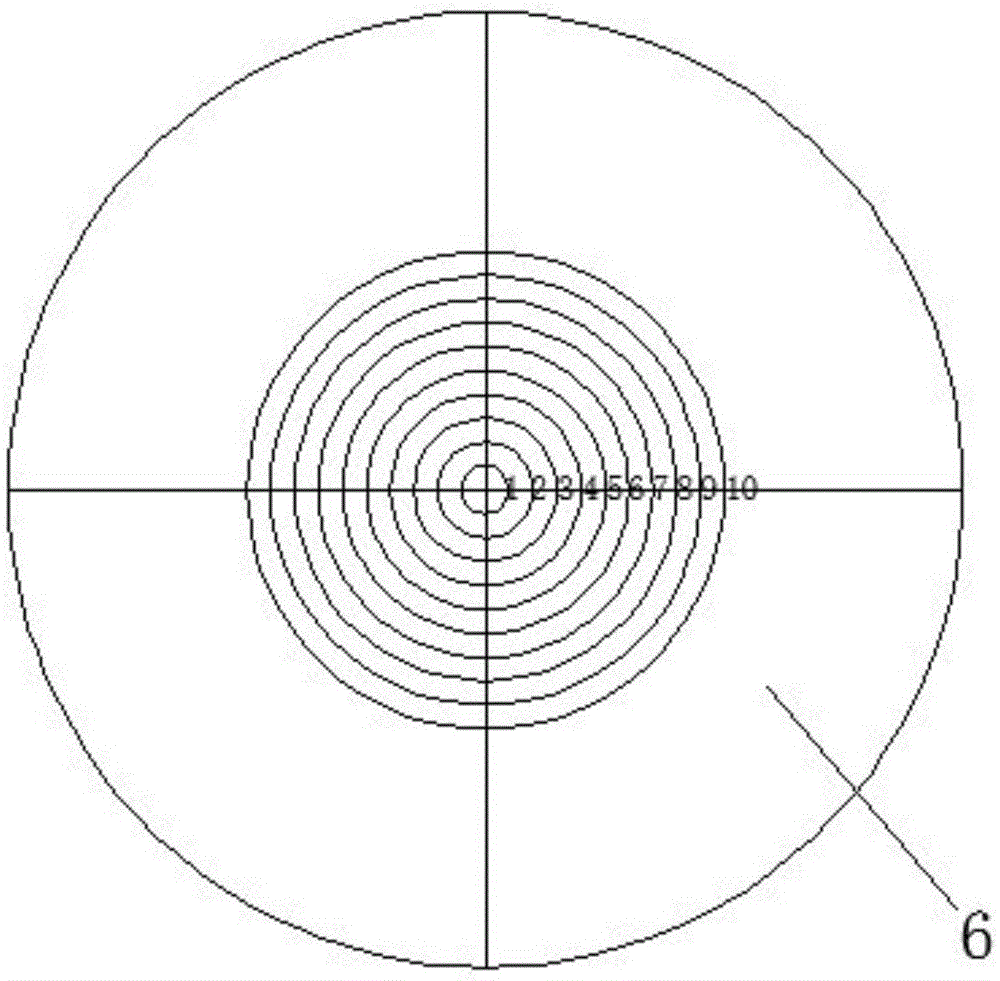

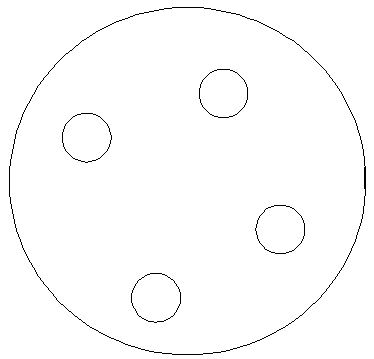

Quantitative box for oil drain ring

ActiveCN105651652BEasy to quantifyQuantitatively accurateSurface tension analysisEngineeringSURFACTANT BLEND

The invention discloses an oil spreading quantifying box, comprising a quantifying box, a sample injection column, sealing plugs and a quantitative dial, wherein the quantifying box is a circular transparent box body; the sample injection column is a solid glass column; the lower end of the sample injection column is fixed in the middle of the bottom in the quantifying box, and a 3cm of gap is reserved between the upper end of the sample injection column and a cover body of the quantifying box; a sample injection hole is formed in the middle of the cover body of the quantifying box and is positioned above the sample injection column; a material injection hole is formed in one side of the cover body of the quantifying box; one of the two sealing plugs is connected with the sample injection hole, and the other sealing plug is connected with the material injection hole; the quantitative dial is made of transparent material; the quantitative dial is provided with ten equally divided rings which are marked with numerical symbols. Compared with the prior art, the oil spreading quantifying box is capable of conveniently, rapidly, accurately and stably measuring the content of a biological surfactant; after the oil spreading quantifying box is used, the quantitation standards for different types of biological surfactants or one biological surfactant in different environments can be established; the oil spreading quantifying box is convenient to use and has popularization and application values.

Owner:OCEAN UNIV OF CHINA

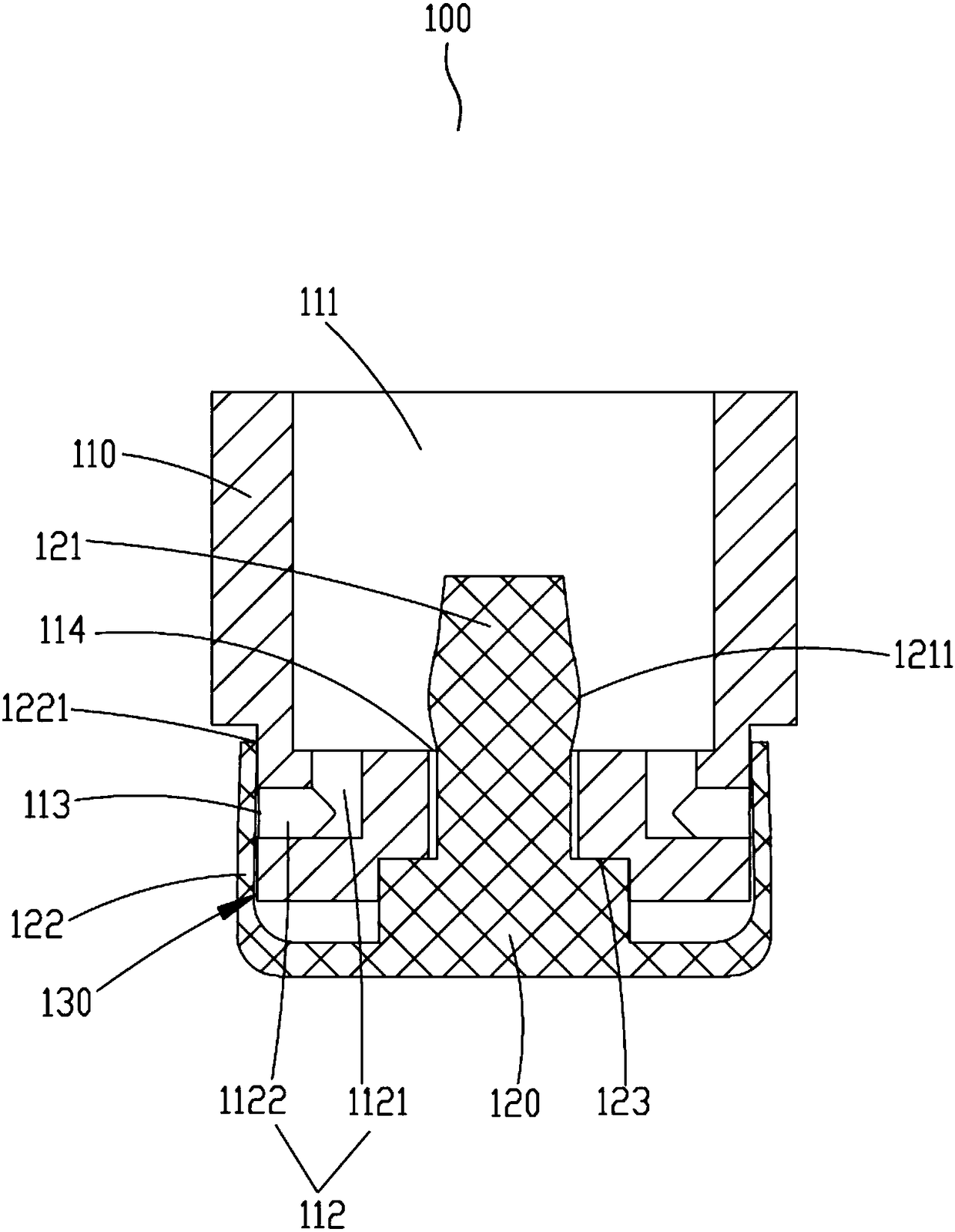

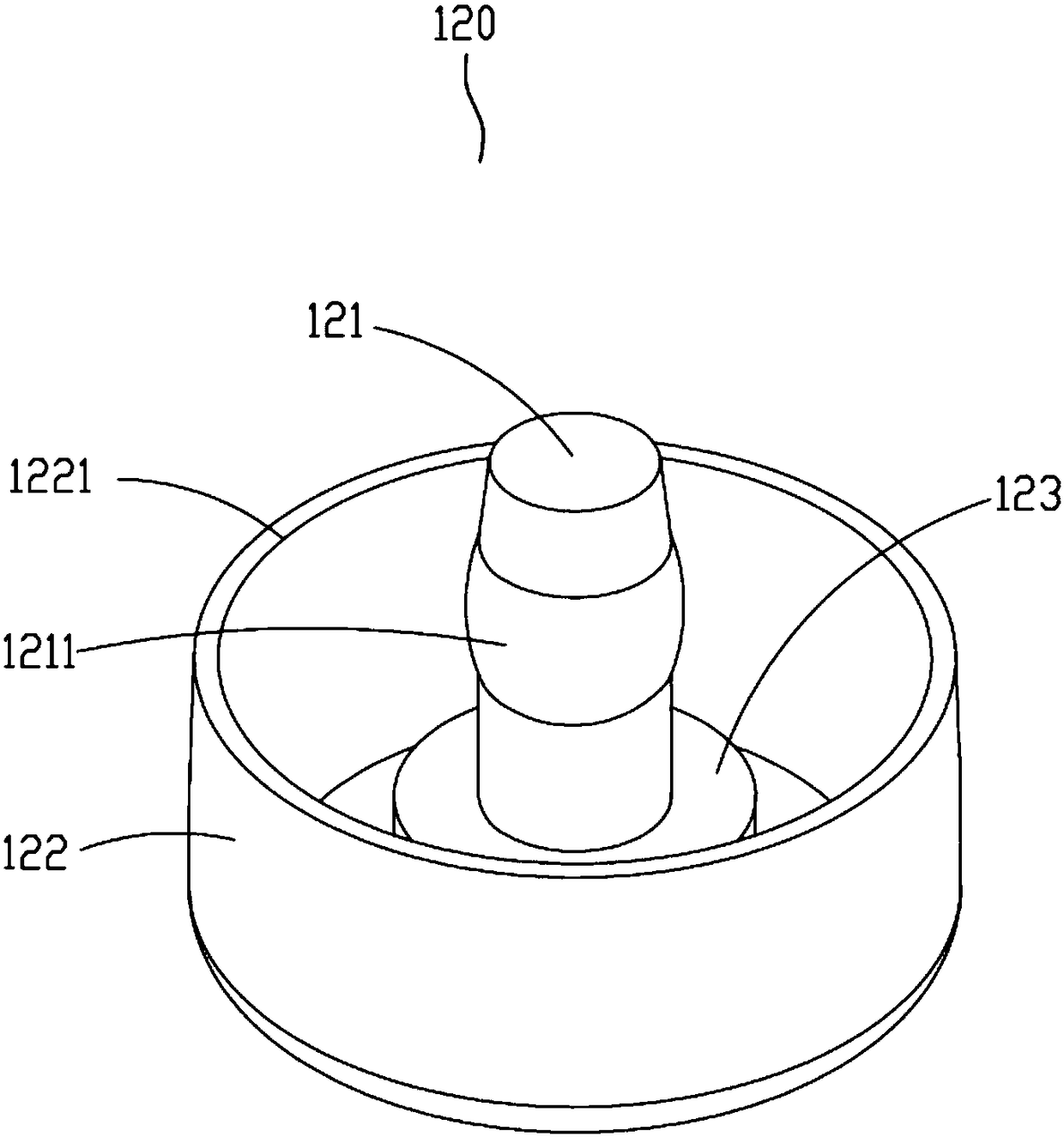

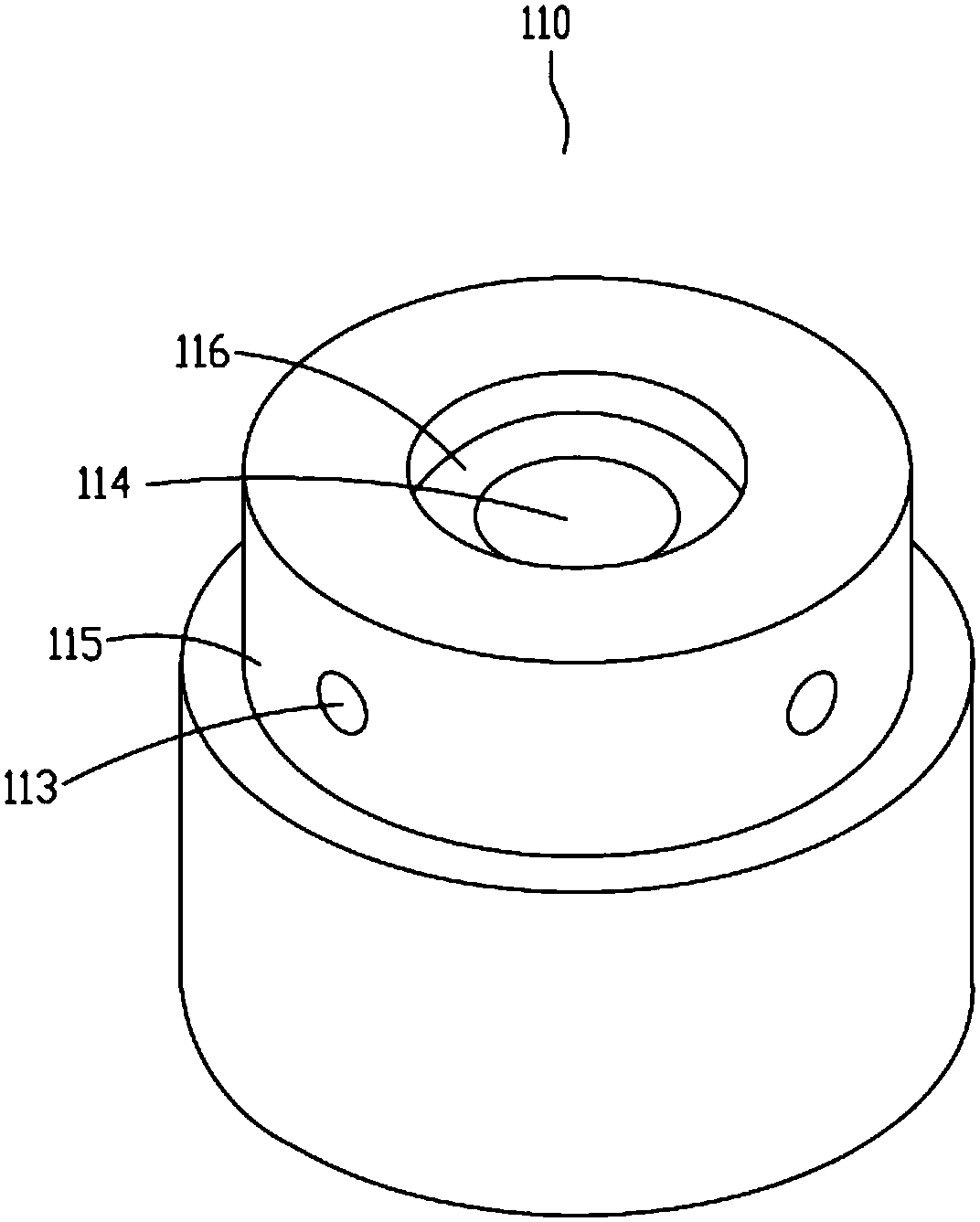

One-way valve structure and quantitative pump

InactiveCN108286617ADirectional flow blockingRealize the role of one-way circulationDiaphragm valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention relates to the technical field of valves, and provides a one-way valve structure and a quantitative pump. The one-way valve structure comprises a valve plate and a valve plate support, the valve plate comprises a mounting portion and a sealing portion, and the sealing portion covers the side wall of the valve plate support; the edge of the sealing portion is attached to the side wallof the valve plate support; compared with a conventional valve, the valve plate and the valve plate support form a coating type sealing, so that the valve plate can be better attached to the valve plate support, and reliability and stability of sealing can be improved. The one-way valve structure is arranged in the quantitative pump so as to control the liquid to flow directionally, so that the sealing is more reliable and more stable, the liquid can be effectively prevented from flowing reversely, and therefore the quantitative precision is achieved; and the valve structure and the quantitative pump solve the problems that in the prior art, the quantitative precision fluctuation is large and the liquid discharge liquid is insufficient are solved.

Owner:SHENZHEN KEYTO FLUID CONTROL

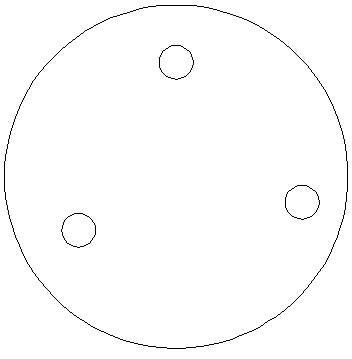

Gold tea cake pressing device

The invention belongs to the field of tea production and processing, and particularly relates to a gold tea cake pressing device, the device comprises a bottom mold base, a bottom mold base rotating device, lower molds, an upper mold, a pressing cylinder connected with the upper mold, a guiding rod, a loading hopper, and a scrapping plate, the number of the lower molds is three, the lower molds are uniformly disposed on the same circumference of the bottom mold base, wherein one lower mold corresponds to the upper mold, the next lower mold in the clockwise direction corresponds to the openingof the loading hopper, and the next lower mold corresponds to the position of the scrapping plate, the rotation tempo of the bottom mold base per cycle is 60 DEG, 60 DEG, 120 DEG, and 120 DEG. Compared with the prior art, the device has the advantages that the operation is simple, each cake has stable quantification, the operation is safe and the production efficiency is high.

Owner:江苏珍香生态农业科技有限公司

Throttle valve system and working method thereof

ActiveCN103244203BQuantitatively stableQuantitative continuousMachines/enginesEngine componentsSpray nozzleEngineering

The invention discloses a throttle valve system and a working method thereof. The throttle valve system comprises a plurality of channels which are in parallel connection to an upstream straight pipe section; every channel comprises a flow regulator, a flow nozzle and a rapid switching valve which are sequentially connected; every rapid switching valve of every channel is communicated with a downstream straight pipe section through a buffer; and every rapid switching valve has a full open state and a full closed state. The throttle valve system and the working method thereof have the advantages of conforming to the basic theory of engineering thermodynamics, being capable of continuously changing the flow area to adjust the fluid flow, effectively reducing throttling losses and meeting the requirements of energy conservation and emissions reduction to the greatest extent.

Owner:STATE GRID CORP OF CHINA +1

Continuous automatic pug mixer

InactiveCN101347818BHigh viscosityThe amount added is stableMould handling/dressing devicesProportional controlDry sand

Owner:济南林青铸造技术有限公司

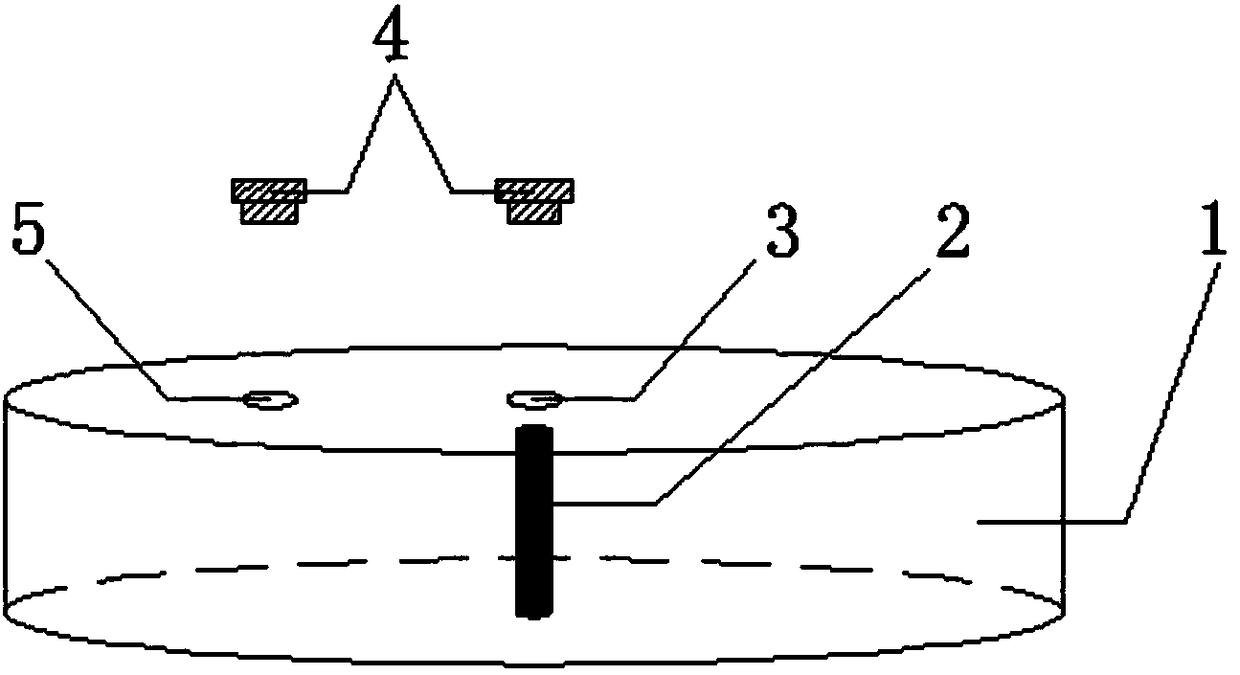

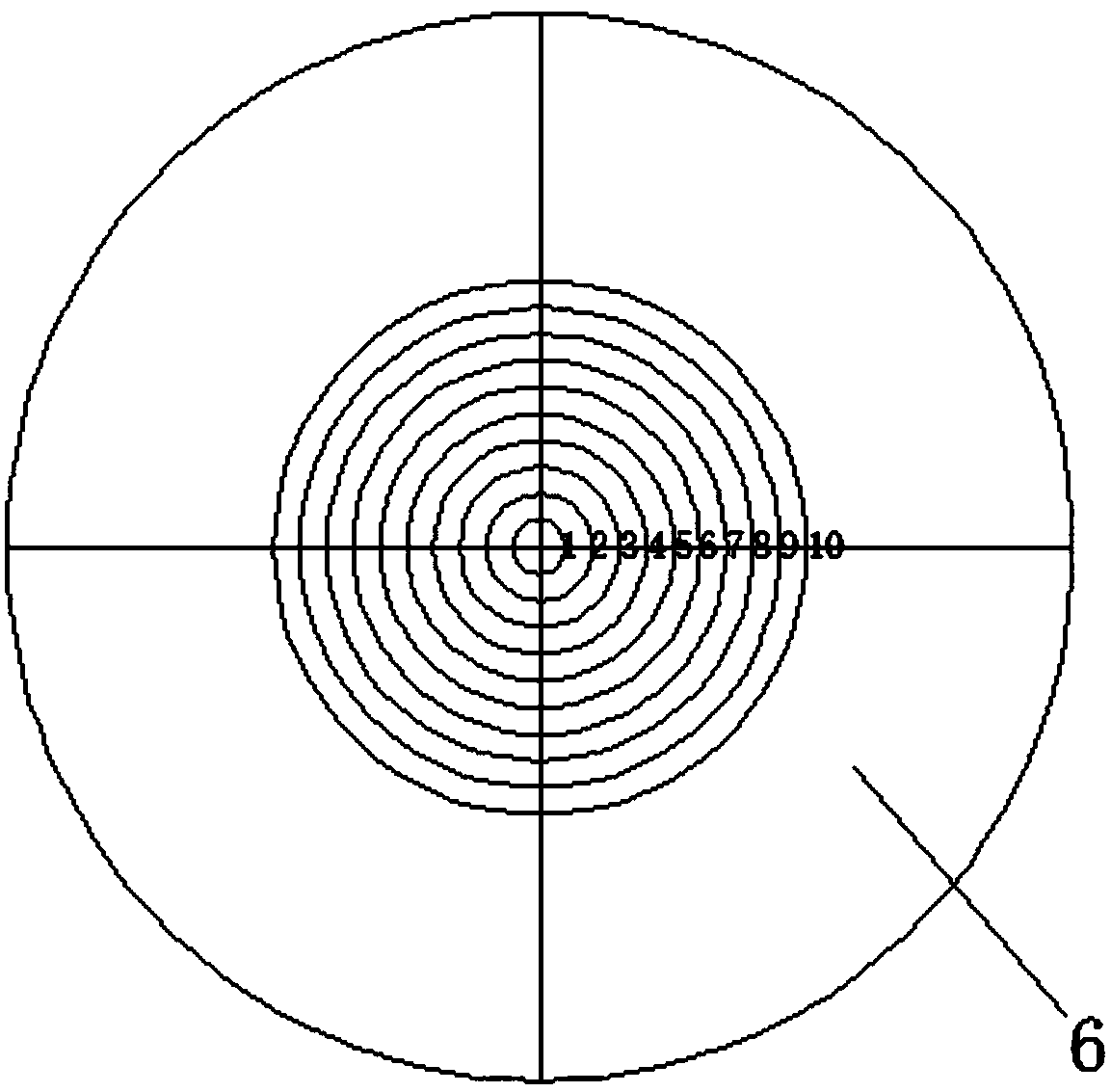

Oil spreading quantifying box

ActiveCN105651652AEasy to quantifyQuantitatively accurateSurface tension analysisEngineeringSURFACTANT BLEND

The invention discloses an oil spreading quantifying box, comprising a quantifying box, a sample injection column, sealing plugs and a quantitative dial, wherein the quantifying box is a circular transparent box body; the sample injection column is a solid glass column; the lower end of the sample injection column is fixed in the middle of the bottom in the quantifying box, and a 3cm of gap is reserved between the upper end of the sample injection column and a cover body of the quantifying box; a sample injection hole is formed in the middle of the cover body of the quantifying box and is positioned above the sample injection column; a material injection hole is formed in one side of the cover body of the quantifying box; one of the two sealing plugs is connected with the sample injection hole, and the other sealing plug is connected with the material injection hole; the quantitative dial is made of transparent material; the quantitative dial is provided with ten equally divided rings which are marked with numerical symbols. Compared with the prior art, the oil spreading quantifying box is capable of conveniently, rapidly, accurately and stably measuring the content of a biological surfactant; after the oil spreading quantifying box is used, the quantitation standards for different types of biological surfactants or one biological surfactant in different environments can be established; the oil spreading quantifying box is convenient to use and has popularization and application values.

Owner:OCEAN UNIV OF CHINA

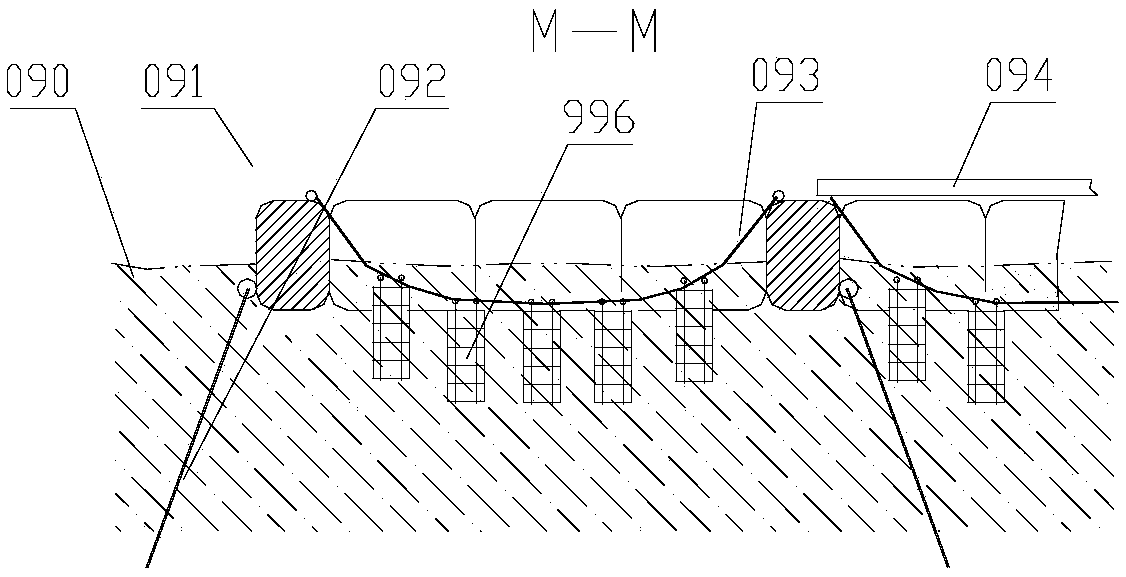

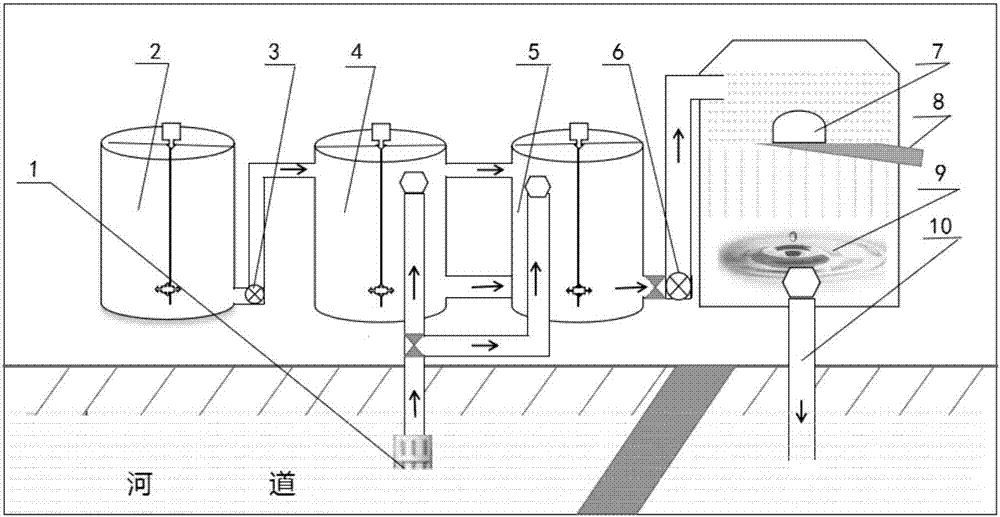

Sewage solid-liquid separation and purification system

PendingCN107162274AQuantitatively accurateQuantitatively stableWater/sewage treatment by centrifugal separationTreatment involving filtrationSludgeSewage

The invention discloses a sewage solid-liquid separation and purification system. The system comprises a sewage transfer pump, a reagent reaction tank, a liquid reagent transfer pump, at least one sewage reaction tank, a mixed solution transfer pump and a solid-liquid separation unit; and the solid-liquid separation unit is provided with a mixed solution inlet, a sludge outlet and a clear outlet, and comprises a centrifuge, a filter screen and a purifying chamber. The sewage solid-liquid separation and purification system realizes accurately-quantified stable and continuous solid-liquid separation and purification of sewage.

Owner:河南北斗众创高新技术研究院有限公司 +1

Quantifying liquid-discharging structure with middle exhaust pipe

InactiveCN102211000BGuaranteed stabilityQuantitatively stableStationary measuring chambersFeed devicesExhaust pipeElectromagnetic valve

Owner:WUXI GREENSTEK

Quartz sand conveying device and method

The invention mainly aims at providing a quartz sand conveying device and method. The device comprises a storage silo, a gas-tight silo, a transport disc arranged in the gas-tight silo, a gas source and a material blowing block. The method comprises the following steps that quartz sand is mechanically conveyed to the material blowing block from the gas-tight silo; the material blowing block comprises a bottom surface opening and a top surface small opening communicating with the bottom surface opening; the bottom surface opening penetrates through one side surface of the material blowing blockthrough a side opening; and the quartz sand is conveyed to a designated position through the side opening of the material blowing block, the bottom surface opening and the top surface small opening in sequence through airflow. According to the device and method provided by the invention, the problems that in the prior art, in a scraper (scraper blade) conveying process, the quartz sand flow is instable and inaccurate due to scraper (scraper blade) abrasion or vibration, scraper (scraper blade) abrasion materials pollute the quartz sand, meanwhile, the mounting position of a conveying device in the prior art is limited by the height, and raw material filling difficulty and safety risks are prone to occurring are solved, and accordingly, the device and method are more practical.

Owner:CHINA BUILDING MATERIALS ACAD

Toner Metering Conveyor System

ActiveCN106364928BImprove applicabilityQuantitative errors that affect the ratioBulk conveyorsLoading/unloadingFiberEngineering

The invention discloses a toner metering and conveying system. According to the technical scheme, the toner metering and conveying system is characterized by comprising a drying tower arranged on a rack and used for storing polylactic acid dry slices, a slice pipeline communicated and connected with the drying tower and used for conveying the polylactic acid dry slices, a stock bin used for storing toner, and a conveying device used for conveying the toner in the stock bin into the slice pipeline. The effect of continuously controlling and quantitatively conveying the toner is achieved, and every time the toner in a metering containing hole is conveyed into the slice pipeline to be mixed with the polylactic acid dry slices; and the effects of accurate metering and conveying of the toner and continuous conveying are achieved, and therefore the coloring quality of colored fiber is improved.

Owner:平顶山三信新材料科技有限公司

High property superthin glass fiber insulation material and its production method

The invention discloses a new-typed hyper-thin high-property glass insulated material, which comprises the following parts: 54 deg alkaline-free glass fiber cotton, 49 deg alkaline-free glass fiber cotton, 44 deg.c alkaline-free glass fiber cotton and PE fiber. The invention possesses high-compaction and high anti-extending strength, which displays excellent insulating property.

Owner:陆剑忠

Tea humidifying device before cake pressing of gold tea cake

PendingCN109924278AQuantitatively stableEasy to operatePre-extraction tea treatmentGraduated cylinderEngineering

The invention relates to a tea humidifying device before cake pressing of gold tea cake, which comprises a base, a humidifier, quantitative cylinders, a quantitative cylinder disc seat, a quantitativecylinder disc seat rotating device, a quantitative cylinder disc seat lifting cylinder, a feeding hopper and a scraping plate, the humidifier is arranged on the base, the quantitative cylinder disc seat is connected with the quantitative cylinder disc seat lifting cylinder, the quantitative cylinder disc seat lifting cylinder is connected with the quantitative cylinder disc seat rotating device,the number of the quantitative cylinders is four, the quantitative cylinders are uniformly disposed on the same circumference of the quantitative cylinder disc seat, wherein one quantitative cylindercorresponds to the humidifier, the next quantitative cylinder in the clockwise direction corresponds to a discharging position, the next quantitative cylinder corresponds to a port of a loading hopper, the next quantitative cylinder corresponds to the position of the scraping plate, the rotation tempo of the quantitative cylinder disc seat per cycle is 90 DEG, 90 DEG, 90 DEG, and 90 DEG. Comparedwith the prior art, the device has the advantages that the operation is simple, each cake has stable quantification, the operation is safe and the production efficiency is high.

Owner:江苏珍香生态农业科技有限公司

Production method of ultra-thin high-permeability oil filter paper

ActiveCN105220573BQuantitative lowQuantitatively stableReinforcing agents additionPaper/cardboardBursting strengthFolding endurance

The invention relates to an ultrathin high-permeability oil filter paper and a preparation method thereof. The filter paper is prepared with the raw materials of hemp pulp, chemical fiber, a wet strength agent and bamboo charcoal powder. Through the steps of pulp beating treatment, auxiliary agent addition, bamboo charcoal powder addition, papermaking and cutting, the ultrathin high-permeability oil filter paper is obtained. The filter paper and the production method have the following advantages: the produced ultrathin high-permeability oil filter paper is ultrathin and has low basis weight; the produced paper has stable basis weight, high air permeability, good filtering and absorption performance, good dry and wet strength, good bursting strength, good high-temperature resistance, good folding endurance, good acid and alkali resistances, good solvent resistance, and good application effect. The filter paper and the production method are suitable for popularization.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com