Patents

Literature

88 results about "Form error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Global calibration for stereo vision probe

ActiveUS8055466B2Low costCost prohibitivePosition fixationUsing optical meansTip positionVision based

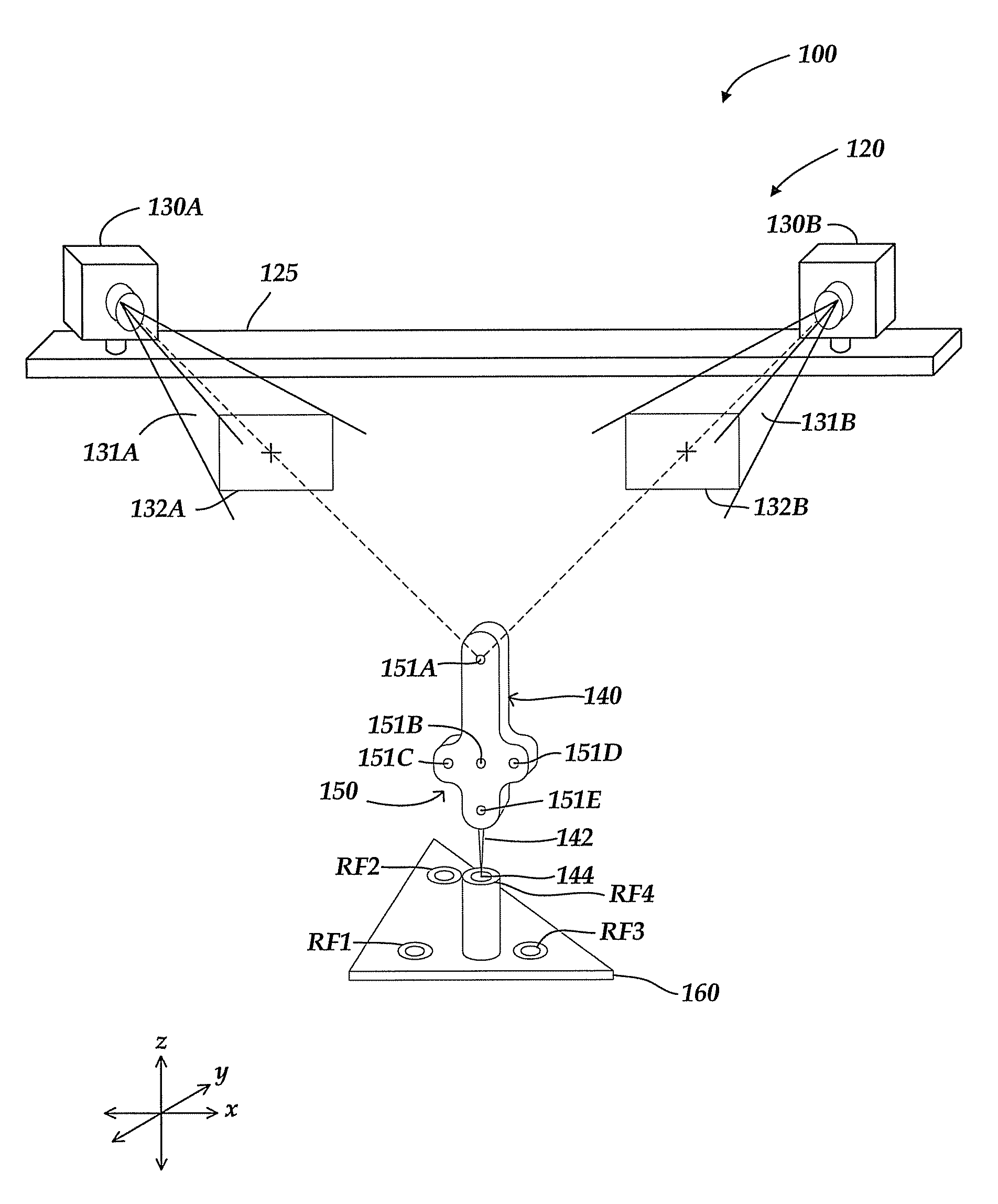

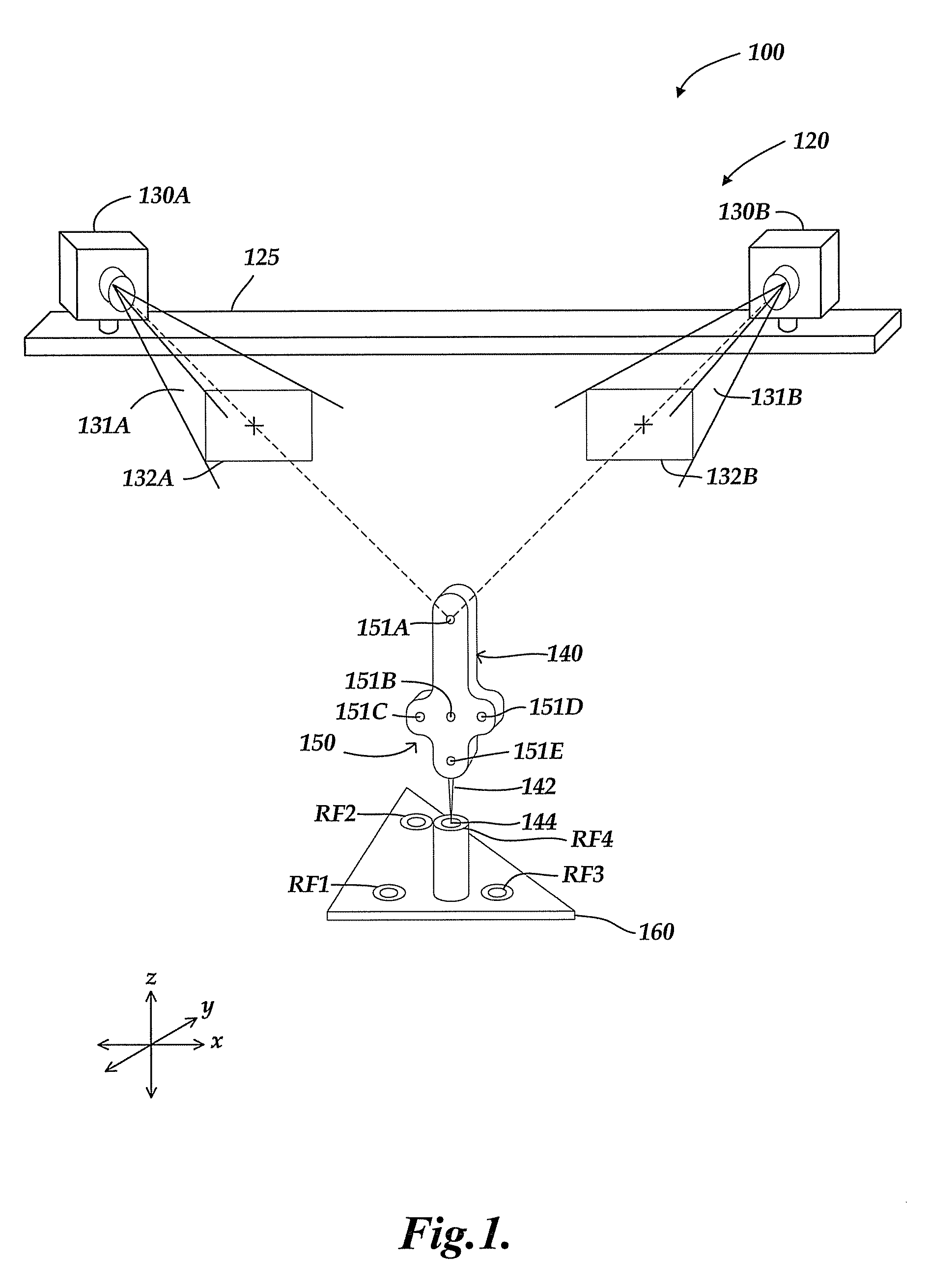

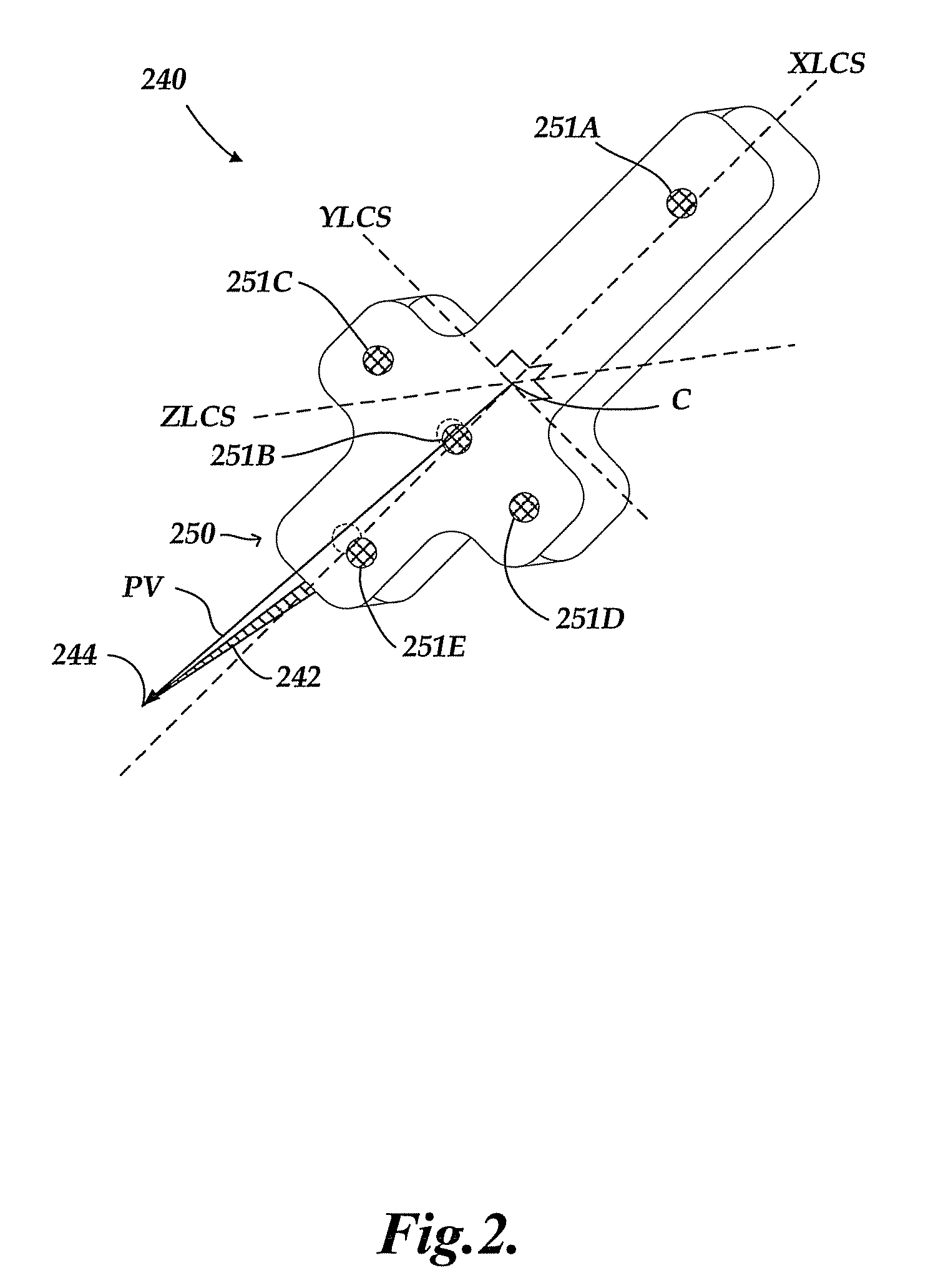

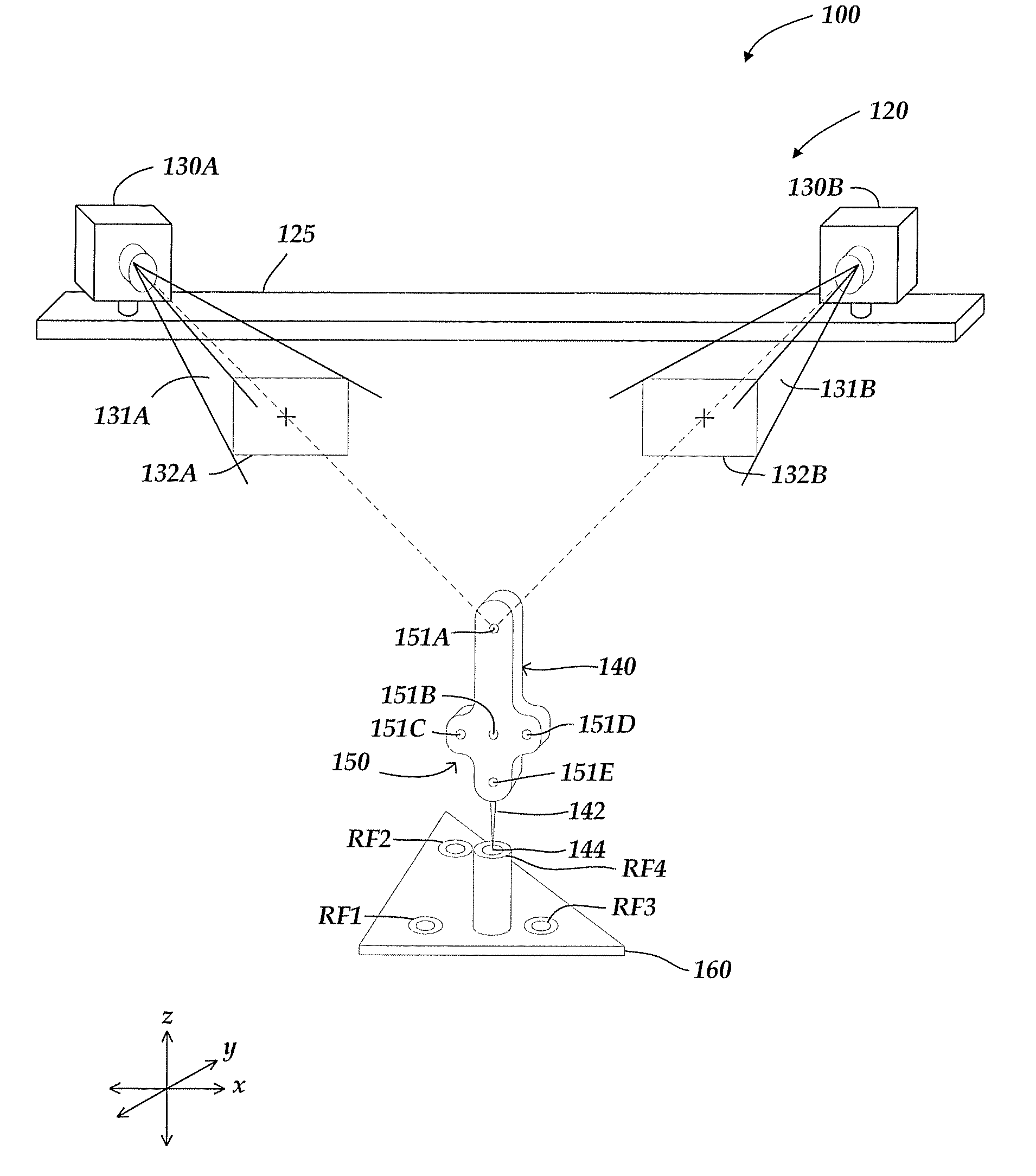

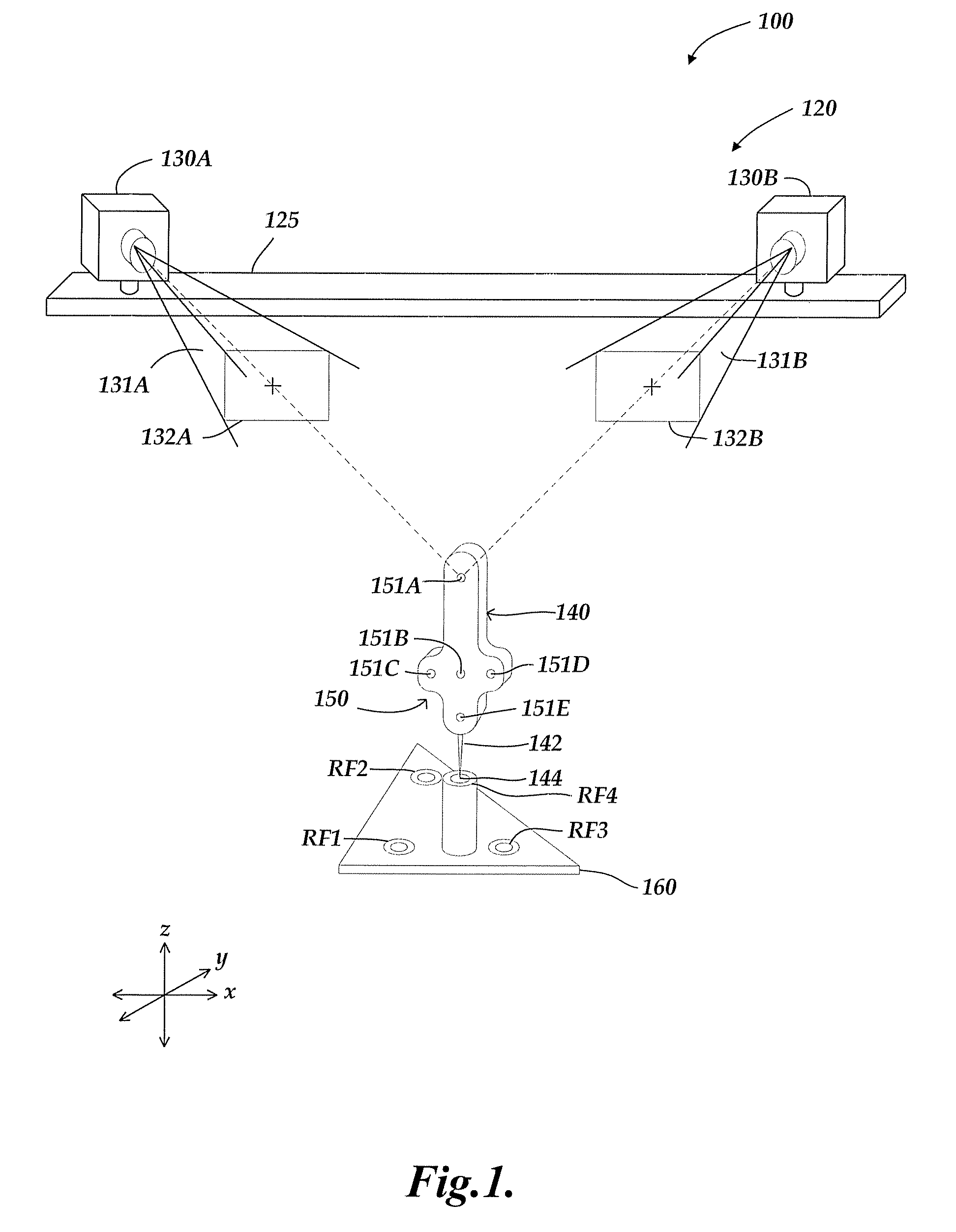

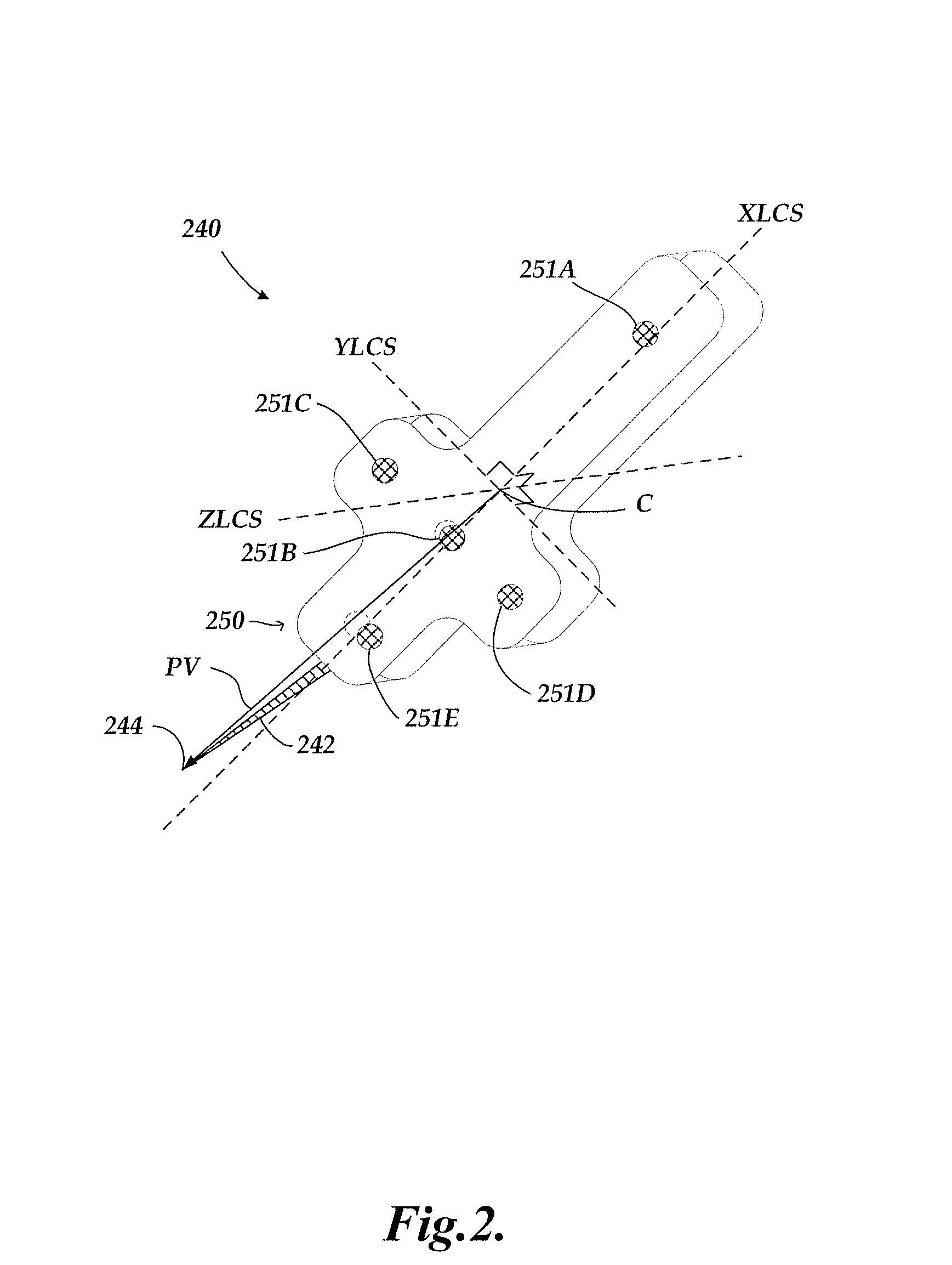

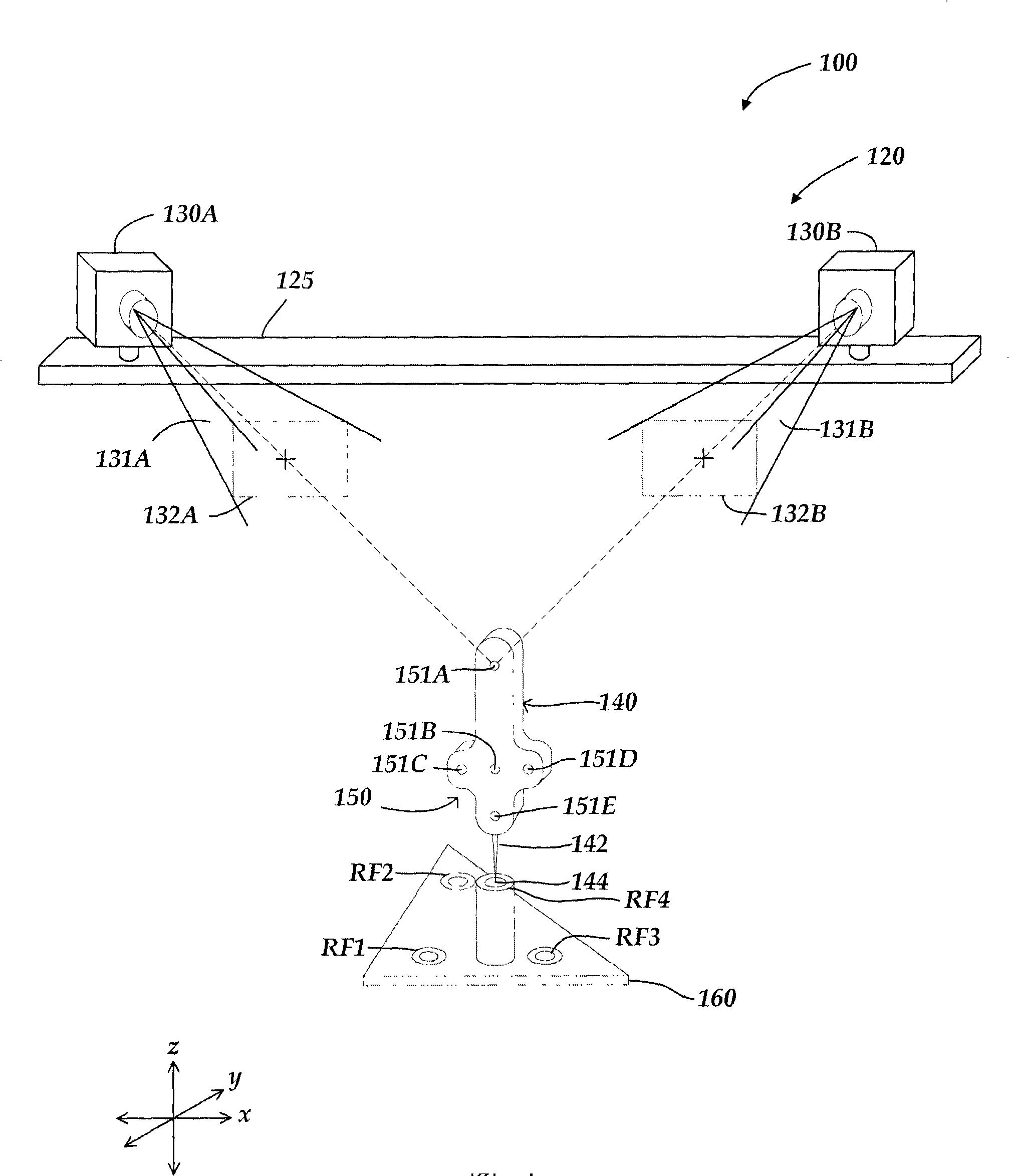

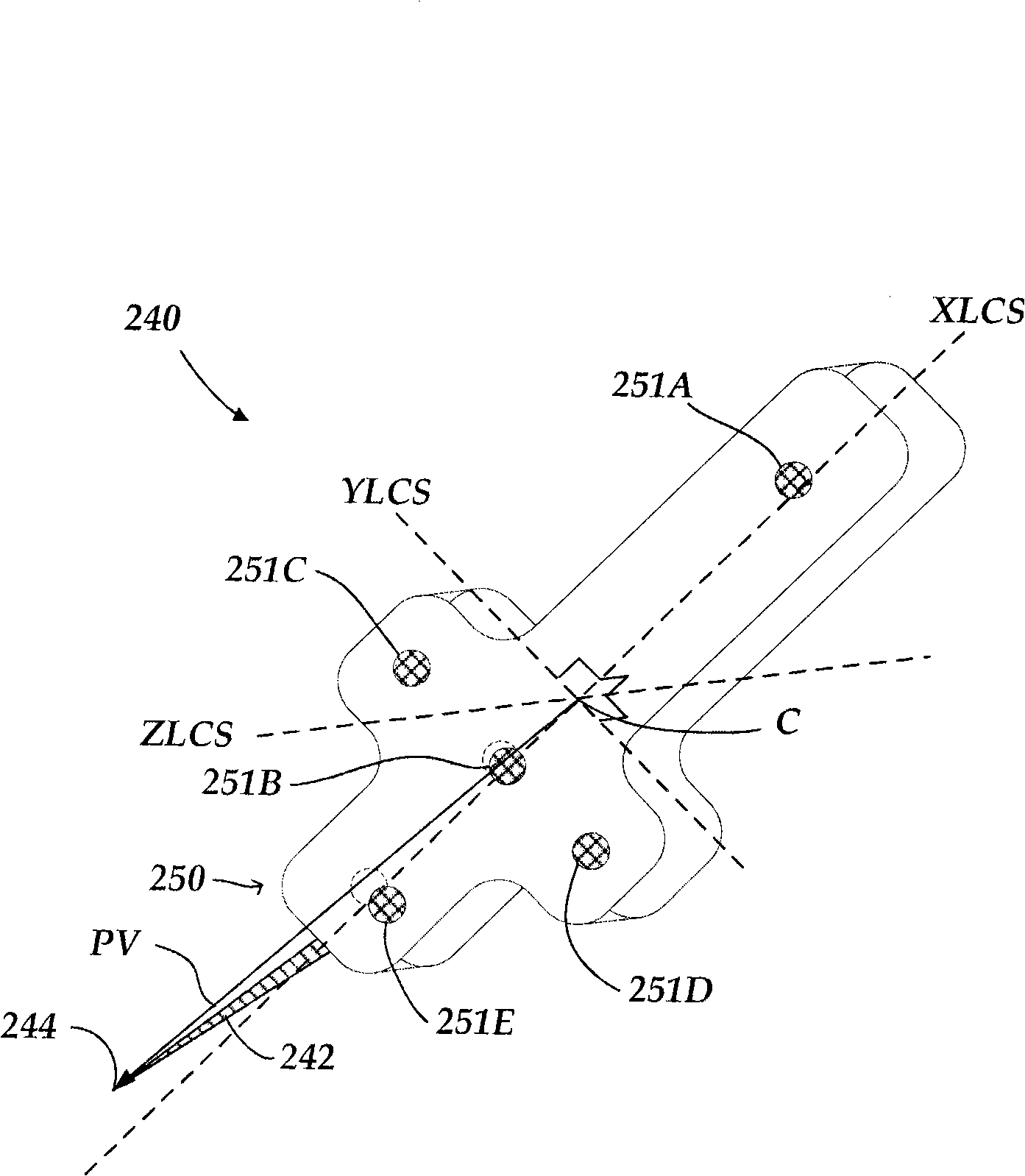

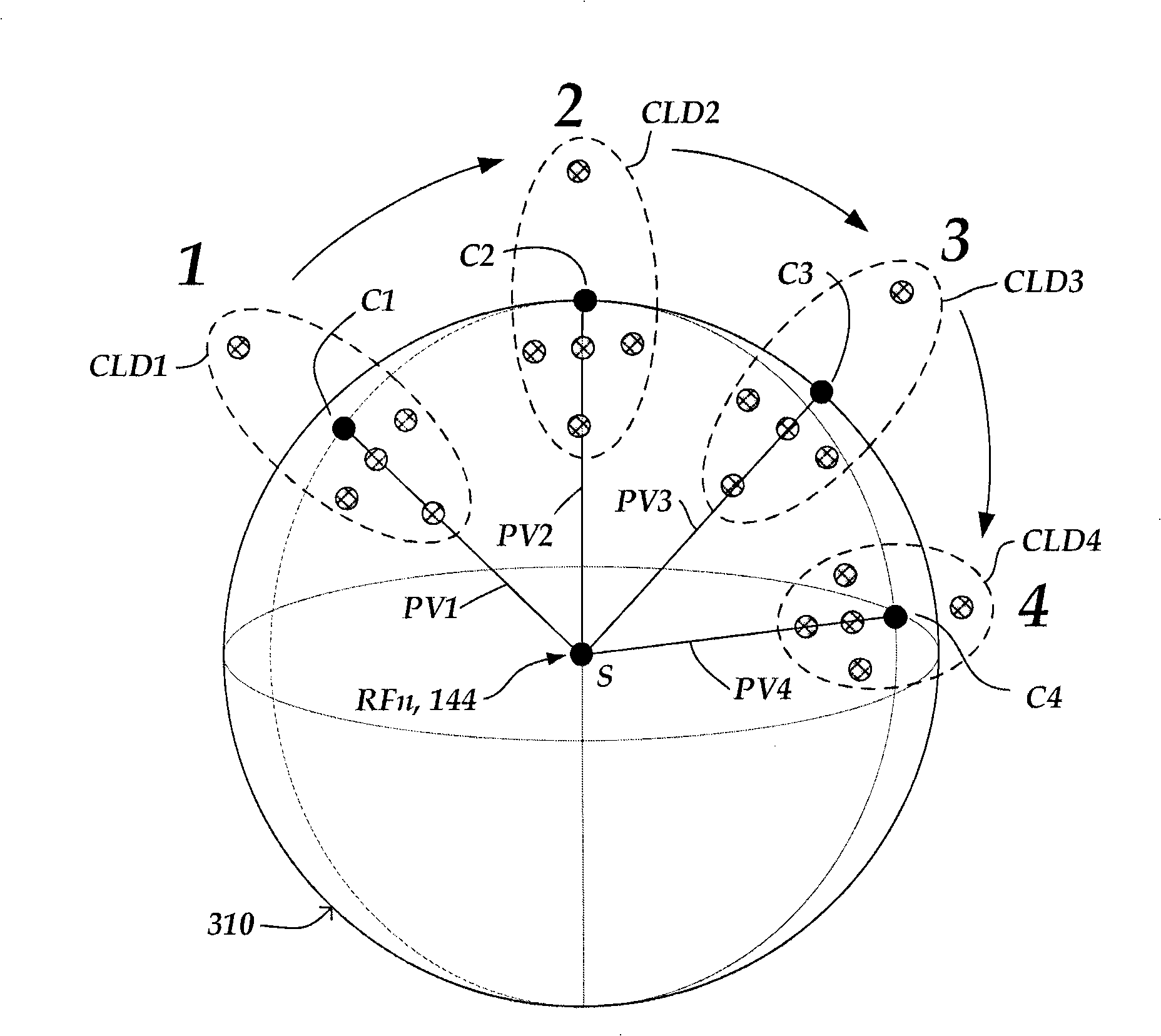

A method for global calibration of a multi-view vision-based touch probe measurement system is provided which encompasses calibrating camera frame distortion errors as well as probe form errors. The only required features in the calibration images are the markers on the touch probe. The camera frame distortion calibration comprises a process that depends on a portable calibration jig and the touch probe, but that process is unaffected by probe form distortion errors in the touch probe and / or tip. The probe tip position calibration depends on applying the results of the camera, frame distortion calibration. When the same probe tip is used throughout the global calibration, the probe tip position calibration uses images from the set of images used by the camera frame distortion calibration. The global calibration method is particularly advantageous for low cost portable versions of multi-view vision-based touch probe measurement systems.

Owner:MITUTOYO CORP

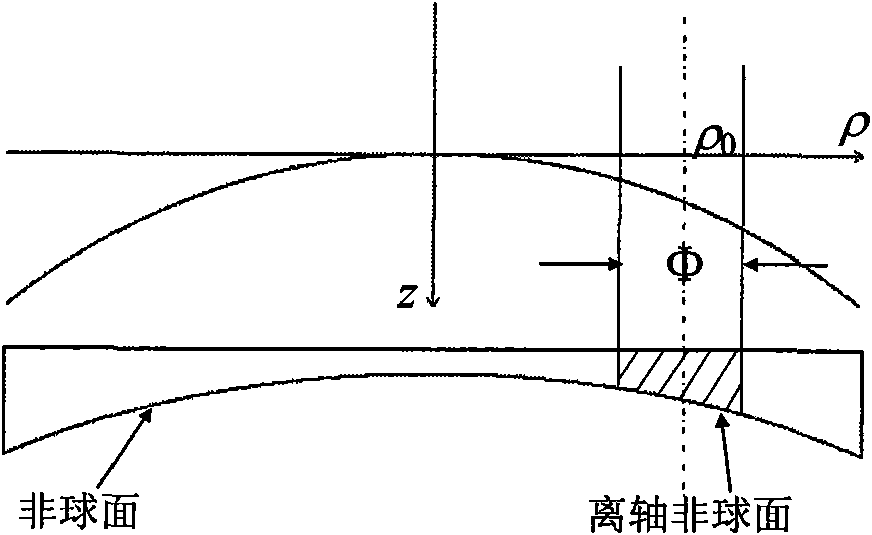

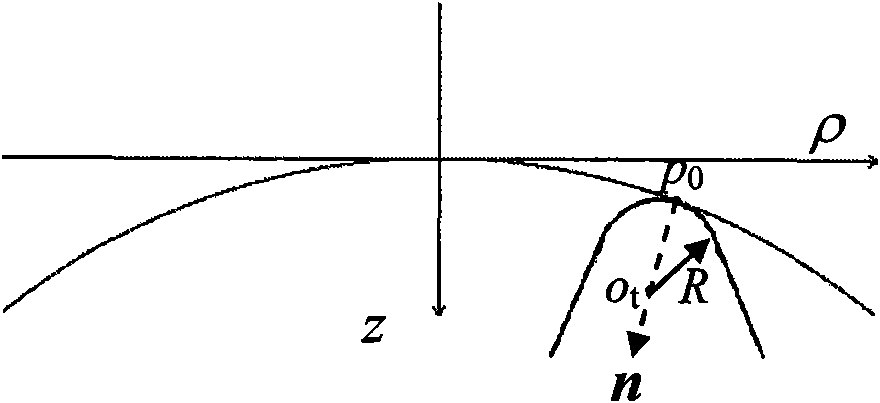

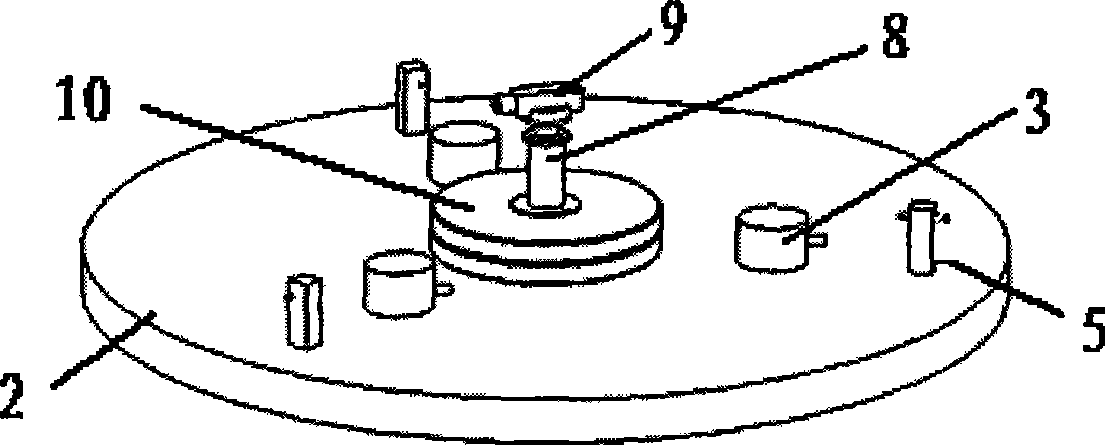

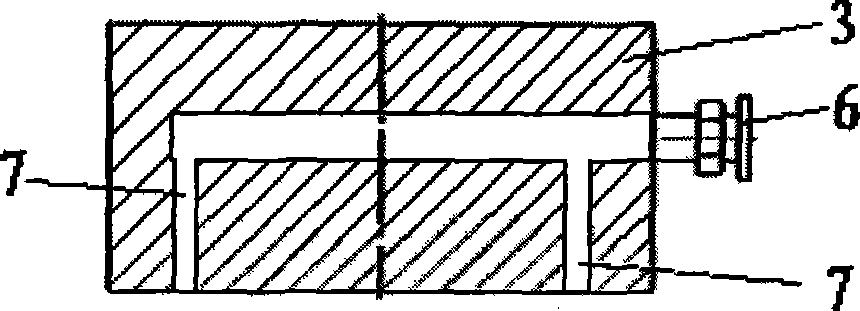

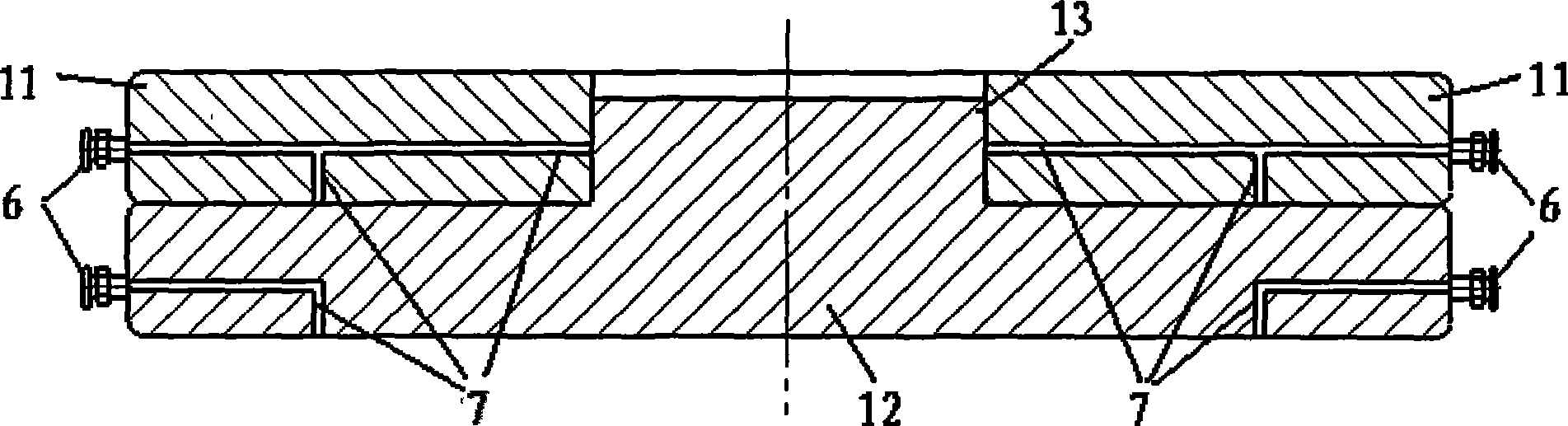

Method for improving shape accuracy and processing efficiency of off-axis aspheric mirror

InactiveCN101670442AEasy to processConsistent processabilityTurning machinesManufacturing technologyComputer science

The invention belongs to the technical field of optical device manufacturing and relates to a method for improving shape accuracy and processing efficiency of an off-axis aspheric mirror, comprising the following steps: (1) designing a rotary aspheric surface as well as a primary and secondary consubstantial structure for the primary body according to the size and the dimension of the off-axis aspheric mirror to be processed, i.e. a secondary body, and determining the amount of the off-axis aspheric secondary bodies to be processed at one time; (2) disposing through holes on a primary body blank piece; (3) placing all secondary body blank pieces into the through holes and fixing on a lathe after integrating into a cylindrical integrated work piece, and processing a spherical surface closest to the rotary aspheric surface on the integrated work piece; (4) generating a processing path of cutting tools based on the shape of the rotary aspheric surface, reprocessing the spherical surface by utilizing an ultra-precision lathe and carrying out form error analysis and compensating processing according to the measured integrated rotary aspheric surface shape. The provided method is simpleand easy to realize, has the advantages of high-efficiency, easy detachability and high shape accuracy and can realize high-efficient processing on an off-axis aspheric surface with high shape accuracy.

Owner:TIANJIN UNIV

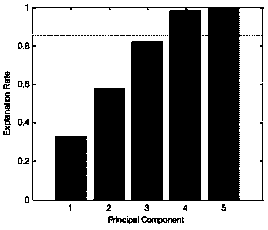

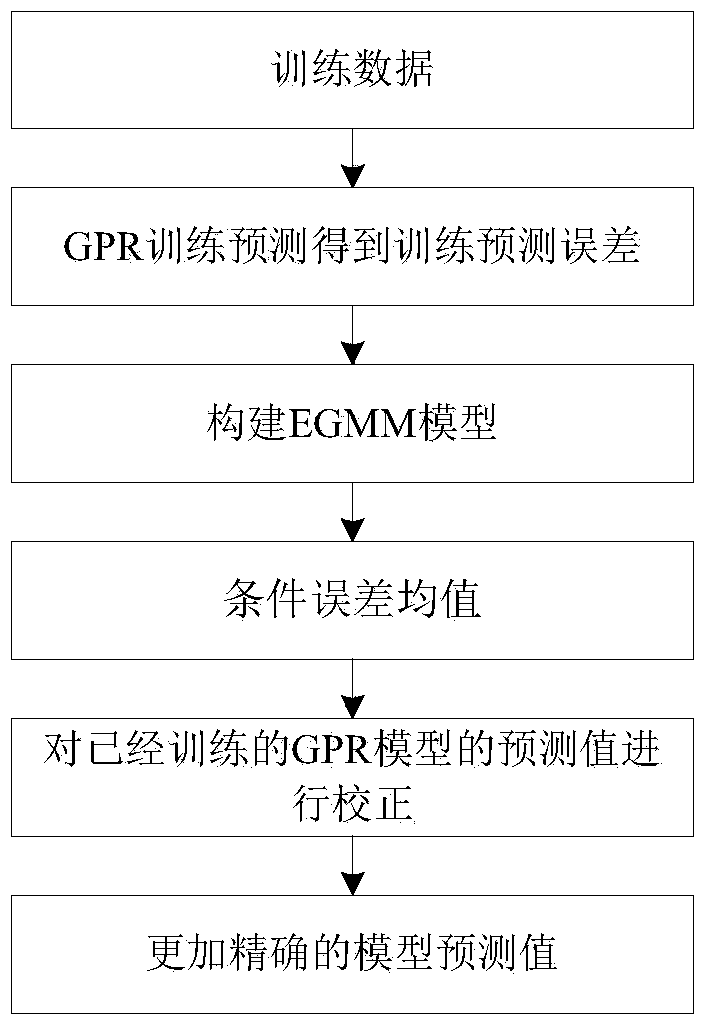

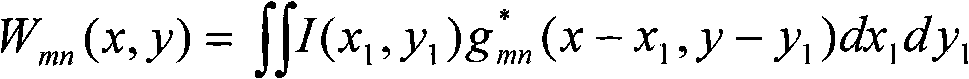

Gaussian process regression soft measurement modeling method based on EGMM (Error Gaussian Mixture Model)

ActiveCN104778298AThe result is accurateIncrease productionSpecial data processing applicationsErrors and residualsGaussian process

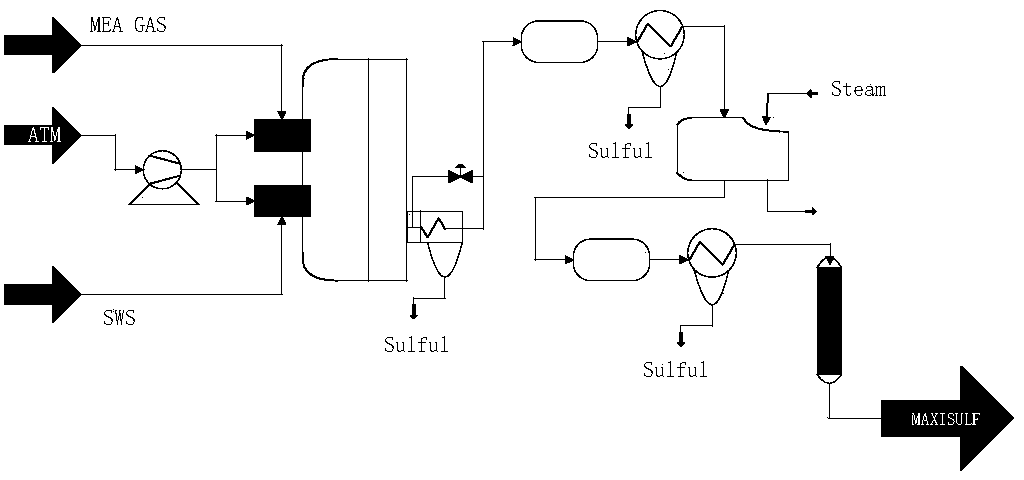

The invention discloses a gaussian process regression soft measurement modeling method based on an EGMM (Error Gaussian Mixture Model), which is used for a complex and changeable chemical process with non-gaussian noise. Prediction errors are frequently generated by a soft measurement prediction model established in an industrial process, however, the model prediction errors frequently contain rich useful information, and therefore, information can be extracted from the prediction errors so as to compensate the output of the model, thereby improving the established soft measurement model. Firstly, appropriate variables are selected to form error data, so as to be optimized to obtain appropriate number of gaussian components; then fitting is performed on the error data by using the EGMM; when new data arrive, prediction output is performed by using established GPR (Gaussian Process Regression), the mean conditional error is obtained through the EGMM, and the output is compensated, so as to obtain more accurate results. Key variables can be accurately predicted, thereby increasing the quality of products and reducing the production cost.

Owner:JIANGNAN UNIV

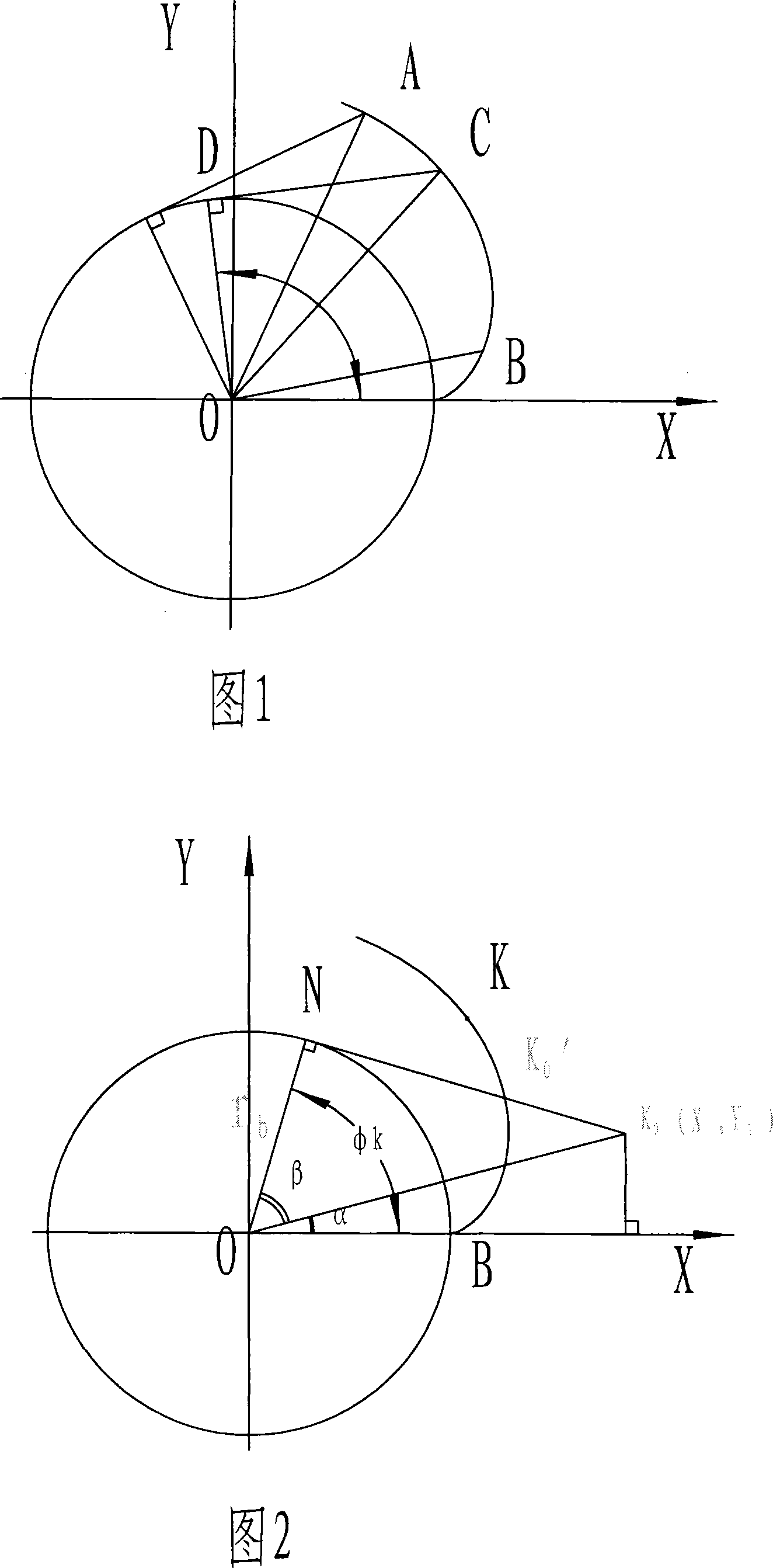

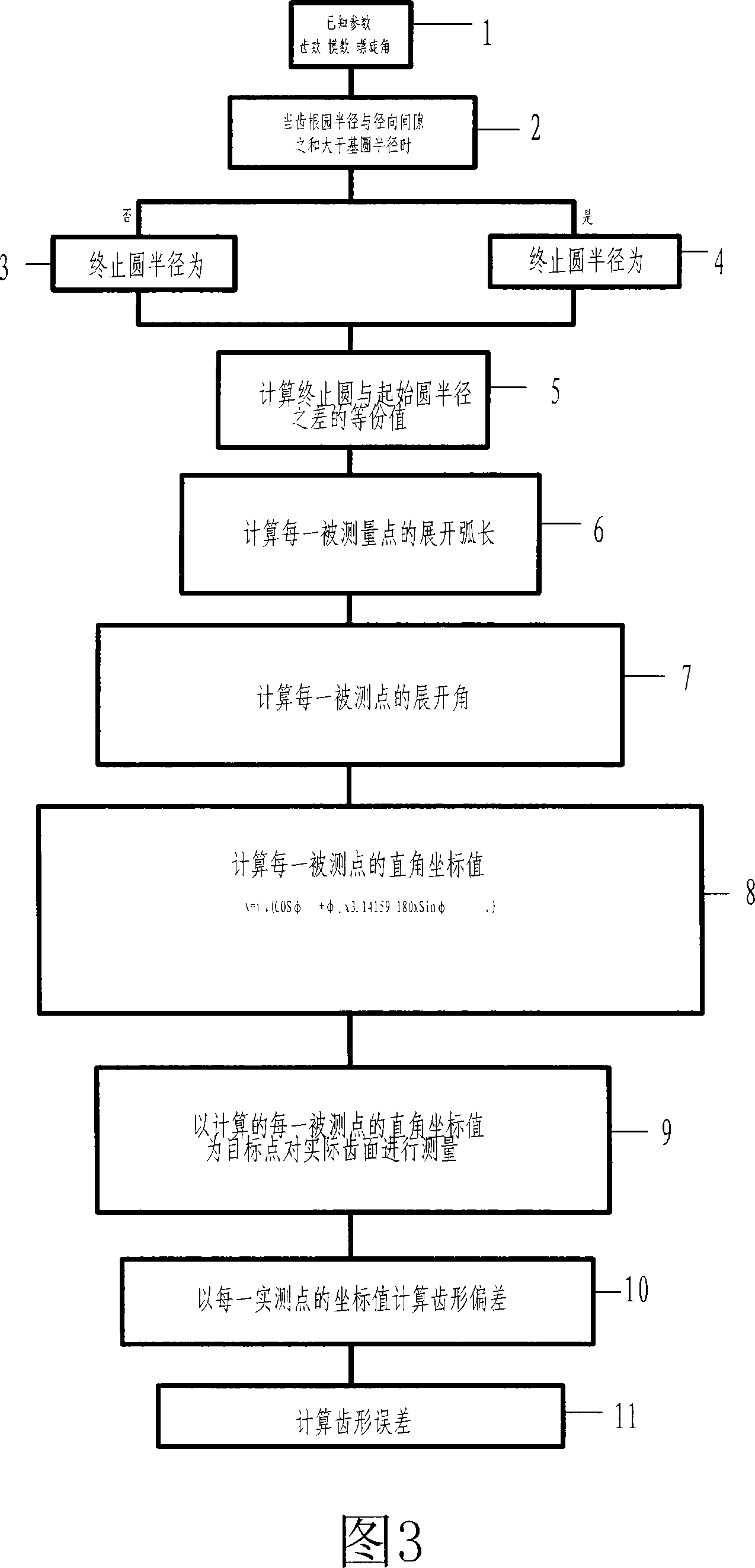

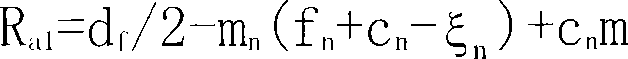

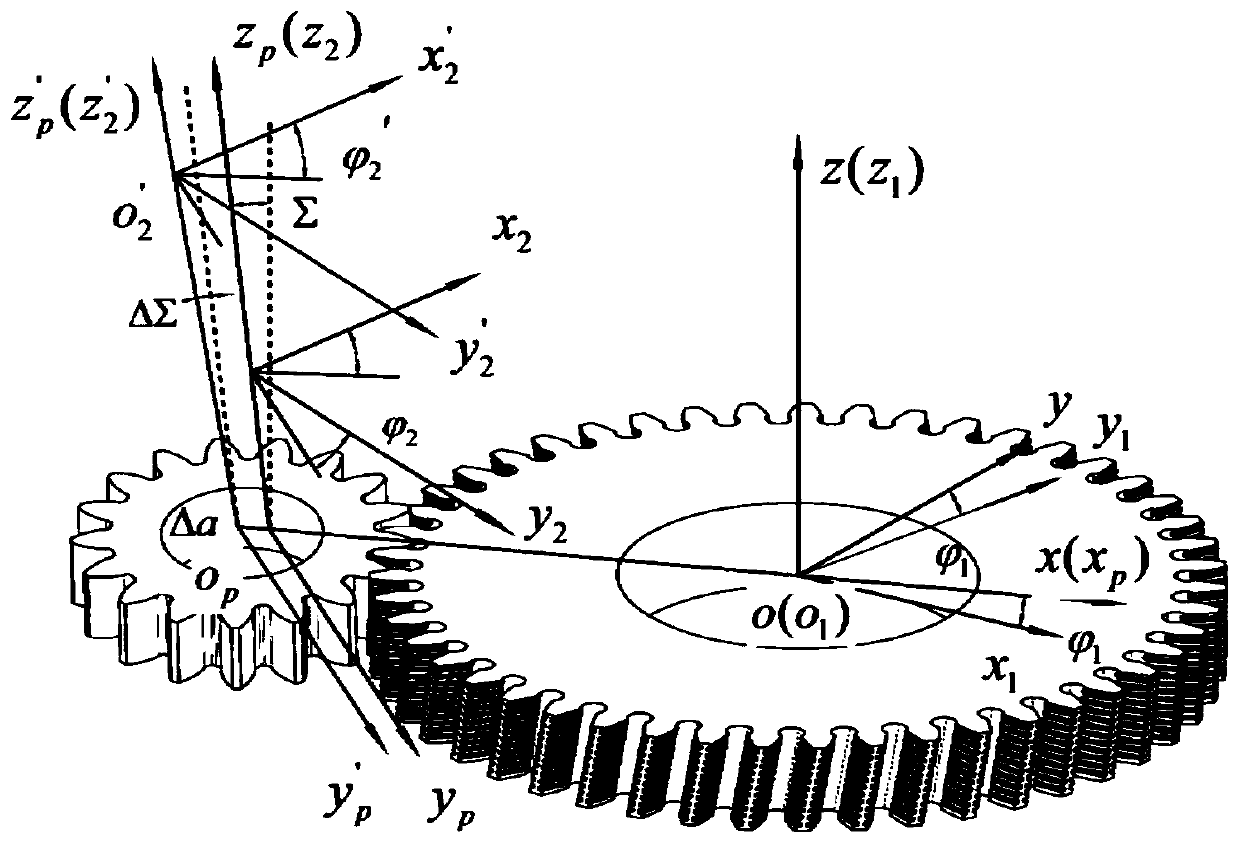

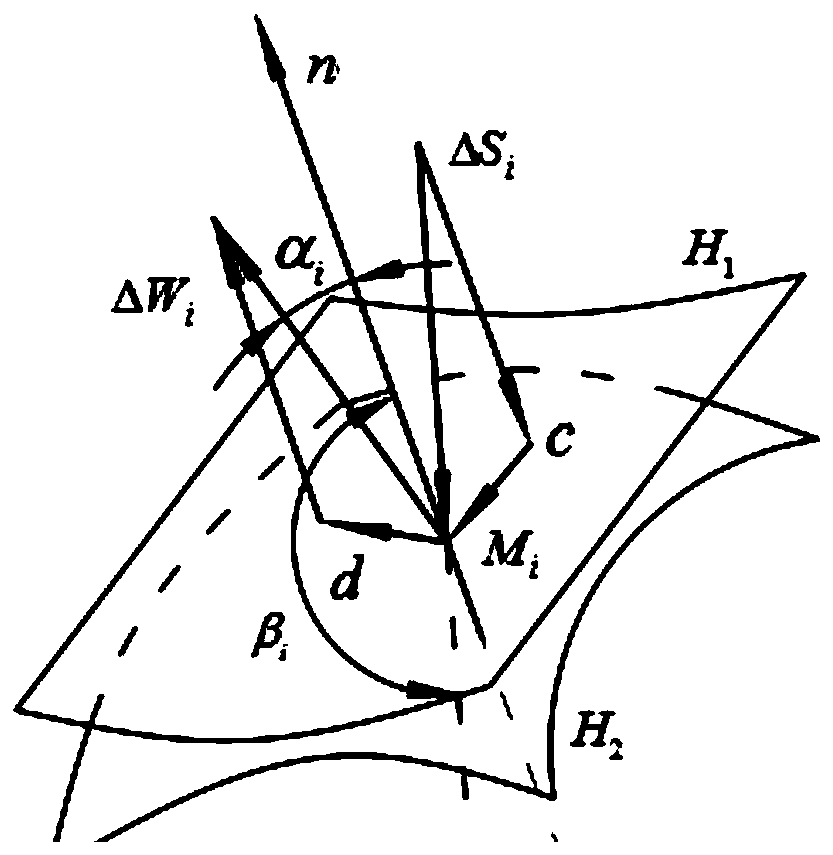

Beveled wheel tooth error three-coordinate measuring method

InactiveCN101191723AEvenly distributedSolve the problem of uneven collection pointsMachine gearing/transmission testingInvolute gearObject point

The invention provides a three-coordinate measuring method for bevel gear tooth form error; the procedures of the method are that: (1) the stop position of measuring bevel gear tooth form error is defined by calculation; (2) positions of other measuring points on the checking part are defined; (3)the actual tooth face is measured by taking the stop position and the theoretical coordinates of measuring points as object points; (4) the tooth form error is worked out. By applying the method of the invention in the tooth form error measurement, the repeatability error can be controlled below 0.004mm, thereby markedly improving the measuring accuracy and being capable of measuring the involute gear below six-grade accuracy. The trend of the involute form of the measuring result is relatively obvious, based on which the depth of the tooth root and the tooth head can be analyzed. According to the measuring result, the gear-cutting machine is guided to be adjusted, achieving good effects.

Owner:AVIC HUIYANG AVIATION PROPELLER

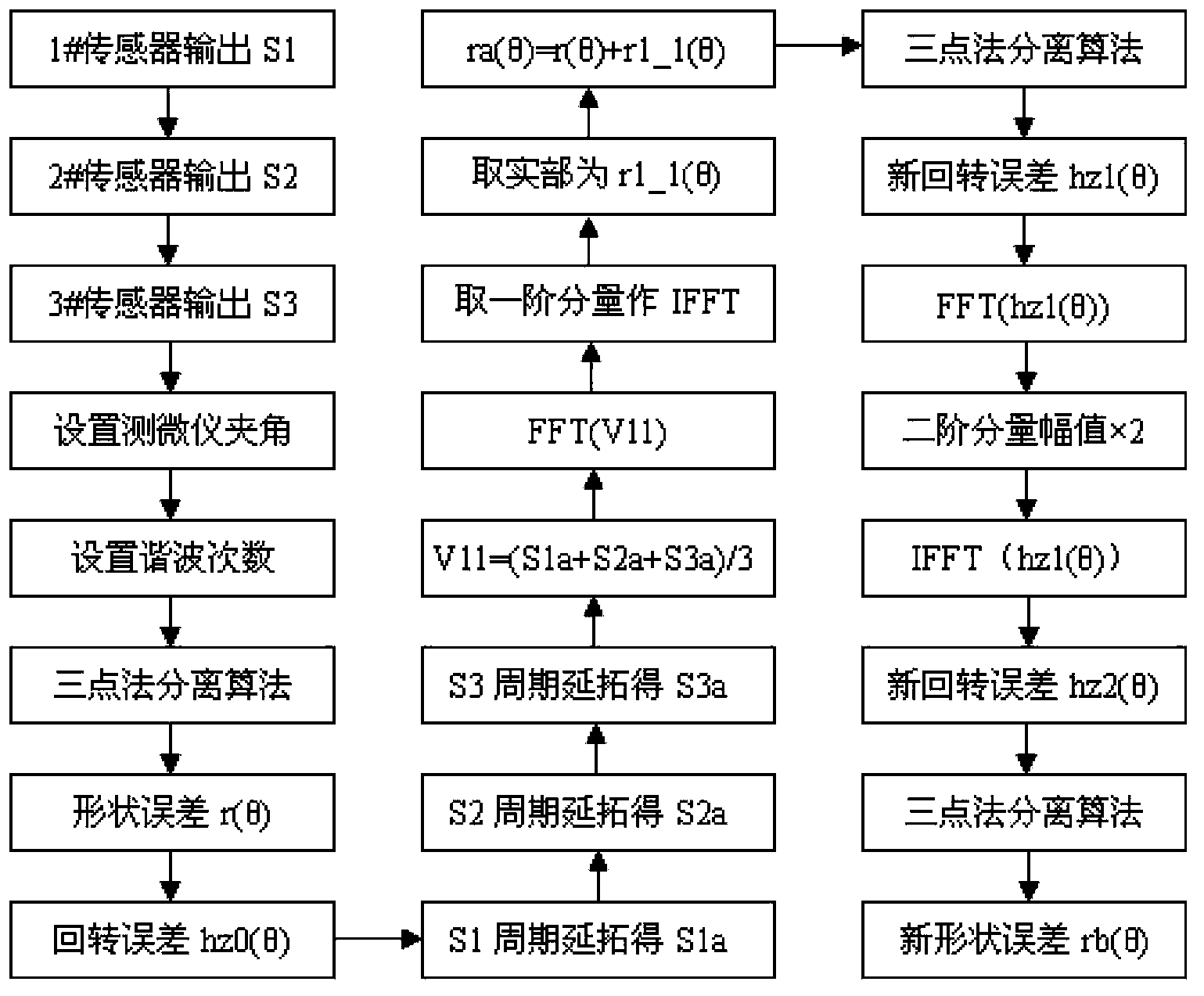

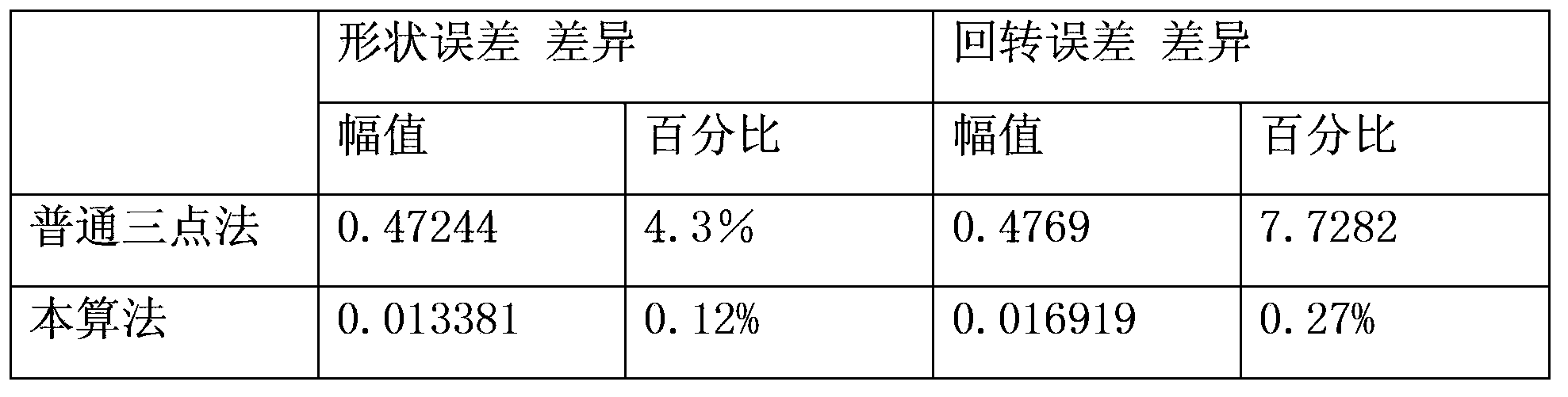

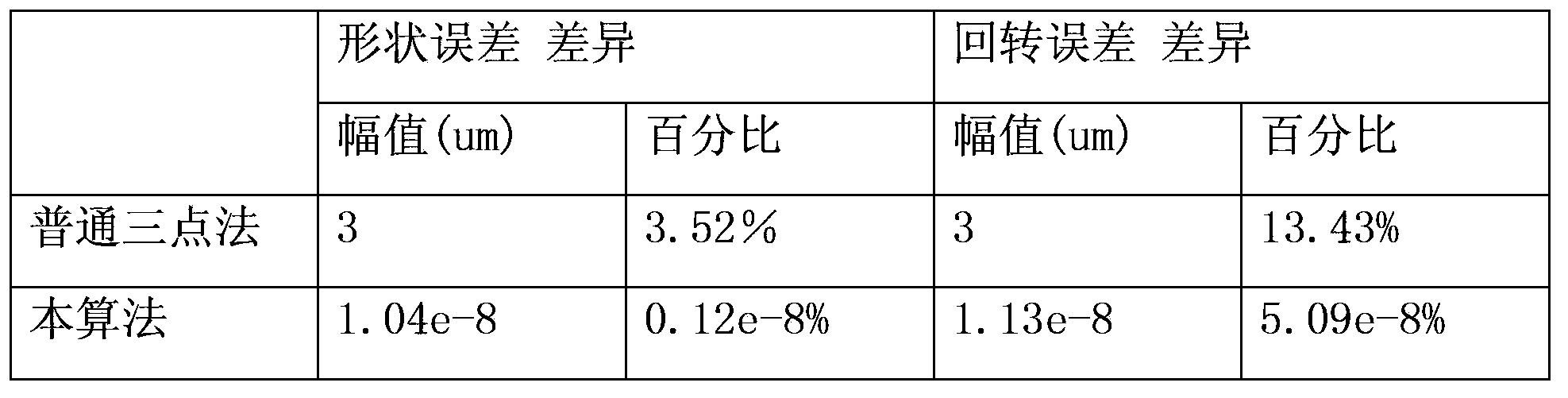

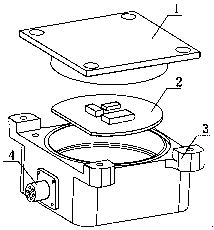

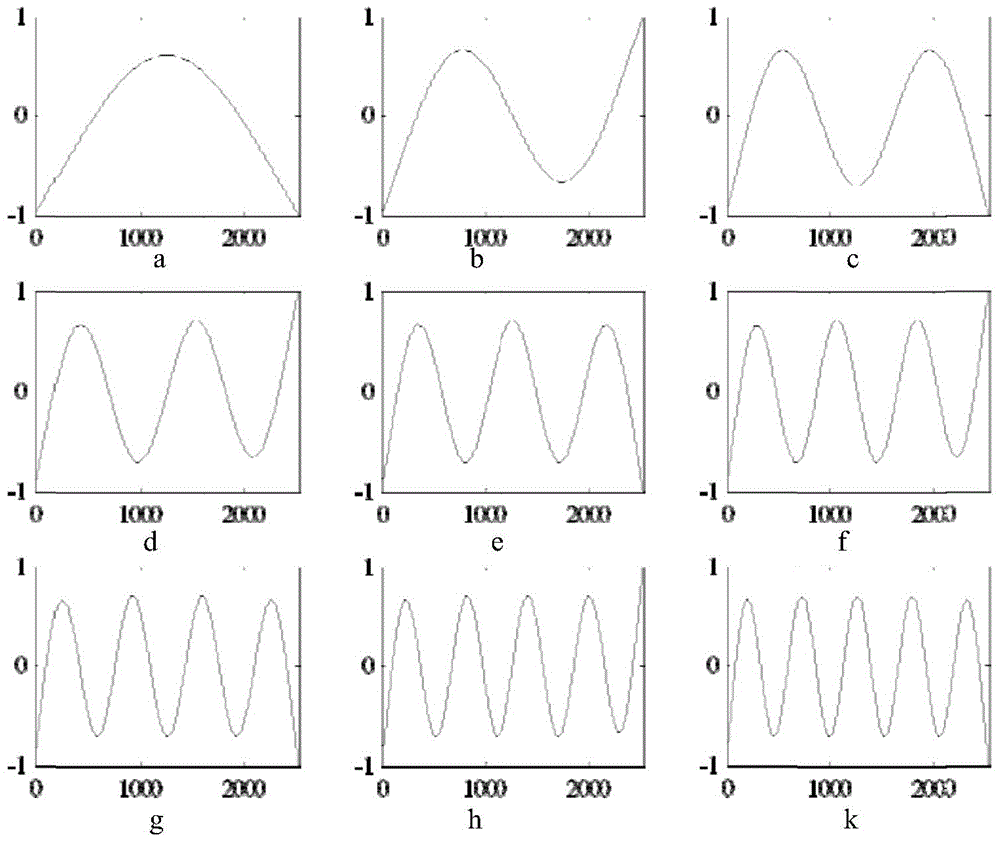

Improved three-point method turning error and roundness error calculation method

ActiveCN103363921ASolve the defect that the first-order component of the shape error cannot be obtainedImprove separation precisionUsing optical meansMeasurement precisionOrder of magnitude

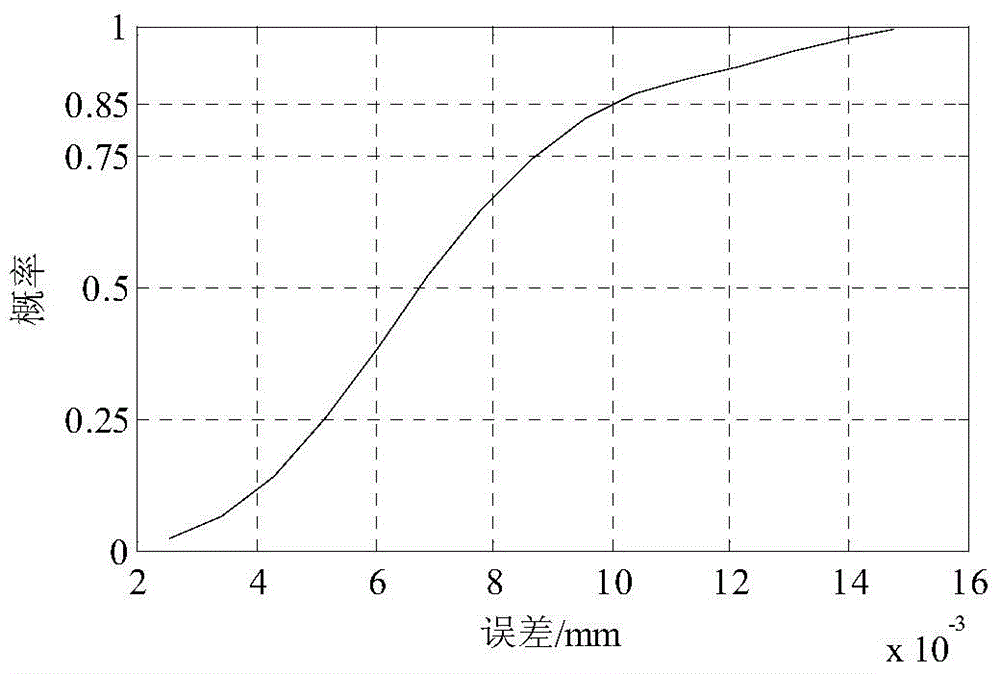

The invention discloses an improved three-point method turning error and roundness error calculation method, which comprises the following steps of: translating and carrying out weighted average on three sensor signals, and carrying out frequency domain filtering to effectively obtain a one-order component of a form error. According to the method, the separation precision of the form error and the turning error can be obviously improved, and a surface is simulated; under the condition that the sensor is free from the noise interference, the separation precision of the form error and the turning error can be 10-8 orders of magnitude; and the measurement precision of the turning error and the roundness error can be effectively improved.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Correction method of electronic compass

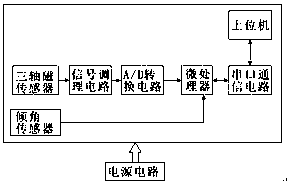

PendingCN108507553ATroubleshoot output functionality issuesInterfering with the Earth's magnetic fieldCompassesField dataCorrection method

The invention discloses a correction method of an electronic compass. The correction method comprises the following steps: (1), acquiring basic error parameters, acquiring geomagnetic field data and inclination data of a current environment through a magnetism sensor and an inclination sensor respectively, and sending into a microprocessor; (2), performing inclination compensation on the magneticfield data; (3), performing azimuth solution according to the data obtained in the step (2); (4), acquiring a hard magnetic interference error parameter and a soft magnetic interference error parameter on a mounting site, and forming error parameters together with the basic error parameters; (5), performing error compensation on the data obtained in the step (3) by using the error parameters to obtain attitude angle data; (6), with the combination of an attitude position compensation method, translating a coordinate origin of an actual coordinate system to an origin of a measuring coordinate system. By the correction method, the problem that the conventional electronic compass only has an attitude position information providing output function is solved; and by virtue of attitude information provided by itself, attitude position compensation is studied while an original hardware system architecture is not changed.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

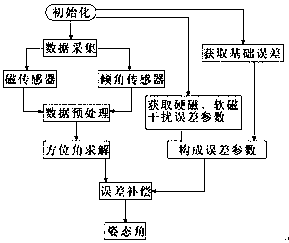

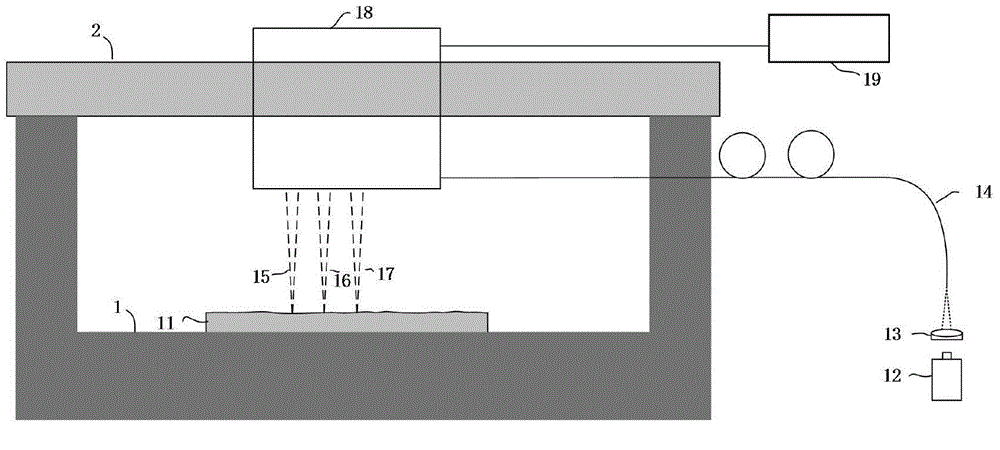

High-spatial-discrimination long-range facial-form detecting device and method

ActiveCN104567719AImprove spatial resolutionEasy to measureUsing optical meansBeam splitterLight beam

The invention discloses a high-spatial-discrimination long-range facial-form detecting device and method. The device comprises a scanning optical head and is characterized in that the scanning optical head comprises a small hole array plate, a beam splitter, a lens array and an array detector, the small hole array plate divides input parallel light beams into a plurality of parallel thin light beams, then the light beams enter the beam splitter, each thin light beam is input to the lens array in a transmission mode through the beam splitter, lens units in the lens array focus the corresponding thin light beams to the surface of an object to be tested respectively, and the light beams reflected by the surface of the object to be tested enter the array detector through the lens array and the beam splitter in sequence. The device is simple in structure and stable in performance, high-space-frequency sampling measuring can be carried out on the surface to be tested, measuring of facial-form errors of high frequency (larger than 1 line / mm) can be expanded, and at least 10 lines / mm can be achieved commonly.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

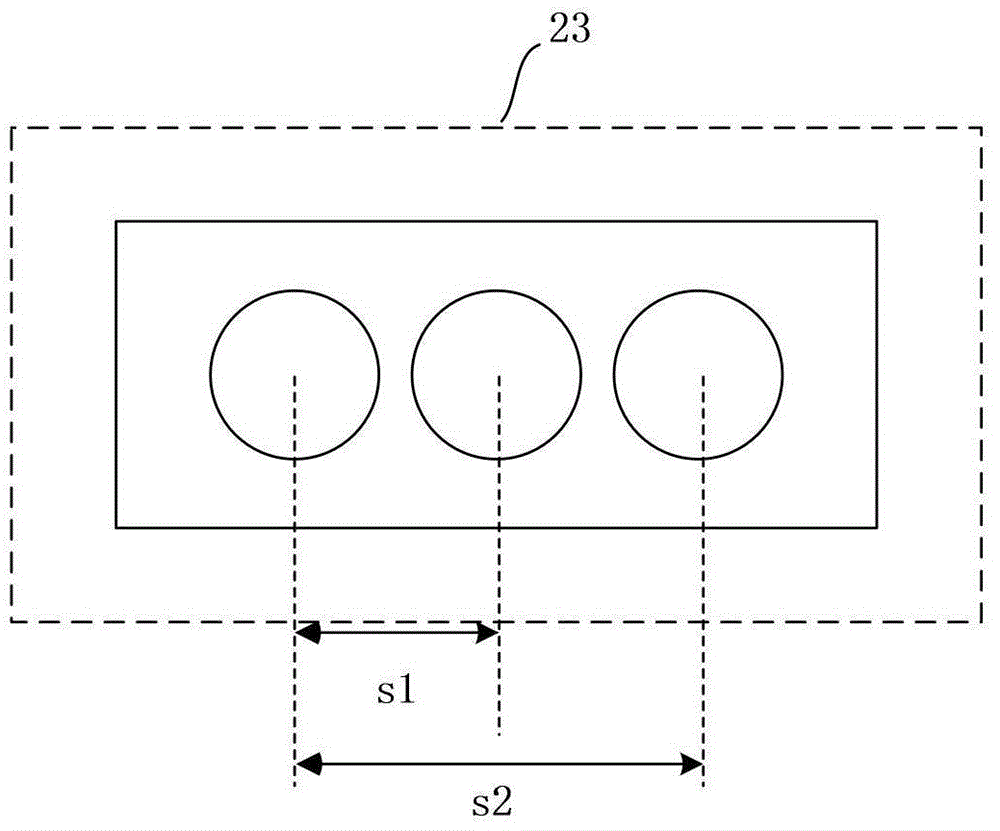

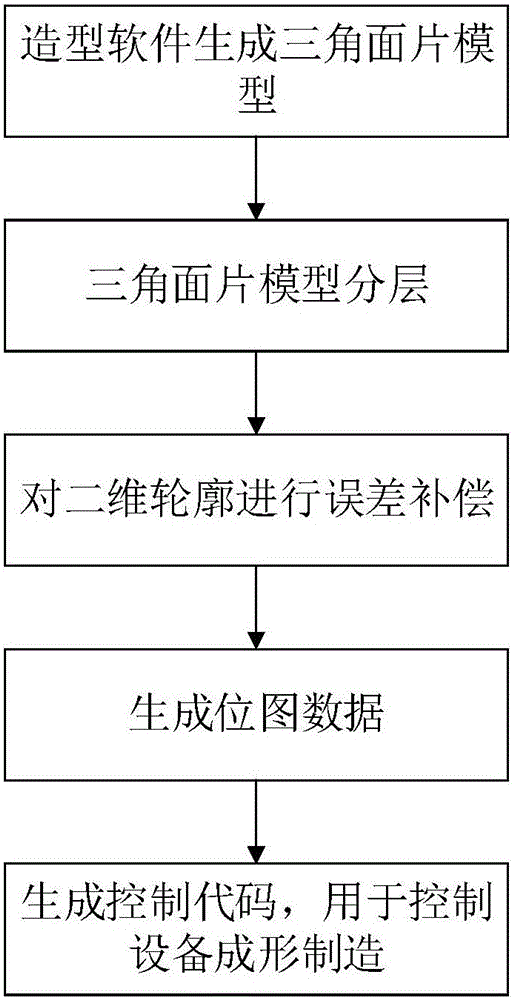

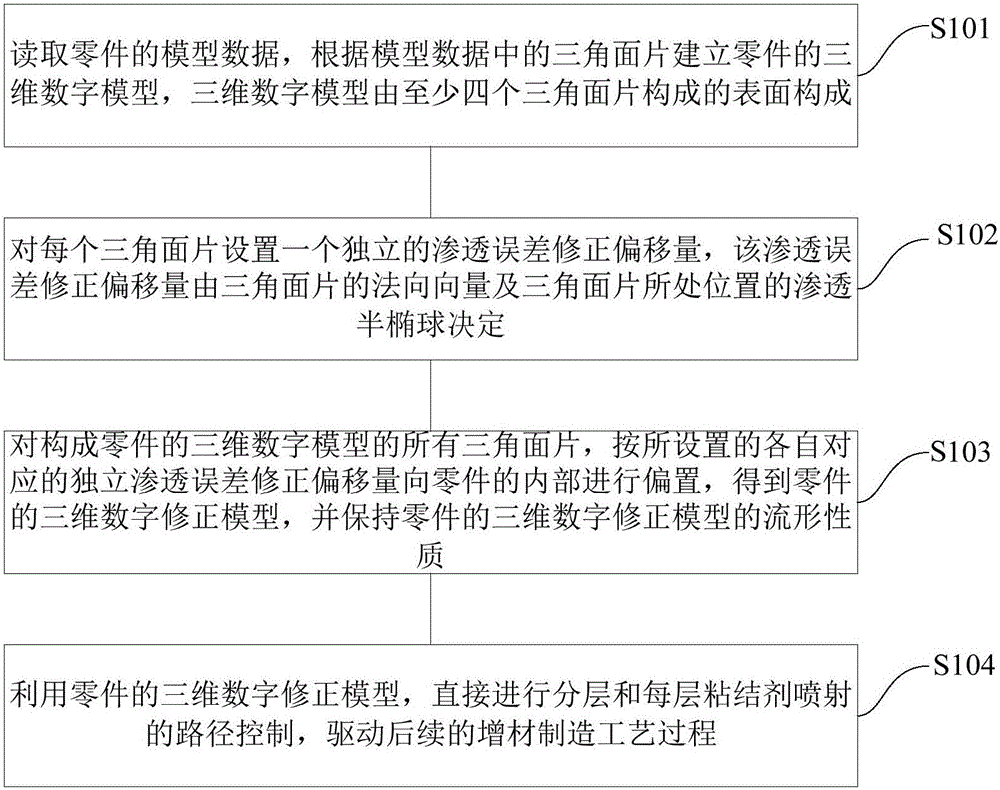

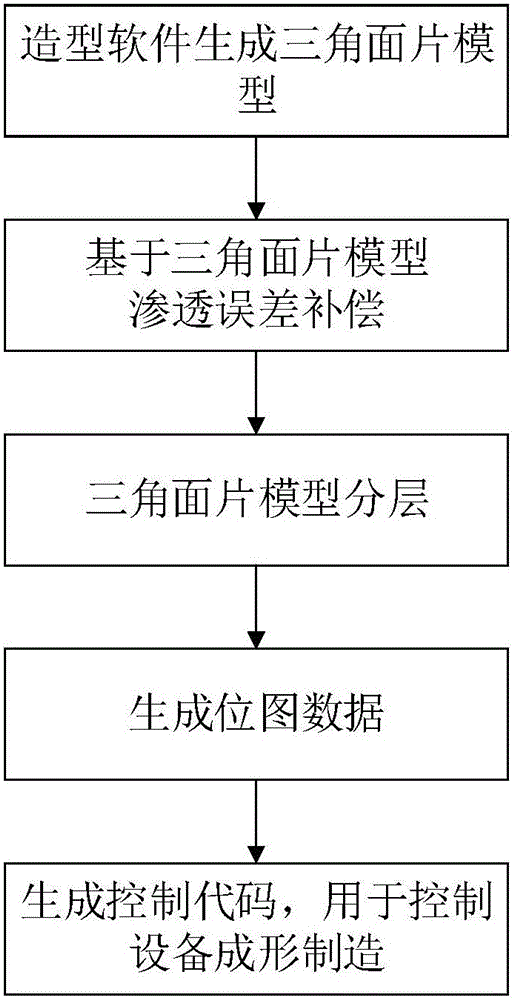

Error compensating method for material-increase manufacturing

ActiveCN105058795AHigh precisionImprove forming qualityAdditive manufacturing apparatusEngineeringAdditive layer manufacturing

The invention provides an error compensating method for material-increase manufacturing. The method includes the steps that model data of a part are read, and a three-dimensional digital model of the part is established according to triangular face sheets; an independent correction offset is set for each triangular face sheet and determined by a normal vector of the triangular face sheet and the semi-ellipsoidal shape of a sedimentation unit at the position where the triangular face sheet is located; all the triangular face sheets forming the three-dimensional digital model of the part are deflected to the interior of the part according to the set independent correction offsets corresponding to the triangular face sheets, a three-dimensional digital correction model of the part is obtained, and the manifold property of the three-dimensional digital correction model of the part is maintained; and layering and material-increase manufacturing of each layer are directly performed to achieve path control of a sedimentation path according to the three-dimensional digital correction model of the part, and a subsequent material-increase manufacturing craft process is driven. The error compensating method can reduce anisotropy forming errors caused by anisotropy of the size of the sedimentation unit during material-increase manufacturing and increase material-increase manufacturing precision and forming quality.

Owner:TSINGHUA UNIV

Global calibration for stereo vision probe

InactiveUS20080243416A1Low costCost prohibitiveCalibration apparatusUsing mechanical meansTip positionVision based

A method for global calibration of a multi-view vision-based touch probe measurement system is provided which encompasses calibrating camera frame distortion errors as well as probe form errors. The only required features in the calibration images are the markers on the touch probe. The camera frame distortion calibration comprises an iterative process that depends on a portable calibration jig and the touch probe, but that process is unaffected by probe form distortion errors in the touch probe and / or tip. The probe tip position calibration depends on applying the results of the camera frame distortion calibration. When the same probe tip is used throughout the global calibration, the probe tip position calibration uses images from the set of images used by the camera frame distortion calibration. The global calibration method is particularly advantageous for low cost portable versions of multi-view vision-based touch probe measurement systems.

Owner:MITUTOYO CORP

Global calibration for stereo vision probe

A method for global calibration of a multi-view vision-based touch probe measurement system is provided which encompasses calibrating camera frame distortion errors as well as probe form errors. The only required features in the calibration images are the markers on the touch probe. The camera frame distortion calibration comprises an iterative process that depends on a portable calibration jig and the touch probe, but that process is unaffected by probe form distortion errors in the touch probe and / or tip. The probe tip position calibration depends on applying the results of the camera frame distortion calibration. When the same probe tip is used throughout the global calibration, the probe tip position calibration uses images from the set of images used by the camera frame distortion calibration. The global calibration method is particularly advantageous for low cost portable versions of multi-view vision-based touch probe measurement systems.

Owner:MITUTOYO CORP

Partition scanning method for thin-walled part additional material manufacture

ActiveCN108889948ASmall shape errorHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMedial axisUltimate tensile strength

The invention discloses a partition scanning method for thin-walled part additional material manufacture. According to all entity areas of layering and slicing of a to-be-machined thin-walled part, inaccordance with the medial axis transformation of the boundary of each entity area, whether the area is divided into a plurality of main areas and a connecting area is determined; scanning paths arecalculated for the main areas and the connecting area, wherein a zigzag scanning path is adopted in the main areas, so that a fused powder material is scanned along a scanning line and a slicing and layering contour line finally through a high energy beam to form a thin-walled part slicing layer entity, so that the whole thin-walled part is formed. The control of a processing process is simple, residual stress and distribution thereof can be controlled, forming errors and buckling deformation of the thin-walled part are reduced, and the density of the thin-walled part and the strength thereofare improved.

Owner:HEFEI UNIV OF TECH

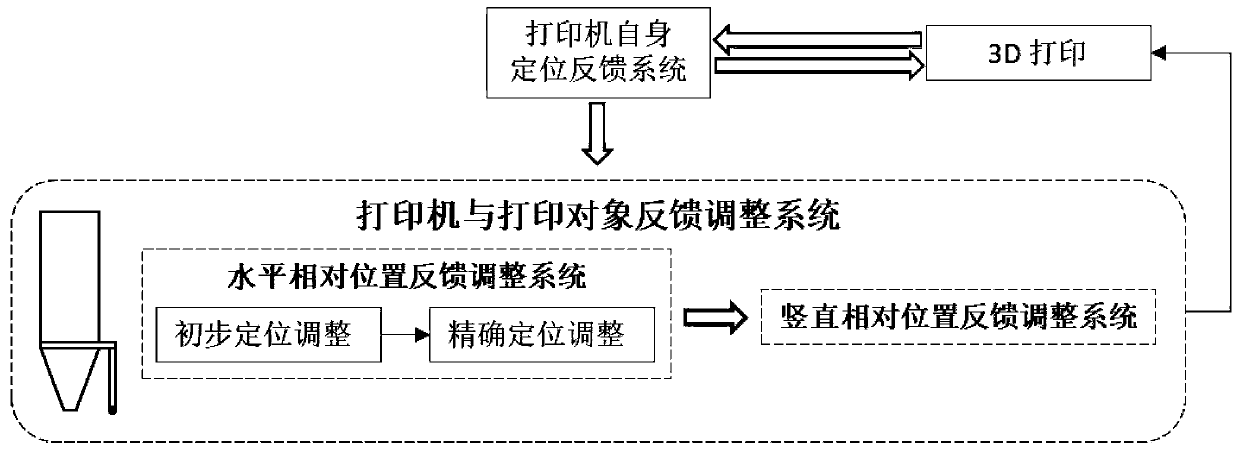

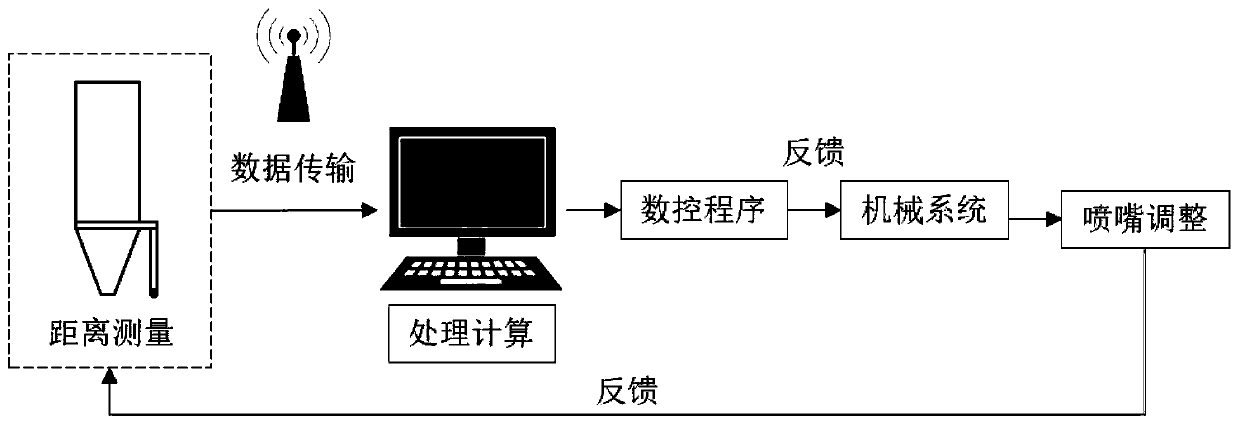

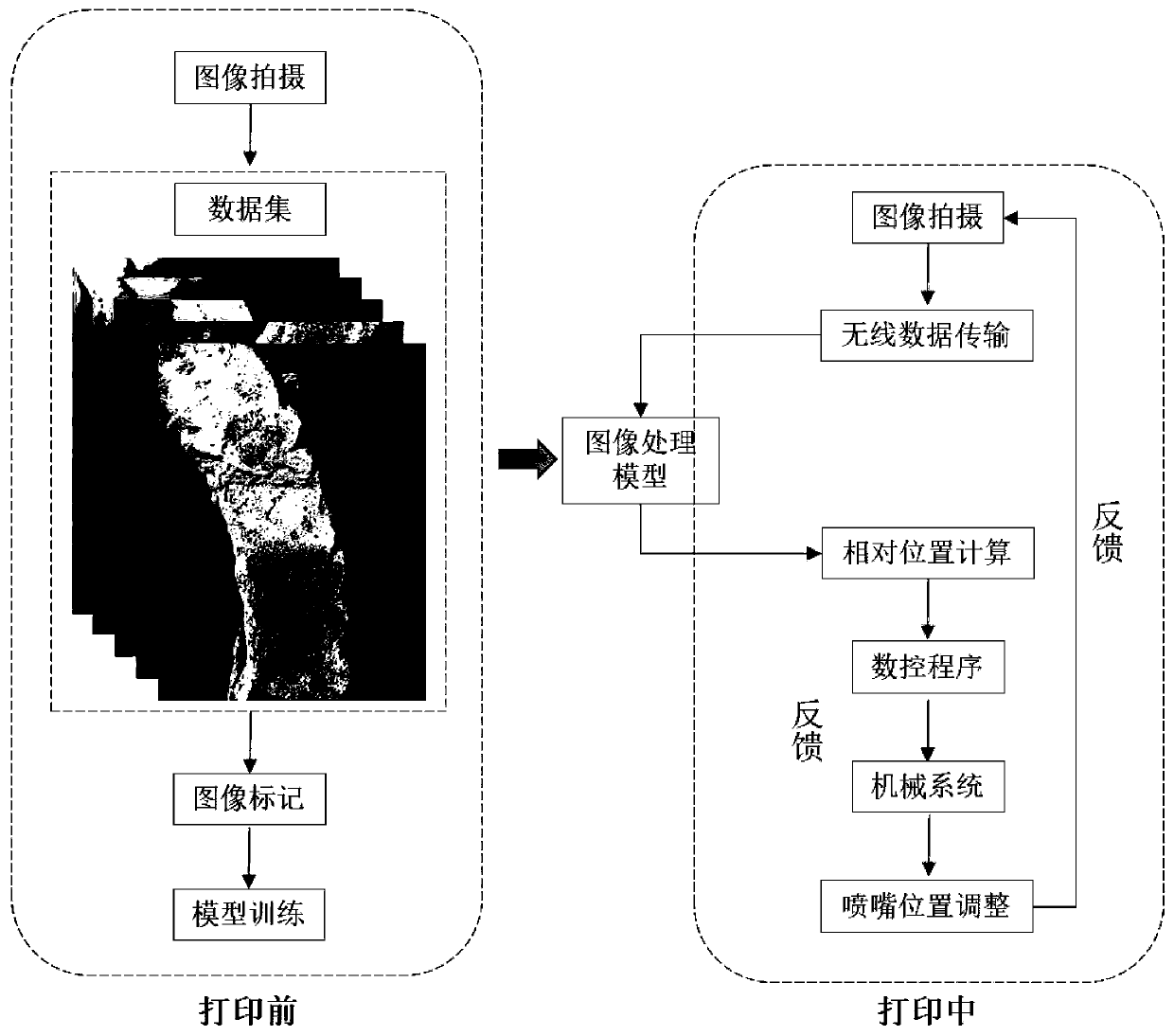

Real-time feedback control method for printing precision of 3D printer

ActiveCN109989585AReduce positioning errorsPrecise determination of relative horizontal positionAdditive manufacturing apparatusCharacter and pattern recognitionControl systemCoupling

The invention discloses a real-time feedback control method for the printing precision of a 3D printer. The method is implemented in the two parts: the first part, the positioning error of a printer machine is reduced through a feedback control system of the printer machine; and the second part, the forming error of a concrete object is reduced through a feedback adjusting system between the printer and a printed object, wherein the second part is a two-stage positioning method, the first stage is a horizontal relative position feedback adjusting system, and the second stage is a vertical relative position feedback adjusting system. The two stages are matched with each other, so that accurate adjustment and positioning between a printing nozzle and the printing object are realized. The twosystems are matched with each other to form a real-time feedback control system for the nozzle position, the coupling error between the printer and the printing object can be effectively reduced, theprinting precision of the 3D printer is improved, and the printing effect is enriched.

Owner:SOUTHEAST UNIV

Method for aligning, online detecting and correcting of gearwheel

InactiveCN101530937AEasy to moveAccurately pinpointMeasurement/indication equipmentsGear teethTurn angleTheodolite

The invention discloses a method for aligning, online detecting and correcting of a gearwheel. The method comprises the following steps that: A, alignment before processing is performed, wherein an air supporting turntable is placed on a workbench, and a bottom slipway is inflated to ensure that the air supporting turntable is suspended on the surface of the workbench, and proper alignment of the air supporting turntable and the work bench is adjusted; a workpiece is placed on an air supporting slide block, the air supporting slide block is simultaneously inflated to jack the workpiece, and a fine regulating device regulates the workpiece to be coaxial with the workbench; an optical theodolite is regulated to be coaxial with the air supporting turntable to complete the alignment; B, online detection is performed, an accurate turn angle of workpiece is detected, and related gear precision and longitudinal form error are detected; and C, based on online measurement, the gear precision is improved through alignment. The method can make the gearwheel easily moved, aligned, online detected and corrected on the workbench of a machine tool through the air supporting slide block and the air supporting turntable, and obviously improve the processing precision of the gearwheel.

Owner:JIANGSU WELM TECH

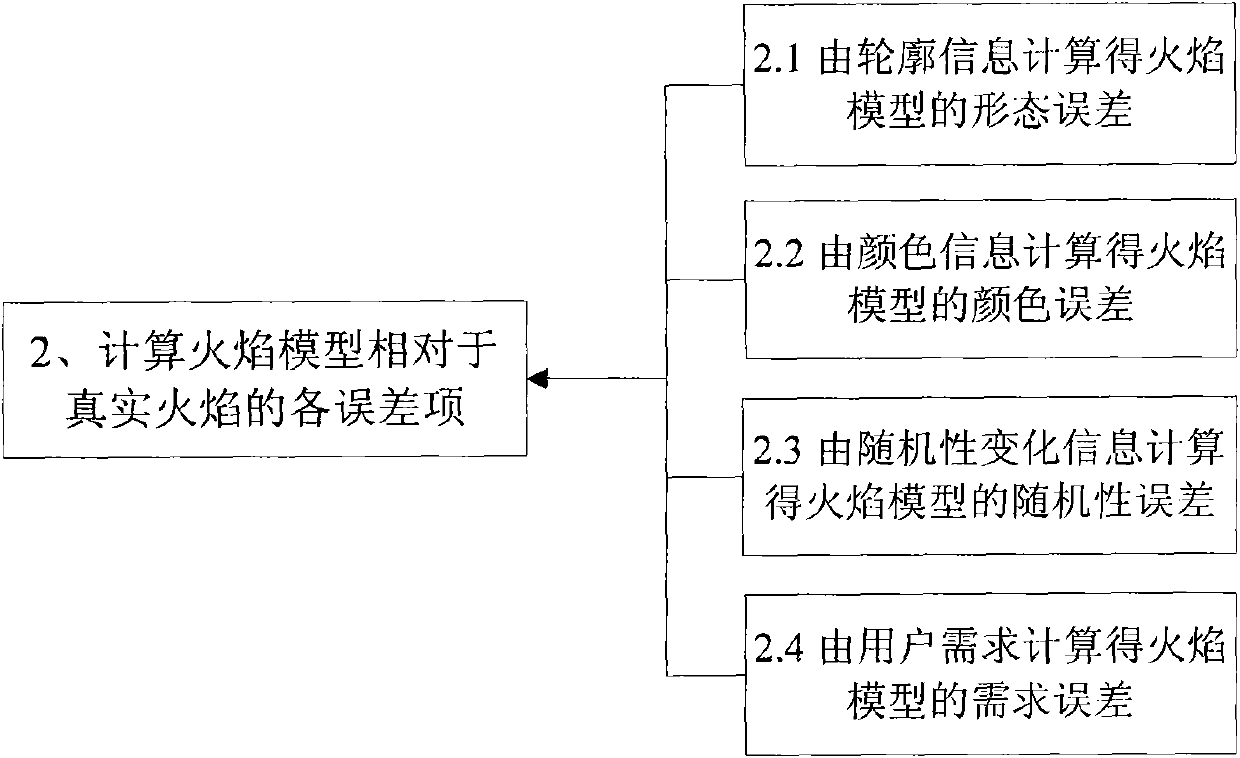

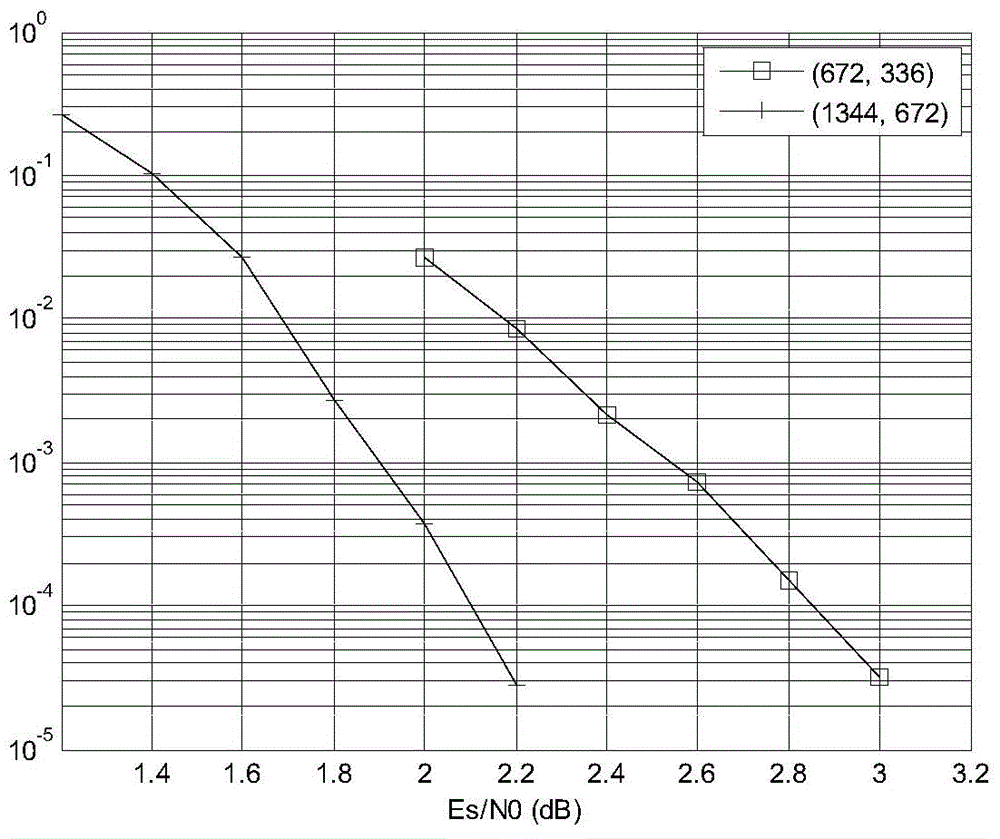

Evaluation method of flame model reliability

The invention relates to an evaluation method of flame model reliability, belonging to the technical field of virtual reality science. The invention has the technical scheme as follows: (1) under a relatively stable environment, sampling flame combustion to obtain a real flame video and a simulated flame three-dimensional time-varying model under the state, and capturing a plurality of images at equal time interval in a video and simulation result; (2) comparing the images obtained in step (1), calculating the form error, the color error and the random error of the flame model relatively to the real flame, and combining with user requirements to calculate the demand error of the flame model relatively to the real flame; (3) generating the error function of the flame model by each error item; and (4) according to the error function, analyzing the flame model reliability. In the invention, the visual parameter information of the flame model and parameter information relative to user demands are fully considered, so that a method for evaluating a flame simulation result is provided, the reliability of a simulation result is analysed and a method basis for choosing and improving a modelling method is provided.

Owner:BEIHANG UNIV

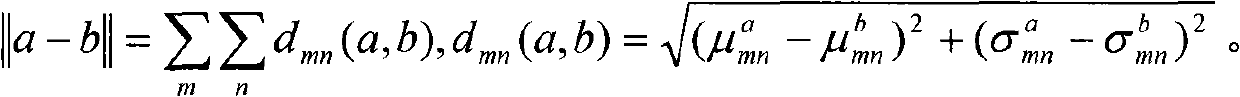

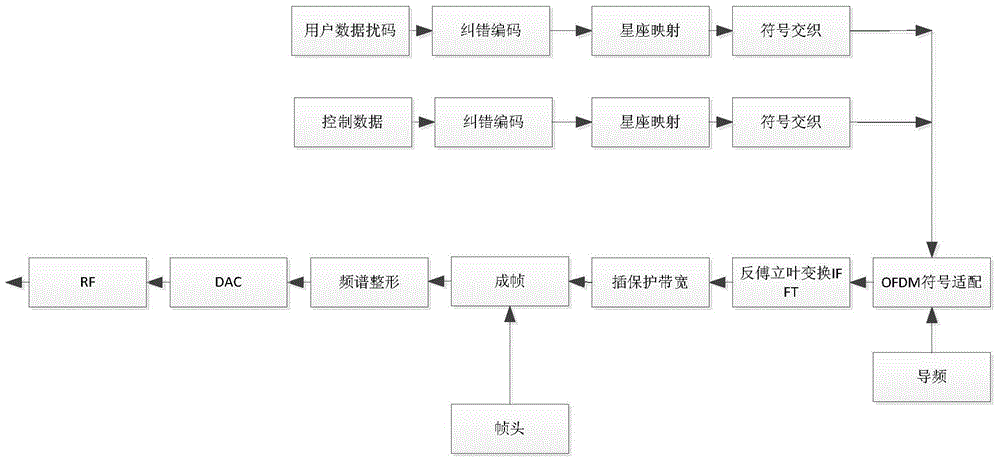

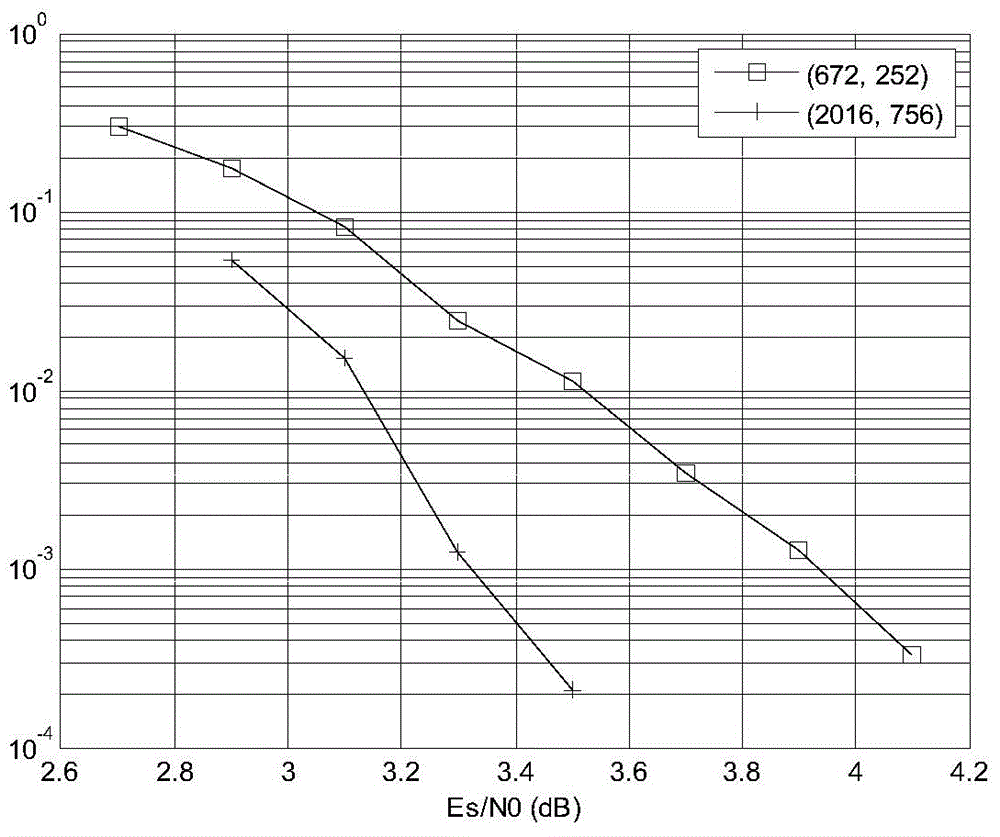

Channel coding method improving transmission reliability of non-line of sight millimeter wave indoor communication system

InactiveCN104917588AImprove adaptabilityForward error control useMillimeter wave communication systemsTransmission channel

The invention discloses a channel coding method improving transmission reliability of a non-line of sight millimeter wave indoor communication system, and brings forward a method that a variable-code-length low-density check code is used to improve communication reliability of a millimeter wave communication system. An error correction system is mainly adopted to generate different-length redundant data on user data having different bit numbers at the same coding rate, the user data and the redundant data are combined to form error correction codes having different code lengths, at least one bit of control information is used in a signaling domain to indicate a selected code length of current transmission, a transmitter selects a code length capable of providing and guaranteeing communication reliability according to various communication channels and quality of a transmission signal, code length information is transmitted to a receiver through control information, and the receiver uses the error correction codes corresponding to the code length to decode the data according to the received control information. The channel coding method effectively improves adaptability of a millimeter wave wireless communication system on a change of the transmission channel, and then transmission reliability of the system is improved.

Owner:李焱

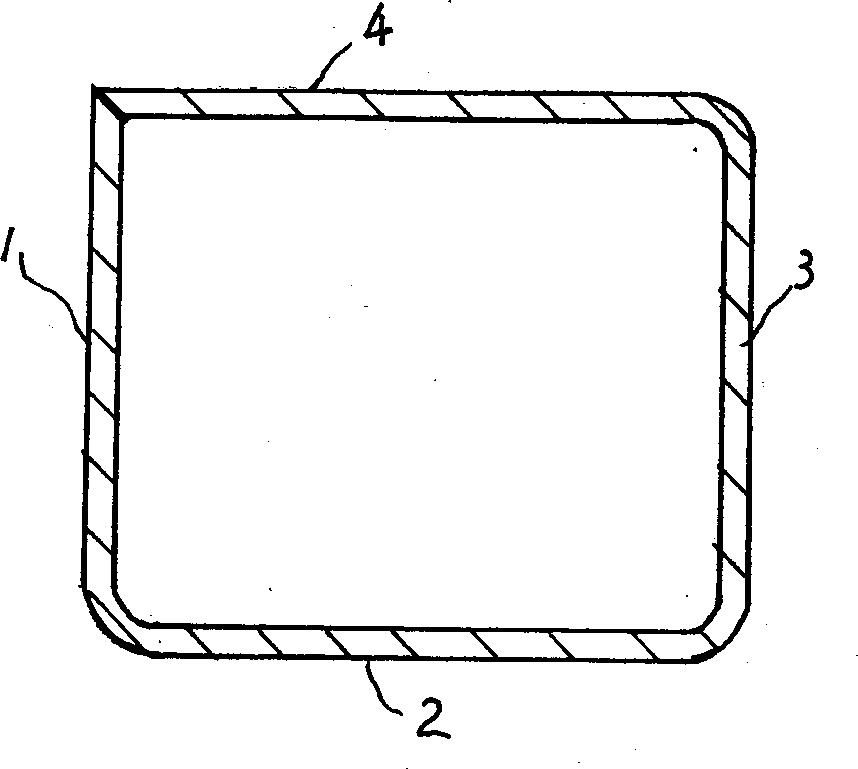

Method for making printed angle rectangle section steel pipe

The method for manufacturing rectangular pipe with sharp corner is characterized by that it uses rolling central line as a diagonal line of formed pipe to make multiple-pass cold-bending symmetrical deformation so that two side ends of steel strip which are made into oblique end face are finally closed on the rolling central line so as to form included angle with 90 deg. of said rectangular pipe. Said method is easy to regulate and operate, small in formed error, weld seam and two side are in symmetrical state, so that its welding effect is good, and its energy consumption also can be reduced.

Owner:TIANJIN HUAIHAI COLD BEND PROFILE STEEL

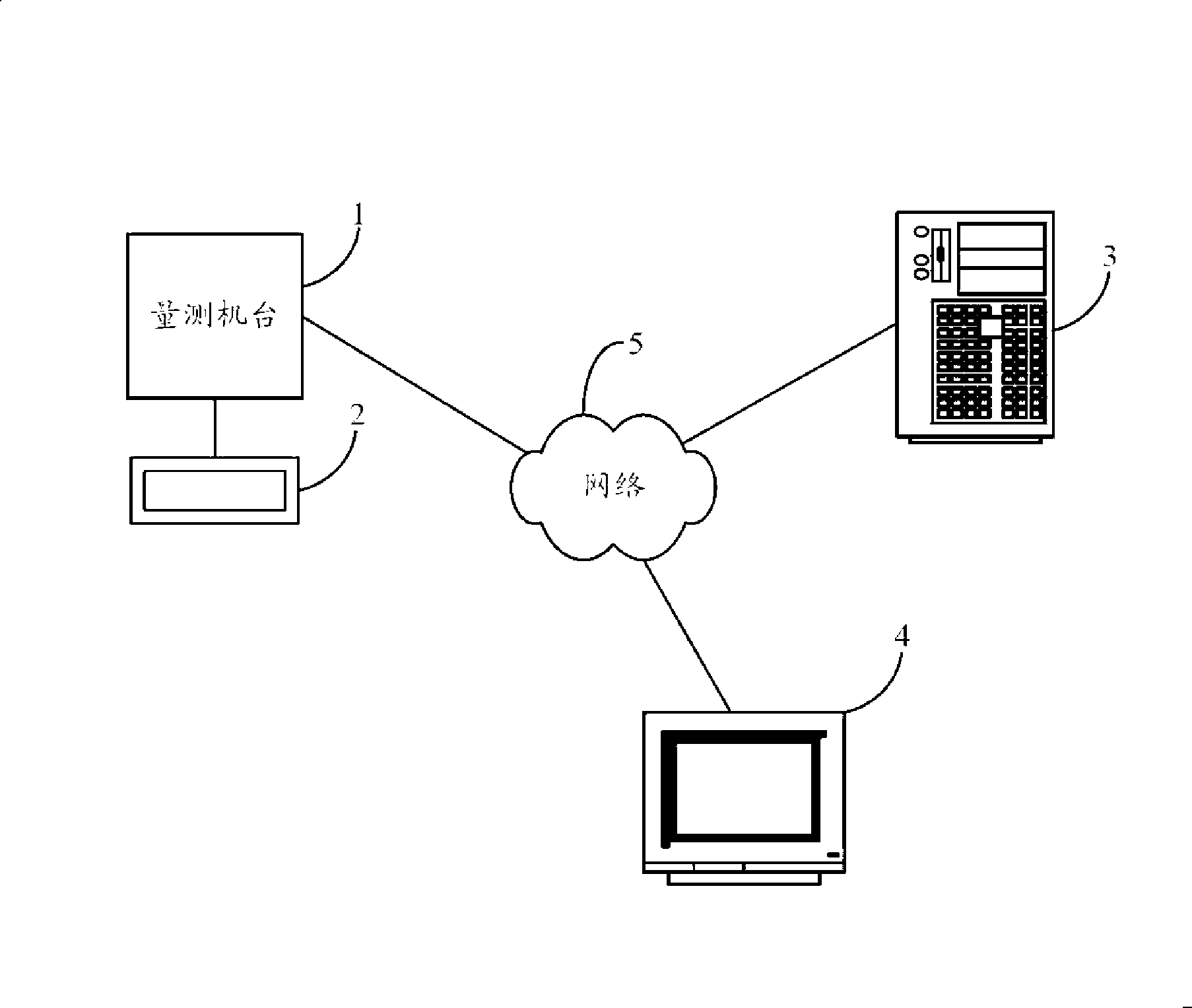

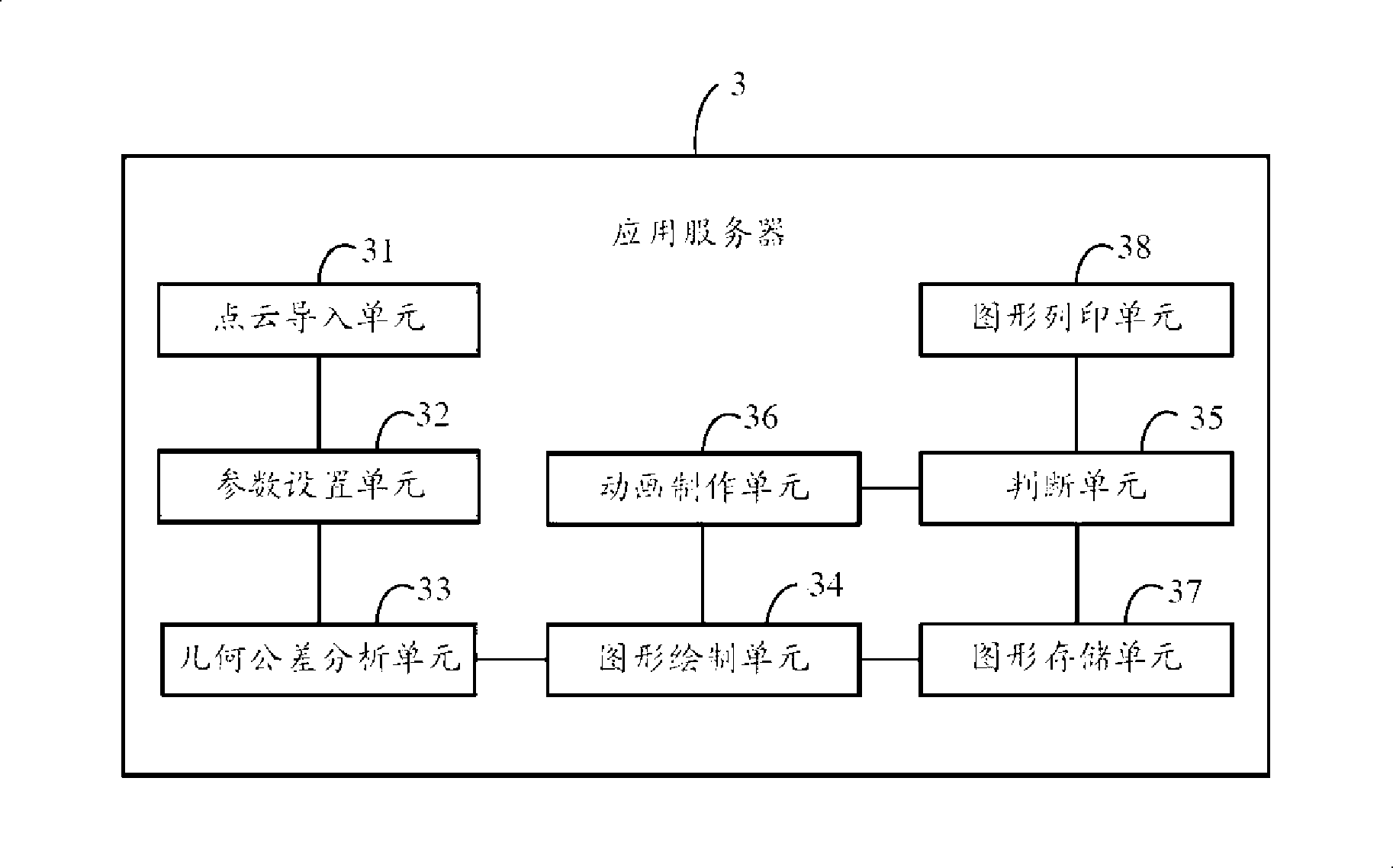

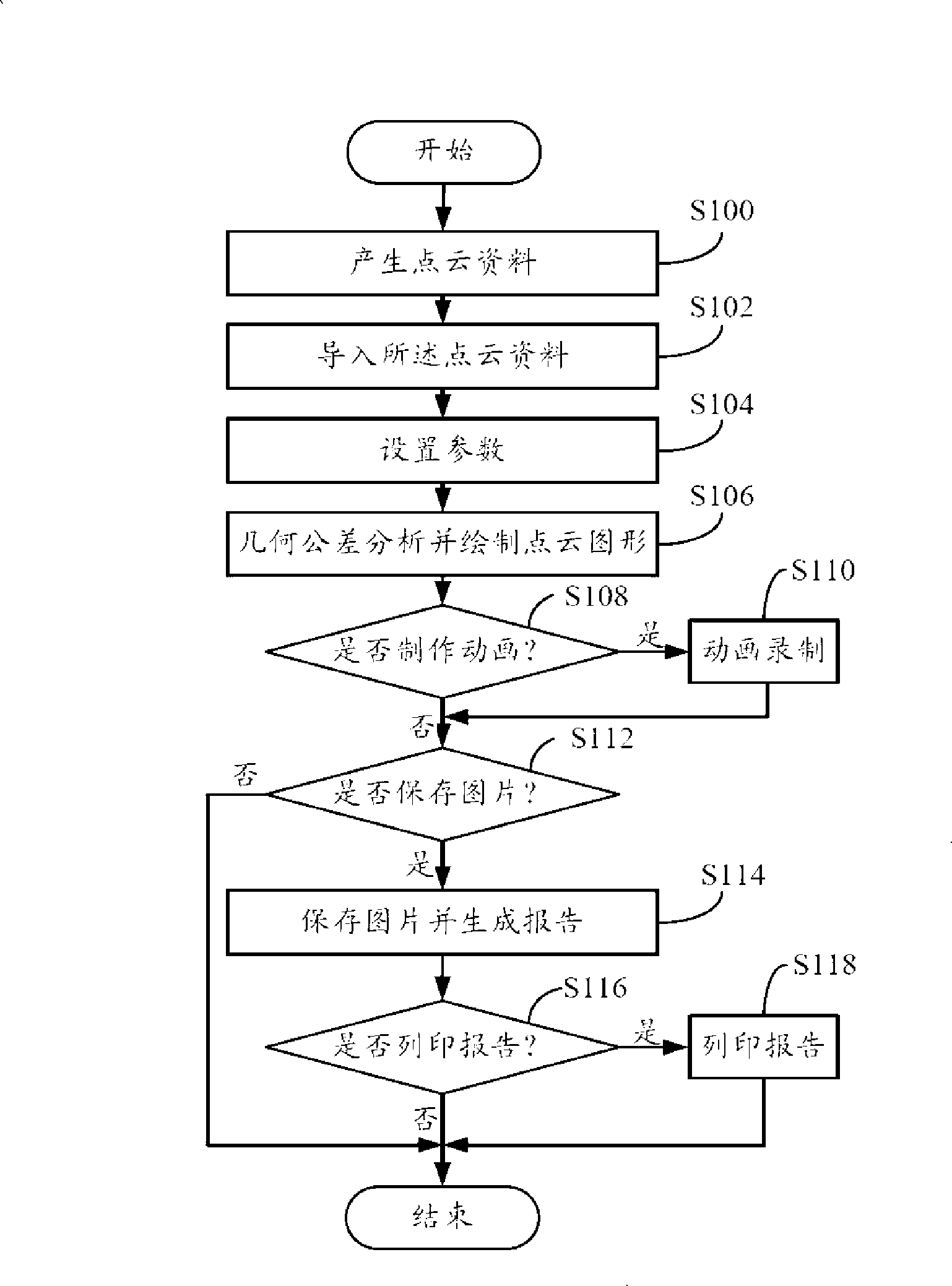

Shape error analytical system and method

The invention provides an analytical method for form error, including inputting the point cloud data of the measured factor of a work piece; setting up the analytical type, the tolerance, the point and line style of the point cloud data, carrying out geometric features fitting with the point cloud data and the best least squares according to the set-up analytical type so as to obtain the fitting figure; calculating the deviation between each point and the fitting figure; comparing the deviation with the set-up tolerance so as to determine whether the size of the work piece is qualified or not; and drawing the fitting figure into the point cloud figure according to the set-up point and line style and generates a graphic written report according to the point cloud figure, the calculated deviation and the result of the comparison. Additionally, the invention also provides an analytical system for form error.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

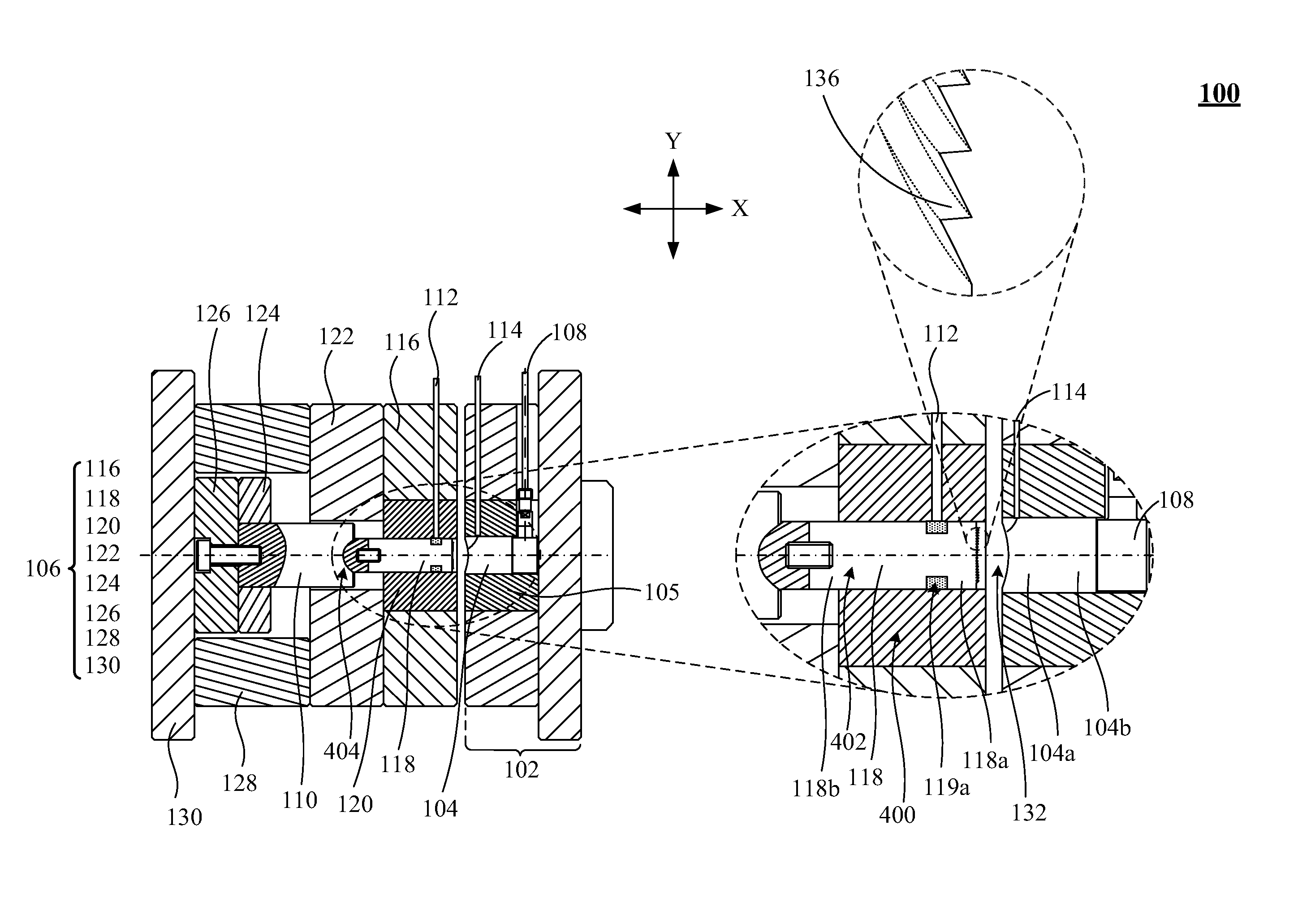

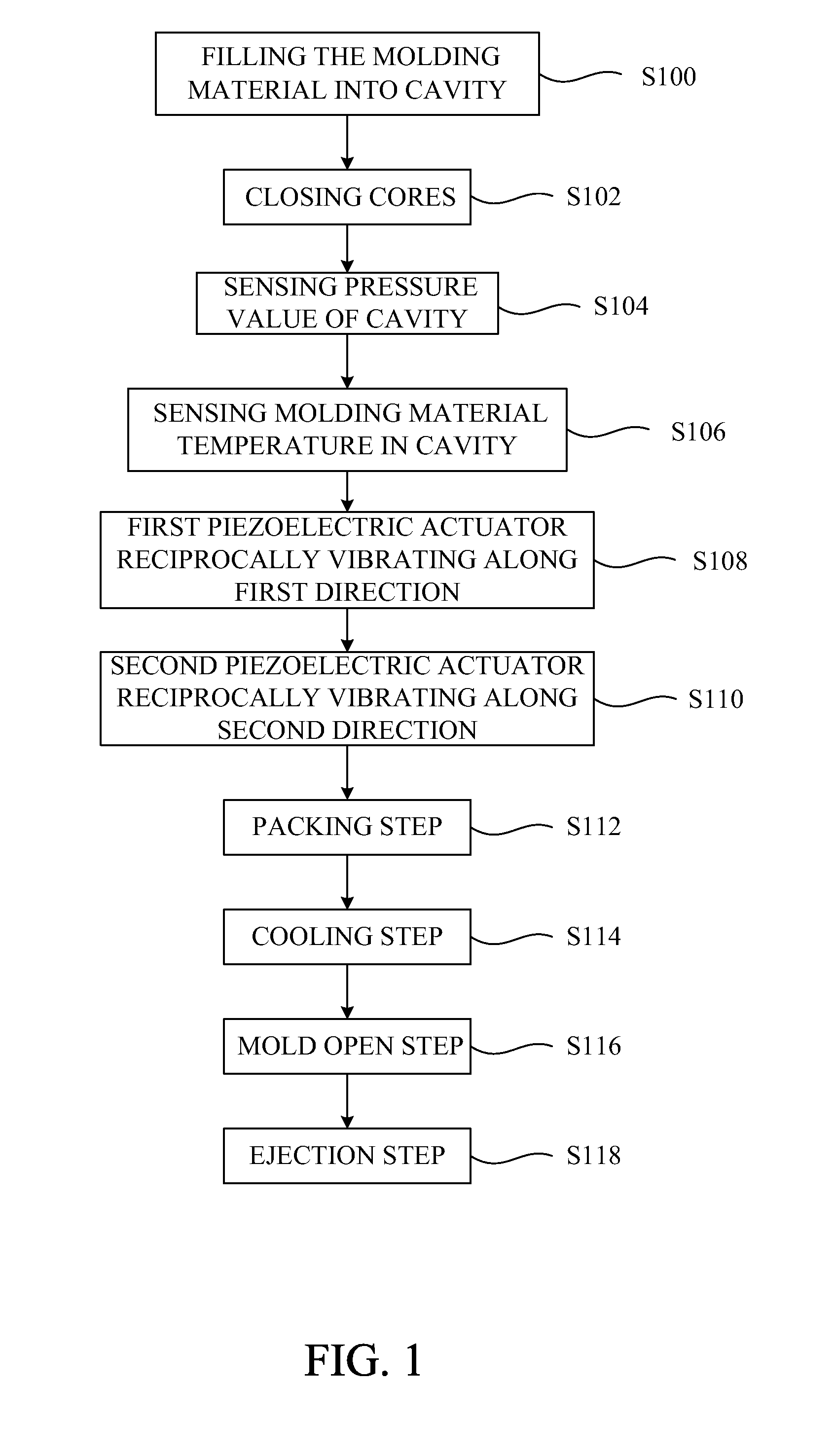

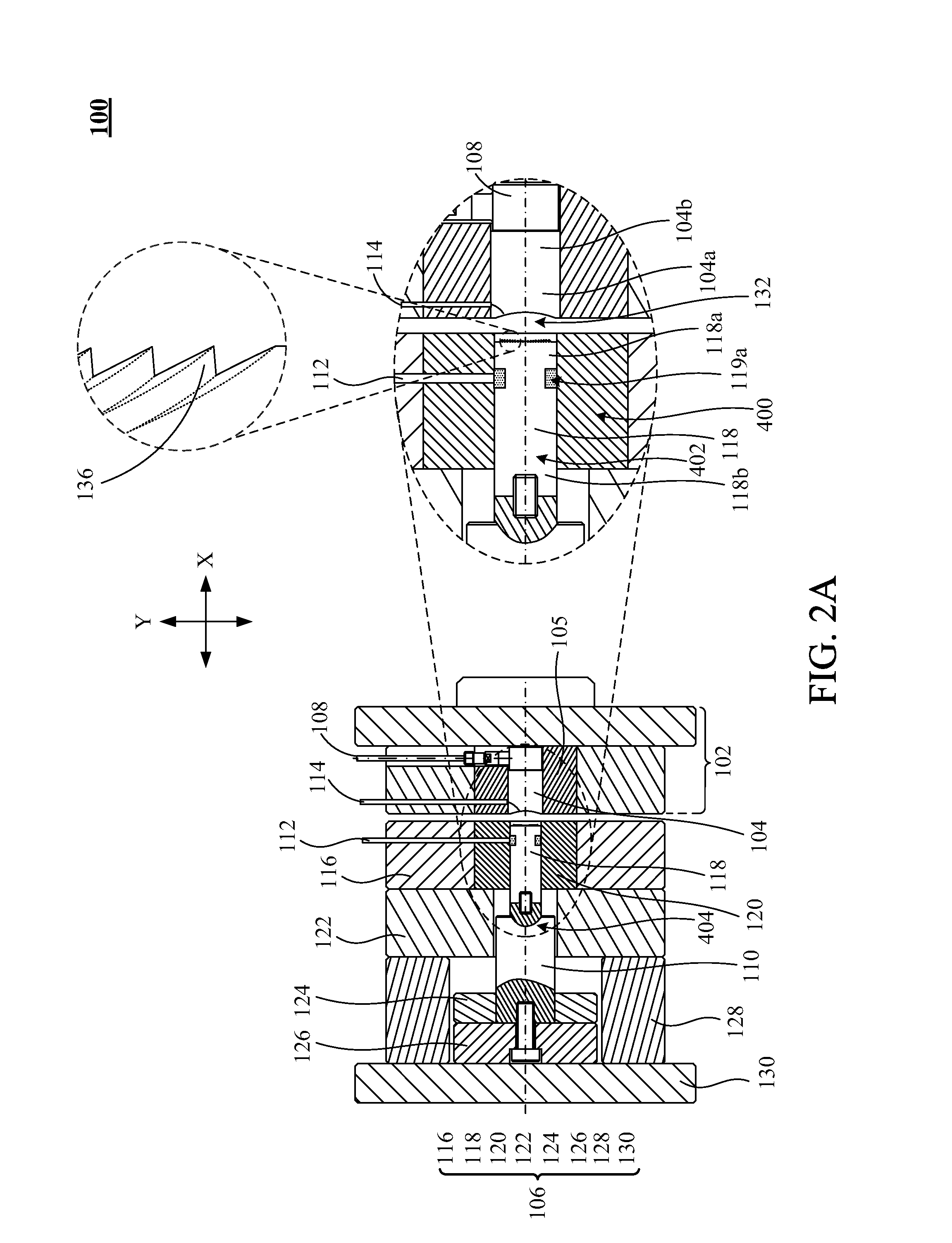

In-mold vibratile injection compression molding method and molding apparatus thereof

ActiveUS20150336316A1Increase shear rateMove quicklyOptical articlesDomestic articlesMicro structureVitrification

An in-mold vibratile injection compression molding method and molding apparatus thereof are described. While performing a filling stage, a first piezoelectric actuator and a second piezoelectric actuator are use to vibrate the molding material along at least two directions for precisely filling the molding material into the micro-structure by adjusting the filling flow velocity of the molding material associated with the proper molding material temperature and by maintaining a molding material temperature of a skin solidified layer in the cavity between a glass transition temperature and a melting temperature in order to avoid the form error, to increase the groove filling rate and to improve the residual stress.

Owner:NAT TAIWAN UNIV OF SCI & TECH

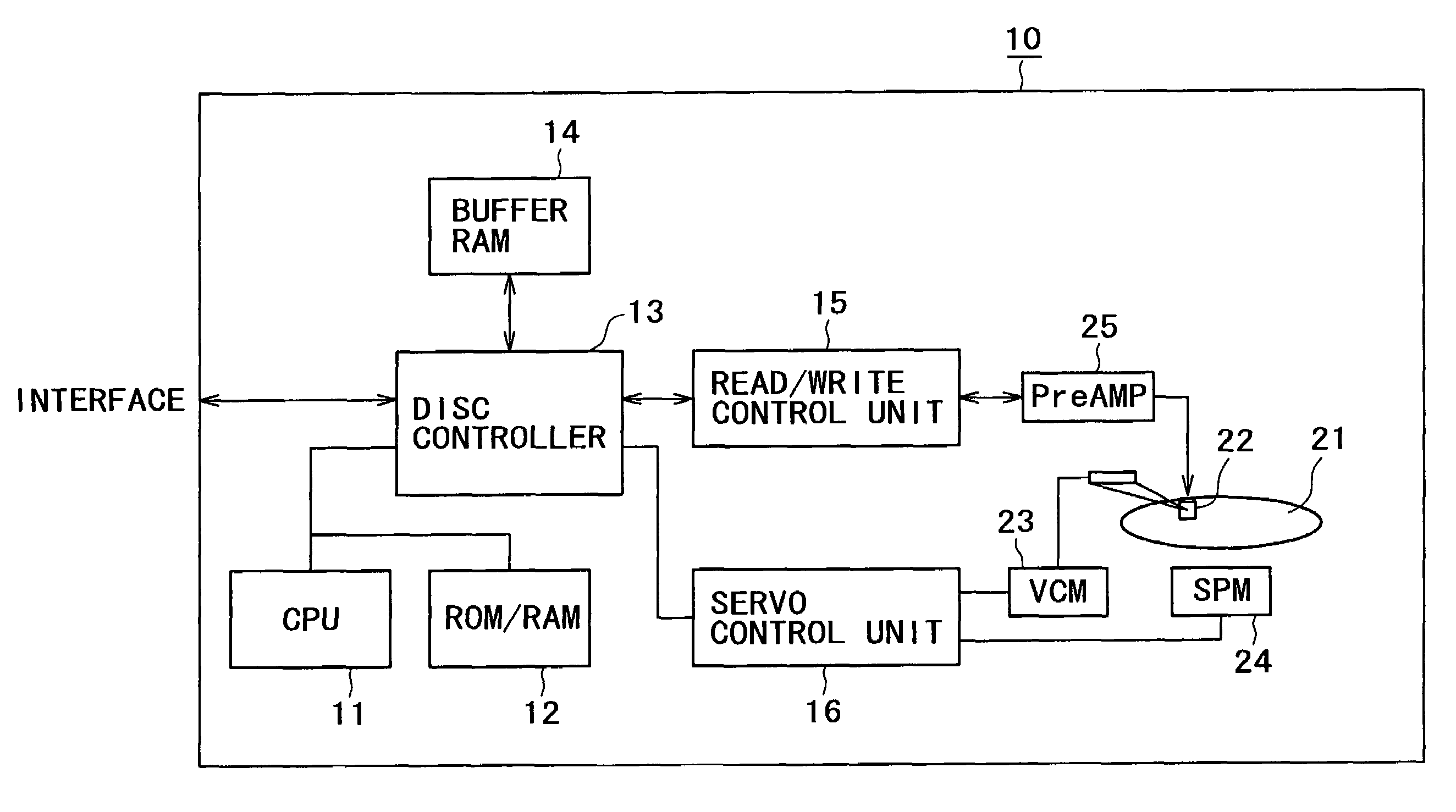

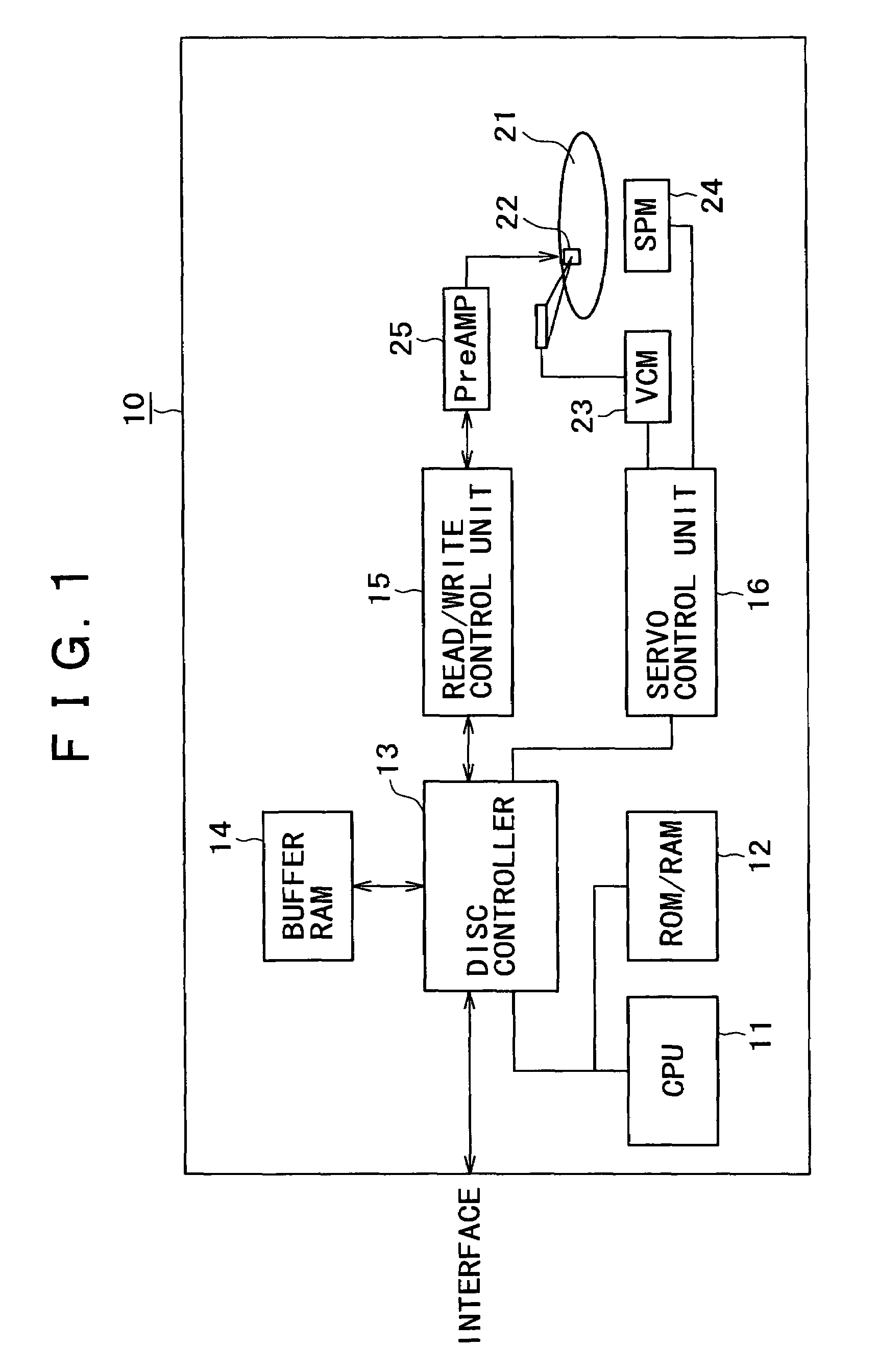

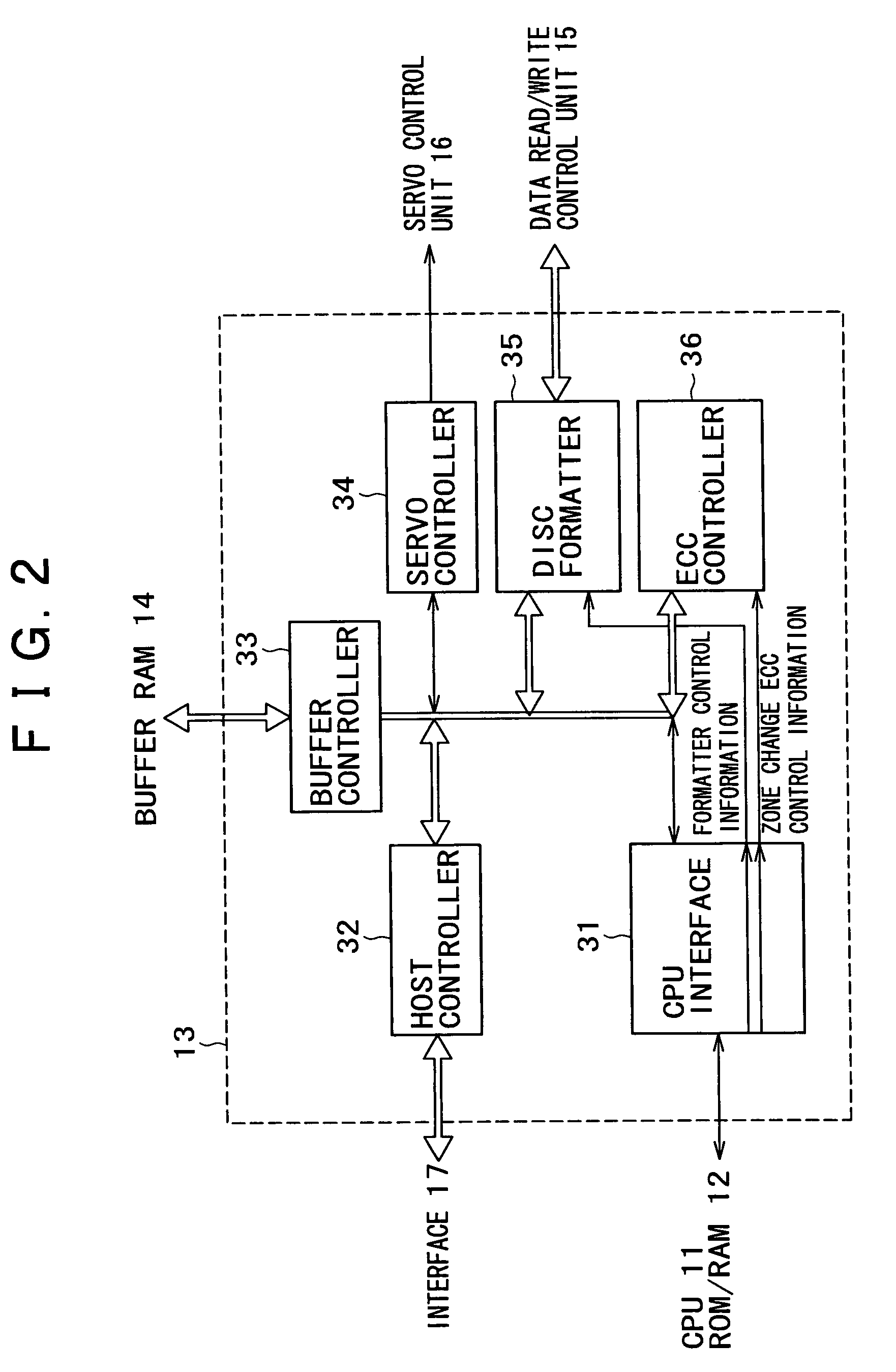

Data recording/reproducing apparatus, data recording/reproducing method, program, and recording medium

InactiveUS7339873B2Shorten access timeShorten the timeTelevision system detailsFilamentary/web record carriersData accessData recording

A data recording / reproducing apparatus for use with a disc recording medium having a plurality of either concentric or spiral tracks formed thereon, each of the tracks being divided into a plurality of sectors is provided. The apparatus includes a seeking element for seeking a target track; a data accessing element for accessing data on the target track reached by the seek; and an error correcting element for correcting error in the data based on an error correction code generated by the error correcting element for error correction purposes. The error correcting element establishes a first error correction code increment per predetermined data quantity, establishes a second error correction code increment for a plurality of first error correction code increments depending on information about status on the disc recording medium, and forms error correction blocks each constituted by a plurality of the first error correction code increments and by the second error correction code increment added to the first error correction code increments.

Owner:SONY CORP

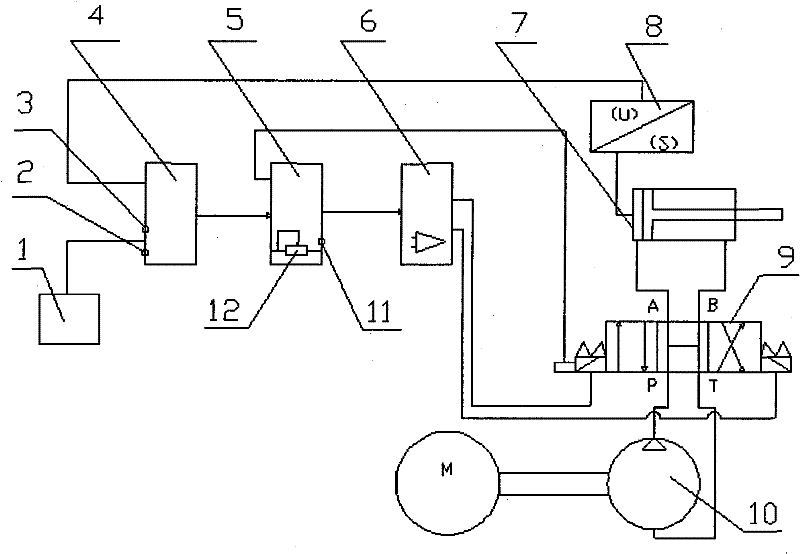

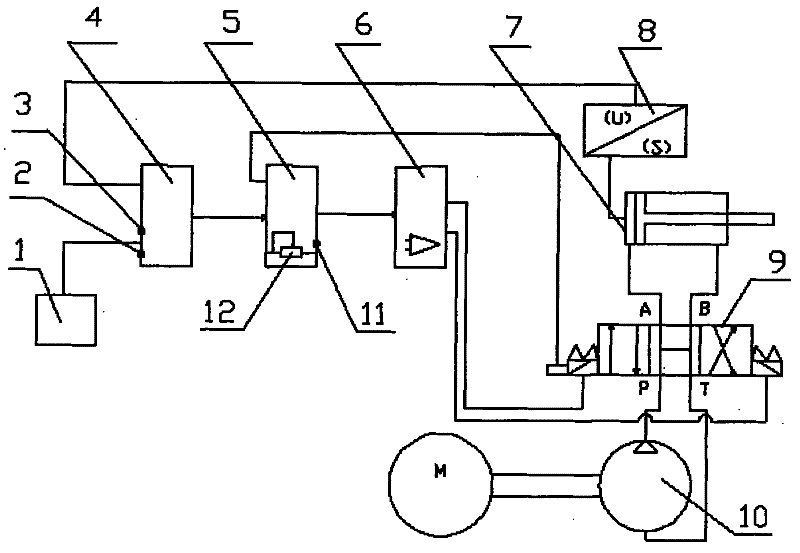

A Proportional Valve Online Zeroing Method

InactiveCN102297282AGuaranteed stabilityAvoid multiple disassemblyOperating means/releasing devices for valvesProgramme control in sequence/logic controllersSpool valveControl system

The invention provides an online zero-adjustment method of a proportional valve, which mainly utilizes a proportional valve control system to feed back a position state signal of a main valve core to judge whether the zero point of the valve core drifts, thereby realizing online accurate zero-adjustment. Since the zero point of the valve is adjusted through the position feedback signal of the main spool, no matter whether the natural zero point of the return spring of the proportional valve is offset or not, the proportional valve can always be guaranteed to work near the real zero point, which overcomes the traditional method due to the mechanical deformation of the spring. The signal error ensures the stability of the proportional valve, and realizes online debugging, which reduces the maintenance workload, does not require investment and purchase of special debugging equipment, can save 8 hours of adjustment and testing time each time, and can reduce downtime by 48 hours throughout the year.

Owner:ANGANG STEEL CO LTD

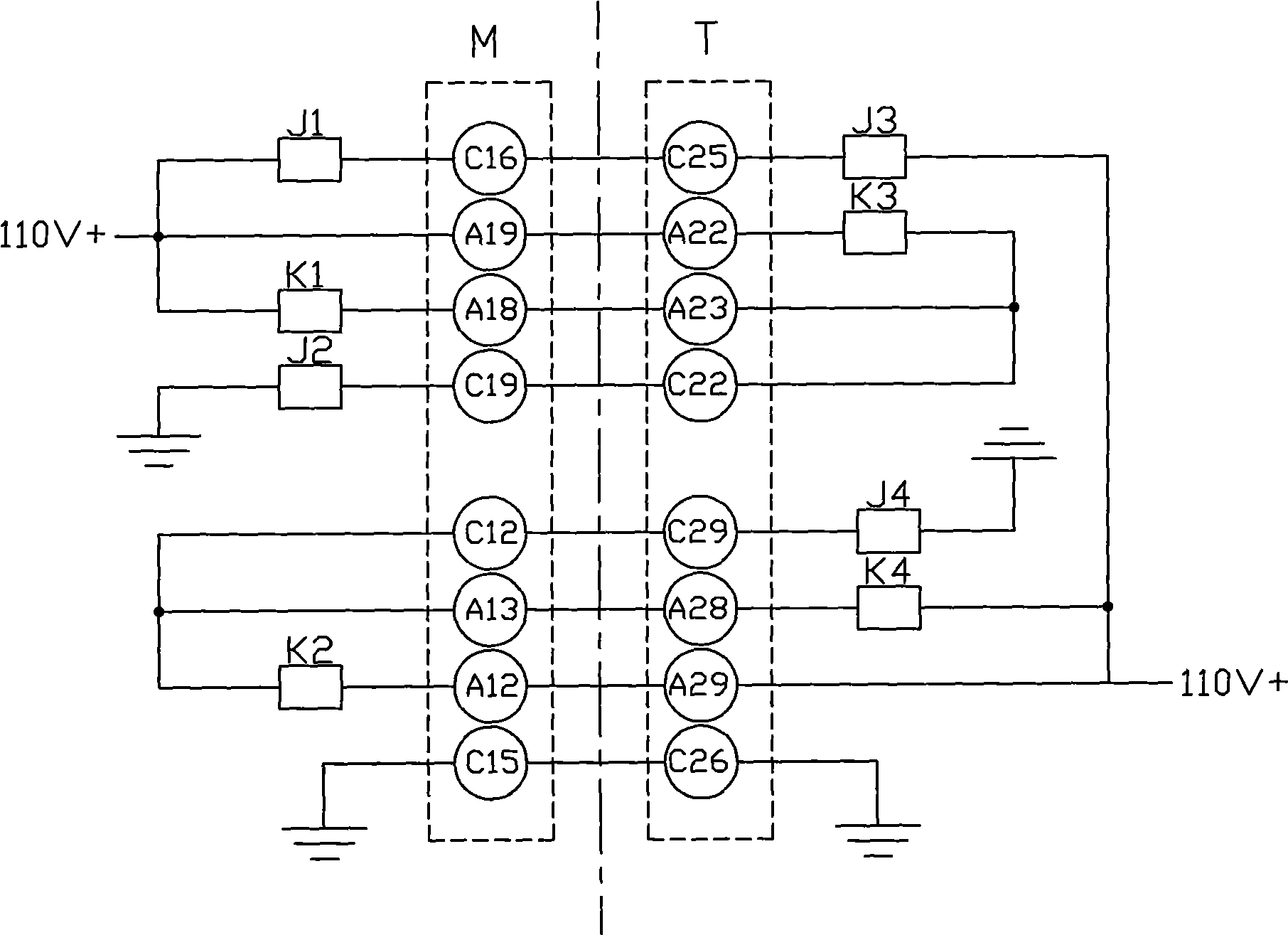

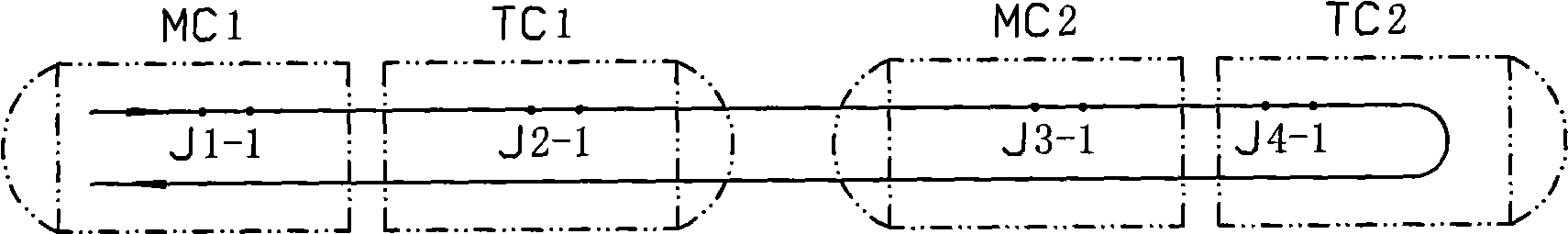

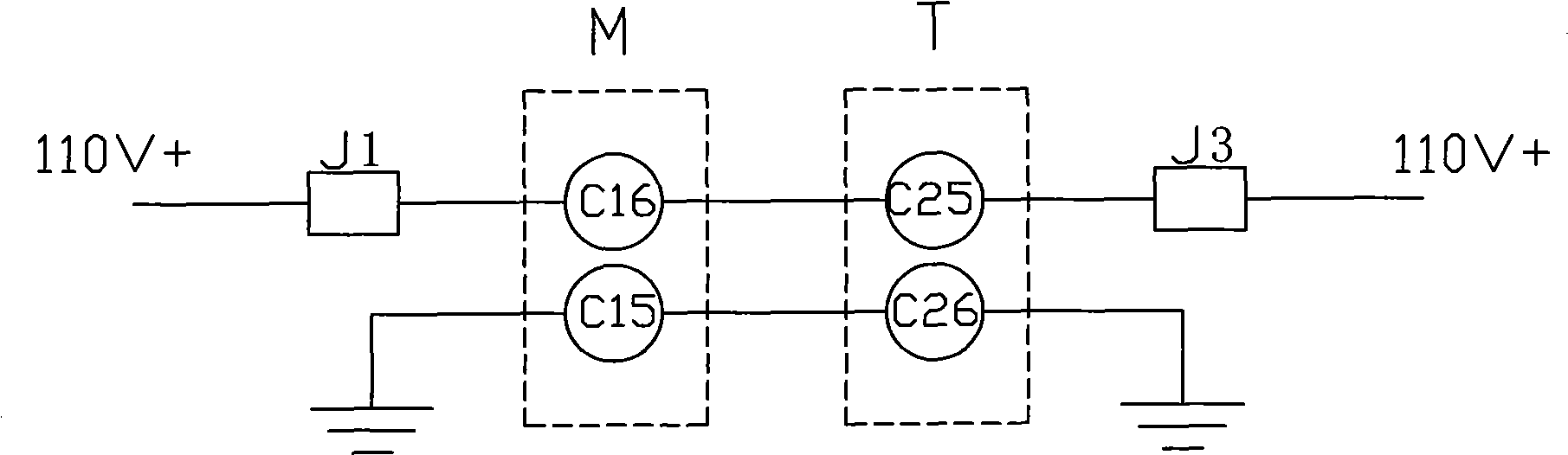

Cityrail train fixed multi-connection device capable of realizing automatic protection

InactiveCN101497341AGuaranteed uptimeReduce labor intensityRailway couplingsRailway signalling and safetyMonitoring and controlAutomatic testing

The invention discloses an urban train fixing and reconnecting device for realizing automatic protection. The device is provided with automatic reconnecting linkers M and T; a relay J1 is connected between a contact pin (C16) of the automatic reconnecting linker M and the positive input end of a power supply; a relay J2 is connected between a contact pin (C19) and the ground; a relay J3 is connected between a contact pin (C26) of the automatic reconnecting linker T and the positive input end of the power supply; a relay J4 is connected between a contact pin (C29) and the ground; and normally-closed contacts J1-1, J2-1, J3-1 and J4-1 of the relays J1, J2, J3 and J4 are connected to a train safety loop wire. The device has a simple structure, low cost and easy realization; when a train is fixed and reconnected, the device can carry out automatic monitoring and control on a marshalling form and a reconnecting option switch; when the marshalling form is wrong or the reconnecting option switch is out of place, the safety loop wire cannot be established between the reconnecting trains, so the hidden trouble of accident is eliminated and safe and reliable operation of the train in reconnection is ensured.

Owner:CRRC DALIAN CO LTD

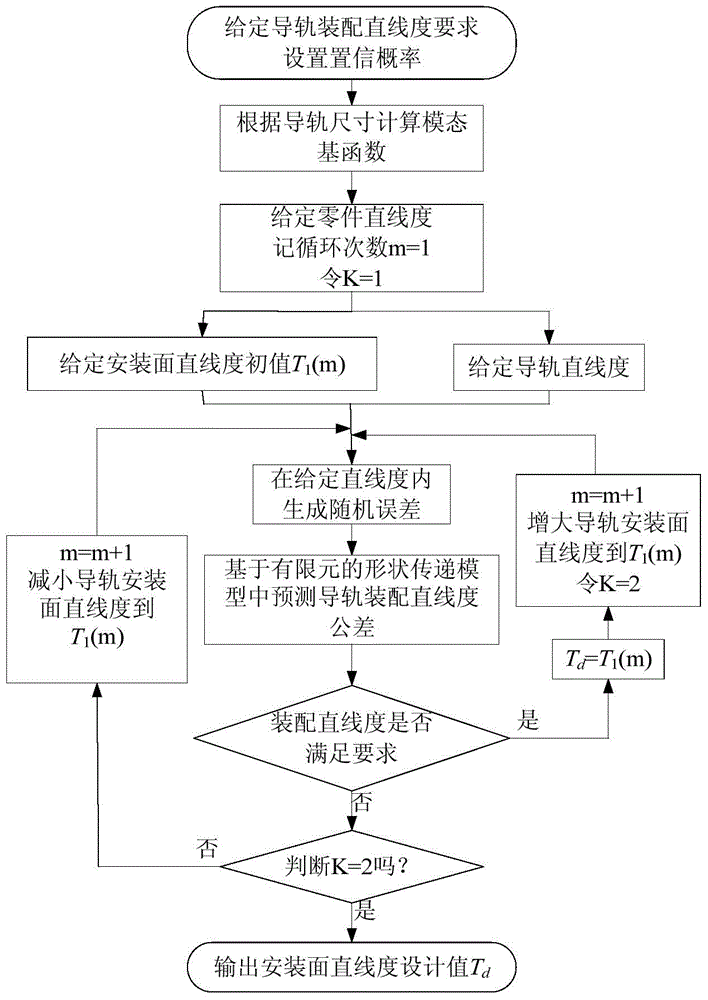

Method for designing linearity of mounting surface for rolling linear guide of precision machine tool

ActiveCN104102774AShorten the development cycleReduce dependenceSpecial data processing applicationsElement analysisBase function

A method for designing linearity of a mounting surface for a rolling linear guide of a precision machine tool includes the steps of first, expressing a form error of a fitting characteristic surface by means of a modal base function based method, and generating a random error sample within a given linearity tolerance; second, establishing a finite element based form error propagation model according to the generated random error sample by means of finite element software ANSYS, acquiring a fitting error of the rolling linear guide by means of finite element analysis, using the Monte-Carlo method to input all random errors generated within a given tolerance zone, into the finite element based form error propagation model and to calculate the random errors so that a post-fitting linearity tolerance is obtained, and establishing a guide fitting tolerance analysis model; and third, on the basis of the guide fitting tolerance analysis model, designing the linearity of the mounting surface for the rolling linear guide according to the concept of cyclic search. The method has the advantages that dependence on experiences is reduced, reliable theoretical guidance is provided for the design of the linearity of the guide mounting surface, product development time can be shortened, cost can be reduced, and economic benefit can be increased.

Owner:XI AN JIAOTONG UNIV

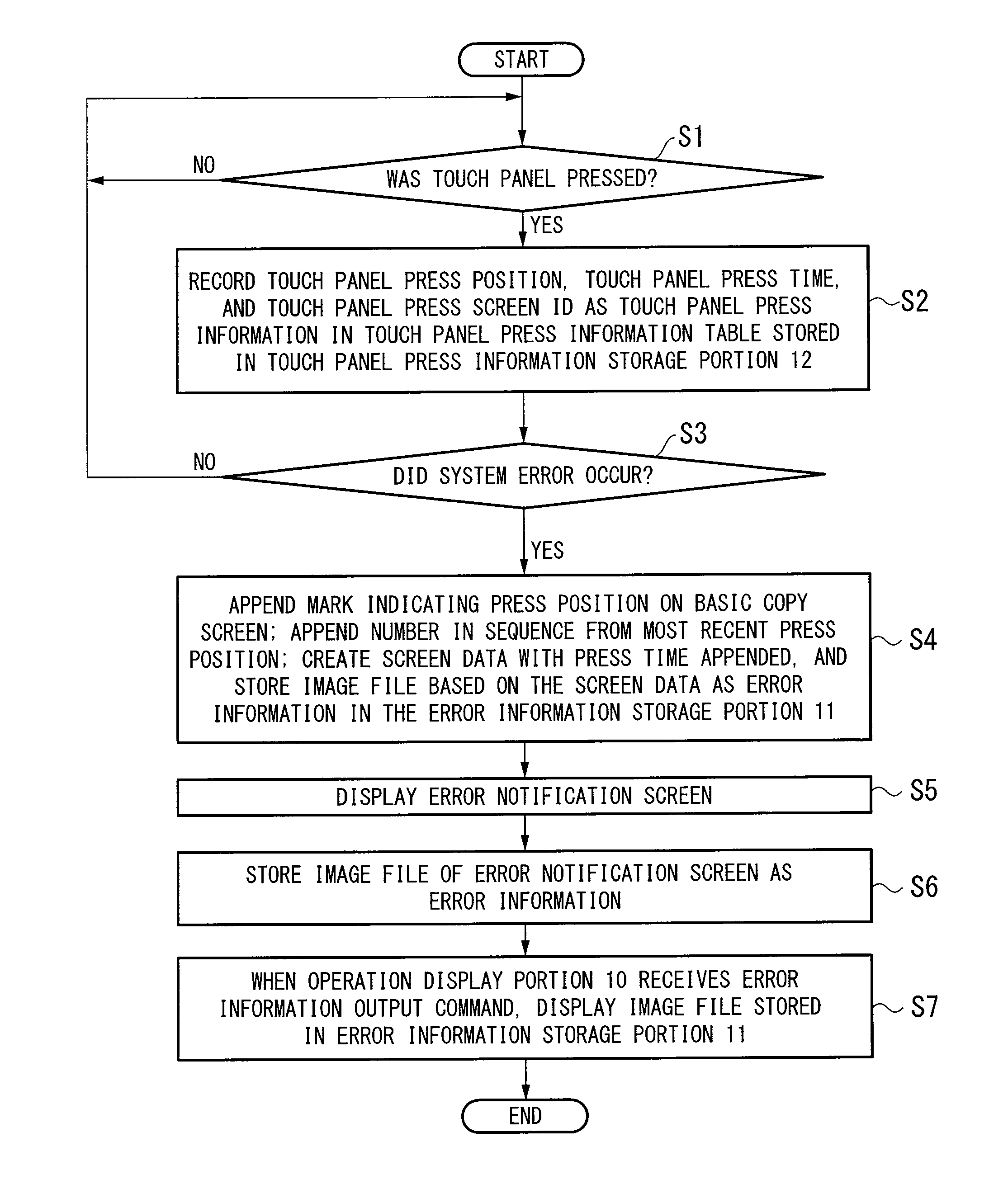

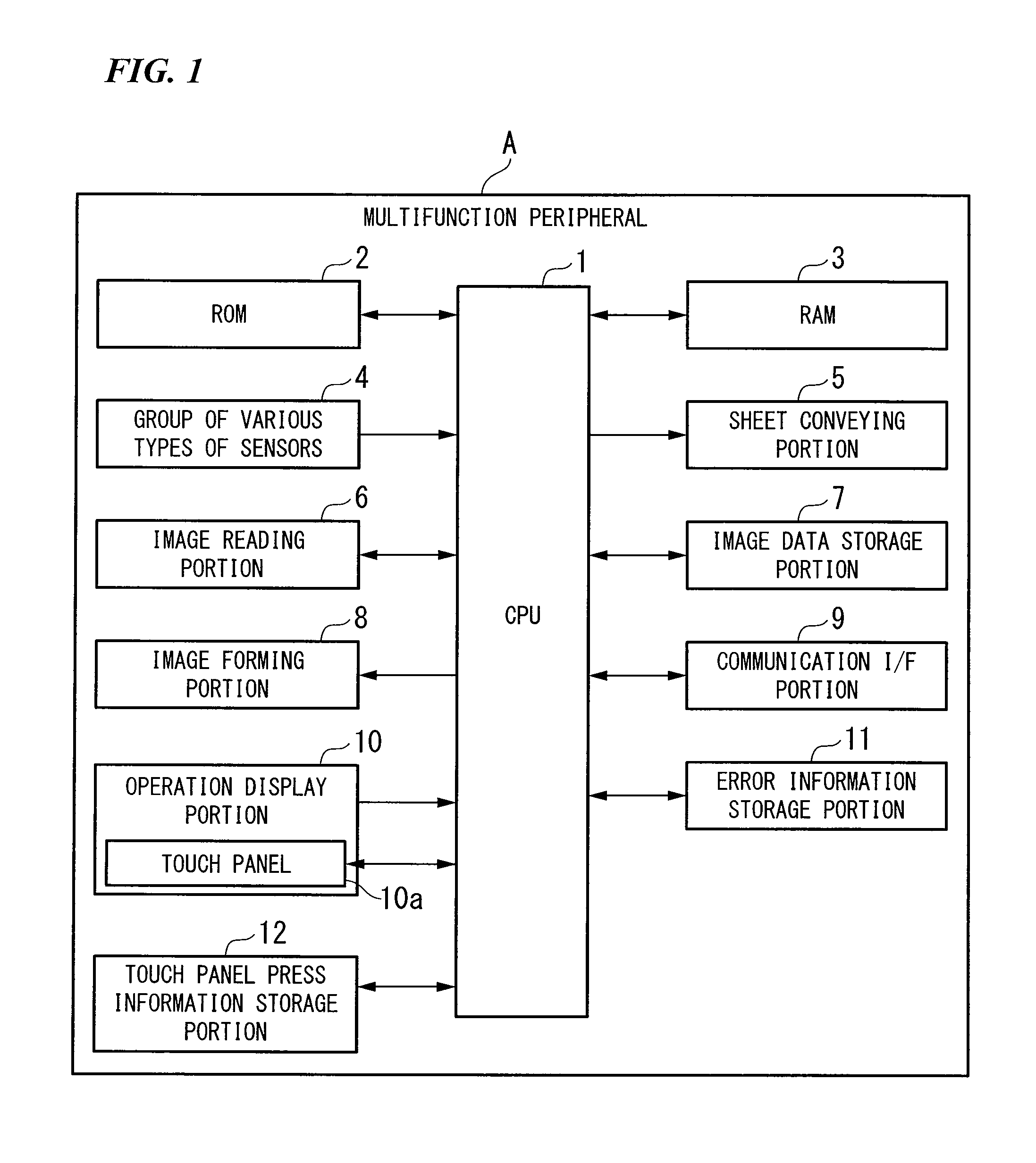

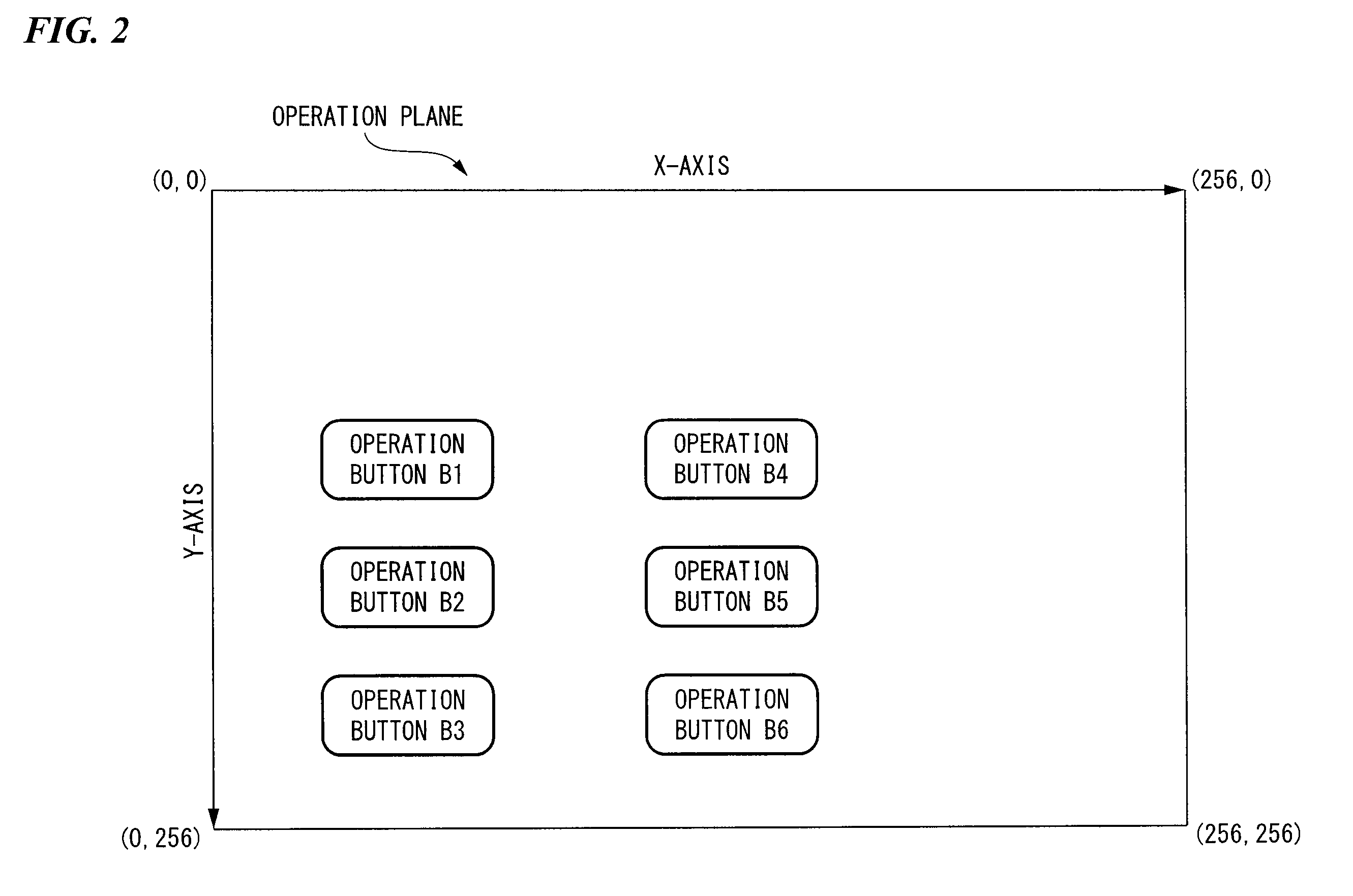

Electronic device, method for forming error information of electronic device, and image forming apparatus

InactiveUS20100119250A1Improve work efficiencyElectrographic process apparatusInput/output processes for data processingImage formationTouch panel

An electronic device includes a touch panel that includes an operation plane displaying various operation screens, and detects a press position on the operation screen as detection signal; a first storage portion that stores press information of the touch panel; a second storage portion that stores error information; a first control unit that stores the press position indicated by the detection signal from the touch panel as first press information in the first storage portion; a second control unit creates screen data with a mark indicating the press position on the operation screen when an error occurred, based on the first press information stored in the first storage portion, and stores the screen data as first error information in the second storage portion, when the error occurs in the electronic device; and a third control unit that outputs the error information based on an error information output command.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

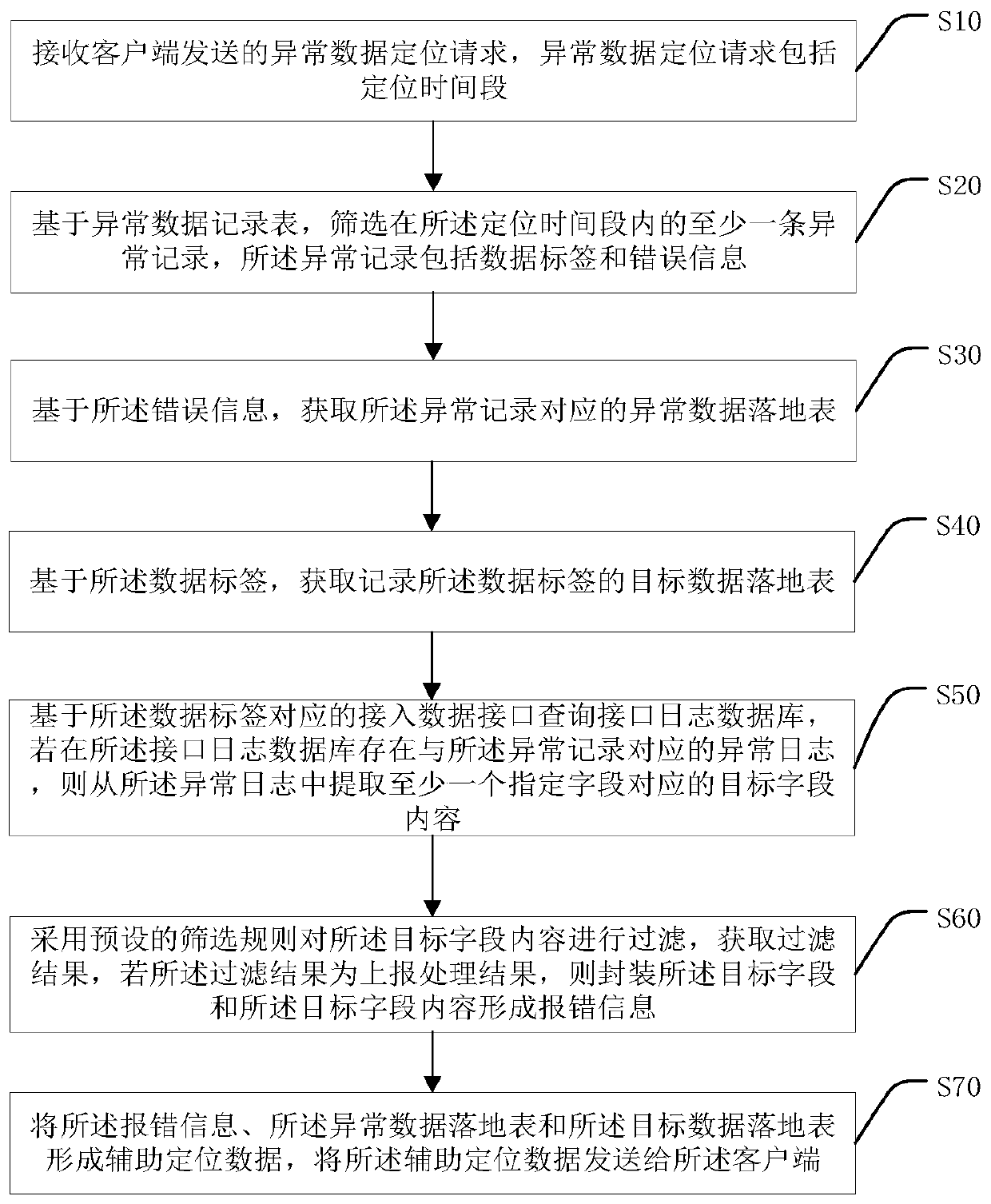

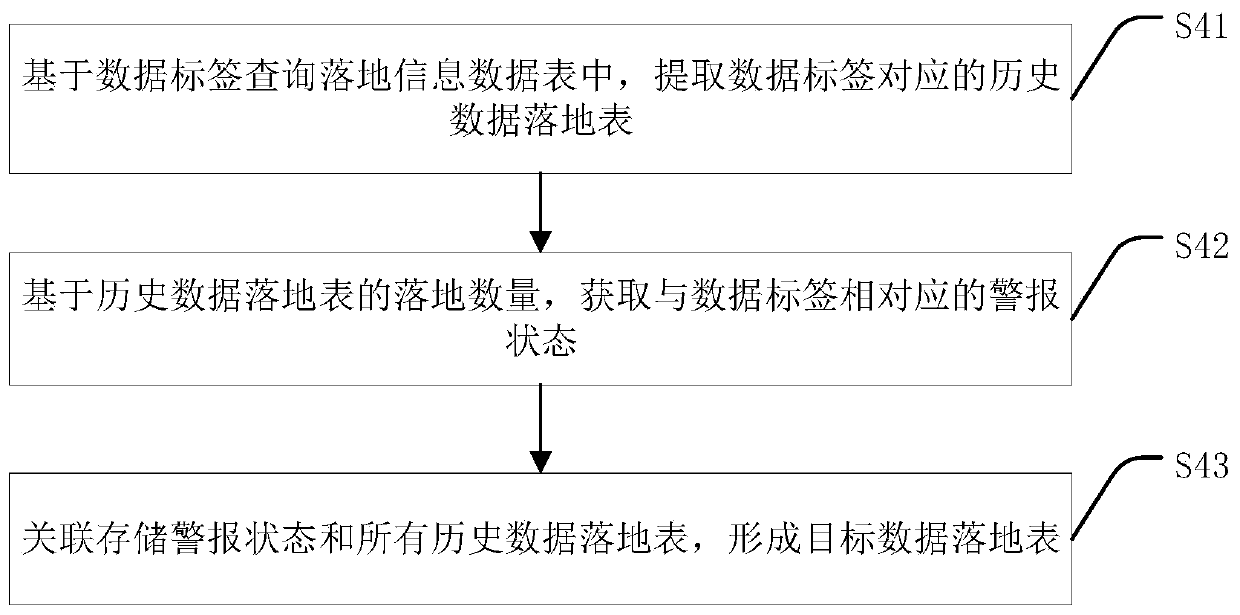

Data auxiliary positioning method and device, computer equipment and storage medium

ActiveCN110162420AConvenience to workImprove positioning efficiencyFault responseError reportingData records

The invention discloses a data auxiliary positioning method and device, computer equipment and a storage medium, and the data auxiliary positioning method comprises the steps: screening at least one abnormal record in a positioning time period based on an abnormal data record table; obtaining an abnormal data landing table corresponding to the abnormal record based on the error information; acquiring a target data landing table for recording the data label based on the data label; if the abnormal log corresponding to the abnormal record exists in the interface log database, extracting target field content corresponding to at least one specified field from the abnormal log; filtering the target field content by adopting a preset screening rule, and if a filtering result is a reporting processing result, forming error reporting information; and forming the error reporting information, the abnormal data landing table and the target data landing table into auxiliary positioning data, and sending the auxiliary positioning data to the client. The data auxiliary positioning method can improve the positioning efficiency and positioning accuracy of abnormal data.

Owner:PING AN TECH (SHENZHEN) CO LTD

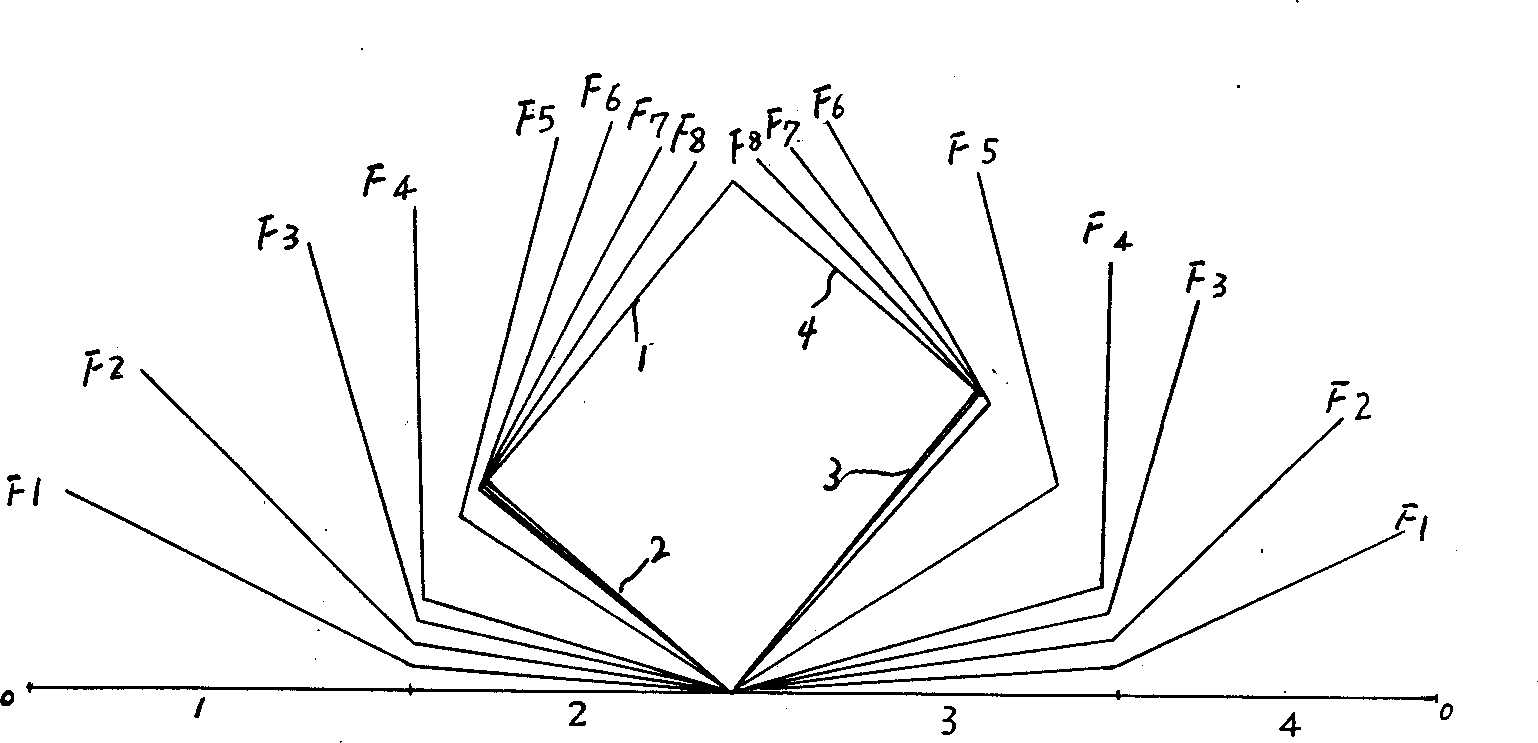

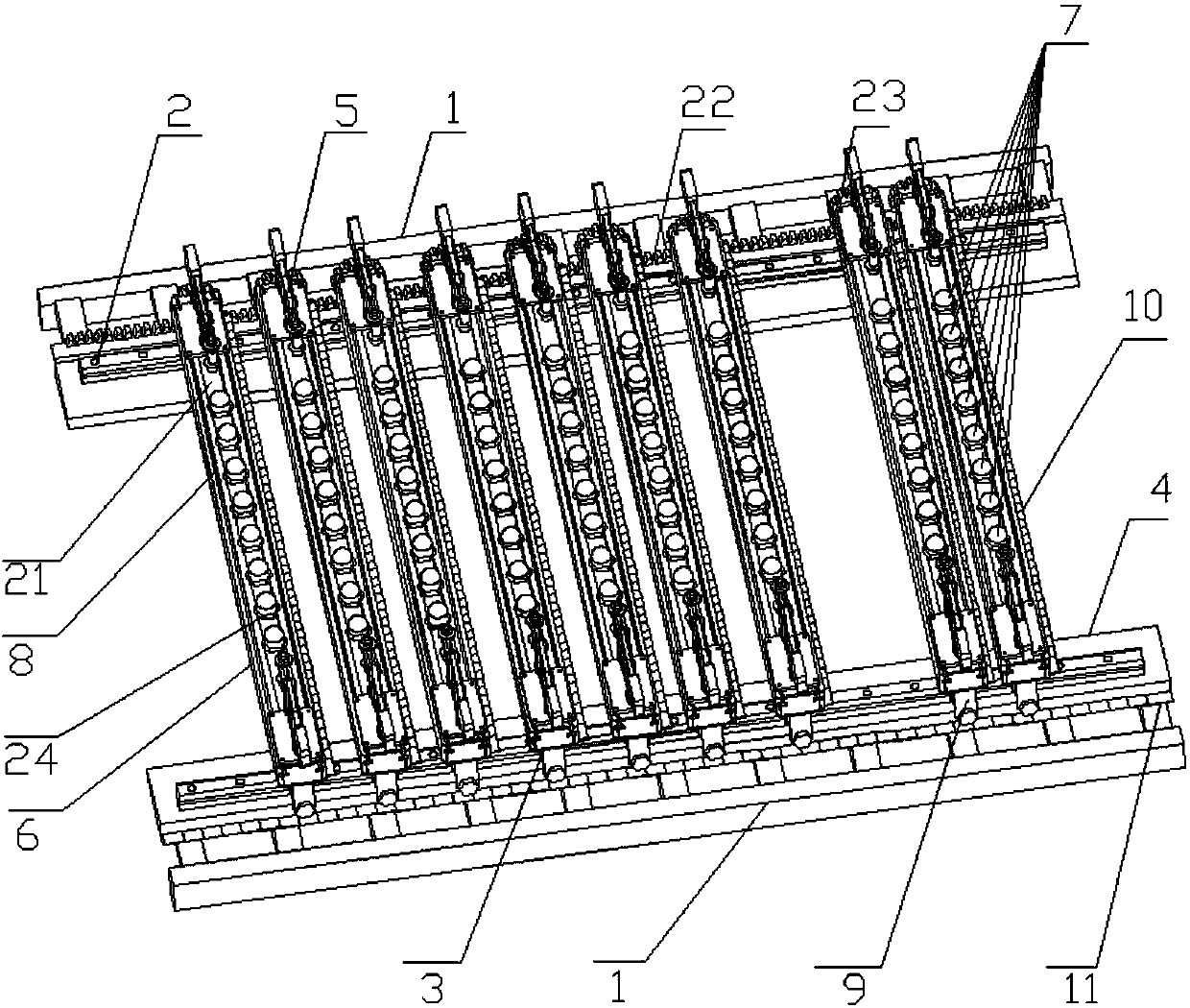

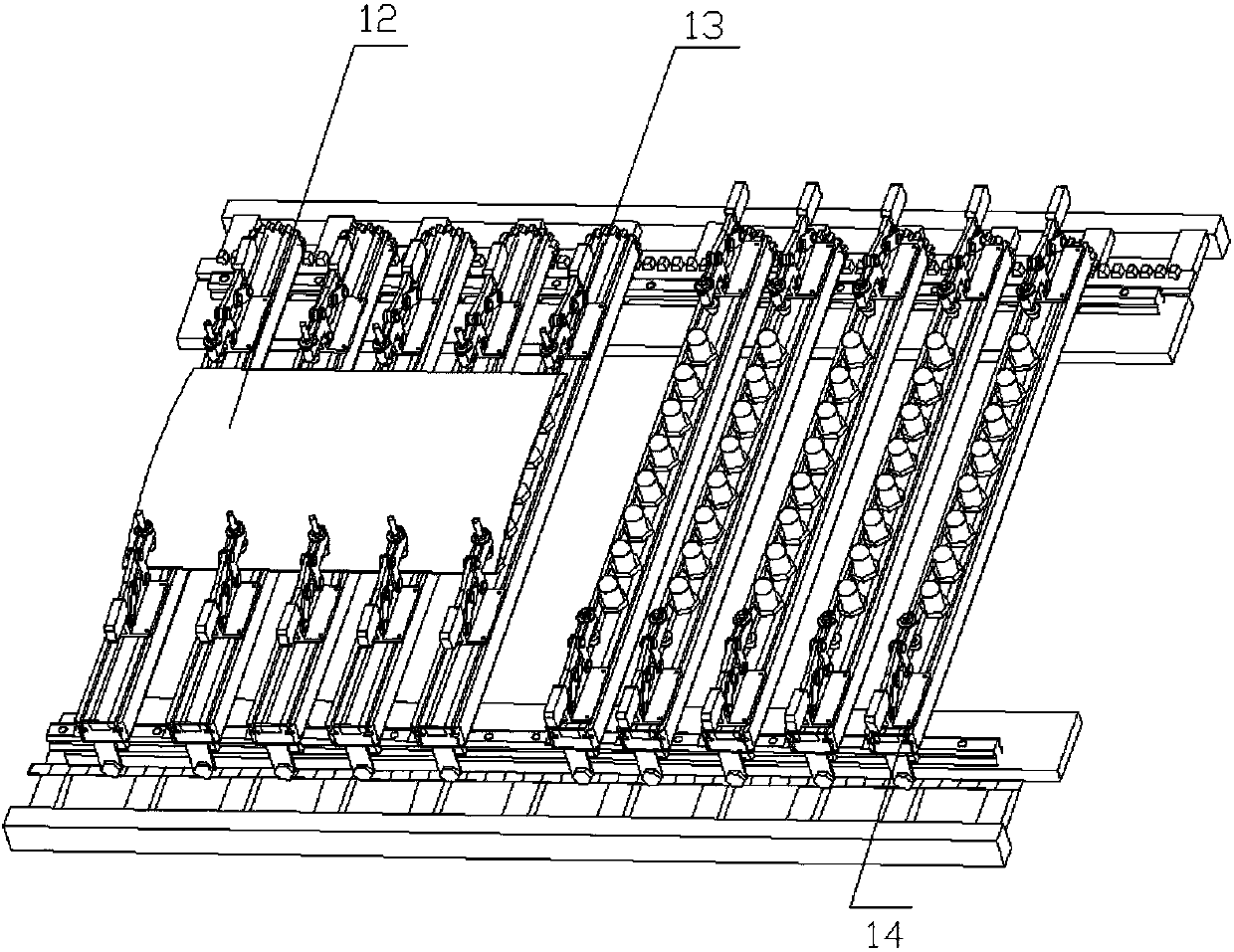

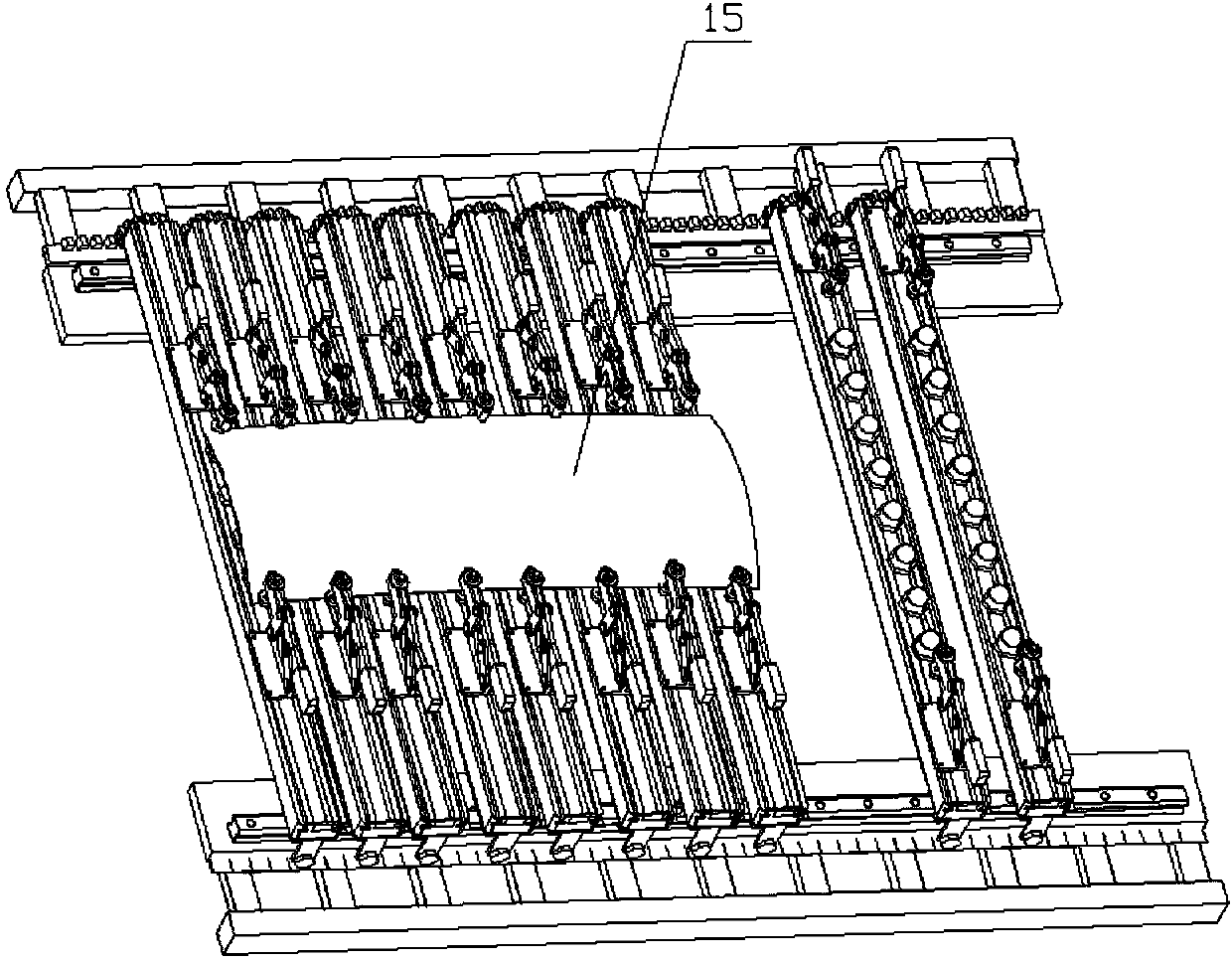

Multi-point active loaded aircraft panel prestressing shot blasting tooling and method

The invention provides a multi-point active loaded aircraft panel prestressing shot blasting tooling and method. The multi-point active loaded aircraft panel prestressing shot blasting tooling is composed of a rigid frame, a longitudinal beam and a plurality of puncher pins. A linear guide rail is designed on the frame, the longitudinal beam is mounted on the linear guide rail, and the puncher pins and a compression mechanism are mounted on the longitudinal beam, wherein the height of each puncher pin can be subjected to digital control adjustment by a computer, and the compression mechanism is used for fixing a wall panel. Each puncher pin is equipped with an integrated digital-controlled driving decelerating motor, the motor rotates to drive a guide screw, the height adjustment of each puncher pin body in the axial direction is achieved, and each puncher pin body can be locked at any position. Compared with a traditional prestressing shot blasting fixture, the digital-controlled puncher pins can form a pre-bending type face to achieve pre-bending of a wall panel piece with any curvature. The multiple puncher pins make the wall panel to bear prestress more evenly, and the phenomenon of partial distortion caused by single point applying force can be avoided effectively. In the forming process of a blasted shot, the heights of the utilized puncher pins can be adjusted in real time according to the deformation situation of the wall panel, and thus the accuracy of forming of the blasted shot is improved. After the blasted shot is formed, the tooling can serve as a test profiling to test the forming error of a curved wall panel.

Owner:JILIN UNIV

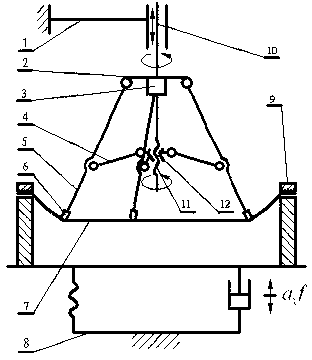

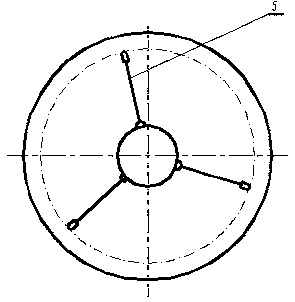

Multi-point symmetric vibration progressive composite and precise forming system for metal plate

The invention discloses a multi-point symmetric vibration progressive composite and precise forming system for a metal plate. The main shaft of the multi-point symmetric vibration progressive composite and precise forming system for the metal plate is vertically installed on a rack; a tool head bracket is hinged to a mounting plate on the lower end of the main shaft; a motor for driving a lead screw is fixedly arranged on the bottom of the mounting plate; a bracket expansion device is installed on the symmetric center position of the tool head bracket; one end of a connecting rod on the bracket expansion device is hinged to a nut on the center position; the other end of the connecting rod is hinged to the middle of the tool head bracket; a tool head is fixedly arranged on the tail end of the bracket; a lower die is installed under the tool head bracket; and a vibration exciter is connected with the position under the lower die. The multi-point symmetric vibration progressive composite and precise forming system for the metal plate has the beneficial effects that a plurality of forming tool heads with the symmetric distribution structure are adopted to rotate and carry out radial expanding and forming movement, so that the movement precision of the tool heads can be more effectively controlled, the forming error is reduced, the stressed state of the plate in the forming process is improved, the stress strain in the plate is homogenized, and the metal plate material can be subjected to efficient progressive composite and precise forming.

Owner:JIANGXI UNIV OF SCI & TECH

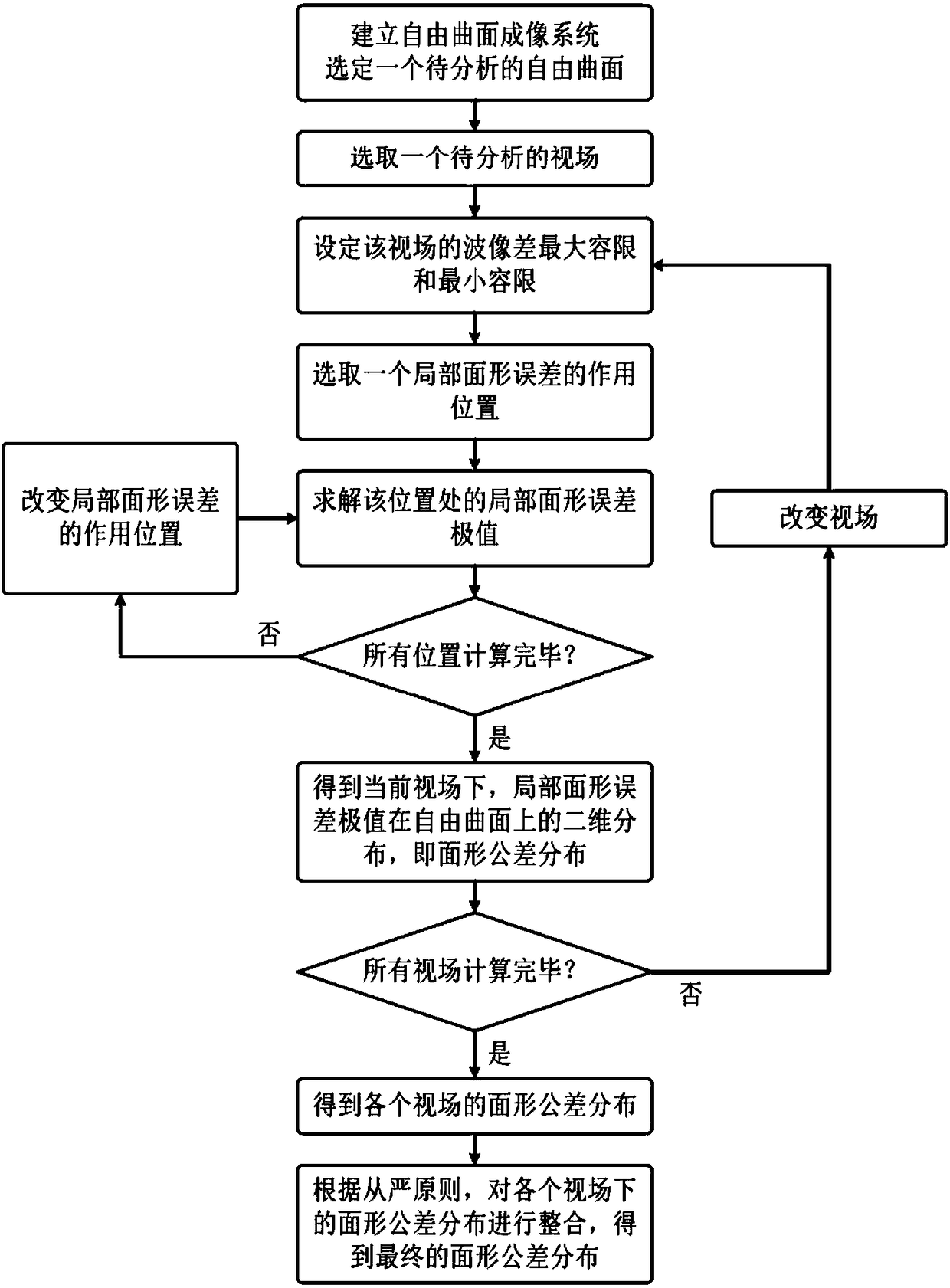

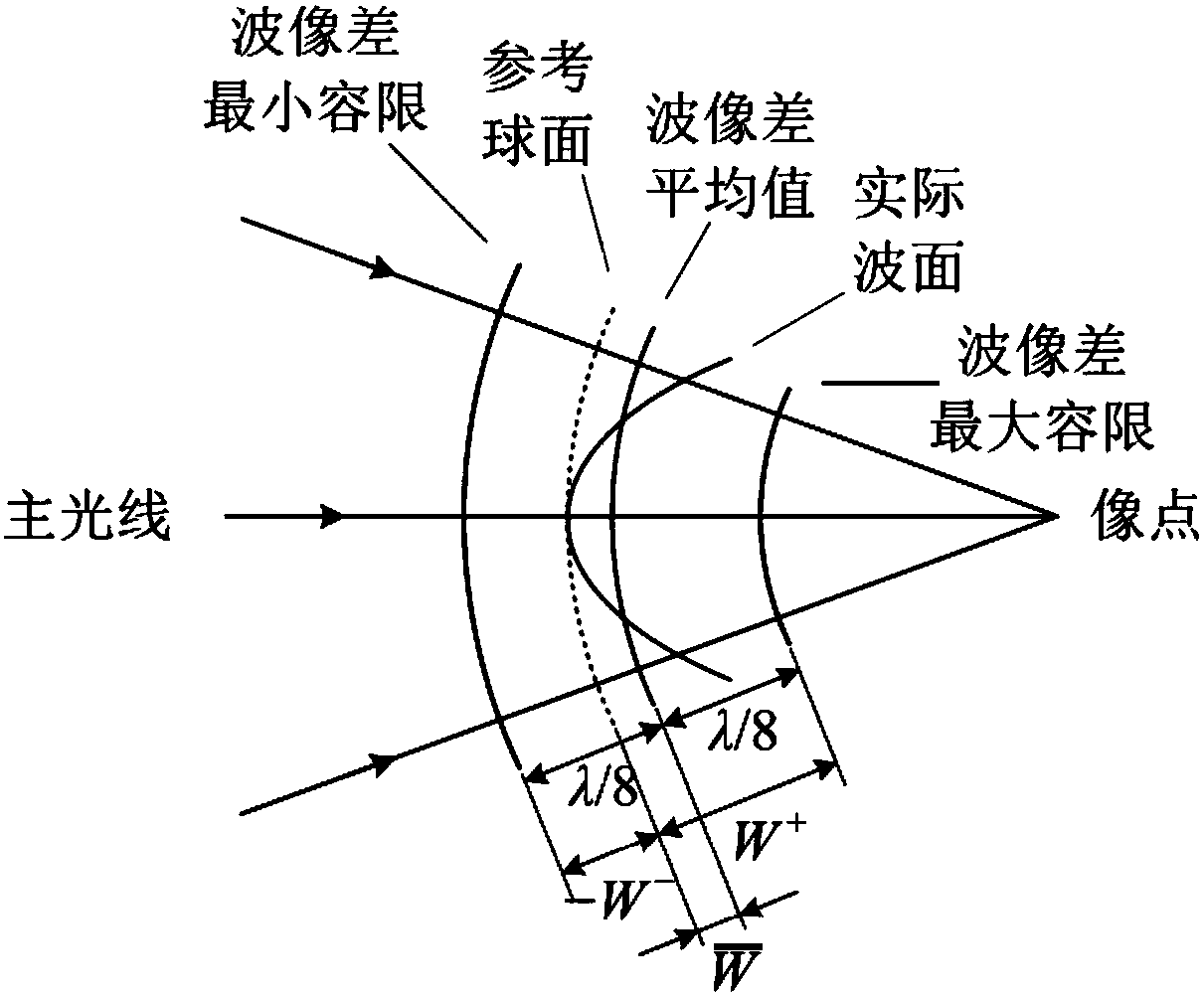

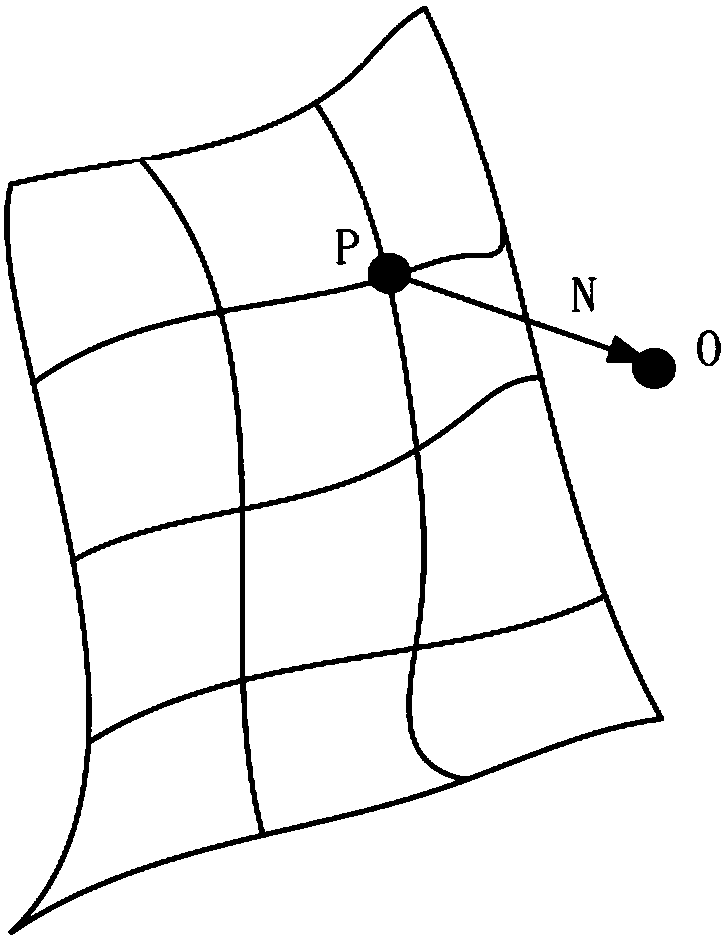

Analysis method for surface form tolerance distribution of free-form curved surface for optical system

ActiveCN109387938AEffectively guide processingReduce processing stepsReflective surface testingOptical elementsImage-forming optical systemForm error

The invention relates to an analysis method for the surface form tolerance distribution of a free-form curved surface for an optical system. The method comprises the following steps: building a free-form curved surface imaging optical system; selecting a plurality of view fields in the free-form curved surface imaging optical system, setting the maximum tolerance and minimum tolerance of the waveaberration of each view field, and selecting any one free-form curved surface in the free-form curved surface imaging optical system; building an isolated point jump model, and sequentially applying the jumping isolated points to different positions of the selected free-form curved surface in each field; performing the inverse solving of a partial surface form error extreme value corresponding toeach view field according to the set maximum tolerance and minimum tolerance of the wave aberration; performing the integration of the partial surface form tolerance distribution of the selected free-form curved surfaces of a plurality of view fields, and obtaining the surface form tolerance distribution of the free-form curved surface.

Owner:TSINGHUA UNIV +1

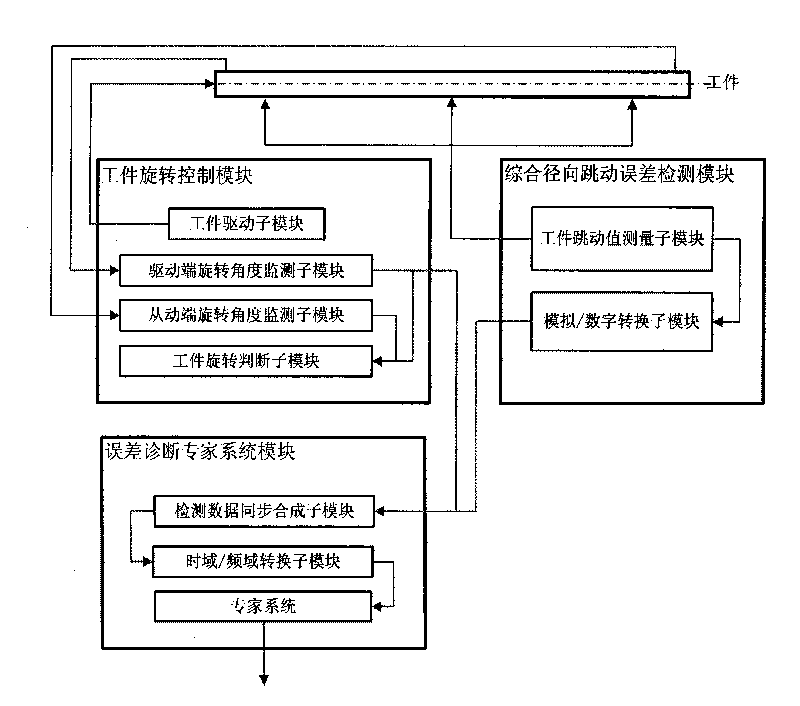

System for automatically detecting and diagnosing flexural deformation of axial line of workpiece

InactiveCN101727091AImprove detection accuracyImprove detection efficiencyProgramme controlComputer controlEllipseFiltration

The invention provides a system for automatically detecting and diagnosing flexural deformation of axial line of workpiece. When the workpiece is driven by a rotation control module to rotate around a rotation axial line, the system records the radial pulsation value of the workpiece and the rotation angle value of the workpirce, screens out the data generated by the form error of the sections, such as ellipse, triangle, bulge, burr and the like after the filtration treatment of an error diagnostician system, and extracts the measurement data generated by the flexure error of the axial line of the workpiece, thereby generating the standard space model of the flexure of the axial line, so as to complete the task of automatically detecting and diagnosing flexural deformation of axial line of the workpiece.

Owner:牛俊华

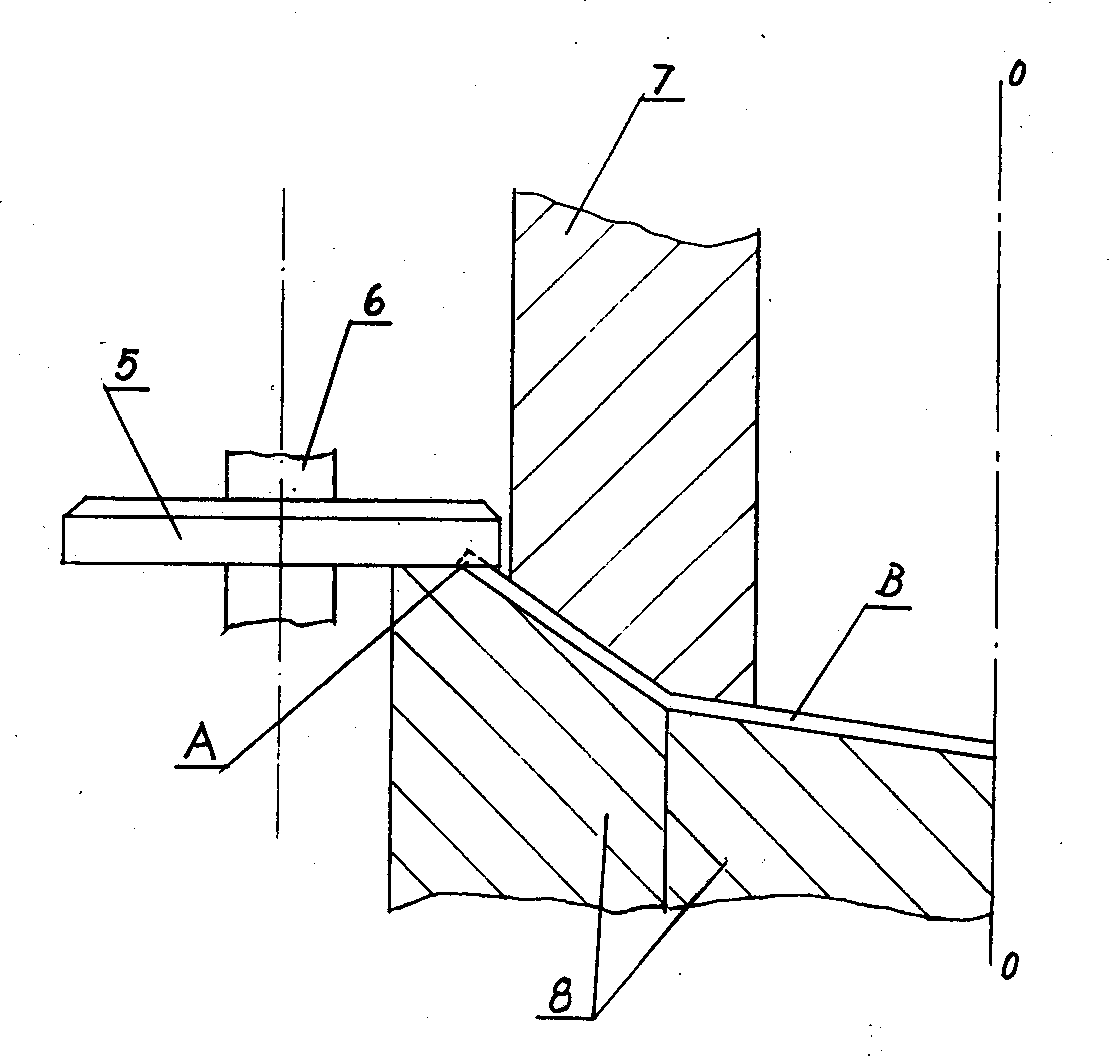

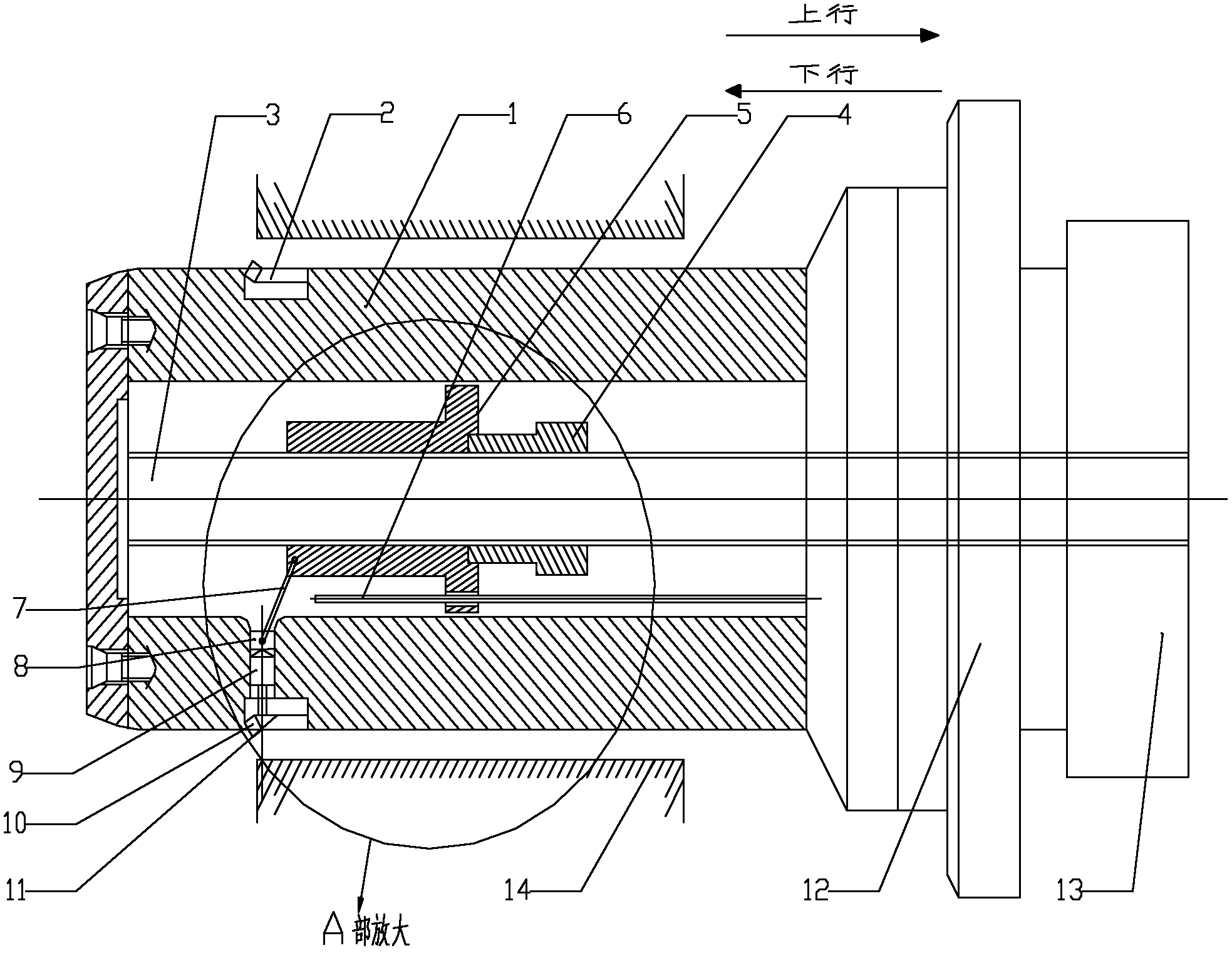

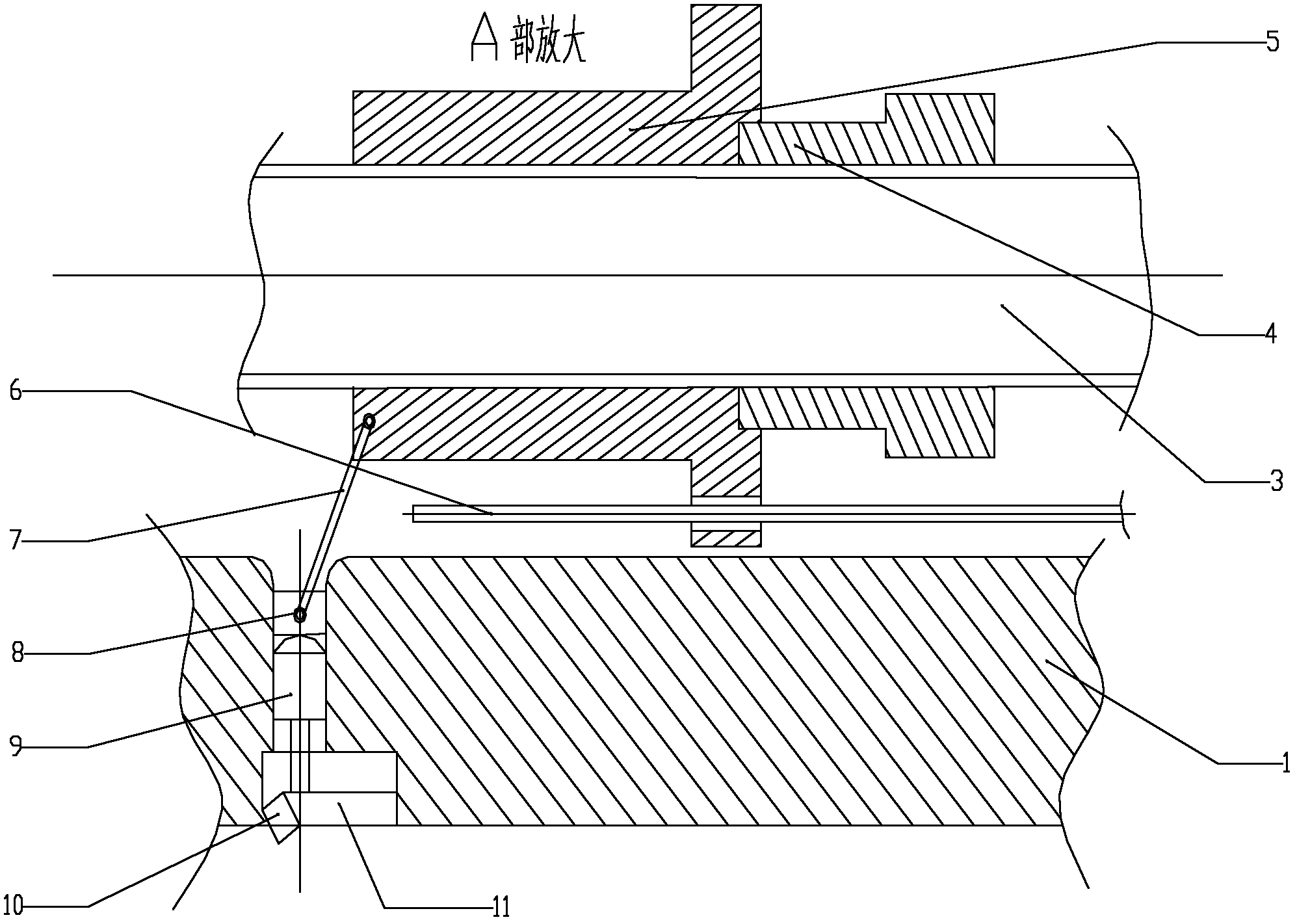

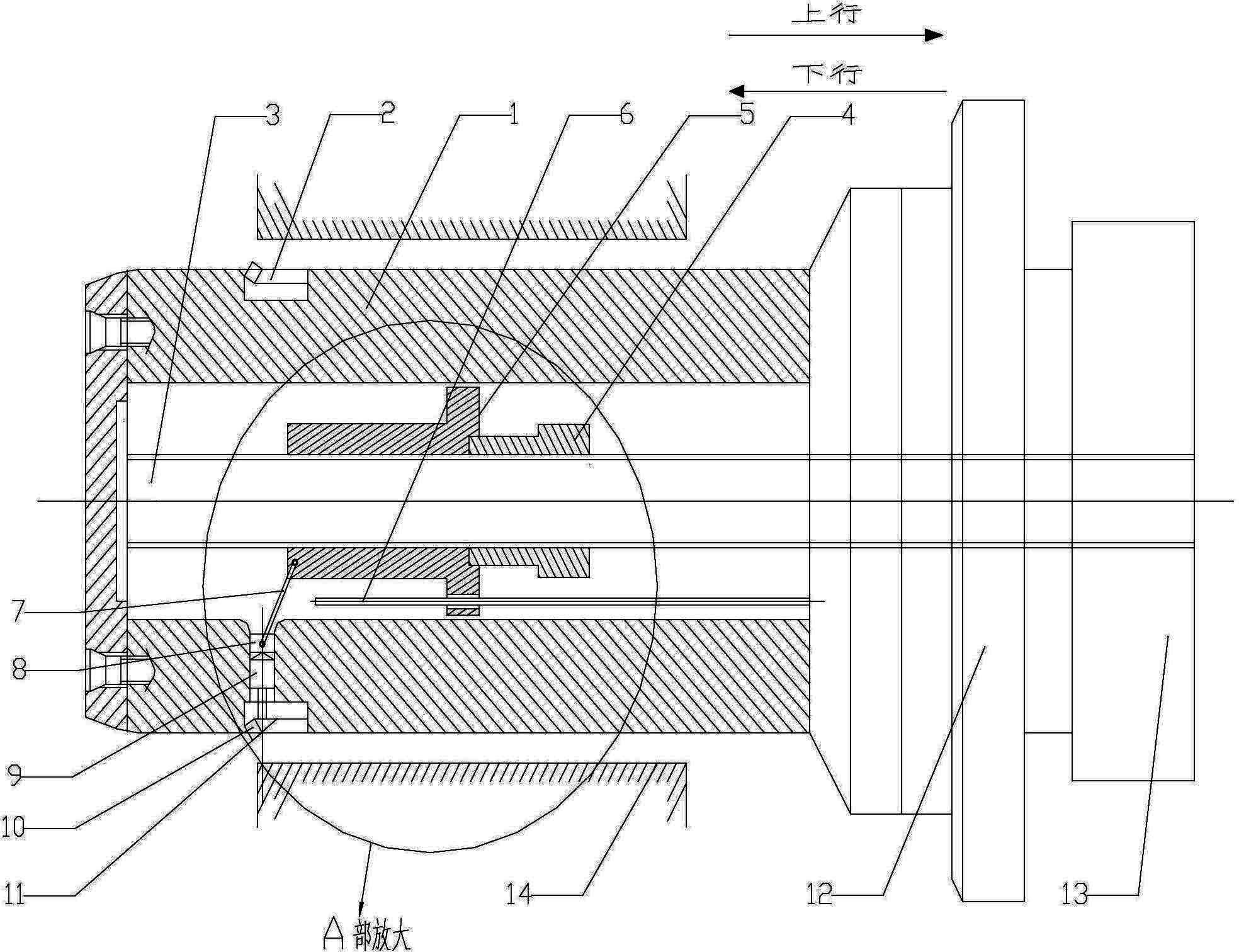

Boring cutter rod error compensating device with slide block structure

InactiveCN102672535AAvoid stayingPrecise wear compensationAutomatic control devicesFeeding apparatusBall screw driveRelative motion

The invention discloses a boring cutter rod error compensating device with a slide block structure. The boring cutter rod error compensating device comprises a boring cutter rod and a cutter compensation servo motor, wherein the boring cutter rod is provided with an axial central hole; one end of a ball screw is connected with an output shaft of the cutter compensation servo motor; the other end of the ball screw stretches into the central hole; a screw nut assembly which can move relatively is sleeved on the ball screw; the ball screw drives the screw nut assembly to move in a straight line relatively; a connecting rod is connected with the screw nut assembly; a slide block is connected with one end of the connecting rod far away from the screw nut assembly; a straight hole slide groove is arranged on the side wall of the boring cutter rod; the slide block is arranged in the straight hole slide groove and can be driven by the connecting rod to slide in the straight hole slide groove; a ball pin is arranged in the straight hole slide groove; one end of the ball pin props against the slide block through an end part ball; and the other end of the ball pin is connected with the boring cutter on the side wall of the boring cutter rod. With the boring cutter rod error compensating device, rough and finish machining can be accomplished for one time; the abrasion of the fine boring cutter is reduced; and precise compensation to the cutter abrasion and the cylinder hole cylindrical form error is realized.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

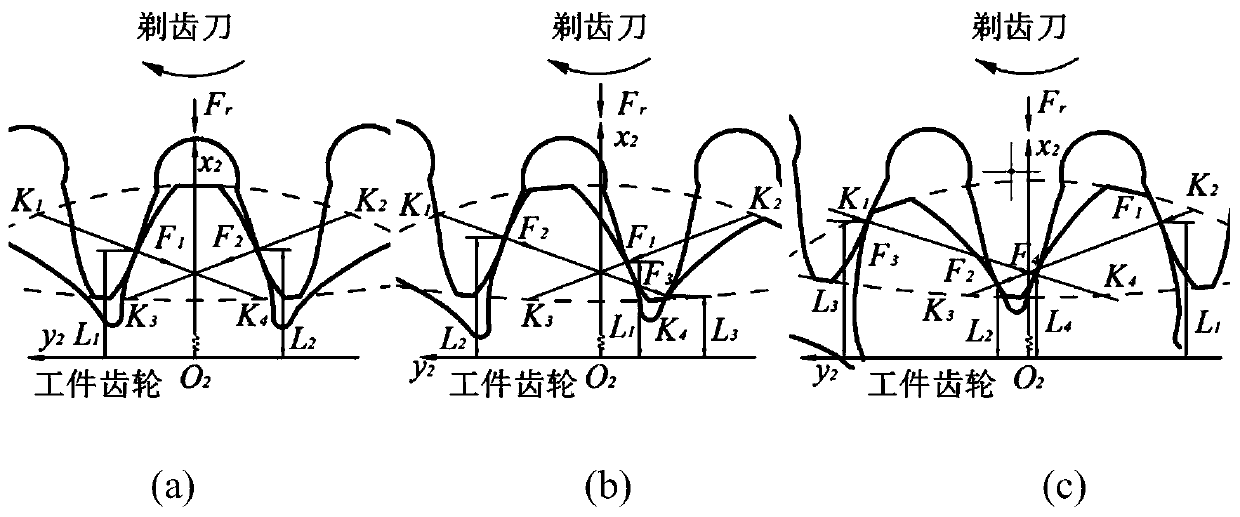

A gear shaving tooth profile error prediction method

ActiveCN109710969AControl or counteract tooth profile errorsHigh precisionForecastingSpecial data processing applicationsElastic plasticProcess guidance

The invention discloses a gear shaving profile error prediction method, which comprises the following steps of: introducing a gear shaving mounting error into a gear shaving motion coordinate system,constructing new coordinate conversion, deducing and calculating a compensation displacement amount caused by the gear shaving mounting error, and enabling the mode of the compensation displacement amount at a normal component vector of a contact point to be a tooth profile cut depth caused by the gear shaving mounting error. And elastic-plastic press-cutting deformation of gear shaving surface contact is given based on the contact mechanics, and the actual press-cutting deformation of gear shaving is calculated by comparing the ultimate strength of the material. And comprehensively considering the gear shaving installation error tooth profile cutting depth and the gear shaving actual pressing and cutting deformation to establish a gear shaving tooth profile error prediction model. By means of the method, prediction of the gear tooth form error of the shaved workpiece can be accurately achieved, the tooth surface precision and the machining efficiency can be effectively improved, and targeted technological guidance is provided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com