Patents

Literature

204results about How to "Great momentum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

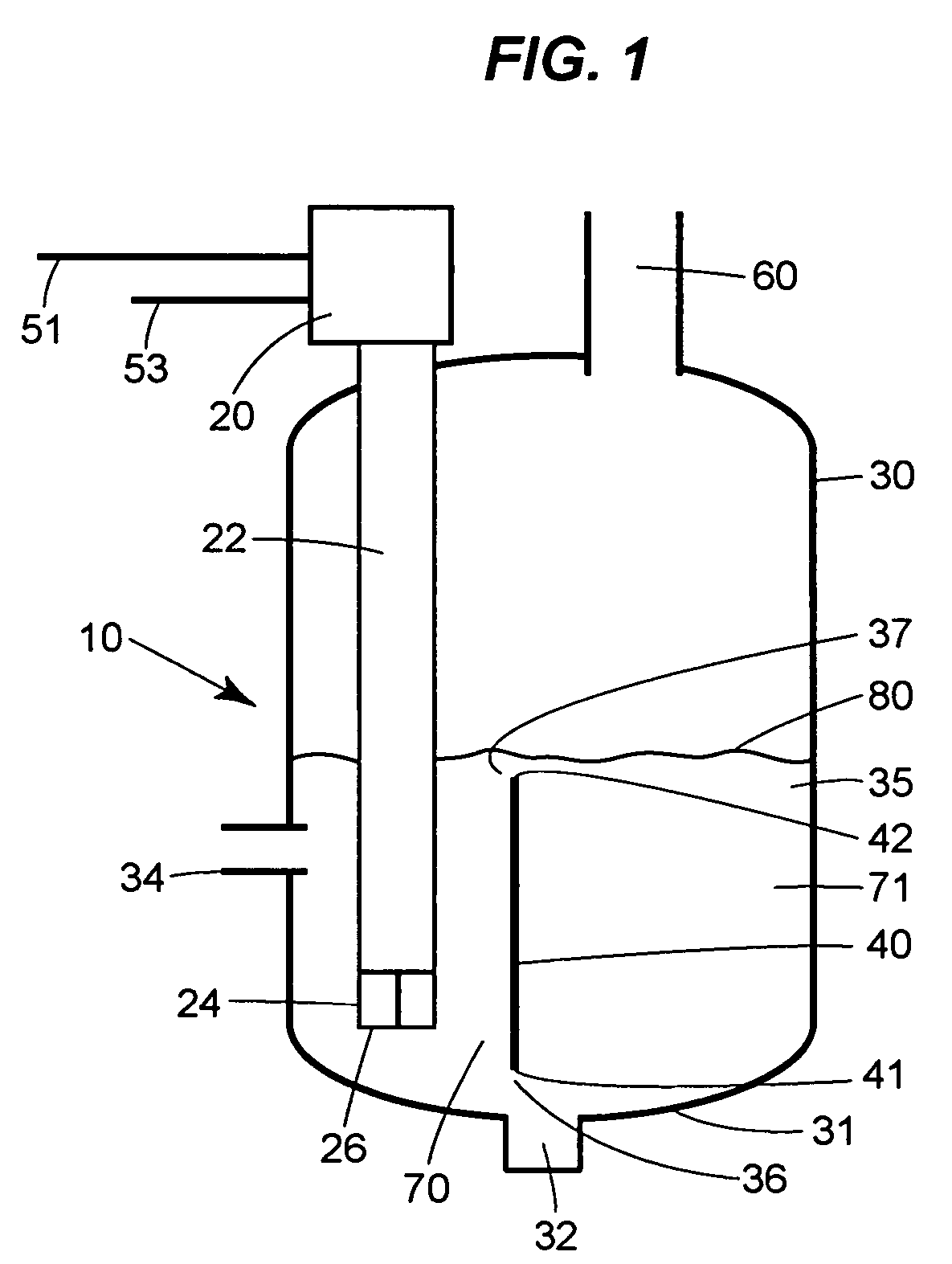

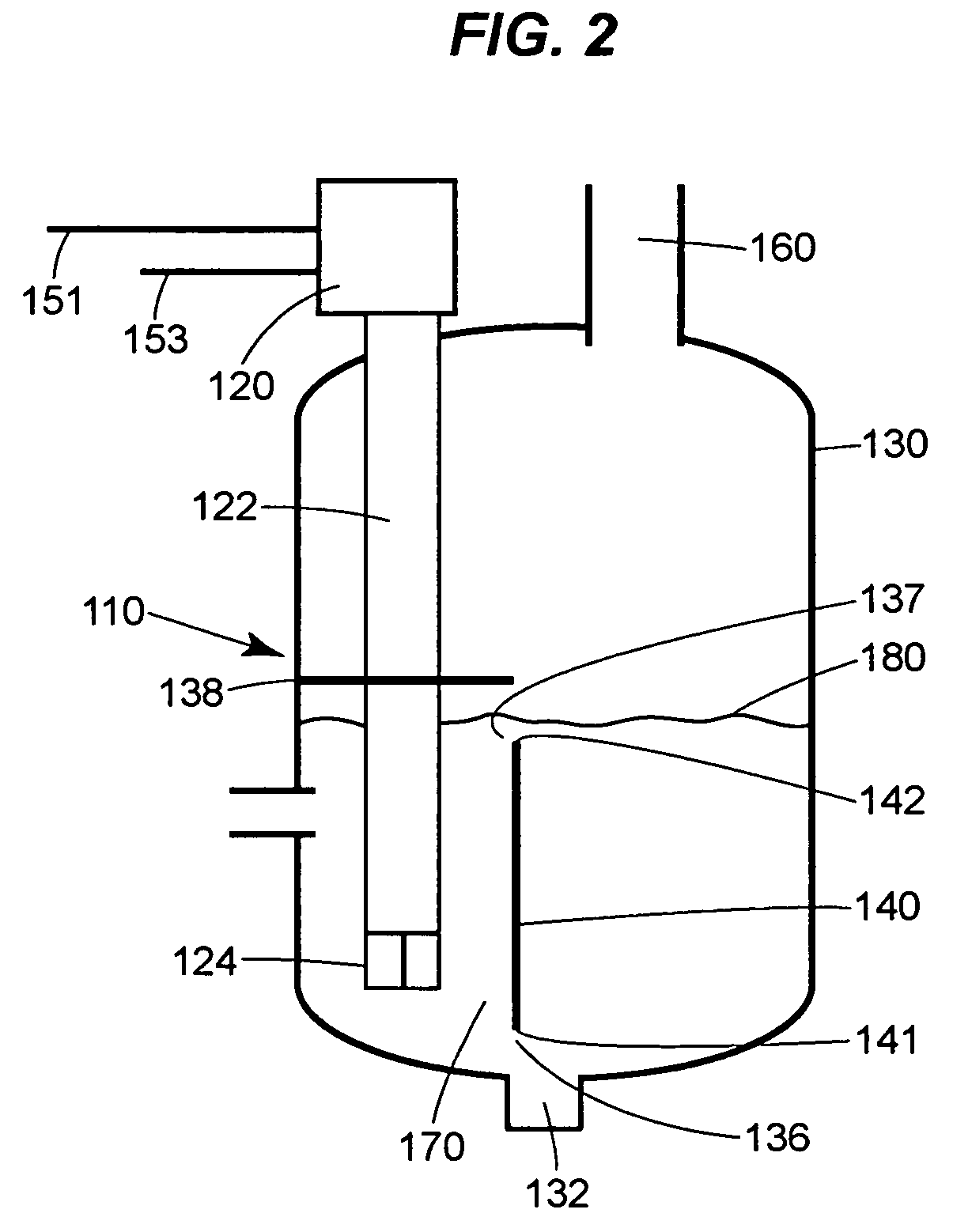

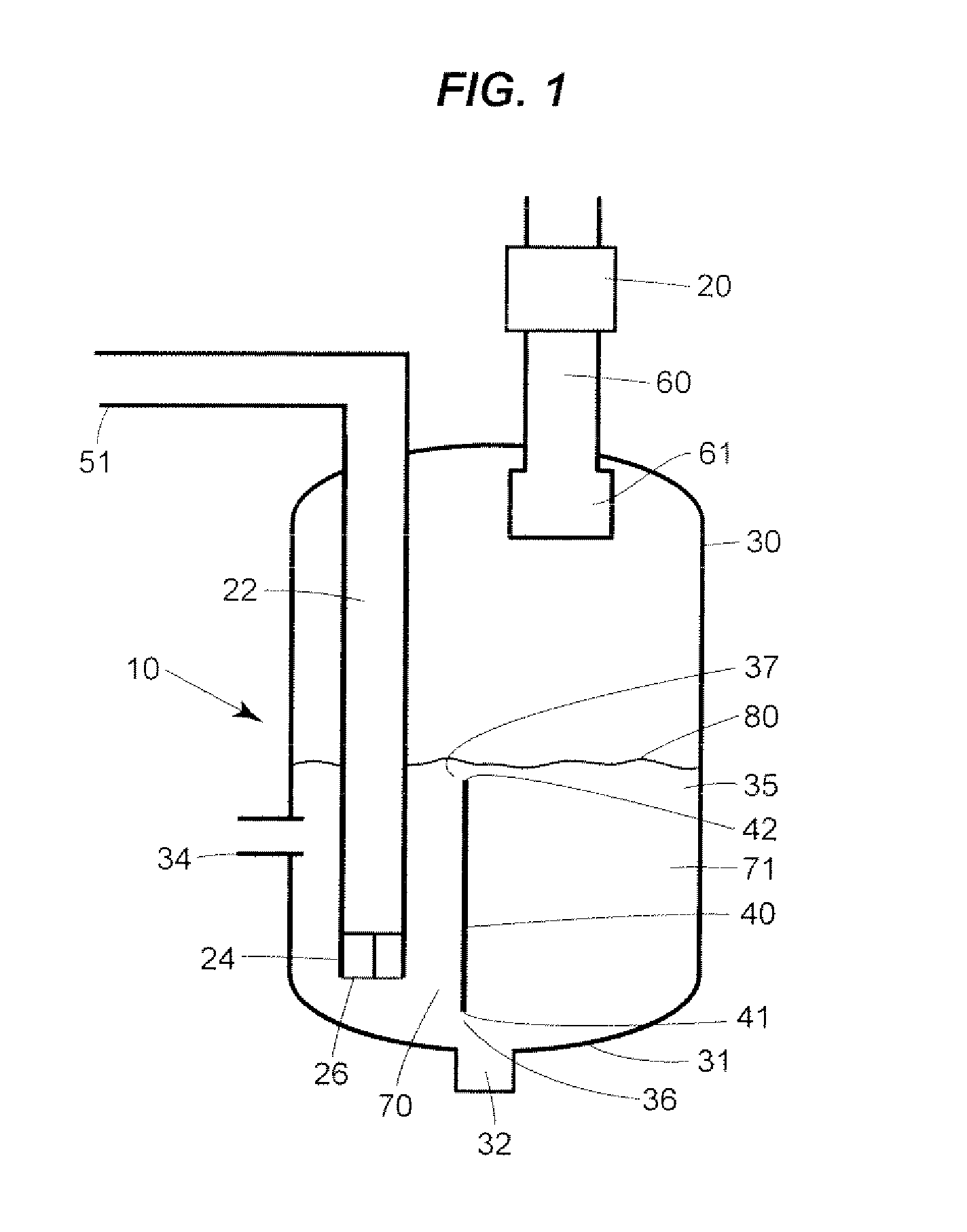

Submerged gas evaporators and reactors

ActiveUS7416172B2Increased turbulenceEnhanced mixing processCarburetting airUsing liquid separation agentChemical reactionHigh rate

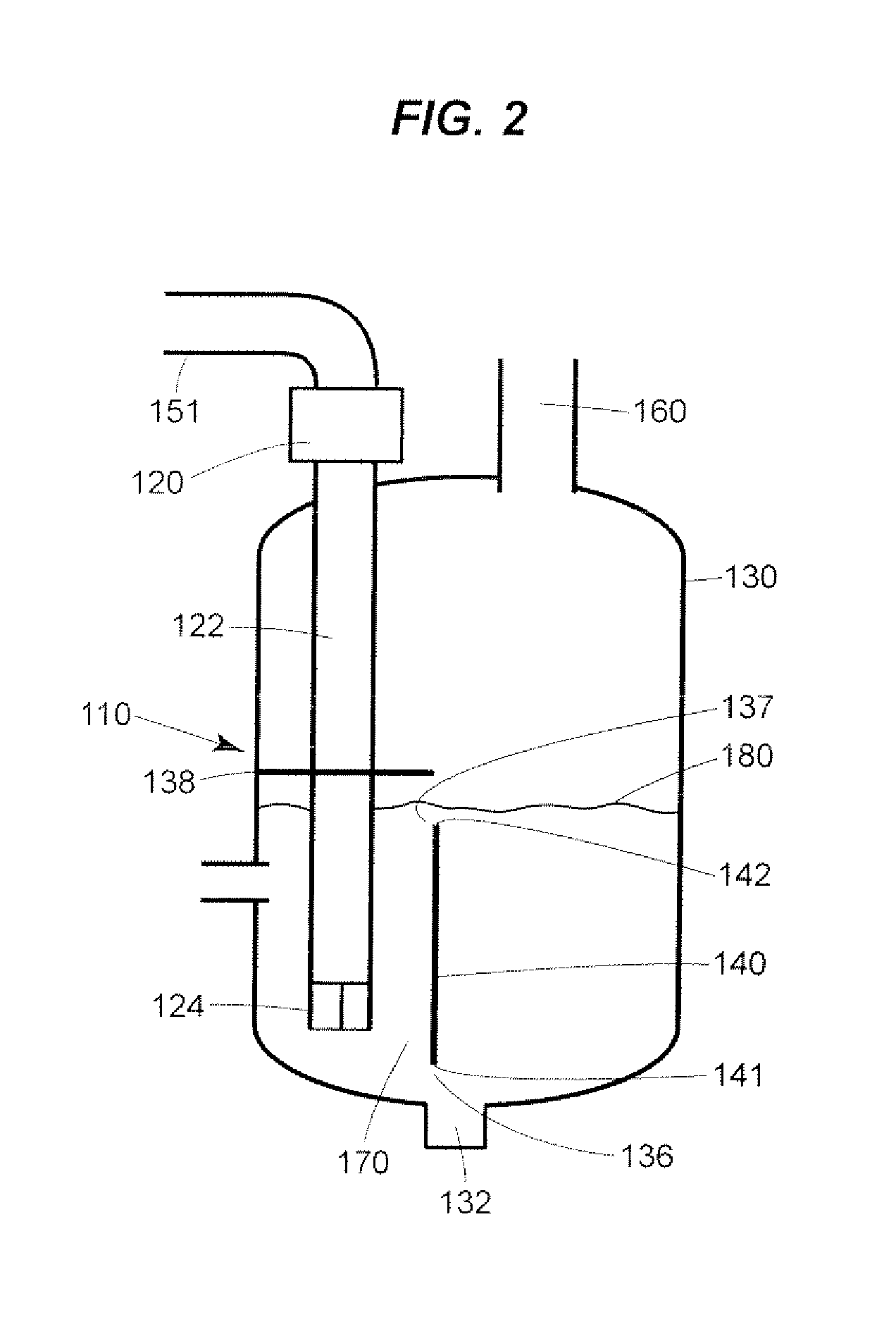

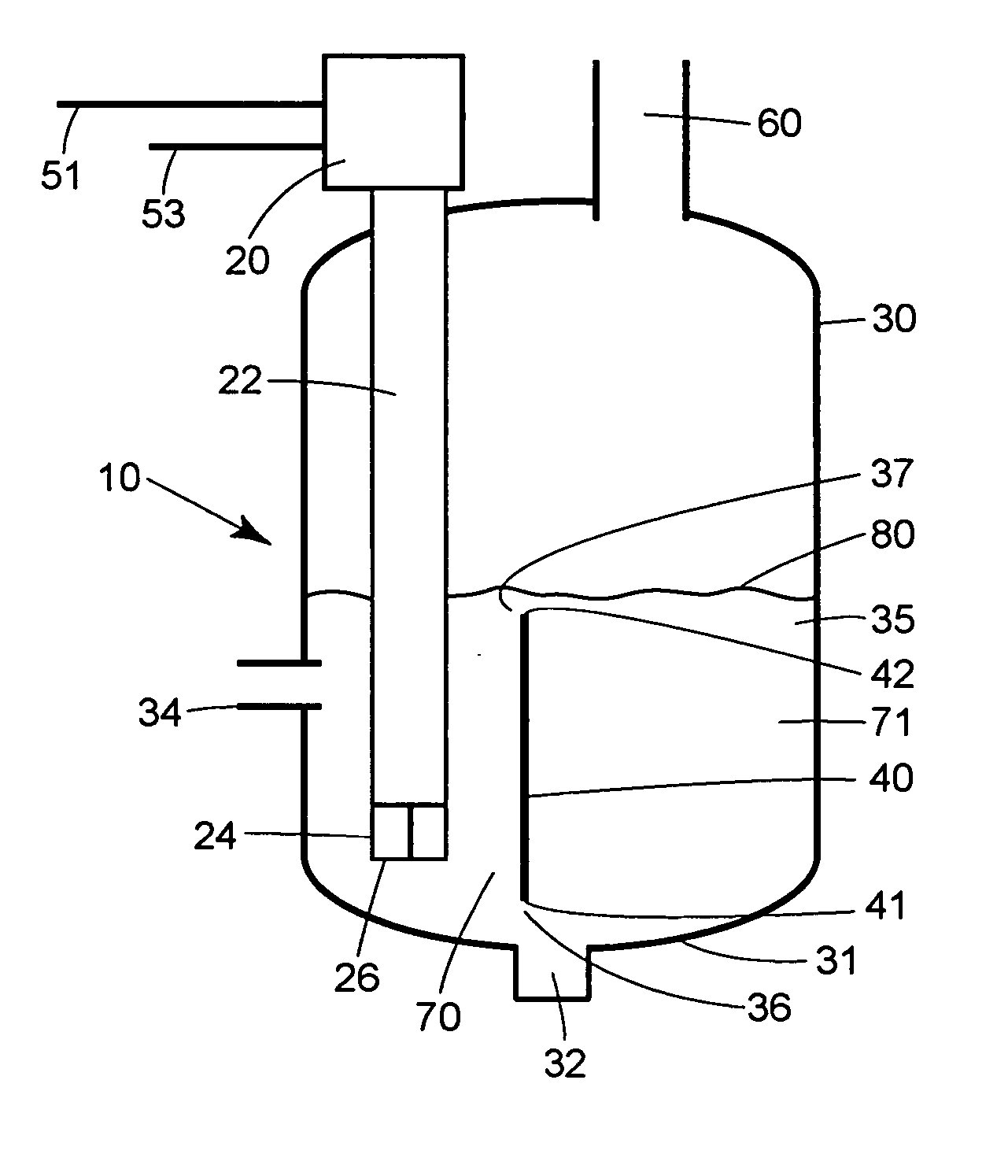

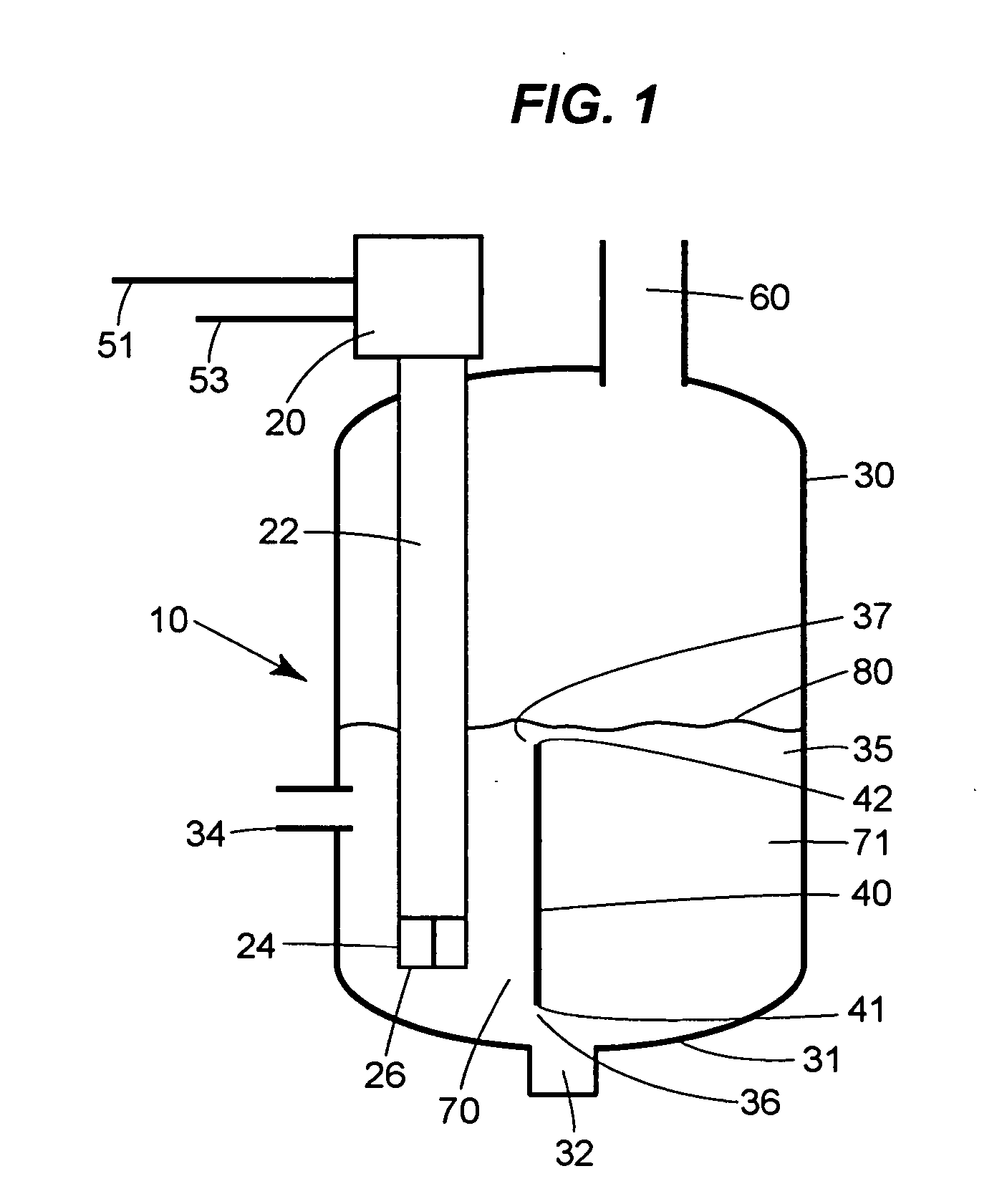

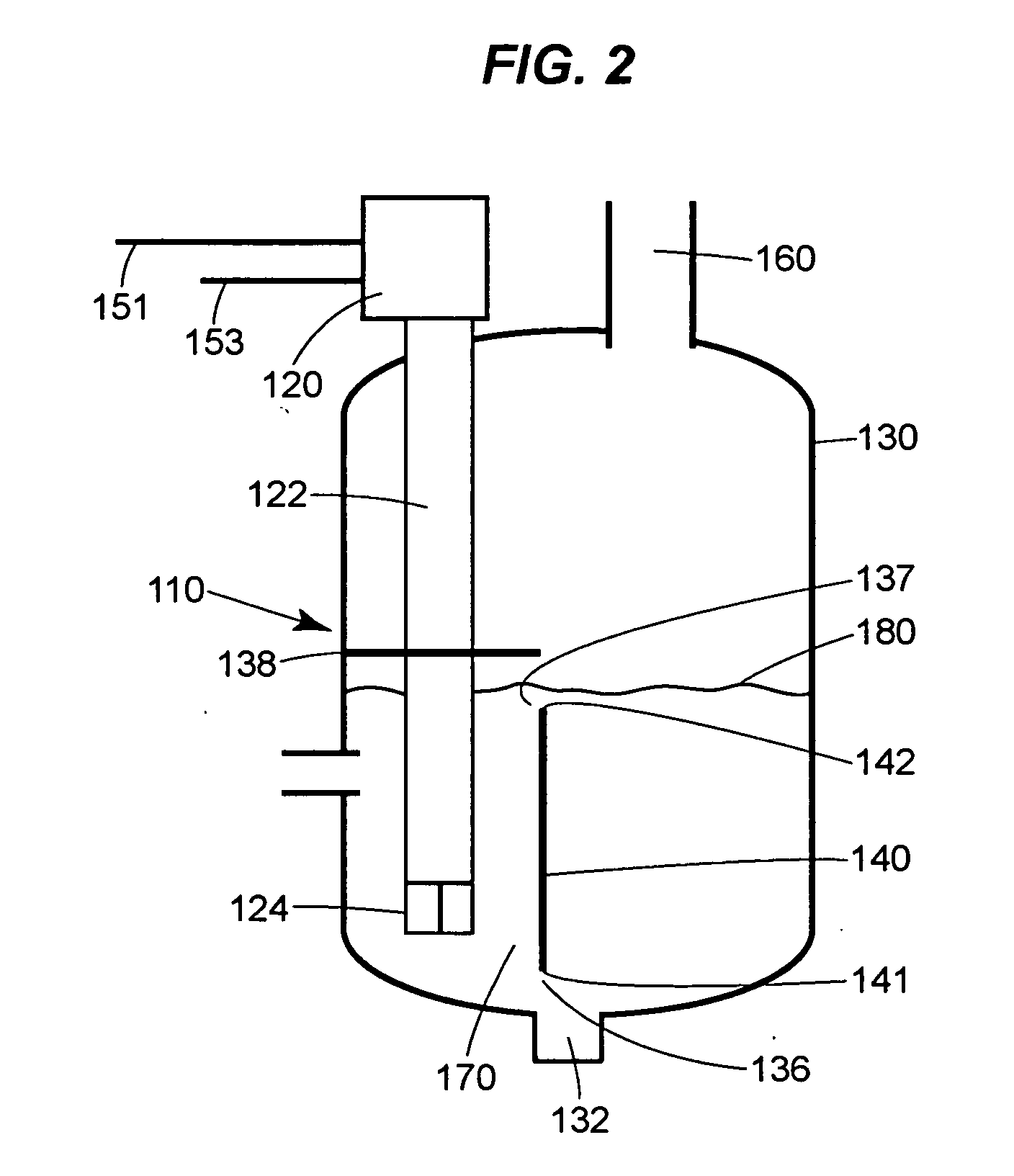

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

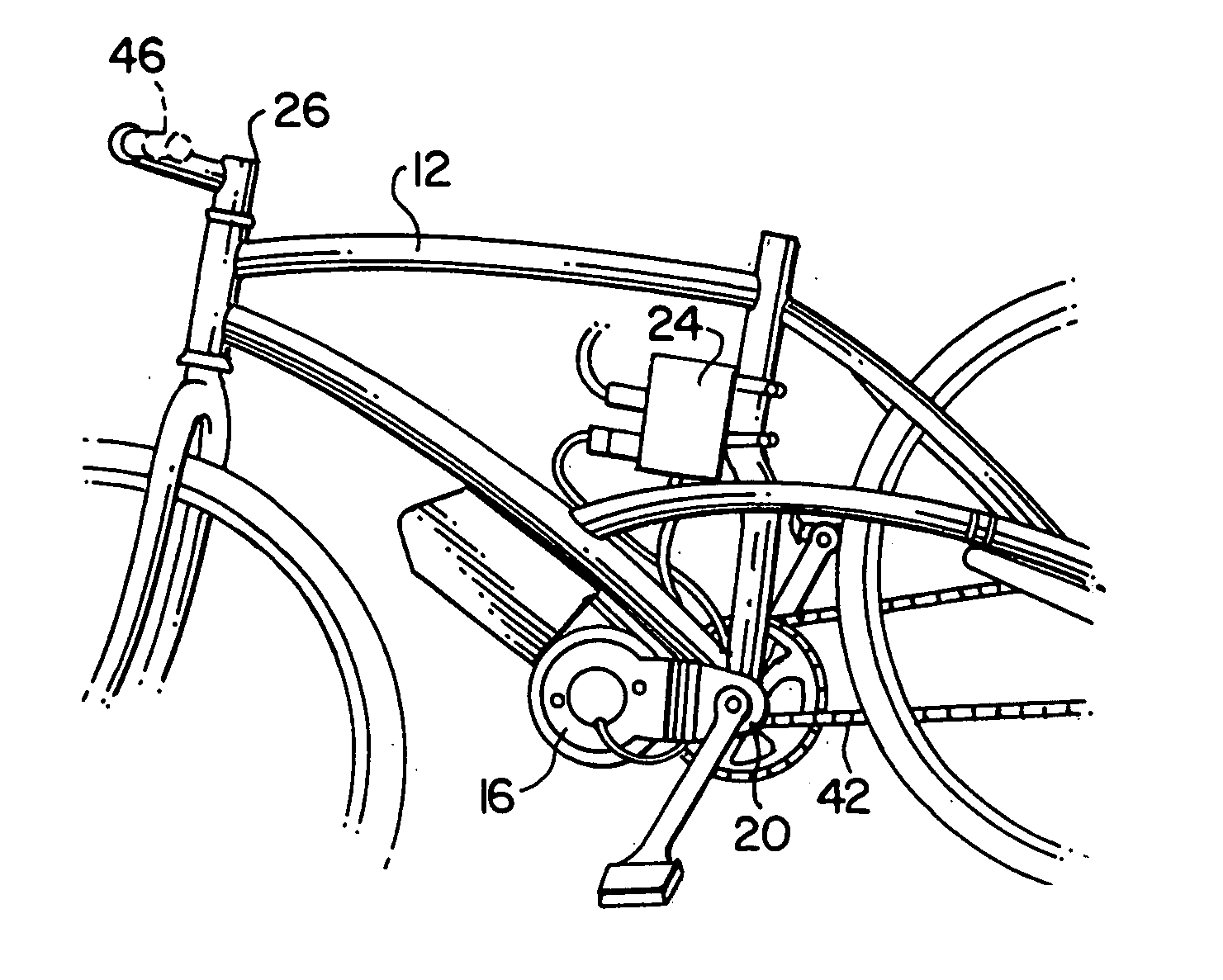

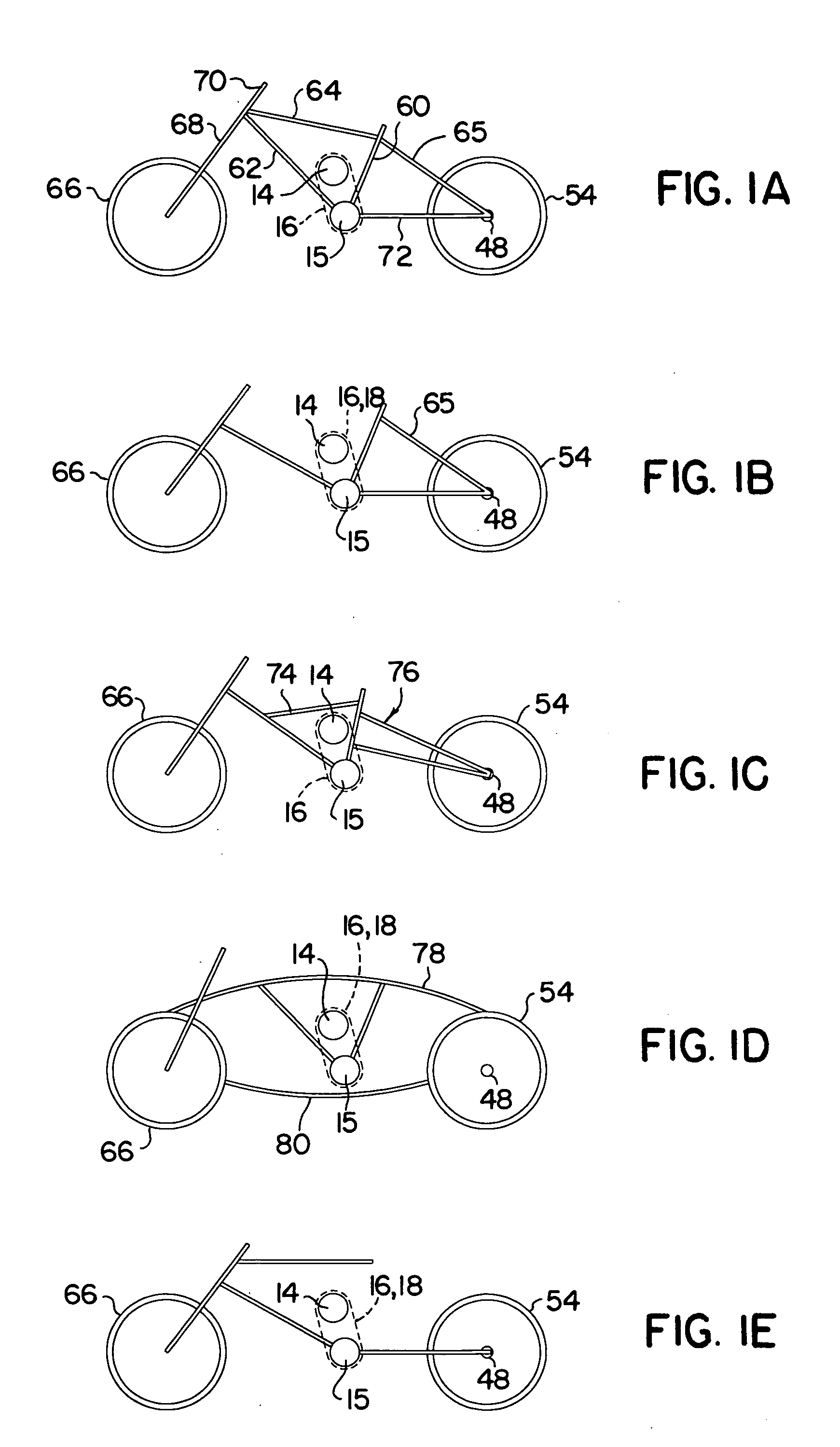

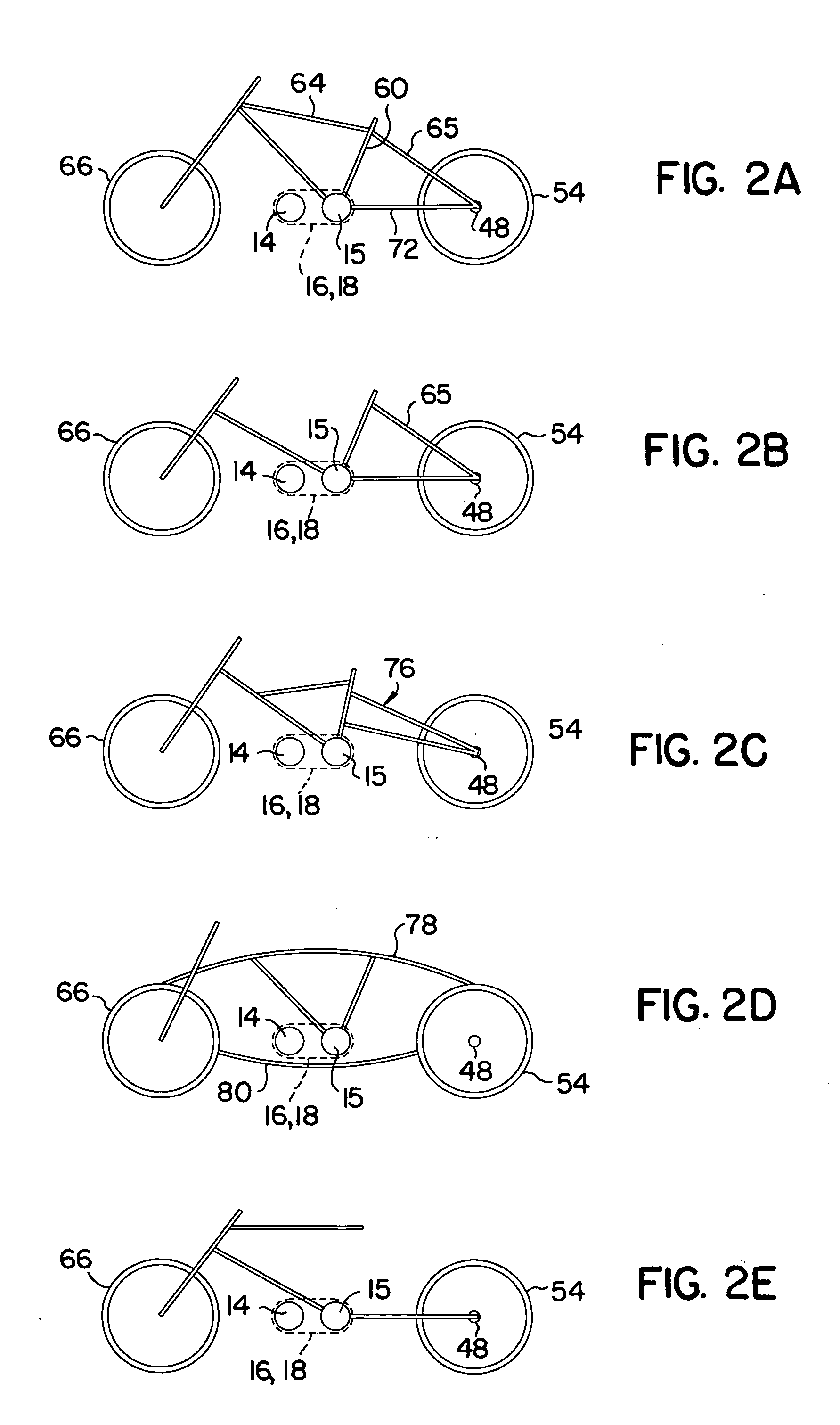

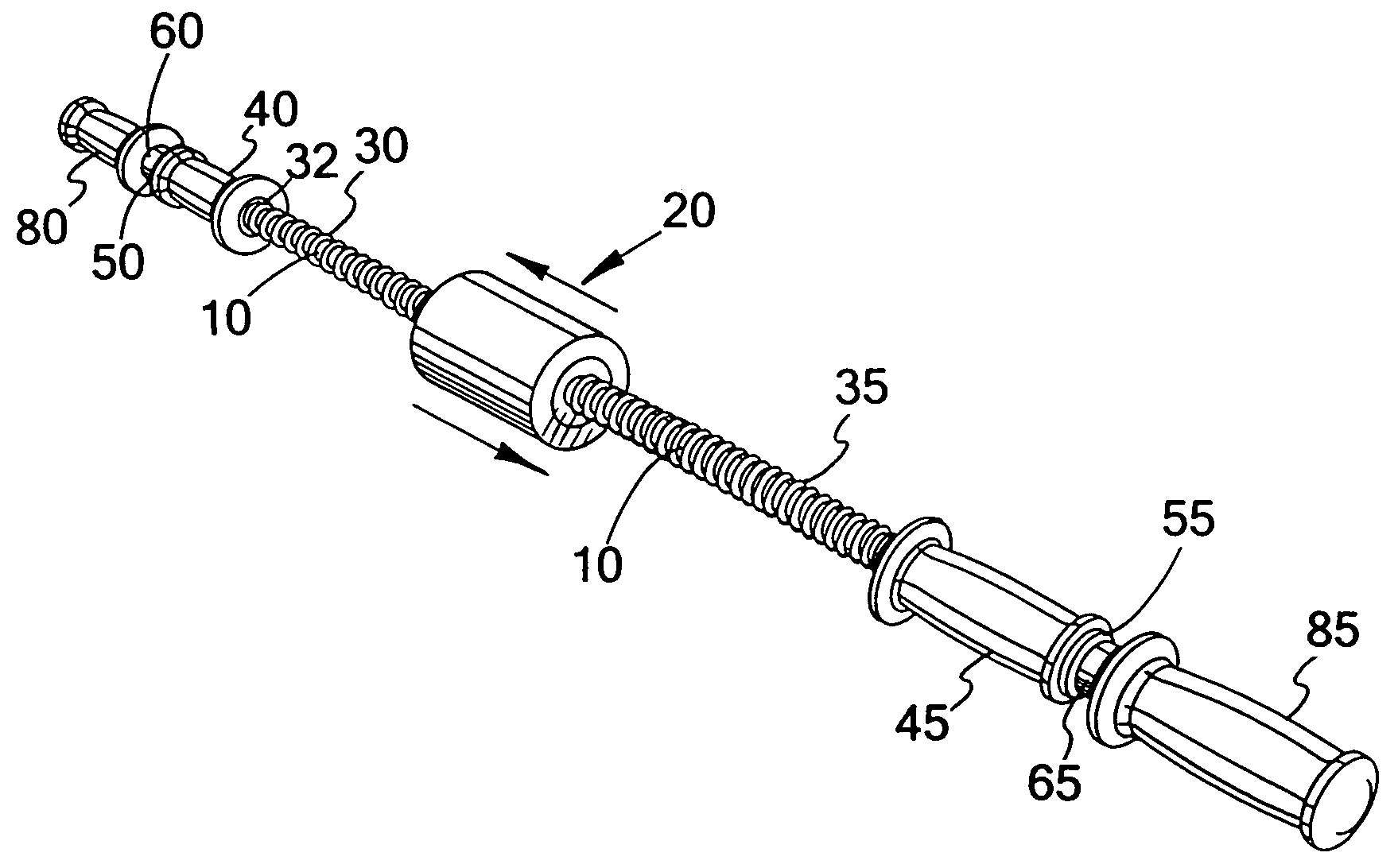

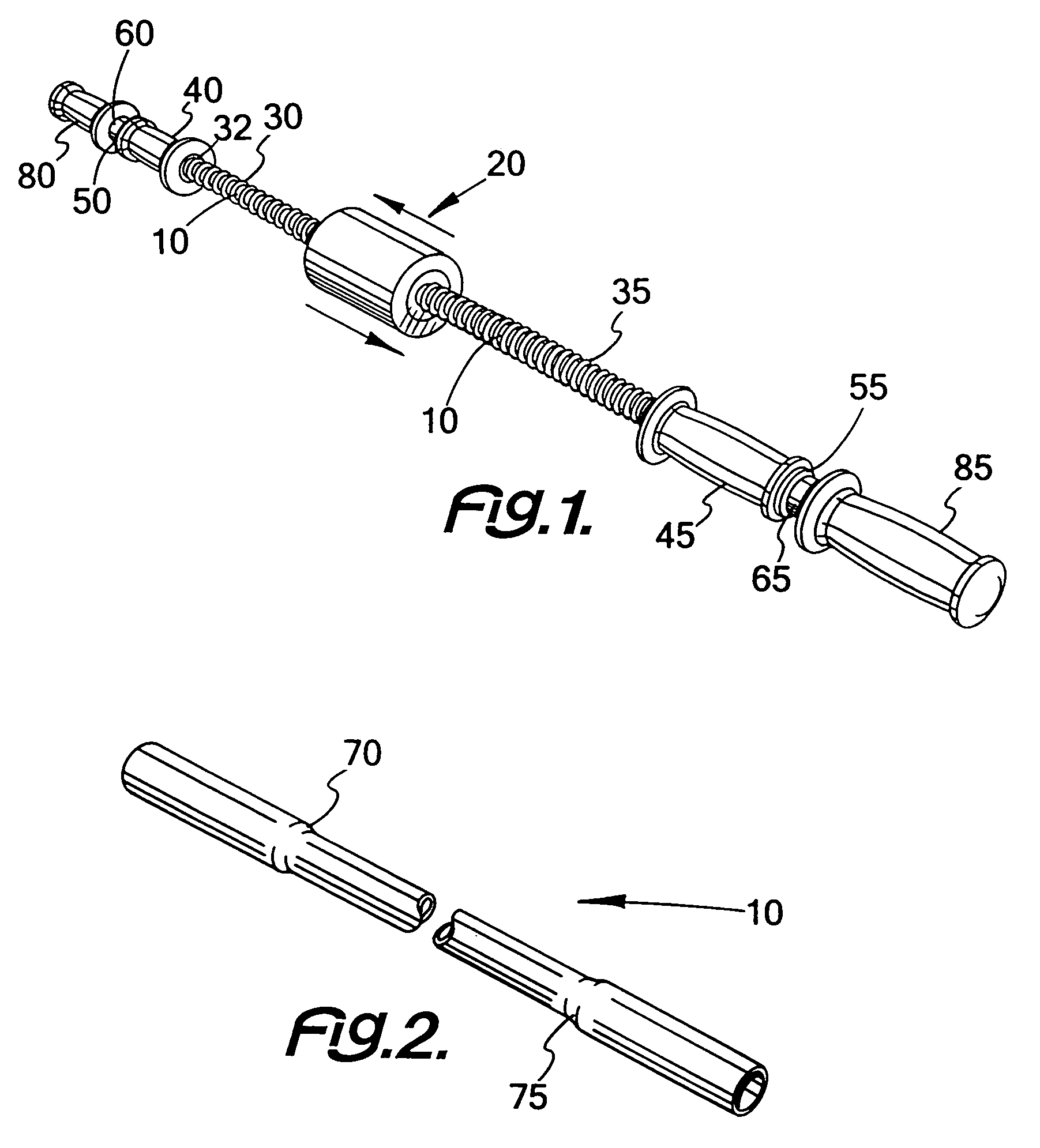

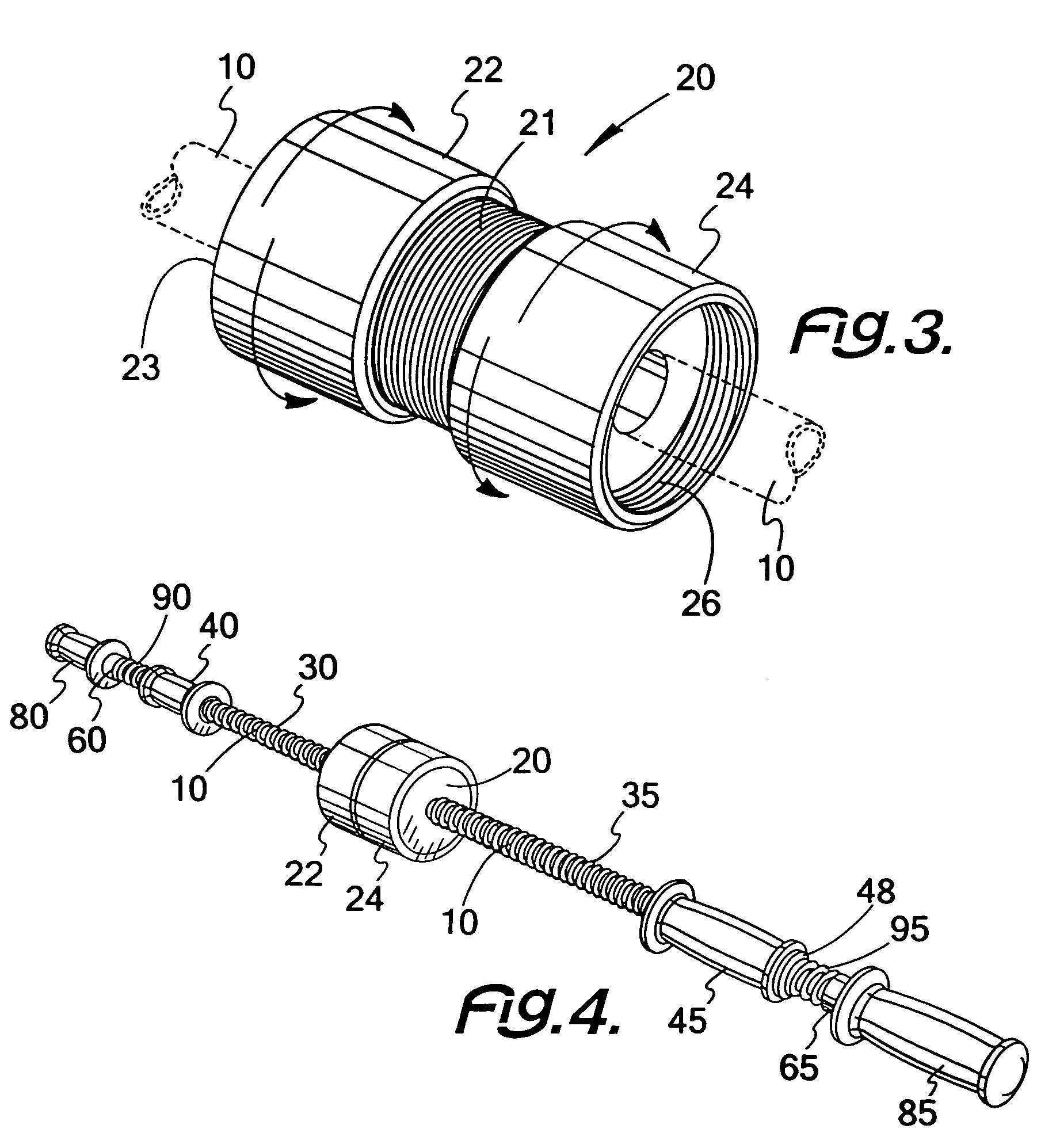

Electric bicycles and retrofit kits

InactiveUS20050189157A1Improve performanceReduce complexityPropulsion by humans/animalsVehicle transmissionGear wheelSprocket

A bicycle has an electric motor and attached single or multiple sprockets, gears, chains, belts, shafts and mounting brackets. Outer sprockets are independently turned by either the motor or the pedals, and these outer sprockets then turn an inner sprocket which drives the drive chain and turns the rear wheel. Either the motor or the pedals, or both, may propel the bicycle. The vehicle also includes a means for detecting gear shifting and thereupon reducing power to the motor for a short time interval.

Owner:ZVO

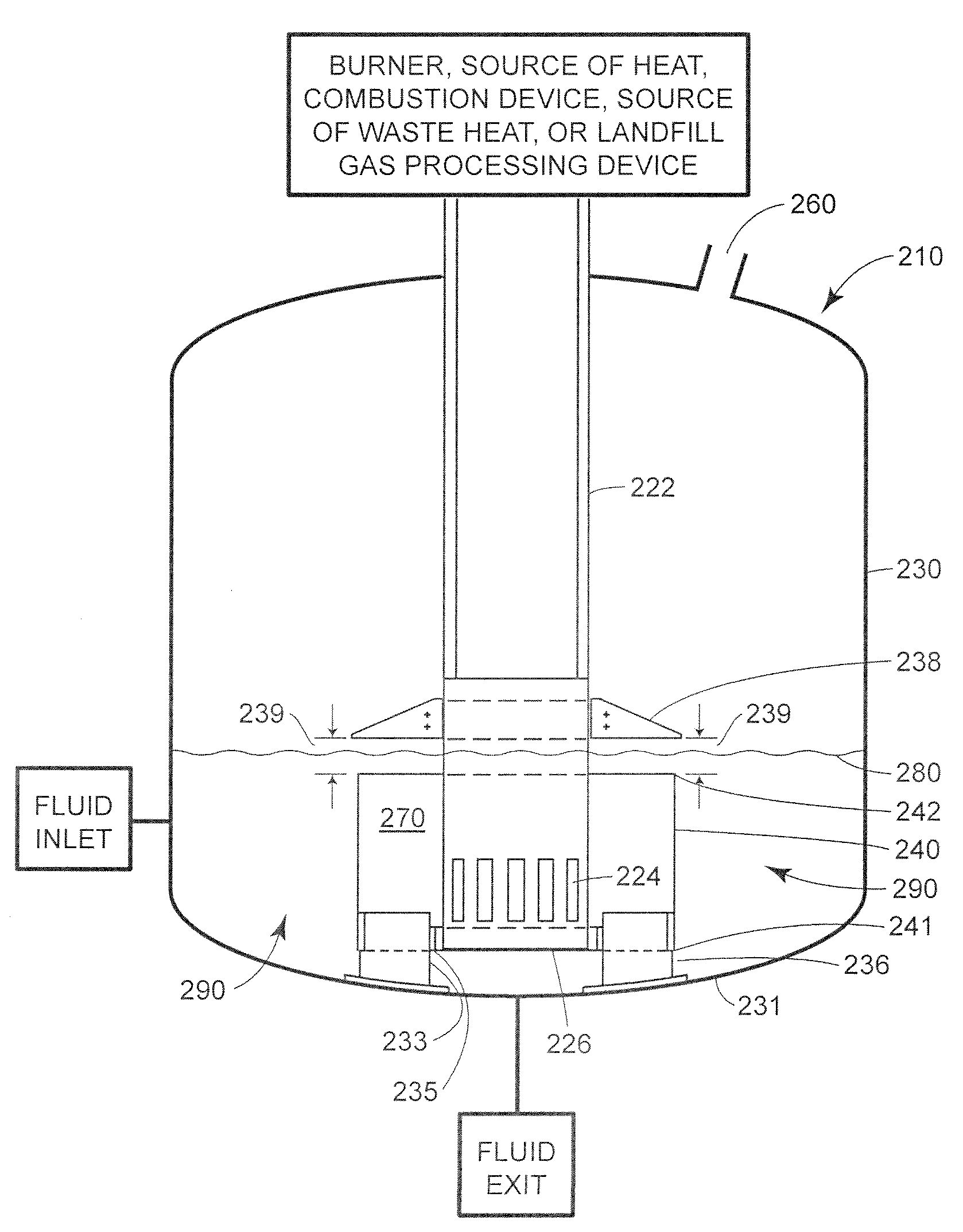

Fluid scrubber

ActiveUS20080173176A1Efficient transferEnhanced mixing processCombination devicesGas treatmentHigh rateChemical reaction

A fluid scrubber in the form of a submerged gas reactor includes a reaction vessel, a gas delivery lube partially disposed within the reaction vessel to deliver a gas into the reaction vessel and a scrubbing liquid inlet that provides a scrubbing liquid to the reaction vessel at a rate sufficient to maintain a controlled, constant level of fluid within the reaction vessel. A weir is disposed within the reaction vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the reaction vessel and a second fluid circulation path between a second weir end and an upper end of the reaction vessel. During operation, gas introduced through the tube mixes with the scrubbing liquid and the combined gas and liquid flow at a high rate with a high degree of turbulence along the first and second, circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the scrubbing liquid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the scrubbing liquid resulting in a reduction of the required residence time of the gas within the scrubbing liquid to achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:HEARTLAND WATER TECH INC

Reciprocating weight exercise apparatus

InactiveUS7175575B1Improve versatilityGreat momentumClubsResilient force resistorsWeight trainReciprocating motion

Owner:DANTOLEN HARRY E

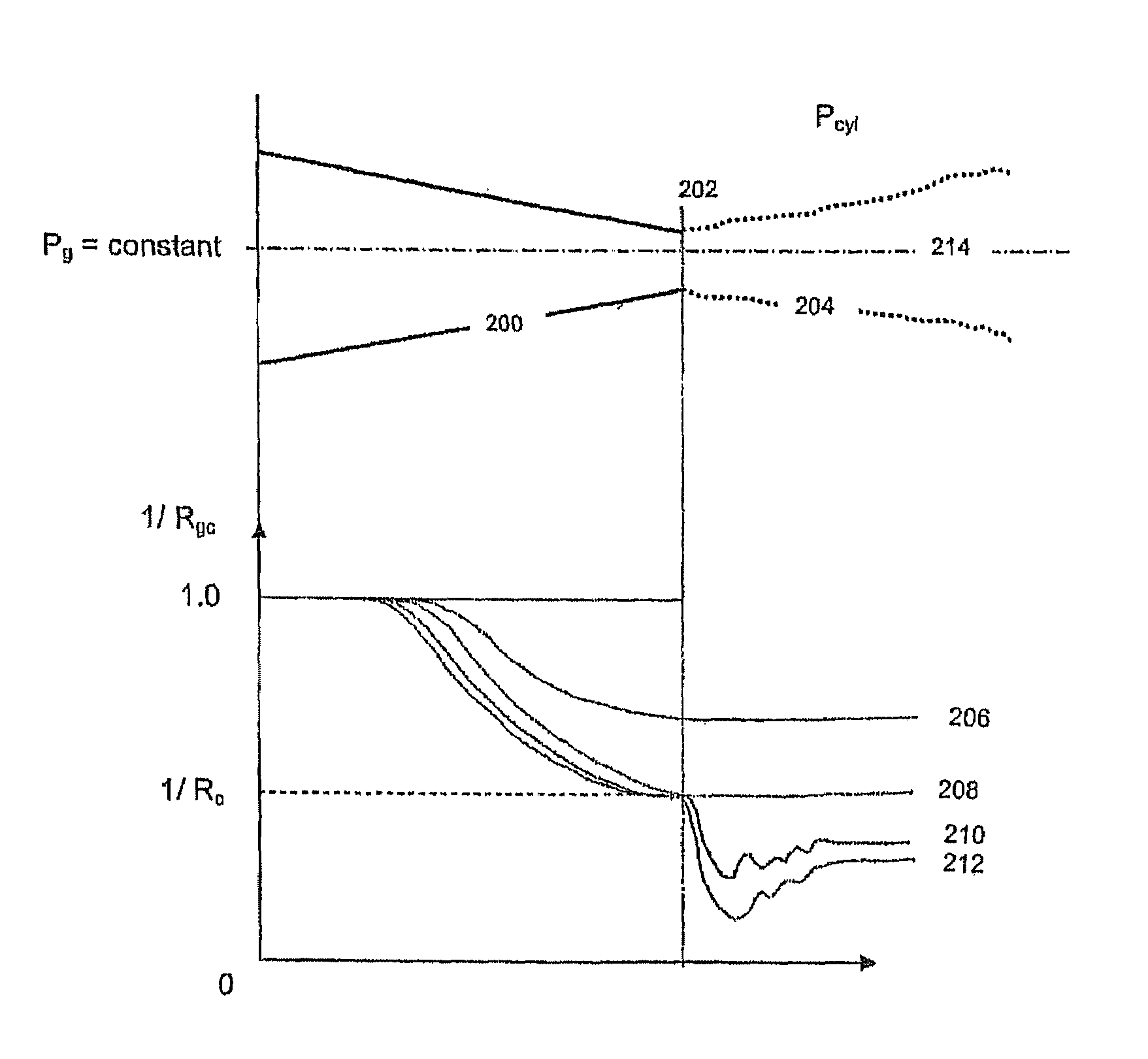

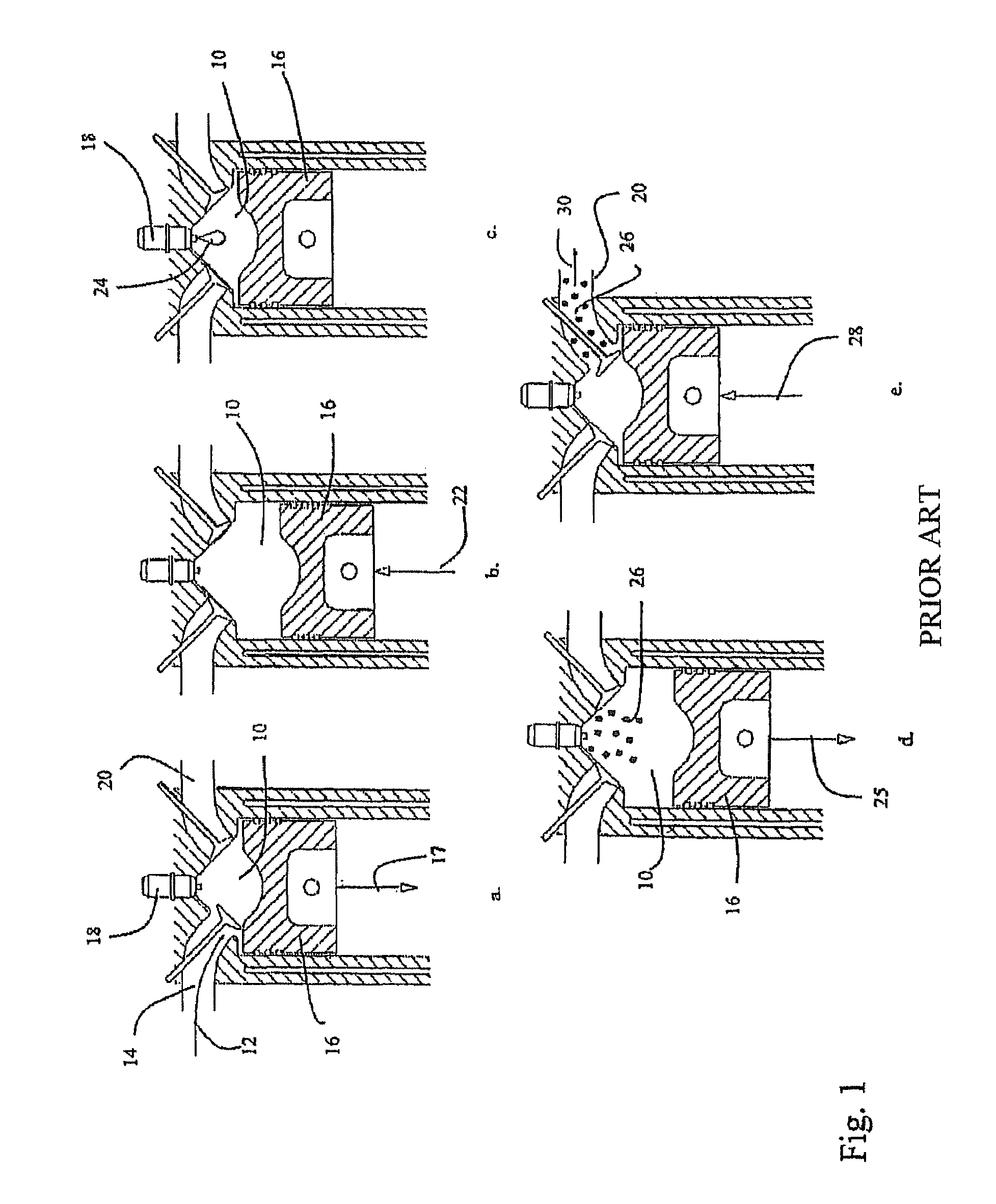

Method for injecting gaseous fuels into an internal combustion engine at high pressures

ActiveUS7162995B2Speed up the flowGreat momentumInternal combustion piston enginesFuel supply apparatusShock waveCombustion chamber

A method directly injects gaseous fuel into the combustion chamber of an internal combustion engine. The compressibility of the gaseous fuel is used to provide a fuel to the combustion chamber that is injected over all engine operating conditions at pressures that result in fuel jet speeds beyond the injector nozzle in excess of sonic speeds as determined in reference to the combustion chamber environment. The resulting fuel injection speed results in the fuel passing through shock waves within the combustion chamber, which, in turn, promotes combustion of the fuel by promoting turbulence and mixing of the fuel and intake charge within the combustion chamber where fuel burns in a non-premixed combustion mode.

Owner:WESTPORT FUEL SYST CANADA INC

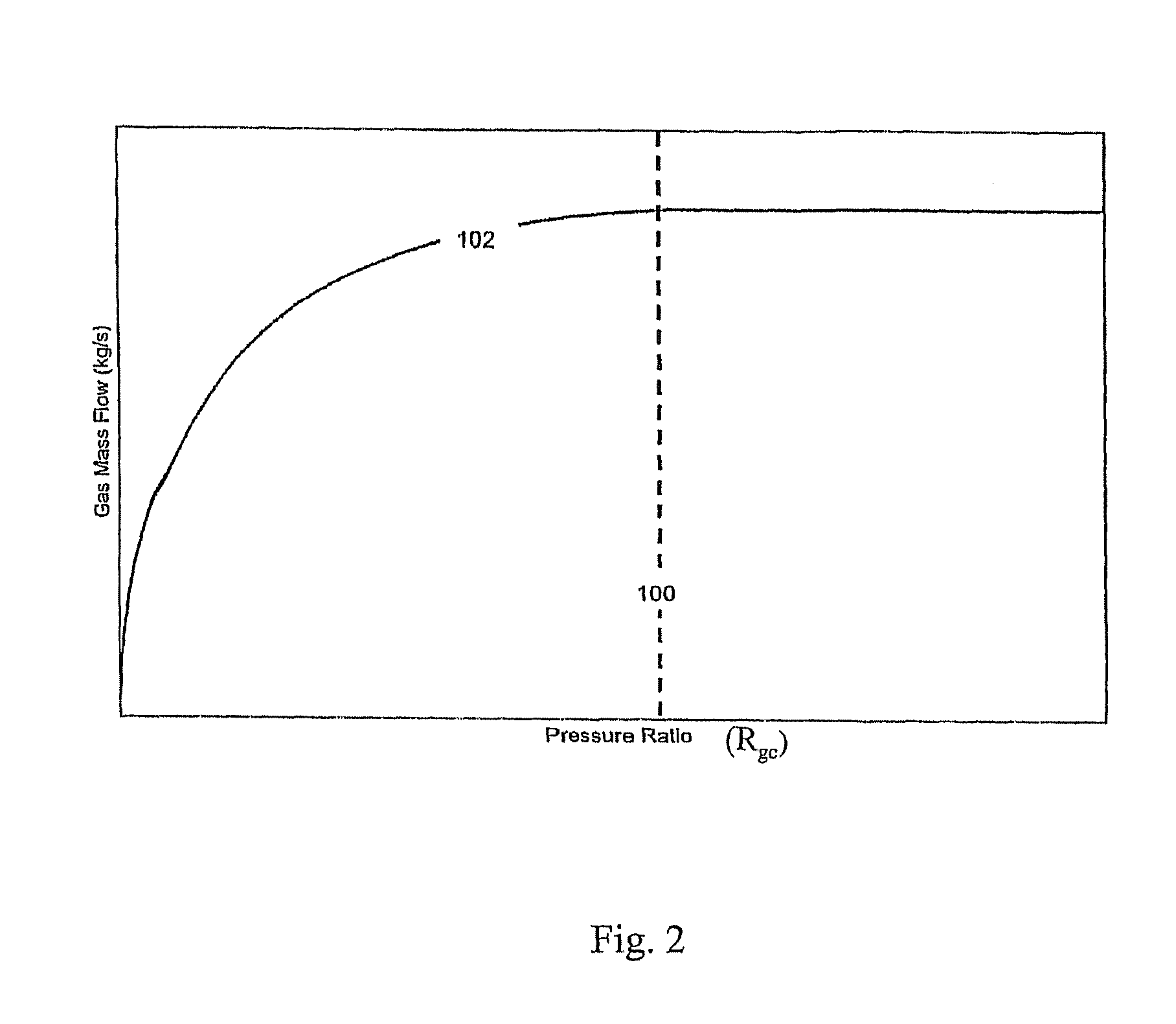

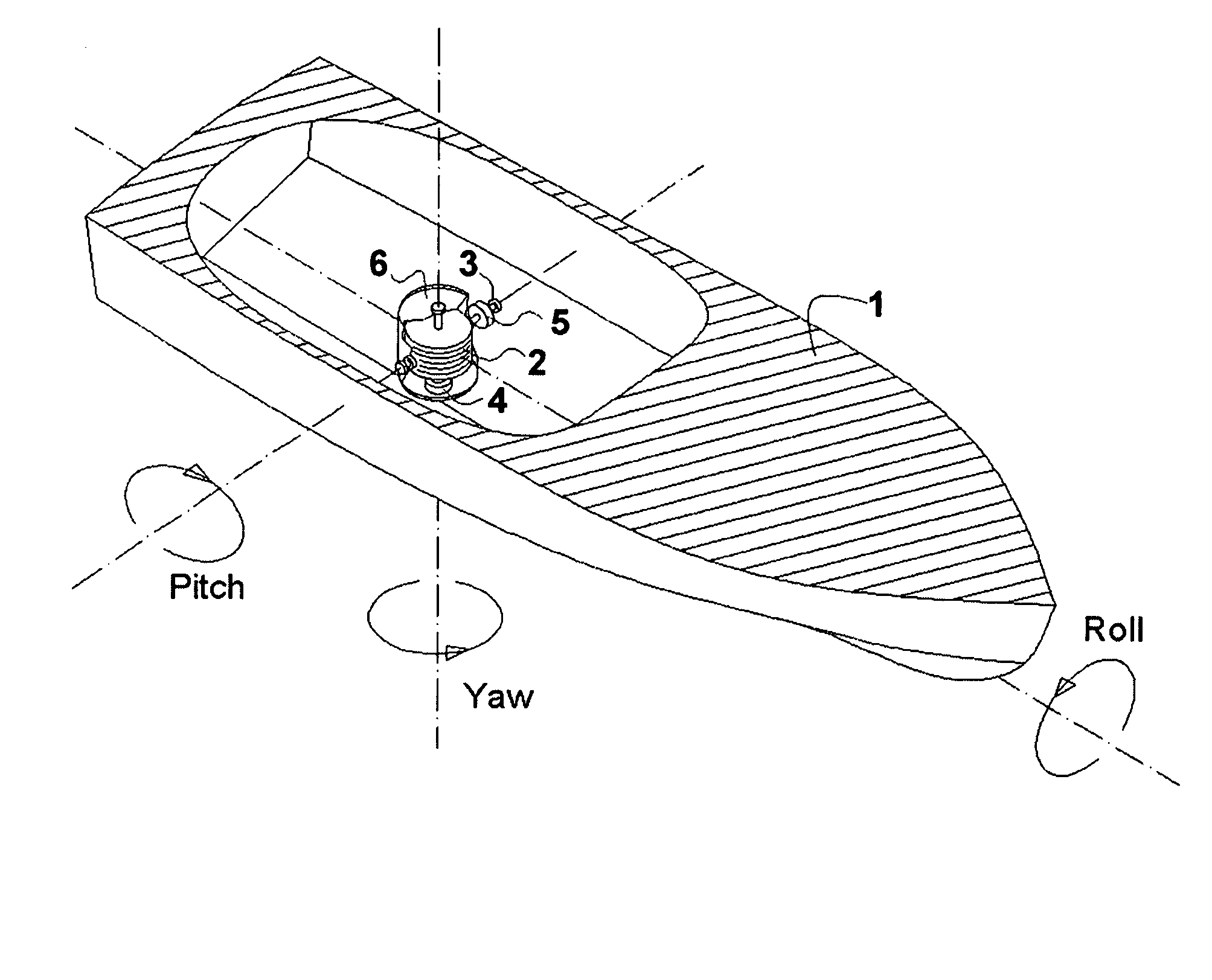

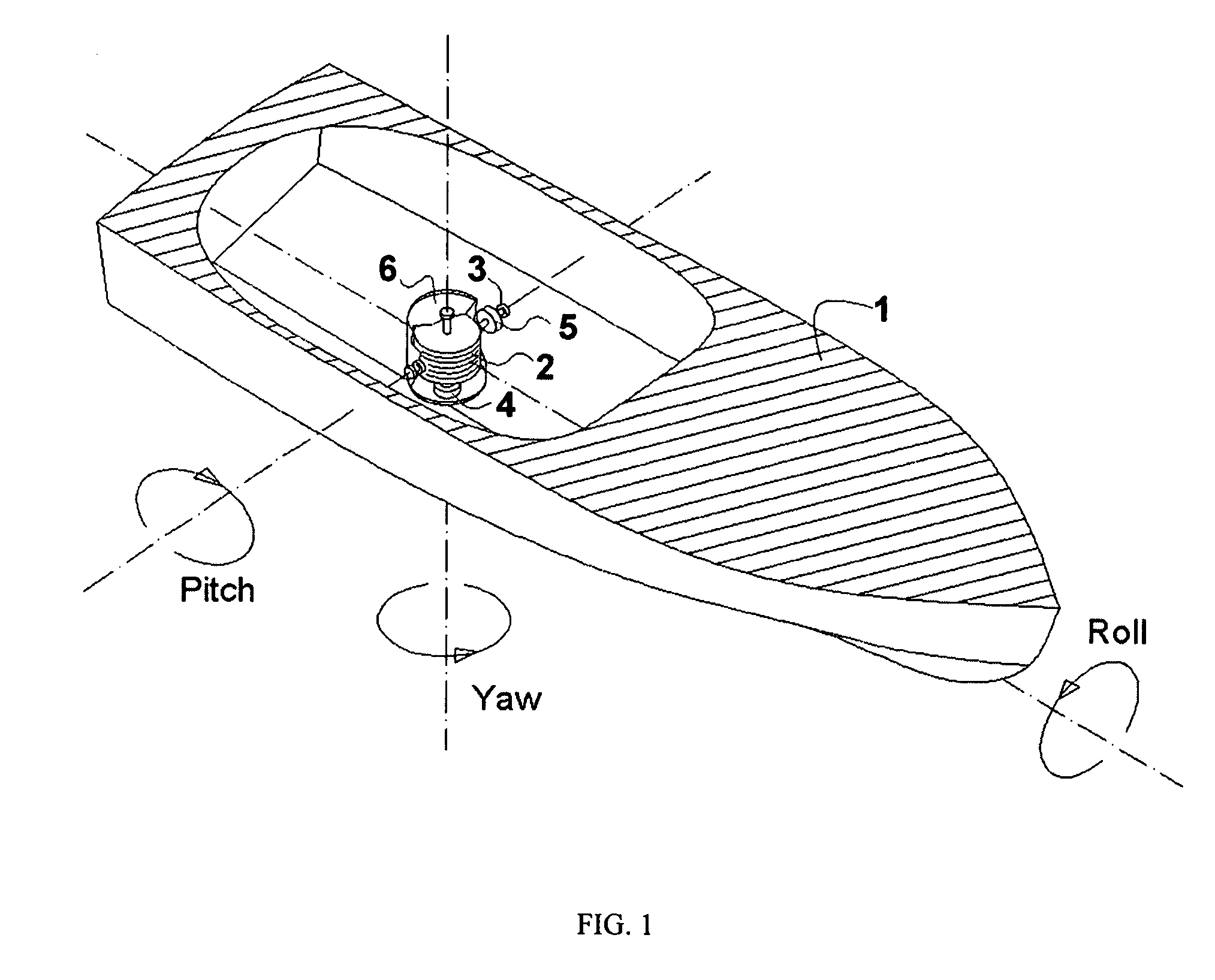

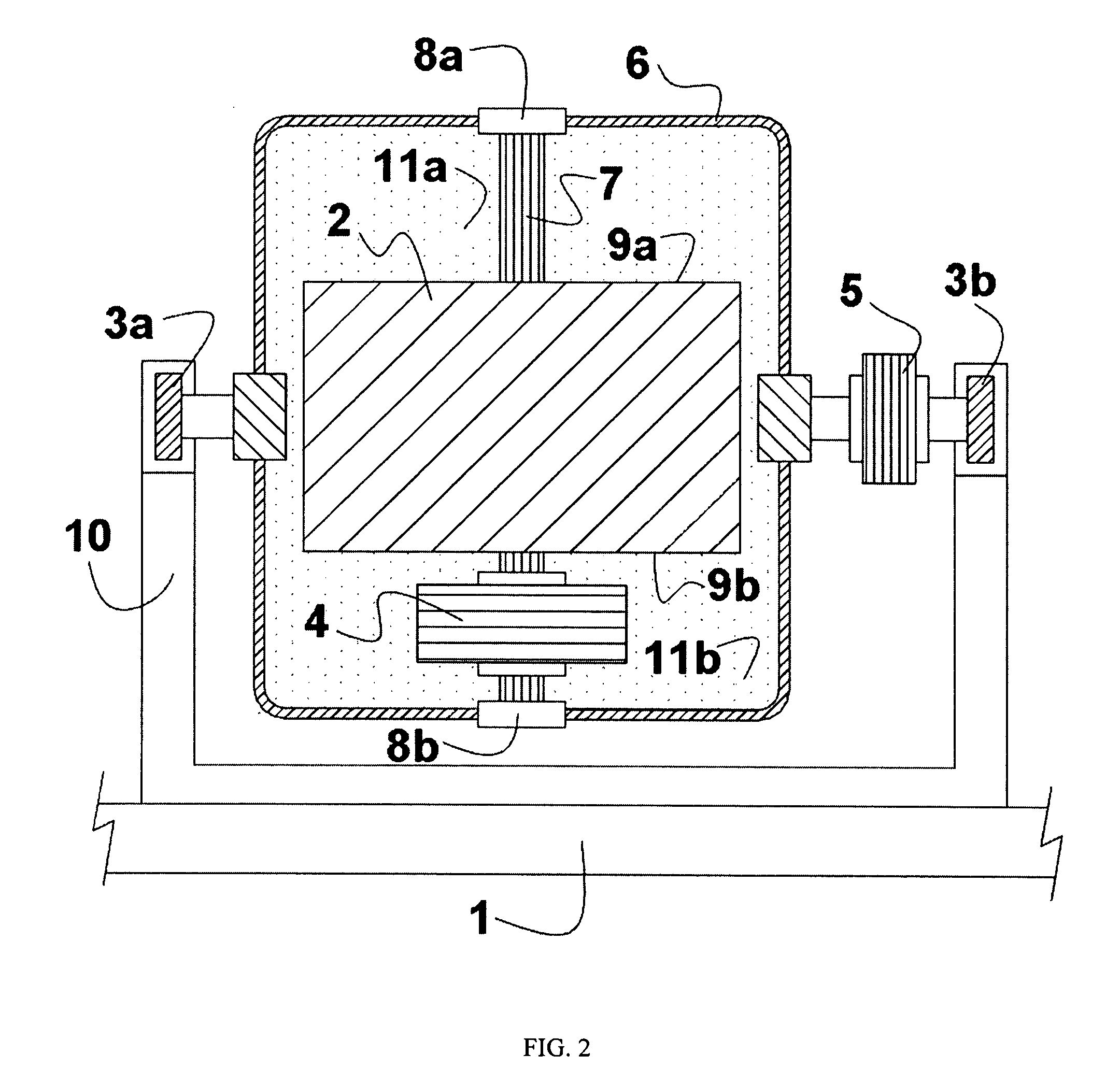

Gyrostabilizer for small boats

InactiveUS7240630B2Large counter roll torqueShorten the timeMechanical apparatusVessel movement reduction by gyroscopesAngular momentumAngular velocity

A gyrostabilizer system that counteracts the natural rolling motion of a small boat or vessel. The invention constitutes an improvement in prior art systems of this type in that the system weighs less because it has a much lighter rotor made of composite materials spinning at much higher speeds. The gyrostabilizer system includes a lightweight rotor spinning at very high speeds to attain a large angular momentum. The mass of the rotor is concentrated away from the spin axis of the rotor to maximize angular momentum while minimizing weight. The rotor is mounted in a frame that, in turn, is mounted on gimbals so that the frame can be rotated about an axis that is normal to the longitudinal roll axis of the vessel. When the rotor is rotated about the gimbals, a torque is created that opposes the torque created by the sea and reduces the rolling motion of the vessel. The rotor may be mounted in an evacuated chamber to reduce air drag. Rotation of the rotor frame around the gimbal axis is controlled by an active servo system using information provided by roll angular position and angular velocity sensors.

Owner:AKERS RICHARD H +1

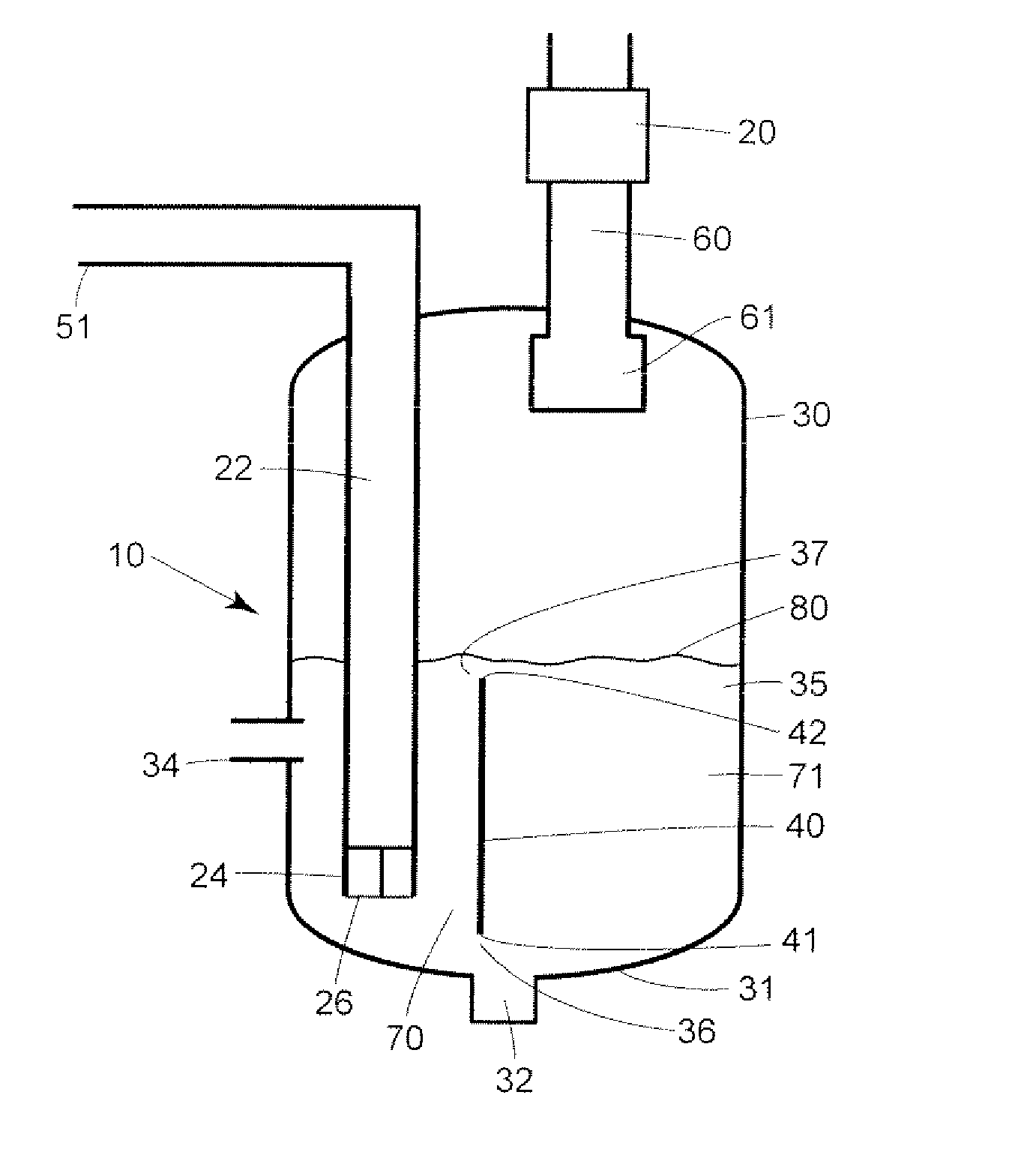

Submerged gas evaporators and reactors

ActiveUS20070114683A1Increased turbulenceEnhanced mixing processCarburetting airMixing methodsChemical reactionHigh rate

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

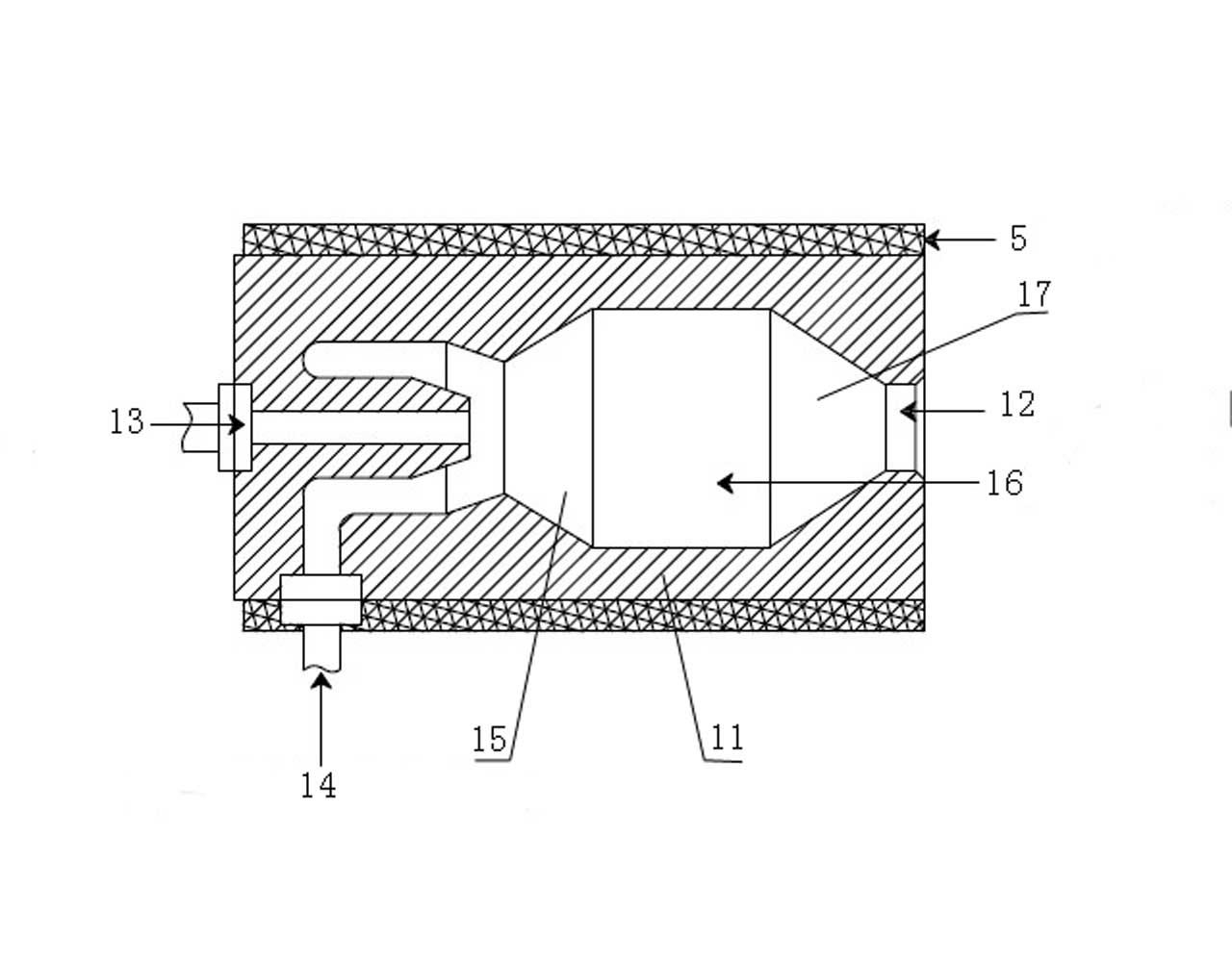

High-pressure extinguishing nozzle with fine spraying for submarine and ship habitation cabin

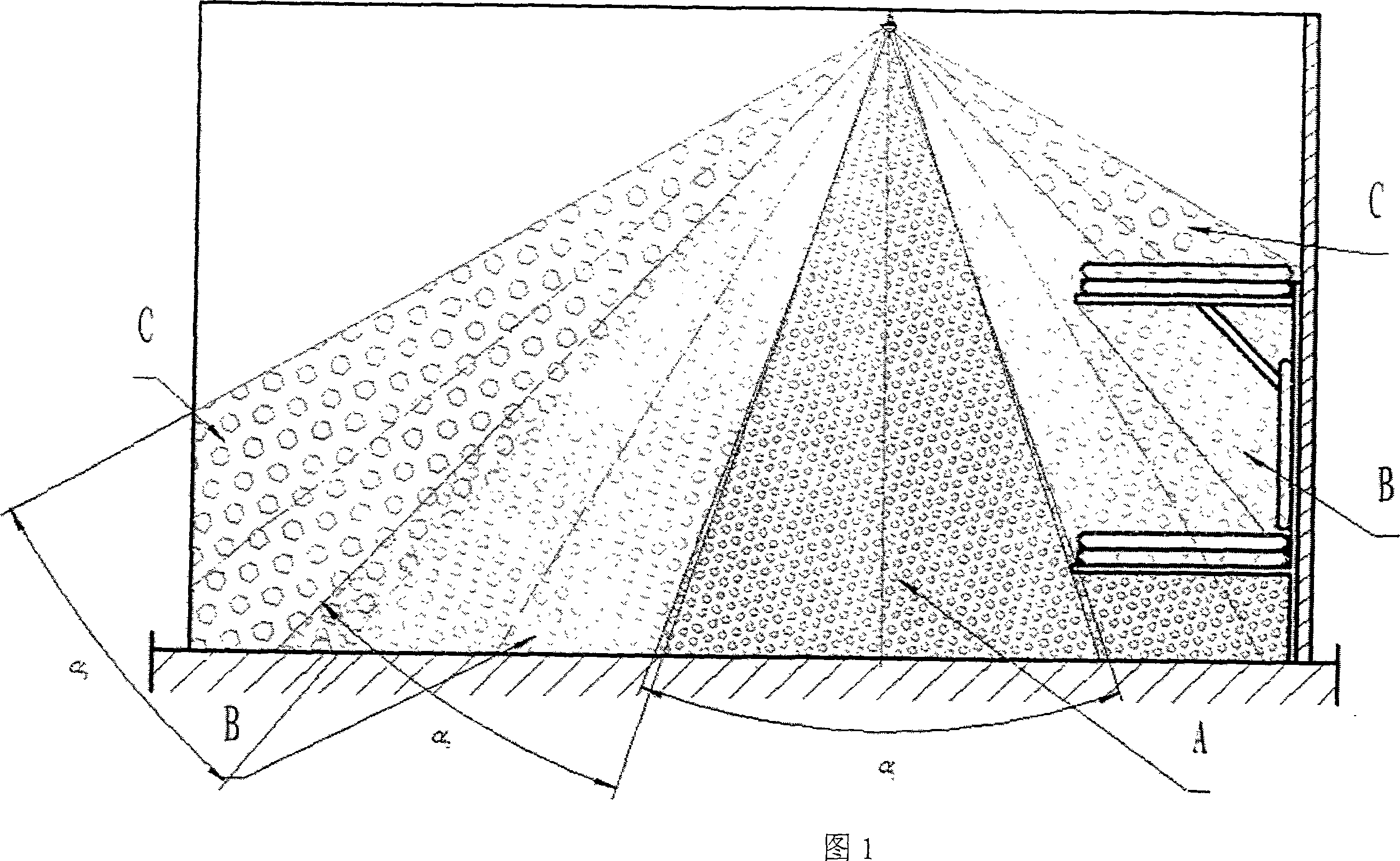

The invention discloses a high-pressure thin water spray fire-fighting injector used in submarine and ship, comprising injector shell, injector patchplug, central air spout, spherical air spout, outer air spout, internal filtering net, metallic sealing bale and dust shield. The shape of injector shell is two conical surfaces, the top of conical surface neat top part is plain, the central part is equipped with air spout; conical surface near to top is distributed with several spherical sir spouts; outer circle of conical surface near to top is next to another conical surface, a plurality of outer air spouts are installed on said conical surface. The air spouts on different installation surface are intercrossed, the injector shell and central air spout, spherical air spout and outer air spout, and injector shell and injector patch plug are all connected with each other through screw. The sealing employs metallic pad. The air spout is connected with the cavity of injector shell; the cavity of injector patch plug is equipped with stainless steel filtering net; another end of injector patch plug is connected with fire-fighting system through screw, and the injector shell is provided with dust cover.

Owner:BEIHANG UNIV

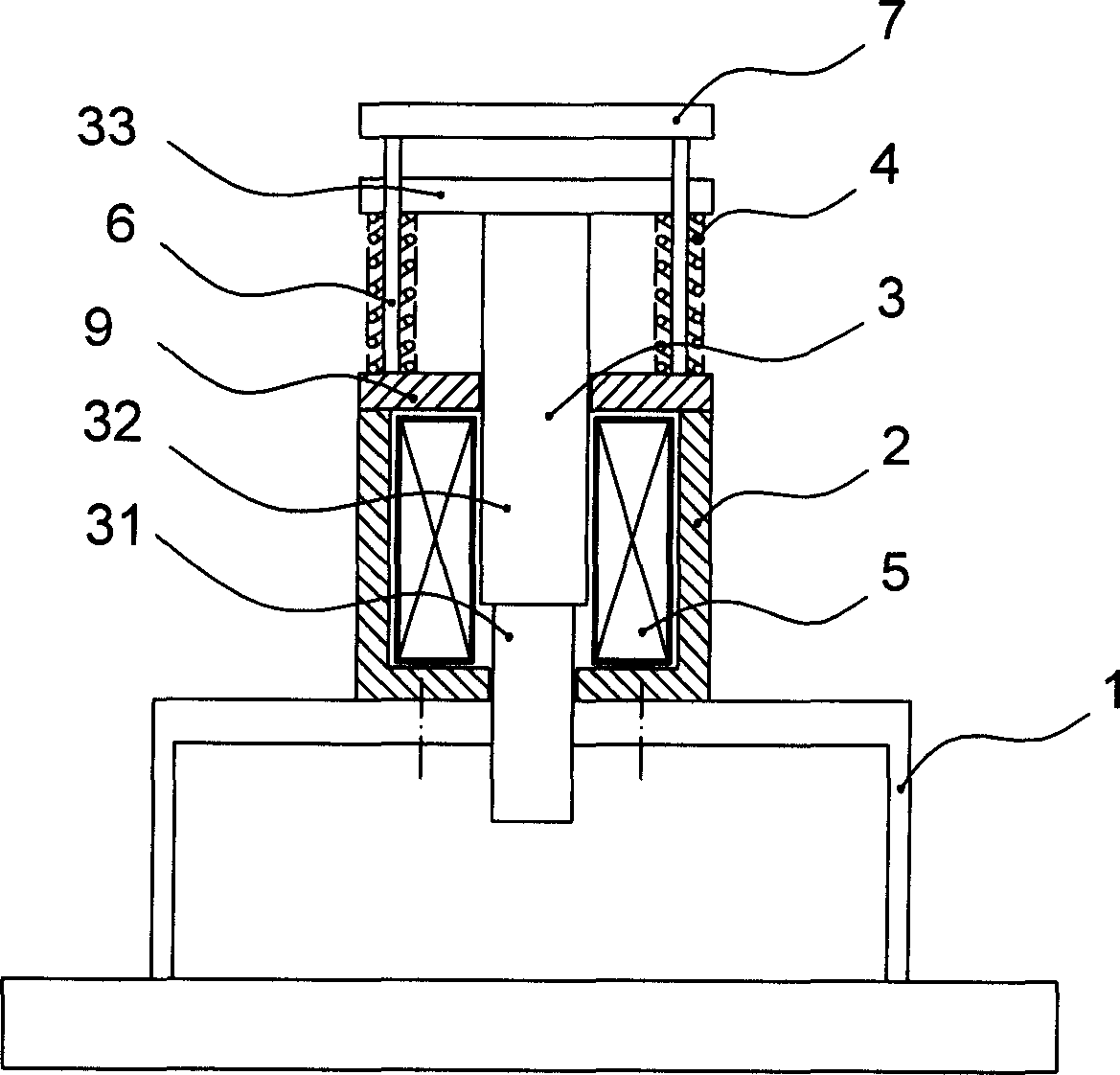

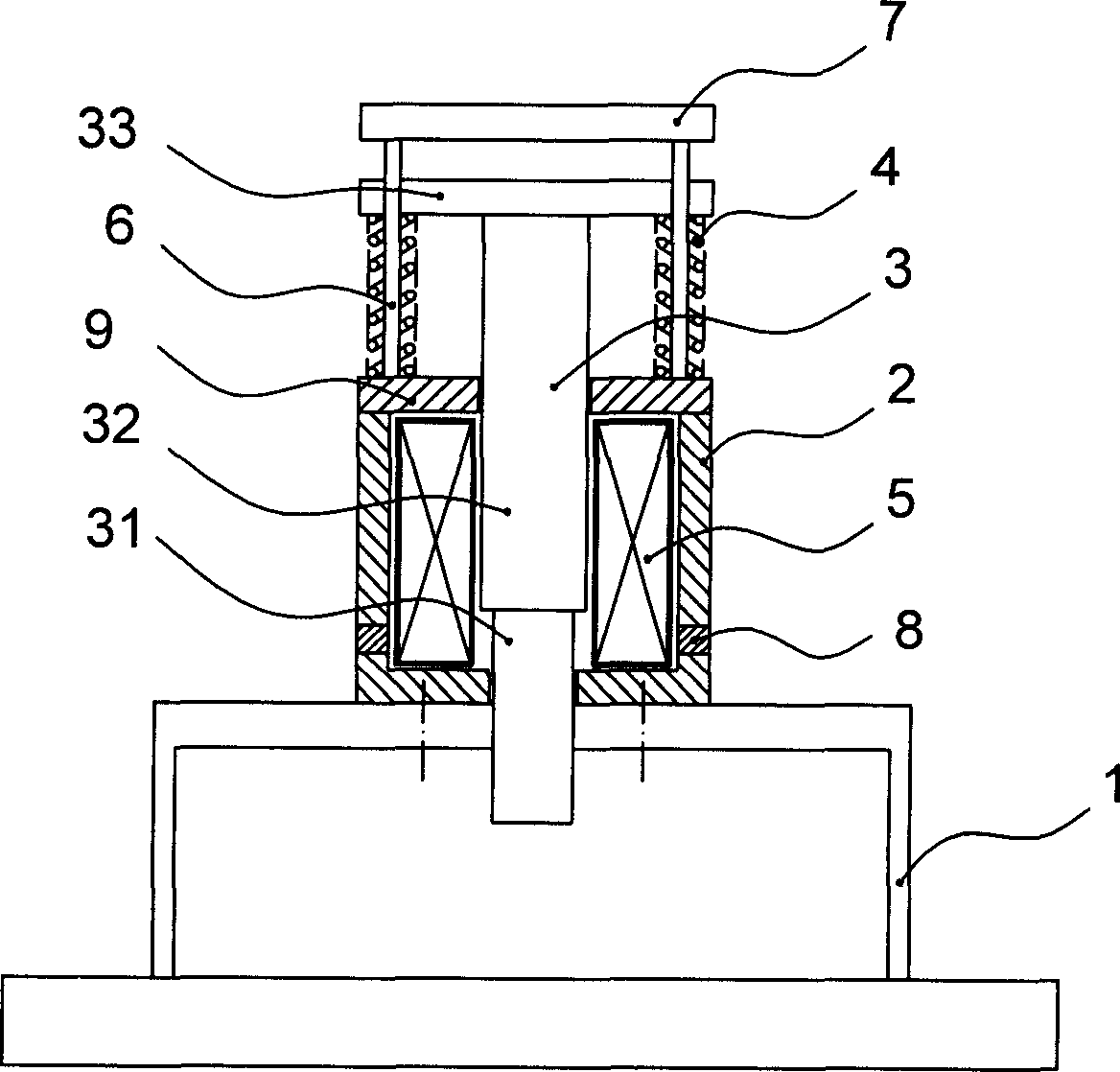

Permanent magnet punching machine

The permanent magnetic punch includes a yoke iron, a punching head reciprocating up and down inside the yoke iron, and an armature connected to the punching head. The present invention features that the permanent magnetic punch includes also a magnetic driving mechanism to make the yoke iron and the armature to constitute one magnetic loop, and the magnetic driving mechanism is provided with electromagnetic mechanism to apply electromagnetic drive force to the armature and permanent magnet to apply permanent magnetic attraction force to the armature. The present invention is superior to available electromagnetic punch, which has great power consumption and complicated control system.

Owner:平南县科学技术情报研究所

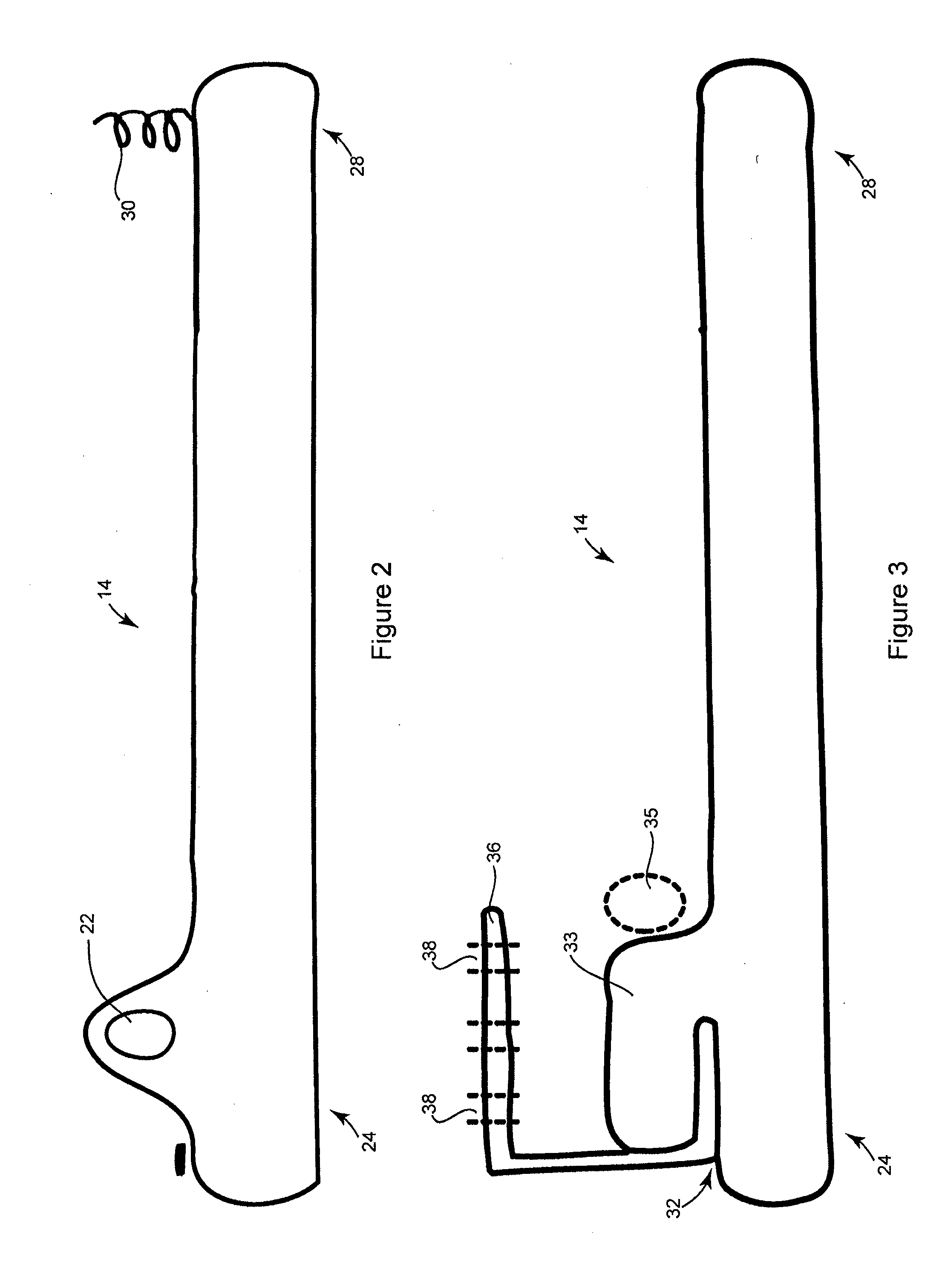

Multi-disk shell and wad

InactiveUS6161482AWide areaStopping powerAmmunition projectilesShotgun ammunitionCushioningCircular disc

The present invention is a multidisk shell and wad for use in a multidisk shell. The wad consists of a wad base, a cushioning section attached at a first end to a top section of the wad base, and at least three alignment arms attached to a second end of the cushioning section. The cushioning section is interposed between the projectile mass and the wad base. The preferred cushioning section comprises a hollow outer cylinder and at least one inner cylinder of polymeric plastic material. Thus, there are at least two concentric cylinders providing the cushioning between the disks and the expanding propellant charge. These at least two concentric cylinders and are attached at first ends to the top side of the wad base. The wad has at least three spatially separated alignment arms having proximal ends and distal ends for maintaining the alignment of projectiles as they travel through the gun barrel. The maintenance of projectile alignment is helpful in reducing the scatter of the projectiles after they exit the gun. The at least three alignment arms are typically attached at the proximal ends to a second end of the cushioning section. The geometry of the at least three alignment arms is useful in the maintenance of the alignment of the projectile under acceleration. A preferred embodiment is a totally symmetrical configuration. Thus when the wad contains three alignment arms the arms are spaced at regular intervals of 120 degrees; four alignment arms are separated by 90 degrees; etc.

Owner:CLARK GEORGE D

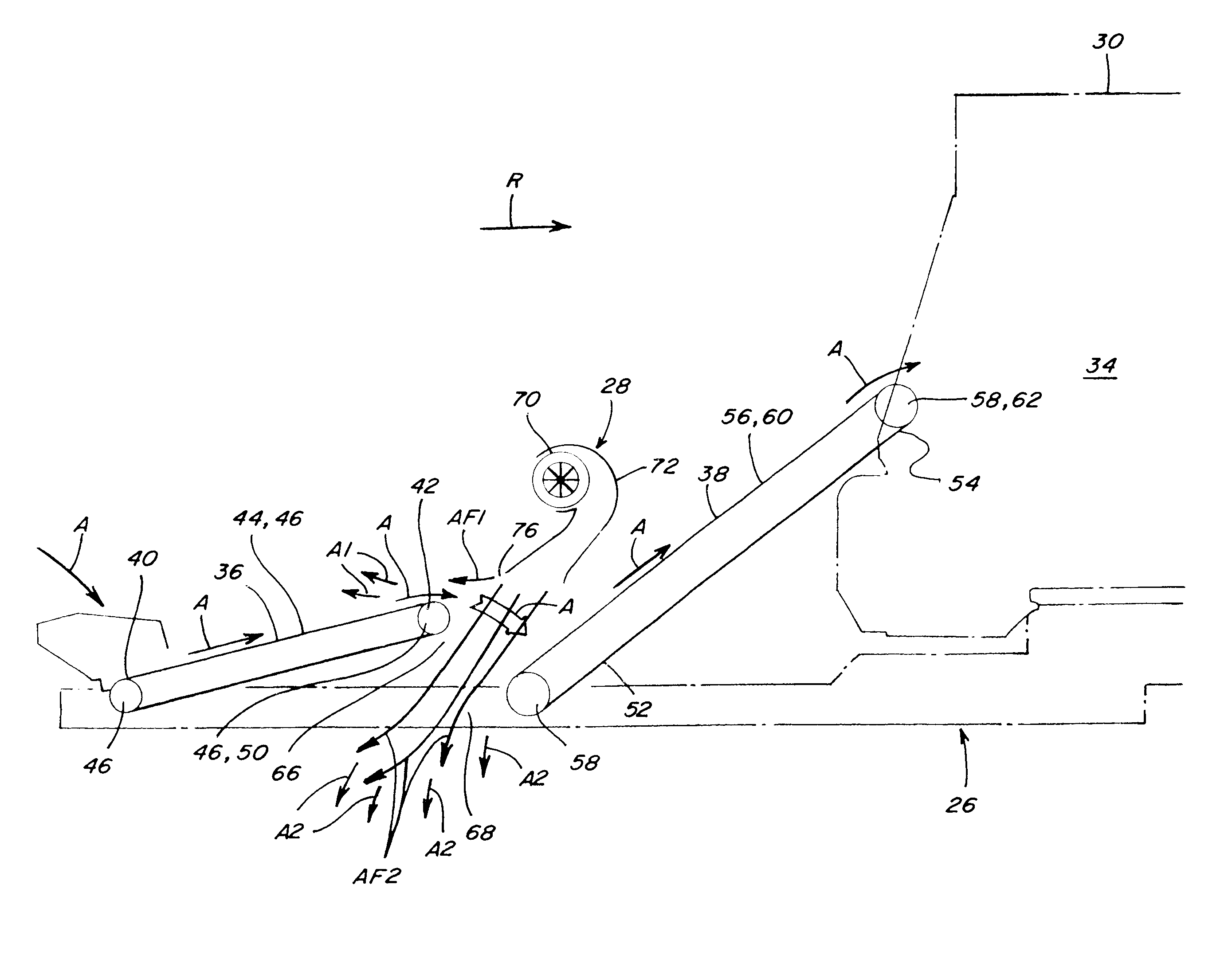

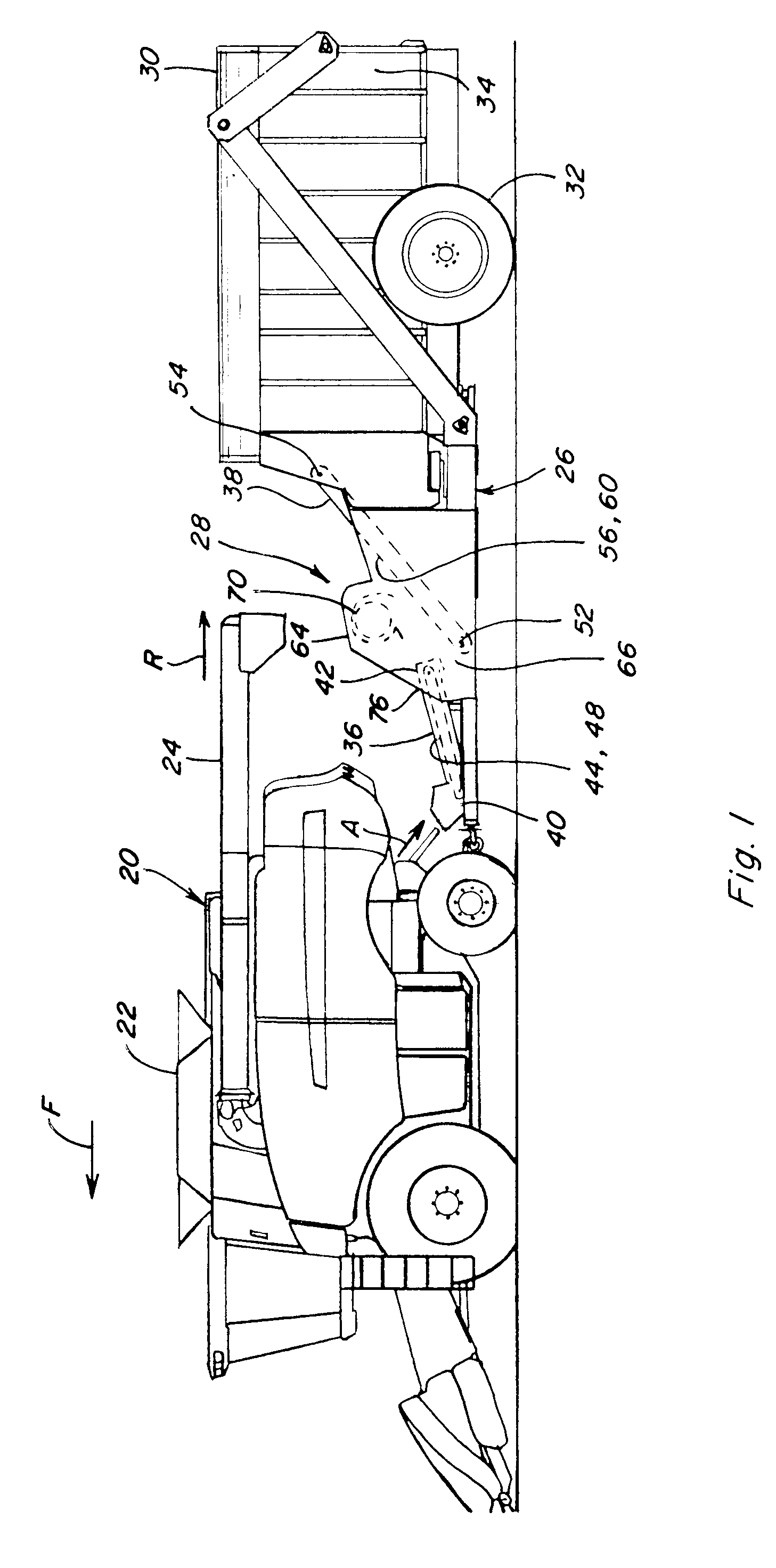

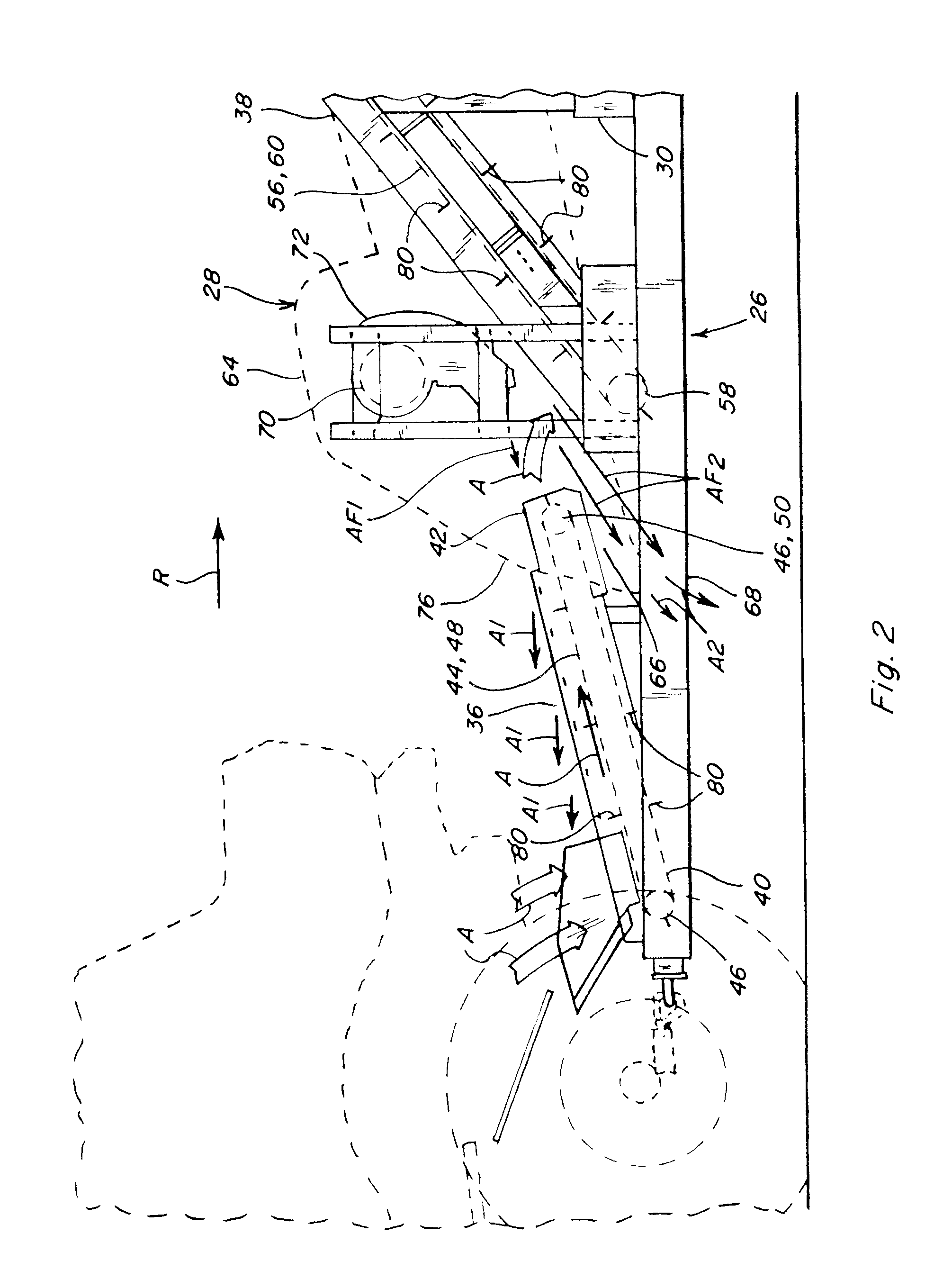

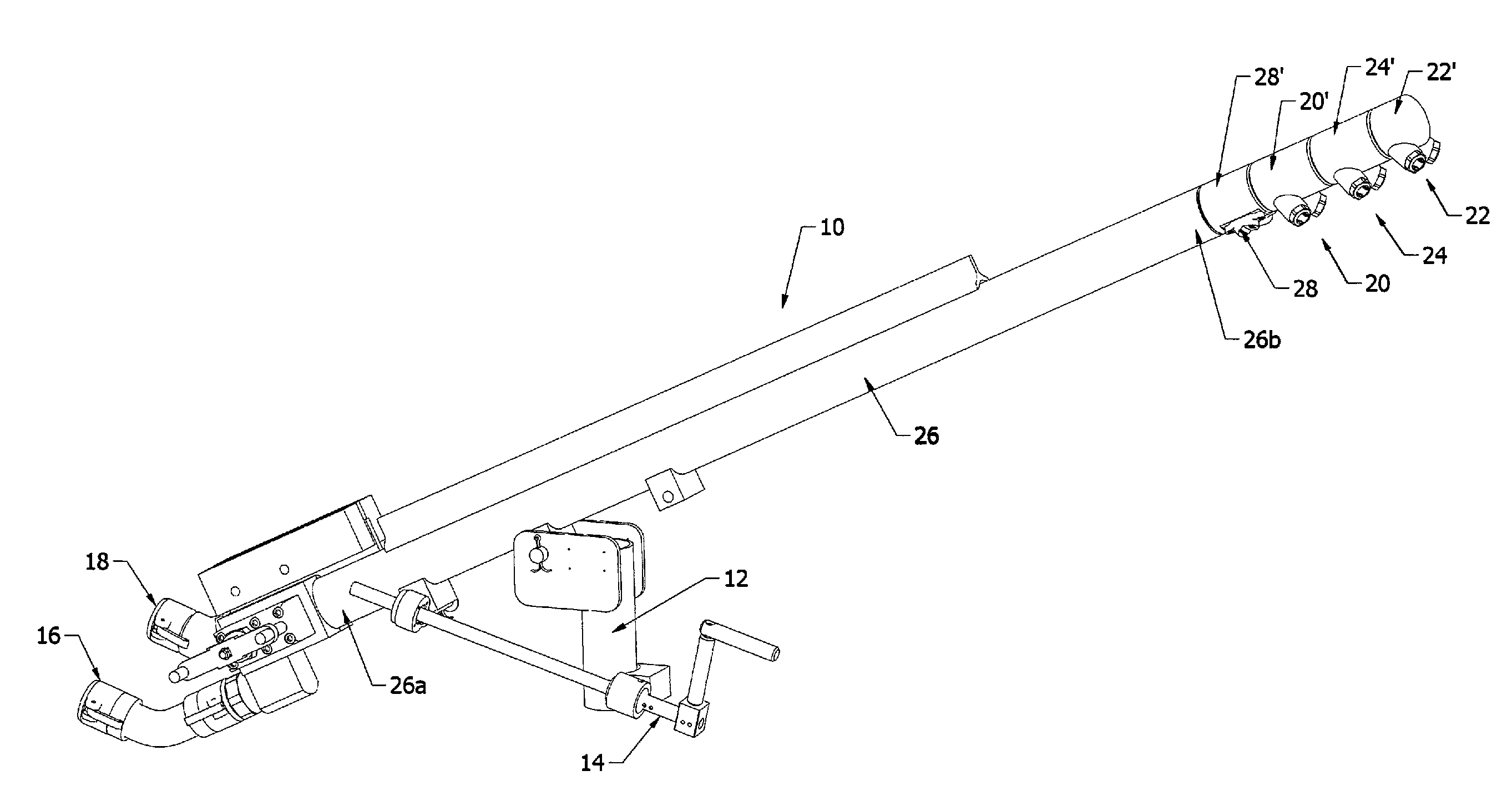

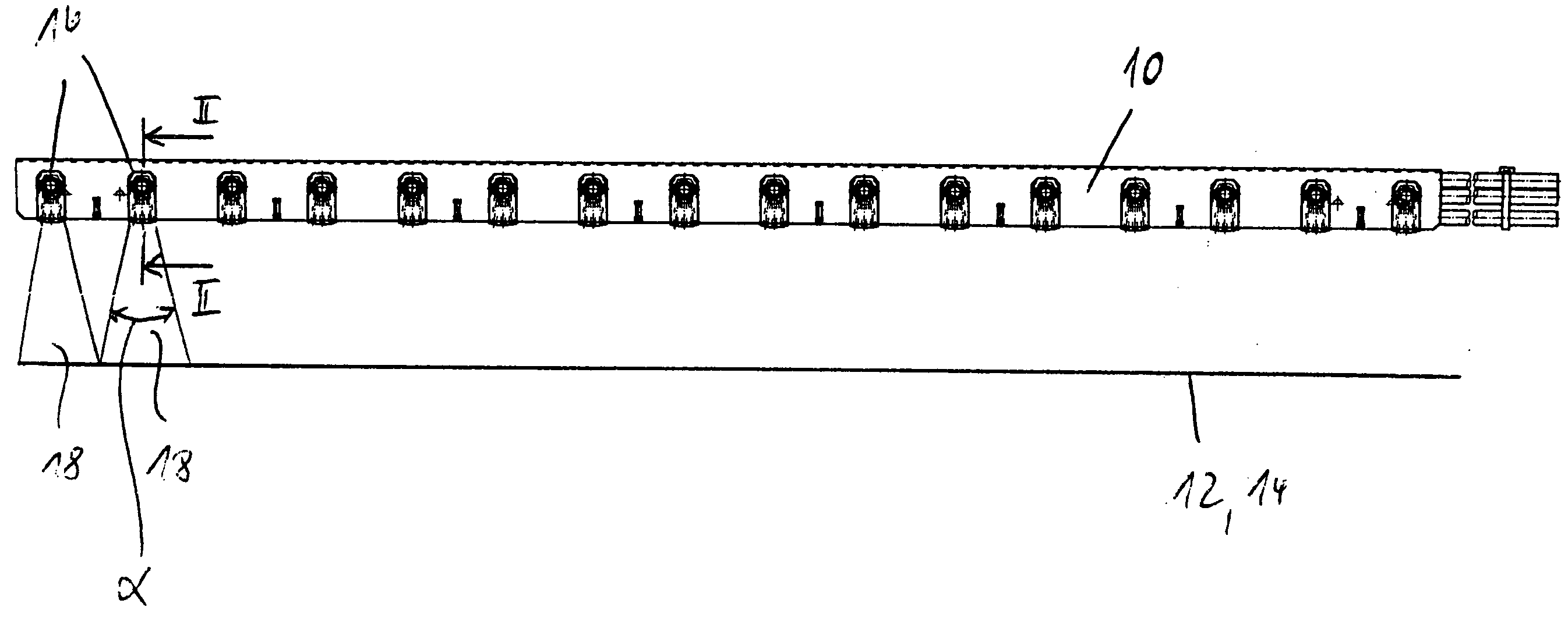

Corn cob cleaning conveyor system

InactiveUS8286798B2Easily redirectedGreat momentumGas current separationHarvestersCrop residueDelivery system

The cob cleaning conveyor system provides a capability for positively removing or cleaning lighter crop residue from a flow of cobs. The system can be incorporated with a cob collection device, such as on a trailer, and can be adjustable in several ways for accommodating varying corn varieties, conditions and the like. The system includes a first conveyor which propels the flow into a gap or passage toward a second conveyor, while a flow of air is directed downwardly through the passage to remove or clean the lighter residue material from the cobs. The angle of attack of the air flow can be selectable, and optionally be directed downwardly along the second conveyor to the passage, and upwardly along the second conveyor to travel with or follow the residue flow, to suit present conditions.

Owner:BLUE LEAF I P INC

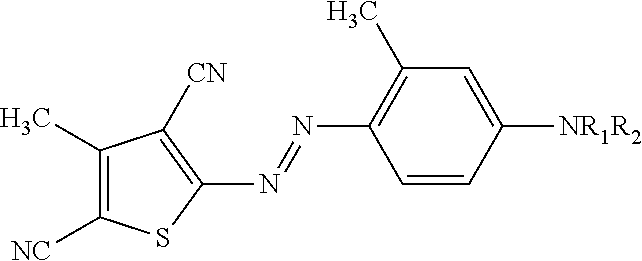

Packaged particulate detergent composition

ActiveUS8883702B2Lower surfaceHigh trafficInorganic/elemental detergent compounding agentsCapsParticulatesWater soluble

A packaged particulate detergent composition, wherein the composition comprises greater than 40 wt % detergent surfactant, at least 70% by number of the particles comprising a core, comprising mainly surfactant, and around the core, a water soluble coating in an amount of from 10 to 45 wt % based on the coated particle, each coated particle having perpendicular dimensions x, y and z, wherein x is from 0.2 to 2 mm, y is from 2.5 to 8 mm, and z is from 2.5 to 8 mm, the packaged particles being substantially the same shape and size as one another.

Owner:CONOPCO INC D B A UNILEVER

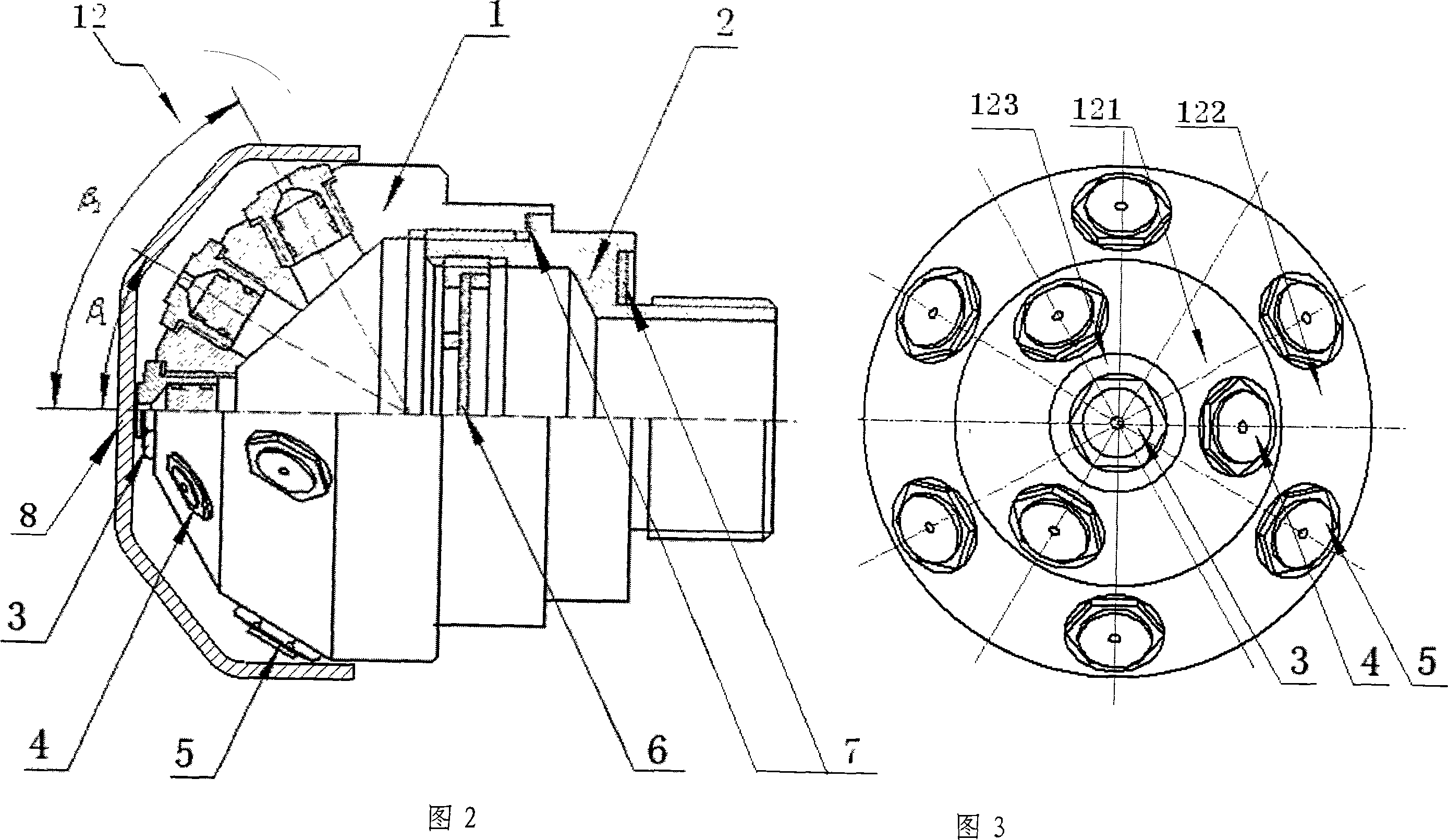

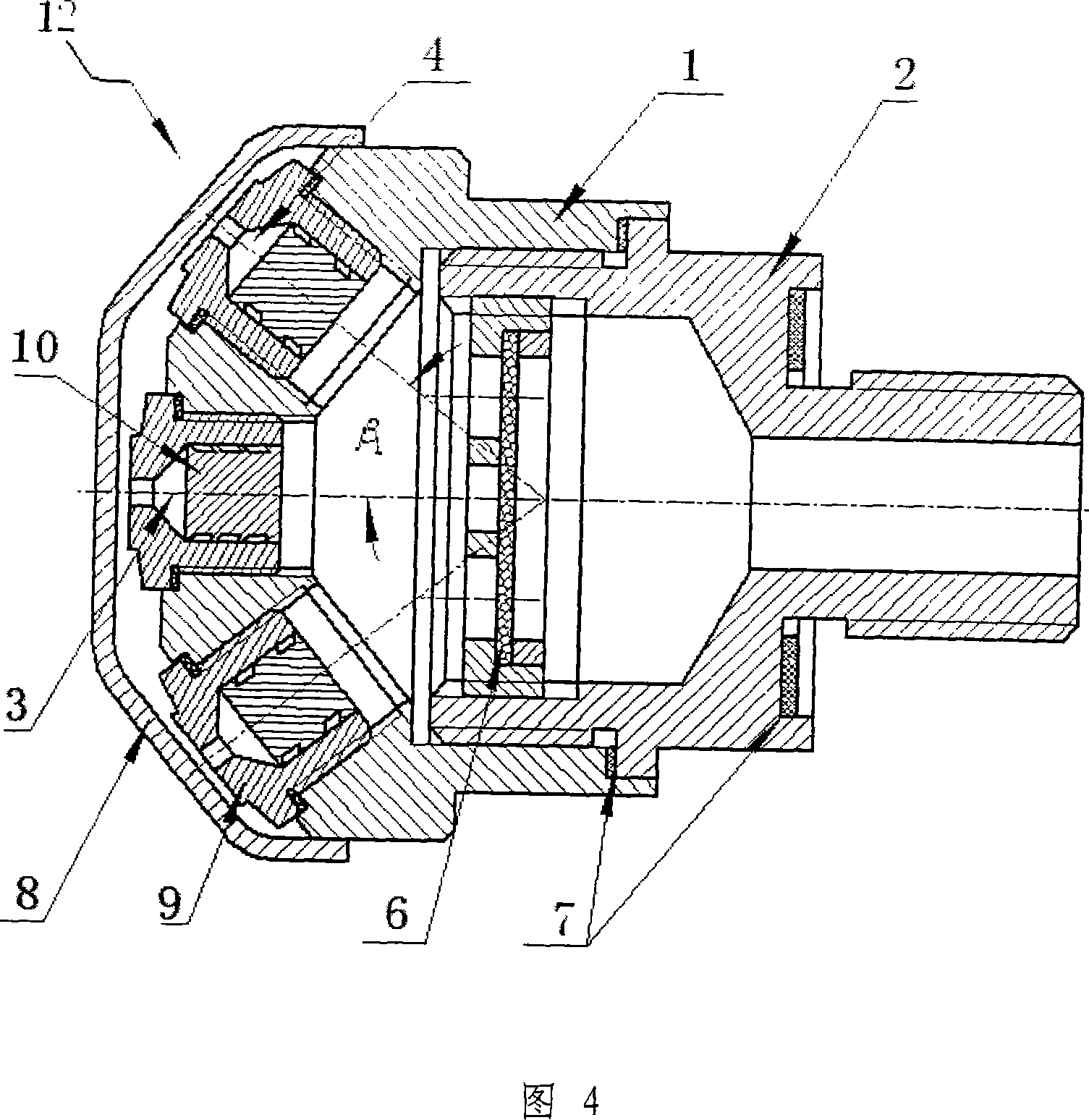

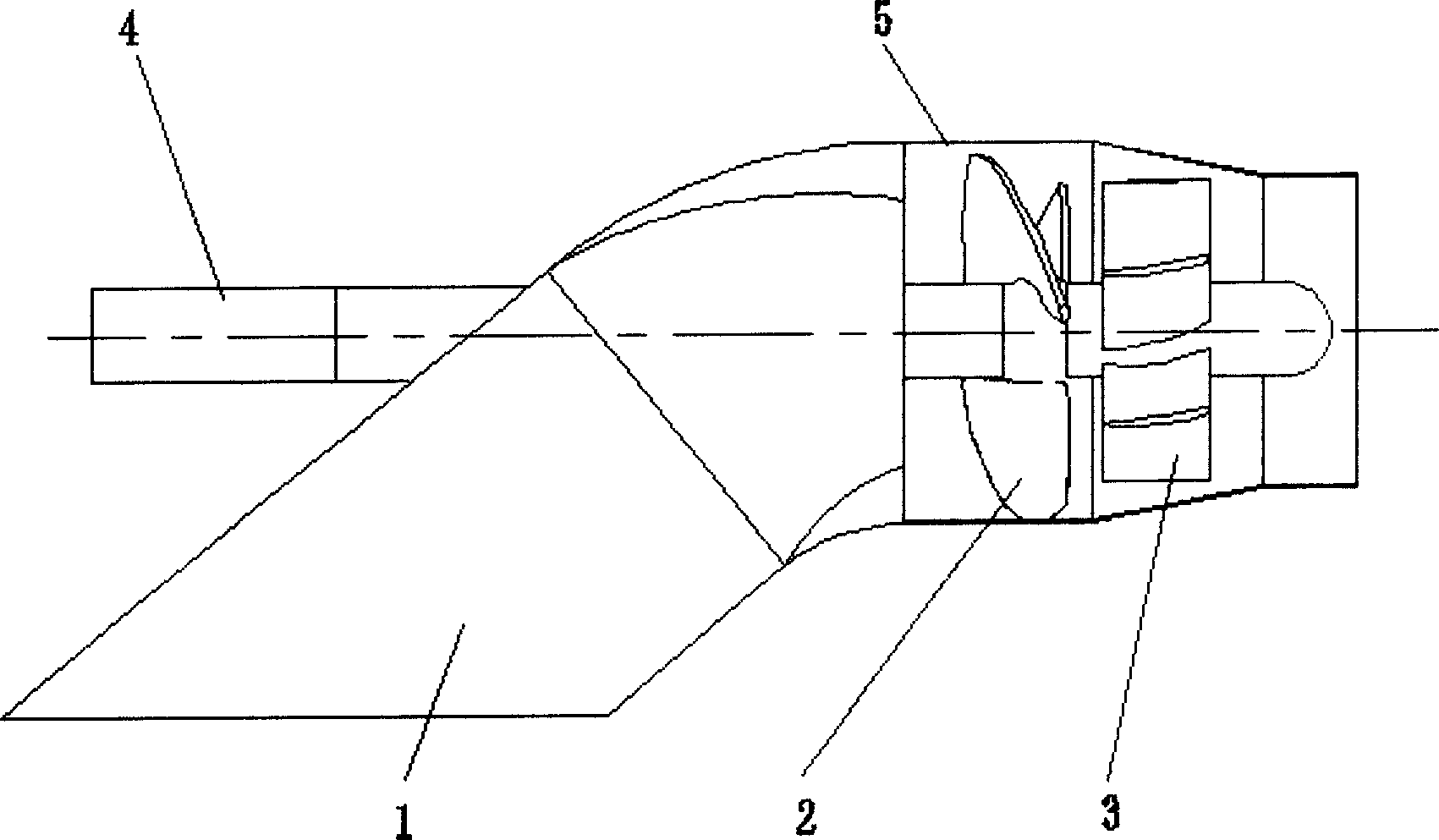

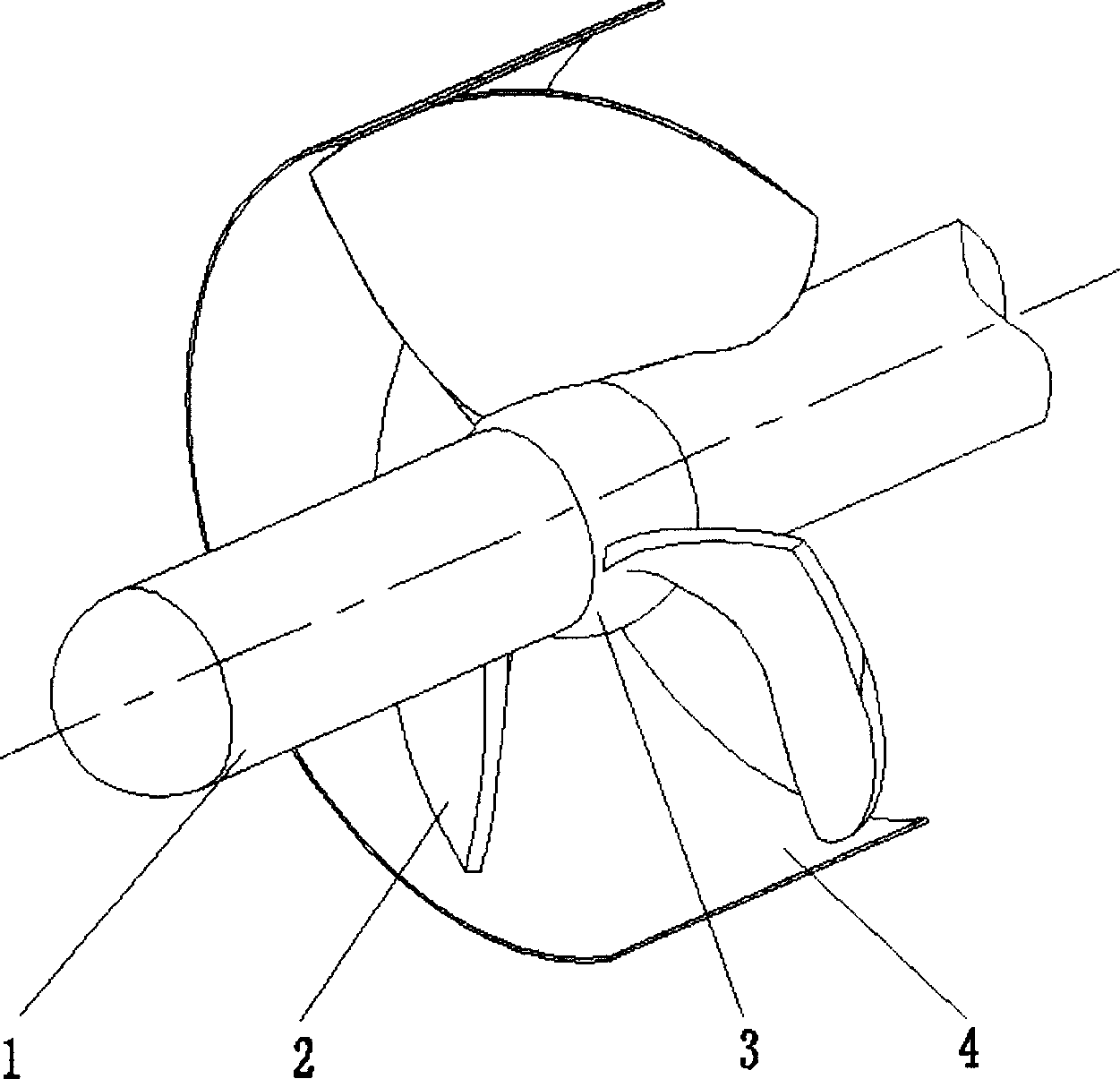

Supercavitation gas-liquid multi-phase water spray propeller

InactiveCN1911729AGreat momentumPressure energy does not increasePropulsive elementsVapor liquidEngineering

The present invention is one kind of water-jetting propulsion system utilizing supercavitation in realizing vapor-liquid two phase propulsion. The water-jetting propulsion system consists of a water uptake chamber, a supercavitation impeller, an impeller chamber, a kinetic energy converter and a shafting. The supercavitation impeller with vanes designed based on Tulin supercavitating foil principle can operate normally under cavitation and supercavitation condition. Both the vapor phase and the liquid phase in the back of the impeller are converted in the kinetic energy converter before being jetted via the thruster to produce thrust in the outlet of the thruster. The kinetic energy converter can guide the flow of both the vapor phase and the liquid phase and convert the rotation kinetic energy of both the vapor phase and the liquid phase in the outlet of the impeller into axial flow kinetic energy without increasing the pressure of the two phase flow. The present invention realizes great power thrusting under cavitation condition.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

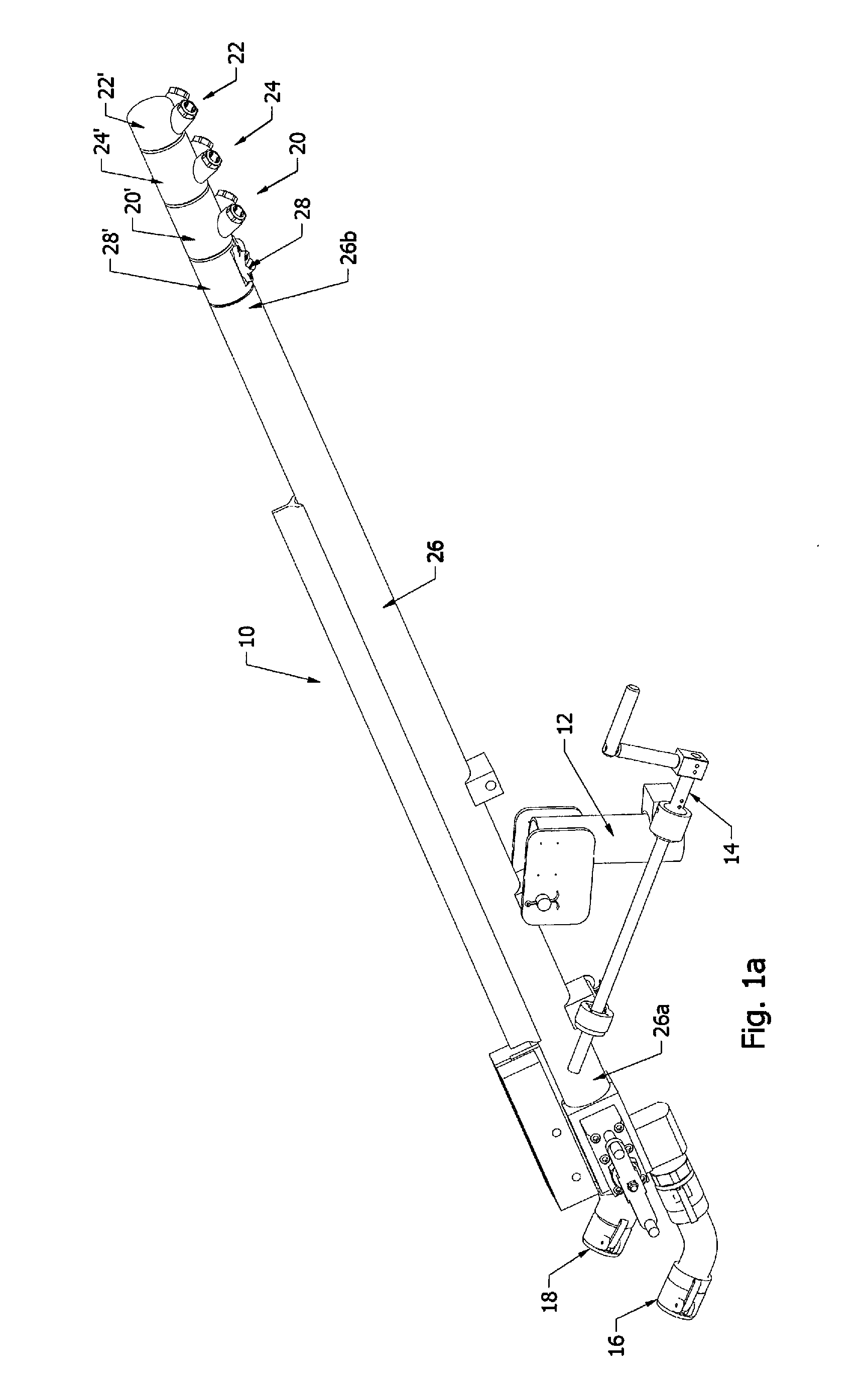

Snow Making Apparatus and Method

ActiveUS20110174895A1Low profileEasily and quickly attach and/or removeRecreational ice productionLighting and heating apparatusPhysicsSnow

A low energy snow making gun having at least one but preferably three operational stages each having at least one pair of small aperture water outlets which are oriented at a divergent angle to generate a respective pair of narrow angled water droplet streams which do not interfere with each other until they have reached a distance from the gun. A second pair of water outlets may be provided on each stage with each pair on each stage oriented at a divergent angle to maintain singularity of the streams over a distance thereby increasing the throwing power of the gun.

Owner:RATNIK IND

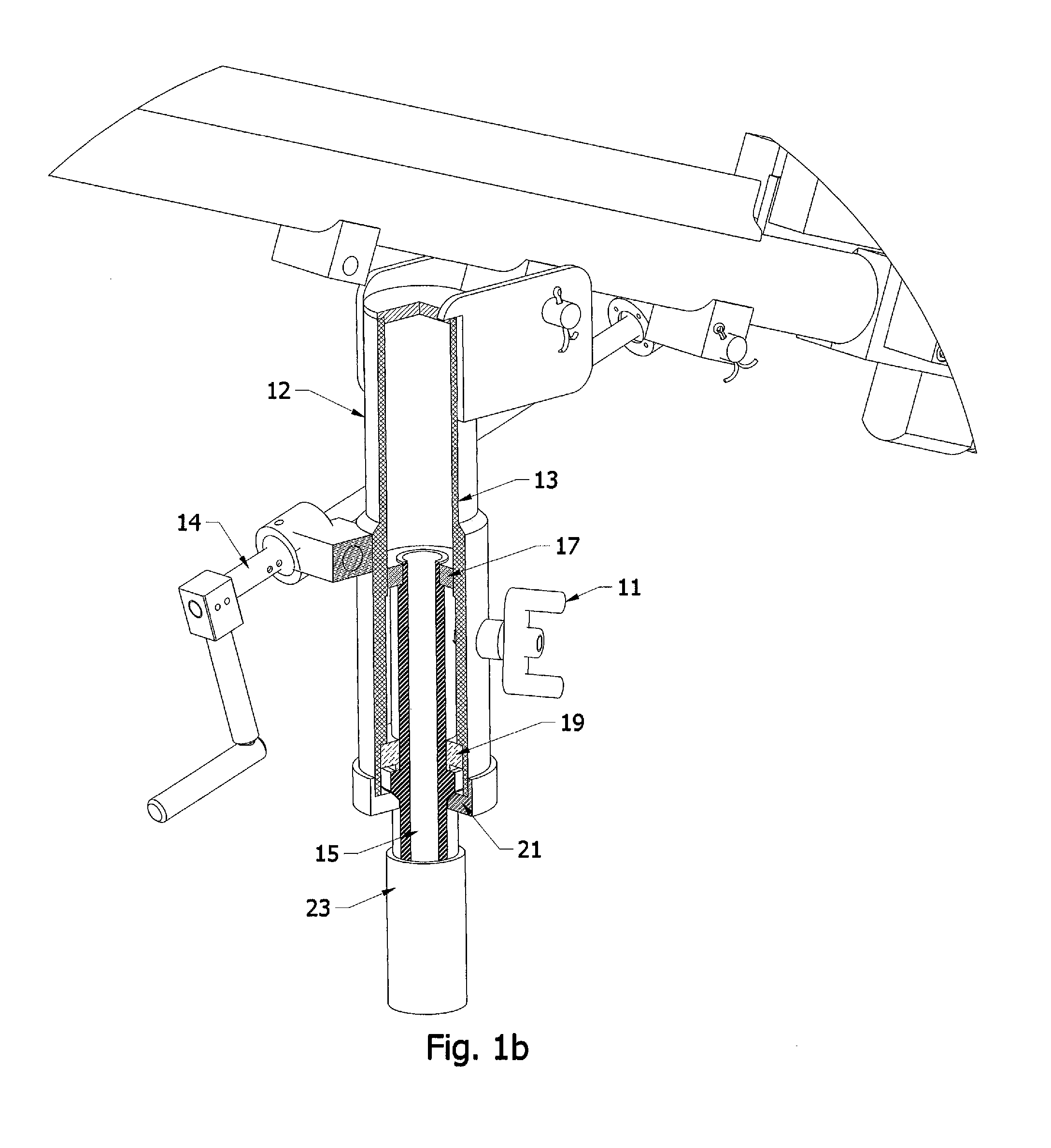

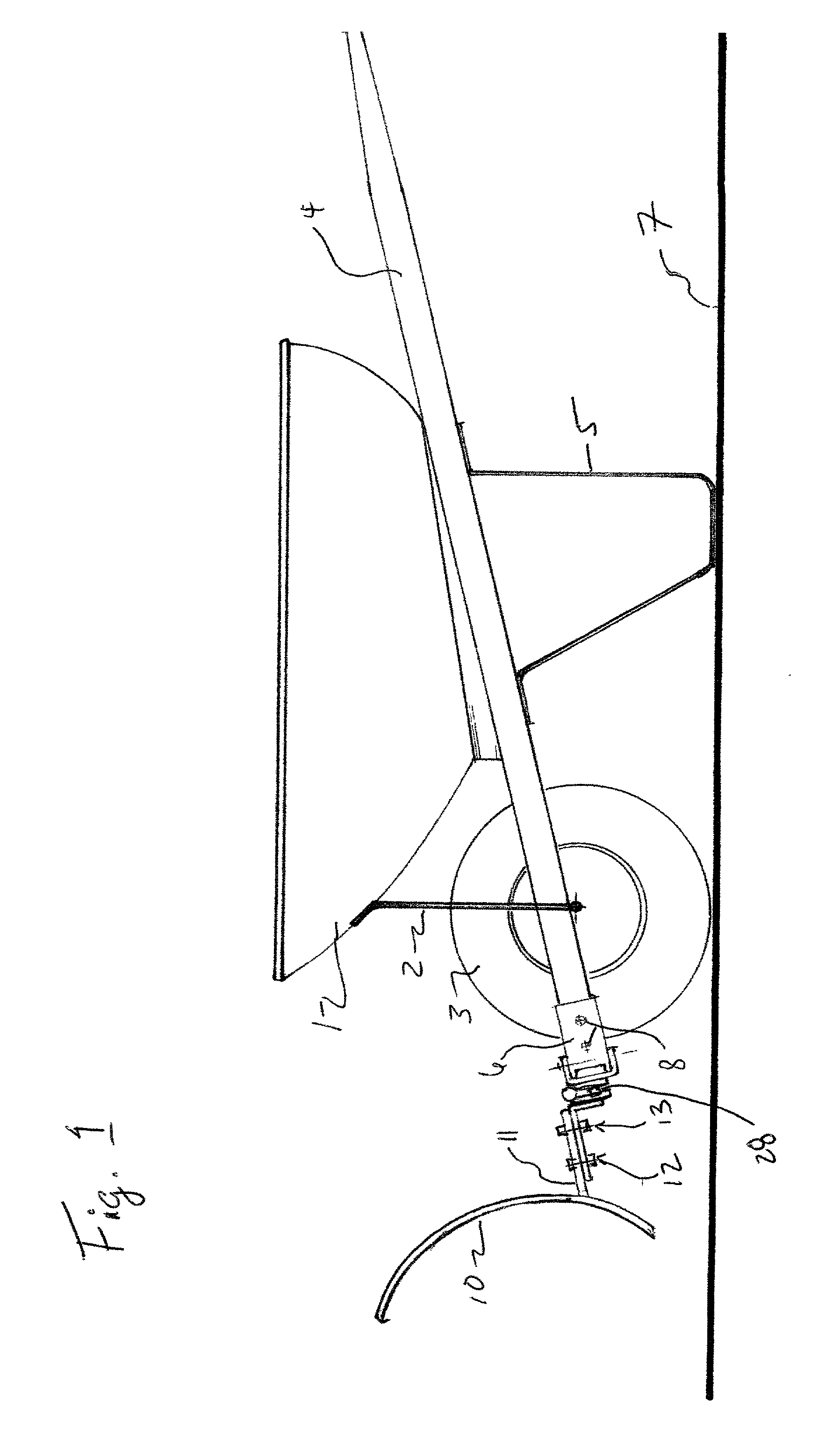

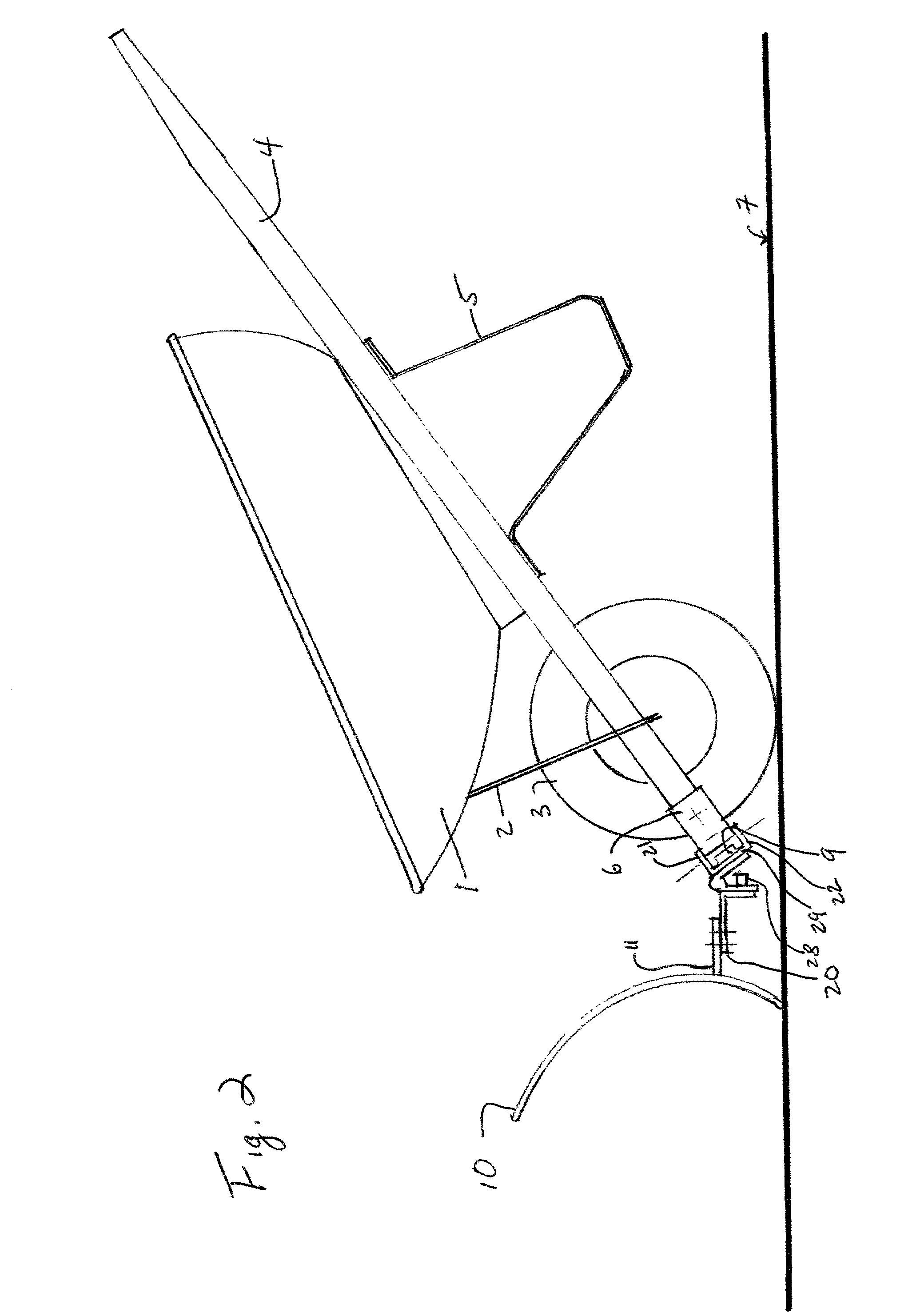

Wheelbarrow mounted snowplow

InactiveUS20010045029A1Not physically demandingTime inefficientCarriage/perambulator with single axisHand carts with one axisSnow removalEngineering

This invention is in the field of snow removal. More particularly, the invention provides a snowplow blade and an attachment apparatus to be secured to the front of a contractors type wheelbarrow and operated manually. Snow removal is facilitated by the ability to add ballast to the wheelbarrow, which preserves momentum, and by the unique design.

Owner:FULTON RICHARD EUSTIS

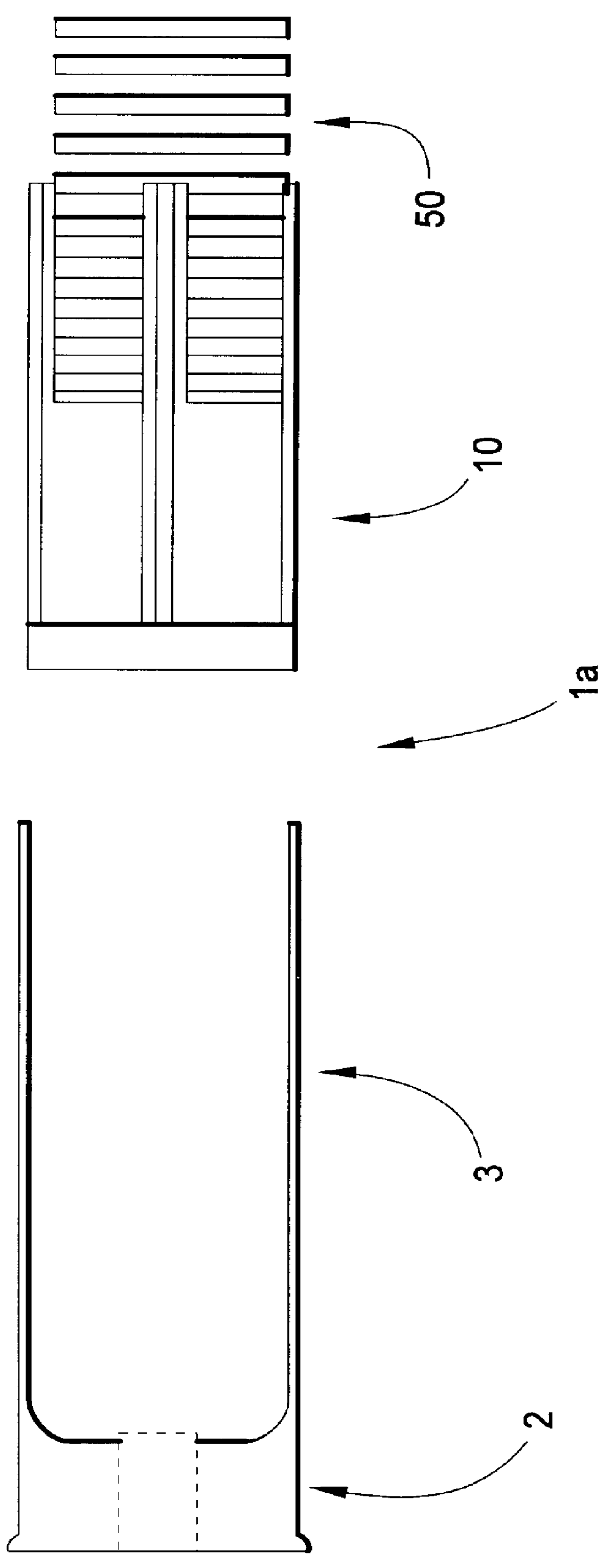

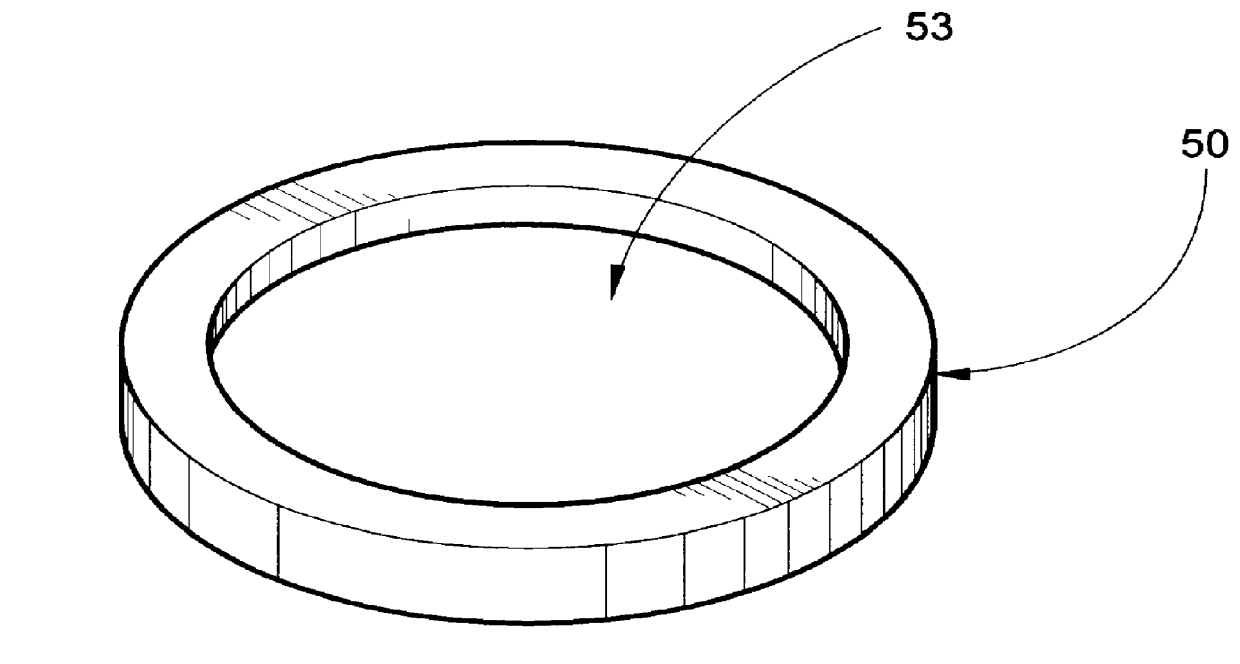

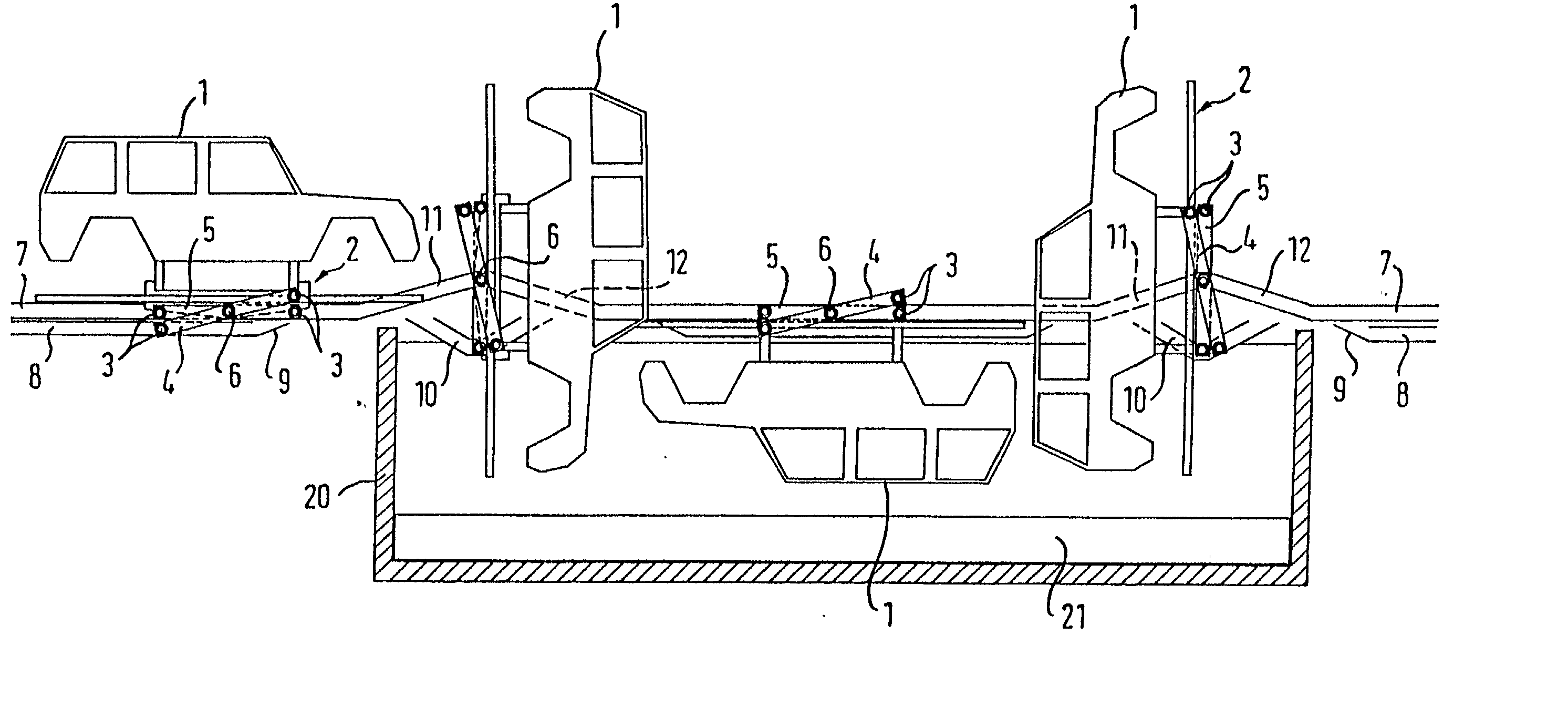

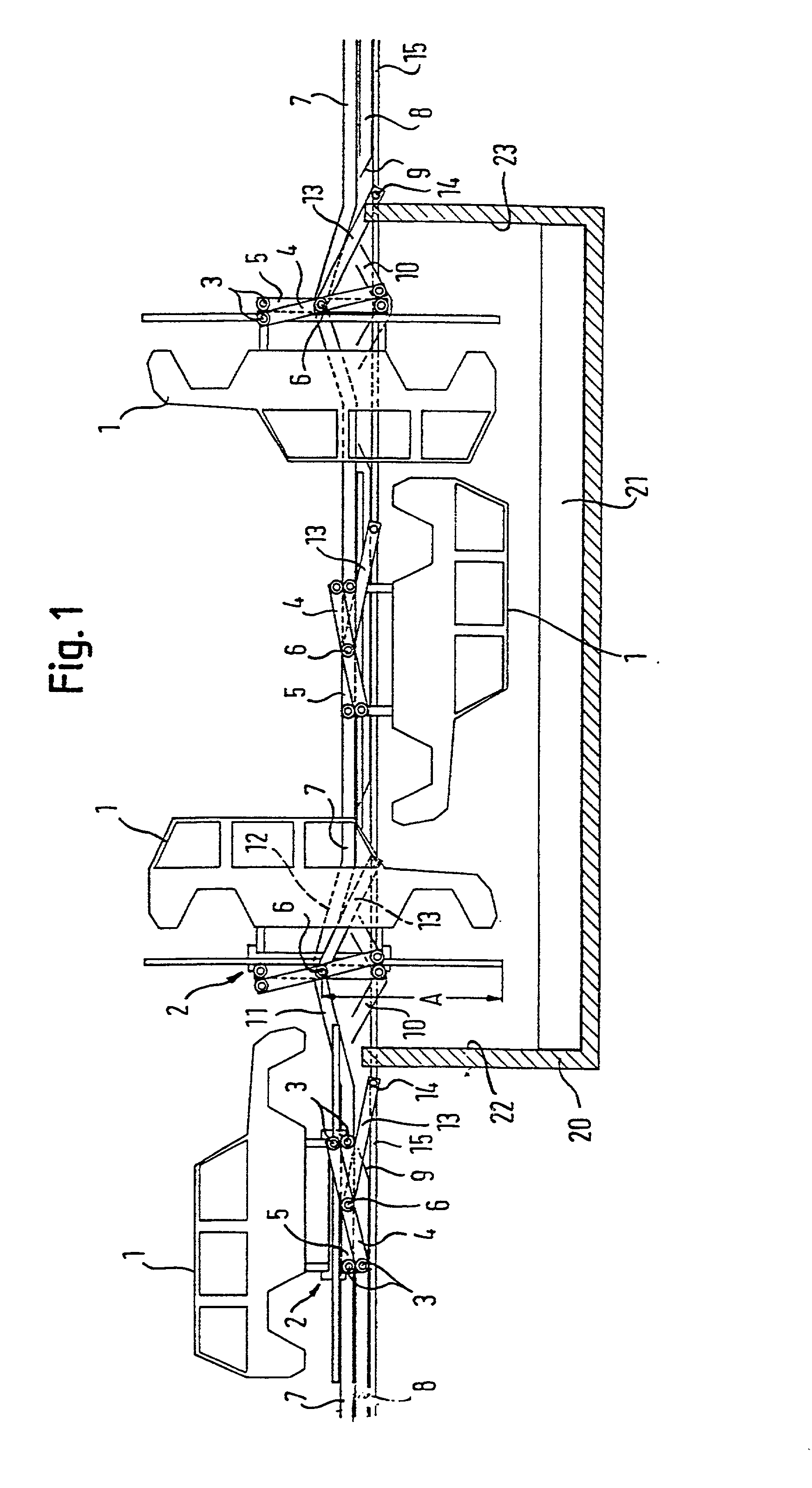

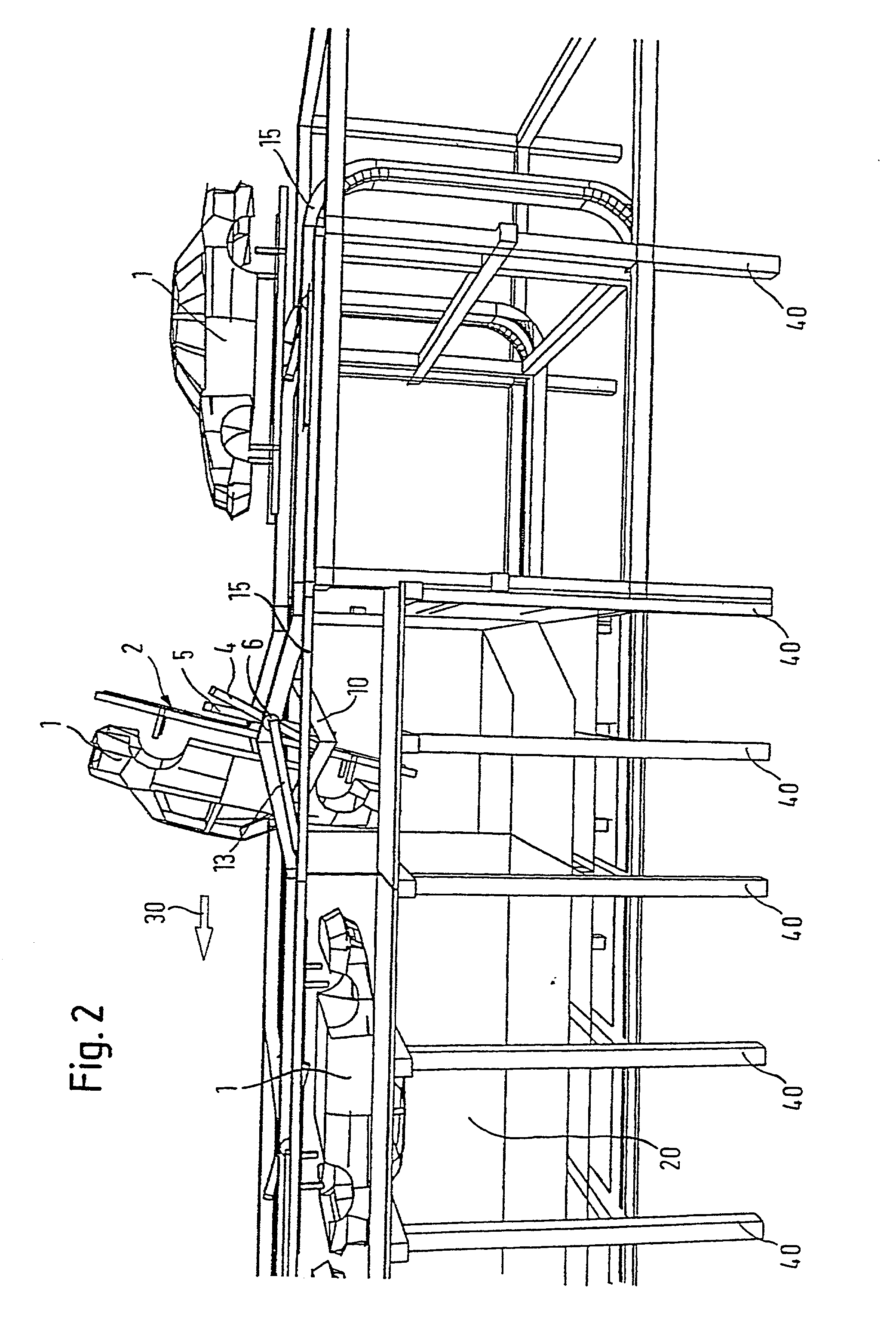

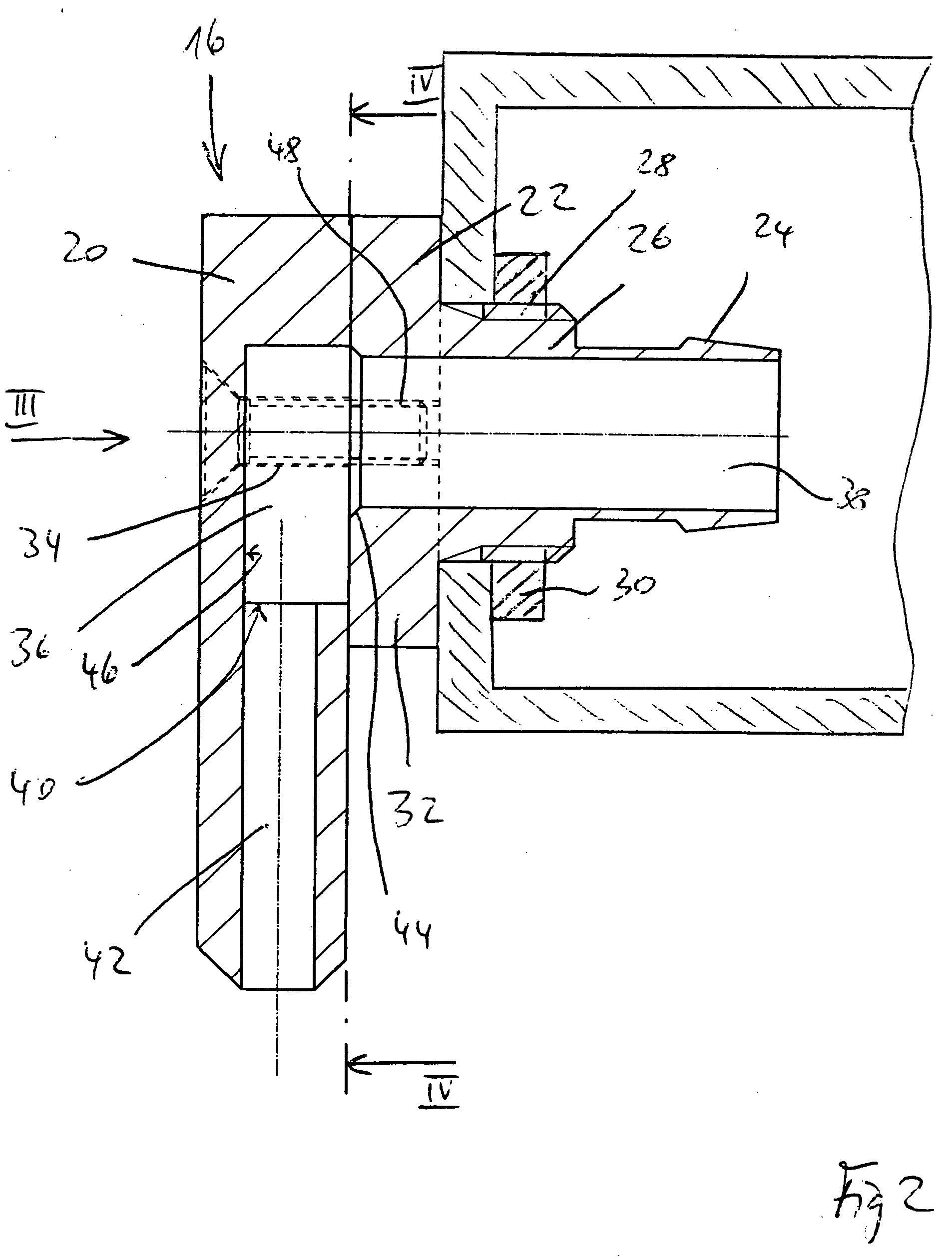

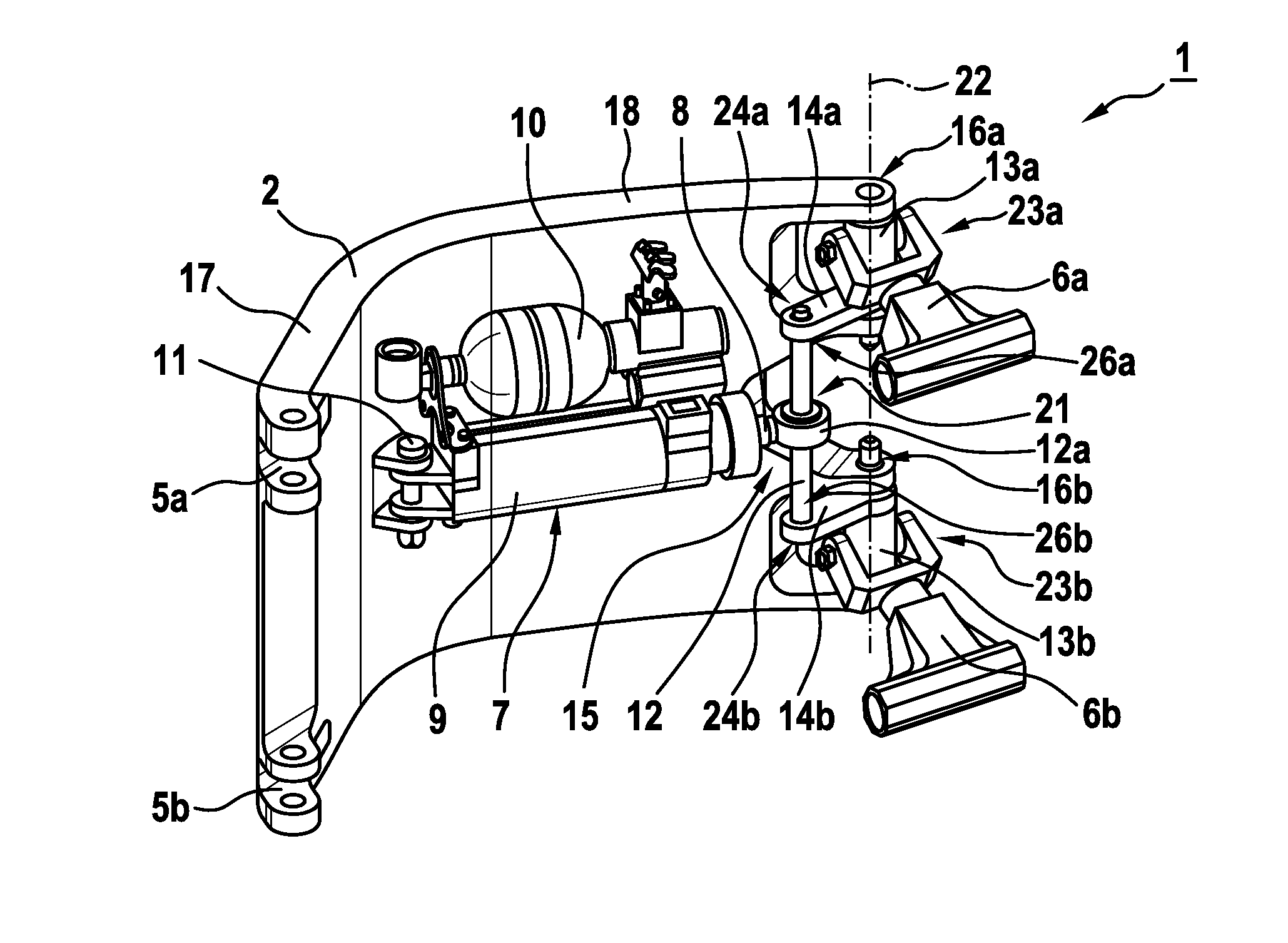

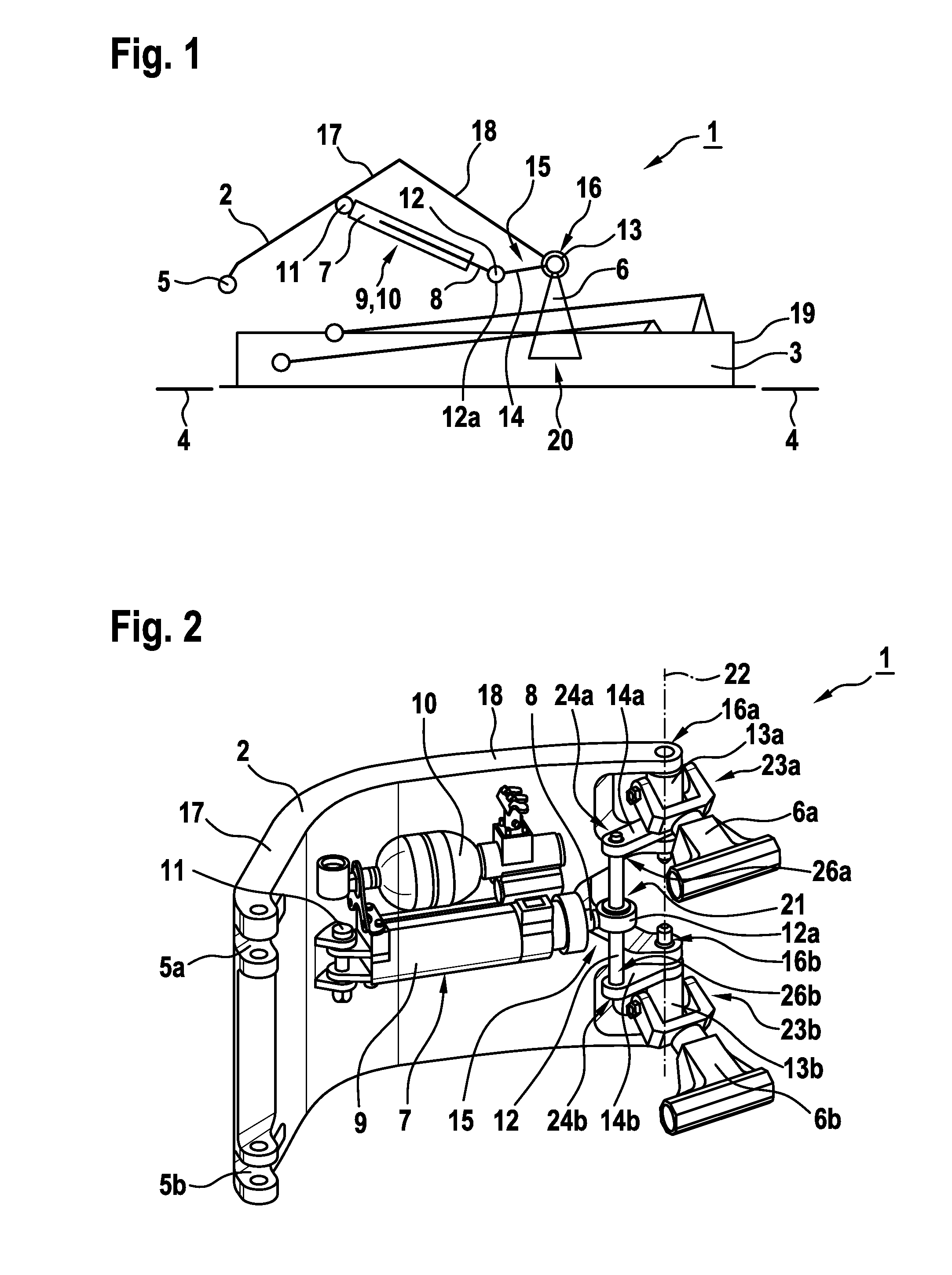

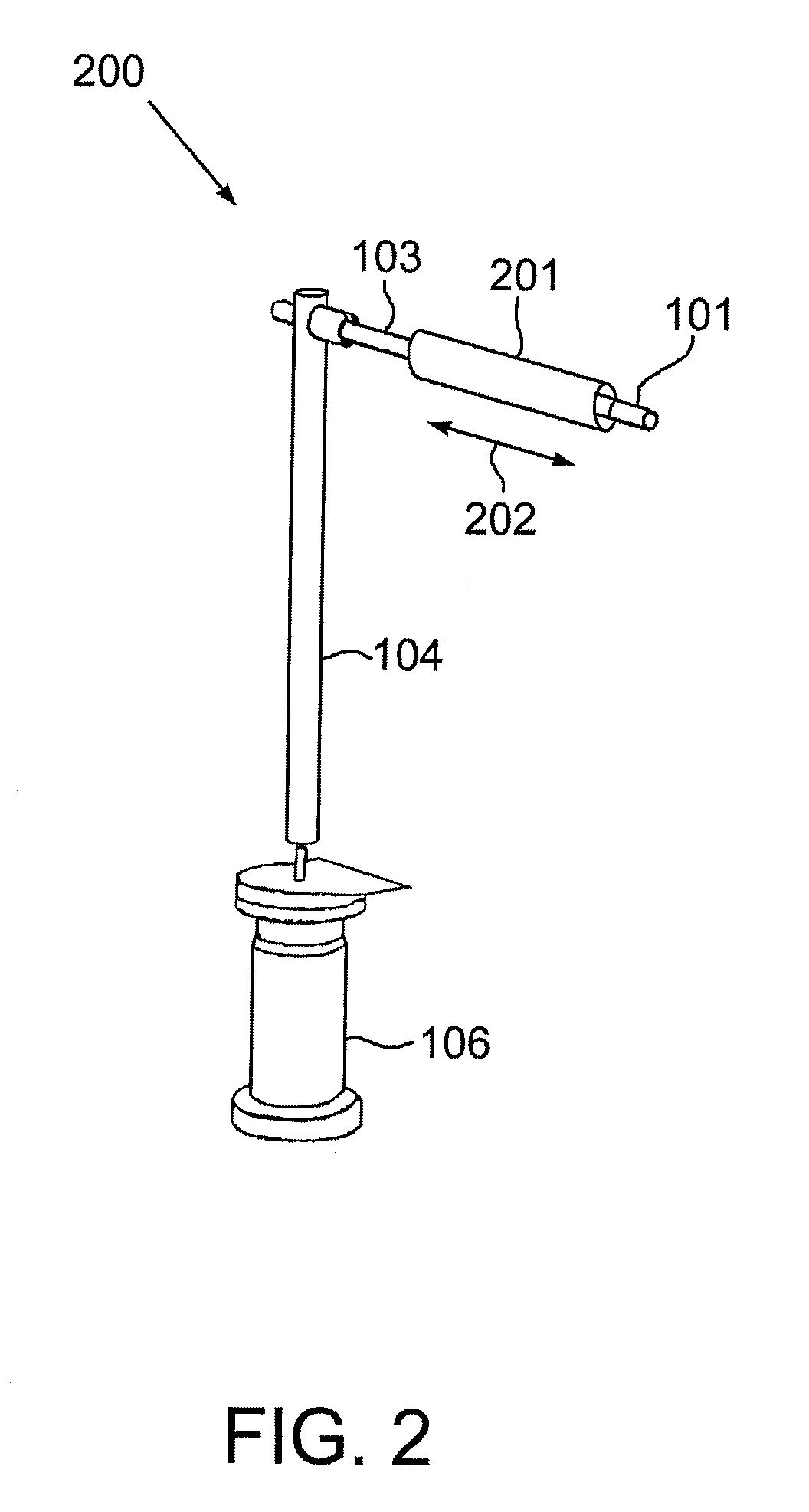

Method for introducing and removing workpieces into or from a surface treatment area, a surface treatment device and an arrangement for surface treatment

InactiveUS20020162504A1Less energyGreat expenditurePretreated surfacesCharge manipulationProcess regionTranslatory motion

The invention relates to a method for introducing and removing workpieces, especially vehicle bodies, into or from a treatment area (20) by rotational movements, whereby the treatment area serves for treating surfaces of the workpieces (1). A workpiece (1) is detachably fixed at a holding frame (2) which is moved together with at least one workpiece that is situated thereon at an essentially constant speed and by a continuous translation. The workpiece (1) is rotated around a rotational axle (6) at least at the beginning and end of the treatment area (20) and simultaneously with the translation movement. The rotational axle (6) is orientated vertically in relation to the moving direction of the holding frame (2) and is lifted and lowered during rotation.

Owner:ABB FLAEKT AB

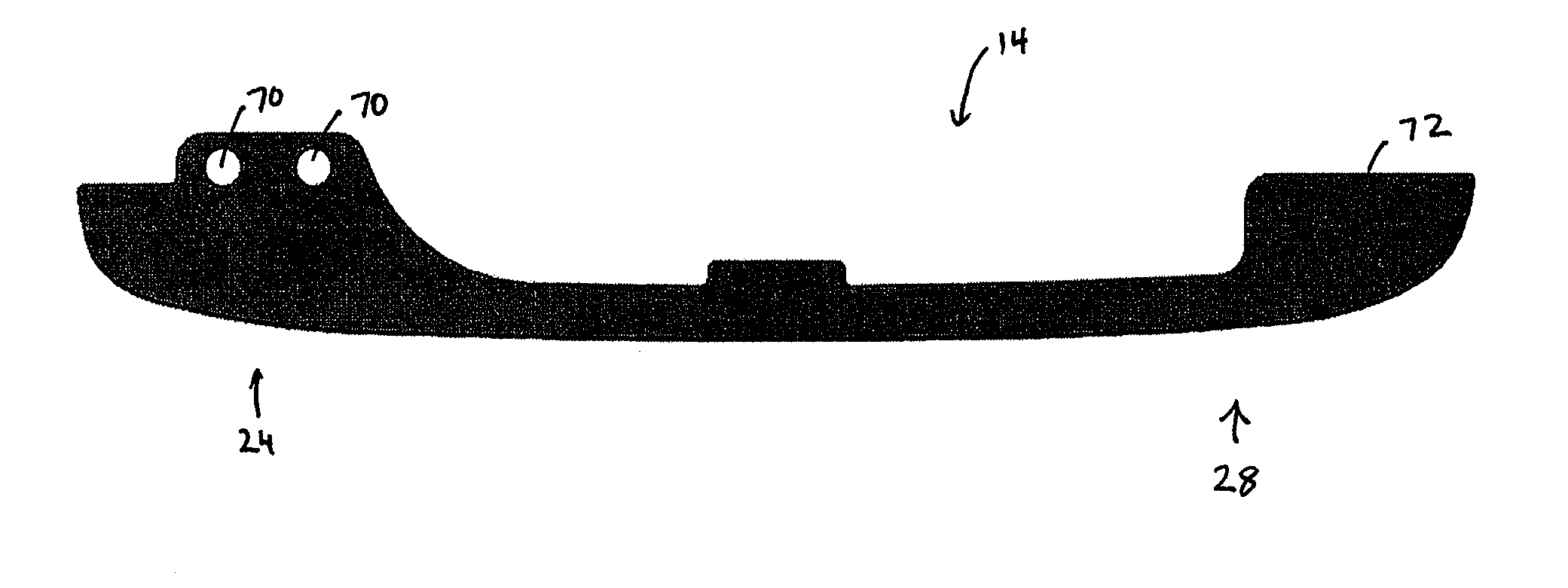

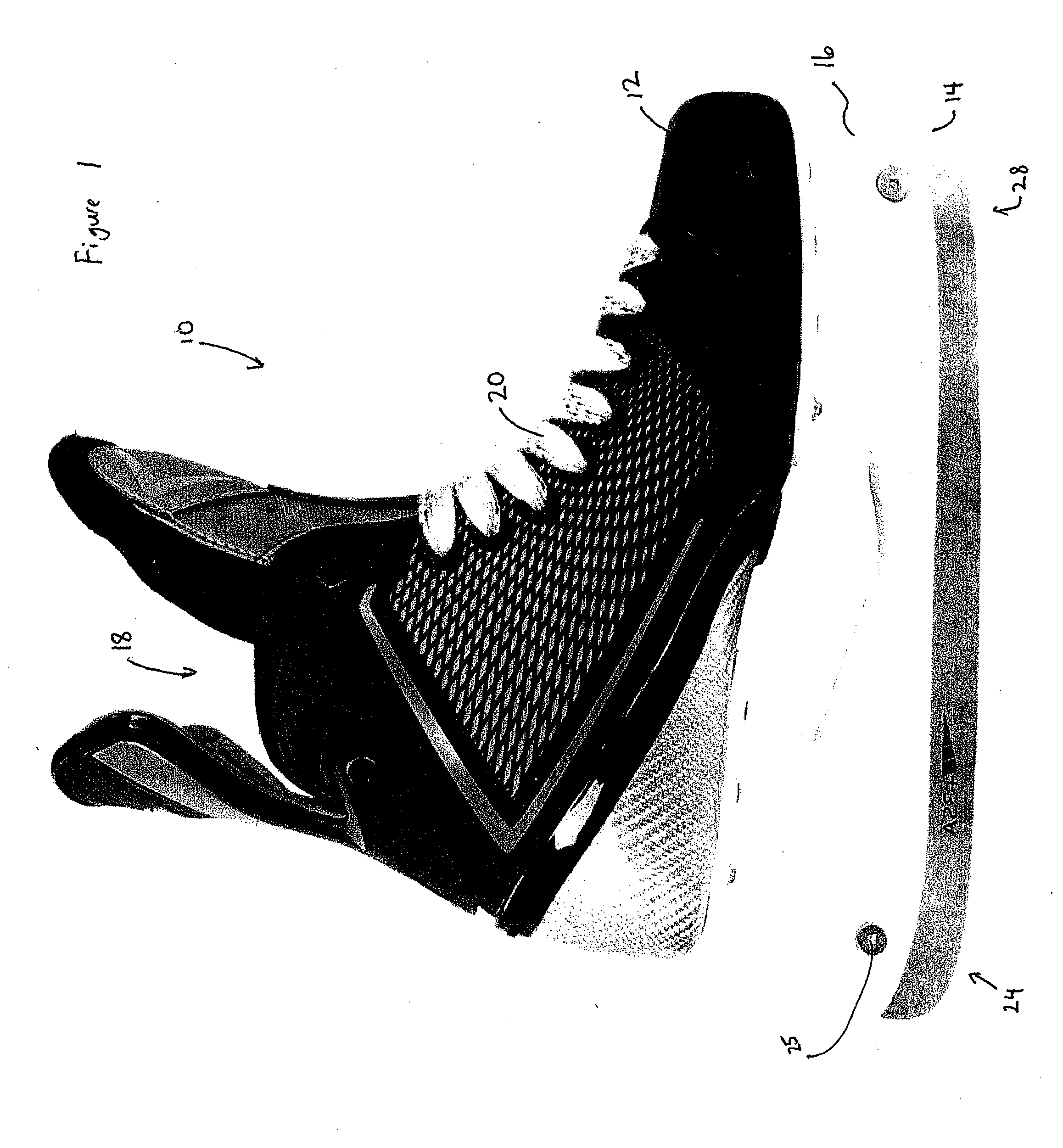

Skate blade system with dynamic movement

ActiveUS20160001162A1Increase skating speedEasy to useSki bindingsSki-brakesEngineeringMechanical engineering

The disclosure is directed at a skate blade system including a boot portion; a blade housing, mounted to a bottom of the boot portion; and a blade portion having a heel and a toe end; wherein the blade portion is fastened at the heel end to the blade housing in a fixed relationship and is unattached from the blade portion blade housing at the toe end.

Owner:AZZOLIN JEFFREY DANIEL BRUNO

Spray nozzle and method for dusting freshly printed products

ActiveUS20060107857A1Smooth connectionAvoid distributingLiquid surface applicatorsLiquid spraying apparatusEngineeringMechanical engineering

The invention concerns a spray nozzle for a powder duster for dusting freshly printed products with a connection for a tube for supplying a powder-air mixture, a distribution chamber and at least two nozzle channels which branch off from the distribution chamber like a fan, wherein the opening angle of the outer nozzle channels limiting the fan subtends an angular range of 5° to 20°, in particular an angular range of 8° to 15°, and preferably 12°. The invention also concerns a spray bar with spray nozzles of this type, a powder duster comprising spray nozzles of this type, and a method for dusting freshly printed products.

Owner:WEITMANN & KONRAD

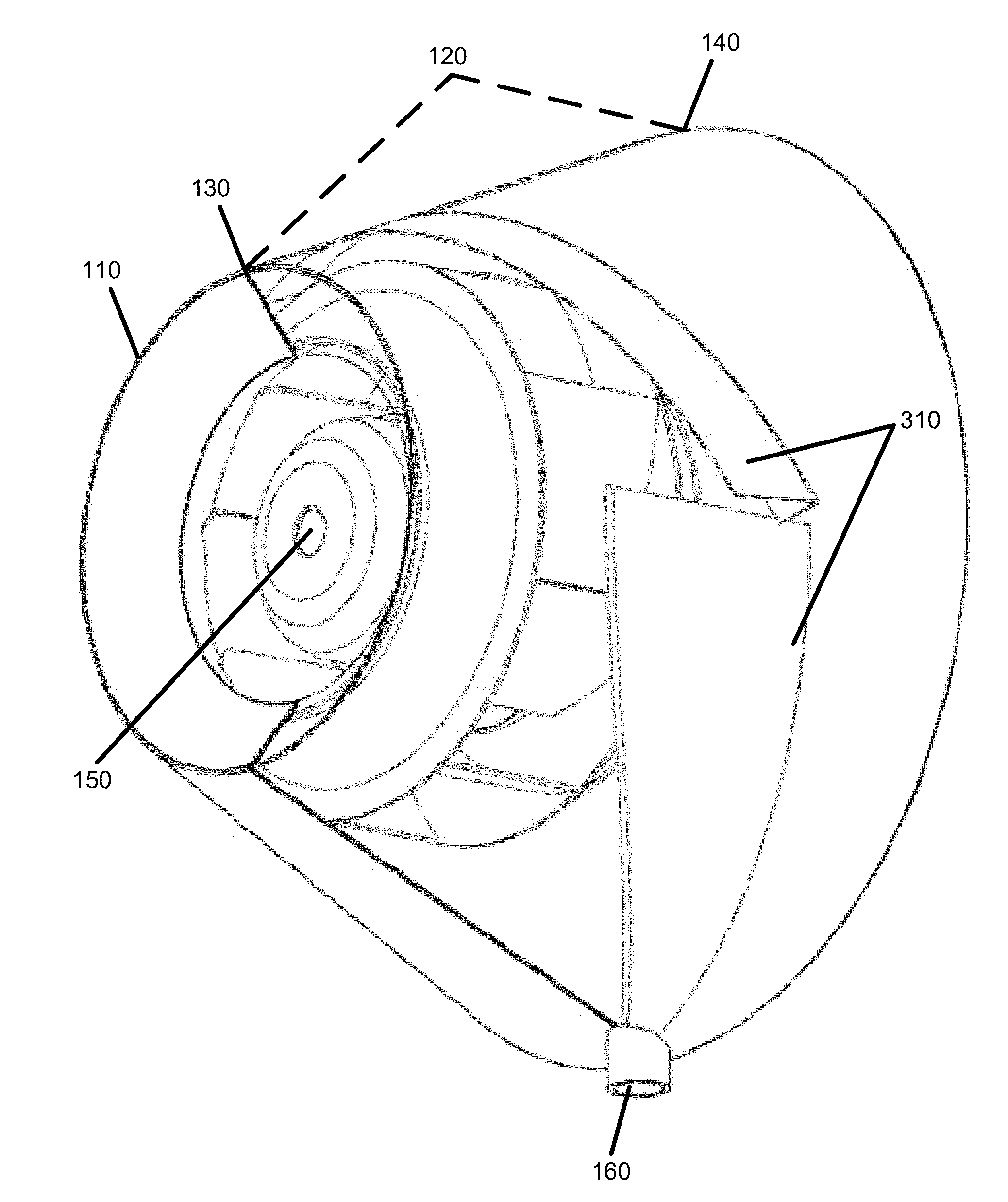

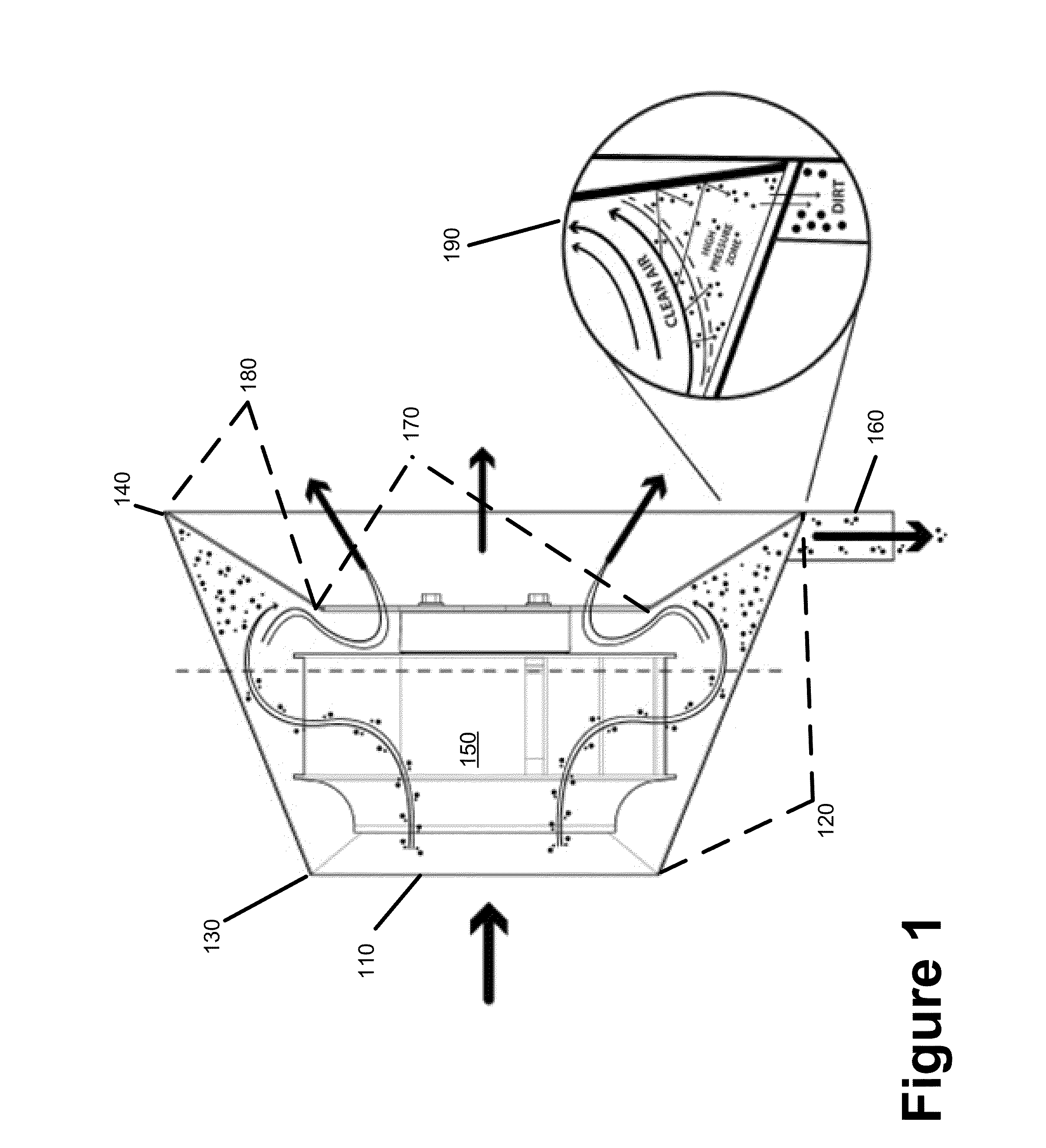

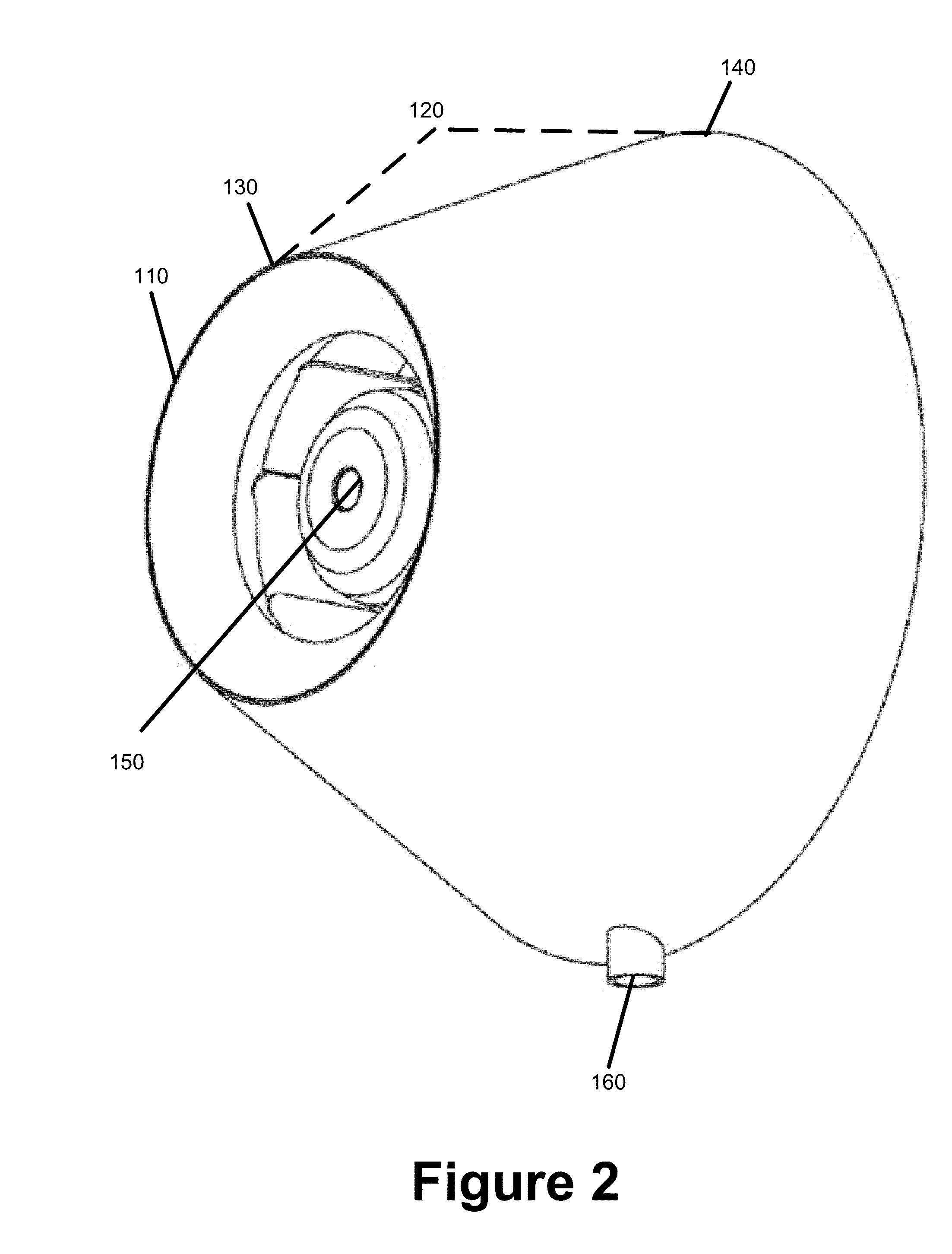

Centripetal Separation System for Cleaning Particulate-Pervaded Air or Gas

ActiveUS20150128544A1Increase pressureEasy to separateCombination devicesAuxillary pretreatmentParticulatesImpeller

Some embodiments provide a centripetal air or gas cleaning apparatus for removing particulates from air or gas. The apparatus comprises an inlet, housing, impeller, a clean air outlet, and a particulate outlet. The housing has an inner conical surface. The impeller's rotation creates negative pressure towards the inlet that intakes particulate-pervaded air or gas into the housing. The rotation also induces an accelerating force that throws the particulate-pervaded air or gas against the outer walls of the housing. Here, the particulates separate from the air or gas, penetrate a high-pressure zone, and are ejected through the particulate outlet located in the high-pressure zone. The air or gas, having less inertia, deflects away from the high-pressure zone where it is then subjected to a centripetal force that drives the air or gas towards the center of the housing behind the impeller where it is ejected through the clean air outlet.

Owner:ANDOVER PROTECTION SYST

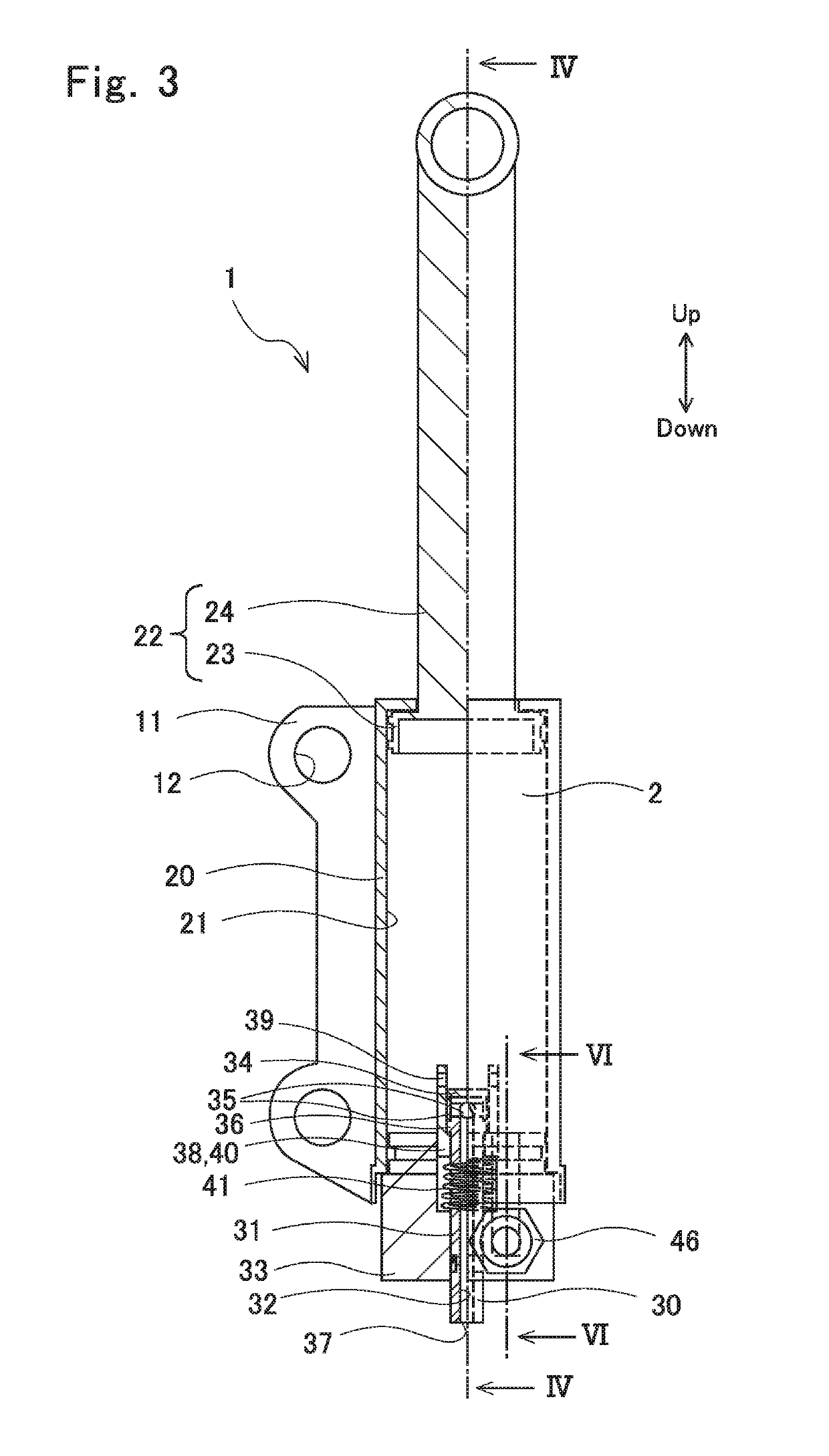

Actuator system for an actuatable door and an aircraft having such an actuatable door

InactiveUS20160083071A1Great momentumEasy maintenanceFluid-pressure actuatorsAircraft doorsEngineeringActuator

An actuator system for an actuatable door, the actuator system comprising a stiff hinge arm, the stiff hinge arm being adapted to pivotally support the actuatable door and to be pivotally mounted to an associated door mounting structure, wherein an actuator with a pneumatically operable actuating rod is provided, the actuating rod comprising a coupling rod joint that is connected to at least one coupling rod, the at least one coupling rod being mounted to at least one torque lever that is pivotally mounted in at least one hinge of the stiff hinge arm by means of at least one torsion bolt, the at least one torsion bolt being drivingly connectable to the actuatable door. The invention is further related to an aircraft having such an actuatable door.

Owner:AIRBUS HELICOPTERS DEUT GMBH

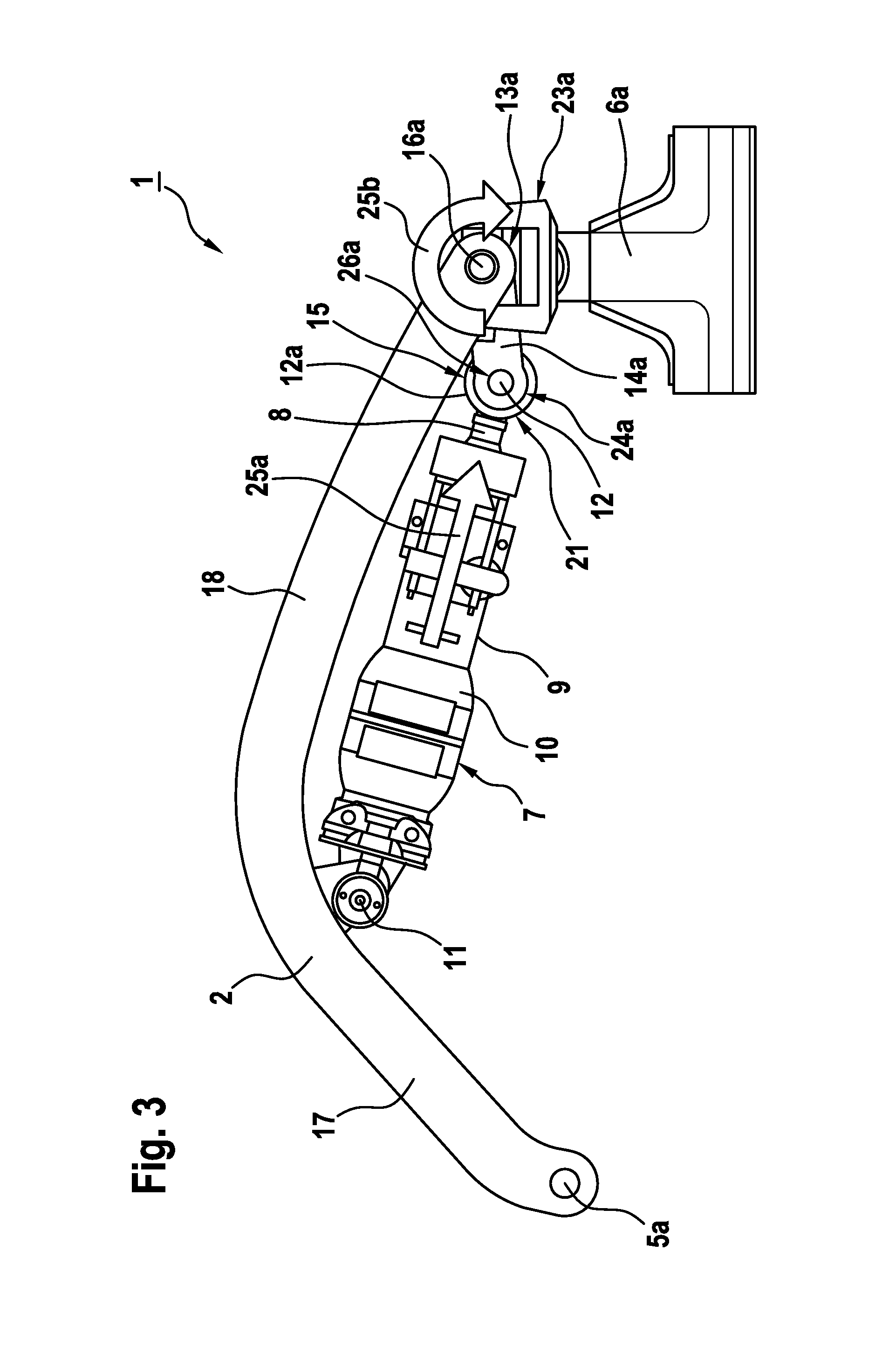

Method for altering steel slag into grain slag

The invention relates to a method for changing steel slag into grain slag, comprising the following steps: adding dry steel slag into liquid blast furnace slag and obtaining the grain slag after the cooling; the granularity of the steel slag grains is less than 3 mm. The invention directly adds the steel slag into the liquid slag, allows the steel slag to react with the blast furnace slag, eliminates residual calcium oxide of lime or dolomite used for steel making so as to obtain calcium silicate or dicalcium silicate through the reaction with the acid blast furnace slag, eliminates dissociative CaO, allowing the reaction of the steel slag so as to obtain the grain slag which can serve as the material needed in the cement industry after the water quenching.

Owner:WUHAN IRON & STEEL (GROUP) CORP

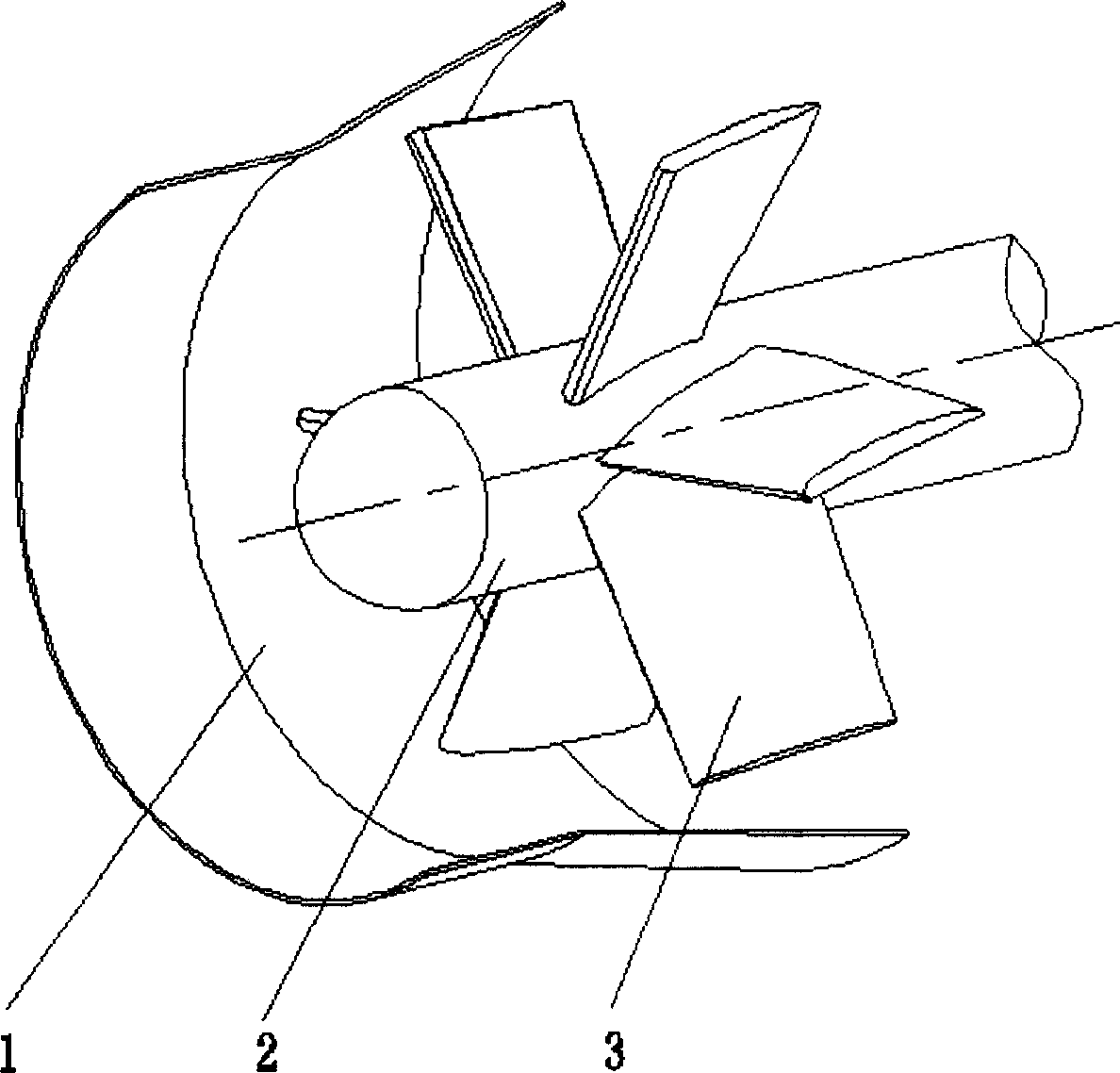

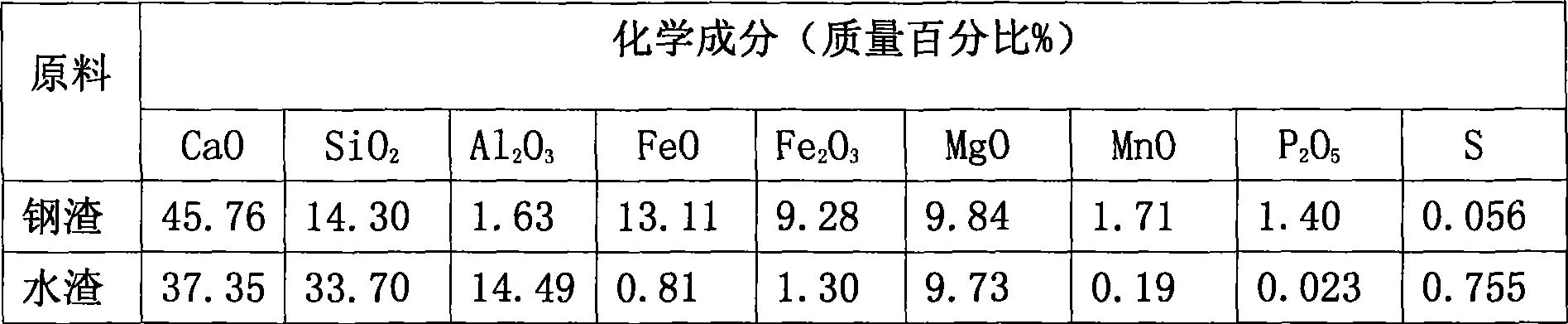

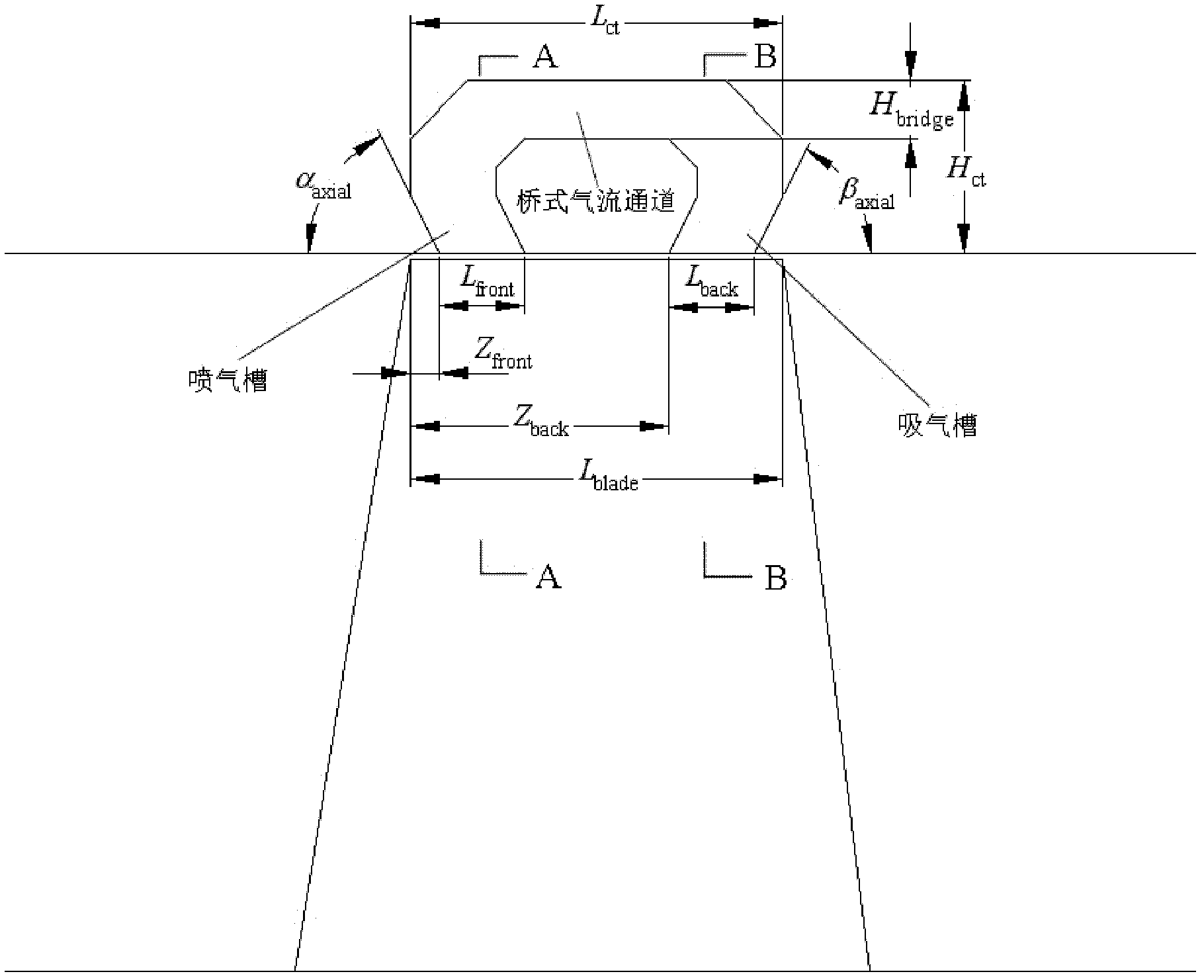

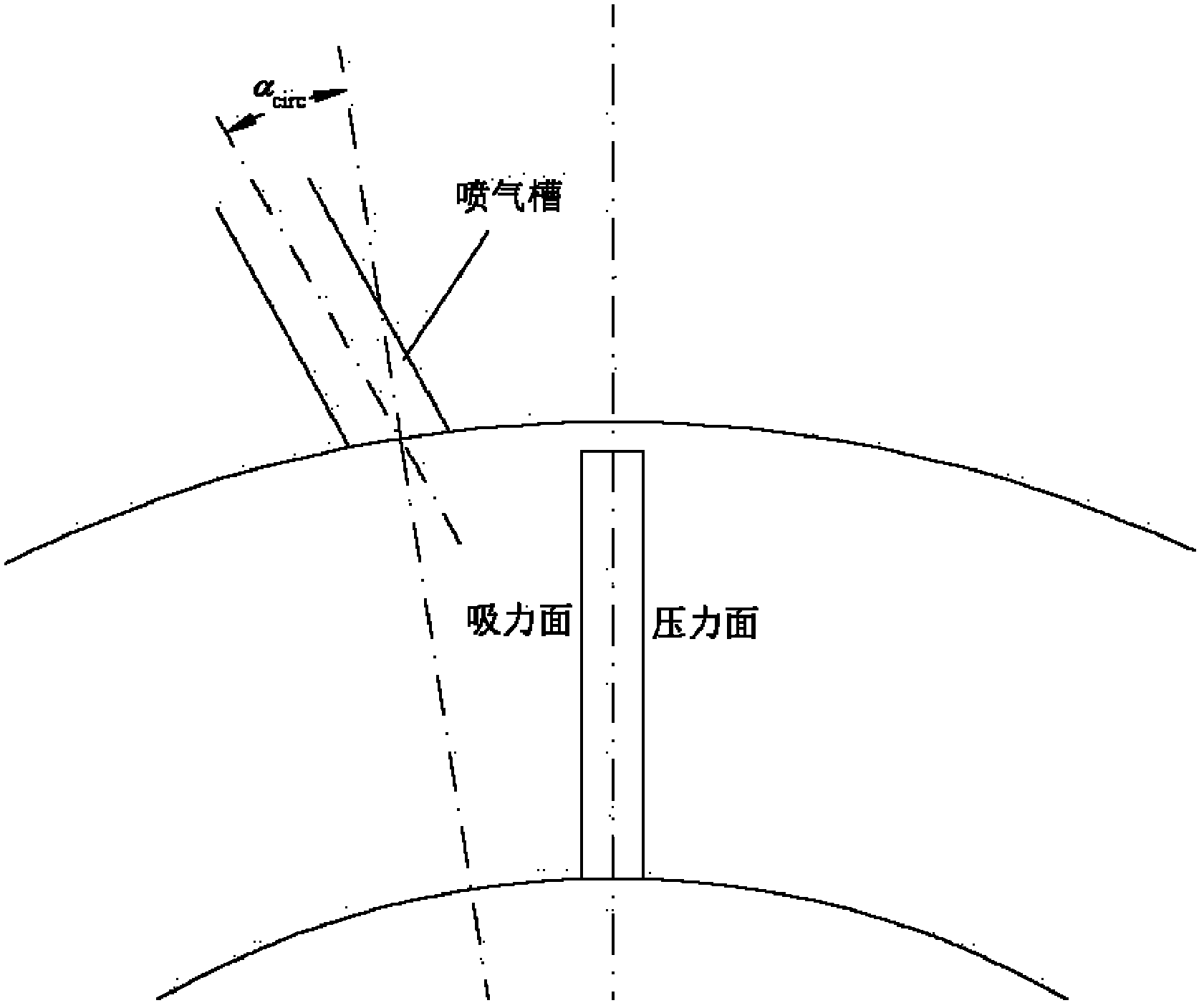

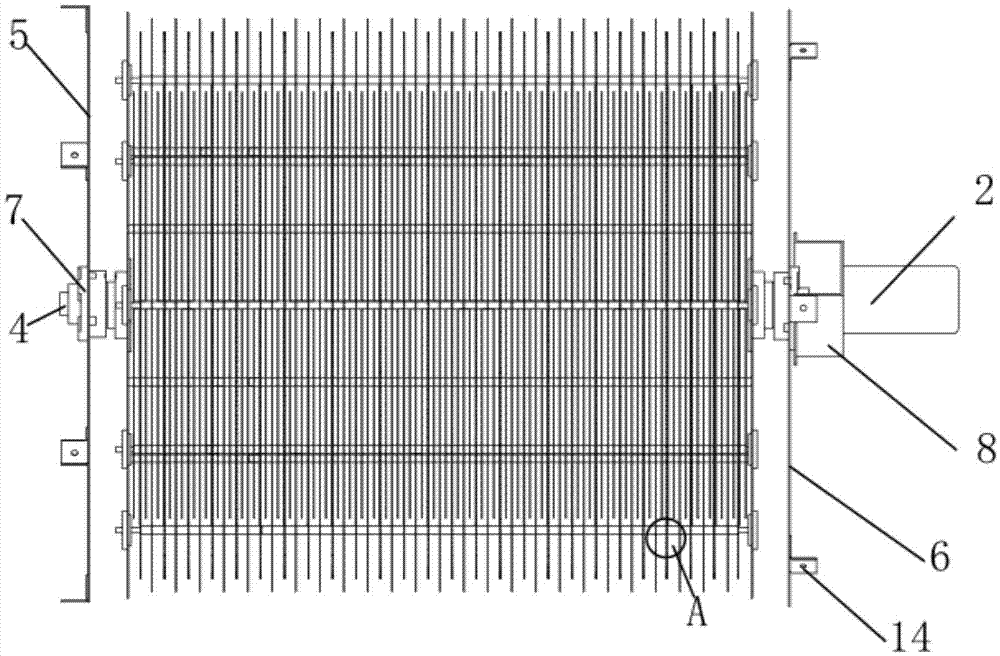

Unsteady standing vortex type treatment casing

The invention relates to a treatment casing applied to an axial-flow air compressor in the field of impeller machinery, in particular to an unsteady standing vortex type treatment casing, which can be used for improving the stability margin of the axial-flow air compressor without reducing efficiency. The unsteady standing vortex type treatment casing comprises an air jet groove, a bridge-type air flow channel and an air suction groove, wherein the air jet groove is arranged at the position of a suction surface of a blade, and the air suction groove is arranged at the position of a pressure surface of the blade. The treatment casing is designed to suppress leakage flow generated on the suction surface of a front edge of the blade, the air suction groove is exactly close to the pressure surface in the rear middle of the blade when the blade sweeps over, and the air jet groove is close to the suction surface of the front edge of the blade. Therefore, differential pressure is formed between the air suction groove and the air jet groove to drive fluids to spray from the downstream of the blade to the upstream of the blade, and the air jet groove is positioned close to the suction surface of the front edge of the blade and exactly aligned to a leakage vortex generating area of the blade, so that leakage flow can be suppressed, and further the stall margin of the air compressor is increased. Moreover, as an air jet direction is consistent with a main flow direction, mixing loss of an air jet area and a main flow area is decreased, the momentum of a boundary layer of the wall surface of the casing is increased, and positive effects are achieved for the efficiency of the air compressor.

Owner:BEIHANG UNIV

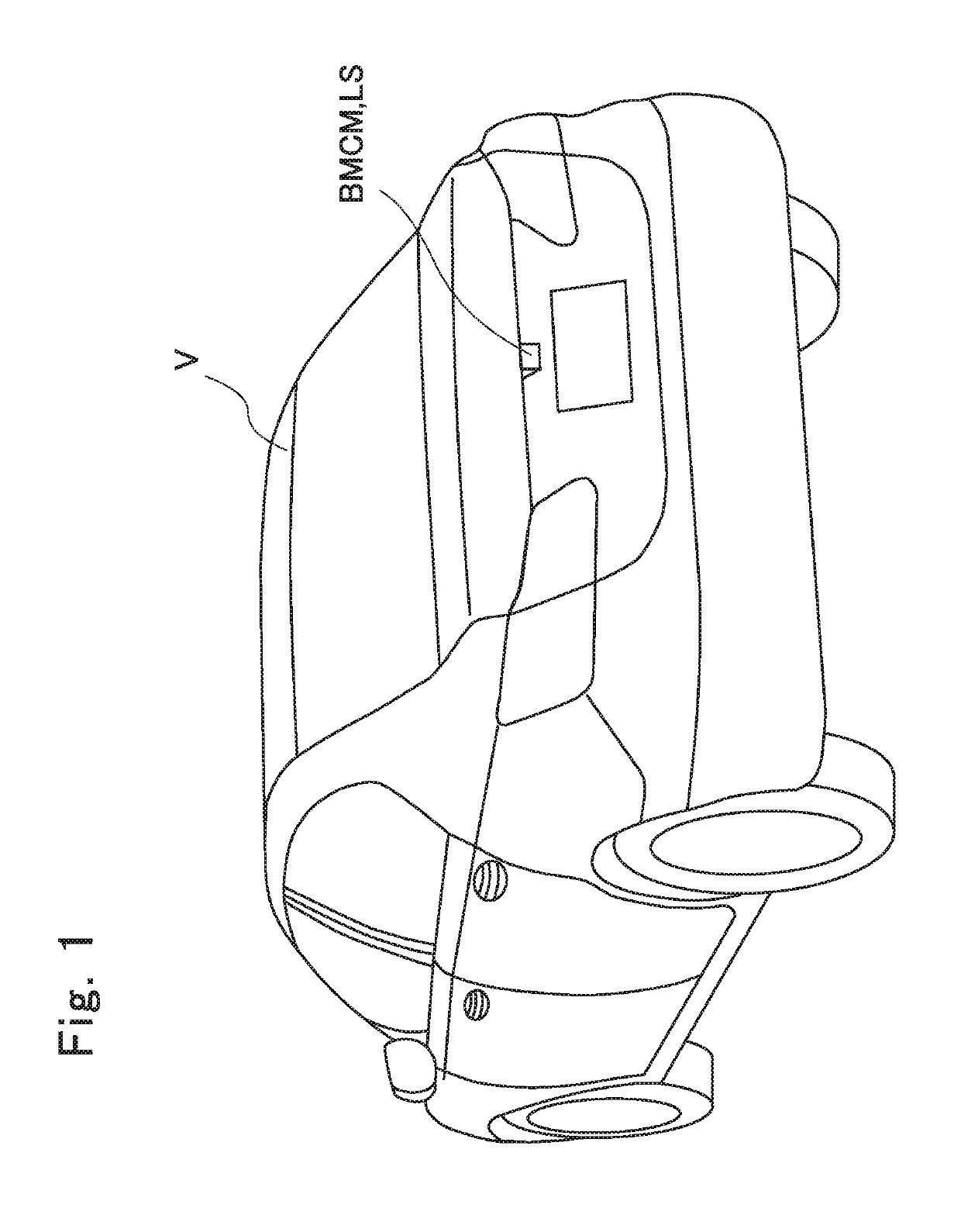

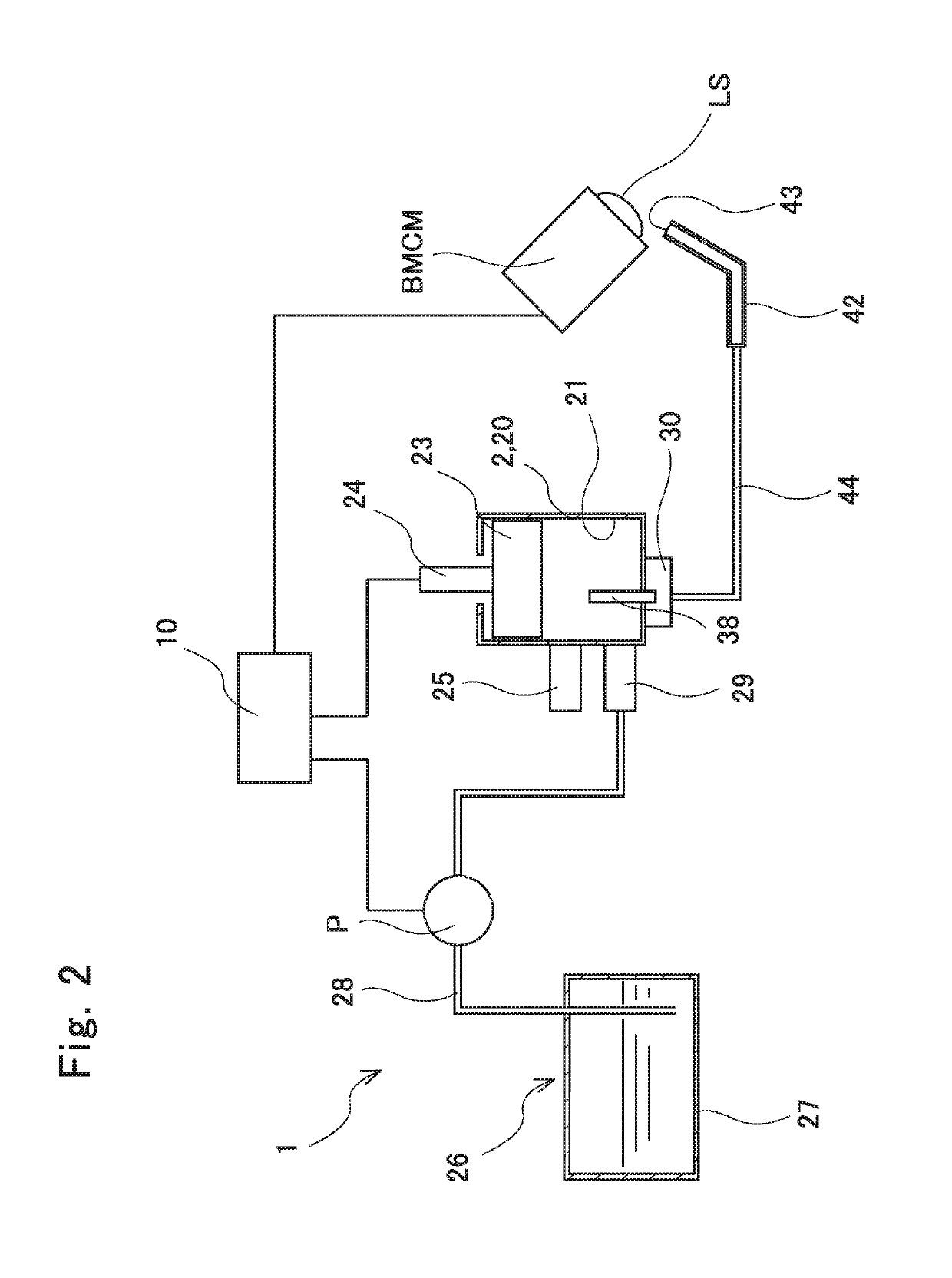

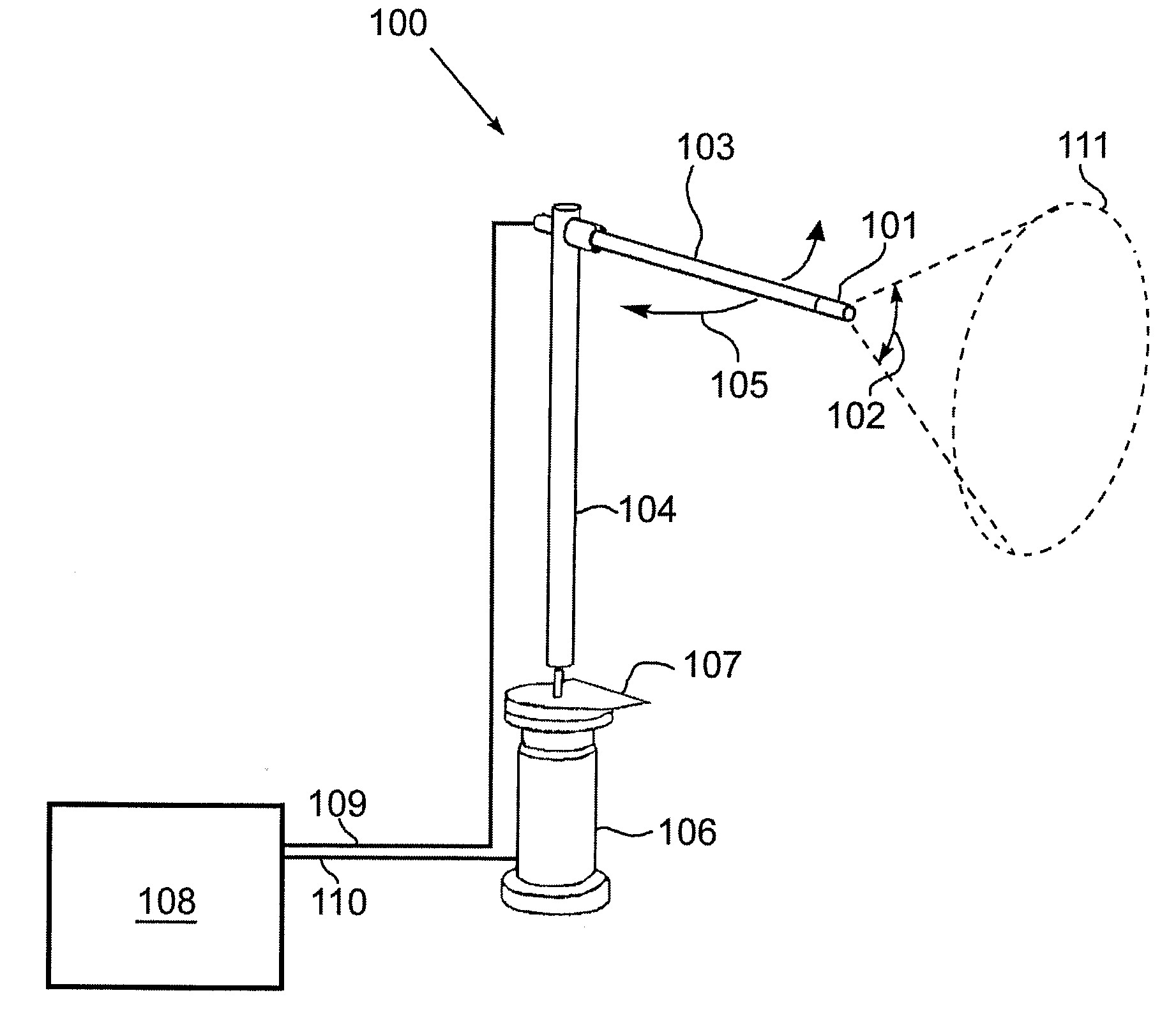

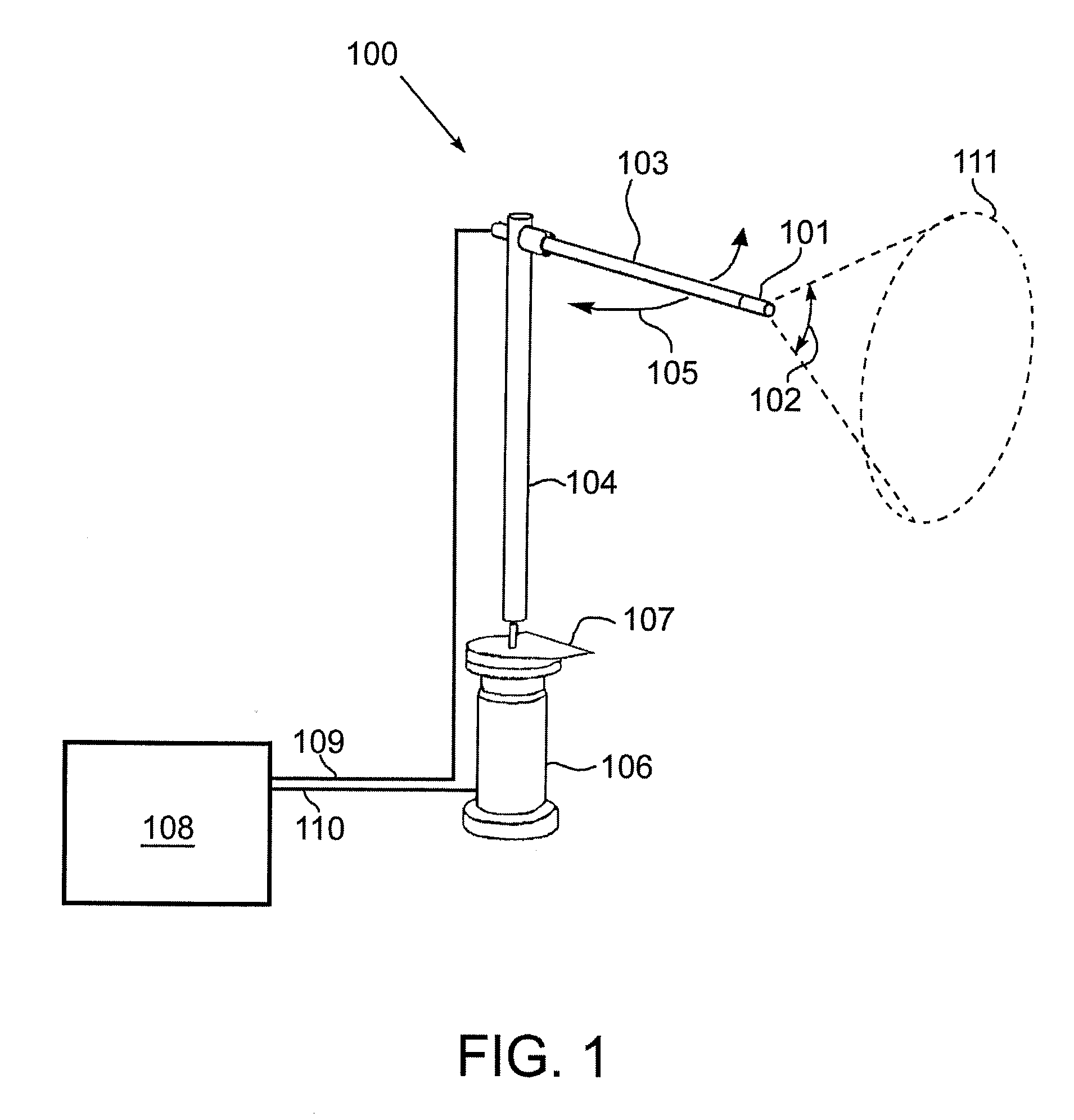

Washing device for on-board camera

InactiveUS20190126891A1Increasing troublesome workImprove washing effectVehicle cleaningCleaning using gasesOn boardEngineering

A washing device for on-board camera includes a spout port, a tank, and a controller. The spout nozzle is directed to the lens surface of a camera installed on a vehicle, and spouts a washing liquid and compressed air. The tank communicates with the spout port, and reserves the washing liquid and compressed air under pressurized condition. The controller controls the washing liquid and compressed air reserved in the tank so as to spout through the spout port.

Owner:TOYODA GOSEI CO LTD

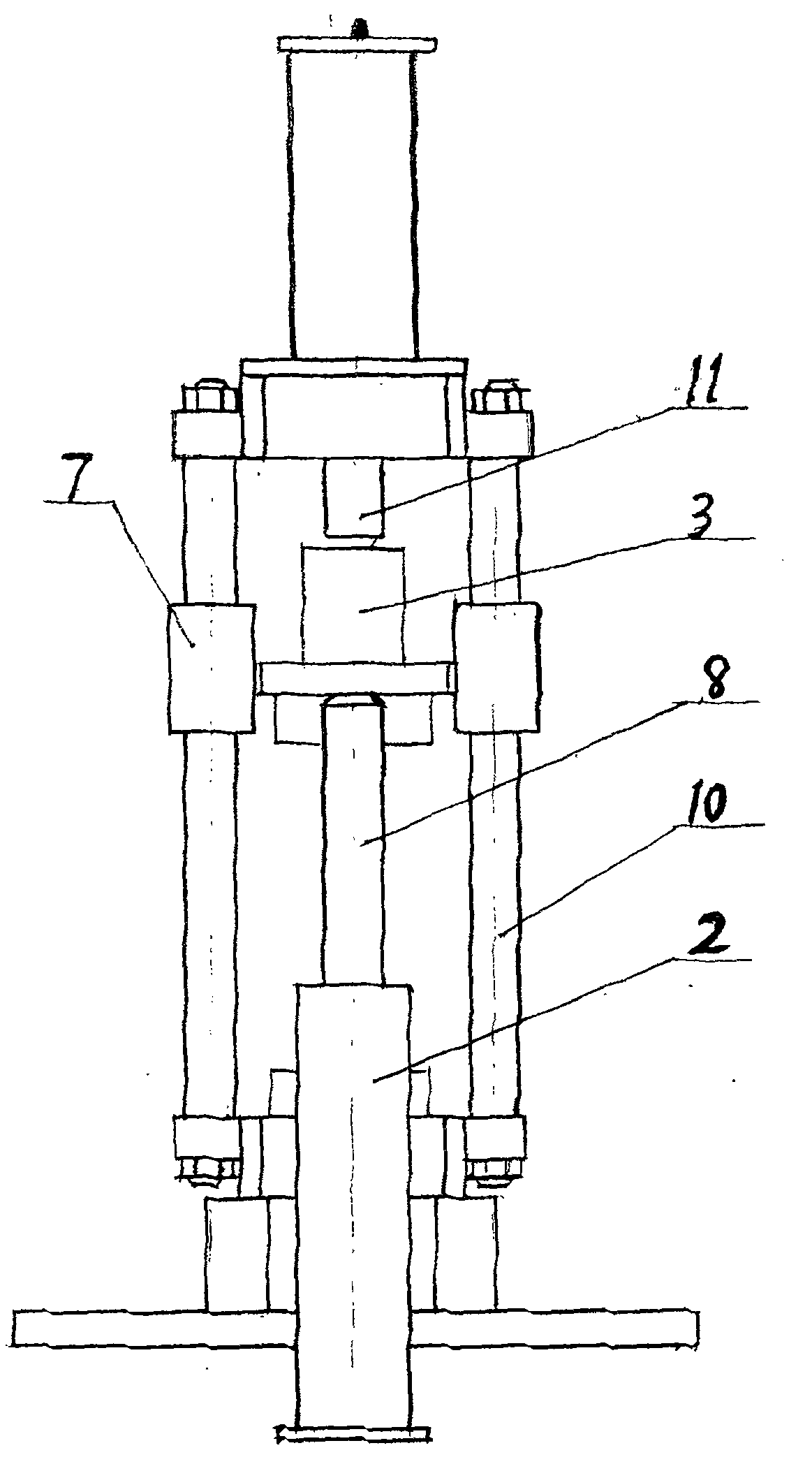

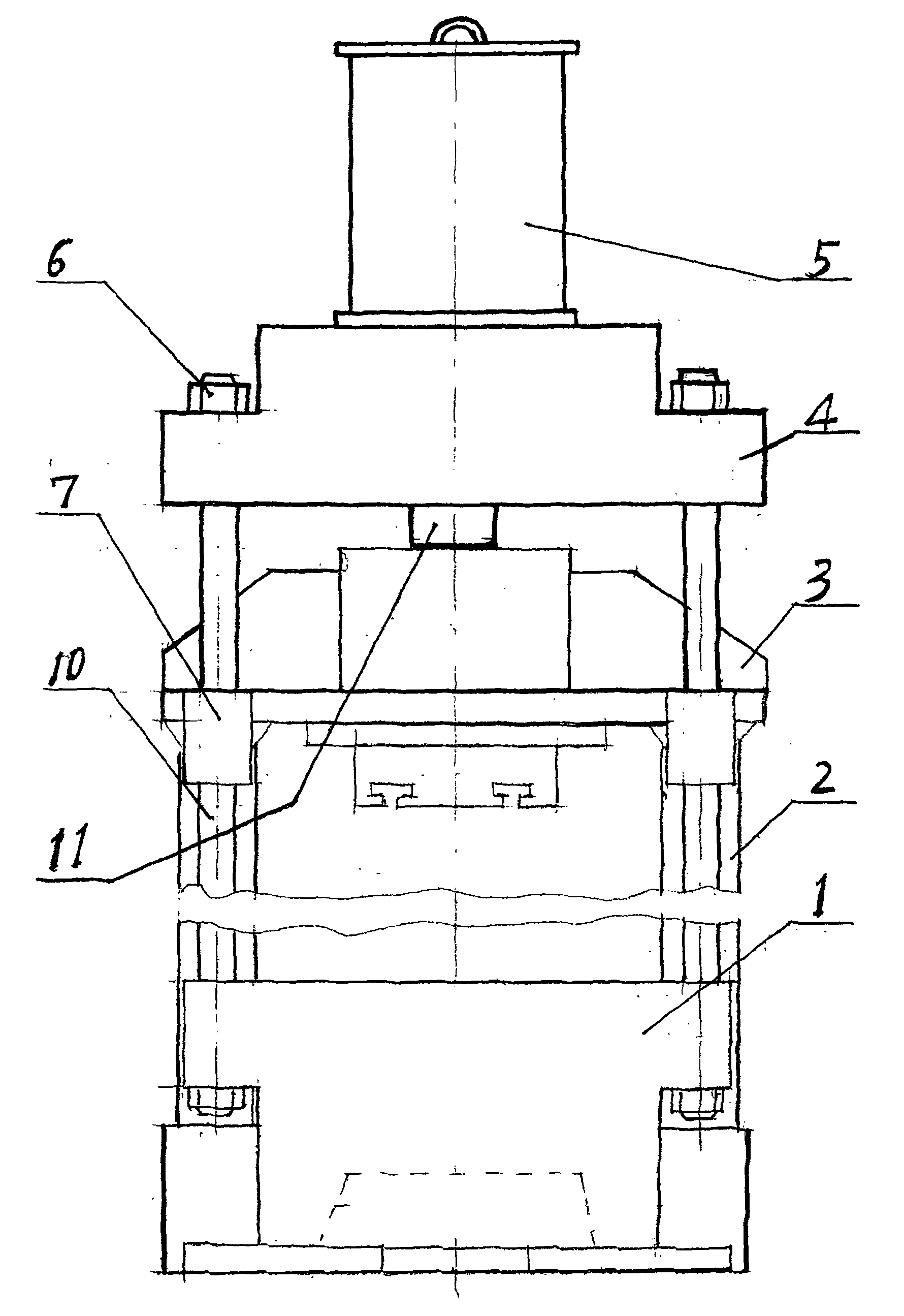

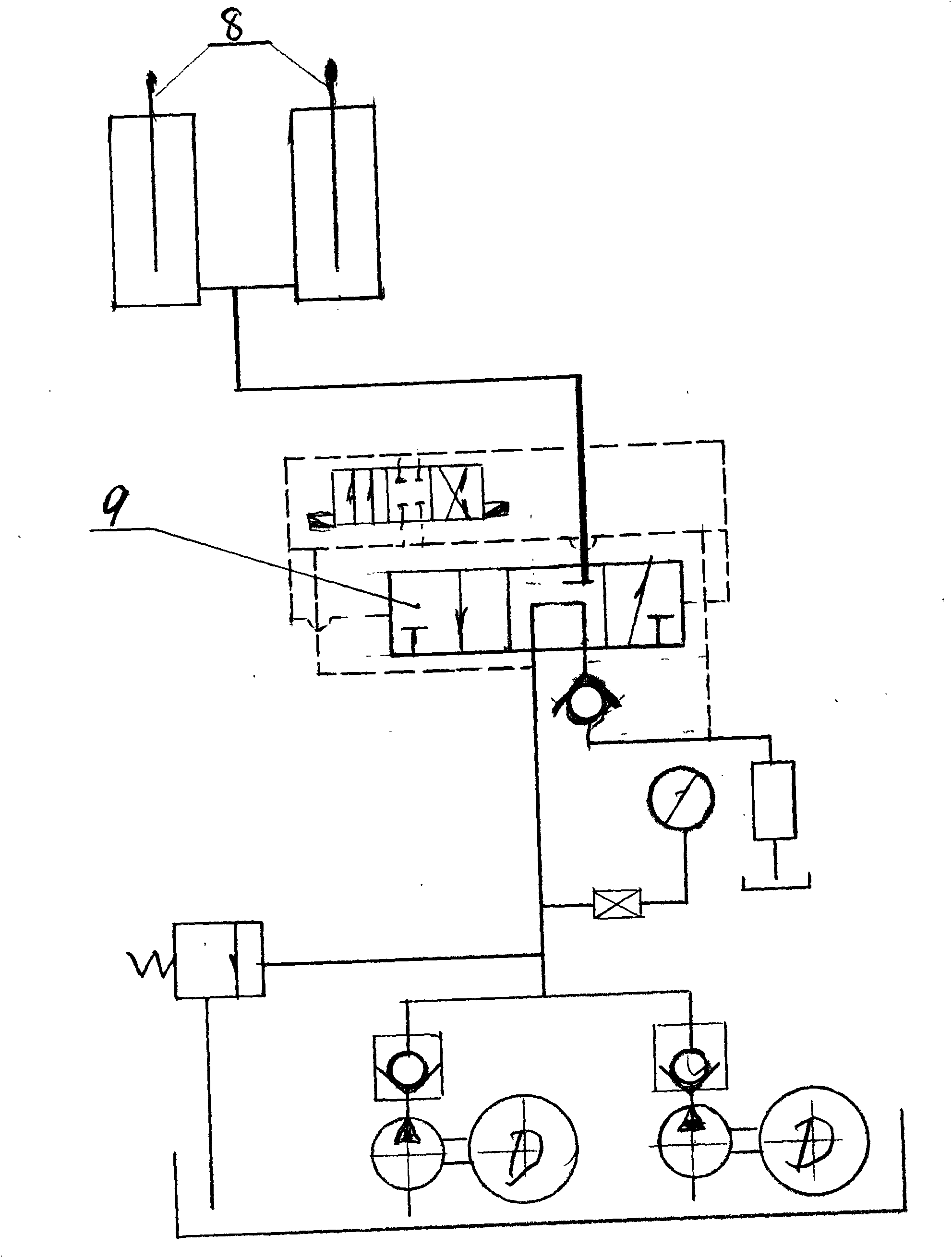

Air compression/hydraulic punching machine

InactiveCN103552267ASimple structureReasonable layoutForging press drivesPress ramPunch pressEngineering

The invention relates to an air compression / hydraulic punching machine. An integral rack consists of a bottom beam, a top beam and four upright posts of a machine body, wherein the bottom beam and the top beam are respectively arranged at the bottom part and the top part of the rack, the four upright posts are supported between the bottom beam and the top beam, a nitrogen compression cylinder is arranged at the upper part of the top beam, a punch is provided with four guide sleeves, the four guide sleeves are respectively sleeved on the four upright posts, and the four guide sleeves can slide on the four upright posts. A piston and a piston rod of the nitrogen compression cylinder are connected to the upper surface of the punch, two one-way hydraulic oil cylinders are arranged on the bottom beam of the machine body, and piston rods of the two one-way hydraulic oil cylinders lean against the punch. Hydraulic oil supplied by a hydraulic station can get in and out of the two one-way hydraulic oil cylinders in the same ratio and the same pressure through a three-position three-way electro-hydraulic directional valve, and punching movements of ascending and descending of the punch can be completed by the air compression / hydraulic punching machine through piston motions of the two one-way hydraulic oil cylinders and the nitrogen compression cylinder. An electrical appliance control system of the air compression / hydraulic punching machine is provided with two travel switches. The air compression / hydraulic punching machine disclosed by the invention is simple, convenient and flexible in operation method, is small in mechanical noise and is a comparatively ideal punching device.

Owner:LIAOCHENG UNIV

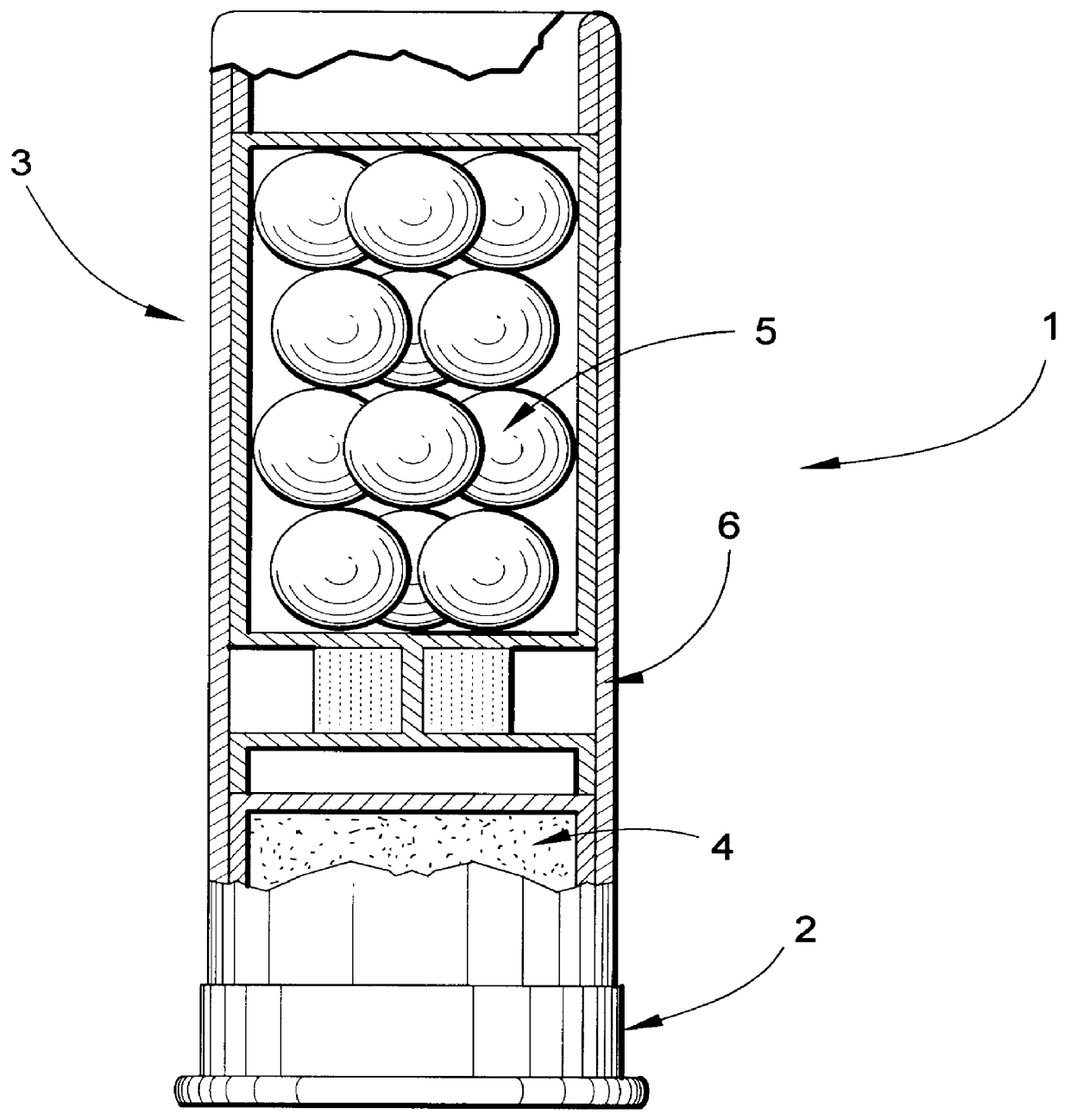

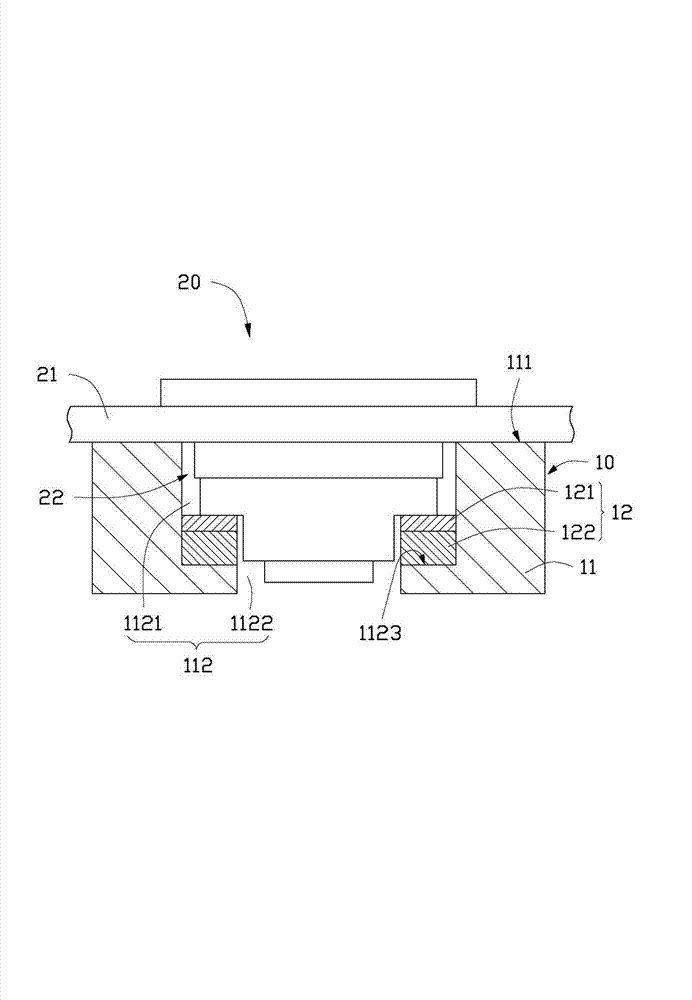

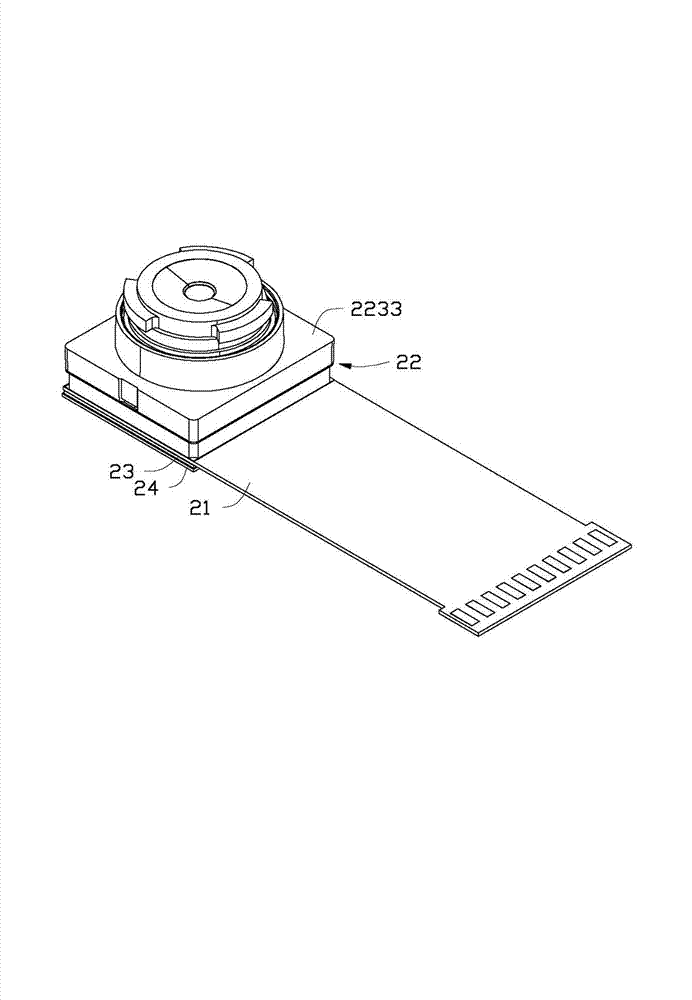

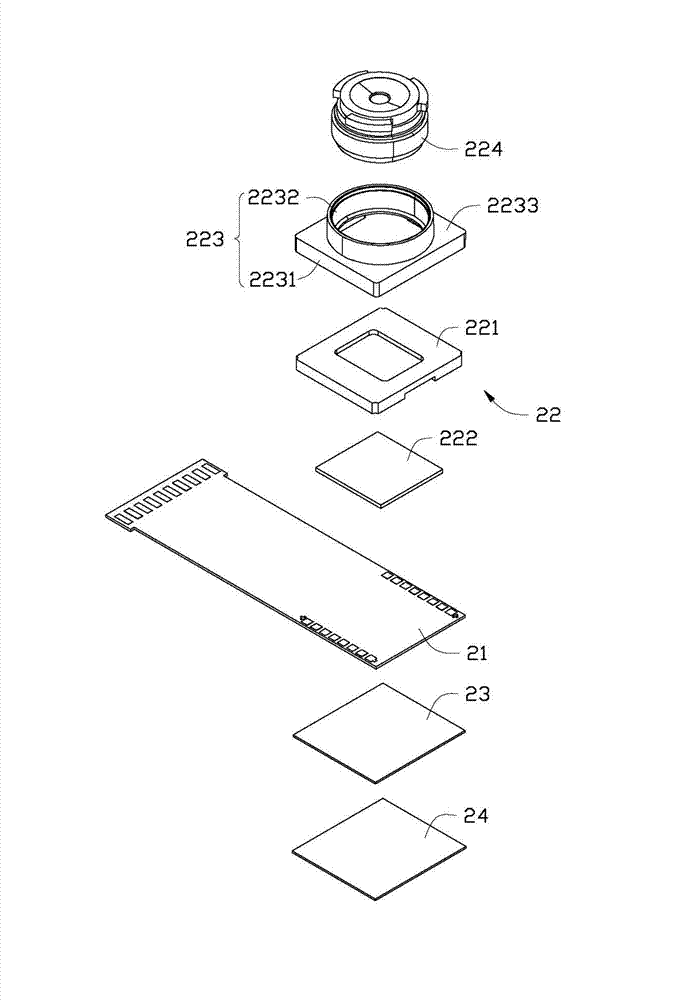

Camera module assembly carrier tool

ActiveCN103595899AUniform momentumGreat momentumTelevision system detailsPrinted circuit aspectsFlexible circuitsEngineering

The invention provides a camera module assembly carrier tool. The camera module assembly carrier tool comprises a flexible circuit board, a camera module disposed on the flexible circuit board, a conductive adhesive layer, and a metal reinforcing plate which is adhered to a side of the flexible circuit board on the back side of the camera module through the conductive adhesive layer. The camera module comprises a first step which is on the back side of the flexible circuit board. The camera module assembly carrier tool comprises a base and an elastic buffer layer. The base comprises a supporting surface used to support the flexible circuit board. The supporting surface is provided with a storage groove used to store the camera module. The storage groove is formed with a second step matching with the first step. The elastic buffer layer is used to buffer impact forces when the camera module assembly is pressed, thereby improving quality of the camera module assembly.

Owner:山东嘉驰新材料股份有限公司

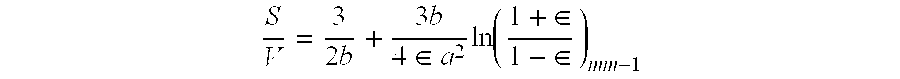

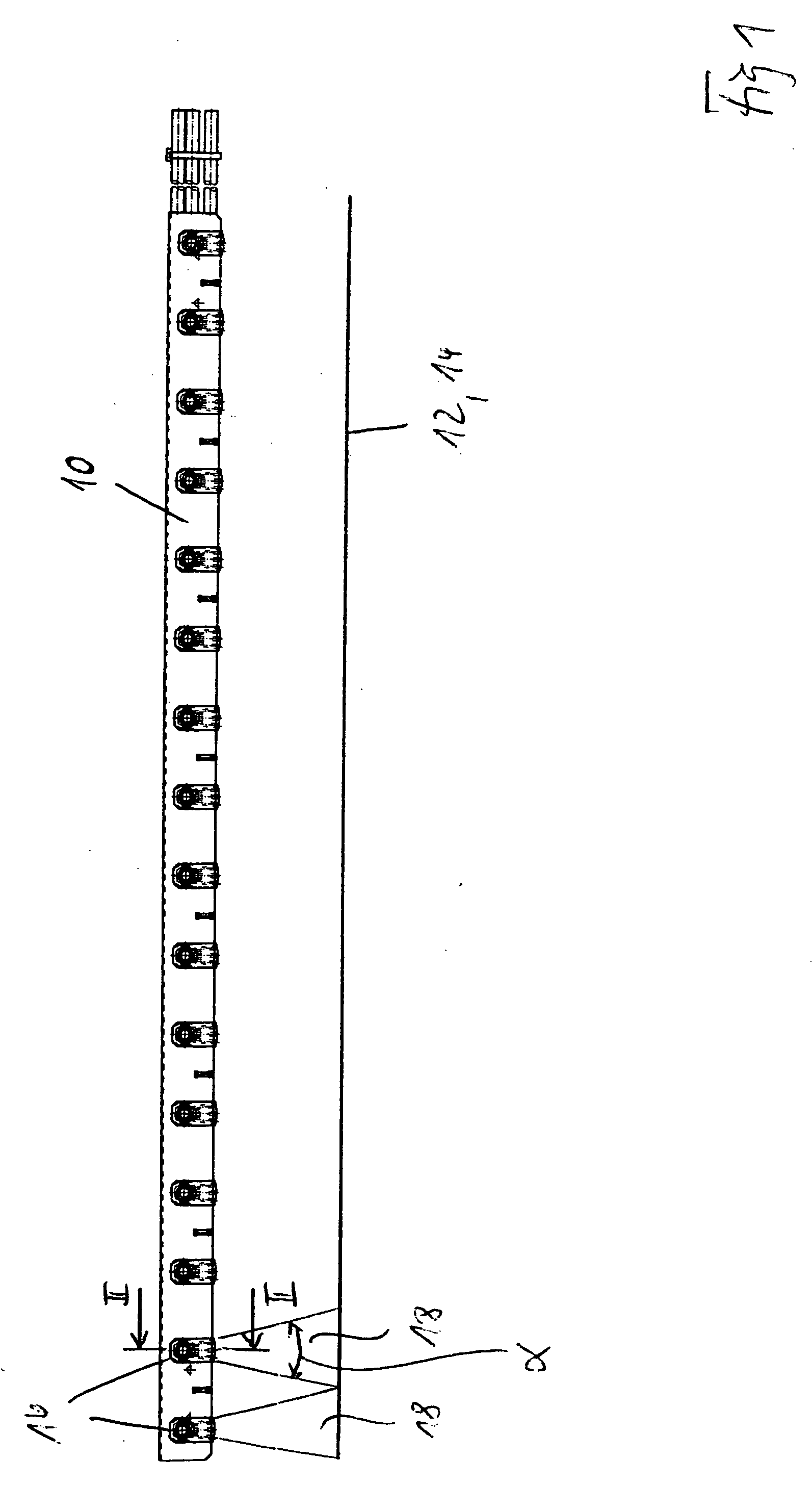

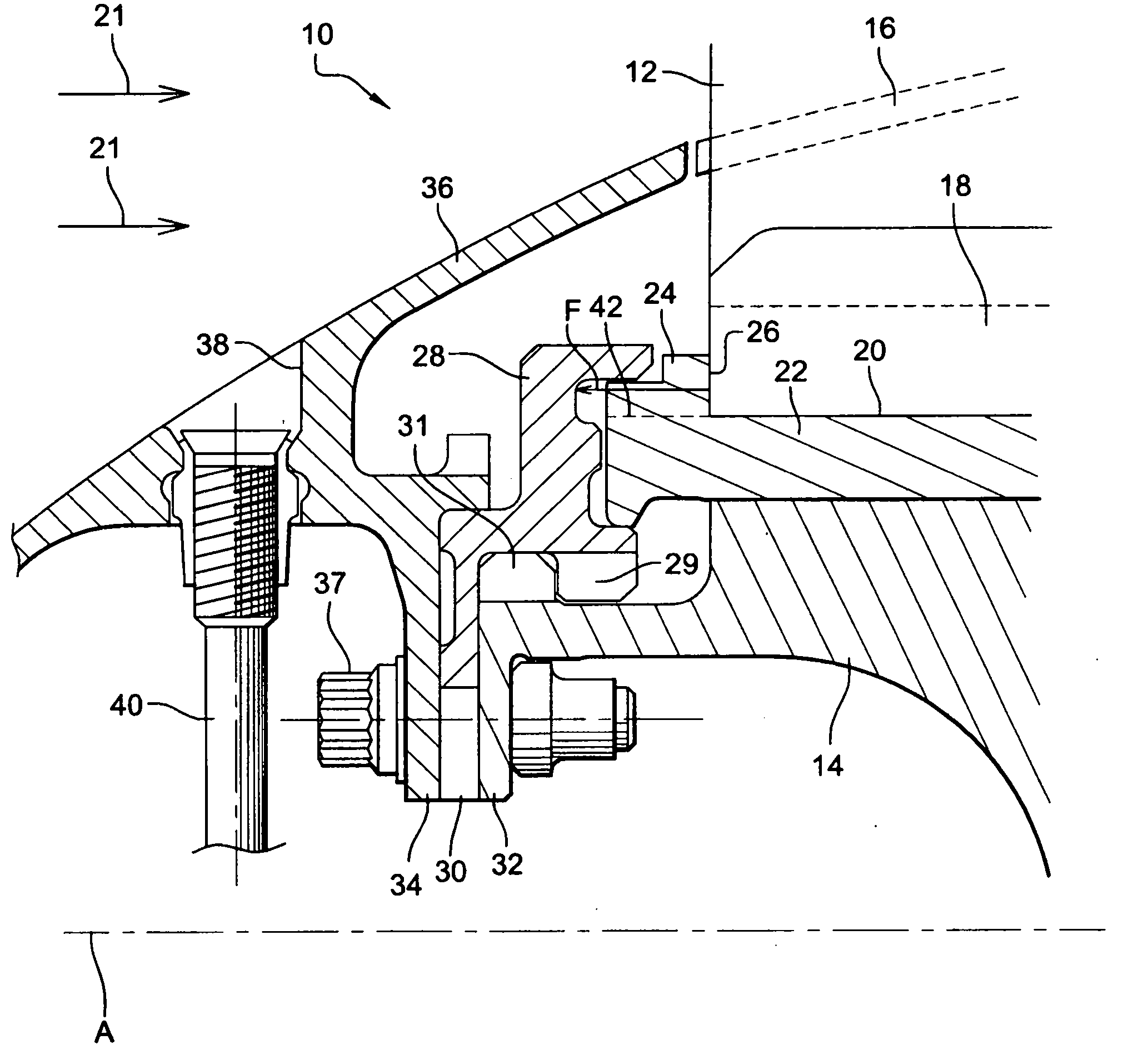

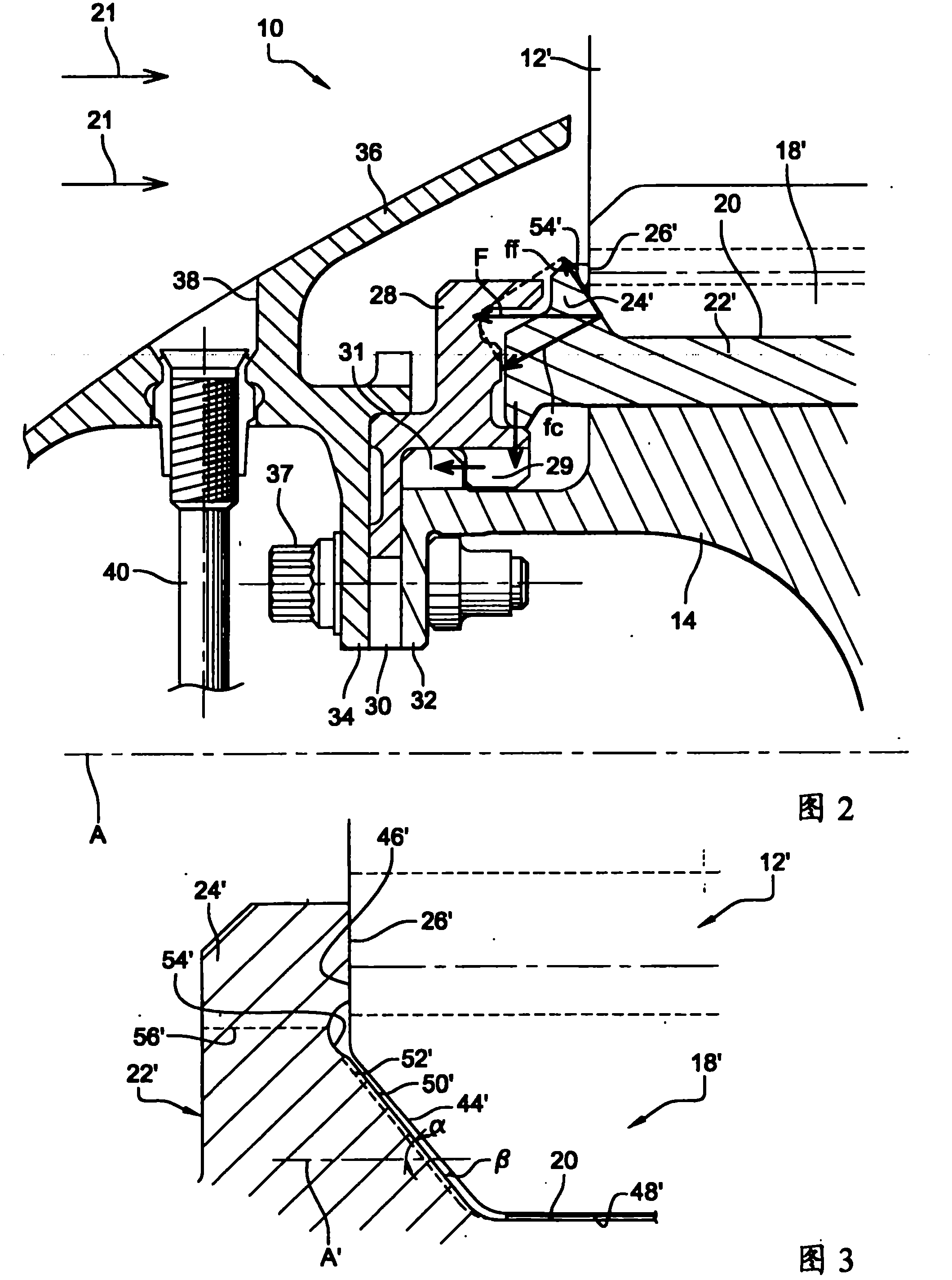

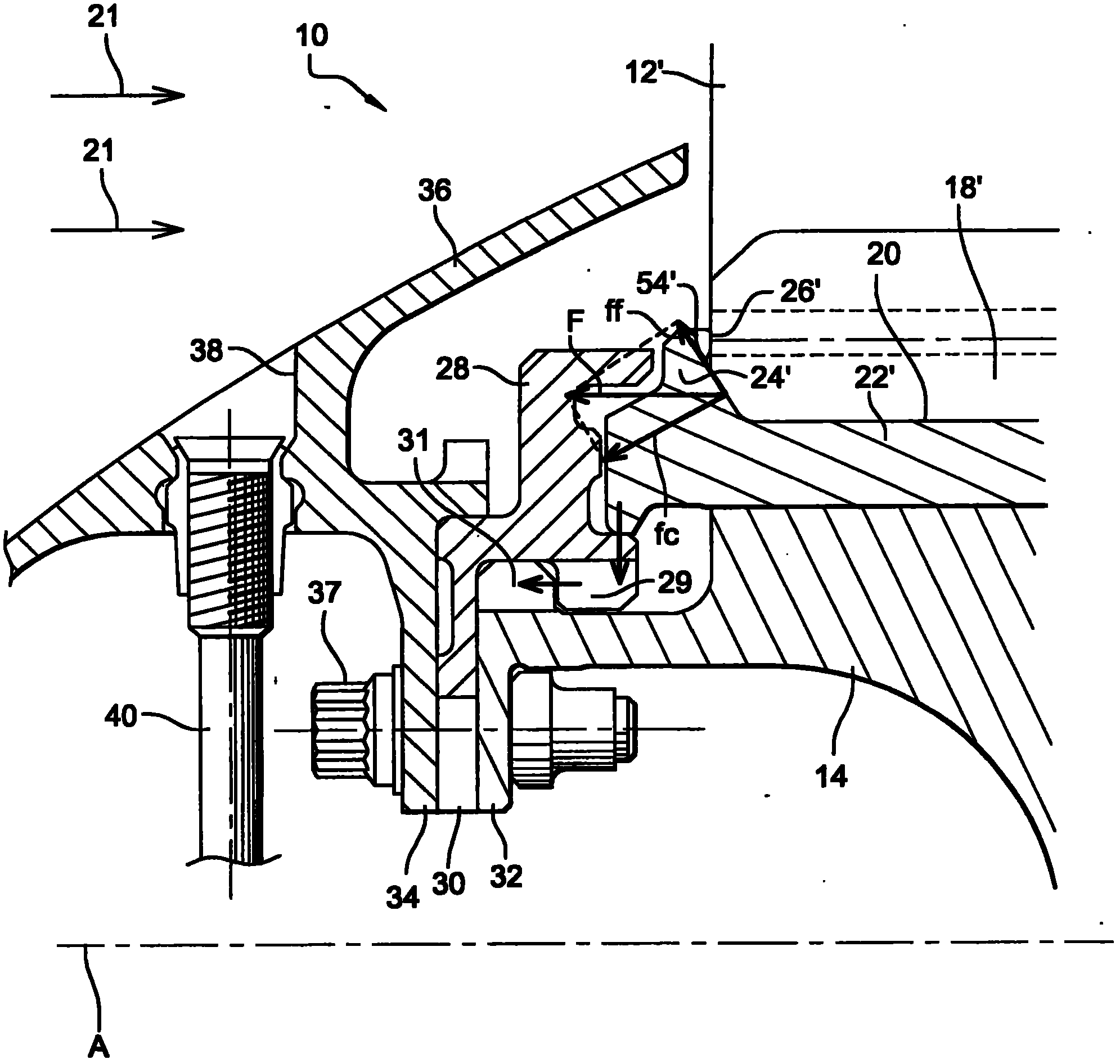

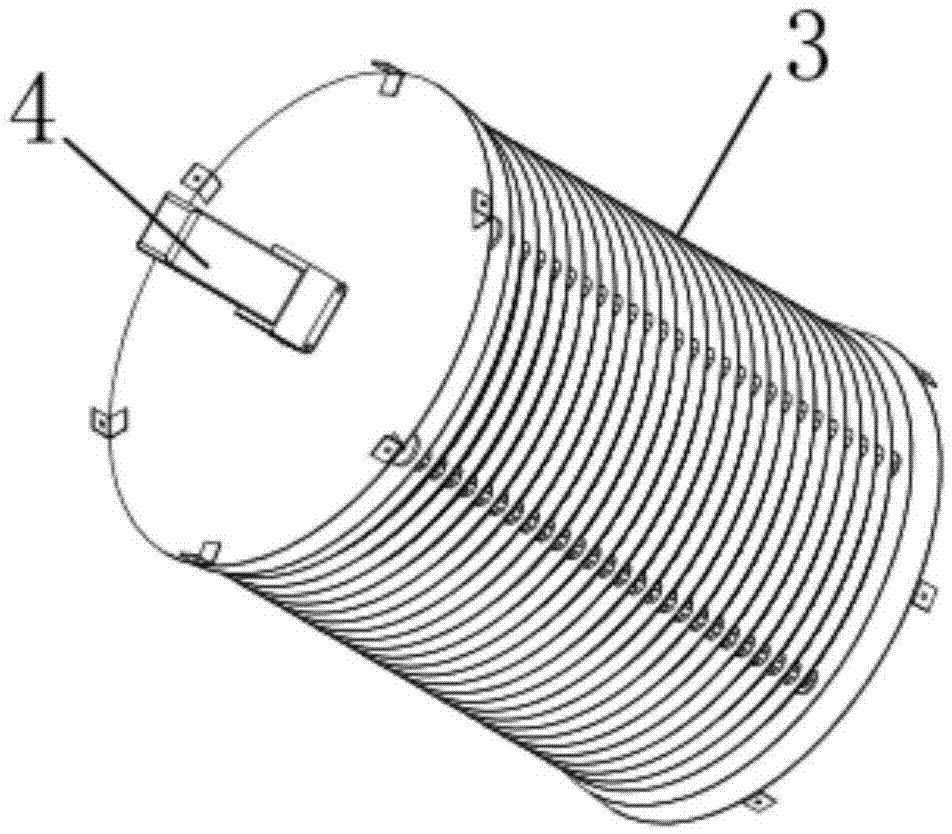

Turbomachine fan rotor

ActiveCN102105655AGreat momentumReduce shear forceBlade accessoriesEfficient propulsion technologiesRotational axisClassical mechanics

The invention relates to a turbomachine fan rotor (10) including a disc (14) bearing blades (12') having roots (18') fitted into axial slots (20) in the disc and a wedge (22') which is inserted between the base of each slot and the corresponding blade root and which is provided with a blade root retaining spoiler (24') at the upstream end thereof, said spoiler including a downstream abutment face against which the upstream end of the blade root presses in the event of a violent force and which is oblique with respect to the axis (A) of rotation of the rotor.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Self-orienting embedded in-situ flux system

ActiveUS20080294356A1Automate the moveRapid responseTesting/calibration apparatusVolume/mass flow measurementFluid fluxThermodynamics

A fluid flux measurement system that includes a heated element fluid flow sensor that is capable of being repositioned relative to a mean fluid flux direction is disclosed. The repositioning may be performed by a motor interconnected to the heated element fluid flow sensor. The heated element fluid flow sensor may be positioned proximate to the measurement region of a sonic anemometer and may be operable to be repositioned relative to the sonic anemometer. The heated element fluid flow sensor may be a three-dimensional hot-film constant temperature anemometer. The fluid flux system may be operable to measure small-scale turbulent fluxes in uncontrolled environments such as remotely located atmospheric monitoring stations. The heated element fluid flow sensor may be calibrated in-situ with data collected by the sonic anemometer.

Owner:UNIV FOR ATMOSPHERIC RES

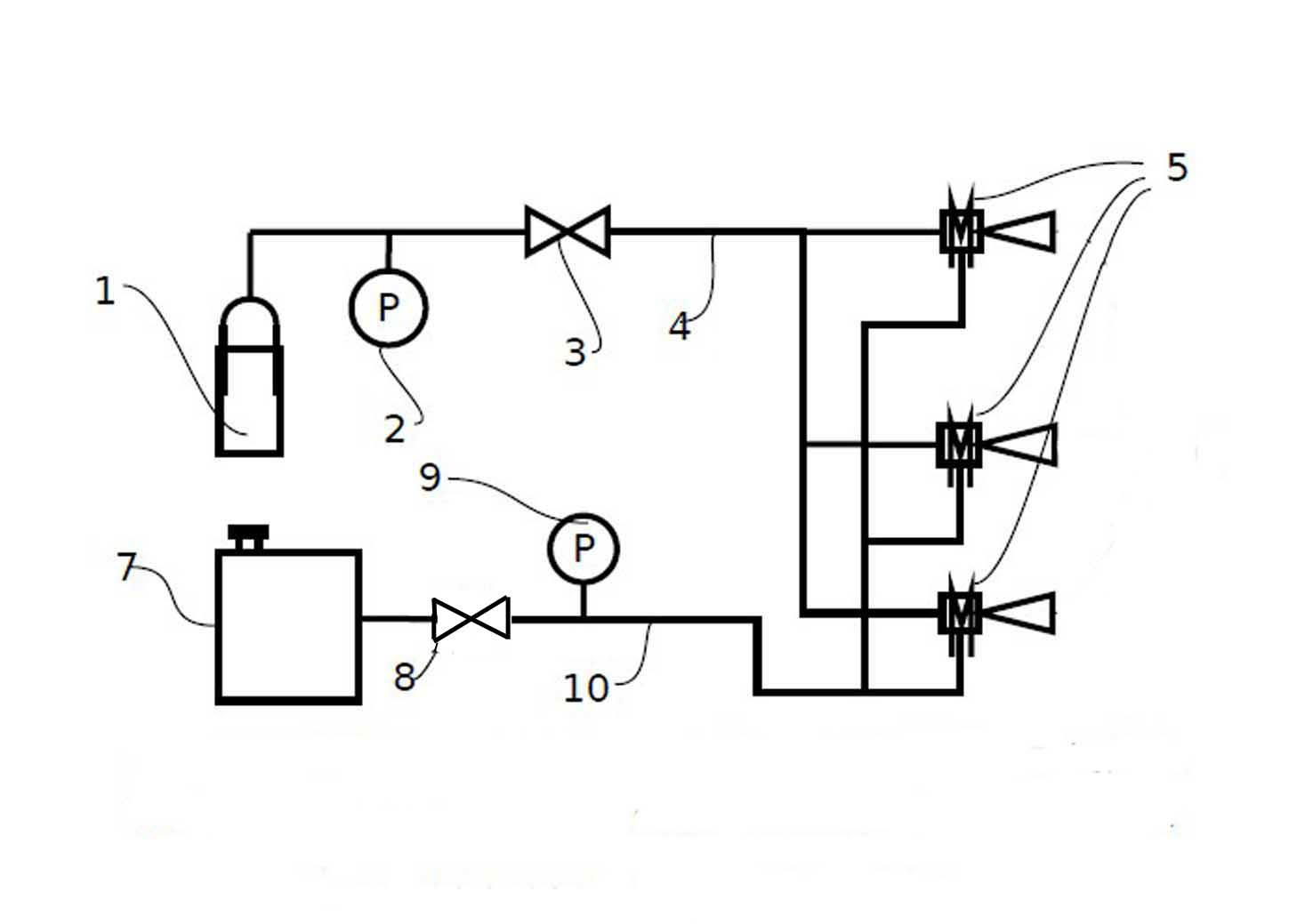

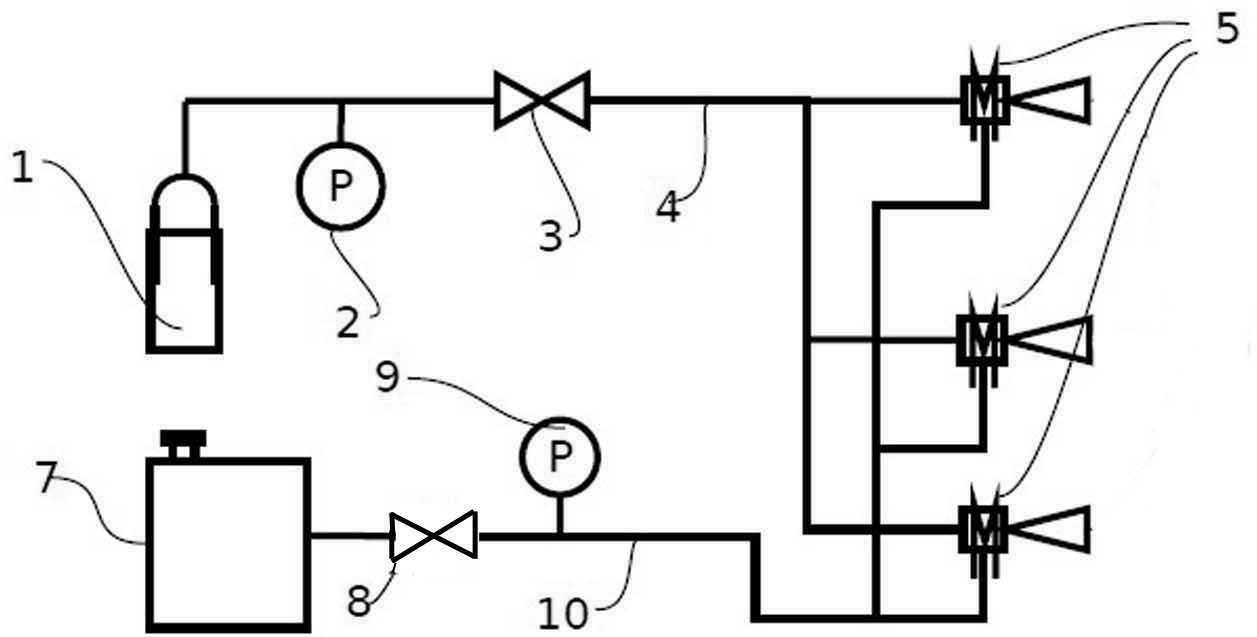

Cold aerosol fire extinguishing device

InactiveCN102688575AGood fire extinguishing efficiencyWide range of fire extinguishing typesFire rescueMonopotassium phosphatePotassium phosphate

The invention relates to the field of fire extinguishing, in particular to a cold aerosol fire extinguishing device, which comprises a dry powder aqueous solution box, a carbon dioxide storage tank and a nozzle, wherein dry powder aqueous solution is stored in the dry powder aqueous solution tank, carbon dioxide is stored in the carbon dioxide storage tank, and a heating jacket covers the outer side of the nozzle. Further, the dry powder aqueous solution is a compound prepared by one or multiple of sodium carbonate, sodium bicarbonate, potassium bicarbonate, monobasic potassium phosphate, sodium chloride, potassium chloride, magnesium chloride, urea, ammonium bicarbonate and ammonium dihydrogen phosphate mixed according to an optional proportion, and is in a saturation state at minus five DEG C. The carbon dioxide storage tank is connected with the nozzle through a high-pressure pipeline provided with a valve, and the pressure of carbon dioxide at an inlet of the nozzle ranges from 7.5Mpa to 8.5Mpa. The dry powder aqueous solution tank is connected with the nozzle through a low-pressure pipeline provided with a water pump, and the pressure of dry powder aqueous solution at the inlet of the nozzle ranges from 0.35Mpa to 0.45Mpa. The mass flow ratio of water in the dry powder aqueous solution and carbon dioxide at the inlet of the nozzle ranges from 1:2.2-1:2.6.

Owner:ZHONGBEI UNIV

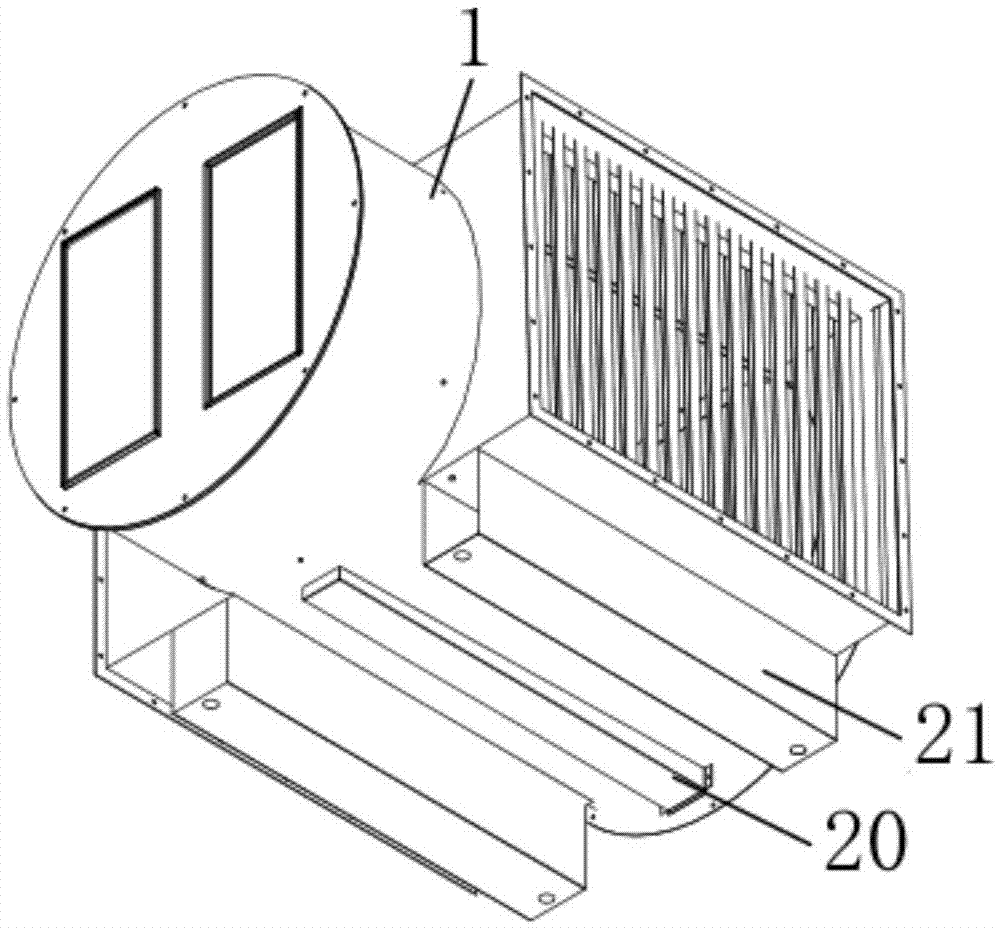

Rotary self-cleaning high-voltage electrostatic type oil fume purifier

InactiveCN107013958AExtended service lifeGreat momentumDomestic stoves or rangesLighting and heating apparatusFixed frameEngineering

The invention discloses a rotary self-cleaning high-voltage electrostatic type oil fume purifier. The oil fume purifier comprises an outer box body and a drive motor arranged in the outer box body, and a high-voltage electrostatic field core is arranged in the outer box body; rotating shafts are arranged on the two sides of the high-voltage electrostatic field core; a left supporting plate is arranged on the left side of the high-voltage electrostatic field core, and a right supporting plate is arranged on the right side of the high-voltage electrostatic field core; the left supporting plate and the right supporting plate are connected to the high-voltage electrostatic field core through supporting by bearings; the drive motor is arranged on the right side of the high-voltage electrostatic field core and is connected to the rotating shafts through a motor fixing frame; the high-voltage electrostatic field core is composed of a high-voltage electrostatic plate set; the outer box body is provided with an air inlet and an air outlet; a spoiler is arranged at the air inlet; and an end cover is arranged at the front end of the outer box body and is provided with an electric appliance cabin door. According to the oil fume purifier, larger impact force can be formed on the surface of the high-voltage electrostatic plate set, so that the cleaning effect is cleaner and more thorough, the purification efficiency is greatly improved, the use cost is reduced, and the service life of the oil fume purifier is effectively prolonged.

Owner:周国梁

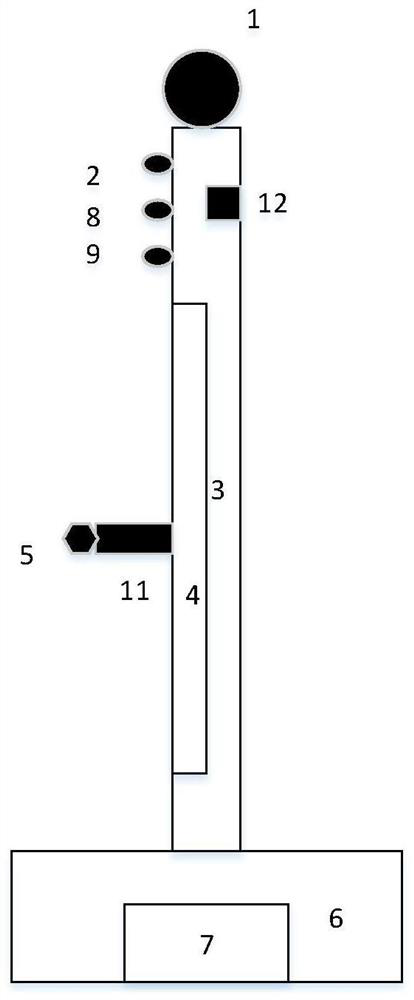

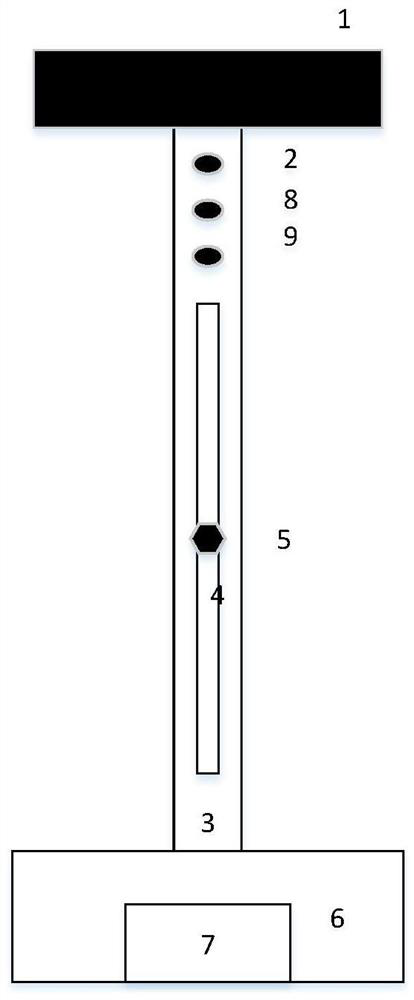

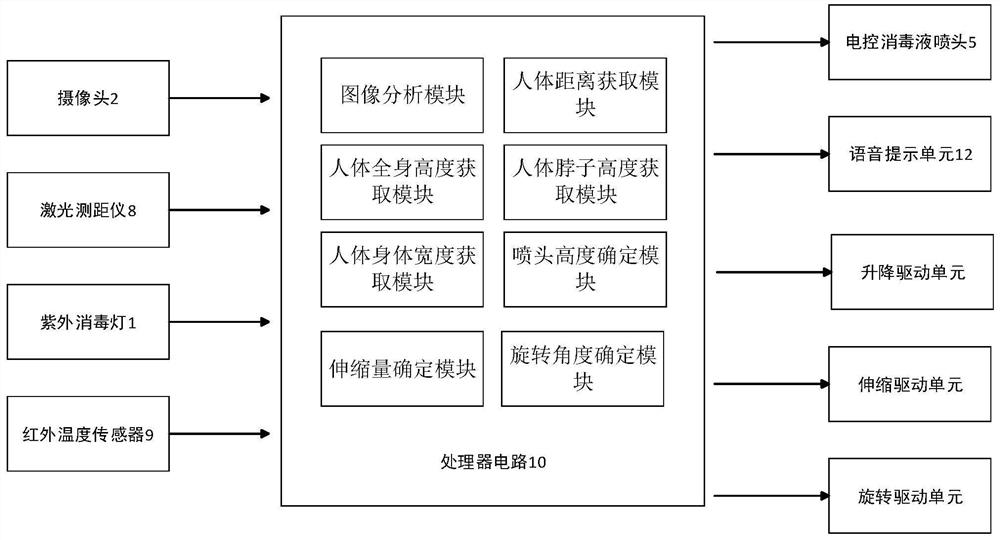

Disinfection device for human body, and disinfection method

ActiveCN112546450AGuaranteed disinfectionGreat momentumLavatory sanitoryMedical applicatorsPhysicsLaser rangefinder

The invention provides a disinfection device for the human body. The disinfection device for the human body comprises an ultraviolet disinfection lamp, a camera, a stand column, a lifting and loweringmechanism, an electronic control disinfectant spray head, a base, a disinfectant container, a laser distance measuring instrument, an infrared temperature sensor, a lifting and lowering driving unit,a telescopic driving unit, a rotation driving unit, a processor circuit, a telescopic rod and a voice prompt unit, wherein the disinfectant container is placed in the base; the stand column is vertically arranged on the base; the lifting and lowering mechanism is positioned on the stand column; the electronic control disinfectant spray head can be lifted and lowered on the lifting and lowering mechanism; the ultraviolet disinfection lamp is laterally arranged above the stand column; the camera, the laser distance measuring instrument and the temperature sensor are adjacently arranged on the side surface of the upper part of the stand column; and the camera, the electronic control disinfectant spray head, the laser distance measuring instrument, the infrared temperature sensor, the liftingand lowering driving unit, the telescopic driving unit, the rotation driving unit and the voice prompt unit are all electrically connected with the processor circuit (10).

Owner:南通优护优家卫生用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com