Quantificational packing machine

A quantitative packaging and stable technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of three-stage feeding difficult to operate stably, long switching time, large drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

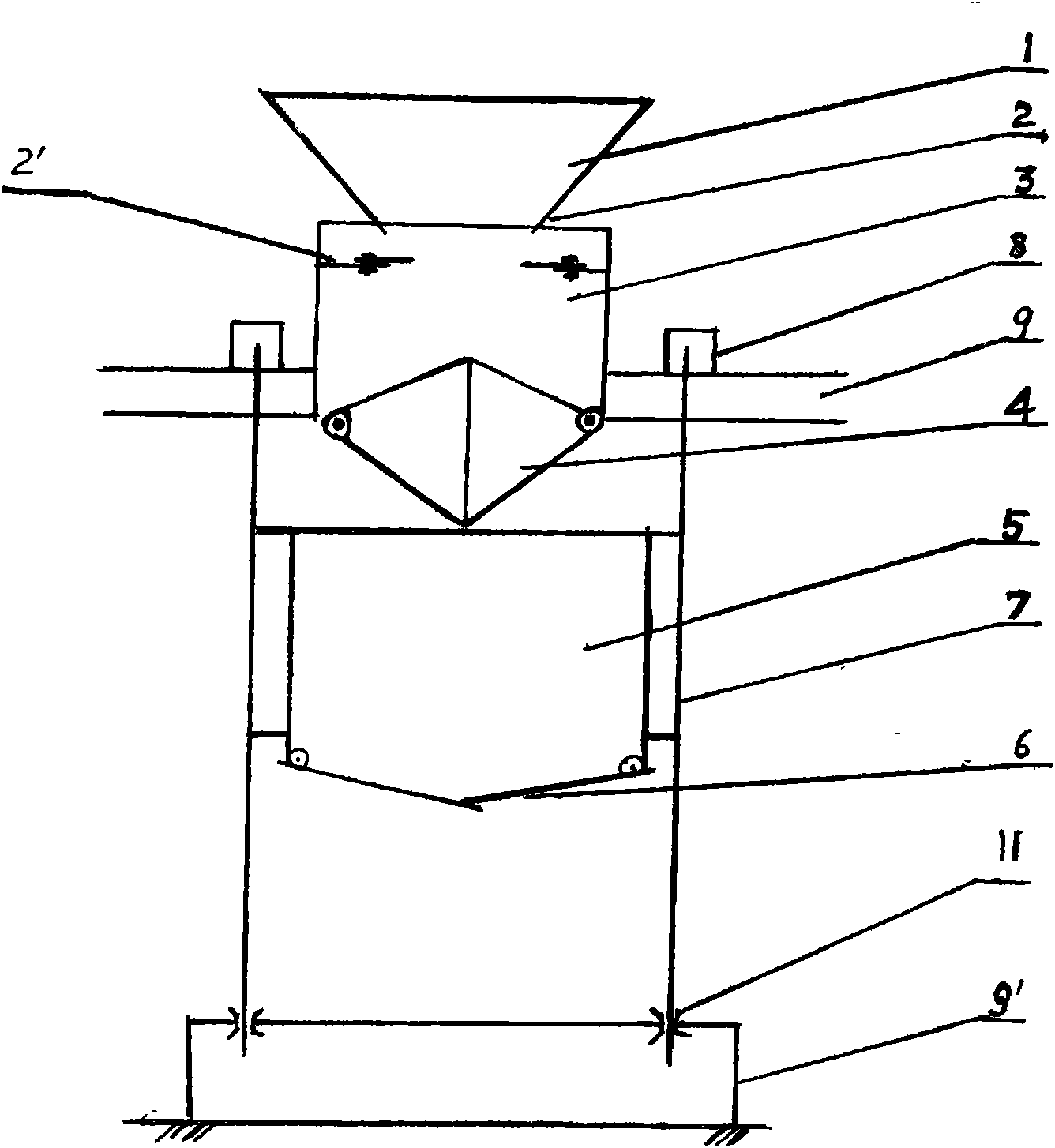

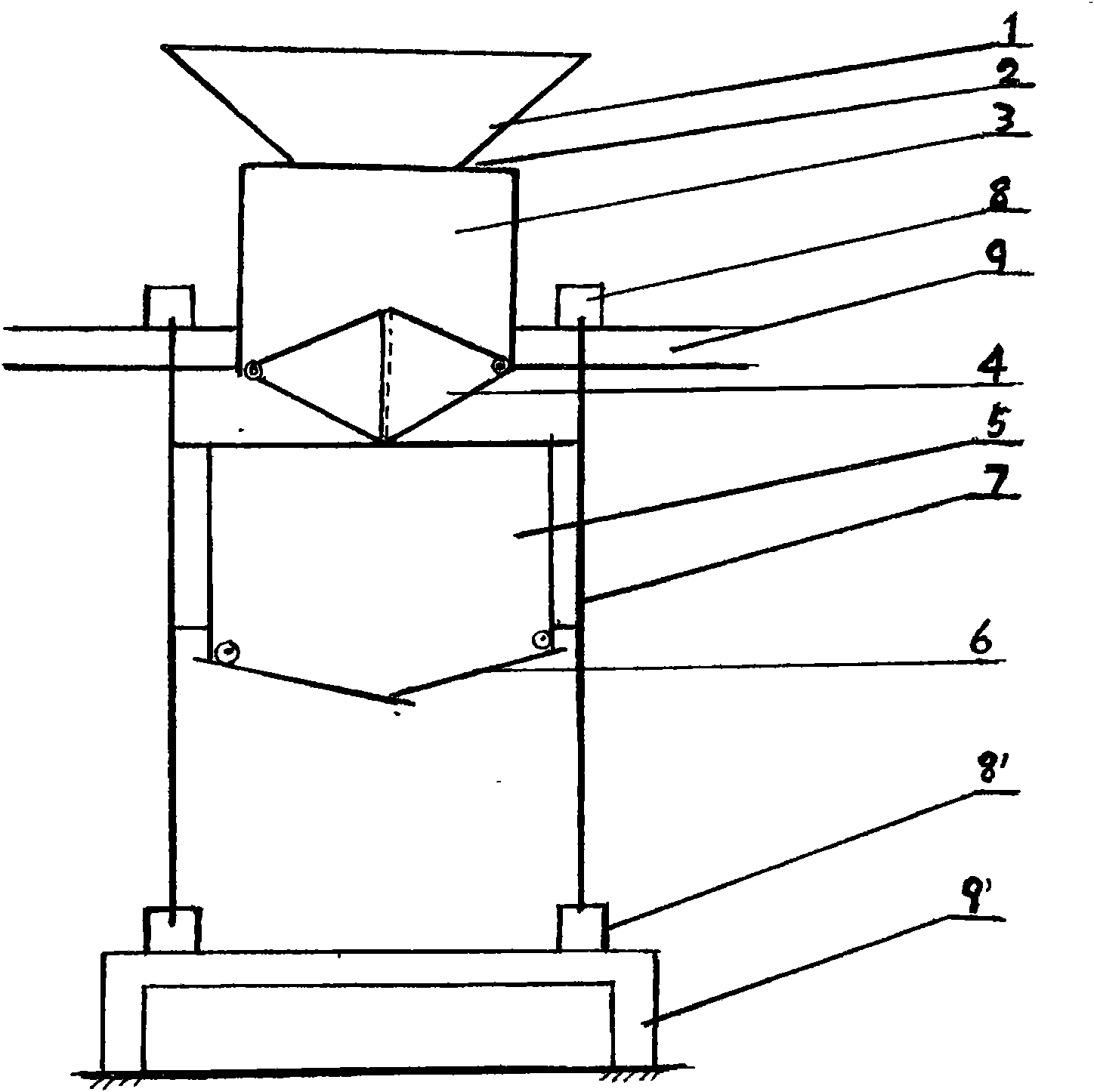

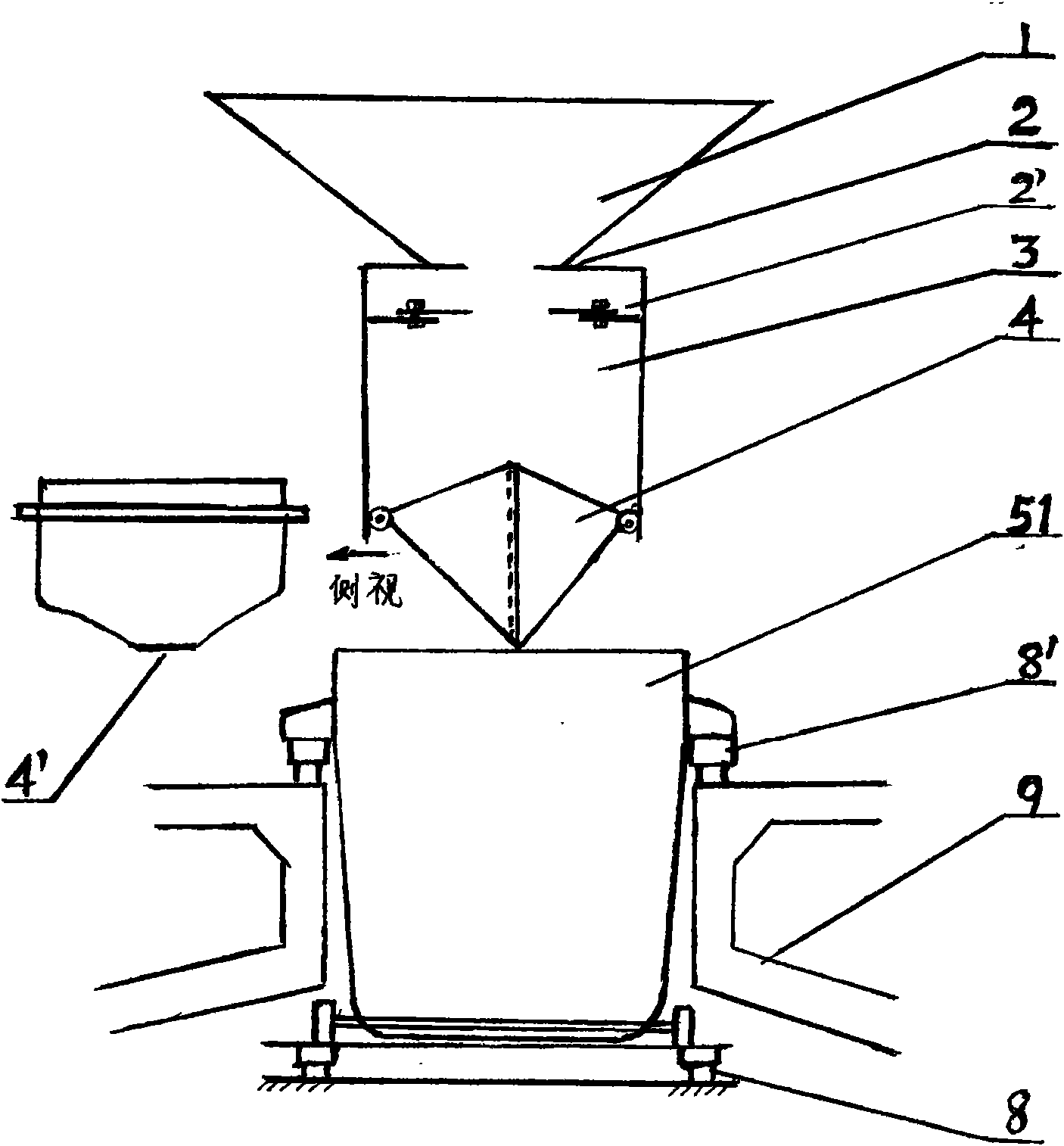

[0023] In order to better understand and implement, below in conjunction with accompanying drawing, provide specific embodiment, describe a kind of quantitative packing machine of the present invention in detail, as figure 1 , Shown in 2, 3, 4, 5, 6, 7, 8, the present embodiment is a quantitative packaging machine, according to the claims it can have multiple schemes to make.

[0024] Make hopper 1 on appropriate height, second stage feed door 2, and feed chute 3, the adjustable second stage feed door 2 ' of device in feed chute 3, make the volume of feed chute 3 supply The material can exceed 30% of the total unit supply, close to 60%.

[0025] In the case that a quantitative packaging machine is a bucketless packaging machine or a large bag packaging machine, a feeder with a fish mouth type material gate 4 is installed on the top, and the setting time for extending the micro-feeding is not lower than the unit third-level feeding time. 50%, to ensure a reasonable structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com