Patents

Literature

295 results about "Involute gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

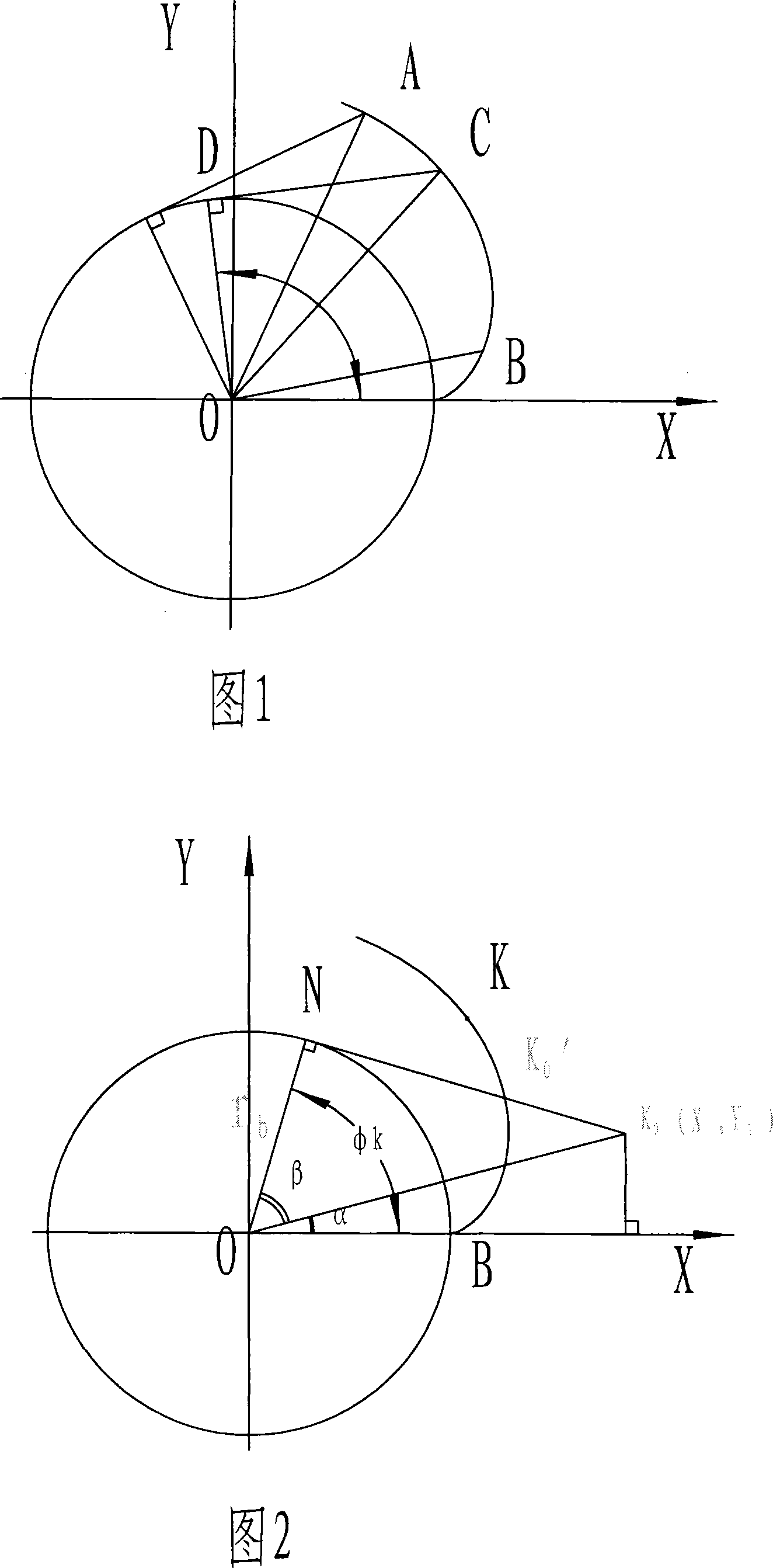

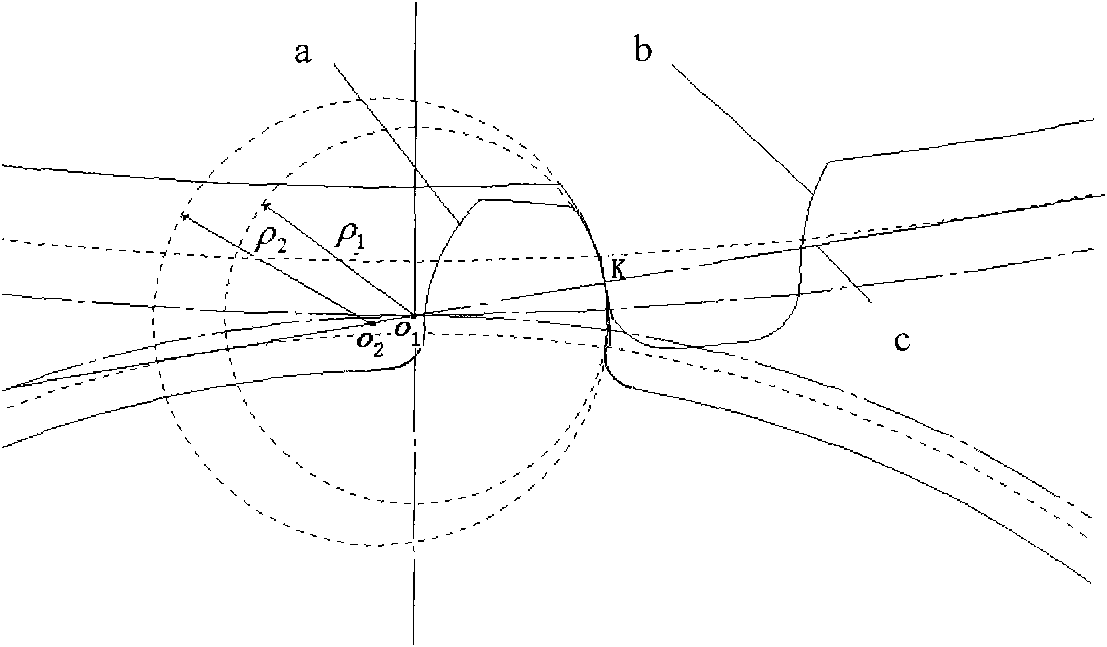

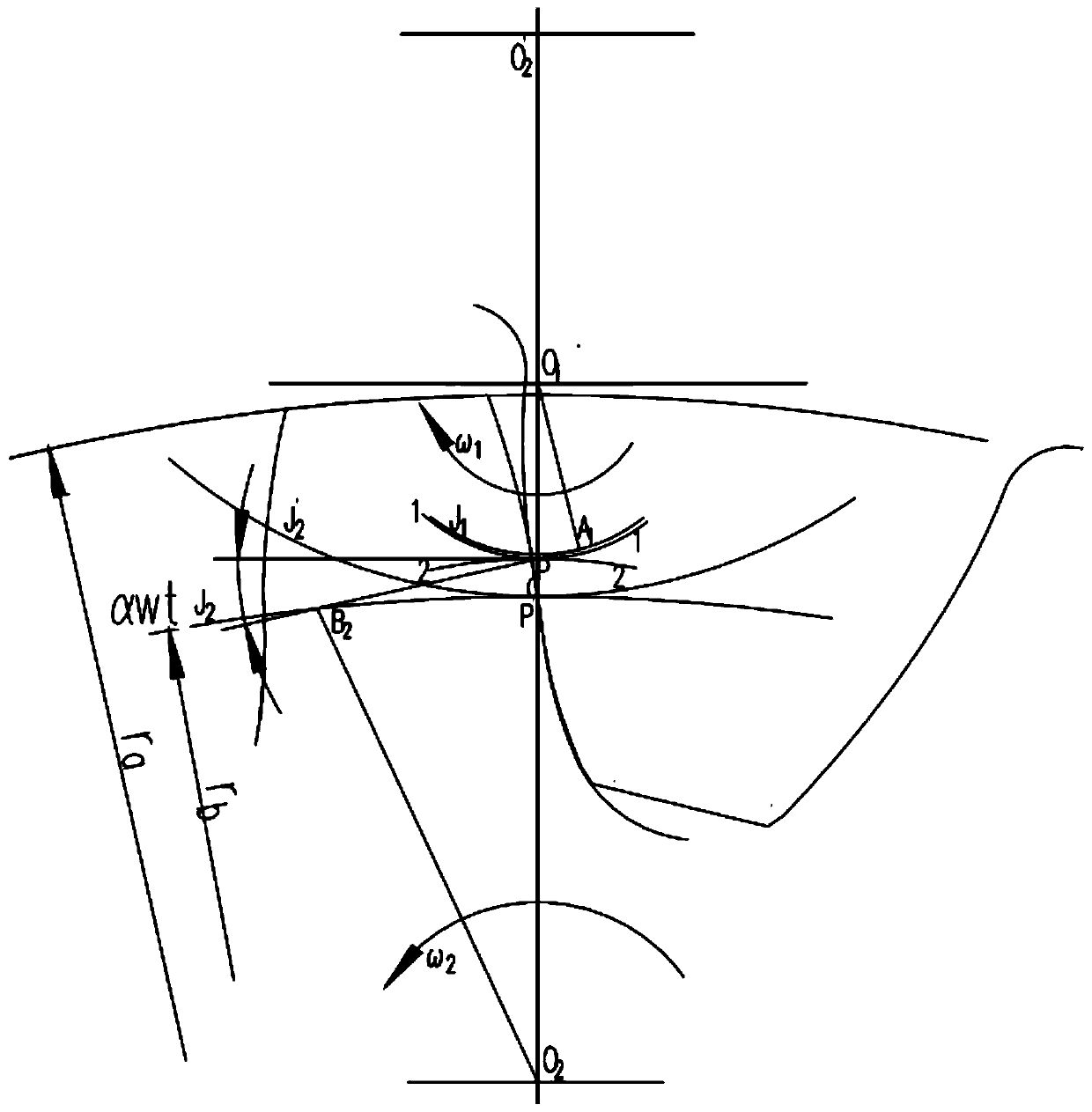

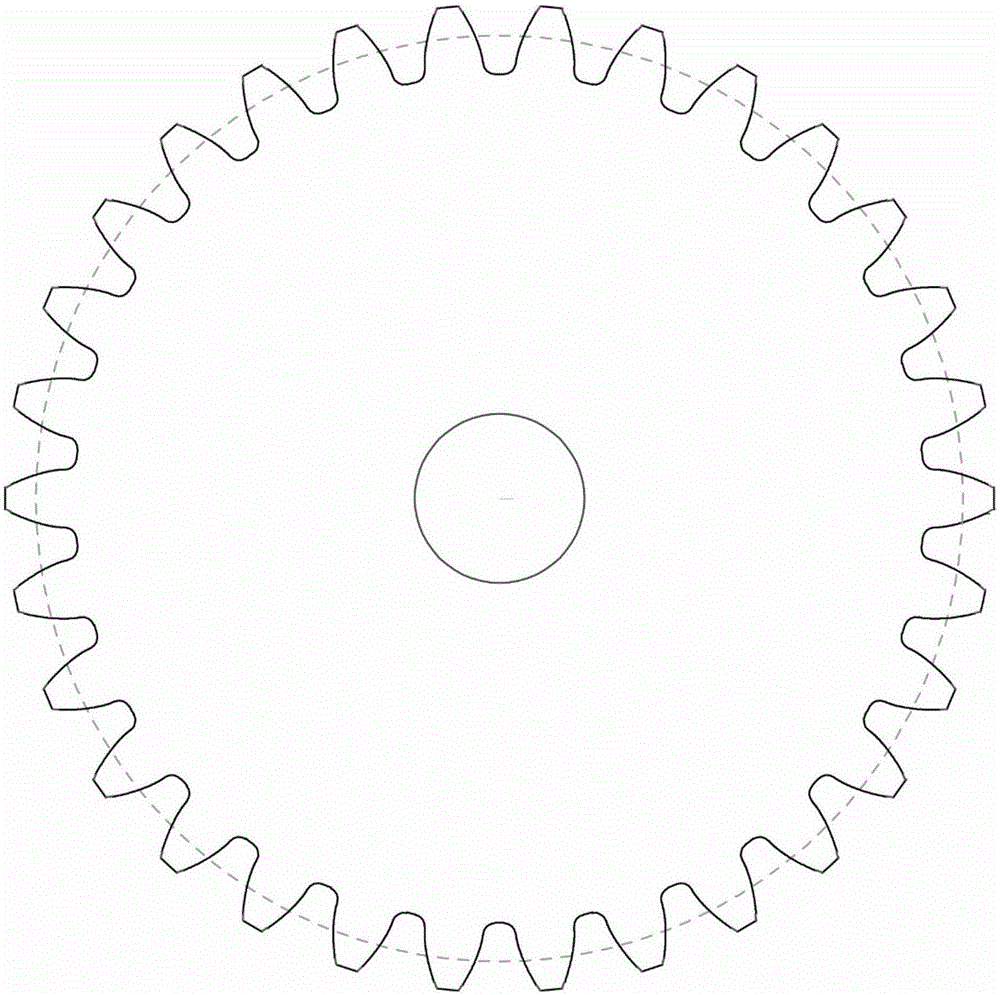

The involute gear profile is the most commonly used system for gearing today, with cycloid gearing still used for some specialties such as clocks. The involute gear profile was a fundamental advance in machine design, since unlike with other gear systems, the tooth profile of an involute gear depends only on the number of teeth on the gear, pressure angle, and pitch. That is, a gear's profile does not depend on the gear it mates with. Thus, n and m tooth involute spur gears with a given pressure angle and pitch will mate correctly, independently of n and m. This dramatically reduces the number of shapes of gears that need to be manufactured and kept in inventory.

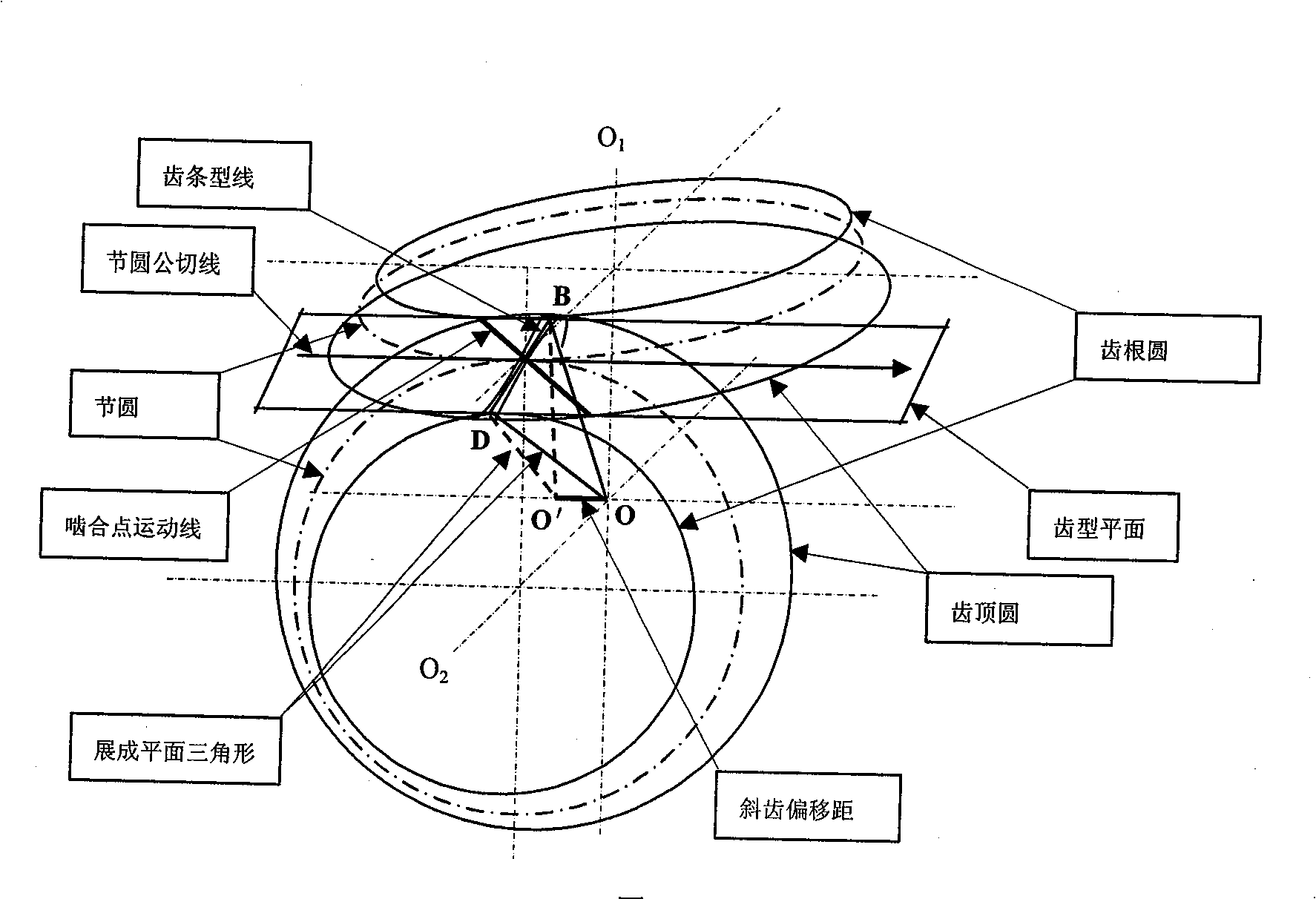

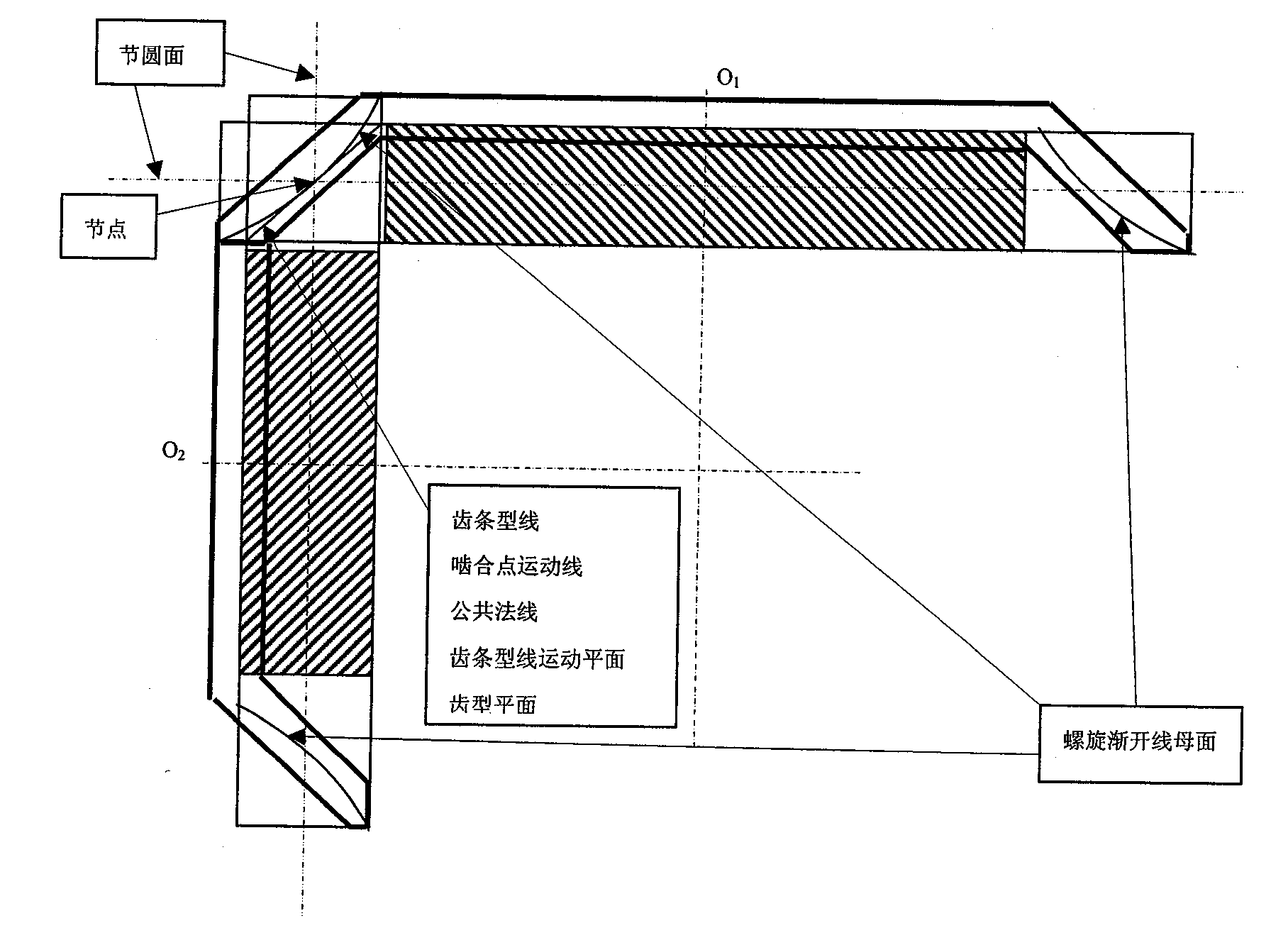

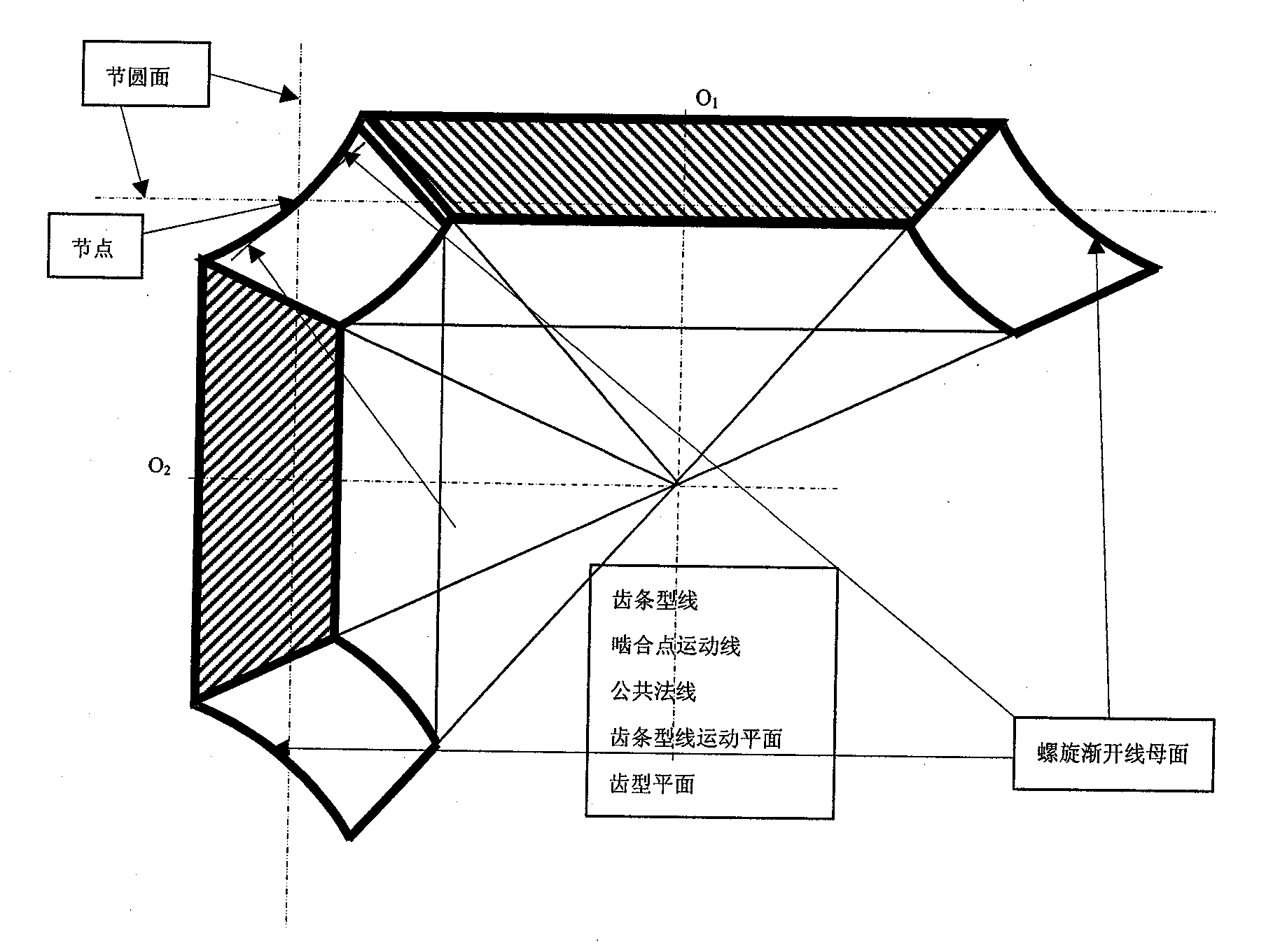

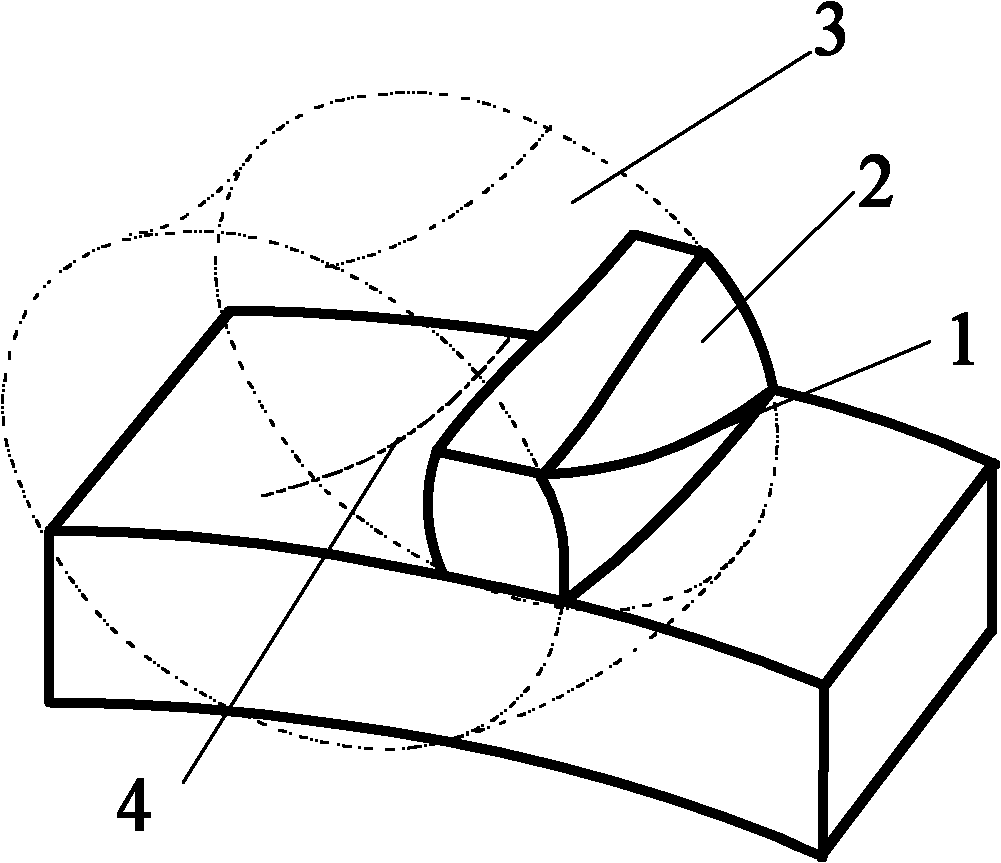

Helical involute gear and processing method thereof

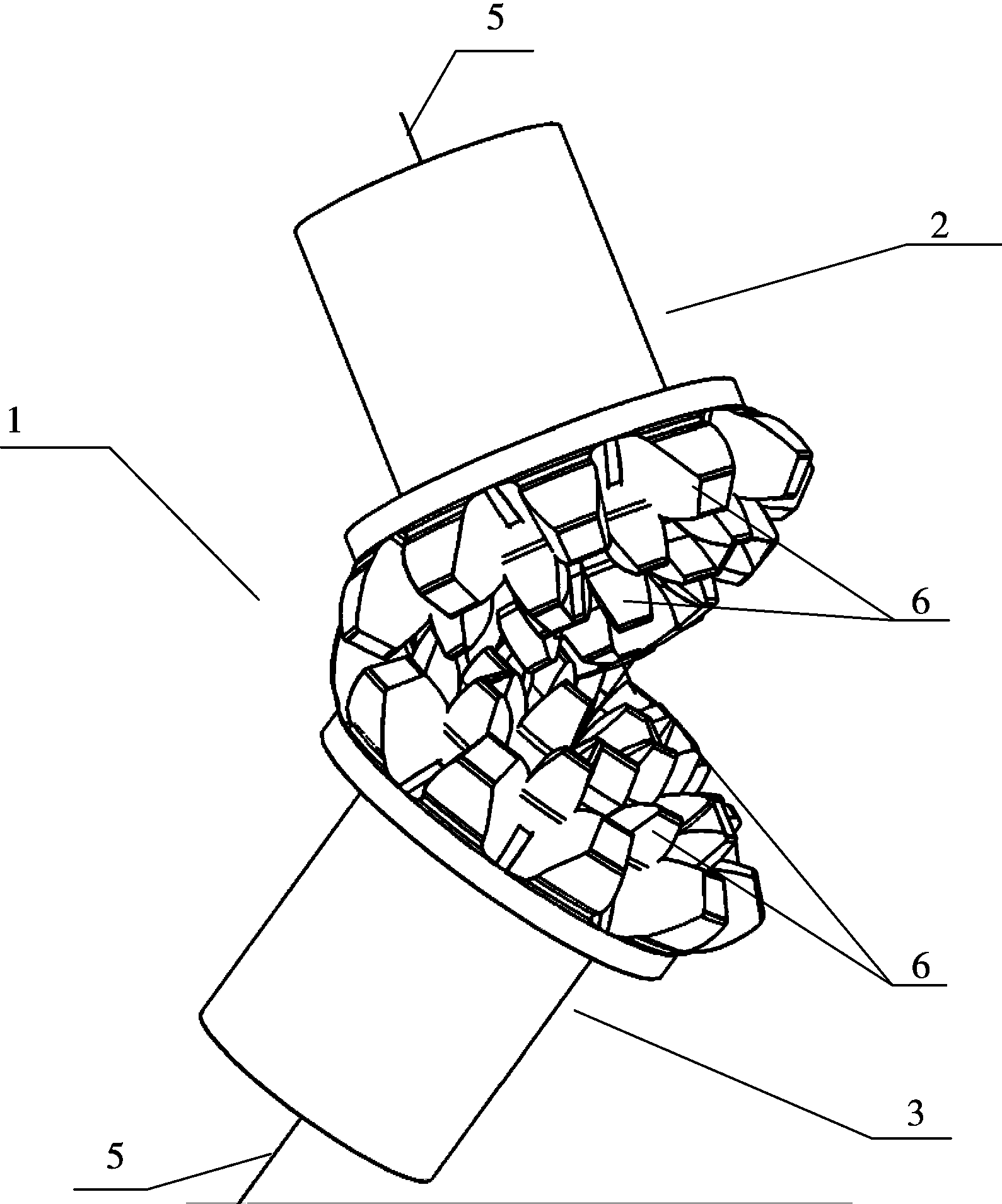

InactiveCN101526129AEasy to processClear and easy to understand the transmission principlePortable liftingGear teethGear driveInvolute gear

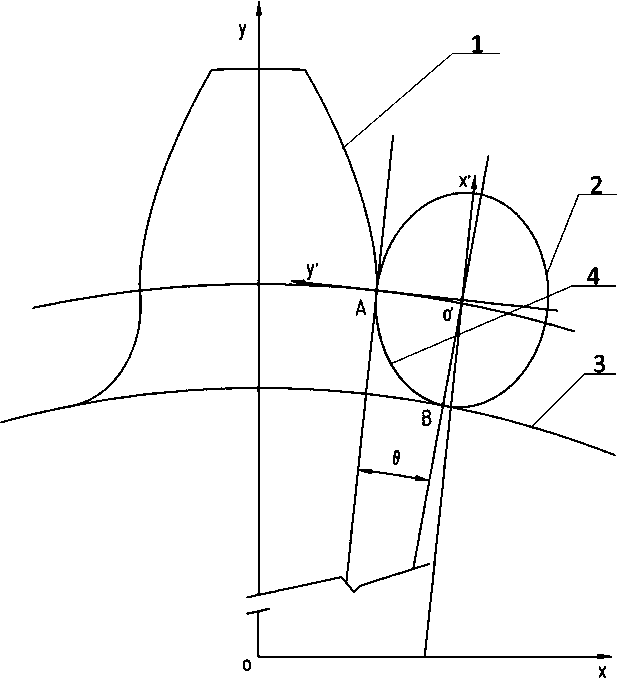

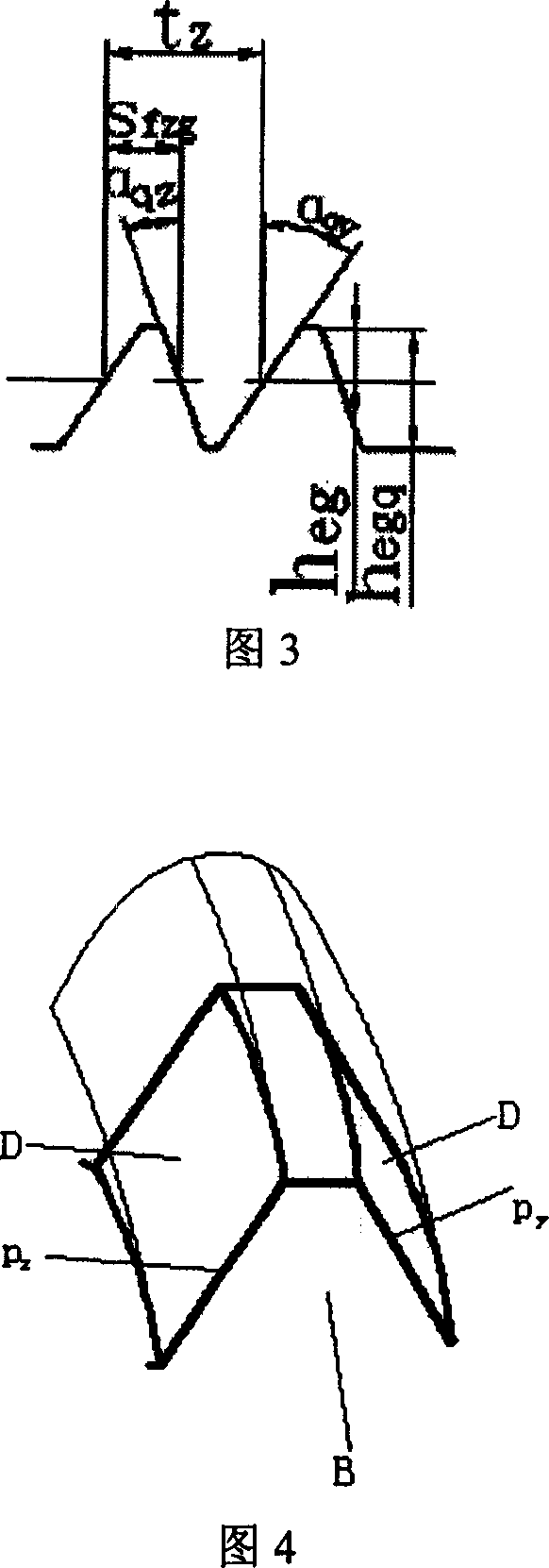

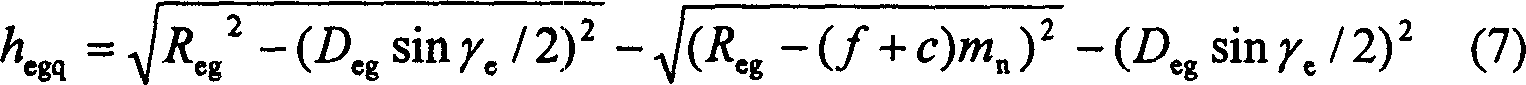

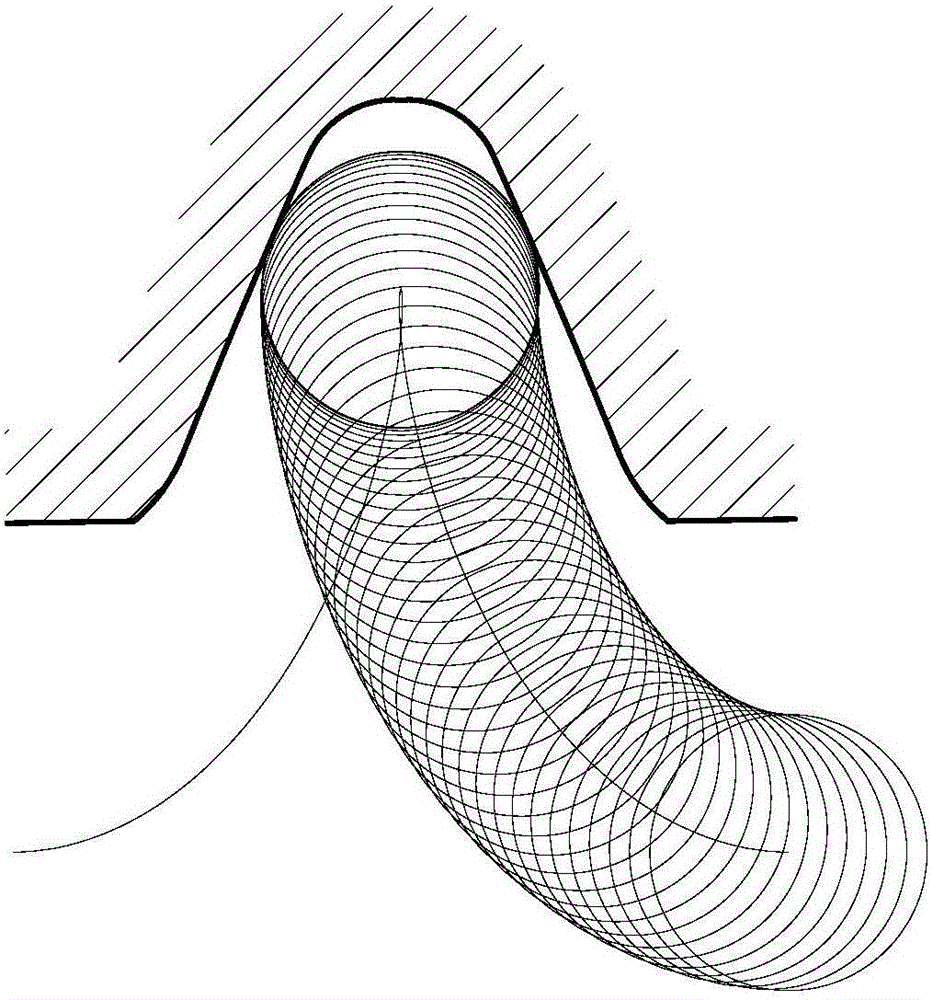

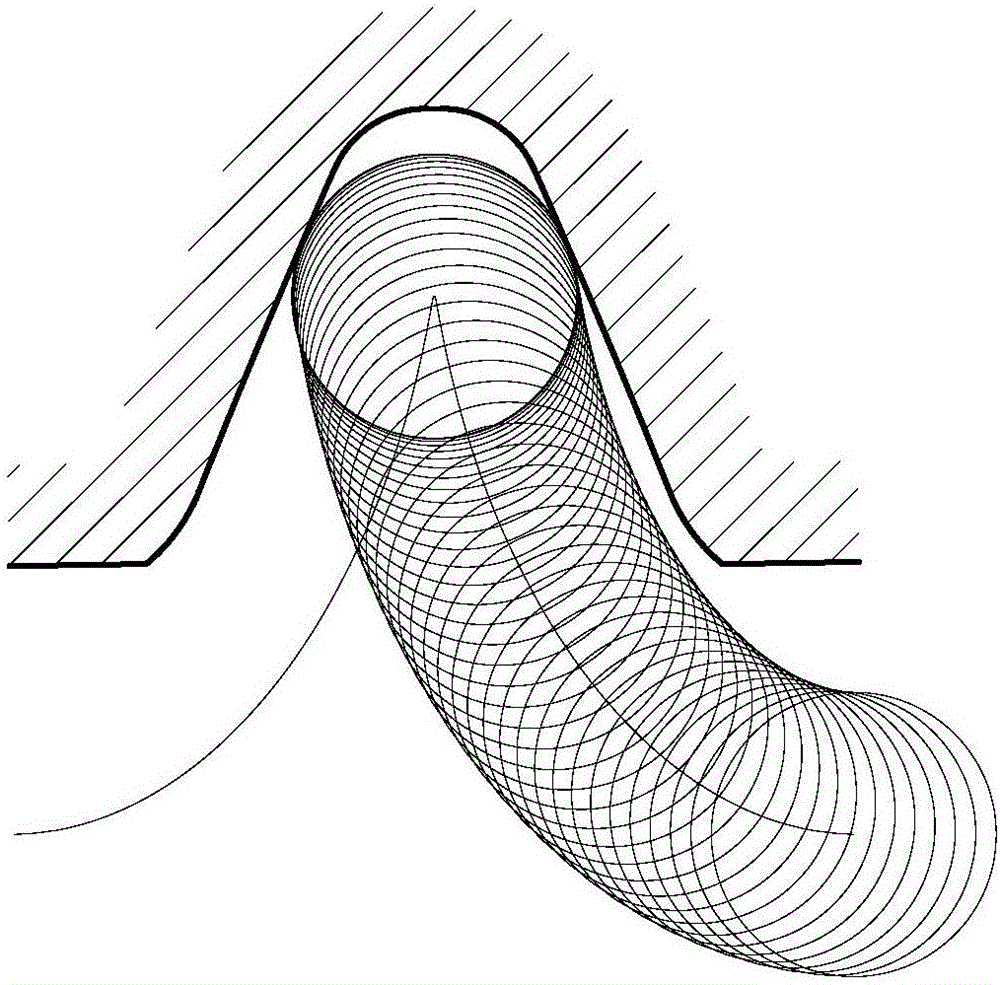

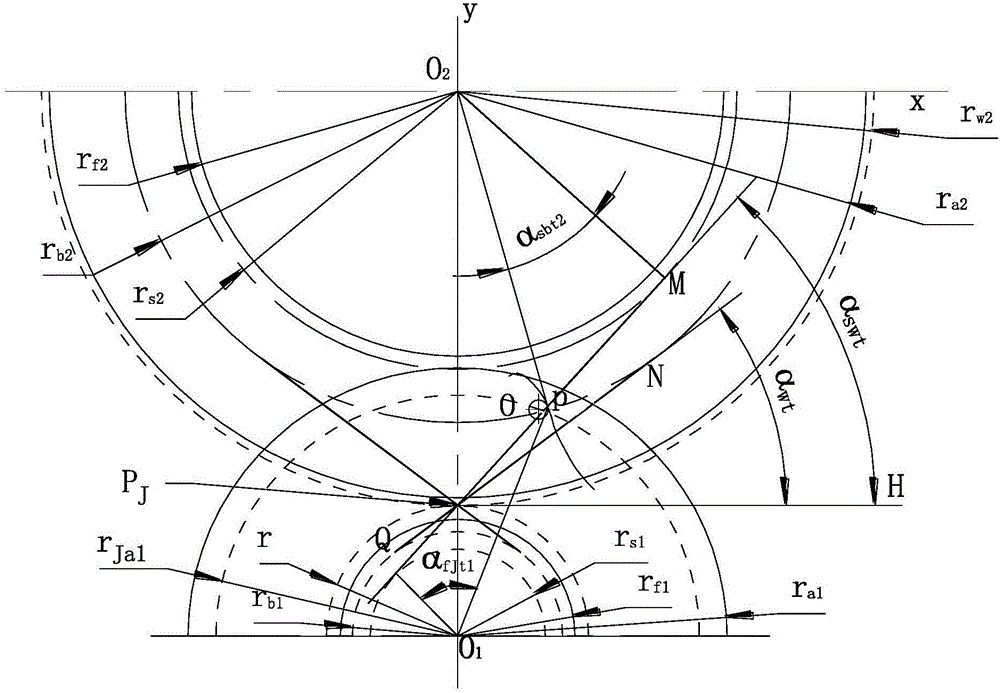

The invention relates to a helical involute gear and a processing method thereof. The helical involute gear is characterized in that a tooth surface molded line is a helical involute which is a curve spread by a rack type line straightly moving along the pitch circle tangent line and pure-rolling with a gear pitch circle. The helical involute gear has clear and easy drive principle, can ensure the drive continuity and the drive uniformity, and can realize surface meshing with large meshing area so that the bearing capacity is strong; the helical involute gear has long meshing line and large superposition coefficient, especially, an inclined helical involute conical gear is easy to implement speed reduction at high speed ratio. The helical involute conical gear can realize the expansion processing, thereby having high processing accuracy, low processing cost and high processing tooth surface hardness, improving the motion stability of the gear and the bearing capacity, and prolonging the service life. Meanwhile, processing equipment required by the helical involute gear can be conveniently processed by utilizing the method, thereby solving the difficulties of large processing difficulty and high cost of a gear drive pair with intersecting axes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

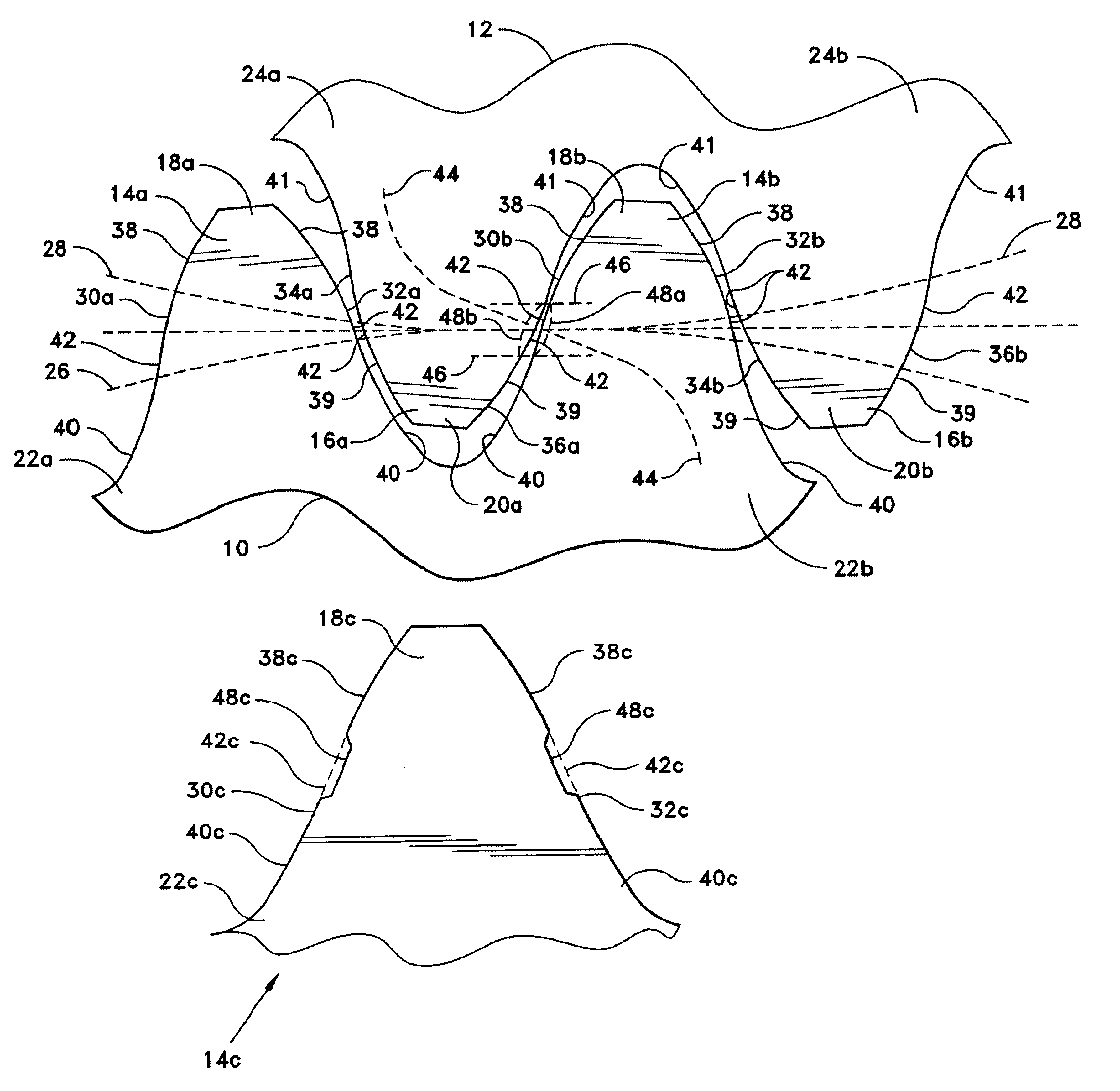

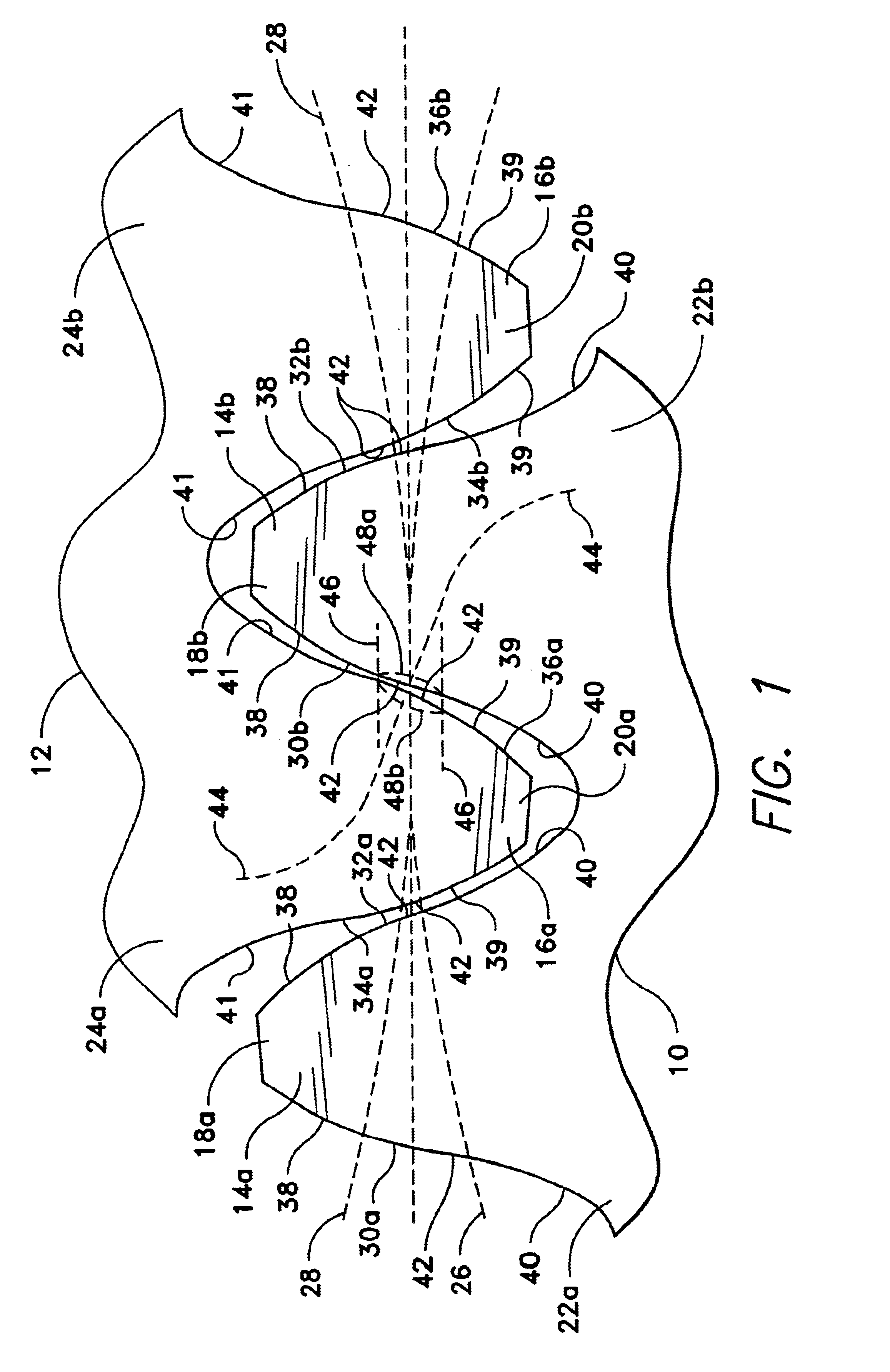

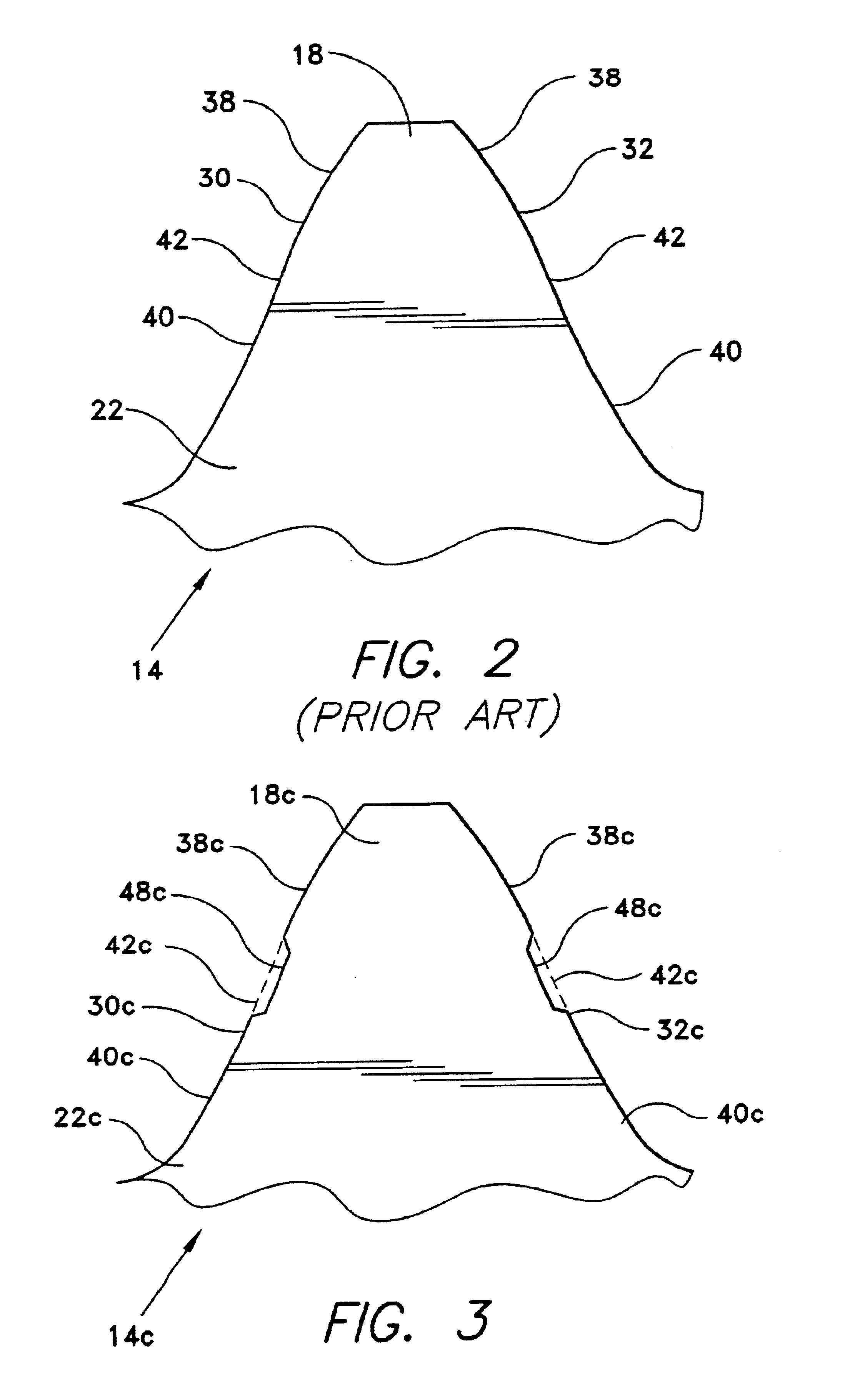

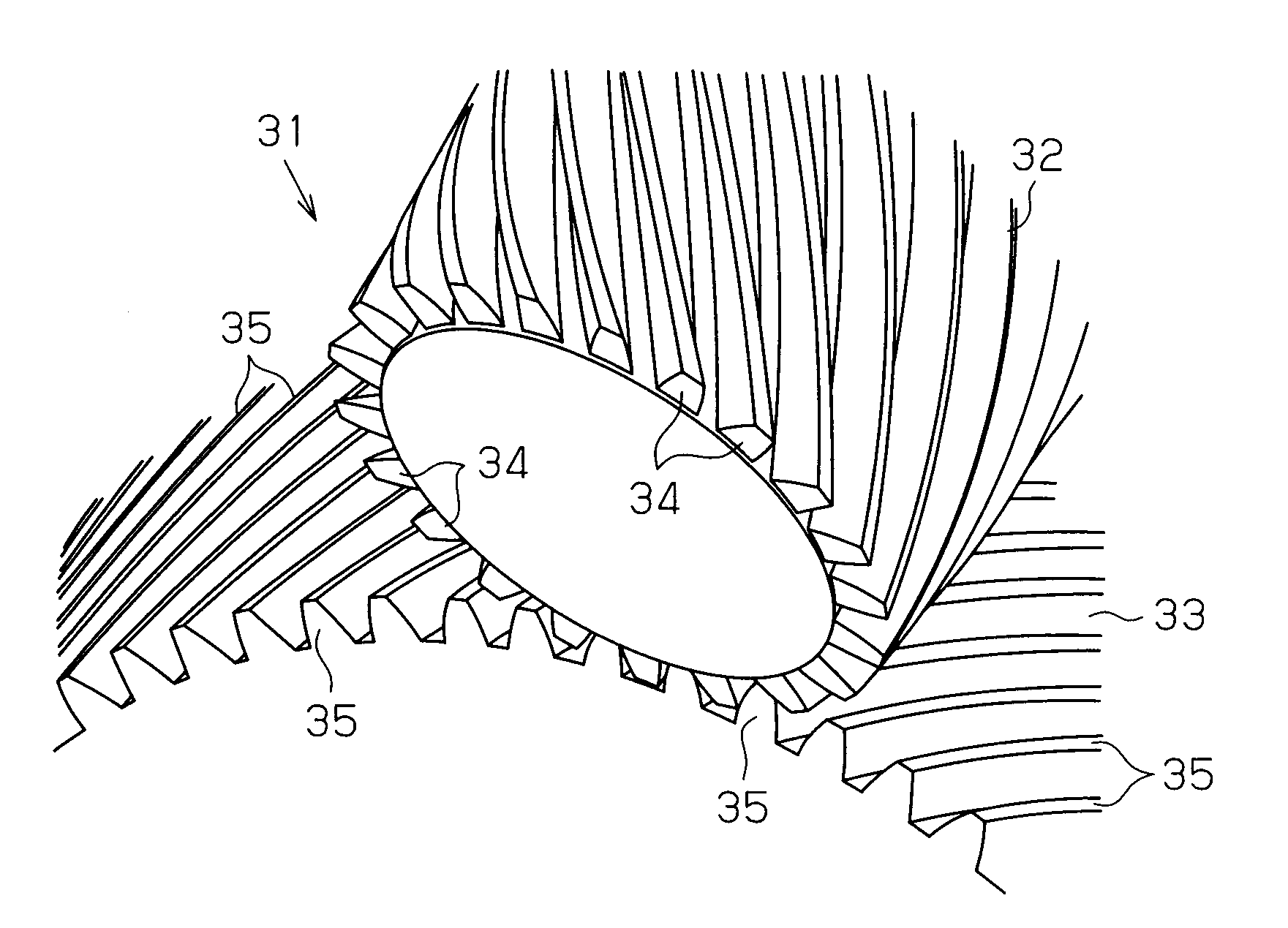

Non-involute gears with conformal contact

InactiveUS6837123B2Eliminate high contact pressure peakEasy to adaptPortable liftingGearing elementsInvolute gearTorque transmission

Several embodiments of various non-involute gear tooth profiles incorporate relief areas formed across the area of the tooth face generally symmetrically to each side of the pitch circle of the gear. The relief area serves to preclude contact across the areas of meshing or mating gear teeth where convex-to-convex contact would otherwise occur, thus precluding high pressure contact between the two gear teeth at the area of the relief. The remainder of the contact of such non-involute gear tooth profiles provides conformal contact, i. e., convex-to-concave mating faces with correspondingly low pressures developed between the tooth portions. The present invention enables a given gear set to absorb considerably greater torque and force than would otherwise be they case, or alternatively allows gear sets to be made considerably smaller and lighter for a given torque transmission, than would otherwise be the case.

Owner:HAWKINS RICHARD M

Method for modifying shape of involute gear

A technology for modifying the profile of involute gear in order to reduce the engaging noise and vibration features that when an involute gear is made up, its involute profile is modified to have a convex part, so its involute curve is more convex than ordinary one. In addition, the profile is further modified in tooth direction to form a convex curve in tooth direction.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

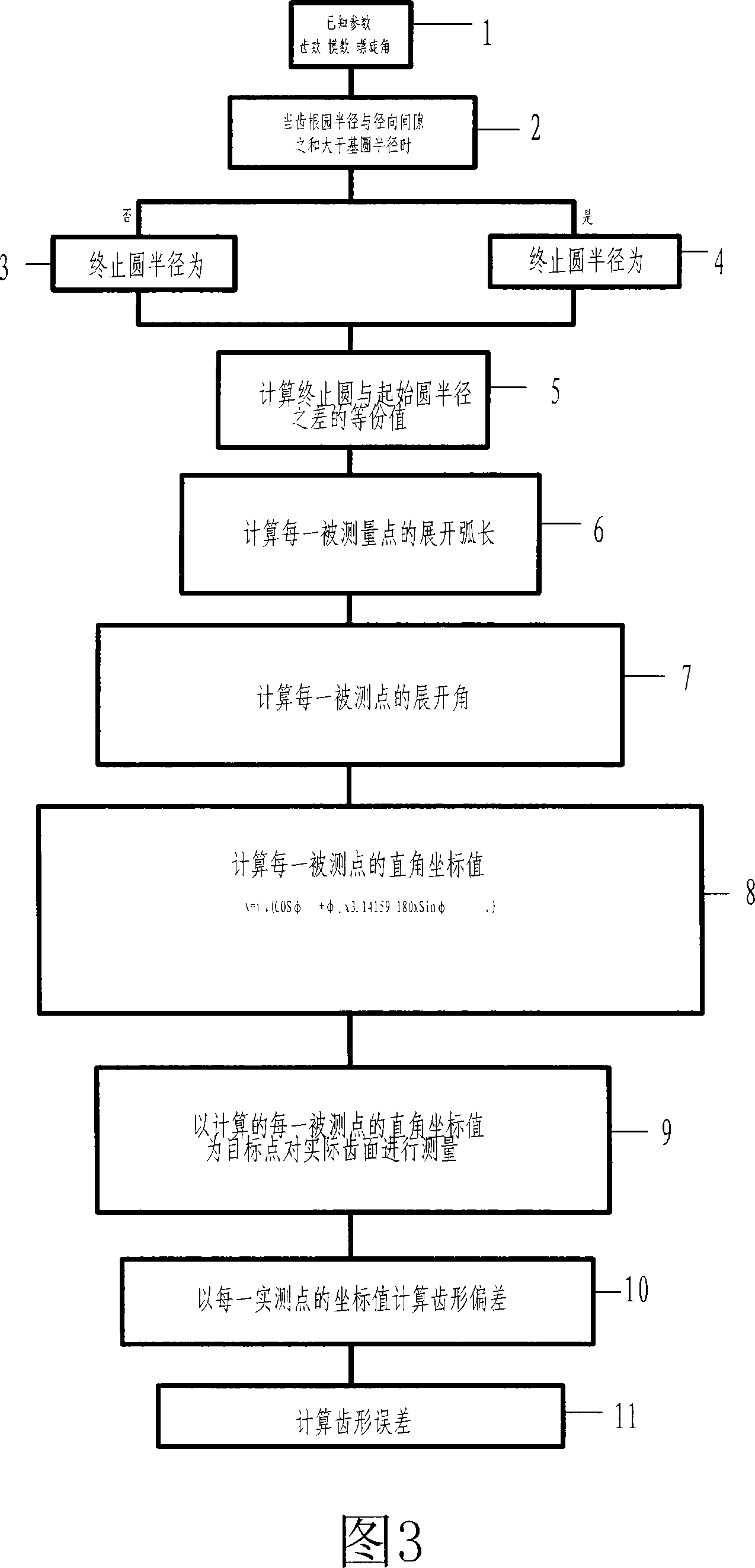

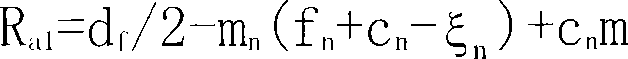

Beveled wheel tooth error three-coordinate measuring method

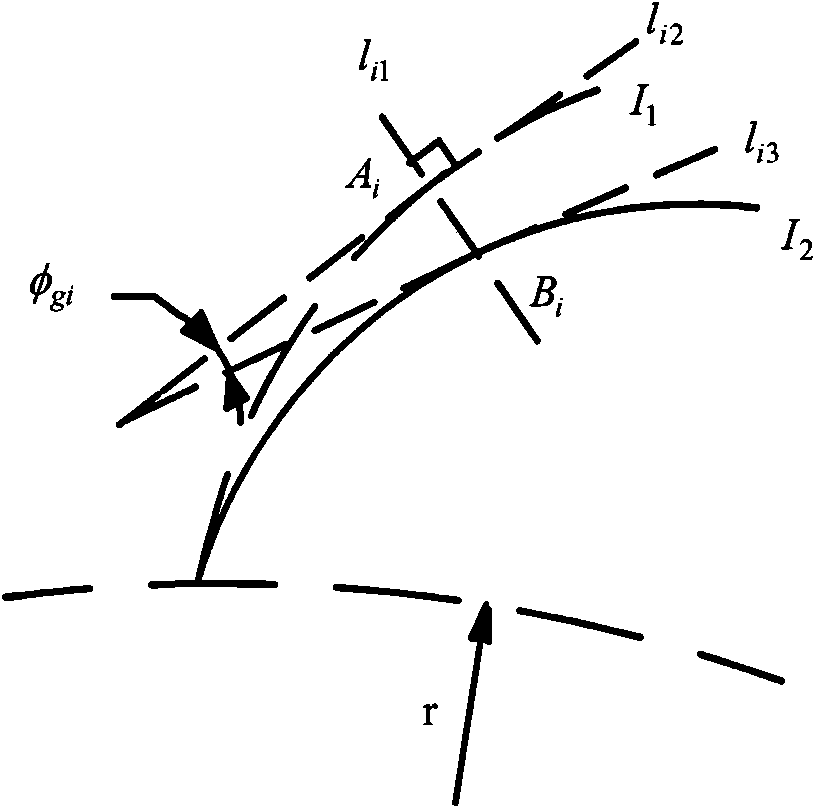

InactiveCN101191723AEvenly distributedSolve the problem of uneven collection pointsMachine gearing/transmission testingInvolute gearObject point

The invention provides a three-coordinate measuring method for bevel gear tooth form error; the procedures of the method are that: (1) the stop position of measuring bevel gear tooth form error is defined by calculation; (2) positions of other measuring points on the checking part are defined; (3)the actual tooth face is measured by taking the stop position and the theoretical coordinates of measuring points as object points; (4) the tooth form error is worked out. By applying the method of the invention in the tooth form error measurement, the repeatability error can be controlled below 0.004mm, thereby markedly improving the measuring accuracy and being capable of measuring the involute gear below six-grade accuracy. The trend of the involute form of the measuring result is relatively obvious, based on which the depth of the tooth root and the tooth head can be analyzed. According to the measuring result, the gear-cutting machine is guided to be adjusted, achieving good effects.

Owner:AVIC HUIYANG AVIATION PROPELLER

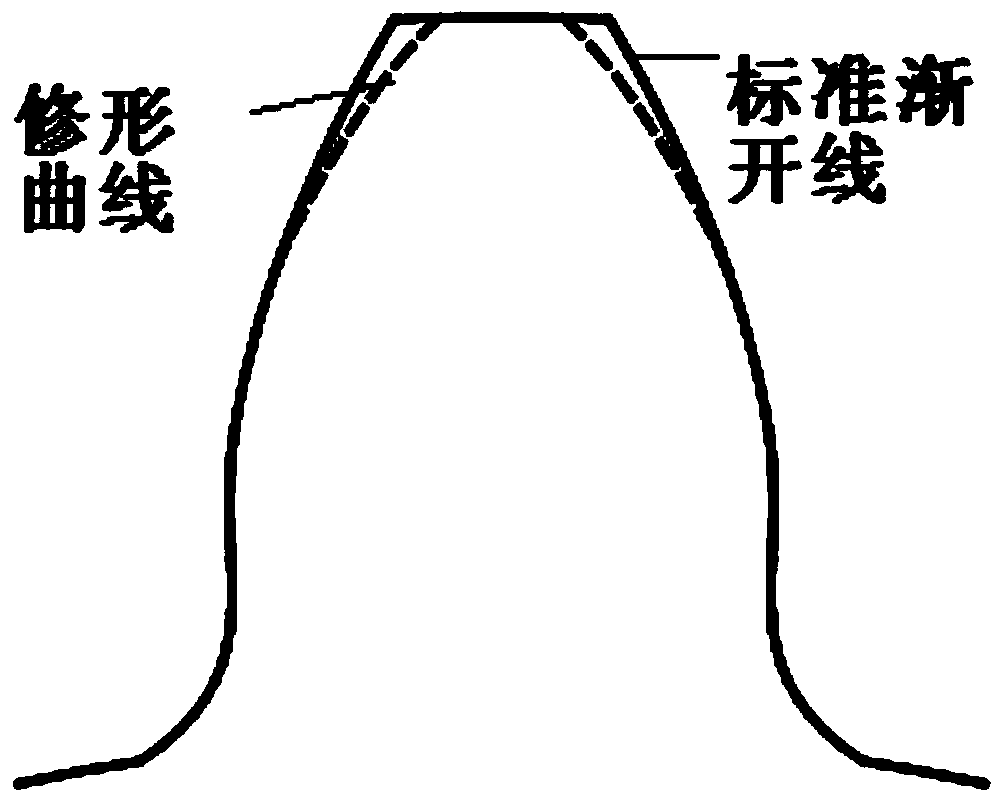

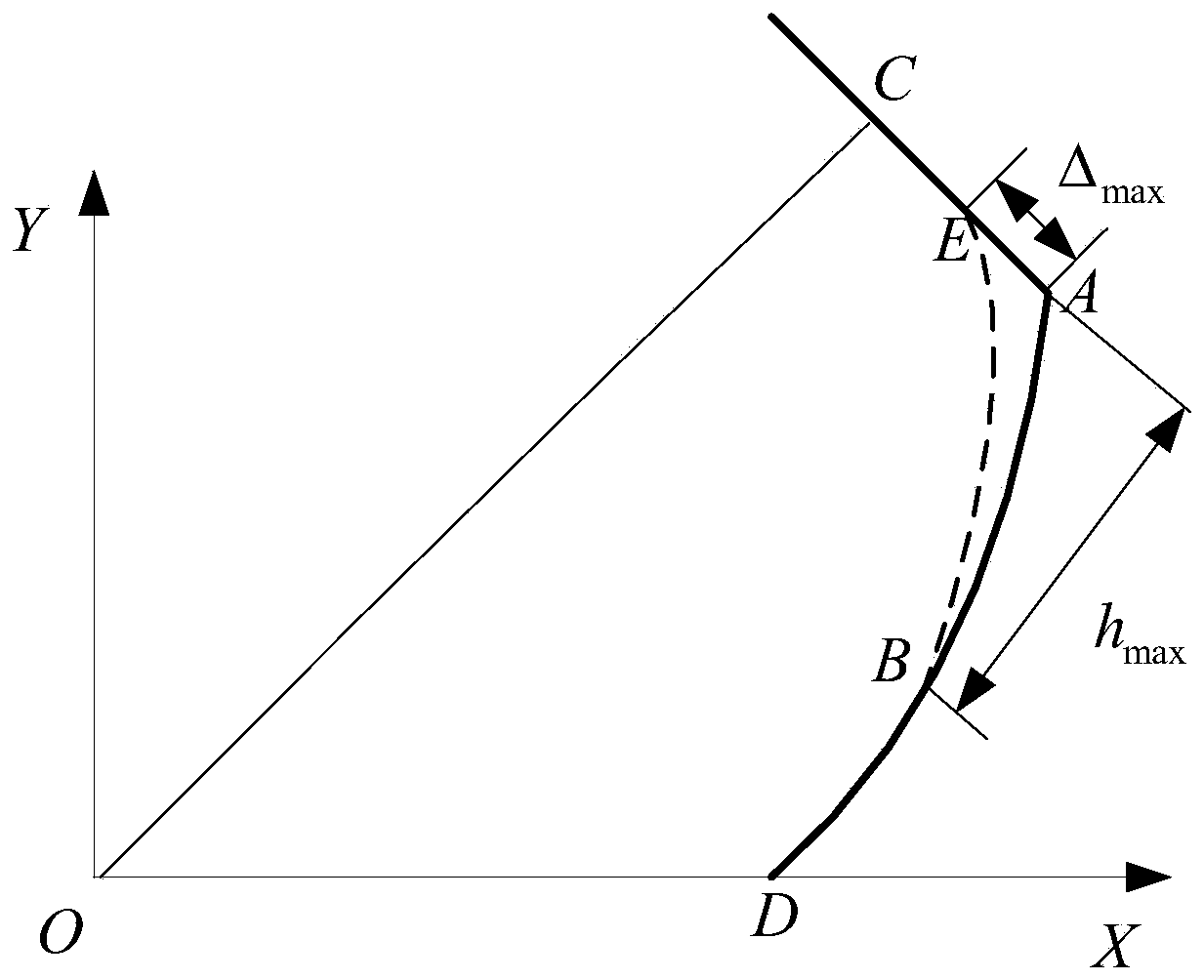

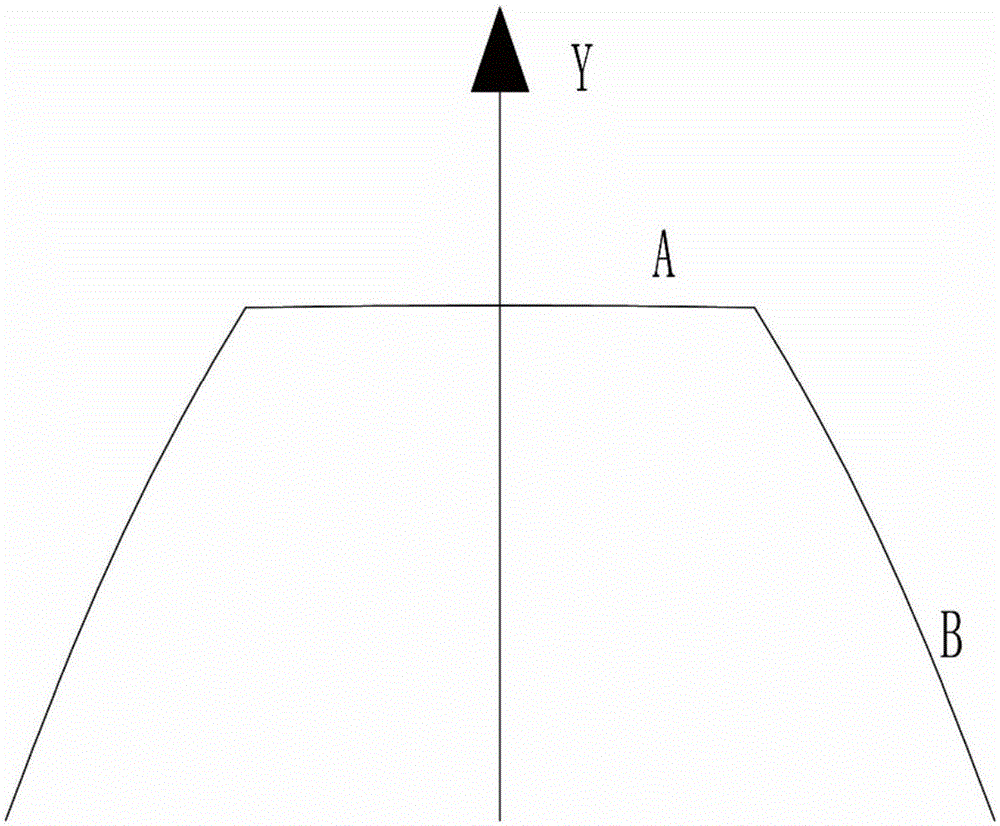

Involute gear tooth profile modification method, modified tooth profile and application of method

ActiveCN103821905ASmooth transitionReduces bite-in and bite-out shocksPortable liftingGearing elementsInvolute gearGear system

The invention discloses an involute gear tooth profile modification method. The method is characterized in that addendum modification is performed on a driving wheel and a driven wheel which are mutually meshed, so that the tooth surface and the addendum of a gear are in transition by a formed modification curve; the modification curve is tangent to a non-modified involute of the tooth surface and the addendum, and the smooth transition of the tooth surface and the smooth transition of the modification curve and the addendum are ensured, so contact deformation and contact stress during the meshing-in and meshing-out of gear teeth are improved. The invention further discloses a tooth profile and the gear which are obtained by the method, and the application of the method. By adopting the method, the smooth transition of the tooth surface and the smooth transition of the modification curve and the addendum are ensured, so that the meshing-in and meshing-out impact of the gear is reduced, the transmission stability is ensured, the vibration and noise reduction of a gear system is benefited, and the service life of the gear is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

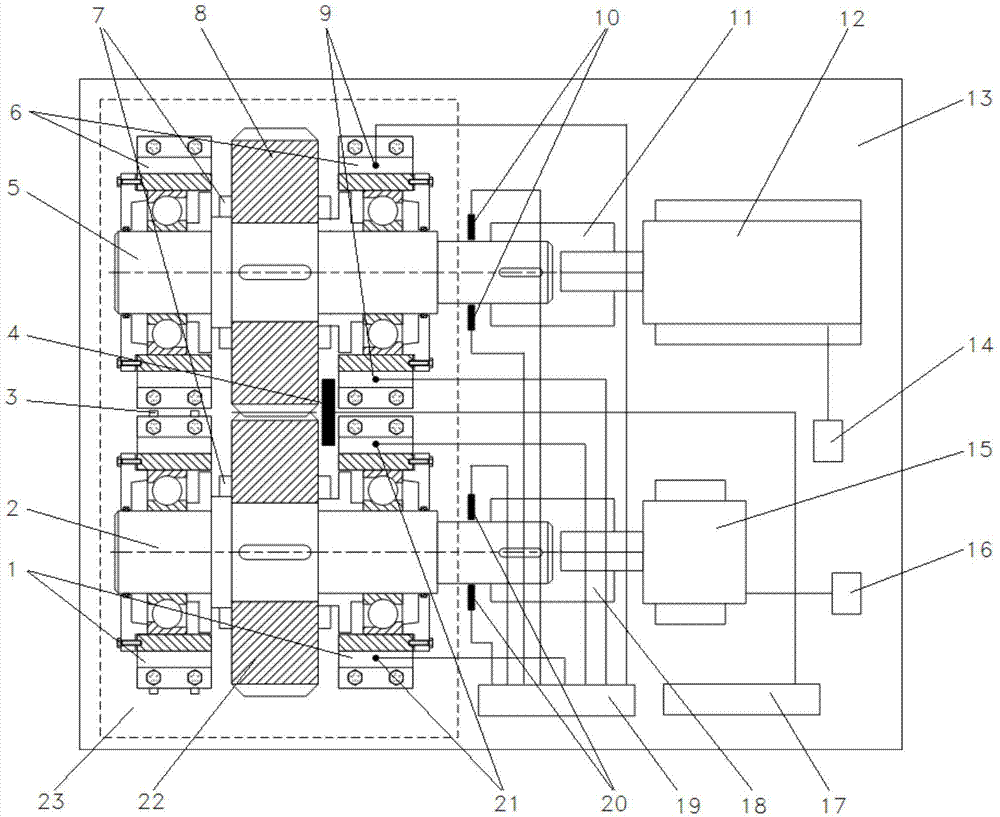

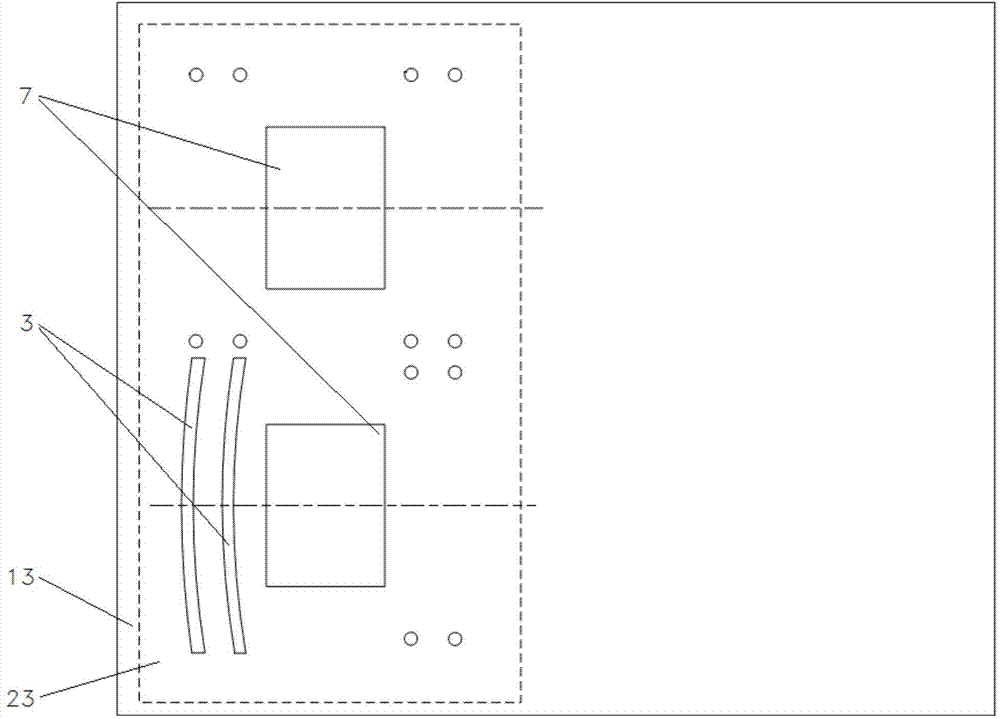

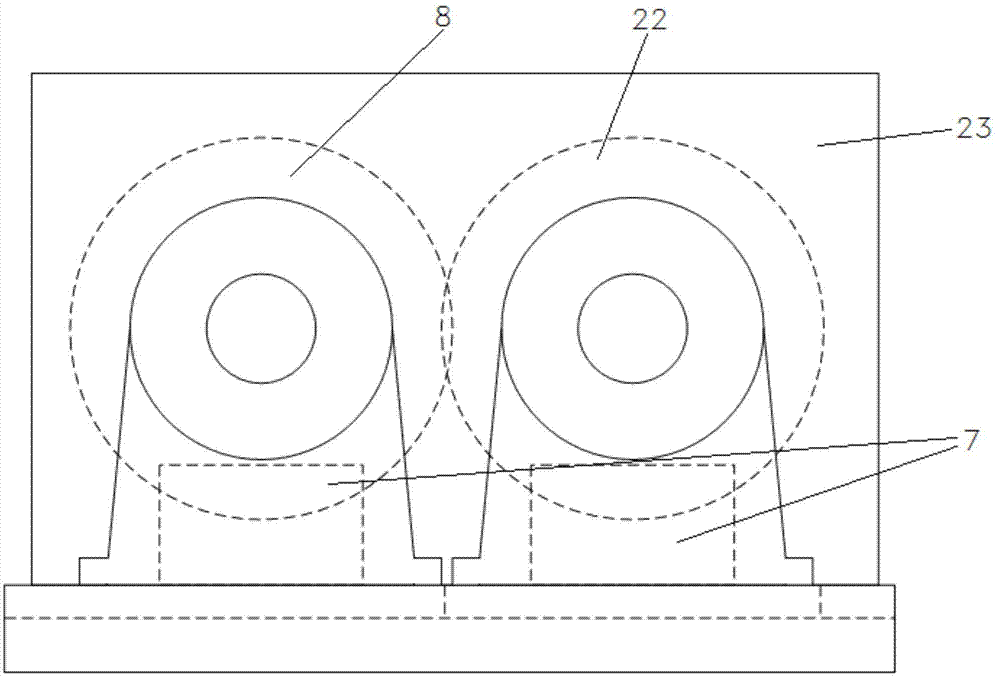

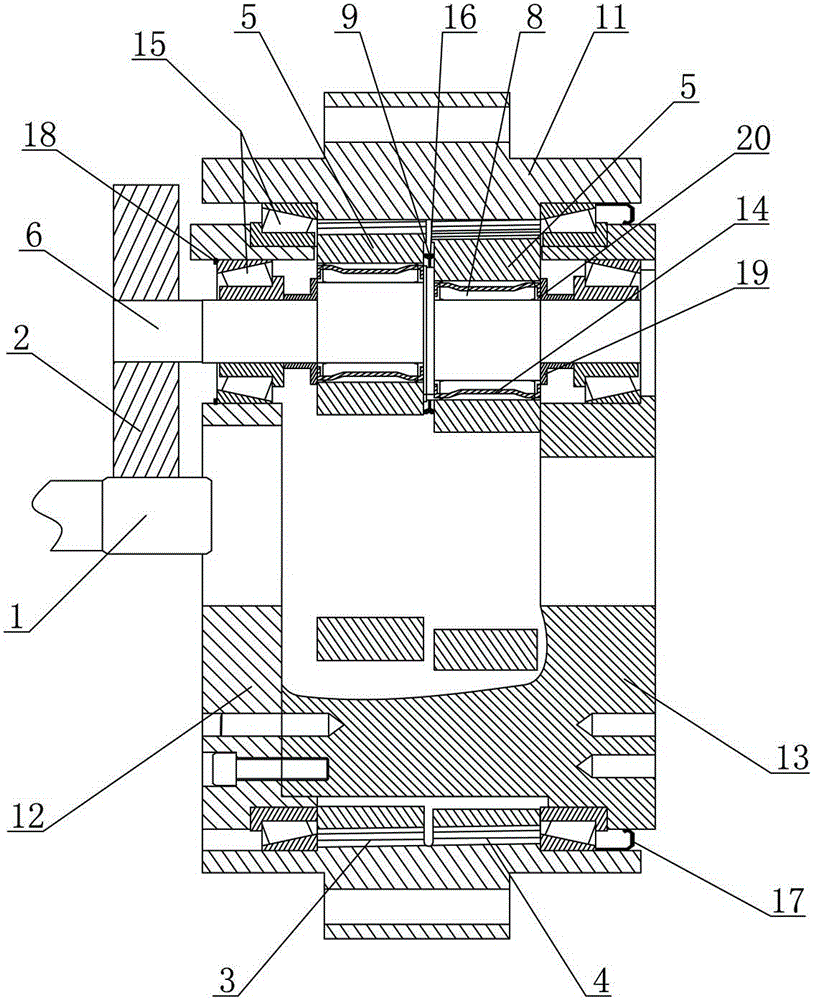

Comprehensive abrasion service life experiment table for involute gear

ActiveCN103884503AReal-time monitoring of vibration displacementReal-time monitoring frequencyMachine gearing/transmission testingCouplingDrive shaft

A comprehensive abrasion service life experiment table for an involute gear is characterized by comprising a bottom plate (13), a drive gear shaft (5), a driven gear shaft (2), a pair of drive gear bearing blocks (6), a pair of driven gear bearing blocks (1), a drive gear (8), a driven shaft coupler (18), a driven gear (22), a drive shaft coupler (11), a drive motor (12) and a load brake (15). The drive motor (12) is connected with the drive gear shaft (5) through the drive shaft coupler (11) to drive a pair of the drive gear (8) and the driven shaft coupler (18) to perform meshed movement. The load brake (15) connected with the driven gear shaft (2) through the driven shaft coupler (18) adjusts system loads. The experiment table is compact in structure, convenient to assemble and capable of achieving mounting error, load and rotation speed adjustment and performing abrasion service life experiment on gears of different machining accuracies.

Owner:NANJING UNIV OF TECH +1

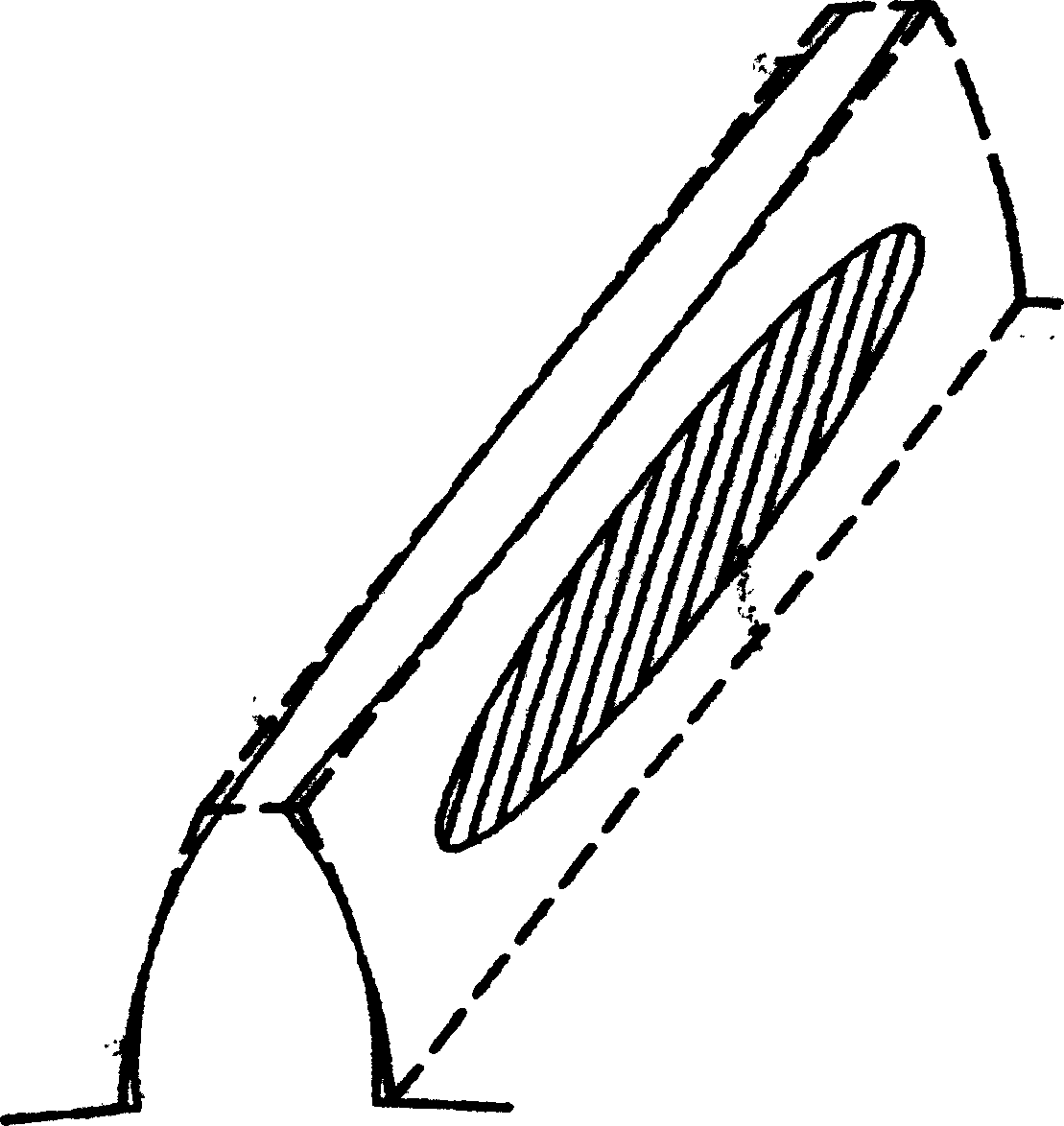

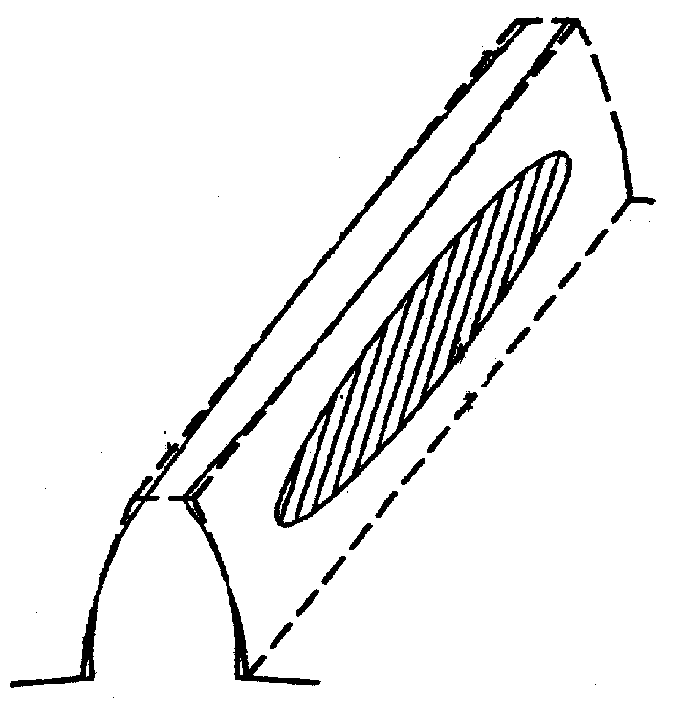

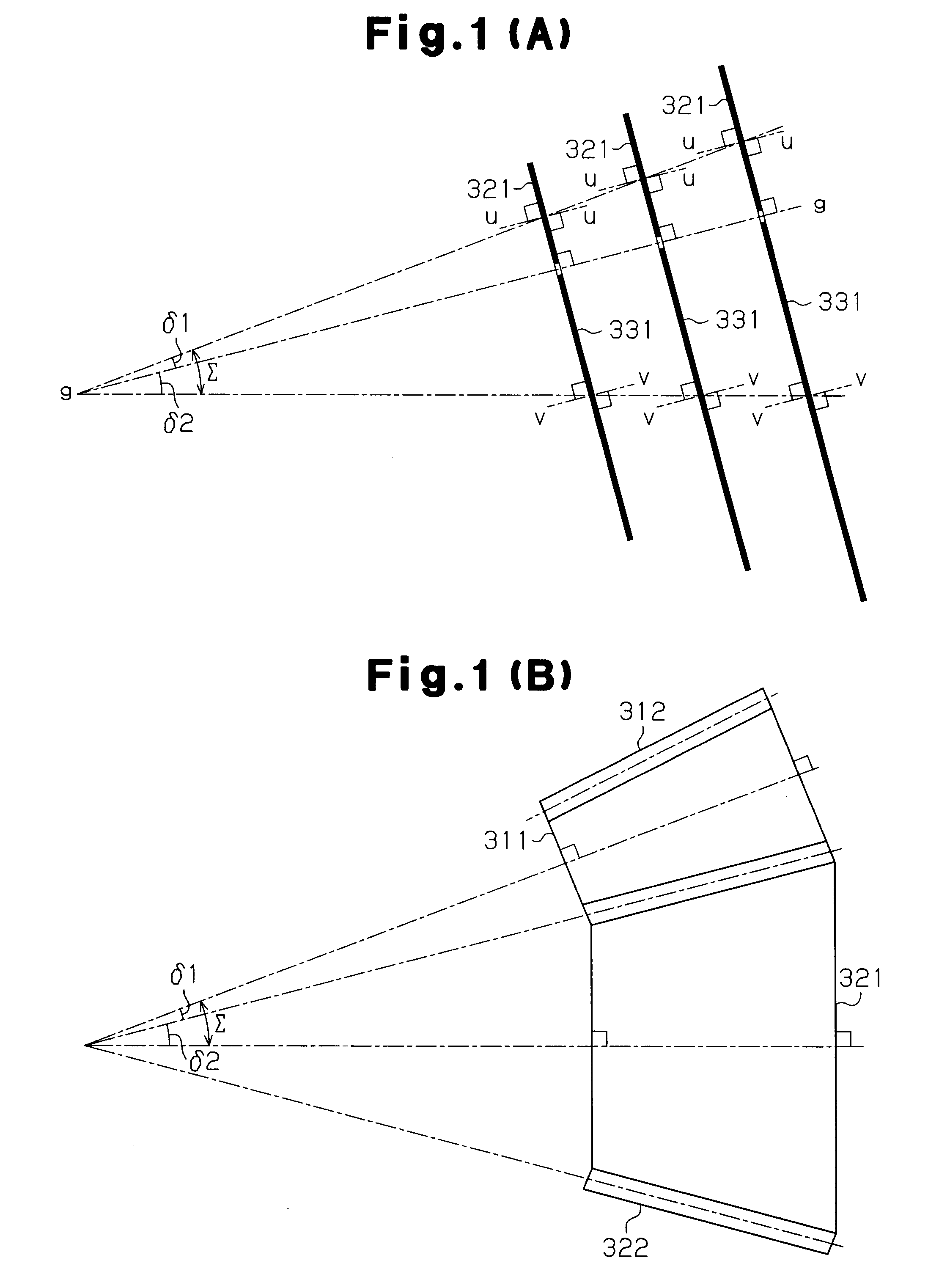

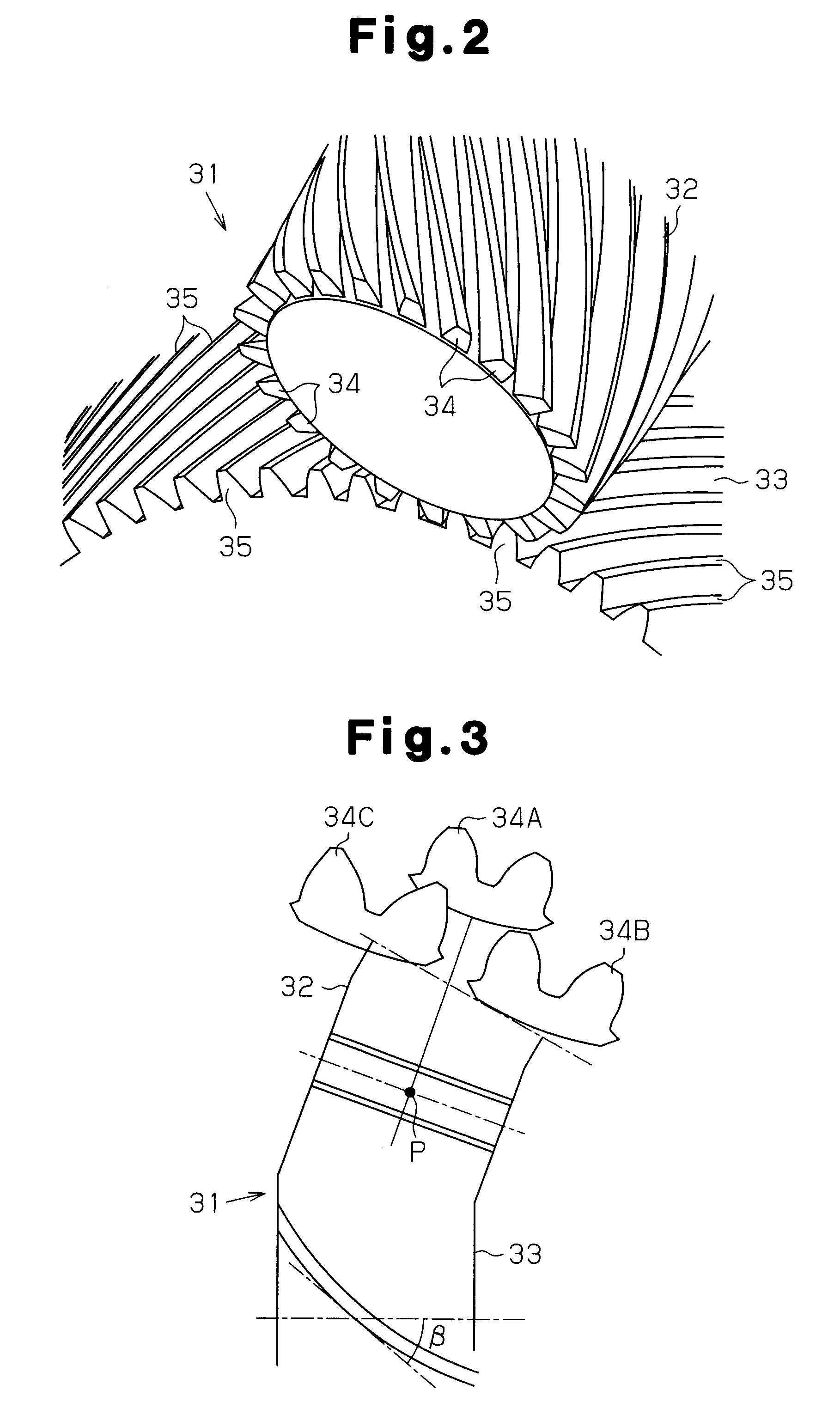

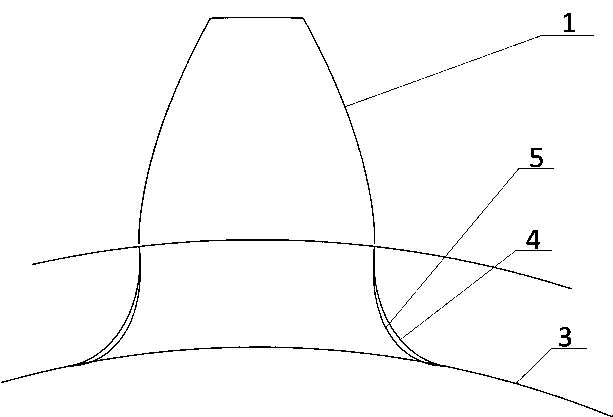

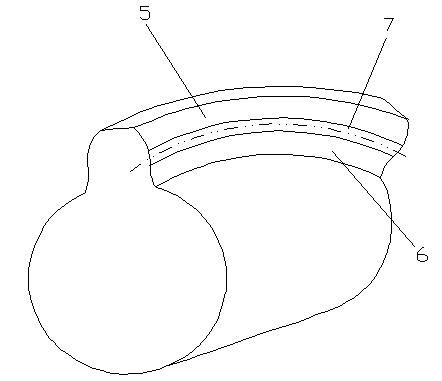

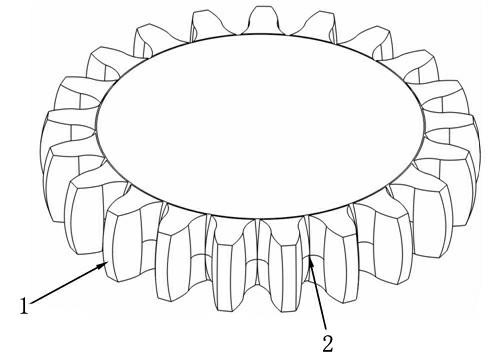

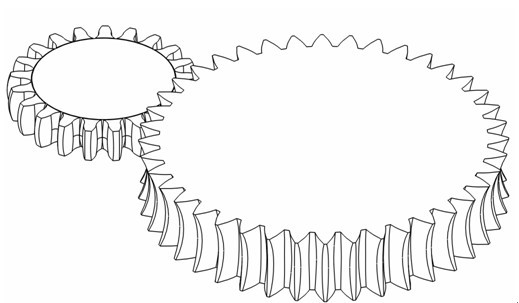

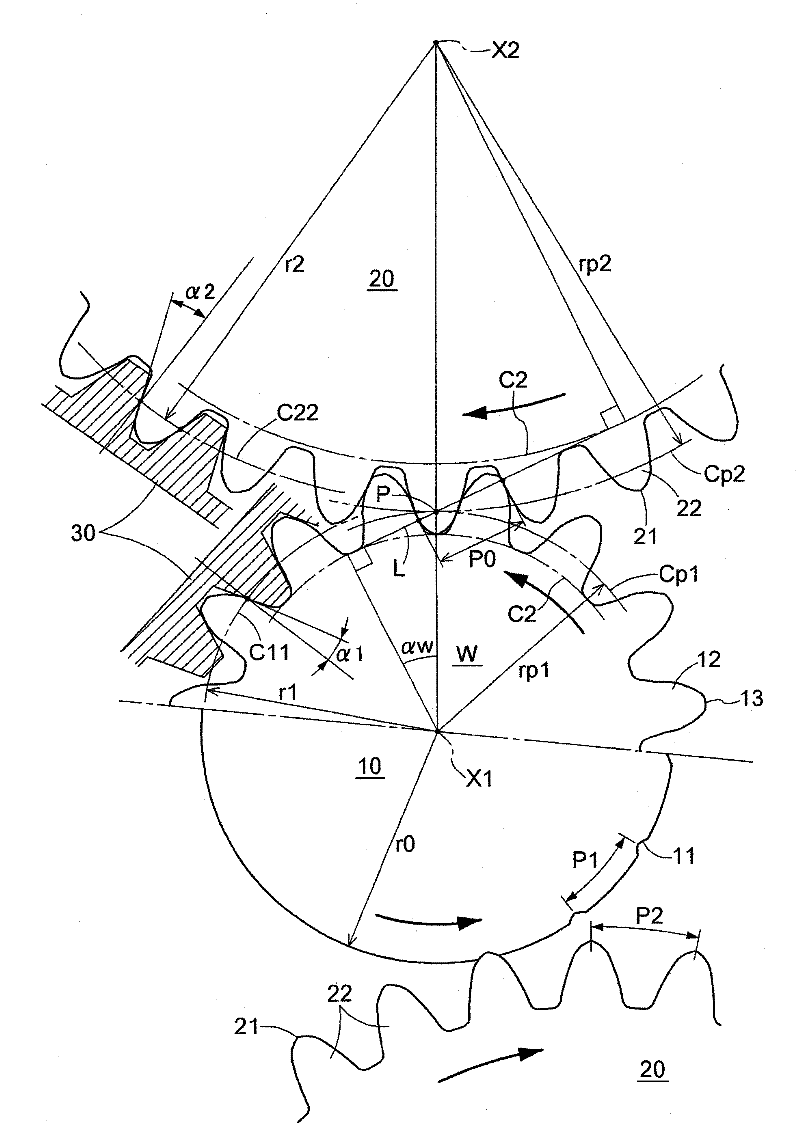

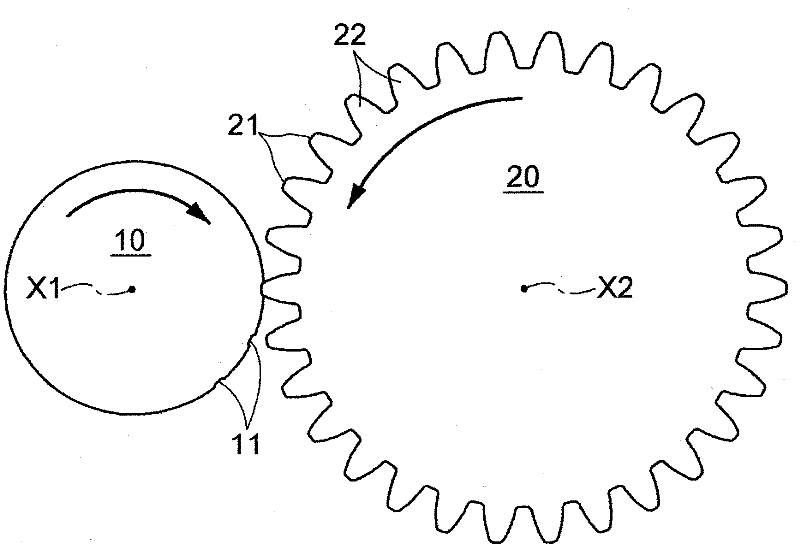

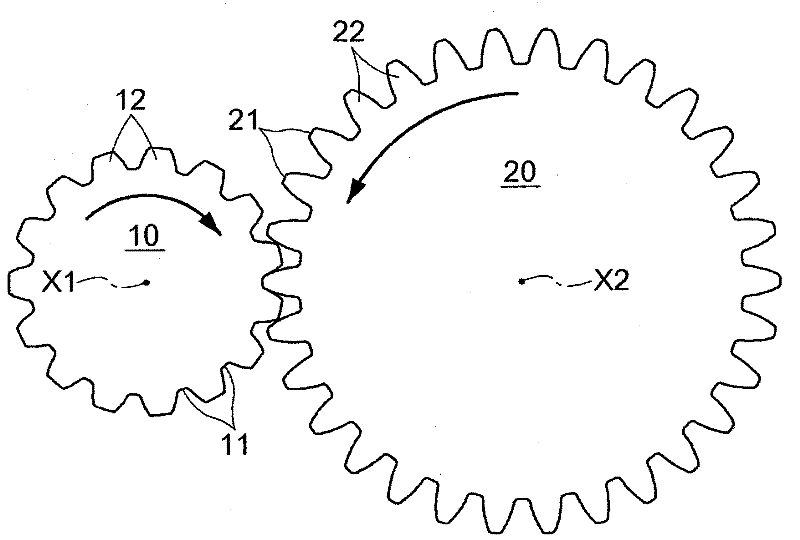

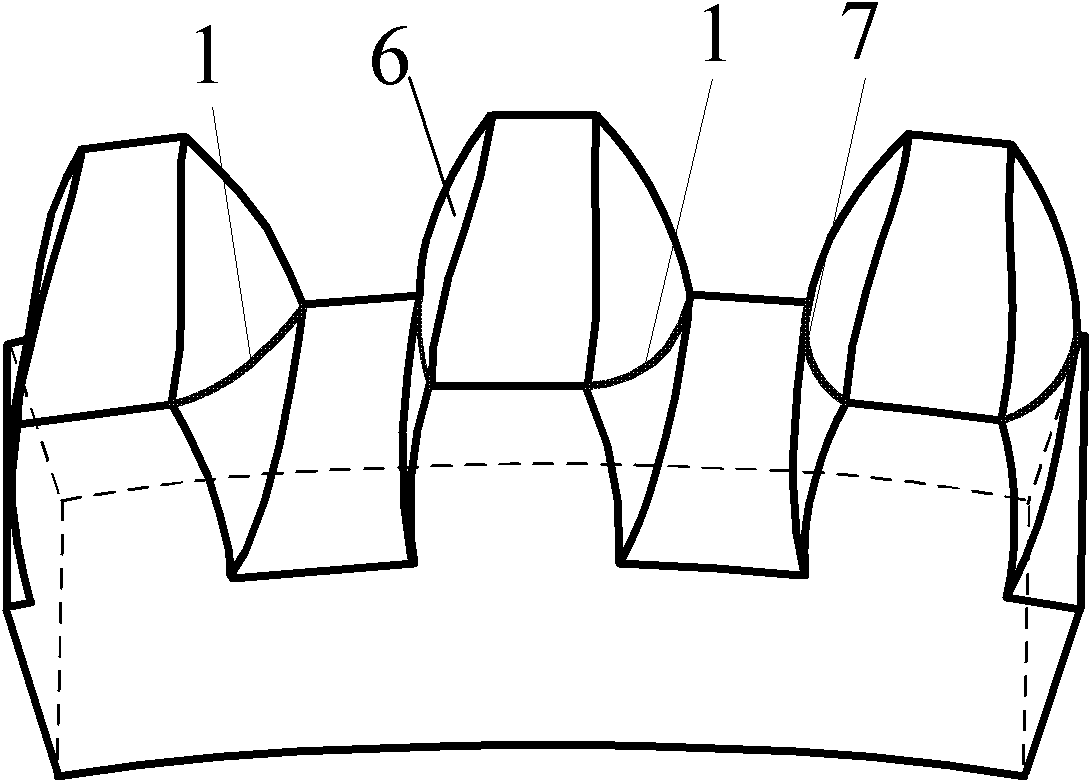

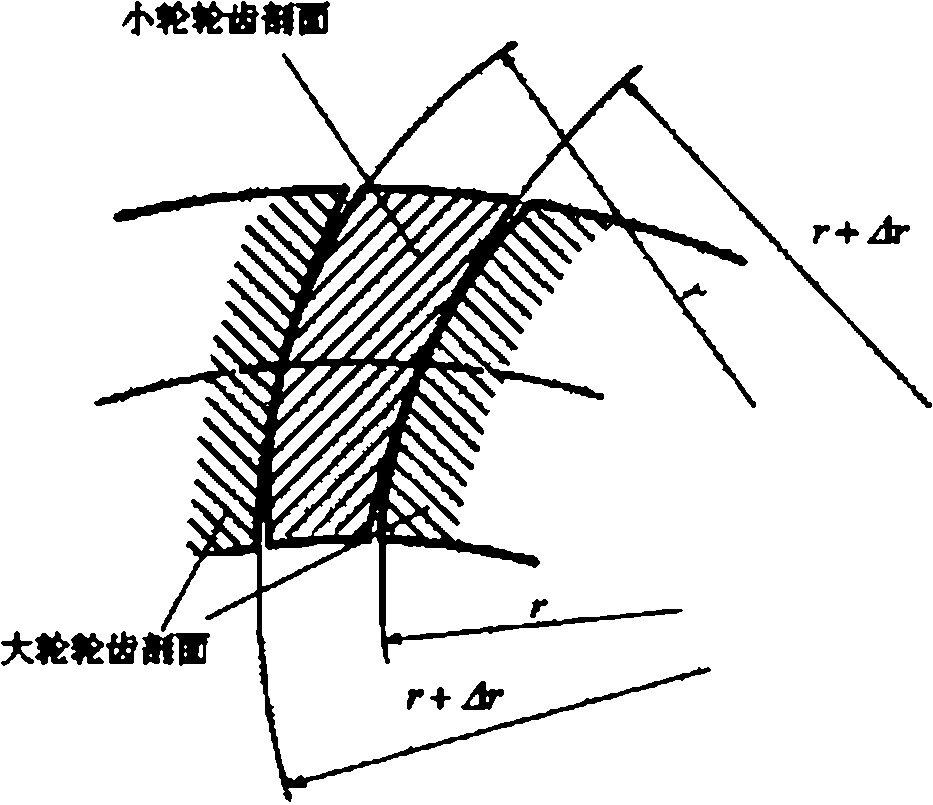

Conical involute gear and gear pair

ActiveUS20080022800A1Easy to manufactureWide conical anglePortable liftingGearing detailsInvolute gearEngineering

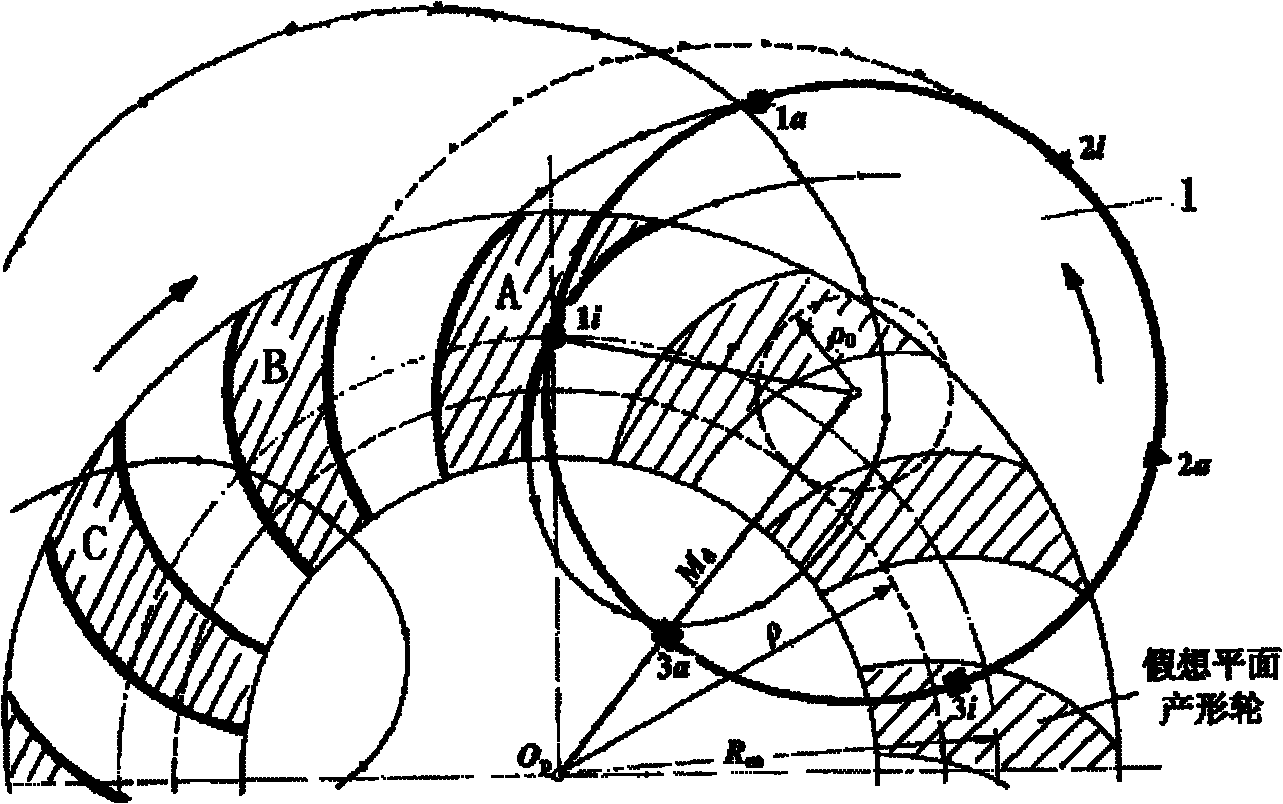

A gear pair includes a small-diameter conical involute gear having a conical angle, and a large-diameter conical involute gear having a conical angle. The small-diameter conical involute gear and the large-diameter conical involute gear are constituted by an aggregate of imaginary cylindrical gears.

Owner:JTEKT CORP

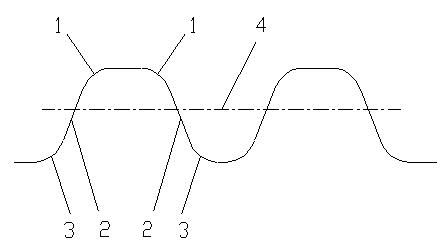

Involute gear waviness sample plate

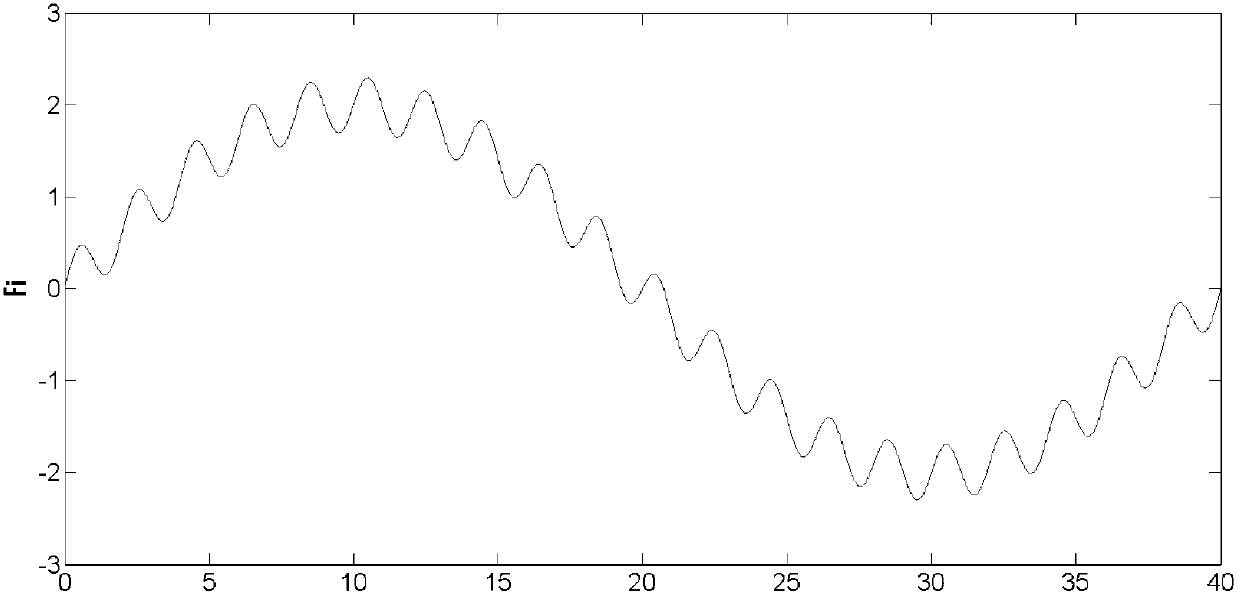

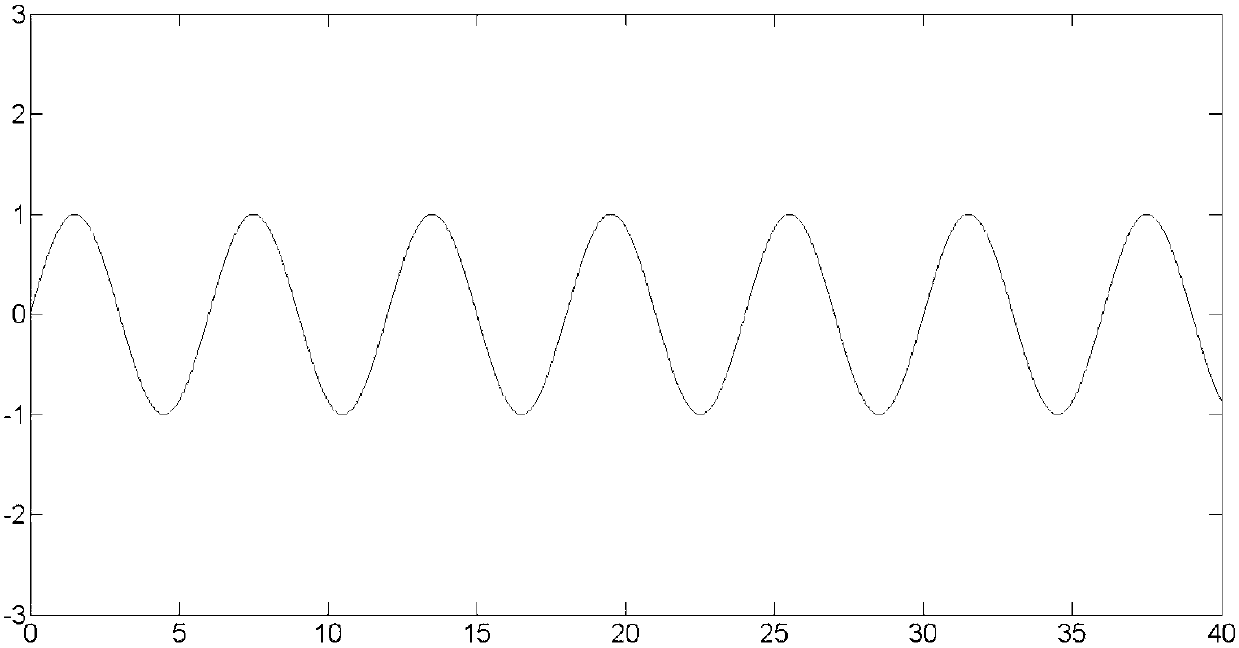

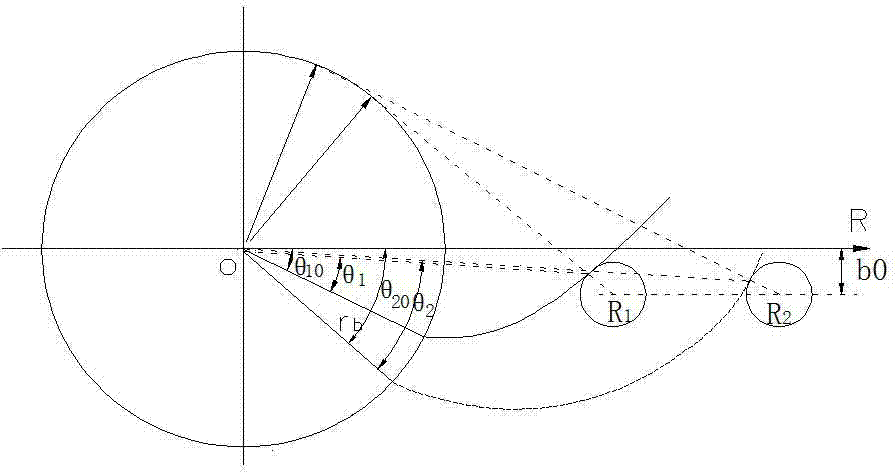

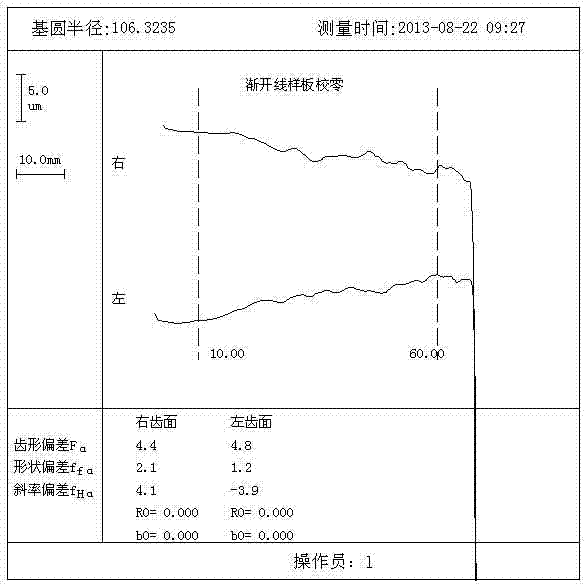

ActiveCN102706306AGuaranteed Phase RelationshipRealize the filtering effectMachine gearing/transmission testingMeasuring instrumentHarmonic

The invention discloses an'involute gear waviness sample plate'. Based on the generation principle of an involute profile, a novel involute gear waviness sample plate is designed. Based on the gear mesh principle, according to the generation principle of the involute, the designed waviness is overlapped to an involute profile along the generation line direction of the involute; a plurality of harmonic waves can be overlapped on each gear surface according to the design aim; the wave lengths of the harmonic waves and the initial phase position are required to be calculated according to the gear waviness theory; the involute gear waviness sample plate overlaps the specific harmonic waves in a standard gear transmission error curve, finally the estimation of the filtering algorithm of a gear measuring instrument is realized, a complete measurement means for the gear noise theory is provided, and the gear standard sample plate system is perfected.

Owner:BEIJING UNIV OF TECH

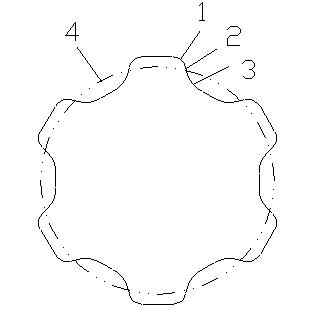

Involute gear

ActiveCN103742625AImprove bending strengthAvoid interferencePortable liftingGearing elementsEllipseInvolute gear

The invention provides an involute gear. The working tooth profile of the involute gear is a standard involute, the part, below the working tooth profile, of the tooth root transition curve is an elliptic arc transition curve, and the curvature radius of the elliptic arc transition curve is greater than that of a traditional tooth root transition curve. According to the involute gear, the elliptic arc transition curve is taken as the tooth root transition curve, so that the gear has higher tooth root bending strength while tooth crest interference of the gear is prevented.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

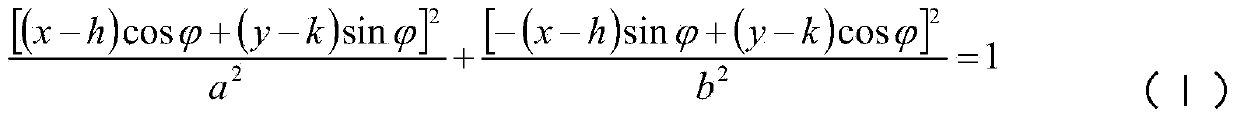

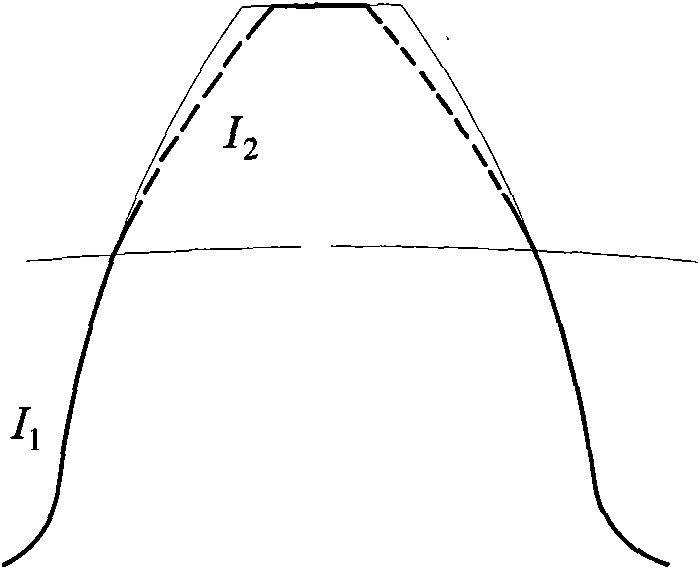

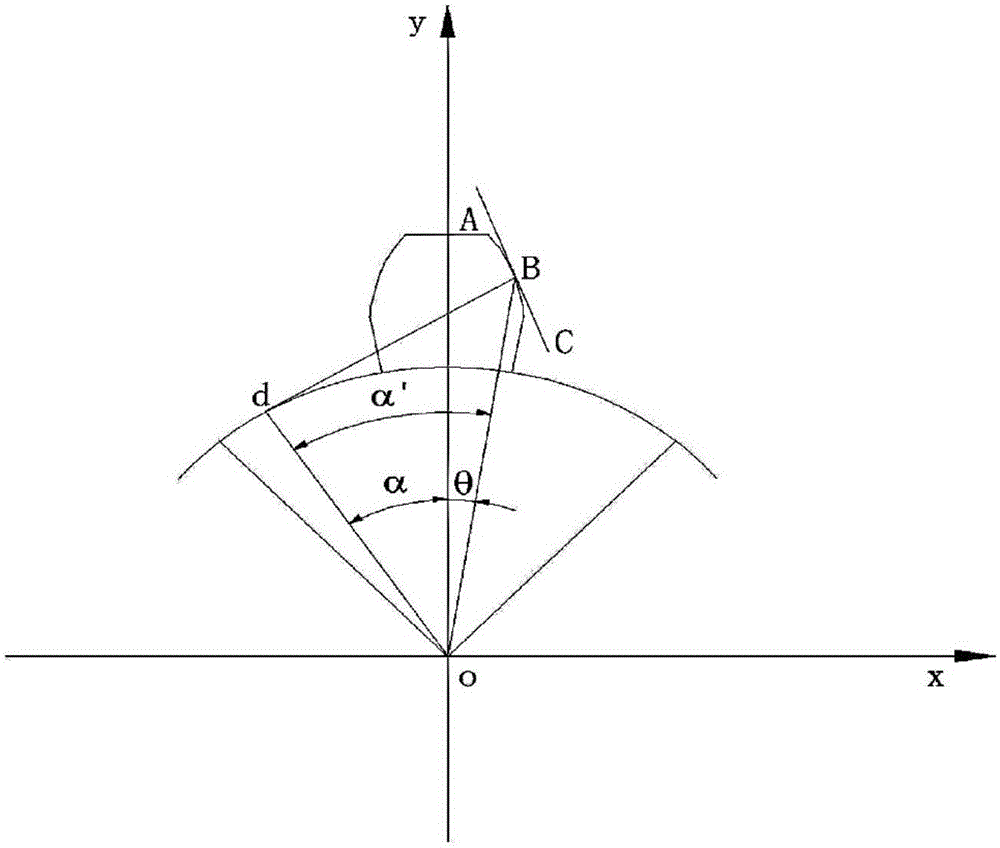

Numerical control grinding and machining method of stepwise variable pressure angle involute gear

InactiveCN101875139ARealize continuous grindingImprove processing efficiencyGear teethInvolute gearGear wheel

The invention discloses a numerical control grinding and machining method of a stepwise variable pressure angle involute gear. The numerical control grinding and machining method is characterized in that: by utilizing a radial and tangential linkage displacement principle of a grinding wheel, a linkage control model for grinding the stepwise variable pressure angle involute gear by adopting an Archimedes worm wheel on the basis of a six-axis five-linkage numerical control system and a real-time interpolation pulse value calculation method directly used for actual design machining of a machine tool are provided. The invention fills a blank of the technology for grinding and machining the stepwise variable pressure angle involute gear by adopting a fix-axis five-linkage numerical control method and can provide the technical basis for high-precision machining of the stepwise variable pressure angle involute gear.

Owner:HEFEI UNIV OF TECH

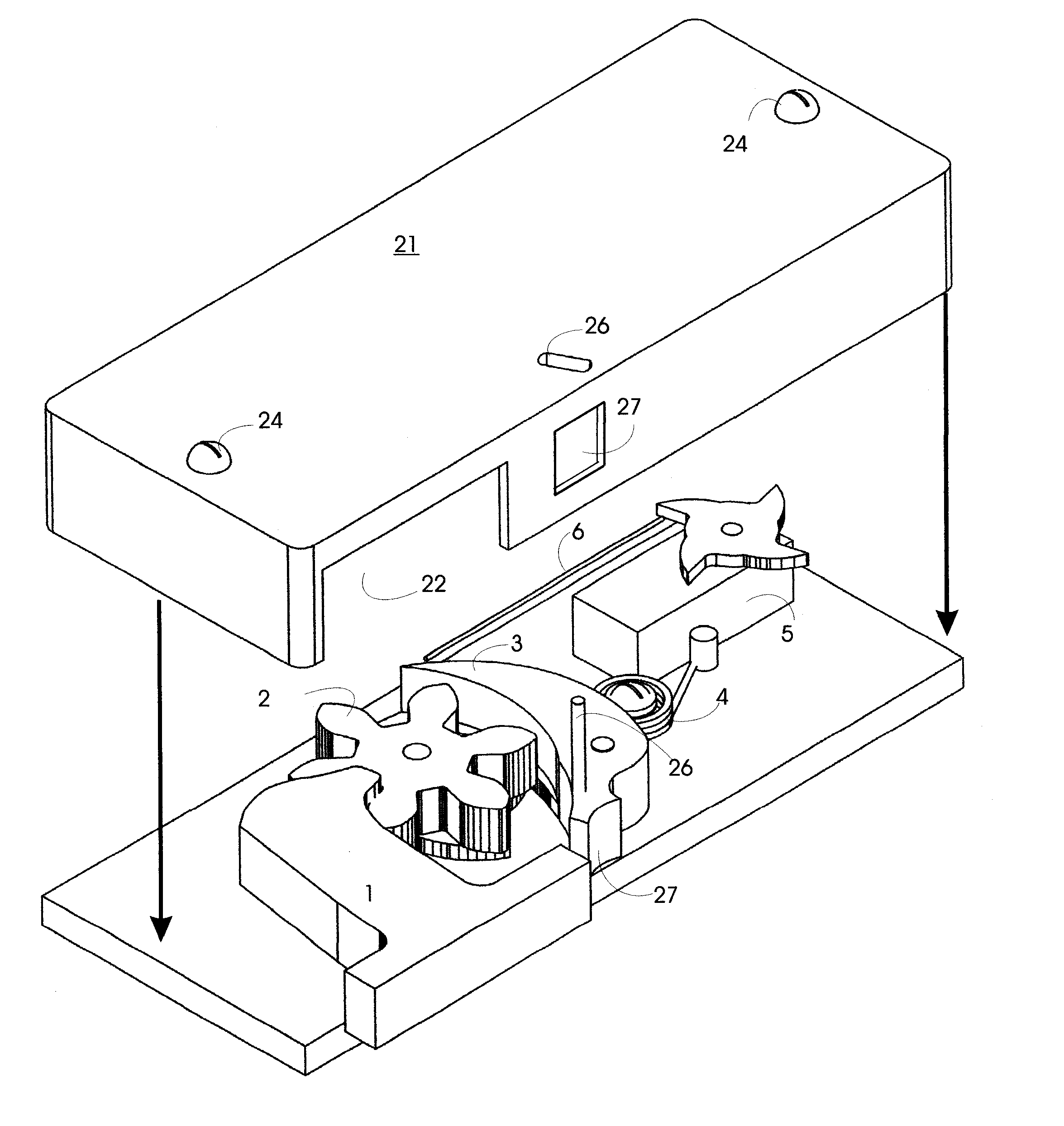

High efficiency brake for agricultural drive systems

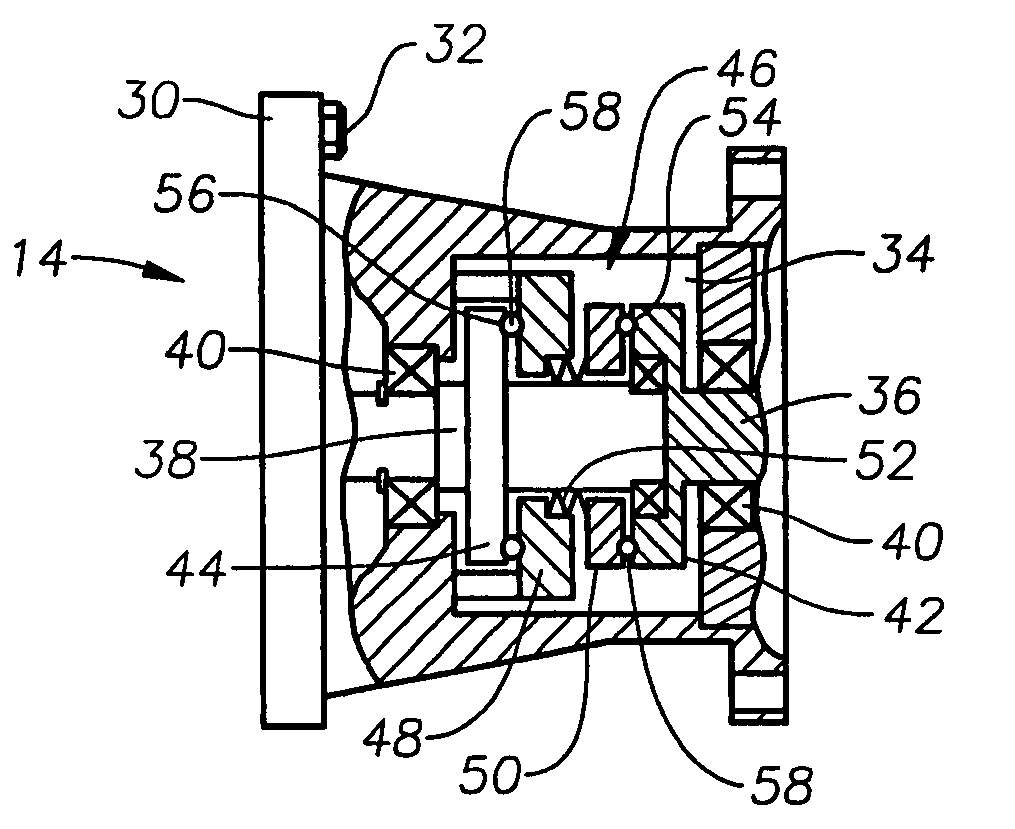

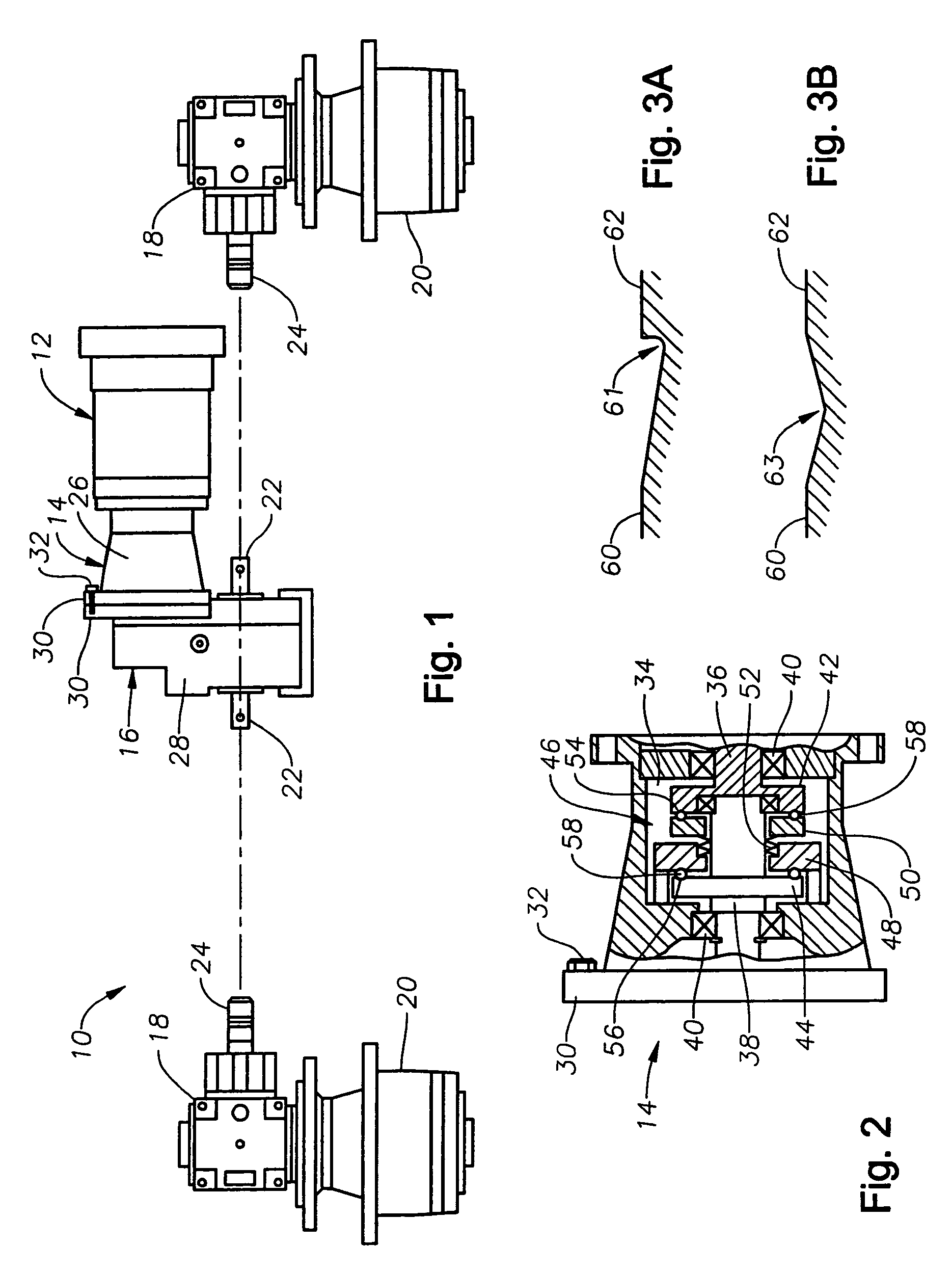

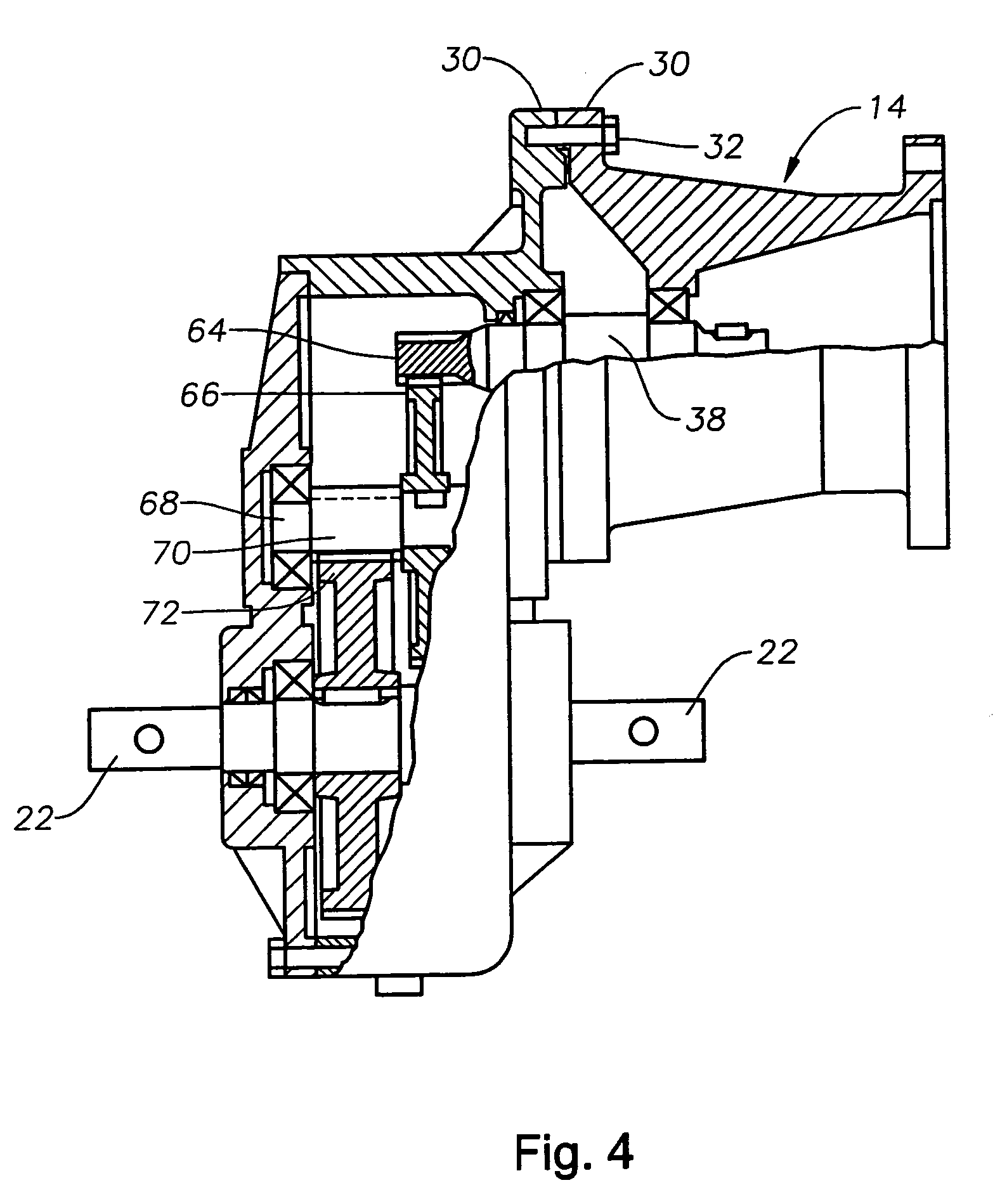

InactiveUS7073638B2Improve efficiencyCorrosion problemBraking element arrangementsToothed gearingsAgricultural irrigationDrivetrain

A high efficiency drivetrain for an agricultural irrigation system is described. The drivetrain includes a ball ramp brake to inhibit movement of a wheel tower when the drive gear motor is not engaged. In one embodiment, the ball ramp brake is a bi-directional ball ramp brake disposed between the drive gear motor and the gearbox of the drivetrain. Utilizing a ball ramp brake such as this, the gearbox can incorporate much more highly efficient gearing mechanisms, such as for example only, involute gears, beveled gears, hypoid gears, planetary gears or the like. The ball ramp brake is enclosed and includes an oil bath that functions to lubricate the components of the brake, preventing corrosion and dissipating heat.

Owner:DANIEL JEFFREY K

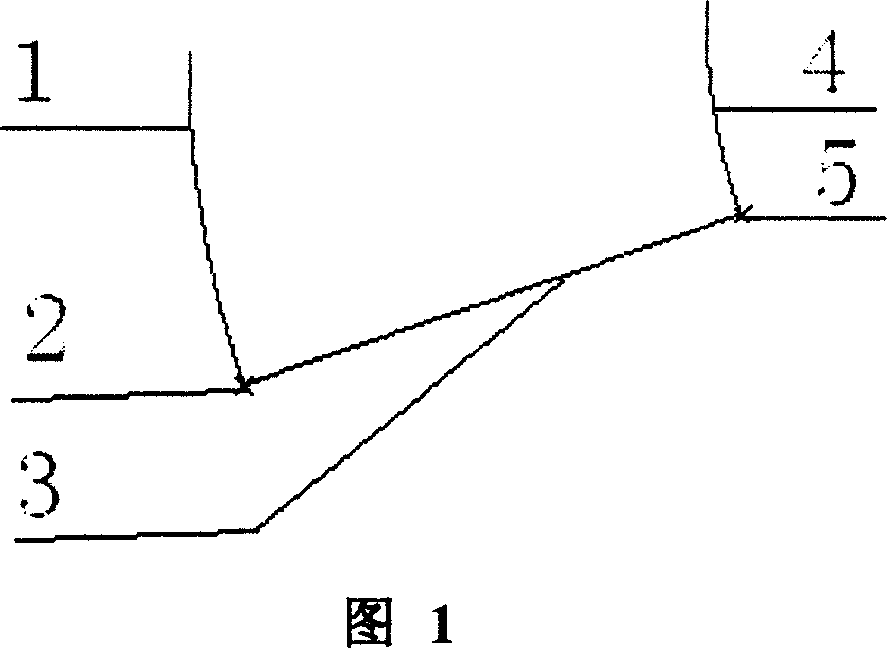

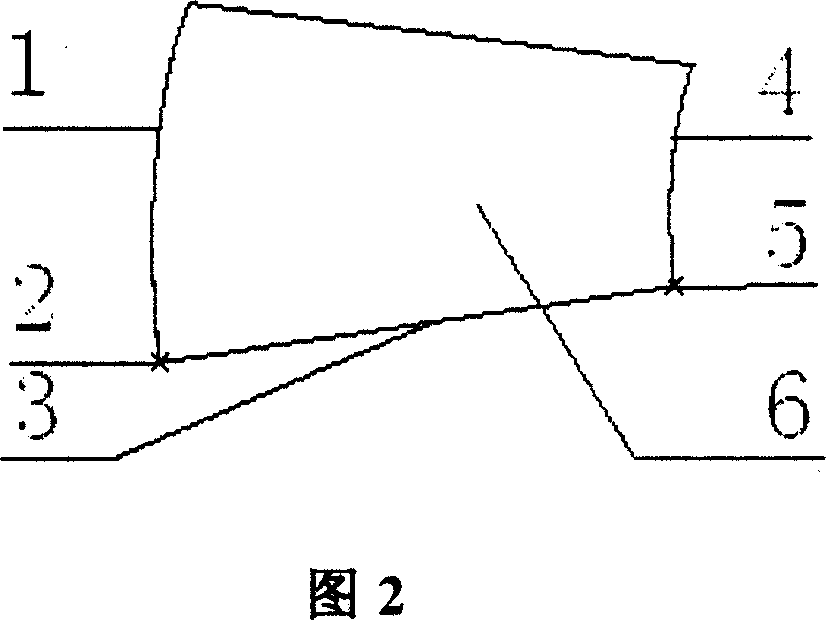

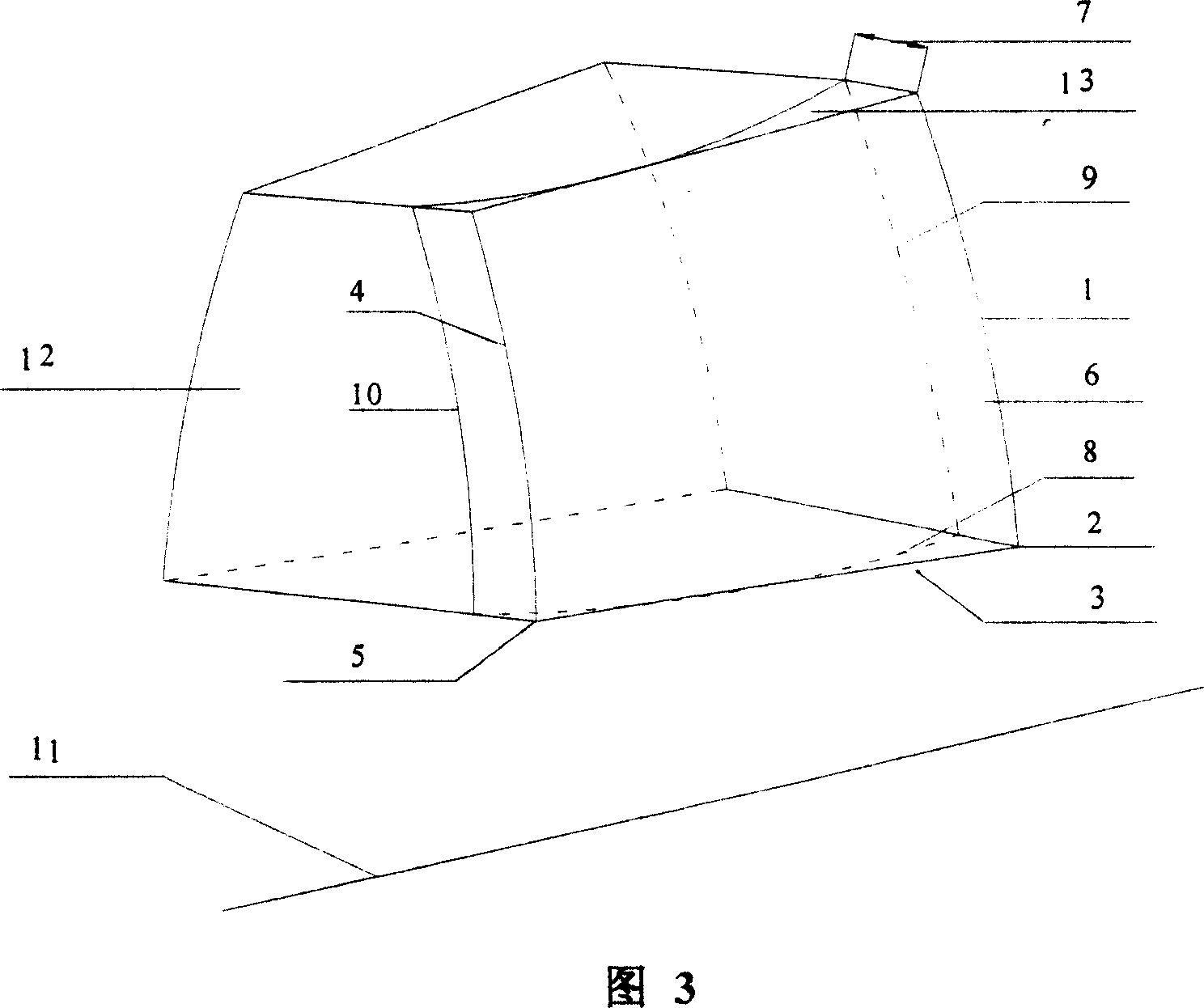

Involute straight-teeth conical gear shaping method

InactiveCN1932707AResolve Mesh ContactsSolve the noiseProgramme controlComputer controlNumerical controlEdge effects

This invention discloses an involute gear shaping technique which includes the following processes: establish theoretic involute for the gear by CAD software; confirm the drum shaped size and maximum tooth profile; shape any one of the conjugate gears; shape the tooth profile of three-dimensional model of the above conjugate gears; convert the three-dimensional model to numeric control code and input to machine tool for machining. This invention simplifies traditional taper gear shaping technique. It reduces vibration & yawps in joggling and prevents edge effect.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Bevel gear with combined arc tooth profile curves and involute tooth profile curves

InactiveCN102072308AImprove contact strengthExcellent running-in performancePortable liftingGearing elementsInvolute gearEngineering

The invention discloses a bevel gear with combined arc tooth profile curves and involute tooth profile curves, wherein the tooth profile curves of the bevel gear comprise a top convex-arc segment, an involute segment and a root concave-arc segment, wherein the top convex-arc segment, the involute segment and the root concave-arc segment are sequentially connected from the top to the root; the top convex-arc segment and the root concave-arc segment are both tangential to the involute segment; and the radius of the root concave-arc segment is larger than that of the top convex-arc segment. The bevel gear of the invention has the advantages of separability of center distance of the involute gear; the bevel gear is simple in manufacturing, convenient in measuring, large in contact strength of the arc gear, excellent in running-in performance and the like; the contact stress of the gear surface can be largely reduced and the loading ability of the gear surface can be largely improved. In addition, the bevel gear does not have undercutting phenomenon, and the minimum number of teeth can be one, so that the bevel gear has remarkable meaning for realizing light weight of the gear and the transmission device thereof.

Owner:CHONGQING UNIV

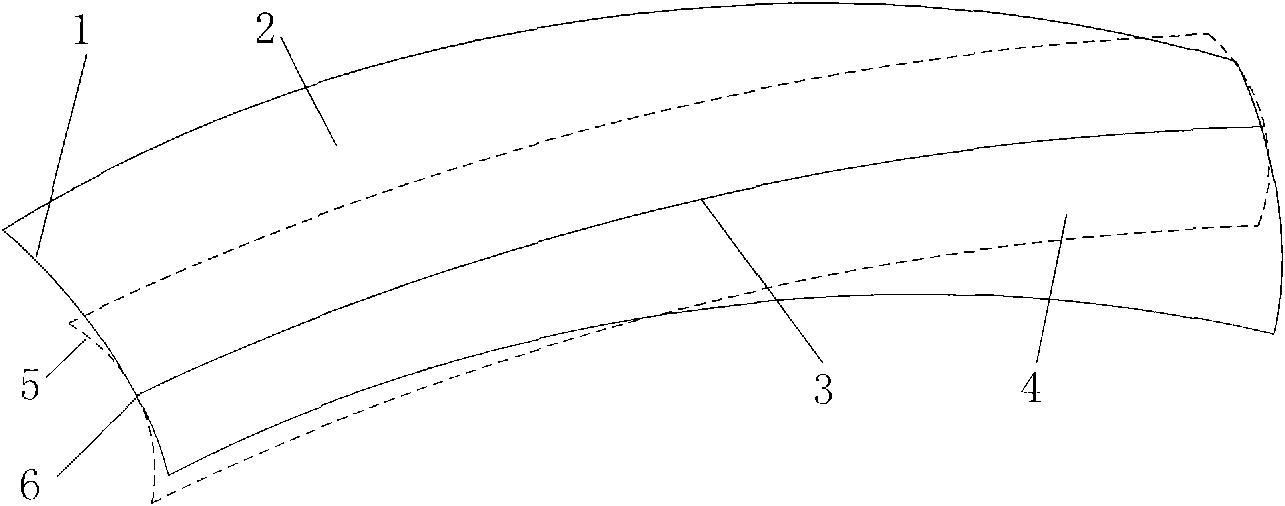

Involute arc tooth profile bevel gear and meshing pair thereof

ActiveCN101975264AImprove carrying capacityReduce contact stressToothed gearingsPortable liftingInvolute gearTooth number

The invention discloses an involute arc tooth profile bevel gear and a meshing pair thereof. The tooth profile curve of bevel gear is formed by the way that an arc does helical motion along the tooth surface contact line on involute helicoids, thus having the advantages that involute gear center distance has separability and is convenient to measure, involute gear is convenient to manufacture and an arc gear has high contact strength and good running-in property, tooth surface contact stress is reduced, tooth surface carrying capacity is greatly improved, and processing is convenient; and the tooth curve of the arc and the radial length of involute participating in meshing are short, thus avoiding undercutting phenomenon of standard gear, so that minimum tooth number of the gear can reach 1. Compared with the gear in the prior art, weight and size are greatly reduced; and the meshing pair adopts the way that a convex gear is meshed with a concave gear, and carrying capacity is high.

Owner:CHONGQING UNIV

Involute gear with concave and convex ring surfaces and method for designing and machining involute gear

ActiveCN102588558AThe process is simple and convenientSimple processPortable liftingGear teethInvolute gearEngineering

The invention relates to a gear and a method for designing and machining the same. The gear is particularly characterized in that each of tooth crest curved surfaces and tooth root curved surfaces is a part of a convex ring surface or a concave ring surface, each of the tooth crest curved surfaces and the tooth root curved surfaces of the involute gear with the concave and convex ring surfaces is a part of a ring surface, an arc circularly rotates around an axis of the gear to form the ring surface, a tooth profile curve of the end section of each gear tooth is an involute, and the teeth are synchronously distributed around a center point of the tooth width. By the aid of the gear, three gear transmission forms can be realized, the gear not only can be used for driving of parallel axes, but also can be used for driving of intersecting axes with small axial intersect angles, high axis deflection installation errors are permitted when the gear is used for driving of parallel axes, the axial intersect angles are allowed to dynamically change when the gear is used for driving of intersecting axes, transmission ratio can keep constant when the gear is used for driving of parallel axes and driving of intersecting axes, and the gear teeth are not interfered with each other. By the aid of the method for designing the gear, the involute gear with the ring surfaces is divided into a plurality of tiny tapered involute gears, geometric parameter design of the involute gear with the ring surfaces is carried out, and a process of the method is carried out simply, conveniently and feasibly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Involute spherical gear transmission pair

The invention discloses an involute spherical gear transmission pair. The involute spherical gear transmission pair comprises two spherical gears, wherein involute gear teeth are uniformly distributed on the circumferences in the weft directions of the spherical surfaces of spherical cap sections on spherical caps; the tooth thickness directions are along the weft directions of the spherical caps; the numbers of the teeth on the wefts at different heights are variable; the number of the teeth on low-latitude parts is large; the number of the teeth on high-latitude parts is small; a plurality of tooth rings from the high latitude to the low latitude are formed. The spherical gears are sectioned over the axis; the outer contours of the sections of the tooth rings form the outer contours of the involute spherical gear teeth along the meridians in the tooth thickness directions; the outer counters of the gear teeth formed by the sections of the tooth rings are divided into two groups; odd-number groups and even-number groups are respectively the same as the shapes of the end surface teeth of two straight gears of which the gear teeth are placed in a staggered way.

Owner:杨兆奎

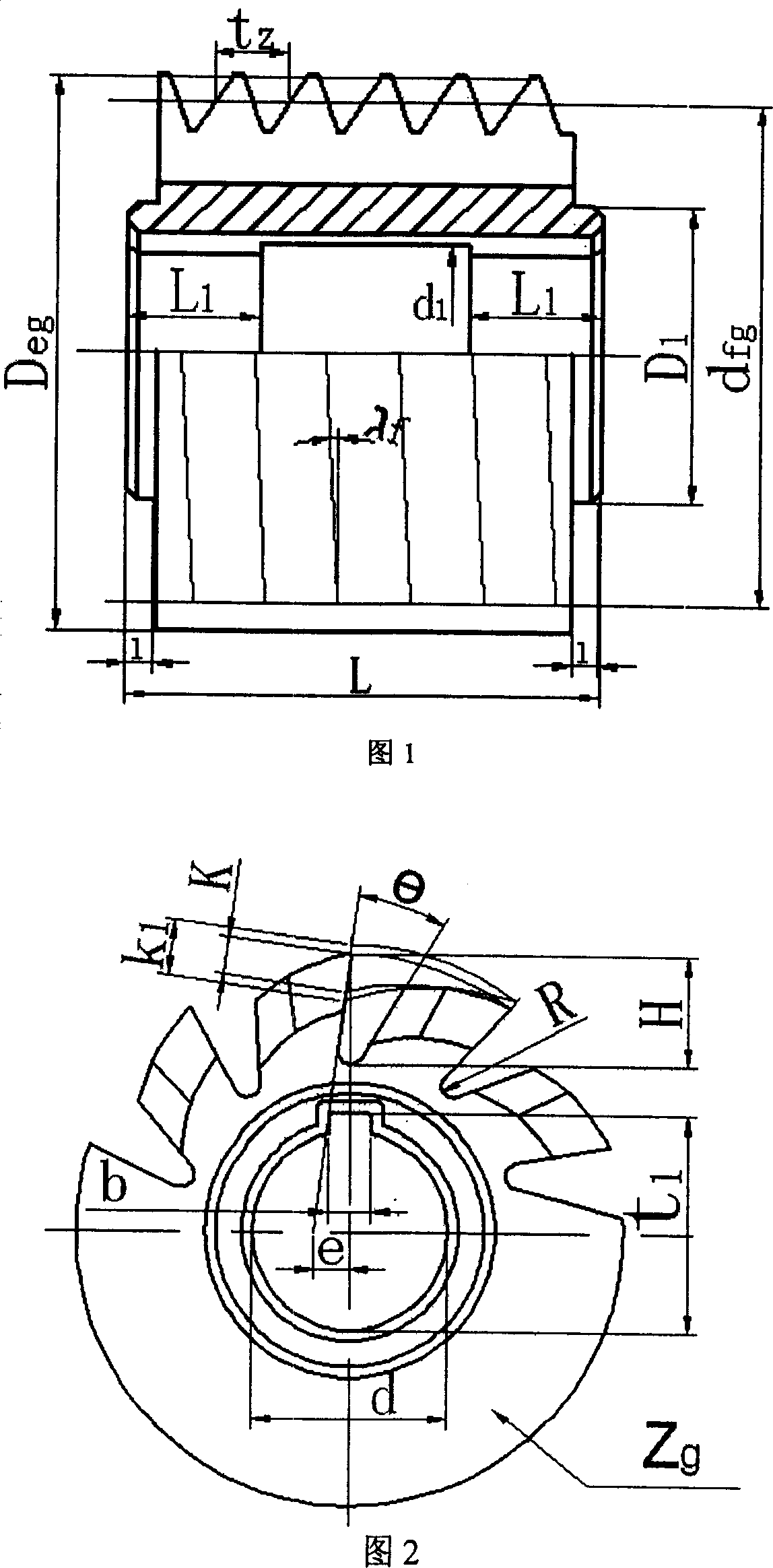

Involute gear hob of asymmetric tooth profile with equal modulus

InactiveCN101003098ASimple configurationEasy to manufactureGear teeth manufacturing toolsGear teethFluteHobbing

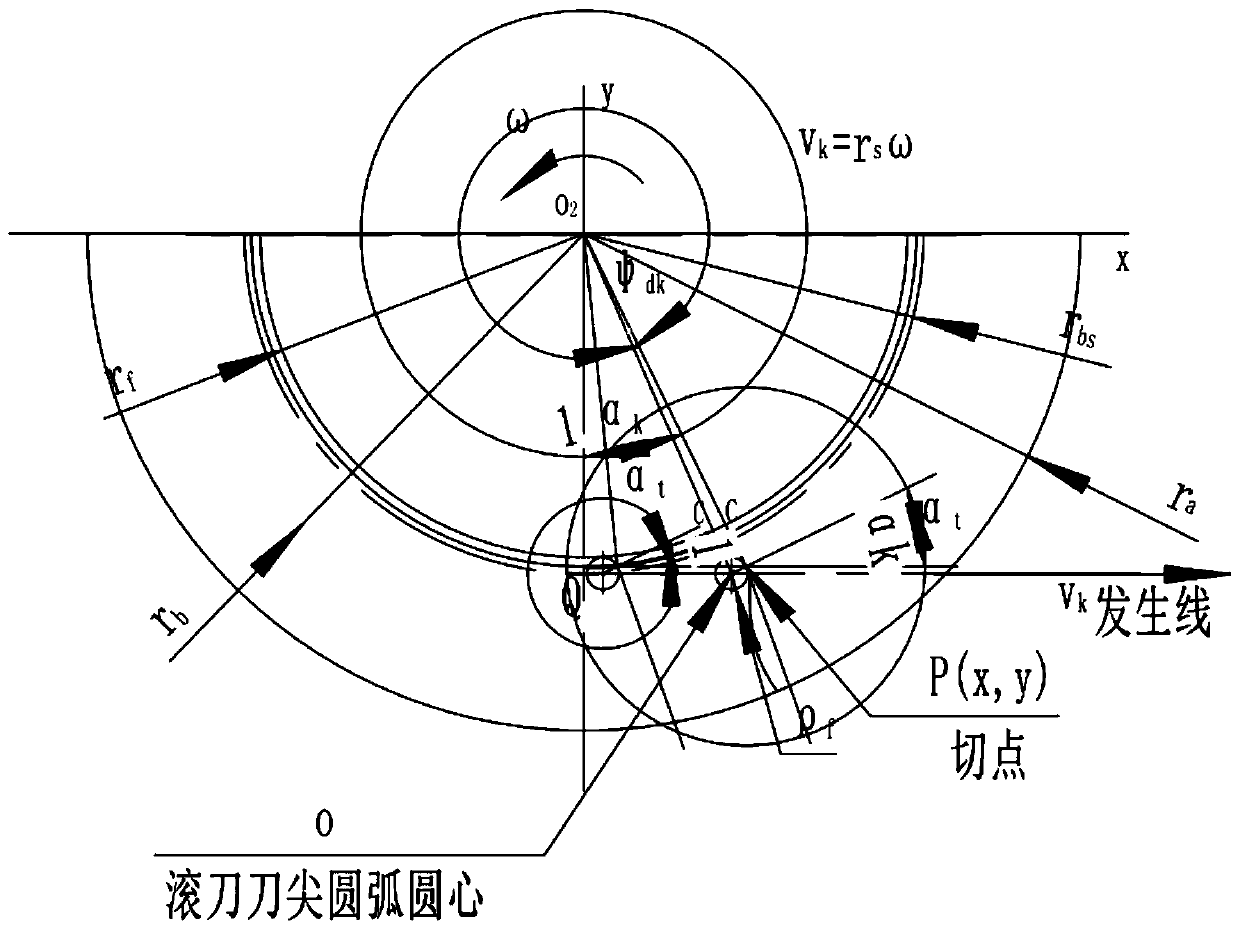

A hobbing cutter for manufacturing the isomodulus asymmetric involute gear has a cutting part formed by a segment of Archimedes' worm. The lateral cutting edge of its cutting tooth is on the spiral surface of said worm. The two cutting edges are the intersecting line between the surface of chip flute and lateral relief surface. A positive lead angle and reasonable back-off angles of top and lateral cutting edges are used. Its installation angle is the spiral lead angle.

Owner:UNIV OF SCI & TECH BEIJING

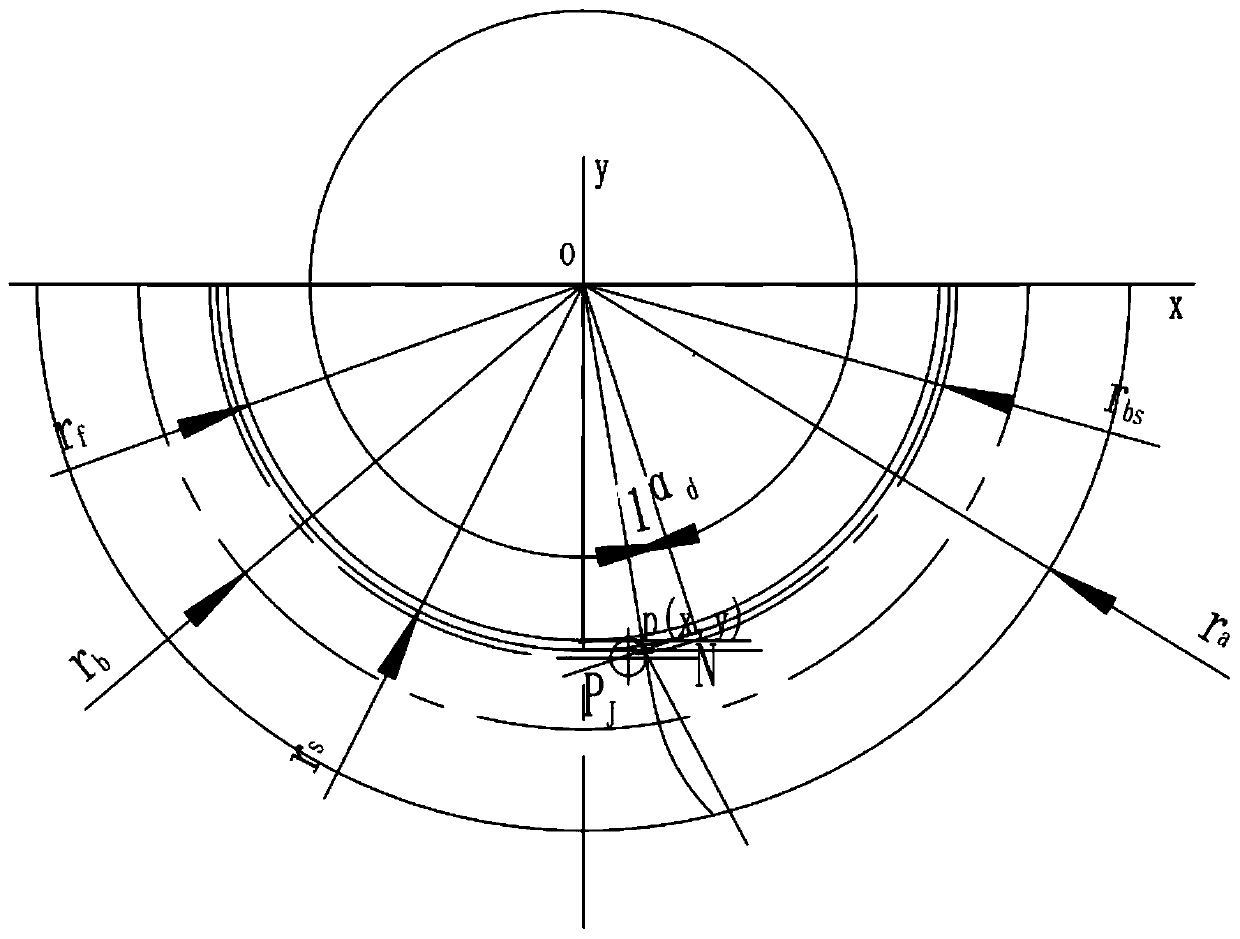

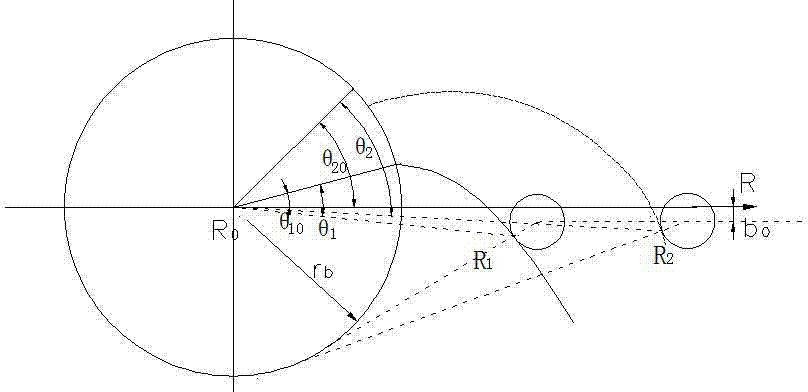

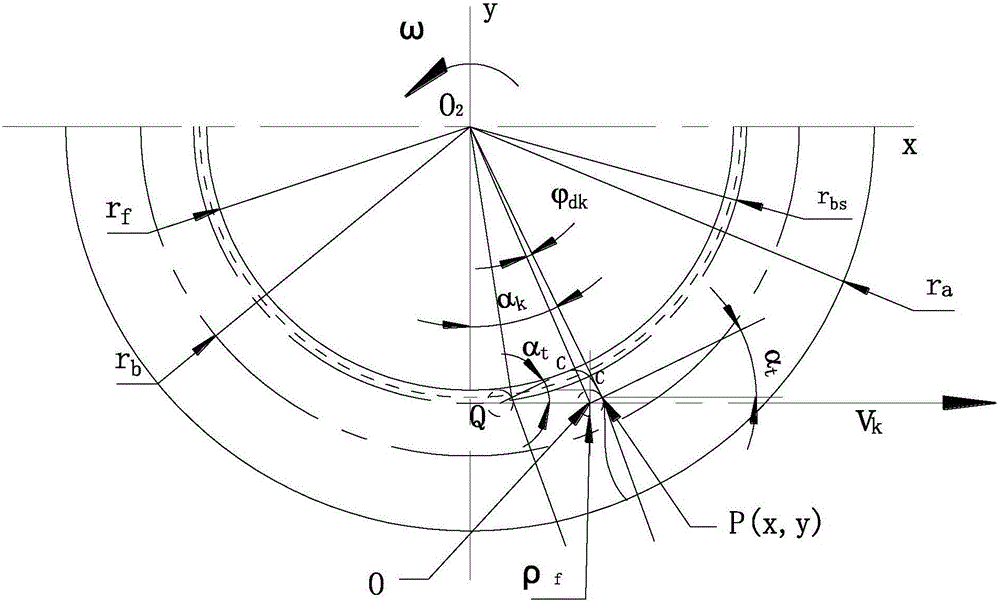

Design calculation method for reverse involute gear transmission meshing

ActiveCN109751386ARelaxation errorReduce difficultyPortable liftingSpecial data processing applicationsInvolute gearEngineering

The invention discloses a design calculation method for reverse involute gear transmission meshing. The design calculation method for the reverse involute gear transmission meshing comprises the following steps that modeling is carried out based on a gear base circle to establish a functional relation of a reverse involute; related meshing equations are deduced; the value of the gear modificationcoefficient of the reverse involute is confirmed; transmission parameters of the reverse involute are calculated; the calculated transmission parameters are checked; and the gear machining quality ischecked. A meshing track of a reverse involute tooth profile is designed on an involute gear, the bearing capacity of a main working face can be improved. Because the elastic deformation is consideredin the design, and the stress deformation of the gear is corrected by using the elastic deformation amount, the requirement of an elastic conjugate tooth profile curve is further met, the manufacturing error of the gear can be relaxed appropriately, and the difficulty of the gear manufacturing meeting the precision requirement is reduced.

Owner:重庆模源齿轮有限公司

Form rolling method for involute gear

A form rolling method for an involute gear, which includes a work piece (10) including a cylindrical outer peripheral surface having a predetermined radius, and a round die (20) with an Involute tooth profile including an addendum pitch corresponding to a pitch defined by dividing a length of an outer circumference of the work piece (10) by number of teeth of the involute gear. The round die (20) is pressed to the work piece(10) while rotating when form rolling the involuete gear.

Owner:AISIN SEIKI KK

Involute gear transmission device based on line and plane conjugation

ActiveCN102162503AImprove contact strengthImprove carrying capacityPortable liftingToothed gearingsGear driveGear wheel

The invention discloses an involute gear transmission device based on line and plane conjugation and particularly relates to an involute gear. The involute gear transmission device disclosed by the invention comprises an involute conjugated meshing pair, wherein a smooth curve shown in the specification is selected from the gear surface of one gear in the meshing pair; the master normal vector direction of the smooth curve is consistent to the normal direction of the gear surface; the curve shown in the specification and the gear surface of the other gear in the meshing pair form line and plane conjugated meshing; the gear surface of the gear is a tubular meshing surface; the tubular meshing surface is a ball race enveloping surface of which the ball center moves along an equidistant line; the equidistant line is a smooth curve with the equidistance a along the master normal vector direction of the curve shown in the specification; the radius of a ball in a ball race is the distance a between an equidistance curve and the curve shown in the specification; and the distance a is less than the minimum curvature radius of the original involute profile meshing section. In the invention, by changing the involute gear transmission into the line and plane conjugated meshing pair, the meshing process adopts point contact and approximately pure rolling meshing, the contact strength is high, the bearing capacity is high, the sliding ratio is greatly reduced, the direction of the end surface is still the direction of the involute meshing pair, and the advantages that the center distance in the involute gear transmission can be divided and the like are succeeded.

Owner:CHONGQING UNIV

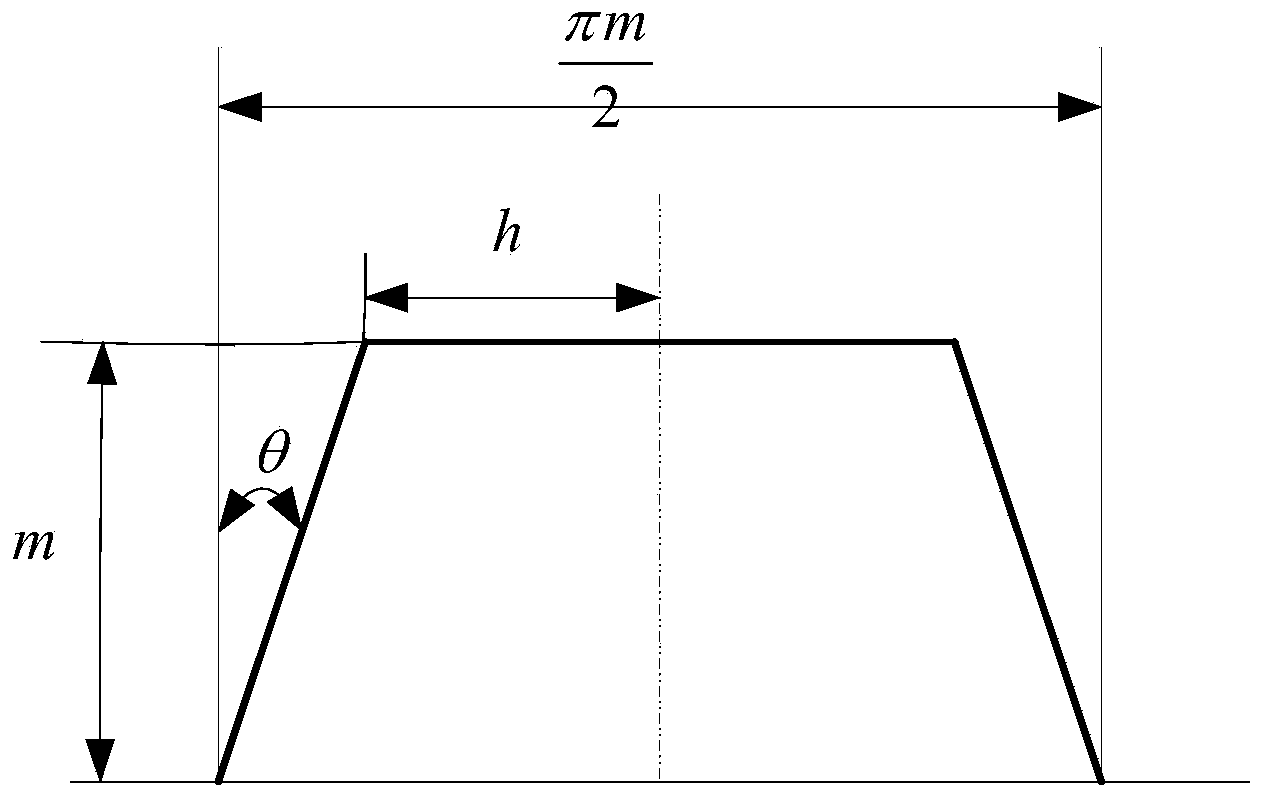

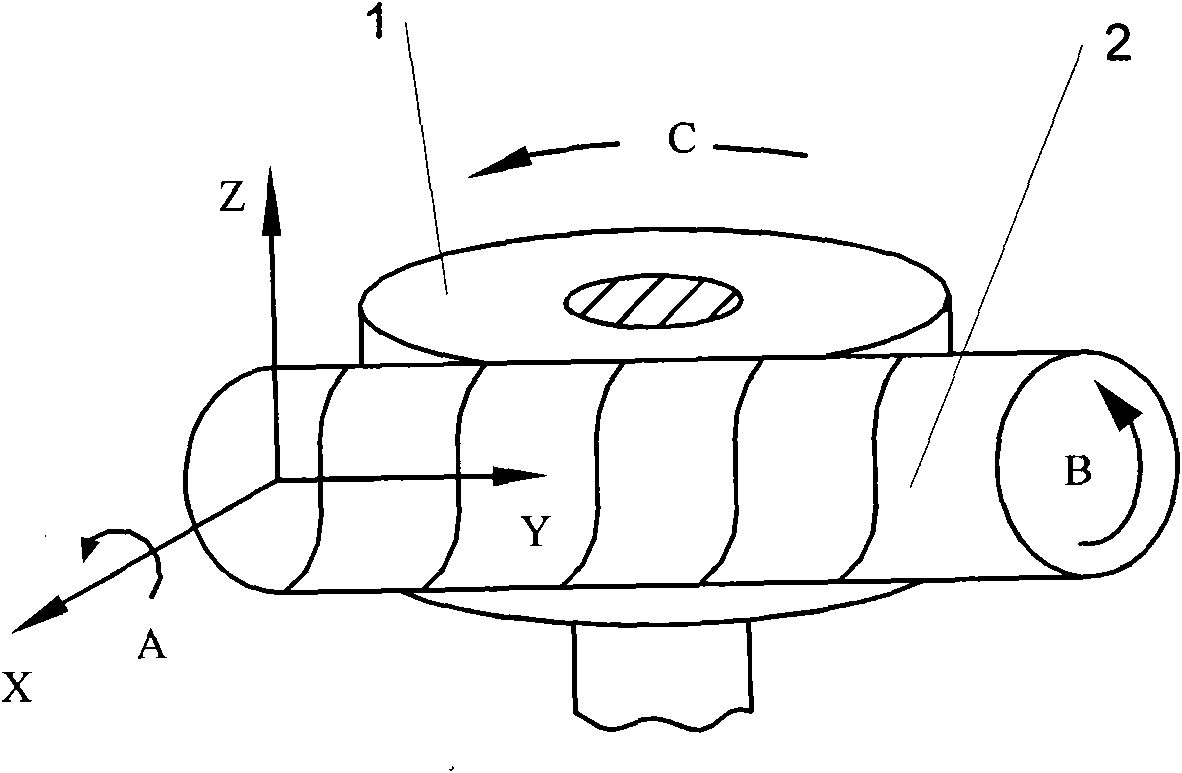

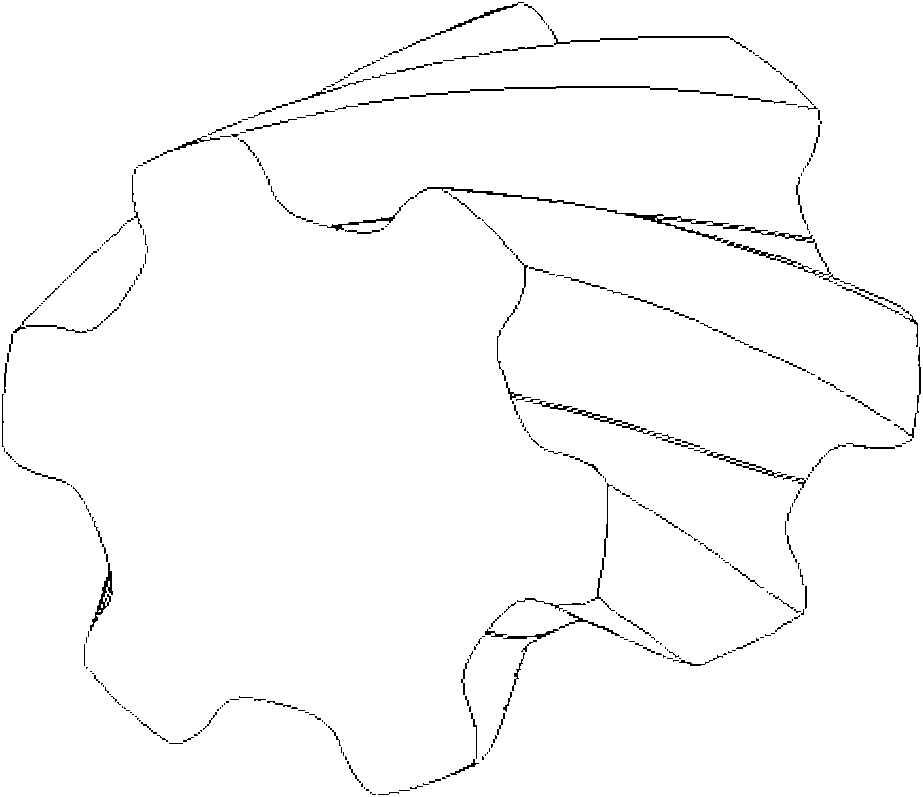

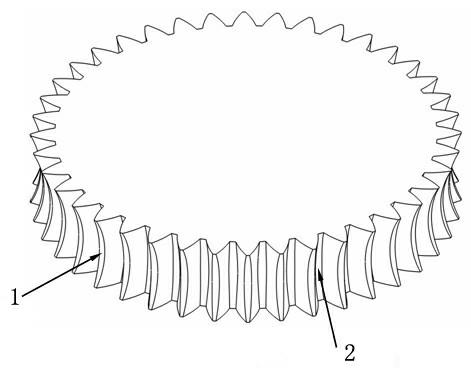

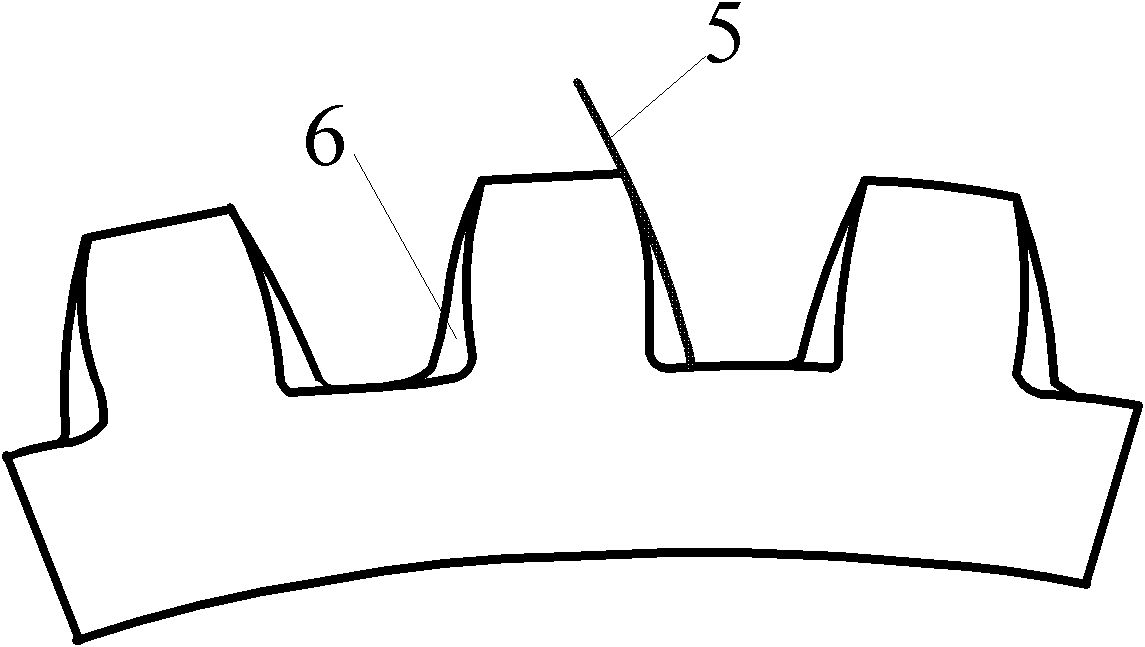

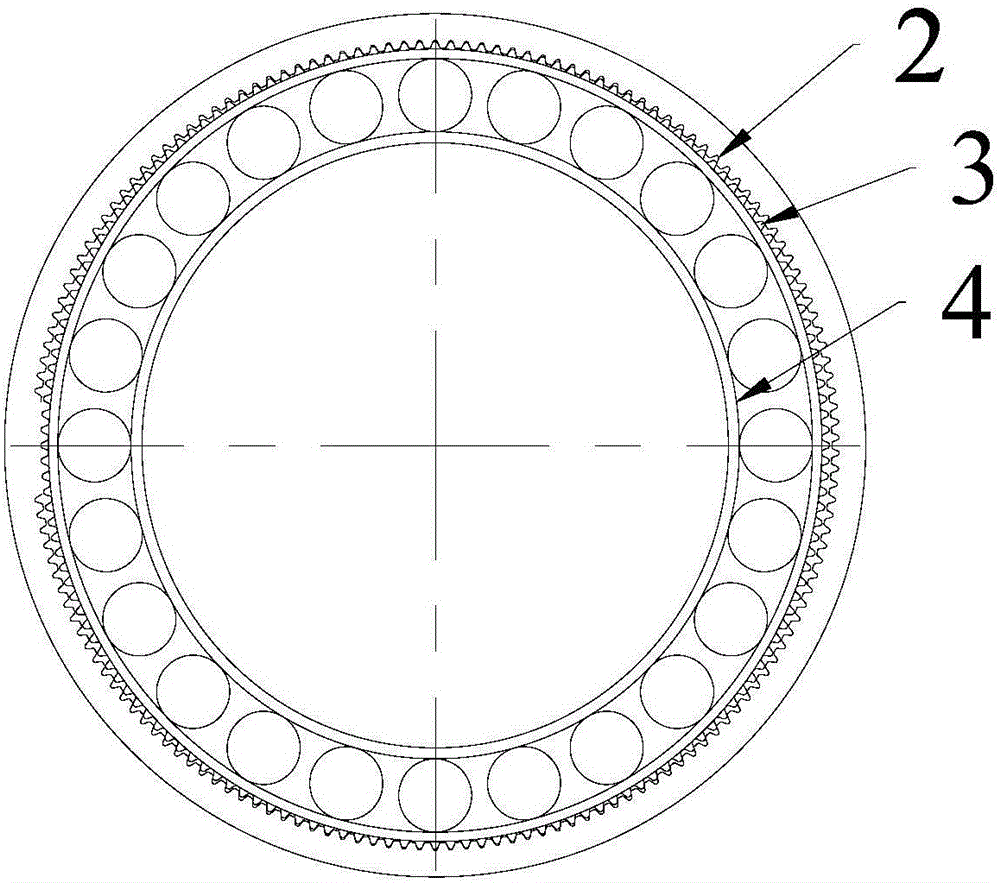

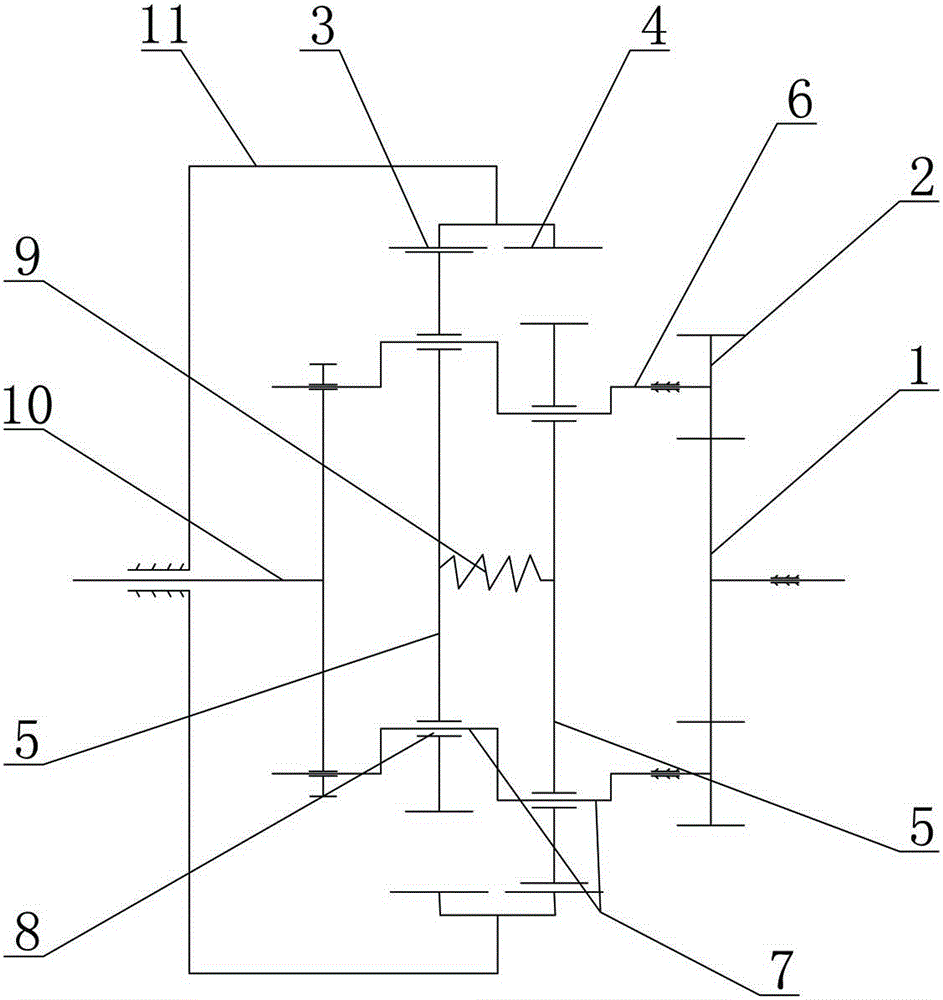

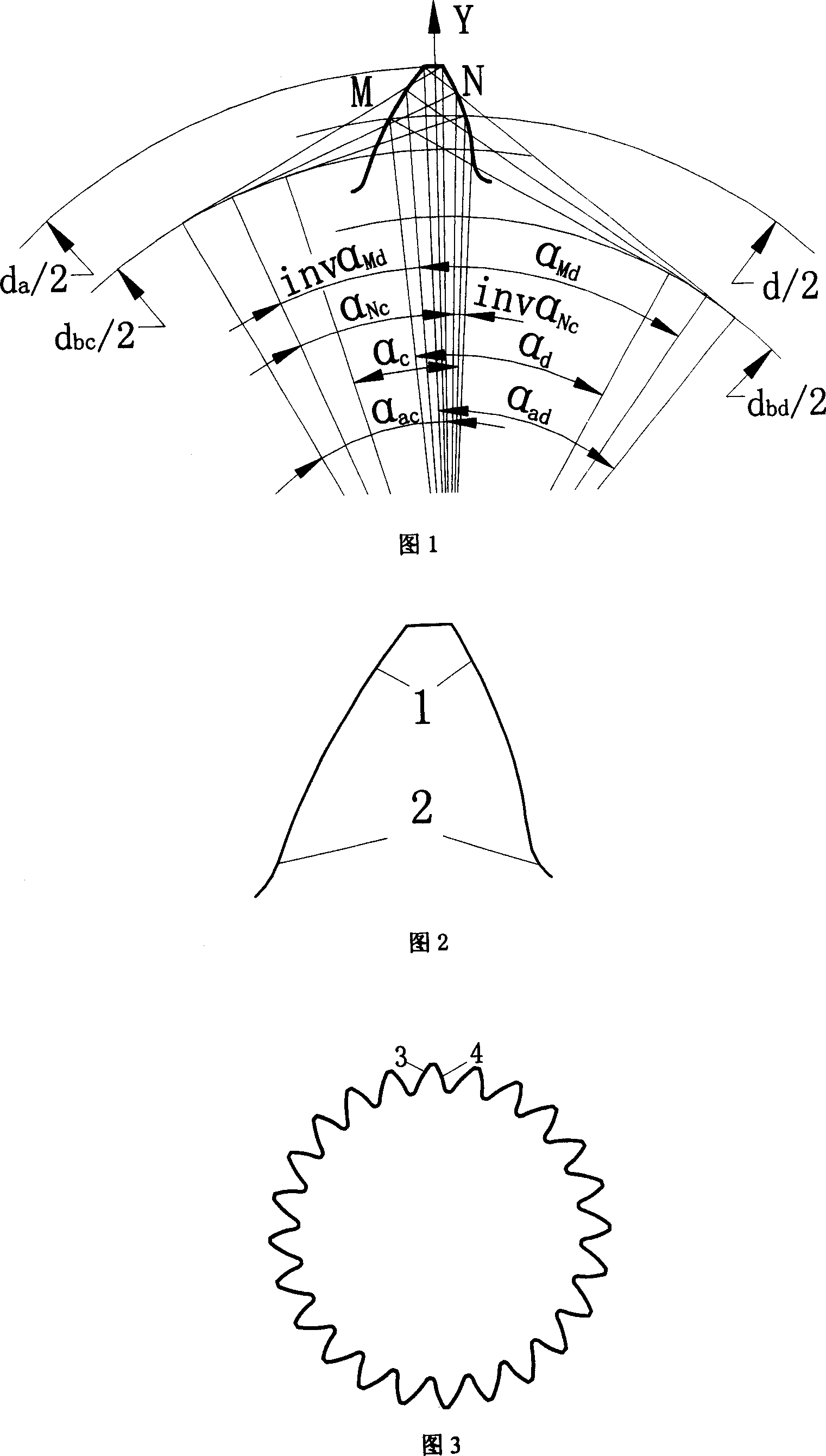

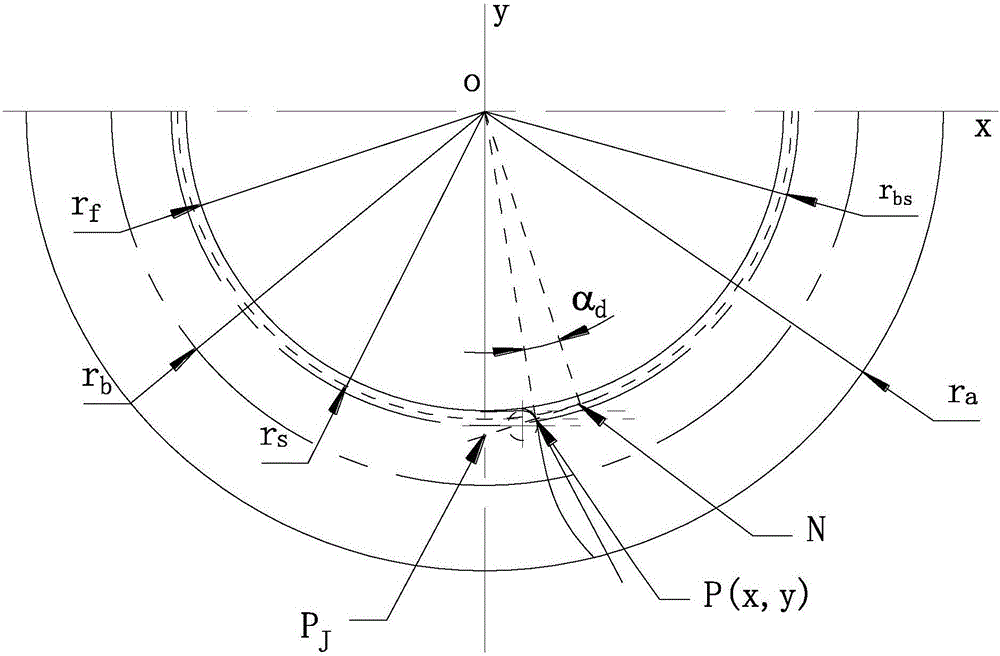

Gear shape design method of three-dimensional high-rigidity harmonic reducer

ActiveCN106090185AImproved ability to resist torsional deformationImprove carrying capacityPortable liftingGear teeth manufacturing toolsHarmonicInvolute gear

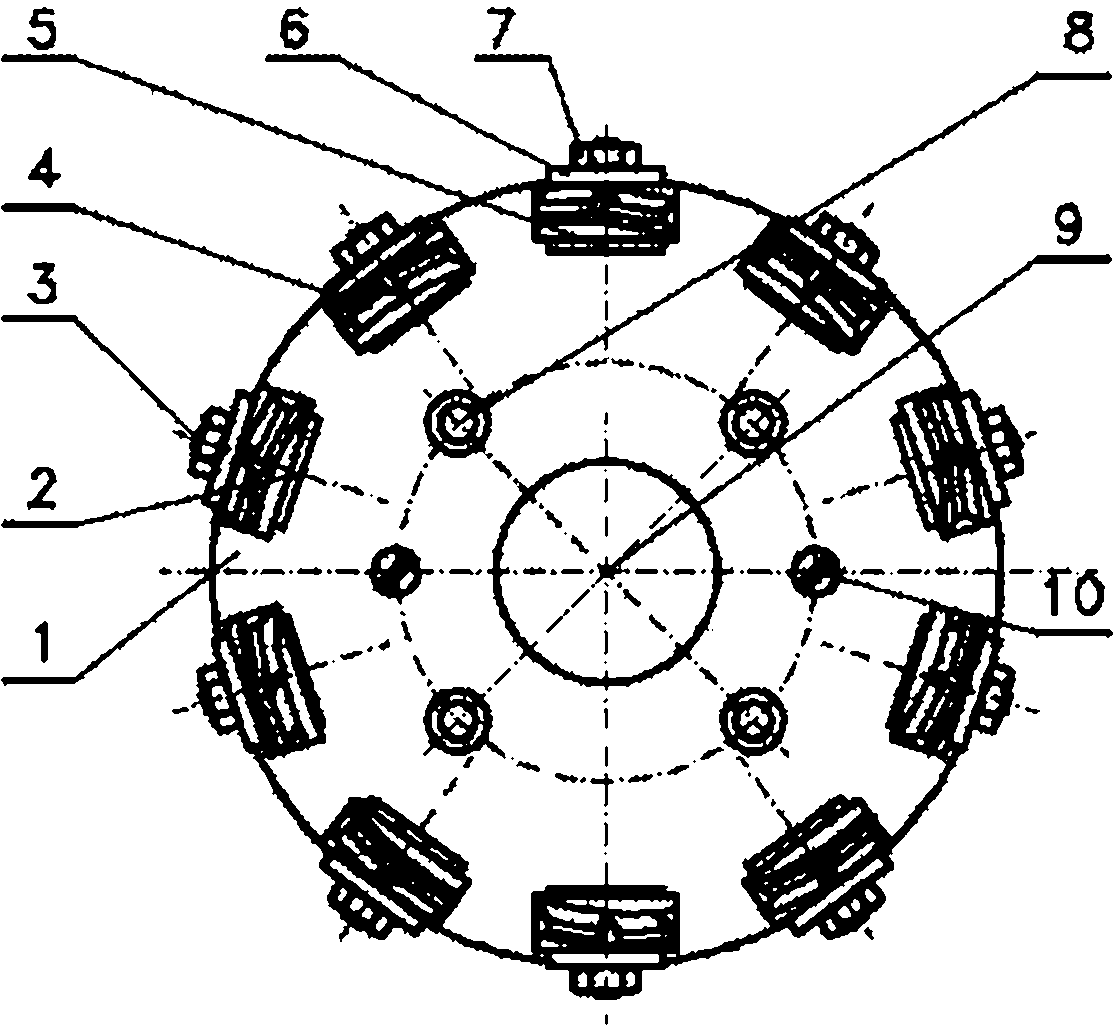

The invention discloses a gear shape design method of a three-dimensional high-rigidity harmonic reducer. The harmonic reducer comprises a wave generator, a rigid gear and a flexible gear. The rigid gear is engaged with the flexible gear. The wave generator is in contact with the inner wall of the flexible gear. Both the rigid gear and the flexible gear are involute gears. The tooth number of the rigid gear is Z1, the tooth number of the flexible gear is Z2, and Z1-Z2=2; the modification coefficient of the rigid gear is x1, the modification coefficient of the flexible gear is x2, x1<x2, and the modification difference delta x=x1-x2; and material removing and shaping treatment is conducted on the two sides or top of the addendum circle of the rigid gear and / or the flexible gear. According to the scheme, implementation is convenient, the machining cost is low, the purpose of large-area engagement is achieved, the torsional deformation resistance and bearing capacity of the harmonic reducer are improved, and the service life of the harmonic reducer is prolonged.

Owner:铂睿(山东)精密工业有限公司

Method for processing cycloid-involute spiral bevel gears and solid cutter

InactiveCN102179570ASimple structureImprove rigidityGear teeth manufacturing toolsGear teethNumerical controlInvolute gear

The invention discloses a method for processing cycloid-involute spiral bevel gears on general digital control gear milling machines and a corresponding solid cutter, and belongs to the field of spiral bevel gear processing. According to the method, a large wheel can be processed by a double-sided method and a small wheel is processed by the double-sided method or a single-sided method. After a gear is subjected to heat treatment, the gear is shaved or ground. The cutter for processing the gear is integral; an installation structure of the cutter body on a machine tool is the same as a cutter installation structure used by the general digital control gear milling machines, and a soft cutting cutter head and a hard cutting cutter head used on the cutter and the assembly structure and method thereof are consistent with those used for the cycloid-involute spiral bevel gears. The cutter adopted in the method is simple in structure and easy to manufacture, and can perform processing on the general digital control machine tools without accessories or special designs, so the cycloid-involute spiral bevel gears can be easily promoted in industrial circles.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

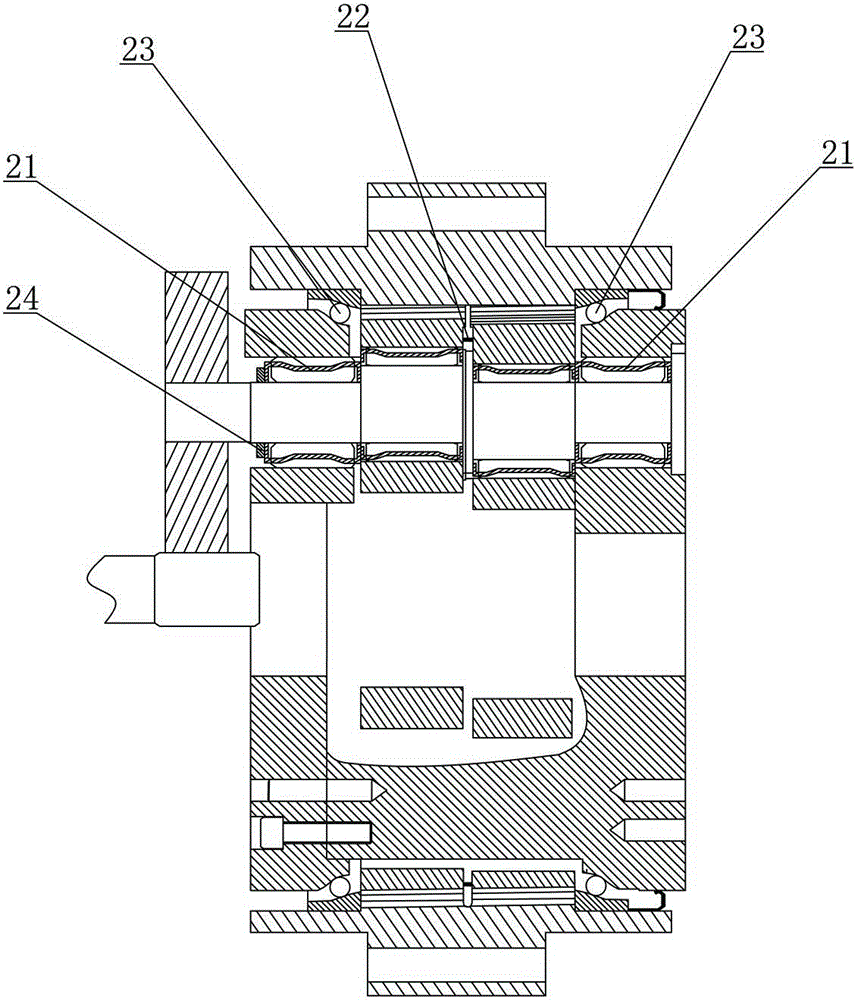

Planetary gear transmission mechanism, robot joint reducer and robot

ActiveCN105221669ARealize deceleration and torque increaseReduce machining accuracyJointsToothed gearingsReduction driveInvolute gear

The invention provides a planetary gear transmission mechanism which comprises a sun wheel, planet wheels and a few-tooth-difference transmission mechanism. In order to improve the precision, gear teeth of two inner gear rings and gear teeth of two few-tooth-difference gears are variable-tooth-thickness involute gear teeth; the rotation directions of the helix angles of the two inner gear rings are opposite, and a clearance-eliminating elastic body is arranged between a pair of few-tooth-difference gears. The planetary gear transmission mechanism has the advantages of being high in rigidity and precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty. The invention further provides a robot joint reducer which comprises the planetary gear transmission mechanism. The robot joint reducer has the advantages of being scientific in design, small in size, high in precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty. The invention further provides a robot which comprises the robot joint reducer. The robot has the advantages of being scientific in design, high in precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty.

Owner:吴建红

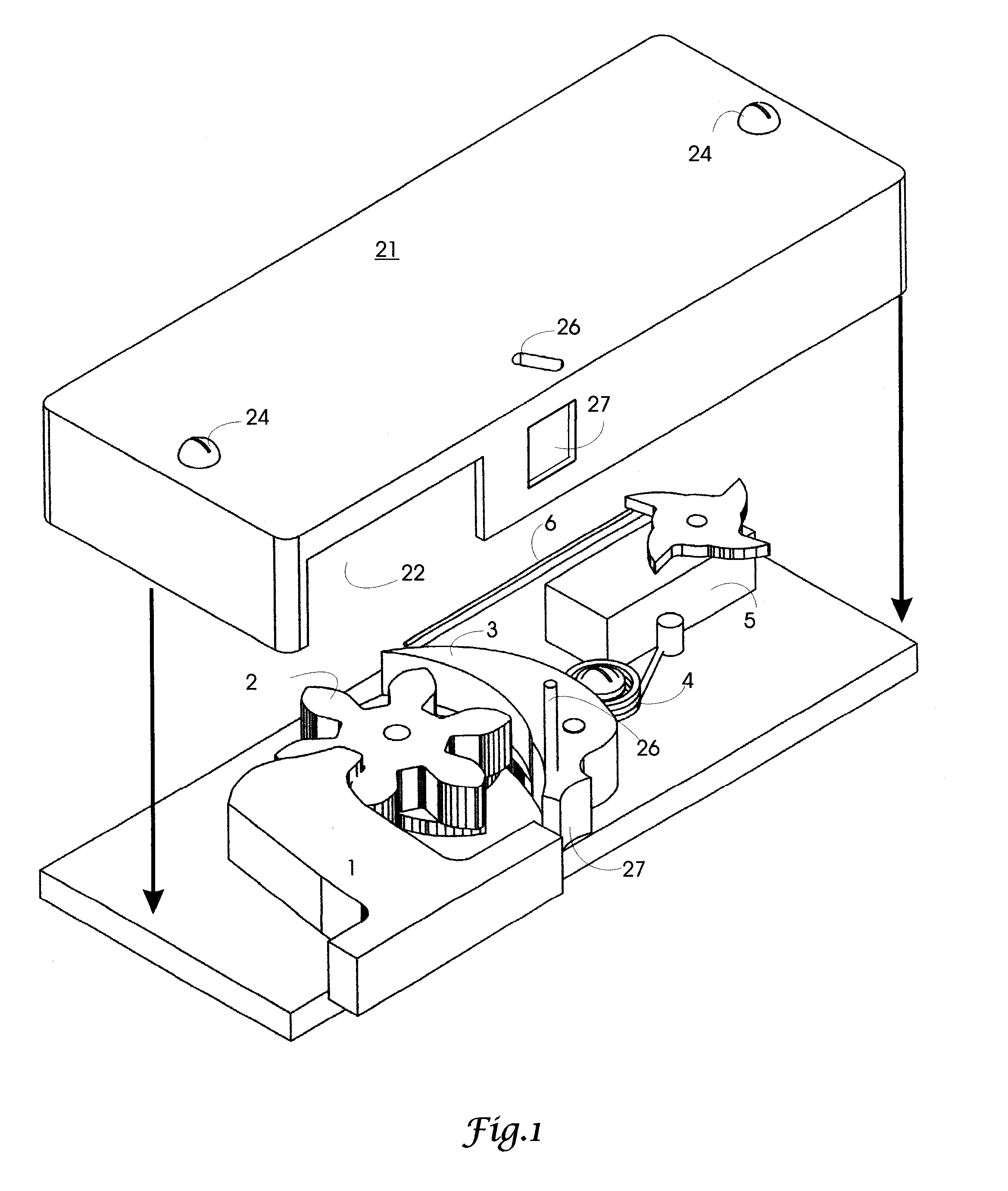

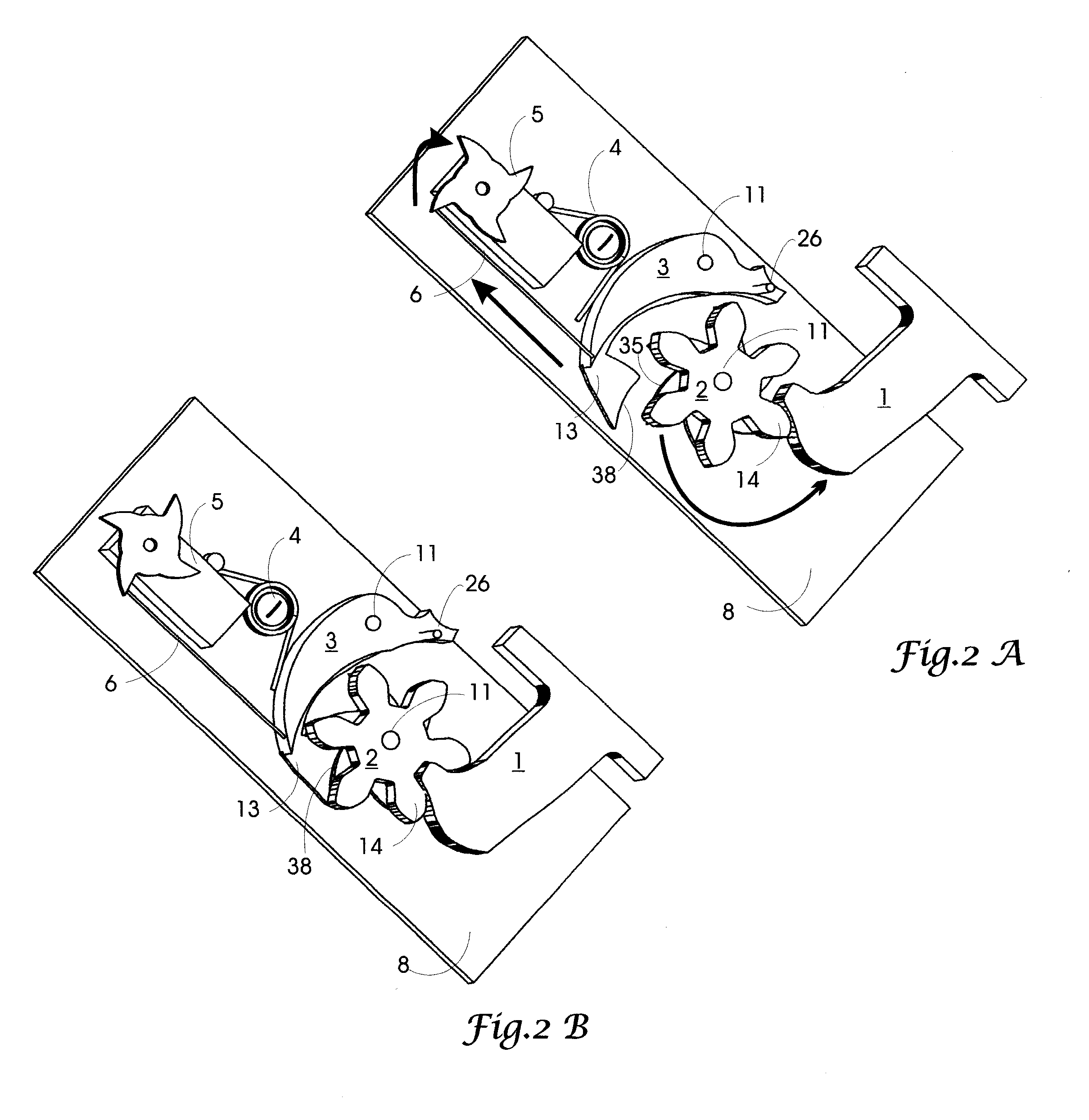

Electromechanical door locks for lifts

InactiveUS20110180353A1Prevent inadvertent movementAvoid accessConstruction fastening devicesBuilding liftsInvolute gearEngineering

An electromechanically actuated safety lock mechanism particularly suited for elevator hall doors, dumb waiters, and similar lift mechanisms and other applications. A door lock and switch comprises a fixed contact member that is attached to a movable door and a movable locking mechanism attached to a door jamb or second moving door. The locking mechanism may comprise, an involute gear and star wheel, a pawl constrained by a torsion spring and an electromechanical means of actuating same.

Owner:ASKINS TIM

Method for automatically calibrating measuring head polarization quantity of polar coordinates gear measuring center

InactiveCN103575244ALow installation accuracy requirementsMeasurement devicesInvolute gearEngineering

The invention relates to a method for automatically calibrating the measuring head polarization quantity of a polar coordinates gear measuring center. According to an existing polar coordinates gear measuring method, basic conditions are that when a measuring head is installed, the center of the measuring head must be located on the R axis, or else, the zero calibration error can be caused. The single side face of an involute gear undergoes the double-face measurement before and after being turned over, two sets of measured values are substituted into the polar coordinates method error calculation formula comprising polarization parameters, the polarization quantity and the offset quantity of the measuring head are worked out and are introduced into the workpiece measurement error calculation modifier formula, and automatic compensation for the measuring head installing error is achieved. According to the automatic correcting method, the offset quantity of the measuring head relative to the original calibration rotation center can be directly solved, the requirement for mechanical installing precision is lowered, the calibration on measuring heads can be carried out in batches, and a foundation is laid for automatically replacing the measuring heads.

Owner:XIAN TECH UNIV +1

Processing method of asymmetric gear with two pressure angles

InactiveCN101007364AEasy to processImprove carrying capacityProgramme controlComputer controlCarrying capacityGear wheel

A double pressure angle asymmetric gear processing method belongs to gear technology field. The processing steps are: installing CAXA wire cutting software, inputting the involute equation and adjustment curve equation of asymmetrical gear work flank and non-work flank into the formula curve of drawing instrument column, inputting parameter into initial value column and stop value column, then inputting the equation of addendum arc into formula curve, setting the initial point of addendum arc parameter as the stop point of non-work flank adjustment curve; working out the tooth profile curve of involute gear, completing the tooth profile of whole involute gear through 360degreearray; transforming the total data of involute all-gear graph into wire cutting processing program order 3B code through the automatic transforming function of wire cutting software; the control system of wire cutting machine processes the involute gear which involute coefficient between 1.0 and 1.3289 through 3B code. The wire cutting process is more flexible, wheel carrying-capacity is higher and vibration is small.

Owner:UNIV OF SCI & TECH BEIJING

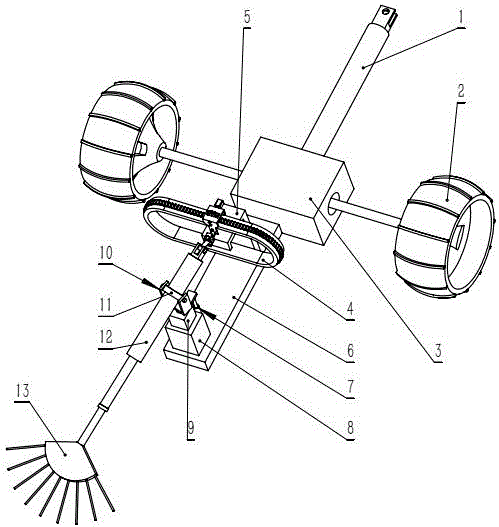

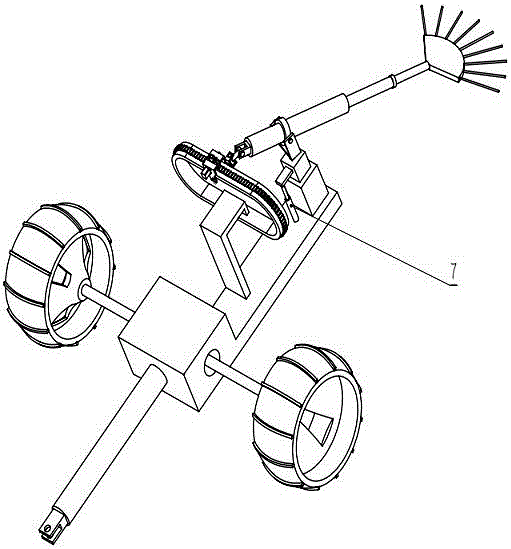

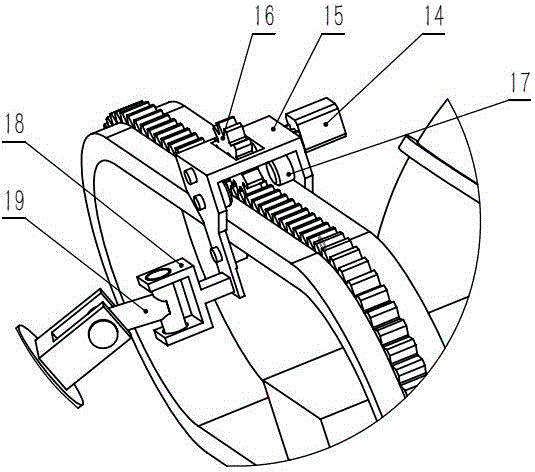

Oscillating type energy-saving road sweeper

The invention provides an oscillating type energy-saving road sweeper which comprises a traction rod, two wheels, an axle, an annular rail, a support and the like. The oscillating type energy-saving road sweeper is characterized in that the two wheels are arranged on the left side and the right side of the axle through a vehicle shaft in a rotary mode, the traction rod is fixedly arranged at the front end of the axle, a bottom plate is fixedly arranged on a rear end face of a rear axle, the support is fixedly arranged above the front end of the bottom plate, the annular rail is arranged on the support, an end face of the annular rail is parallel to a rear end face of the axle, and an involute gear is arranged at the periphery of the annular rail. A U-shaped movable frame is arranged on an annular guide rail through four idler wheels in a rolling mode, the four idler wheels are divided into two pairs which are arranged on two sides of an inner wall of the U-shaped movable frame, and the annular guide rail is clamped between the upper idler wheel and the lower idler wheel which are arranged on the same side. A broom is controlled to oscillate through movement of the U-shaped movable frame on the annular guide rail. Therefore, the front end of the broom is prevented from exceeding the width position of the two wheels during sweeping through structural arrangement.

Owner:江苏国能建设有限公司

Transmission device in manner of same-directional involute gear pair engagement

ActiveCN105134910AExtended service lifeHigh transmission reliabilityPortable liftingGearing elementsInvolute gearEngineering

The invention discloses a transmission device in a manner of same-directional involute gear pair engagement. The transmission device comprises a pair of mutually-engaged gears, and is characterized in that the working tooth profiles located at tooth roots, of the gear teeth of one gear are concave involutes; the working tooth profiles located at tooth tops, of the gear teeth of the other gear are convex involutes; and the concave involutes and the convex involutes are engaged by convex-concave arcs. The transmission device disclosed by the invention has the advantages of being long in service life, high in transmission reliability, low in maintenance expense, easy to install, and the like.

Owner:重庆市綦江区余江齿轮有限公司

Involute straight tooth gear modification optimization method

InactiveCN105156634AImprove optimization accuracyImprove efficiencyPortable liftingGearing elementsNumerical controlProcess optimization

The invention provides an involute straight tooth gear modification optimization method; and the method comprises the steps of: building engaged three-dimensional gear pair models; primarily selecting modification optimization parameters; respectively performing the primary modification processing for the three-dimensional gear pair models; performing the primary modification optimization analysis to obtain optimal primary analysis optimization parameters; obtaining more precise optimization samples in finite element analysis software according to the optimization parameters; and screening the samples. After screening, the secondary modification processing is performed for a pair of standard three-dimensional involute gears to obtain multiple sets of secondarily processed optimization parameters, optimal modification optimization gear parameters, one set of parabola modification and one set of arc modification; the three-dimensional diagram drawing is performed for gears optimized by the secondarily processed optimization parameters; and optimally modified three-dimensional diagrams are leaded in a numerical control machine tool to machine blanks to finished products. The method is more precise in modification, is more obvious in optimization effect, can preferably reduce the engagement noise and vibration, and reduces such adverse effects as load concentration.

Owner:梅文杰

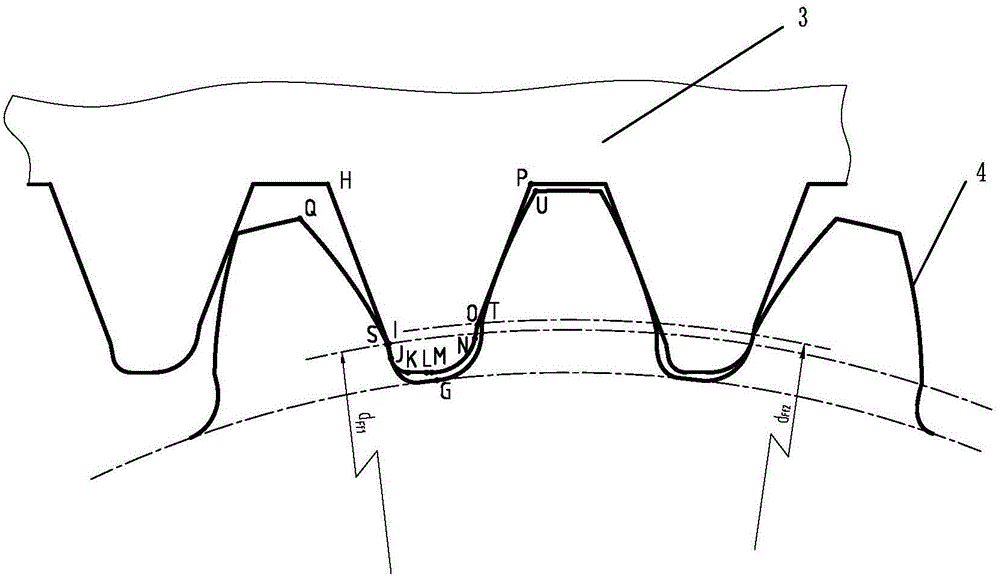

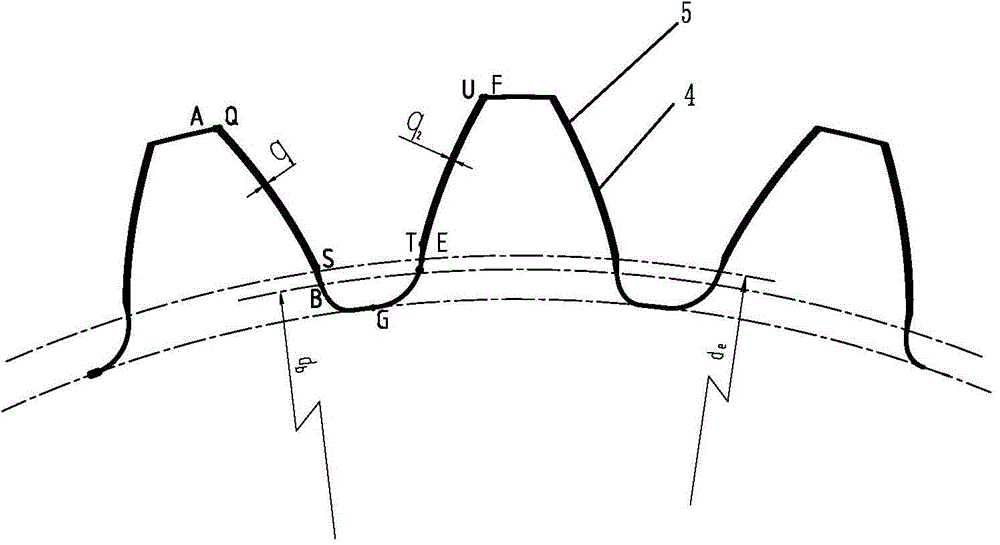

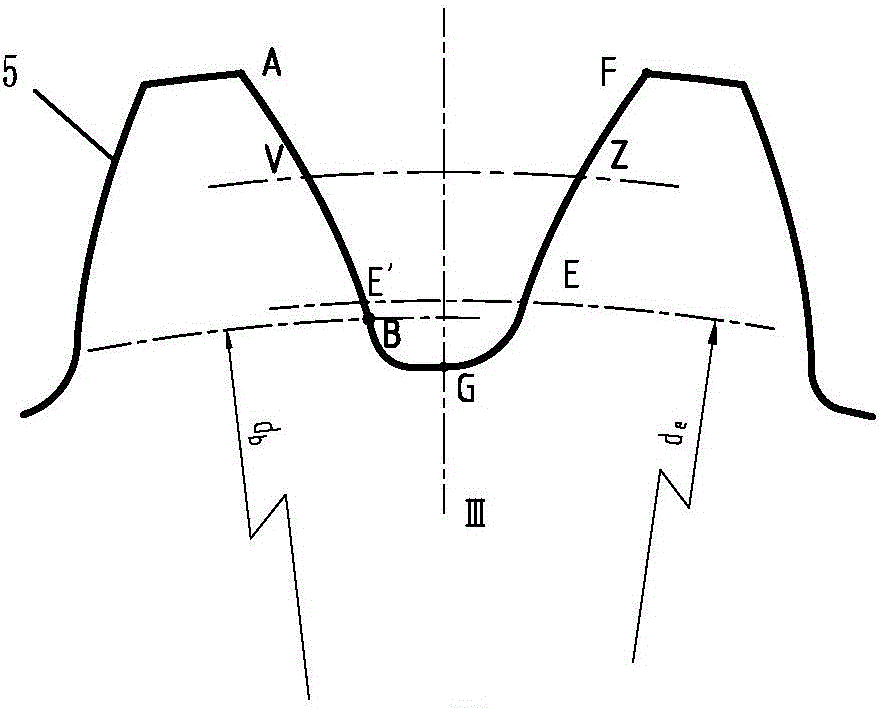

Non-full-symmetry involute gear, gear cutting hob special for same, and machining method of non-full-symmetry involute gear

ActiveCN104889501ADifferent bending strengthPortable liftingGear teeth manufacturing toolsHobbingInvolute gear

The invention discloses a non-full-symmetry involute gear, a gear cutting hob special for the same, and a machining method of the non-full-symmetry involute gear. The method includes five steps which include: preparing a gear blank which can be used for hobbing, selecting the gear cutting hob special for the non-full-symmetry involute gear, and the like. The axial tooth profile of the gear cutting hob comprises a left tooth profile and a right tooth profile, wherein the left tooth profile comprises linear segments HI, IJ and KL and an arc-shaped segment JK, and the right tooth profile comprises linear segments PO, ON and ML and an arc-shaped segment NM. The end face tooth groove tooth profile of the non-full-symmetry involute gear comprises an involute segment AB, an involute segment EF, a tooth groove left tooth root curve BG and a tooth groove right tooth root curve GE. The non-full-symmetry involute gear has the advantage that the left side and the right side of the teeth of the gear can have different tooth root bending strength. The gear cutting hob can obtain different involute starting points of the a left tooth face and a right tooth face and different tooth root curve curvature radiuses while the left tooth face and the right tooth face of the gear are allowed to have different grinding amount, and defects such as grinding bosses are avoided favorably.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com