Beveled wheel tooth error three-coordinate measuring method

A three-coordinate measurement and tooth profile error technology, applied in the field of measurement, can solve problems such as helical gear tooth profile error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

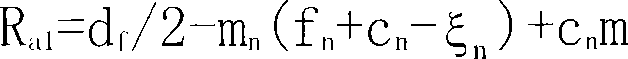

[0058] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

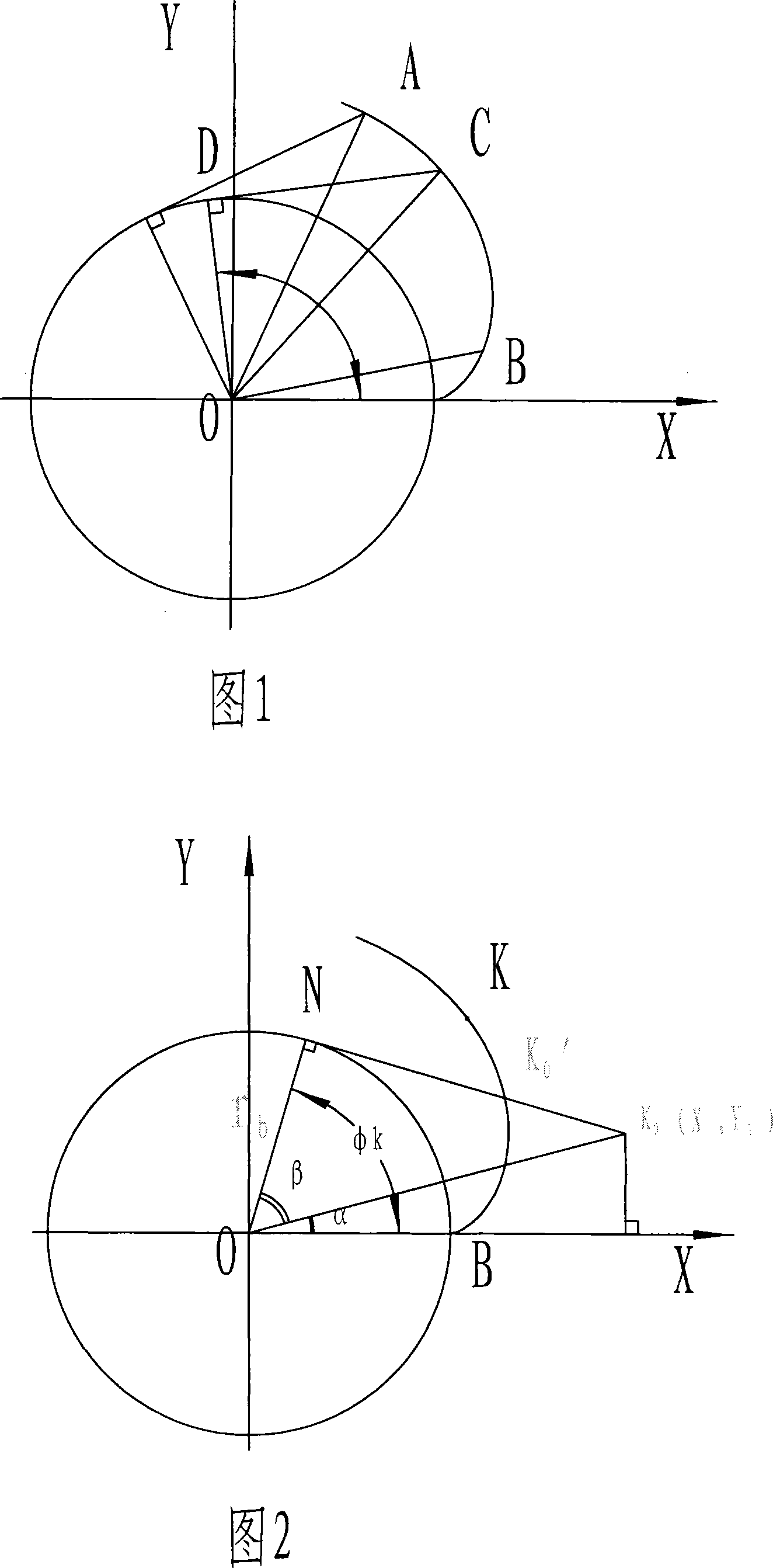

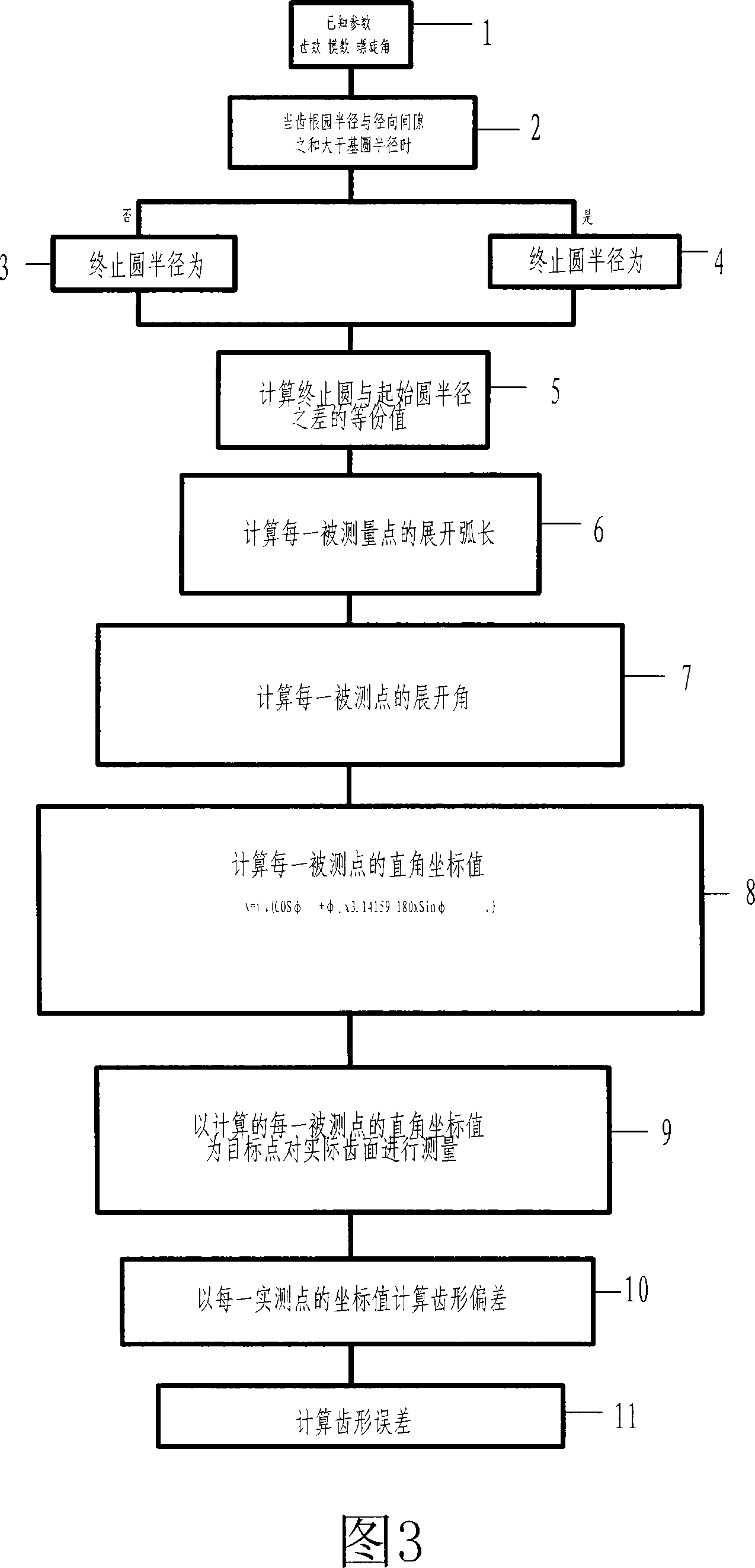

[0059] Referring to the accompanying drawings 1 to 3, the three-coordinate measurement method of the helical gear tooth profile error is realized by programming, and the program is stored in the central computer of the three-coordinate measuring machine, and its operation process is according to this The steps of the inventive method are carried out:

[0060] (1) Determine the end position of helical gear tooth profile error measurement by calculation

[0061] First determine the tooth shape data of the helical gear to be measured, including the number of teeth, modulus and helix angle, and input it into the central computer of the three-coordinate measuring machine, as shown in box 1 in Figure 3.

[0062] 1.1 Determine the radius of the termination circle at the termination position, which can be judged in the following two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com