Air compression/hydraulic punching machine

A technology of hydraulic press and nitrogen, applied in the fields of hydraulic press and steam, can solve the problems of high mechanical noise, cracked bed, scrapped press, etc., and achieve the effects of low mechanical noise, low steel consumption and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

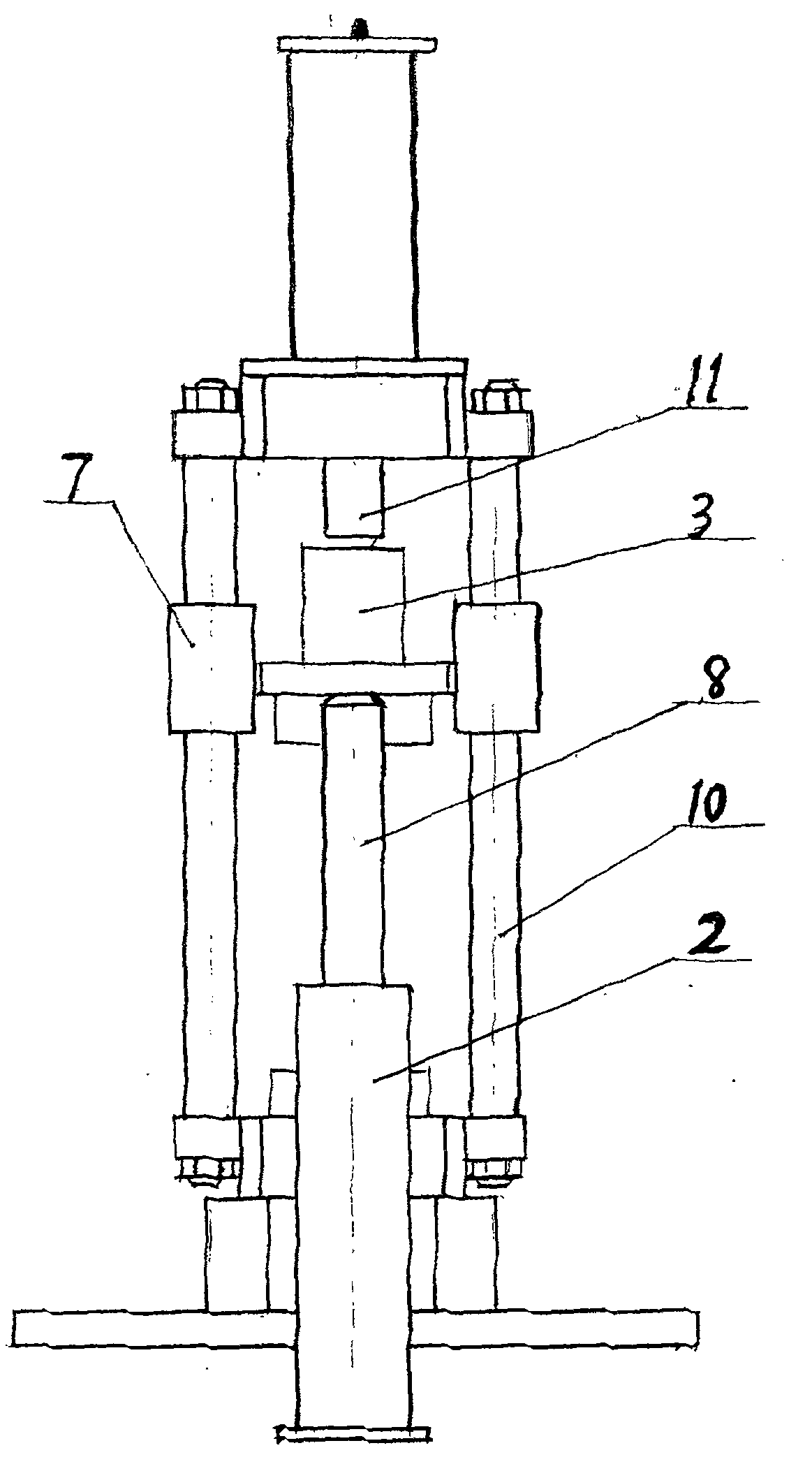

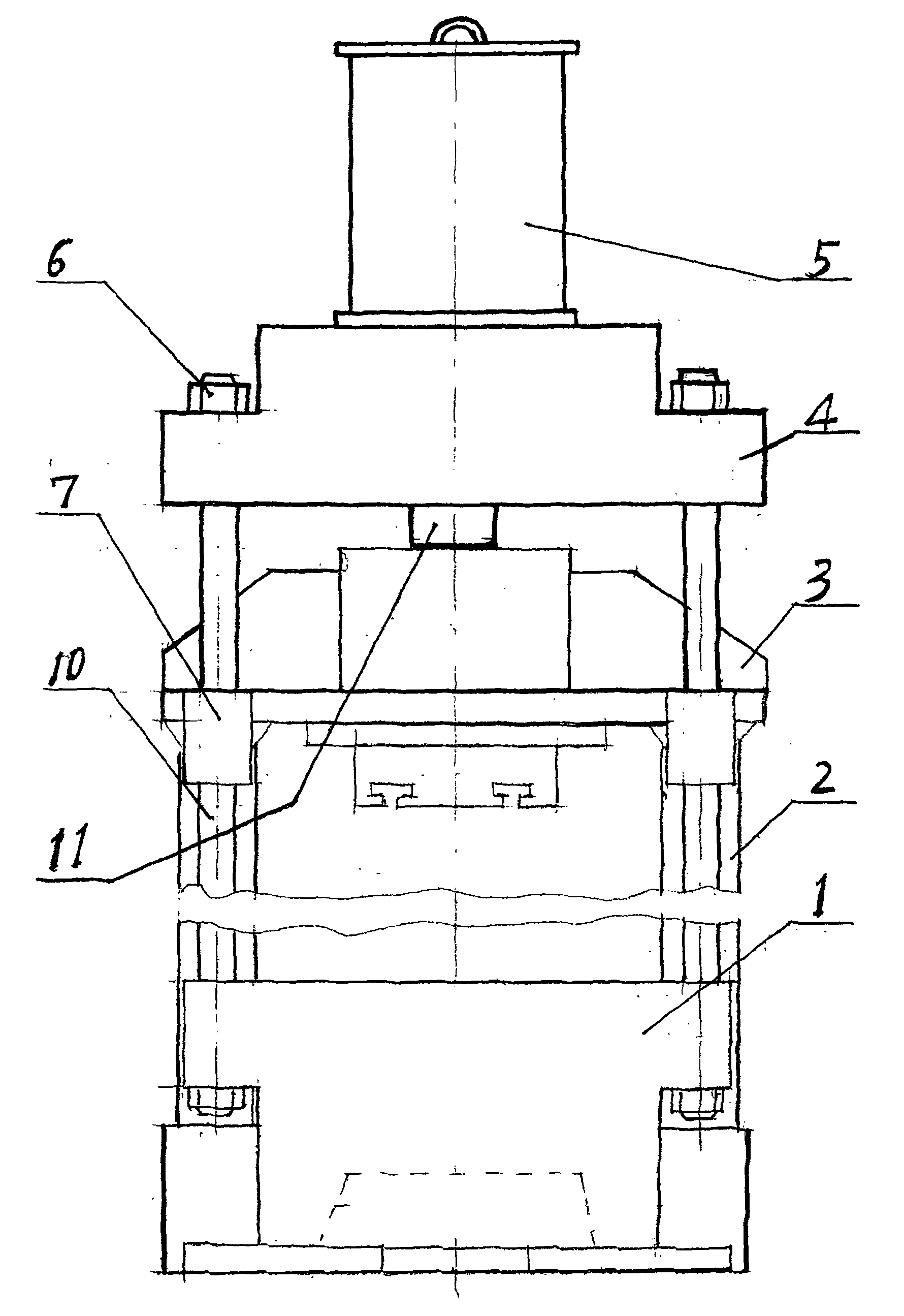

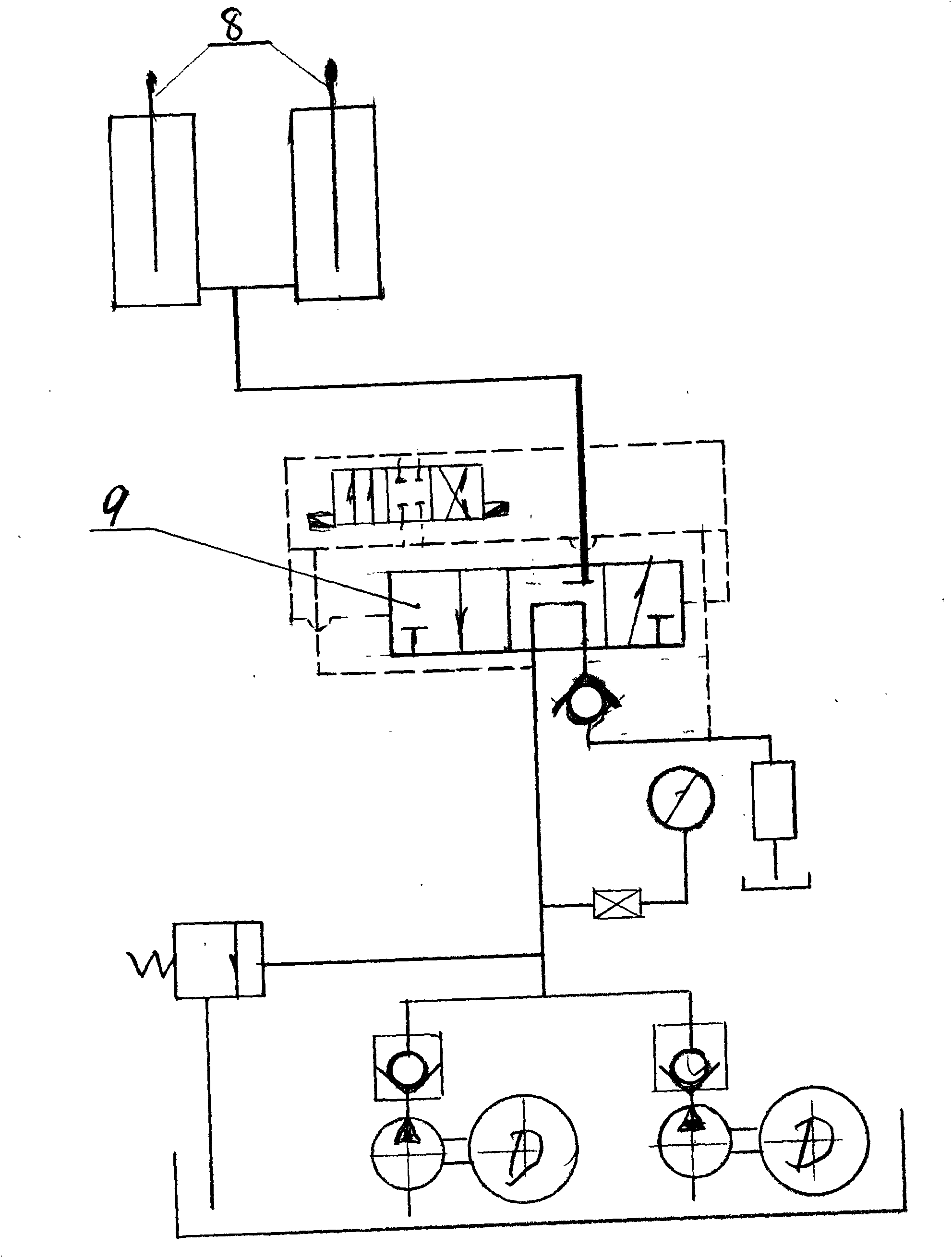

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0012] Pneumatic and hydraulic presses, such as figure 1 , 2 , shown in 3, nut 6 is arranged at both ends of four columns 10, bottom beam 1 and top beam 4 are fixed on the bottom and the top of four columns 10 with nut 6 respectively, form integral frame. Bottom beam 1 and top beam 4 are respectively located at the bottom and top of the frame, nitrogen compression cylinder 5 is installed on the top beam 1, two one-way hydraulic cylinders 2 are respectively installed on both sides of frame bottom beam 1, two single The cylinder piston rod 8 of the hydraulic cylinder 2 is pushed against the two ends of the punch 3 below. The punch 3 is provided with four guide sleeves 7, and the guide sleeves 7 are respectively sleeved on the four columns 10, and can slide up and down along the four top beams 4. The nitrogen compression cylinder piston rod 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com