Patents

Literature

843 results about "Translatory motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Translatory motion definition is - motion in which all points of a moving body move uniformly in the same line or direction. motion in which all points of a moving body move uniformly in the same line or direction…

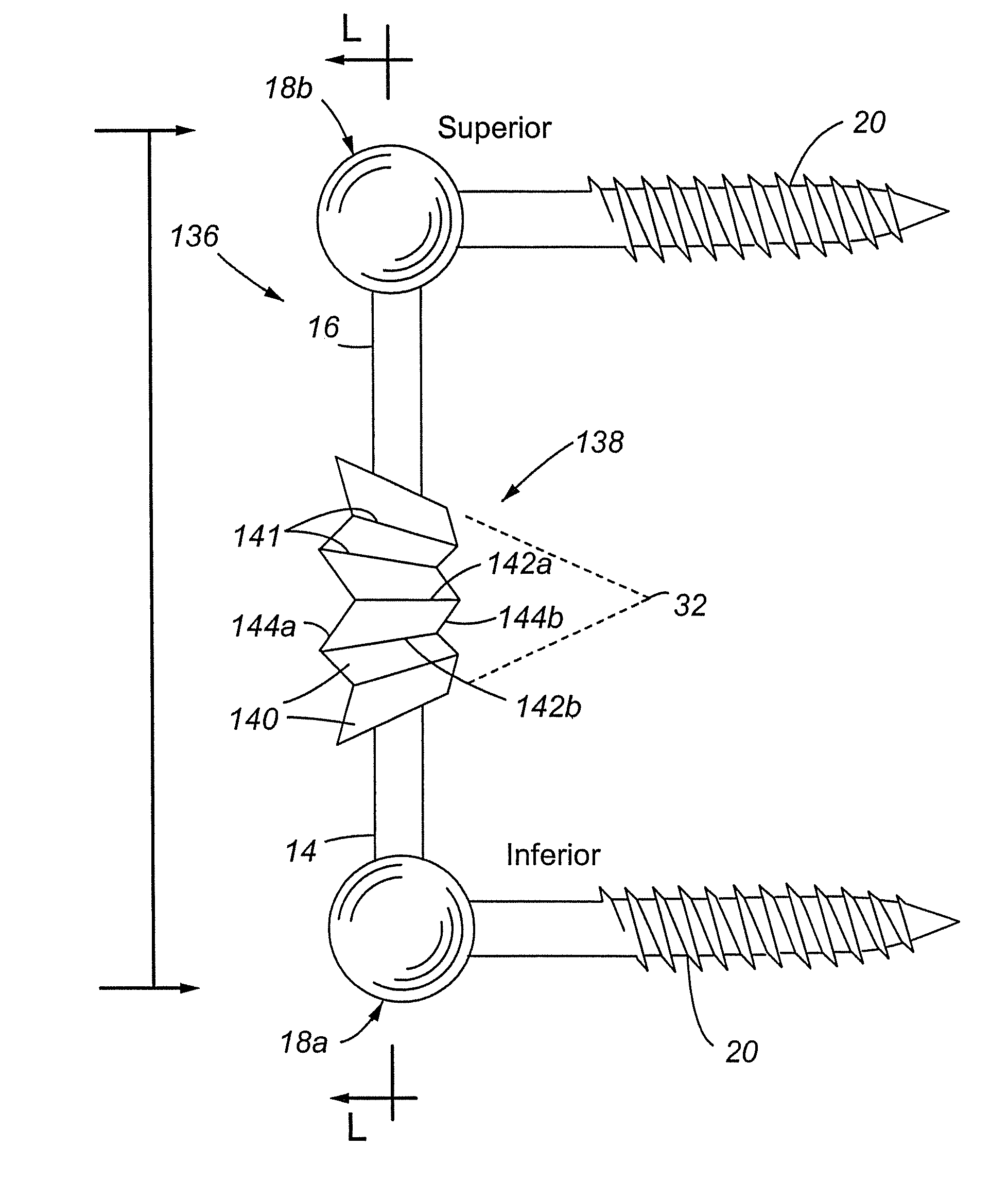

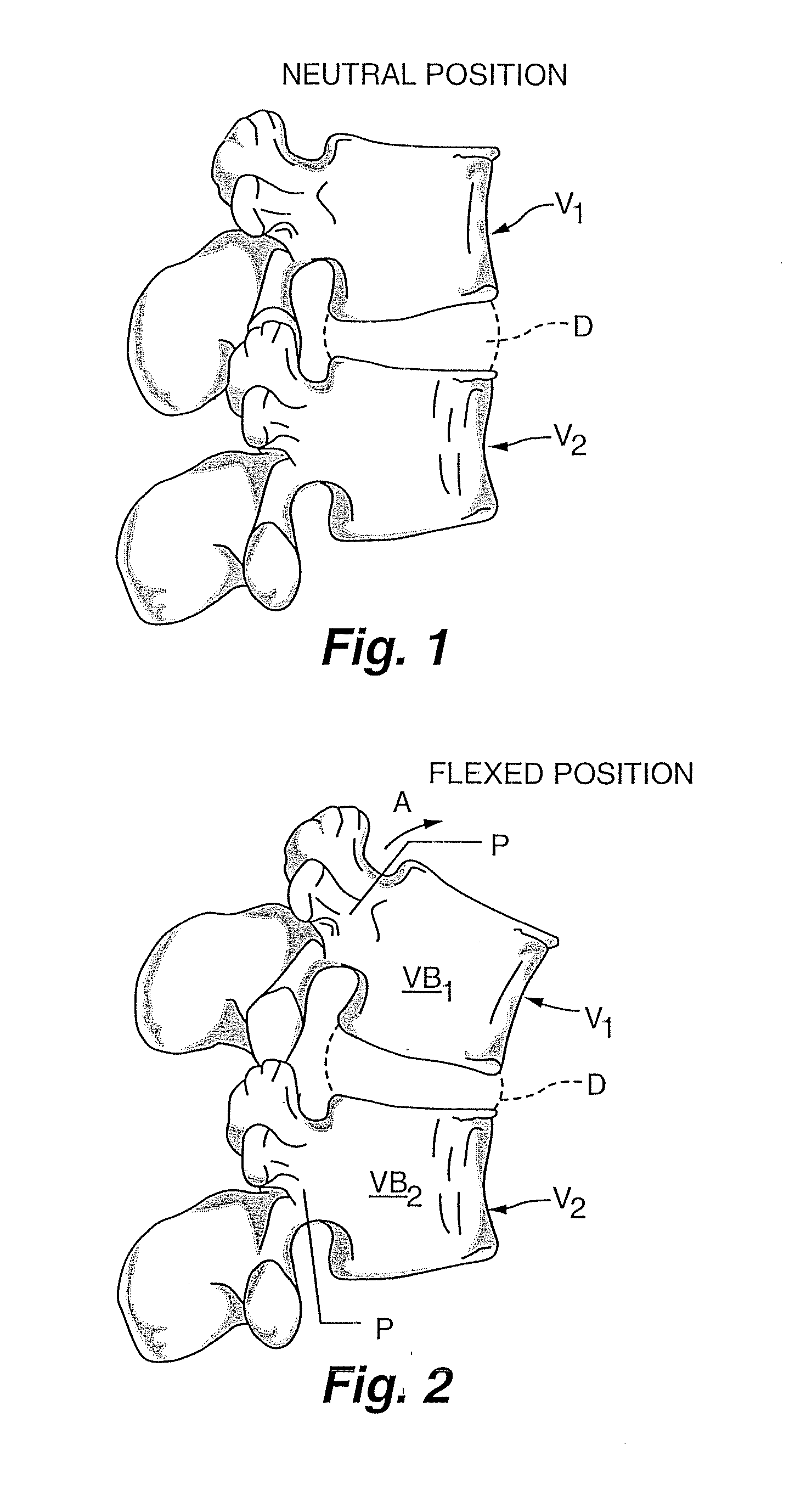

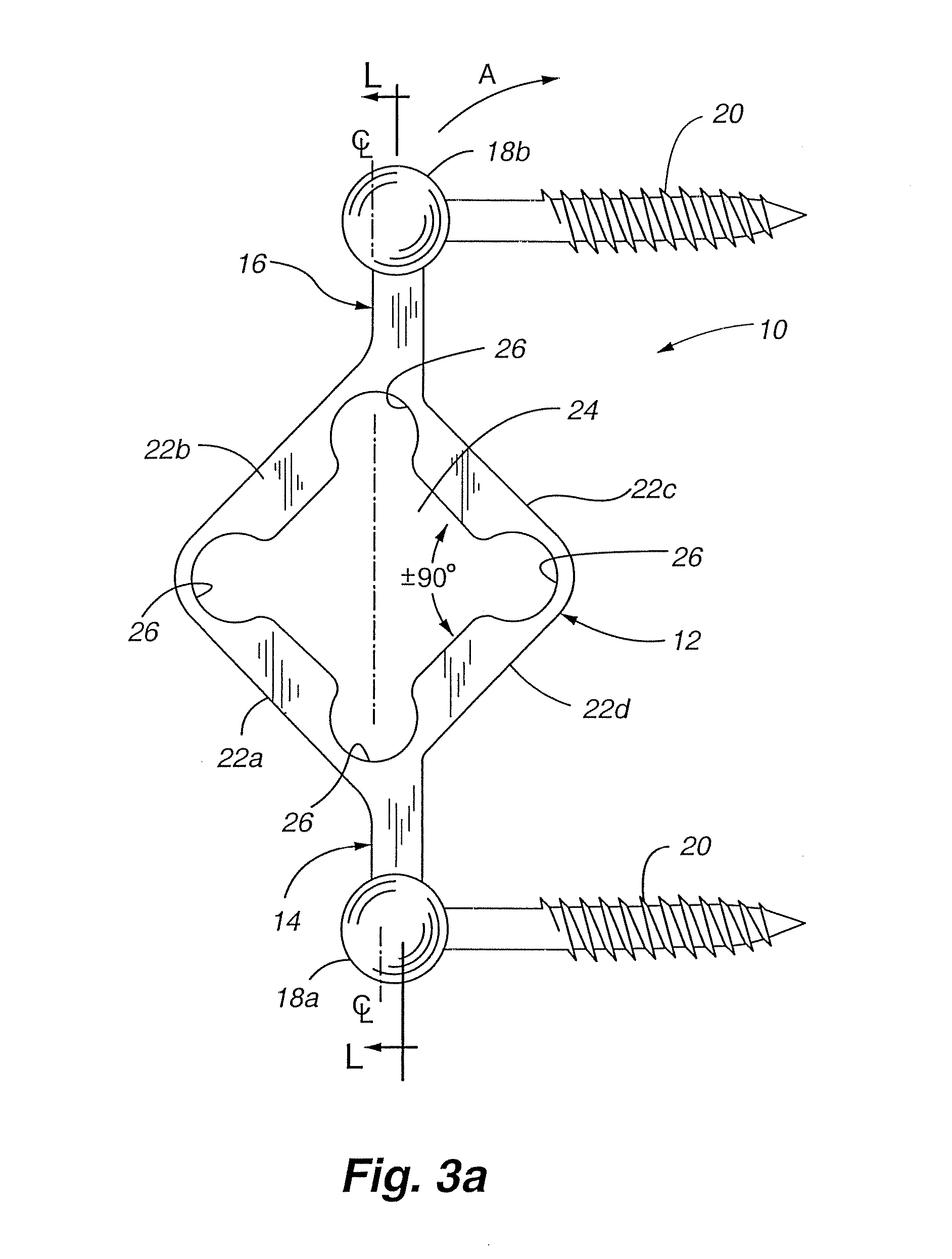

Dynamic fixation device and method of use

InactiveUS20070016193A1Avoid developmentPain minimizationInternal osteosythesisJoint implantsDynamic fixationPedicle screw

A dynamic fixation device is provided that allows the vertebrae to which it is attached to move in flexion within the normal physiological limits of motion, while also providing structural support that limits the amount of translation motion beyond normal physiological limits. The present invention includes a flexible portion and two ends that are adapted for connection to pedicle screws. In at least one embodiment of the present invention, the normal axis of rotation of the vertebrae is substantially duplicated by the dynamic fixation device. The flexible portion of the dynamic fixation device can include a flexible anterior-posterior segment, an anterior-posterior segment bounded by one or more zones with cuts in the rod portions, a flexible accordion-like segment, and / or a hinge portion.

Owner:RITLAND STEPHEN

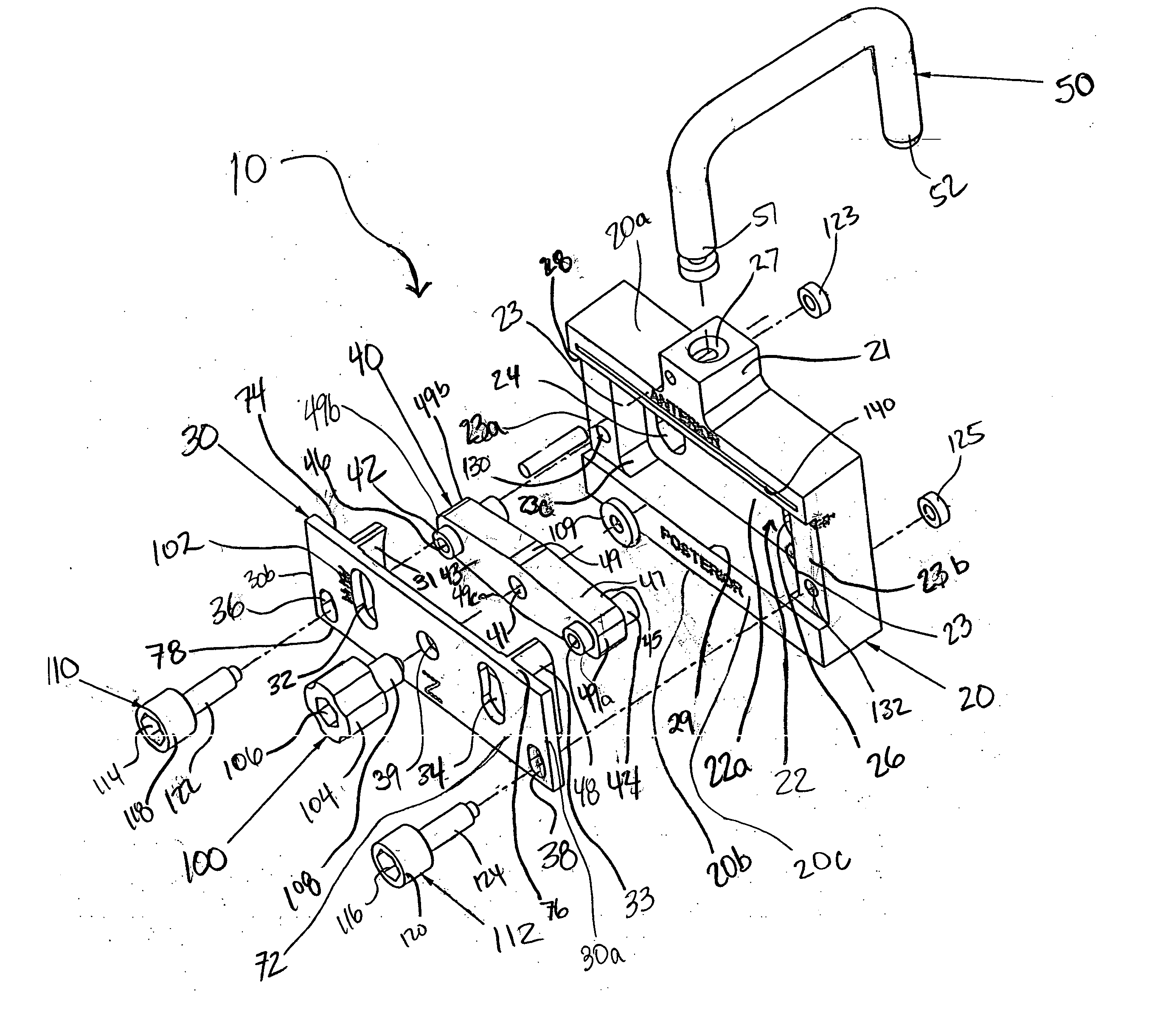

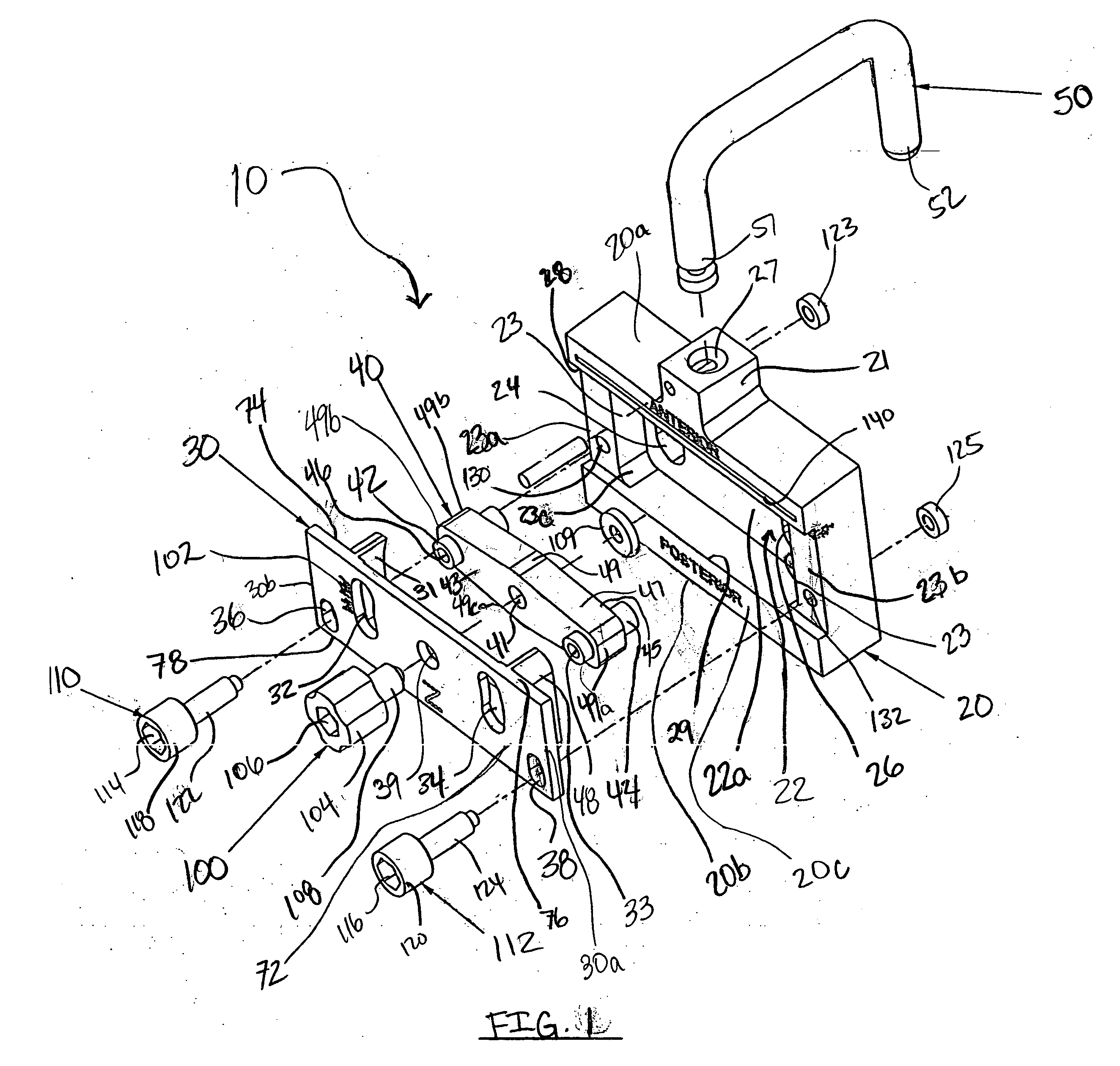

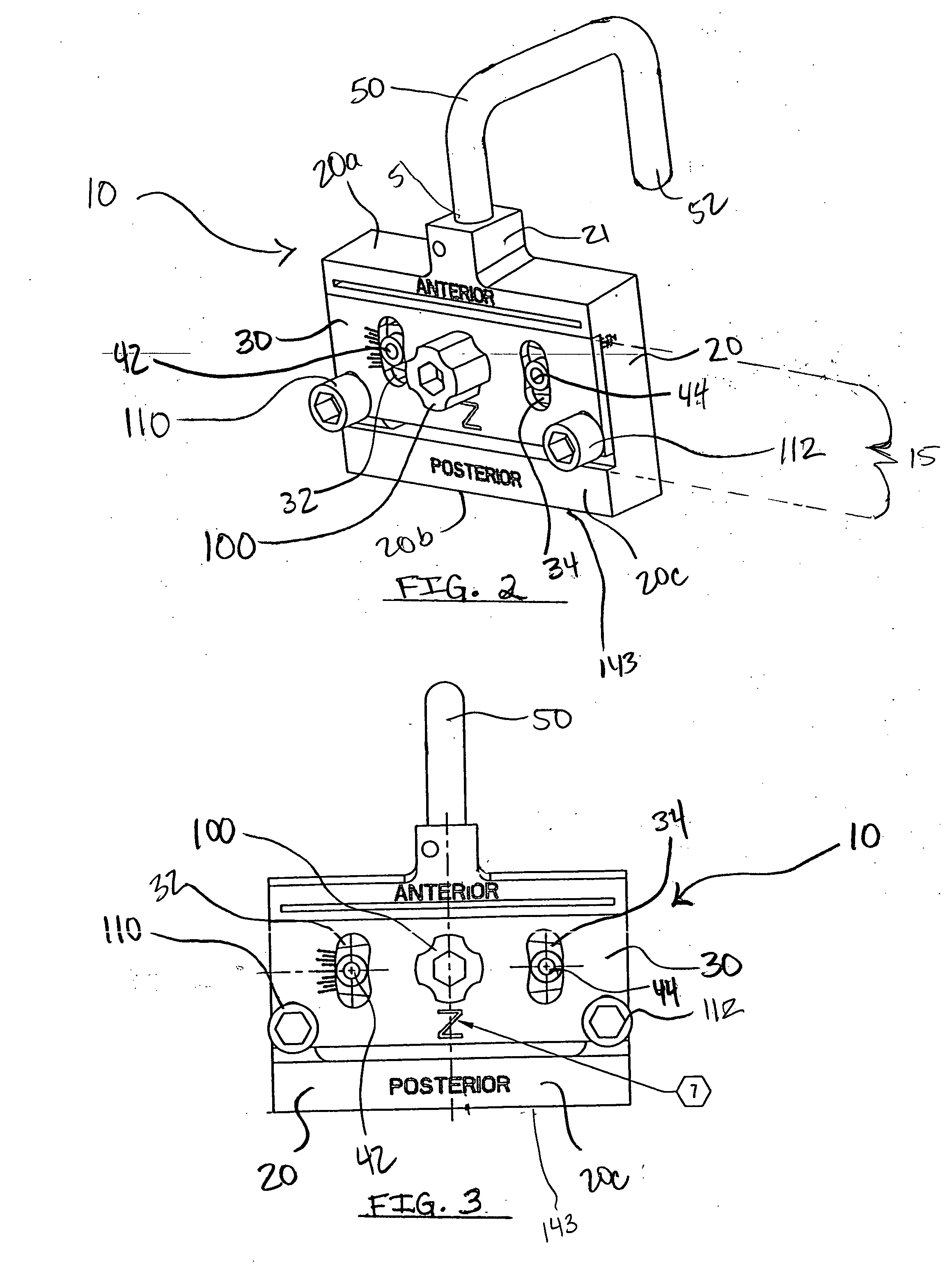

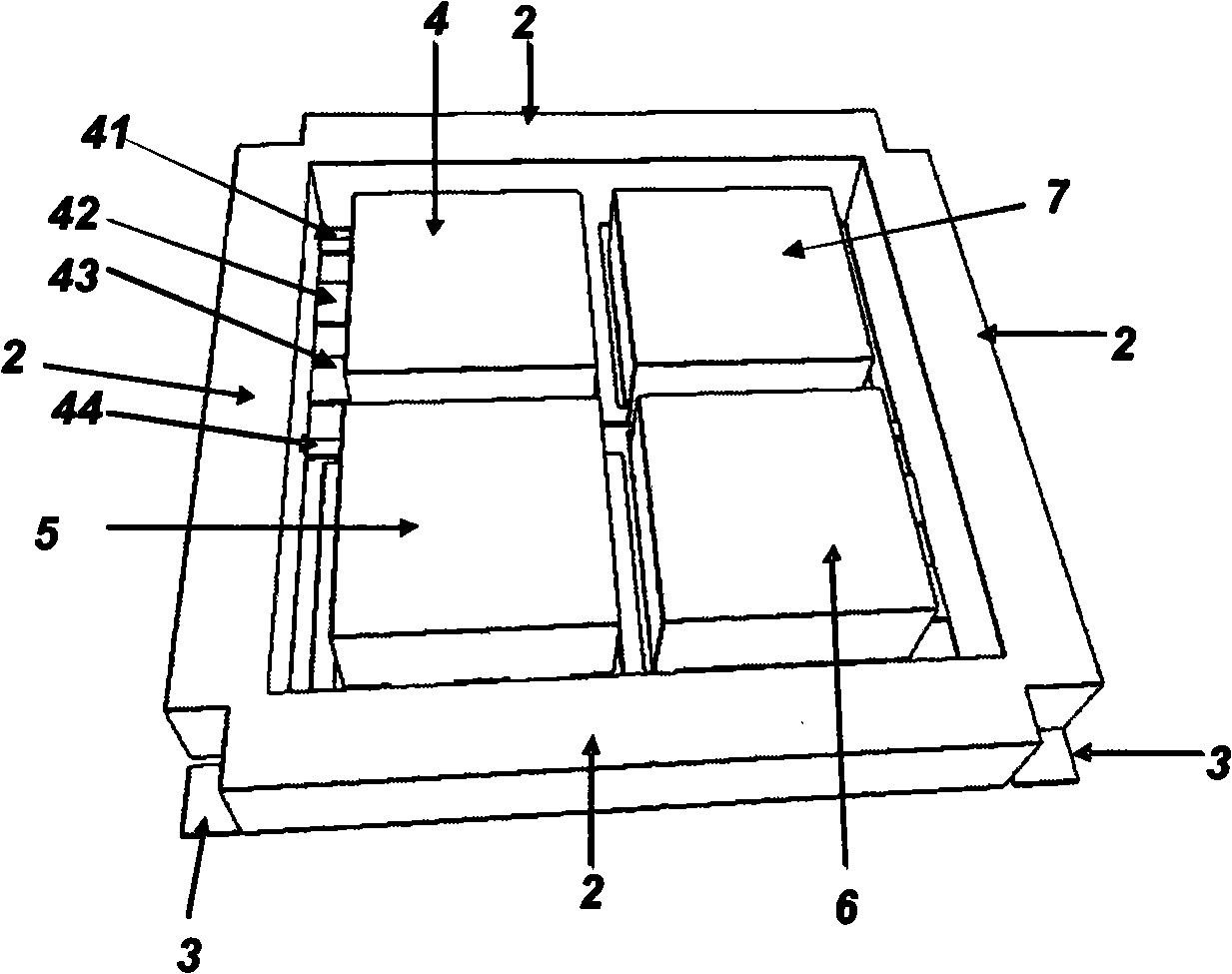

Knee balancing block

ActiveUS20050049603A1Non-surgical orthopedic devicesSurgical sawsBiomedical engineeringCutting guide

An orthopedic A / P cutting guide device, including a cut guide member, a support member and a positioning member for permitting both (i) rotational, and (ii) translational movement after the A / P cutting guide device has been attached to the distal femur by quick pins or other securing devices, is disclosed. Rotational movement may occur by loosening a knob thereby releasing the positioning member and the cut guide member from the support member, which may be fixed in position by the quick pins, and rotating the positioning member and the cut guide member together. Translational movement may occur by loosening a plurality of knobs thereby releasing the cut guide member from the support member and the positioning member, and moving the cut guide member anteriorly or posteriorly. After the device has been rotated and translated, the knobs may be tightened, thus securing the device from further movement.

Owner:ORTHO DEV CORP

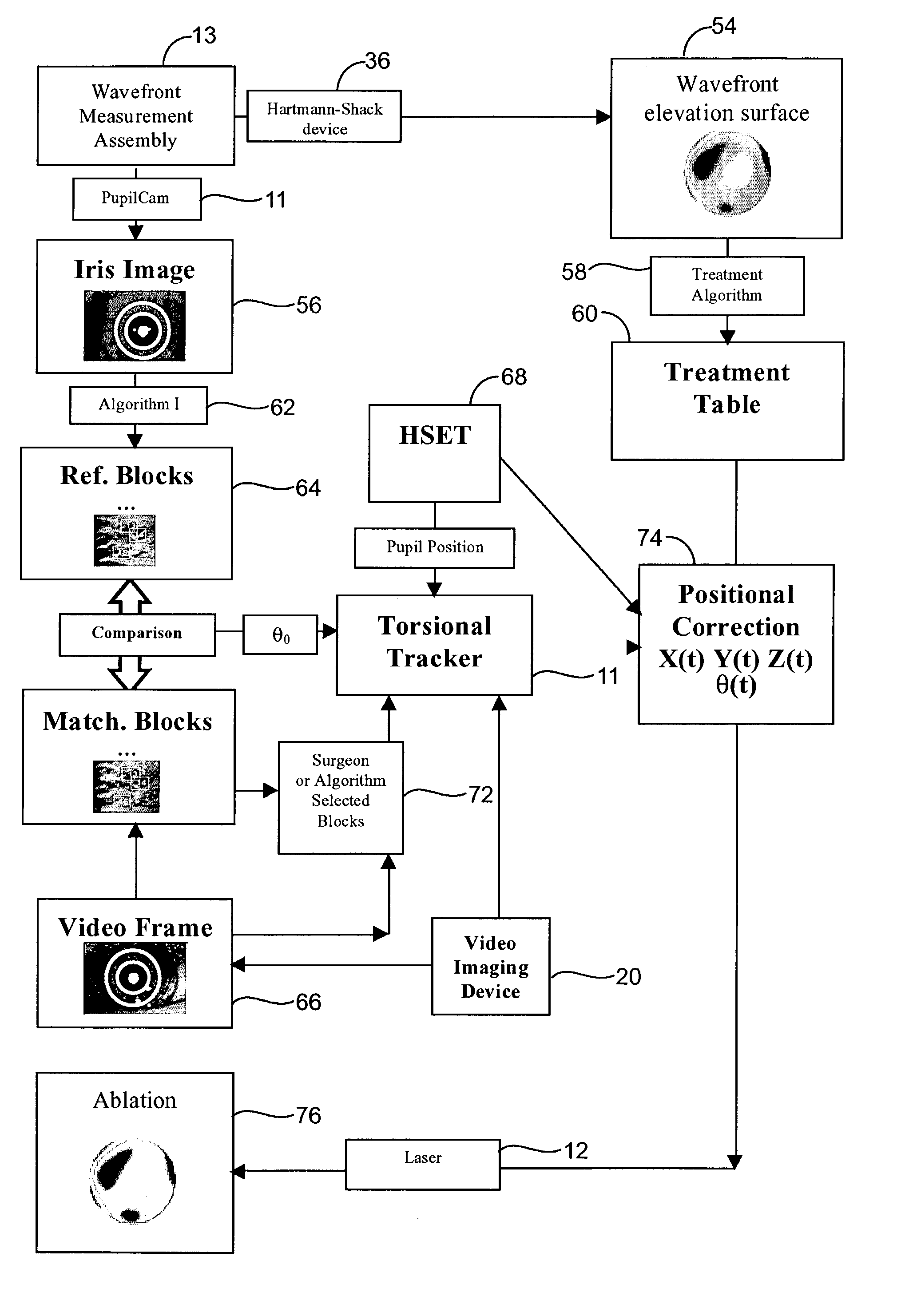

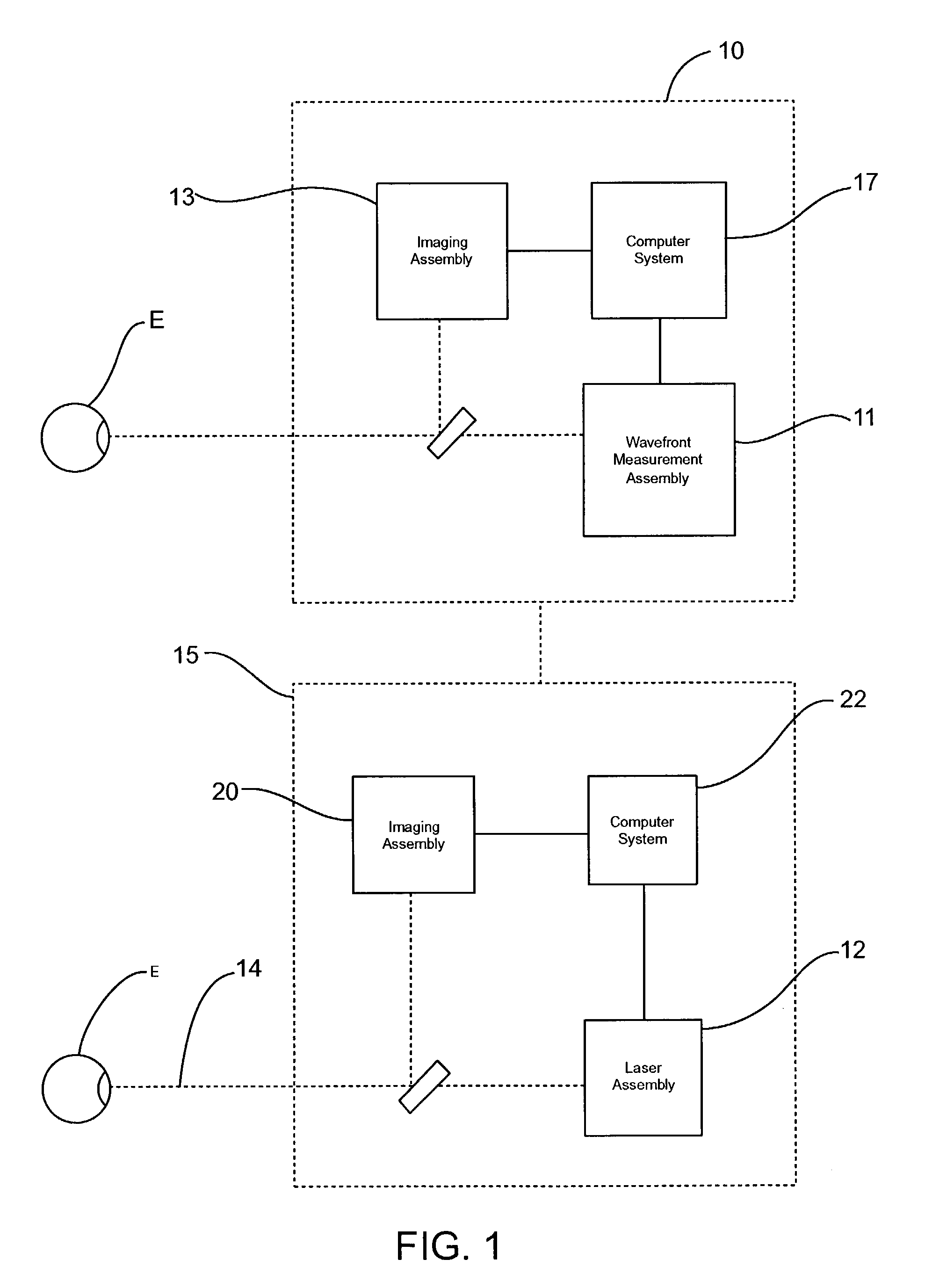

Methods and systems for tracking a torsional orientation and position of an eye

Methods and systems for tracking a position and torsional orientation of a patient's eye. In one embodiment, the present invention provides methods and software for registering a first image of an eye with a second image of an eye. In another embodiment, the present invention provides methods and software for tracking a torsional movement of the eye. In a particular usage, the present invention tracks the torsional cyclorotation and translational movement of a patient's eye so as to improve the delivery of a laser energy to the patient's cornea.

Owner:AMO MFG USA INC

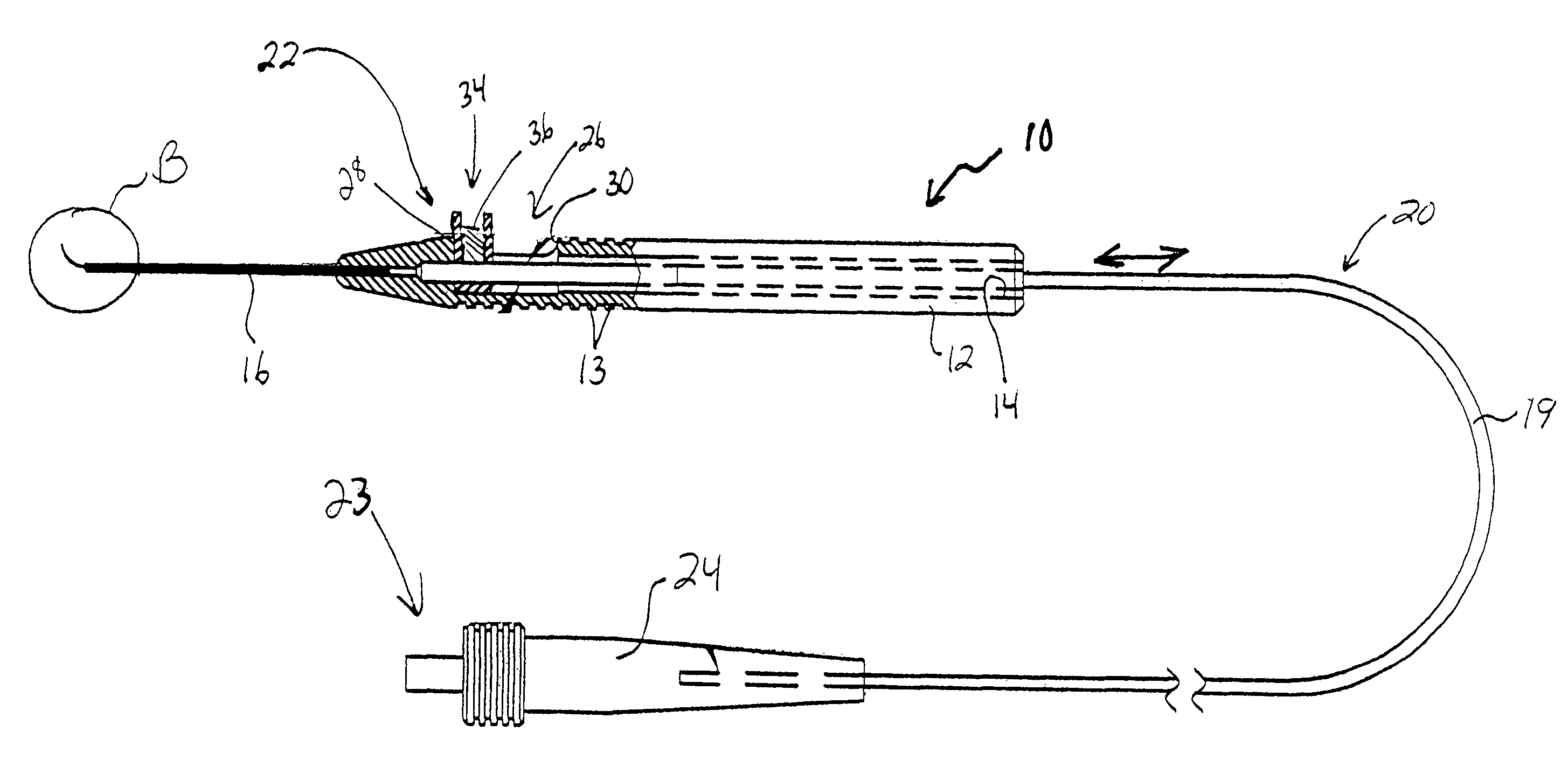

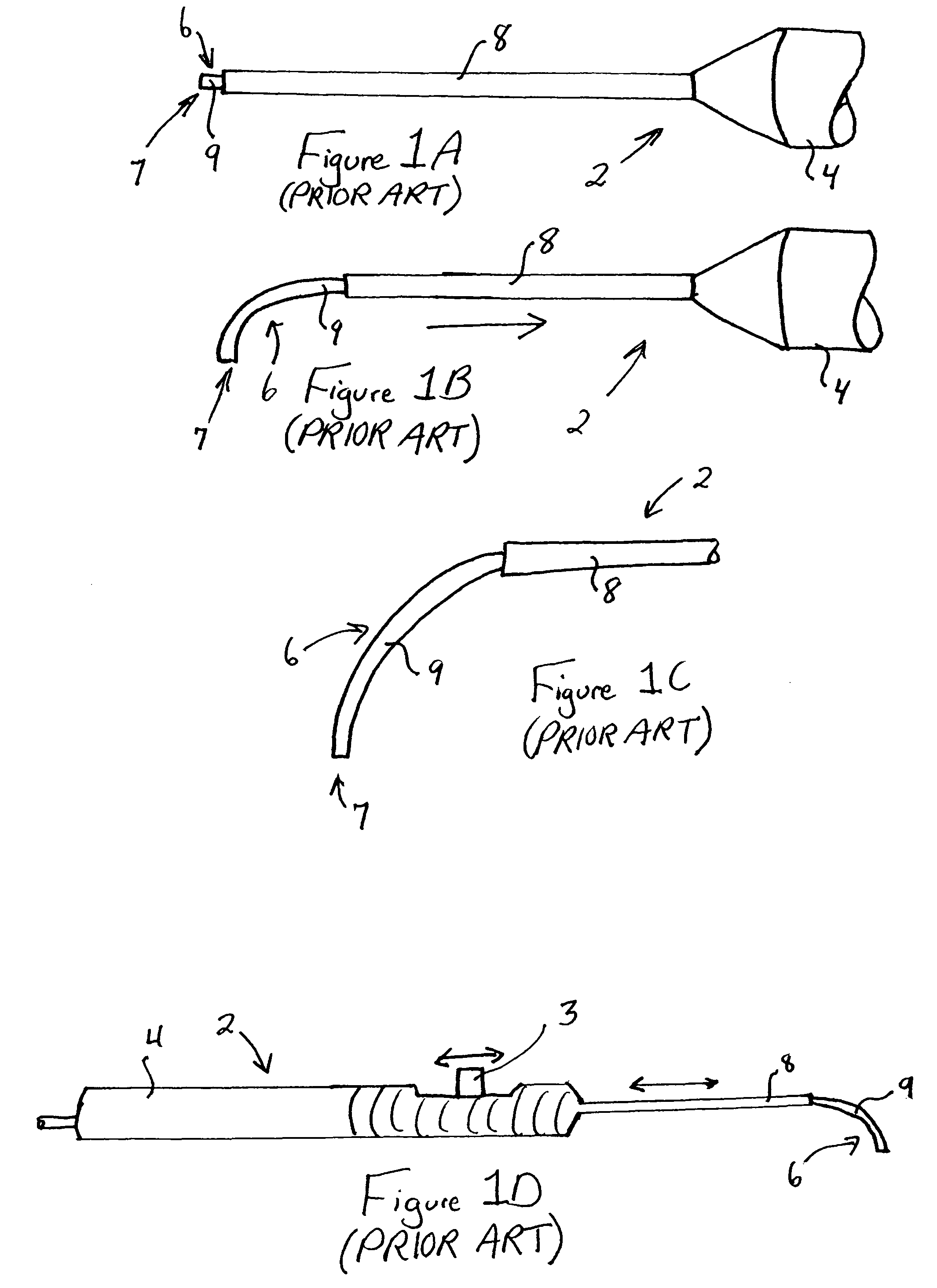

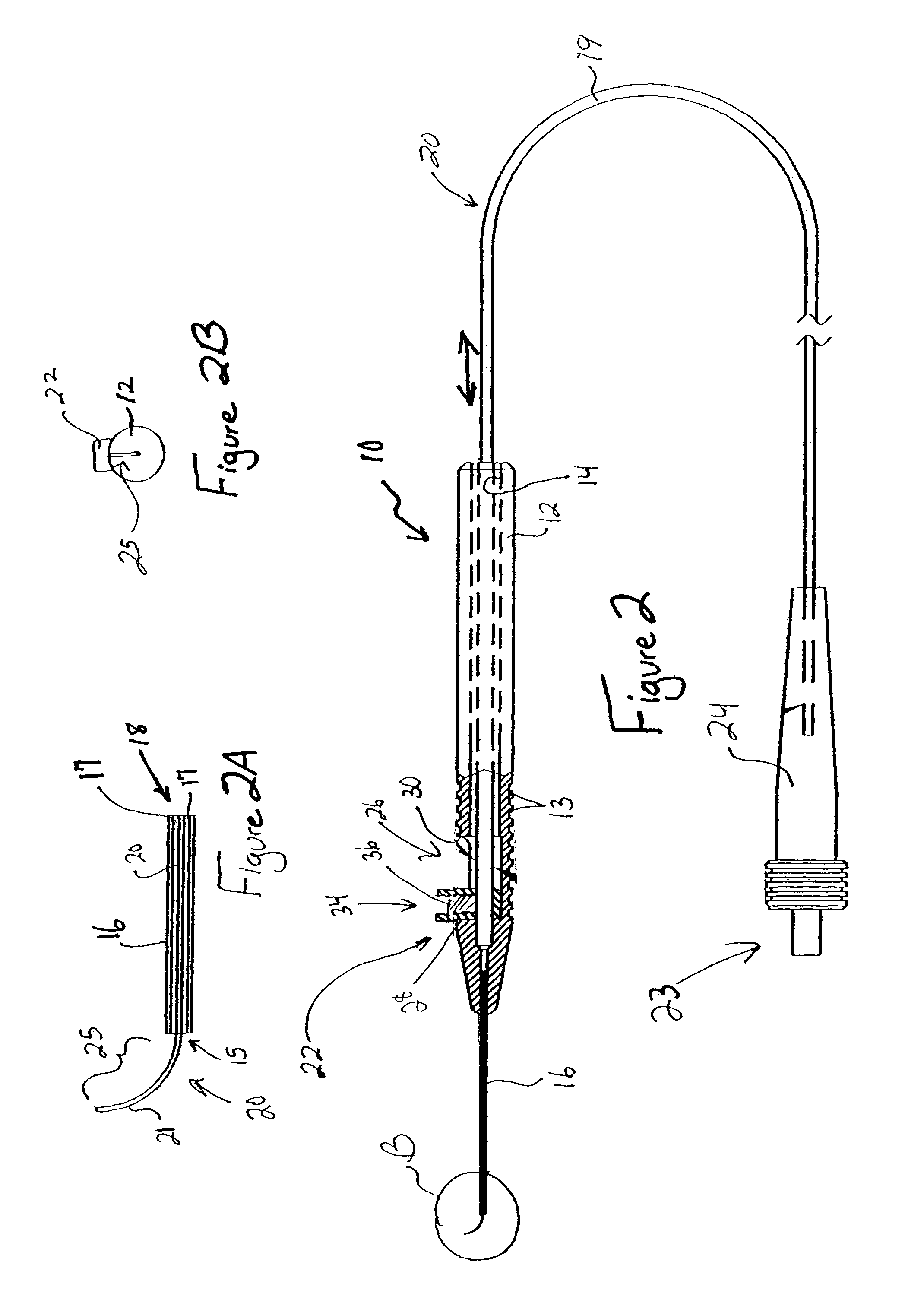

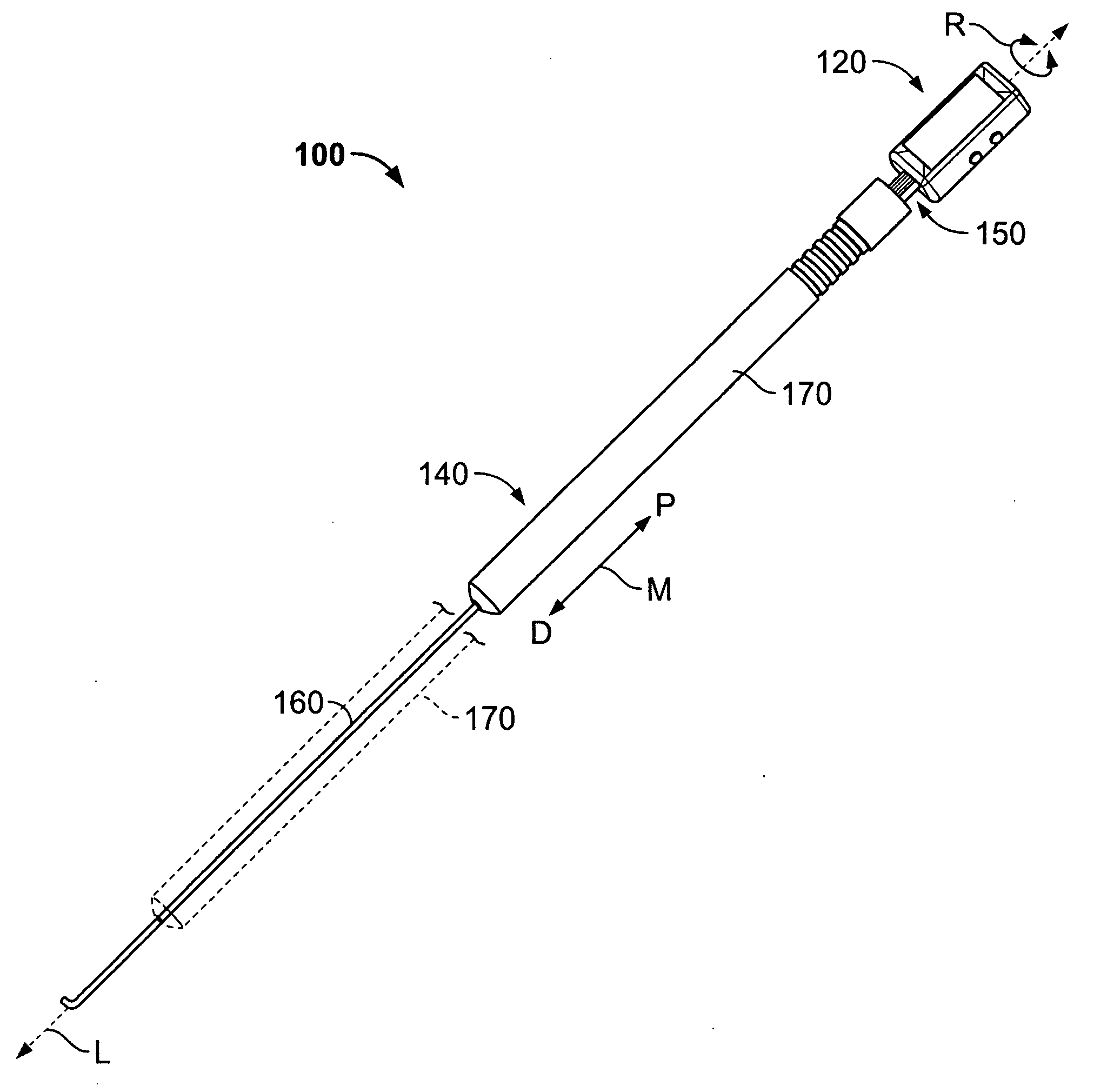

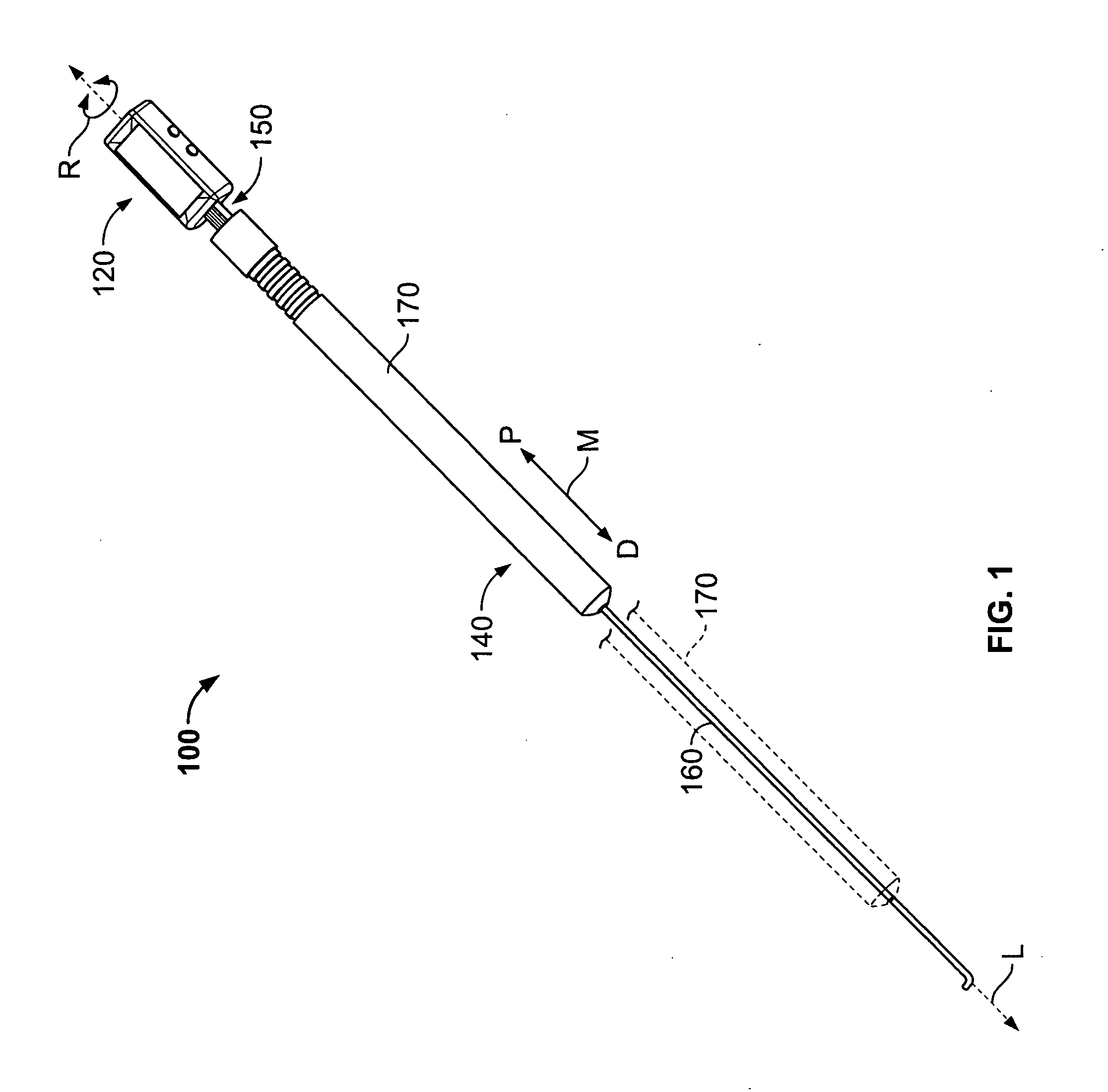

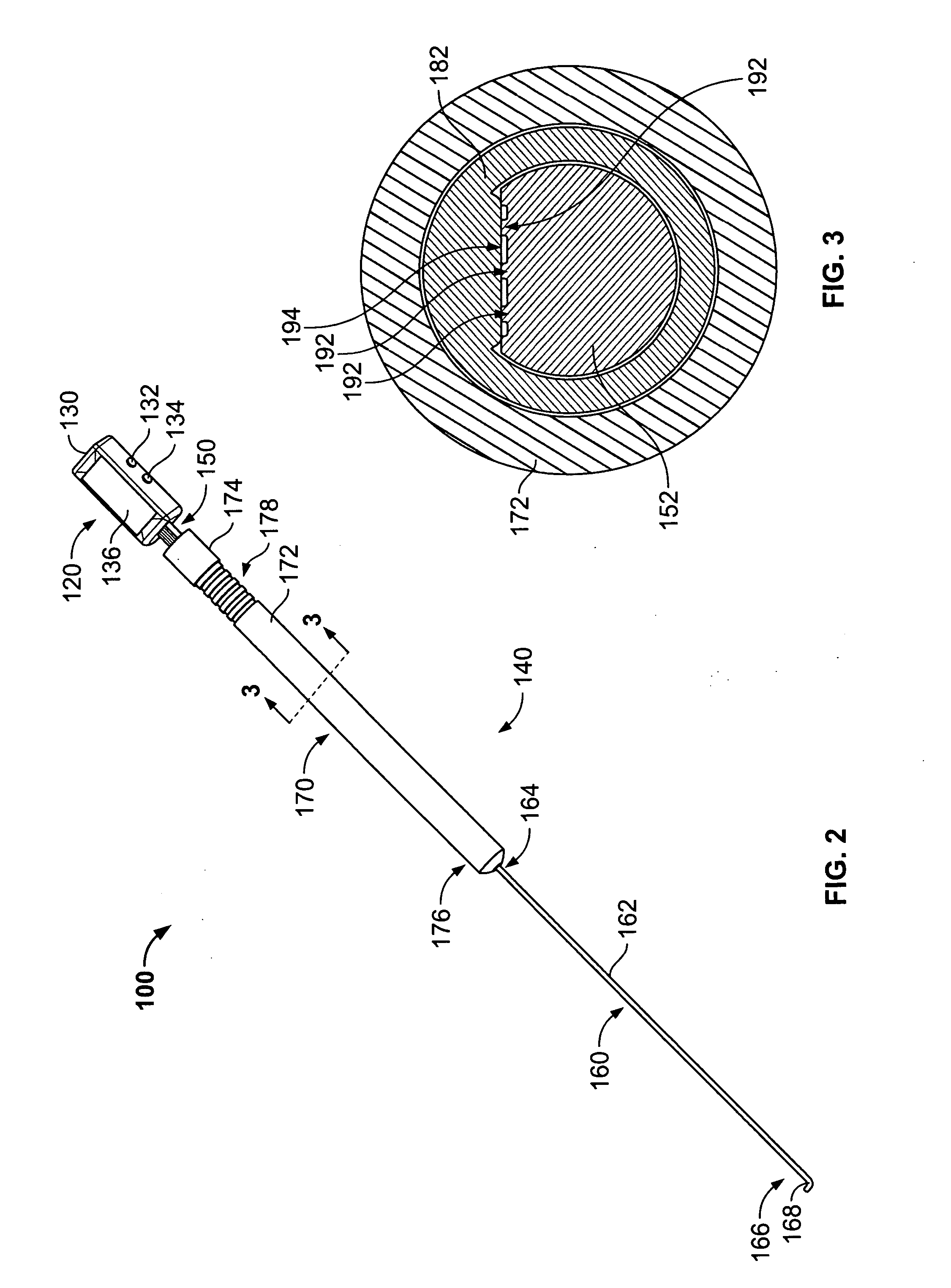

Adjustable laser probe for use in vitreoretinal surgery

ActiveUS7766904B2Avoid damagePrevent movementLaser surgerySurgical instrument detailsFiberLaser probe

A laser probe including a handpiece and a rigid cannula fixed to the handpiece to prevent relative translational movement-therebetween. An optical fiber for delivering laser energy is supported for translational movement relative to the handpiece. A slidable button is fixed to the optical fiber via a rigid sleeve such that the button and optical fiber move together in the same direction during operation. The fiber may be selectively positioned relative to the button to cause the button to act as a visual indicator of the direction in which the fiber will extend from the cannula. The button may be specially configured with an enlarged head portion to enhance grippability and smooth operation of the button.

Owner:IRIDEX CORP

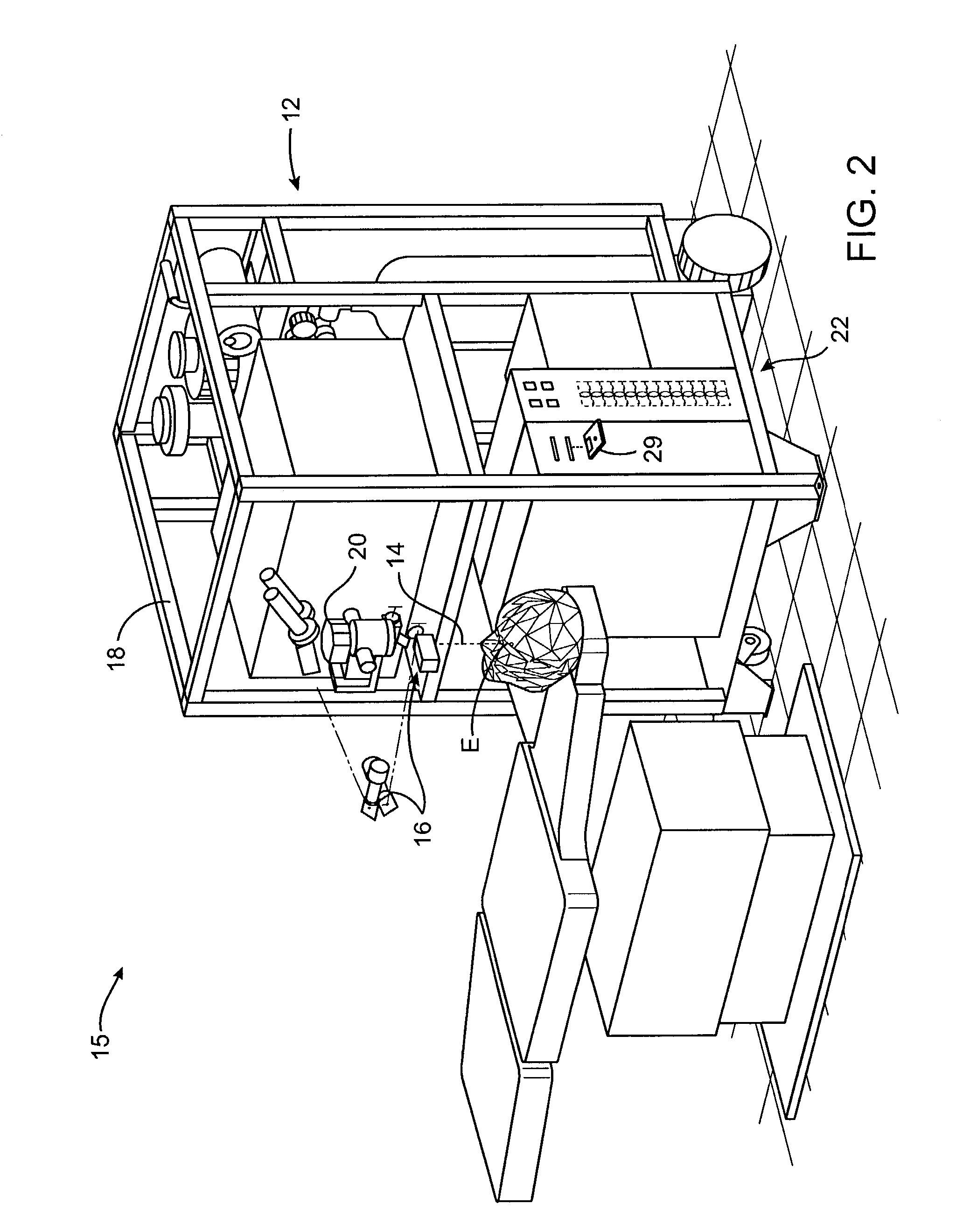

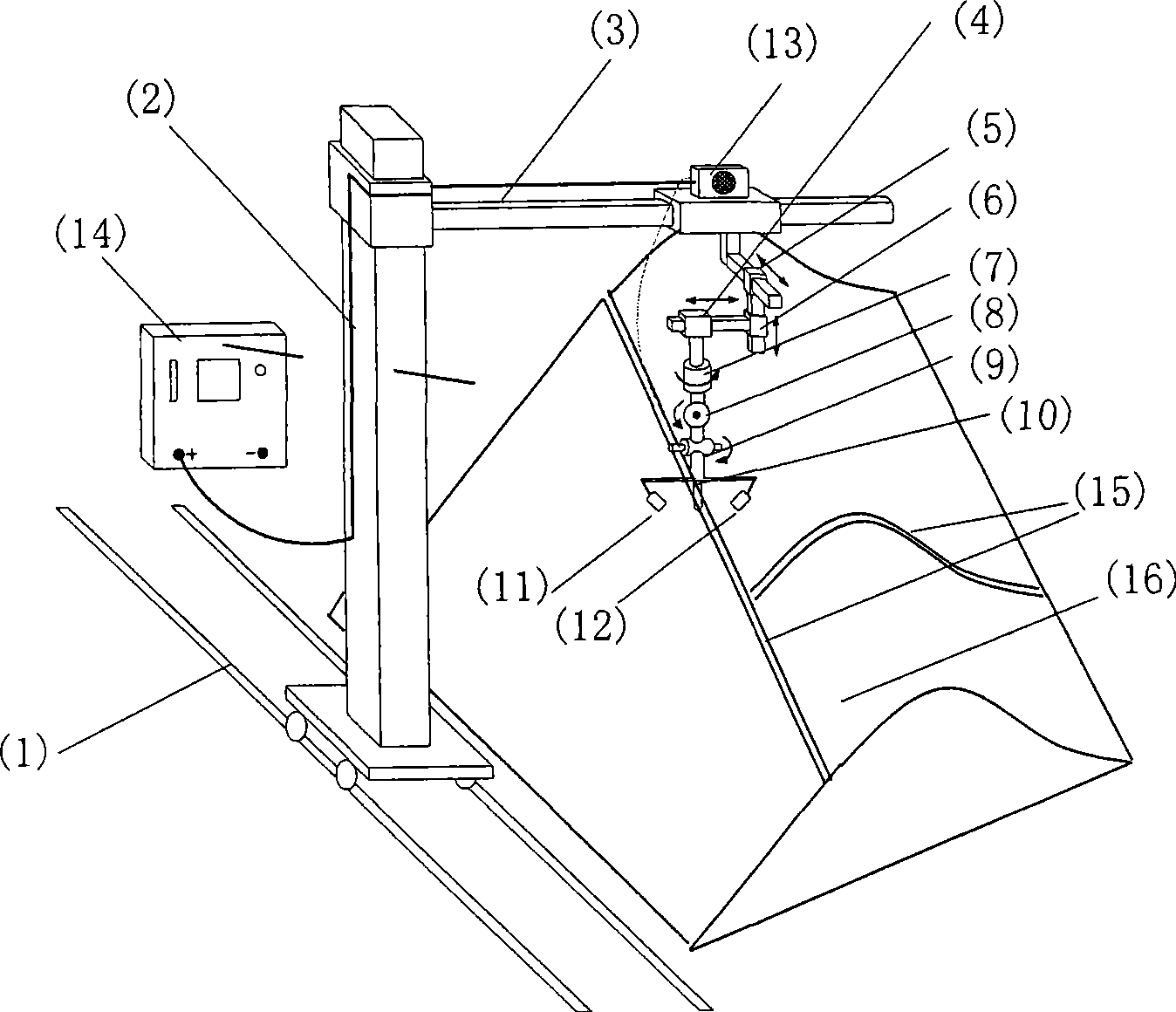

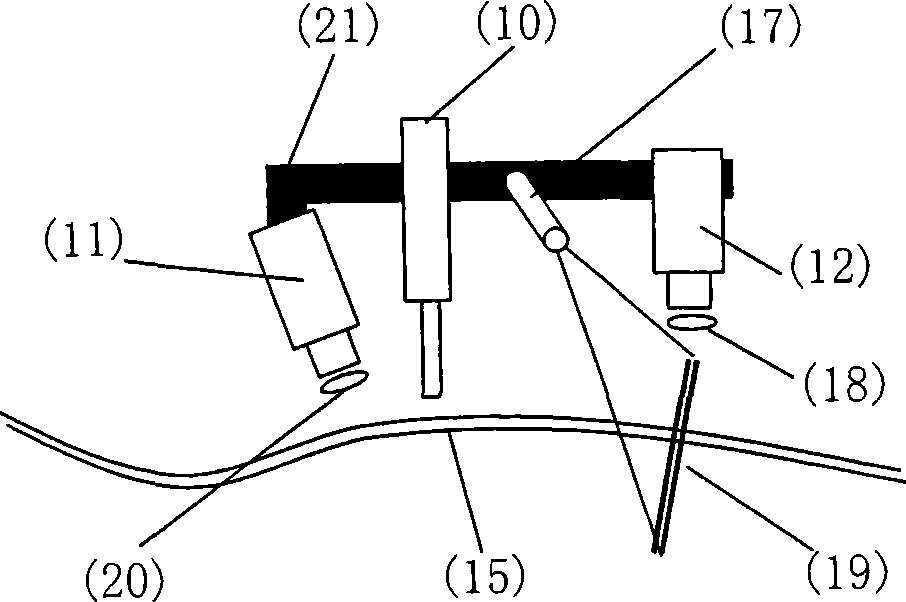

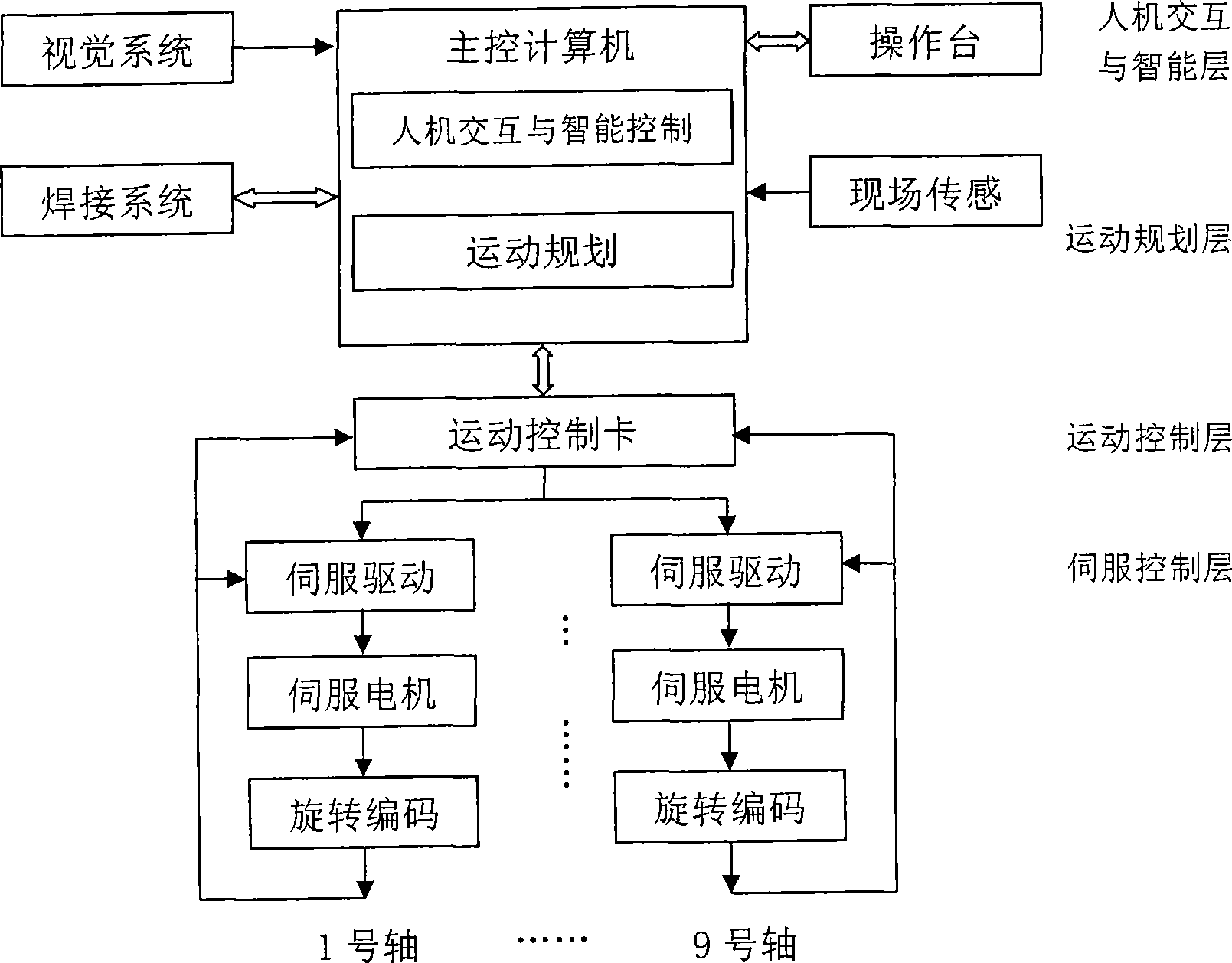

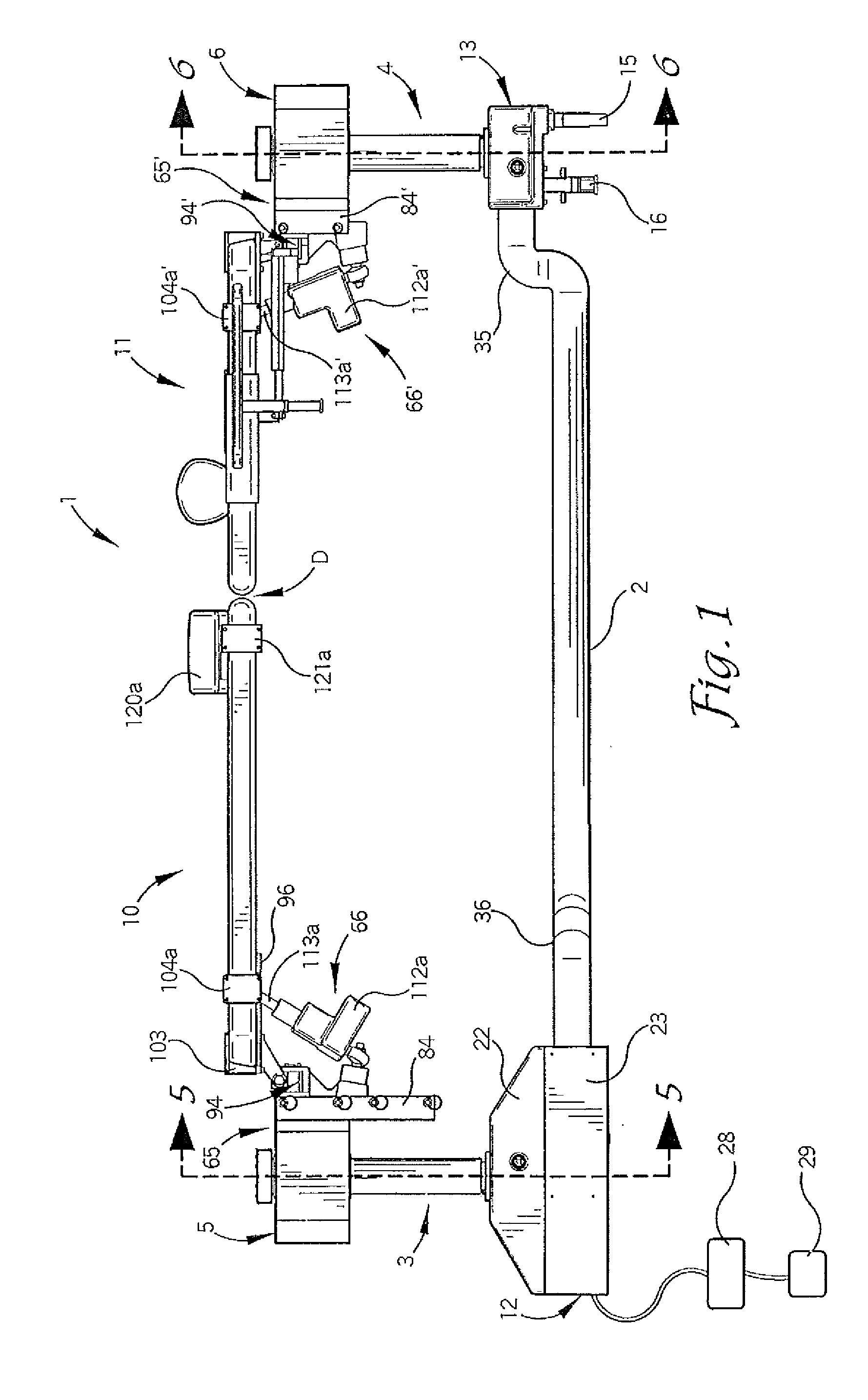

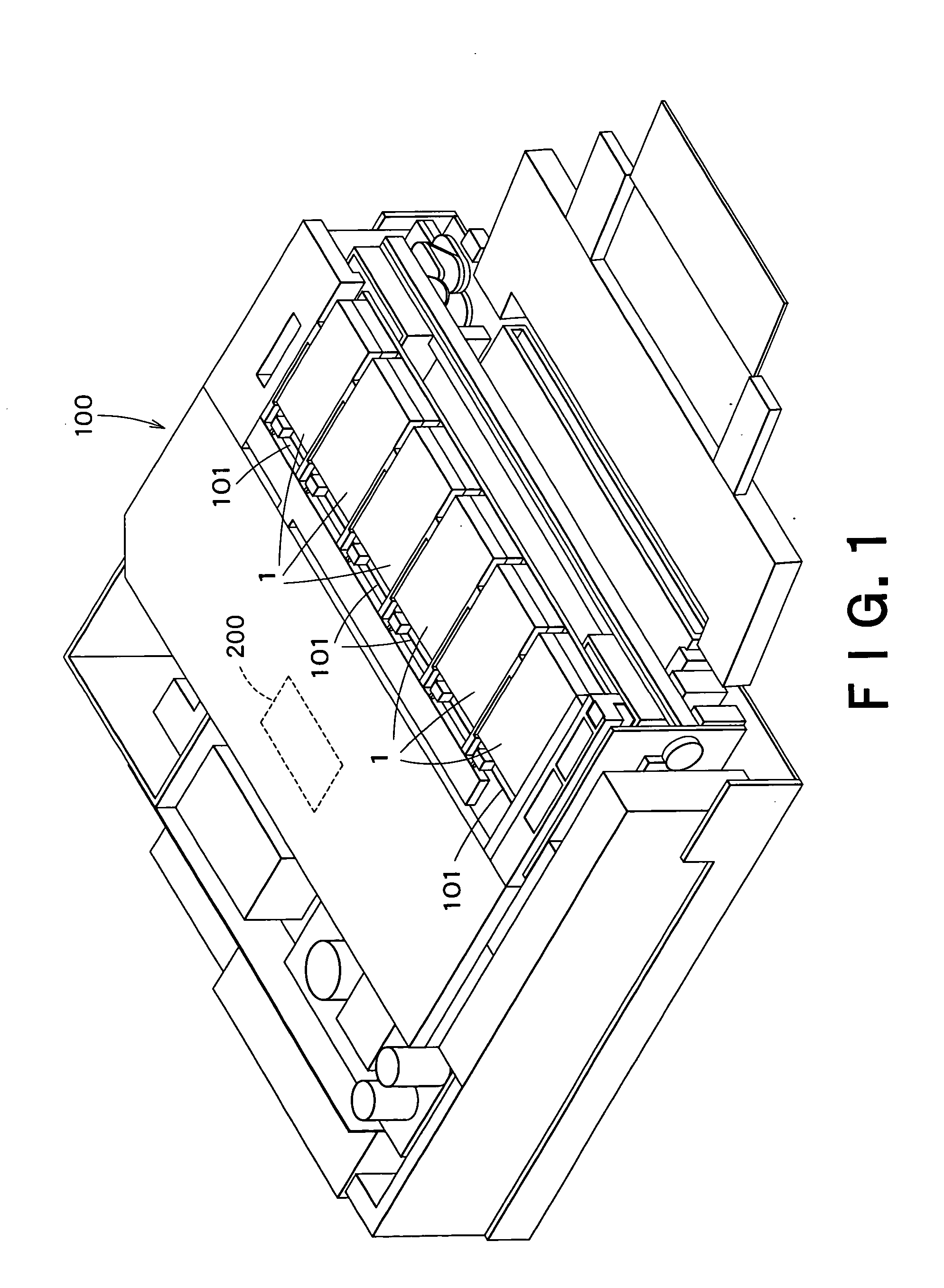

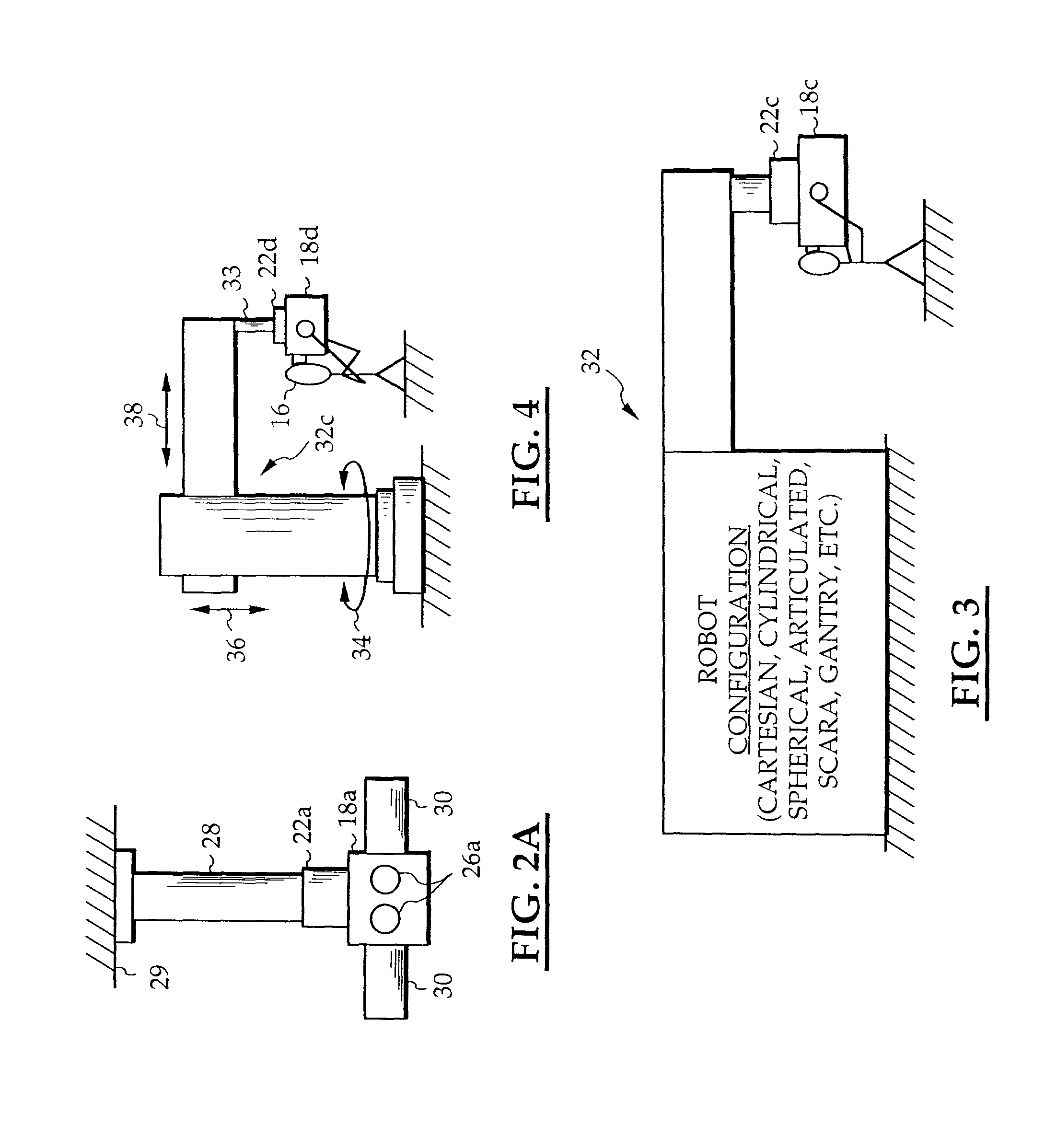

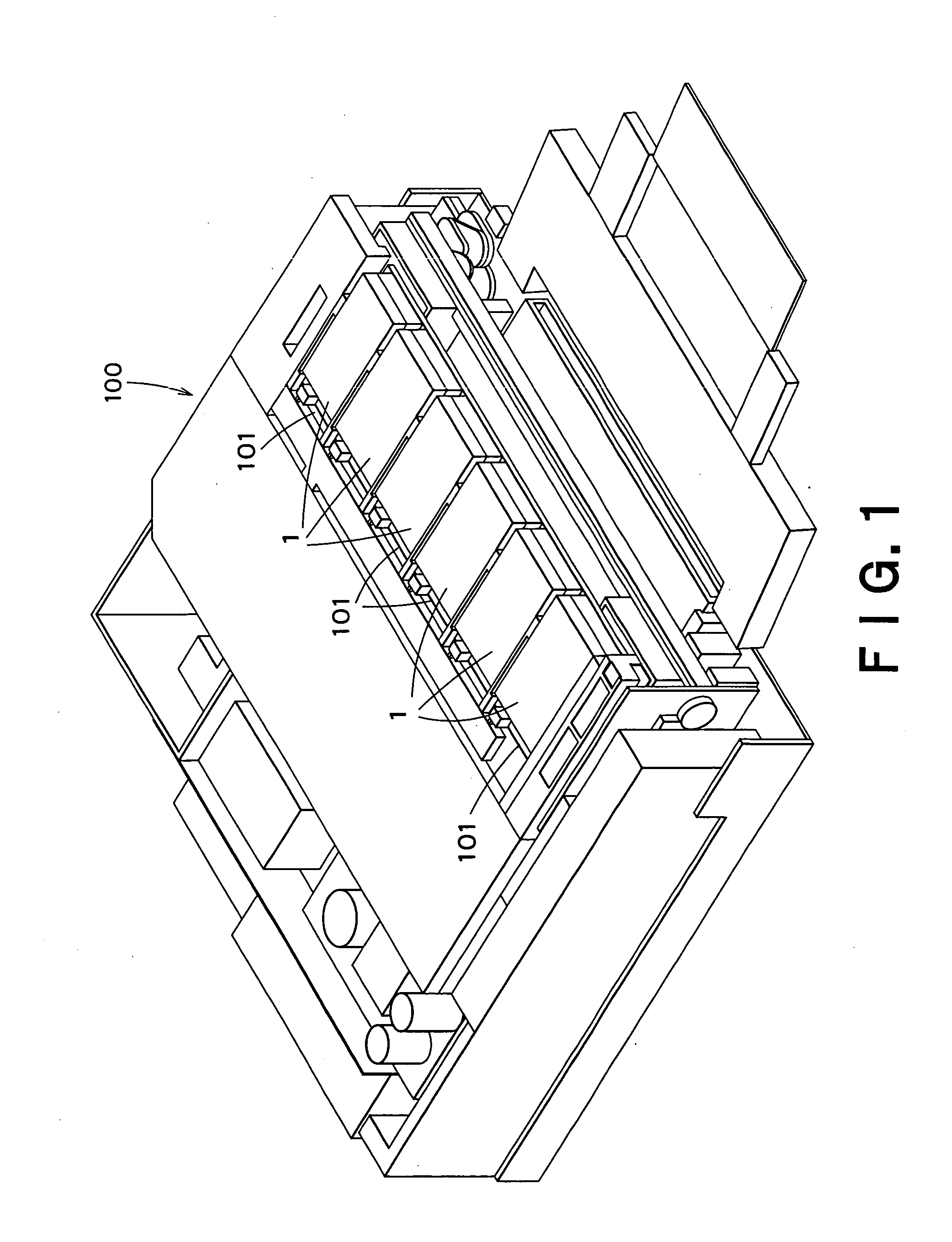

Intelligent robot welding device using large-scale workpiece

InactiveCN101456182AWith visual functionSimple motion controlProgramme-controlled manipulatorArc welding apparatusRotational axisRotational degrees of freedom

The invention discloses a large-sized workpiece welded intelligent robot device, relates to robot technology, in particular to the robot device based on visual control technology. The device consists of a robot body, a sensing system, a robot controller and a welding auxiliary mechanism. The welded robot is provided with nine moving shafts, including three macrographic moving translational moving shafts, three microscopic moving translational moving shafts and three rotating shafts. The robot body comprises a robot frame and a robot head which is arranged on a transverse arm of the robot frame, and the robot frame consists of the three macrographic moving translational moving shafts, namely a horizontal lead rail, an upright post and the transverse arm. The robot head consists of the three microscopic moving translational moving shafts, the three rotating shafts and a welding gun. The robot frame provides the large-scale three-dimensional movement of the robot; the precision of macrographic moving movement is compensated by the microscopic moving mechanisms of the robot head which also provides rotating freedom of motion. The robot device can meet the movement requirements of large scale and precise positioning for the welding operation of large-sized workpieces. Through the visual sensing technology and intelligent visual controlling technology, the device can improve the automatic welding quality and efficiency of the welded robot.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

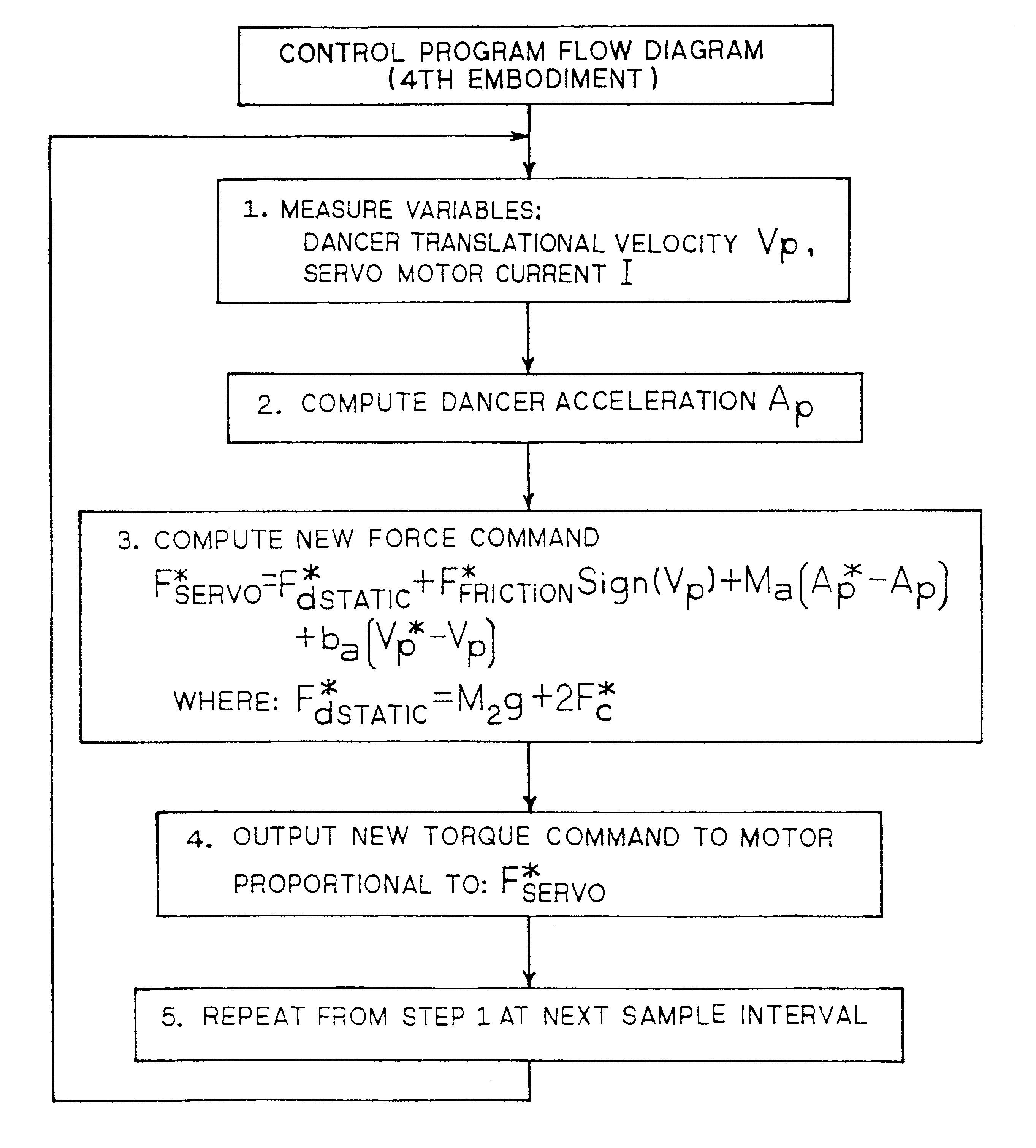

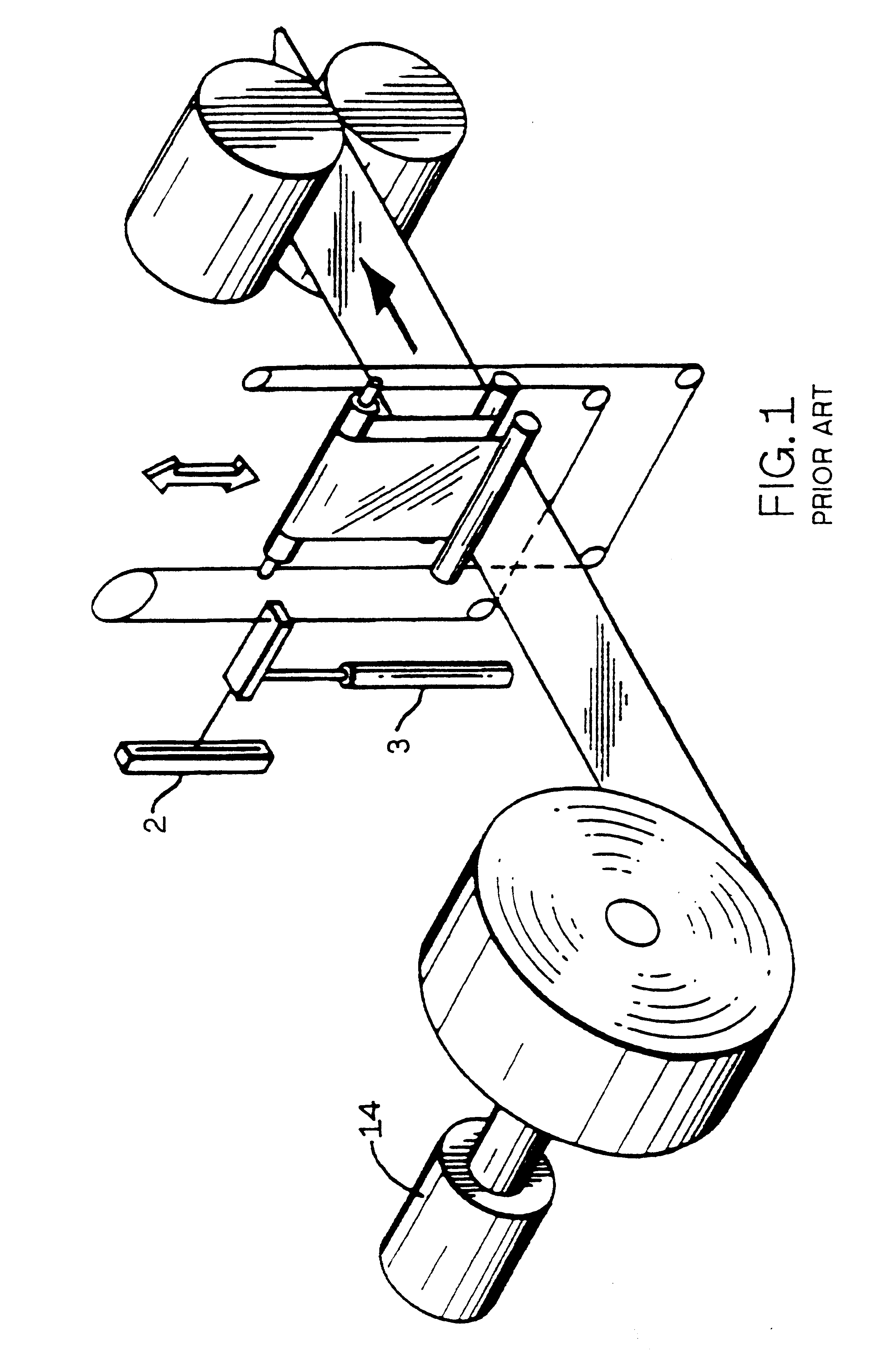

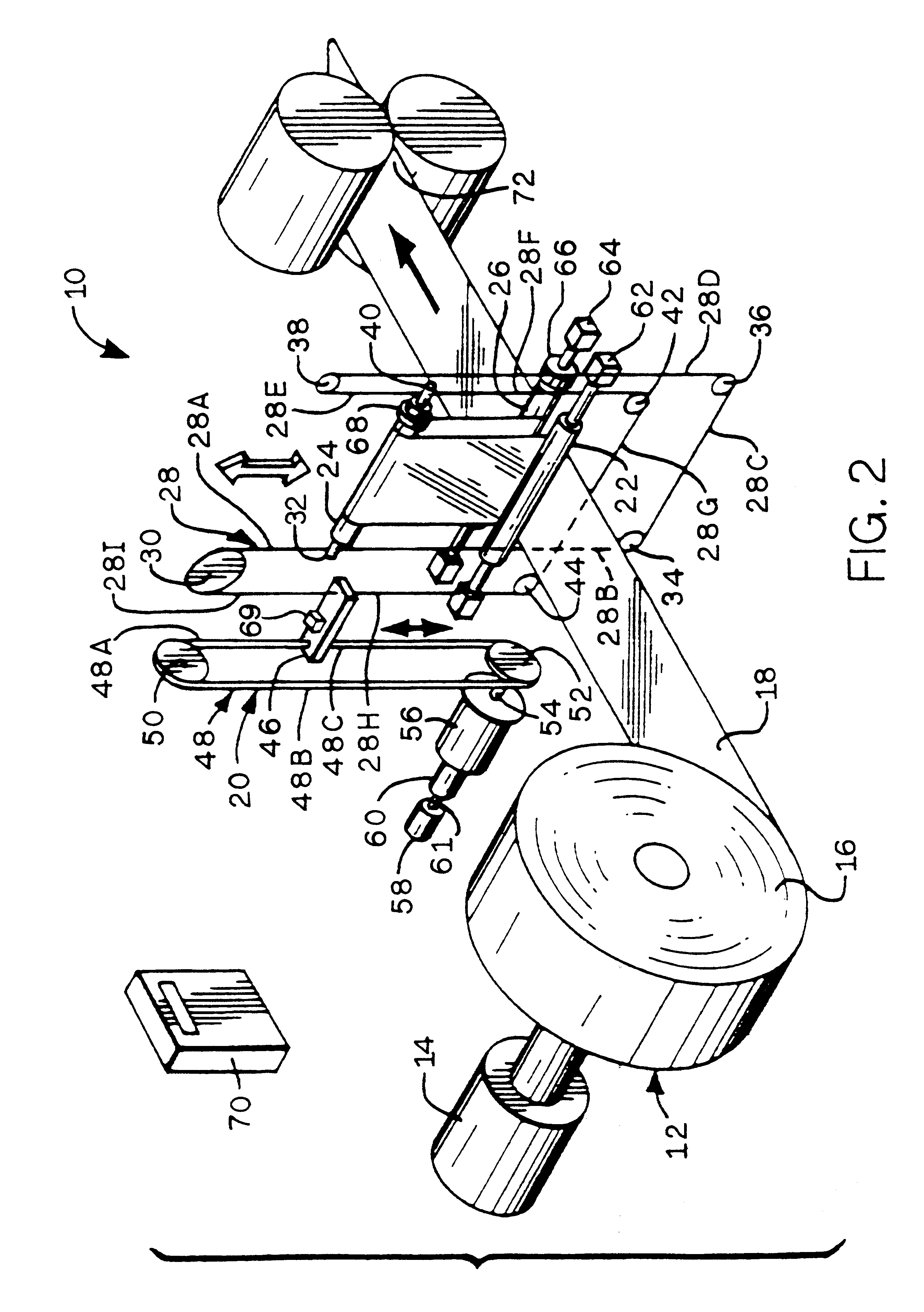

Method and apparatus for controlling web tension by actively controlling velocity and acceleration of a dancer roll

InactiveUS6314333B1The result is accurateAutomatic control devicesPrecision positioning equipmentControl systemEngineering

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to controlling tension in such continuous webs during the processing operation. Tension is controlled in a dancer control system by connecting a corresponding dancer roll to an actuator apparatus or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the dancer roll, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the dancer roll to control tension disturbances in the web. In some applications of the invention, the dancer control system is used to attenuate tension disturbances. In other applications of the invention, the dancer control system is used to create tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

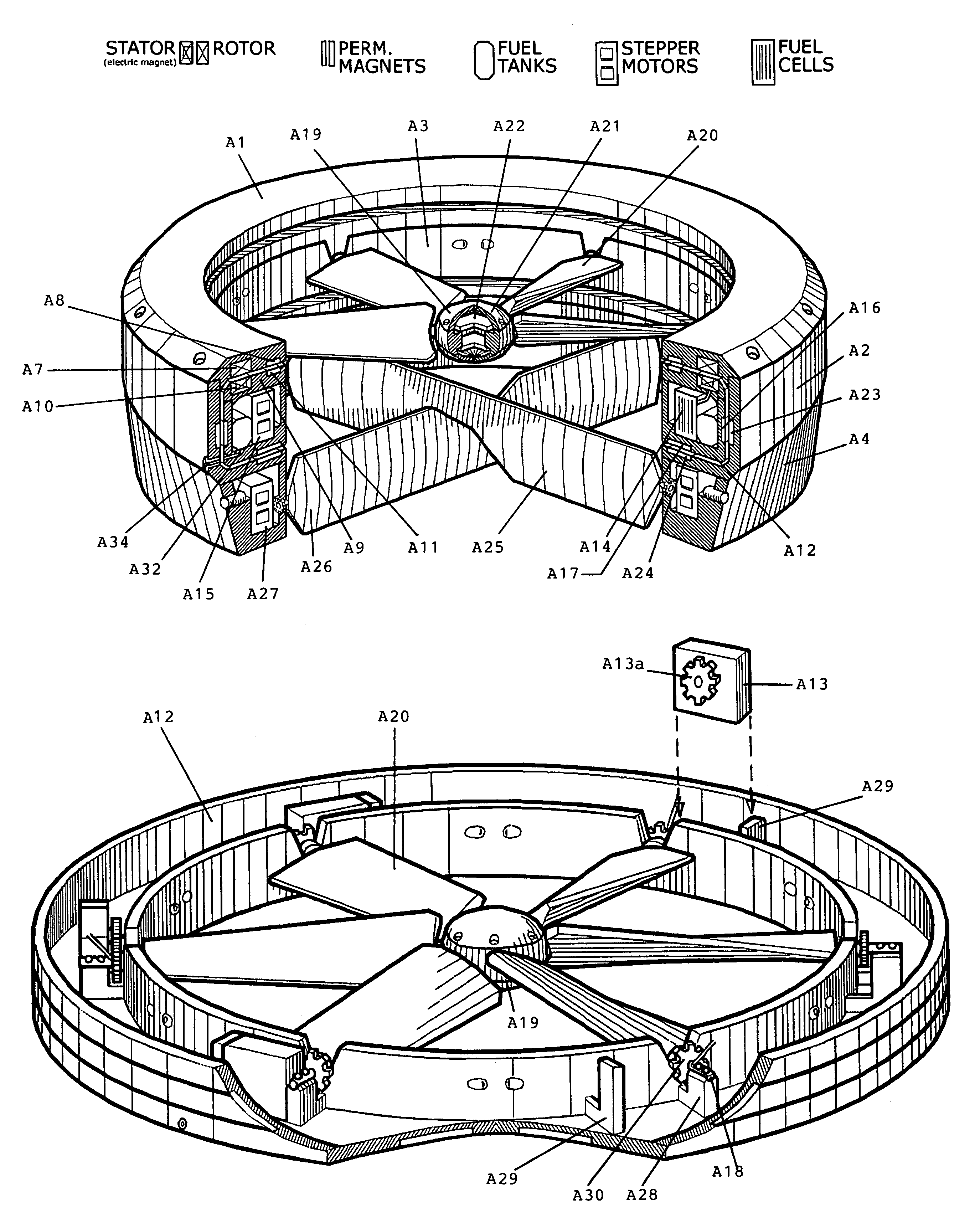

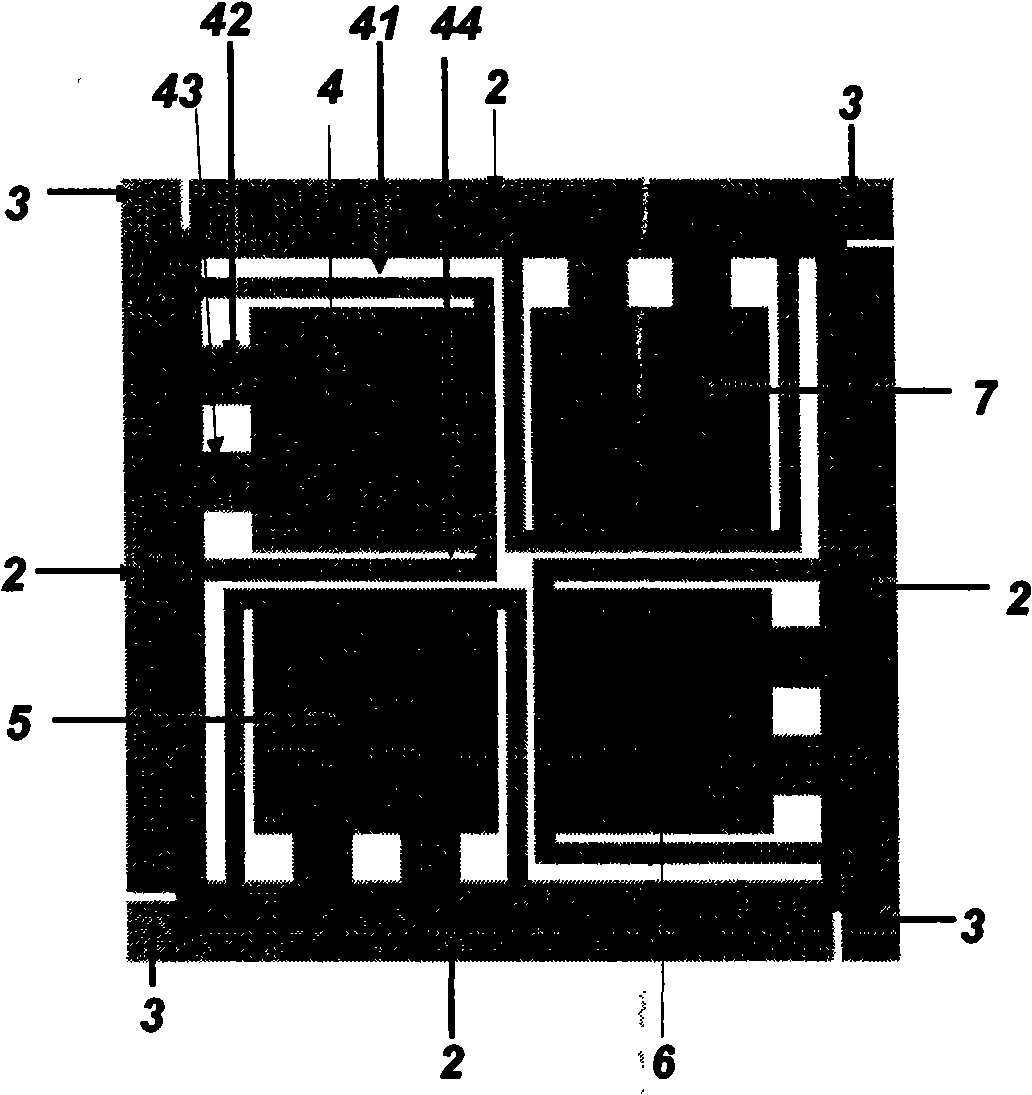

Quiet vertical takeoff and landing aircraft using ducted, magnetic induction air-impeller rotors

InactiveUS7032861B2Improve performanceImprove stabilityAircraft navigation controlUnmanned aerial vehiclesFlight control modesRudder

A hover aircraft employs an air impeller engine having an air channel duct and a rotor with outer ends of its blades fixed to an annular impeller disk that is driven by magnetic induction elements arrayed in the air channel duct. The air-impeller engine is arranged vertically in the aircraft frame to provide vertical thrust for vertical takeoff and landing. Preferably, the air-impeller engine employs dual, coaxial, contra-rotating rotors for increased thrust and gyroscopic stability. An air vane assembly directs a portion of the air thrust output at a desired angle to provide a horizontal thrust component for flight maneuvering or translation movement. The aircraft can employ a single engine in an annular fuselage, two engines on a longitudinal fuselage chassis, three engines in a triangular arrangement for forward flight stability, or other multiple engine arrangements in a symmetric, balanced configuration. Other flight control mechanisms may be employed, including side winglets, an overhead wing, and / or air rudders or flaps. An integrated flight control system can be used to operate the various flight control mechanisms. Electric power is supplied to the magnetic induction drives by high-capacity lightweight batteries or fuel cells. The hover aircraft is especially well suited for applications requiring VTOL deployment, hover operation for quiet surveillance, maneuvering in close air spaces, and long duration flights for continuous surveillance of ground targets and important facilities requiring constant monitoring.

Owner:SANDERS JR JOHN K +3

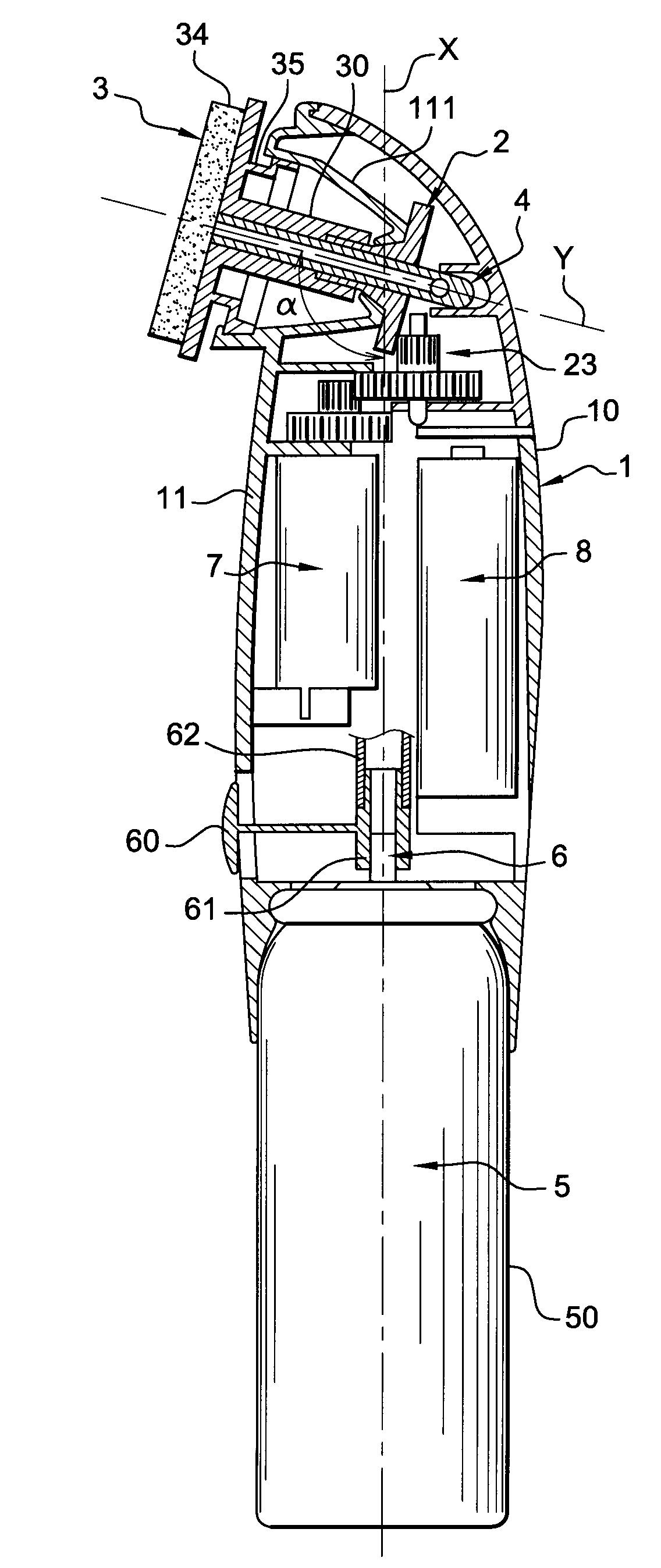

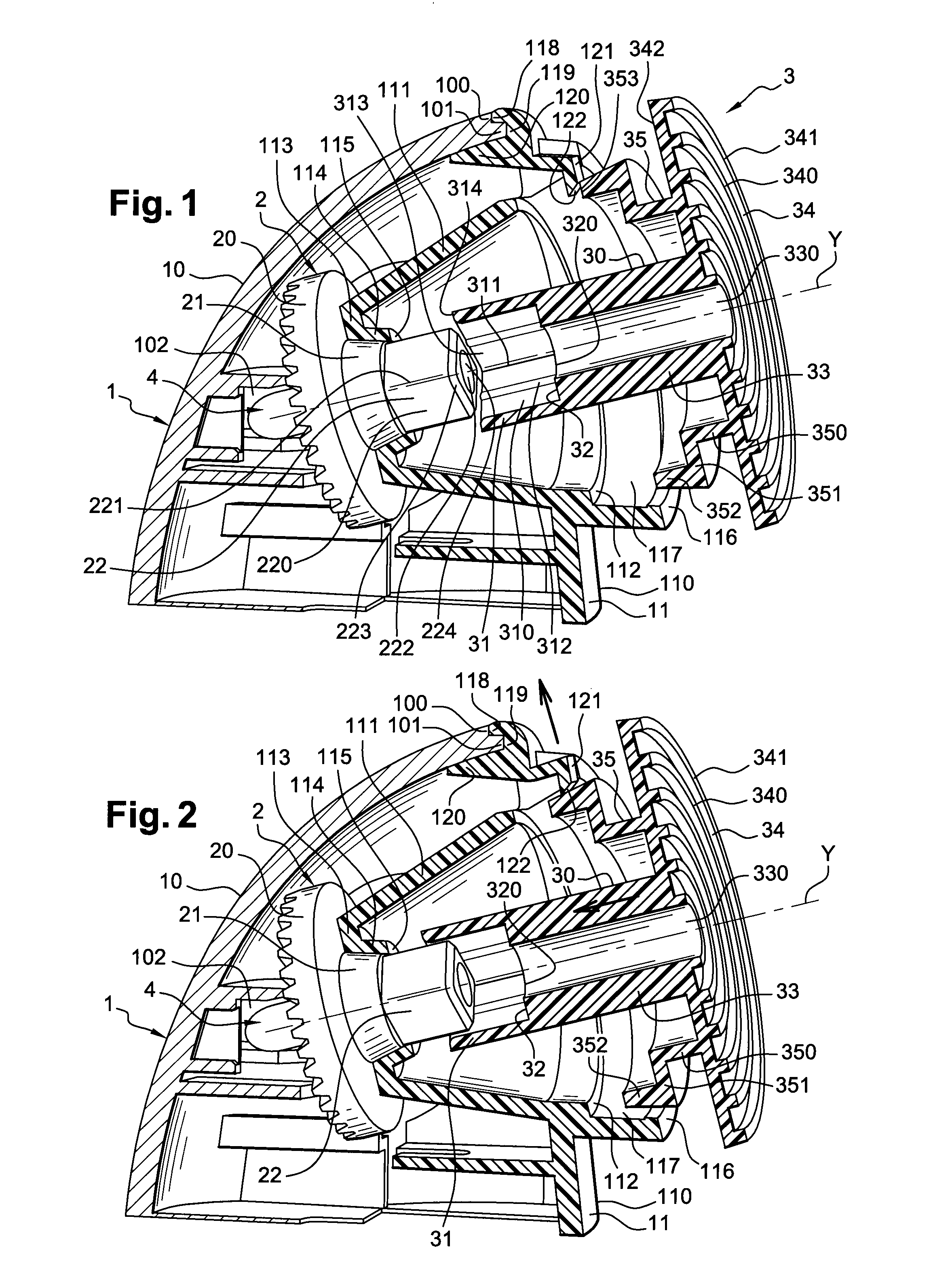

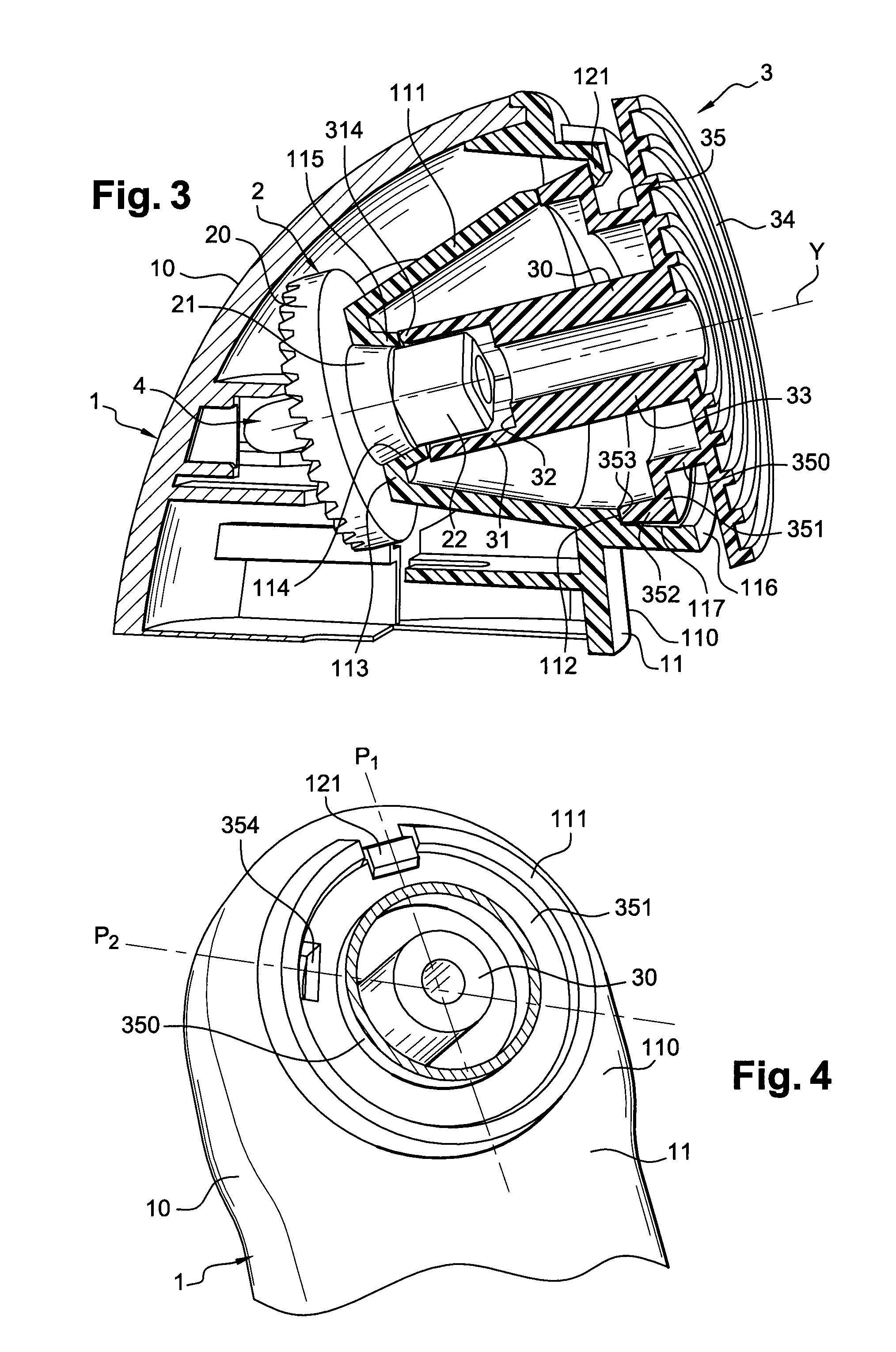

Head for massaging and/or dispensing a product and device provided with such a head

A head for applying a product includes a removable member. The member may be used to dispense a product or for massage. The head includes a body that rotates the removable member about an axis of rotation, the removable member being removably coupled to the body; and a part including a movement restriction tab that restricts movement of the removable member along the axis of rotation, the rotation of the removable member being relative to this part. The removable member is configured to be secured to the part independently of its orientation relative to the restriction tab and to be detached from the part by being moved through two movements including a rotational movement and a translational movement. Additionally, the head can be connected to a container and drive mechanism to dispense and massage a product, such as a cosmetic product, into the user's skin.

Owner:LOREAL SA

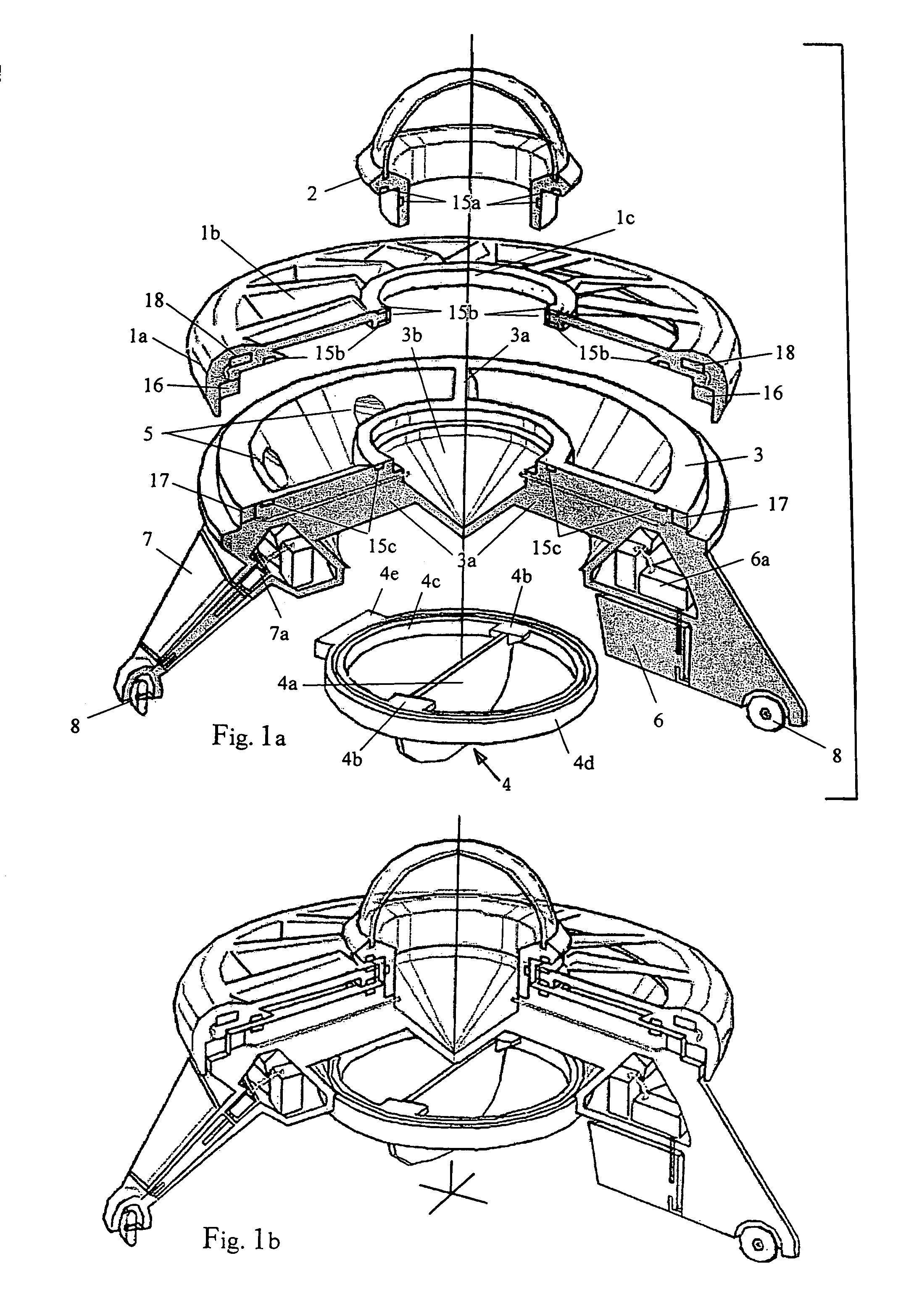

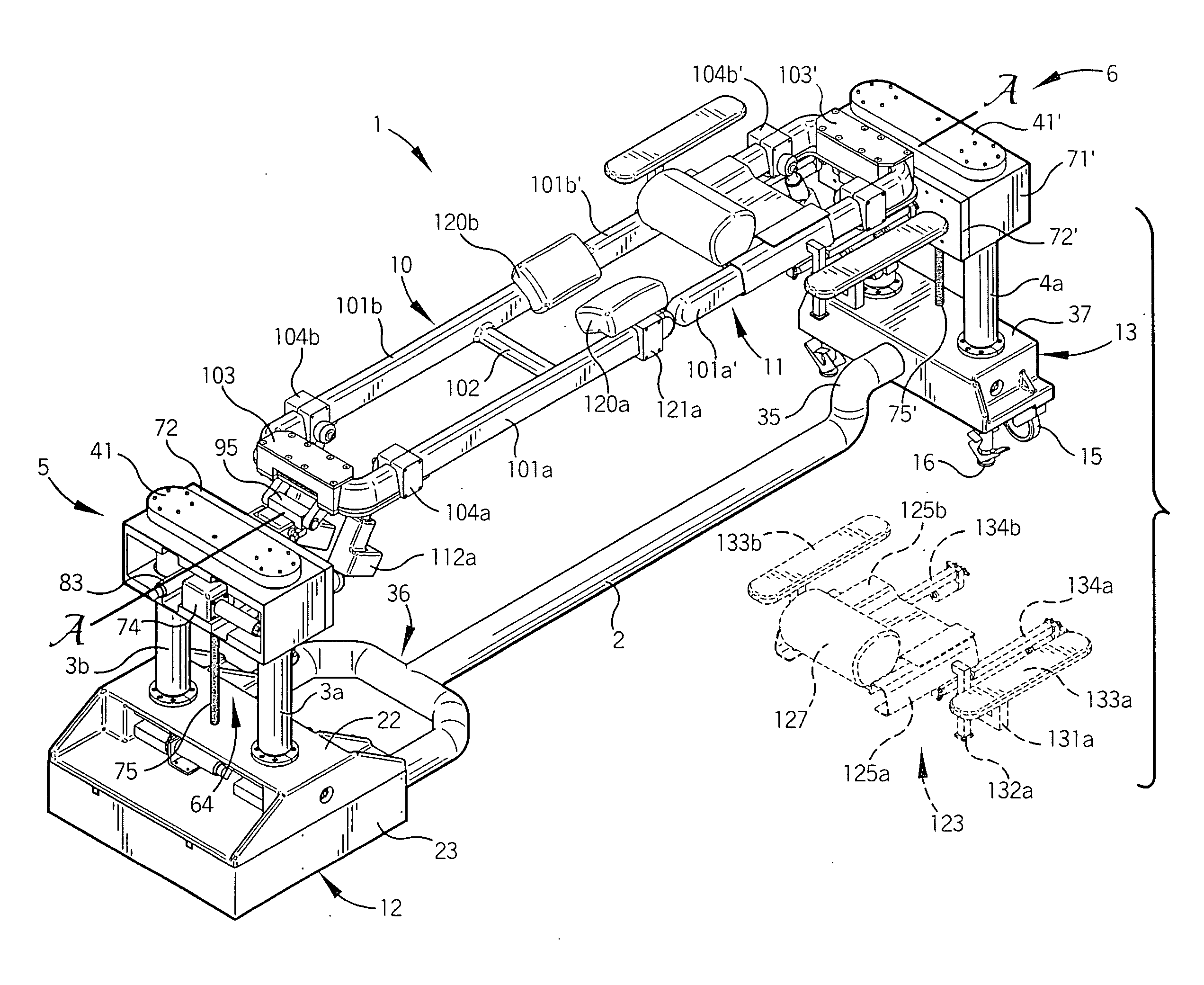

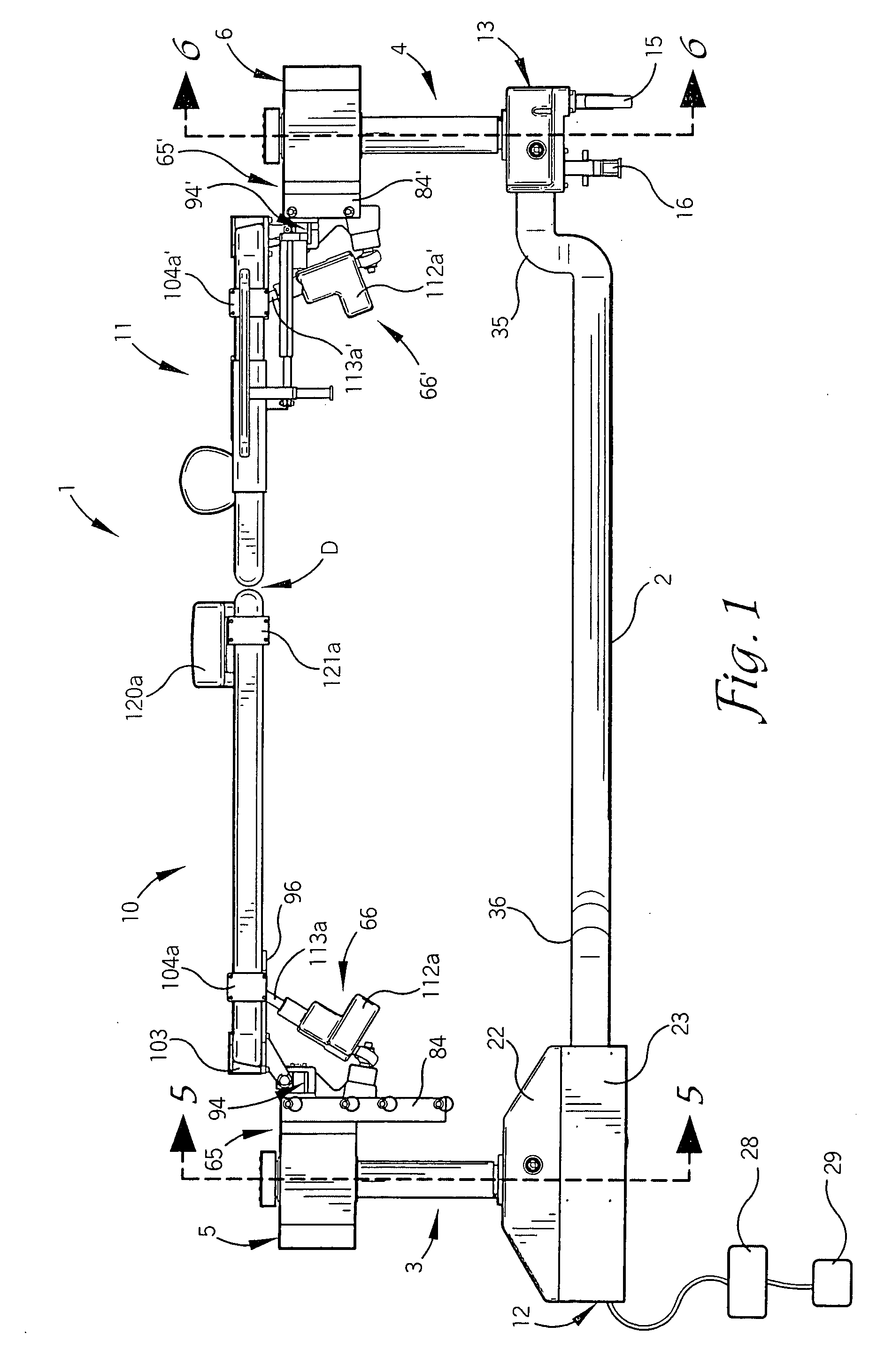

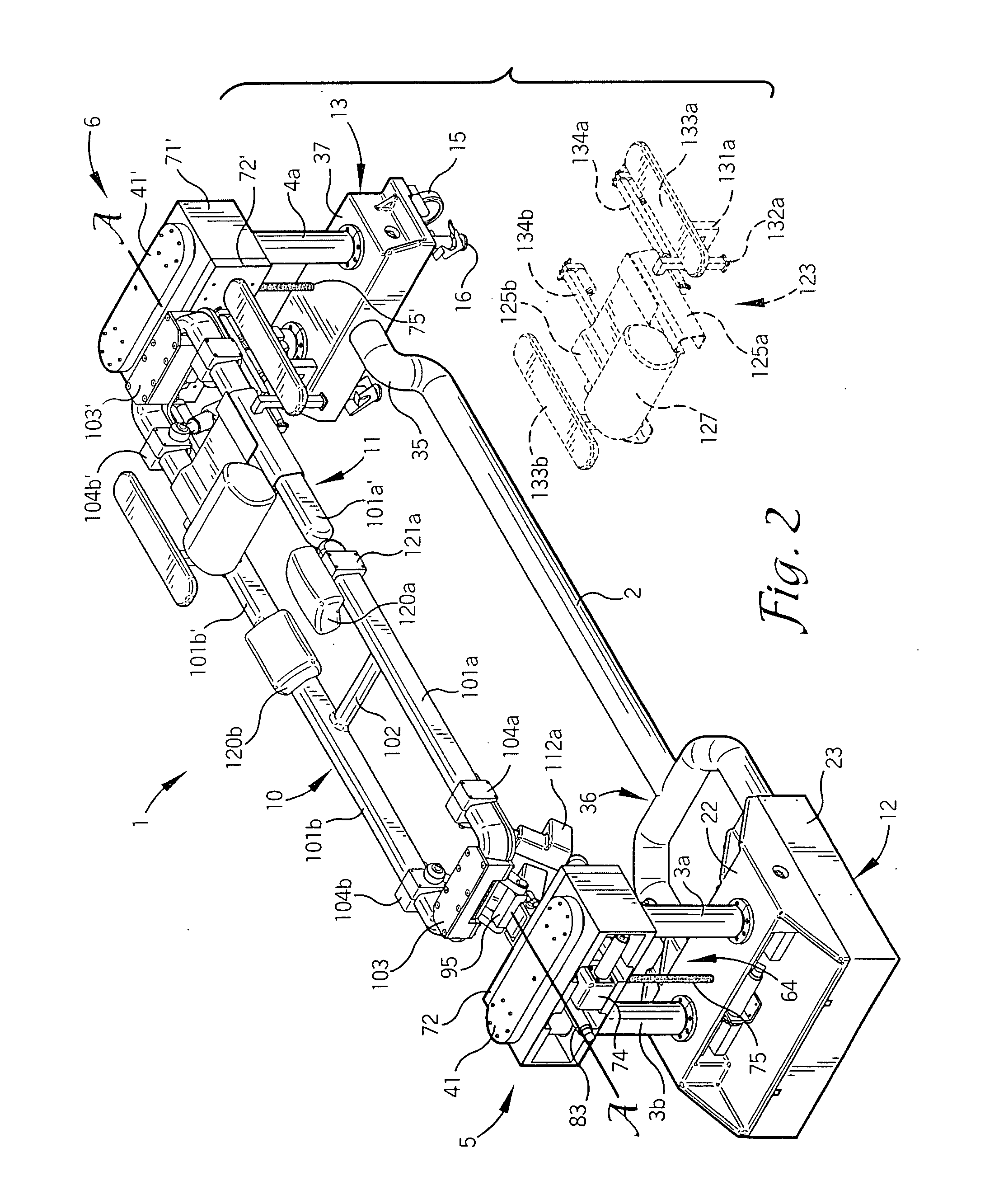

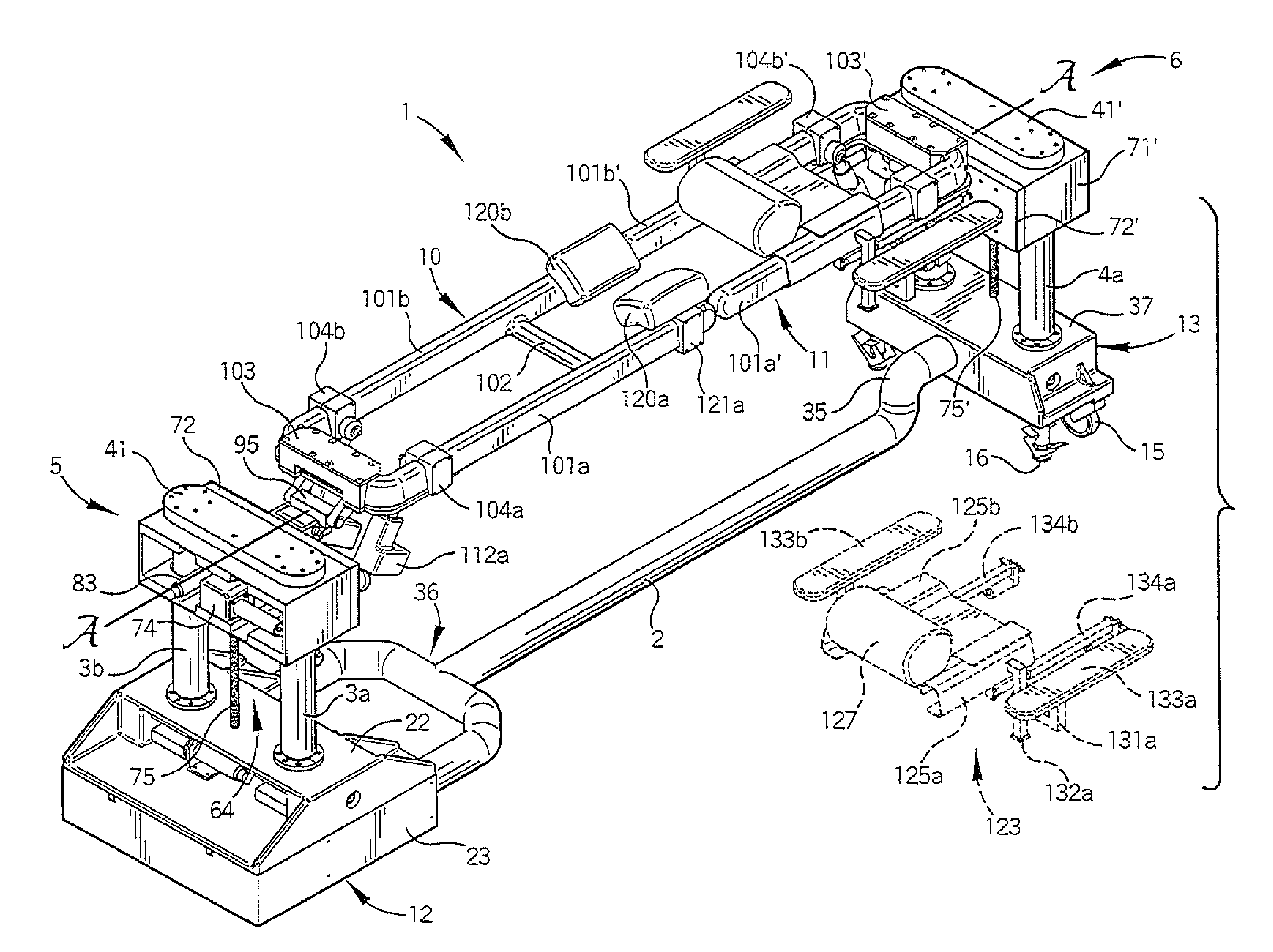

Patient positioning support structure

InactiveUS20130219623A1Keep distanceAvoiding undueOperating tablesRigid tablesEngineeringPosition sensor

A patient support structure includes a pair of independently height-adjustable supports, each connected to a patient support. The supports may be independently raised, lowered, rolled or tilted about a longitudinal axis, laterally shifted and angled upwardly or downwardly. Position sensors are provided to sense all of the foregoing movements. The sensors communicate data to a computer for coordinated adjustment and maintenance of the inboard ends of the patient supports in an approximated position during such movements. A longitudinal translator provides for compensation in the length of the structure when the supports are angled upwardly or downwardly. A patient trunk translator provides coordinated translational movement of the patient's upper body along the respective patient support in a caudad or cephalad direction as the patient supports are angled upwardly or downwardly for maintaining proper spinal biomechanics and avoiding undue spinal traction or compression.

Owner:WARSAW ORTHOPEDIC INC

Patient positioning support structure with trunk translator

A patient support structure includes a pair of independently height-adjustable supports, each connected to a patient support. The supports may be independently raised, lowered, rolled or tilted about a longitudinal axis, laterally shifted and angled upwardly or downwardly. Position sensors are provided to sense all of the foregoing movements. The sensors communicate data to a computer for coordinated adjustment and maintenance of the inboard ends of the patient supports in an approximated position during such movements. A longitudinal translator provides for compensation in the length of the structure when the supports are angled upwardly or downwardly. A patient trunk translator provides coordinated translational movement of the patient's upper body along the respective patient support in a caudad or cephalad direction as the patient supports are angled upwardly or downwardly for maintaining proper spinal biomechanics and avoiding undue spinal traction or compression.

Owner:WARSAW ORTHOPEDIC INC

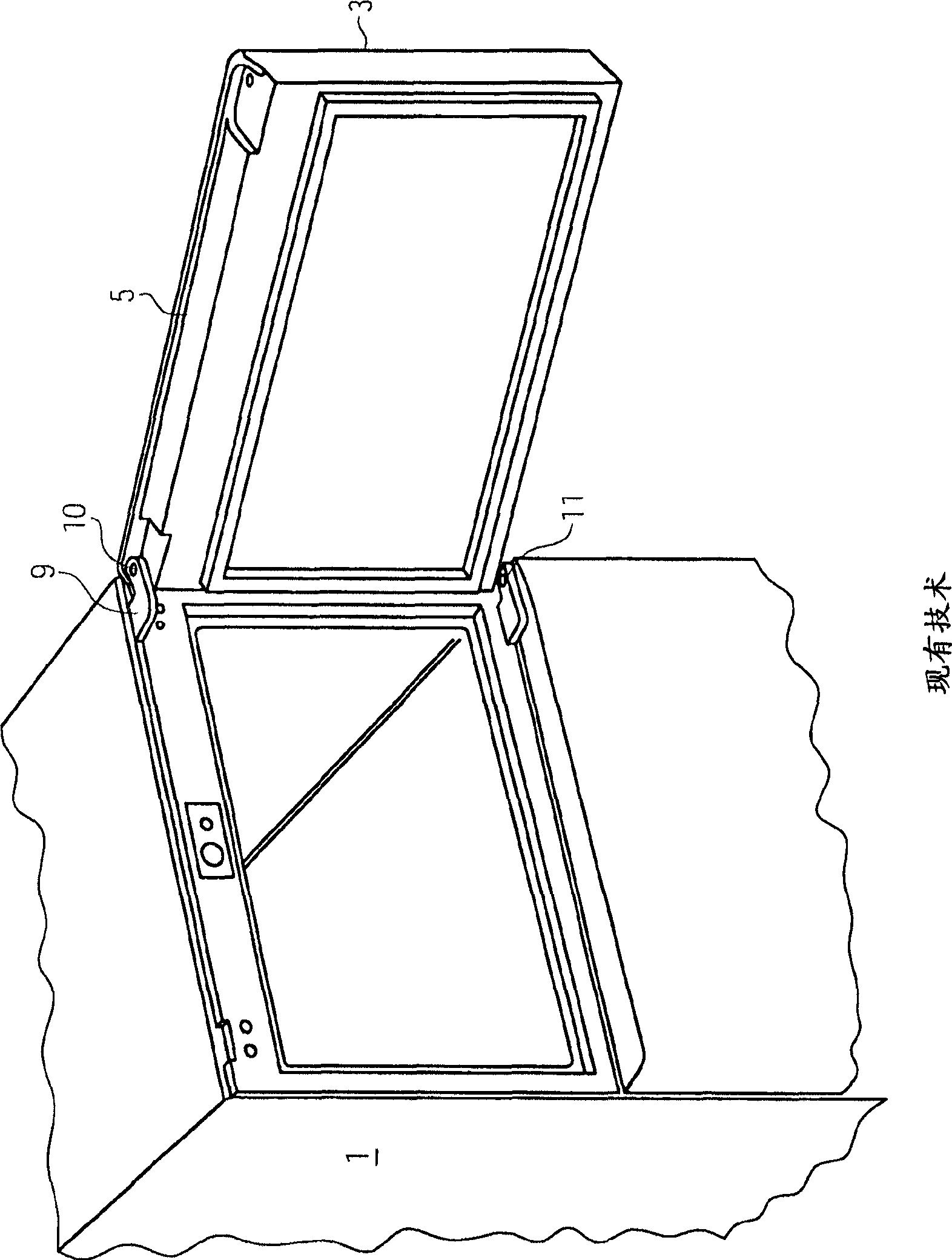

Domestic appliance with concealed hinge

A domestic appliance for built-in installation, comprising: a housing having at least two sides; a front door; a hinge mechanism, provided at or adjacent one of the sides, coupling the door to the housing and permitting relative movement thereof, wherein the door is movable between a first position, in which the door is closed, and a second position, in which the door is fully open; wherein the hinge mechanism is attached to the door and to the housing at points spaced apart from the vertical extremities thereof, whereby, when the door is in said first position, the hinge mechanism is not visible from a position in front of the appliance, and / or wherein the hinge is so shaped and dimensioned whereby, in use, the extent of protrusion of the door laterally beyond said one side when the door is in said second position is less than or equal to that when the door is in said first position. Preferably, the hinge mechanism is shaped and arranged whereby double movement, for example both rotational and translational movement, of the door relative to the housing is facilitated during movement between said first position and said second position. At the top and bottom of the device, a pair of hinge members (brackets) are used, with connecting pins, and different shaped slots in each of the hinge members permits two different motions of the hinge members relative to each other during door opening.

Owner:PANASONIC MFG UK

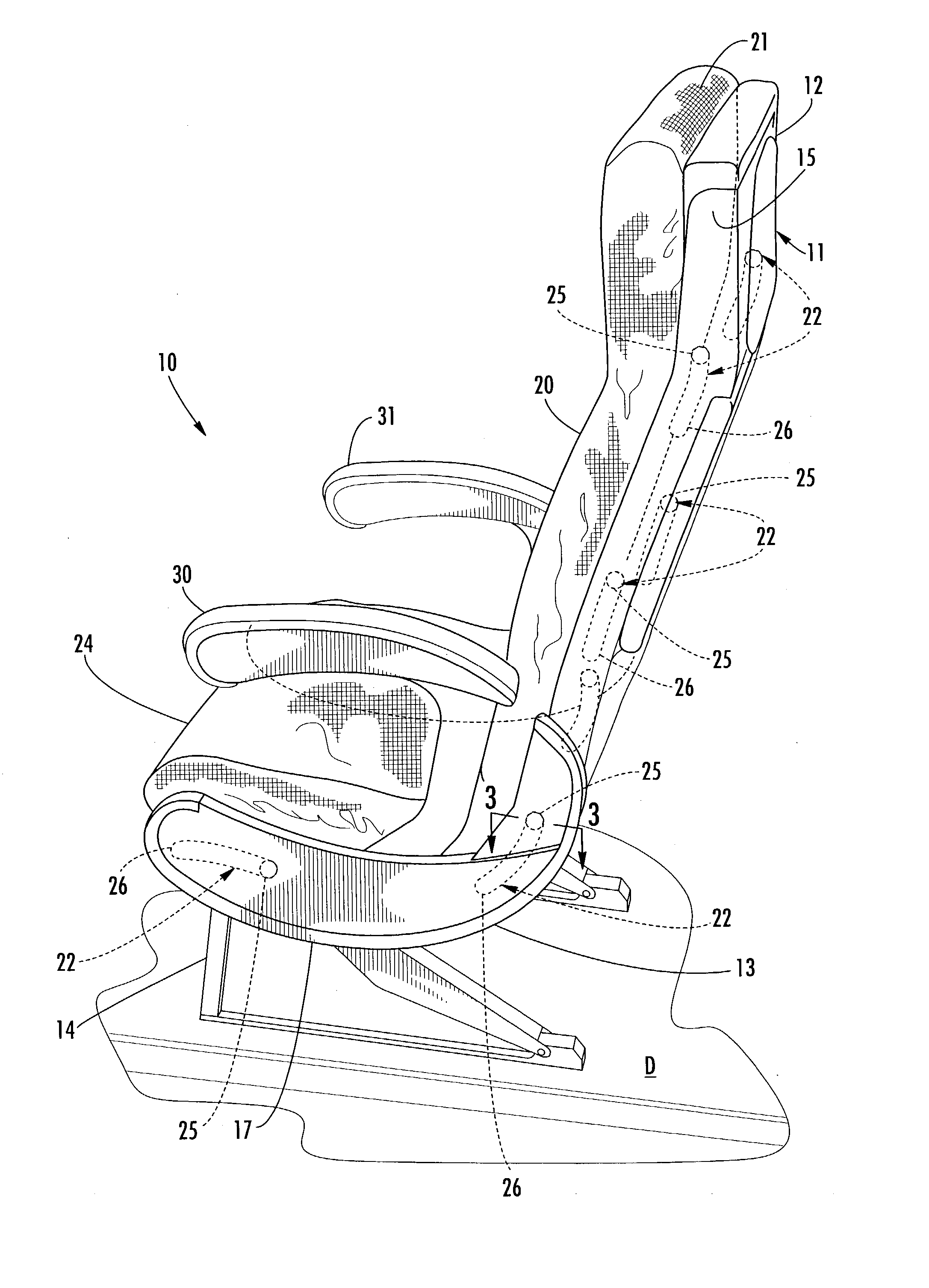

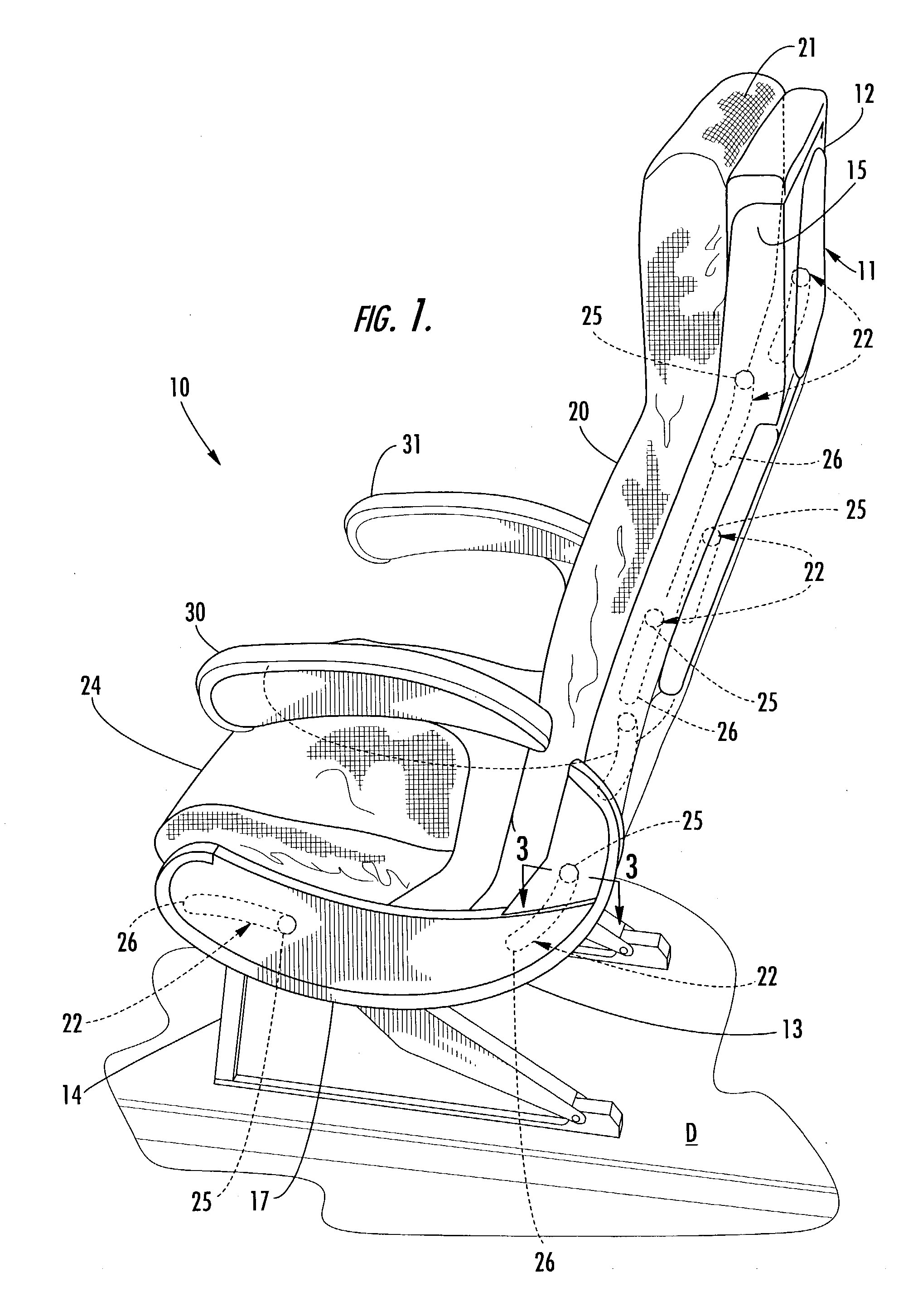

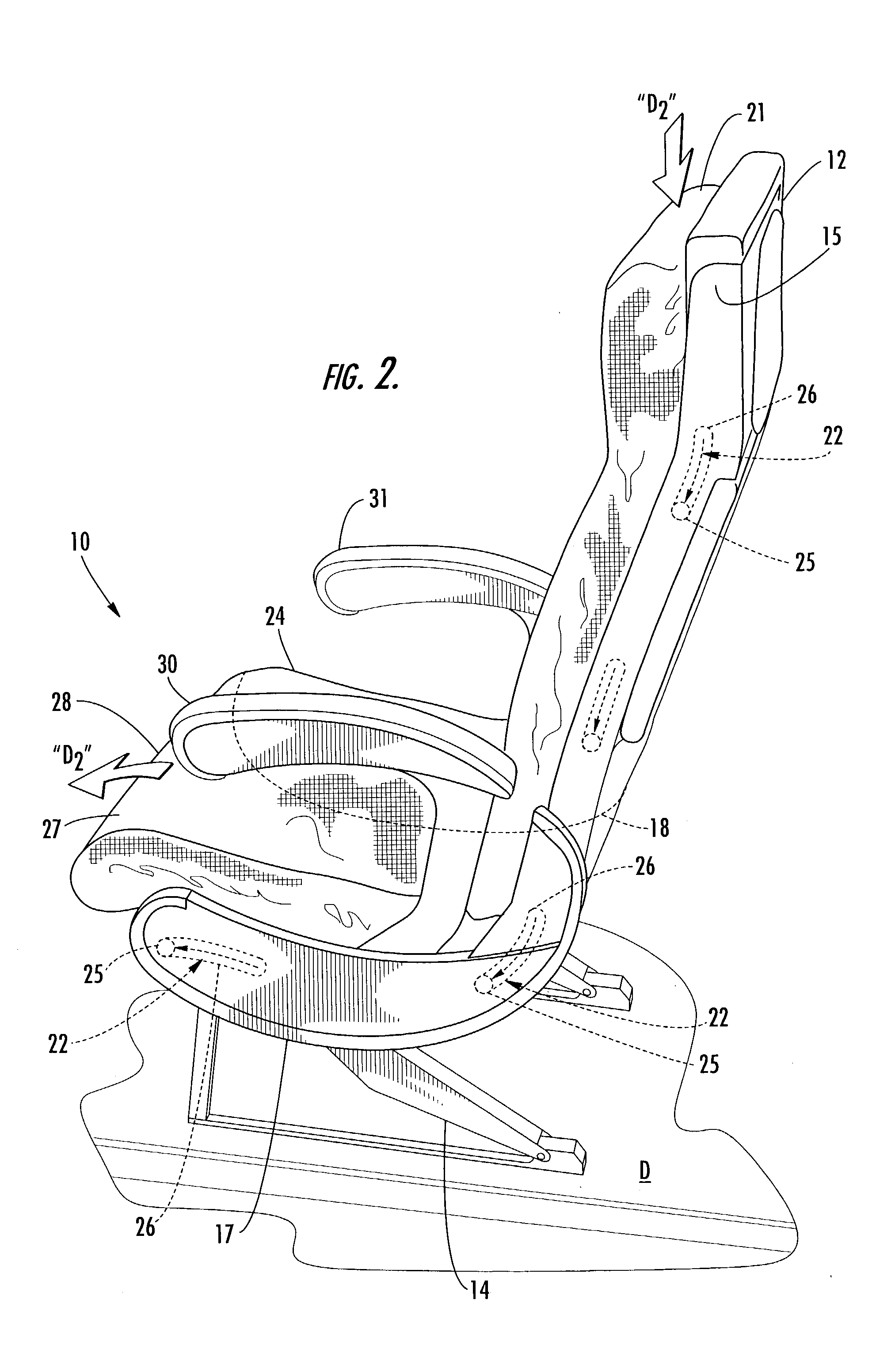

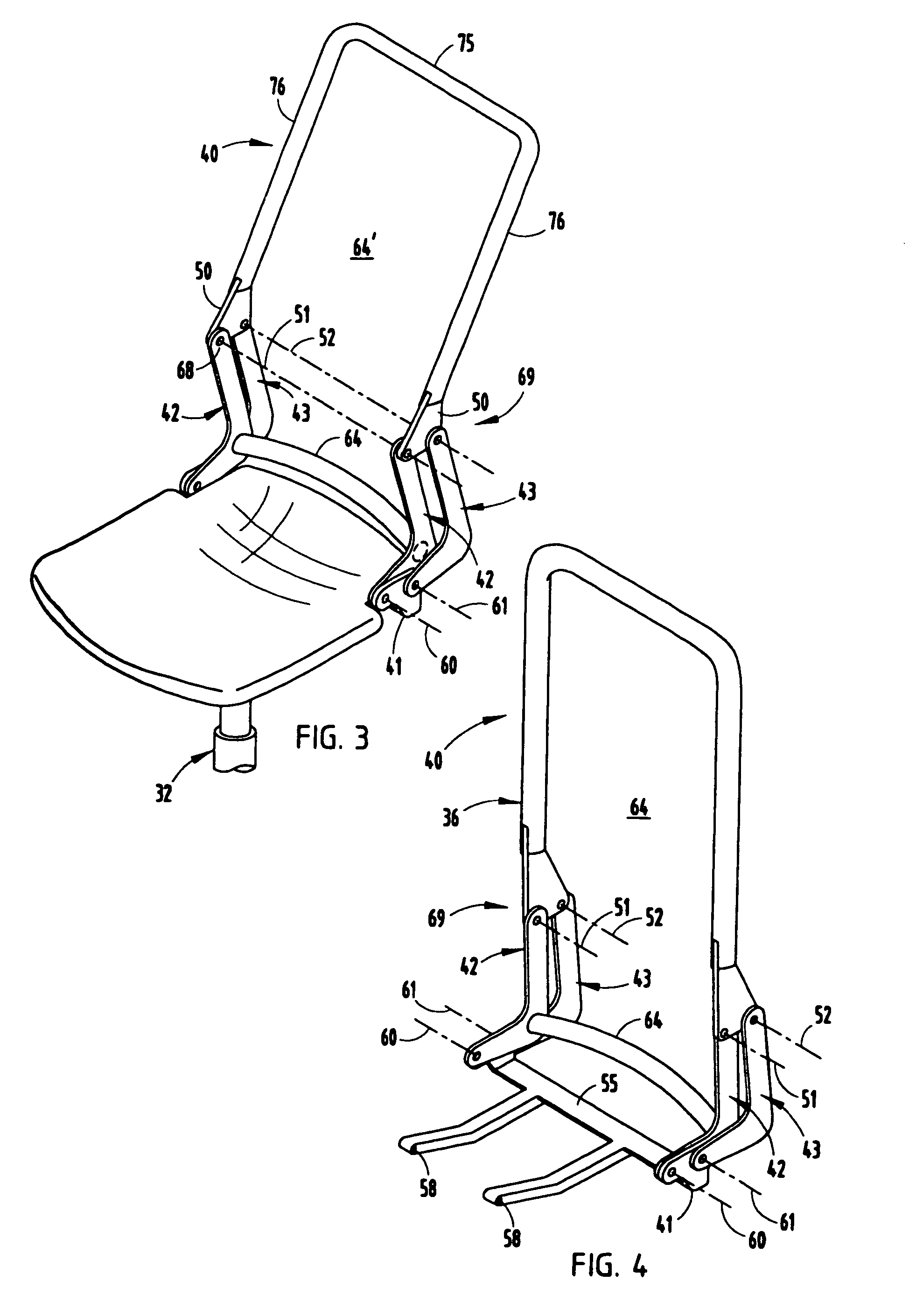

Vehicle passenger seat

A passenger seat including a seat base for being mounted on a support surface. A seat frame is carried by the seat base, and includes a seat bottom frame member and a seat back frame member is positioned in a fixed angular relation to each other and the seat base. A seat bottom pan is positioned on the seat bottom frame member. A seat back pan is positioned on the seat back frame member. Guide means cooperate with the bottom pan and bottom frame members and the back pan and back frame members, respectively, for unison translational movement of the back pan and the bottom pan between an upright position when the bottom pan is in the aft position and a recline position when the bottom pan is in the forward position.

Owner:BE AEROSPACE INCORPORATED

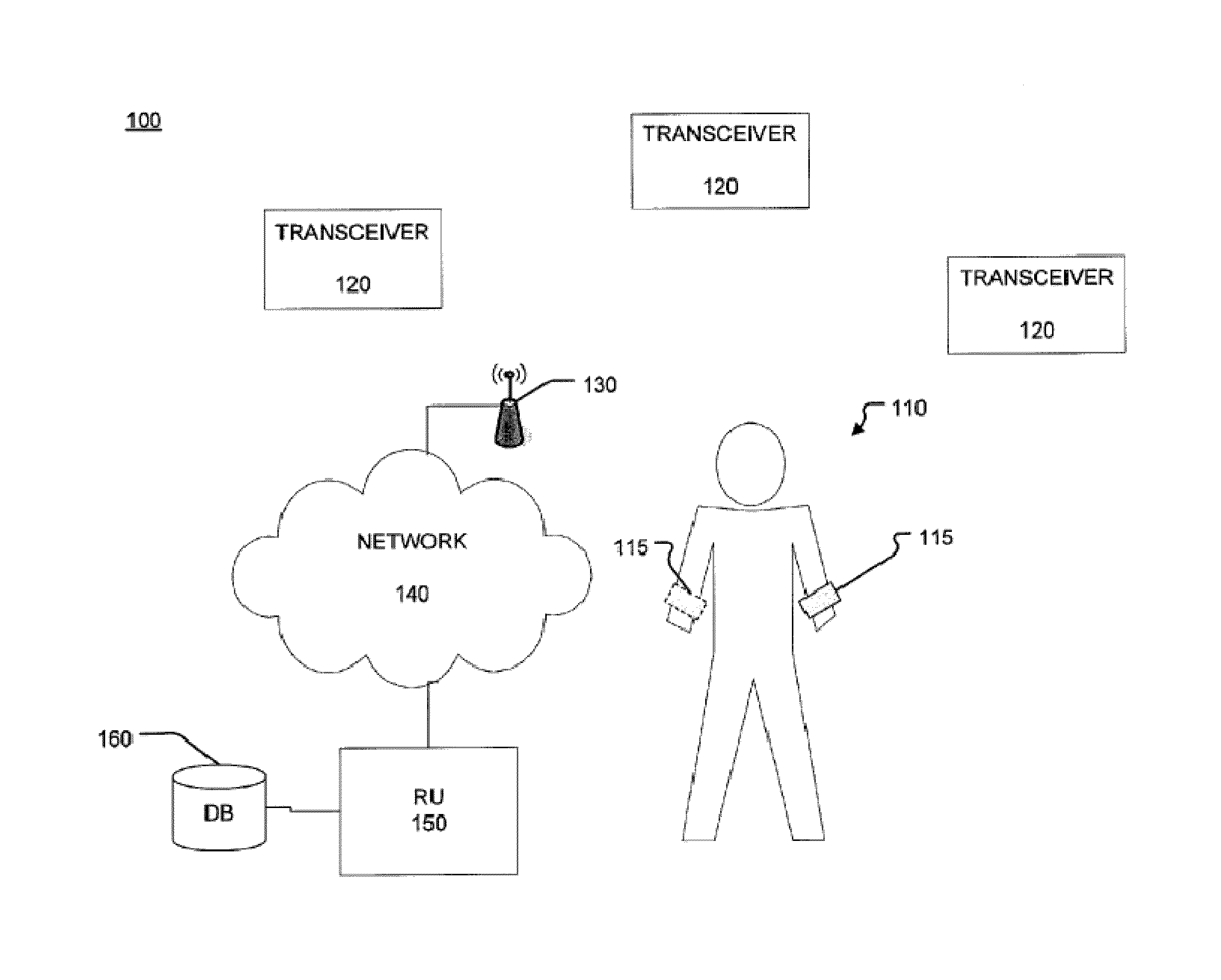

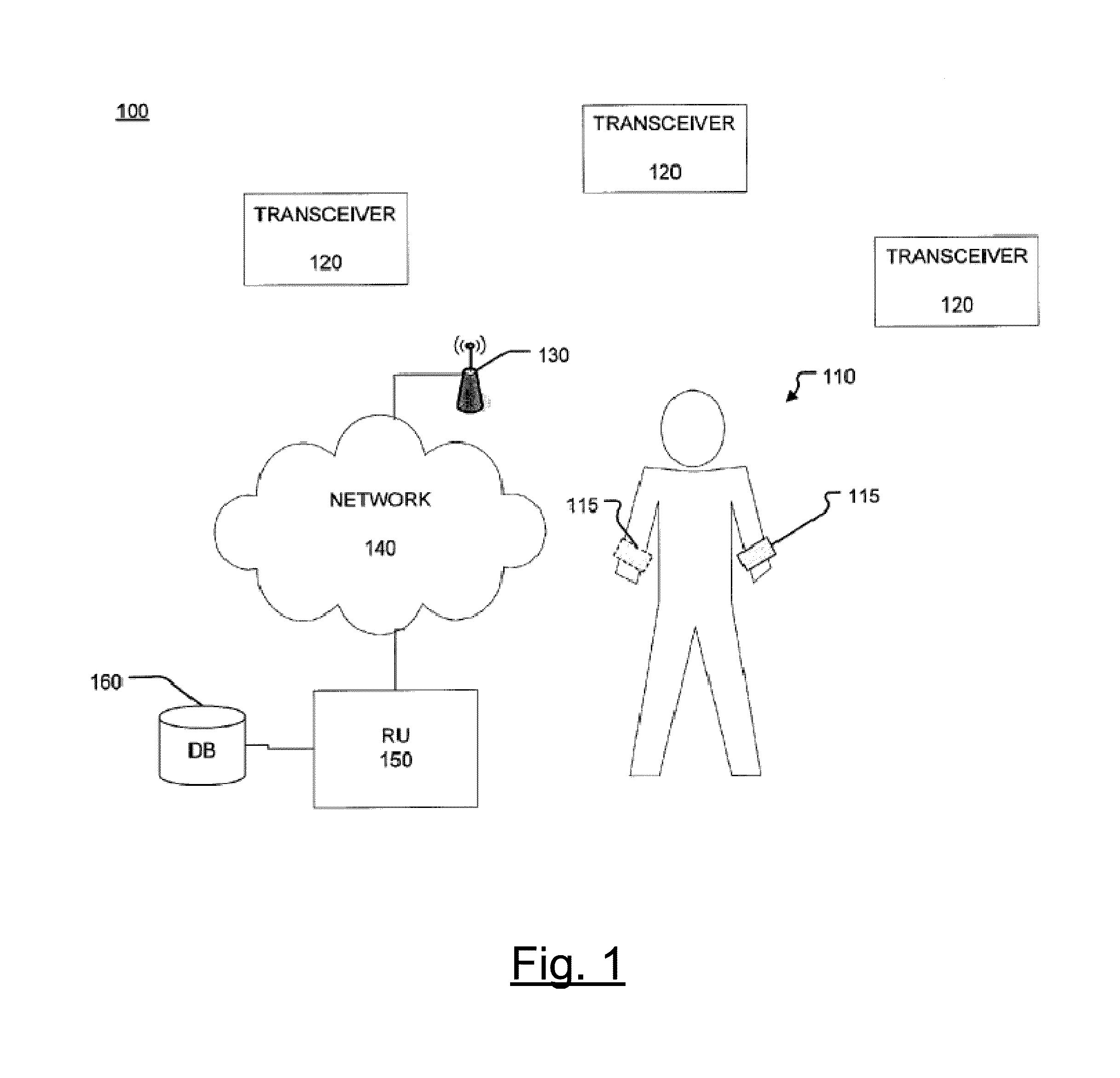

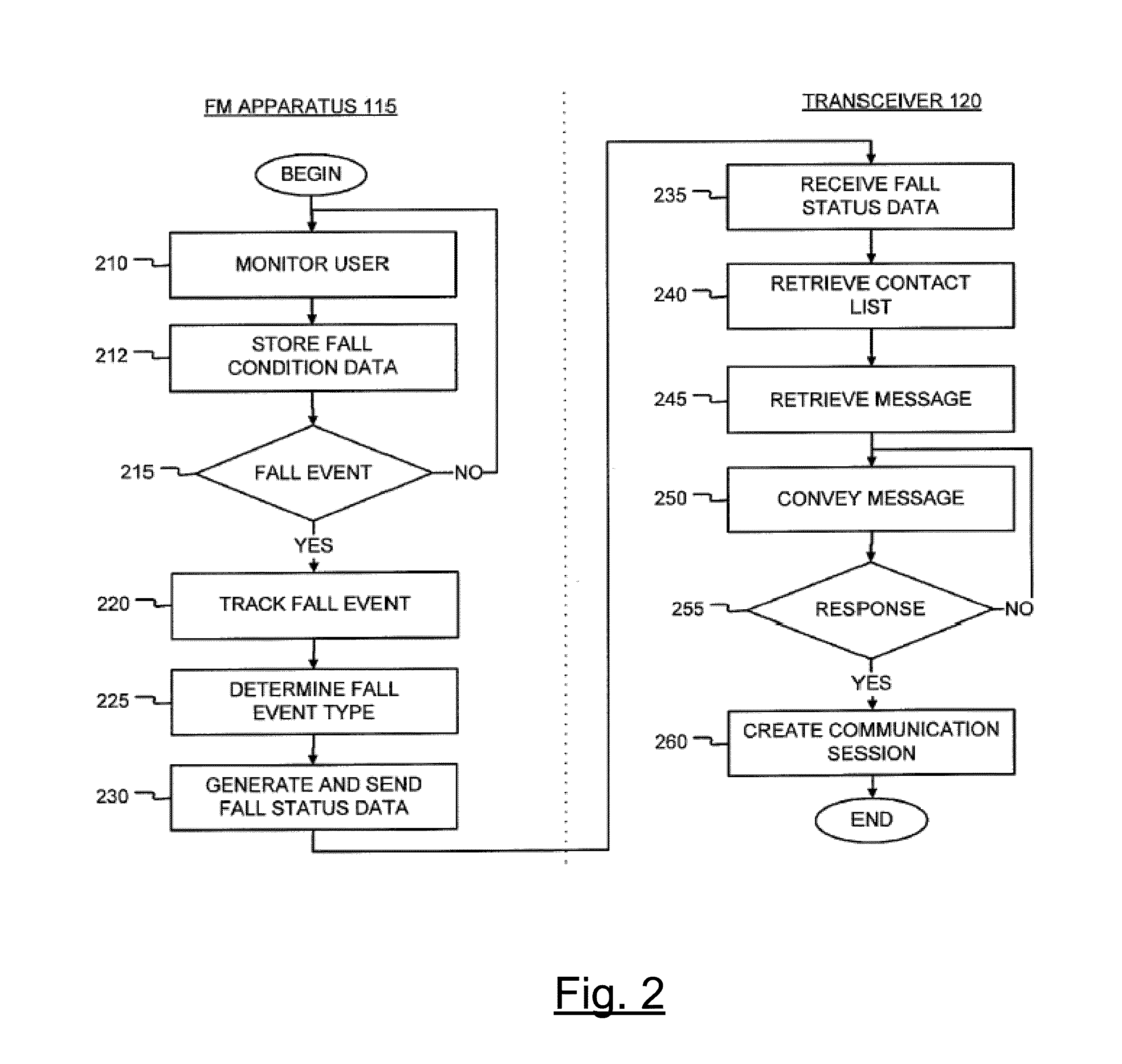

Autonomous Fall Monitor

ActiveUS20140375461A1Susceptibility to fallIncrease pressureTransmission systemsInertial sensorsEngineeringAltimeter

A system, a method and an apparatus for autonomous monitoring, detecting and tracking of at least one of movement and orientation of a body or portion of a body. The apparatus comprises a device configured to monitor the translational movement and / or rotational movement of the body; and an altimeter including at least one pair of opposed high sensitivity sensors configured to measure changes in height of the body. An alert condition is determined based on the translational and / or rotational movement of the body and changes in height of the body or portion of the body. The alert condition may comprise a hard fall event, a soft fall event, a susceptibility to a fall, or a near fall event.

Owner:BARRON ASSOCS

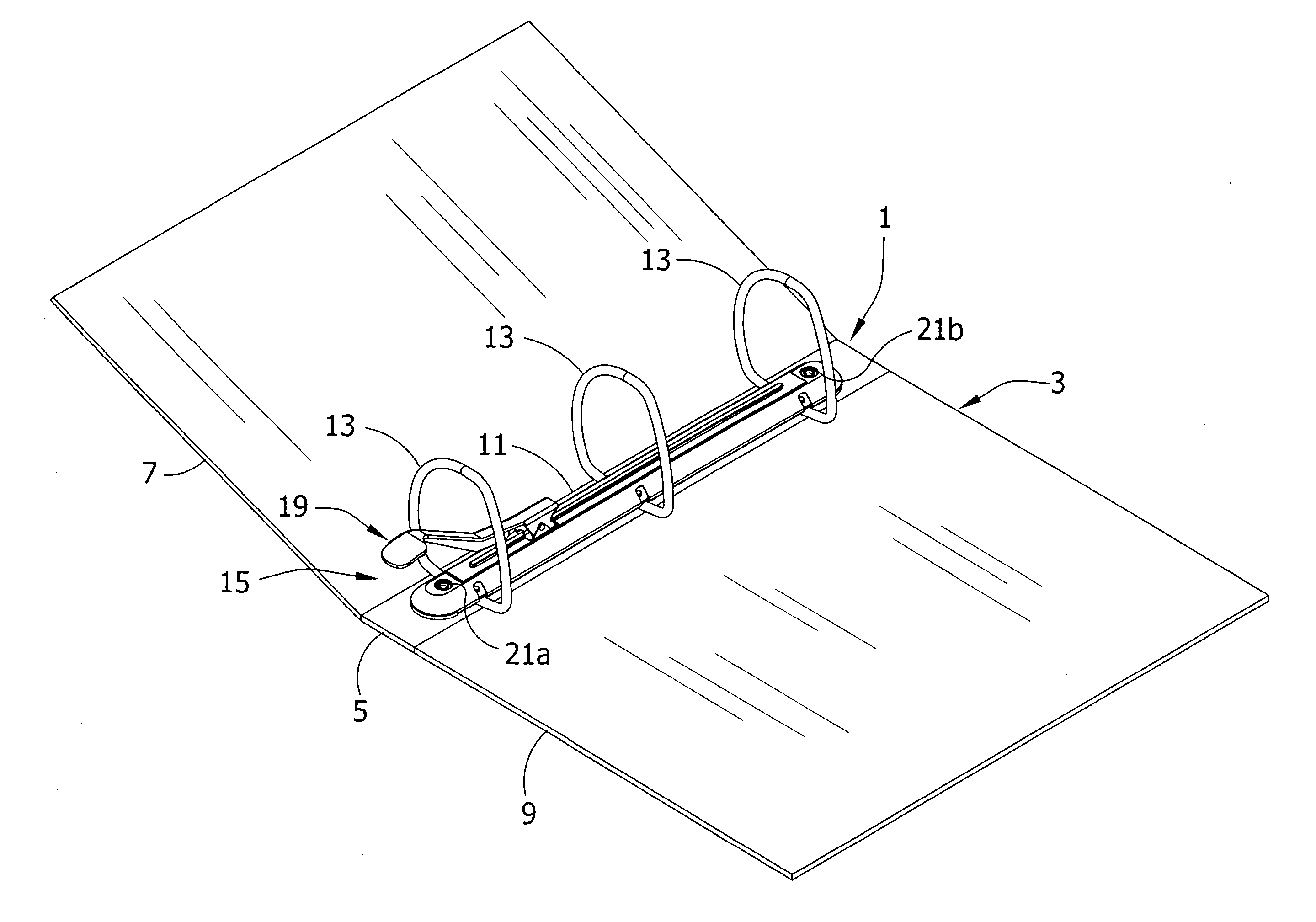

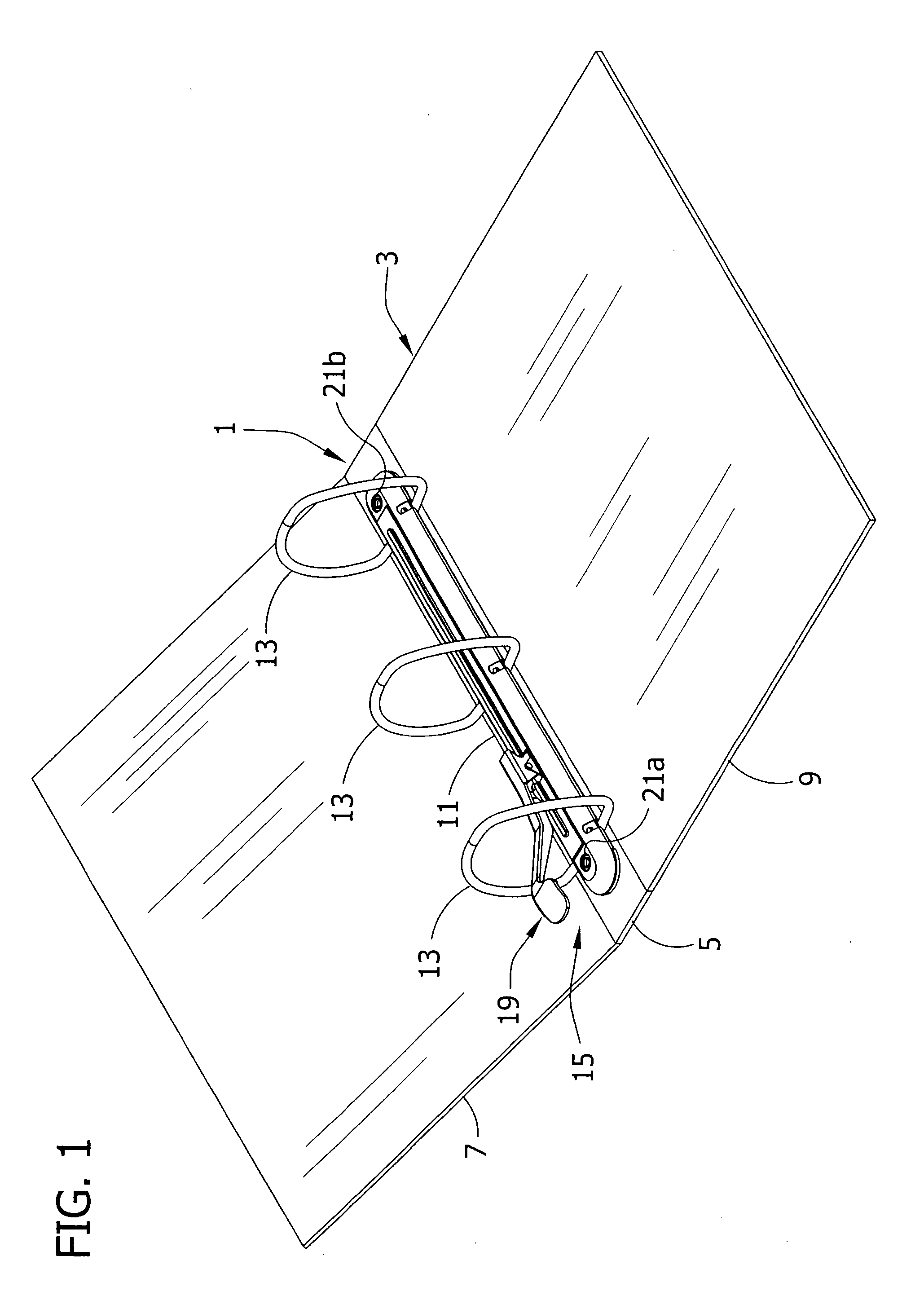

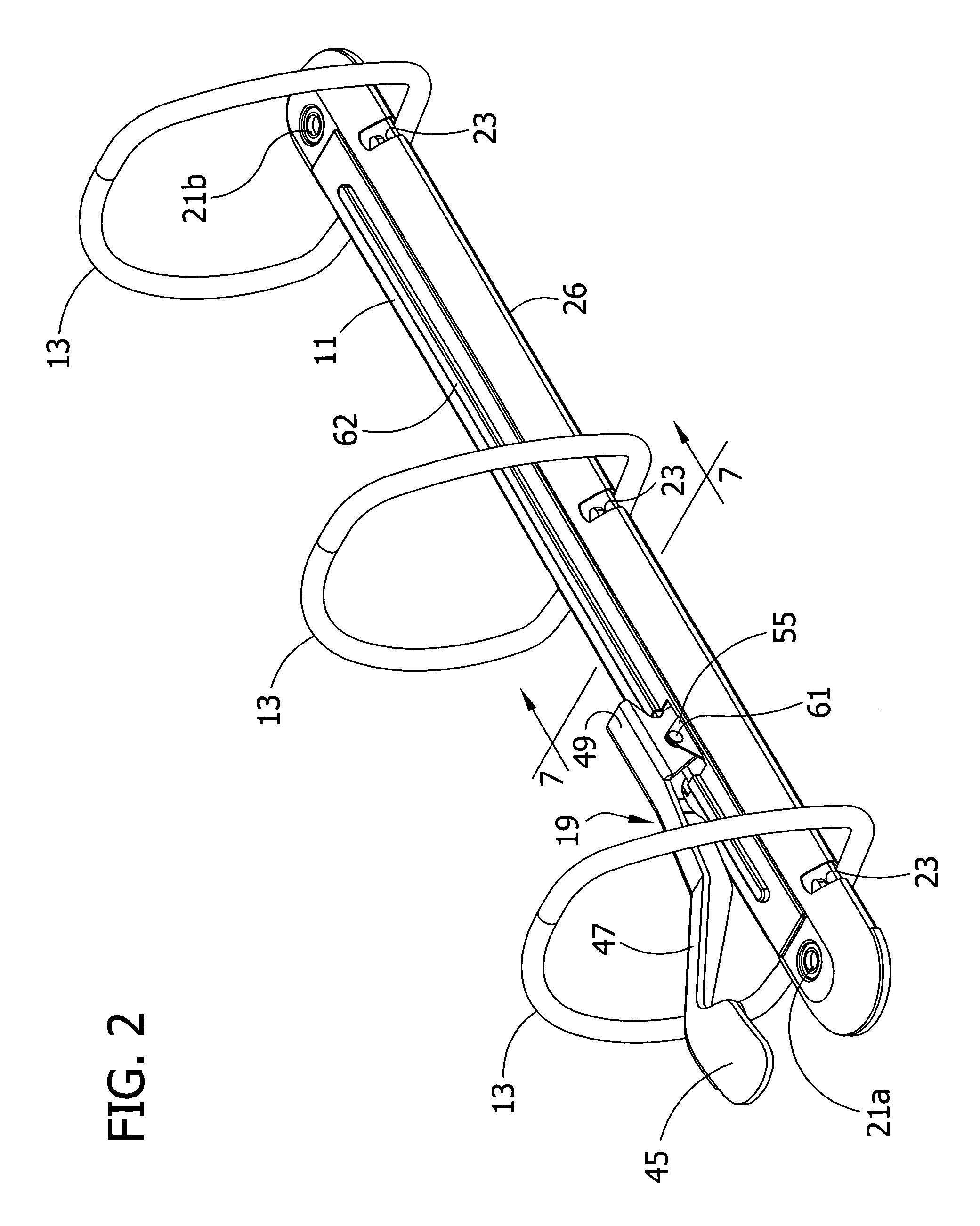

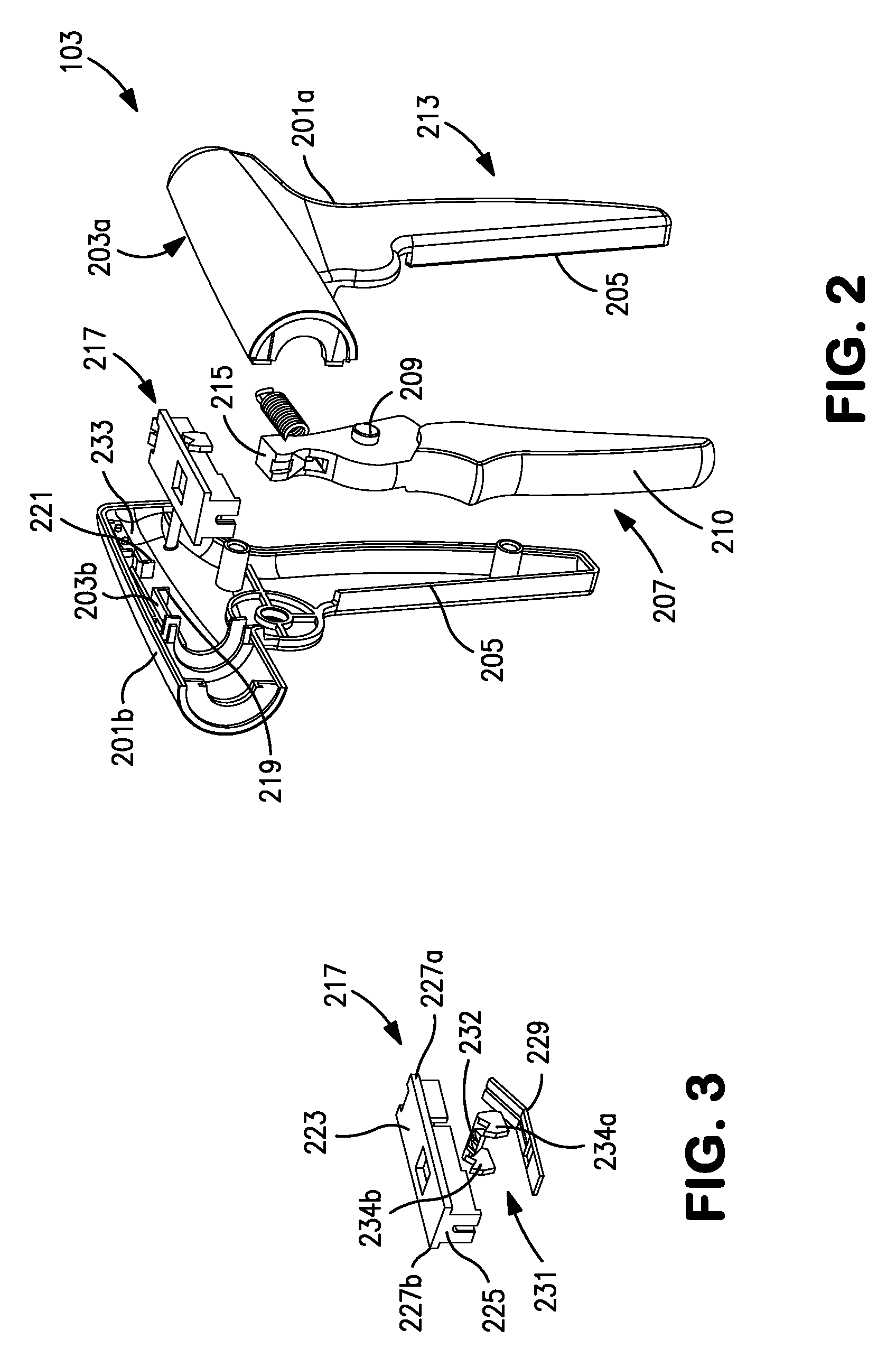

Ring binder mechanism with operating lever and travel bar

A ring mechanism for retaining loose-leaf pages having a housing, hinge plates, and ring members. The housing supports the hinge plates for pivoting motion relative to the housing to open and close ring members mounted thereon. The mechanism includes a travel bar mounted for translational movement along the longitudinal axis of the housing. An actuating lever is provided secured for pivotal movement to the housing. The actuating lever has a handle portion projecting above the housing for manually pivoting movement of the actuating lever. An actuator portion which extends through an opening in the central top portion of the housing is engageable with the hinge plates to pivot them between the open and closed positions and further is engageable with the travel bar to move it between locked and unlocked positions.

Owner:WORLD WIDE STATIONARY MFG CO LTD

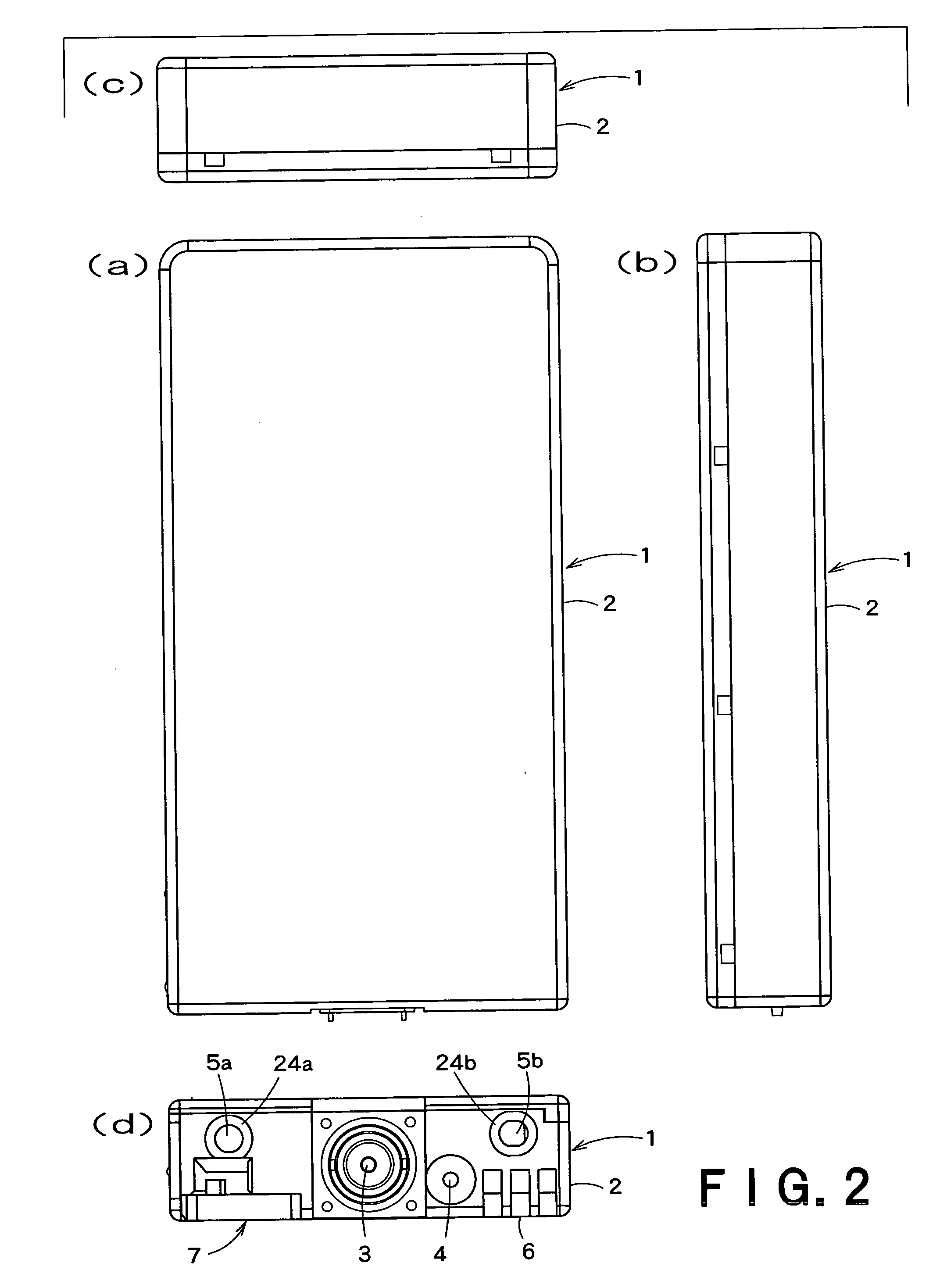

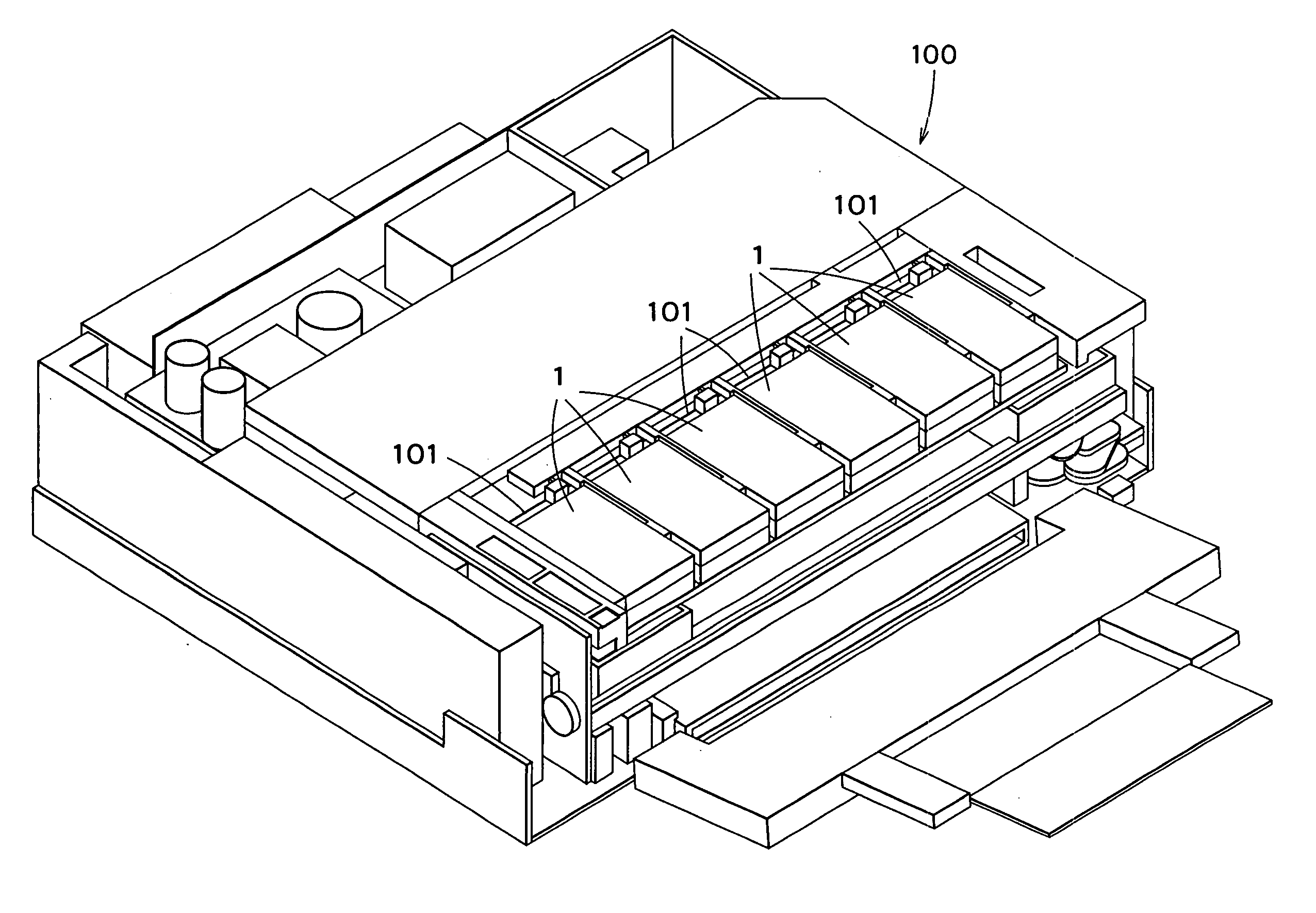

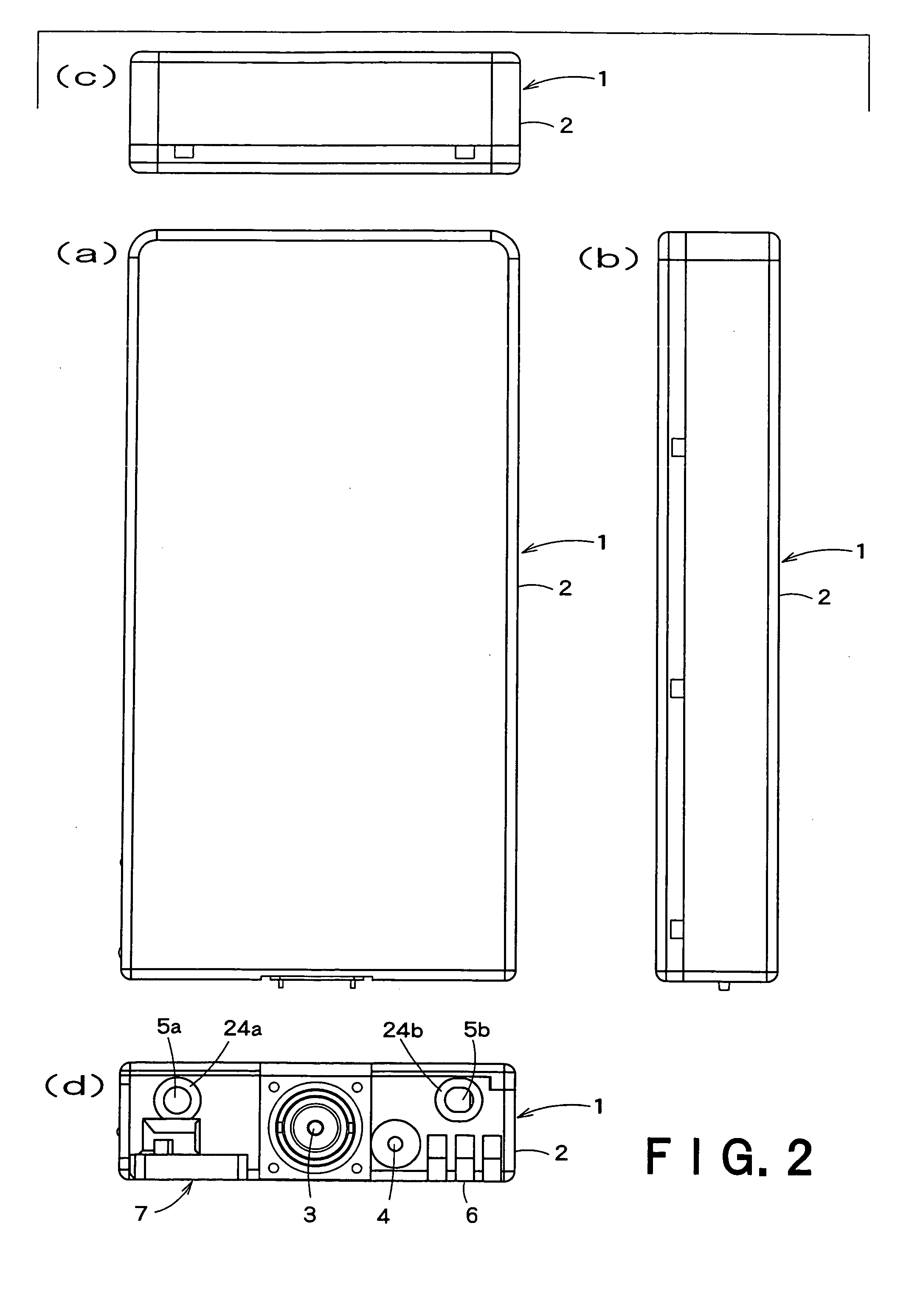

Liquid ejecting apparatus and liquid container holder thereof

Owner:SEIKO EPSON CORP

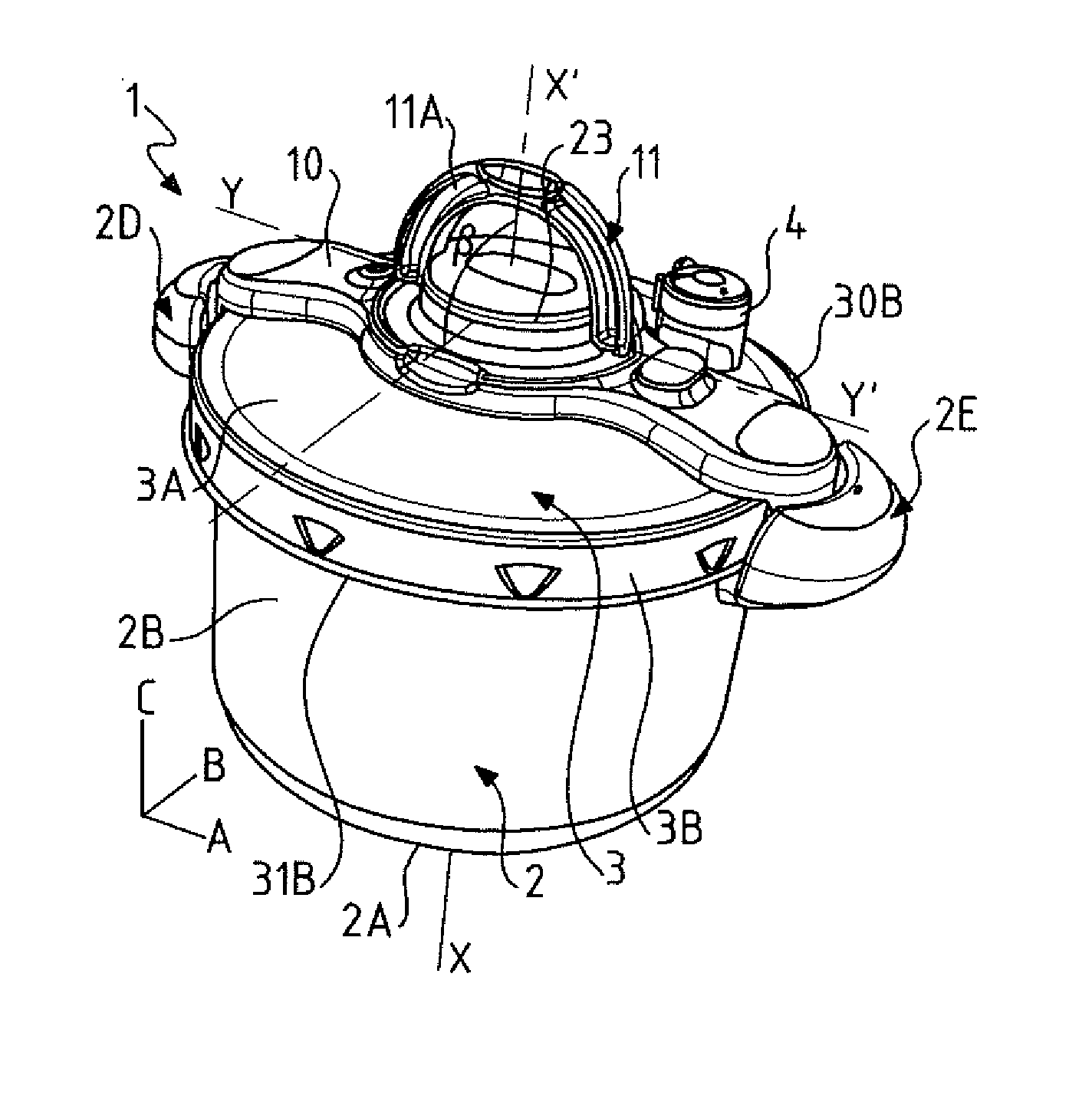

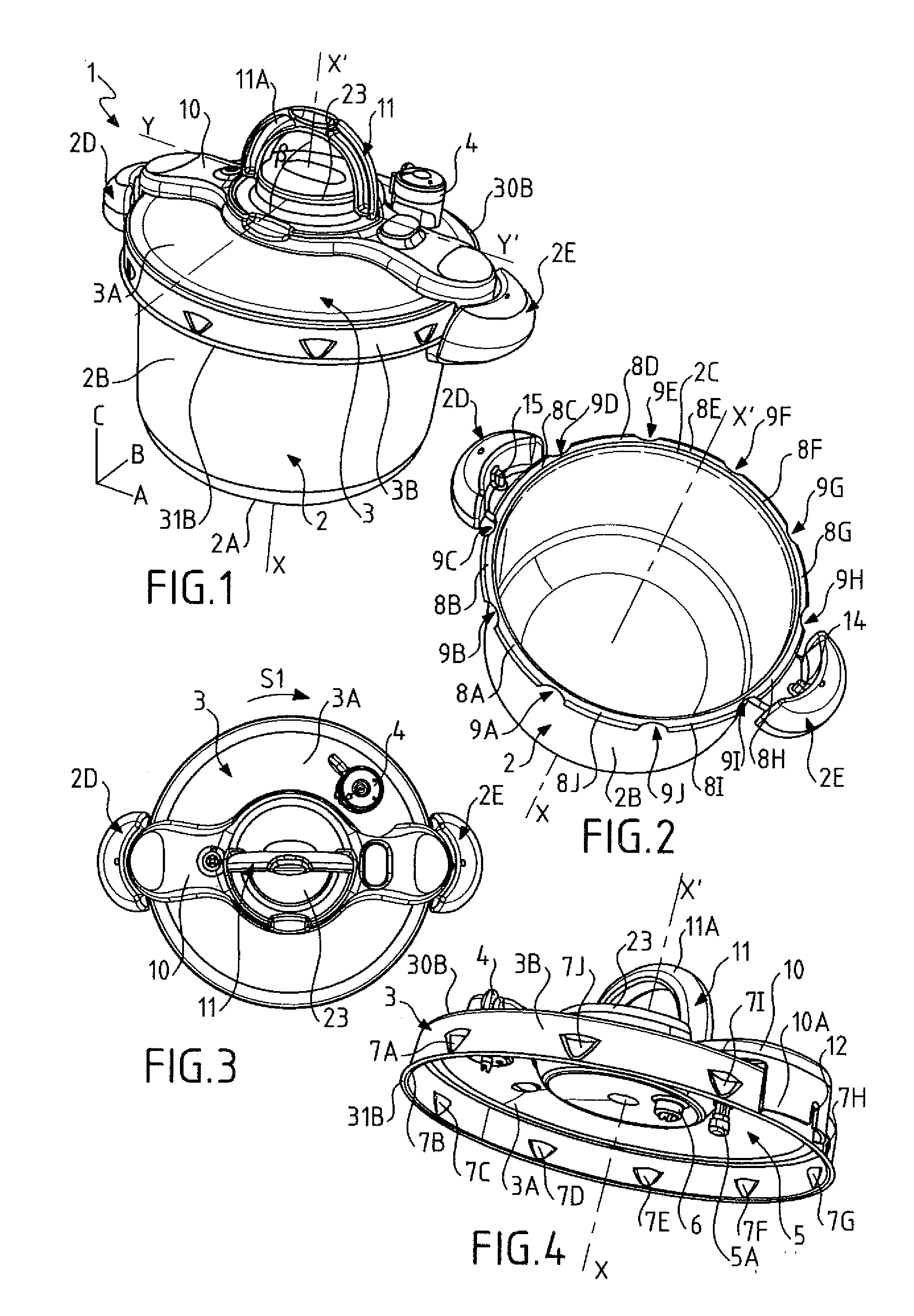

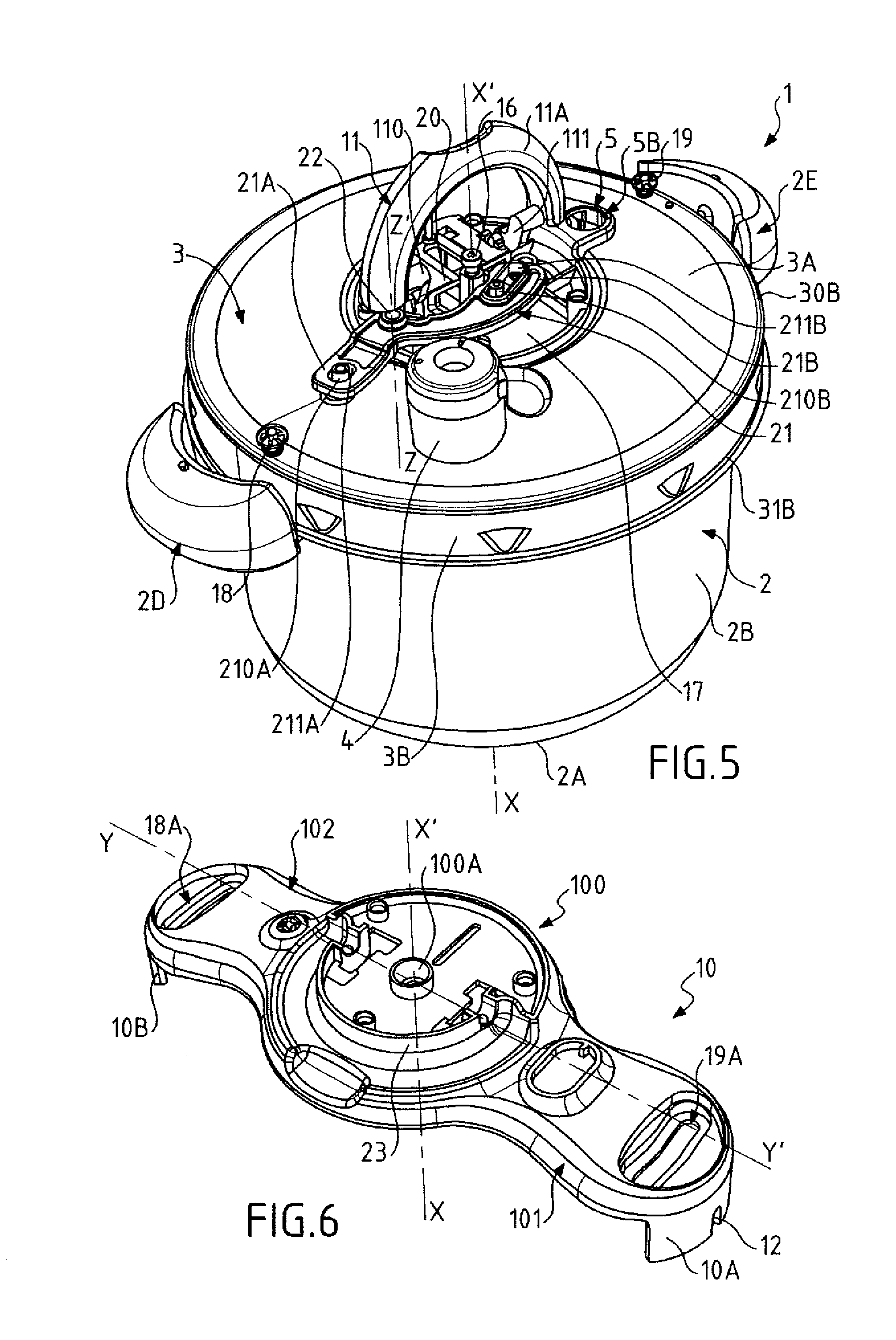

Pressure cooker provided with a manual control for controlling locking

ActiveUS20160353914A1Minimize manual forceEasy to operateRefuse receptaclesPressure-cookersCouplingEngineering

The invention relates to a cooking utensil for cooking food under pressure including a vessel, a lid, and a bayonet-fitting locking system, said cooking utensil includes a control member for controlling locking that is attached to said support via a mechanical coupling allowing said control member to be moved, and is connected to the lid via a movement transformation device for transforming said movement of the control member into pivoting of the lid, said mechanical coupling being configured so that said manual movement of the control member is formed by a movement in rotation about an axis of rotation (Y-Y′) parallel to the central vertical axis (X-X′) and / or by a movement in translation.

Owner:SEB SA

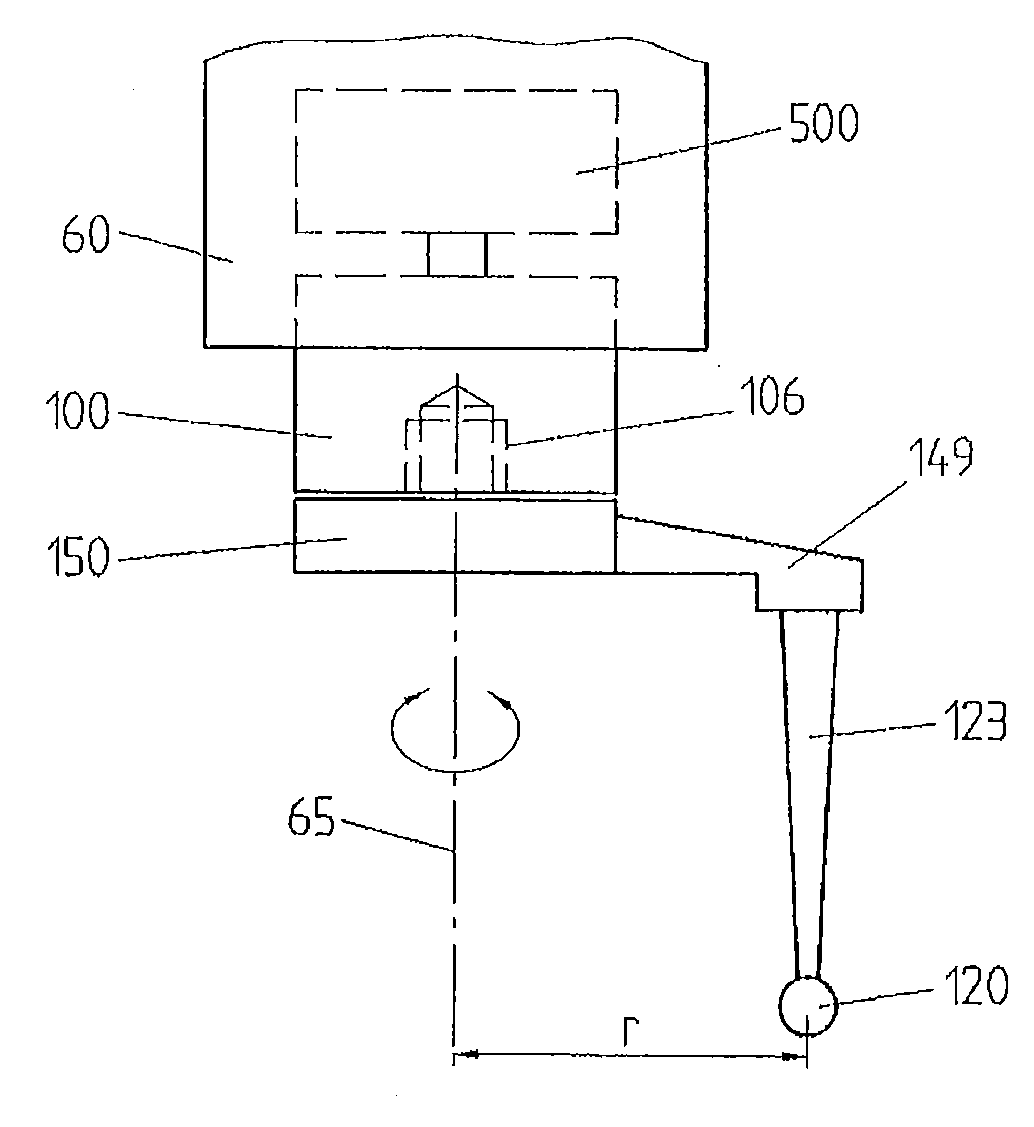

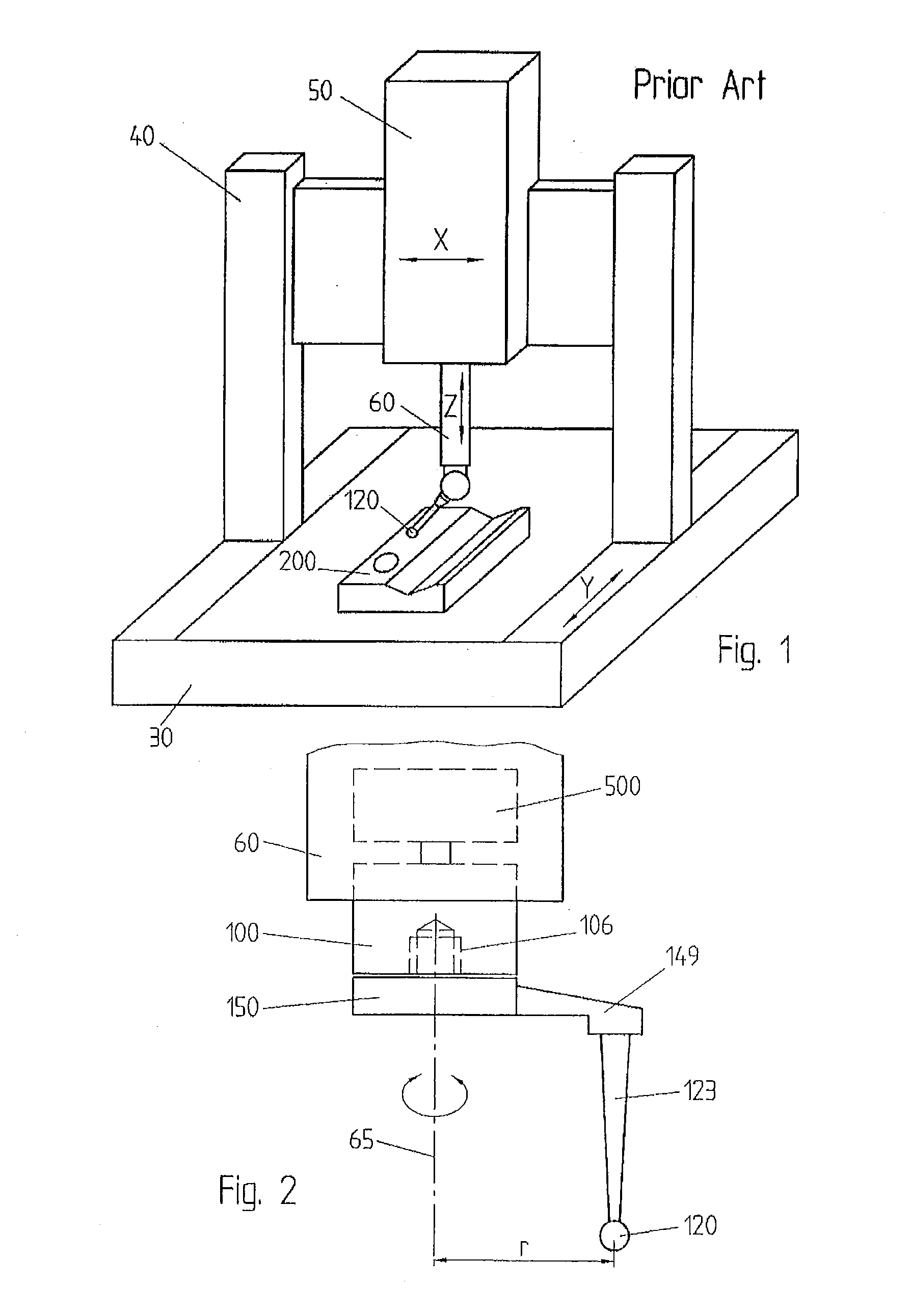

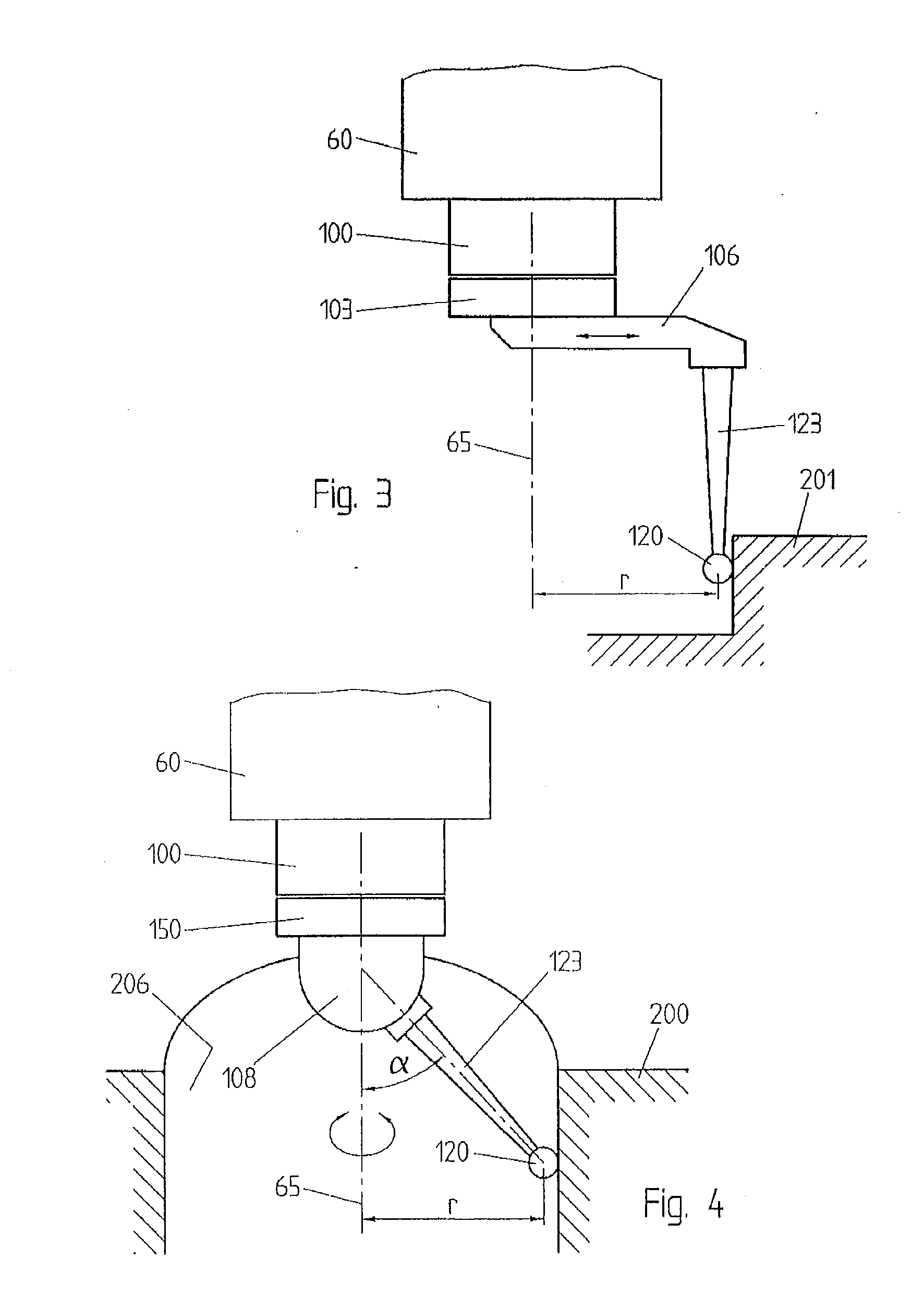

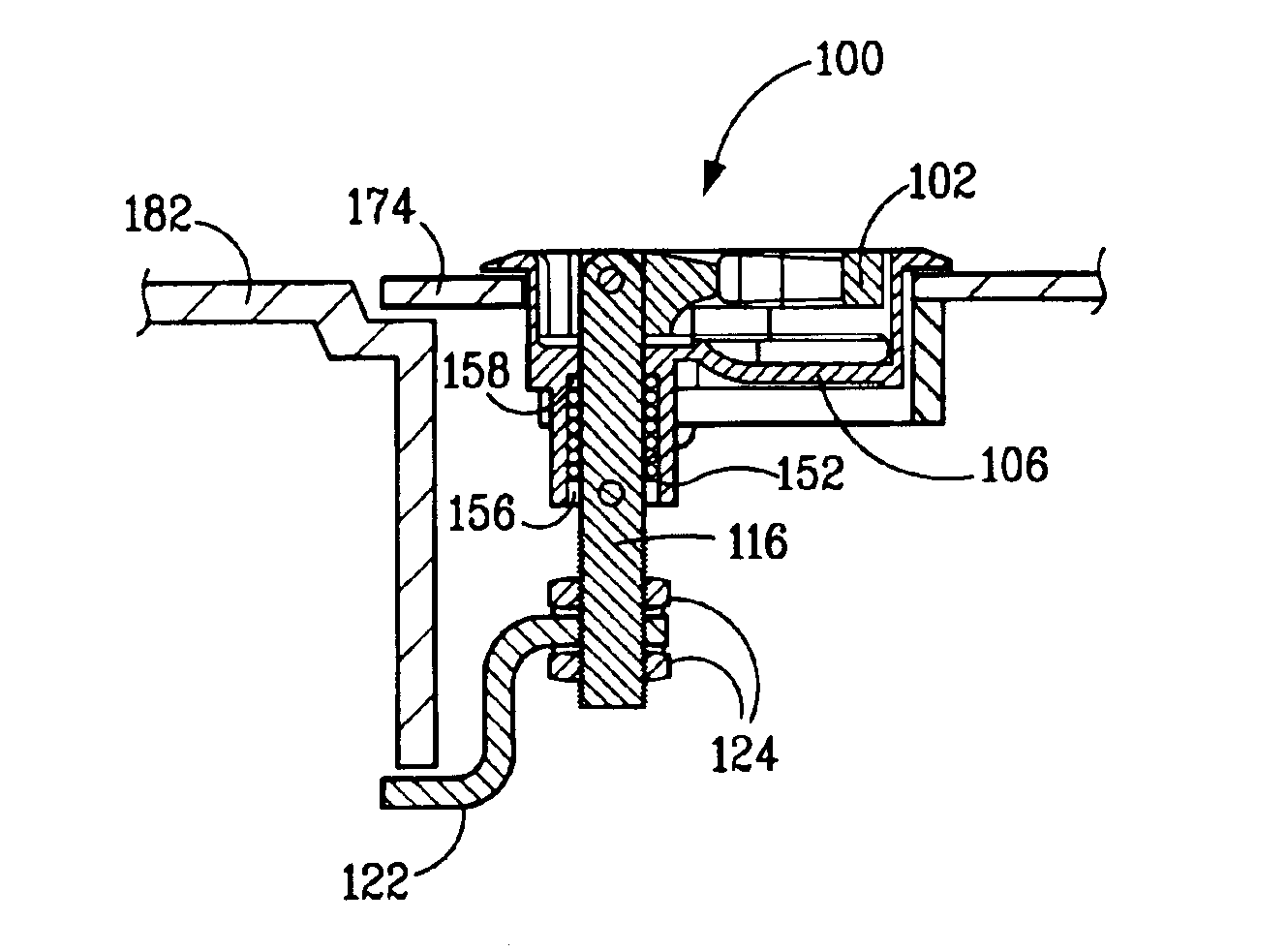

Multi-axis positioning and measuring system and method of using

ActiveUS20080235969A1Increase speedReduce errorsUsing optical meansMechanical measuring arrangementsRotational axisClassical mechanics

The positioning and measuring system includes a coordinate positioning machine comprising a movable spindle (60) movable relative to a reference surface 30, a rotor (100) rotatably connected with the movable spindle, an actuator (500) for driving the rotor (100) in rotation around a rotation axis (65), and a coordinate probe (150, 190) detachably connectable to the rotor (100) for measuring coordinate of points (350) of a workpiece (200, 201, 250) along a path resulting from the composition of a translation movement of the spindle (60) and a rotation of the rotor (100). The points (350) are offset (r) with respect to the rotation axis (65) of the rotor (100).

Owner:HEXAGON TECH CENT GMBH

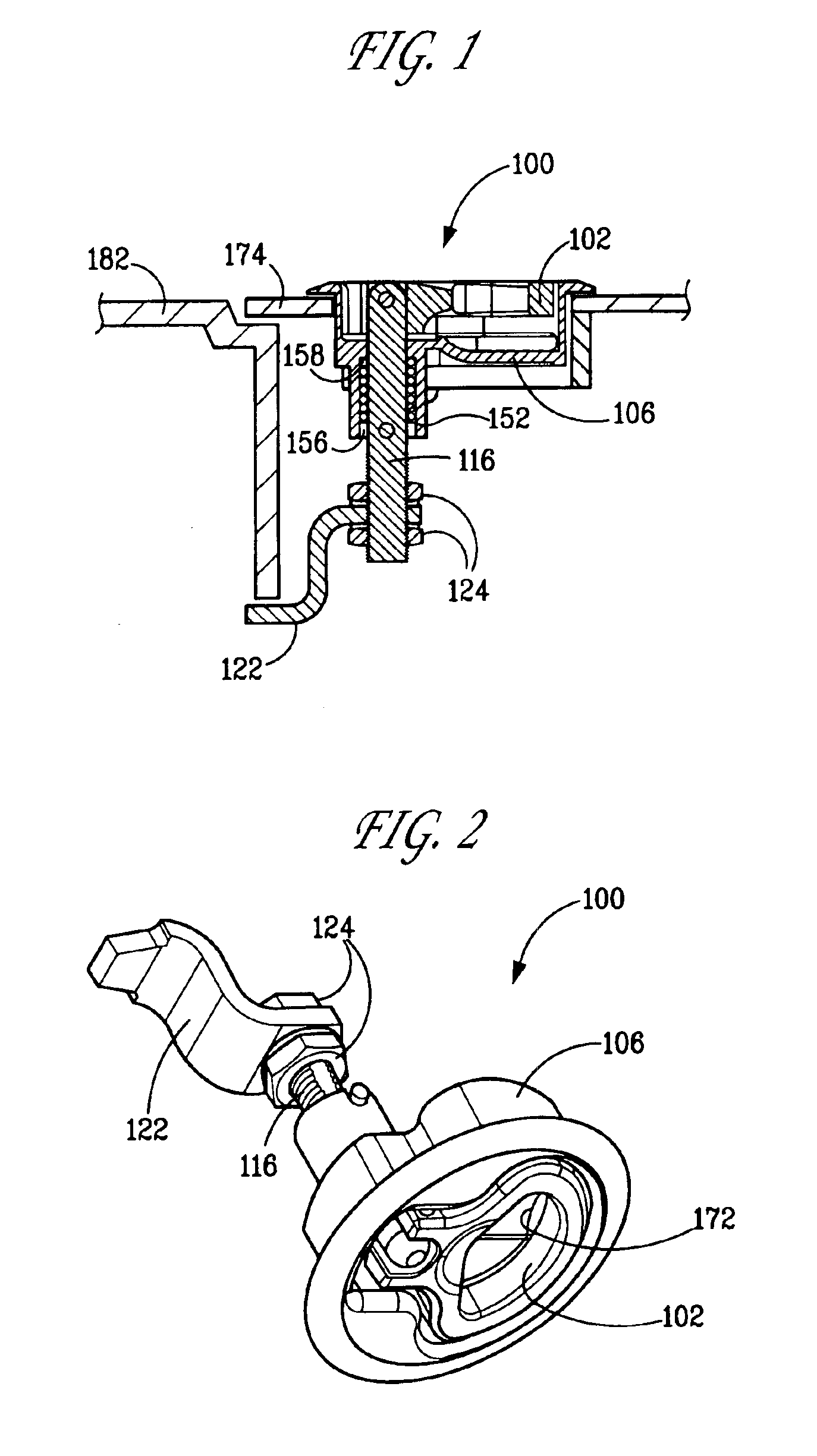

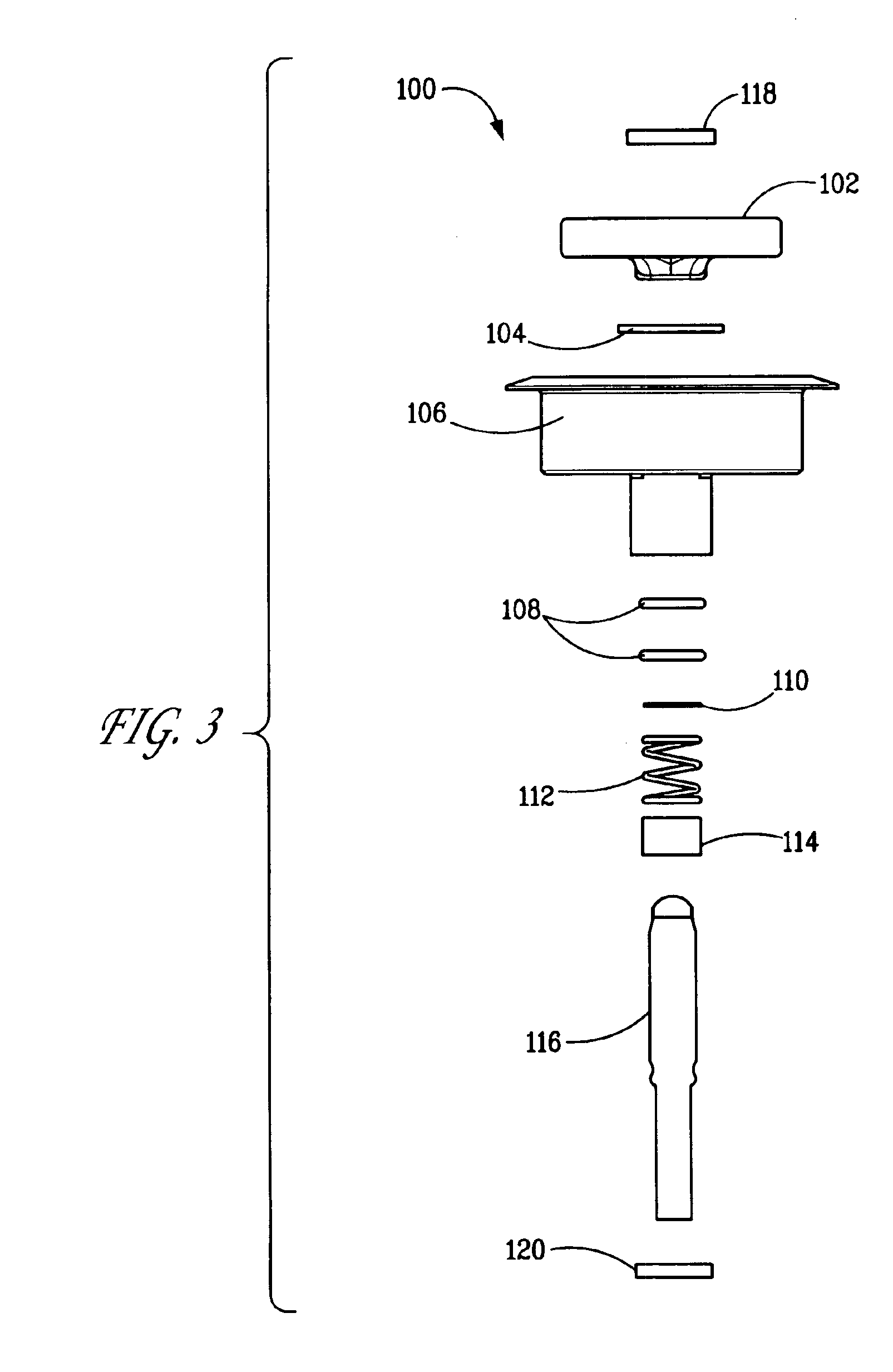

Compression latch

A compression latch with a folding handle for selectively holding a door closed. The latch includes a housing with a cup portion for receiving the handle in the folded down position such that the projection of the latch handle above the exterior surface of the door is minimized in the folded-down position. The handle functions to move a pawl in a combination of rotational and linear translational movements as the pawl is moved between latched and unlatched positions.

Owner:SOUTHCO

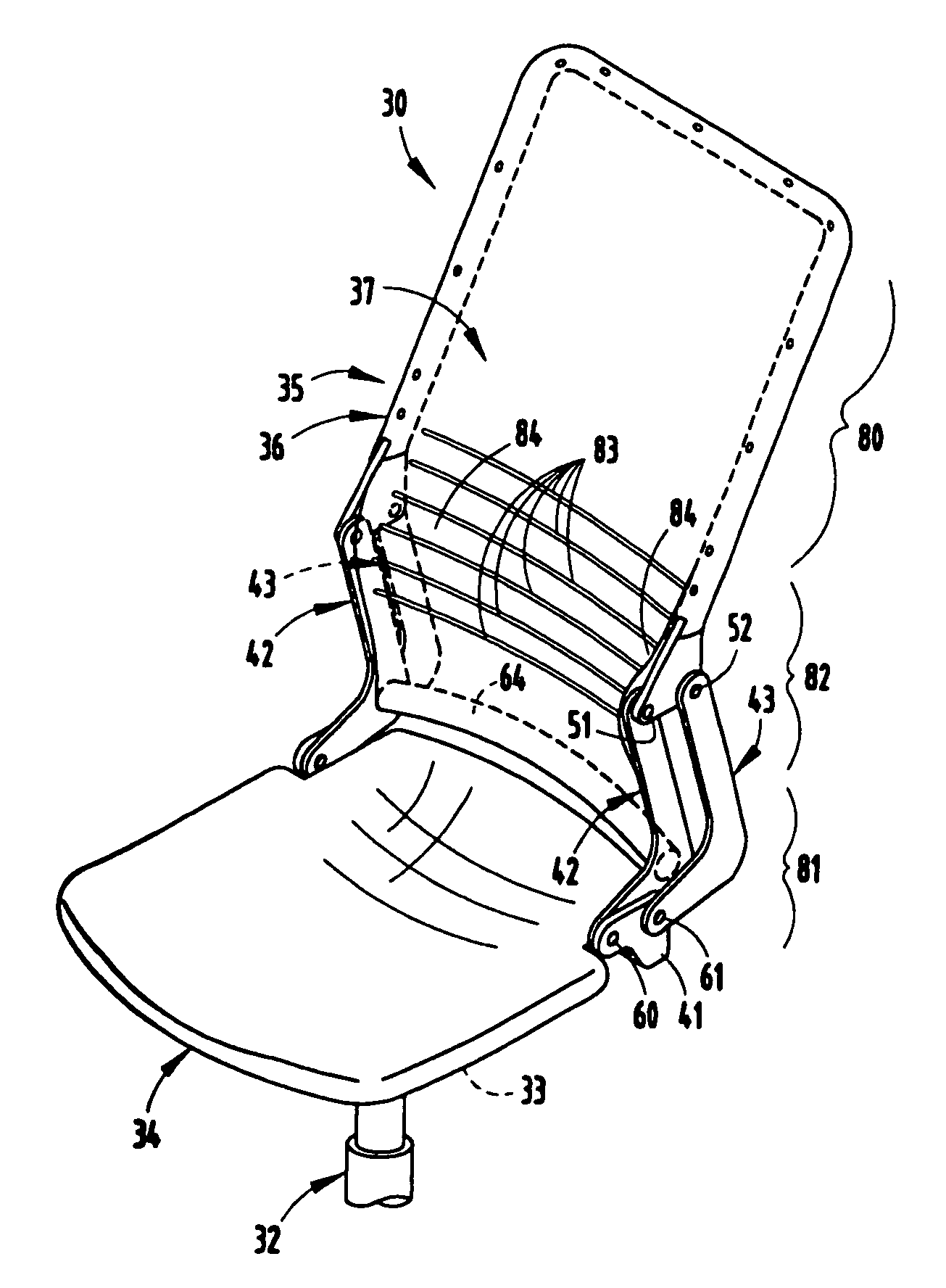

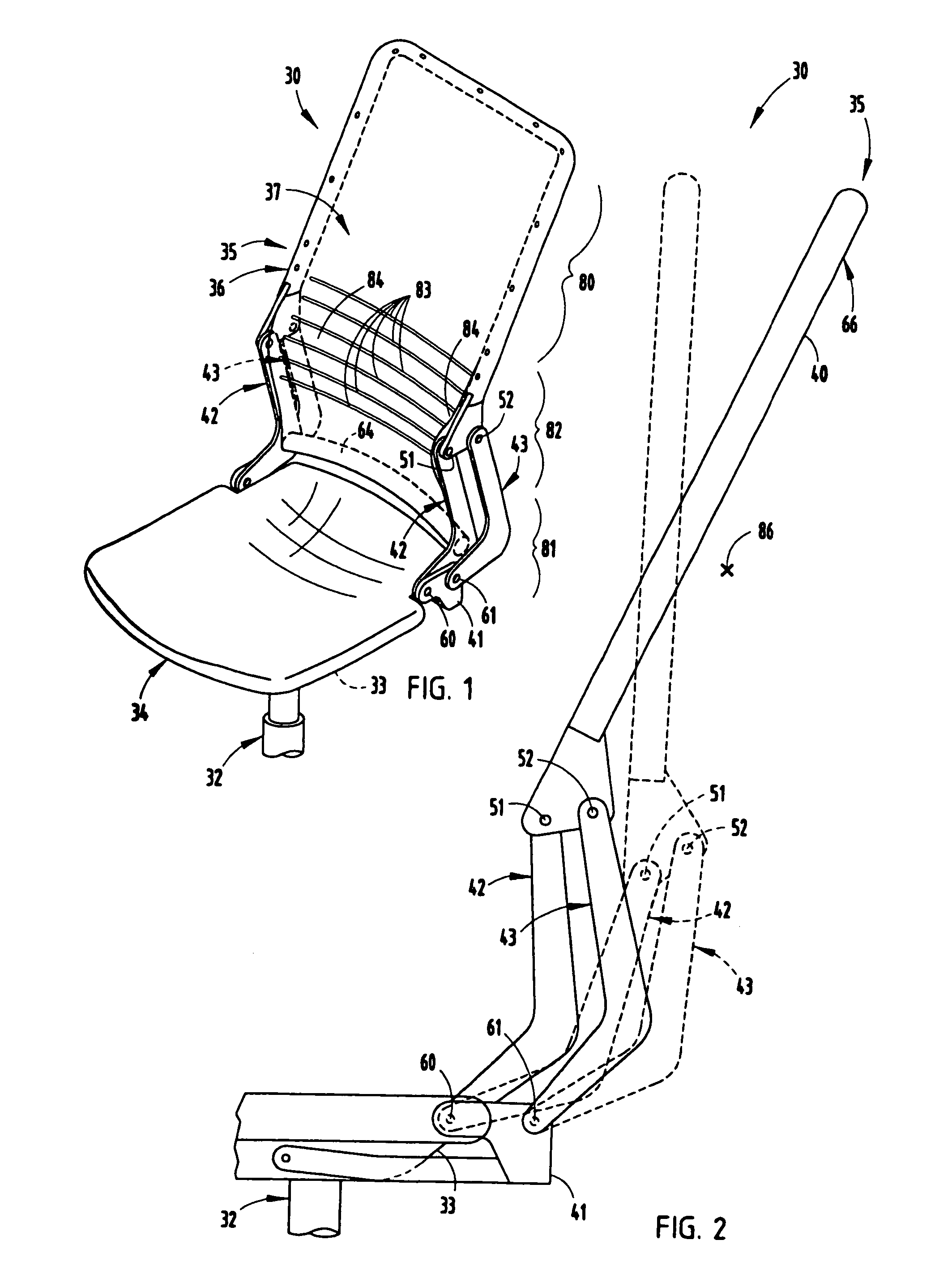

Seating with shape-changing back support frame

A back includes an integrated articulating back frame and a back support. The back frame has a lower segment pivoted to a chair control, an upper segment for thoracic support, and links forming a four-bar linkage with the upper and lower segments, with a joint being formed at the lumbar region. The back support is stretchable in limited directions to accommodate shape change in the articulating back frame but to provide adequate support to a seated user. Upon receiving a rearward pressure on the lumbar joint, the back frame itself changes shape. The pivot locations in the four bar linkage create a mechanism that simultaneously controls rotational and translational movement of the upper segment during flexure of the lumbar. The back frame is close to the back support to provide significant design flexibility, but permit substantial lumbar flexure. Various back supports are contemplated that accommodate articulation of the back frame.

Owner:STEELCASE INC

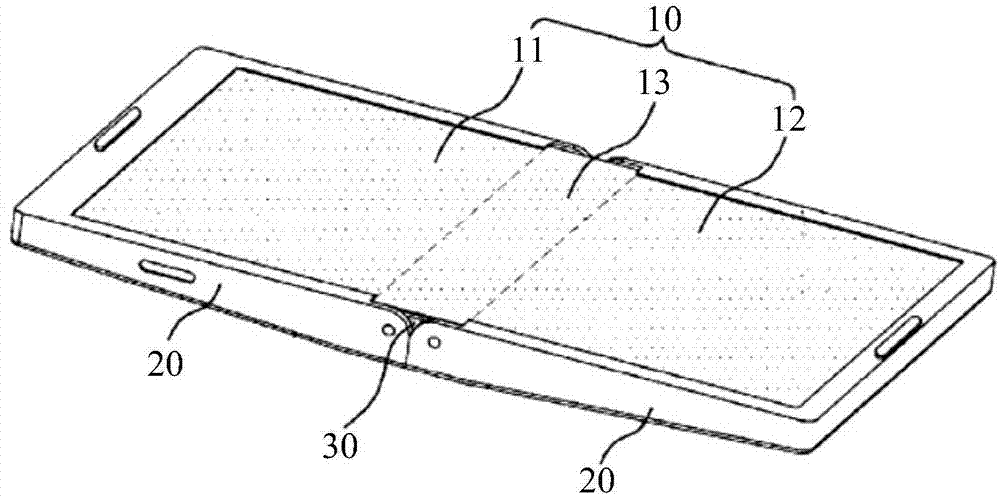

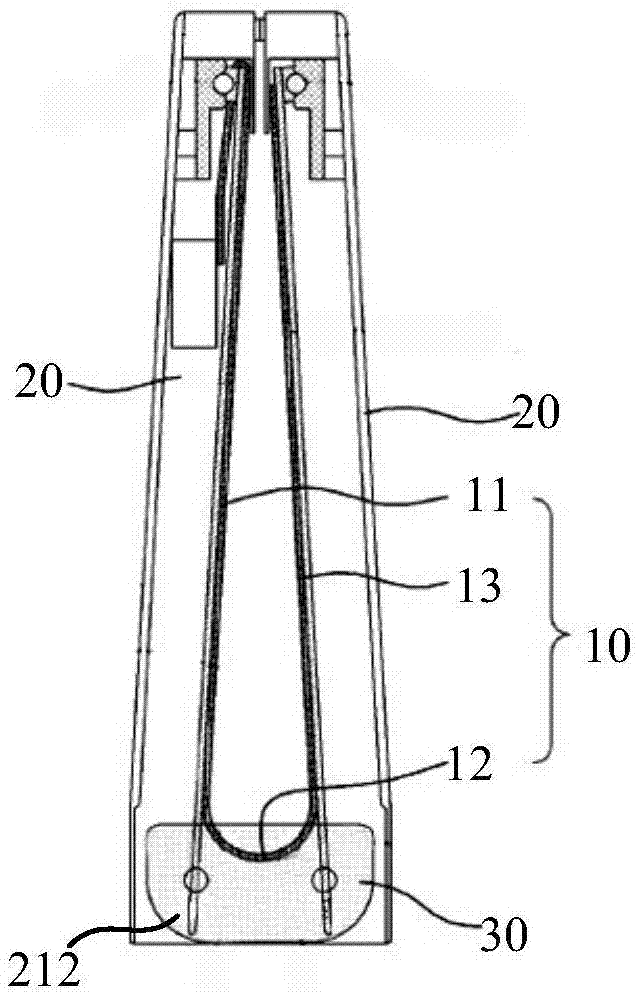

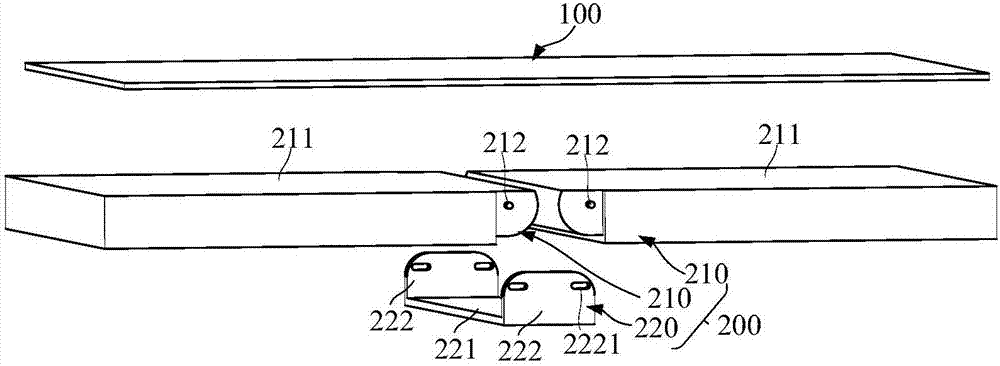

Flexible display device

ActiveCN107358874AImprove the stability of useIncrease bend radiusIdentification meansFlexible displayBend radius

The invention discloses a flexible display device. The flexible display device comprises a flexible display screen and a folding mechanism. The folding mechanism comprises at least two supporting pieces and at least one connecting piece, each supporting piece is movably connected with the corresponding connecting piece, and each supporting piece can rotate and conduct translational movement relative to the corresponding connecting piece, so that when the two supporting faces of each two adjacent supporting pieces are in a folded state; each two supporting pieces can move on the contrary to enlarge the gap between each two supporting faces, therefore the bending radius of a bending part is increased, and the time that a crack and a bending mark are generated on the bending part after the bending part is bent for a long time is delayed; and further the service life of the bending part is prolonged, and the using stability of the flexible display screen is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

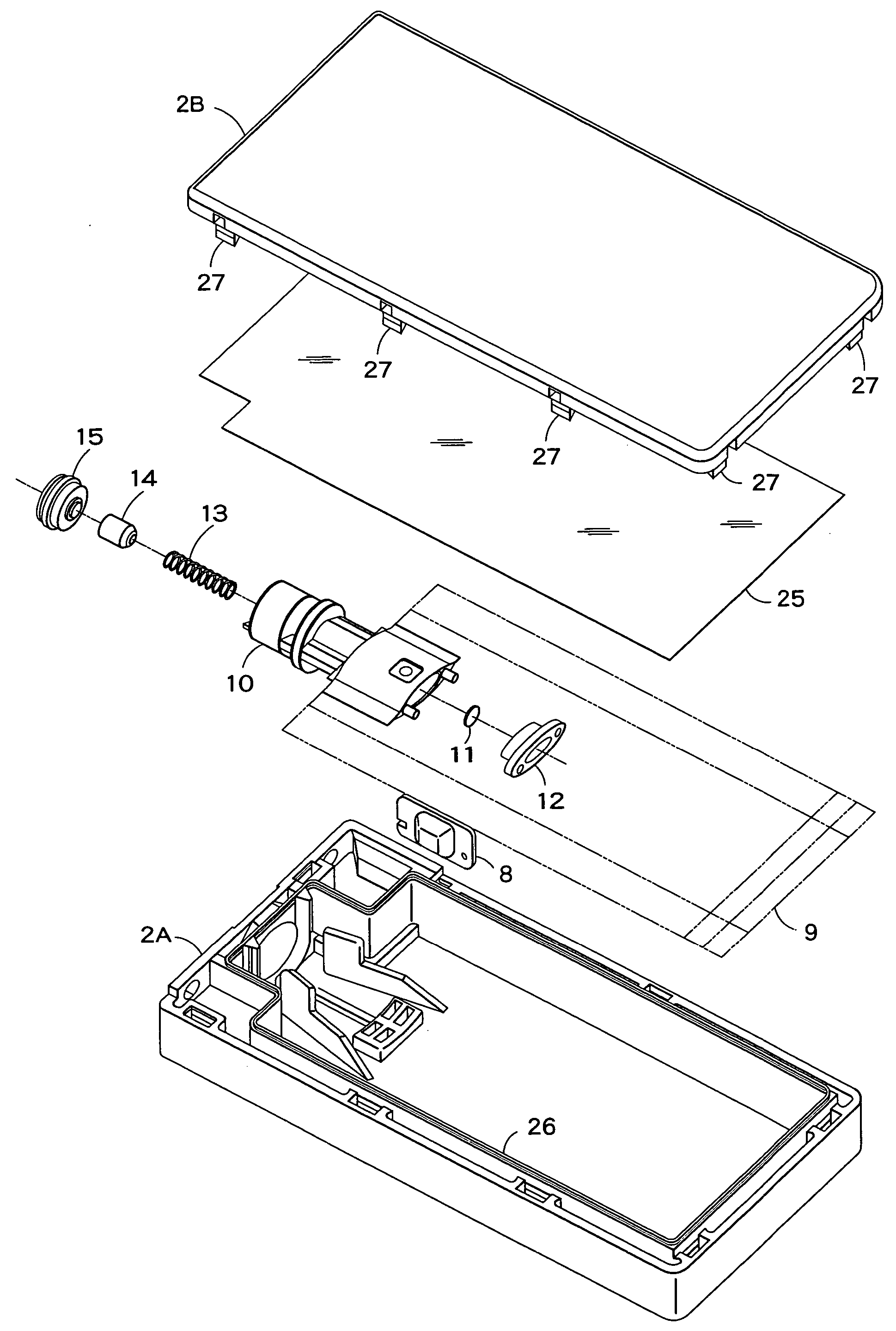

Method and Apparatus for Reversing a Piston Rod in an Injection Device

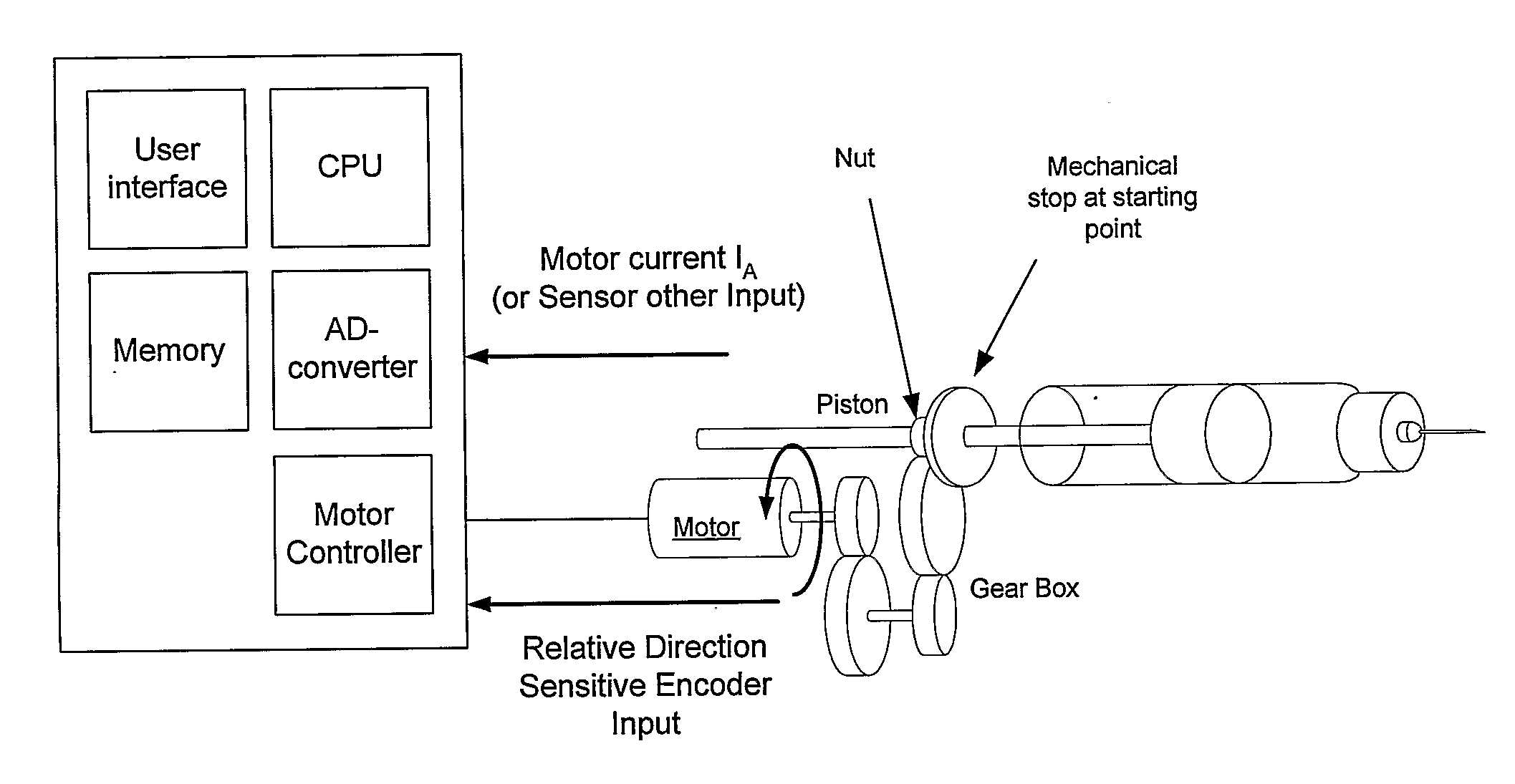

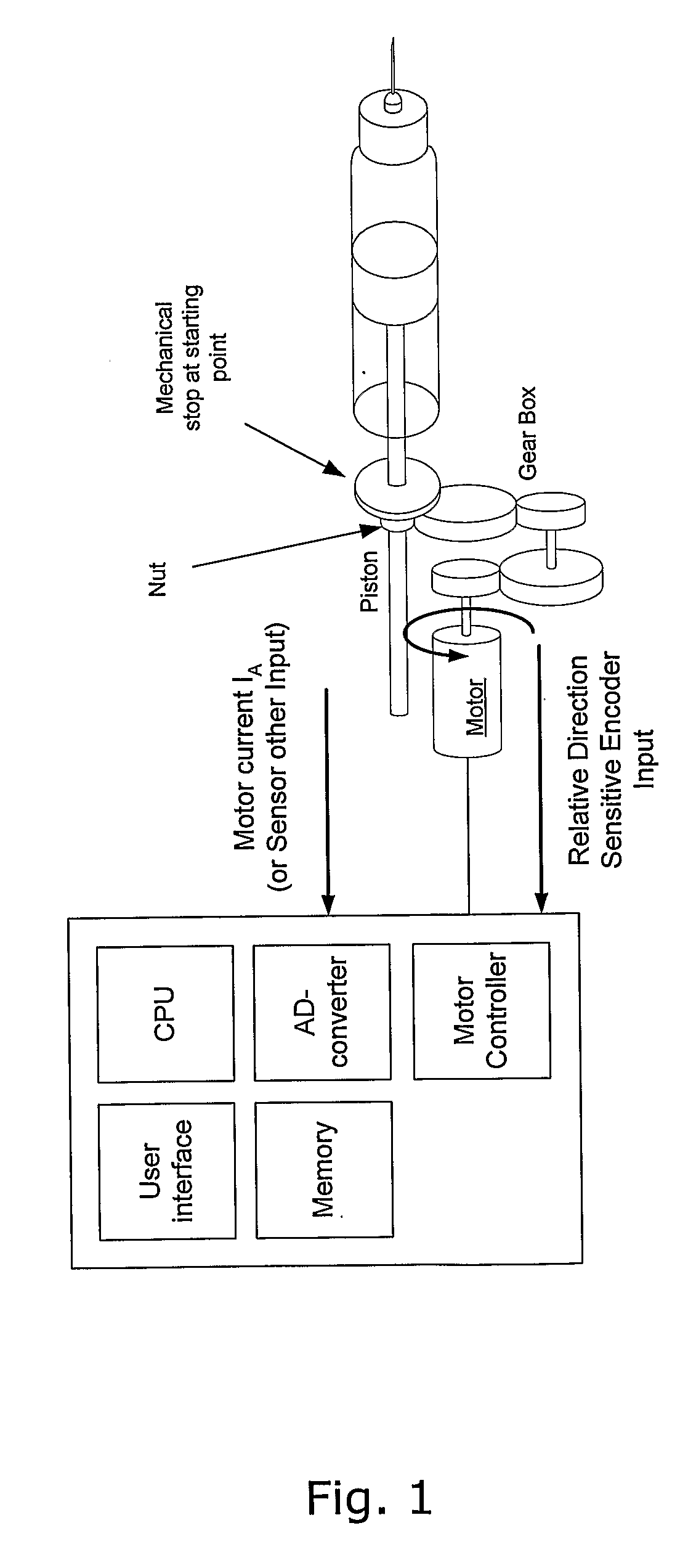

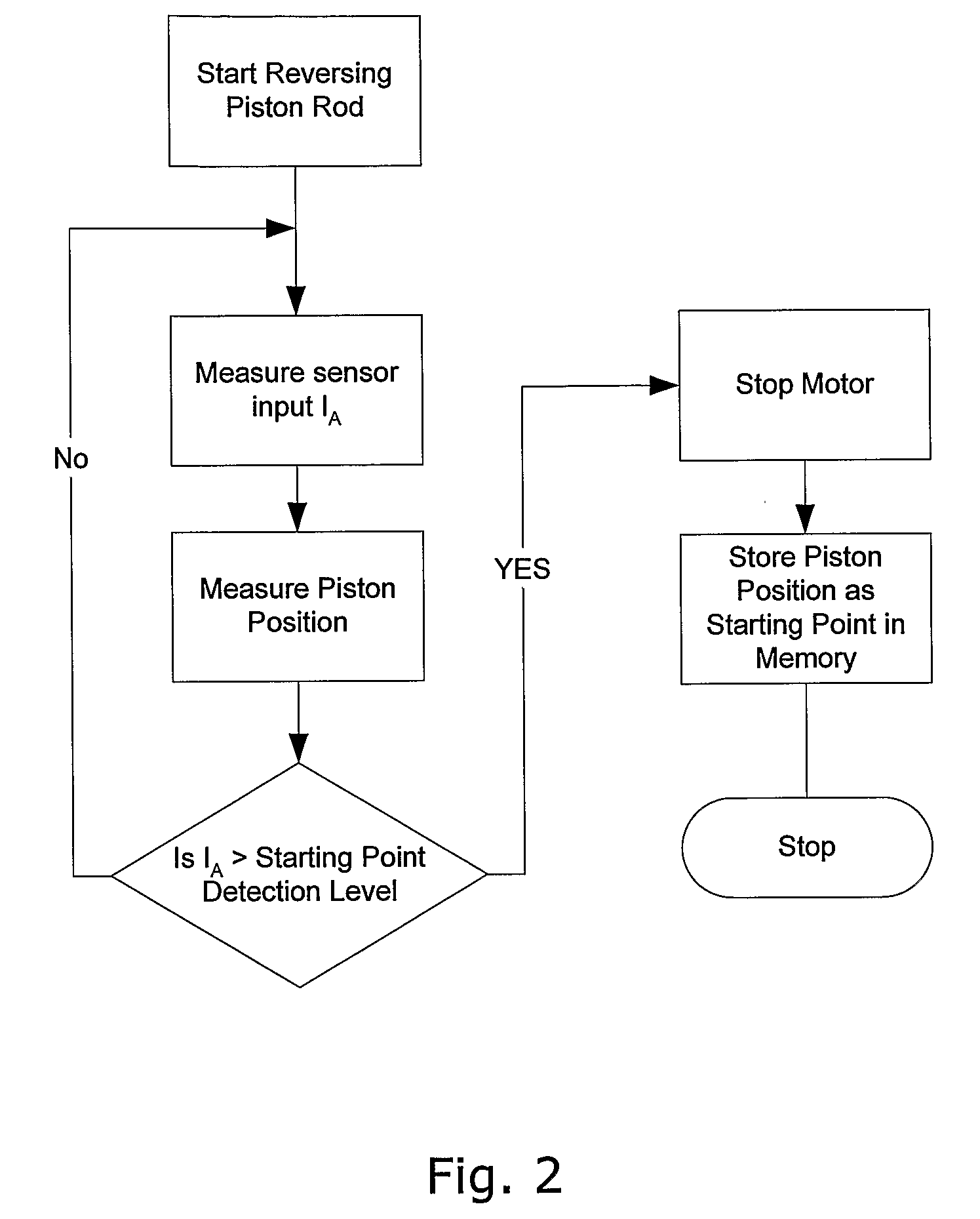

InactiveUS20090124977A1Unnecessary wearPrecise processingMedical devicesPressure infusionControl theoryMotor shaft

The present invention relates to a method for moving a piston rod in an injection device, the piston rod being operatively connected to a motor shaft of an electrical motor so that a rotational movement of the motor shaft is transformed to a translational movement of the piston rod, the piston rod being adapted to be moved between two end positions, the method comprising the steps of providing a first supply voltage level to the electrical motor, measuring sets of corresponding values of current provided to the motor and a corresponding position of the piston rod, and providing a second supply voltage level to the electrical motor when the measured position of the piston rod equals predetermined positions, the second supply voltage level having a RMS value being smaller than the RMS value of the first supply voltage level. The present invention further relates to an apparatus for carrying out the method.

Owner:NOVO NORDISK AS

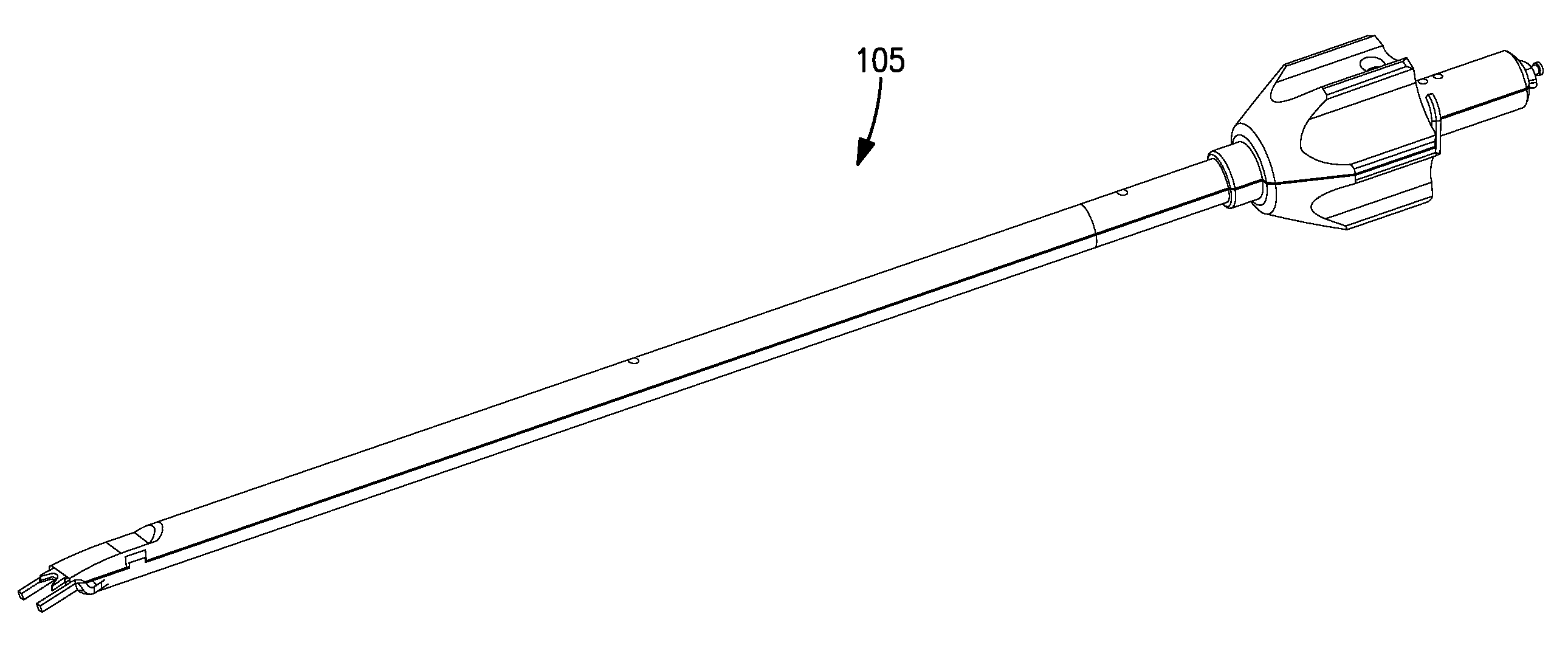

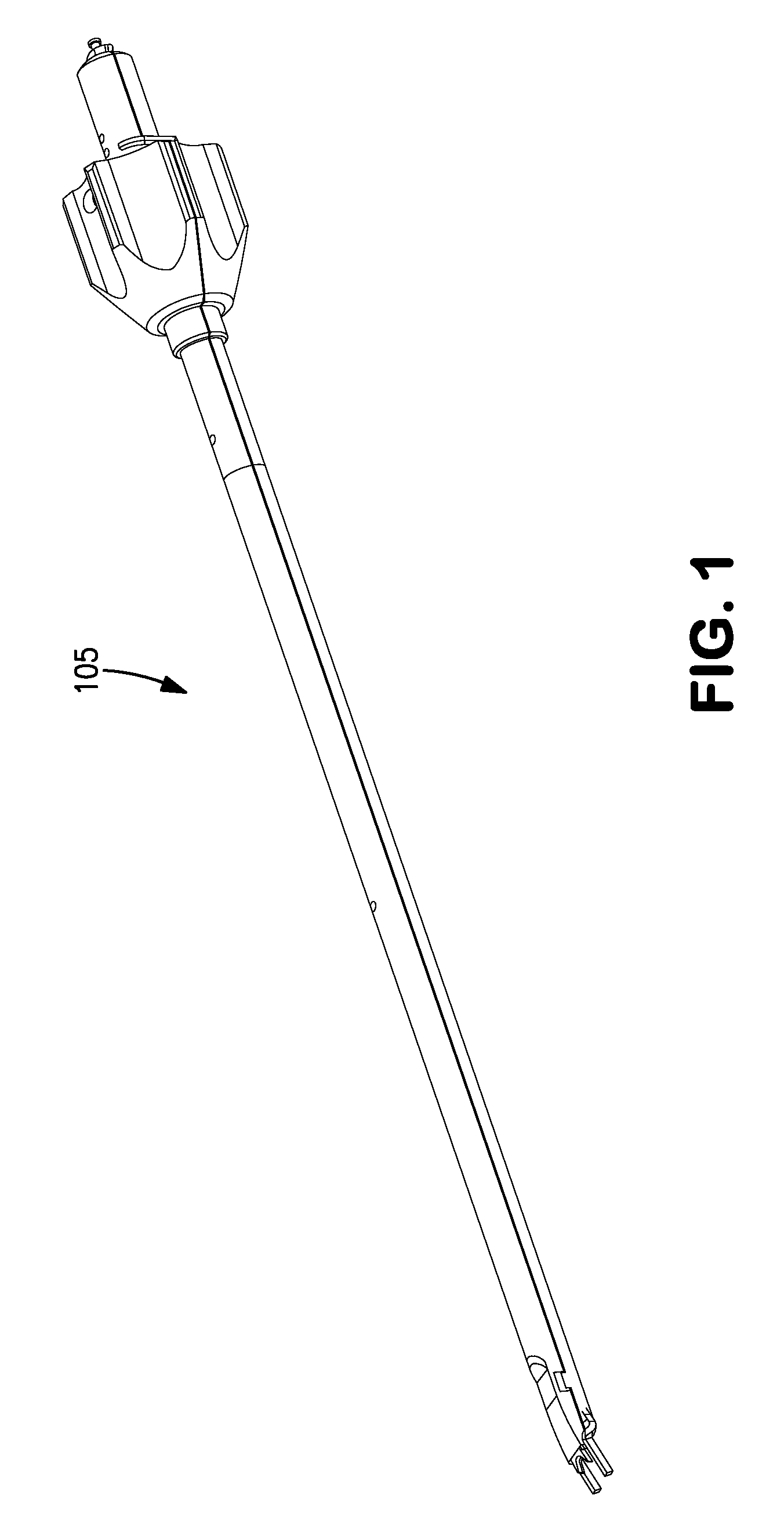

Digital depth gauge

A digital depth gauge is provided for measuring a depth of a hole in an object. In one embodiment the gauge includes: a user interface with a display and at least one actuator; a reader shaft with a distal end and a proximal end connected to the user interface; a probe that extends from the distal end of the reader shaft and which includes a tip configured to locate a distal surface of the hole; a sleeve member with a distal end configured to abut a proximal surface of the hole, the sleeve member being coupled with the reader shaft for relative translational and rotational movement; and a sensor interposed between the reader shaft and the sleeve member for measuring relative translational movement between the reader shaft and the sleeve member. In some embodiments, the gauge may include a means for aligning elements of the sensor.

Owner:EDGE SURGICAL INC

Surgical clip applicator

ActiveUS9433422B2Lower requirementHigh operating requirementsWound clampsSurgical ClipsBiomedical engineering

A surgical clip applicator includes a handle configured to produce translational movement; a cartridge containing a plurality of clips arranged in a row, the cartridge including a jaw assembly for receiving and closing a clip; a jaw closing mechanism for closing the jaw assembly; a clip feed mechanism for serially feeding a lead clip from the row to the jaw assembly; a clip advance mechanism for advancing the row as the lead clip is fed to the jaws; and a rocker mechanism for translating translational movement from the handle opposite translational movement of the haw closing mechanism in one direction and the clip feed mechanism and clip advance mechanism in an opposite direction.

Owner:DESIGN STANDARDS CORP

Multi-shaft inertial sensor and method for measuring multi-shaft translation and rotation acceleration

InactiveCN101270988AHigh-resolutionReduced cross-talk sensitivity between axesAcceleration measurement using interia forcesTurn-sensitive devicesEnvironmental noiseSymmetric axis

The invention discloses a multi-axial inertial sensor and a method for measuring multi-axial translatory motion and rotating acceleration. The sensor includes a frame moving along a spindle, one or more pair of inductive mass blocks and an outer elastic structure. Each inductive mass block is hanged on the frame by an inner elastic structure, the symmetric axis of the inner elastic structure is consistent with the symmetric axis of the hanged inductive mass block, the frame is hanged on a sensor platform by the outer elastic structure; the inner elastic structure and the inductive mass block are installed to lead the centers of mass to deviate with each other along the direction of the spindle, and the outer elastic structure and the frame are also installed to lead the centers of mass to deviate with each other along the direction of the spindle. The multi-axial inertial sensor of the invention can measure a plurality of axial acceleration and rotation at the same time, which has high resolution, rather low inter-axle crosstalk sensitivity and strong resistance to environmental noise, and produces with low cost and mass.

Owner:江苏英特神斯科技有限公司

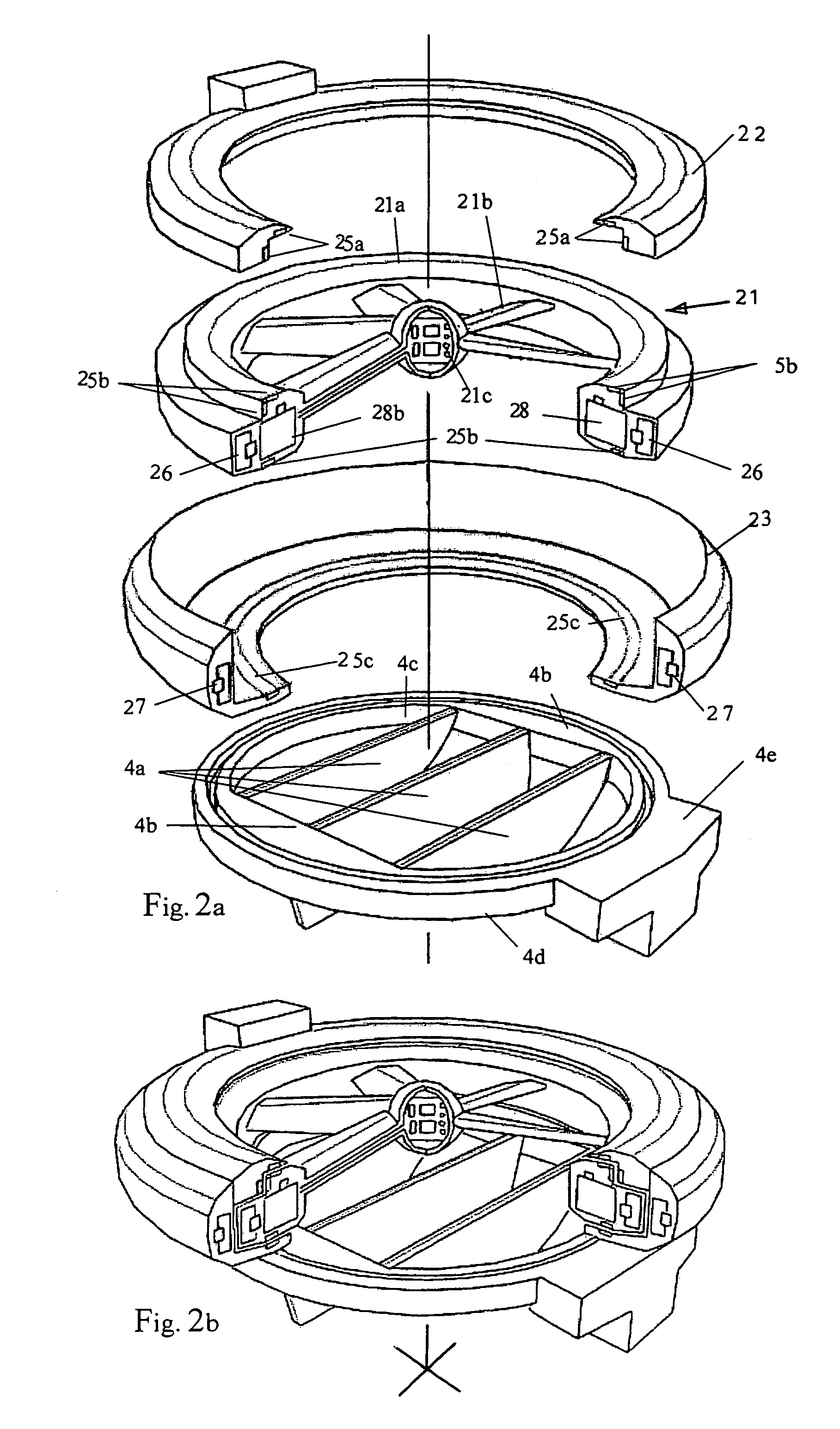

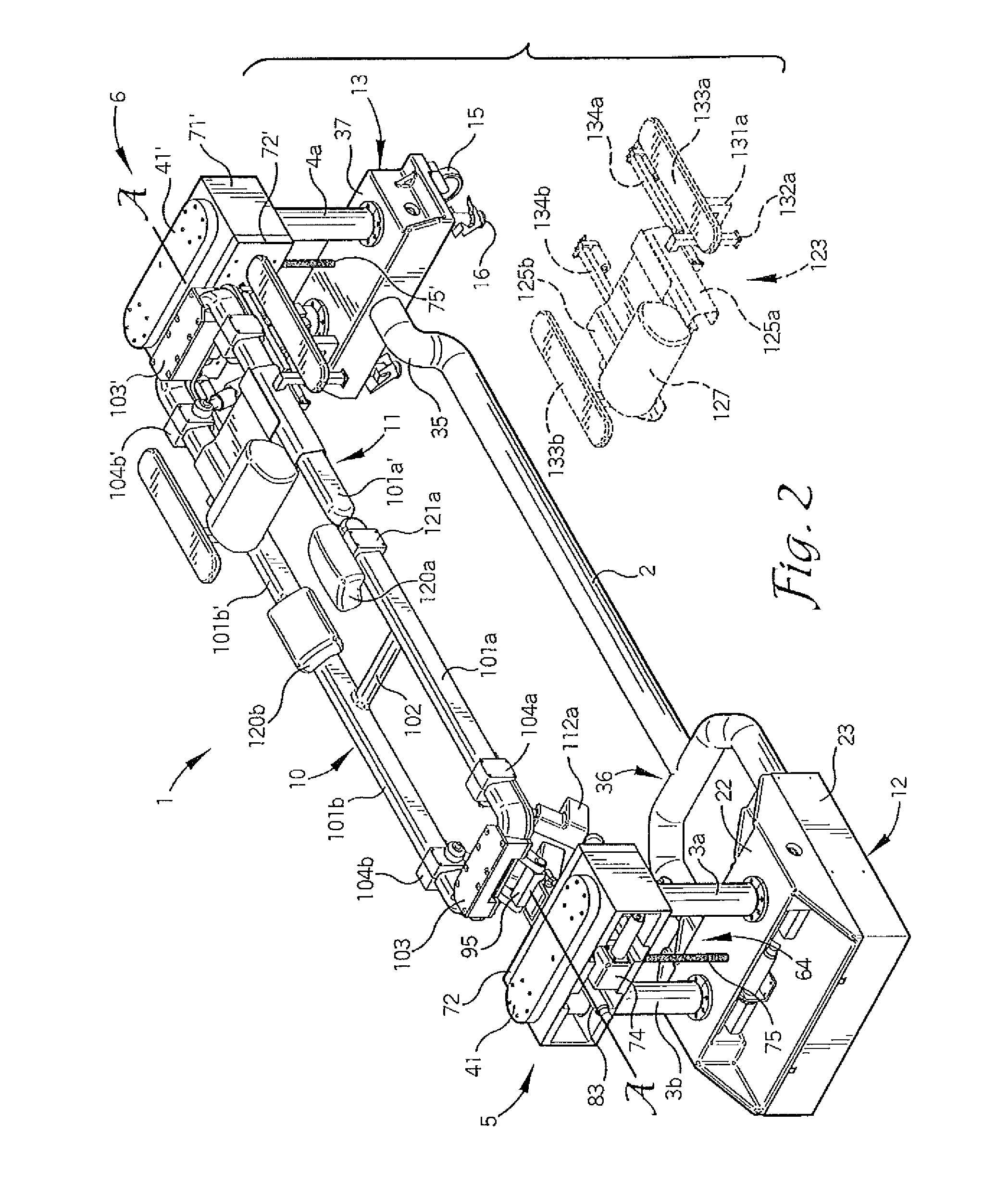

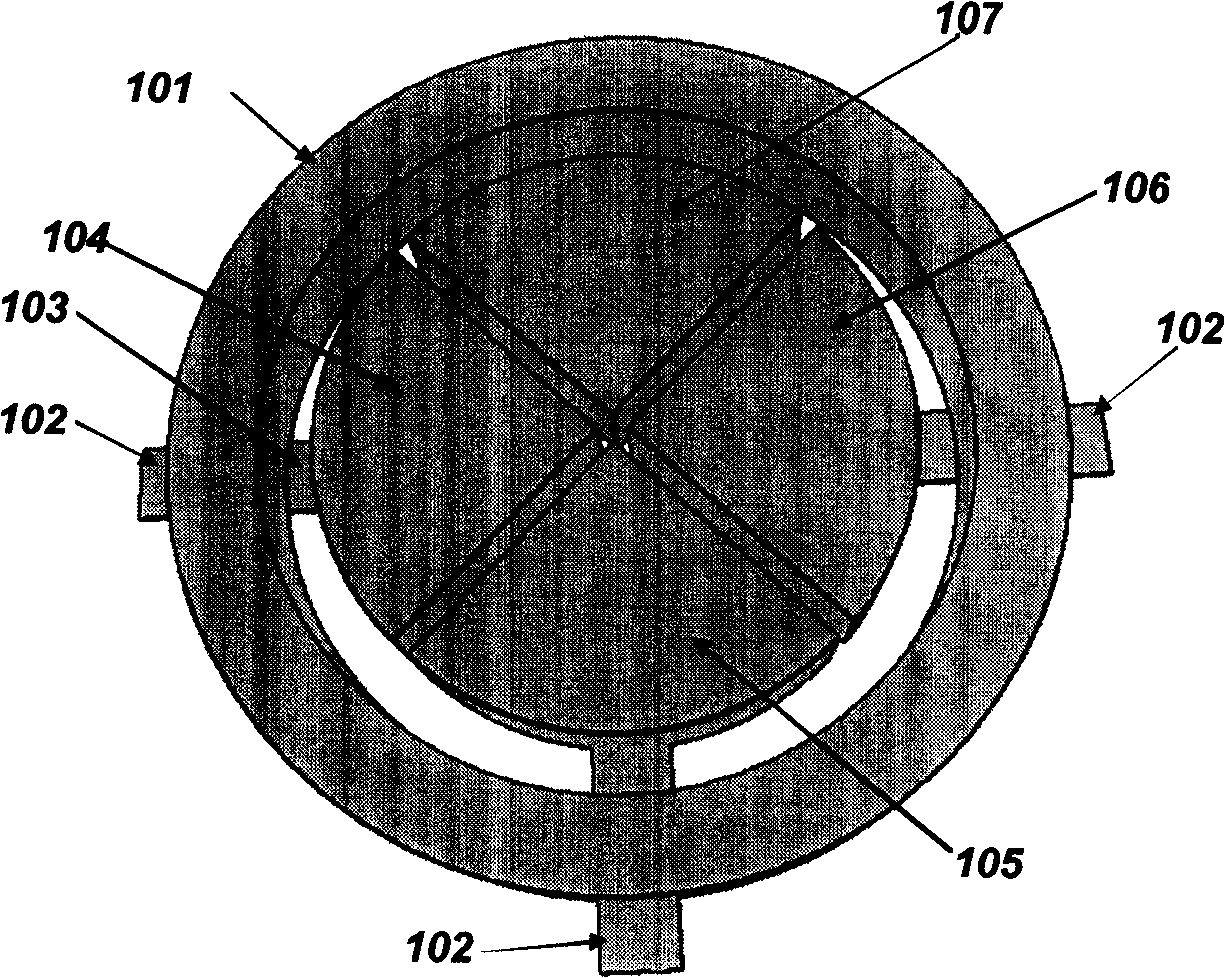

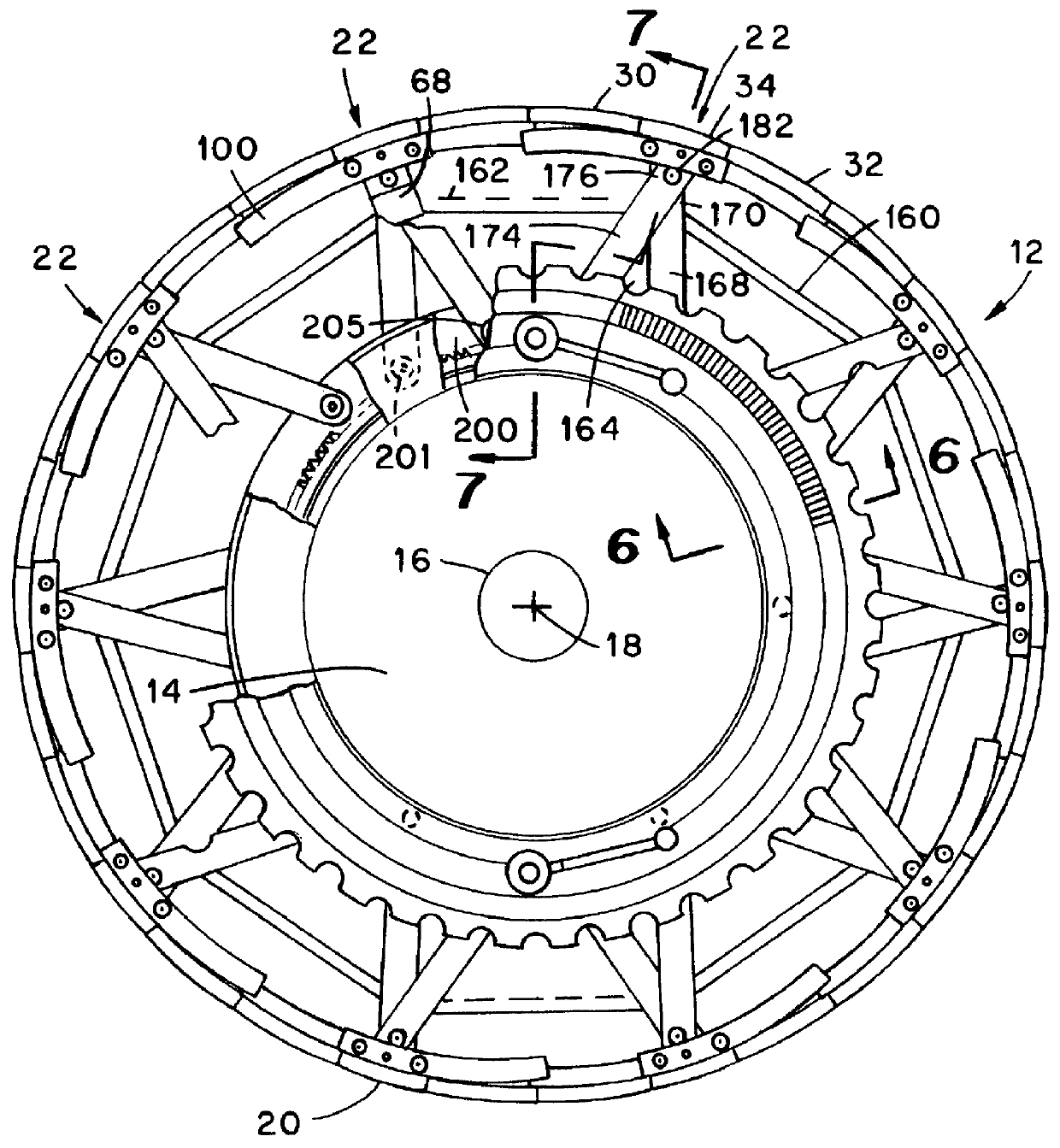

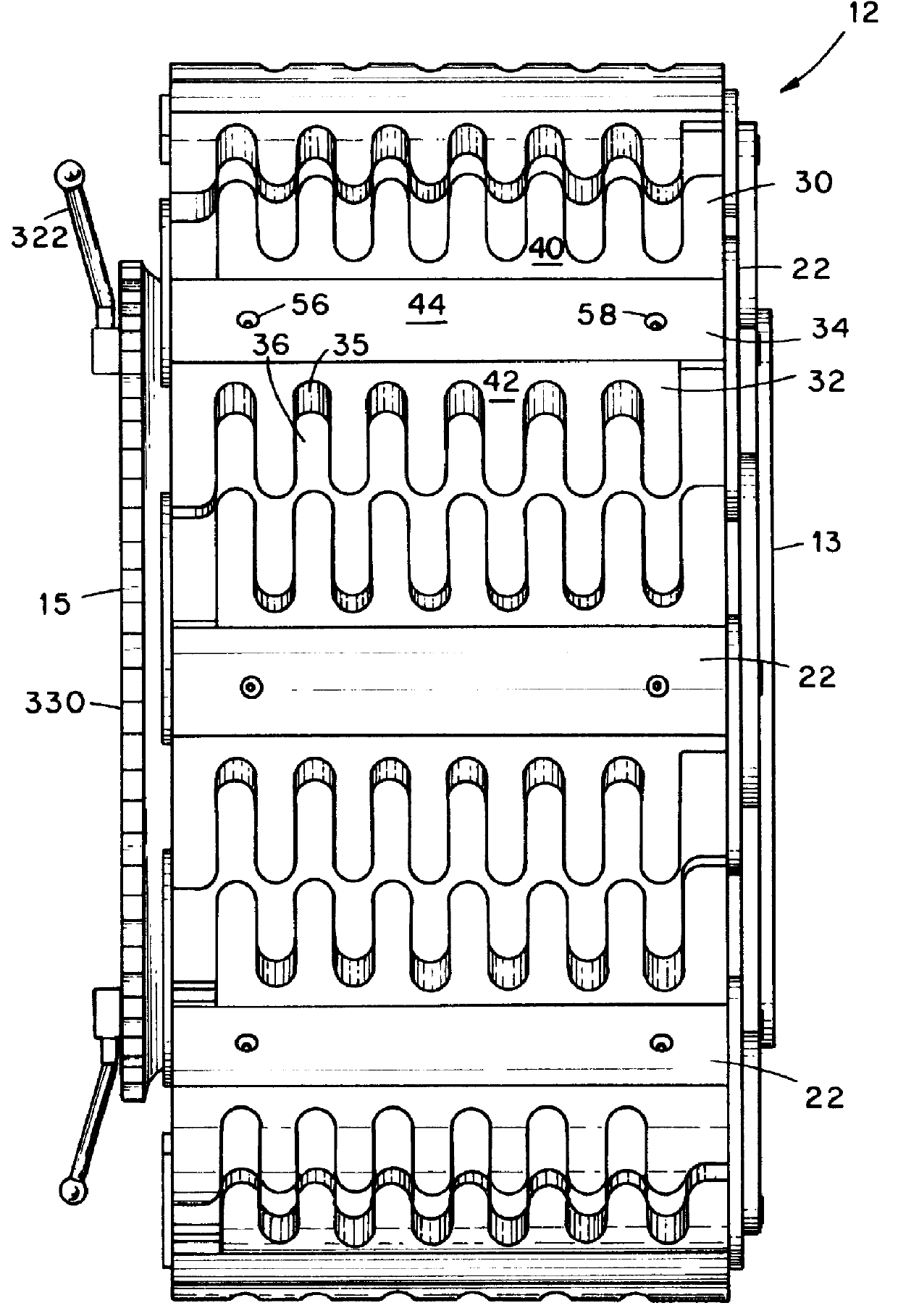

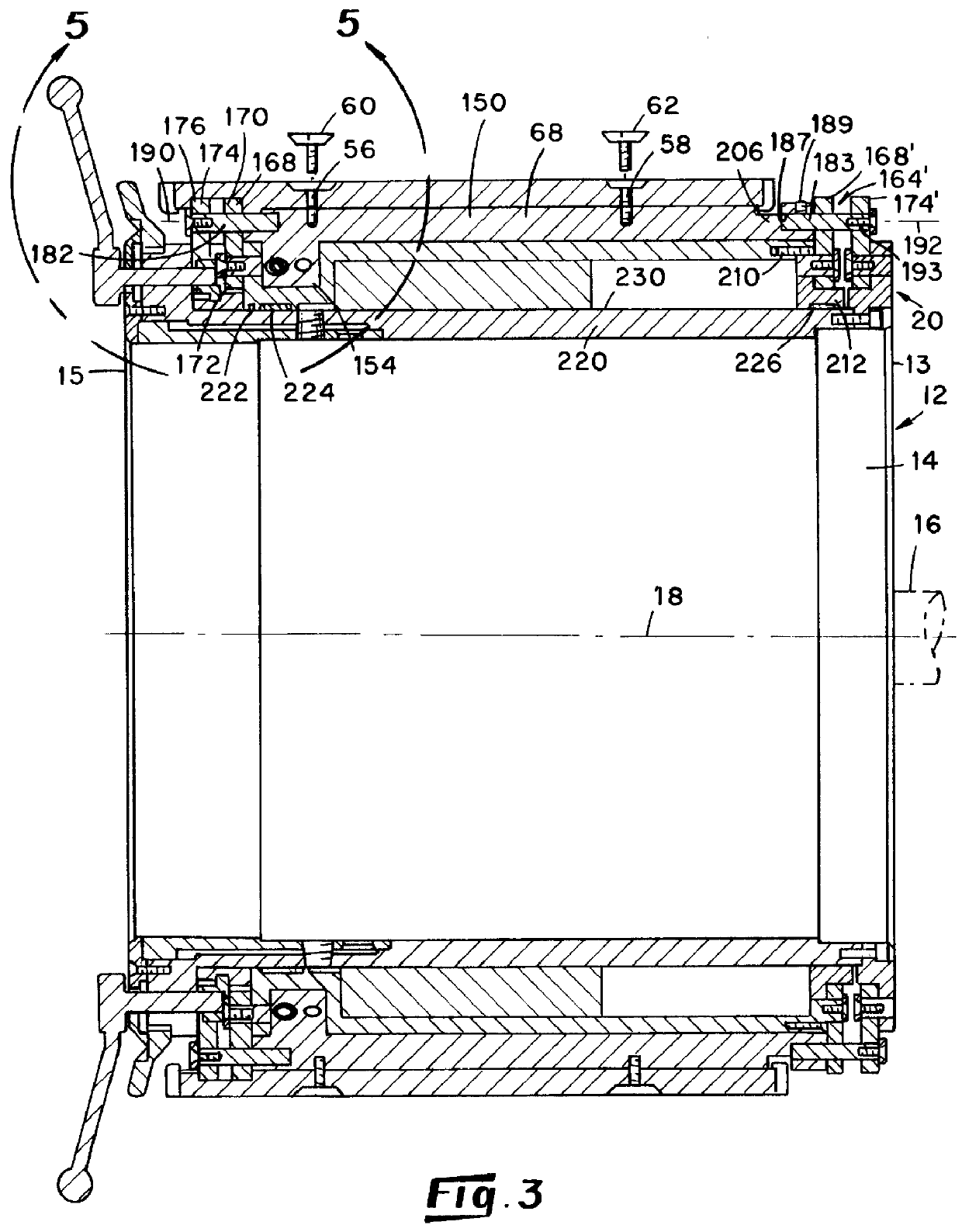

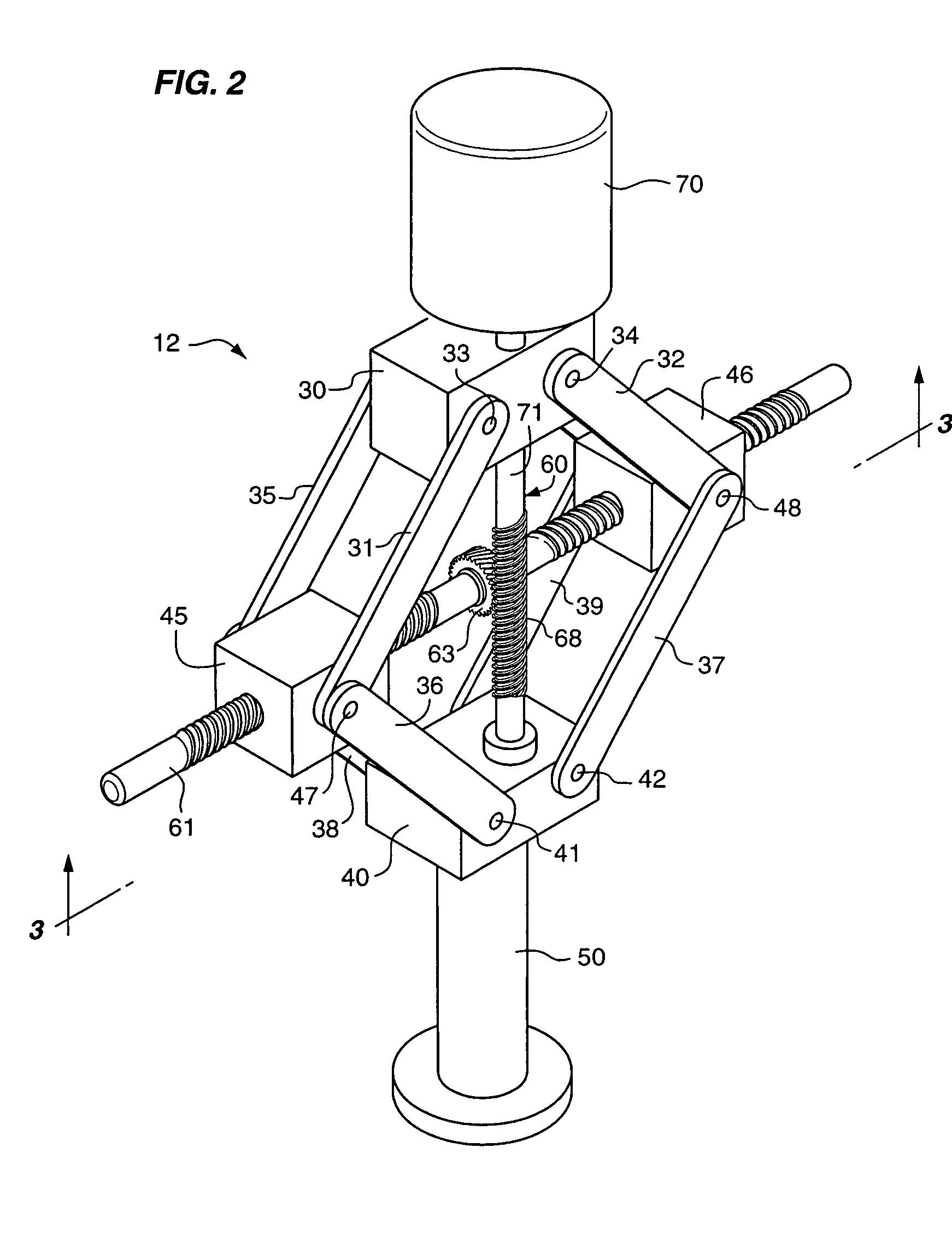

Expandable belt and tread drum

A belt and tread drum having an annular shell comprising a plurality of circumferentially spaced segments, each of which is mounted on a carrier which disposed in circumscribing relationship to a generally cylindrical actuator rotatably connected with a reciprocating piston disposed within a cavity defined between the actuator and a hub fixed to a central core of the drum. Translational movement of the piston between extended and retracted positions in a direction parallel to the rotational axis of the drum is converted into selected rotational movement of the actuator relative to the hub. A plurality of sets of links interposed between the segments and the actuator and hub have their first ends commonly pivotally pinned to a segment. The second end of one link of each set of links is pivotally pinned to the actuator and the second end of the other link of each set of links is pivotally pinned to the hub. Rotation of the actuator relative to the hub controls the arcuate separation of these second ends such that bringing these second ends toward contiguity moves the segments radially outwardly, and conversely, moving these second ends arcuately apart serves to move the segments radially inwardly of the drum. A hand wheel establishes maximum and minimum rotational movement of the actuator and provides a visual indication of the radial positions of the several segments, i.e. the diameter of the drum.

Owner:DAVIAN ENTERPRISES LLC

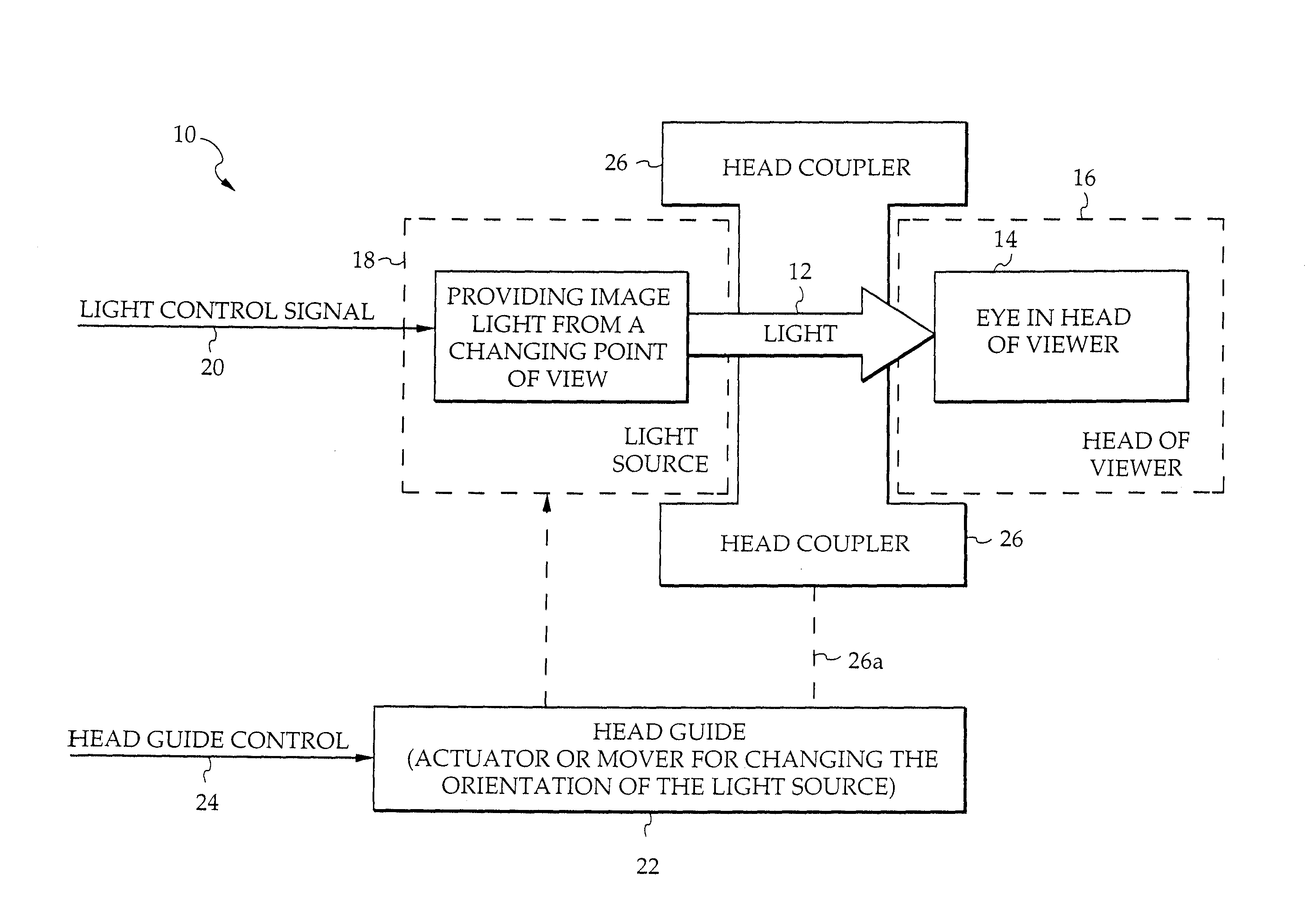

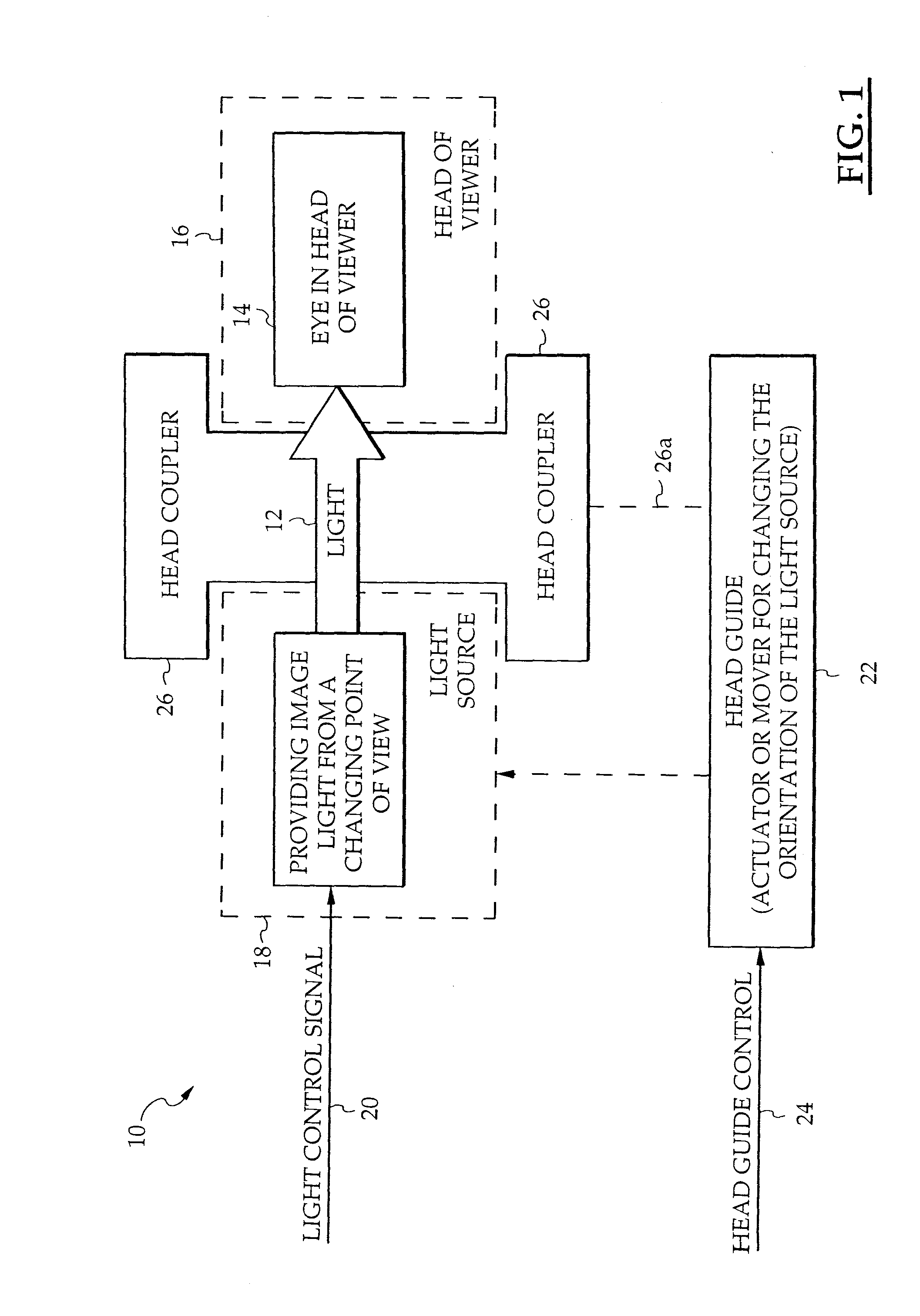

Storage medium for storing a signal having successive images for subsequent playback and a method for forming such a signal for storage on such a storage medium

InactiveUS20100231706A1Input/output for user-computer interactionCosmonautic condition simulationsWorkstationMotion synchronization

A method of (1) navigating a camera with both translatory movements and attitudinal movements while capturing successive images in an object space and at the same time sensing the translatory and attitudinal movements of the camera with respect to a three-dimensional reference frame of the object space, (2) providing successive computer generated images produced by a computer workstation from the successive images in synchronization with the sensed translatory and attitudinal movements of the camera with respect to the three-dimensional reference frame, and (3) storing the successive computer generated images on a non-transitory storage medium for later retrieval by a playback device for presentation by the playback device of said successive computer generated images to at least one eye of a viewer in an image space for perception of the successive computer generated images. A non-transitory storage medium for storing the successive images is also provided.

Owner:LLC SIMULATED PERCEPTS

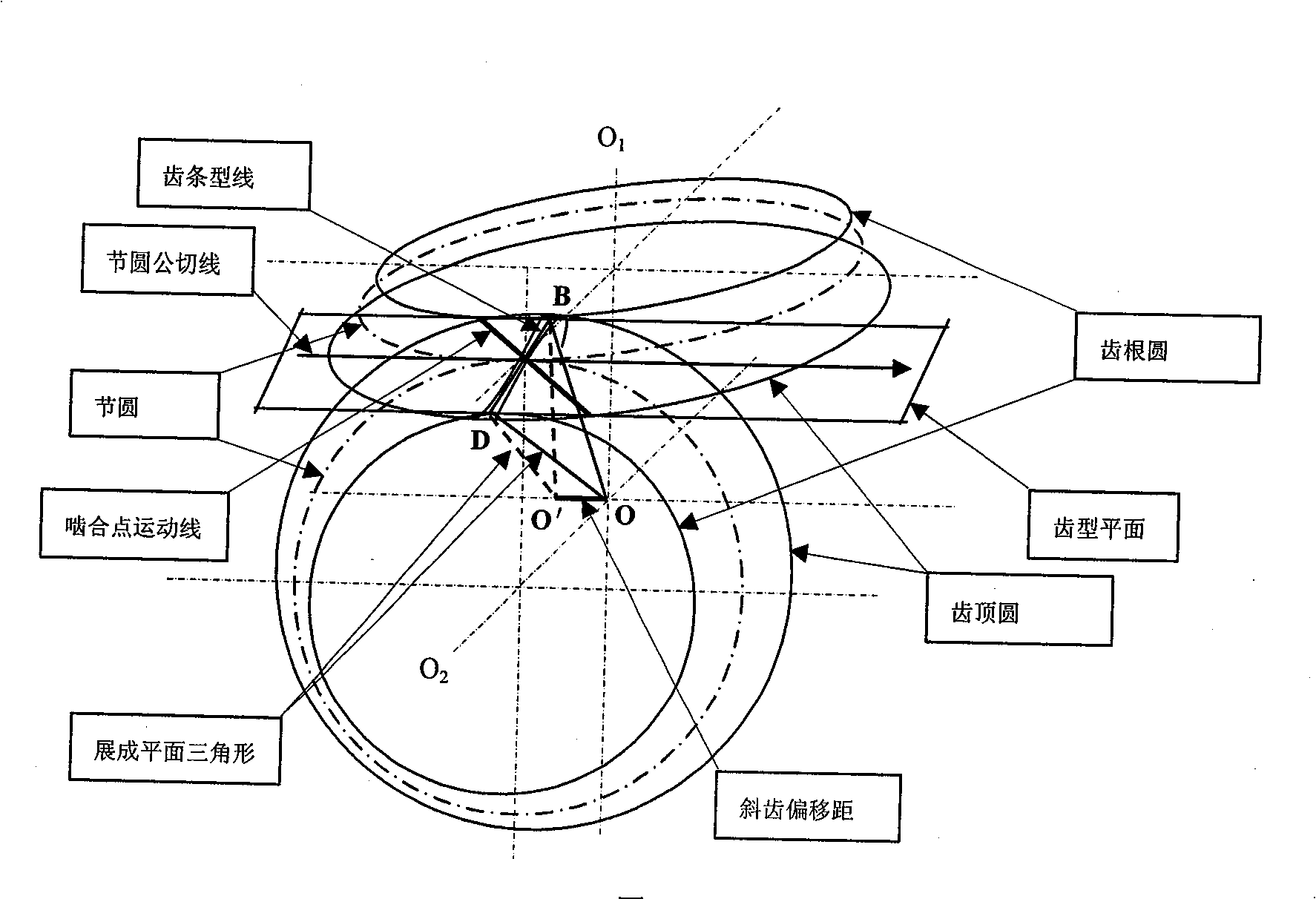

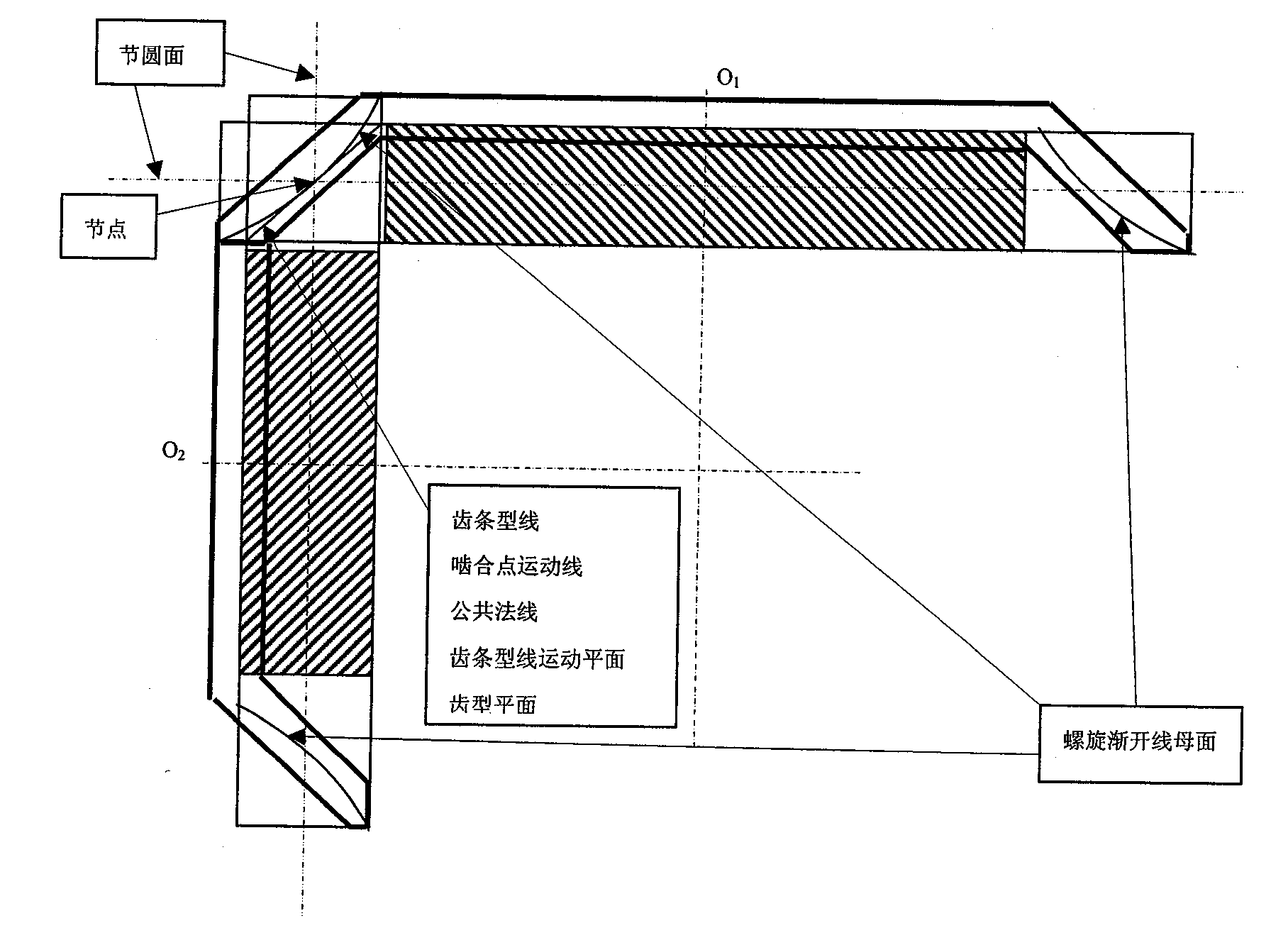

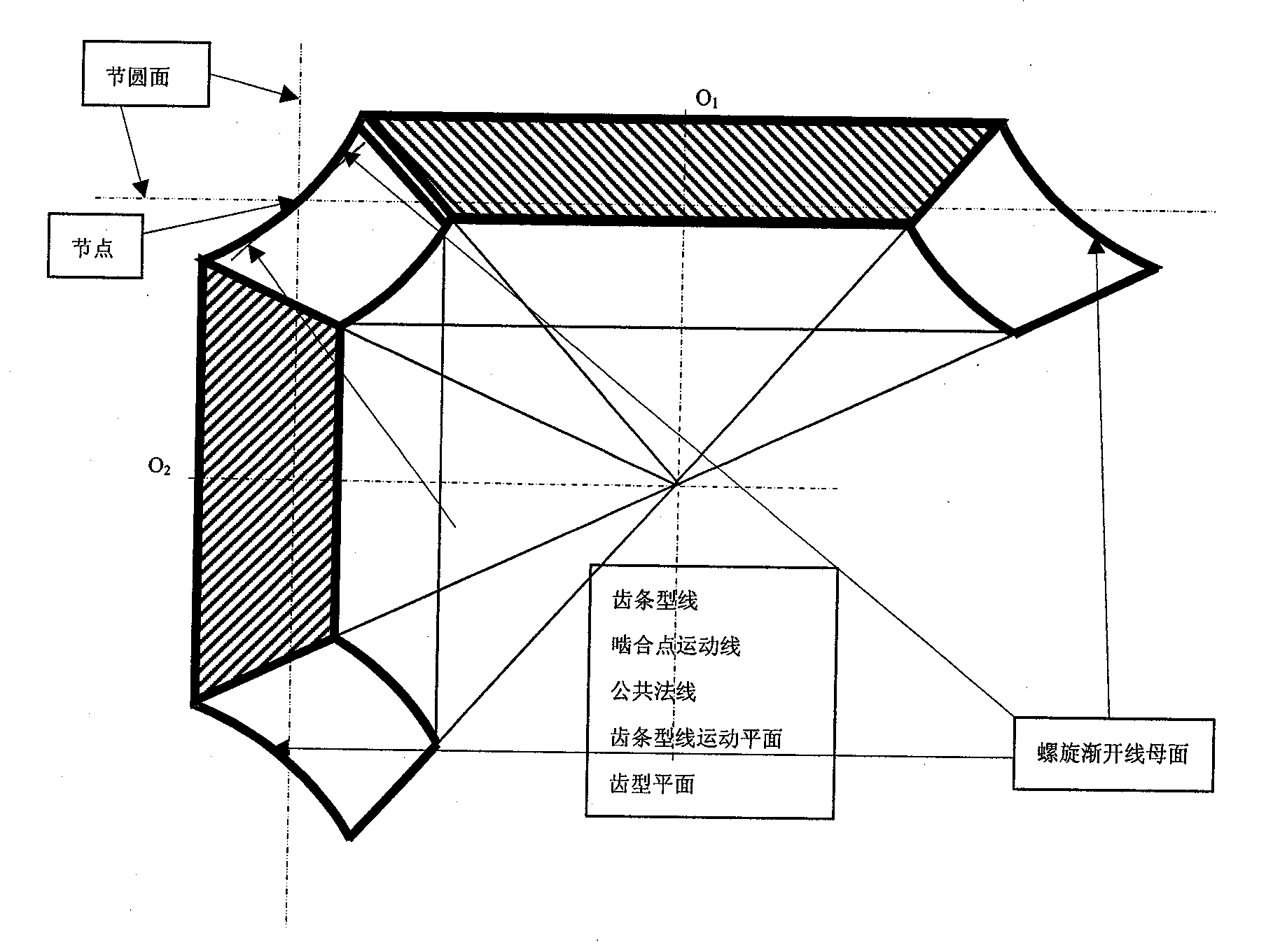

Helical involute gear and processing method thereof

InactiveCN101526129AEasy to processClear and easy to understand the transmission principlePortable liftingGear teethGear driveInvolute gear

The invention relates to a helical involute gear and a processing method thereof. The helical involute gear is characterized in that a tooth surface molded line is a helical involute which is a curve spread by a rack type line straightly moving along the pitch circle tangent line and pure-rolling with a gear pitch circle. The helical involute gear has clear and easy drive principle, can ensure the drive continuity and the drive uniformity, and can realize surface meshing with large meshing area so that the bearing capacity is strong; the helical involute gear has long meshing line and large superposition coefficient, especially, an inclined helical involute conical gear is easy to implement speed reduction at high speed ratio. The helical involute conical gear can realize the expansion processing, thereby having high processing accuracy, low processing cost and high processing tooth surface hardness, improving the motion stability of the gear and the bearing capacity, and prolonging the service life. Meanwhile, processing equipment required by the helical involute gear can be conveniently processed by utilizing the method, thereby solving the difficulties of large processing difficulty and high cost of a gear drive pair with intersecting axes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

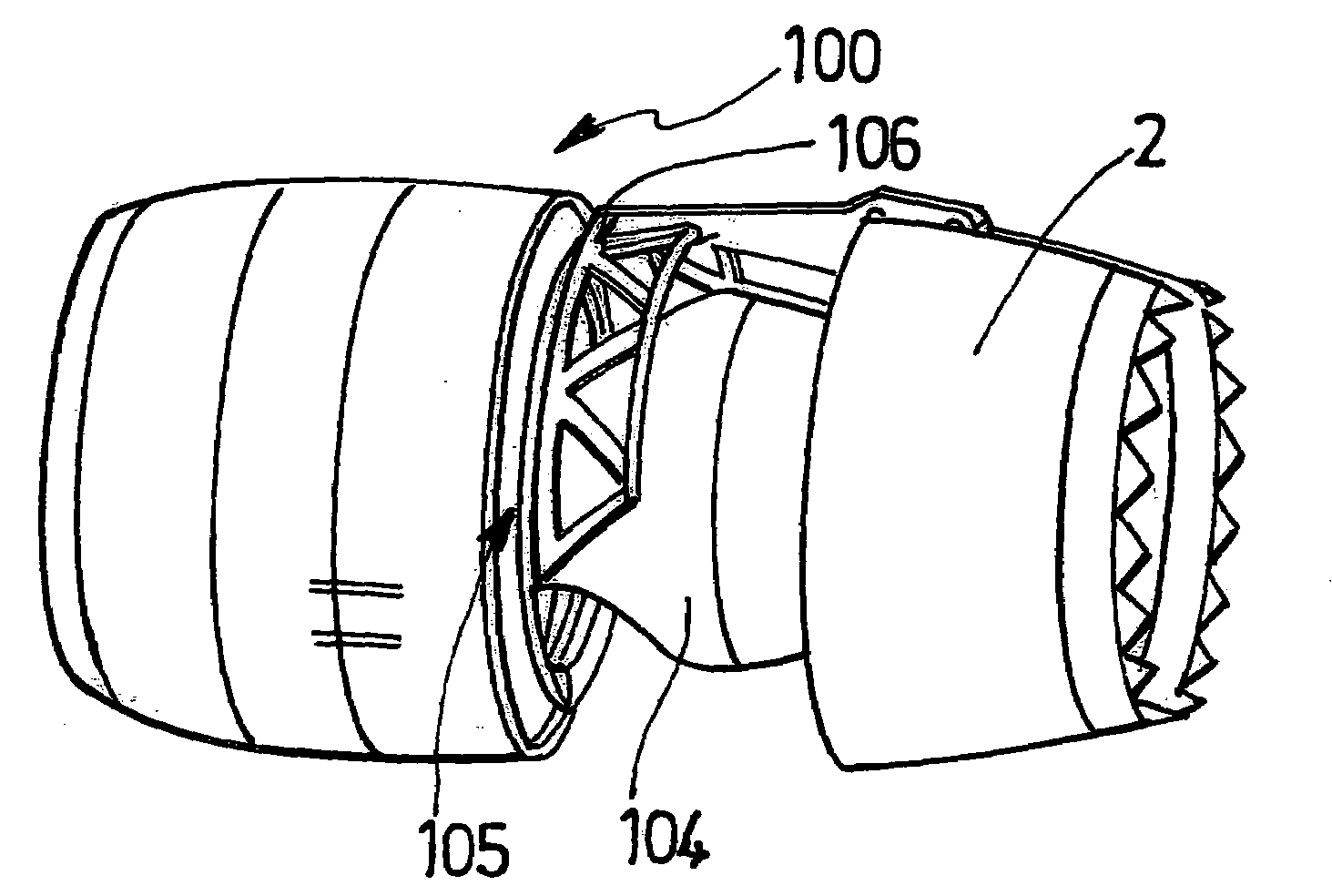

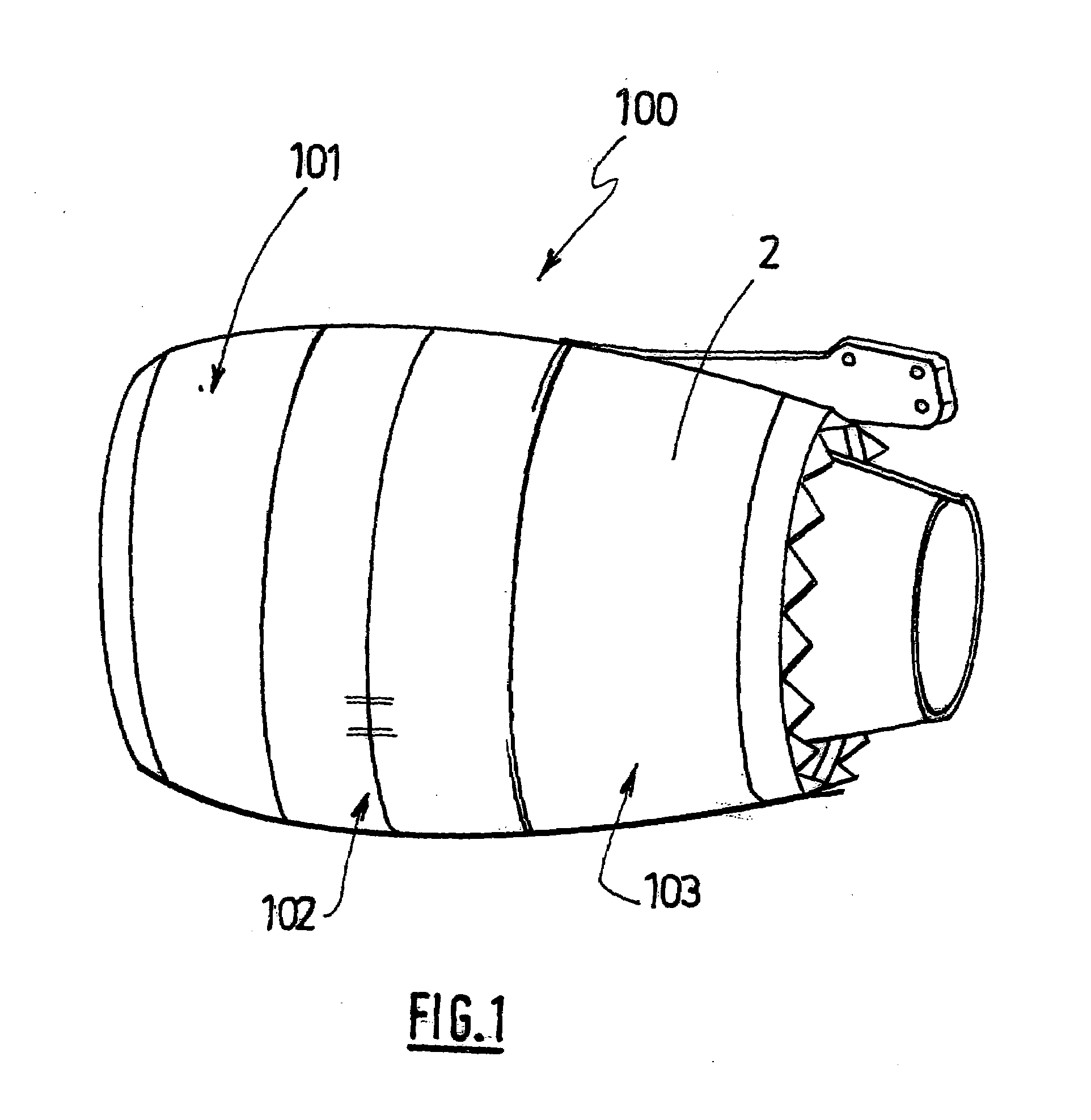

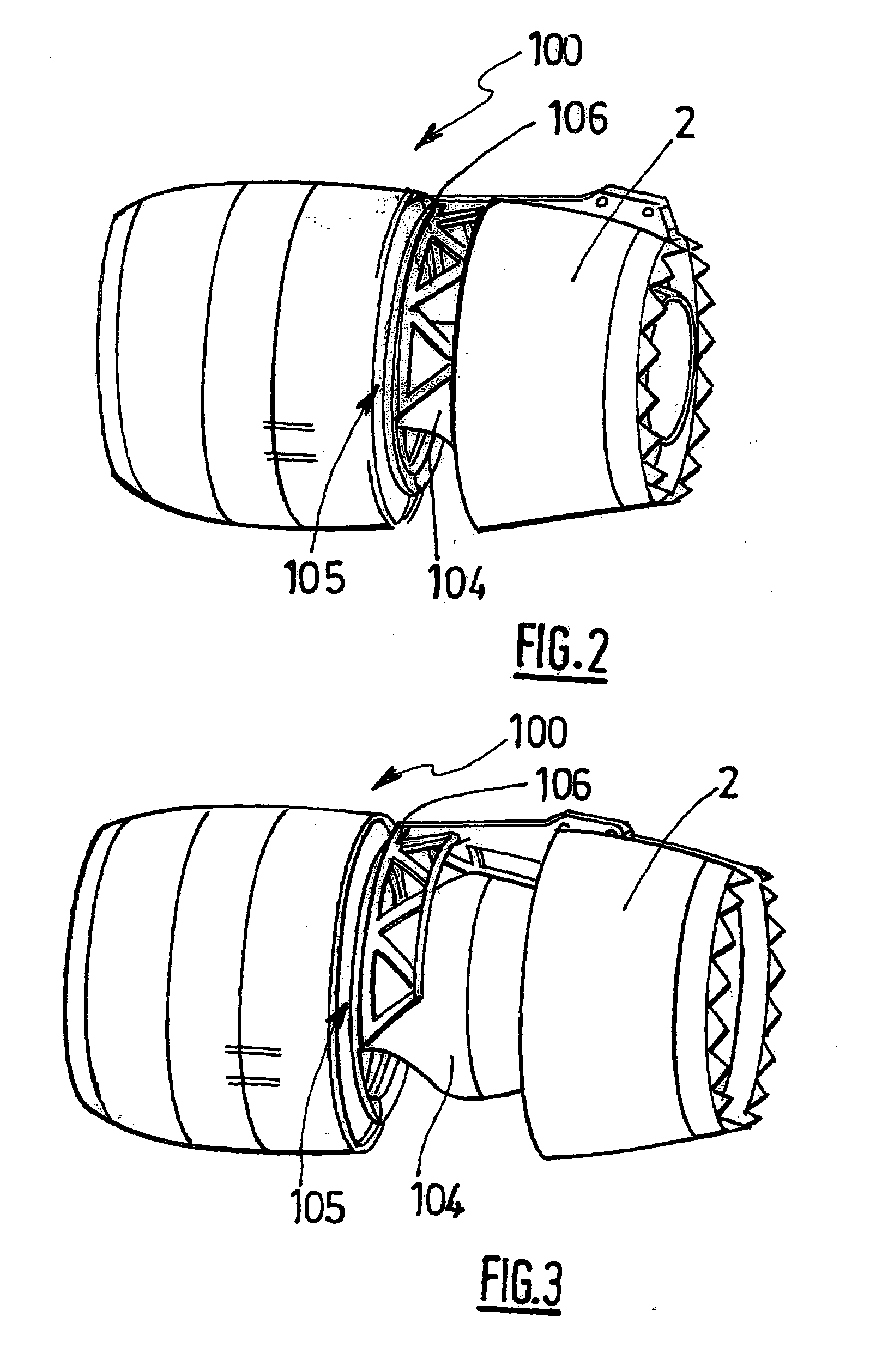

Translatable thrust inverter for jet engine

InactiveUS20100001123A1Simply openedPower plant arrangements/mountingAircraft power plant componentsNacelleJet engine

Owner:SAFRAN NACELLES

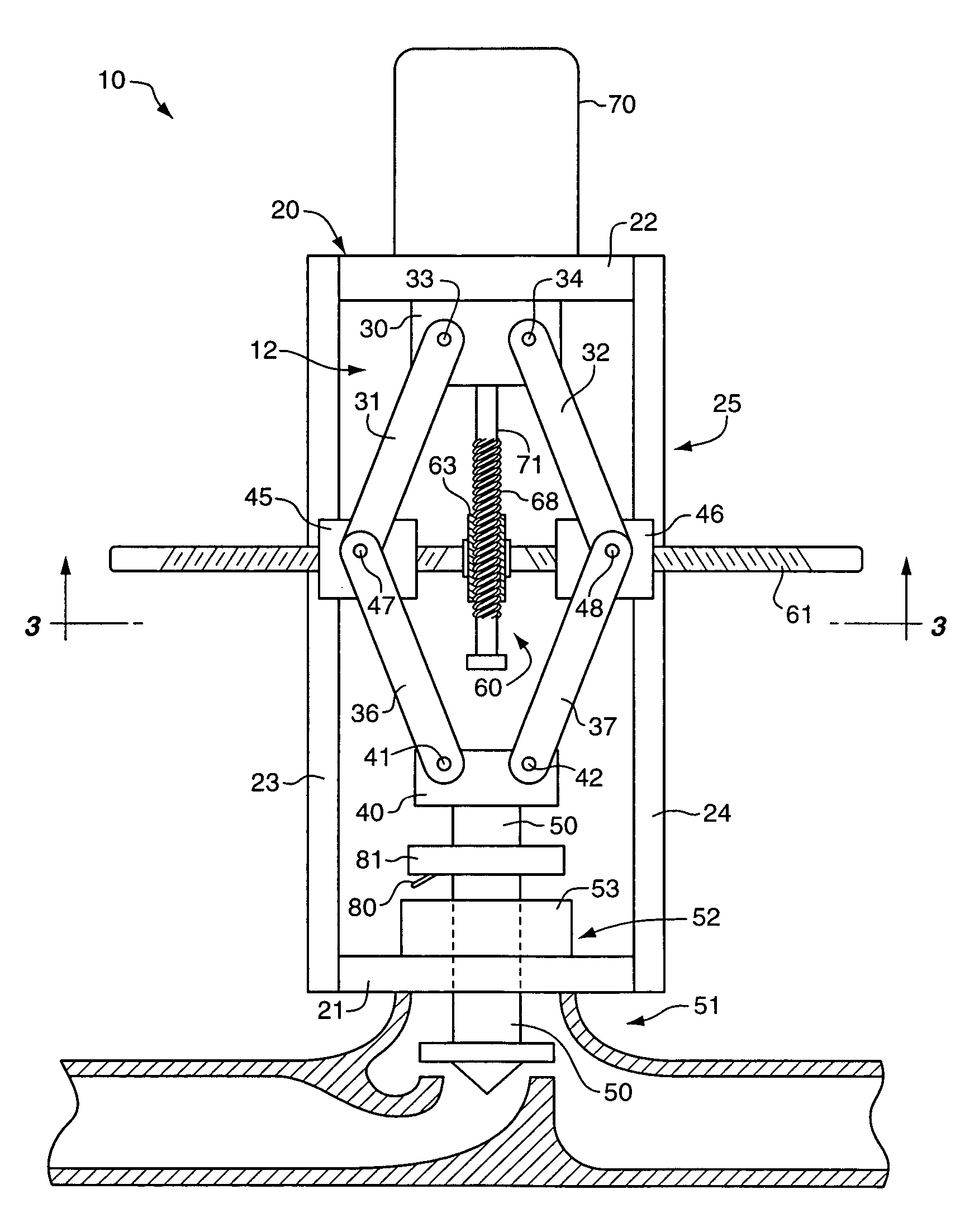

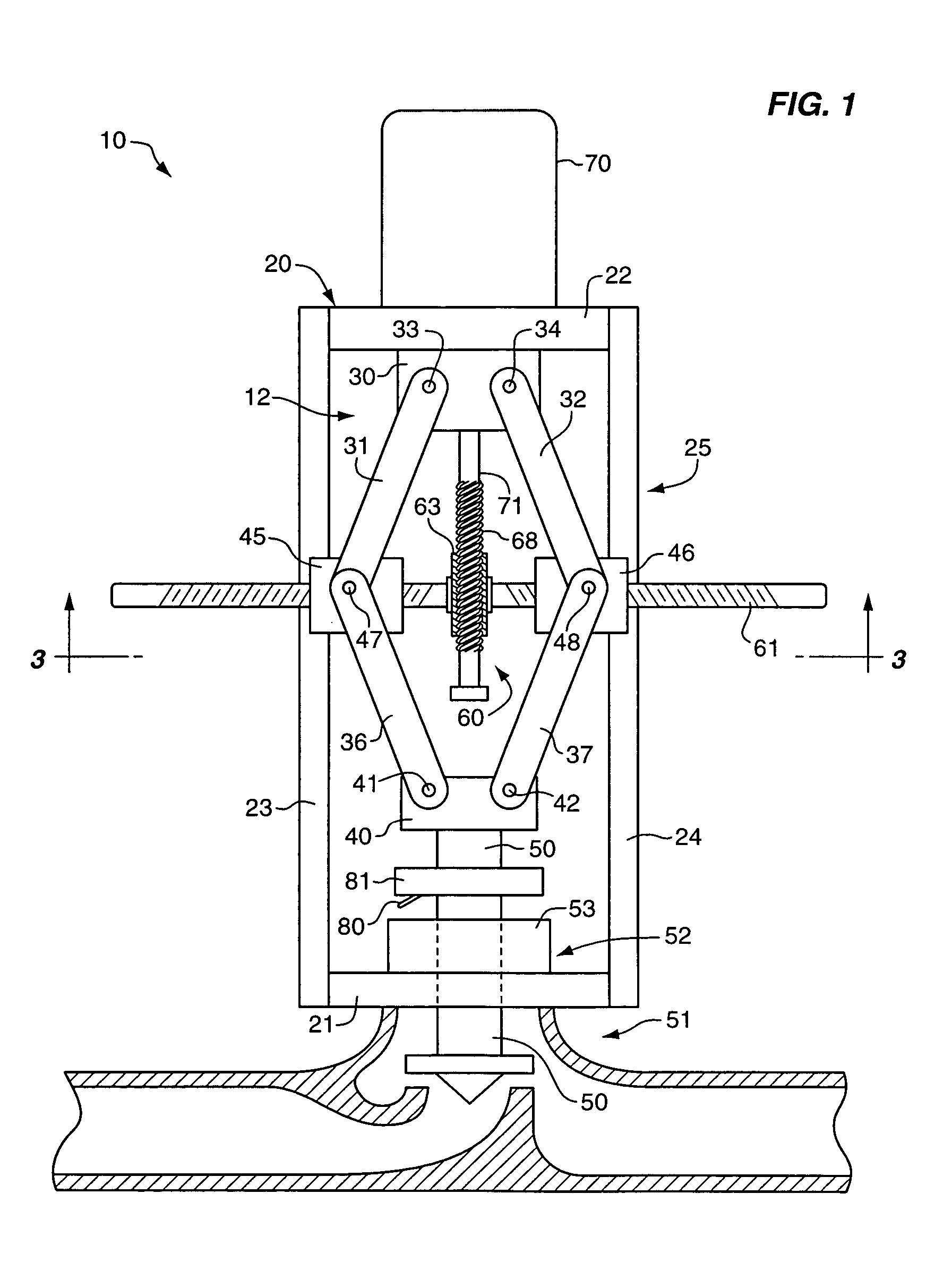

Scissor thrust valve actuator

InactiveUS7097148B2Operating means/releasing devices for valvesPipeline systemsMotor driveSensory control

Apparatus for actuating a valve includes a support frame and at least one valve driving linkage arm, one end of which is rotatably connected to a valve stem of the valve and the other end of which is rotatably connected to a screw block. A motor connected to the frame is operatively connected to a motor driven shaft which is in threaded screw driving relationship with the screw block. The motor rotates the motor driven shaft which drives translational movement of the screw block which drives rotatable movement of the valve driving linkage arm which drives translational movement of the valve stem. The valve actuator may further include a sensory control element disposed in operative relationship with the valve stem, the sensory control element being adapted to provide control over the position of the valve stem by at least sensing the travel and / or position of the valve stem.

Owner:BATTELLE ENERGY ALLIANCE LLC

Liquid ejecting apparatus and liquid container holder thereof

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com