Error compensating method for material-increase manufacturing

A technology of additive manufacturing and error compensation, which is applied in the field of additive manufacturing, can solve the problems of large Z-direction dimensional error, deformation, and inability to deal with Z-direction penetration errors, etc., and achieve the effect of improving precision and forming quality and reducing dimensional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] There are many ways of additive manufacturing, a typical way is binder jet additive manufacturing.

[0102] For ease of understanding, in this embodiment, the error compensation method for additive manufacturing in the above embodiments of the present invention is further described by taking the binder jet additive manufacturing method as an example.

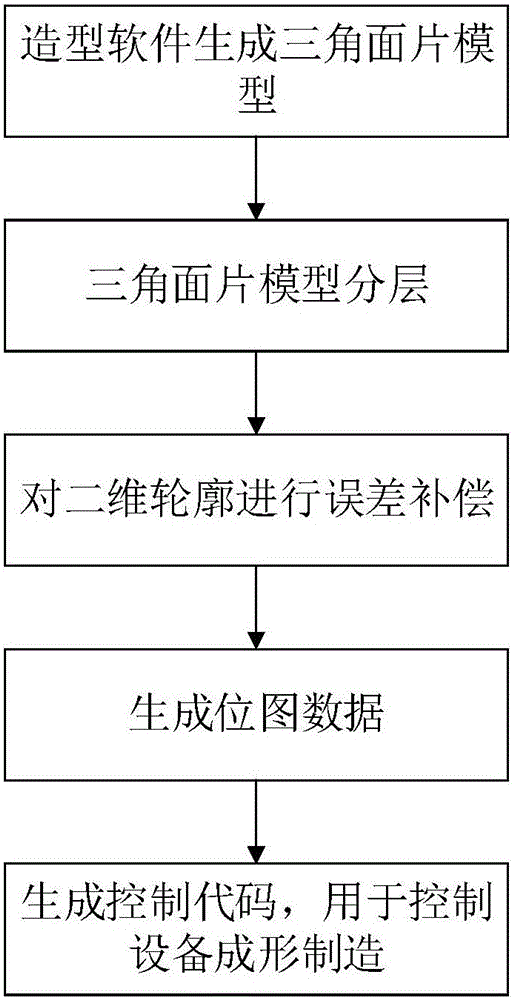

[0103] In this embodiment, the penetration error compensation method for binder jet additive manufacturing specifically includes the following steps:

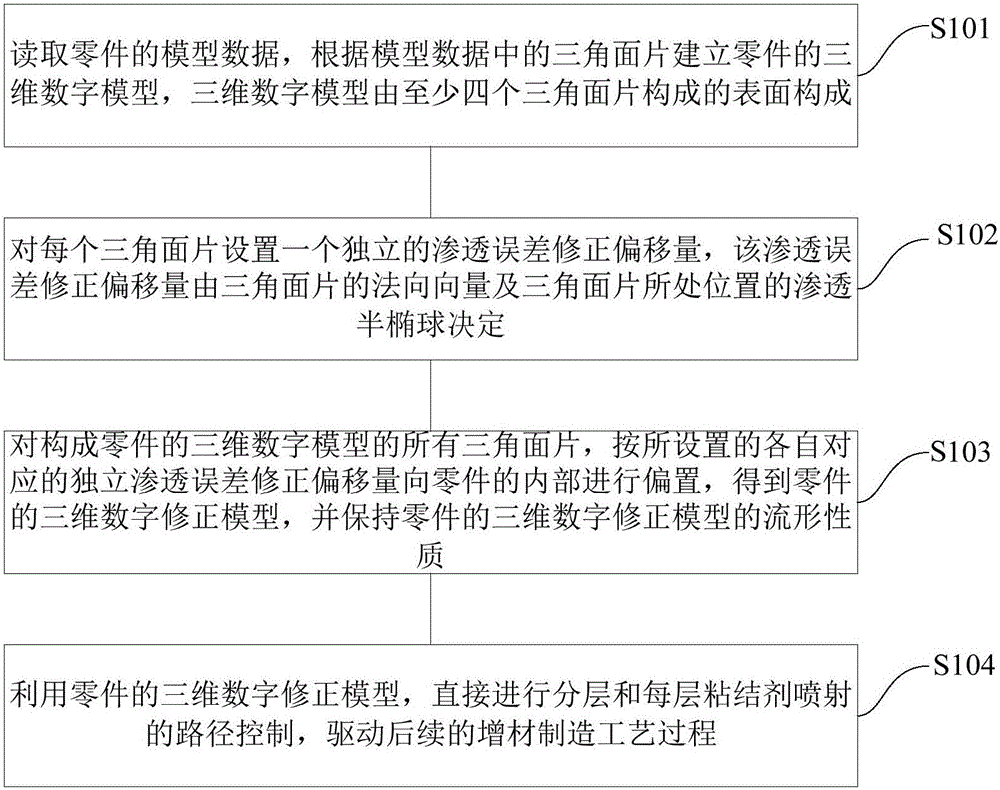

[0104] Step a: read the model data of the part, and establish a three-dimensional digital model of the part according to the triangular faces in the model data, and the three-dimensional digital model is composed of surfaces composed of at least four triangular faces. Among them, the three-dimensional digital model of the part has the topological relationship of point-line, point-plane and line-plane.

[0105] Step b: Set an independent penetration error correction offset...

Embodiment 2

[0110] In this embodiment, taking the error compensation method of binder jet additive manufacturing as an example, the specific operation process is as follows:

[0111] 1 Equipment: Binder jet additive manufacturing equipment and other necessary parts. In this example, the PCM technology developed by the Mechanical Engineering Department of Tsinghua University is selected.

[0112] 2 data: the sample triangular patch model, which is a cube model, for example Figure 10 (a) and Figure 10 (b) shown.

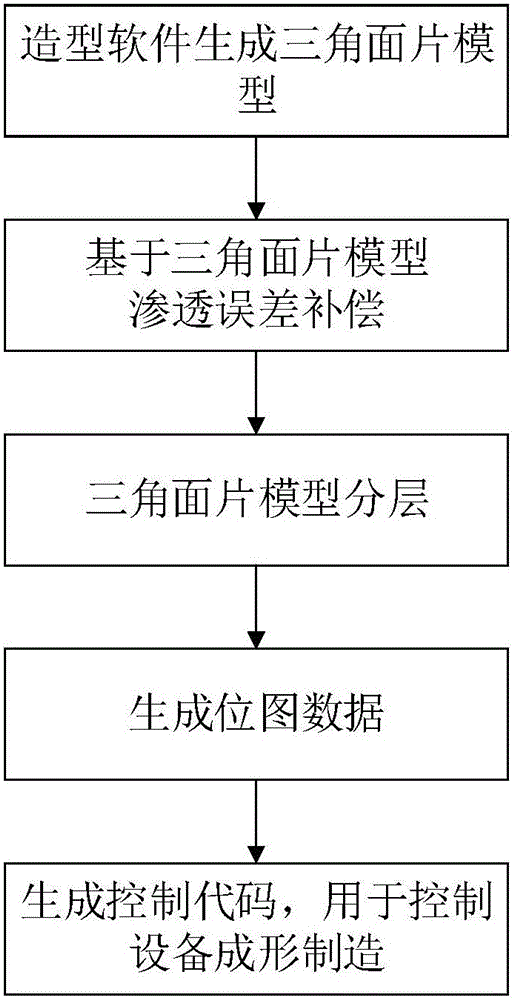

[0113] 3. Purpose of the experiment: To compensate the penetration error of the sample model by using the compensation method of the penetration error based on the triangular patch model.

[0114] 4 Implementation steps:

[0115] A: Reconstruct the topological relationship of the sample triangular mesh model data, and repair the topological errors to generate a 3D mesh model.

[0116] B: According to the theoretical seepage model, perform theoretical seepage error compensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com