Helical involute gear and processing method thereof

An involute gear and involute technology, applied in the field of mechanical parts, can solve the problems of poor processing versatility, high cost, and difficult processing of intersecting shaft transmission gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

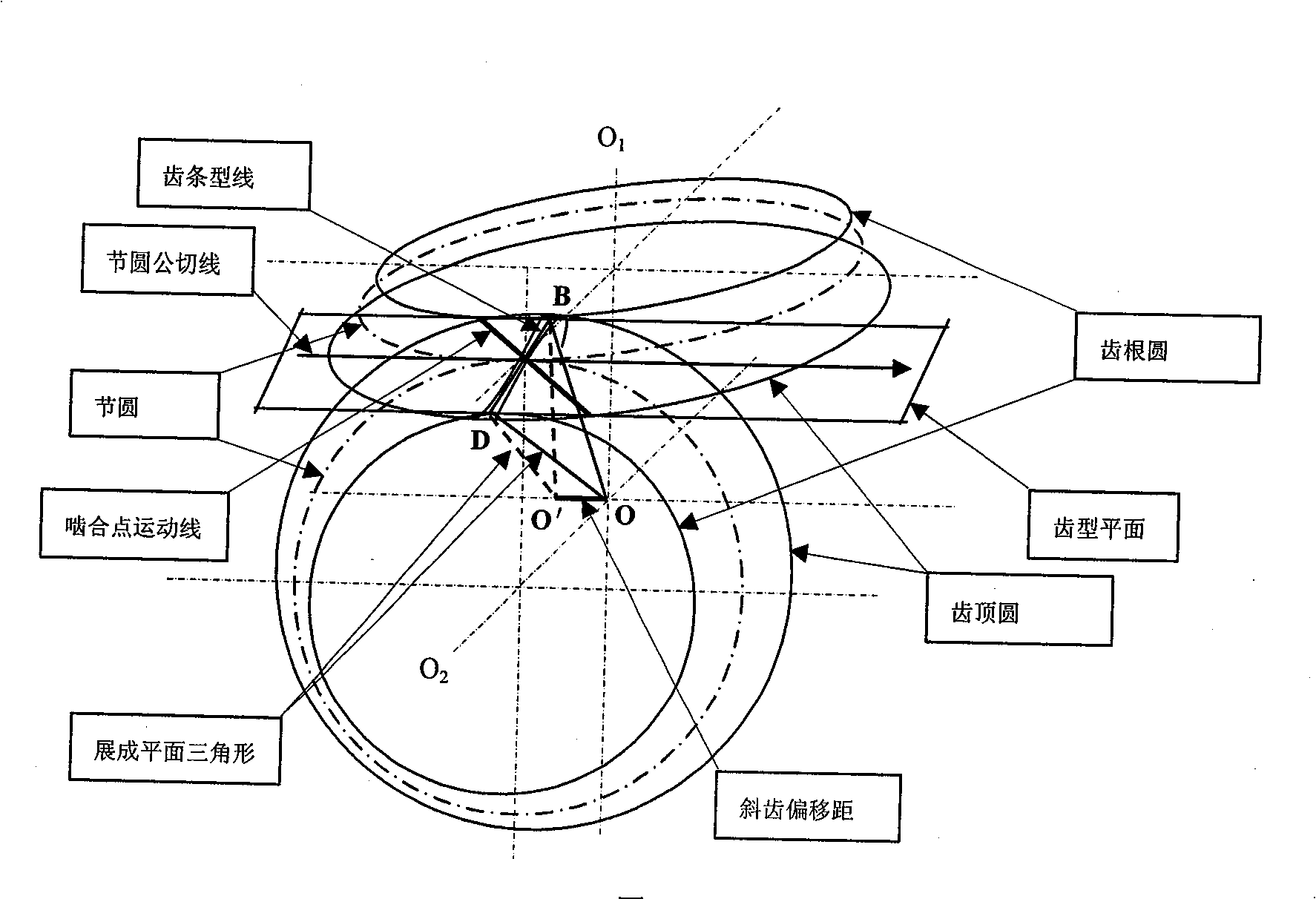

[0065] Such as figure 1 , 13 , 18 shown.

[0066] A spiral involute gear, no matter what kind of transmission pair it is used in, its tooth surface profile adopts a spiral involute; the spiral involute is the involute base circle in the process of generating the involute At the same time, the space curve is generated by uniform linear motion along the axis of the base circle and uniform rotation around the axis of the base circle. The cylindrical coordinate parameter equation of the spiral involute is:

[0067] ρ = R 0 cos α

[0068] Z=k·R 0 ·tgα

[0069] ψ=k·c·tgα+tgα-α

[0070] In the formula,

[0071] ρ—cylindrical coordinate radial vector,

[0072] R 0 ——involute base circle radius,

[0073] ψ——cylindrical coordinate angle vector,

[0074] Z——cylindrical coordinate axial vector,

[0075] α—parametric equation parameter, involute pressure a...

Embodiment 2

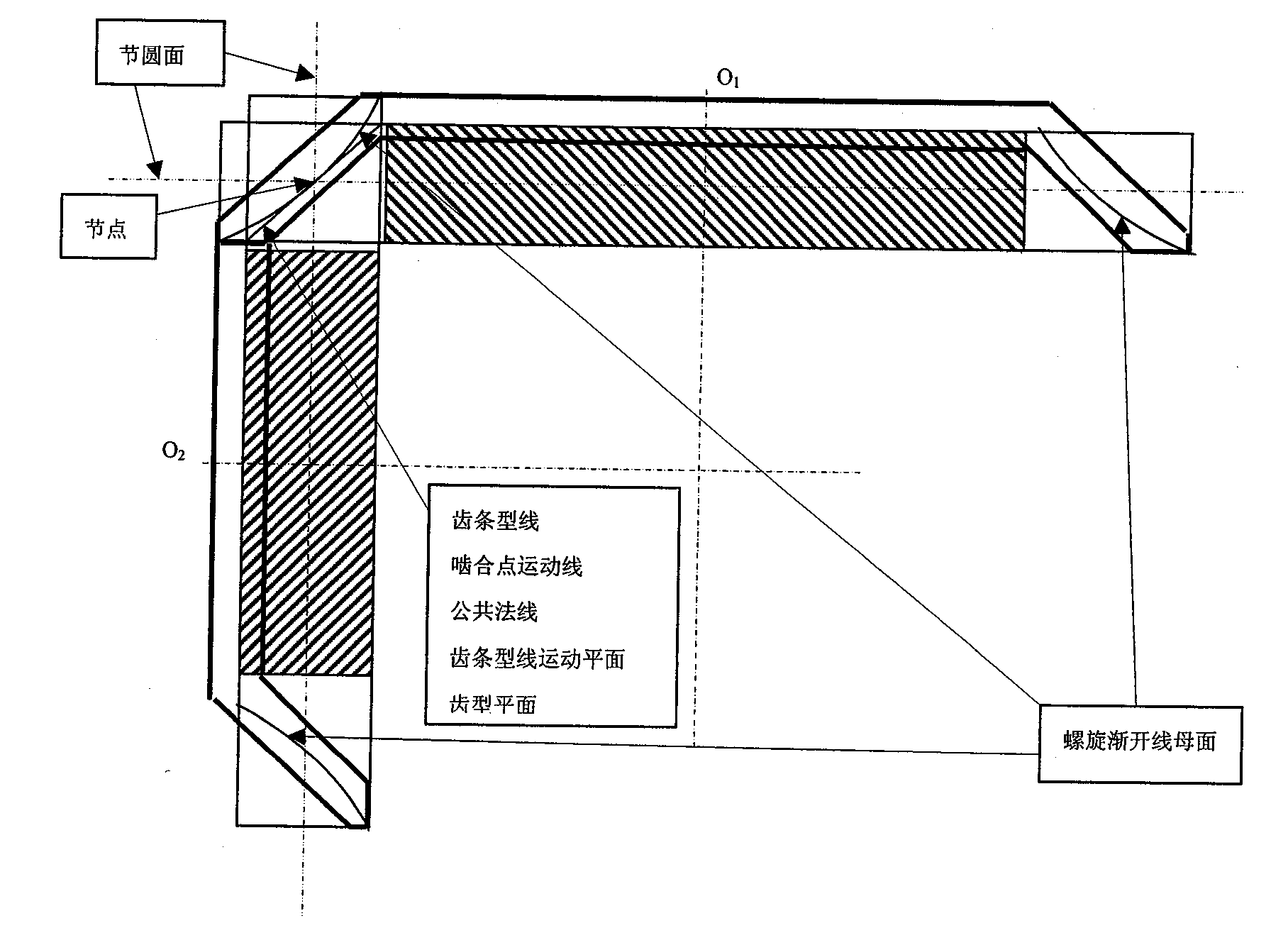

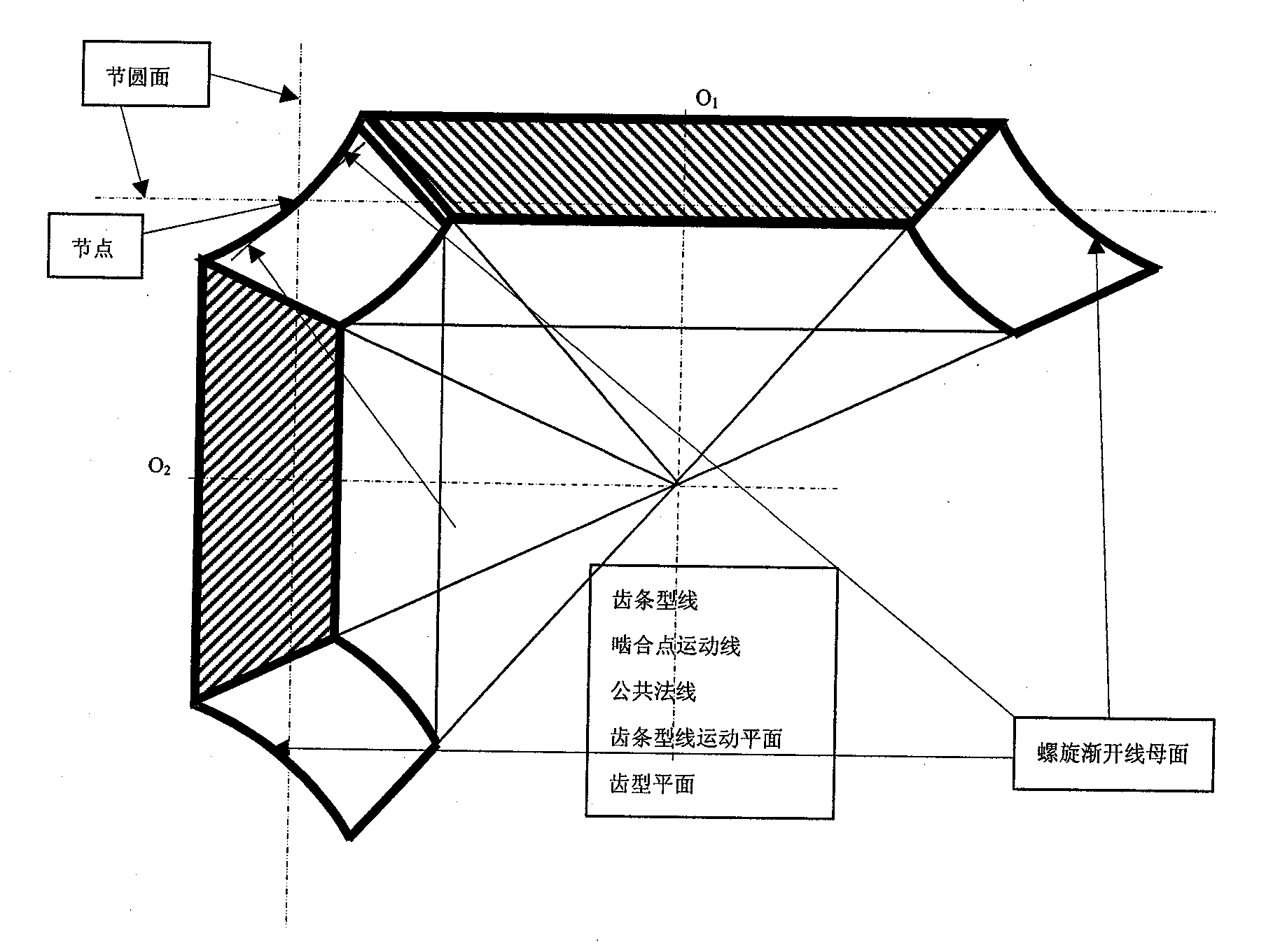

[0079] Such as Figure 1-3 shown.

[0080] A helical involute gear that can be used in vertical intersecting shaft transmission pairs, and it can also be used in general intersecting shaft transmission pairs. The characteristic of this gear is that its tooth surface profile is a spiral involute. The said spiral involute is a spiral involute that is tangent to the pitch circle, intersects the axes of the base circle to form an angle λ, and satisfies the condition of intermeshing; these two spiral involutes each have two base cylinder tangent planes that pass through the nodes ,Such as Figure 18 As shown, the corresponding tangent plane forms two symmetrical intersection lines on the left and right, and these two intersection lines are the meshing point motion lines of the two spiral involutes, as shown in Figure 13 The slash CE in 0 , which is also their meshing common normal; the radii of the two base circles of the two helical involutes, the pressure angle α of the pitc...

Embodiment 3

[0084] A processing method for a cylindrical helical involute gear, which should first manufacture a special hob with only a half-side tooth shape that matches the pressure angle of the gear as a cylindrical helical gear, and can hob and cut two Side tooth surface; with a dish-shaped grinding wheel, both sides of the tooth surface can be ground separately on an ordinary gear grinding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com